Patents

Literature

110results about How to "Coordination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

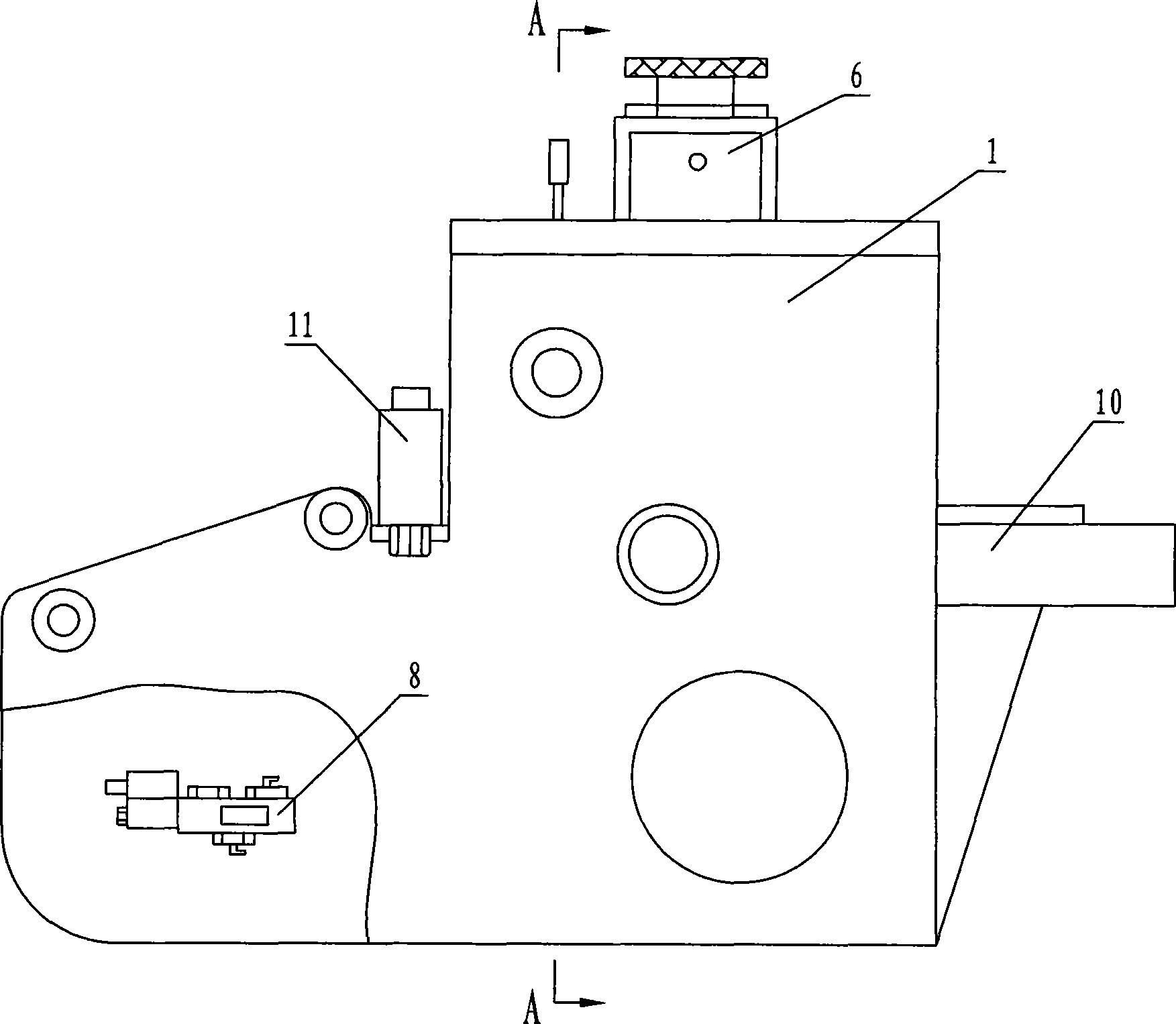

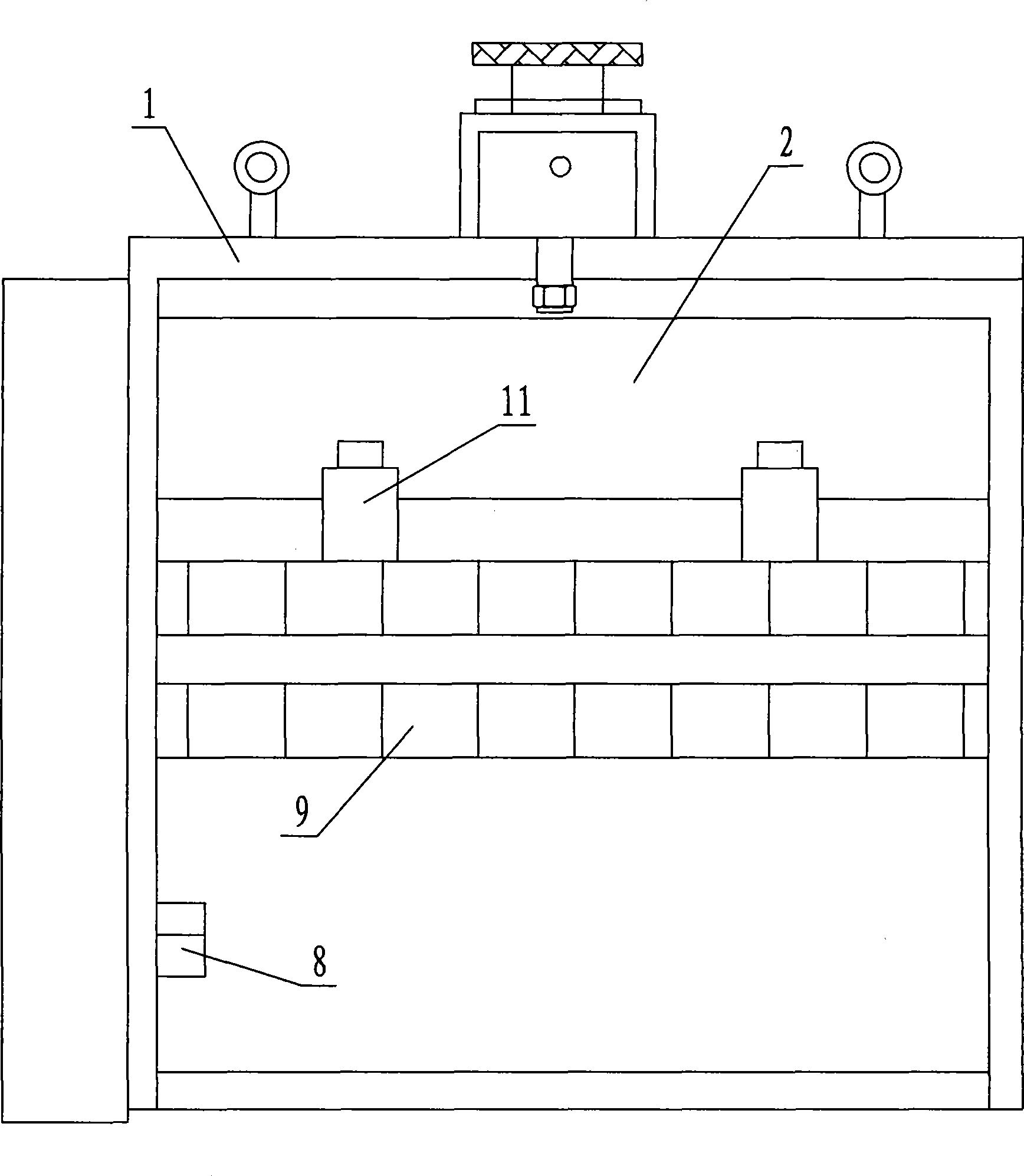

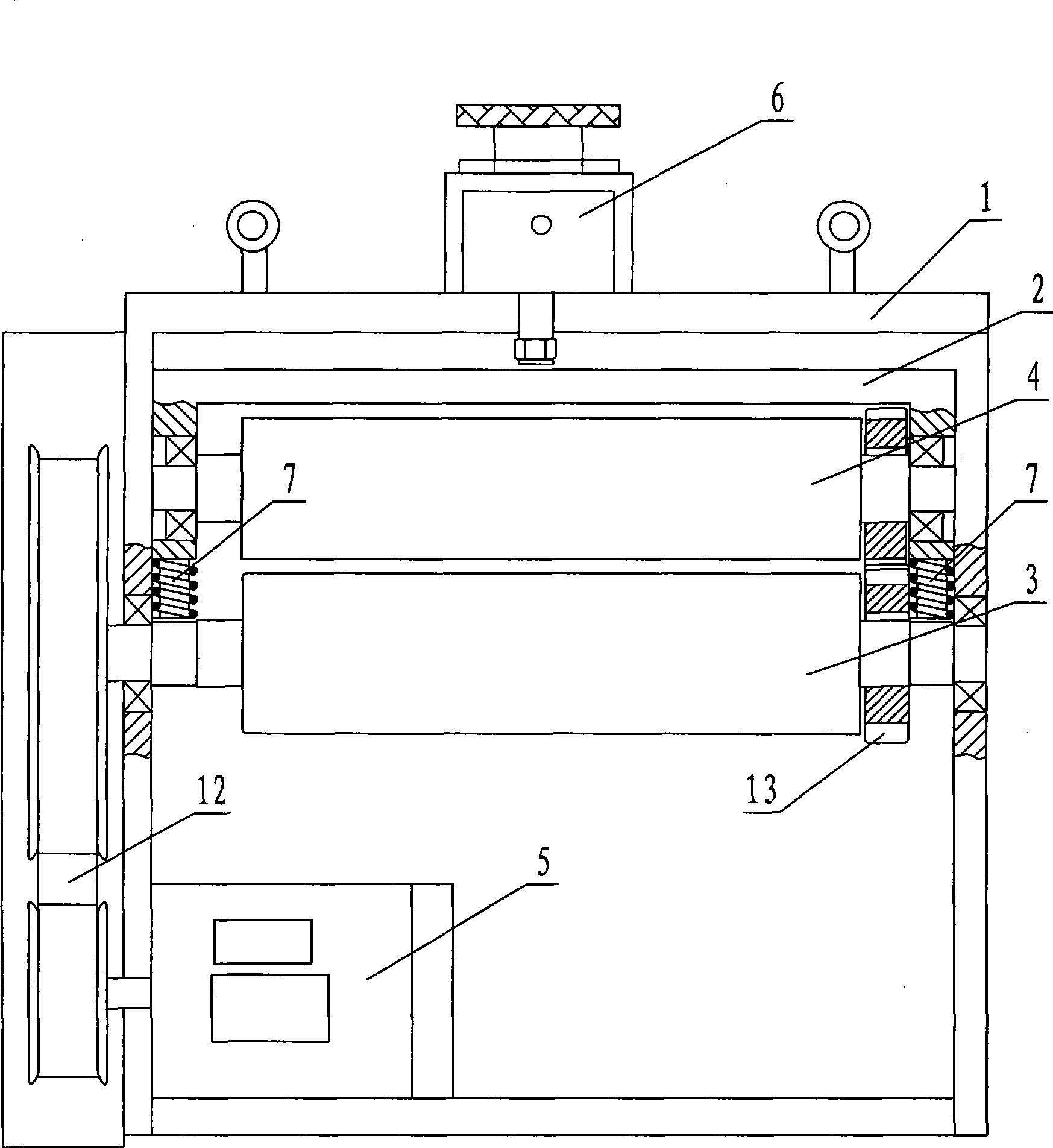

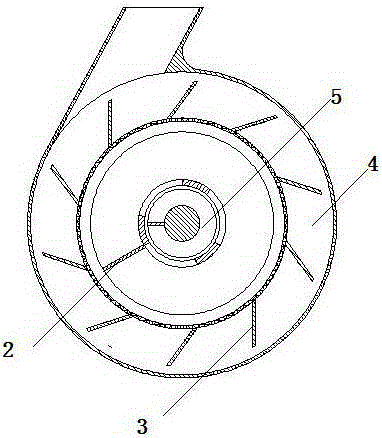

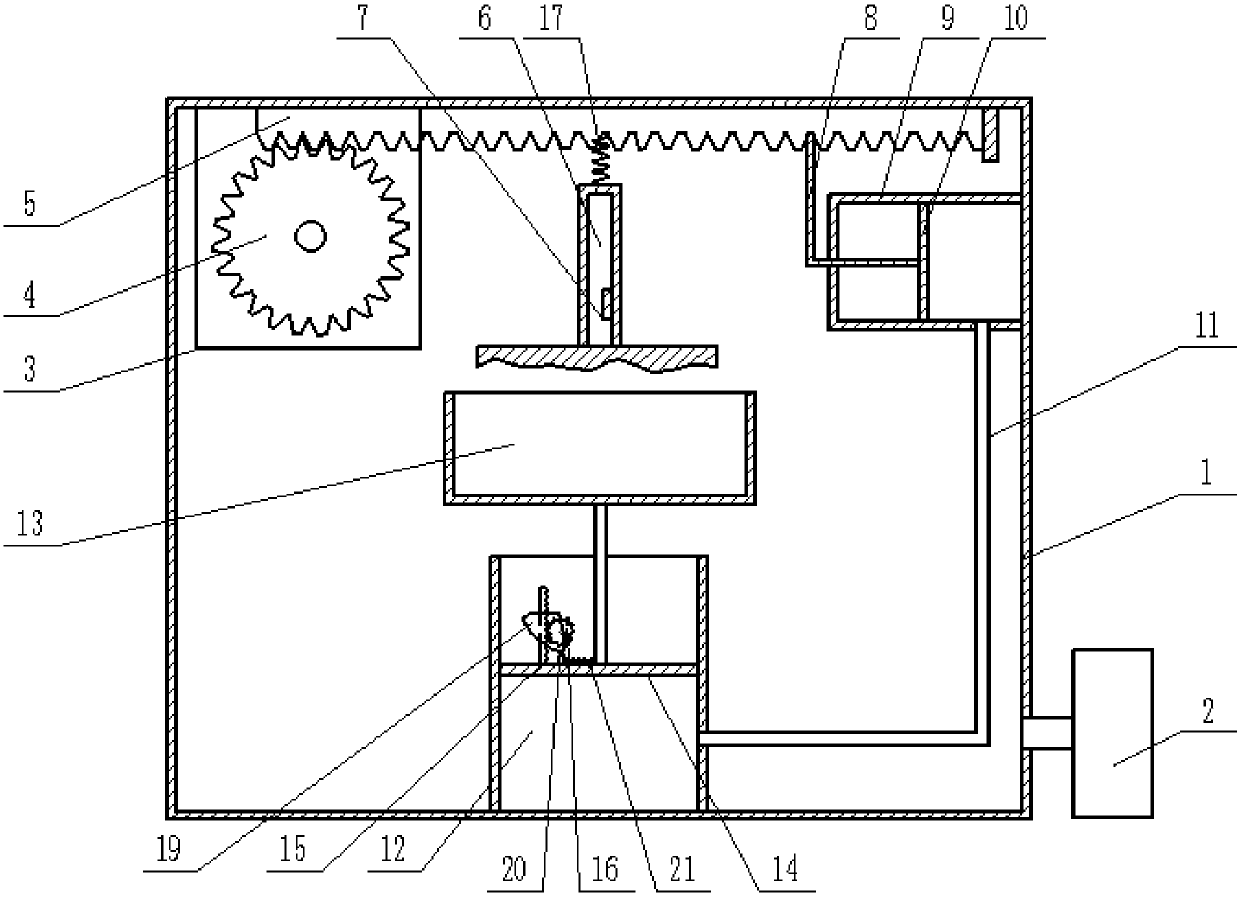

Feeding machine with rolling wheel

InactiveCN101376151ACoordinationAccurate relaxation pointMetal-working feeding devicesPositioning devicesPunch pressElectric machinery

The invention discloses a feeder with rollers, which is provided with a frame. An upper roller seat is moveably arranged in the frame; an upper roller is fixed on the upper roller seat; a lower roller is arranged on the frame; a servo motor is arranged at the lower part of the frame and in transmission connection with the lower roller; the lower roller is in transmission connection with the upper roller; a cylinder and an electromagnetic reversing valve are arranged on the frame; a piston rod of the cylinder passes through the upper plane of the frame to fixedly connect the upper roller seat; the electromagnetic reversing valve is connected with a pipeline of the cylinder; a spring is connected to the upper roller seat, and the upper roller arranged on the upper roller seat is driven under the action of the spring to move towards the lower roller and clamp board material tightly. The invention adopts the servo motor and a structure of the spring clamping feed and the cylinder loosening, feeding and loosening signals are sent to the feeder by the punch, and the movement of the cylinder is controlled through the electromagnetic reversing valve, so as to realize the feeding during clamping and no feeding during loosening. Therefore, the feeder and the punch can be harmoniously matched with good stability and wide applicability.

Owner:常州市佳王精密机械有限公司

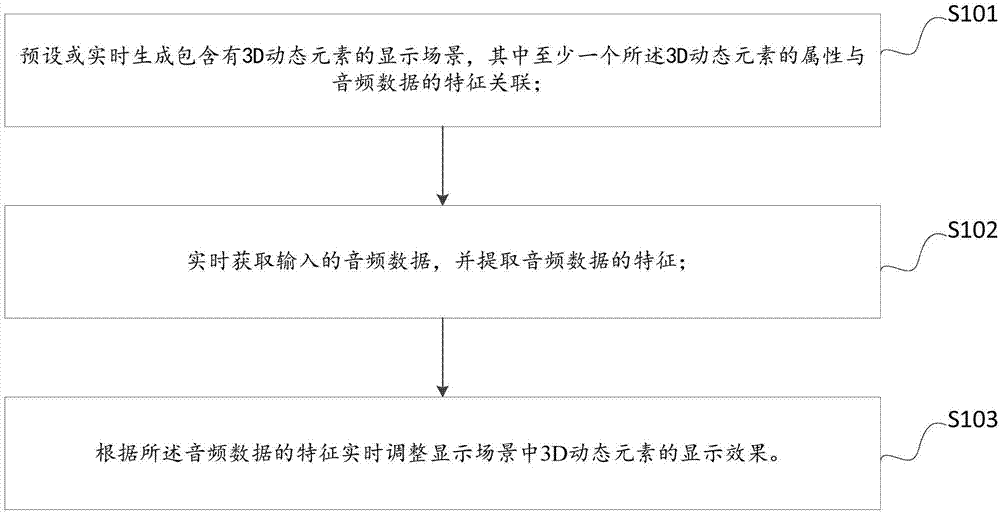

Real-time interactive display method and storage device based on voice frequency

ActiveCN107329980AImprove visual effectsCoordinationClosed circuit television systemsSound input/outputEngineeringComputer vision

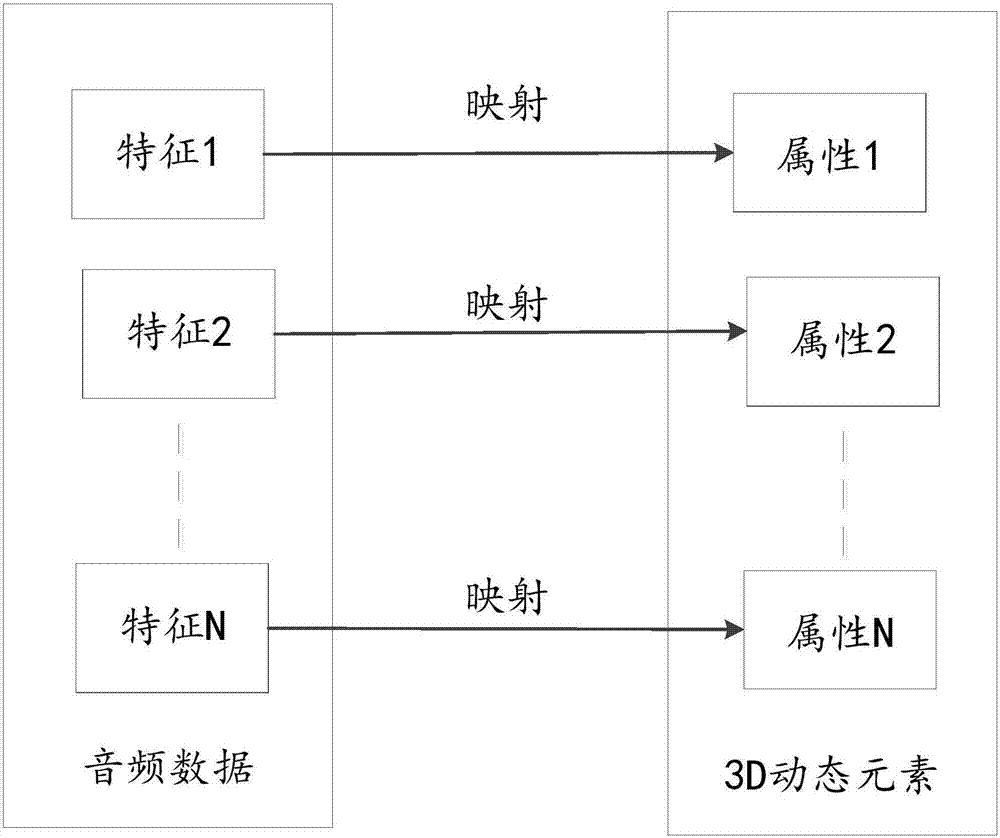

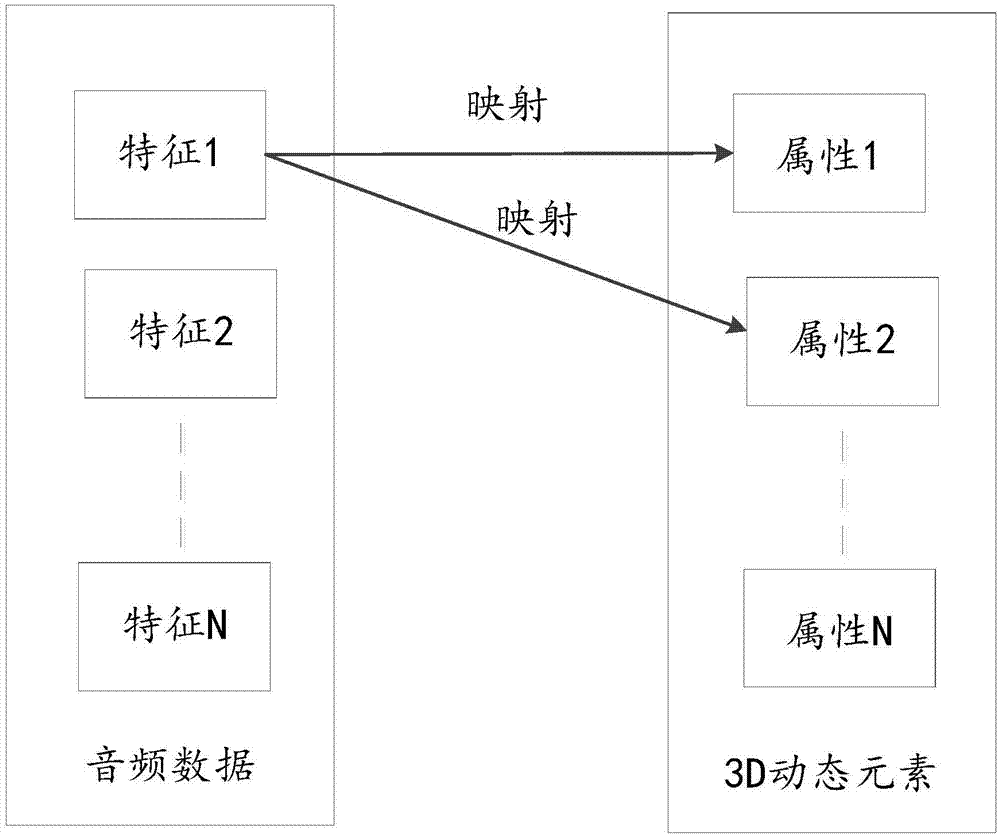

The invention discloses a real-time interactive display method and a storage device based on the voice frequency. The real-time interactive display method based on the voice frequency includes the following steps that a display scene containing 3D dynamic elements is pre-set or generated in real time; input voice frequency data is obtained in real time, and characteristics of the voice frequency data are extracted; according to the characteristics of the voice frequency data, the attribute parameters of 3D dynamic elements in the display scene can be adjusted in real time, and displaying of the 3D dynamic elements can be updated in real time. According to the technical scheme, the 3D dynamic elements are preset in the display scene, so that attributes of the 3D dynamic elements are associated with characteristics of the voice frequency data; according to the characteristics of the voice frequency data, the attribute parameters of the 3D dynamic elements are adjusted in real time, so that on the display basis of the original display scene, a cool voice dynamic scene is formed, the combination of the display scene and the voice frequency data is thus more coordinated, and the visual effect of the display scene and the experience feeling of a user are greatly improved.

Owner:FUJIAN STAR NET EVIDEO INFORMATION SYST CO LTD

Laser hard-surface coating process method of titanium alloy vane of gas turbine

InactiveCN101613860AEasy to adjustImprove physicsMetallic material coating processesLaser processingStructural geometry

The invention belongs to a laser processing technology for enhancing the surface hardness, i.e. the wearing resistance of titanium or titanium alloy, in particular to a laser hard-surface coating process method of a titanium alloy vane of a gas turbine. In the invention, corresponding mantle clamping fixture is adopted according to the geometrical shapes of structure of vane apex or damping convex shoulders of the vane, powder is placed in the mantle clamping fixture in advance, a static powder bed is formed by the mantle clamping fixture and the powder added in the mantle clamping fixture, powder is uniformly placed on the vane apex of the vane or the damping convex shoulders of the vane in advance by the static powder bed, and inert gases or N2 is adopted to protect a laser radiation area and carry out laser radiation on the vane. A hard-surface coating with the hardness of 35 to 62 HRC and the thickness of 0.05 to 2.0mm can be formed on the vane apex or the damping convex shoulder of the titanium alloy vane when the invention is adopted. The invention has the advantages that vacuum is not needed; laser cladding can be carried out only under the protection of inert gases of Ar, He, and the like in atmosphere conditions; the operation is convenient; and the formed hard-surface coating and basal body of the vane have good adapter properties in physics and chemistry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production method for ceramic brick with natural concave-convex surface

The invention relates to a production method for ceramic tile with natural rough surface. It is characterized by the following steps: spraying right amount of water onto the dry green body surface, roasting the green brick surface under high temperature to quickly vaporize the water on the surface so as to crack the green brick surface irregularly, then removing the cracked clay on the surface to form natural rough surface, finally roasting the green brick in the ceramic tile roller kiln. The ceramic tile produced by the invented method has natural, stereo, variable patterns on surface.

Owner:FOSHAN OCEANO CERAMICS

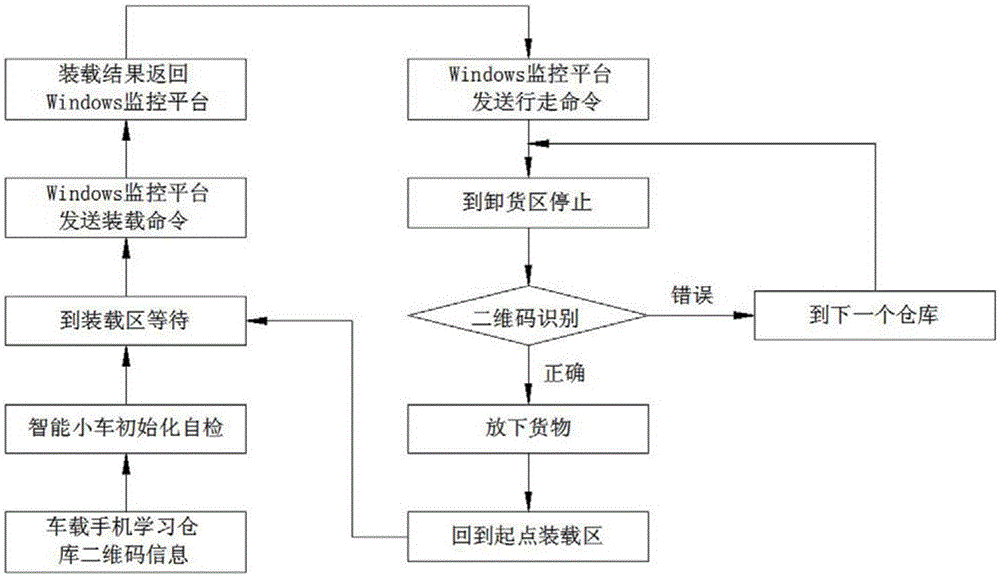

Two-dimensional code navigation based logistics delivery system and delivery method thereof

InactiveCN105574695ACoordinationAvoid unexpected situationsCo-operative working arrangementsLogisticsData transmissionCode navigation

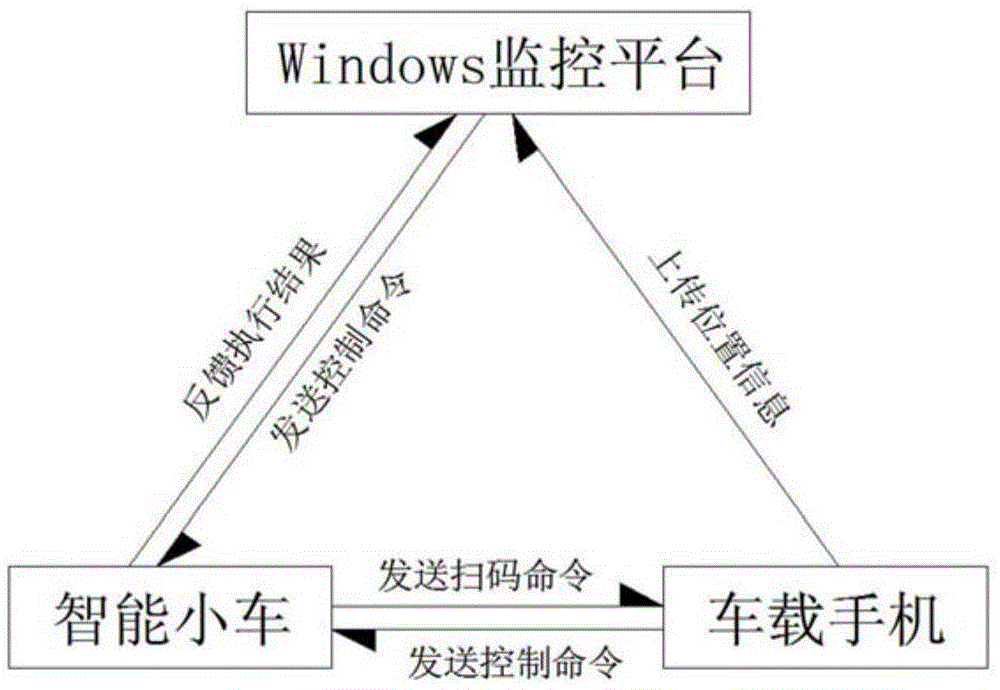

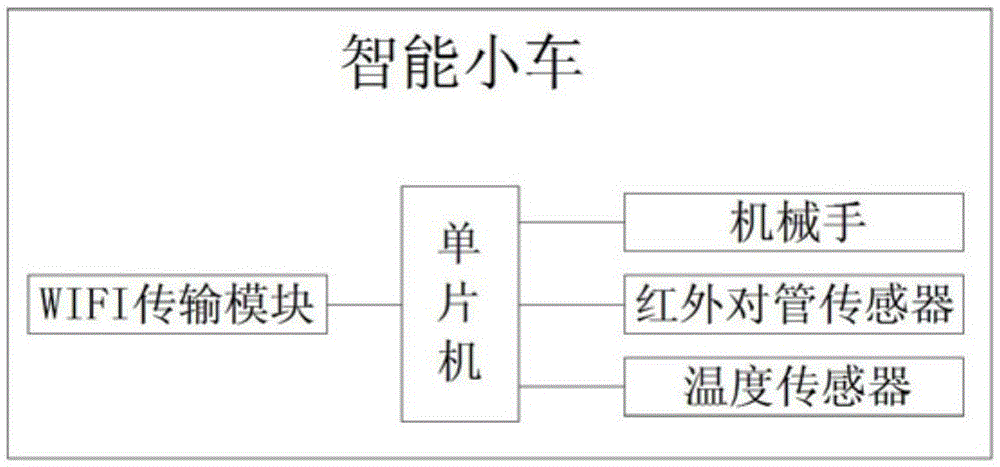

The invention discloses a two-dimensional code navigation based logistics delivery system and a delivery method thereof. The logistics delivery system comprises an intelligent vehicle, a vehicle-mounted cellphone and a Windows monitoring platform which form a local area network and are communicated by using a WIFI technique, wherein duplex exchange data is carried out based on a TCP / IP communication protocol, the control of the intelligent vehicle adopts a singlechip, and the singlechip is communicated with the vehicle-mounted cellphone and the Windows monitoring platform through a WIFI transmission module. The logistics delivery system has the advantages that the three platforms of the vehicle-mounted platform, the singlechip and the Windows monitoring platform are integrated, cross-platform data transmission and intelligent vehicle control are perfectly fulfilled; a two-dimensional code technology is first used for storing positional information of the vehicle and controlling shipping of the vehicle, the positional information of the vehicle is rapidly recorded and also restored by 100%, and an important guarantee is provided for rapidly and accurately judging the position of the intelligent vehicle.

Owner:XIAN UNIV OF SCI & TECH

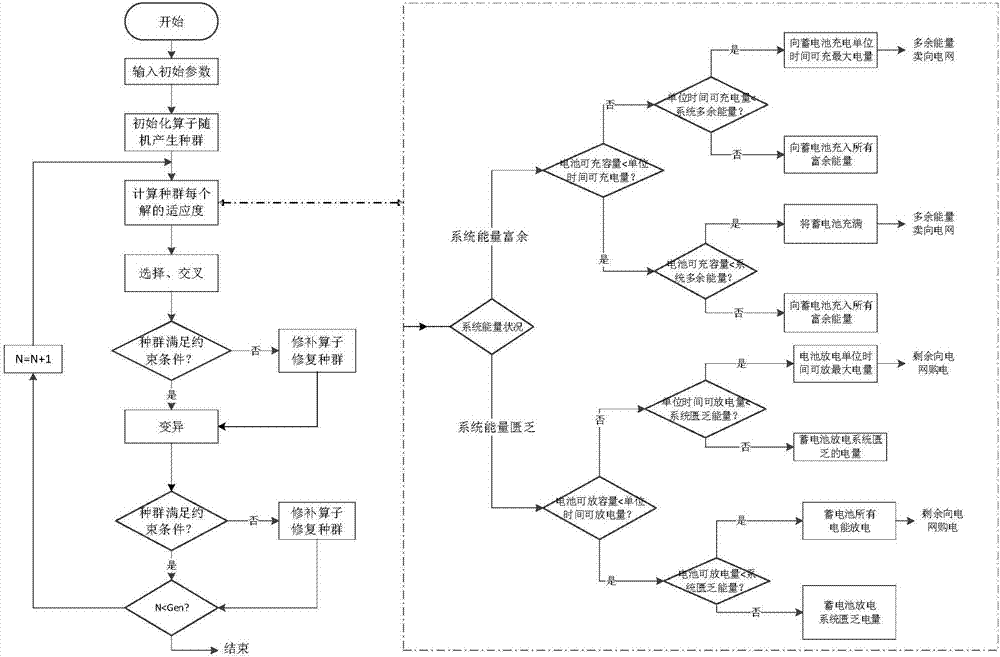

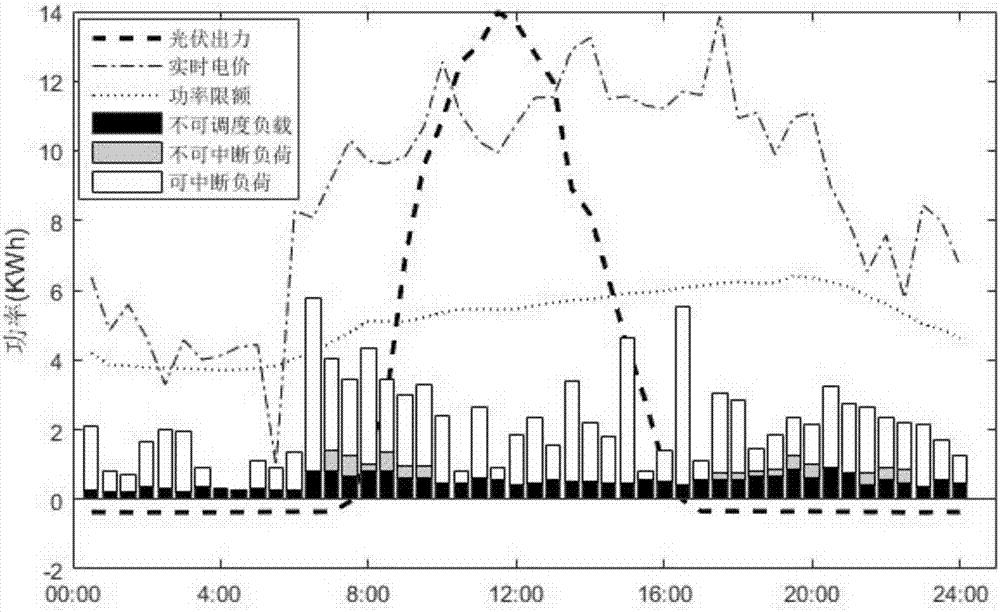

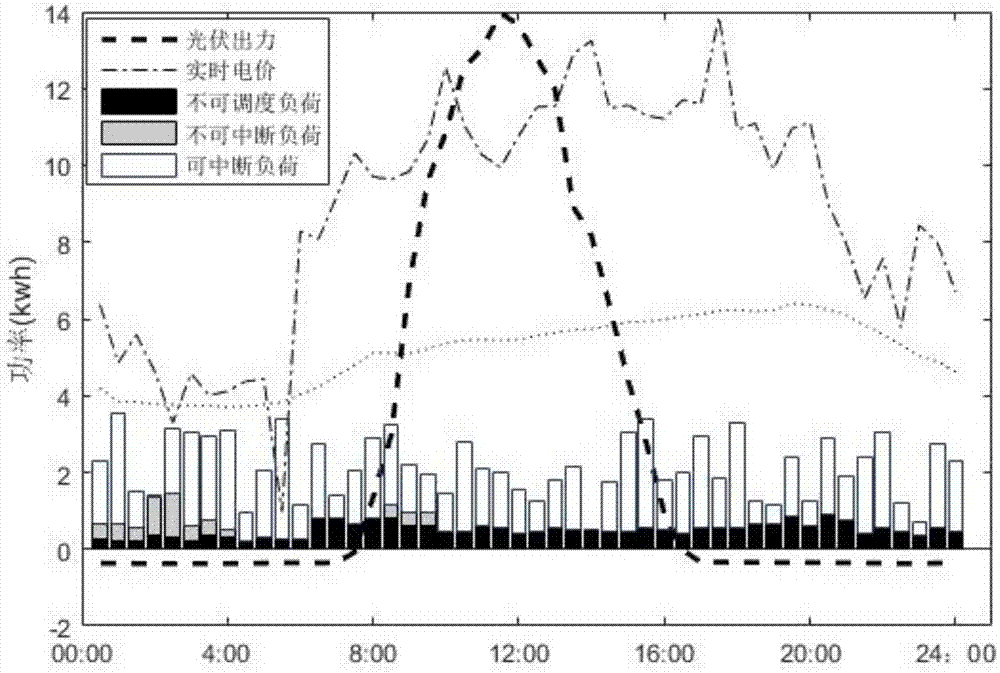

Demand response-based intelligent control method for home energy management system

InactiveCN107392420ALower electricity billsOptimize the objective functionResourcesInformation technology support systemEngineeringGenerating capacity

The invention relates to a demand response-based intelligent control method for a home energy management system. The method comprises the following steps that initial parameters are input, and a population is randomly generated by an initialization operator; a target function for spending the least electricity fee is built, constraint conditions are set, and a fitness model is constructed; the fitness model is solved to obtain the equipment states in all the scheduling time periods, and storage battery charging and discharging are conducted according to the equipment states in the scheduling time periods; a selection operation and a crossover operation are conducted in sequence, whether the population meets the constraint conditions or not is judged, and if not, variation is conducted after population repairing; if yes, variation is directly conducted; and whether the population obtained after variation meets the constraint conditions or not is judged, and if not, population repairing is conducted. Compared with the prior art, the method has the advantages of adopting peak-load shifting to transfer part of the distributed energy generating capacity, being more flexible in application, adopting the repairing method to meet the constraint conditions, being more suitable for some complex non-linear integer model problems and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

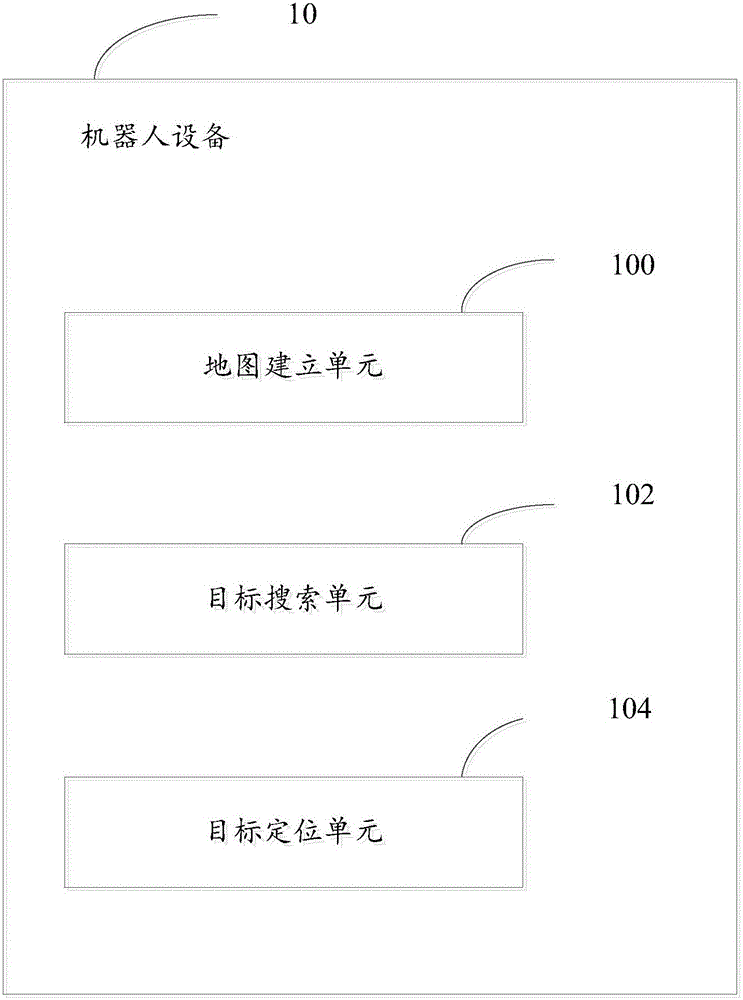

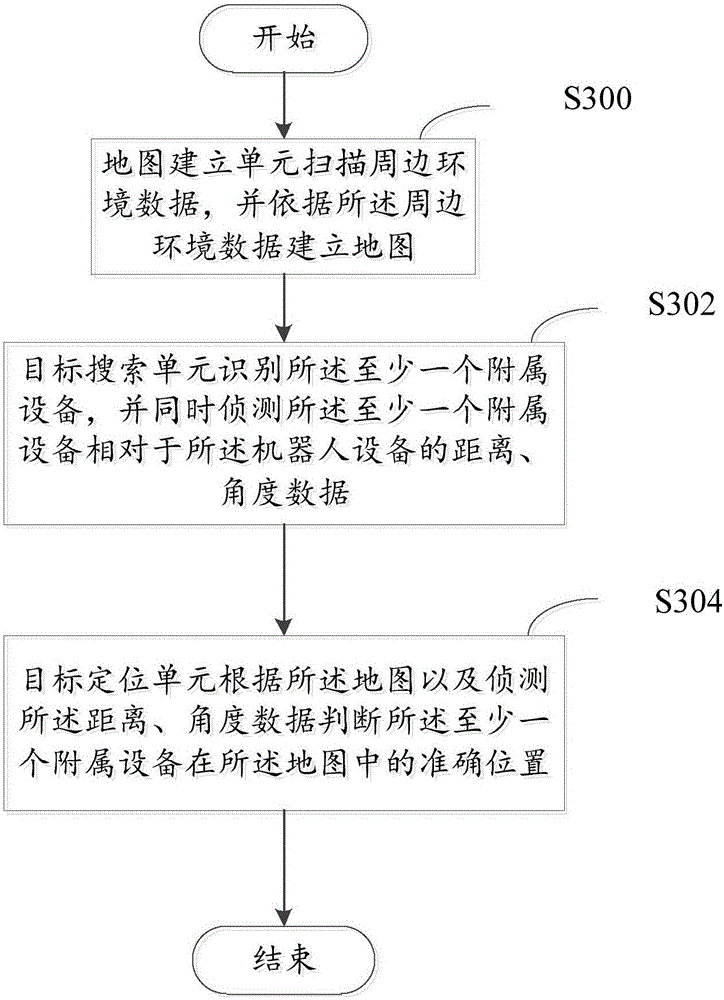

Robot device and method for locating target

A robot device comprises at least accessory equipment. The robot device further comprises a map building unit used for scanning surrounding environment data and building a map according to the surrounding environment data; a target search unit used for identifying the at least accessory equipment and simultaneously detecting distance and angle data of the at least accessory equipment relative to the robot device; and a target location unit used for judging the accurate position of the at least accessory equipment in the map according to the map and the detected distance and angle data. The invention also provides a method for locating a target by the robot device. Through the robot device and its target location method, cooperation between the robot device and the accessory equipment can be more accurate and flexible.

Owner:SHENZHEN LDROBOT CO LTD

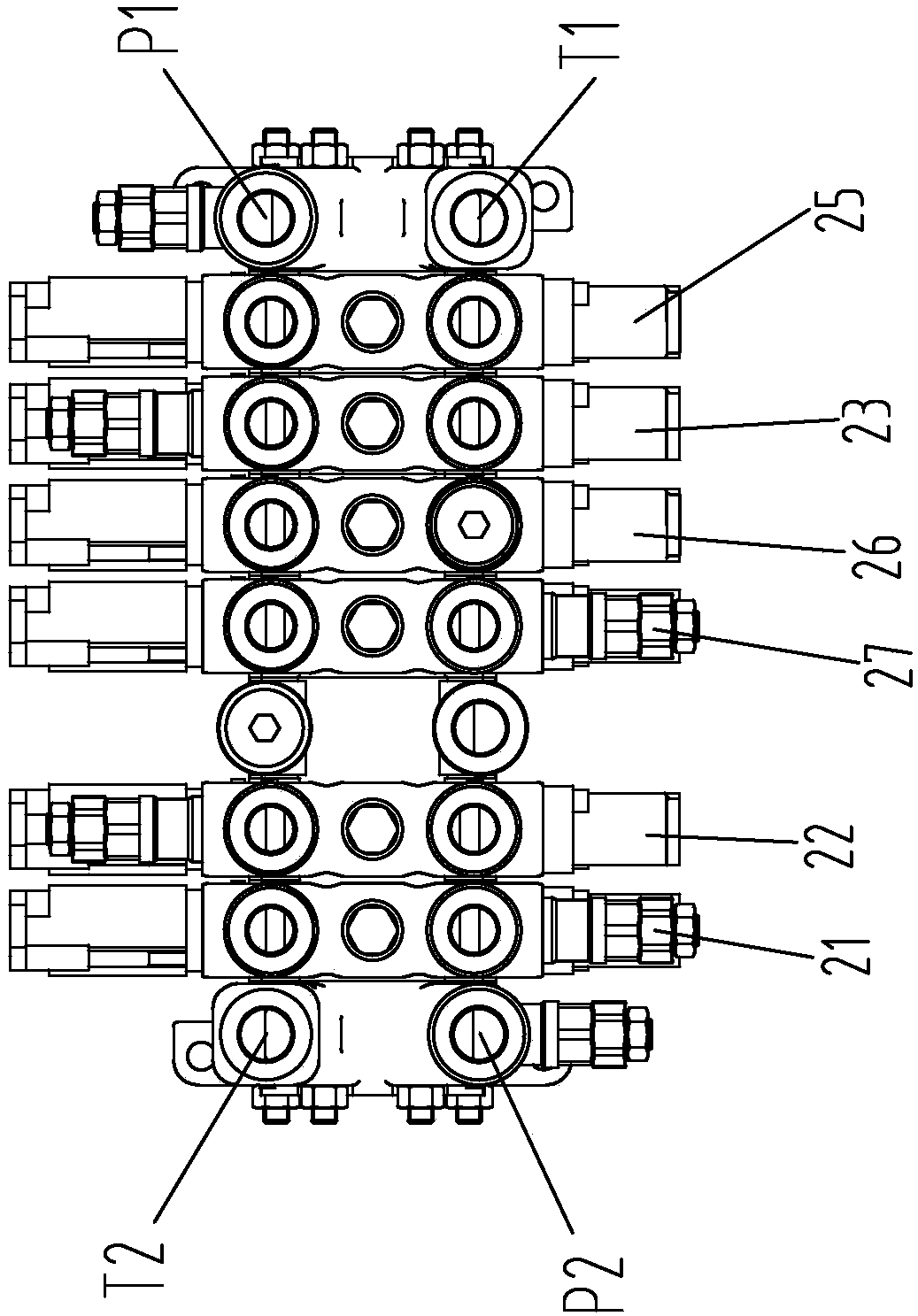

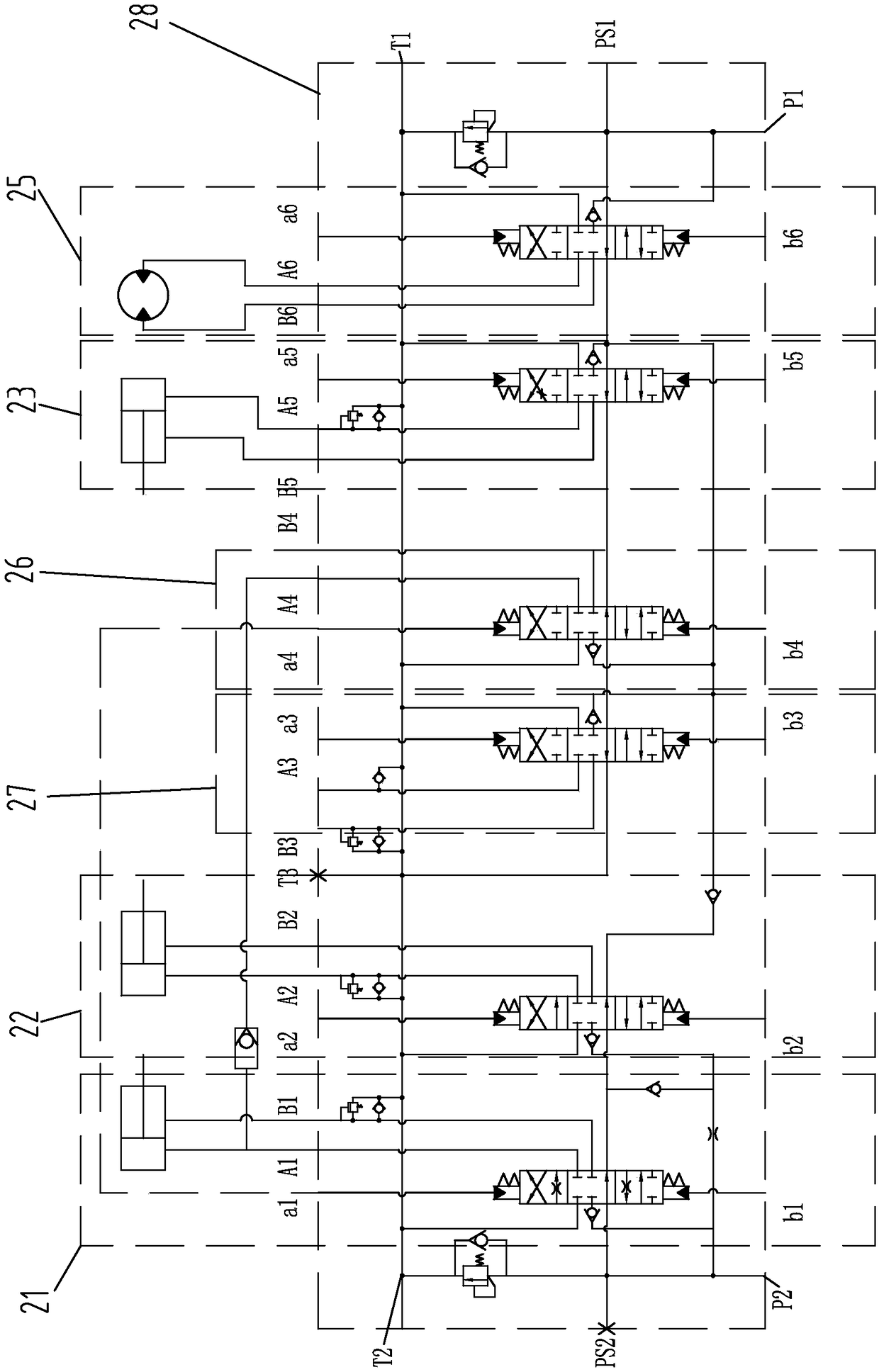

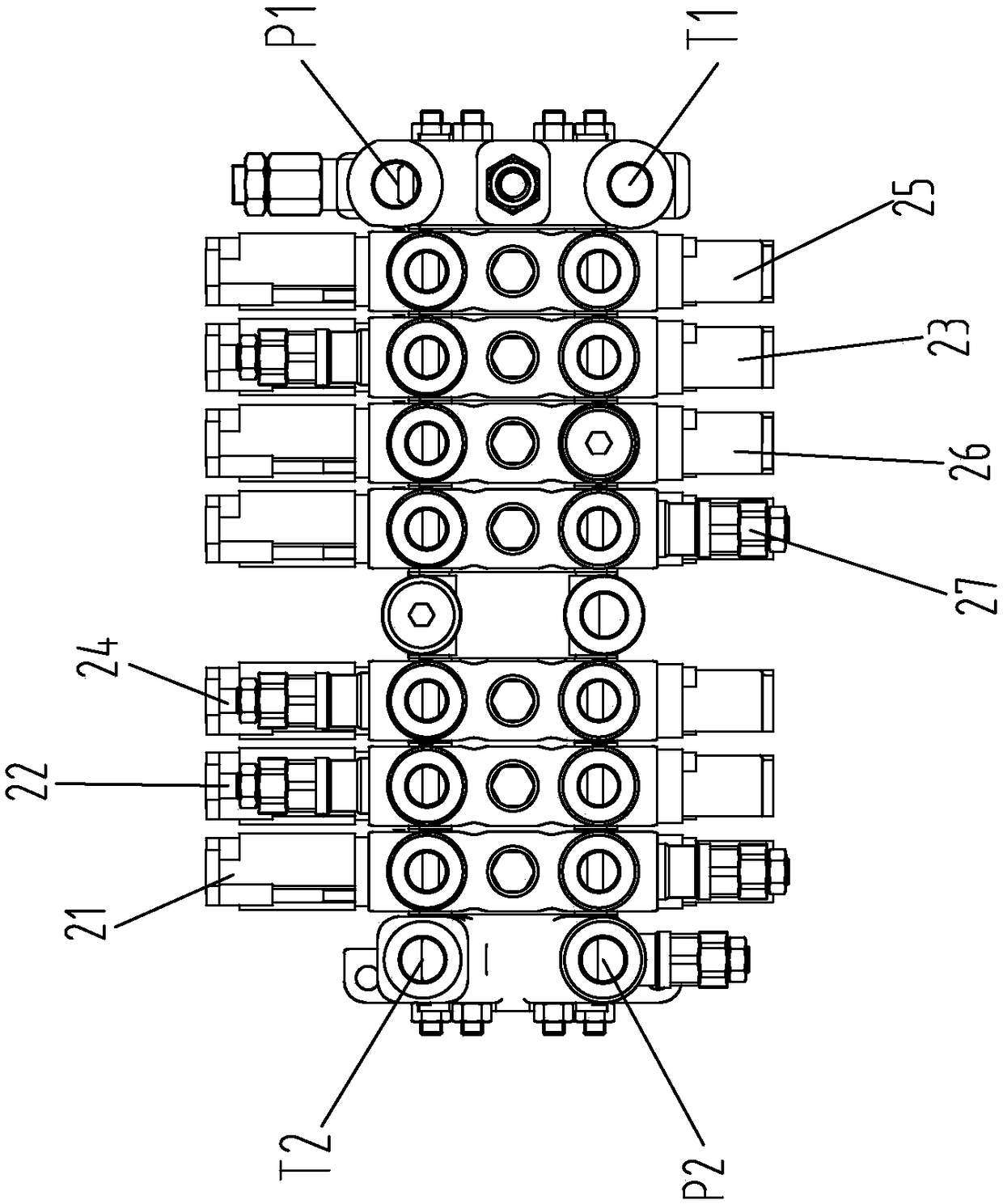

Multi-path valve for wheel excavator

The invention discloses a multi-path valve for a wheel excavator. The multi-path valve for the wheel excavator comprises a second oil inlet, a first oil inlet, an oil returning opening, a movable armoil linkage path, a bucket oil linkage path, a bucket rod oil linkage path and a guiding oil way. All the oil ways communicate with one another in series and communicate with the second oil inlet andthe oil returning opening to form a loop, and the bucket rod oil linkage path communicates with the first oil inlet. The multi-way valve for the wheel excavator is further provided with a third oil inlet, a movable arm oil cylinder, a bucket oil cylinder, a bucket arm cylinder and an auxiliary oil linkage way. The movable arm oil linkage path is further provided with a corresponding movable arm reversing valve, the bucket oil linkage path is further provided with a corresponding bucket reversing valve, the bucket rod oil linkage path is further provided with a bucket rod reversing valve, and the auxiliary oil linkage path is further provided with an auxiliary reversing valve. The third oil inlet communicates with the auxiliary reversing valve. The movable arm oil cylinder is connected withthe movable arm reversing valve, the bucket oil cylinder is connected with the bucket reversing valve, and the bucket arm cylinder is connected with the bucket rod reversing valve. Compared with theprior art, the multi-path valve has the beneficial effects that the coordination of composite actions of the excavator is improved, and therefore the working efficiency is improved.

Owner:FUJIAN JINGONG MACHINERY

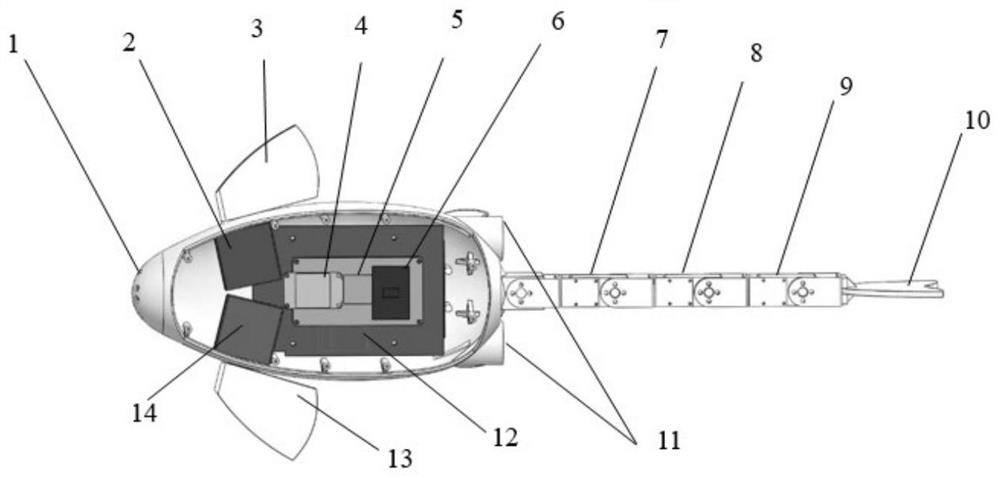

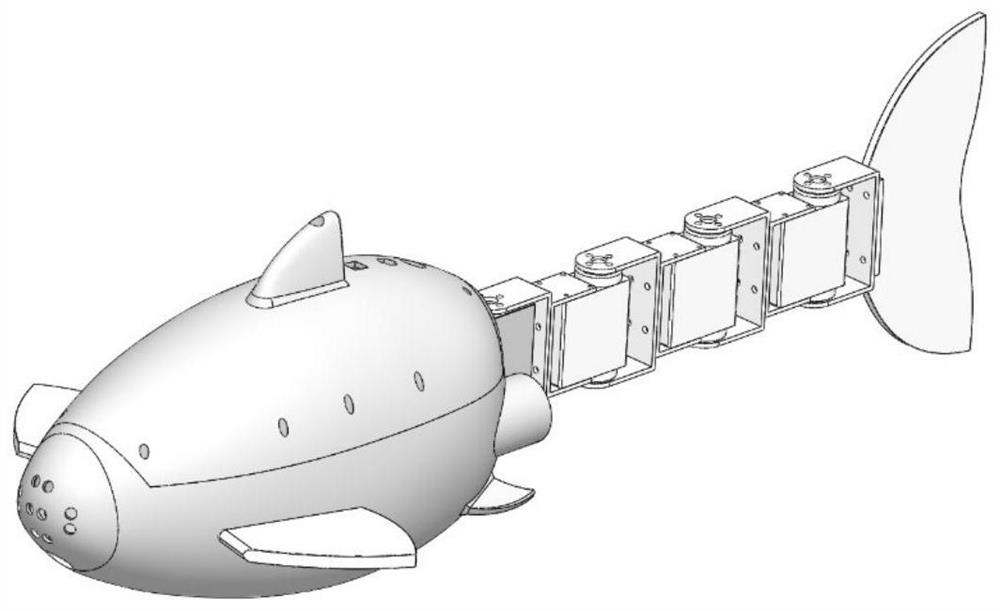

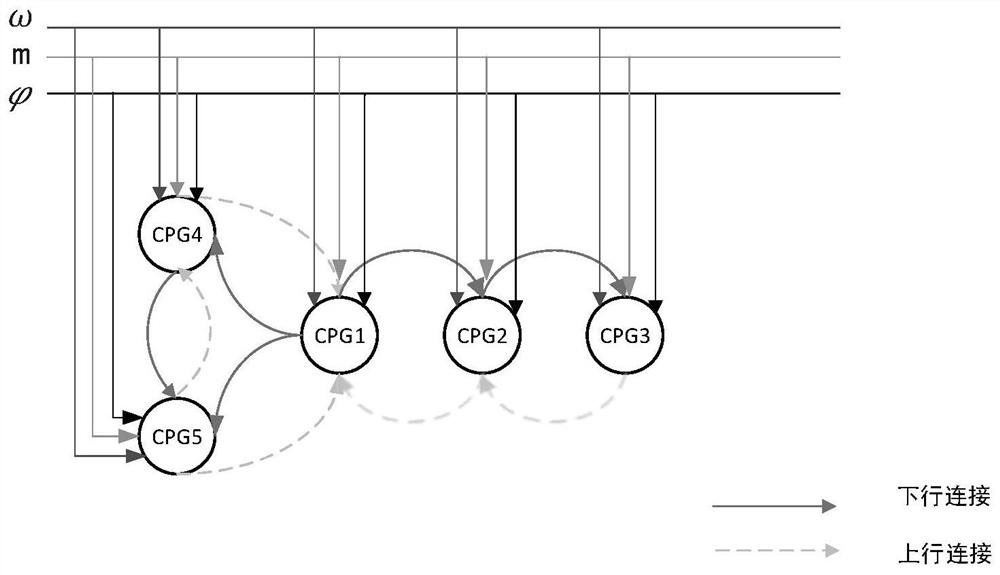

Multi-joint robotic fish and motion control method thereof

ActiveCN113636048AImprove interactivityMovement precisionClimate change adaptationNavigation by speed/acceleration measurementsControl engineeringEngineering

The invention discloses a multi-joint robotic fish and a motion control method thereof. The multi-joint robotic fish comprises a closed fish body structure, a sensor set is arranged on the fish body structure, and the two sides of the fish body structure are symmetrically connected with a right pectoral fin and a left pectoral fin which drive the fish body structure to move up and down; a right pectoral fin steering gear joint and a left pectoral fin steering gear joint which are connected with the right pectoral fin and the left pectoral fin respectively and drive the right pectoral fin and the left pectoral fin to move are arranged in the fish body structure, and a controller, a positioning module and a communication module are further arranged in the fish body structure; the tail end of the fish body structure is connected with a tail joint mechanism for driving the fish body structure to horizontally swim, the tail joint mechanism comprises at least three groups of tail steering engine joints which are connected in sequence, and the tail end of the tail steering engine joint at the tail is further connected with a tail fin; and the sensor group at least comprises an infrared sensor, a water quality detection sensor and an inertial navigation sensor. According to the multi-joint robotic fish, accurate, efficient, natural and coordinated automatic cruise and obstacle avoidance of the multi-joint robotic fish can be realized.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

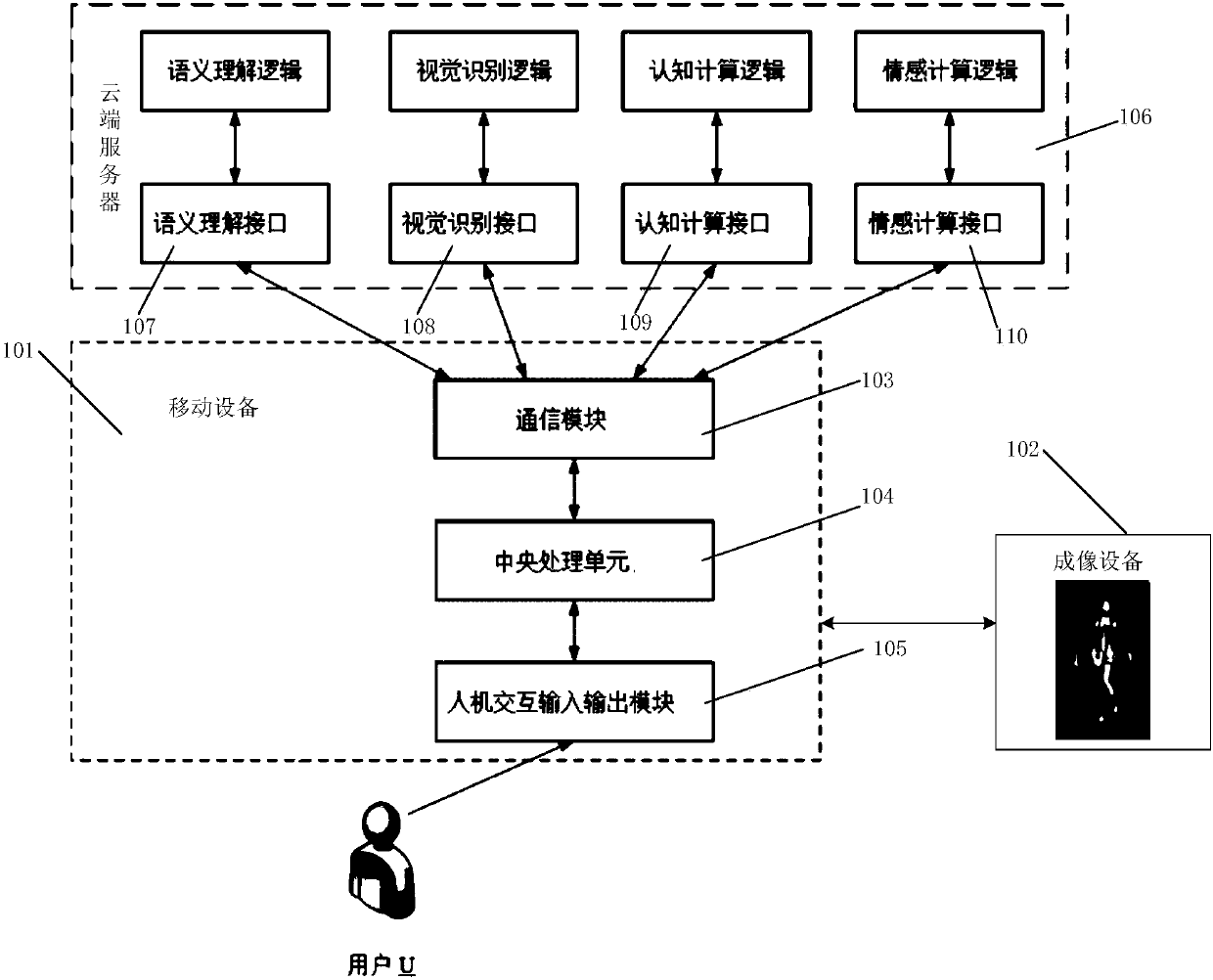

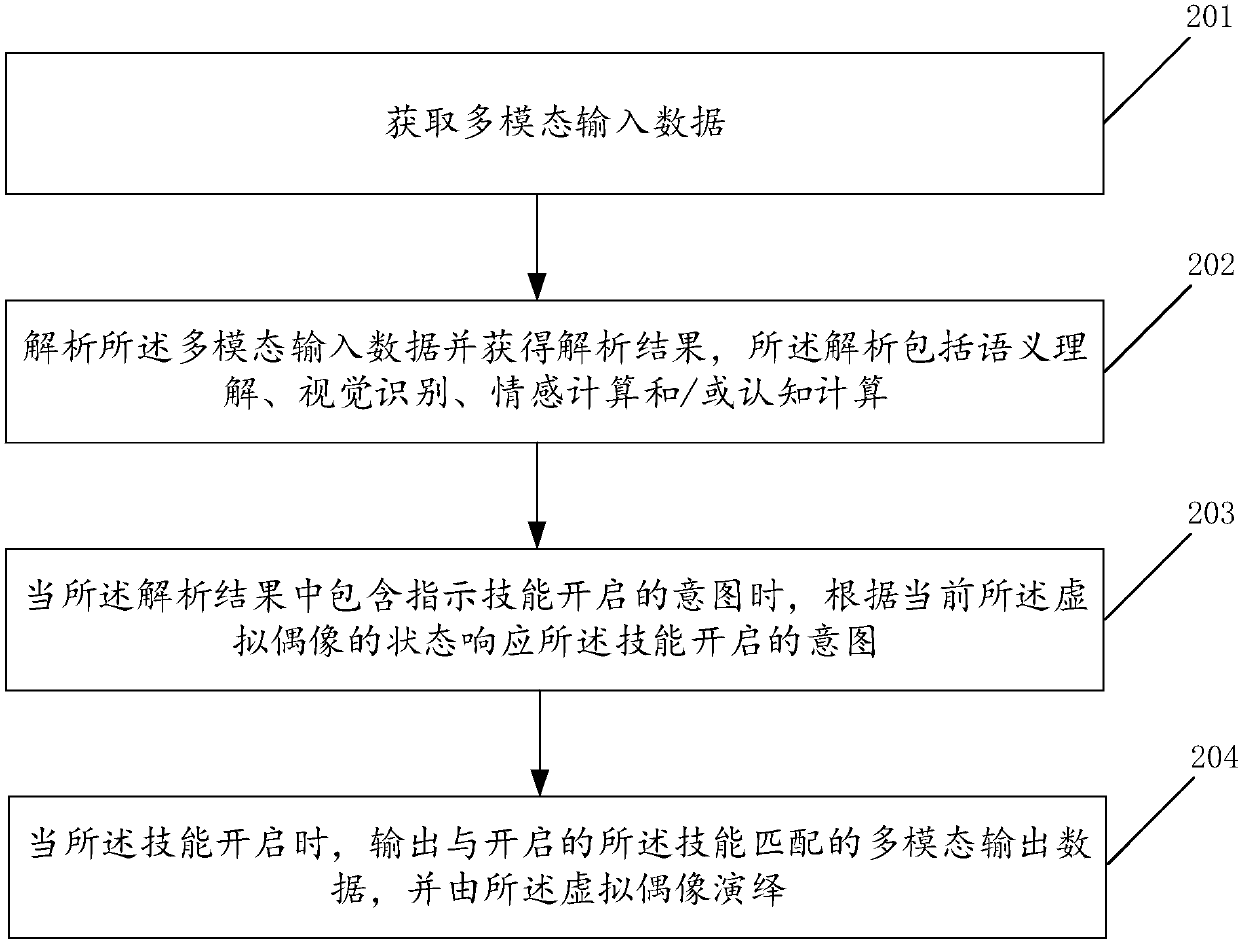

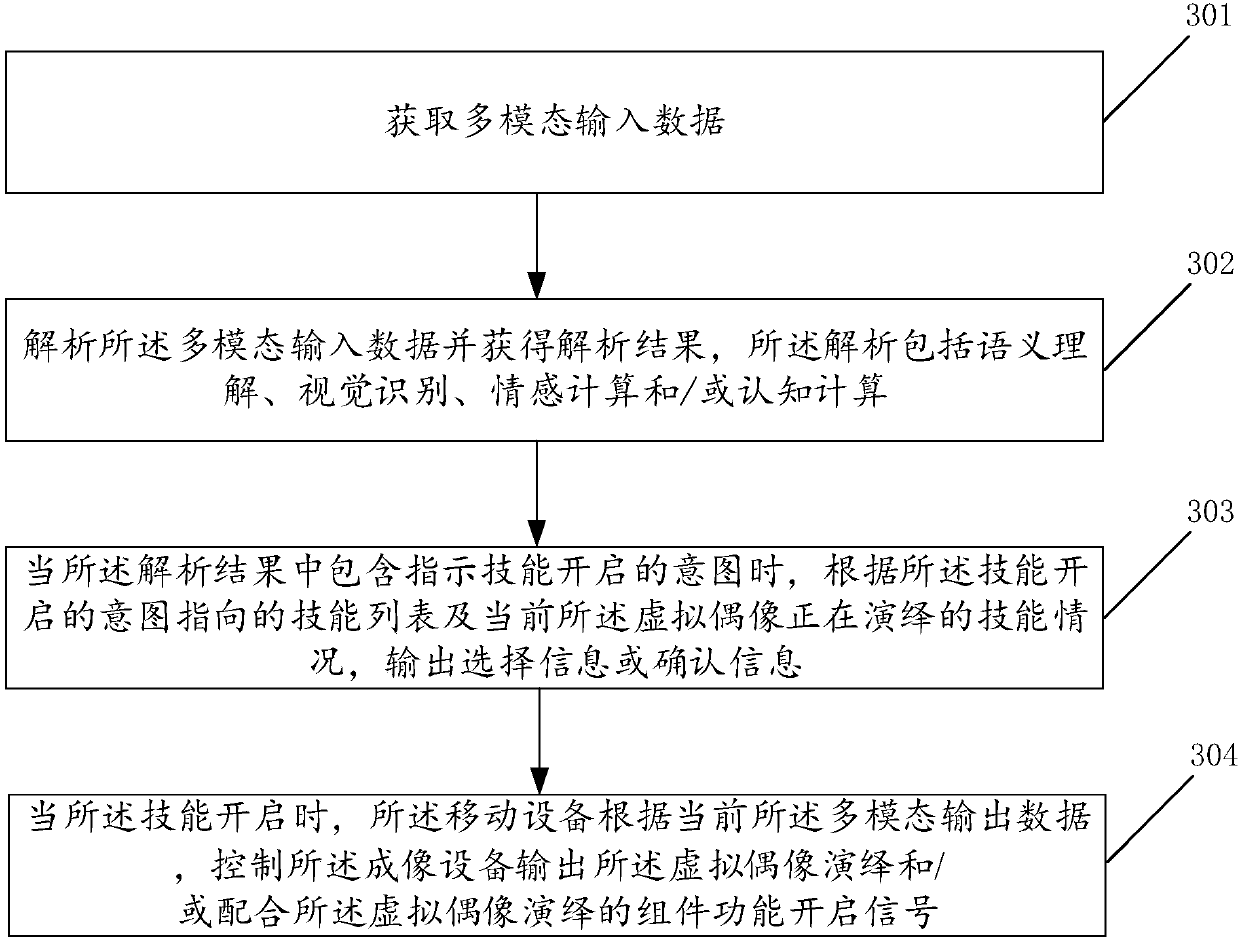

Method and system for starting and performing skill of virtual idol

InactiveCN108037825AThree-dimensional effectImprove experienceInput/output for user-computer interactionSound input/outputSkill setsFacial expression

The invention provides a method and system for starting and performing a skill of a virtual idol. The method comprises the steps of acquiring multimodal input data; parsing the multimodal input data and obtaining a parsing result; when the parsing result contains an intention for indicating starting of the skill, responding to the intention for starting of the skill according to the current stateof the virtual idol; when the skill is started, outputting multimodal output data matched with the started skill, and performing the skill by the virtual idol. According to the method and system for starting and performing the skill of the virtual idol, the virtual idol starts and performs the skill by using multimodal interactive input, the virtual idol can present the more realistic, stereoscopic and three-dimensional effects through holographic projection equipment, the cooperation of five sense organs, facial expressions and body movements of the virtual idol when the system and the user conduct multimodal interaction is more coordinated and realistic, and the user experience effect is good.

Owner:BEIJING GUANGNIAN WUXIAN SCI & TECH

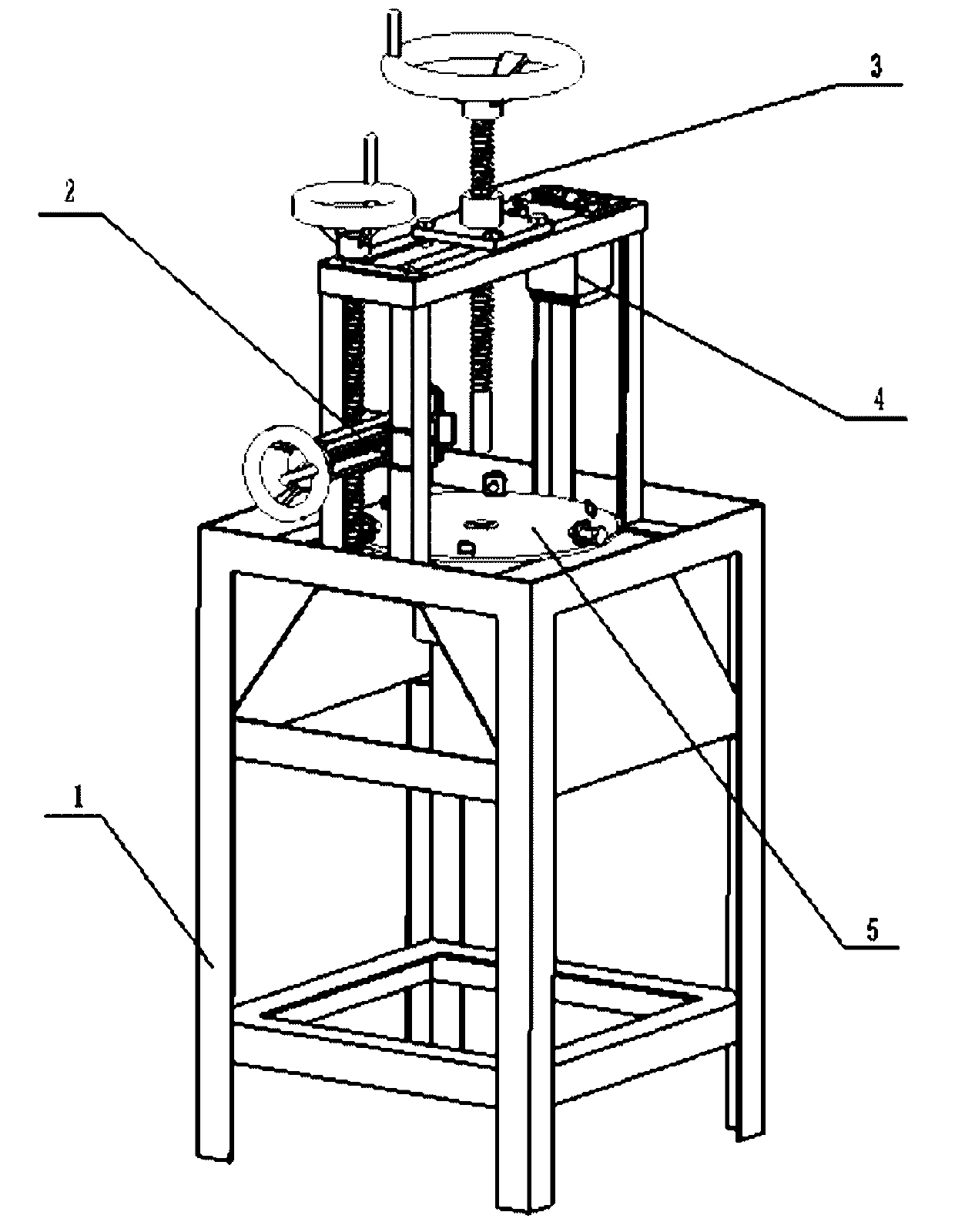

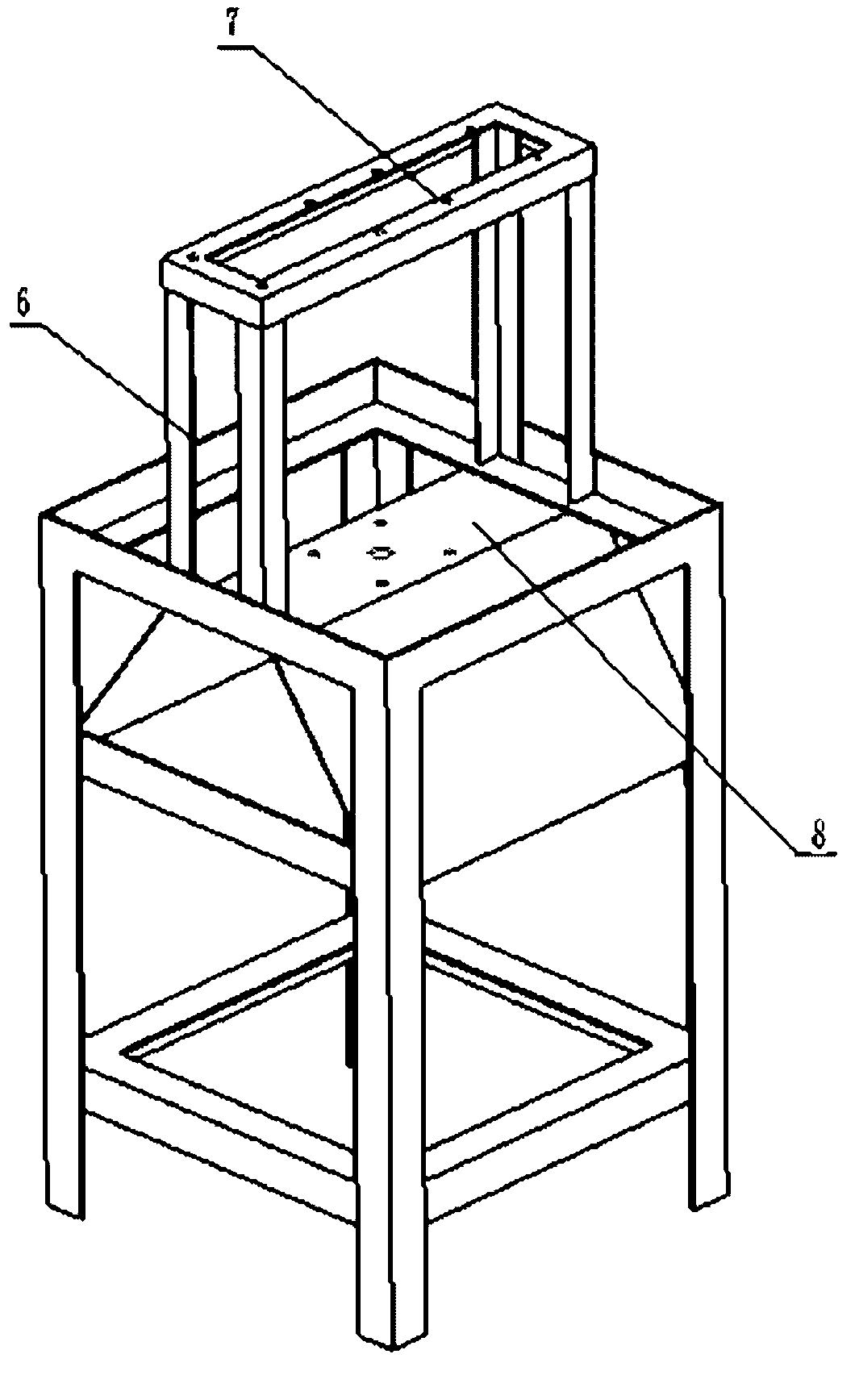

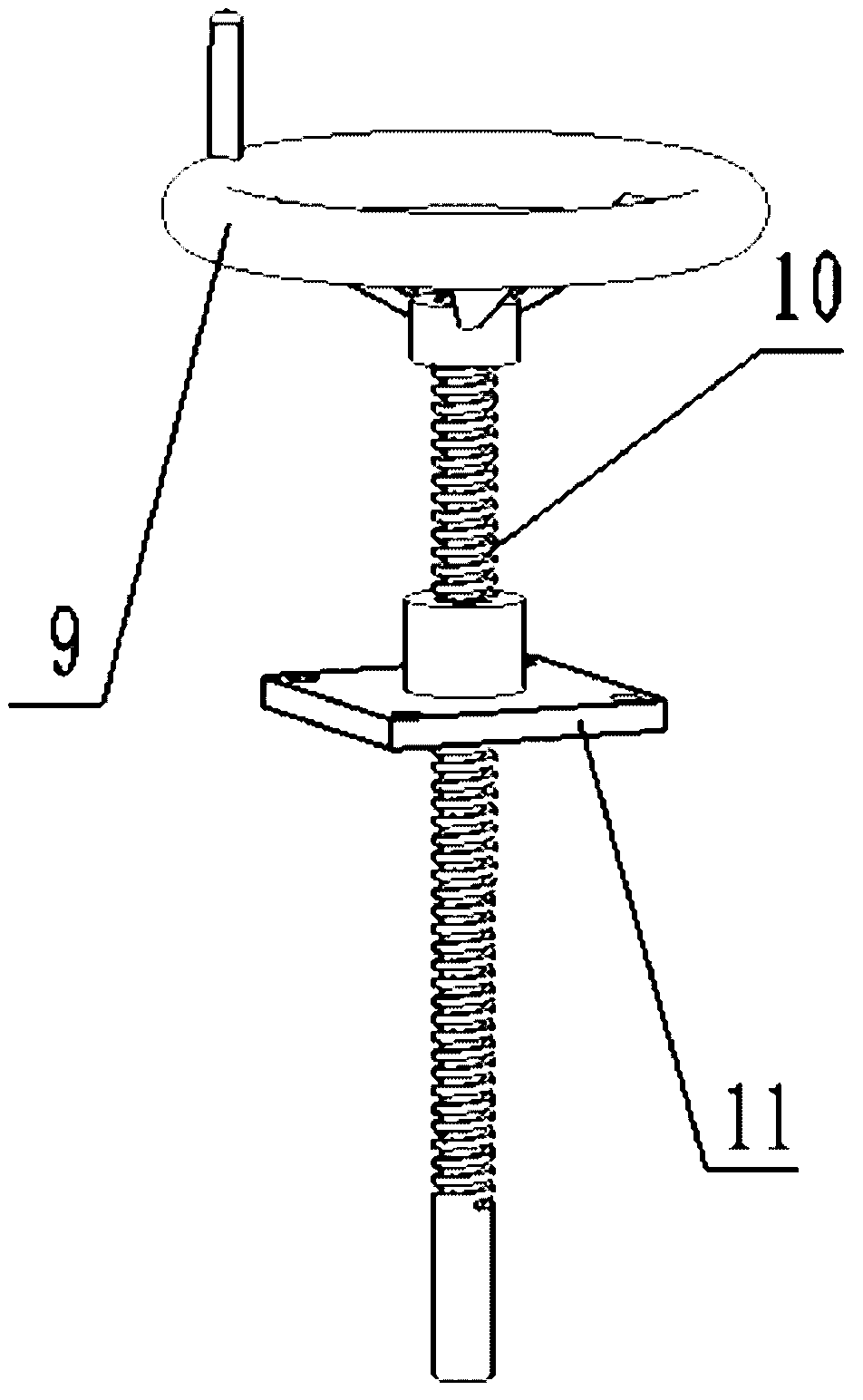

Soil cutting device for accurately obtaining non-rhizosphere soils at different distances from rhizosphere

The invention relates to a soil cutting device for accurately obtaining non-rhizosphere soils at different distances from rhizosphere. A circular root box soil block tray device, a soil block locating lead screw device, a blade regulating device, an adjustable-speed motor switch and the like are arranged on a bracket, the bottom of a circular tray is connected with a rotating shaft of an adjustable-speed motor, anti-sliding soil block stop sheets are circumferentially uniformly distributed on the edge of the circular tray and fixed by soil block locating bolts; a first hand wheel in the soil block locating lead screw device and the upper end of a first lead screw are welded together; a second hand wheel in the blade regulating device and the upper end of a lead screw are welded together, the lead screw is matched with a thread on an auxiliary blade holding frame, the auxiliary blade holding frame is connected with a blade holding frame through a third lead screw, one end of the third lead screw and a third hand wheel are welded together, a blade is fixed on the blade holding frame; a first lead screw locating block in the soil block locating lead screw device is sleeved on the first lead screw and is connected with a bracket main cross beam bolt; the first lead screw is concentric with the rotating shaft of the adjustable-speed motor, and the blade regulating device is fixed on the lead screw.

Owner:HUAZHONG AGRI UNIV

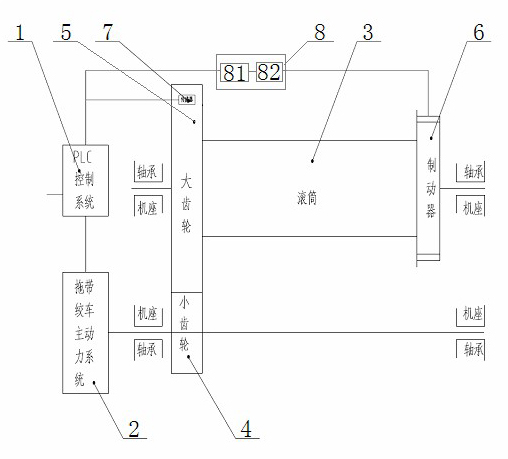

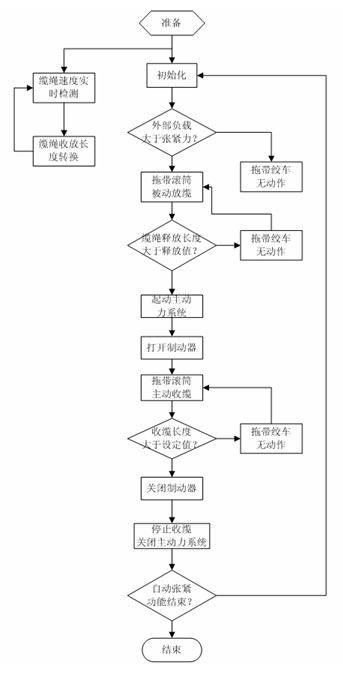

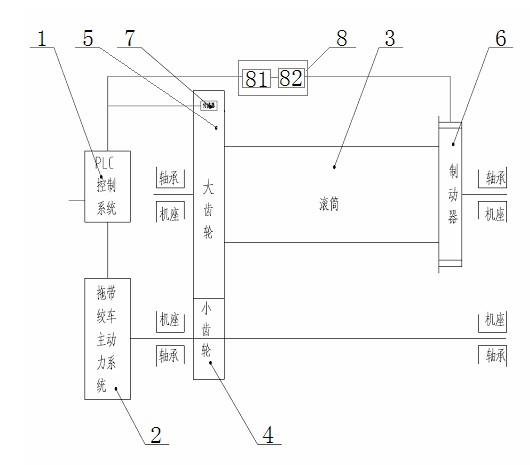

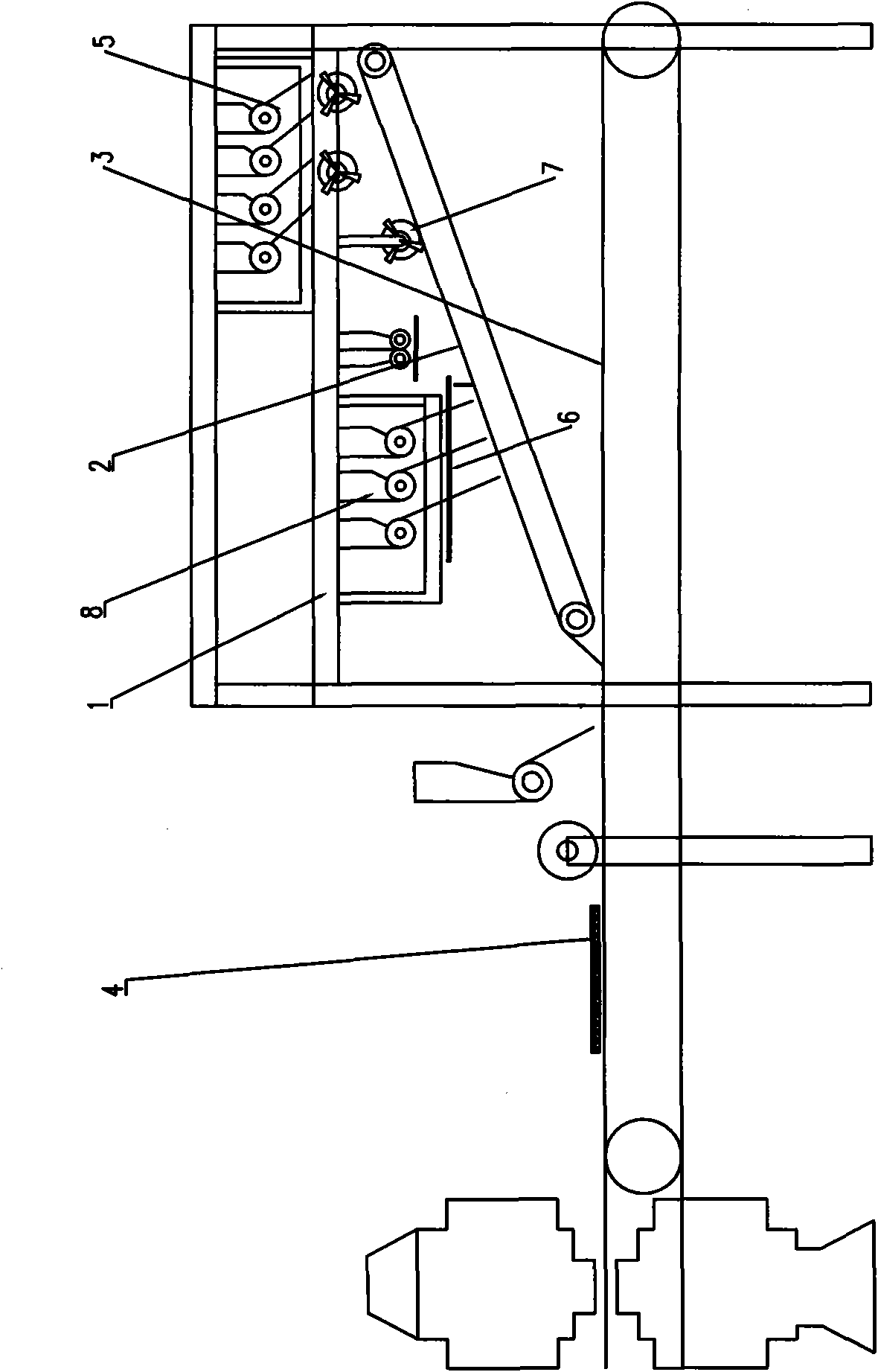

Towing winch with automatic tensioning function and implementation method thereof

ActiveCN102139839AReduce energy consumptionReduce exhaust emissionsWinding mechanismsProgrammable logic controllerBrake force

The invention relates to a towing winch with automatic tensioning function; the towing winch comprises a PLC (programmable logic controller) control system, a main power system and a roller, wherein the PLC control system is connected with the main power system; the other end of the main power system is sequentially connected with a pinion gear and a big gear; the roller is provided with a stepless adjusting brake which is connected with the PLC control system; and the big gear is provided with a speed sensor. When the towing winch is used, firstly the PLC control system is started so as tocollect field data, then the automatic tensioning function is selected as the working mode of the PLC (programmable logic controller) control system and finally the maximum gathering length and braking force of a mooring rope is set; when an external load is greater than the braking force in the towing process, the main power system is started to reversely drive the roller so as to realize the gathering of the mooring rope; and when the length of the gathered mooring rope is equal to the maximum gathering length, the main power system stops gathering the mooring rope. The design of the towingwinch can consume few energy sources and has faster response speed; and the towing winch has batter stability and lower failure rate during long-time running.

Owner:WUHAN MARINE MACHINERY PLANT

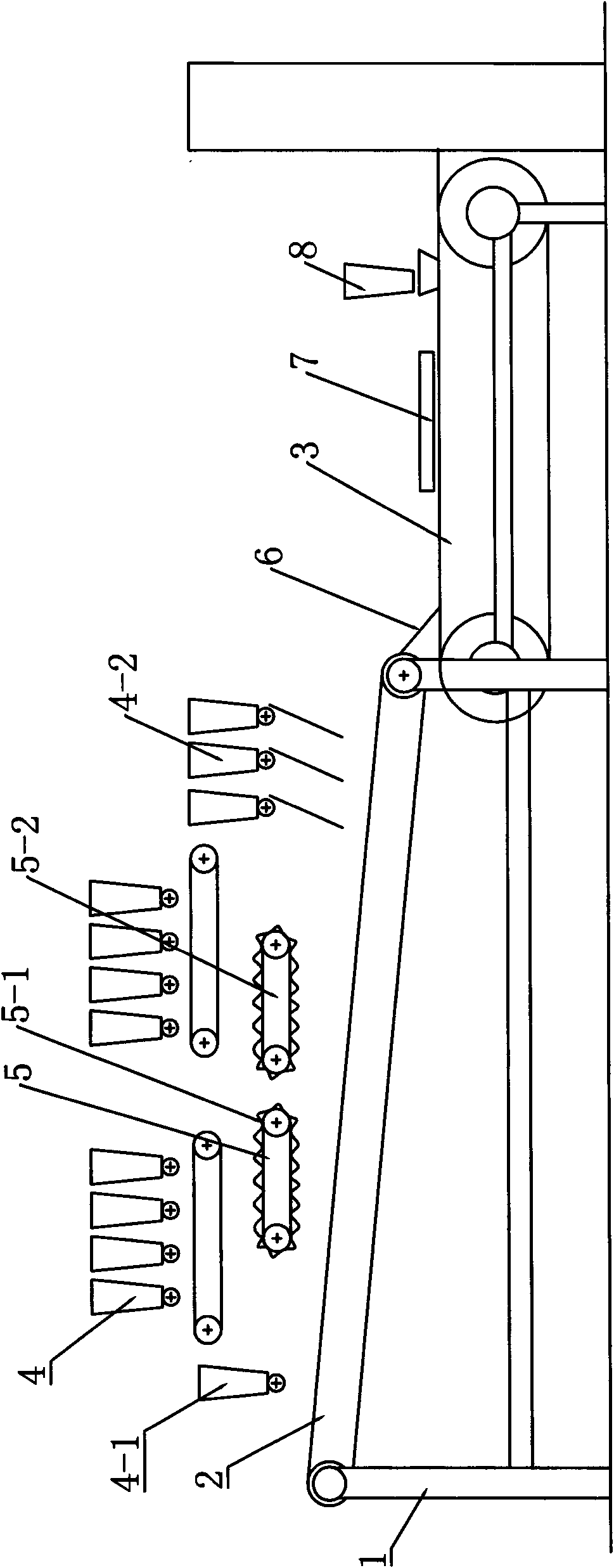

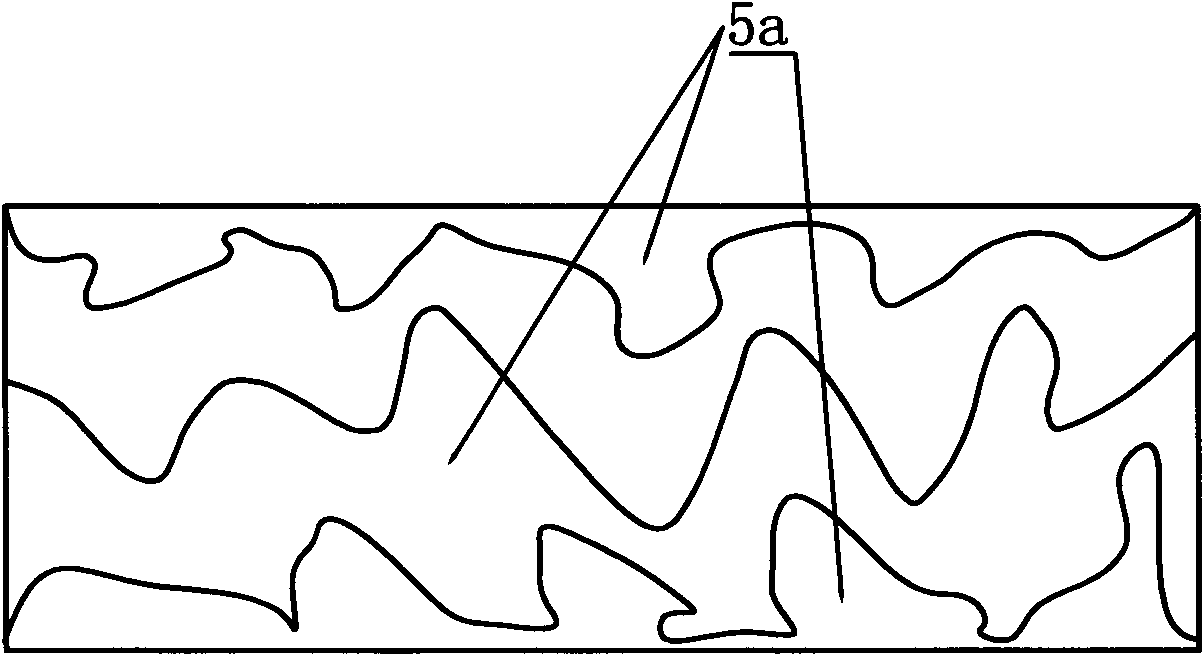

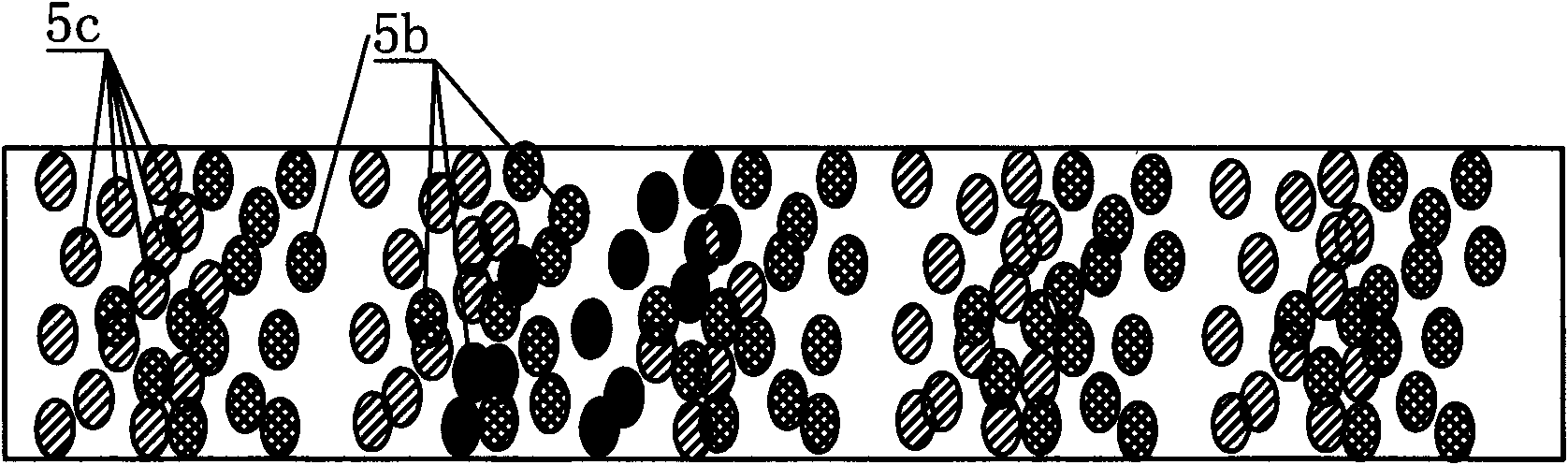

Process and equipment for distributing ceramic brick micro powder

The present invention discloses a process and an apparatus for distributing the ceramic brick micro powder, characterized in that the existing line micro powder distribution process is added with a preparation and a distribution process of a vertical peak belt and a striation fine line coarctation powder belt, combing a line distribution process, a simultaneous distribution of the vertical peak belt, the striation fine line dense belt and a common accidental line is implemented, such that a ceramic micro powder brick product combining various lines organically is formed. The ceramic micro powder brick of the invention has a natural and sharp veins, a various and rich gradation, and a harmony and decency color collocation, has a similar veins of the granite of a natural stone market, comparing with the common wood-grain imitating decorative brick, the taste and exquisite mettle of the brick ensures the decorative effect to be refulgent.

Owner:霍镰泉

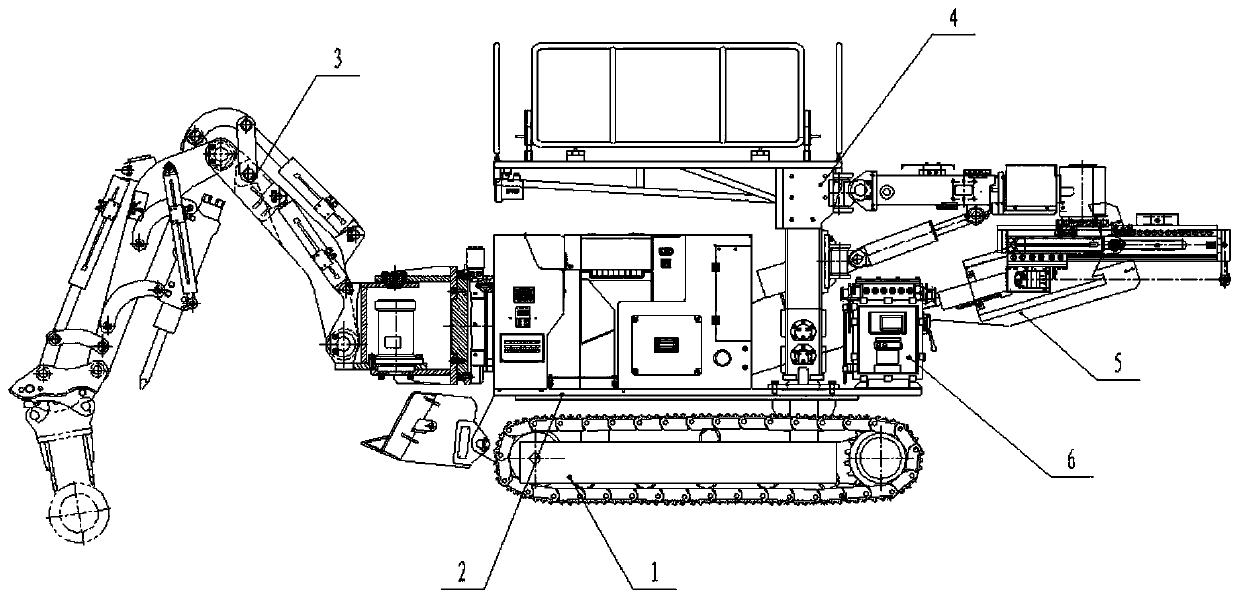

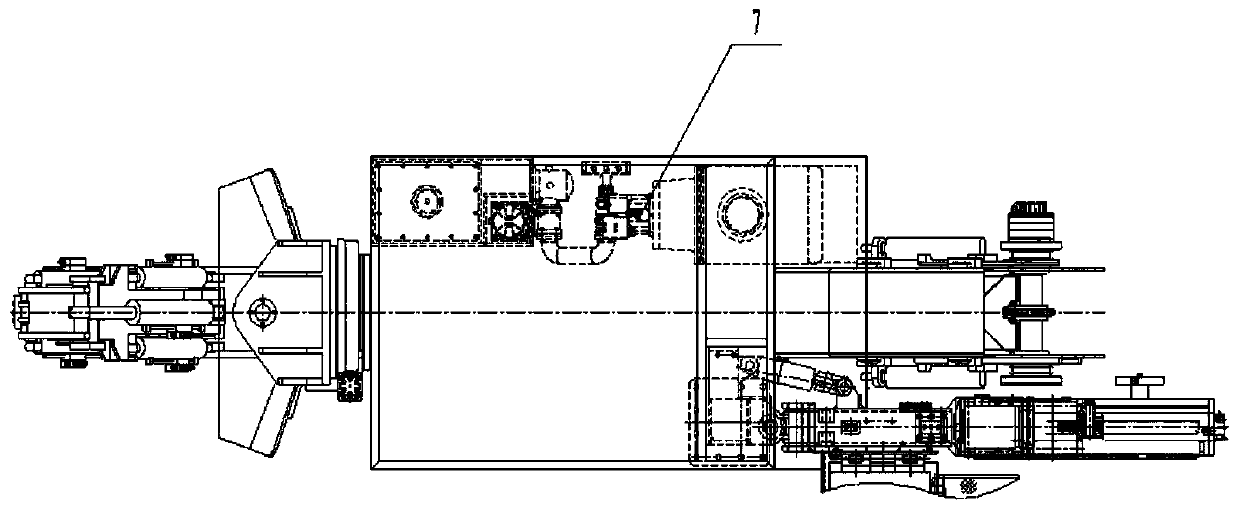

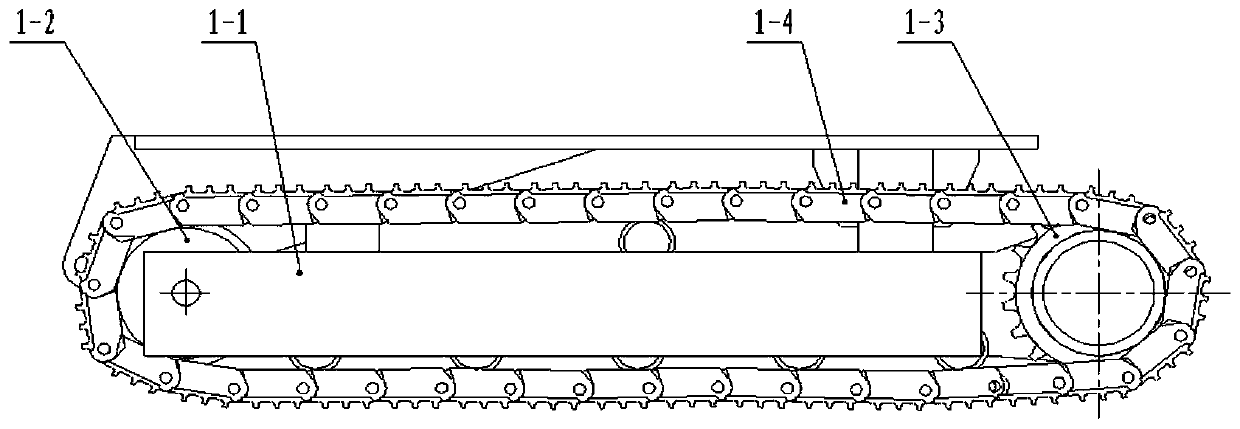

Multifunctional roadway maintenance and repair machine

PendingCN111411655AMeet construction needsCompact structureDerricks/mastsMechanical machines/dredgersArchitectural engineeringMachine

The invention belongs to the technical field of coal mine underground roadway maintenance and repair equipment, and particularly relates to a roadway maintenance and repair machine which is suitable for an underground coal mine and integrates the functions of milling, digging, crushing, loading, transportation, anchor rod support and the like into a whole. According to the technical scheme, the multifunctional roadway maintenance and repair machine comprises a walking part, a machine body part, a cutting assembly, a drill arm part, a conveying part, an electrical system and a hydraulic system;and the walking part is arranged below the machine body part, the cutting assembly is arranged at the front end of the machine body part, the drill arm part is arranged at the left side of the machine body part, the conveying part is arranged in the middle of the machine body part, the electrical system is arranged at the left side of the machine body part, and the hydraulic system is arranged atthe right side of the machine body part. The machine can rotate by 180 degrees in the horizontal direction and the vertical direction, and the use range of equipment is greatly expanded. Operation isstable, maintenance is convenient, and 360-degree omnibearing positioning can be carried out on an anchor cable hole of an anchor rod through matched rotation of two swing oil cylinders.

Owner:SHANXI TIAN JU HEAVY IND

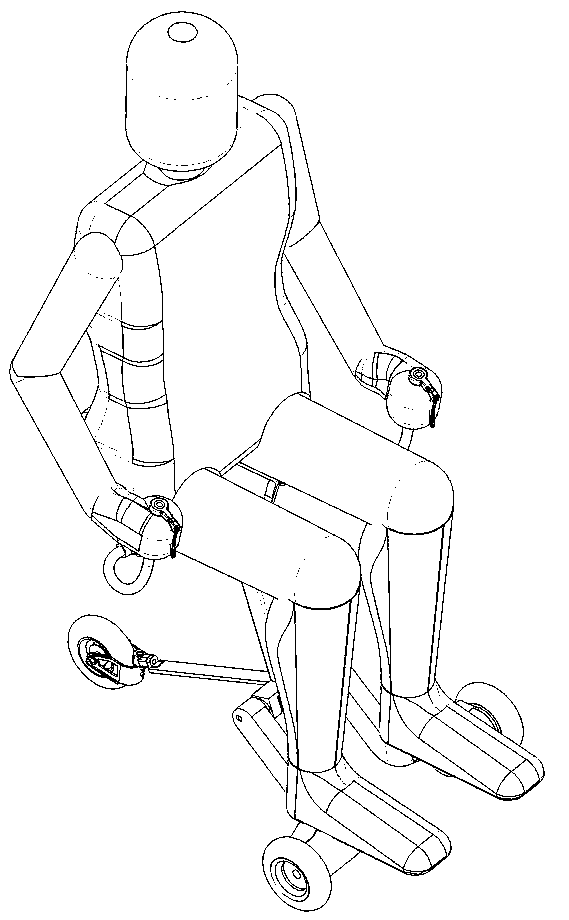

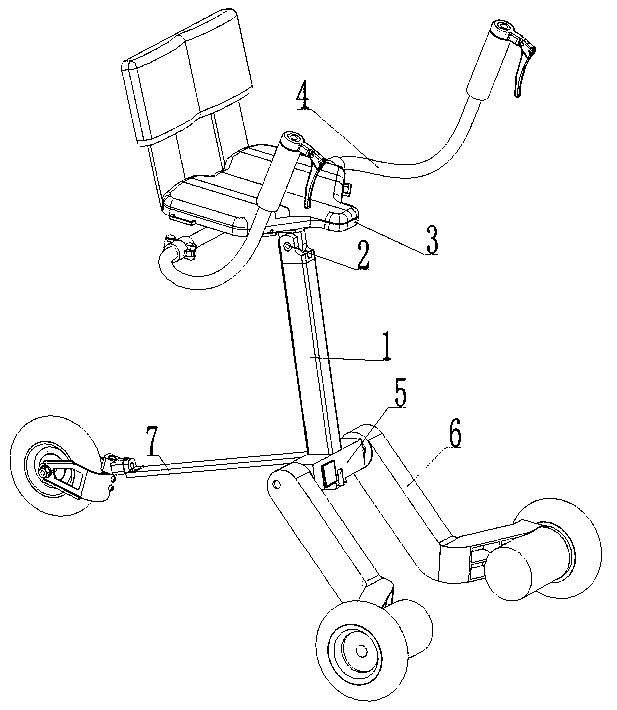

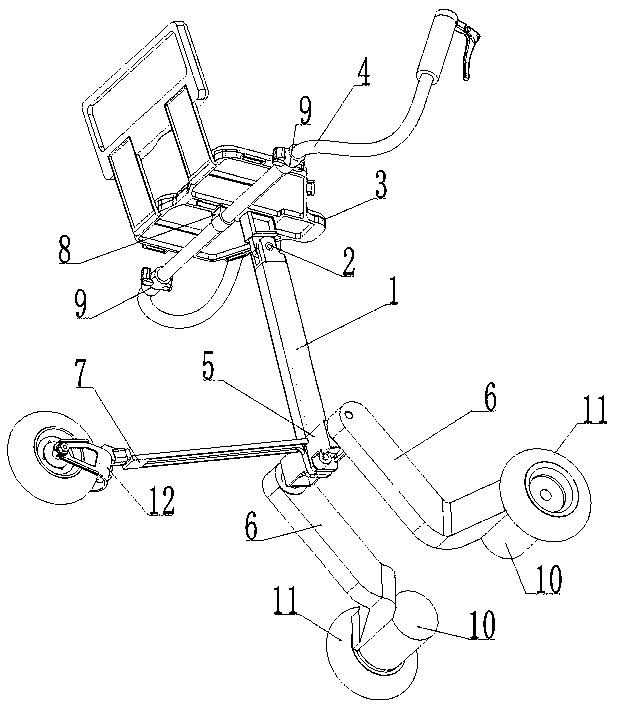

Knapsack type folding tricycle

ActiveCN103466028AReduce space consumptionCoordinate foldFoldable cyclesShortest distanceEngineering

The invention relates to a knapsack type folding tricycle which can be folded to be in the size of a knapsack. The knapsack type folding tricycle has the advantages of being small in size, light in weight, comfortable and safe to ride, convenient to operate, and capable of being used for short distance or the last journey between a bus station and a home.

Owner:江苏鸿迅机车有限公司

Wooden cabinet transfer equipment

PendingCN112141873AEasy to moveReduce the adverse effects of inertiaConveyorsBase supporting structuresElectric machineryEngineering

The invention relates to the technical field of transfer equipment, in particular to wooden cabinet transfer equipment. The wooden cabinet transfer equipment comprises a support frame, a moving assembly, a lifting plate, a clamping assembly and a lifting assembly. Lead screws are driven by corresponding first motors to rotate, a nut moves on the lead screws, a connecting plate is driven by the nutto move in the direction of the lead screws, so as to drive two clamping plates to move, the clamping plates at two ends of the lifting plate are driven by the two first motors to correspondingly move, so as to clamp a wooden cabinet, and the two first motors are used for driving, so that accurate control for clamping operation of the wooden cabinet is increased, control for the clamping force can be improved, the wooden cabinet is clamped more firmly by the wooden cabinet transfer equipment, the safety of subsequent transfer operation is improved, and the wooden cabinet can be prevented frombeing extruded and damaged in the operation process.

Owner:萧县八宝畜禽养殖农民专业合作社

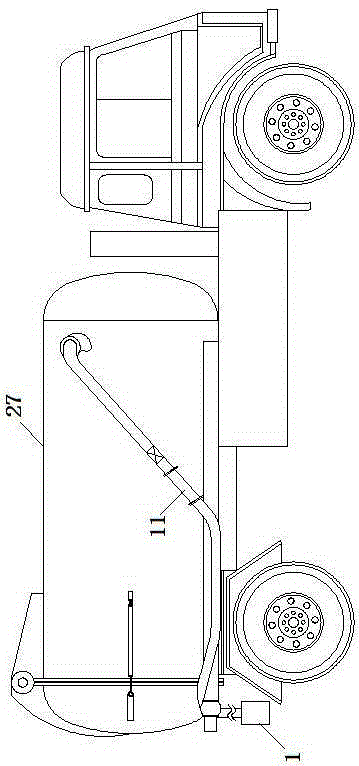

Suction sewage truck

The invention discloses a suction sewage truck. The suction sewage truck comprises a transport vehicle and further comprises a sludge suction system and a carriage. The sludge suction system and the carriage are arranged on a frame of the transport vehicle. The sludge suction system comprises a suction device, a connecting device for the suction device, and a gas exhaust device for tail gas of an engine of the transport vehicle. The suction device comprises a suction pipe, a transmission sleeve, a motor, a crushing cutter and a ventilation pipe. The connecting device comprises a connecting pipe made of transparent materials. The gas exhaust device comprises a main gas exhaust pipe and an auxiliary gas exhaust pipe. The carriage comprises a carriage body, a first-level separation device, a feeding device and a second-level separation device. The first-level separation device comprises a first-level auger and a first-level separation cavity. The feeding device comprises a feeding cavity and a feeding opening. The second-level separation device comprises a second-level auger and a second-level separation cavity. The second-level auger is arranged in the second-level separation cavity and fixedly connected with the outer cavity wall of the first-level separation cavity.

Owner:HUNAN JINSONG AUTOMOBILE CO LTD

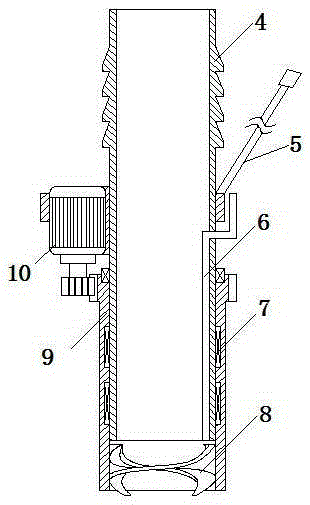

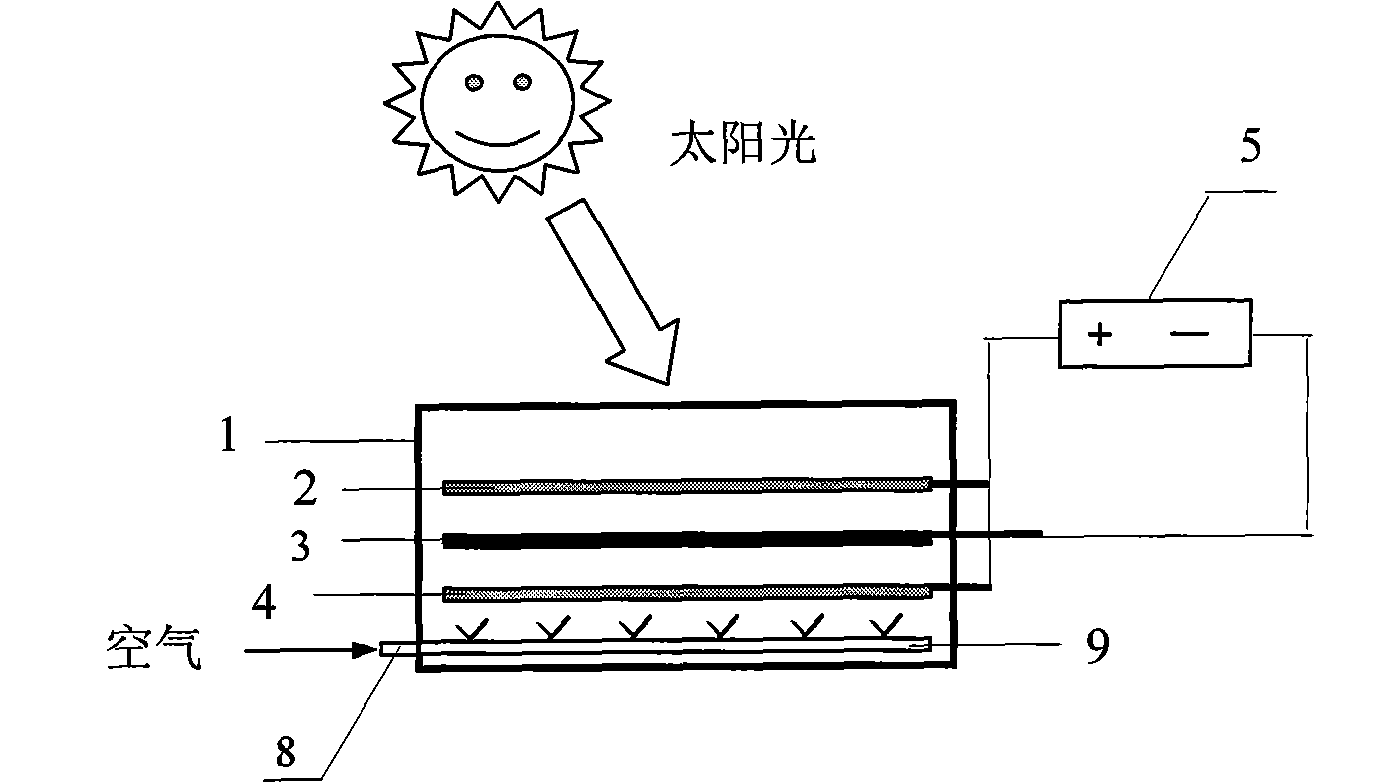

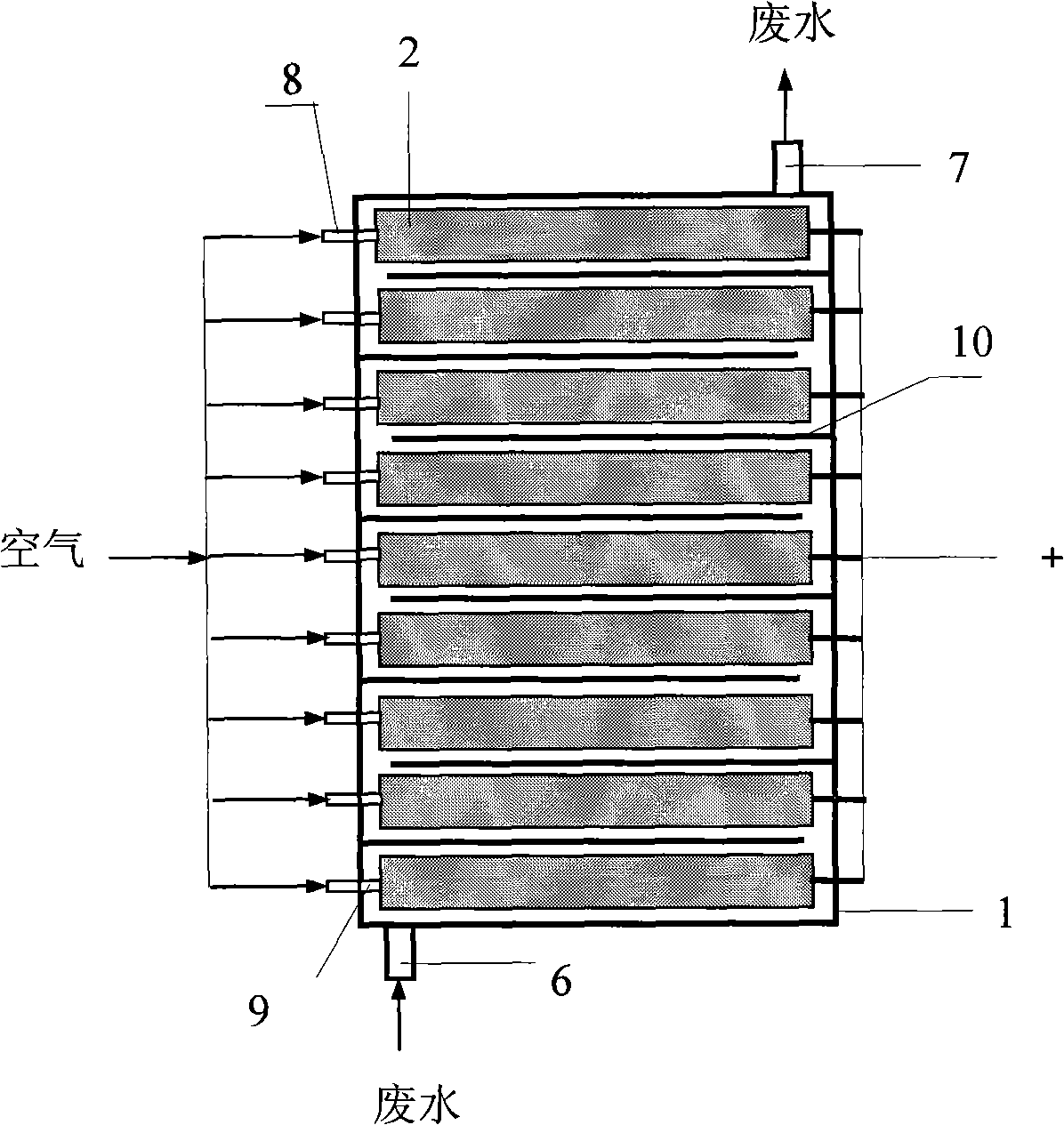

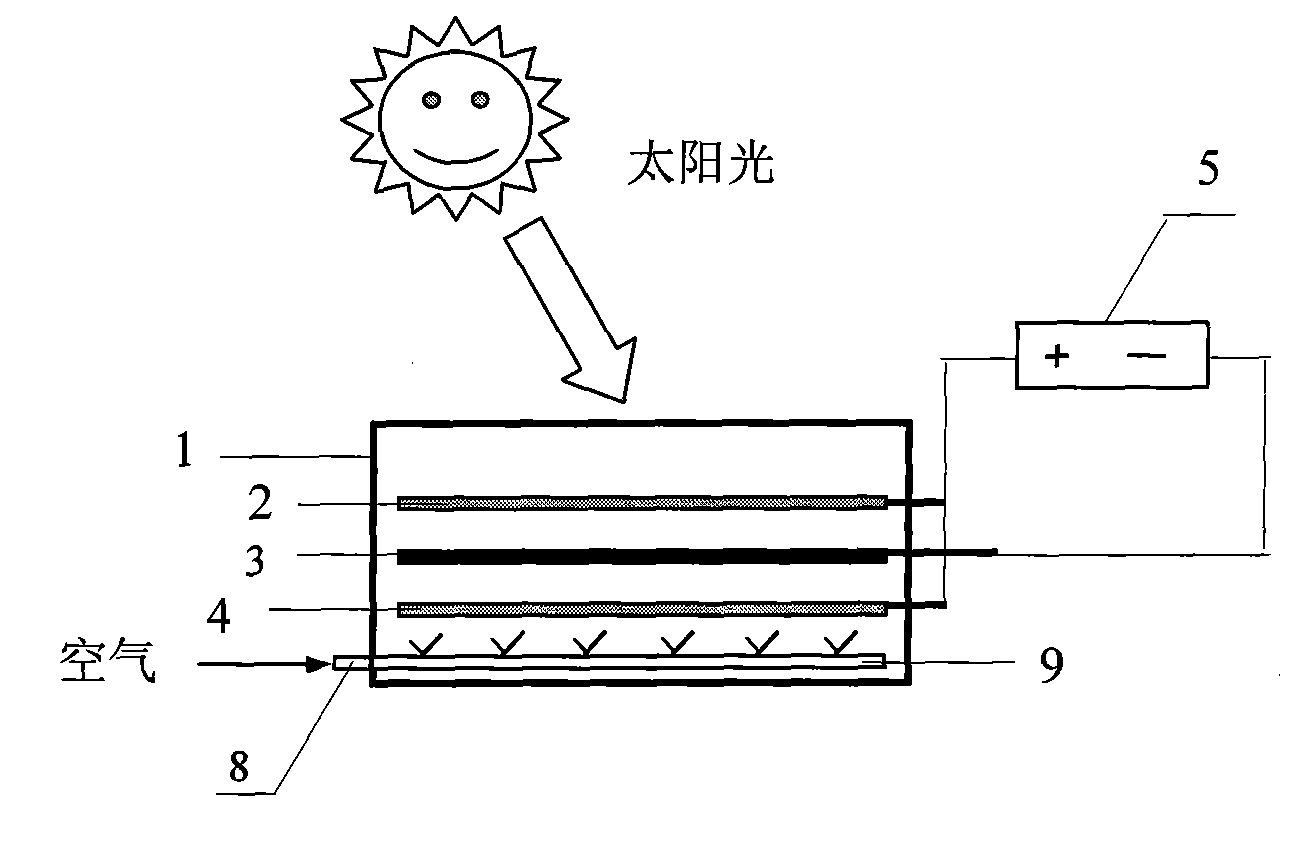

Apparatus for photoelectric catalytic oxidation of subaqueous organics by solar energy

InactiveCN101486499BLeverage science and optimizeEasy to separateWater/sewage treatment by irradiationWater treatment compoundsTin dioxideReaction rate

The invention discloses a solar device used for photoelectrocatalysis oxidation of organics in water, which pertains to the field of advanced photocatalytic oxidation technology for water treatment in environmental chemical engineering, more particularly relates to a photoelectrocatalysis organic water treatment device which can directly utilize the ultraviolet light and the visible light in the sunlight. The device comprises a shell body 1, a solar photocatalytic anode 2, a carbon-material cathode 3, a Ti-based stibium-doped tin dioxide electrode 4 and deflection baffles 10. A plurality of the parallel deflection baffles 10 arranged in the device cause the reaction device to have the functions of a plate-column water treatment device, and the number of the baffles can be designed, calculated and determined according to the waste water entrance depth and the requirements on the quality of outflow water. The device has simple structure, directly utilizes the clean and renewable solar energy and clean electrical energy, is especially suitable for in-water reaction rate control and the treatment of organics which are hard to be oxidized, has high oxidation efficiency and is environment-friendly.

Owner:TAIYUAN UNIV OF TECH

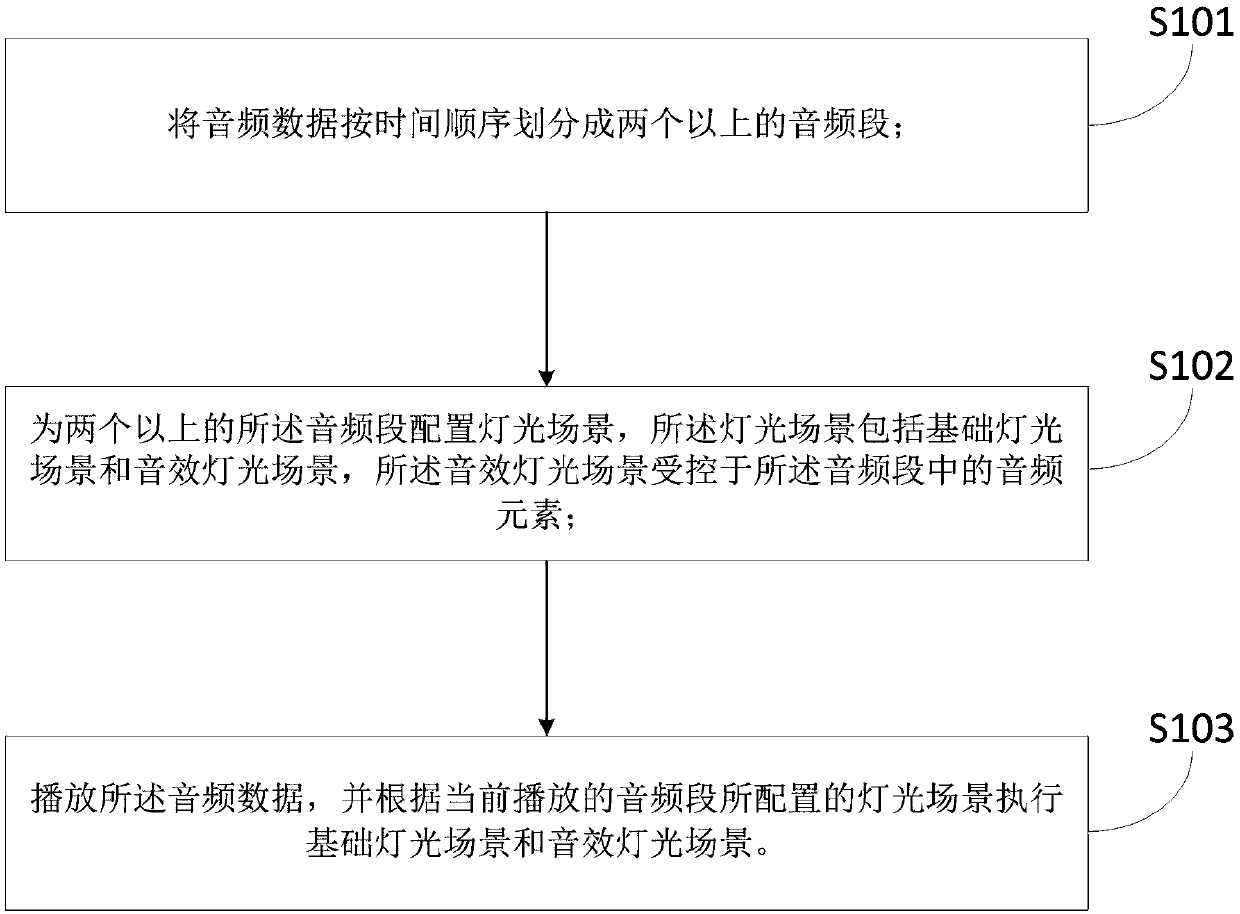

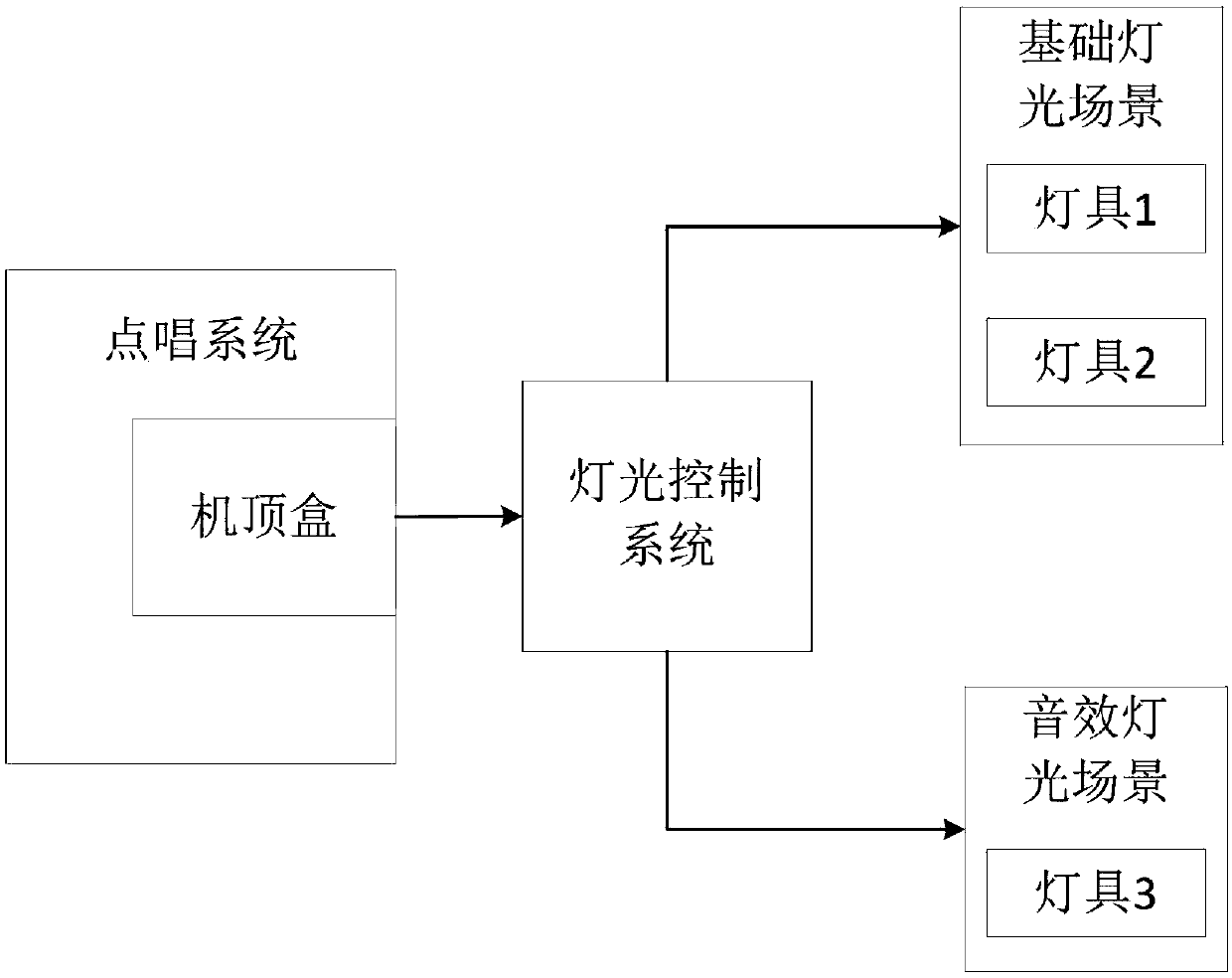

Light scene control method and storage medium for digital audio-visual place

ActiveCN109661082ARich lighting scene effectsCoordinationElectrical apparatusElectric light circuit arrangementTime sequenceAudio segment

The invention relates to the technical field of light effect control, and provides a light scene control method and a storage medium for a digital audio-visual place. The light scene control method comprises the following steps: dividing the audio data into two or more audio segments according to time sequence; configuring a light scene for the two or more audio segments, wherein the lighting scene includes a basic lighting scene and a sound lighting scene and the sound lighting scene is controlled by an audio element in the audio segment; and playing the audio data, and according to the lighting scene configured based on the currently played audio segment, executing the basic lighting scene and the sound lighting scene. According to the invention, the corresponding lighting scene is automatically executed according to different audio segments; automatic switching of different lighting scenes is achieved; the lighting scene effect of the digital audio-visual place is enriched; and thesound effect lighting scene in the lighting scene is controlled by the audio segment, so the lighting scene well cooperate with the audio data is quite harmonious and the atmosphere is quite harmonious.

Owner:FUJIAN STAR NET EVIDEO INFORMATION SYST CO LTD

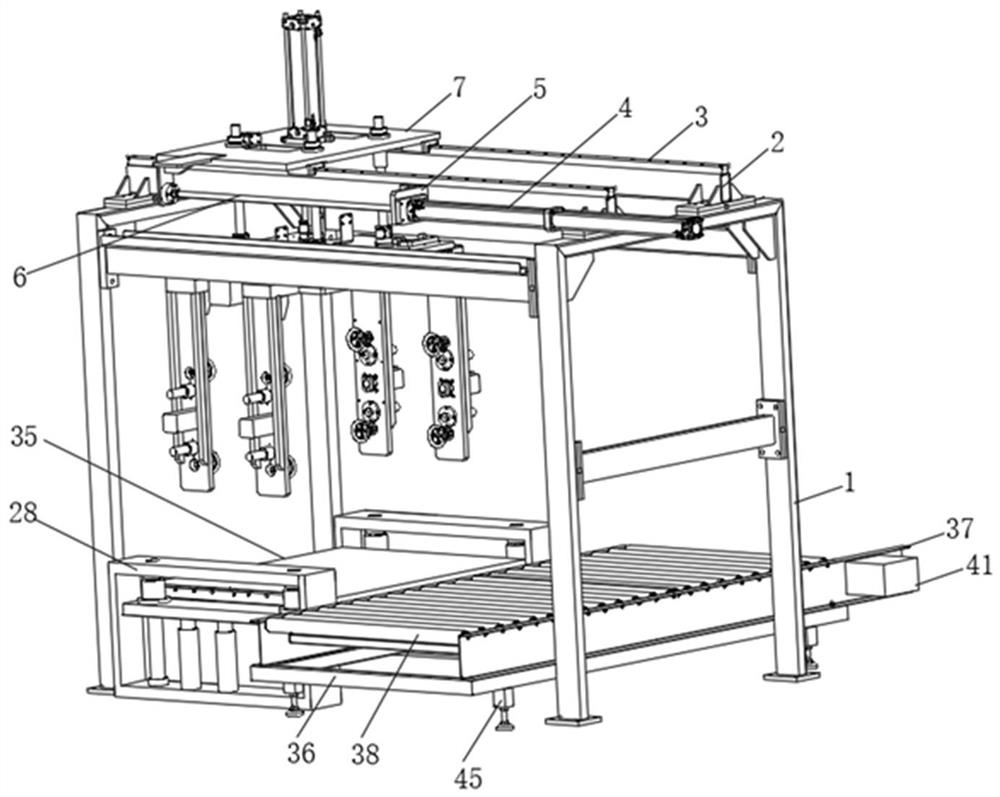

Process and equipment for distributing ceramic micro powder bricks

The invention discloses a process and equipment for distributing ceramic micro powder bricks. The process comprises the following steps of: a, laying strip raw materials on an inclined conveying belt; b, arranging opacified raw materials of different types in a flat strip material layer at intervals in a multi-station interval distributing way to wrap and embed the opacified raw materials and the strip materials, arranging transparent materials of different types into the flat strip material layer at intervals to wrap and embed the transparent materials and the strip materials, and alternatively and intermittently distributing the opacified materials and the transparent materials on a plate surface; c, replenishing the strip materials into gap positions of a distributing station; and d, extruding different types of raw materials onto a circular conveying belt to form layered deposits, replenishing, scraping, and feeding into a grinding frame with a grate for performing press molding. Compared with the popular sedimentary rock cross sectional linear stone in the current market, the ceramic micro powder bricks obtained in the process have more plentiful colors, more coordinated matching and more vivid grains.

Owner:霍镰泉

Solid-liquid separator for environmental sanitation truck

The invention discloses a solid-liquid separator for an environmental sanitation truck. The solid-liquid separator comprises a first-grade auger, a first-grade separation cylinder, a discharge device, a second-grade auger blade and a second-grade separation cylinder, wherein the first-grade separation cylinder is fixedly connected with a shell, is provided with a feed area, an exchange area and a recovery area in sequence, and coats the first-grade auger; the feed area is positioned at the front end of the first-grade separation cylinder, and is provided with a feed hole in the cylinder wall; the exchange area is positioned behind the feed area, and is provided with a grading hole in the cylinder wall; the recovery area is positioned behind the exchange area, and is provided with a recovery hole in the cylinder wall; the discharge device is positioned in an opening at the tail end of the first-grade separation cylinder for controlling the discharge of the first-grade separation cylinder; the cylinder wall of the second-grade separation cylinder is provided with a water filter hole, coats the exchange area and the recovery area of the first-grade separation cylinder,and is isolated from the feed area; and the inner wall of the second-grade separation cylinder and the outer wall of the first-grade separation cylinder are movably connected through a sealing bearing.

Owner:HUNAN JINSONG AUTOMOBILE CO LTD

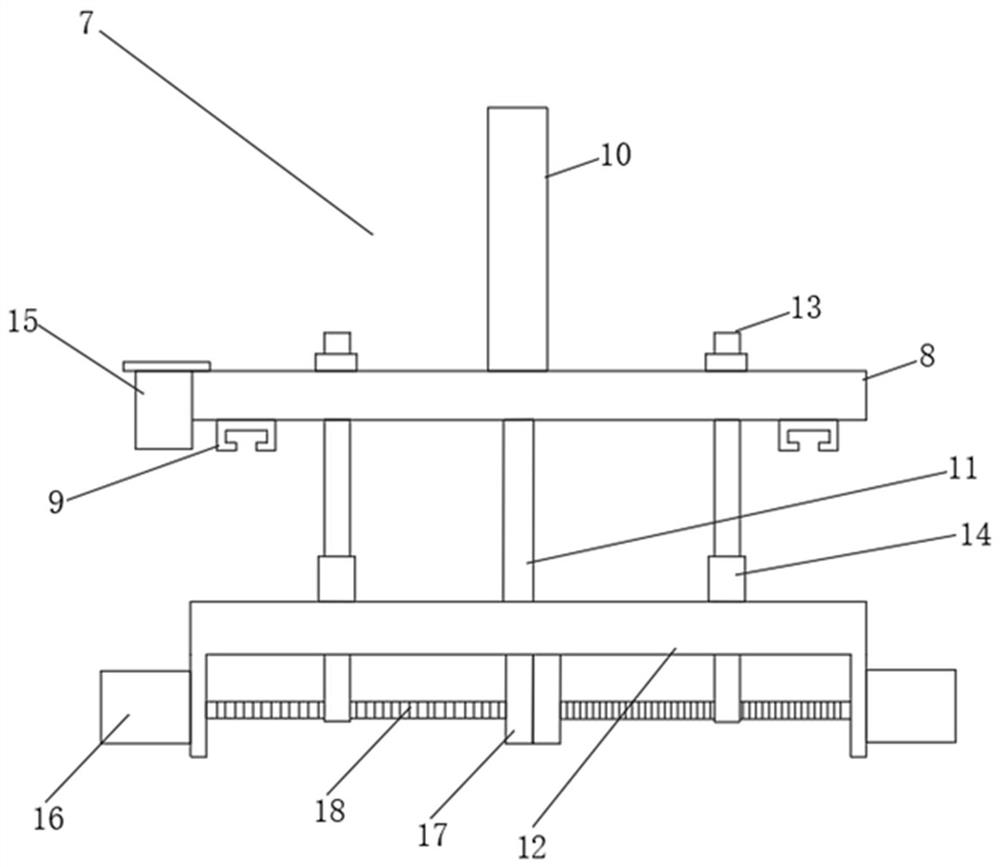

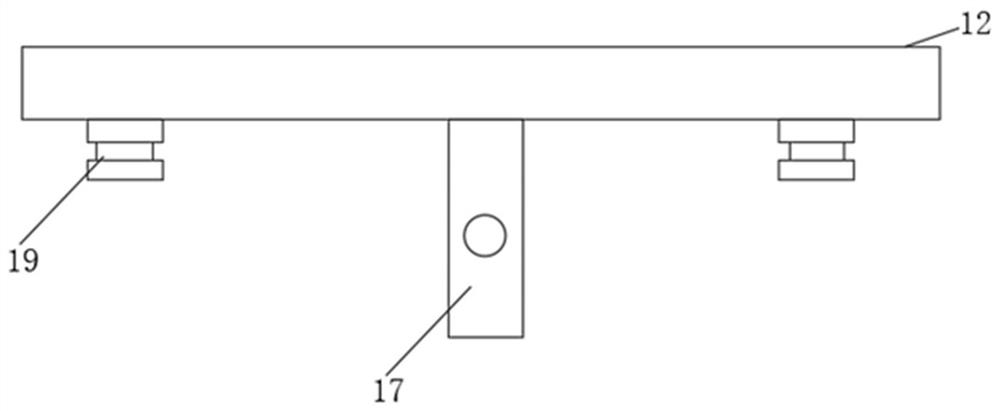

Special-shaped glass powder feeding device

ActiveCN108031622AAvoid the problem of accumulation on the concave surface of special-shaped glassPowder evenlyLiquid surface applicatorsCoatingsReciprocating motionEngineering

The invention relates to the technical field of surface coating devices, and particularly discloses a special-shaped glass powder feeding device. The device comprises a box body, a vacuum pump, a power mechanism, a working mechanism and a transmission mechanism; the power mechanism comprises a motor, a first gear and a first rack meshed with the first gear, and the middle section of the first rackis provided with a paw for fixing special-shaped glass; the transmission mechanism comprises an L-shaped handle arranged on the first rack and a cylinder body, wherein a first piston is arranged inside the cylinder body in a sliding fit mode, and the free end of the handle is fixedly connected with the first piston; the working mechanism comprises a groove body communicating with the cylinder body and a bearing groove arranged above the groove body, the size of the bearing groove is larger than the size of the special-shaped glass, and the groove body is arranged at the bottom of the box body; and a second piston is arranged in the groove body in a sliding fit mode, and the second piston is fixedly connected with a crank sliding block mechanism for driving horizontal reciprocating motionof the bearing placing groove. According to the technical scheme, the surface of the special-shaped glass can be uniformly coated with powder, and therefore, the device can be widely applied to the powder feeding of the special-shaped glass.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

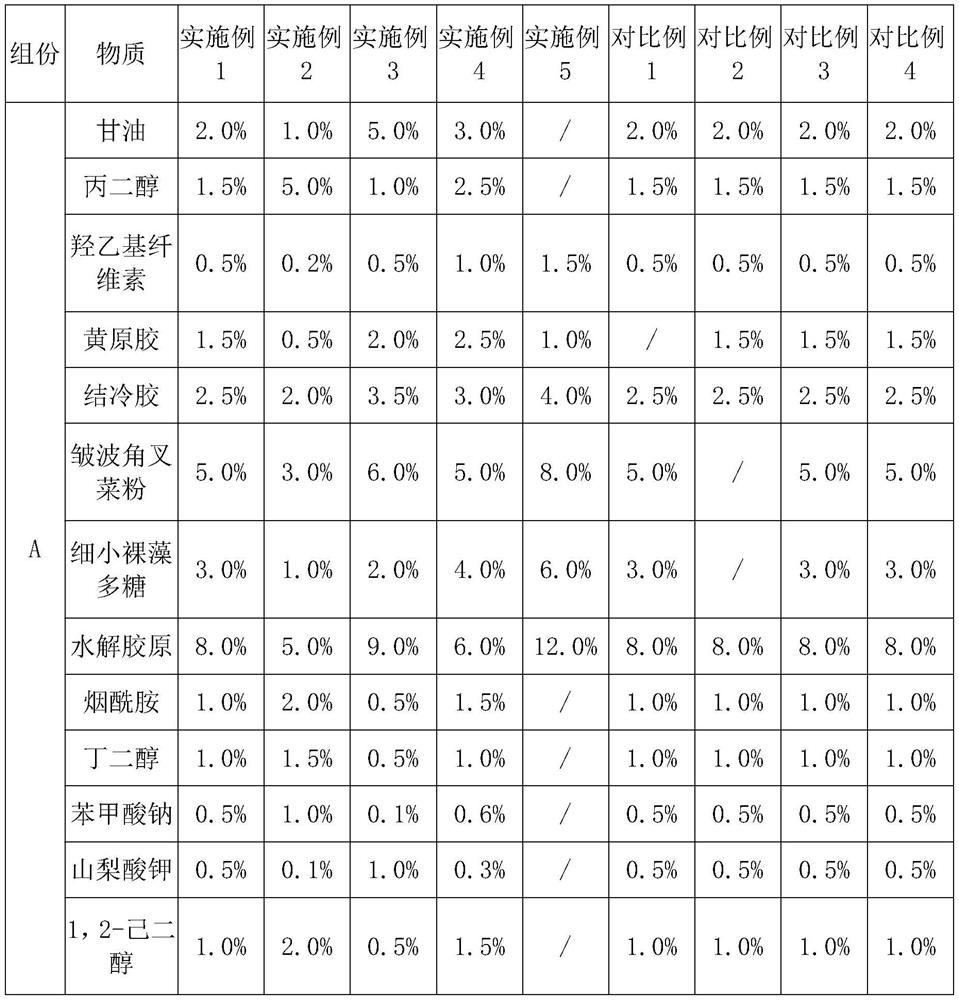

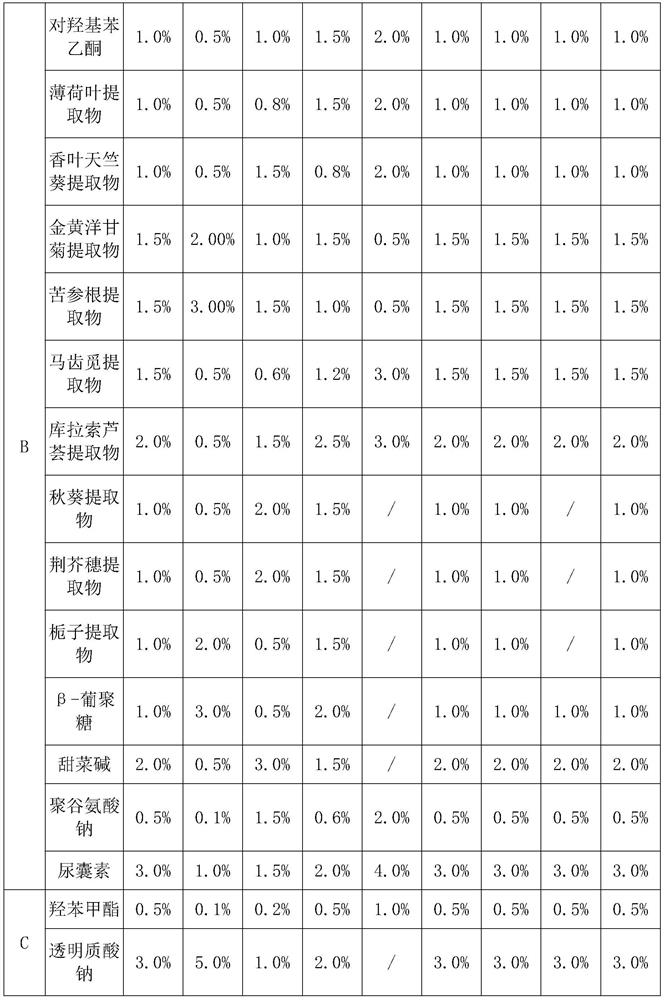

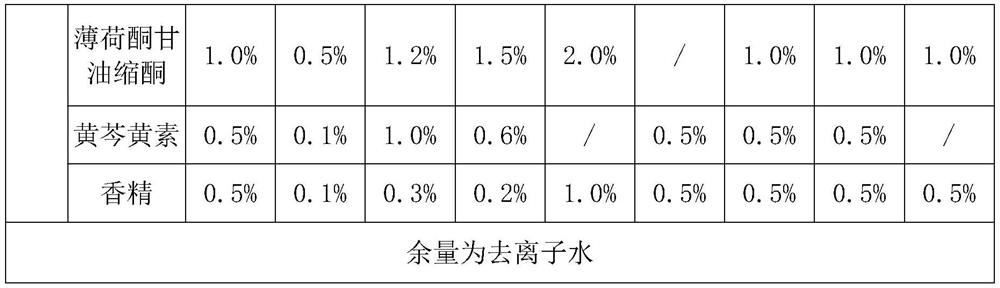

Collagen jelly mask as well as preparation and use methods thereof

InactiveCN112263528APromote hydrationGood whitening effectCosmetic preparationsToilet preparationsCelluloseMenthone

The invention discloses a collagen jelly mask as well as preparation and use methods thereof, and belongs to the technical field of skin care products. The collagen jelly mask comprises a component A,a component B and a component C, wherein the component A comprises hydroxyethyl cellulose, xanthan gum, gellan gum, chondrus crispus powder, euglena gracilis polysaccharide and hydrolyzed collagen; the component B comprises p-hydroxyacetophenone, a plant extract, sodium polyglutamate and allantoin; the component C comprises methylparaben and menthone glycerin ketal. The mask further comprises deionized water. Stirring and heating, cooling, mixing, high-speed transfer, heat preservation defoaming and cooling and molding are performed to obtain the finished collagen jelly mask. The mask disclosed by the invention can be utilized after being applied, is more efficient and environment-friendly, can adapt to different facial forms, and fits the facial skin, so that the facial absorption is more comprehensive and sufficient.

Owner:广东美集科技有限公司

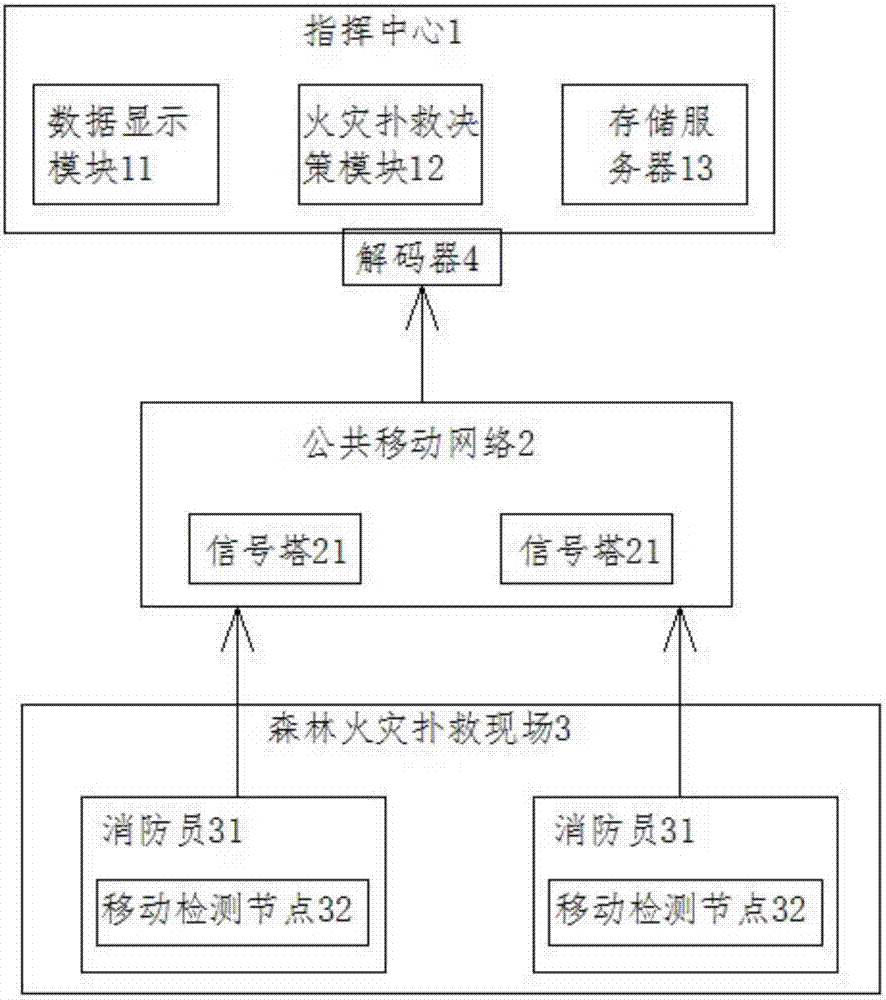

Mobile forest fire fighting environment monitoring and early warning platform

InactiveCN106940920AProtect life safetyImprove timelinessClimate change adaptationForest fire alarmsData displayInformation transmission

The invention relates to a mobile forest fire fighting environment monitoring and early warning platform, and belongs to the technical fields of environment monitoring and early warning. The mobile forest fire fighting environment monitoring and early warning platform comprises a command center, a public mobile network and a forest fire fighting site; the command center comprises a data display module, a fire fighting decision-making module and a storage server; a plurality of signal towers are arranged in the public mobile network; the public mobile network is connected with the command center by a decoder; the forest fire fighting site consists of firemen and mobile detection nodes on bodies of the firemen. The mobile forest fire fighting environment monitoring and early warning platform has real-time performance in information transmission, is high in reliability, good in flexibility and simple to maintain, does not need to be released in a large scale in the integral forest, and is mainly used for forest fire fighting site environment monitoring; decision reference is provided for fighting commanding and personnel hedging; efficiency of transmitting front data and information of the command center in a forest fire fighting process can be improved; an injury frequency of firemen and other loss caused by a forest fire are reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

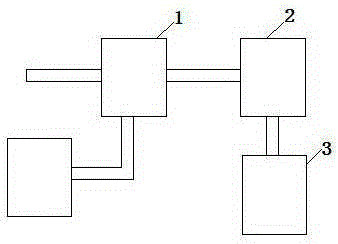

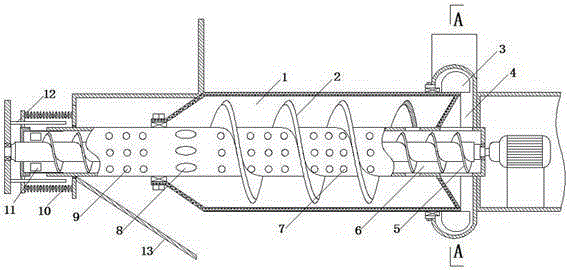

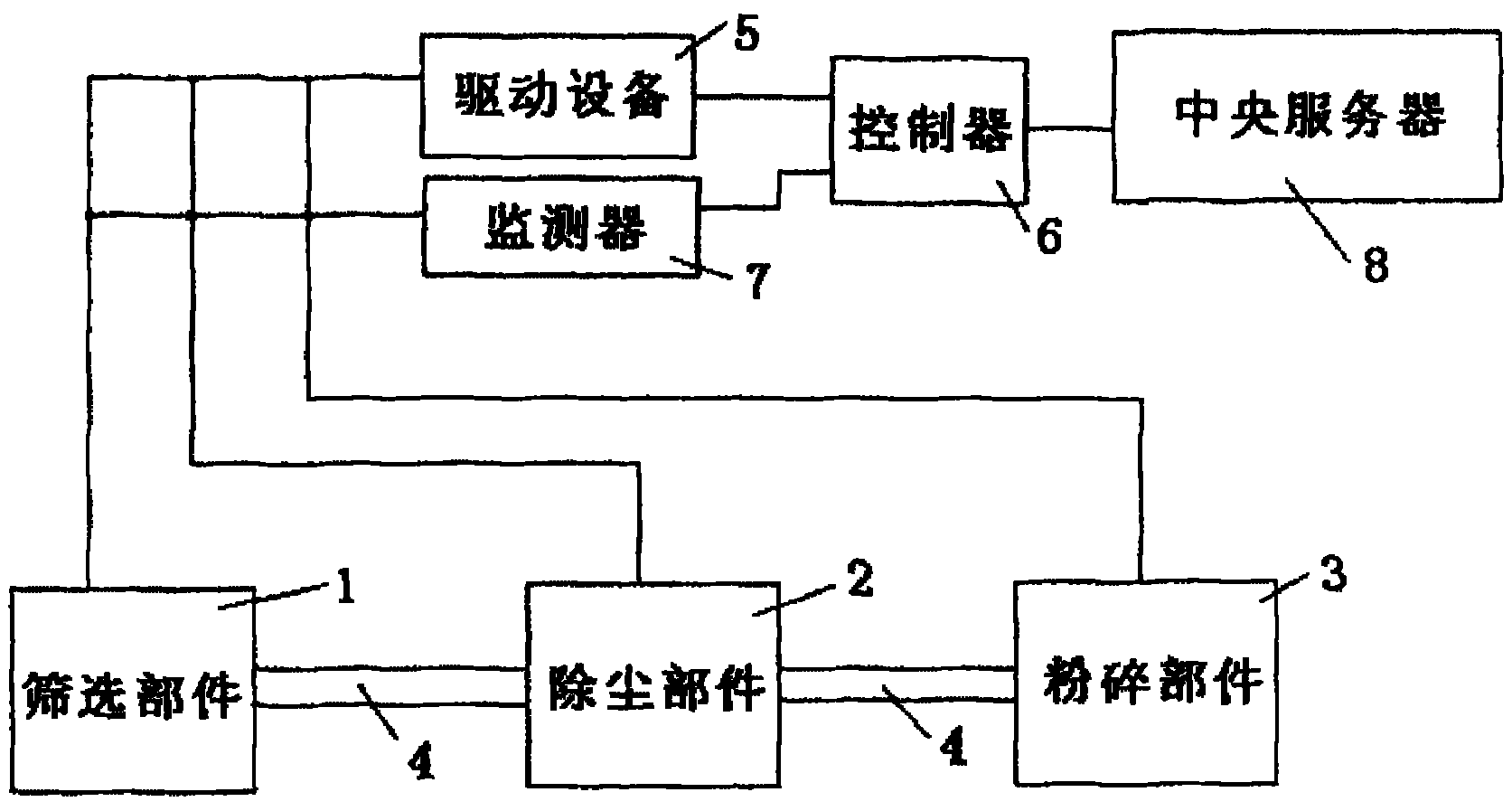

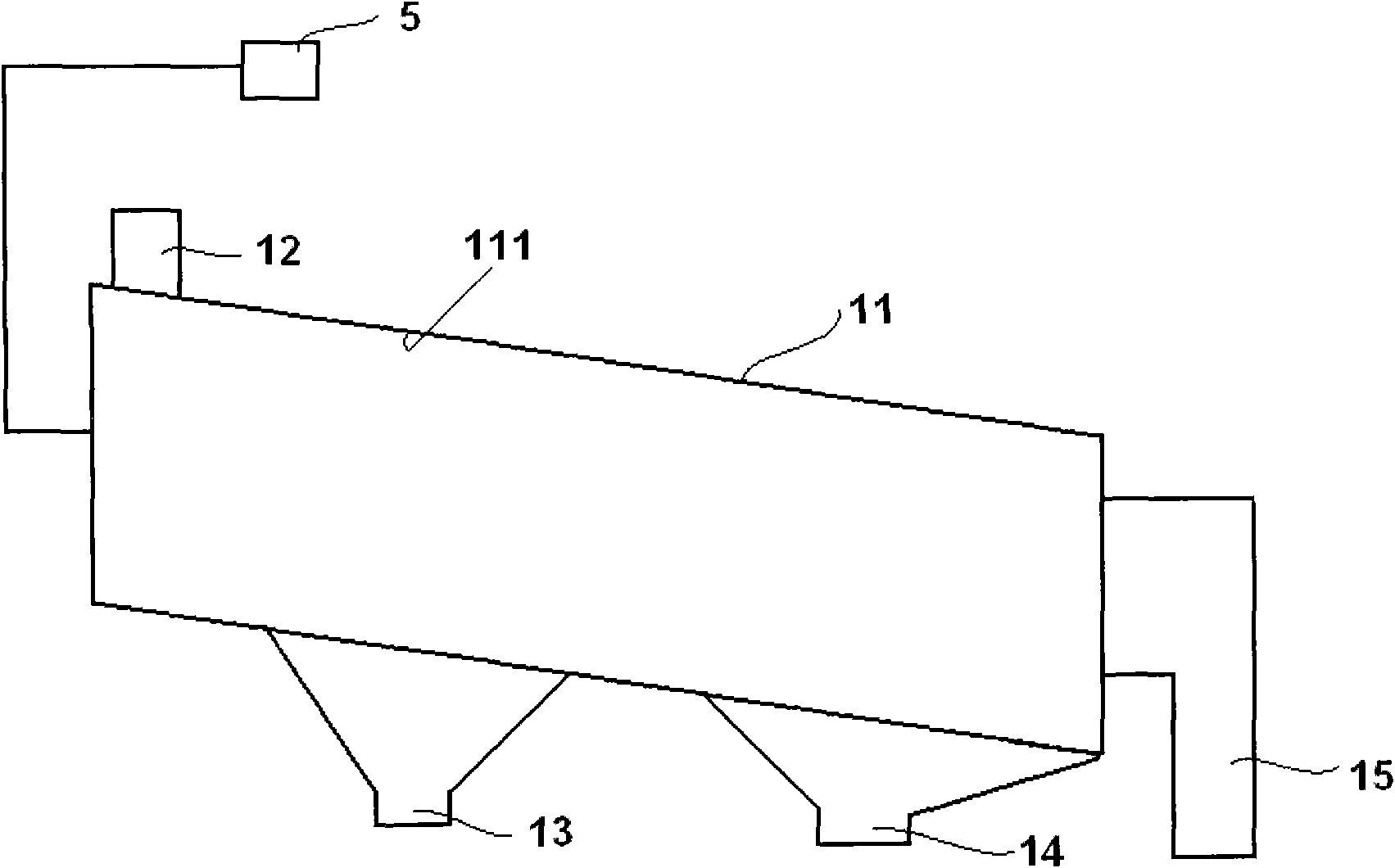

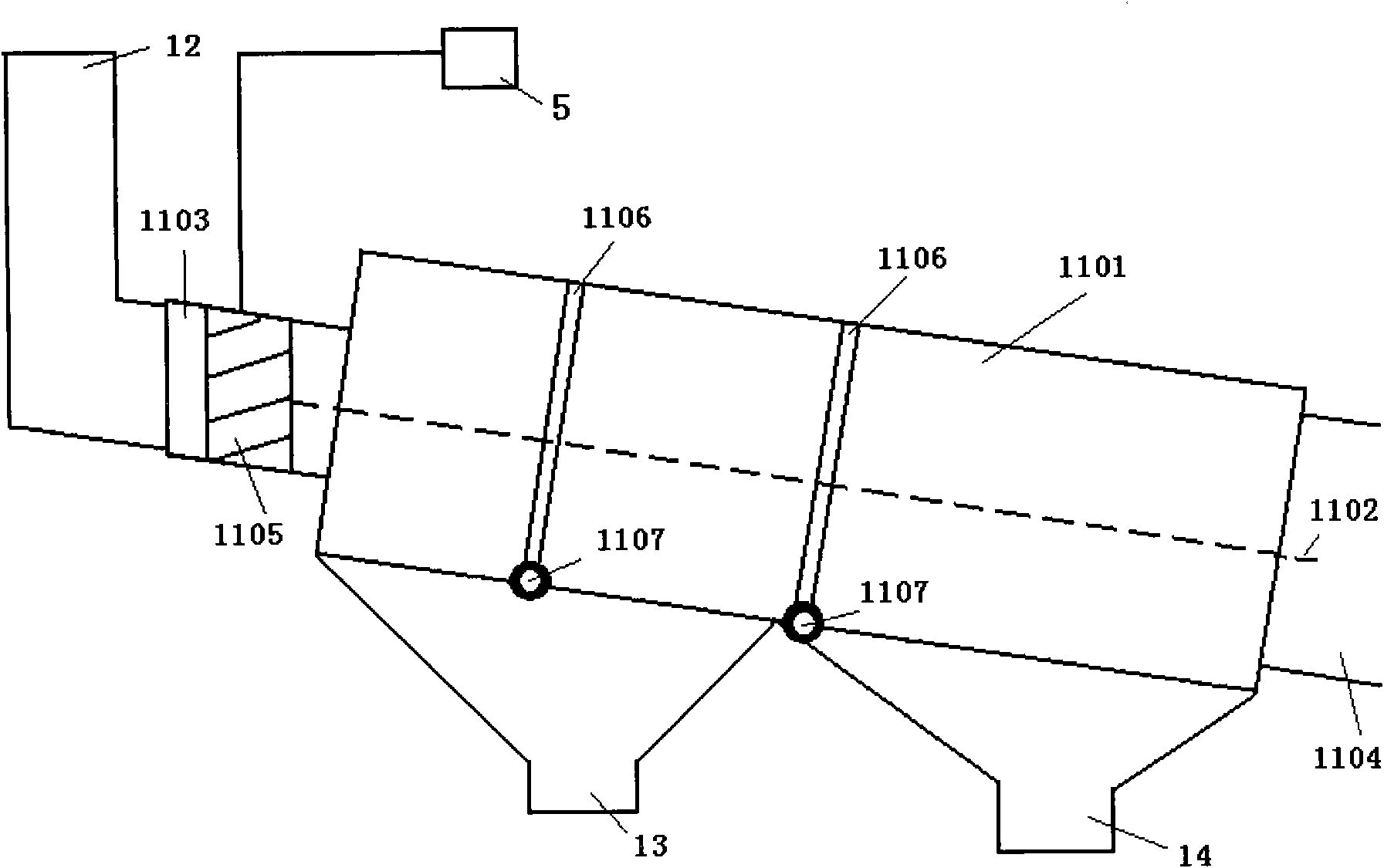

Intelligent complete device for pulverizing cereals

InactiveCN101850283ARealize intelligent managementCoordinationSievingGas current separationDevice failureComputer technology

The invention relates to an intelligent complete device for pulverizing cereals. The intelligent complete device for pulverizing the cereals comprises a screening part, a dust-removing part, a pulverizing part, a sealed conveying channel, driving equipment, a controller, a monitor and a central server, wherein the screening part, the dust-removing part and the pulverizing part are arranged sequentially and are connected with one another through the sealed conveying channel; the screening part, the dust-removing part and the pulverizing part are connected with the driving equipment and the monitor respectively; and the driving equipment and the monitor are connected with the central server through the controller respectively. The intelligent complete device for pulverizing the cereals has the advantages of combining a complete device for pulverizing the cereals with a computer technique, processing faults of equipment in time, coordinating the cooperation among equipment, realizing intelligent management of the complete device for pulverizing the cereals and greatly improving the work efficiency of the complete equipment.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

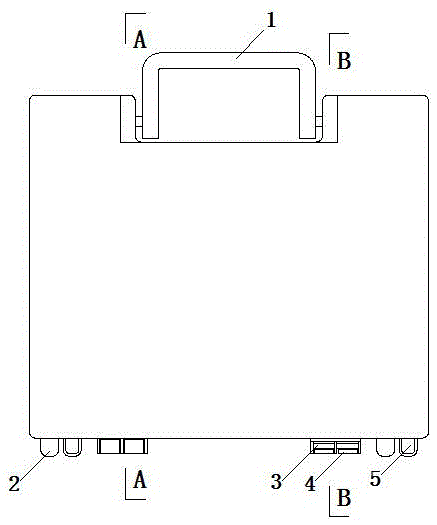

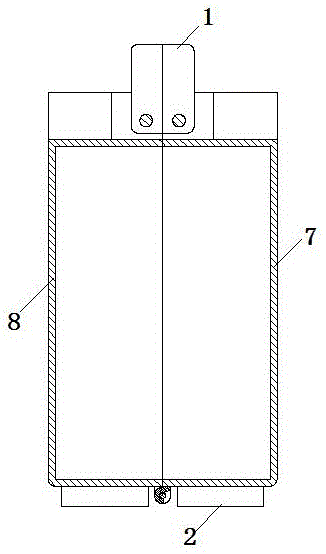

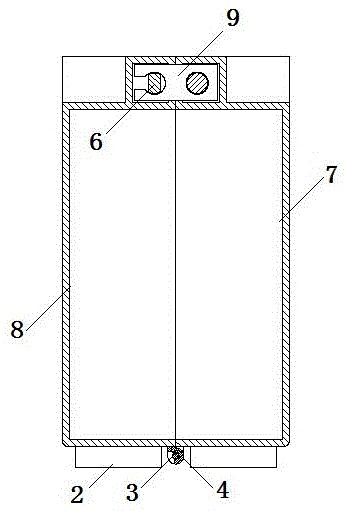

Packing box

ActiveCN105460355AEasy to processEasy to useRigid containersContainer handlesEngineeringCounter rotation

The invention discloses a packing box. The packing box comprises a box cover, a box body, a connecting block, a lifting handle and a clamping bolt, wherein the box cover is movably connected to one adjacent side of the box body; an open slot and a clamping hole are formed in one end of the connecting block, and the other end of the connecting block is fixedly connected with the box cover or / and the box body; the open slot of the connecting block is communicated with the clamping hole, and the opening width of the open slot is less than the width of the clamping hole along the vertical direction of the center line of the open slot; both ends of the lifting handle are movably connected to the box cover or / and the box body by virtue of pin shafts; the clamping bolt is fixedly connected to one end or both ends of the lifting handle; the clamping bolt and the connecting block are correspondingly arranged on the box cover and the box body respectively; after the box cover covers the box body, the clamping bolt can enter the clamping hole of the connecting block through the open slot of the connecting block and is rotated by virtue of the lifting handle so as to be clamped into the clamping hole of the connecting block, so that the box cover is fixed to the box body, and after the clamping bolt is rotated in reverse by virtue of the lifting handle, the clamping bolt can exit from the open slot of the connecting block, so that the packing box is opened.

Owner:HUNAN YUANDA TOURIST PROD CO LTD

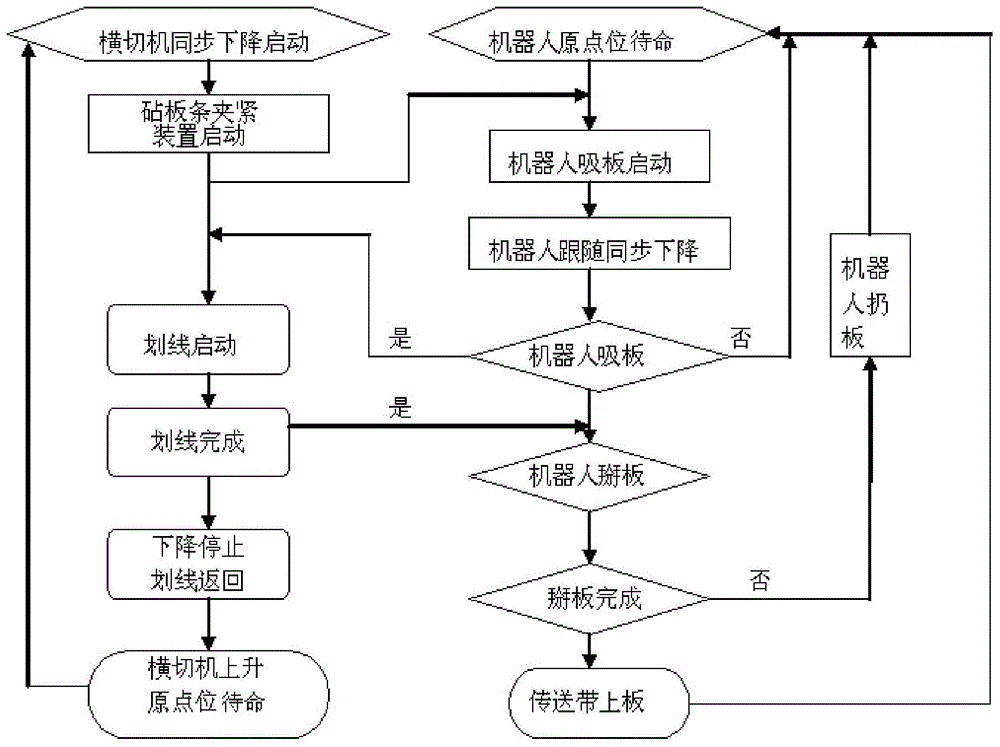

How to break LCD glass

A method for breaking liquid crystal glass plates. In the first step, when the formed glass plate is sent out from the furnace, the cross-cutting machine is synchronously lowered and started; in the second step, after the cutting board strip clamping device on the cross-cutting machine is clamped, the plate is broken The robot sucks the formed glass plate from outside the effective surfaces on both sides of the formed glass plate, and descends synchronously with the formed glass plate; the third step, the cross-cutting machine draws the formed glass plate according to the set size; the fourth step, the cross-cutting machine After the scribing is completed, the blade returns, and the cross-cutting machine returns to the original position for standby; after the board breaking robot confirms that the marking is completed, it breaks the board according to the board breaking angle of 7 to 10 degrees, otherwise it does not perform the board breaking action, and returns to the original position for waiting The next cycle starts; in the fifth step, after the plate-breaking robot finishes breaking the plate, the intact glass plate is placed on the conveyor belt and sent to the next process, the damaged glass plate is thrown into the waste chute, and the plate-breaking robot returns to the original position to stand by. The invention reduces the probability of abnormal failure of the equipment and improves the yield rate of the molding process.

Owner:陕西彩虹电子玻璃有限公司

Special emulsion paint for textured paint topcoat employing non-whole body process and preparation method of special emulsion paint

The invention relates to special emulsion paint for a textured paint topcoat employing a non-whole body process and a preparation method of the special emulsion paint. The emulsion paint is prepared from the following components in parts by weight: 6-15 parts of deionized water, 0.5-1.5 parts of polybasic acid copolymer dispersing agent, 0.1-0.5 part of a multi-functional assistant, 0.1-0.3 part of a non-ionic wetting agent, 2-4 parts of a coalescing agent, 1-25 parts of a pigment, 5-30 parts of filler, 40-55 parts of resin, 0.3-0.5 part of a mineral oil antifoaming agent, 0.2-0.3 part of a preservative, 0.5-2.5 parts of a polyurethane thickener, 10-15 parts of 120-mesh fine quartz sand and 0.5-1 part of wood fiber. The emulsion paint for the textured paint topcoat is soft and natural in luster, good in weather resistance, aqueous in system, safe and environment-friendly; a lapping defect is not easily generated in the process of painting the textured paint topcoat through the non-whole body process; and the paint is uniform and beautiful in color, has good weather resistance, does not generate the problems of cracking, peeling and discoloration even if being exposed to the sun and rain for a long period of time, and is durable.

Owner:厦门富思特新材料科技有限公司

Novel aerated concrete mortar and preparing method thereof

The invention discloses novel aerated concrete mortar. The novel aerated concrete mortar is prepared from fly ash, desulphurization gypsum, an air entraining agent, a triethanolamine solution, water-based polymer resin, ferroferric oxide, portland cement and quick lime. A preparing method includes the following steps that 1) water is added into the fly ash and the desulphurization gypsum, and a mixture is mixed, stirred, subjected to standing and precipitated; 2) water is clarified to be drained, fly ash and desulphurization gypsum are taken out respectively and dried, impurities precipitatedat the bottommost portion are removed, and then the obtained fly ash and the obtained desulphurization gypsum are smashed into powder respectively to be screened out through a screening net; 3) wateris added into the screened fly ash, the screened desulphurization gypsum, the ferroferric oxide, the portland cement, the quick lime and the triethanolamine solution, the mixture is evenly stirred andmixed to be prepared into mixed mortar; 4) the mixed mortar is polished through a wet-type ball mill, then the air entraining agent and the water-based polymer resin are added, grinding is carried out, then water is added, the mixture is stirred to be even, and the novel aerated concrete mortar can be obtained. The novel aerated concrete mortar is even in fineness, few in internal pouring cavity,not prone to appearing of cracking and model collapsing and high in loading capacity, and properties in all the respects are greatly improved.

Owner:遵义市旭辉新型节能建材有限公司

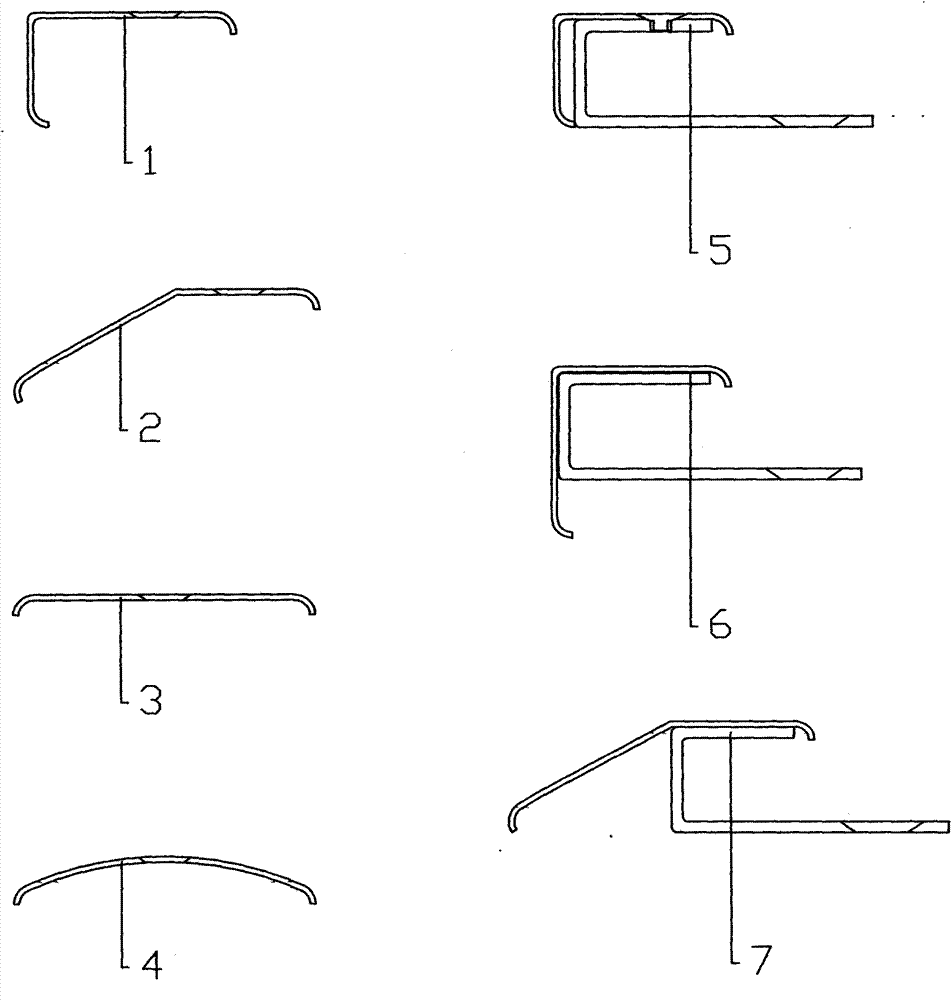

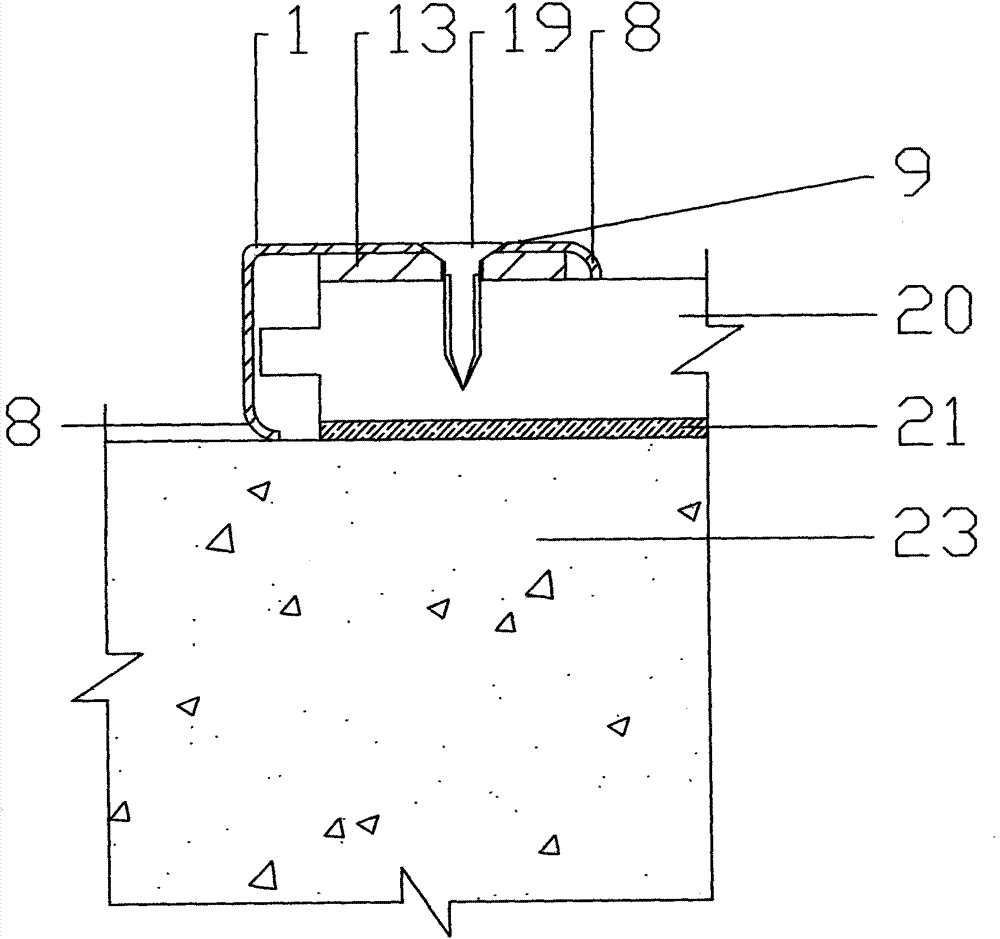

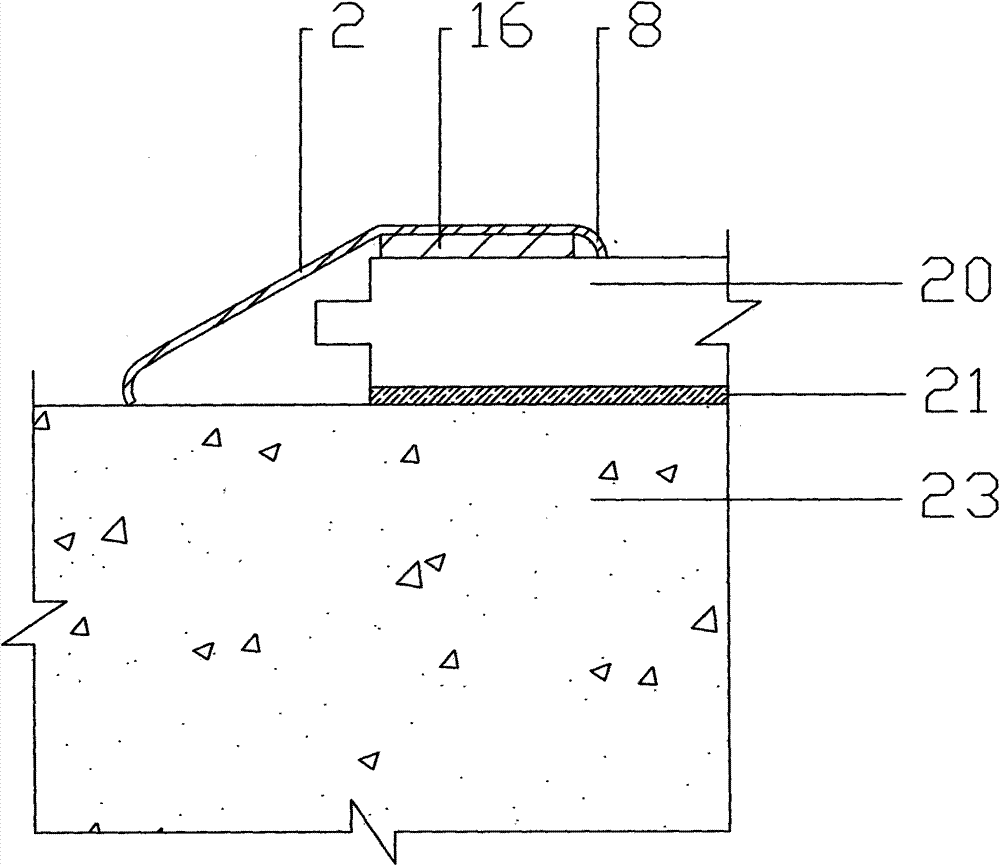

Steel floor buckling strip structures with edge being bent into arc shapes

The invention discloses steel floor buckling strip structures with edge being bent into arc shapes. The buckling strip structures with edge being bent into the arc shapes comprise a right angle buckling strip, a high-low buckling strip, a butt joint buckling strip, a universal buckling strip, a C-shaped buckling strip, a stair buckling strip and a C-shaped high-low buckling strip. The buckling strip structures with edge being bent into the arc shapes are characterized in that the right angle buckling strip, the high-low buckling strip, the butt joint buckling strip and the universal buckling strip are respectively formed by bending thin steel plates into about 90-degree angle, a bending obtuse angle, a no-bending arc shape and a bending arc shape and sections of thin steel plate edges which are bent into arc shapes extend to two ends; the C-shaped buckling strip and the stair buckling strip are assembled by the right-angle buckling strip and a groove-shaped gasket; the C-shaped high-low buckling strip is assembled by the high-low buckle and the groove-shaped gasket. The steel plate buckling strips assembling various required components to construct structures with required structures have functions of previous floor buckling strips, improve the attractive and abrasion-resistant capabilities, are cheap in construction costs, convenient to package and transport and easy, time-saving and flexible to install.

Owner:王舜泳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com