Patents

Literature

563results about How to "Achieve restoration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

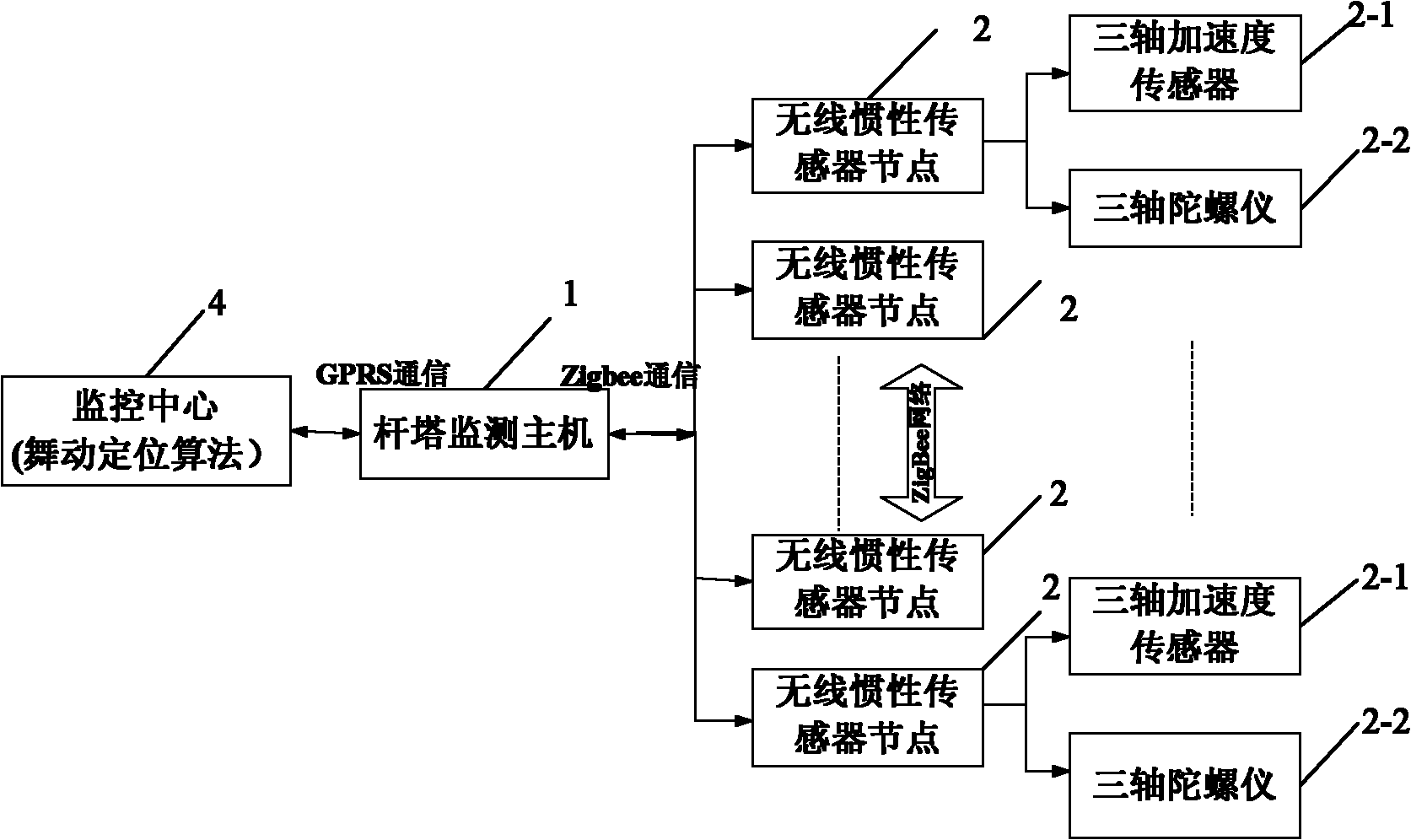

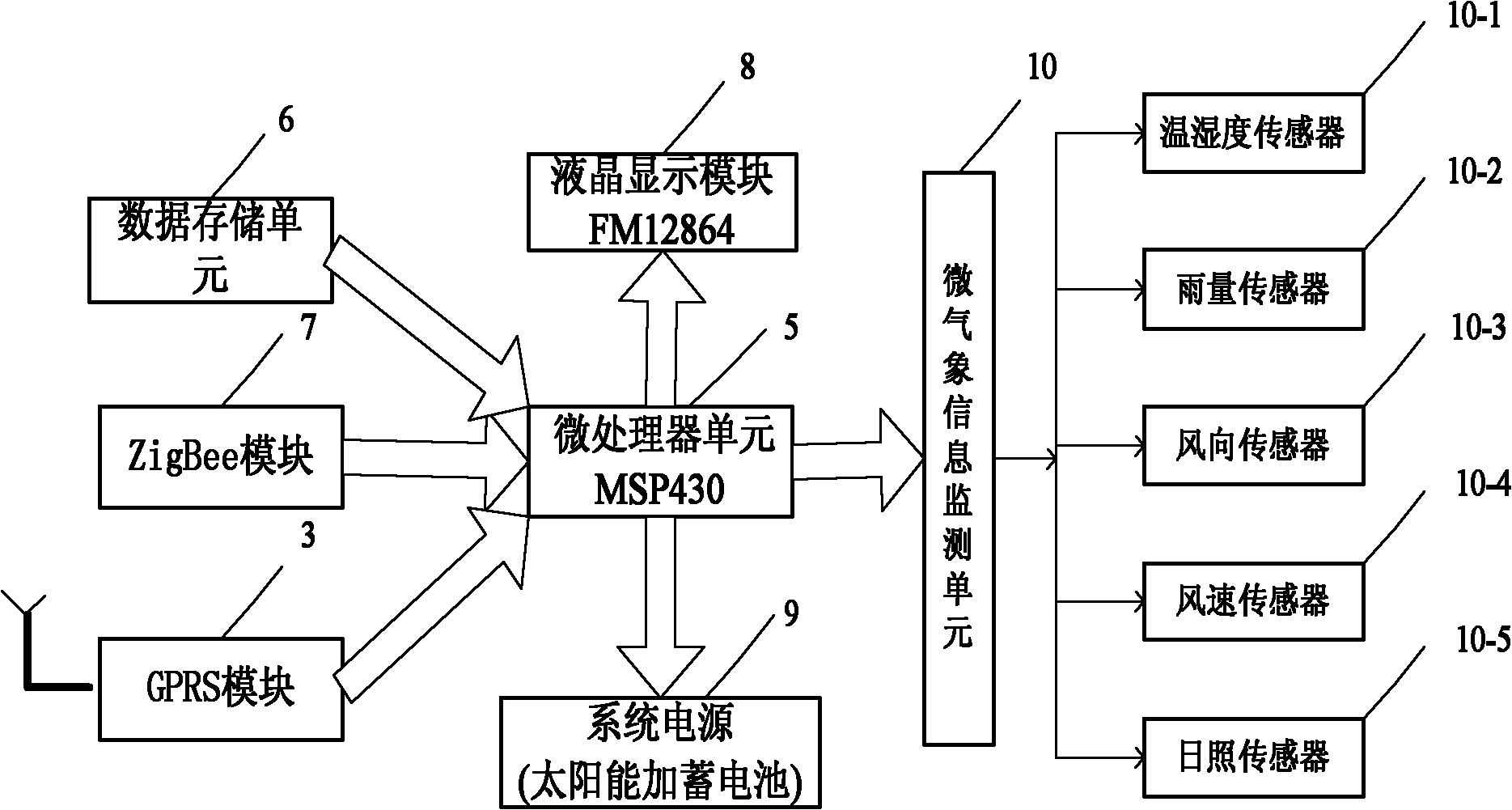

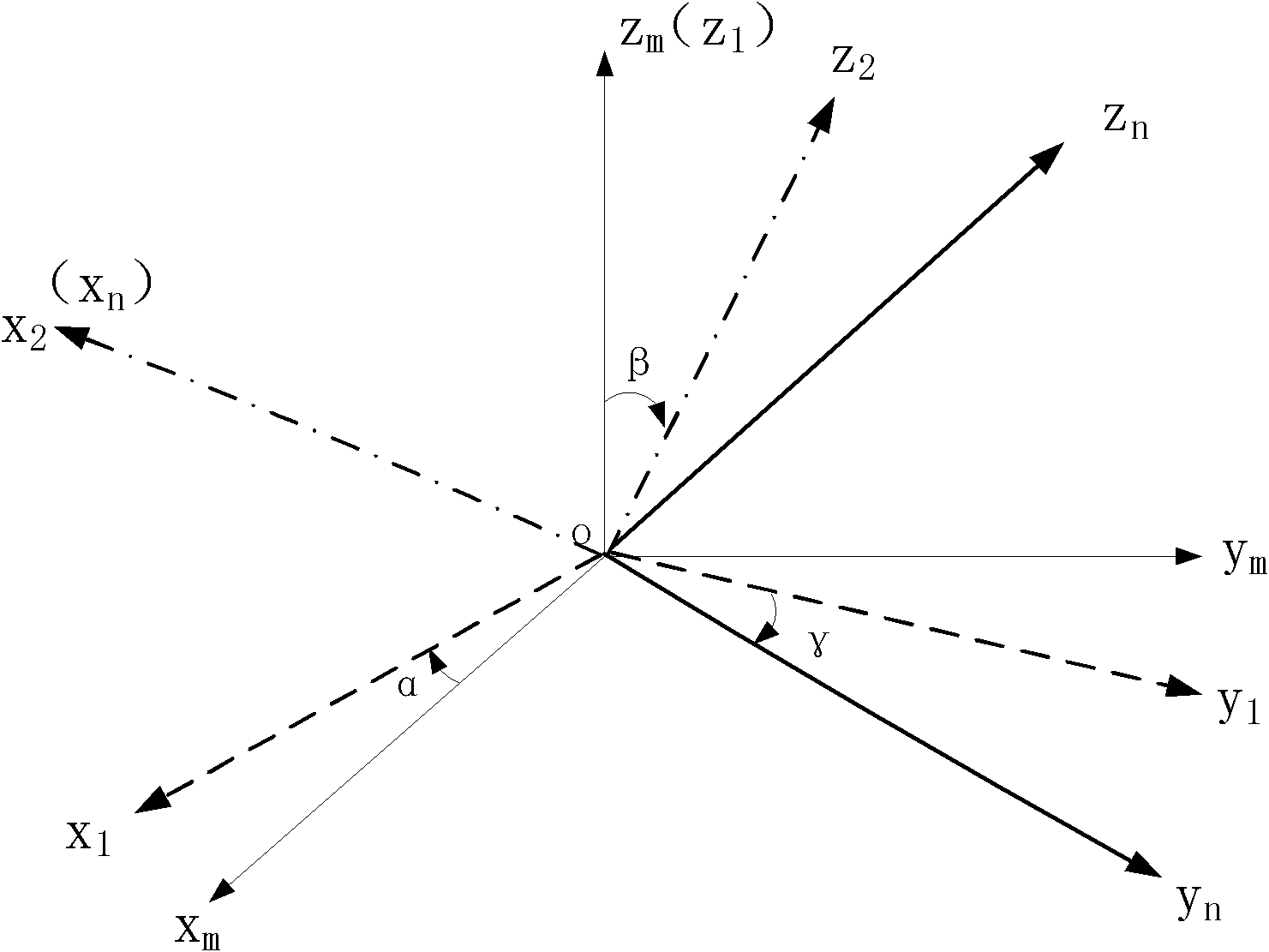

Galloping positioning system and positioning method of transmission conductors based on micro-inertial measurement combination

ActiveCN102279084AHigh precisionMeet the needs of long-term operation in the fieldVibration testingGyroscopeMathematical model

The invention discloses a transmission line oscillation positioning system based on micro inertial measurement combination. The transmission line oscillation positioning system comprises a monitoring center and a pole and tower monitoring host machine which are connected with each other, wherein the pole and tower monitoring host machine is wirelessly connected with at least two wireless inertialsensor nodes; and each wireless inertial sensor node comprises a triaxial acceleration sensor and a triaxial gyroscope. By the method for positioning by adopting the system, the wireless inertial sensor nodes acquire acceleration values and state space angles of a lead wire monitoring point in three directions; the monitoring center processes and analyzes the data of each monitoring point by adopting algorithms, such as Fourier transformation, a least square method, digital filtering, Kalman filtering, matrix coordinate transformation, frequency domain integral operation so as to fit to acquire an oscillation trace of a whole line, and corrects the oscillation line according to a digital model of a relation between an oscillation characteristic value and a micro meteorological condition; therefore, the precision of oscillation monitoring is improved and the most direct and intuitive monitoring of transmission line oscillation can be realized.

Owner:西安金源电气股份有限公司

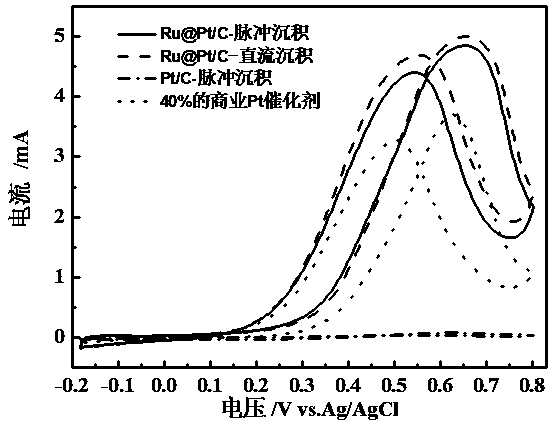

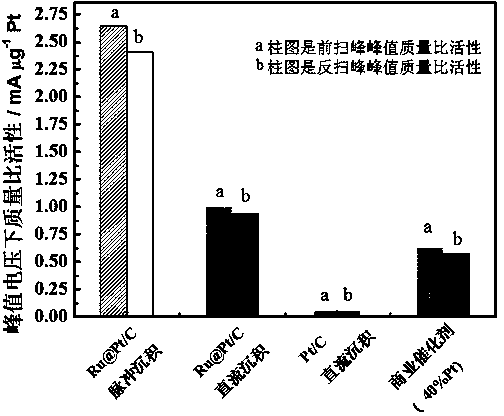

Core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method

ActiveCN103638925AIncrease profitReduce usageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlatinumPtru catalyst

The invention discloses a core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method. The active component of the catalyst is a nanoparticle with a core-shell structure, and an active metal is cladded in the form of an ultrathin shell on the surface of a carbon carrier loaded metal or alloy nanoparticle serving as a core. The catalyst takes a non-platinum noble metal or transition metal as the core, and adopts more than one of Pt, Ir or Au as the shell. The preparation method includes: preparation of the nanoparticle serving as the core, making of a working electrode for pulse electrodeposition, and preparation of the catalyst by pulse electrodeposition. The catalyst can be used as an anode or cathode catalyst of a low temperature fuel cell. The obtained catalyst has very high stability. Compared with underpotential deposition, the method is simple to operate, has no need for inert atmosphere protection, and is more suitable for large-scale industrial production, also can greatly reduce the noble metal consumption of fuel cells, and greatly reduce the cost of fuel cells, thus having great significance in promoting the commercialization process of fuel cells.

Owner:SOUTH CHINA UNIV OF TECH

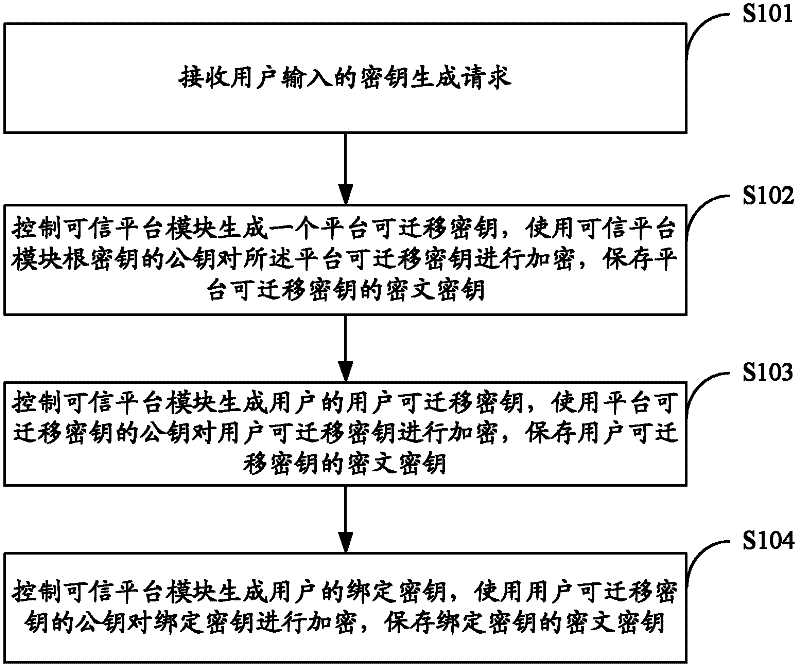

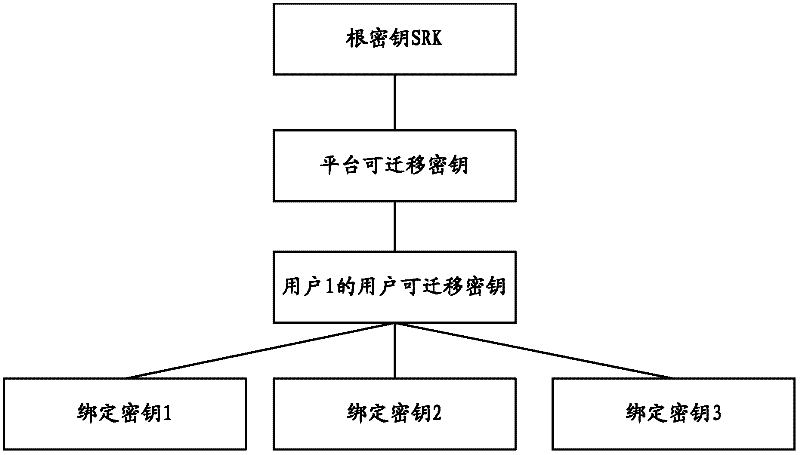

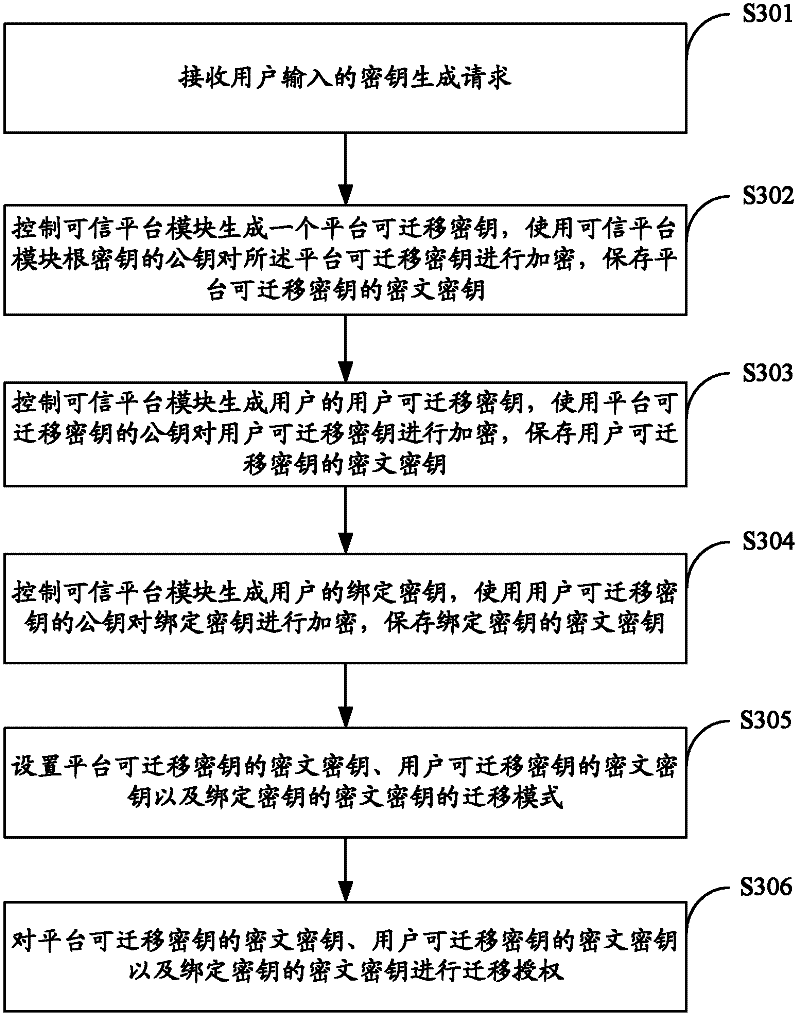

Key generation, backup and migration method and system based on trusted computing

InactiveCN102355351ARealize generationImplement backupKey distribution for secure communicationMultiple keys/algorithms usageUser inputCiphertext

The invention is suitable for the technical field of computers, and provides a key generation, backup and migration method and system based on trusted computing. The method comprises the following steps of: receiving a key generation request input by a user; controlling a trusted platform module to generate a platform migratory key, encrypting the platform migratory key by a public key of a root key of the trusted platform module, and storing a cipher text key of the platform migratory key; controlling the trusted platform module to generate a user migratory key, encrypting the user migratory key by using the public key of the platform migratory key, and storing the cipher text key of the user migratory key; and controlling the trusted platform module to generate a binding key of the user, and encrypting the binding key by using the public key of the user migratory key, and storing the cipher text key of the binding key. According to the method and the system, the generation, backup, recovery and migration of the key are realized based on a trusted computing module in the trusted computing, and the security of the key in the generation, backup, recovery and migration processes is improved.

Owner:HUAWEI TECH CO LTD +1

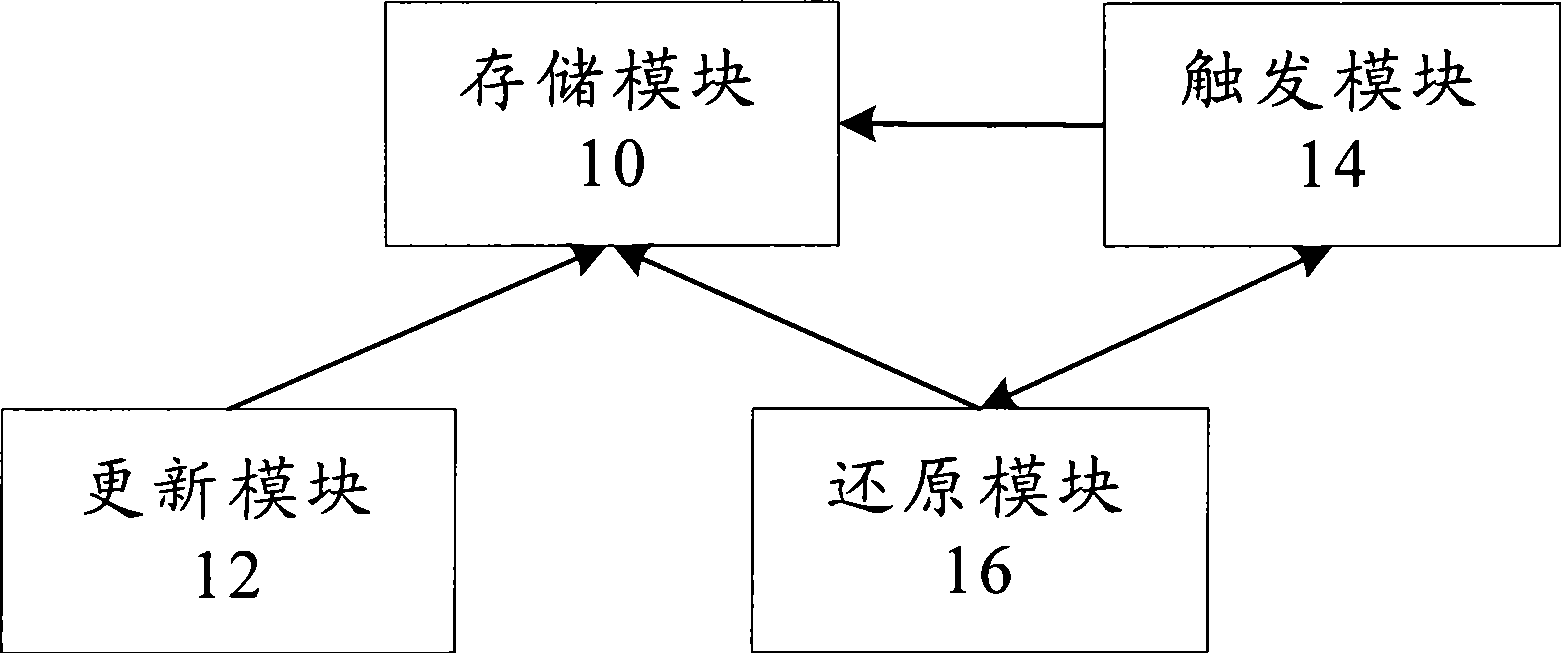

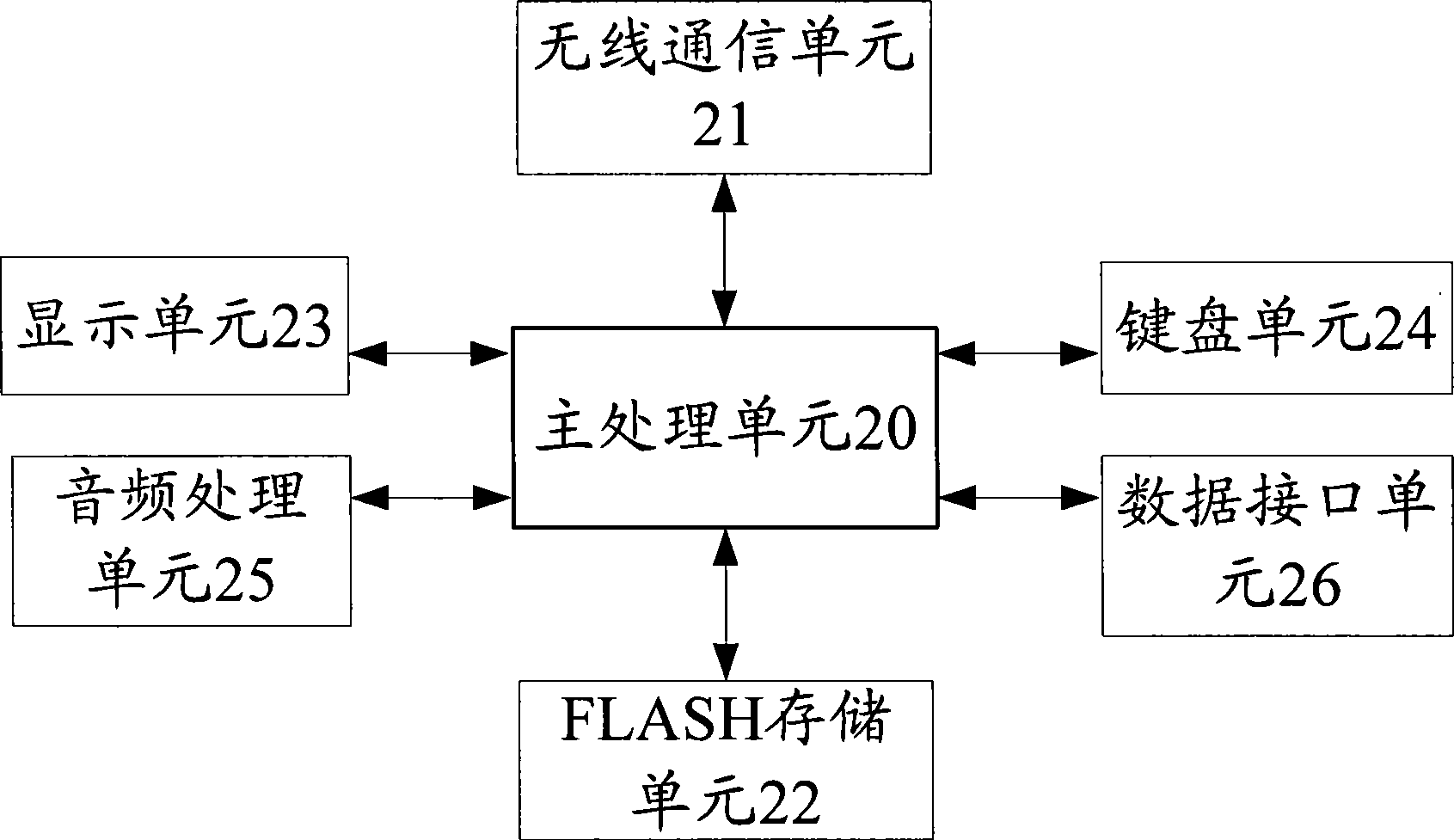

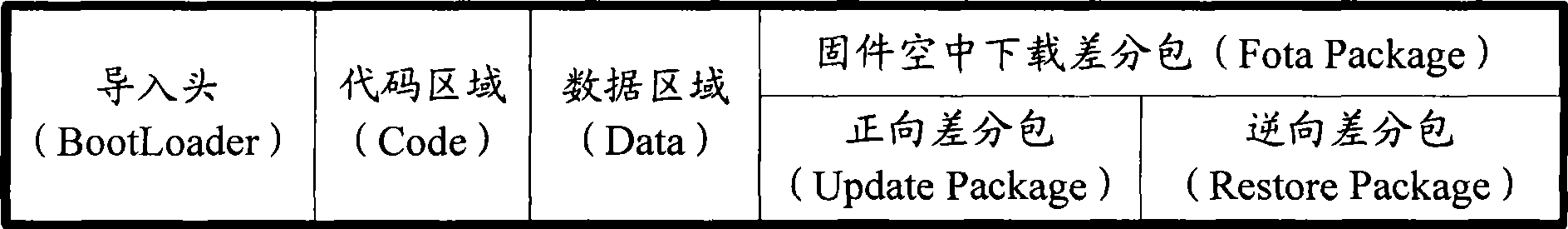

FOTA server, terminal and software version processing method and system therefor

ActiveCN101420431ALow costAchieve restorationProgram loading/initiatingTransmissionDifferential algorithmTerminal cost

The present invention provides a firmware over-the-air downloading server, a terminal and a method thereof for processing the software version, wherein the method for processing the software version comprises a step of obtaining a forward differential package and a reverse package of firmware over-the-air downloading server by the terminal, wherein, the forward differential package comprises the information required for updating a present version to a new version, and the reverse differential package comprises the information required for restoring the new version to the present version. After the terminal schedules the forward differential package through a differential algorithm and updates the software version to a new version, the reverse differential package can be scheduled through the differential algorithm for restoring the new version to the present version if necessary. The firmware over-the-air downloading server, the terminal and the method of the invention overcome the problem that more resource is required when old version of software is stored in FLASH storing unit in the wireless terminal in the prior art, thereby reducing the terminal cost.

Owner:建湖上冈产业园服务有限公司

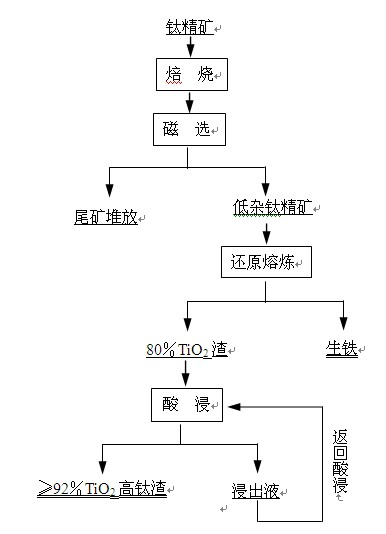

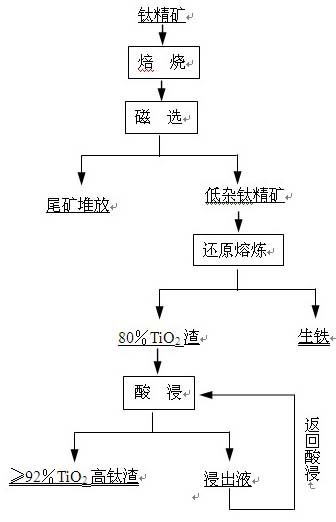

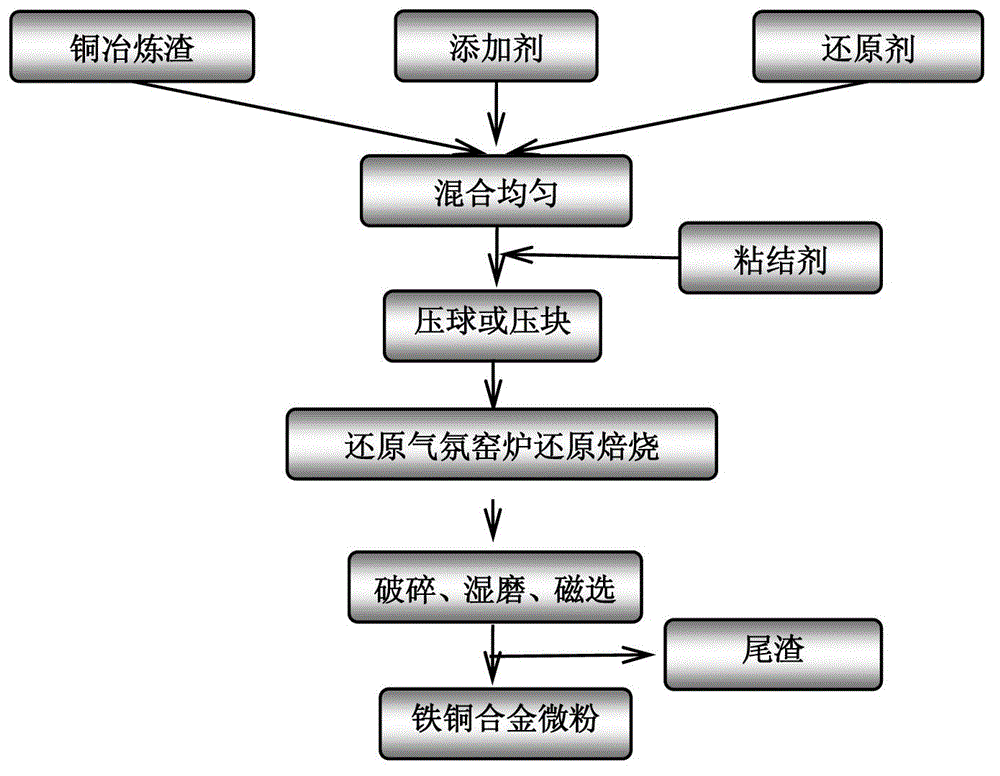

Method for preparing titanium-enriched material from high-impurity-content ilmenite concentrate

The invention discloses a method for preparing a titanium-enriched material from high-impurity-content ilmenite concentrate, which relates to the technical field of a preparation method of a titanium-enriched material. The technical route is as follows: raw ore, magnetic separation, iron concentrate, tailings, floatation, ilmenite concentrate, roasting, magnetic separation, reduction smelting, titanium slag, purification and titanium-enriched material. The invention integrates the advantages of an electric-furnace smelting method and an acid leaching method, and overcomes the defects of the two methods; and thus, the method provided by the invention can be used for treating high-impurity-content rock-type ilmenite concentrate, and can also be used for producing a high-quality titanium slag product.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

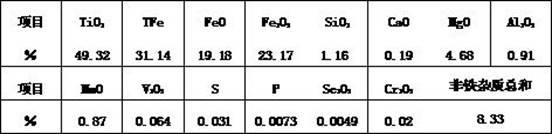

Method for rapidly reducing copper slags to produce iron-copper alloys in kiln in reducing atmosphere

ActiveCN102719676AIncrease added valueAchieve restorationProcess efficiency improvementSilicic acidReducing atmosphere

A method for rapidly reducing copper slags to produce iron-copper alloys in a kiln in a reducing atmosphere is characterized by including the steps: proportionally mixing the copper slags, reducing agents and additives, crushing or levigating the mixture to 200 meshes to obtain 20%-40% of residues on sieve; doping agglomerants and water occupying 5-20% of all materials on a dry mass basis, uniformly mixing, producing the uniformly mixed mixture to pellets with the diameters ranging from 15mm to 30mm and small cylindrical briquettes with all the heights ranging from 15mm to 30mm by a pellet press or a briquetting machine, and drying the pellets or small cylindrical briquettes; flatly laying the dried pellets or small cylindrical briquettes at the bottom of the kiln, wherein the material layer thickness ranges from 20mm to 45mm, the material layer reducing temperature ranges from 1250 DEG C to 1450 DEG C, and the reducing time is 10-40min; and subjecting the reduced pellets or the briquettes to cooling, crushing, wet grinding and wet separation so that iron-copper alloy powder with the iron recovery rate of 85%-99% is obtained. According to the method, iron in a great quantity of silicate iron in the copper slags, which cannot be separated out by the traditional technology, is extracted and turns into the iron-copper alloy micro powder with high added value so that iron and copper in the copper slags are extracted and used simultaneously, and physical and chemical heat energy in strong reducing waste gas can be completely recovered during rapid depth reduction.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

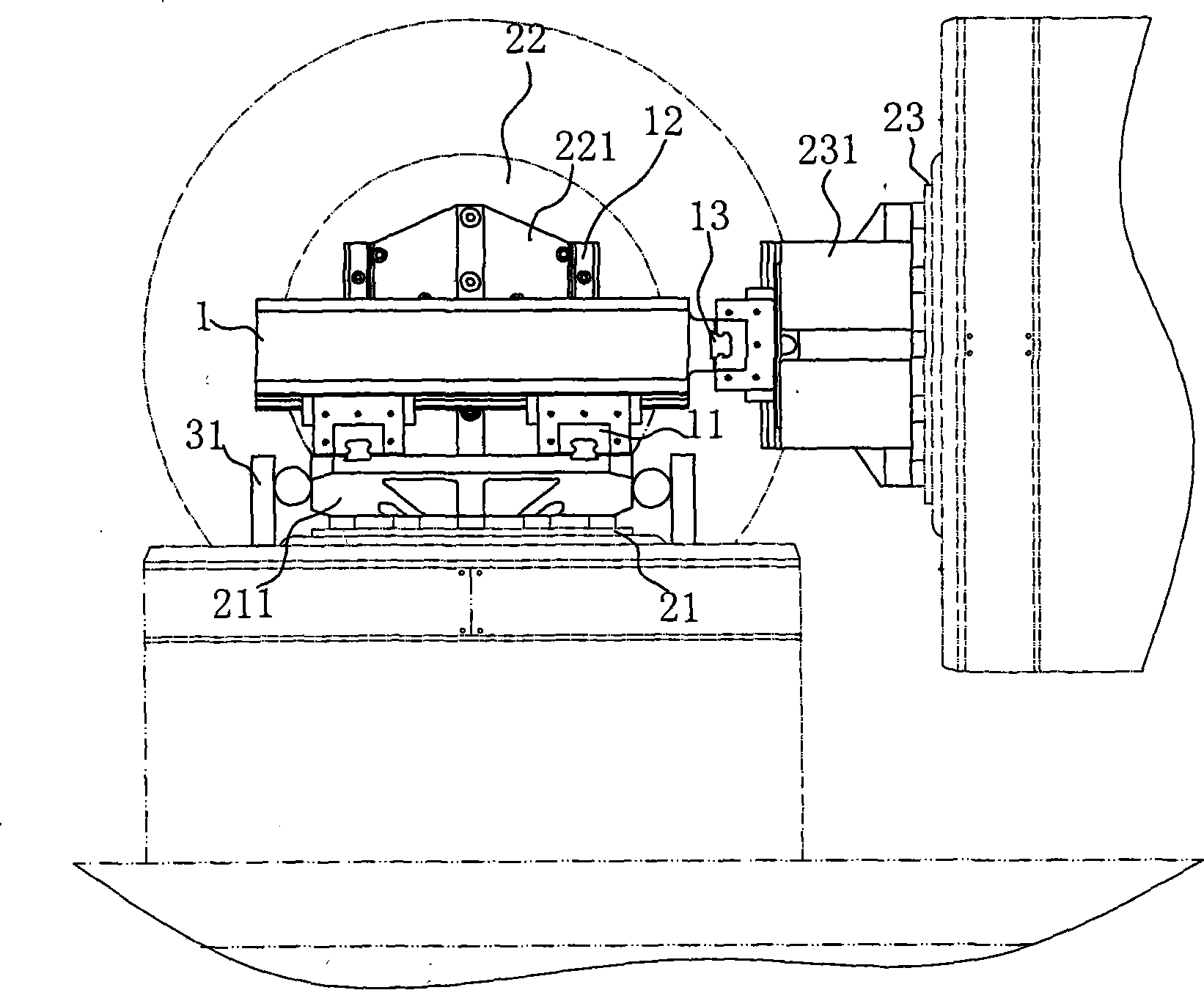

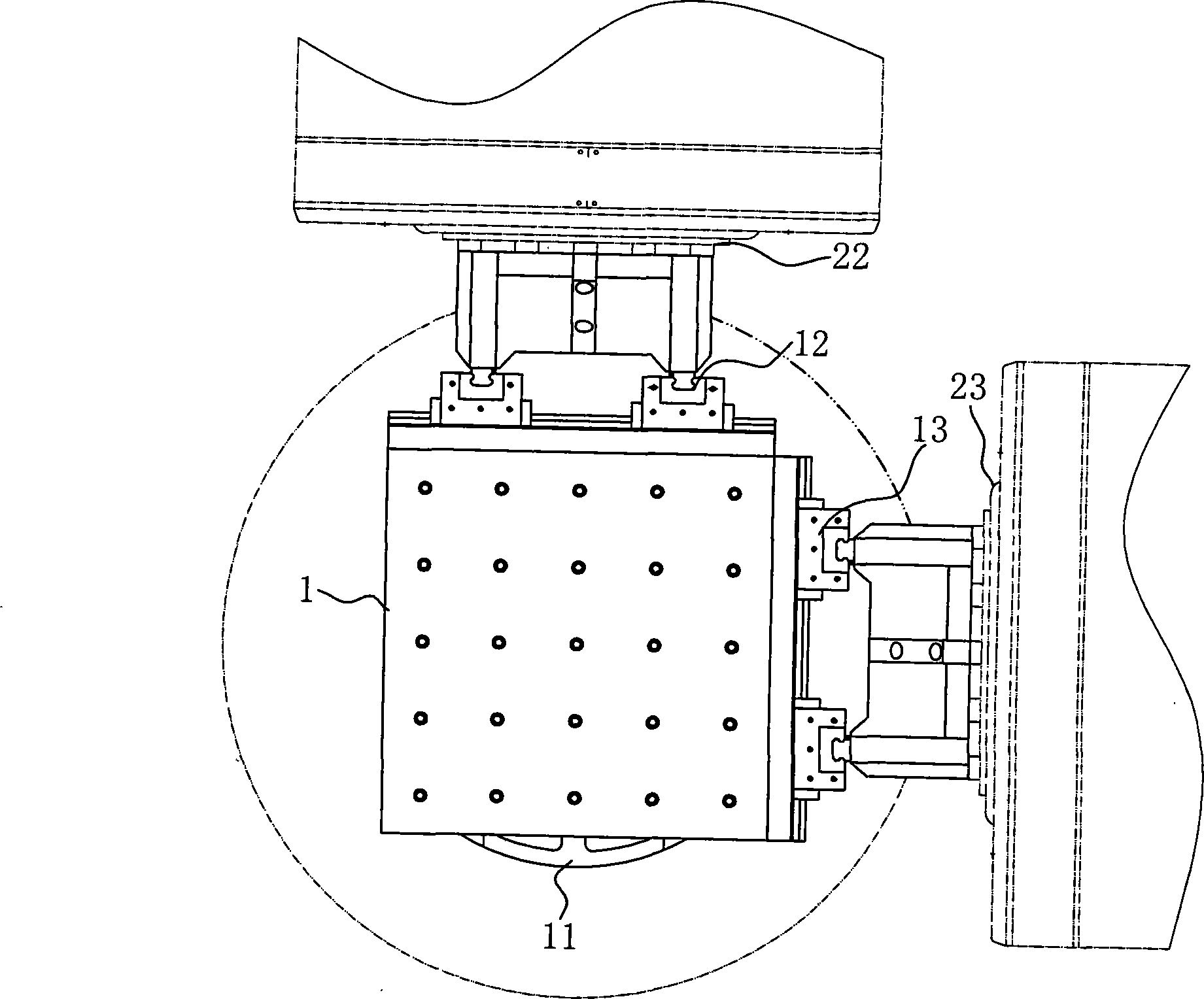

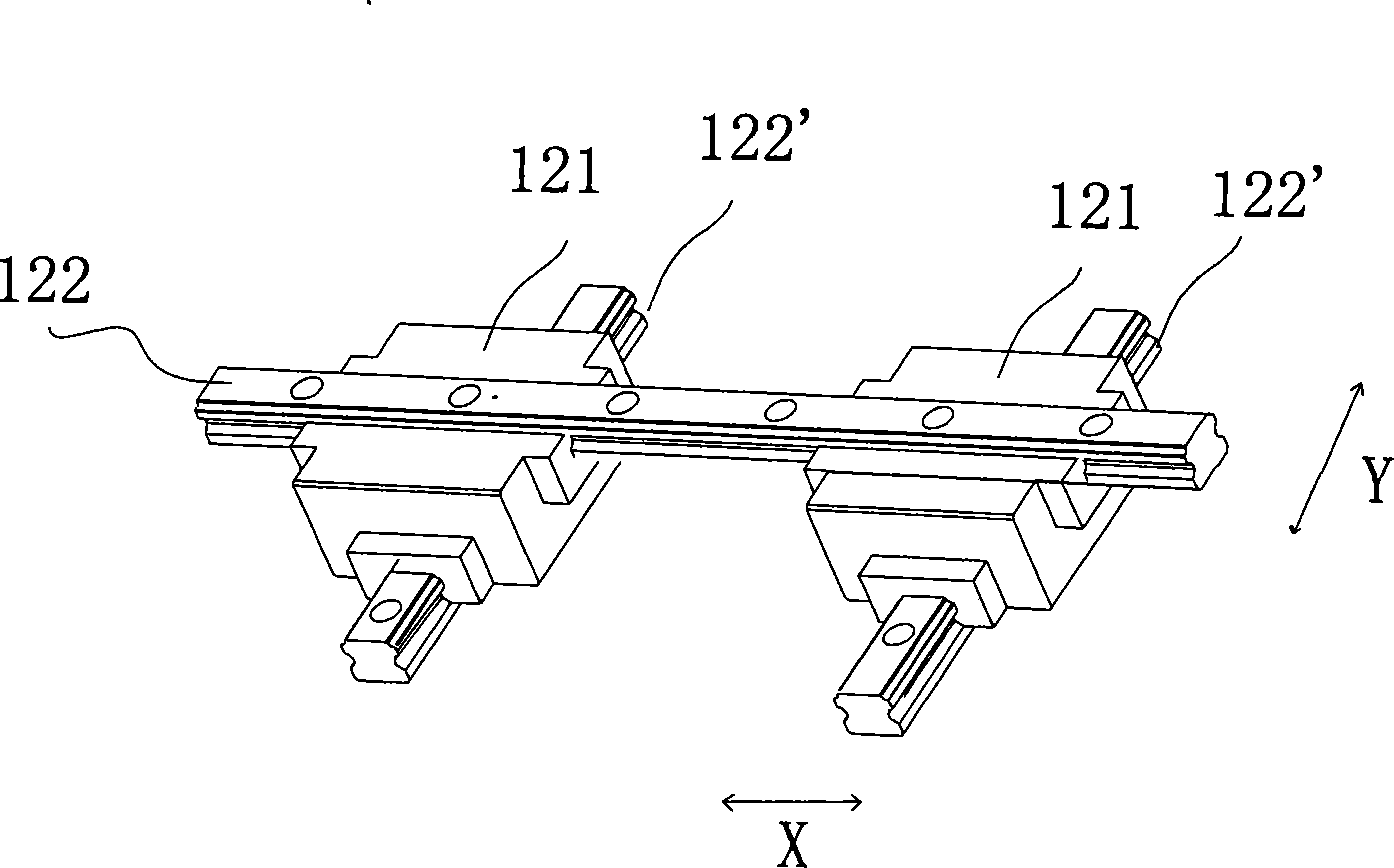

Jigging platform three-way excitation platform connecting mechanism

InactiveCN101241036AReasonable designReduce manufacturing costVibration testingEngineeringRational design

A connecting mechanism of vibration table three-directional shocking platform comprises force a passing mechanism which enable the platform for placing sample connect the vibration table at lateral side adjacent to the platform and bottom side of the platform respectively. Said force passing mechanism comprises a sliding block and a horizontal sliding track and a vertical sliding track which are respectively connected to the upper and lower end surfaces of the sliding block. Said connecting mechanism of vibration table three-directional shocking platform has rational design, low making and maintaining cost, and can satisfy the experimental request for achieving simultaneous vibration three-axially by using the three-directional shocking platform. And the connecting mechanism is able to achieving restoration of actual vibration environment furthest, which has light weight, small volume and be easy to assemble and maintain and manage. The mechanism is able to simplify the device of the entire simultaneous shocking apparatus three-axially, and the mechanism does not generate producing source such as public hazard noise and so on.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

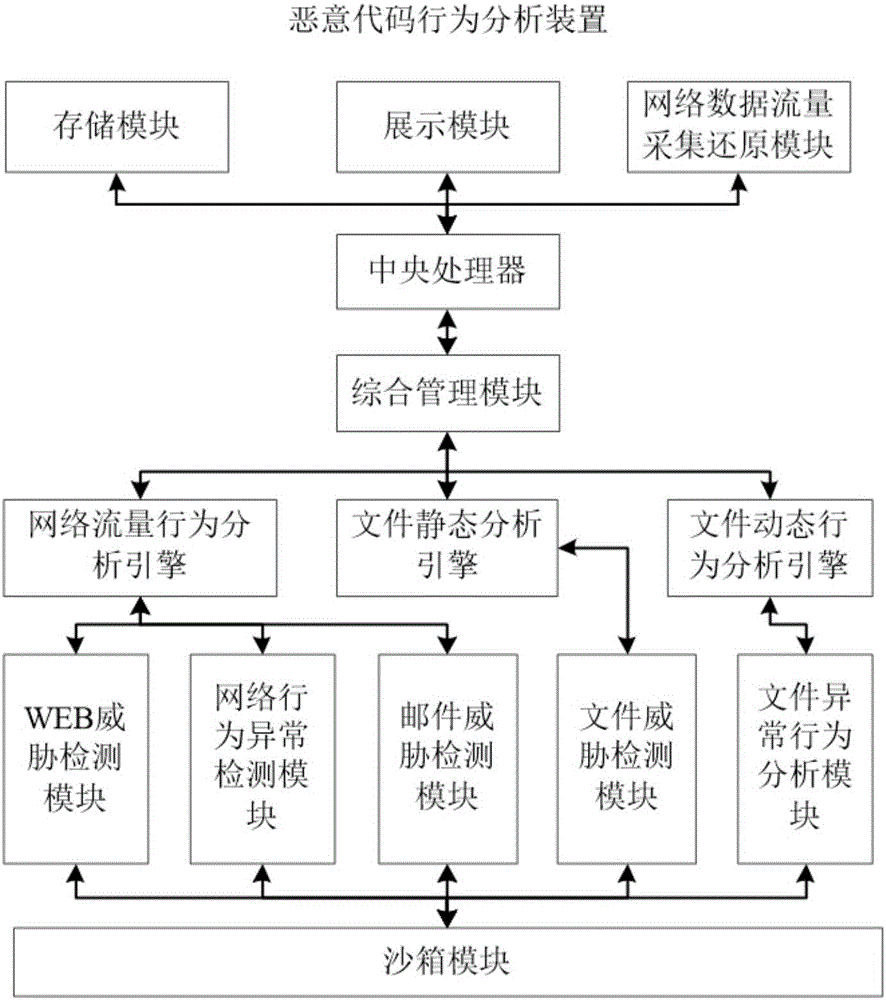

Malicious code behavior analyzer

InactiveCN106341282AAchieve reorganizationAchieve restorationData switching networksWeb threatBehavioral analytics

The invention provides a malicious code behavior analyzer which comprises a storage module, a display module, a network data flow collecting and reducing module, a central processor, an integrated management module, a network flow behavior analysis engine, a file static analysis engine, a file dynamic behavior analysis engine, a WEB threat detection module, a network behavior abnormity detection module, a threat detection module, a file threat detection module, a file abnormal behavior module and a sandbox module. According to the analyzer, the network data flow can be recombined and reduced, abnormal network behaviors are detected, suspected files can be reduced, extracted and analyzed, and placed in a sandbox template to monitor and analyze file behaviors dynamically, results of static analysis and dynamic analysis are combined to provide the degree of information safety risk of the suspected files, and the technical problem that high-level malicious code attacks which is increasingly serious cannot be handled is solved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

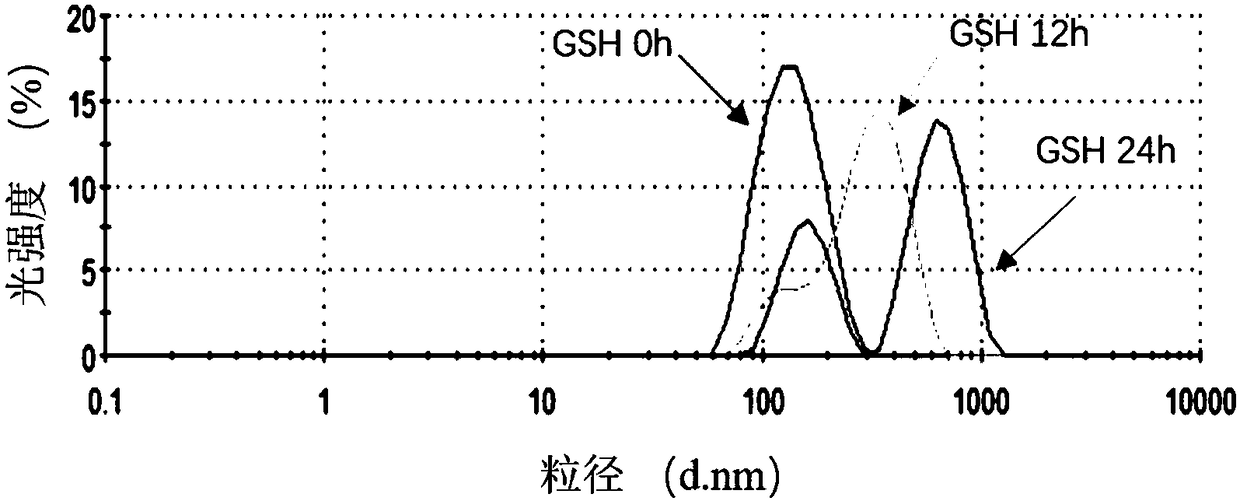

Folate-targeted reduction sensitive drug-carrying polymer nano-micelle as well as preparation method and application thereof

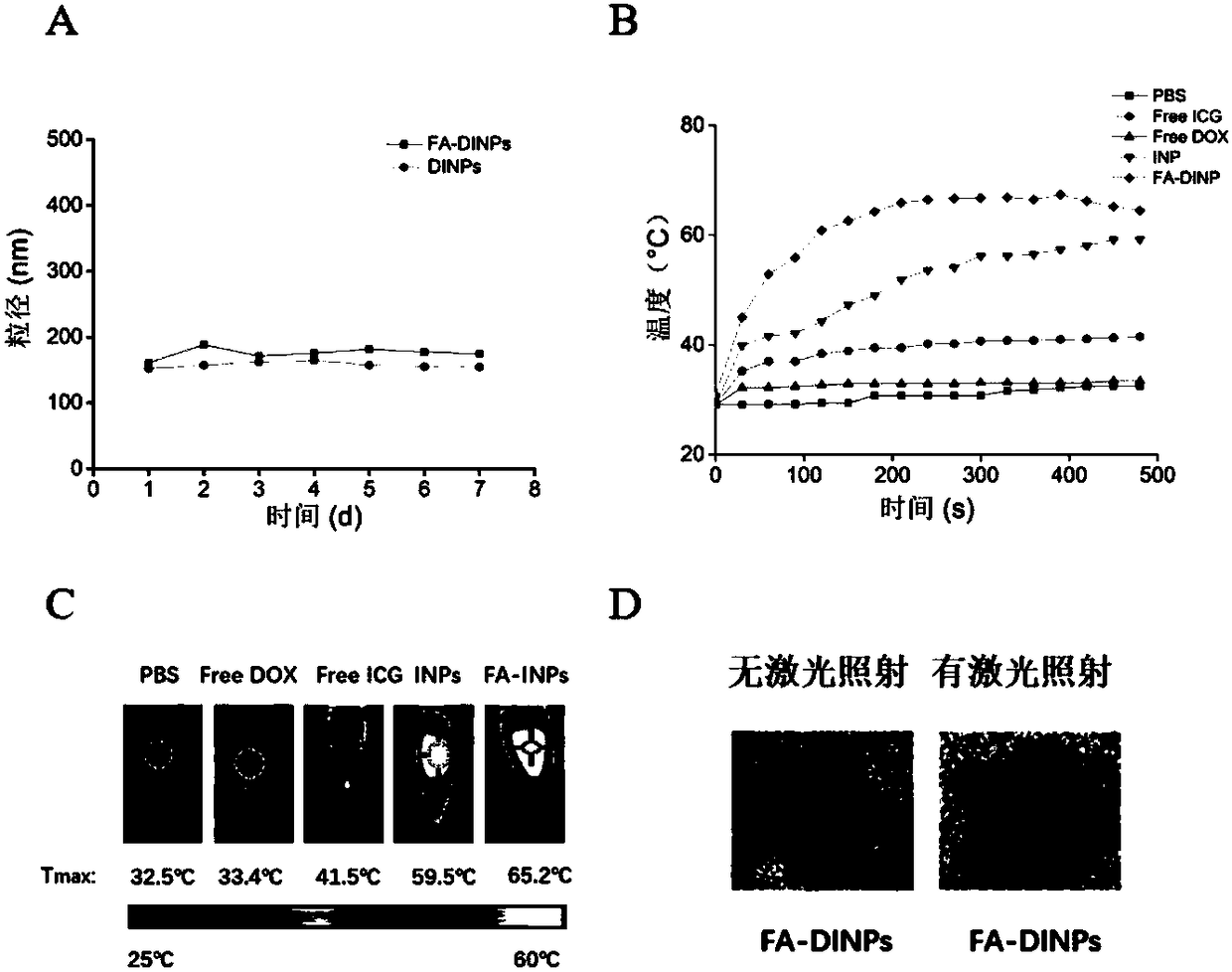

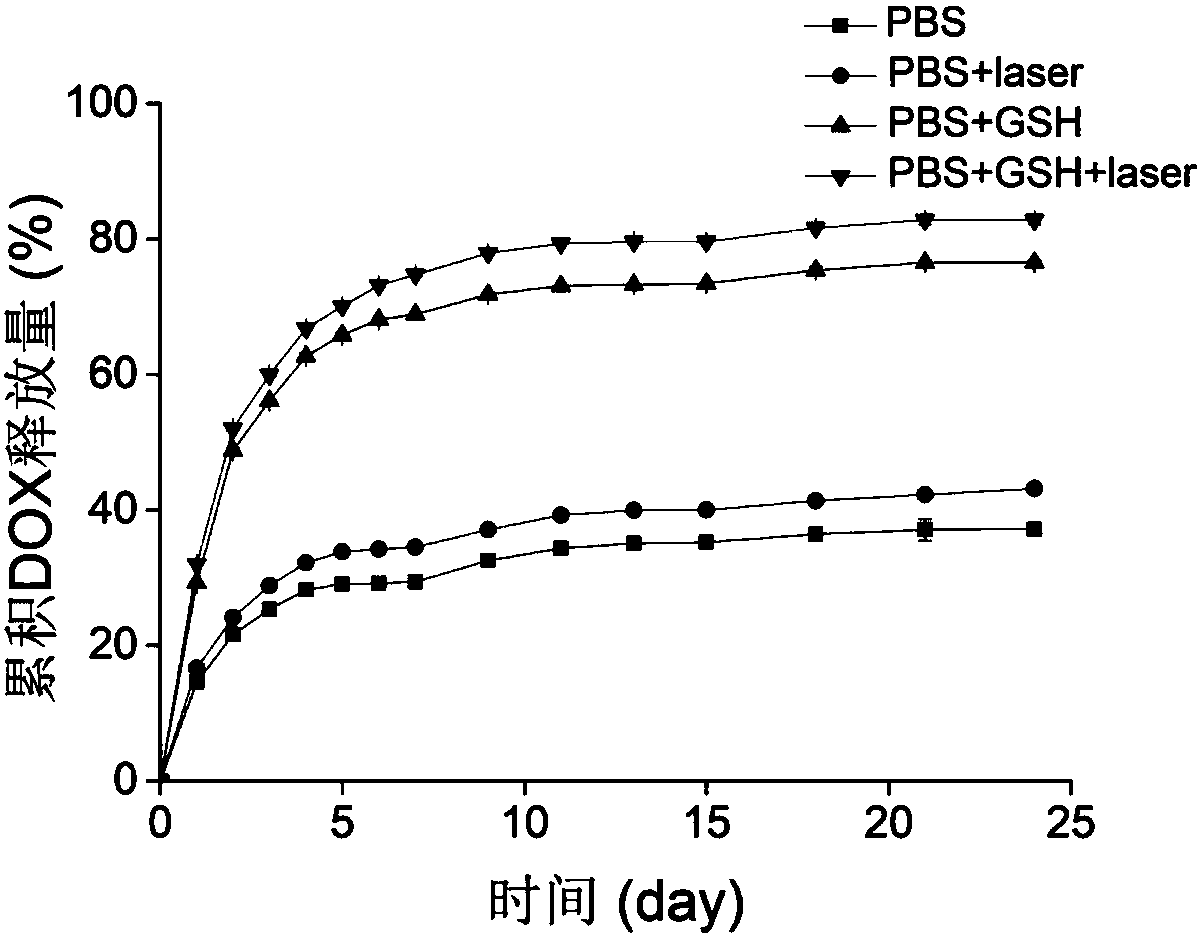

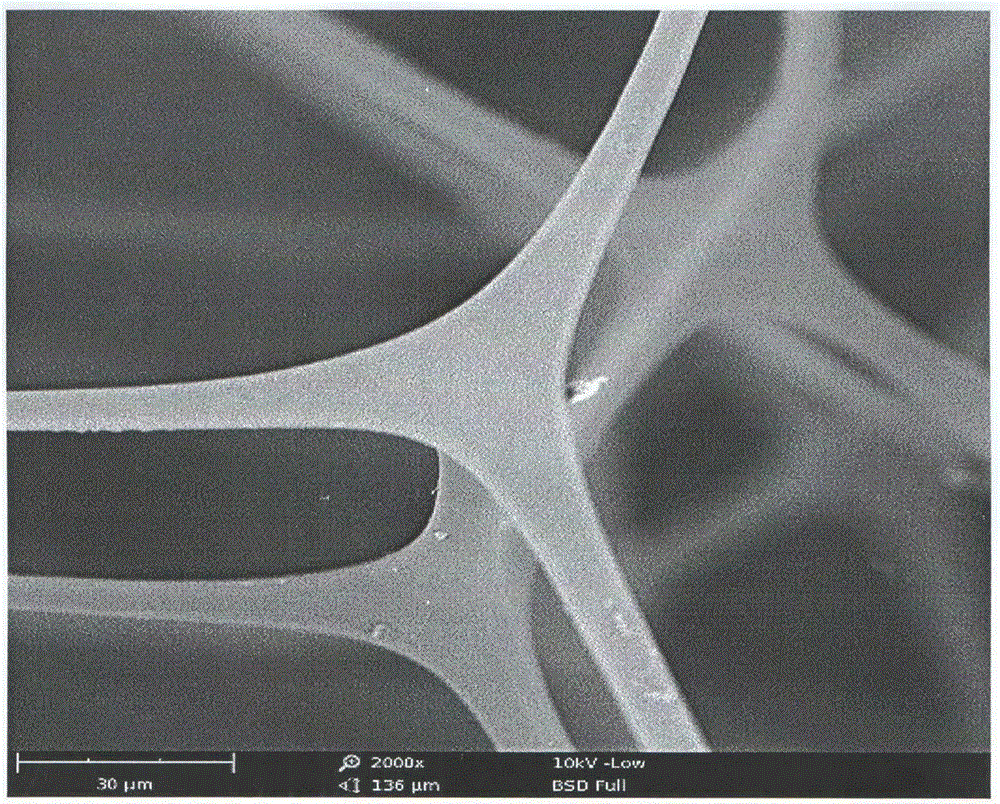

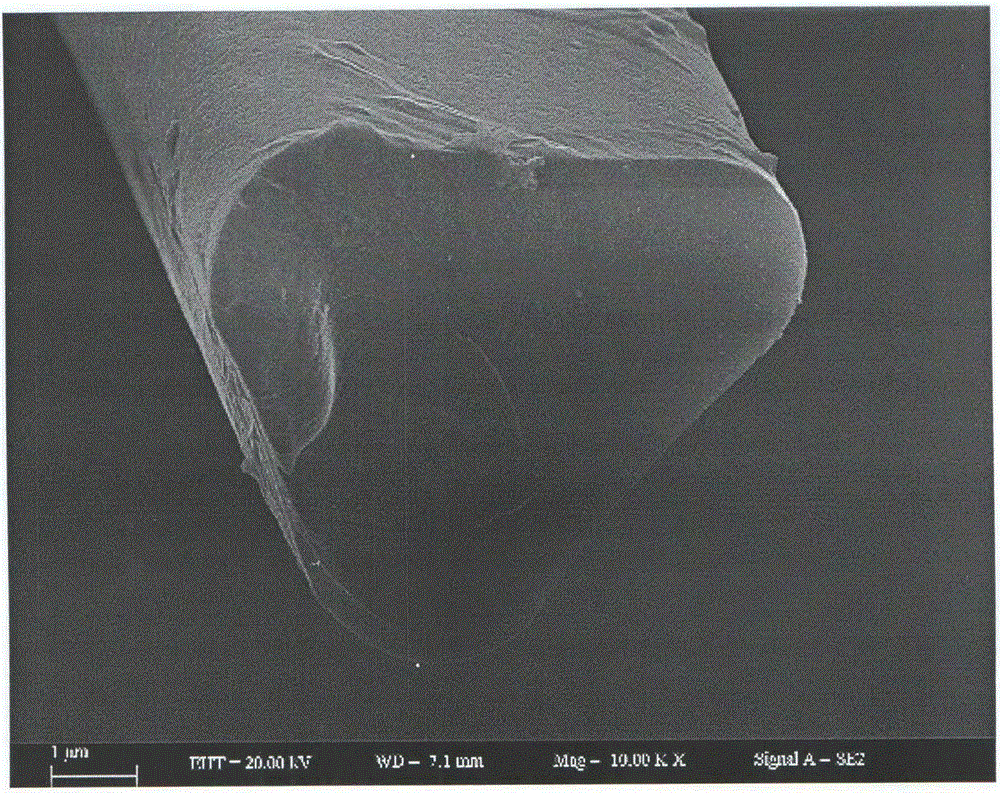

InactiveCN108478531AEfficient packagingEfficient entryOrganic active ingredientsEnergy modified materialsTumor targetPolymer science

The invention relates to a folate-targeted reduction sensitive drug-carrying polymer nano-micelle as well as a preparation method and application thereof. The delivery carrier is prepared by taking anamphiphilic triblock copolymer PCL-ss-PEG-ss-PCL as a material, and a chemotherapeutic drug adriamycin amycin and a photosensitizer indocyanine green are entrapped in a hydrophobic core of the micelle. Besides, phospholipid DSPE-PEG-NH2 with an active group is introduced into the preparation process, the DSPE end of the phospholipid has strong hydrophobic property and is inserted into the hydrophobic PCL core of the polymer micelle, the flexible hydrophilic PEG long chain exists on the outer surface of the micelle, FA with a targeting effect is connected to a PEG active distal end of the surface of the polymer micelle, and functions of active tumor targeting and reduction response drug release are integrated. The folate-targeted reduction sensitive drug-carrying polymer nano-micelle disclosed by the invention has the advantages of being small in particle size, high in dispersion property, high in drug loading capacity and encapsulation efficiency and excellent in photothermal conversion effect, can realize reduced trigger drug release, fluorescence imaging of tumor sites, tumor targeting drug delivery and chemotherapy-photothermal combination therapy and improve the tumor inhibition effect, and has wide application prospects in the targeted combination therapy aspect of tumors.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

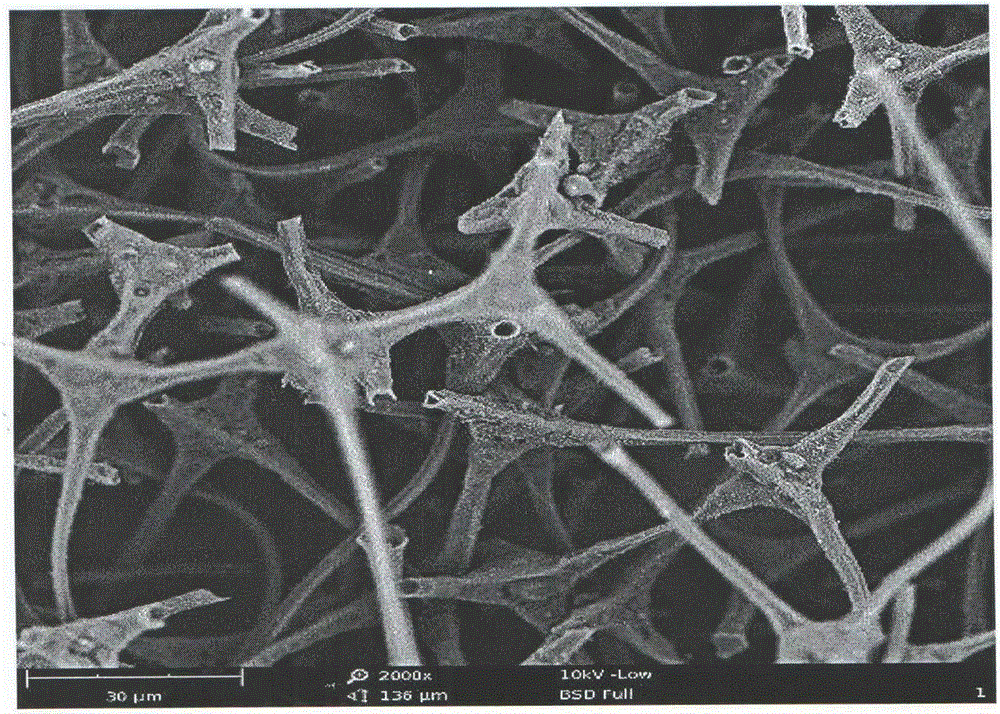

Preparing method for carbon nano tube foam material

ActiveCN105217603AExtensive sources of materialsLow costMaterial nanotechnologyMultiple dimensionControlled experiment

The invention provides a preparing method for a carbon nano tube foam material. The method comprises the steps that cheap polymer foam serves as a template, the processes of in-situ formation of a catalyst, partial thermal cracking removing of the polymer template, growth of carbon nanomaterials and the like are synchronously carried out by controlling experiment conditions, and the carbon nano tube foam material efficiently grows, wherein the carbon nano tubes are wound and woven into a mesh structure in the three-dimensional directions of a carbon framework and have distributed pore diameters of multiple dimensions, and the obtained material has the large specific surface area, the controllable porosity, good hydrophobicity, excellent electrical conductivity, a unique hollow frame structure, and application value in the fields of composite materials, sensing, oil and water separation and the like. According to the method, reaction conditions such as gas flow, gas introducing time, the reaction temperature and the catalyst are optimized, and thus the carbon nano tube foam material of a foam structure is obtained and has excellent adsorption performance on various kinds of oil and organic solvent. The defect of an existing carbon nano tube foam material preparing method is overcome.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +2

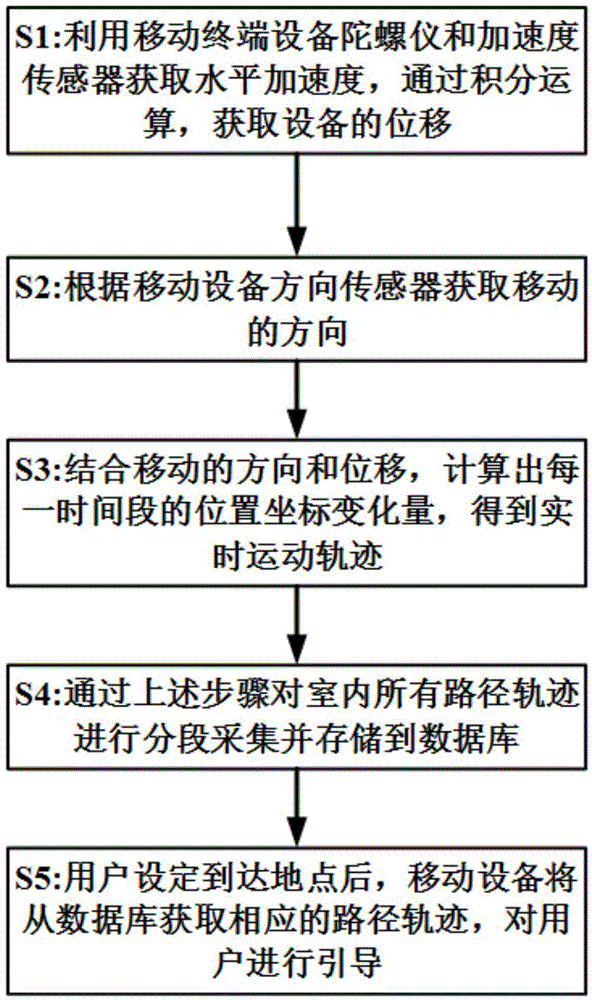

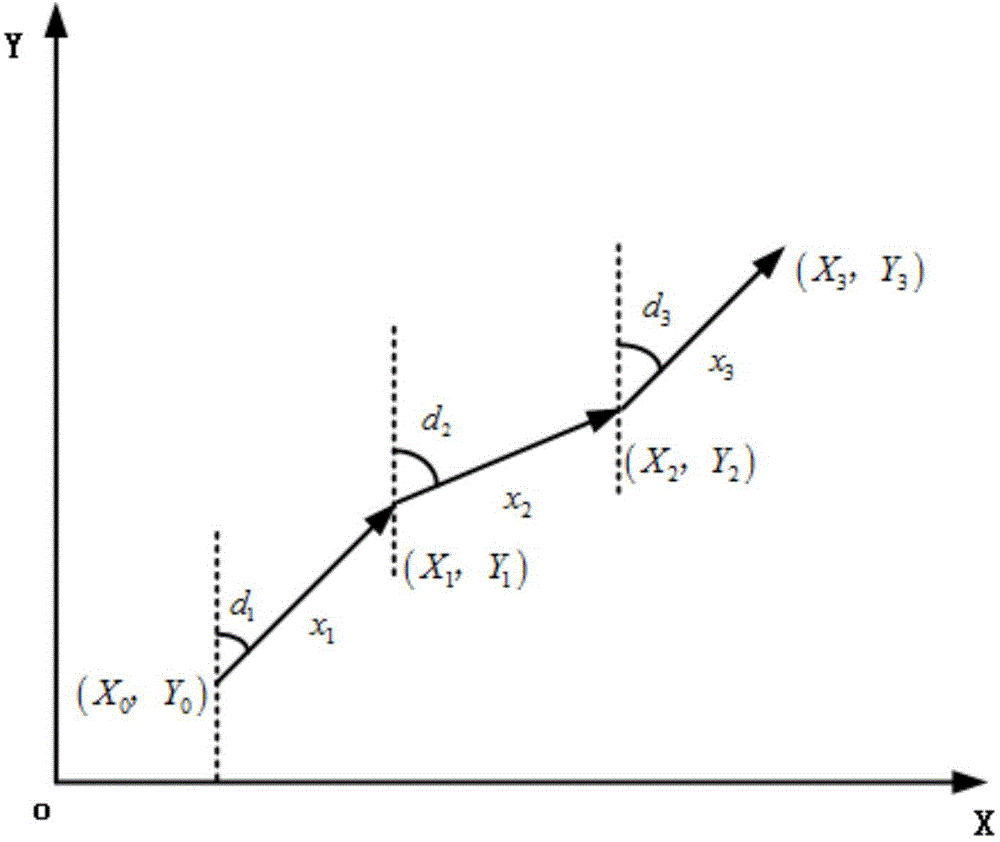

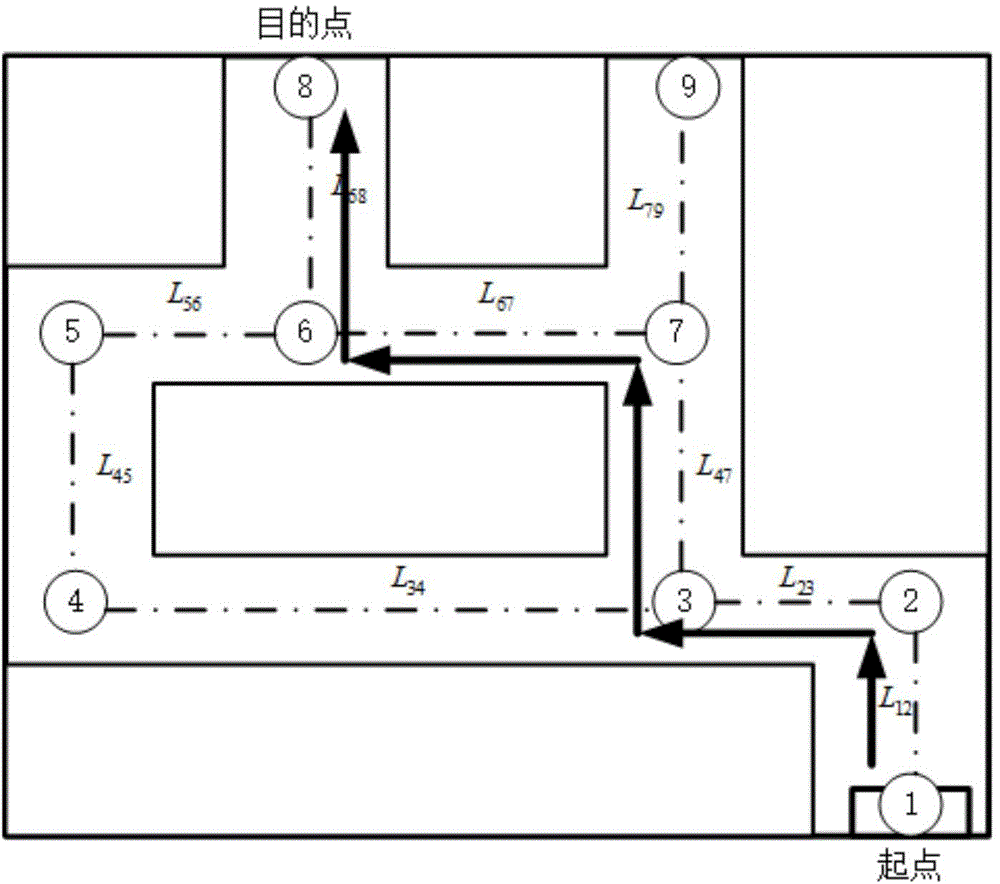

Indoor positioning and path leading method based on mobile terminal inertial navigation

InactiveCN104864871AImplement storageAchieve restorationNavigational calculation instrumentsShort path algorithmMobile device

The invention discloses an indoor positioning and path leading method based on mobile terminal inertial navigation. The indoor positioning and path leading method comprises the following steps: firstly collecting indoor path trajectory data in a subsection manner; performing optimizing processing on history path trajectory data by using a shortest path algorithm to obtain optimal path trajectory data; storing the optimal path trajectory data and uploading the stored optimal path trajectory data to a database; when a place of arrival is set by a user, obtaining corresponding most optimal path trajectory data from the database by mobile equipment, and performing path display and guidance. No extra equipment is needed, indoor inertial navigation and path guidance with relatively high precision can be achieved by just utilizing a built-in sensor of the mobile equipment, and the method has the characteristics of high practicability, high universality and low cost.

Owner:CHONGQING UNIV

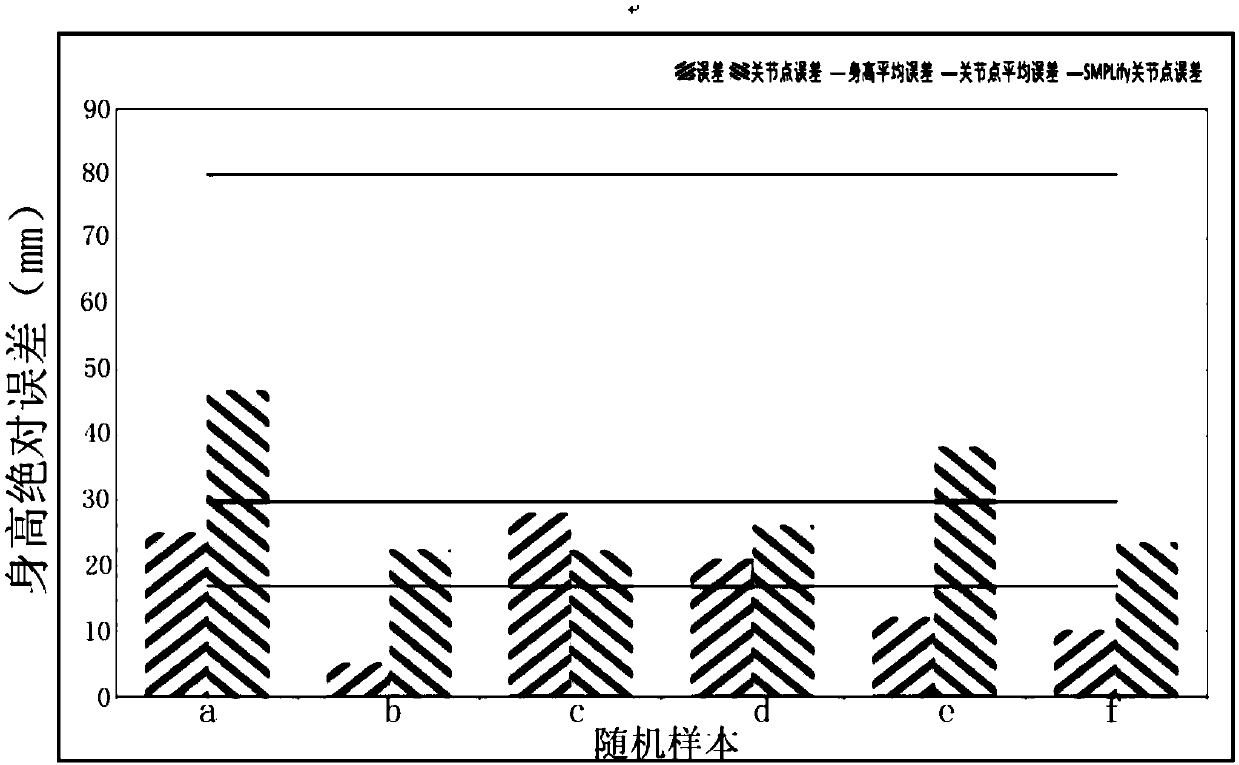

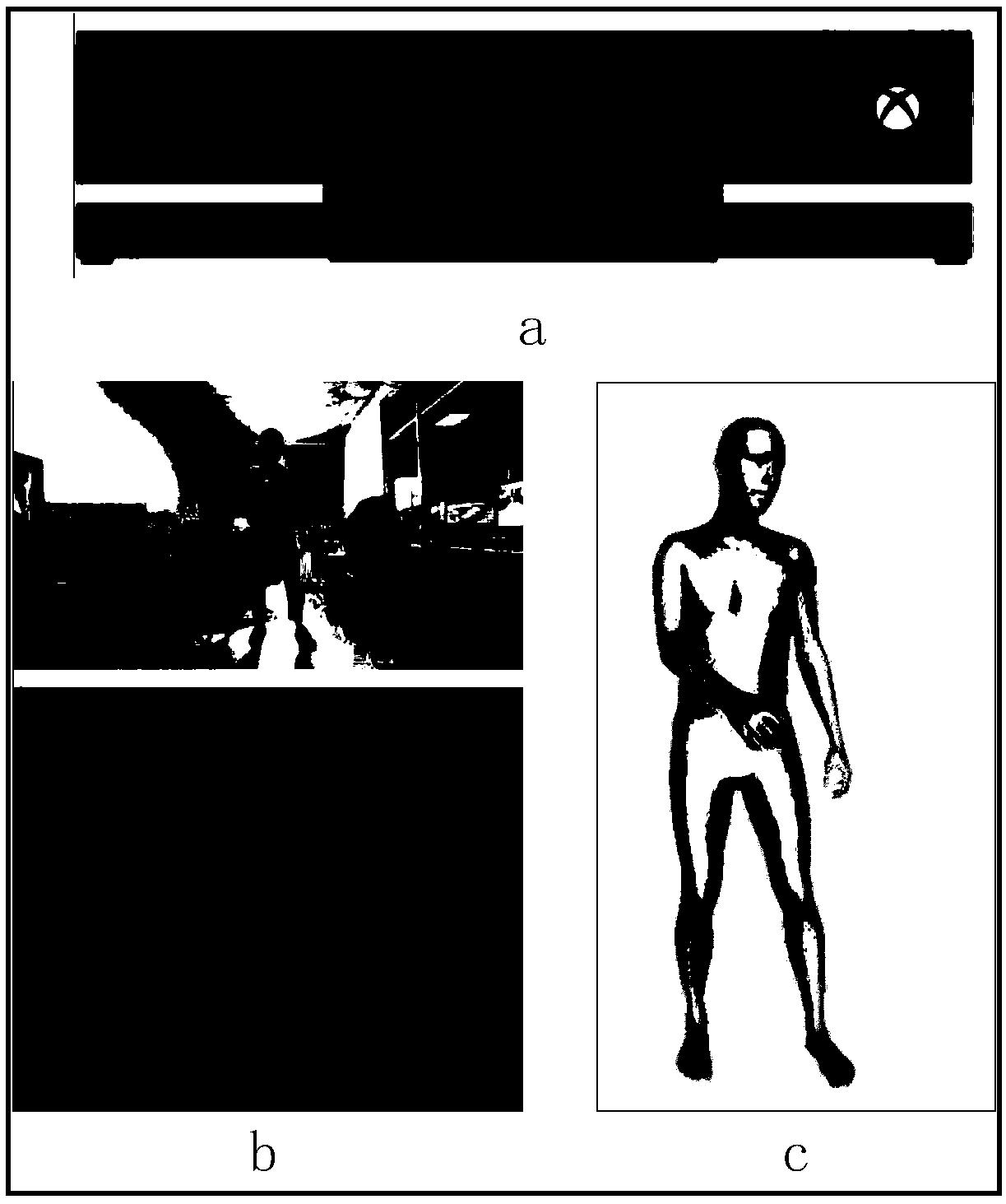

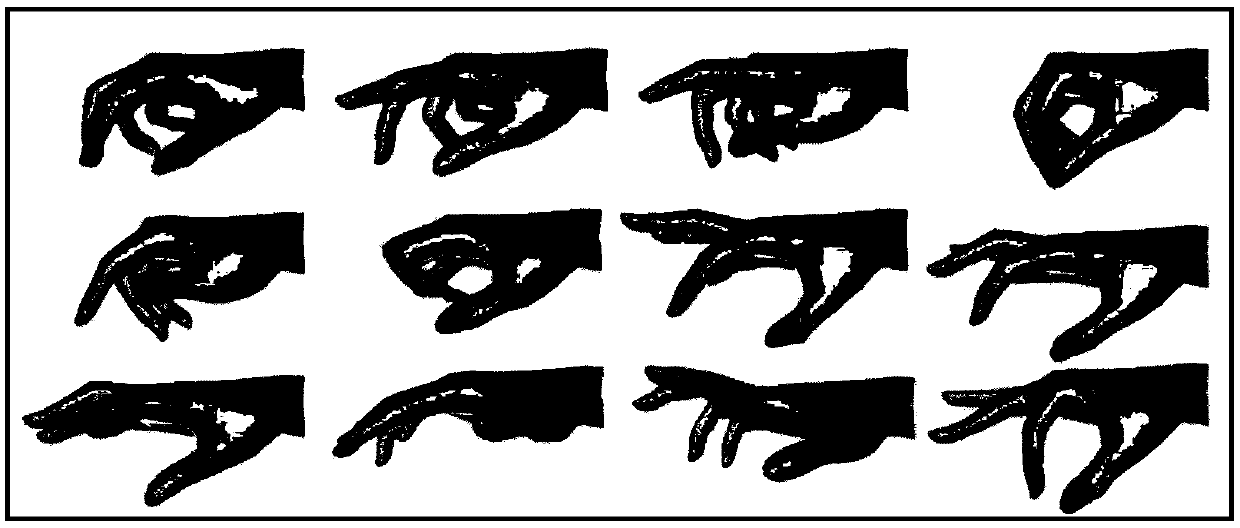

A method for estimating three-dimensional human body postures and hand information

ActiveCN109636831AResolving Steering Non-Conformance IssuesAchieve restorationImage enhancementImage analysisSurface pointSacroiliac joint

The invention relates to a method for estimating three-dimensional human body postures and hand information, in particular to a novel unique method for automatically and accurately estimating the postures of a human body and a hand and the actual figure of the human body at the same time through single-frame data of a color depth camera. Firstly, joint prediction of a depth camera and deep learning are combined with a method for predicting joints from a color map, and meanwhile steering of the head of a human body is obtained to solve the problem that the head posture cannot be matched in theprior art. Meanwhile, the gesture of the hand is restored in the human body estimation process, so that the human body result is more vivid and specific, the 3D gesture of the hand is predicted from the color image by using a deep learning method, and then the fitting of the human body gesture and the latest parameterized human body model SMPL + H is completed by using a 3D human body joint fitting energy model. And finally, the obtained human body surface point cloud is registered with the fitted model to improve the accuracy of human body shape estimation. Therefore, an accurate three-dimensional human body model containing the real hand posture is estimated.

Owner:ANHUI UNIVERSITY

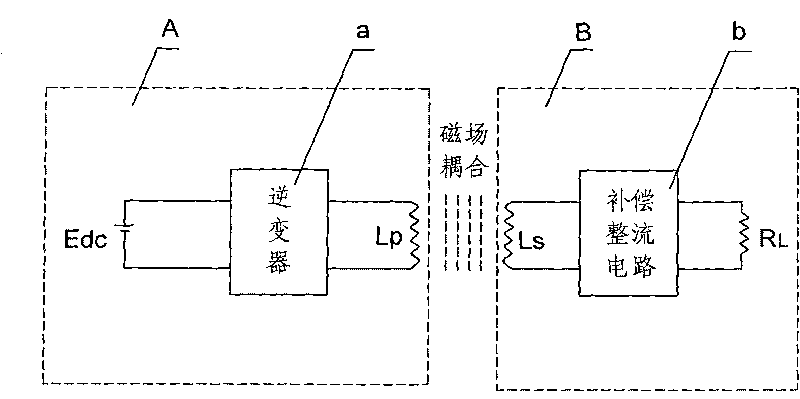

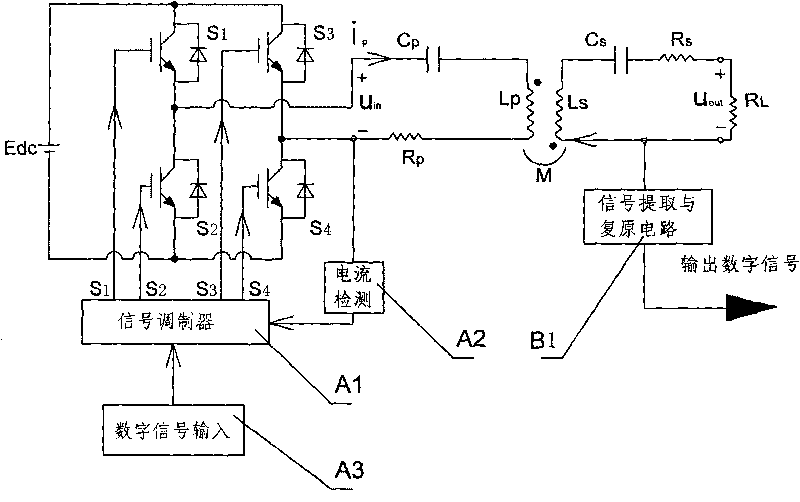

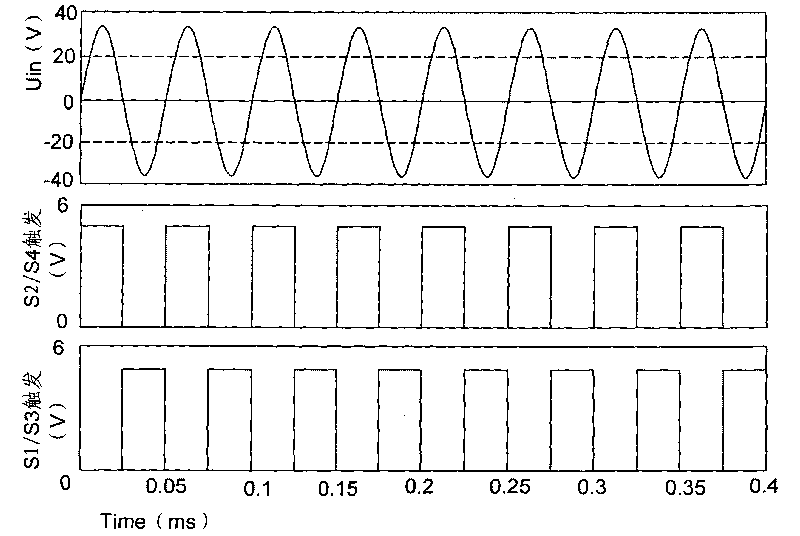

Method and device for non-contact type synchronous transmission of energy and signal

ActiveCN101719726ARealize contactless synchronous transmissionSimple methodDc-dc conversionConversion without intermediate conversion to dcSecondary loopEngineering

The invention discloses a method for the non-contact type synchronous transmission of energy and signal. The method is characterized by comprising the following steps: establishing an AC electric energy transmission system of non-contact type; mounting a signal modulator in a primary loop; providing a digital signal for the signal modulator; extracting signal characteristics from a secondary loop and restoring the digital signal when the secondary loop receives electric energy; and finally realizing the non-contact type synchronous transmission of the energy and the signal. The non-contact type device for synchronously transmitting energy and signal, which is used for realizing the method, is provided with a DC power supply, an inverter and an exciting coil in the primary loop and characterized in that the signal modulator in the inverter is connected with a digital signal input unit and provided with a signal extracting and restoring circuit; and the output end of the signal extracting and restoring circuit outputs the restored digital signal. The invention has the advantages of easiness, practicability and low cost, restores the energy as a digital signal and has higher system reliability.

Owner:重庆前卫无线电能传输研究院有限公司

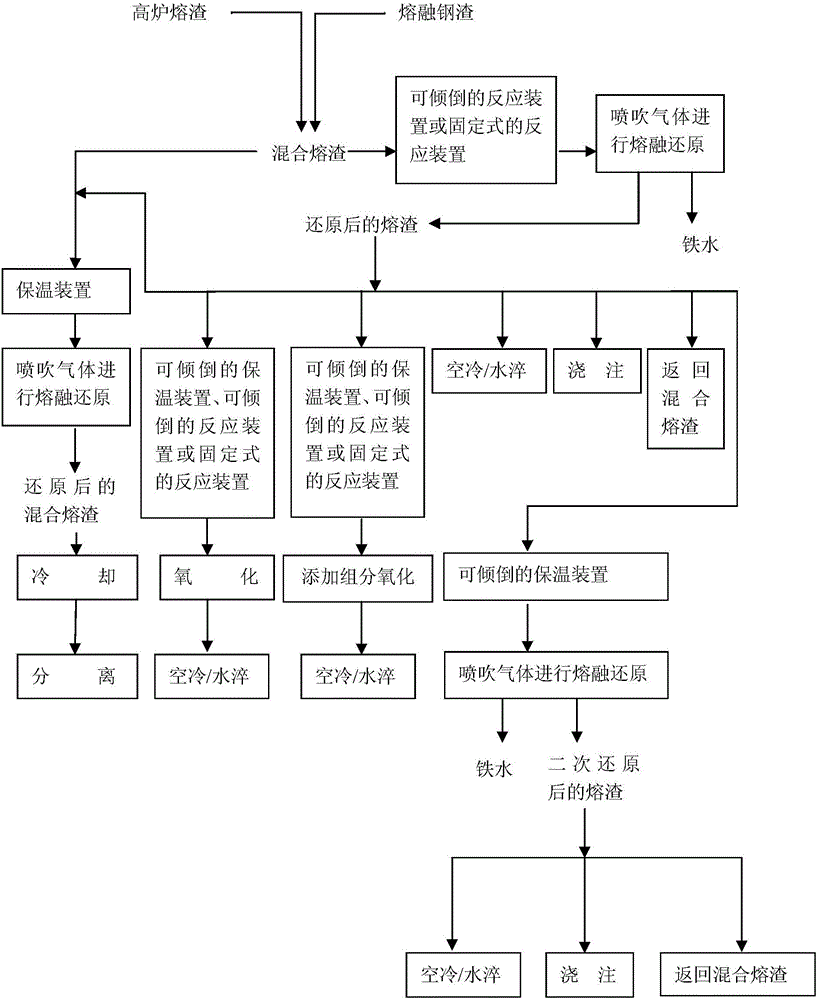

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

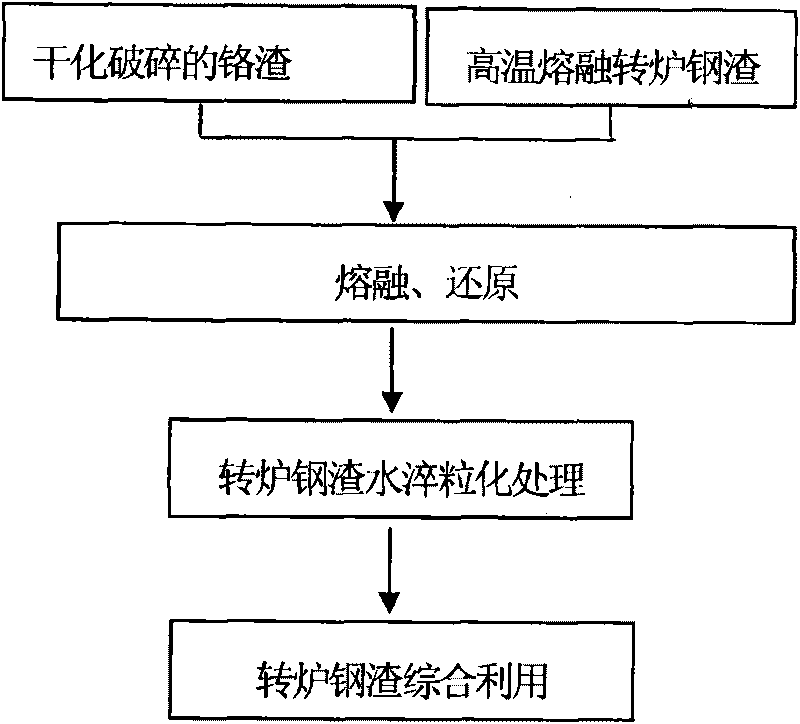

Harm-free and recycling treatment method for chromium slag

The invention provides a harm-free and recycling treatment method for chromium slag. In the method, after being made into dried particles with the grain diameter of 0.5-10mm, the chromium slag is mixed with tapped melting converter steel slag; the addition amount of the chromium slag is 0.5-5 percent of the weight of the melting converter steel slag; after the chromium slag is mixed with the melting converter steel slag, the mixture carries out melting reaction for 1-8 minutes. The method has simple procedure and processes the chromium slag directly by the melting converter steel slag without consuming an external energy source; and the processed chromium slag is melted into the converter steel slag and comprehensively utilized according to a utilization approach of the converter steel slag, thereby realizing the safe recycling utilization of the chromium slag.

Owner:BAOSHAN IRON & STEEL CO LTD

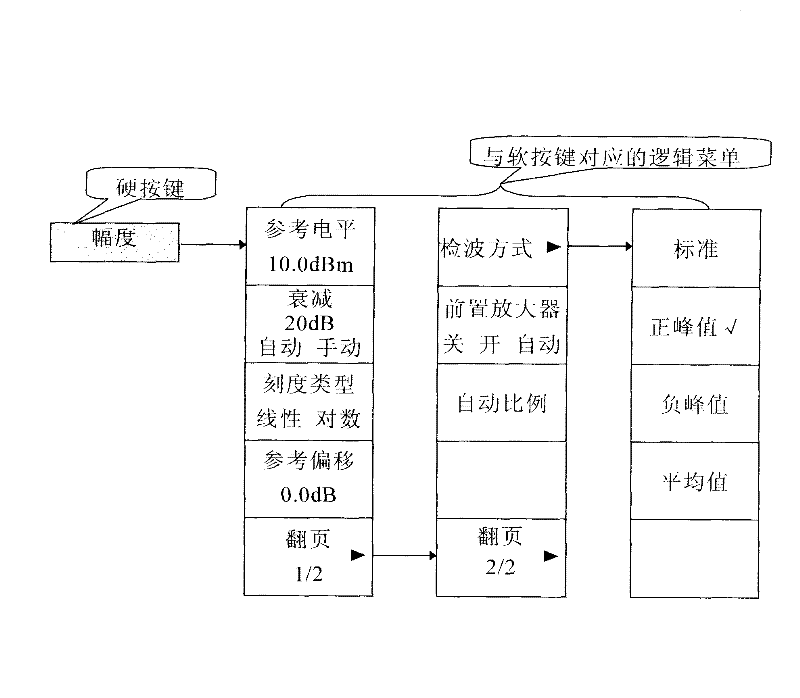

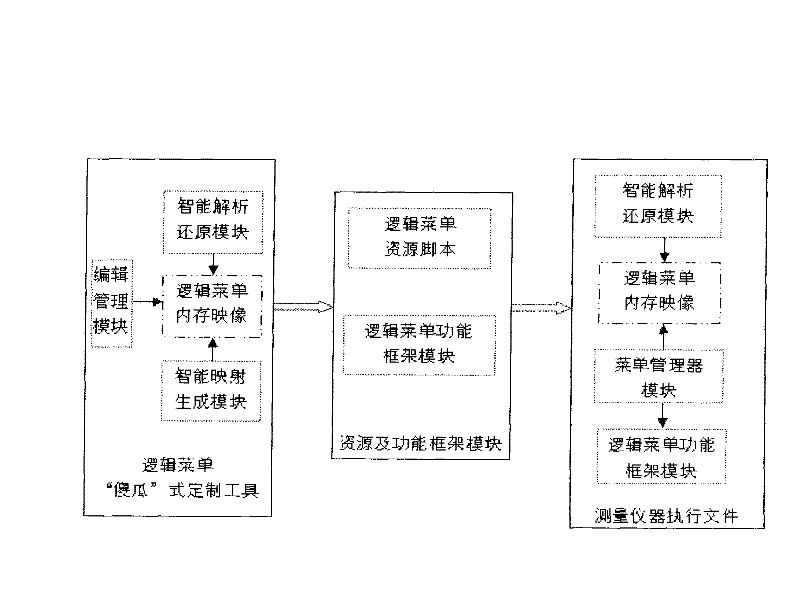

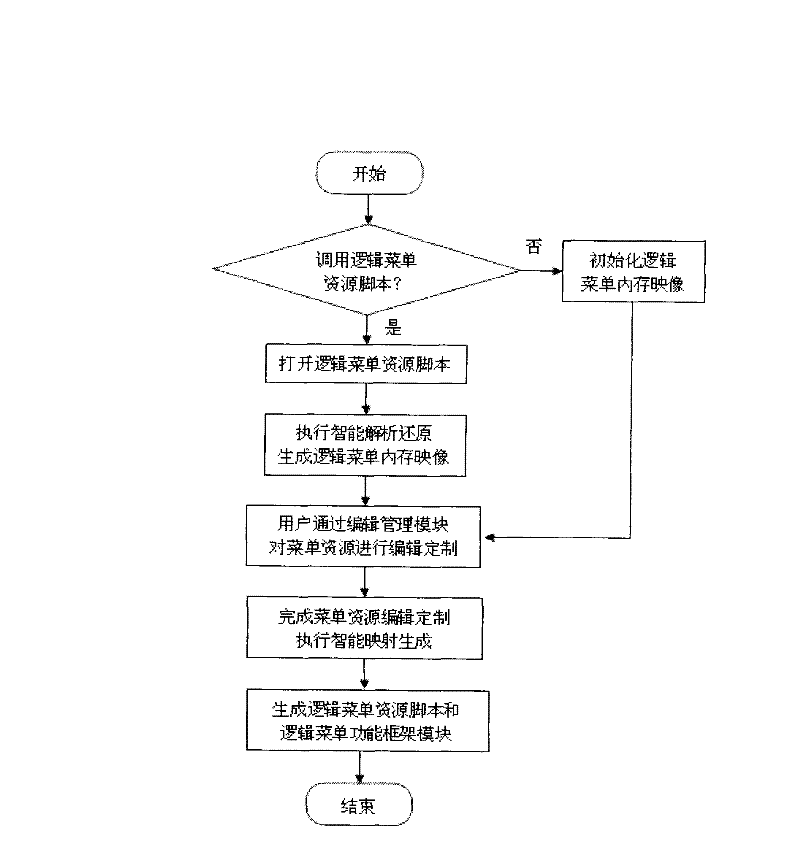

Intelligent configuration method for logic menu resources on basis of measurement instruments

ActiveCN102609252ARealize automatic generationRealize "fool" customizationSpecific program execution arrangementsMeasuring instrumentSoftware development

The invention provides an intelligent configuration method for logic menu resources on the basis of measurement instruments, which includes customizing a logic menu tree and attributes of different menu items in an interacting manner by the aid of an automatic logic menu customizing tool, calling an intelligent mapping generation module to generate logic menu resource scripts and a logic menu function frame module, integrating the logic menu function frame module generated into a measurement instrument software development module, and finally generating measurement instrument executable files after link compiling. By the intelligent configuration method, automatic customizing of logic menu resources, intelligent generation and restoration of the logic menu resources and automatic generation of the logic menu function frame module can be realized. Besides, if multiple menus sets are required to be implemented by the measurement instruments, the process of initializing resources of all menu sets at one step is omitted, required menus can be generated and configured according to needs, and accordingly the resources are saved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

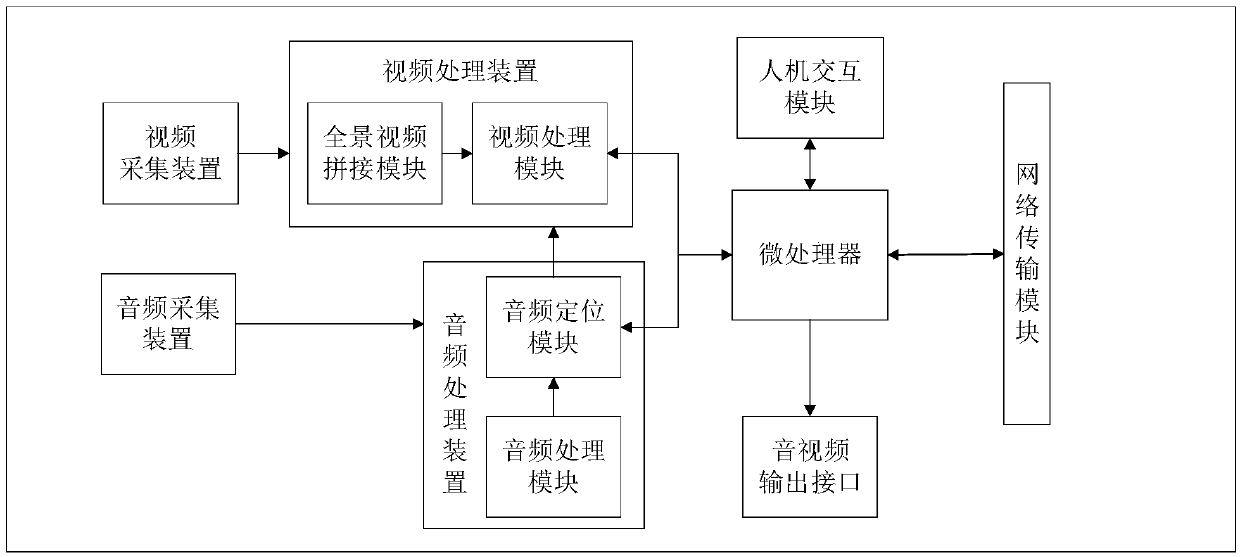

Audio tracking based panoramic video recording device and method

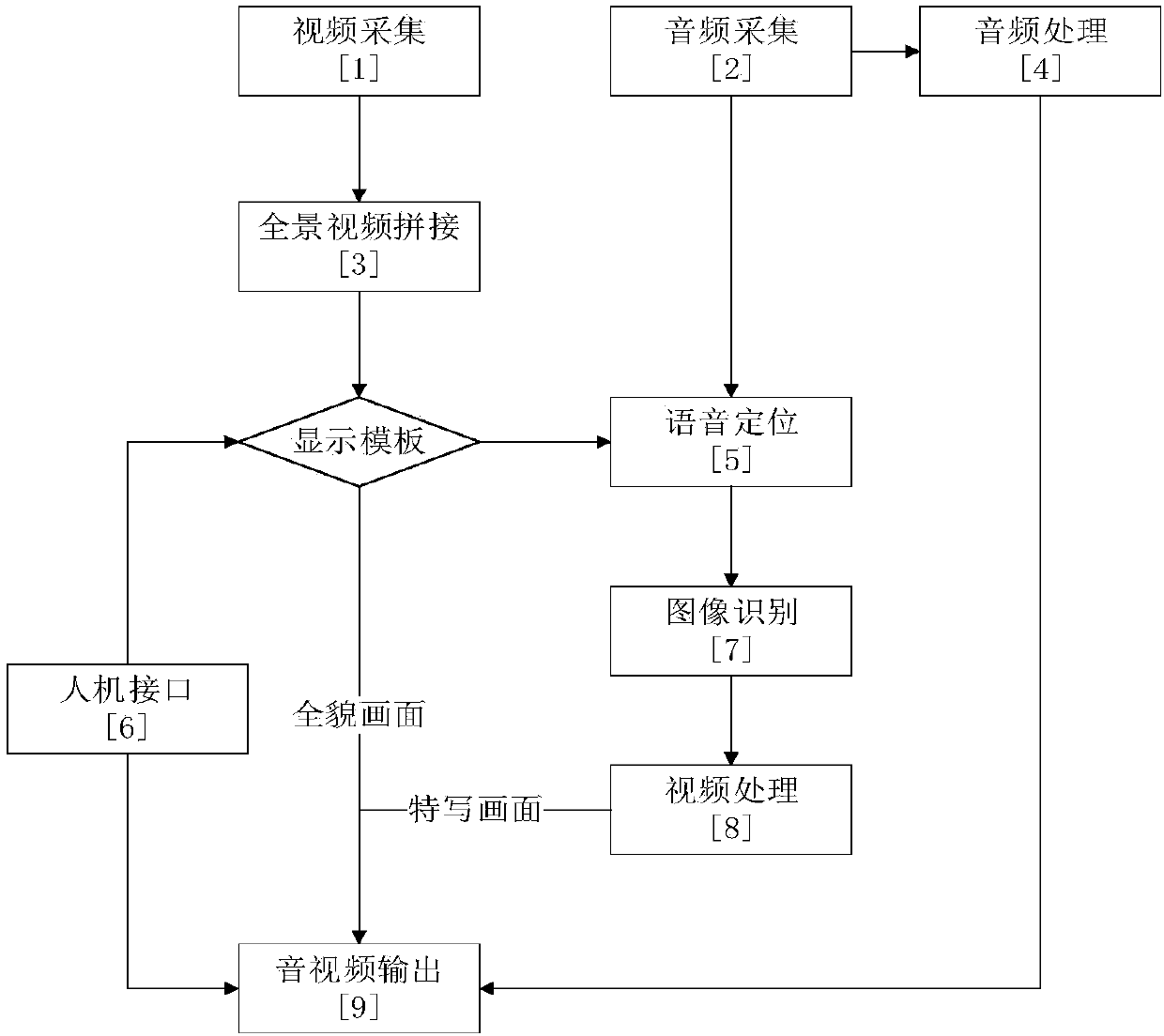

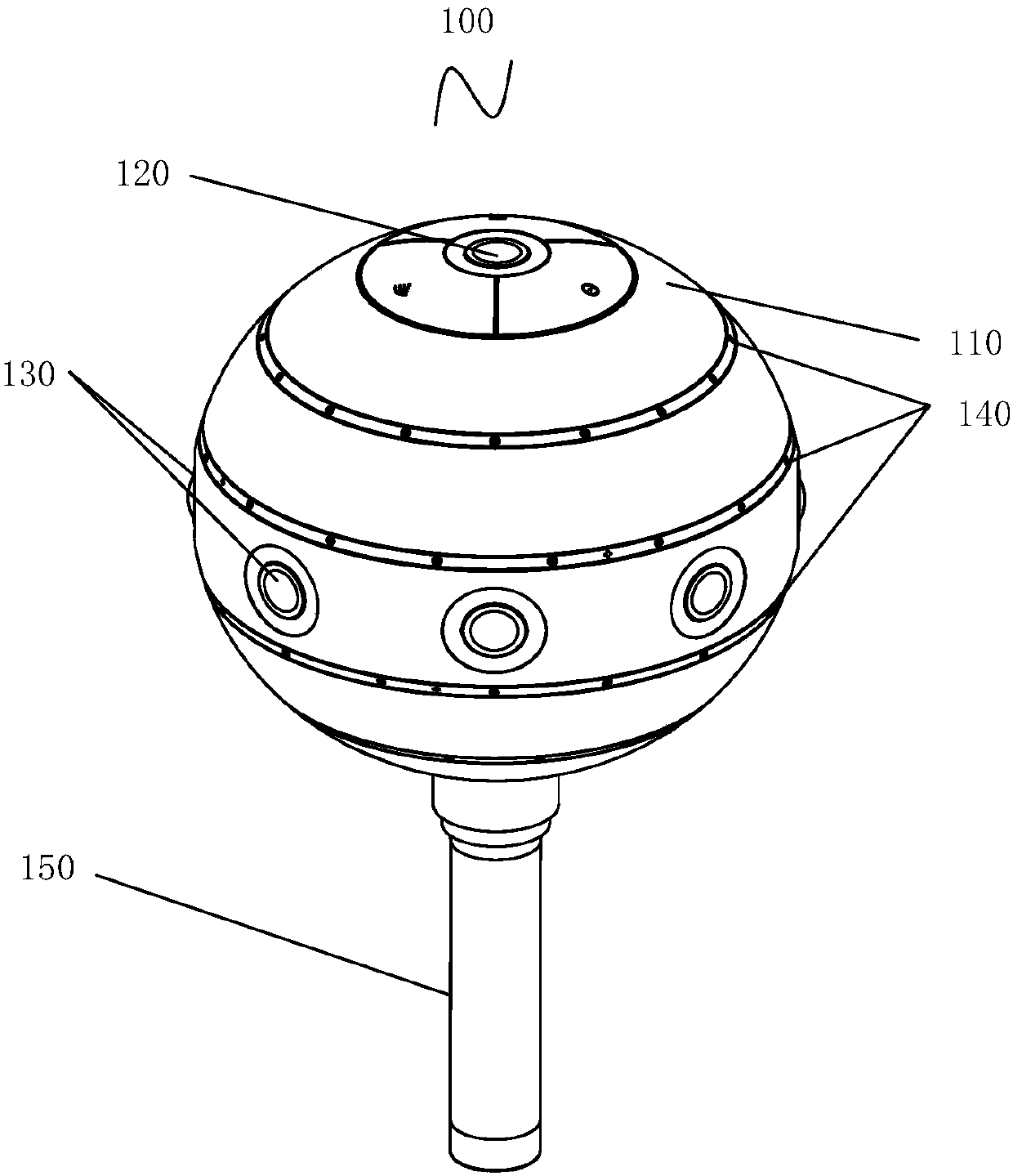

PendingCN107613243AImplement automatic trackingImplement featuresTelevision system detailsTelevision conference systemsVideo processingVideo record

The invention discloses an audio tracking based panoramic video recording device and method. The audio tracking based panoramic video recording device comprises a shell, a video acquisition unit and an audio acquisition unit are arranged on the shell, and a video processing unit, an audio processing unit, a microprocessor, a man-machine interaction module and a network transmission module are arranged in the shell. In the method, close-up tracking of a speaker is realized by adopting panoramic video combined with voice positioning and image recognition. The audio tracking based panoramic videorecording device and method has the advantages that tracking and close-up functions of the speaker in video are realized by adopting the single highly-centralized recording device, a function of seamless switching of close-up and full view of a meeting is achieved, cost can be further lowered, and promotion of recording system is benefited.

Owner:深圳市裂石影音科技有限公司

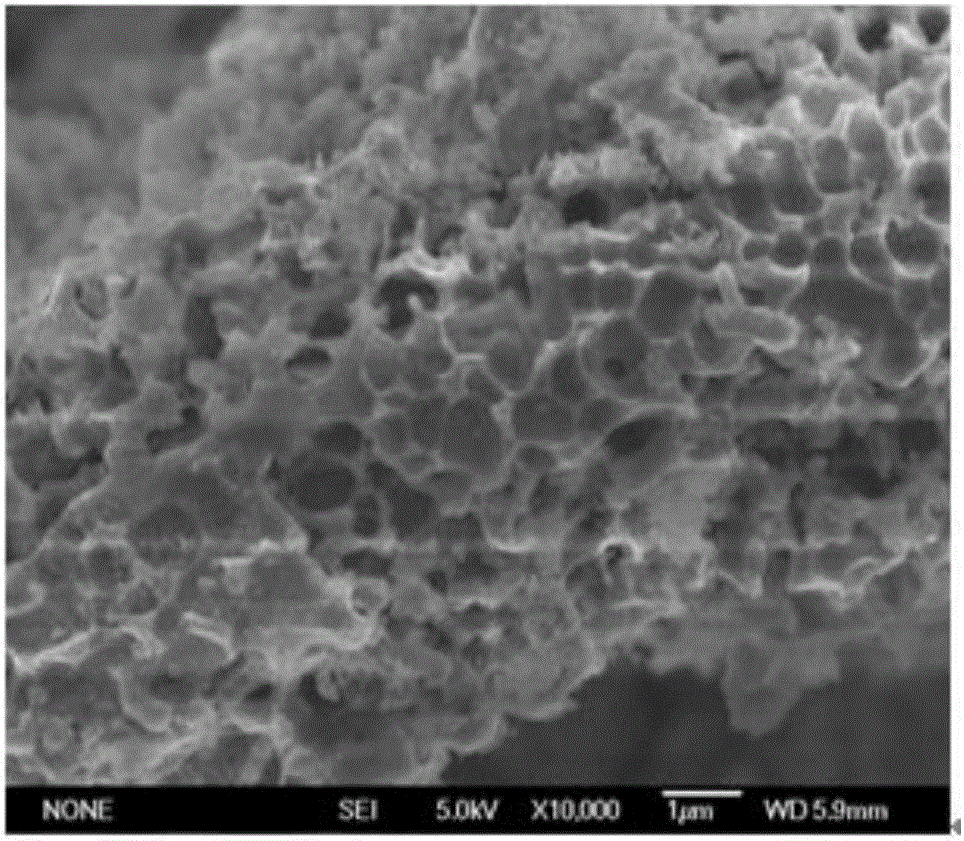

Method for preparing porous silicon carbon nanotube composite negative electrode material of lithium ion battery by diatomite

InactiveCN105845911AUnique pore structurePore structure retentionCell electrodesSecondary cellsCarbon compositesPtru catalyst

The invention relates to a method for preparing a porous silicon carbon nanotube composite negative electrode material of a lithium ion battery by diatomite. The method is characterized in that the diatomite is a silicon source, comprises the steps of preparing porous silicon, preparing a porous silicon matrix surface supported catalyst precursor and preparing a porous silicon carbon nanotube composite material, has the advantages of availability in raw material, low cost, clearness in morphology of the prepared porous silicon, high capacity of the silicon carbon composite material, cycle stability, high production efficiency, low cost and the like, and is suitable for industrial production. Under the test in which current density is 100mA / g, the initial reversible specific capacity of a negative electrode, prepared from the material, of the lithium ion battery reaches 1,529.1mAh / g, the reversible specific capacity reaches 885.4mAh / g after circulation of 40 times, and the subsequent cycle capacity is almost unchanged; and through the rate performance test, the reversible specific capacity is restored to about 800mAh / g when the current density is restored to 100mA / g, and the test shows that the material is high in connection tightness performance.

Owner:NORTHEAST DIANLI UNIVERSITY

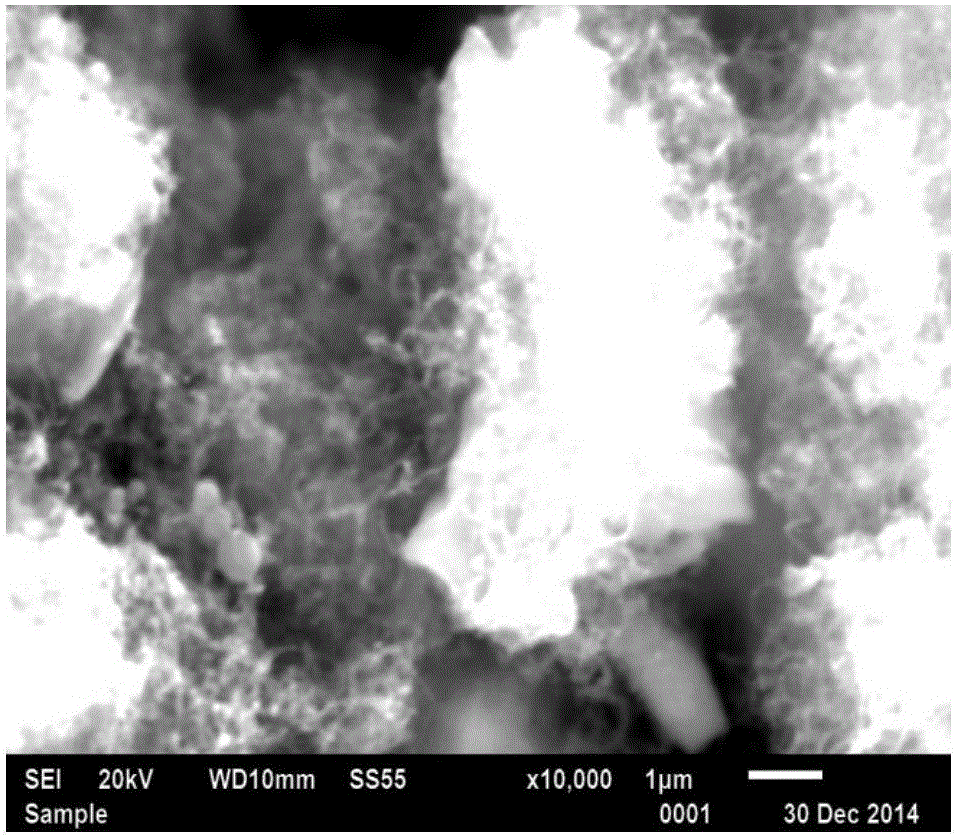

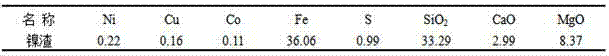

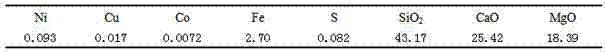

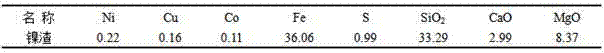

Method for recovering valuable metals from nickel-copper molten slag through selective reduction

InactiveCN102851513AAchieve restorationControl the degree of restorationProcess efficiency improvementSteelmakingMolten state

The invention belongs to the technical field of solid waste comprehensive utilization, and relates to a method for recovering valuable metals from nickel-copper molten slag through selective reduction. A process comprises the steps that: nickel-copper smelting slag is subjected to selective reduction under a high-temperature molten slag state, such that nickel, cobalt, and copper valuable metals in the slag can be completely reduced; the reduction of a small amount of iron is controlled, such that an intermediate alloy rich in nickel, cobalt, and copper is produced; most of the rest molten slag exists in a form of iron silicate; a solvent and a reducing agent are added, such that iron in the molten slag is completely reduced, and crude iron containing trace nickel, cobalt, and copper can be produced; and crude iron is adopted as an iron alloy and steelmaking raw material. The method provided by the invention has the advantages that a high-temperature nickel-copper smelting molten slag stepped selective reduction process is adopted, and nickel-copper smelting slag is utilized under a molten state, such that slag secondary heating cost is saved, valuable metal graded utilization is realized, product market application field is widened, and solid waste economical and effective utilization is realized.

Owner:JINCHUAN GROUP LIMITED

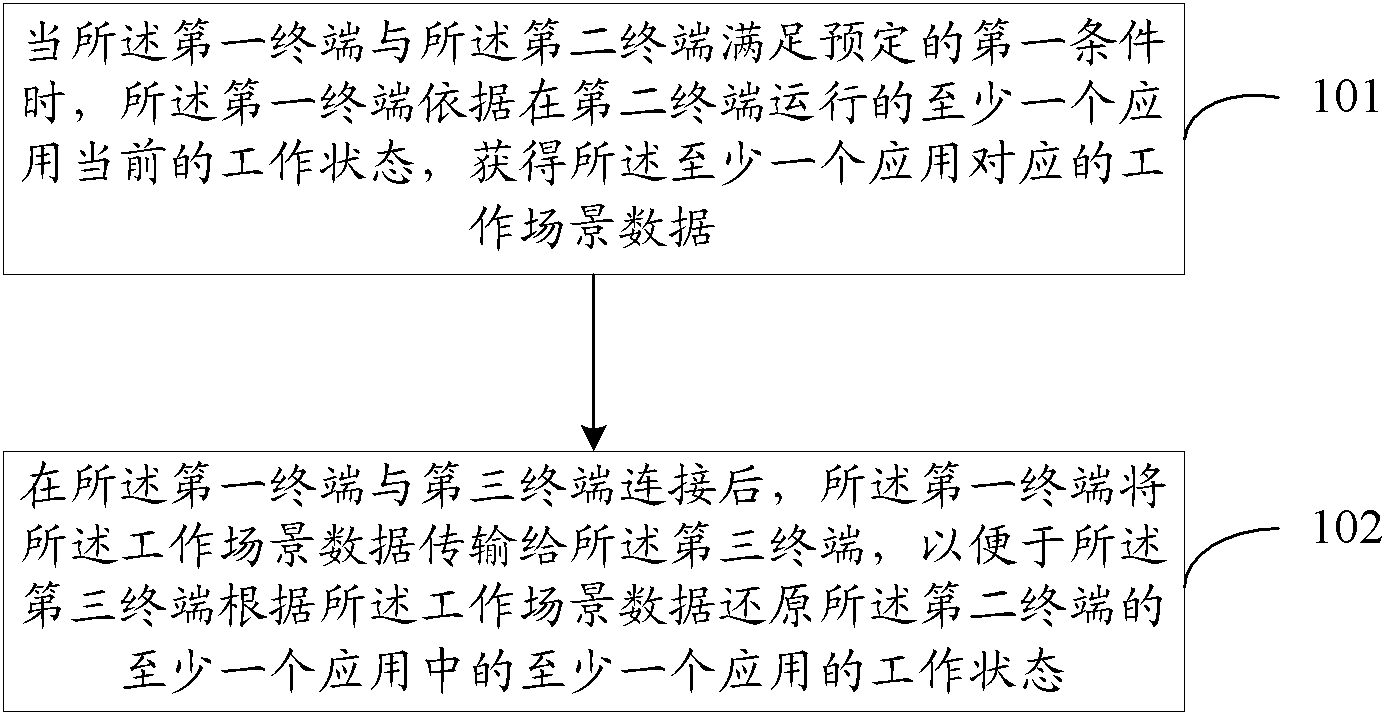

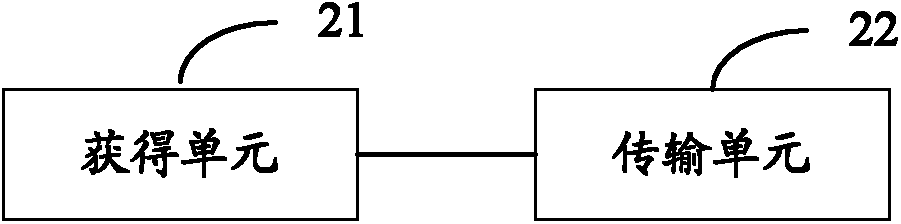

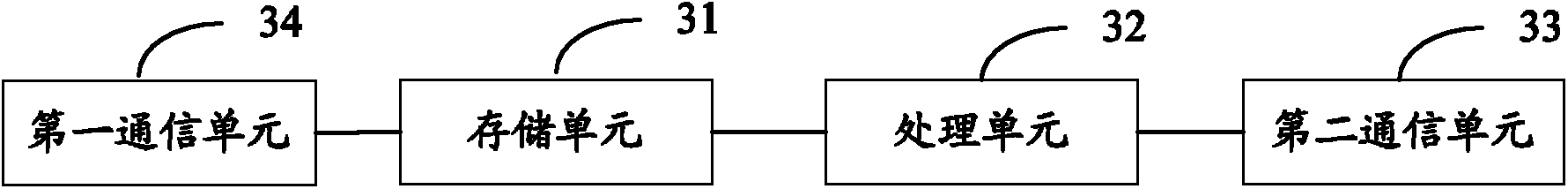

Data transmission method, terminal and terminal system

ActiveCN102932383AImprove data continuityPromote reductionTransmissionData transmissionTerminal system

The embodiment of the invention provides a data transmission method, a terminal and a terminal system. The data transmission method is applied to a first terminal and the first terminal is connected with the second terminal. The data transmission method is characterized by comprising the steps that: when the first terminal and the second terminal meet the preset first condition, the terminal obtains working scene data corresponding to at least one application according to a current working state of the at least one application operating in the second terminal; and after the first terminal is connected with a third terminal, the first terminal transmits the working scene data to the third terminal so as to restore a working state of at least one application of the second terminal by the third terminal according to the working scene data. The embodiment of the invention is used for carrying output backup and seamless restoration on a working scene of a user by using an application mode cooperative to an extension device, thus the convenience of mobile officing is improved.

Owner:LENOVO (BEIJING) LTD

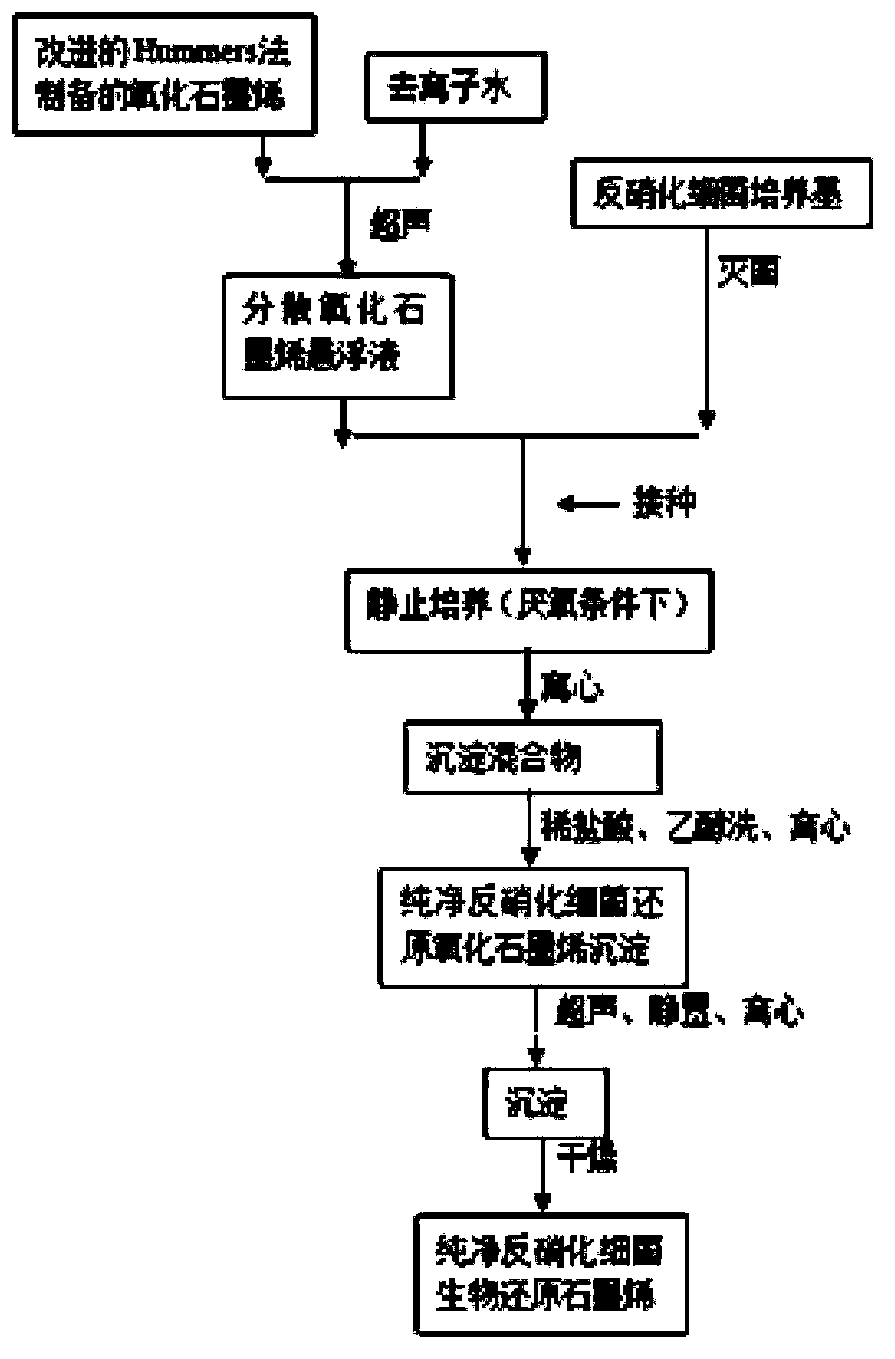

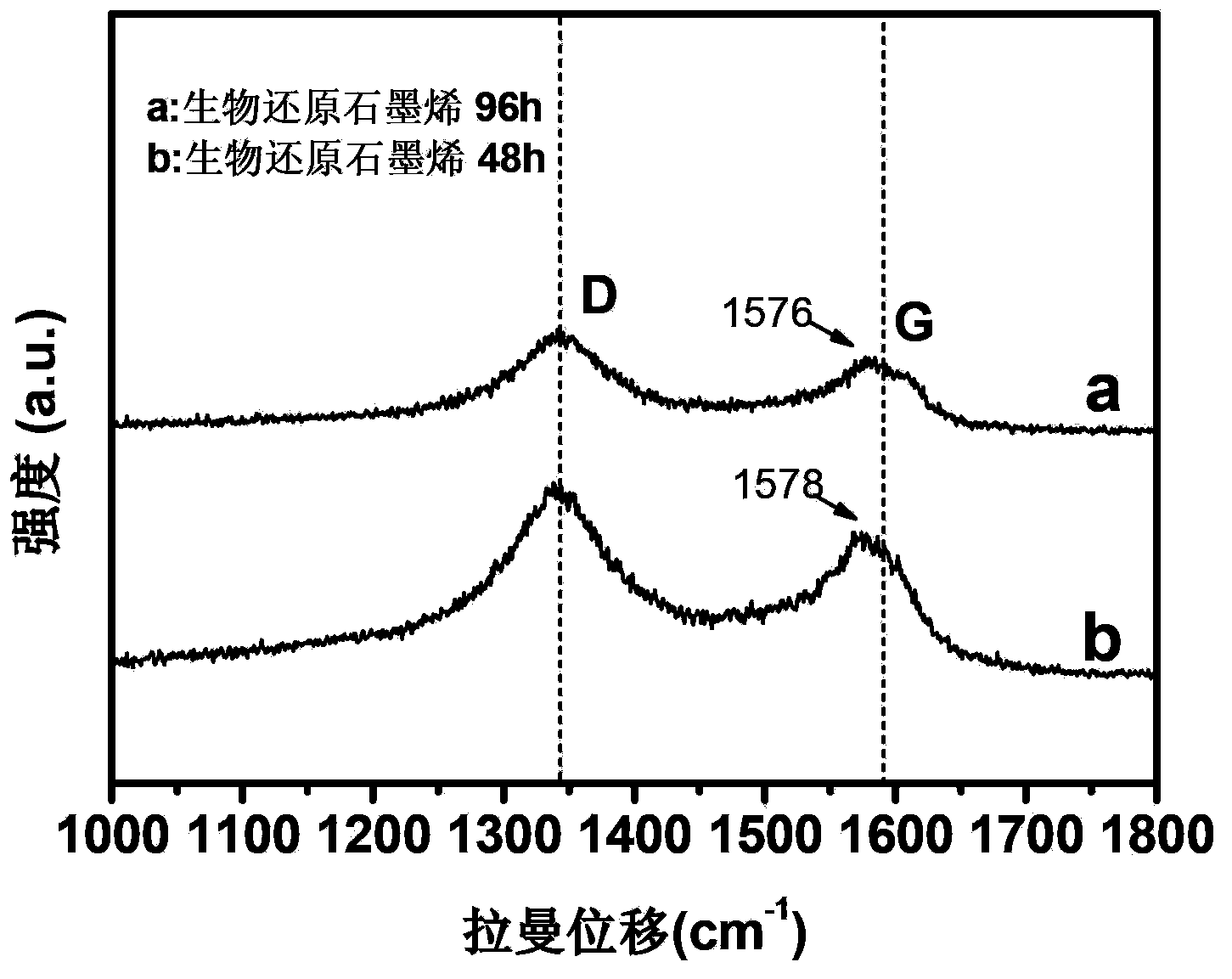

Microbial reduction of graphene oxide and preparation method for graphene

The invention discloses a microbial reduction of graphene oxide and a preparation method for graphene. The method comprises the following steps: dispersing graphene oxide in water to form a graphene oxide suspending solution with better dispersion; mixing denitrifying bacteria culture medium being subjected to sterilization and cooling with the graphene oxide suspending solution; inoculating a seed solution; culturing in still standing state in anaerobic condition for a few days, removing the oxygen-containing functional group of the dispersed graphene oxide with the effect of denitrifying bacteria to form graphene; after finishing the culturing, using hydrochloric acid, alcohol, and deionized water to remove bacterial cells, metabolite, and other ions produced in the reduction process, using water to cleaning until the water is neutral finally, and drying to obtain pure graphene. The method using microorganism denitrifying bacteria capable of reducing high valence state inorganic nitrogen and carbon as the microbial strain to conduct microbial reduction on graphene oxide; compared with similar reducing bacteria of Shewanella, the denitrifying bacteria has the advantages that the environmental safety is good, the reaction condition is mild and controllable, the medium component is simple, and the graphene obtained by preparation has less defects and layers.

Owner:NANJING UNIV OF SCI & TECH

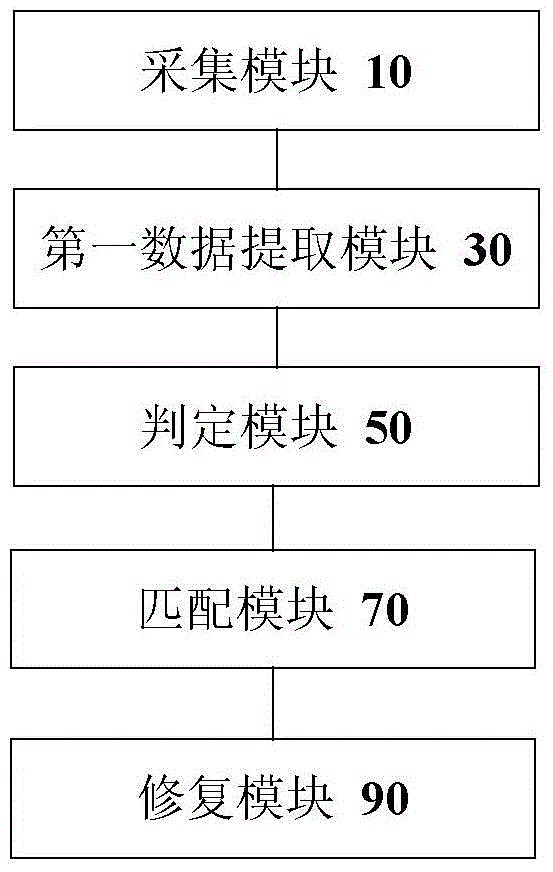

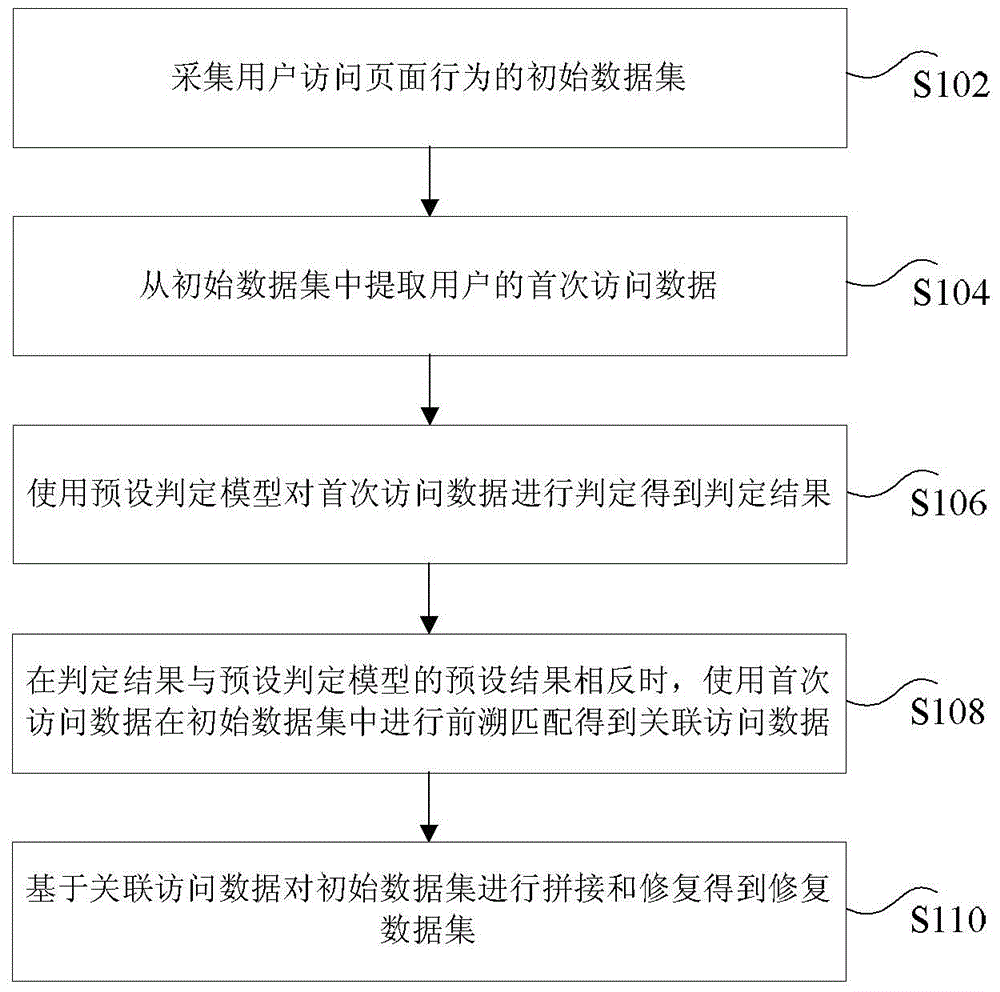

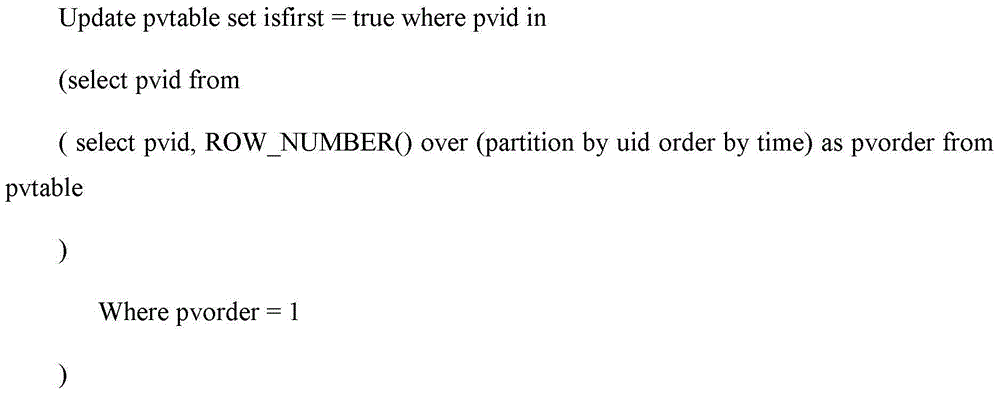

Webpage access data statistical method and webpage access data statistical device

ActiveCN103605738APoor precisionStatistically accurateError detection/correctionWebsite content managementData setData mining

The invention discloses a webpage access data statistical method and a webpage access data statistical device. The method includes collecting an initial dataset of user access page behaviors, wherein the initial dataset includes initial page browsing data of one or multiple user access target websites; extracting first-time access data of a user from the initial dataset; using a preset judging model to judge the first-time access data to acquire a judgment result; when the judgment result is opposite to a preset result of the preset judgment result, subjecting the first-time access data to forward-trace matching in the initial dataset to acquire associated access data; performing splicing and restoring on the initial dataset on the basis of the associated access data to acquire a restoration dataset. By the method and the device, the problem of poor accuracy in user recognition due to loss of Cookie information in the prior art is solved, and the objectives of accurate counting of user access page data, resisting of side effect brought by Cookie loss and serial connecting of behaviors of the user to restore real user behaviors are realized.

Owner:BEIJING GRIDSUM TECH CO LTD

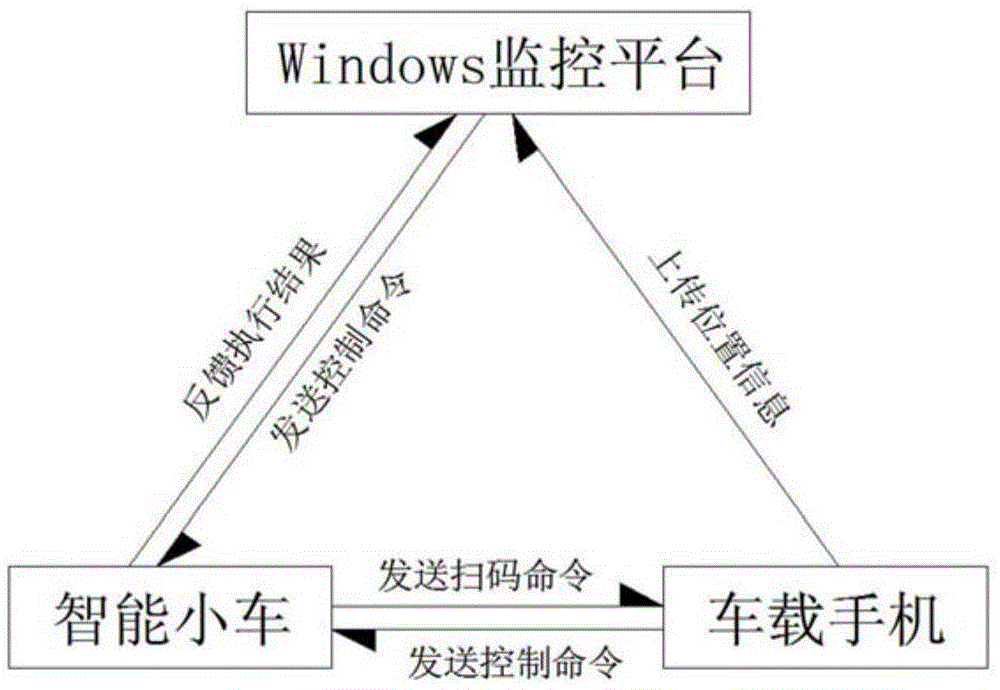

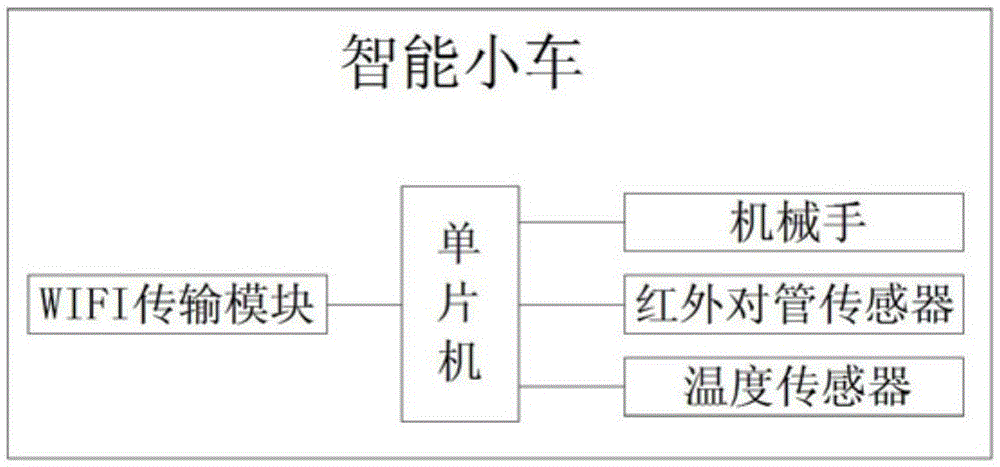

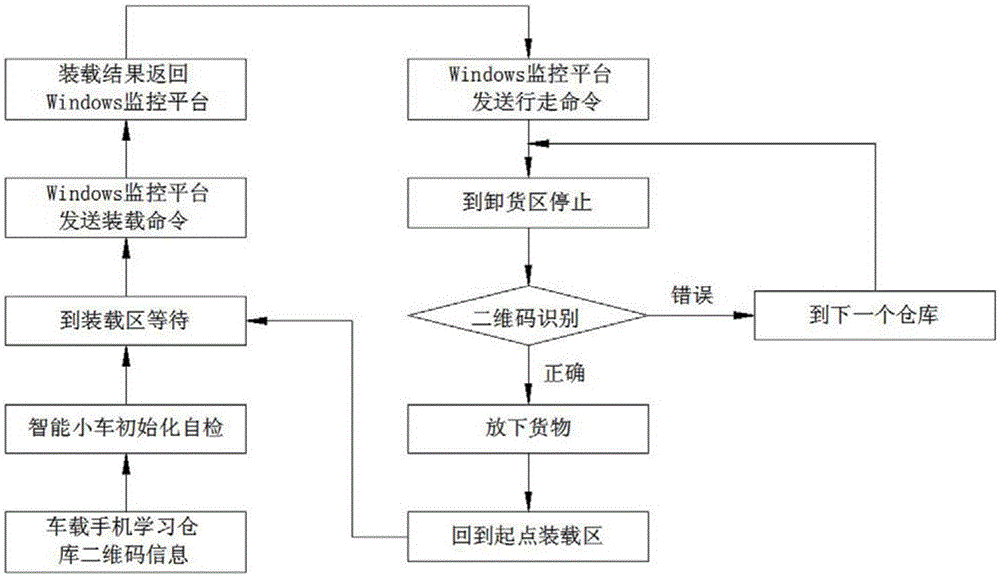

Two-dimensional code navigation based logistics delivery system and delivery method thereof

InactiveCN105574695ACoordinationAvoid unexpected situationsCo-operative working arrangementsLogisticsData transmissionCode navigation

The invention discloses a two-dimensional code navigation based logistics delivery system and a delivery method thereof. The logistics delivery system comprises an intelligent vehicle, a vehicle-mounted cellphone and a Windows monitoring platform which form a local area network and are communicated by using a WIFI technique, wherein duplex exchange data is carried out based on a TCP / IP communication protocol, the control of the intelligent vehicle adopts a singlechip, and the singlechip is communicated with the vehicle-mounted cellphone and the Windows monitoring platform through a WIFI transmission module. The logistics delivery system has the advantages that the three platforms of the vehicle-mounted platform, the singlechip and the Windows monitoring platform are integrated, cross-platform data transmission and intelligent vehicle control are perfectly fulfilled; a two-dimensional code technology is first used for storing positional information of the vehicle and controlling shipping of the vehicle, the positional information of the vehicle is rapidly recorded and also restored by 100%, and an important guarantee is provided for rapidly and accurately judging the position of the intelligent vehicle.

Owner:XIAN UNIV OF SCI & TECH

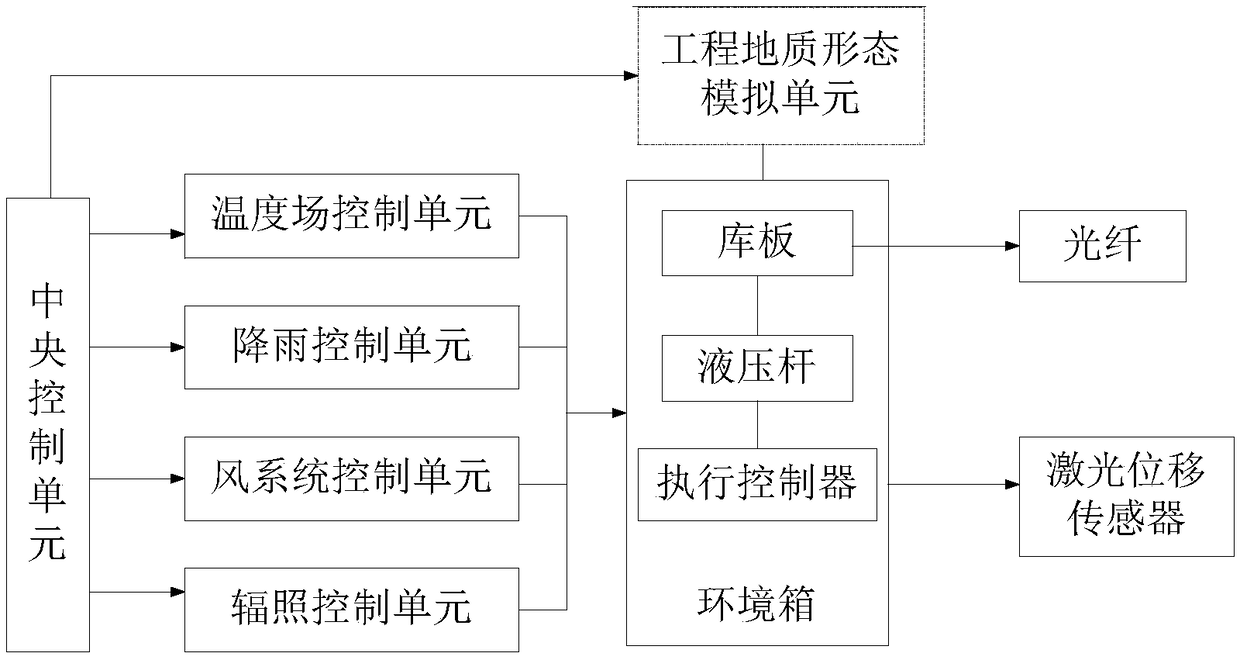

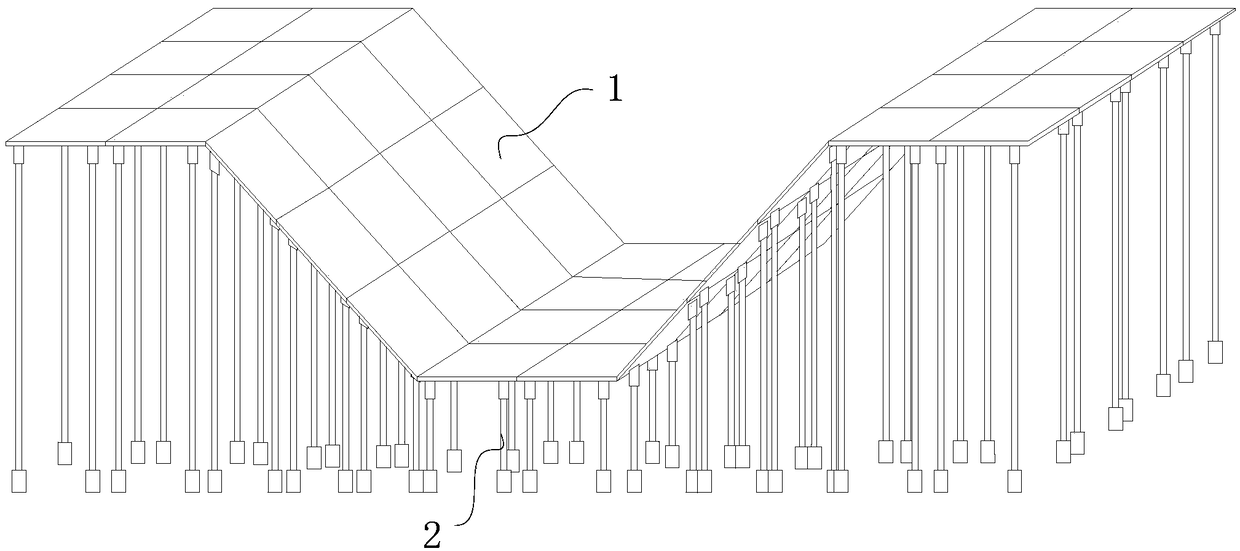

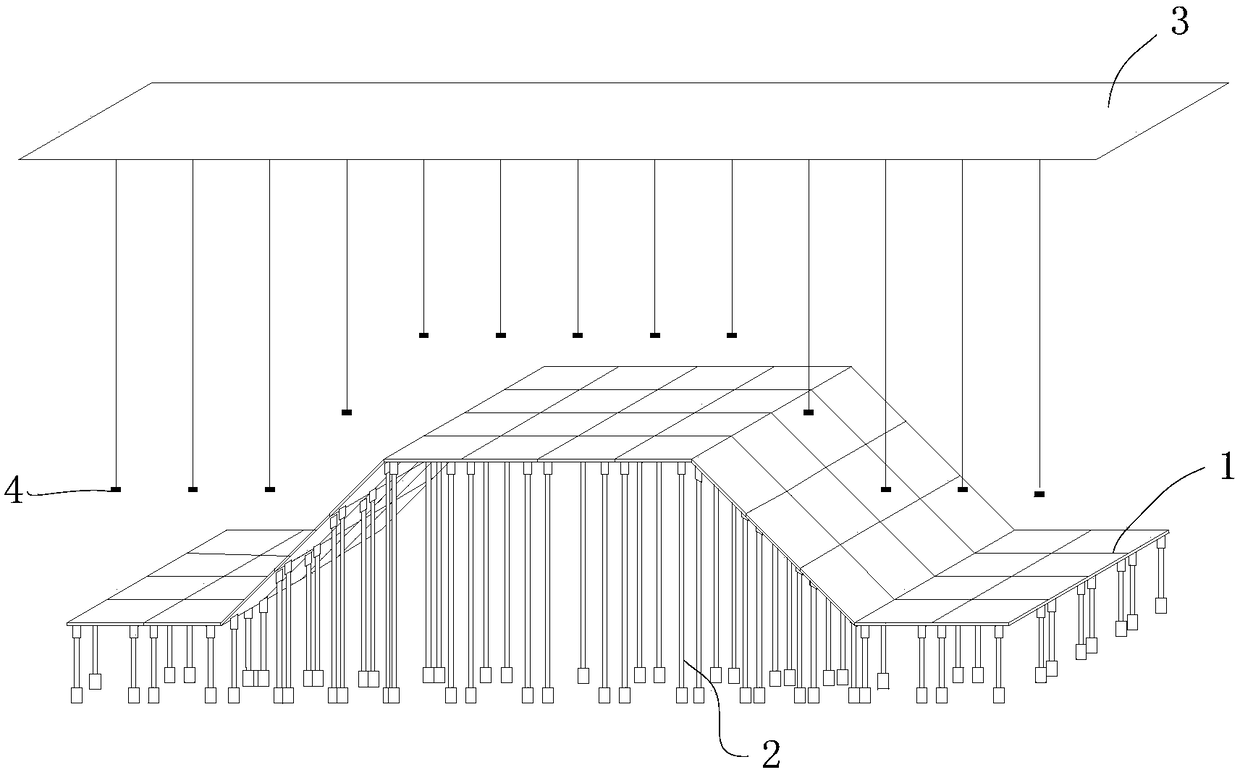

Environmental simulation test system achieving multiple physical field coupling

ActiveCN108760609AAchieve full coverageAchieve thermal insulationWeather/light/corrosion resistanceSuction forceWind system

The invention discloses an environmental simulation test system achieving multiple physical field coupling, which comprises an environmental cabinet, a temperature field control unit, a rainfall control unit, a wind system control unit, an irradiation control unit, an engineering geological form simulation unit and a central control unit, wherein the engineering geological form simulation unit comprises a plurality of reservoir plates, hydraulic rods and an execution controller; extension and vibration frequency and amplitudes of the hydraulic rods are controlled by a hydraulic rod extension control module and a frequency control module; the height and the angle of each rectangular reservoir plates can be adjusted; various engineering geological forms and borne dynamic loads under a natural working condition are simulated actually; optical fibers and suction force sensors are distributed on the reservoir plates; laser displacement sensors are distributed at the top of a cabinet body; parameters such as a water content and a temperature of a soil body are monitored; and omnibearing coverage of surface displacement of each model in the cabinet body can be achieved. The system is ingenious in structural design and low in cost, and can achieve coupling of one or more of rainfall, humidity, temperature, ultraviolet irradiation and the like in a natural environment.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

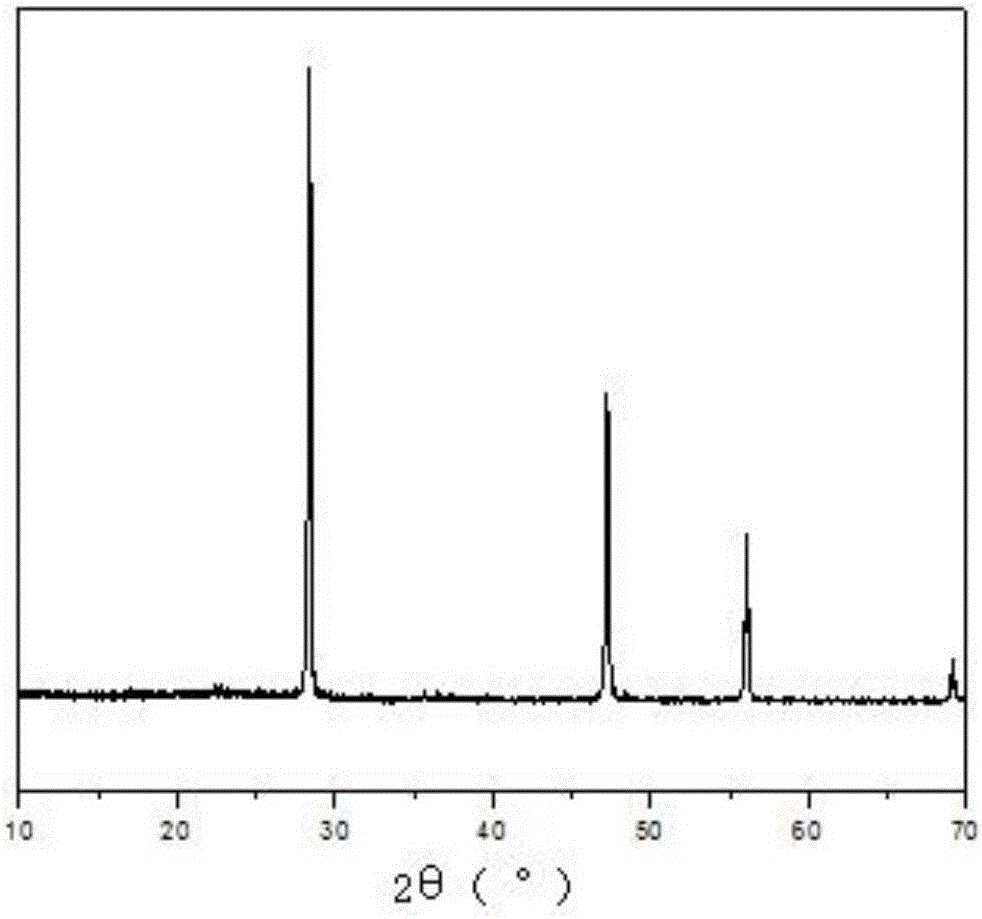

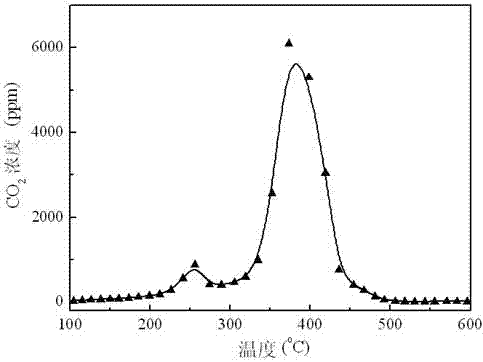

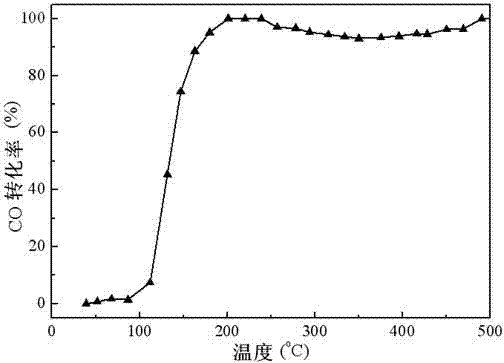

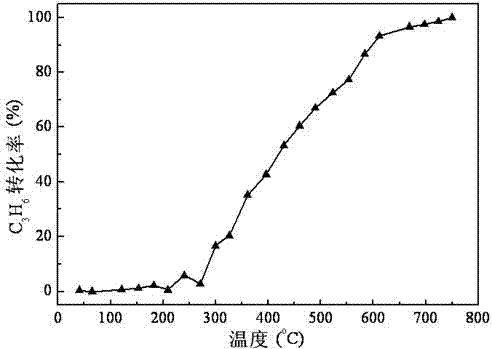

Quadruple effect catalyst of diesel tail gas and preparation method and application of quadruple effect catalyst

ActiveCN102188971AIncrease storage capacityPromote combustionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesPotassium

The invention discloses a quadruple effect catalyst of diesel tail gas. The catalyst consists of carrier magnesium-aluminium (Mg-Al) hydrotalcite composite oxide, potassium (K) and noble metal, wherein the K and the noble metal are loaded on the carrier Mg-Al hydrotalcite composite oxide; the noble metal is palladium (Pd), platinum (Pt) or rhodium (Rh); the load capacity of the K is 7 to 10 weight percent; and the load capacity of the noble metal is 1 to 2 weight percent. Meanwhile, the invention also discloses a preparation method and application of the catalyst. The catalyst is simple in preparation and easy to operate; the prepared catalyst can remove four main pollutants, namely carbon smoke particles (PM), nitrogen oxide (NOx), carbon oxide (CO) and unburned hydrocarbons (HC); and after being coated on a diesel particle filter, the catalyst can be directly applied to post-treatment of the diesel tail gas, has a good treatment effect and is applied to industrial promotion.

Owner:UNIV OF JINAN

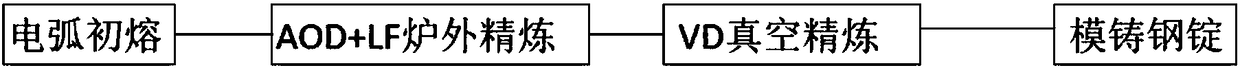

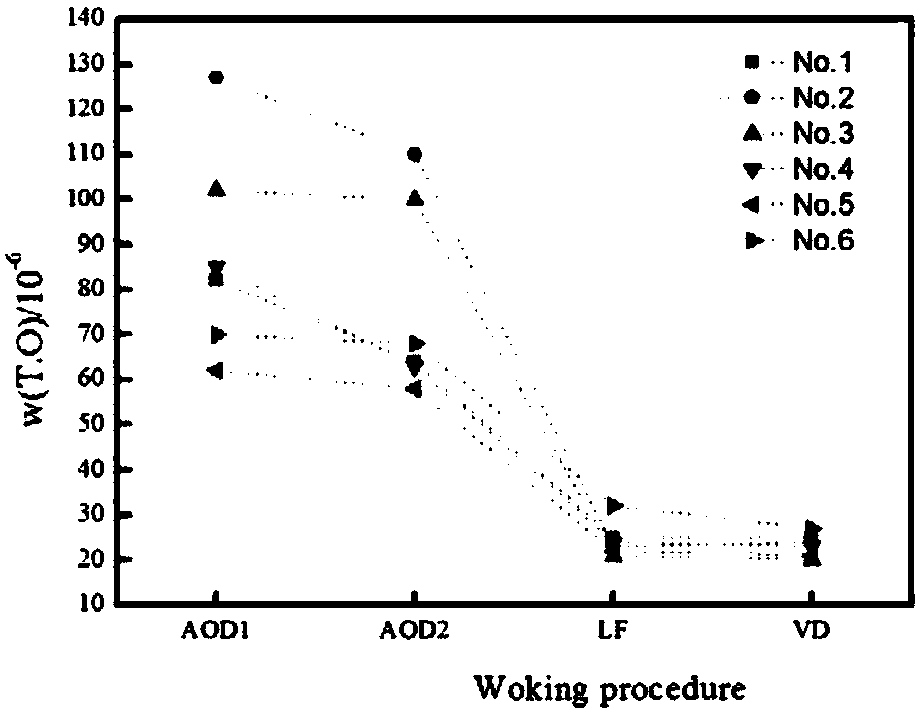

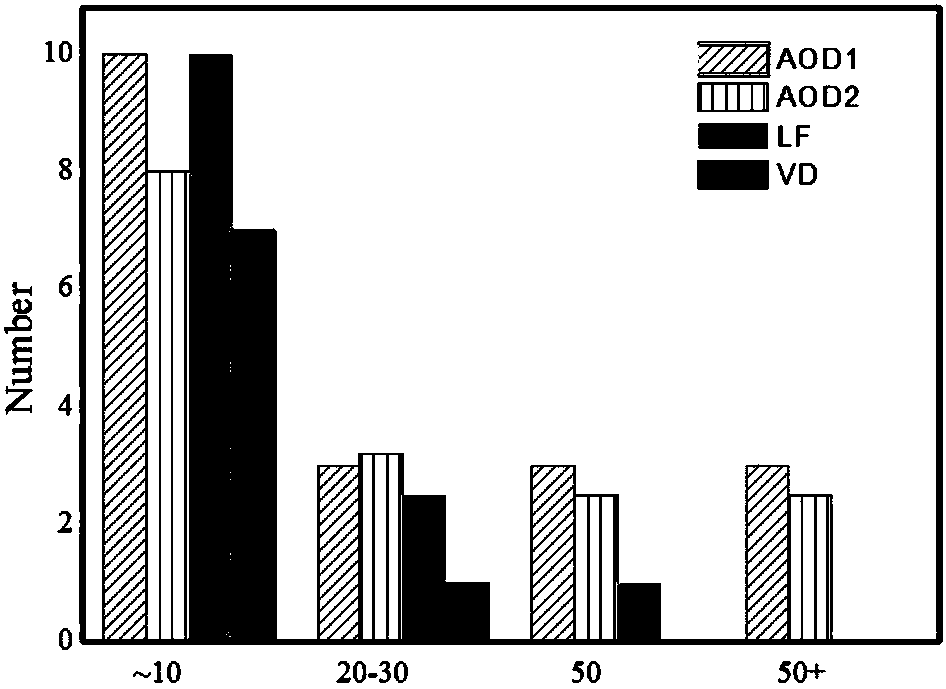

Stainless steel high-pureness smelting method

ActiveCN108330245APollution controlReduce contentProcess efficiency improvementElectric furnaceSmelting processIngot

The invention discloses a stainless steel high-pureness smelting method. The method comprises the following steps: under high-purity argon protection, employing electric arc for mother alloy melting,performing AOD and LF external refining, performing VD vacuum refining, and casting steel ingot to obtain a stainless steel ingot with low impurity content. The smelting is carried out through the electric arc, high-purity argon is introduced during a smelting process, alloy oxidation can be effectively prevented, penetration of an impurity element can be prevented, burning loss of a volatile element is reduced, at the same time, the P content in steel is reduced through large slag amount and multi-time slag flowing during a smelting process, and steps of LF refining, aluminum particles addition and pre-deoxidation are carried out. The preparation method is used for producing the stainless steel during an industrial production process.

Owner:NANJING UNIV OF SCI & TECH

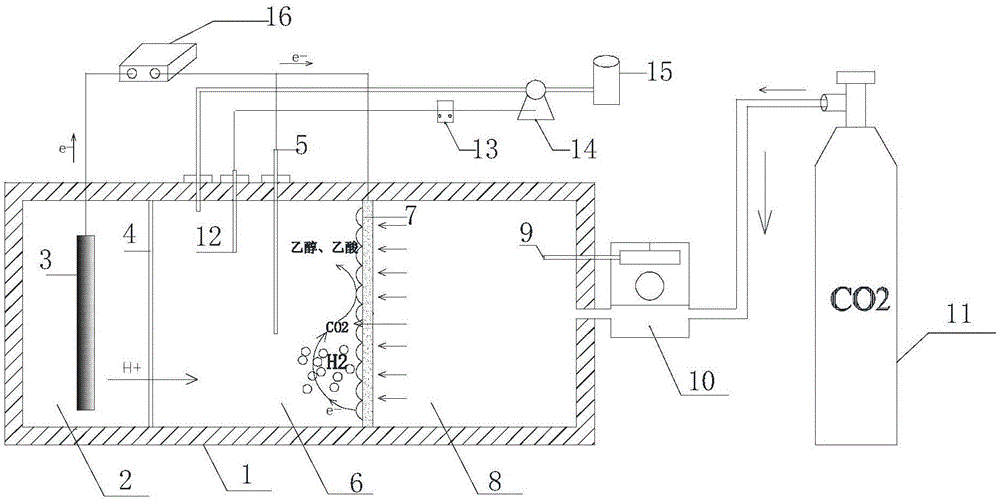

Bioelectricity synthesis system and method for synthesizing acetic acid and/or ethyl alcohol through same

ActiveCN105695319AAchieve restorationAvoid mass transfer processBioreactor/fermenter combinationsCellsPh controlEngineering

The invention discloses a bioelectricity synthesis system and a method for synthesizing acetic acid and / or ethyl alcohol through the same. The bioelectricity synthesis system comprises a reactor, an online pH control system, an air supply system and a power source. The reactor is a three-chamber reactor and comprises an air chamber, a negative electrode chamber and a positive electrode chamber, wherein the air chamber is connected with the air supply system; the negative electrode chamber is externally connected with the online pH control system, the negative electrode chamber and the air chamber are partitioned by an air negative electrode, and the negative electrode chamber is further internally provided with a reference electrode; the positive electrode chamber is internally provided with a positive electrode, the positive electrode chamber and the negative electrode chamber are partitioned by a cation exchange membrane, and the positive electrode, the air negative electrode and the reference electrode are externally connected with the power source through wires. Positive electrode electrolyte is added into the positive electrode chamber, a bioelectricity synthetic nutrient solution obtained after sterile and anaerobic treatment is added into the negative electrode chamber, and electrosynthesis bacteria are inoculated into the negative electrode chamber; carbon dioxide is sent into the air chamber through metering of the air supply system, and carbon dioxide penetrates through the air negative electrode and is converted into acetic acid and / or ethyl alcohol in the negative electrode chamber.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

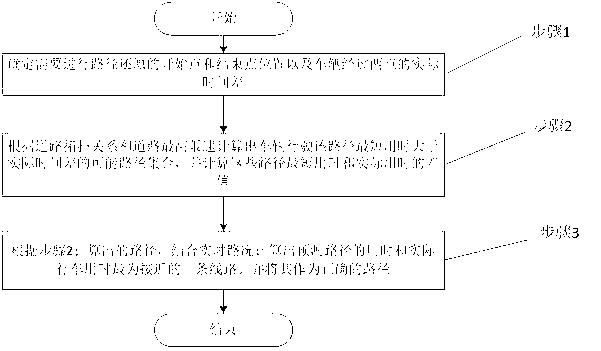

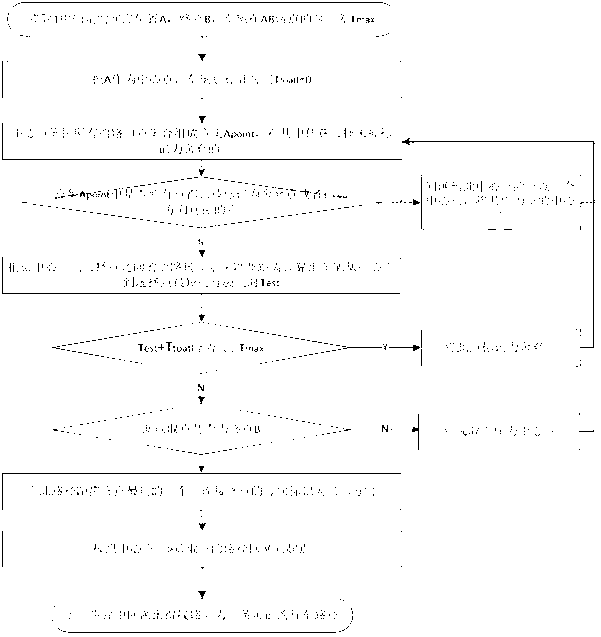

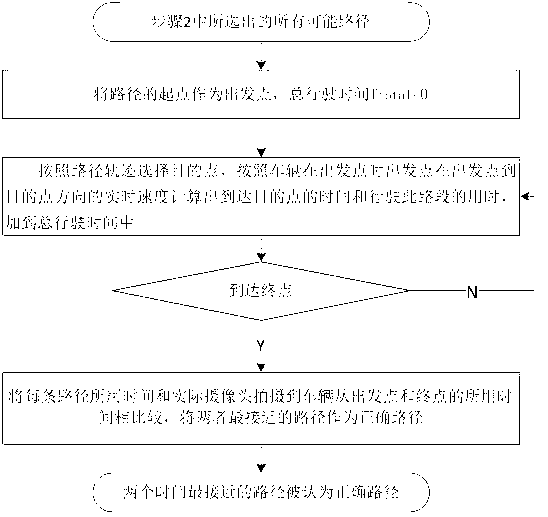

Algorithm for restoring wheel path based on road attributes and real-time road conditions

The invention relates to an algorithm for restoring a wheel path based on road attributes and real-time road conditions, wherein the algorithm is applied in the field of traffic control. The algorithm for restoring the wheel path based on the road attributes and the real-time road conditions comprises the steps: confirming positions of a starting point and an ending point in a road network, wherein the restoring of the wheel path needs to be conducted on the starting point and the ending point, confirming the time when a vehicle is located at the starting point and the ending point, calculating a time difference Tmax, calculating all possible paths and used time of the possible paths, and finally, calculating grades of each path in a quantitative mode by being combined with actual used time of the vehicle to select the path with the highest grade as a correct path. In the network with a complex topological relation, the problem that the actual wheel path is difficult to confirm and restore is solved.

Owner:TONGJI UNIV

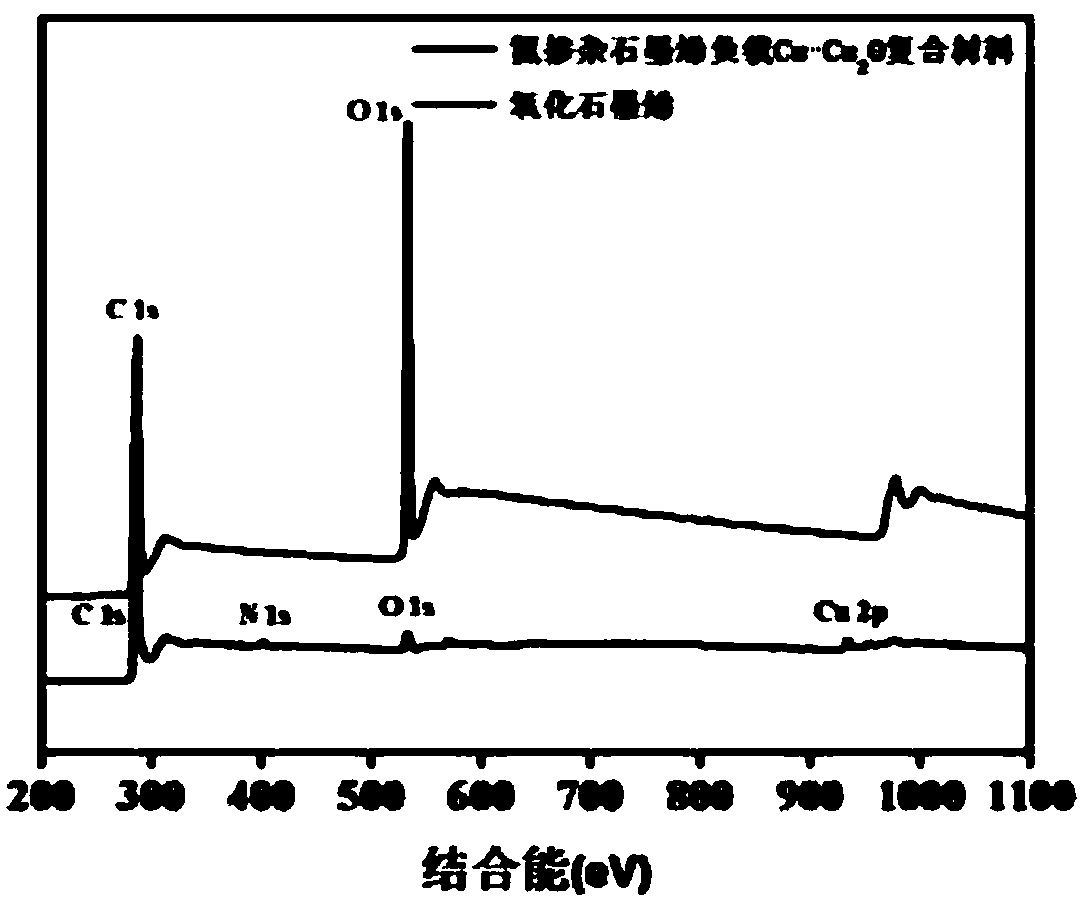

Preparation method of nitrogen doped and graphene loaded Cu-Cu2O nanocomposites

ActiveCN103990484AIncrease productionThe preparation method is simple and safeHybrid capacitor electrodesCatalyst activation/preparationArgon atmosphereOxygen

The invention relates to a preparation method of nitrogen doped and graphene loaded Cu-Cu2O nanocomposites. Copper phthalocyanine is used for providing a nitrogen source and a copper source, and the high-heat treatment is performed on mixed powder of the copper phthalocyanine and oxidized graphene in an argon atmosphere, so as to prepare the nitrogen doped and graphene loaded Cu-Cu2O nanocomposites. In the prepared nitrogen doped and graphene loaded Cu-Cu2O nanocomposites, Cu-Cu2O nanoparticles are loaded on nitrogen doped graphene sheets. The preparation method provided by the invention has the advantages of safety and simplicity, the yield is high and the recurrence and the industrial production are easy. The nitrogen doped and graphene loaded Cu-Cu2O nanocomposites which are produced by adopting the preparation method have good application prospects and economic values in aspects of photocatalysis, oxygen catalysis, supercapacitors and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

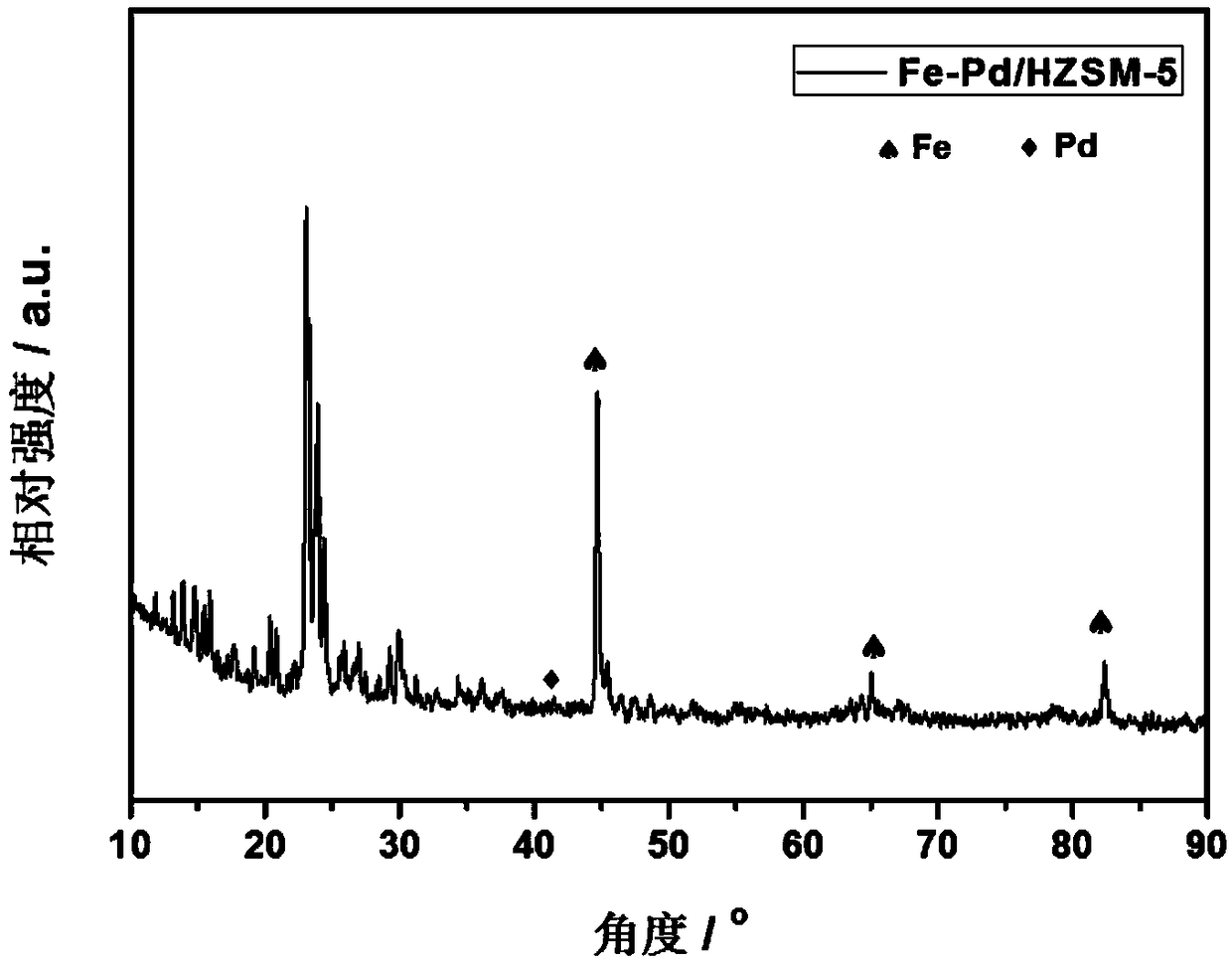

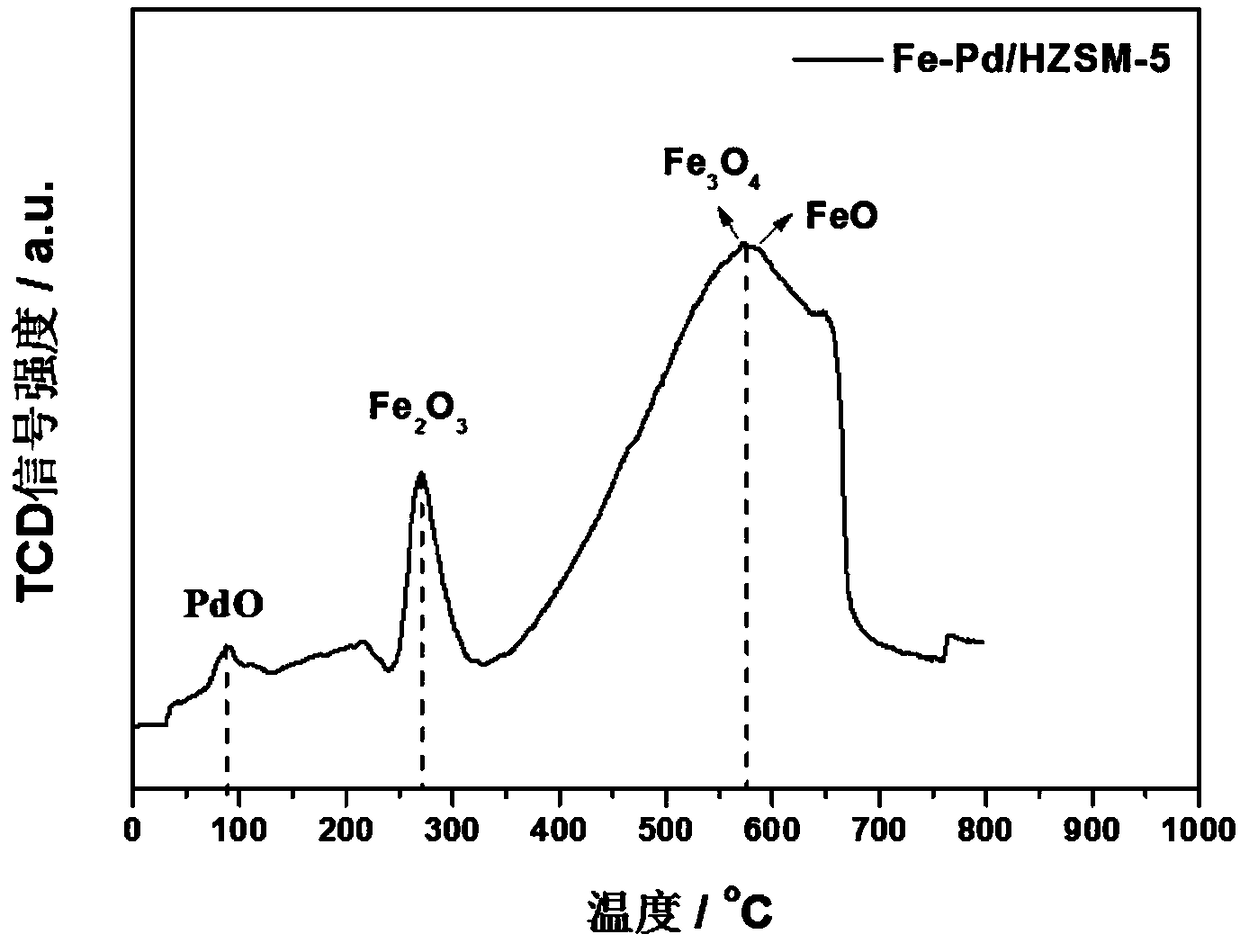

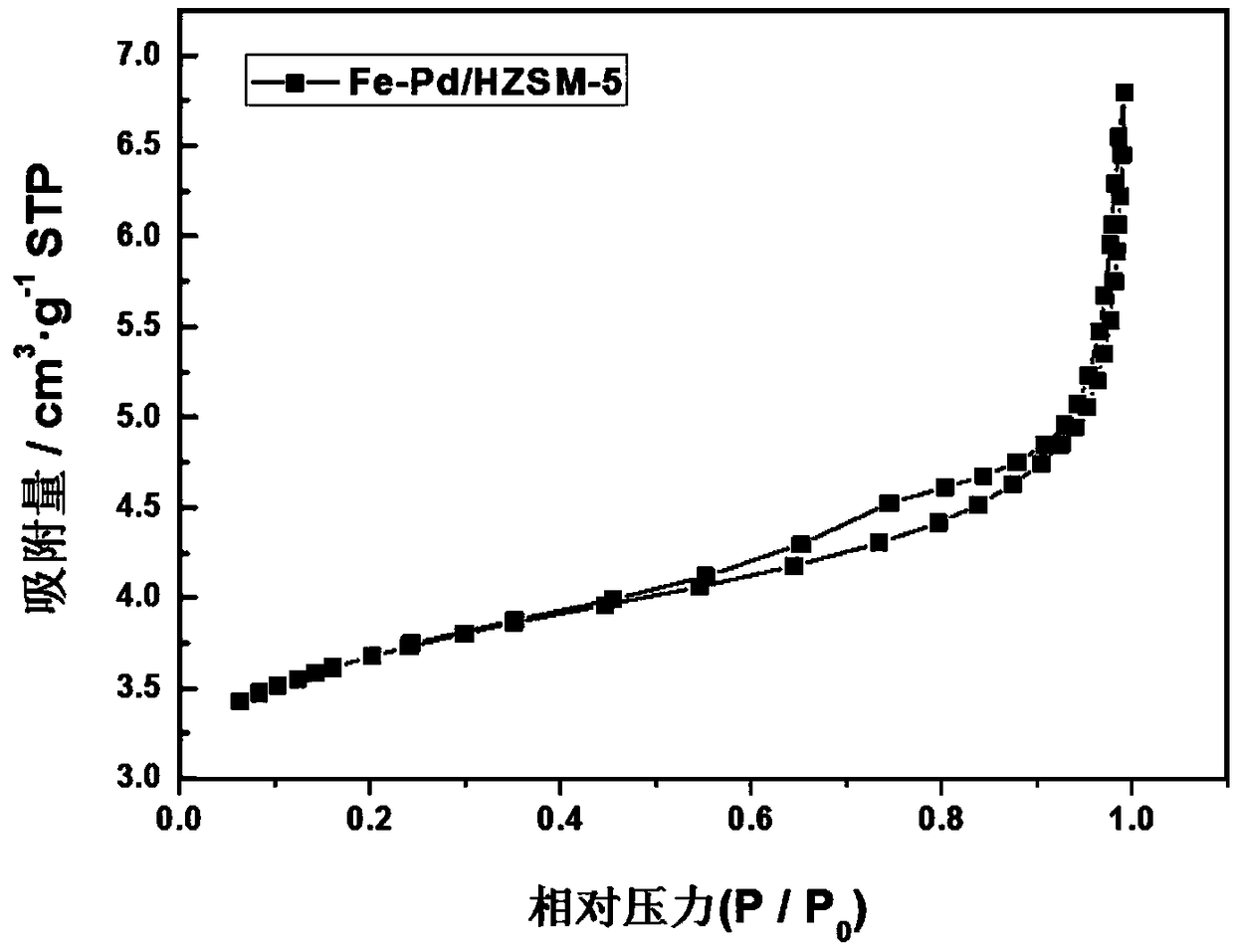

HZSM-5 supported Fe-Pd bimetallic catalyst for lignin hydrogenation and depolymerization and preparation method thereof

ActiveCN109289903AHigh activityGood dispersionMolecular sieve catalystsLiquid hydrocarbon mixture productionDepolymerizationCalcination

The invention belongs to the technical field of catalysts, and discloses a HZSM-5 supported Fe-Pd bimetallic catalyst for lignin hydrogenation and depolymerization and a preparation method thereof. The preparation method of the invention uses an iron source and a palladium source as raw materials, the materials are dispersed on the surface of a HZSM-5 molecular sieve by an impregnation method, andthe catalyst is prepared by high-temperature calcination and hydrogen reduction. The method of the invention simultaneously loads Fe and Pd onto a carrier to realize the reduction of elemental iron,the Fe promotes the high dispersion of Pd, and improves the catalytic efficiency and the catalytic selectivity; a molecular sieve HZSM-5 is used as the carrier to improve the dispersibility and activecatalytic sites of the active metal, and the catalytic activity can be improved, the obtained HZSM-5 supported Fe-Pd bimetallic catalyst for lignin hydrogenation and depolymerization is applied to catalytic hydrogenation and depolymerization of lignin, the conversion rate of lignin hydrogenolysis is 98.1wt%, the yield of bio-oil is 78.5 wt%, and the yield of a monophenol compound is as high as 27.9wt%.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com