Lateral PNP transistor and the method of manufacturing the same

a technology of pnp transistor and lateral pnp, which is applied in the direction of transistors, semiconductor devices, electrical devices, etc., can solve the problems of complex circuit design, increased process complexity, and cost, and achieves the elimination of multiple alignment mismatches, accurate control of the width of the base and the collector, and enhanced product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

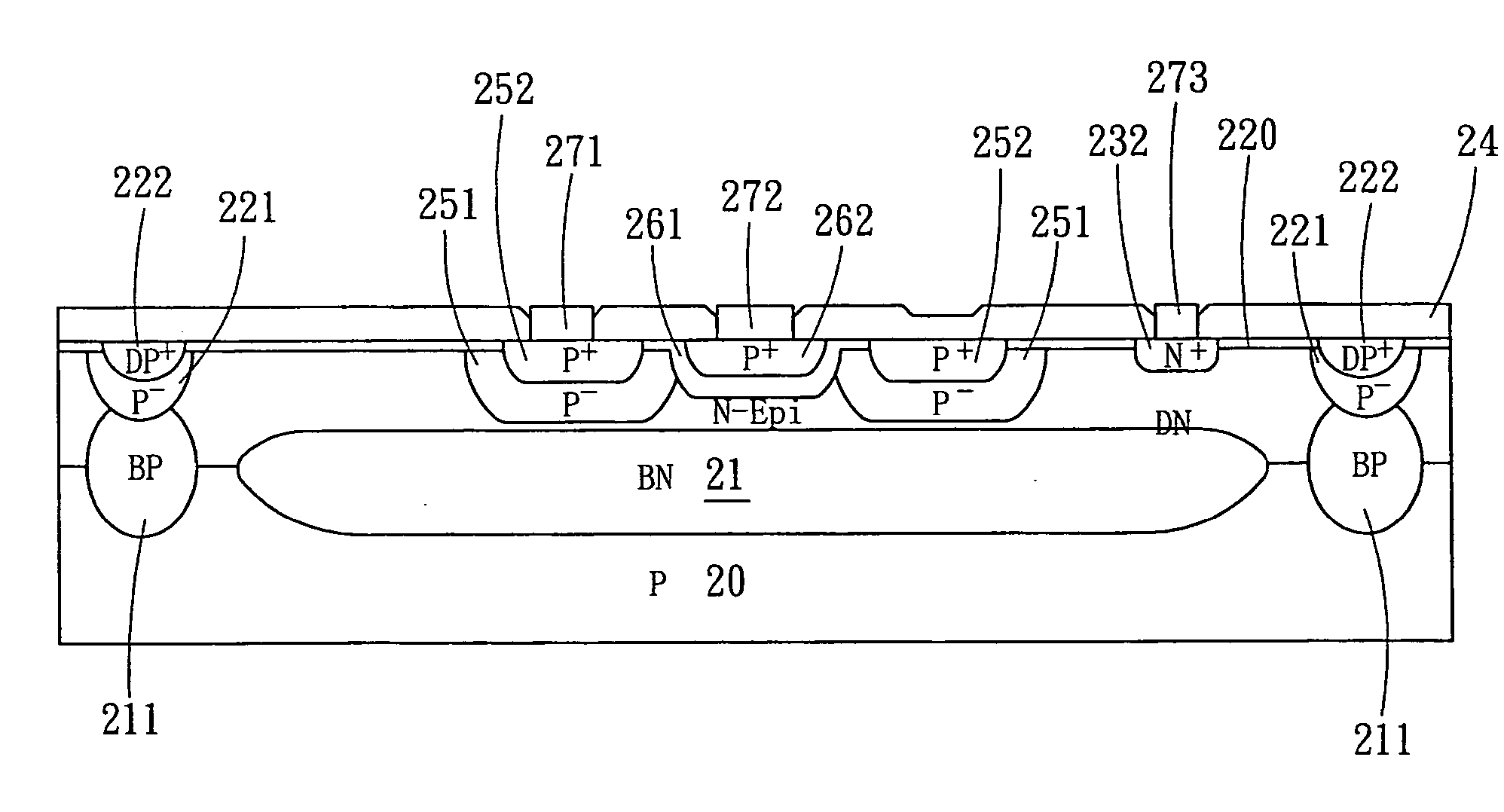

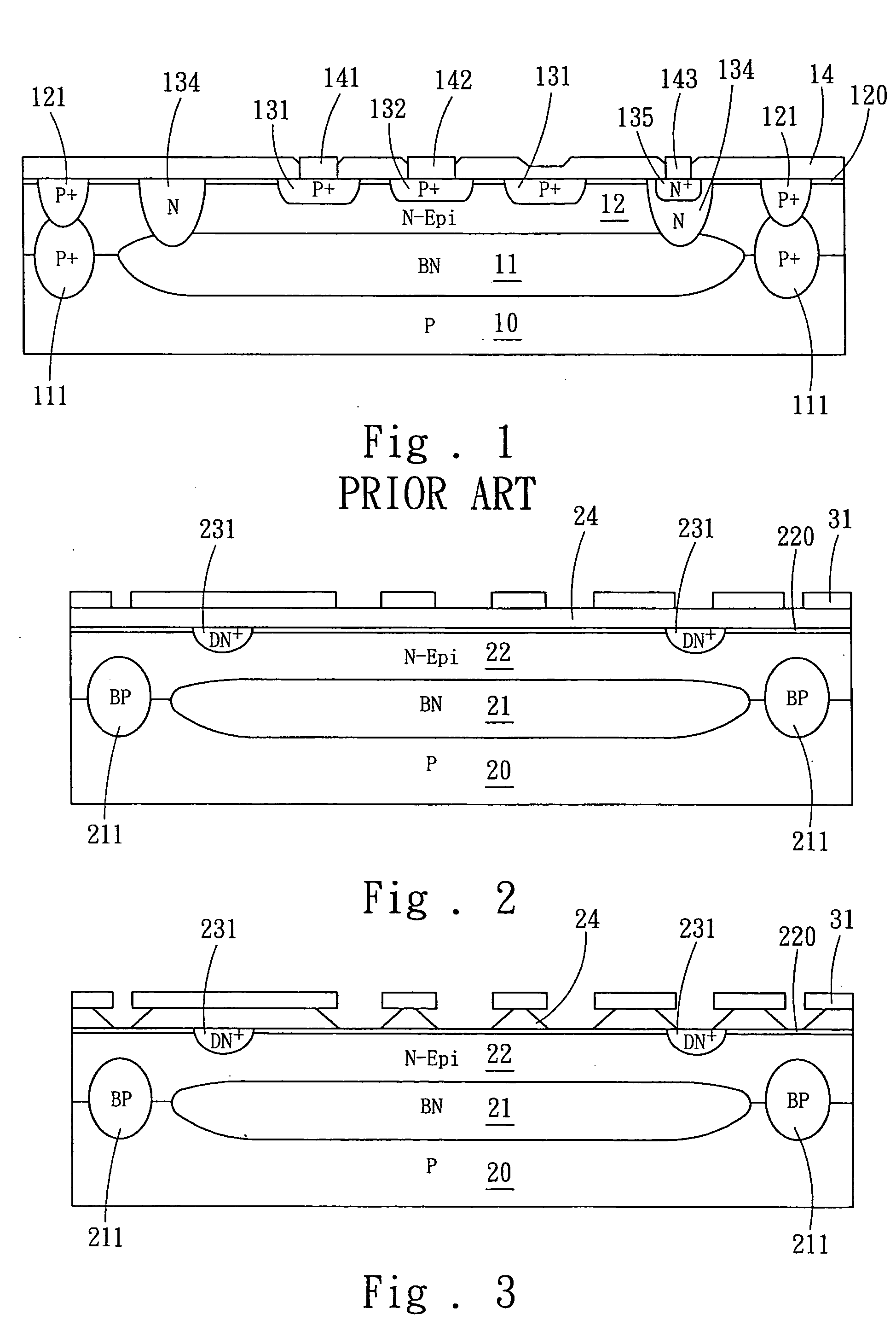

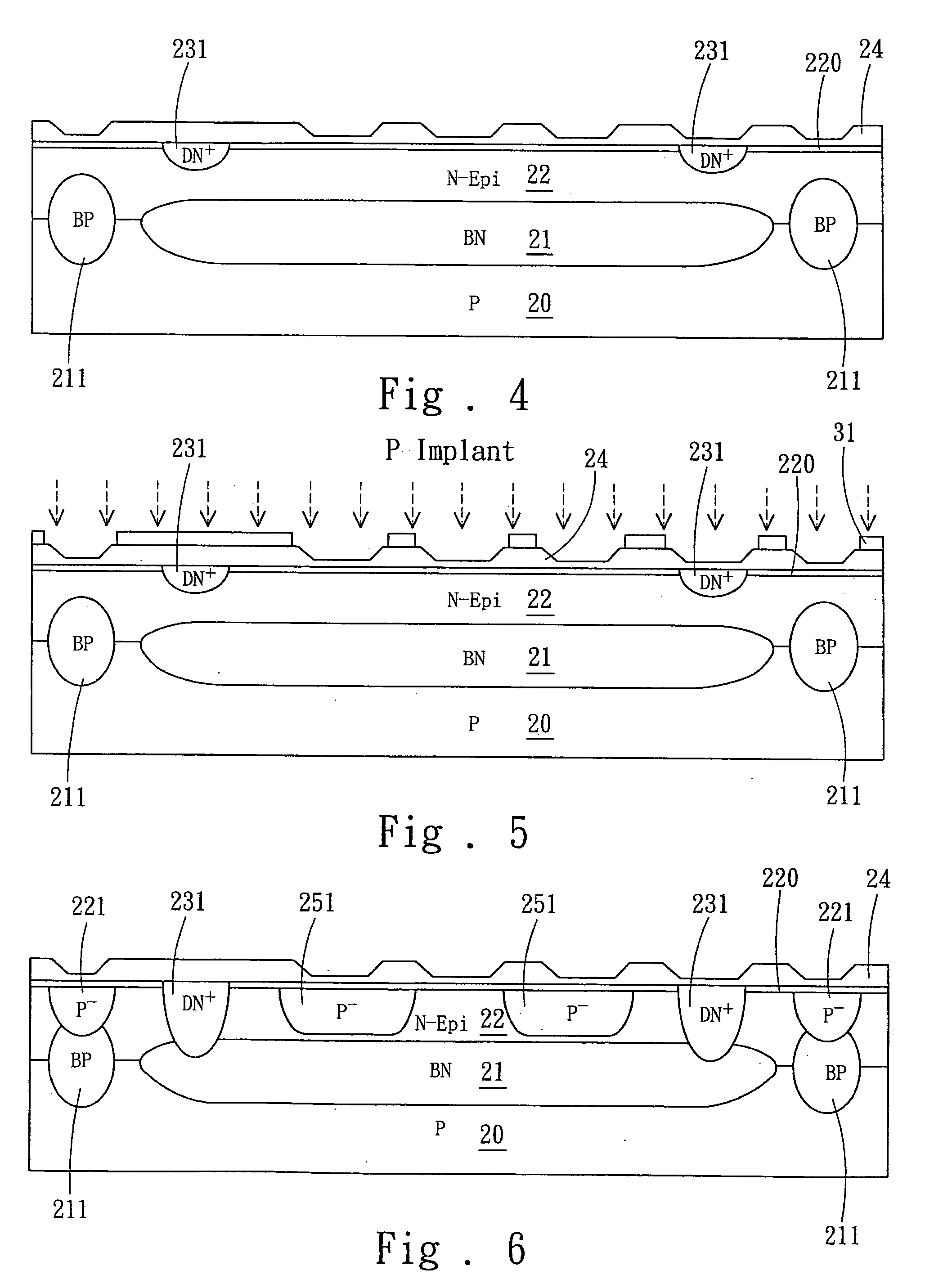

[0021] Please referring FIG. 2˜FIG. 10 at the same time, the descriptions of these figures show as below:

[0022] Referring now to the FIG. 2, an N-type buried layer 21, which is made by N-type implant and drive-in, is formed on the surface of P-type doping substrate 20. These layers all formed according to well-known semiconductor processing techniques. The P-type buried layers 211 , which is made by P-type implant and drive-in processes, surround around the N-type buried layer 21. Next, the N-type epi layer 22 and N-type field implant layer 220 are formed sequentially on the surface of substrate 20, N-type buried layer 21, and P-type buried layers 211. Furthermore, the deep N+-type sinker areas, which are made by photolithography, etch, and N+-sinker doping processes downward the surface of field implant layer 220, formed on top of the buried layer 21. Next, the oxide layer 24 is formed on the N-type field implant layer 220. Finally, the resist mask layers 31, which define the regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com