Patents

Literature

62results about How to "Eliminate jamming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paper containing preggregated filler and process for producing the same

InactiveUS20090162642A1Less blisteringReduce delaminationNatural cellulose pulp/paperCoatings with pigmentsPolymer sciencePolysaccharide

Provide a paper offering good paper strength properties in terms of strength and stiffness, high smoothness and excellent printing quality by adjusting the ash content in paper to a range of 3 to 40 percent by solid weight and allowing the paper to contain a pre-coagulated filler having an average particle size of 10 to 80 μm as measured by the laser diffraction method, wherein such filler is obtained by processing a filler using a composite acrylamide copolymer comprising (A) an anionic polysaccharide and (B) a cationic and / or amphoteric acrylamide copolymer.

Owner:NIPPON PAPER IND CO LTD +1

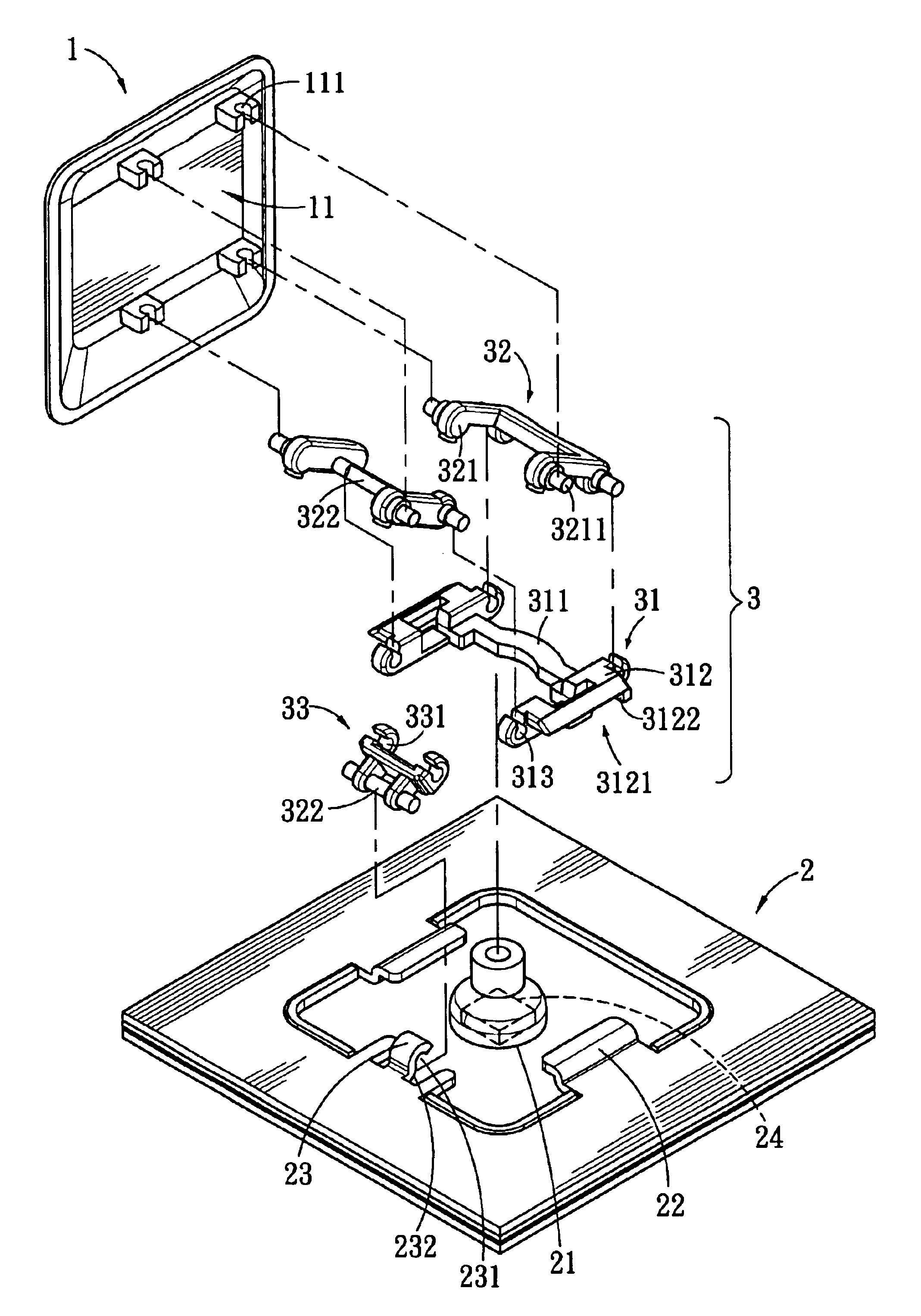

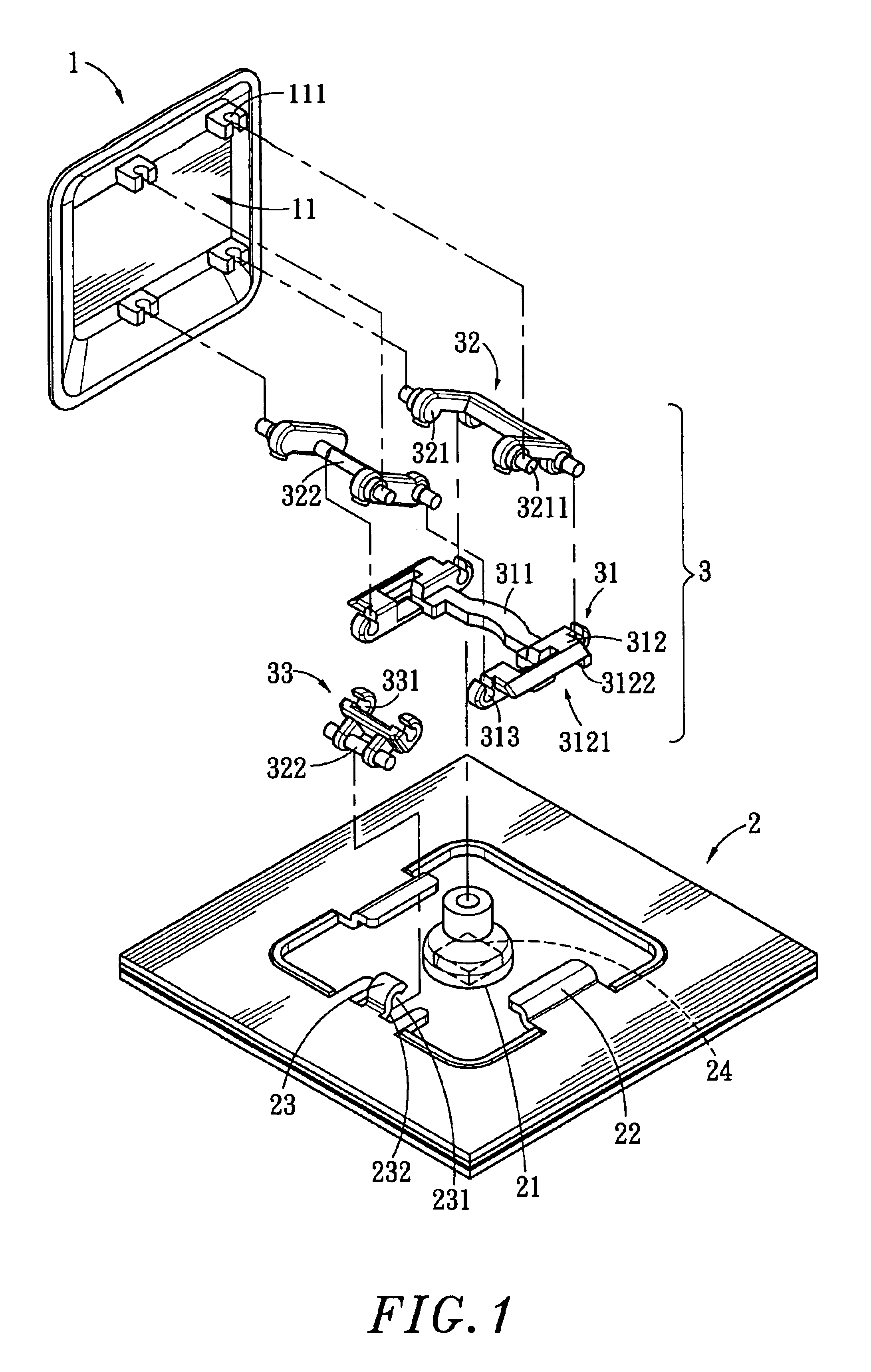

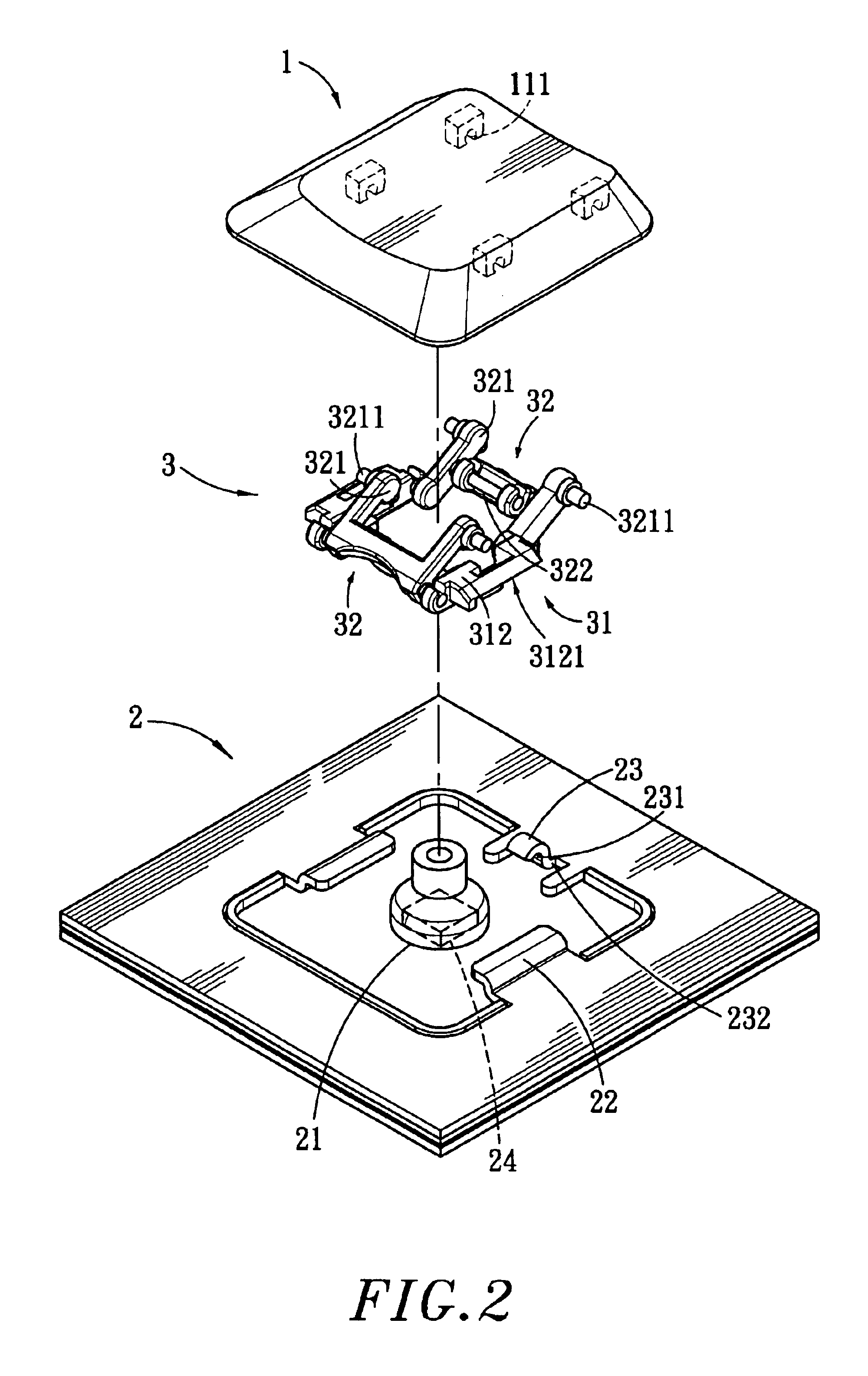

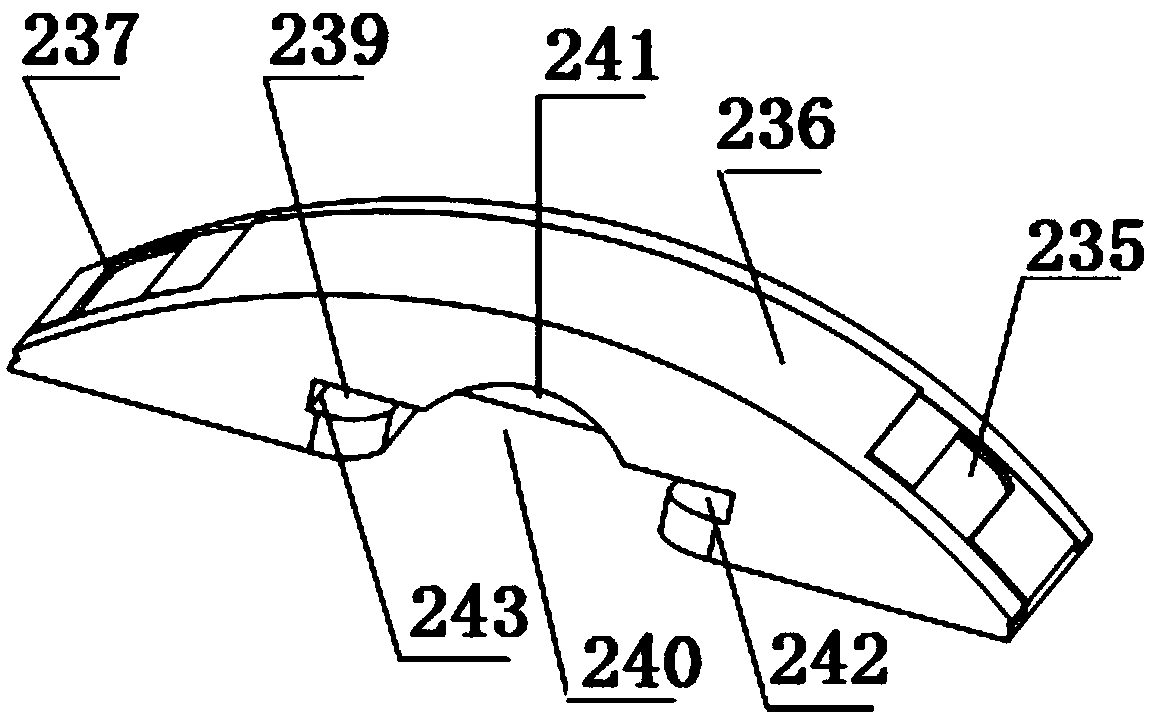

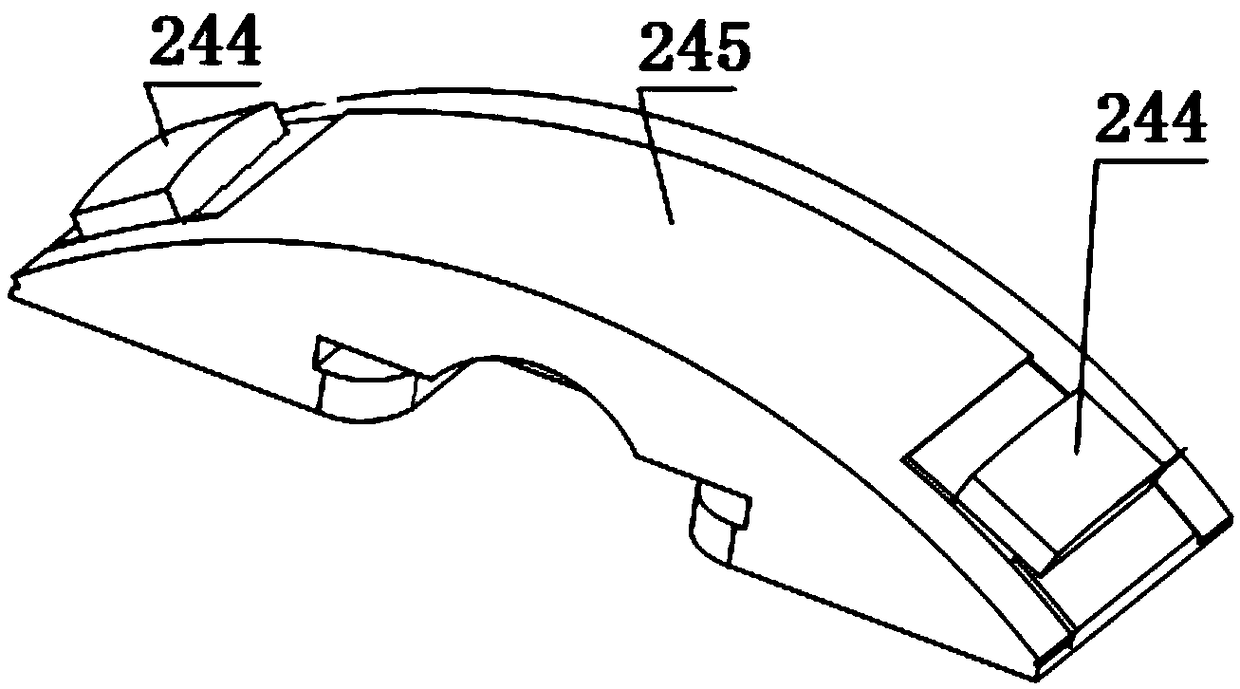

Structure of button for electronic product

A structure of button for an electronic product has an upper lid, a chassis having a switch and a parallel bar set, which positioned between the upper lid and the chassis, such that the upper lid can move down upon being depressed by an external force to activate the switch of the chassis and can substantially return to its original position upon removing the external force. The parallel bar set has a base, two supporting racks, positioned parallel to each other above the base, wherein a side of one of the two supporting racks is connected to a positioning bar and the positioning bar is buckled to the base, the positioning bar and two supporting racks are positioned between the chassis and the upper lid to enable the upper lid to move towards the chassis under the influence of a movement of the parallel bar set.

Owner:PATEN WIRELESS TECH

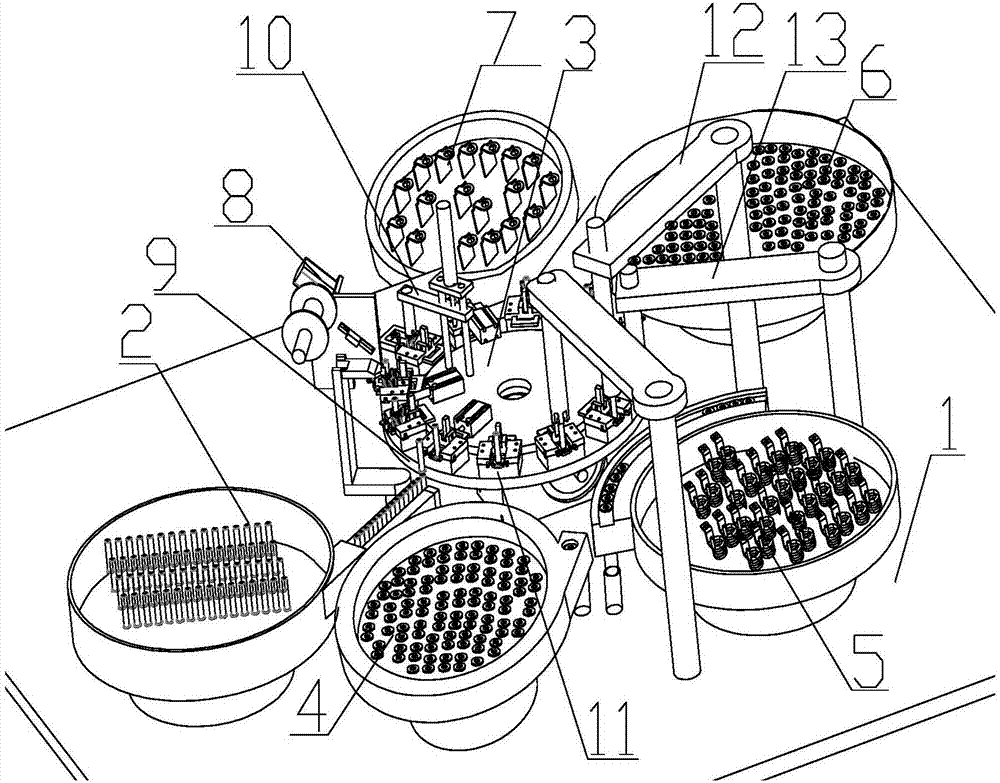

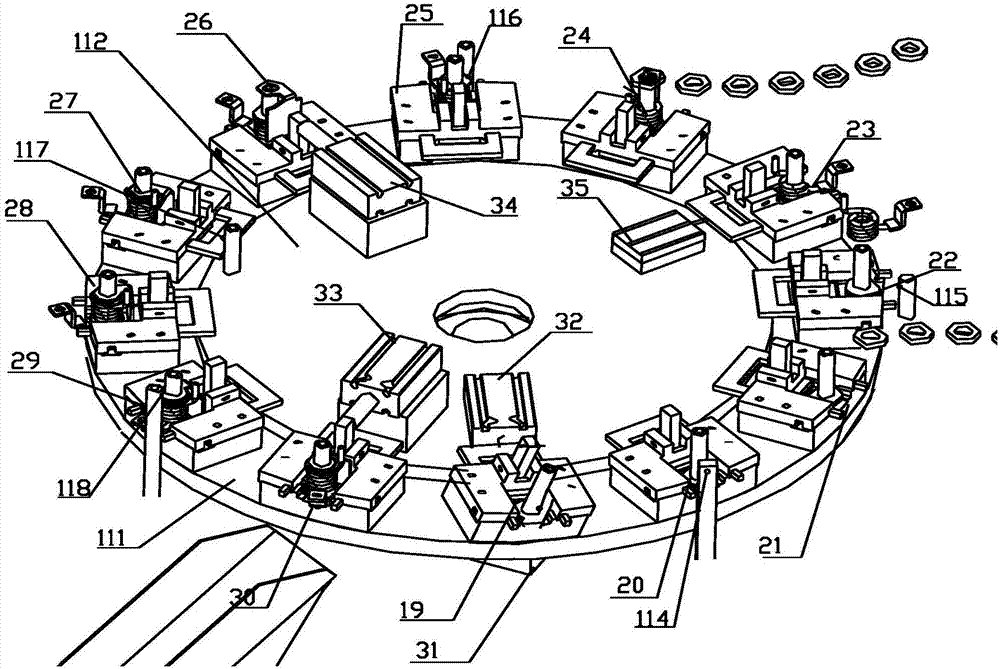

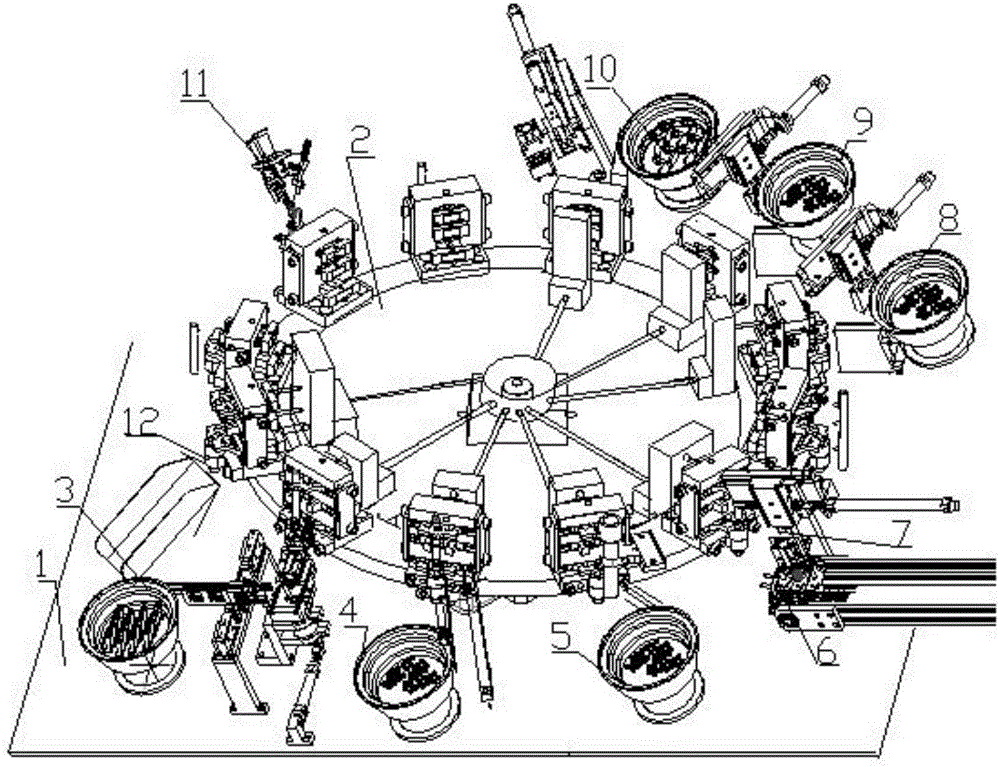

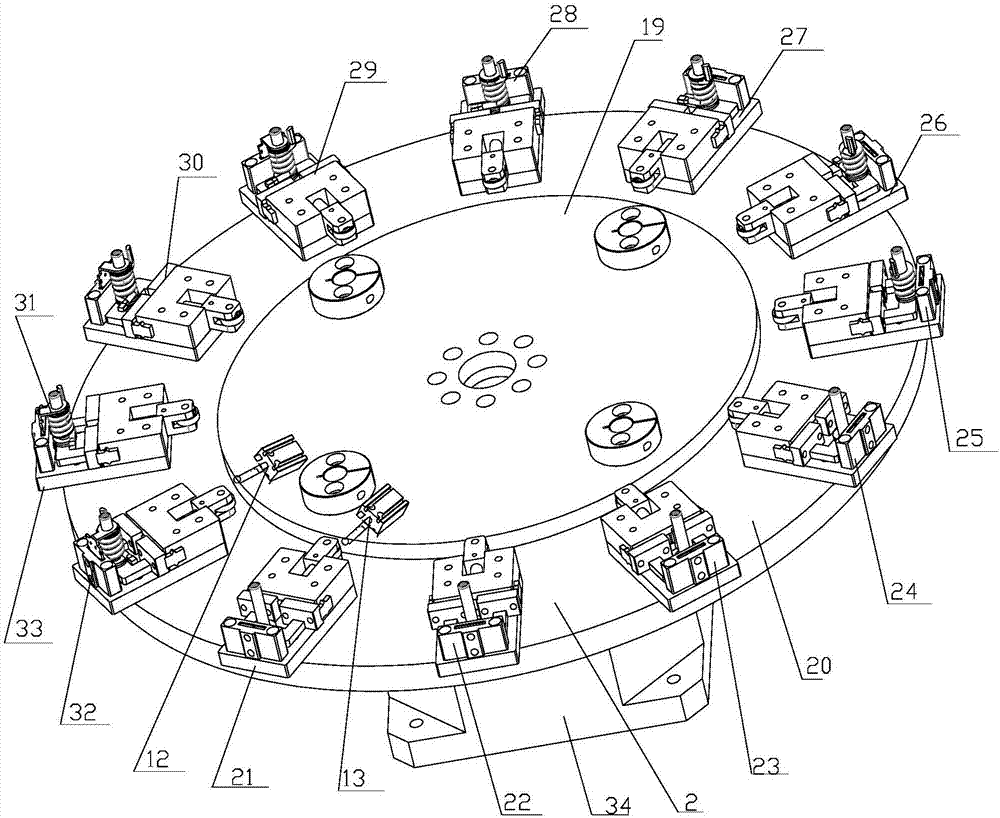

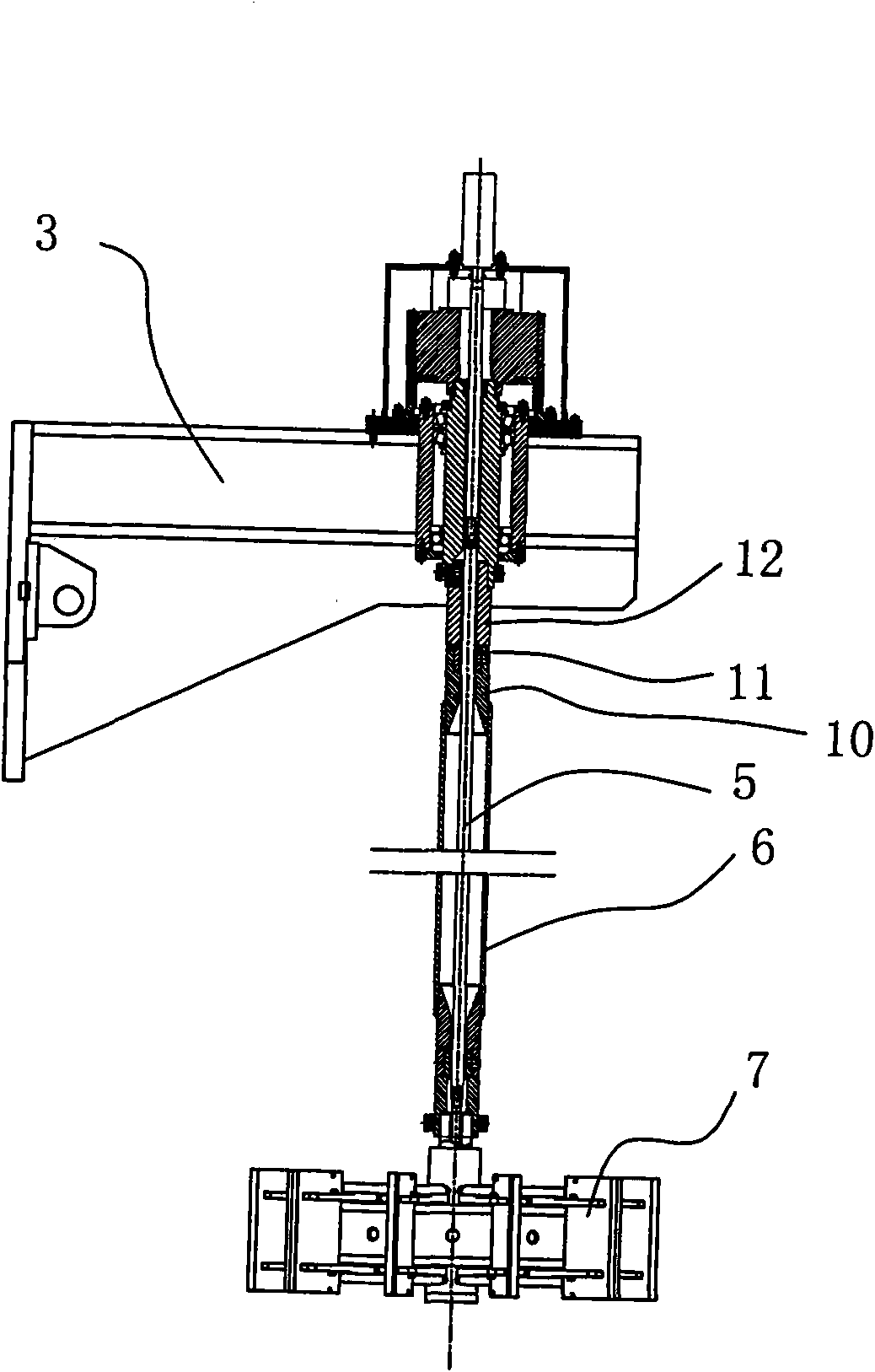

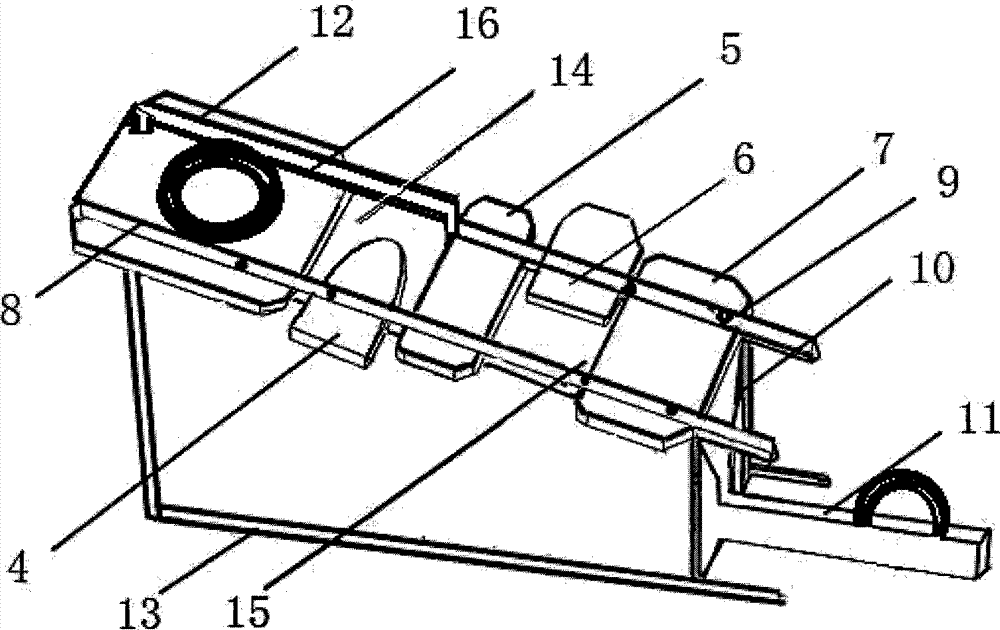

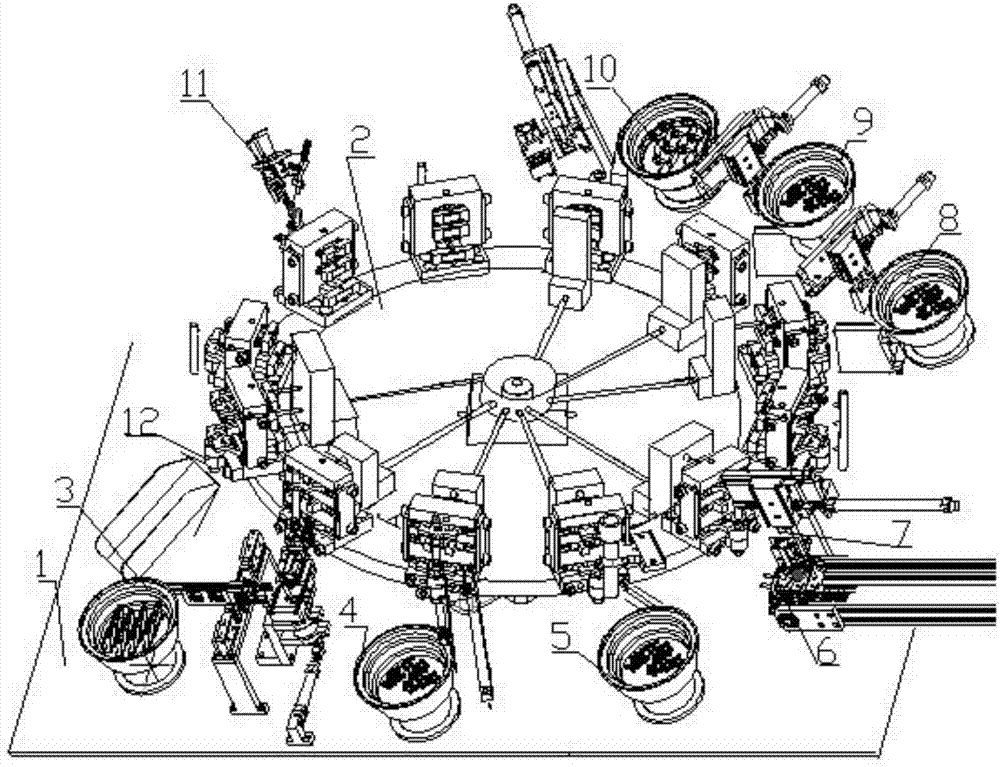

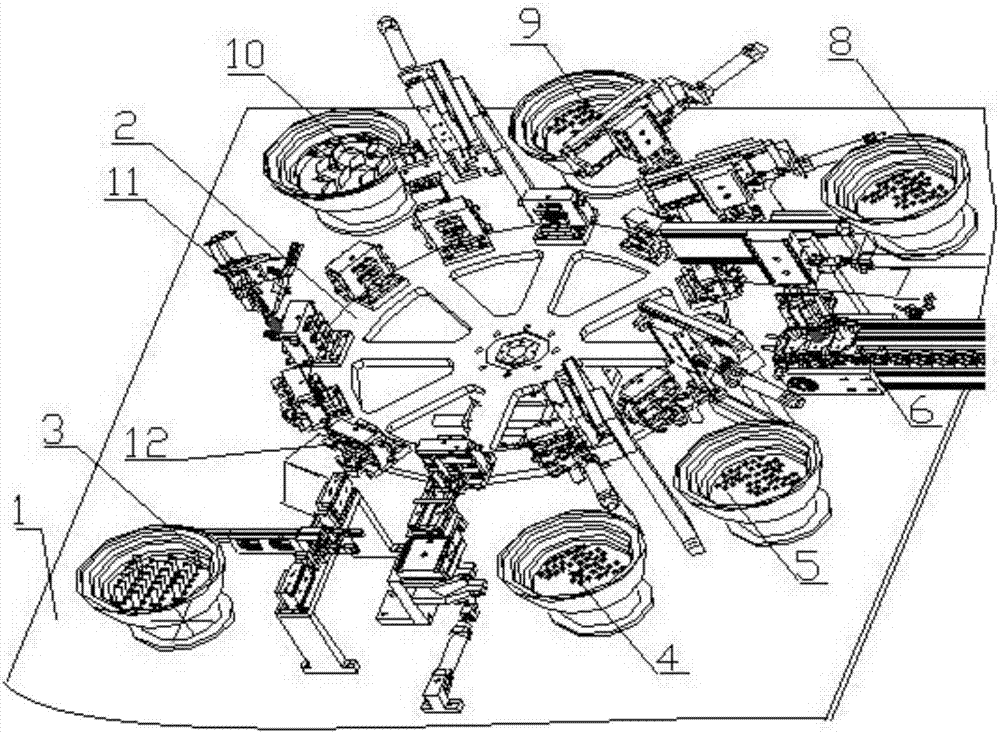

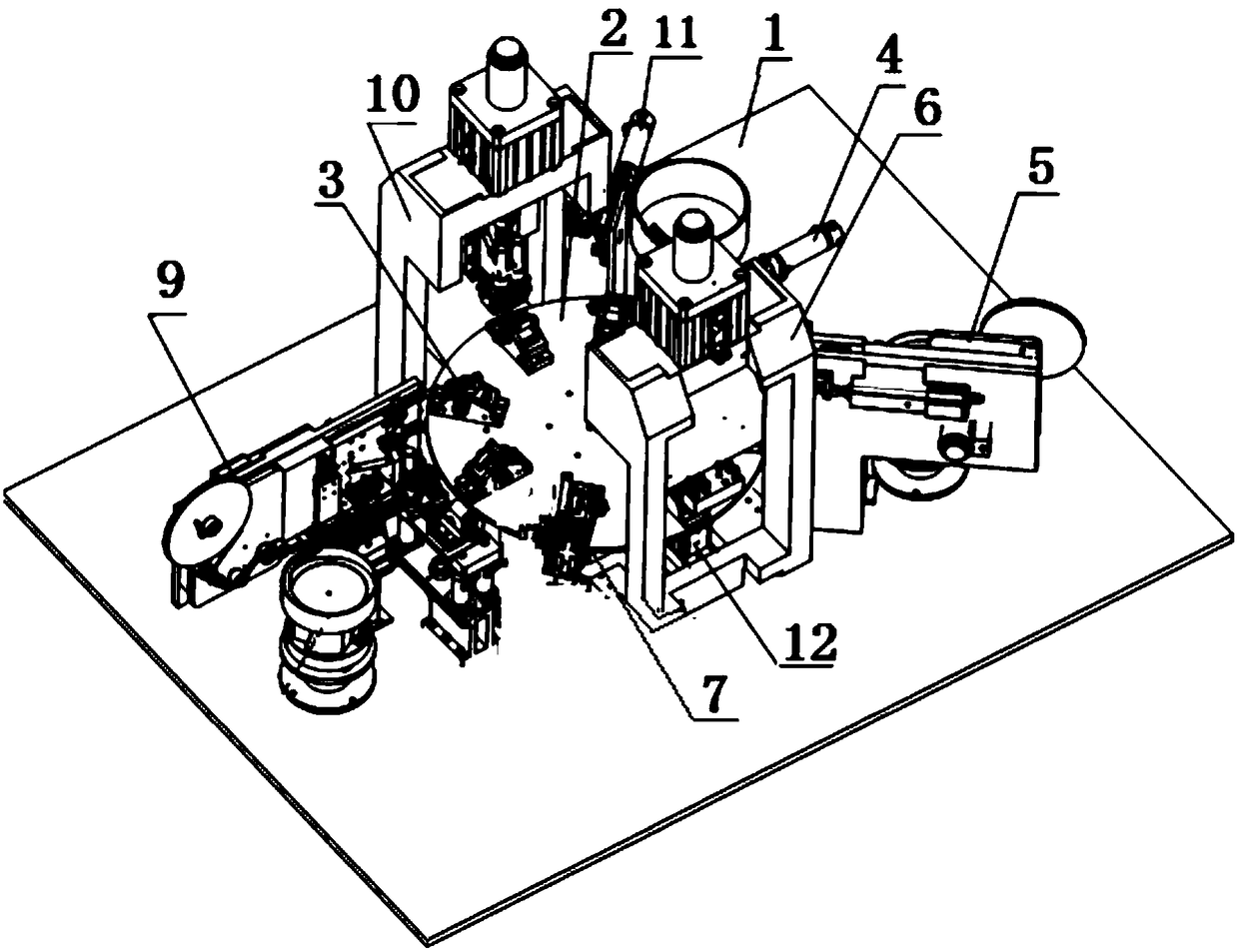

Full-automatic assembling-welding system for electric conduction assembly of low-voltage plastic-shell circuit breaker

ActiveCN107225304AEliminate weldsEliminate jammingMetal working apparatusSoldering auxillary devicesLow voltageCircuit breaker

The invention discloses a full-automatic assembling-welding system for an electric conduction assembly of a low-voltage plastic-shell circuit breaker. A rotating disc assembly is arranged on a horizontal table facet and comprises an inner disc and an outer rotating disc. The lower end of the inner disc is connected with a scale division mechanism. A first driving mechanism, a second driving mechanism, a third driving mechanism and a fourth driving mechanism are arranged on the upper surface, close to the outer edge, of the inner disc. Twelve clamp assemblies with the consistent structure are uniformly arranged on the outer rotating disc along the circumference. The twelve clamp assemblies are uniformly arranged as twelve rotating stations and are in one-to-one correspondence with feeding mechanisms, discharging mechanisms, a welding mechanism and a detector which surround the circumference of the rotating disc assembly. The structure is compact, the working efficiency is high, and the welding quality of a product is stable.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

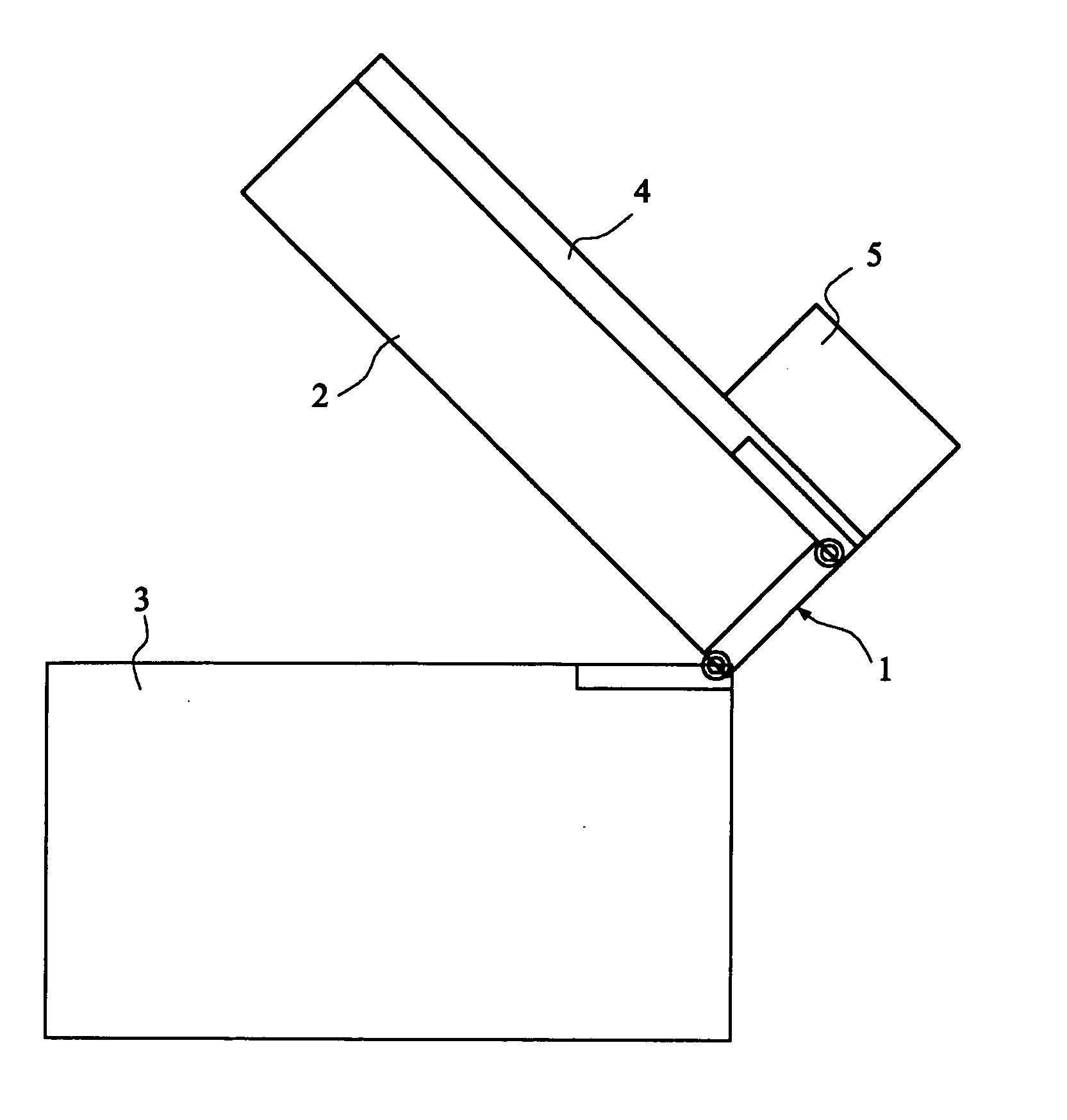

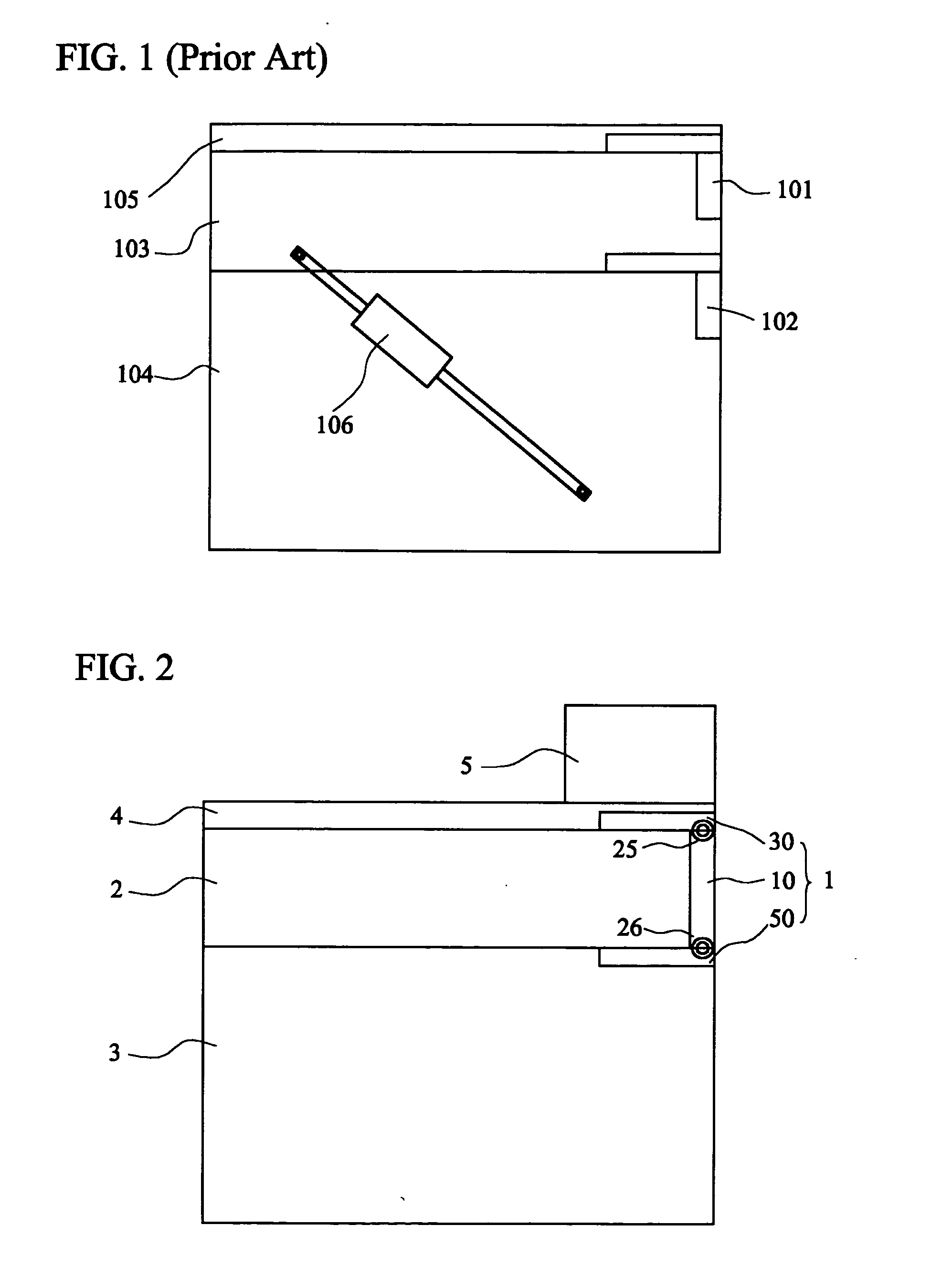

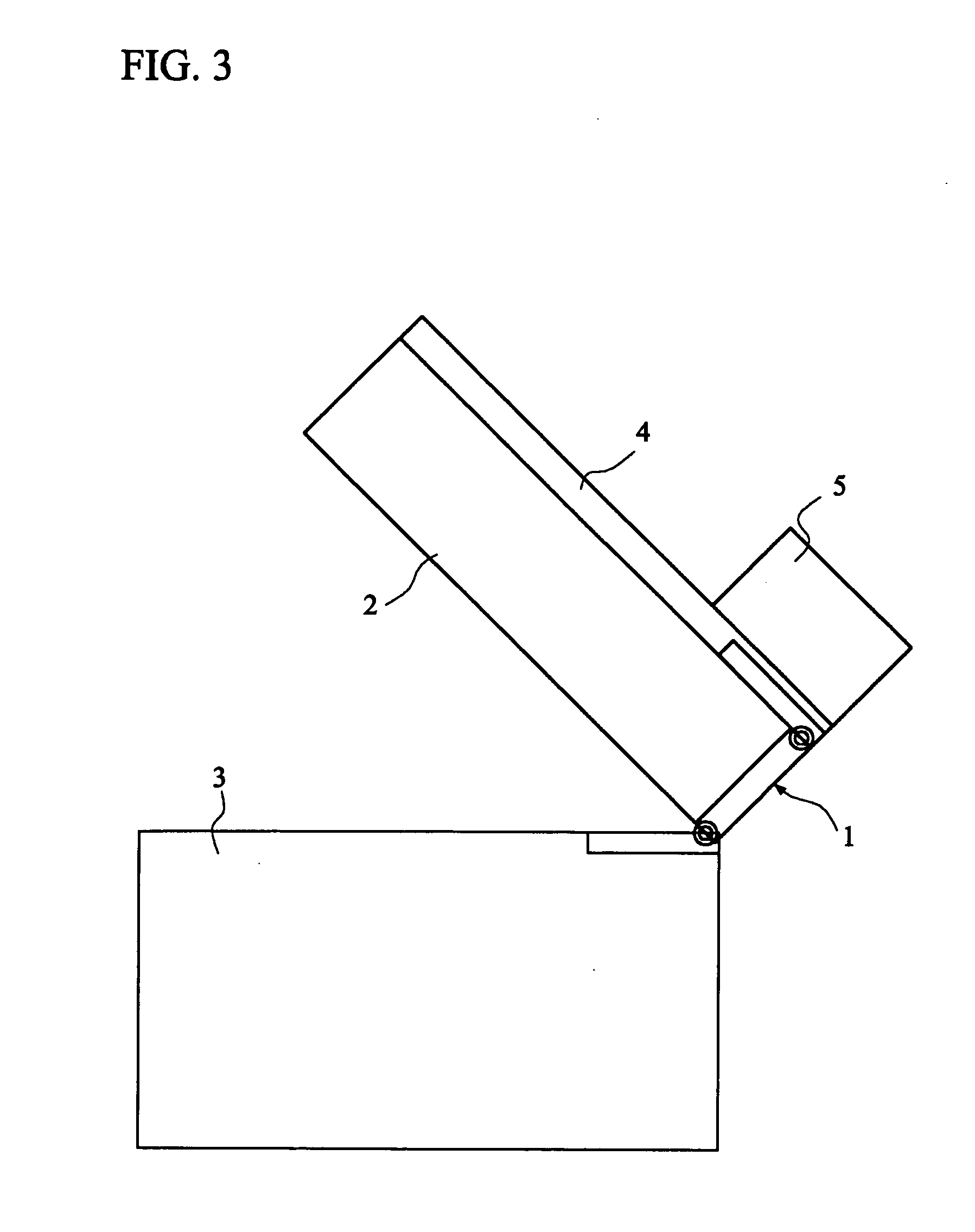

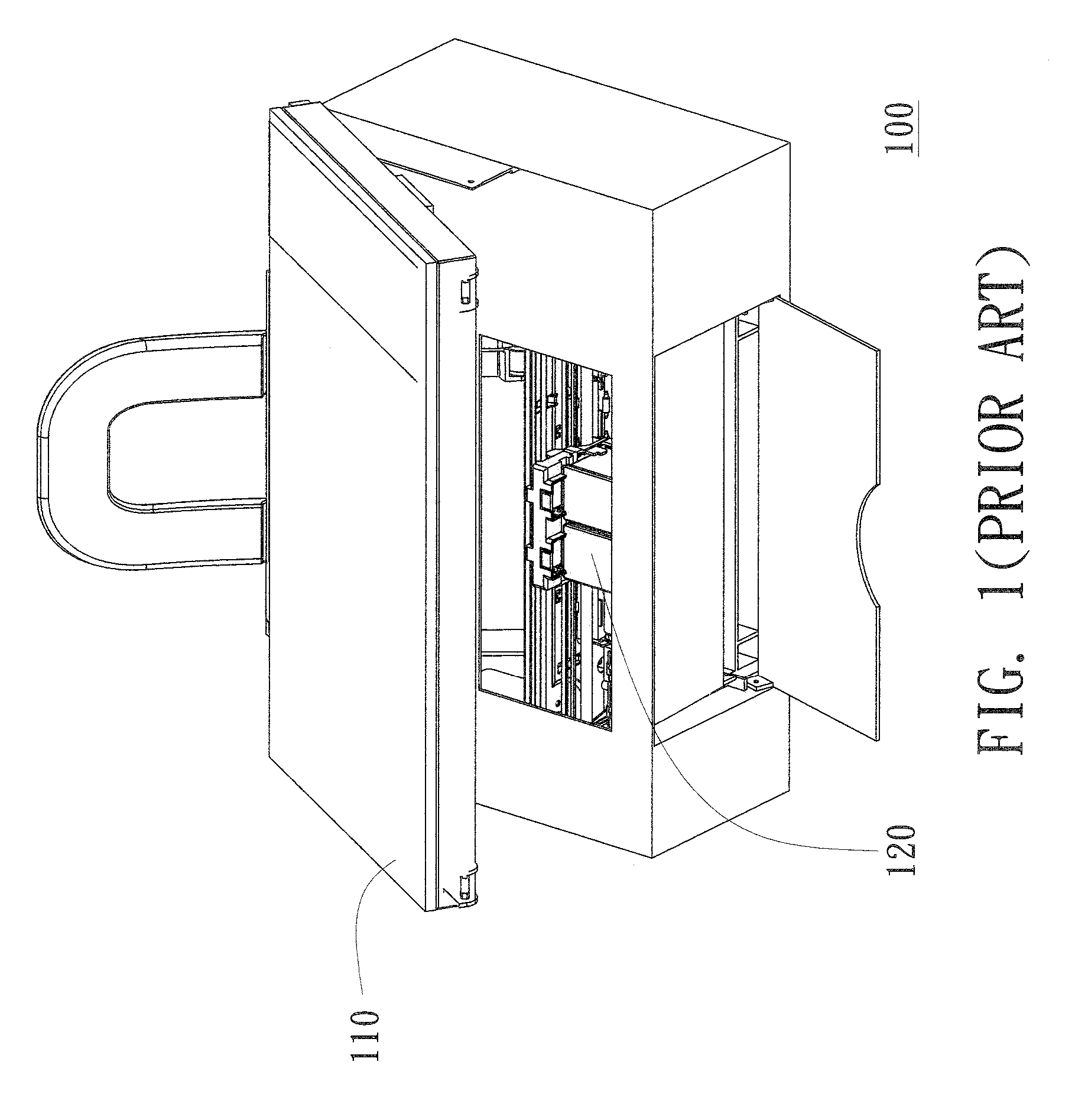

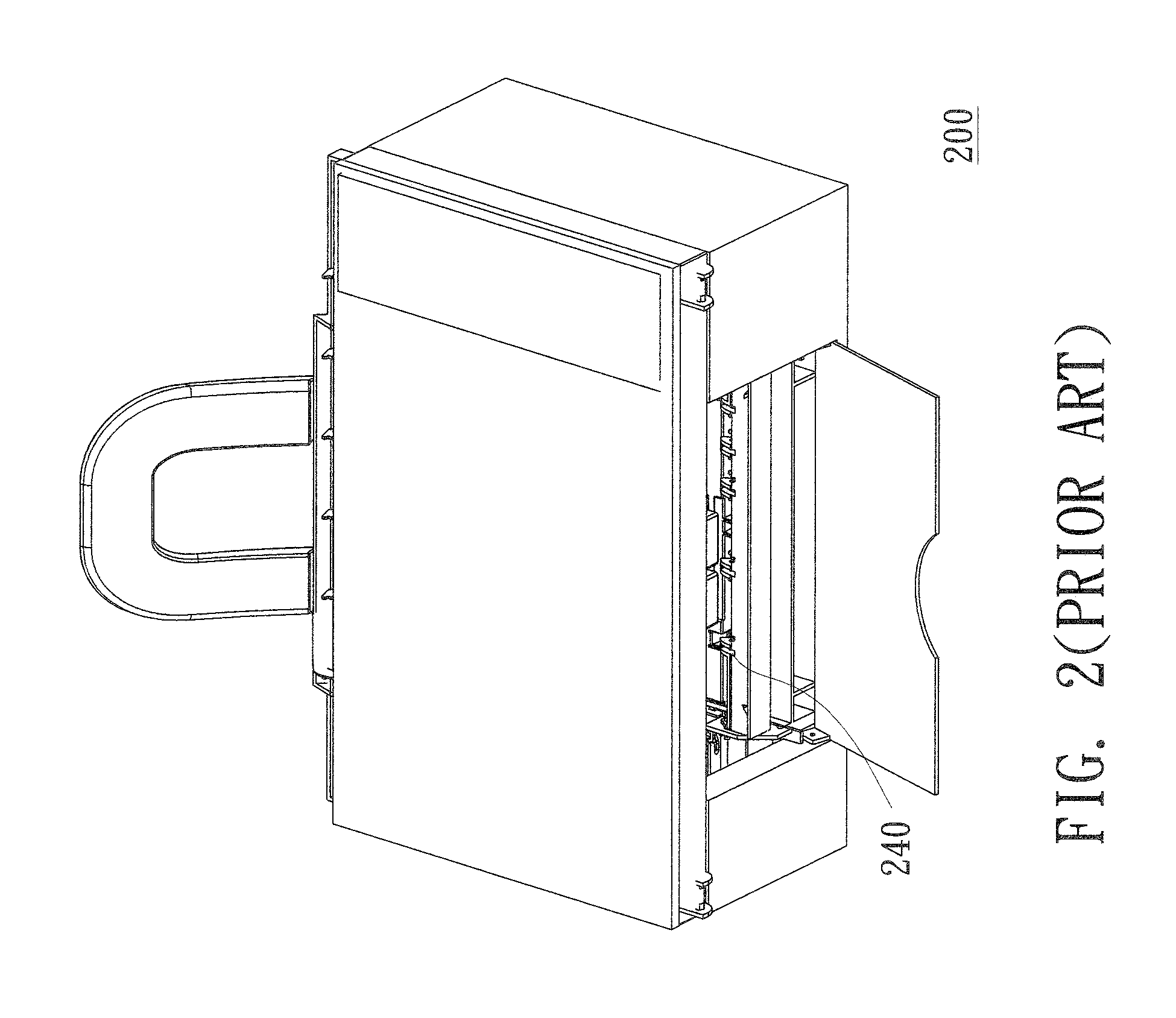

Duplex hinge device and a multi-function peripheral using the same

InactiveUS20050134940A1Eliminate jammingEasy to assembleHingesElectrographic process apparatusEngineeringMechanical engineering

A duplex hinge device includes a hinge body having a first end and a second end, a first mounting plate hinged to the first end, and a second mounting plate hinged to the second end. A scanning unit for scanning a to-be-scanned document and generating a print signal is fixed to the hinge body. A printing unit for receiving the print signal and printing a to-be-printed document is fixed to the second mounting plate. A cover for pressing the to-be-scanned document placed on the scanning unit is fixed to the first mounting plate. The duplex hinge device also has a mechanism for locking itself at a plurality of positions.

Owner:AVISION

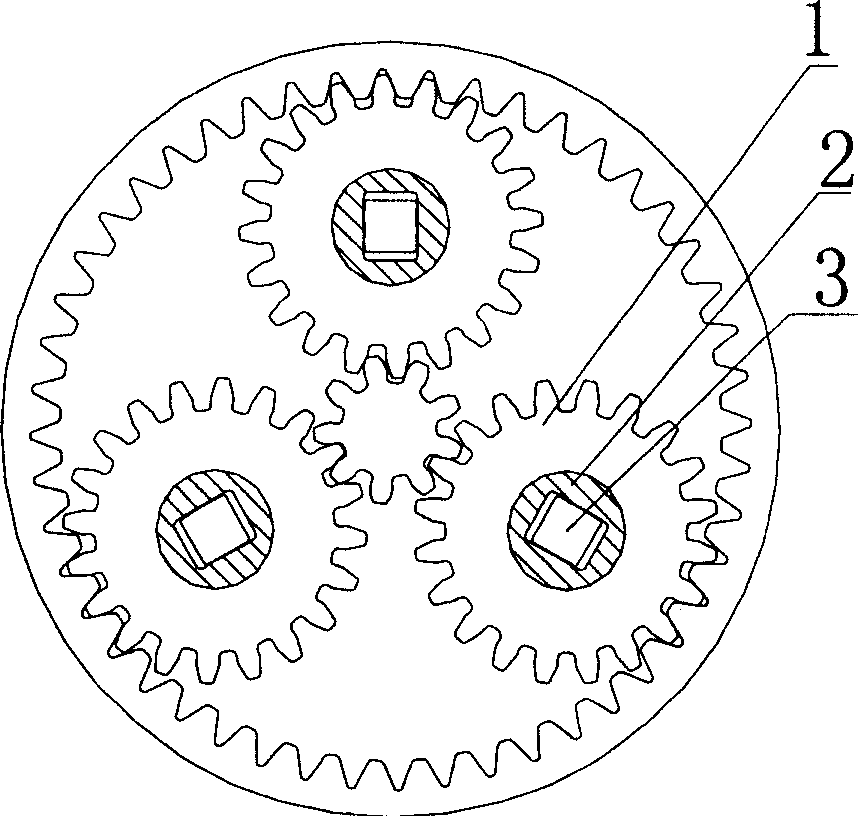

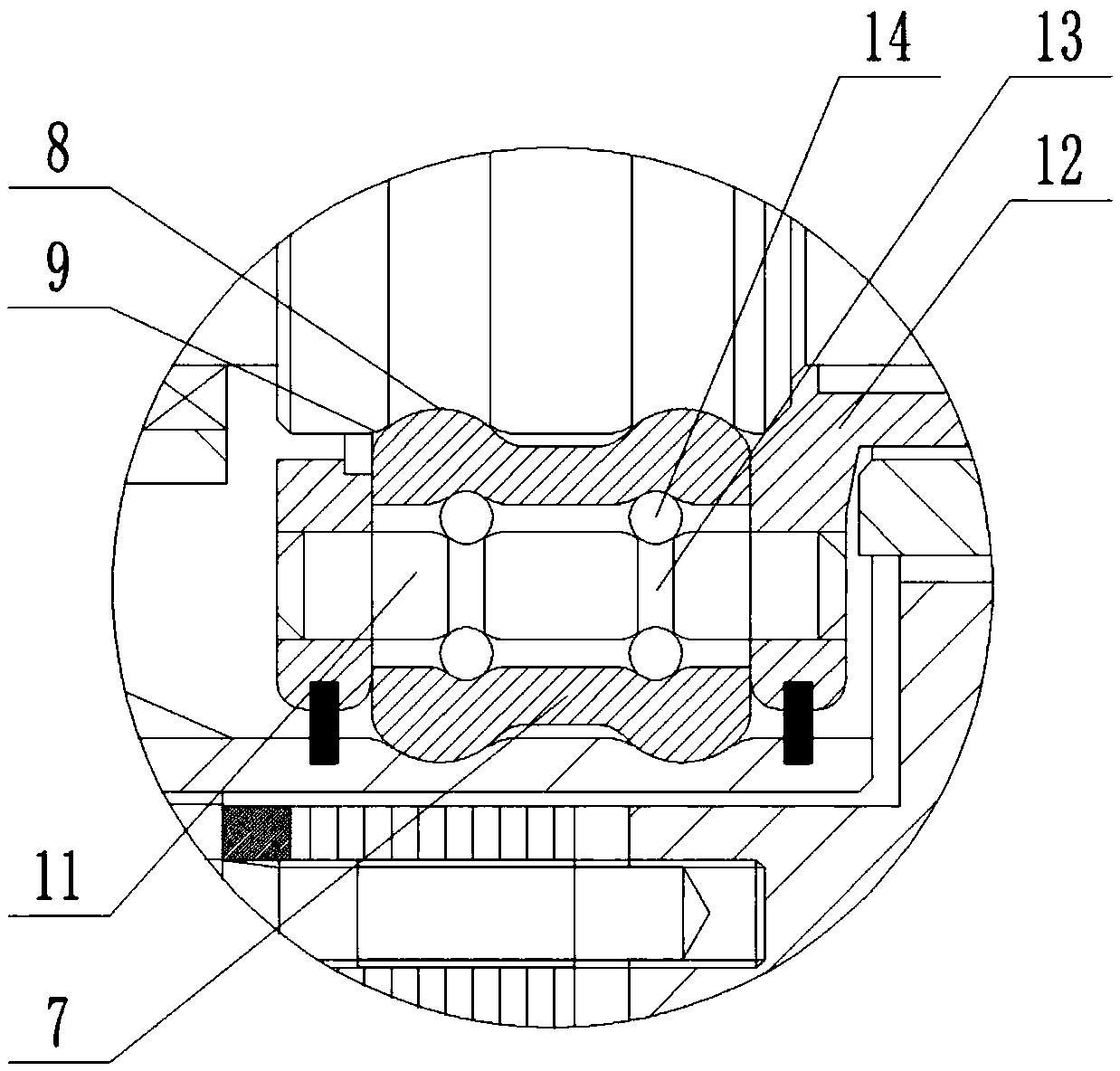

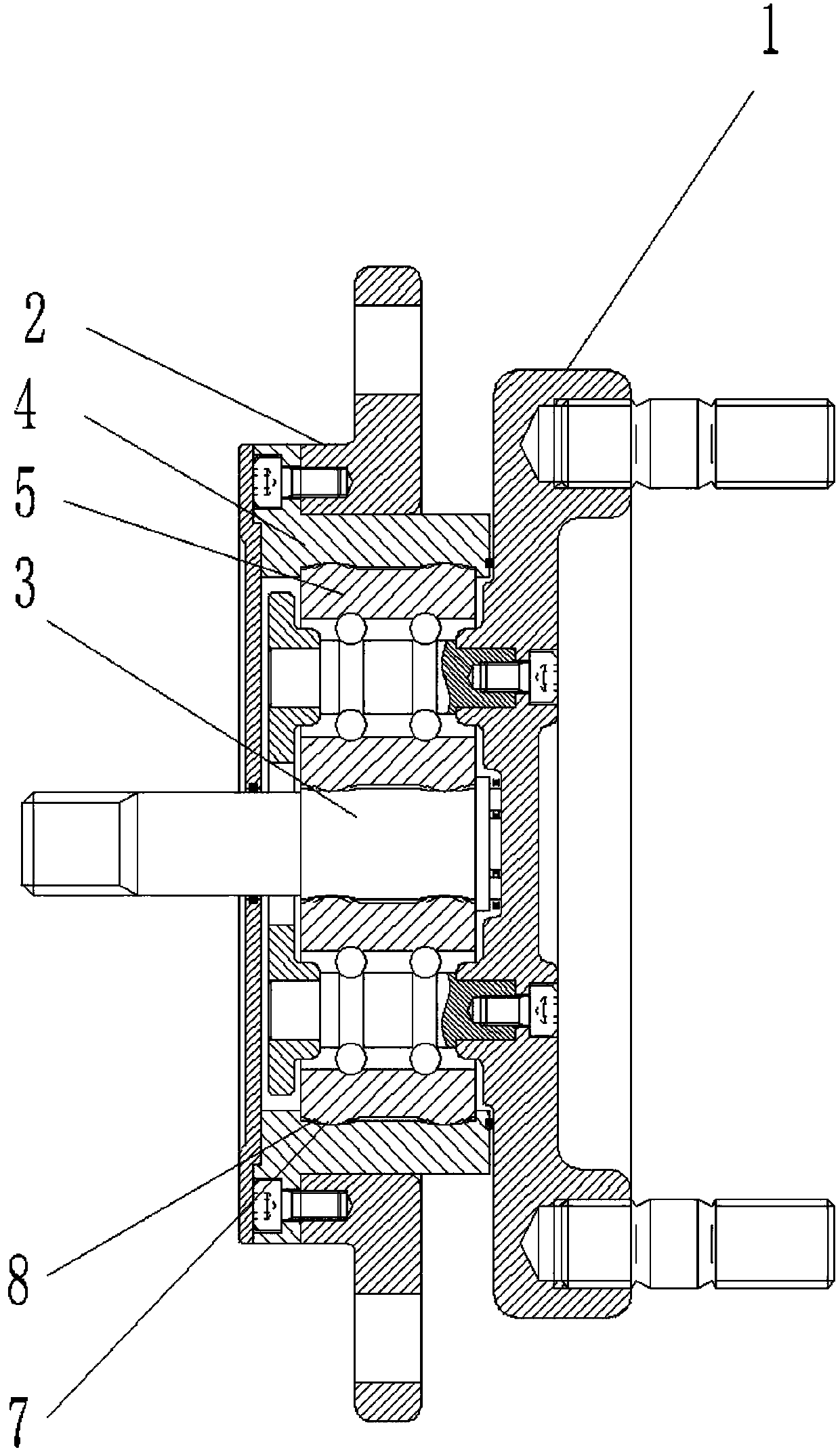

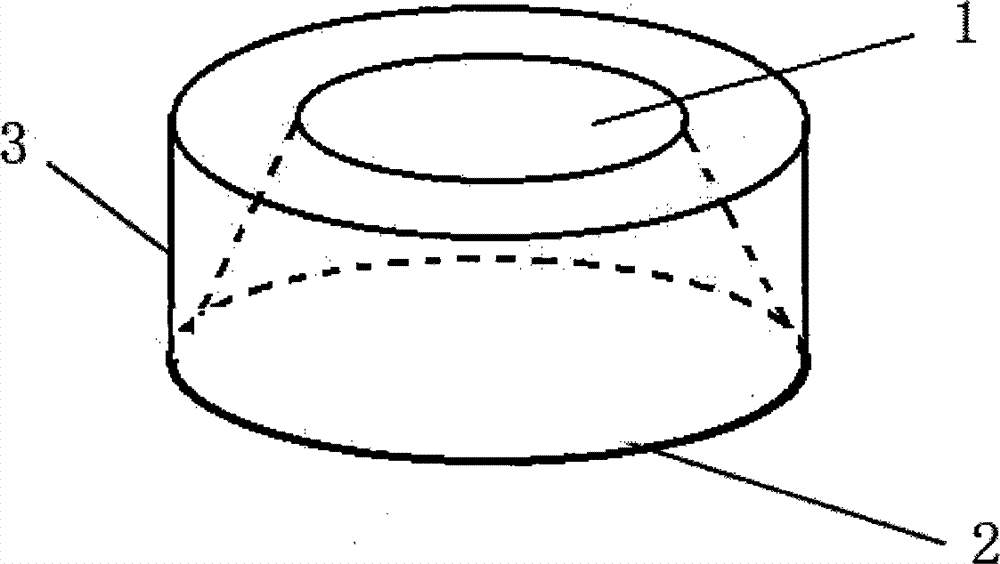

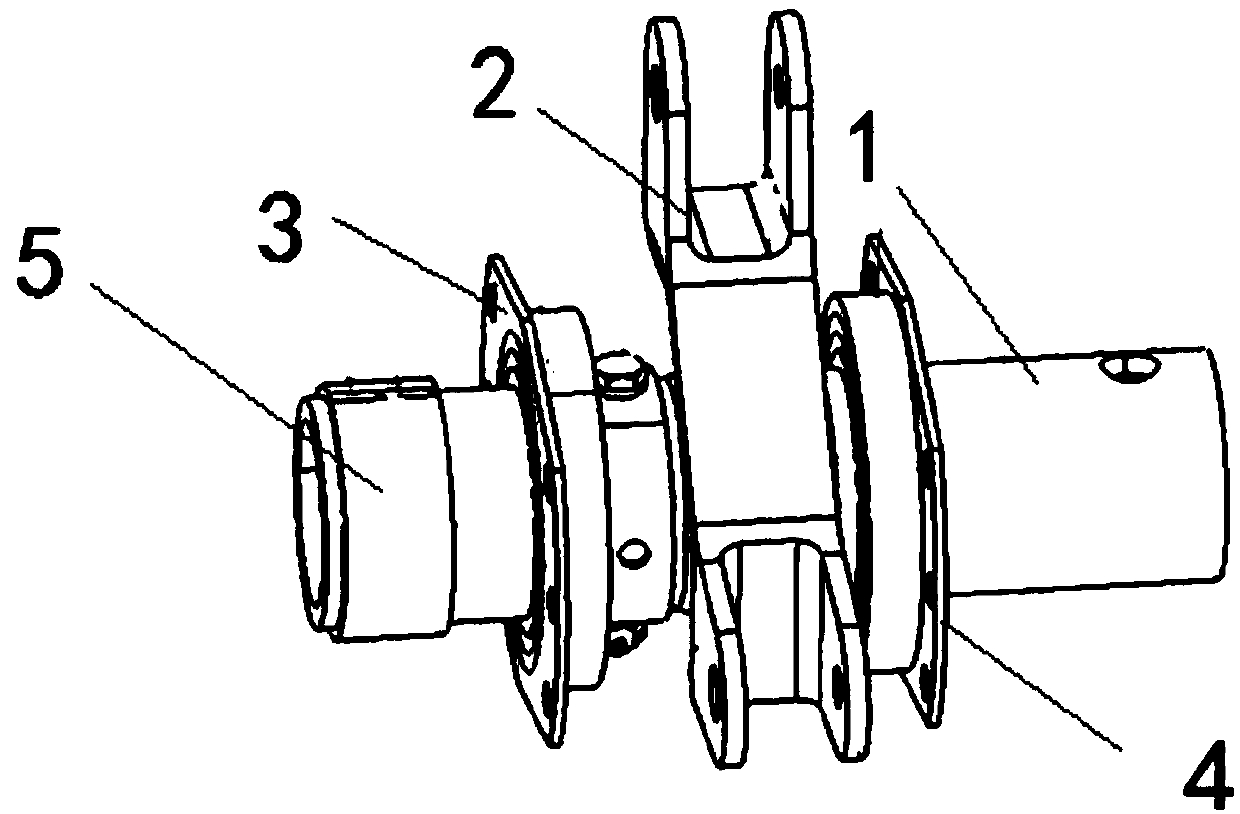

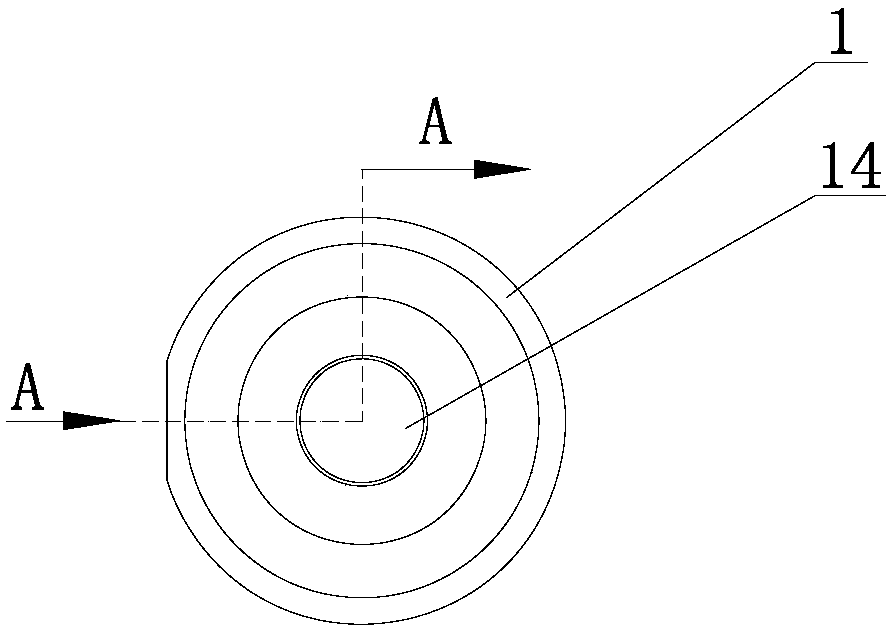

Floating load balancing mechanism for planet wheels and speed reducer thereof

InactiveCN1844703AExtend your lifeGood load balancing performanceToothed gearingsReduction driveGear wheel

The invention discloses a planet wheel float equal-load device and a speed reducer. Wherein, it has a inner tooth ring; the tooth of planet wheel is meshed to the outer tooth of sun wheel and the inner tooth of inner tooth wheel; the fixing axle is integrated with the planet support. It is characterized in that: the fixing axle and the planet wheel are float connected, while the fixing axle on the planet wheel support is a flat square axle mounted with a flat square sleeve; the inner hole of said sleeve can move along the axle of flat square axle but can not rotate; the planet wheel is mounted on the flat square sleeve, whose inner hole is movably matched with the outer circle of sleeve; the planet wheel can rotate on the outer circuit and move on the axle of flat square axle, to form a float equal load. The inventive speed reducer, via equal load, can improve the load strength of tooth surface, prolong the service life of gear wheel, confirm the transmission stability and reduce the noise.

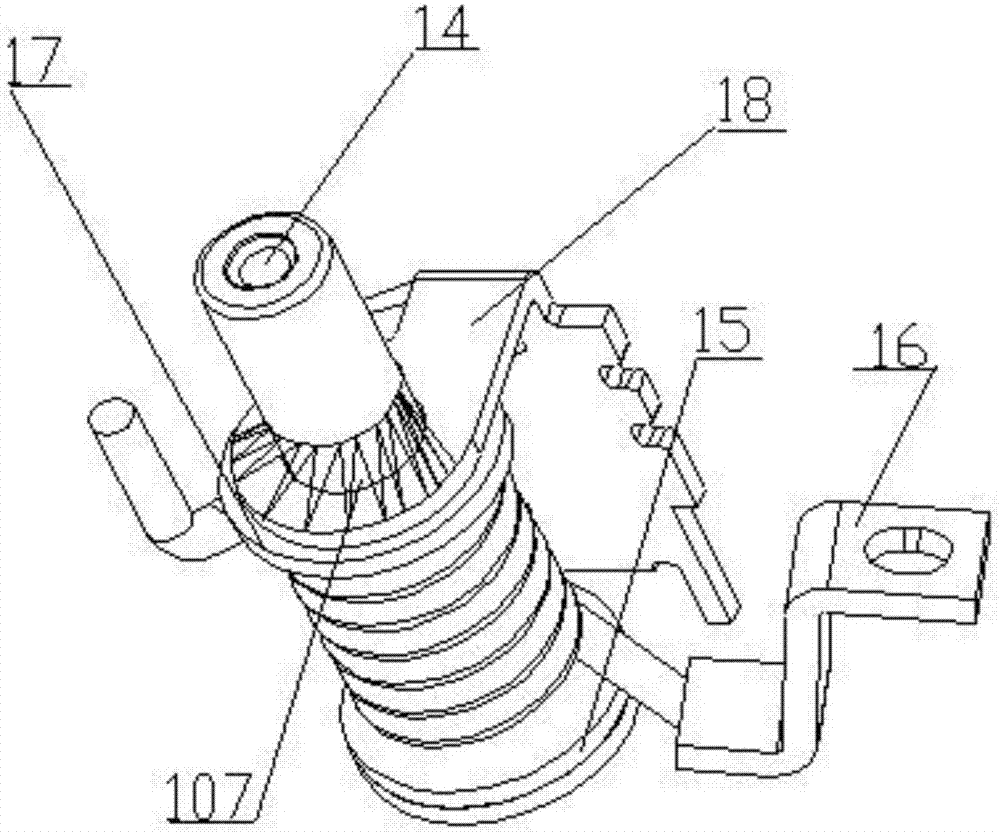

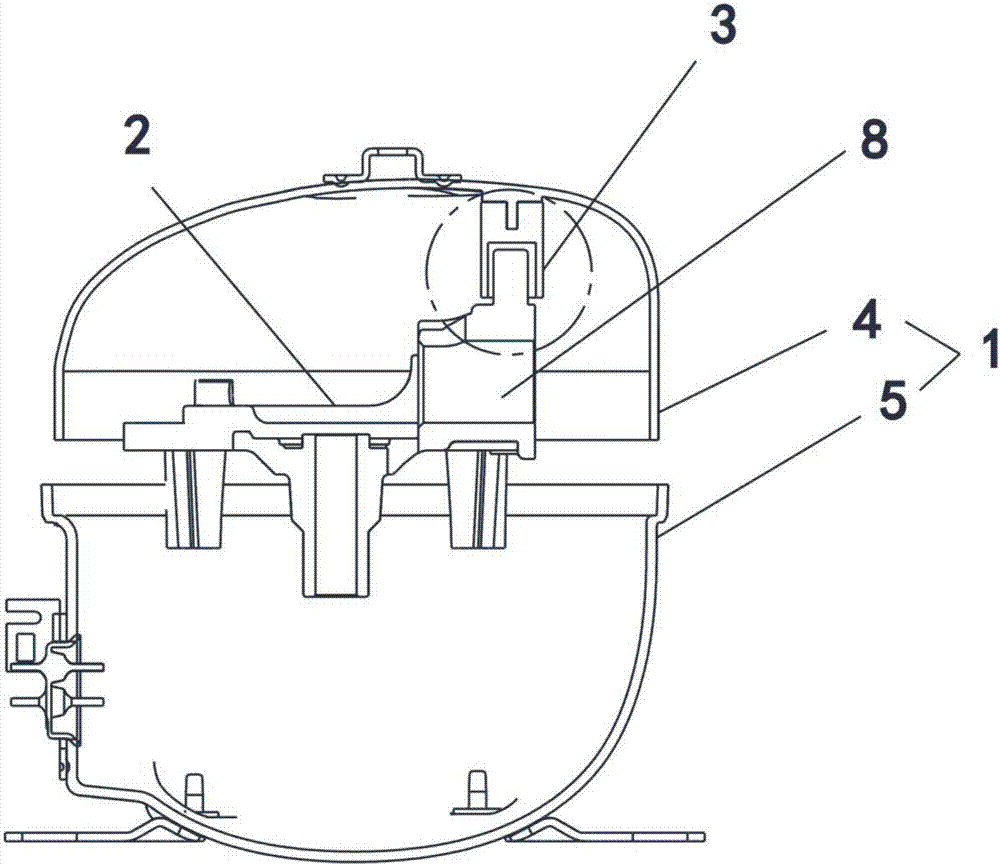

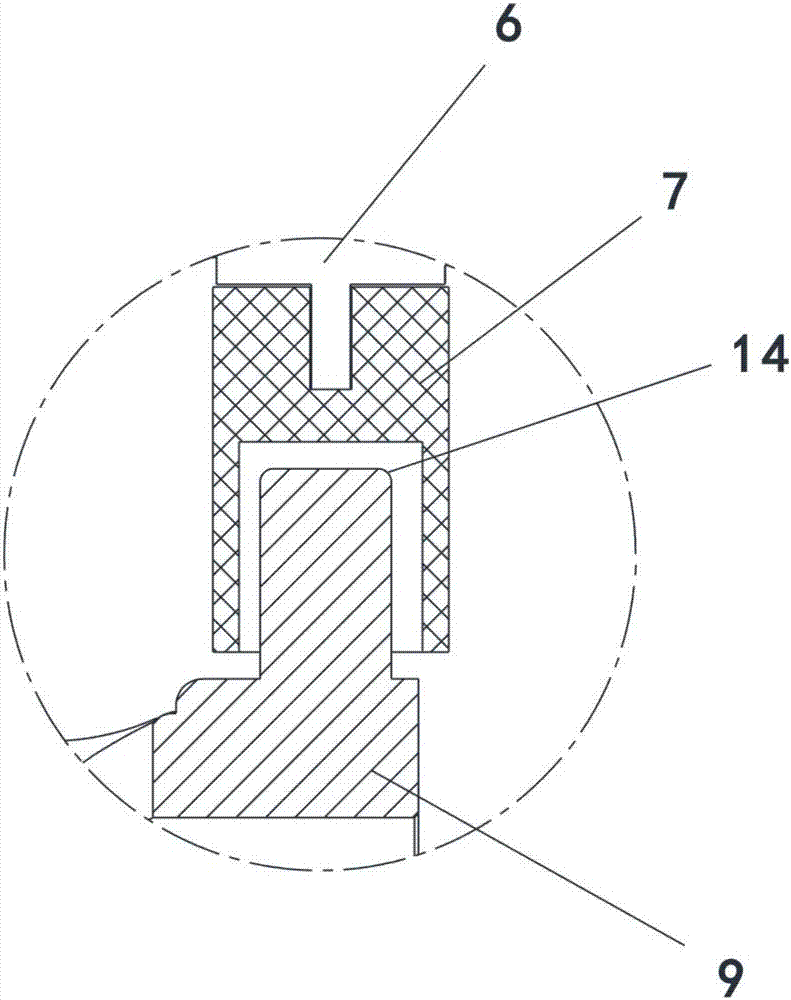

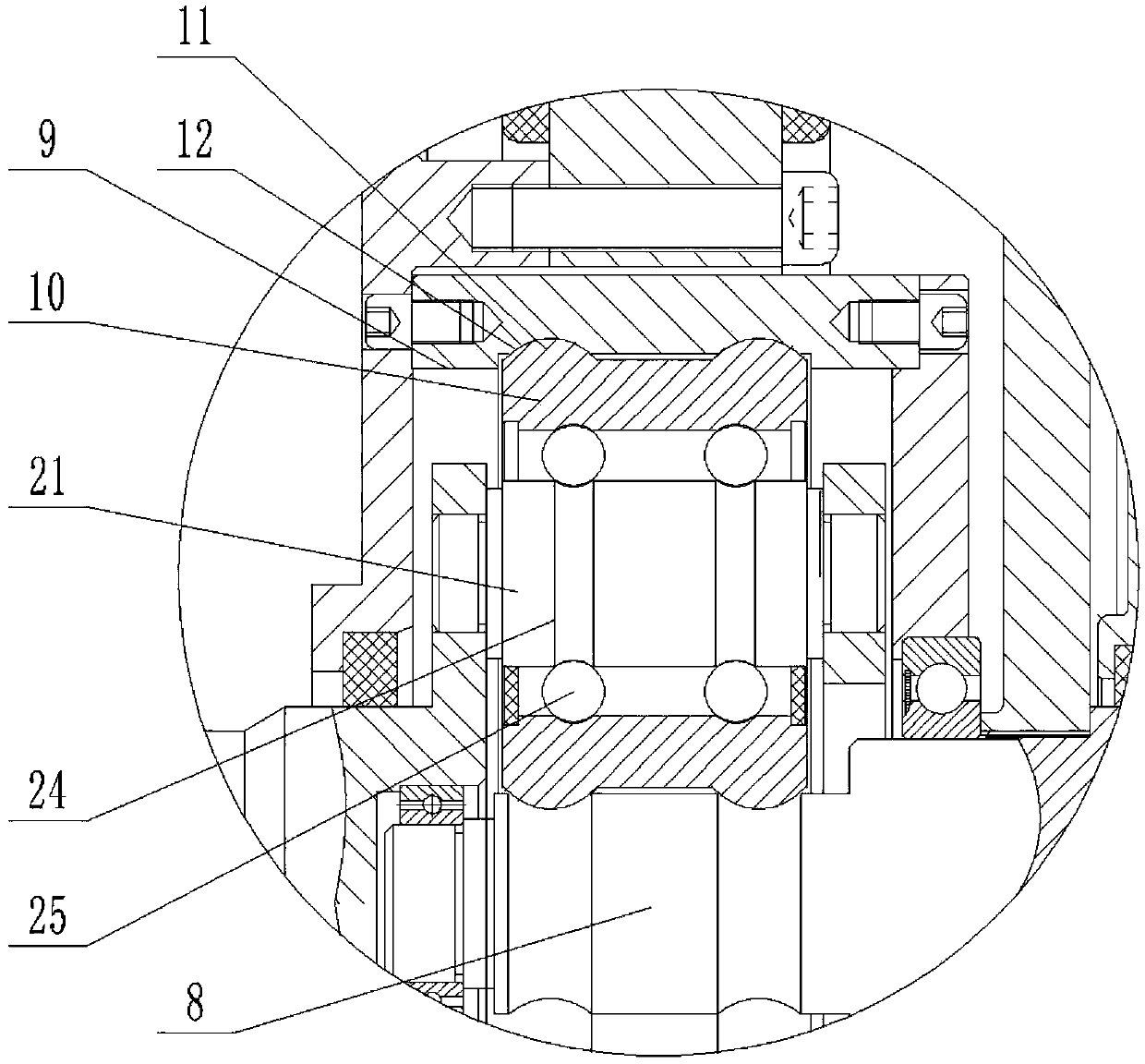

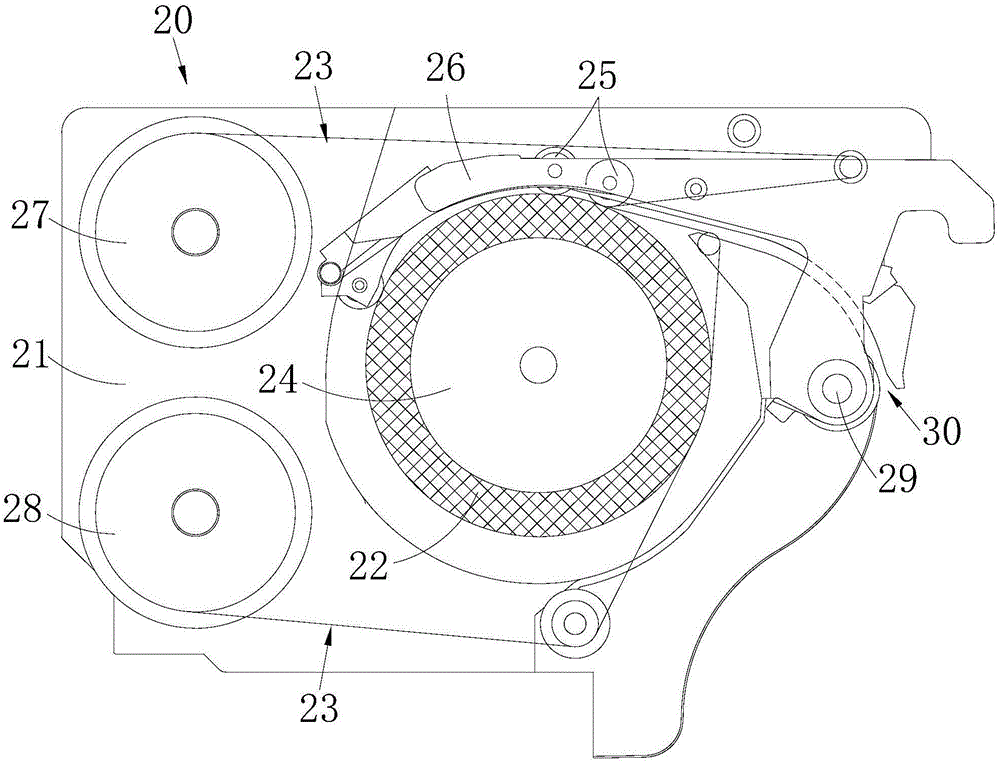

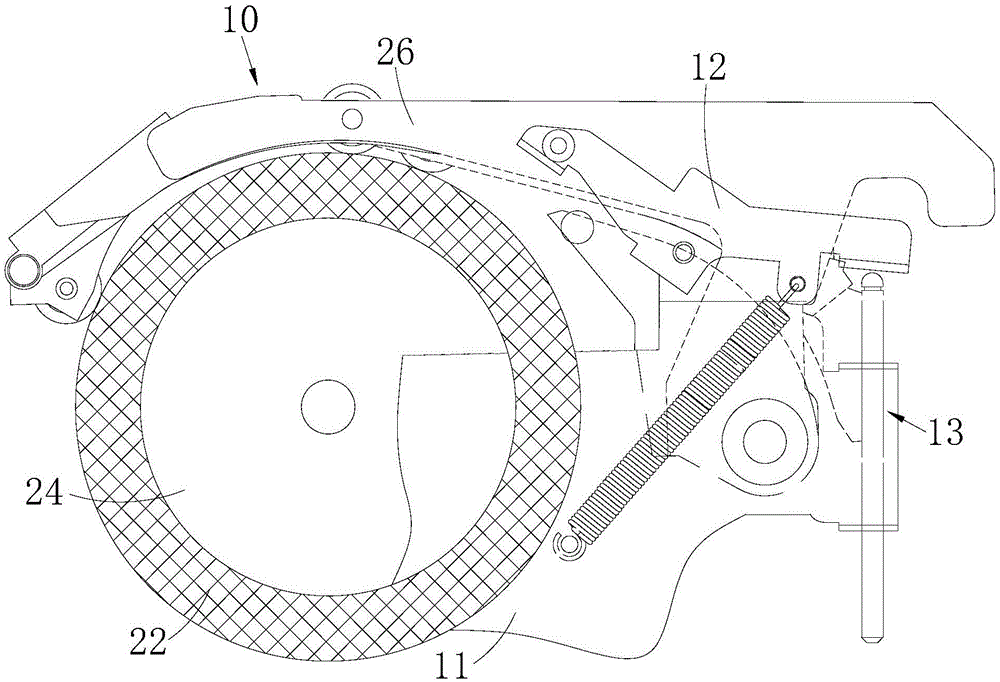

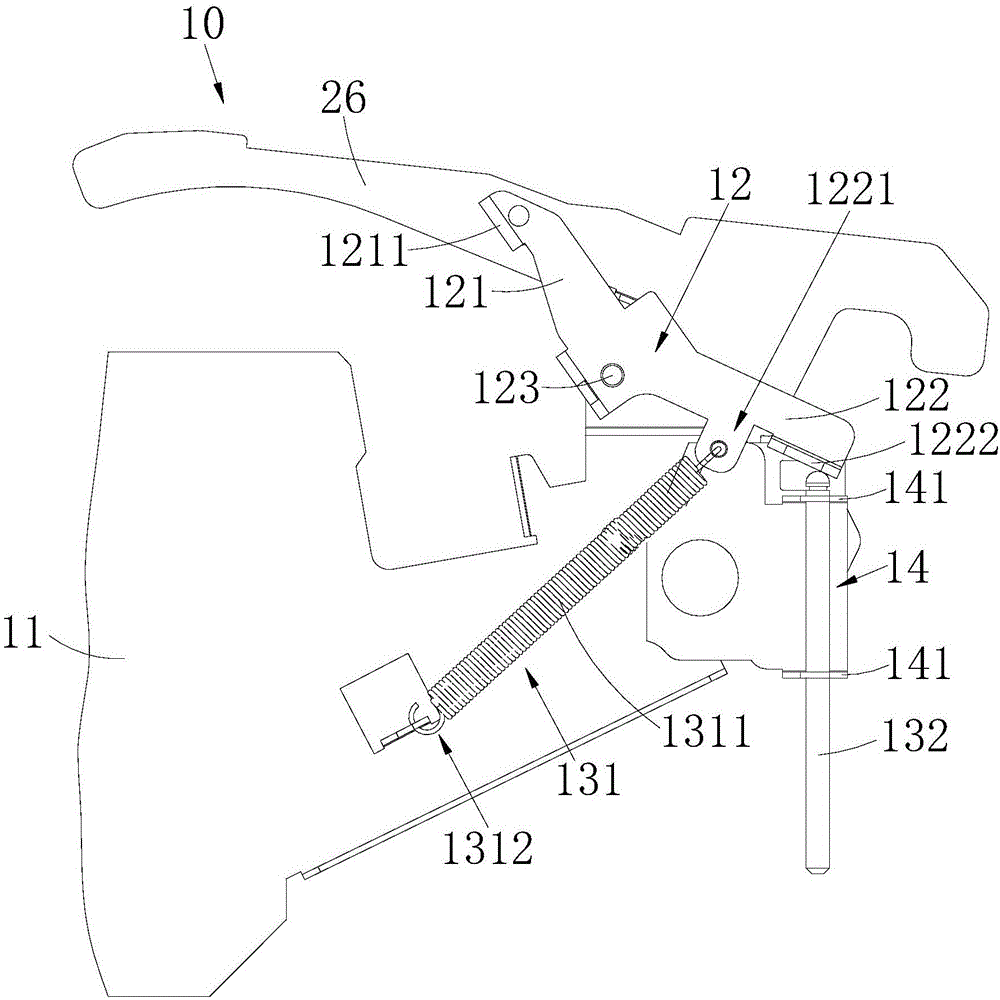

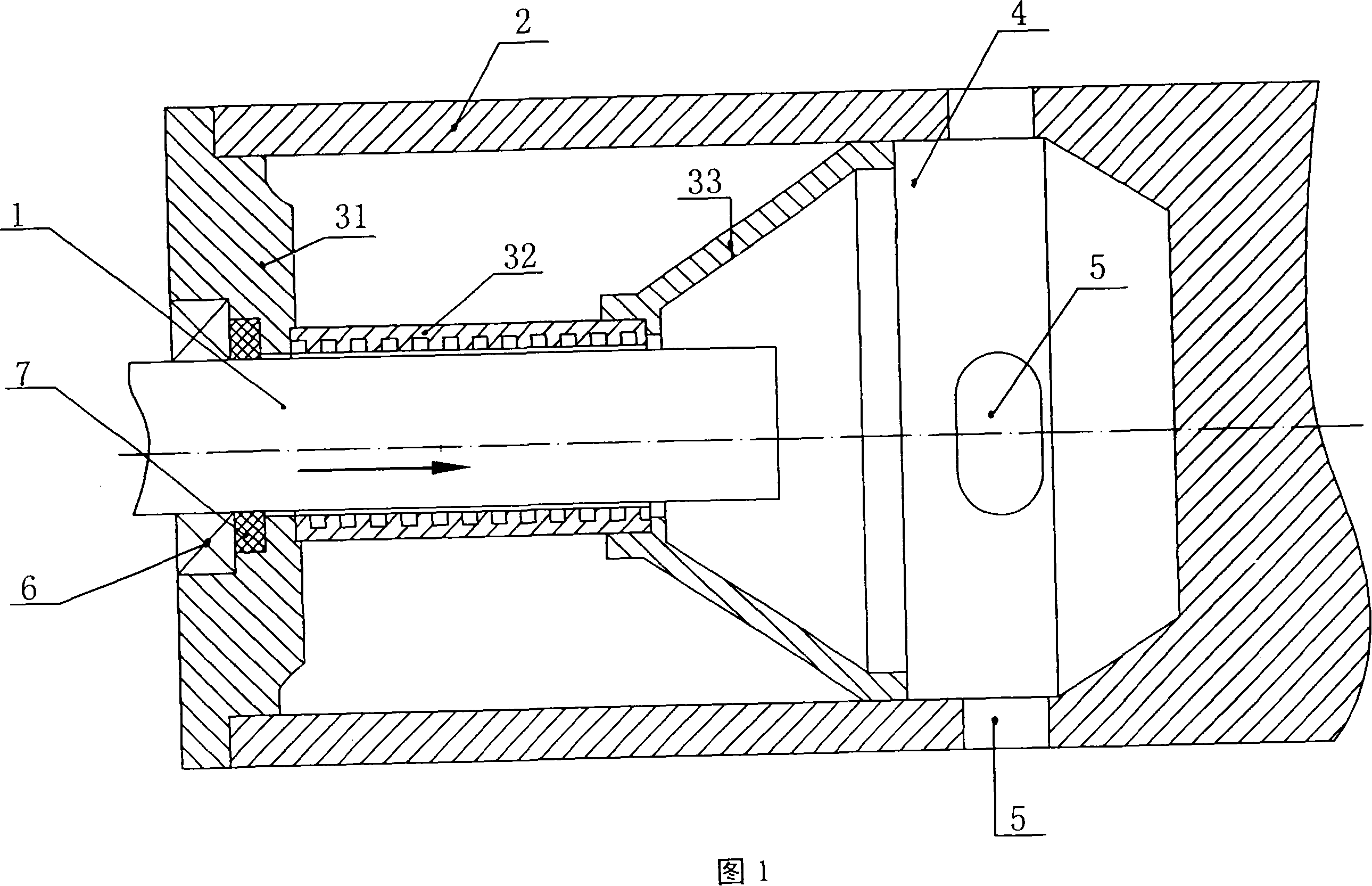

Limiting and collision preventing structure of cooling refrigerator compressor

ActiveCN107269536AGuaranteed service lifeEliminate jammingRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorCylinder head

The invention relates to the technical field of refrigerator cooling compressors, in particular to a limiting and collision preventing structure of a cooling refrigerator compressor. The limiting and collision preventing structure of the cooling refrigerator compressor comprises a shell, a crankcase and a collision preventing assembly. The crankcase and the collision preventing assembly are arranged in the shell. The collision preventing assembly is arranged between the crankcase and the shell. The shell comprises an upper shell body and a lower shell body. The collision preventing assembly comprises a collision preventing convex pin and a collision preventing bushing. A crankcase cylinder head is arranged on the upper portion of the crankcase. The upper portion of the crankcase cylinder head is provided with a collision preventing convex point. The lower surface of the collision preventing bushing is provided with a collision preventing convex point installation hole. The collision preventing convex pin is welded to the upper shell body. A collision preventing convex pin hole is formed in the upper surface of the collision prevention bushing. A semicircular edge is arranged on one side of the collision preventing convex pin. A semicircular clamping groove is formed in the collision preventing convex pin hole. The cross section of the collision preventing convex point is round or polygonal.

Owner:JIAXIPERA COMPRESSOR

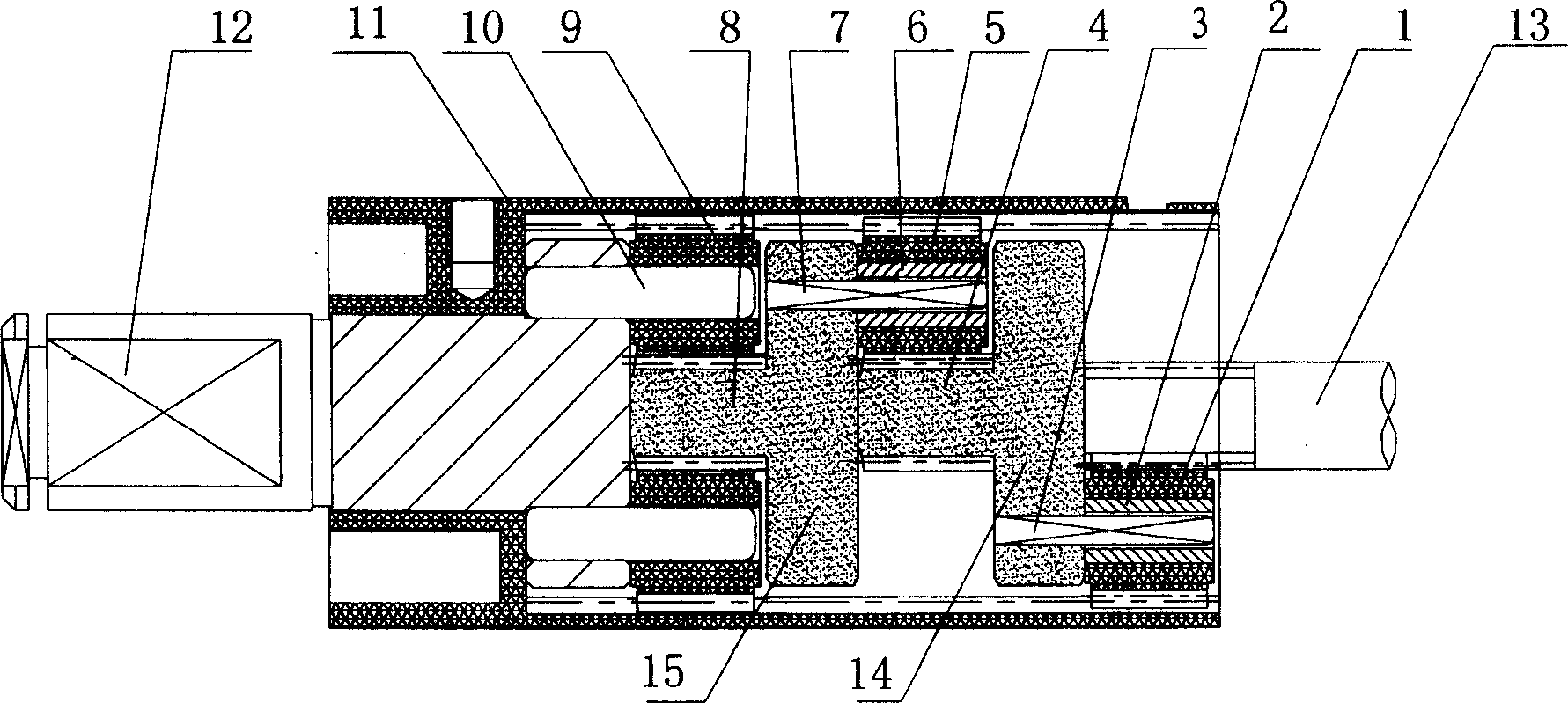

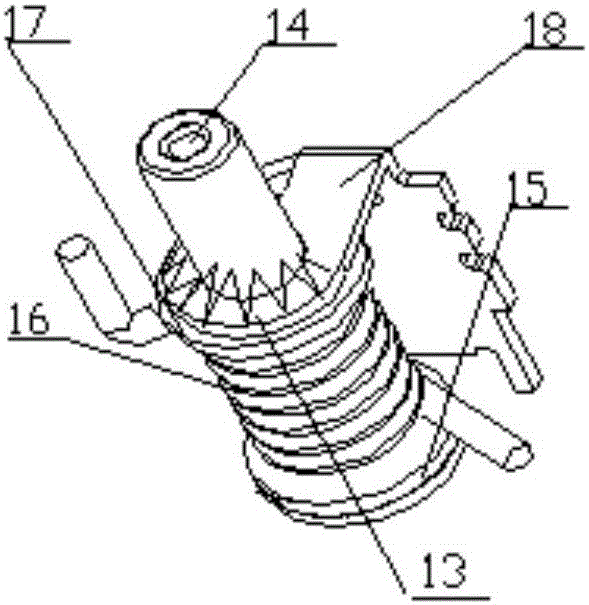

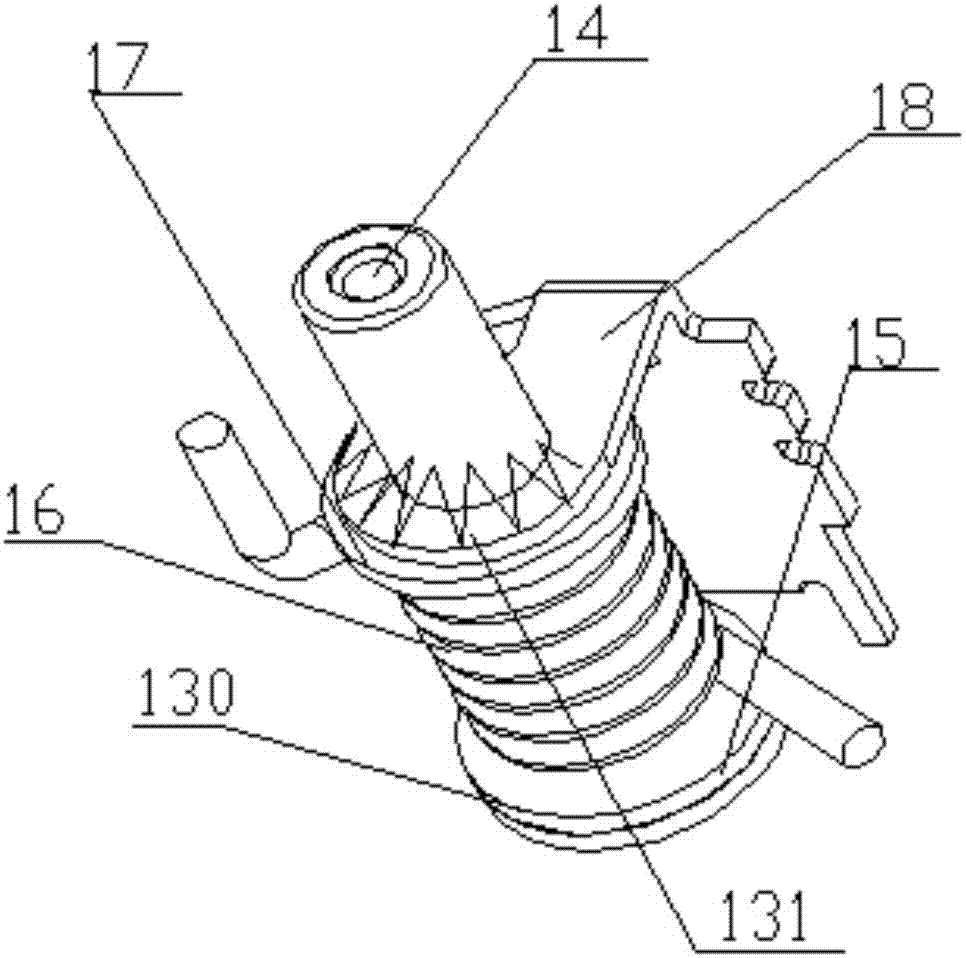

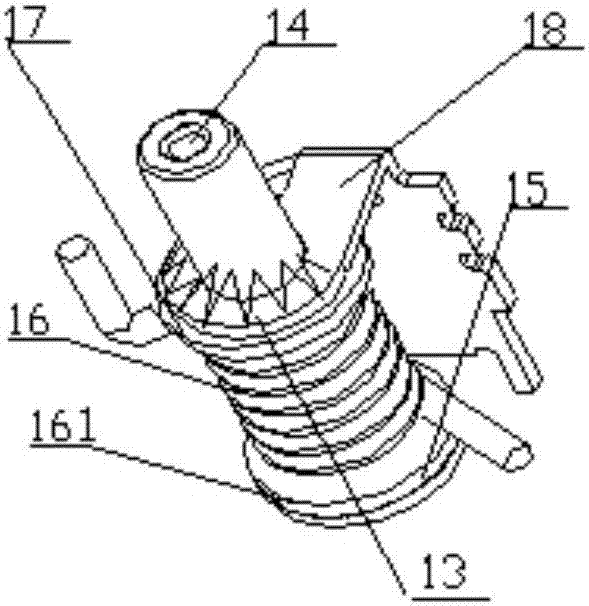

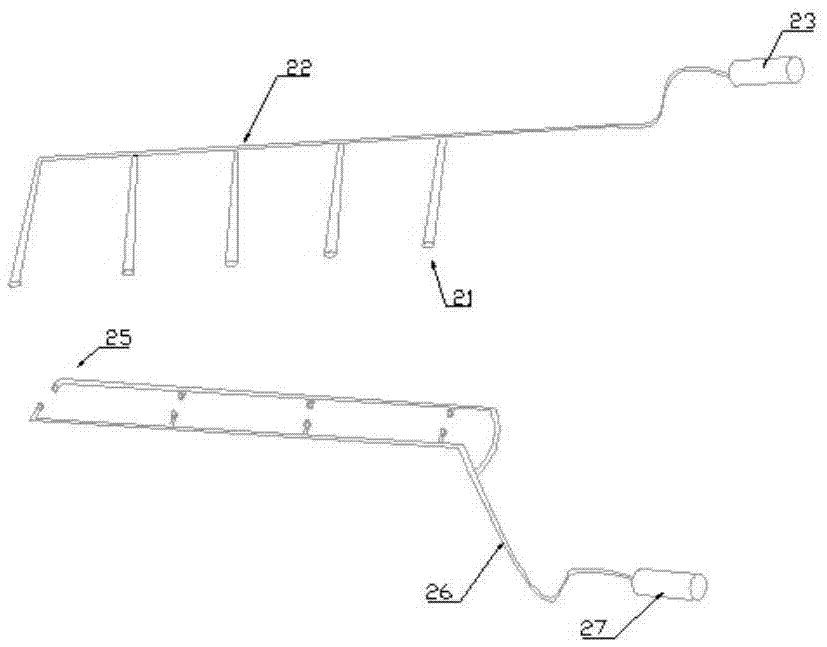

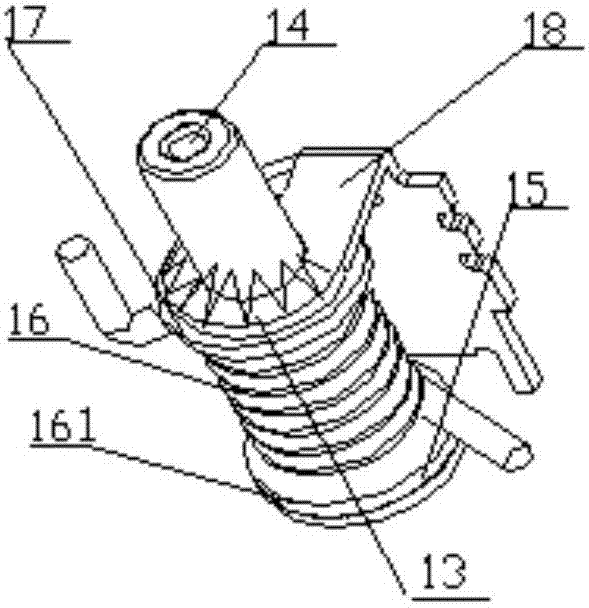

Automatic tin soldering mechanism of coil conductive assembly of low-voltage circuit breaker and welding system of coil conductive assembly of low-voltage circuit breaker

ActiveCN107433375AEliminate WeldingEliminate high failures and jamsMetal working apparatusSoldering auxillary devicesSolderingEngineering

The invention discloses an automatic tin soldering mechanism of a coil conductive assembly of a low-voltage circuit breaker and further discloses a welding system of the coil conductive assembly of the circuit breaker. The welding system of the coil conductive assembly of the circuit breaker comprises a rotating disk assembly. The rotating disk assembly is arranged on a horizontal tabletop. Nine feeding and discharging mechanisms and three detectors are sequentially arranged on the horizontal tabletop around the periphery of the rotating disk assembly. The rotating disk assembly comprises an inner disk and an outer rotating disk. Twelve stations are evenly arranged on the outer rotating disk and are close to the outer side in the circumference direction. The inner disk is provided with eight station starting mechanisms used for driving station clamps to be opened or closed in the circumferential direction. Each station starting mechanisms is connected with a station starting transmission mechanism through a connection rod. The twelve stations are each provided with a station clamp. The twelve station clamps are evenly arranged on the outer rotating disk and are close to the outer side of the outer rotating disk, and the twelve station clamps correspond to the nine feeding and discharging mechanisms surrounding the outer circumference of the rotating disk assembly in position. The welding system of the coil conductive assembly of the low-voltage circuit breaker is compact in structure, reliable in work and high in welding quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

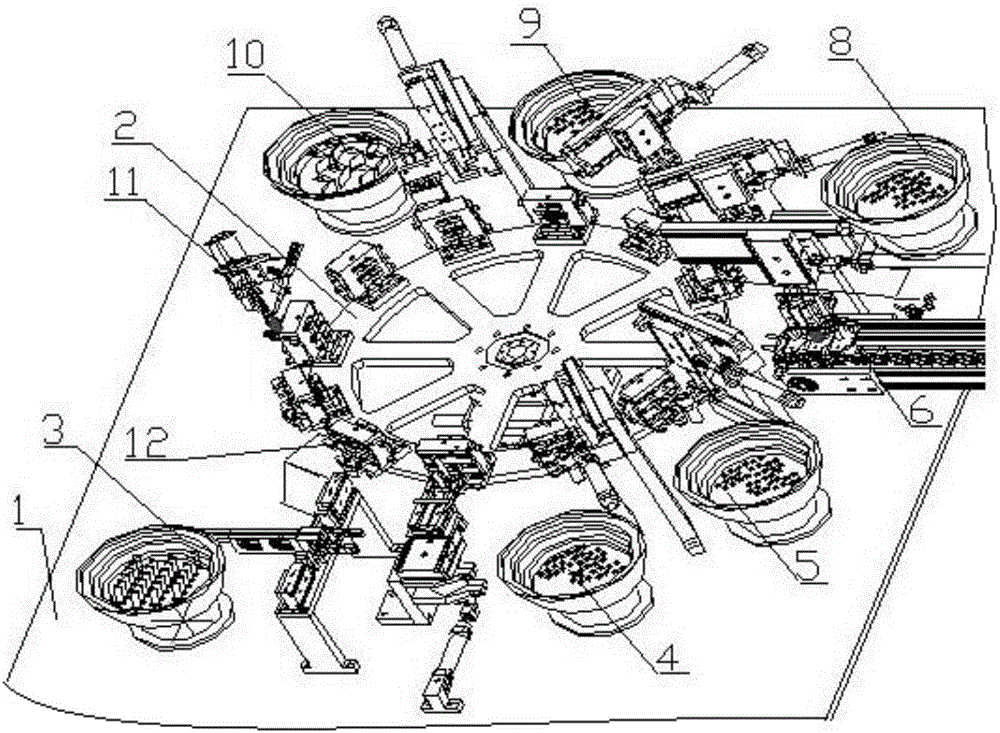

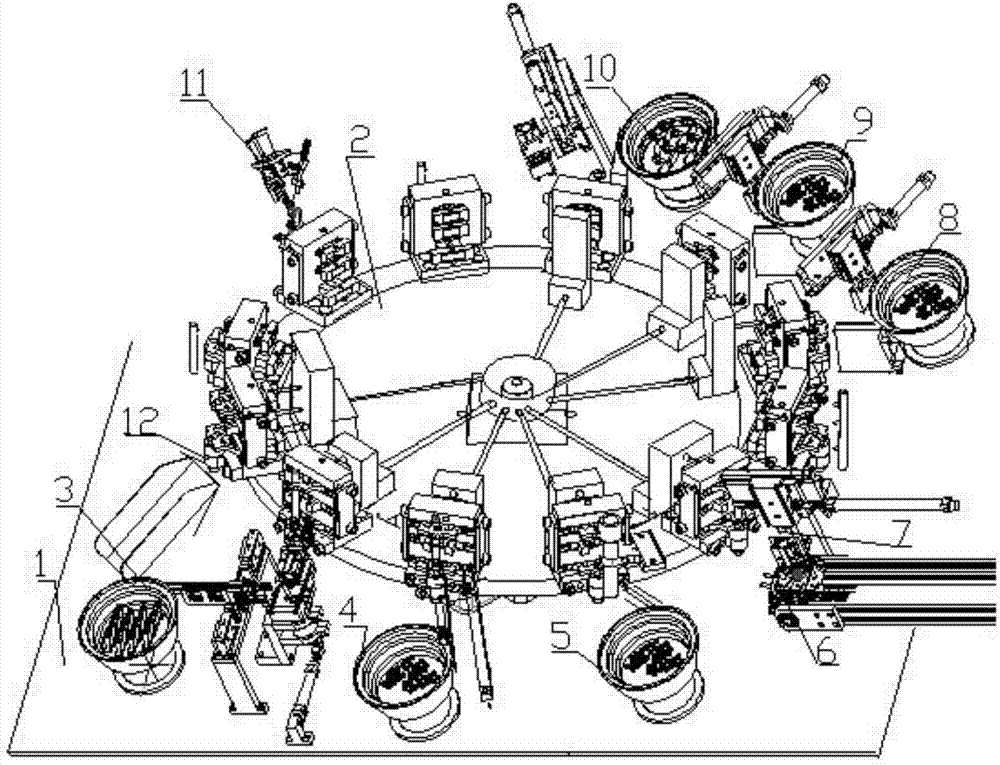

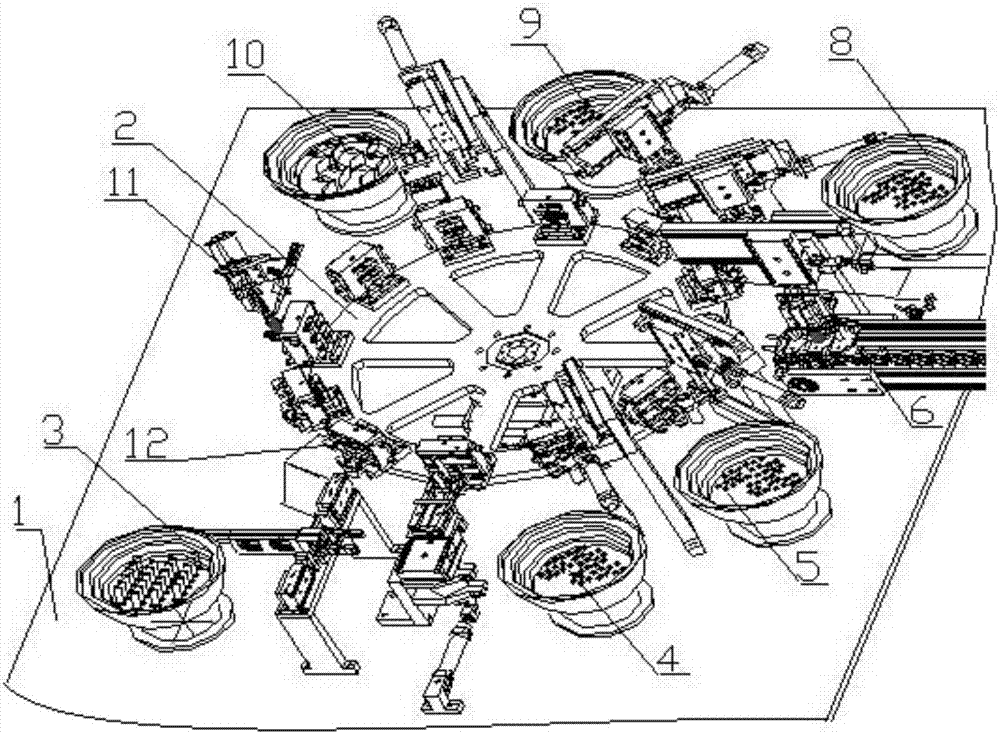

Full-automatic assembling and welding system for conductive components of circuit breaker coil

ActiveCN107293451AEliminate weldsEliminate jammingEmergency protective device manufactureEngineeringManipulator

The invention discloses a full-automatic assembling and welding system for conductive components of a circuit breaker coil. The full-automatic assembling and welding system comprises a turntable assembly arranged on a horizontal table board, wherein the turntable assembly comprises an inner turntable and an outer turntable, a synchronous high-speed material grabbing mechanism is arranged above the inner turntable, and an indexing mechanism is arranged below the outer turntable; 12 stations are evenly arranged along the outer circumference of the outer turntable, each station is equipped with a set of station fixture; an ejecting-pushing cylinder 1 and an ejecting-pushing cylinder 2 are arranged on the inner turntable; the circumferential outer side of the outer turntable is provided with an oil cup loading mechanism, a lower gasket loading mechanism, a coil loading mechanism, an upper gasket loading mechanism, a magnetic yoke loading mechanism, a soldering mechanism and an unloading mechanism; and a triaxial mechanical arm of the synchronous high-speed material grabbing mechanism is arranged above each of the oil cup loading mechanism, the lower gasket loading mechanism, the coil loading mechanism, the upper gasket loading mechanism, the magnetic yoke loading mechanism and the unloading mechanism correspondingly. The full-automatic assembling and welding system has the advantages of compact structure, coordination and cooperation, and stable and reliable product quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

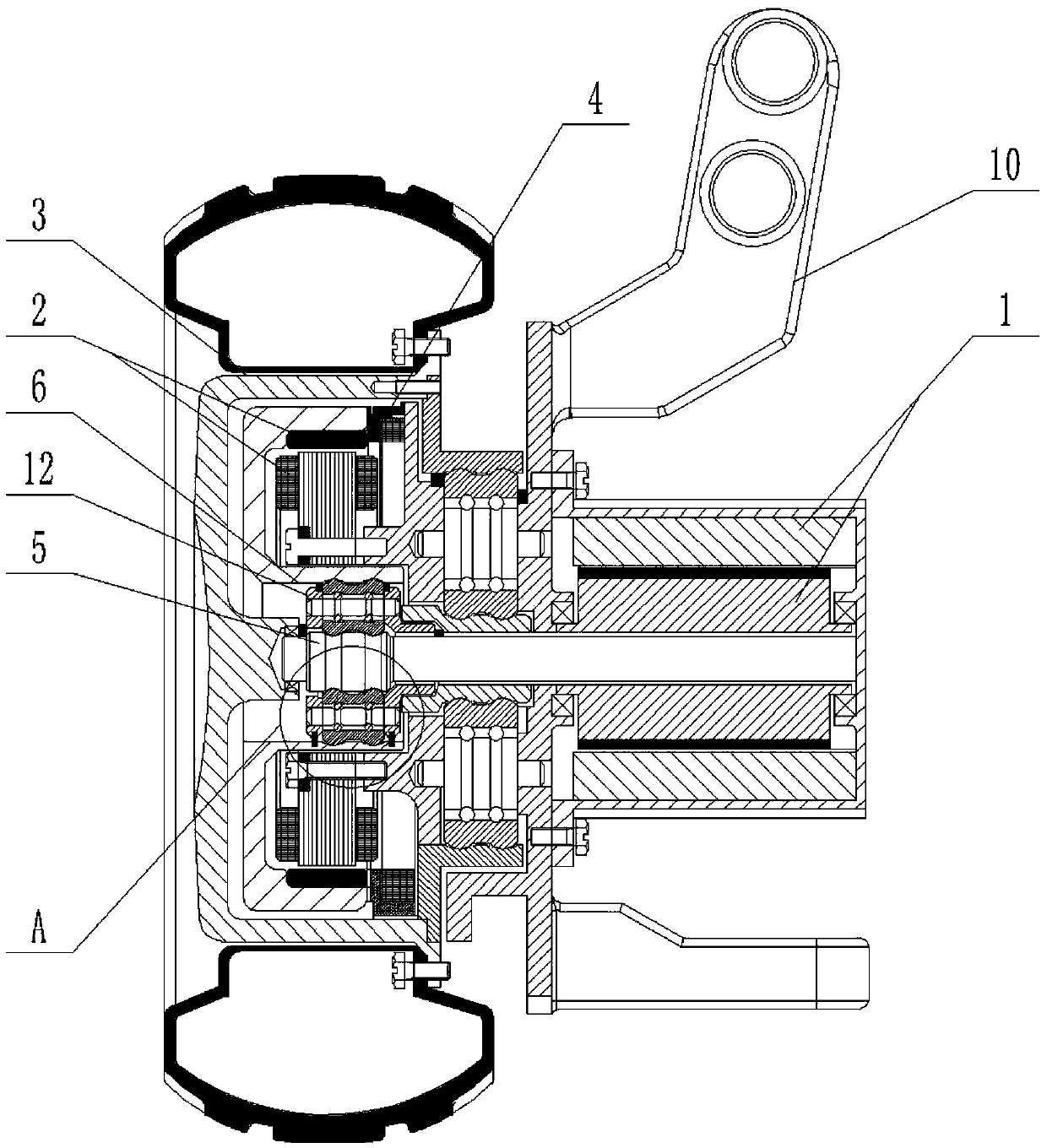

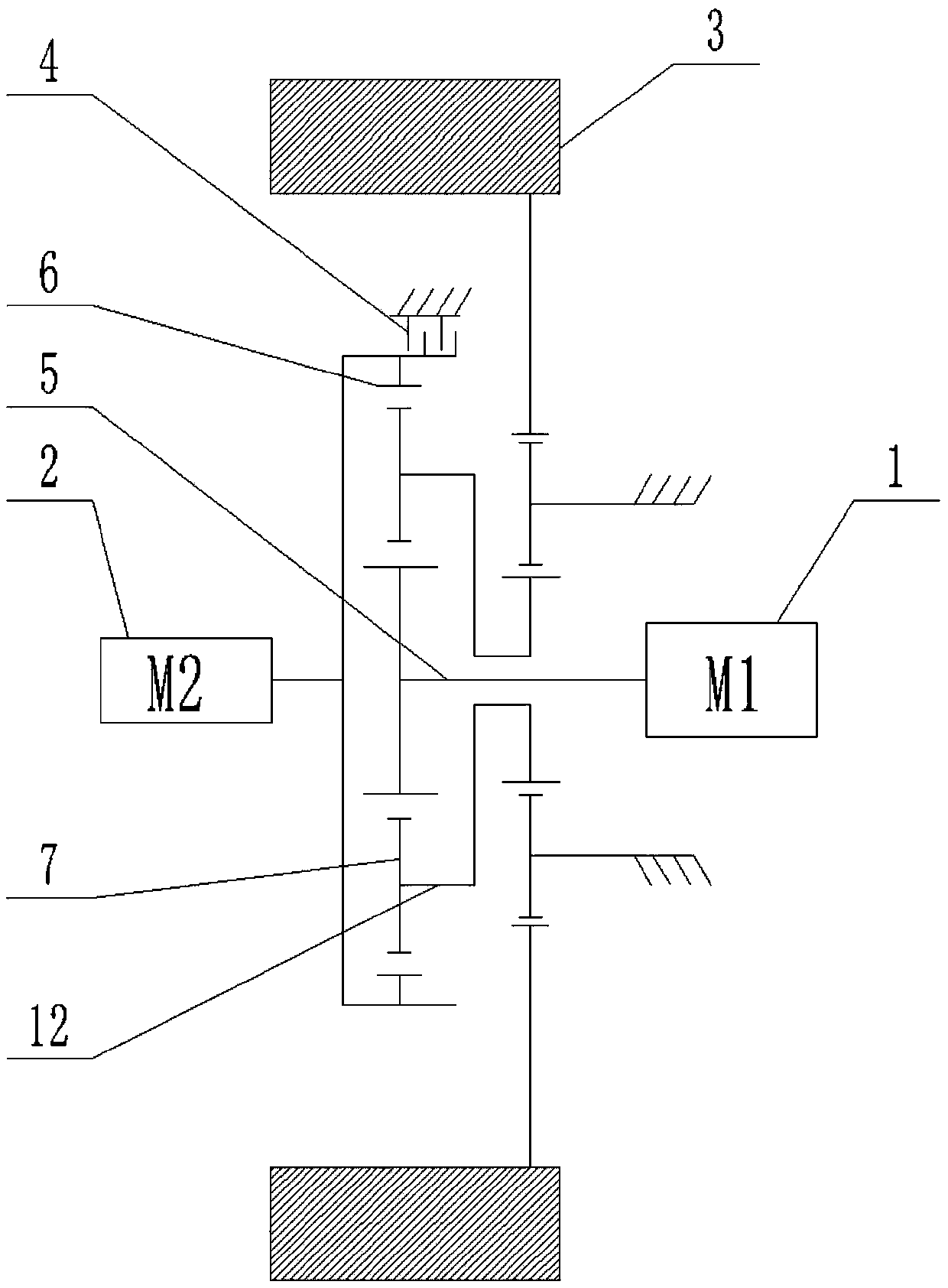

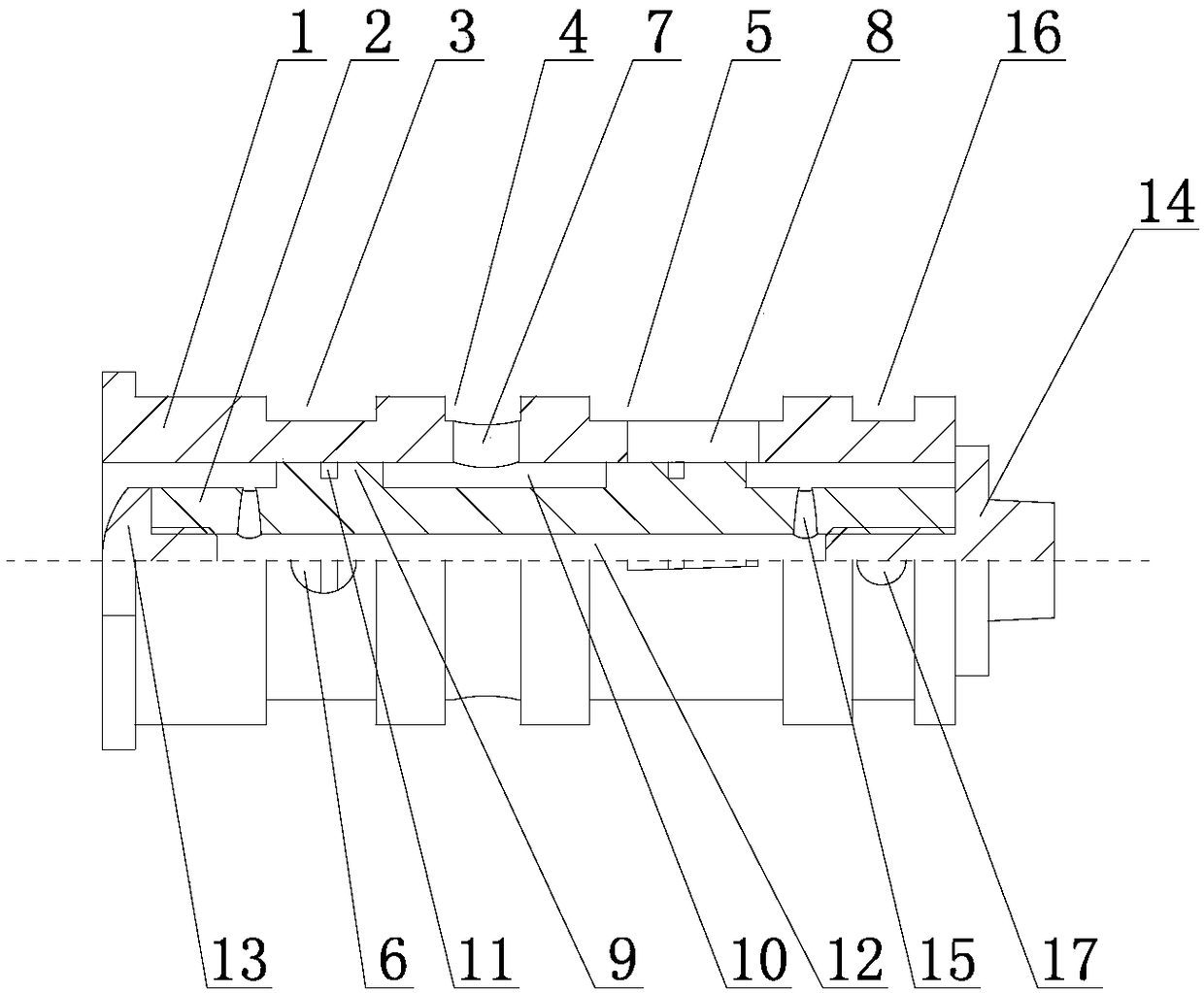

Double-motor coupling planetary traction transmission shaft bearing type deceleration electric hub

InactiveCN109532462ARealize stepless speed regulationSufficient powerMotor depositionControl devicesReduction driveCoupling

The invention discloses a double-motor coupling planetary traction transmission shaft bearing type deceleration electric hub, which comprises a hub, a planetary traction transmission shaft bearing type speed reducer arranged in a hub cavity, a first motor and a second motor. Any sequence combination of a sun gear, a planet carrier and an outer ring in the planetary traction transmission shaft bearing type speed reducer respectively corresponds to a power input end, a power output end and an intermediate transmission part in the planetary traction transmission shaft bearing type speed reducer,the first motor is used for driving the power input end to provide power and driving the hub to rotate through the power output end, and the second motor is used for driving the intermediate transmission part for speed coupling. According to the planetary traction transmission shaft bearing type speed reducer, the cooperation of the two motors is realized through the planetary traction transmission shaft bearing type speed reducer, so that each motor can always work in a high-efficiency working range, the working efficiency of the hub is improved, and the purposes of saving energy and prolonging endurance mileage are achieved.

Owner:CHONGQING UNIV

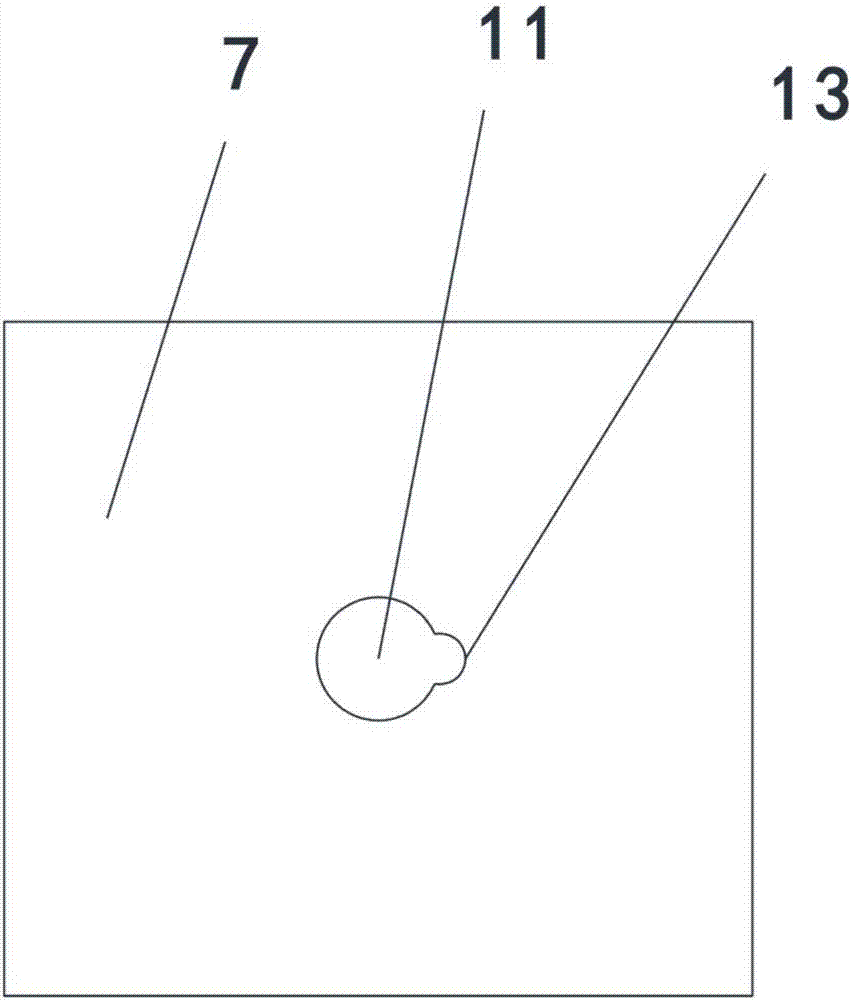

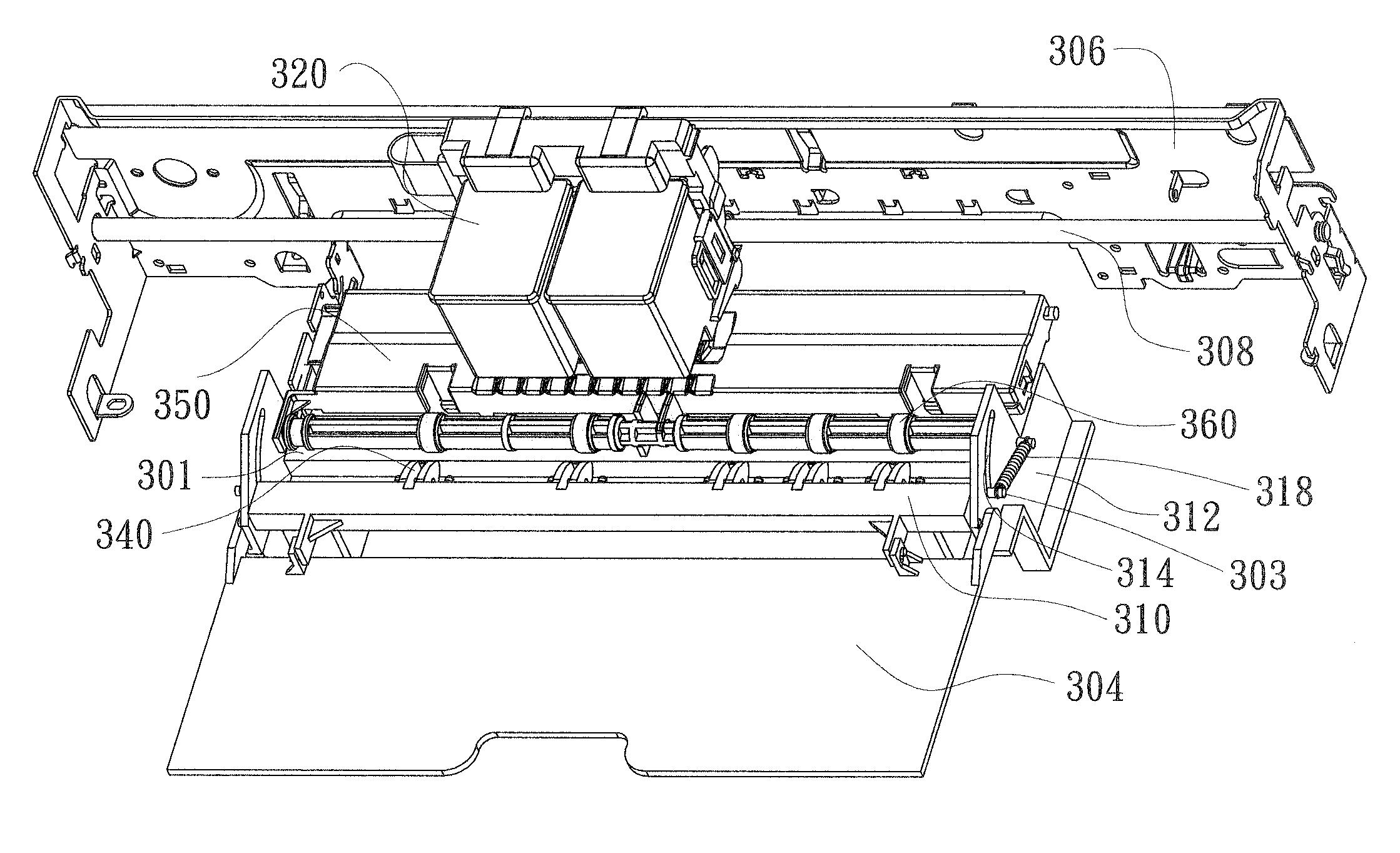

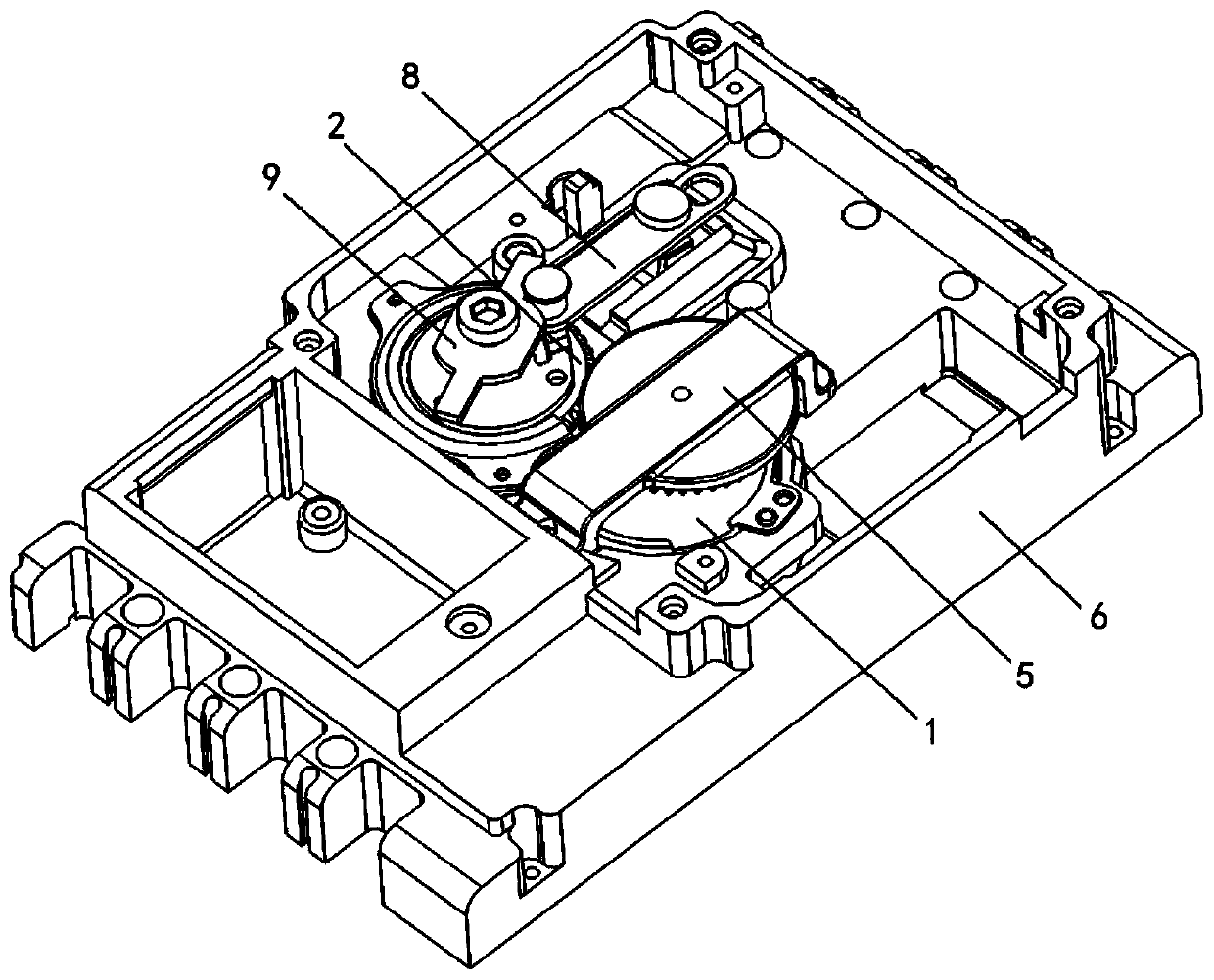

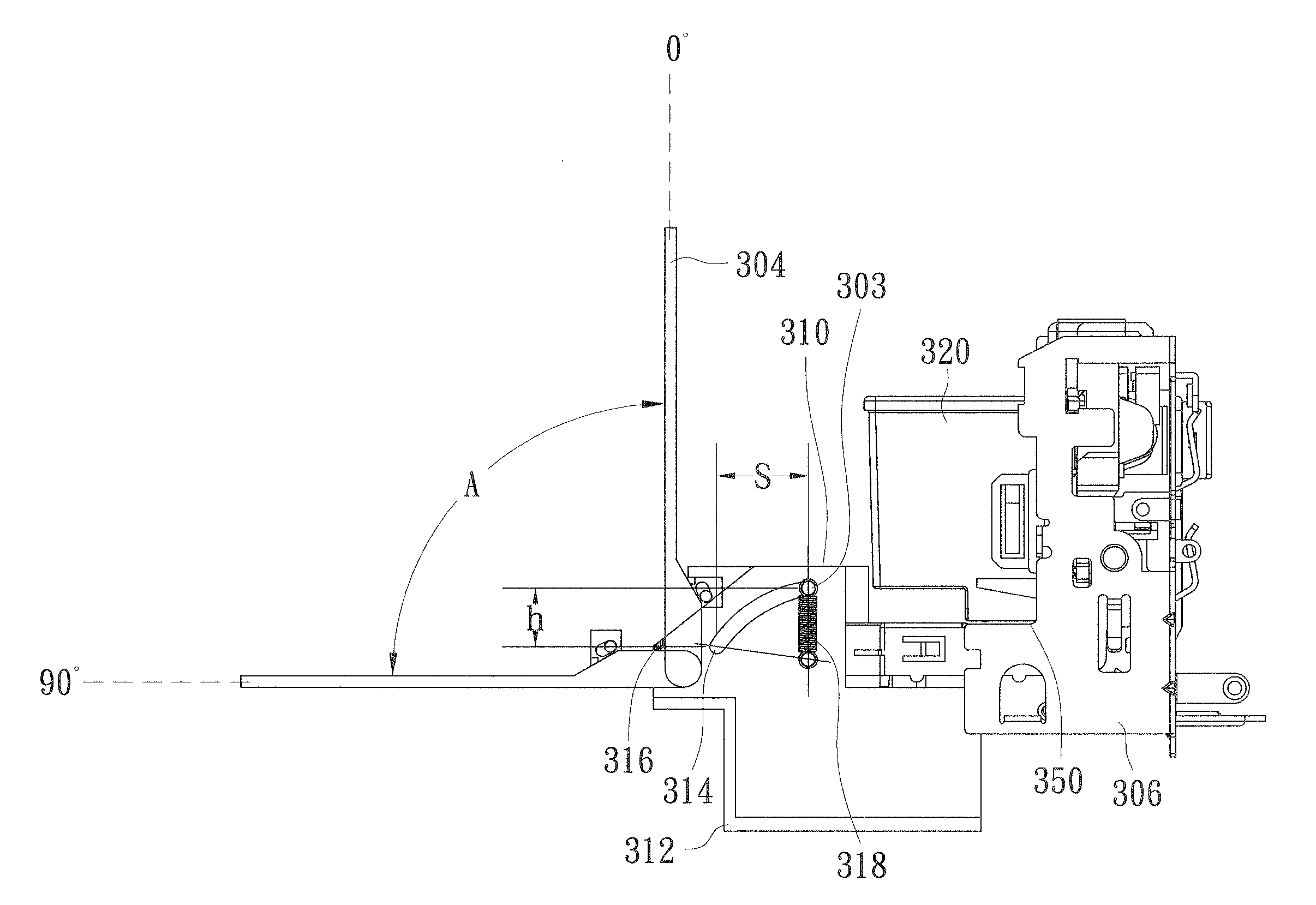

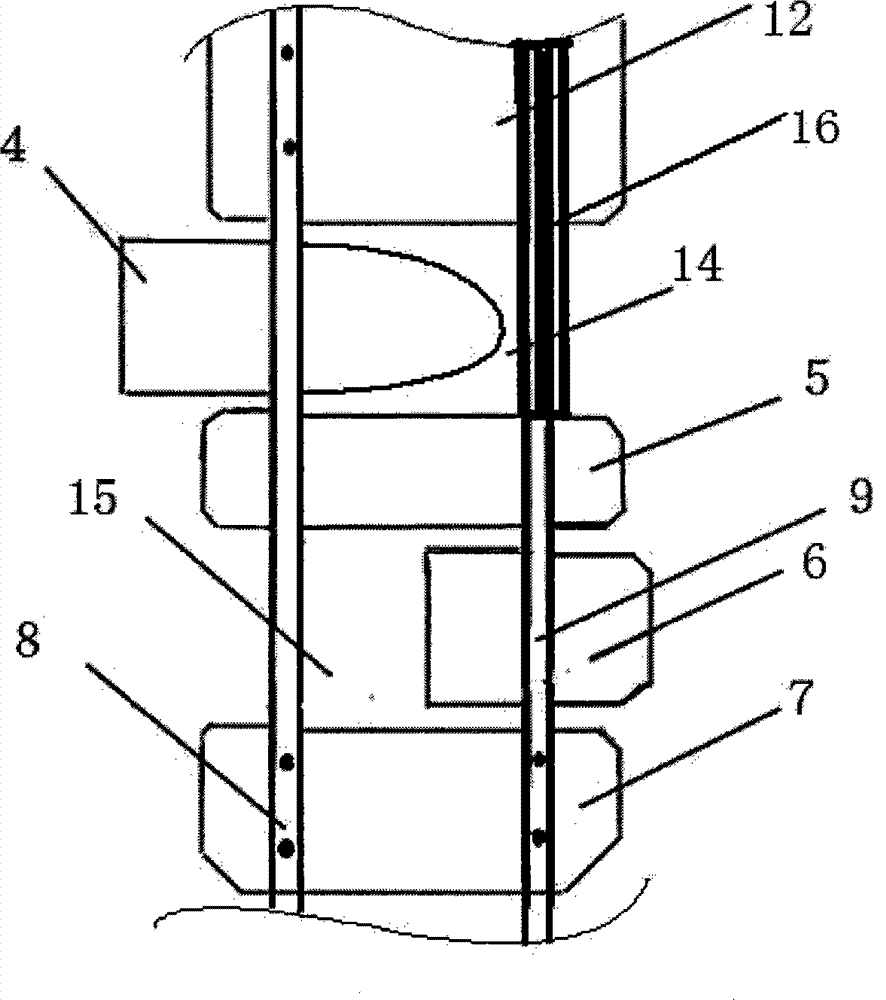

Star wheel releasing mechanism of printing apparatus

InactiveUS7641331B2Improve space utilizationEliminate jammingOther printing apparatusArticle deliveryEngineeringFront cover

A star wheel releasing mechanism for a printing apparatus is described. The star wheel releasing mechanism comprises a base, the exit wheels disposed at the base, a star wheel module, a pair of supporting plates and a front cover. The base includes a first side and a second side. The star wheel module having a plurality of star wheels is movably disposed on the base. The supporting plates are oppositely disposed at the first side and the second side of the base. Each supporting plate has an arc slot. Two ends of the star wheel module are respectively slidable within the arc slots of two supporting plates. The front cover pivoted on the supporting plates and connected to the star wheel module is movable between a first position and a second position.

Owner:QISDA CORP

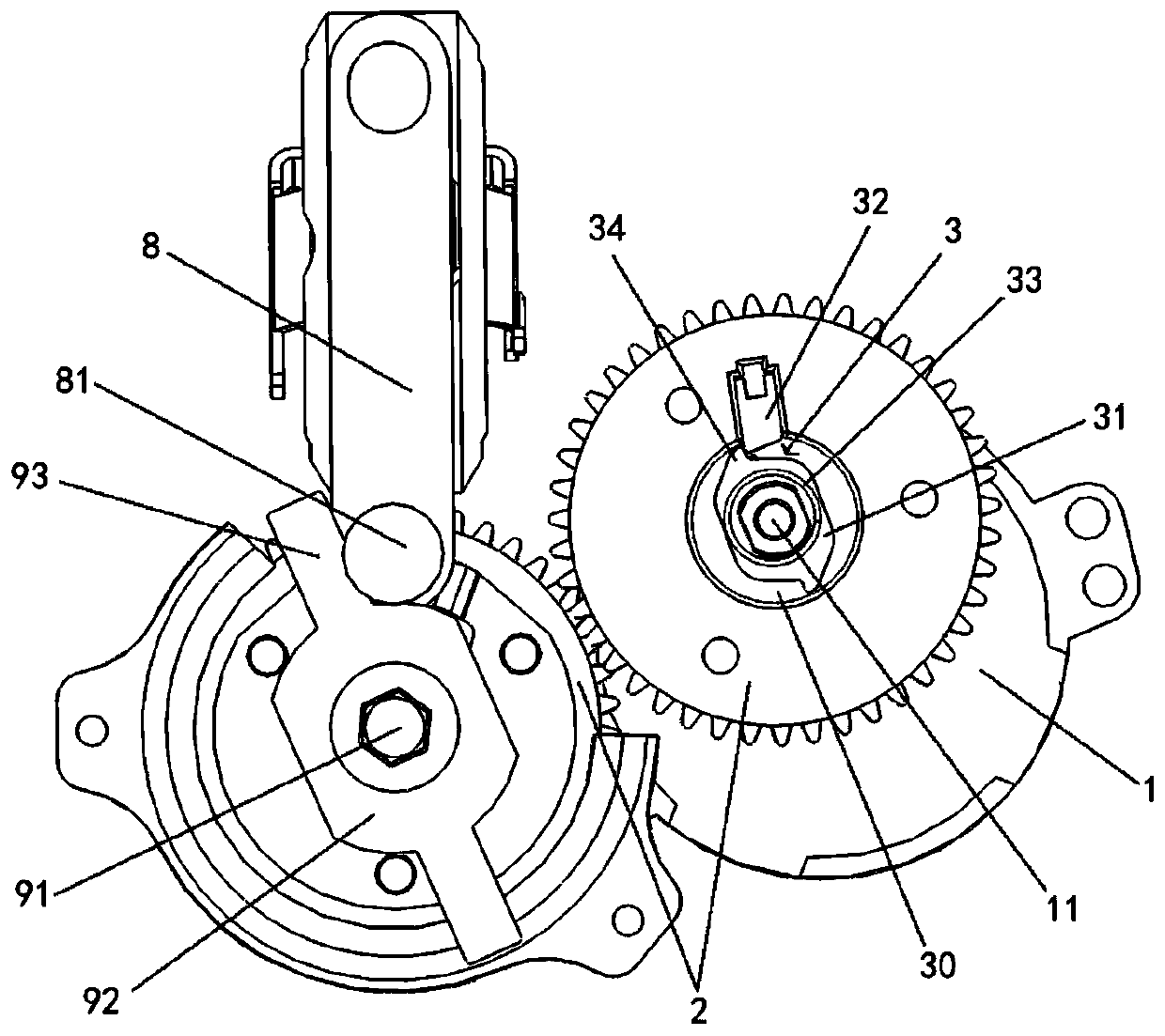

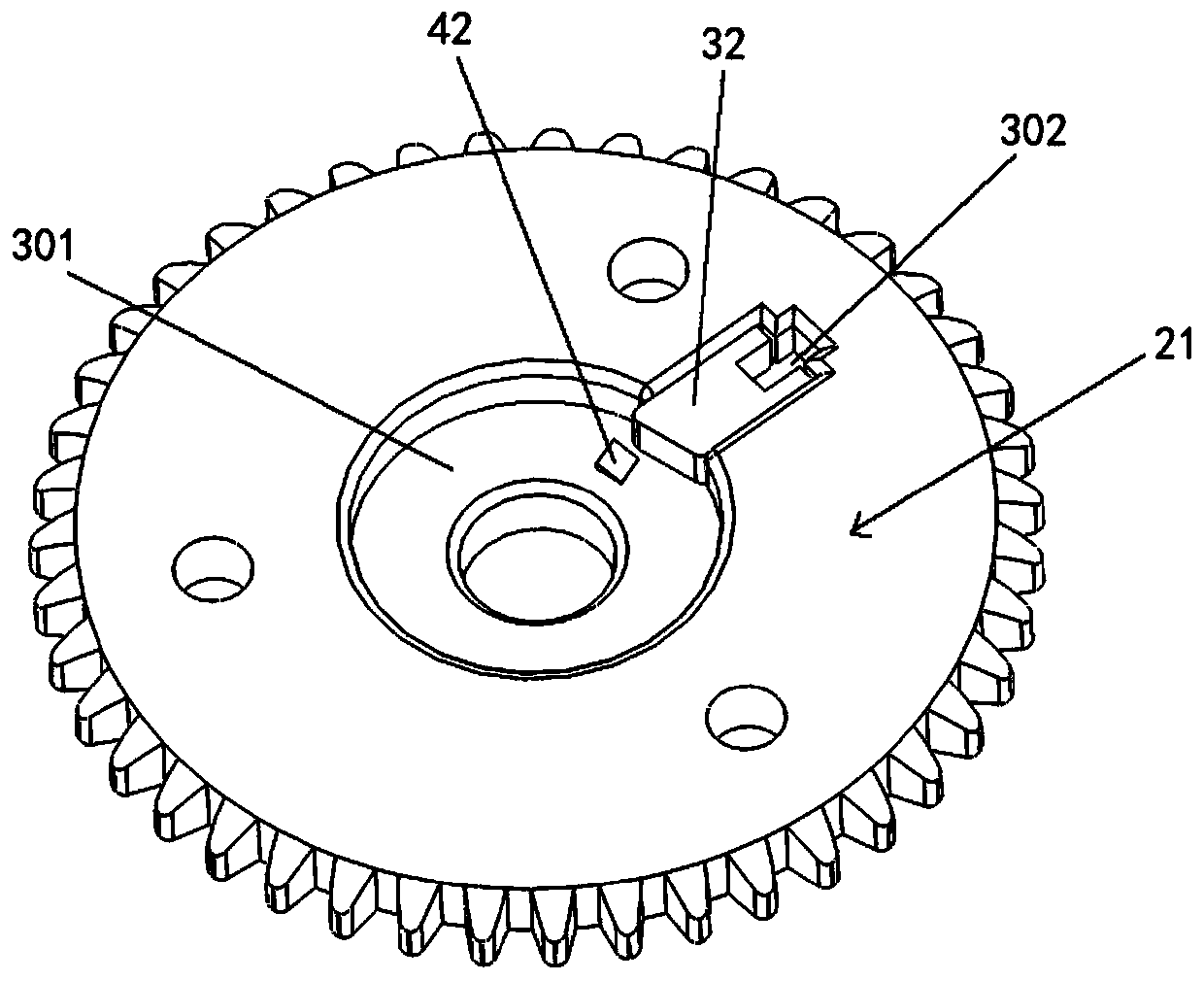

Reclosing device of circuit breaker

PendingCN111128620AShorten closing timeTouch speedContact driving mechanismsProtective switch operating/release mechanismsRatchetGear wheel

The invention discloses a reclosing device of a circuit breaker. The device comprises a driving structure, a gear set and a clutch structure arranged between a driving gear and the driving structure,and the clutch structure comprises a mounting groove arranged in the gear set, a clutch wheel, a limiting piece and an elastic piece, wherein the clutch wheel and the limiting piece are arranged in the mounting groove, and the elastic piece is arranged on a top surface of the clutch wheel in an abutting mode; a one-way positioning structure is arranged between the mounting groove and the clutch wheel so that a pre-positioning effect on a ratchet wheel in the mounting groove is achieved; a triggering distance between the clutch wheel and a pawl can be greatly shortened; and when a power structure drives the gear set to carry out one-way closing rotation through the clutch structure, a long idle stroke between the clutch wheel and the pawl can be avoided, waiting time is greatly reduced, closing time of the circuit breaker is shortened, closing time is ensured to be within a reclosing prescribed range, and use performance of products is improved.

Owner:ZHEJIANG TENGEN ELECTRIC

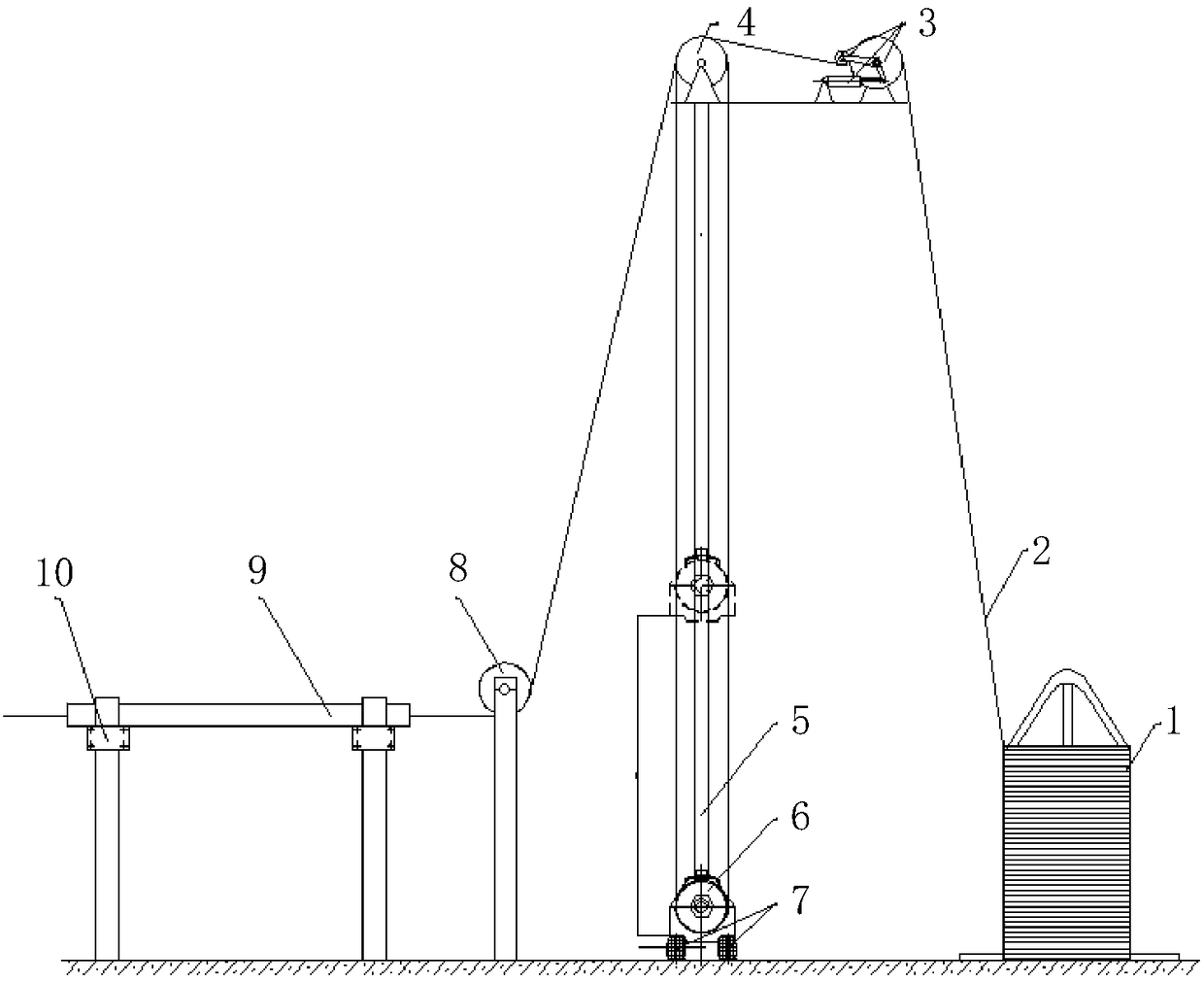

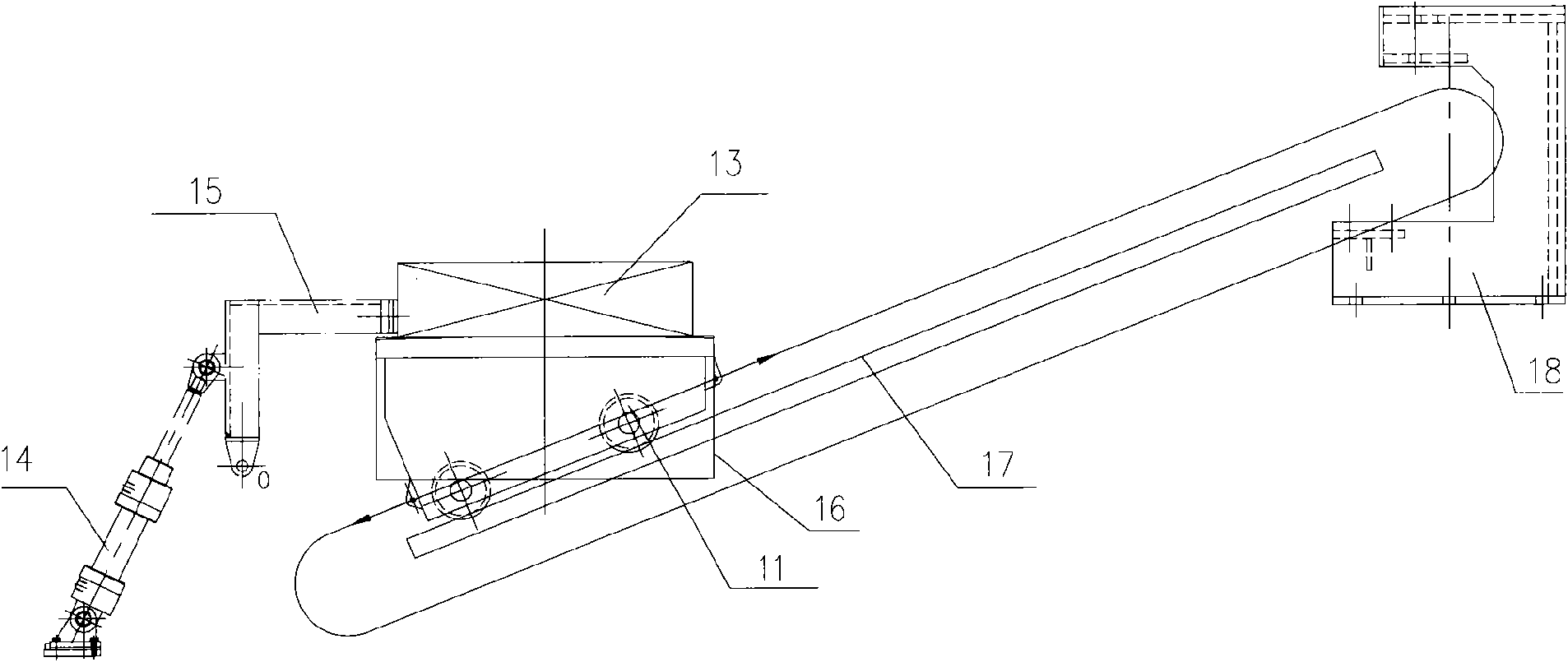

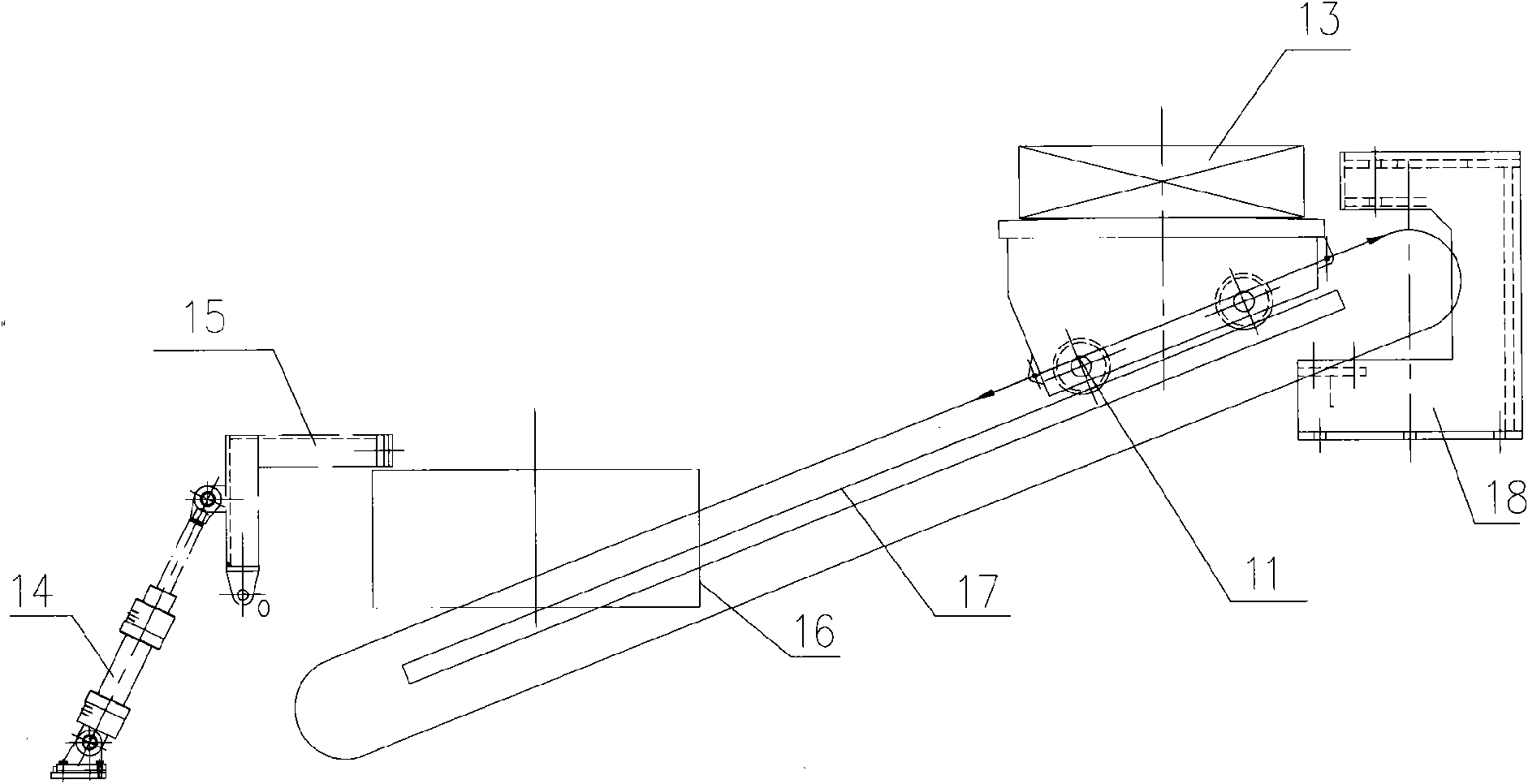

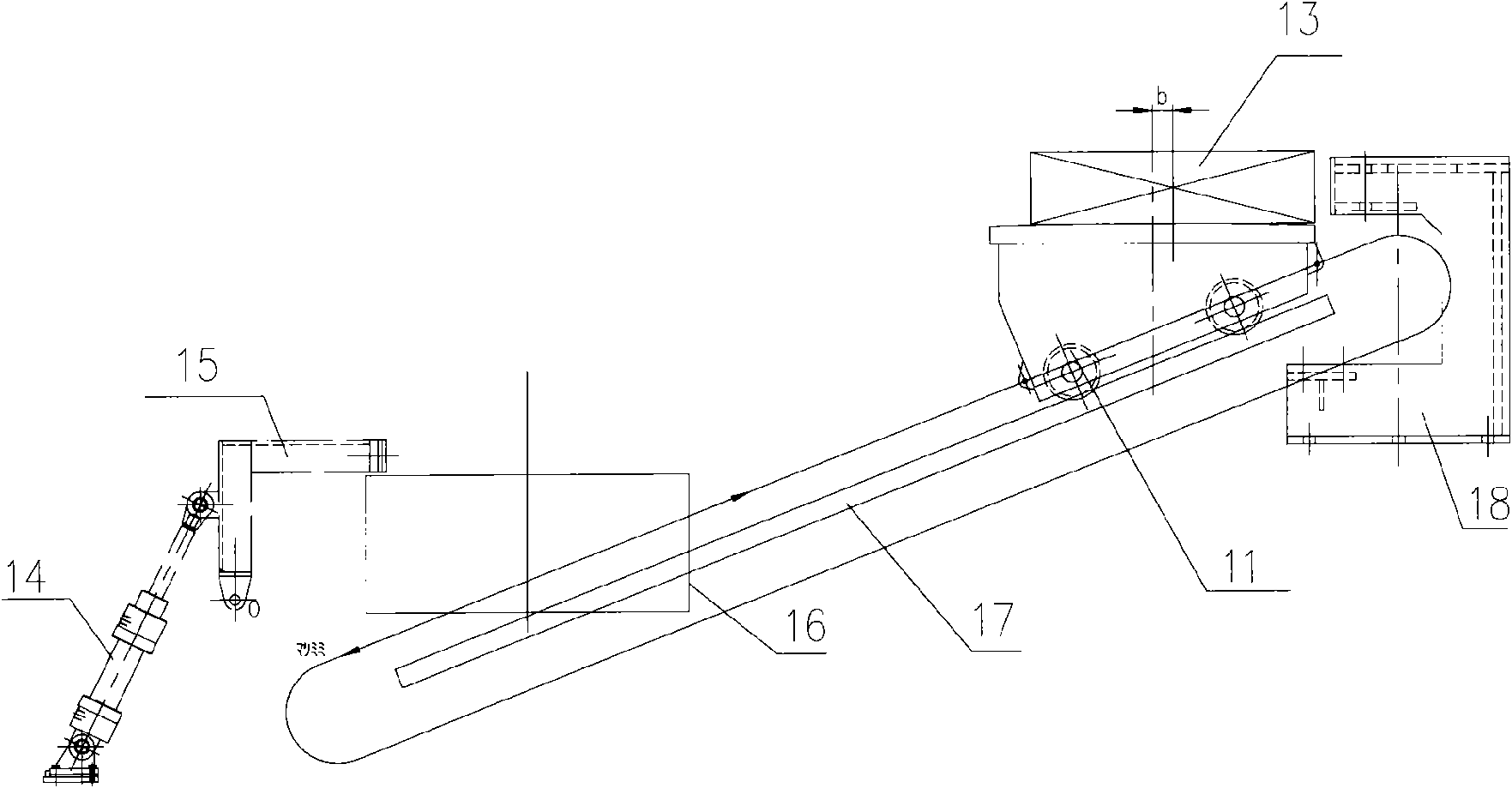

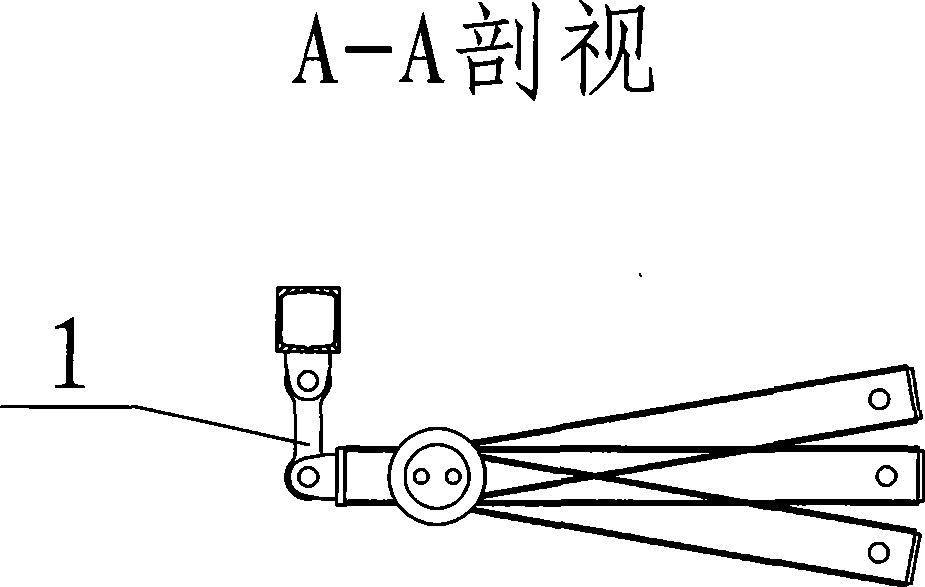

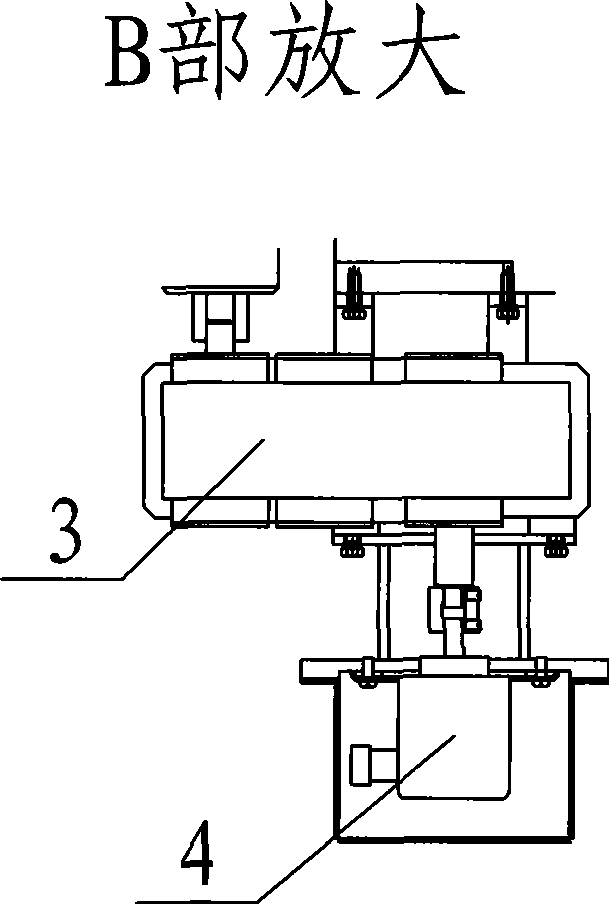

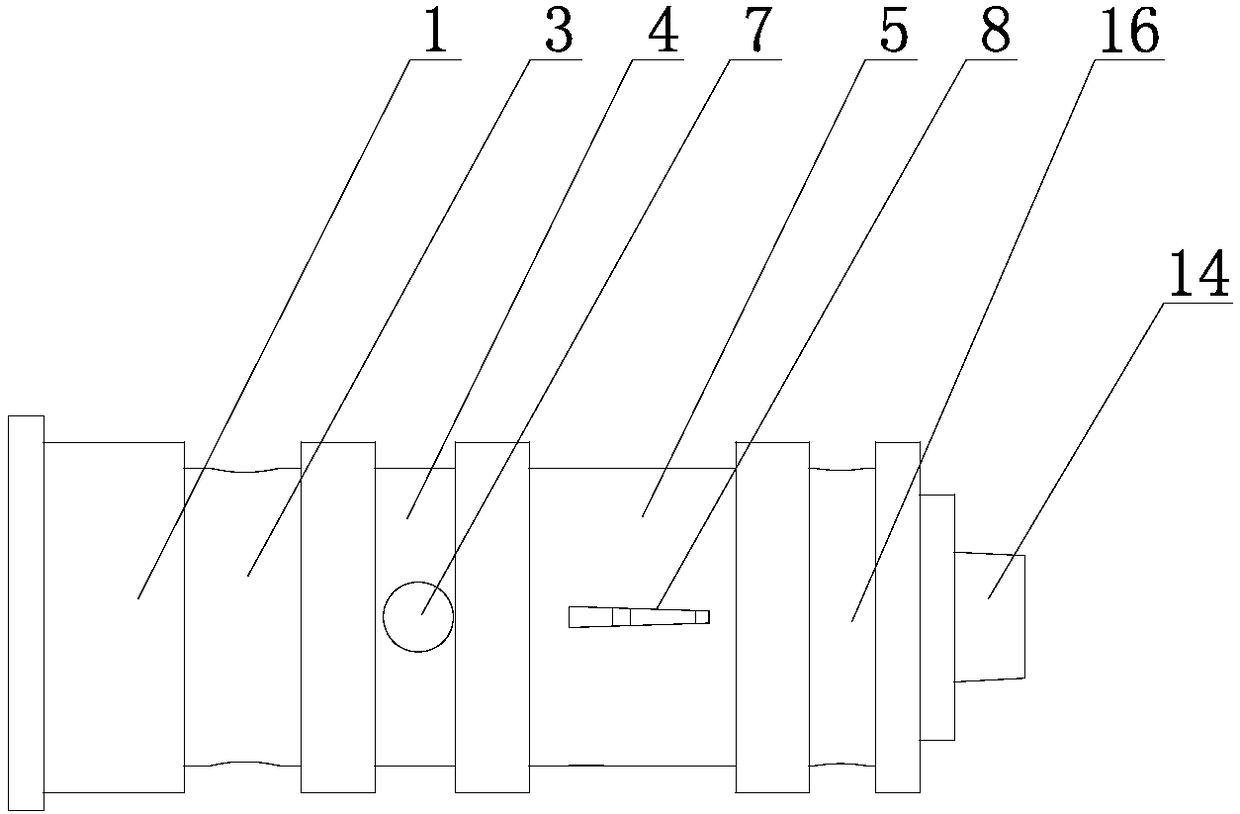

Pay-off system for automatic packer of high-speed wire rods

PendingCN108394577AIncrease buffer timeReduce the cushioning forceFilament handlingBundling machine detailsYarnWire rod

The application provides a pay-off system for an automatic packer of high-speed wire rods. The pay-off system comprises a packing silk yarn warehouse, a pneumatic wire brake mechanism, a fixed pulleyset, a guiding upright, a wire weight device and a ground bumper, wherein the wire weight device is sequentially provided with a movable pulley set, a guiding mechanism and a balance weight; the fixedpulley set is arranged at the upper end of the guiding upright; the ground bumper is arranged at the lower end of the guiding upright; and the wire weight device is connected with the guiding uprightthrough the guiding mechanism in a sliding manner. Through cooperation between the fixed pulley set and the movable pulley set, the lifting height of a wire weight is reduced; as the balance weight is added, a labor-saving function of the movable pulley set is canceled, and accordingly, a tensile force of a packing silk which bypasses the pulley sets is equal to the original value; meanwhile, thegravity center of the wire weight can be adjusted, so that the wire weight can be kept horizontal in a lifting process, and accordingly, a jamming elimination role can be played; and the ground bumper is modified to prolong the impact time, so that synthetic actions of reducing damages to the wire weight and the ground bumper, saving the working space and eliminating potential safety hazards areachieved.

Owner:SHANDONG IRON & STEEL CO LTD

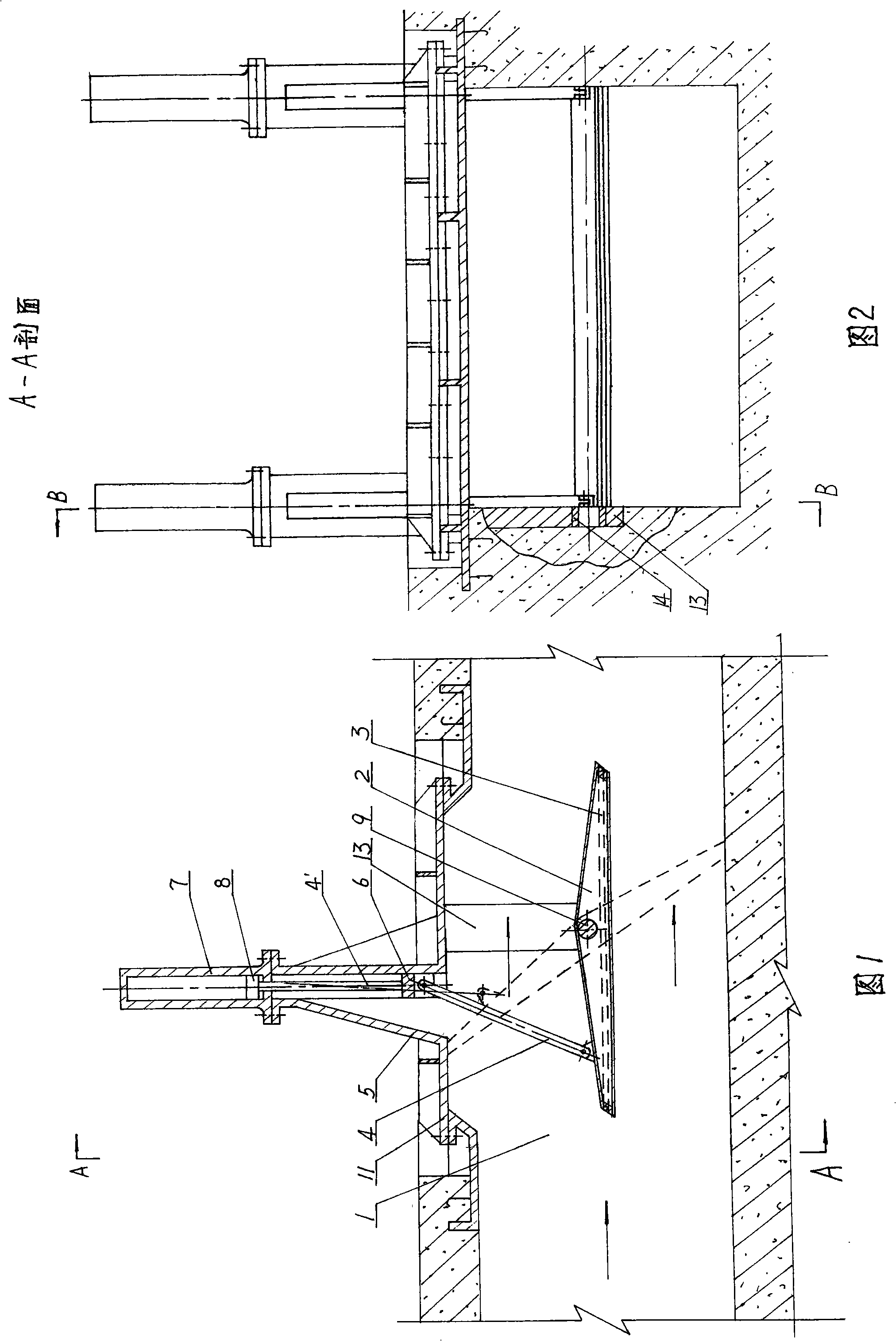

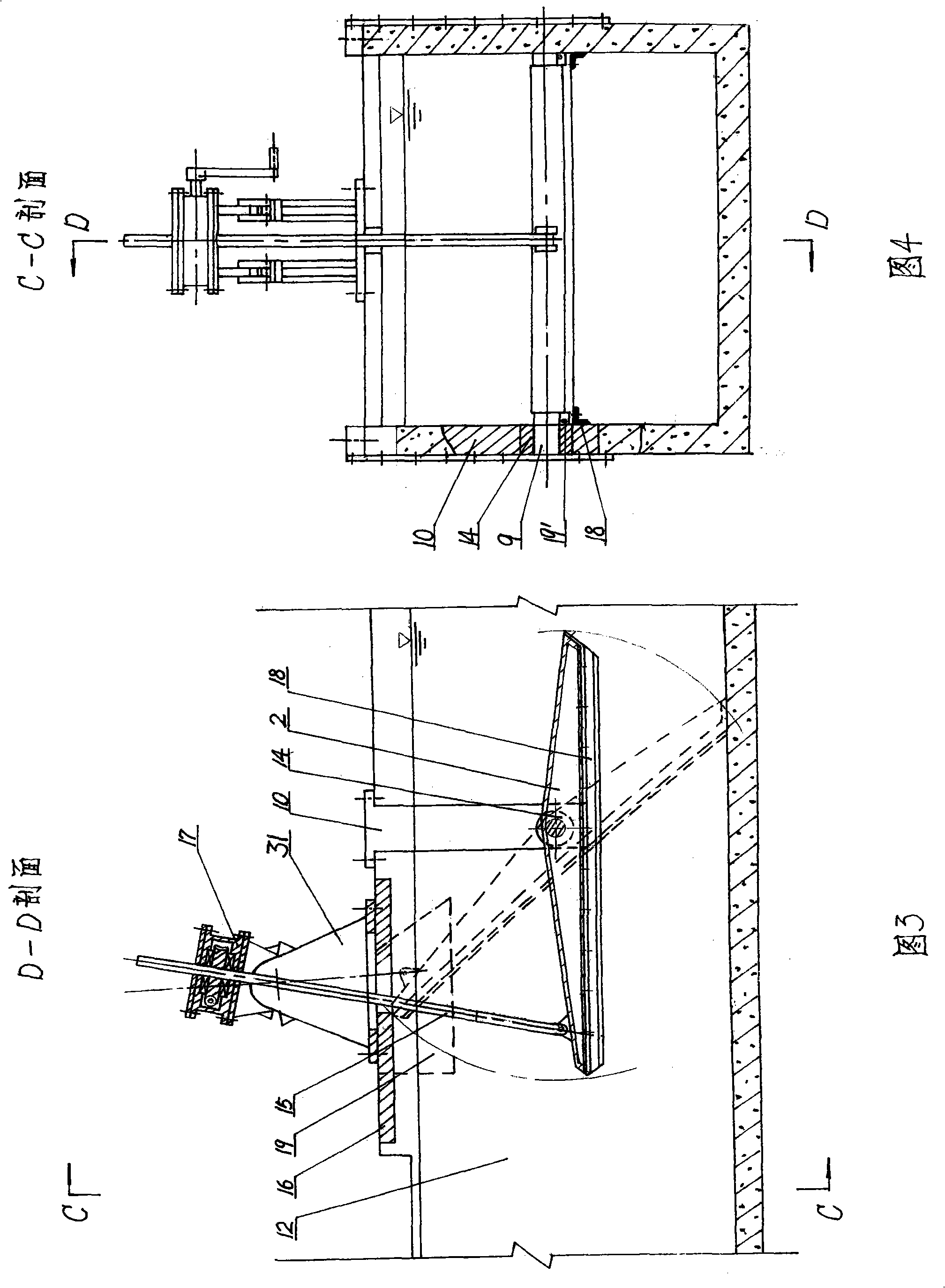

Dummy bar storing device for continuous casting machine

The invention relates to a dummy bar storing device for a continuous casting machine, comprising dummy bars, a carrying trolley, a supporting seat and a positioning device connection rod. The carrying trolley is used for carrying the dummy bars back and forth on a track; the is arranged at a high part of the track, used for supporting the track and is provided with a positioning block; and the positioning device connection rod is arranged at the lower part of the track and used for adjusting the position of the dummy bars on a roller surface,. When the dummy bar is at the higher part of the track, the positioning block limits the position of the dummy bar so that the central line of the dummy bar deviates toward the left relative to the central line of the carrying trolley. The lower end par of a contact surface of the positioning device connection rod and the dummy bar is a circular bead. The invention ensures that the dummy bar can be accurately inserted into a crystallizer every time, greatly improves the reliability of the safe operation of the dummy bar storing device for the continuous casting machine, and reduces the the labor intensity of operation workers.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

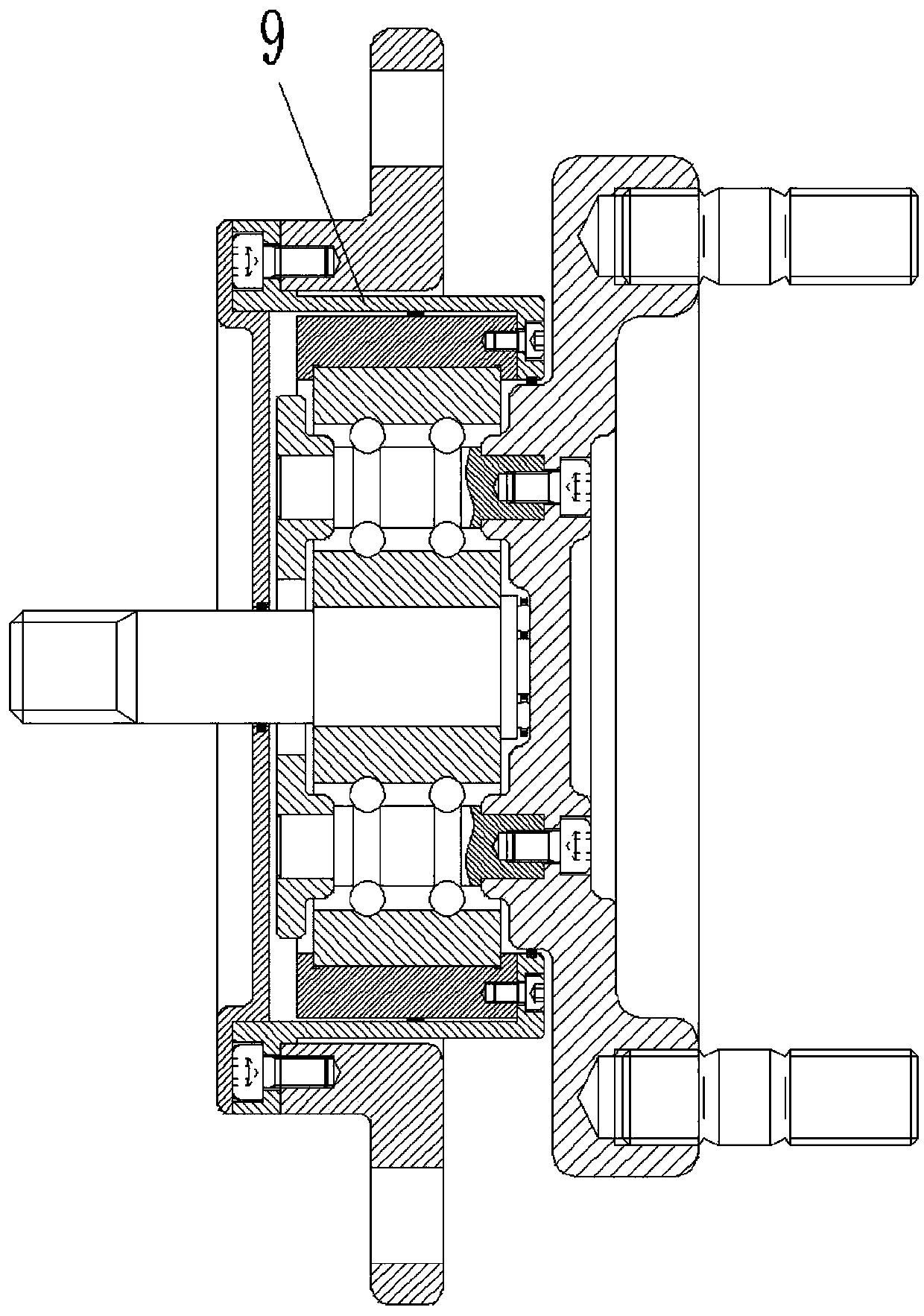

Planetary traction drive bearing type integral reduction hub

InactiveCN109538704AReduce axial sizeImprove compactnessToothed gearingsBearing componentsReduction driveReducer

The invention discloses a planetary traction drive bearing type integral reduction hub which comprises a hub body and a planetary traction drive bearing type reducer; the planetary traction drive bearing type reducer comprises a planetary traction drive gear train collectively formed by a reducer drive inner shaft, a reducer outer ring, a planetary rolling body and a planetary carrier; the planetary rolling body is matched with the reducer drive inner shaft and the reducer outer ring in a friction drive manner; and the power output end of the planetary traction drive gear train is in drive connection to the hub body. The planetary traction drive bearing type integral reduction hub simplifies combination of a wheel-side reducer and a hub bearing, enables the hub bearing to be organically integrated to a planetary traction reduction drive structure, integrates functions of speed reduction and a bearing as well as is simple and compact in structure, small in size and low in processing size.

Owner:CHONGQING UNIV

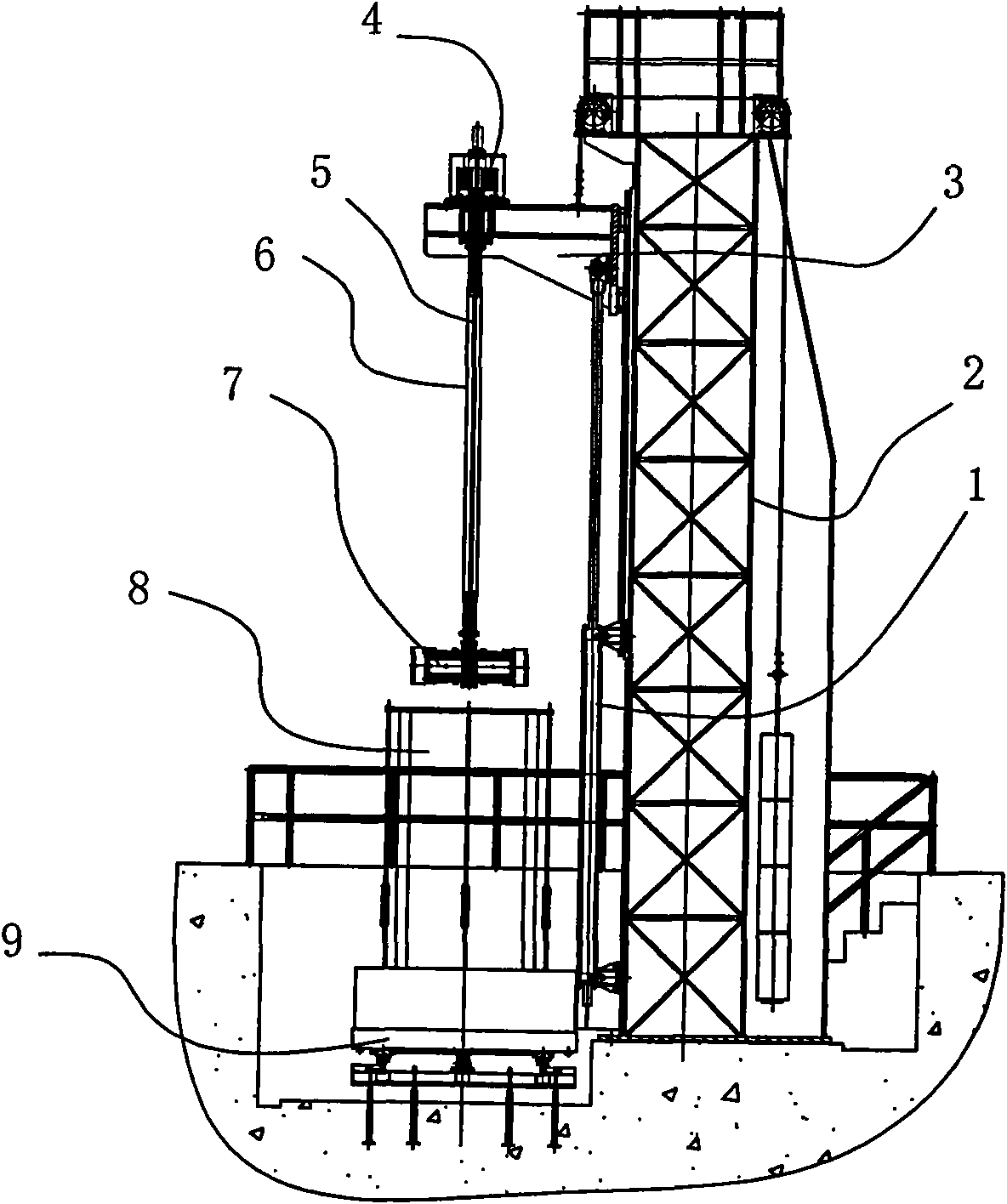

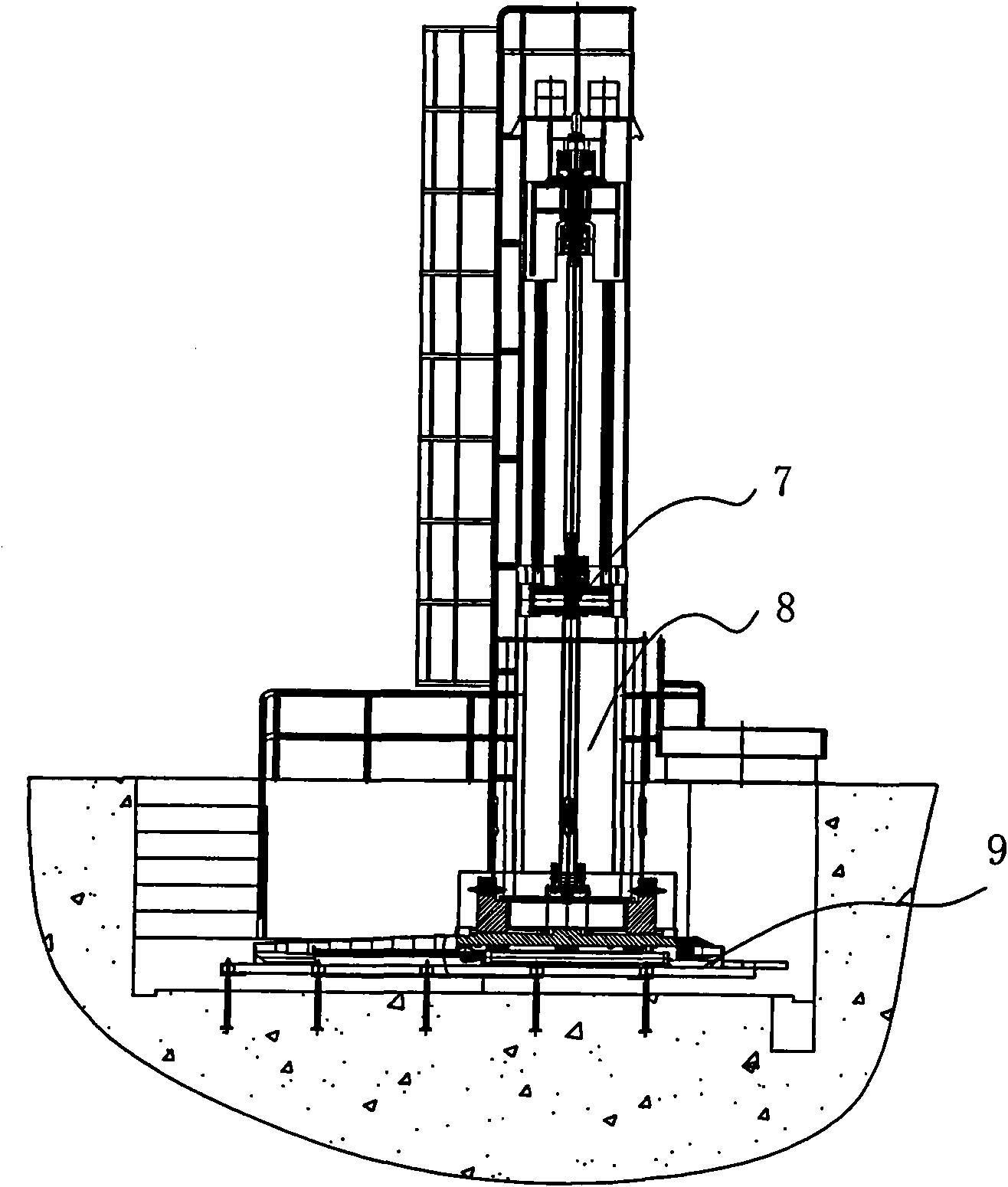

Vertical single-column cantilever type large-aperture honing machine

InactiveCN101890674ASimplify the alignment processAvoid bearing eccentric loadsHoning machinesHydraulic motorEngineering

The invention relates to a vertical single-column cantilever type large-aperture honing machine which relates to a hole-honing special machine. In the honing machine, the lifting drive mechanism of a honing head device comprises a cantilever type pedestal and a lift cylinder, wherein the lift cylinder drives the pedestal to move up and down; the honing head device is a collapsible honing head device containing a drive hydraulic motor, a hollow shaft, a mandrel, a wedge cylinder, a honing head disk with a center hole, a push rod and an abrasive stick; the abrasive stick is vertically and movably connected on the outside cylinder surface of the honing head disk through the push rod; the wedge cylinder is arranged in the center hole of the honing head disk; the lower end of the hollow shaft is fixedly connected with the top surface of the honing head disk to drive the honing head disk to rotate; the mandrel is arranged in the hollow shaft, the lower end of the mandrel is connected with the wedge cylinder to drive the wedge cylinder to move up and down; and the push rod is movably connected in the honing head disk along the radial direction of the honing head disk, the inner end of the push rod sticks to the wedge face of the wedge cylinder, and the outer end is connected with the abrasive stick. By using the honing machine of the invention, the use reliability of equipment is greatly improved, the service life of equipment is prolonged, and the maintenance cost of equipment is reduced.

Owner:YANGZHOU METALLURGICAL MACHINERY

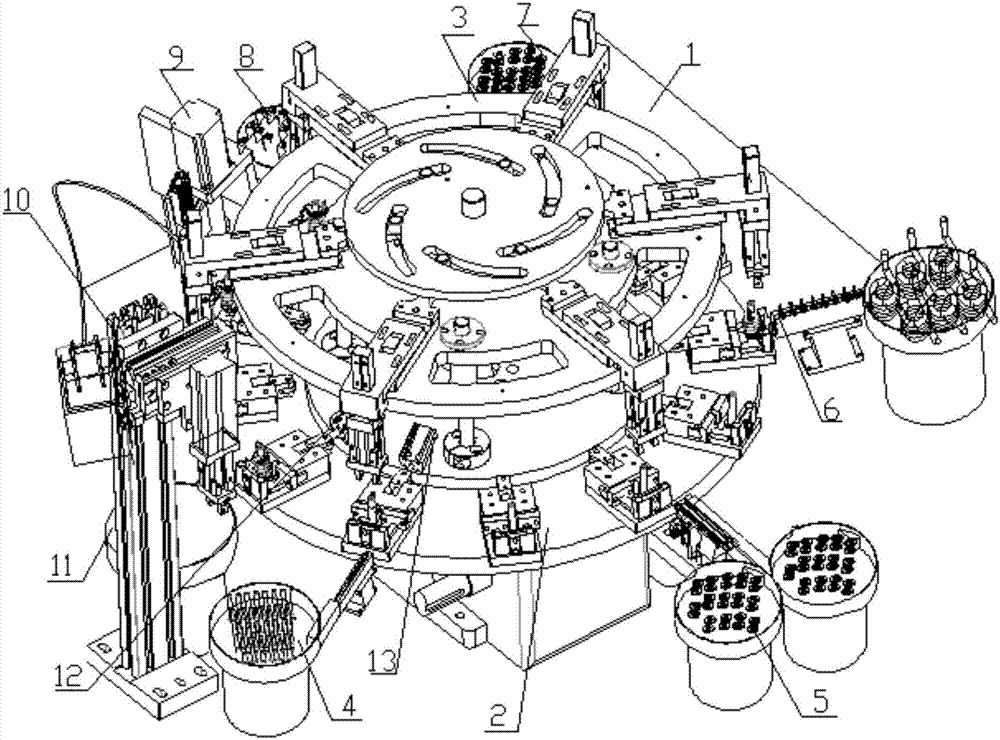

Automatic tin soldering and welding system for circuit breaker coil conductive assembly

ActiveCN107248482AEliminate weldsEliminate high failureEmergency protective device manufactureEngineeringSoldering

The invention discloses an automatic tin soldering and welding system for a circuit breaker coil conductive assembly. Nine feeding and discharging mechanisms and three detectors are arranged on the periphery of a rotary plate assembly on a horizontal platform surface in sequence; the nine feeding and discharging mechanisms comprises a tin soldering mechanism, an oil cup, a lower gasket, a coil, an upper gasket, and a feeding mechanism of a magnetic yoke; a finished product discharging box is arranged outside the tin soldering mechanism; the rotary plate assembly comprises an inner plate and an outer rotary plate; twelve stations are arranged towards the outer side of the outer rotary plate in the circumferential direction uniformly, comprising eight station starting mechanisms; each of the twelve stations is provided with a set of station clamp separately; and the twelve station clamps are uniformly arranged on the outer side of the outer rotary plate in the circumferential direction uniformly and are corresponding to the positions of the nine feeding and discharging mechanisms on the circumference of the rotary plate assembly. The automatic tin soldering and welding system is compact in structure, reliable in operation and high in welding quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Star wheel releasing mechanism of printing apparatus

InactiveUS20060244802A1Improve space utilizationEliminate jammingOther printing apparatusEngineeringFront cover

A star wheel releasing mechanism for a printing apparatus is described. The star wheel releasing mechanism comprises a base, the exit wheels disposed at the base, a star wheel module, a pair of supporting plates and a front cover. The base includes a first side and a second side. The star wheel module having a plurality of star wheels is movably disposed on the base. The supporting plates are oppositely disposed at the first side and the second side of the base. Each supporting plate has an arc slot. Two ends of the star wheel module are respectively slidable within the arc slots of two supporting plates. The front cover pivoted on the supporting plates and connected to the star wheel module is movable between a first position and a second position.

Owner:QUISDA CORP

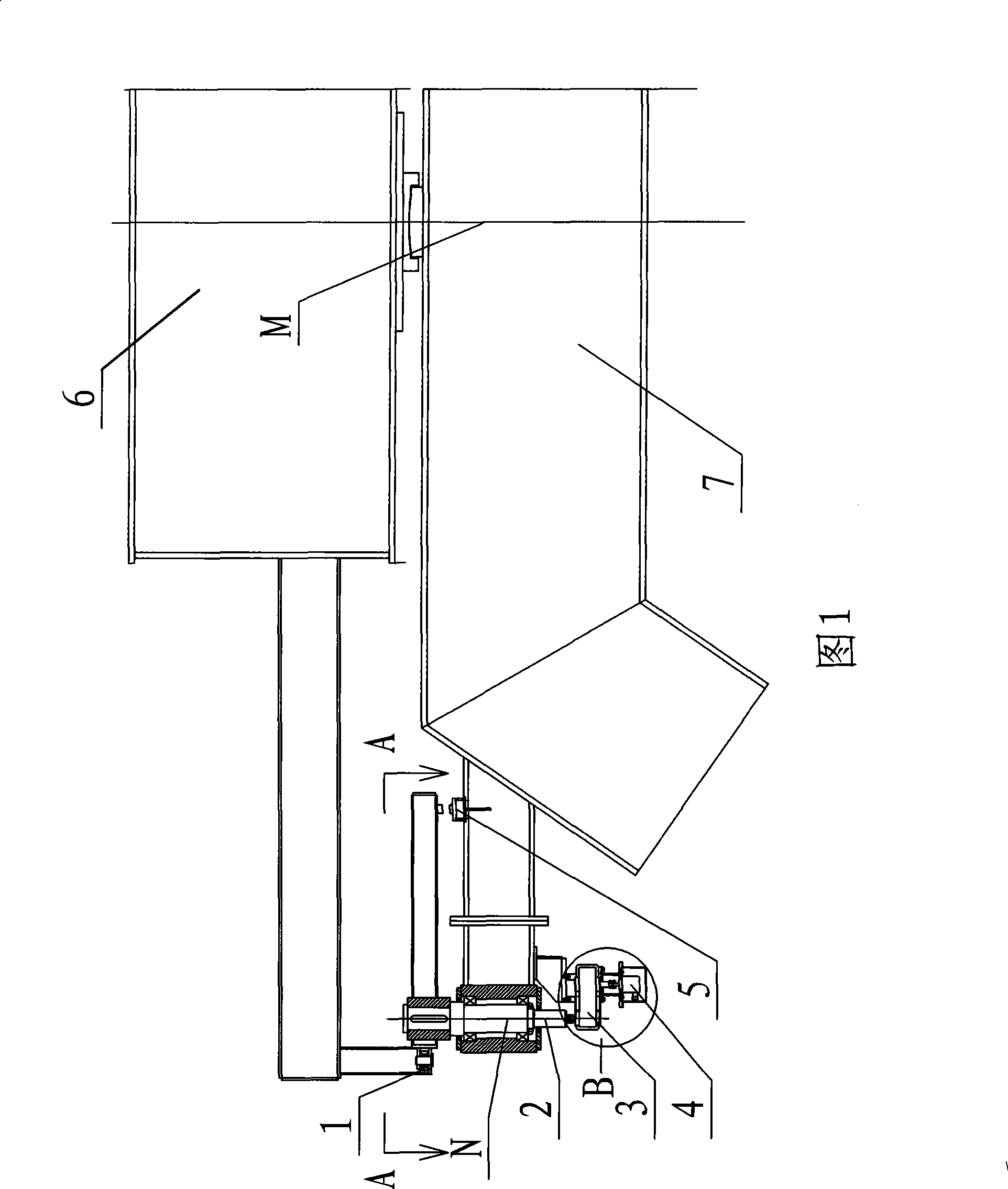

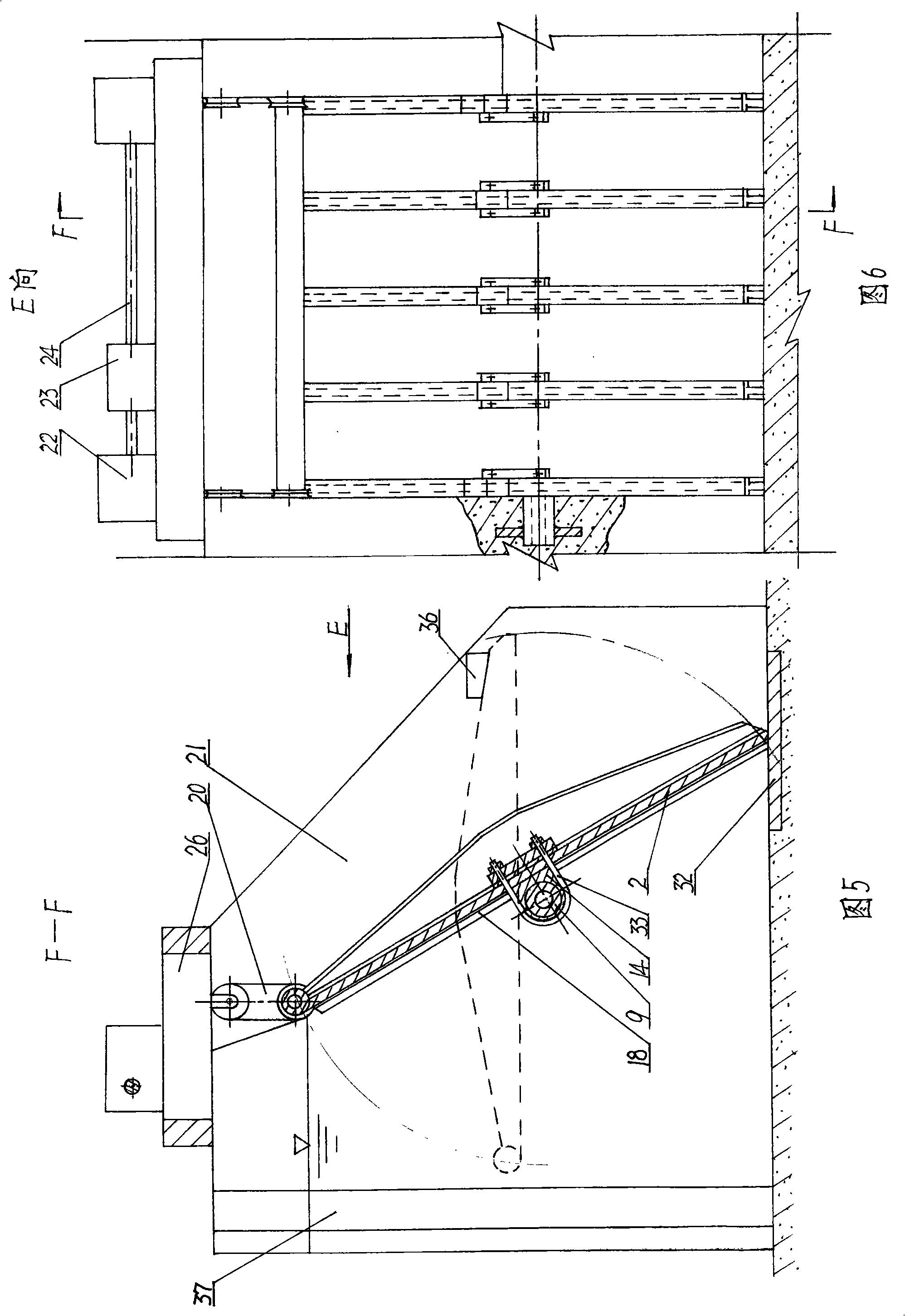

Drum material-fetching machine moving avertence detection device and working method thereof

InactiveCN101424528AHigh precisionGuaranteed accuracyMeasurement devicesControl devices for conveyorsAutomatic controlControl system

The invention discloses a line feed deflexion detecting device of a roller reclaimer, comprising a connecting rod amplifying system, a rotational shaft device, a speed increaser, an encoder and a protecting device, wherein connecting rod reamed points of the connecting rod amplifying system are maintenance-free self-lubricating joint bearings, and the rotational device adopts a rolling bearing and a sealing structure. When the roller relcaimer generates line feed deflexion, a bridge frame and a door leg generate miniature rotor angle around the central line M, and the rotor angle is further amplified by the connecting rod amplifying system, the rotational shaft device and the speed increaser and is transmitted to the encoder which transmits the deflexion rotor angle to a control system of the roller relaimer, the deflexion correction is performed by the control system of the roller reclaimer, and the protecting device realizes the protection function in the failure state. The device can remove the jammed phenomenon of the line feed deflexion detecting device caused by the structural error, realizes the flexible rotation of the rotational shaft, accurate detection and the automatic control, and does not have maintenance workload.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

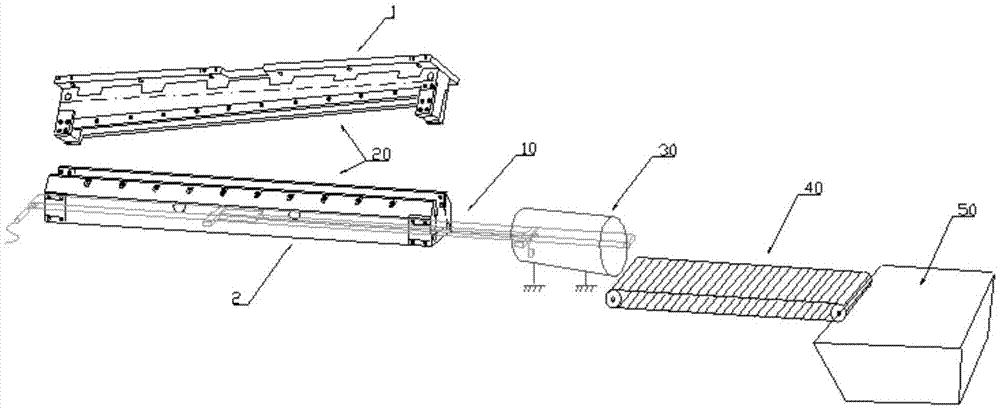

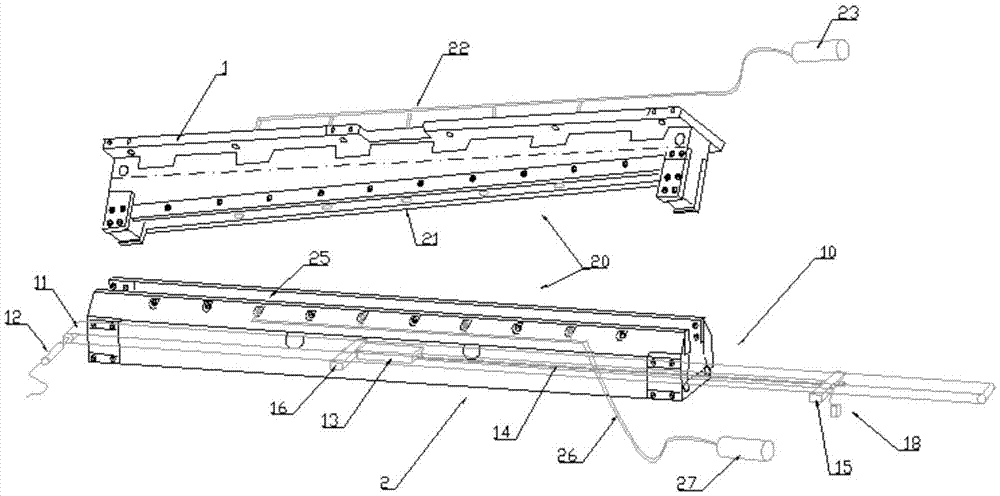

Conveying method and system device of side wires obtained by cutting of welding machine

The invention discloses a conveying method of side wires obtained by cutting of a welding machine. The conveying method is used for conveying elongated wastes such as side wires obtained by cutting of a cold-rolling laser welding machine. A conveying system device of side wires obtained by cutting of the welding machine comprises a sucking and conveying mechanism (10) for side wires obtained by cutting, a gas blowing and pressing mechanism (20), a side wire guiding and blowing mechanism (30) and an external outputting and conveying mechanism (40), and is characterized in that: during the secondary cutting process of the welding machine, a longitudinal gas injecting and blowing assembly arranged in upper shears of the gas blowing and pressing mechanism (20) injects and blows compressed gas from a nozzle in the bottoms of the upper shears and blows off the side wires cut off onto a waste conveying belt (11 ) arranged in lower shears. According to the conveying method disclosed by the invention, the conveying of the side wires obtained by cutting of the laser welding machine is effectively improved, and the quality of a welding seam welded by the laser welding machine is stabilized.

Owner:BAOSHAN IRON & STEEL CO LTD

Adjustable conical bearing outer ring turnover device

The invention relates to an adjustable conical bearing outer ring turnover device, and belongs to the technical field of bearing production equipment. When conical bearing outer rings are machined on a grinding machine, it is required that the orientation of the end faces of the conical bearing outer rings entering the machine tool is uniform. A front screening opening and a rear screening opening are formed in the same plane of a feeding plate, a Y-type groove is formed under the front screening opening and the rear screening opening, the front screening opening is composed of a left adjusting clamp plate, the feeding plate, a right lifting steel plate, a U-type inserting plate, and a middle movable plate, and the rear screening opening is composed of the left adjusting clamp plate, the middle movable plate, a right adjusting clamp plate, a rectangular inserting plate and a rear movable plate. The conical bearing outer rings can be mechanically turned over fully automatically through the adjustable conical bearing outer ring turnover device, and the conical bearing outer rings turned over are regularly output from the device. The adjustable conical bearing outer ring turnover device has the advantages of being ingenious in concept, simple in structure, low in manufacturing cost and convenient to machine and saving labor cost and is suitable for the production flow of the various conical bearing outer rings.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Full-automatic assembling and welding system for circuit breaker coil conductive assembly

ActiveCN107398618AEliminate weldsEliminate high failureAssembly machinesSoldering auxillary devicesEngineeringCircuit breaker

The invention discloses a full-automatic assembly and welding system for a circuit breaker coil conductive assembly. The system comprises a rotating disc assembly, wherein the rotating disc assembly is arranged on a horizontal tabletop, and nine charging and discharging mechanisms and three detectors are sequentially arranged on the horizontal tabletop around the periphery of the rotating disc assembly; the rotating disc assembly comprises an inner disc and an outer rotating disc, and twelve stations are uniformly arranged on the outer side of the outer rotating disc in a circumferential direction; eight station opening mechanisms used for driving station clamps to be opened and closed are distributed on the inner disc along the circumference, and the eight station opening mechanisms are connected with a station opening transmission mechanism through connecting rods; and the twelve stations are each provided with a station clamp, and the twelve station clamps are uniformly arranged on the outer side of the outer rotating disc in the circumferential direction, and correspond to the nine charging and discharging mechanisms around the outer circumference of the rotating disc assembly in position. The system has the advantages of being compact in structure and reliable in work.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Transmission type sluice turning apparatus

The invention discloses a drive-typed turning strobe device which relates to a strobe device that quickly and fully blocks water current in a flow channel or adjusts the excess flow rate. The device is composed of a rotatable strobe which is installed in the flow channel, a transmission component arranged at one end of the strobe and a power plant thereof, or a power plant arranged at one of the strobe and a transmission component thereof. The device not only has simple and reasonable structure as well as safe and reliable working performance, but also convenient and simple production, installation and maintenance. Furthermore, the device can also adapt to various large excess flow channels.

Owner:黄国宏

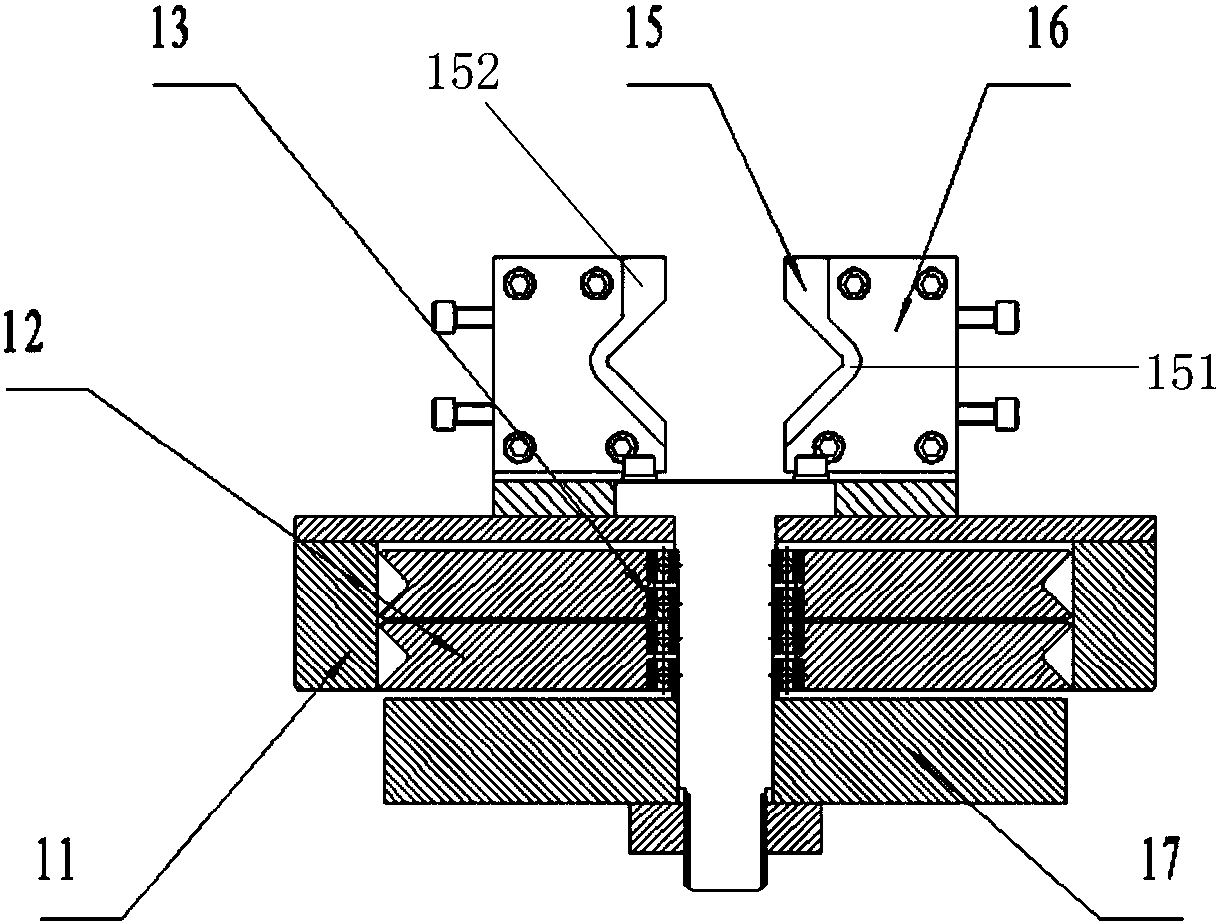

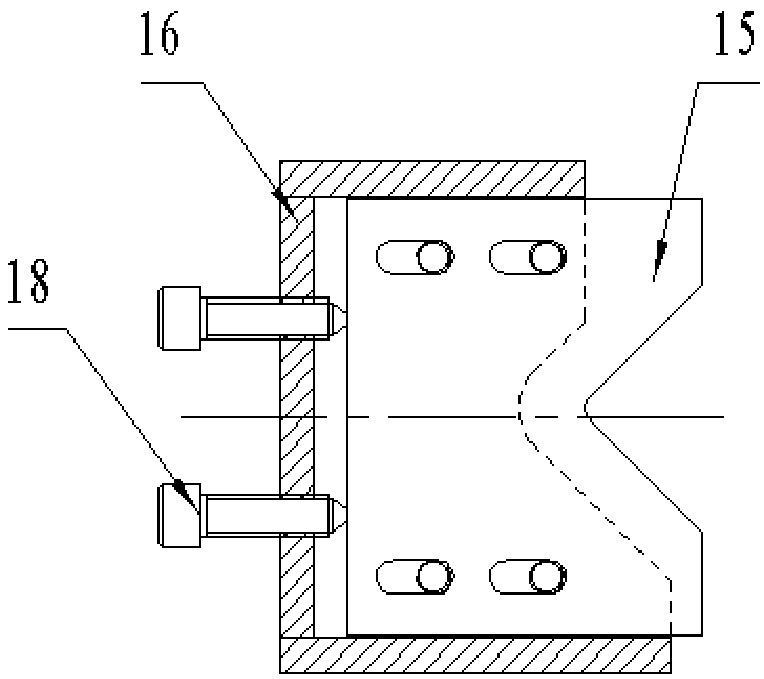

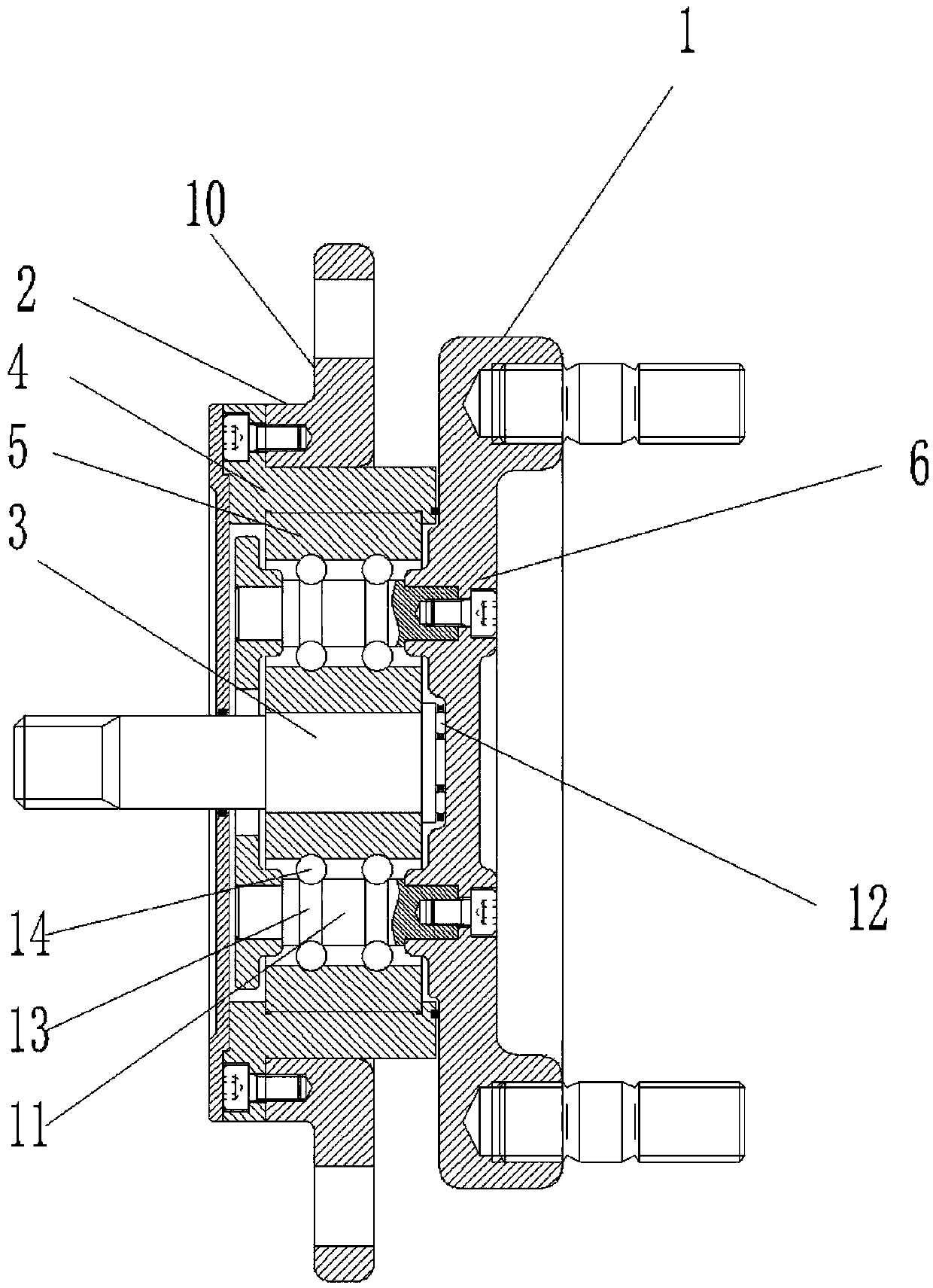

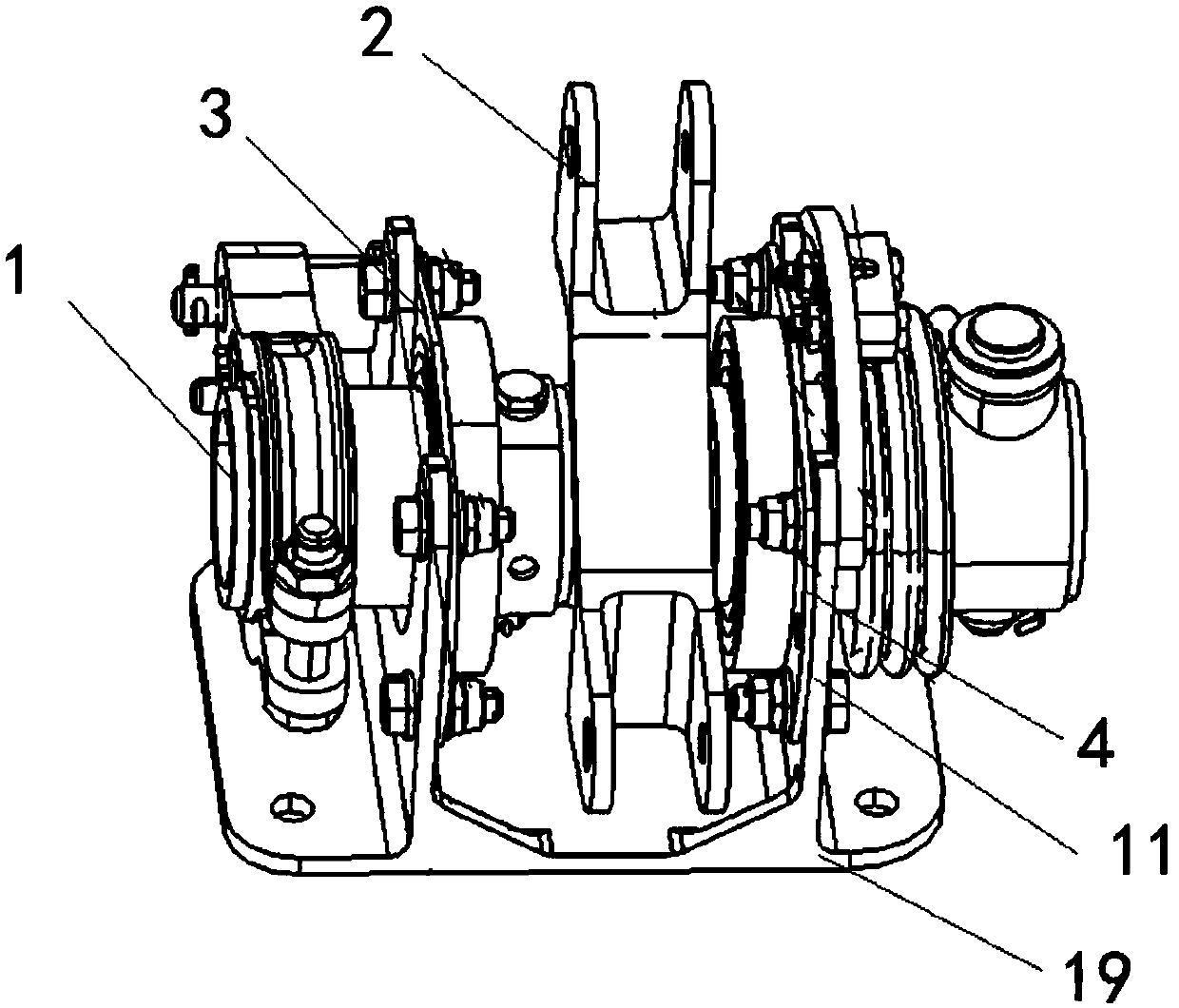

Control force adjusting device

ActiveCN108050169AReduce harmful deformationLower tiltMechanical actuated clutchesControl systemEngineering

The invention discloses a control force adjusting device and belongs to the technical field of control systems. The control force adjusting device comprises a friction assembly, a torsion transfer assembly, a gradient adjusting assembly and a mounting support. The mounting support is composed of a bottom plate and fixing mounting plates arranged on the left side and the right side. The torsion transfer assembly is provided with a torsion shaft, a rocker, a left axial rotary supporting element, a right axial rotary supporting element and a friction plate, wherein the rocker is fixed to the middle portion of the torsion shaft, the left axial rotary supporting element is arranged on the left side of the rocker, the right axial rotary supporting element is arranged on the right side of the rocker, and the left axial rotary supporting element and the right axial rotary supporting element are fixed to the fixing mounting plates. The two ends of the torsion shaft penetrate through the mounting support to be connected with the friction assembly and the gradient adjusting assembly separately. The friction assembly can adjust the clamping force of one end of the torsion shaft. The gradient adjusting assembly can adjust the gradient force of the torsion shaft by adjusting the mounting position of a torsion spring of the gradient adjusting assembly. Control force enters the adjusting device via the input end of the rocker, and is output from the output end of the rocker after being adjusted.

Owner:CHINA HELICOPTER RES & DEV INST

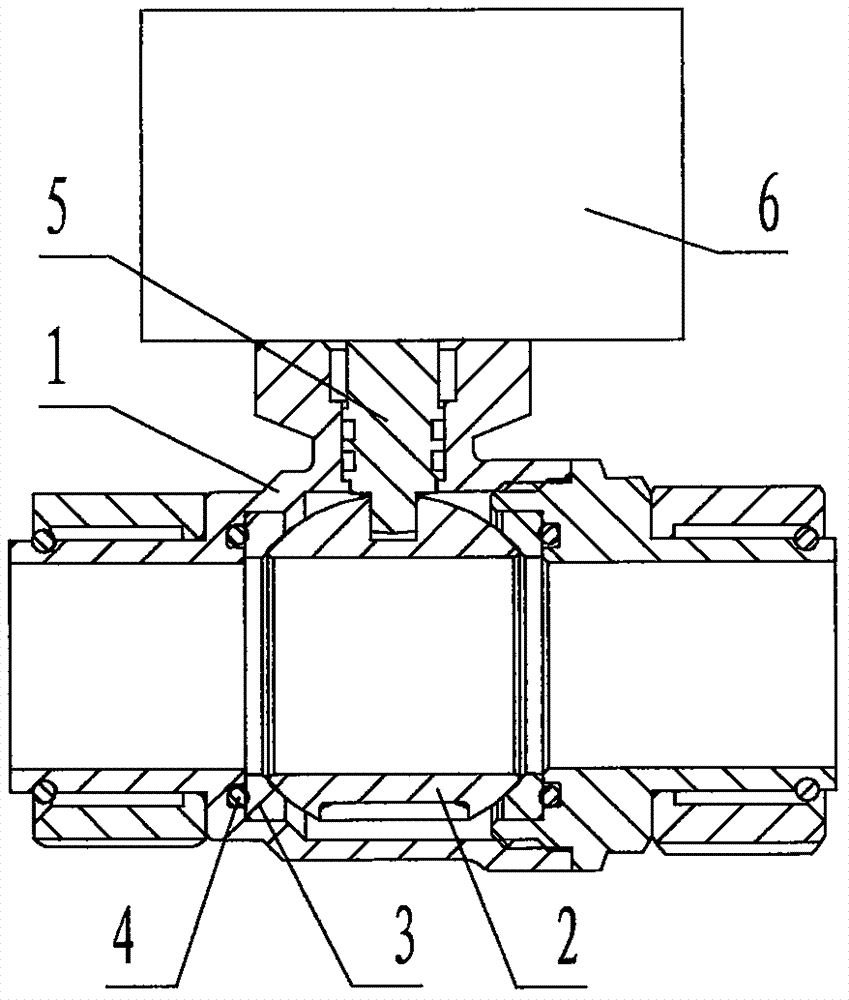

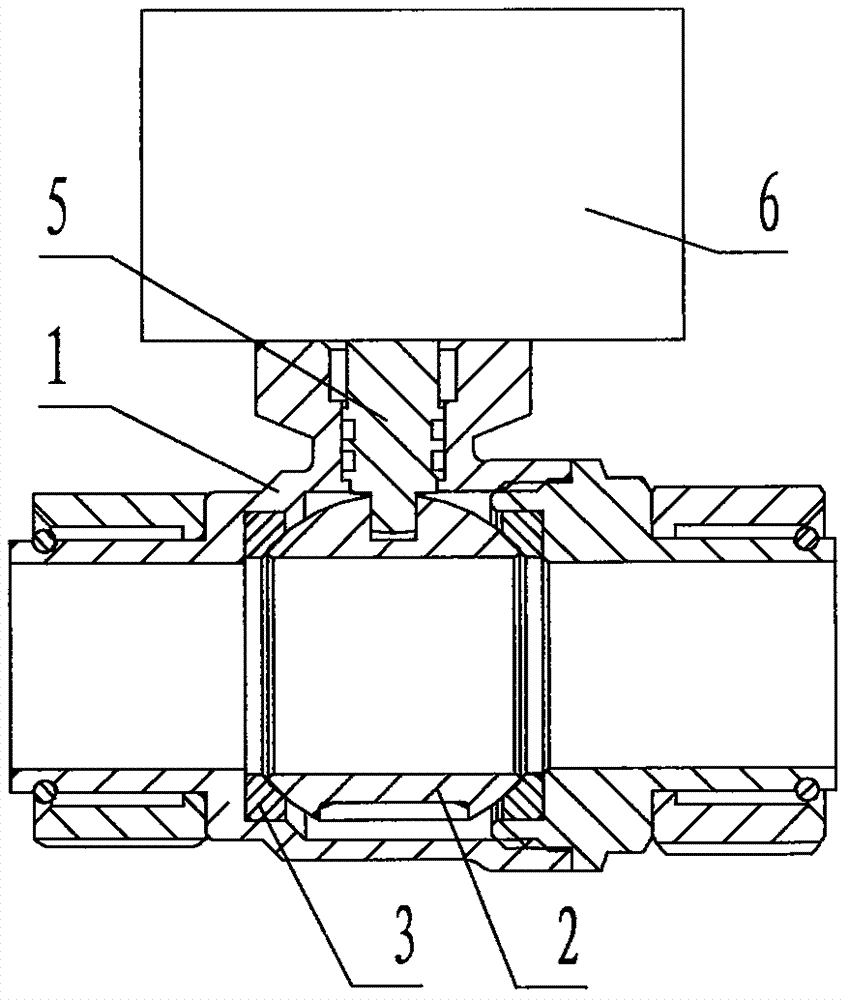

Small-torque electric ball valve

InactiveCN107084257ADecreased static adhesionStatic adhesion overcomePlug valvesOperating means/releasing devices for valvesStatic frictionEngineering

The invention discloses a small torque electric ball valve, which comprises a valve body (1), a ball valve core (2), a sealing ring (3), an O-ring (4), a valve stem (5) and an electric driver (6). In the present invention, an elastic and silicon rubber O-ring is arranged between the sealing ring and the valve body. When the electric ball valve is started, a shearing and sliding tendency occurs between the ball valve core and the sealing ring, and the elasticity of the O-ring is used to make the sealing ring produce Elastic retreat, reducing and overcoming the static adhesion between the ball valve core and the sealing ring, using a small torque to make the static friction between the ball valve core and the sealing ring transition to dynamic friction, thereby reducing the technical scheme of the starting torque, making the electric ball valve , to achieve the purpose of reducing the starting torque and turning torque.

Owner:华英伦科技(宁波)有限公司

Bypass throttling electric-hydraulic proportional servo valve

PendingCN108302076AImprove dynamic response performanceLight in massServomotor componentsSlide valveHigh pressureMechanical engineering

The invention relates to a bypass throttling electric-hydraulic proportional servo valve. The bypass throttling electric-hydraulic proportional servo valve comprises a valve sleeve and a valve element, wherein the valve element is movably arranged in the valve sleeve; an oil inlet annular groove, a primary oil inlet annular groove and an oil outlet annular groove are formed in a spaced manner in the outer wall of the valve sleeve; a plurality of oil inlet through holes are formed in the valve sleeve wall in the oil inlet annular groove; a plurality of primary oil inlet through holes are formedin the valve sleeve wall in the primary oil outlet annular groove; a plurality of oil outlet control grooves are formed in the valve sleeve wall in the oil outlet annular groove; the oil outlet control grooves are of trapezoidal structures; two bosses are formed on the outer wall of the valve element; and an adjusting annular groove is formed between the two bosses. The bypass throttling electric-hydraulic proportional servo valve has the advantages of being reasonable in structural design, simple to process and low in cost, capable of working at a high pressure and high in resolution, beingunlikely to be clamped hydraulically and the like.

Owner:SHANDONG STAR HI-TECH MASCH EQUIP CO LTD

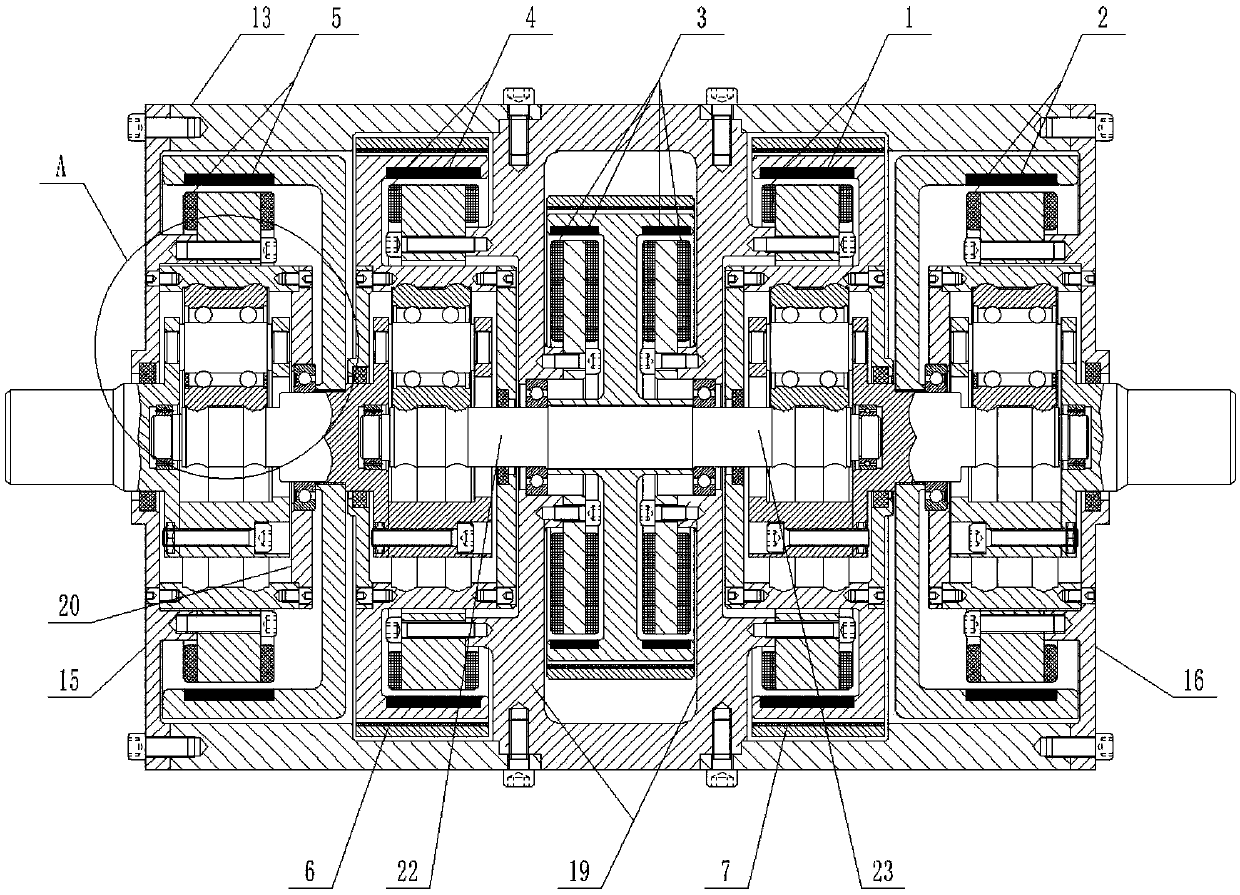

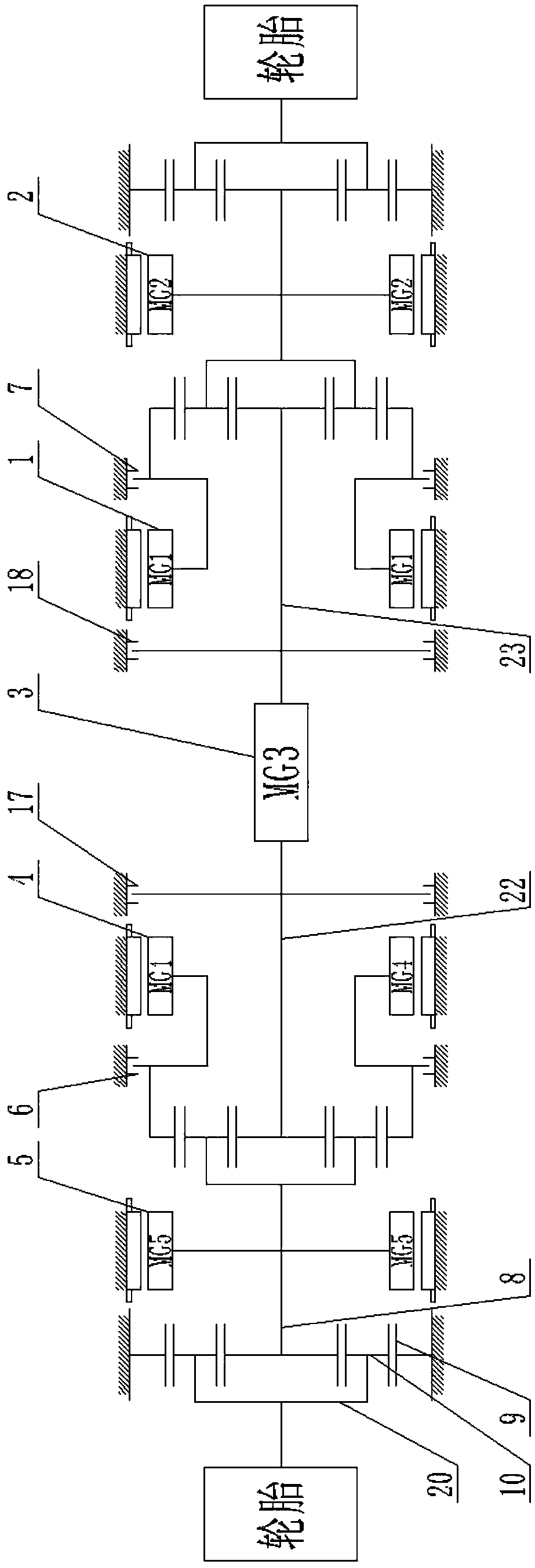

Multi-sub-motor coupling planet traction drive bearing type speed reduction driving system

PendingCN109624679AImprove work efficiencyImprove battery lifeElectric propulsion mountingControl devicesReduction driveCoupling

The invention discloses a multi-sub-motor coupling planet traction drive bearing type speed reduction driving system which comprises a left planet traction drive bearing type speed reducer, a right planet traction drive bearing type speed reducer, a number one motor, a number two motor, a number three motor, a number four motor and a number five motor; random order combination of a sun wheel, a planet carrier and an outer ring in the speed reducer is corresponding to a power input end, a power output end and a middle transmission part in the speed reducer respectively, the number three motor is used for providing power, the number one motor and the number four motor are used for speed coupling, and the number two motor and the number five motor are used for torque coupling; according to the multi-sub-motor coupling planet traction drive bearing type speed reduction driving system, through the cooperative working of the four motors, the speed can be coupled so that the wheel high rotation speed or differential speed requirement of two-wheel-drive during turning during vehicle high speed driving can be met, a differential speed device structure is not required to be equipped, the driving system structure is simplified, the structure is compact, and the cost of the driving system is reduced.

Owner:CHONGQING UNIV

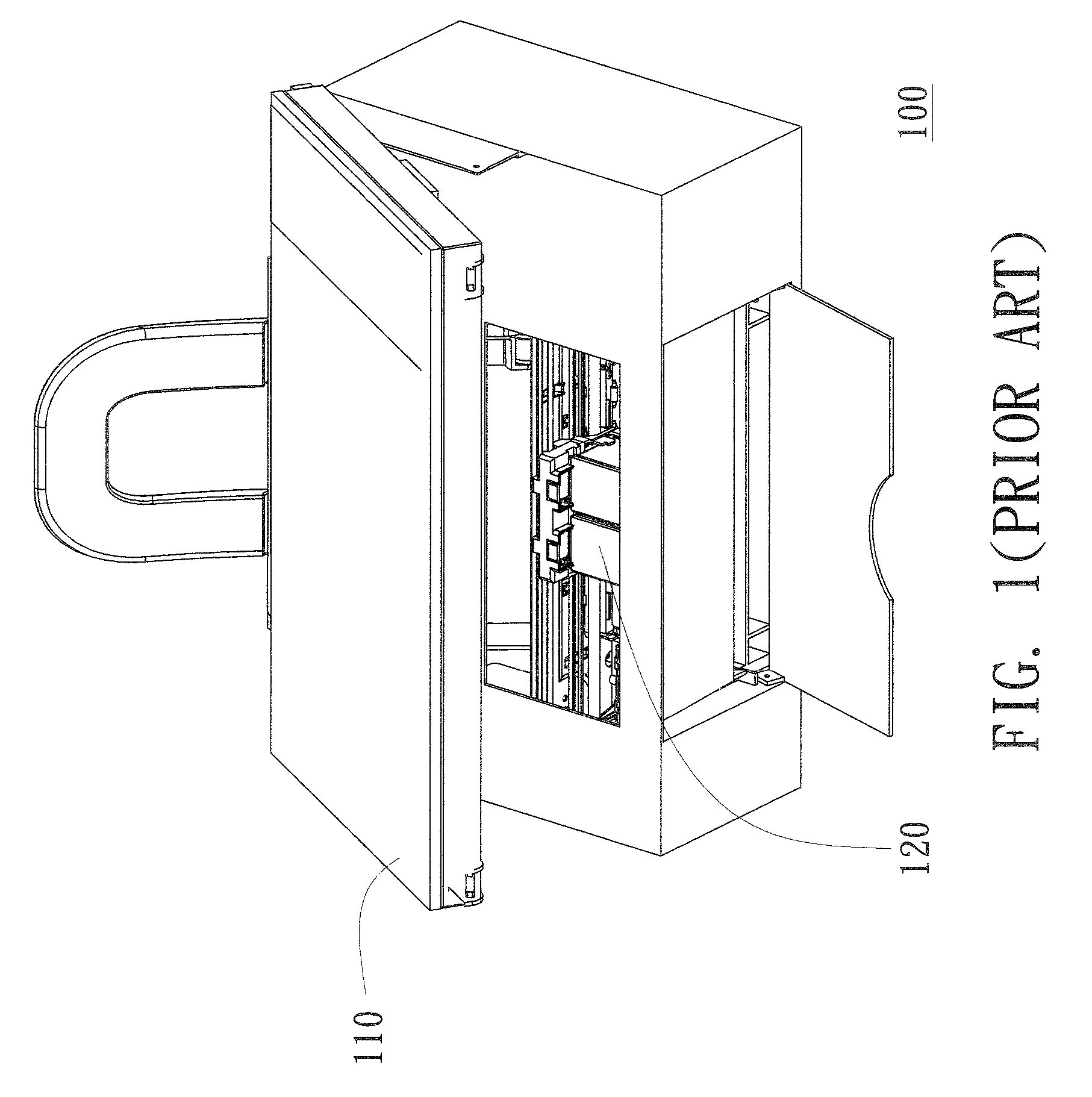

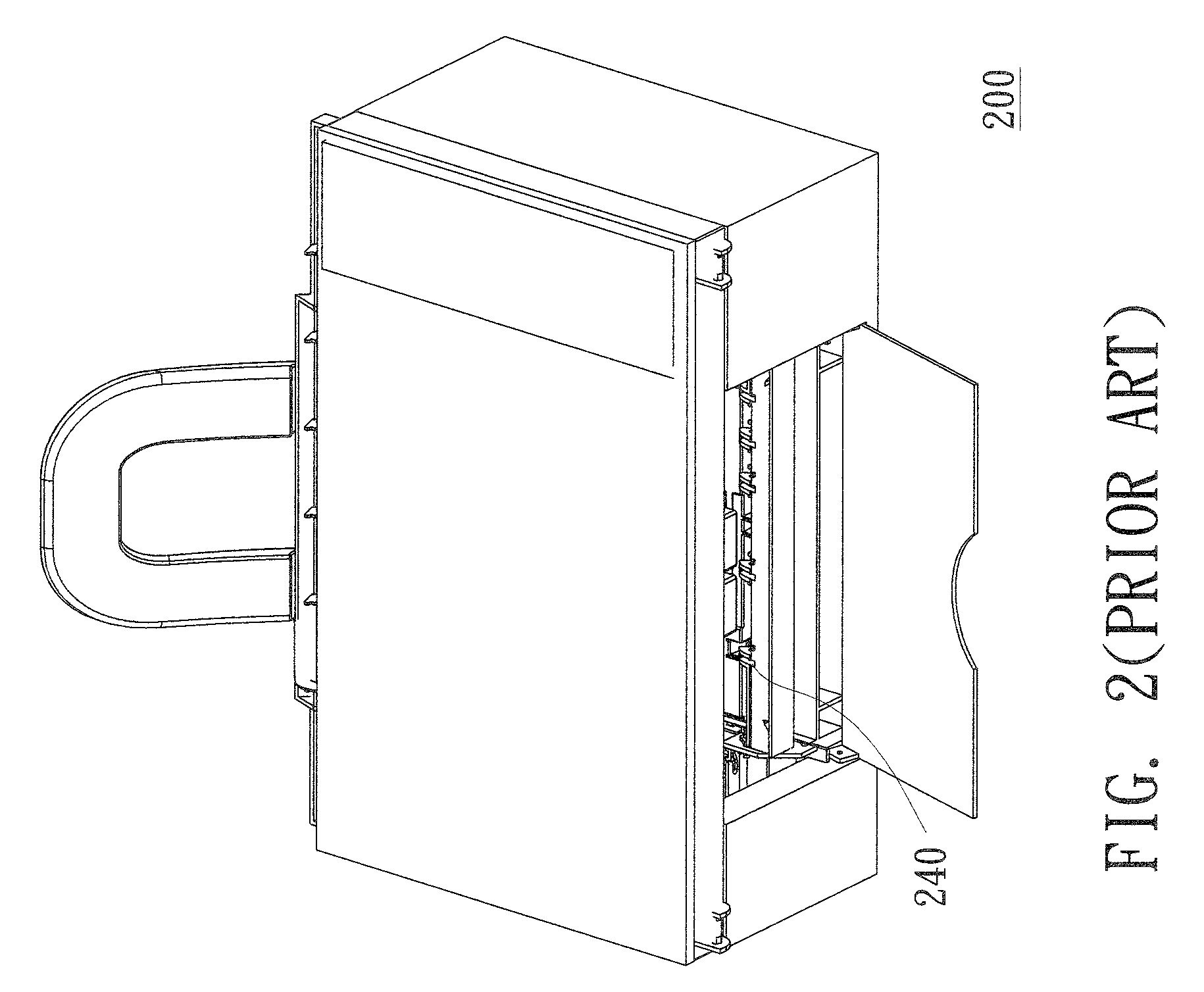

Automatic jacking device of ATM (Automatic Teller Machine)

InactiveCN105741407AEasy to take outEliminate JamsCoin/currency accepting devicesArticle deliveryPulp and paper industryTemporary storage

The invention belongs to the automatic jacking technical field and provides an automatic jacking device of an ATM (Automatic Teller Machine). The automatic jacking device is applied to the temporary storage mechanism of the ATM. The automatic jacking device includes a fixing plate arranged in a base, a jack-out plate which is pivoted onto the fixing plate and is used for rotating and jacking or releasing a cover plate, and a driving mechanism which drives the jack-out plate to rotate and perform jacking or to descend. When gapped paper money is jammed between the cover plate and a paper money drum, the paper money is required to be taken out manually, and the driving mechanism acts to drive the jack-out plate on the fixing plate to rotate so as to jack the cover plate, and therefore, a larger space can be left between the cover plate and the paper money drum, and the gapped paper money can be taken out manually and conveniently, and after paper money jam is eliminated, the driving mechanism drives the jack-out plate to descend so as to release the cover plate, and a press wheel group can press the paper money on the paper money drum again, and the ATM can perform normal operation further. With the automatic jacking device of the ATM adopted, paper money jam can be eliminated effectively, normal paper money depositing and discharging operation can be carried out, and operation is simple.

Owner:SHENZHEN YIHUA COMP +2

Dual-power-supply contact bridge full-automatic welding system

ActiveCN108941957AEliminate surface deformationEliminate splashWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManipulator

The invention discloses a dual-power-supply contact bridge full-automatic welding system. The dual-power-supply contact bridge full-automatic welding system comprises a rotary disc arranged on a table; the upper surface of the rotary disc is uniformly and fixedly provided with eight locking fixtures which are identical in structure in the circumferential direction, and each locking fixture corresponds to one station; the table is provided with a plurality of mechanisms around the rotary disc; and the outer side of the first station is provided with a contact bridge feeding mechanism, the outerside of the second station is provided with a first feeding mechanism, the outer side of the third station is provided with a first welding mechanism, the outer side of the fourth station is providedwith a detection mechanism, the fifth station serves as a transposition station, the outer side of the six station is provided with a second feeding mechanism, the outer side of the seventh station is provided with a second welding mechanism, and the outer side of the eighth station is provided with a discharging mechanical hand. According to the dual-power-supply contact bridge full-automatic welding system, four-stage buffer pressurization and four-stage flexible heat generation are adopted, the system is suitable for multiple types of contacts and contact bridges, the production efficiencyis obviously improved, electric current consumption and pressure consumption are remarkably reduced, the electrode service life is prolonged, the percent of pass reaches 100%, and the equipment costis low.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

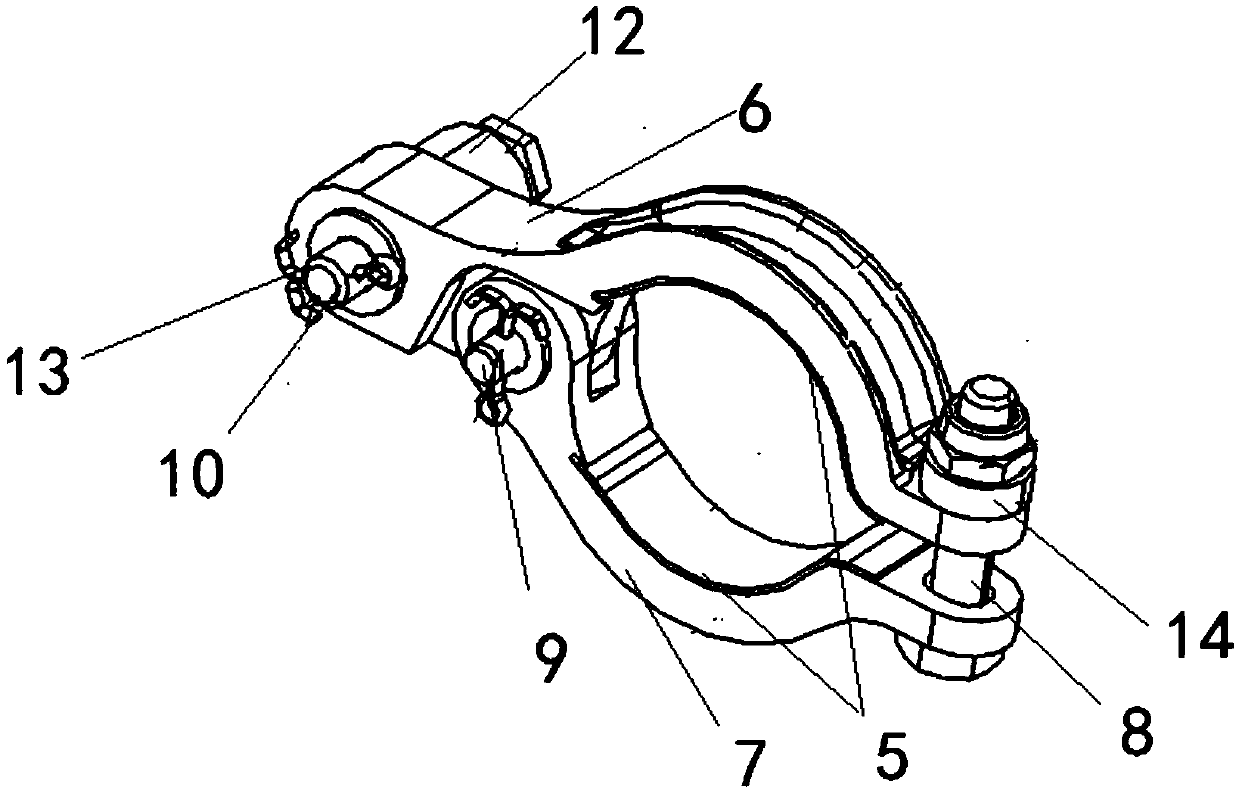

Anti-block device for horizontal centrifugal machine feeding tube

The present invention relates to a horizontal spiral centrifuger feeding pipe anti-blocking device. It includes feeding pipe, main shaft and machine frame. The feeding pipe is fixed on the machine frame, the feeding pipe is mounted in the inner hole of feeding end of main shaft by means of anti-blocking cover, the inner hole of the described anti-blocking cover is a screw-thread hole, and its right end is made into the horn form. Besides, said invention also provides the working principle of said anti-blocking device and its concrete operation method.

Owner:JIANGSU HENGLIANG CENTRIFUGE MFG

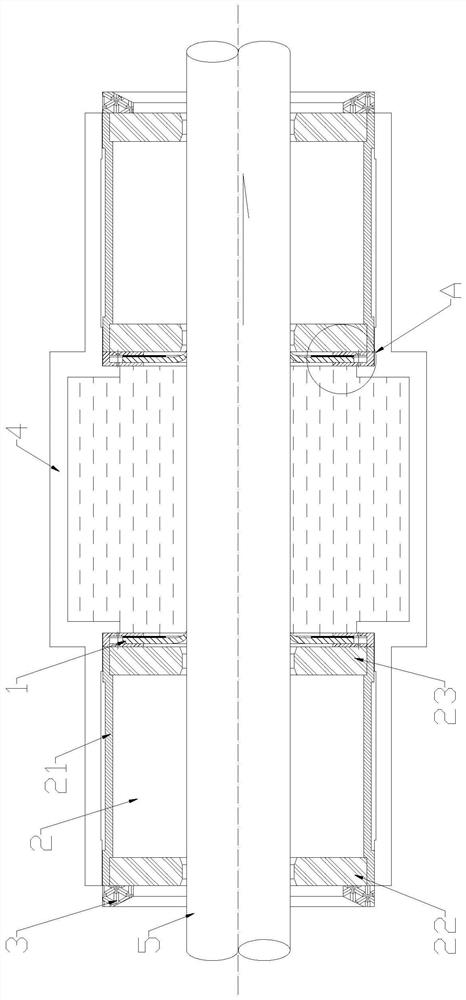

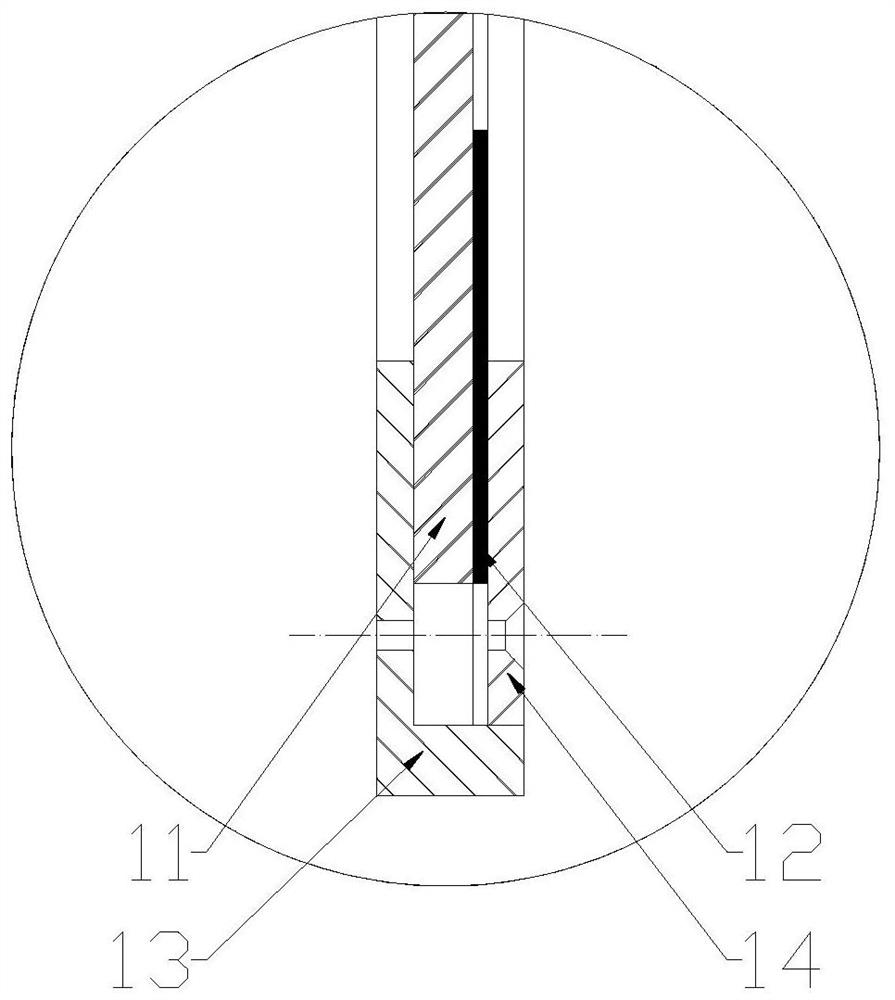

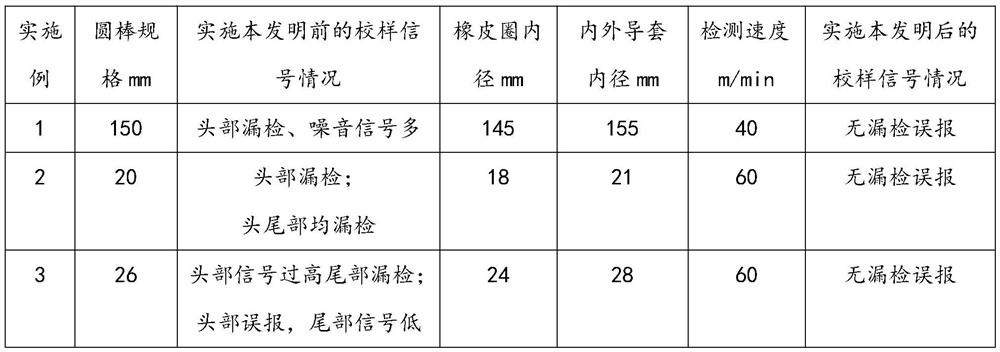

Method for ensuring reliability of rotary ultrasonic detection of round rod

PendingCN113552214AIncrease contactReduce or even eliminate wobbleAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasonic testing

The invention relates to a method for ensuring the reliability of rotary ultrasonic detection of a round bar, which comprises the following steps: a mounting step: respectively mounting water scraping devices in cylinders on two sides of ultrasonic detection equipment, and respectively positioning the two water scraping devices on two sides of a rotary cavity in the middle of the ultrasonic detection equipment; installing guiding devices in the cylinder bodies on the two sides, fixing the water scraping devices on the same side to the outside of the end opening of the rotating cavity through the guiding devices, and fixing the guiding devices into the cylinder bodies through pressing rings; The detection method comprises the following steps: leading in a round rod from a barrel on one side of the ultrasonic detection equipment at a constant speed, sequentially penetrating through a leading-in side guide device and a water scraping device to enter a rotating cavity to be subjected to spiral scanning detection, then leading out the round rod from a barrel on the other side, sequentially penetrating through a leading-out side water scraping device and a guide device to leave the ultrasonic detection equipment, and when penetrating through the water scraping devices, the round bars are in tight elastic contact with the water scraping devices on the two sides respectively. Rotation ultrasonic detection reliability of the head section and the tail section of the round rod is ensured, and meanwhile the phenomena that the round rod collides with equipment, clamps steel and scratches the surface in the detection process are avoided.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com