Patents

Literature

231results about How to "Eliminate misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

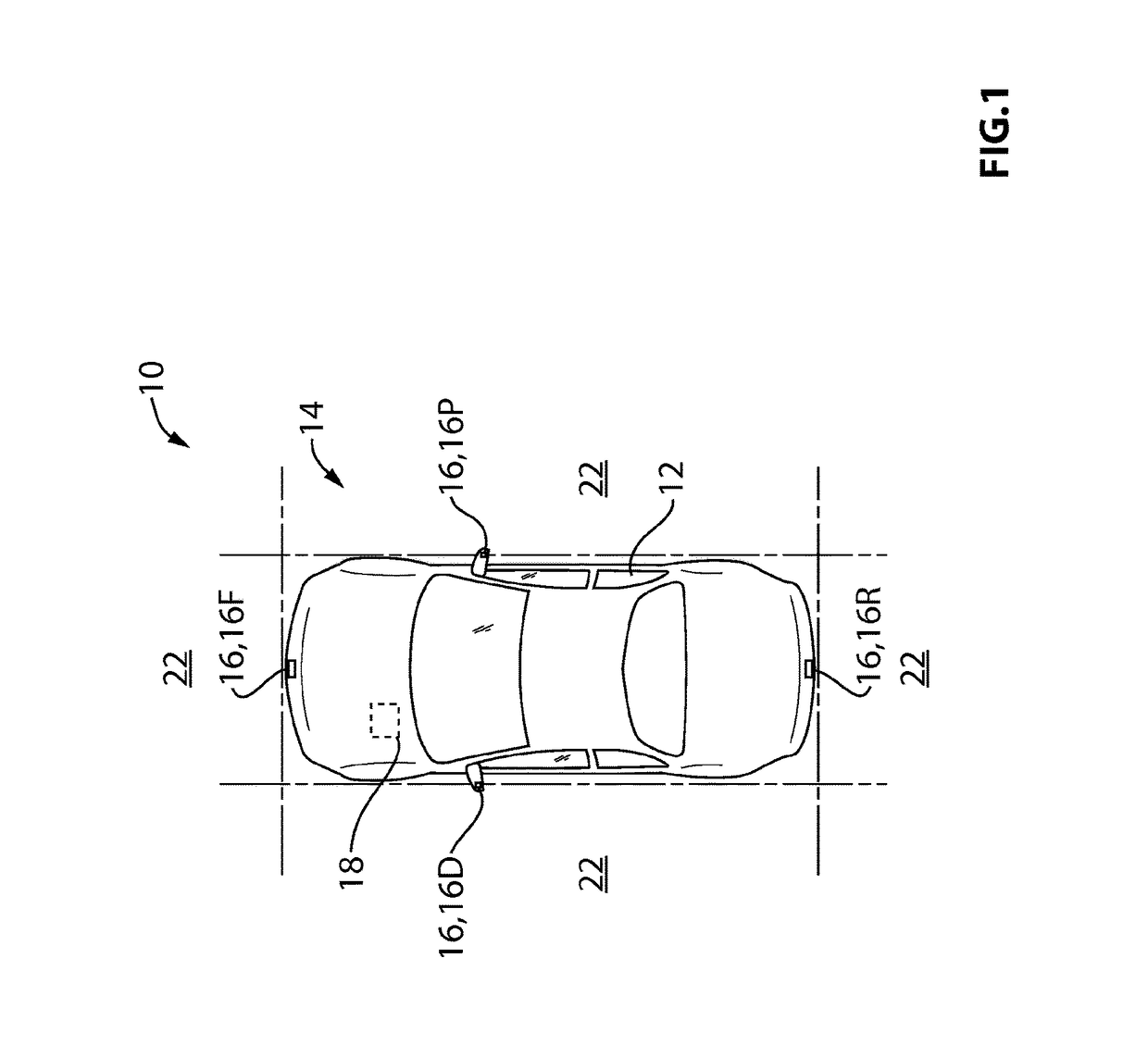

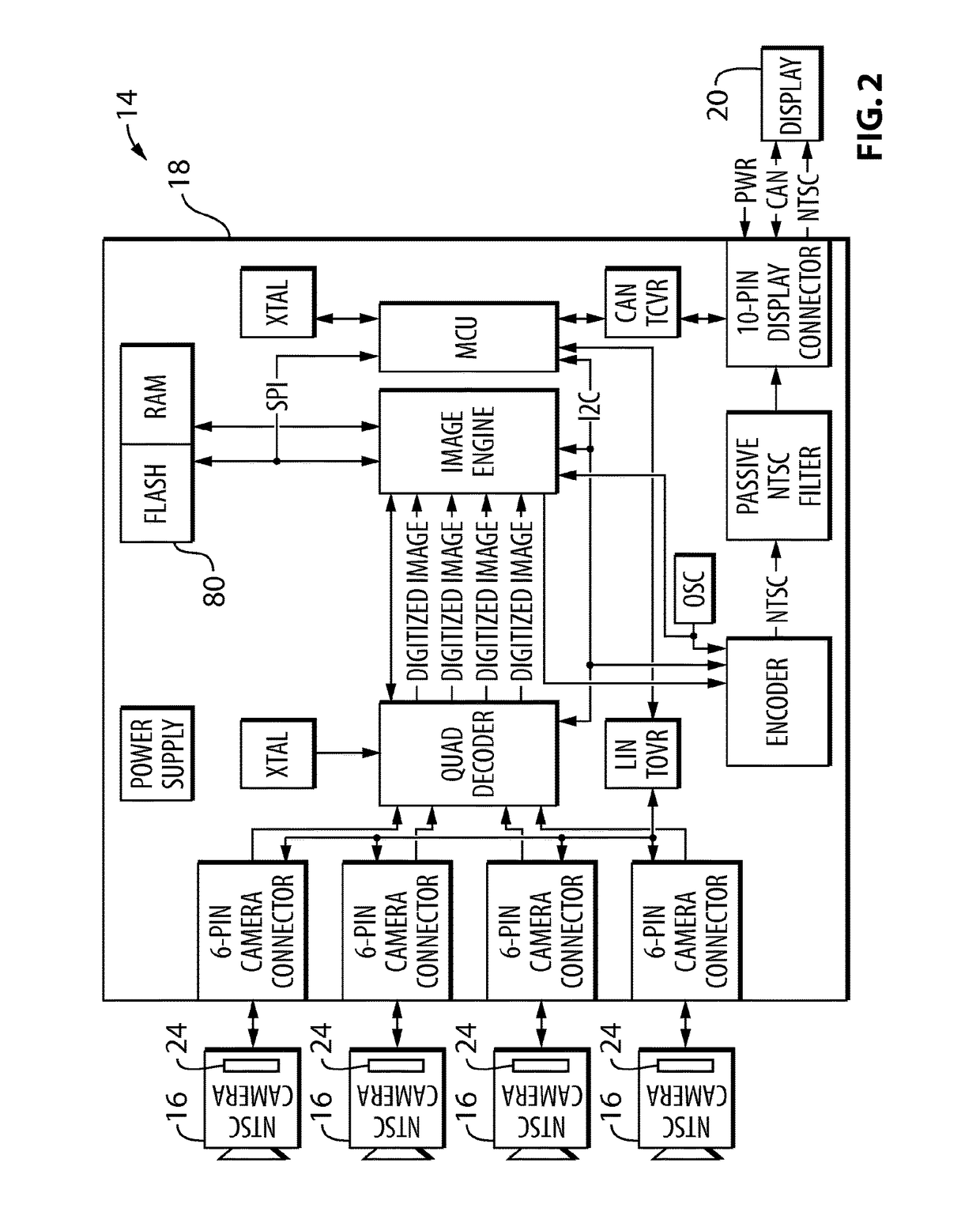

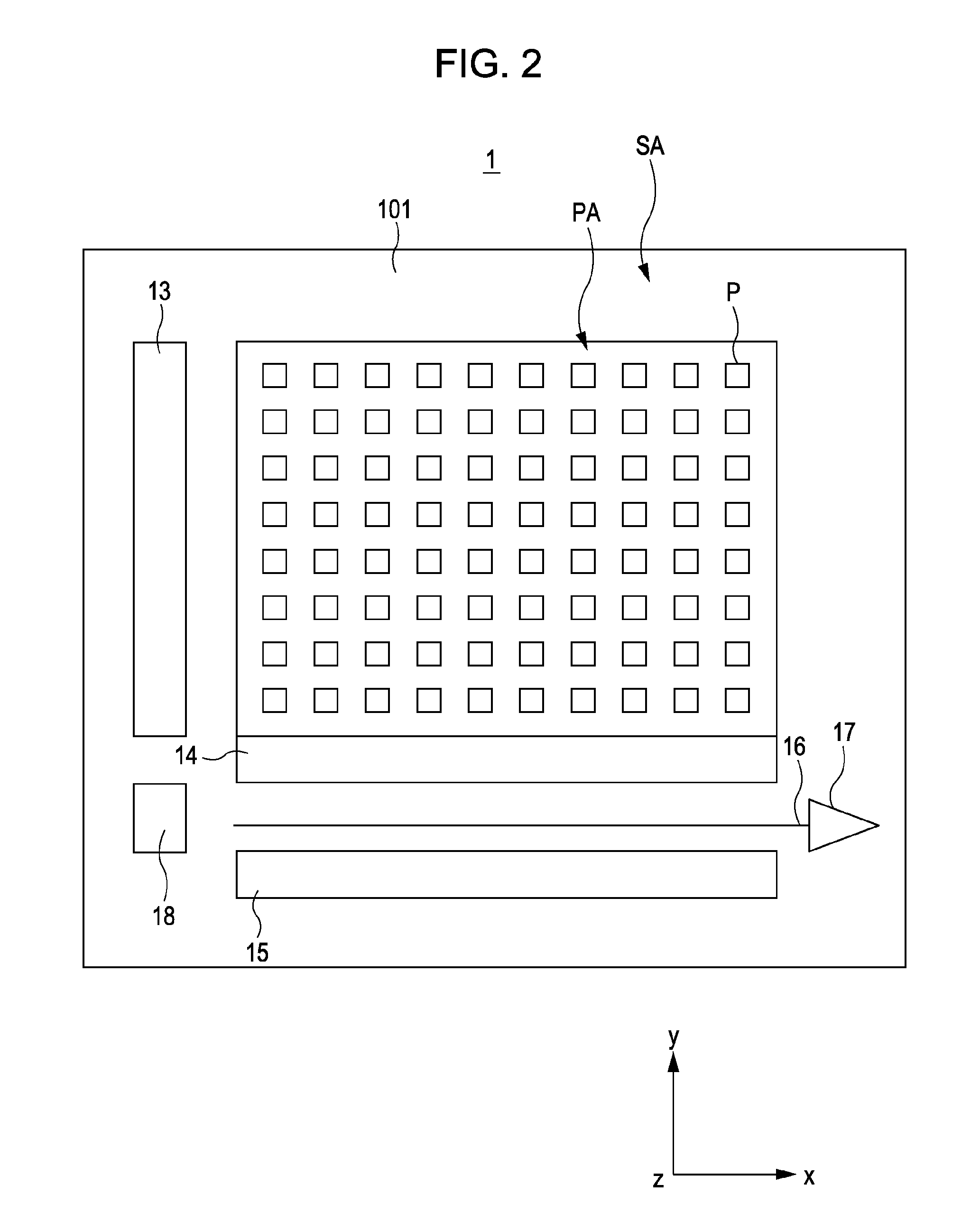

System and method of establishing a multi-camera image using pixel remapping

ActiveUS9900522B2Eliminate misalignmentTelevision system detailsGeometric image transformationCamera imageComputer graphics (images)

Owner:MAGNA ELECTRONICS INC

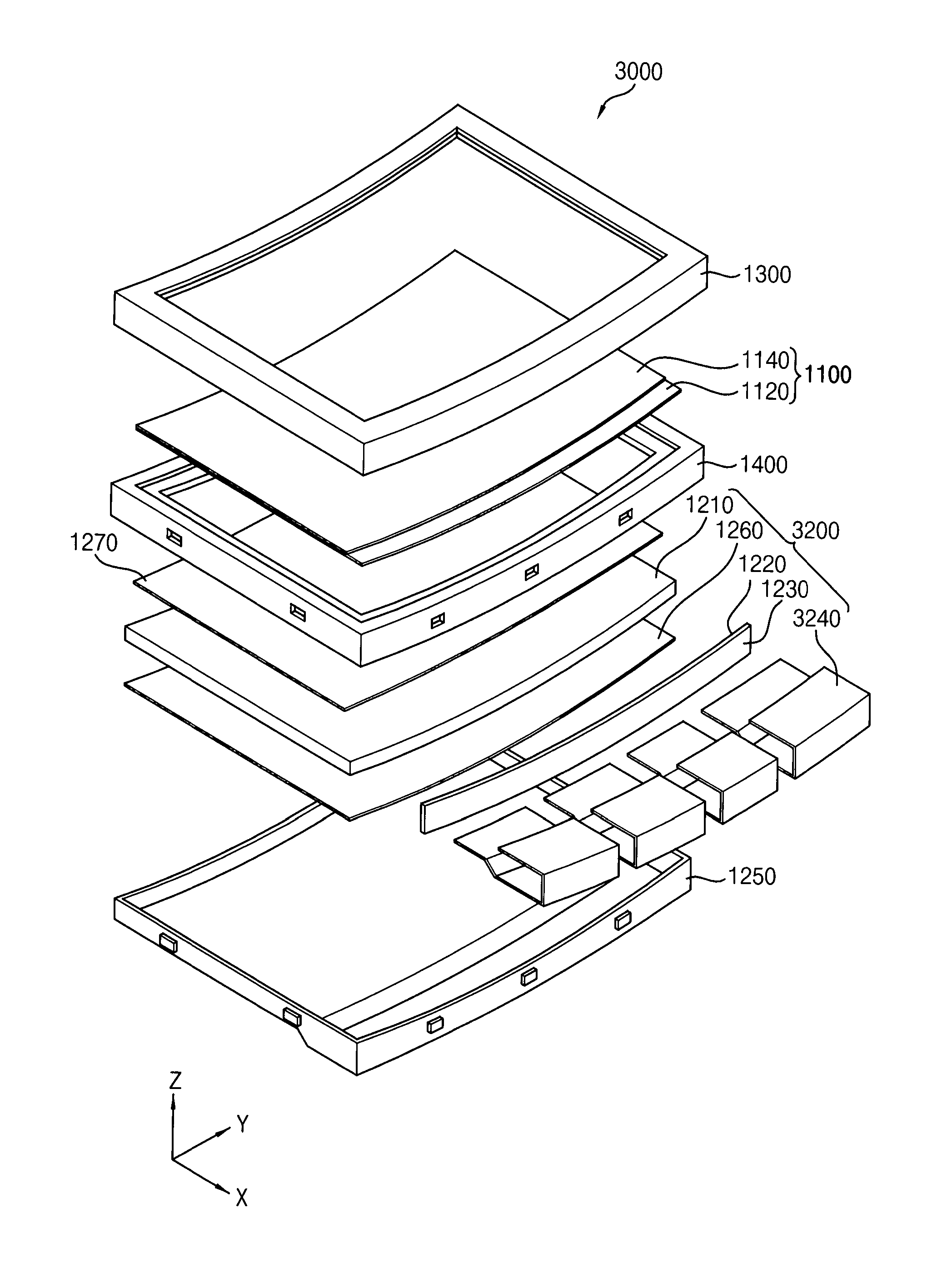

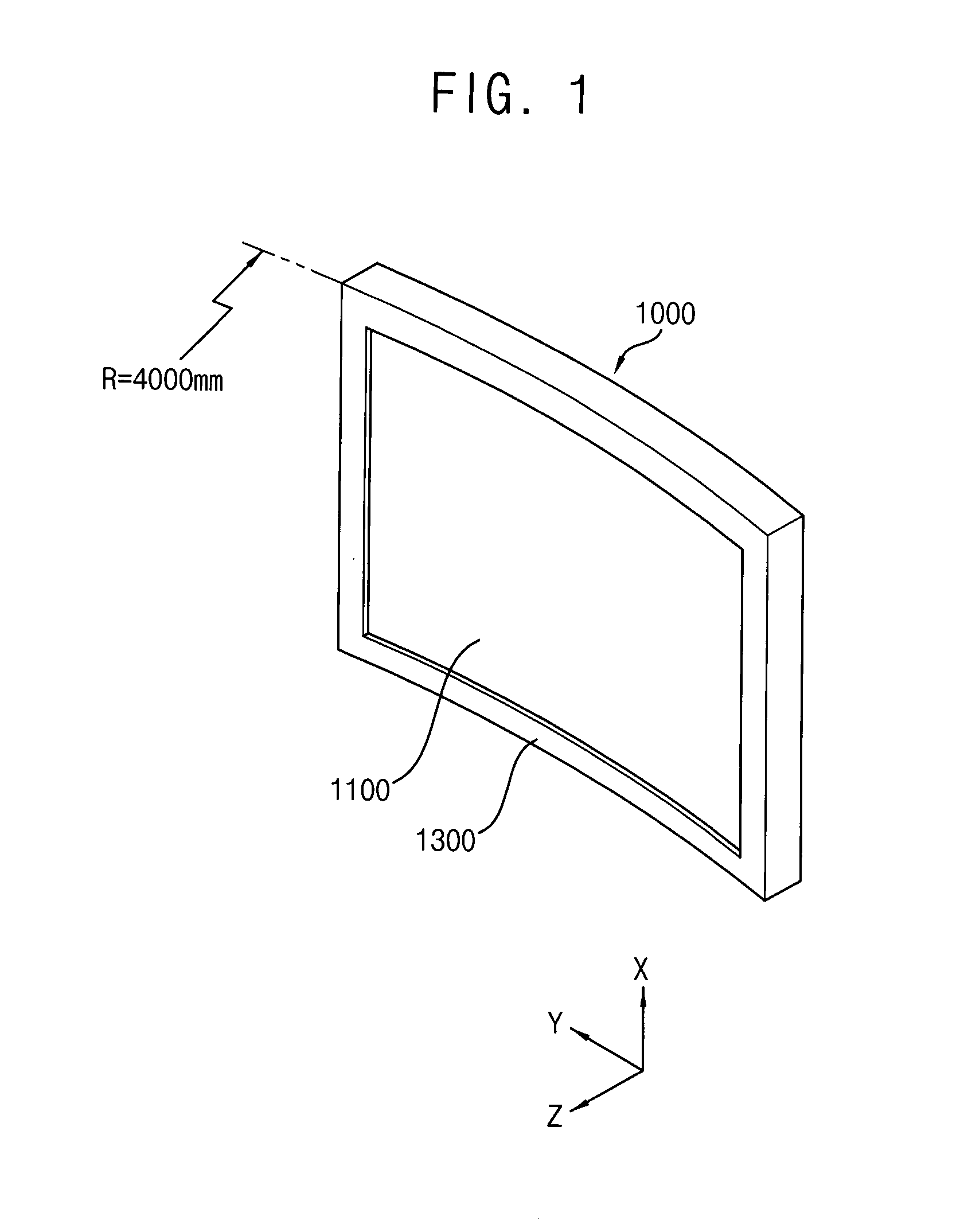

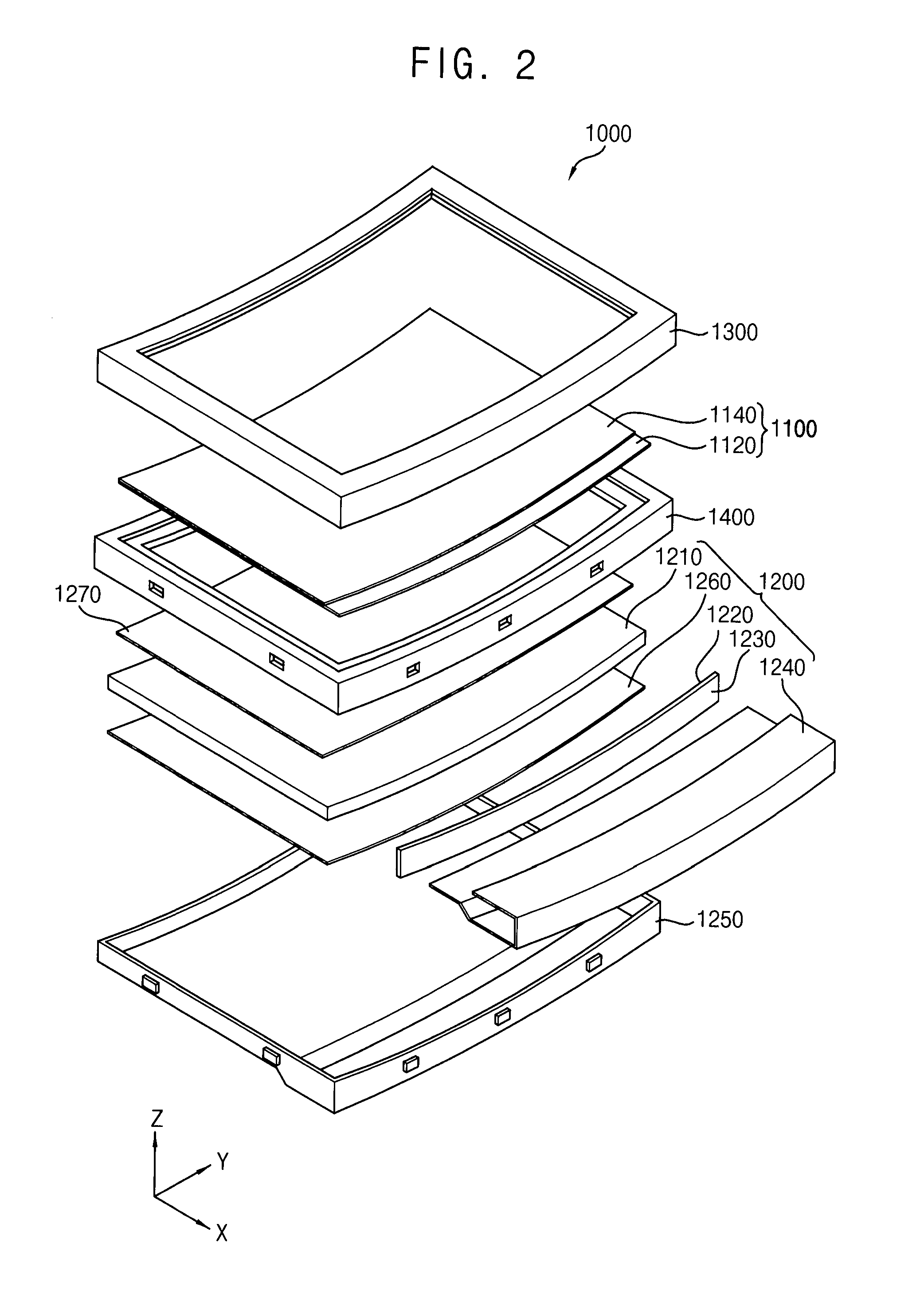

Curved backlight assembly and curved display device having the same

InactiveUS20150219940A1Reduce generationUniform light emissionMechanical apparatusPoint-like light sourcePrinted circuit boardEngineering

A curved backlight assembly includes a curved light guide plate (“LGP”), at least one light-emitting diode (“LED”), a printed circuit board (“PCB”) and a curved LED cover. The LGP includes a first side and a second side. The LED generates lights. The PCB has the LED mounted thereon to be disposed adjacent to the first side of the curved LGP. The curved LED cover receives the PCB to be bent along the first side of the curved LGP. Therefore, a generation of a hot-spot phenomenon may be prevented, so that it may emit uniform lights.

Owner:SAMSUNG DISPLAY CO LTD

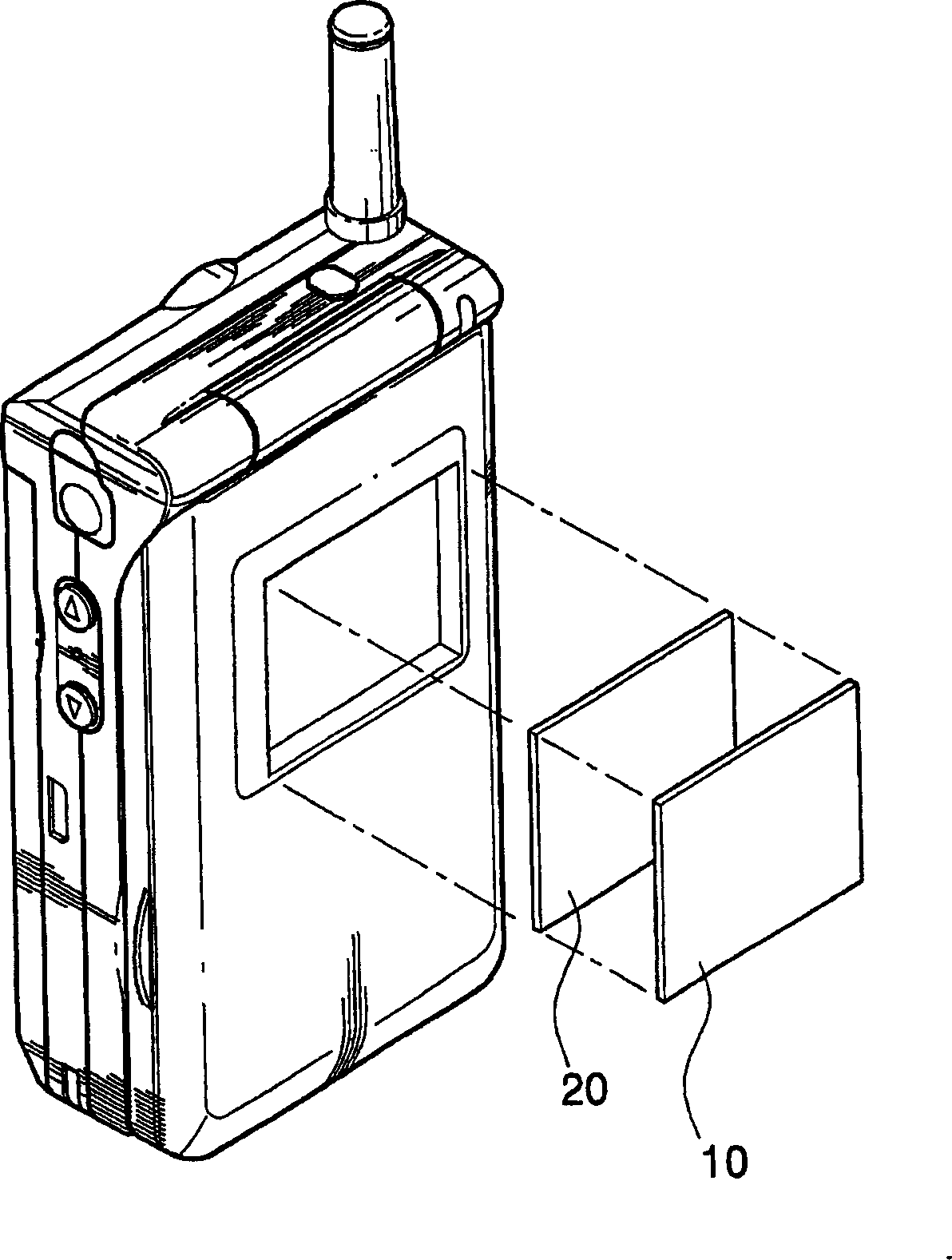

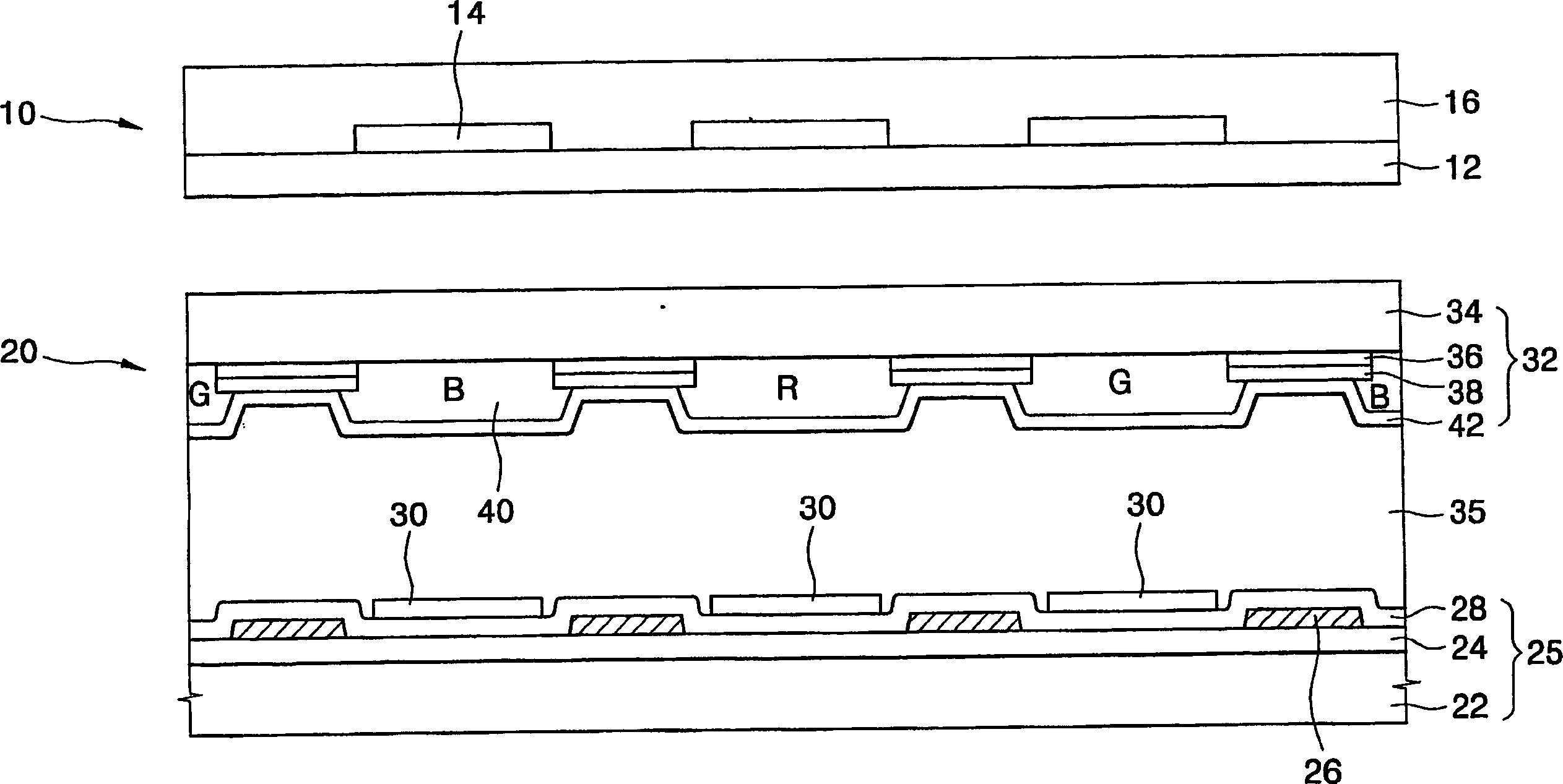

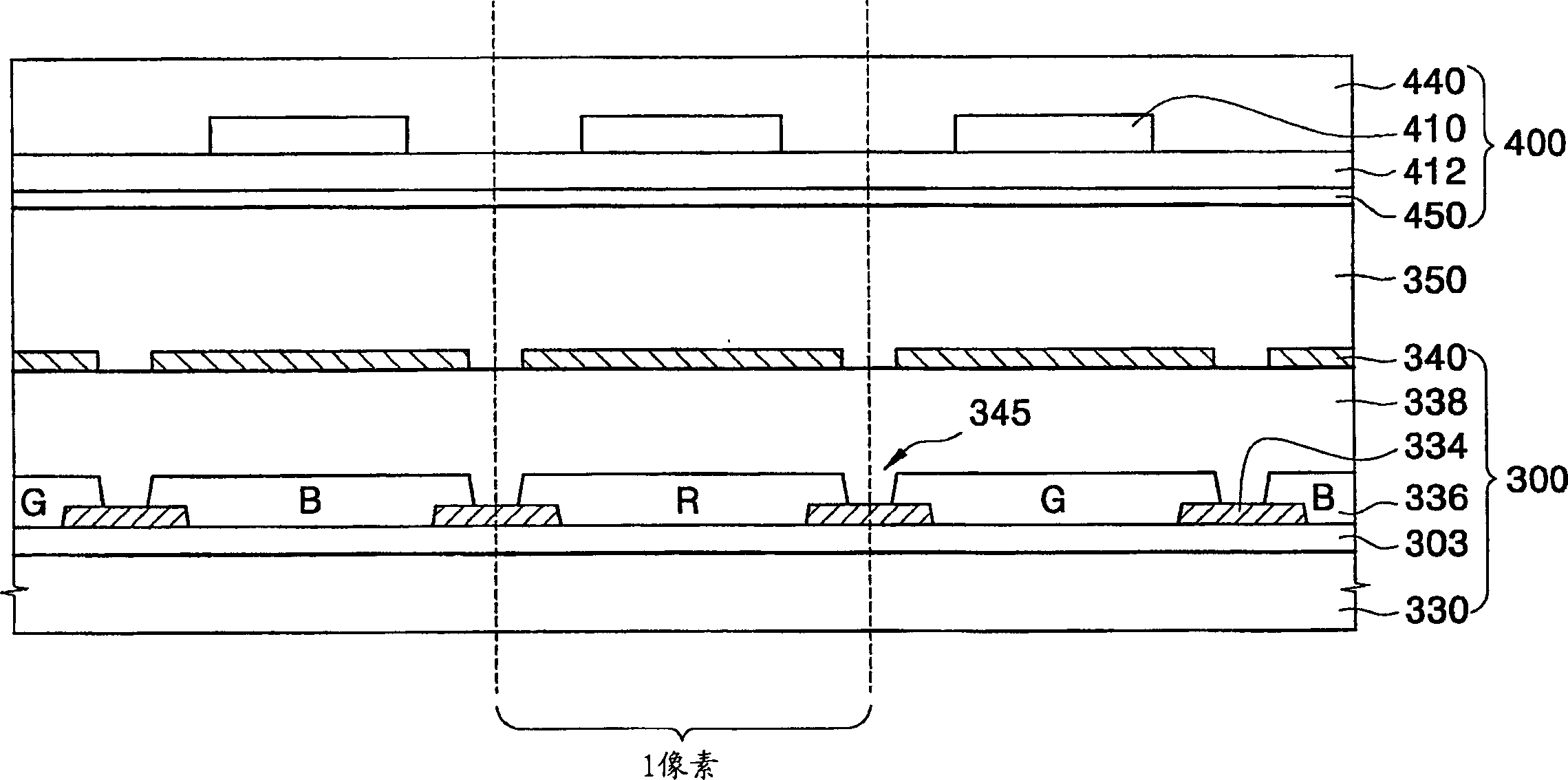

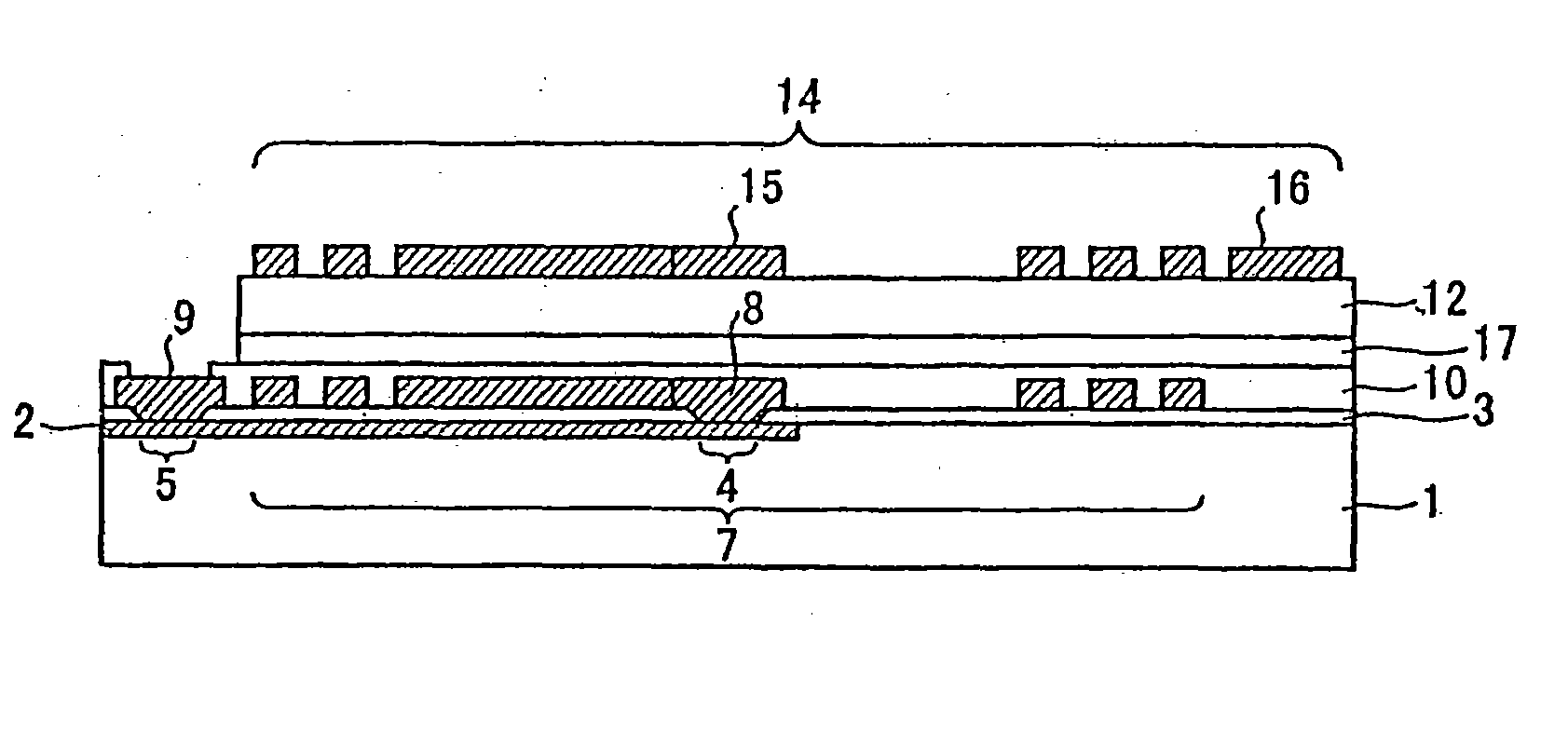

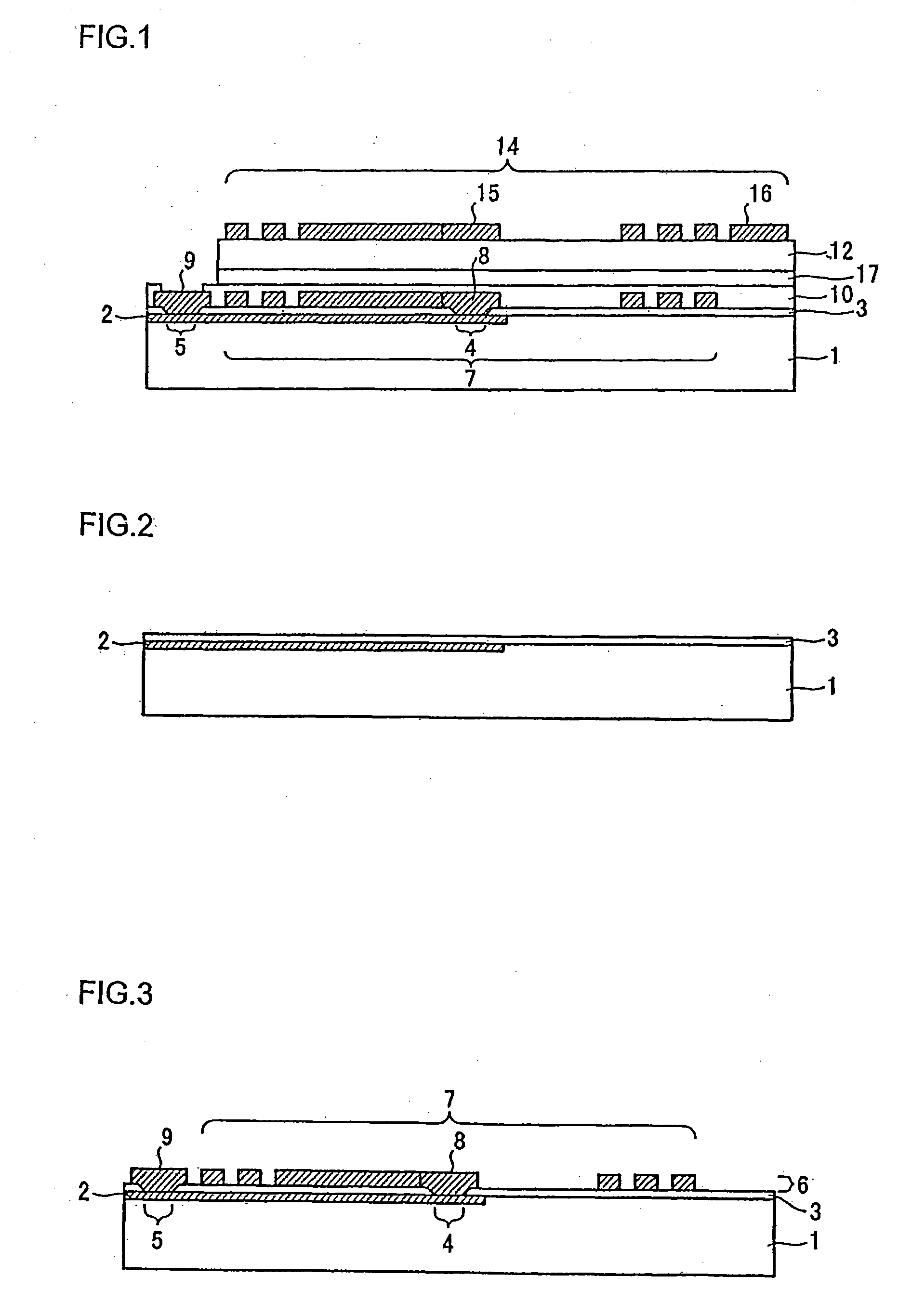

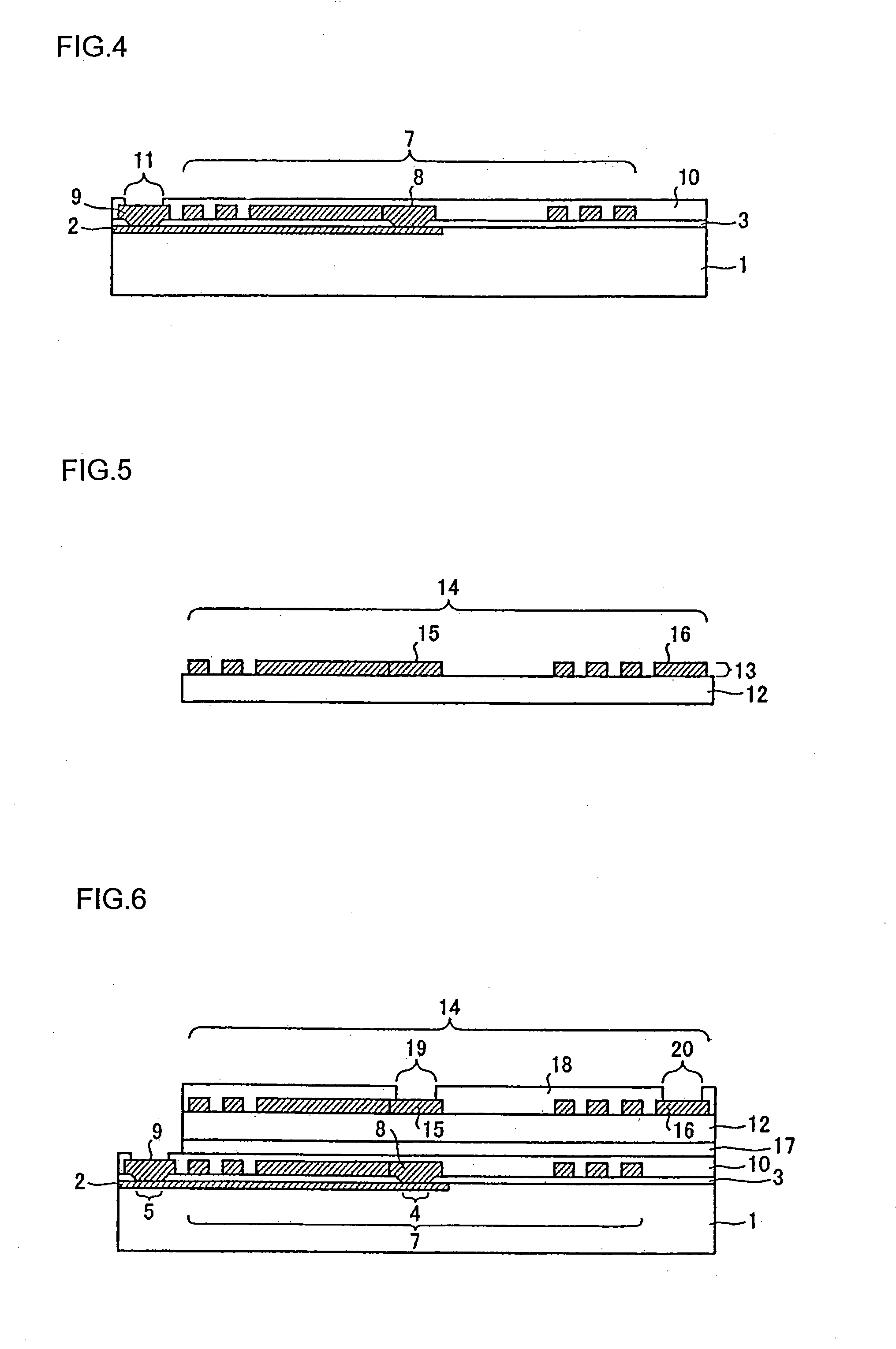

Liquid crystal display device built-in finger printing device and method of manufacturing the same

InactiveCN1689025AReduce in quantityReduce thicknessStatic indicating devicesPrint image acquisitionColor gelTransmittance

A liquid crystal display device having fingerprint identification device for enhancing aperture ratio and transmissivity of a TFT-LCD panel is disclosed. A fingerprint identification substrate (400) is attached to a TFT substrate (300). The TFT substrate has color-filter-on-array structure in which the color filters (336) and the thin film transistors can be eliminated, the aperture ratio is increased, and the quality of image display is enhanced. In addition, the transmissivity is increased according to the decrease of the number of glass substrate used in the liquid crystal display device, so that the sensitivity of fingerprint identification is enhanced.

Owner:SAMSUNG ELECTRONICS CO LTD

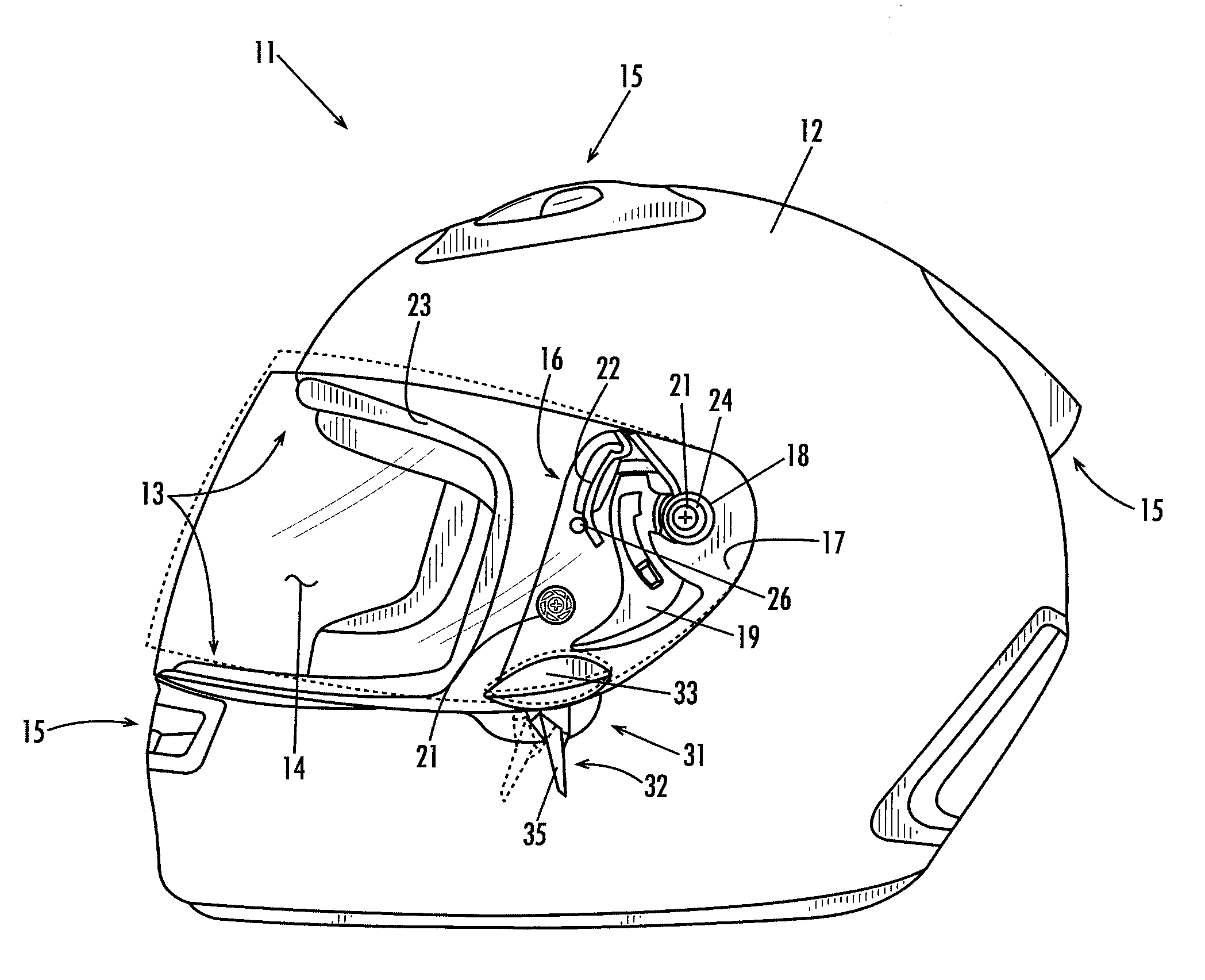

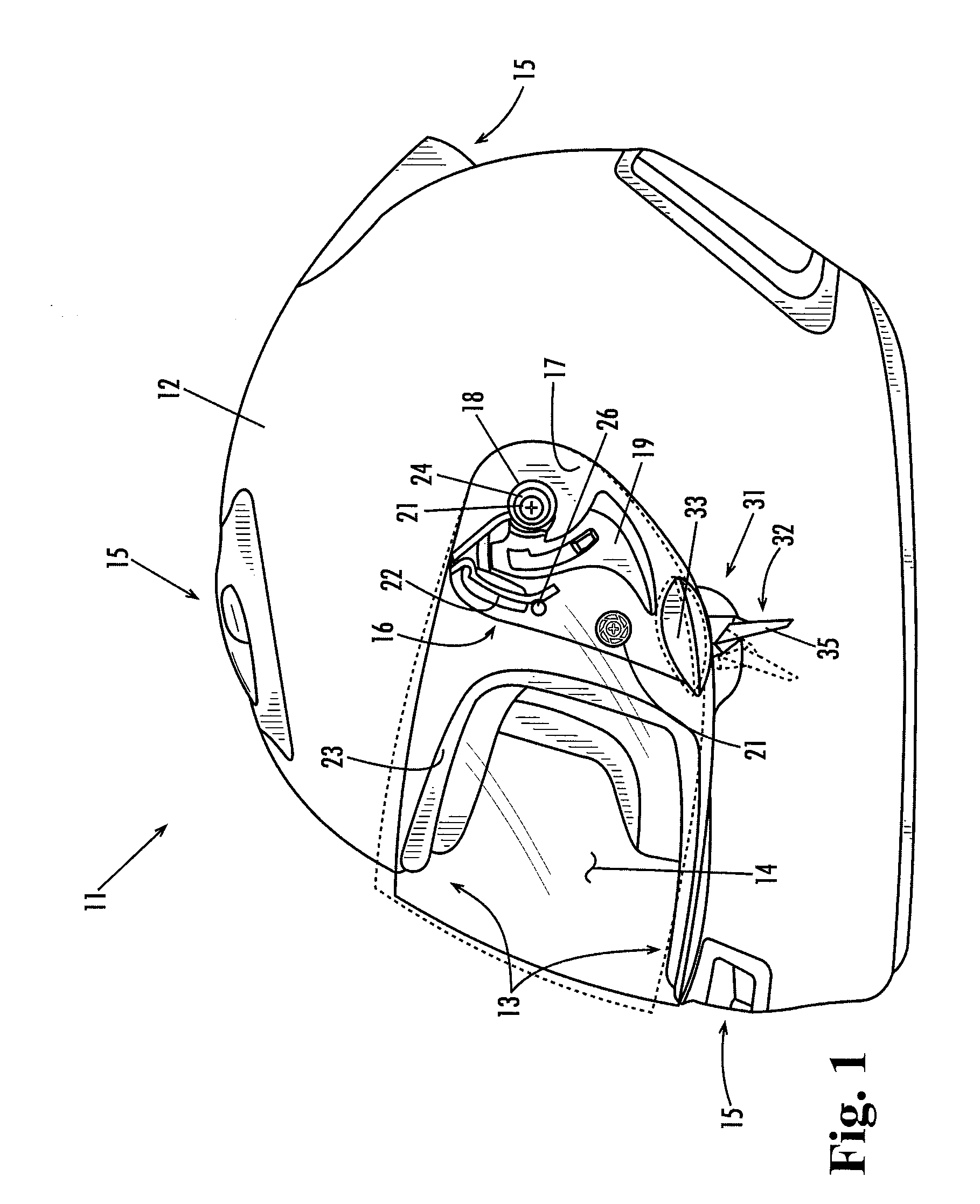

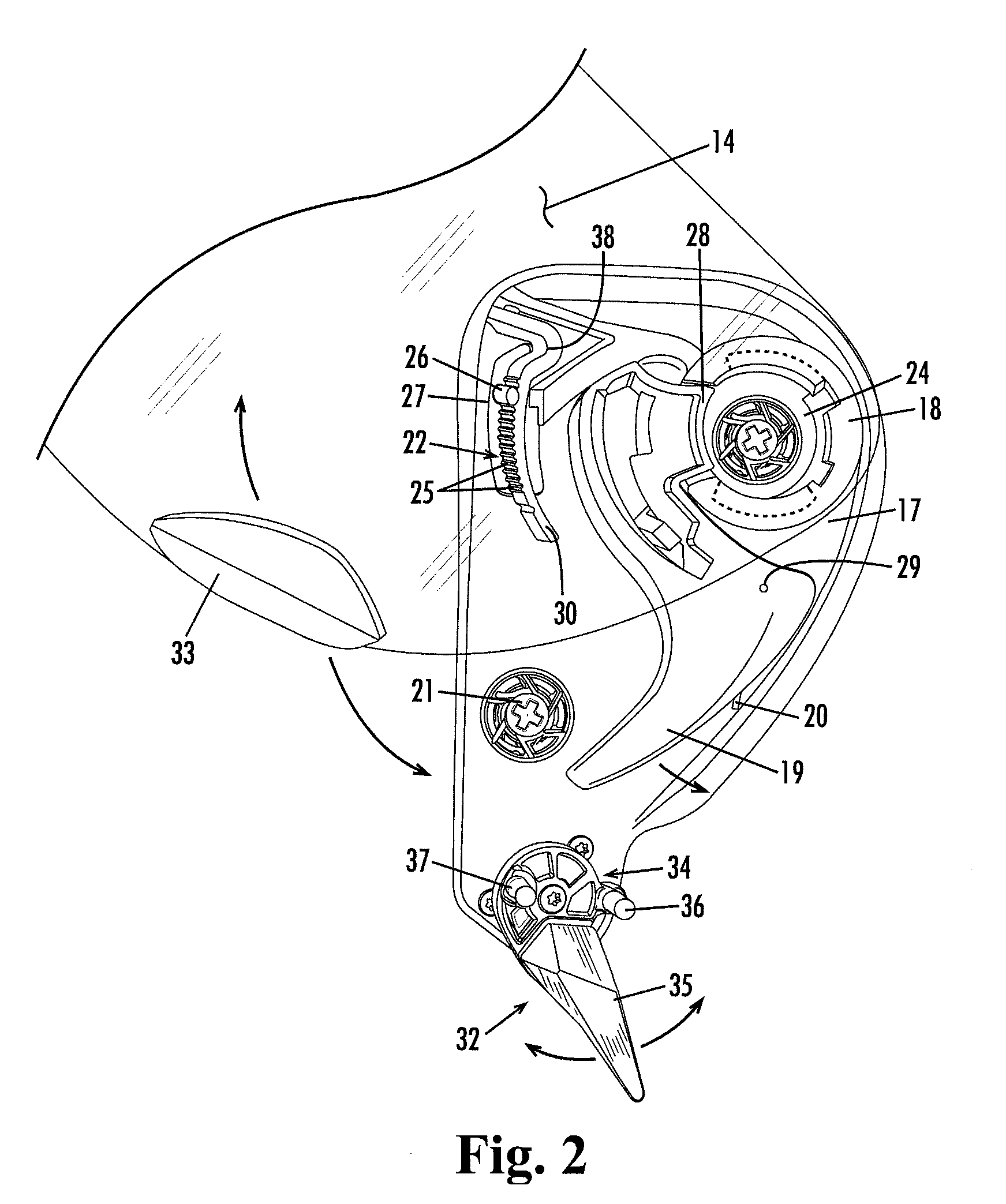

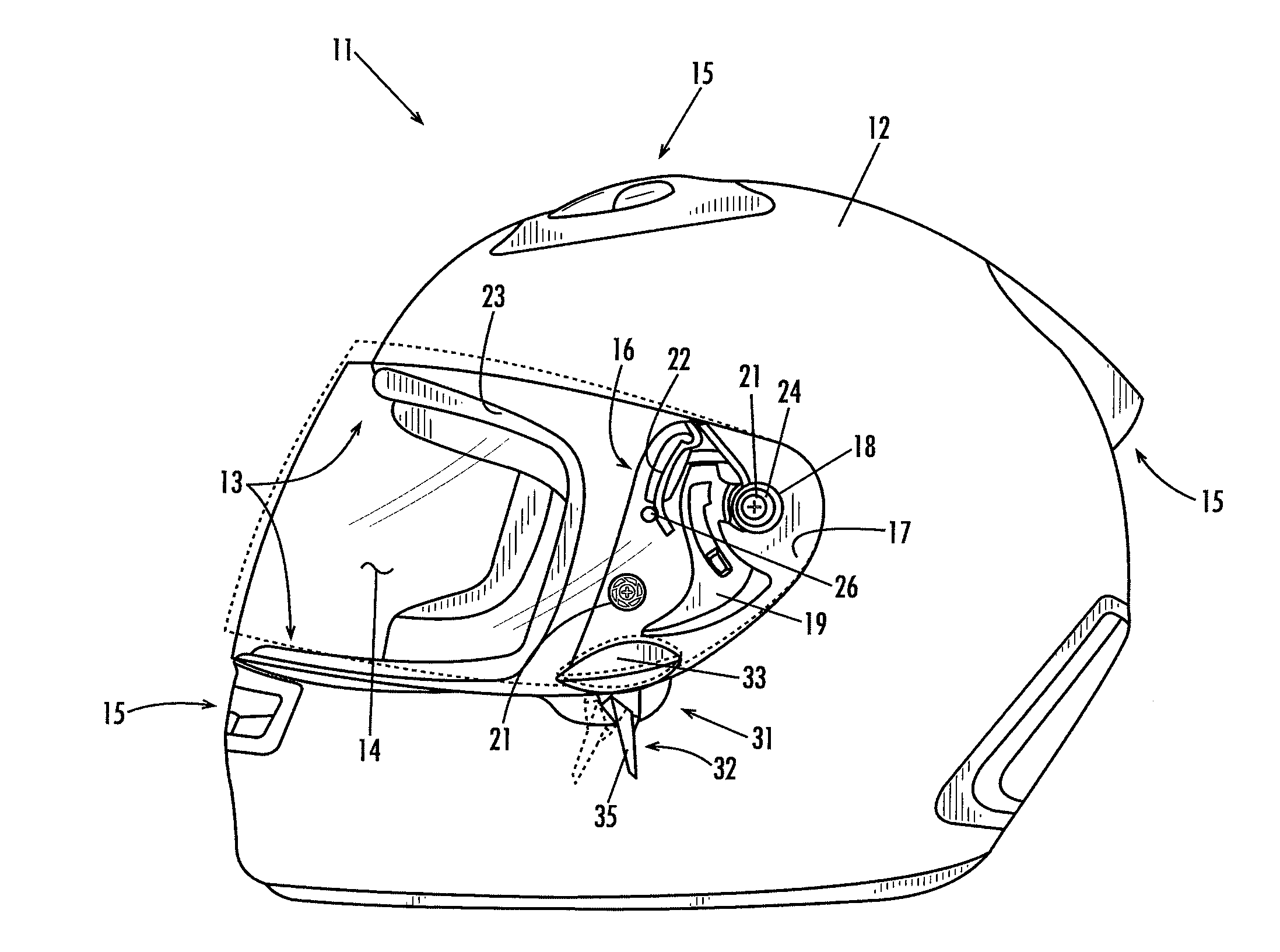

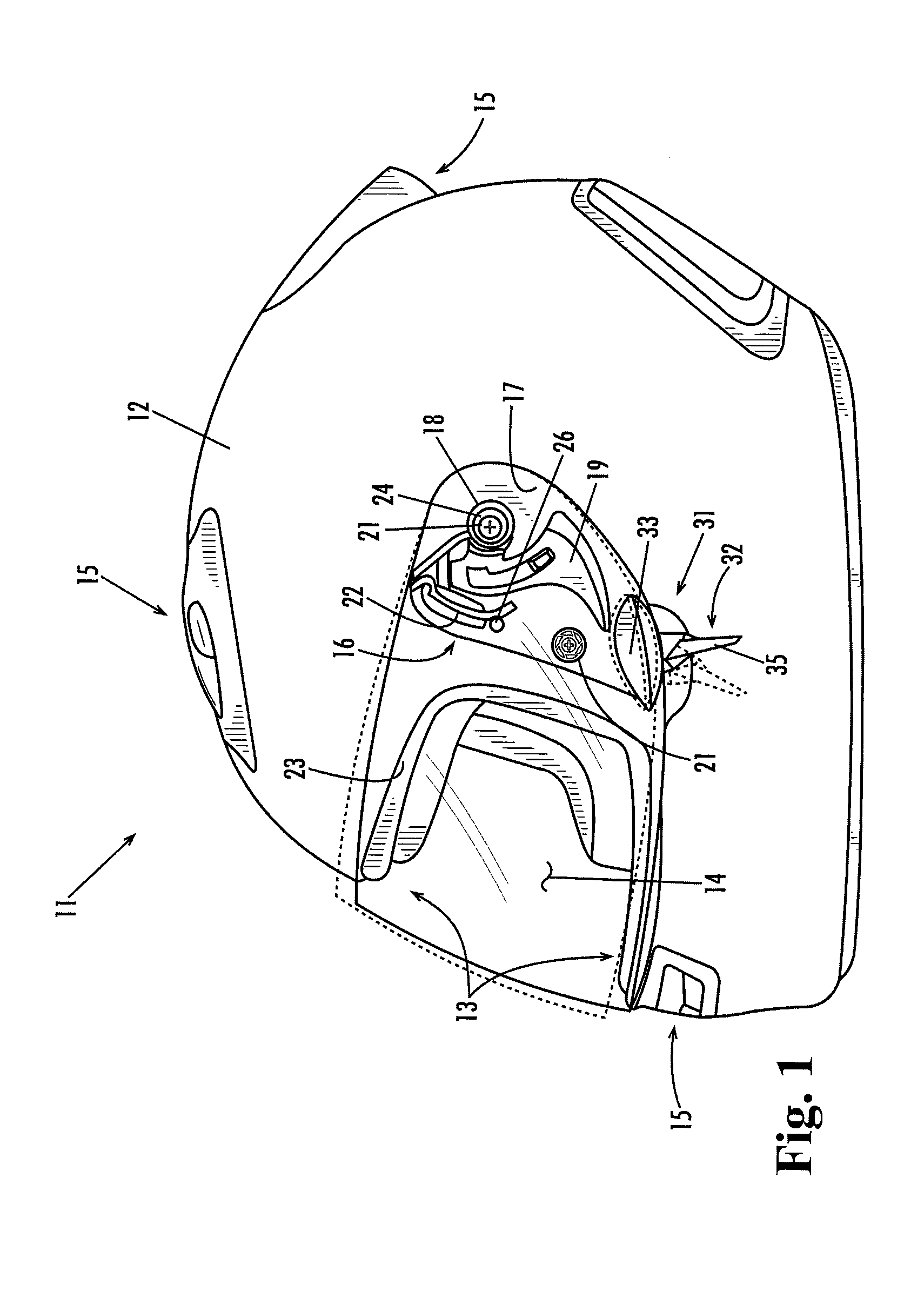

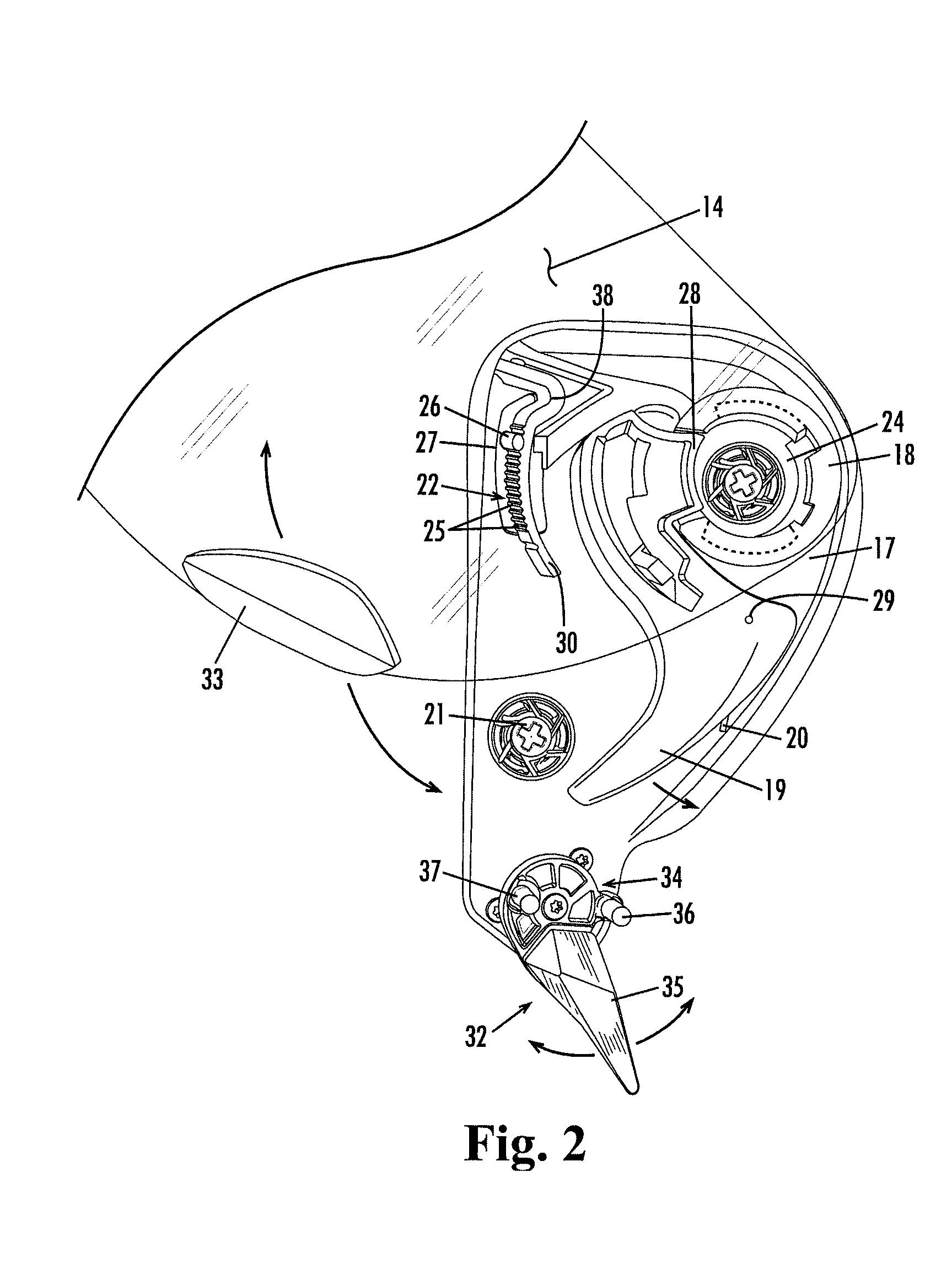

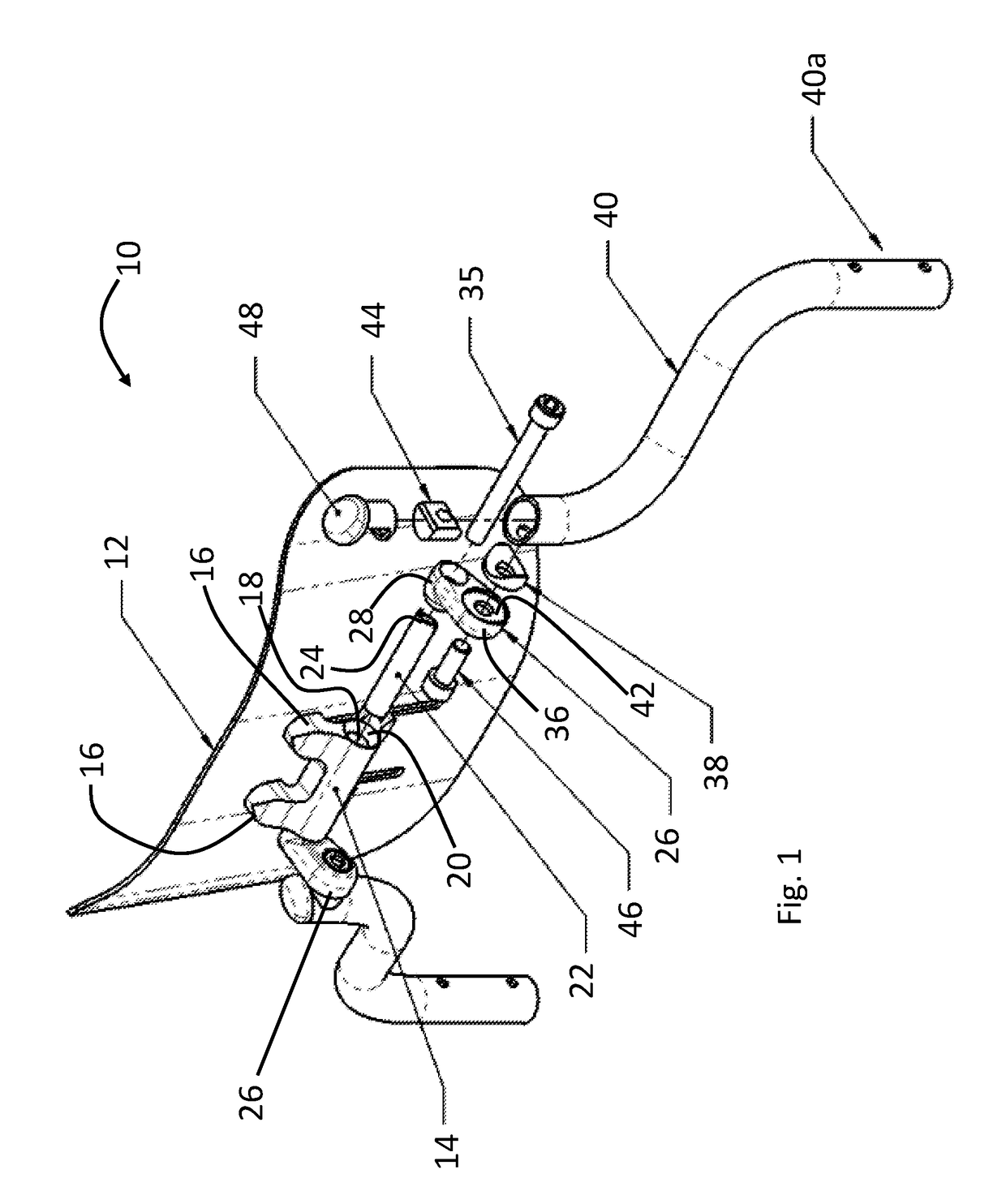

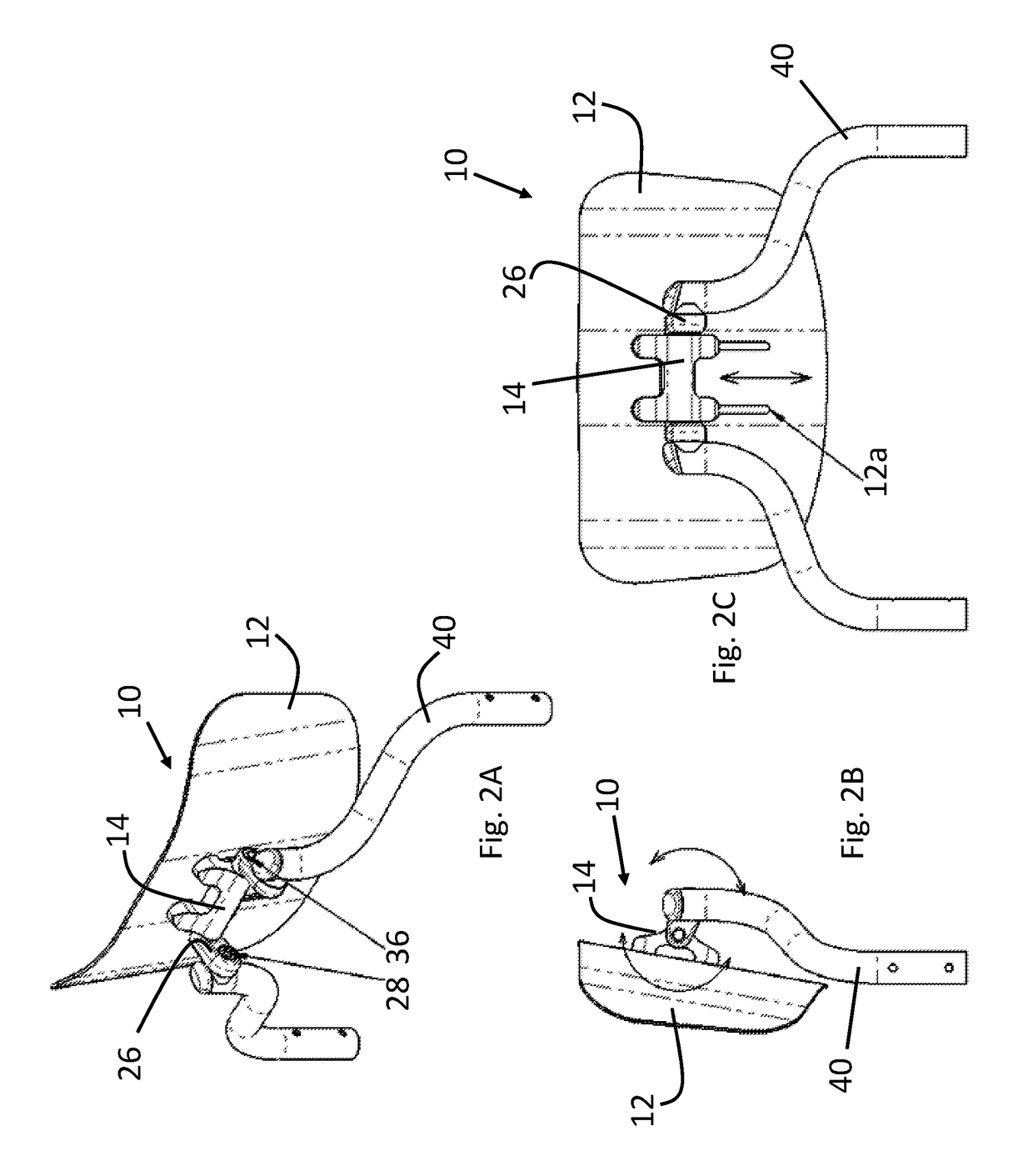

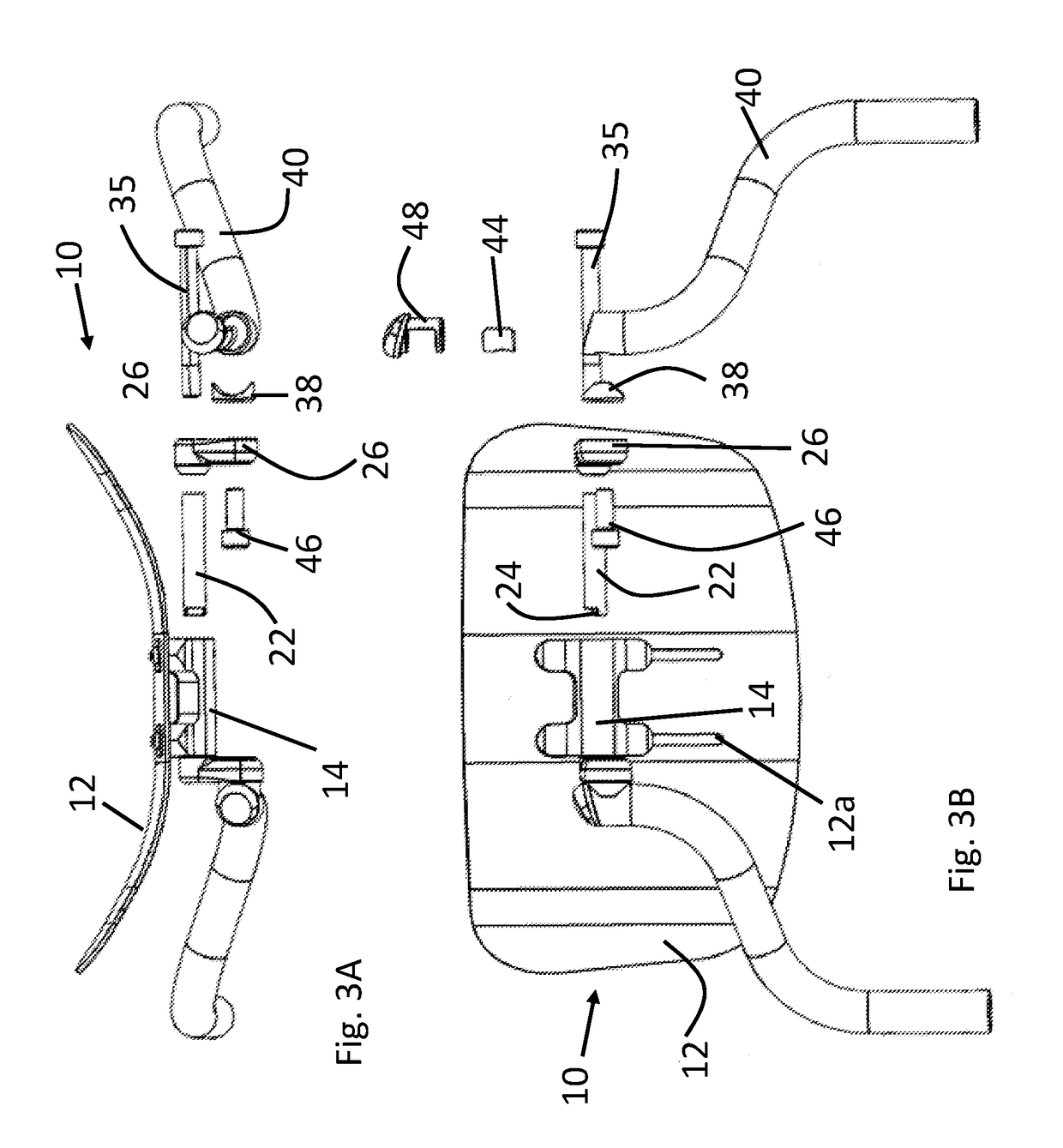

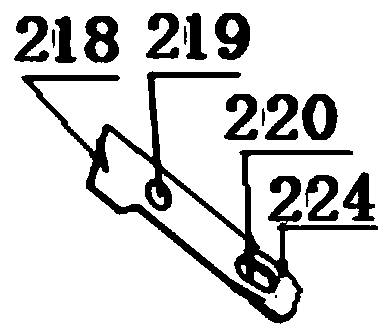

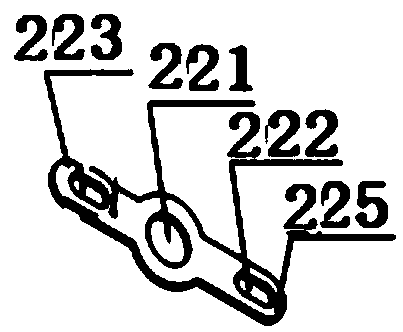

Helmet with Improved Shield Mount and Precision Shield Control

A closed face motorcycle helmet includes a shell with an eyeport and a shield attached for hinged motion between a closed position covering and sealing the eyeport and an open position displaced above the eyeport. A hinge plate is attached to the shell on each side and includes a socket into which a hub of the shield is rotatably disposed for hinged movement of the shield. A lever assembly having a downwardly extending lever and a hub with two dowels is attached to the bottom of the hinge plate. The lever assembly is manually movable between a central home position, a forwardly rotated shield cracking position, and a rearwardly rotated shield restraining position. A motion plate is attached to a lower edge of the shield and covers the hub and dowels of the lever assembly when the shield is closed. Surfaces on the inside of the motion plate interact with the dowels of the lever assembly to provide multiple precision shield control functions. Specifically, flipping the lever forward cracks the shield slightly open to eliminate fog and flipping it rearwardly applies an additional restraining force to the shield preventing it from being blown open by aerodynamic forces, especially at high speeds. A live beam mechanism with micro detents interacts with a projection on the shield to provide fluid-like operation of the shield and the ability to position the shield at virtually any location between fully closed and fully opened.

Owner:BELL SPORTS INC

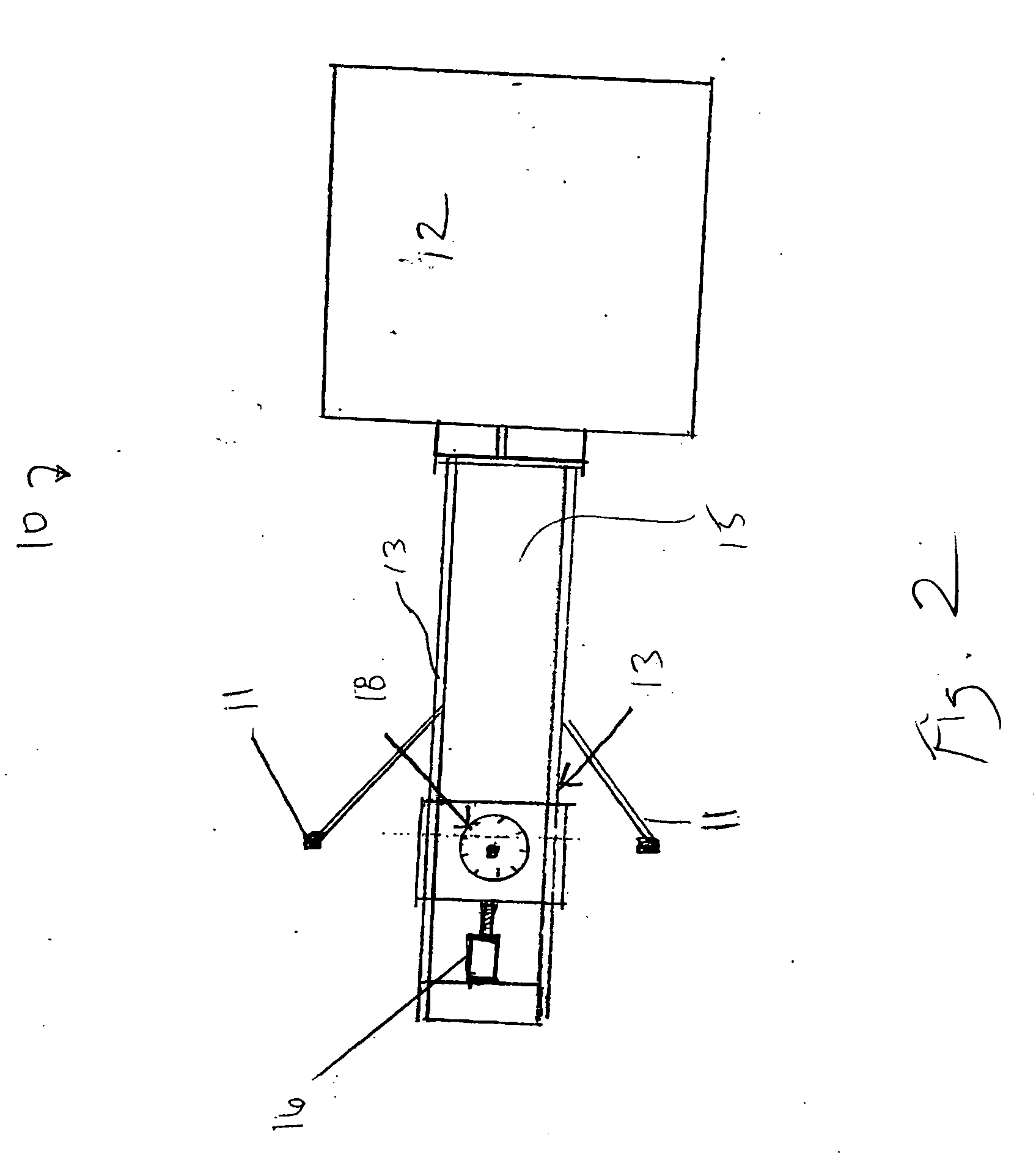

Automatic Shoe Cover Dispensing Device

InactiveUS20090152312A1Less-reliable performanceMechanism is bulkyApparel holdersFootwearEngineeringActuator

Owner:ASIAN TRADING

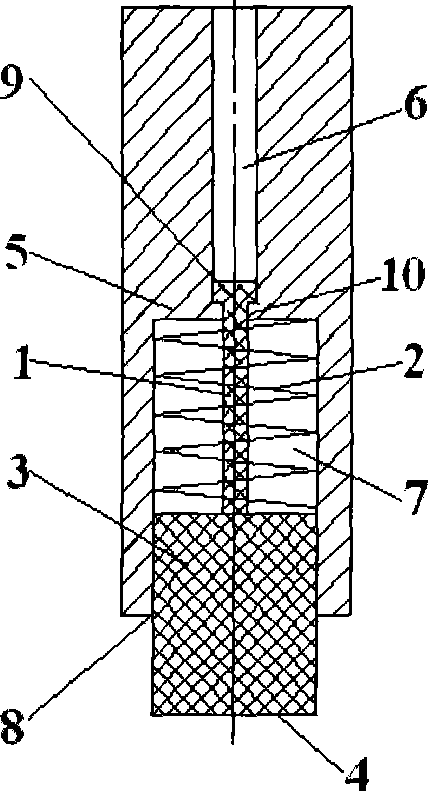

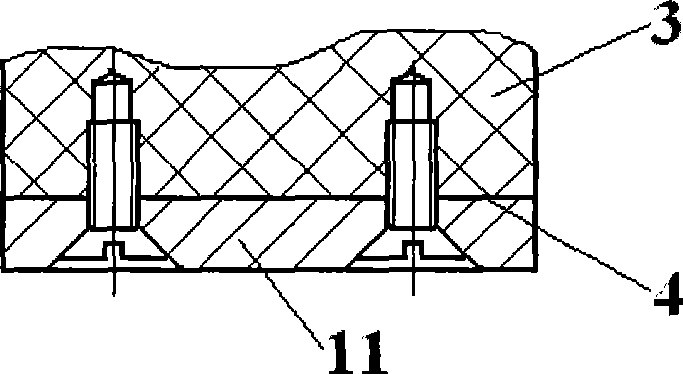

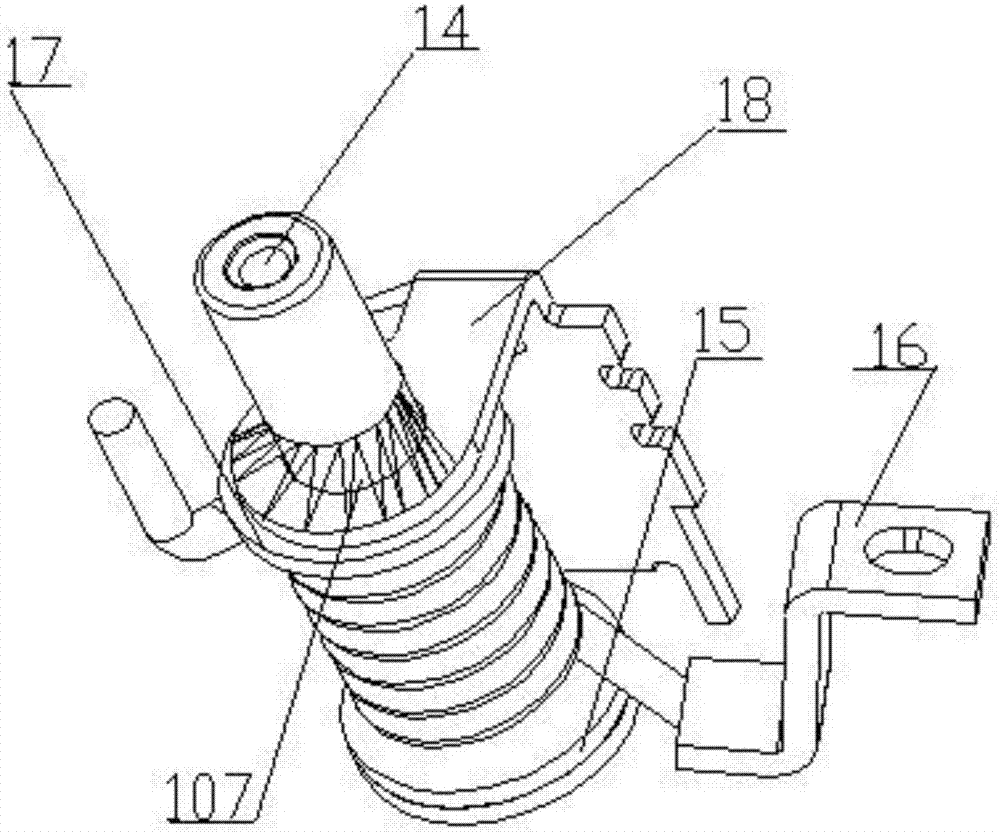

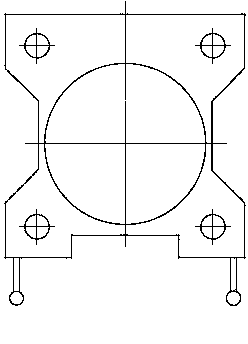

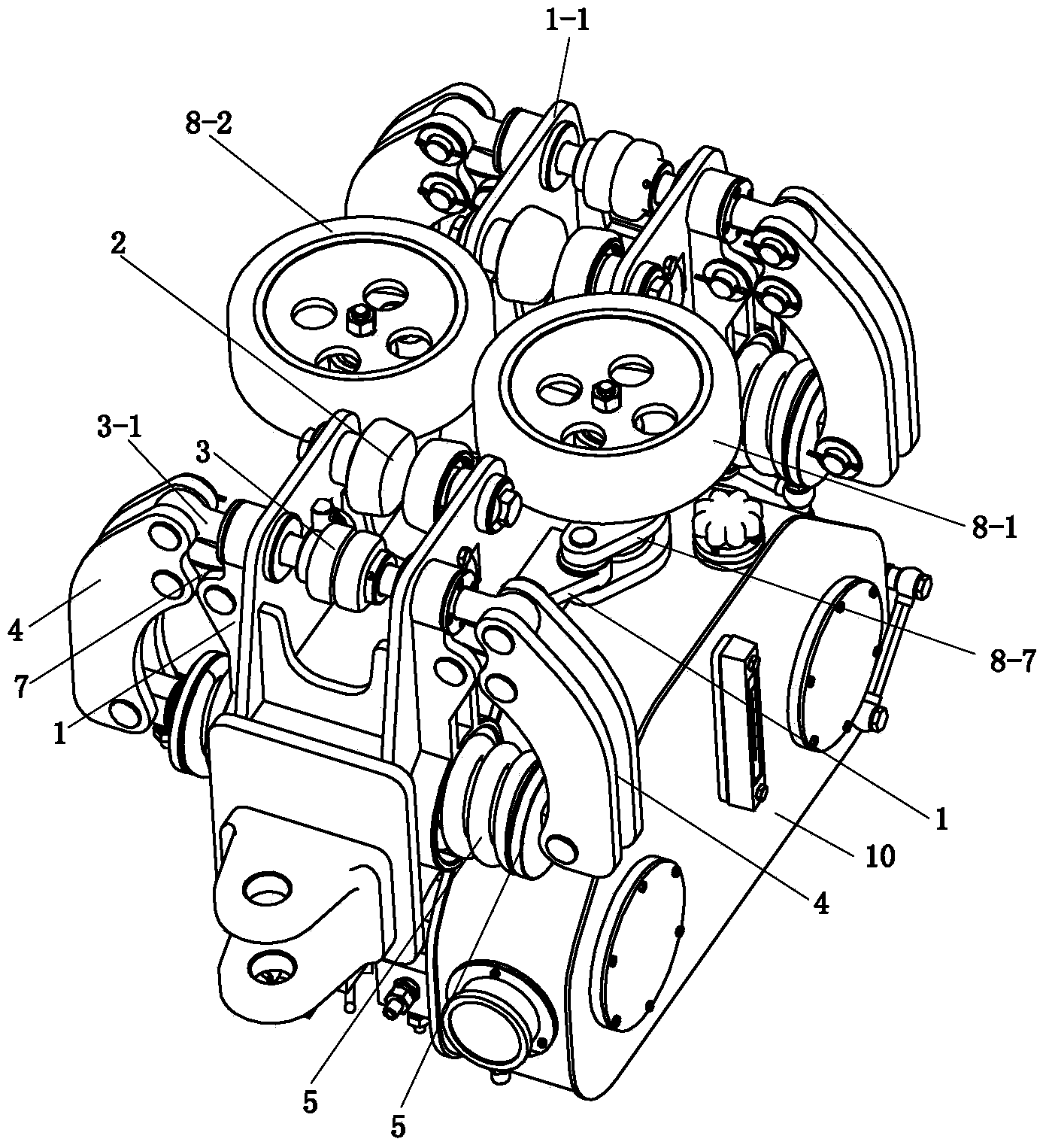

Clamping structure for fastening motion self-compensation

InactiveCN101367171AGuaranteed sizeEliminate misalignmentWelding/cutting auxillary devicesAuxillary welding devicesSelf compensationEngineering

The invention discloses a clamp structure for clamping and autocompensation; a clamping block (3) is arranged on a clamp; the surface of the clamping block (3) for clamping a workpiece is a clamping surface (4); and the clamping block (3) is made of an elastic material. With the technical proposal adopted, abrasion occurring in a clamping part and the change of the surface of the clamped workpiece are subjected to compensation by a simple elastic structure so as to ensure that a gripping jaw has enough clamping force in clamping and to guarantee the dimension of the workpiece after various machining processes (such as welding).

Owner:CHERY AUTOMOBILE CO LTD

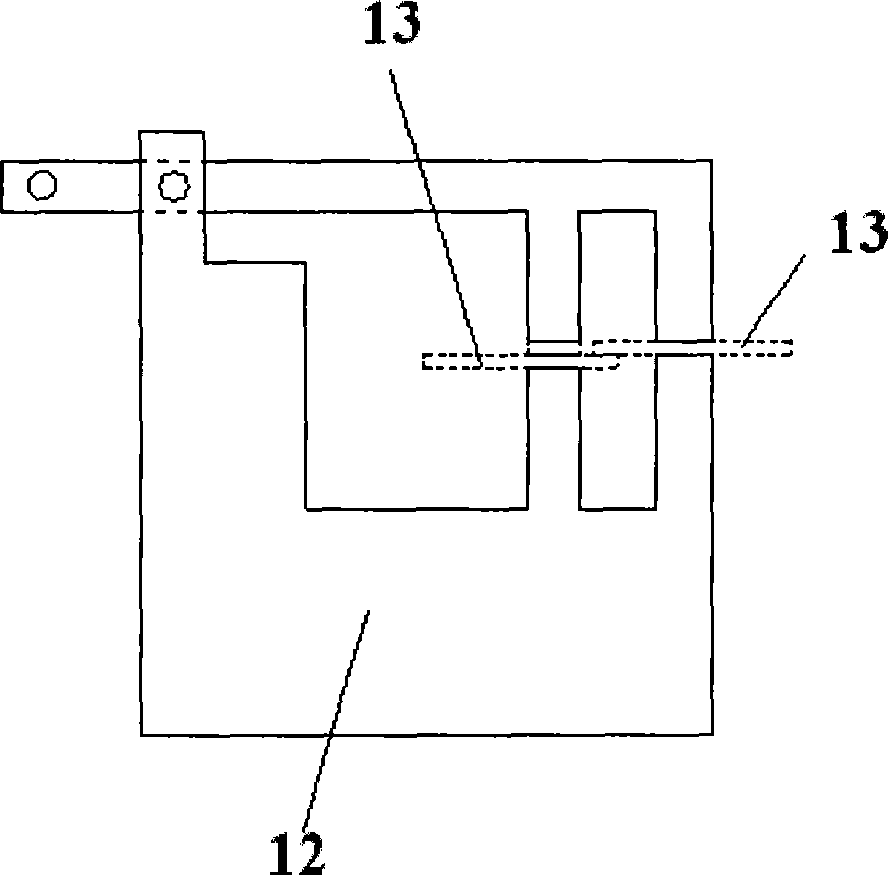

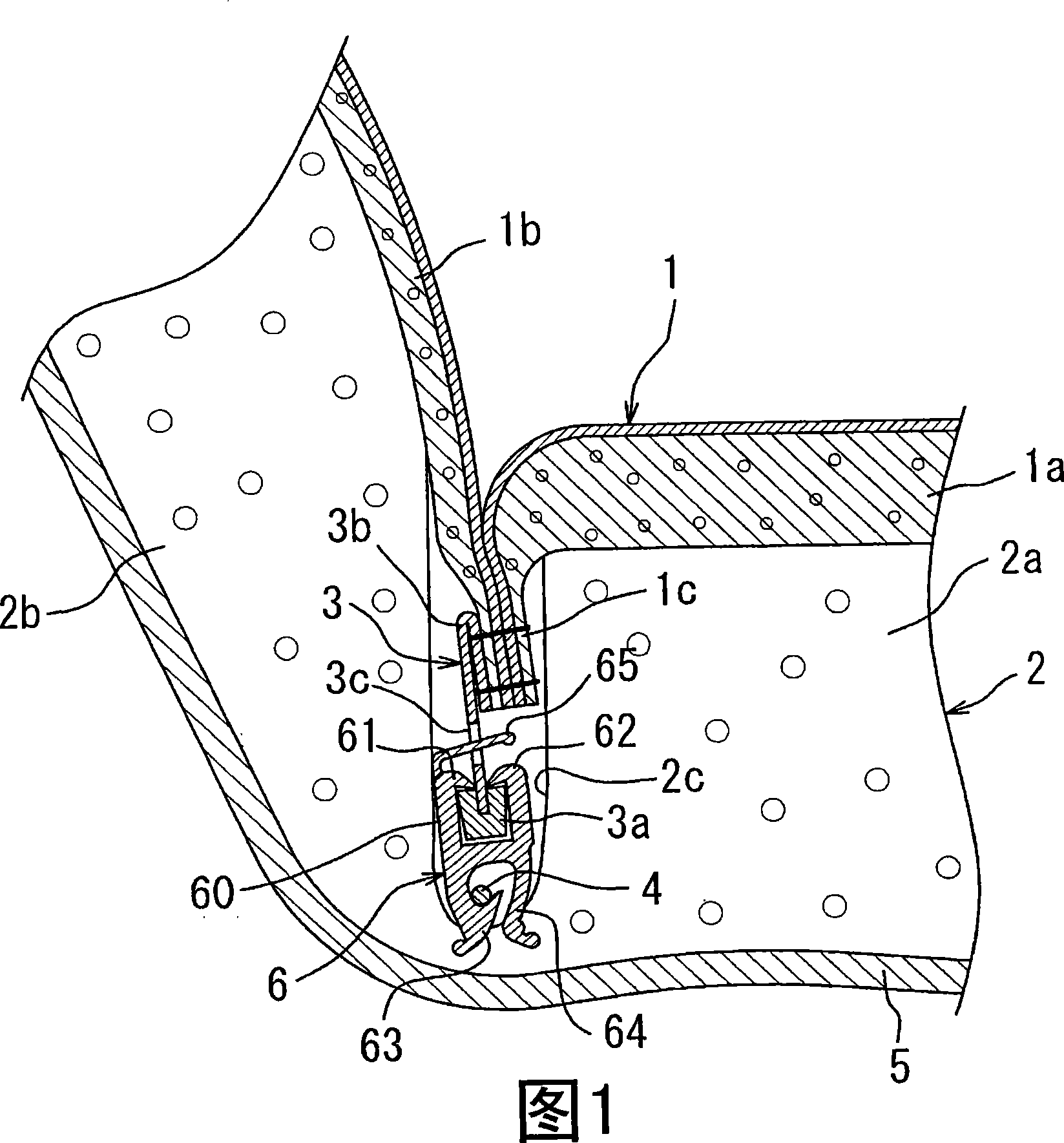

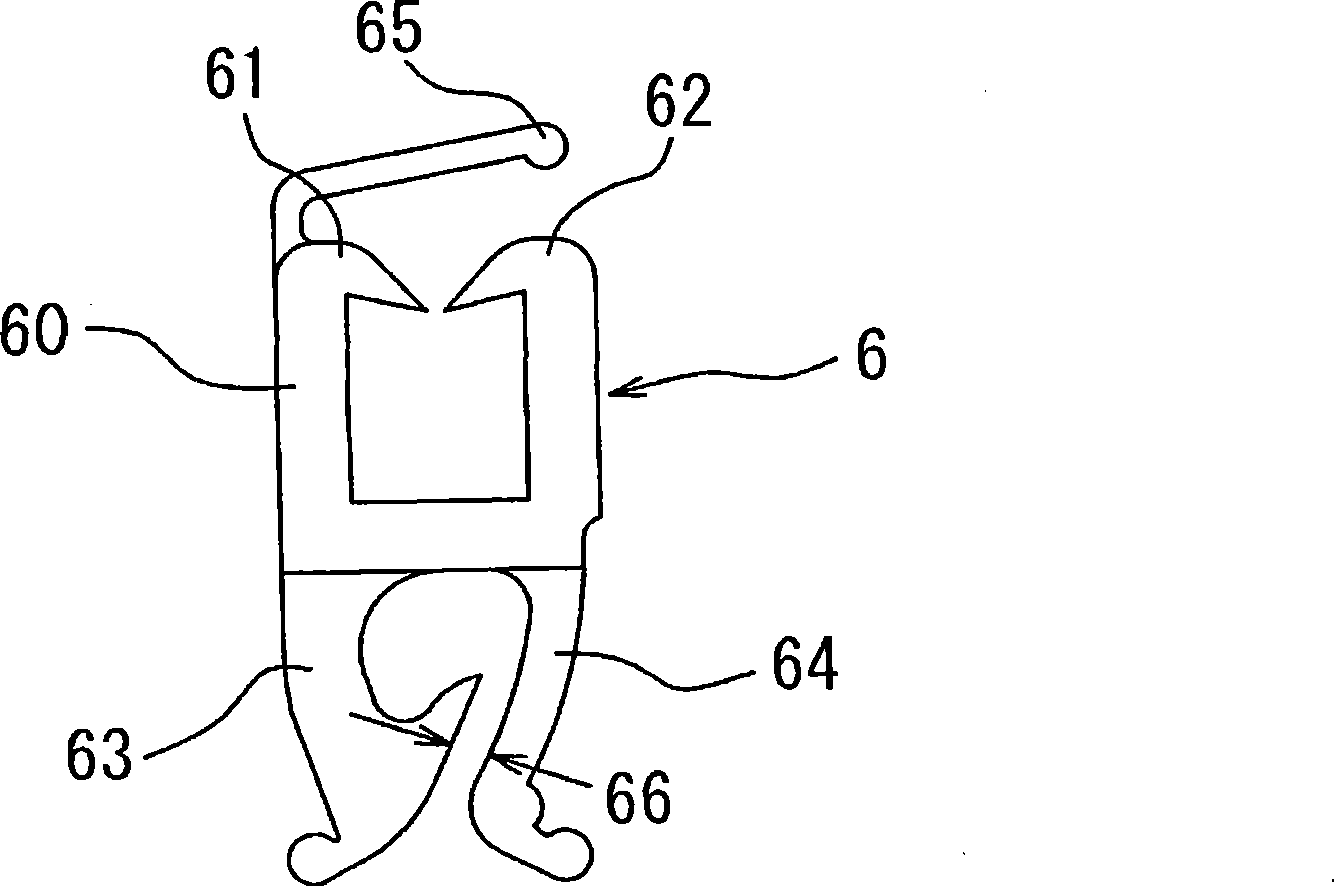

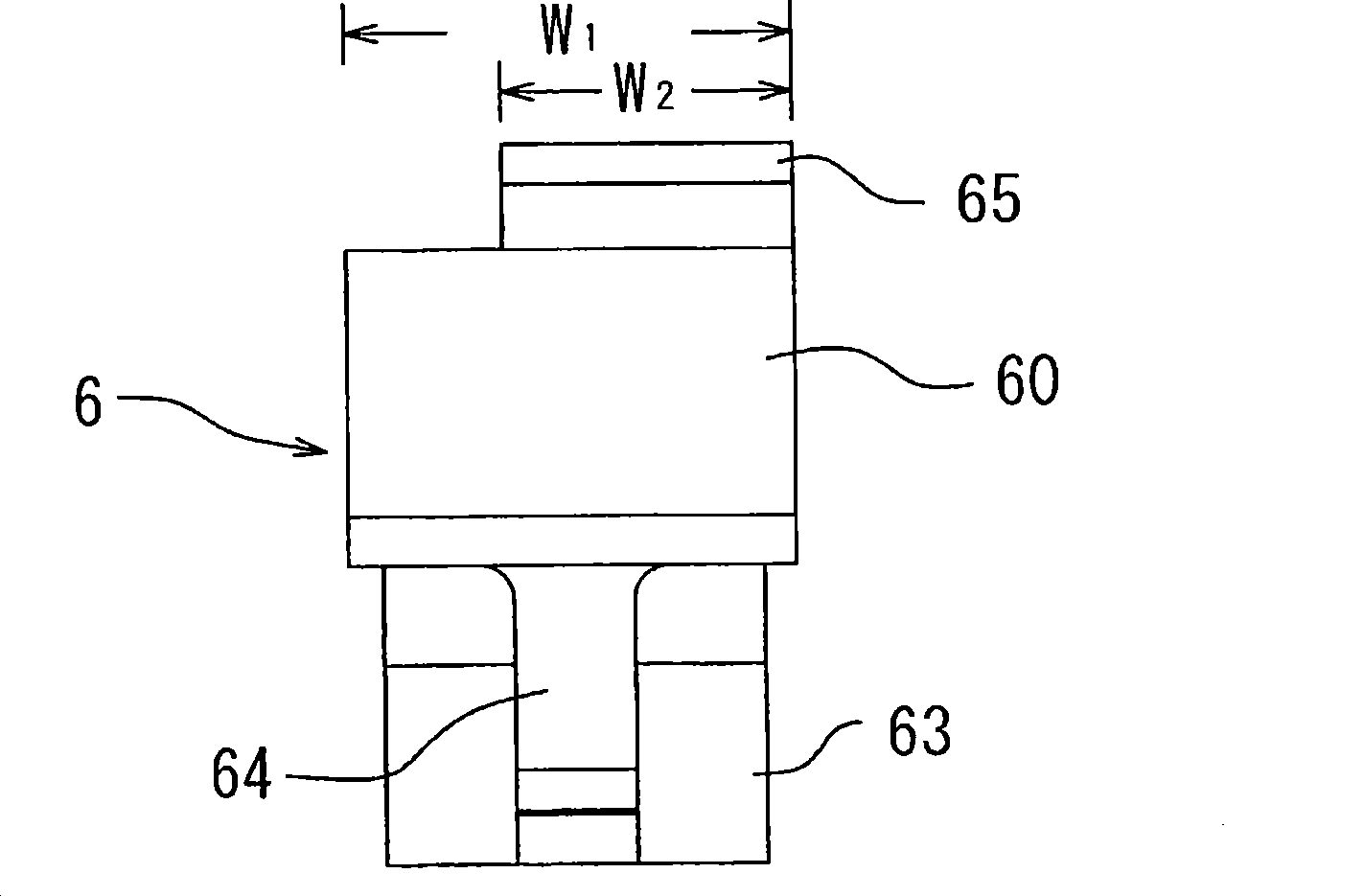

Clip for tensioning and attaching trim cover and vehicle seat

InactiveCN101416829AStable end fixationImprove performanceVehicle seatsSeating furnitureBase planeGasket

The present invention provides a clip for drawing and fixing a decorating cover, and a vehicular seat thereof. The commercial property of the vehicular seat is increased through installing the clip in the length direction of drawing flexible wire for forming a structure in which the misplacement travelling is difficult to generate and the clip is consistent with the axial line position of inserting line exposing from the gasket. The clip comprises the following components: a frame part (60) which is in an approximate U-shape upwards; a pair of inverted pawls (61, 62) which face the inner side from each projected plane of the frame part (60); a hook part (63) which extends from the base plane of the frame part to a reverse direction, and a stopper piece (65). A projected strip (3a) integratedly arranged along the edge of the length direction of drawing flexible wire (3) which is installed on the end of the decorating cover (1) is clamped through the frame part. The stopper piece (65) is used for preventing the misplacement for causing the standing of the stopper piece from one projection end of the frame part. The stopper piece is set to at least penetrate the reverse claw channel and in a reverse L-shape facing to the other projected end of the frame part, and the stopper piece is inserted into a through hole (3c) of the drawing flexible wire.

Owner:TS TECH CO LTD

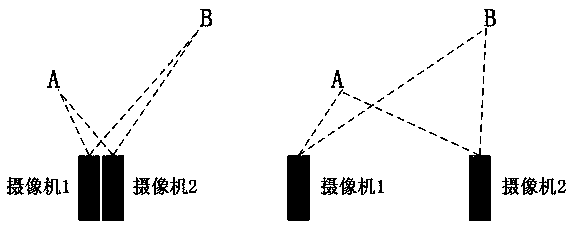

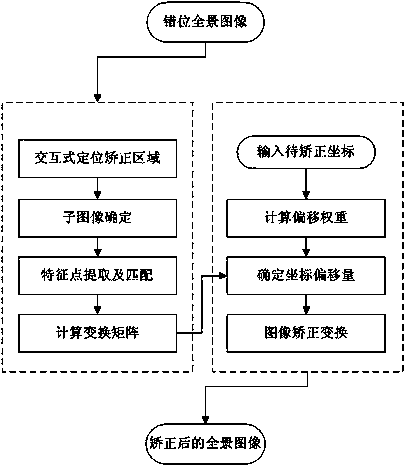

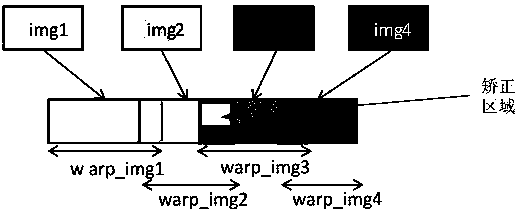

Method for correcting misplaced partial image splicing

ActiveCN107945113AEliminate misalignmentAvoid counterproductiveImage analysisGeometric image transformationWeight coefficientComputer vision

The invention relates to a method for correcting misplaced partial image splicing. The method comprises the following steps: in step 1, a misplaced spliced area in a panoramic spliced image with misplacement is determined, two spliced sub-images for splicing the area are determined, and the misplaced spliced area is taken as an area to be corrected; in step 2: exact matching is performed on the two spliced sub-images in the area to be corrected, a transformation matrix for exactly matching the two spliced sub-images in the area to be corrected, and initial coordinate offset used to correct themisplacement can be calculated accordingly; in step 3, weighted correction is performed, correction transformation is performed via weighted corrected coordinate offset, an offset weight coefficientis 1 in a central area of the area to be corrected and is 0 in an edge region of the area to be corrected, and the offset weight coefficient gradually transits between the area with the offset weightcoefficient being 1 and the area with the offset weight coefficient being 0. The method disclosed in the invention helps ensure that the correction transformation of a specified area is completed while that images in the area to be corrected and images beyond the area to be corrected are spliced is ensured, and a panoramic spliced image with eliminated misplacement is obtained.

Owner:北京天睿空间科技股份有限公司

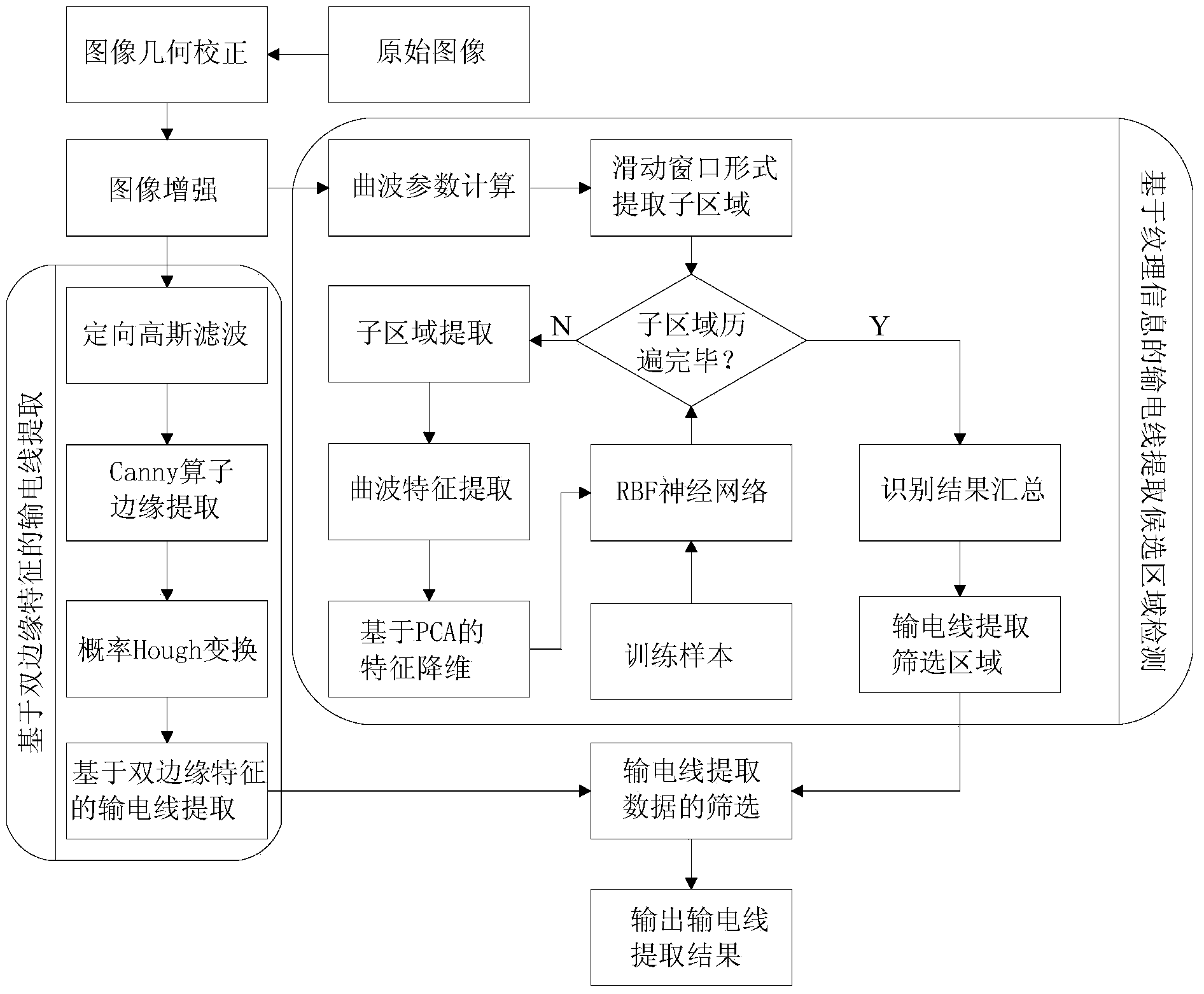

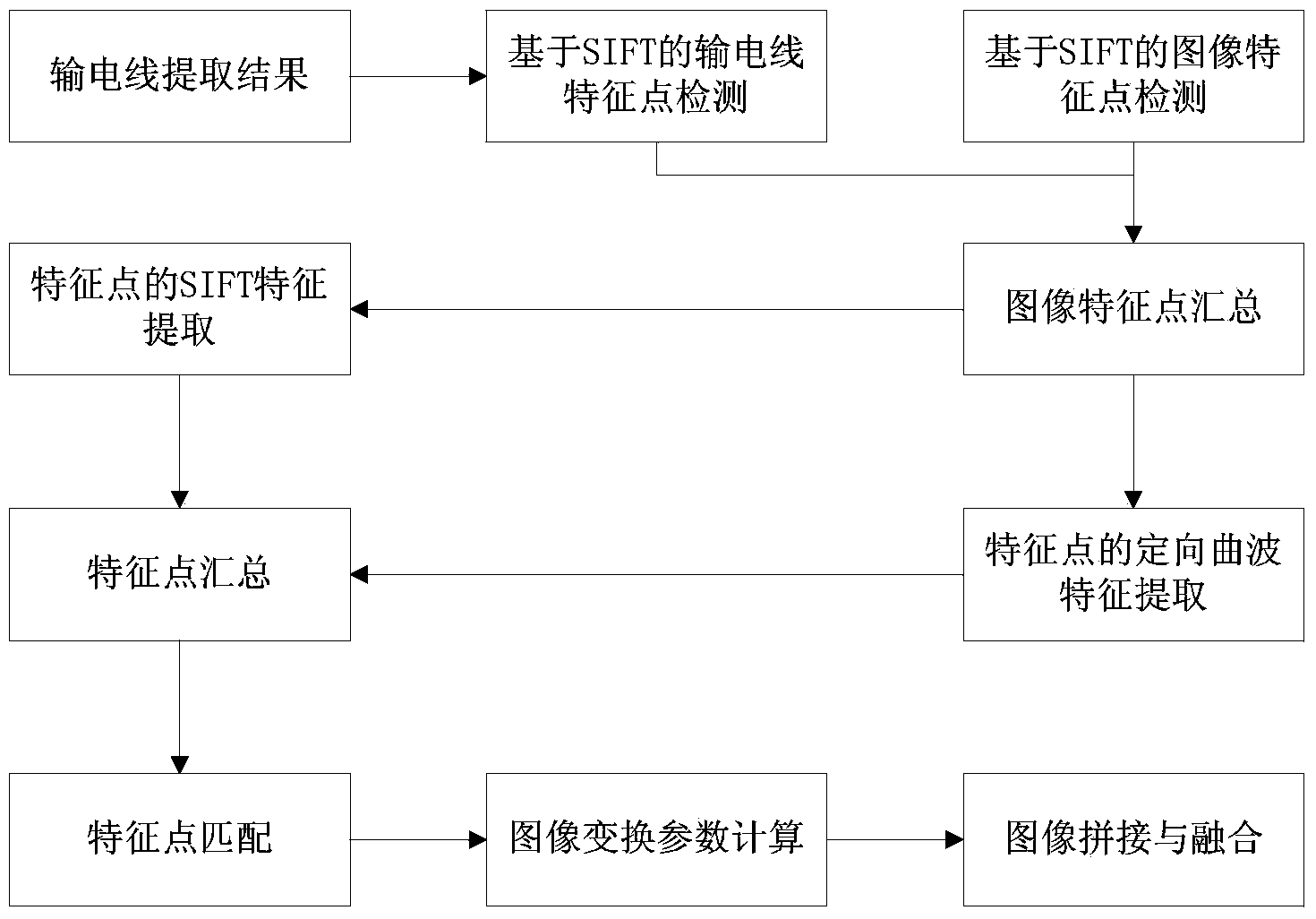

Fixed wing unmanned aerial vehicle touring image accurately-splicing method for power transmission line

ActiveCN103761722AReliable extraction resultsIntegrity guaranteedImage enhancementGeometric image transformationFeature extractionUncrewed vehicle

The invention discloses a fixed wing unmanned aerial vehicle touring image accurately-splicing method for a power transmission line. The accurately-splicing method includes the following steps: (1) conducting data preparation and sample training; (2) conducting feature extraction on the power transmission line based on textural features and straight line features to obtain a power transmission line distributing area and power transmission line extraction data, screening the power transmission line extraction data through the power transmission line distributing area, and obtaining power transmission line extracting results through power transmission line double-edge features; (3) conducting SIFT image registration and fusing based on power transmission line customization on the power transmission line extracting results. According to the fixed wing unmanned aerial vehicle touring image accurately-splicing method, curvelet transformation is adopted for achieving extraction on power transmission line texture information and detection on power transmission line distribution, and the power transmission line double-edge features in high-resolution unmanned aerial vehicle images are further adopted for obtaining the reliable and accurate power transmission line extracting results.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID +1

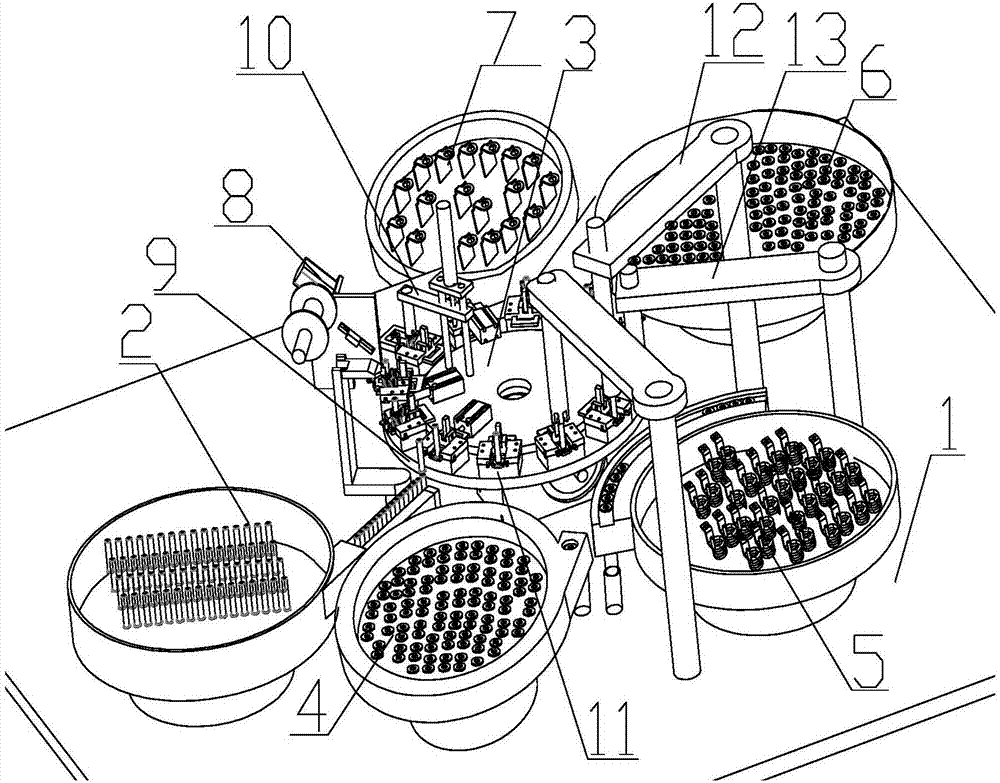

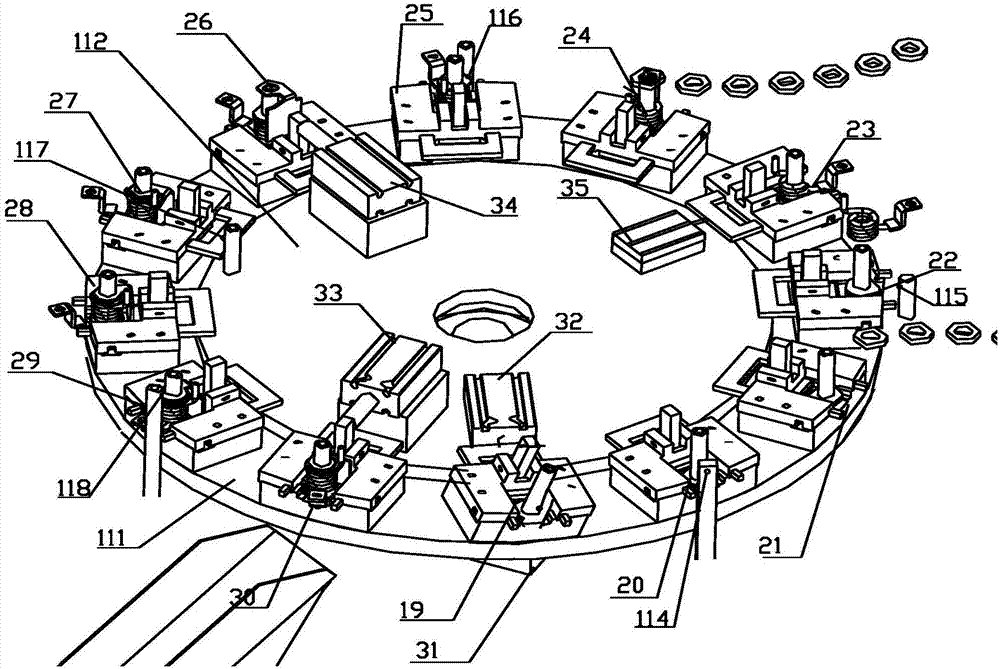

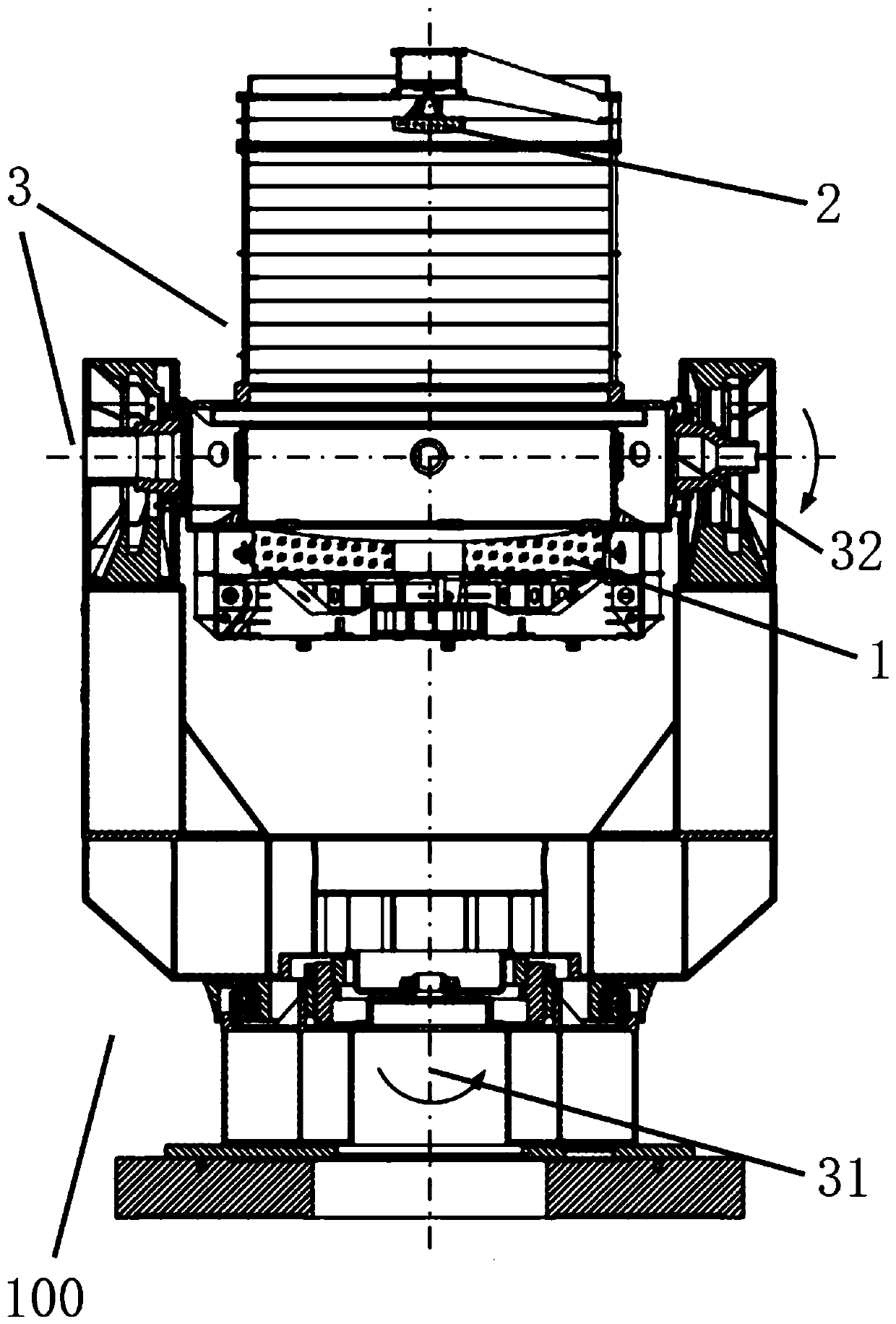

Full-automatic assembling-welding system for electric conduction assembly of low-voltage plastic-shell circuit breaker

ActiveCN107225304AEliminate weldsEliminate jammingMetal working apparatusSoldering auxillary devicesLow voltageCircuit breaker

The invention discloses a full-automatic assembling-welding system for an electric conduction assembly of a low-voltage plastic-shell circuit breaker. A rotating disc assembly is arranged on a horizontal table facet and comprises an inner disc and an outer rotating disc. The lower end of the inner disc is connected with a scale division mechanism. A first driving mechanism, a second driving mechanism, a third driving mechanism and a fourth driving mechanism are arranged on the upper surface, close to the outer edge, of the inner disc. Twelve clamp assemblies with the consistent structure are uniformly arranged on the outer rotating disc along the circumference. The twelve clamp assemblies are uniformly arranged as twelve rotating stations and are in one-to-one correspondence with feeding mechanisms, discharging mechanisms, a welding mechanism and a detector which surround the circumference of the rotating disc assembly. The structure is compact, the working efficiency is high, and the welding quality of a product is stable.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

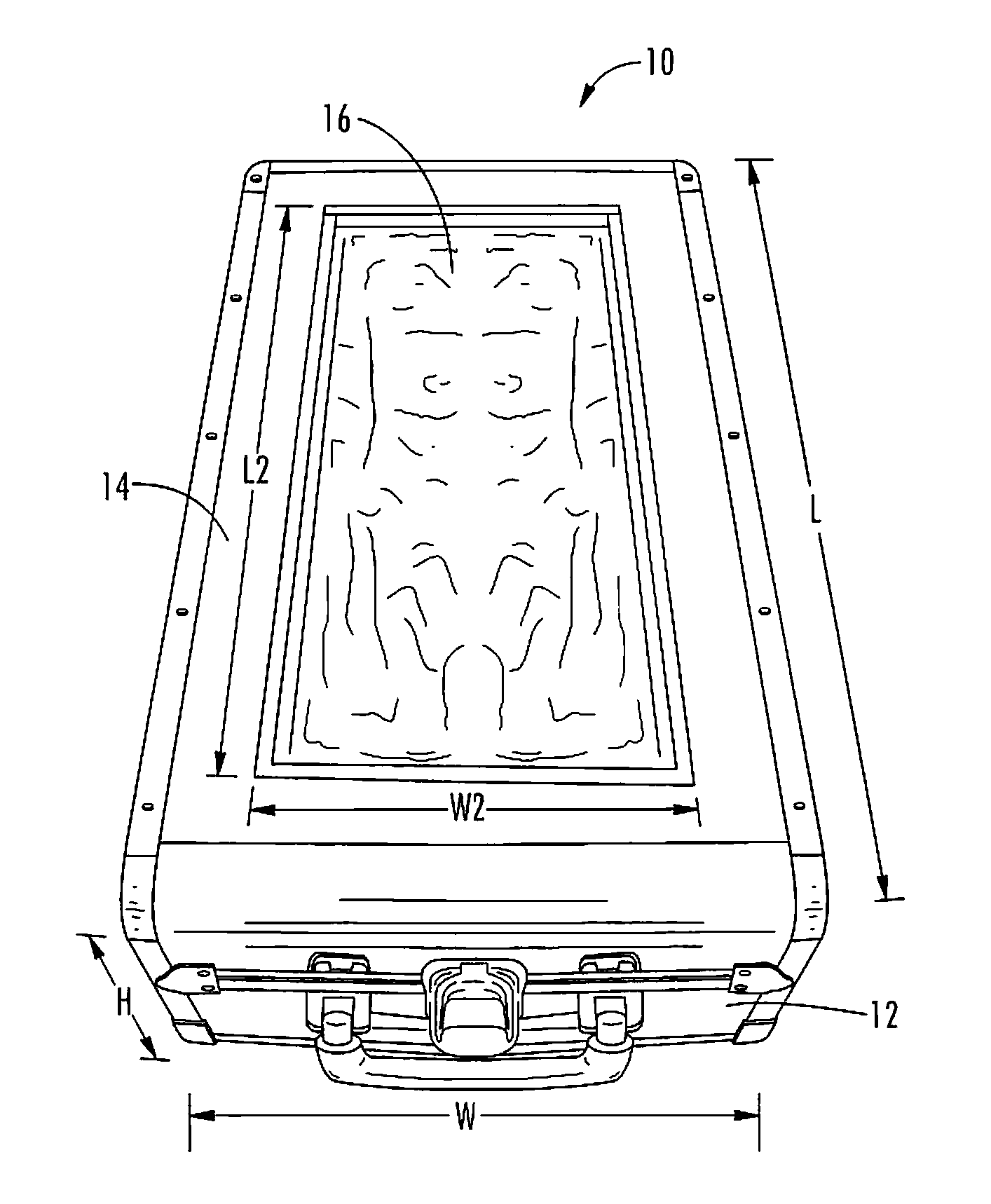

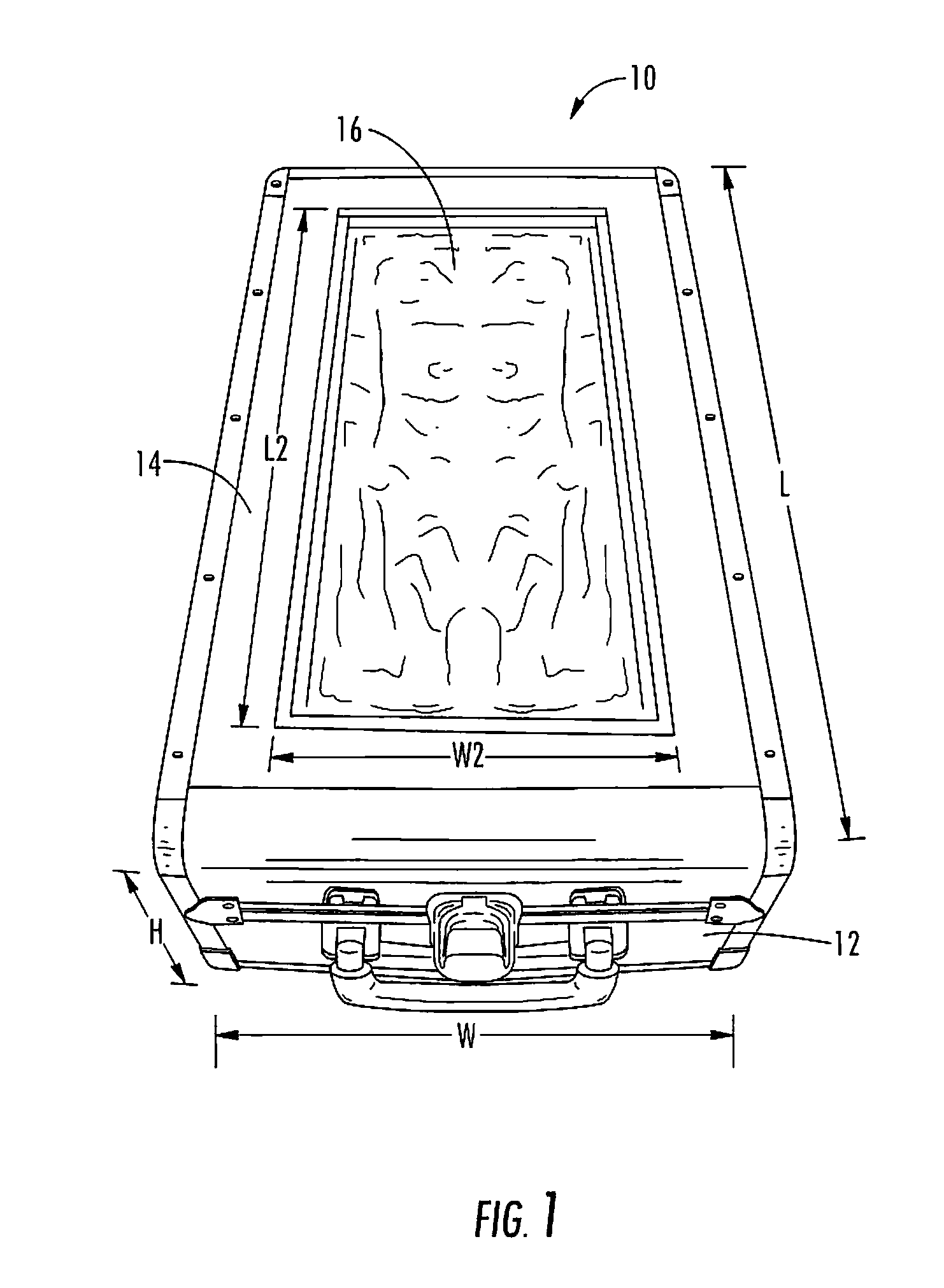

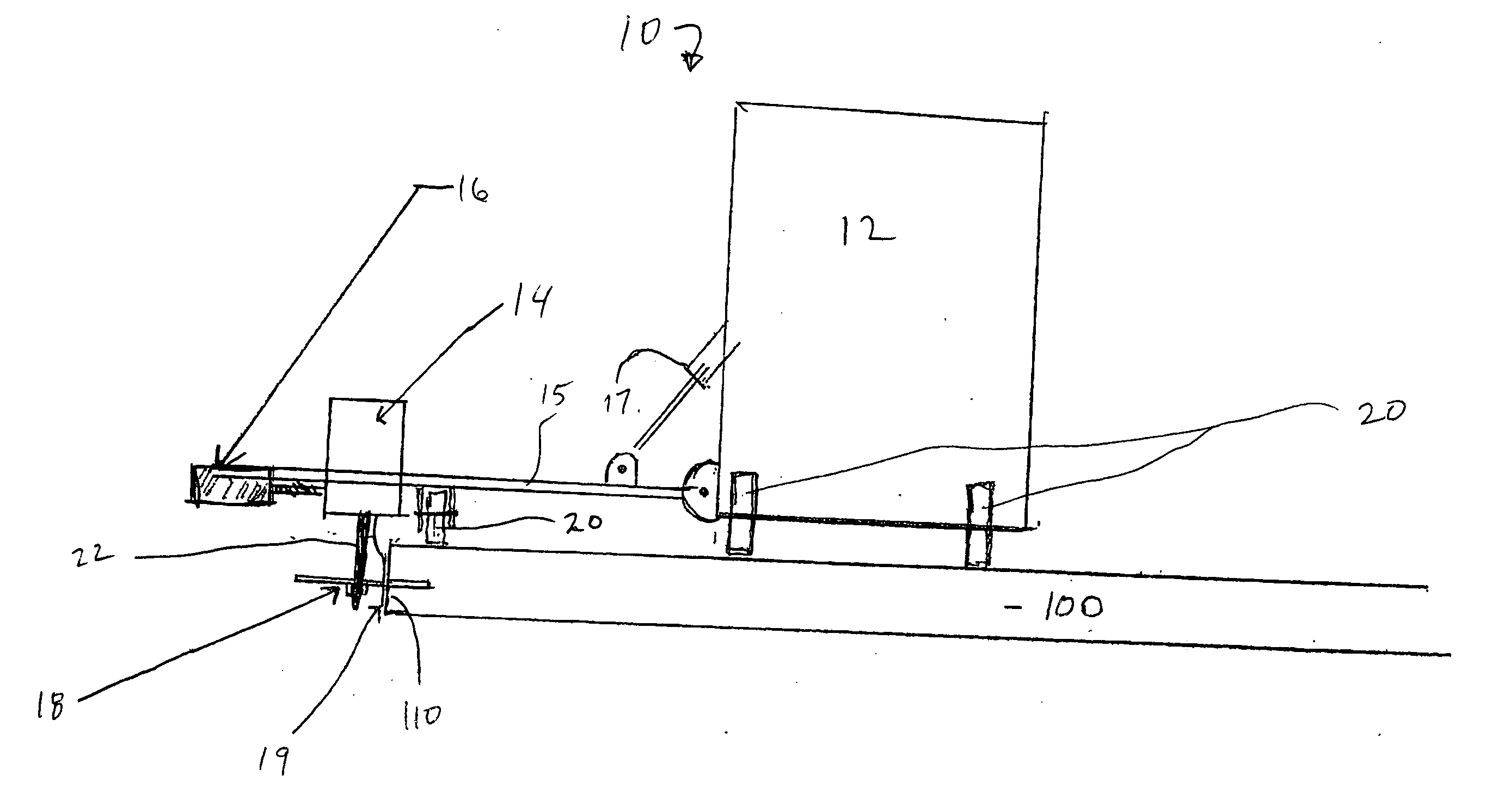

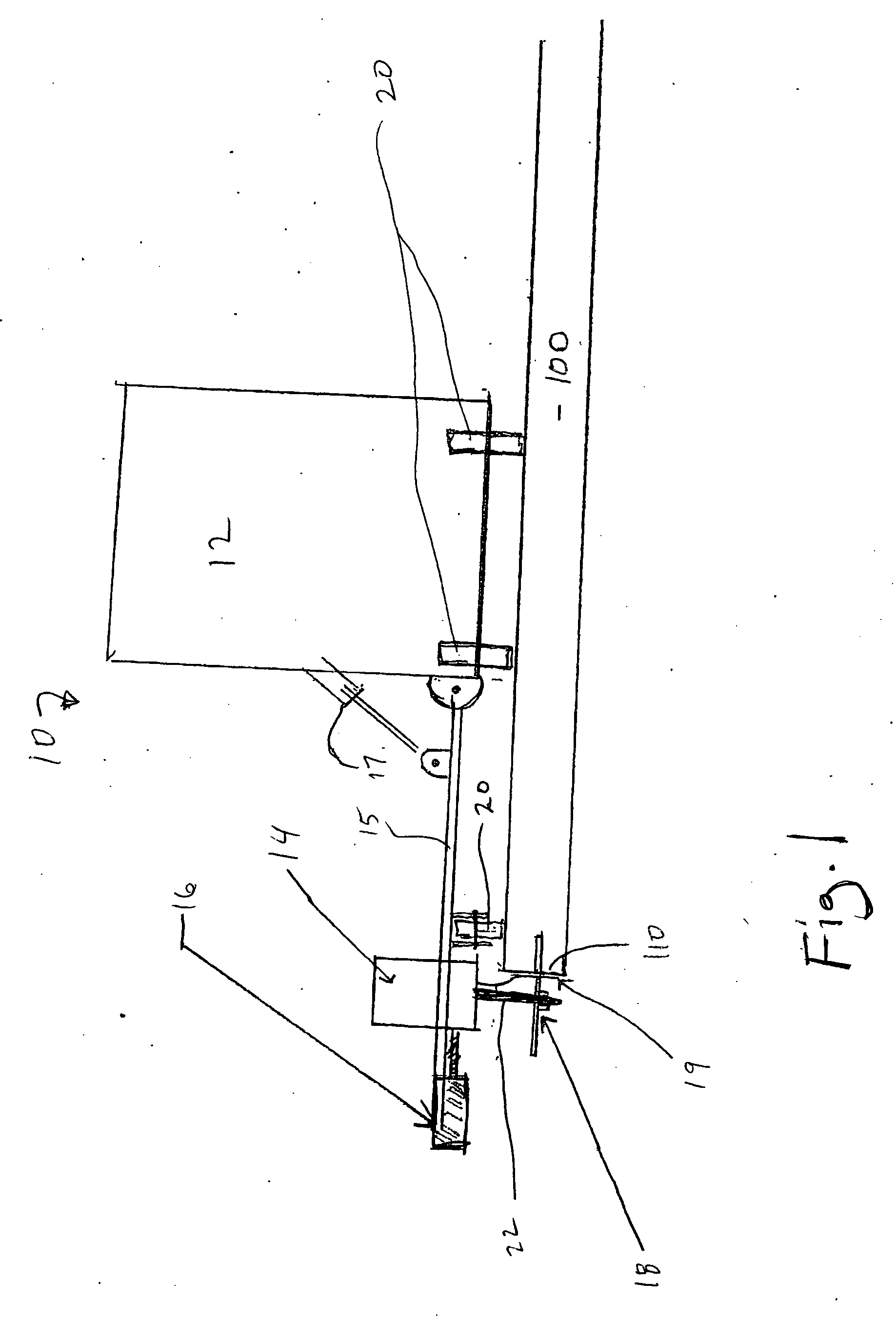

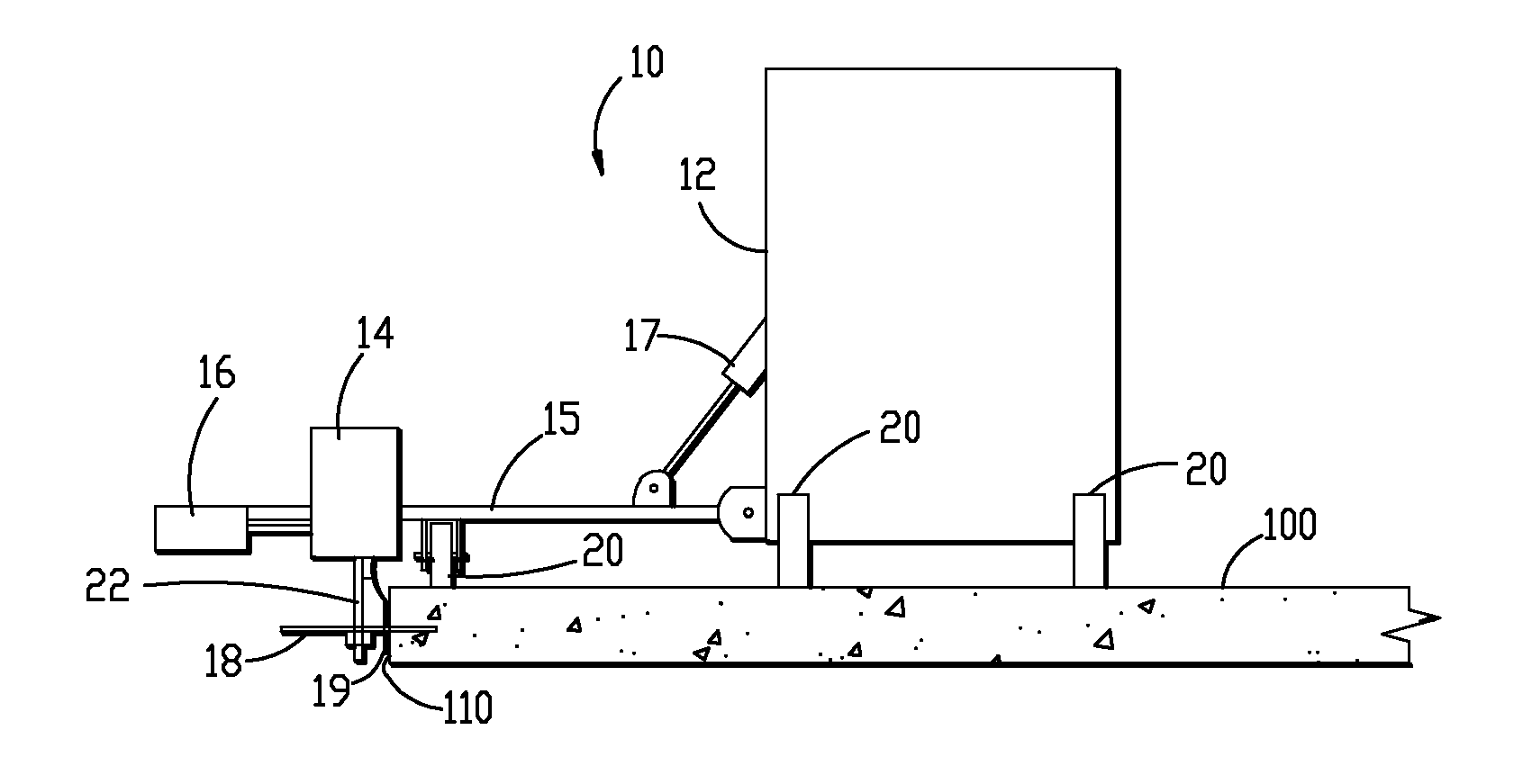

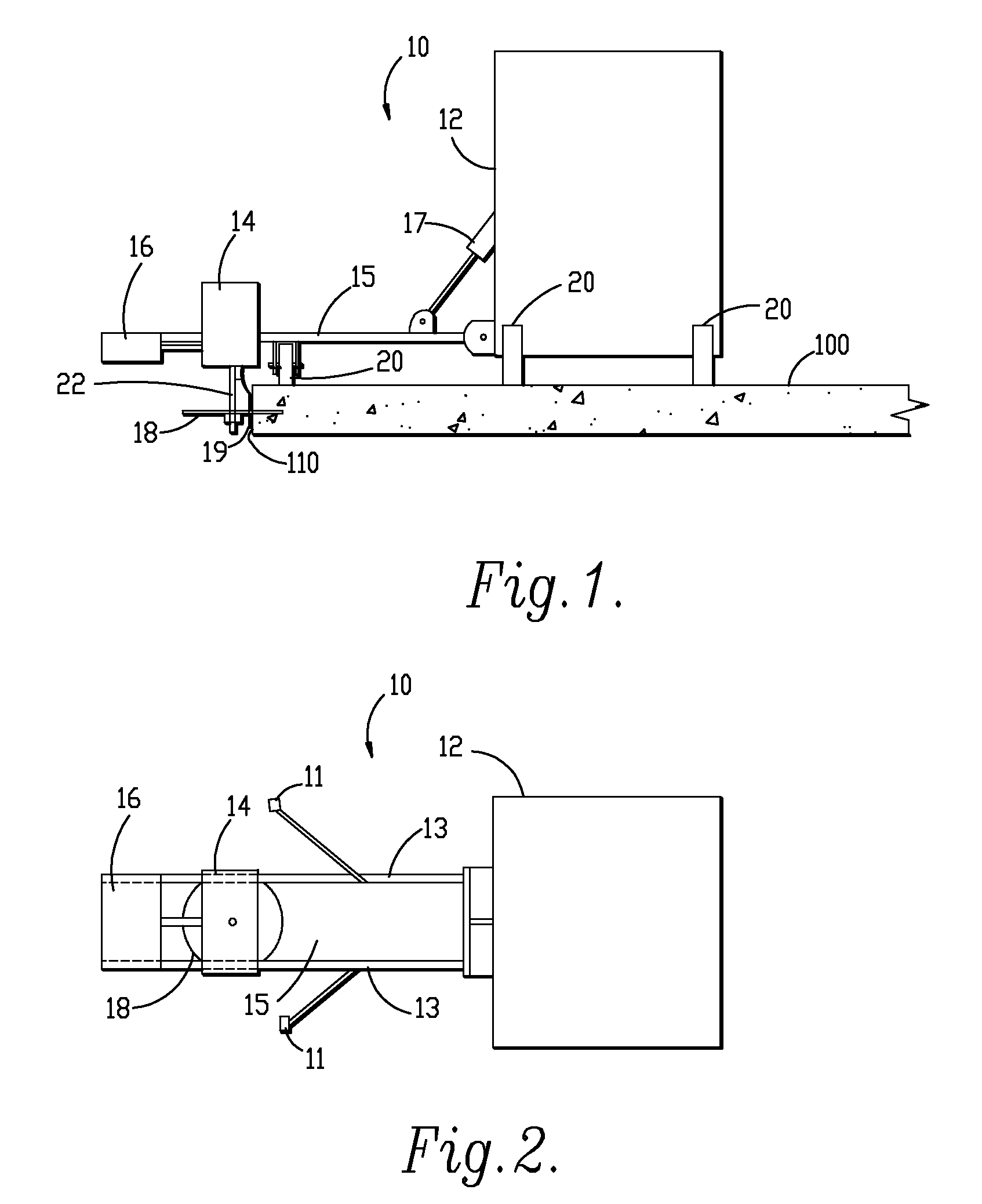

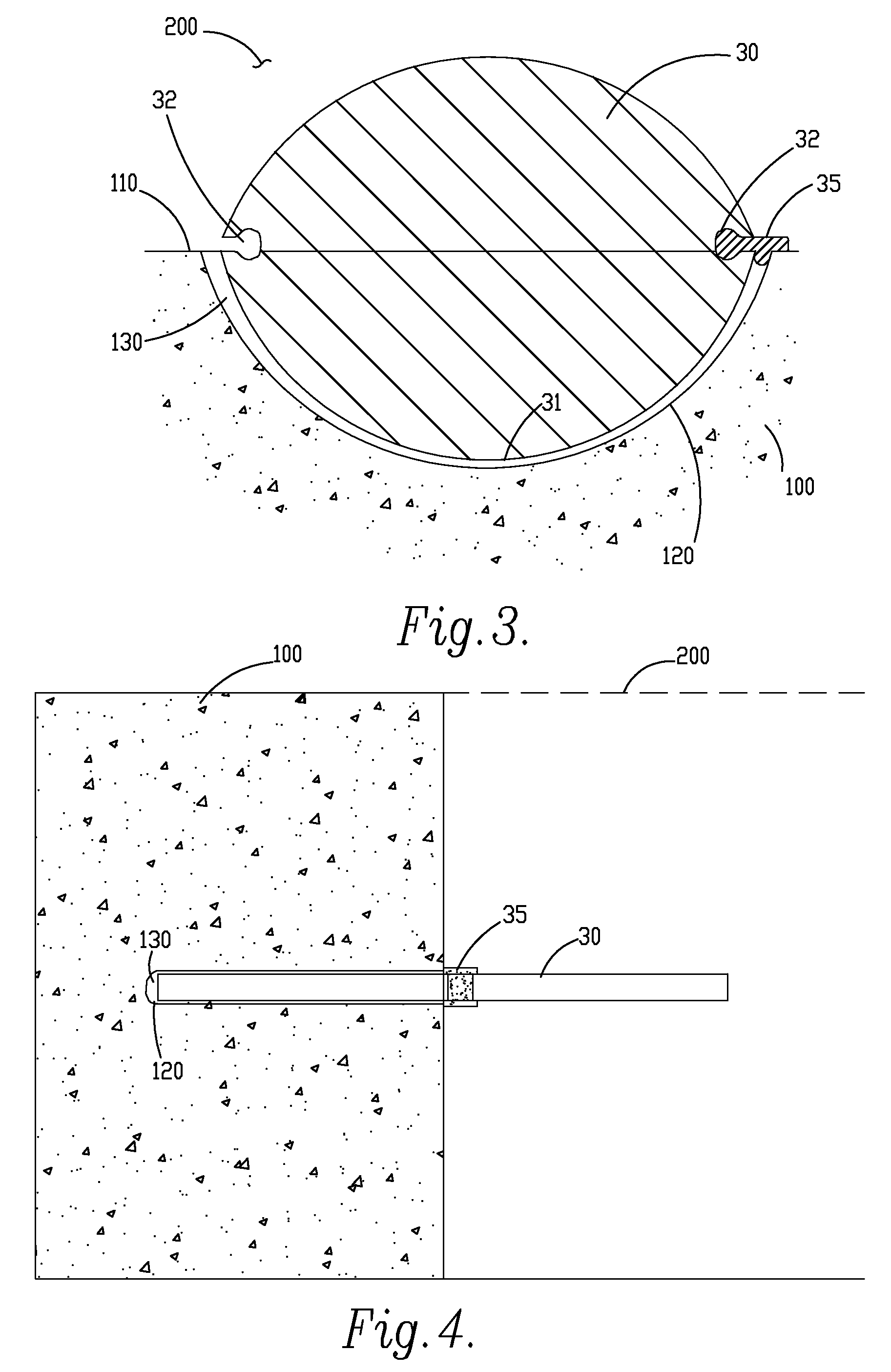

System and method for concrete slab connection

InactiveUS20060127179A1Quantity minimizationQuick cleanPaving detailsRoads maintainenceSection planeEngineering

Systems and methods of transferring loads between adjacent cast-in-place slabs, such as concrete slabs, and for accurately positioning dowels between adjacent sections of slabs are provided. A generally planar plate-type dowel is used which may be positioned within a cutaway in a preexisting slab of concrete. The dowel is shaped to generally conform to the shape of the cutaway, which is made by a saw blade. Once the dowel is positioned within the preexisting slab, a new slab is poured adjacent the preexisting slab. Rubber seals are included on the edges of the dowels to provide spacing or a gap between the dowel and the preexisting slab to allow for lateral independent movement of the adjacent slabs, and to prevent concrete from the newly poured second slab from entering into the gap. A saw unit for making a generally planar cut horizontally into an edge of a hardened concrete slab is also provided.

Owner:ILLINOIS TOOL WORKS INC

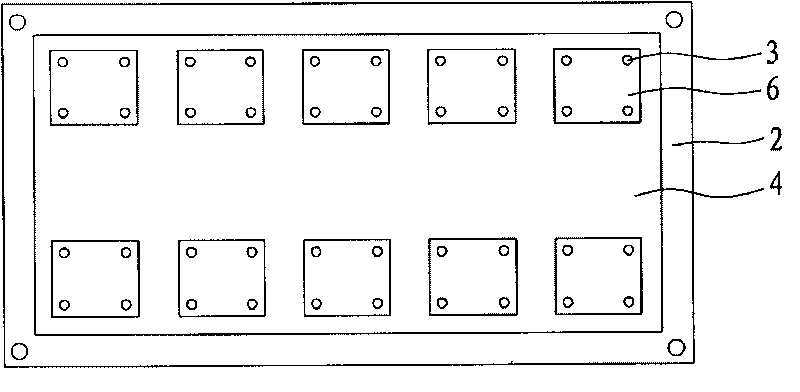

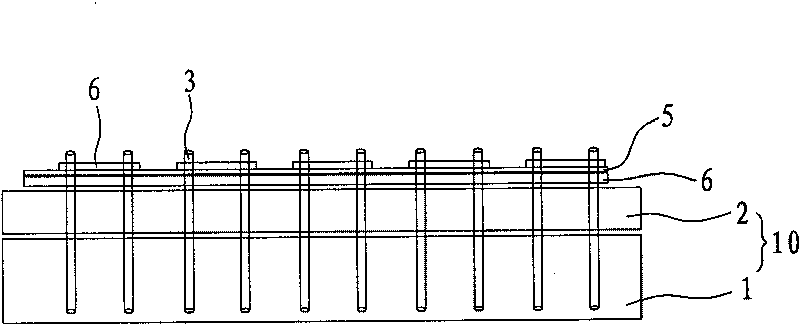

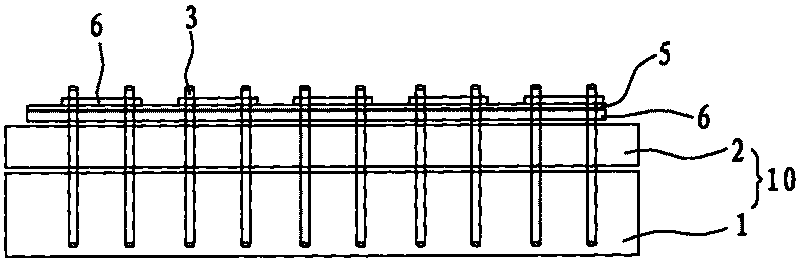

Flexible printed circuit board steel disc reinforcing hot-pressing making process

InactiveCN101720169ANot easy to fall offPromote sheddingPrinted circuit manufactureFlexible circuitsPrinted circuit board

The invention discloses a flexible printed circuit board steel disc reinforcing hot-pressing making process, including that pure glue is firstly adhered on the steel disc reinforcing position of the flexible printed circuit board and then steel disc is adhered, lamination curing is carried out to complete steel disc reinforcing, and the steel disc is fixed by steel disc adhesion jig. The invention adopts electric iron to preheat the steel disc firstly, so that certain stickiness is kept between the steel disc and the flexible printed circuit board and the steel disc can not drop in the process that the flexible printed circuit board is taken out and transferred; and the pure glue used for adhering the flexible printed circuit board and reinforcing the steel disc in steel disc hot-pressing process is thermosetting glue, namely glue system capable of being molten and cohered under heating condition and can be cured after curing at certain temperature for a while, so that the steel disc is firmly adhered on the flexible printed circuit board and can not drop in post making processes. The invention has simple making process and strong feasibility, can thoroughly avoid steel disc dropping and deviation problems and has wide applicability and higher production efficiency.

Owner:XIAMEN HONGXIN ELECTRON TECH

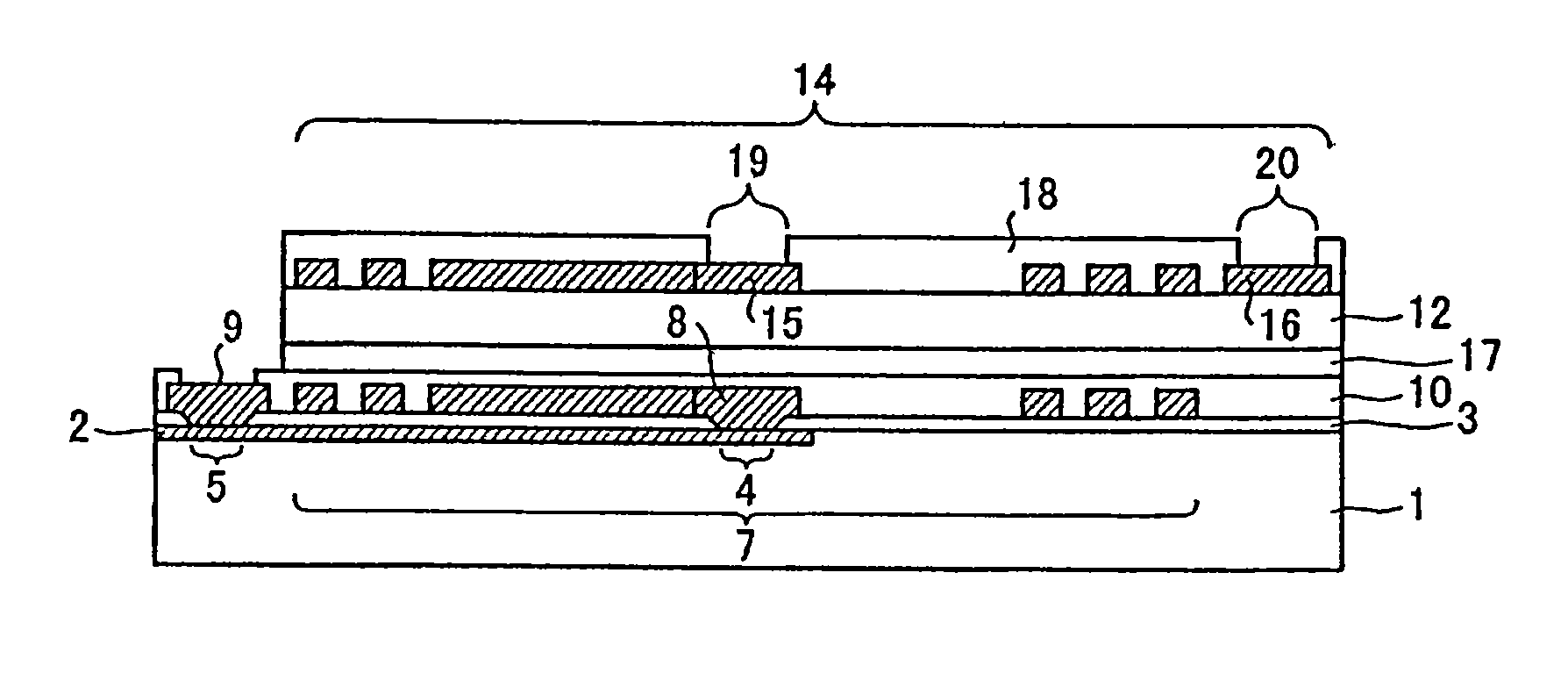

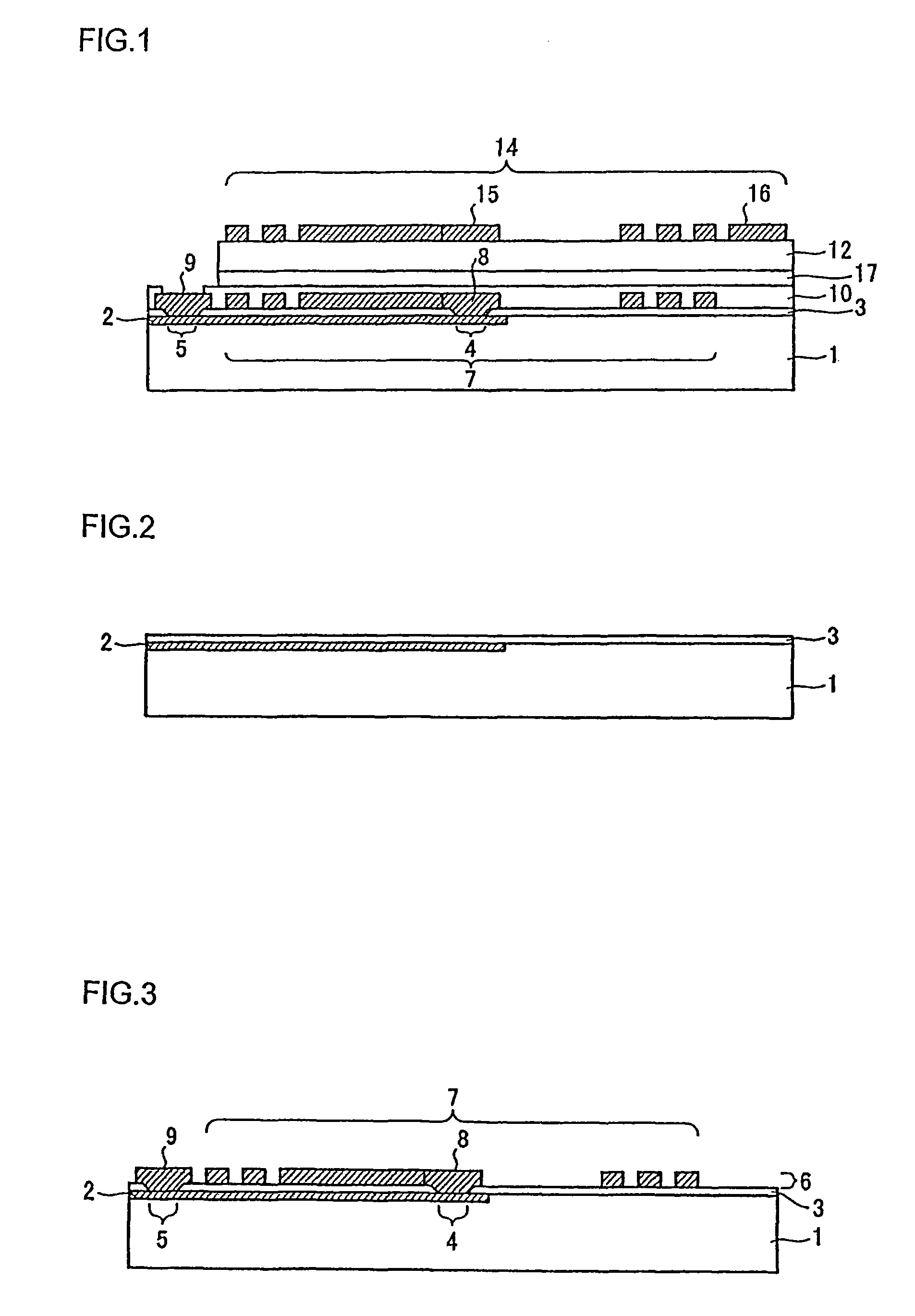

Manufacturing method for micro-transformers

InactiveUS20090280646A1Eliminate dislocationImprove throughputSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A micro-transformer manufacturing method is provided, which can improve throughput, prevent a crack from entering an insulating film between coils, and manufacture the micro-transformer without using a mask material having a high selection ratio. An insulating film is deposited on the whole face of a semiconductor substrate having an impurity-diffused region. This insulating film is partially removed to form a first opening and a second opening. A primary coil is formed such that a center pad contacts the impurity-diffused region through the first opening. A thin insulating film is deposited on the primary coil. An insulator material having a secondary coil formed thereon is adhered onto the insulating film on the primary coil by adhesive tape. The insulator material is sized to not cover both a pad, connected with the center pad of the primary coil through the impurity-diffused region, and an outer-end pad of the primary coil.

Owner:FUJI ELECTRIC CO LTD

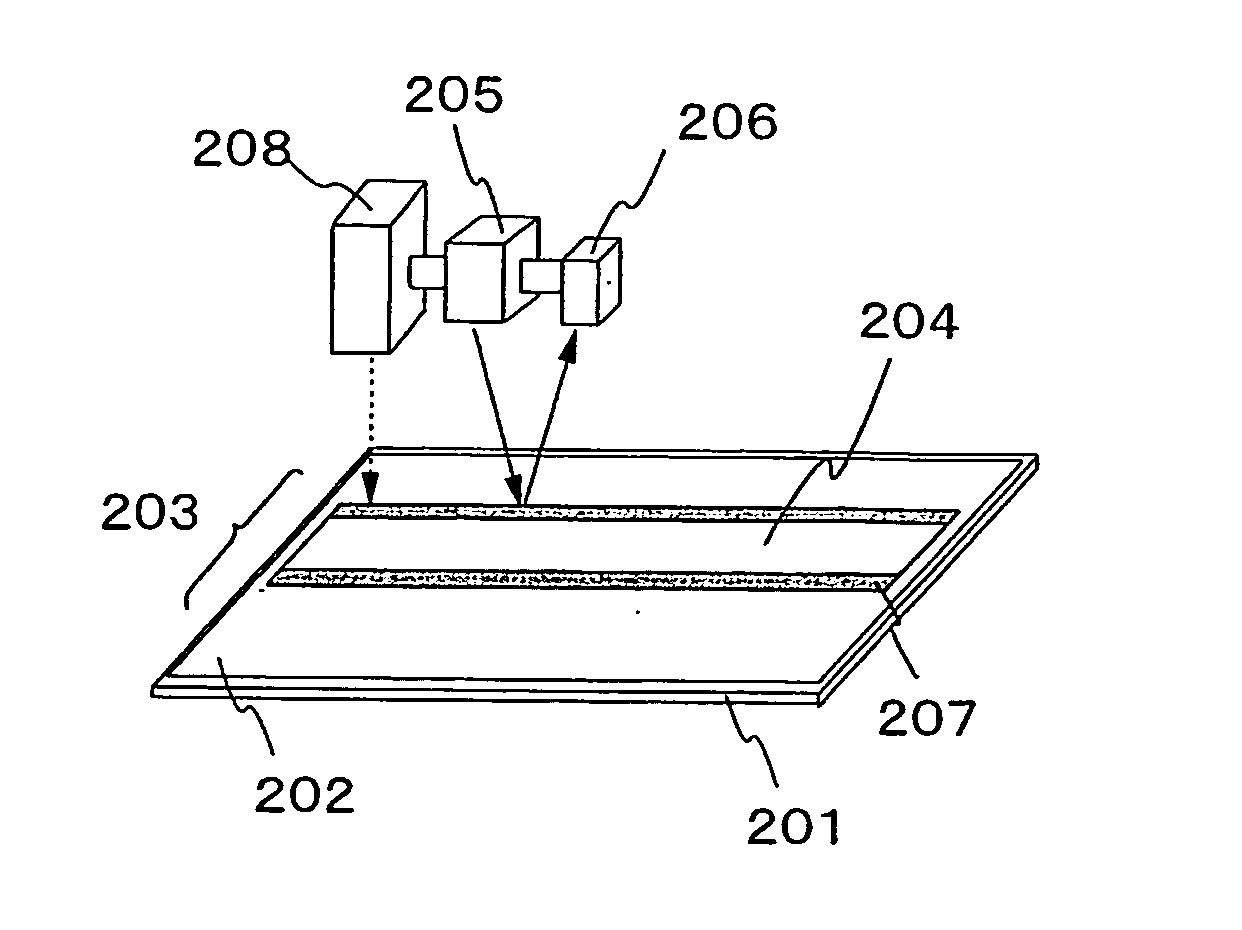

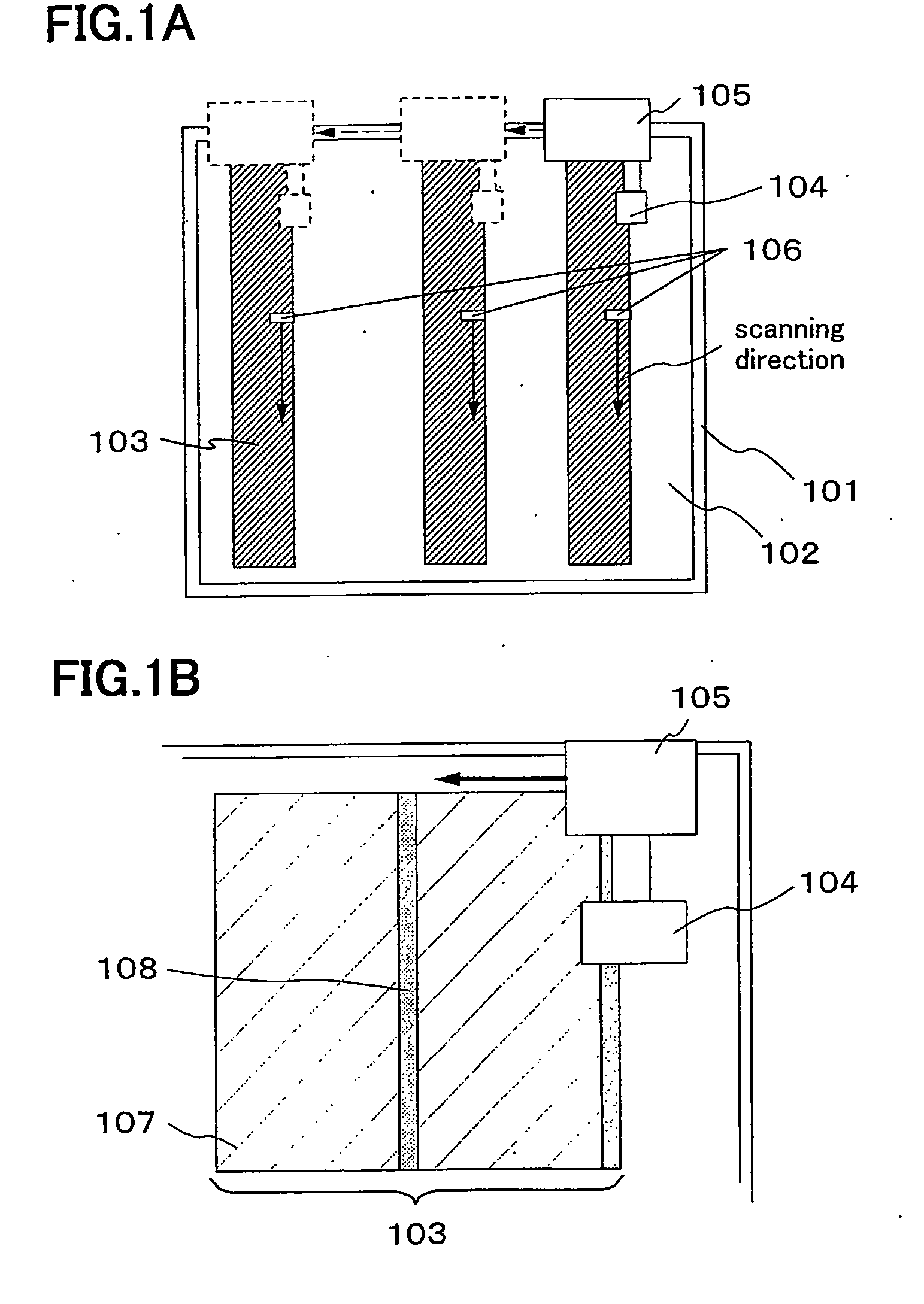

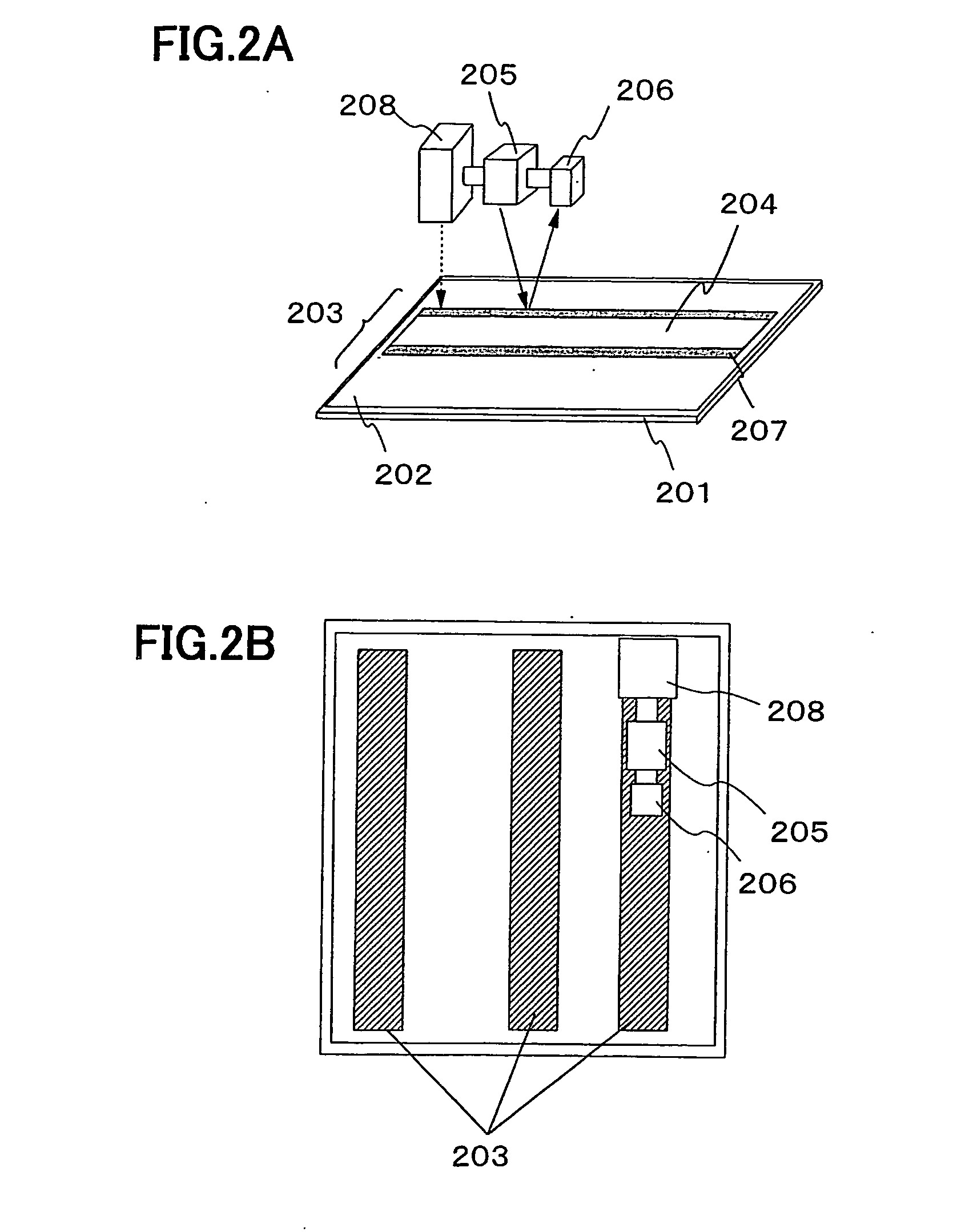

Light Exposure Apparatus and Manufacturing Method of Semiconductor Device Using the Same

InactiveUS20080151262A1Improve throughputEliminate misalignmentSolid-state devicesPhotomechanical apparatusLithographic artistLight exposure

When annealing of a semiconductor film is conducted using a plurality of lasers, each of the distances between laser irradiation regions is different. When a lithography step is conducted in accordance with a marker which is formed over a substrate in advance after the step, light-exposure is not correctly conducted to a portion crystallized by laser. By using a laser irradiation region obtained on a laser irradiation step as a marker, light-exposure is conducted by making a light-exposure position of a stepper coincide with a large grain size region in the laser irradiation region. A large grain size region and a poorly crystalline region are detected by utilizing a thing that scattering intensity of light is different between the large grain size region and the poorly crystalline region, thereby determining a light-exposure position.

Owner:SEMICON ENERGY LAB CO LTD

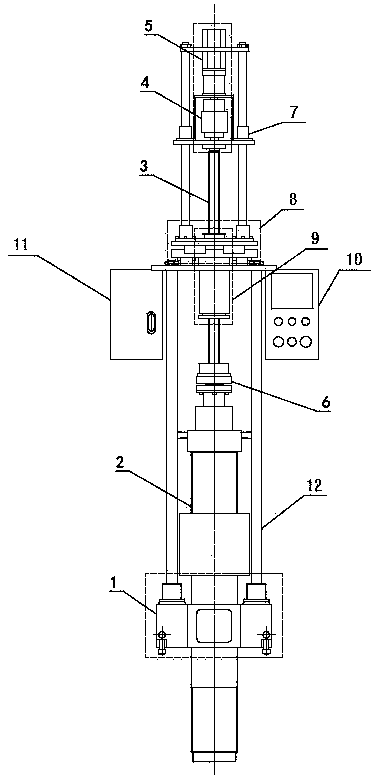

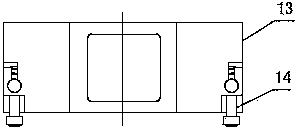

Implanting machine for nuclear power plant reactor king bolt and method for implanting bolt

ActiveCN103612115AAchieve fixationFast and reliable fasteningMetal working apparatusControl engineeringProcess engineering

The invention discloses an implanting machine for a nuclear power plant reactor king bolt and a method for implanting the bolt. A support is arranged between a machine base and a drive assembly, a self-adaptive centering assembly is fixed to the support, the drive assembly is connected with a lead screw, the lead screw is sleeved with a load balancer assembly, a clutch is connected with a chuck, the implanting machine is connected with the king bolt in a sleeved mode, an electromagnetic coil is energized, and the chuck is connected with the head of the king bolt after the clutch is disengaged; the king bolt stops when being close to a reactor container king bolt hole; the king bolt is guided into the king bolt hole, and a balance load is adjusted to be at an ideal value; when the king bolt moves downwards to a preset position, the load of a load balancer is reduced to be at an initial value, and the chuck of the implanting machine is lifted to an original position. The implanting machine is quick to locate, the king bolt guide-in process is stable, impact force is small, centering errors of the king bolt and the king bolt hole are automatically eliminated, pressure and impact on a thread auxiliary surface can be reduced to the maximum, stable load balance capacity is kept, and the change situation of the gravity of the king bolt can be tracked in real time in the whole course.

Owner:CHENGDU HAIGUANG NUCLEAR POWER TECH SERVICE CO LTD

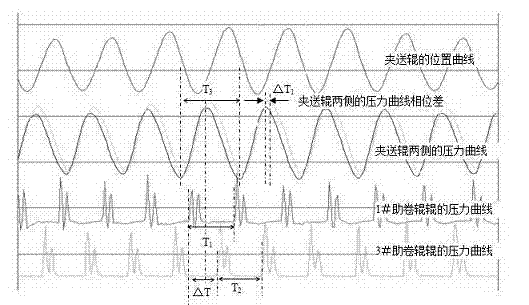

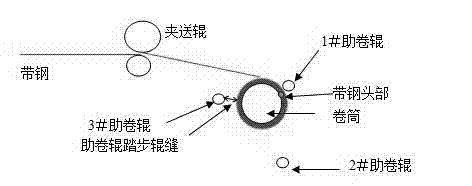

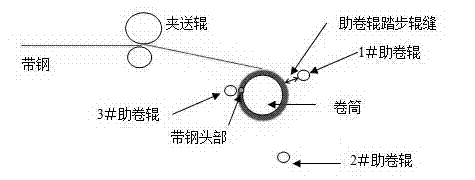

High-strength, low-temperature, and thick-gauge hot-rolled plate strip coil shape control method

The present invention relates to a high-strength, low-temperature and thick-gauge hot-rolled plate strip coil shape control method, which is characterized in that the control method comprises that: 1) before a strip steel reaches a coiler, a clamping and conveying roller and auxiliary coiling rollers are in roller gap control manners; 2) after the clamping and conveying roller bites the strip steel, the roller gap control manner of the clamping and conveying roller is switched into a pressure control manner; 3) during coiling of the previous several circles of the strip steel by a coiling cylinder, the auxiliary coiling rollers 1#, 2# and 3# are in the pressure control manners or roller gap control manners; 4) after coiling of the previous several circles of the strip steel by the coiling cylinder, the number of the circles is set as the X0 and is manually set, the auxiliary coiling roller 2# is completely opened so as to make a coil unloading trolley lift and be ready for unloading, and the auxiliary coiling rollers 1# and 3# enter a stepping control manner and the roller gap control and pressure control alternate control manner, wherein the phenomenon that the auxiliary roller always presses on the strip steel so as to cause the strip steel surface scratch can be avoided; and 5) the clamping and conveying roller both-side pressure control PID adjuster control parameters P value and I value are adjusted.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Helmet with Improved Shield Mount and Precision Shield Control

A closed face motorcycle helmet includes a shell with an eyeport and a shield attached for hinged motion between a closed position covering and sealing the eyeport and an open position displaced above the eyeport. A hinge plate is attached to the shell on each side and includes a socket into which a hub of the shield is rotatably disposed for hinged movement of the shield. A lever assembly having a downwardly extending lever and a hub with two dowels is attached to the bottom of the hinge plate. The lever assembly is manually movable between a central home position, a forwardly rotated shield cracking position, and a rearvardly rotated shield restraining position. A motion plate is attached to a lower edge of the shield and covers the hub and dowels of the lever assembly when the shield is closed. Surfaces on the inside of the motion plate interact with the dowels of the lever assembly to provide multiple precision shield control functions. Specifically, flipping the lever forward cracks the shield slightly open to eliminate fog and flipping it rearwardly applies an additional restraining force to the shield preventing it from being blown open by aerodynamic forces, especially at high speeds. A live beam mechanism with micro detents interacts with a projection on the shield to provide fluid-like operation of the shield and the ability to position the shield at virtually any location between fully closed and fully opened.

Owner:BELL SPORTS INC

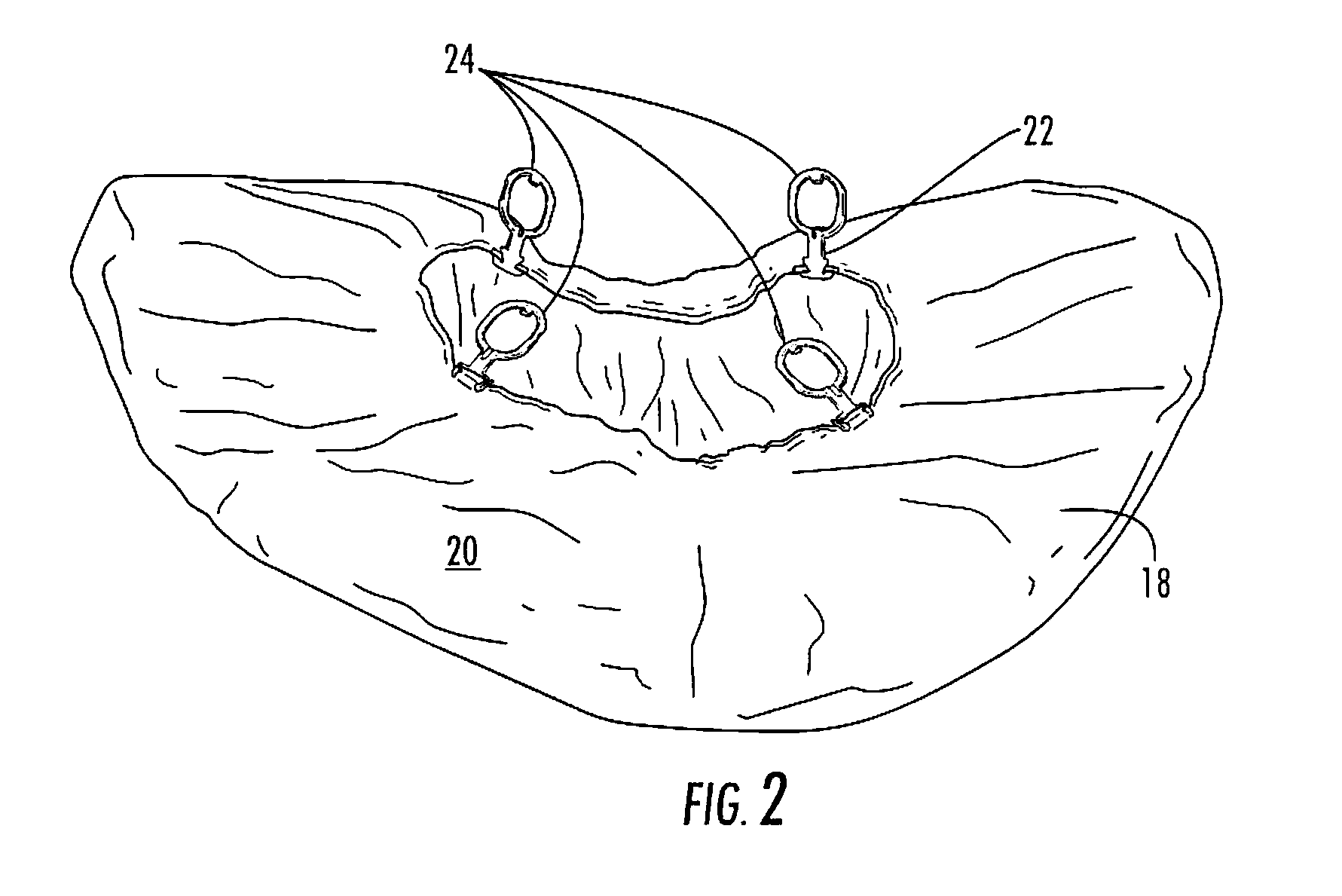

Wheelchair backrest mounting system

ActiveUS10182953B2Eliminate dependenciesGreat freedomWheelchairs/patient conveyanceStoolsWheelchairEngineering

A backrest mounting system provides angular and height adjustment of a backrest shell independent of backrest canes. The backrest mounting system attaches to a centrally located mounting structure on the backrest shell and defines at least two pivot axes that determine the angular position of the backrest shell relative to a wheelchair seat.

Owner:SUNRISE MEDICAL (US) LLC

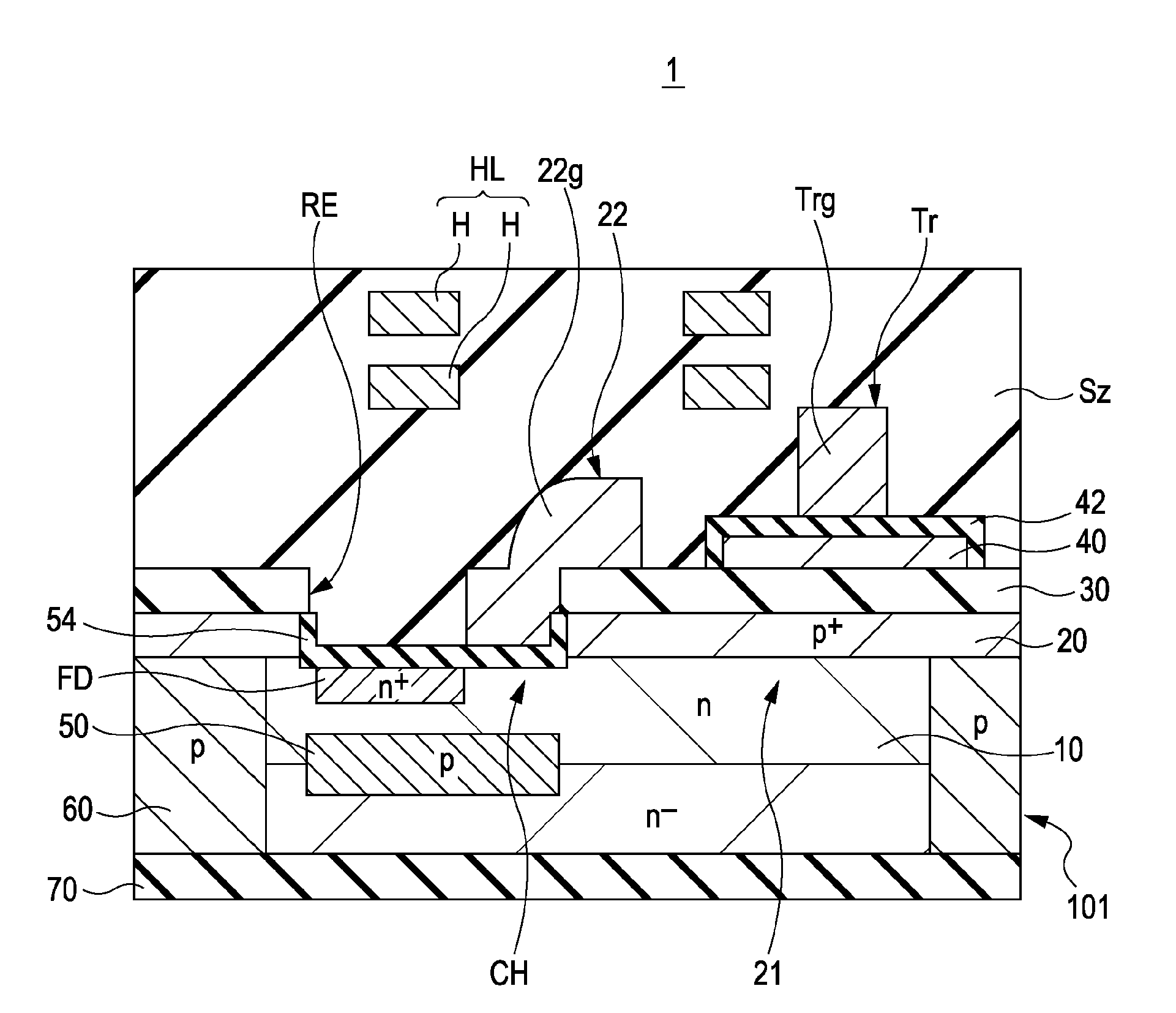

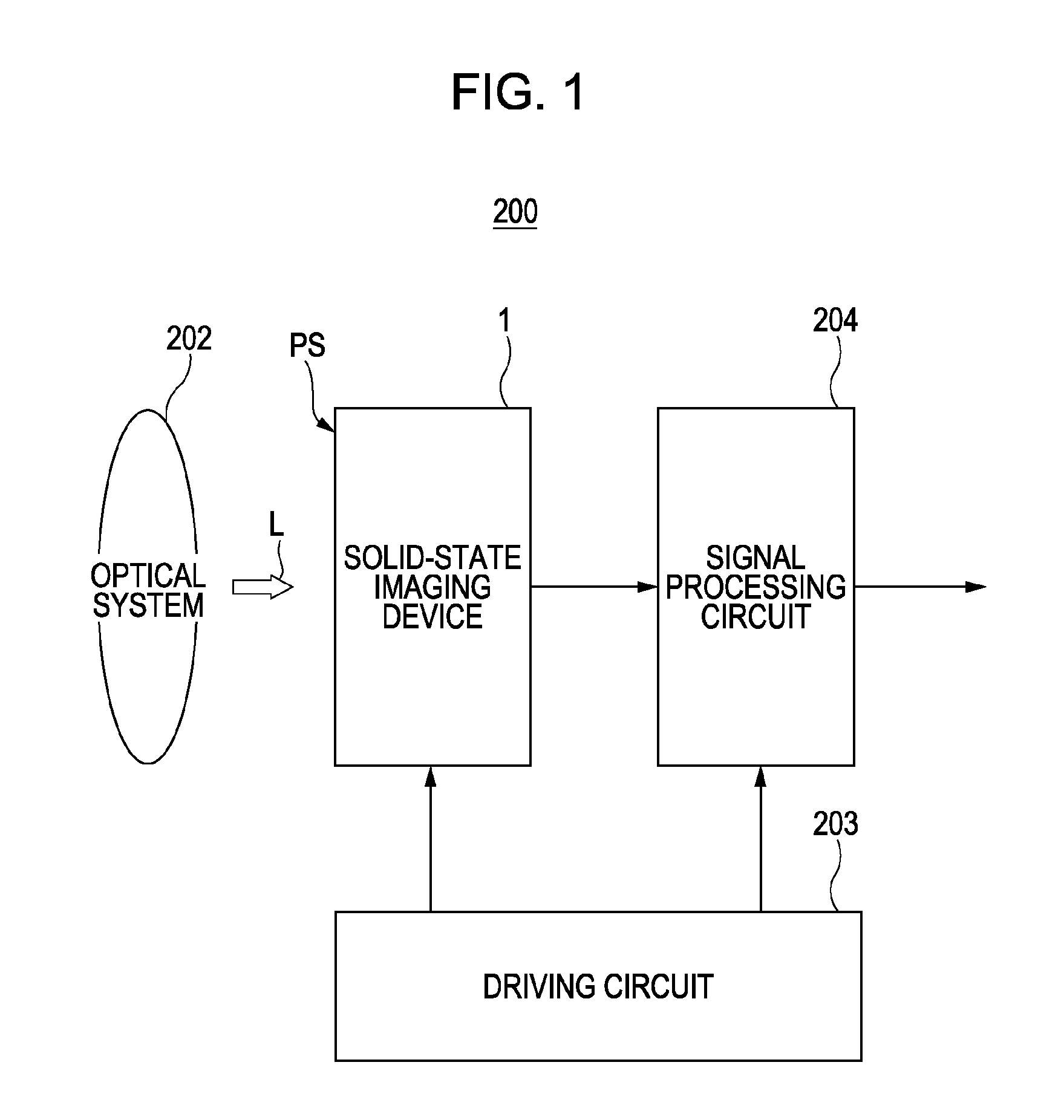

Solid-state imaging device, electronic apparatus, and method for making solid-state imaging device

InactiveUS20110042723A1Eliminate misalignmentReduce transmission efficiencyTransistorSolid-state devicesPhotoelectric conversionEngineering

A solid-state imaging device includes a photoelectric conversion unit that includes a first region of a first conductivity type and a second region of a second conductivity type between which a pn junction is formed, the first region and the second region being formed in a signal-readout surface of a semiconductor substrate, the second region being located at a position deeper than the first region; and a transfer transistor configured to transfer signal charges accumulated in the photoelectric conversion unit to a readout drain through a channel region that lies under a surface of the first region and horizontally adjacent to the photoelectric conversion unit, the transfer transistor being formed in the signal-readout surface. The transfer transistor includes a transfer gate electrode that extends from above the channel region with a gate insulating film therebetween to above the first region so as to extend across a step.

Owner:SONY CORP

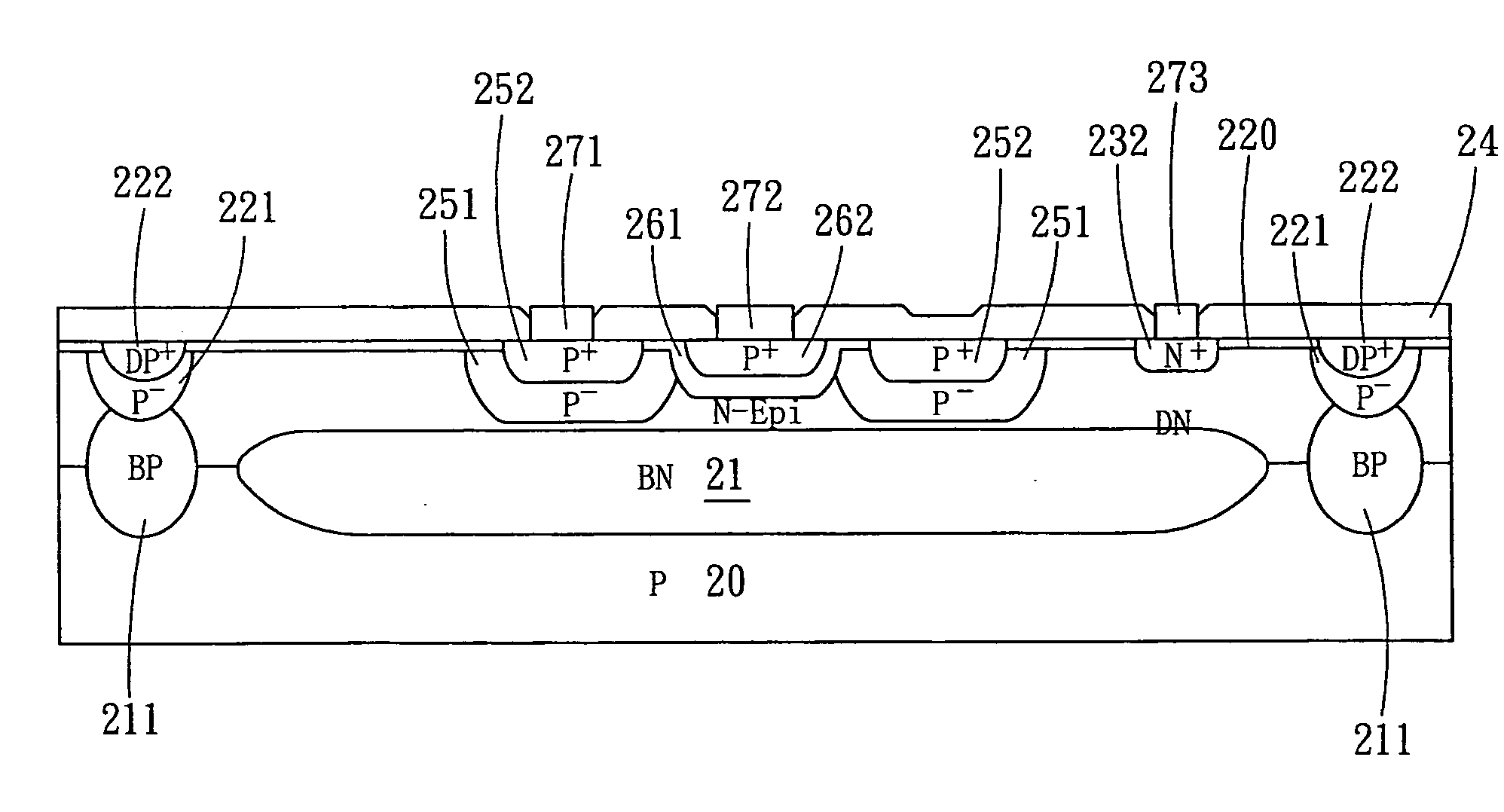

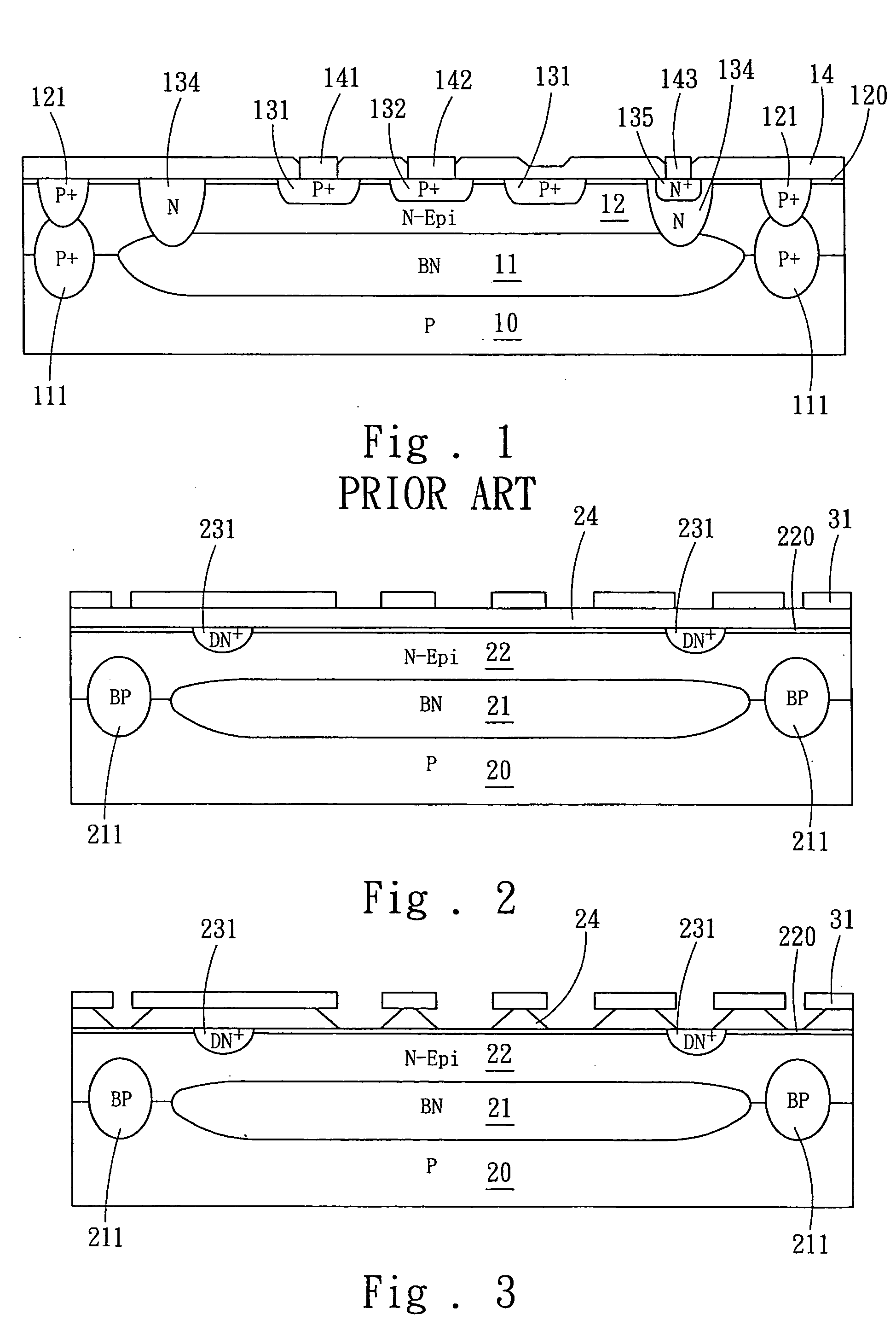

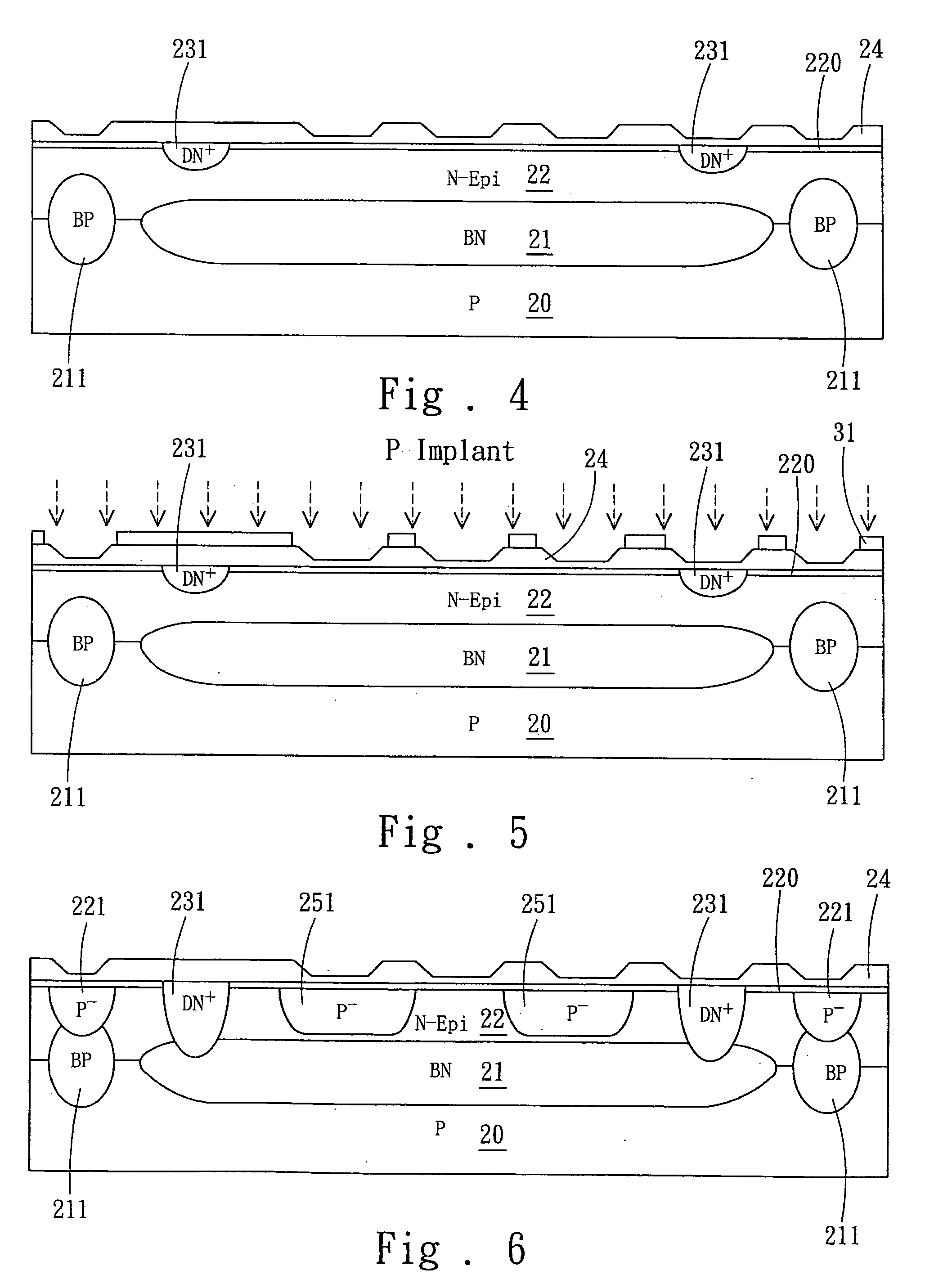

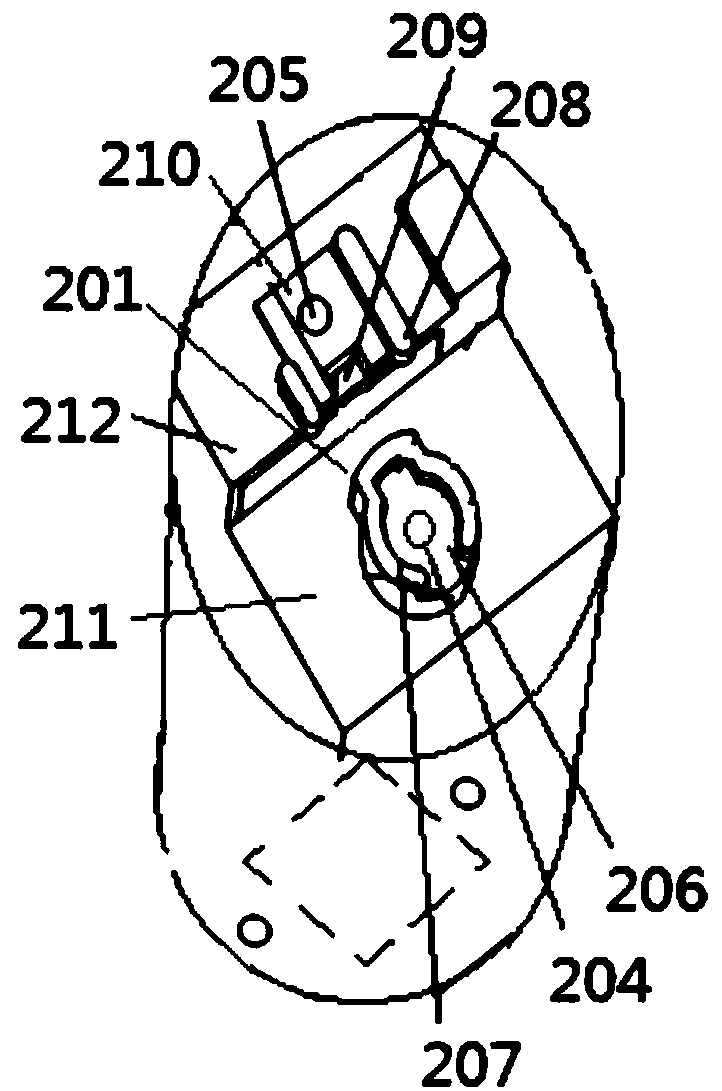

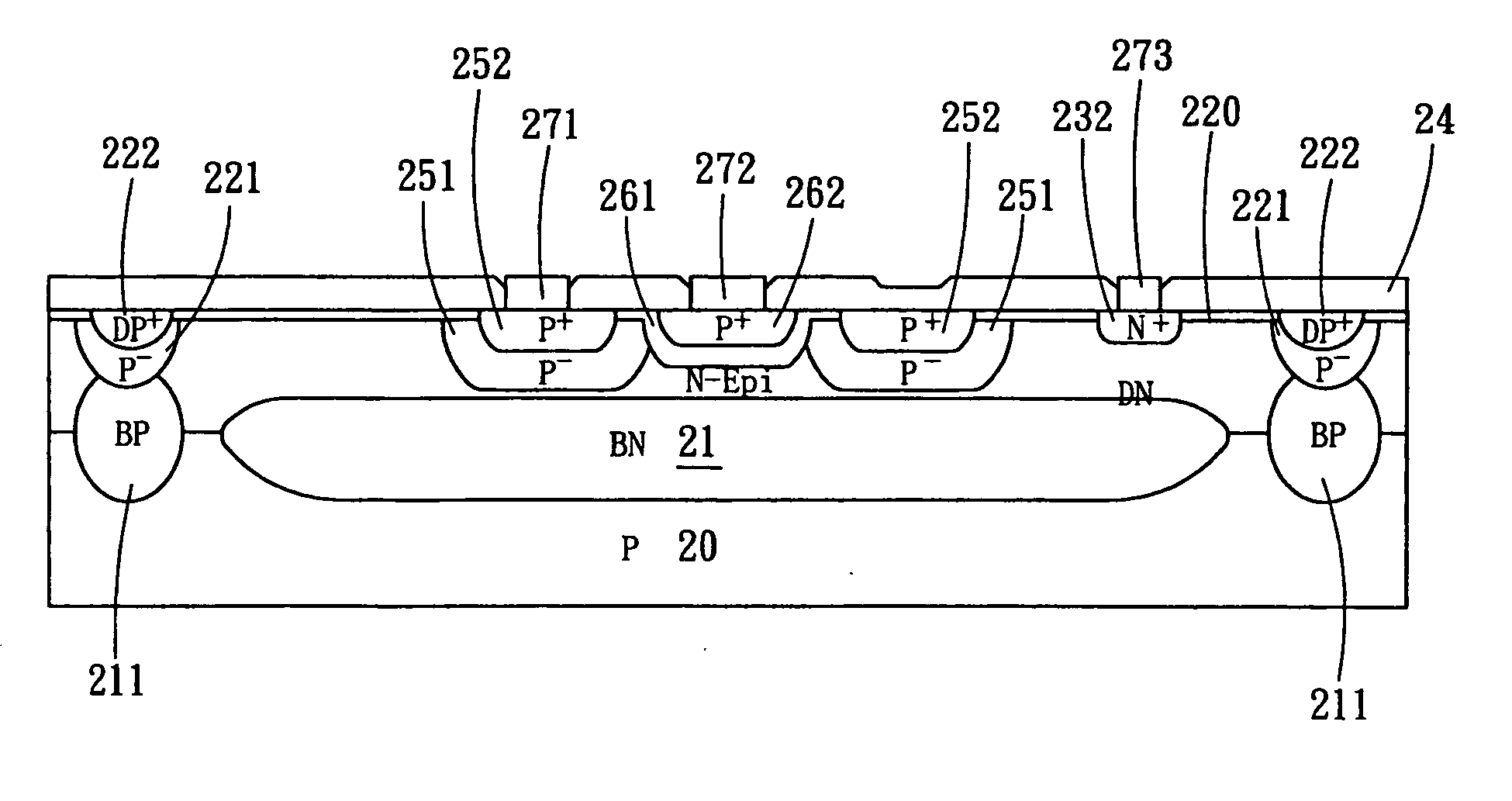

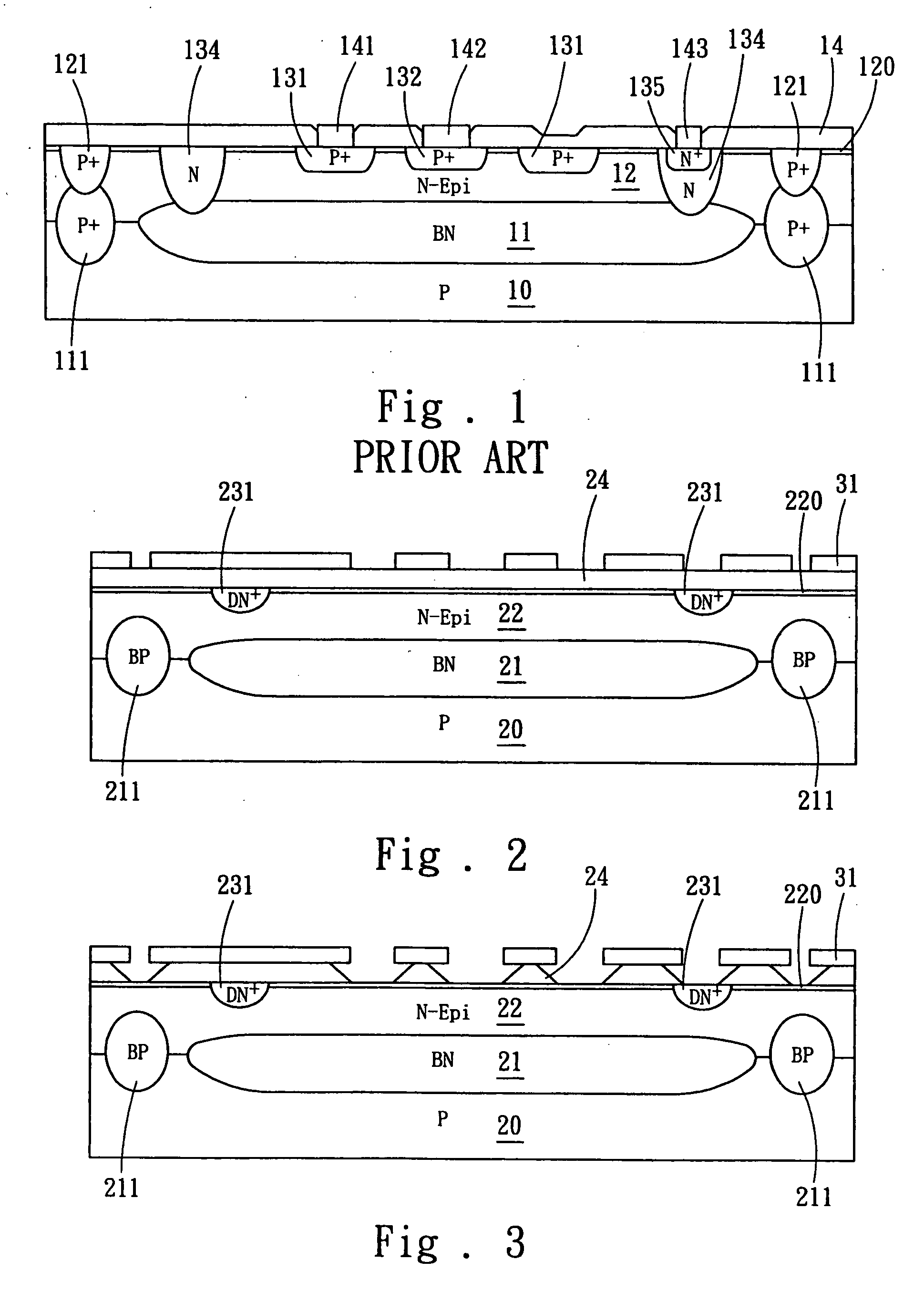

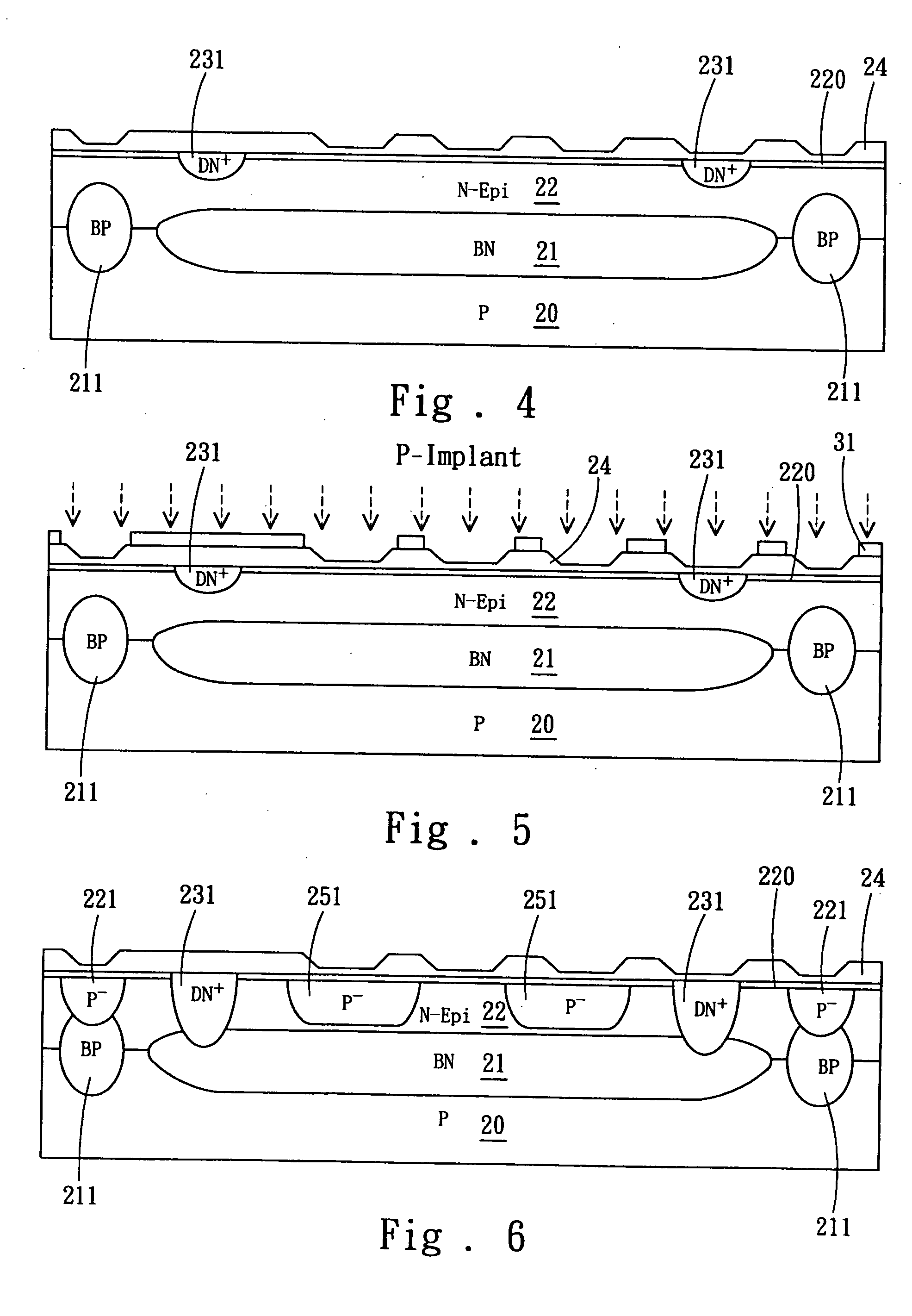

Lateral PNP transistor and the method of manufacturing the same

InactiveUS20060043528A1Increase production capacityEliminate alignment issuesTransistorSemiconductor/solid-state device manufacturingBreakdown voltageDoping profile

The present invention relates to a lateral PNP transistor and the method of manufacturing the same. The medium doping N-type base area and the light doping P− collector area were first introduced in the structure before the formation of P+ doping emitter area and the collector area. The emitter-base-collector doping profile in the lateral and the base width of LPNP were similar to NPN. The designer can optimize the doping profile and area size of each area according to the request of the current gain (Hfe), collector-base breakdown voltage (BVceo), and Early voltage (VA) of LPNP transistor. These advantages may cause to reduce the area and enhance performance of the LPNP transistor.

Owner:BCD SEMICON MFG

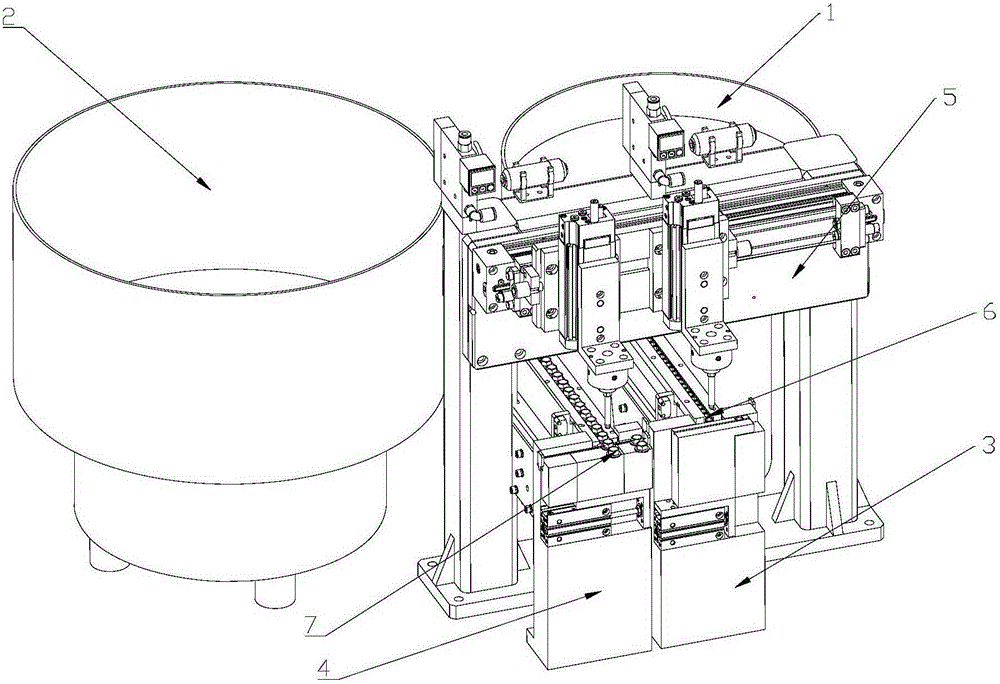

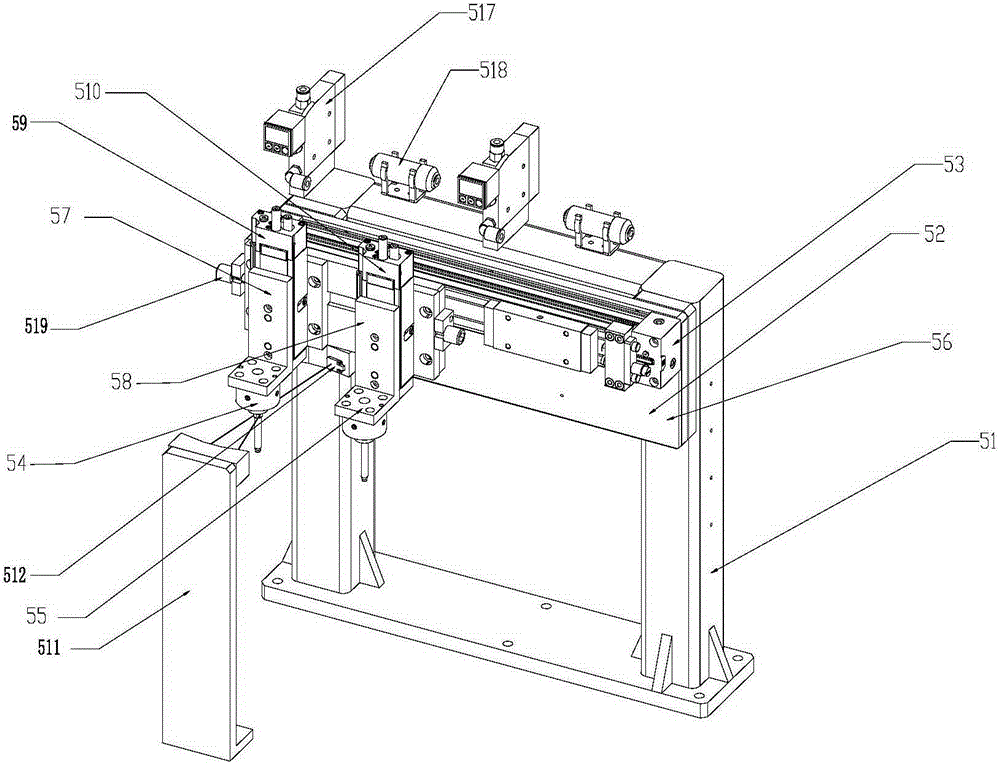

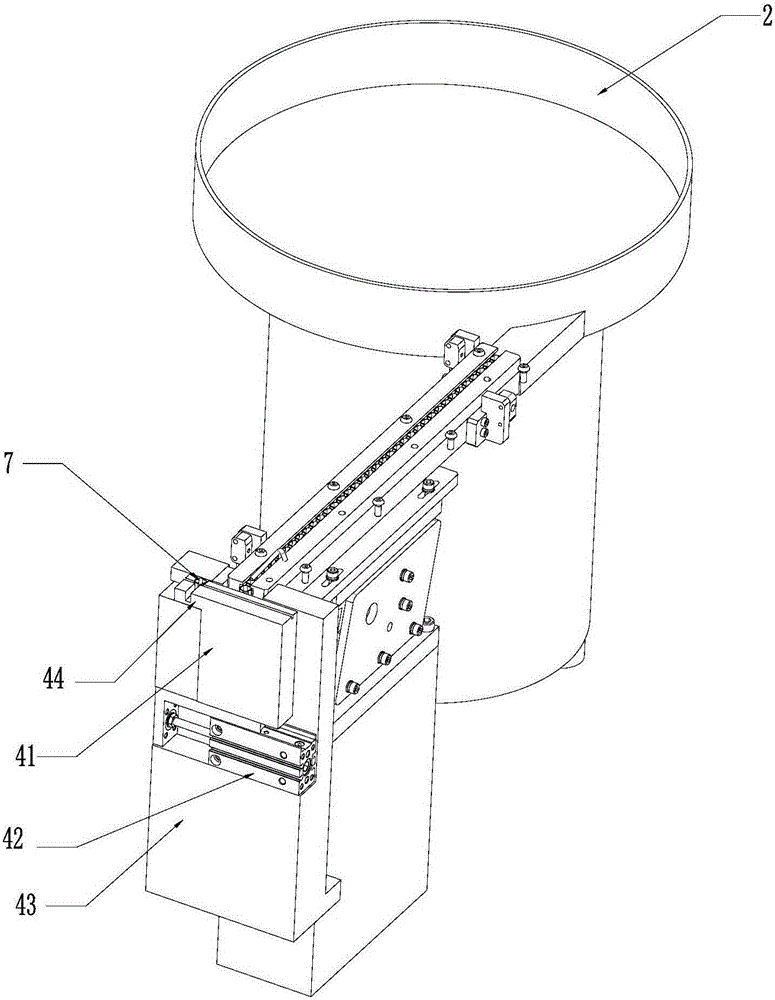

Gap removing device for assembling workpieces by inserting

ActiveCN105215662AEliminate misalignmentEliminate poor assemblyMetal working apparatusElectrical and Electronics engineeringEngineering

The invention discloses a gap removing device for assembling workpieces by inserting. The device comprises a first vibrating discharging mechanism, a second vibrating discharging mechanism, a first workpiece staggering mechanism, a second workpiece staggering mechanism and an assembling carrying detecting mechanism, wherein the first vibrating discharging mechanism is connected with the first workpiece staggering mechanism; the second vibrating discharging mechanism is connected with the second workpiece staggering mechanism; a first workpiece sequentially runs through the first vibrating discharging mechanism and the first workpiece staggering mechanism and then is conveyed to the assembling carrying detecting mechanism; a second workpiece sequentially runs through the second vibrating discharging mechanism and the second workpiece staggering mechanism and then is conveyed to the assembling carrying detecting mechanism; the first workpiece and the second workpiece are assembled and detected through the assembling carrying detecting mechanism. According to the gap removing device, an adjustable floating gripping device is utilized to remove the factors such as inaccurate centering, poor assembling and wear damage on the workpieces in assembling, and the processed workpieces are free of the requirements on high processing precision and matching precision.

Owner:TZTEK TECH

Telescope pointing error correction method and telescope

ActiveCN110361829AEliminate misalignmentGood optical performanceTelescopesMountingsControl systemOptical axis

The invention provides a telescope pointing error correction method comprising the concrete steps: a master control unit obtains the data measured by a position sensor, calculating the first deviationbetween the current optical axis position of a primary mirror and the ideal optical axis position and outputting the first deviation to a frame spindle servo control system to make the frame spindleservo control system perform correction; and the master control unit obtains the attitude of the telescope, calculates the current optical axis position of a secondary mirror, then calculates the second deviation of the current position of the secondary mirror according to the current optical axis position of the primary mirror and the calculated current optical axis position of the secondary mirror and outputs the second deviation to a six-degree-of-freedom platform to enable the six-degree-of-freedom platform to perform correction. The invention also provides a telescope. Compared with the methods in the prior art, the beneficial effects are that the correction method can correct the pointing error caused by the spindle jitter of the telescope due to the external interference and can also correct the pointing error caused by the alignment of the primary and secondary mirrors so as to improve the optical performance of the telescope.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

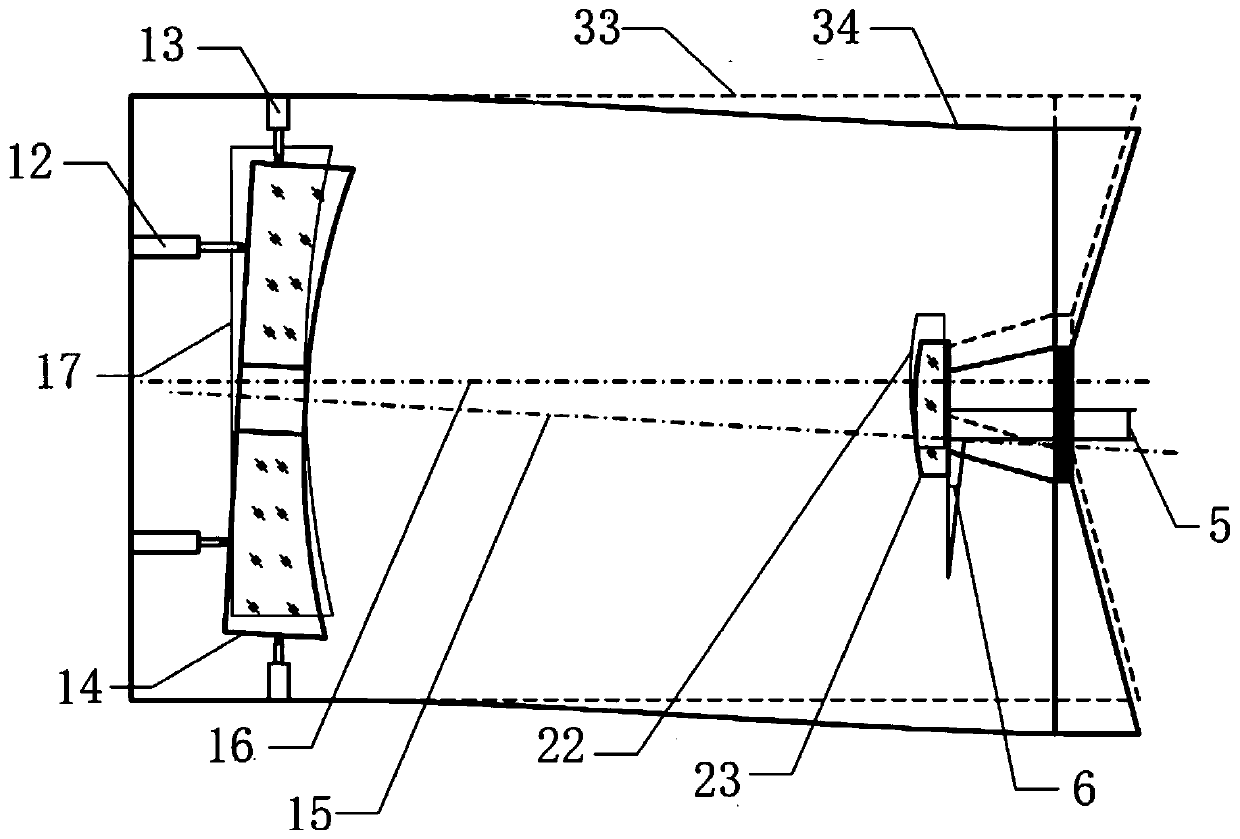

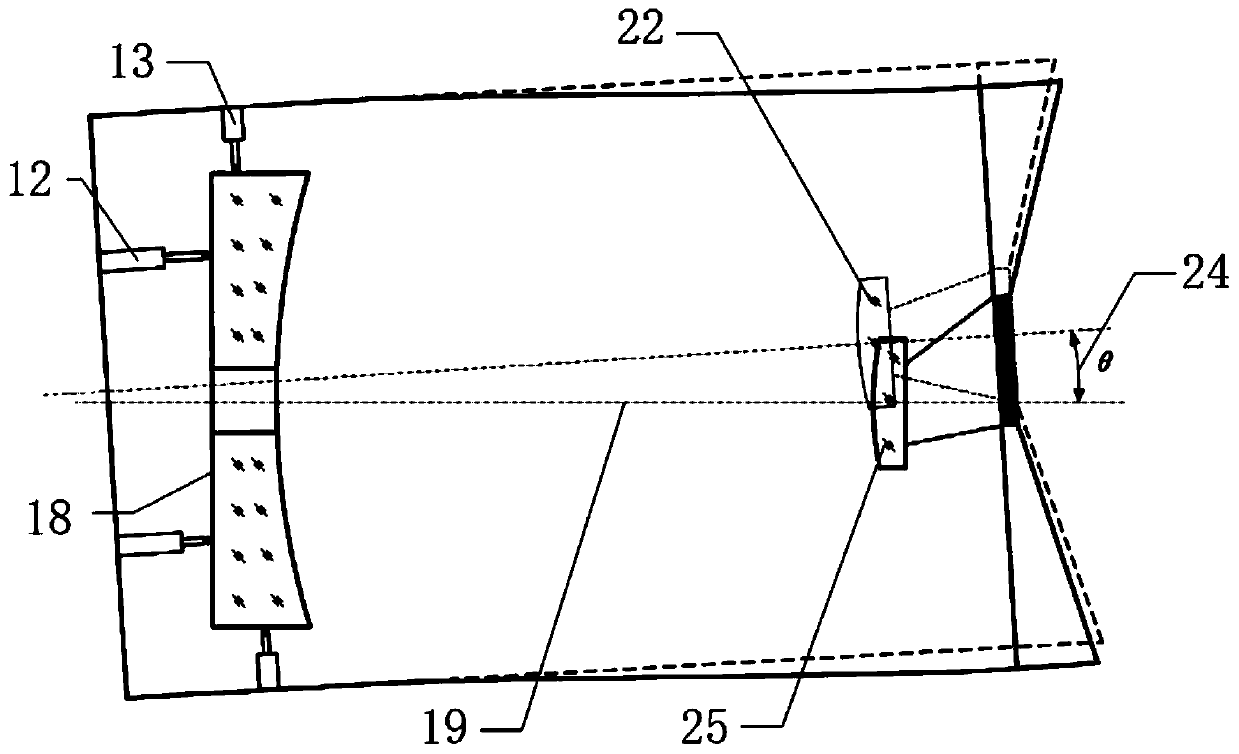

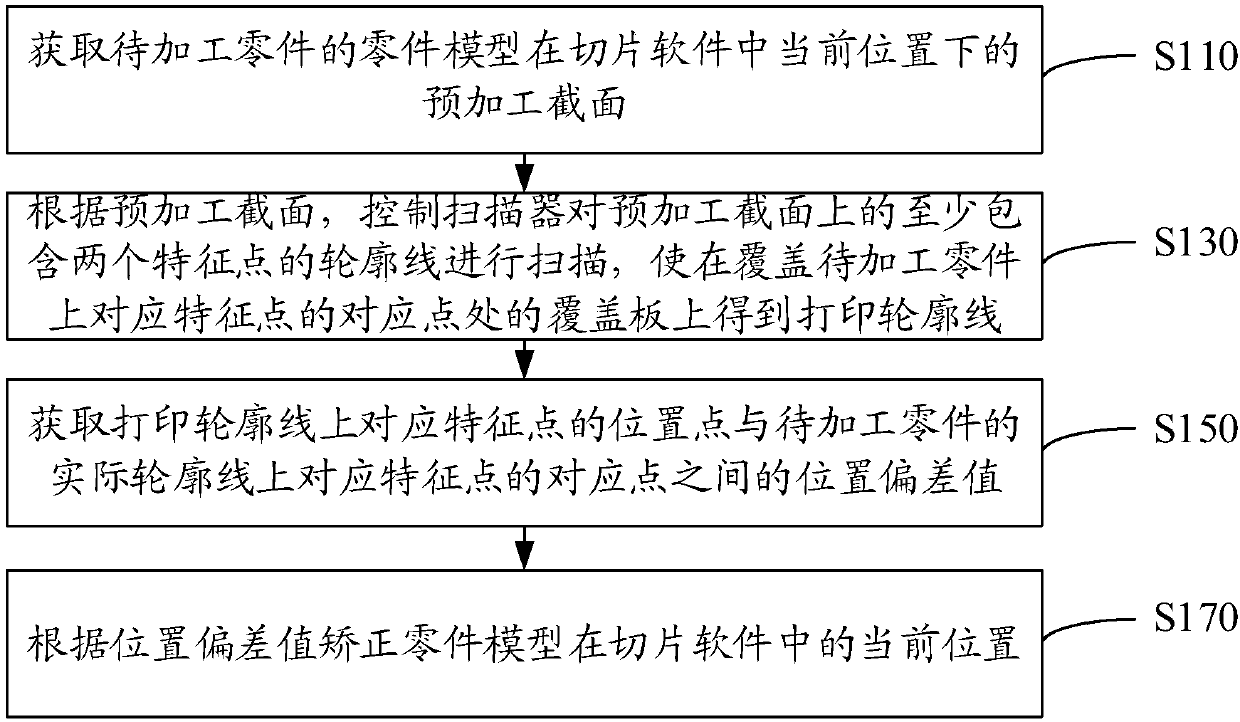

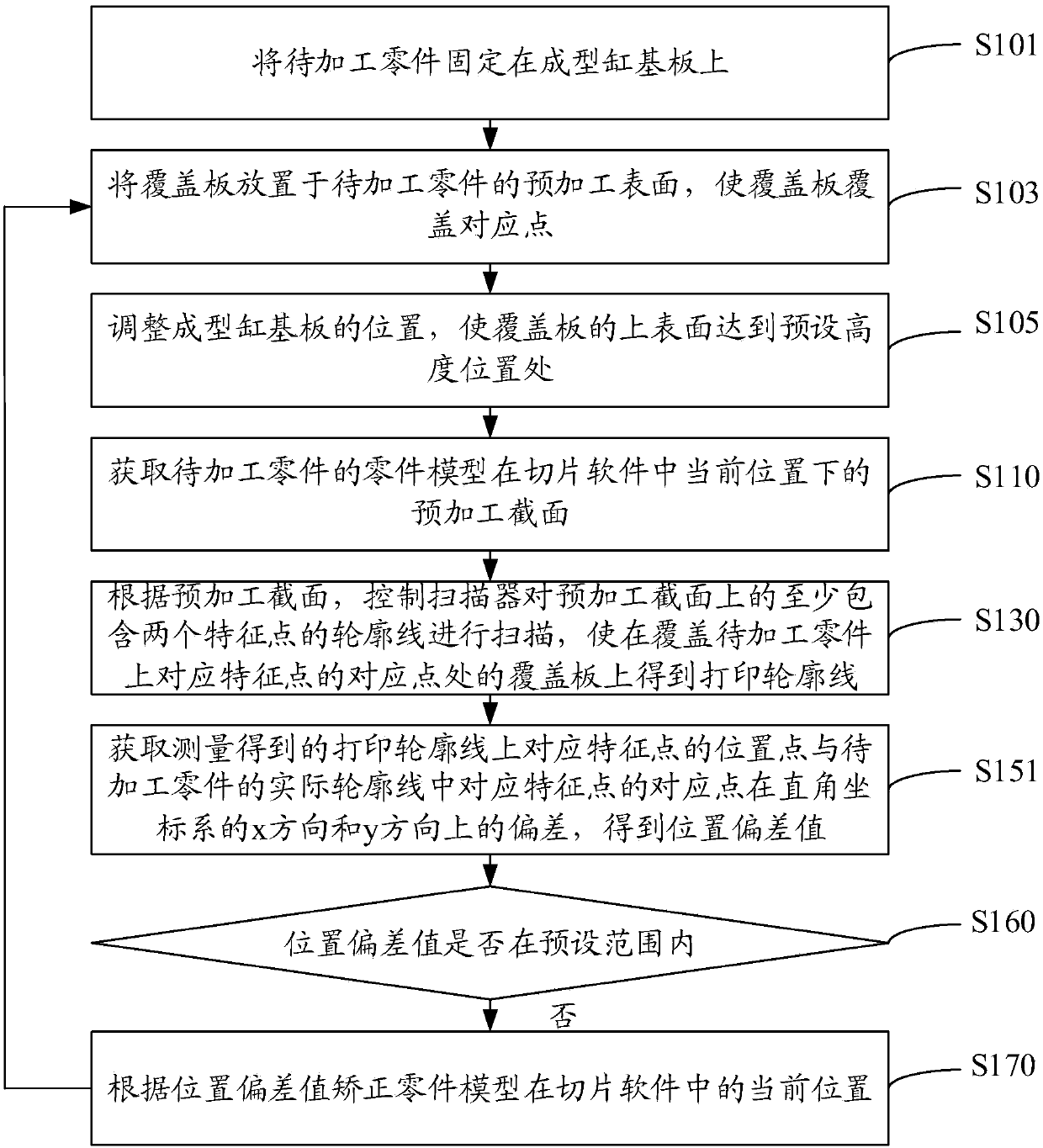

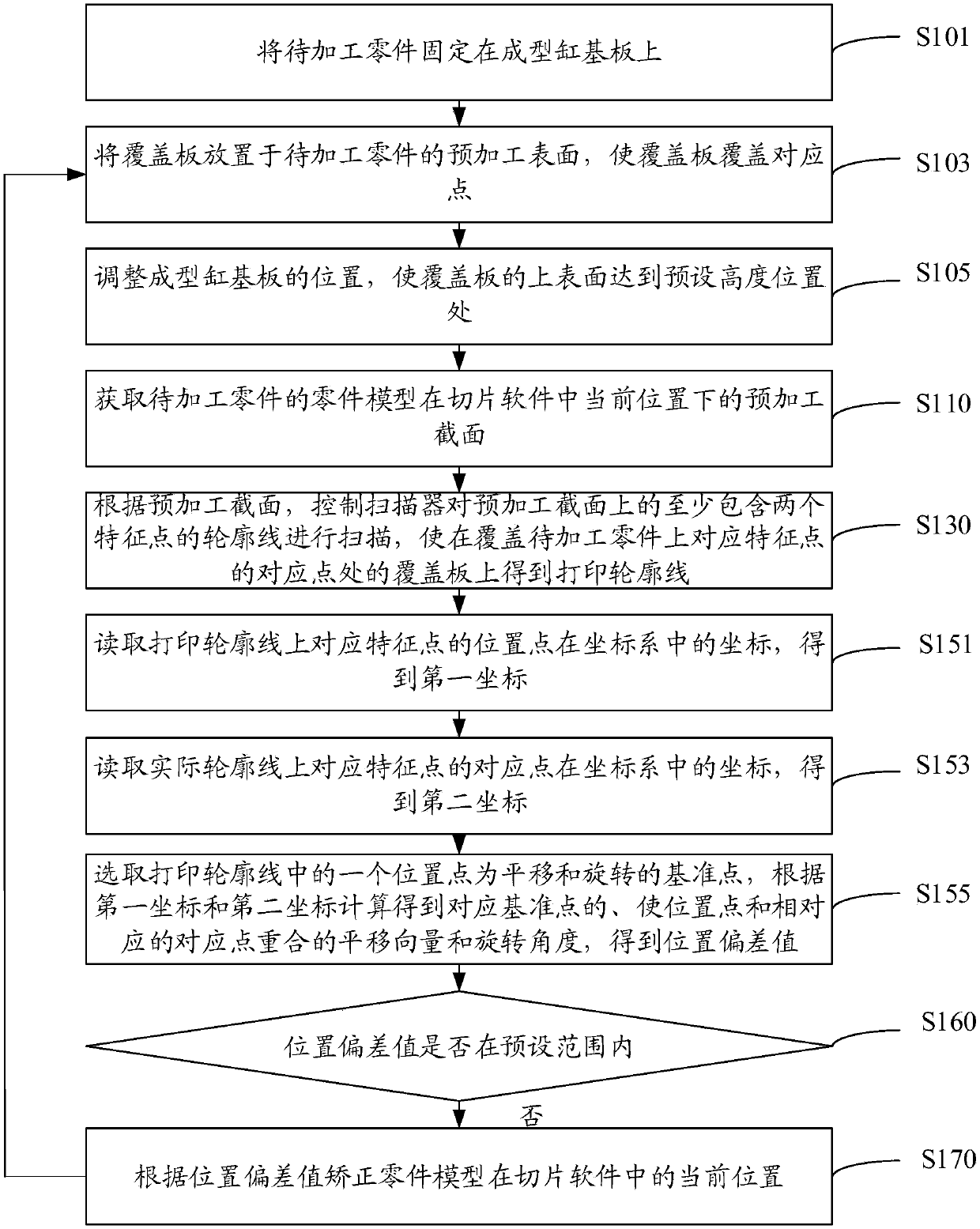

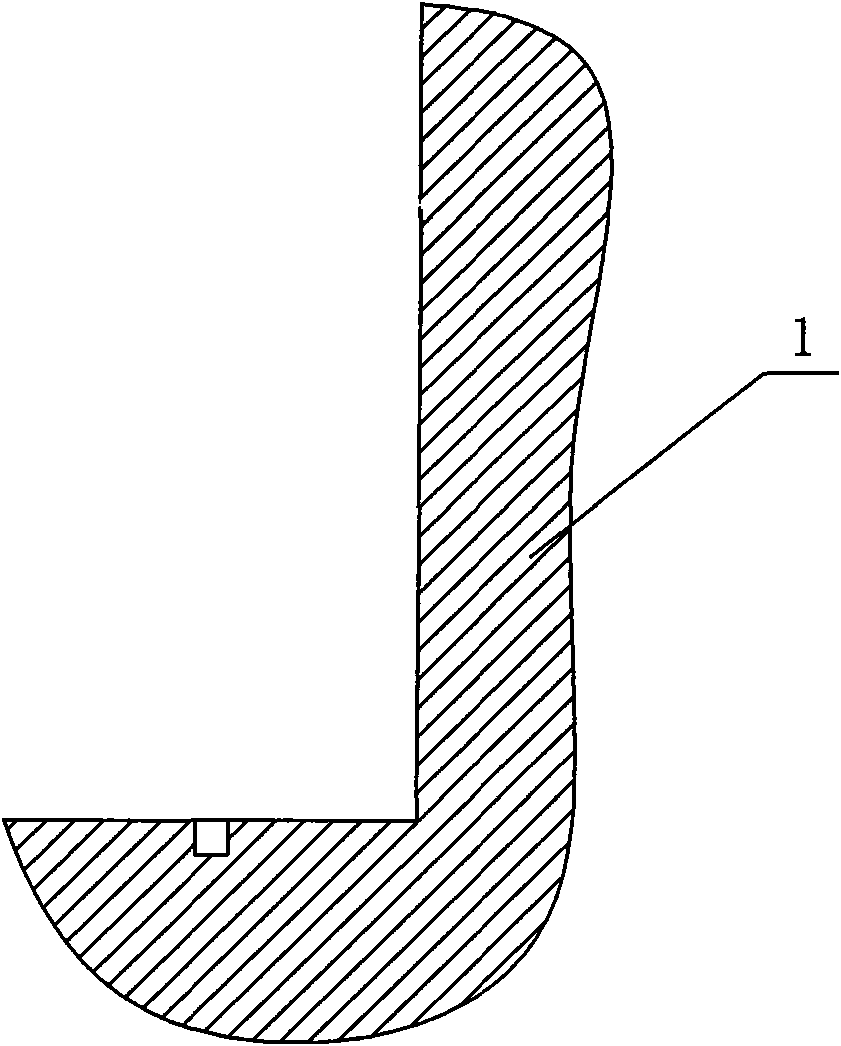

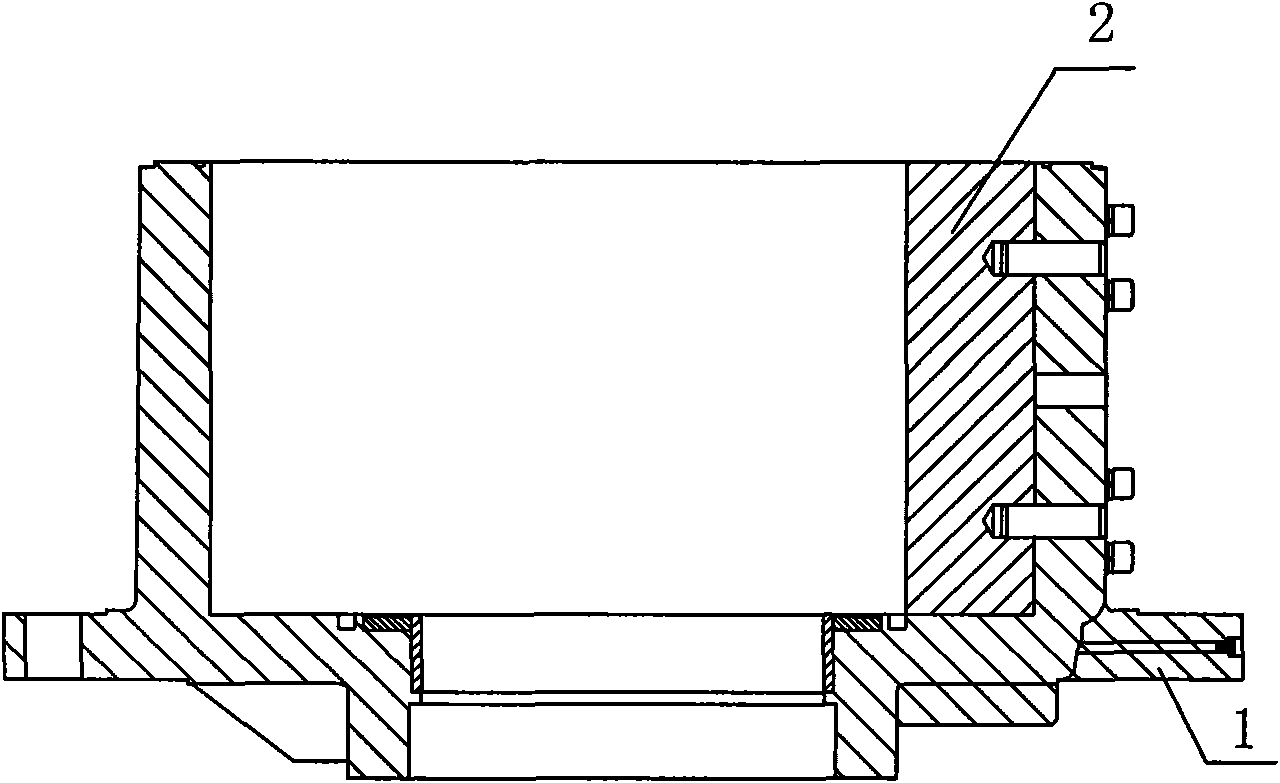

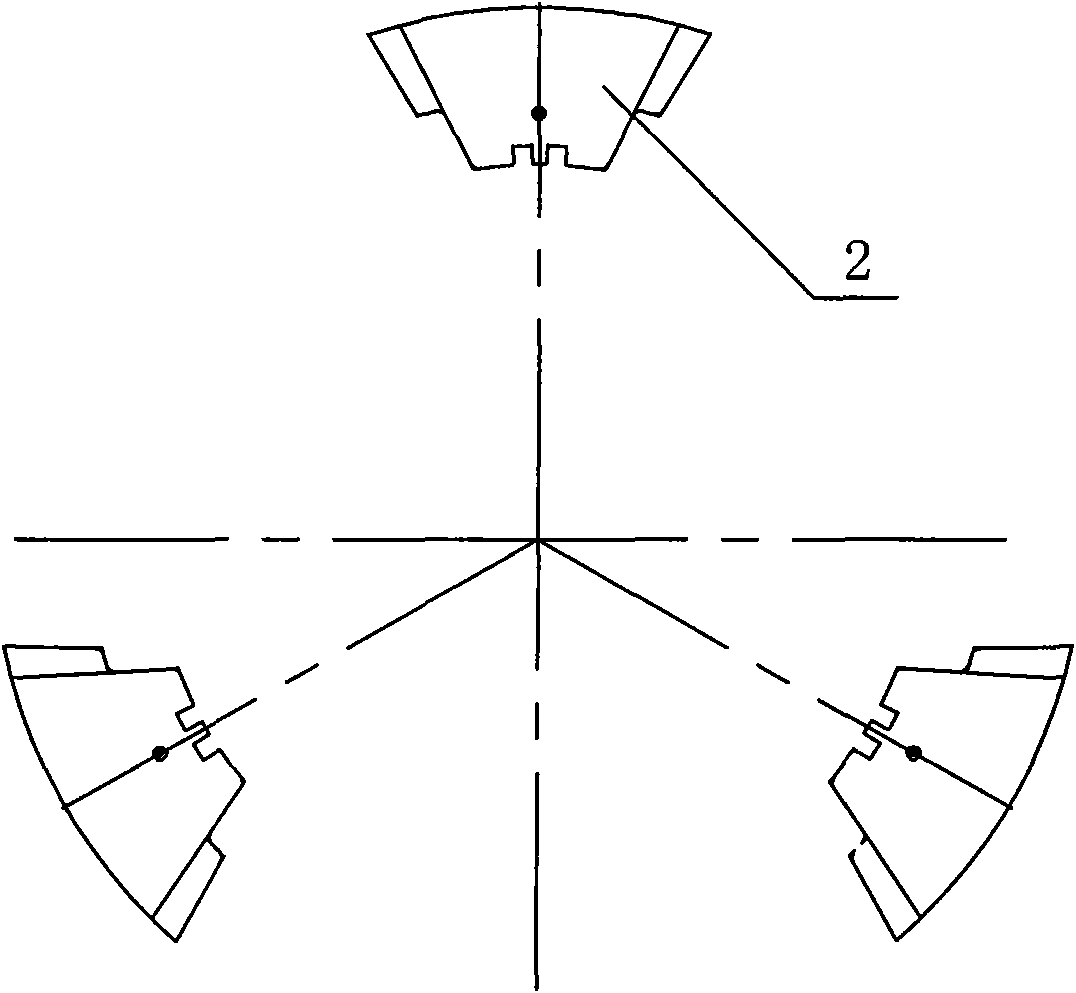

Position correction method, scanning control method, medium and equipment for selective laser melting

ActiveCN107718540AEliminate misalignmentImprove scan size accuracyAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser meltingDislocation

The invention relates to a position correction method, a scanning control method, a medium and equipment for selective laser melting. The position correction method comprises the following steps of: acquiring a pre-machining section of a part model of a part to be machined at a current position in slicing software; controlling a scanner to scan a contour line containing at least two characteristicpoints according to the pre-machining section so as to obtain a printed contour line on a covering plate covering corresponding points of corresponding characteristic points on the part to be machined; obtaining a position deviation value between position points of the corresponding characteristic points on the printed contour line and corresponding points of the corresponding characteristic points on the actual contour line of the part to be machined; and correcting the current position of the part model based on the position deviation value. Therefore, the position deviation value can accurately reflect the deviation between the position of the part model and the actual position of the part to be machined in the slicing software, thereby correcting the position of the part model in theslicing software according to the position deviation value, effectively eliminating dislocation, improving the scanning dimension precision and improving the forming precision of printing manufacturing.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Machining technology for rotary blade type hydraulic steering gear

InactiveCN101537569AImprove consistencyReduce manufacturing costOther manufacturing equipments/toolsEngineeringCopper

The invention relates to the machining technology for a steering gear, in particular to the machining technology for a rotary blade type hydraulic steering gear, comprising a machining procedure for an inside hole of a cylinder body and a sealing surface at the lower end of the cylinder body, a machining procedure for a sealing groove on the sealing surface at the lower end of the cylinder body, a machining procedure for appearance of a stationary blade and a machining procedure for the stationary blade and a connecting hole of the cylinder body, a combination machining procedure for the cylinder body, the stationary blade and a copper sleeve, a machining procedure for an inside conical hole of a rotor and a machining procedure for an incomplete arc surface of the rotor. The machining procedures of the invention can greatly improve the machining accuracy and efficiency of each main part of the rotary blade type hydraulic steering gear, lower the production cost, as well as improve the working efficiency and the product quality.

Owner:CSSC NANJING LUZHOU MACHINE

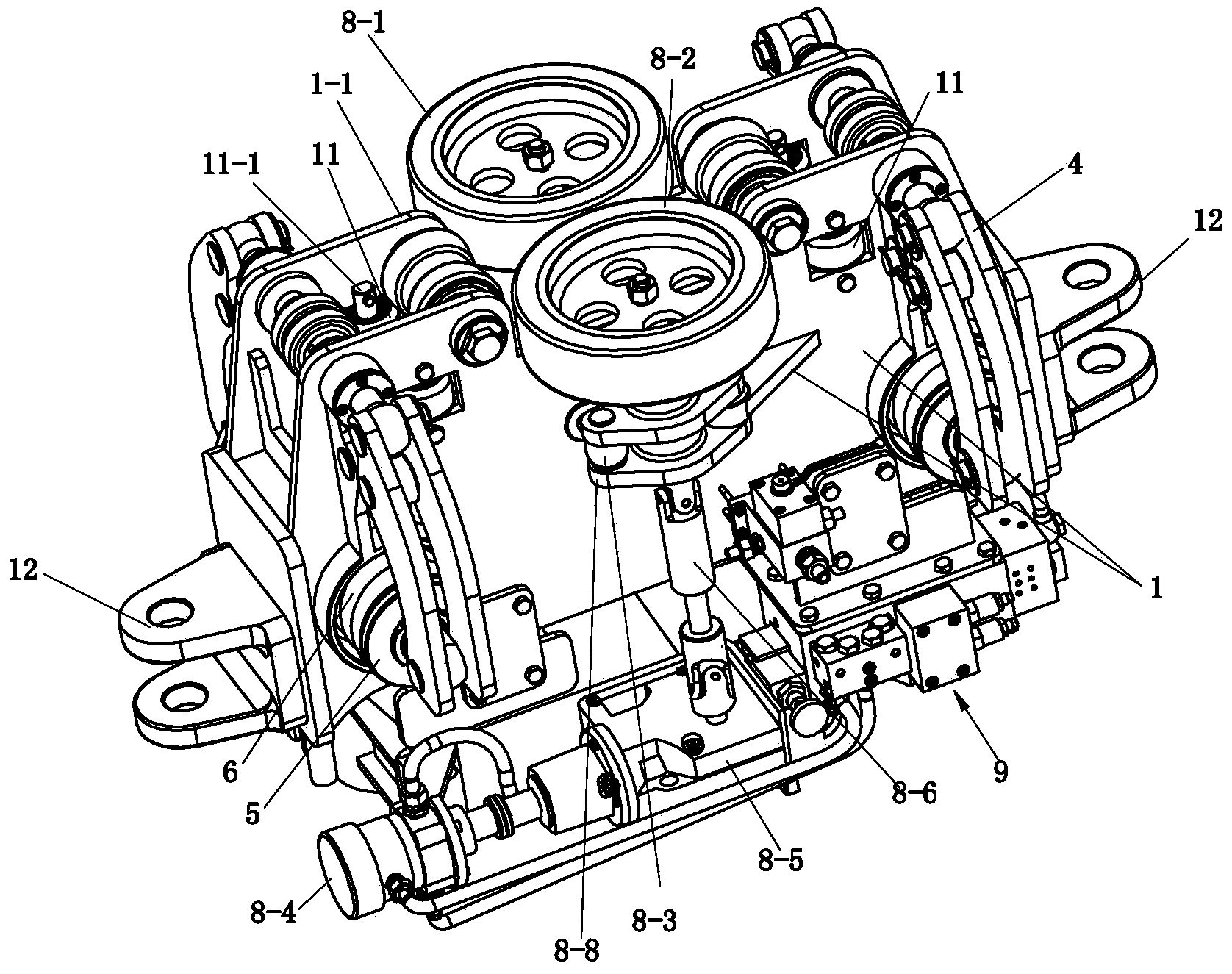

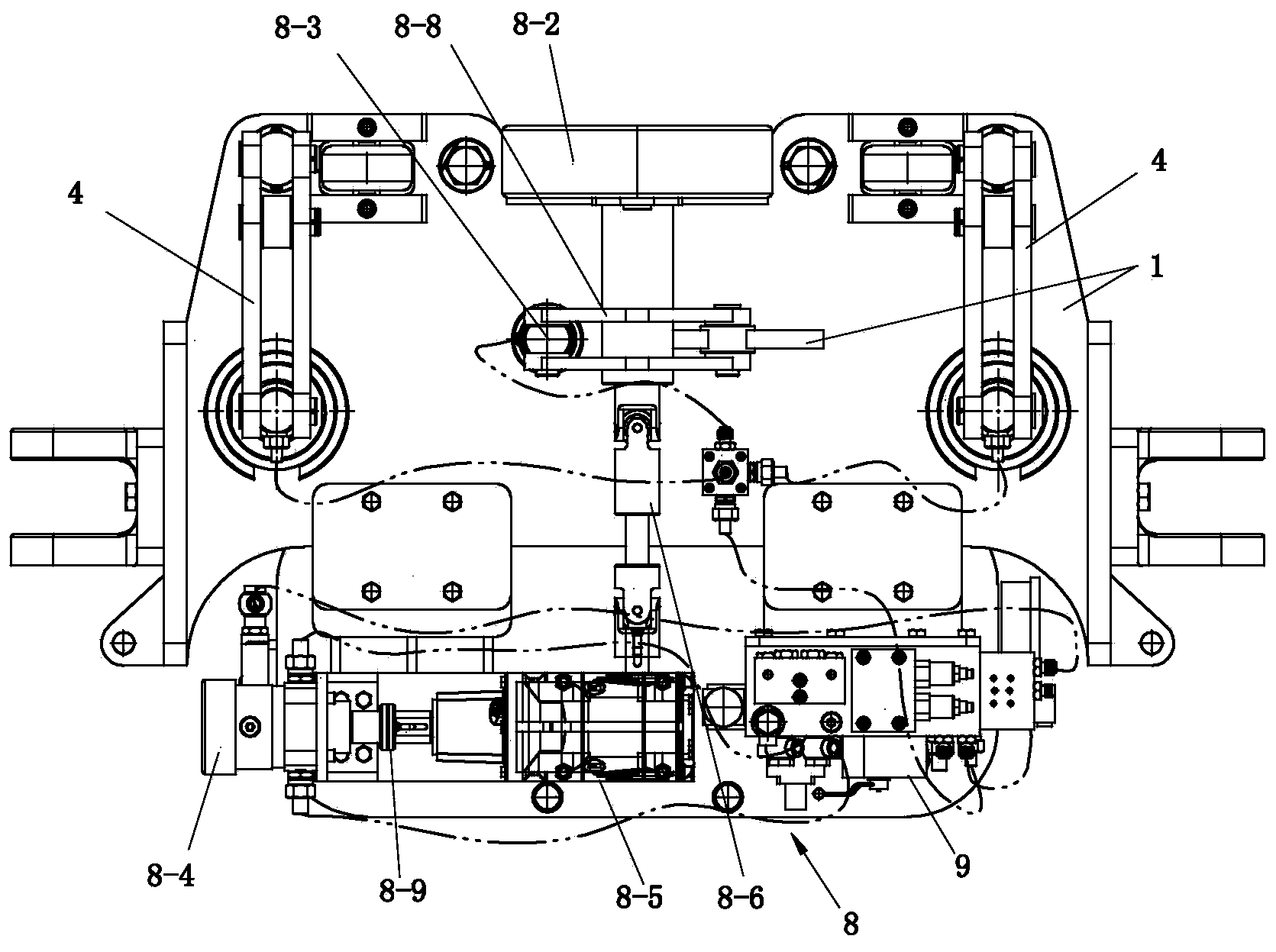

Rope traction monorail crane system braking vehicle

ActiveCN104260744ADriving safetyFully absorb liquidTrack-braking member co-operationHydraulic motorVehicle frame

The invention discloses a rope traction monorail crane system braking vehicle, and the rope traction monorail crane system braking vehicle comprises a frame, two pairs of walking wheels and two pairs of brake shoes are arranged between two sidewalls of the frame, two pairs of brake shoes are driven by a pair of brake arms, two pairs of brake arms are driven by brake oil cylinder, the frame is provided with a speed selecting and increasing device, the speed selecting and increasing device comprises a first speed selecting wheel, a second speed selecting wheel, a clamping oil cylinder, a dual-direction hydraulic motor and a gearbox, the first speed selecting wheel shaft and the second speed selecting wheel shaft are supported by the first wheel shelf and the second wheel shelf, the shaft of the second speed selecting wheel is connected to the low speed shaft of the gearbox through cross-shaped universal coupler, the high speed shaft of the gearbox is connected to the drive shaft of the dual-direction hydraulic motor through elastic coupler. The speed selecting and increasing device controls two pairs of brake shoes of the braking vehicle by selecting speed judgment, the brake shoes on the other vehicles can also be controlled for guaranteeing the safe drive for the rope traction monorail crane system.

Owner:CHANGZHOU DEV & MFR CENT

Manufacturing method for micro-transformers

InactiveUS7947600B2Improve throughputAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesTransformerImpurity

A micro-transformer manufacturing method is provided, which can improve throughput, prevent a crack from entering an insulating film between coils, and manufacture the micro-transformer without using a mask material having a high selection ratio. An insulating film is deposited on the whole face of a semiconductor substrate having an impurity-diffused region. This insulating film is partially removed to form a first opening and a second opening. A primary coil is formed such that a center pad contacts the impurity-diffused region through the first opening. A thin insulating film is deposited on the primary coil. An insulator material having a secondary coil formed thereon is adhered onto the insulating film on the primary coil by adhesive tape. The insulator material is sized to not cover both a pad, connected with the center pad of the primary coil through the impurity-diffused region, and an outer-end pad of the primary coil.

Owner:FUJI ELECTRIC CO LTD

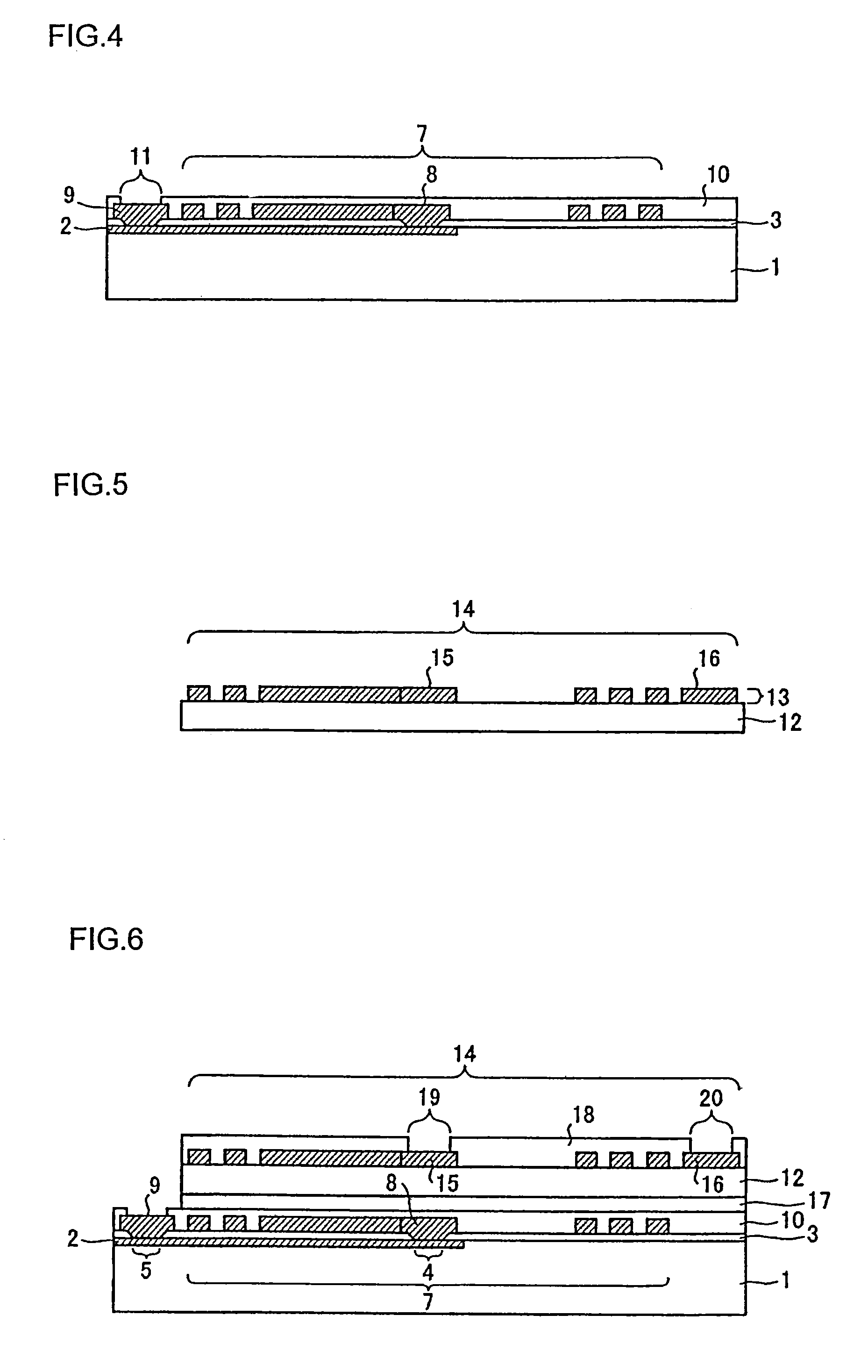

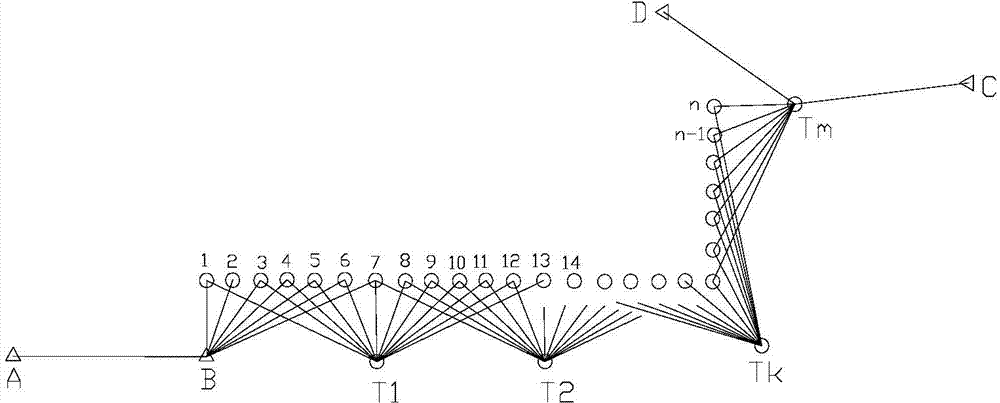

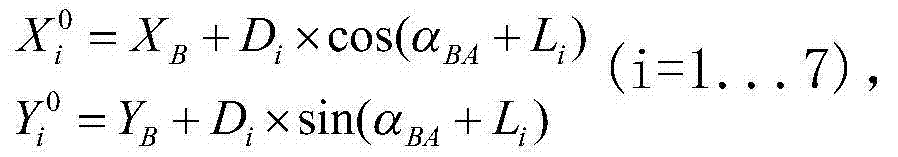

Multi-common-turning-point lateral intersection traverse surveying method

ActiveCN104729489AGuaranteed StrengthImprove reliabilitySurveying instrumentsUnderground cavernEstimation methods

The invention belongs to a multi-common-turning-point lateral intersection traverse surveying method used for narrow underground caverns short in intervisibility distance and changed in traverse extending paths in the technical field of engineering surveying. The multi-common-turning-point lateral intersection traverse surveying method includes the steps of arranging at least two survey stations on a traverse extending path, arranging a plurality of public survey turning points on the other sides of connection lines among the survey stations uniformly, and adopting a high-precision total station for automatic observation; correcting surveyed slope distance and using the same to compute an independent coordinate for each survey station; computing three converting parameters between the independent coordinate and an integral coordinate of each public turning point between adjacent survey stations by the aid of a least-square indirect adjustment method and a robust estimation method, and converting the independent coordinates into integral coordinates. The multi-common-turning-point lateral intersection traverse surveying method has the advantages that enough redundant observation objects for traverse transferring and high precision are achieved, influence of lateral refraction is avoided, influence of error of centralization of an instrument and a prism during traverse transferring is eliminated, influences of gross observation error on an adjustment result are reduced, and the multi-common-turning-point lateral intersection traverse surveying method is suitable for places in difficult conditions, such as narrow underground caverns, curve paths and visualizing obstacles, and capable of improving precision and reliability of traverse transferring.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

System and Method for Concrete Slab Connection

Systems and methods of transferring loads between adjacent cast-in-place slabs, such as concrete slabs, and for accurately positioning dowels between adjacent sections of slabs are provided. A generally planar plate-type dowel is used which may be positioned within a cutaway in a preexisting slab of concrete. The dowel is shaped to generally conform to the shape of the cutaway, which is made by a saw blade. Once the dowel is positioned within the preexisting slab, a new slab is poured adjacent the preexisting slab. Rubber seals are included on the edges of the dowels to provide spacing or a gap between the dowel and the preexisting slab to allow for lateral independent movement of the adjacent slabs, and to prevent concrete from the newly poured second slab from entering into the gap. A saw unit for making a generally planar cut horizontally into an edge of a hardened concrete slab is also provided.

Owner:ILLINOIS TOOL WORKS INC

Full-automatic assembly line for rotating disc type button switch conductive system

ActiveCN109014902AEliminate deformationEliminate misalignmentAssembly machinesElectric switchesAssembly linePosition sensor

The invention discloses a full-automatic assembly line for a rotating disc type button switch conductive system. The full-automatic assembly line for the rotating disc type button switch conductive system is characterized in that a rotating disc is arranged on a table board I; eight stations are uniformly arranged on the upper surface of the rotating disc along the circumference; a group of locking fixtures is arranged at each station; various execution mechanisms are arranged on the table board I around the rotating disc and comprise a housing feeding mechanism, a pair of recognition sensors,a lower contact piece distributing, feeding and screwing mechanism, a lower contact piece bending assembly, an upper contact piece distributing, feeding and screwing mechanism, an upper contact piecebending assembly, a pair of position sensors and a discharging assembly. The full-automatic assembly line for the rotating disc type button switch conductive system provided by the invention is compact in structure, high in automation degree, and high in assembling quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Lateral PNP transistor and the method of manufacturing the same

InactiveUS20060118881A1Increase production capacityEliminate alignment issuesSolid-state devicesSemiconductor/solid-state device manufacturingBreakdown voltageDoping profile

The present invention relates to a lateral PNP transistor and the method of manufacturing the same. The medium doping N-type base area and the light doping P− collector area were first introduced in the structure before the formation of P+ doping emitter area and the collector area. The emitter-base-collector doping profile in the lateral and the base width of LPNP were similar to NPN. The designer can optimize the doping profile and area size of each area according to the request of the current gain (Hfe), collector-base breakdown voltage (BVceo), and early voltage (VA) of LPNP transistor. These advantages may cause to reduce the area and enhance performance of the LPNP transistor.

Owner:BCD SEMICON MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com