Patents

Literature

32results about How to "High yarn strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

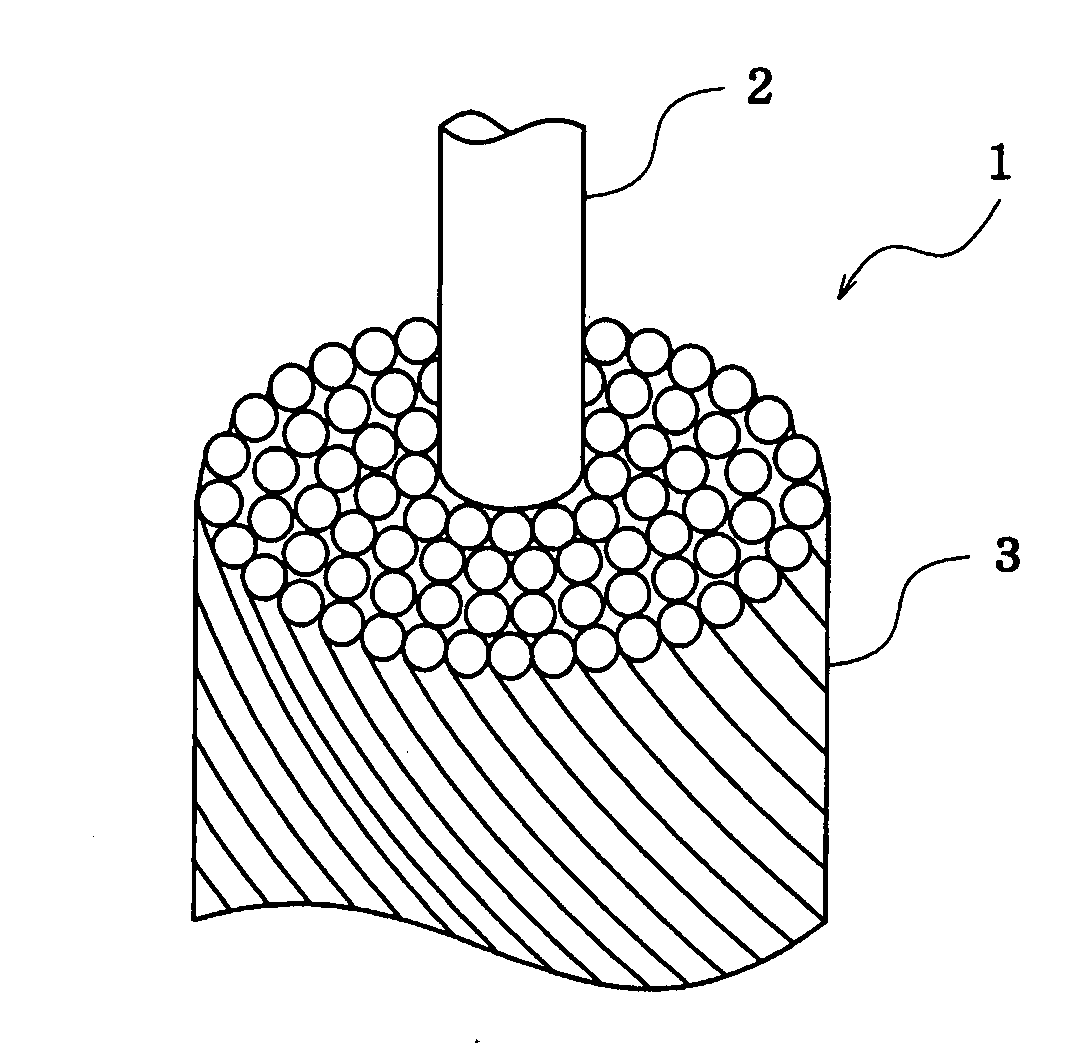

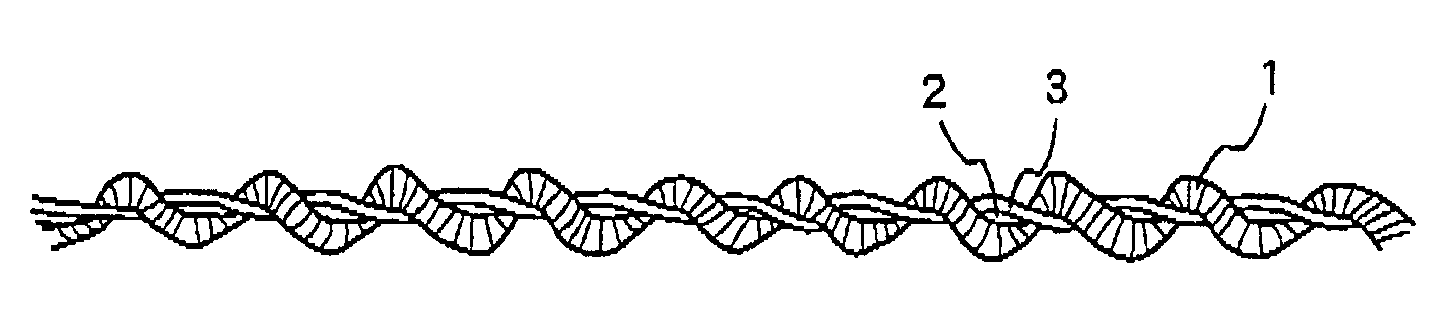

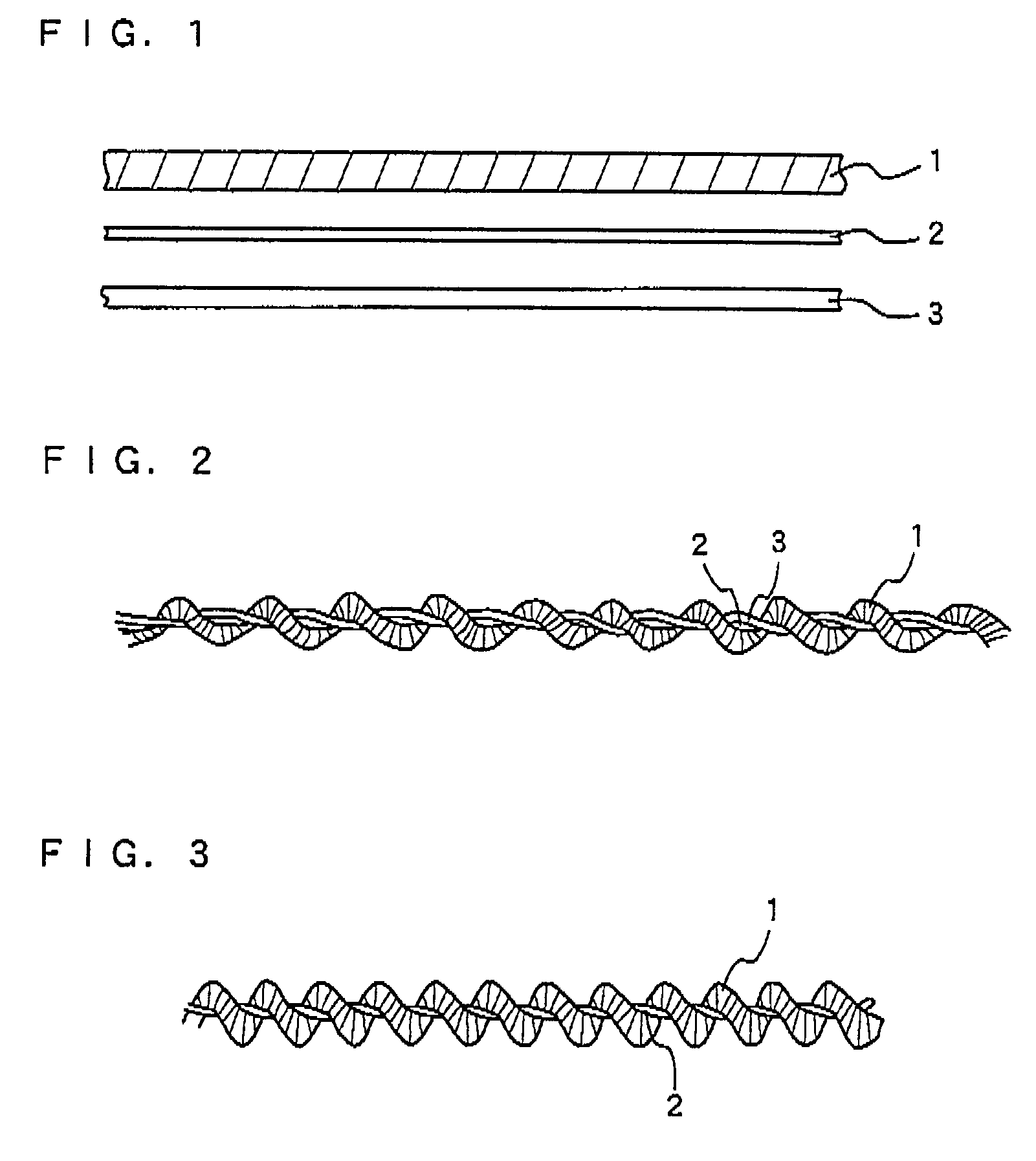

Core yarn and woven and knitted fabric

InactiveUS20080299855A1Increase ratingsHigh strengthWarp knittingCircular knitting machinesLower gradeLow graded

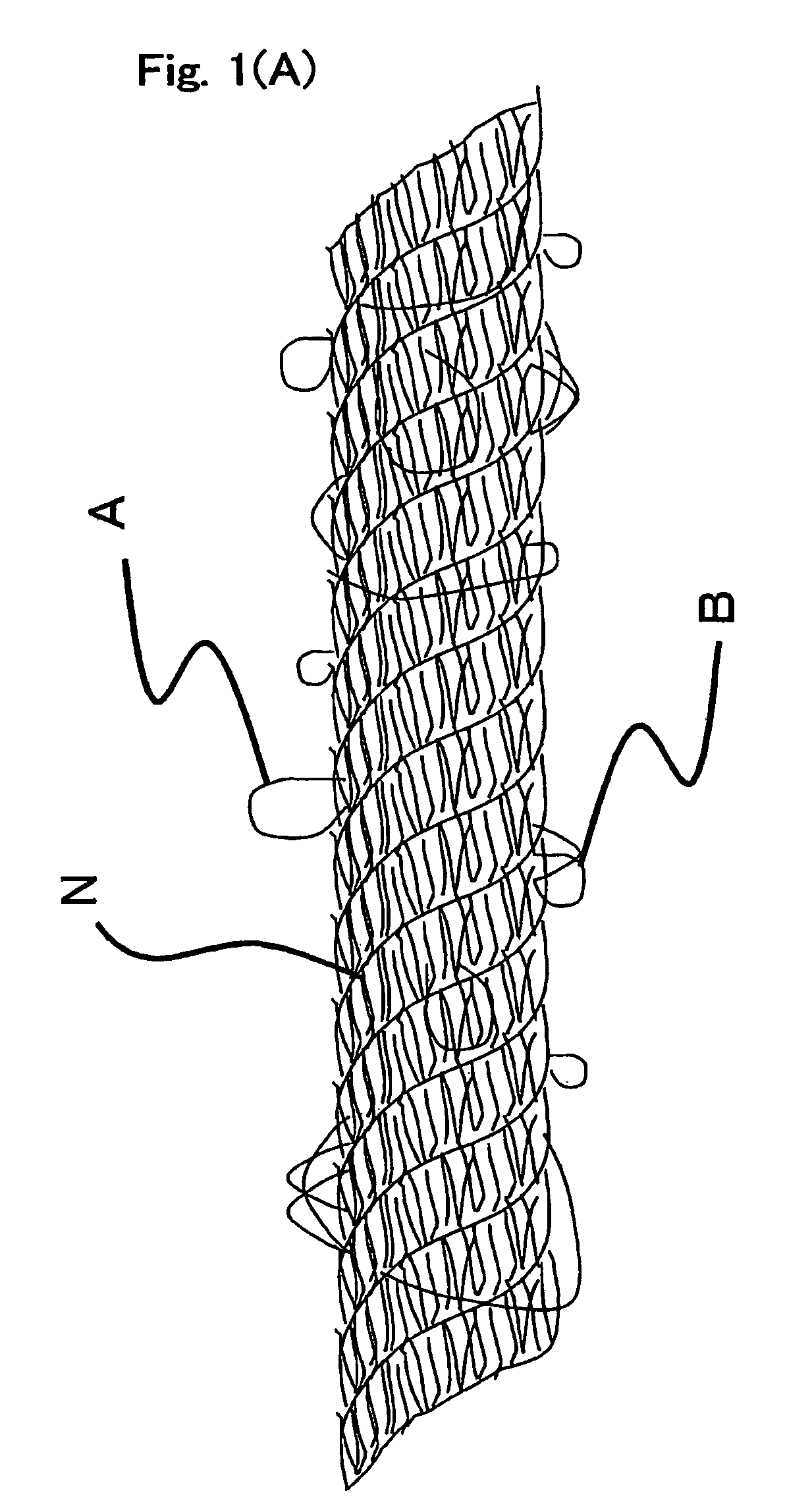

It is an object of the present invention to provide a core yarn capable of spinning the higher-grade yarn having the higher yarn count from specified lower-grade raw material and the core yarn makes its texture-feeling, strength and extension rate equal to that of natural fibers. The core yarn is formed of spun yarn including the core formed of filament yarn and the sheath formed of staple, and the filament yarn is a monofilament false twist textured yarn.

Owner:MORIHASHI TOSHIFUMI

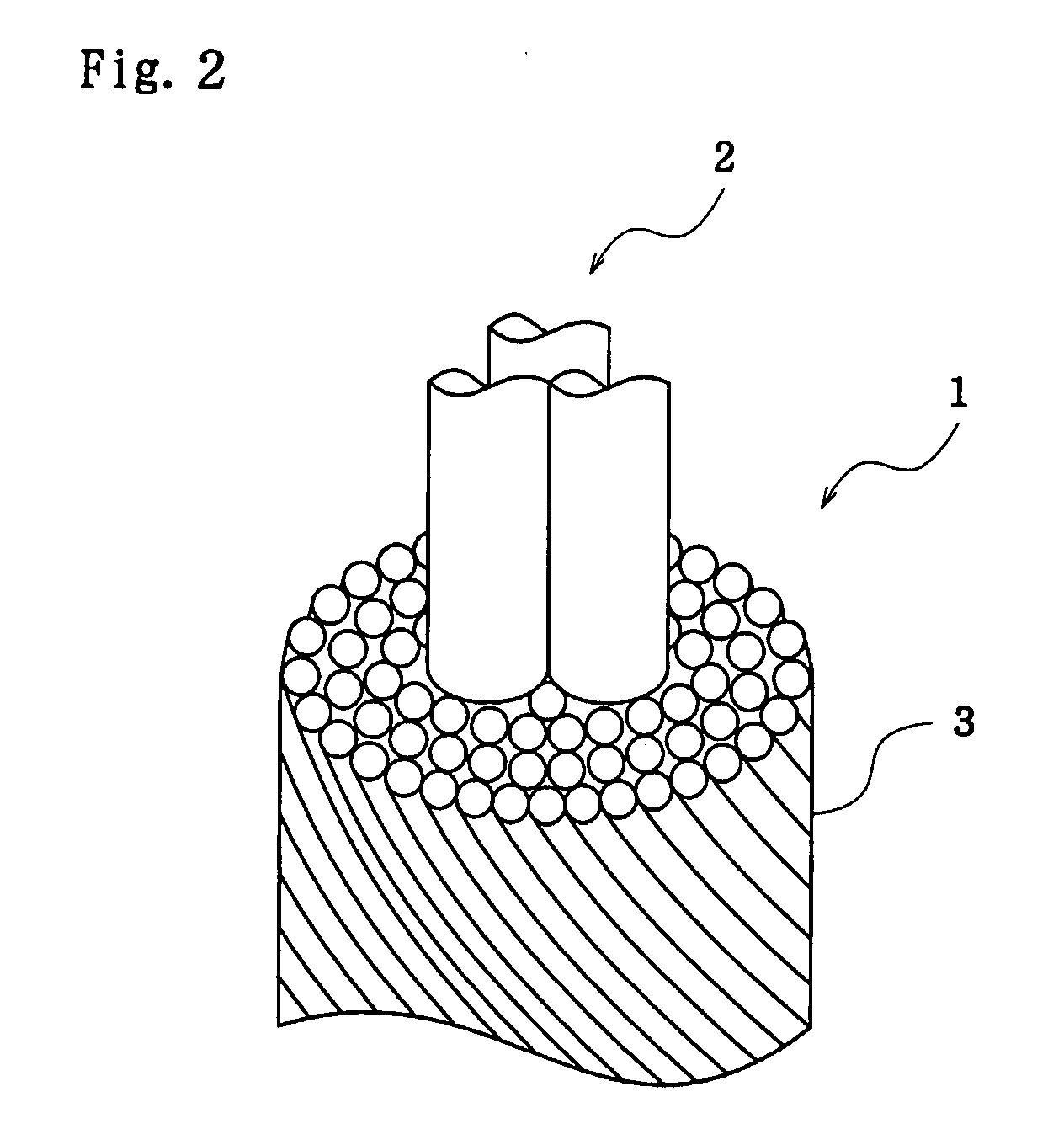

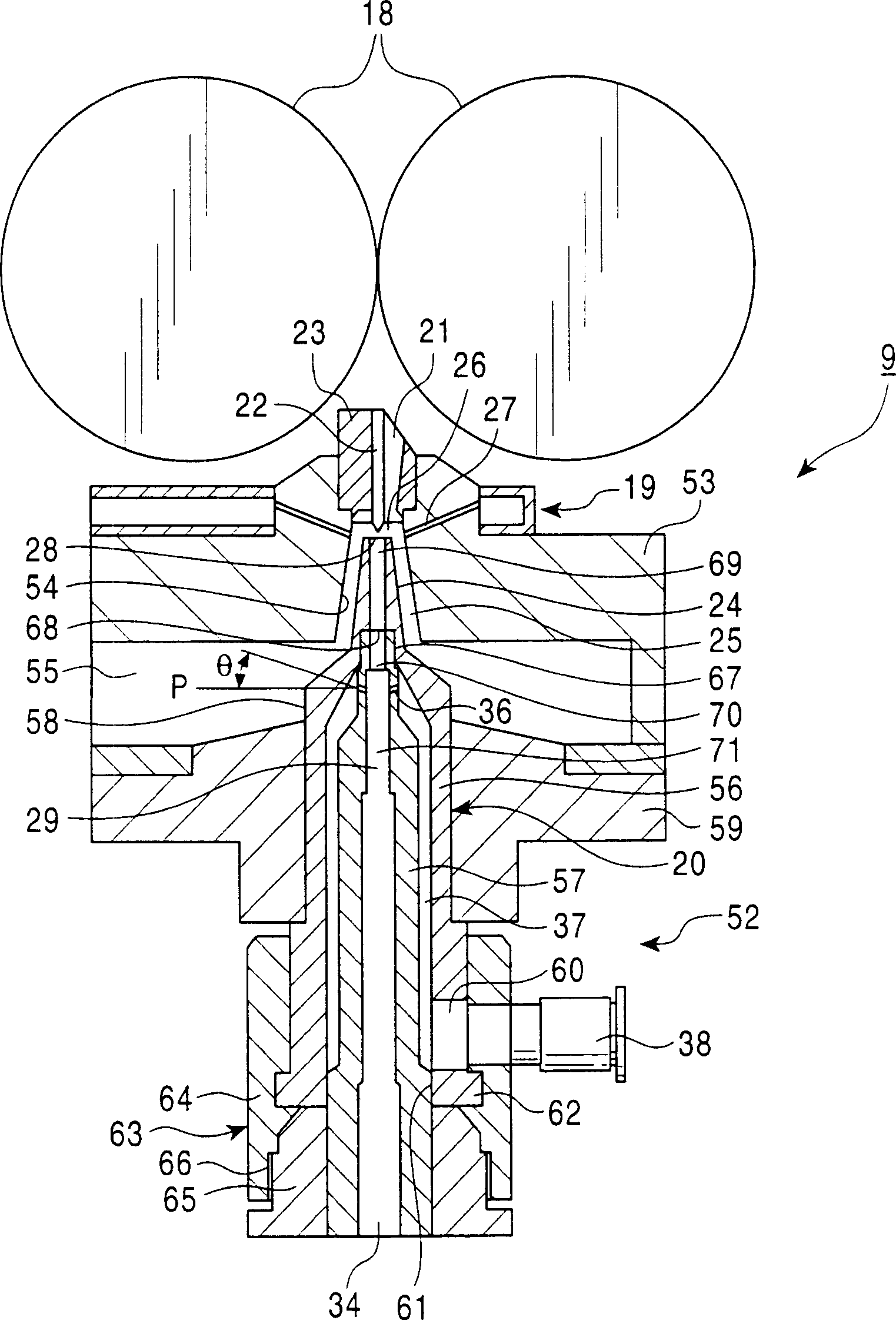

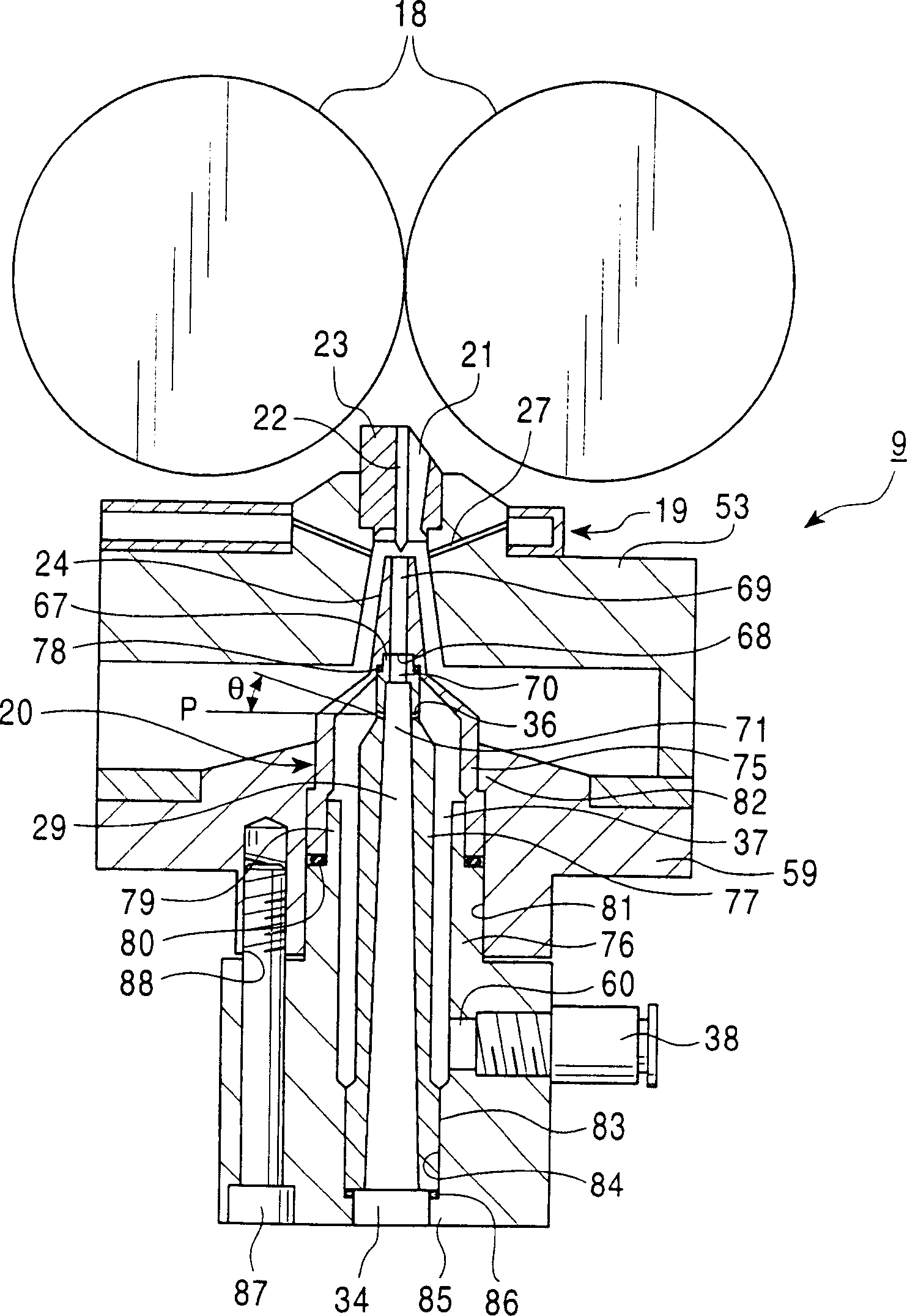

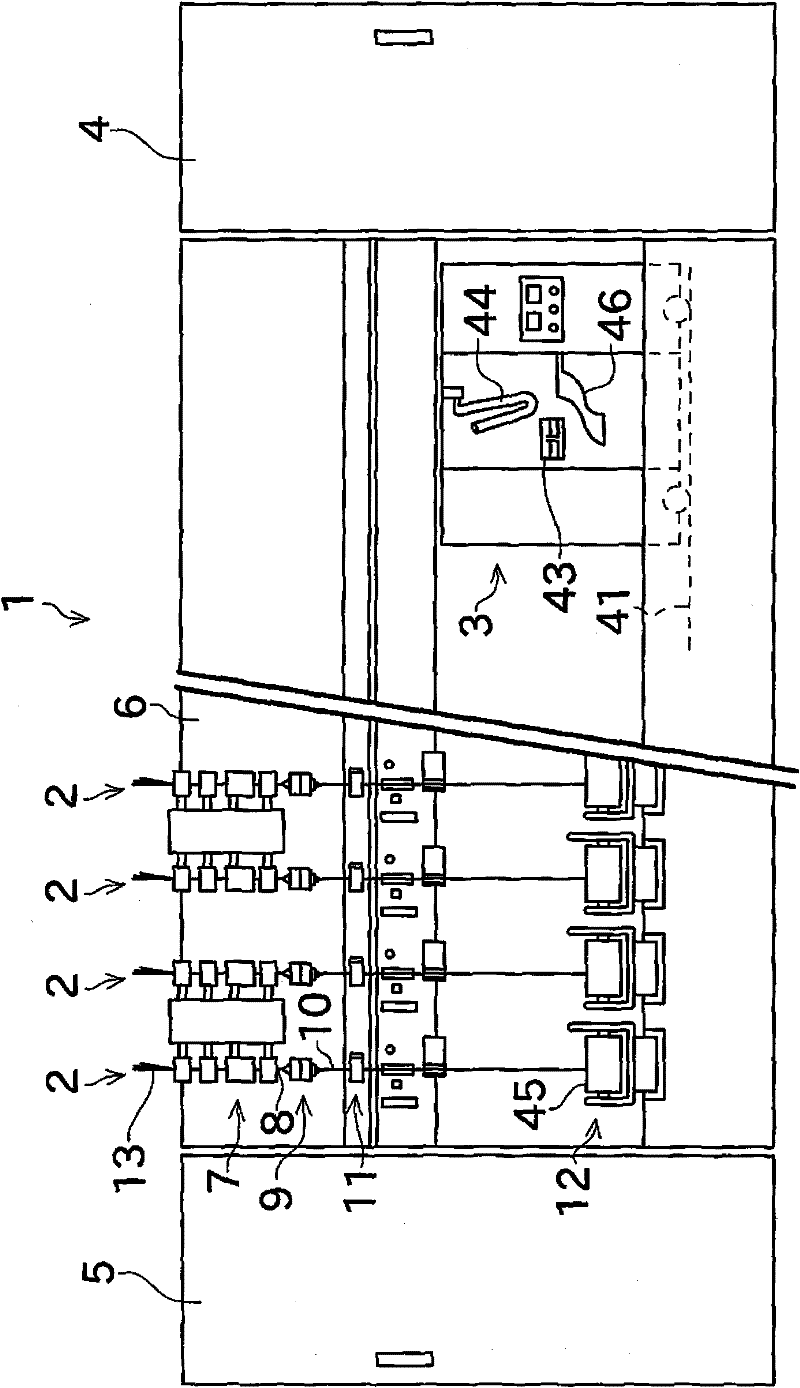

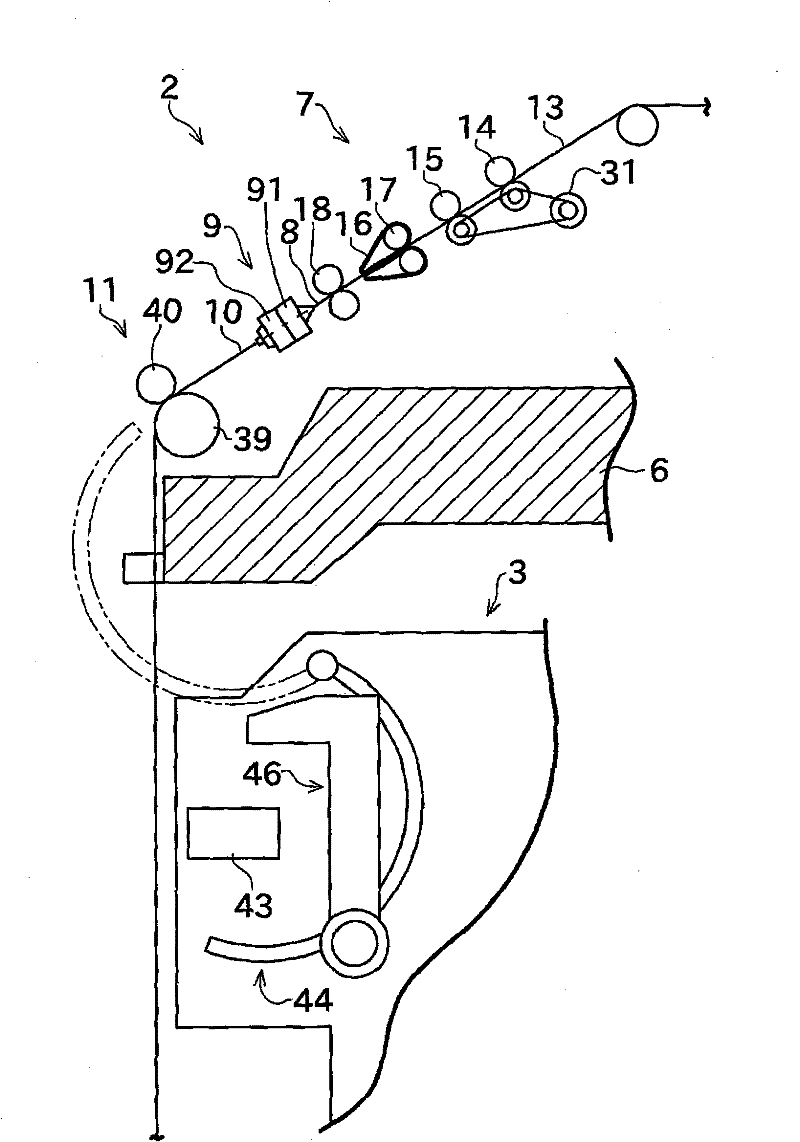

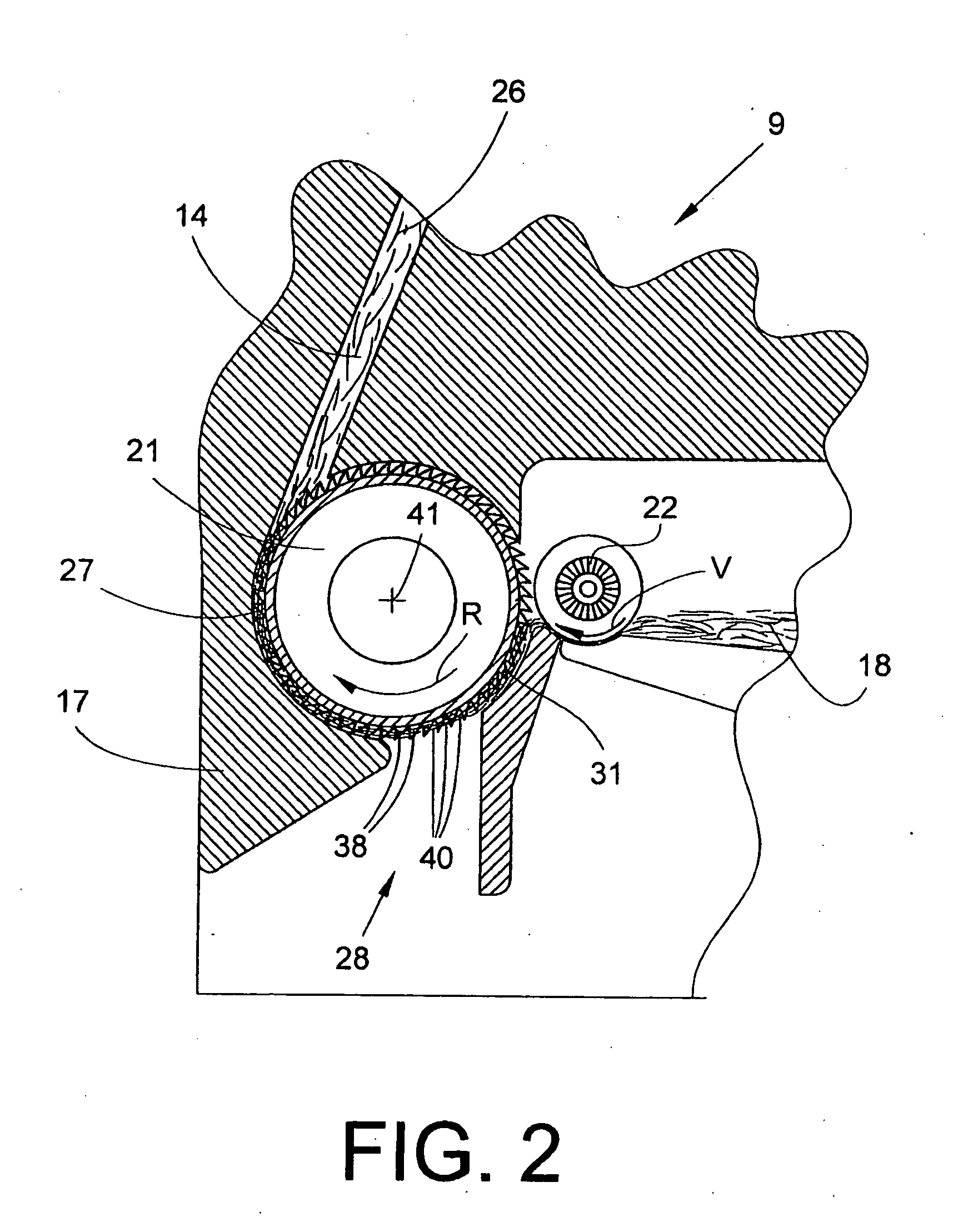

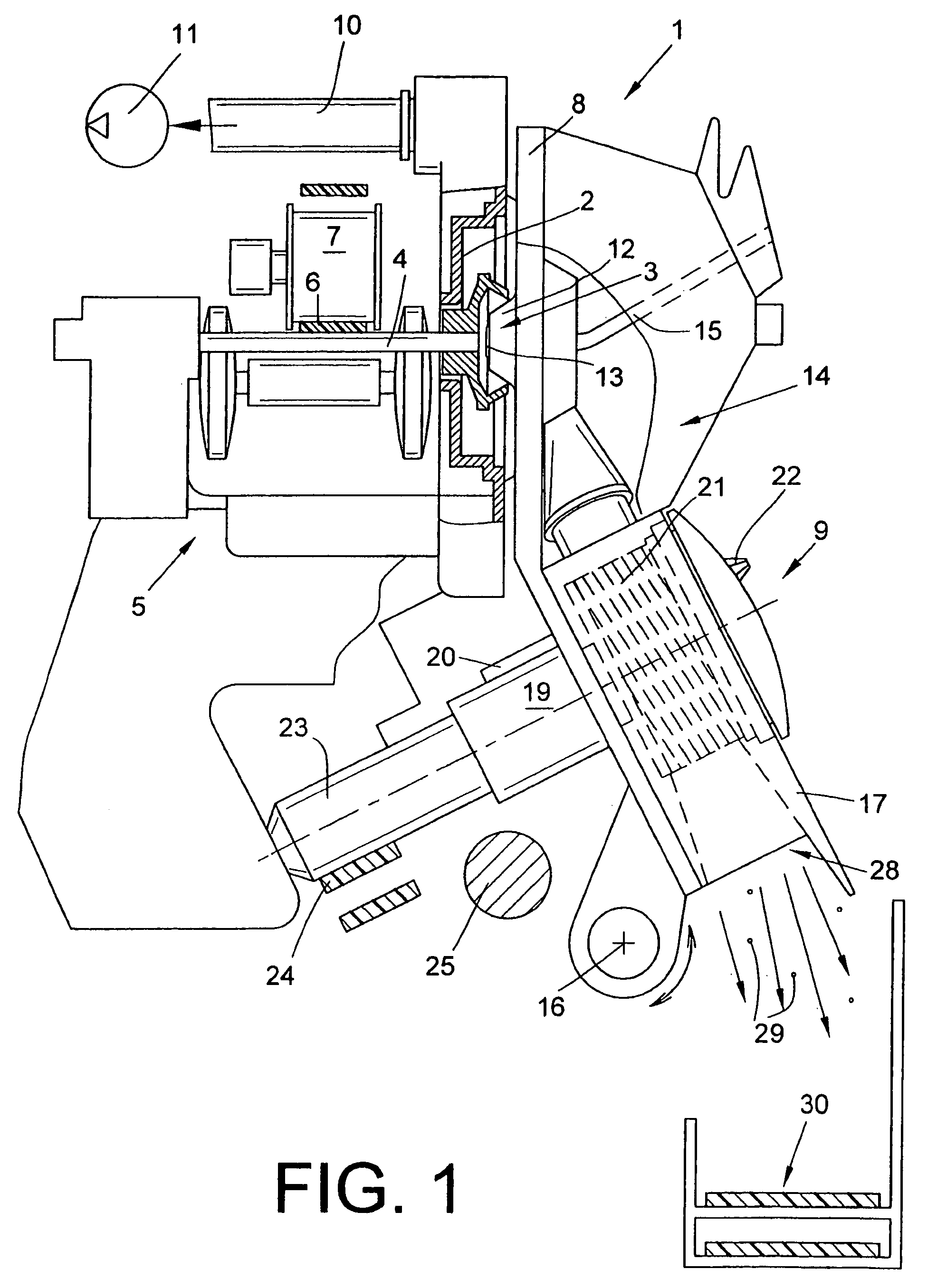

Spinning devices

InactiveCN1407153AAvoid yarn breakageIncrease success ratePiercing arrangementsContinuous wound-up machinesEngineeringYarn strength

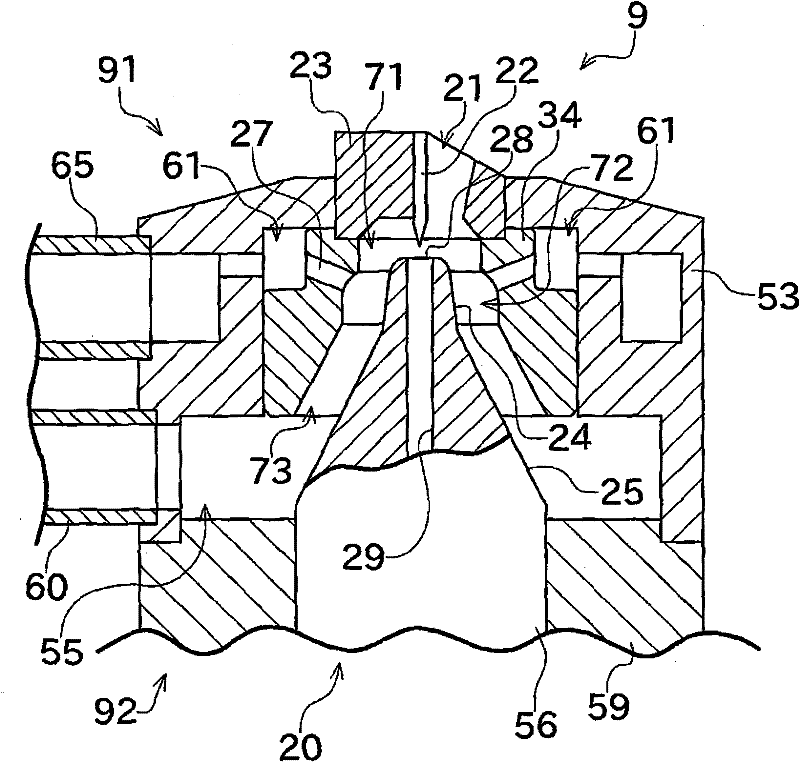

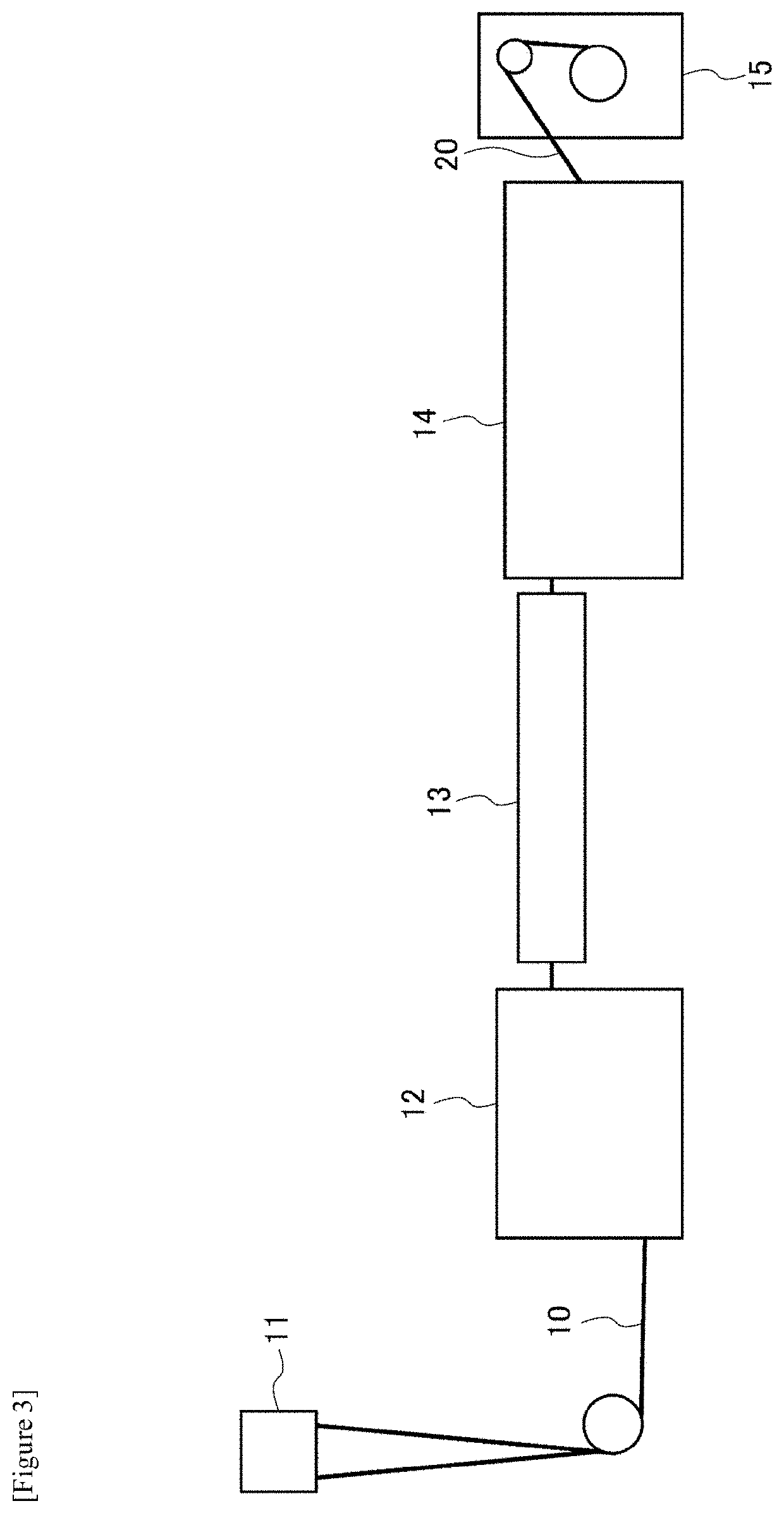

The invention provides a high-speed spinning by increasing success rates of the taking-out of a yarn and the piecing of the yarn. This spinning frame has a pneumatic spinning nozzle 27 for generating a rotational gas flow at the vicinity of a tip part 24 of a hollow guide shaft 20 and an assistant nozzle 36 for generating the rotational gas flow in a yarn passage 29 in a hollow guide shaft 20. The assistant nozzle 36 is tilted so as to be directed to the downstream side based on the plane P orthogonal to the yarn passage 29. The tilting angle of the assistant nozzle 36 is preferably 10-35 degrees, more preferably 20 degrees. As a result, the component of the flow directed to the downstream side, and accompanied by the rotational gas flow generated by the assistant nozzle is enlarged, and the sucking power into the yarn passage is enhanced. The balance between the components in the downstream direction and the rotational direction is corrected and the yarn strength of a bound yarn to be discharged is increased to prevent the yarn break or the like.

Owner:MURATA MASCH LTD

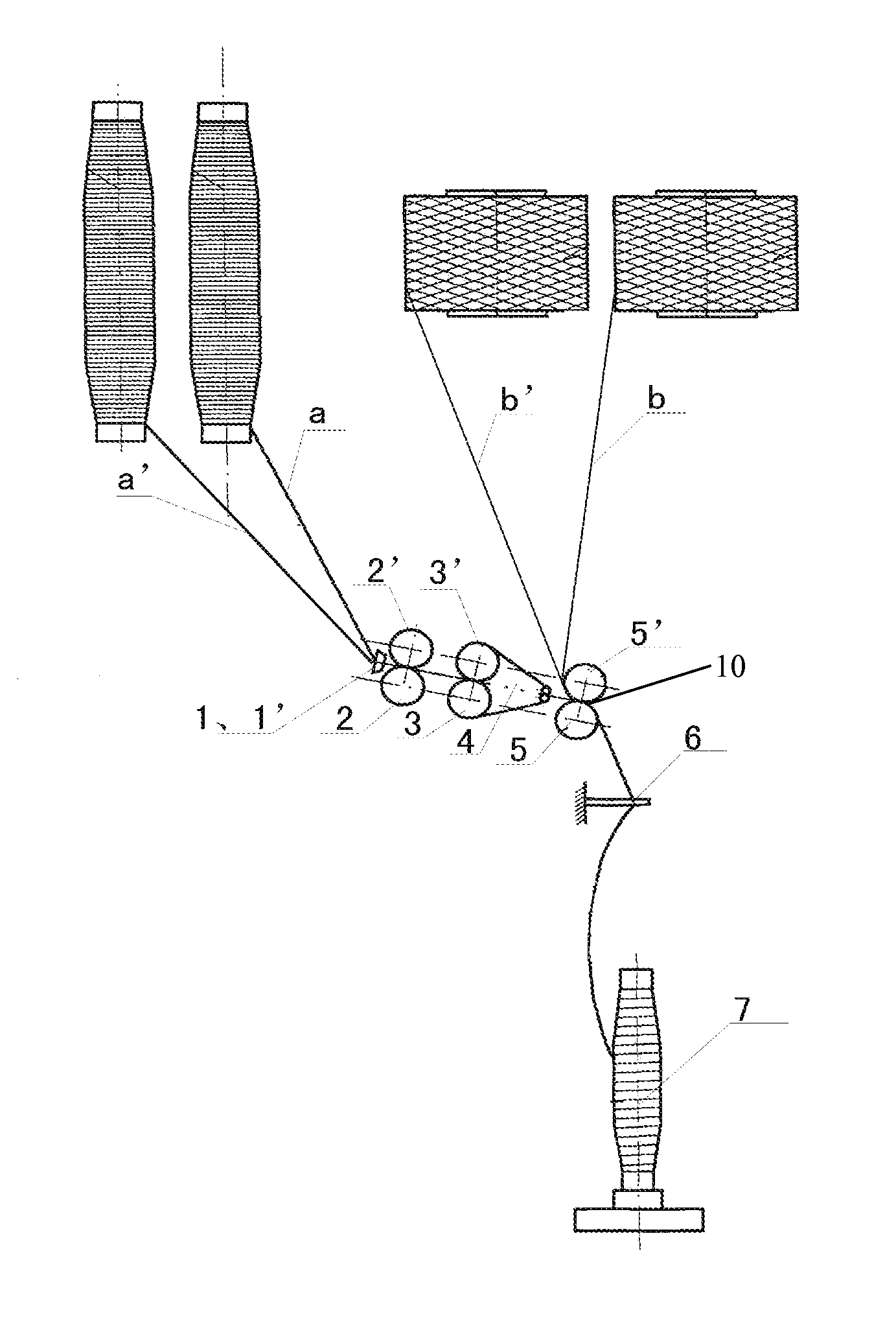

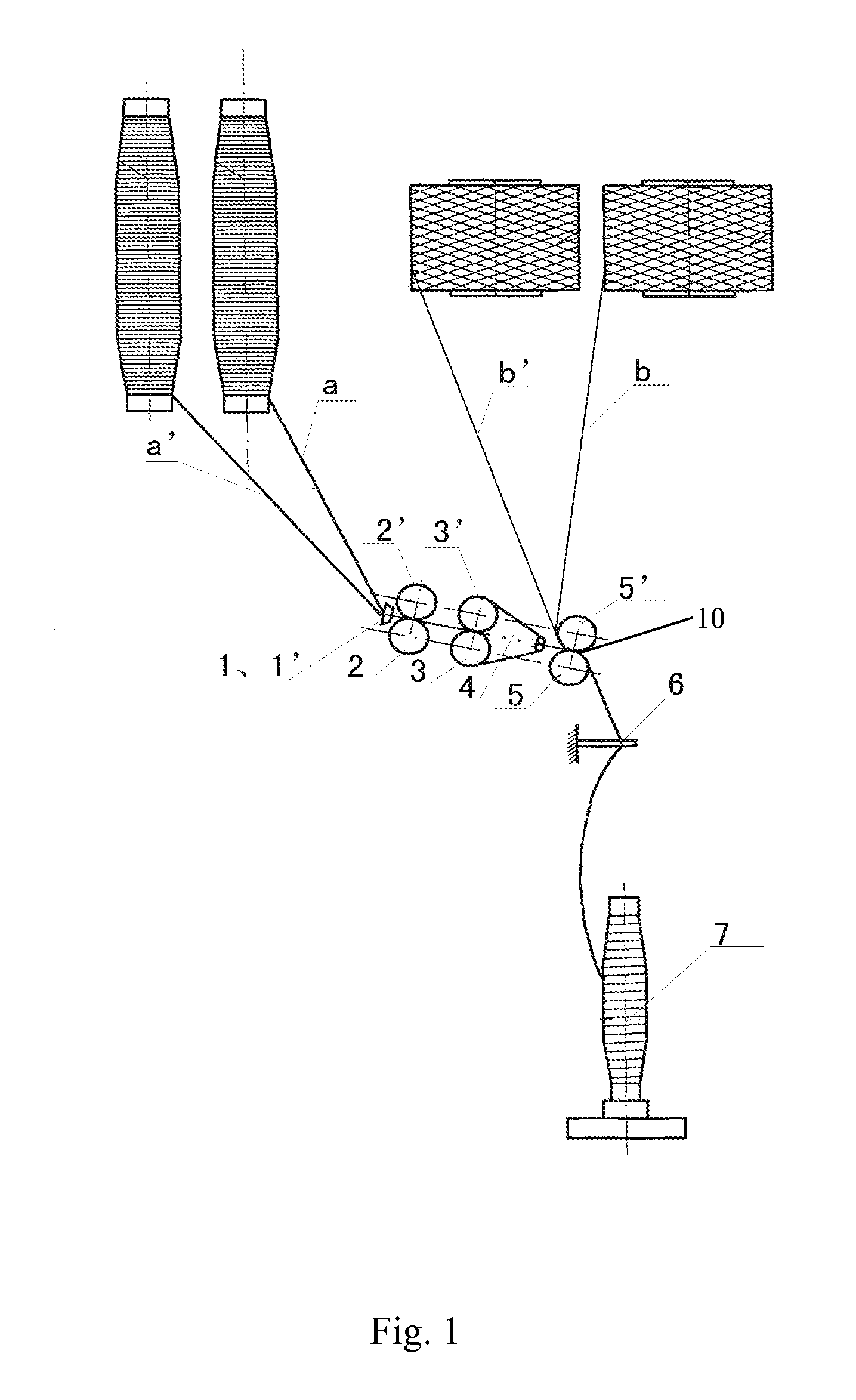

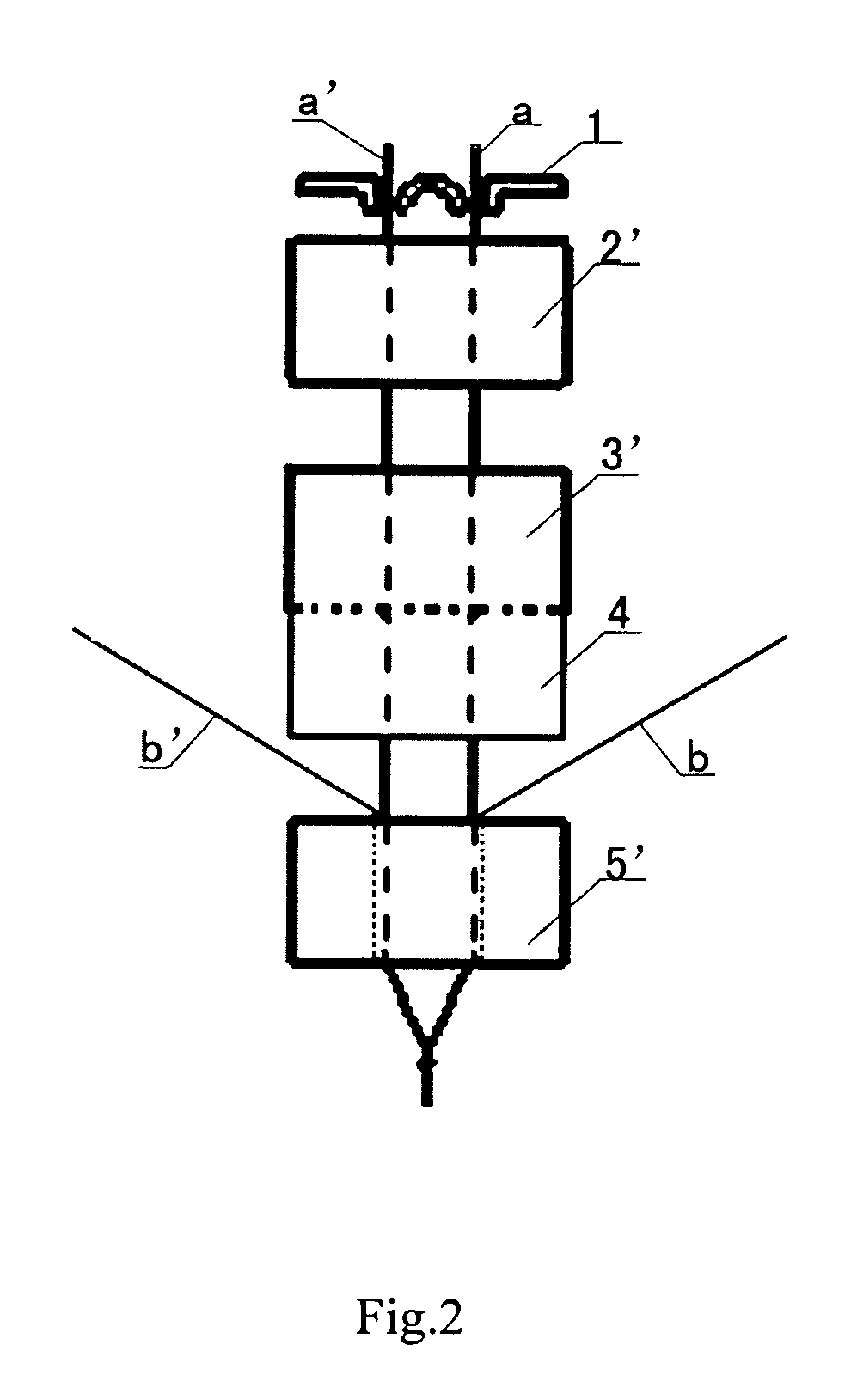

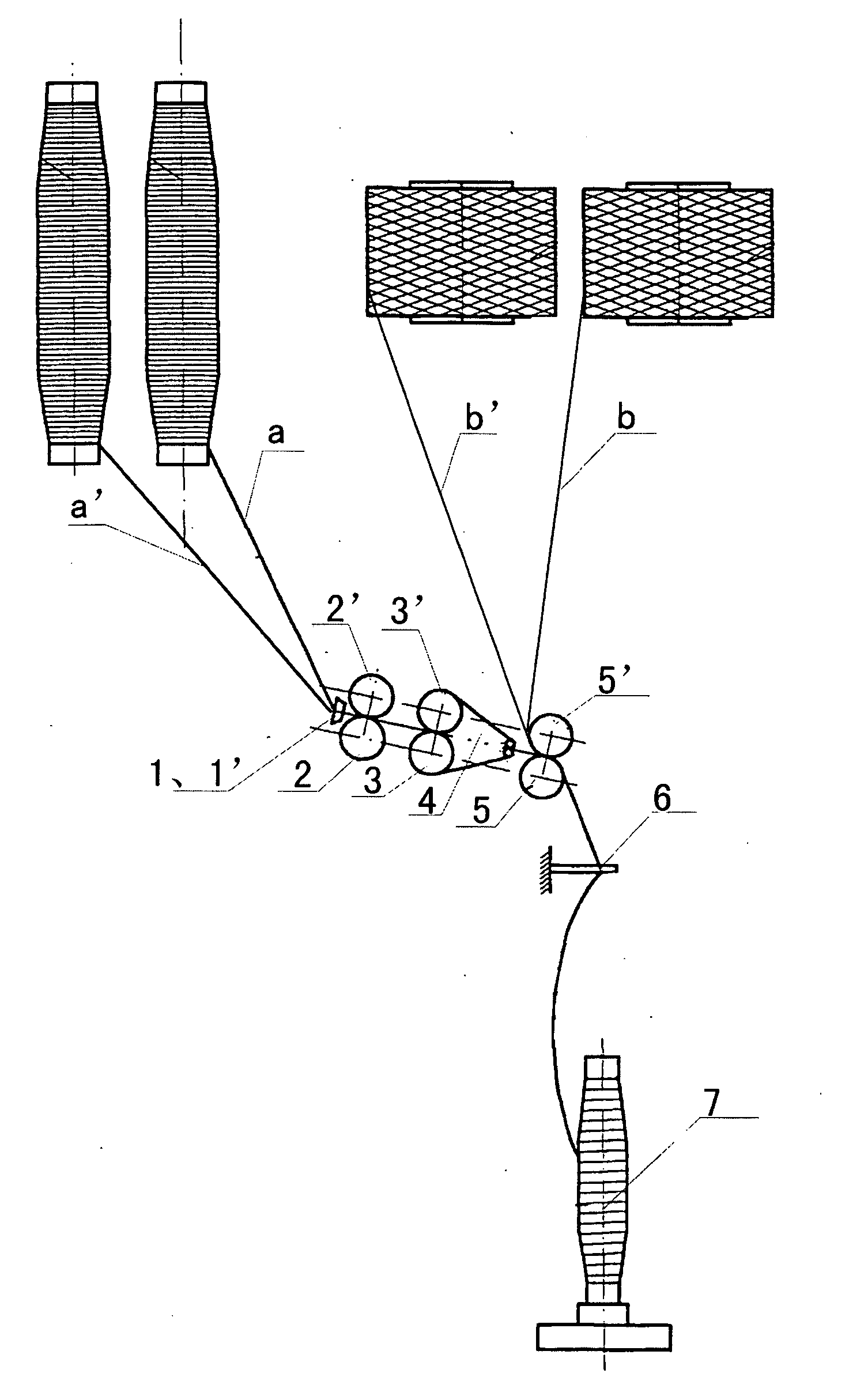

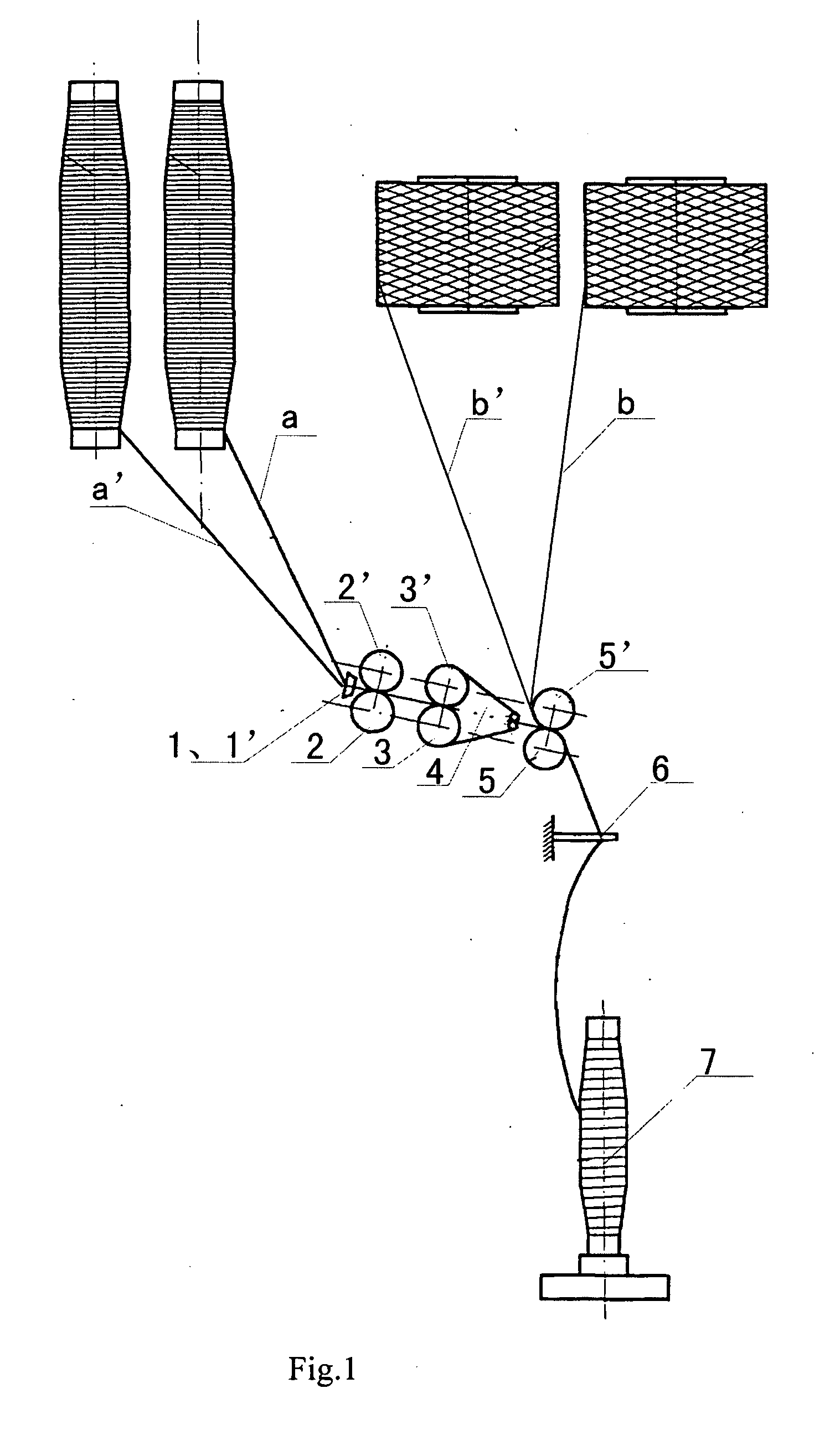

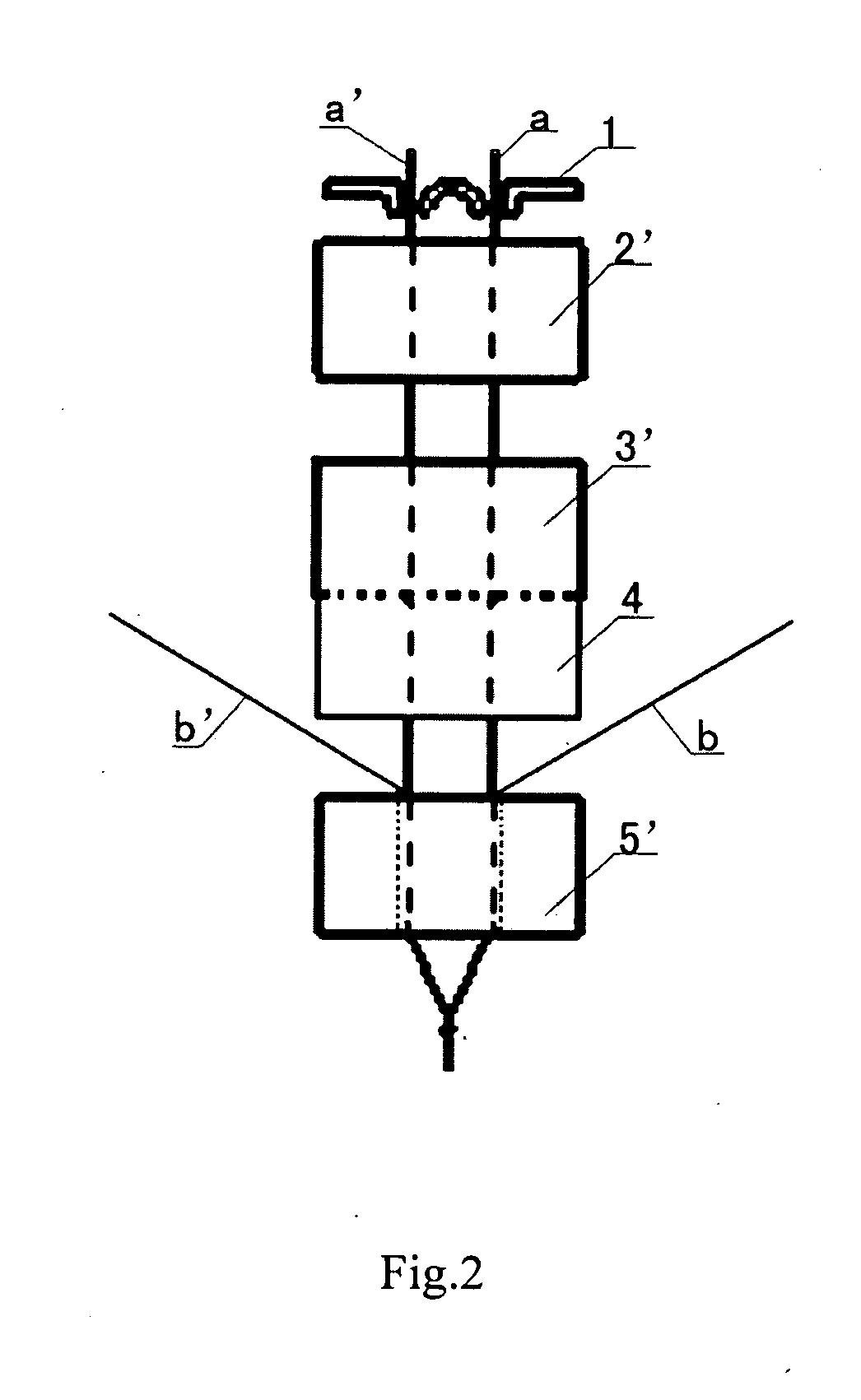

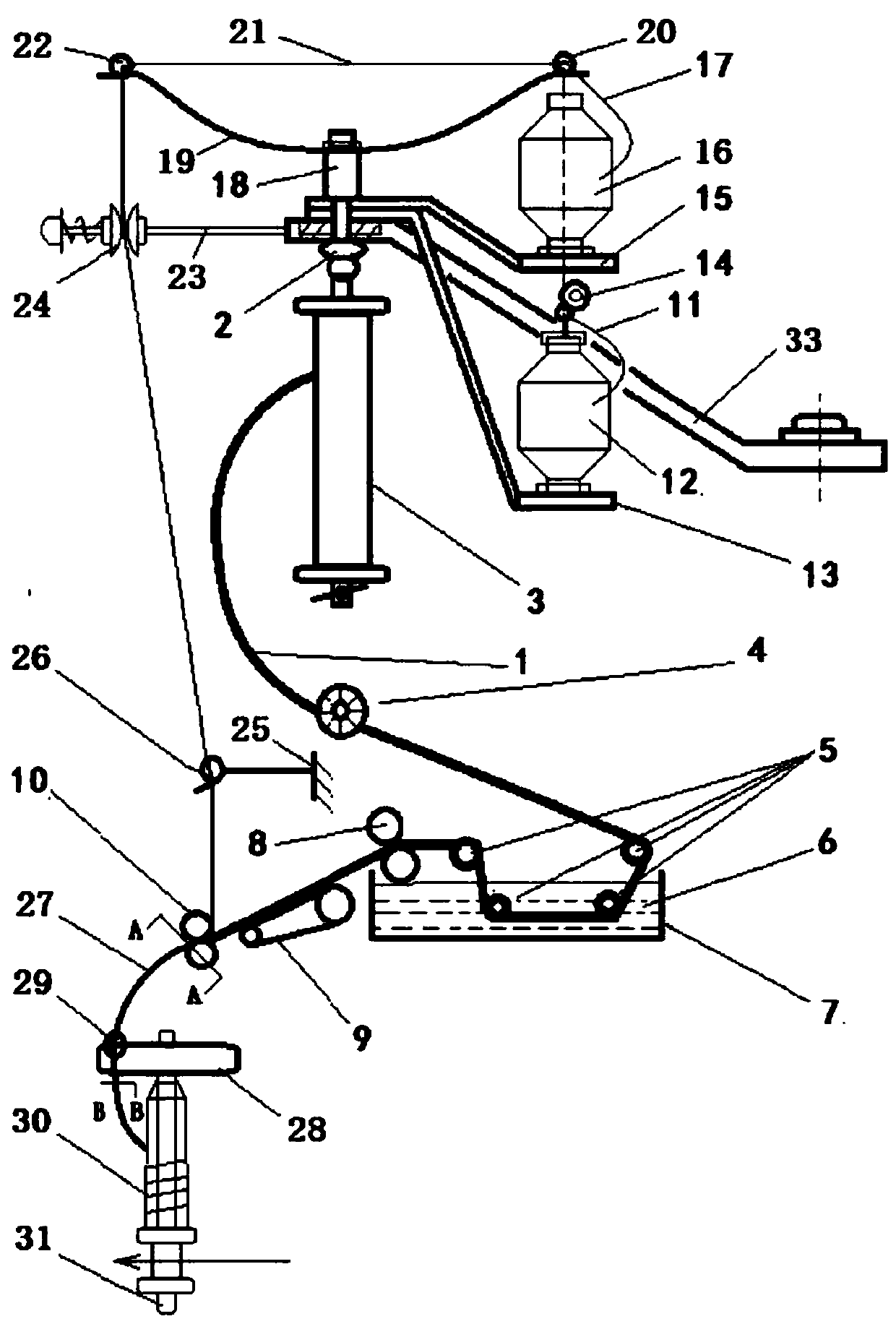

Embedded type system positioning spinning method

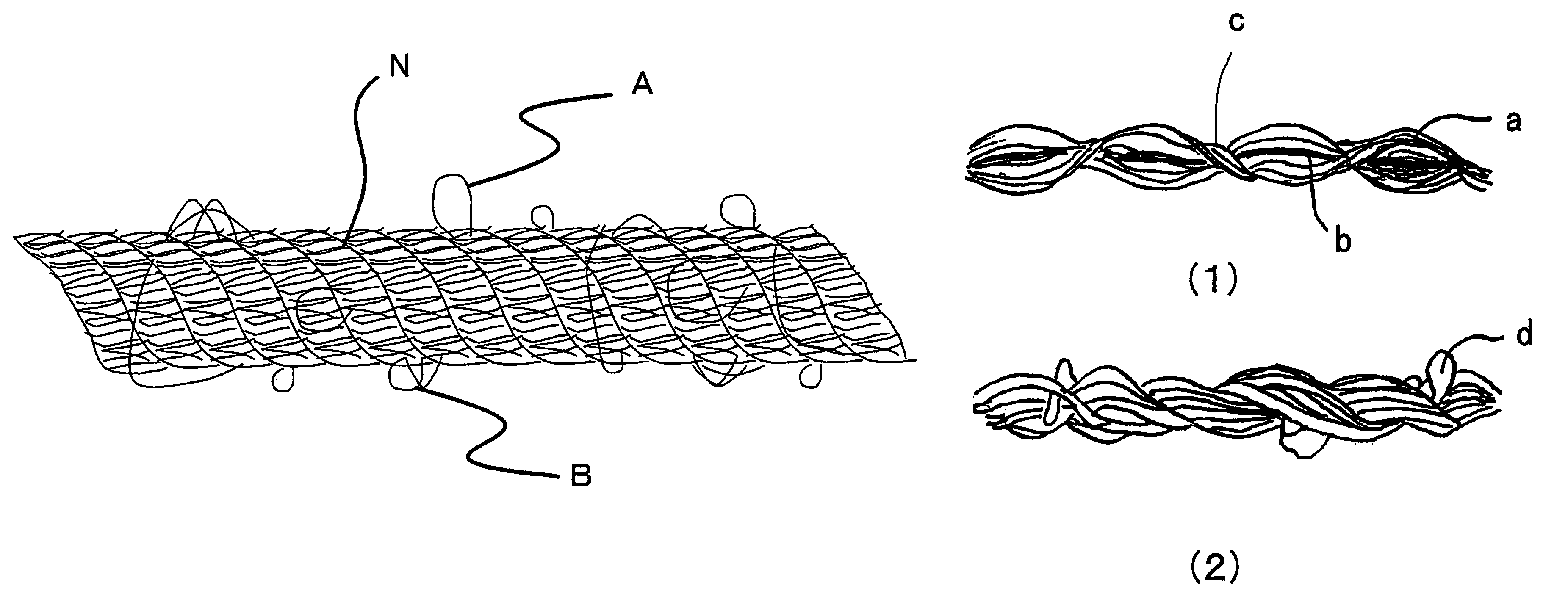

On each draft element of a ring spinning frame, two pieces of short-staple roving from the roving bobbin enter into the draft mechanism to be drafted though a guide funnel in parallel, two pieces of filament are fed from the back of the front roller, and combine with two pieces of roving at front jaw respectively. The drafted two pieces of roving and filament are output from the front jaw and enter into the twisting triangle area to be twisted, and then are wound onto a yarn bobbin to produce yarn. Based on the relative position of the two pieces of roving and two pieces of filament, different yarns can be produced. Furthermore, multi-component yarn, such as core structure, wrapped structure, strand-like structure, can be produced on a ring spinning frame. The structure of yarn can be precisely determined. Special fiber yarn can be produced on traditional spinning frame.

Owner:SHANDONG RUYI SCI & TECH GRP +2

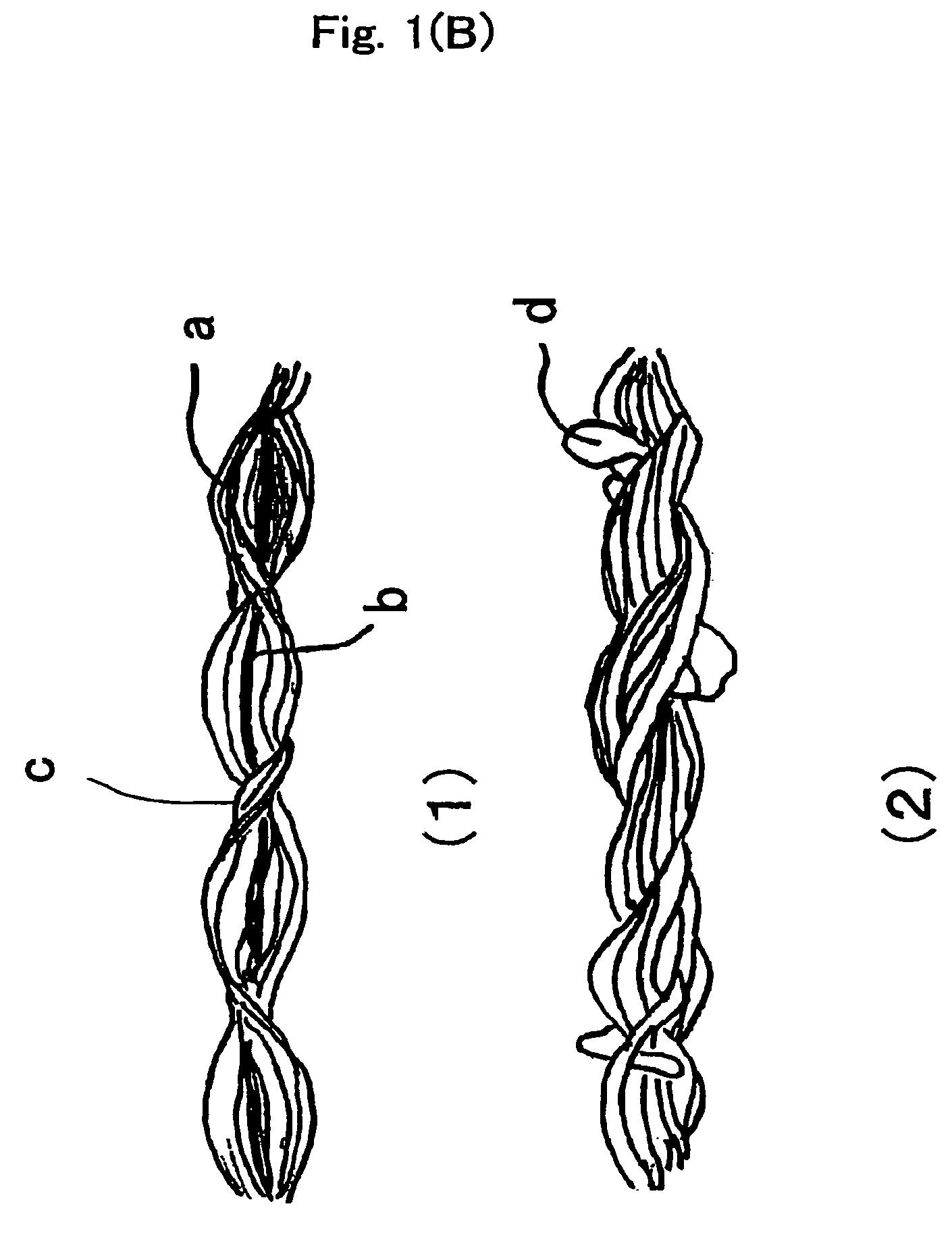

Composite twisted yarn

A textile includes a composite twisted yarn, including a spun yarn and a water-soluble yarn. The spun yarn has a twist direction that is a reverse of a twist direction of the composite twisted yarn. The water-soluble yarn is twisted with the spun yarn. A twist number of the composite twisted yarn is 1.3 to 3 times a twist number of the spun yarn, and a weight ratio of the spun yarn relative to the water-soluble yarn [spun yarn] / [water-soluble yarn] is 20 / 80 to 98 / 2. An other textile may also include an elongated elastic yarn having an elongation of 2 to 5 times an original length of the elastic yarn in a non-elongated position, and the elongated elastic yarn is twisted with the water-soluble yarn and the spun yarn. A twist number of the composite twisted yarn is 0.3 to 3 times a twist number of the spun yarn.

Owner:KURARAY TRADING CO LTD +1

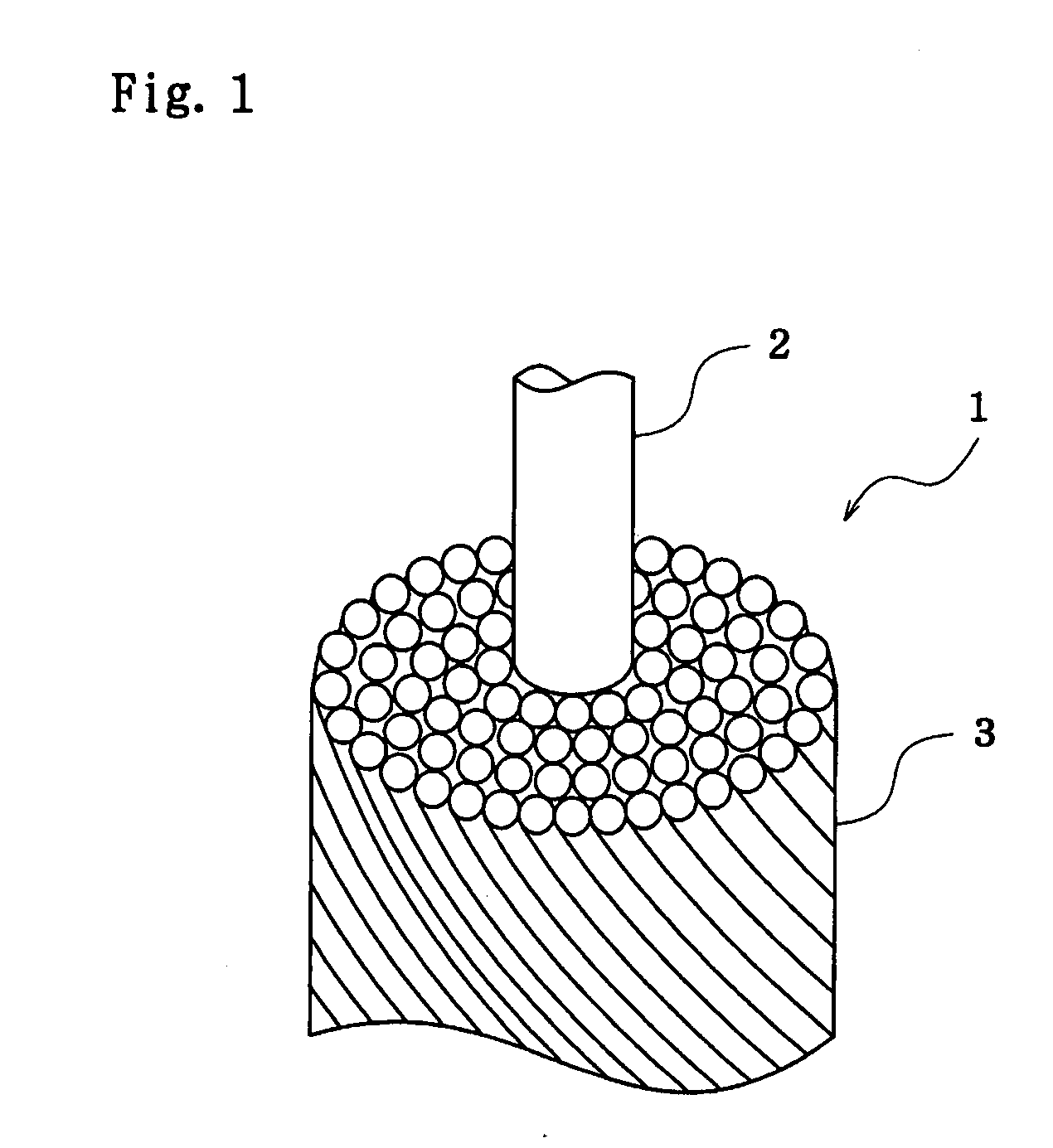

Embedded type system positioning spinning method

InactiveUS20100162677A1Enlarge rangeAlteration be simpleContinuous wound-up machinesYarnEngineeringBobbin

On each draft element of a ring spinning frame, two pieces of short-staple roving from the roving bobbin enter into the draft mechanism to be drafted though a guide funnel in parallel, two pieces of filament are fed from the back of the front roller, and combine with two pieces of roving at front jaw respectively. The drafted two pieces of roving and filament are output from the front jaw and enter into the twisting triangle area to be twisted, and then are wound onto a yarn bobbin to produce yarn. Based on the relative position of the two pieces of roving and two pieces of filament, different yarns can be produced. Furthermore, multi-component yarn, such as core structure, wrapped structure, strand-like structure, can be produced on a ring spinning frame. The structure of yarn can be precisely determined. Special fiber yarn can be produced on traditional spinning frame.

Owner:SHANDONG RUYI SCI & TECH GRP +2

Weaving method of cotton-vinylon blended hollow yarn home textile fabrics

InactiveCN109208146AImprove maintenance effectGood yarn strengthDry-cleaning apparatus for textilesMonocomponent synthetic polymer artificial filamentEngineeringSlurry

The invention relates to a weaving method of cotton-vinylon blended hollow yarn home textile fabrics. The method comprises steps of 1) of water-soluble polyvinyl alcohol spinning, the polyvinyl alcohol is spun through a dry spinning method, the polyvinyl alcohol solution with the concentration of 30-40% is made to flow through a spinning device and is pressed into a hot air passage from small holes of a spinning jet, and the hot air is utilized to evaporate the water of the polyvinyl alcohol solution so that the polyvinyl alcohol solution is made to coagulate into filament fiber in fine flow;2) of spinning of core-spun yarns; 3) of weaving, pure cotton yarns and the core-spun yarns obtained in the 2) are subjected to sizing at the temperature of 50-75 DEG C, and the fabrics are woven at intervals; and 4) of desizing and vinylon-dissolving, the fabrics obtained in the 3) are simultaneously subjected to desizing and vinylon-dissolving, the desizing liquid is kept for 30-45 minutes at the temperature of 90-98 DEG C, and the fabrics after complete desizing and vinylon-dissolving are obtained. The weaving method is advantaged in that good vinylon-dissolving of the core-spun yarns and high yarn strength in the weaving process are achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Composite copper-ion-modified acrylic fiber blended yarn

InactiveCN105544036AStrong and long-lasting antibacterialEliminate odorUltrasonic/sonic fibre treatmentYarnYarnCopper

The invention discloses a composite copper-ion-modified acrylic fiber blended yarn. The composite copper-ion-modified acrylic fiber blended yarn is prepared from, by weight, 20-40 parts of viscose, 20-40 parts of modified bamboo fibers and 20-40 parts of copper-ion-modified acrylic fibers. A blending process is adopted for spinning the materials into the yarn. The composite copper-ion-modified acrylic fiber blended yarn is large in cohesive force, high in fiber strength, good in durability and excellent in waterproof and breathable performance.

Owner:ANHUI WUWEI TIANCHENG TEXTILE

Production process of flax socks

The present invention relates to the production process of socks with flax yarn as main amterial and belongs to the field of textile technology. Flax material is combined with other fibers to produce comfortable and durable socks capable of rpeventing smelly foot. Technologically, the present invention features that flax yarn and cotton yarn are double and then matched with Chinlon yarn and urethane elastic fiber yarn in knitting socks and the flax content in the material is 25-55%. The socks are penetrant, hygroscopic, bacteriostatic, bad smell preventing and comfortable.

Owner:姜元麒 +1

Sewing thread and process for producing the same

ActiveUS7678450B2High-speed sewabilityReduce frictional resistanceYarnThin material handlingYarnEngineering

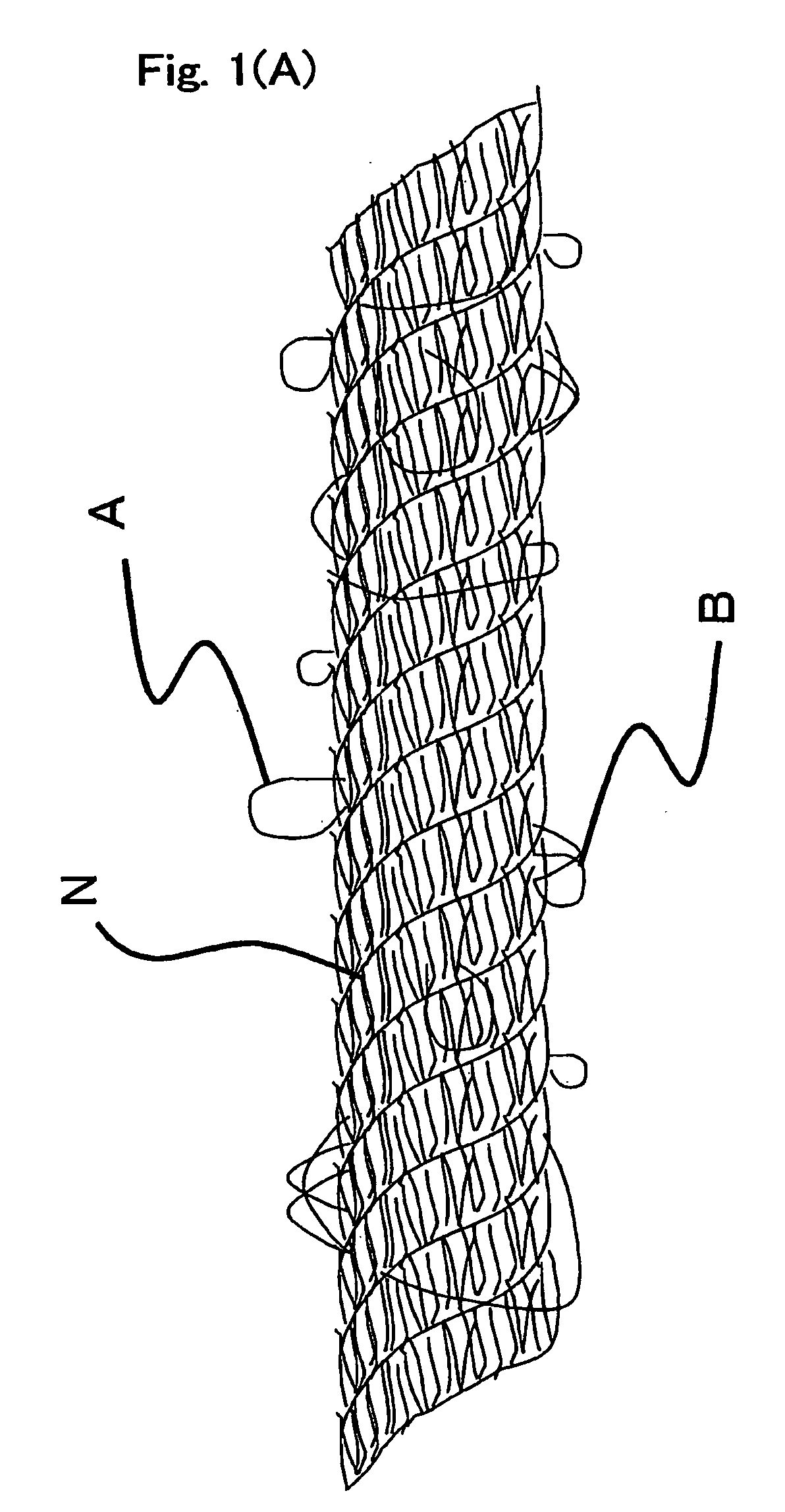

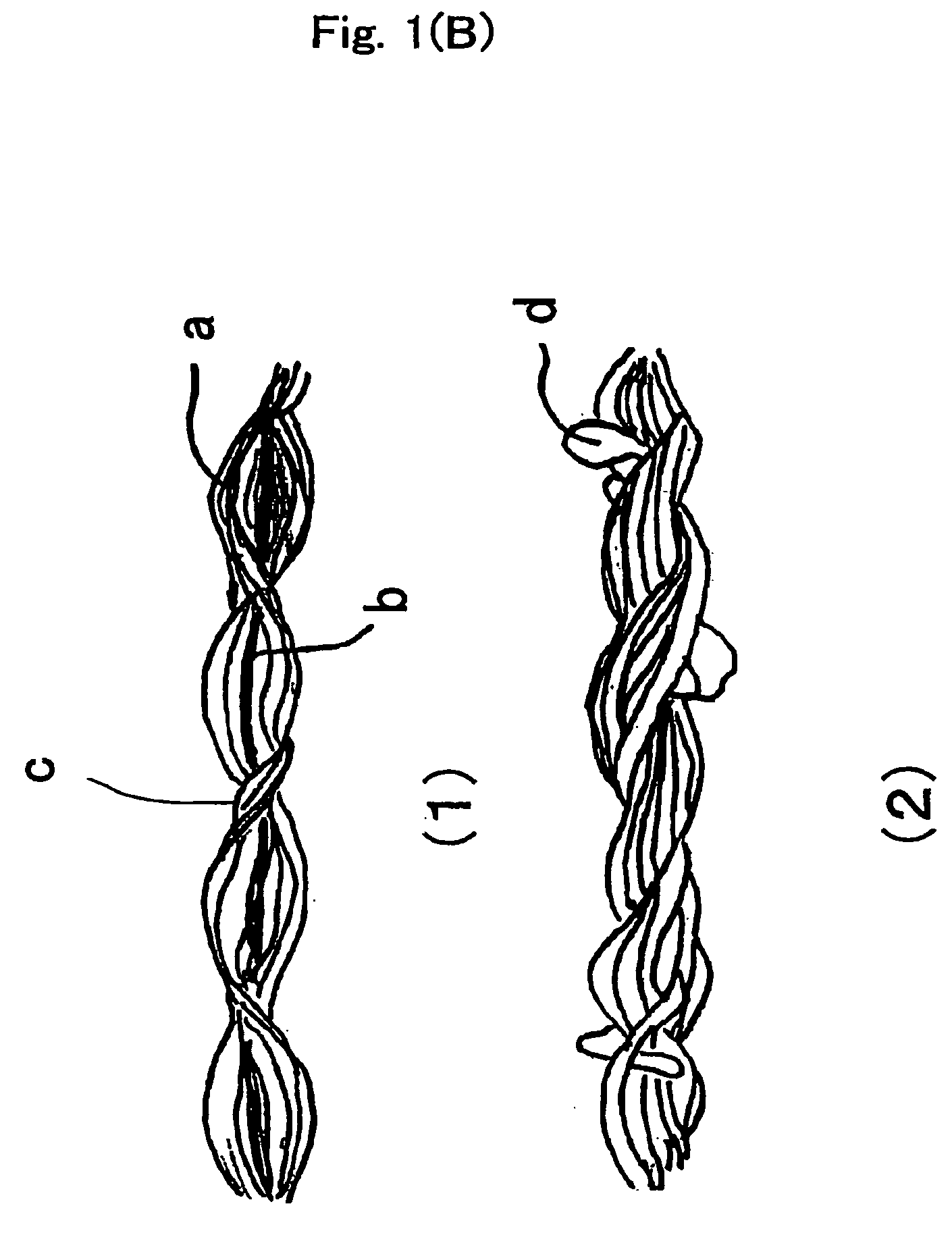

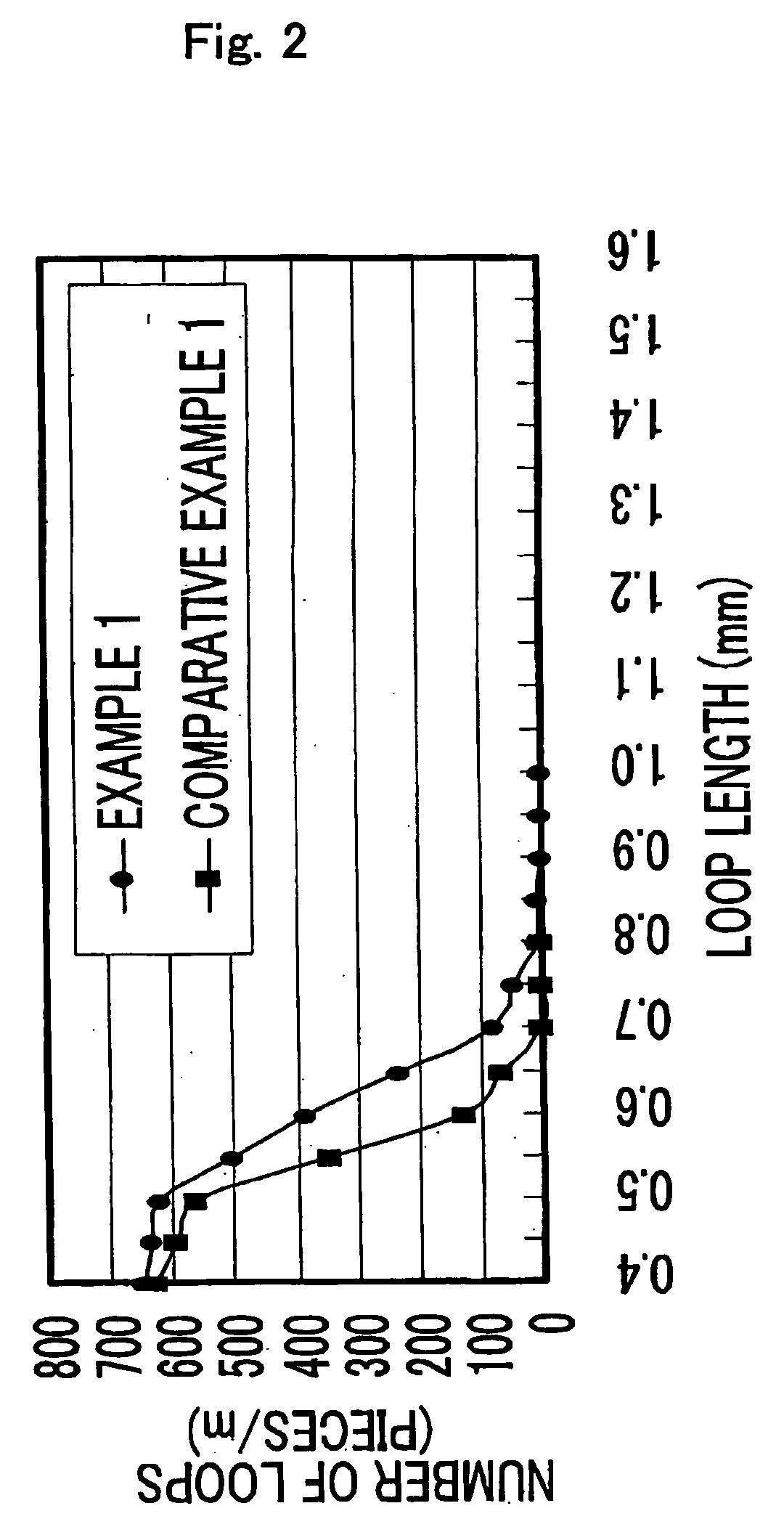

To provide a sewing thread that is excellent in high-speed sewability and automatic sewing characteristics. A sewing thread includes a plurality of under-twisted yarns provided with upper-twist, the yarns each being composed of a sheath-core structure yarn composed of two or more multifilament yarns, wherein part of the sheath-core structure yarn protrudes as loops on a yarn surface, the loops being composed of 50 to 300 loops / m with 0.7 to less than 1.2 mm length and 10 or less loops / m with 1.2 mm or more length, and wherein the yarns have a strength of 4 to 6 CN / dtex.

Owner:TORAY IND INC

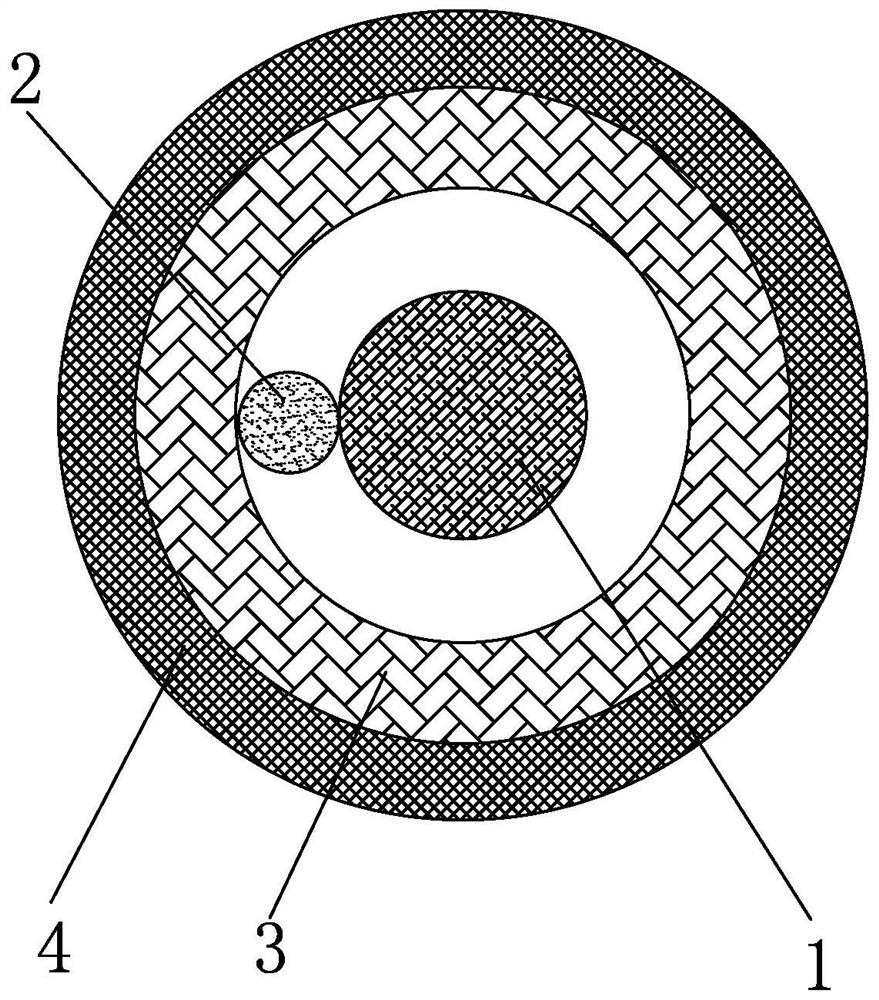

Air vortex spun viscose yarn

The invention discloses air vortex spun viscose yarn. The air vortex spun viscose yarn comprises a yarn body, wherein the yarn body comprises core yarn, winding yarn, a flax fiber layer and a bamboo viscose fiber layer; the core yarn is PTT yarn, and the PTT yarn is made of PTT fibers; the winding yarn is formed by twisting and stranding viscose strong yarns, and the winding yarn is spirally woundaround the outer portion of the core yarn; and the flax fiber layer is formed by spirally coating the winding yarn with flax fibers, and the bamboo viscose fiber layer is formed by spirally coating the flax fiber layer with bamboo viscose fibers. The air vortex spun viscose yarn is soft and comfortable to touch, high in yarn strength, good in elasticity, not prone to break, good in antibacterialperformance, good in moisture absorption and release performance and excellent in comprehensive performance.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

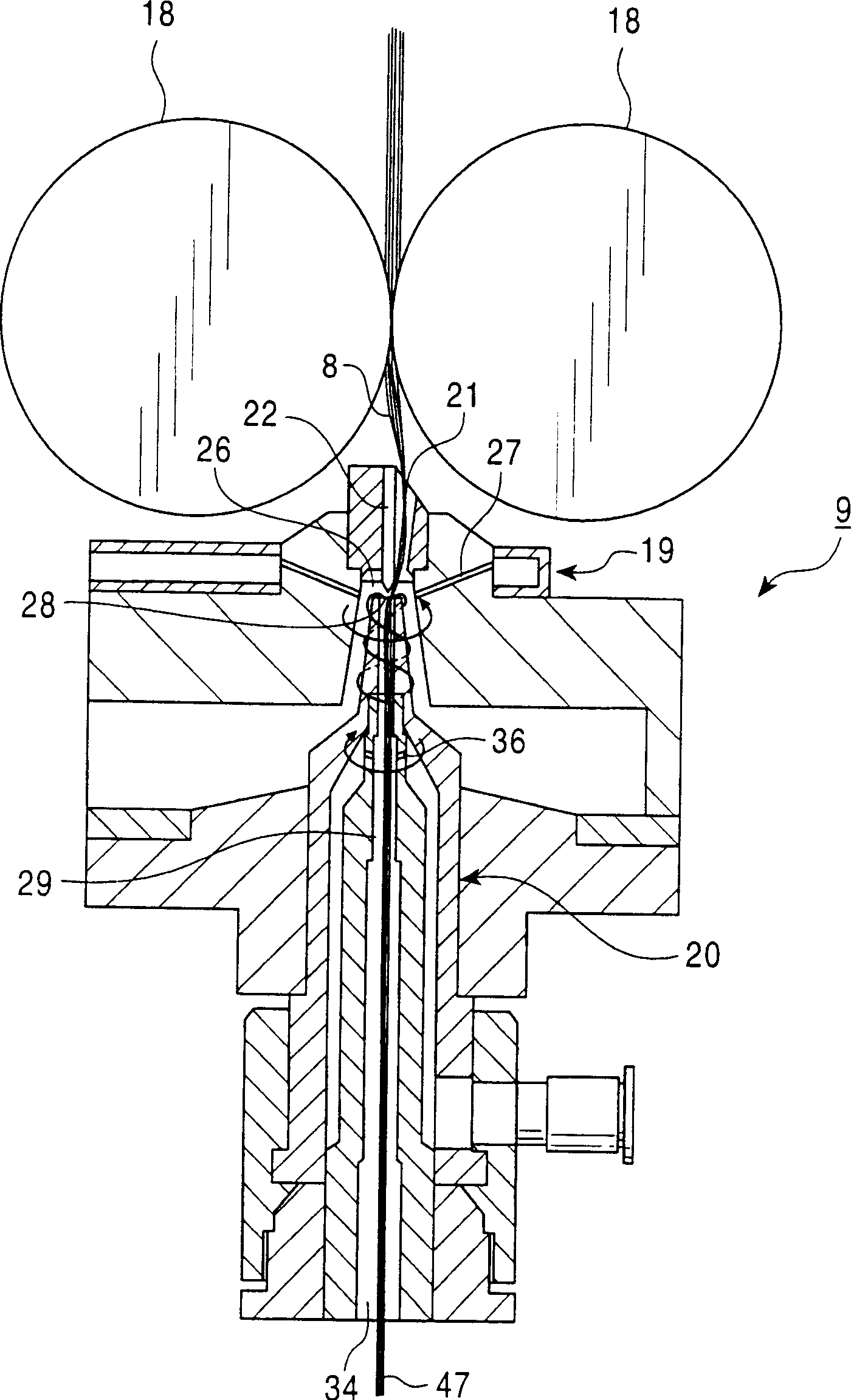

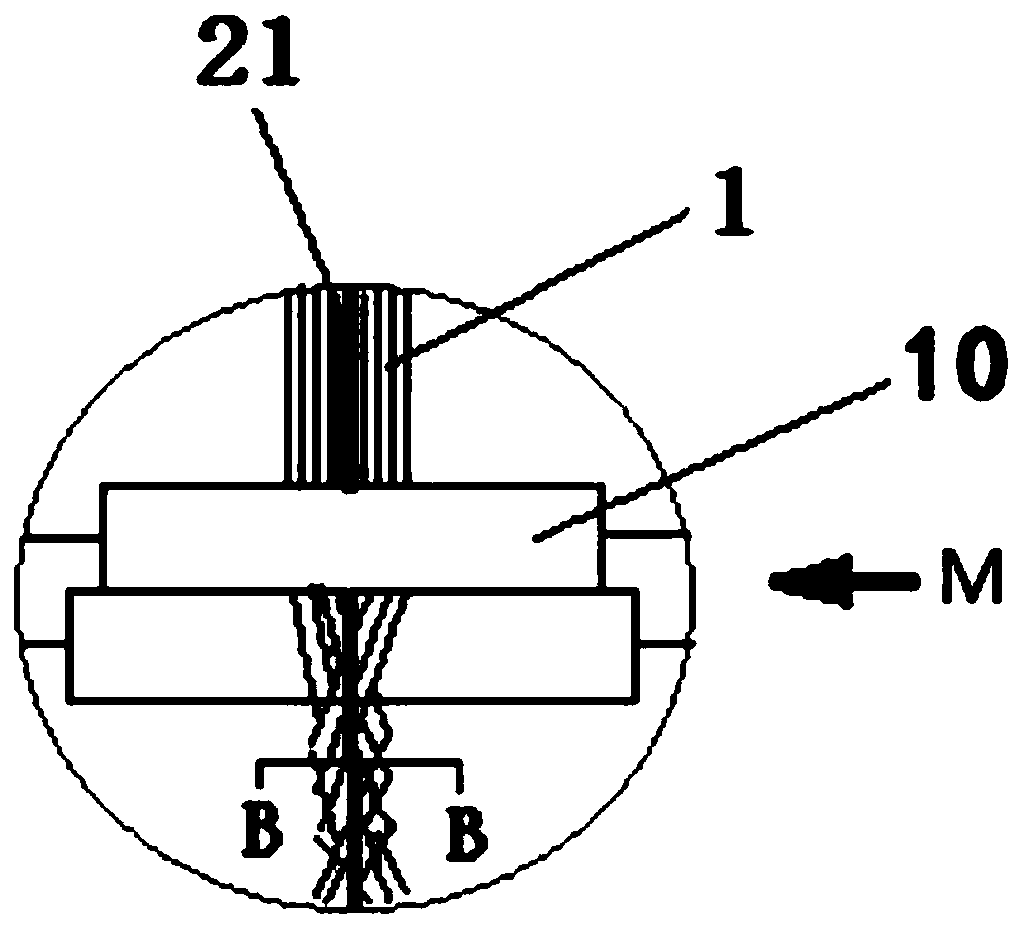

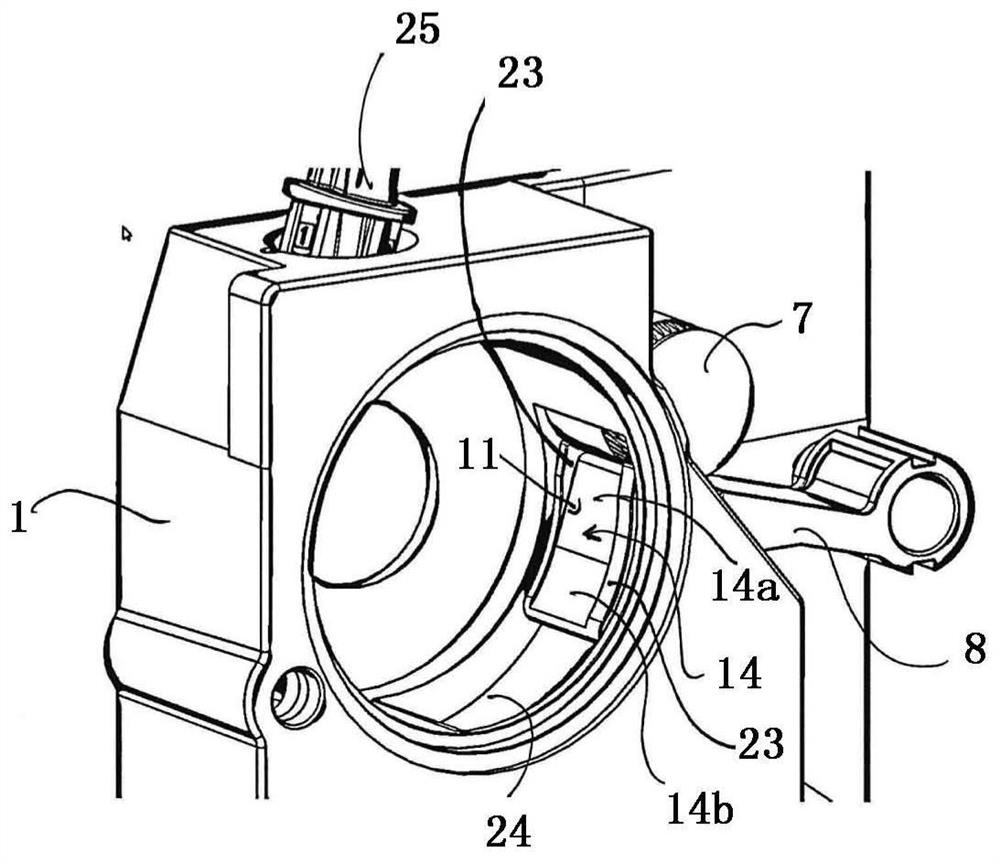

Pneumatic spinning device and spinning machine

ActiveCN102199817AHigh yarn strengthImprove qualityContinuous wound-up machinesOpen-end spinning machinesFiberEngineering

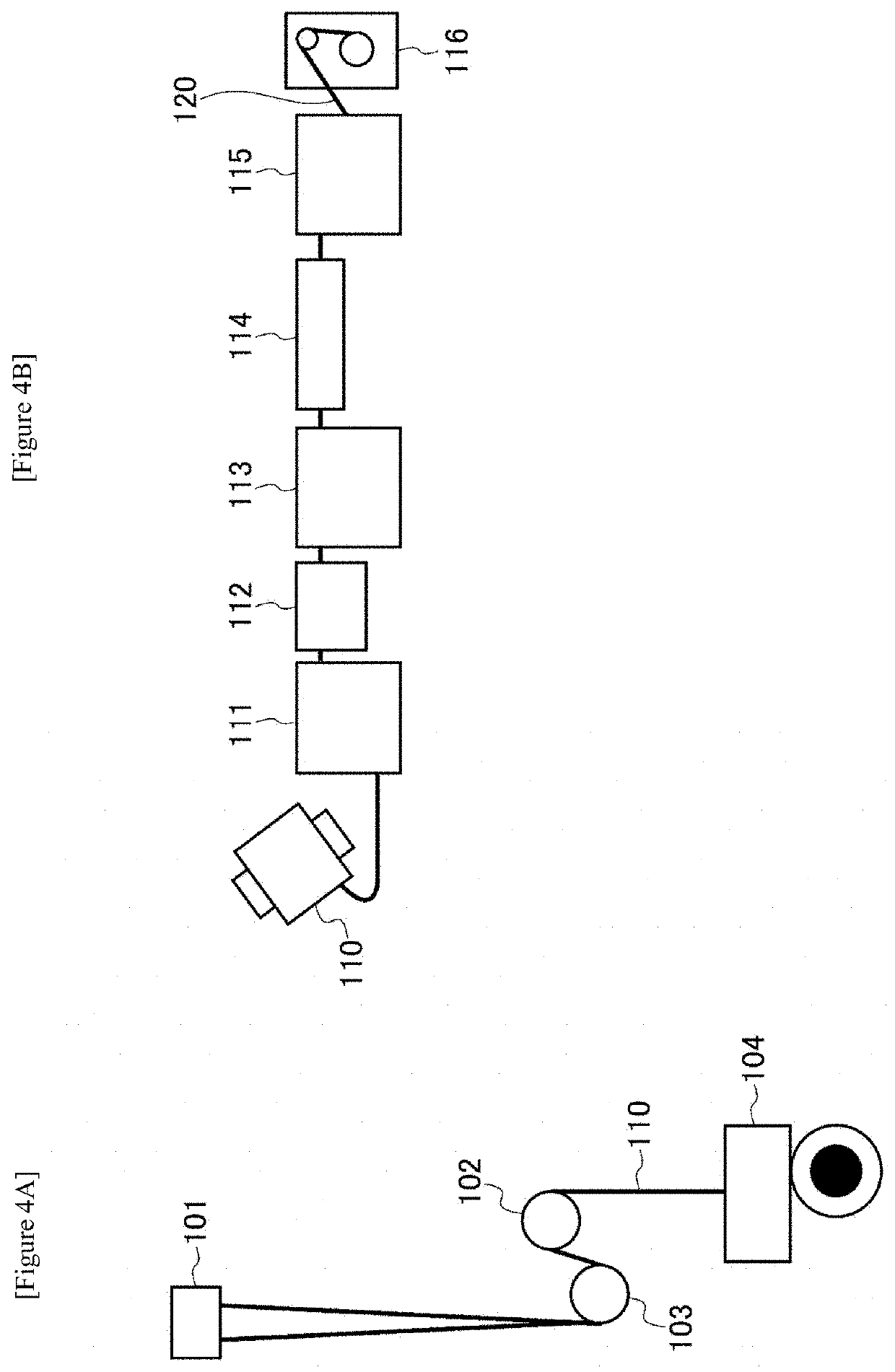

A pneumatic spinning device includes a hollow guide shaft (20), and a nozzle block (34). A portion of the hollow guide shaft (20) is located within a whirling chamber. A whirling chamber is formed in the nozzle block (34). Four air injecting nozzles (27) that inject compressed air from a nozzle opening (27a) opening into the whirling chamber to generate whirling airflow in the whirling chamber are formed in the nozzle block (34). The whirling chamber has a columnar portion formed as a substantially columnar shape having a constant diameter (D2). A height (H1) of the whirling chamber is equal to or smaller than the diameter (D2). A flow path cross-sectional area at a downstream end of the whirling chamber in a fiber feeding direction (a position A2) is formed smaller than a flow path cross-sectional area of the whirling chamber at a position where the nozzle opening (27a) is formed.

Owner:MURATA MASCH LTD

Sewing thread and process for producing the same

ActiveUS20050202240A1High-speed sewabilityReduce frictional resistanceYarnThin material handlingYarnEngineering

To provide a sewing thread that is excellent in high-speed sewability and automatic sewing characteristics. A sewing thread includes a plurality of under-twisted yarns provided with upper-twist, the yarns each being composed of a sheath-core structure yarn composed of two or more multifilament yarns, wherein part of the sheath-core structure yarn protrudes as loops on a yarn surface, the loops being composed of 50 to 300 loops / m with 0.7 to less than 1.2 mm length and 10 or less loops / m with 1.2 mm or more length, and wherein the yarns have a strength of 4 to 6 CN / dtex.

Owner:TORAY IND INC

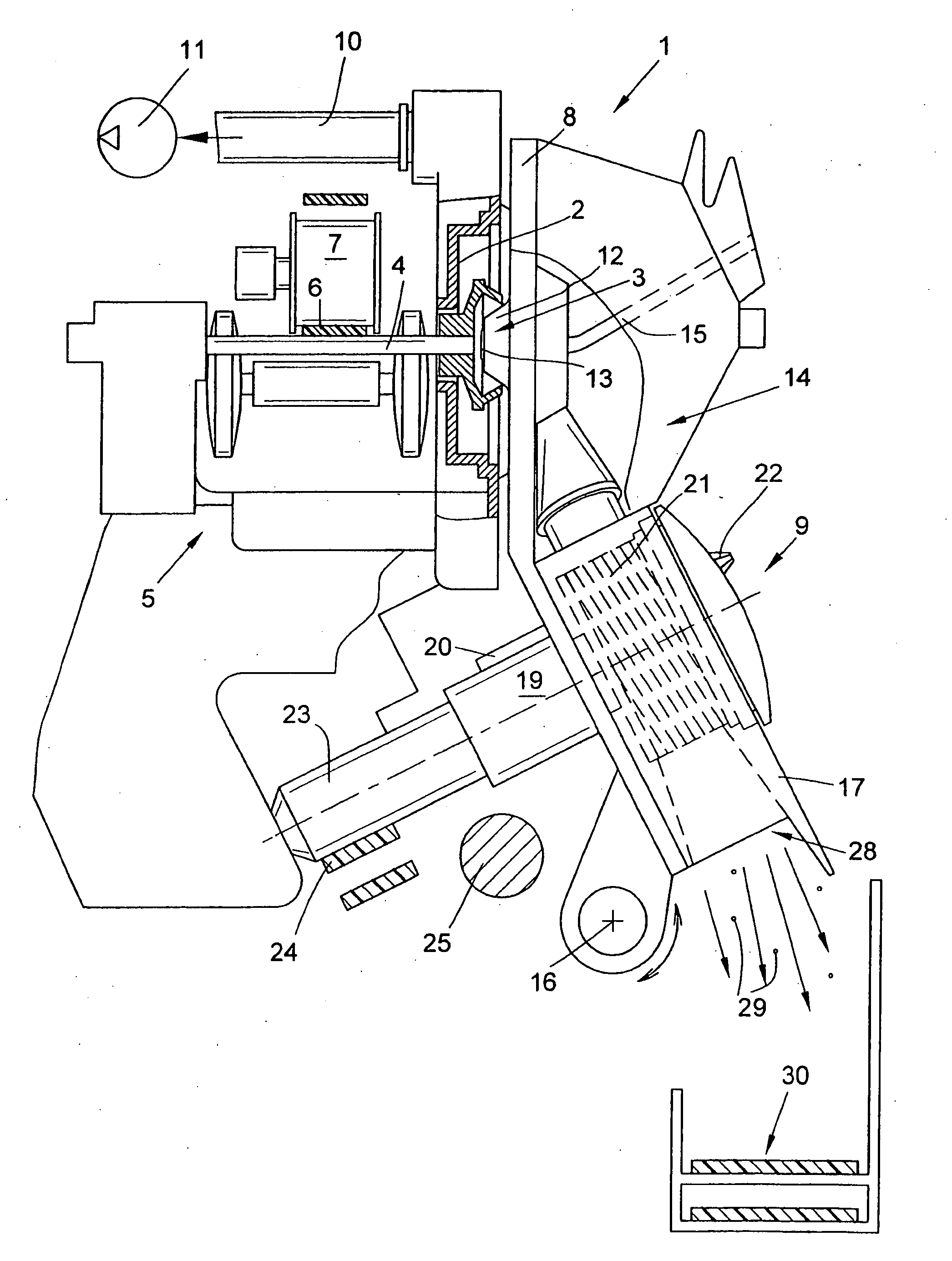

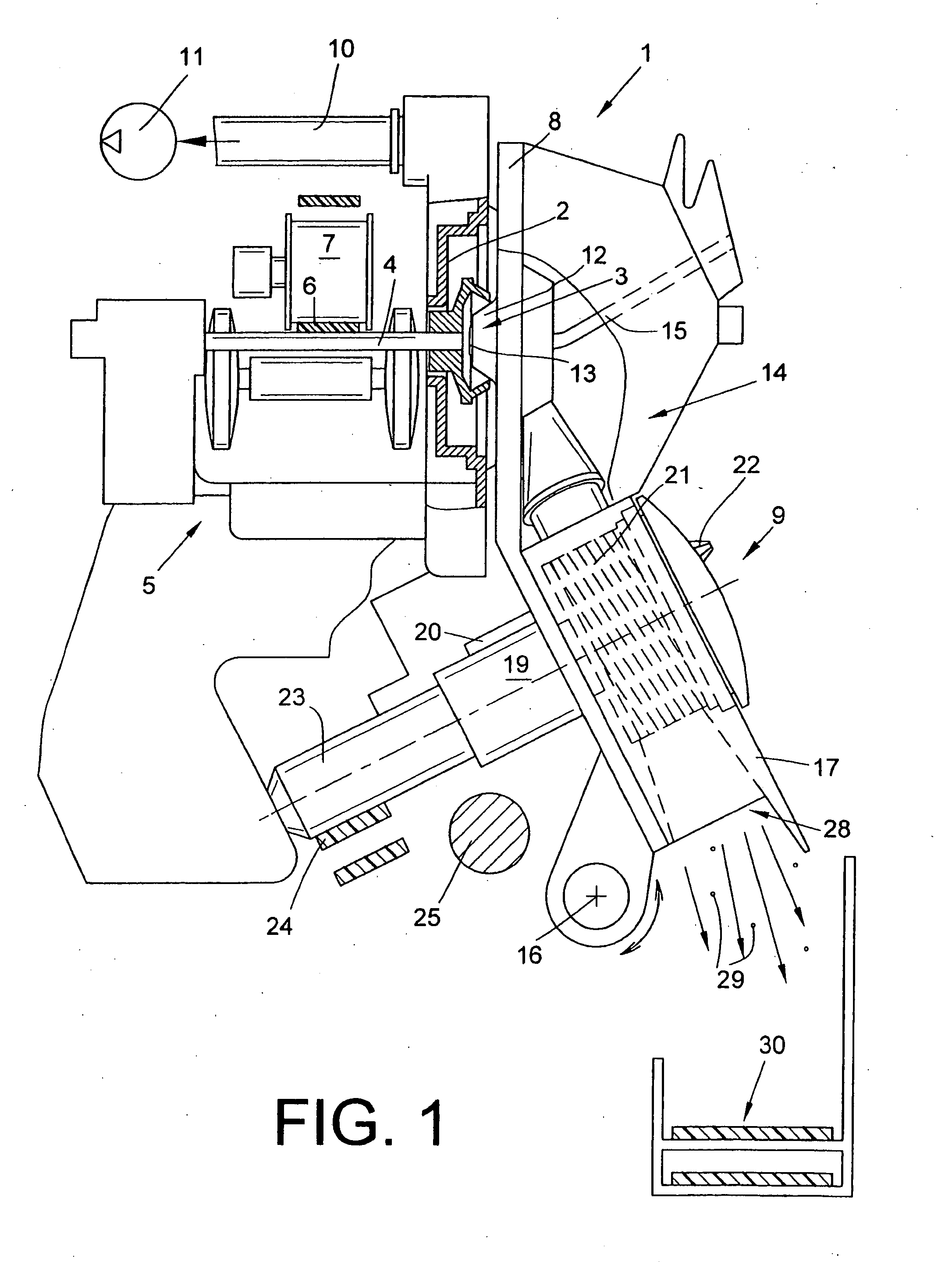

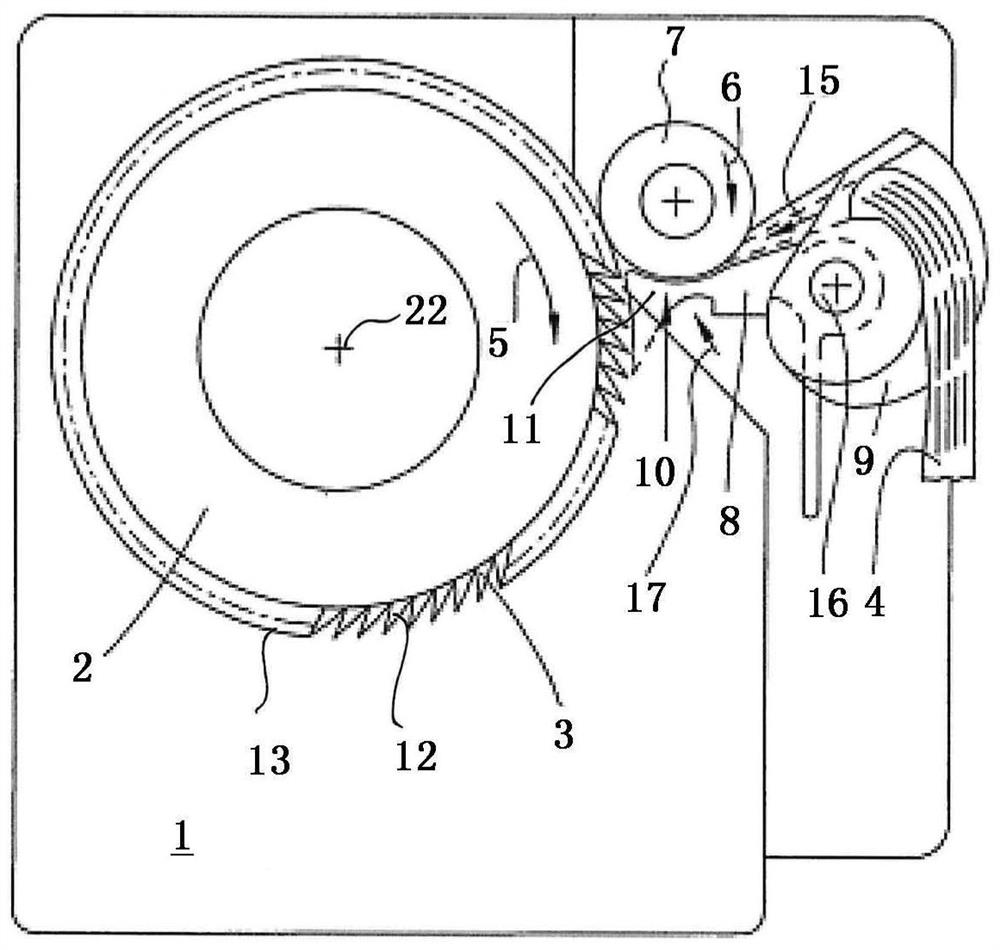

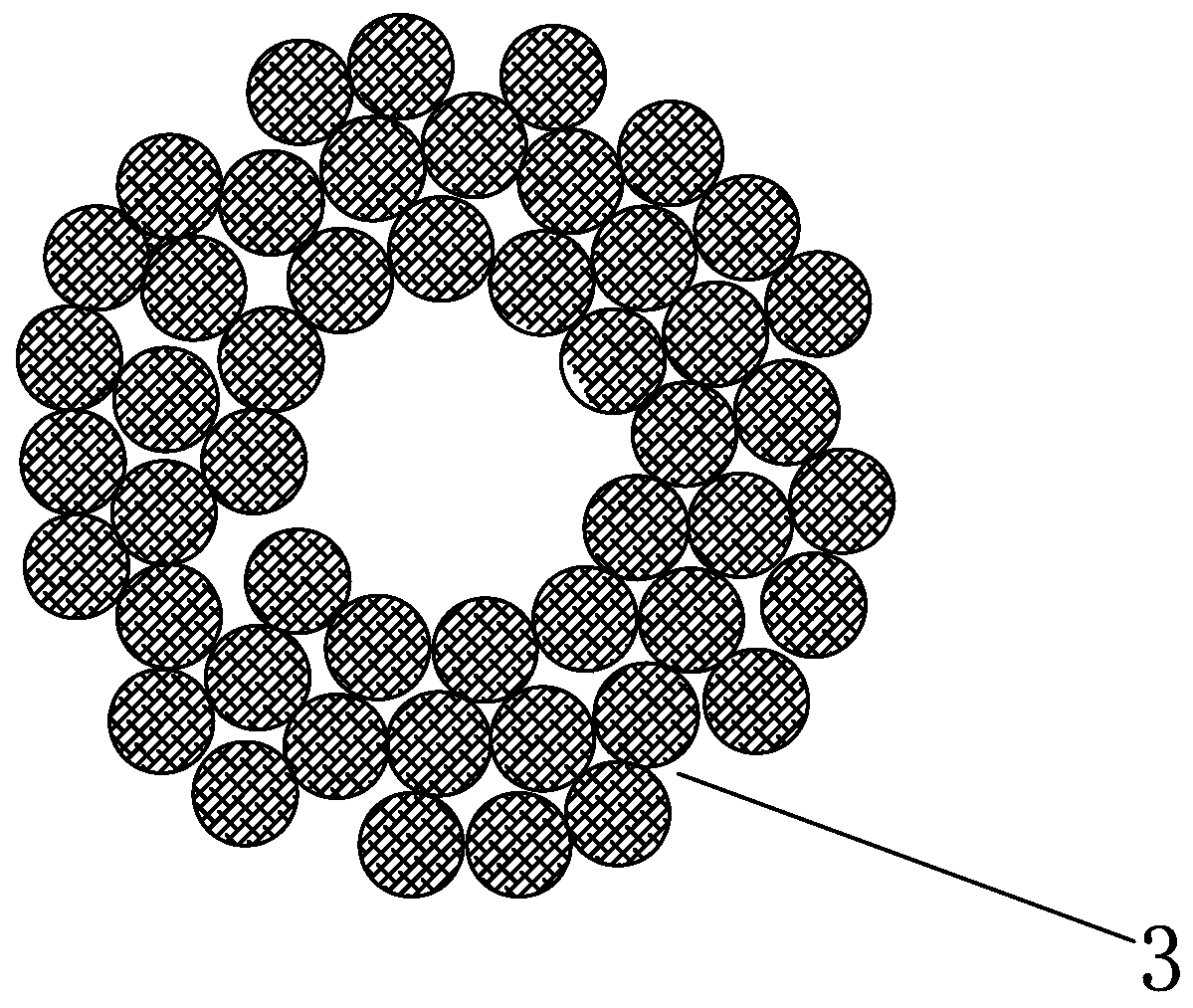

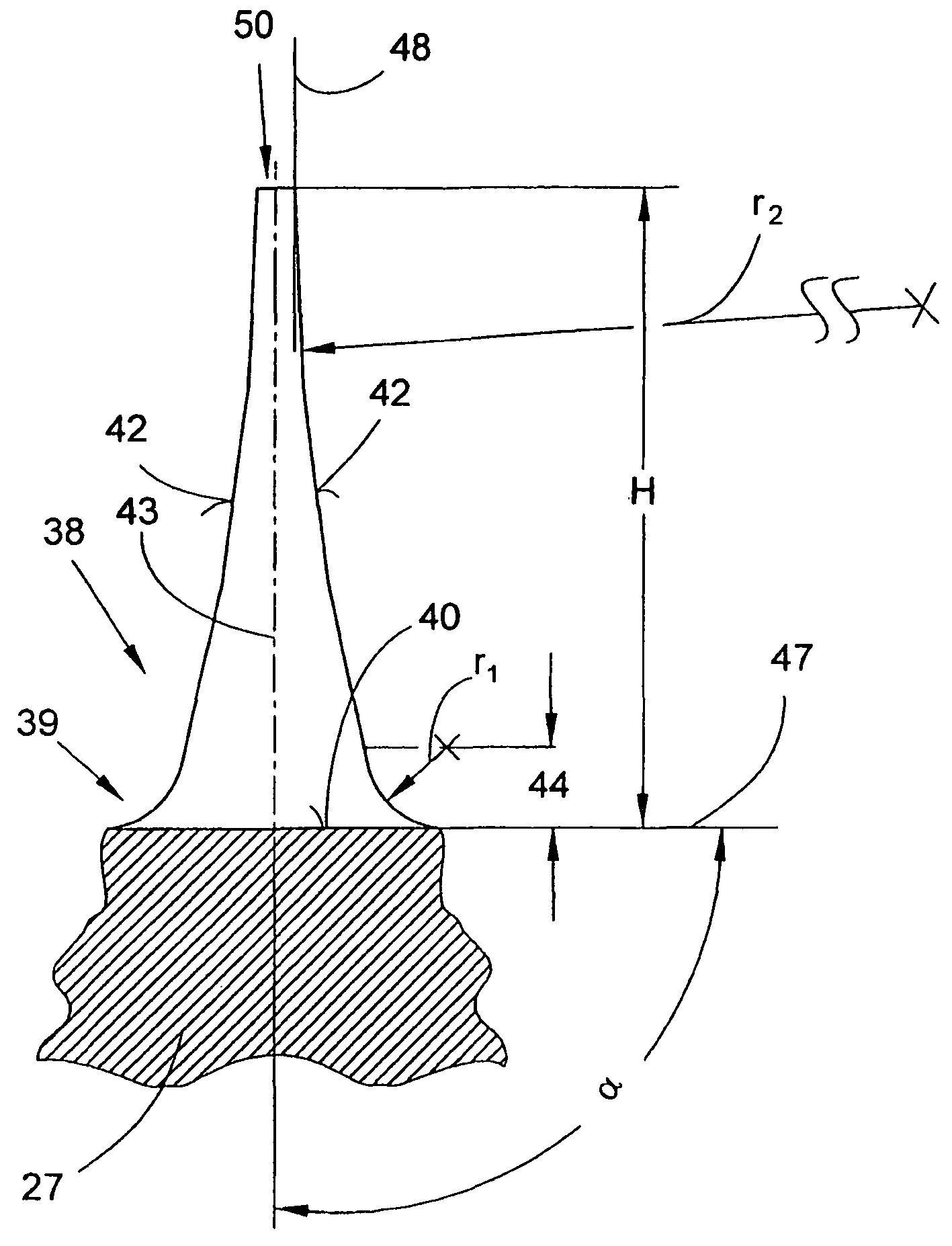

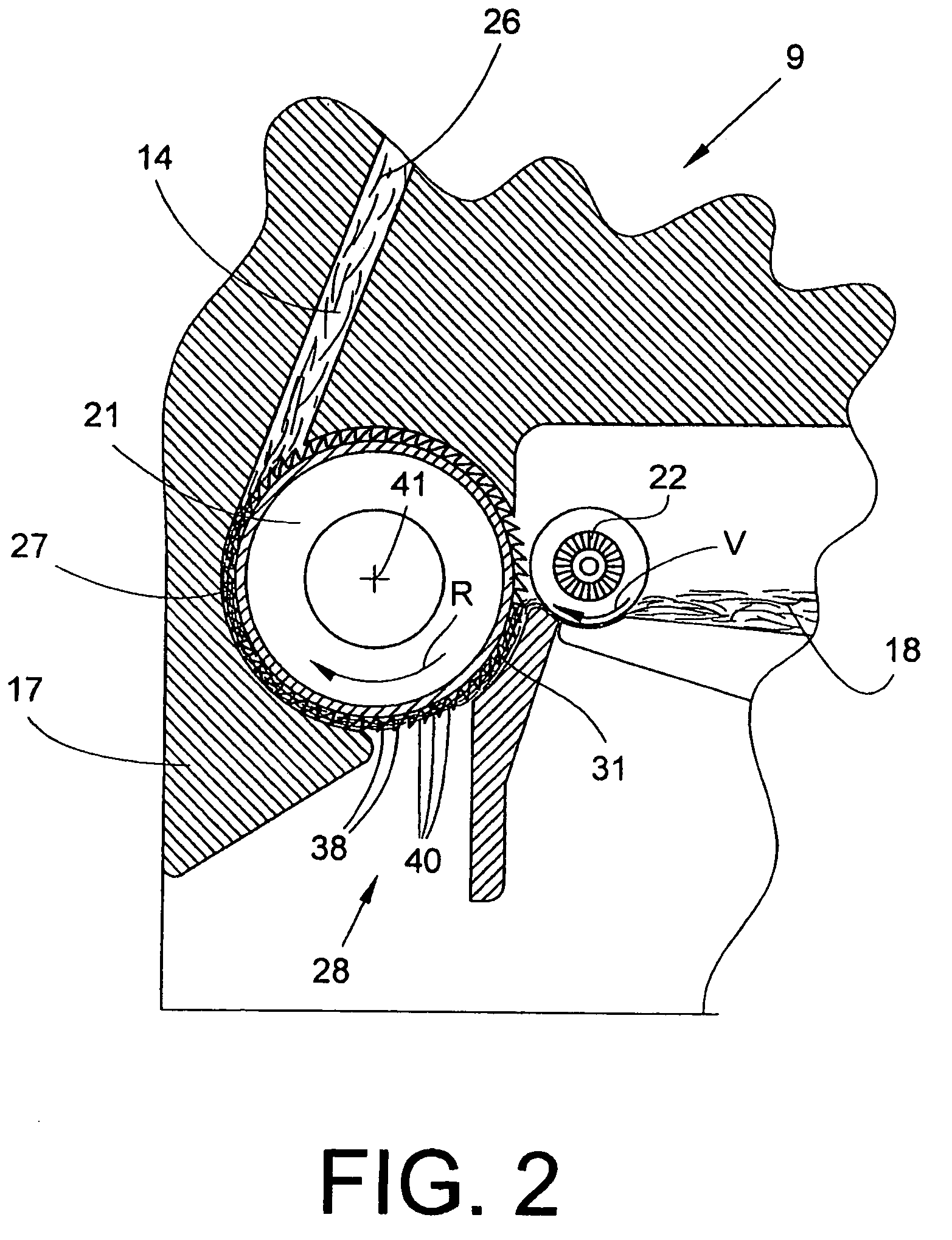

Fitting Ring for an Opening Roller of an Open-End Spinning Device

InactiveUS20100154379A1Advantageously configurePrecise transportationContinuous wound-up machinesOpen-end spinning machinesEngineering

Clothing ring (27) for an opening roller (21) of an open-end spinning device (1), comprising teeth (38) which are formed by at least one groove (39) incorporated in the peripheral face of a basic body (45) and running in the peripheral direction, and a plurality of indents (40) arranged substantially in the axial direction. An axial separation spacing (t) of the teeth (38) is predetermined by the groove (39) and is significantly smaller than the height (H) of the teeth (38). The teeth (38) have tooth flanks (42) which are continuously concavely curved into the groove (39).

Owner:SAURER GERMANY GMBH & CO KG

Tancel bamboo charcoal denim-simulated fabric

The invention belongs to the technical field of textile fabrics and particularly relates to a tencel bamboo charcoal denim-simulated fabric. The tencel bamboo charcoal denim-simulated fabric is wovenby tencel, bamboo charcoal fibers, spandex, terylene and cotton and formed by interweaving warp yarn and weft yarn, wherein the warp yarn consists of 20-25 parts by mass of tencel and 35-45 parts by mass of cotton, the weft yarn consists of 8-15 parts of bamboo charcoal fibers, 25-35 parts of terylene and 2-5 parts of spandex and is slub yarn formed by blending tencel and cotton, and the specification of the slub yarn is 20SB-21SB. The warp yarn of the fabric is the slub yarn formed by compactly blending the tencel and the cotton, has a unique slub feeling and more gloss and a better sagging effect on the surface of the yarn and is high in yarn strength, and meanwhile, the characteristics of high softness, great moisture absorption performance, high air permeability and the like of cottonproducts can be maintained. The weft yarn adopts bamboo charcoal fibers, terylene filaments and spandex for doubling, high elasticity of the spandex and the high strength and wear resistance of the terylene are maintained, and the weft yarn has the advantages of good bacteriostasis, high elasticity and strength, great wear resistance and the like.

Owner:江苏工匠服饰科技有限公司

Spinning process of multi-fiber blended yarn

InactiveCN108754692AHigh cationic degreeHigh yarn strengthContinuous wound-up machinesDyeing processCardingEngineering

The invention discloses a spinning process of a multi-fiber blended yarn, which comprises the following steps of: (1) cotton fiber modification; (2) selecting a spinning raw material; (3) flower clearing and cotton carding; (4) drawing; (5) spinning. Compared with the prior art, the process has the advantages that the cotton fiber obtained after modification has higher cationic degree, the adsorption of the cotton fiber to the dyestuff is greatly improved, and the dyeing effect of the cotton yarn is improved; the blended yarn obtained by blending the modified cotton fiber, the ramie fiber andthe viscose fiber has the advantages of the three fibers, the blended yarn produced by using vortex spinning has the advantages of less feather, high yarn strength and good strip evenness.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

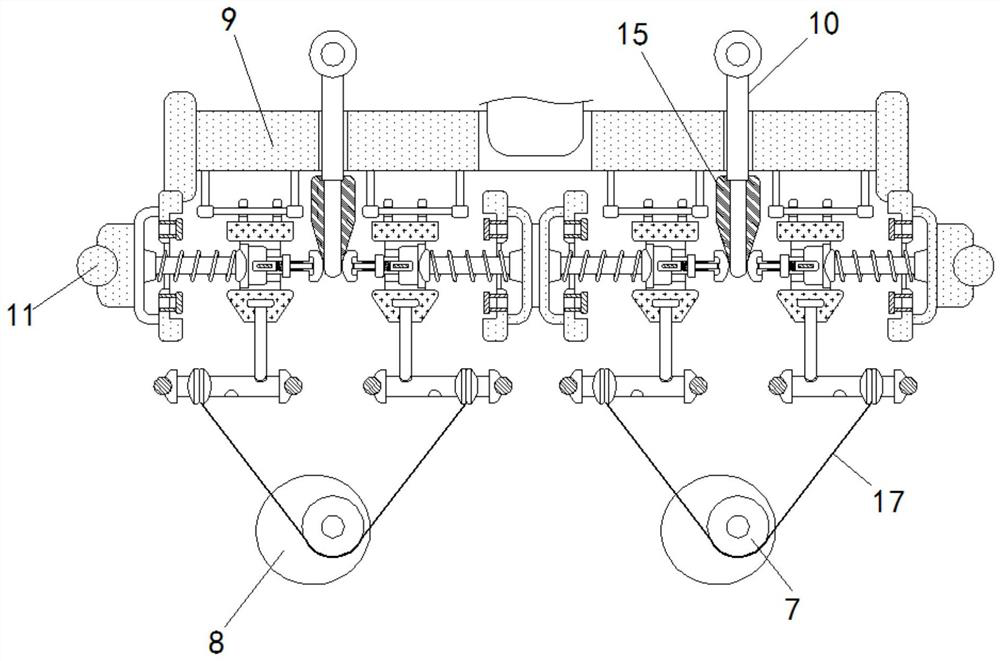

Linen/polyester filament self-adhesive core-spun yarn production equipment and method

The invention discloses linen / polyester filament self-adhesive core-spun yarn production equipment and method. The linen / polyester filament self-adhesive core-spun yarn production equipment comprisesa linen staple roving, a dope dyeing polyester filament yarn and a low-melting-point polyester filament yarn; the linen staple roving is transported to a front roller in front through a back roller and a roving stretch apron; the dope dyeing polyester filament yarn is unwound from a bobbin and bypasses a guide wire tension wheel upwards, and passes through a low-melting-point polyester filament yarn bobbin bracket and a bobbin core of a low-melting-point polyester filament yarn bobbin; the low-melting-point polyester filament yarn is unwound from the bobbin and meets with the dope dyeing polyester filament yarn above the bobbin and bypasses a yarn guide, and a low-twist combined filament yarn is formed; and the low-twist combined filament yarn meets with fibers that are stretched by the linen staple roving at the front roller, a linen / polyester filament core-spun yarn is formed under the action of a twisting triangular space, and the linen / polyester filament core-spun yarn passes through a steel collar on a linen spinning frame steel collar and is wound on a ring bobbin. According to the linen / polyester filament self-adhesive core-spun yarn production equipment provided by the invention, the effect of improving the yarn strength and reducing the yarn hairiness falling off can be achieved, the dyeing depth of linen blended yarn fabrics can be improved, the color fastness of thefabrics can be improved, and the good settability and conformality of the fabrics can be improved.

Owner:SHAOXING HENGXING LINEN TEXTILE TECH

Fitting ring for an opening roller of an open-end spinning device

ActiveCN101374983AFine and even openingReduce curvatureContinuous wound-up machinesOpen-end spinning machinesEngineering

The invention relates to a fitting ring (27) for an opening roller (21) of an open-end spinning device (1), having teeth (38) which are formed by at least one groove (39) which is machined into the circumferential face of a basic body (45) and extends in the circumferential direction and by a multiplicity of indents (40) which are arranged substantially in the axial direction, wherein the separation spacing (t) of the teeth (38) which is predefined by the groove (39) is considerably smaller than the height (H) of the teeth (38). There is provision according to the invention for the teeth (38) to have tooth flanks (42) which are of concavely arched configuration continuously as far as into the groove (39).

Owner:SAURER GERMANY GMBH & CO KG

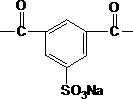

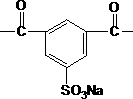

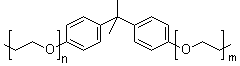

Cationic dyeable copolyester

InactiveCN109467686AImprove dyeing effectFeel goodMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentCopolyesterColor tone

The invention discloses cationic dyeable copolyester which is mainly prepared by copolymerizing diol and aromatic dibasic acid or a derivative thereof, wherein the copolyester contains 0.05 to 2.00 percent by weight of a sulfonate structural unit A relative to the total amount of the copolyester based on a sulfur element, and 0.1 to 10.0 percent by weight of a bisphenol A polyoxyethylene ether structural unit B relative to the weight of the copolymer. The cationic dyeable copolyester has good color tone and is low in filtration pressure during spinning. A prepared fiber can be dyed with a cationic dye, has a bright color and excellent dyeing characteristics, and is high in yarn strength and good in fabric handfeel.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Multi-material blended yarn and preparation method thereof

The invention provides multi-material blended yarn which is prepared from mixing flax, viscose and cotton in a certain ratio and the mixing ratio of the flax, the viscose and the cotton is 35-55:15-35:10-50. According to mixture of three kinds of materials, the produced yarn has the advantages of being high in strength, good in breathability and tensile performance, superior in extending performance, beautiful and bright in color and not easy to fade.

Owner:芜湖富春纺织有限公司

Production method of skincare fiber blended yarn

The invention discloses a production method of skincare fiber blended yarn, in particular to a production method which is beneficial for processing, free of device upgrading, economical and applicable. The method includes the steps of fiber dyeing, material weighing, material mixing, cotton carding, drawing, roving, spinning, spooling, doubling and two-for-one twisting. The method is mainly used for the textile field.

Owner:珠海励联纺织染工业有限公司

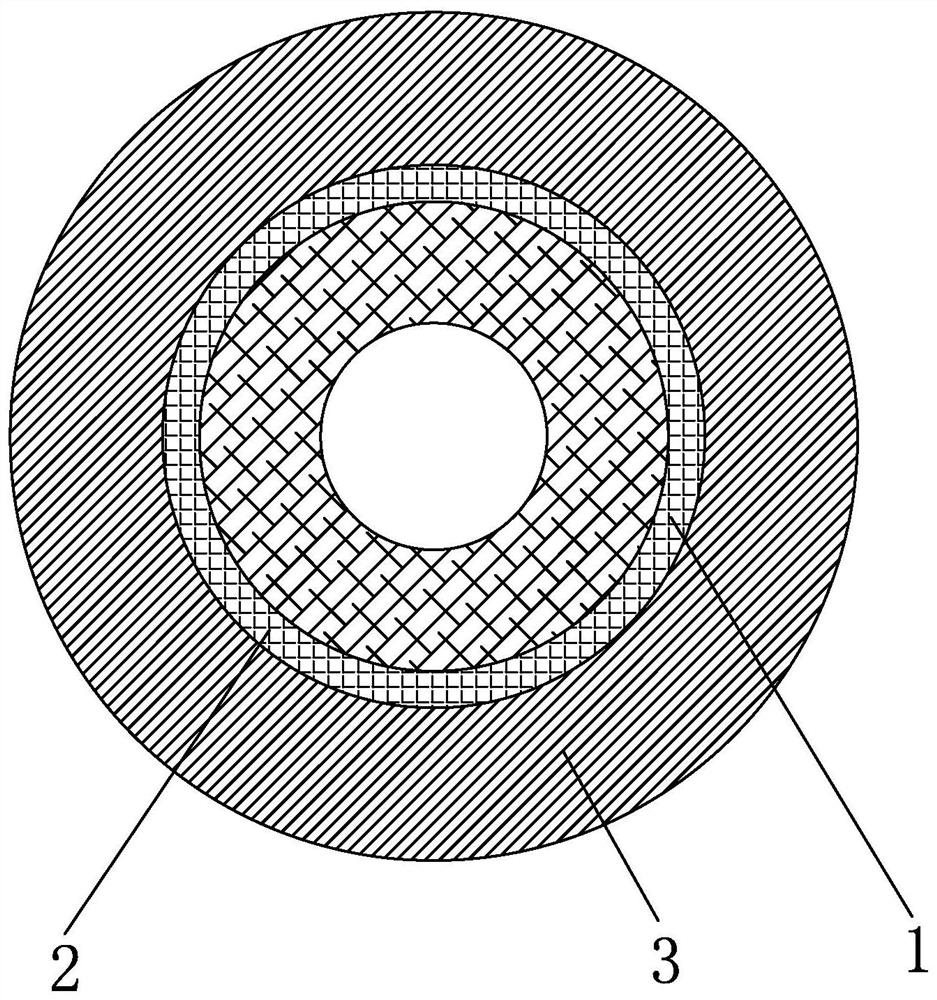

Blended yarn deeply developed from silkworms and spinning process

The invention discloses blended yarn deeply developed from silkworms and a spinning process of the blended yarn. The blended yarn comprises a yarn body, wherein the yarn body is hollow yarn and comprises a hollow inner core layer, a sericin film layer and a winding skin layer which are sequentially arranged from inside to outside, the hollow inner core layer is made of mulberry bark fibers, the mulberry bark fibers are spirally wound outside a hollow core hole of the yarn body, the sericin film layer is formed by coating sericin outside the hollow inner core layer to form a film layer structure, the winding skin layer adopts winding filaments, and the winding filaments are spirally wound outside the sericin film layer to form an outer wrapping structure. According to the blended yarn deeply developed from the silkworms and the spinning process of the blended yarn, the silkworm industry is deeply developed, resources are fully utilized, and the mulberry fibers, the sericin, pupa proteinviscose filaments or spun silk are used for spinning the novel blended yarn; and the blended yarn is low in cost, high in yarn strength, soft and smooth in touch, washable, good in shrink-proof and crease-resistant performance, good in water absorption and air permeability and excellent in comprehensive performance.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

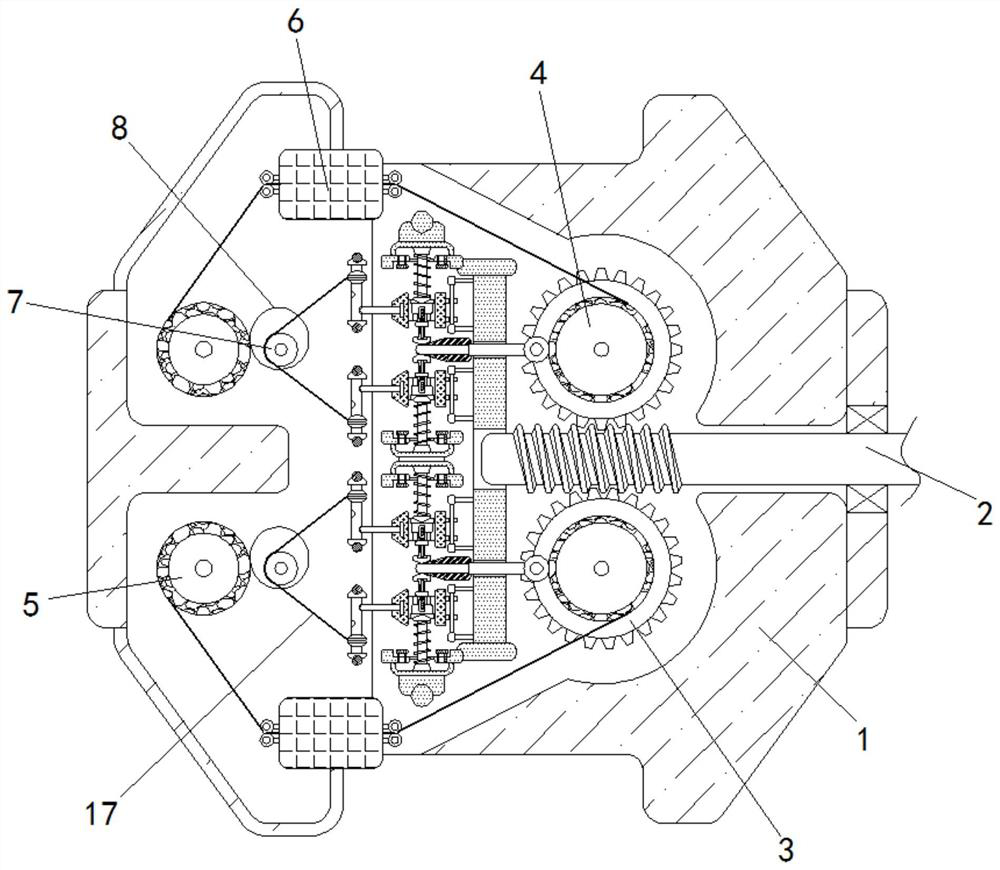

A spinning and twisting mechanism that can improve the strength of twisted yarn

ActiveCN112301474BHigh yarn strengthEasy to twistContinuous wound-up machinesGear wheelYarn strength

The invention relates to the technical field of spinning and twisting, and discloses a spinning and twisting mechanism capable of improving the strength of the twisted yarn, comprising a casing, a drive screw is rotatably connected to the right part of the casing, A transmission gear is rotatably connected to the upper and lower parts of the driving screw in the inner cavity of the casing, a yarn winding roller is fixedly connected to the front end of the transmission gear, and a symmetrical yarn release roller is rotatably connected to the left part of the inner cavity of the casing. , the top and bottom of the inner cavity of the casing are fixedly installed with a twisting body. The spinning and twisting mechanism, which can improve the strength of the twisted yarn, gradually increases the thickness of the yarn on the winding roller, so that the abutment rod abutting on the winding roller will be forced, and will correspond to a The symmetrical telescopic column on the side is squeezed apart, so that the guide column drives the winding roller to rotate and wind the cable, and then the bearing disc drives the paraffin disc to deflect and apply wax, so that the yarn strength after twisting is effectively improved.

Owner:SHANG HAI YINAI NEW MATERIAL TECH LTD

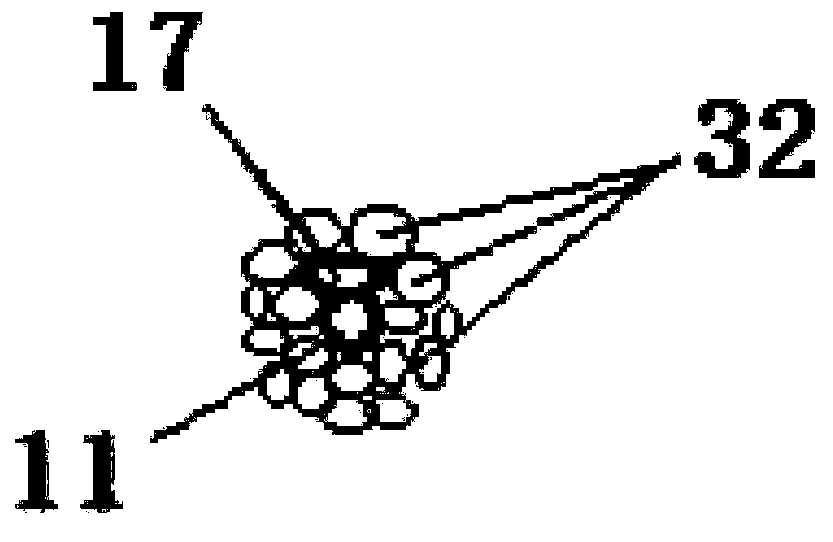

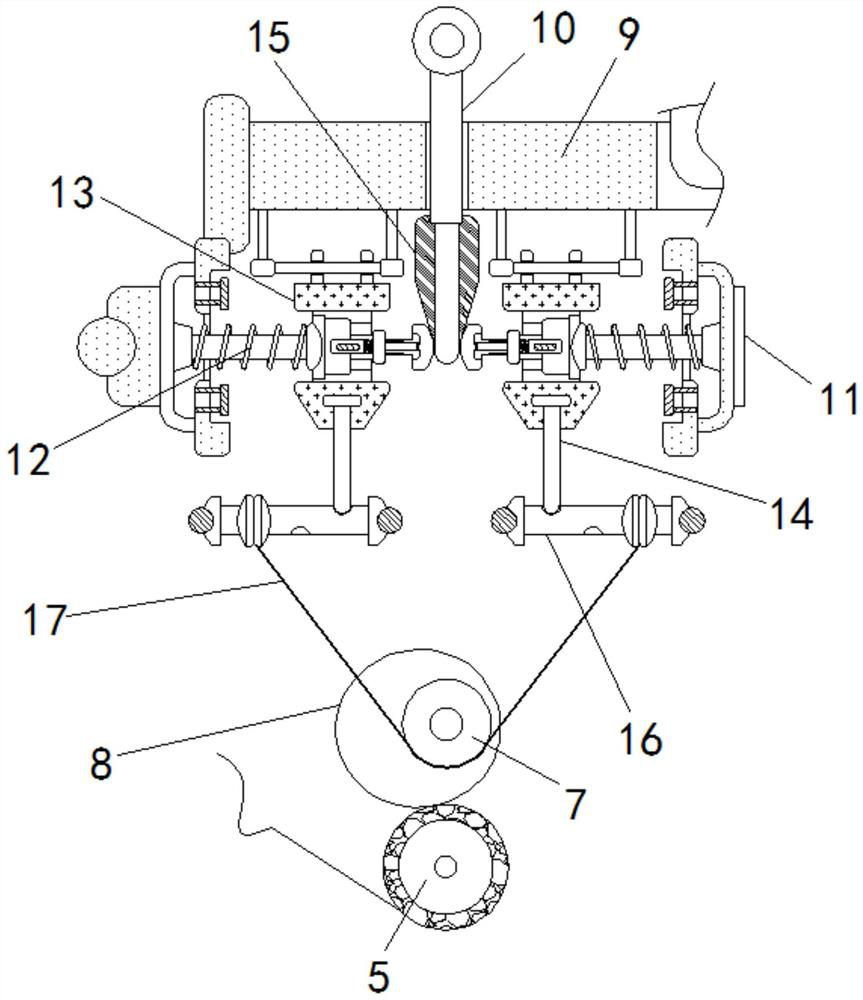

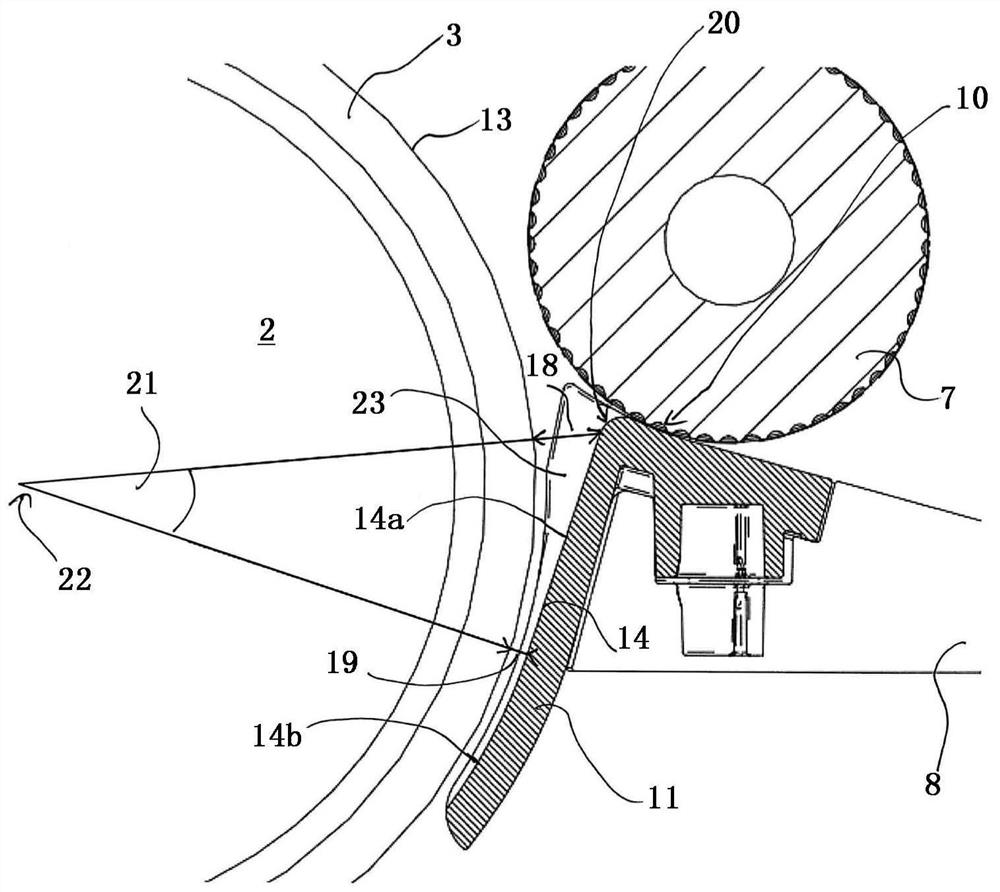

Fibre bundle opening device for an open-end spinning device and feeding trough for the fibre bundle opening device

ActiveCN112111814AImproved Yarn ValueHigh yarn strengthDrafting machinesContinuous wound-up machinesFiberSpinning

Fibre band opening device for an open-end spinning device and feed tray for the fibre band opening device are provided. The feed tray (11) has a clamping surface (10), which is designed to transport,in conjunction with a fibre band pull-in cylinder (7), a feed fibre band (4) towards an opening roller (2) having an opening roller clothing (3), the tips (12) of which lie on a circular cylindrical surface, a support surface (14) for fixing a fibre tuft, which is processed by the opening roller (2) by combining, the distance of which support surface from the circular cylindrical surface (13) is tapered in the fibre transport direction to a minimum distance, and a transition area (20) having a convex curvature between the clamping surface (10) and the support surface (14). The support surface(14) has a distance (18) of between 4 and 8 millimetres from the circular cylindrical surface (13) at the beginning of the support surface (14) with respect to the fibre transport direction, and the minimum distance (19) of the support surface (14) from the circular cylindrical surface (13) is less than 1.5 millimetres.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

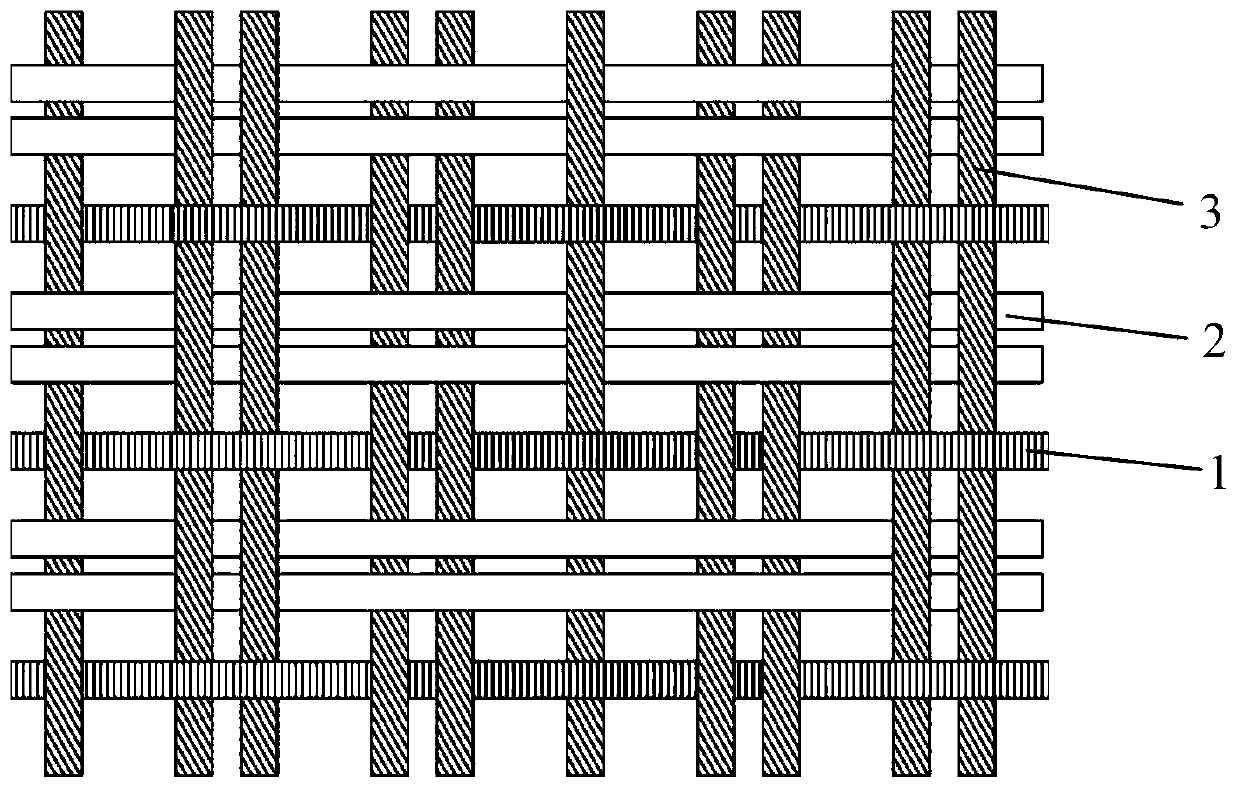

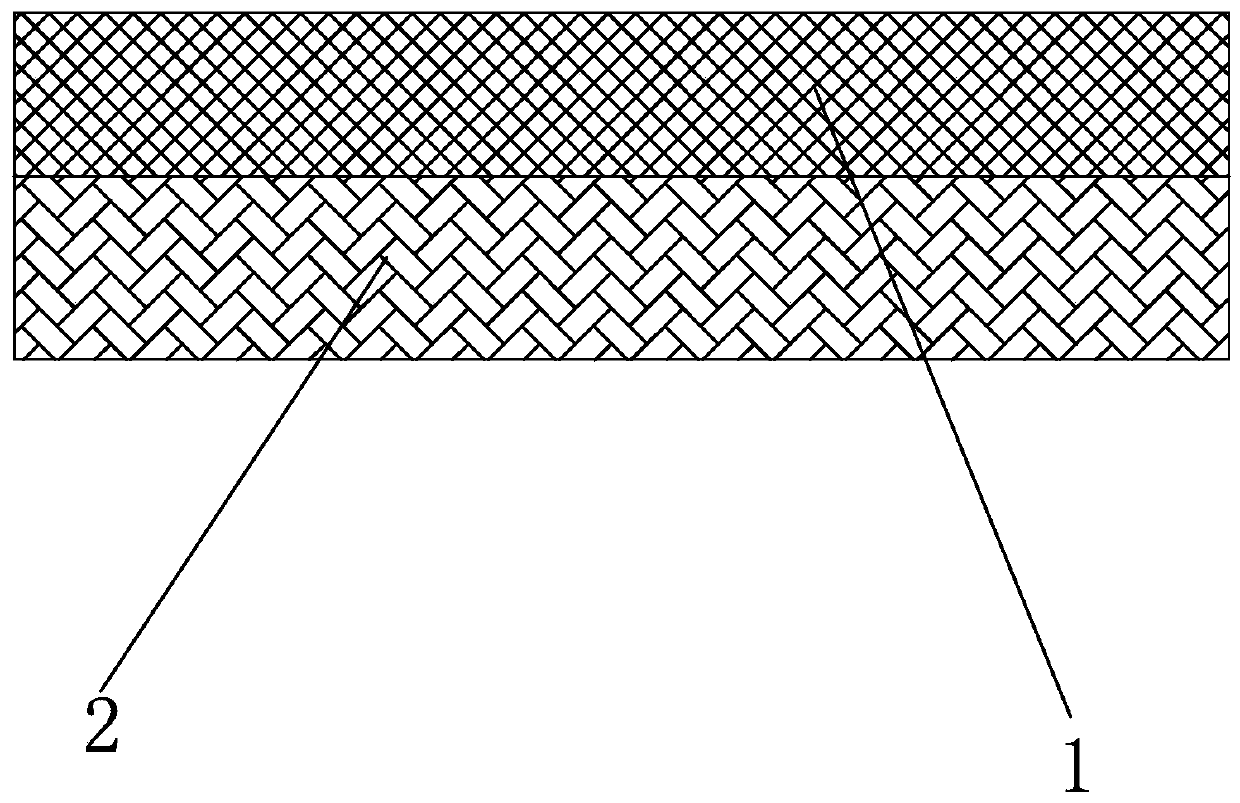

Vortex-spun high-count high-density fabric and production method thereof

PendingCN110592769ASimple production methodReduce manufacturing costMulti-ply fabricsLiquid/gas/vapor yarns/filaments treatmentHigh densitySurface layer

The invention discloses a vortex-spun high-count high-density fabric and a production method thereof. The vortex-spun high-count high-density fabric comprises a fabric body; the fabric body is of a double-layer plain weave structure and comprises a surface-layer shell fabric and an inner-layer shell fabric; surface warps and surface wefts of the surface-layer shell fabric are both DTY 50D / 72F differential fine denier yarns, and inner warps and inner wefts of the inner-layer shell fabric are pure cotton twisted yarns; each of the pure cotton twisted yarns is formed by twisting and stranding twosingle hollow combed cotton yarns; a combined tying mode is adopted for the surface-layer shell fabric and the inner-layer shell fabric, tying units are two adjacent warp and weft tying nodes and aremutually restricted, and each tying unit is composed of a warp tying node and a weft tying node which are adjacent. The surface-layer shell fabric of the vortex-spun high-count high-density fabric has a silk-like effect, is smooth in touch feeling, fine, bright and clean, good in staining resistance and air permeability, stiff and smooth and resistant to crease, and the inner-layer shell fabric is soft and comfortable in touch feeling, not prone to pilling, good in skin friendliness, good in moisture absorption and warm-keeping effects and comfortable to wear.

Owner:WUJIANG JINGYI SPECIAL FIBER

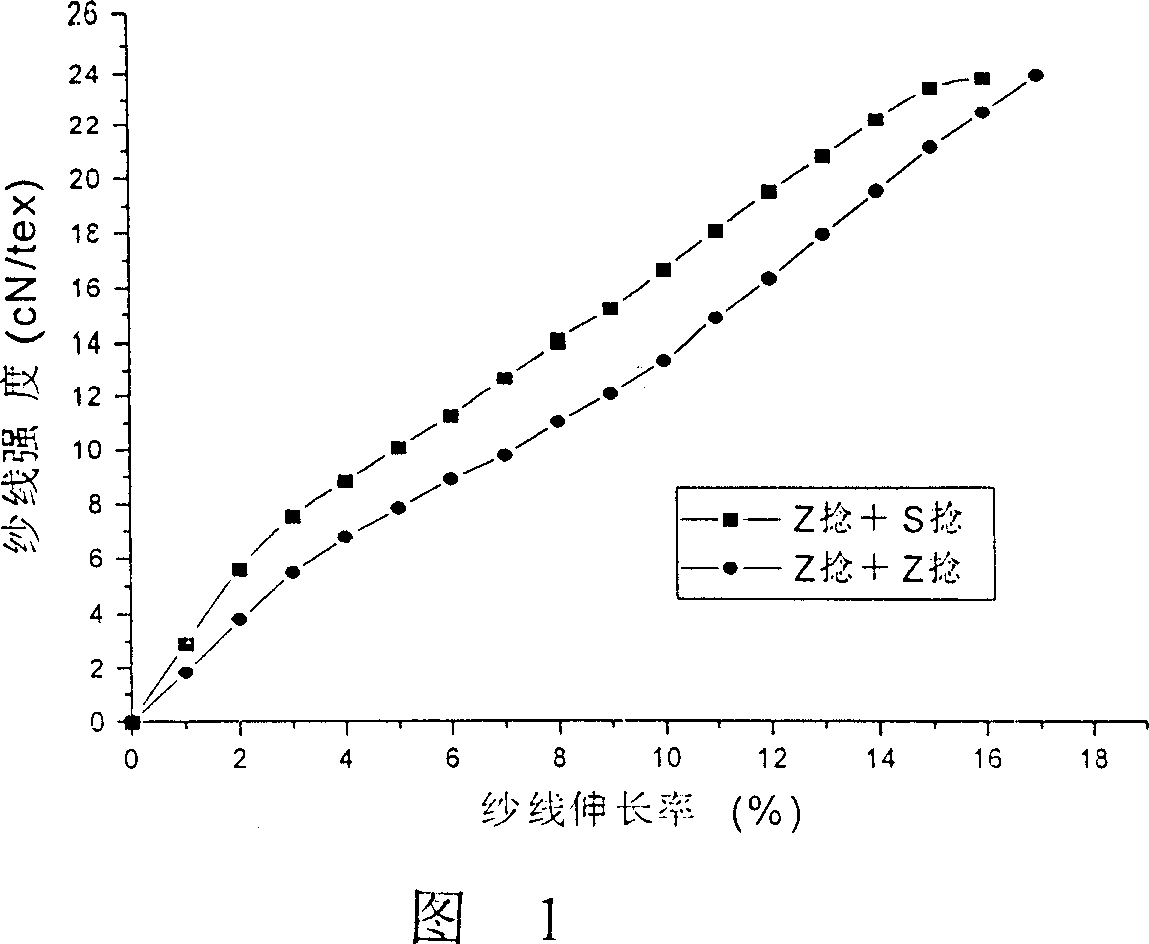

Cabling twisted composite yarn cabling

The invention refers a cabling complexing yarn made of long thread of synthetical fiber and short fiber yarn. Its character: twisting direction of the complexing yarn is consistent with that of single yarn of short fiber yarn; the long thread of synthetical fiber is Terylene thread and the short fiber yarn is simple yarn spun by cotton and wool.

Owner:JIANGSU JIANLU WOOLEN

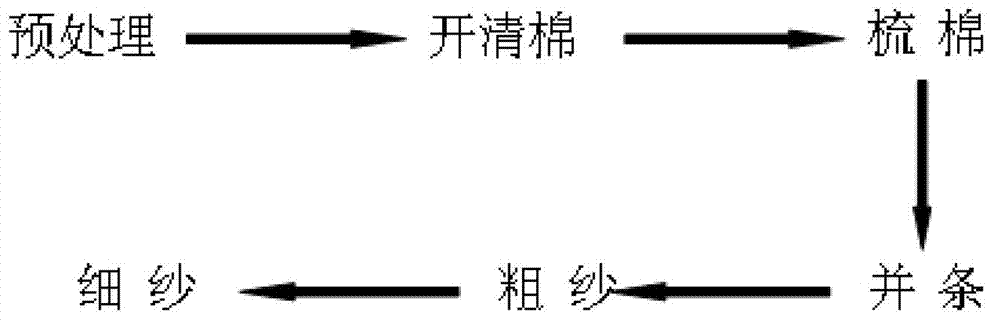

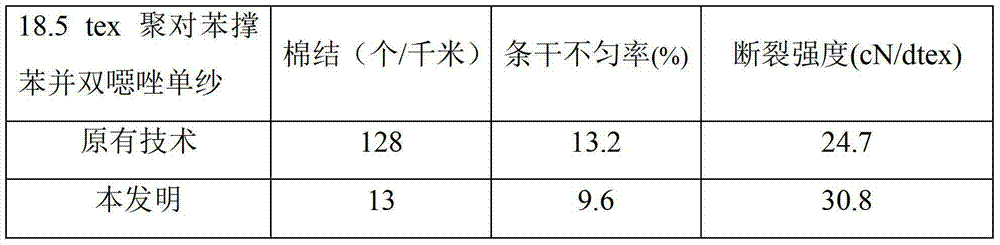

Method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres

The invention discloses a method for spinning poly-p-phenylenebenzobisthiazole (PBO) fibres. The method comprises the steps of pre-treatment, cotton opening and picking, cotton teasing, drawing, rough spinning and fine spinning. The method solves the difficult problem of spinning the poly-p-phenylenebenzobisthiazole fibres, and establishes a technical foundation of pure spinning of the PBO fibres, which is performed on cotton spinning equipment; yarns obtained via spinning have the advantages of glabrous surface, smoothness, less neps, uniform evenness and the like, can be widely applied to high-grade protective textiles and industrial textiles.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

Method for weaving large-fabric width fabric with high-count high-density low-tenacity yarns

InactiveCN110453336AEnvironmentally friendly and less irritatingHigh yarn strengthSucessive textile treatmentsGrip property fibresYarnHigh density

The invention discloses a method for weaving a large-fabric width fabric with high-count high-density low-tenacity yarns. The whole operation process sequentially includes the steps of warping, sizing, weaving, softening, shaping, dehydrating and calendering. According to the method, cotton and linen blended yarn is adopted for weaving tight type warp yarn, the fabric is environmentally friendly and small in irritation, the yarn is high in strength, braiding is conducted through a high-speed ultra-wide heavy water jet loom, the yarn of the fabric is neater, and the surface is soft and flat through softening, shaping, dehydrating and calendering. The method overcomes the defects that yarn of a large-width fabric is not neat, and the hardness of the fabric is too high.

Owner:苏州林驰纺织整理有限公司

Rotor spinning plush yarn and production process thereof

InactiveCN102242433AImprove tidinessReduce manufacturing costContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a rotor spinning plush yarn and a production process thereof. The rotor spinning plush yarn comprises raw material cotton and terylene chemical fiber, wherein the cotton is saw ginned cotton, the average level of which is level 3, the main body length of which is 29mm and the micronaire value of which is B, and is made into 15.65-16.15kg cotton coils; the terylene chemical fiber, the fineness of which is 1.56dtex and the main body length of which is 38mm, is made into 13.9-14.3kg terylene coils. The production process comprises the following specific steps: 1) respectively carding the cotton coils and the terylene coils into card slivers by using a carding machine, wherein the linear density of the captured cotton card slivers is 20-23g / 5m and the linear density of the captured terylene card slivers is 24-26g / 5m; 2) simultaneously feeding two cotton card slivers and five terylene card slivers into a drawing frame and drawing three times, thereby acquiring 16.5g / 5m drawn slivers; and 3) forming yarns by feeding the acquired drawn slivers into a rotor spinning machine. The rotor spinning plush yarn has the advantages that the production cost of the products is low, the cotton impurities are fewer, the neatness of cloth cover is excellent, and the yarn intensity is high. The production process is simple and practical and the production efficiency is high.

Owner:BAOYING HONGYANG TEXTILE

Fitting ring for an opening roller of an open-end spinning device

InactiveUS7779618B2Precise transportationReliable transmissionDrafting machinesContinuous wound-up machinesEngineering

Clothing ring (27) for an opening roller (21) of an open-end spinning device (1), comprising teeth (38) which are formed by at least one groove (39) incorporated in the peripheral face of a basic body (45) and running in the peripheral direction, and a plurality of indents (40) arranged substantially in the axial direction. An axial separation spacing (t) of the teeth (38) is predetermined by the groove (39) and is significantly smaller than the height (H) of the teeth (38). The teeth (38) have tooth flanks (42) which are continuously concavely curved into the groove (39).

Owner:SAURER GERMANY GMBH & CO KG

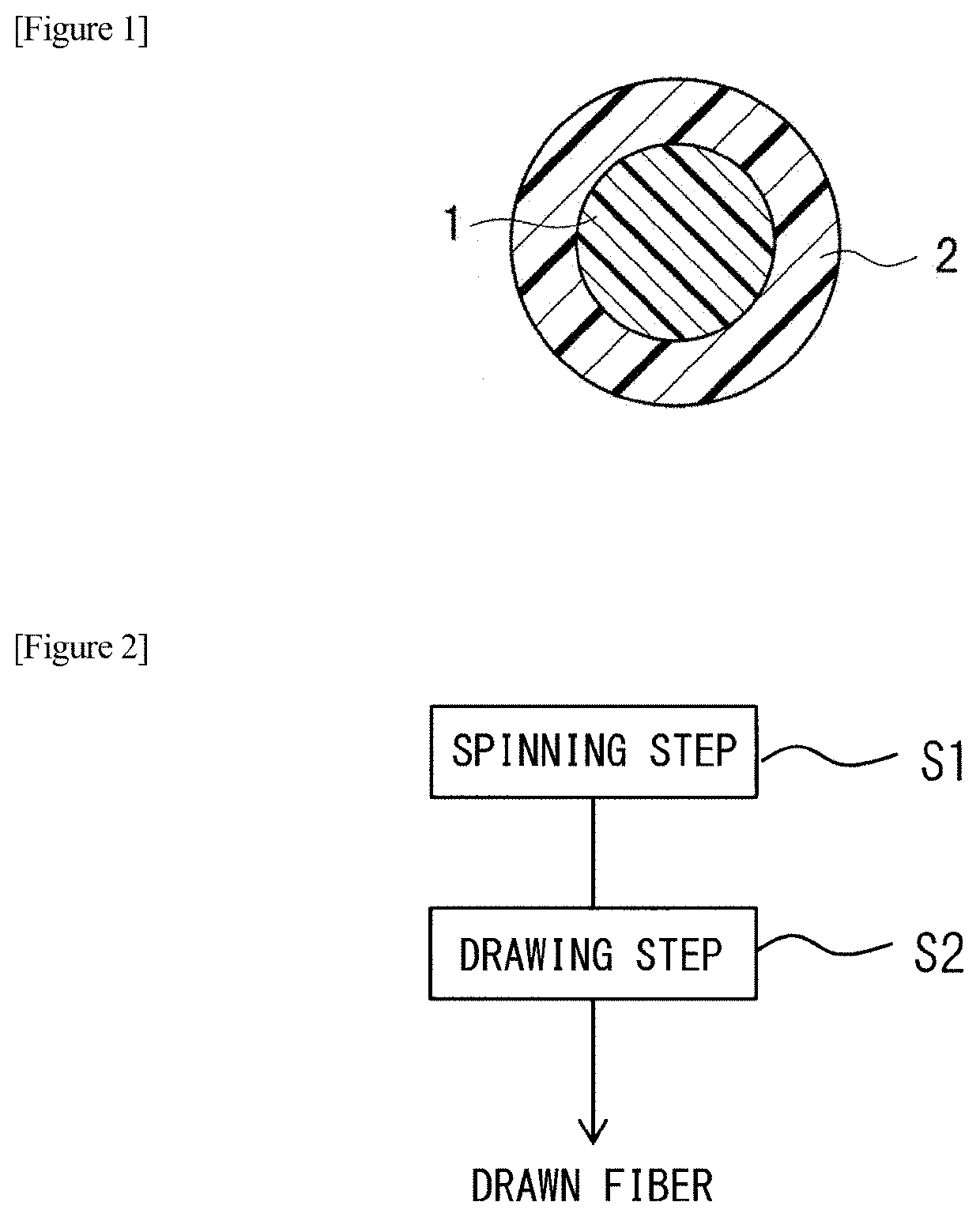

Drawn composite fiber, non-woven fabric, and method of producing drawn composite fiber

PendingUS20220018044A1Improve yarn strengthHigh yarn strengthMelt spinning methodsConjugated synthetic polymer artificial filamentsPolymer scienceNonwoven fabric

Embodiments relate to a drawn composite fiber having a low thermal shrinkage, and a high single yarn strength, a non-woven fabric using the same, and a method of producing the same. The drawn composite fiber has a fineness of 0.6 dtex or less, a ratio between the cross-sectional areas of a sheath material and a core material (sheath material / core material) of 50 / 50 to 10 / 90, and a single yarn elastic modulus of 70 cN / dtex or more. The drawn composite is obtained by melt-spinning and a drawing treatment of an undrawn fiber having a sheath-core structure, in which the core material includes a resin containing a crystalline propylene-based polymer and having a melt flow rate of 10 to 30 g / 10 min at a load of 21.18 N at 230° C., and the sheath material includes a resin containing an olefinic polymer where the melting point is lower than that of the core material.

Owner:UBE NITTO KASEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com