Bent U-shaped box shell bending and splicing structure

A box shell and splicing angle technology, which is applied in lighting and heating equipment, household appliances, household refrigeration devices, etc., can solve the problems that affect the appearance of the box shell and production efficiency, require high precision of the splicing structure, and easily form burrs, etc. Achieve the effect of reducing the market and inspection complaint rate, facilitating processing and adjustment, and reducing sharp corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

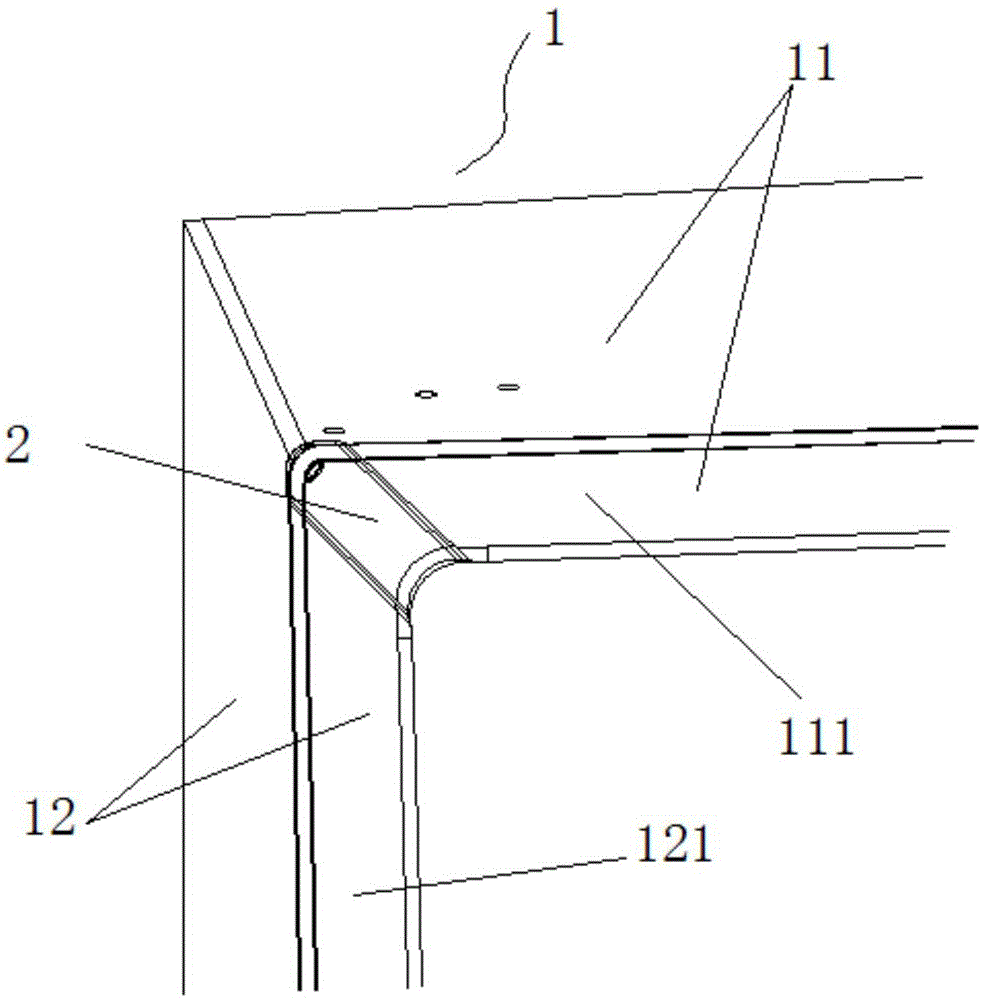

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

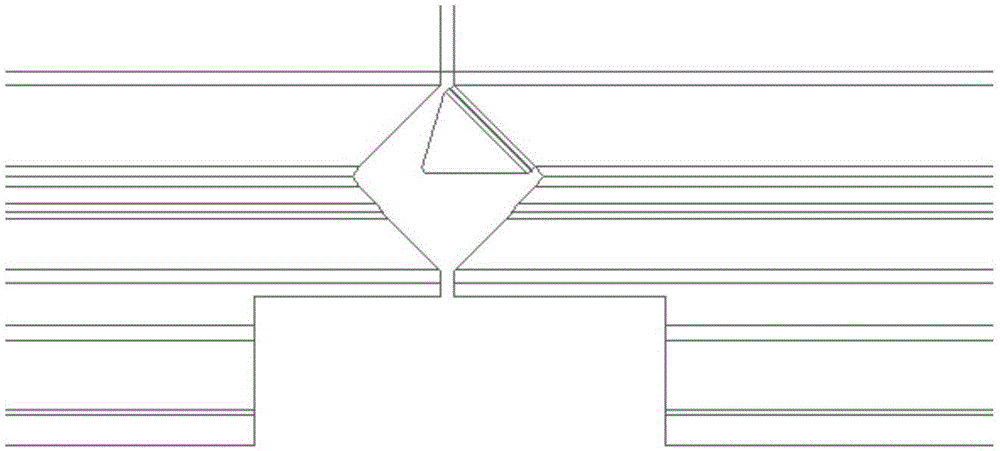

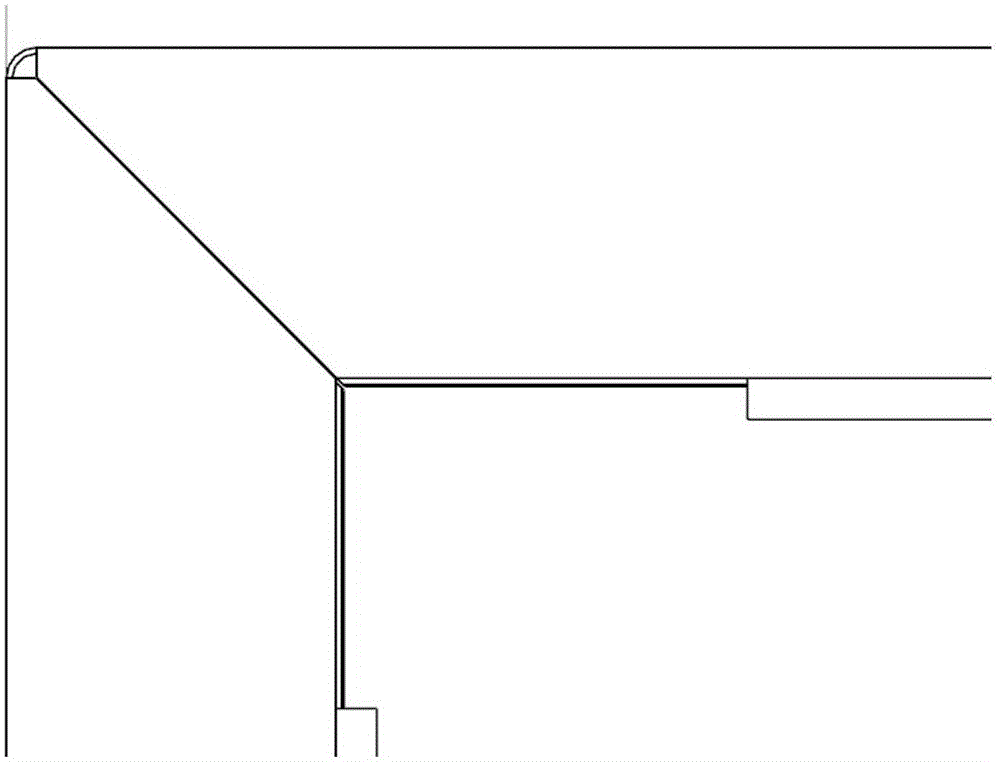

[0030] Such as image 3 As shown, a U-shaped box shell bending splicing structure, the U-shaped box shell includes a first spliced plate 11 with a first folded edge 111 and a second spliced plate 12 with a second folded edge 121, the first spliced The plate 11 and the second splicing plate 12 are spliced to form a splicing angle structure 1, and one end of the first folded edge 111 and the second folded edge 121 is provided with a 45-degree spliced edge, and the first folded edge 111 and the second folded edge 121 Through the splicing of the 45-degree splicing edge, the splicing part is provided with a cover 2 detachably connected to the first folded edge 111 and the second folded edge 121 .

[0031] Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com