Patents

Literature

1795 results about "Weld strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

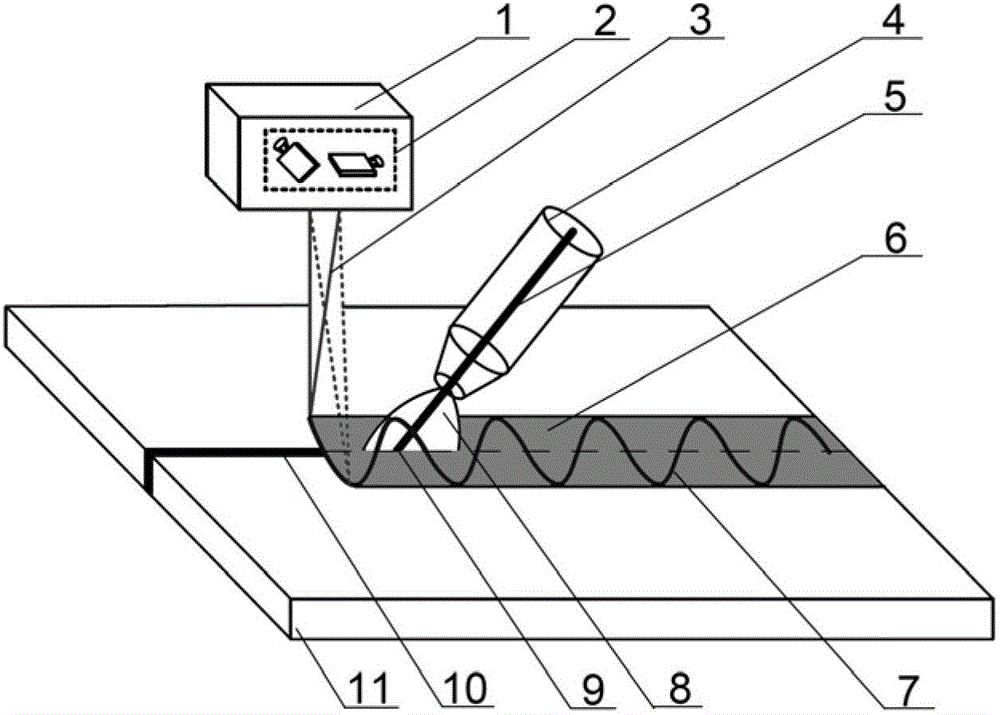

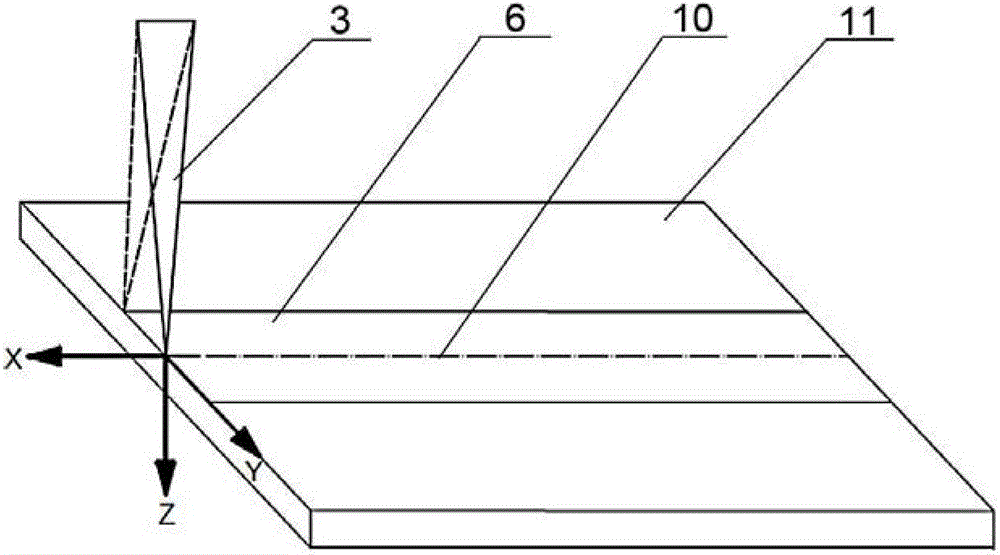

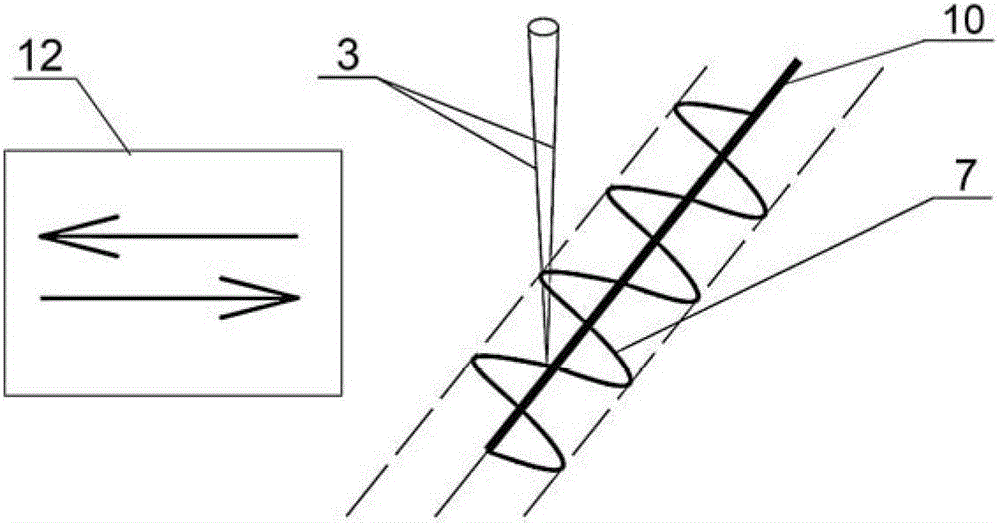

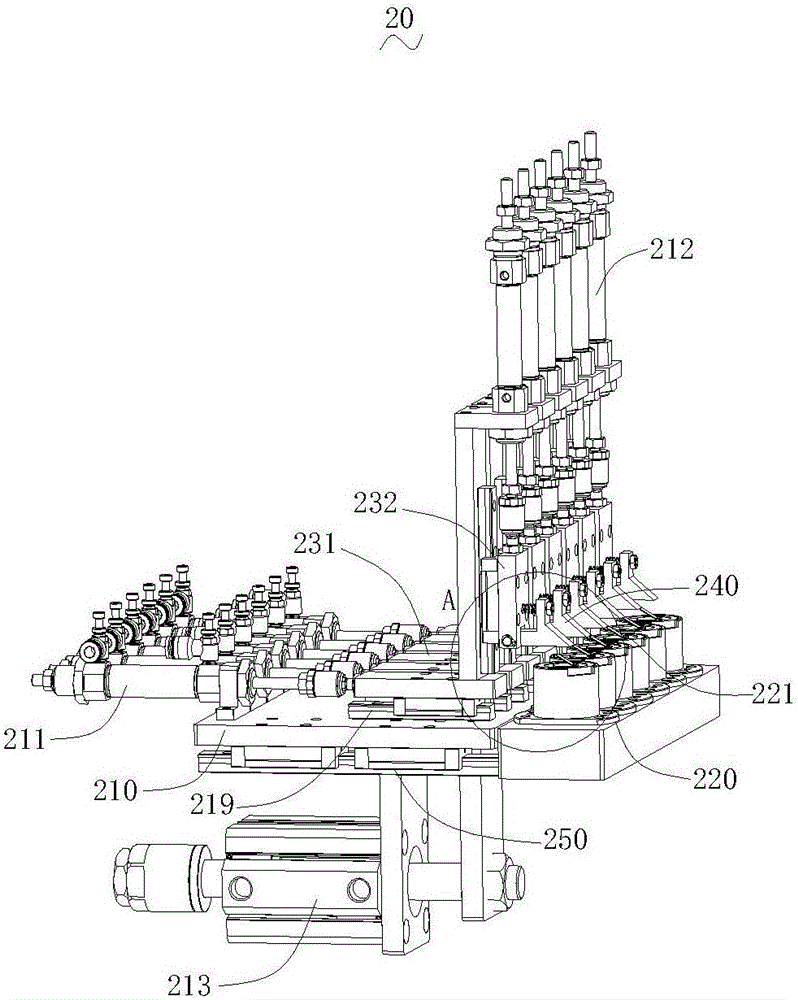

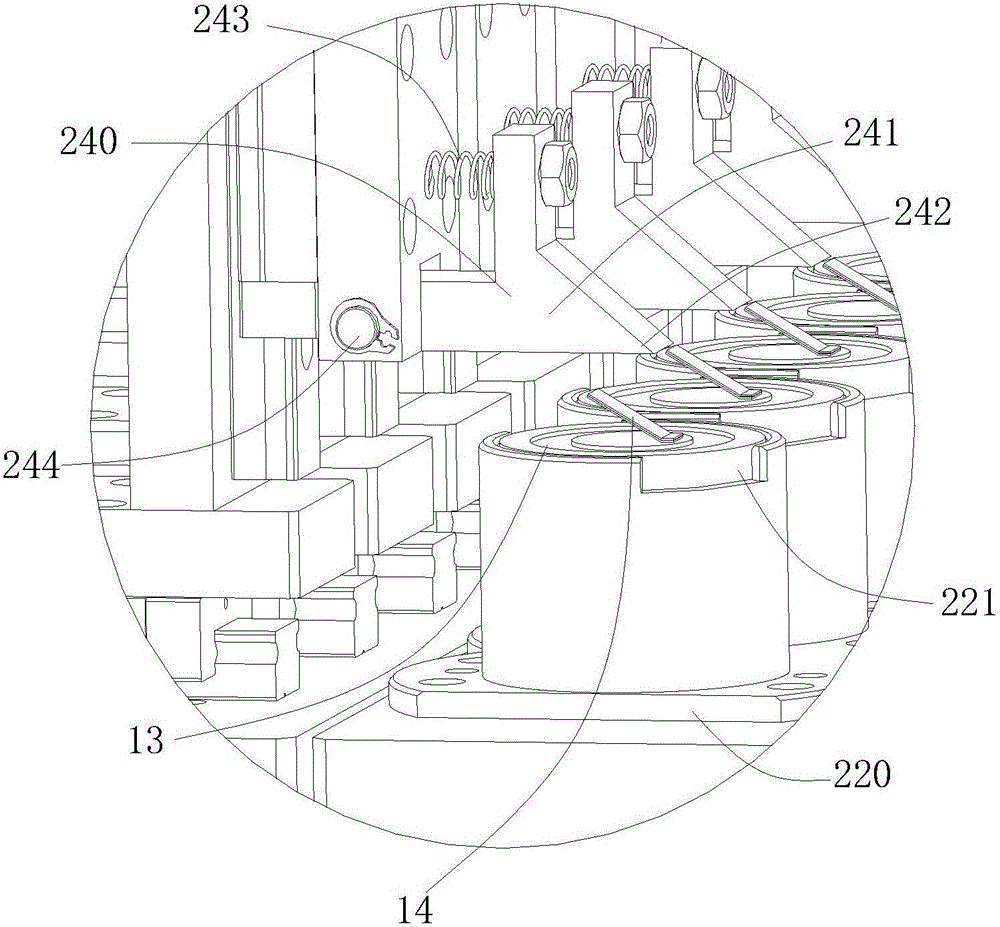

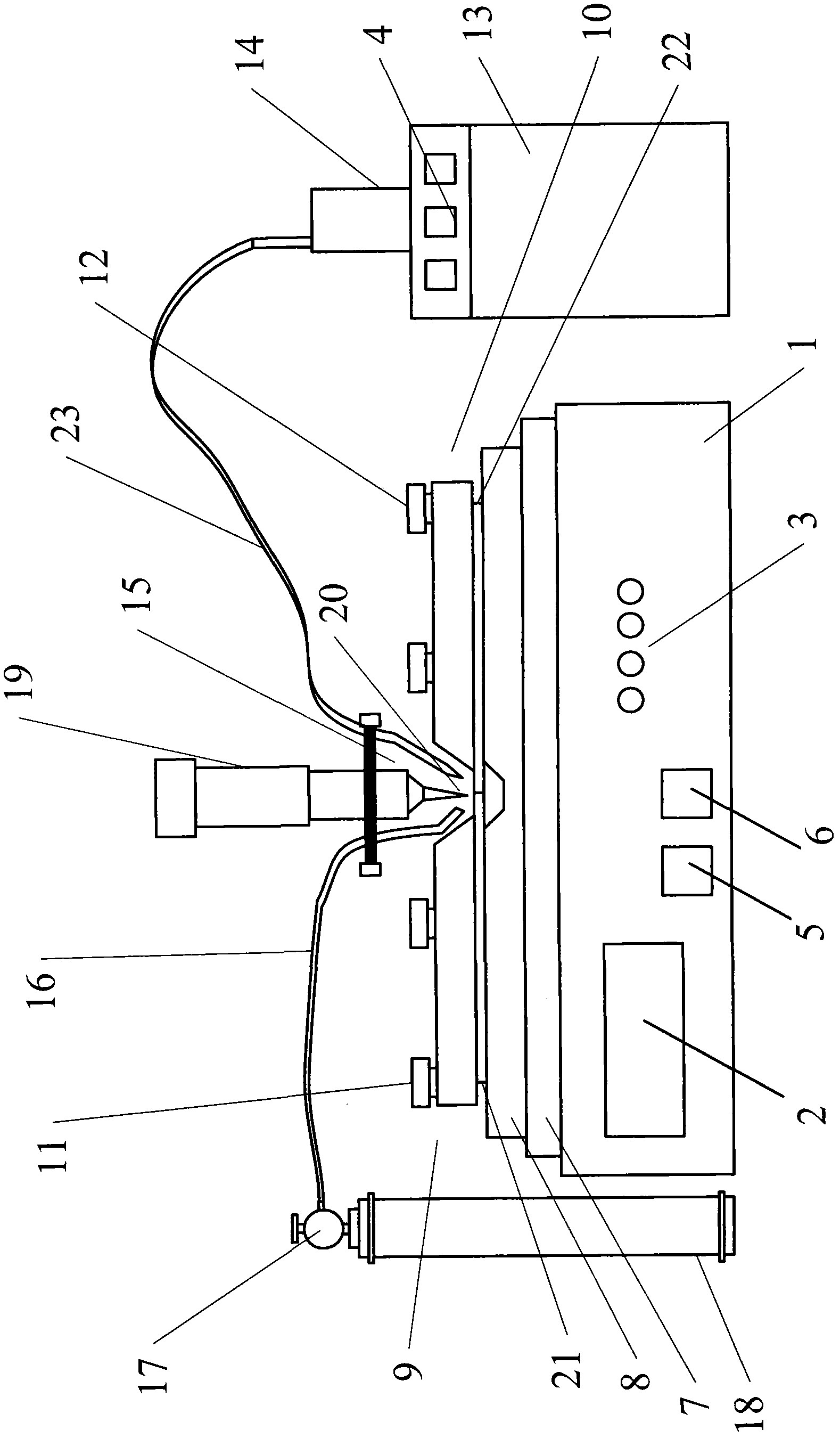

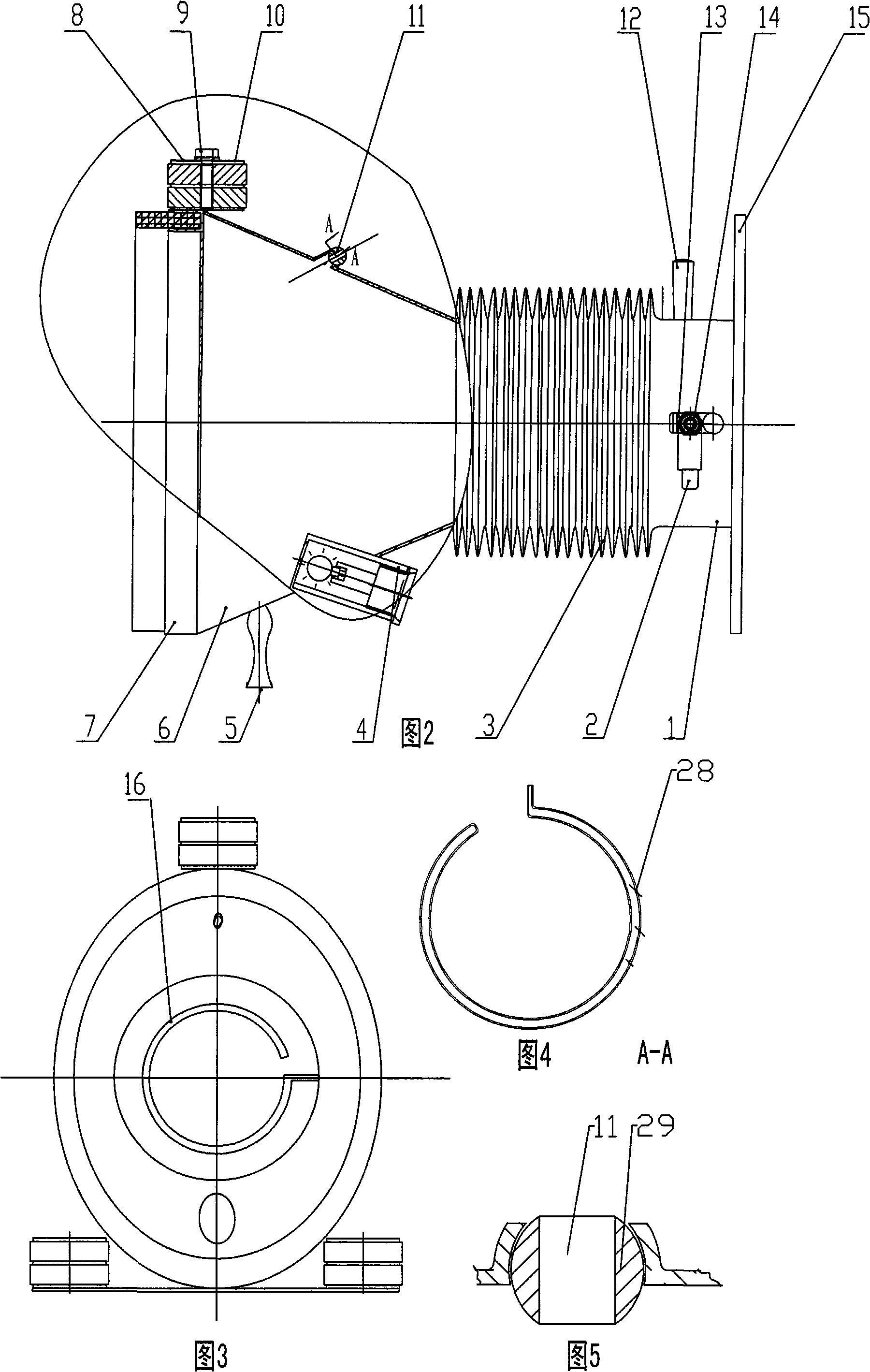

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

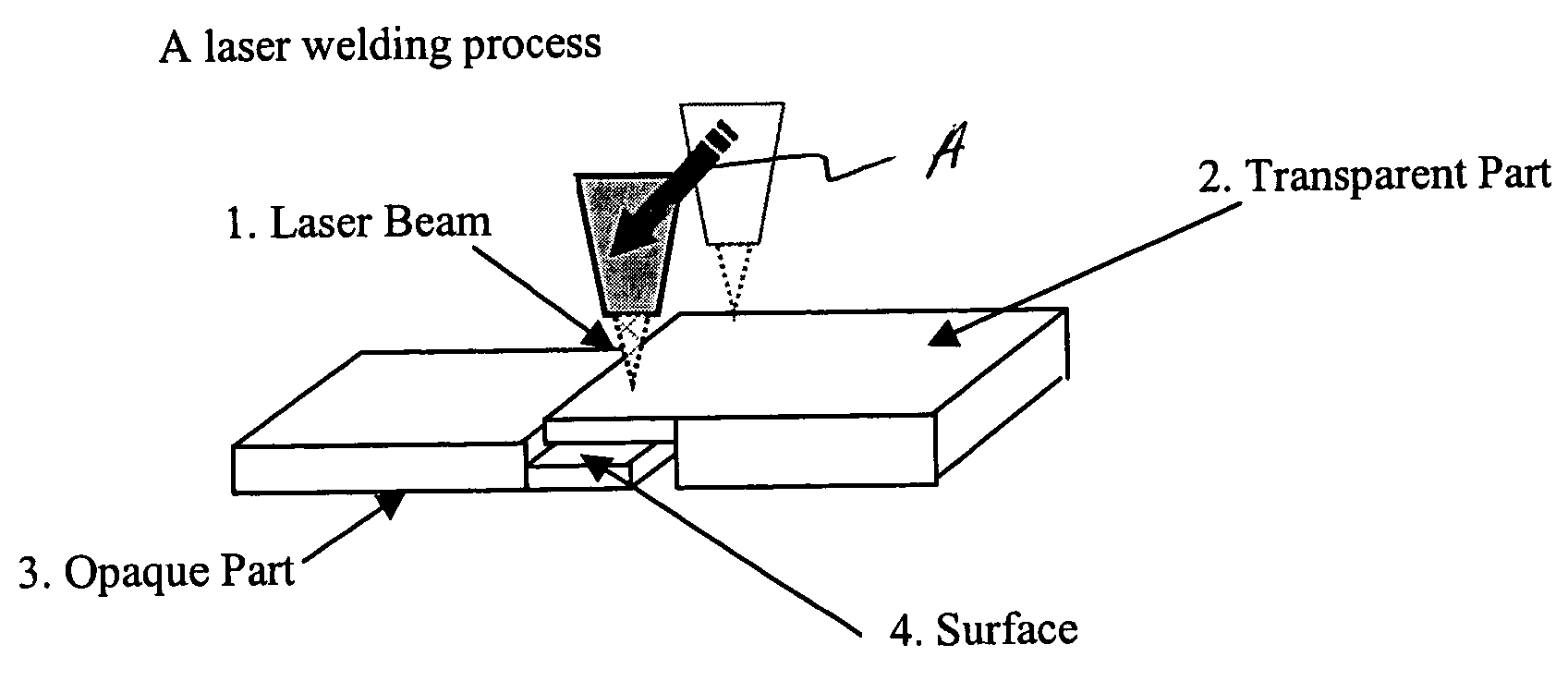

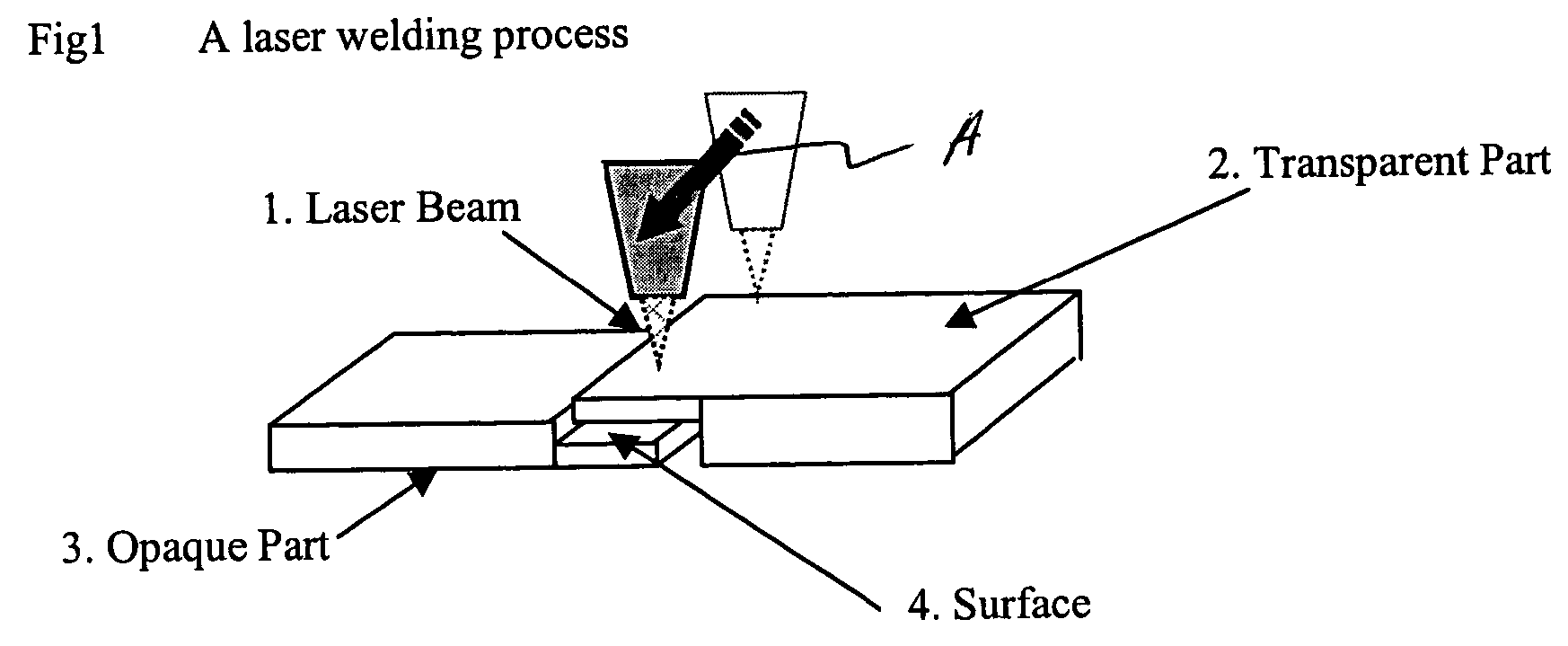

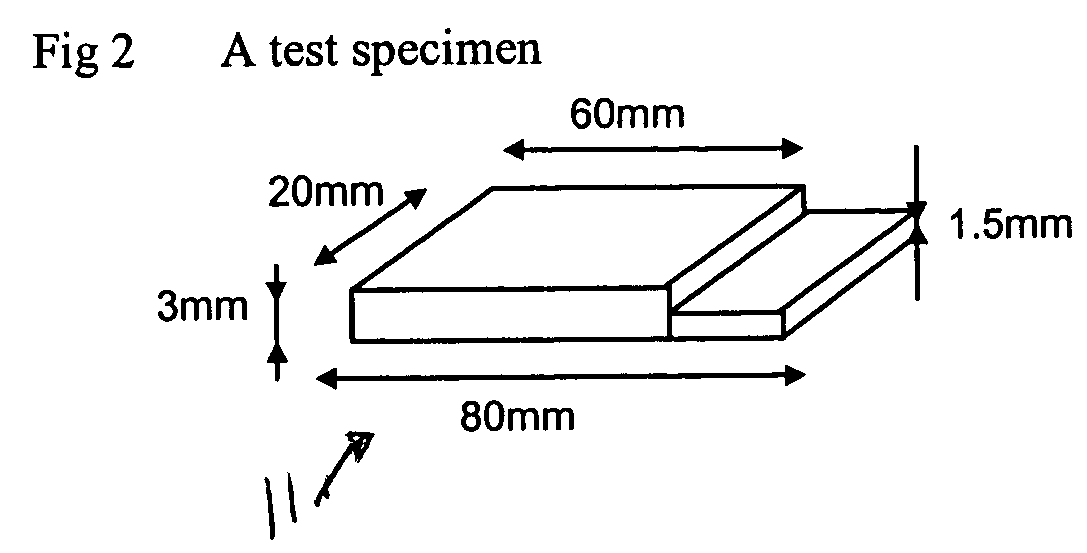

Process for laser welding together articles of polyester resin compositions and related products

InactiveUS20040112519A1Improve flame retardant performanceImprove heat resistanceLamination ancillary operationsLaminationPolyester resinWeld strength

A process for laser welding together a laser beam transparent polyester article and a laser beam opaque polyester article. The method limits the use of a laser beam at an energy level not greater than 100 W at a scanning speed not greater than 1000 cm / min., thus causing the articles to be welded together and maintaining a high weld strength.

Owner:EI DU PONT DE NEMOURS & CO

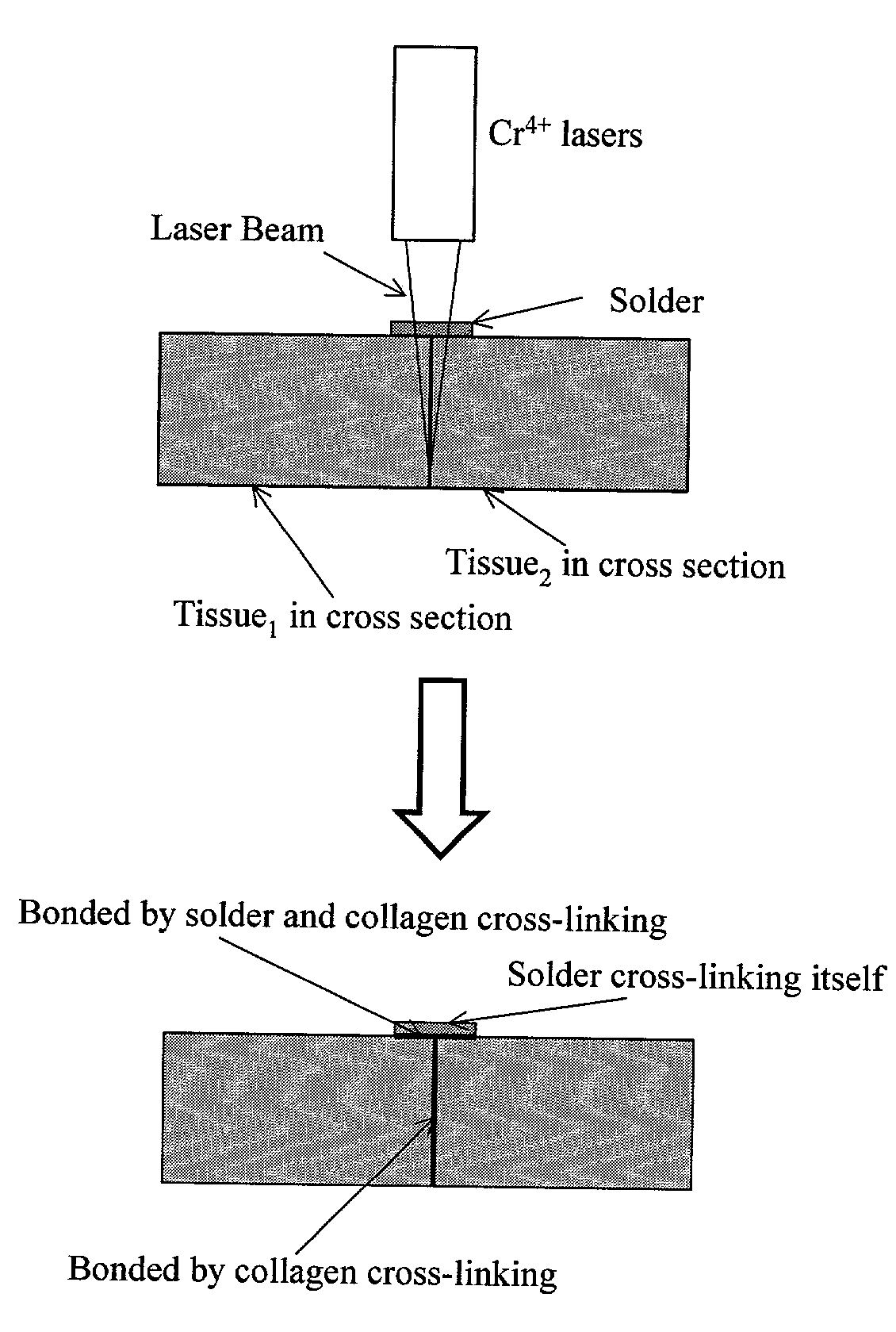

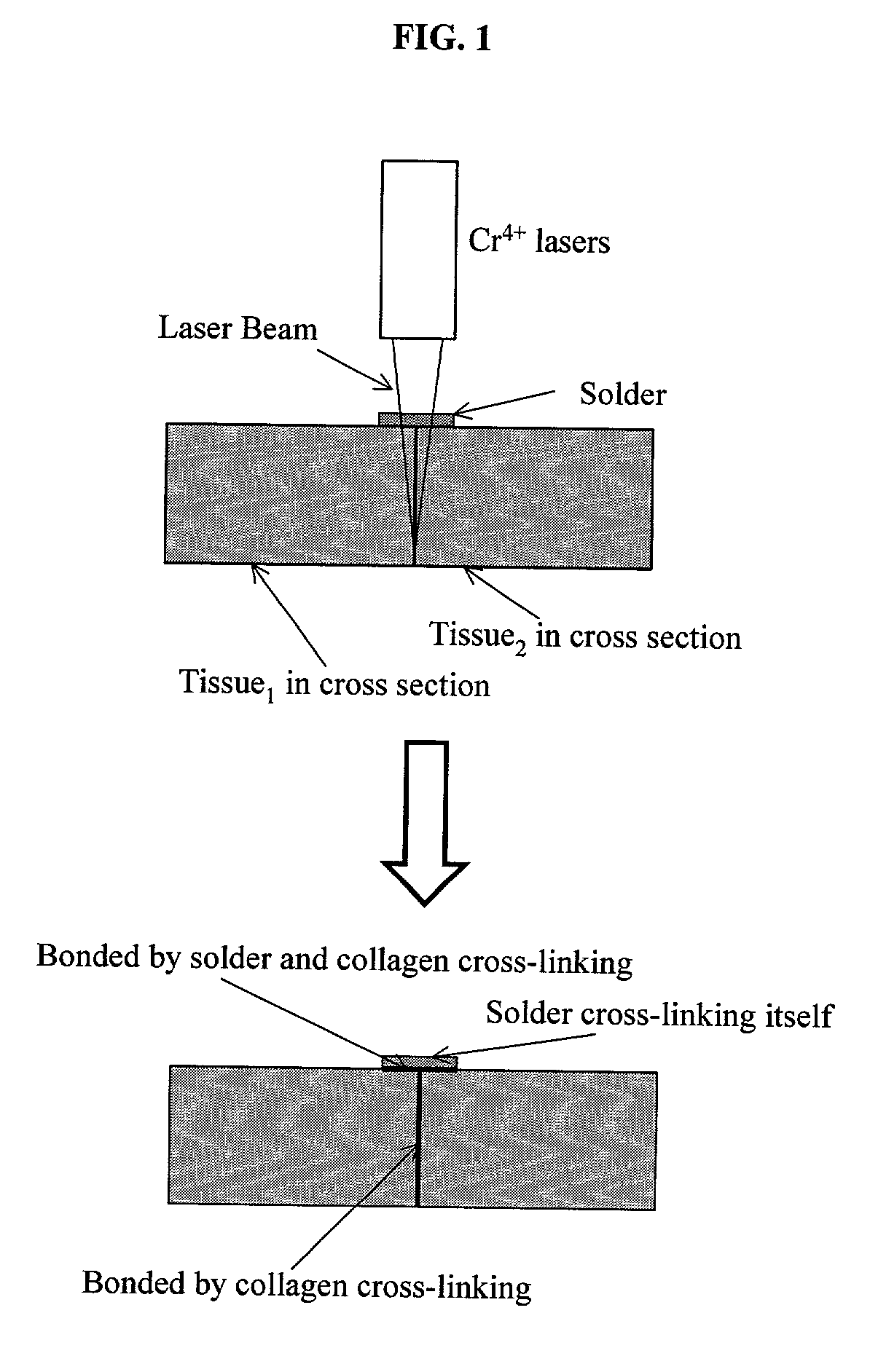

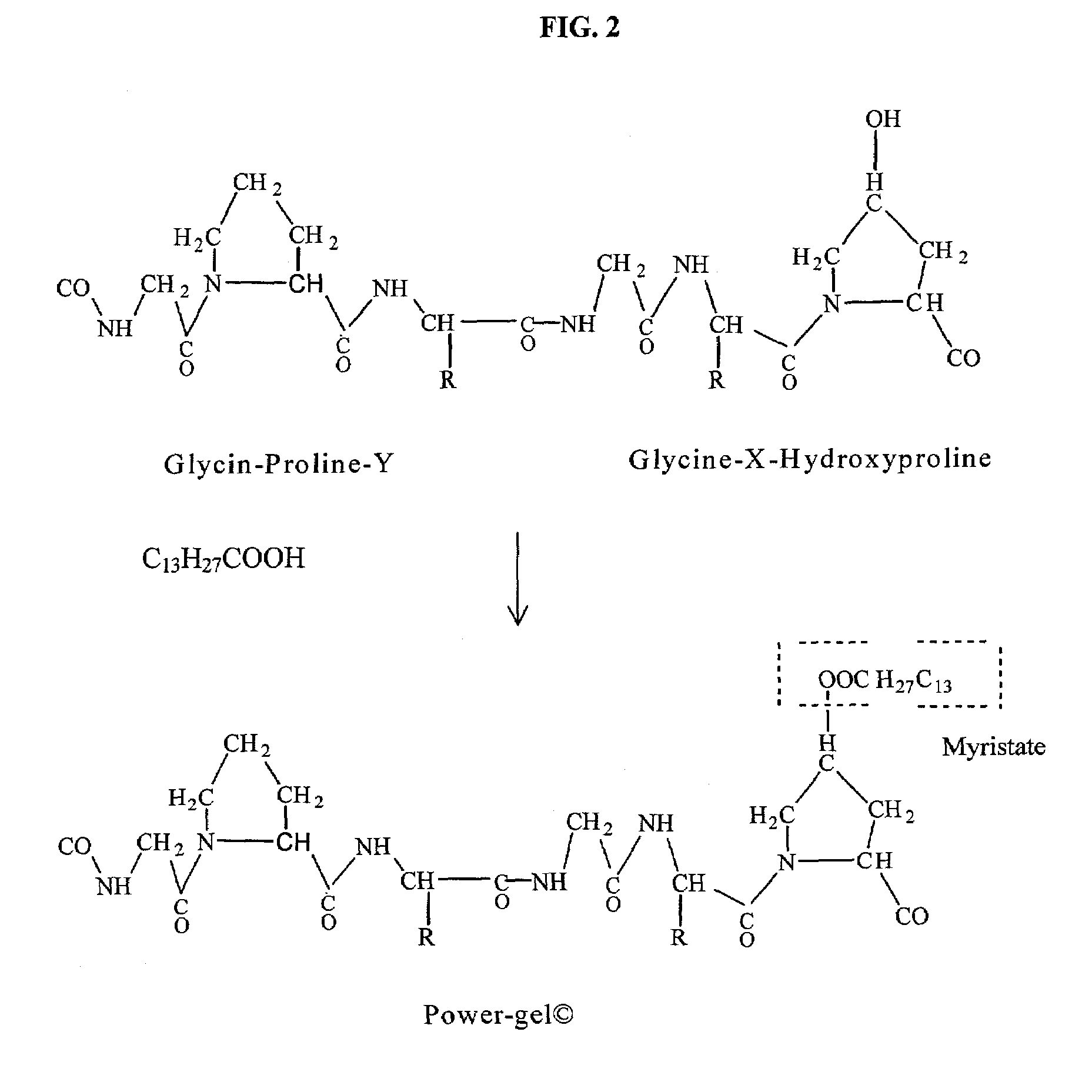

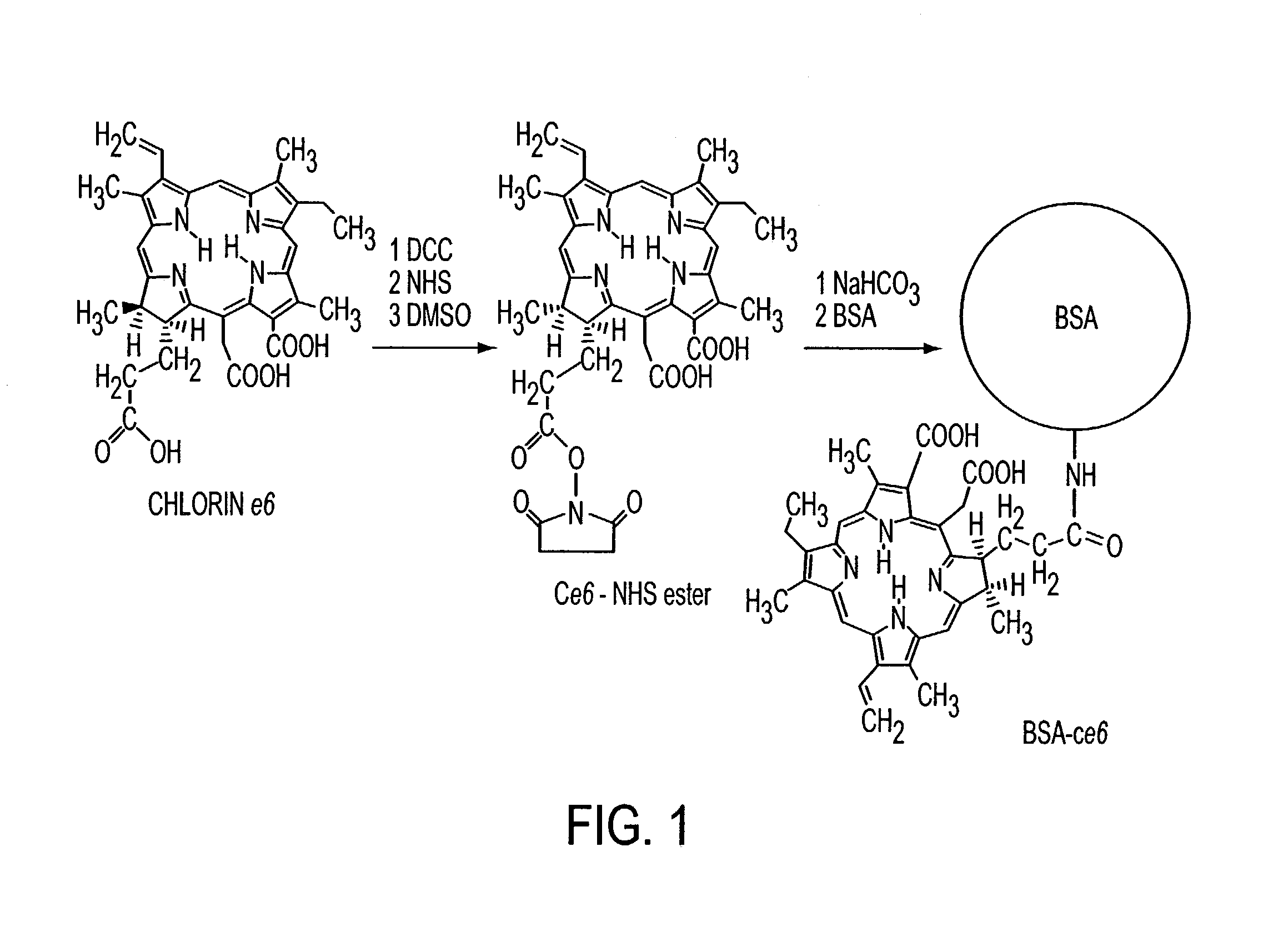

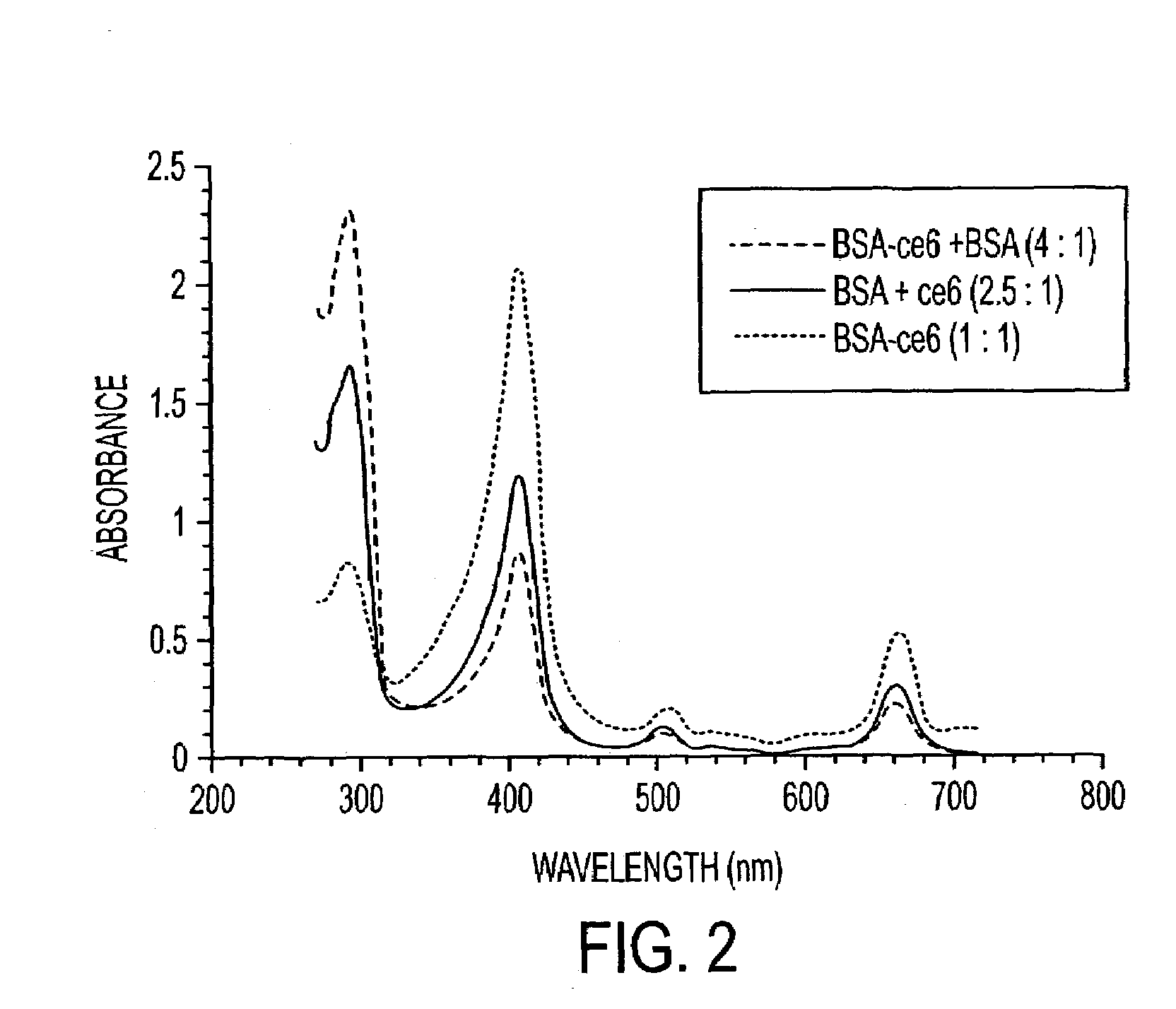

Gelatin based on Power-gel(TM) as solders for Cr4+laser tissue welding and sealing of lung air leak and fistulas in organs

InactiveUS7033348B2Enhancement in post-procedure effectivenessImprove welding strengthDiagnosticsSurgical instrument detailsEngineeringWeld strength

Laser tissue welding can be achieved using tunable Cr4+ lasers, semiconductor lasers and fiber lasers, where the weld strength follows the absorption spectrum of water. The use of gelatin and esterified gelatin as solders in conjunction with laser inducted tissue welding impart much stronger tensile and torque strengths than albumin solders. Selected NIR wavelength from the above lasers can improve welding and avoid thermal injury to tissue when used alone or with gelatin and esterified gelatin solders. These discoveries can be used to enhance laser tissue welding of tissues such as skin, mucous, bone, blood vessel, nerve, brain, liver, pancreas, spleen, kidney, lung, bronchus, respiratory track, urinary tract, gastrointestinal tract, or gynecologic tract and as a sealant for pulmonary air leaks and fistulas such as intestinal, rectal and urinary fistulas.

Owner:RES FOUND OF THE CITY UNIV OF NY THE

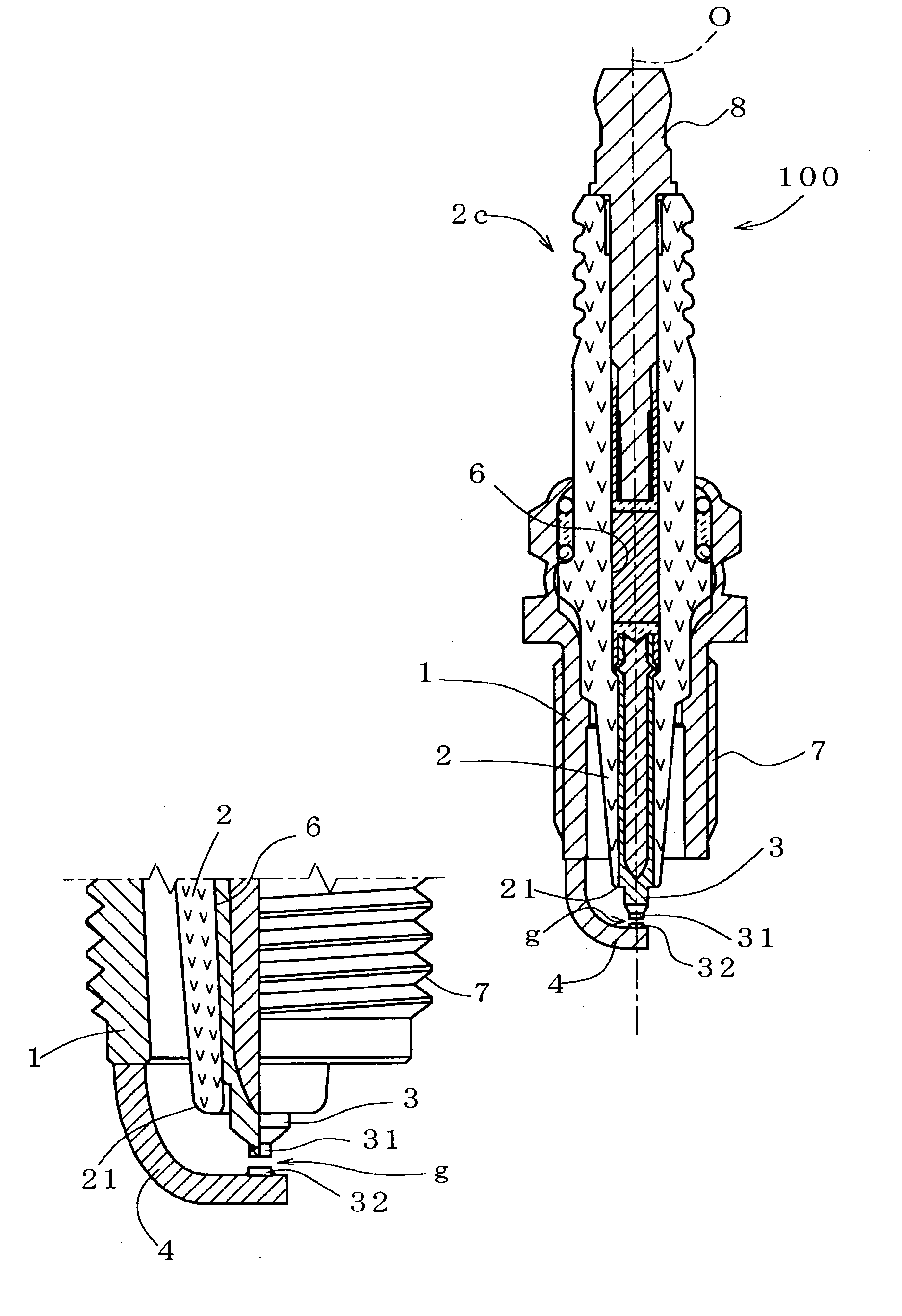

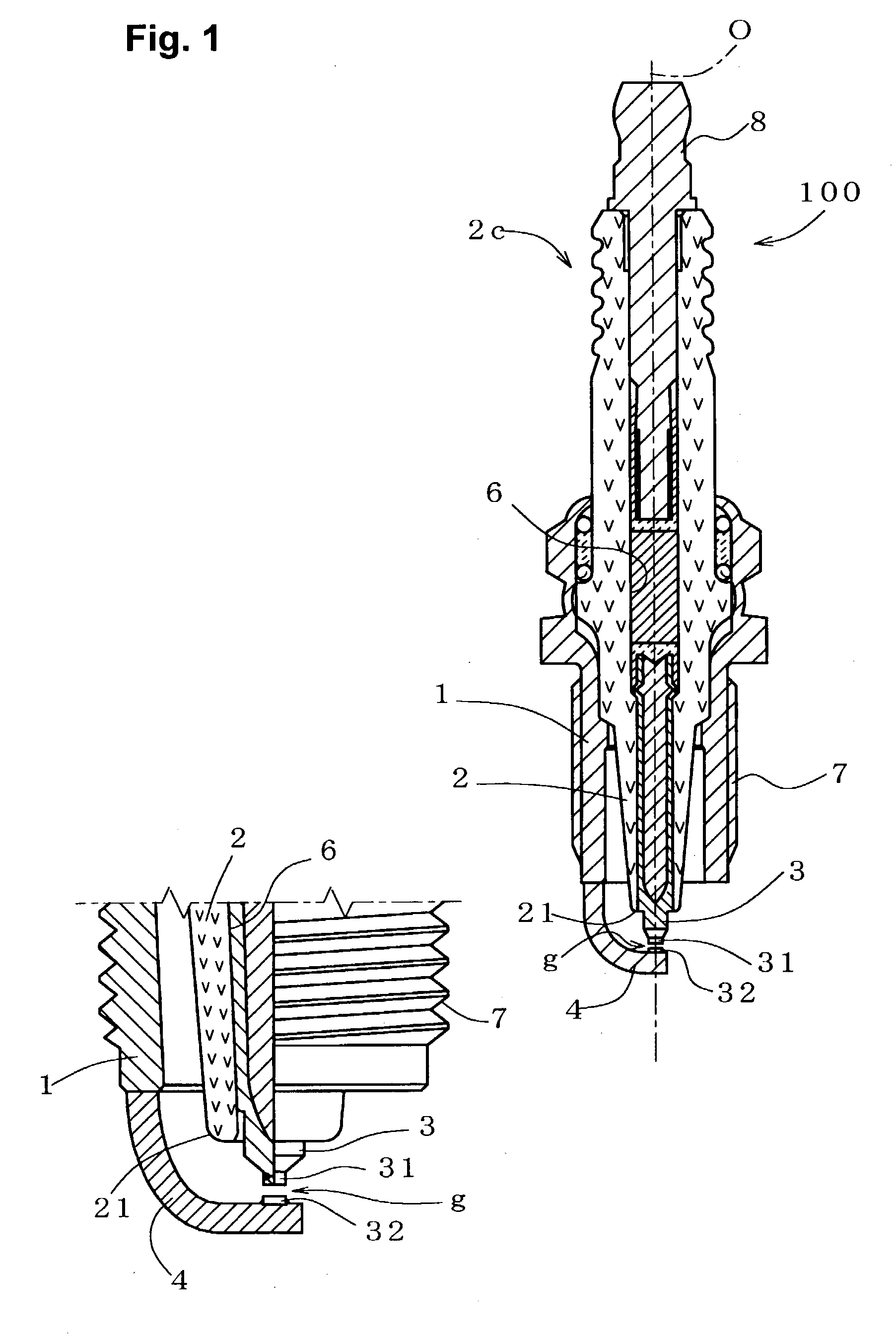

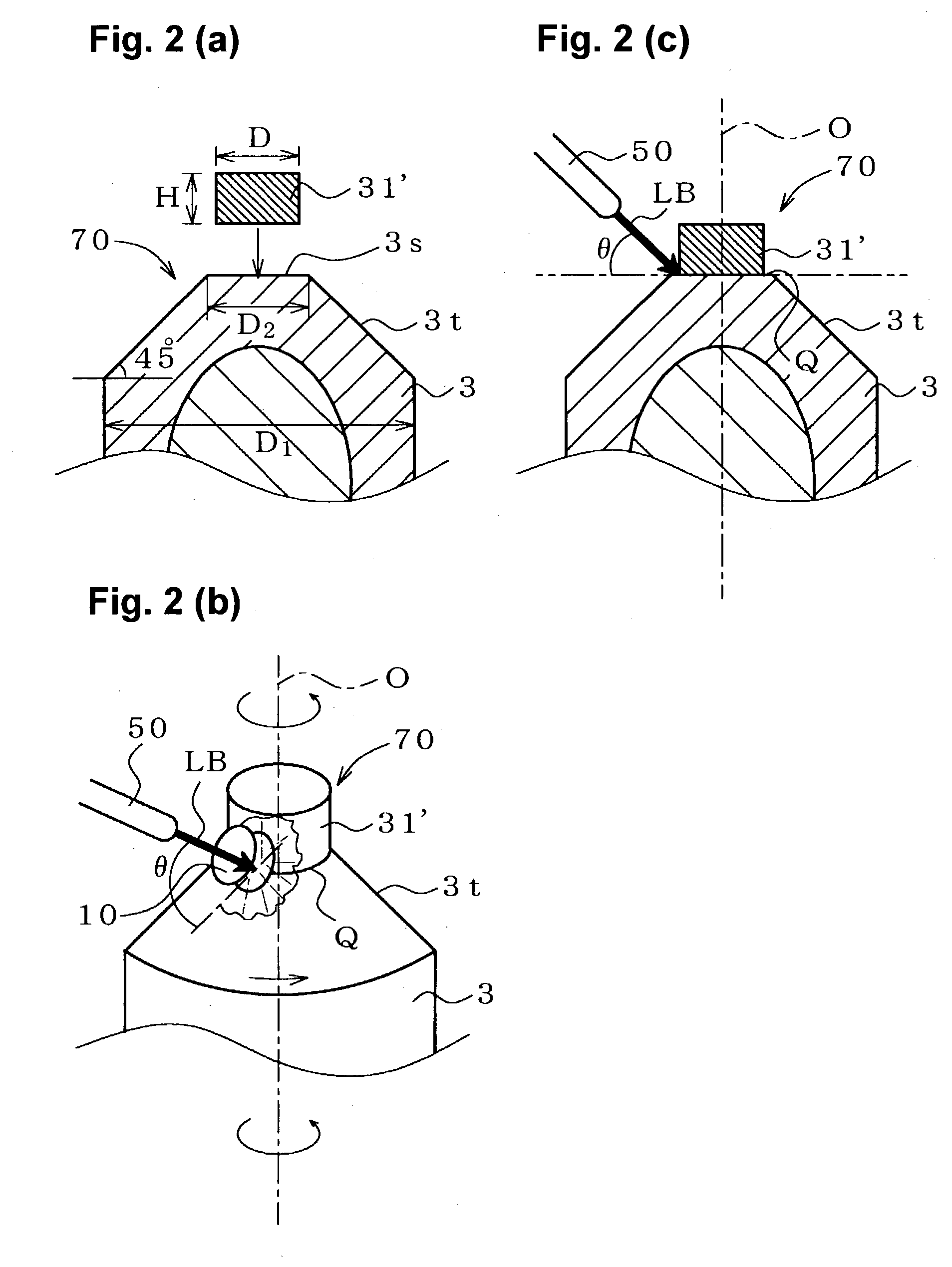

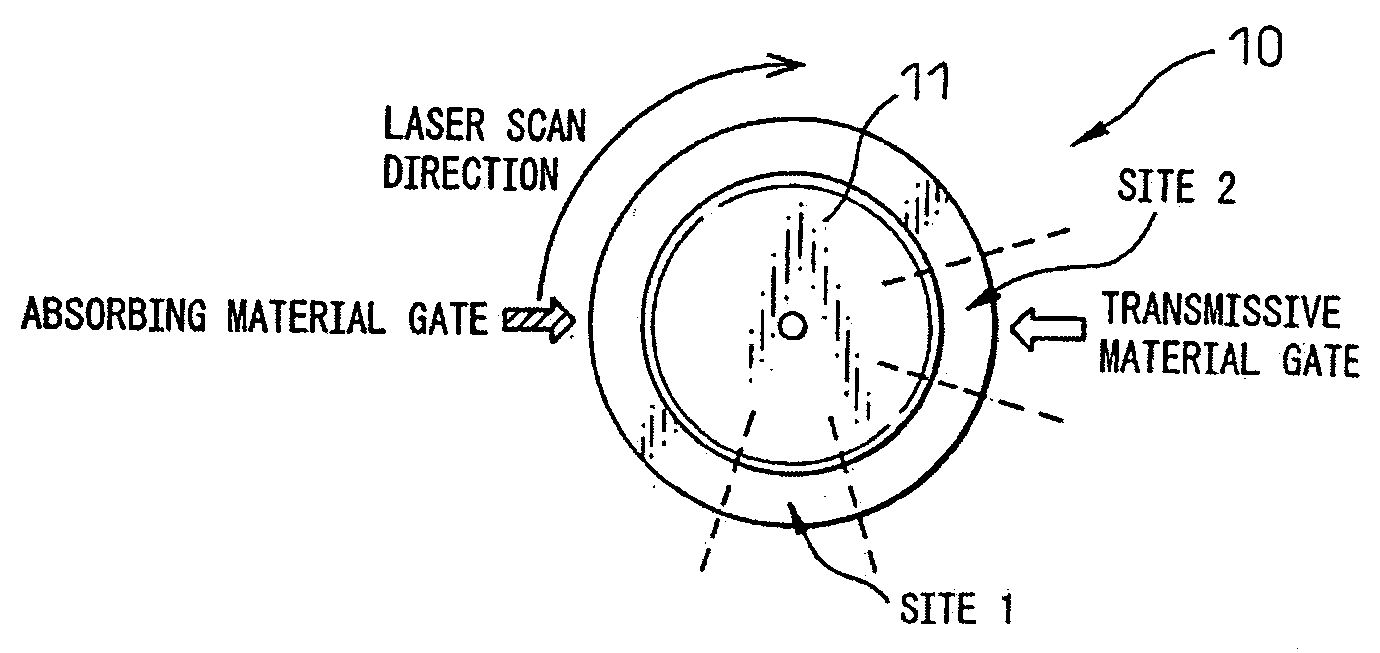

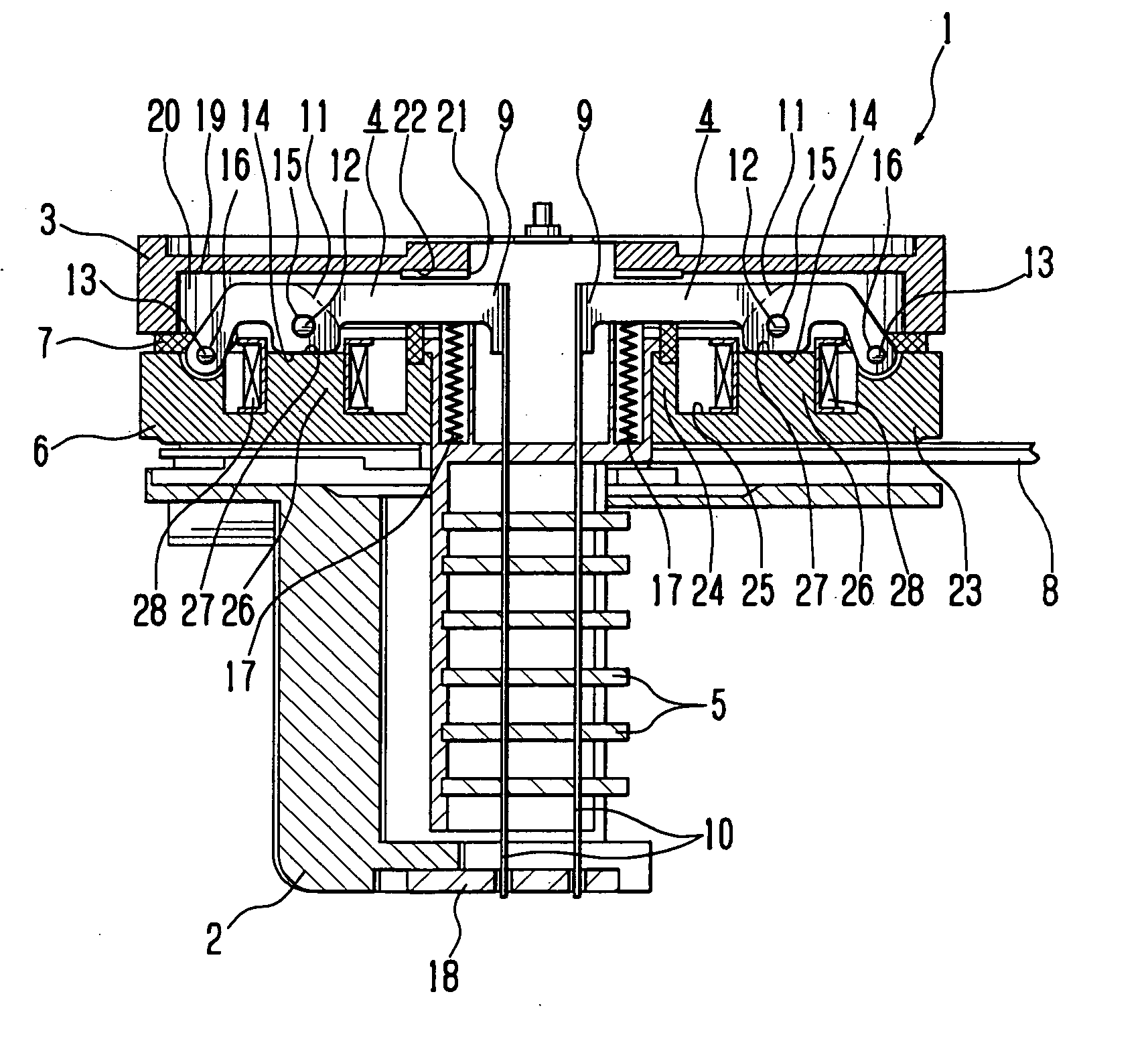

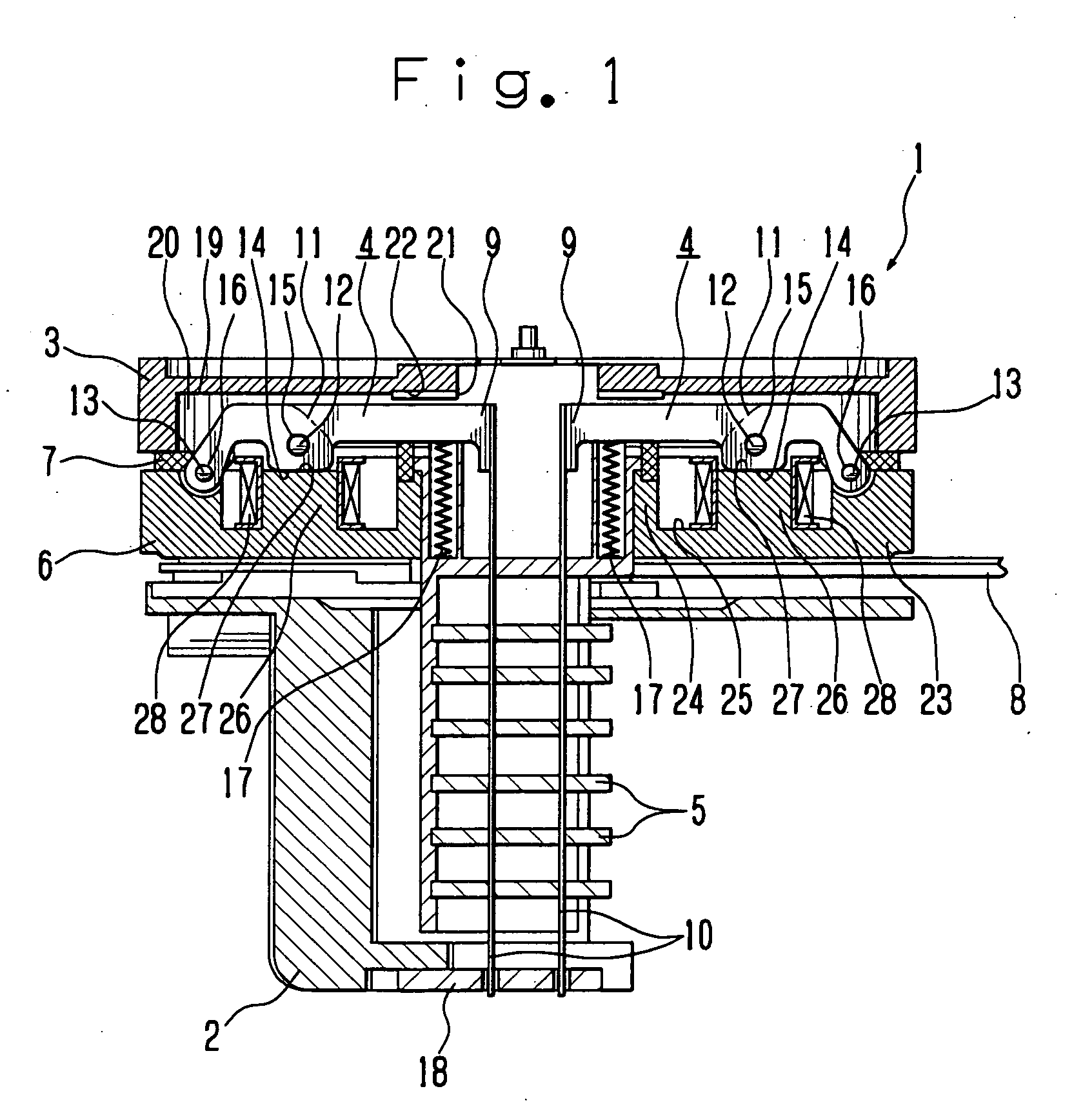

Method for manufacturing a spark plug, and spark plug

A method for manufacturing a spark plug which reduces the generation of spatters and the possibility of insufficient weld strength resulting from penetration depth insufficiency of a weld metal portion is disclosed. In accordance with the method, a chip joint face formation portion of a center electrode is formed from a heat-resistant alloy predominantly containing Fe or Ni. A noble metal chip is attached to a chip joint face of the chip joint face formation portion to thereby form a chip-attached assembly. A full-circled laser-beam weld metal portion is formed on the chip-attached assembly in such a manner as to intrude into the noble metal chip and into the chip joint face formation portion. A graded-index-type fiber optic cable is used as an optical transmission path extending between a laser beam generator and an optical emission section. A laser beam which is transmitted from the laser beam generator through the cable irradiates the chip-attached assembly while being condensed.

Owner:NGK SPARK PLUG CO LTD

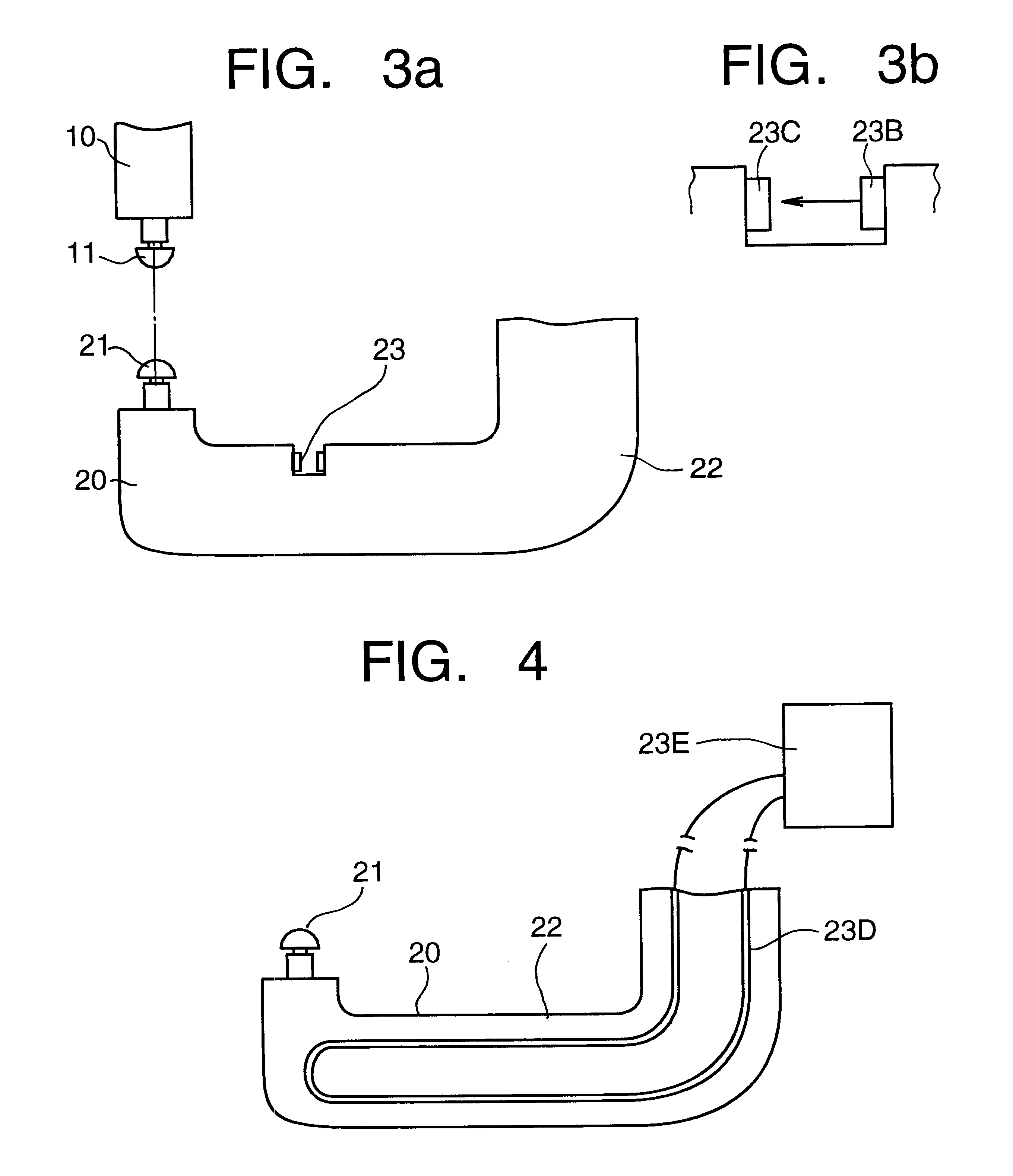

Joined Body of Dissimilar Materials Comprising Steel Material and Aluminum Material, and Joining Method Therefor

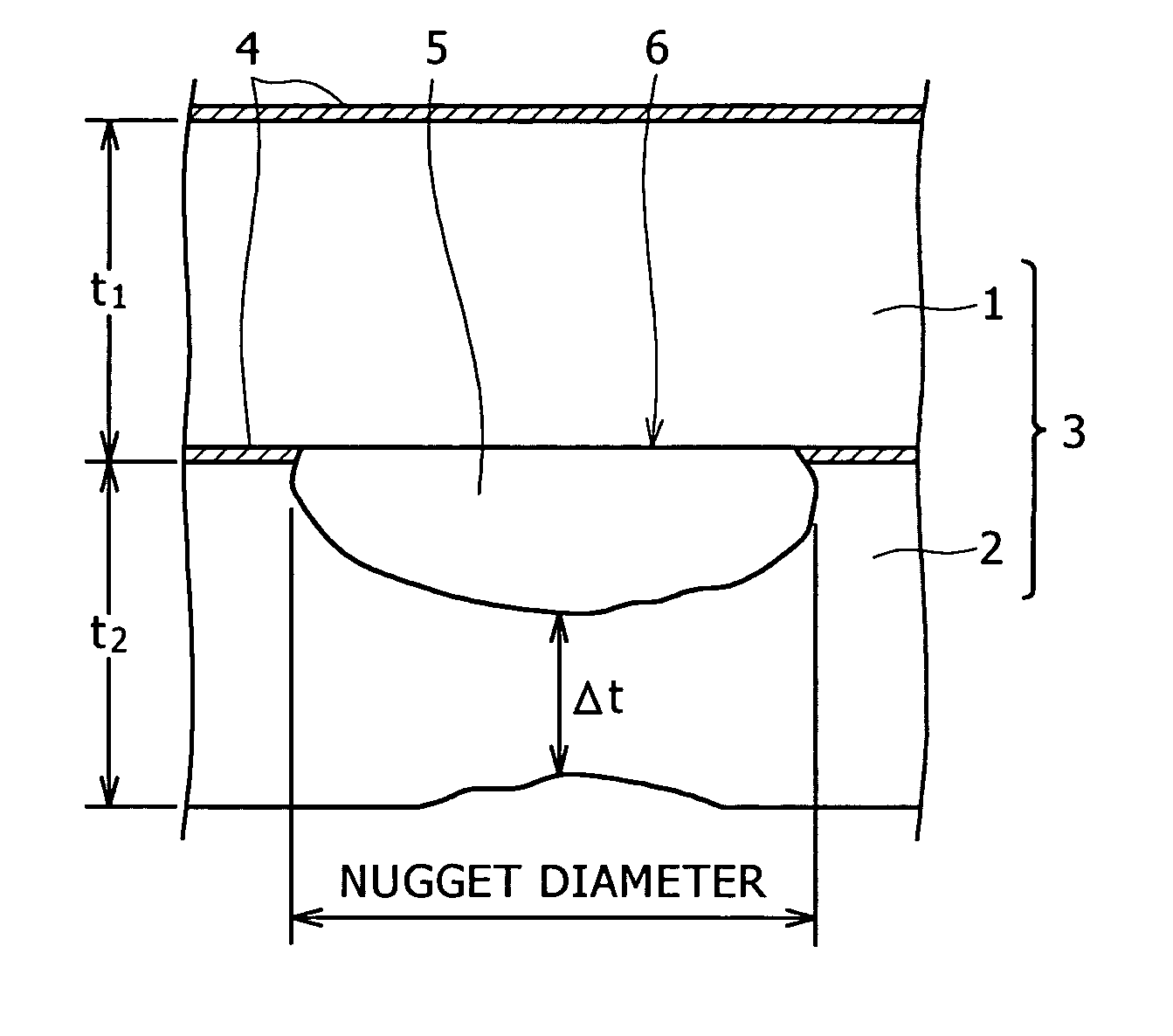

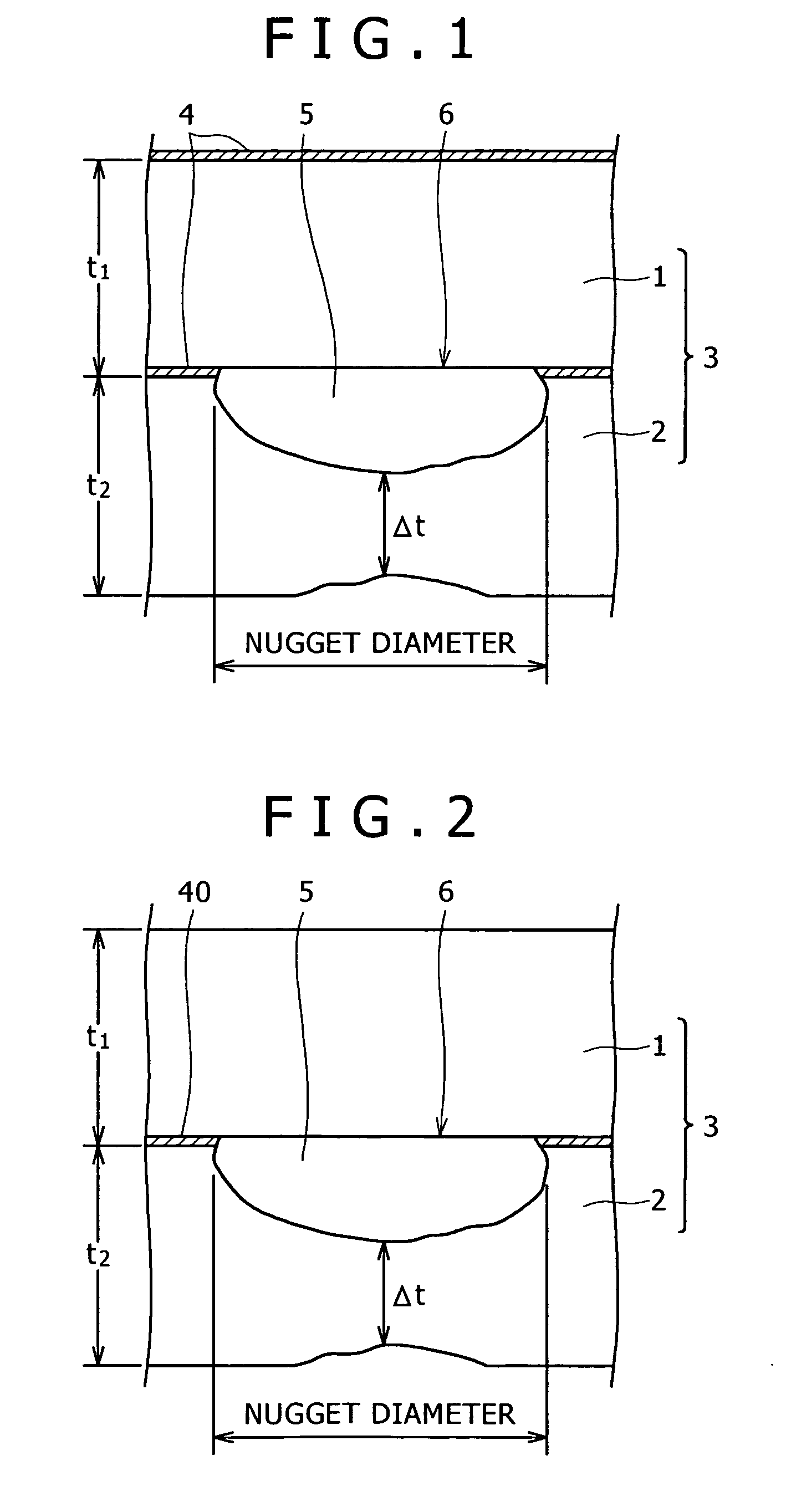

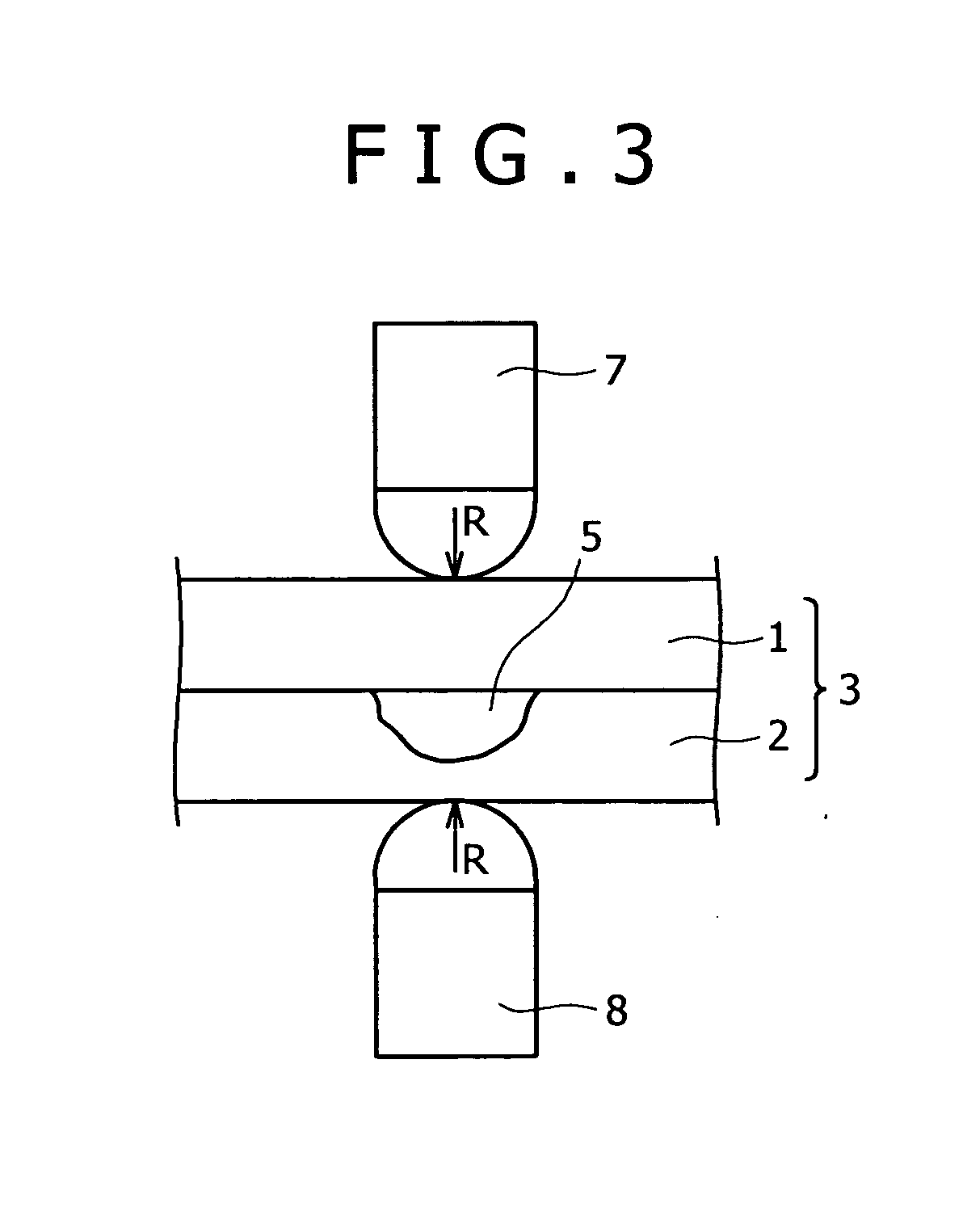

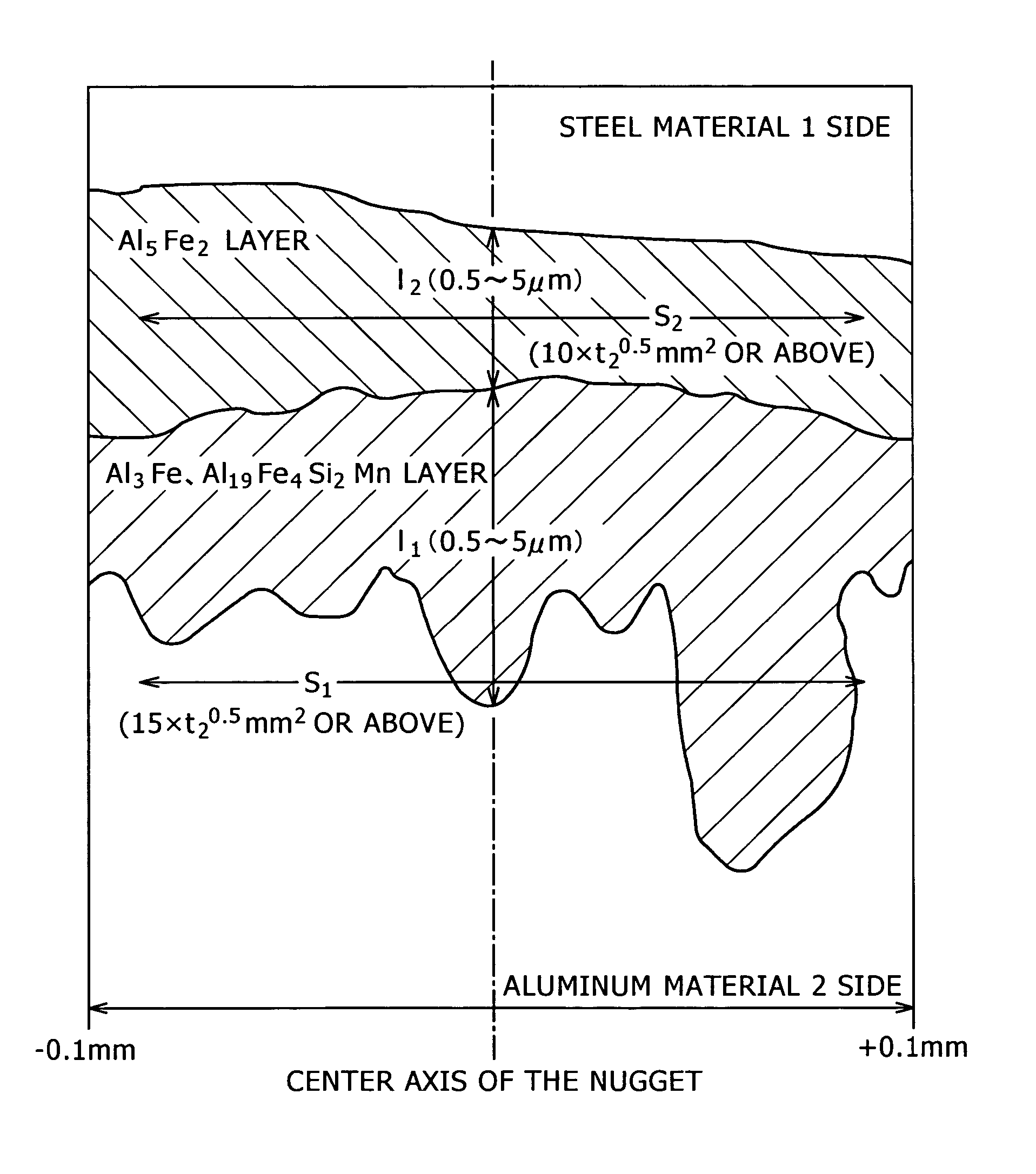

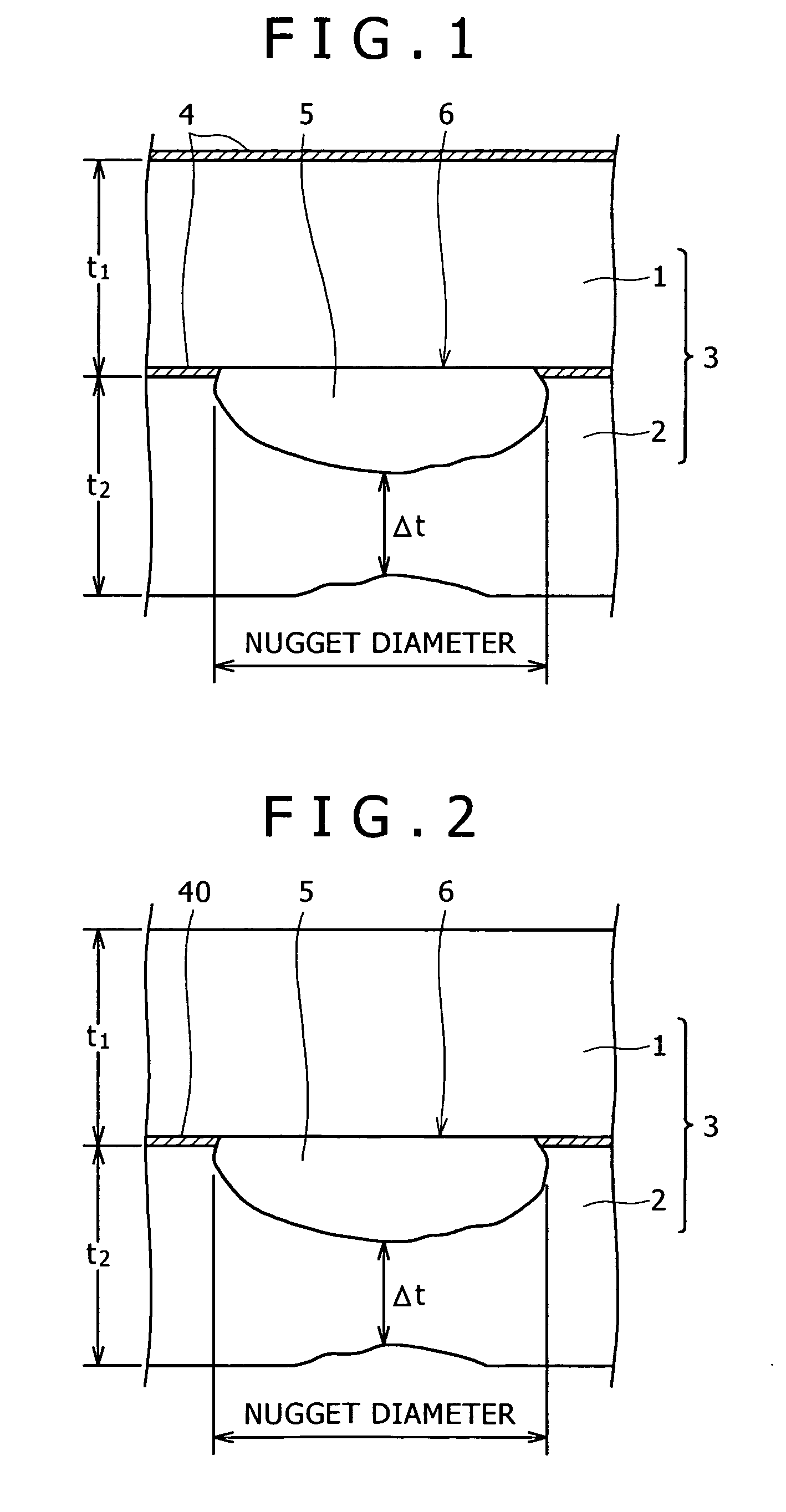

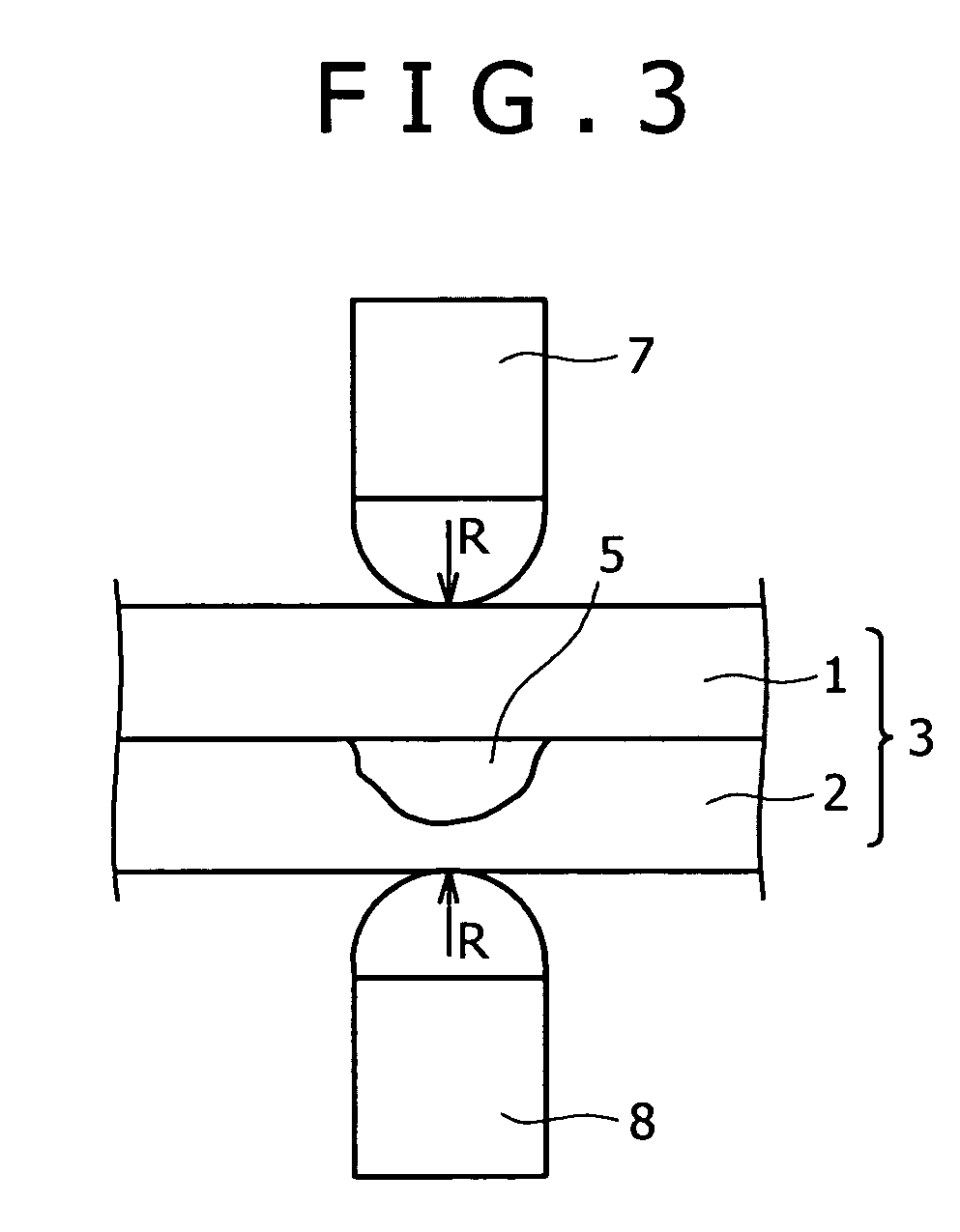

ActiveUS20070212565A1Improve welding strengthSatisfactory repeatabilityHot-dipping/immersion processesContact member assembly/disassemblyAluminiumWeld strength

To provide a steel-aluminum welded material and a spot welding method therefor having high weld strength. The steel-aluminum welded material 3 includes a steel material 1 and an aluminum material 2 having predetermined widths. The area of a nugget 5 of a spot-welded part is determined as a function of the thickness of the aluminum material 2, and the area of a part of the nugget 5 corresponding to a part having a thickness in a range between 0.5 and 10 μm of an interface reaction layer 6 is defined as a function of the thickness of the aluminum material 2.

Owner:KOBE STEEL LTD

High-weld-strength Al-Mg-Si alloy and section bar preparation method thereof

The invention provides a high-weld-strength Al-Mg-Si alloy which comprises the following components in percentage by weight: 0.5-0.9% of Si, 0.4-0.7% of Mg, less than 0.5% of Mn, less than 0.3% of Cr, 0.12-0.5% of (Mn+Cr), less than 0.35% of Fe, less than 0.2% of Zn, less than 0.1% of Ti and 0.2-0.5% of Cu. In addition, the alloy further comprises one of more of 0.2-0.8% of Er, 0.2-0.6% of Zr and 0.3-1.2% of Sc, less than or equal to 0.15% of the balance of other components of the alloy and the balance of Al. Meanwhile, the invention further provides a method for preparing an alloy section bar. According to the Al-Mg-Si alloy provided by the invention, the weld strength is remarkably improved, and the alloy section bar preparation method provided by the invention is further simpler in process.

Owner:SNTO TECH GRP

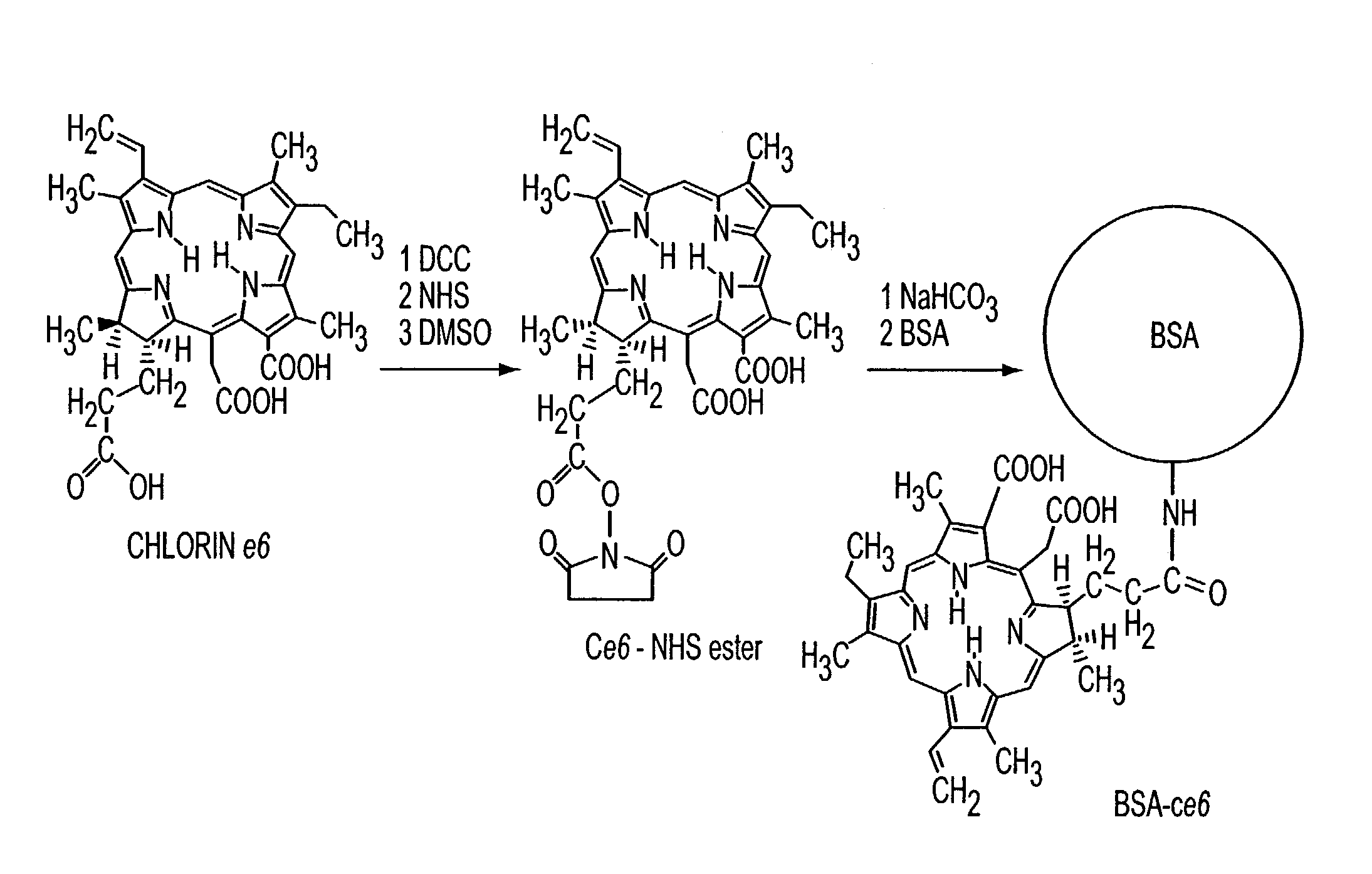

Methods for tissue welding using laser-activated protein solders

Various tissue glues have drawback such as toxicity, causing inflammatory reactions or insufficient bonding strength. The present invention is directed to methods of form tissue adhesion by administering to tissues compositions comprising proteins conjugated to one or more novel photosensitizers and irradiating the composition. The composition may further comprise one or more proteins not conjugated to the photosensitizer. Additionally, the present invention relates to compositions and methods wherein increased ratios of protein to photosensitizer enhance weld strength.

Owner:THE GENERAL HOSPITAL CORP

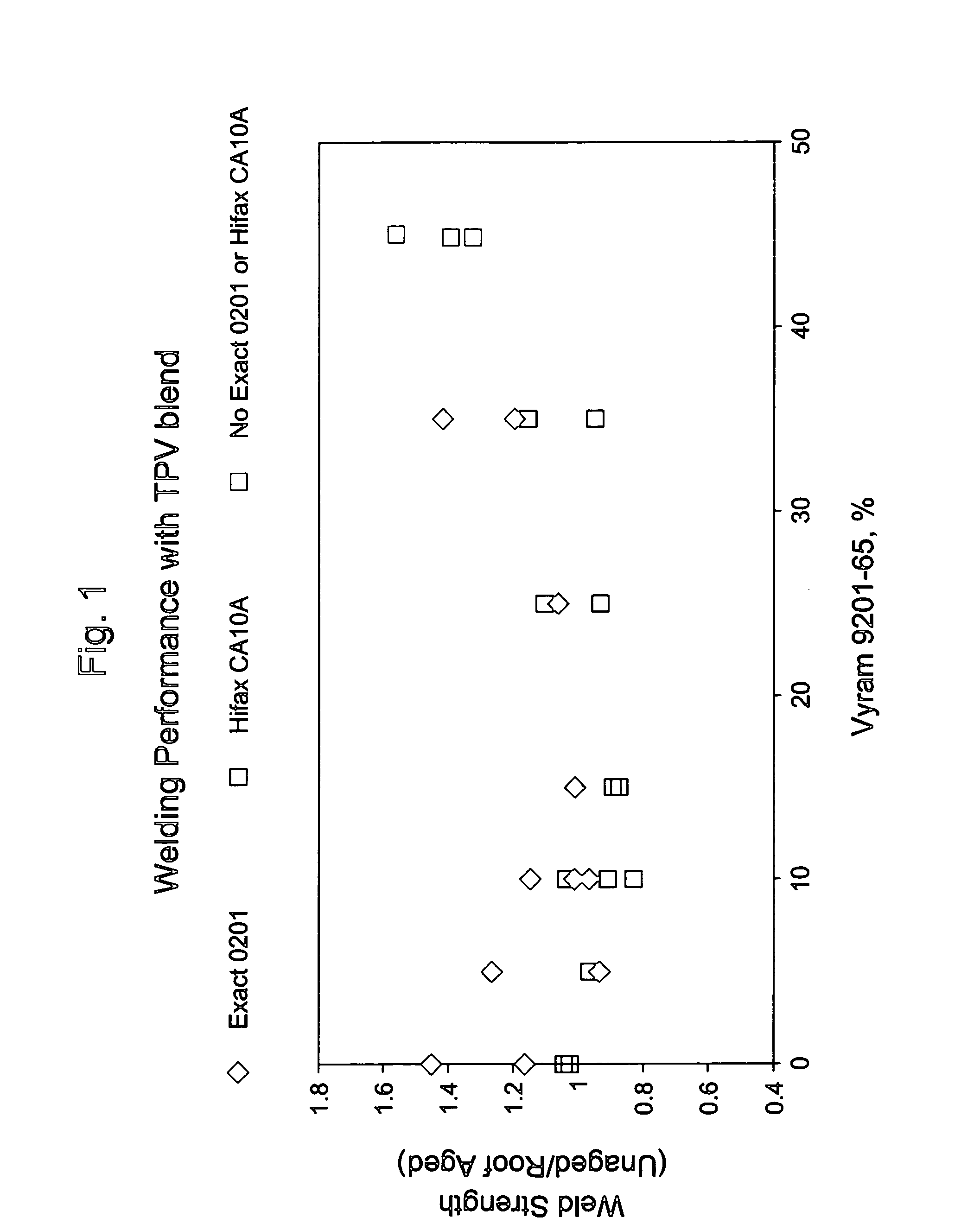

Weldable thermoplastic sheet compositions

InactiveUS20070208139A1Improve balanceMaintain good propertiesRoof covering using flexible materialsThermoplasticVulcanization

This disclosure in certain embodiments relates to thermoplastic sheet compositions and applications incorporating such materials. More specifically this disclosure addresses thermoplastic sheets comprising: a) from 5 to 98.5 wt % of an essentially uncross-linked, random ethylene copolymer having from 20 wt % to 90 wt % repeat units from ethylene and from 10 wt % to 80 wt % of repeat units from one or more other ethylenically unsaturated monomers based upon the weight of the random ethylene copolymer; b) from 0.3 to 83.5 wt % of a polypropylene-based thermoplastic; and c) from 0.3 to 24.5 wt % of a vulcanized rubber dispersed phase. The disclosure also relates to methods of making the sheet compositions. One method includes incorporating a thermoplastic vulcanizate to provide the c) vulcanized rubber and in come cases, to supplement the b) polypropylene thermoplastic. Another method relates to melt blending polymer blends in appropriate proportions in the presence of a curing agent to effect dynamic vulcanization of a cross-linkable rubber component. Improved welding characteristics and weld strength of the sheets and reduced blocking in the extrusion step of producing the sheets is achieved.

Owner:ADVANCED ELASTOMERS SYST

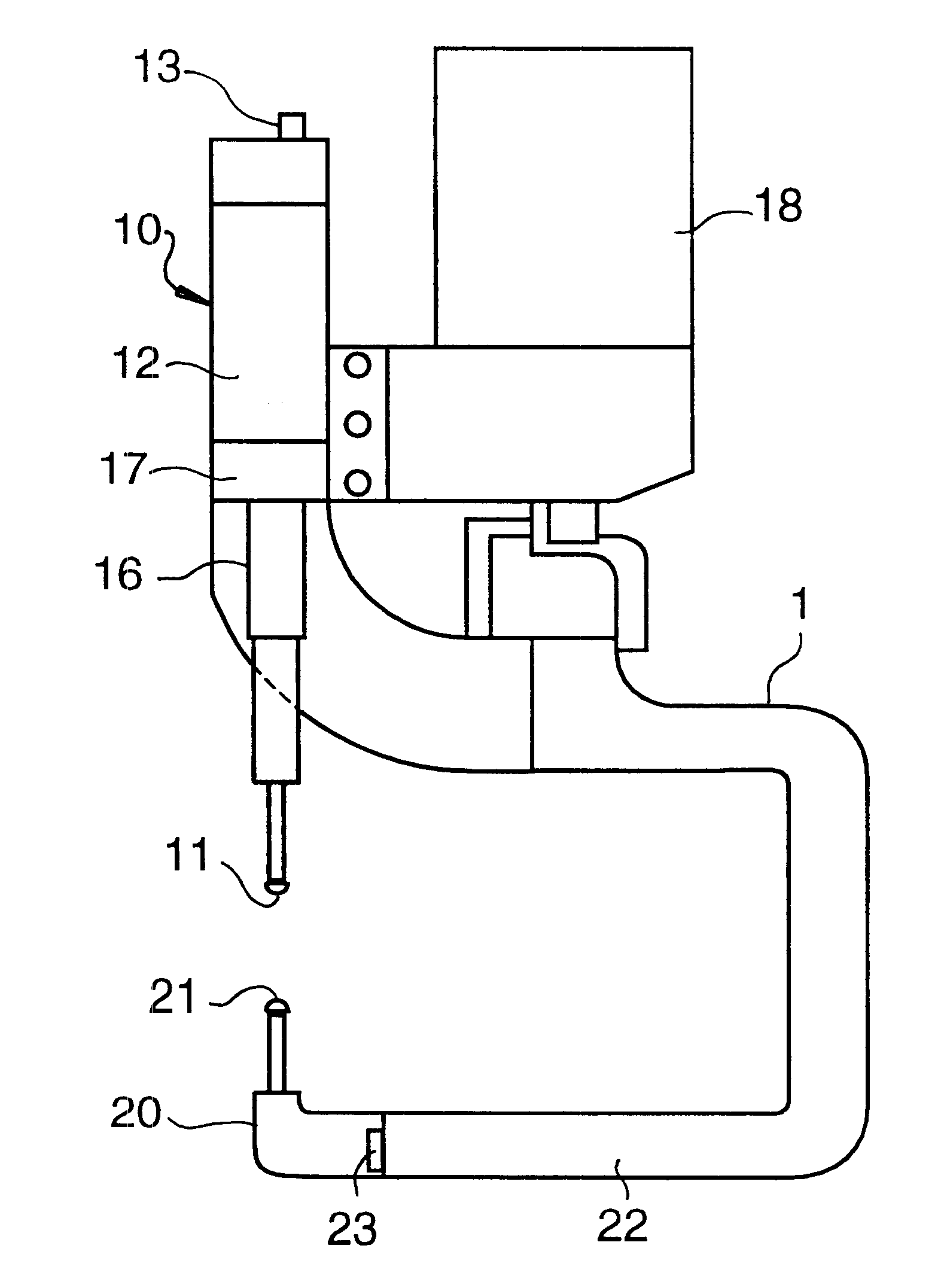

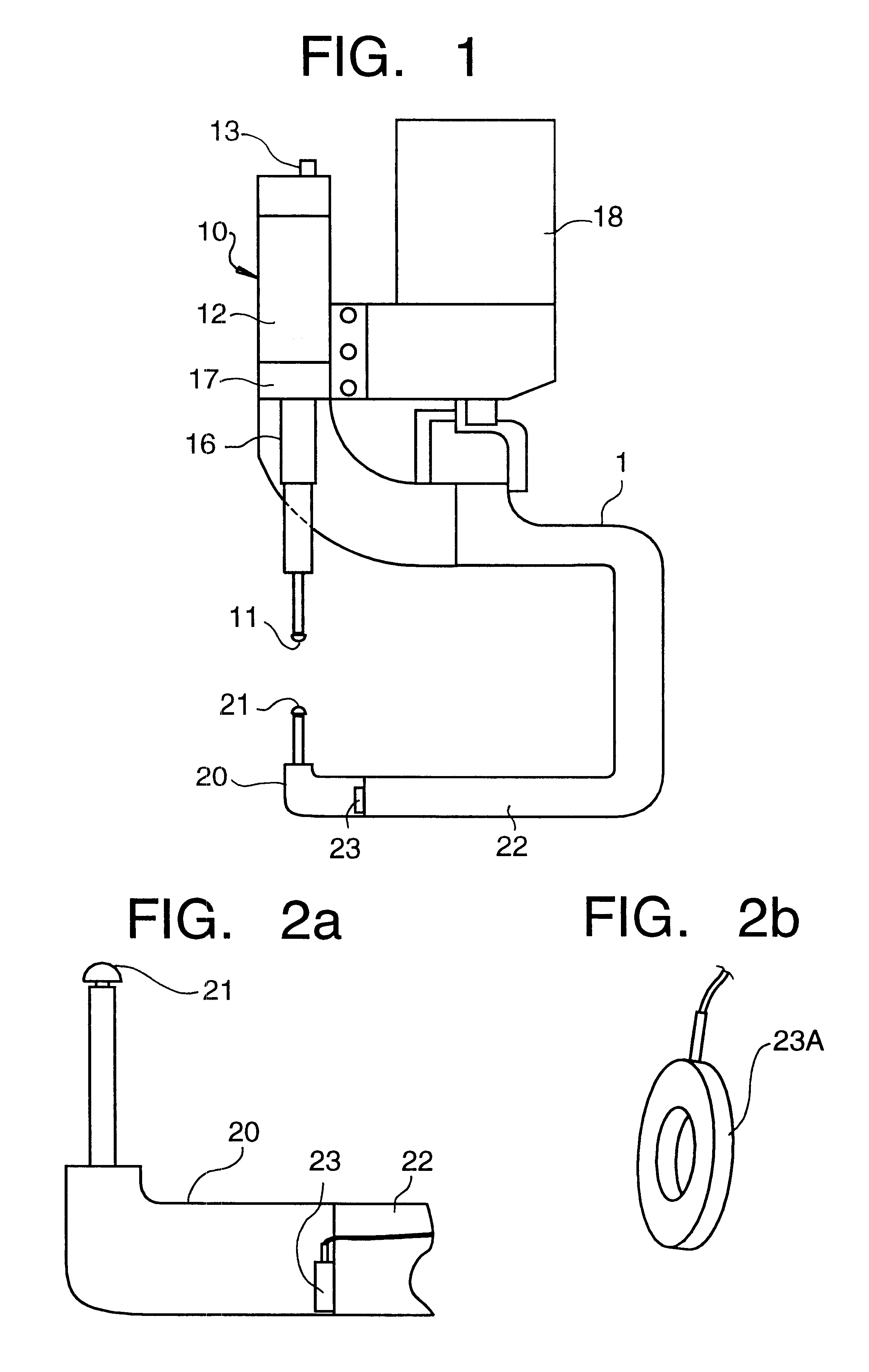

Welding gun and methods conducted using the same

InactiveUS6313427B1Decreased in size and rigidityEliminate gapsResistance electrode holdersArc welding apparatusEngineeringWeld strength

An intelligent welding gun is provided with a fixed side sensor in a fixed side portion. The mechanical impedance of the fixed side portion is kept small, which permits the mechanical impedance to be set in a range where the fixed side sensor can effectively detect at least one of a position of a fixed side welding tip and a pressing force imposed on the fixed side welding tip. The fixed side sensor and a moving side sensor constitute a redundant sensor measurement system. Various kinds of methods conducted using the above welding gun include a method of calibrating a sensor (including calibration of a reference point and a gain), a control method of suppressing a welding expulsion, a re-welding feedback control method, a control method of a welding strength, a control method of reducing a clearance between workpieces, a method of correcting a welding robot track, and a method of managing a positional accuracy change at a welding point.

Owner:TOYOTA JIDOSHA KK

Seamless explosive core aluminium welding wire and manufacturing method thereof

The invention relates to a seamless flux-cored aluminum welding wire, which consists of a sheath and a core part, is conducive to adding an additive conveniently, quantificationally and efficiently during aluminum welding process and does not result in absorption of moisture, slag inclusion and scattering of core active substrates when removing an oxide film. The seamless flux-cored aluminum welding wire has the advantages of convenient application, high welding efficiency, no subsequent cleaning, environmental protection, etc. when being applied to soldering. The seamless flux-cored aluminum welding wire has high welding wire deposition efficiency and large deposition efficiency, while being applied to argon-arc welding and compared with solid core welding of the same specification, weld width is comparatively wide, penetration is increased, shape factor and weld reinforcement are reduced and the weld strength is 15 percent higher. Compared with flux-cored aluminum welding wire made of bite straps, the invention is characterized by less air holes and slag inclusion and high welding reliability.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

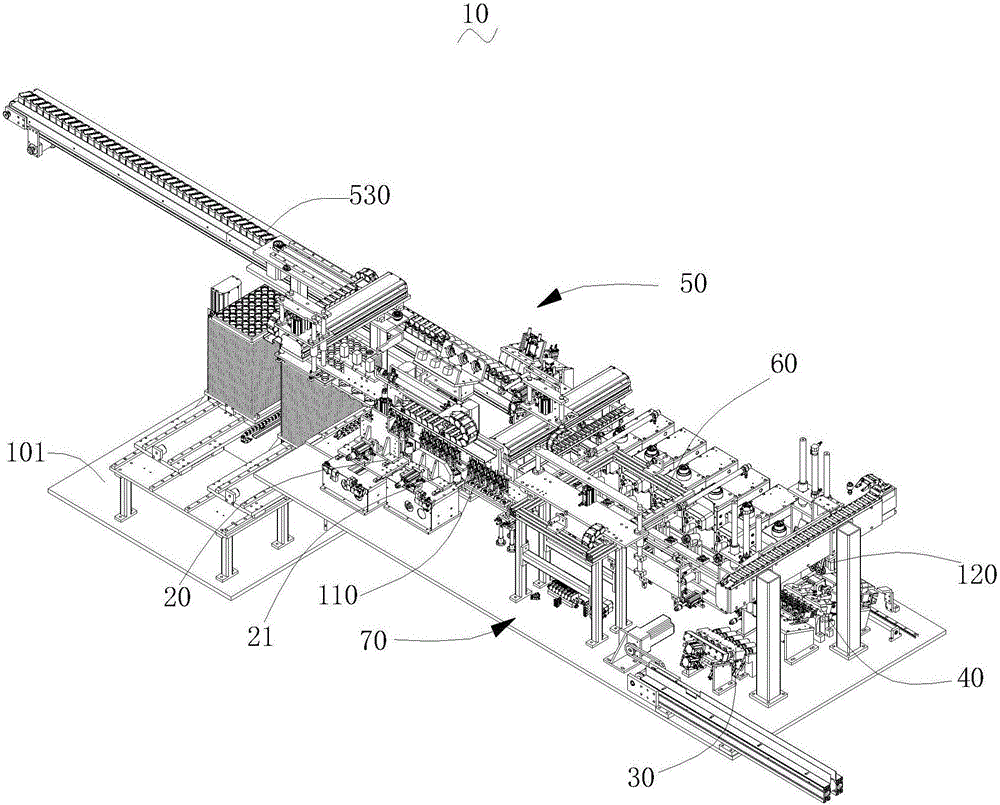

Battery cap welding machine

InactiveCN106041375ARealize automated productionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesPull forceEar shaping

The invention provides a battery cap welding machine, comprising: a frame, on which are provided a pole piece device, a tab correction device, a cap rotation device, a welding telescopic device, a tensile testing device, and a cap cap tab shaping device, The cap rotating device and the welding telescopic device are arranged oppositely, the pole piece device is set at one end of the cap rotating device, the tab correction device is set at the end of the welding telescopic device close to the pole piece device, and the tensile test device is set at the other end of the welding telescopic device , the gland cap lug shaping device is set parallel to the tensile testing device. The electrode piece device pulls up the pole piece on the cap, and the tab correction device rotates the tab on the battery case to align with the pole piece. The battery case and the cap are placed on the welding telescopic device and the cap rotating device to align and weld, and the welded battery is in the The tensile test device is used to test the welding strength, and the tab cap tab shaping device is used to complete the shaping of the tab and the compression of the cap, realizing automatic welding and greatly improving production efficiency.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

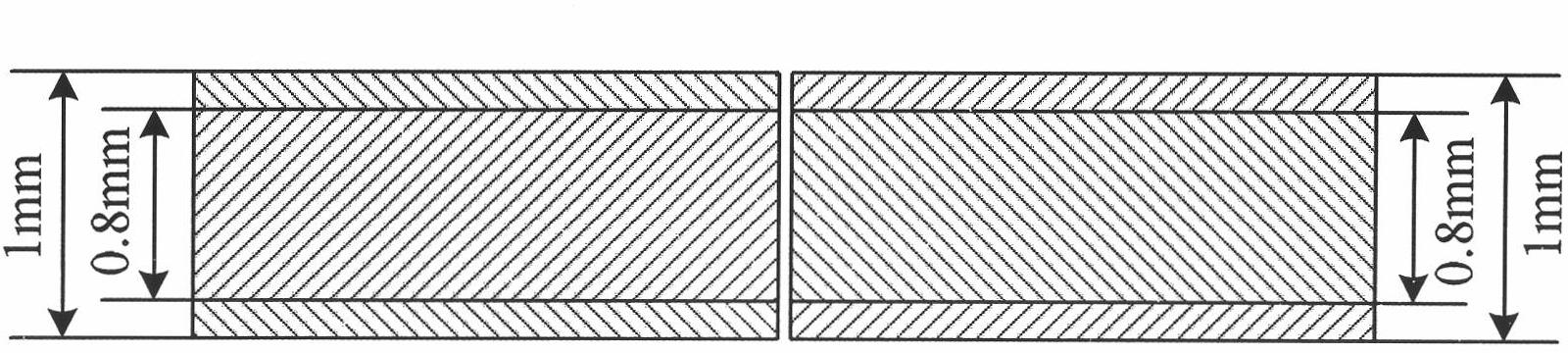

Laser welding method for thin stainless steel composite plate

ActiveCN102632339AAdvanced technologyFilling the Butt Welding GapFurnace typesWelding/cutting media/materialsComposite plateWeld strength

The invention relates to a laser welding method for a thin stainless steel composite plate. According to the structural characteristics of the thin stainless steel composite plate, the outside of carbon steel is wrapped with a stainless steel plate, the stainless steel plate is thin, large-area and elastic, and great difficulty in double-sided welding is caused. By the aid of the laser welding method, the thin stainless steel plate is firstly pretreated and smoothly mounted, welding powder is prepared, argon shield is realized, the feeding quantity of the welding powder and the strength of a laser beam are controlled by means of computer program, and welding of the thin stainless steel composite plate is made possible. The welding method is advanced in process, high in welding quality, fine in corrosion resistance and high in welding strength, provides full and accurate data, and is safe, stable and reliable. The average tensile strength of a welding joint reaches 450.9MPa and accounts for 98.2% of that of base metal, the welding blank of the thin stainless steel composite plate is filled, and the laser welding method for the thin stainless steel composite plate is quite ideal.

Owner:太原理工技术转移有限公司

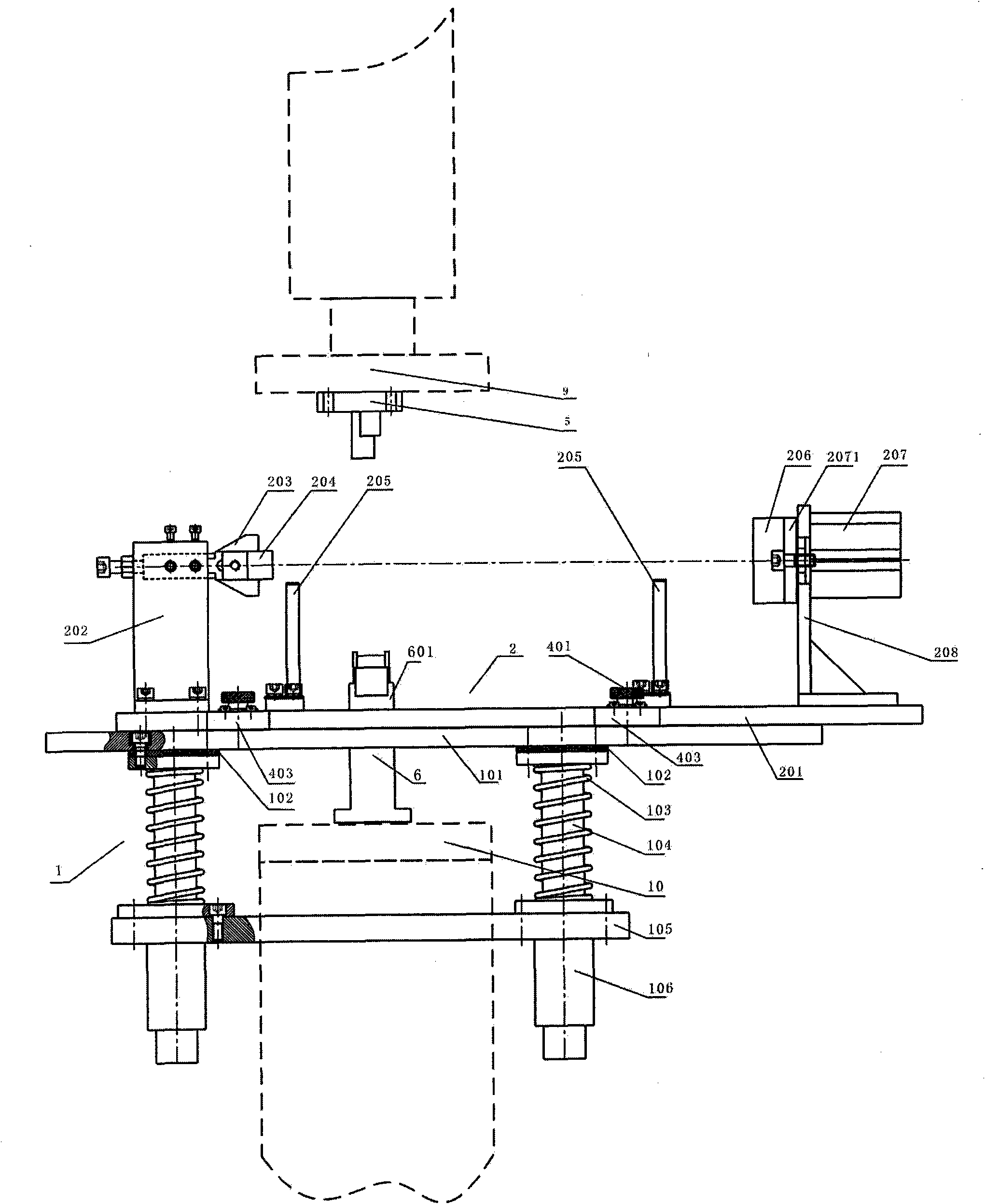

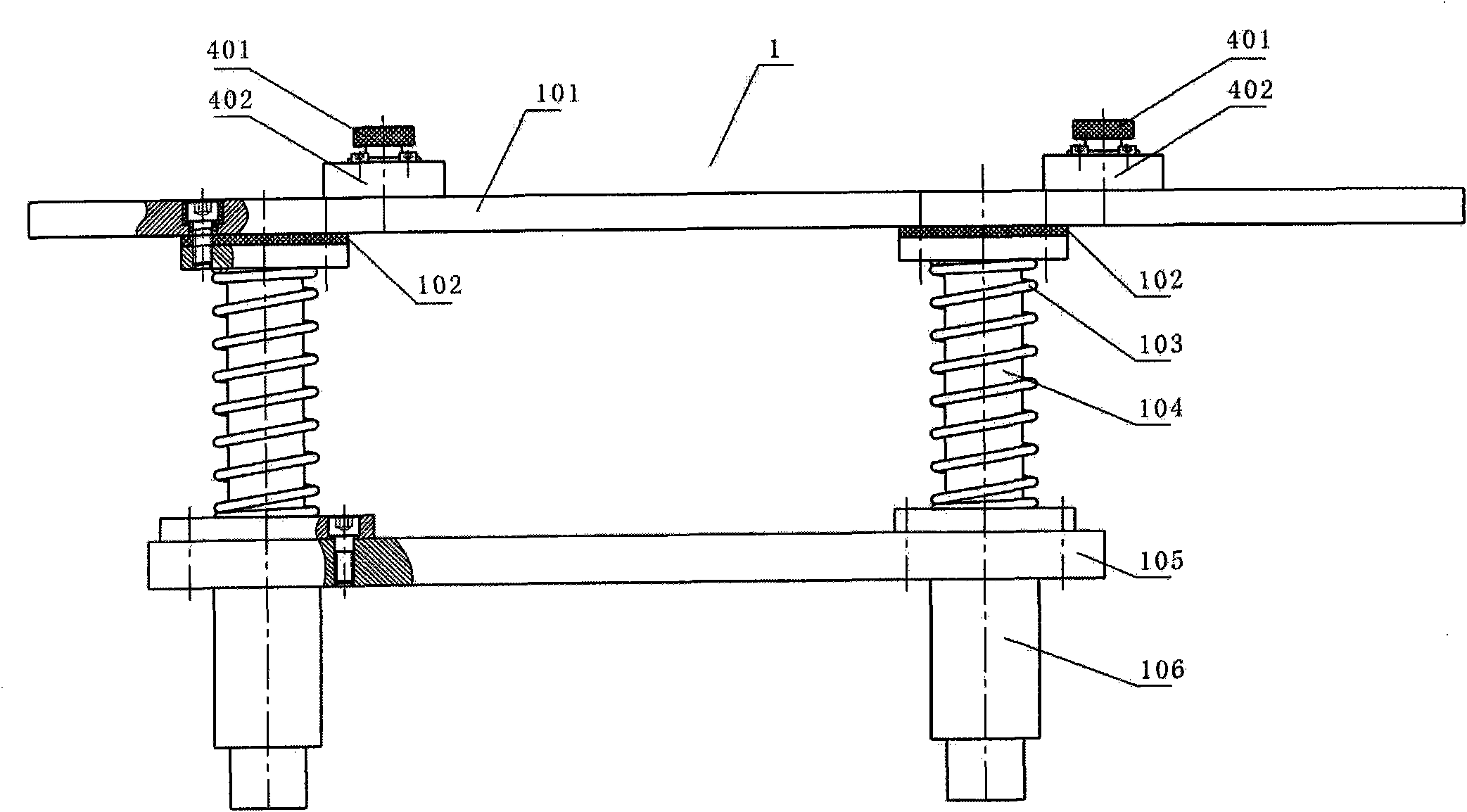

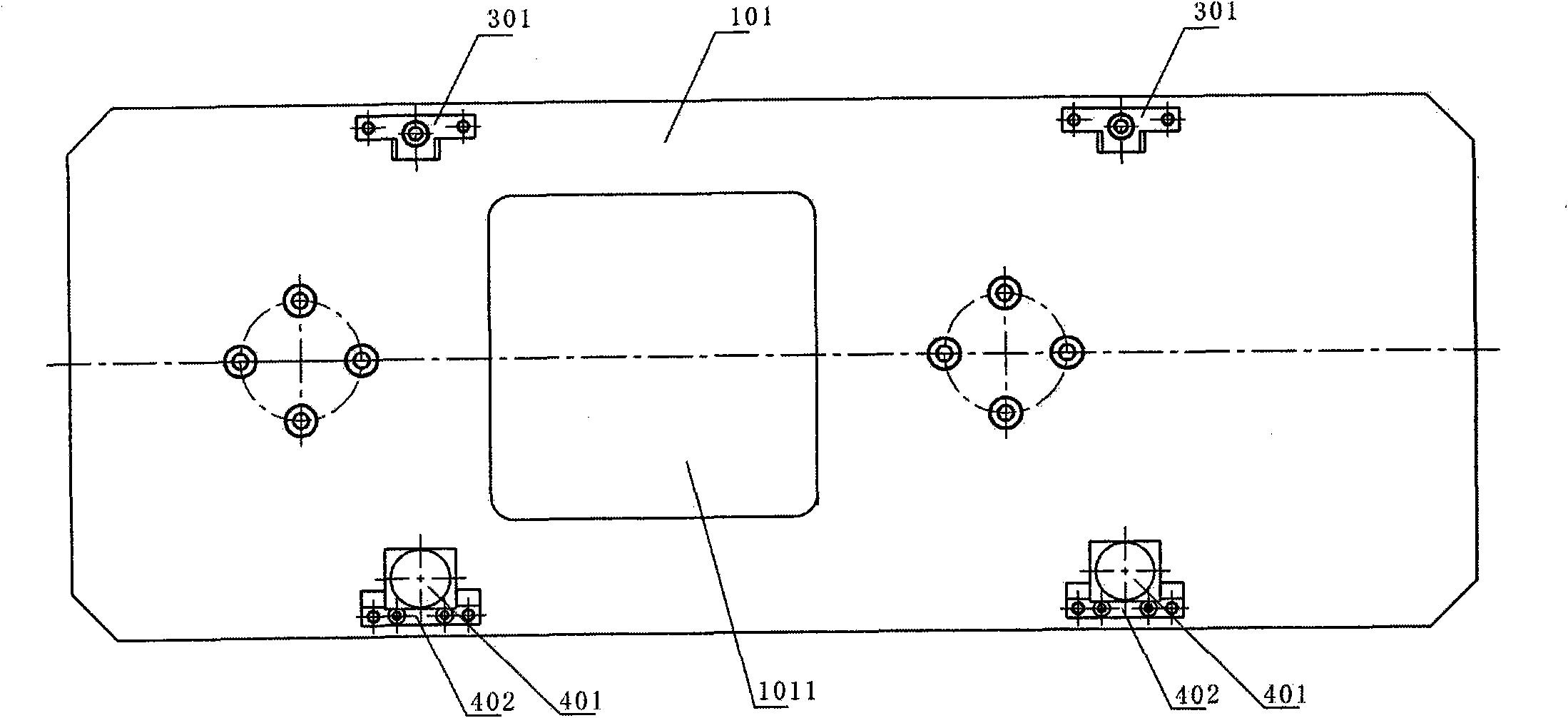

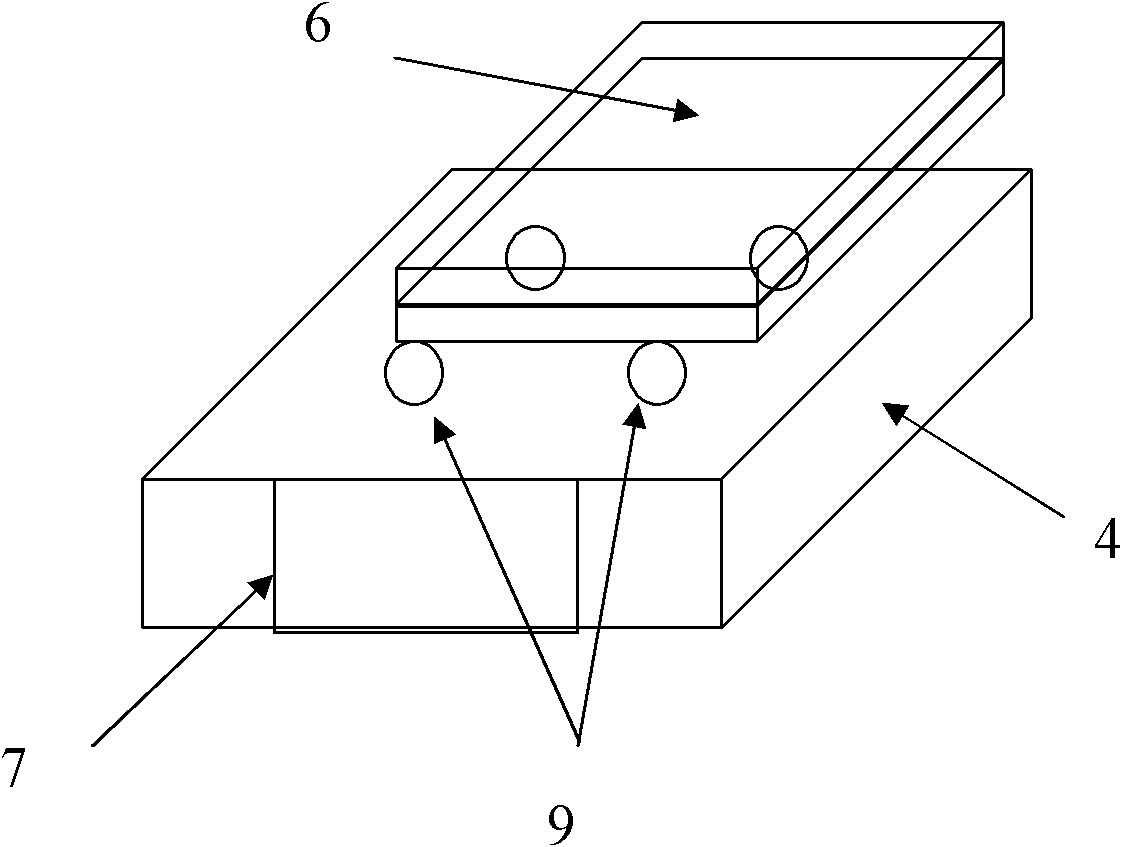

Automobile shock absorber support projection welding floating tool

The invention discloses an automobile shock absorber support frame projection welding floating tool, which relates to spot welding equipment and consists of a projection welding floating universal base, a replaceable automobile shock absorber support positioning frame, a replaceable positioning frame positioning mechanism, a wedge-shaped pressing mechanism, an upper electrode seat and a lower electrode seat, wherein the replaceable automobile shock absorber support positioning frame is arranged on the projection welding floating universal base through the replaceable positioning frame positioning mechanism and the wedge-shaped pressing mechanism, the projection welding floating universal base is arranged on a casing of a projection welder, the upper electrode seat is arranged under an upper electrode plate of the projection welder, and a lower electrode is arranged on a lower electrode plate of the projection welder. A spring is used for buffering in welding contact moment, thus the tool is stable and reliable, the salient point plastic deformation can not be caused, the salient point size is prevented from being changed by the upper electrode cylinder impact, and the welding strength stability is good.

Owner:浙江鼎信航天科技有限公司

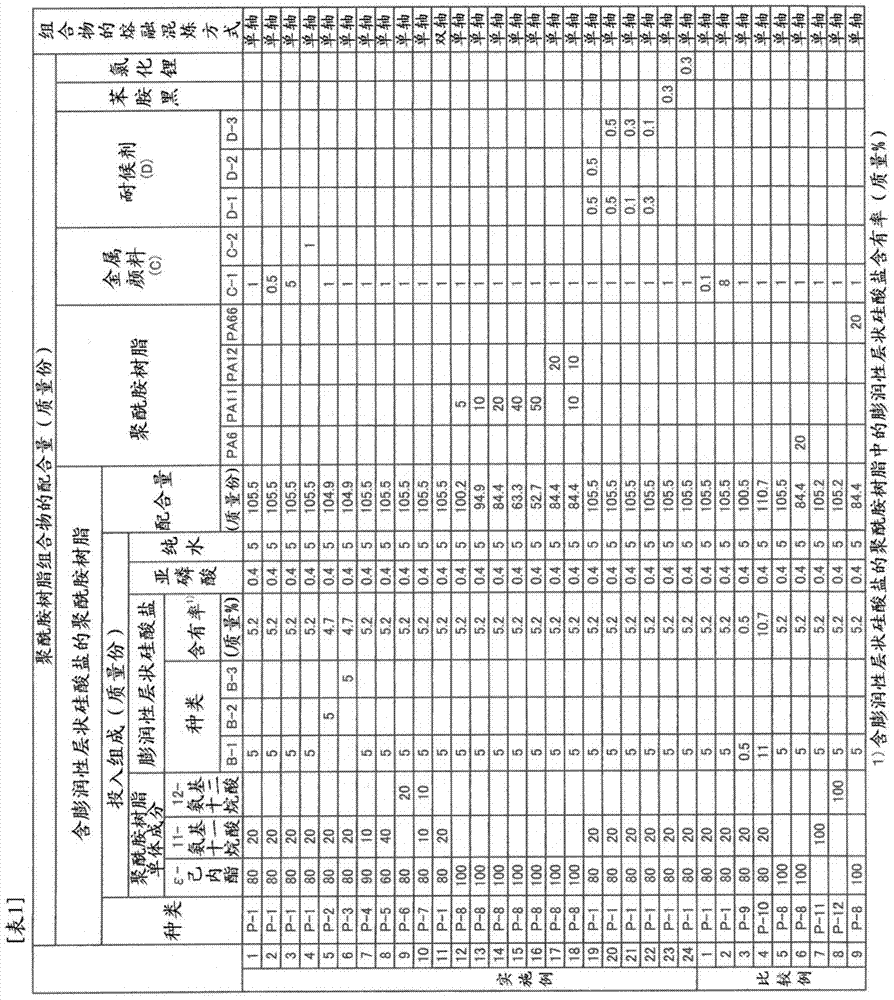

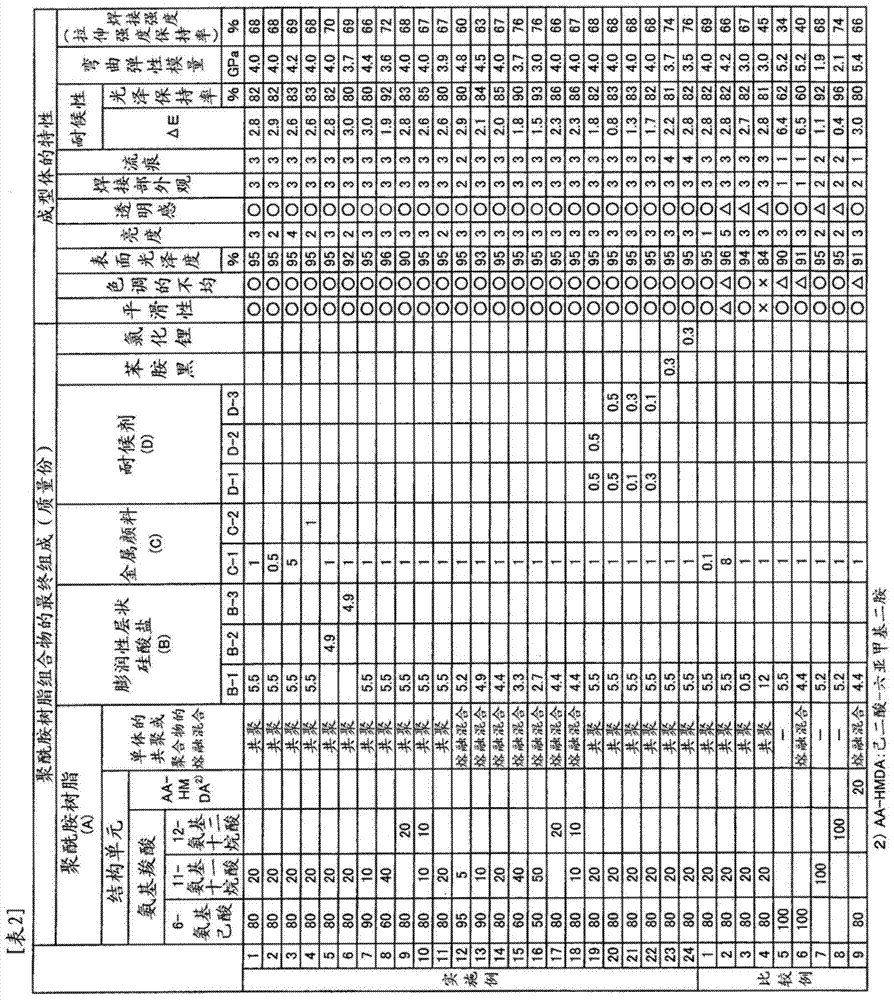

Polyamide resin composition and molded body molded with the same

The present invention relates to a polyamide resin composition and molded body molded with the same. The polyamide resin composition can mold the polyamide resin molded body excellent in weld strength and luminance, having rigidity. The polyamide resin composition is characterized that 100 parts by mass of polyamide resin (A), 1-10 parts by mass of swelling sheet silicates (B), and a polyamide resin composition which is a polyamide resin composition containing 0.5-5 parts by mass of metallic pigment (C), and is characterized by polyamide resin (A) comprising 2 or more type of aminocarboxylic acid units.

Owner:UNITIKA LTD

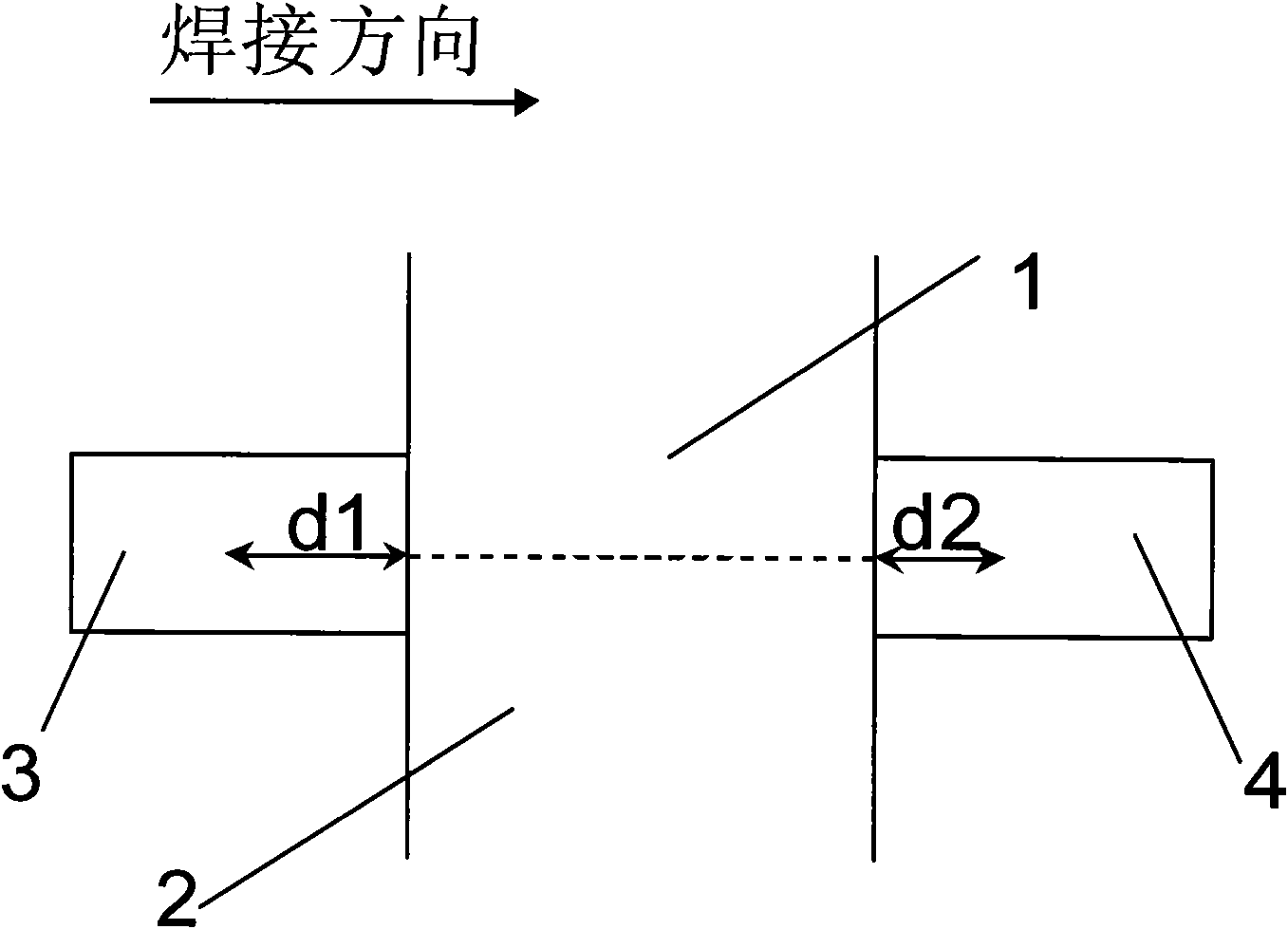

Laser welding method for butting two pieces of metal sheets

ActiveCN101569961AHigh strengthEliminate consumptionWelding/soldering/cutting articlesMetal working apparatusMetal sheetAbutment

The invention discloses a laser welding method for butting two pieces of metal sheets, comprising the following steps: determining the size of facula according to the metal sheets; selecting a corresponding laser welding device and determining welding height according to the size of the facula; closely arranging a first welding guide plate at the initiating end of an abutment joint of the two pieces of metal sheets and arranging a second welding guide plate at the tail end of the abutment joint; with certain welding frequency, single welding energy and certain welding movement speed, carrying out movement and laser release from the first welding position of the first welding guide plate to the second welding position of the second welding guide plate along the abutment joint. The method of the invention ensures the same welding strength at the initial end and other positions of the welding lines, improves welding quality and increases welding strength. The welding lines welded by the method of the invention maintain the same strength property as the parent metal after a plurality times of distortion and tearing, thus having no weak spots in terms of strength.

Owner:HANS LASER TECH IND GRP CO LTD

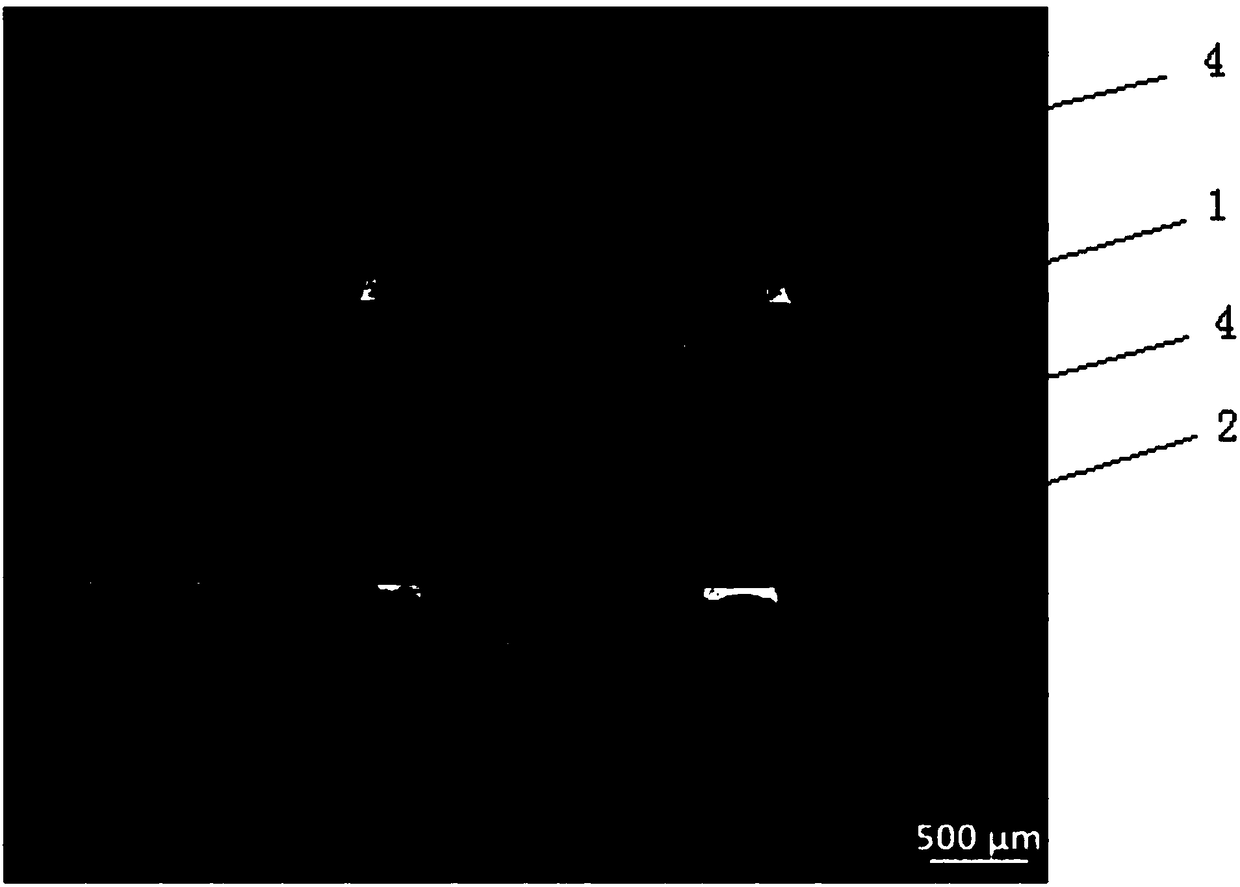

Joined body of dissimilar materials comprising steel material and aluminum material, and joining method therefor

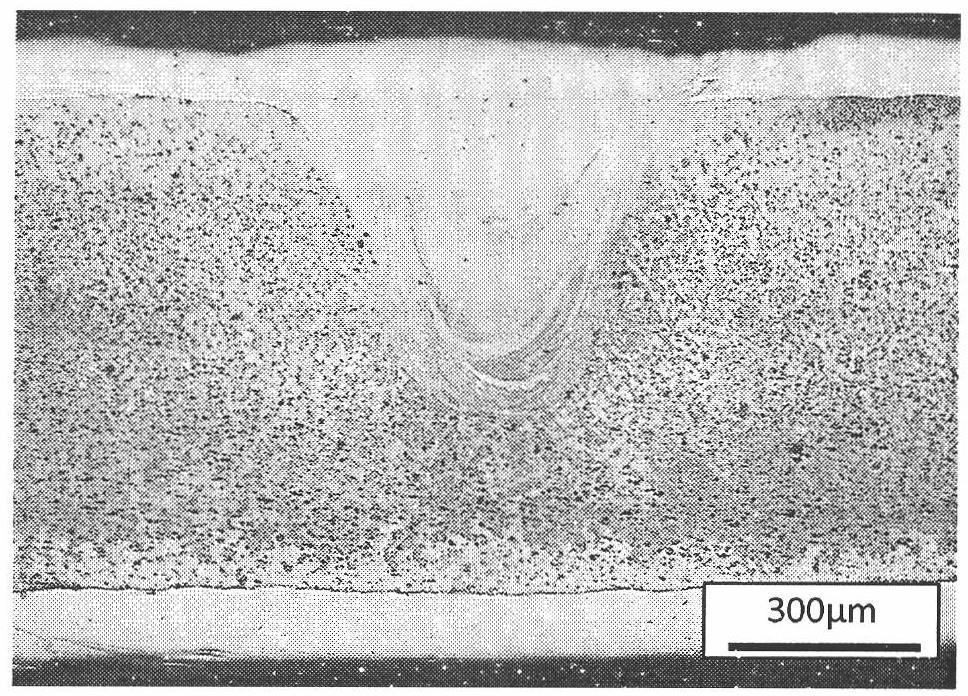

InactiveUS7951465B2Improve welding strengthSatisfactory repeatabilityHot-dipping/immersion processesContact member assembly/disassemblyReaction layerSpot welding

To provide a steel-aluminum welded material and a spot welding method therefor having high weld strength.The steel-aluminum welded material 3 includes a steel material 1 and an aluminum material 2 having predetermined widths. The area of a nugget 5 of a spot-welded part is determined as a function of the thickness of the aluminum material 2, and the area of a part of the nugget 5 corresponding to a part having a thickness in a range between 0.5 and 10 μm of an interface reaction layer 6 is defined as a function of the thickness of the aluminum material 2.

Owner:KOBE STEEL LTD

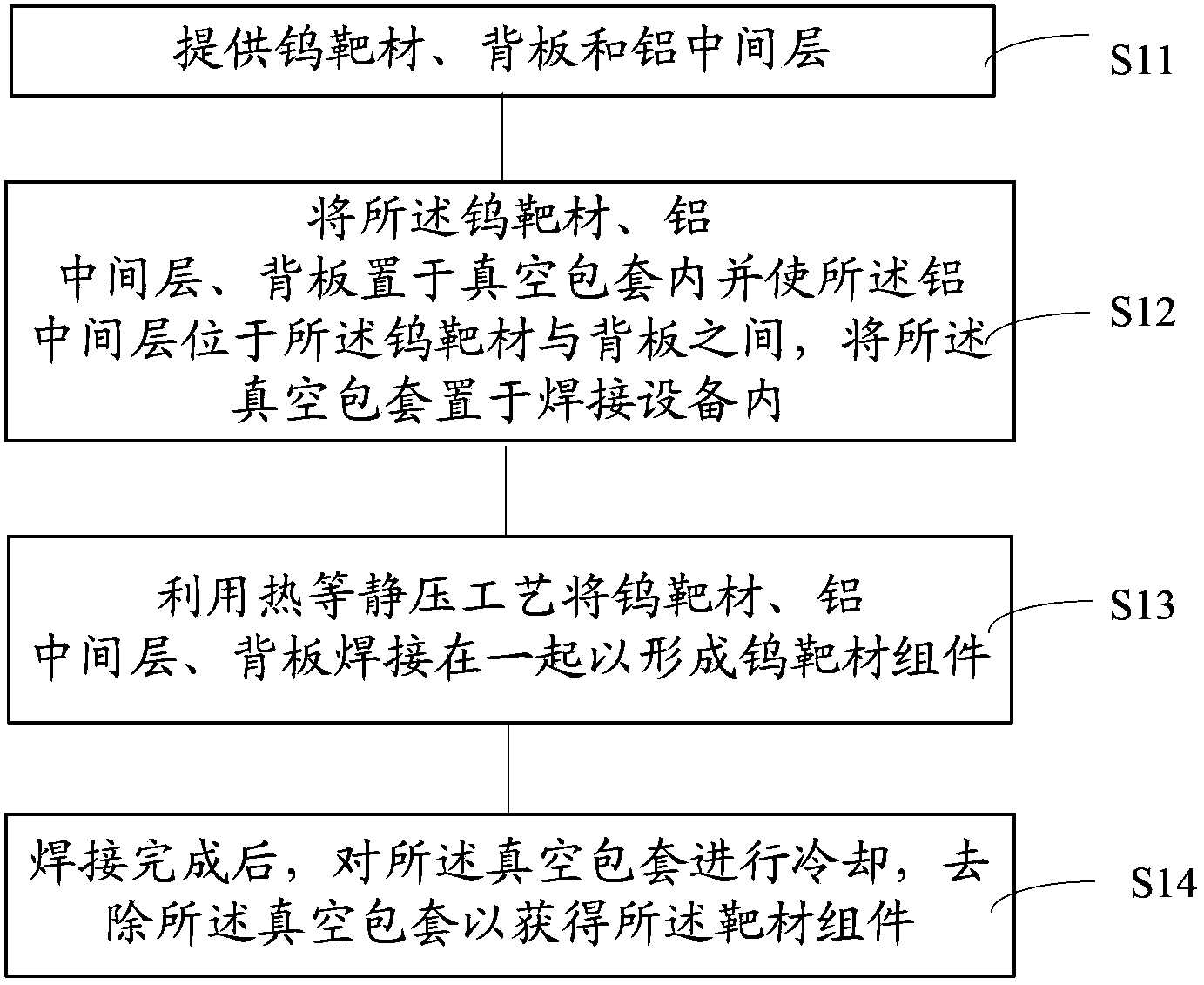

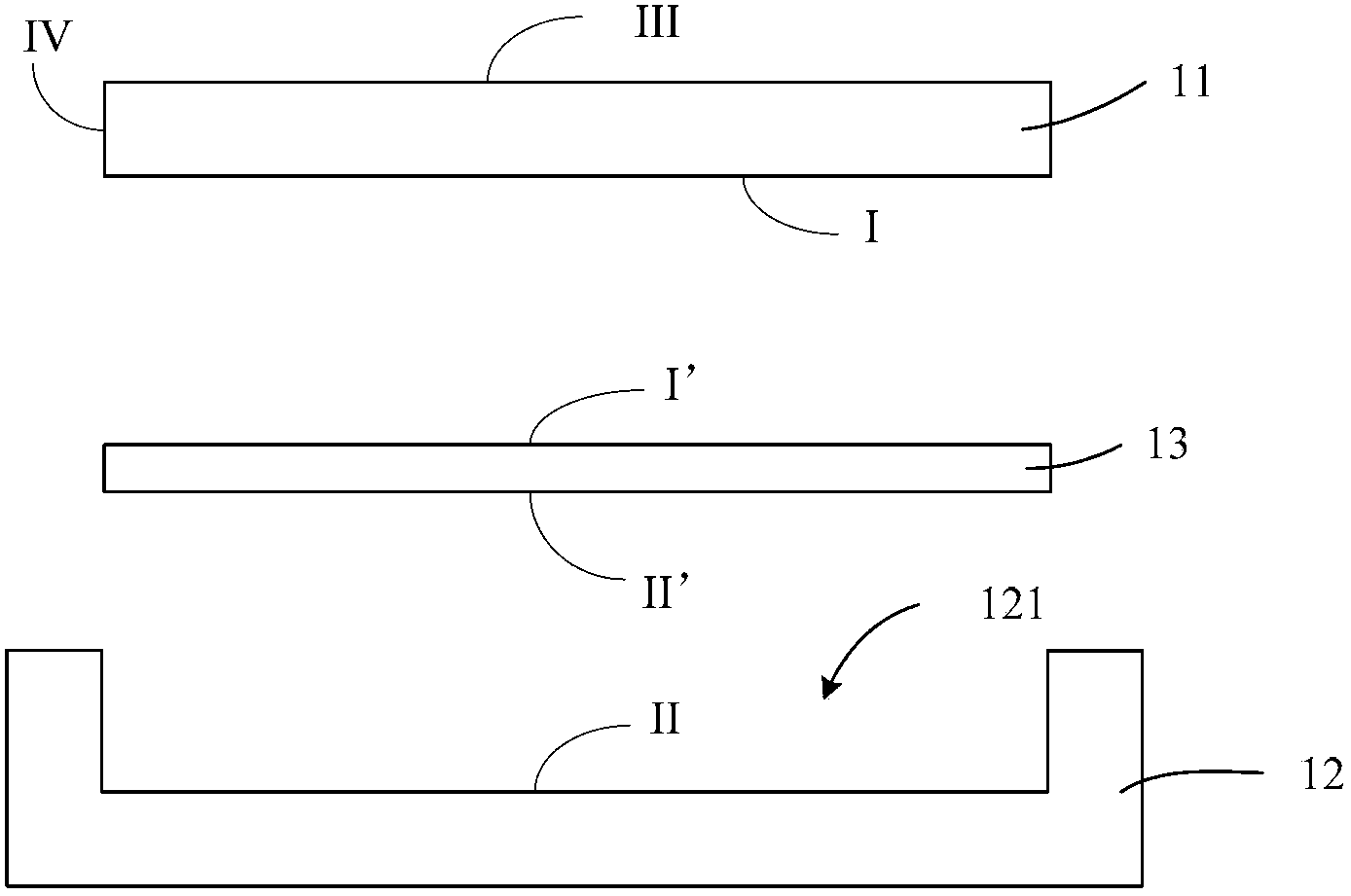

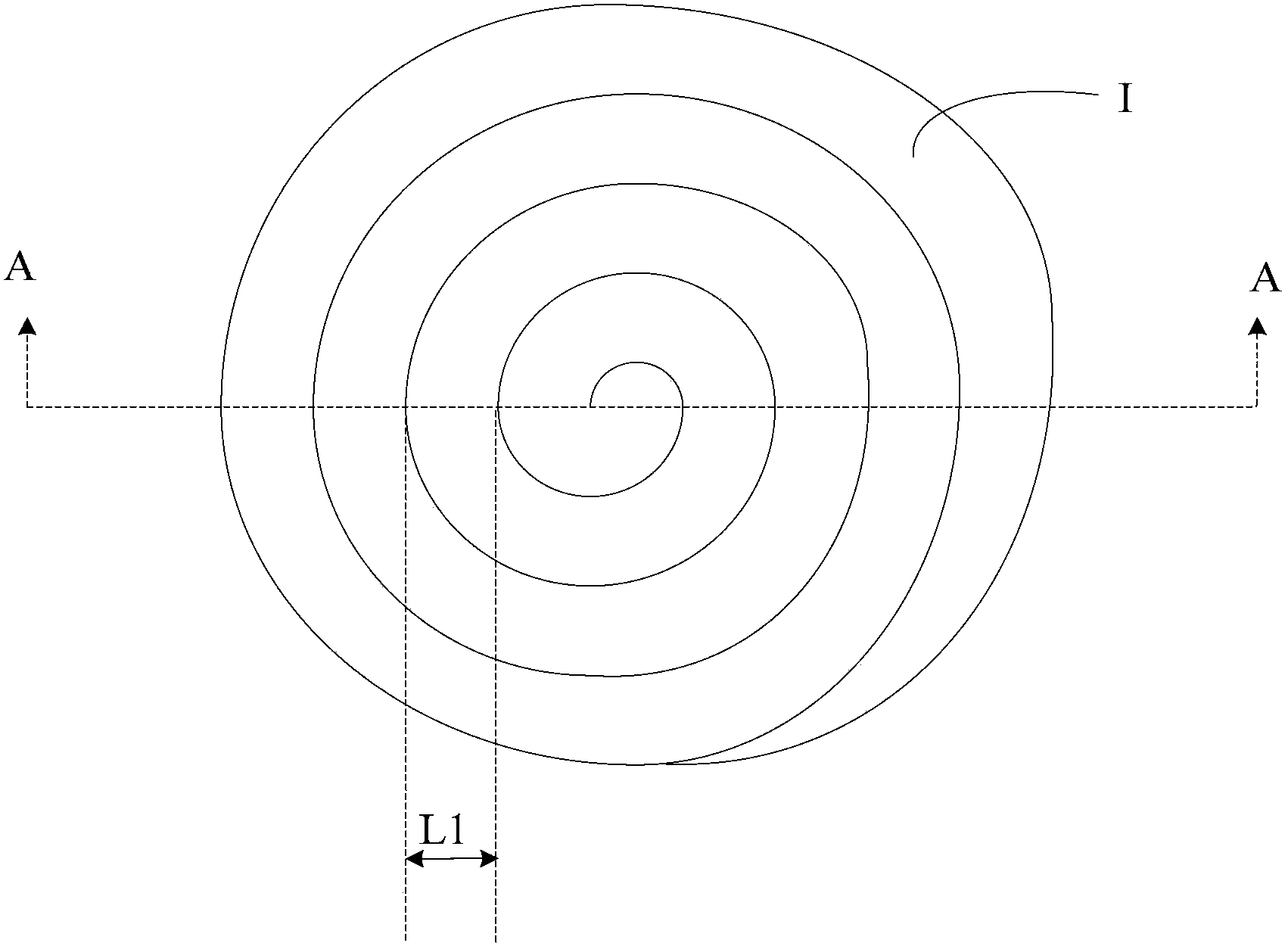

Method for target material component welding

InactiveCN103521916AEasy to spreadAvoid the disadvantage of not being able to realize large-size target weldingNon-electric welding apparatusWeld strengthUltimate tensile strength

The invention provides a method for target material component welding. The method comprises the following steps that a tungsten target material, a back board and an aluminum middle layer are provided; the tungsten target material, the aluminum middle layer and the back board are placed in a vacuum bag, the aluminum middle layer is located between the tungsten target material and the back board, and the vacuum bag is arranged in a welding device; the hot isostatic pressure technology is used for welding the tungsten target material, the aluminum middle layer and the back board together to form a target material component; after welding is completed, the vacuum bag is cooled and removed, so that the target material component is obtained. Due to the fat that the aluminum middle layer is additionally arranged between the tungsten target material and the back board, and the hot isostatic pressure technology is used for welding the tungsten target material and the back board together, welding efficiency is improved, the formed target material component is good in welding binding rate, high in welding strength and small in deformation, large-area welding can be achieved, and therefore the requirements for long-term stable production and using of target materials can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

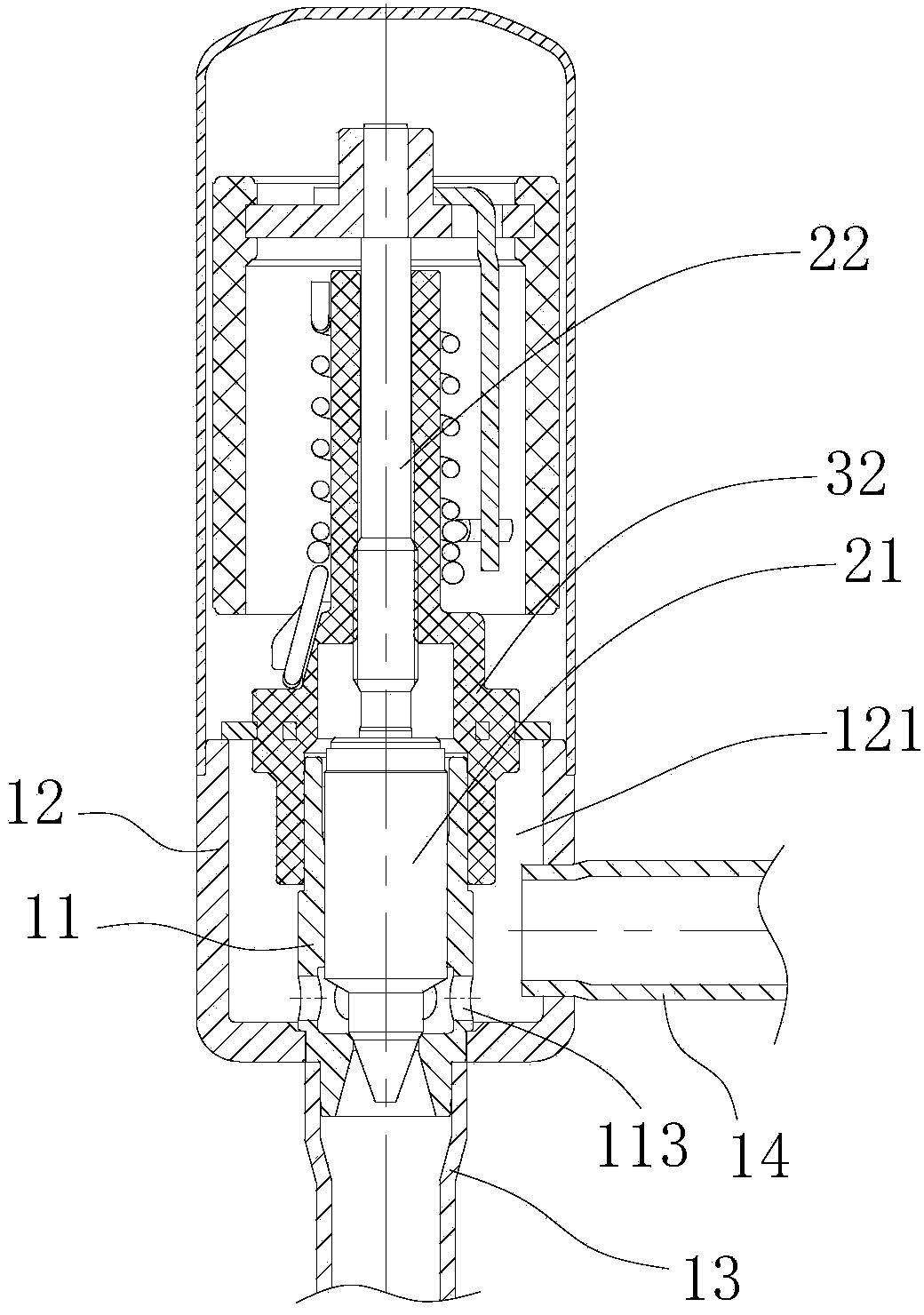

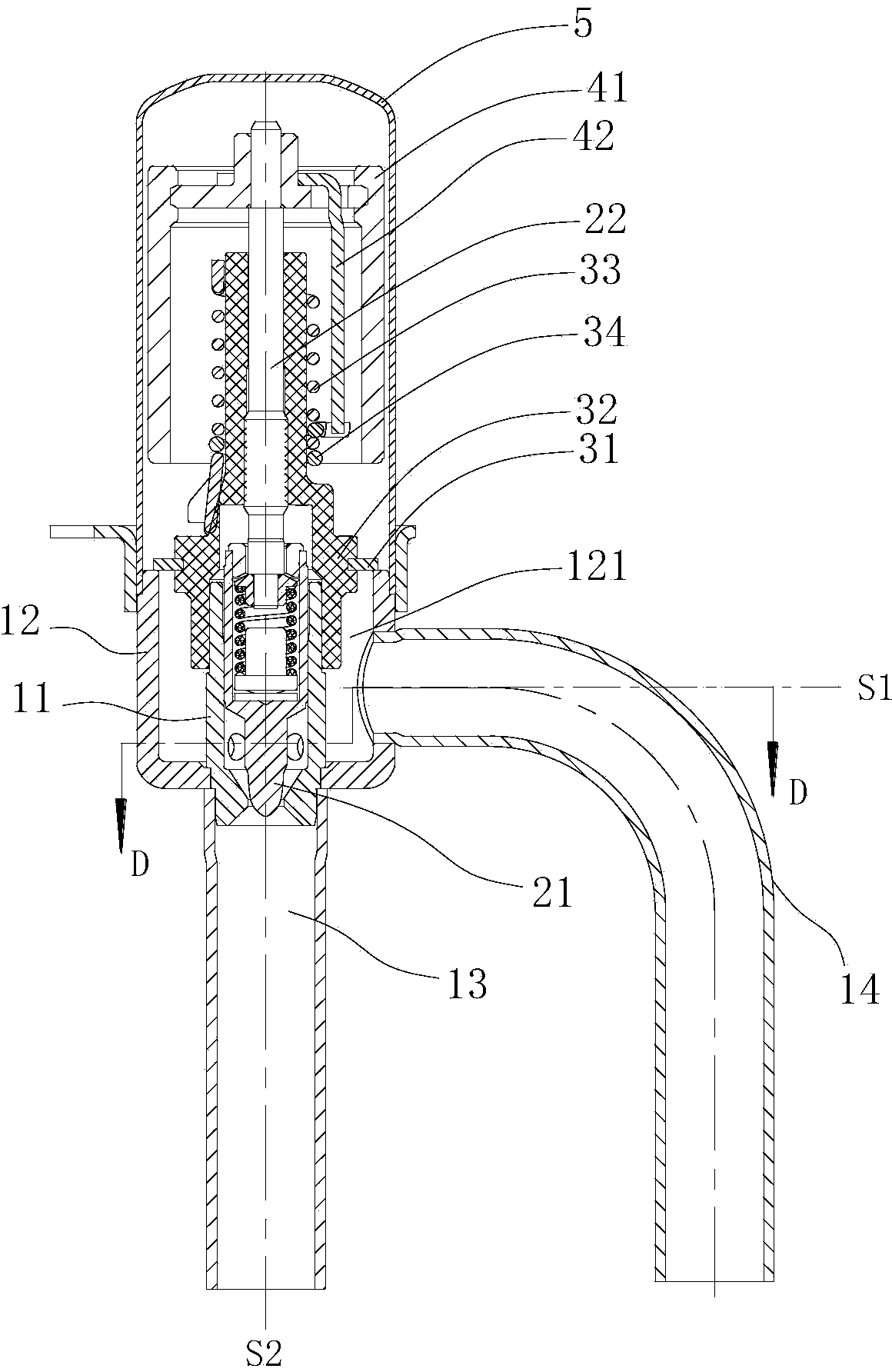

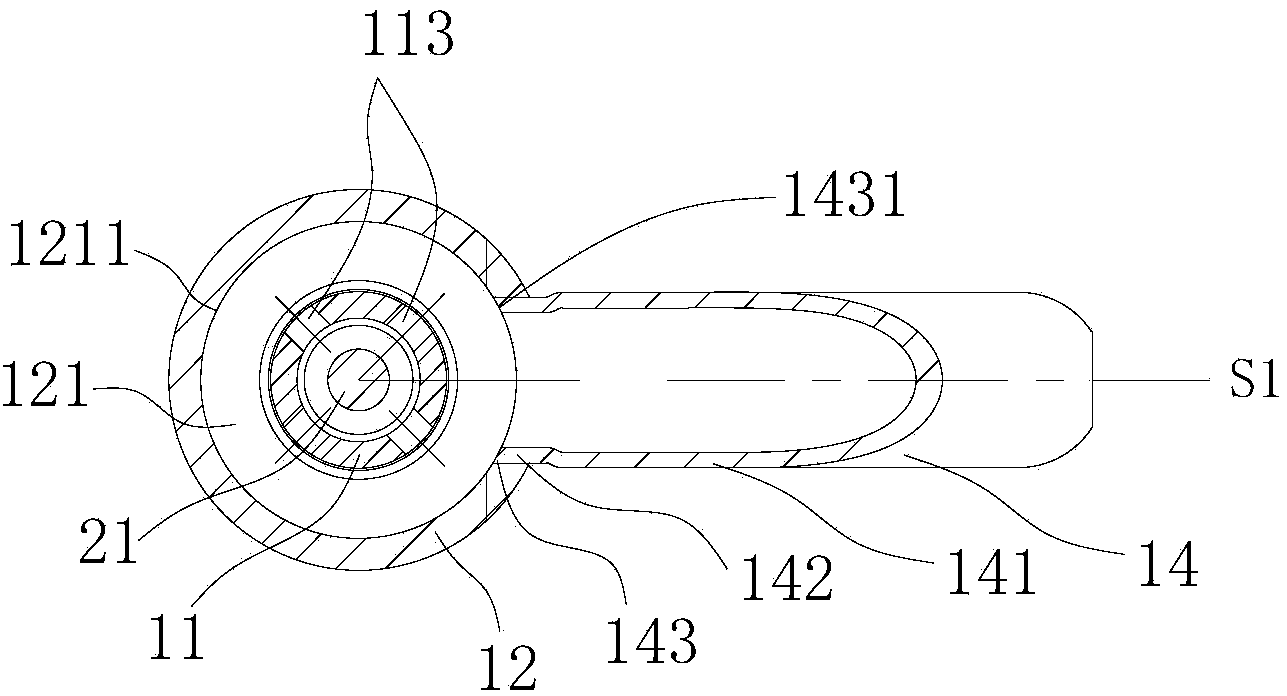

Valve seat assembly of electronic expansion valve and manufacturing method of valve seat assembly

InactiveCN103836211ADoes not compromise integrityImprove noiseEfficient regulation technologiesFluid circulation arrangementEngineeringWeld strength

The invention discloses a valve seat assembly of an electronic expansion valve. The valve seat assembly of the electronic expansion valve is characterized by comprising a valve seat and a second connecting pipe, wherein the valve seat is provided with a valve cavity, the second connecting pipe is fixedly connected with the side wall of the valve seat, the first central axis of the second connecting pipe is perpendicular to the second central axis of the valve seat, and the edge face of the second connecting pipe does not exceed the inner circumferential face of the valve cavity in any section where the first central axis is located. The invention further provides a manufacturing method of the valve seat assembly of the electronic expansion valve. According to the valve seat assembly of the electronic expansion valve, it is ensured that the end of the second connecting pipe cannot extend into the valve cavity or damage the integrality of the valve cavity, the noise caused by irregular shape of the valve cavity when a refrigerant flows can be lowered, moreover, the matching length of the connecting pipe and the valve seat can be fully ensured, welding strength is improved, and the uniformity of the assembly size of the connecting pipe can be ensured.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Laser welding tractable polycarbonate composition and preparation method thereof

The invention relates to a laser welding tractable polycarbonate composition and a preparation method thereof. The composition comprises the following components in parts by weight: 50-80 parts of polycarbonate (PC) resin, 15-40 parts of ABS resin, 5-10 parts of amelt reinforcing agent, 0.1-1 part of a near infrared laser absorbent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method of the alloy comprises the following steps: (a) mixing the PC resin, the ABS resin, the melt reinforcing agent, the near infrared laser absorbent, the antioxidant and the lubricant in a mixing agitator; and (b) performing blending granulation on the mixture obtained in the step (a) by virtue of a twin-screw extruder to obtain a product. Compared with the prior art, the polycarbonate composition provided by the invention is higher in melt strength after the melt reinforcing agent is added, so that the surface of a product after welding has no bulges orbreakdowns, welding can be performed under a higher laser intensity, the obtained product is higher in welding strength at the same time, a processing window of a laser welding process of the polycarbonate composition is broadened, and the laser welding tractable polycarbonate composition is obtained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

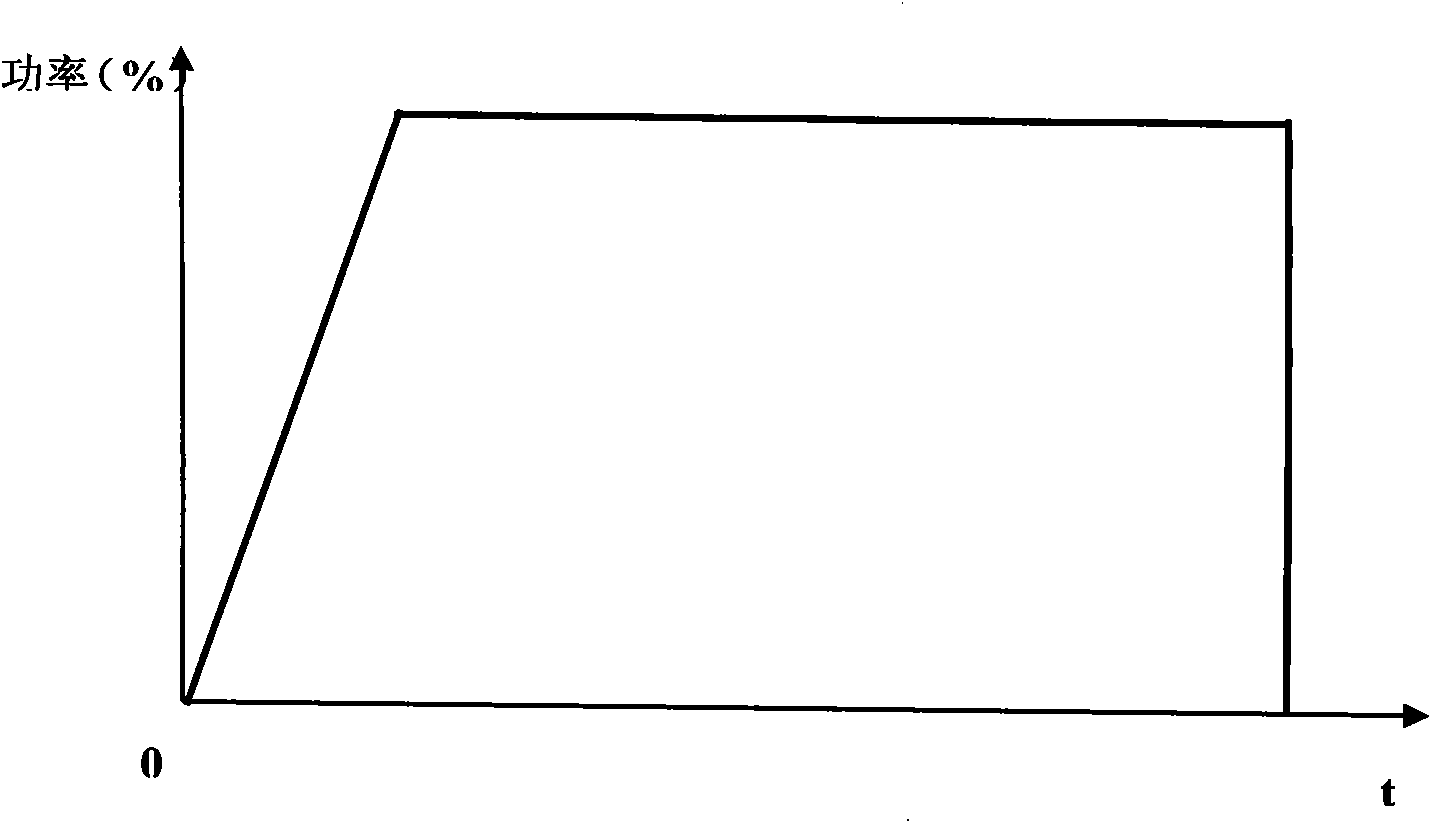

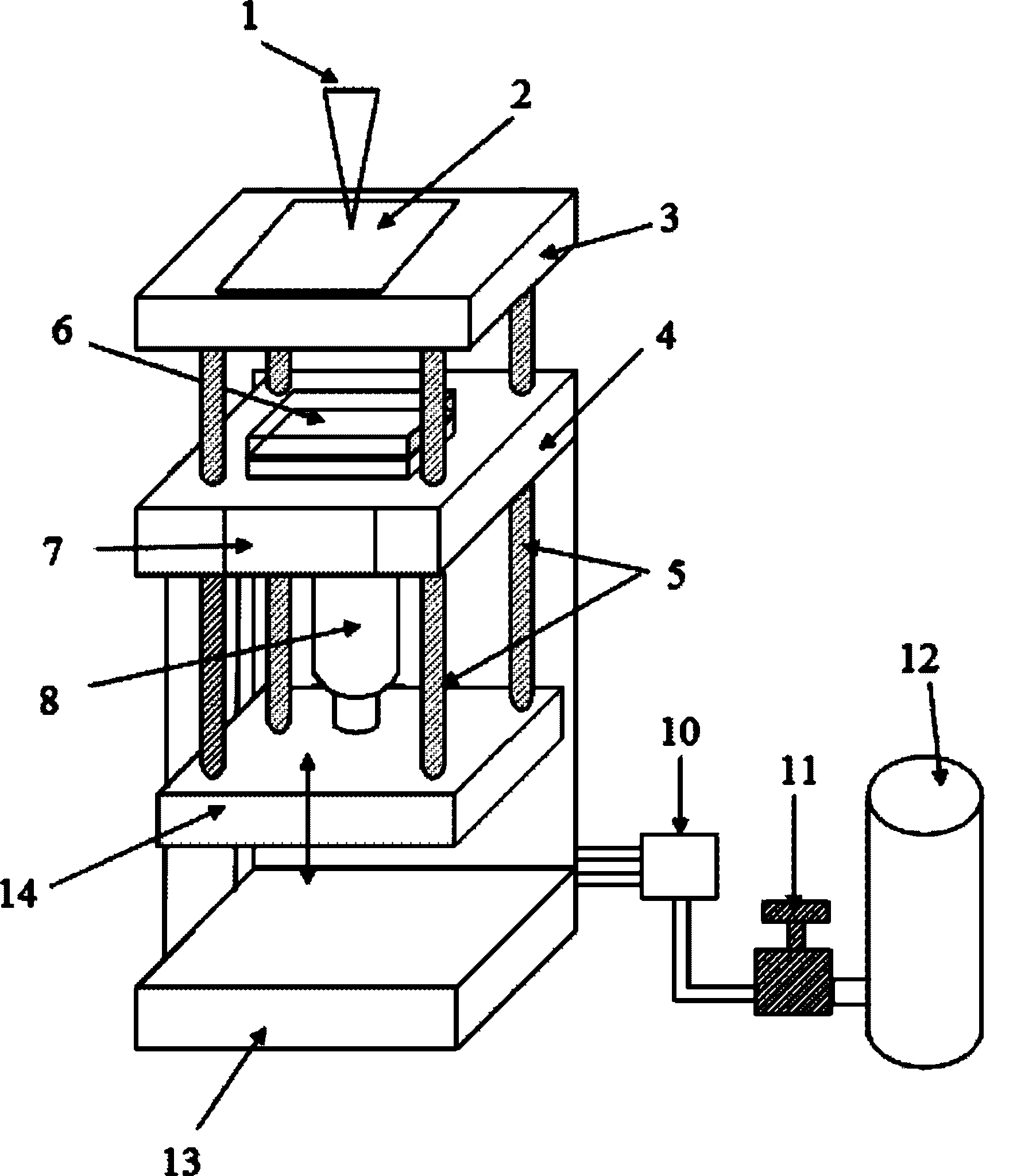

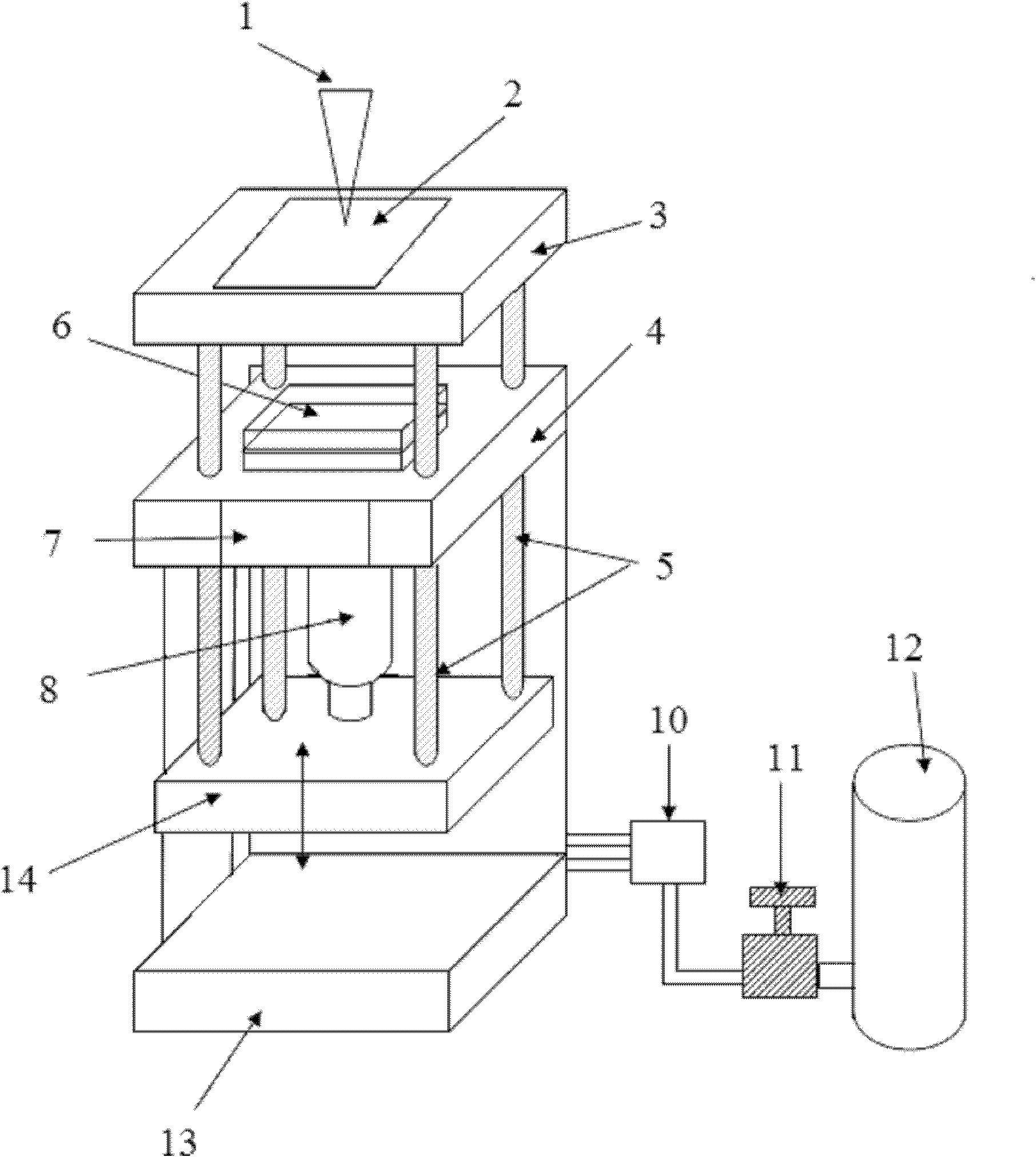

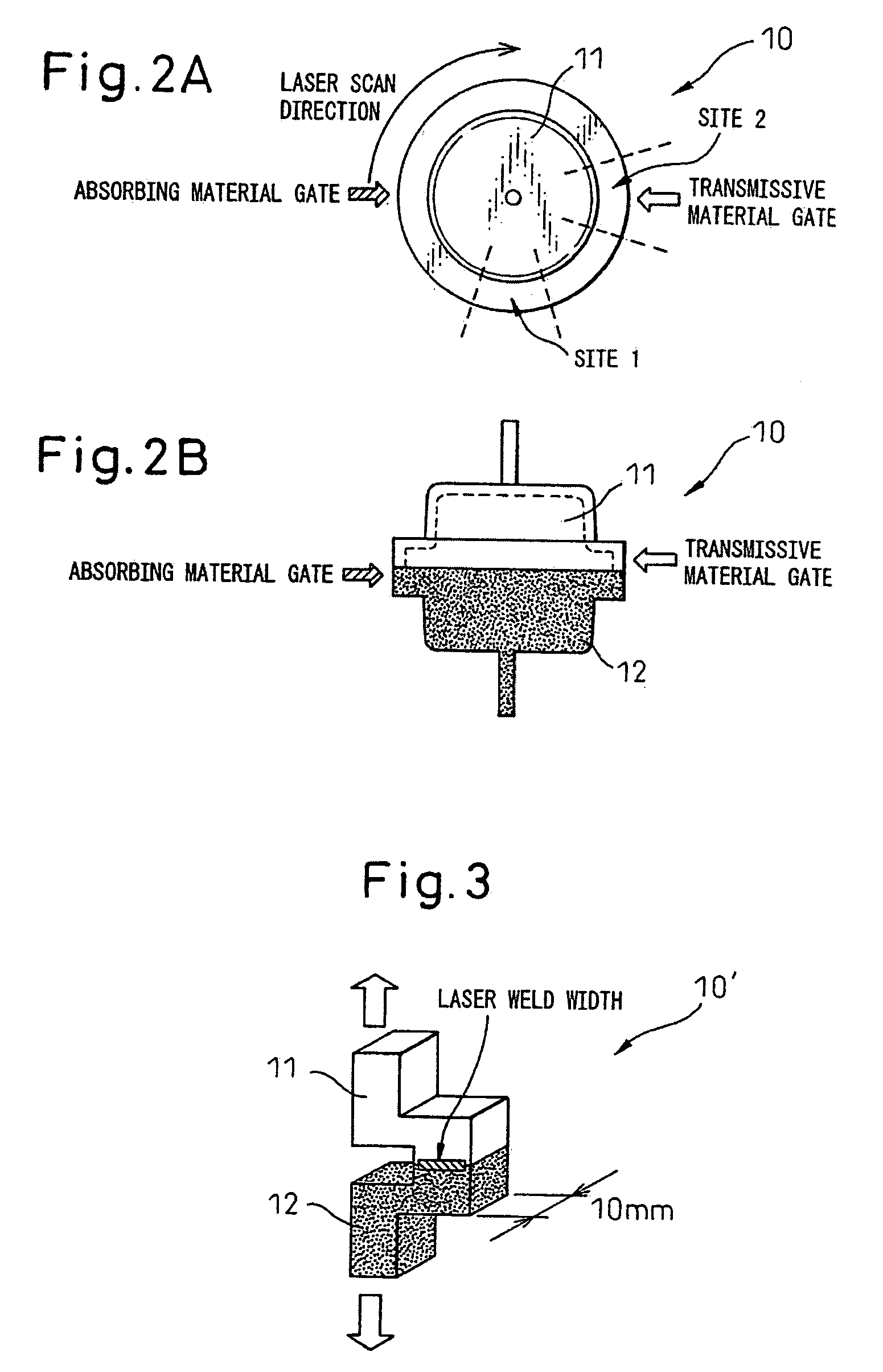

Device and method for welding plastic materials in laser transmission manner

The invention provides a device for welding plastic materials in a laser transmission manner. The device comprises a supporting plate, a laser light source and a pressure regulating mechanism, wherein the pressure regulating mechanism comprises a pressing plate mechanism, a supporting plate, a guide rail and a drive mechanism; the pressing plate mechanism is connected with the drive mechanism andis connected with the supporting plate through the guide rail; the pressing plate mechanism is provided with a light-transmitting window consisting of a light-transmitting window opening and a light-transmitting window body; plastic materials to be welded are positioned on the supporting plate and correspondingly arranged below the light-transmitting window; and the laser light source is sequentially connected with the light-transmitting window and the plastic materials to be welded through laser beams. The invention also provides a welding method realized by the device. According to the invention, the plastic materials to be welded are under proper pressure, and further generate secondary polarization to be combined together, thus welding quality and welding strength are ensured.

Owner:光机电(广州)科技研究院有限公司

Thermoplastic resin composition and shaped article

A resin composition comprises 1 to 60 parts by weight of a wollastonite fiber (in which the number-average fiber length is 1 to 30 μm, the number-average fiber diameter is 0.1 to 10 μm, and the proportion of the number of a fiber having a fiber length of 5 to 25 μm relative to the total number of the fiber is 20 to 75%) and 0.1 to 20 parts by weight of an acid- or epoxy-modified olefinic resin having a melting point of 100 to 170° C., relative to 100 parts by weight of a thermoplastic resin (e.g., a polycarbonate-series resin). The weight-average molecular weight of the modified olefinic resin may be about 2.5×104 to 30×104. The resin composition may comprise a flame retardant. The combination use of the wollastonite fiber and the modified olefinic resin improves heat resistance, impact resistance and weld strength, even in the case of using a wollastonite fiber having a number-average fiber diameter of about 4 to 7 μm and an average aspect ratio of about 1.5 to 3. The present invention provides a thermoplastic resin composition for improving the impact resistance, weld strength and surface property without deteriorating the heat resistance.

Owner:DAICEL POLYMER LTD

Elastic body material for refrigerator sealing strips and preparation method thereof

ActiveCN101983984AReduce weightIncrease elasticityDomestic cooling apparatusLighting and heating apparatusElastomerPolymer science

The invention discloses an elastic body material for refrigerator sealing strips and preparation method thereof. The elastic body material for refrigerator sealing strips consists of hydrogenation styrene resin, rubber filling oil, polypropylene, mineral filler, weather resistant agent, compatibilizer and processing aids. The elastic body material for refrigerator sealing strips is manufactured by extrusion graining with counter-rotating twin-screw extruder after the raw material is mixed in high-speed mixer. Halogen material and o-benzene plasticizer which is harmful to human health will not be introduced in practical production process of the elastic body material for refrigerator sealing strips. The thermoplastic elastomer material produced in the invention has the advantages of light weight, high resilience, high welding strength, easy colorizing and good low-temperature resistance. There is no need for the treatment of high temperature sulfidation when extrusion moulding is operated with the above material. Decomposion of toxic gas and corrosion of production equipments will not happen during the process of extrusion moulding, and scraps can be recovered and re-used.

Owner:KINGFA SCI & TECH CO LTD +1

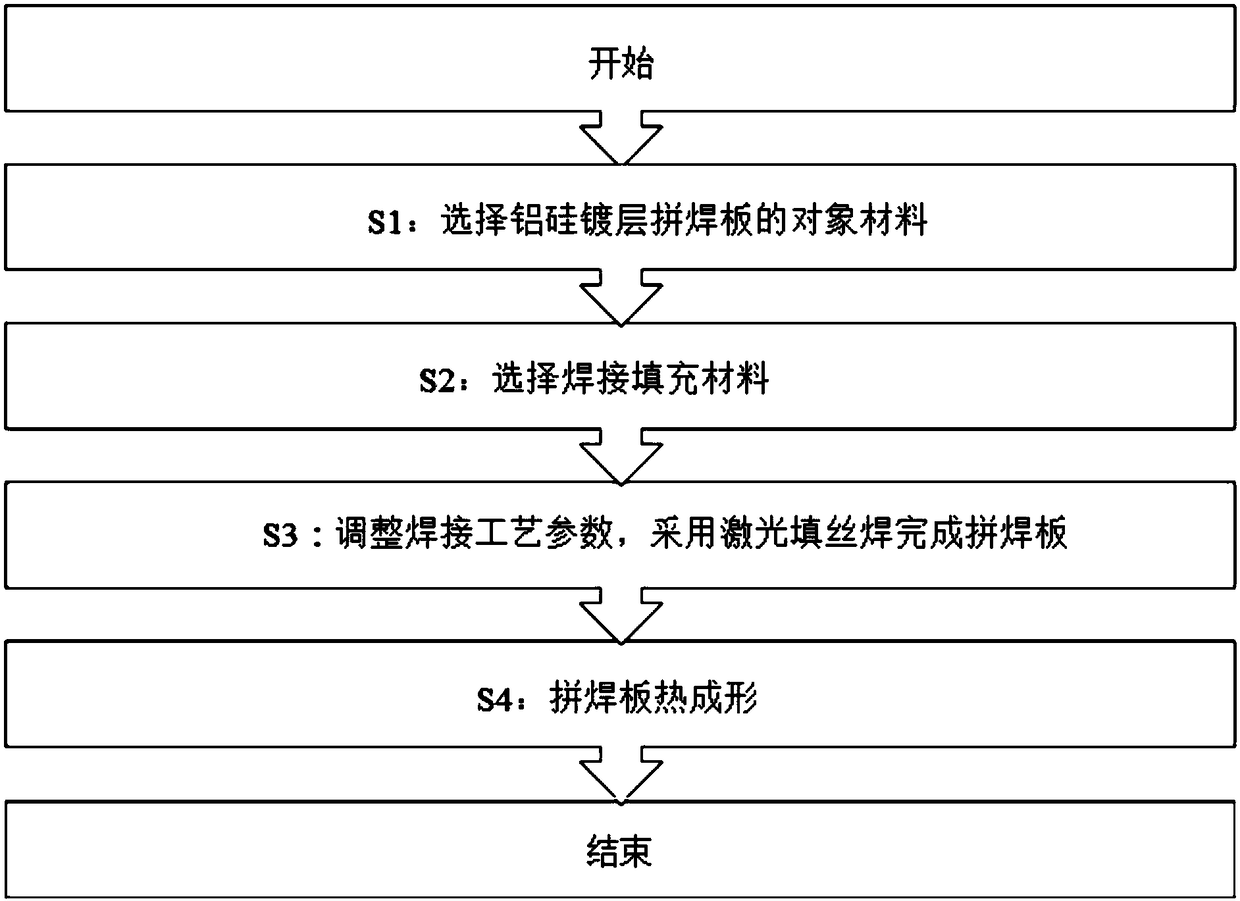

Method for manufacturing aluminum-silicon clad layer hot forming steel tailor-welded blank through laser filler wire welding process

InactiveCN108213711ASimple processReduced precision requirementsWelding/soldering/cutting articlesMetal working apparatusFilling materialsWeld strength

The invention discloses a method for manufacturing an aluminum-silicon clad layer hot forming steel tailor-welded blank through a laser filler wire welding process. The method comprises the steps of selecting object materials of the tailor-welded blank, selecting welding filling materials, adjusting welding process parameter and completing blank tailor welding and hot forming. According to the method, aiming at the thickness of a blank to be subjected to tailor welding, the ingredients of a base material and other characteristic parameters, welding wire ingredients are reasonably selected, thewelding process parameters are adjusted, the hot forming process is adjusted, and a weld metal microstructure matched with the strength requirement is improved and obtained. Compared with a traditional laser tailor-welded blank method (such as laser self-fusion welding), according to the method, the process step of removing an aluminum-plated silicon plate clad layer is not needed, the weld quality can be guaranteed, the steps of the technological process of the tailor-welded blank are simplified, and production efficiency is improved; and high equipment investment needed by removal of a cladlayer does not need to be additionally increased, and production cost is remarkably reduced. The method can be used for laser TIG filler wire welding and laser MIG hybrid welding processes, and has the beneficial effects of being capable of reducing the requirement for the precision of a sheet splicing clamp, improving the weld strength and the like.

Owner:SHANGHAI JIAO TONG UNIV

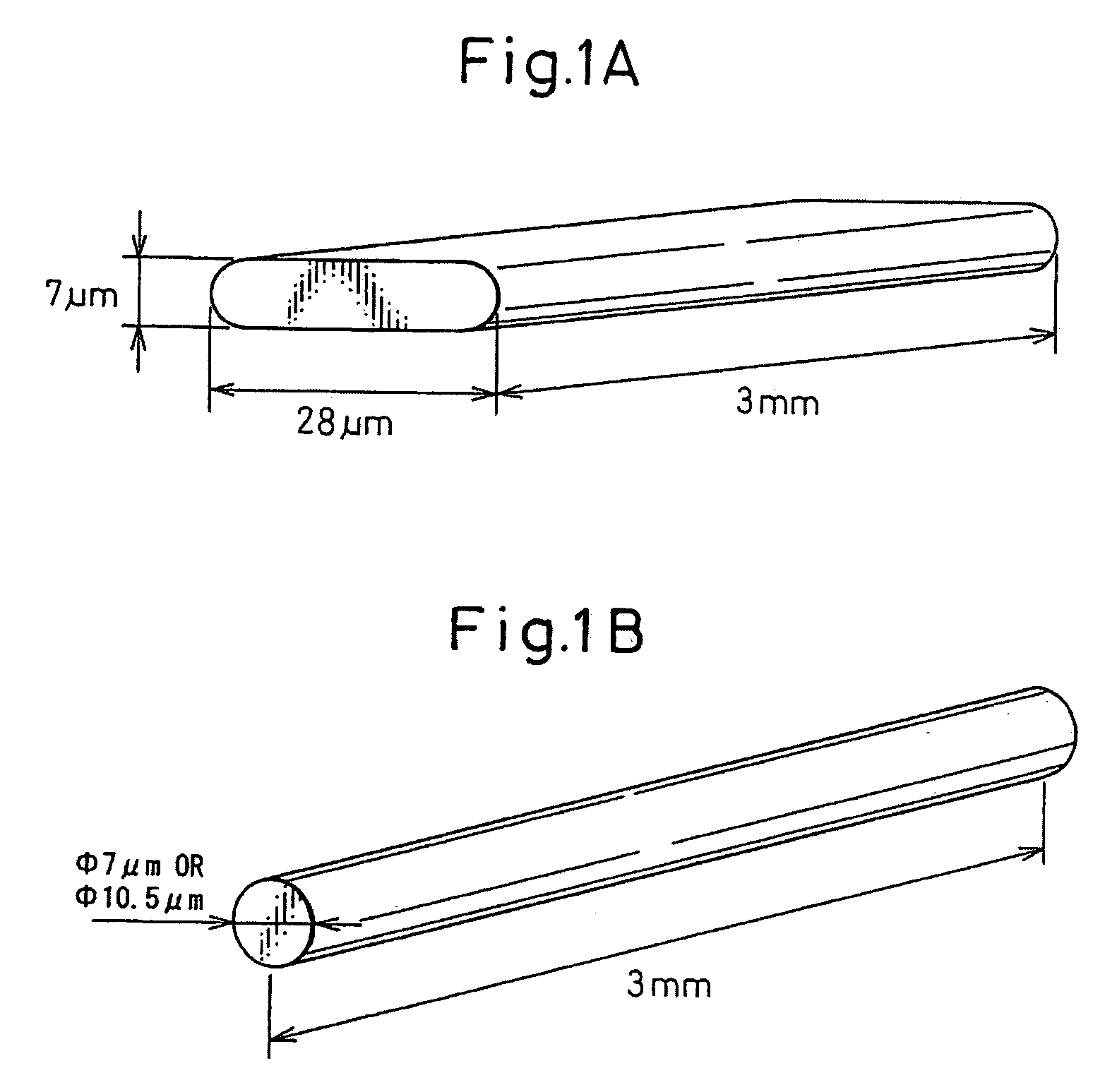

Material for Laser Welding

InactiveUS20090159034A1Excellent in laser transmittanceReduce warpageSynthetic resin layered productsSpecial tyresGlass fiberPolymer science

To provide a material for laser welding, which is excellent in laser transmittance, as well as low warpage and enables a shaped article to be obtained with high weld strength and uniform weld strength by laser welding. This material for laser welding comprises a thermoplastic resin composition containing (A) a thermoplastic resin and (B) a glass fiber having a non-circular cross-section with the ratio between the long diameter and the short diameter in the cross-section at right angles to the length direction being from 1.2 to 10.

Owner:UBE IND LTD

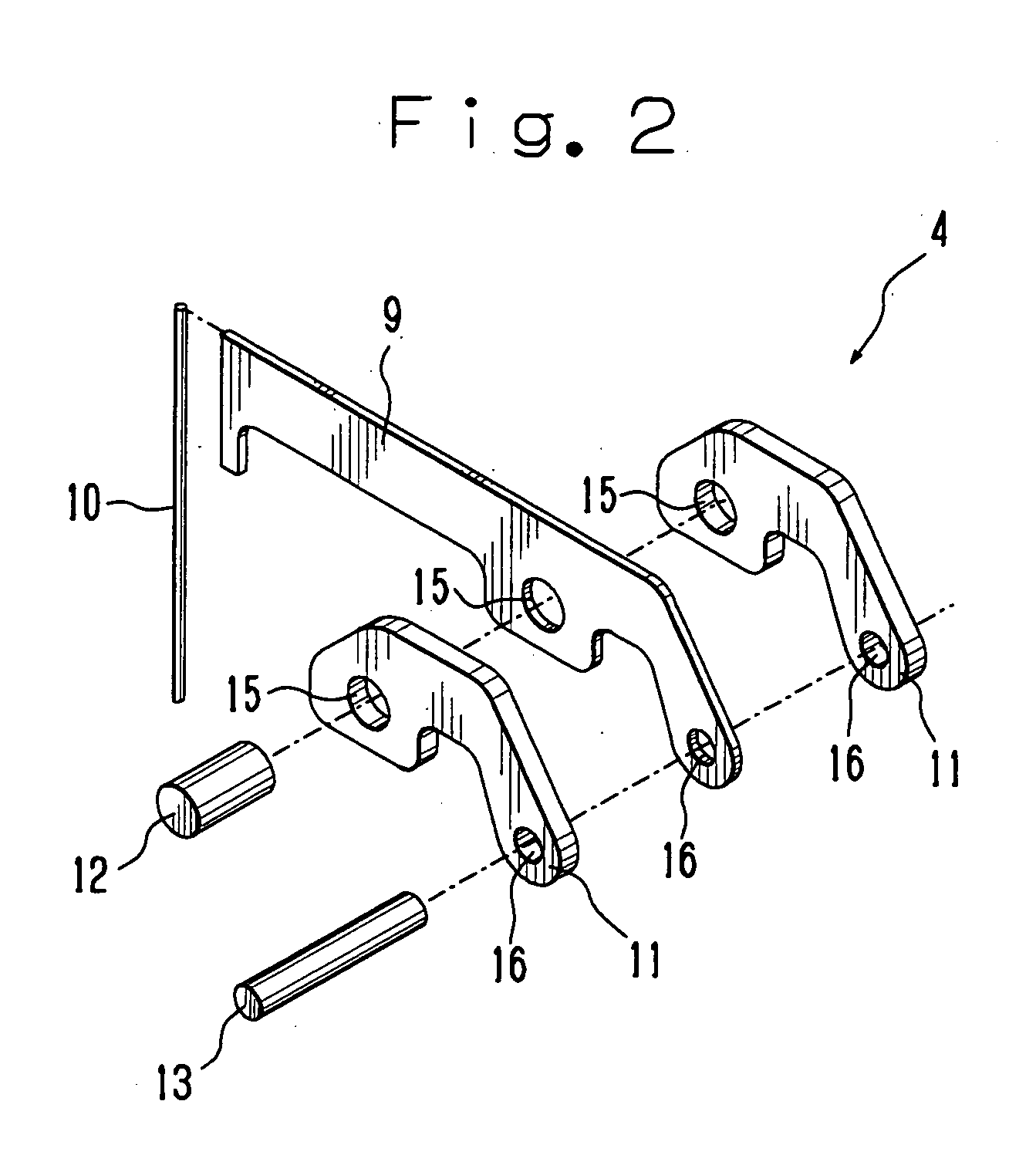

Method for manufacturing an armature

ActiveUS20050160576A1Improve joint strengthTypewritersPrinted circuit manufactureElectrical resistance and conductanceEngineering

An armature manufacturing method of forming an armature including an arm holding a printing wire, and magnetic circuit forming members attached to the arm places the magnetic circuit forming members on the arm with a resistive layer of a resistive material having high electric resistance sandwiched between the arm and each of the magnetic circuit forming members, and welds together the arm and the magnetic circuit forming members with the resistive films sandwiched between the arm and the magnetic circuit forming members by spot welding. The arm and the magnetic circuit forming members of the armature can be joined together by welds having a high weld strength.

Owner:TOSHIBA TEC KK

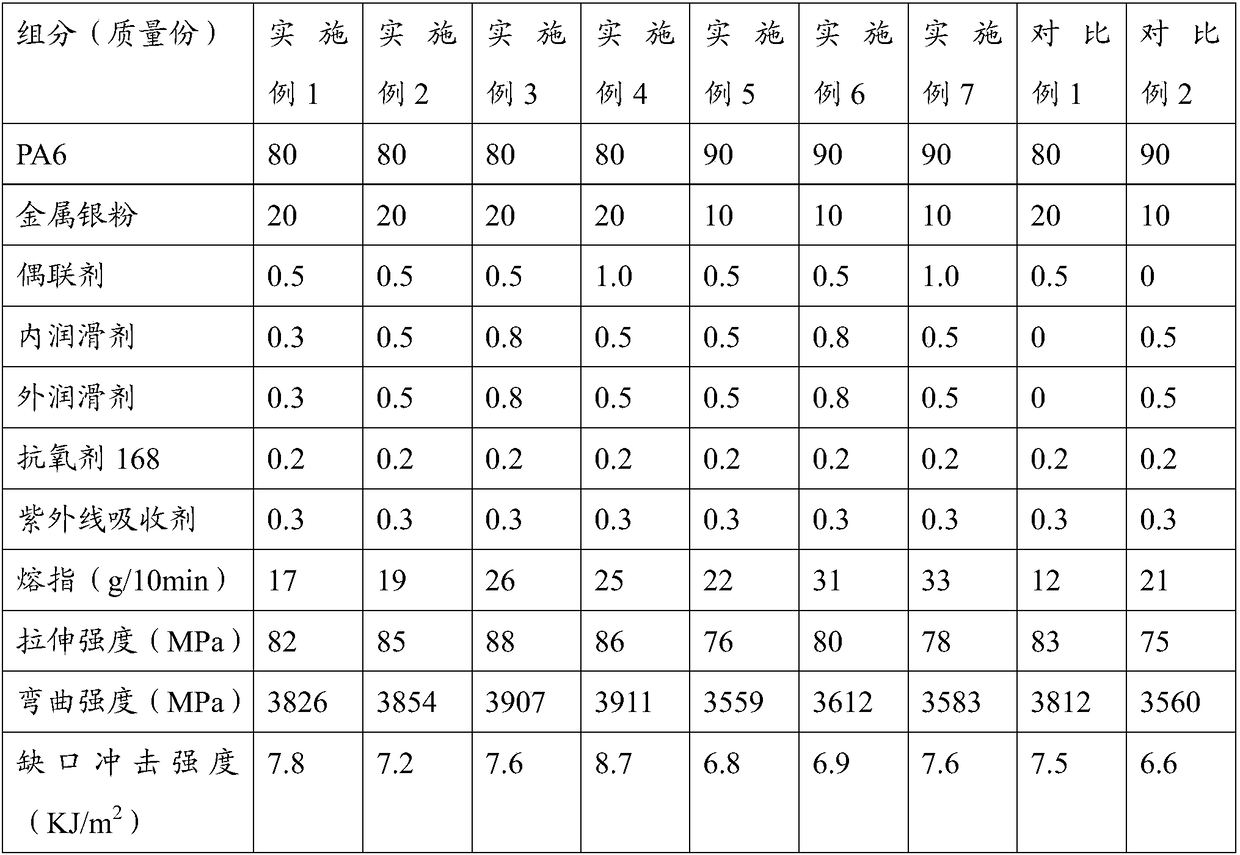

High flow non-spraying metallic silver polyamide composition and preparation method thereof

The application discloses a high flow non-spraying metallic silver polyamide composition and a preparation method thereof. The high flow non-spraying metallic silver polyamide composition is preparedfrom the following raw materials: PA6 resin, a metallic silver powder, a coupling agent, an internal lubricant, an external lubricant, an antioxidant, an ultraviolet light absorber, amino-silicone oil, a flame retardant, calcium stearate, MBS, SMA, silicon dioxide, a magnesium salt whisker, hollow glass-beads, EBS, glass fiber, a compatilizer and ABS; the composition has good flowability; injection molding parts are easy to be welded at welding lines; meanwhile, by adding the coupling agent, the welding strength is better, and the appearance of the weld lines is ensured; the composition has high flow characteristic and solves the problem of obvious welding lines of a product. The composition nylon resin has better compatibility with metal powder particles and ensures the welding strength of the welding lines of the product; the composition has non-spraying properties and replaces an electroplating or vacuum plating metal mode, so that the cost is significantly reduced and environment friendliness is achieved.

Owner:南京跃贝新材料科技有限公司

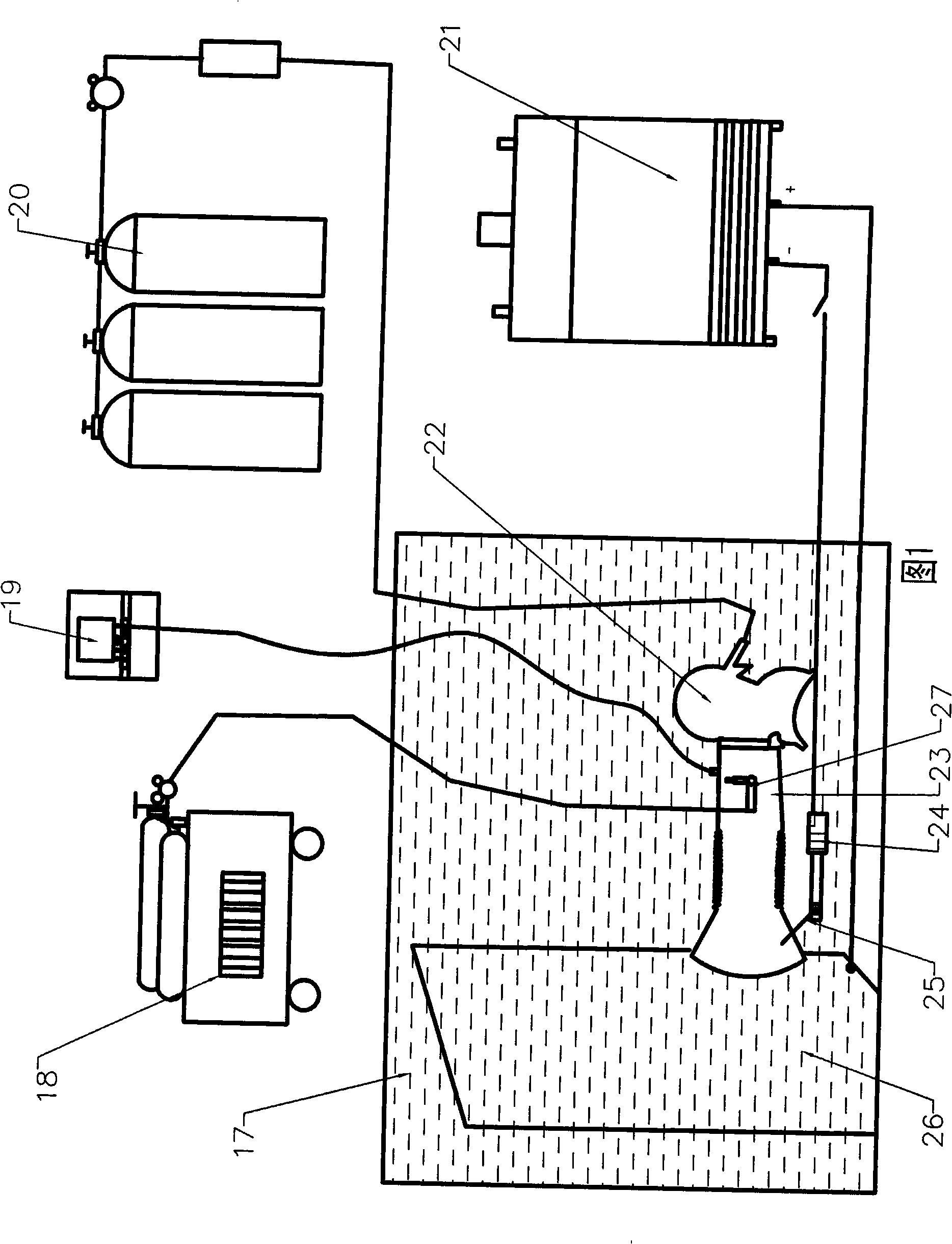

Portable underwater dry-type welding device

InactiveCN101254563AEasy to carryImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesVisibilityShielding gas

The invention relates to a portable underwater dry-type welding device, which comprises an electric welding machine, an air compressor, and a welding handle and a common welding rod under water. The portable underwater dry-type welding device is characterized in that the welding device comprises a welding cover, a seal gasket arranged at the mouth of the welding cover, an air inlet device arranged on the surface of the cover housing, and a welding rod entrance; the air compressor is connected with the air inlet device; and the welding device can generate a local dry welding space under water by draining water through air or other protection gas to weld a welding seam having a welding strength similar to that on the ground. The device can implement underwater welding by using common ground welding rod, and divers and workers on the ground can view the arc burning process clearly in the welding process. The welding can be carried out while the welding cover is moved when the welding region is kept dry. The device can be used for muddy water environment or underwater environment with low visibility.

Owner:中国人民解放军91872部队上海研究室

Thermoplastic resin composition and shaped article

A resin composition comprises 1 to 60 parts by weight of a wollastonite fiber (in which the number-average fiber length is 1 to 30 μm, the number-average fiber diameter is 0.1 to 10 μm, and the proportion of the number of a fiber having a fiber length of 5 to 25 μm relative to the total number of the fiber is 20 to 75%) and 0.1 to 20 parts by weight of an acid- or epoxy-modified olefinic resin having a melting point of 100 to 170° C., relative to 100 parts by weight of a thermoplastic resin (e.g., a polycarbonate-series resin). The weight-average molecular weight of the modified olefinic resin may be about 2.5×104 to 30×104. The resin composition may comprise a flame retardant. The combination use of the wollastonite fiber and the modified olefinic resin improves heat resistance, impact resistance and weld strength, even in the case of using a wollastonite fiber having a number-average fiber diameter of about 4 to 7 μm and an average aspect ratio of about 1.5 to 3. The present invention provides a thermoplastic resin composition for improving the impact resistance, weld strength and surface property without deteriorating the heat resistance.

Owner:DAICEL POLYMER LTD

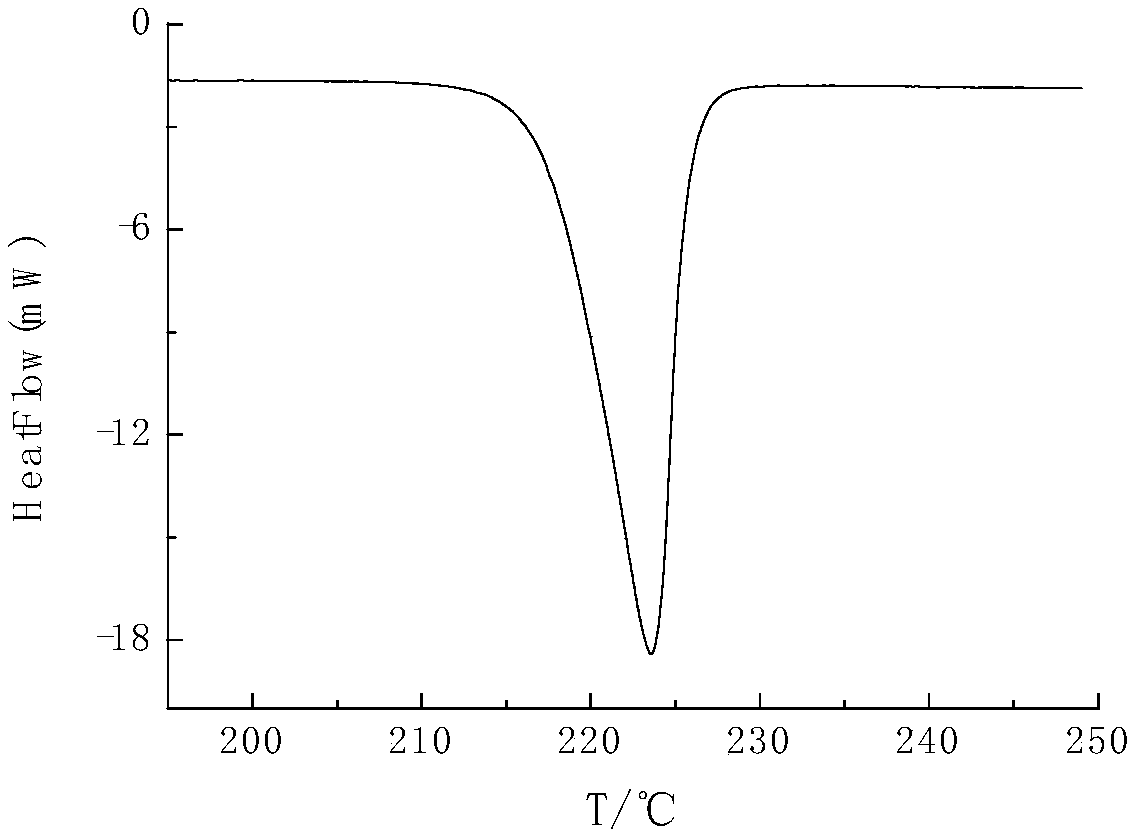

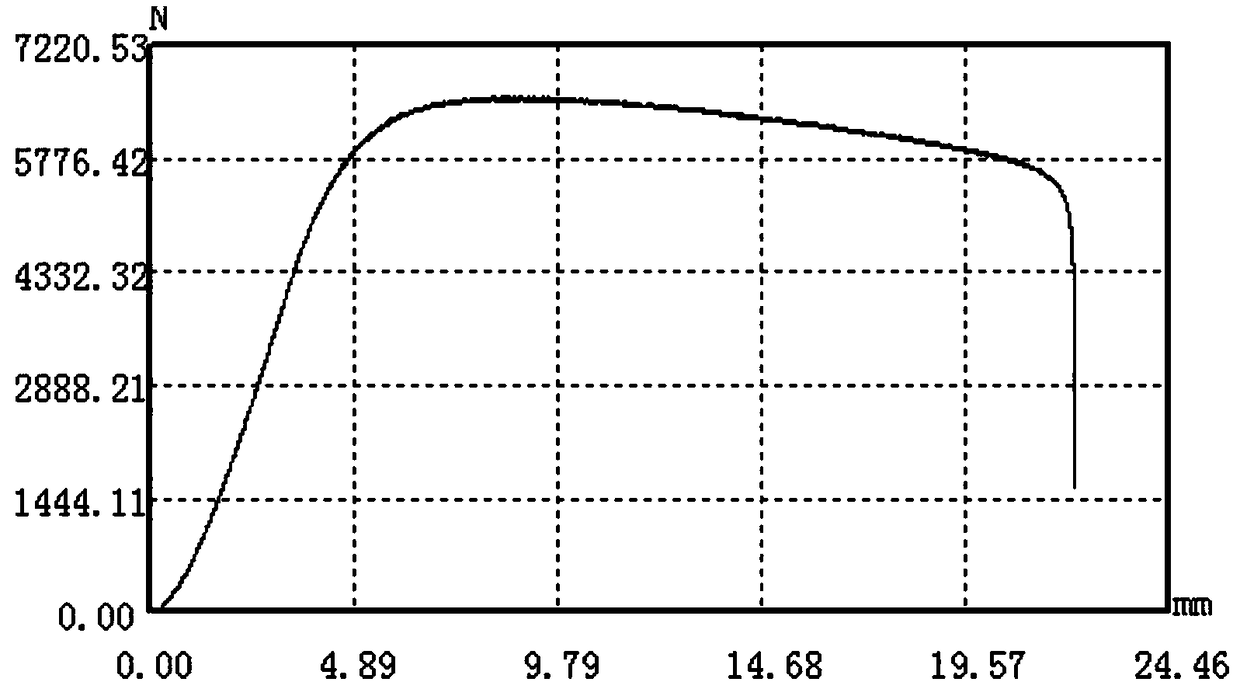

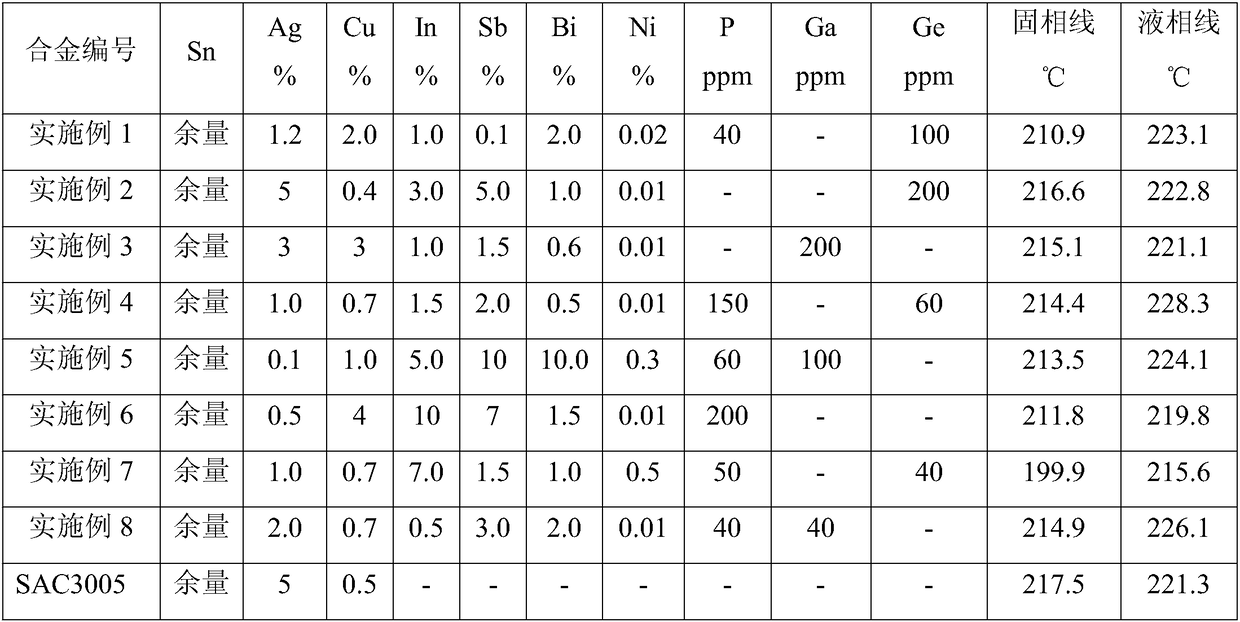

SnBiAgCu high-reliability lead-free solder alloy

InactiveCN108994480AImprove wettabilityGood welding performanceWelding/cutting media/materialsSoldering mediaMechanical propertyImpurity

A SnBiAgCu high-reliability lead-free solder alloy comprises, by weight percent, 0.1% to 5% of Ag, 0.4% to 4% of Cu, 0.5% to 10% of In, 0.1% to 10% of Sb, 0.5% to 10% of Bi, 0.01% to 0.5% of Ni, totally 0 to 0.1% of P or Ge or Ga and the balance Sn and inevitable impurities. According to the SnBiAgCu high-reliability lead-free solder alloy, by adding Sb, Ni, In and other alloy elements, after welding spots are formed, enrichment of Bi can be hindered on an interface, forming of SnBi eutectic structures is avoided, and damage to the mechanical performance of a welding connector is reduced; andthe welding strength is improved, and meanwhile high oxidation resistance is achieved at different process temperatures.

Owner:云南锡业锡材有限公司

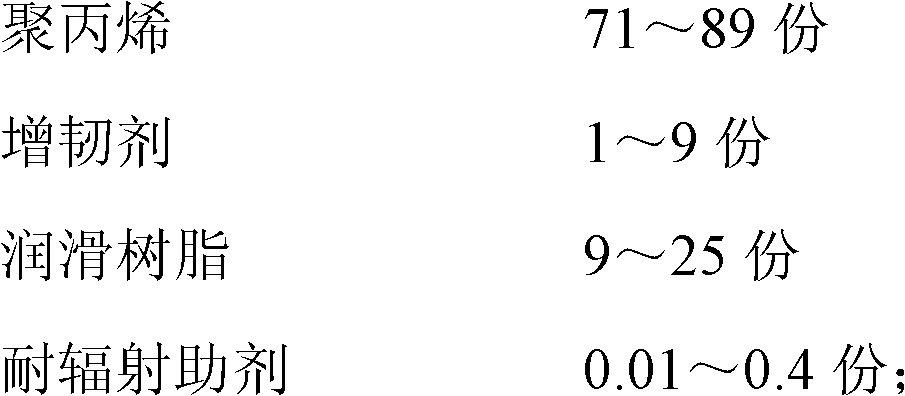

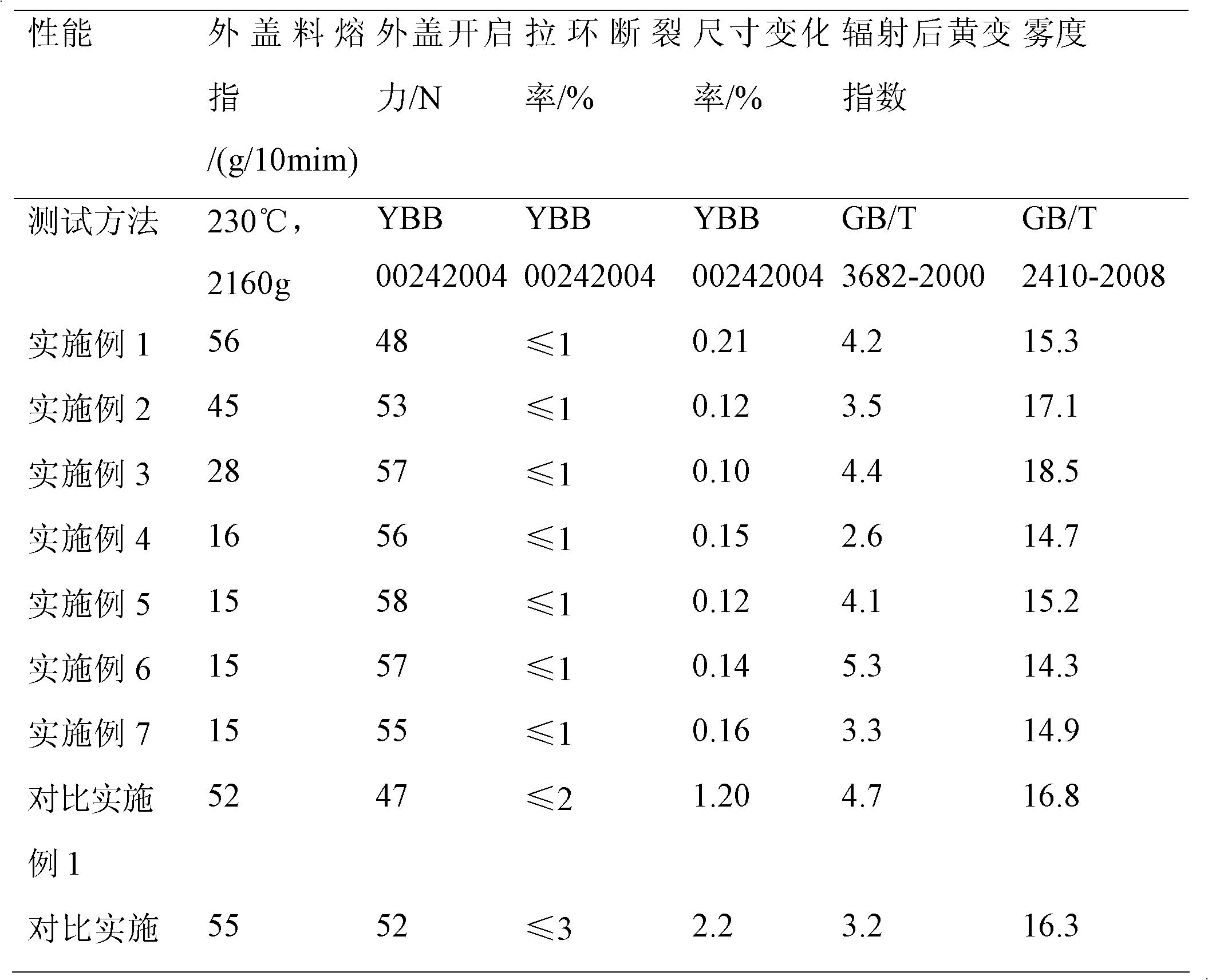

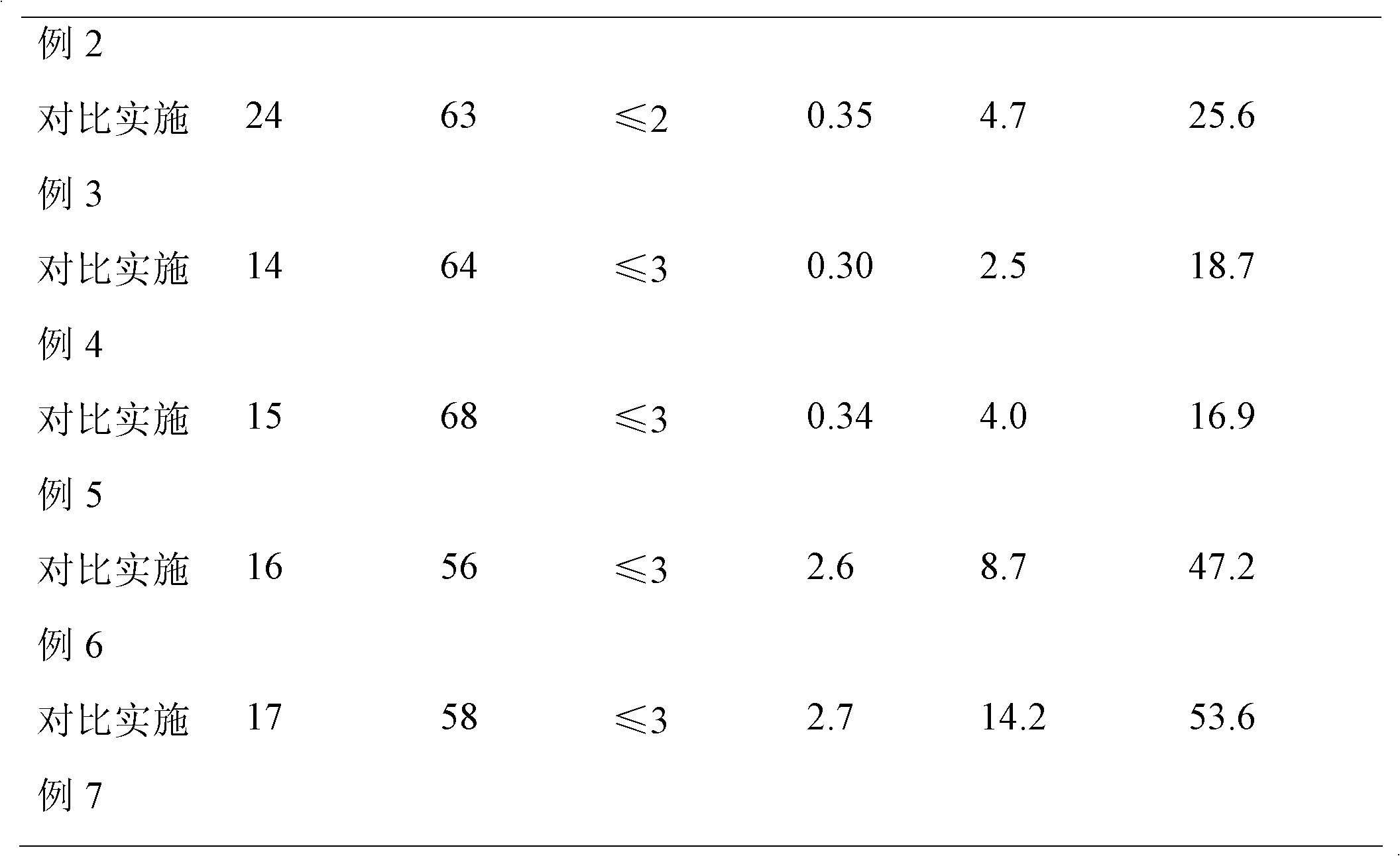

A kind of pull-tab outer cover material for infusion bottle or bag and preparation method thereof

ActiveCN102276932AGuaranteed melting temperatureGuaranteed welding strengthPharmaceutical containersMedical packagingRadiation resistantSize change

The invention discloses a pull-tab outer cover material used for infusion bottles or bags, and the material provided by the invention comprises the following components in parts by weight: 71-89 parts of polypropylene, 1-9 parts of flexibilizer, 9-25 parts of lubrication resin and 0.01-0.4 part of radiation-resistant accessory ingredient. The melting index of the pull-tab outer cover material used for infusion bottles or bags is 9-60g / min under the condition of 230DEG C and 2160g, and the outer cover material can be directly injected to prepare the pull-tab outer cover material used for infusion bottles or bags. A cover body and the infusion bottles or bags have high welding strength, a pull tab is easy to open, an opening edge is tidy, and the opening force is less than or equal to 60N; the pull tab has small possibility of being ruptured, and the fracture rate of the pull tab is less than or equal to 1%; no low-molecule ingredients are separated out, the size stability is good, and the size change rate of the outer cover is less than or equal to 0.5% before and after disinfection; and the radiation-resistant performance is good, the yellow index is less than or equal to 7 after the material is radiated by 60Co-gamma ray of 25kGy dose, and the material haze is less than or equal to 20.

Owner:合诚技术股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com