How to break LCD glass

A technology of liquid crystal glass and glass plates, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as broken plates in the forming process, production interruption, and unstable robot movements, so as to achieve stable operation of equipment and reduce abnormal failures chances, cost and time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

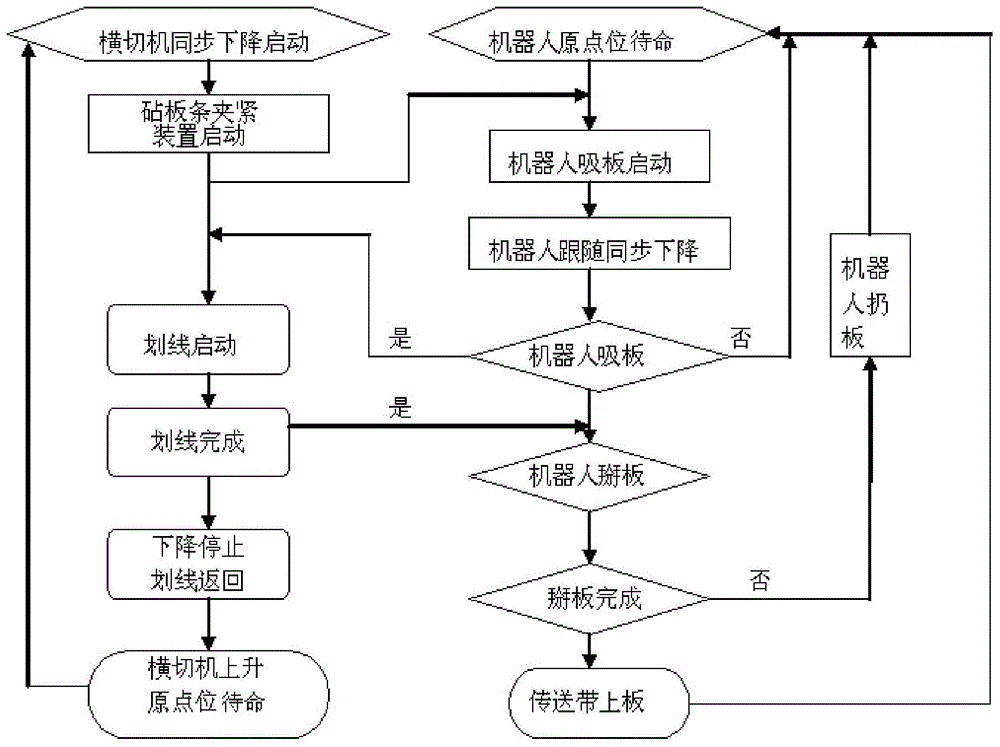

[0025] Embodiment 1: see figure 1 , the board breaking method of the present invention comprises the following steps:

[0026] In the first step, when the formed glass plate is sent out from the furnace, the cross-cutting machine will be lowered and started synchronously;

[0027] The second step is to start the cutting board strip clamping device on the cross-cutting machine. When the cutting board strip clamping device clamps the formed glass plate, the board breaking robot on standby at the origin position starts the suction board. The board breaking robot is a six-axis robot with a suction cup A spring is installed to make the flexible connection between the suction cup holder and the forming glass plate, and the plate breaking robot sucks the forming glass plate outside the effective surfaces on both sides of the forming glass plate, and descends synchronously with the forming glass plate;

[0028] In the third step, after the plate-breaking robot sucks the plate, the cr...

Embodiment 2

[0031] Example 2: see figure 1 , the board breaking method of the present invention comprises the following steps:

[0032] In the first step, when the formed glass plate is sent out from the furnace, the cross-cutting machine will be lowered and started synchronously;

[0033] The second step is to start the cutting board strip clamping device on the cross-cutting machine. When the cutting board strip clamping device clamps the formed glass plate, the board breaking robot on standby at the origin position starts the suction board. The board breaking robot is a six-axis robot with a suction cup A spring is installed to make the flexible connection between the suction cup holder and the forming glass plate, and the plate breaking robot sucks the forming glass plate outside the effective surfaces on both sides of the forming glass plate, and descends synchronously with the forming glass plate;

[0034] In the third step, after the plate-breaking robot sucks the plate, the cross...

Embodiment 3

[0037] Embodiment 3: see figure 1 , the board breaking method of the present invention comprises the following steps:

[0038] In the first step, when the formed glass plate is sent out from the furnace, the cross-cutting machine will be lowered and started synchronously;

[0039] The second step is to start the cutting board strip clamping device on the cross-cutting machine. When the cutting board strip clamping device clamps the formed glass plate, the board breaking robot on standby at the origin position starts the suction board. The board breaking robot is a six-axis robot with a suction cup A spring is installed to make the flexible connection between the suction cup holder and the forming glass plate, and the plate breaking robot sucks the forming glass plate outside the effective surfaces on both sides of the forming glass plate, and descends synchronously with the forming glass plate;

[0040] In the third step, after the plate-breaking robot sucks the plate, the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com