Patents

Literature

281 results about "Yarn strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

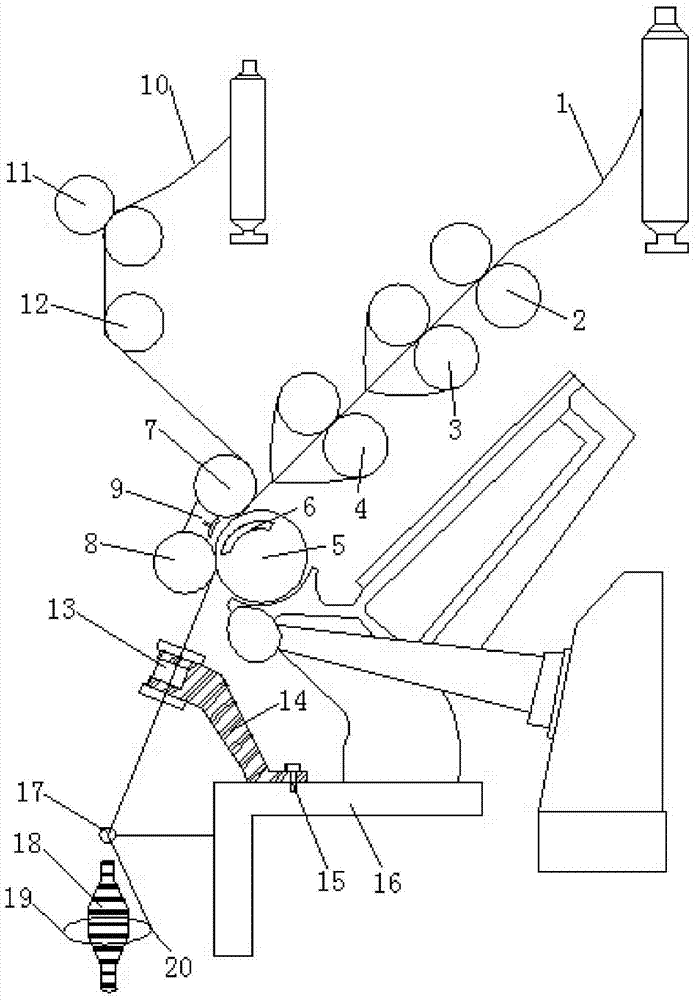

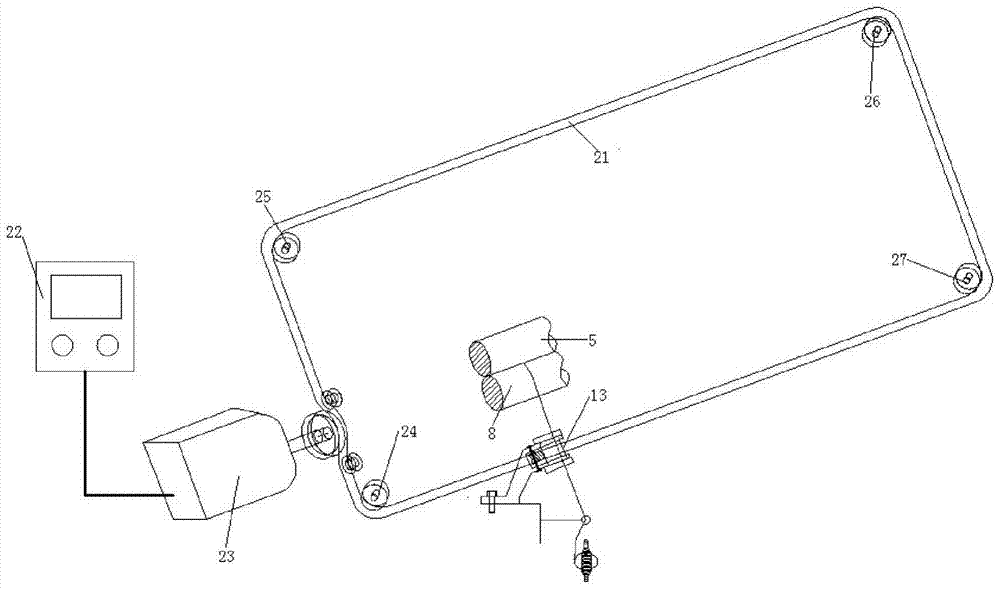

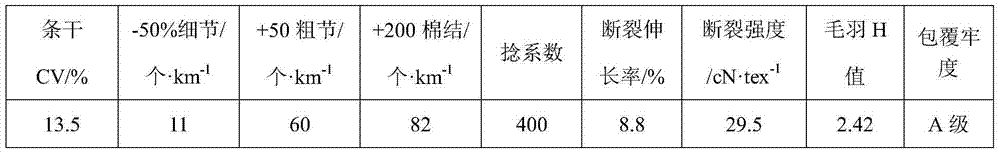

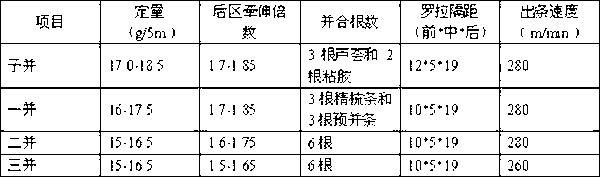

Low-twist, high-strength and little-fuzz yarn production method and yarn

The invention discloses a low-twist, high-strength and little-fuzz yarn production method and yarn. The method includes the opening picking process, the cotton carding process, the fine carding process, the drawing process, the roving process and the yarn spinning process. A larger-diameter and narrow-groove negative pressure hollow roller and a corresponding air draft assembly are adopted for the method, and therefore generated fuzz can be effectively reduced; under the condition that a mechanical friction twist device is adopted in the yarn spinning segment to reduce the twist coefficient by 15-30%, the single yarn strength is kept unchanged, polyester filament yarn serves as core silk so that the kind adaptability of the yarn can be effectively improved, the yarn strength is enhanced, the rotating direction of the twist device is opposite to that of a spindle, the twist stopping effect can occur, the width of a twisting triangular area is increased, the wrapping effect of core yarn is favorable for being improved, and a foundation is laid for developing fabric with good soft comfort. The low-twist, high-strength and little-fuzz yarn is produced with the method. Under the condition that the designed twist coefficient is reduced by 16-28%, compared with a normal designed twist coefficient, the strength is improved by 3-5%, resultant yarn is 3mm or longer, and the harmful fuzz is reduced by 80-95% compared with harmful fuzz in ring spun yarn.

Owner:WUJIANG JINGYI SPECIAL FIBER

Activated carbon-EVA composite emulsion coated polypropylene-based non-woven sound absorbing material for automobile interior decoration

InactiveCN104553172AHigh strengthIncrease the areaFlame-proof filament manufactureFibre typesNoise reductionYarn strength

The invention relates to a non-woven sound absorbing material and in particular relates to an activated carbon-EVA composite emulsion coated polypropylene-based non-woven sound absorbing material for automobile interior decoration. The material is prepared from the following raw materials in parts by weight: 20-24 parts of polypropylene, 10-14 parts of polyurethane, 0.2-0.3 part of an antioxidant DLTP, 5-8 parts of mineral cotton fibers, 0.5-0.8 part of activated carbon micro powder with the granularity being 400-600 meshes, 1-2 parts of rosin, 1-2 parts of silicone oil, 14-18 parts of tetrapod-like zinc oxide whiskers, 0.1-0.2 part of ammonium polyphosphate, 10-12 parts of EVA emulsion with the solid content being 10-12 percent and 1-2 parts of aids. The surface of fiber yarns formed by performing melt-blowing on modified polypropylene-based master batch is coated by the EVA composite emulsion, the prepared material has the advantages of the traditional polypropylene non-woven material, the mechanical property is improved, the scour and wear resistance, fiber yarn strength and specific surface area are improved, the sound absorption and noise reduction effects are obvious, the odor in an automobile can be eliminated, and the material is fireproof, flame-retardant, light, environmentally friendly, tough and tight and is a novel and practical sound absorbing material for vehicles.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

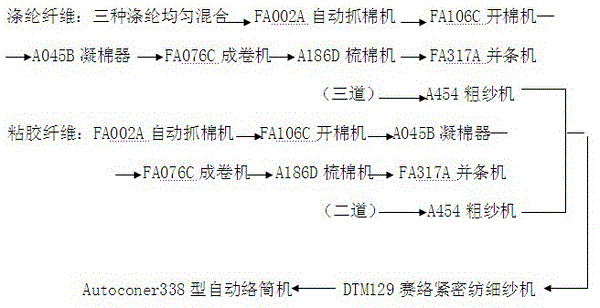

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

Airbag base fabric

An airbag base fabric is formed of thermoplastic synthetic filament yarns, wherein the yarn strength of the filament yarn is 7.0 g / denier or more and the fineness of the filament yarn is 200-250 denier. The fabric is thin and lightweight, which is thus excellent in accommodation, and is effective in reducing the size and weight of an airbag module.

Owner:JOYSON SAFETY SYST JAPAN KK

Cotton fiber and jutecell fiber blended yarn and spinning process thereof

The invention discloses a cotton fiber and jutecell fiber blended yarn and a spinning process thereof. The blended yarn comprises jutecell fiber with fiber content blending ratio as 70% and 30% fine staple cotton. The fibers are spun into yarns through the blended spinning process. Raw materials of the yarns are composed of the jutecell fiber and the fine staple cotton. Compared with the prior art where long staple cotton and jutecell fiber are used for blended spinning, the process is low in cost and high in cost performance. The blending mode of one pre-blending and three mixed-blending is adopted, so that the blending spinning ratio is accurate, and components are even. The blended yarns produced in the production process are high in single yarn strength, even in yarn levelness and few in nep and yarn fault. The yarn structure can further improve textile comfortableness, improve textile hand feel and improve lining grade.

Owner:山东超越纺织有限公司

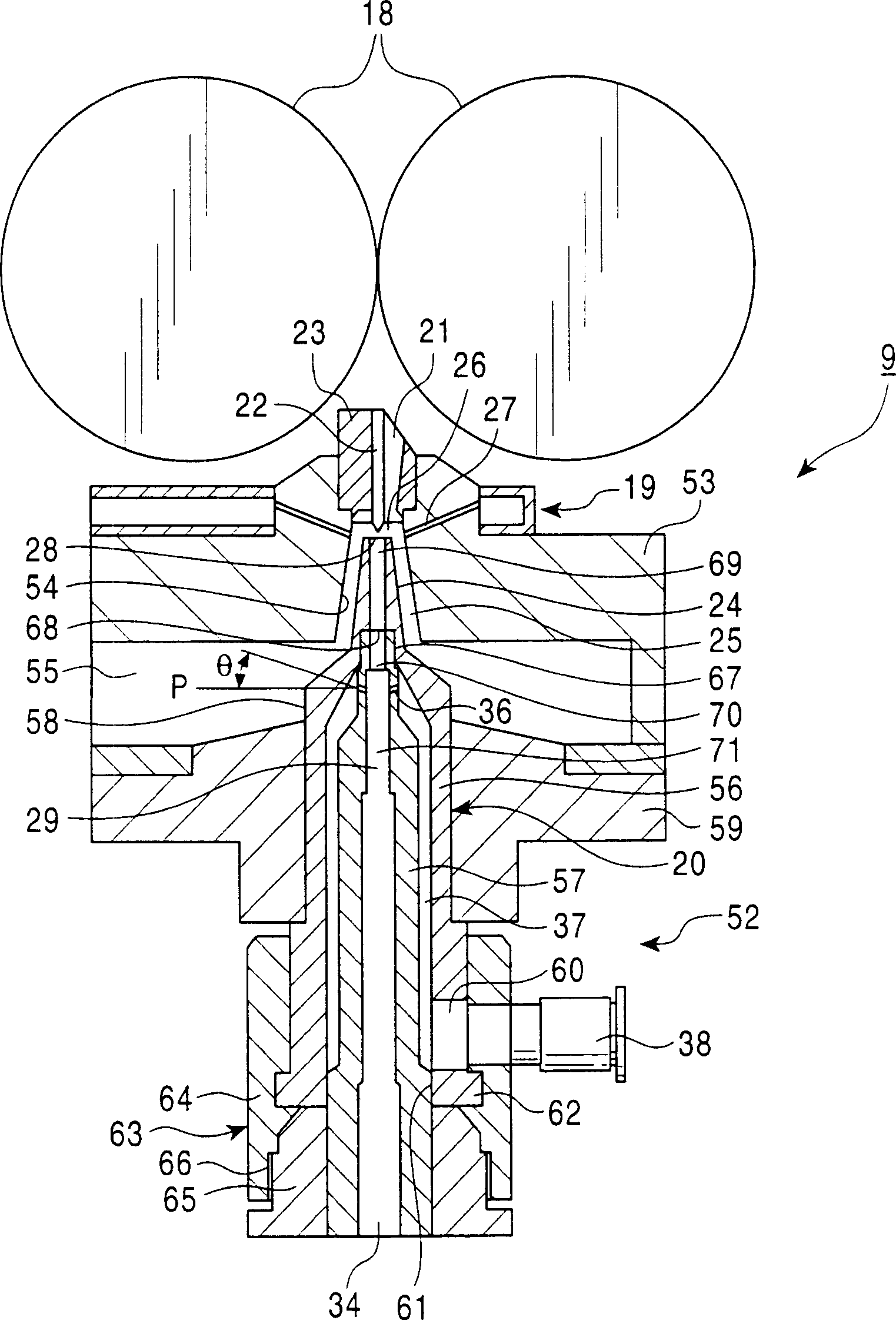

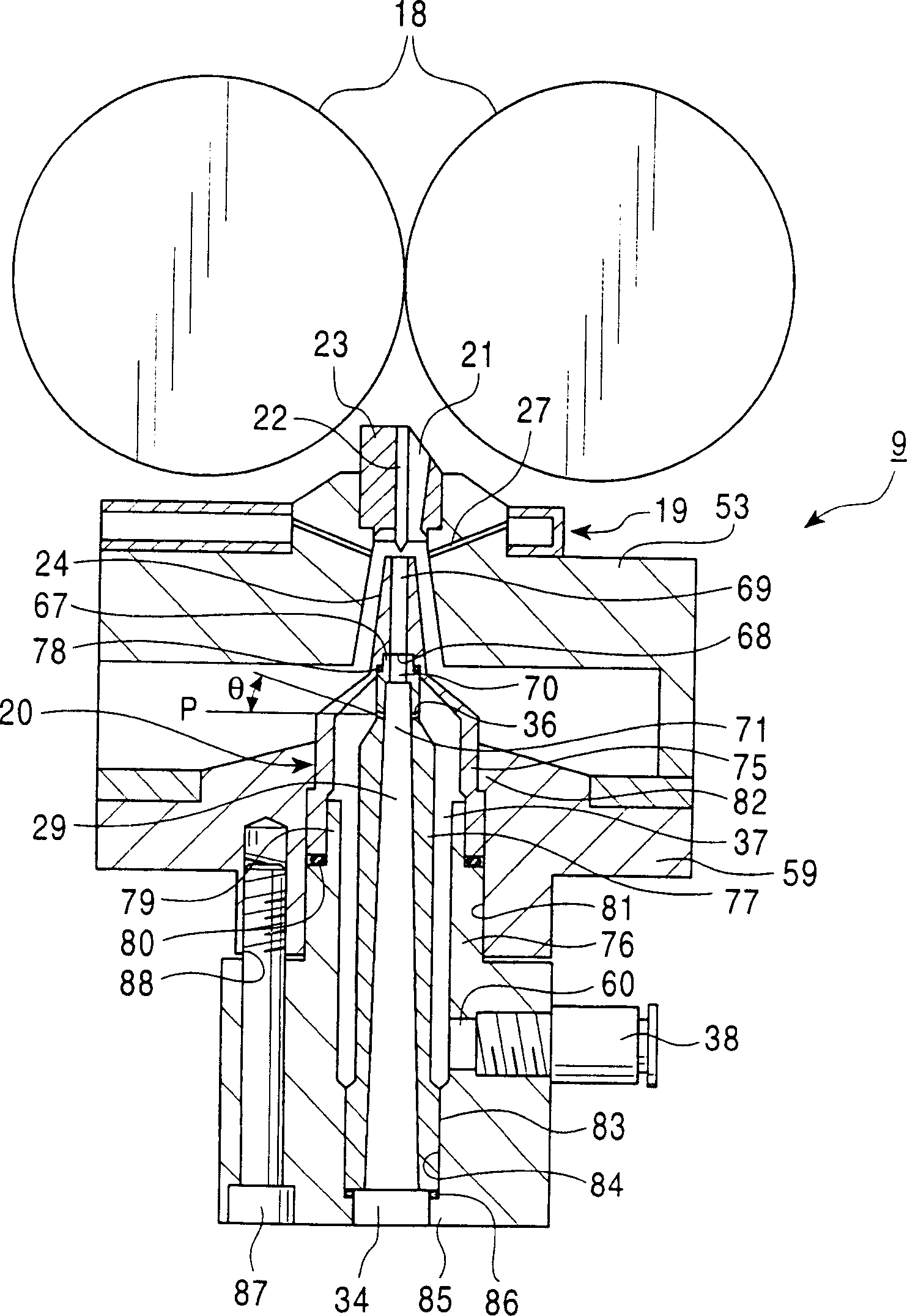

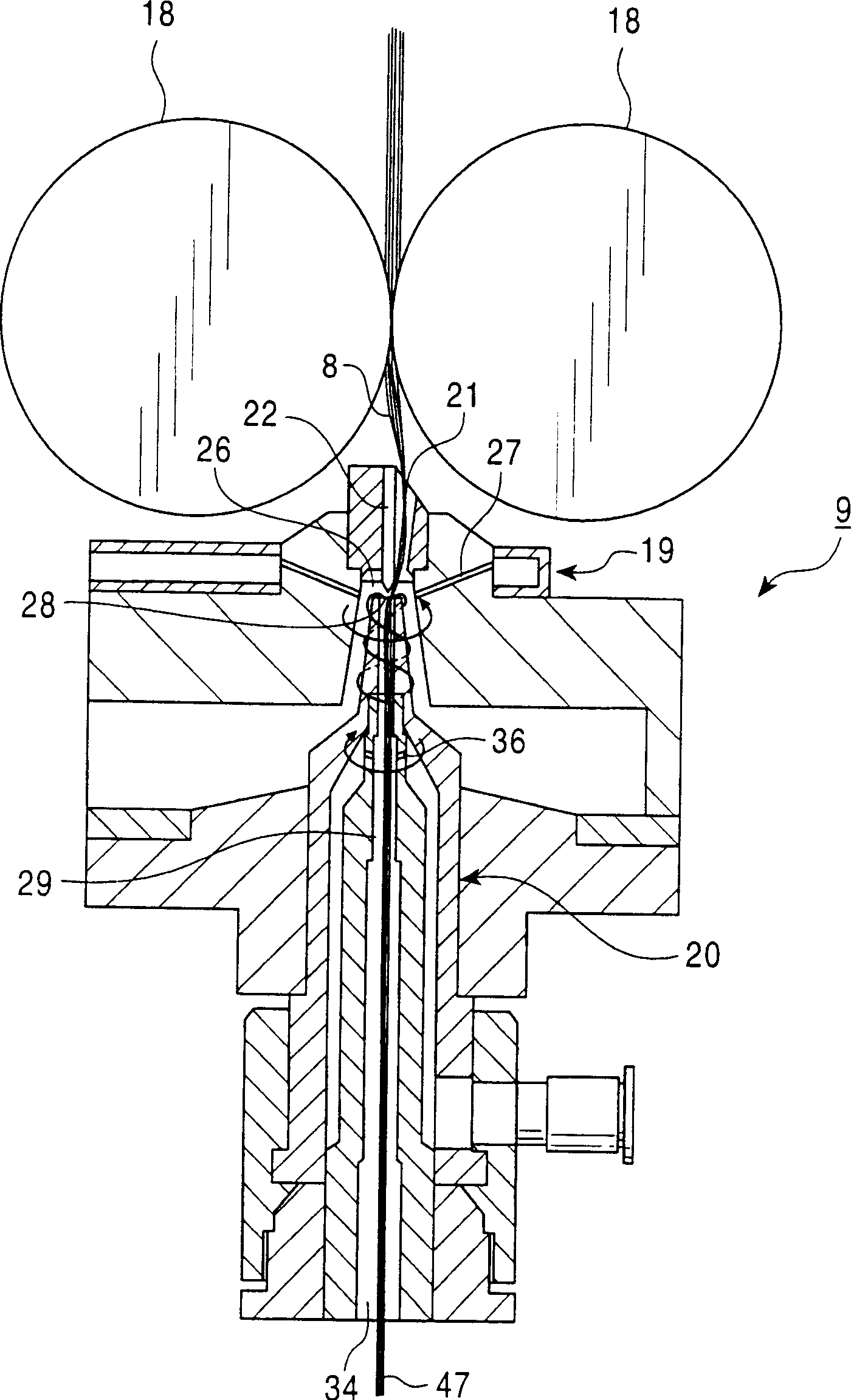

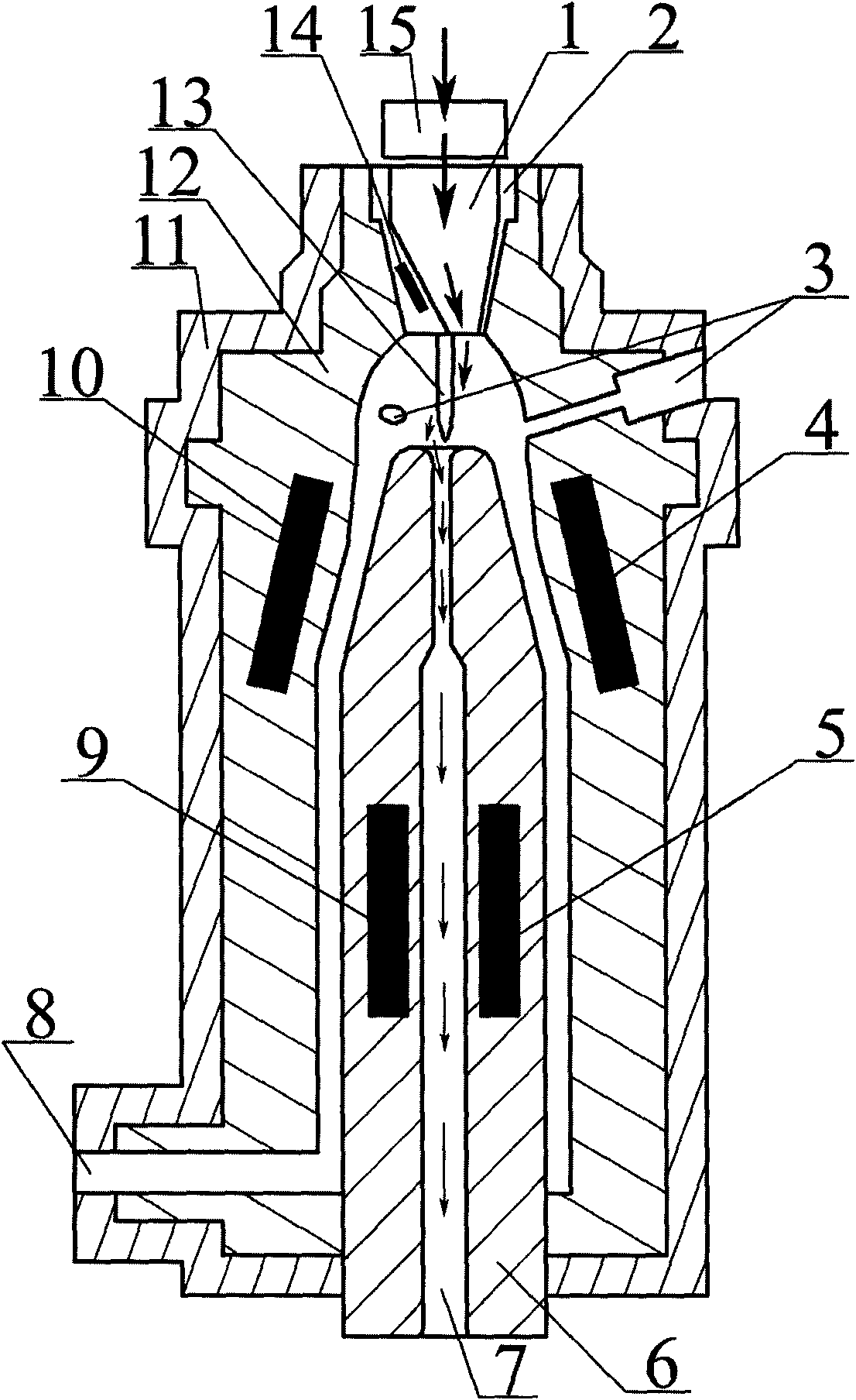

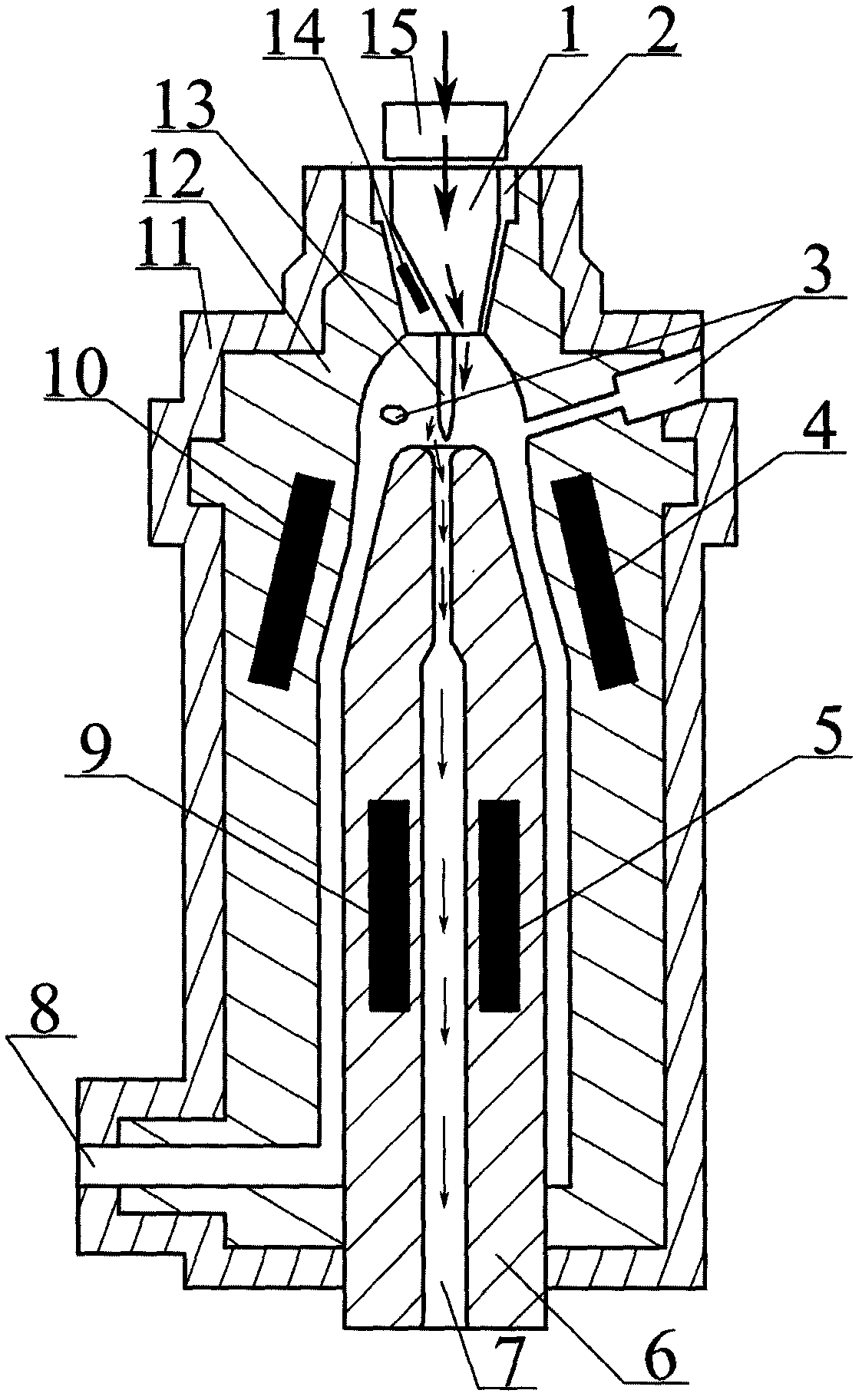

Spinning devices

InactiveCN1407153AAvoid yarn breakageIncrease success ratePiercing arrangementsContinuous wound-up machinesEngineeringYarn strength

The invention provides a high-speed spinning by increasing success rates of the taking-out of a yarn and the piecing of the yarn. This spinning frame has a pneumatic spinning nozzle 27 for generating a rotational gas flow at the vicinity of a tip part 24 of a hollow guide shaft 20 and an assistant nozzle 36 for generating the rotational gas flow in a yarn passage 29 in a hollow guide shaft 20. The assistant nozzle 36 is tilted so as to be directed to the downstream side based on the plane P orthogonal to the yarn passage 29. The tilting angle of the assistant nozzle 36 is preferably 10-35 degrees, more preferably 20 degrees. As a result, the component of the flow directed to the downstream side, and accompanied by the rotational gas flow generated by the assistant nozzle is enlarged, and the sucking power into the yarn passage is enhanced. The balance between the components in the downstream direction and the rotational direction is corrected and the yarn strength of a bound yarn to be discharged is increased to prevent the yarn break or the like.

Owner:MURATA MASCH LTD

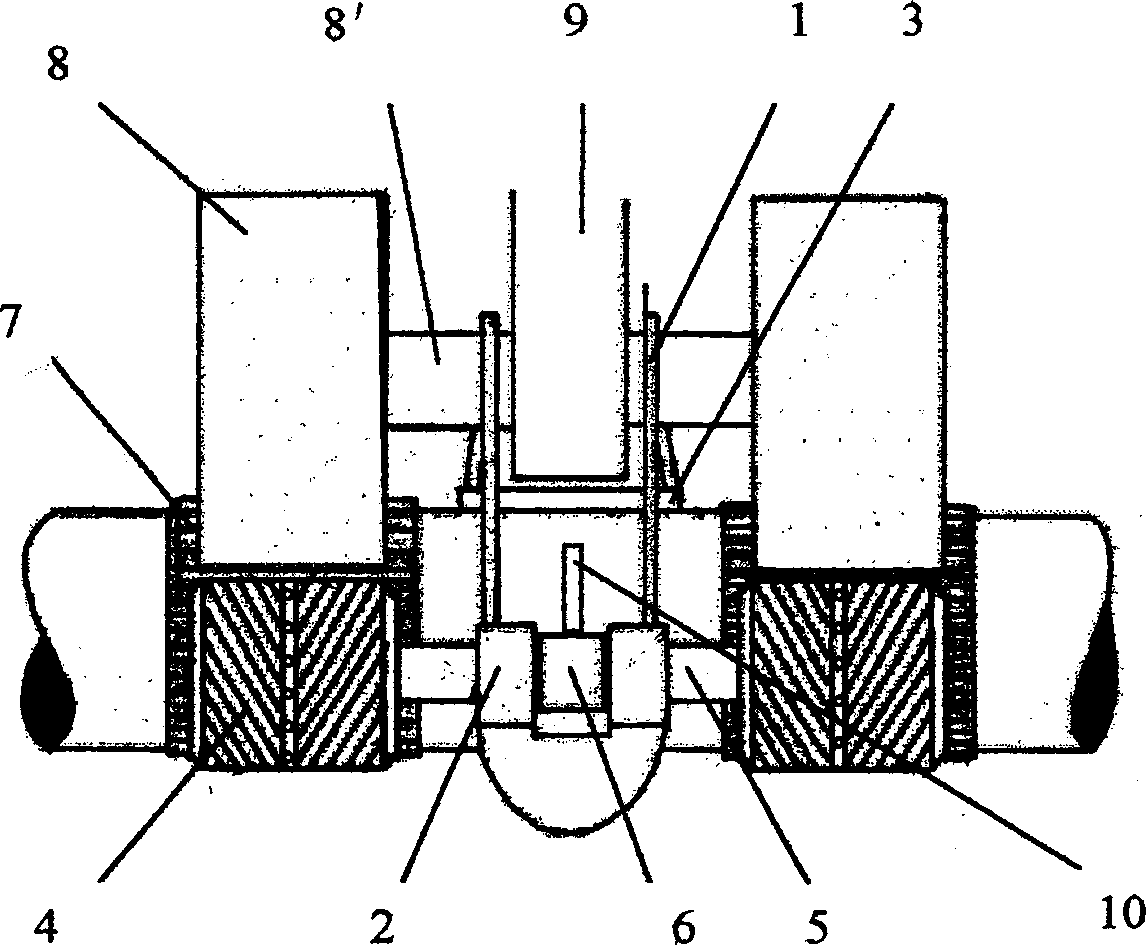

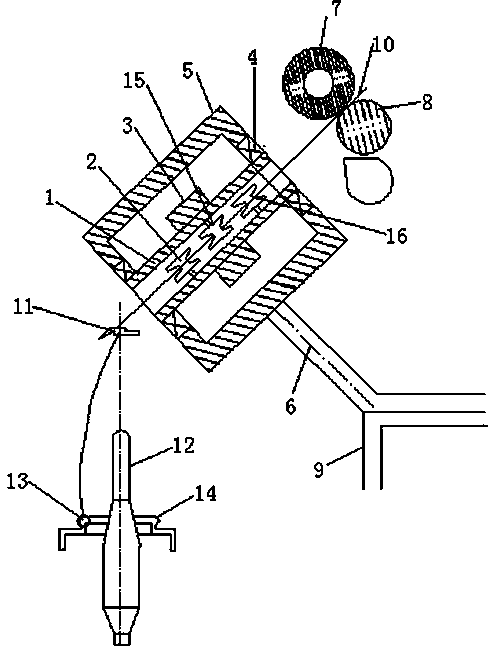

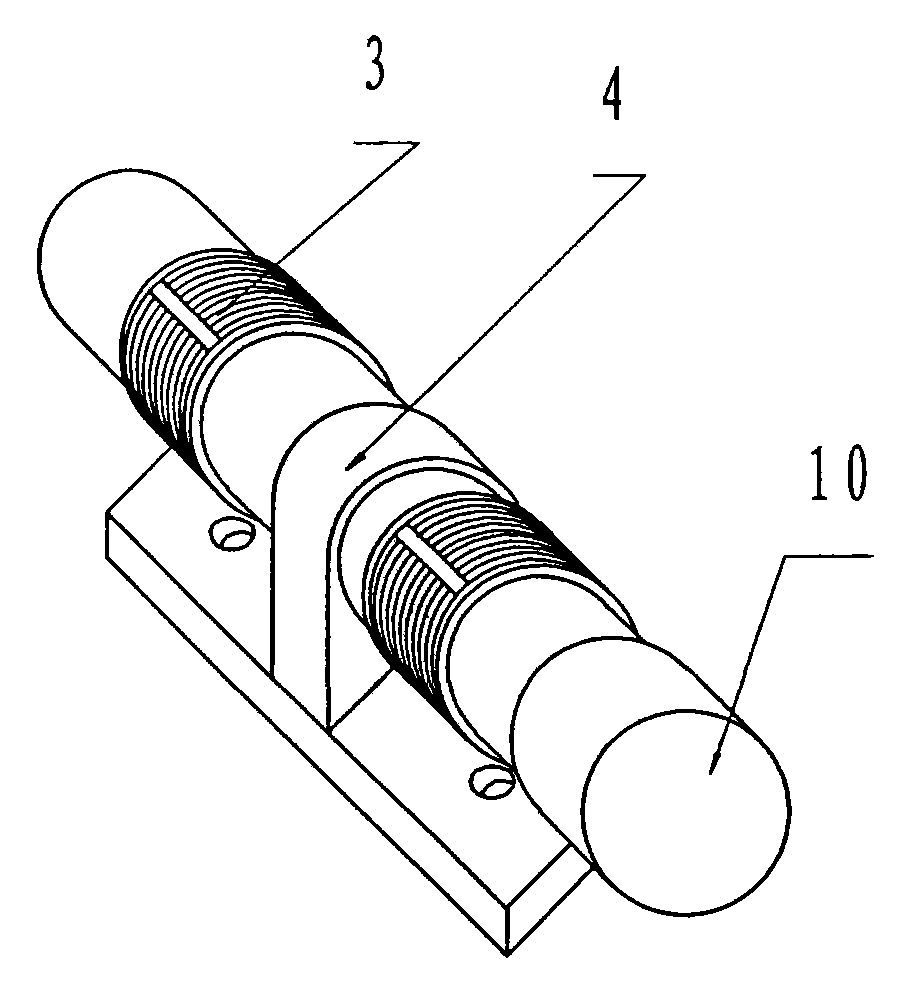

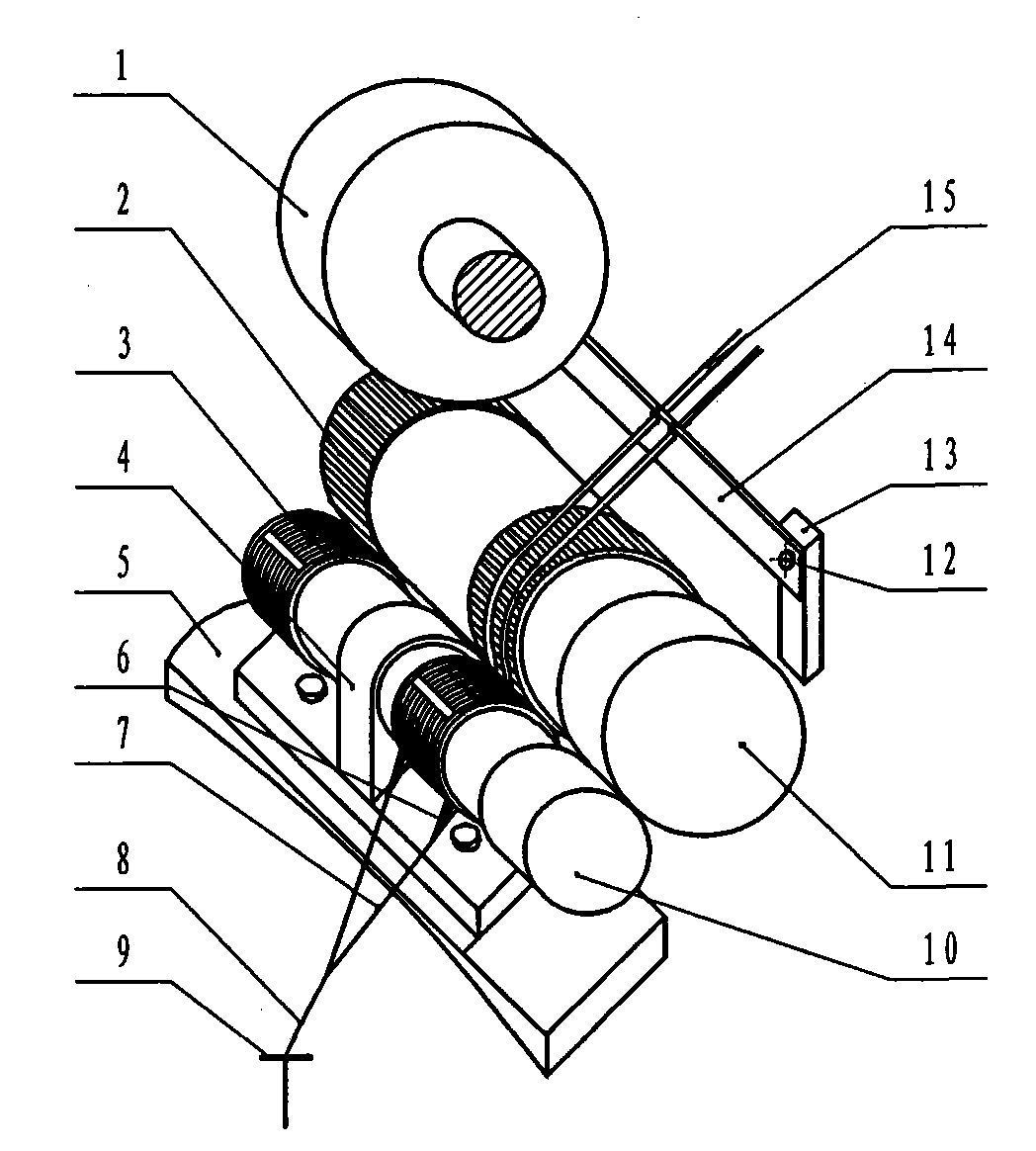

Fiber strand aggregating device for air slide

InactiveCN1388279AHigh glossImprove wear resistanceDrafting machinesContinuous wound-up machinesEngineeringHigh intensity

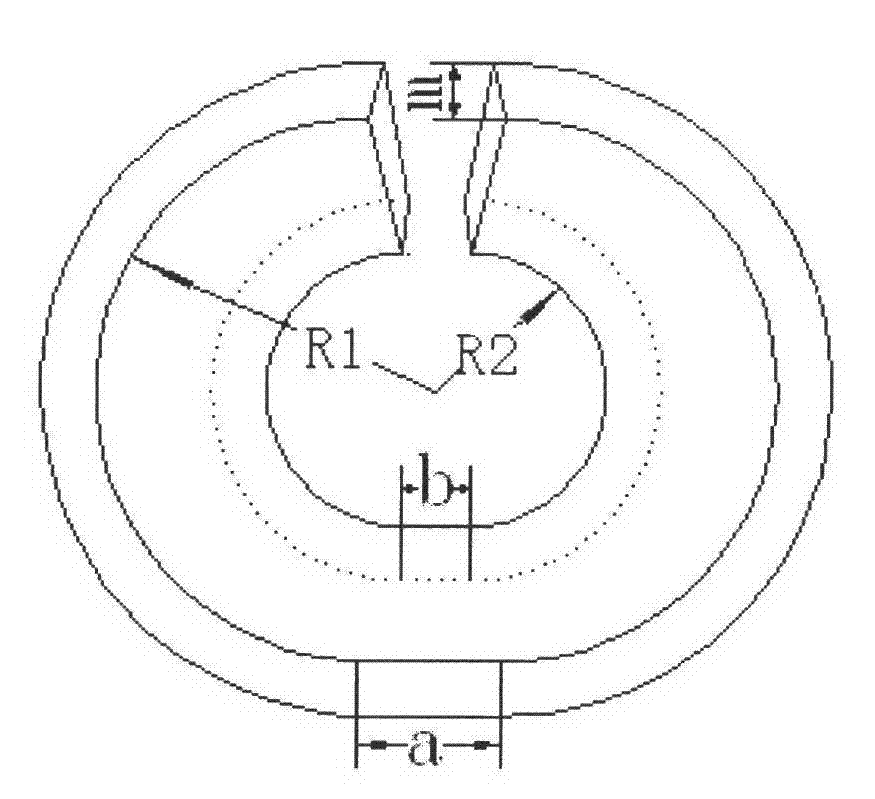

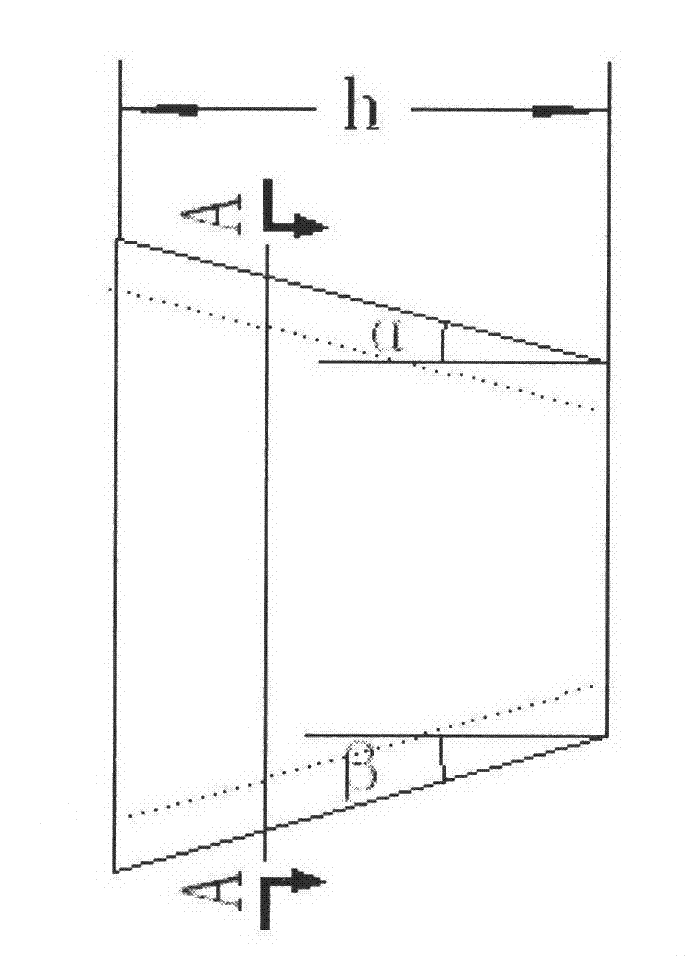

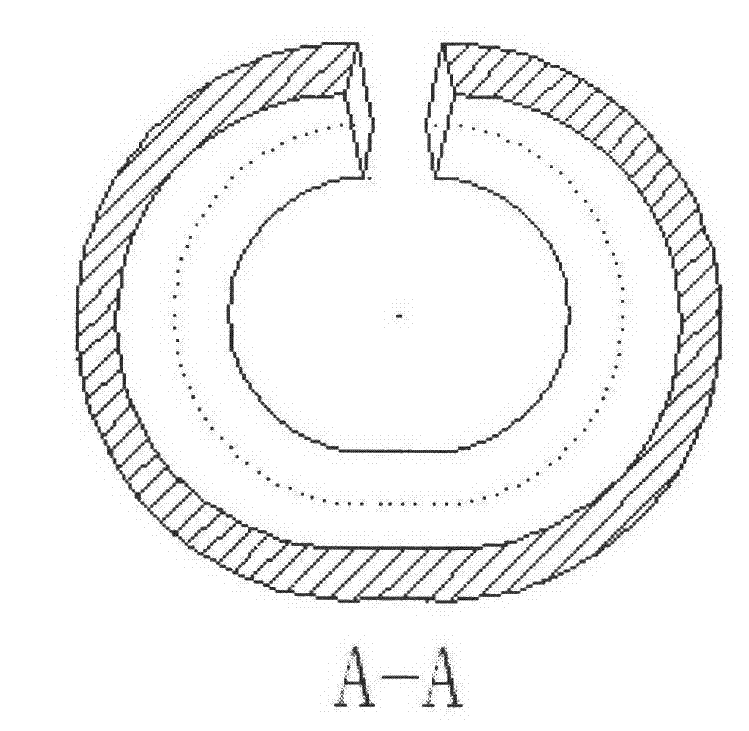

The present invention is fiber strand aggregating device for air slide, and its novel design is its aggregating roller with new splitting guide flute and porous aggregating flute. It is installed between the front jaw and the spinning section in the drawing area of spinnin frame, and the air slide fiber strand aggregating device and the front roller form one fiber jaw. By means of the additional aggregating air flows, one flow field for fiber inside the guide flute and the aggregating flute is provided. By means of splitting and guide of the guide flute and the aggregating flute and the aggregation of fiber strand in the aggregating flute, the fiber strand is twisted closely in the aggregating flute. The yarn of the present invention has improved axial parallel degree, decreased hairy feather amount outside the yarn and raised yarn strength.

Owner:DONGHUA UNIV

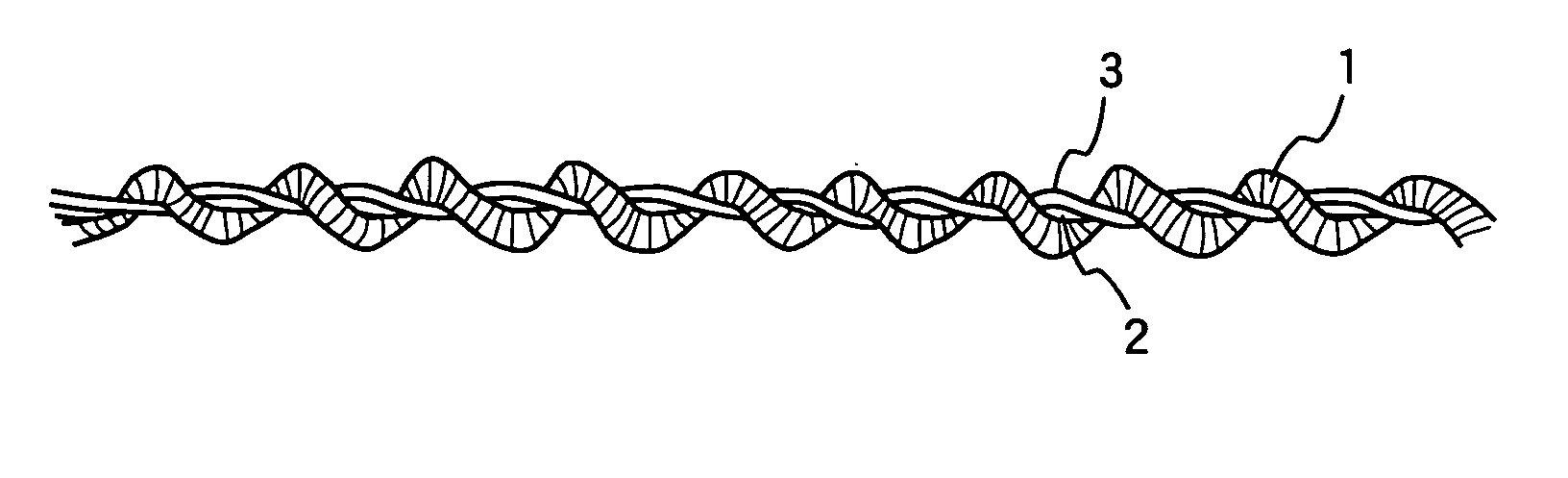

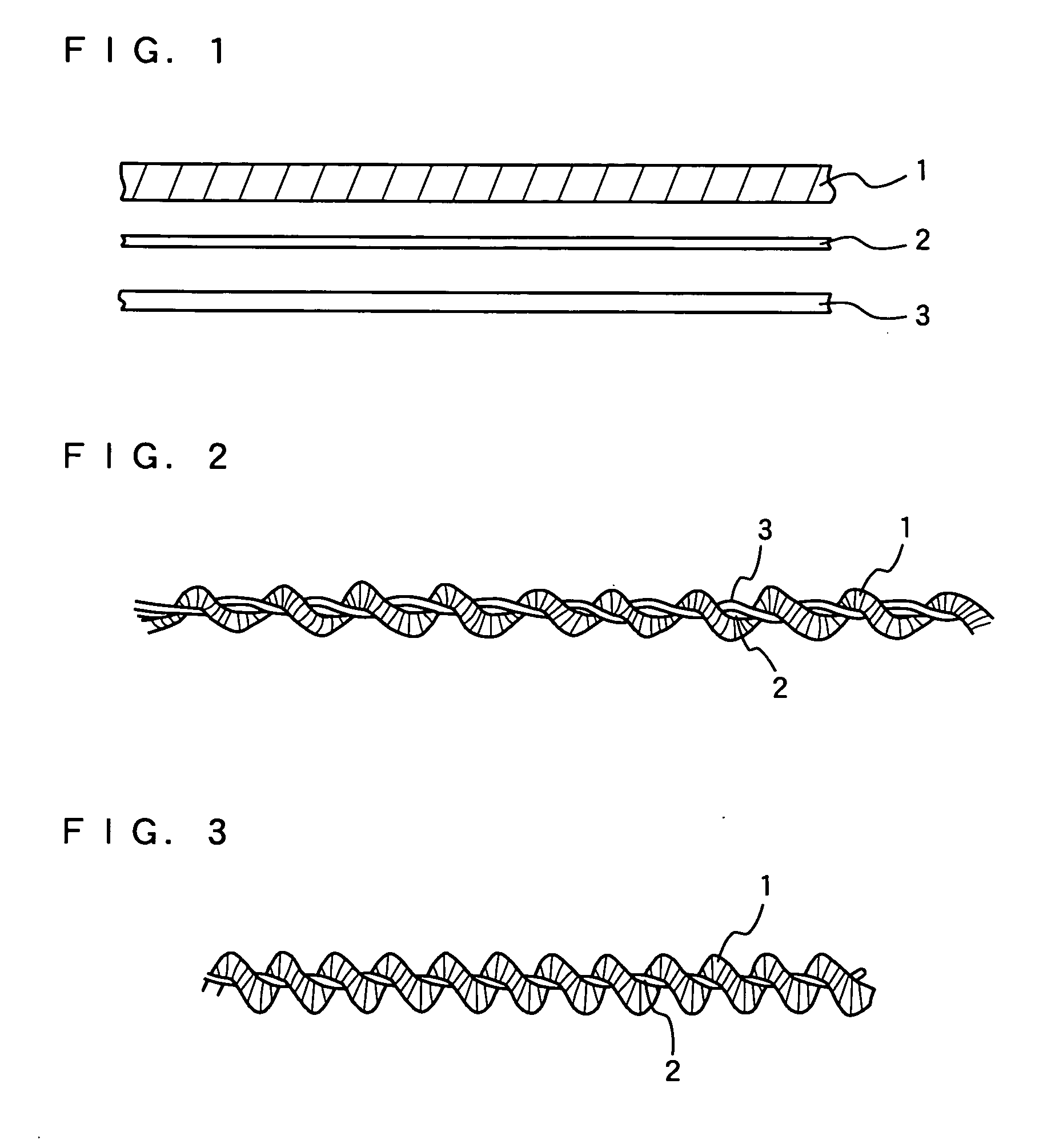

Composite Twisted Yarn

ActiveUS20070214765A1High yarn strengthLess fluffDrafting machinesAdhesivesPolymer scienceYarn strength

To produce a textile or fabric having a high yarn strength and a high stretching property. The textile or fabric does not cause troubles such as a thread breakage even in weaving or knitting with a high-speed weaving or knitting machine. To prepare a composite twisted yarn which at least comprises a spun yarn and a water-soluble yarn twisted with the spun yarn, wherein the twist direction of the composite twisted yarn is reverse to the twist direction of the spun yarn, and the composite twisted yarn fulfils the following requirement (1) or (2) (1) the twist number of the composite twisted yarn is 1.3 to 3 times of the twist number of the spun yarn, and the weight ratio of the spun yarn relative to the water-soluble yarn is 20 / 80 to 98 / 2, (2) the composite twisted yarn further comprises an elongated elastic yarn having an elongation of 2 to 5 times of the original length; the spun yarn, the water-soluble yarn, and the elongated elastic yarn are twisted together; the twist number of the composite twisted yarn is 0.3 to 3 times of the twist number of the spun yarn; the weight ratio of the spun yarn “1” relative to the elastic yarn “2” is 50 / 50 to 99.9 / 0.1; and the weight ratio of the total amount of the spun yarn “1” and the elastic yarn “2” relative to the water-soluble yarn “3” is 30 / 70 to 99 / 1.

Owner:KURARAY TRADING CO LTD +1

Method for improving performances of yarns formed by vortex spinning

InactiveCN102691143AImprove yarn tightnessLow modulusContinuous wound-up machinesOpen-end spinning machinesEngineeringYarn strength

The invention relates to a method for improving performances of yarns formed by vortex spinning by reducing the modulus and the rigidity of fibers on line and belongs to the field of textile processing. According to the method disclosed by the invention, a sectional softening treatment method is applied for carrying out progressive softening treatment on fibers subjected to vortex spinning on a vortex spinning machine, and thus the fiber modulus and the bending rigidity are quickly reduced on line and the performances of the resultant yarns prepared from fibers by vortex are improved. For a vortex yarn structure, the structure compactness is improved, the yarn strength is enhanced and residual torque of the yarns is small; in addition, the non-spinning fibers can be subjected to vortex spinning on the vortex spinning machine; the fibers with poorer quality for the resultant yarns formed by the vortex spinning are subjected to high-quality spinning on the vortex spinning machine; and particularly, the improvement on the spun count of the fibers on the vortex spinning machine is facilitated and the smooth production of high grade cotton yarns formed by vortex spinning is realized. The method disclosed by the invention has the advantages of short work procedure flow, strong pertinence, high efficiency, lower cost, reasonable structure, convenience in operation and easiness in large-area popularization and use.

Owner:WUHAN TEXTILE UNIV

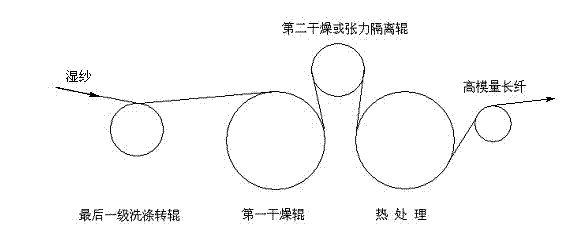

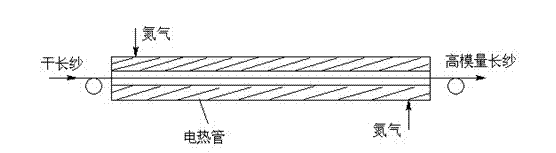

High-modulus poly(p-phenylene terephthalamide) (PPTA) fiber and preparation method thereof

ActiveCN102251306AImprove performanceLow spinning efficiencyArtificial filament heat treatmentArtificial filament supportPolymer scienceYarn strength

The invention discloses a high-modulus PPTA fiber which is prepared from PPTA polymers with inherent viscosity of 5.5 to 8.0 dL / g obtained through the method of low-temperature solution polycondensation by drawing undried wet strands in the procedures of washing, neutralizing and drying in the process of dry-jet wet spinning and carrying out heat treatment under high temperature and high tension on dry strands in the procedure of drying or after drying; the modulus of the PPTA fiber is 800 to 1000 g / denier and the inherent viscosity of 5.0 to 7.5 dL / g. The fiber product obtained through the method provided in the invention has excellent yarn strength, high modulus, luster of high crystallinity, a bright color, little fuzziness, superior properties and a wider application scope, and fills in gaps in market.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Ice-cold polyester functional fabric and production method thereof

InactiveCN106567175AHigh strengthReduce the temperatureFibre treatmentWoven fabricsPolyesterPulp and paper industry

The invention belongs to the technical field of textile production and specifically relates to ice-cold polyester functional fabric and a production method thereof. The fabric is satin fabric which is formed by warp yarn and weft yarn, wherein the wrap yarn is blended yarn formed by ice-cold polyester fiber and tencel fiber and the weft yarn is doubling yarn formed by doubled bamboo fiber. The production method comprises following steps: 1) beam-warping process; 2) sizing process; 3) denting; 4) weaving process. The yarn strength is increased by adopting blended yarn; the yarn feather is reduced so as to facilitate later sizing and weaving; the blended yarn is processed with sizing agent, which can effectively reduce the shrinkage of ice-cold polyester fiber and is convenient for weaving; doubled bamboo fiber is used as weft yarn; the cross sectional area of the weft yarn is doubled so that the weft direction strength is increased so as to facilitate the later high speed weaving; the production method is simple and efficient. The ice-cold polyester functional fabric has smooth hand feel, high strength and good anti-static-electricity performance and color fastness performance; the fabric is quick in cooling and heat dissipating.

Owner:JIHUA 3509 TEXTILE

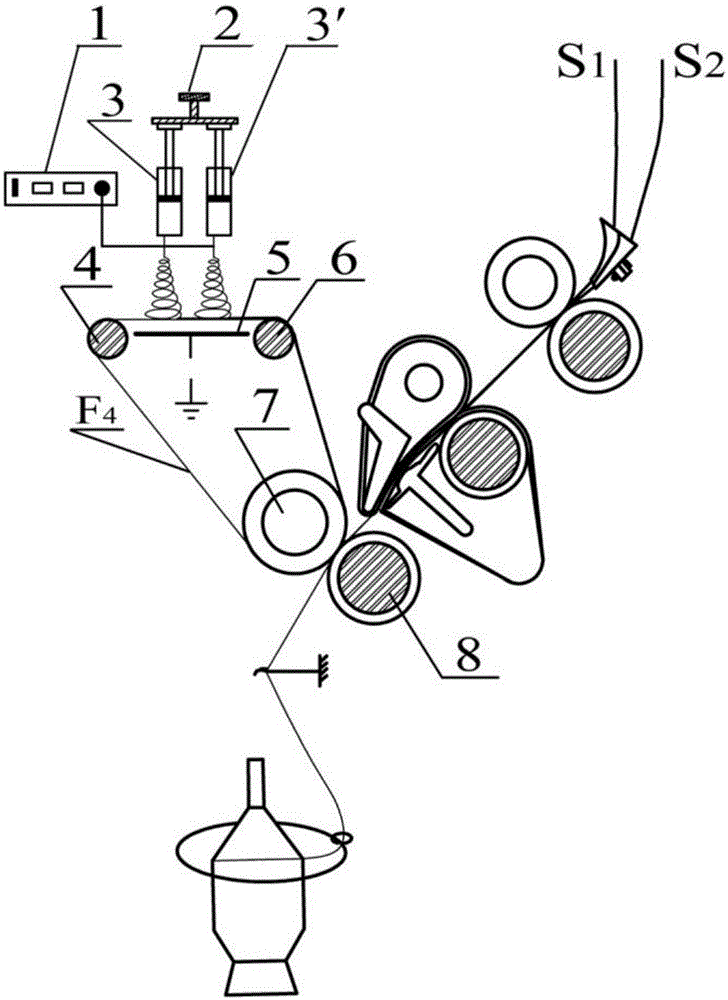

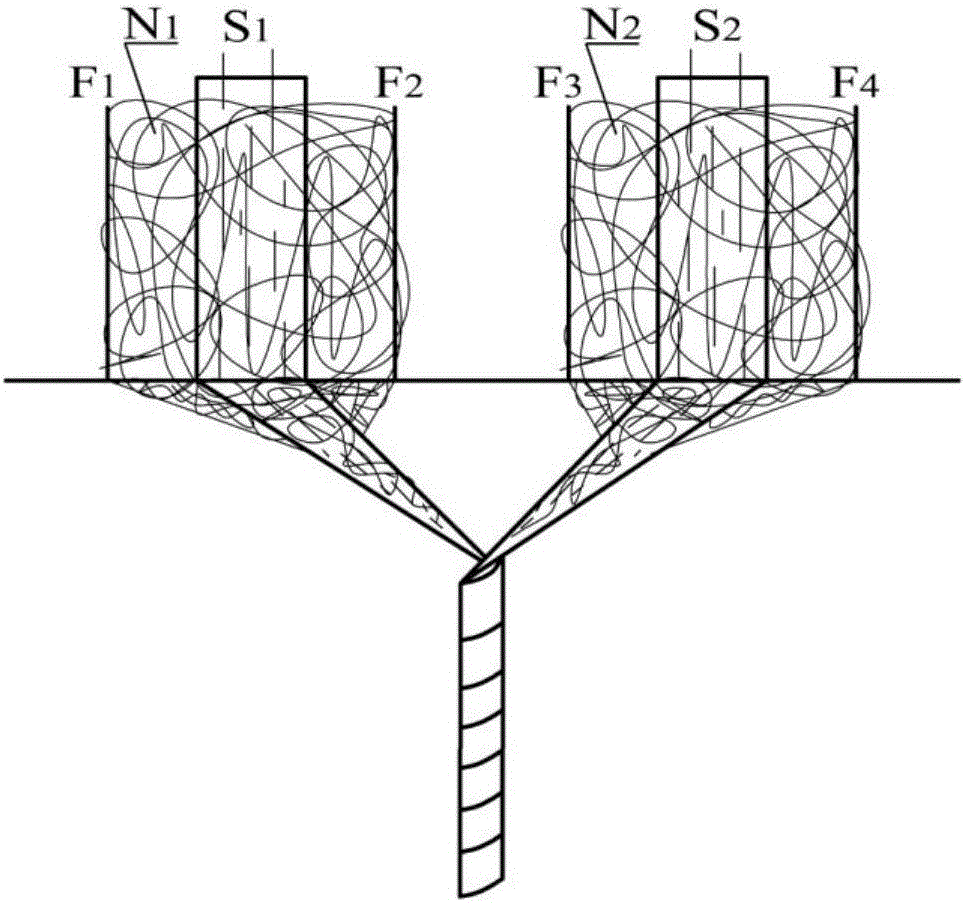

Siro spinning method of nano-microscale reinforced short staple resultant yarn

ActiveCN106480566AIncrease yarn cohesionGuaranteed smooth productionFilament/thread formingYarnBobbinElectrospinning

The invention relates to a siro spinning method of nano-microscale reinforced short staple resultant yarn, and belongs to the technical field of textile processing. The method applies the placement of a nanofiber web above a front roller of a ring bobbin to bear the weight of a transmission input area and an electrostatic spinning area. The nano-fiber produced by two nano-electrostatic spinning nozzles in the electrostatic spinning area is continuously ejected to two bearing silk tapes to form two nano-fiber webs which are loaded by two bearing silk tapes to be conveyed to a roller nip, and to be mixed with two pieces of extended short staple roving, thus forming nano-micro fiber mixed stripe. When the nano-micro fiber mixed stripe is underway of being twisted into yarn, the nano-fiber effectively fills and reinforces the contact and blending between different micro-short-staples. The organic combination of the nano-electrostatic spinning and the normal siro spinning considerably enhances the properties such as the weight and thickness uniformity and yarn strength of the yarn processed by nano-micro fiber blending spinning, thus achieving the production of high performance, high quality nanoscale yarn.

Owner:WUHAN TEXTILE UNIV

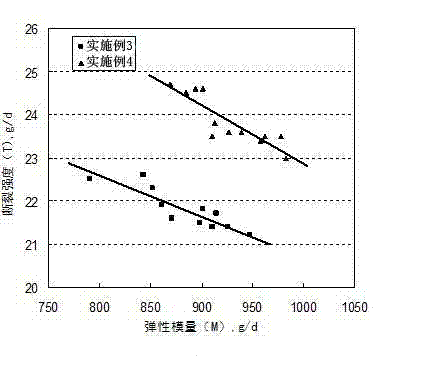

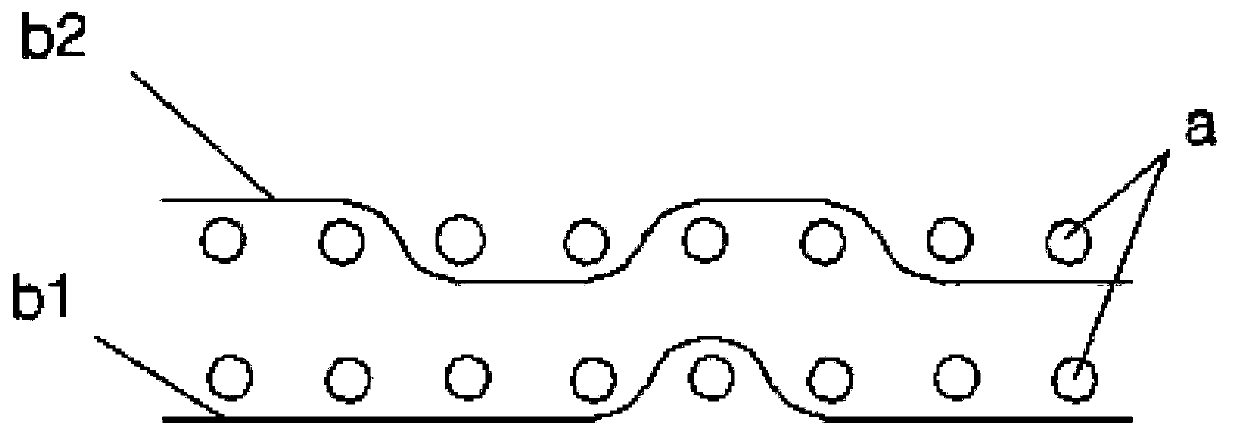

Low-twist high-strength yarn and spinning technology thereof

ActiveCN103397419AImprove breed adaptabilityHigh strengthContinuous wound-up machinesYarnCardingEngineering

The invention relates to the spinning technical field, in particular to a low-twist high-strength yarn and the spinning technology of the low-twist high-strength yarn. Blending is carried out on terylene and cotton which are blended according to the feeding mass ratio of 50-70:30-50, the opening picking procedure, the cotton carding procedure, the combing procedure, the drawing procedure, the roving procedure and the spinning procedure are carried out, and a terylene / cotton blending yarn with the fineness degree of 7.4-36.7tex, the twist coefficient of 260-300 and the strength of 20-35cN / tex is spun. According to the low-twist high-strength yarn and the spinning technology, the variety adaptation of the low-twist high-strength yarn is improved, the yarn strength is improved, under the condition that the design twist coefficient is reduced by 10%-35%, the tensile strength of the blending yarn is 5%-10% higher than that when the twist coefficient is normally designed, and the foundation is laid for the development of the shell fabric with the good softness and comfort performance.

Owner:NANTONG DOUBLE GREAT TEXTILE

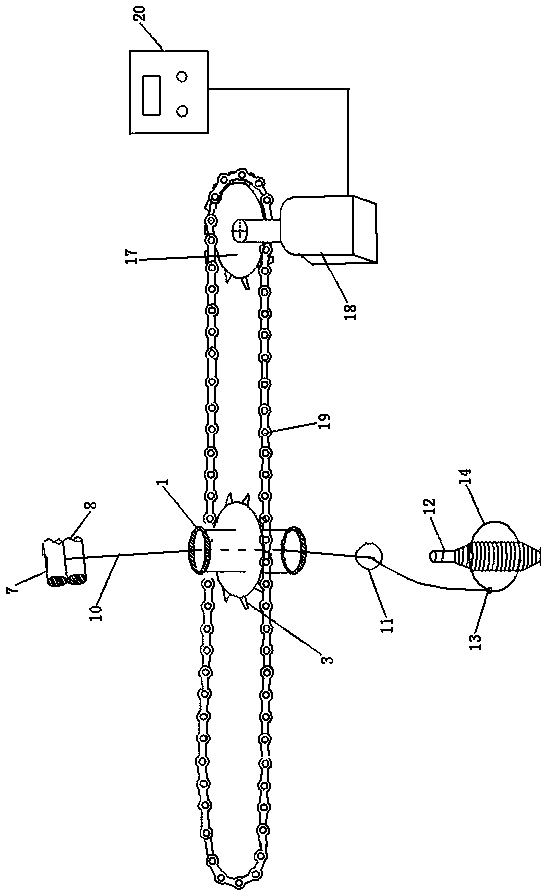

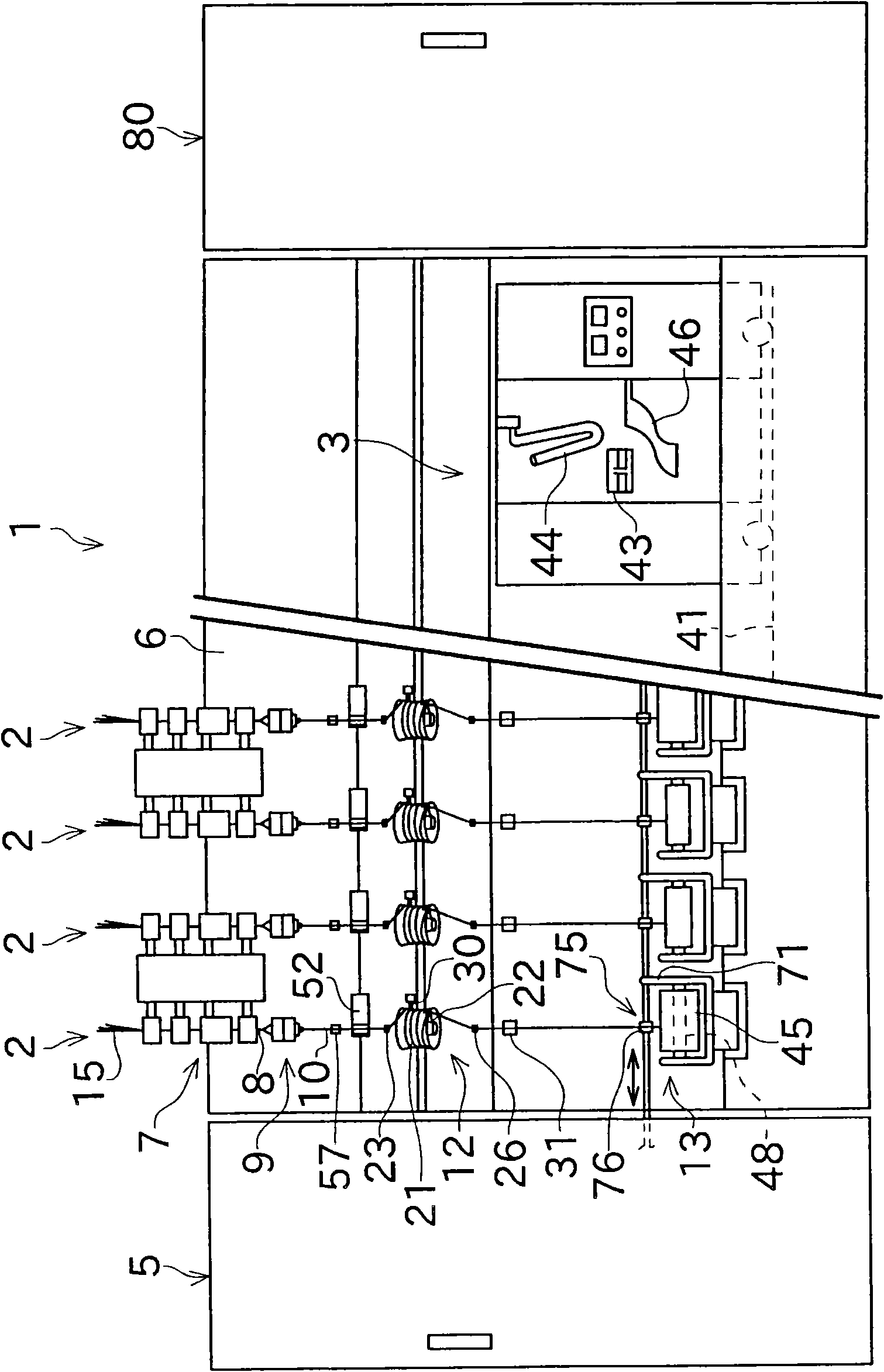

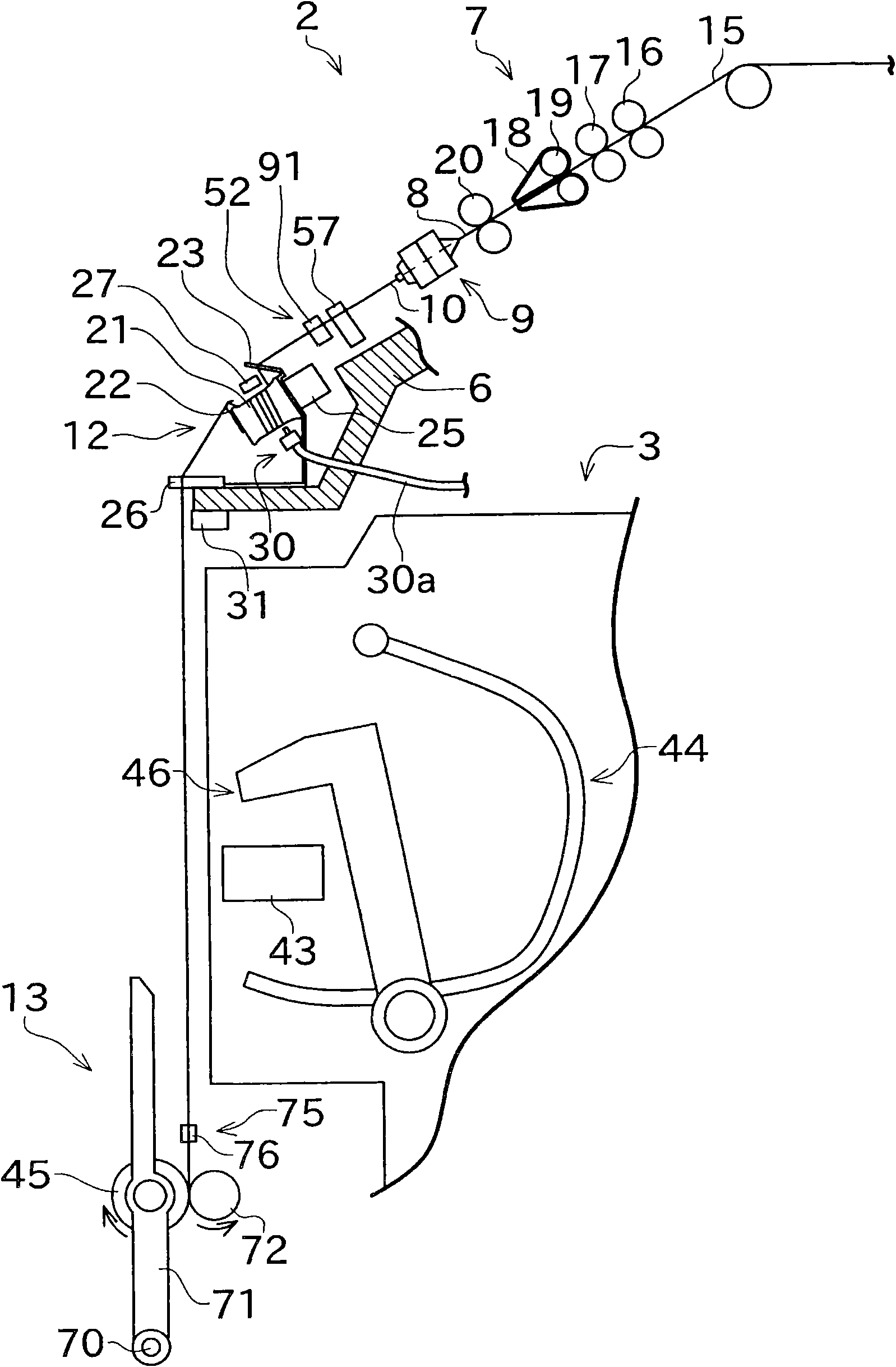

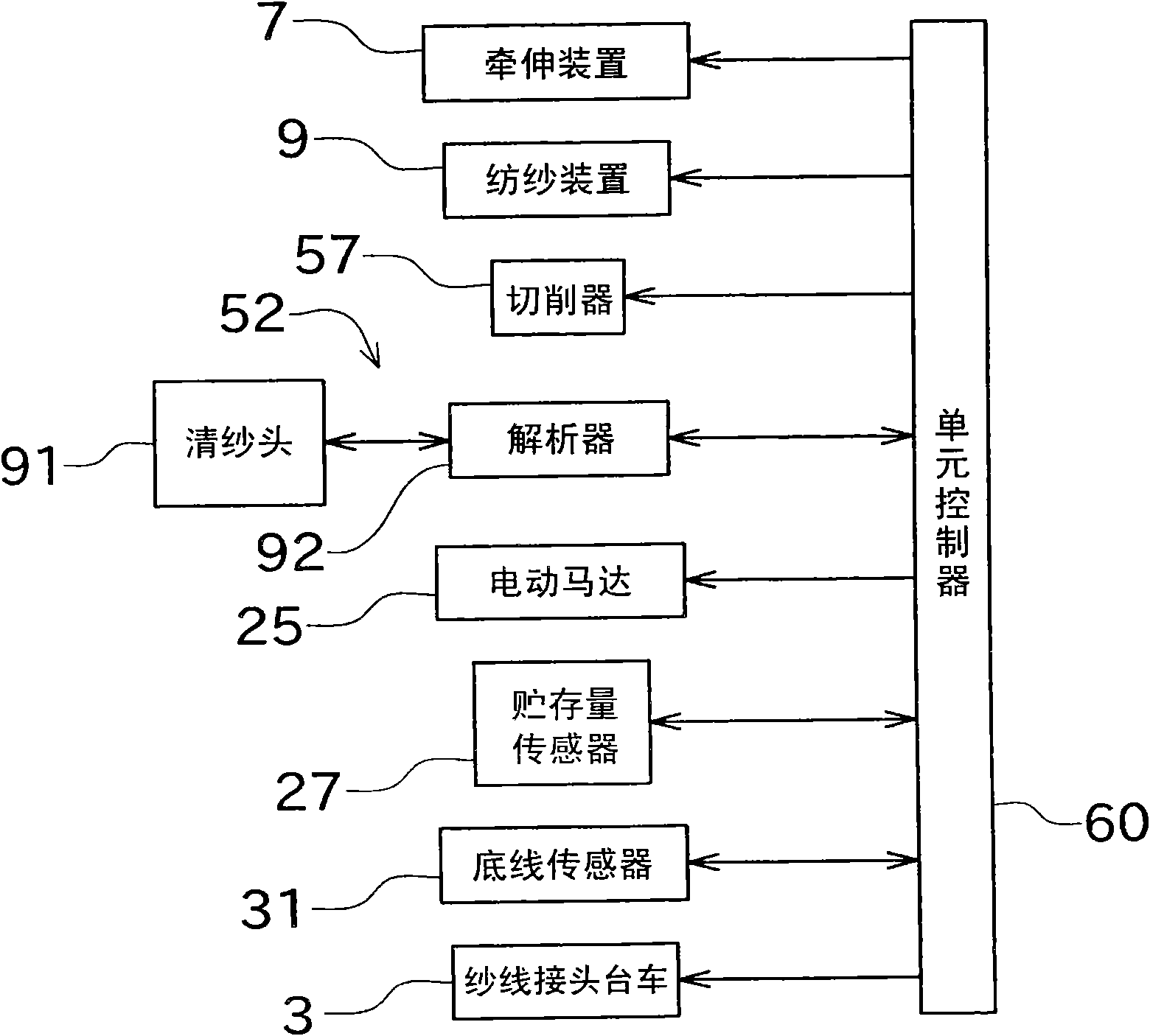

Spinning machine and yarn removing method for removing yarn remaining on yarn accumulating roller

ActiveCN101994175AEasy to attractEfficient spinning operationsPiercing arrangementsFilament handlingEngineeringYarn strength

A spinning frame (1) includes a spinning device (9), a yarn clearer (52), a yarn accumulating roller (21), a suction opening (46), a suction device (30), and a unit controller (60). The spinning device produces spun yarn by applying twists to a fiber bundle. The yarn clearer (52) is arranged downstream of the spinning device and detects a yarn defect in the travelling spun yarn. The yarn accumulating roller (21) is arranged downstream of the yarn clearer and accumulates the spun yarn by rotating while winding the spun yarn around an outer peripheral surface thereof. The suction opening of the suction device is arranged near a base end of the yarn accumulating roller (21). The suction device (30) can generate suction airflow at the suction opening (46). The unit controller (60) delays a stoppage timing, which is a timing at which feeding of the spun yarn is stopped, when the yarn clearer (52) detects a prescribed yarn defect in which yarn strength is low, compared with when other type of yarn defect is detected, and stops the yarn accumulating roller (21) after the stoppage timing.

Owner:MURATA MASCH LTD

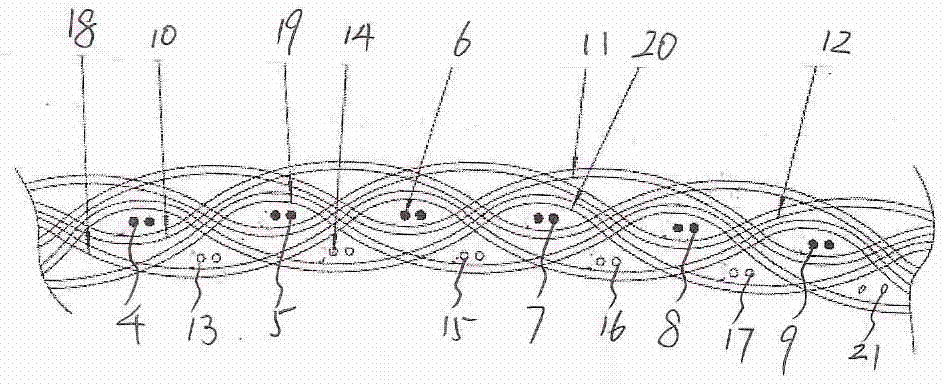

High-strength fiber double-layer interweaved composite hose and production method thereof

InactiveCN103879036AGood flexibilityImprove pressure resistanceLayered productsMulti-ply fabricsRubber materialWhole body

The invention discloses a high-strength fiber double-layer interweaved composite hose and a production method of the composite hose. The high-strength fiber double-layer interweaved composite hose comprises a hose blank, wherein in an inner surface and an outer surface of the hose blank, a rubber material layer is composited on at least the inner surface of the hose blank; the hose blank is a double-layer fabric with a double-layer section, and six paths of warps form a circulative weaving tissue; the double-layer fabric comprises an inner layer and an outer layer, the outer layer comprises an outer-layer warp and an outer-layer weft, the inner layer comprises an inner-layer warp and an inner-layer weft, and the inner-layer weft is interweaved with the inner-layer warp and is also interweaved with the outer-layer warp, so that the inner layer and the outer layer are interweaved into a whole body. According to the high-strength fiber double-layer interweaved composite hose disclosed by the invention, the woven hose blank has good flexibility, high pressure resistance, a few interweaving points, small yarn strength loss and small torsion degree; superlarge-aperture and high-pressure-resistance hoses meeting the market demand can be produced without special modification on the original device; the production process is simple; the practical value is high, and the production generalization performance is excellent.

Owner:蔡宝祥

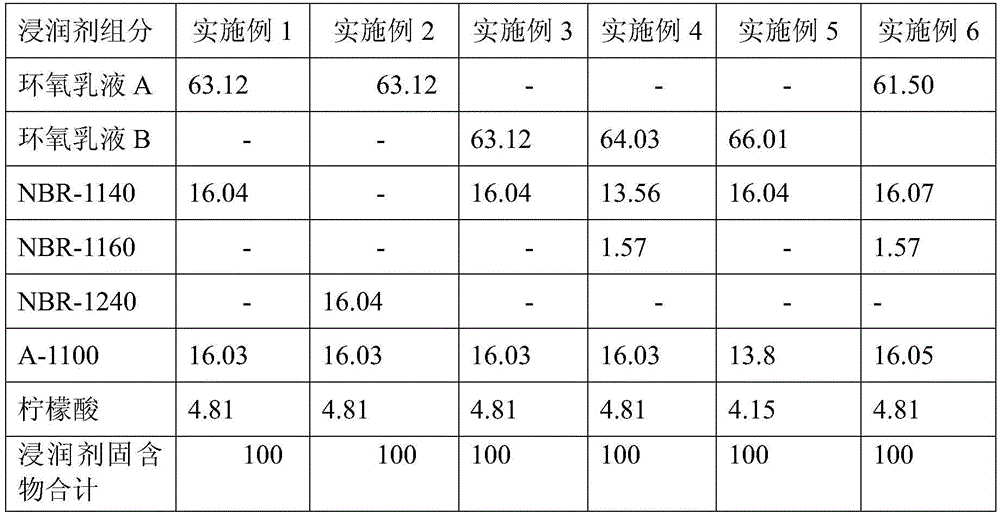

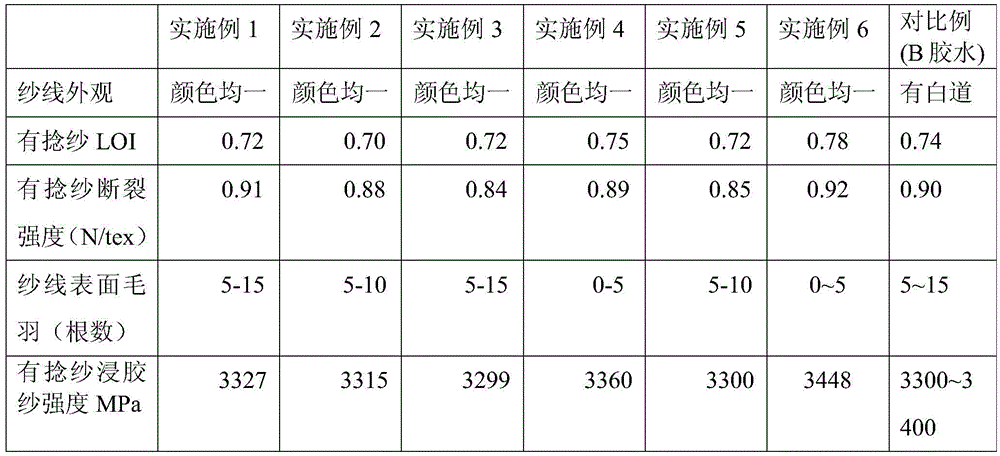

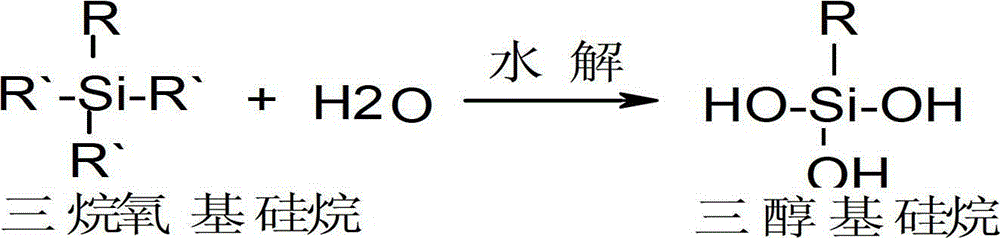

Resin compatible type glass fiber yarn impregnation agent, and preparation method thereof

The invention relates to a resin compatible type glass fiber yarn impregnation agent. The solid content of the impregnation agent accounts for 5-10% by mass of the total amount of the impregnation agent, the balance being deionized water. The solid content of the impregnation agent comprises the following components, based on the weight of the impregnation agent solid content as 100%: 50-80% of the epoxy resin emulsion, 10-25% of a non-ionic lubricant, 0-5% of a cationic lubricant, 8-20% of a silane coupling agent, and 1-6% of a pH adjusting agent. Compared with a traditional enhanced yarn impregnation agent, the impregnation agent formula has the advantage of simple composition. Mono-component epoxy resin is adopted as a film-forming agent, and two high-efficiency lubricants are combined. The impregnation agent has good compatibility with resin. With the formula, yarn strength is high. The formula also has excellent textile processing performance.

Owner:SINOMA SCI & TECH

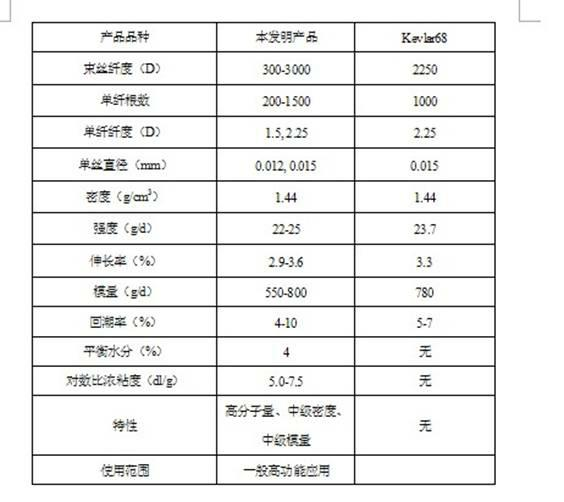

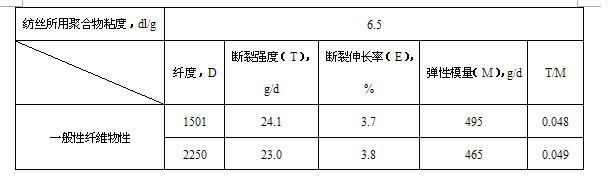

Middle modulus poly (p-phenyl-terephthalamide) fiber and preparation method thereof

ActiveCN102154726AImprove performanceLow spinning efficiencyMonocomponent polyamides artificial filamentStretch-spinning methodsPolymer scienceYarn strength

The invention discloses a middle modulus poly (p-phenyl-terephthalamide) fiber, which is prepared by the following steps of: adopting a poly (p-phenyl-terephthalamide) polymer with the logarithmic viscosity of 5.5 to8.0dL / g as a raw material, wherein the poly (p-phenyl-terephthalamide) polymer is obtained by a low-temperature solution polycondensation method, and stretching undried wet yarns to preparing the middle modulus poly (p-phenyl-terephthalamide) fiber before washing, neutralizing and drying working procedures of a dry-jet wet spinning process. For the middle modulus poly (p-phenyl-terephthalamide) fiber, the modulus is 550 to 800g / denier and the logarithmic viscosity is 5.0 to 7.5 dL / g. A fiber product obtained by adopting the method not only has gloss of high crystal degree, bright colors, few broken filaments, but also has excellent yarn strength, middle-class modulus and wider application range.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Impregnating agent for high-strength industrial glass fibre spun yarns and preparation method thereof

The invention discloses an impregnating agent for high-strength industrial glass fibre spun yarns and a preparation method thereof. The impregnating agent comprises the following raw materials by weight percent: 4-5% of modified starch, 0.2-0.3% of hydrogenated vegetable oil, 0.72-1.02% of vegetable oil emulsifying agent, 0.4-0.5% of water-borne epoxy resin, 0.1-0.2% of softening agent, 2.0-2.5% of polyethylene glycol, 0.03-0.05% of glacial acetic acid, 0.4-0.6% of coupling agent and the balance of water, wherein the coupling agent is an aminosilane coupling agent; the emulsifying agent is a polyoxyalkyl emulsifying agent; and the softening agent is a cationic softening agent. The impregnating agent has the advantages that the impregnating agent can endow yarns with weaving performances needed when the yarns are used as industrial fabrics; the yarns have good wear resistance and high strength and are not easy to break in the weaving process; meanwhile, the bondability between the yarns and resins can be improved; and the impregnating agent is relatively simpler to prepare and is easy to achieve.

Owner:山东中玻节能环保发展有限公司 +1

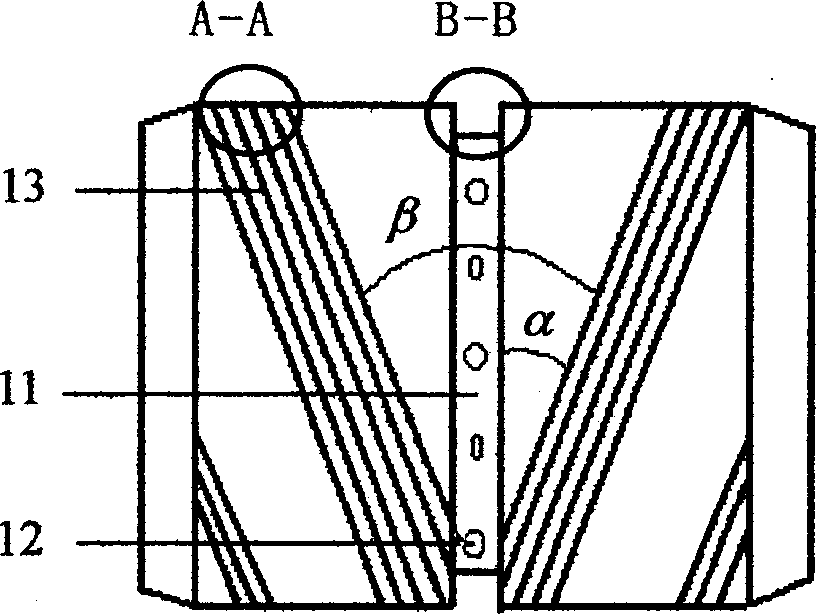

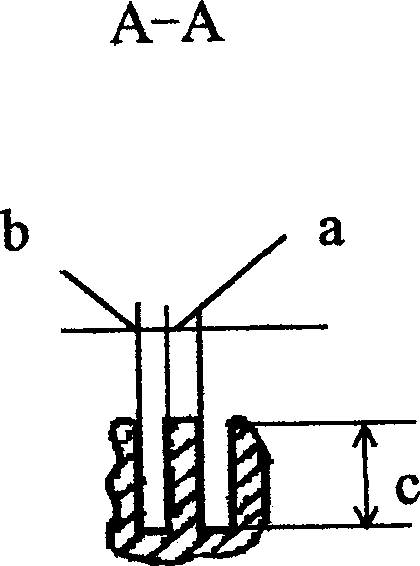

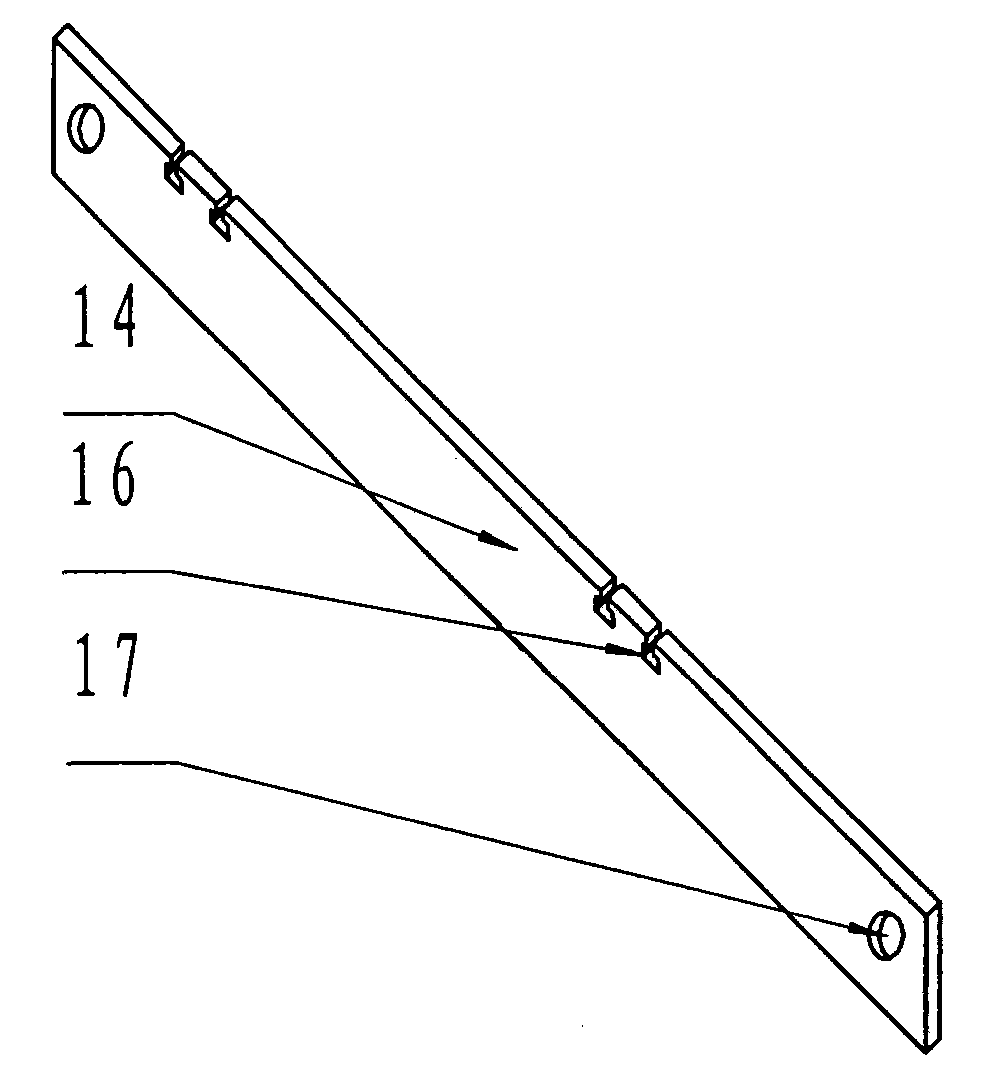

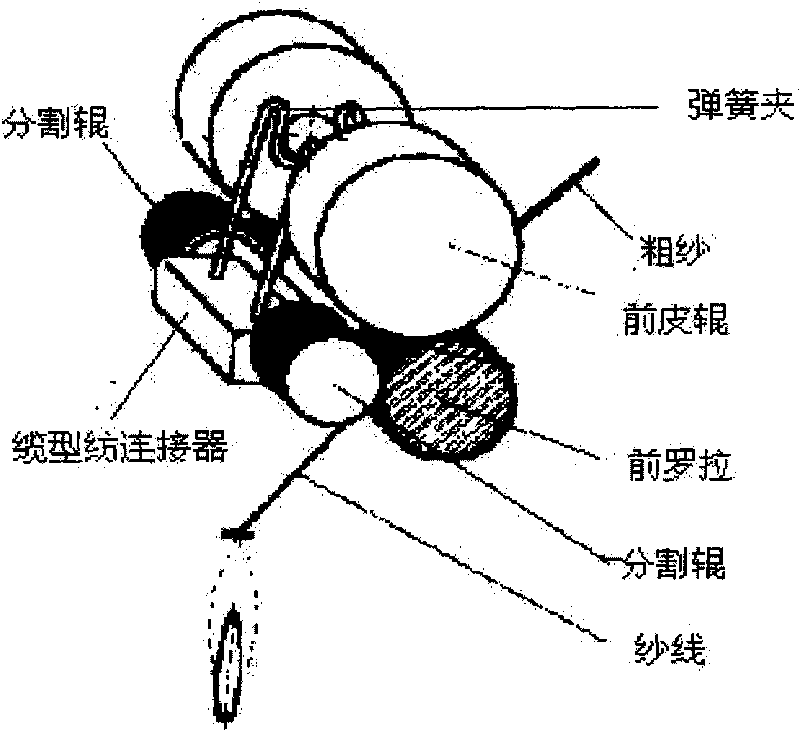

Beam-splitting compound spinning method and special equipment thereof

InactiveCN101586274AReduce head exposureLess hairyContinuous wound-up machinesFiber bundleBeam splitting

The invention provides a beam-splitting compound spinning method for ring spinning, which includes the steps: feeding with two roves, dividing the feeding roves into several strands of fiber bundles on the front tongs mouth output point, after being drafted by the conventional spinning frame drafting mechanism, rotating and twisting the divided fiber bundle surround the center of rotation into one-ply yarn, and twisting two one-ply yarns into completed product yarn. The device includes a separating plate for separating two feeding roves and a separating wheel component for dividing roves into fiber bundles; a separating plate is fixed on the back roller base, and the separating wheel component is fixed on the vehicle panel and includes a separating wheel shaft, a separating wheel and a transmission friction wheel. The separating wheel is equipped correspondingly to the front leather roller zone, and annular deep-and-swallow, wide-and-narrow separating grooves and a groove perpendicular to the separating groove are equipped on the surface, and the bottom of the groove is parallel to the bottom of the separating groove; The transmission friction wheel is attached to the friction wheel of the front roller. The invention has the advantages that the rove fiber strand has twice beam-splits, three times twistings, the fibre in the yarn transferred multitimes, which reduces hair feather, improves yarn strength and antifriction performance.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

Special yarn for thermal underwear and producing method thereof

InactiveCN101403151AMeet the needs of cohesionImprove yarn strengthDrafting machinesCombing machinesYarnCarding

The invention discloses muslin dedicated for thermal underwear, and a manufacturing method thereof, wherein, long stapled mutton and viscose fiber are adopted as raw materials; a combing technology is adopted for the long stapled mutton to manufacture combed sliver; a carded cotton carding technology is adopted for viscose fiber to manufacture viscose fiber stripe; after drawing, roving and spun yarn are carried out to the combed sliver and the viscose fiber, high-woven yarn dedicated for the thermal underwear with the weight blend ratio of 68-72 percent of the long stapled mutton and 28-32 percent of the viscose fiber is manufactured. With the adoption of current spinning equipment, the manufacturing method can manufacture the high-woven yarn used for manufacturing high range clothing fabric or knitwear such as thermal underwear, and the like; besides, the number of fibrogen inside the cross section of the manufactured high-woven yarn can fully satisfy the need of cohesive force between fiber and fiber; the yarn strength is improved, thus being entirely capable of adapting to the requirements for manufacturing high range clothing fabric or knitwear such as thermal underwear, and the like.

Owner:丁宏利

Spun yarn collector

InactiveCN103361784ASolve problems affecting yarn qualityImprove yarn qualityDrafting machinesContact modeEngineering

The invention discloses a spun yarn collector. The section of the spun yarn collector is similarly circular, the radius of a contact arc of the collector and the surface of a roller is properly increased, and a double-point contact mode of the original collector is replaced by an arc contact mode, so that the problem of high friction factor due to obvious corner angles of the traditional collector is solved, sliver squeezing frequency of the inner wall of the collector is reduced, the yarn quality is improved, the width of each sliver is effectively reduced, spinning triangular space is reduced, the slivers are compact in structure and smooth in appearance, hairiness is reduced, and the yarn strength is improved. Compared with the traditional collector, the spun yarn collector has the advantages that the width of an outlet of the collector is reduced, and sliver collecting and finishing effects are good on the premise that the yarn quality is guaranteed.

Owner:JIANGNAN UNIV

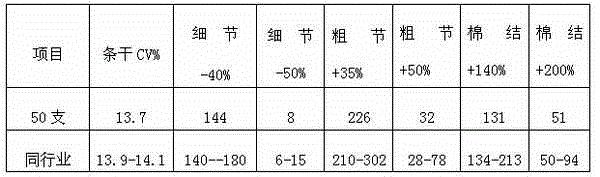

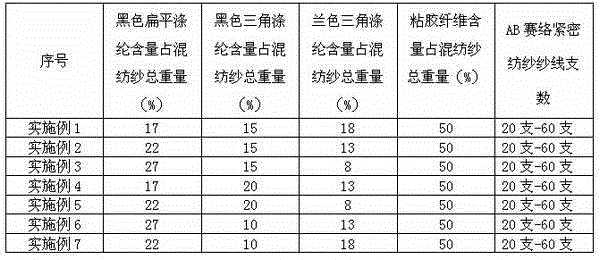

Colored polyesters and viscose blended siro-and-compact spinning yarns and manufacturing process

The invention relates to colored polyesters and viscose blended siro-and-compact spinning yarns. Thick yarns spun by black flat polyesters, black triangular polyesters and blue triangular polyesters are fed on a siro-and-compact spinning machine together with equal-quantitative thick yarns spun by white viscose fibers through two thick yarns in order to form gray siro-and-compact spinning yarns. The number of blended siro-and-compact yarns is 20 to 60. A manufacturing process comprises following steps of a blowing process, a combing process, a drawing process, a roving process, a spinning process and a rewinding process. As for the spinning machine, the number of roving suspended spindles and siro-spinning bell mouths is doubled and a compact spinning device is added. The colors of spinning steel wire rings are darken by 1 to 2 degrees. Double bell mouths and a large-power fan are adopted in the region behind the spinning machine. The relative humidity of production environment in all processes is within the range of 52% to 58%.The colored polyesters and viscose blended siro-and-compact spinning yarns are compact in structure, few in features and defects and high in yarn strength and are energy-efficient and eco-friendly without dyeing.

Owner:JIHUA 3542 TEXTILE CO LTD

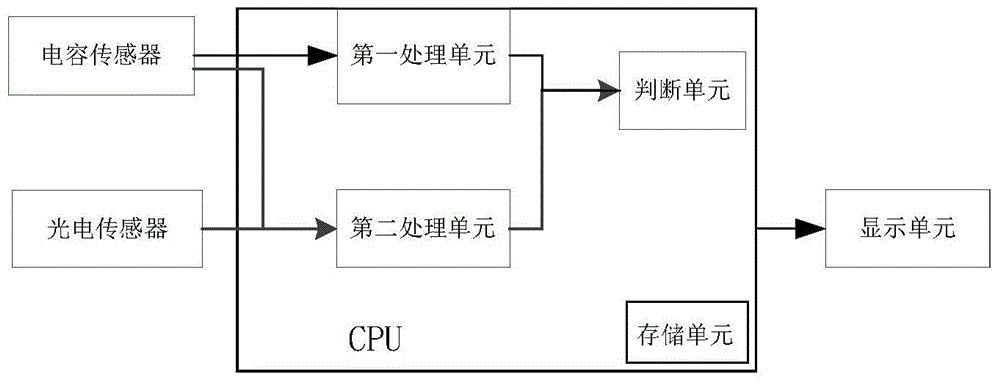

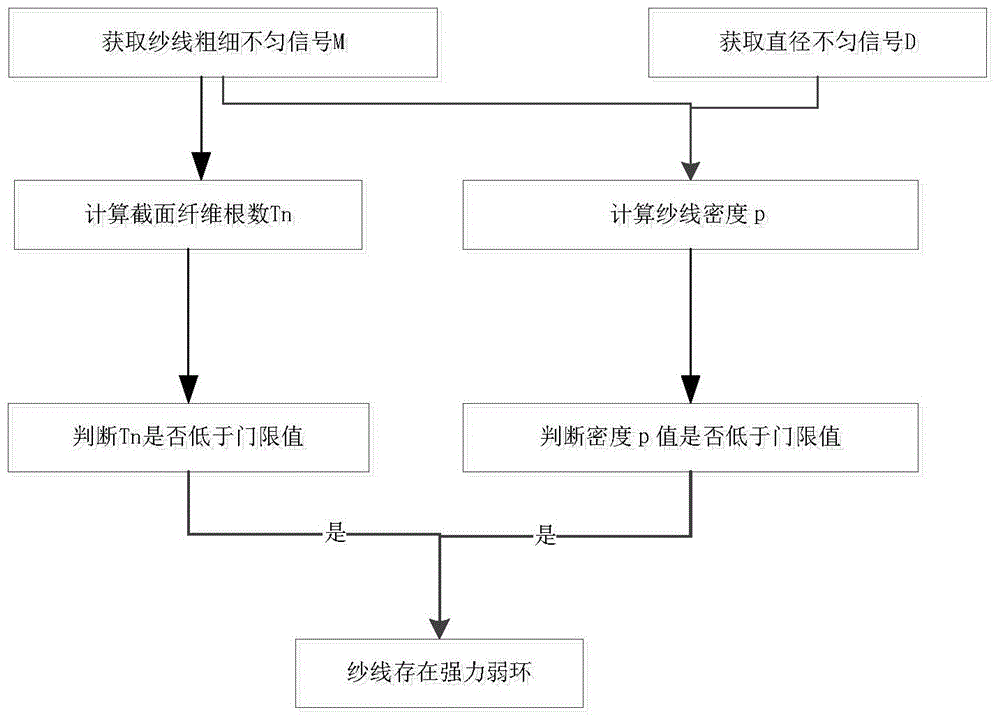

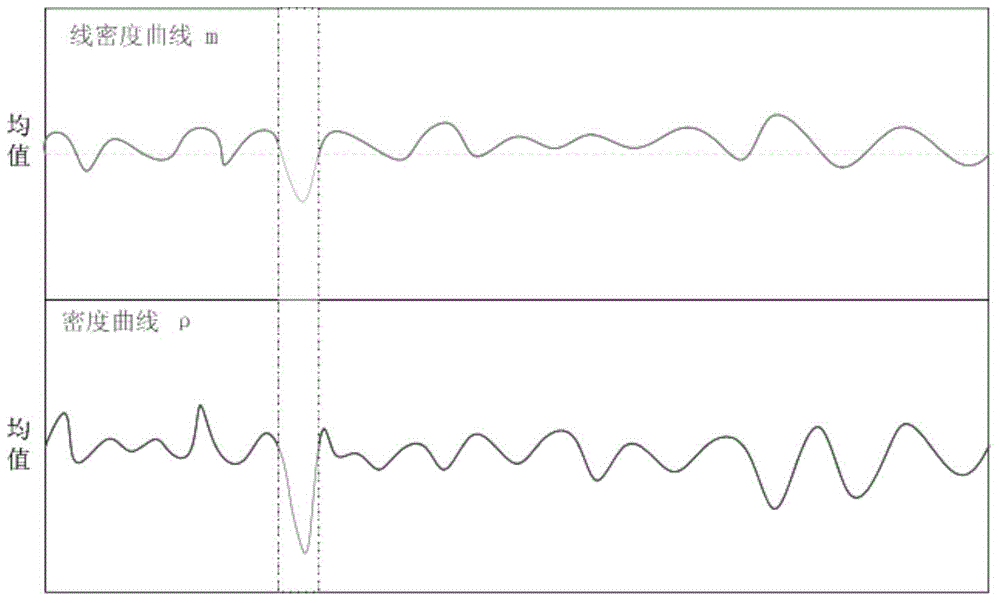

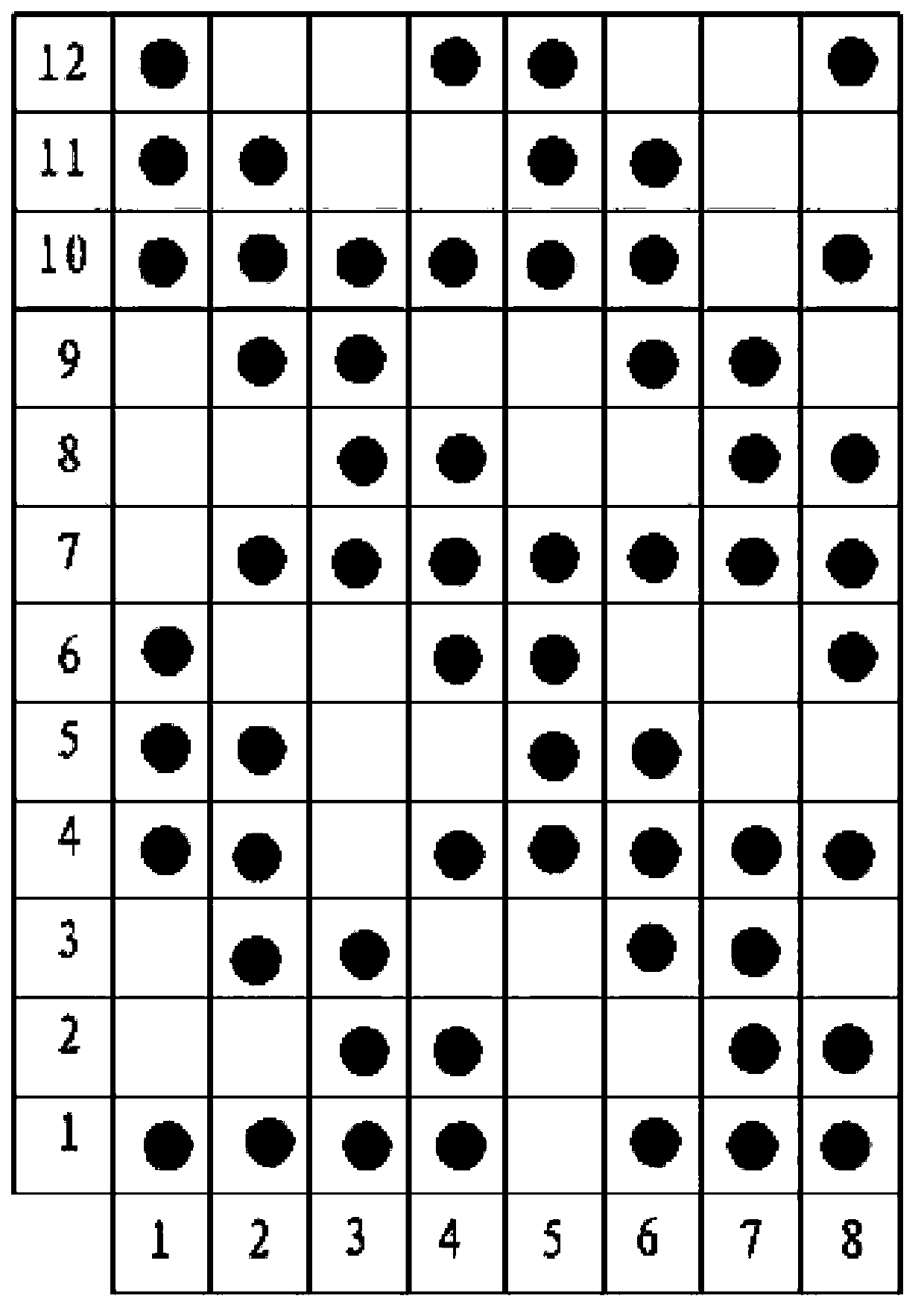

Yarn strength weak ring detection and elimination method and apparatus

ActiveCN104975388AAccurate and objective guidanceReduce downtime parkingTextiles and paperEconomic benefitsEngineering

The invention discloses a yarn strength weak ring detection and elimination method and apparatus. The apparatus is formed by a capacitance type sensor, a photoelectric sensor and a plurality of processing units; Yarns pass through the capacitance type sensor and the photoelectric sensor at the same time; signals of uneven yarn thickness and uneven diameter signals are sent to related processing units; uneven thickness signals of yarns are output by the capacitance type sensor after the yarns passing through the sensor are sent to the processing unit and cross section yarn numbers (Tn) can be calculated via uneven yarn density; wand hen a certain yarn is Tn and lower than a certain value and a Rho value is lower than a threshold value, the yarn section possesses a strong weak ring. The invention provides a yarn weak ring online detection method and apparatus; and the weak ring can be eliminated as needed; yarn break and machine stop due to yarn strength weak ring can be reduced; and production efficiency and economic benefits can be improved.

Owner:江苏圣蓝科技有限公司

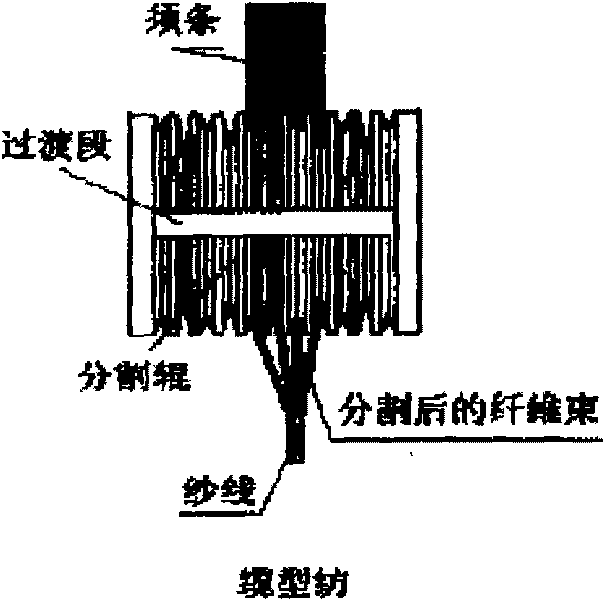

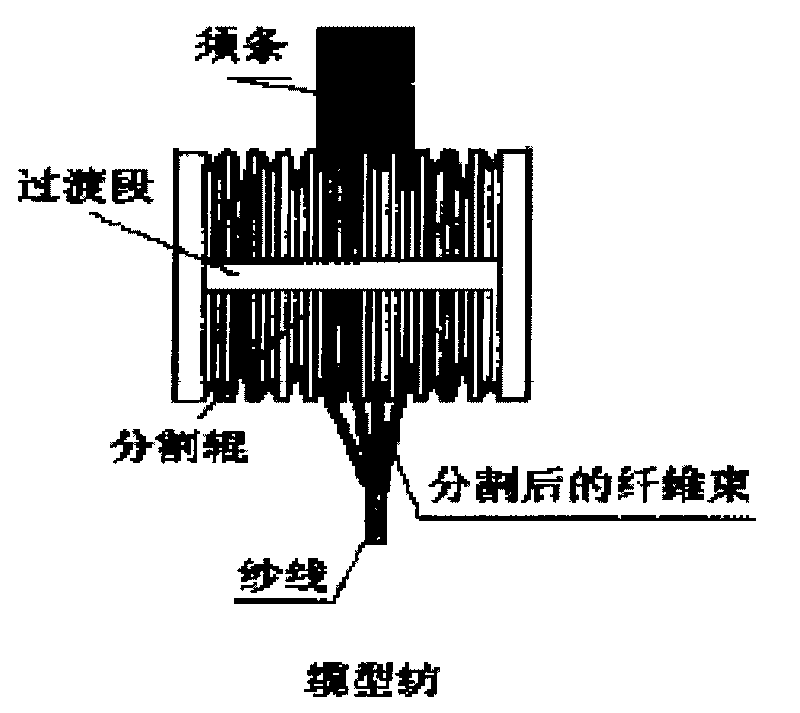

Polysulphonamide fiber cable type spinning method

The invention belongs to spinning technologies and relates to a polysulphonamide fiber cable type spinning method. Polysulphonamide fiber has high volume specific resistance, high initial modulus, low friction factor and low crimp stability, thereby being unfavorable to spinning, weaving, dyeing and the like of the fiber, and the adoption of the traditional spinning technology has the disadvantages of difficult yarn formation, high yarn hairiness and influence on yarn quality. The polysulphonamide fiber cable type spinning method comprises the following steps: using a separating roller for separating a strand into more than two shares of fiber bundles when being discharged from a front jaw of a spinning frame; leading the fiber bundles after separation to enter into a separating slot under the action of spinning tension; leading the fiber bundles in the separating slot to rotate around the twisting center under the action of spinning twisting force; and leading the fiber bundles with a certain twist to move downwards along with the winding of a yarn, and leading all the fiber bundles to converge at one point and carry out the rotary motion around the twisting center of the whole yarn, thereby forming a cable type spun yarn. The polysulphonamide fiber cable type spinning method has the advantages that the polysulphonamide fiber cable type spun single yarn has low hairiness and high single yarn strength; and the elongation at break of the single yarn is small.

Owner:SHANGHAI UNIV OF ENG SCI

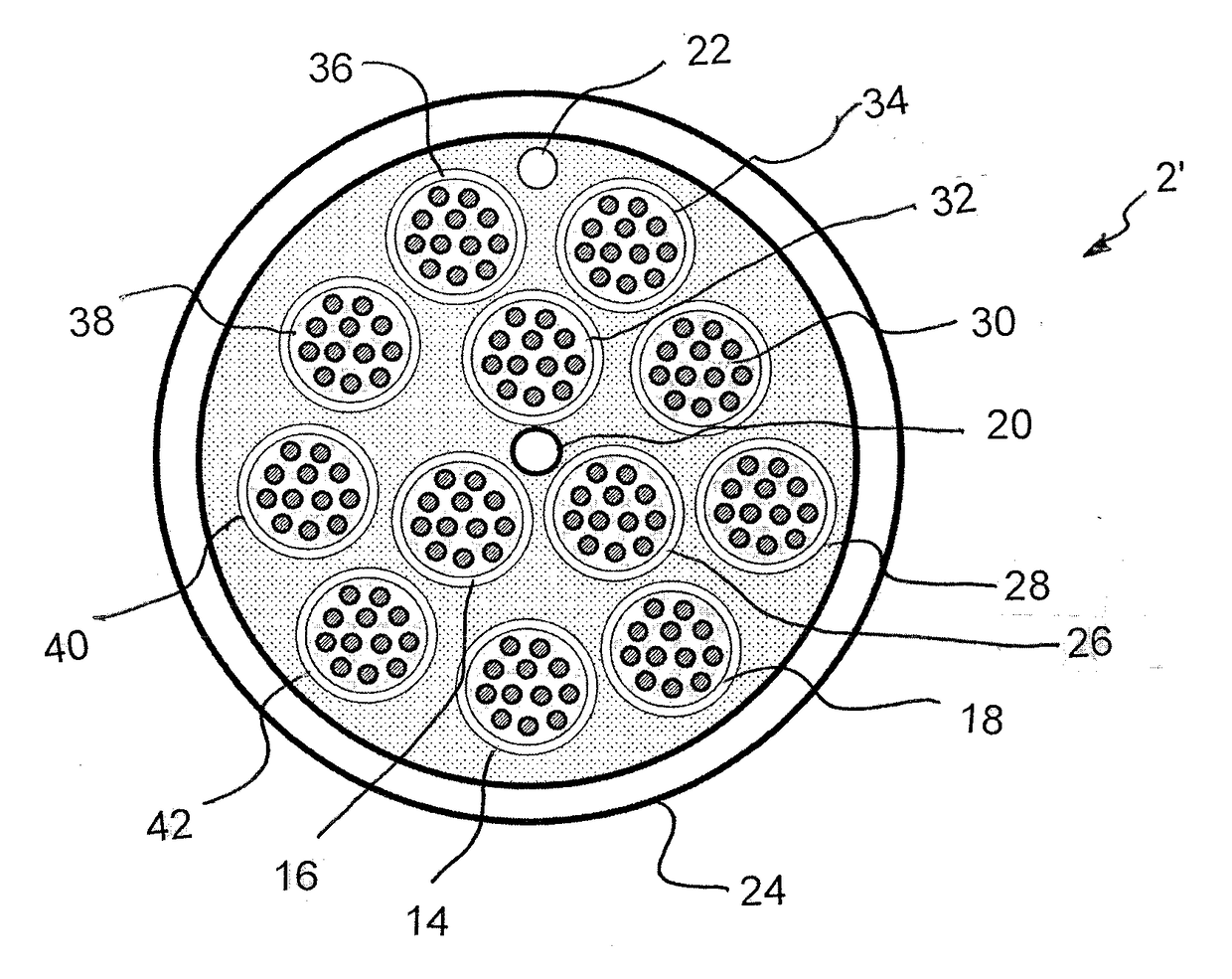

Small form factor flame resistant low smoke halogen free fiber optic cable

ActiveUS20170192189A1Minimizes shrinkageAvoid high optical attenuation and optical lossFibre mechanical structuresBundled fibre light guideSmall form factorFlexural modulus

A fiber optic cable which comprises at least one subassembly. Each subassembly comprises 1 to 12 optical fibers, a plurality of yarn strength members free halogens, and a first jacket free of any halogens and having a thickness of between about 0.254 to about 0.305 mm. The first jacket surrounds and completely encases the 1 to 12 optical fibers and the plurality of yarn strength members to form the subassembly. The first jacket is manufactured from a material which has a limiting oxygen index (LOI) of at least 40 and a shrinkage of the first jacket being no greater than about 3.5%. The fiber optic cable has a crush resistance of at least 35 N / cm, allows less than a 0.4 db / km increase of optical attenuation from −20 to 70 C and meets requirements according to each of IEC 60332-3-24 (Flame Spread), IEC 61034-2 (Low smoke), and IEC 60754-1&2 (non-Halogen); and the fiber optic cable has a flexural modulus of about 40,000 psi.

Owner:PROTERIAL CABLE AMERICA INC

High-count high-density cotton-nylon double-layer cloth and weaving process thereof

The invention relates to high-count high-density cotton-nylon double-layer cloth and a weaving process thereof. Warps are made with high-count combed all-cotton 9.7tex compact-spun yarns; wefts are made with all-cotton 58.3tex-7.8tex covered spandex yarns and 4.4tex-2.2tex nylon filament spandex covered yarns, and 11.1tex-4.4tex nylon filament spandex covered yarns according to the ratio of 1:1:1, in a weft-backed weave structure of 2 / 2 twill and eight irregular stains. The components and ratio of environment-friendly size which has good mobility, soft coat and fitting hairs is adopted for sizing in weaving; low pressure, maceration and coating are balanced for sizing; accordingly, yarn strength increase, friction decrease and elongation retention are achieved, and leasing difficulty and dent impact are avoided. a high-elastic reed is used in weaving, a loom is controlled to open in advance and close late, stable and reasonable pressure and weaving pressure are provided, the height of a back rest and a drop rack is decreased, balance of the back rest is decreased, weaving defects are fewer, filaments of different specifications are added to the weft-wise front, all-cotton spandex covered yarns are added to the weft-wise rear, and the double-layer weave is constructed with different basic weaves. The high-count high-density cotton-nylon double-layer cloth has the advantages that the cloth cover is thick and elegant with cross bands hidden in the diagonal direction, the cloth is more three dimensional, free of wrinkle and hair and comfortable to wear and is elastic, weaving machines are more efficient, and energy consumption is low.

Owner:ZHEJIANG XIANGJIA TEXTILE

Spinning process for superfine wool

The invention relates to a spinning process for superfine wool, which comprises the following production steps: producing the superfine wool with the fineness of between 13.0 and 14.5 mu m into rove through a pre-spinning process, and then producing the rove into high-count wool yarn through a post-spinning process. The spinning process has the advantage that the produced high-count wool yarn has little filoplume, even yarn levelness, smooth yarn and good luster, and can meet the requirements of post production on yarn strength, abrasion resisting property and extensibility.

Owner:JIANGSU SUNSHINE +1

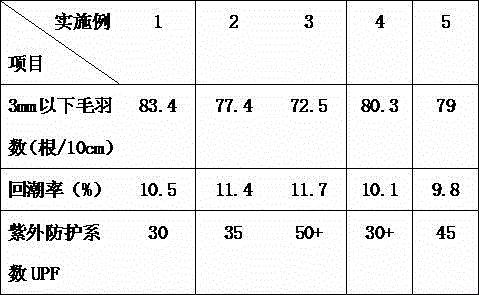

Bacteriostatic wicking anti-ultraviolet bamdal blended yarn and method for manufacturing same

ActiveCN103911707ACircle to hairiness reductionImproved anti-pilling propertiesFilament/thread formingYarnPolymer scienceCarding

The invention discloses a bacteriostatic wicking anti-ultraviolet bamdal blended yarn. Bamdal fibers and wicking anti-ultraviolet ultra-spun cotton are blended with one another to form the bacteriostatic wicking anti-ultraviolet bamdal blended yarn, the bamdal fibers account for 30-50% of the weight of a main yarn, wicking anti-ultraviolet ultra-spun cotton fibers account for 50-70% of the weight of the main yarn, the cross section of each wicking anti-ultraviolet ultra-spun cotton fiber is crossed, and nanometer-sized titanium dioxide powder is added into the yarn in spinning procedures; the yarn is spun via blowing, carding, drawing, roving and spinning procedures. The bacteriostatic wicking anti-ultraviolet bamdal blended yarn has the advantages that the yarn has an anti-ultraviolet function and is excellent in wicking property and breathability, a quick wicking effect can be realized by a fabric made of the yarn, and a wearer can wear the fabric comfortably; technological parameters of the carding, drawing, roving and spinning procedures can be reasonably adjusted, so that yarn hairiness of the resultant yarn can be reduced, and the yarn strength and the anti-pilling performance of the fabric can be improved.

Owner:RUGAO CITY DINGYAN TEXTILE

Colored yarn quality detection method

ActiveCN103808912AGood and even dyeing effectSoft and comfortable feelColor measuring devicesTextile testingEngineeringYarn strength

The invention provides a colored yarn quality detection method; according to the method, the strength, shade and color fastness of colored yarn, the weaving effect and the color aberration of three layers of inner, middle and outer layers of yarn on cones are detected for determining if the dyeing effect of the colored yarn achieves production standards and meets follow-up production requirements, the production standards of the colored yarn are completely detected, the high accuracy of detection effect of each aspect can be ensured by the detection mode, the colored yarn which does not meet the production requirements can be effectively removed, single yarn strength detection of the colored yarn can ensure that the yarn has enough strength, shade and color fastness, the detection of the color aberration of the three layers of inner, middle and outer layers of the yarn on cones can ensure that the colored yarn has a good and uniform dyeing effect, and the detection of the weaving effect can ensure that a fabric knitted by the dyed colored yarn is soft and comfortable in hand feeling.

Owner:WUHU FUCHUN DYEING & WEAVING

Weaving method of cotton-vinylon blended hollow yarn home textile fabrics

InactiveCN109208146AImprove maintenance effectGood yarn strengthDry-cleaning apparatus for textilesMonocomponent synthetic polymer artificial filamentEngineeringSlurry

The invention relates to a weaving method of cotton-vinylon blended hollow yarn home textile fabrics. The method comprises steps of 1) of water-soluble polyvinyl alcohol spinning, the polyvinyl alcohol is spun through a dry spinning method, the polyvinyl alcohol solution with the concentration of 30-40% is made to flow through a spinning device and is pressed into a hot air passage from small holes of a spinning jet, and the hot air is utilized to evaporate the water of the polyvinyl alcohol solution so that the polyvinyl alcohol solution is made to coagulate into filament fiber in fine flow;2) of spinning of core-spun yarns; 3) of weaving, pure cotton yarns and the core-spun yarns obtained in the 2) are subjected to sizing at the temperature of 50-75 DEG C, and the fabrics are woven at intervals; and 4) of desizing and vinylon-dissolving, the fabrics obtained in the 3) are simultaneously subjected to desizing and vinylon-dissolving, the desizing liquid is kept for 30-45 minutes at the temperature of 90-98 DEG C, and the fabrics after complete desizing and vinylon-dissolving are obtained. The weaving method is advantaged in that good vinylon-dissolving of the core-spun yarns and high yarn strength in the weaving process are achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com