Cabling twisted composite yarn cabling

A kind of yarn and single yarn technology, applied in yarn, textile and papermaking, etc., can solve the problems of small yarn package and low processing speed, and achieve the effect of moderate tightness, stable structure and satisfactory fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

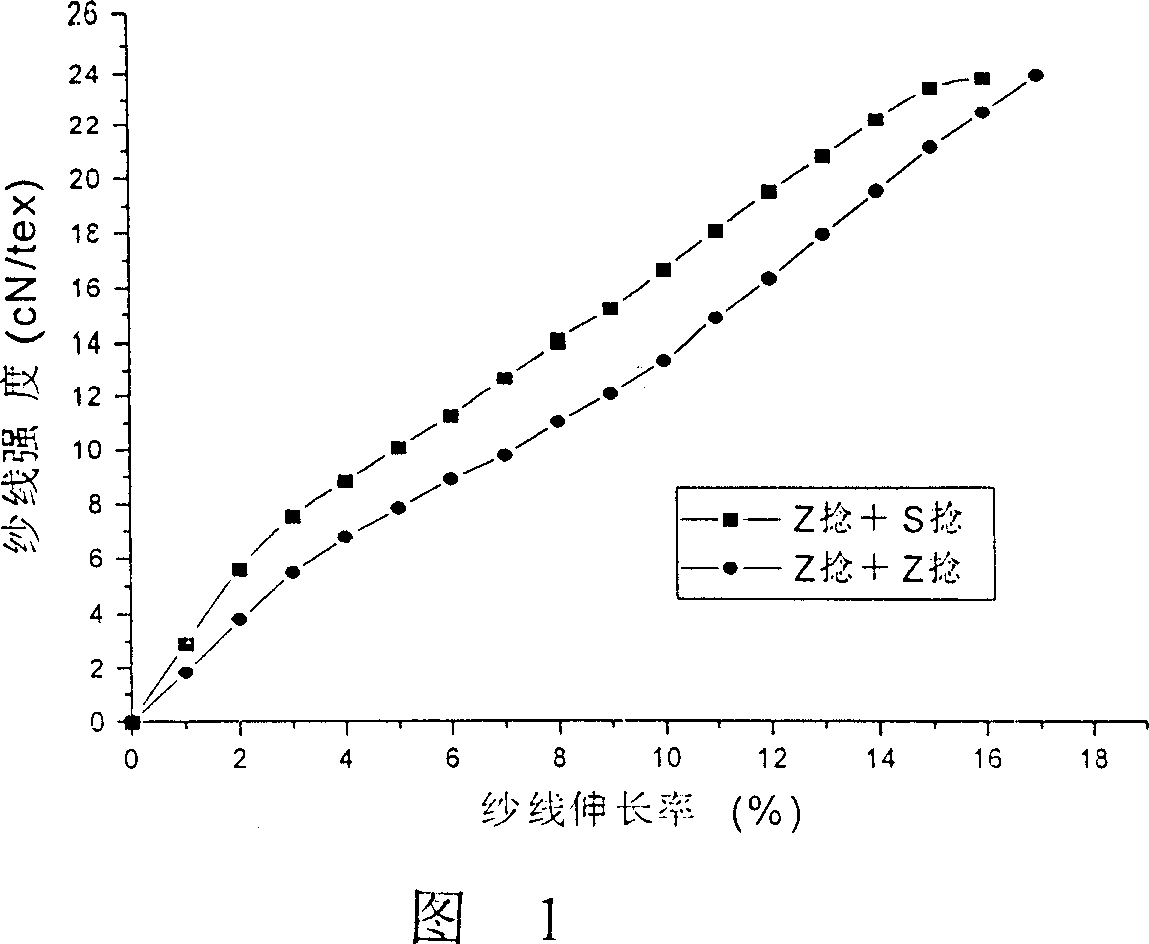

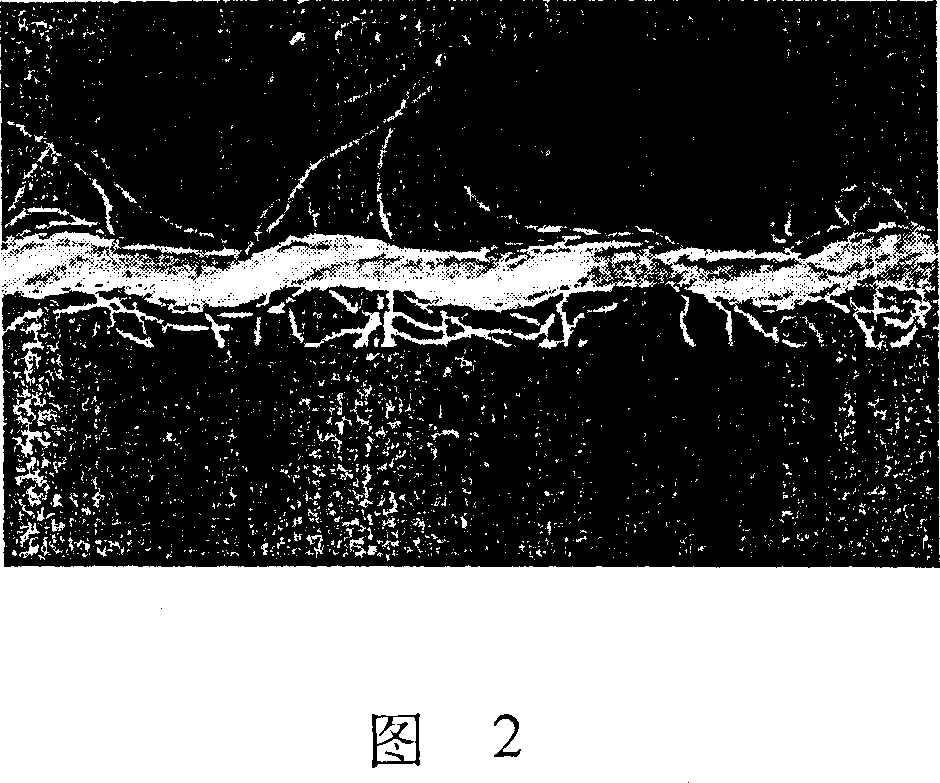

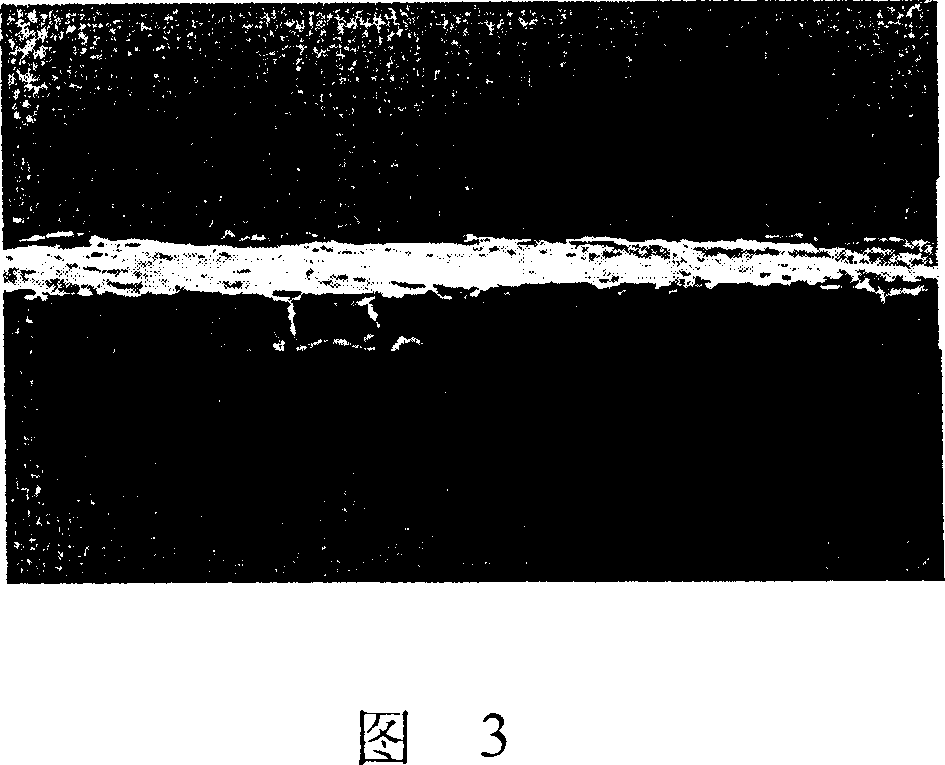

[0017] Fig. 2 is the enlarged picture of the appearance of the yarn spun by the prior art, and Fig. 3 is the enlarged picture of the appearance of the yarn spun by the present invention. The twisting tension of the polyester-cotton 65 / 35 combed spun yarn is 20cN. Apply the double twist twist (40 twist / cm) in the same direction as the single yarn (Z twist+Z twist, i.e. the present invention) and reverse (Z twist+S twist, i.e. traditional twist) to the parallel twisted composite yarn respectively, to obtain The tensile curve of the yarn is shown in Figure 1. It can be seen that its strength does not decrease due to the change of the twist direction; as shown in Figure 2 and Figure 3, the appearance of the (Z twist + Z twist) parallel twisted composite yarn is much The appearance of the parallel-twisted composite yarn is better than (Z-twist + S-twist).

[0018] Under the premise of reasonable tension matching and twist direction design, the double-twisted composite yarn can ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com