Patents

Literature

382results about How to "Easy production control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

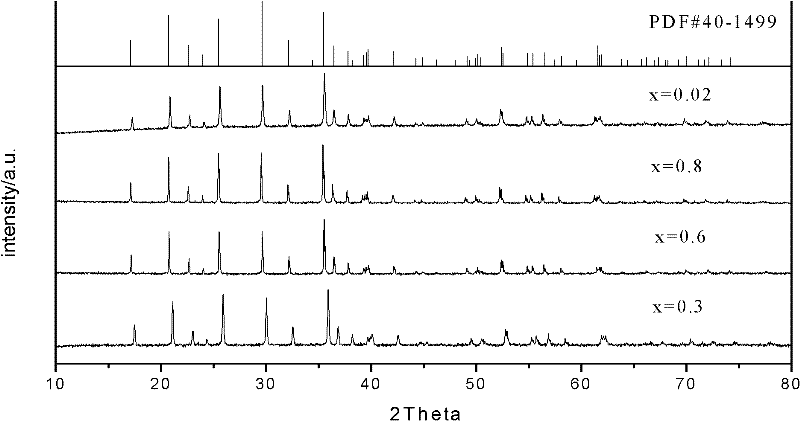

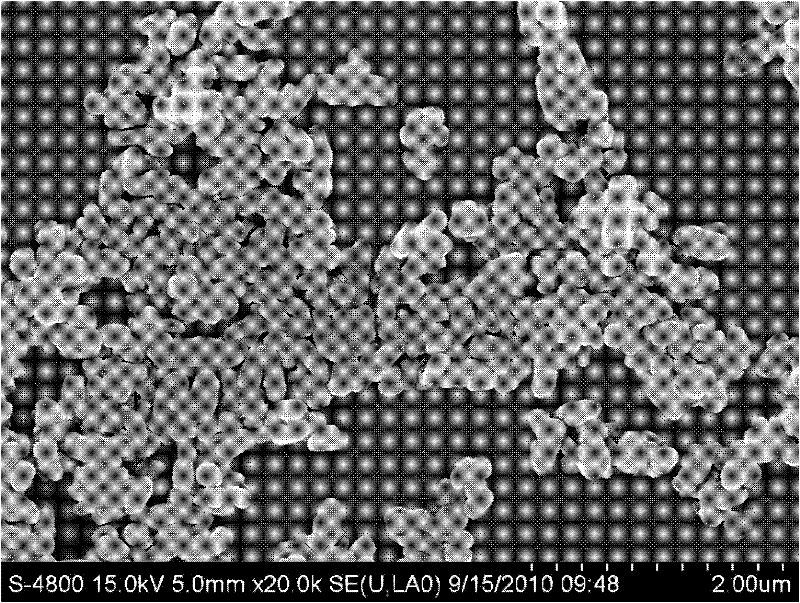

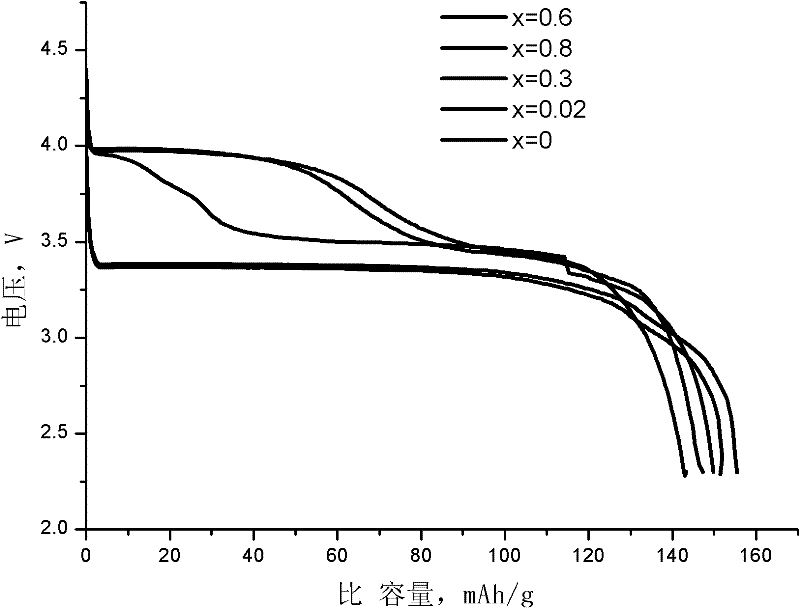

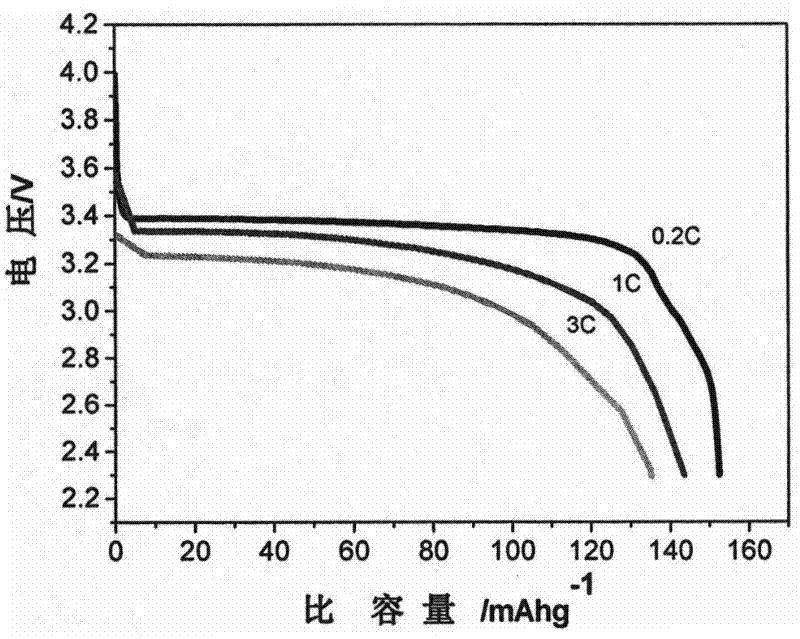

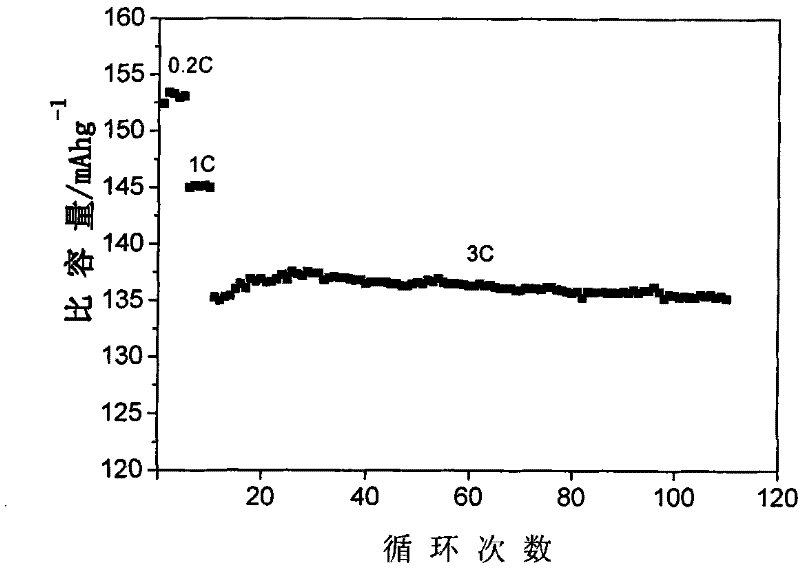

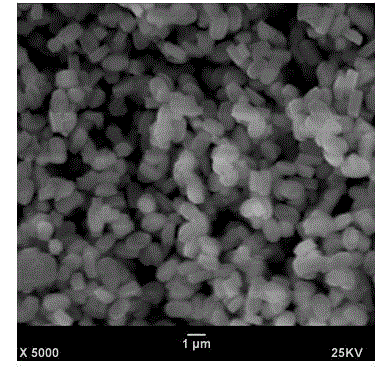

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

Method for catalyzing cyclone oxide to synthesizing lactone by using nano magnesium-base catalyst

InactiveCN101186601AHigh catalytic activityHigh selectivityPhysical/chemical process catalystsOrganic chemistryCyclohexanoneCatalytic oxidation

The invention relates to chemical technical field, in particular to a method for using magnesia catalyst to catalyze and oxidize cyclone to synthesize lactone. The invention uses some nanometer sheet magnesia compound as catalyst, uses mixture of cyanobenzene and 1, 4-dioxane at a certain proportion as solvent, at a special reaction temperature, to catalyze and oxidize cyclone to synthesize lactone compound. The invention uses commercial cyclopentanone, cyclohexanone and adamantaneketone as raw materials, at mild condition, to reach the total yield of lactone compound more than 90%. The invention uses hydrogen dioxide water solution as oxidant, to eliminate the environment pollution of traditional oxidation process as peroxyacid, to realize environment-friend catalysis conversion. The invention has low cost, which can be used for industrialized lactone compound production.

Owner:FUDAN UNIV

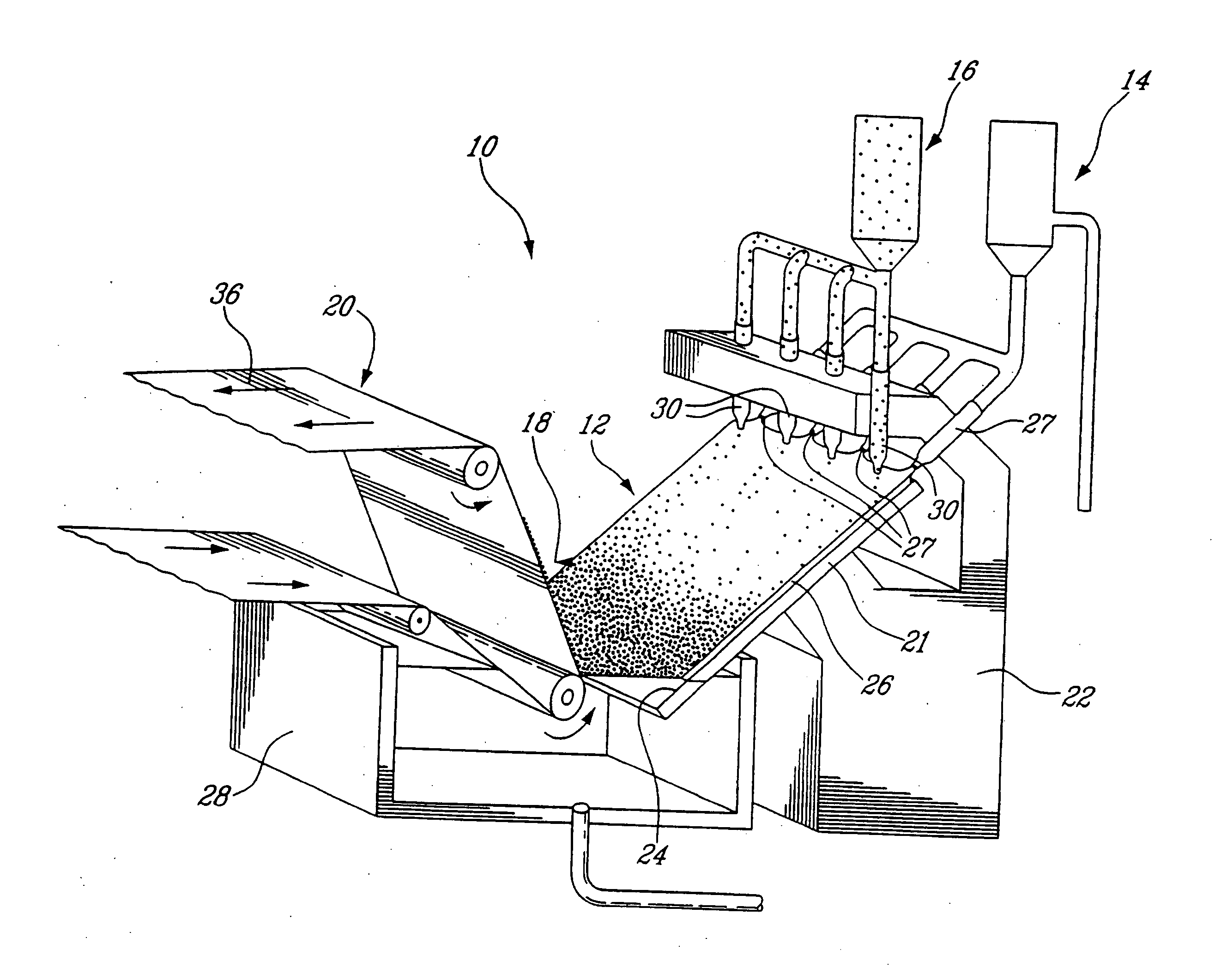

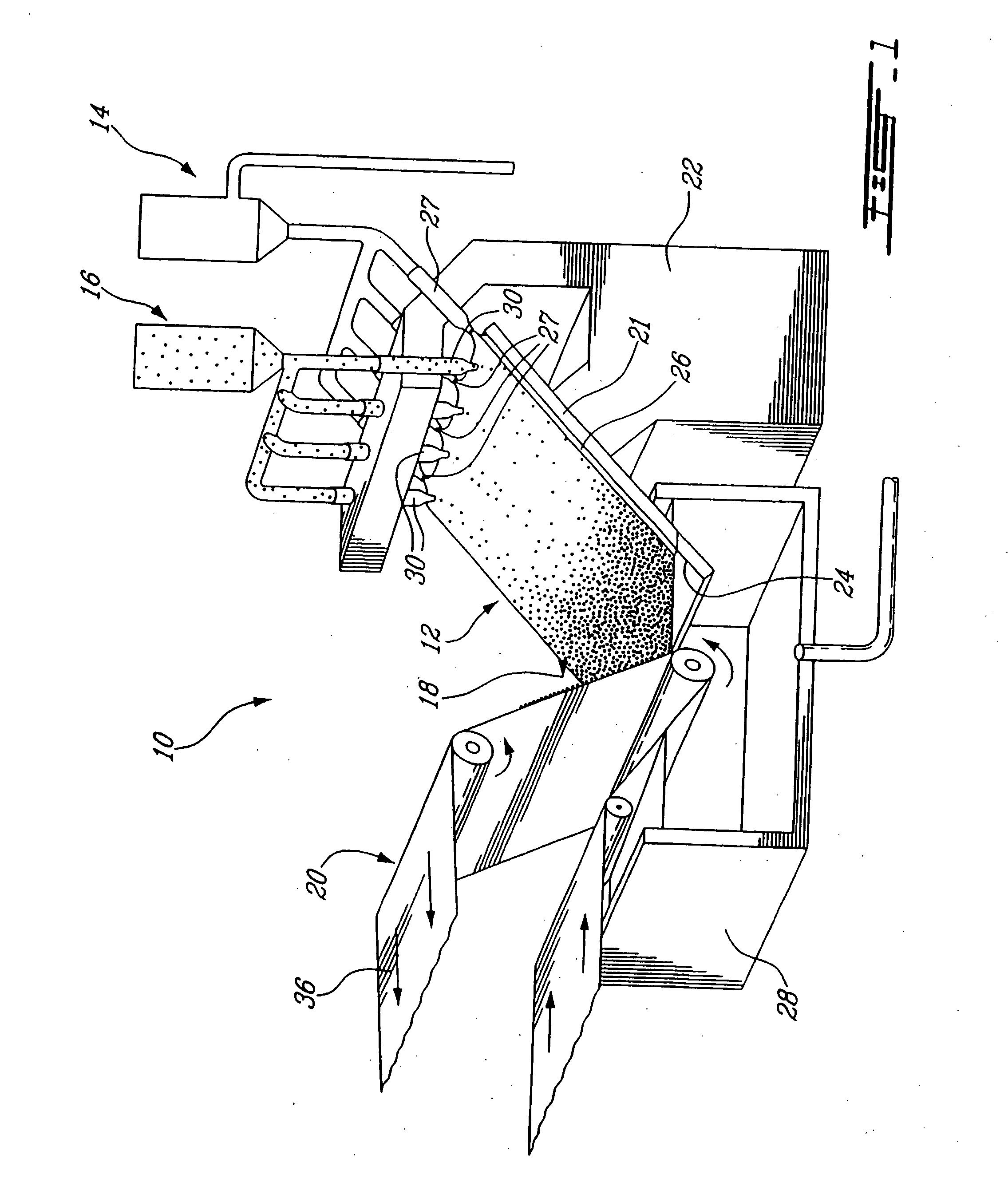

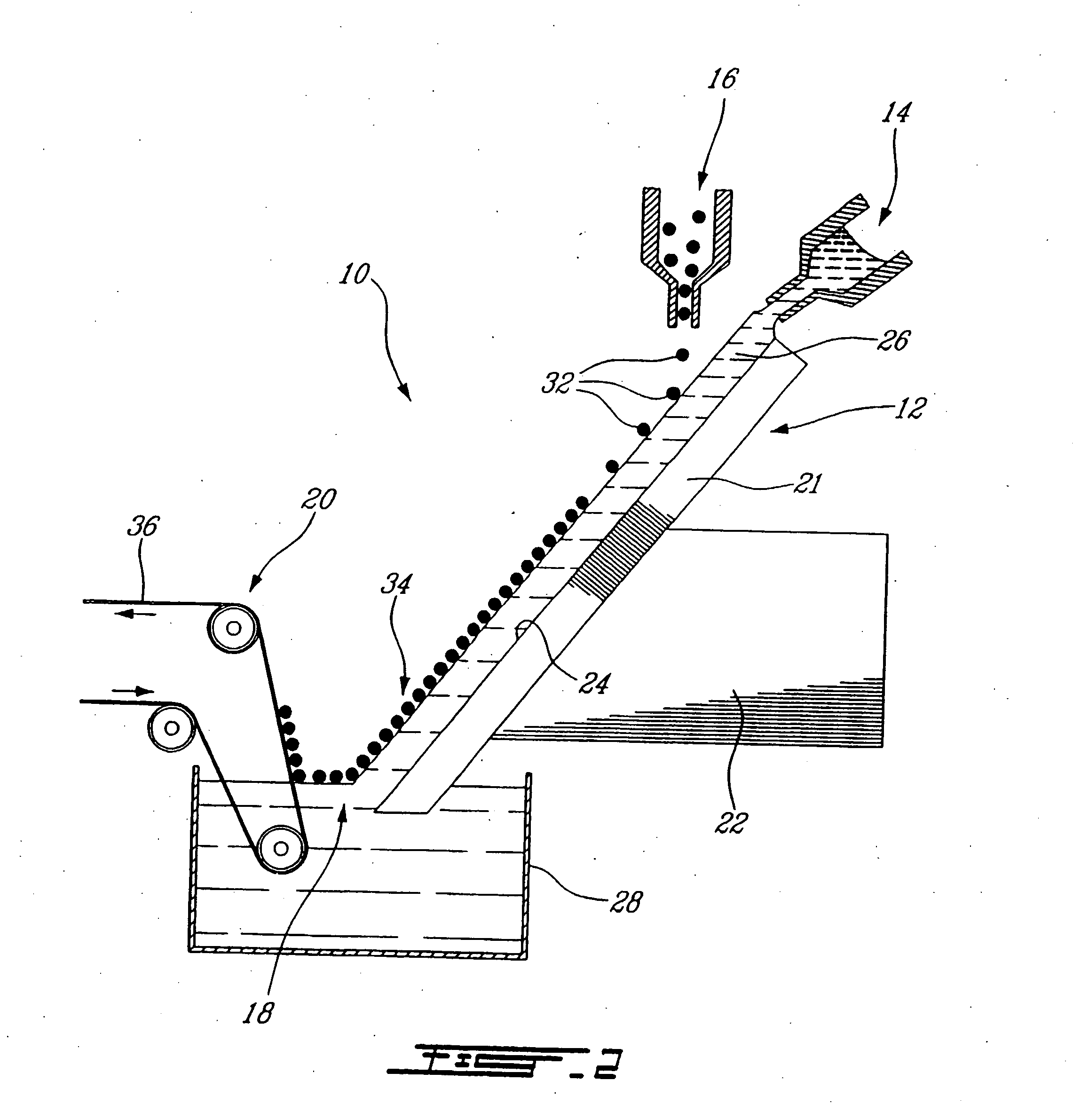

Method and apparatus for two dimensional assembly of particles

InactiveUS20050129867A1Provide flexibilityEasy production controlSemi-permeable membranesLiquid surface applicatorsThin layerEngineering

A method and an apparatus (10) for making thin layers from particles, wherein the particles are deposited on a carrier fluid flowing by gravity along a ramp (12) leading to a dam (18). The particles are held back at the bottom of the ramp (12), thereby causing the particles to be piled up one against the other in a monolayer configuration.

Owner:VERSATILIS

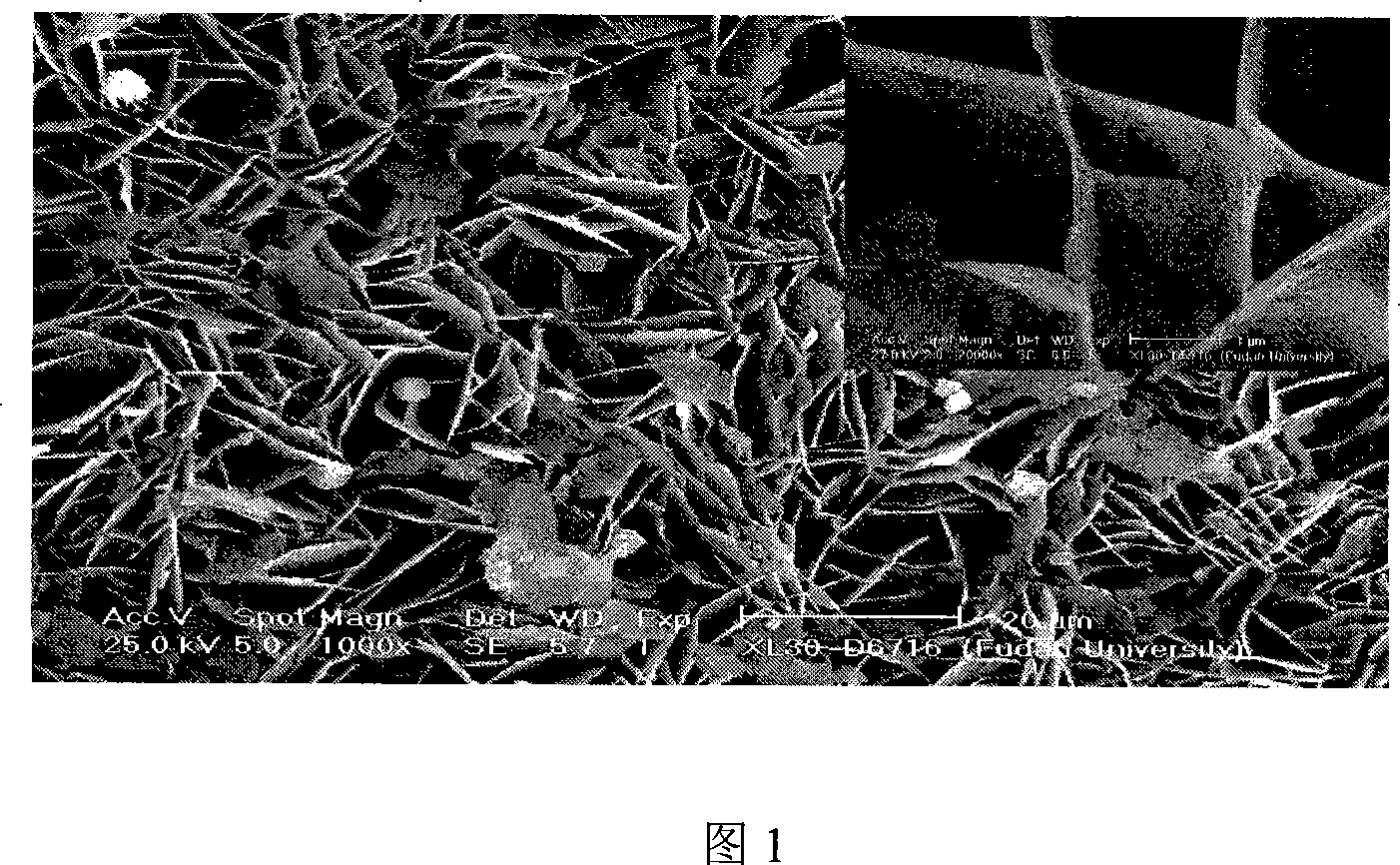

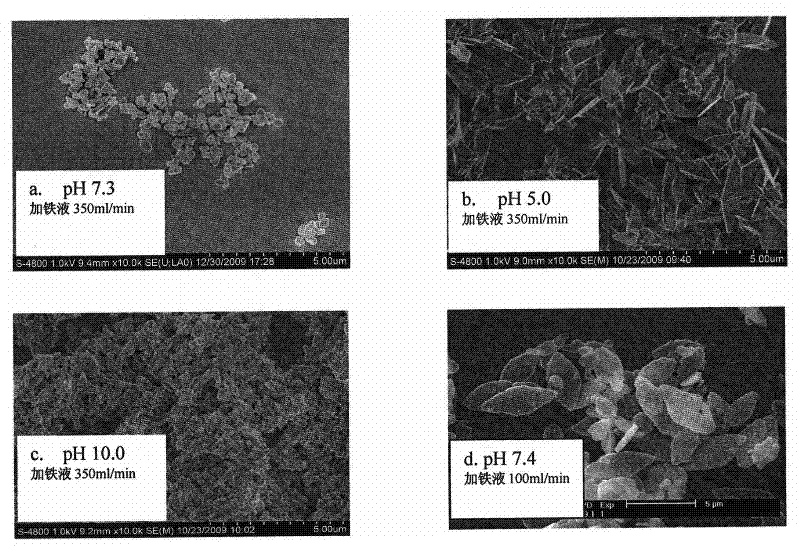

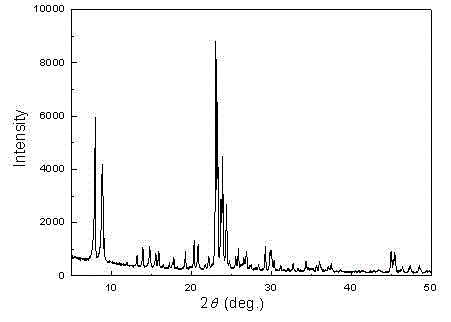

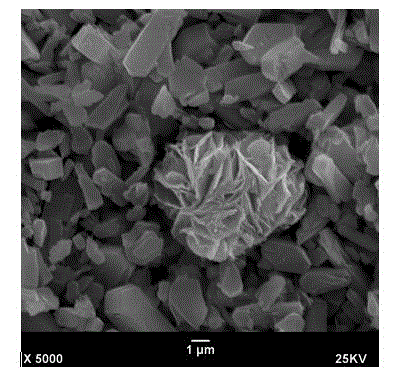

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

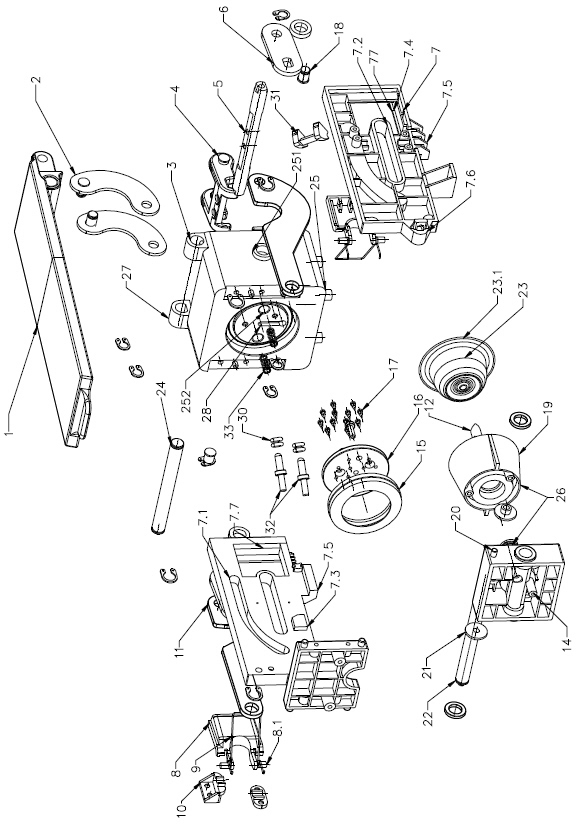

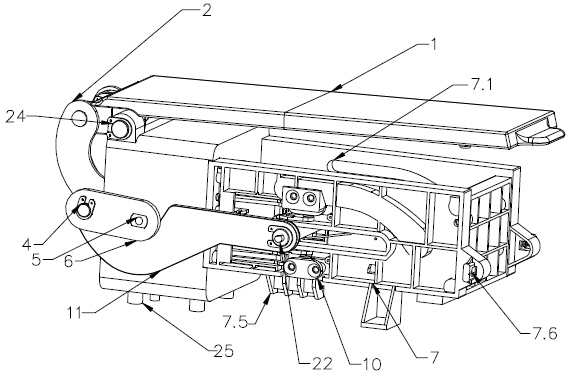

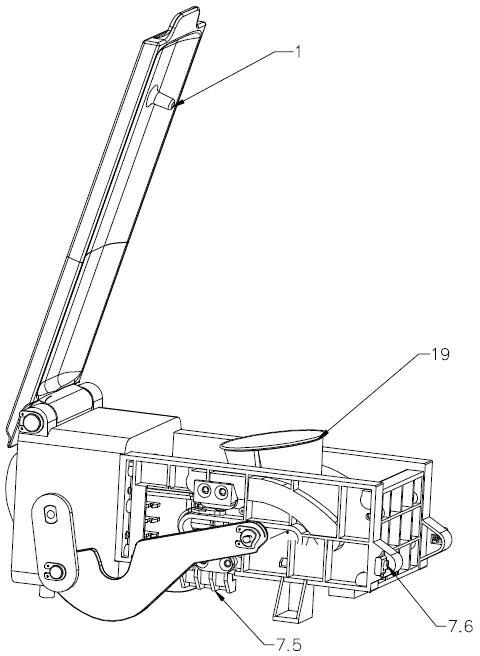

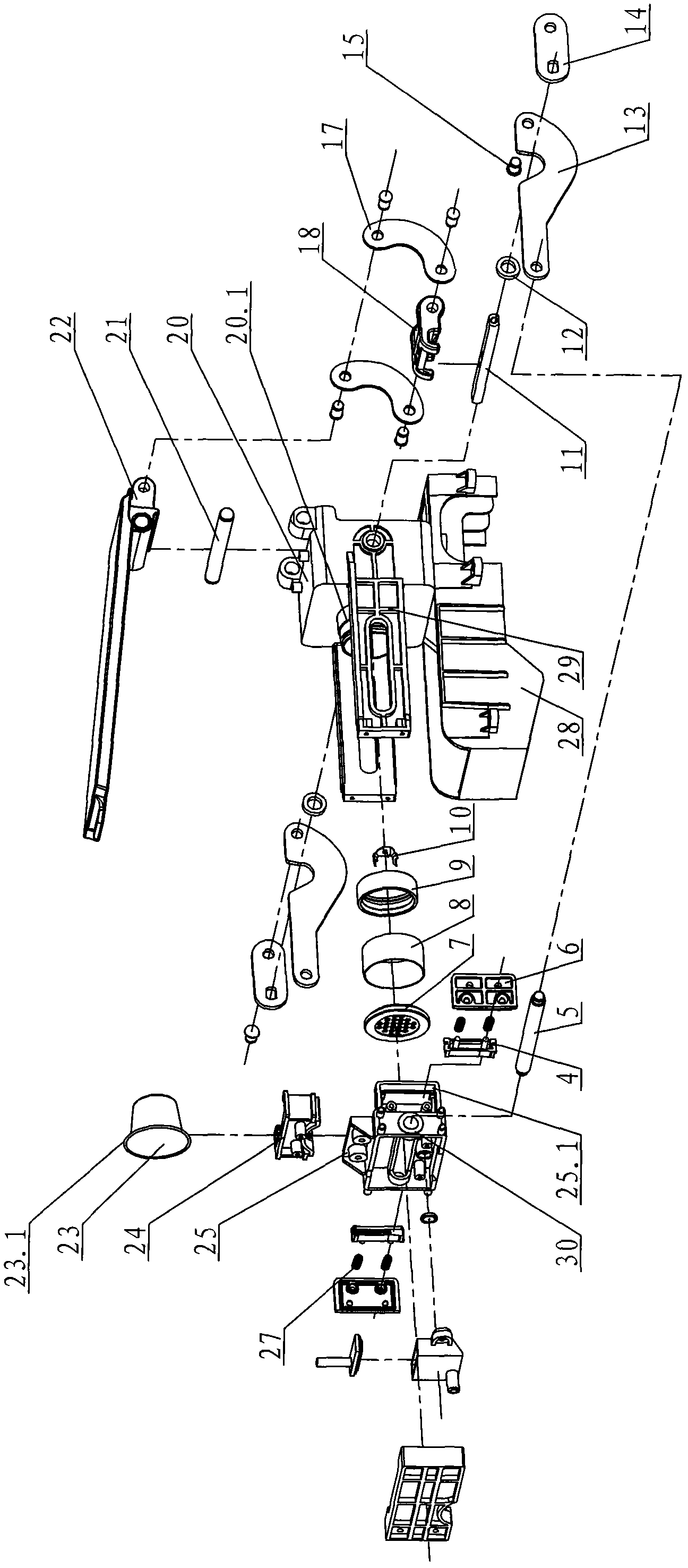

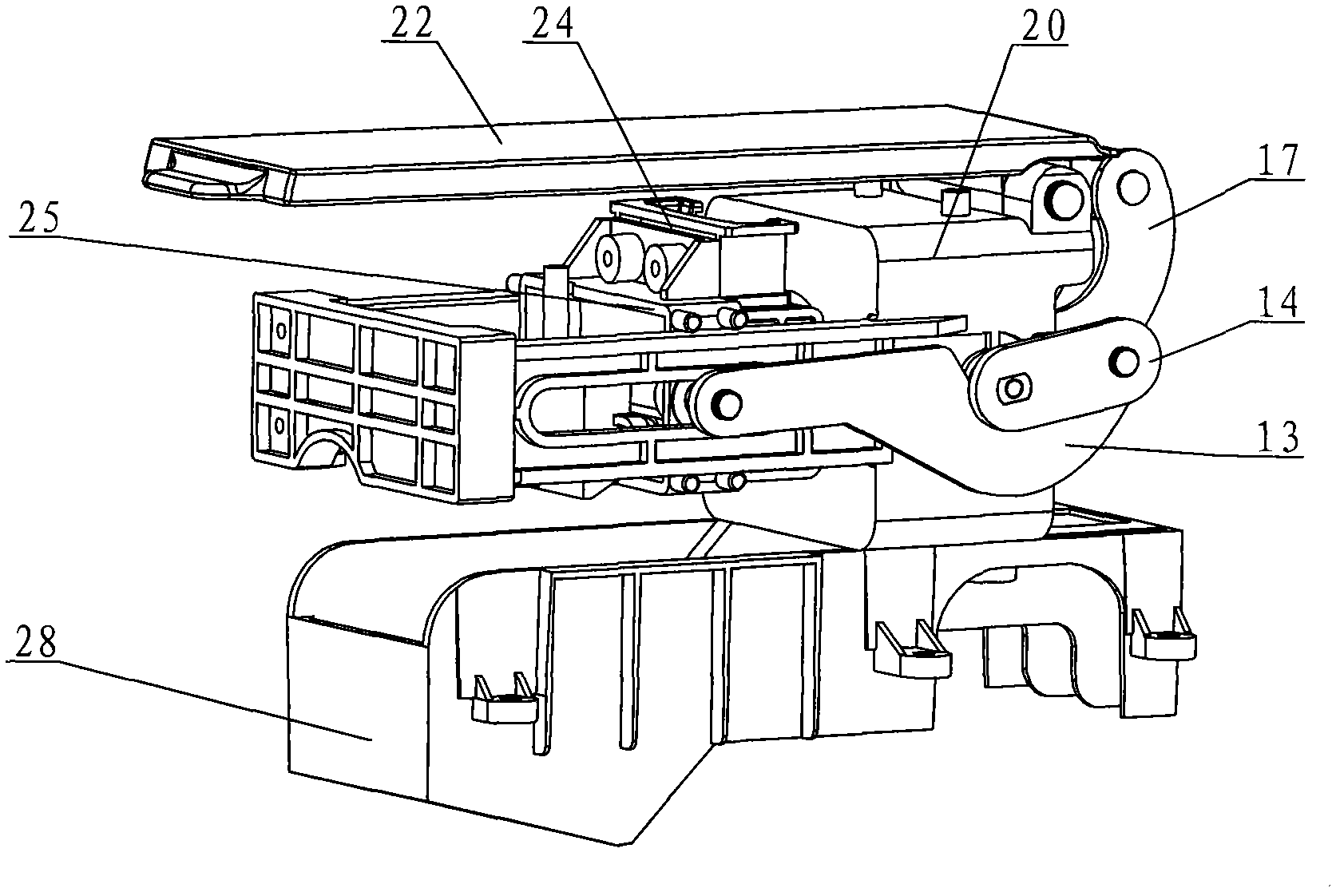

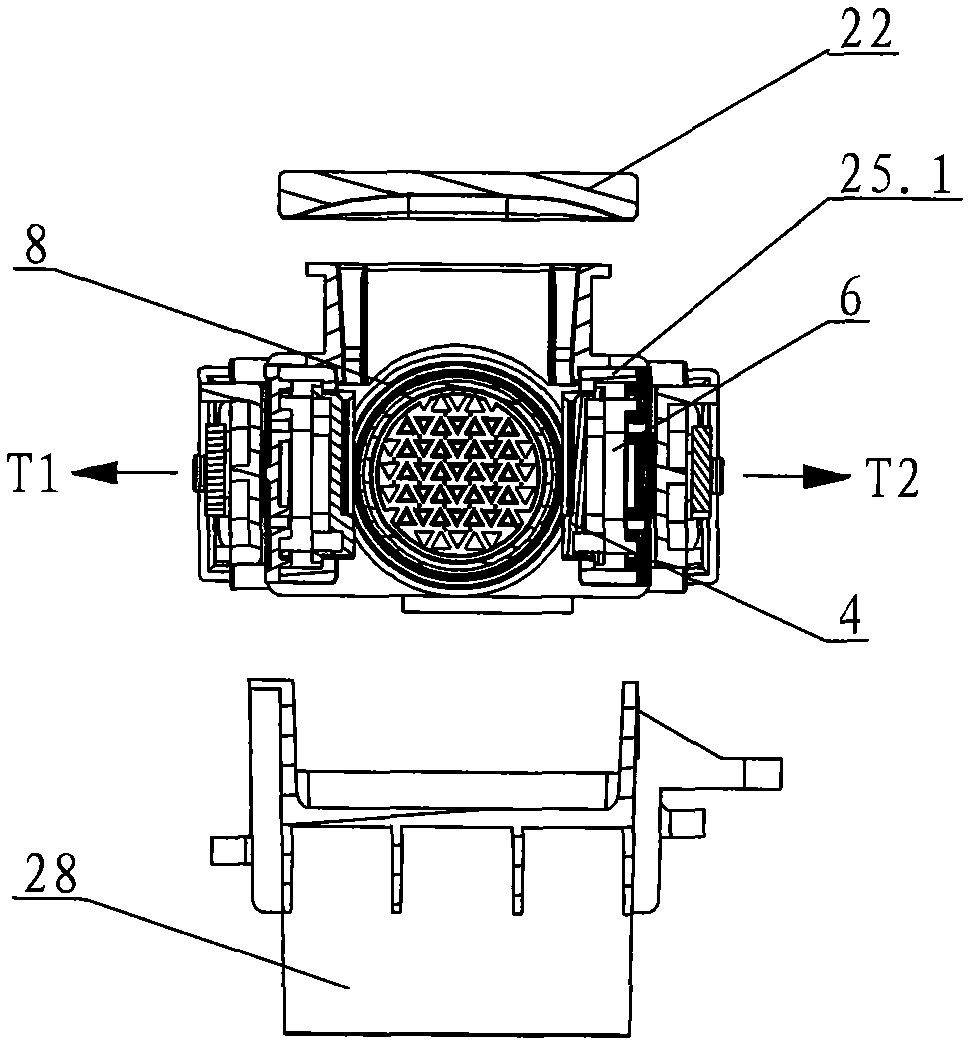

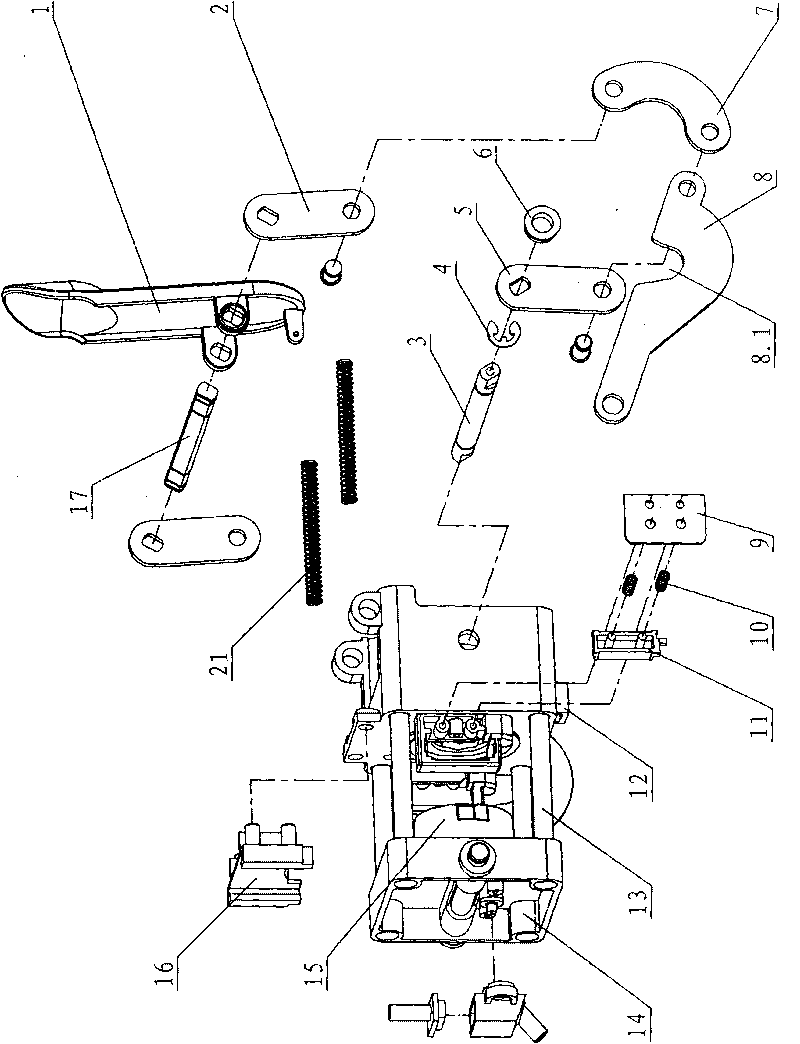

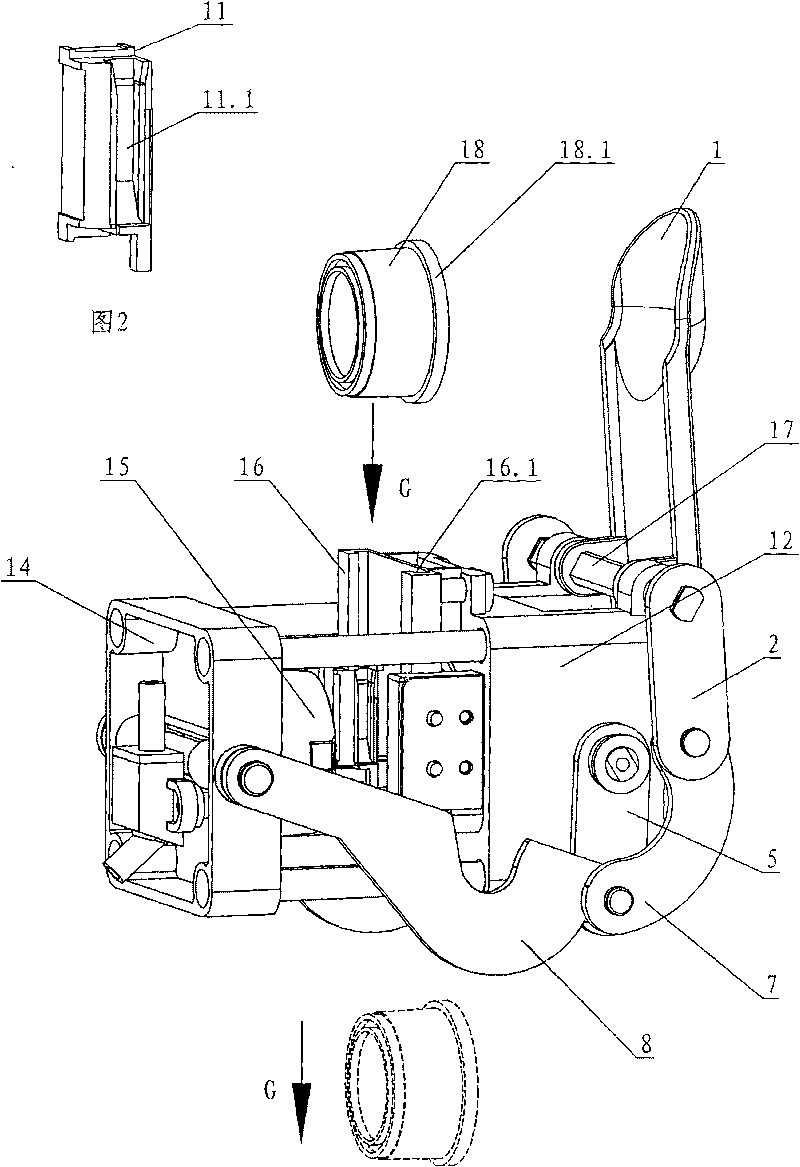

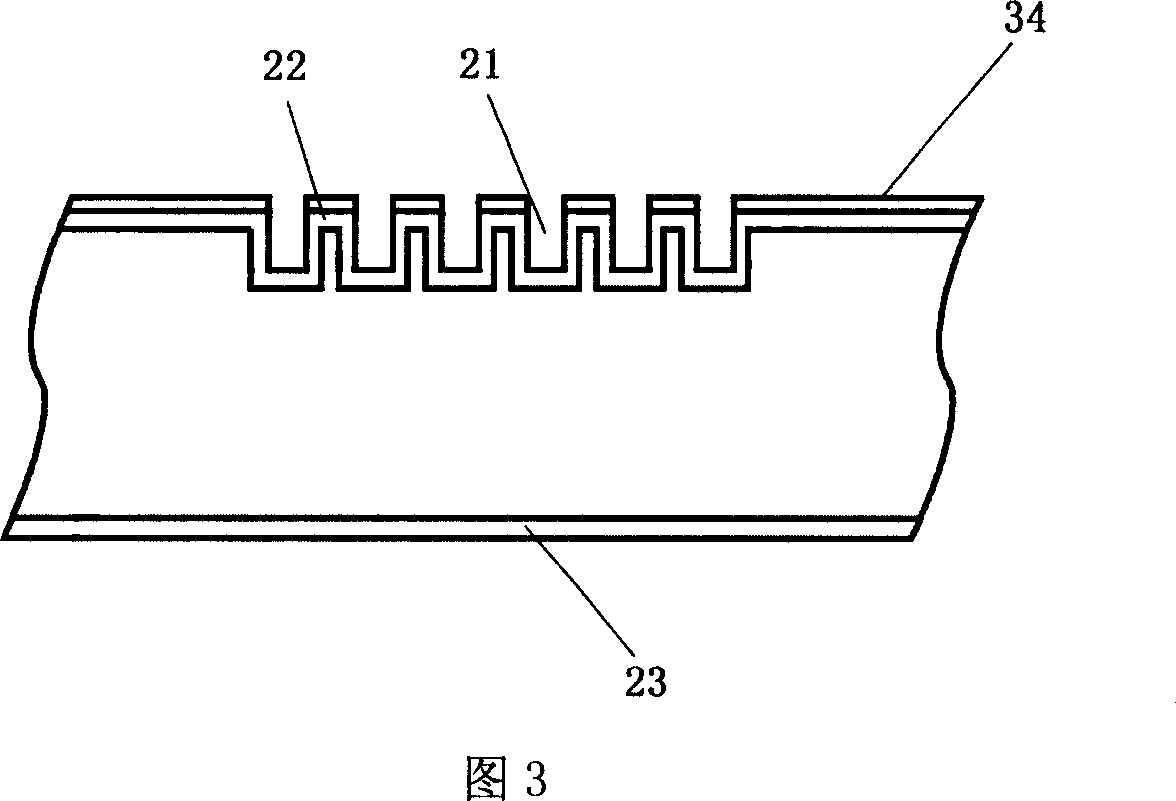

Drink extraction mechanism

ActiveCN102429582ASmooth and automatic fall offEasy to operateBeverage vesselsEngineeringMechanical engineering

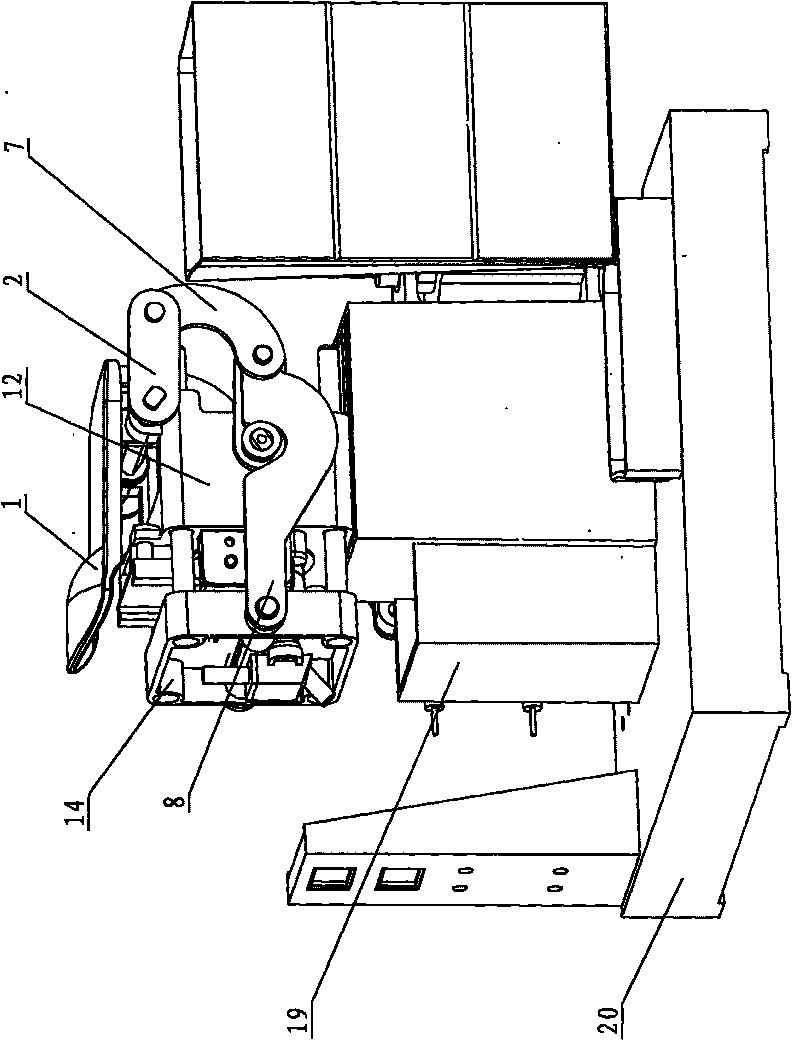

The invention relates to a drink extraction mechanism, which comprises a drink brewing mechanism (26) assembled on a brewing base (25) and a driving mechanism (27) for driving the drink brewing mechanism (26) to be opened, closed and turned; the drink extraction mechanism is characterized in that the driving mechanism (27) is guided by a motion guide mechanism (7) to drive the drink brewing mechanism (26) to be opened, closed and turned; furthermore, when the drink brewing mechanism (26) is opened and closed, the opening part of a brewing cavity is upward or inclined upwardly; and the driving mechanism (27) is also connected to a pushing mechanism, which is used for ejecting out a capsule (23) still adsorbed on the brewing base (25) after coffee is brewed and boiled by the dink brewing mechanism (26) and the brewing cavity (19) in the dink brewing mechanism (26) is gradually separated from the coffee capsule (23). Tshe drink extraction mechanism disclosed by the invention is simple and rational in structure, more convenient for holding capsules, high in safety degree and more reliable in performance.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

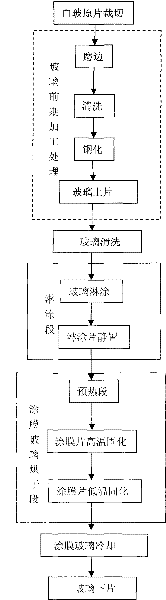

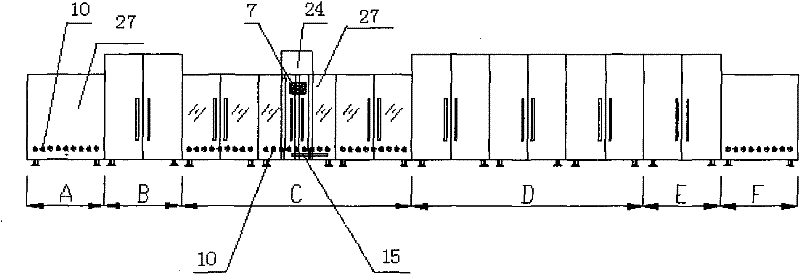

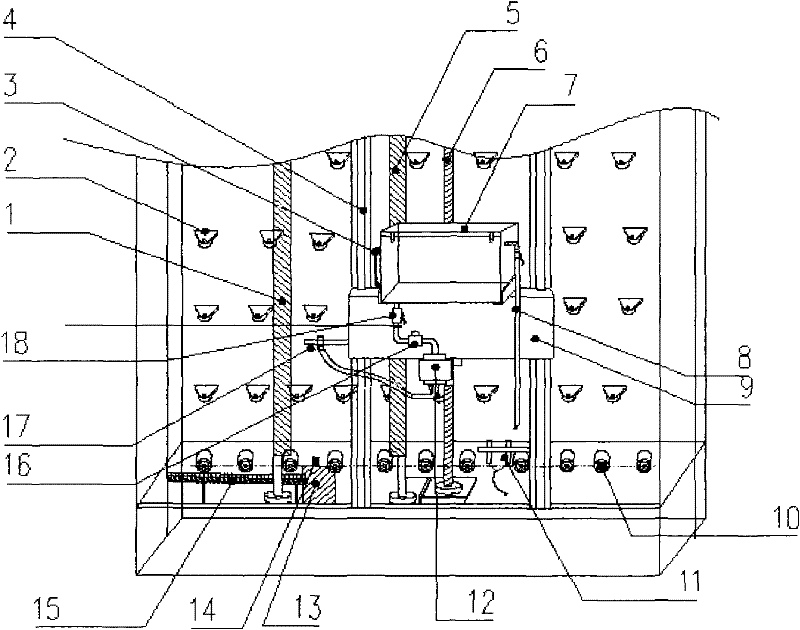

Process and device for coating film on glass

The invention discloses a process and device for coating a film on glass. Glass film coating processing process flow steps include an earlier stage glass treatment procedure, a glass sheet loading procedure, a glass cleaning procedure, a spraying section procedure, a film-coated glass drying section procedure, a film-coated glass cooling procedure and a glass sheet unloading procedure. The entire glass film coating processing device designed by the invention consists of a sheet loading section (A), a cleaning section (B), spraying section (C), a drying section (D), a cooling section (E) and a sheet unloading section (F), wherein the bottom end of a glass support frame (27) is provided with a plurality of drying wheels (10) which are driven to bear and move glass sheets by using a controlled servo motor (23); and a spraying device in the spraying section (C) mainly comprises the glass support frame (27), a front storage box (7), an upper sealing cover at the spraying position of a coating recovering groove (15), and the like. Due to the adoption of the process and the device, the glass film coating quality is ensured, and the problem that the treatment requirement of surface coating on glass with a low-viscosity coating is difficult to meet is solved.

Owner:BEIJING BUILDING TECH DEV +1

Method for processing high-moisture fresh cooked noodles

InactiveCN104543775AExtended shelf lifeFresh tasteFood preservationFood preparationPreservativeEdible oil

The invention discloses a method for processing high-moisture fresh cooked noodles. Any preservative or additive is not added, and according to multiple production processes comprising vacuum dough mixing, cooking, spraying edible oil, performing vacuum packaging under sterile conditions, and performing intermittent microwave sterilization and high-temperature wet heat sterilization, the high-moisture fresh cooked noodles with the moisture content of 60 percent and the storage period of over 45 days are made. In the preparation of the high-moisture fresh cooked noodles disclosed by the invention, a process of sequentially steaming and cooking is used, and the edible oil is sprayed to the surfaces of the noodles, so that a denatured protein protective film is formed on the noodle surface and is uniformly coated on the noodle surface, and moisture loss in the fresh cooked noodles is effectively avoided; the fresh cooked noodles have chewiness and elastic mouthfeel; and moreover, the noodles are not adhered to one another, and the original shape of the fresh cooked noodles is maintained during long-term storage. The modes of intermittent microwave sterilization and high-temperature wet heat sterilization are combined, so that the quality guarantee period of the fresh cooked noodles is effectively prolonged.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Coffee machine capable of automatically discharging capsule

ActiveCN102028407ASimple structureEasy production controlBeverage vesselsWater dischargeHigh pressure

The invention relates to a coffee machine capable of automatically discharging capsules, comprising a water discharging component for outputting from water and a water charging component which can mutually carry out the open and close movement along a straight line by a driving mechanism, wherein the right side and the left side of the water discharge component are provided with moveable fixture blocks capable of sliding right and left, the water charging component is provided with a brewing chamber component filled with coffee capsules, and the water discharging component is connected with the water charging component in a sliding way by a guide rail. The water discharging component is provided with chute holders corresponding to the movable fixture blocks. The movable fixture blocks are arranged in the chute holders in a sliding way, and the flanges of the movable fixture blocks, which correspond to the coffee capsules, are provided with clamp slots. The brewing chamber component comprises a brewing chamber, and the outside of the brewing chamber is orderly sheathed with a seal ring and a lantern ring. When the water discharging component is separated from the water charging component, the coffee capsules is vertical, and is added into by aligning the fringes of the capsules to the clamp slots of the movable fixture blocks; then high-pressure hot water is added into the brewing chamber, after the brewing is completed, the water discharging component is opened, and the coffee capsules automatically falls off under the action of the right and left fixture blocks and the gravity.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Method for synthesizing ZSM-5 molecular sieve through two-segment temperature change

InactiveCN102745716AHeating evenlyImprove liquidityPentasil aluminosilicate zeoliteMolecular sievePhysical chemistry

The invention relates to a method for synthesizing a ZSM-5 molecular sieve through a two-segment temperature-changing crystallizing process, which comprises the following steps of using a water-soluble liquid silicon source and a water-soluble liquid aluminum source as raw materials, wherein the molar ratios of the raw materials calculated by oxides are as follows: SiO2 / Al2O3=50-70, Na2O / SiO2=0.05-5, H2O / SiO2=50-70, and a template agent / SiO2=0.05-0.4; mixing the silicon source and the template agent according to formula amounts with deionized water which is added by accounting for 15-33.3wt% of the total usage amount of the required water under a dynamic state of overall-process stirring to prepare an A solution, mixing the aluminum source and sulfuric acid according to the formula amounts with the water which is added by accounting for 24-44.4wt% of the total usage amount of the required water to prepare a B solution, slowly adding the B solution into the A solution, adding the residual water, adding ZSM-5 crystal seeds into initial gel which is obtained by stirring the mixture for 0.5-2 hours, crystallizing for 10-20 hours at the temperature of 80-110 DEG C, and then crystallizing for 10-40 hours after increasing the temperature to 115-130 DEG C.

Owner:吉林市品前化工技术开发有限公司

Automatic capsule dropping coffee machine

The invention relates to an automatic capsule dropping coffee machine, which comprises a water outlet assembly and a water inlet assembly which carry out open and close movement mutually along a straight line through a driving mechanism. The water outlet assembly is provided with a brewing cavity for containing a coffee capsule; an inner end of the water inlet assembly is provided with a hot water channel and a one-way valve for brewing the coffee capsule; the surface of the coffee capsule is provided with a flange annularly; the brewing cavity of the coffee capsule is fixedly arranged at an inner end of the water outlet assembly; an opening containing the coffee capsule faces the hot water channel and the one-way value; both left and right sides of the inner end of the water inlet assembly are provided with movable fixture blocks which slide leftwards and rightwards; and the movable fixture blocks are provided with clamping grooves corresponding to the coffee capsule. When the water outlet assembly is separated from the water inlet assembly, the automatic capsule dropping coffee machine enables the coffee capsule to be vertical and the flange of the coffee capsule to be placed aiming at the clamping grooves of the movable fixture blocks; when the flange is in place, the water outlet assembly is closed; the brewing cavity pushes the movable fixture blocks off outwards gradually, and simultaneously the coffee capsule is sleeved in and is pushed to the hot water channel and the one-way value; and after brewing is completed, the water outlet assembly is opened, and the coffee capsule automatically drops off due to the action of gravity.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Method for continuously producing water-soluble monoammonium phosphate by using wet-process phosphoric acid

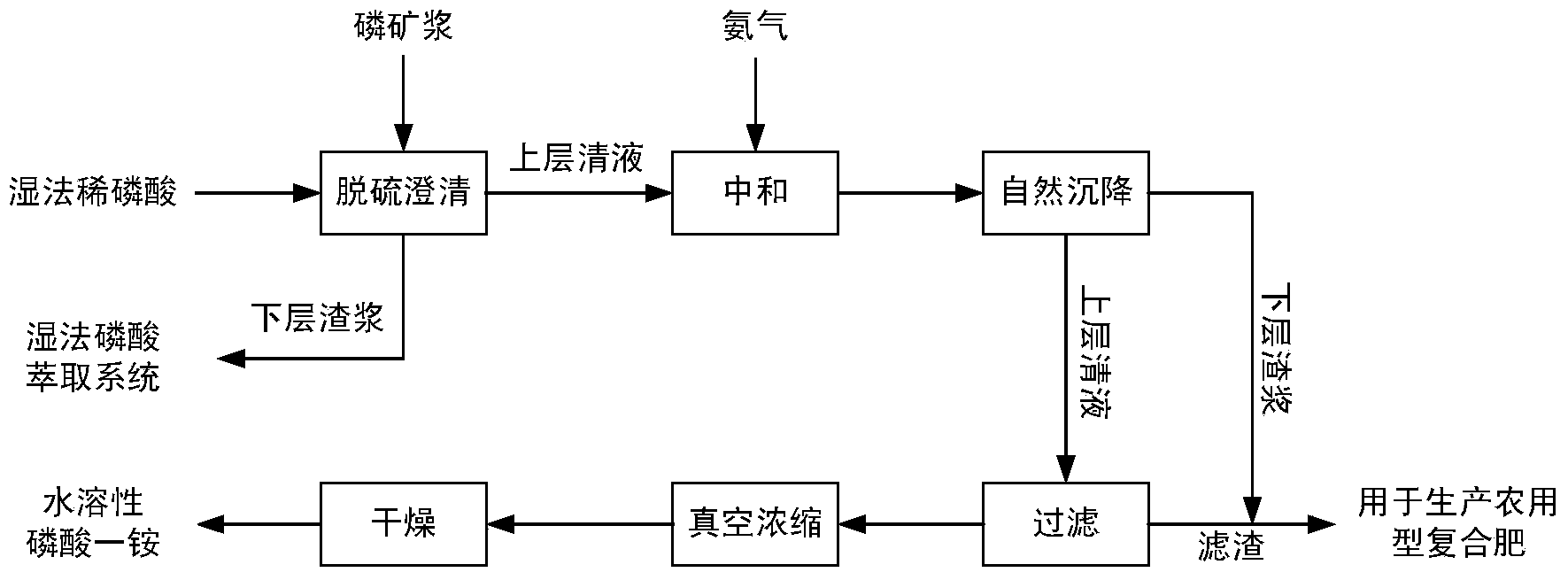

The invention discloses a method for continuously producing water-soluble monoammonium phosphate by using wet-process phosphoric acid. The method comprises the following steps: adding phosphoric ore pulp to wet-process dilute phosphoric acid; after natural sedimentation, carrying out neutralization reaction between clear desulfurated dilute phosphoric acid at the top and ammonia gas, wherein the neutralization degree of slurry is 0.95-1.05; carrying out natural sedimentation of the neutralized slurry in a settlement trough; filtering ammonium phosphate supernatant in a filter; concentrating and drying the obtained supernatant, so as to prepare the water-soluble monoammonium phosphate, wherein a filter cake and filter residue which are obtained after filtering can be used for preparing an agricultural compound fertilizer. According to the method, the problem of a traditional method that corresponding impurity removal depth can be reached by means of improving the neutralization degree of the slurry and carrying out neutralization reaction many times is avoided, neutralization reaction is carried out only once, and operation is facilitated. Meanwhile, the production efficiency is also improved, the obtained water-soluble monoammonium phosphate is good in quality, and the content of insoluble matter is low. In addition, the method is short in technological process and relatively simple in production control and can be put into continuous production easily.

Owner:云南云天化国际化工有限公司

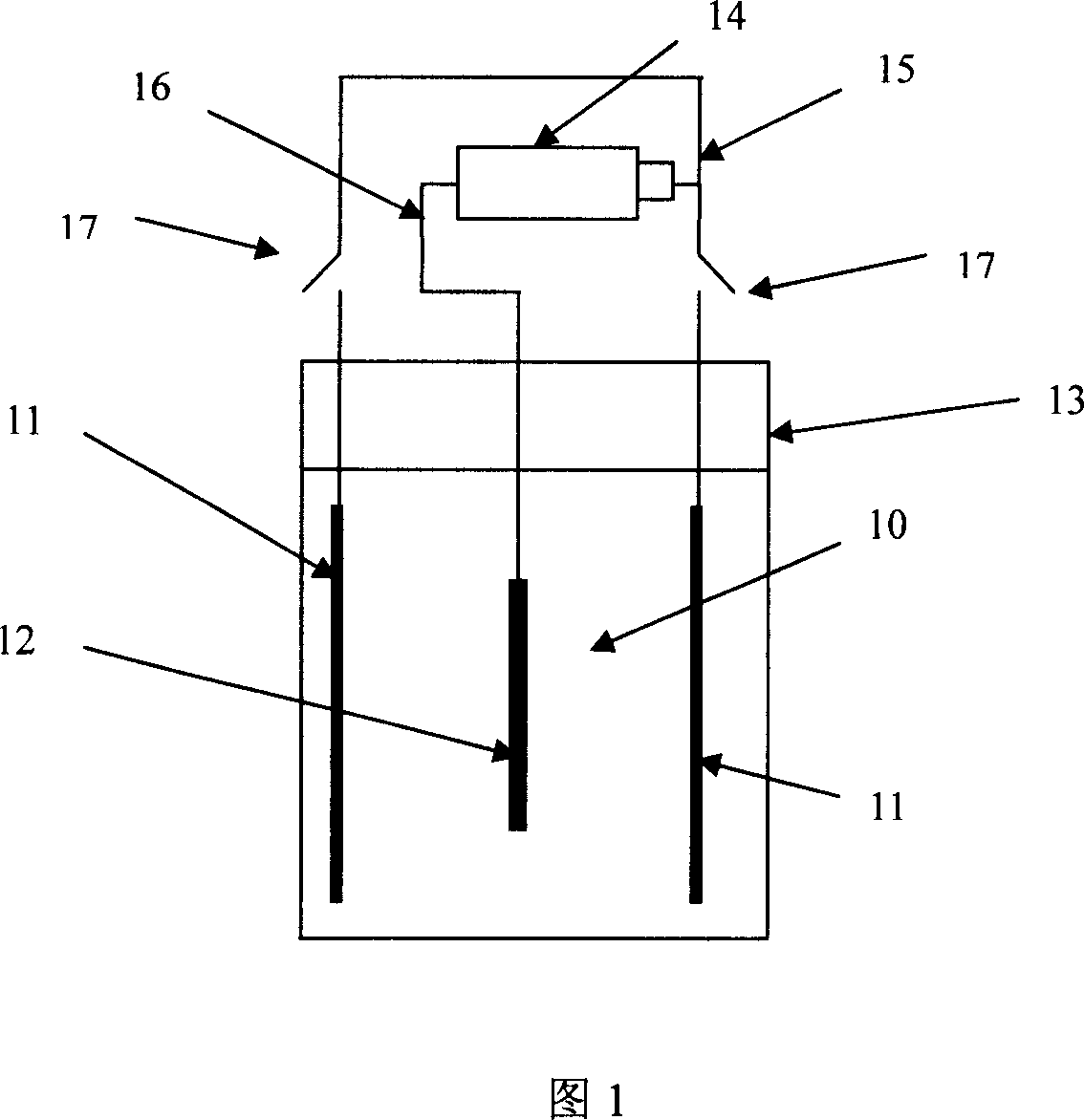

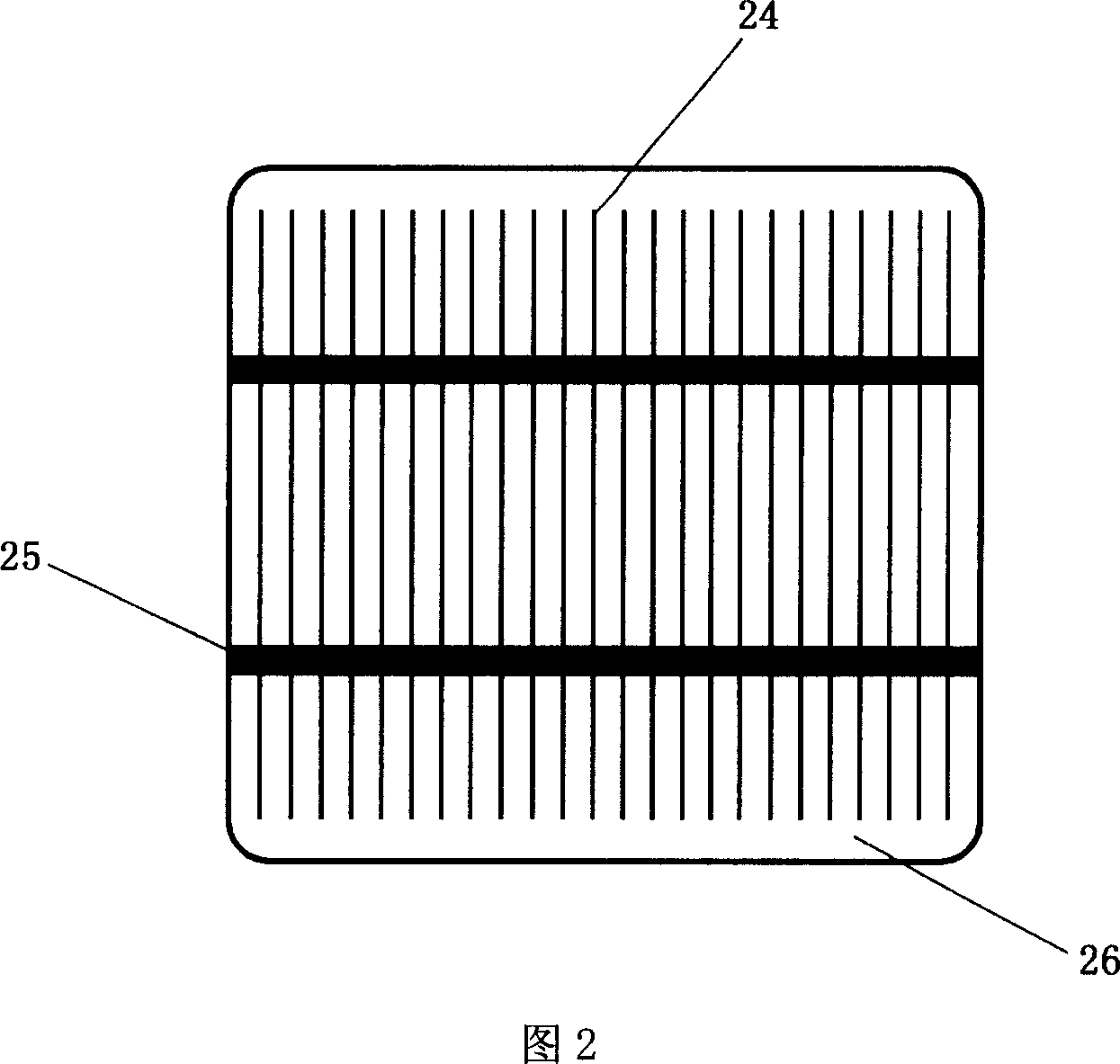

A manufacture method of pole for solar cell and its electrochemical deposition device

ActiveCN101060145ASimple compositionExpand the scope of operationElectrolysis componentsPhotovoltaic energy generationMetal alloyWastewater

The disclosed preparation method for solar cell electrode applies electrochemical deposition or metal alloy technique. This invention improves photoelectric conversion efficiency, reduces cost, and easy to treat waste.

Owner:WUXI SUNTECH POWER CO LTD

DE type air purification filter material and method for processing the same

ActiveCN101219308AImprove density uniformitySimple structureFiltration separationDomestic articlesFiberPolyester

The invention adopts hollow polyester fiber, polyester short fiber and ES fiber according to mixture ratio of 1-4:1-4:2-8, including the steps of loosening-> quantitative feeding-> hot melting->cold roll forming->hot rolling->air cooling->trim cutting. The fiber of the invention is conglutinated after hot melting treatment; therefore, fiber pad has good toughness and uniform density and stable structure; the produced filtering material has large pore space, good loading capacity which is difficult to be deformed with small resistance and large dust holding performance and good filtering effect.

Owner:丹东天皓净化材料有限公司

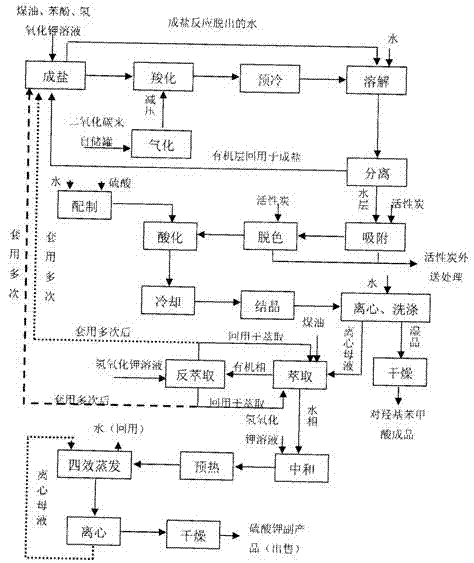

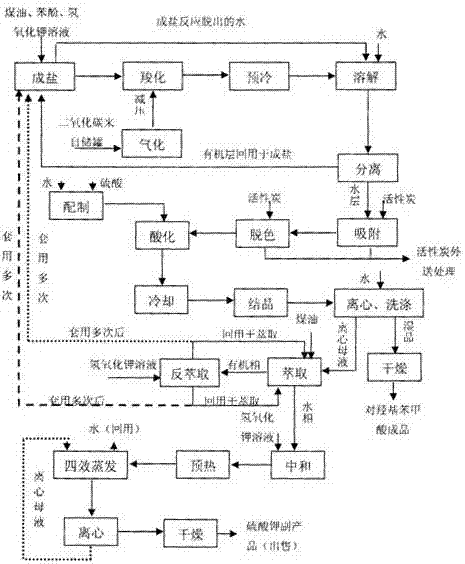

Para-hydroxybenzoic acid continuous production technique by liquid-phase method

InactiveCN102690195AAdvanced production technologyAchieve serializationOrganic compound preparationSulfate/bisulfate preparationPotassium hydroxideSolvent

The invention relates to a para-hydroxybenzoic acid continuous production technique by a liquid-phase method, belonging to para-hydroxybenzoic acid production techniques. According to the invention, phenol and potassium hydroxide are subjected to salification reaction, subjected to carboxylation reaction with carbon dioxide, and acidified with concentrated sulfuric acid to obtain the para-hydroxybenzoic acid product. The technique comprises the following steps: reaction: proportioning a potassium hydroxide solution, phenol and a solvent, and adding into a salification reaction kettle to carry out salification reaction, thereby obtaining potassium phenate; filtering: sending the material containing solid para-hydroxybenzoic acid to a centrifugal machine, separating, washing with water to obtain the solid para-hydroxybenzoic acid, and drying to obtain the para-hydroxybenzoic acid; extraction and recycling: sending the filtrate obtained in the filtering step and a washing solution to an extraction column, and extracting with an extractant in the extraction column; and potassium sulfate preparation: drying the wet material with a continuous evaporator to obtain the potassium sulfate product. The invention has the advantages of high unit volume productivity, easy control on production, less environmental pollution, shorter technical process and low production equipment investment, and can easily implement continuous production.

Owner:JIANGSU TIANXIN BIO ENG

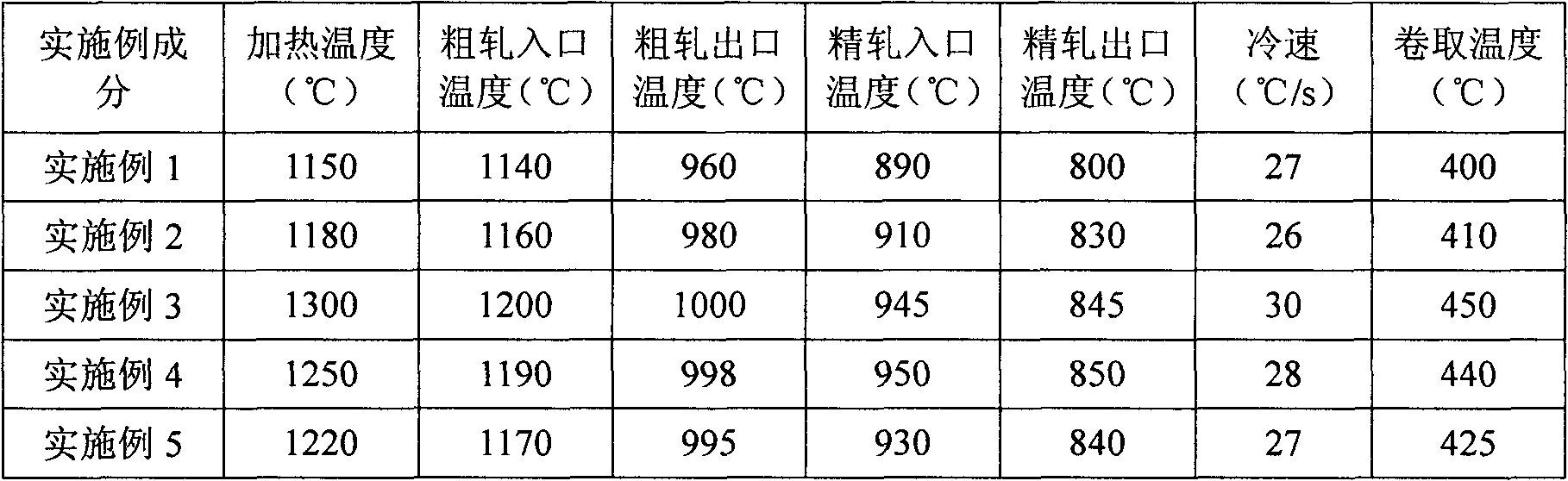

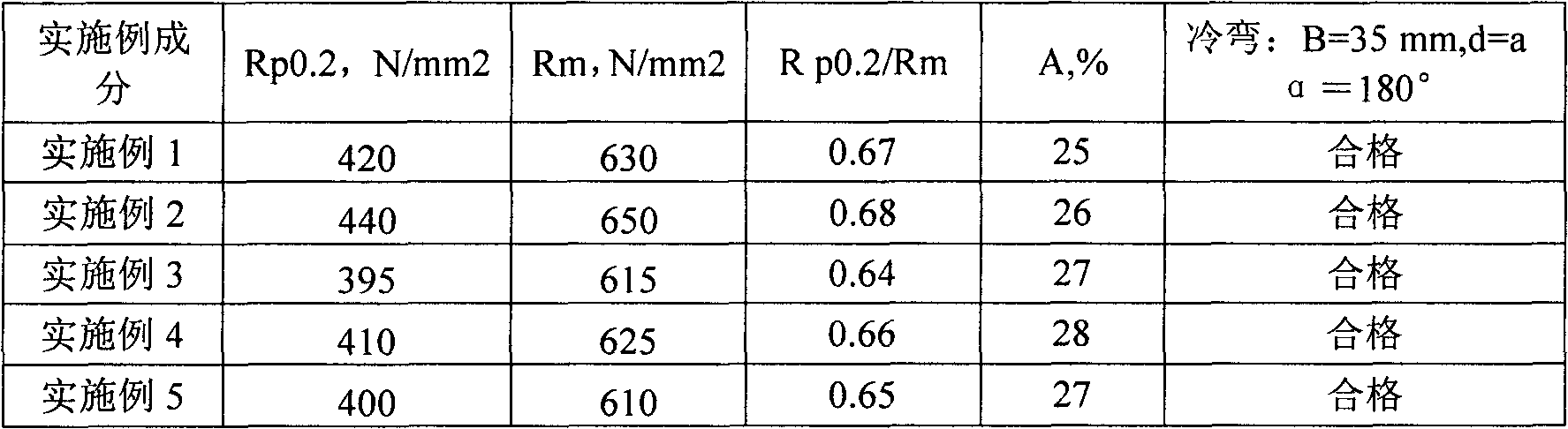

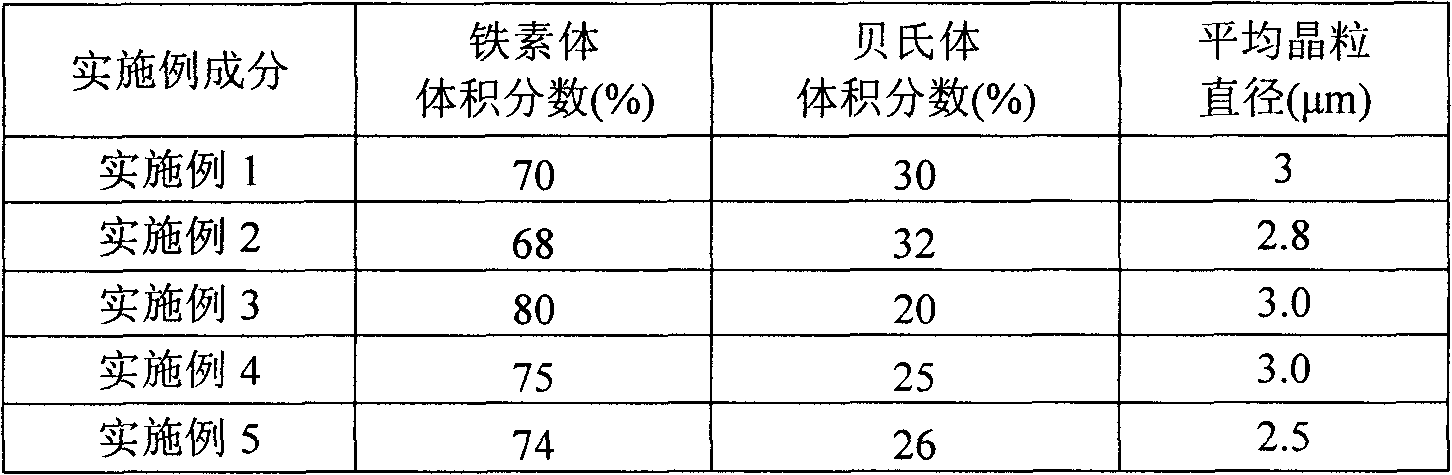

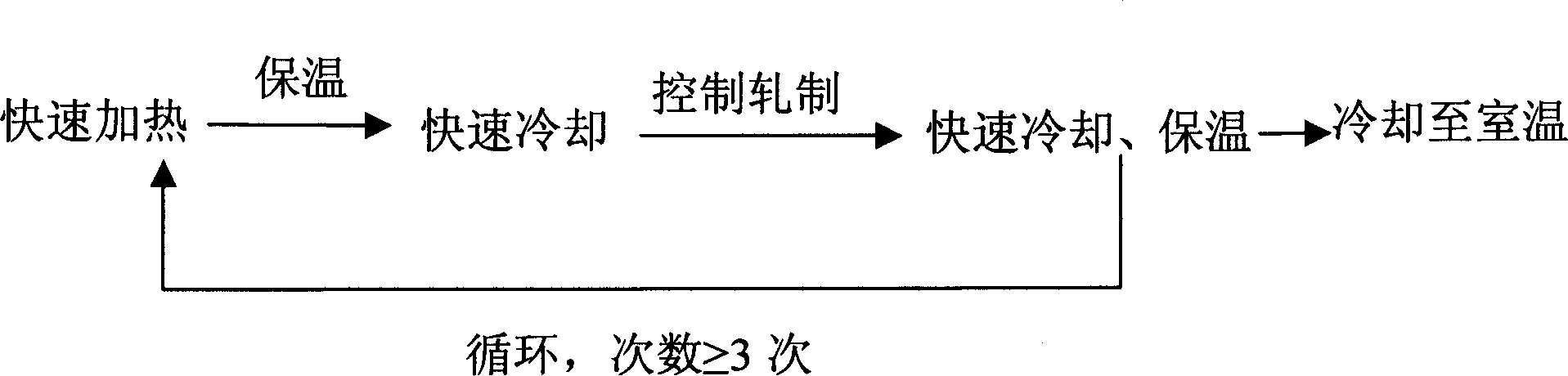

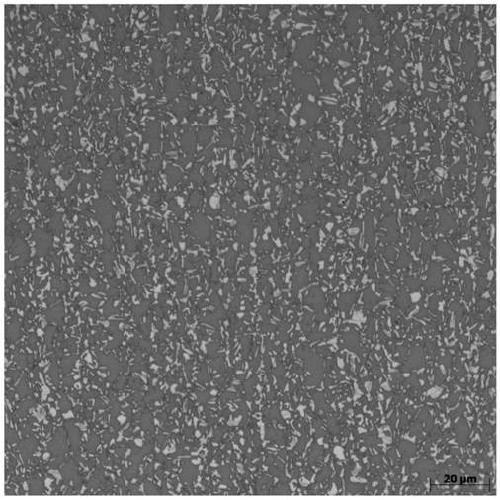

Ultrafine-grain hot-rolling dual phase steel plate for automobile and production method thereof

InactiveCN102719735ALow costImprove performanceTemperature control deviceChemical constituentsImpurity

The invention discloses an ultrafine-grain hot-rolling dual phase steel plate for automobiles and a production method thereof. The chemical constituent of the steel plate comprises, by mass, 0.07%-0.09% of C, 0.2%-0.5% of Si, 1.3%-1.5% of Mn, 0.03%-0.05% of Nb, less than 0.02% of P, and less than 0.01% of S, and the balance being iron and ineluctable impurities, wherein the volume fraction of ferrite is between 60% and 80%, the volume fraction of bainite is between 20% and 40%, the average grain diameter is between 2-3 mu m. The production method comprises that: continuous casting blanks are heated to 1150-1300 DEG C and insulated for 2-3 h. The rolling temperature is between 1100-1200 DEG C and the finishing temperature>950 DEG C during rough rolling. During finish rolling, the initial rolling temperature is between 890-950 DEG C and the final rolling temperature>800 DEG C. A laminar flow cooling technology is utilized and rapid cooling is carried out. The cooling speed is controlled between 25-35 DEG C / s and coiling is carried out when the temperature is between 400-450 DEG C finally. The steel plate and the production method thereof have the advantages of low cost without adding noble metals such as Cr, Mo; simple technology without subsection cooling, easy production control; uniform and consistent product performance and good formability. The steel plate and the production method thereof are mainly used for stamping workpieces of automobile wheels and girders.

Owner:ANGANG STEEL CO LTD

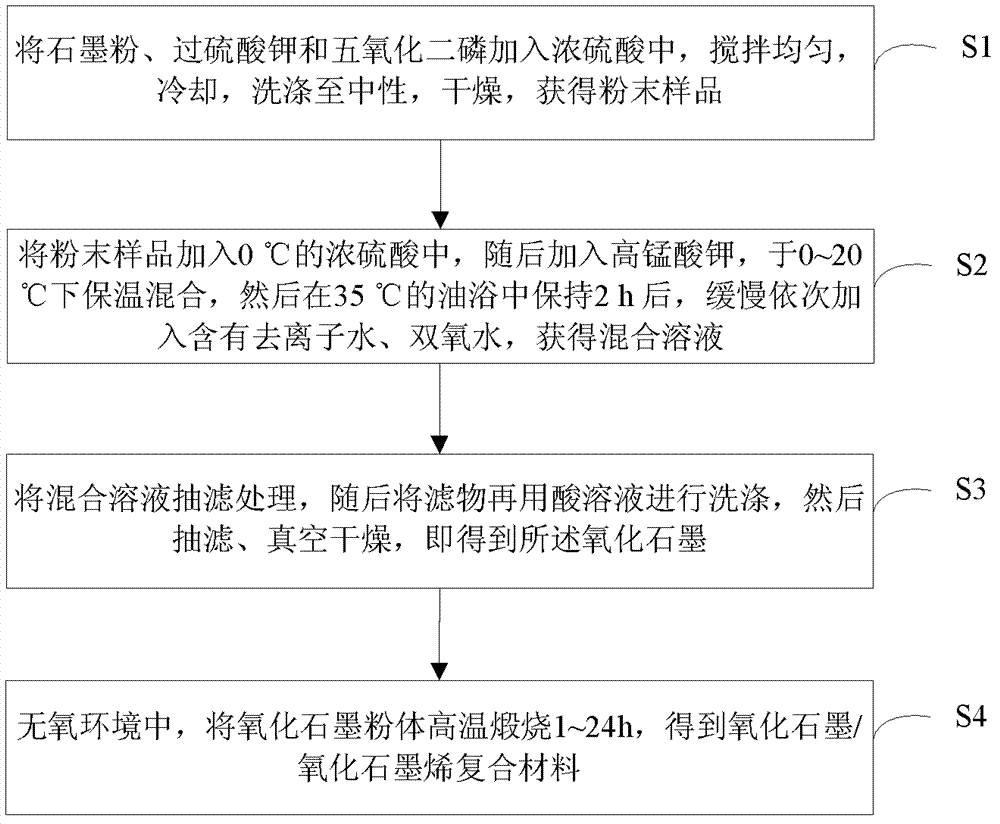

Graphite oxide/graphene oxide composite material, preparation method thereof, battery anode and capacitor battery

The invention belongs to the field of electrochemical materials and discloses a graphite oxide / graphene oxide composite material, a preparation method thereof, a battery anode and a capacitor battery. Graphene oxide in the graphite oxide / graphene oxide composite material only contains epoxy and hydroxyl groups. The graphite oxide / graphene oxide composite material contains the epoxy and hydroxyl groups, and after the graphite oxide / graphene oxide composite material is prepared into the battery anode, the epoxy group and lithium ions from a cathode can be subjected to reaction and ring opening to form hydroxyl lithium during discharging in the battery charging / discharging process, so that the capacitance can be increased.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

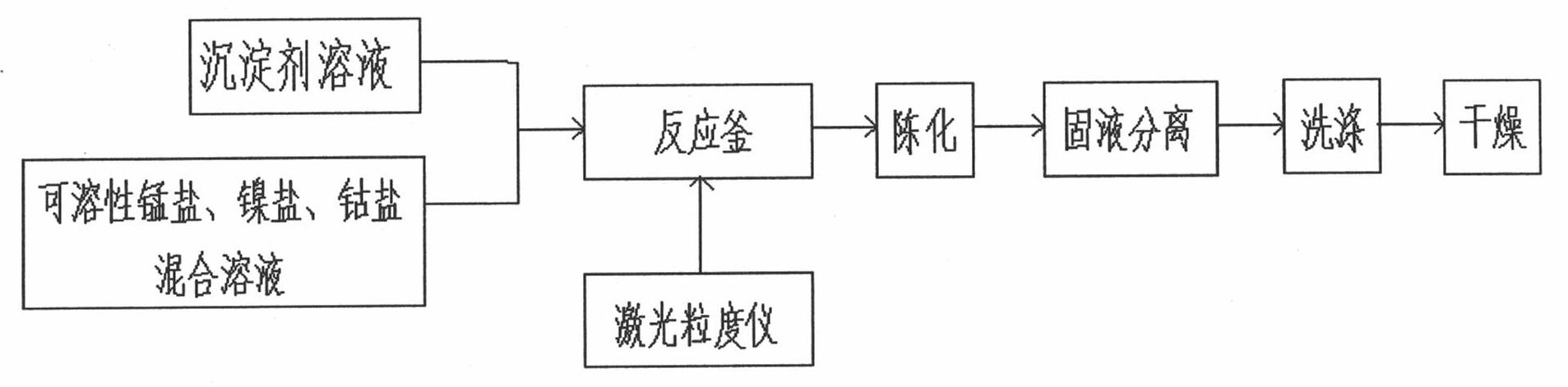

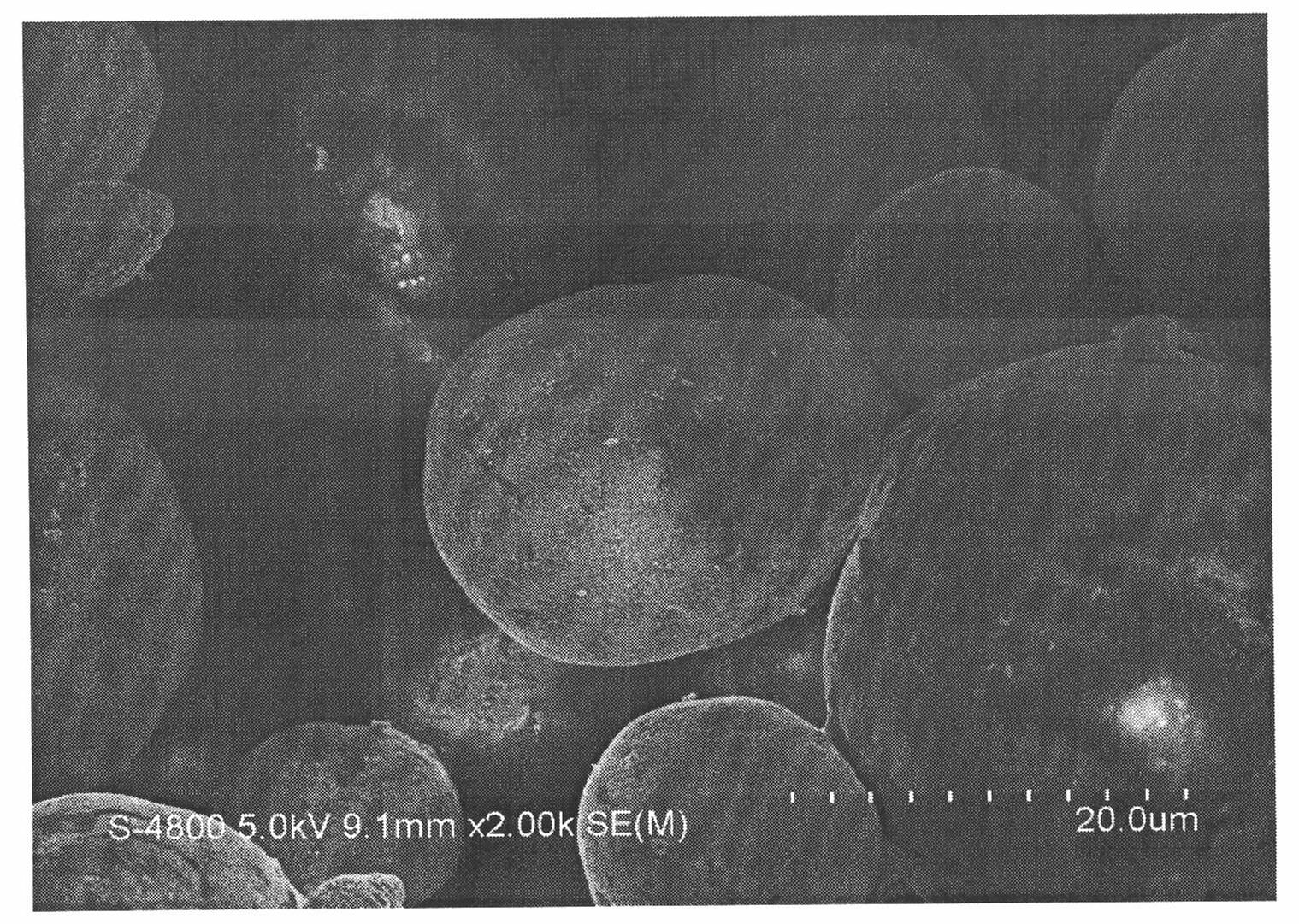

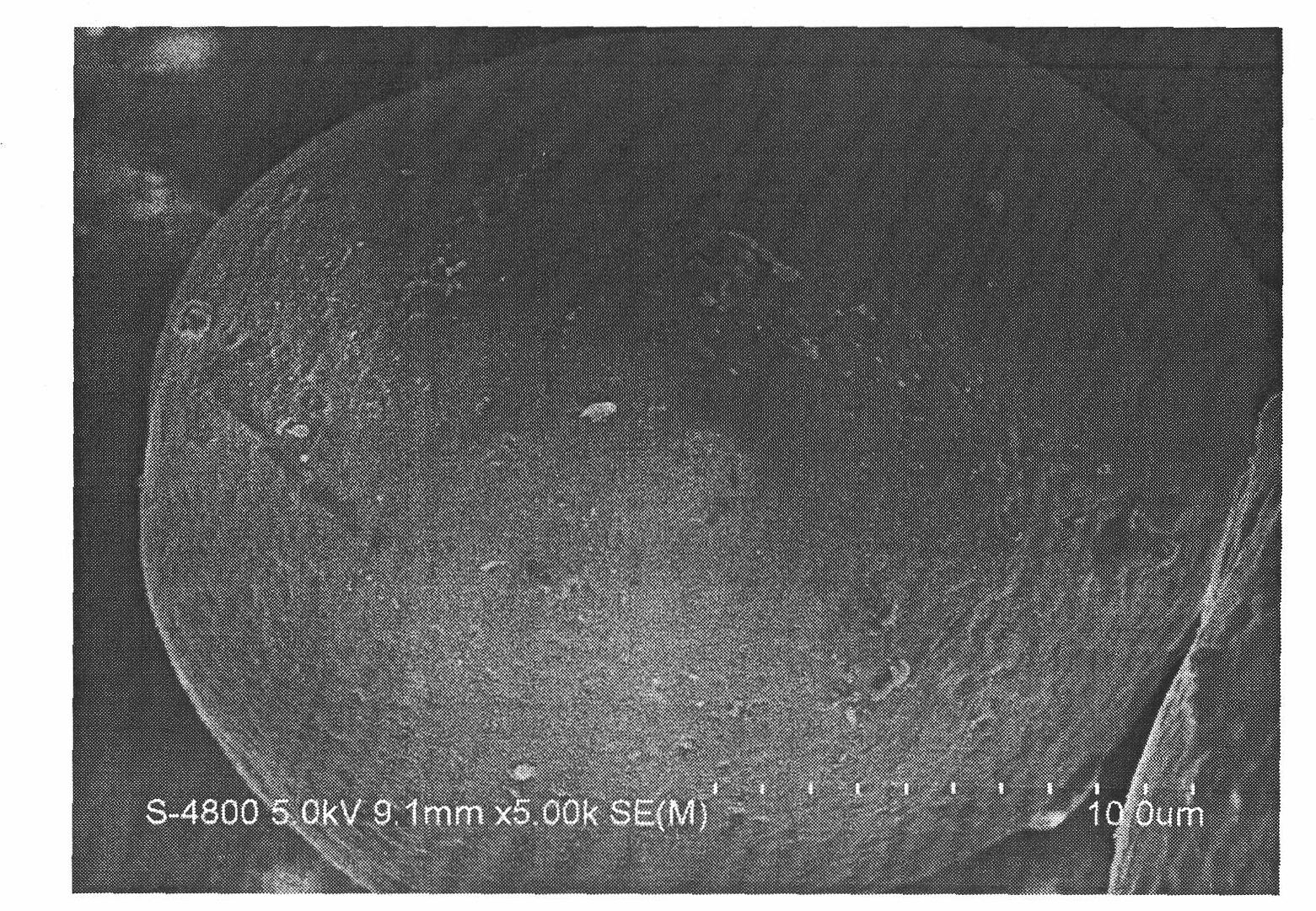

Method for preparing spherical carbonate ternary precursor

InactiveCN102070179AEasy production controlIncrease productivityCell electrodesNickel carbonatesAlkalinityManganese

The invention discloses a method for preparing a spherical nickel-manganese-cobalt carbonate ternary precursor, which comprises the following steps of: continuously adding nickel-manganese-cobalt metal salt mixed solution of certain concentration and precipitant into reaction equipment, controlling the pH of the reaction system to be between 6.5 and 7.5, controlling the alkalinity at 5 to 40g / L, controlling the solid content of the slurry at 70 to 130g / L, and aging, washing and drying the slurry to obtain the spherical nickel-manganese-cobalt carbonate ternary precursor. The prepared spherical nickel-manganese-cobalt carbonate ternary precursor granules are relatively uniform, have good spherical degree, smooth spherical surface, good liquidity and controllable size, and are suitable for industrialized continuous production.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

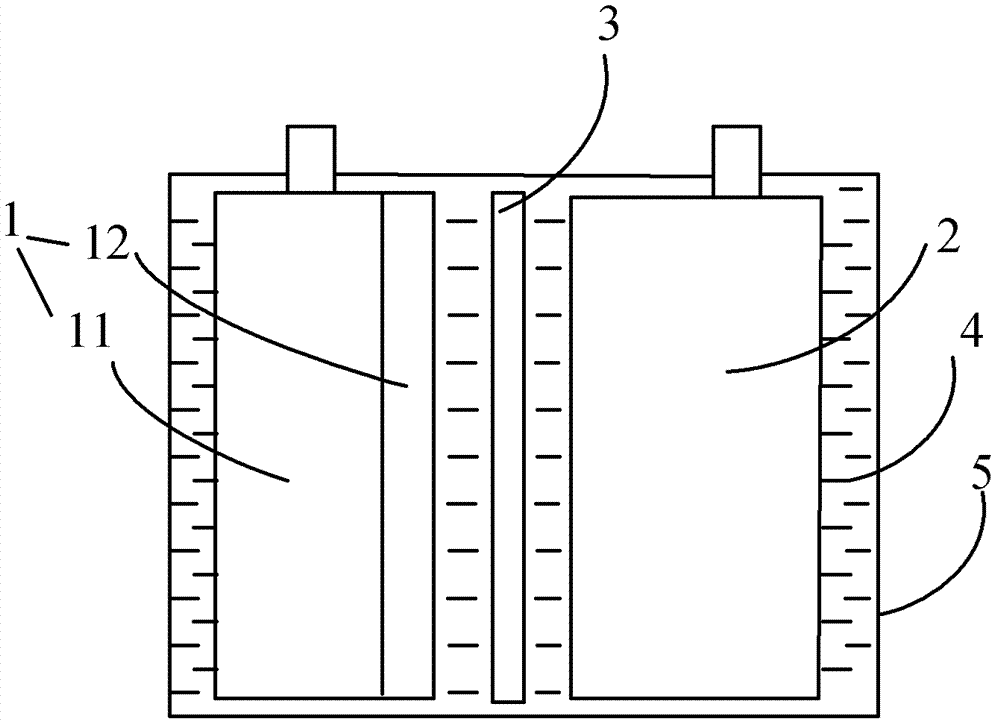

Gel type ionic liquid electrolyte for lithium ion battery as well as preparation method and application thereof

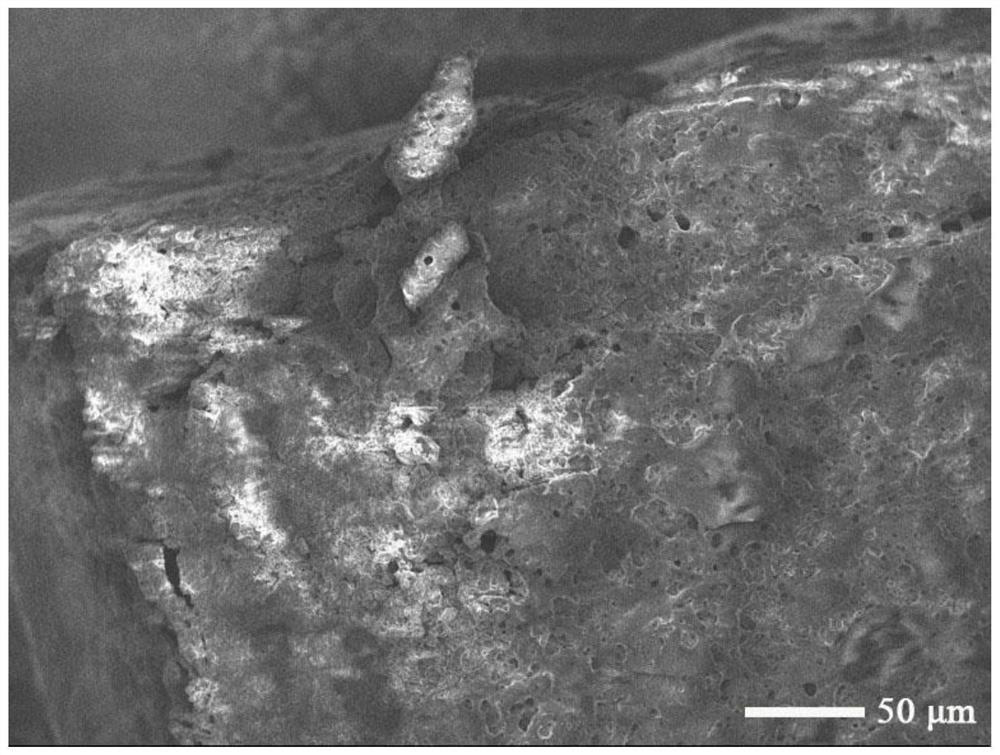

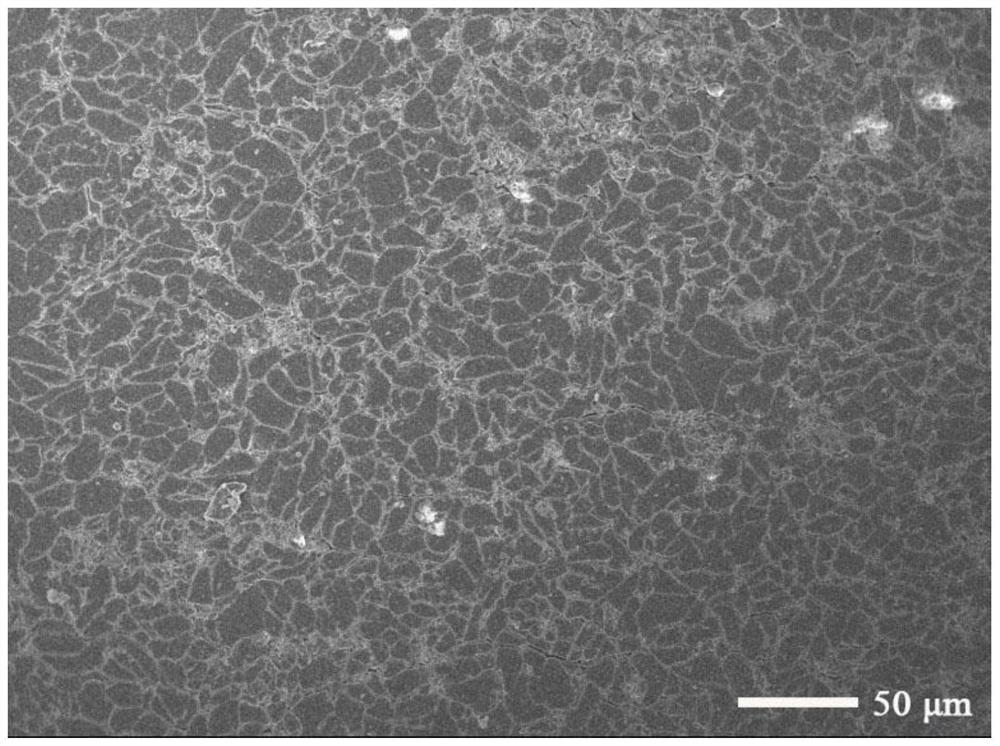

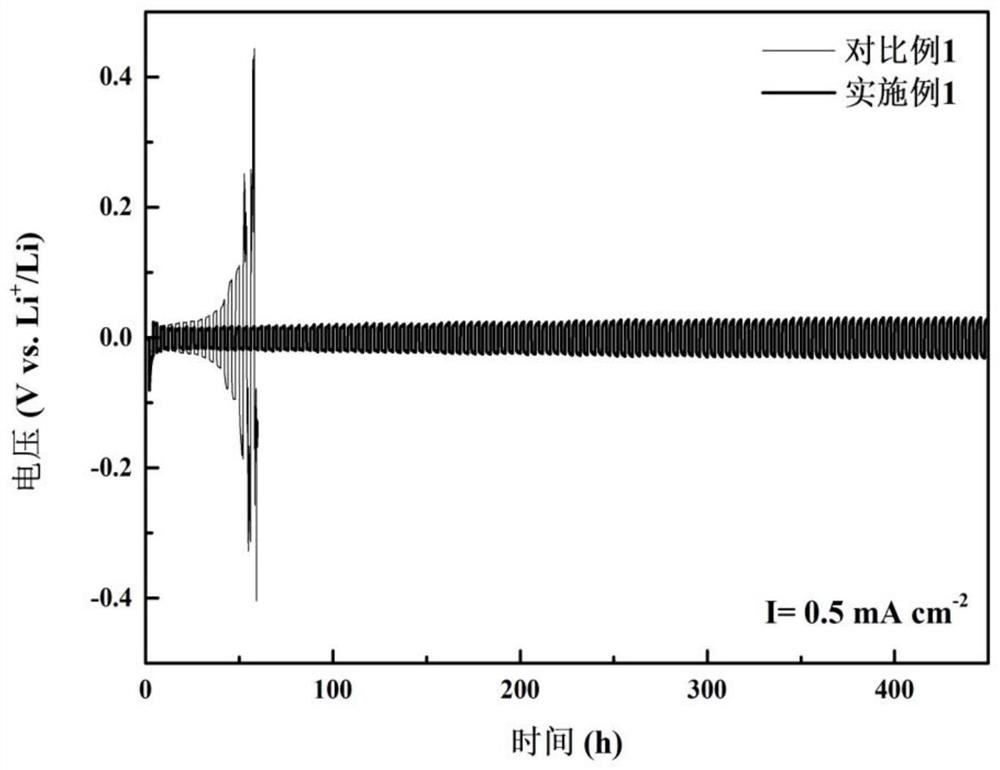

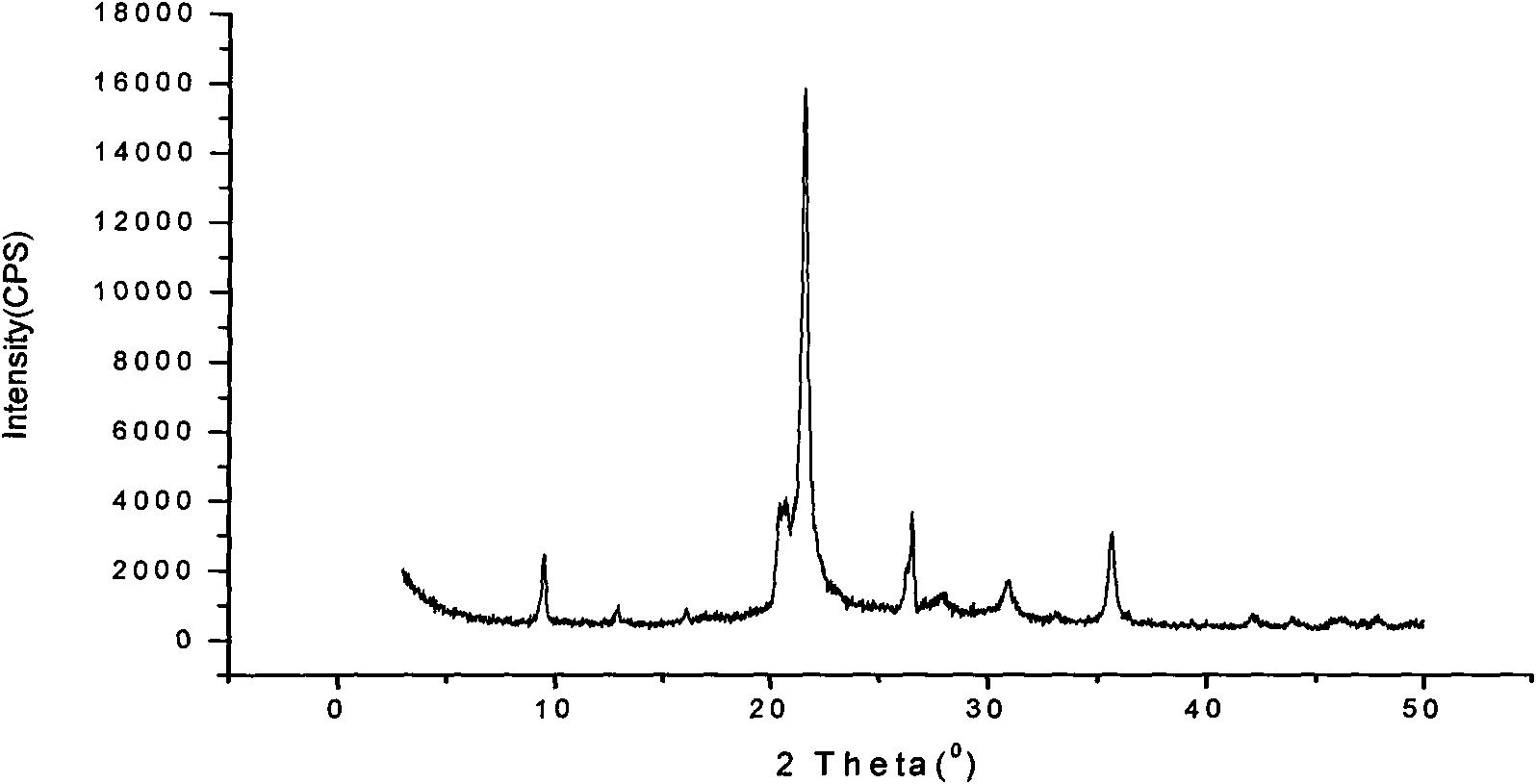

ActiveCN111653822AFully contactedGrowth inhibitionFinal product manufactureLi-accumulatorsInterface impedanceCyclic ether

The invention provides a gel type ionic liquid electrolyte for a lithium ion battery as well as a preparation method and application thereof. The method comprises the following steps: adding a Lewis acid type lithium salt initiator; initiating in-situ ring-opening polymerization of a cyclic ether organic solvent at a low temperature to form a three-dimensional cross-linked network polymer; and limiting the ionic liquid, the lithium salt and the like in a three-dimensional polymer structure by taking the polymer as a skeleton structure. Therefore, the in-situ preparation of the gel-type ionic liquid electrolyte is realized, the sufficient contact between the electrolyte and an electrode material as well as a diaphragm is ensured, the interface impedance can be effectively reduced, a Lewis acid type lithium salt initiator and a multi-lithium salt solute form a multi-lithium salt system, and the improvement of the cycle performance and stability of the gel-type ionic liquid electrolyte isfacilitated; besides, the ionic liquid is introduced, so that the thermal stability and the electrochemical window of the electrolyte are improved while the growth of lithium dendrites is remarkablyinhibited, and the safety performance of the electrolyte is effectively improved.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of low abrasion microsphere catalyst produced in situ

ActiveCN101612592AImproved Diffusion LimitationIncrease profitMolecular sieve catalystsCatalyst activation/preparationSynthesis methodsMicrosphere

The invention relates a preparation method of low abrasion microsphere catalyst produced in situ, comprising following steps: preparing porous carrier microspheres by spray drying method and finally adopting hydro-thermal synthesis method to obtain the low abrasion microsphere catalyst after high temperature roasting at 800-1000 DEG C and phosphorus source modification treatment.

Owner:SHANGHAI RES INST OF CHEM IND +1

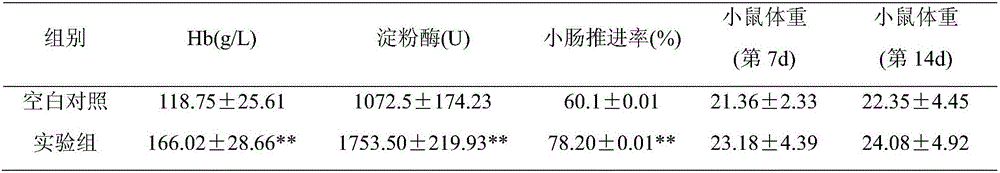

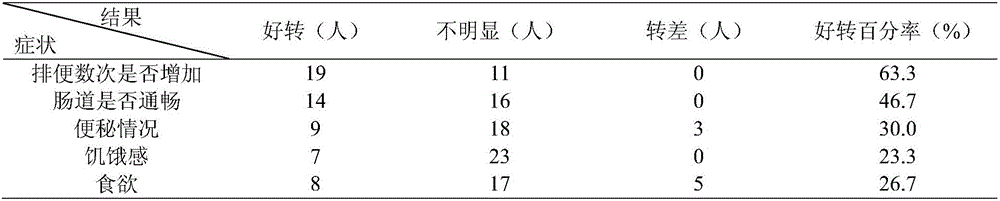

Composite micro-ecological preparation for regulating intestinal flora and preparing method of composite micro-ecological preparation

InactiveCN106136236AWell mixedGood effectFood ingredient functionsIsomaltooligosaccharideFreeze-drying

The invention provides a composite micro-ecological preparation for regulating the intestinal flora. The composite micro-ecological preparation is mainly prepared from, by weight, 1 part of probiotics and 8-15 parts of prebiotics, wherein the probiotics are enteric coating coated freeze-dried powder including lactobacillus acidophilus and bifidobacterium longum, and the prebiotics include inulin, fructo-oligosaccharide, isomalto-oligosaccharide and pectin dietary fibers. The composite micro-ecological preparation for regulating the intestinal flora is prepared from the probiotics and the prebiotics in a composite mode, the special composite including various substances with inulin as the main material serves as the prebiotics, beneficial multiplication help is provided for the probiotics composed of lactobacillus acidophilus and bifidobacterium longum, and thus the comprehensive, balanced and remarkable dual-directional intestinal flora regulating effect is performed in the intestinal tract. Besides, the composite micro-ecological preparation is high in stability, free of limitation of product dosage forms and suitable for being taken by people suffering from intestinal flora disorder.

Owner:廊坊市思科农业技术有限公司

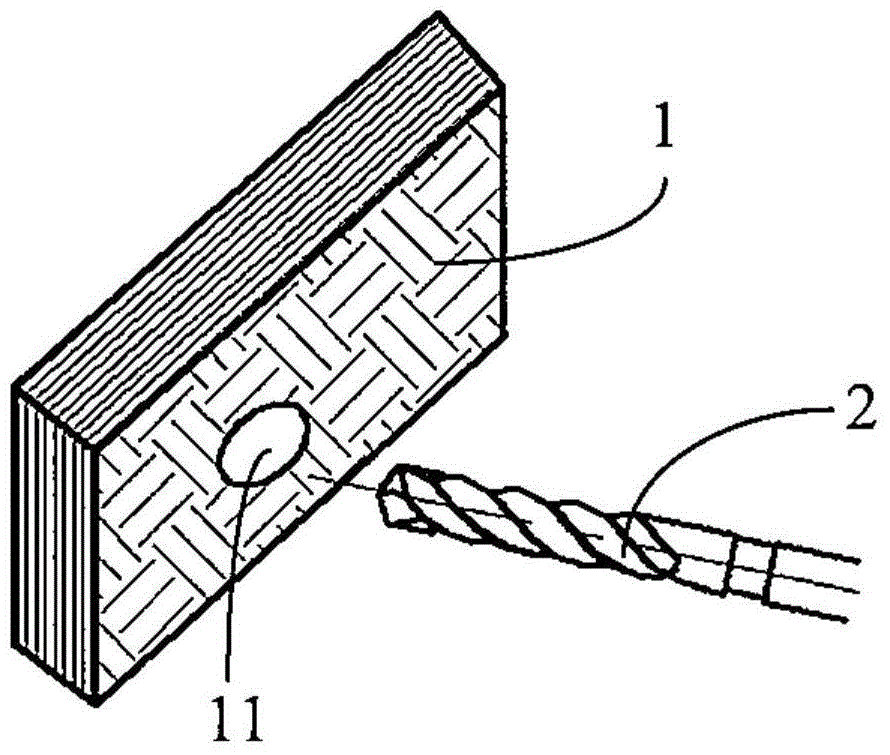

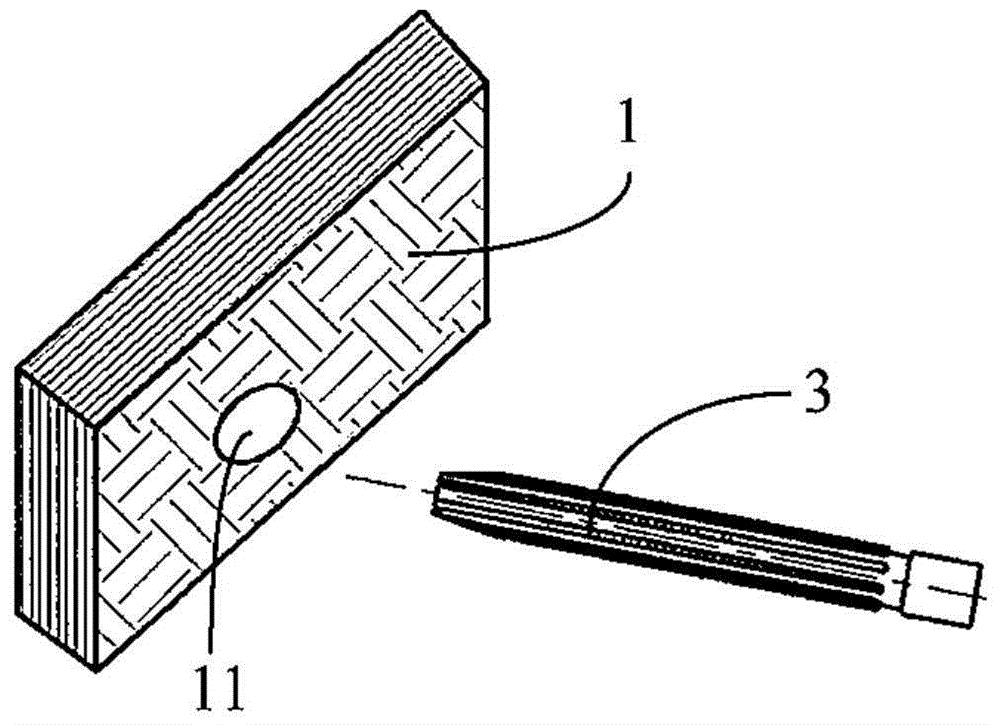

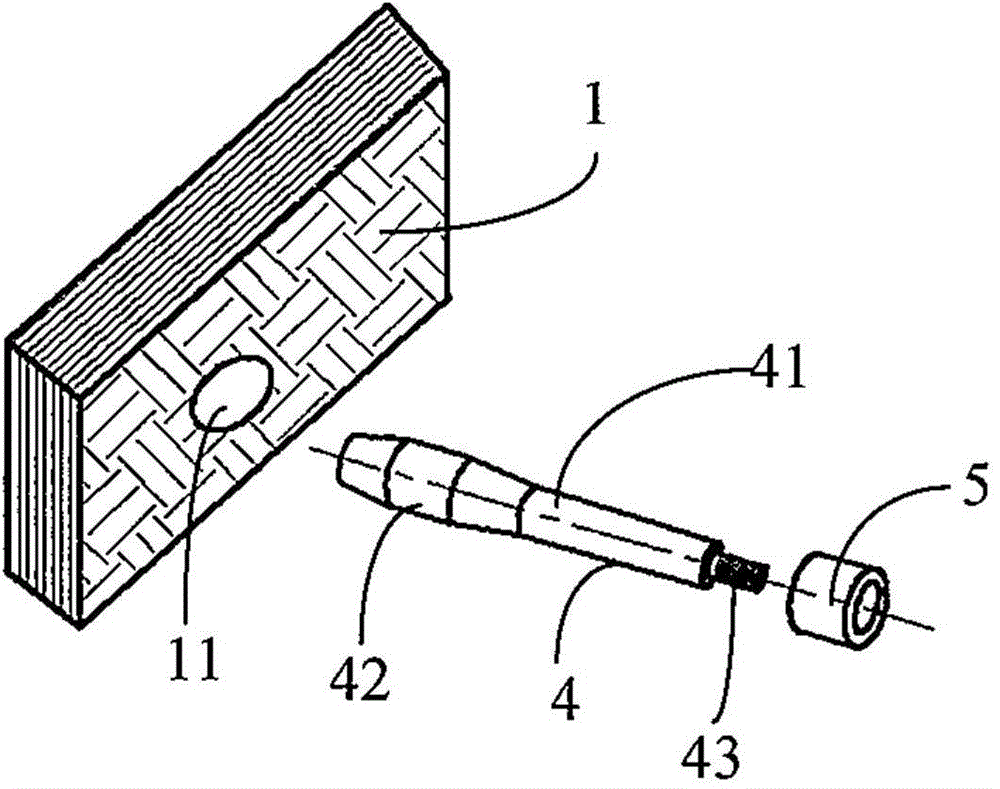

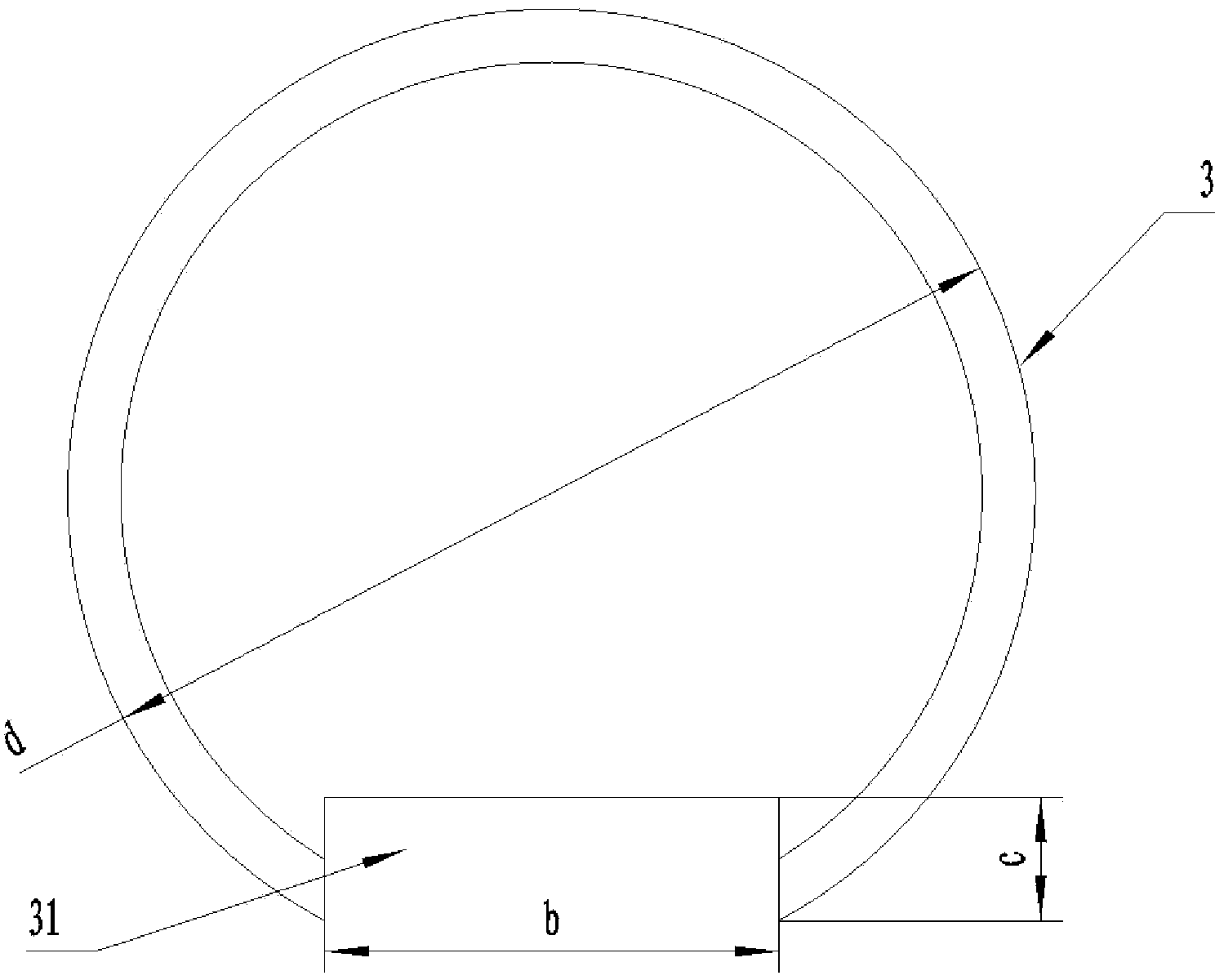

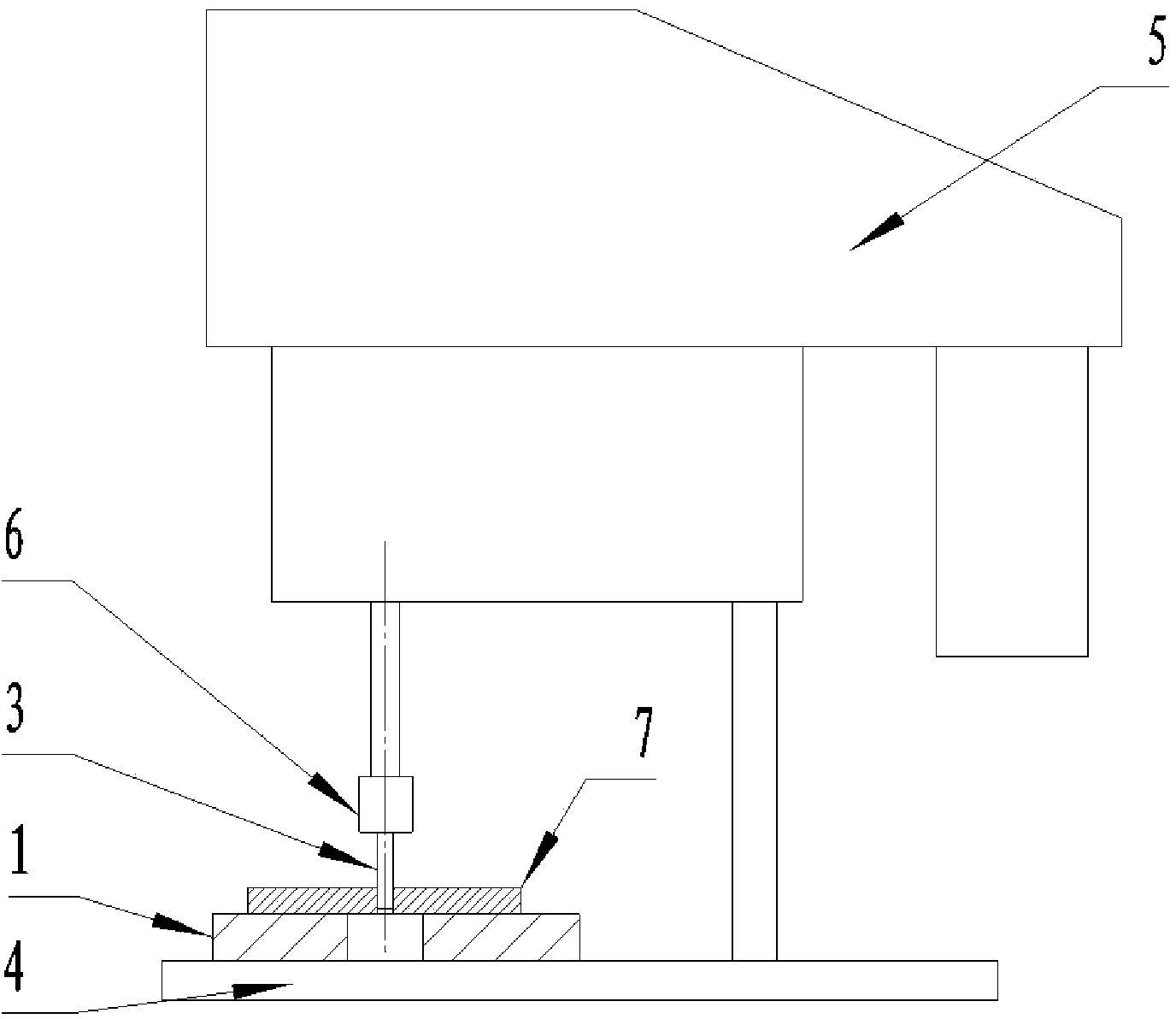

Cold extrusion strengthening method for assembling hole of CFRP composite material laminate

InactiveCN104626726AImprove fatigue lifeEasy maintenanceLamination ancillary operationsLaminationEngineeringAxial force

The invention provides a cold extrusion strengthening method for an assembling hole of a CFRP composite material laminate. The method comprises the following steps: (a) providing a bush, wherein the bush can be assembled in the assembling hole; (b) providing a metal core rod with the taper, and inserting the core rod into the bush; (c) arranging the bush in the assembling hole; (d) applying axial force to the core rod by virtue of extrusion equipment, so that the bush is extruded by the part, with the largest diameter, of the core rod; and (e) removing the core rod, so that the bush is fixedly arranged in the assembling hole. Aiming at the assembling hole of the CFRP composite material laminate, the bush is adopted and is matched with a cold extrusion strengthening process, so that the fatigue life of parts can be effectively prolonged, and the service time of an aircraft is prolonged. Because the bush is fastened in the assembling hole, the wear resistance of the connecting structure is improved, and the detachment of assembling fasteners and the maintenance of the parts can be promoted.

Owner:COMAC +1

Production method for alumina

InactiveCN1876569AReduce the liquid-solid ratioGood for recyclingAlkali metal oxidesFiltration separationL&D processSeed crystal

The invention provides the preparing method of aluminum oxide, comprising preparing ore pulp, digest, diluting ore pulp, separating and washing red mud, disassembling seed crystal, separating and washing aluminum hydroxide, calcining aluminum hydroxide, evaporating mother liquid and causticizing soda solution. The invention adopts pressing filter to replace hydro-separator at the course of separating and washing red mud. The method is in favor of the reclamation of Na2O and Al2O3, and the invention has the advantages of saving cost, short process flow and little apparatus.

Owner:娄进

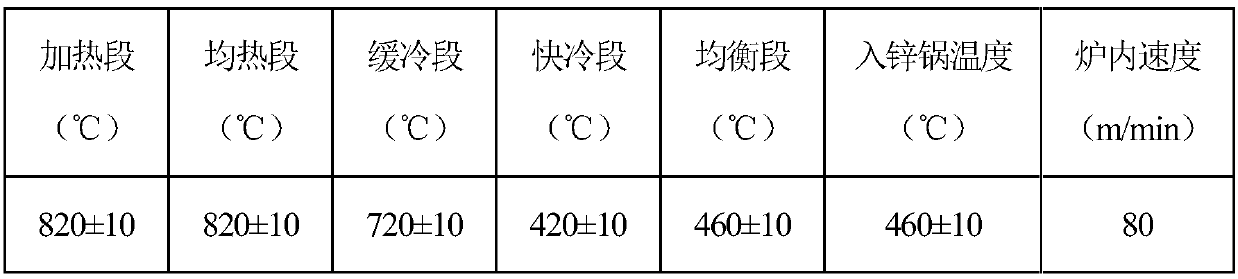

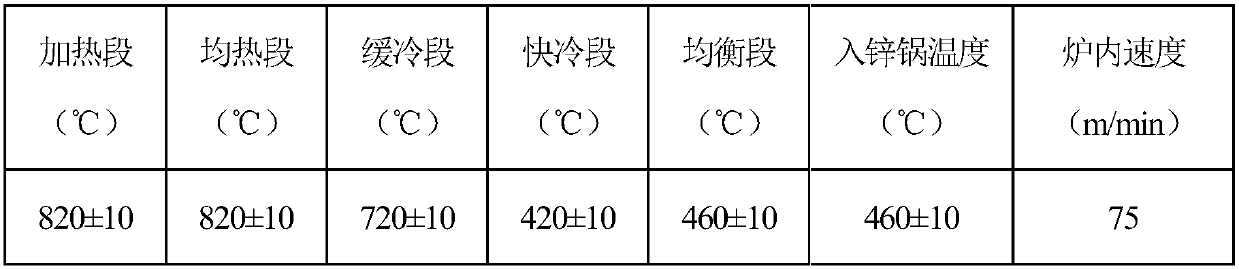

Low-cost hot-galvanizing transformation-induced plasticity steel and preparation method thereof

InactiveCN110878386AReduce manufacturing costSimple production controlHot-dipping/immersion processesFurnace typesAlloy elementSteel plates

The invention relates to the field of transformation induced plasticity steel, in particular to low-cost hot-galvanizing transformation induced plasticity steel and a preparation method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.1-0.3% of C, 0.4-2.0% of Si, 1.0-2.5% of Mn, 0.02% or below of P, 0.03% or below of S, 0.08% or below of Al, and the balance Fe. The method comprises the following technological processes of molten iron pretreatment, converter smelting, external refining, continuous casting, heating, controlled rolling and controlledcooling, coiling, acid pickling, continuous annealing, hot galvanizing, finishing, function inspection, and packaging and warehousing. The low-price C-Mn-Si alloy component design is adopted, and precious alloy elements such as Cr and Mo do not need to be added. By adopting a pre-oxidation process and proper dew point matching control, the platability of silicon-containing TRIP steel is improved.The technical problems of surface quality, mechanical properties and the like of the TRIP steel plate are solved by properly controlling cooling after plating.

Owner:BENGANG STEEL PLATES

Mg-Al-Zn-RE wrought magnesium alloy containing Ce-La mixed rare earth and production method and application thereof

ActiveCN101824571AImprove mechanical propertiesImprove antioxidant capacityExtrusion control devicesFire protectionMaterial consumption

The invention relates to an Mg-Al-Zn-RE wrought magnesium alloy containing Ce-La mixed rare earth as well as a production method and application thereof, belonging to the field of light metal materials. The preparation method comprises the following steps of: adding Mg-Ce-La intermediate alloy in the process of melting AZ31 of Mg, Al and Zn under the protection of gases of SF6 and CO2; introducing argon when the temperature of a melt is 710-730 DEG C, refining and stirring; standing, and then casting to form the Mg-Al-Zn-RE wrought magnesium alloy containing Ce-La mixed rare earth; heating to 330-350 DEG C, keeping the temperature for 3-5h, extruding on a horizontal extruder, wherein the temperature of a mould is 380-400 DEG C and the extruding speed is 1.5-2.5m / min; and stretching and straightening to obtain a heat resistant and anti-corrosion magnesium alloy thermal extruded section containing Ce-La mixed rare earth. The invention needs no special fire protection process in the deformation process and has less material consumption, high precision, small thickness and light weight.

Owner:扬州宏福铝业有限公司 +1

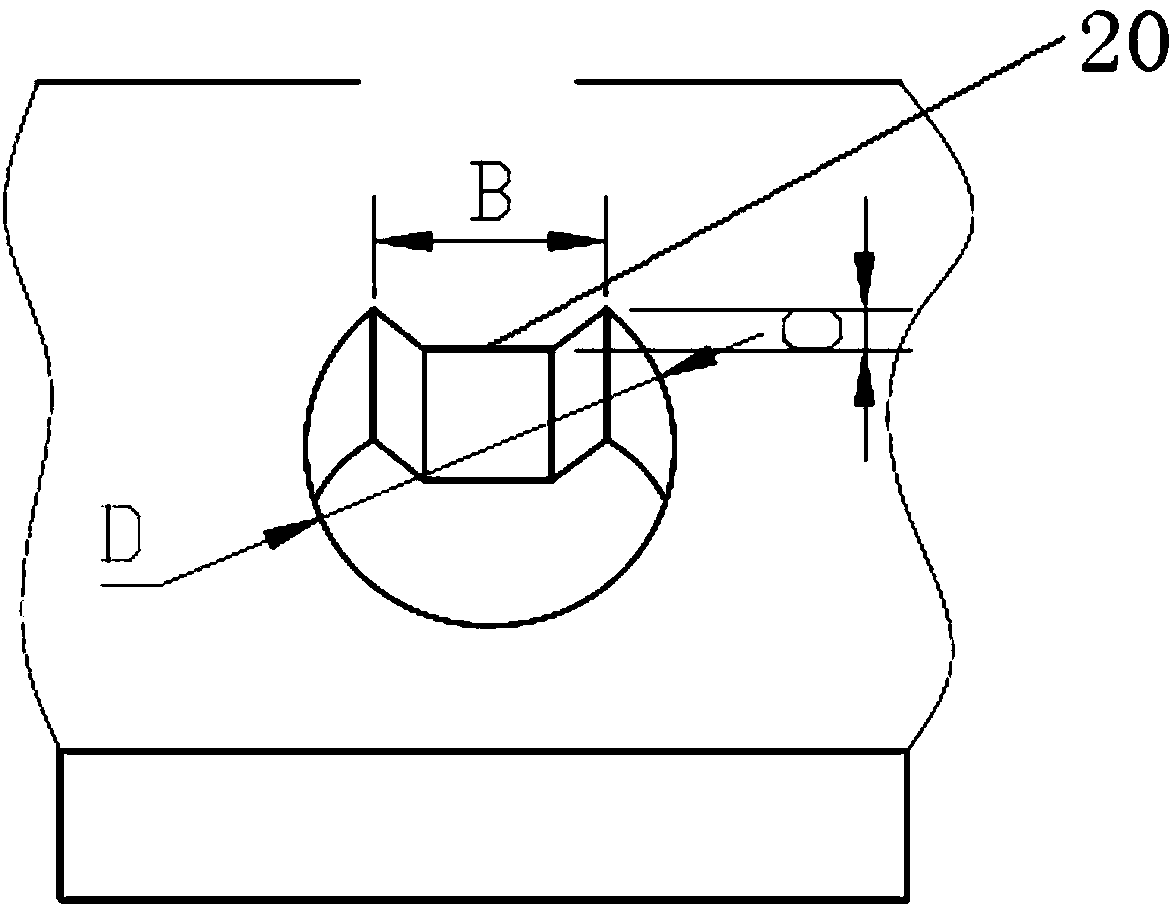

Oil sleeve steel ball and manufacturing process thereof

ActiveCN103556084AComply with steel requirementsReduce steelmaking costsMetal rolling arrangementsIn process controlSmelting

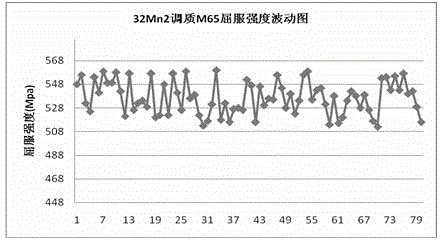

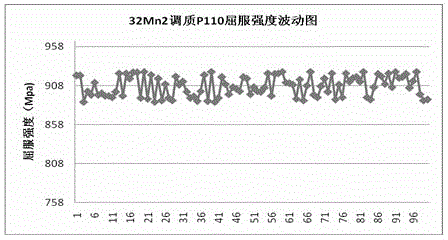

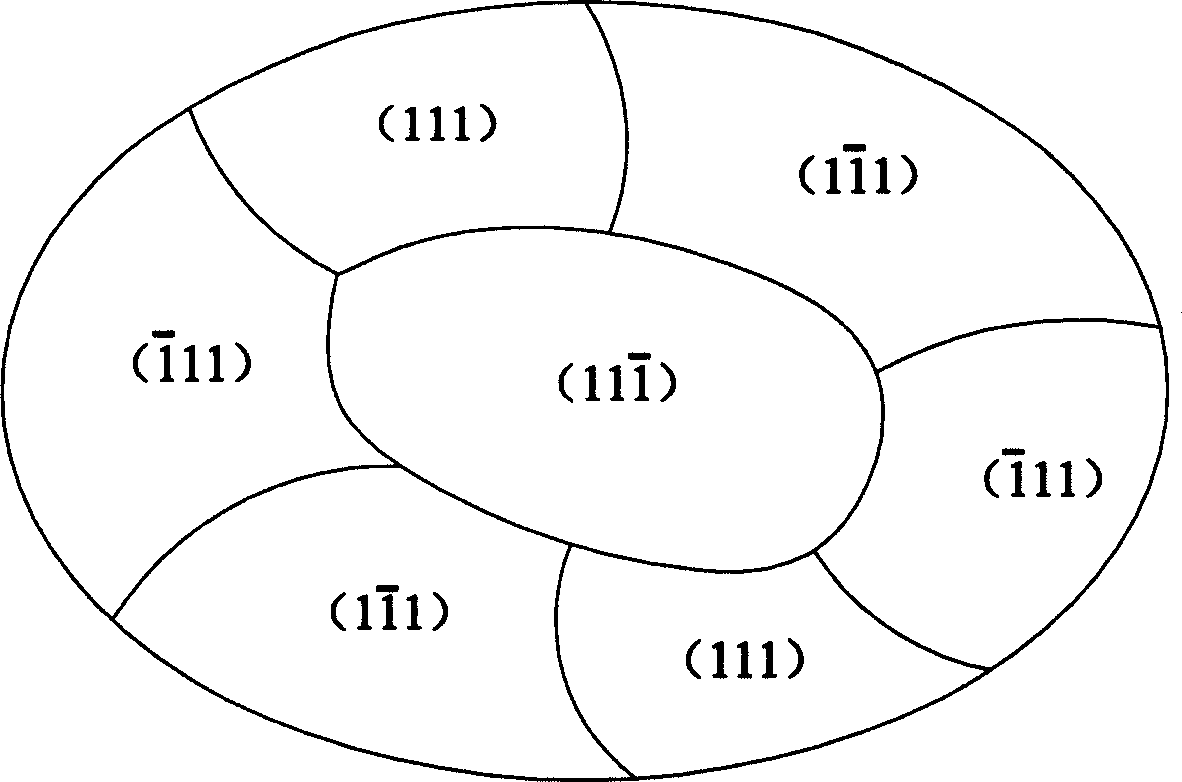

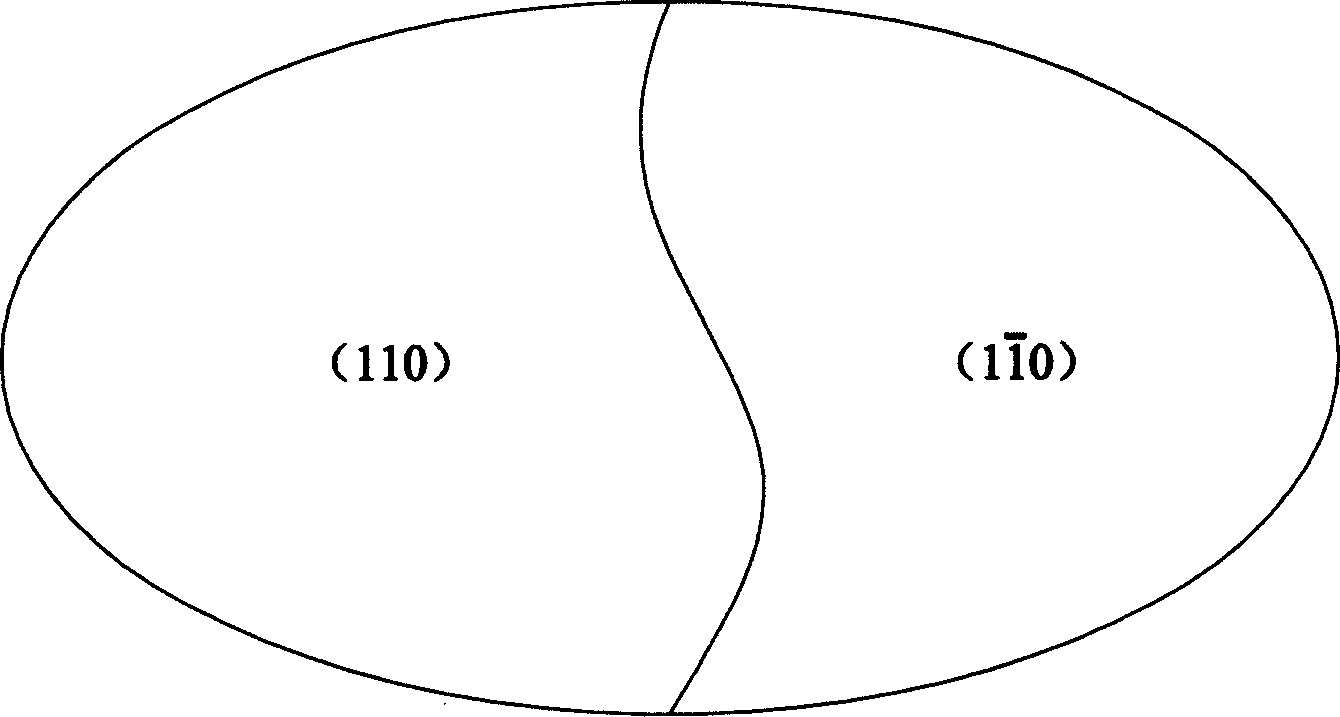

The invention discloses an oil sleeve steel ball. The oil sleeve steel ball consists of the following components by weight percent: 0.28-0.36% of C, 0.17-0.32% of Si, 1.10-1.60% of Mn, less than or equal to 0.02% of P, less than or equal to 0.2% of S, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ni, less than or equal to 0.25% of Cr, less than or equal to 0.1% of Mo, less than or equal to 0.08% of V, 0.008-0.03% of Al, less than or equal to 0.15% of other elements and the balance of Fe. The manufacturing process comprises the steps of converter smelting, external refining, continuous casting of a round billet, hot rolling of seamless pipes and heat treatment of an oil sleeve pipe. 0.008-0.030% of Al is specially added in the oil sleeve steel ball for refining grains, the toughness of steel pipes is improved, and the requirement that the steel for oil sleeves by API5CT is fine-grain killed steel. The steel ball is low in steel-making cost and easy in process control, and multi-steel-grade oil sleeves of J55, M65, N80Q, L80-1, R95 and P110 with wide intensity range can be produced by a proper process, so that the marks of steel for oil sleeves can be reduced, so that the oil sleeve steel ball is economical and practical, on one hand, the management of blanks and production are facilitated, on the other hand, stocks are reduced, and overstocked funds are lowered.

Owner:JIANGSU VALIN XIGANG SPECIAL STEEL

Nb containing low-carbon low-alloyed steel with ultra-fine ferrite grain structure and method for producing same

InactiveCN1566390AEliminate unevennessEliminate low temperature deformationUltra fineGrain structure

The invention discloses an Nb containing low-carbon low-alloyed steel with ultra-fine ferrite grain structure which comprises (by weight percentage) C 0.02%-0.20%, Nb 0.01%-0.10%, Si<0.80%, Ti 0.007%-0.025%, N 0.0035%-0.0083%, balancing Fe and unavoidable impurities. The invention also discloses its preparation method.

Owner:BAOSHAN IRON & STEEL CO LTD

Combined strengthening method of alloy structural hole

InactiveCN103952651AImprove fatigue resistanceThe implementation effect is goodAluminium alloyFatigue resistance

The invention provides a combined strengthening method of an alloy structural hole. The combined strengthening method comprises the following steps: step 1) designing an initial hole diameter and a final hole diameter according to interference value, strengthening amount and an interference bolt; step 2) making an initial hole on the surface on an alloy plate according to the initial hole diameter in the step 1); step 3) forming a final hole by performing cold extrusion on the initial hole; step 4) mounting the interference bolt in a final hole. The combined strengthening method of the alloy structural hole combines the characteristics of good implementation and high efficiency of a hole cold extrusion strengthening process and small damages and relatively uniform expansion of an electromagnetic riveting interference mounting method; by adopting the combined strengthening method, the anti-fatigue performance of the 7050-T7451 aluminum alloy structural hole is greatly improved.

Owner:北京航为高科连接技术有限公司

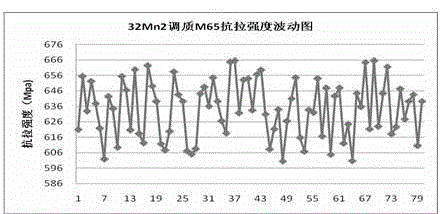

800 MPa-grade low-cost tempered dual-phase steel and preparation method thereof

InactiveCN110029269AGuaranteed mechanical propertiesQuality assuranceContinuous annealingMechanical property

The invention provides 800 MPa-grade low-cost tempered dual-phase steel and a preparation method thereof. The 800 MPa-grade low-cost tempered dual-phase steel comprises, by mass, 0.10%-0.30% of C, 0.10%-0.60% of Si, 1.60%-2.20% of Mn, 0.10%-0.50% of Cr, 0.01%-0.04% of Ti, less than or equal to 0.05% of P, less than or equal to 0.01% of S, less than or equal to 0.08% of Al, and the balance Fe and inevitable impurities. The technological process for preparing the dual-phase steel comprises the following steps of molten iron pretreatment, converter smelting, external refining, continuous casting,heating, controlled rolling and controlled cooling, reeling, acid pickling, cold rolling, continuous annealing, leveling, function inspection and packaging and delivery. According to the preparationmethod, original grain tissues are obtained through hot rolling and controlled rolling and controlled cooling, the hardness of martensite is controlled by adopting continuous annealing and overaging tempering, the mechanical property and the surface quality of the steel are ensured, and the requirements of the 800 MPa-grade dual-phase steel are met.

Owner:BENGANG STEEL PLATES

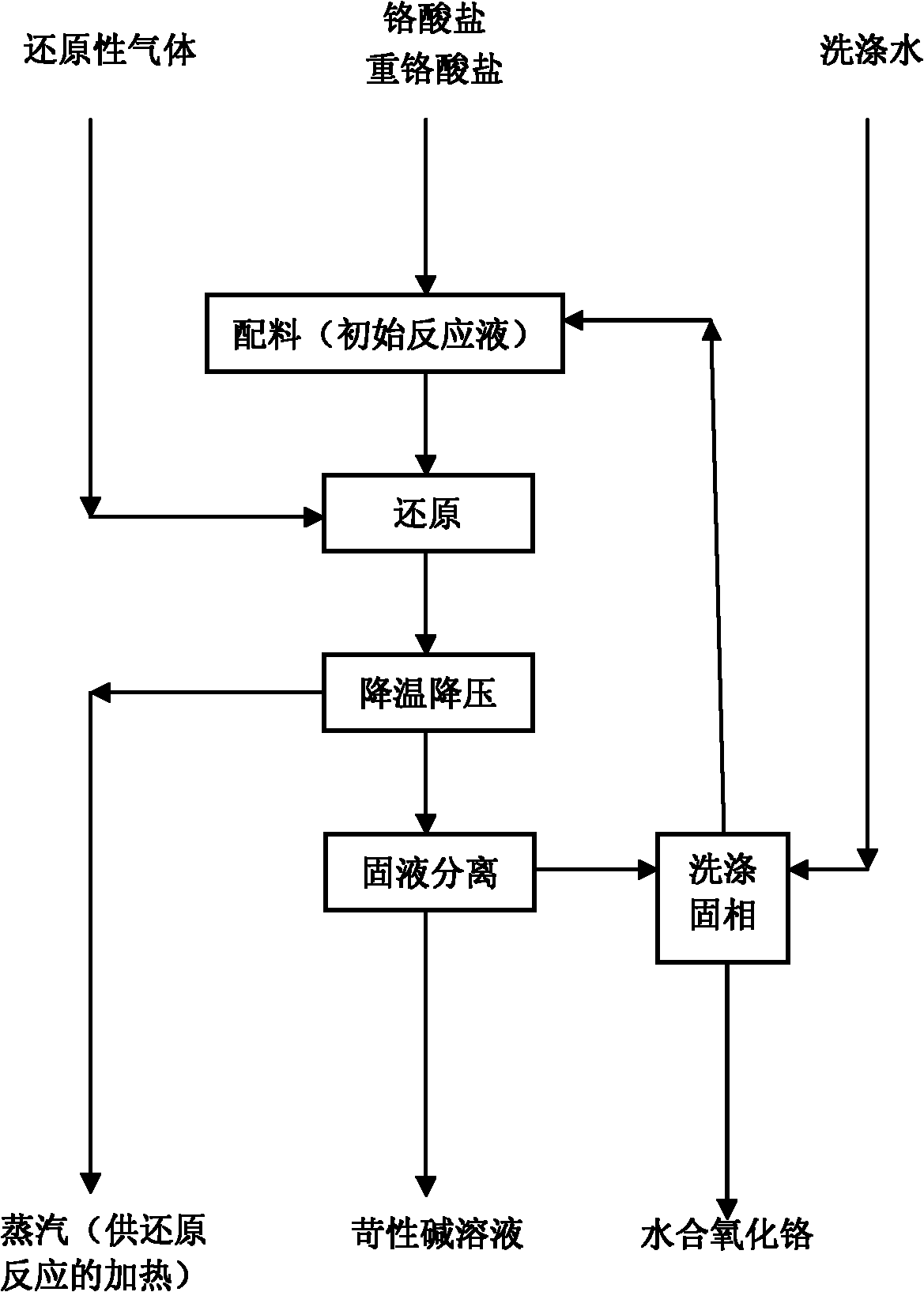

Method for preparing chromic oxide

InactiveCN102010005AAchieve restorationEfficient productionChromium oxides/hydratesChromium sesquioxideHydrogen

The invention provides a method for preparing chromic oxide. The method comprises the following steps of: introducing reduction gas containing hydrogen into a high-temperature high-voltage reaction kettle to perform a reduction reaction on alkali metal salt of chromic acid or dichromic acid which serves as a raw material; cooling and depressurizing a reacted solution; and performing solid-liquid separation to obtain hydrated chromium sesquioxide and corresponding caustic alkali solution. By the process method provided by the invention, the corresponding caustic alkali product and the hydrated chromium sesquioxide can be prepared at the same time, and series of chromic oxide products can be prepared by further modifying the hydrated chromium sesquioxide; and the high-temperature high-pressure reaction kettle is adopted as a reactor, the reaction efficiency can be improved, and self-heat reaction can be simultaneously implemented by utilizing system reaction heat to achieve the aims of saving energy and reducing carbon emission. No waste water, waste residues or waste gas is generated in the process of preparing the chromic oxide and caustic alkali products, so that high-efficiency, energy-saving and pollution-free production of the chromic oxide can be implemented.

Owner:TIANJIN PAISEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com