Core yarn and woven and knitted fabric

a technology of core yarn and woven and knitted fabric, which is applied in the field of core yarn, can solve the problems of difficult to spin cotton yarn having desired fine yarn count, yarn strength and extension rate, and inability to have fine yarn count, and achieve excellent texture-feeling, high extension rate, and high yarn strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

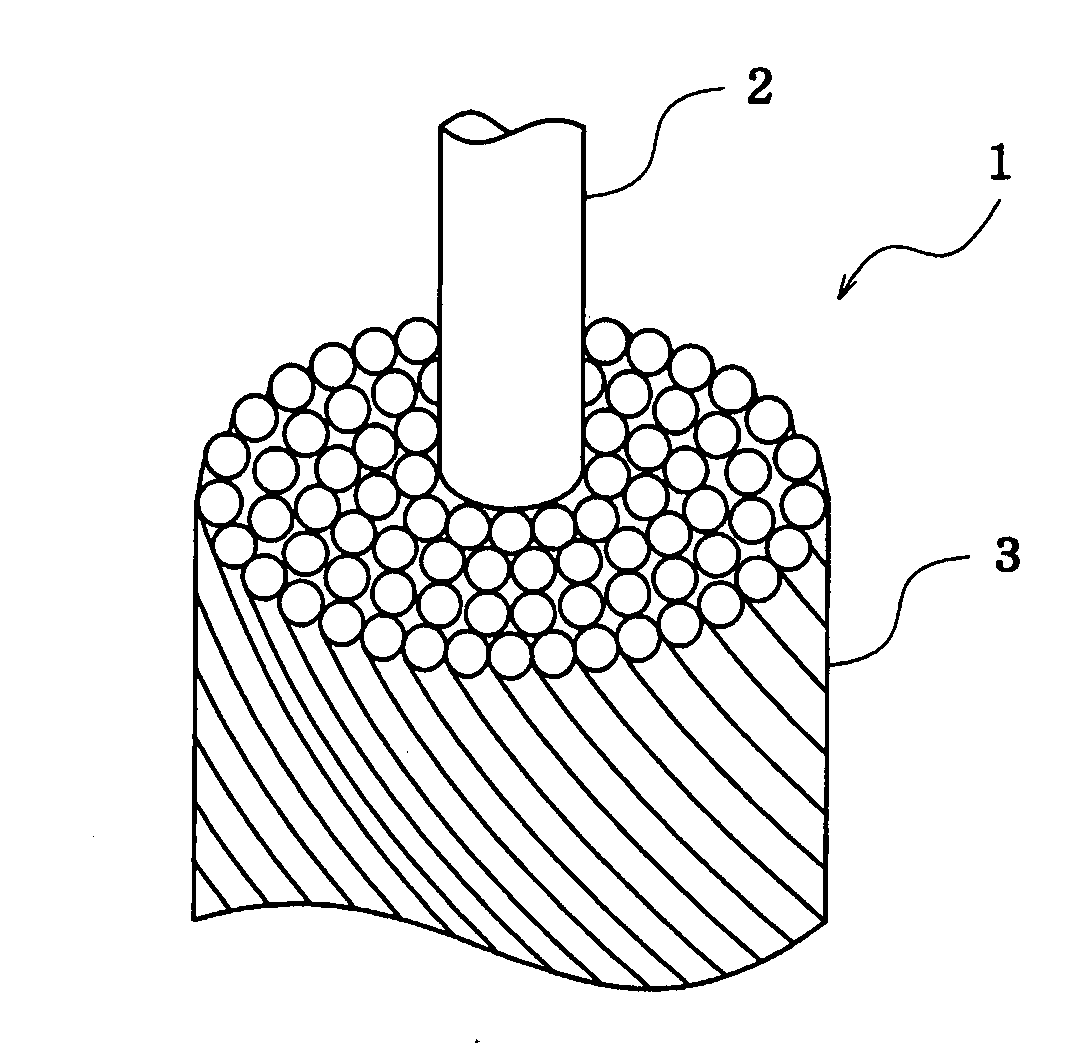

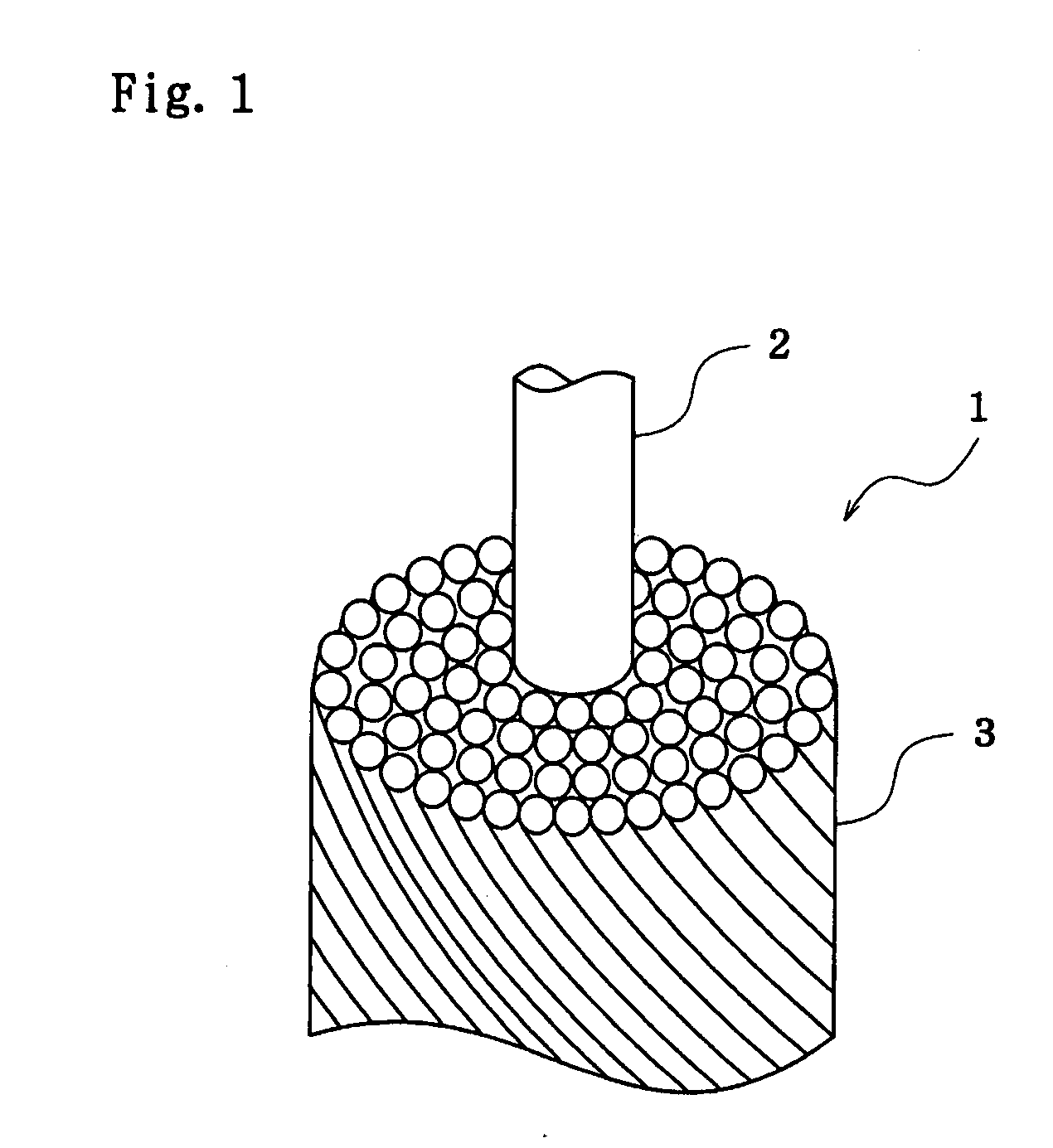

[0036]Embodiments of the core yarn and woven and knitted fabric related to the present invention will be described with reference to FIGS. 1 to 3.

[0037]As shown in FIG. 1, the core yarn 1 related to the present invention is a core-sheath composite fiber comprising core 2 and sheath 3. The core 2 is a piece a single filament, or a monofilament and the sheath 3 is spun yarn twisted together with staple fibers. For example, many staple fibers are wound around the above-mentioned core 2 while being twisted. And as shown in FIG. 2, the core yarn 1 is a core-sheath composite fiber comprising core 2 and sheath 3. The core 2 consists of plural monofilament and the sheath 3 is spun yarn twisted together with staple fibers.

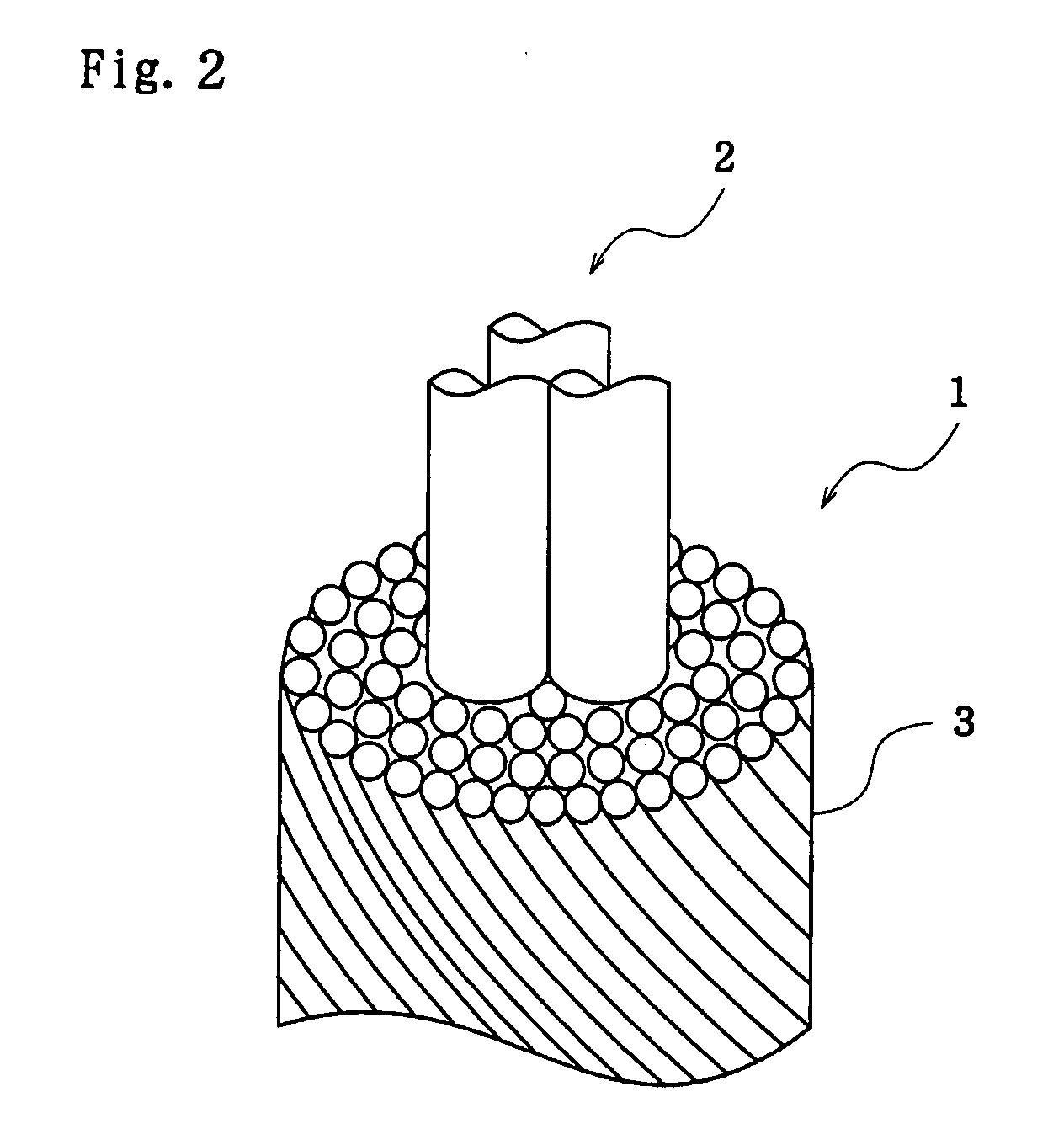

[0038]Here, preferred embodiment of the air spinning machine for manufacturing the above mentioned core yarn 1 is explained with reference to FIG. 3. In the spinning method of the spinning machine, sliver L is delivered to a draft apparatus DR and drawn into the specified t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness rate | aaaaa | aaaaa |

| fiber-length | aaaaa | aaaaa |

| yarn strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com