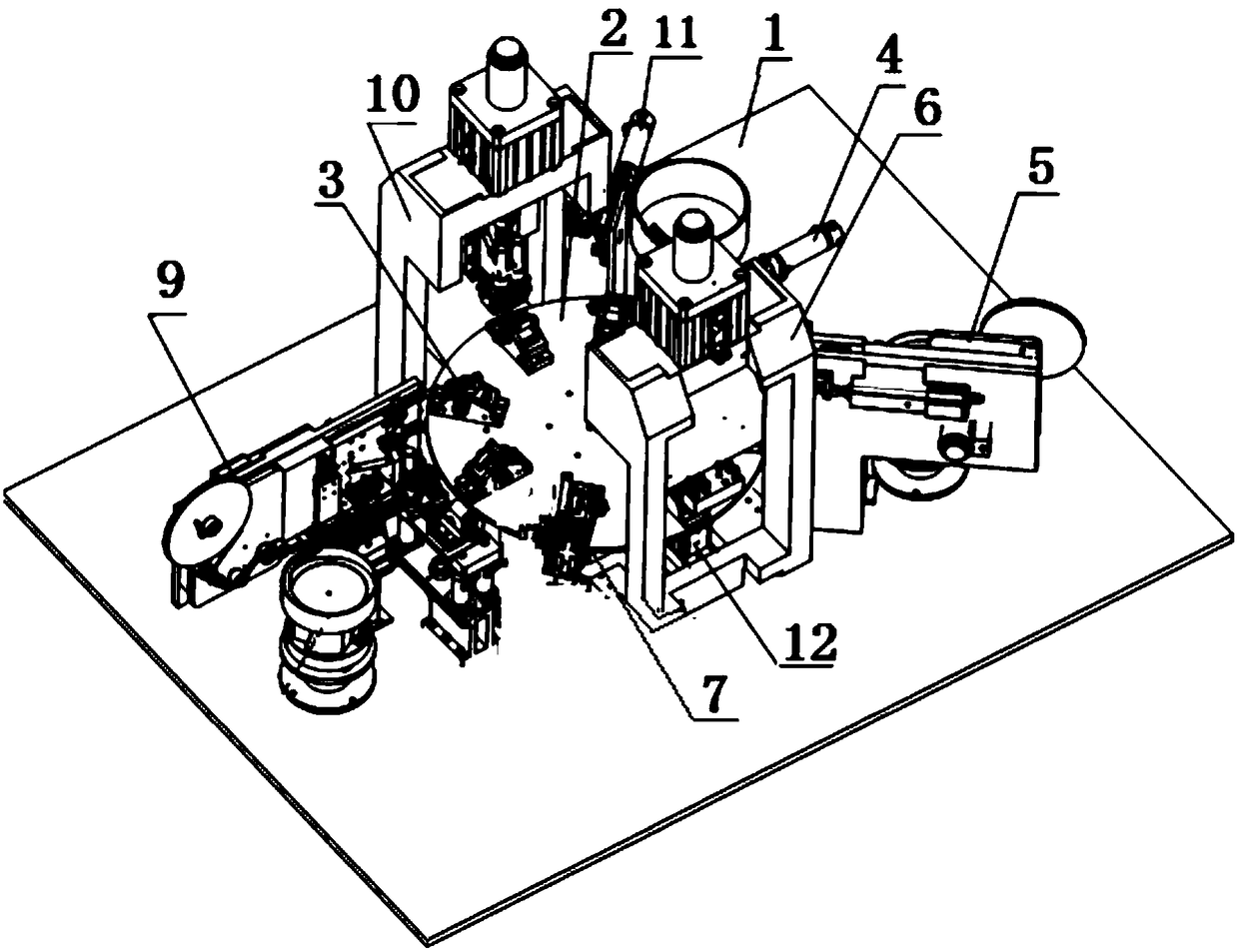

Dual-power-supply contact bridge full-automatic welding system

A fully automatic welding, dual power supply technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency, inability to automate, low product quality, etc., to improve production efficiency, reduce current and pressure consumption The effect of decreasing and increasing the life of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

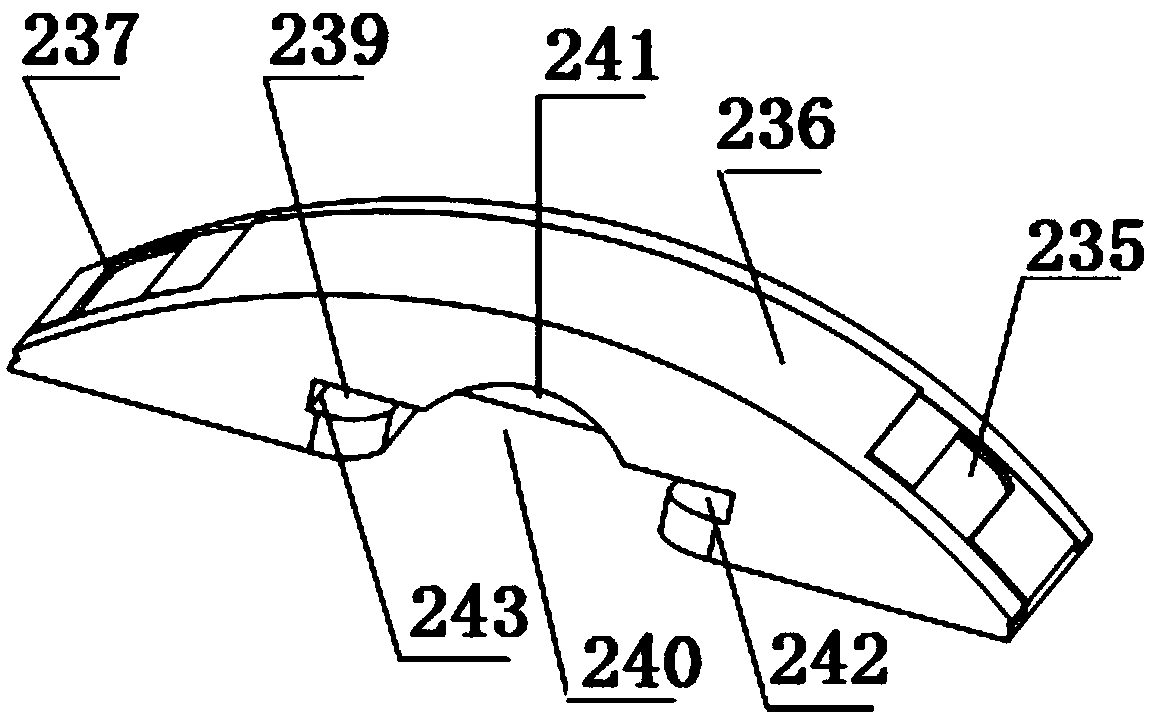

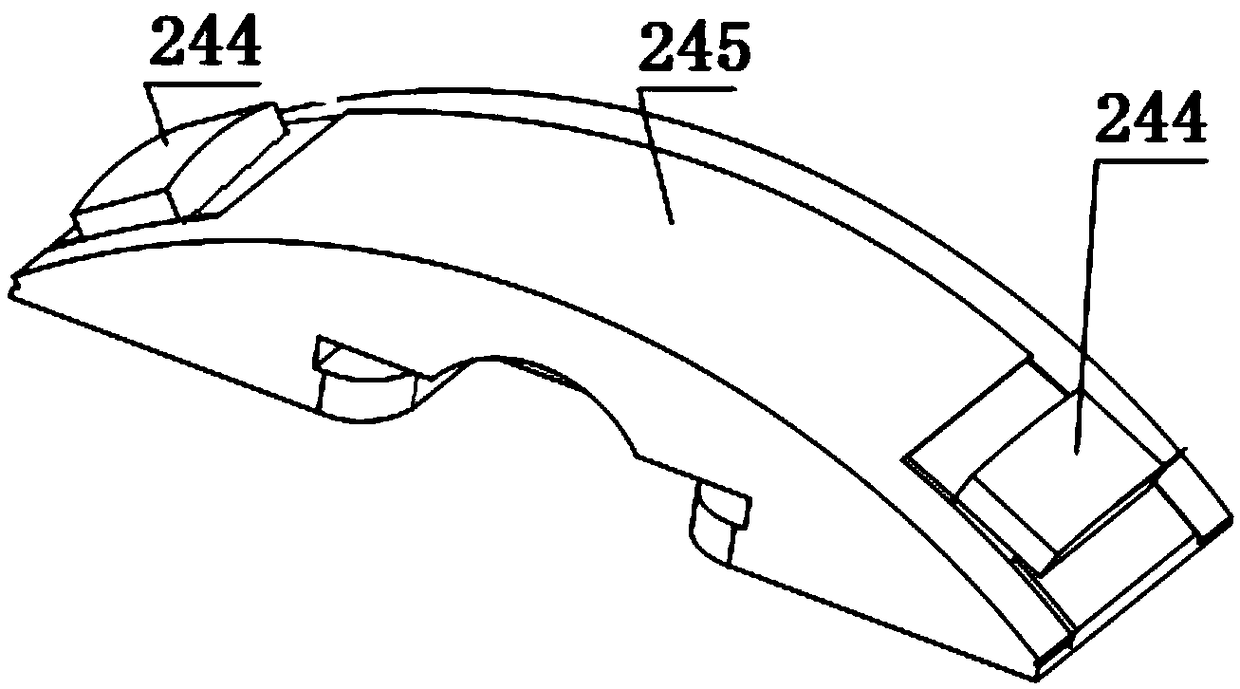

[0031] Such as Figure 1a , Figure 1bThe upper surface of the contact bridge 245 is an arc surface 236, and the two ends of the arc surface 236 are respectively provided with a contact groove two 237 and a contact groove one 235, and the bottoms of the contact groove two 237 and the contact groove one 235 are both It is in the shape of an arc, and is used to add welding conductive glue and assemble contacts 244; the middle part of the chord section of the contact bridge 245 is an axial middle through groove 240, and the middle position of the middle through groove 240 is provided with a semicircular groove 241, and the middle through groove 240 Both sides of the chord are respectively provided with L-shaped groove one 239 and L-shaped groove two 242 (for locking), and the depth of L-shaped groove one 239 and L-shaped groove two 242 is less than two-thirds of the length of the middle through groove 240; L The end face of groove one 239 is provided with an identification groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com