Patents

Literature

58results about How to "Fix appearance problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulping equipment and pulping method for cow card paper

ActiveCN102493263AFix appearance problemsReduce manufacturing costPaper recyclingWaste paper working-upDeinkingFibre treatment

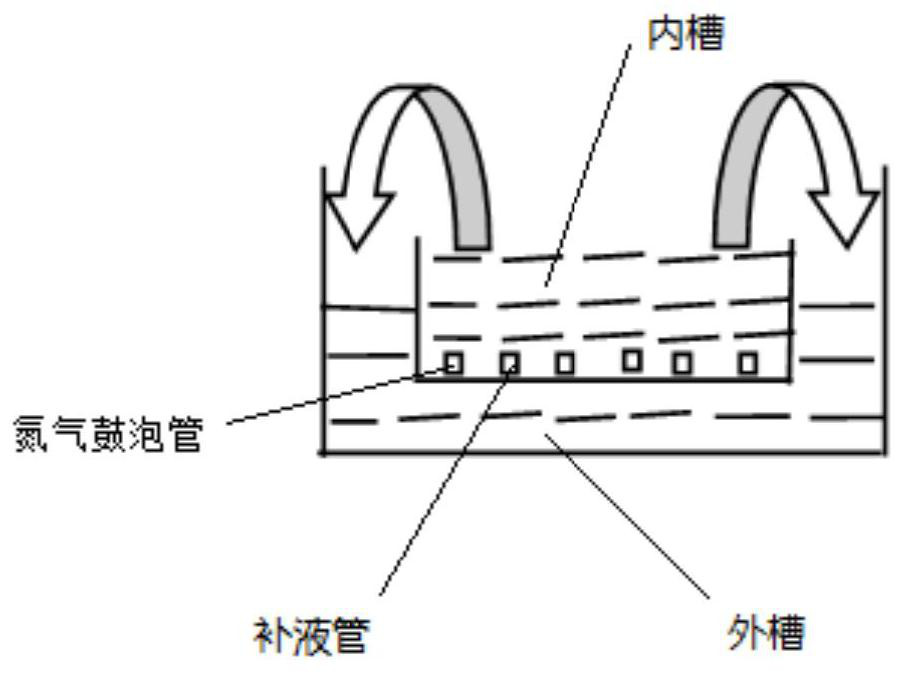

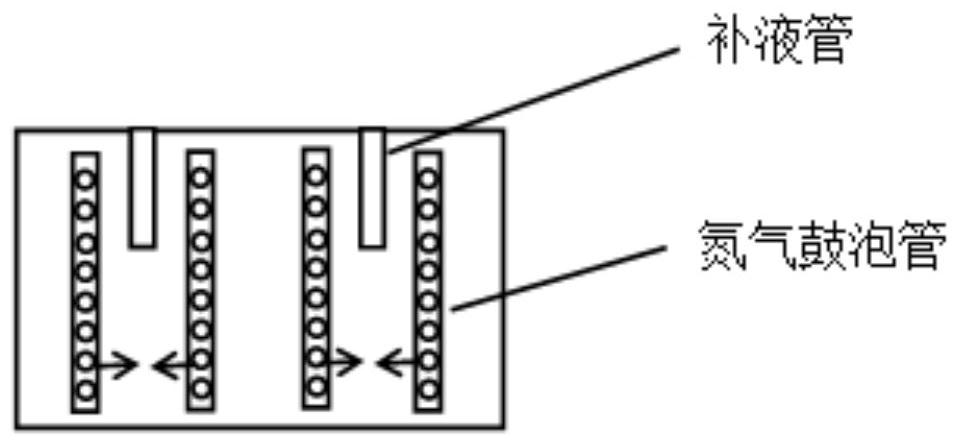

The invention relates to the technical field of cow card paper manufacture, in particular to pulping equipment and a pulping method for cow card paper. The pulping equipment comprises a pulper, rough sizing equipment, a grading sieve, long fiber treating equipment and short fiber treating equipment, wherein the long fiber treating equipment comprises fine sizing equipment, a heat dispersion deinking machine and a dise mill; and the short fiber treating equipment comprises a low-concentration desander, a light slag remover and another heat dispersion deinking machine. The pulping method comprises the following steps: a, pretreating wastepaper; b, sorting long fiber and short fiber; c, treating long fiber; and d, treating short fiber. Wherein, long fiber pulp stock is used for making the bottom layer of the cow card paper; 100 percent of the sandwich layer of the cow card paper and 30 to 50 percent of the surface layer of the cow card paper are short fiber pulp stock; and the surface layer contains 50 to 70 percent of wood pulp. The invention radically solves the appearance problems of paraffin points and black spots in the cow card paper, and reduces the production cost of the cow card paper.

Owner:东莞理文造纸厂有限公司

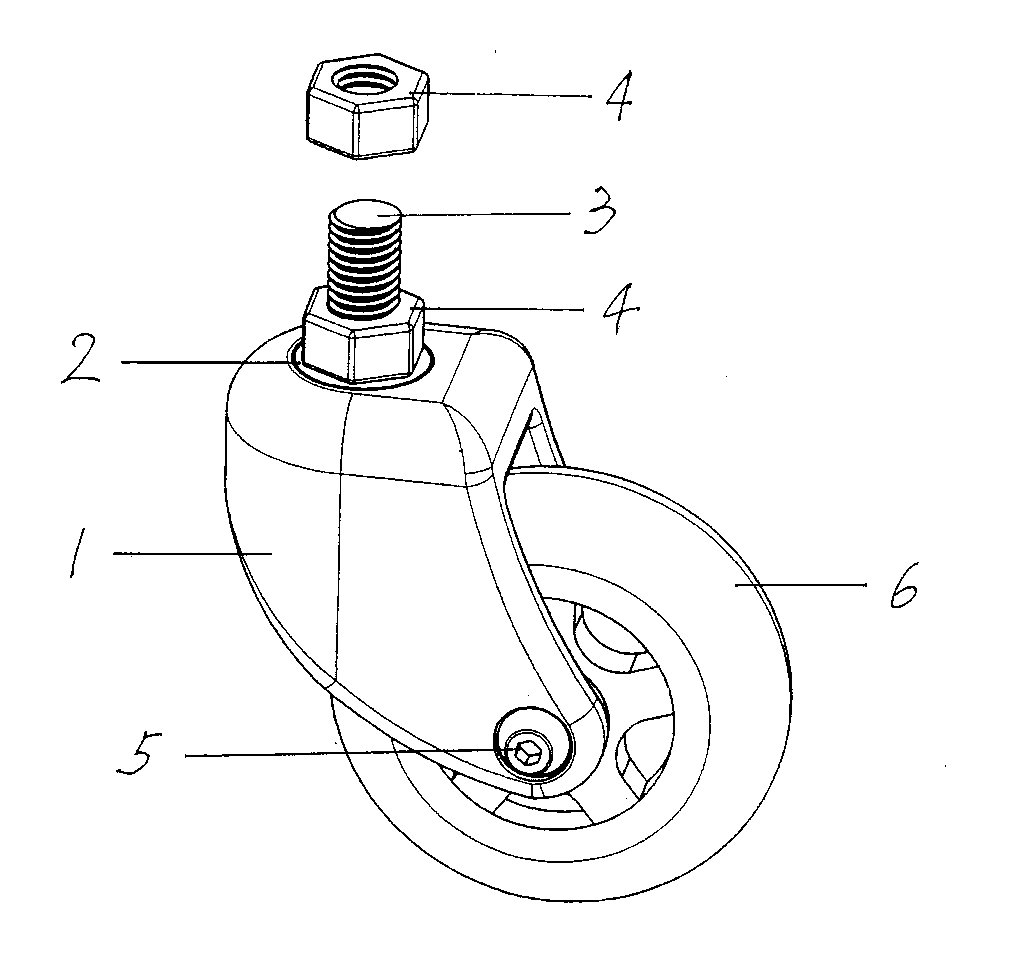

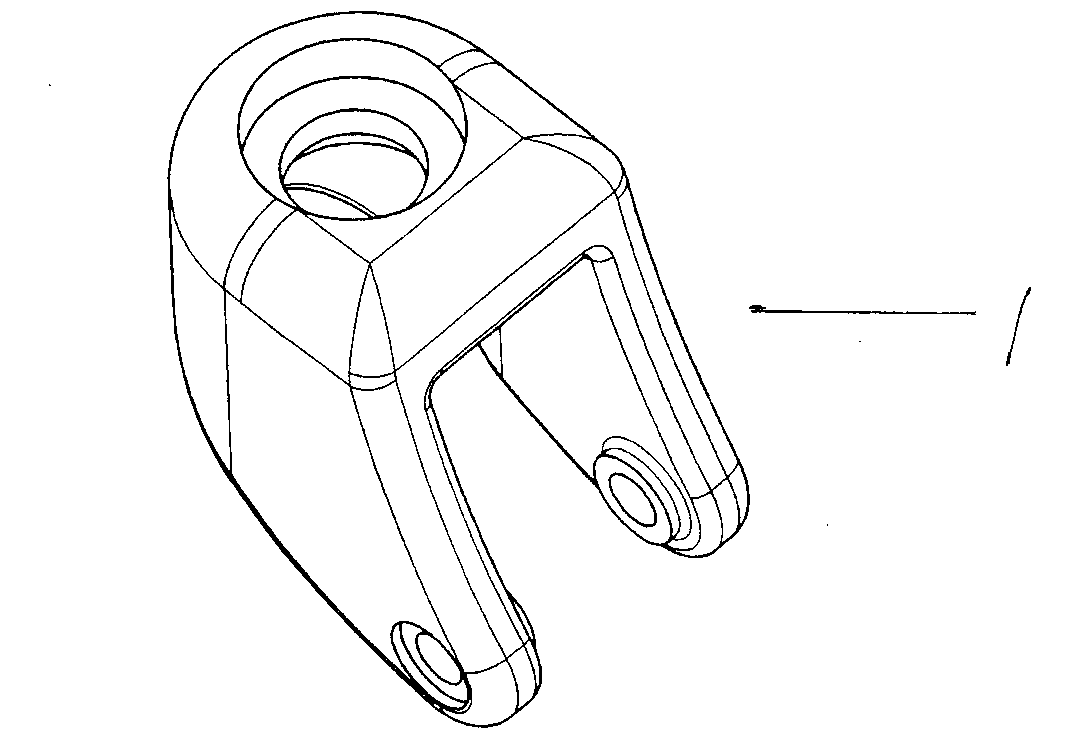

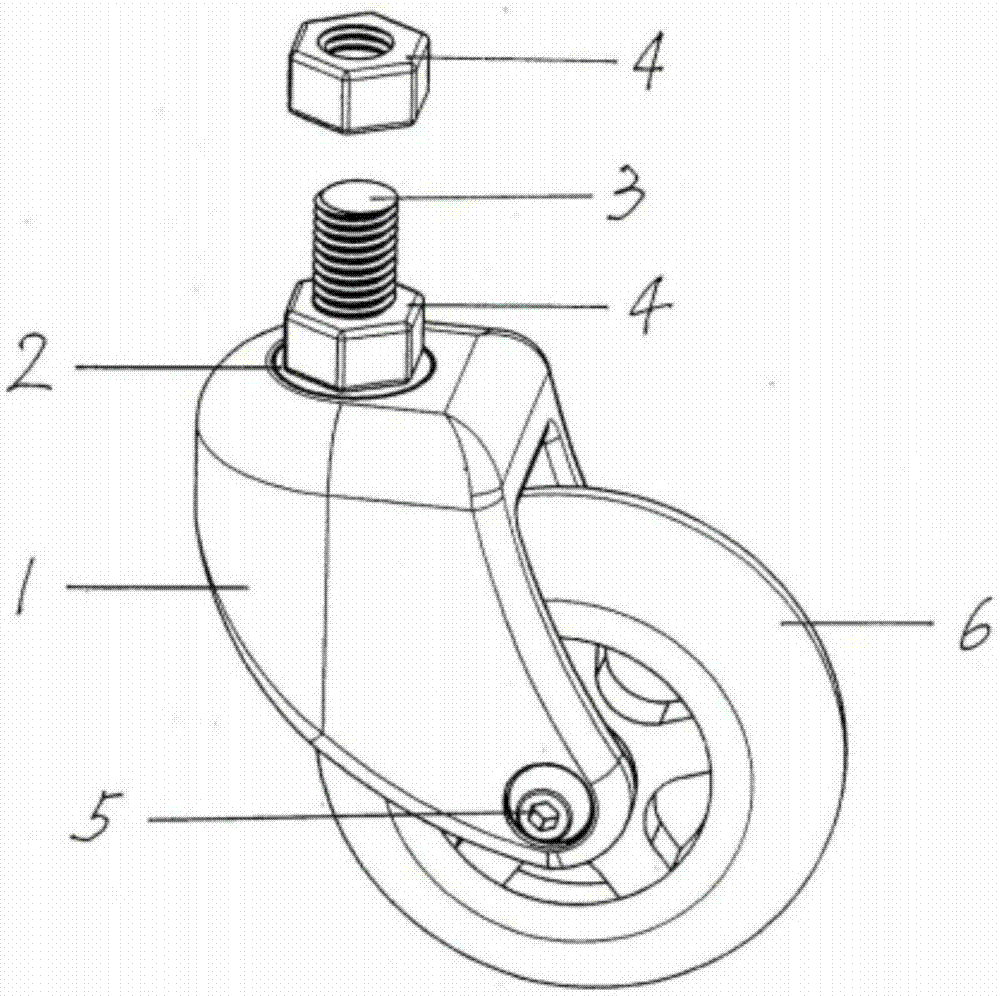

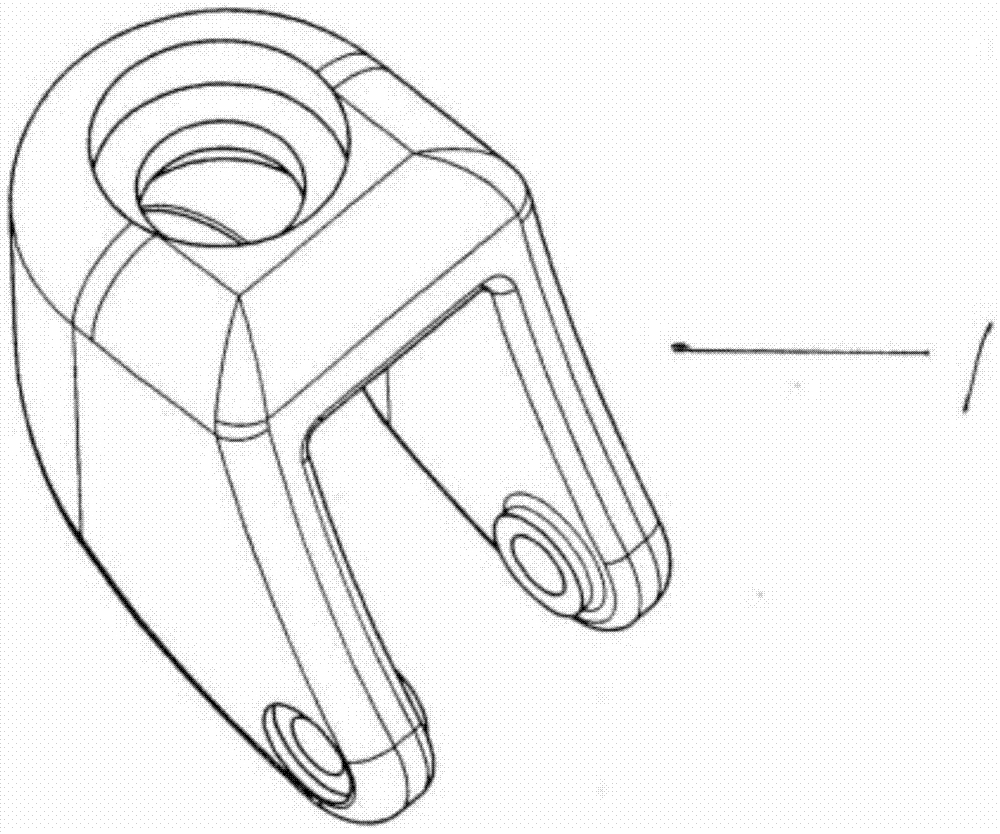

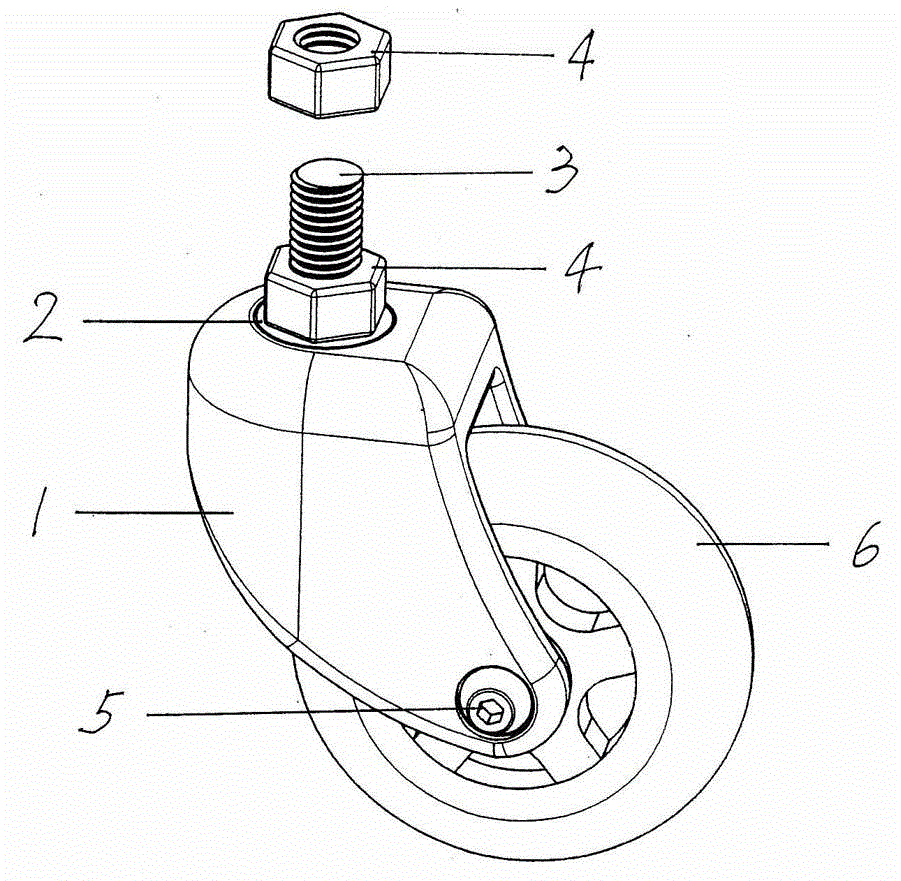

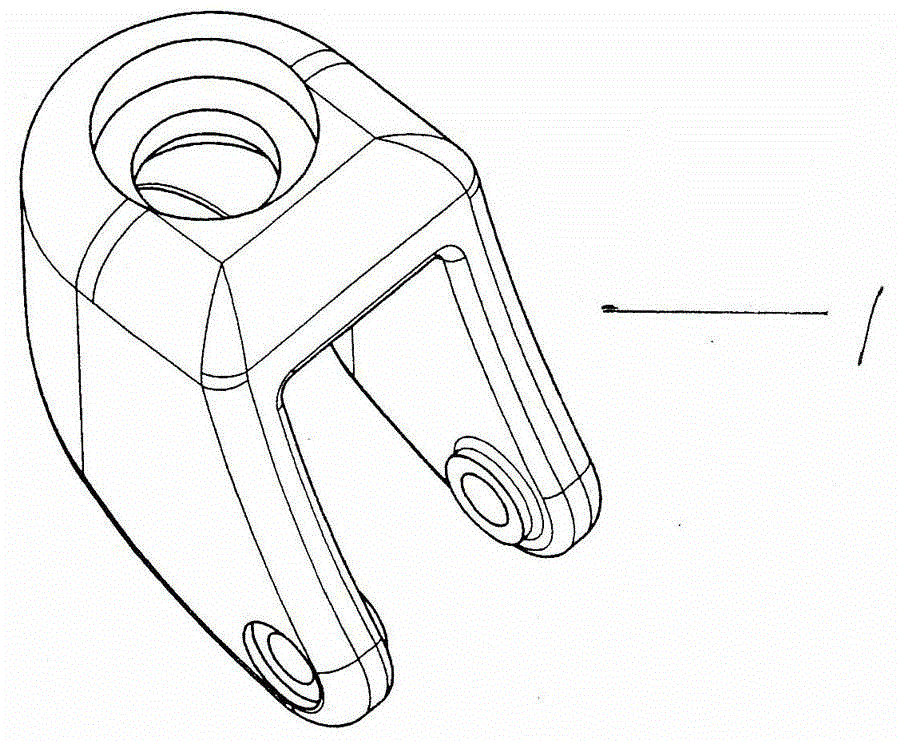

Universal wheel with plastic wheel fork

A universal wheel with a plastic wheel fork comprises the plastic wheel fork, two wheel fork bearings, a round head bolt, a nut, a lock bolt and a PU (polyurethane) wheel with two bearings at the hole center. The universal wheel is characterized in that two counter bored holes are arranged above and below the top of the plastic wheel fork respectively, a through hole is arranged between the upper counter bored hole and the lower counter bored hole of the plastic wheel fork, mutually-communicated holes are arranged on two wheel forks at the lower end of the plastic wheel fork, a wheel fork bearing is embedded in each of the upper counter bored hole and the lower counter bored hole of the plastic wheel fork respectively, the round head bolt penetrates into inner holes of the two wheel fork bearings, the nut is screwed on the round head bolt penetrating into the inner holes of the two wheel fork bearings, the lock bolt comprises a screw cylinder and a bolt, and the screw cylinder penetrates into the mutually-communicated holes and two inner holes of bearings of the PU wheel to be screwed with the bolt. The universal wheel with the plastic wheel fork after assembly can use a screw rod screwed on the round head bolt in two wheel fork bearing holes at the top of the plastic wheel fork to be connected with a recreational vehicle.

Owner:TAICANG CHEZHONGBAO LEISURE ARTICLES +1

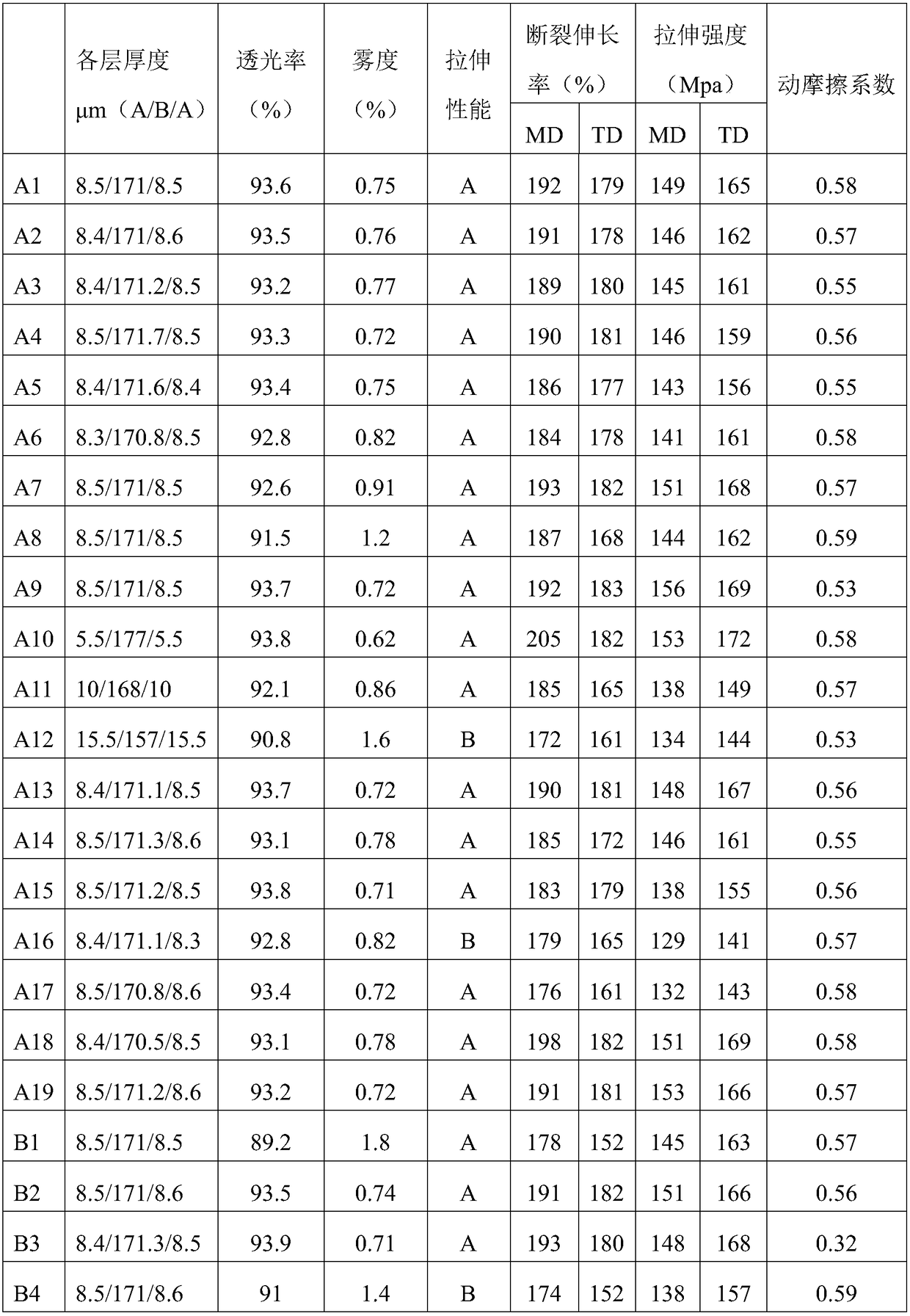

High-transmittance polyester thin film and preparation method thereof

ActiveCN109054314AImprove binding abilityReduce voidsSynthetic resin layered productsChemistryPolyethylene terephthalate glycol

The invention belongs to the technical field of polyester thin films and in particular relates to a high-transmittance polyester thin film and a preparation method thereof. The high-transmittance polyester thin film comprises a core layer and a surface layer arranged at one side or two sides of the core layer, wherein the surface layer is prepared from the following components in percentage by mass: 93 to 97 percent of polyethylene terephthalate, 0.08 to 0.25 percent of inorganic particles and 2.75 to 6.92 percent of other auxiliary agents, wherein the inorganic particles are subjected to coating and modification treatment through a compatilizer. According to the high-transmittance polyester thin film provided by the invention, the inorganic particles subjected to the coating and modification treatment through the compatilizer are added into the surface layer, so that the binding capability of the inorganic particles and polyethylene terephthalate in the surface layer of the polyesterthin film is improved; a gap formed at the periphery of the inorganic particle in the biaxially-stretched and molded polyester thin film is reduced, so that the problem that the inorganic particles exist so that the light penetration rate is low is remarkably reduced; the binding force between the inorganic particles subjected to the coating and modification treatment through the compatilizer andpolyethylene terephthalate is relatively strong, and a series of appearance problems caused by the fact that the inorganic particles fall off are prevented.

Owner:金华市星火塑料制品有限公司

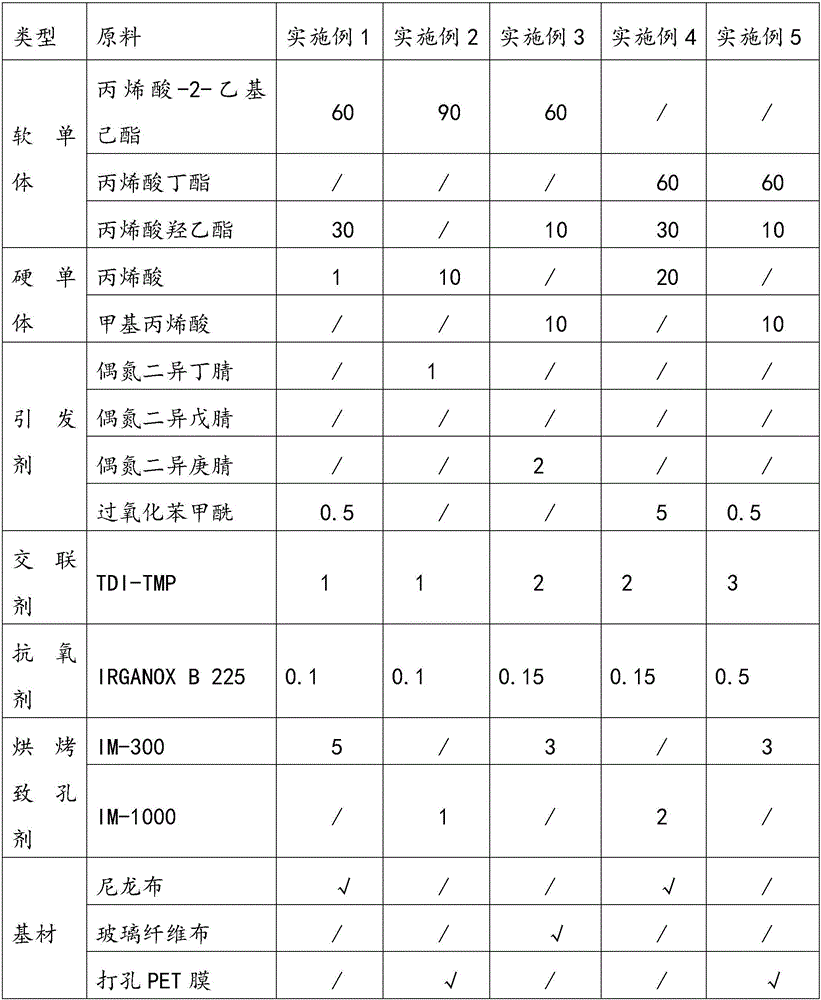

Solar double-glass photovoltaic module laminating and edge sealing adhesive tape and preparation method thereof

ActiveCN106589434AGood adhesion and complianceSolve problems caused by drillingMacromolecular adhesive additivesEster polymer adhesivesCross-linkWater vapor

The invention relates to a solar double-glass photovoltaic module laminating and edge sealing adhesive tape. The adhesive tape comprises a substrate layer and a pressure-sensitive adhesive layer located on the substrate layer, and a pressure-sensitive adhesive is prepared from, by weight, 70-90 parts of soft monomers, 1-20 parts of hard monomers, 0.5-5 parts of a polymerization initiator, 1-2 parts of a cross-linking agent, 0.1-0.5 part of an antioxidant and 1-5 parts of a baking pore-forming agent. The edge sealing adhesive tape has the good adhering fitness to a glass substrate, uniform through holes can be formed in a tape body through the volatilization action of water vapor when baking is conducted due to presence of the baking pore-forming agent, therefore, an air ventilation function is achieved, and the problems generated when holes are formed in common high-temperature adhesive tape through a physical method are solved; after the edge sealing adhesive tape is used, edge trimming is not needed, the adhesive tape is directly torn off after laminating is finished, and meanwhile overflowed high-molecular polymers are taken away, so that the labor intensity of workers is reduced, the cost of existing edge sealing adhesive tape is reduced, the appearance problems such as burrs are solved, and the uniform edge thickness requirement of a double-glass module is met.

Owner:YANTAI DARBOND TECH

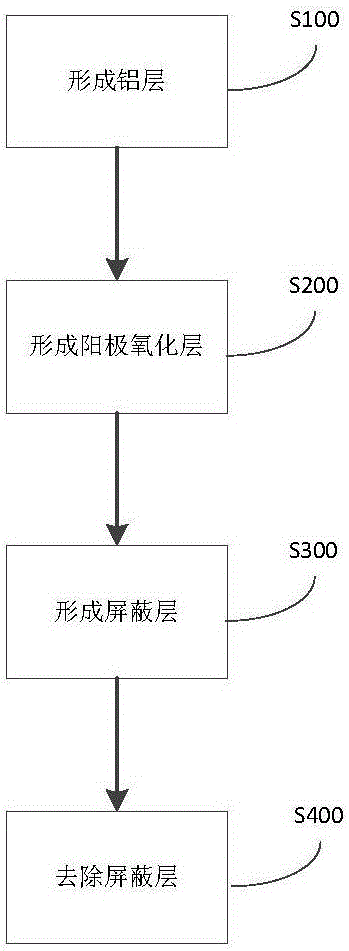

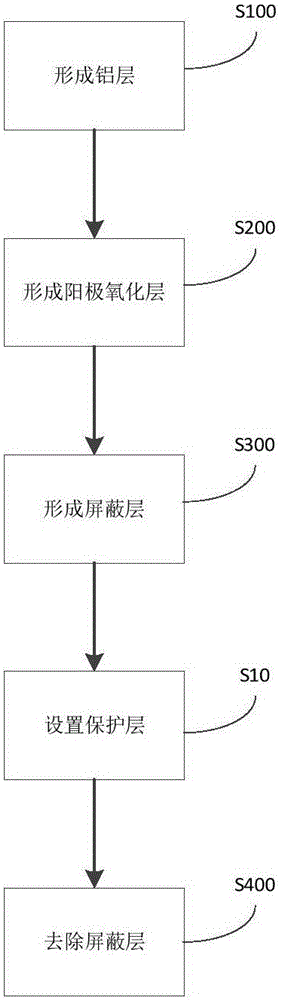

Stainless steel sheet, preparation method and electronic equipment

ActiveCN105862037AFix appearance problemsSolve the problem that the product surface has stepsOrnamental structuresSpecial ornamental structuresElectronic equipmentTextile dye

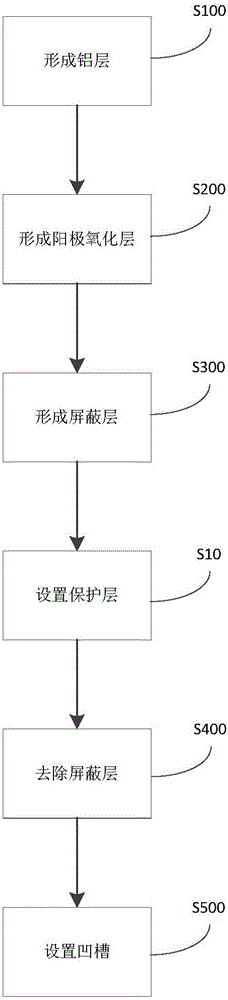

The invention provides a stainless steel sheet, a preparation method and electronic equipment. The preparation method comprises the steps that 1, an aluminum layer is formed on the upper surface of a stainless steel substrate; 2, an anode oxidation layer is formed on the upper surface of the aluminum layer; 3, a shielding layer is formed on a presumptive area of the upper surface of the anode oxidation layer, and the parts, outside the presumptive area, of the anode oxidation layer and the aluminum layer are removed; and 4, the shielding layer is removed. Thus, a stainless steel appearance and an anode oxidation appearance can be simultaneously arranged on the upper surface of the stainless steel sheet, and on the basis that the stainless steel appearance of the surface of the stainless steel sheet is maintained, the stainless steel sheet is subjected to dyeing, specific pattern setting and other ornamenting; and accordingly, the appearance effect can be enhanced, and the surface treatment method for the stainless steel sheet is enriched.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Thermal expansion technology for high-energy rubber-molded fiber composite product

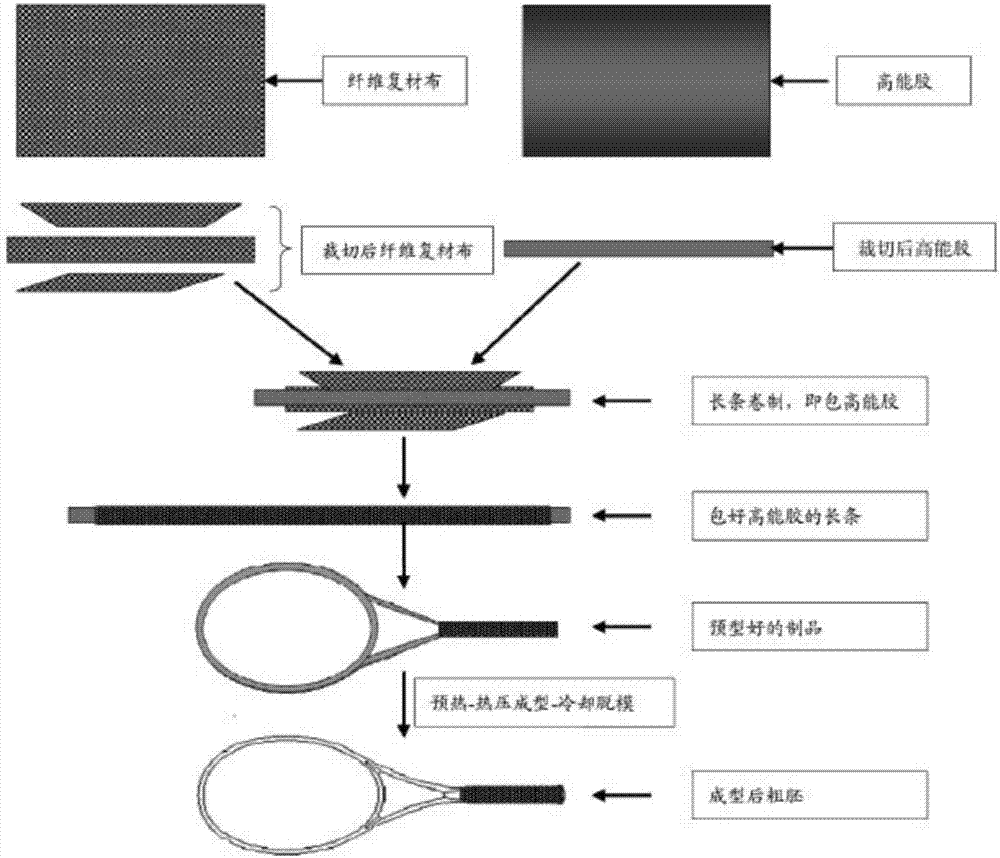

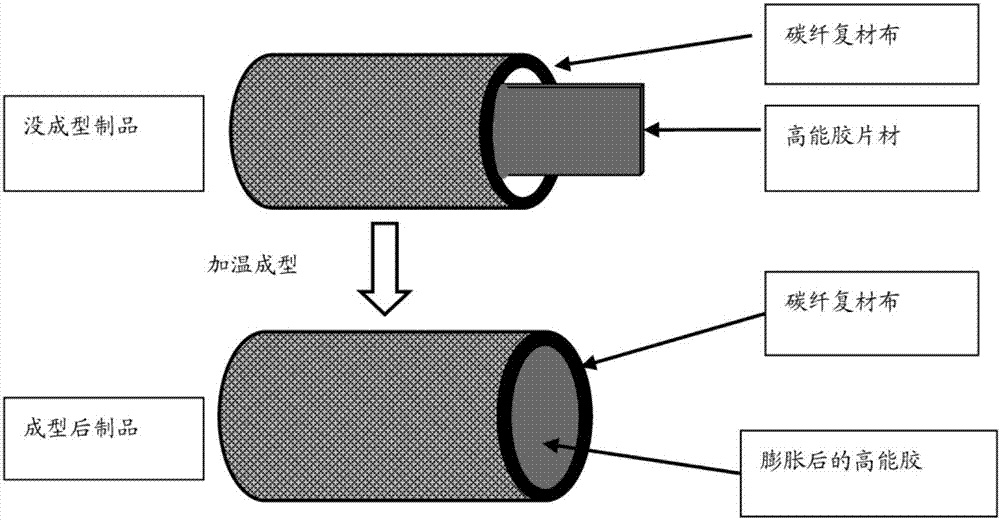

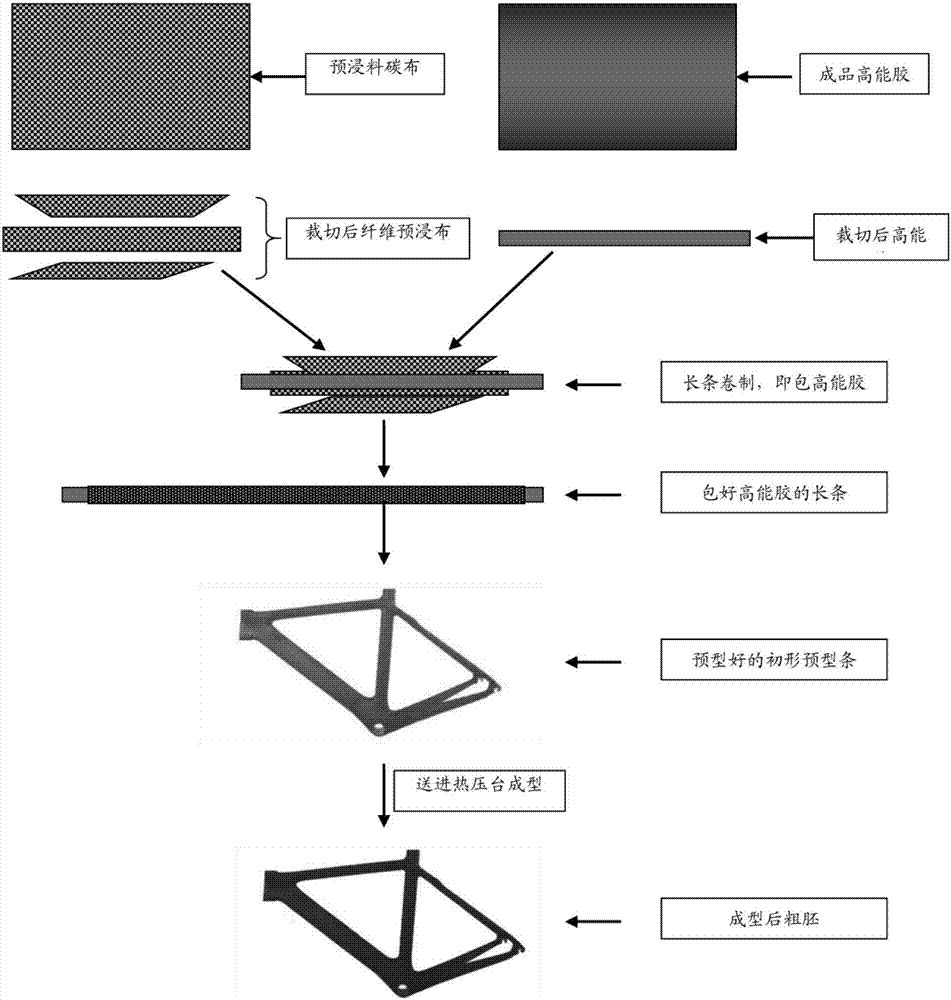

The invention discloses a thermal expansion technology for a high-energy rubber-molded fiber composite product. The thermal expansion technology particularly comprises the steps that fiber composite cloths and high-energy rubber are cut according to the structural design specification size and then cleared up for use; the fiber composite cloths are folded in a rowed mode and layered up according to the mechanical structural design requirements, and a rolled product is obtained by arranging the fiber composite cloths outside the high-energy rubber in a wrapping mode; the obtained rolled product is put on a heating platform with the temperature ranging from room temperature to 80 DEG C to be preheated for 3-60 min, gas among layers is exhausted in an extruding mode as much as possible, the product is pressed to be smooth and then put into a pre-molding mold, pre-molding is conducted according to the shape designed by the pre-molding mold, and a pre-molded product is obtained; the obtained pre-molded product is put into a preheating oven with the temperature ranging from 35 DEG C to 75 DEG C to be preheated for 3-60 min and then taken out to be put into a molding mold, and the mold is closed tightly; the mold is delivered to a thermal compression molding platform, the high-energy rubber is expanded and not shrunk or is expanded first and then shrunk under the action of the heating procedure, and product molding is completed; the molded mold is delivered to a cooling platform to be cooled and then delivered to a demolding platform, and the product is taken out by opening the mold. The technology method replaces a traditional nylon duct method.

Owner:XIAMEN HOWER MATERIAL

Algae removing type polishing liquid

InactiveCN101096576ANo significant changesExtended WarrantySemiconductor/solid-state device manufacturingPolishing compositionsAlgaeChemistry

The invention discloses an algaecide typed polishing liquid, which comprises the following parts: 25%-45% SiO2 sol, 5%-10% pH value modifier, 1%-4% surface activator, 0.02-2% germicidal algaecide, 0.1-3% chelant and 30 %-65% water, wherein the scale of pH value is 9-13.5; the grain size is between 10nm and 130nm. The invention lengthens the preserving time obviously to solve the appearance and pollution problem, which simplifies the operation with reasonable industrialization.

Owner:天津晶岭电子材料科技有限公司

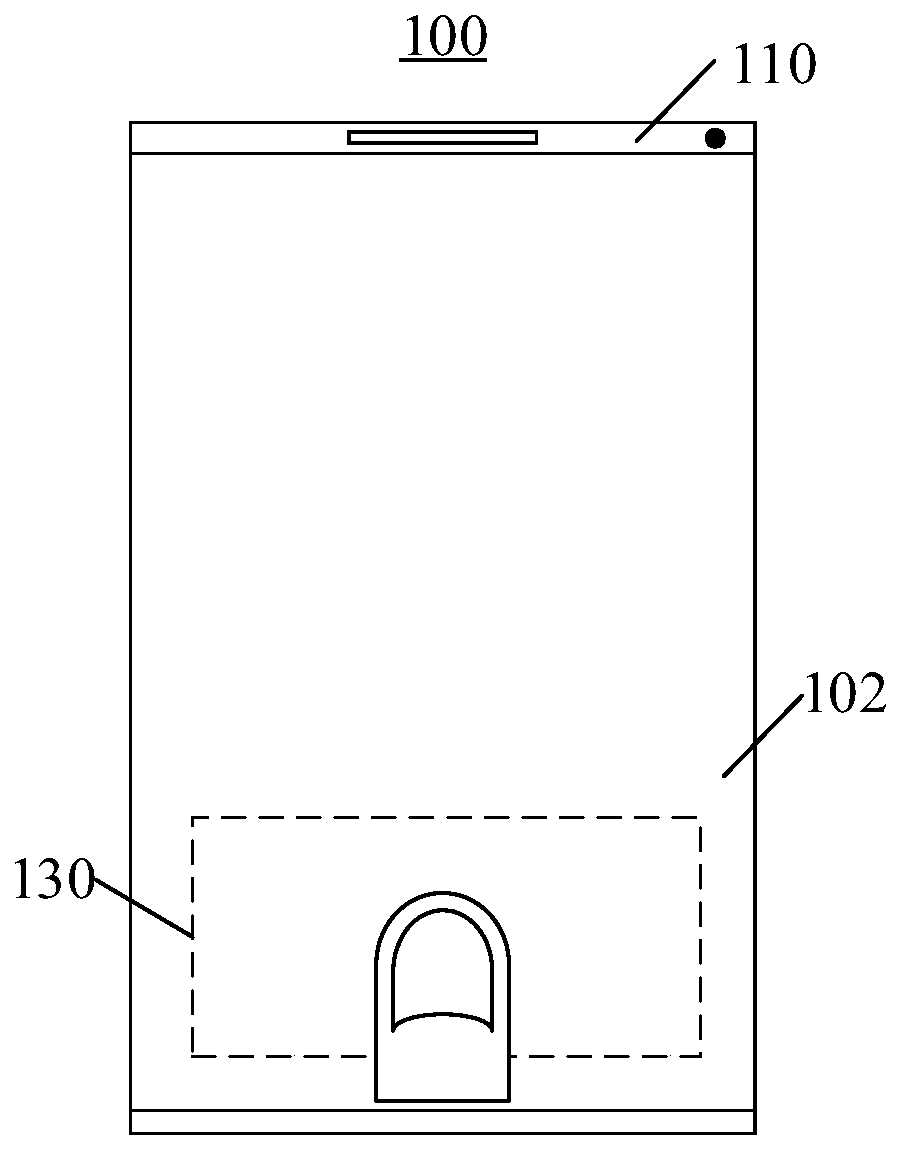

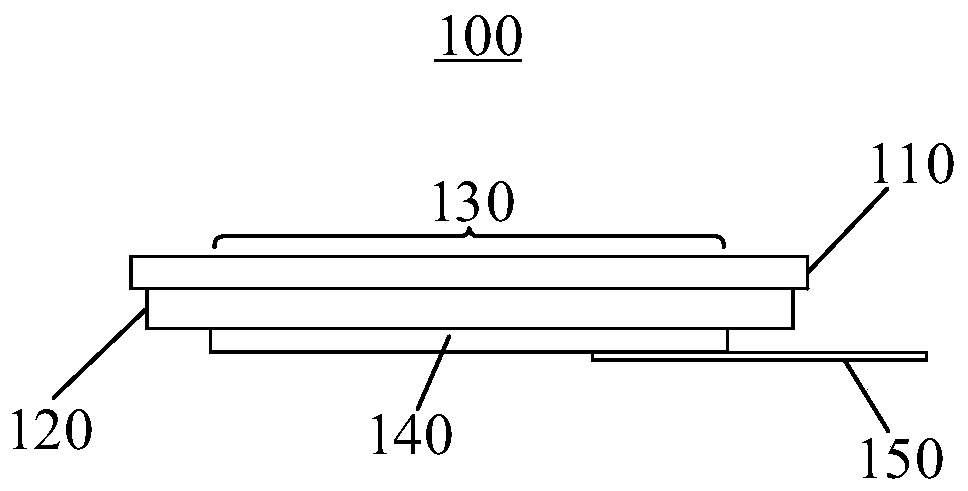

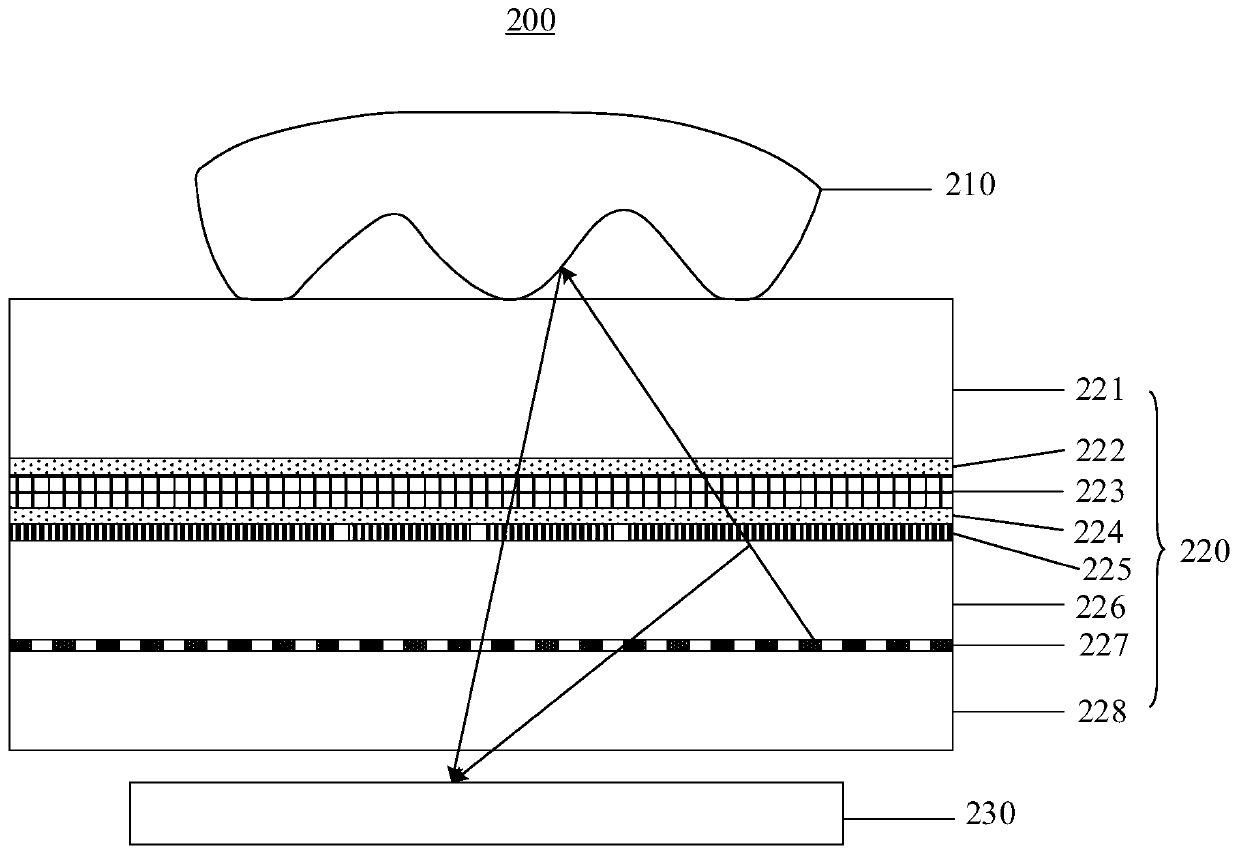

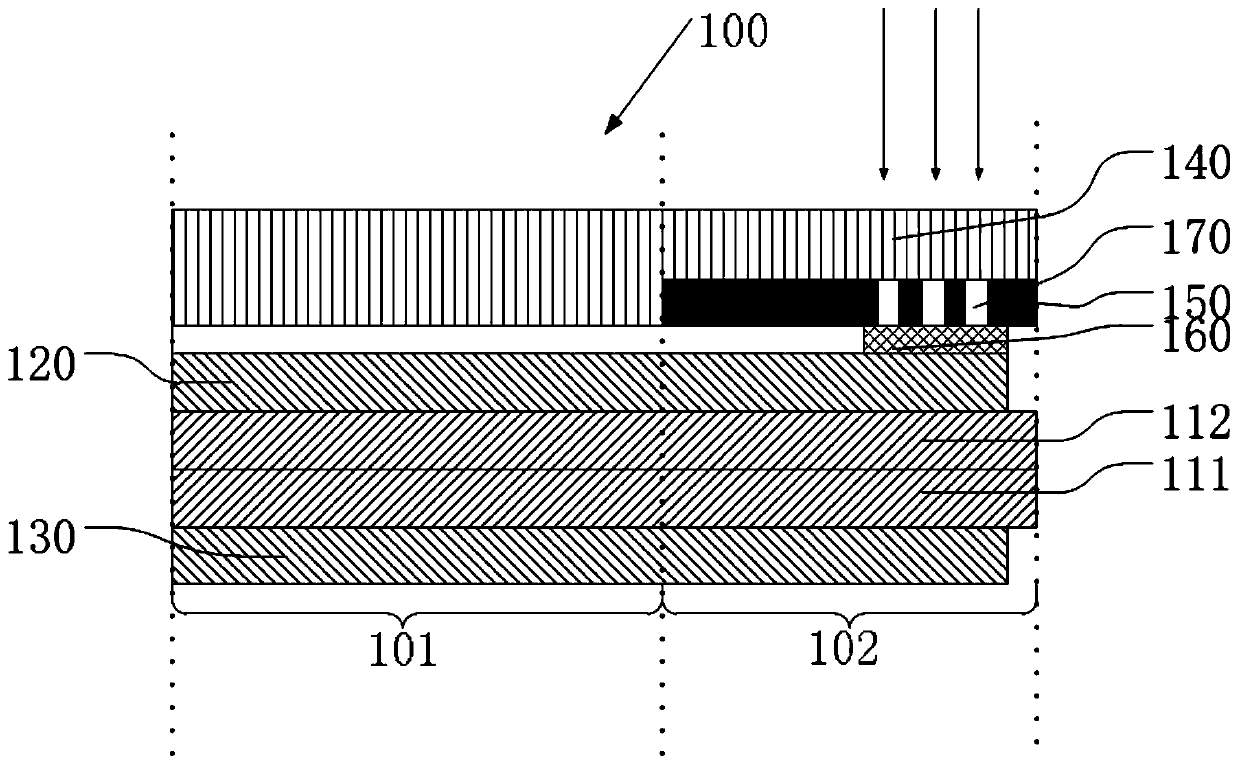

Fingerprint identification device and electronic equipment

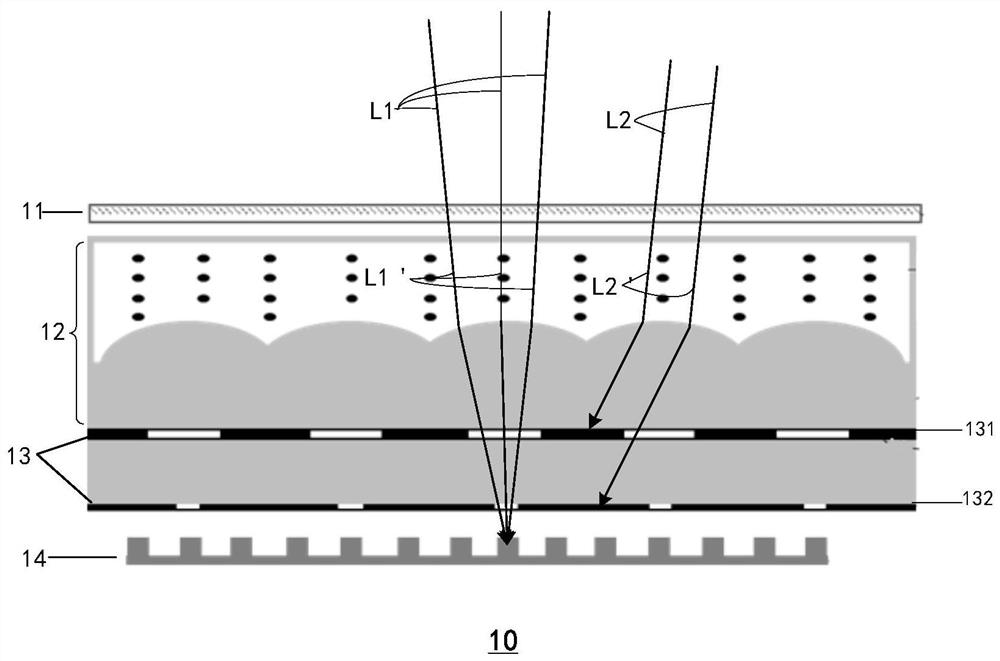

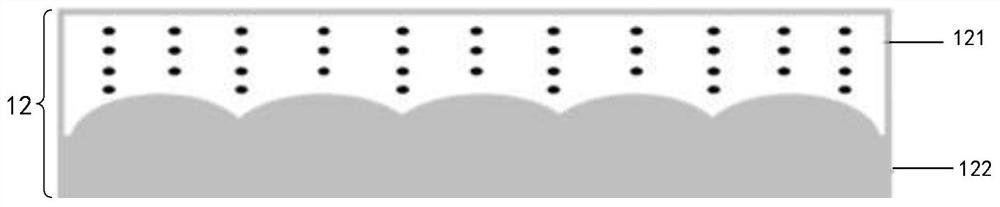

PendingCN110730968AImprove performanceIncrease the proportionSolid-state devicesPrint image acquisitionEngineeringPolarizer

The invention provides a fingerprint identification device and electronic equipment. The fingerprint identification device is applied to the electronic equipment with a display screen, is used for being arranged below the display screen, and comprises a micro-lens array; a small hole array which is arranged below the micro lens array; an optical fingerprint sensor array which is arranged below thesmall hole array and is used for receiving an optical signal which is converged to the small hole array through the micro lens array and passes through the small hole array; and a first 1 / 4 wave plate and a first linear polarizer which are disposed in an optical path from the display screen to the optical sensor array, wherein the first 1 / 4 wave plate is disposed above the first linear polarizer.According to the fingerprint identification device and the electronic equipment, through the first 1 / 4 wave plate and the first linear polarizer arranged on the first 1 / 4 wave plate, the performanceof fingerprint identification under a screen can be improved.

Owner:SHENZHEN GOODIX TECH CO LTD

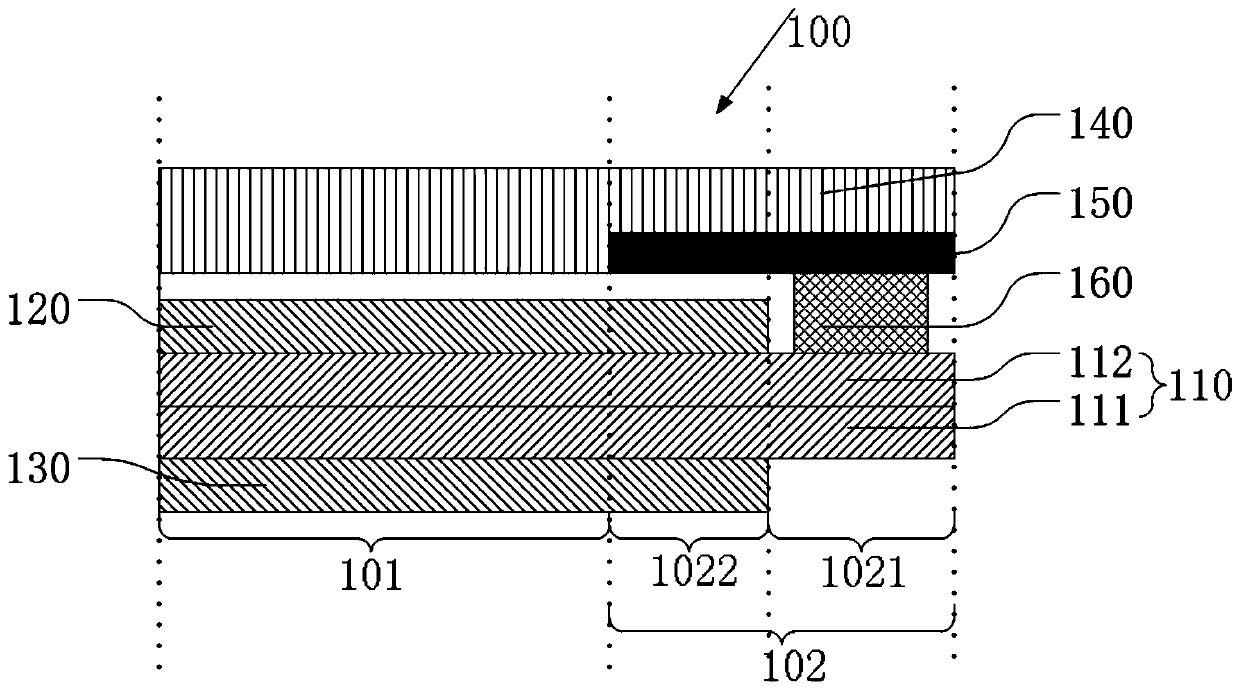

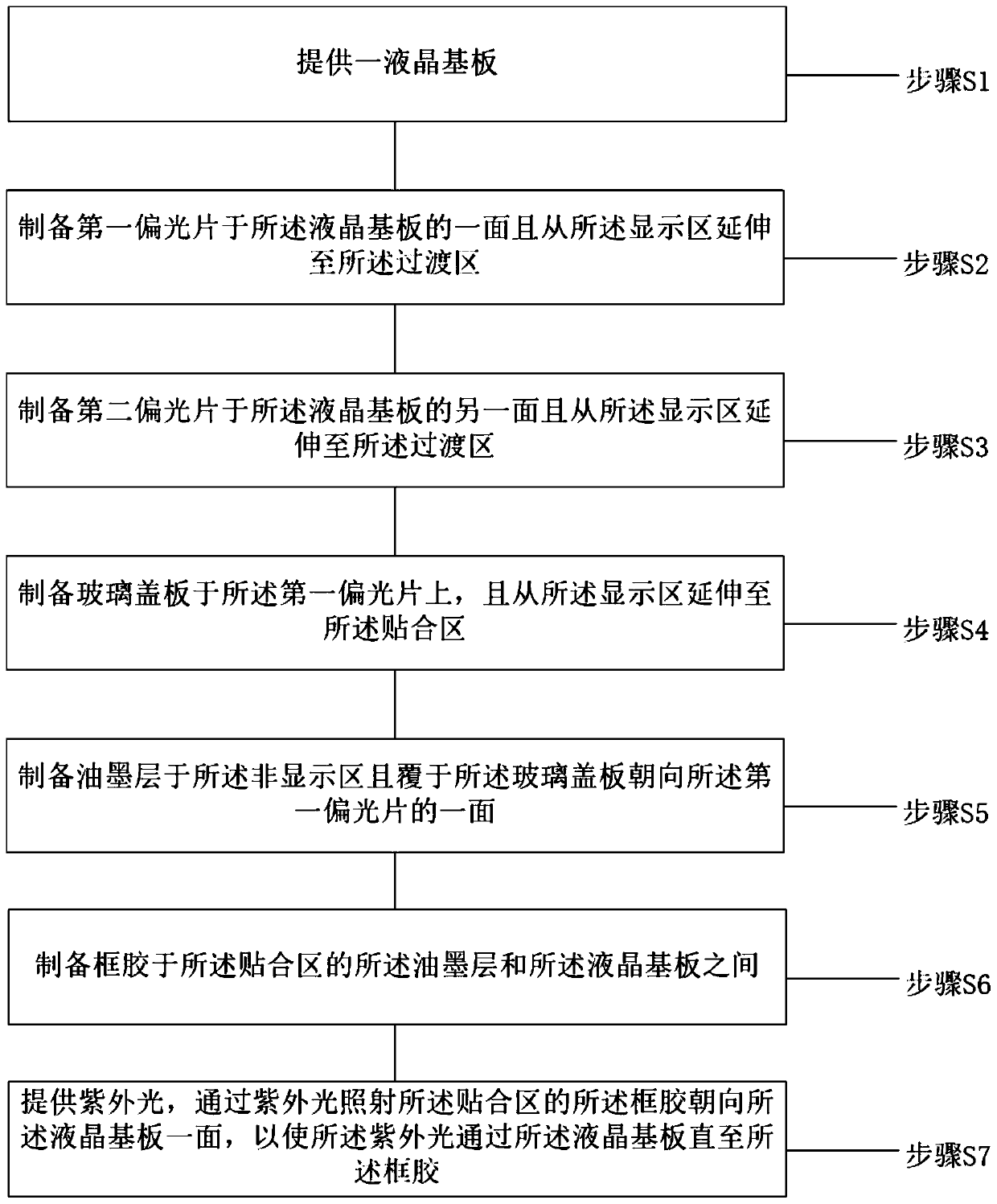

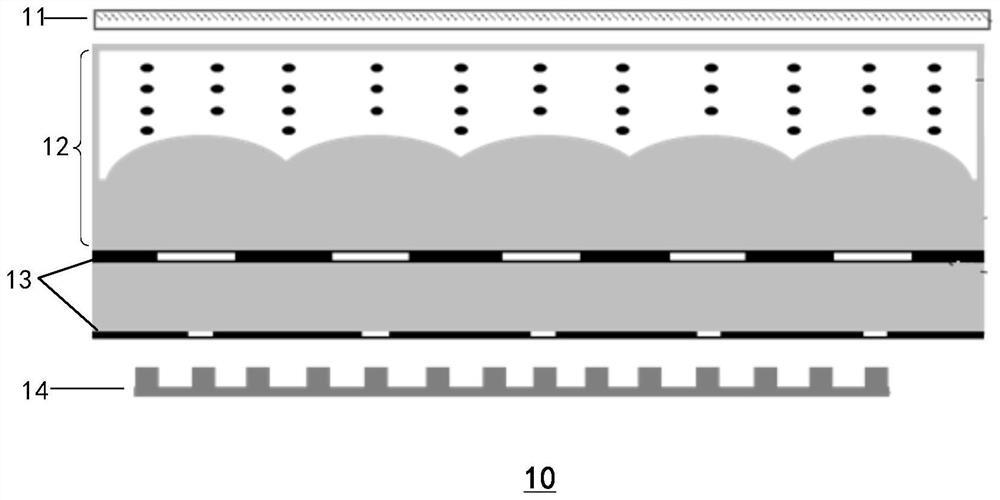

Liquid crystal display panel, preparation method thereof and display device

The invention discloses a liquid crystal display panel, a preparation method thereof and a display device. The liquid crystal display panel has a display region and a fitting region surrounding the display region, and further comprises a liquid crystal substrate extending from the display region to the fitting region; the first polaroid is arranged on one surface of the liquid crystal substrate inthe display region; the second polaroid is arranged on the other surface of the liquid crystal substrate in the display region; a glass cover plate; the second polaroid is arranged on the first polaroid and extends from the display region to the fitting region; the ink layer is arranged in the fitting region and covers one surface, facing the first polaroid, of the glass cover plate; and the frame glue is arranged between the ink layer and the liquid crystal substrate in the fitting region. The frame glue is arranged between the liquid crystal substrate and the ink layer in the attaching region, and the liquid crystal substrate in the attaching region is free of wiring, so that ultraviolet light can enter from the attaching region to the frame glue, then the frame glue is cured, and the appearance problem caused by the fact that an ink silk-screen region needs to be perforated is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

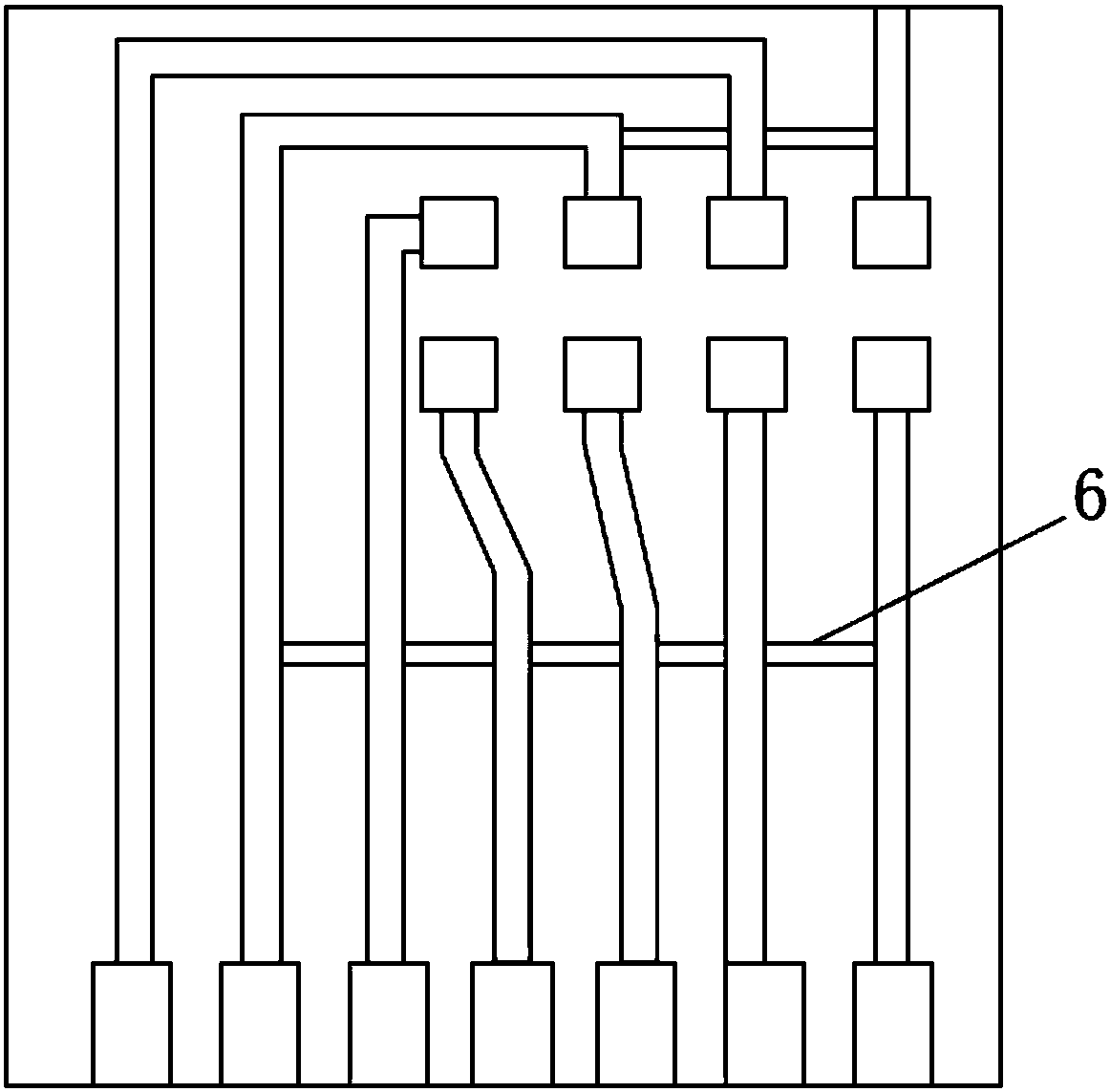

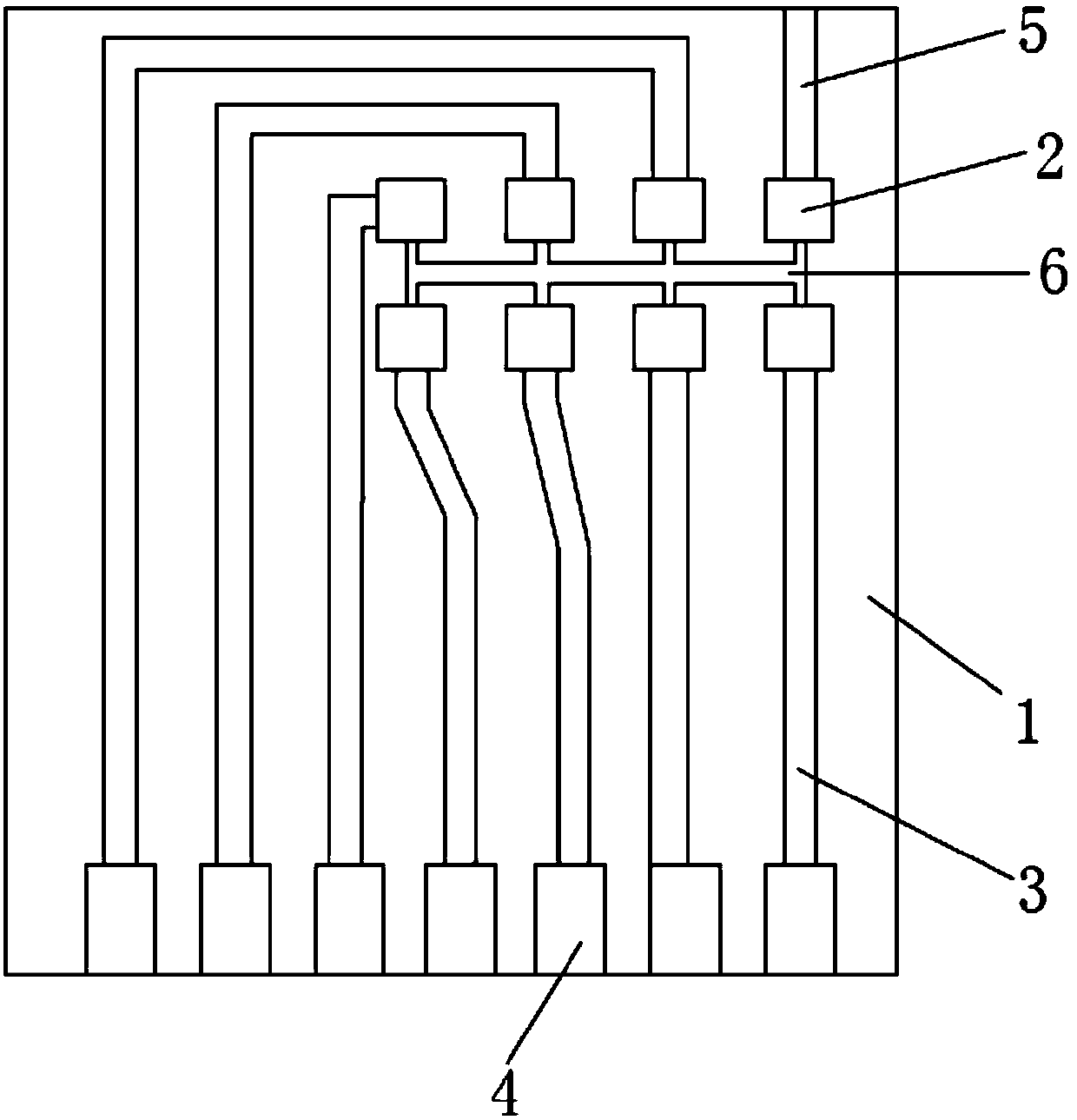

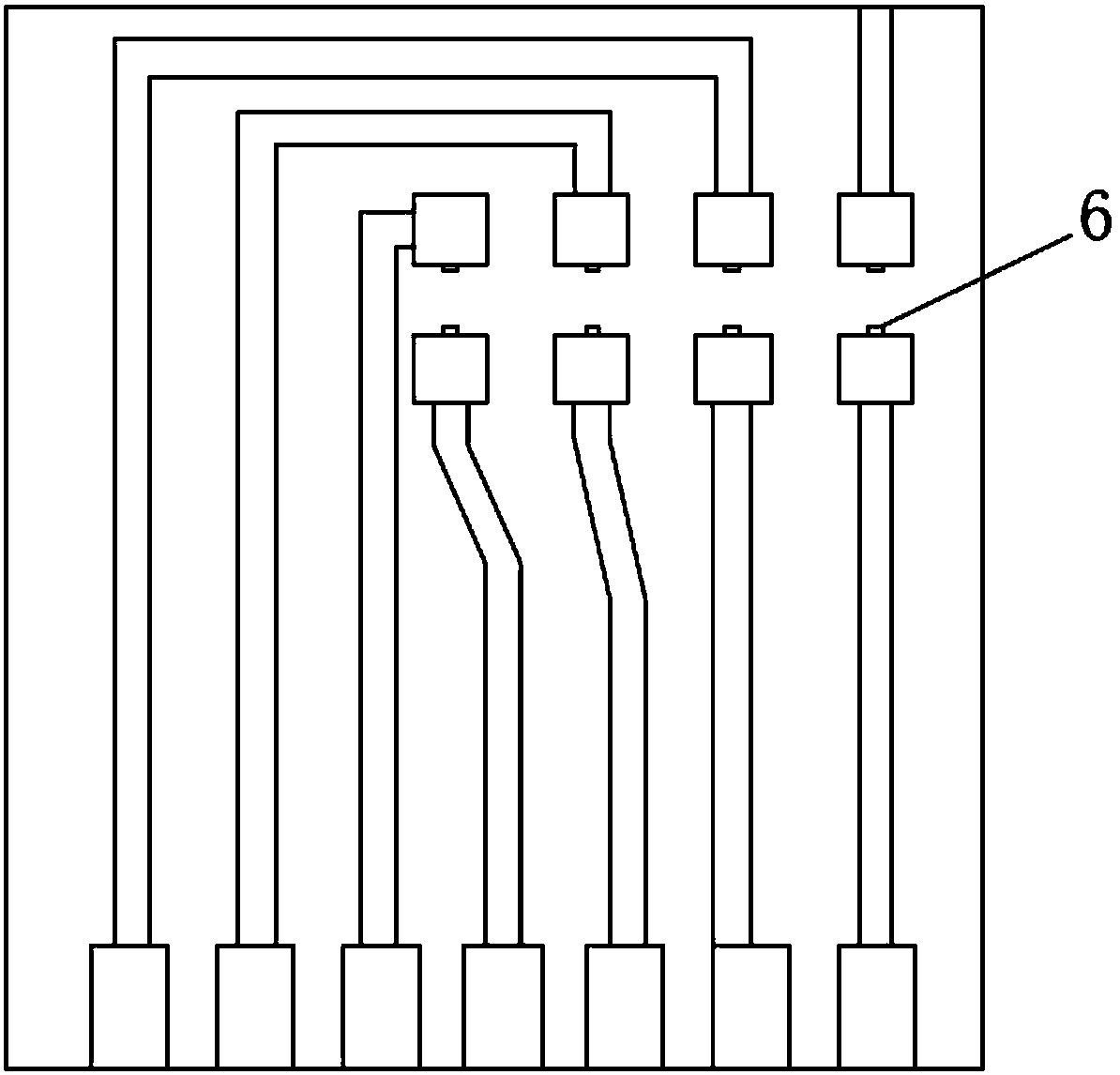

Bonding pad-based electroplating lead design

InactiveCN107708297AFix appearance problemsDoes not cause appearance problemsElectrical connection printed elementsPrinted element electric connection formationEngineeringPrinted circuit board

The invention discloses a bonding pad-based electroplating lead design. The bonding pad-based electroplating lead design comprises a plurality of bonding pads, wherein the plurality of bonding pads are arranged on a circuit board and are arranged adjacent to one another in a concentrated way, an electroplating lead is arranged among the plurality of bonding pads and is connected with the bonding pads at two sides, so that the bonding pads communicate with one another via the electroplating lead and finally communicate with an electroplating current. According to the method, the electroplatinglead is arranged among the bonding pads, the problem that an existing electroplating lead is additionally arranged on a signal line and the lead is resided after etching to cause signal completeness is solved, the problem of line thinness and line breakage caused by signal line etching in an existing etching electroplating process is prevented, and the appearance problem caused by resided lead after a printed circuit board assembly (PCBA) is assembled is prevented.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

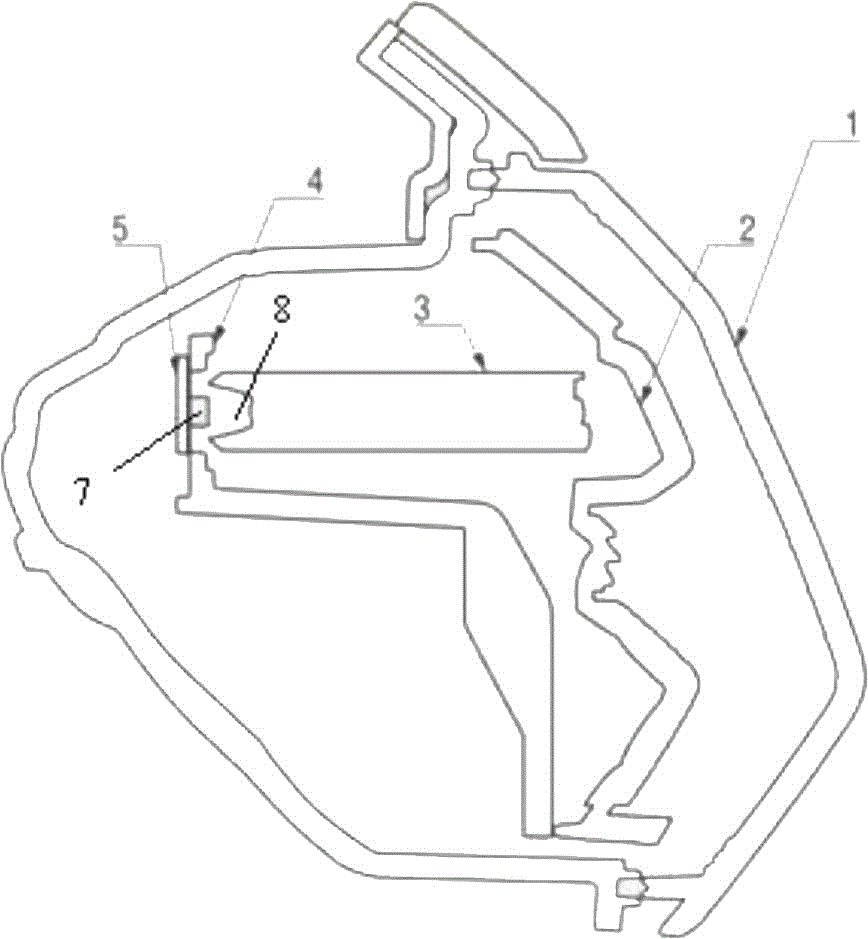

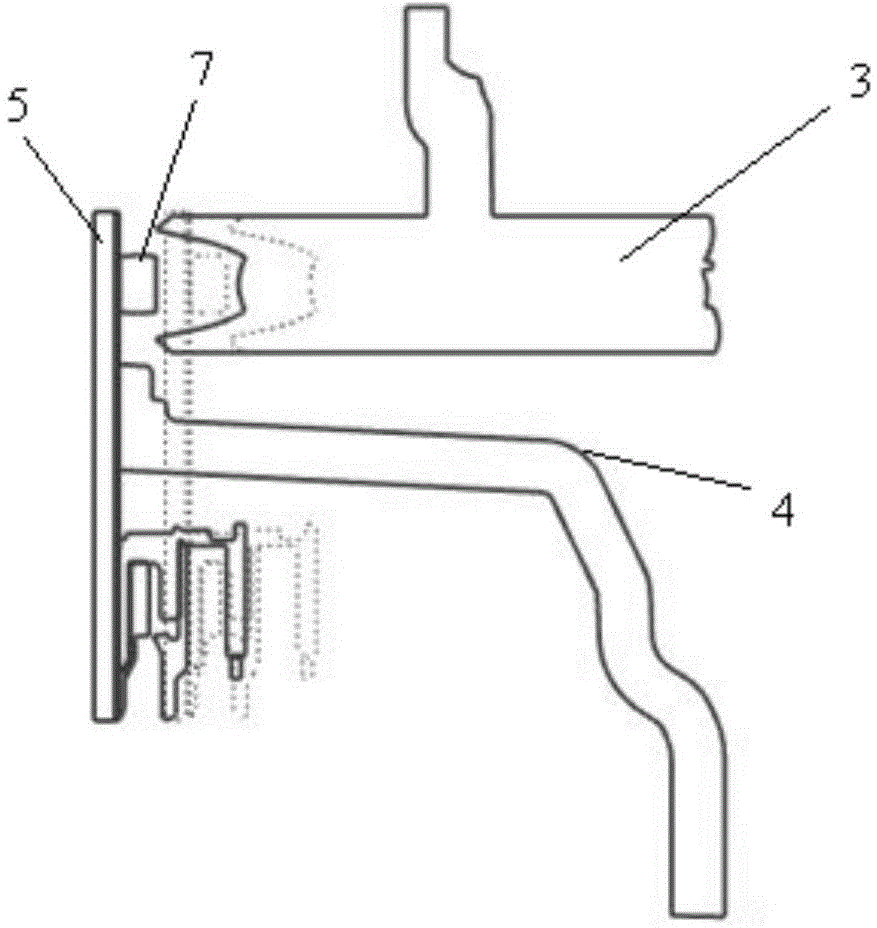

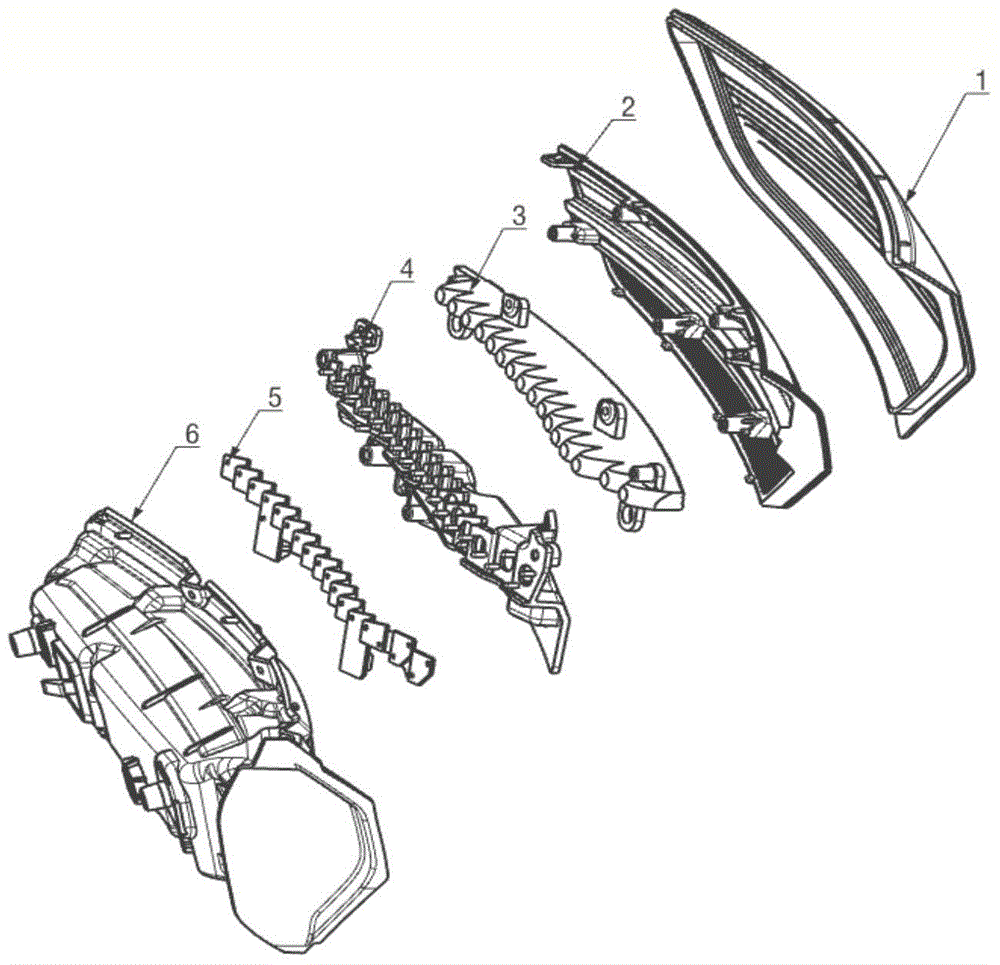

Automobile tail lamp functional module and LED circuit board installation method thereof

ActiveCN104913255AGood for lighting continuitySolve the problem of insufficient internal space to install LEDsPoint-like light sourceOptical signallingLight guideEffect light

The invention relates to an automobile tail lamp functional module and an LED circuit board installation method thereof. The functional module comprises a plurality of LED light sources, a transparent light guide plate, an LED installation support and an LED circuit board. The transparent light guide plate is fixed to the LED installation support. One end of the transparent light guide plate is of a sawtooth structure, and grooves are formed in the other end of the transparent light guide plate. Each groove is internally provided with one LED light source. The transparent light guide plate is located on the front face of the LED installation support. The LED circuit board is located on the back face of the LED installation support and used for adding the thickness of the LED circuit board on the depth of the grooves in the transparent light guide plate. Through holes are formed in the portions, corresponding to the LED light sources fixed to the LED circuit board, of the LED installation support. The LED light sources penetrate through the through holes to be correspondingly arranged inside the grooves in the transparent light guide plate. According to the automobile tail lamp functional module, LED installation and lighting effect uniformity and continuity are better facilitated.

Owner:HASCO VISION TECHNOLOGY CO LTD

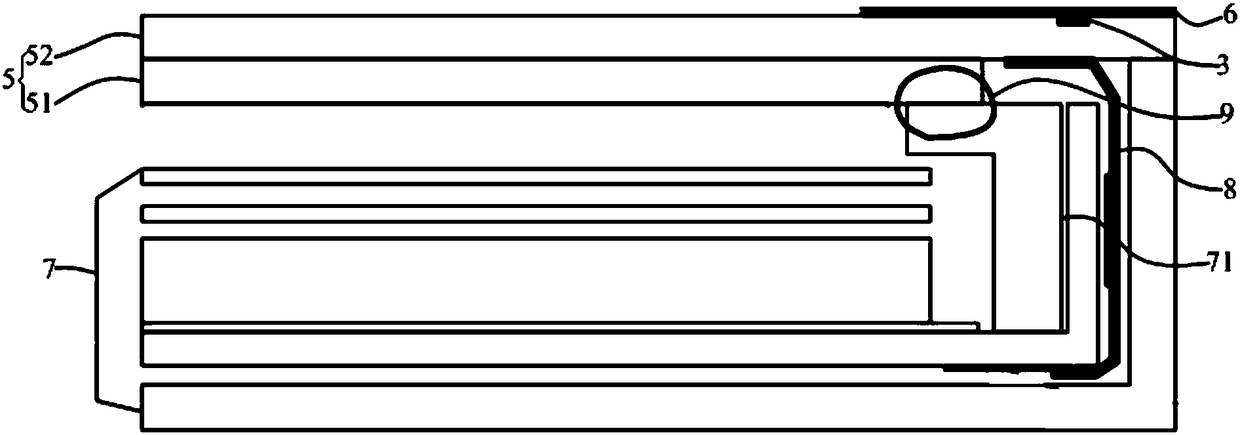

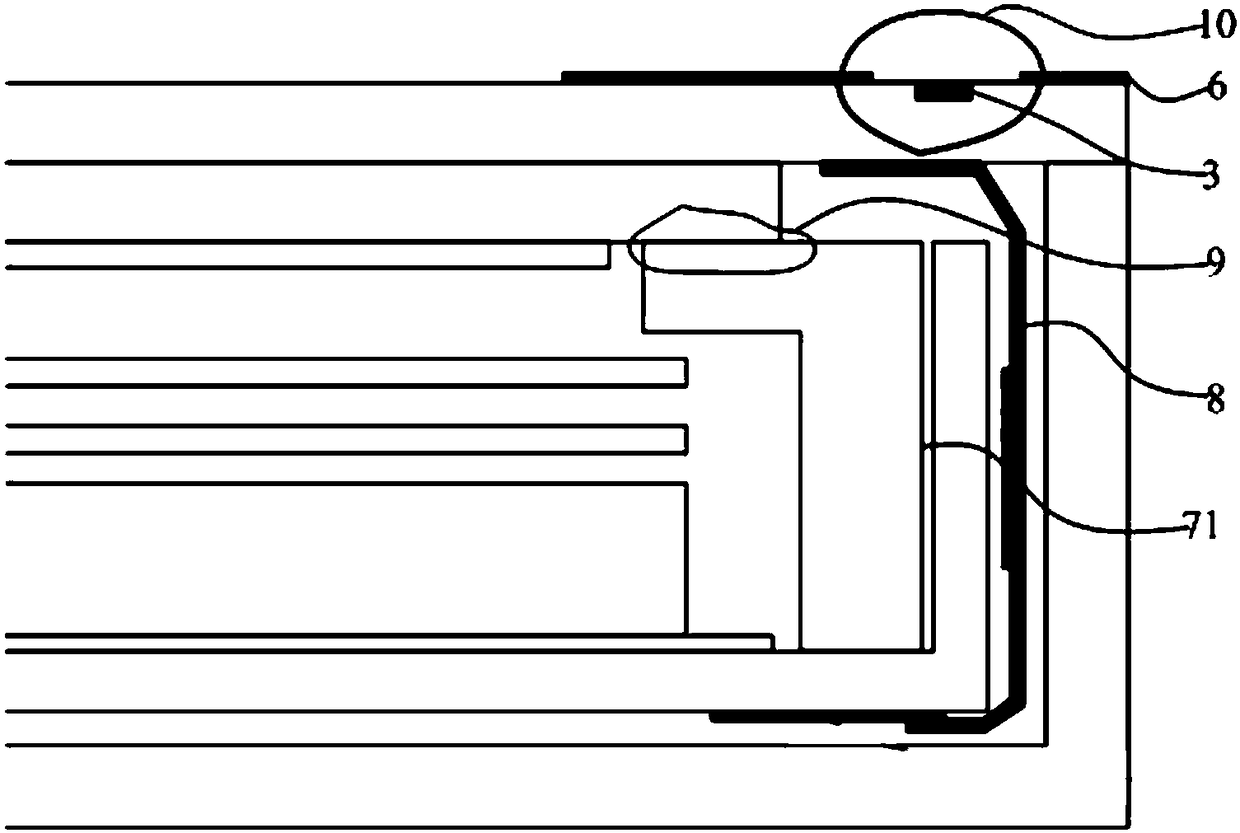

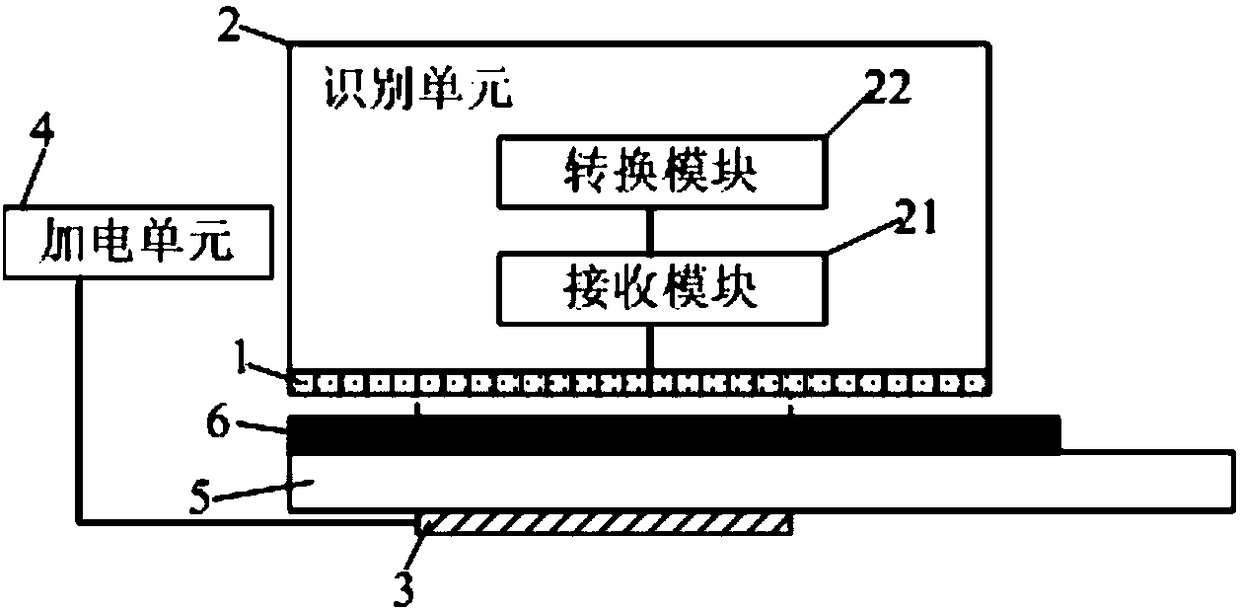

Binding mark identification device and binding device

ActiveCN108427216AFix appearance problemsReduce processing requirementsNon-linear opticsDisplay deviceEngineering

The invention provides a binding mark identification device and a binding device. The binding mark identification device comprises a sensing unit and an identifying unit; a setting position of the sensing unit corresponds to a binding mark; the sensing unit can induce a charge when the binding mark is powered; the identifying unit is connected to the sensing unit and used for receiving the inducedcharge of the sensing unit, and identifying the binding mark according to the induced charge. The binding mark identification device can induce the charge through the sensing unit when the binding mark is powered, and the identifying unit can identify the binding mark according to the induced charge, so that the binding mark can be recognized normally while being covered by blank ink, thereby avoiding the appearance problem of a display caused by the binding mark opening design in the prior art, and avoiding the black ink material which can transmit light in a certain wavelength range in theprior art, and avoiding the problem of a high process demand due to the black ink material.

Owner:BOE TECH GRP CO LTD +1

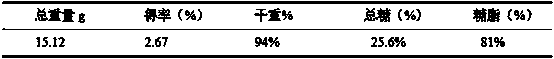

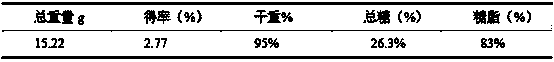

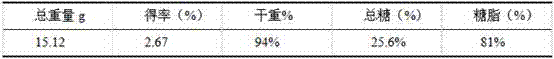

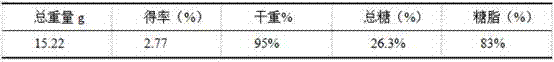

Glycolipid separation and purification method

ActiveCN104356172AHigh yieldSolve problems affecting the appearance of phospholipid productsSugar derivativesSugar derivatives preparationMaillard reactionSolubility

The invention discloses a glycolipid separation and purification method. The method comprises steps as follows: dissolving coarse phospholipid with n-hexane, then performing extraction with an ethanol aqueous solution, finally, collecting the ethanol aqueous solution, and removing the ethanol aqueous solution with a vacuum concentration method to obtain a glycolipid product. The method has the advantages that glycolipid is separated from the coarse phospholipid and purified by the aid of the difference of the solubility of the phospholipid and the glycolipid in the ethanol aqueous solution, and the obtained glycolipid is subjected to vacuum drying to form the glycolipid product with the glycolipid content higher than 80%. On one hand, the method is simple and efficient, and the glycolipid yield is high; on the other hand, the problem that the Maillard reaction affects the appearance of the phospholipid product during phospholipid processing is solved.

Owner:广州海莎生物科技有限公司

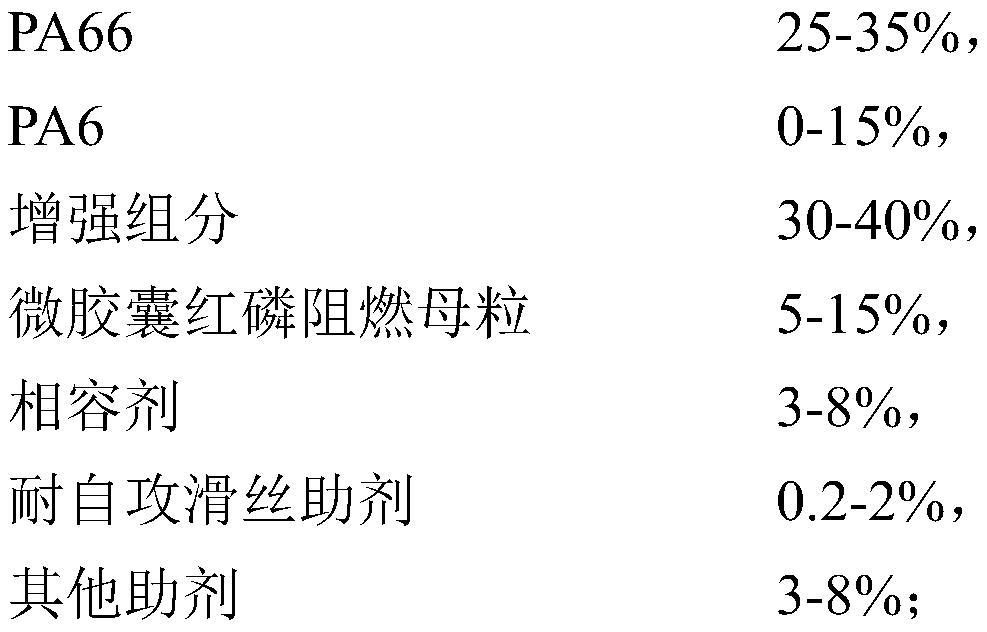

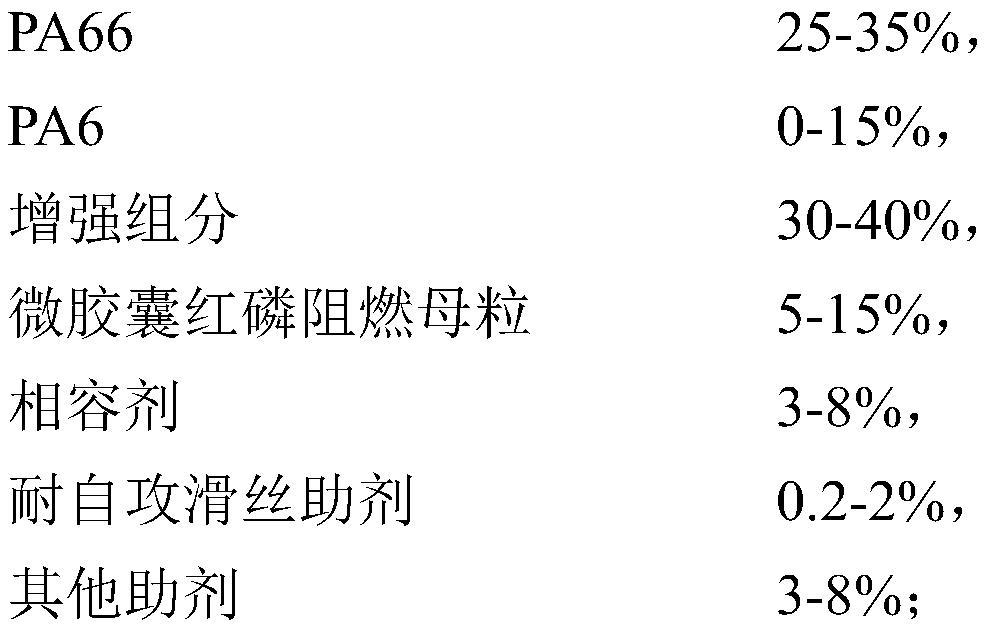

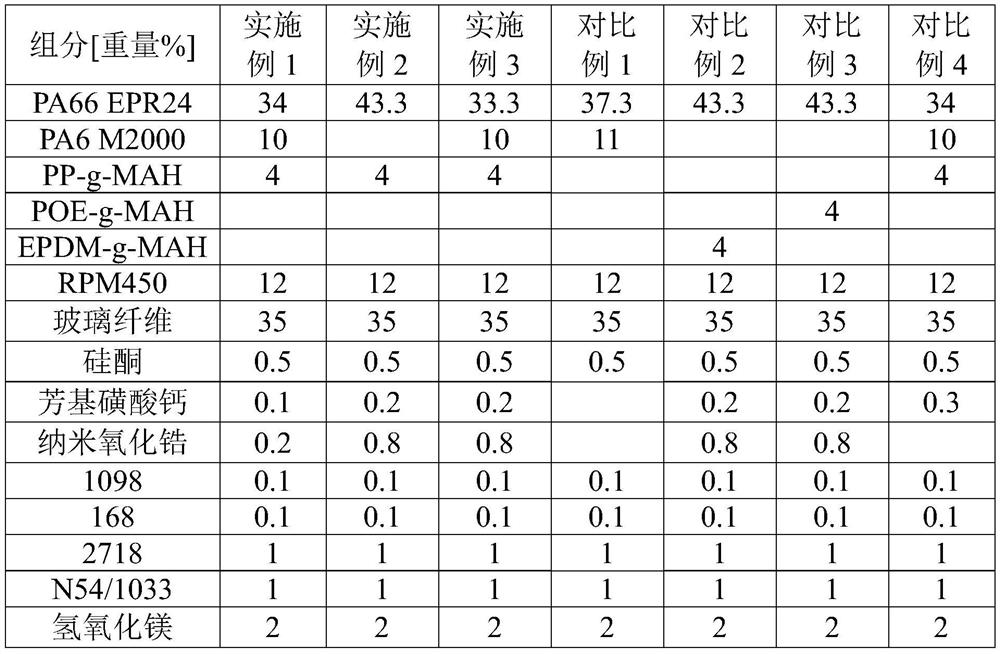

Polyamide material with excellent appearance, low water absorption and self-tapping slipping resistance, preparation method and application thereof

The invention discloses a polyamide material with excellent appearance, low water absorption and self-tapping slipping resistance, a preparation method and application of the polyamide material to preparation of an electric kettle temperature controller. The polyamide material is prepared from the following raw materials by weight percentage: 25-35% of PA66, 0-15% of PA6, 30-40% of a reinforcing component, 5-15% of microencapsulated red phosphorus flame-retardant master batch, 3-8% of a compatilizer, 0.2-2% of a self-tapping slipping resistant aid and 3-8% of other aids; wherein the compatilizer is at least one of polypropylene grafted maleic anhydride and polyethylene grafted maleic anhydride, and the melt index of the compatilizer is 35-150g / 10min under the conditions of 190DEG C and 1.2kg; and the self-tapping slipping resistant aid is prepared from calcium aryl sulfonate and nano zirconium oxide. The preparation method comprises the following steps of: uniformly blending the raw material components except the reinforcing component according to a ratio to obtain a premix, adding the premix into a double-screw extruder from a feeding port, adding the reinforcing component from afirst exhaust port of the double-screw extruder, and carrying out melt extrusion, cooling, drying and pelletizing to obtain the polyamide material.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Preparation method of suede structure of crystalline silicon solar cell

ActiveCN106449808AAffect stabilityAffect uniformityAfter-treatment detailsFinal product manufactureHydrofluoric acidPorous layer

The invention discloses a preparation method of a suede structure of a crystalline silicon solar cell. The preparation method comprises the following steps: (1) forming a porous layer structure on the surface of a silicon wafer; (2) treating the porous layer structure of the step (1) with the mixed solution; (3) using the cleaning fluid to remove residual metal particles; (4) and then using the first chemical etching solution for surface etching, you can get the suede structure of the crystalline silicon solar cell. The preparation method greatly prolongs the service life of the mixture of hydrofluoric acid and nitric acid and ensures the stability and uniformity of the suede structure.

Owner:CSI CELLS CO LTD

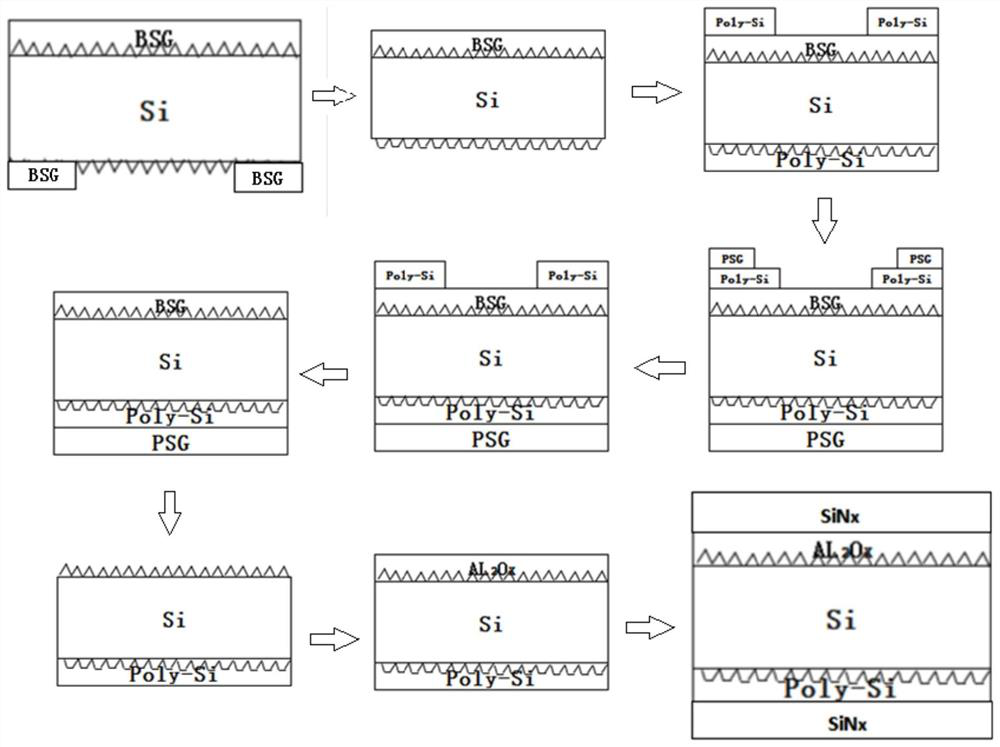

De-winding plating method for TOPCon battery and preparation method of TOPCon battery

ActiveCN112349584AGood removal effectNot volatileFinal product manufactureSemiconductor/solid-state device manufacturingHydrofluoric acidPhysical chemistry

The invention relates to the technical field of solar cells, and particularly discloses a winding and plating removing method for a TOPCon cell and a preparation method of the TOPCon cell. The methodcomprises the following steps: manufacturing a water film on the back surface of a phosphorus-doped silicon wafer, and removing phosphorus-doped layers wound and plated on the front surface and the side surface by using a hydrofluoric acid solution; soaking the obtained silicon wafer in a KOH solution or NaOH solution containing an additive, removing polycrystalline silicon on the front surface ofthe silicon wafer, taking out the silicon wafer, and washing with water; placing the obtained silicon wafer in a KOH or NaOH and H2O2 mixed solution to be soaked and then placing the silicon wafer ina hydrochloric acid solution to be soaked after washing, taking out the silicon wafer to be washed, completing the soaking treatment in a corresponding reaction tank, and arranging two sets of circulating bubbling systems in the reaction tank. According to the winding-plating-removing method provided by the invention, the winding plating phenomenon of the TOPCon battery can be effectively solved,the excellent rate of products is ensured, the appearance problem and EL disqualification problem caused by winding plating are solved, and the battery conversion efficiency is improved.

Owner:YINGLI ENERGY CHINA +1

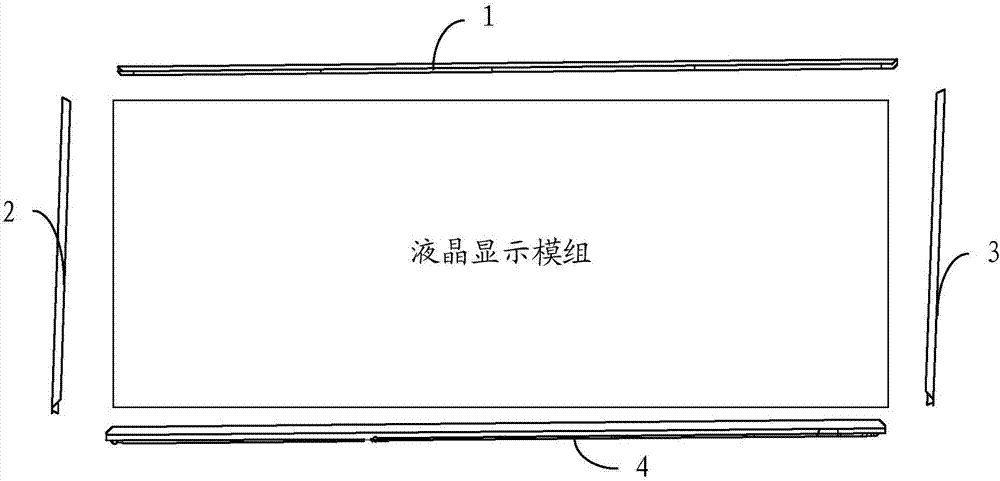

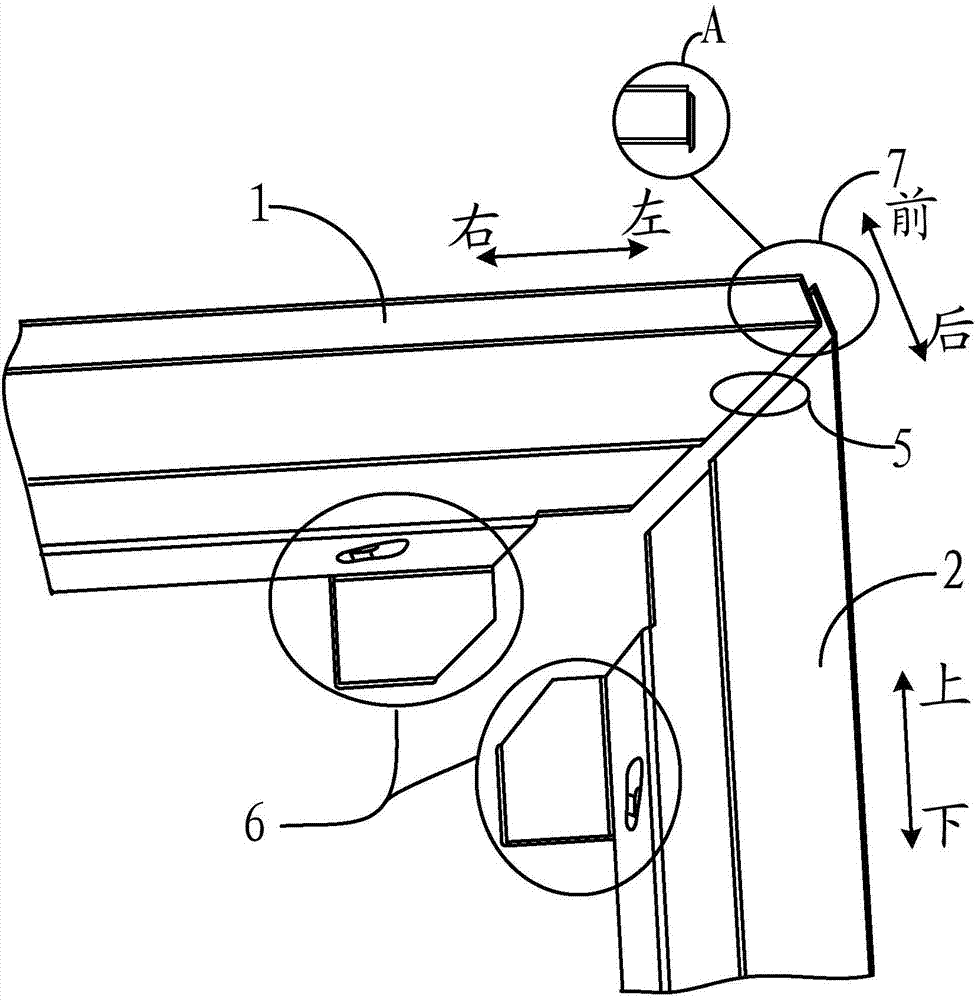

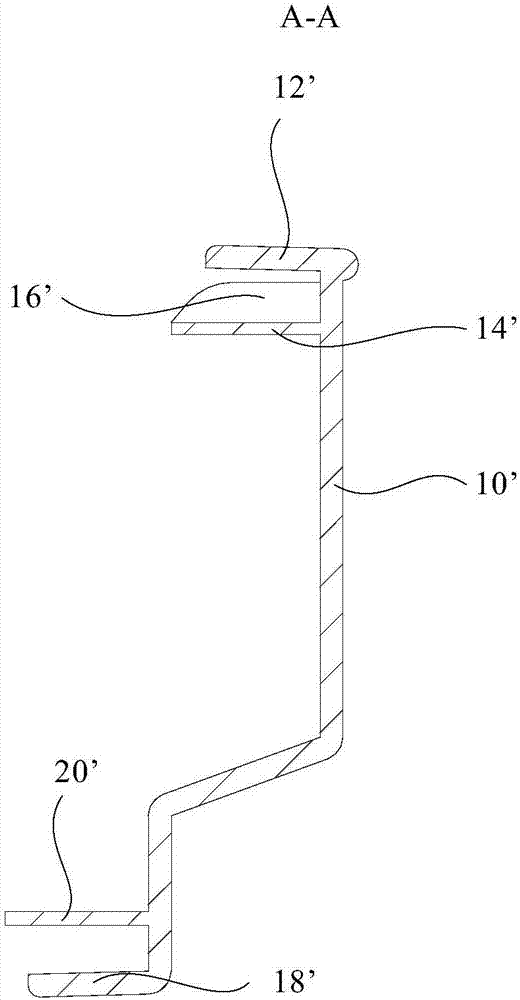

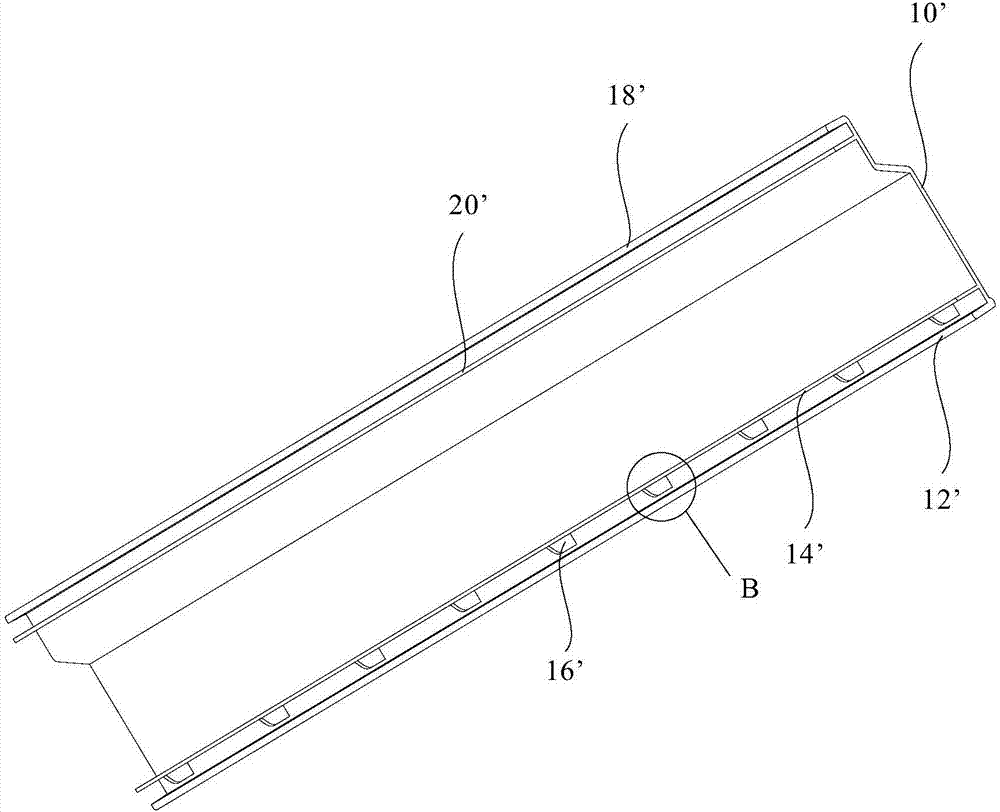

Screen metal frame assembly and liquid crystal display device

InactiveCN106959537AAvoid flippingPrevent collapseNon-linear opticsLiquid-crystal displayEngineering

An embodiment of the invention provides a screen metal frame assembly and a liquid crystal display device, relates to the field of display screen assembling and solves the problem of splicing errors of a screen metal frame. The screen metal frame assembly comprises a first frame and a second frame, wherein a first splicing surface formed at one end of the first frame is correspondingly attached to a second splicing surface formed at one end of the second frame; an elastic piece is arranged at one end, close to the first splicing surface, of the inner wall bottom surface of the first frame; one end of the elastic piece is attached to the inner wall bottom surface of the first frame; the other end of the elastic piece is connected with the inner wall bottom surface of the second frame. The screen metal frame assembly and the liquid crystal display device are applied to metal frame splicing of the liquid crystal display screen.

Owner:HISENSE VISUAL TECH CO LTD

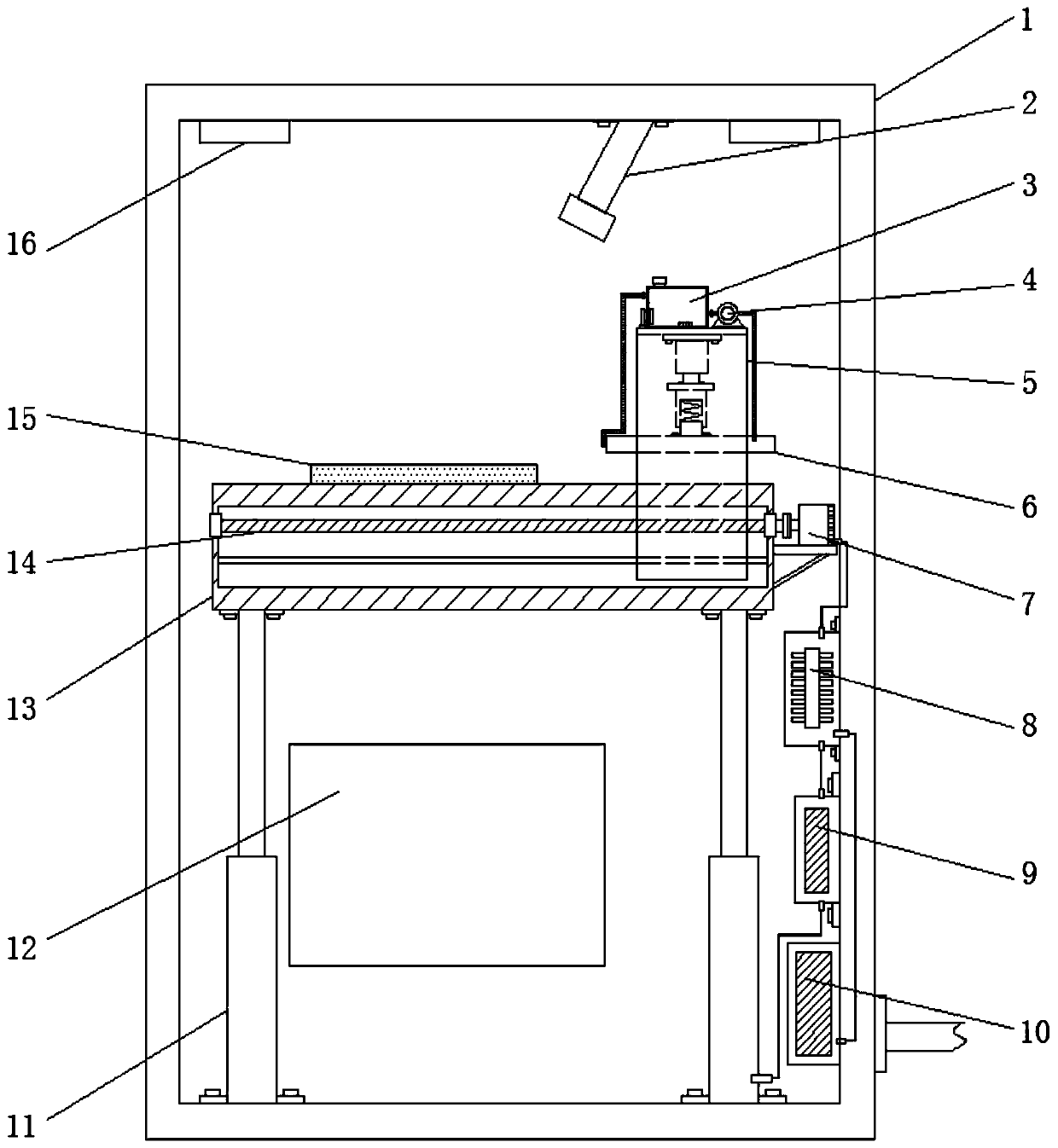

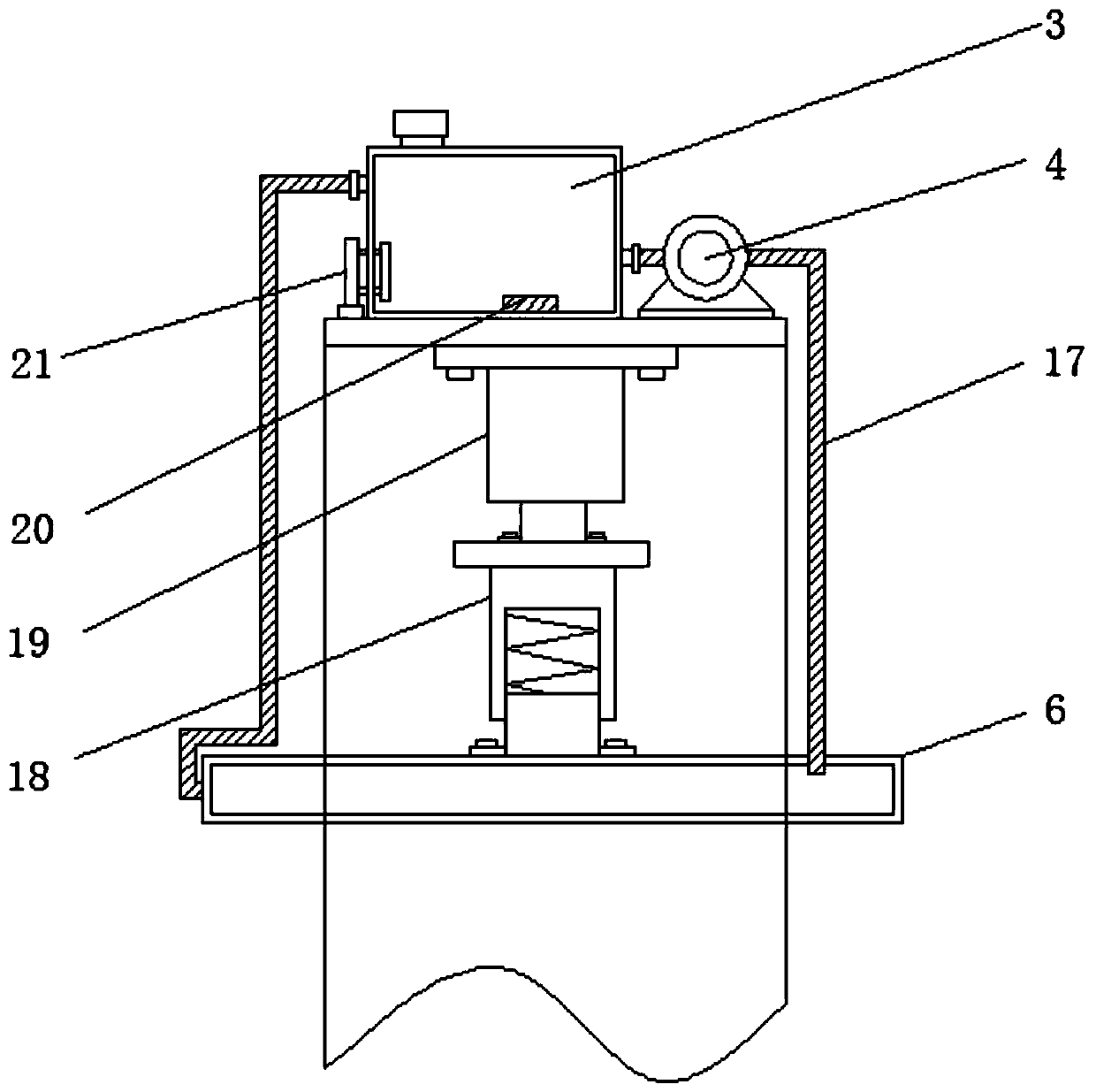

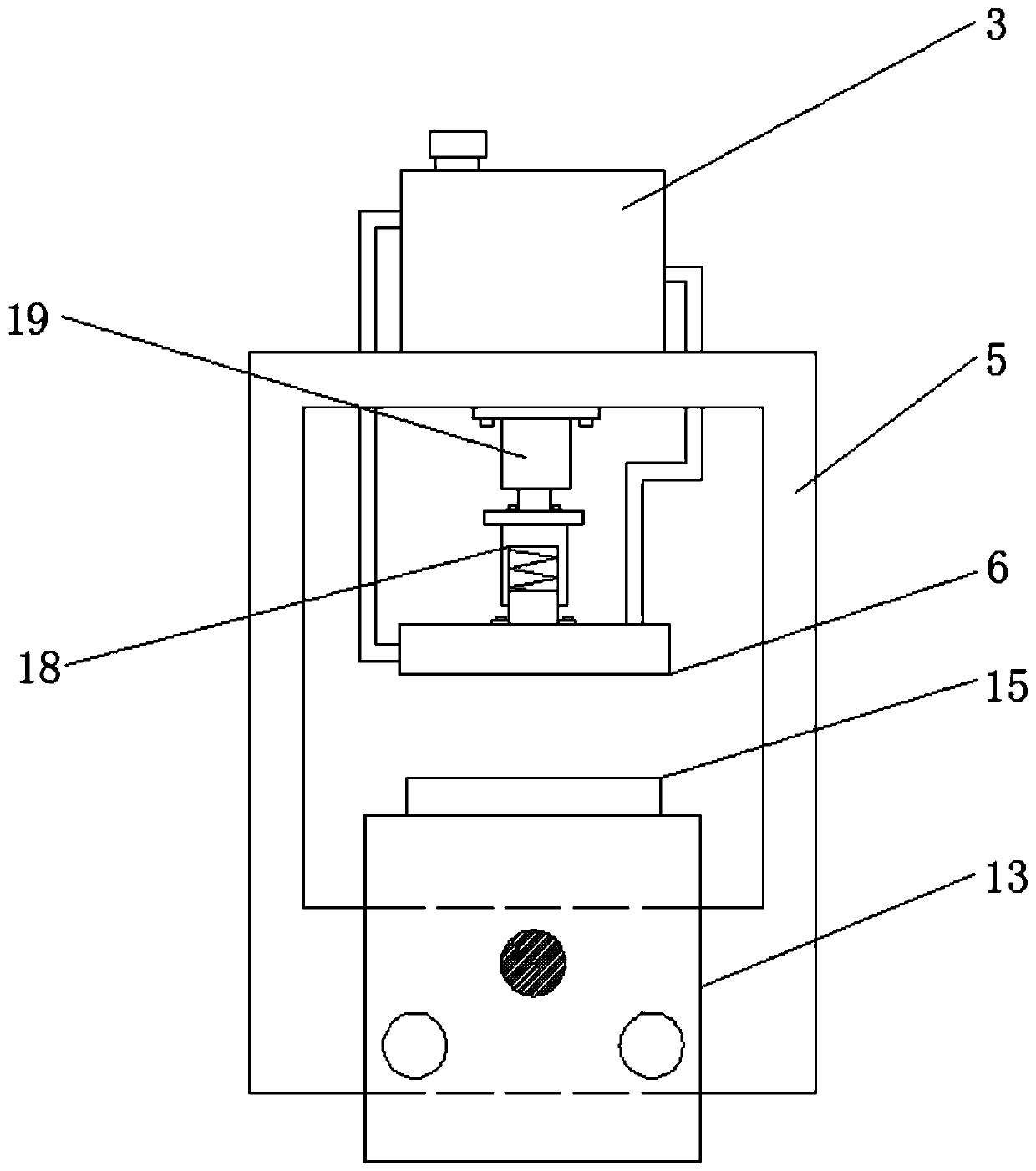

Anti-wrinkling structure with detection function of custom-made self-service vending machine for T-shirt

InactiveCN110303777ASolve the problem that wrinkles are prone to affect the appearance of cultural shirtsFix appearance problemsTypewritersOther printing apparatusEngineeringLED lamp

The invention discloses an anti-wrinkling structure with a detection function of a custom-made self-service vending machine for a T-shirt. The anti-wrinkling structure comprises a detection camera, ahot water tank, a first telescopic motor, an LED lamp, a second telescopic motor and a temperature sensor, wherein the detection camera is arranged on the upper right side of the T-shirt, the detection camera is electrically connected with a single-chip microcomputer, the hot water tank is fixedly arranged on the upper side of a movable block, the hot water tank communicates with the interior of ahot water pipe and the interior of an ironing plate through a hot water pump, the single-chip microcomputer is electrically connected with an image sensor, a storage battery is installed on the lowerside of the image sensor, a telescopic rod of the first telescopic motor is fixed to the bottom of a workbench through a bolt, and a screw rod is arranged inside the workbench through a bearing. According to the anti-wrinkling structure with the detection function of the custom-made self-service vending machine for the T-shirt, the attractiveness and integrity of a pattern are ensured, and the problem that the appearance of the T-shirt is influenced due to the fact that the T-shirt is prone to wrinkles is solved.

Owner:蔡赟

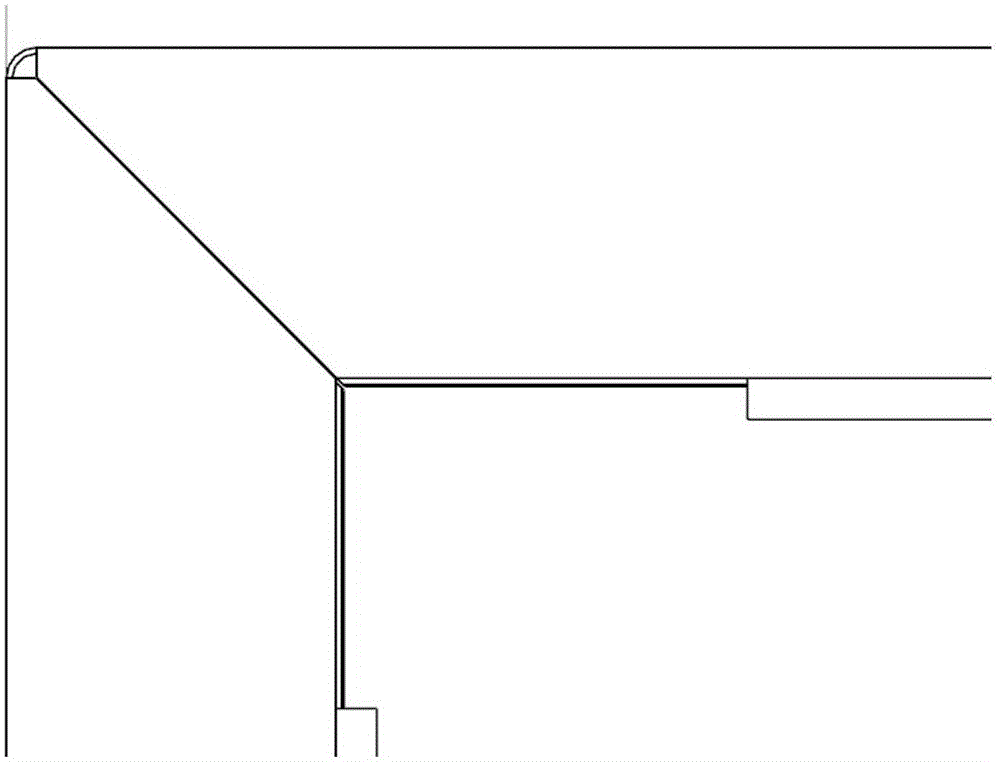

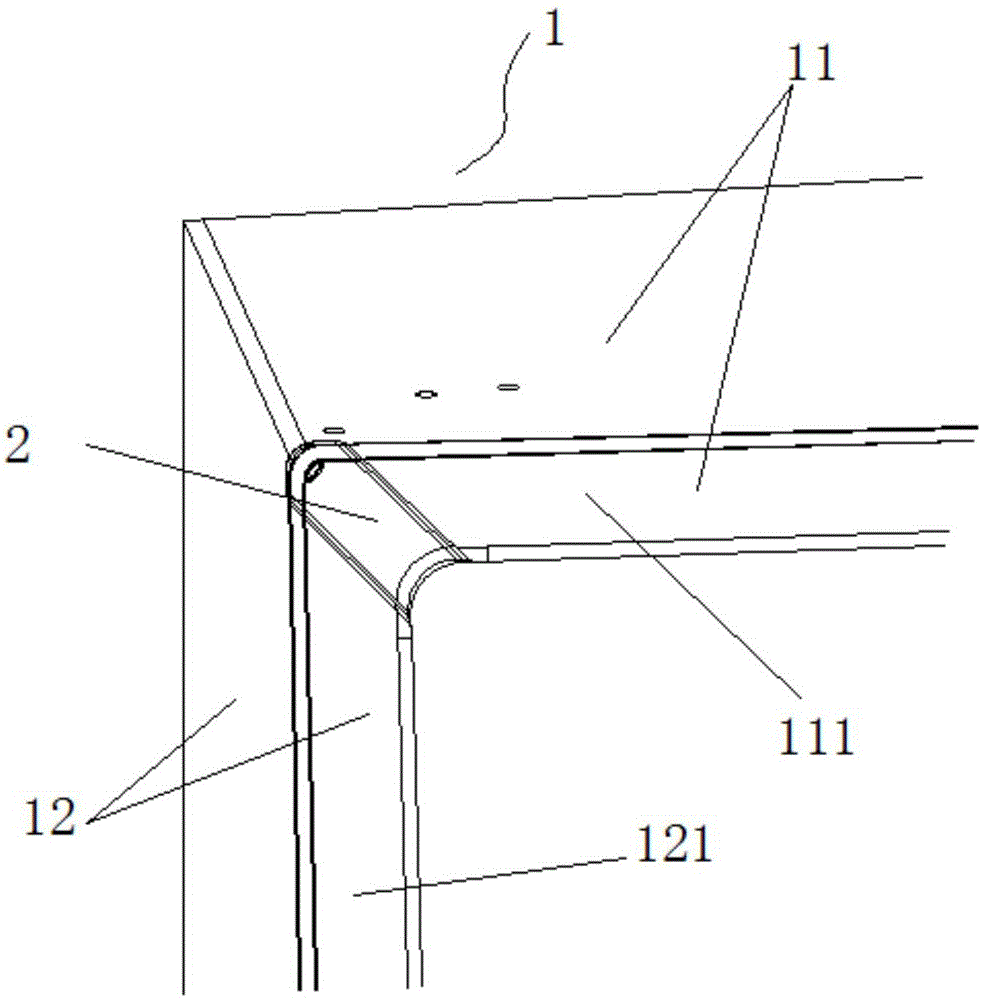

Opening frame structure and refrigerating device

ActiveCN107120908AImprove appearance qualityAffect appearance qualityDomestic cooling apparatusLighting and heating apparatusEngineeringInjection molding process

The invention provides an opening frame structure used for a refrigerating device. The refrigerating device comprises a box body. The opening frame structure is arranged at the opening end of the box body and comprises an appearance panel and a first reinforcing rib. A first side plate is arranged on the side, opposite to the outer portion of the box body, of the appearance panel. An arc protrusion is arranged at the position, at the connecting position of the first side plate and the appearance panel, on the outer surface of the appearance panel. The first reinforcing rib is arranged on the inner surface of the appearance panel, and a first insertion groove is formed by the first reinforcing rib and the first side plate. A transition section is arranged at the portion, between the connecting position of the first reinforcing rib and the appearance panel and the arc protrusion, on the outer surface of the appearance panel. The transition section covers the connecting position of the first reinforcing rib and the appearance panel. By means of the opening frame structure and the refrigerating device, due to the fact that the connecting position between the first reinforcing rib and the appearance panel is covered with the transition section, vision transfer can be caused, the problem that the connecting position shrunk in the injection molding process, and consequently the appearance panel is not attractive is effectively avoided, and the appearance quality of the opening frame structure is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

Under-screen fingerprint identification module, under-screen fingerprint identification method and electronic equipment

PendingCN111832429AImprove performanceReduce intensityCharacter and pattern recognitionLensEngineeringMicro lens array

The invention provides an under-screen fingerprint recognition module. The under-screen fingerprint recognition module sequentially comprises a quarter-wave plate, a polarization bifocal microlens array, alight blocking layer, and a photoelectric sensor. The polarization bifocal microlens array is configured to diverge incident light polarized along a first direction or propagate the incident light along an original light path, and focus the incident light polarized along a second direction, wherein the first direction is perpendicular to the second direction; the light blocking layer is configured to allow a portion of the incident light to pass therethrough; and the photoelectric sensor is configured to receive part of incident light passing through the light blocking layer and convert the incident light into an electric signal.

Owner:江西微瑞光学有限公司

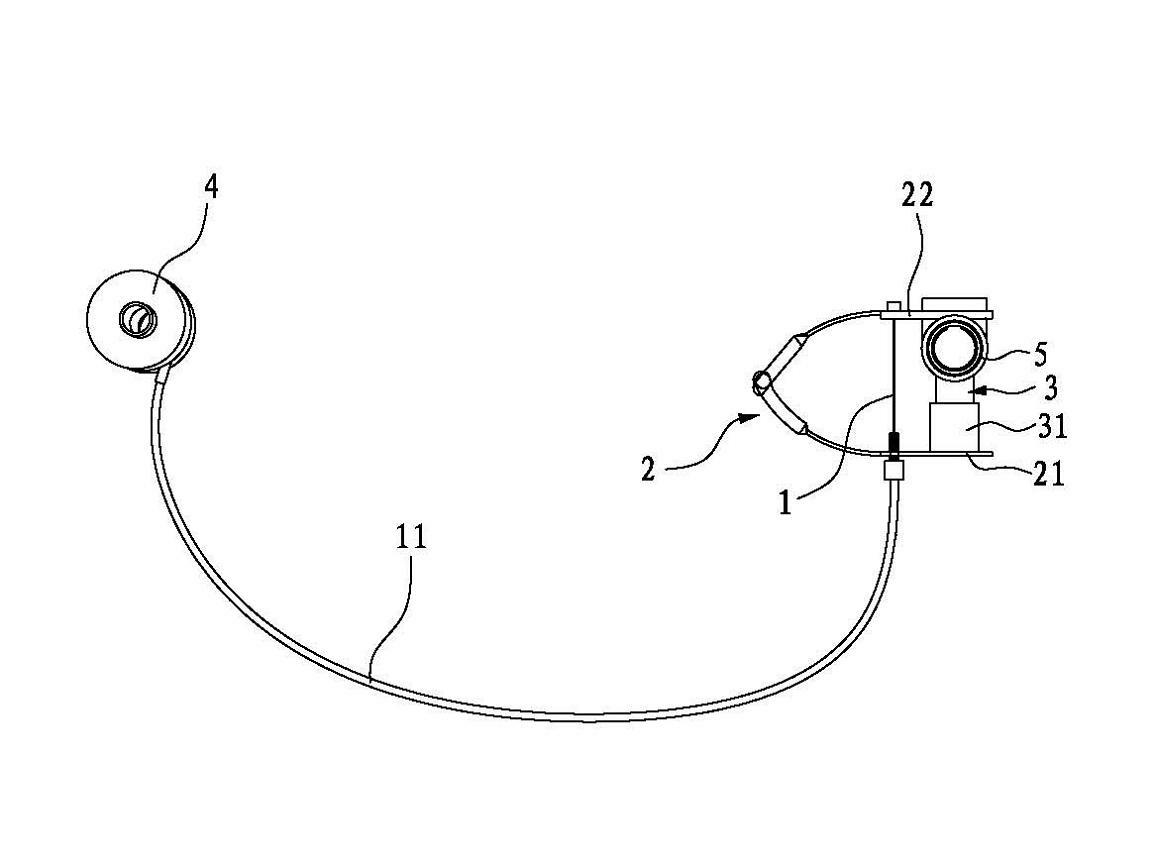

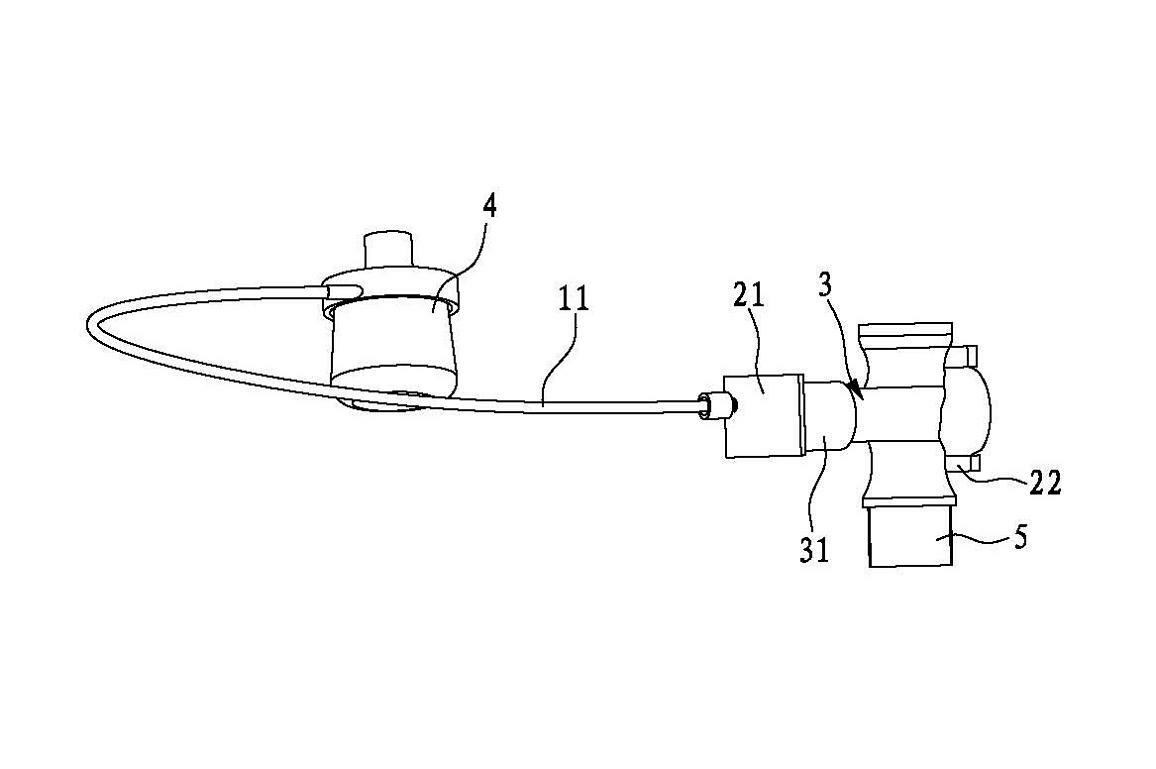

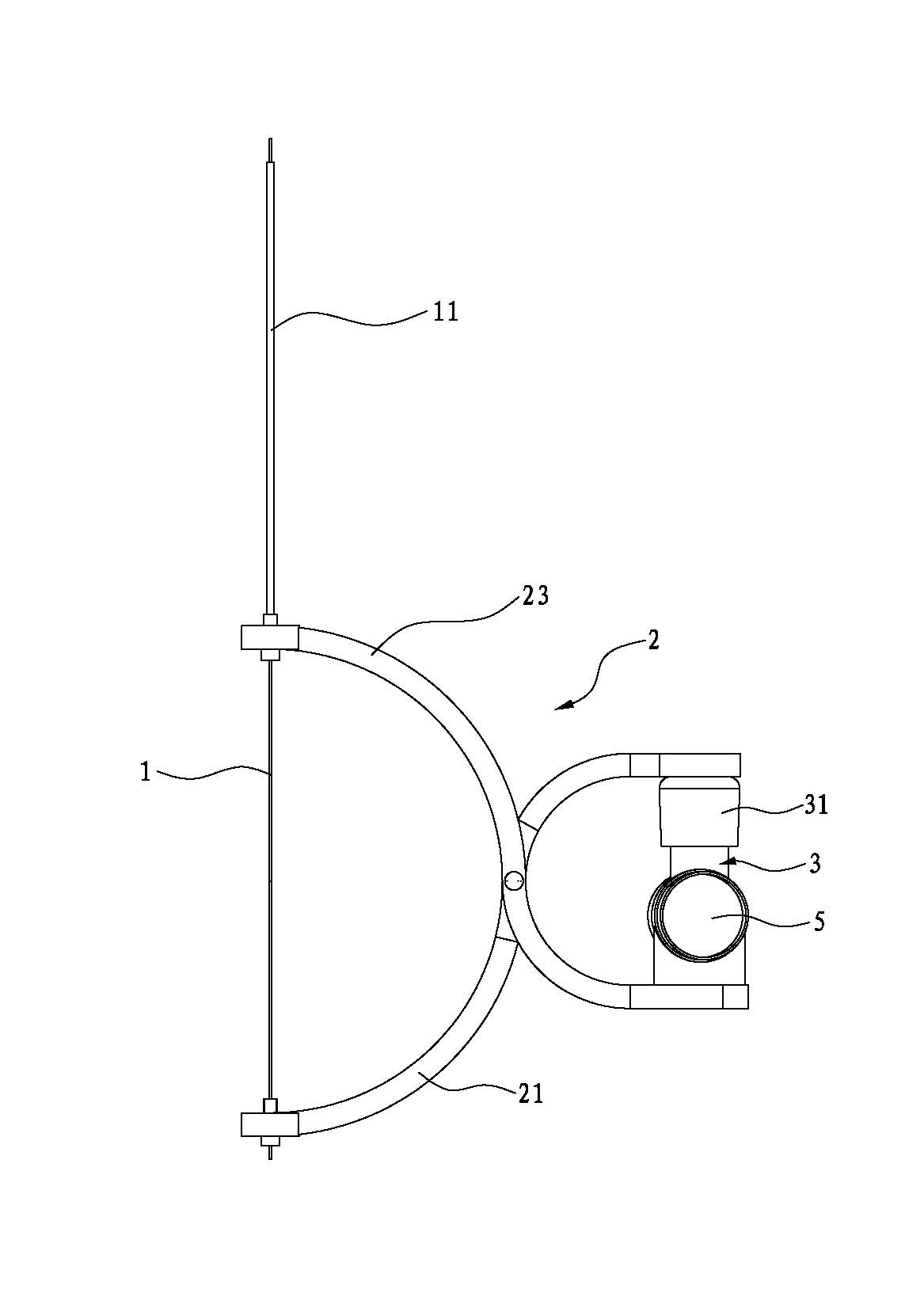

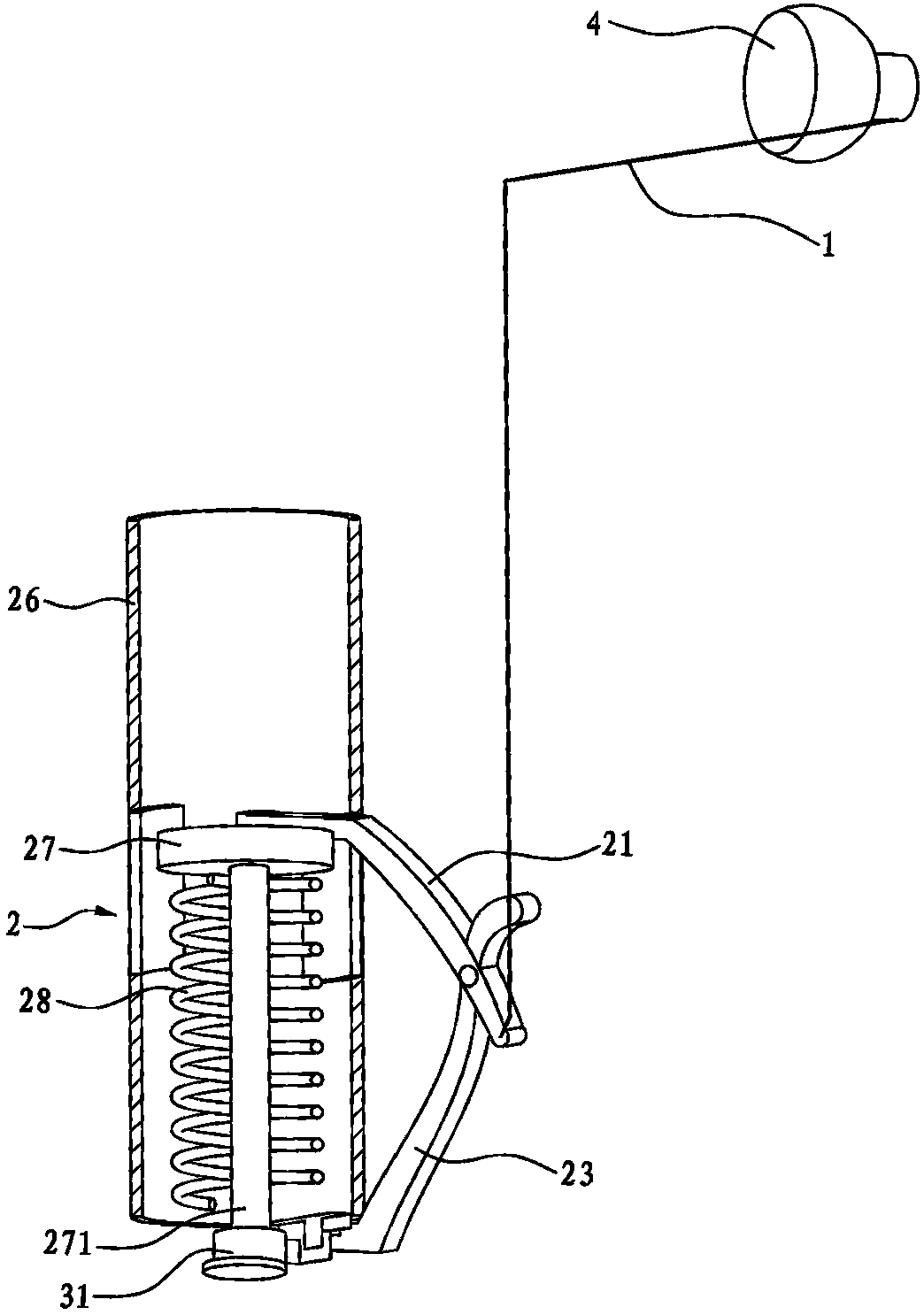

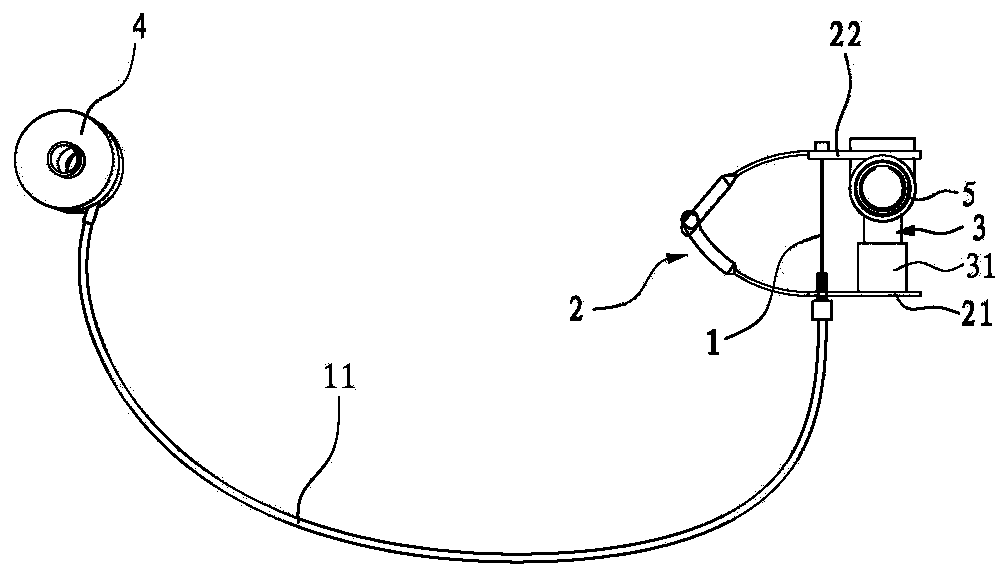

Automatic flushing device

The invention discloses an automatic flushing device, which comprises a brake cable and a push mechanism. One end of the brake cable is connected with an action mechanism of a door lock device, the other end of the brake cable is connected with the push mechanism, the push mechanism is provided with a push part pulled by the brake cable to act, and the push part is in direct or indirect linkage with a button of a toilet flushing device. The automatic flushing device is in linkage with the door lock device of a door, and when the door is opened, unlocking action of the door lock can be transmitted to the button of the toilet flushing device through the brake cable, and a toilet can be automatically flushed only by opening the door. The automatic flushing device recovers door opening force, needs no external power and can guarantee cleanness of a public lavatory.

Owner:XIAMEN UNIV OF TECH

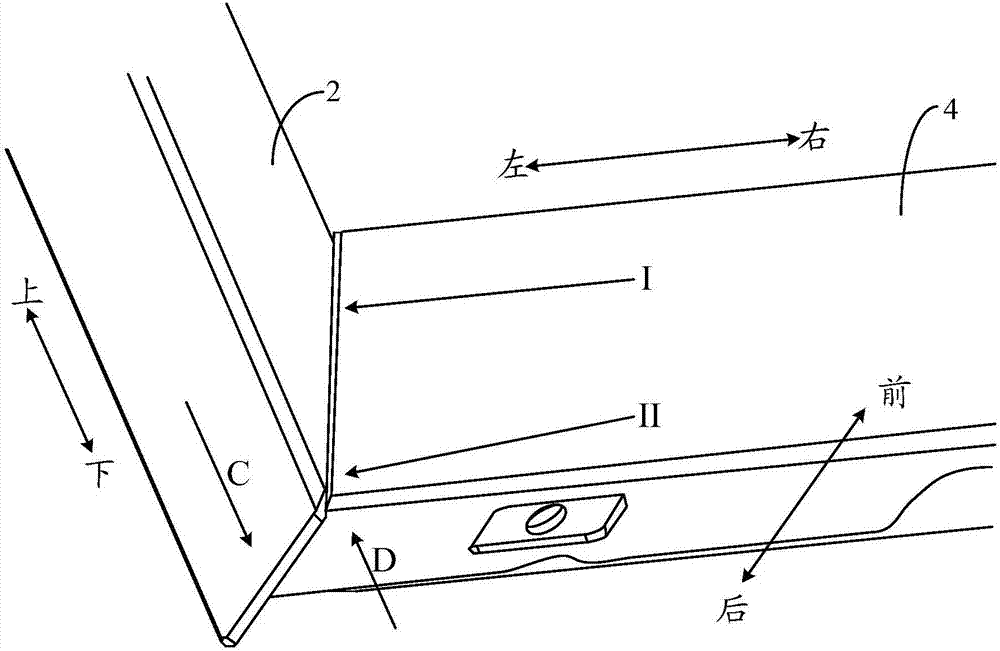

Bent U-shaped box shell bending and splicing structure

InactiveCN105004134AFix appearance problemsBeautiful appearanceDomestic cooling apparatusLighting and heating apparatusPunchingEngineering

The invention relates to a bent U-shaped box shell bending and splicing structure. The structure comprises a first splicing plate with a first folded edge and a second splicing plate with a second folded edge. The first splicing plate and the second splicing plate are spliced to form a spliced corner structure. One end of the first folded edge and one end of the second folded edge are each provided with a 45-degree splicing edge. The first folded edge and the second folded edge are spliced through the 45-degree splicing edges. The spliced part is provided with a covering element capable of being detachably connected with the first folded edge and the second folded edge. Sharp corners, burrs, malposition and other problems caused by insufficient strength or insufficient punching precision of a punching die can be reduced. Besides, the structure is attractive after splicing, and the surface of a box shell is clean. Cut corners, smaller than 2 mm, of the punching die can be eliminated and optimized, and reliability of the punching die is improved. The splicing structure is simple, consistency is good in the production process, the yield is high, and the market and inspection complaint rate is reduced.

Owner:HEFEI HUALING CO LTD +1

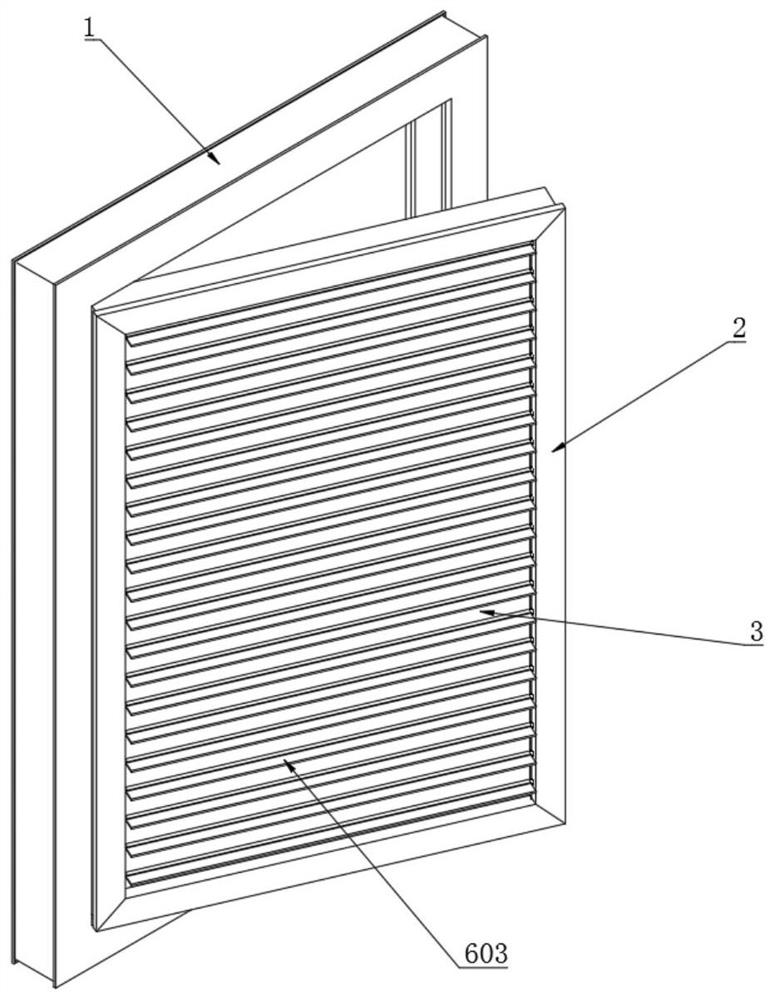

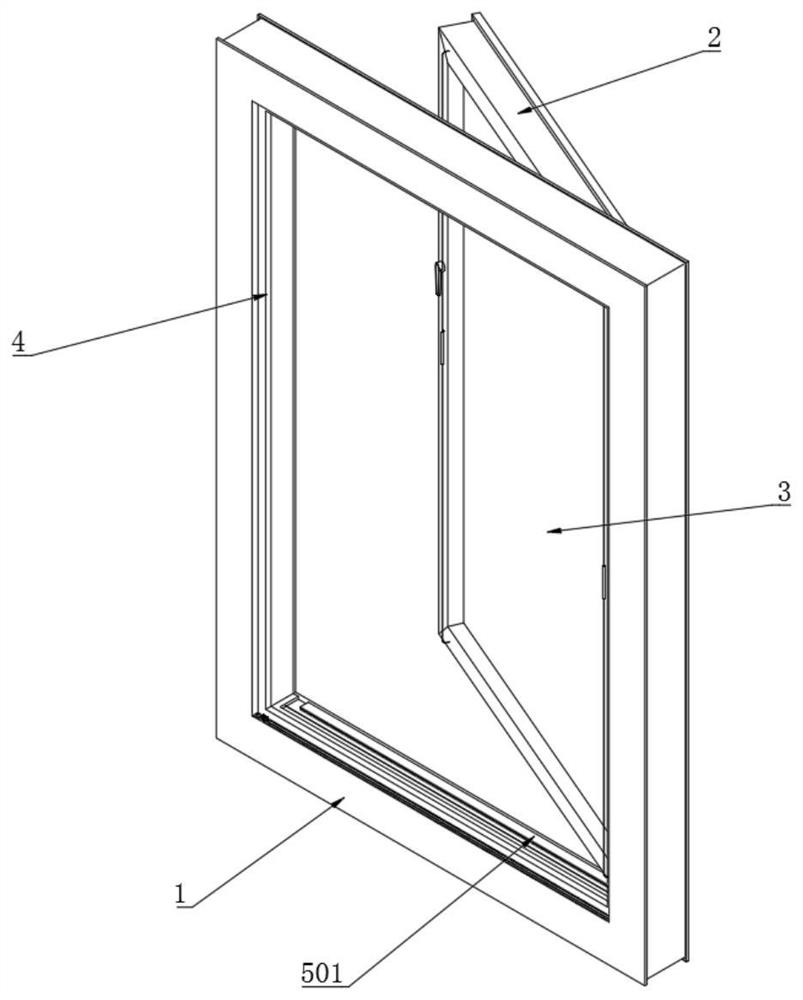

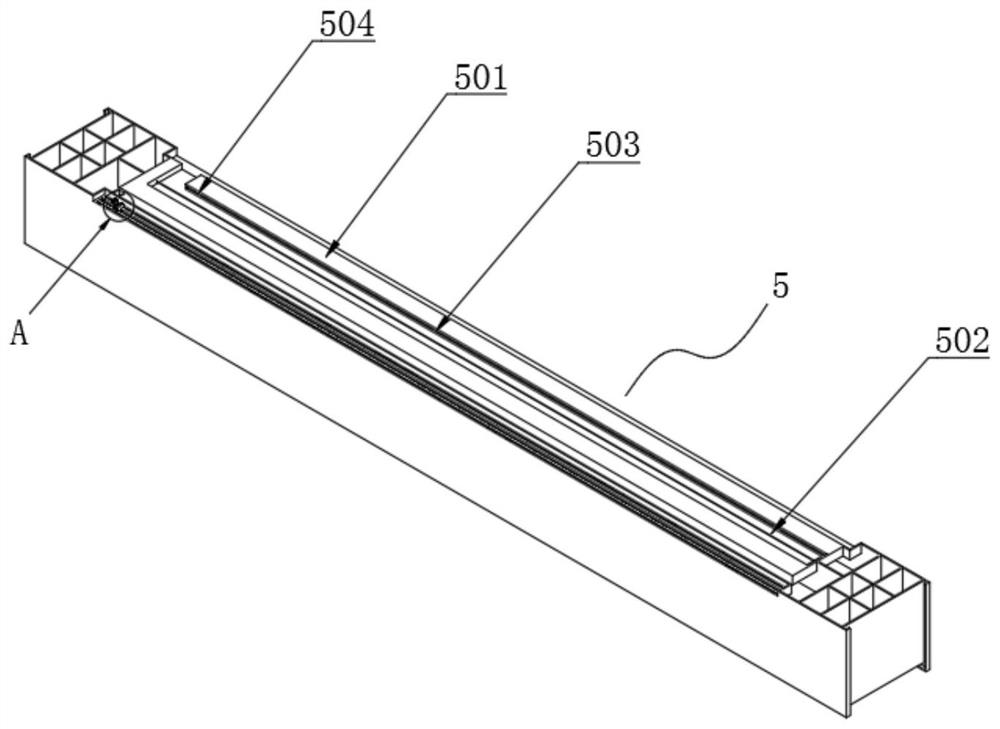

Heat insulating door and window capable of preventing aging and fading

InactiveCN111827851AReduce dust accumulationImprove cleaning convenienceDoor/window protective devicesFireproof doorsStructural engineeringMechanical engineering

The invention discloses a heat insulating door and window capable of preventing aging and fading. The heat insulating door and window comprise a mounting window frame. An overturning window frame is rotationally mounted at one end of the mounting window frame, double-layer glass is pasted on the inner side of the overturning window frame, and sealing adhesive tape is pasted at the joint of the double-layer glass and the overturning window frame. The heat insulating door and window are scientific and reasonable in structure and safe and convenient to use, through the arrangement of a cleaning groove, a cleaning plate, a connecting wire, a reset spring, a movable groove, a movable plate and a push handle, the inner wall of the bottom end of the mounting window frame can be cleaned, the cleaning difficulty of the inner wall of the bottom end of the mounting window frame is reduced, and the danger generated when the mounting window frame is cleaned is reduced; and through the arrangement of rotary connecting seats, sun-shading baffles, L-shaped grooves, conduction wires and an adjusting handle, the double-layer glass can be shielded through the sun-shading baffles, the double-layer glass is subjected to sun-shading protection, aging and fading of the double-layer glass during use are reduced, temperature rise caused by illumination can be reduced, and the heat insulating effect when the heat insulating door and window are used is improved.

Owner:徐双伟

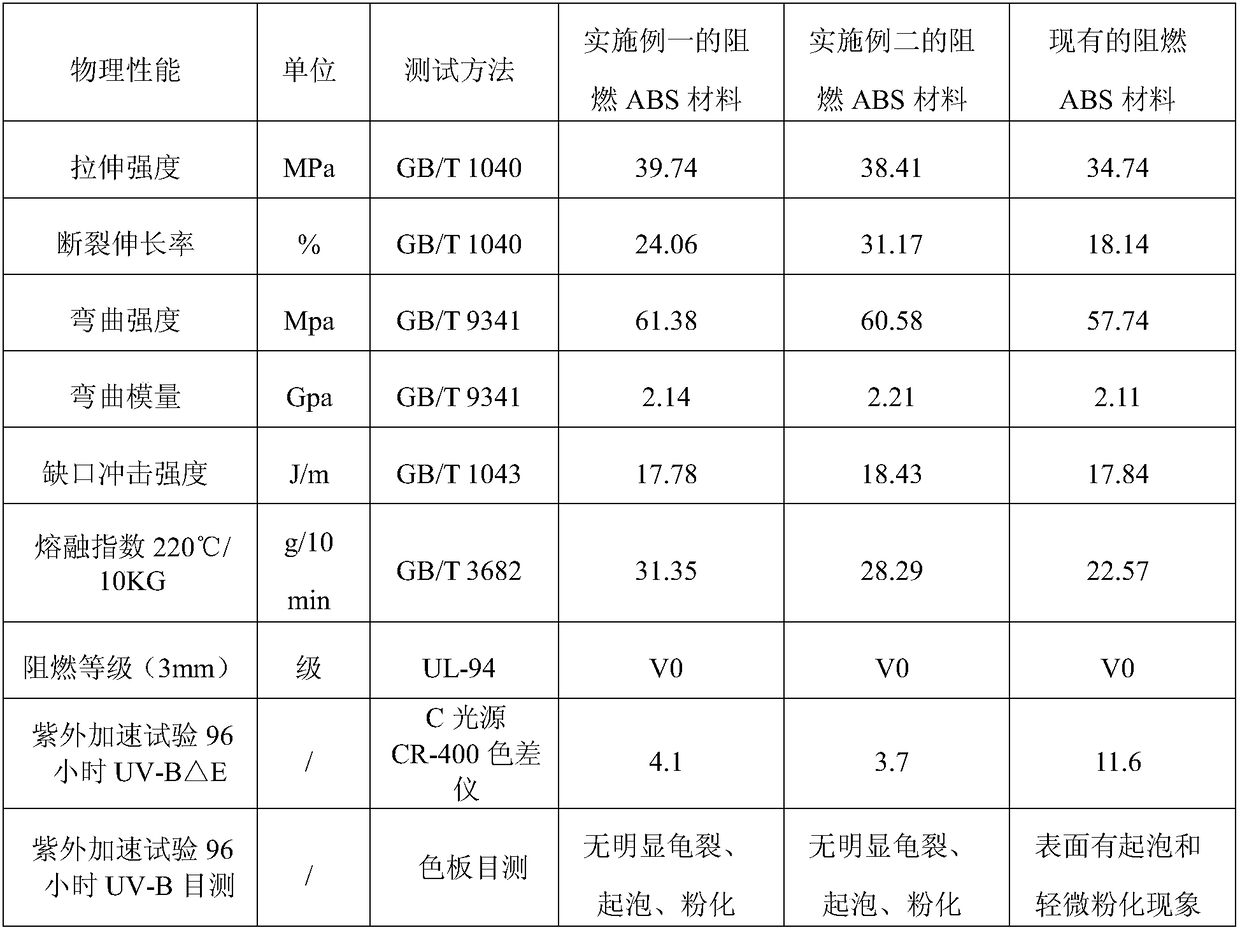

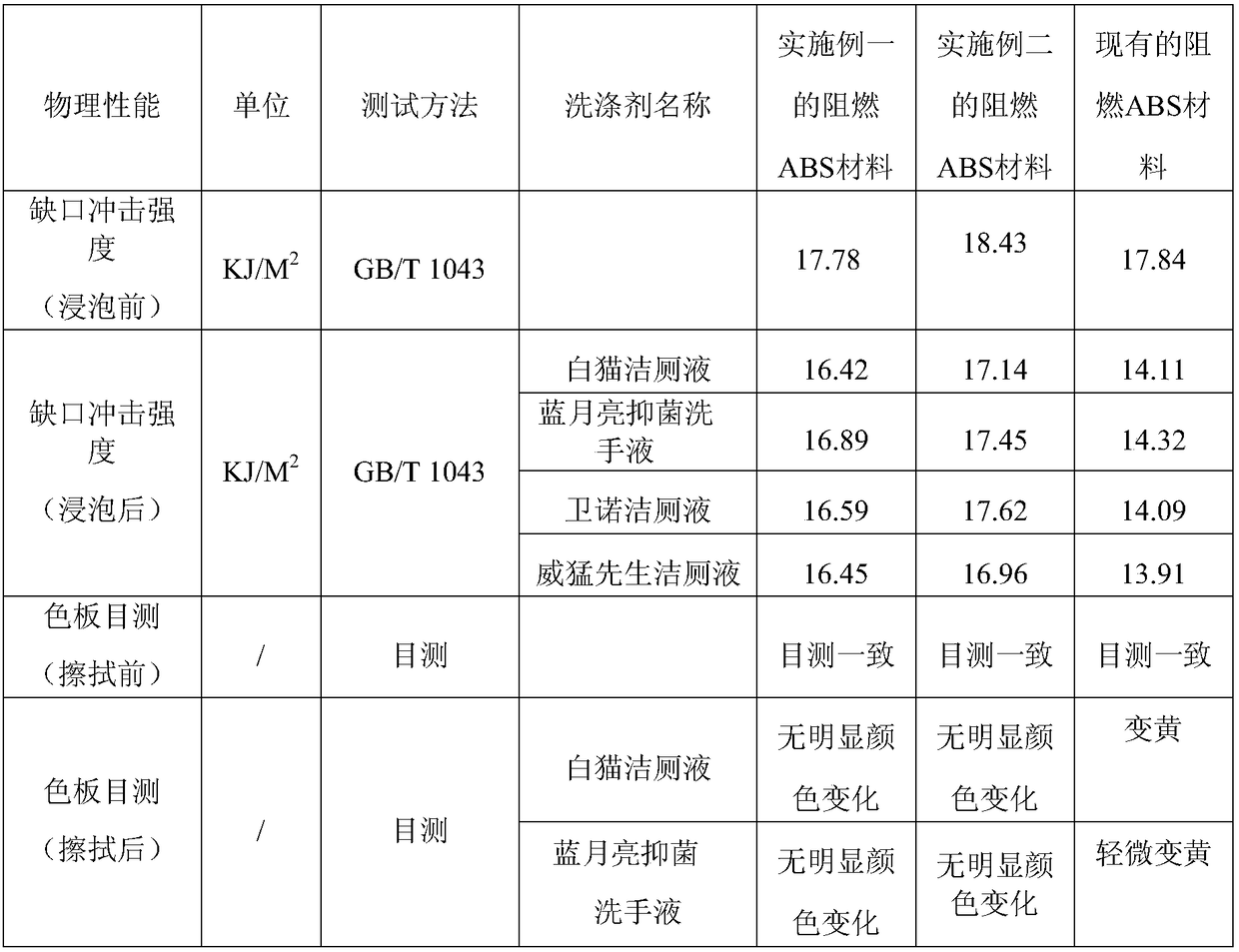

Flame-retardant ABS material for weather-resistant washing-resisting closestool and preparation method thereof

The invention provides a flame-retardant ABS material for a weather-resistant washing-resisting closestool. The ABS material is prepared from the following ingredients in percentage by weight: 59 to 61 percent of ABS resin, 4 to 6 percent of AS resin, 5 to 7.5 percent of toughening agent, 17.6 to 17.8 percent of flame retardants, 5 to 6 percent of precipitated barium sulfate, 0.5 percent of wetting dispersing agents, 0.2 percent of anti-dripping agents, 0.4 percent of antioxidants, 0.3 percent of optical stabilizing agents, 0.3 percent of UV absorbents and 3 to 4 percent of titanium pigment. Auxiliary agents such as flame retardants, lubricating dispersing agents and antioxidants with the purity being 96 percent or more are used; the flowability of the ABS material is effectively improved;the product appearance problem is solved. In addition, through the addition of a proper amount of precipitated barium sulfate, the product dimension stability is improved; the tolerance of a producton the washing agent is improved; then, by selecting the proper optical stabilizing agents to be matched with the UV absorbents, the weather-resistant performance of the ABS material is effectively improved.

Owner:广东顺威赛特工程塑料开发有限公司

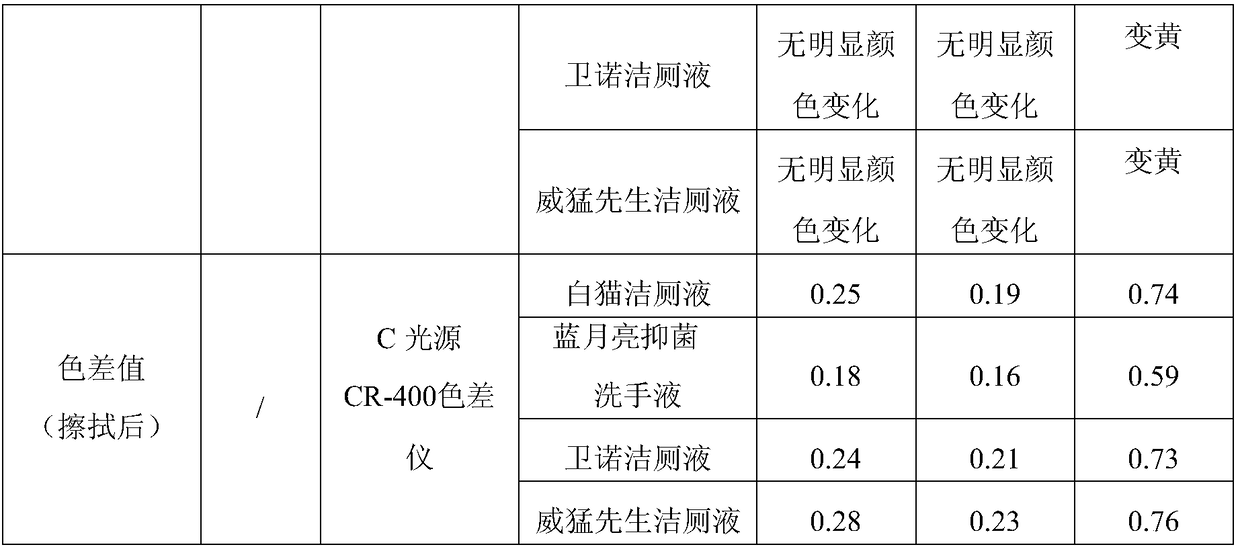

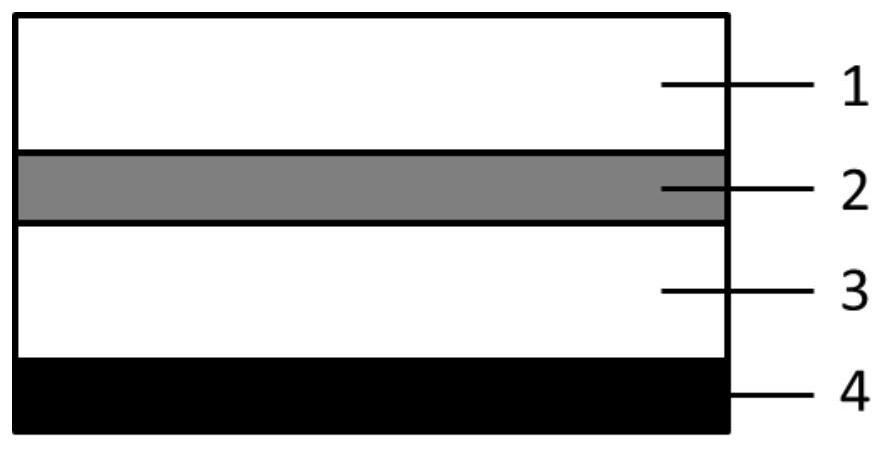

Back shell of display and film for protecting back shell

ActiveCN112111237AFix appearance problemsEster polymer adhesivesFilm/foil adhesive release linersForeign matterDisplay device

The invention provides a thin film and a shell made of the same thereby forming a back shell of an electronic product display and realizing shell protection. The film provided by the invention does not warp in the gluing and printing processes, the problem of adsorption or positioning sliding between films does not occur, and the subsequent processing and production efficiency is not influenced. The film has the advantages of few foreign matters inside, low haze, high full-light transmittance and no influence on the appearance decoration effect. And the molding performance and the fitting performance are excellent, the curved surface molding or fitting requirement can be met, the appearance is free of wrinkles or deformation and other undesirable phenomena before and after molding or fitting, the method can be suitable for plane and curved surface shells and shell protection, and the appearance quality is high. The shell made of the film provided by the invention can be subjected to UVphotoetching, and is suitable for high-end machine types and overseas brand machine types.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

Universal wheel with plastic wheel fork

The invention discloses a universal wheel of a plastic wheel fork, which comprises a plastic wheel fork, two wheel fork bearings, a ball head bolt, a nut, a pair of lock bolts and a PU wheel with two bearings in the center of a hole, the plastic wheel fork There is a sink hole at the top and bottom respectively, and there is a through hole between the upper and lower sink holes of the plastic wheel fork. The two wheel forks at the lower end of the plastic wheel fork have mutual perforations, and the upper and lower sink holes of the plastic wheel fork are respectively inlaid with a wheel fork bearing. , A round-head bolt is inserted into the inner hole of the two-wheel fork bearing, and a nut is screwed on the round-head bolt inserted into the inner hole of the two-wheel fork bearing. The fork and the fork of the wheel are in the mutual piercing holes and the inner holes of the two bearings of the PU wheel, and then screwed with the bolt and the screw barrel. The present invention adopts the plastic wheel fork as the wheel fork of the universal wheel, which solves the problems of appearance, surface treatment and production process of the wheel fork of the universal wheel. Compared with the ordinary universal wheel, the production process is simpler and the cost is lower .

Owner:慈溪市甬联电子有限公司

Universal wheels for plastic forks

Owner:TAICANG CHEZHONGBAO LEISURE ARTICLES +1

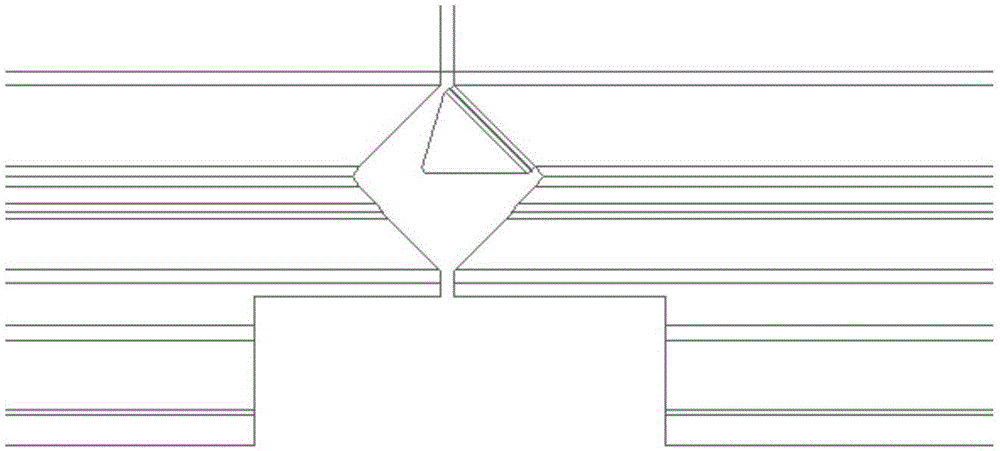

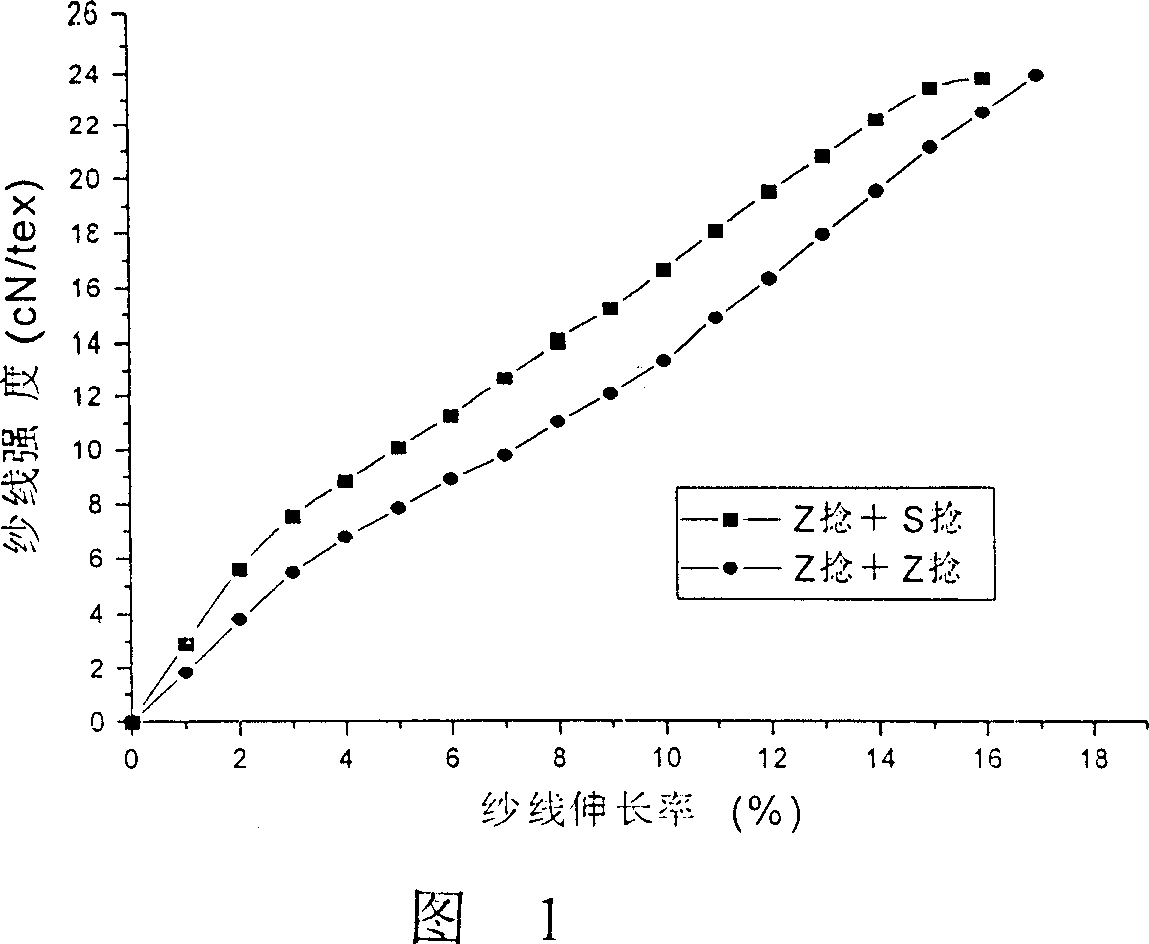

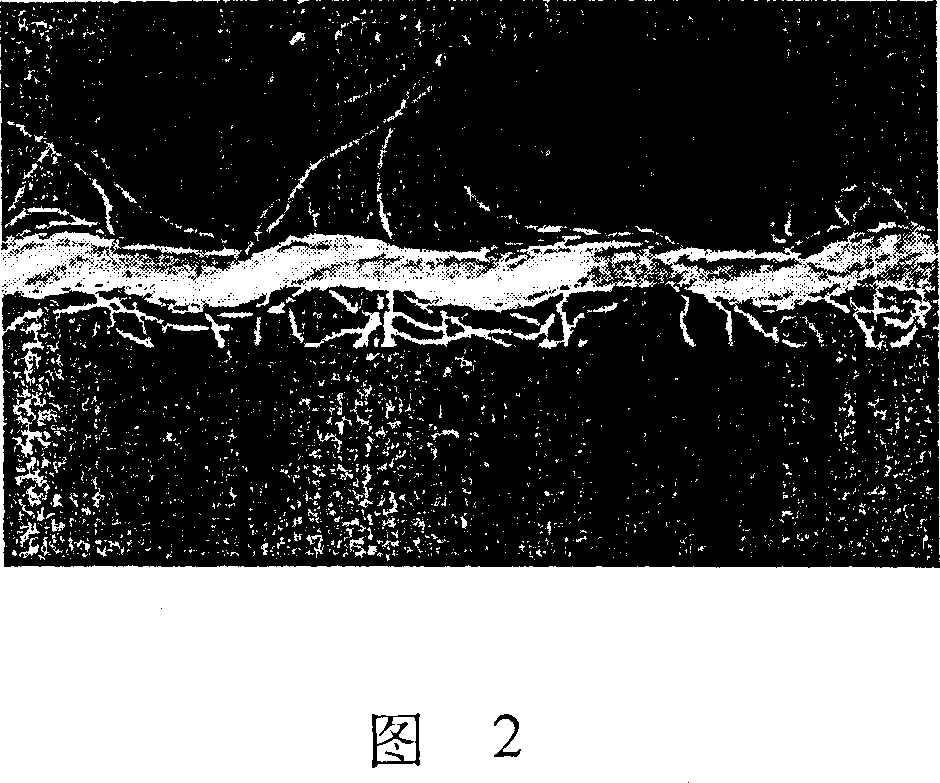

Cabling twisted composite yarn cabling

The invention refers a cabling complexing yarn made of long thread of synthetical fiber and short fiber yarn. Its character: twisting direction of the complexing yarn is consistent with that of single yarn of short fiber yarn; the long thread of synthetical fiber is Terylene thread and the short fiber yarn is simple yarn spun by cotton and wool.

Owner:JIANGSU JIANLU WOOLEN

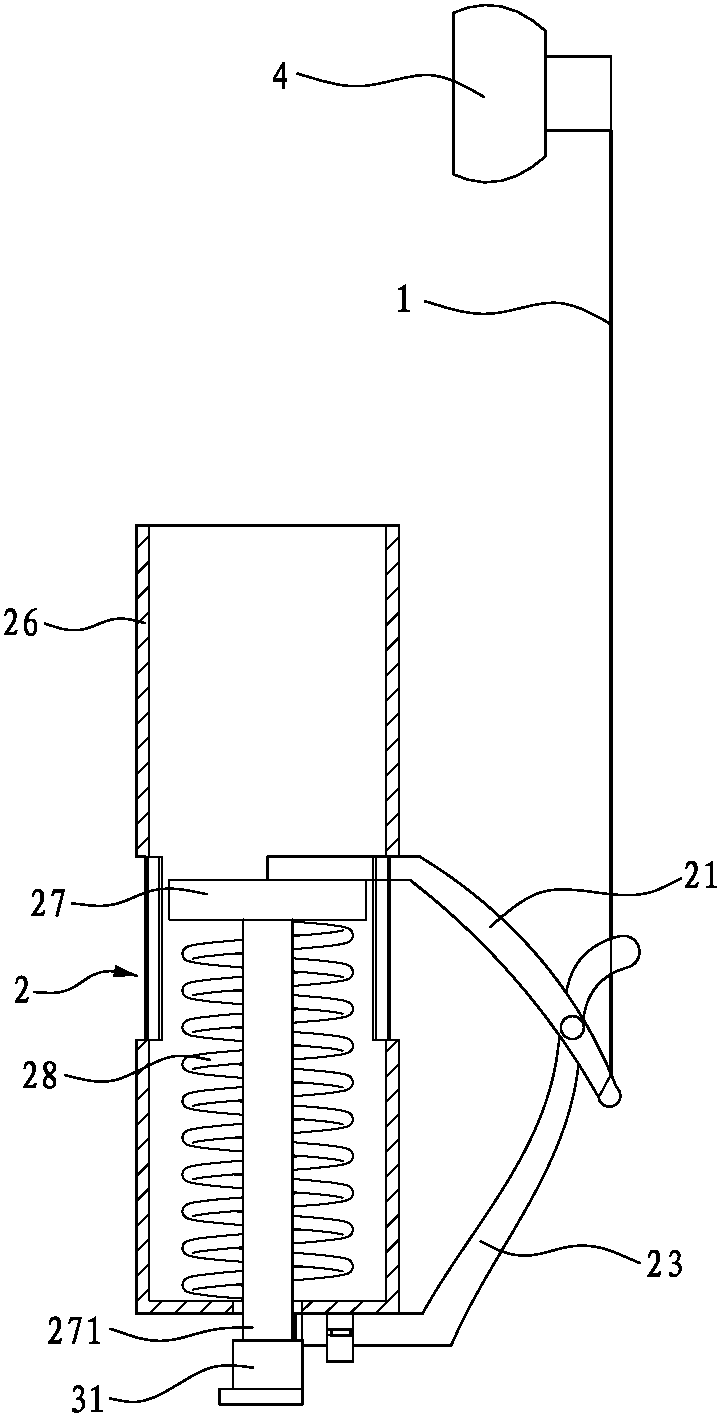

Automatic flushing device

The invention discloses an automatic flushing device, which comprises a brake cable and a push mechanism. One end of the brake cable is connected with an action mechanism of a door lock device, the other end of the brake cable is connected with the push mechanism, the push mechanism is provided with a push part pulled by the brake cable to act, and the push part is in direct or indirect linkage with a button of a toilet flushing device. The automatic flushing device is in linkage with the door lock device of a door, and when the door is opened, unlocking action of the door lock can be transmitted to the button of the toilet flushing device through the brake cable, and a toilet can be automatically flushed only by opening the door. The automatic flushing device recovers door opening force, needs no external power and can guarantee cleanness of a public lavatory.

Owner:XIAMEN UNIV OF TECH

A method for separating and purifying glycolipids

ActiveCN104356172BHigh yieldSolve problems affecting the appearance of phospholipid productsSugar derivativesSugar derivatives preparationSolubilityMaillard reaction

The invention discloses a glycolipid separation and purification method. The method comprises steps as follows: dissolving coarse phospholipid with n-hexane, then performing extraction with an ethanol aqueous solution, finally, collecting the ethanol aqueous solution, and removing the ethanol aqueous solution with a vacuum concentration method to obtain a glycolipid product. The method has the advantages that glycolipid is separated from the coarse phospholipid and purified by the aid of the difference of the solubility of the phospholipid and the glycolipid in the ethanol aqueous solution, and the obtained glycolipid is subjected to vacuum drying to form the glycolipid product with the glycolipid content higher than 80%. On one hand, the method is simple and efficient, and the glycolipid yield is high; on the other hand, the problem that the Maillard reaction affects the appearance of the phospholipid product during phospholipid processing is solved.

Owner:广州海莎生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com