Feeding machine with rolling wheel

A feeder and roller technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as single function, uncoordinated action coordination, and economic loss of enterprises, and achieve low failure rate, accurate relaxation point, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

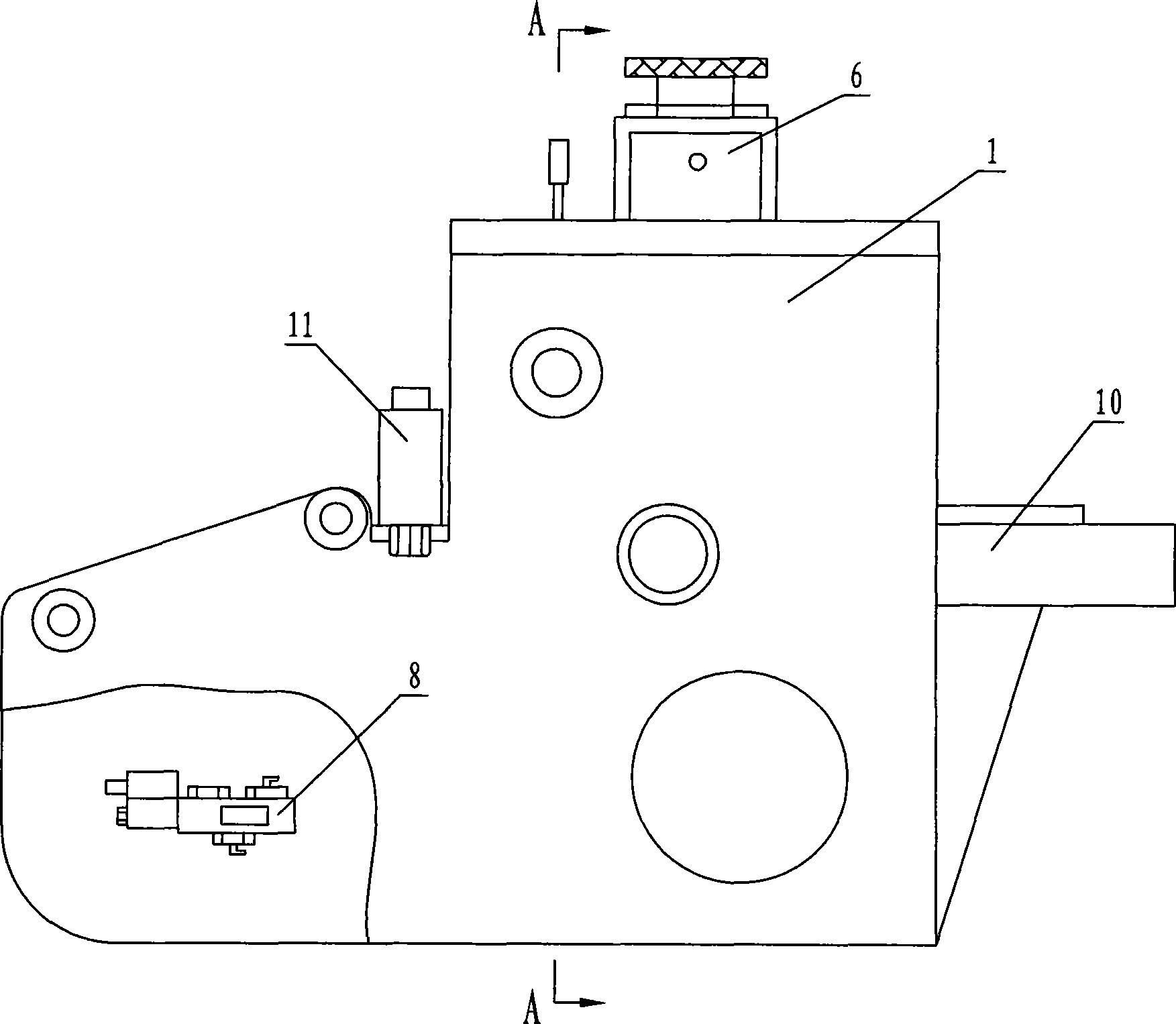

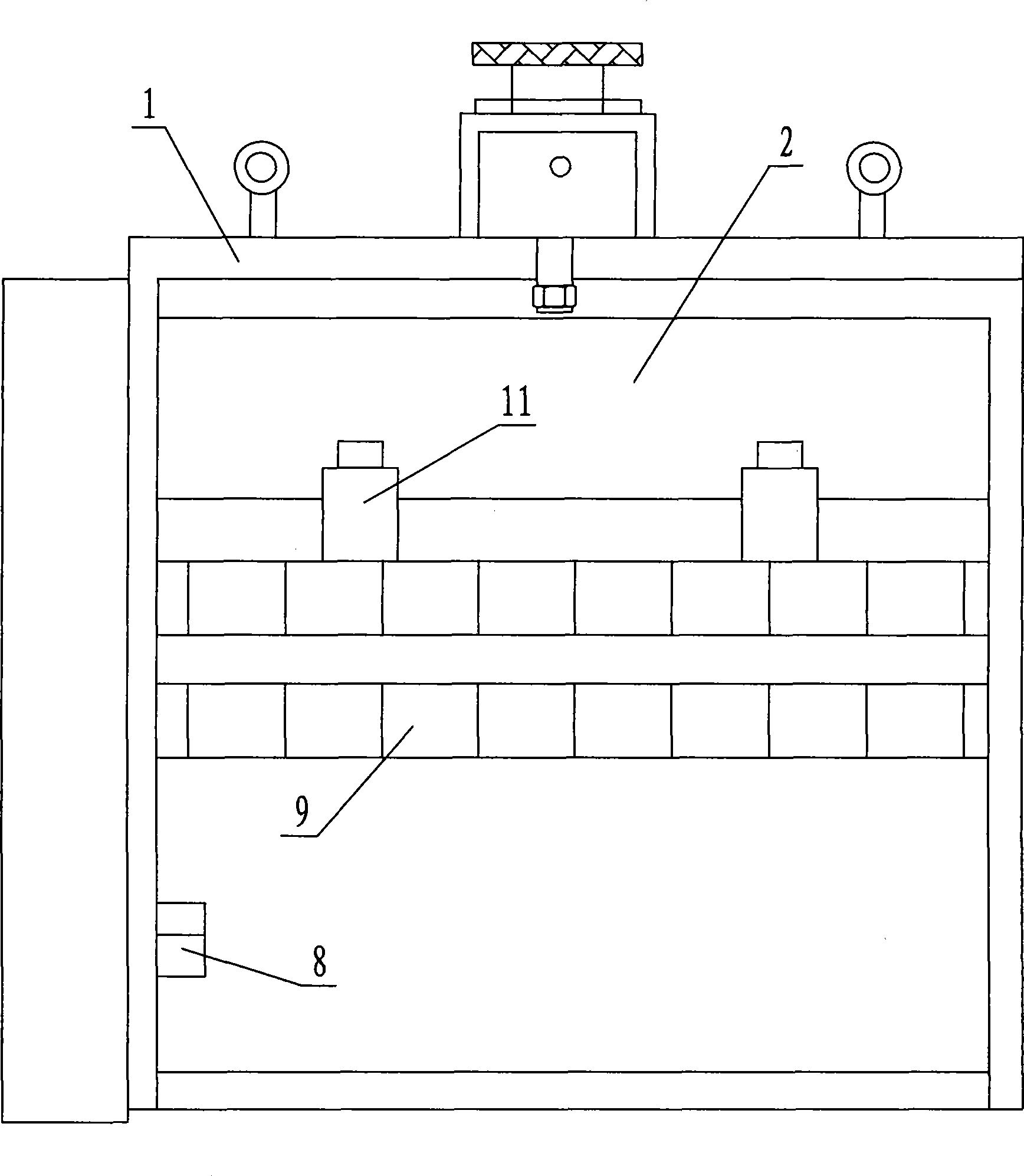

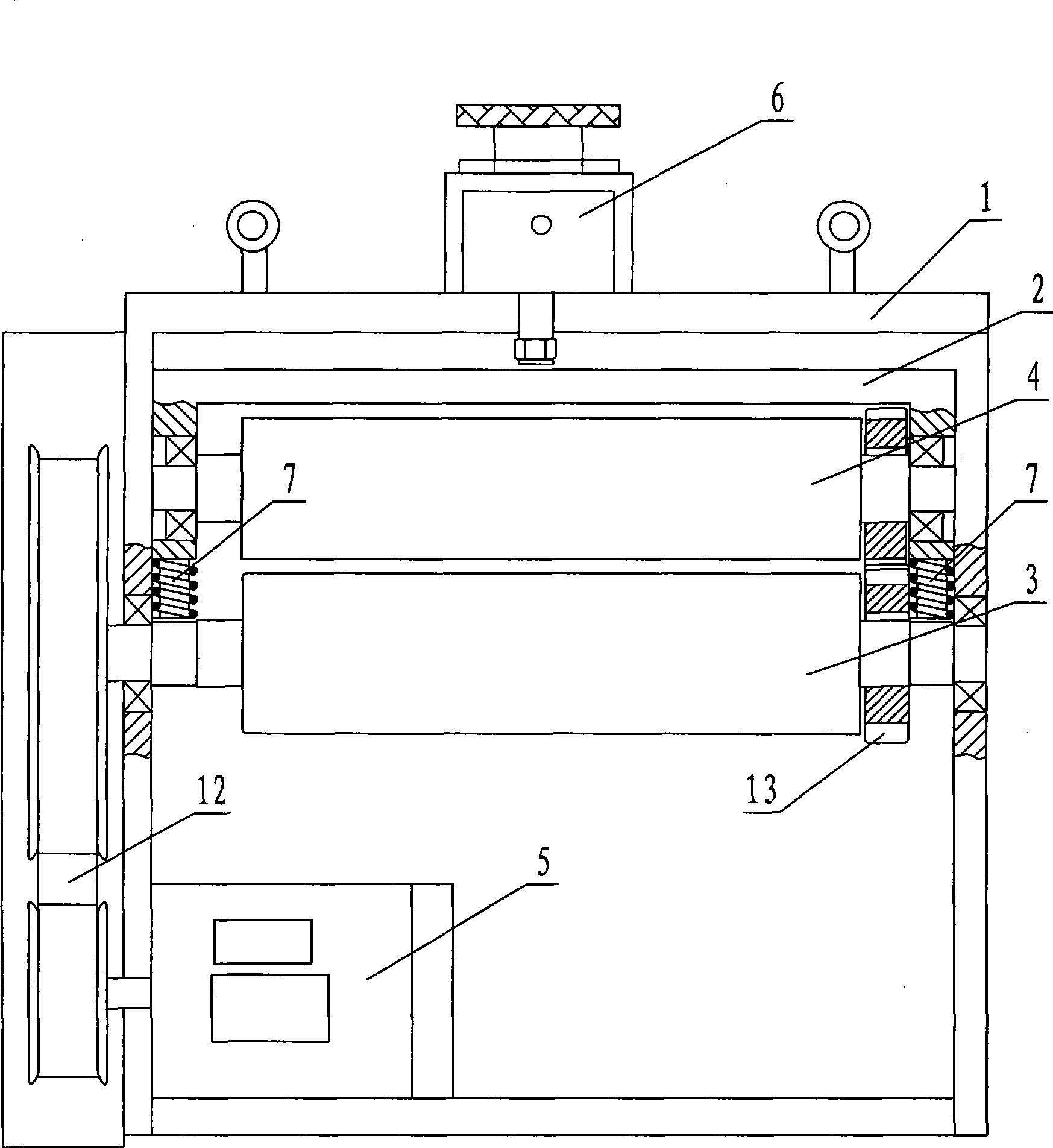

[0013] Such as figure 1 figure 2 image 3 A kind of roller feeding machine shown has a frame 1, and an upper roller seat 2 is movably arranged in the frame 1, an upper roller 4 is fixed on the upper roller seat 2, and a lower roller 3 is fixed on the frame 1, and the machine A servo motor 5 is provided at the lower part of the frame 1, which starts when feeding and stops when not feeding. The servo motor 5 drives the lower roller 3 to rotate through the synchronous belt 12, and the lower roller 3 and the upper roller 4 are connected through a gear 13 transmission. A cylinder 6 is provided at the top of the frame 1. The piston rod of the cylinder 6 passes through the upper plane of the frame 1 and is fixedly connected with the upper roller seat 2. A spring 7 is connected to the lower part of both ends of the upper roller seat 2. Through the action of the spring 7, it can drive The upper roller 4 arranged on the upper roller seat 2 moves to the lower roller 3 and clamps the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com