High flow non-spraying metallic silver polyamide composition and preparation method thereof

A polyamide composition and spray-free technology, which is applied in the field of high-flow spray-free metal silver polyamide composition and its preparation, can solve the problems of high cost, prone to weld lines, and not being environmentally friendly, and achieve good fluidity and relative good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

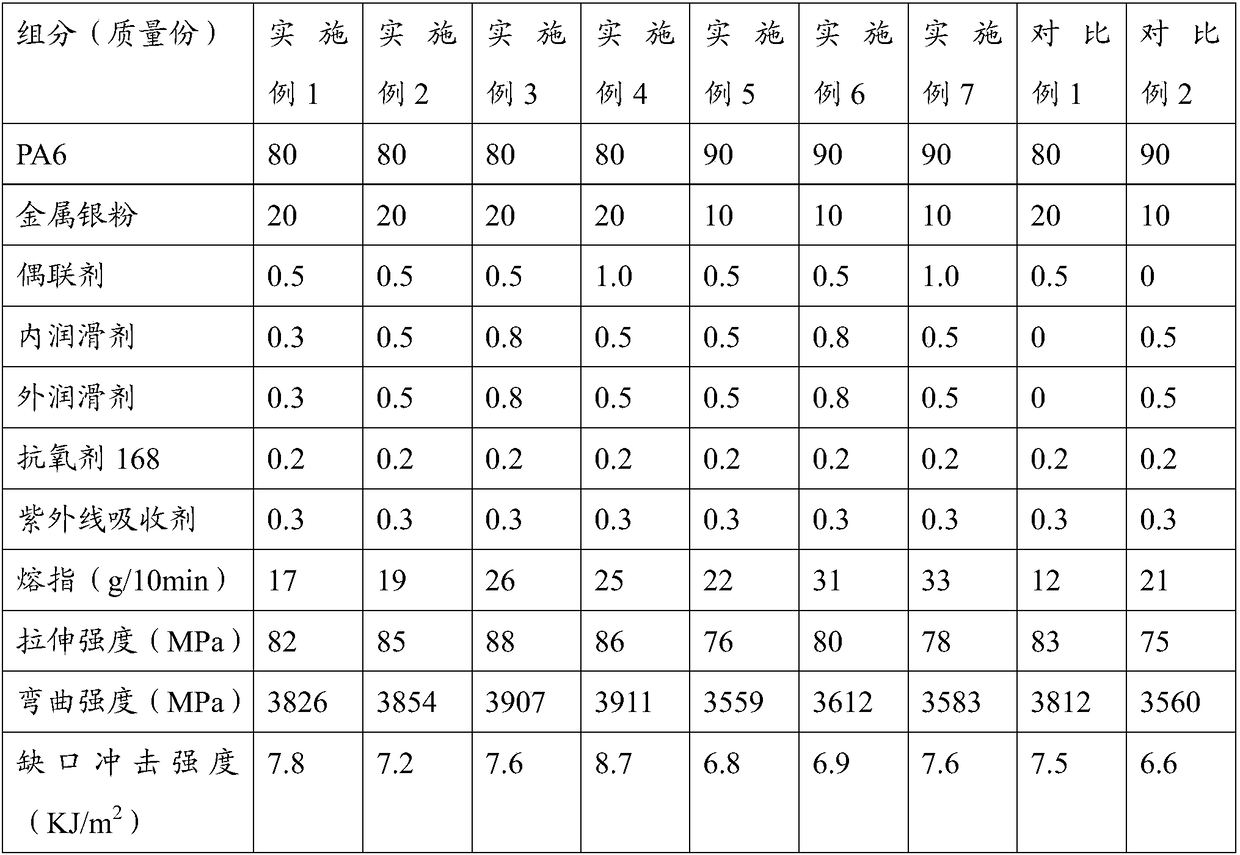

Examples

Embodiment 1

[0032] A high-flow spray-free metal silver polyamide composition, the preparation steps of which are:

[0033] Step 1: Weigh 80 parts of PA6 resin, 20 parts of metal silver powder, 0.5 part of KH-550 silane coupling agent, 0.3 part of internal lubricant stearic acid amide, 0.3 part of external lubricant liquid paraffin, 0.2 parts of antioxidant 168, 0.3 parts of UV-327 ultraviolet absorber, 10 parts of amino silicone oil, 10 parts of flame retardant MPP, 20 parts of calcium stearate, 20 parts of MBS, 5 parts of SMA, 1 part of silicon dioxide, magnesium salt crystal 1 part of silk, 5 parts of hollow glass microspheres, 0.5 parts of EBS, 10 parts of glass fiber, 3 parts of SEBS-g-MAH compatibilizer and 20 parts of ABS;

[0034] The second step: Put PA6 resin, metal silver powder, KH-550 silane coupling agent, internal lubricant stearic acid amide, external lubricant liquid paraffin, antioxidant 168, UV-327 ultraviolet absorber into the mixer, and mix it at 100r Mix for 5min at ...

Embodiment 2

[0039] A high-flow spray-free metal silver polyamide composition, the preparation steps of which are:

[0040] Step 1: Weigh 80 parts of PA6 resin, 20 parts of metal silver powder, 0.5 part of KH-550 silane coupling agent, 0.5 part of internal lubricant stearic acid amide, 0.5 part of external lubricant natural paraffin, 0.2 parts of antioxidant 168, 0.3 parts of UV-327 ultraviolet absorber, 15 parts of amino silicone oil, 15 parts of flame retardant antimony trioxide, 30 parts of calcium stearate, 20 parts of MBS, 5 parts of SMA, 1 part of silicon dioxide , 3 parts of magnesium salt whiskers, 10 parts of hollow glass microspheres, 2.5 parts of EBS, 30 parts of glass fiber, 10 parts of PP-g-MA compatibilizer and 30 parts of ABS;

[0041] The second step: Put PA6 resin, metal silver powder, KH-550 silane coupling agent, internal lubricant stearic acid amide, external lubricant natural paraffin, antioxidant 168, UV-327 ultraviolet absorber into the mixer, and heat at 250r Mix for...

Embodiment 3

[0046] A high-flow spray-free metal silver polyamide composition, the preparation steps of which are:

[0047] Step 1: Weigh 80 parts of PA6 resin, 20 parts of metal silver powder, 0.5 part of KH-550 silane coupling agent, 0.8 part of internal lubricant stearic acid amide, 0.8 part of external lubricant natural paraffin, 0.2 parts of antioxidant 168, 0.3 parts of UV-327 ultraviolet absorber, 11 parts of amino silicone oil, 11 parts of flame retardant magnesium hydroxide, 22 parts of calcium stearate, 20 parts of MBS, 5 parts of SMA, 1 part of silicon dioxide, 1.2 parts of magnesium salt whiskers, 6 parts of hollow glass microspheres, 1 part of EBS, 15 parts of glass fiber, 4 parts of PE-g-MAH compatibilizer and 22 parts of ABS;

[0048] The second step: Put PA6 resin, metal silver powder, KH-550 silane coupling agent, internal lubricant stearic acid amide, external lubricant natural paraffin, antioxidant 168, UV-327 ultraviolet absorber into the mixer, and heat it at 120r Mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com