Method for preparing spherical carbonate ternary precursor

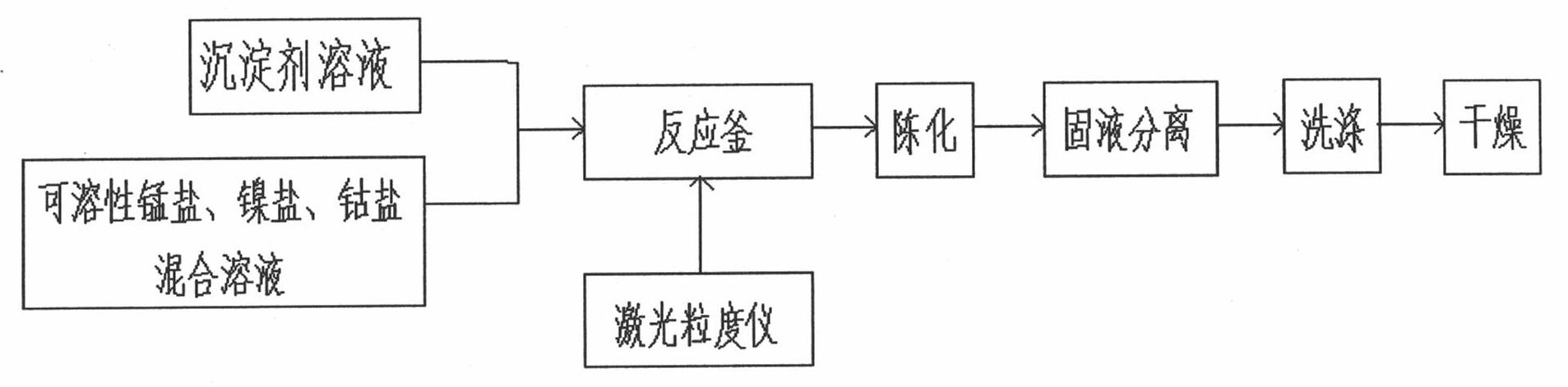

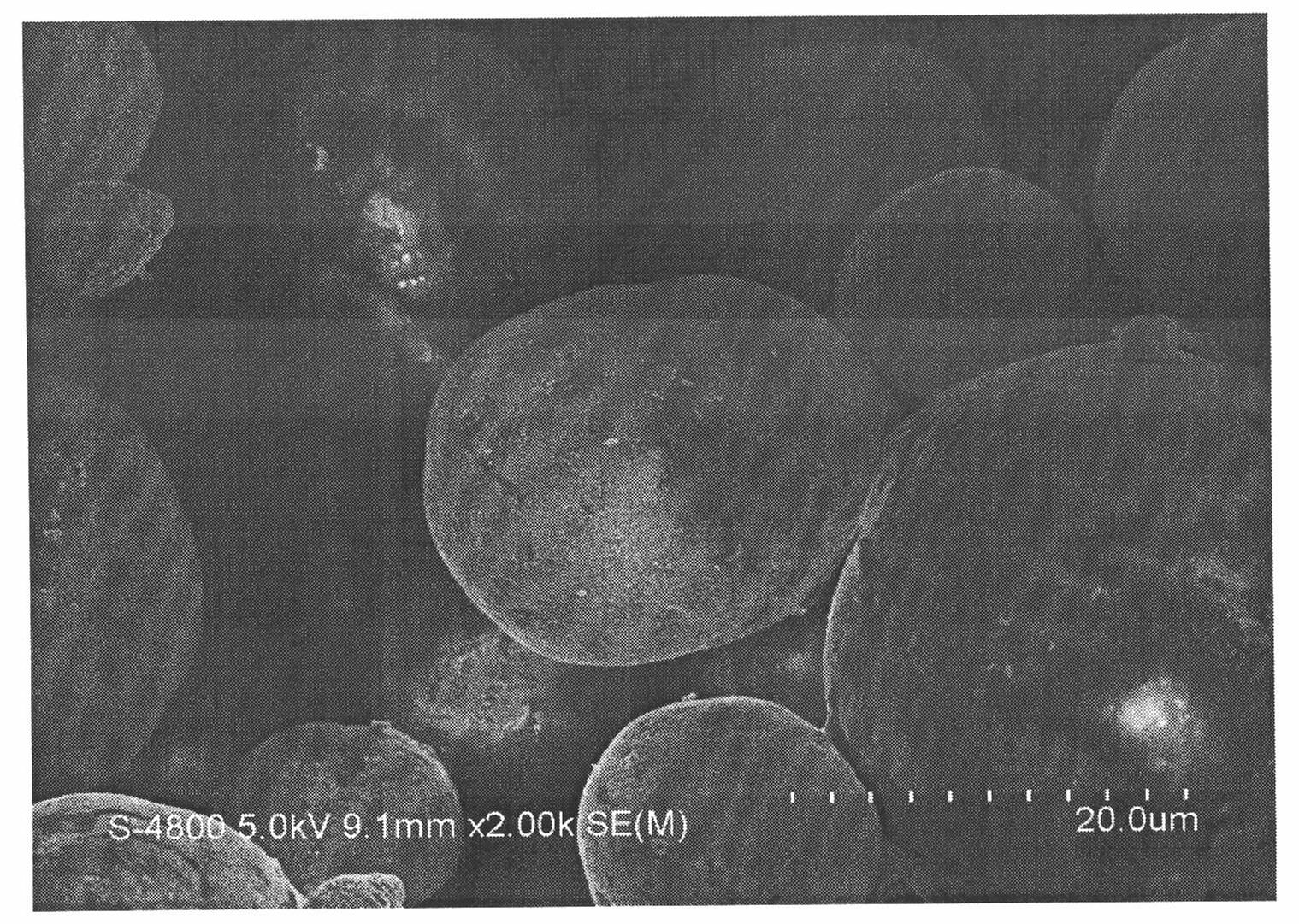

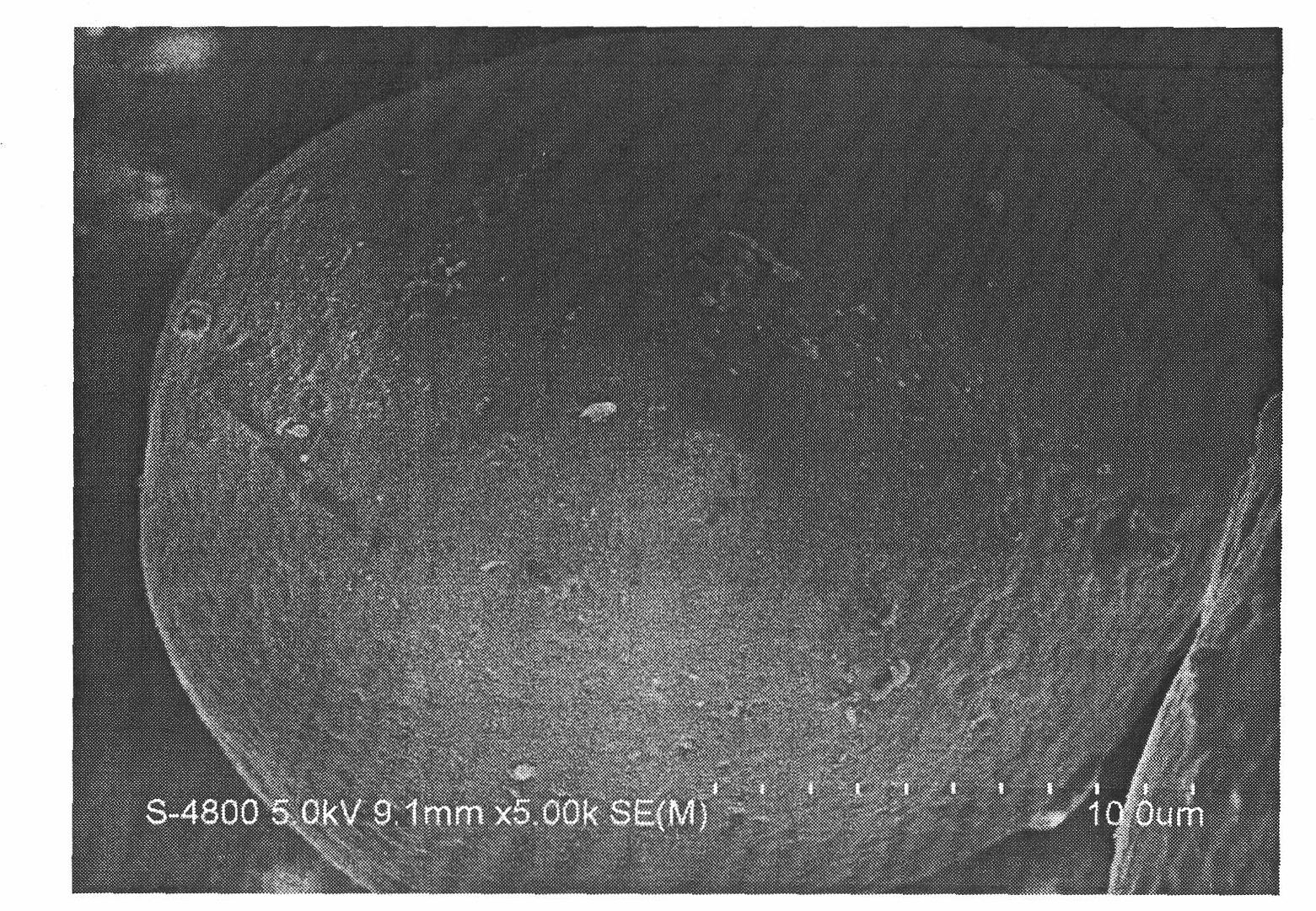

A carbonate and precursor technology, which is applied in the field of preparation of spherical carbonate ternary precursors, can solve problems such as poor fluidity of sphericity, low production efficiency, and inability to continue production, and achieve good sphericity, Simplified production control, uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] ① Use pure water to prepare a mixed solution with a molar ratio of nickel, manganese and cobalt elements of 4:4:2 and a concentration of 130g / L, in which the soluble nickel, manganese, and cobalt salts are nickel sulfate, manganese sulfate, and cobalt sulfate, respectively.

[0032] ② Use pure water to prepare ammonium bicarbonate solution with a concentration of 155g / L.

[0033] ③Pump ①solution and ②solution into the reaction kettle, and keep the stirring speed at 180r / min and the temperature at 65-85℃ for continuous production. By adjusting the flow rate of ①solution and ②solution, control the pH at 6.9 and control the alkalinity at 5 ~ 40g / L, control the solid content of the slurry at 70 ~ 130g / L, after the reaction is complete, the slurry will naturally overflow into the aging tank through the overflow port of the reactor.

[0034] In addition, a laser particle size analyzer can be used to detect the particle size of the spherical carbonate ternary precursor in the ...

Embodiment 2

[0039] ① Use pure water to prepare a mixed solution with a molar ratio of nickel, manganese and cobalt elements of 5:3:2 and a concentration of 90g / L, in which the soluble nickel, manganese, and cobalt salts are nickel sulfate, manganese chloride, and cobalt sulfate, respectively.

[0040] ② Use pure water to prepare ammonium bicarbonate solution with a concentration of 115g / L.

[0041] ③ Turn on the ① solution metering pump and ② solution metering pump, pump the ① solution and ② solution into the reaction kettle, keep the stirring speed at 140r / min, and the continuous production at a temperature of 65-85°C. By adjusting the ① solution and ② solution The flow rate is controlled at 6.7, the alkalinity is 5-40g / L, and the solid content of the slurry is 70-130g / L. After the reaction is complete, the slurry naturally overflows into the aging tank through the overflow port of the reactor.

[0042] In addition, a laser particle size analyzer can be used to detect the particle size o...

Embodiment 3

[0047] ① Use pure water to prepare a mixed solution with a molar ratio of nickel, manganese and cobalt elements of 3:3:3 and a concentration of 80g / L, in which the soluble nickel, manganese, and cobalt salts are nickel sulfate, manganese nitrate, and cobalt sulfate, respectively.

[0048] ② Use pure water to prepare ammonium bicarbonate solution with a concentration of 135g / L.

[0049] ③ Turn on the ① solution metering pump and ② solution metering pump, pump the ① solution and ② solution into the reaction kettle, and keep the stirring speed at 170r / min and the temperature at 65-85°C for continuous production. By adjusting the ① solution and ② solution The flow rate is controlled at 6.5, the alkalinity is 5-40g / L, and the solid content of the slurry is 70-130g / L. After the reaction is complete, the slurry naturally overflows into the aging tank through the overflow port of the reactor.

[0050] In addition, a laser particle size analyzer can be used to detect the particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com