Full-automatic assembling-welding system for electric conduction assembly of low-voltage plastic-shell circuit breaker

A technology for molded case circuit breakers and conductive components, which is applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of poor welding, low production efficiency, and low product quality of the conductive components of the oil cup yoke coil, and eliminates the need for High failure and jam, high production efficiency, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

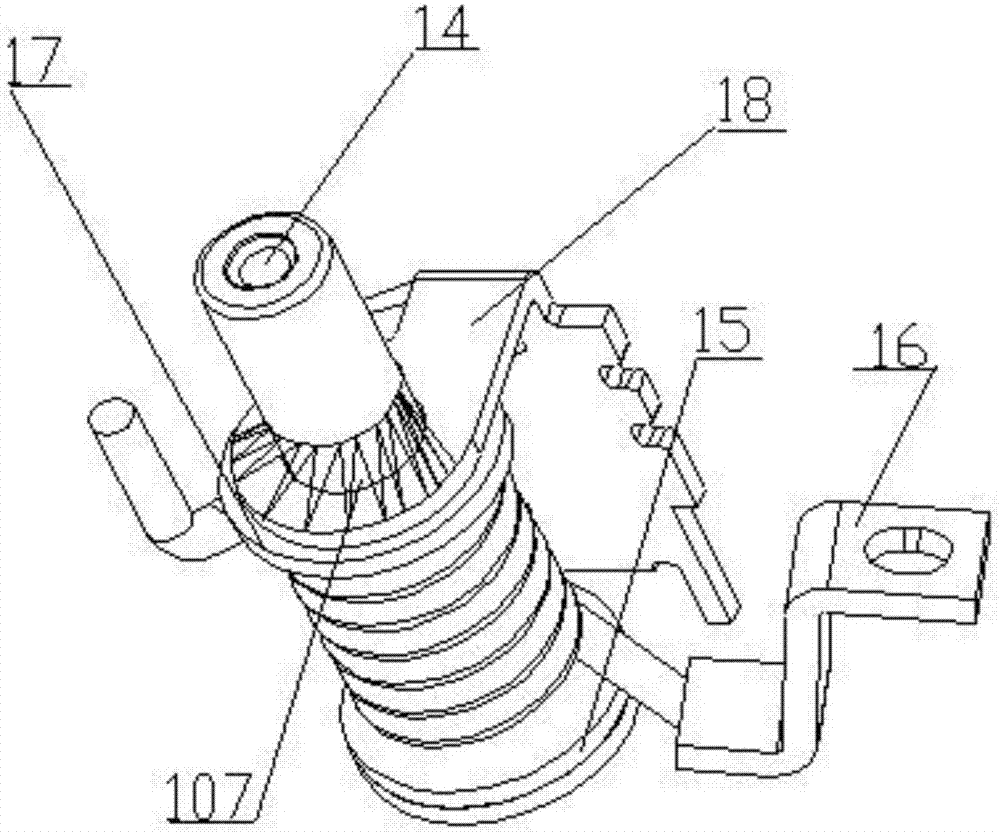

[0040] Such as figure 1 As shown, the working object of the welding system of the present invention is a conductive component used in a low-voltage molded case circuit breaker. Its structure is to include an oil cup 14. The large end section of the oil cup 14 is a circular plate pole with an inverted T-shaped structure. Boots, on the outer circumference of the oil cup 14, from bottom to top, a multilayer ring-shaped paper lower gasket 15, a multi-turn coil 16, a multilayer ring-shaped paper upper gasket 17, an inverted L-shaped structure yoke 18. After soldering, a welding seam 107 with a triangular cross-section is formed, the maximum thickness of the welding seam 107 is 2mm, and the extension length of the welding seam 107 is not less than 1 / 3 circle along the circumference.

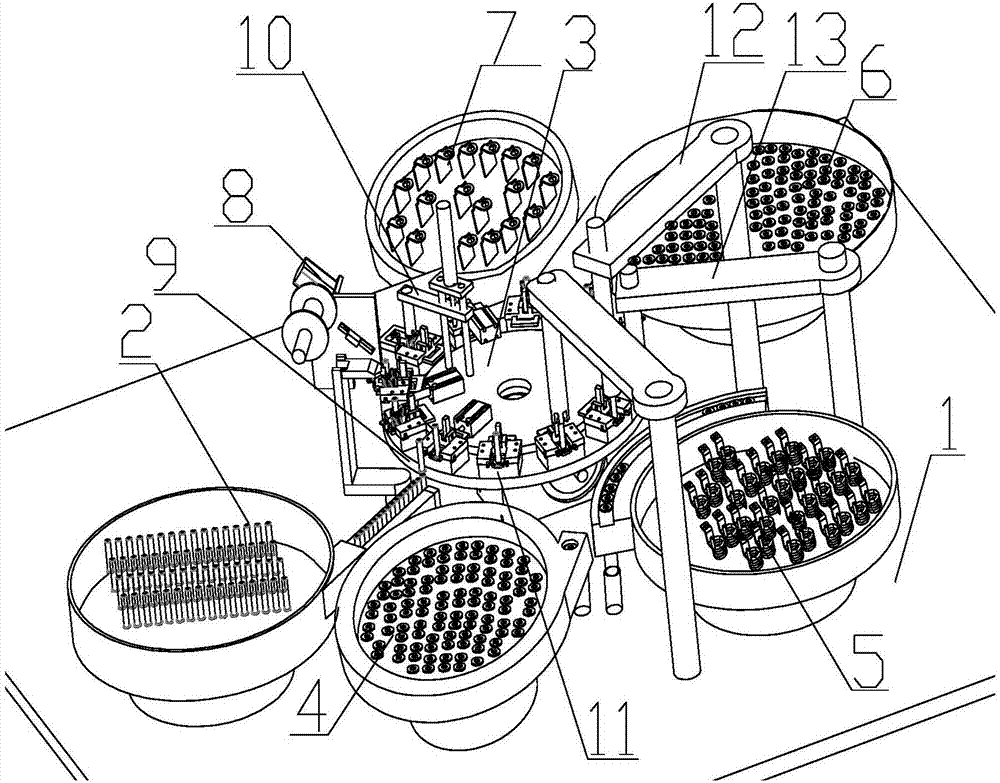

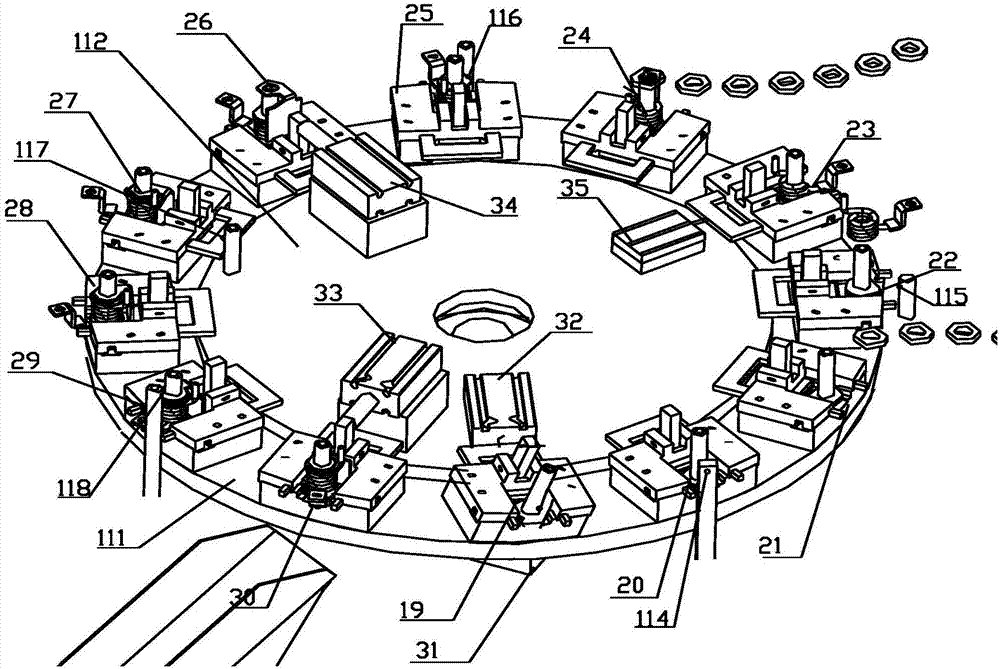

[0041] The welding system of the present invention is to automatically assemble and weld together the oil cup 14, the lower gasket 15, the coil 16, the upper gasket 17, and the magnetic yoke 18 of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com