Clamping structure for fastening motion self-compensation

A technology of automatic compensation and clamping, which is applied in the direction of clamping, manufacturing tools, supports, etc., can solve problems such as clamping is not tight, and achieve the effect of convenient maintenance and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

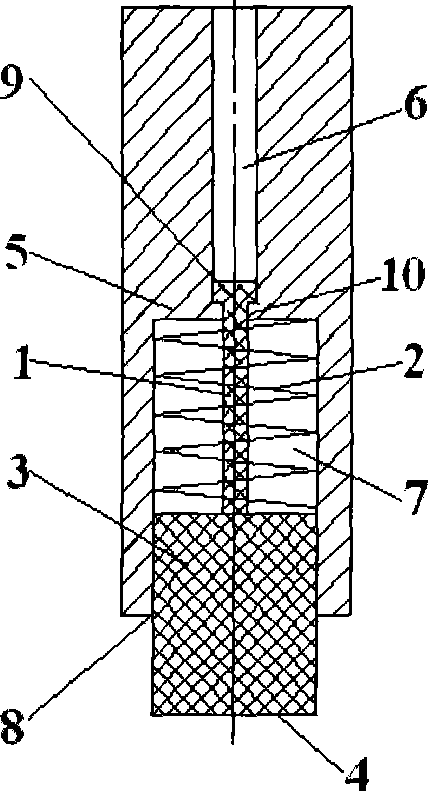

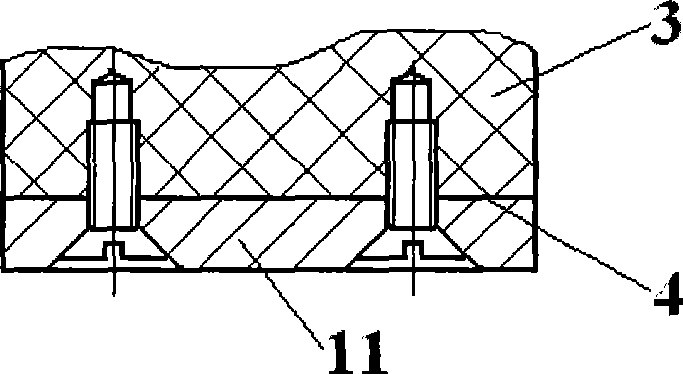

[0035] A clamping sleeve 5 is provided on the clamp structure, and one end thereof is provided with a clamping block installation counterbore 8, and the clamping block 3 is set in the clamping block installation counterbore 8, and the sides of the clamping block 3 and The inner wall of the clamping block mounting counterbore 8 forms a tight fit, and the clamping surface 4 is higher than the port of the clamping block mounting counterbore 8 .

Embodiment 2

[0038] A closed clamping air chamber 7 is formed between the bottom surface of the clamping block installation counterbore 8 and the end surface of the clamping block 3 inside the clamping block installation counterbore 8 .

[0039] The clamping air chamber 7 is provided, and the compressibility of the air is used to better realize the effect of increasing the elastic force.

Embodiment 3

[0041] A spring 2 is provided in the clamping air chamber 7, and the spring 2 is a compression spring, and the direction of expansion is to make the clamping block 3 move toward the outside of the clamping block mounting counterbore 8, and a spring is provided to limit it. The limit structure 9 of the clamping block moves outward to the maximum position, and this position makes the spring 2 have a pre-compression amount in the state of not clamping the workpiece.

[0042] The effect of setting the compression spring is the same as that of the second embodiment, and also solves the problem of possible air leakage in the second embodiment, because when the spring 2 is not clamped, it can make the capacity of the clamping air chamber 7 The cavity is enlarged to compensate for the gas. However, since the spring 2 is provided, there will inevitably be a problem of pushing the clamping block 3 out of the clamping sleeve 5. Therefore, a clamping block limiting structure 9 must be pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com