Low-cost hot-galvanizing transformation-induced plasticity steel and preparation method thereof

A phase transformation-induced plasticity, hot-dip galvanizing technology, applied in hot-dip plating process, heat treatment equipment, heat treatment furnace, etc., can solve the problems of insufficient strength, easy blockage of mold nozzle, poor coating adhesion, etc. The effect of good quality, easy realization of process parameters and simple production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the low-cost hot-dip galvanized phase-change-induced plasticity steel plate is based on the weight percentage content. The chemical composition of the control steel plate is C: 0.19%, Si: 1.3%, Mn: 1.7%, P: 0.010%, S: 0.002% , Al: 0.033%, and the balance is Fe.

[0027] The preparation method of the low-cost hot-dip galvanized phase transformation-induced plastic steel plate in this embodiment includes the following process flow:

[0028] Hot metal pretreatment→converter smelting→external refining→continuous casting→heating→controlled rolling and controlled cooling→coiling→pickling→continuous annealing→hot-dip galvanizing→pass finishing→functional inspection→packing for delivery;

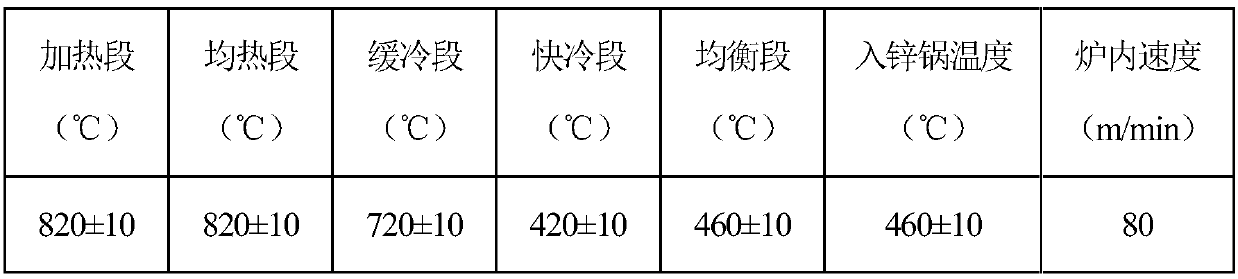

[0029] Among them, the heating temperature of the controlled rolling and controlled cooling process is 1250°C, the rolling start temperature is 1100°C, the final rolling temperature is 920°C, laminar cooling is adopted after rolling, the cooling rate is 30°C / s, and the coi...

Embodiment 2

[0036] In this embodiment, the low-cost hot-dip galvanized phase-change-induced plasticity steel plate is based on the weight percentage content. The chemical composition of the control steel plate is C: 0.18%, Si: 1.4%, Mn: 1.8%, P: 0.013%, S: 0.001% , Al: 0.035%, and the balance is Fe.

[0037] The preparation method of the low-cost hot-dip galvanized phase transformation-induced plastic steel plate in this embodiment includes the following process flow:

[0038] Hot metal pretreatment→converter smelting→external refining→continuous casting→heating→controlled rolling and controlled cooling→coiling→pickling→continuous annealing→hot-dip galvanizing→pass finishing→functional inspection→packing for delivery;

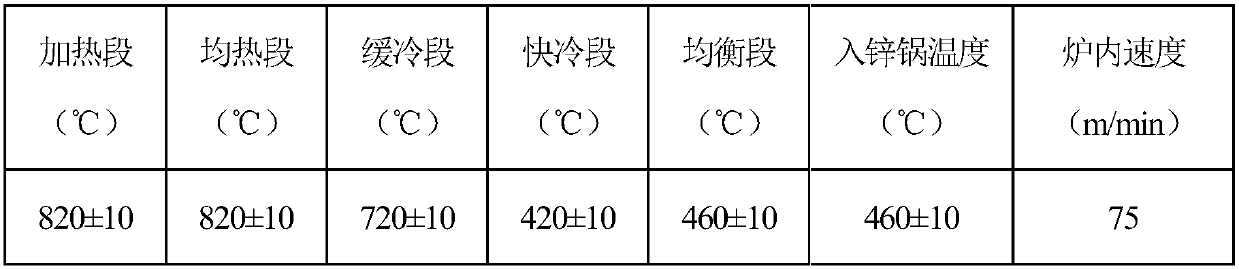

[0039]Among them, the heating temperature of the controlled rolling and controlled cooling process is 1230°C, the rolling start temperature is 1080°C, the final rolling temperature is 900°C, laminar cooling is adopted after rolling, the cooling rate is 25°C / s, and the coil...

Embodiment 3

[0046] In this embodiment, the low-cost hot-dip galvanized phase-change-induced plasticity steel plate is based on the weight percentage content. The chemical composition of the control steel plate is C: 0.19%, Si: 1.4%, Mn: 1.7%, P: 0.012%, S: 0.003% , Al: 0.032%, and the balance is Fe.

[0047] The preparation method of the low-cost hot-dip galvanized phase transformation-induced plastic steel plate in this embodiment includes the following process flow:

[0048] Hot metal pretreatment→converter smelting→external refining→continuous casting→heating→controlled rolling and controlled cooling→coiling→pickling→continuous annealing→hot-dip galvanizing→pass finishing→functional inspection→packing for delivery;

[0049] Among them, the heating temperature of the controlled rolling and controlled cooling process is 1280°C, the rolling start temperature is 1120°C, the final rolling temperature is 950°C, laminar cooling is adopted after rolling, the cooling rate is 35°C / s, and the coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com