Method for continuously producing water-soluble monoammonium phosphate by using wet-process phosphoric acid

A technology of monoammonium phosphate and wet-process phosphoric acid, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems affecting the quality of monoammonium phosphate products, the quality of supernatant liquid is difficult to guarantee, and the quality of products is unqualified, so as to achieve easy continuous Modernized production, continuous production, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

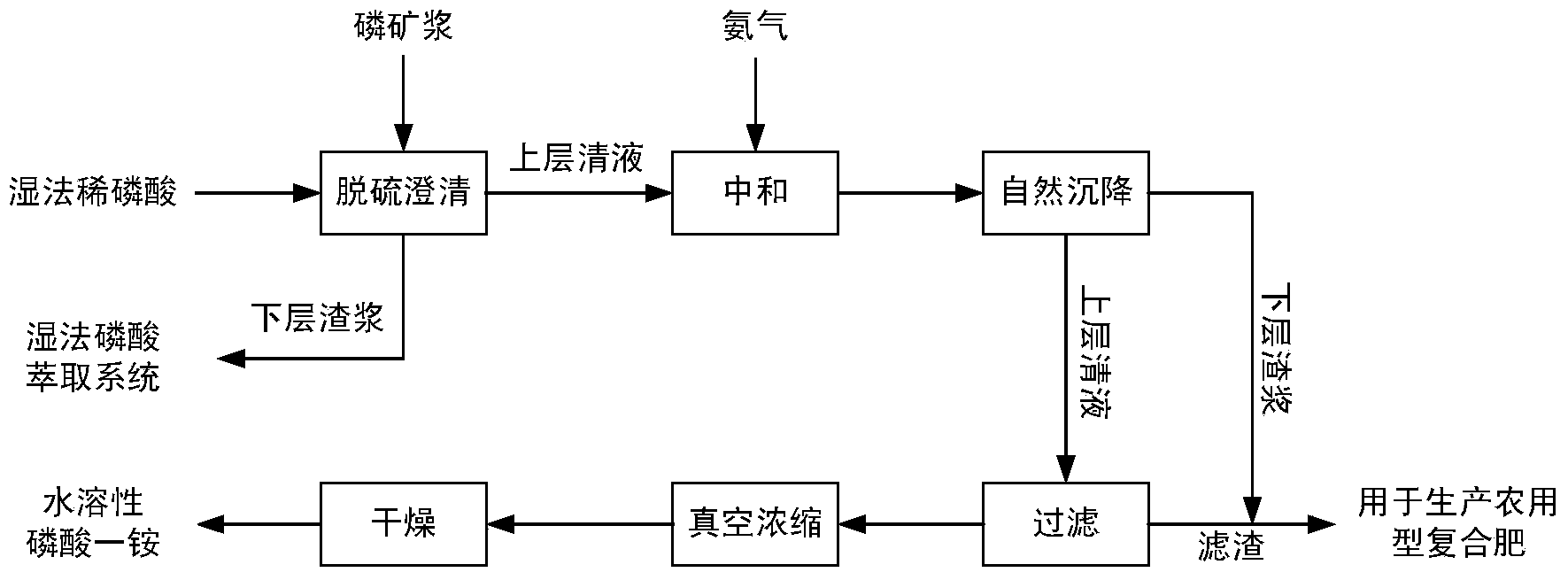

Method used

Image

Examples

Embodiment 1

[0035] Take 1500.0g of wet-process dilute phosphoric acid, according to 20% of the stoichiometric amount of sulfate radical, add phosphate rock slurry for reaction, after natural clarification, adjust to 26%P 2 o 5 Introduce ammonia gas into the clarified desulfurized dilute phosphoric acid for neutralization reaction until the neutralization degree of the slurry is 0.95. After the neutralized slurry is naturally settled, the obtained supernatant is filtered, and the filtrate is concentrated and dried to obtain water-soluble Monoammonium Phosphate Products. Gained water-soluble monoammonium phosphate analysis index is: effective P 2 o 5 %=54.27, water soluble P 2 o 5 %=53.58, N%=11.76, water-insoluble %=0.43, H 2 O% = 1.20, pH = 4.32.

Embodiment 2

[0037] Take 1500.0g of wet dilute phosphoric acid, according to 50% of the stoichiometric amount of sulfate, add phosphate rock slurry for reaction, after natural clarification, adjust to 26%P 2 o 5 Introduce ammonia gas into the clarified desulfurized dilute phosphoric acid for neutralization reaction until the neutralization degree of the slurry is 1.00. After the neutralized slurry is naturally settled, the obtained supernatant is filtered, and the filtrate is concentrated and dried to obtain water-soluble Monoammonium Phosphate Products. The resulting monoammonium phosphate analysis index is: effective P 2 o 5 %=54.78, water soluble P 2 o 5 %=54.38, N%=12.34, water-insoluble %=0.21, H 2 O% = 0.50, pH = 4.43.

Embodiment 3

[0039] Take 1500.0g wet dilute phosphoric acid, according to 100% of the sulfate radical stoichiometry, add phosphate rock slurry for reaction, after natural clarification, adjust to 24%P 2 o 5 Introduce ammonia gas into the clarified desulfurized dilute phosphoric acid for neutralization reaction until the neutralization degree of the slurry is 1.02. After the neutralized slurry is naturally settled, the obtained supernatant is filtered, and the filtrate is concentrated and dried to obtain water-soluble Monoammonium Phosphate Products. Gained water-soluble monoammonium phosphate analysis index is: effective P 2 o 5 %=56.69, water soluble P 2 o 5 %=56.12, N%=11.85, water-insoluble %=0.17, H 2 O% = 1.27, pH = 4.53.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com