Device and method for welding plastic materials in laser transmission manner

A technology of laser transmission welding and plastic materials, which is applied in the field of laser welding, can solve the problems of non-existence of welding devices, loss of plastic melt, and affecting welding strength, etc., and achieve the effect of ensuring welding quality, welding strength and compact structure

Active Publication Date: 2011-09-21

光机电(广州)科技研究院有限公司

View PDF9 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the actual plastic laser welding process, the contact surfaces of the plastic parts that need to be welded together are not absolutely flat, so in order to ensure the maximum welding area, it is usually necessary to apply a certain pressure to the welded parts, but the pressure is not too high. The bigger the better, excessive pressure will cause the loss of plastic melt, which is not conducive to the secondary polymerization between plastic materials and affect the welding strength

Due to the different melting points of different plastic materials, the fluidity in the molten state is also different, so the pressure required for the sample during laser transmission welding is also different, which makes the welding device with adjustable pressure function indispensable, but there is no such thing at present. Aspect welding device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

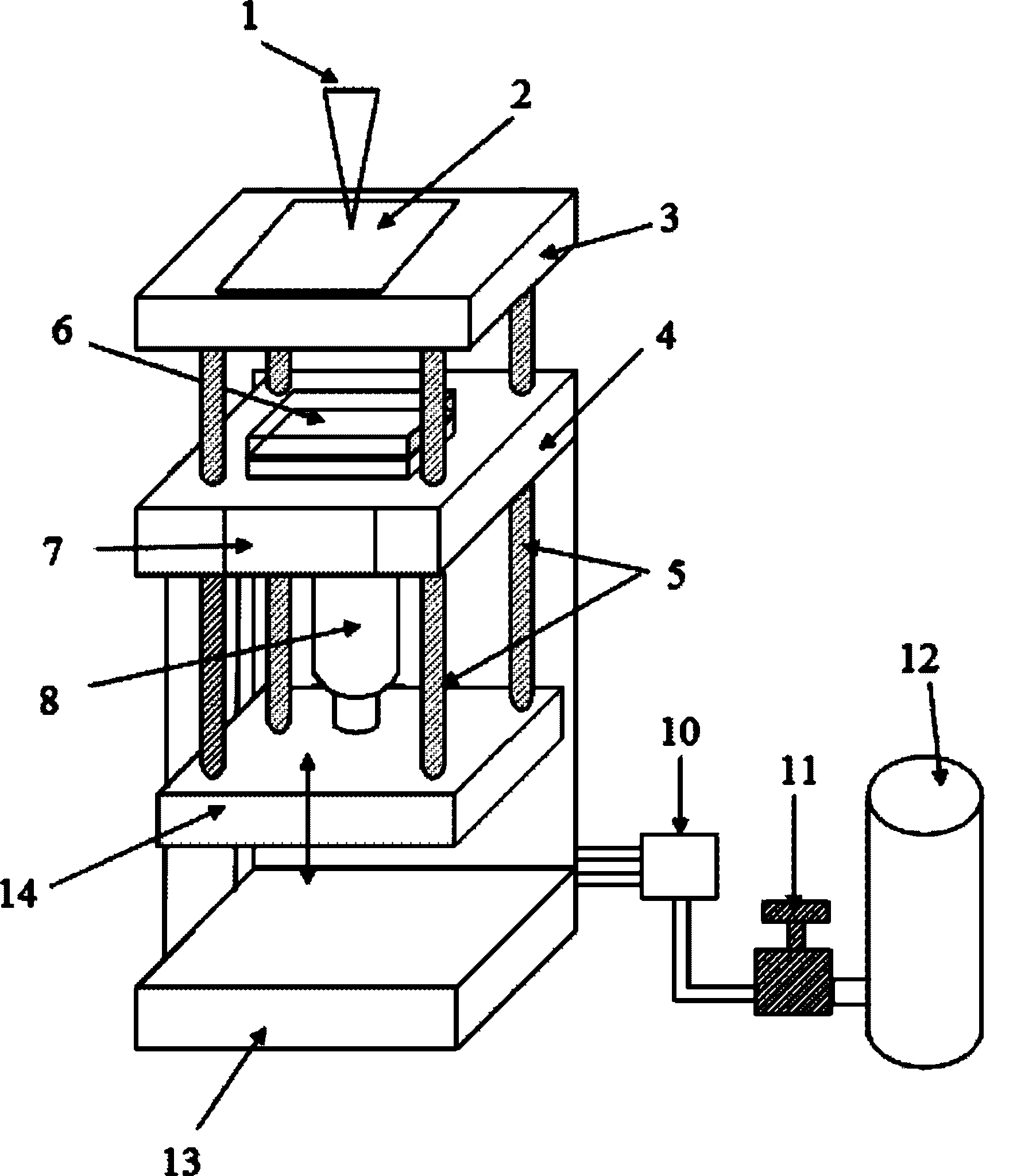

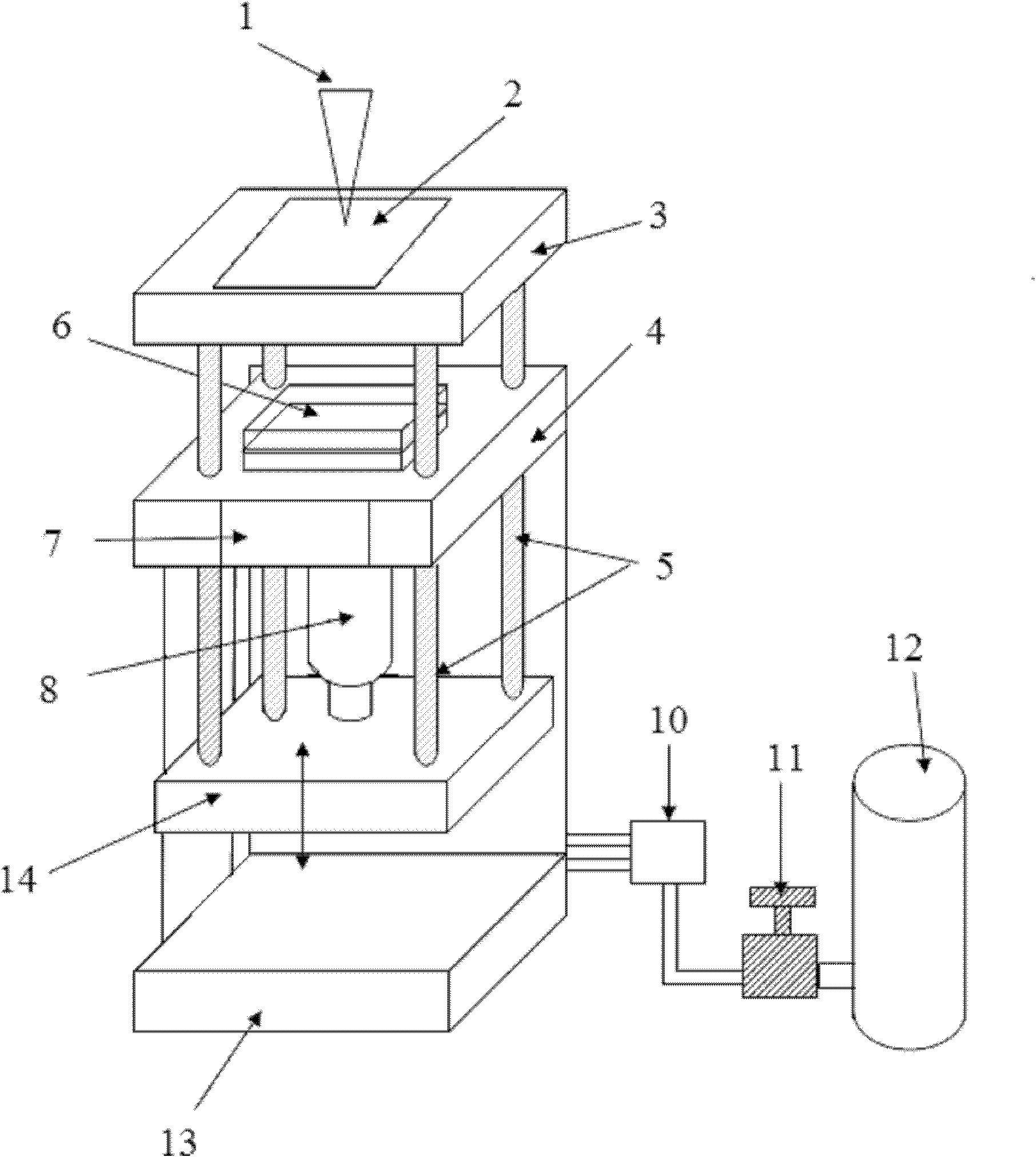

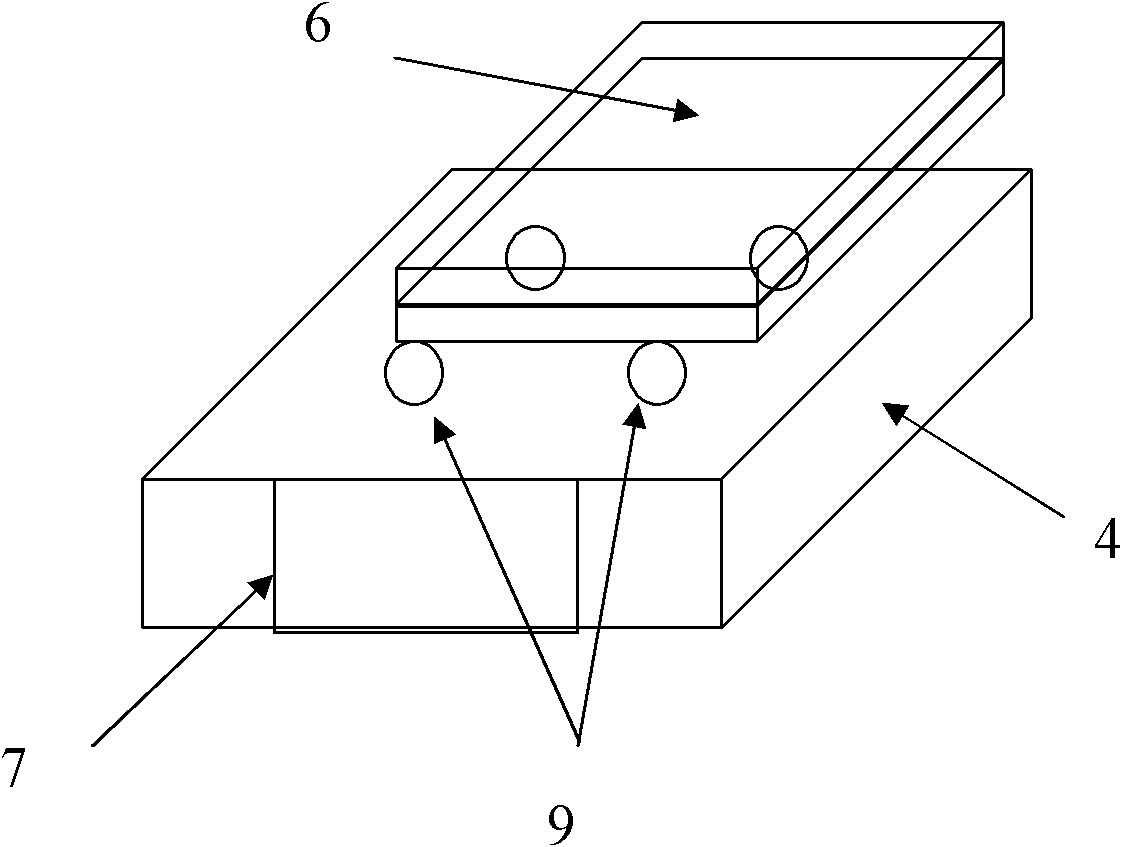

The invention provides a device for welding plastic materials in a laser transmission manner. The device comprises a supporting plate, a laser light source and a pressure regulating mechanism, wherein the pressure regulating mechanism comprises a pressing plate mechanism, a supporting plate, a guide rail and a drive mechanism; the pressing plate mechanism is connected with the drive mechanism andis connected with the supporting plate through the guide rail; the pressing plate mechanism is provided with a light-transmitting window consisting of a light-transmitting window opening and a light-transmitting window body; plastic materials to be welded are positioned on the supporting plate and correspondingly arranged below the light-transmitting window; and the laser light source is sequentially connected with the light-transmitting window and the plastic materials to be welded through laser beams. The invention also provides a welding method realized by the device. According to the invention, the plastic materials to be welded are under proper pressure, and further generate secondary polarization to be combined together, thus welding quality and welding strength are ensured.

Description

Welding device and welding method for laser transmission welding of plastic materials technical field The invention relates to the technical field of laser welding, in particular to a welding device and a welding method for laser transmission welding of plastic materials, which adopt the principle of transmission welding to perform laser welding on plastic materials. Background technique Plastic materials, as an important part of polymer materials, have unique structures and excellent performance, and are widely used in various fields of science and technology, national defense construction and national economy. Plastic, steel, wood, and cement are listed as the four pillar materials. Substituting plastic for steel and plastic for wood is the future development direction of our country, which also provides opportunities and markets for high-tech plastic processing methods. As a high-tech processing technology with distinctive characteristics, laser welding technology is w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C65/16

CPCB29C65/1616B29C65/1635B29C66/1122B29C66/41B29C66/45B29C66/73921B29C66/81267B29C66/8242B29C66/8322B29C66/92211B29C66/9241B29C66/9674B29K2995/0027

Inventor 庞振华宋杰赵博梁锡辉

Owner 光机电(广州)科技研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com