Low-twist high-strength yarn and spinning technology thereof

A high-strength, high-tech technology, applied to spinning machines, continuous winding spinning machines, yarns, etc., can solve problems affecting yarn quality, twist transmission loss, etc., to improve variety adaptability, high pass rate, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

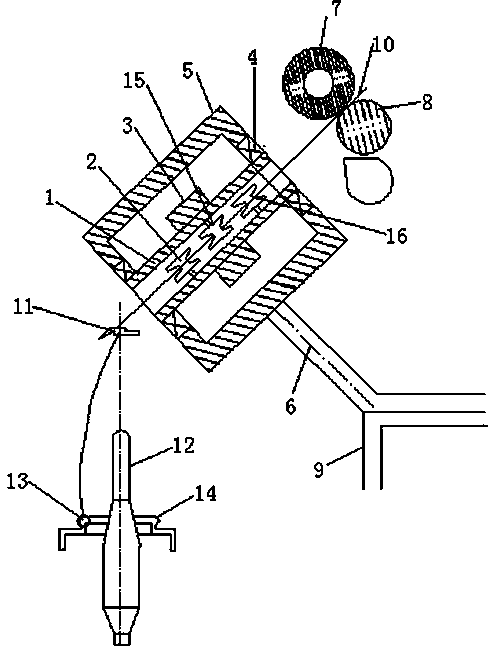

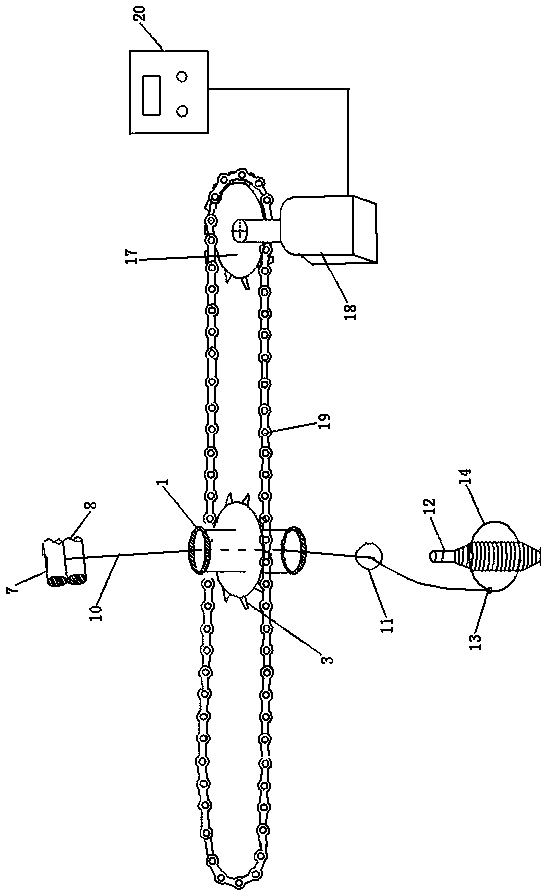

[0020] 1. Spinning false twisting device and its installation structure:

[0021] like figure 1 , 2 As shown, when the present invention spun yarn, the support 5 of the false twisting device is fixed on the yarn guide plate 9 through the connector 6 .

[0022] A cylindrical barrel 1 is supported on a bracket 5 through a pair of bearings 4 .

[0023] The driven gear 3 is coaxially fixedly connected outside the cylinder body 1, and three pulleys 16, 15, 2 are respectively arranged through the support shaft along the length direction of the cylinder body 1 in the cylinder body 1, and the axial directions of each pulley are parallel to each other and parallel to the cylinder body 1 are perpendicular to each other. The inner diameter of the cylinder 1 is 10-15mm, the length is 60-65mm, the axial distance between adjacent pulleys is 20-25mm, the distance between the pulley 16 and the port of the cylinder 1 is 5-10mm, the distance between the pulley 2 and the cylinder The distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com