Patents

Literature

483 results about "Cross cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

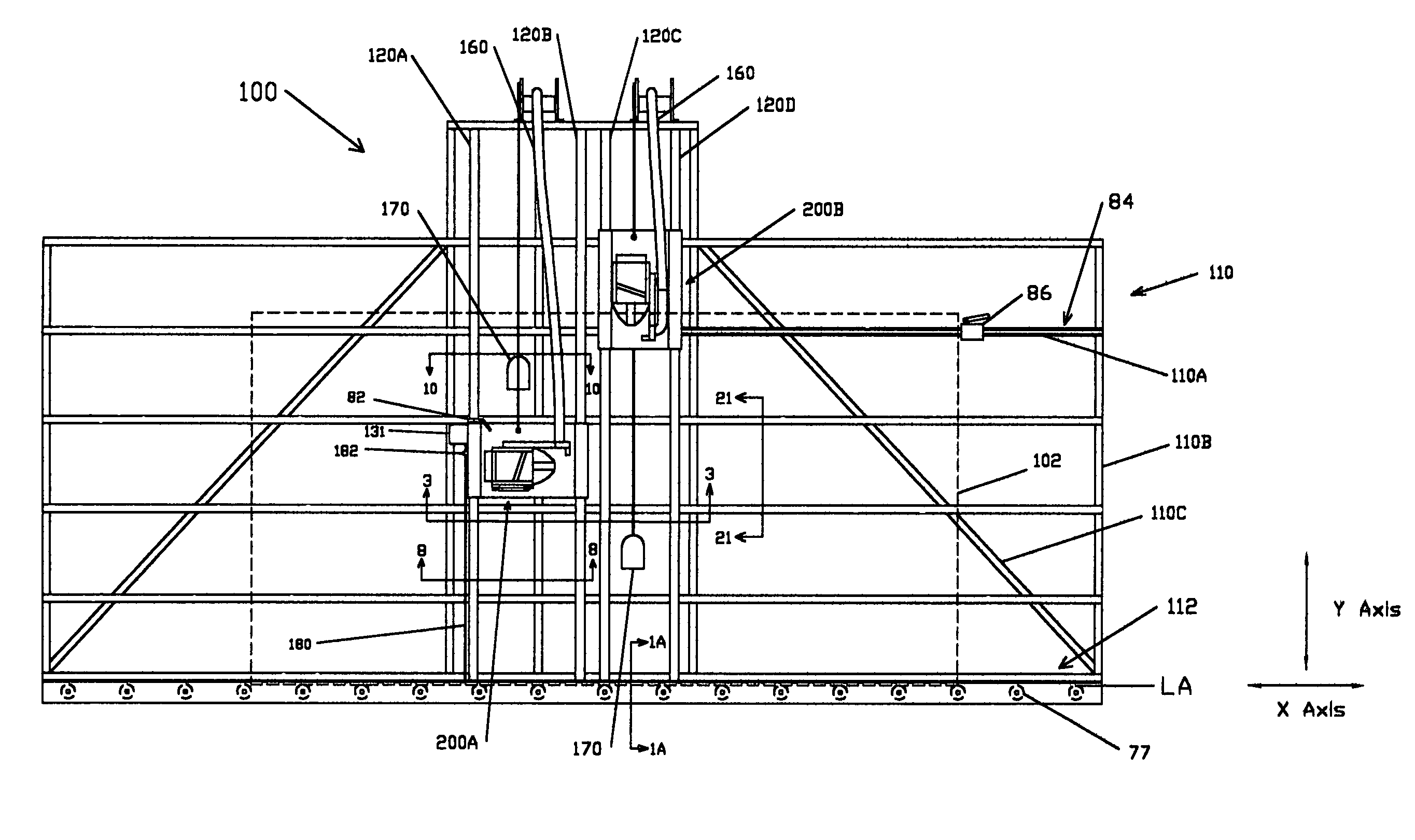

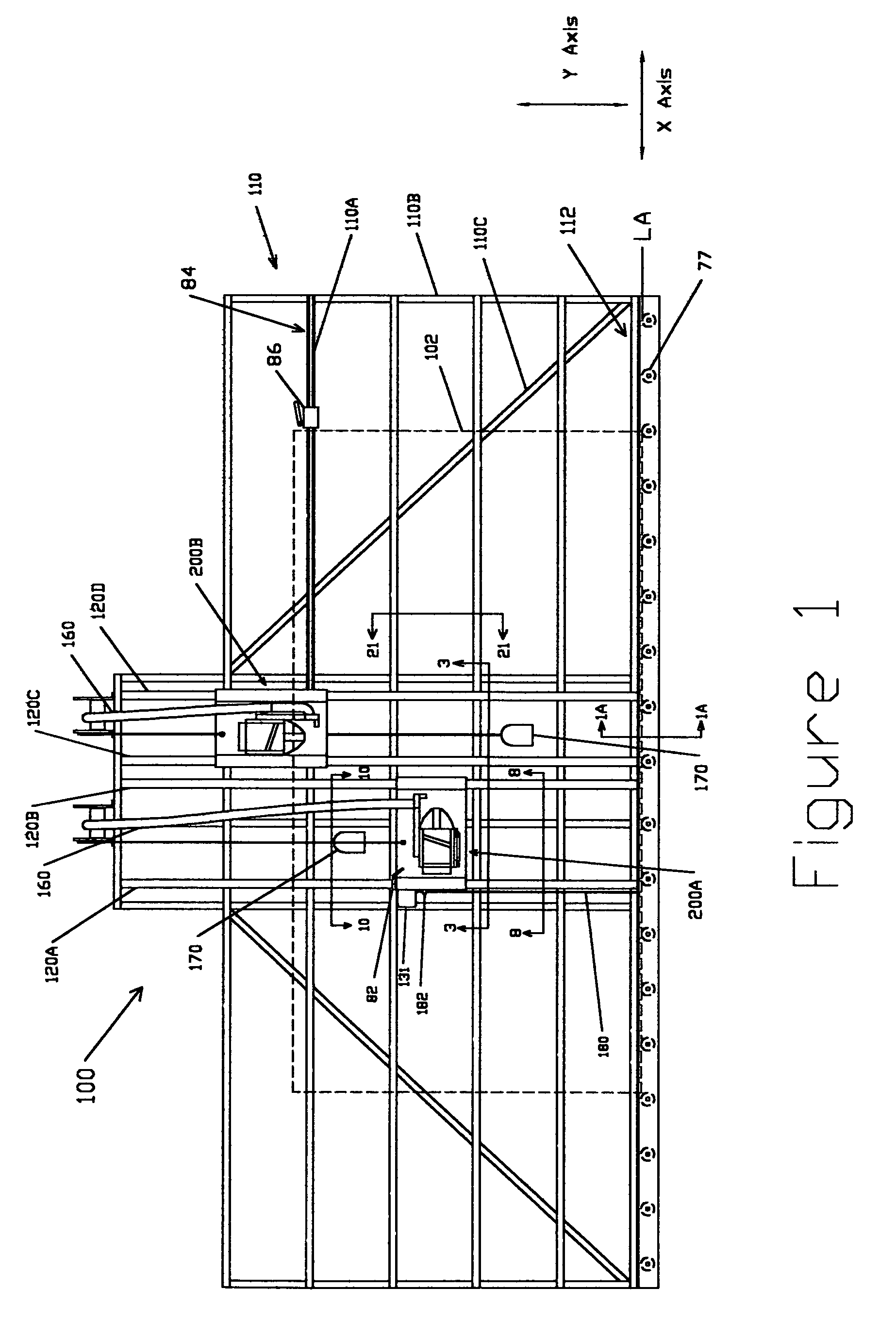

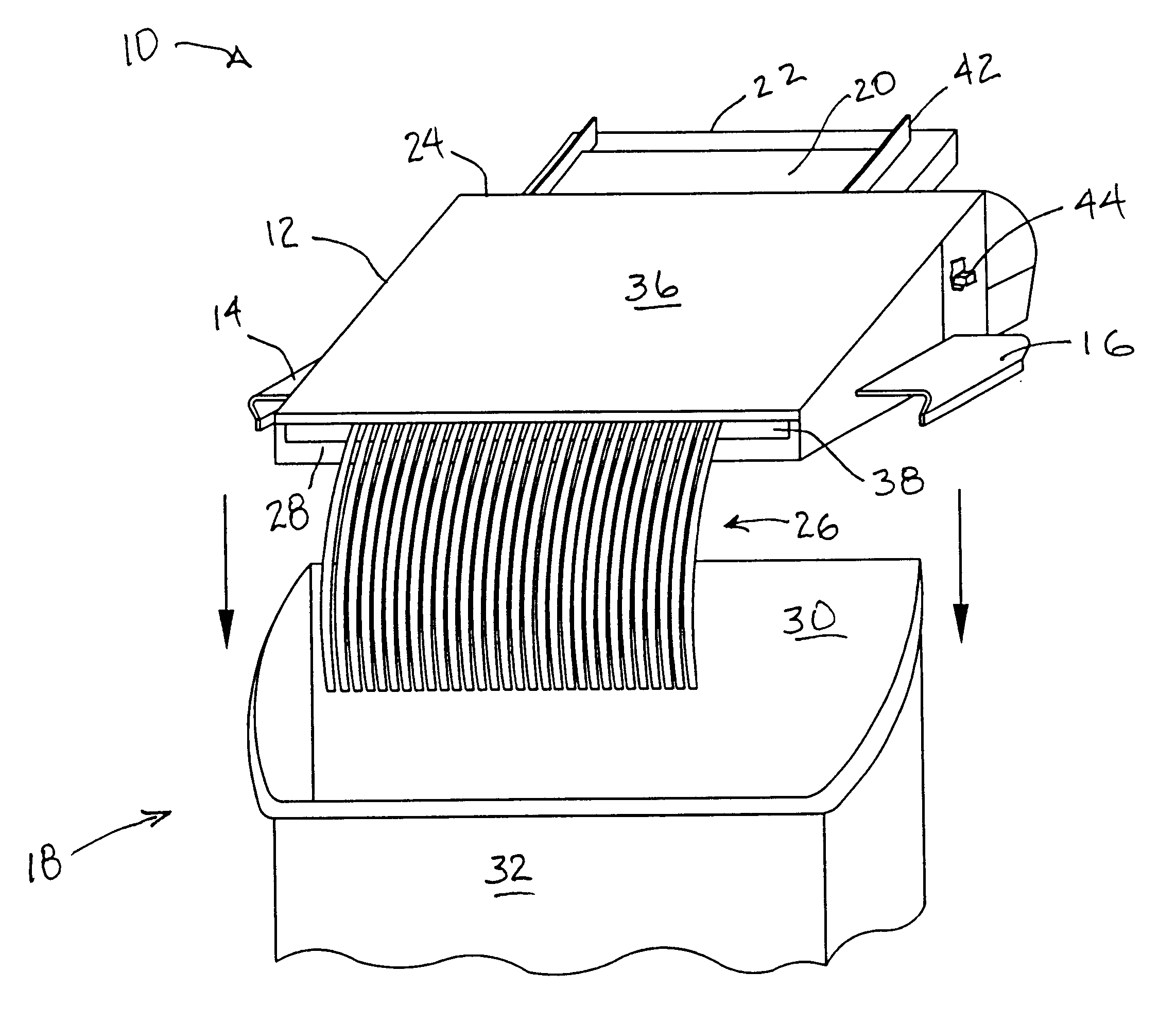

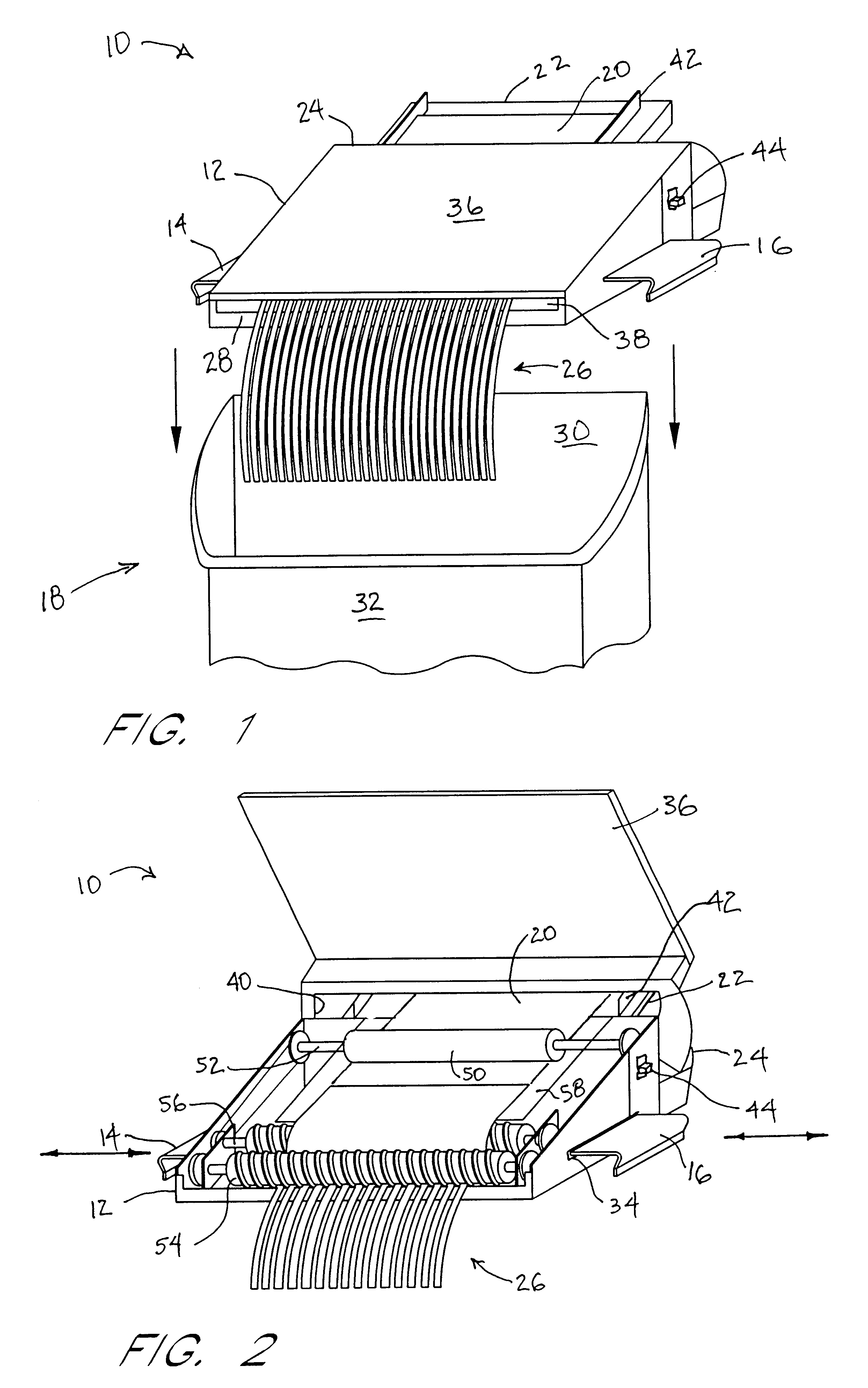

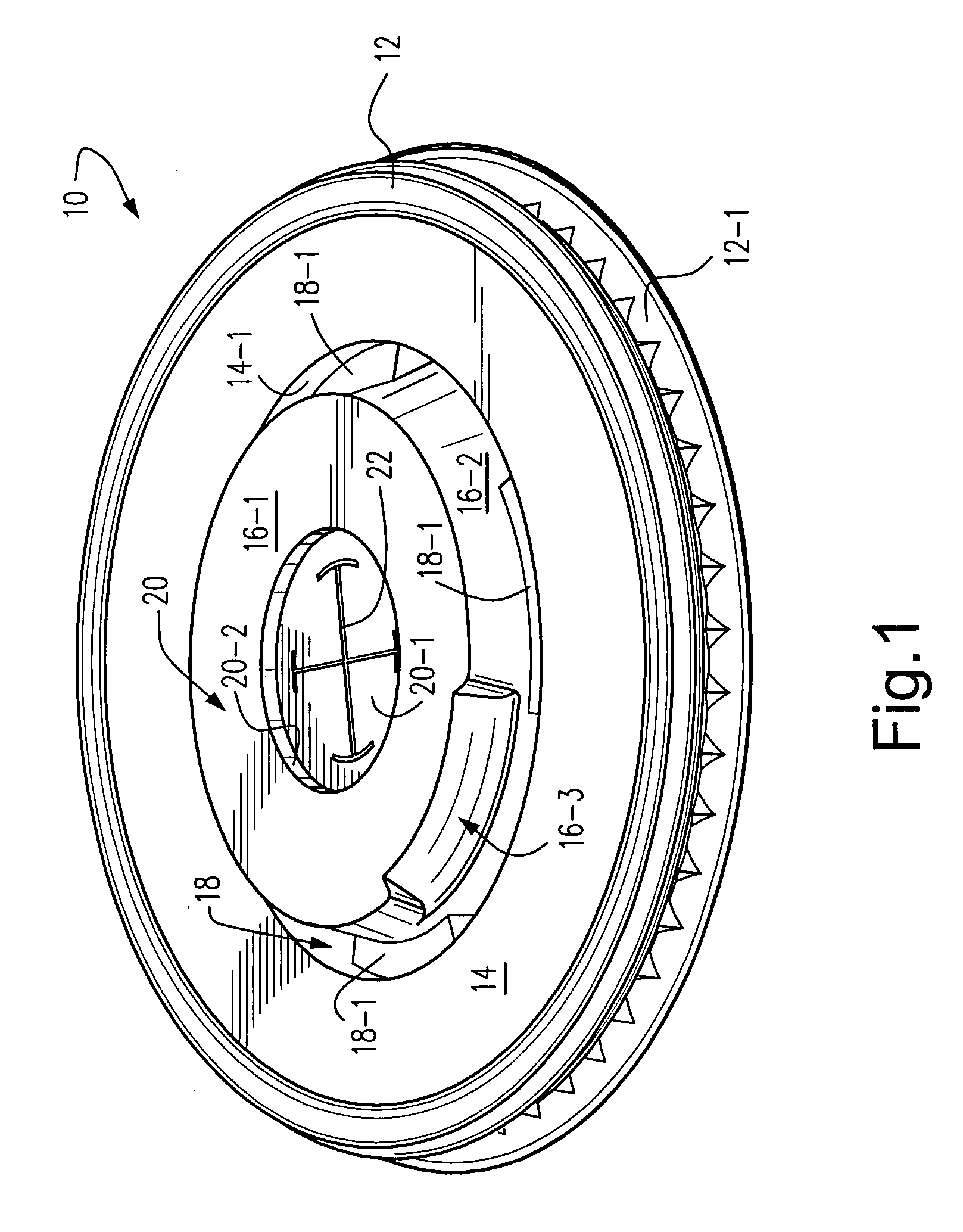

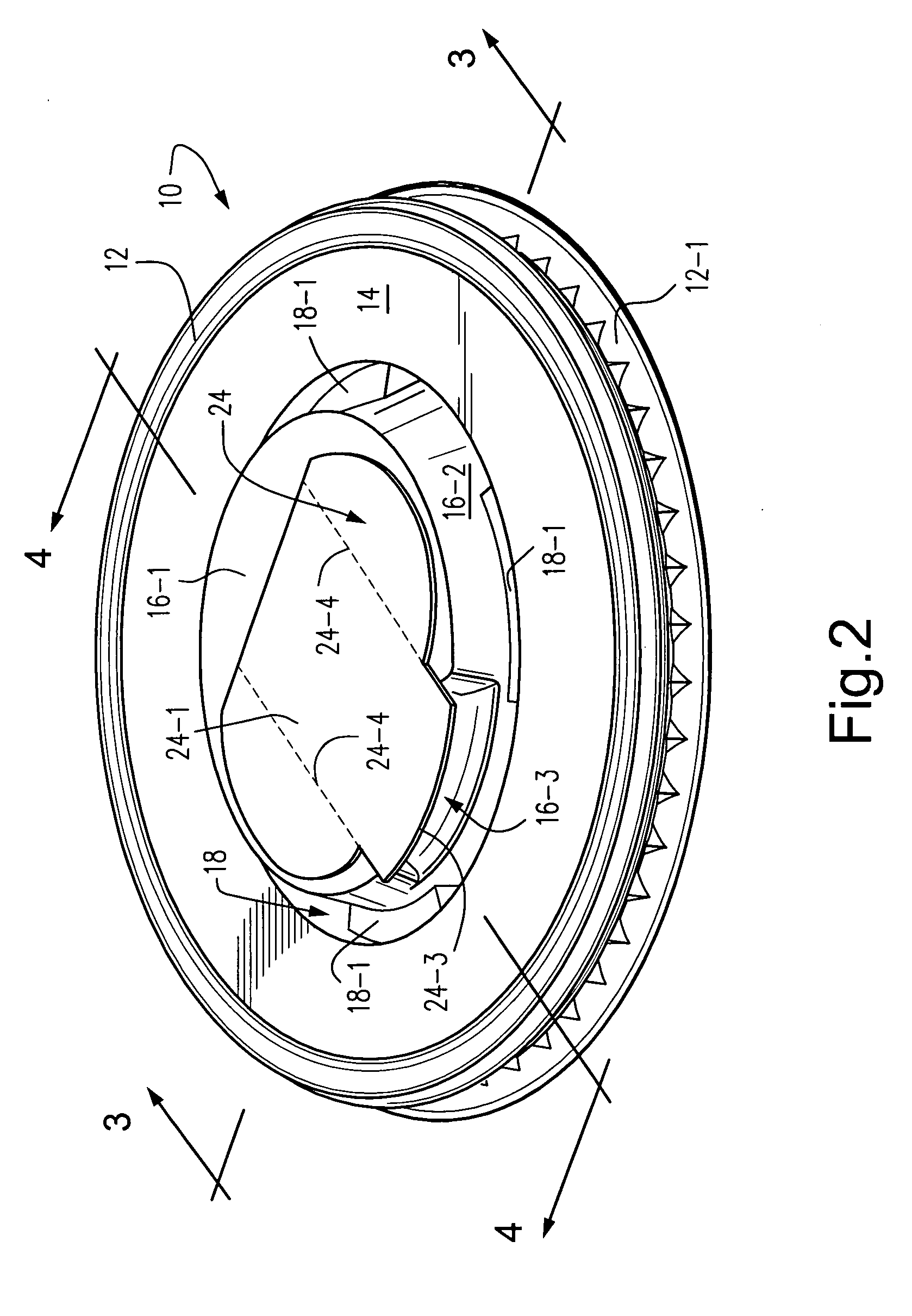

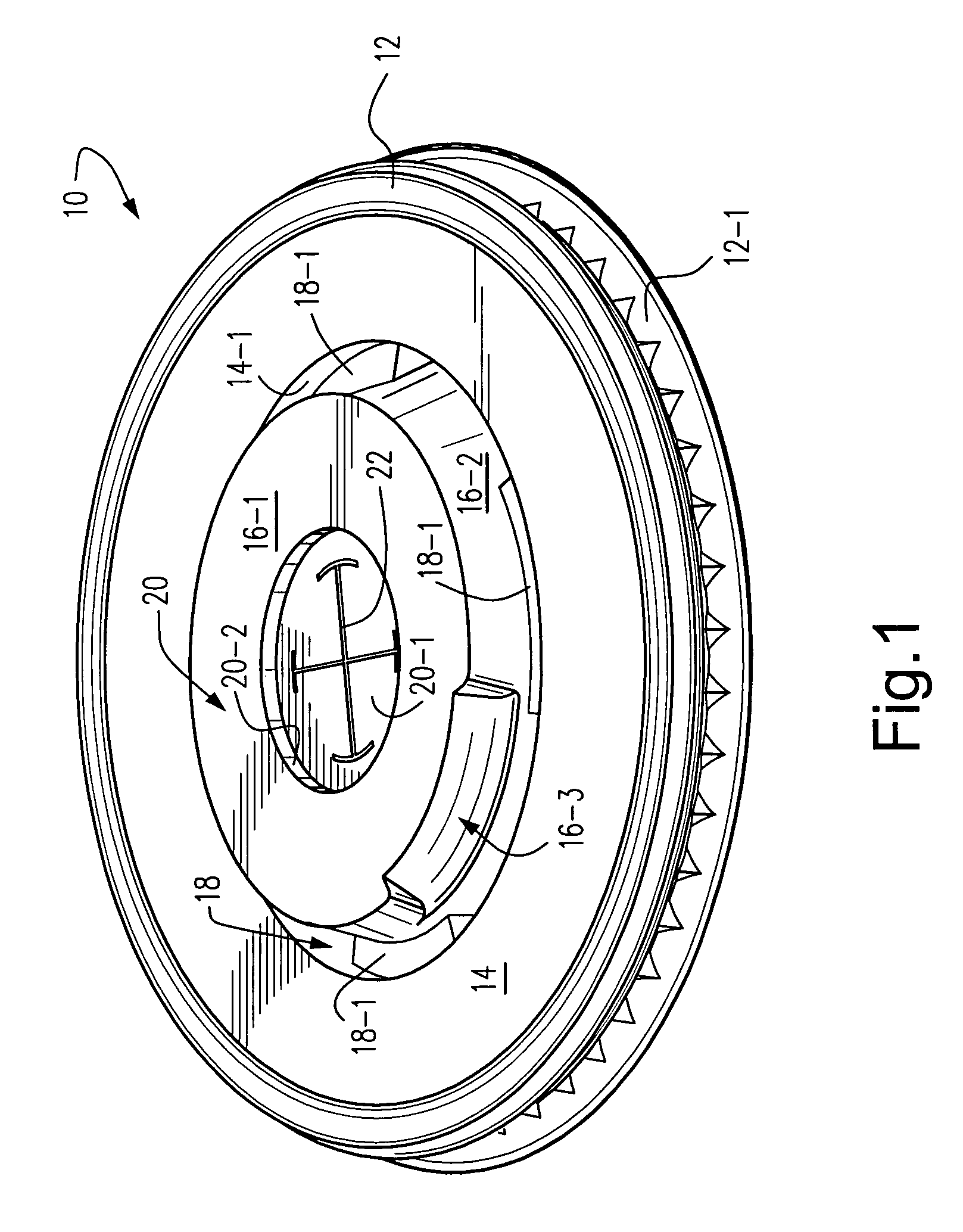

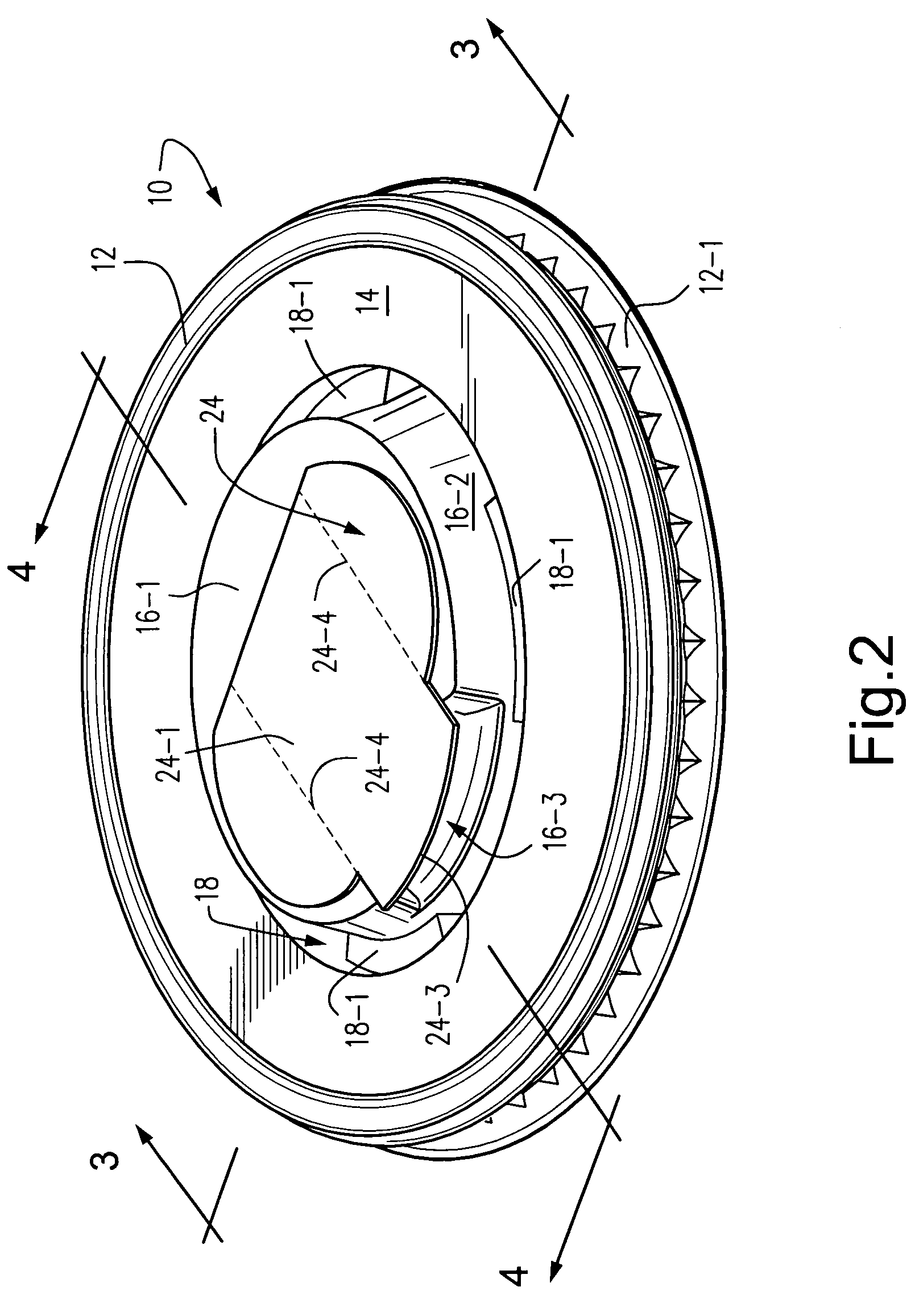

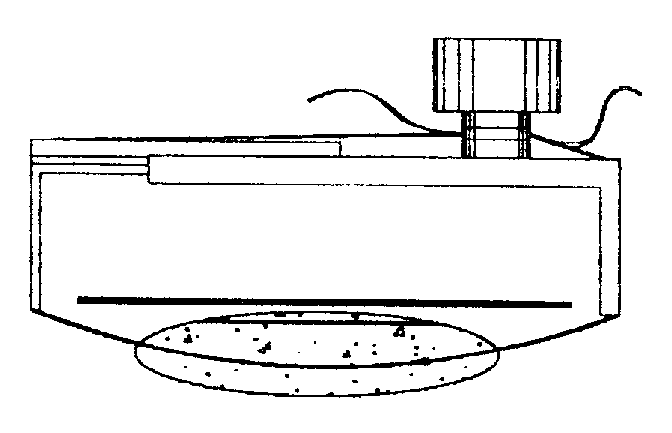

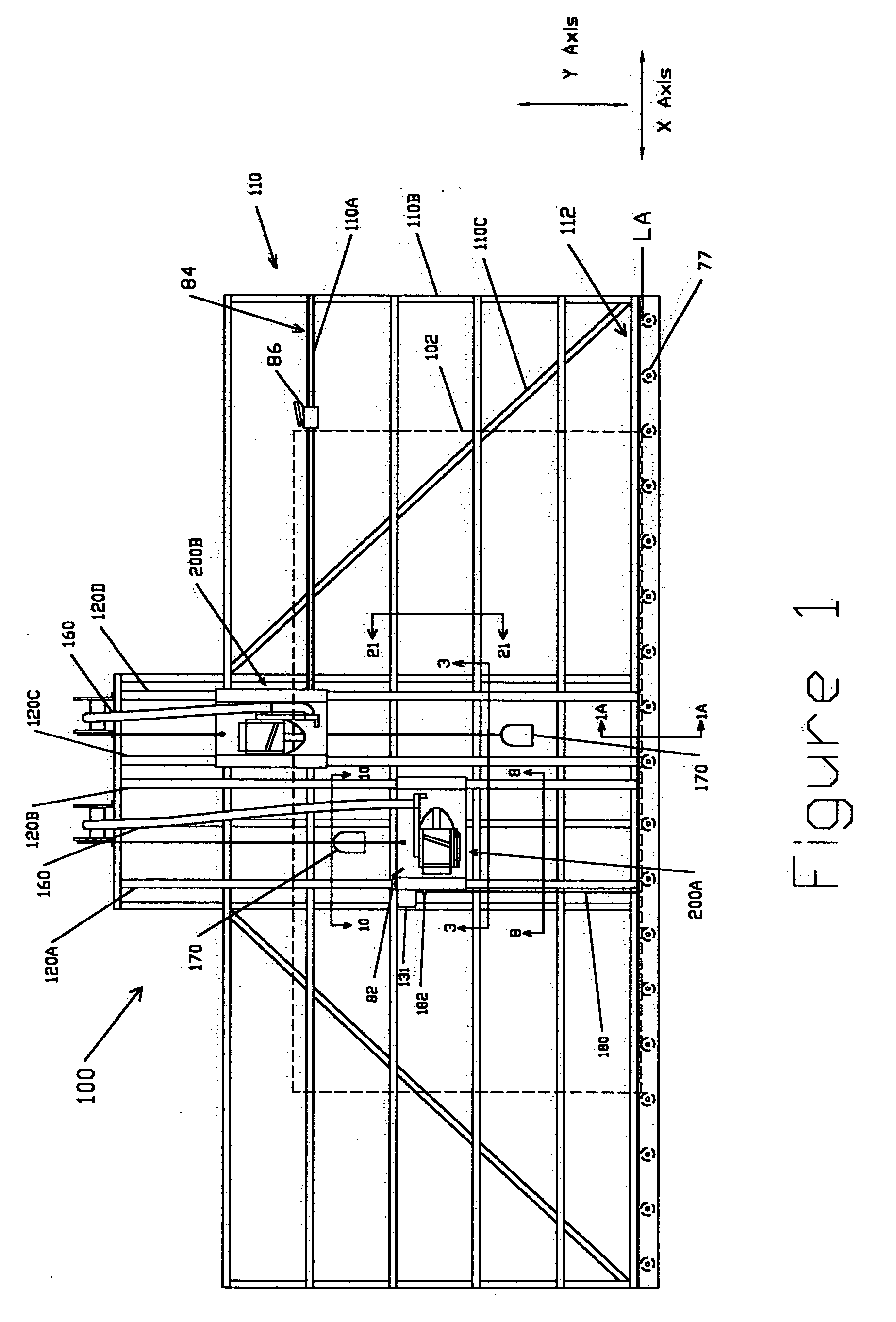

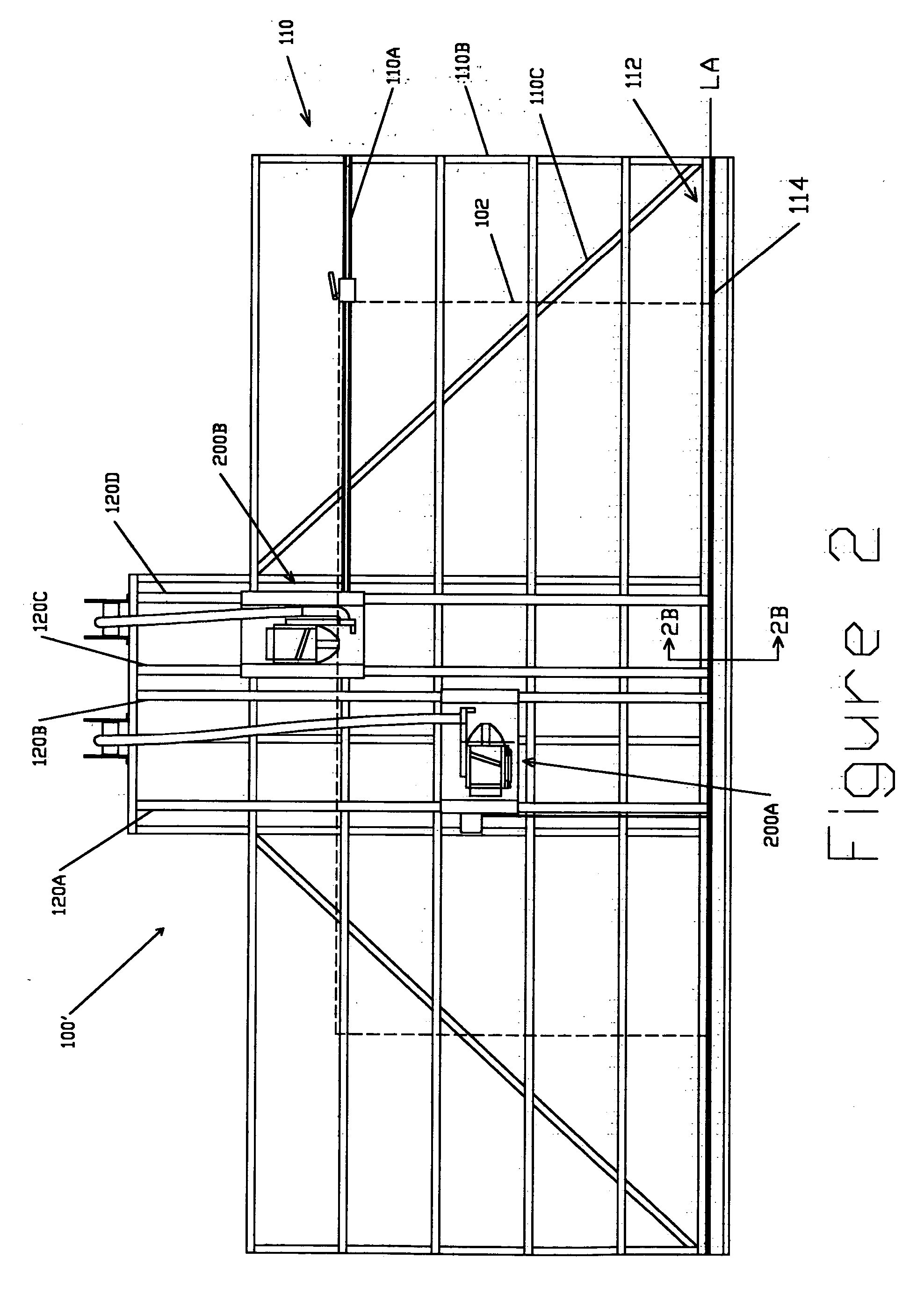

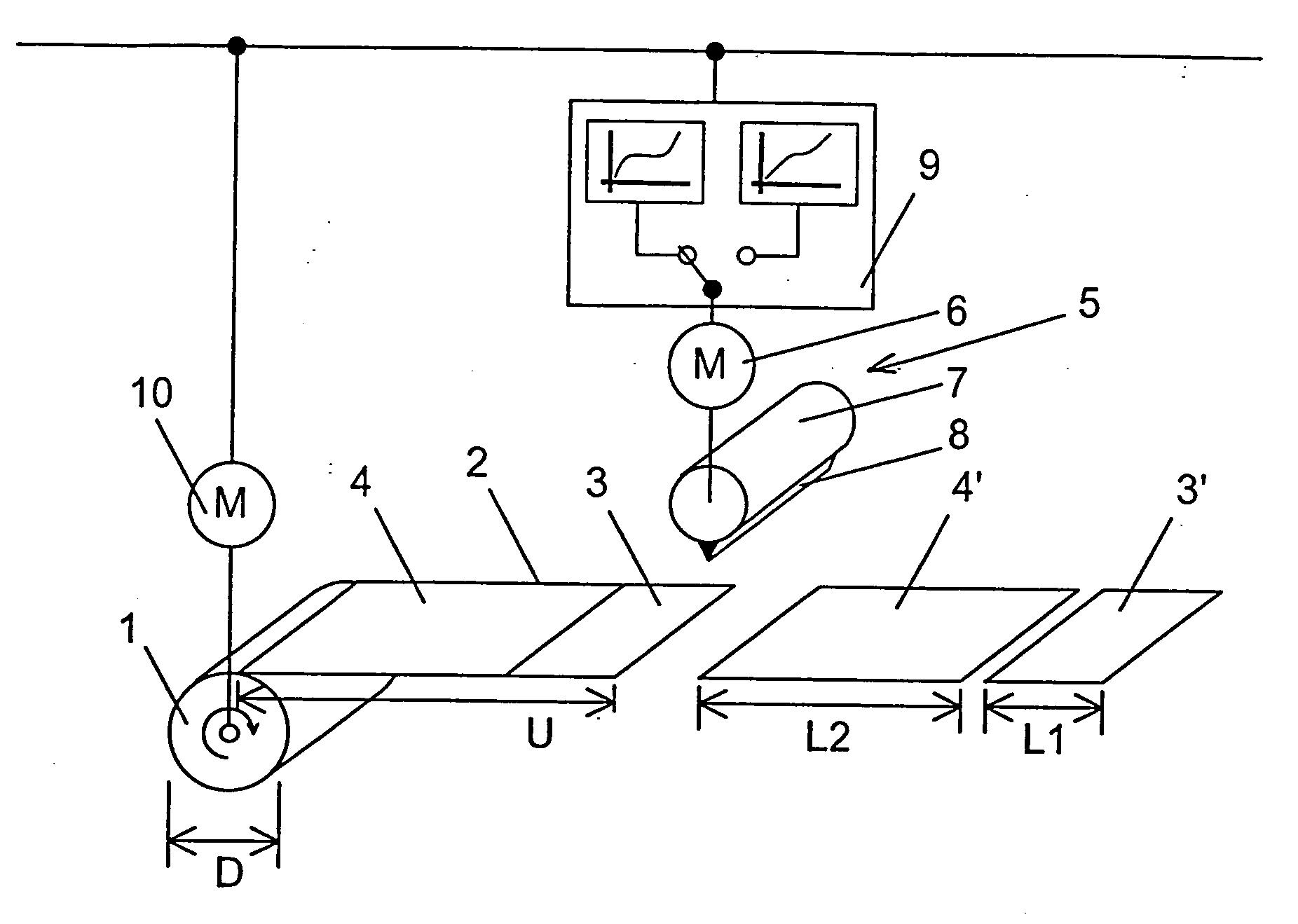

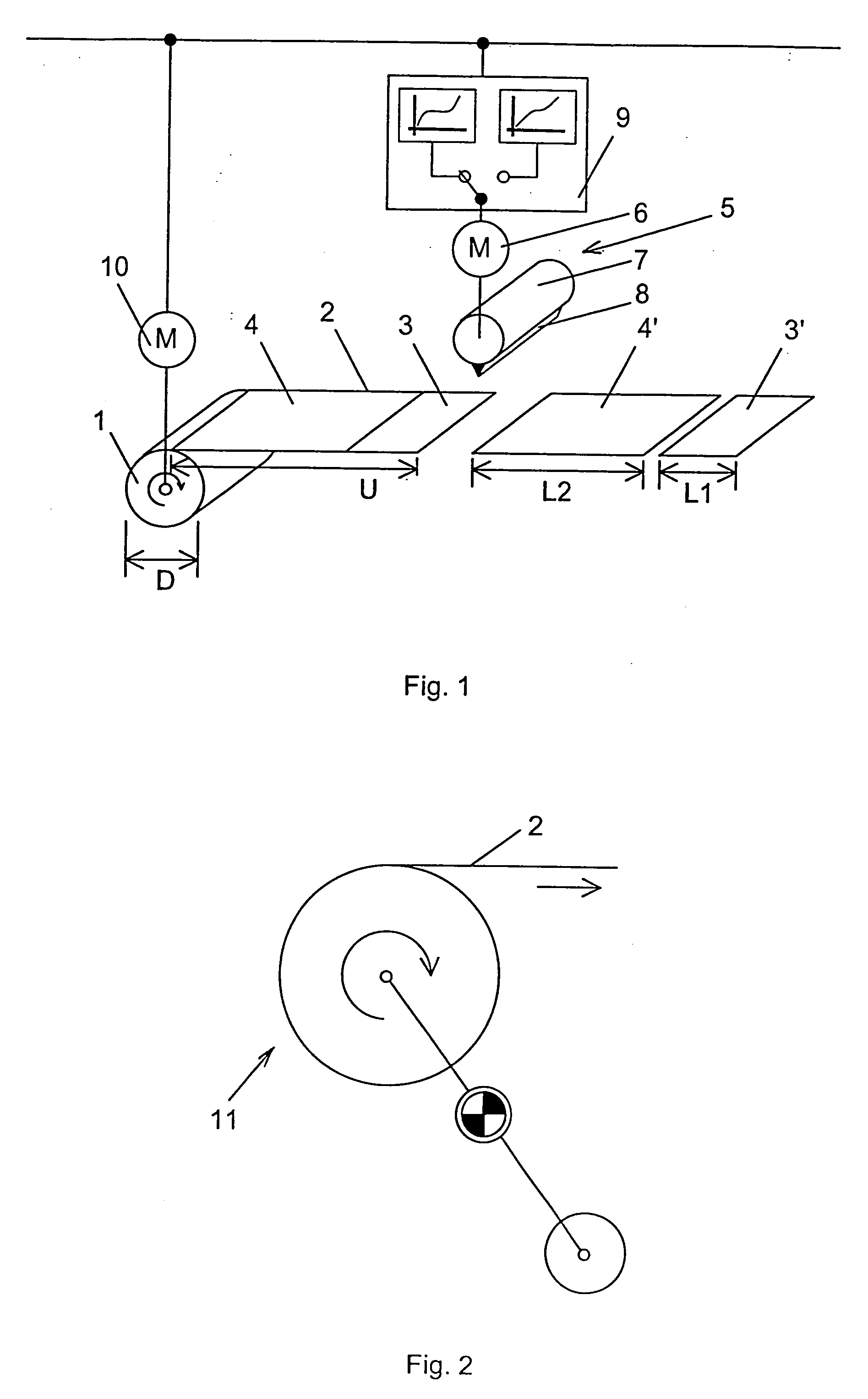

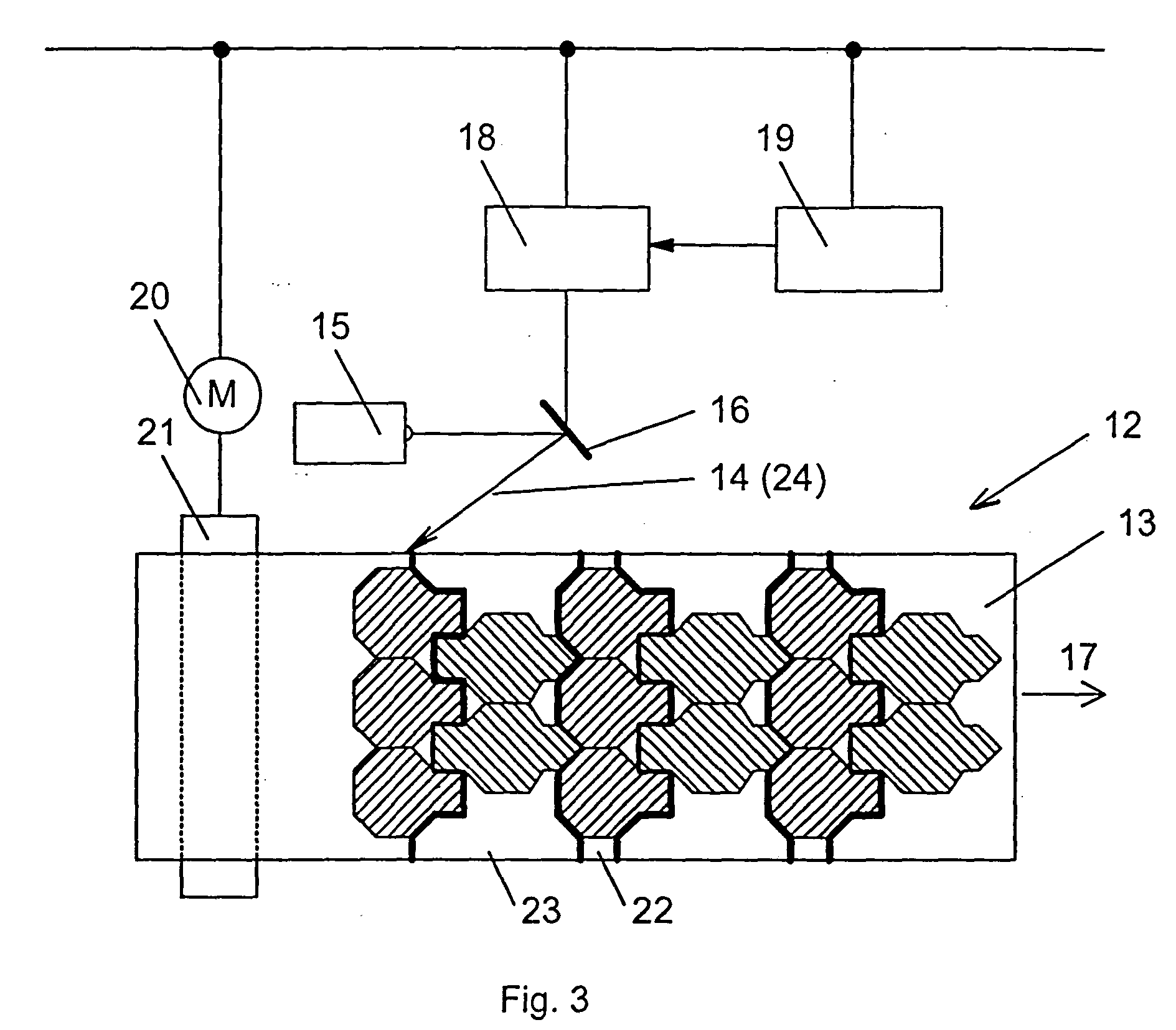

Multi-axis panel saw

A panel saw has a first cutting blade for cutting stock in a first axis and a second cutting blade for cutting the stock in a second axis. The first blade moveable from a cutting position to a position in which stock can be slid between the cutting blade and a supporting frame of the panel saw. The panel saw allows repeated cross cuts and rip cuts without changing the cutting location of the first cutting blade. A control system is configured to retract the first cutting blade from contact with the stock if the current draw exceeds a value. The control system may also retract a cutting blade when it senses the end of a panel being cut.

Owner:CHISEL WORKS L L C THE

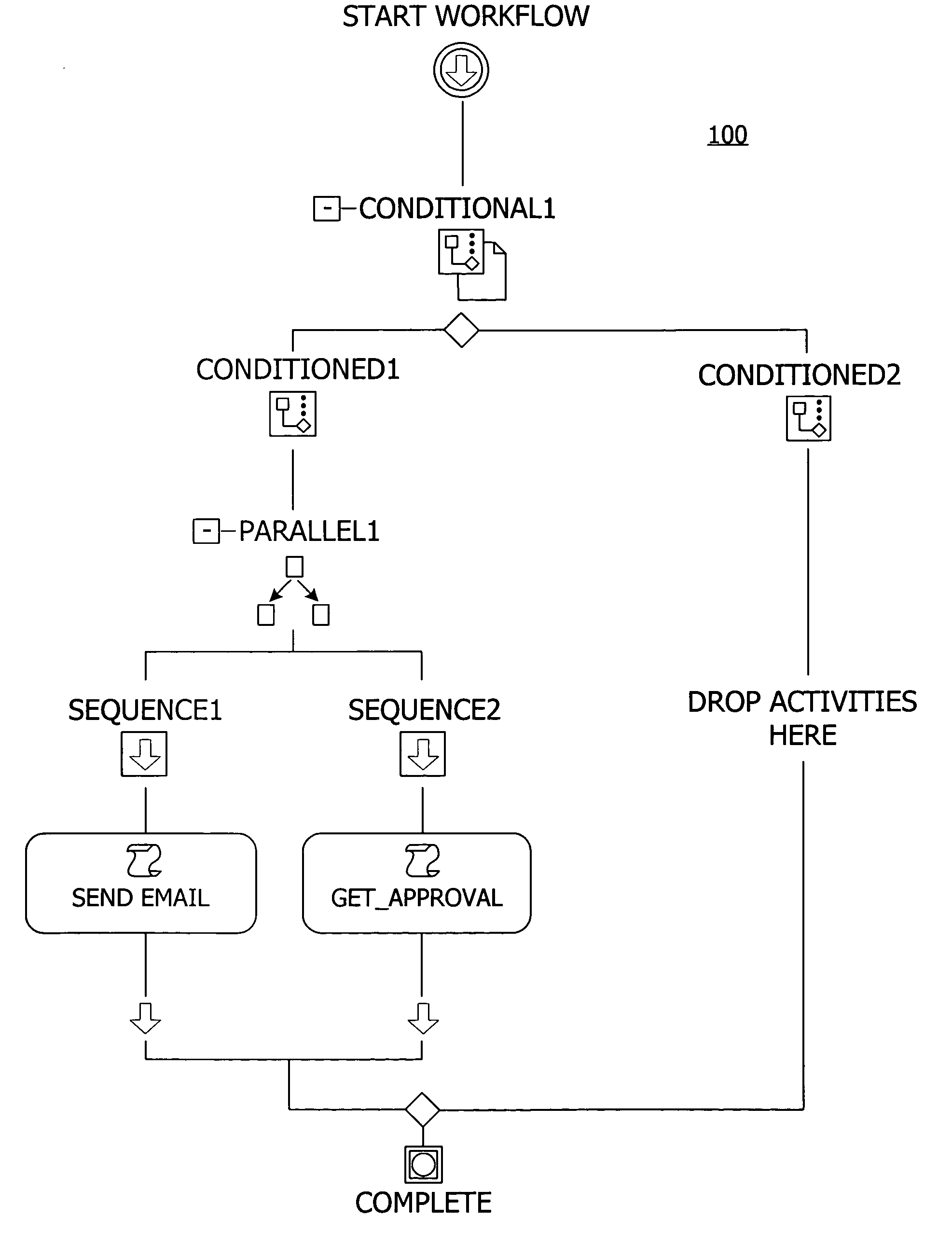

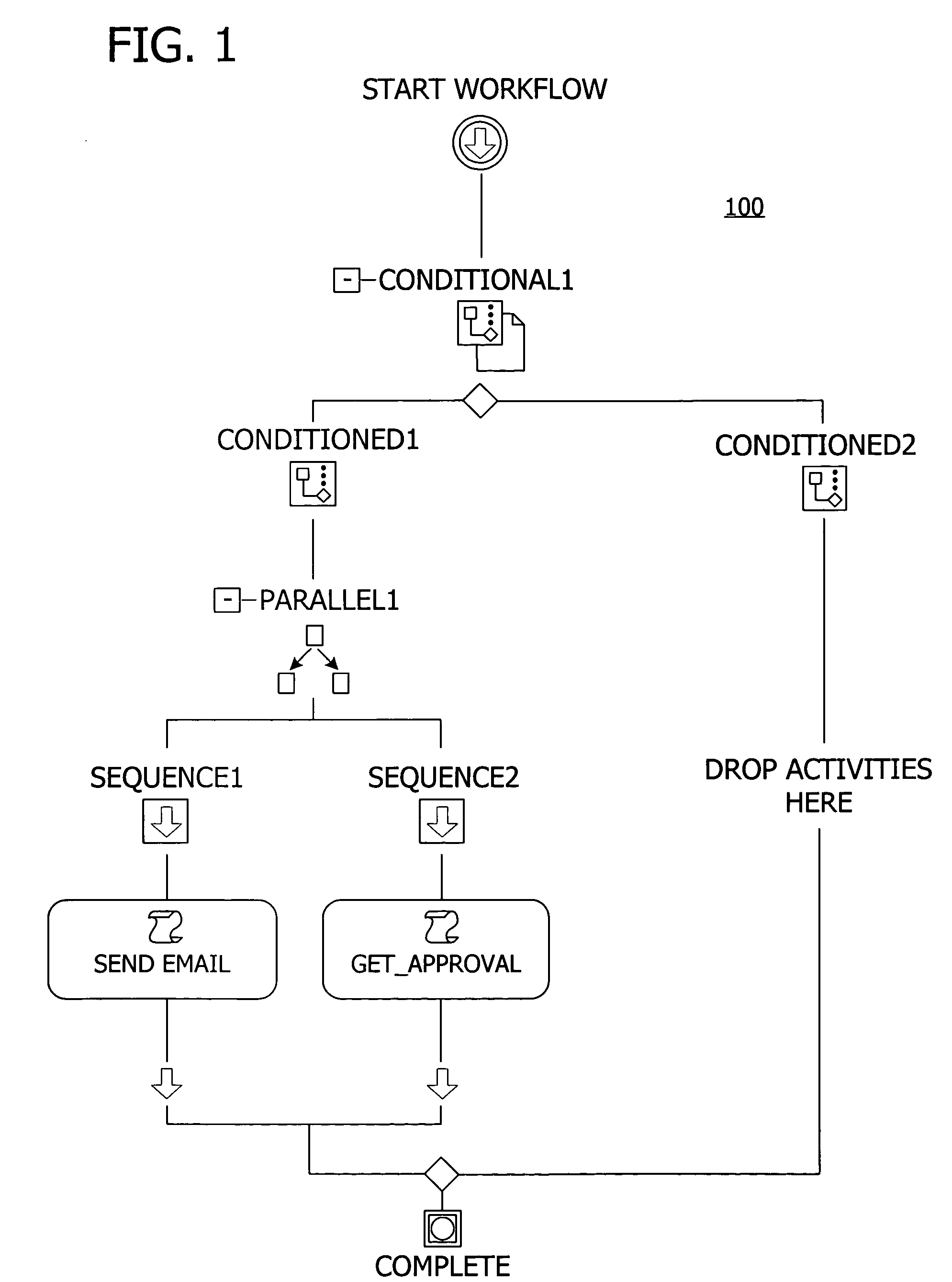

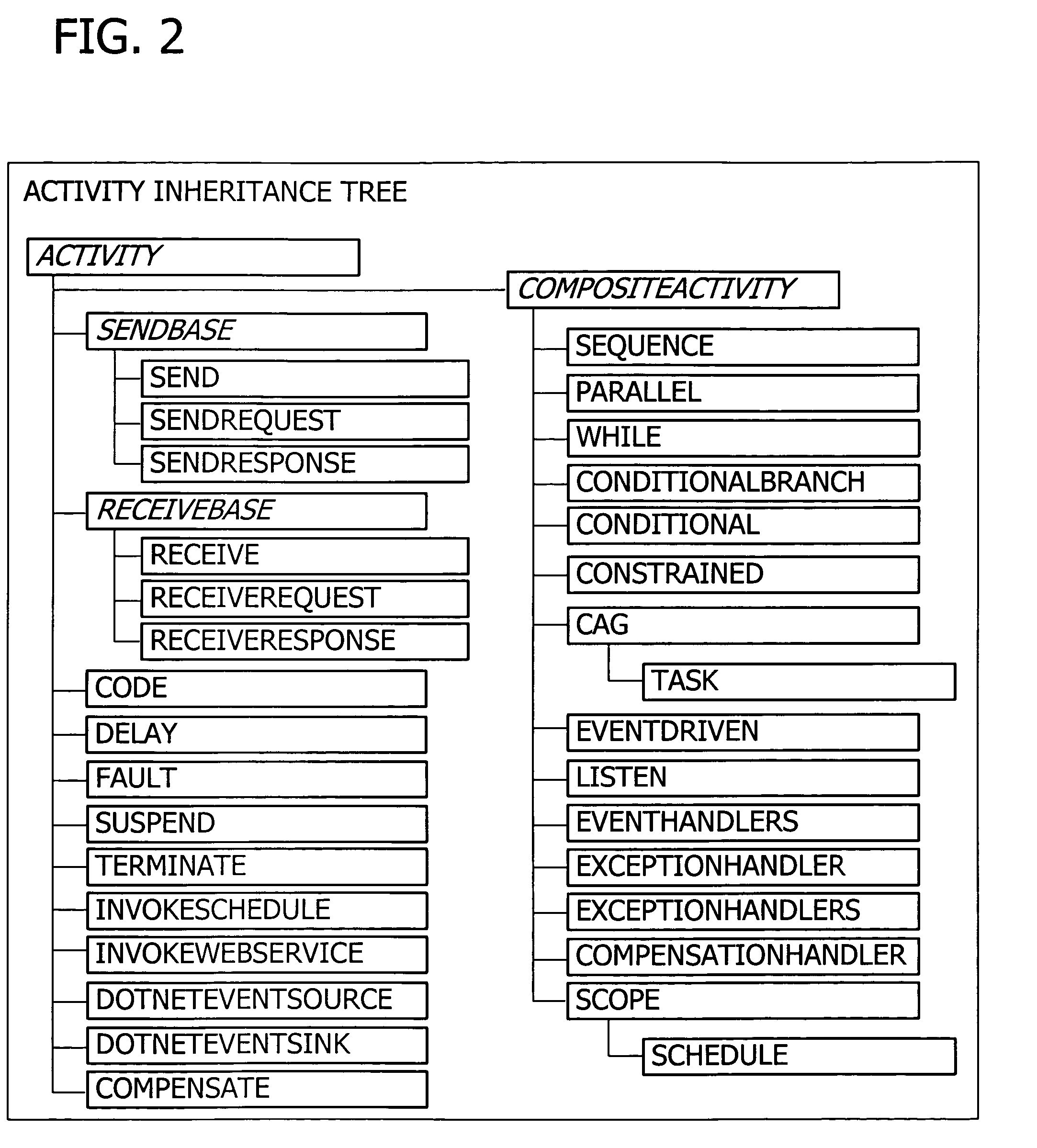

Framework to model cross-cutting behavioral concerns in the workflow domain

InactiveUS20060074704A1Extend the workflow modelSoftware designResourcesCross cutTheoretical computer science

Selecting and applying a behavioral component to a portion of a componentized workflow. The behavioral component defines error and exception handling, among other concerns, to the portion of the workflow selected by a user. During execution of the workflow, the behavioral components executes responsive to output from the selected portion of the workflow.

Owner:MICROSOFT TECH LICENSING LLC

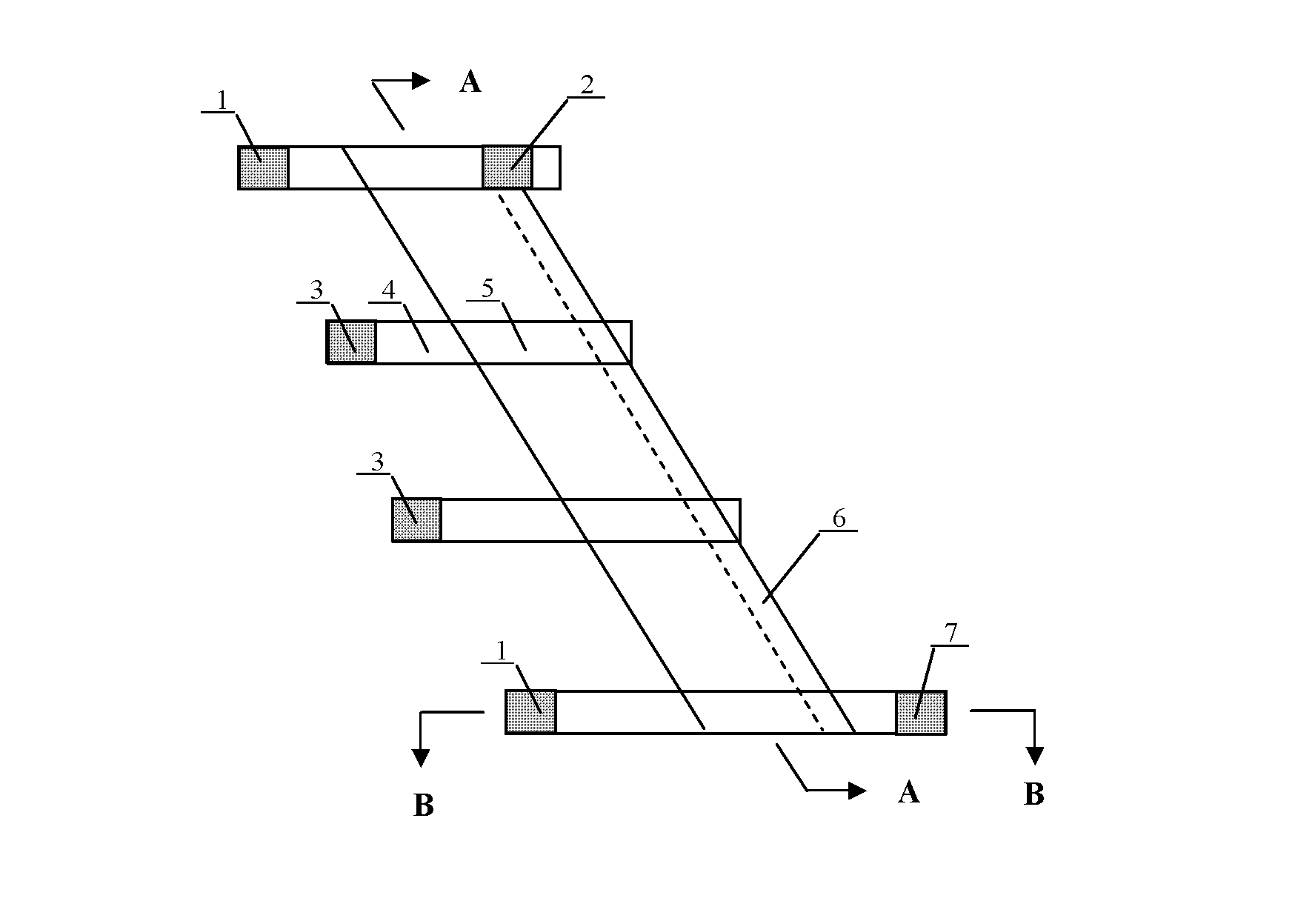

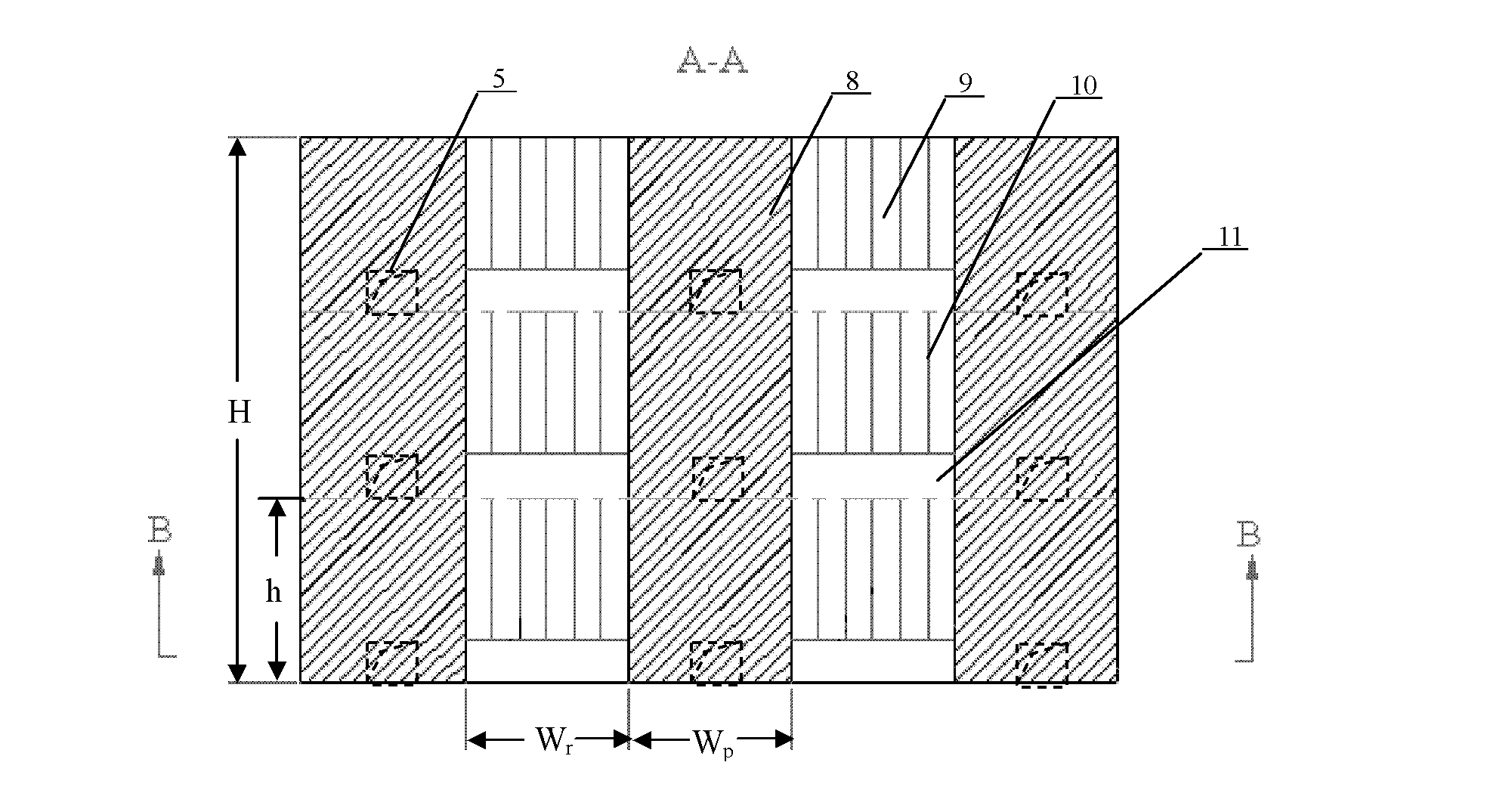

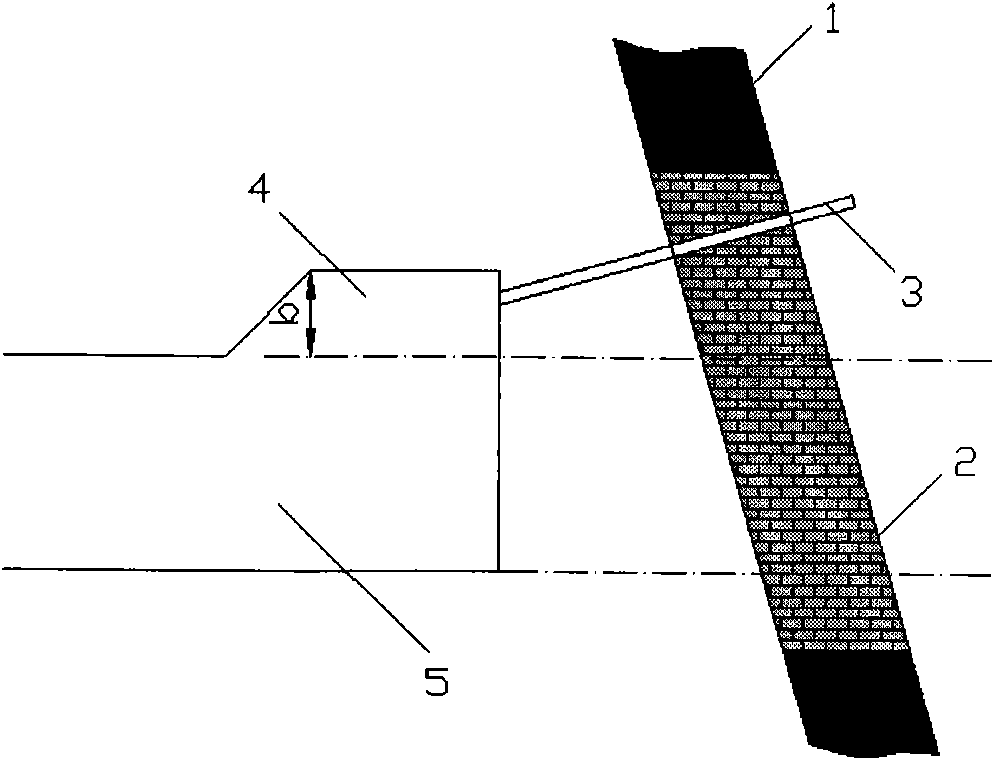

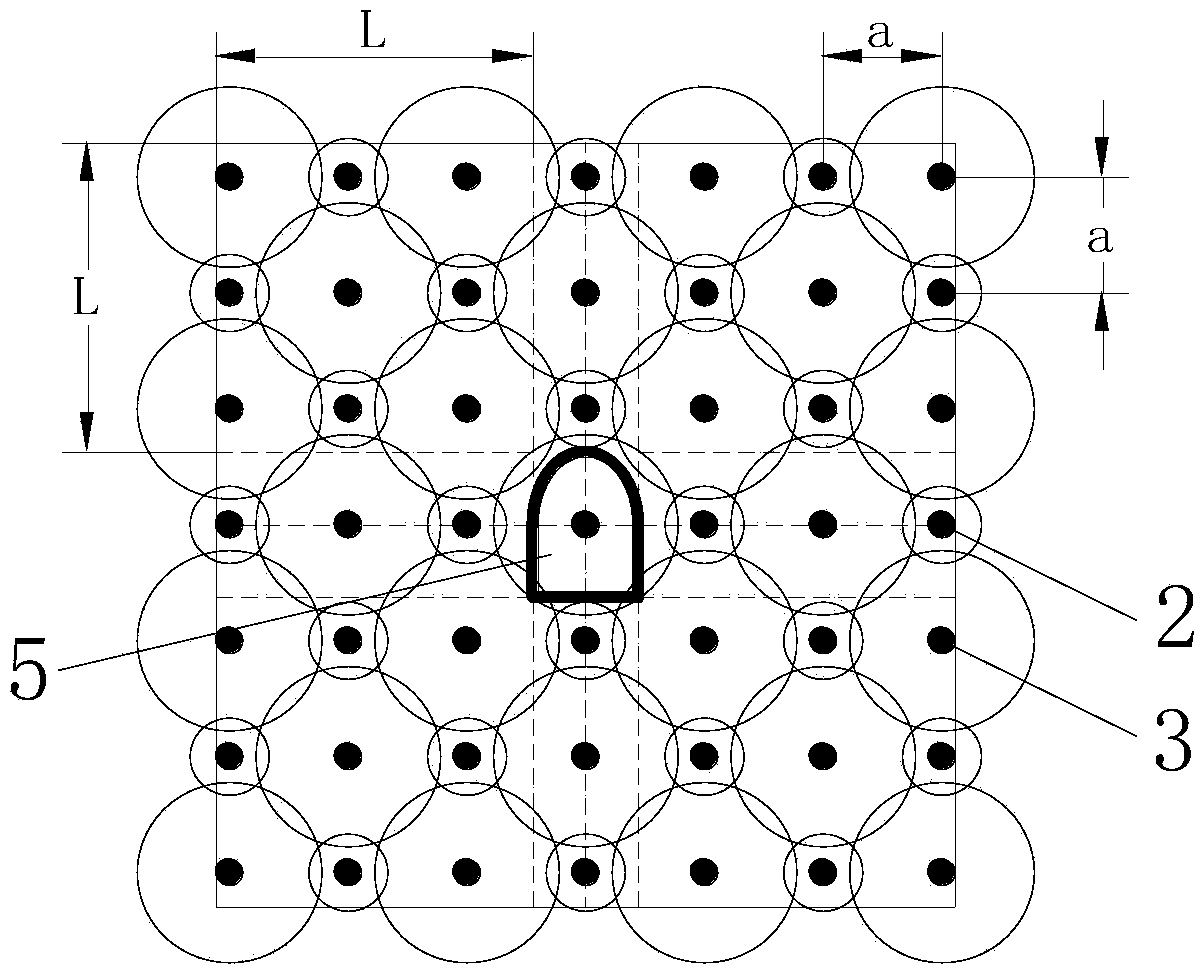

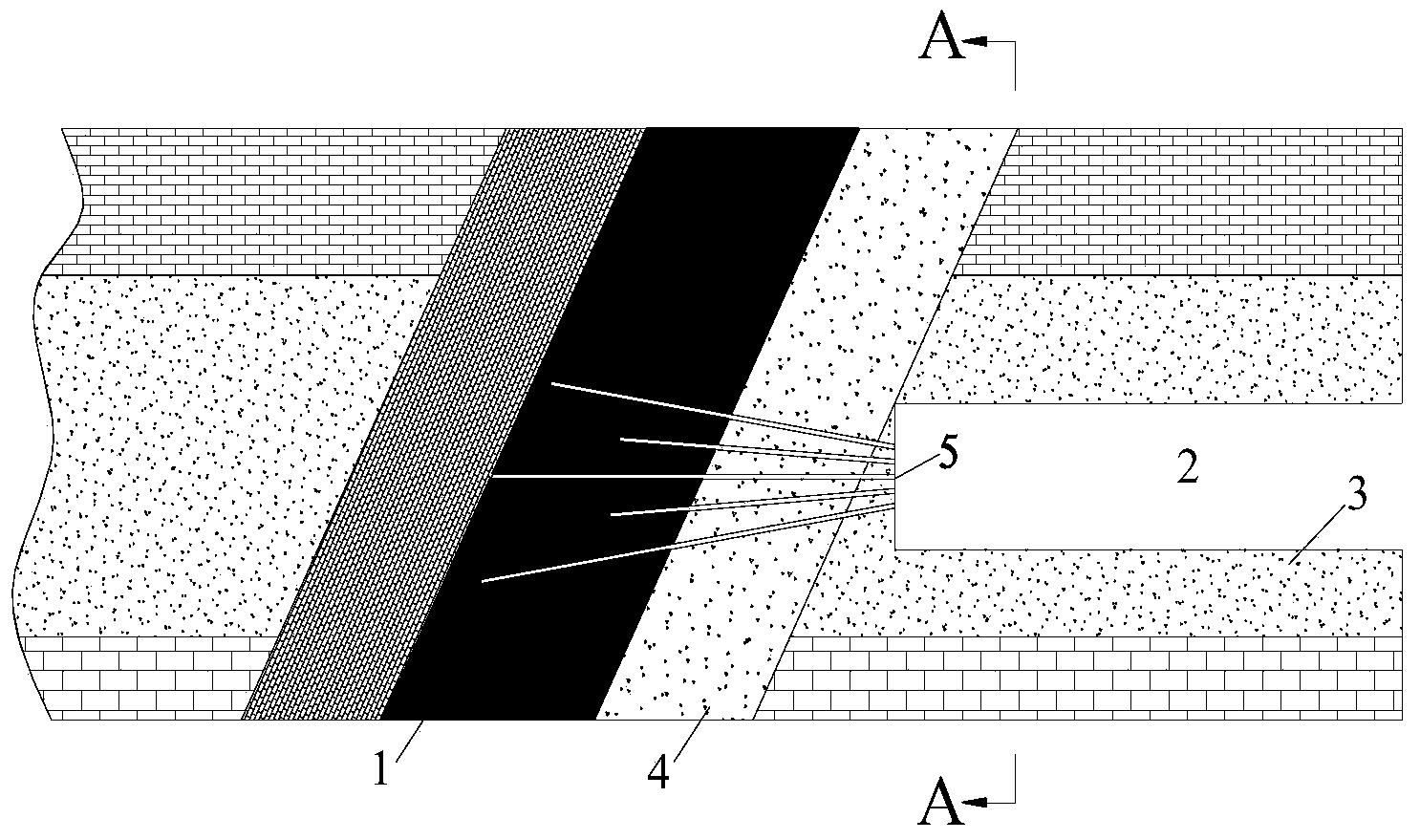

Sublevel open-stop and delayed filling mining method

InactiveCN102562065AImprove drilling positioning accuracyNo lossUnderground miningSurface miningTailings damFilling materials

The invention relates to a sublevel open-stop and delayed filling mining method. According to the method, cutting crosscuts are wholly undercut along the width of chambers and pillars so that the space of scope rock drilling is shared with ore drawing, drilling operations of vertical parallel blast holes are achieved in undercutting space, positioning accuracy of drilling the vertical parallel blast holes is high, the intervals among the blast holes are even, and the defect of high blasting boulder yield caused by drilling sector blast holes in traditional rock drilling cross cuts is avoided; during chamber (or pillar) scoping, driving of ore drawing gateways and ore drawing admission passages in fill materials of adjacent pillars (or chambers) isn't needed, and accordingly the safety is improved; simultaneously, ores are directly drawn from the undercutting space of the chambers and the pillars, the space of ore drawing is large, mutual interference is small, ore drawing efficiency is high, and ores are drawn completely without any dead space and secondary ore loss; artificial sill pillars are constructed, ore sill plates aren't needed to be reserved, the ores are free of primary loss, and the rate of resource recycling is high. Barren rocks and ore beneficiation tailings are used for filling gobs, the barren rocks are not taken out of pits, constructions of tailing dams and barren rock yards are reduced, and land occupation is small.

Owner:UNIV OF SCI & TECH BEIJING

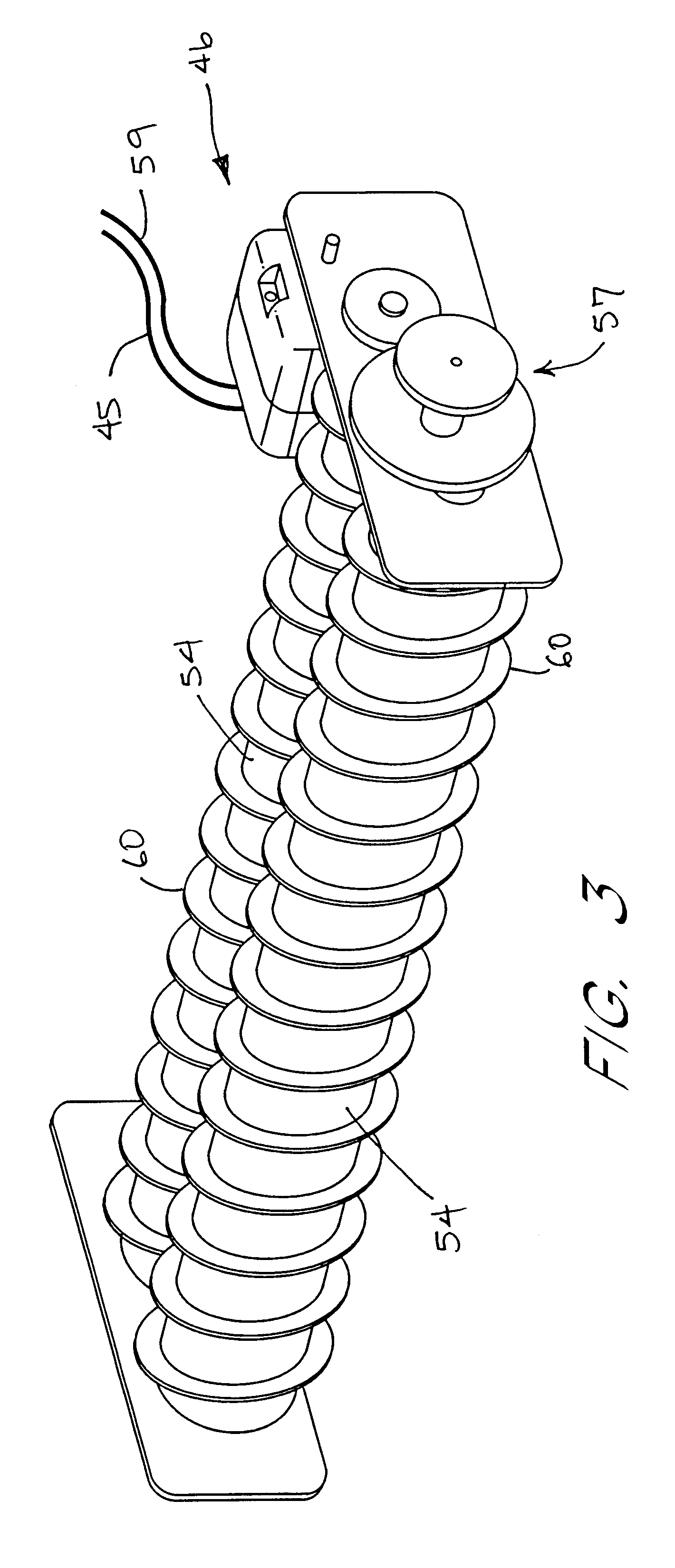

Paper shredding device

An automatic paper shredder is capable of sequentially cutting up to 20 sheets of 20-lb bond paper, up to 9 inches wide. The device has adjustable holders for attachment to conventional wastebaskets of varying shapes. A feed tray holds the stack of paper. Upon selection of either manual (ON) or automatic (AUTO) operation of the machine, a single sheet of paper is fed into the machine by a roller as are subsequent sheets, if any. With the three-way switch set to AUTO, any sheets on the tray are detected by a sensor and are automatically fed into the machine for shredding. A plug-in motor contained in the housing of the machine drives a plurality of shafts for the feed roller and knife rollers. The knife rollers are configured to either shred the paper into about ⅜-inch wide strips or to cross-cut the paper into a plurality of smaller pieces.

Owner:TECHKO

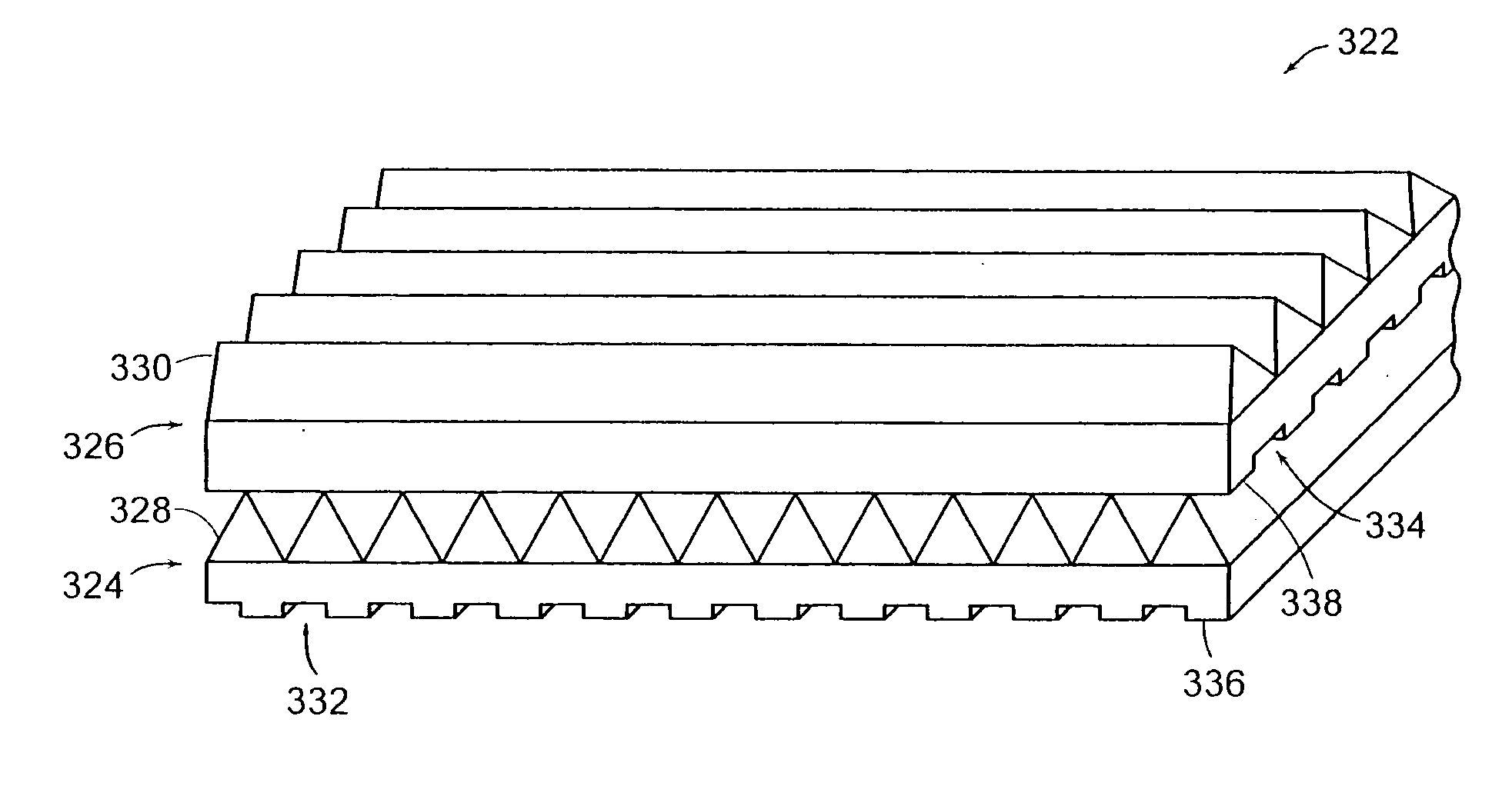

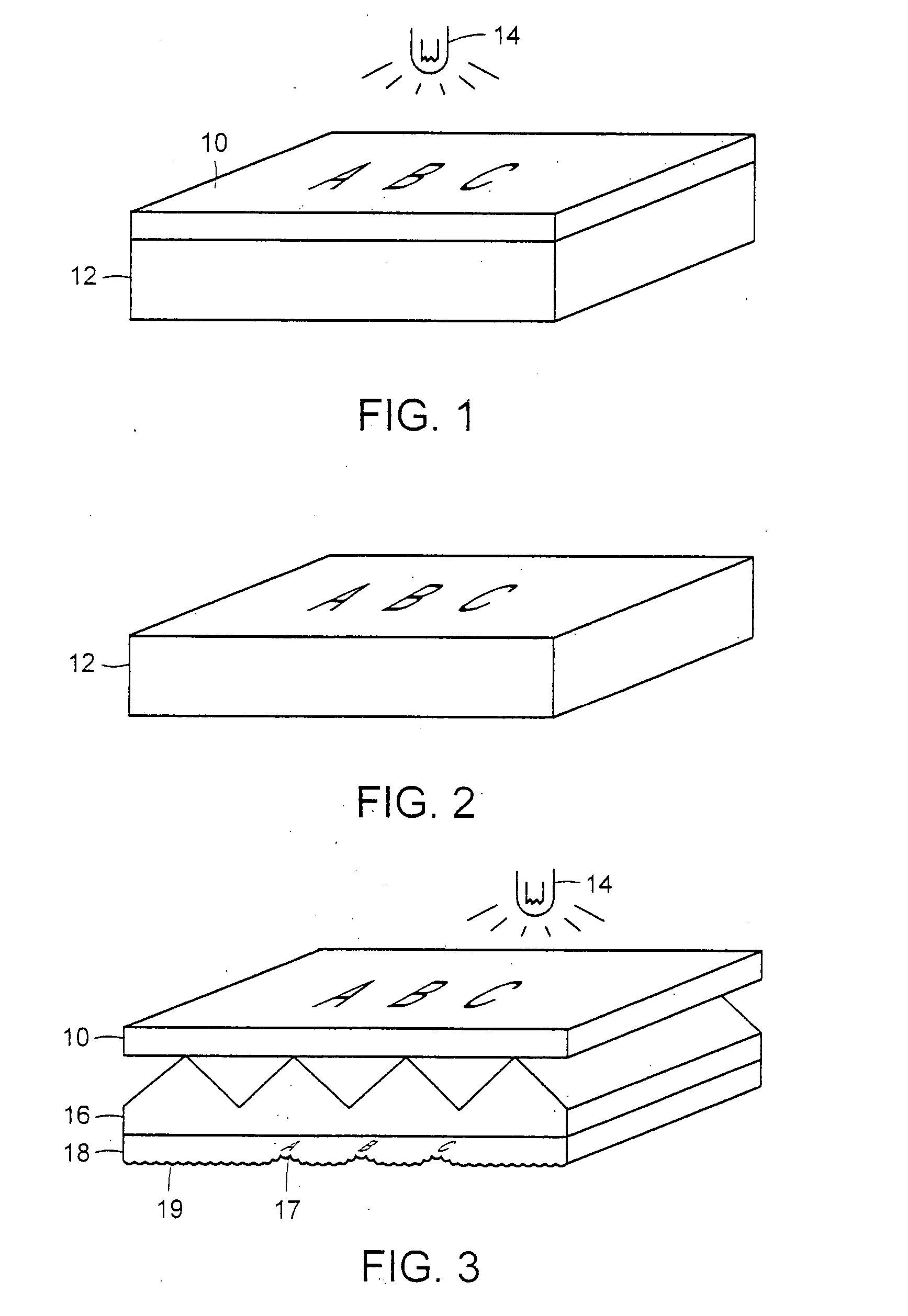

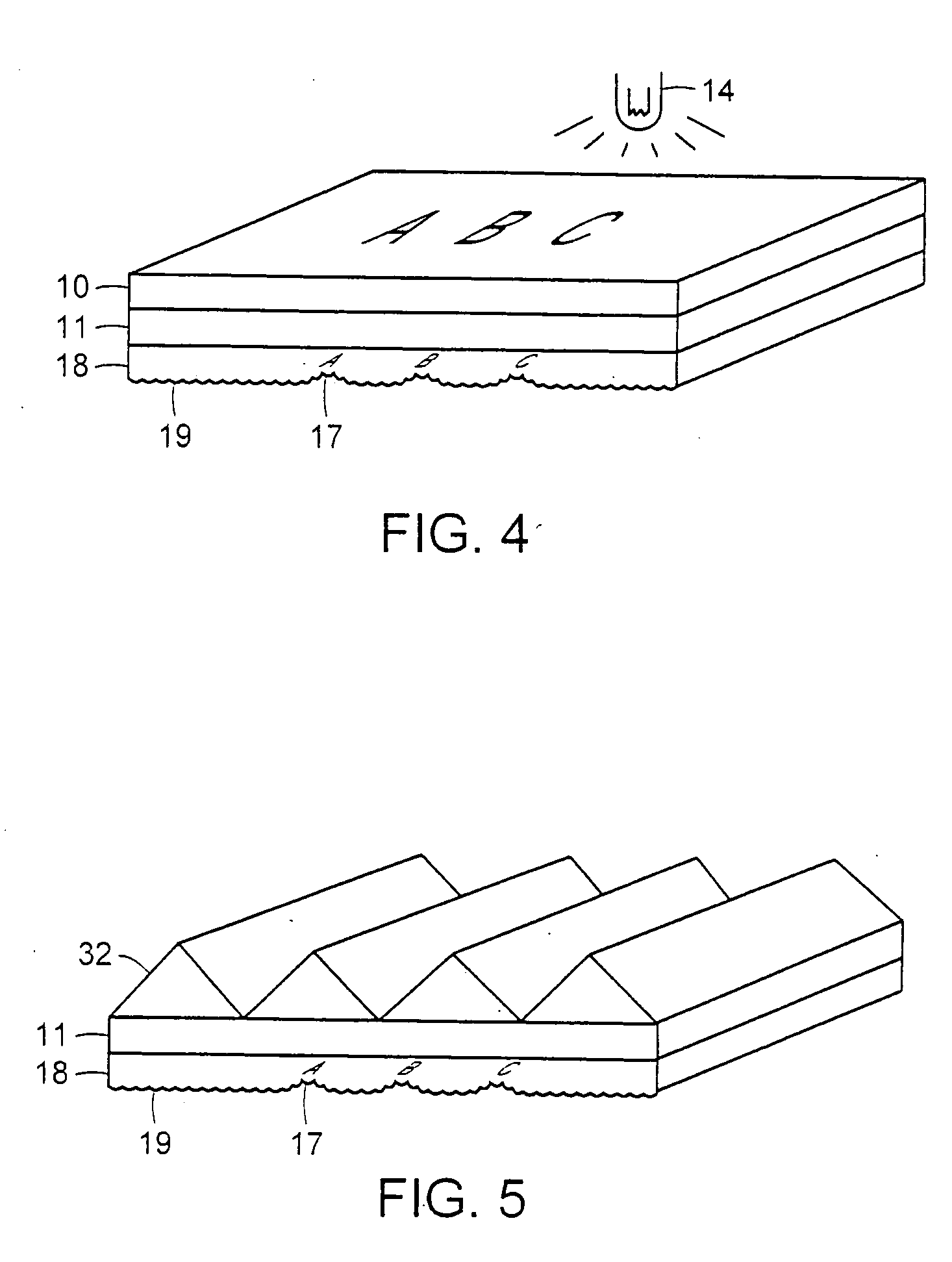

Differentially-cured materials and process for forming same

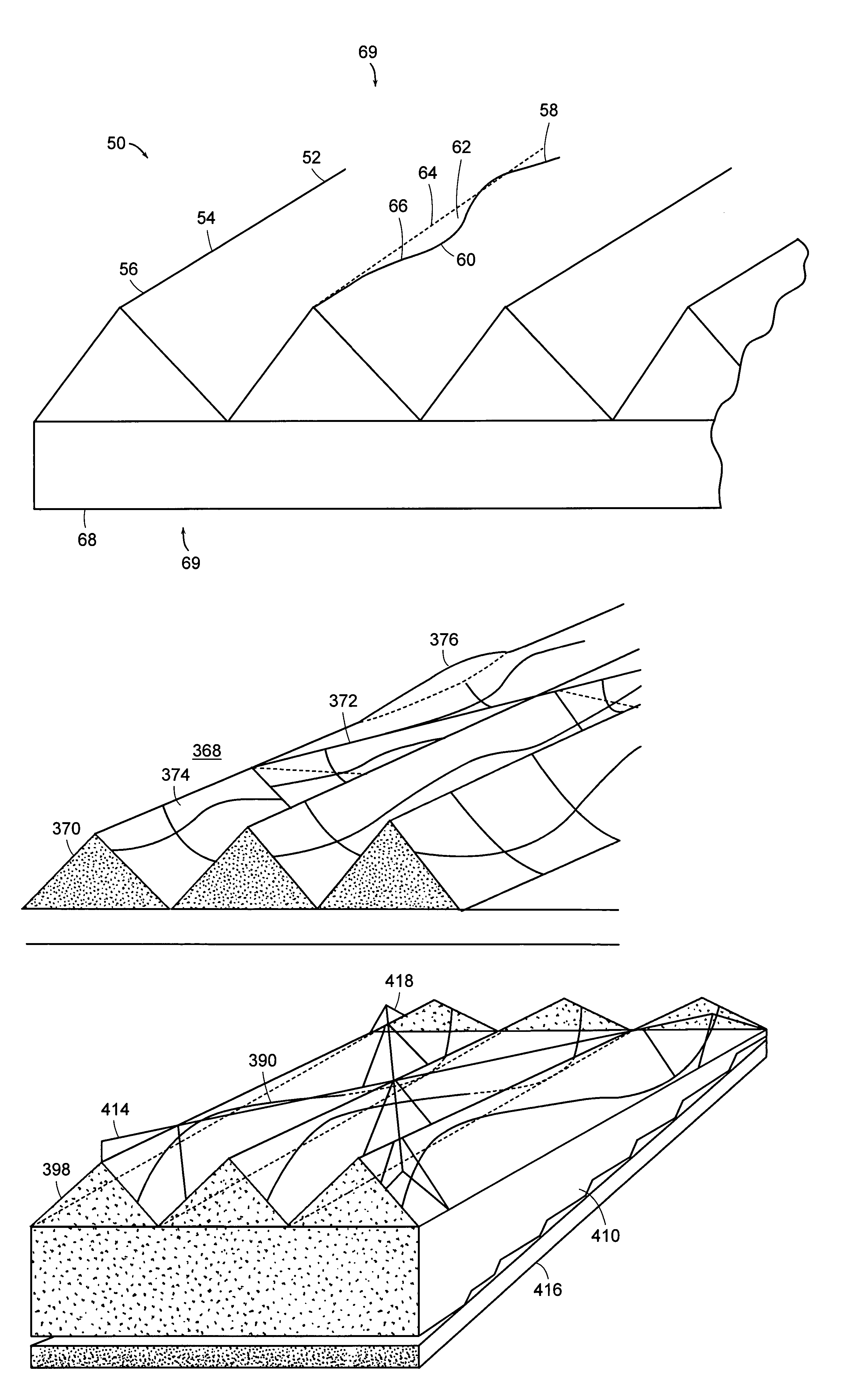

A light-redirecting optical structure includes a first side and a second side, the first side including plurality of linear prisms having a visibly random shaped surface on the prisms and a plurality of cross-cut prisms on first side which are oriented at an angle such that it is greater than zero degrees but less than 180 degrees.A backlight wedge includes a stepped structure on a bottom side that decreases in size traversing the wedge away from a light source which is positioned at an end and having a visibly random shaped surface on said wedge.

Owner:ORAFOL AMERICAS

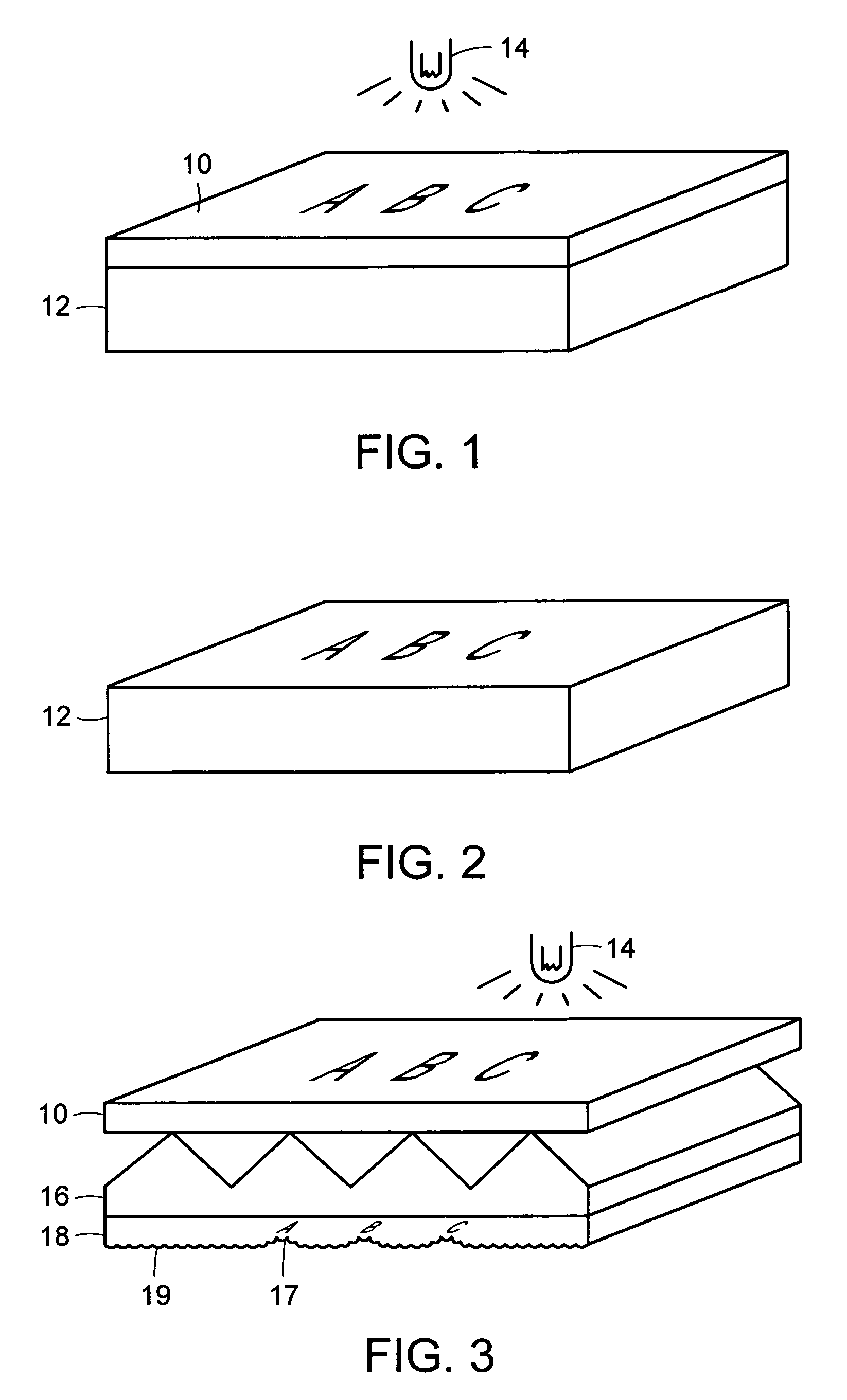

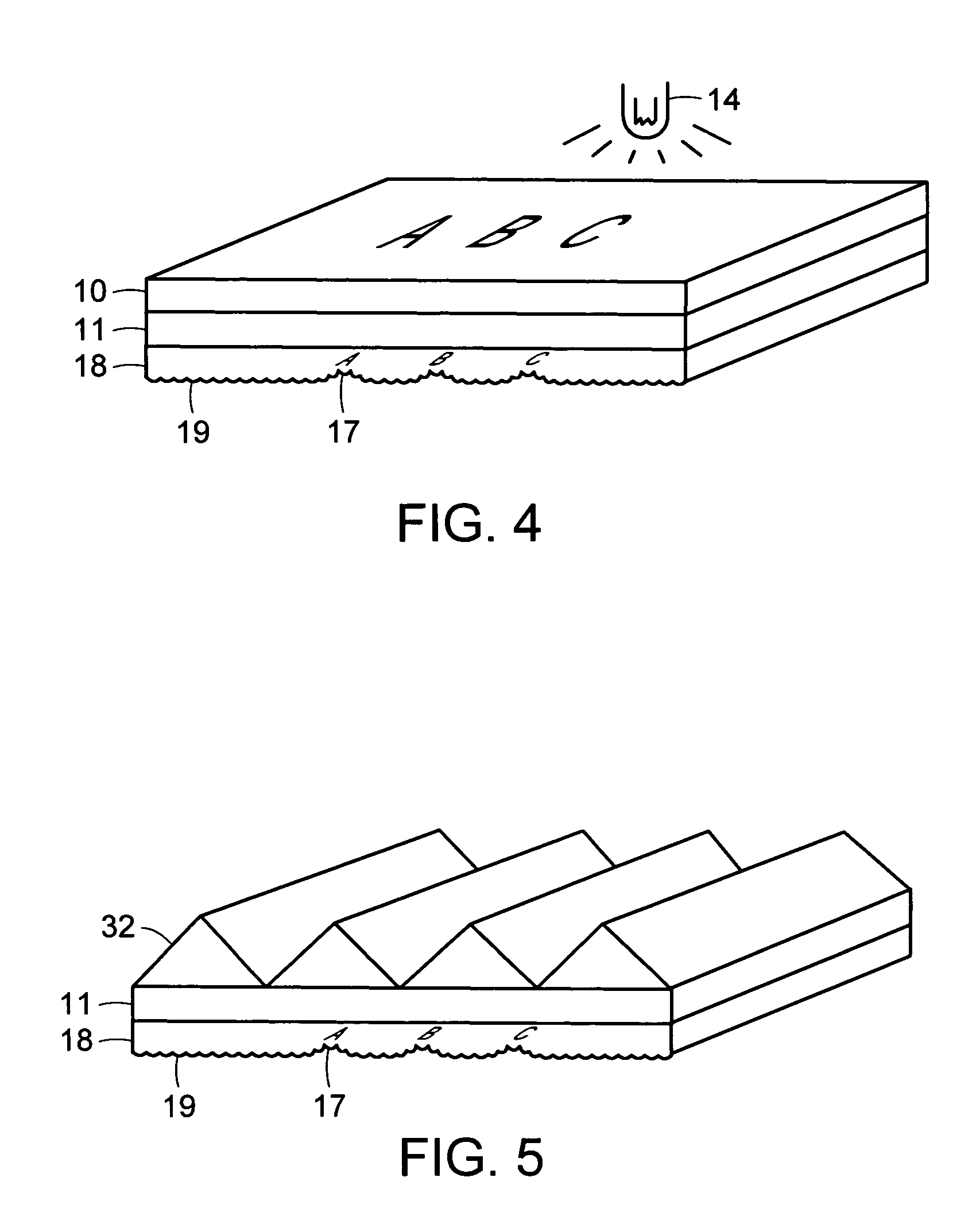

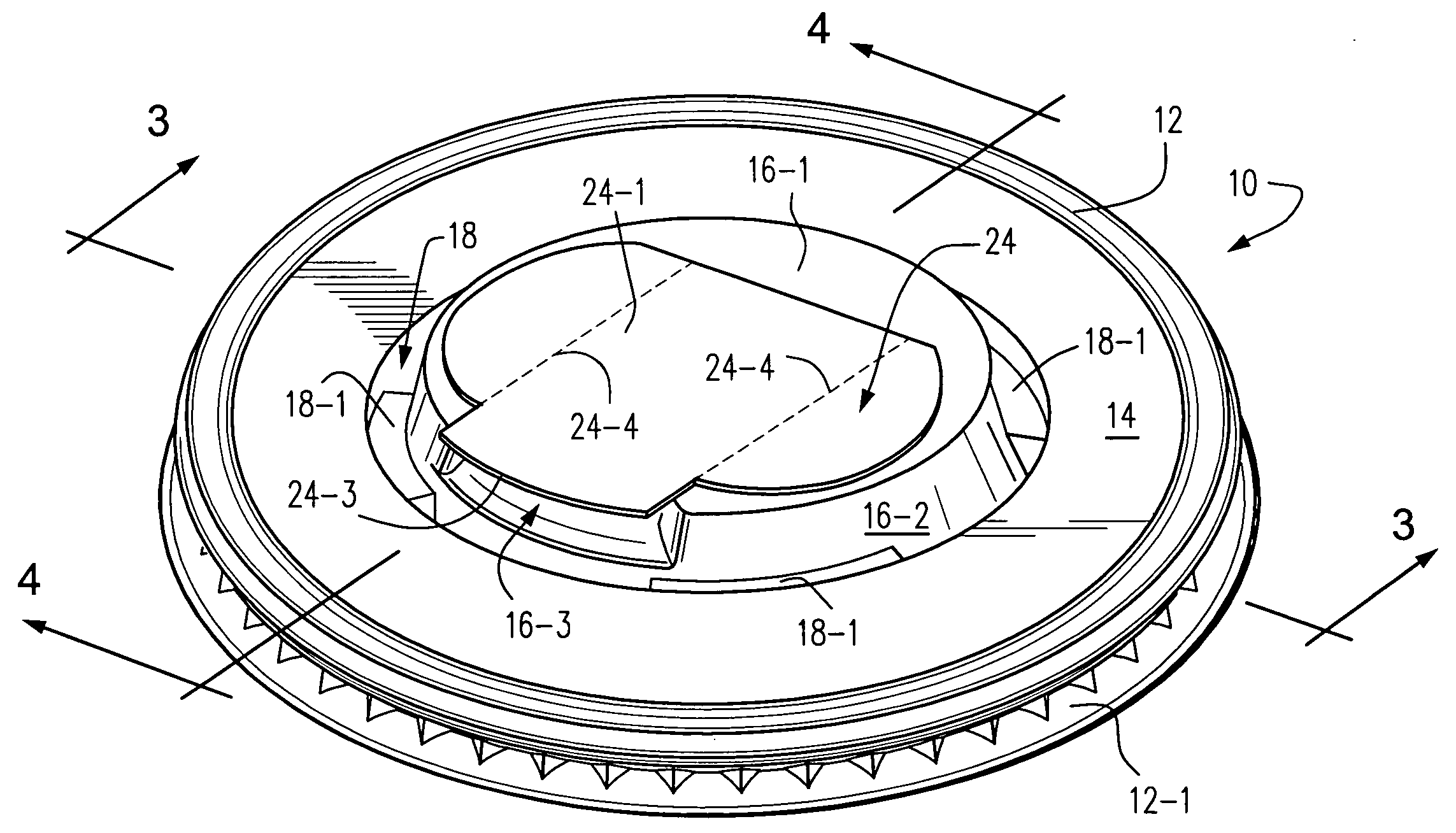

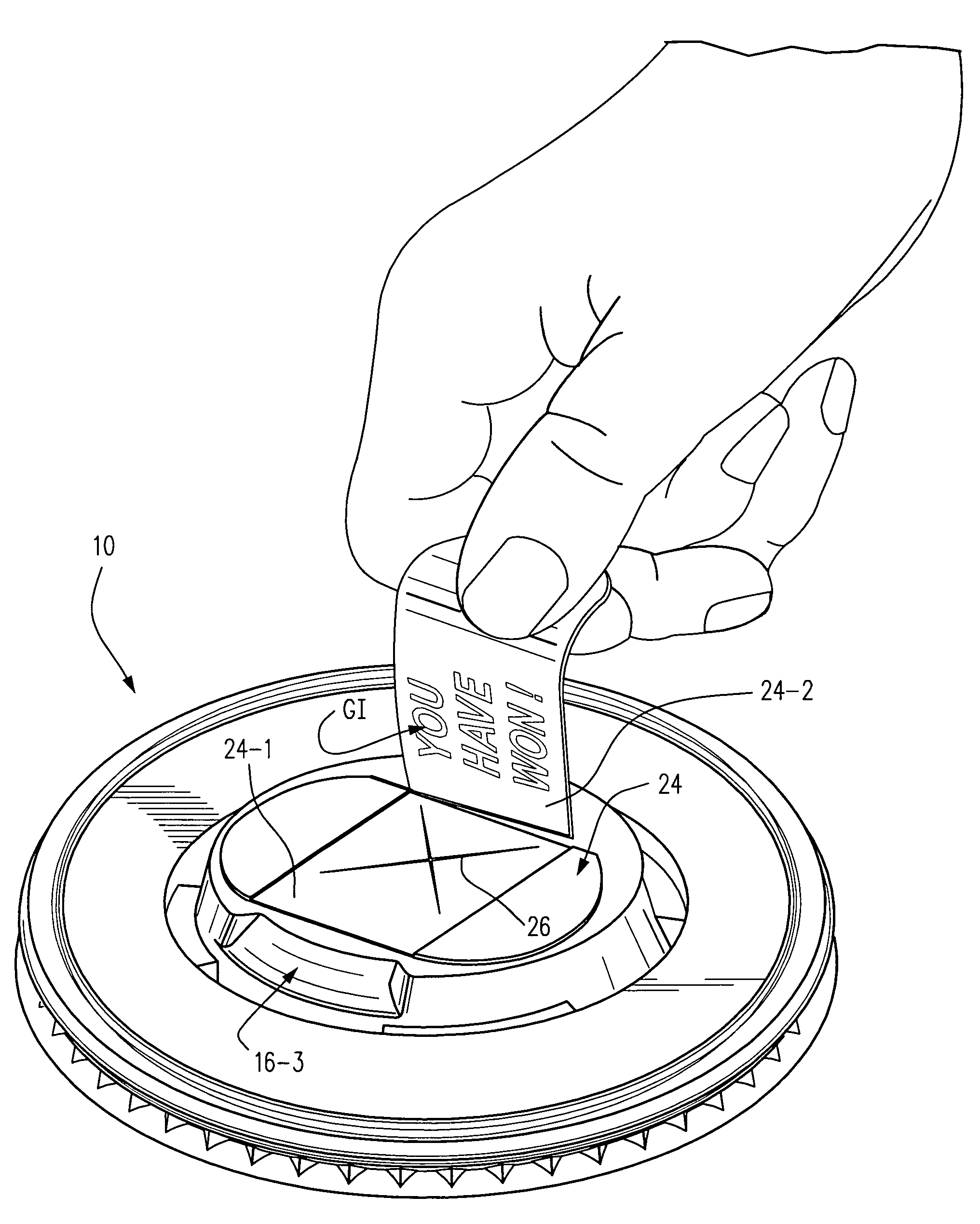

Drinking cup lids with promotional game piece

InactiveUS20050109780A1Great ease of manufactureEasy to graspStampsContainer decorationsCross cutEngineering

Drinking cup lids are especially adapted and configured to afford some measure of protection to the game piece from beverage seepage through a straw opening. Preferably, the cup lid is configured so that a game piece is spaced above the straw opening co-located within a recessed well of the lid thereby allowing beverage seepage to remain physically separated from the game piece. Access to the beverage within the cup is facilitated by providing a cross-cut straw aperture in the game piece which is in substantial alignment to the straw opening formed in the lid. A beveled segment of a raised plateau on which the game piece is affixed allows a tab associated with the game piece to be more easily grasped and removed by a customer to reveal the printed text / indicia of the game piece.

Owner:SOLO CUP OPERATING CORP

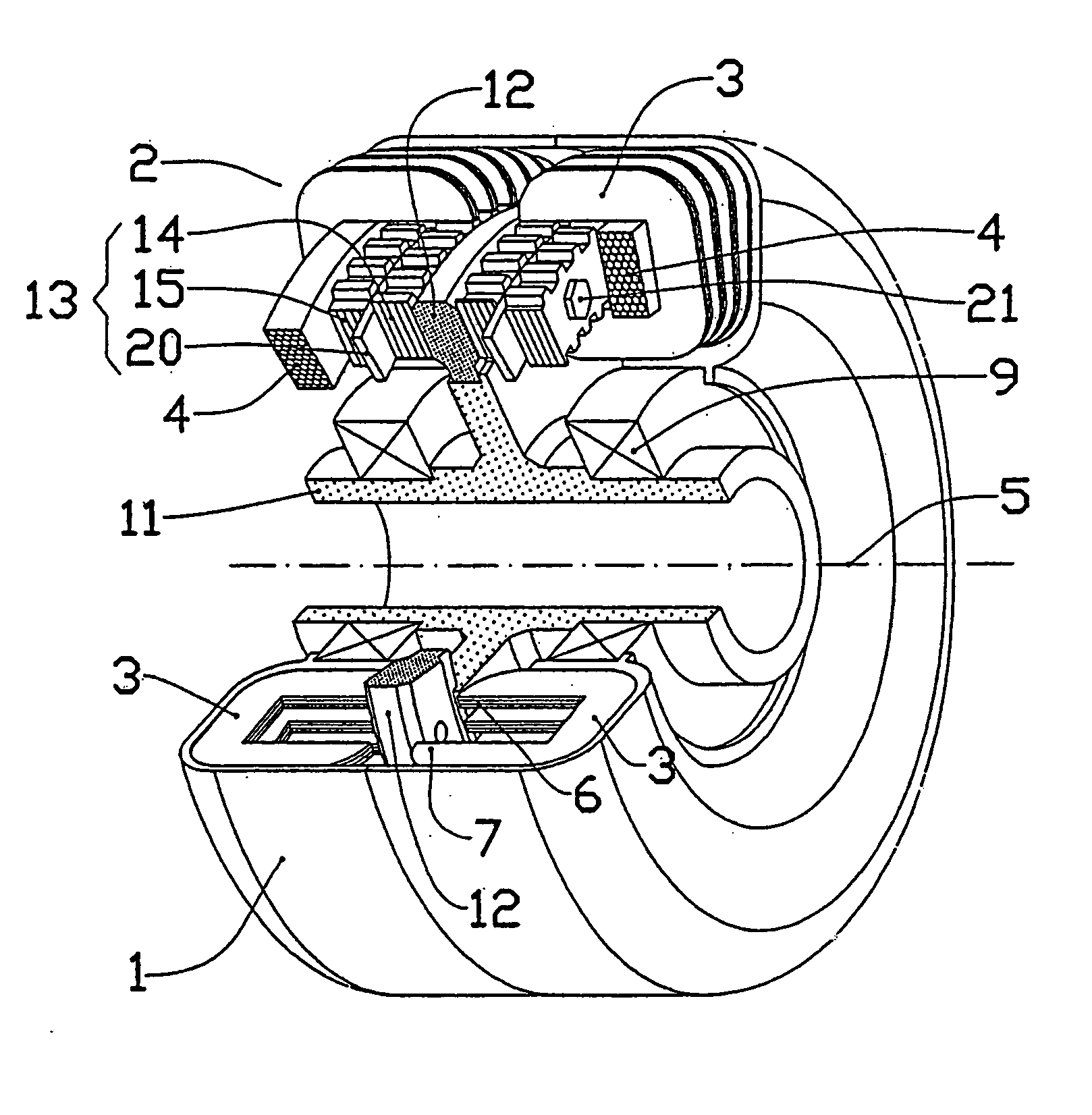

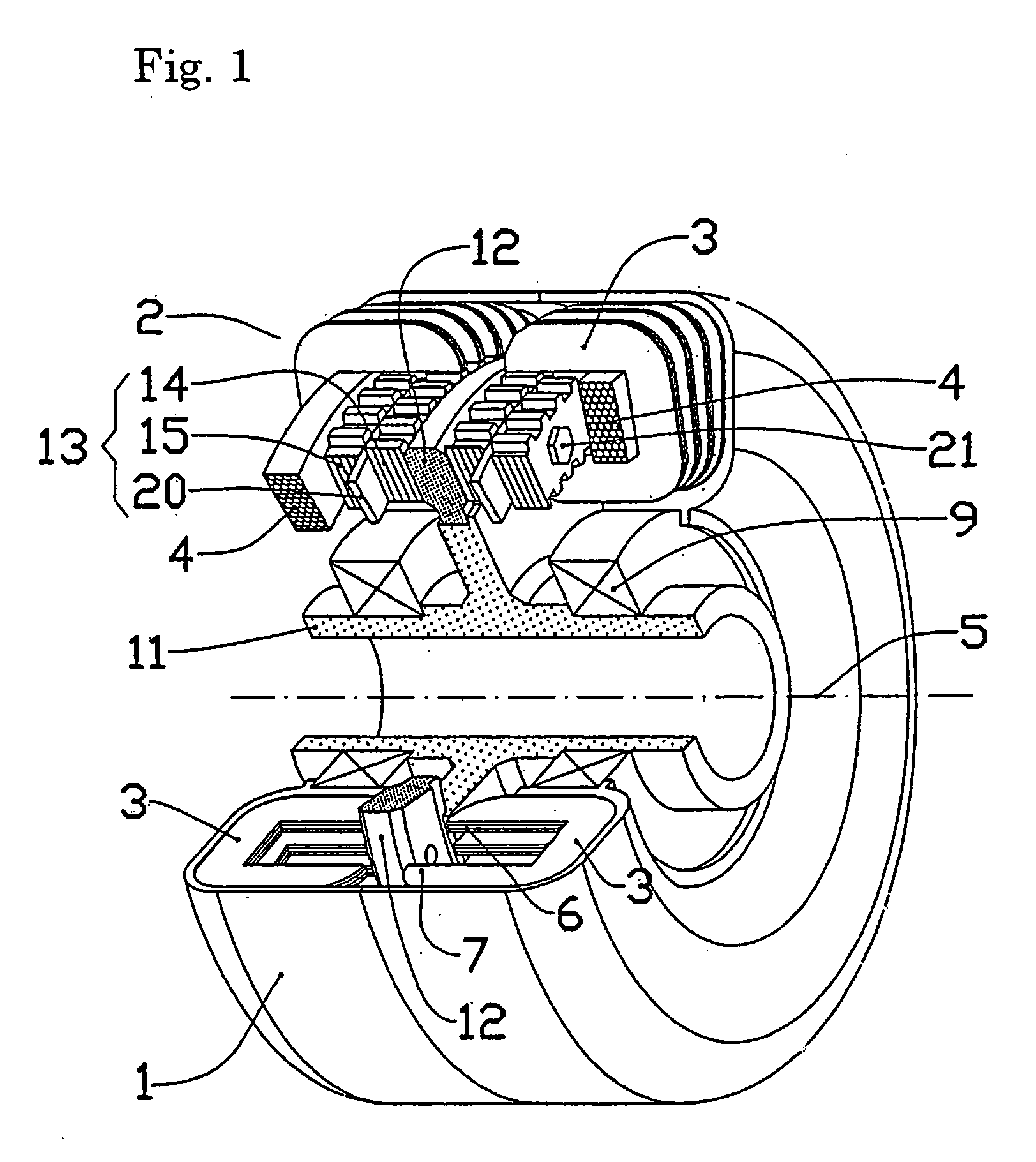

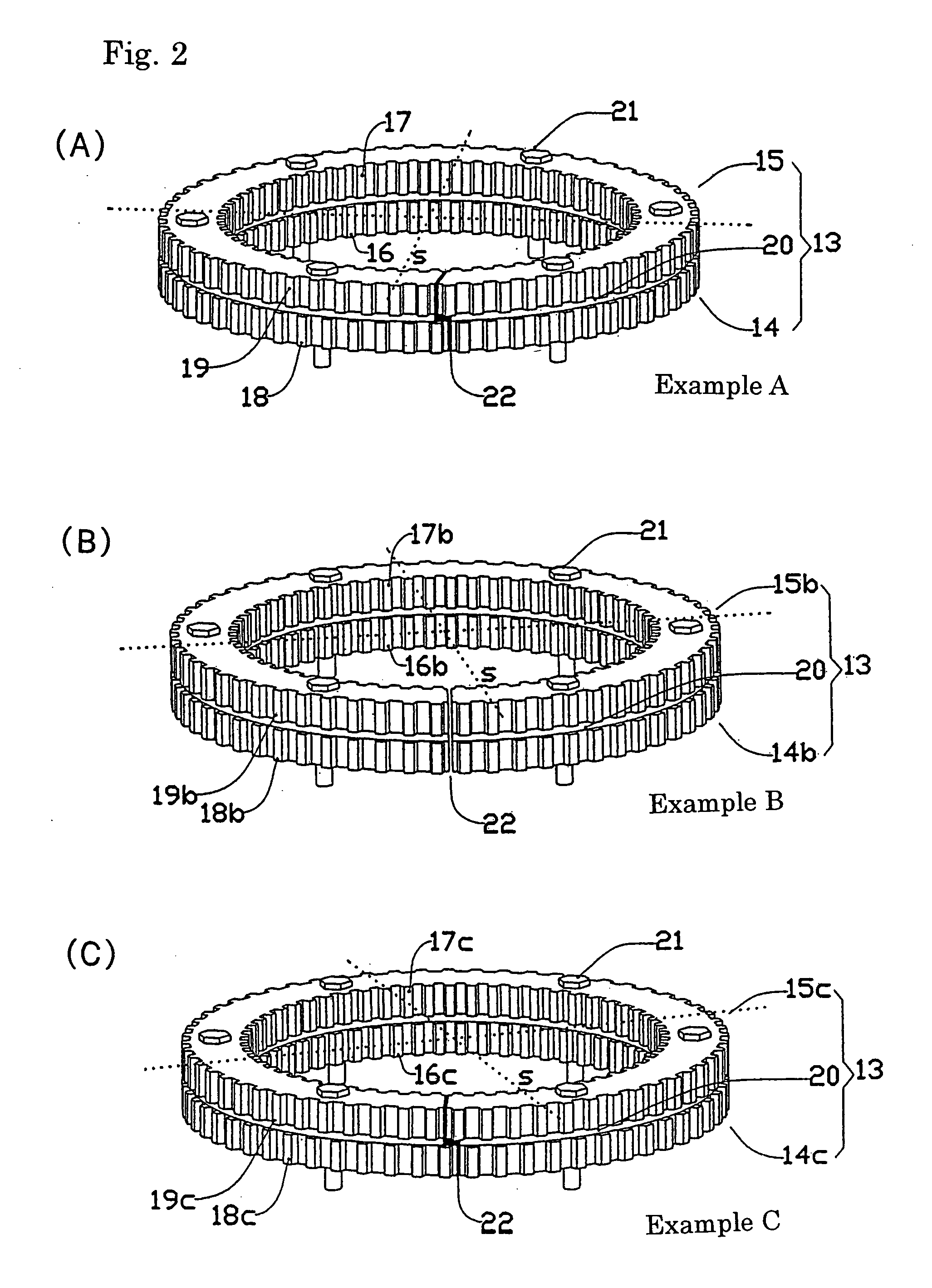

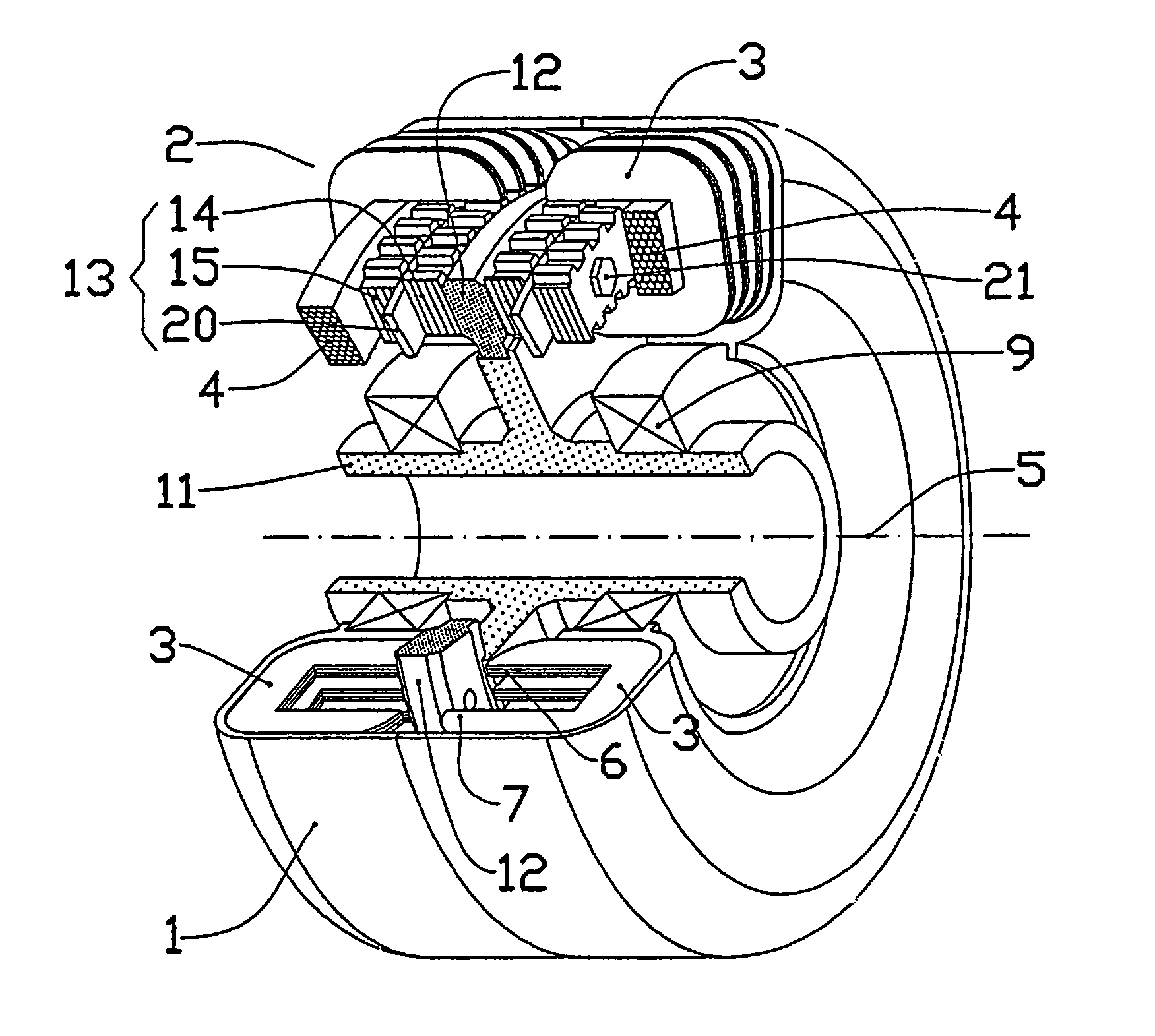

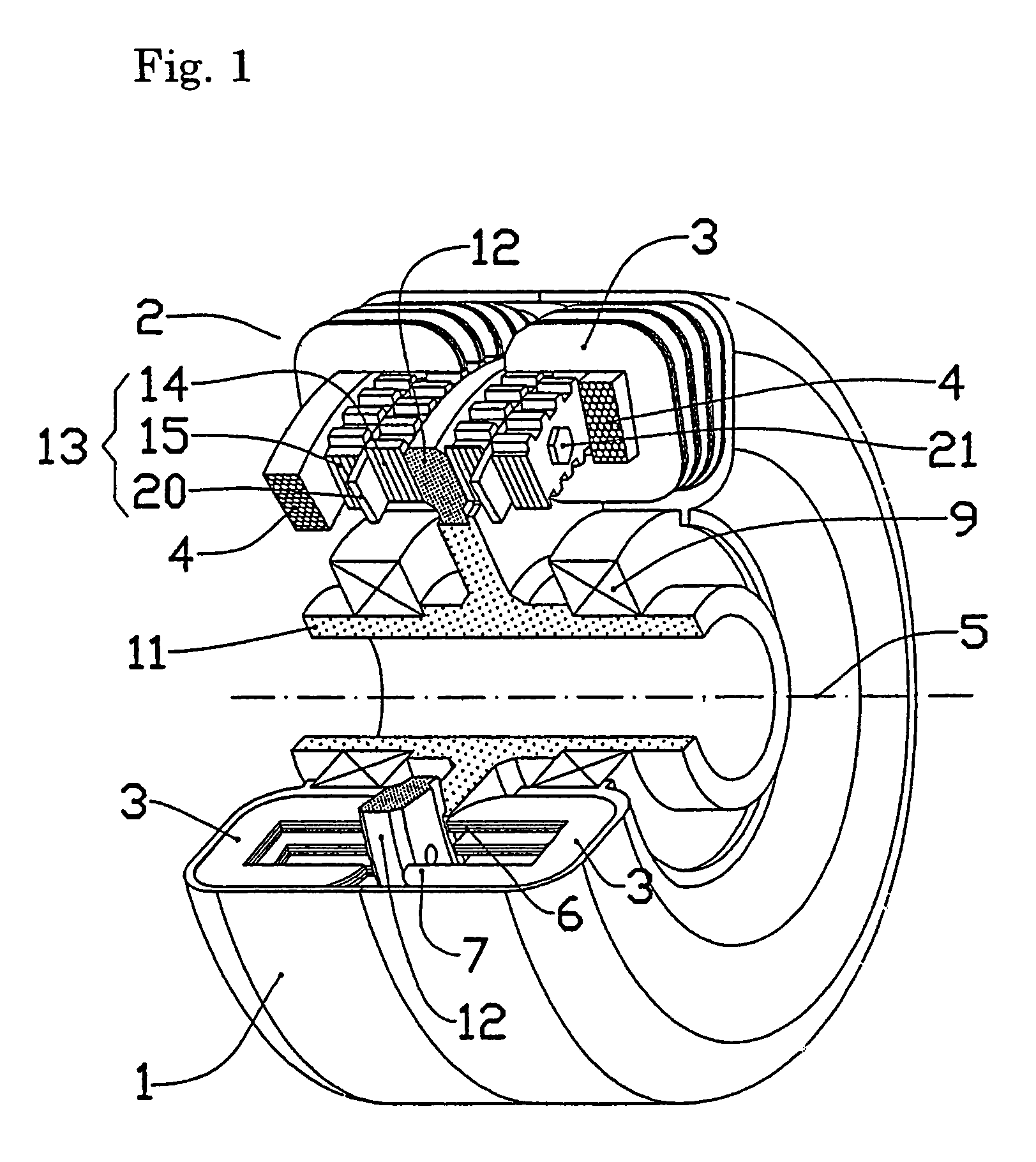

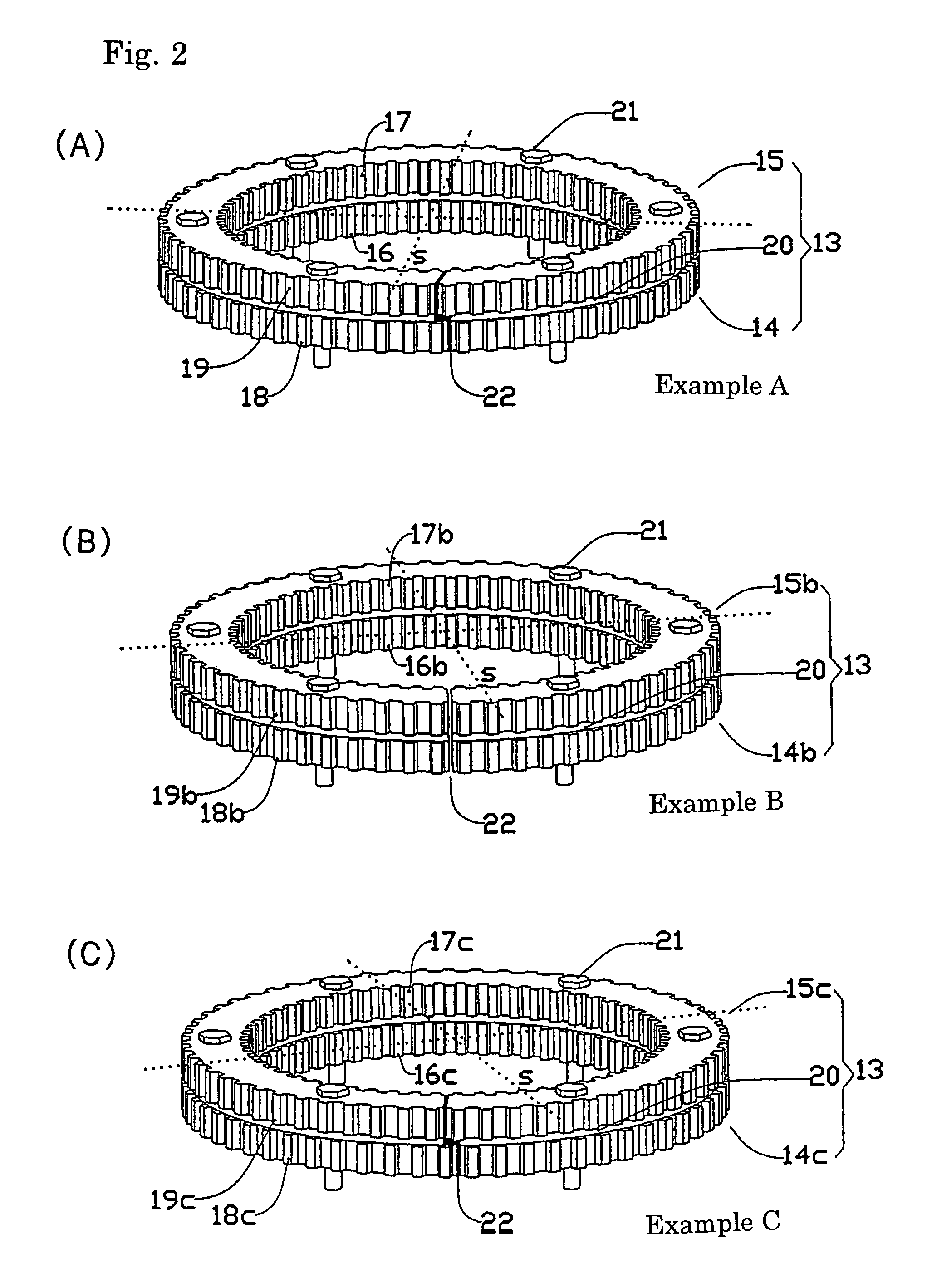

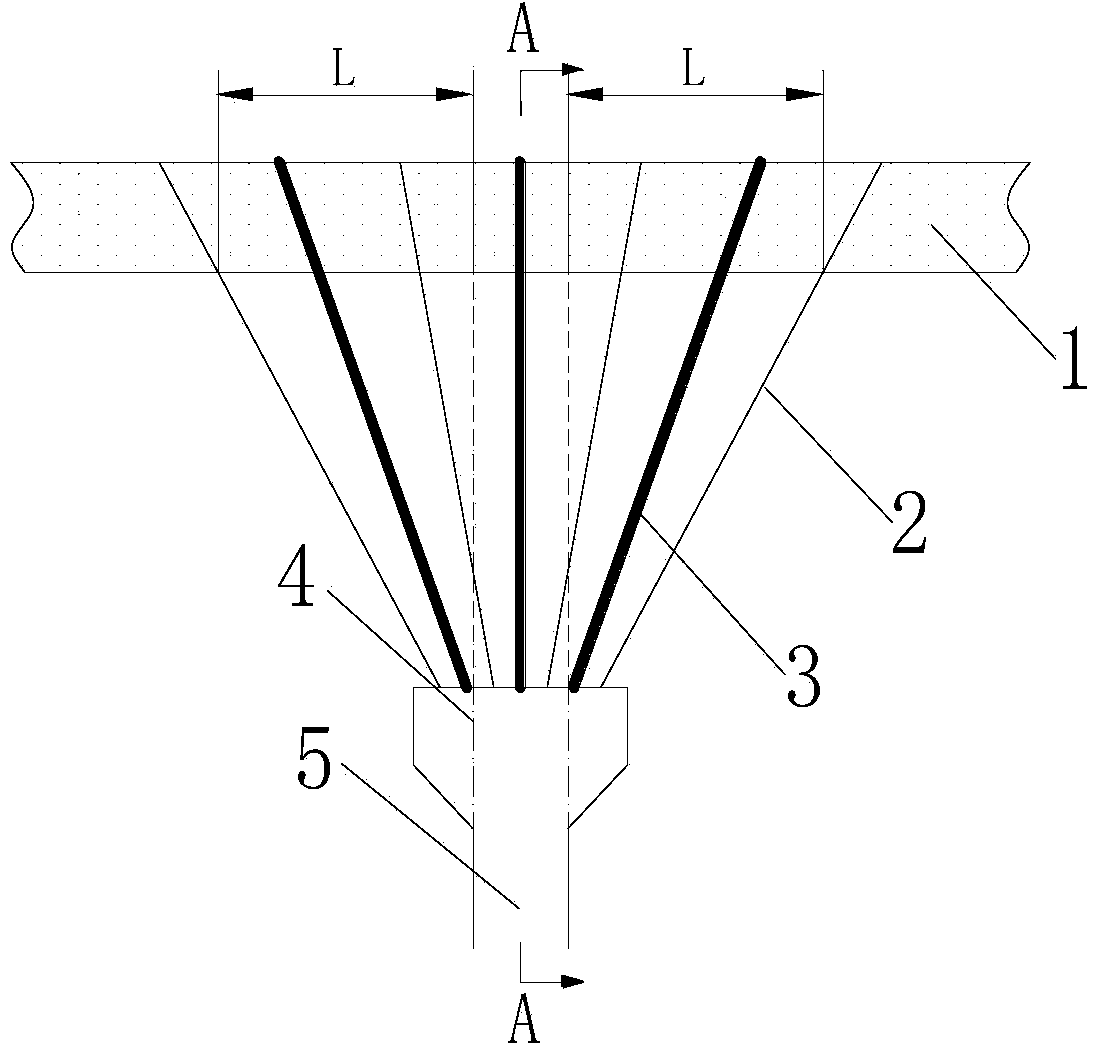

Hybrid synchronous electric machine

InactiveUS20040207281A1Low eddy current lossLower average currentMagnetic circuit rotating partsSynchronous motorsBall bearingHigh energy

A hybrid synchronous electric machine driven by the transverse magnetic flux has a rotor and a stator, the rotor armature has a massive cogged iron rings (12) in close vicinity of active parts of the motor, and cogged iron rings (14, 15) as component parts of the rotor are provided with cross-cut insulating gaps. Eddy current losses are low because eddy currents in cogged iron rings are impeded by cross-cut insulating gaps therein. Eddy currents in all passive parts of the motor (rotor armature (11), stator armature (1), ball bearing (9) and the like) are negligible since the current induced in the copper ring (12) neutralizes all the dissipated magnetic flux outside the active area of the motor. A hybrid synchronous electric machine which has low eddy current losses and high energy efficiency can be realized.

Owner:HARMONIC DRIVE SYST IND CO LTD

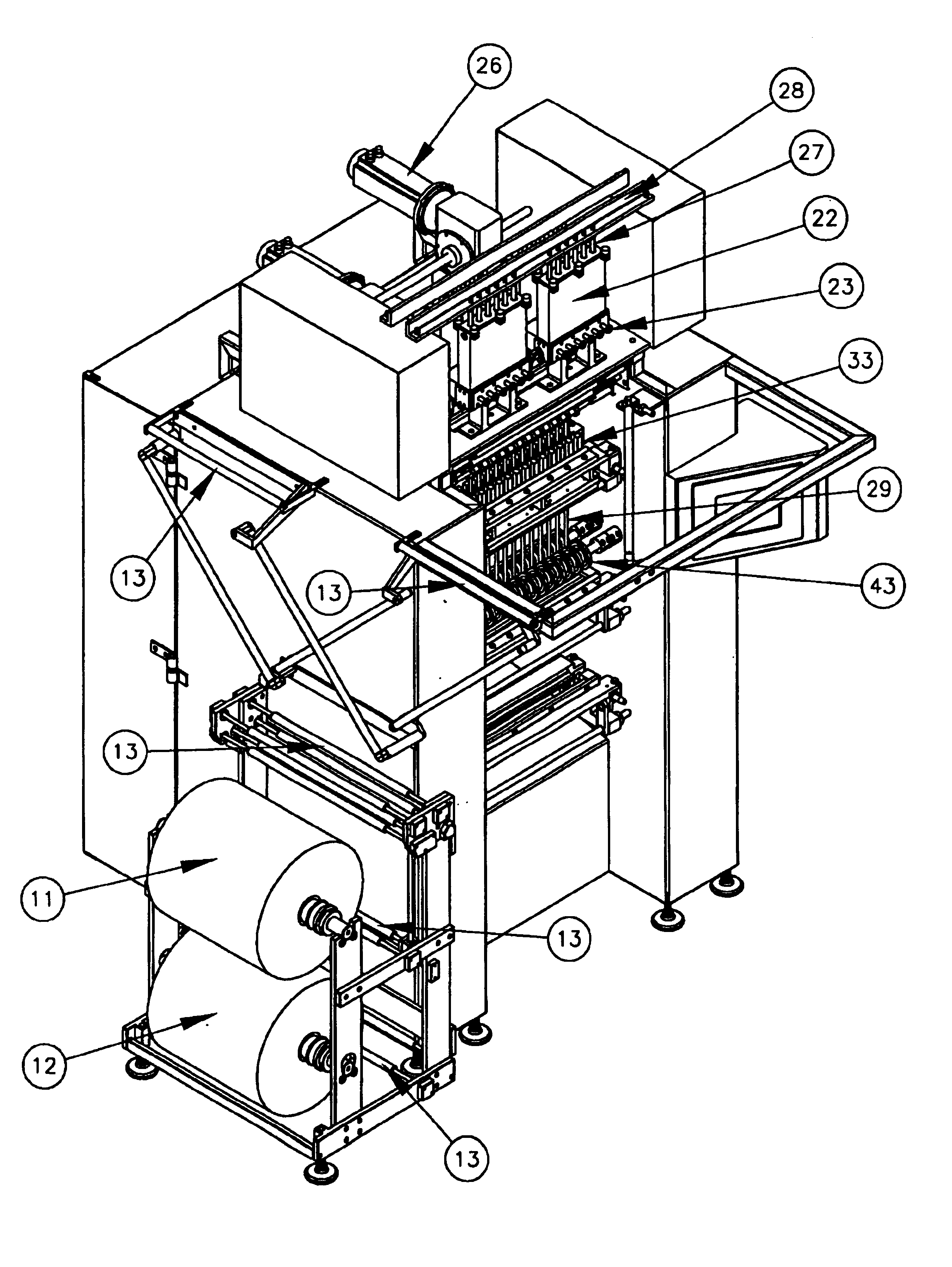

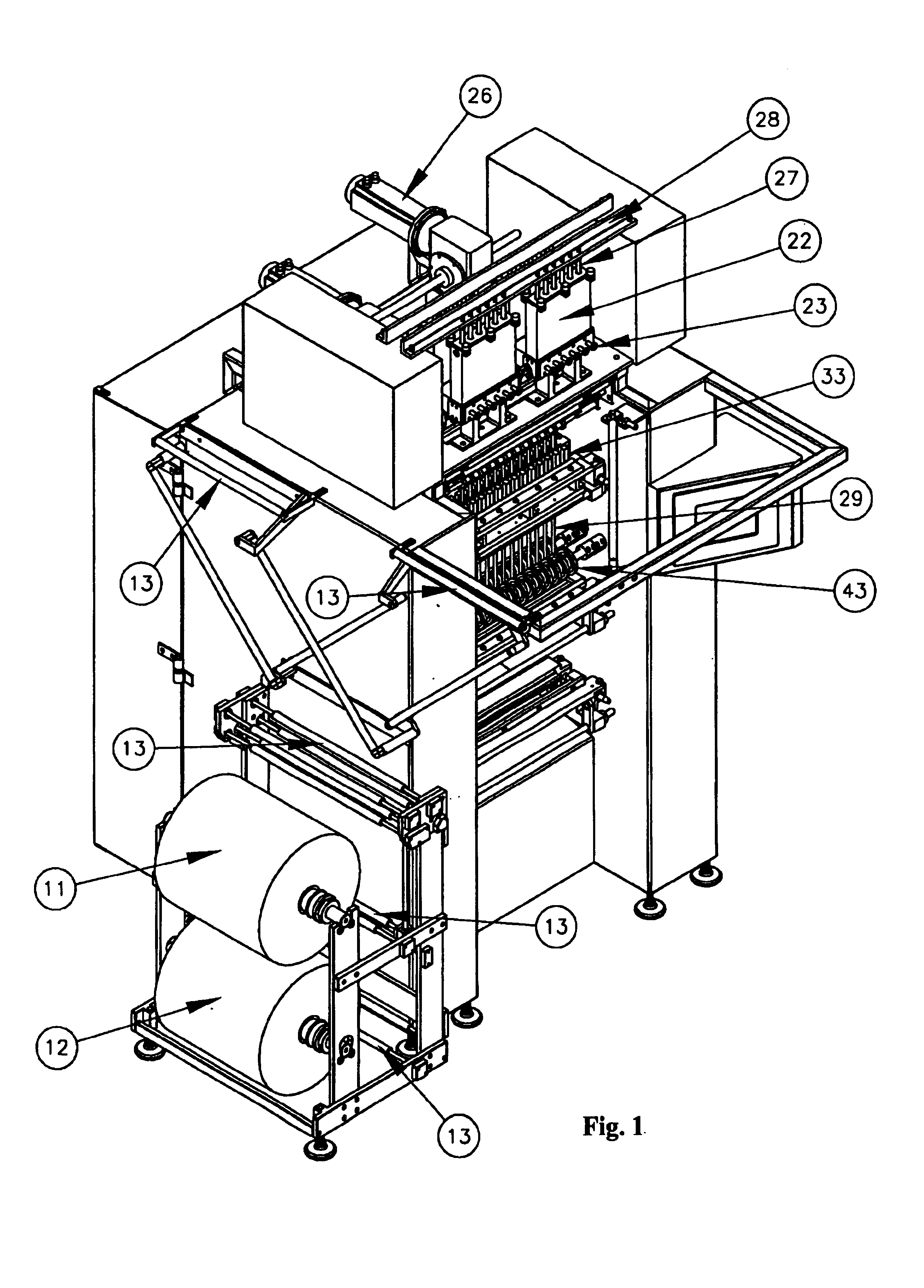

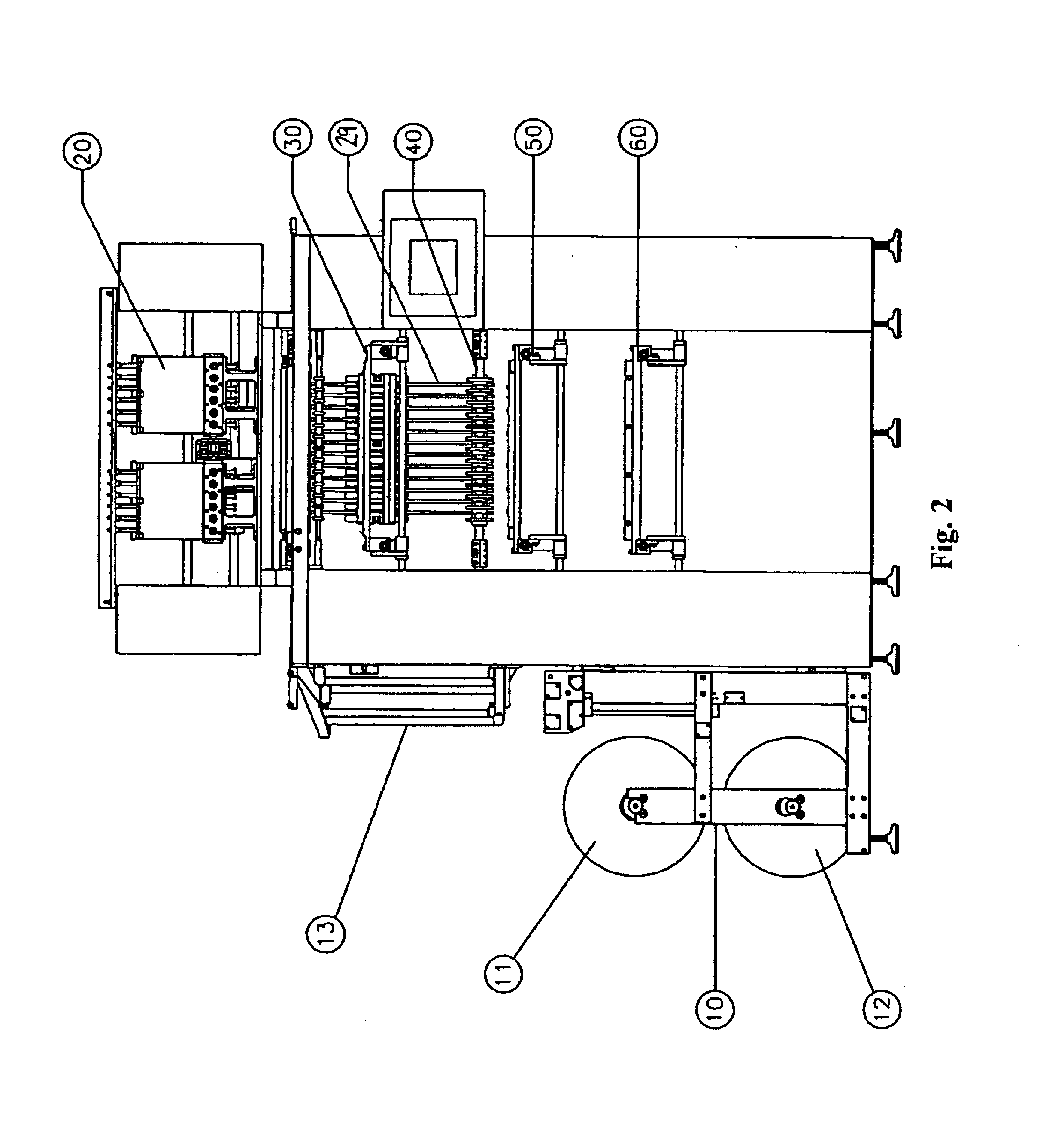

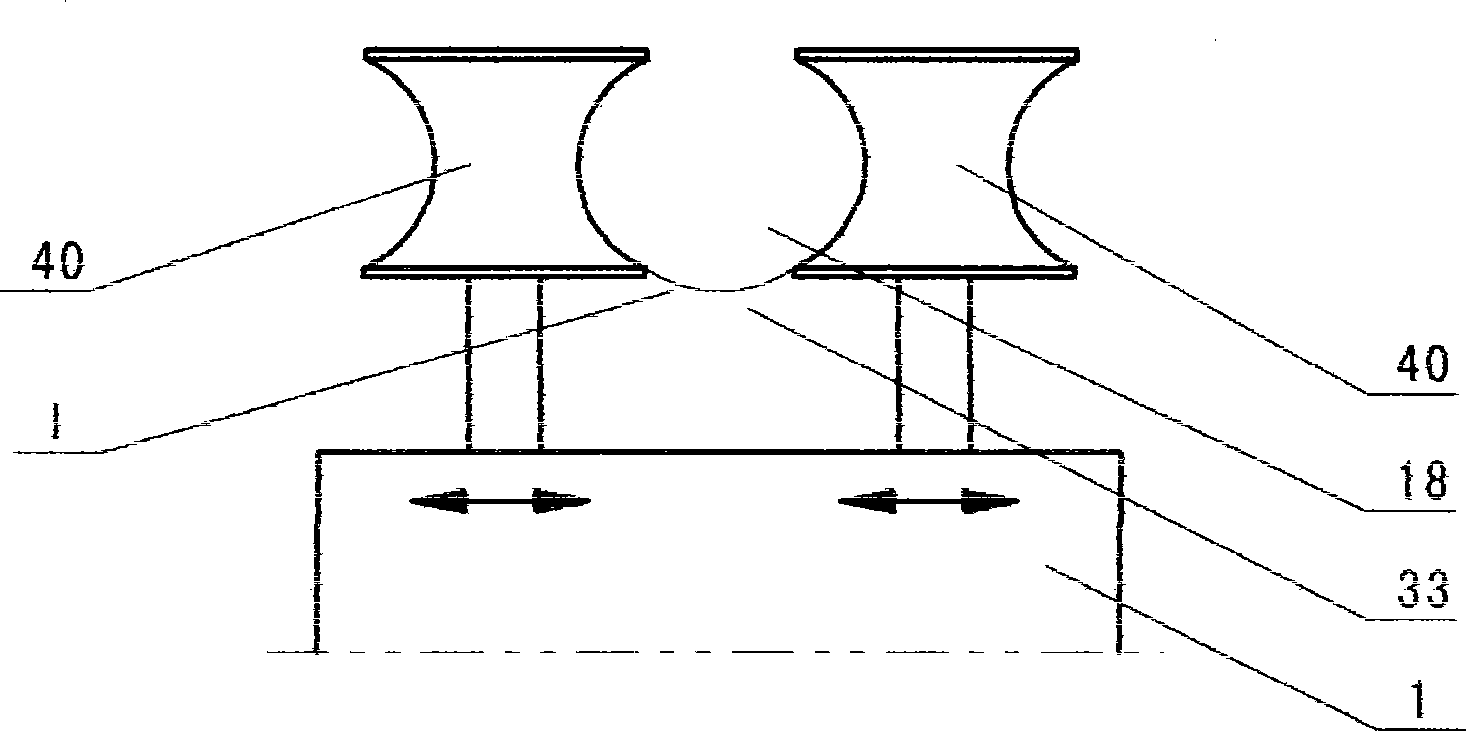

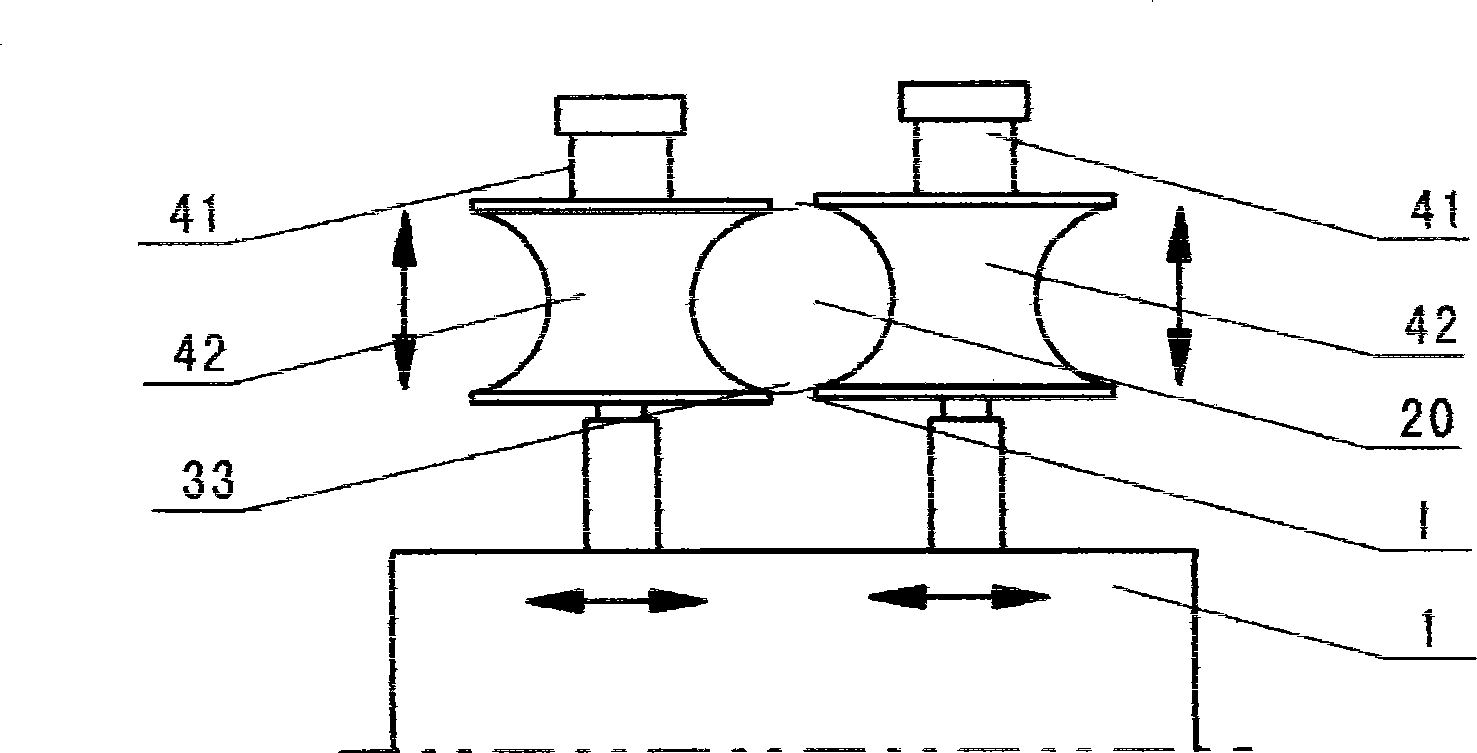

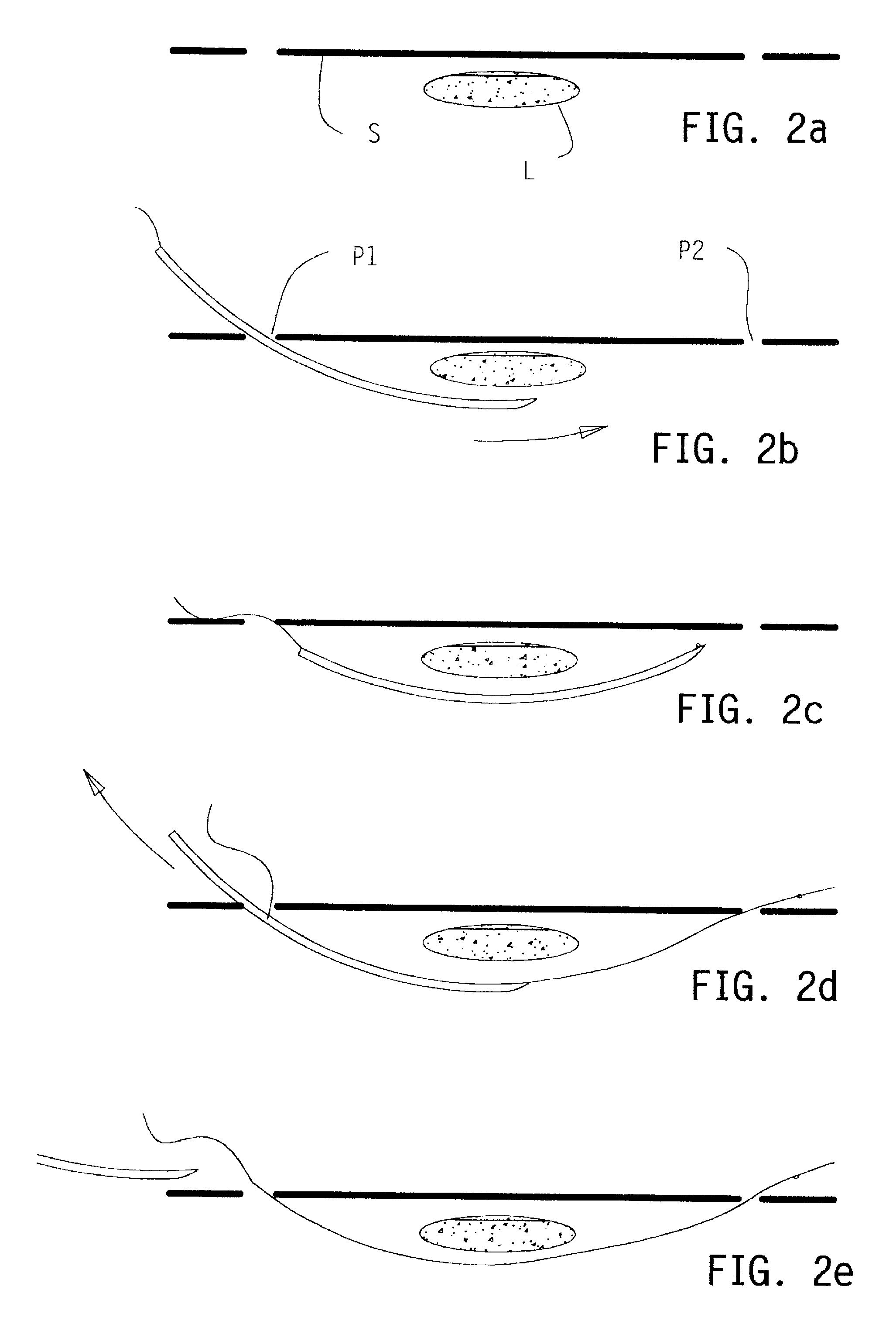

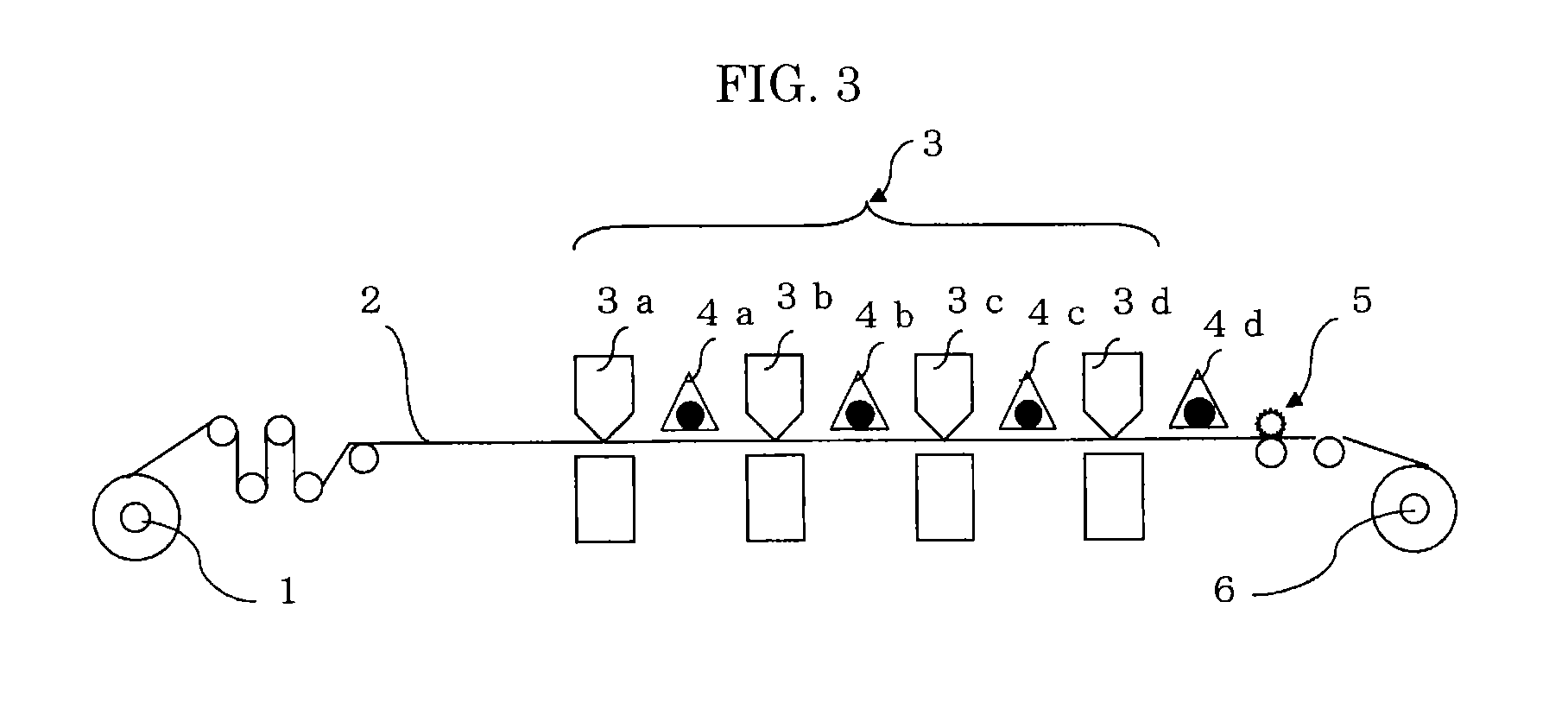

High-speed continuous action form-fill-seal machine and methods

This is a high-speed, multi-lane machine and method for the continuous forming, filling and sealing of plastic or film pouches of various sizes commonly used to hold fluids, liquids, and viscous materials or other substances. The machine includes a film roll station, a pump station, a side seal station, a pull wheel station, a cross seal station, and a cross cut station. The invention provides for continuous production of pluralities of pouches without stops or delays by utilizing one or more moveable reciprocating carriages that travel with the flow of film through the machine, the carriages supporting each of the side sealing, cross sealing, and cross cutting stations. Coordination of the various stations is accomplished through electronic computer control, working in conjunction with a plurality of motion imparting devices such as servo motors, cam systems, linkages and the like. The various components of the machine are adjustable so that pouches of various lengths and / or widths may be formed using the same machine.

Owner:SWF CO INC +1

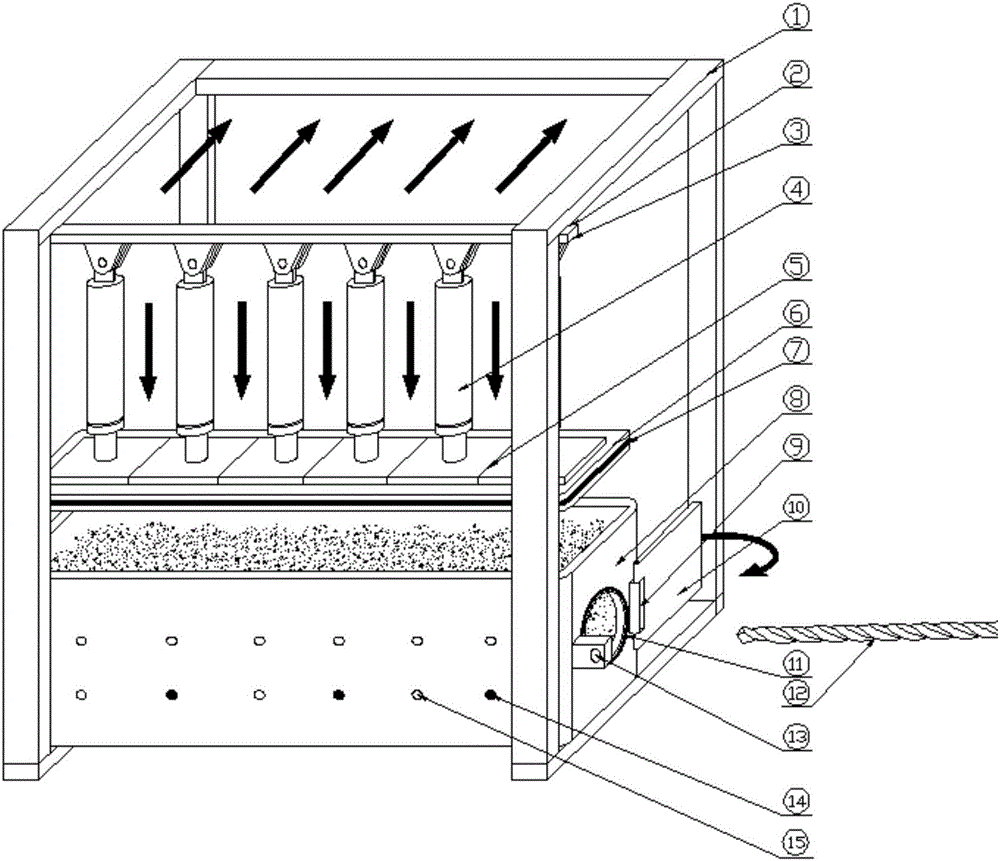

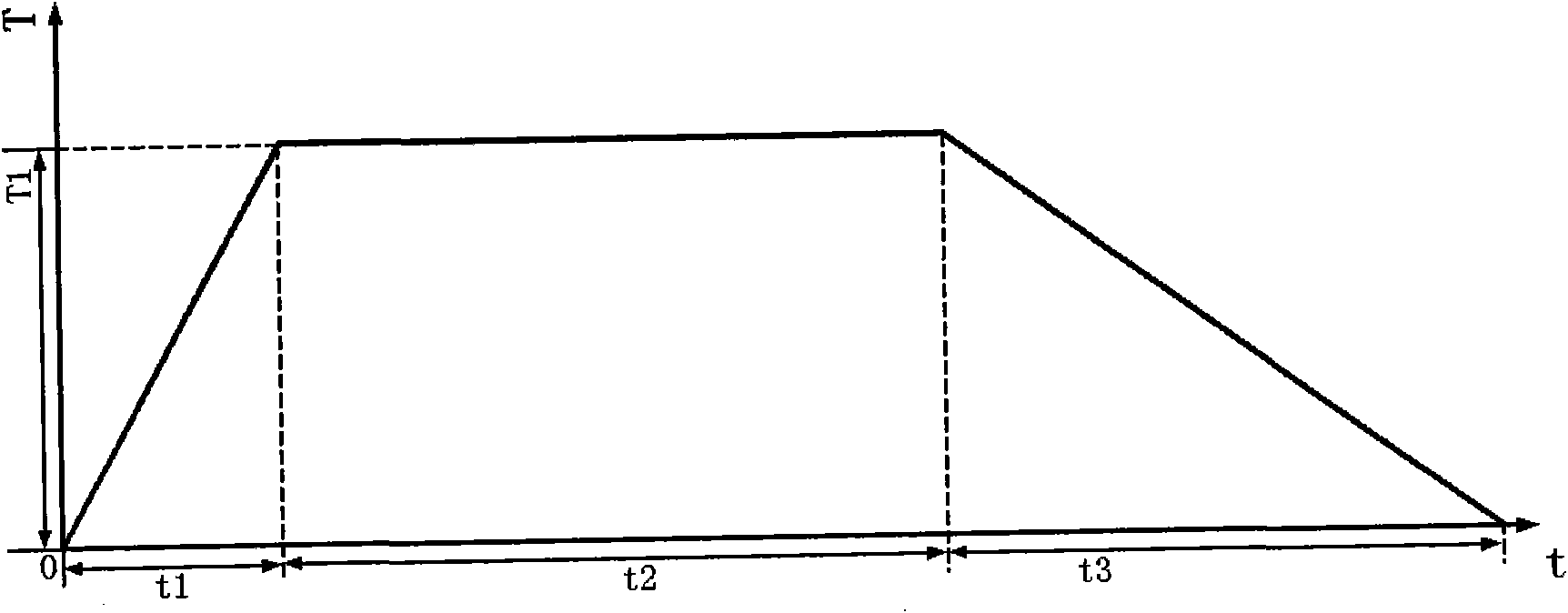

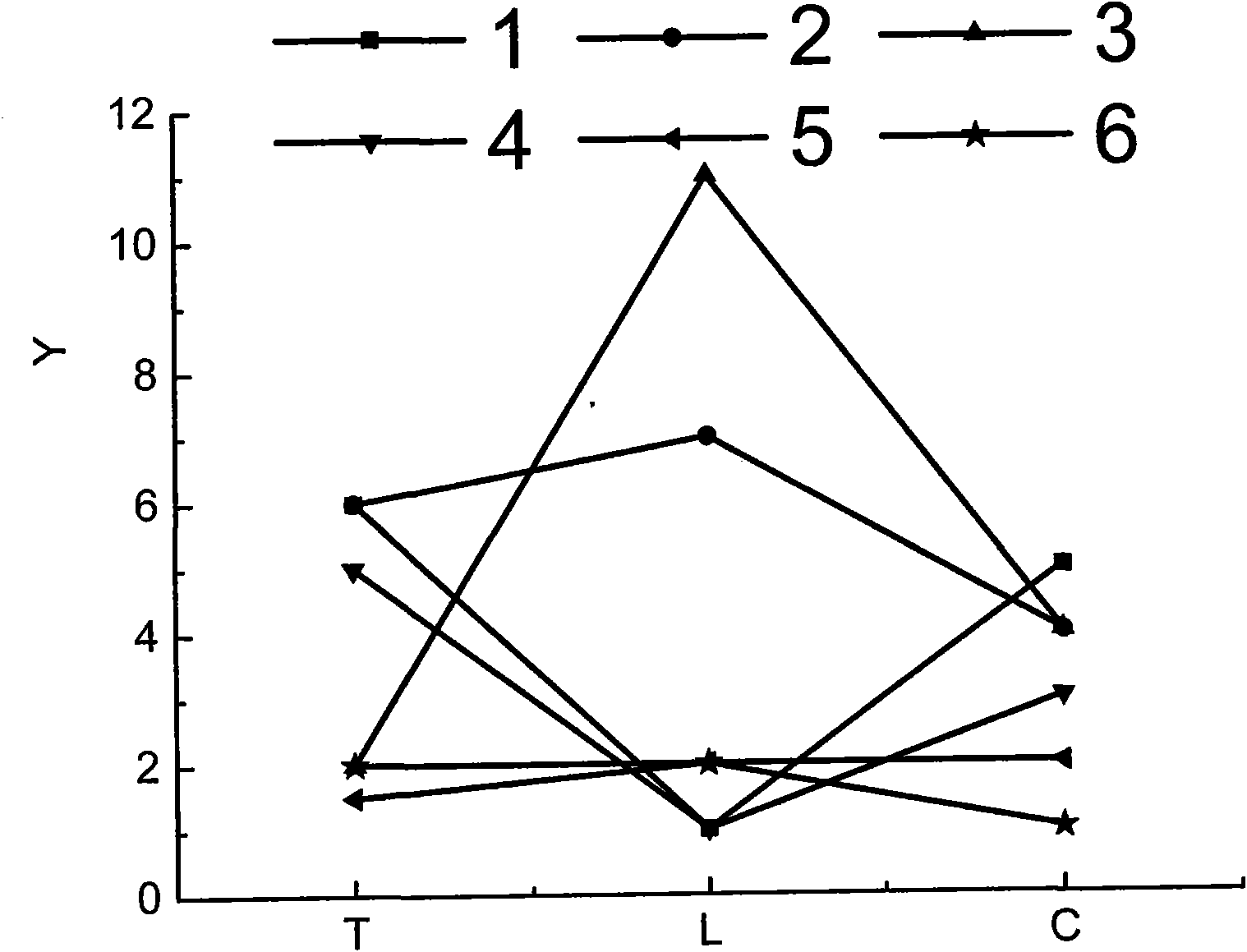

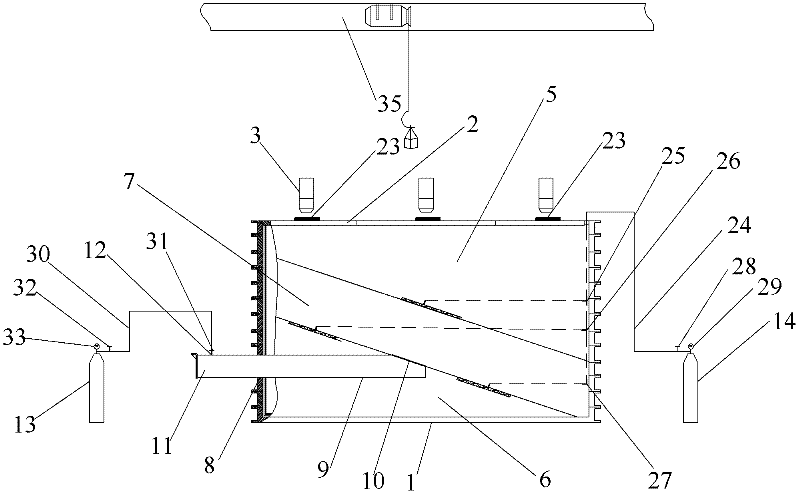

Verisimilitude briquette coal and gas outburst simulation test device and method

ActiveCN106483267ASimulate the realRealize the whole spaceFuel testingEnergy transferGeneration process

Owner:CHINA UNIV OF MINING & TECH +1

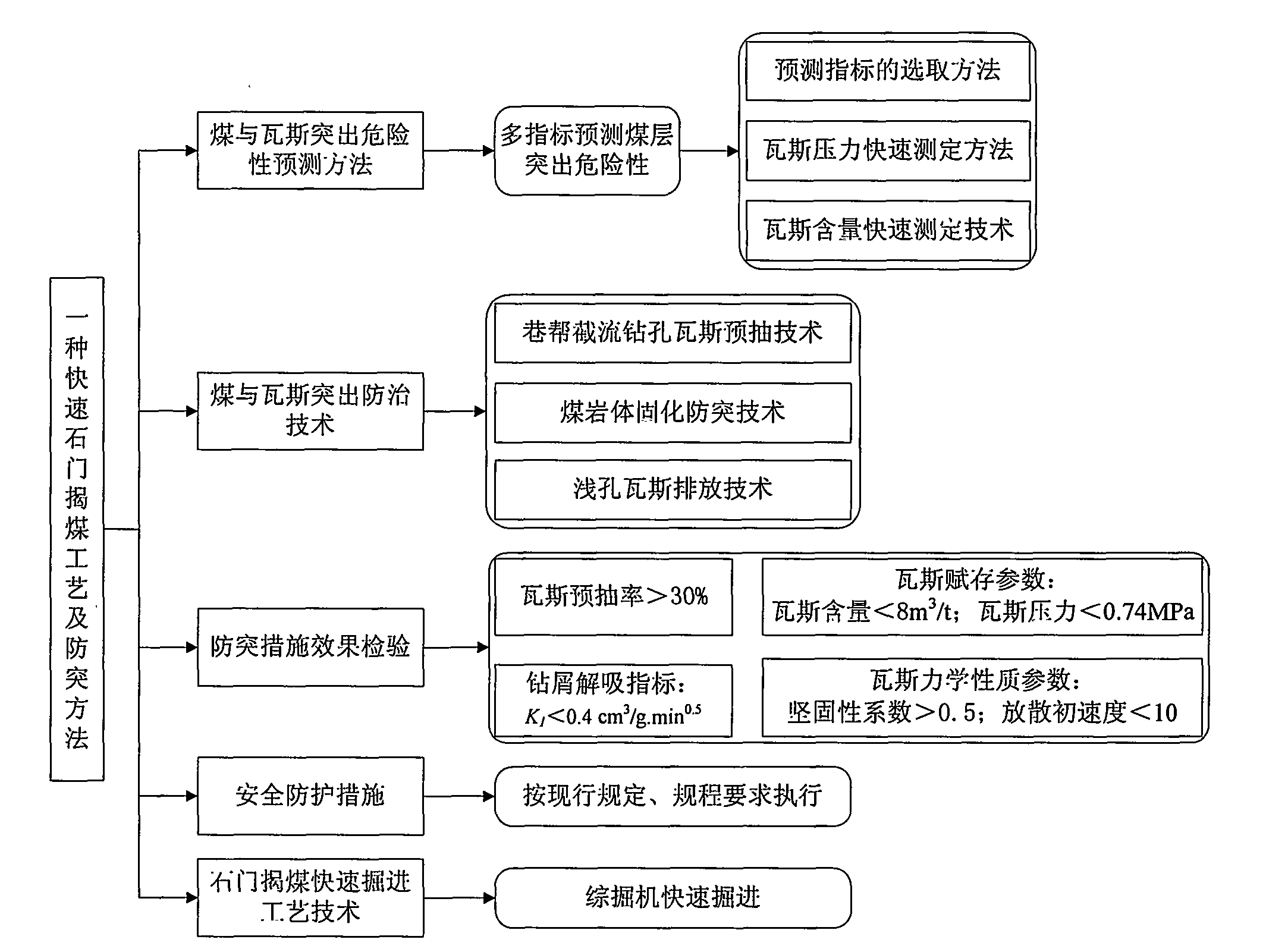

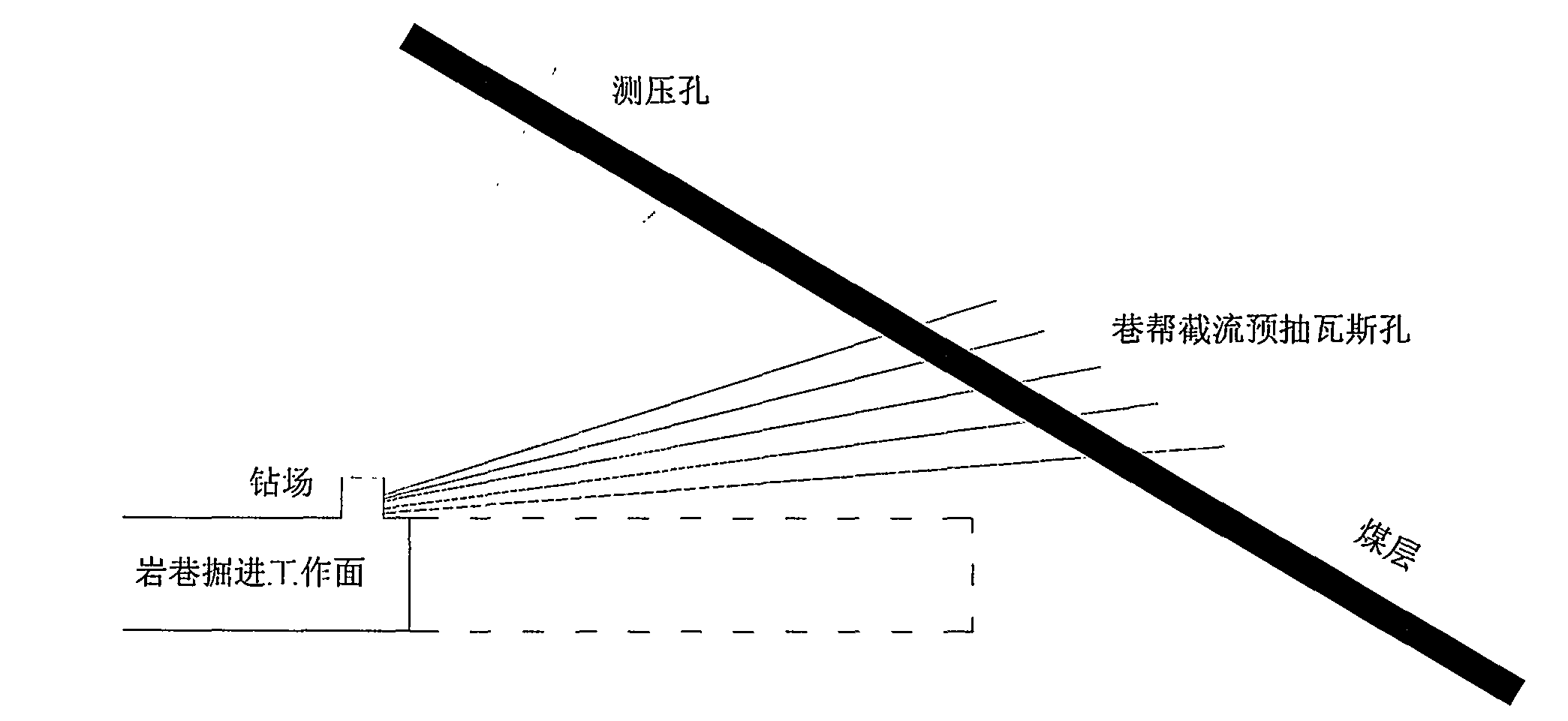

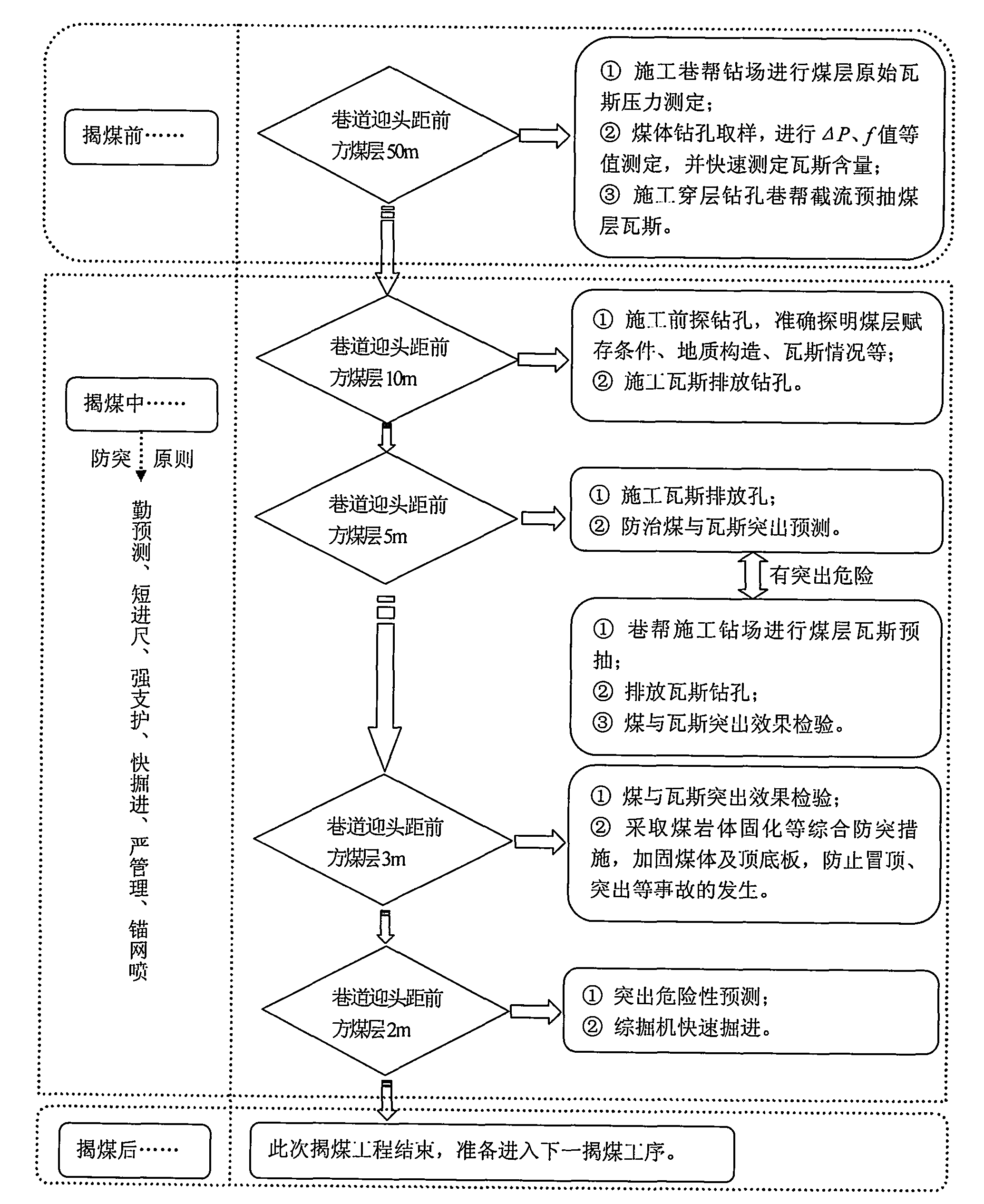

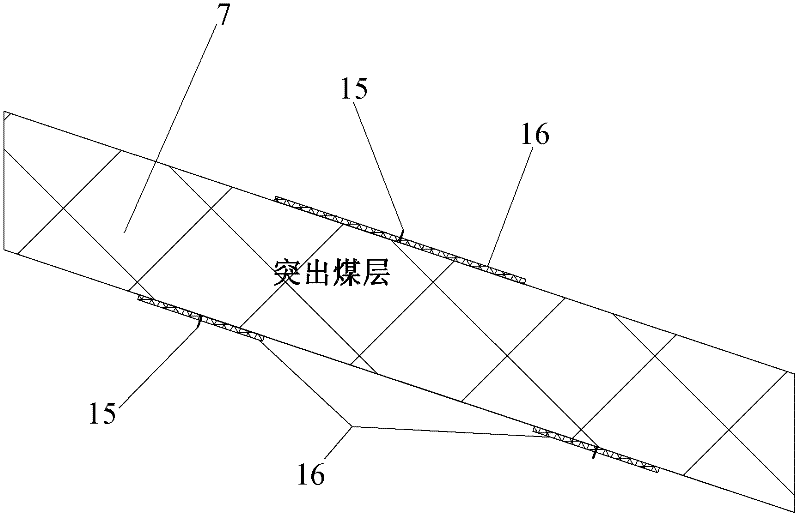

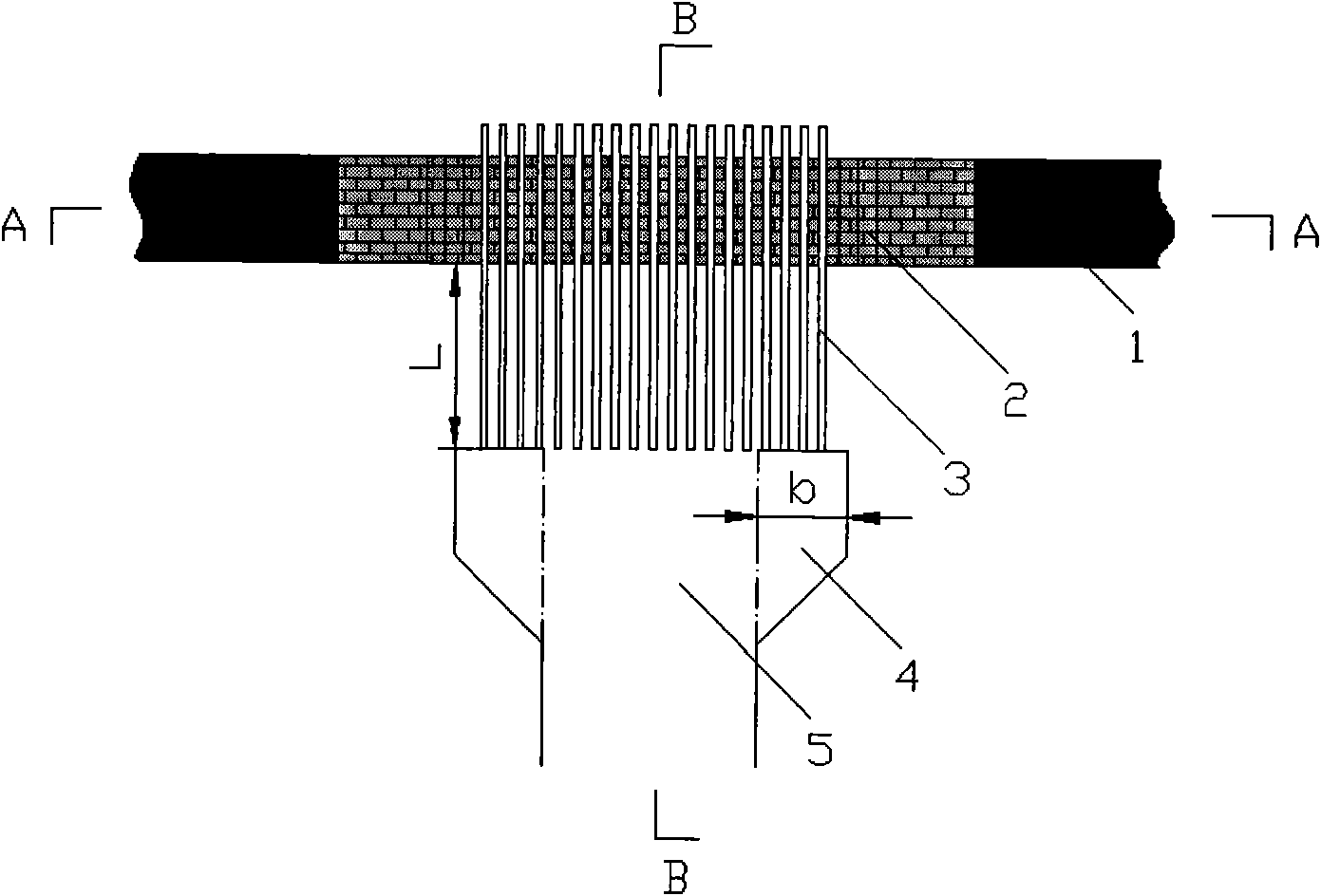

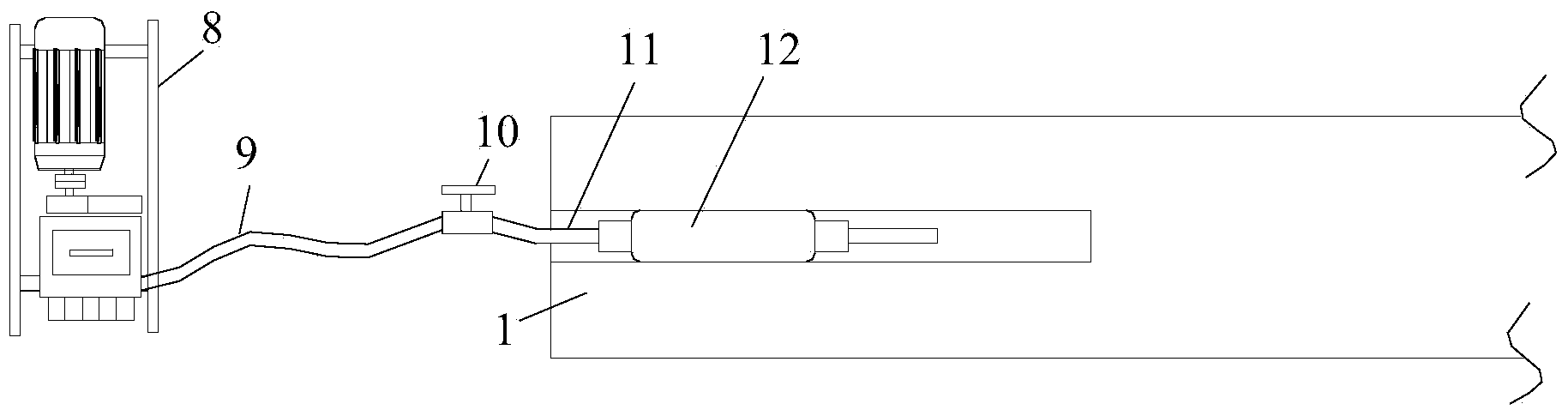

Rapid rock cross-cut coal uncovering process and outburst prevention method

InactiveCN103306677AImprove accuracyShorten the timeUnderground miningSurface miningDrill siteCross cut

The invention relates to a rapid rock cross-cut coal uncovering process and an outburst prevention method. The rapid rock cross-cut coal uncovering process comprises the following steps: performing lane drill site construction advance borehole during rock drivage period, performing penetration drilling to measure the gas pressure of the coal seam and rapidly measuring the gas content, the mechanical property of the coal and other parameters by utilizing extraction drilling and sampling under the conditions that the rock gangway construction is not influenced and the coal seam to be uncovered is subjected to gas interception and extraction in advance, and realizing the outburst danger of the multi-index prediction coal seam; increasing the specific coal and rock mass curing measures in addition to the gas outburst prevention measures with the uncovering related regulations and standard requirements, so that the rock cross-cut is excavated by employing an integrated excavator after the rock cross-cut uncovering working face is subjected to complete outburst removal, and rapid rock cross-cut coal uncovering is realized. The whole set of coal uncovering process and the outburst prevention are used for the experimental coal mine 937m roadways, and 18 layers of coal are uncovered totally, so that the whole construction period is shortened by 1.63 years and is only 1 / 3 of the expected coal uncovering time. The method is easy and convenient to operate, safe in construction, short in overall coal uncovering time and good in outburst prevention effect and has wide practicability.

Owner:GUIZHOU INST OF COAL SCI

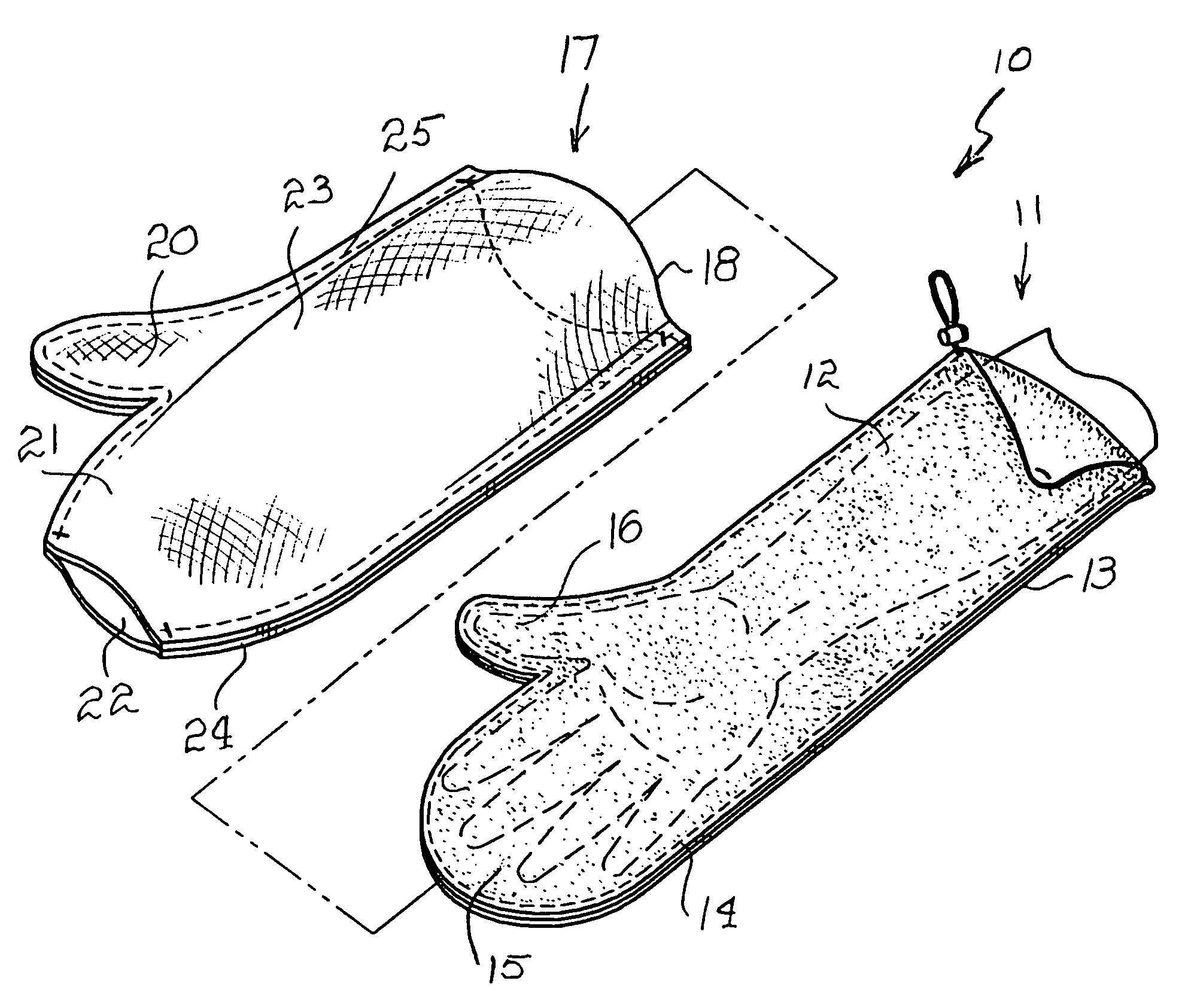

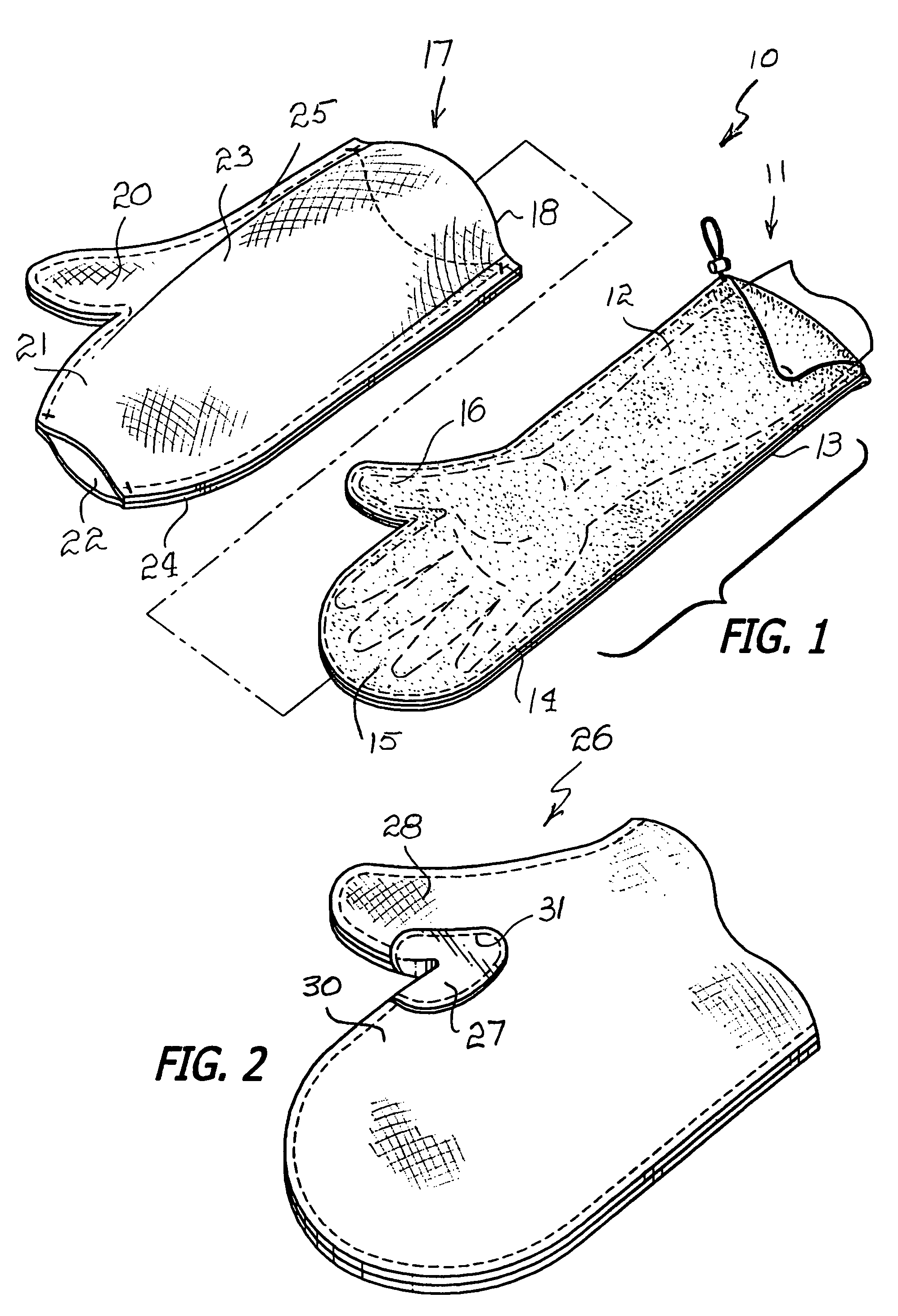

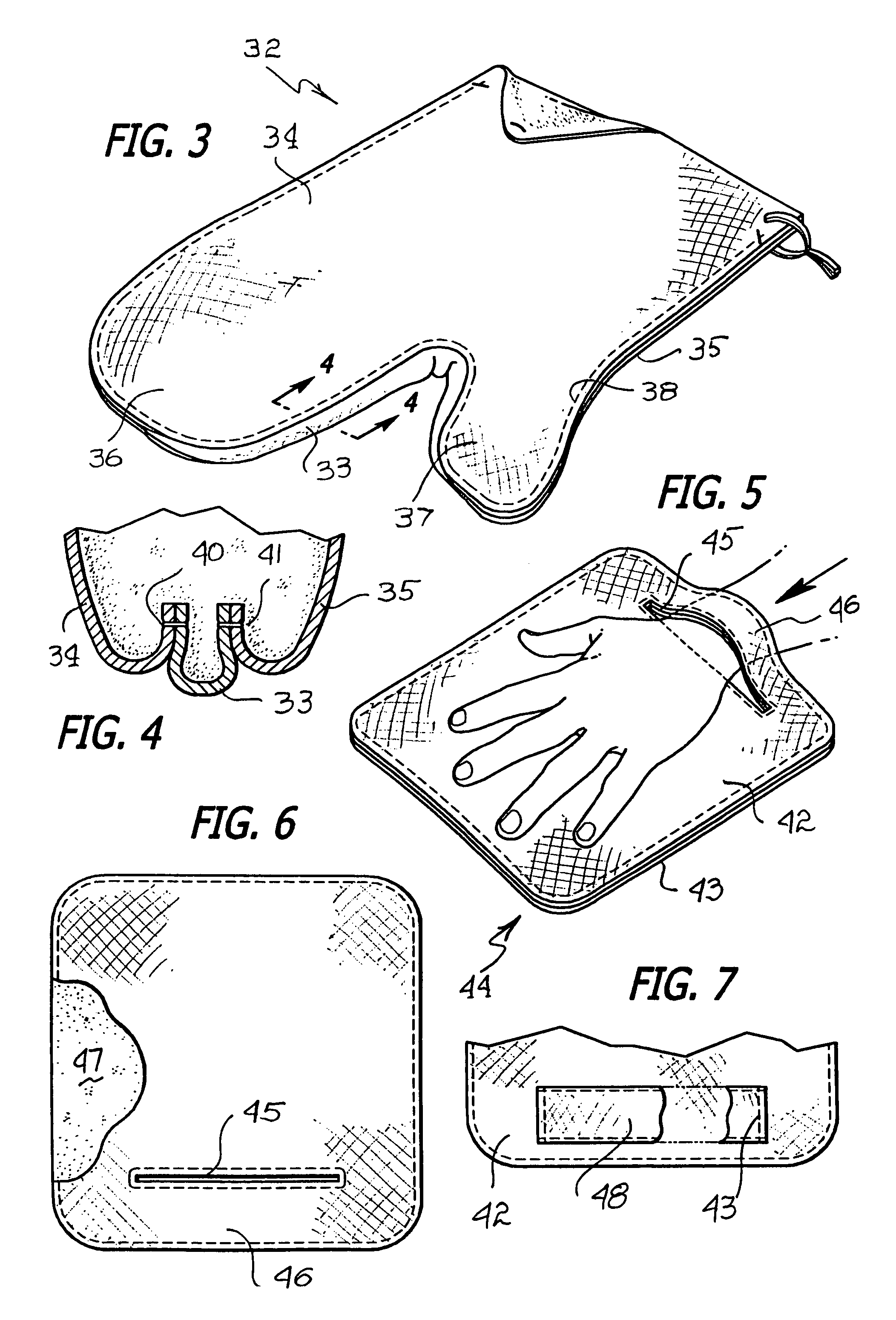

Multipurpose hand grip

InactiveUS7383590B1Stay flexibleMaintaining hand protectionGarment special featuresGlovesTemperature controlPolyester

A hand grip and arm protection device composed of a water-resistant and stain-proof material, having temperature control characteristics and having a pair of sheets, with each sheet having a textured, recessed imprint on one surface providing a non-slip contact surface, while the opposite surface of the sheet, composed of a close fabricated fabric, is affixed to the sheet of textured, non-slip contact surface material. The fabric sheet of nylon / polyester composition is affixed to the non-slip contact surface sheet composed of a chloride rubber composition. The two-piece pair of sheets are sewn together by means of a zigzag lock stitch employing nylon thread. Both exterior surfaces include a cross-cut textured recessed imprint.

Owner:DUNCAN DAVID

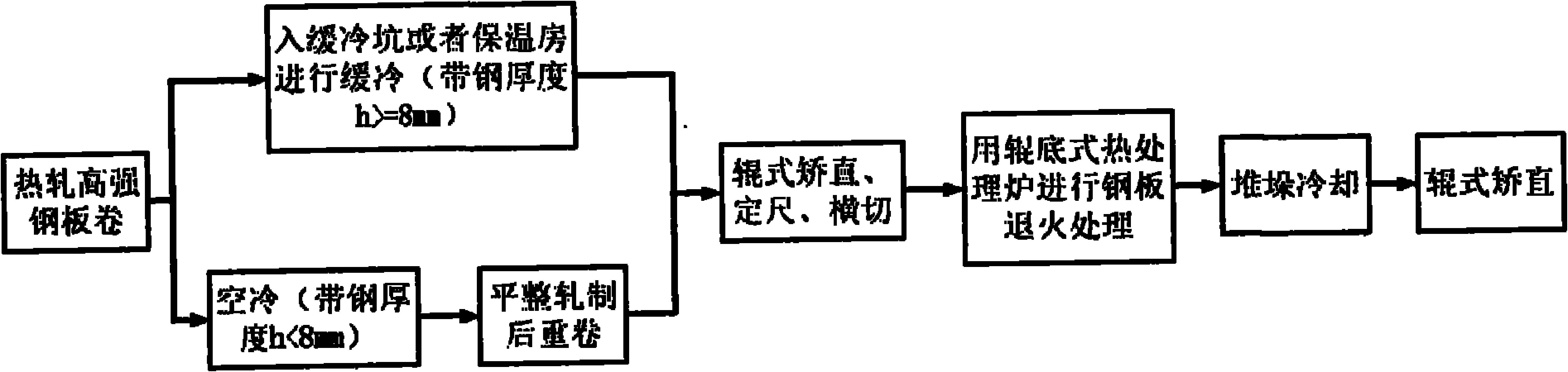

Method for removing residual stress of hot-rolling high-strength steel

ActiveCN101844162AAchieve development goalsImprove shape qualityFurnace typesProcess efficiency improvementCross cutStress relief

The invention relates to a method for removing residual stress of hot-rolling high-strength steel, which comprises the production flows of: (1) putting a steel coil of which the thickness is more than or equal to 8 millimeters into a slow cooling pit for slow cooling treatment; and (2) performing air cooling on a steel coil of which the thickness is less than 8 millimeters, and after the steel coil is cooled to reach room temperature, performing temper rolling and performing reeling again to form a coil. A roller-type straightening unit is adopted to perform straightening, flattening, dimensioning and cross-cut on the treated high-strength steel coil to form a steel plate. A roller-hearth heat treatment furnace is adopted to perform stress relief annealing on the flattened steel plate, so that the internal stress of the steel plate is eliminated; and after being tapped off, the steel plate is cooled slowly by adopting a stacking cooling mode, and finally the steel plate is straightened by using the straightening unit, so that the high-strength steel plate has the excellent plate shape stability and can meet the strict requirements of users on flatness of less than or equal to 2 mm / m of the high-strength steel plate. The conventional heat treatment furnace and roller-type straightening equipment can be utilized, so that the investment cost and machining cost are reduced, the annealing treatment time is shortened, and the effect of the plate shape improvement of hood-type annealing is achieved. Thus, the method has an important economic and social significance for the development of the high-strength steel.

Owner:SHOUGANG CORPORATION

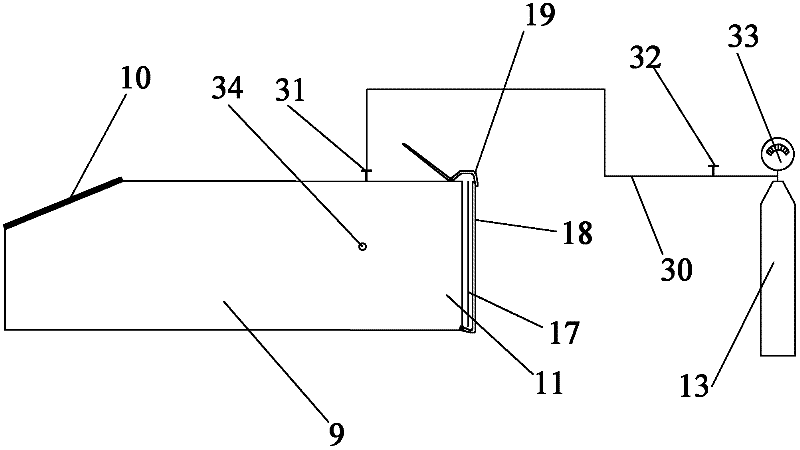

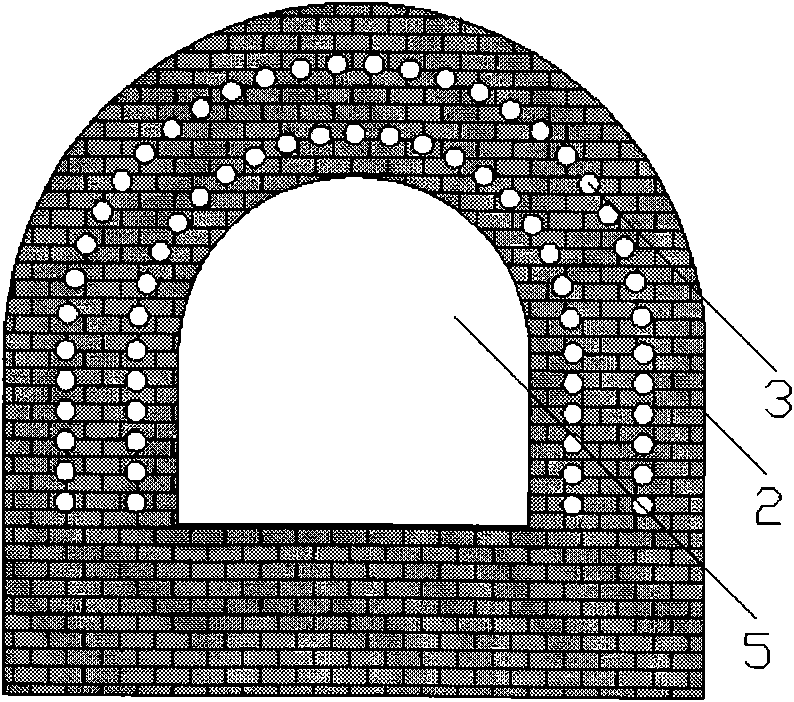

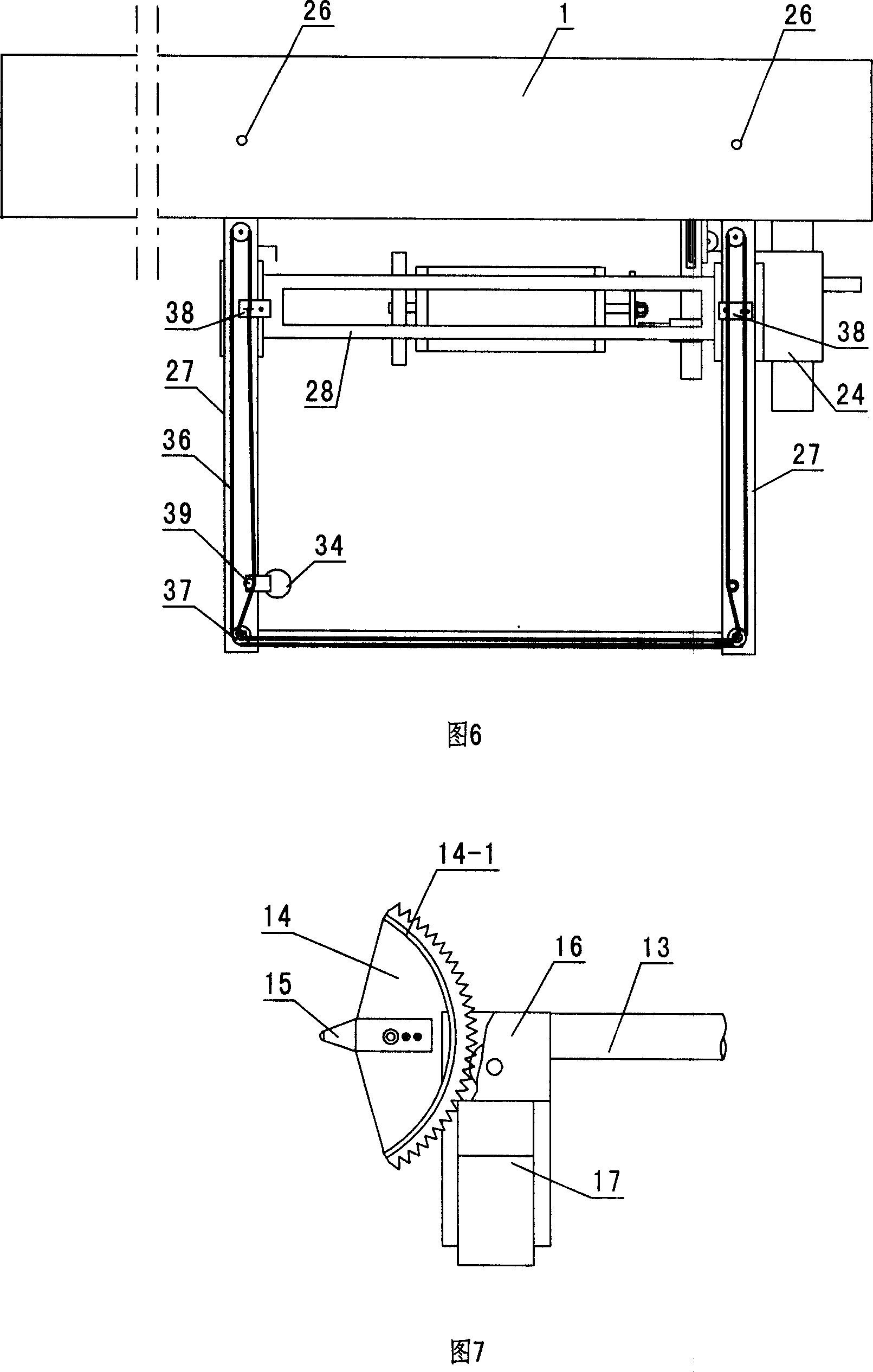

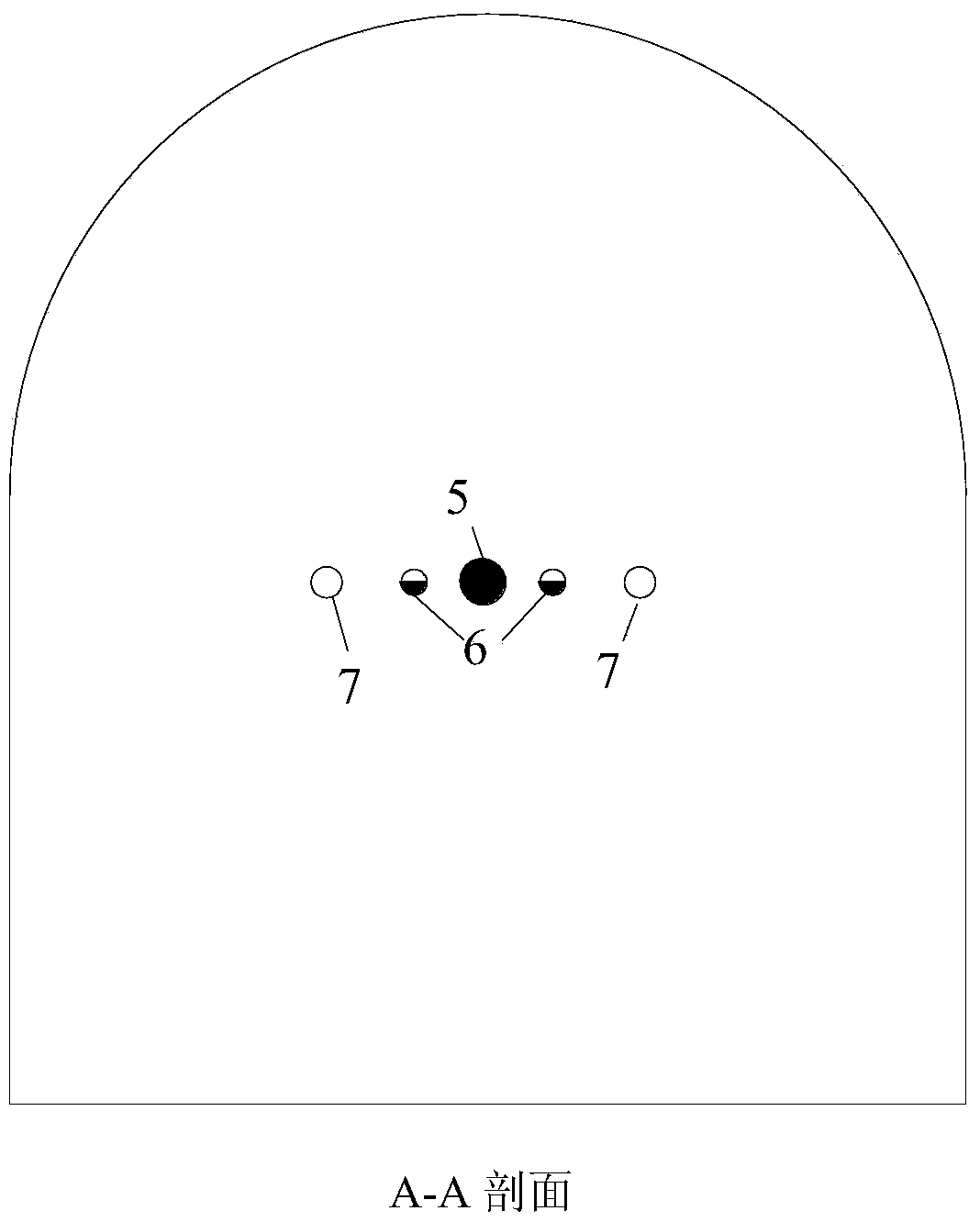

Simulation test system of coal-gas outburst during rock cross-cut coal uncovering

The invention discloses a simulation test system of coal-gas outburst during rock cross-cut coal uncovering, comprising a box provided with an opening at the top thereof, wherein the opening is equipped with a loading steel plate; a top plate and a bottom plate are paved in a closed cavity; a coal layer is paved between the top plate and the bottom plate; a slant angle is formed between the coal layer and the horizontal plane; an outburst simulation roadway is stretched in the bottom plate till being intersected with the coal layer; a notch attached to the coal layer is arranged at the intersection of the outburst simulation roadway; a diaphragm is arranged at the notch; an outburst opening and a gas balance opening are arranged at a part of outburst simulation roadway, which is exposed out of the box; the outburst opening is provided with a quick-opening seal structure; the gas balance opening is communicated with an air pressure tank; surface inflatable structures are respectively arranged on the contact surface of the coal layer and the top plate as well as the contact surface of the coal layer and the bottom plate; and the surface inflatable structures are communicated with a gas pressure tank. According to the invention, a mechanical release-diaphragm rupture method is adopted to ensure that the whole-process simulation of the coal-gas outburst during the rock cross-cut coal uncovering is realized.

Owner:SHANDONG UNIV OF SCI & TECH

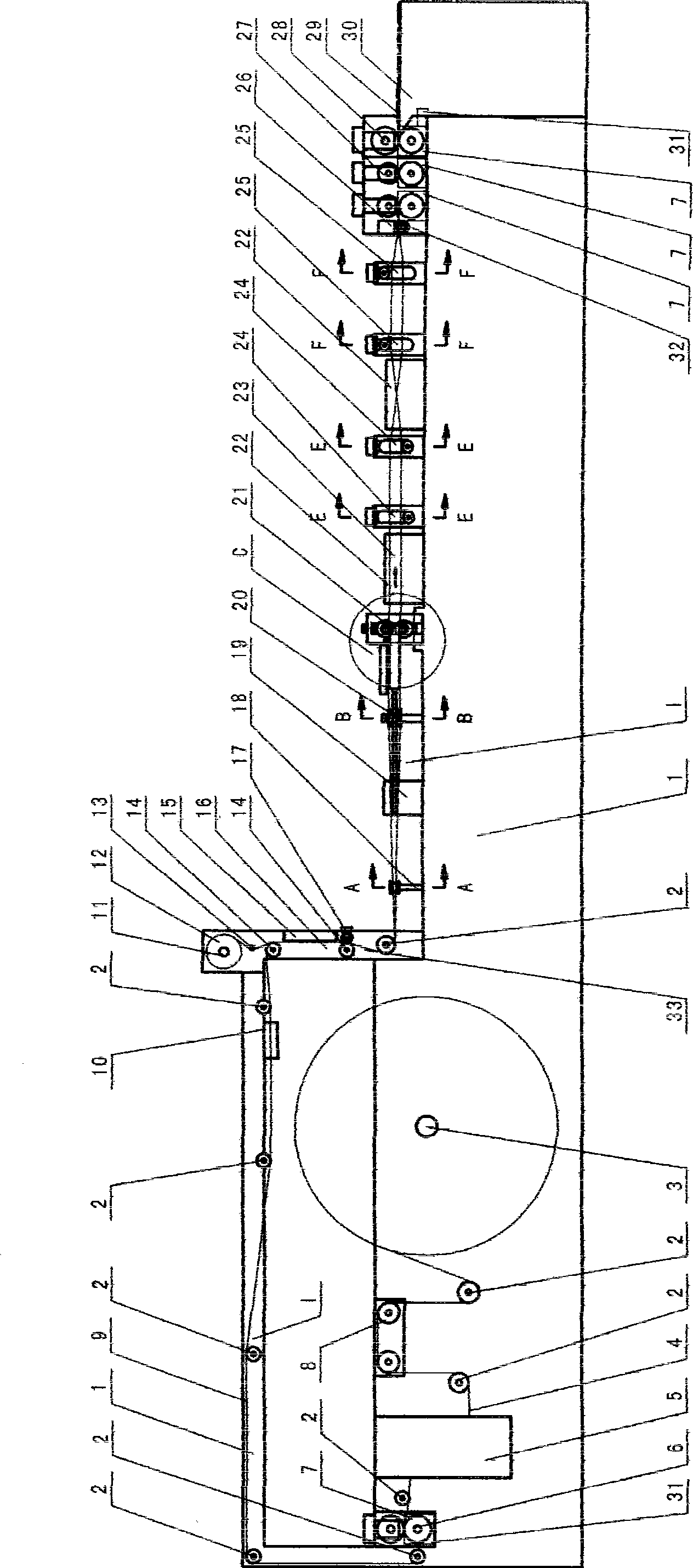

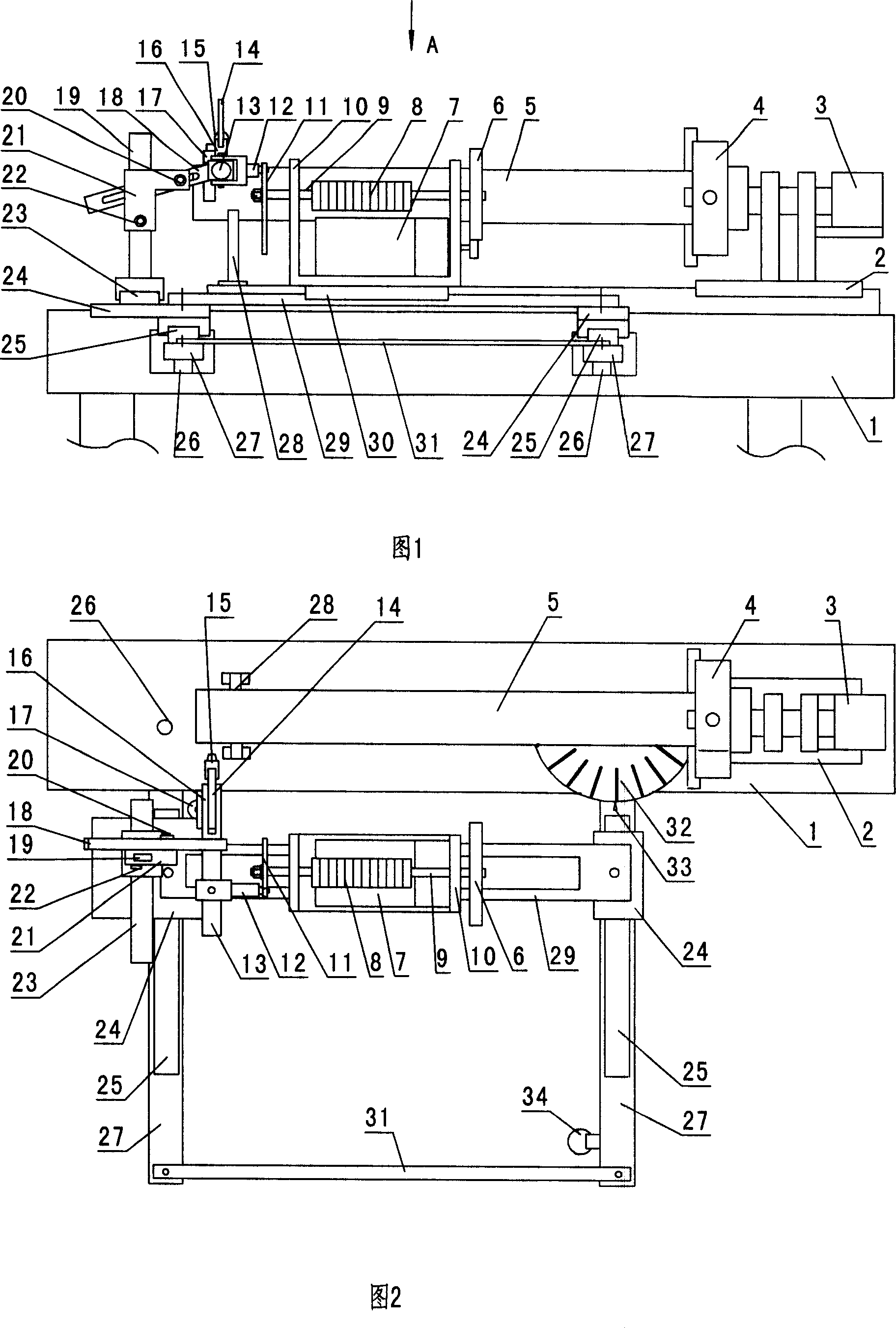

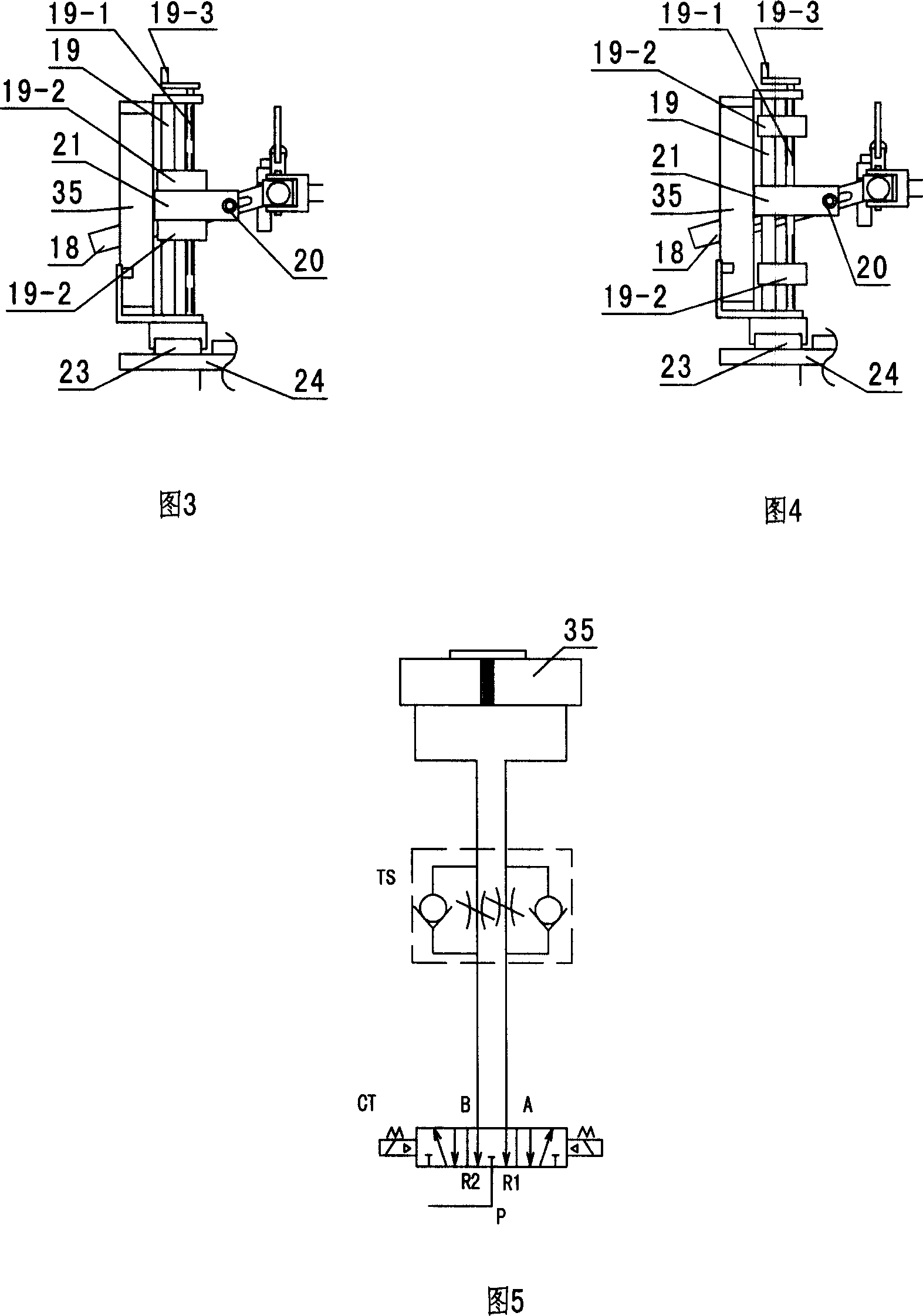

Technique and equipment for processing package piece of packaging box

InactiveCN101474889AEasy to produceSimple processBox making operationsPaper-makingCross cutStore food

The invention relates to a technique and an apparatus for producing a packing piece of a packing box which is made of paper composite material and is used for storing foods for a long time in asepsis. In the prior art, the packing piece of the packing box is produced by performing impressing, cross cutting into uniwafers, cutting edges and sealing on the composite and printed wound roll packing material. The prior art needs a plurality of apparatuses for cooperation. The invention aims to provide a technique and an apparatus for producing the packing piece of the packing box. The technique comprises that: the packing material is wound, the axial position is corrected automatically by rectifying a deviation, printing marks are aligned, the indentation line is pressed, a sealing film is adhered, the product enters processes of vertically sealing, hot adhering and press fit after preformation to finish the vertical sealing to produce a paper pipe; the vertical sealing position of the paper pipe is cooled, the paper pipe is pressed flat left and right along the indentation line and is positioned and cut, and the packing piece of a packing box is produced by automatic calibration and collected into a pile. The invention has the advantages that one apparatus finishes the whole production technique, the working procedure is simplified, the number of fault points is small, the rate of finished product is high, the production efficiency is high, the product quality is stable, the production cost is low, and the invention is suitable for large-scale industrial production.

Owner:李玉龙

Differentially-cured materials and process for forming same

A light-redirecting optical structure includes a first side and a second side, the first side including plurality of linear prisms having a visibly random shaped surface on the prisms and a plurality of cross-cut prisms on first side which are oriented at an angle such that it is greater than zero degrees but less than 180 degrees. A backlight wedge includes a stepped structure on a bottom side that decreases in size traversing the wedge away from a light source which is positioned at an end and having a visibly random shaped surface on said wedge.

Owner:MULLEN PATRICK W +2

Drinking cup lids with promotional game piece

InactiveUS7195130B2Great ease of manufactureEasy to graspContainer decorationsLevel indicationsCross cutEngineering

Drinking cup lids are especially adapted and configured to afford some measure of protection to the game piece from beverage seepage through a straw opening. Preferably, the cup lid is configured so that a game piece is spaced above the straw opening co-located within a recessed well of the lid thereby allowing beverage seepage to remain physically separated from the game piece. Access to the beverage within the cup is facilitated by providing a cross-cut straw aperture in the game piece which is in substantial alignment to the straw opening formed in the lid. A beveled segment of a raised plateau on which the game piece is affixed allows a tab associated with the game piece to be more easily grasped and removed by a customer to reveal the printed text / indicia of the game piece.

Owner:SOLO CUP OPERATING CORP

Method for reinforcing outburst-prone coal seam cross-cut coal uncovering

InactiveCN101603431AHigh strengthImprove toughnessUnderground chambersGas removalCross cutDrainage time

The invention discloses a method for reinforcing cross-cut coal uncovering at an outburst-prone coal seam and is particularly suitable for cross-cut quick coal uncovering at a coal seam having outburst dangers and a horizontal thickness of less than 8 meters in a coal mine. The method comprises the following steps: firstly, drilling and pre-extracting gas in a coal seam in front of a cross cut to reduce the gas content and gas potential of the coal seam; manufacturing an reinfrocing ring having a thickness which is 0.4 to 1 time of that of the cross cut on the periphery of the cross cut and using an anchor cable for joint reinforcement to improve the reinforcing effect of the coal seam and realize safe coal uncovering; drilling discharge holes inside the reinforcing ring, controlling distances within 4 to 8 meters on the two sides of a laneway and connecting pipes to drain the gas, reduce gas pressure and the destructive effect of a high gas pressure on the coal seam; and after the drainage of gas, using related gas discharge holes as injection holes and injecting a reinforcing material around the cross cut to reinforce coal rocks, form a reinforcing structure with a framework and improve the reinforcing effect. The method can reduce outburst elimination work amount by 20 to 40 percent under a condition of ensuring safe coal uncovering, reduce gas drainage time construction period and improve safe coal uncovering speed by 25 to 50 percent.

Owner:CHINA UNIV OF MINING & TECH

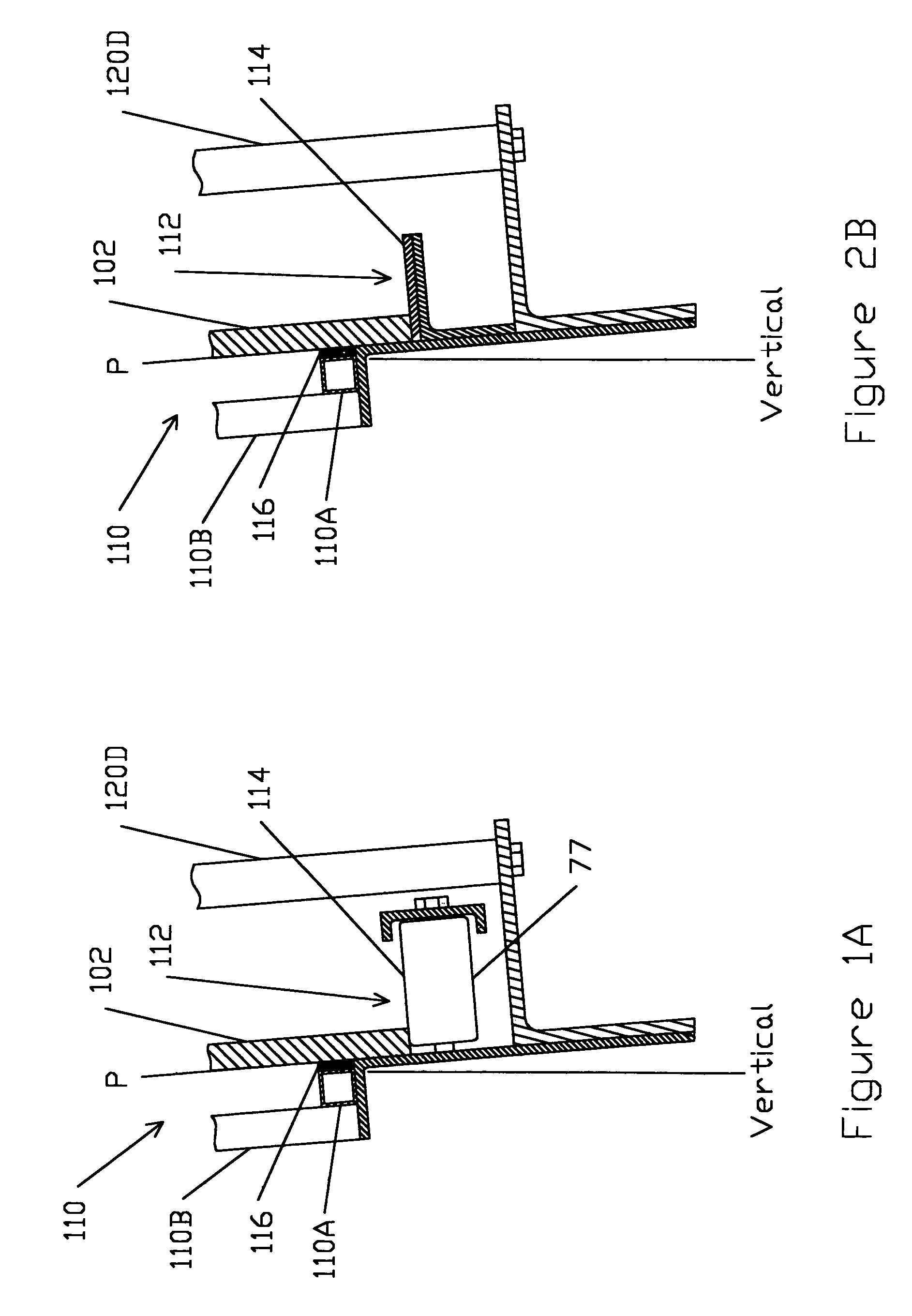

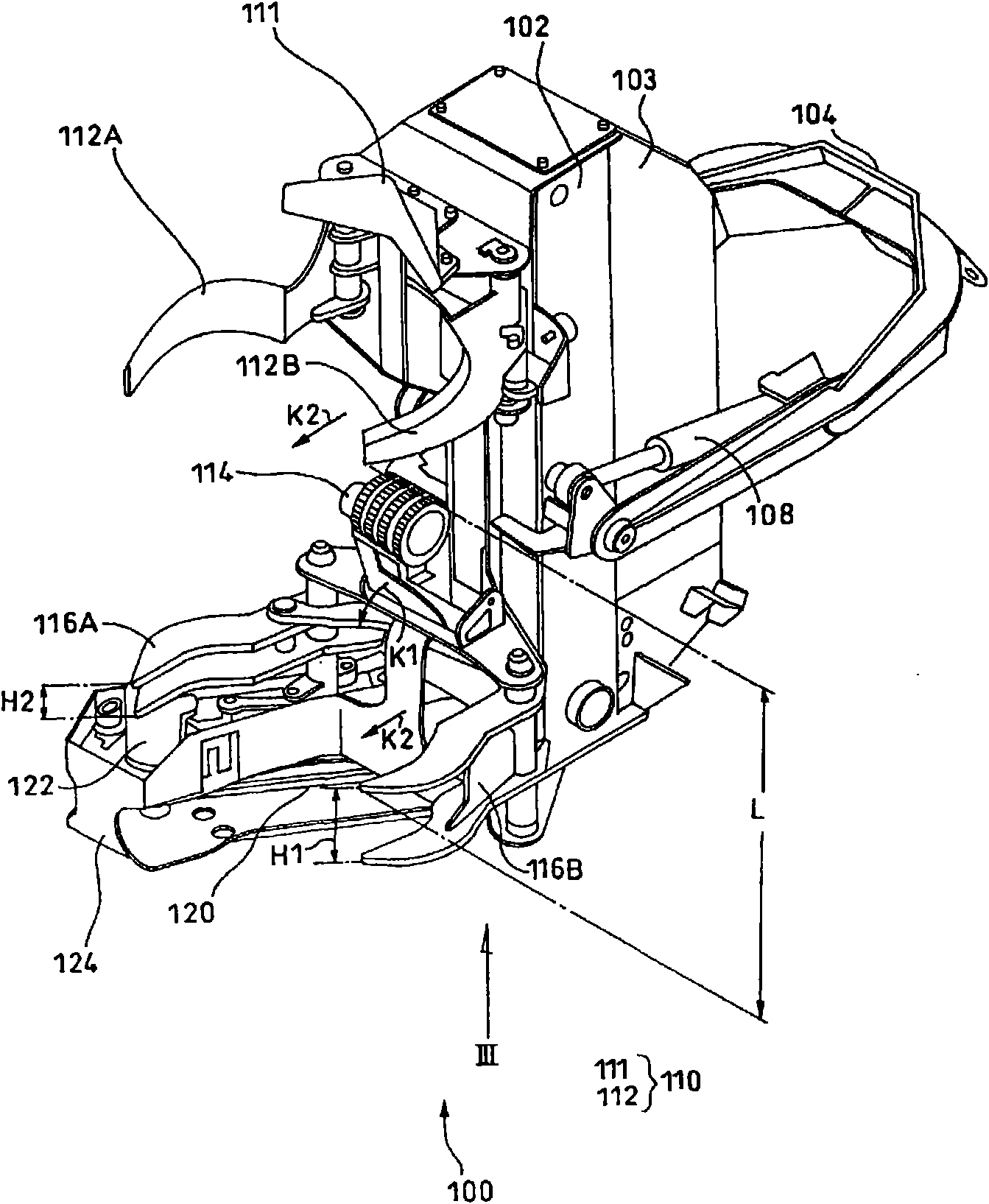

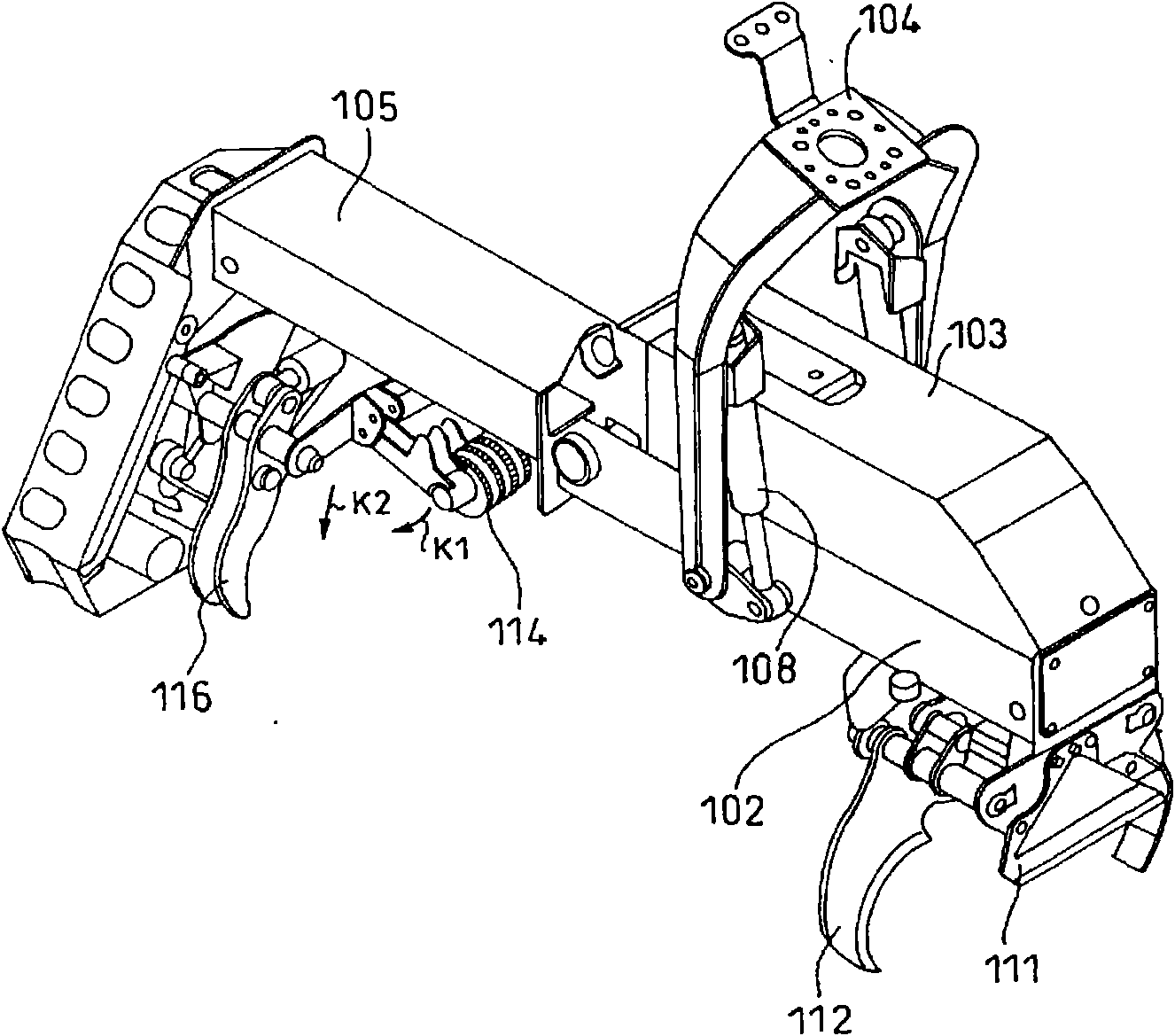

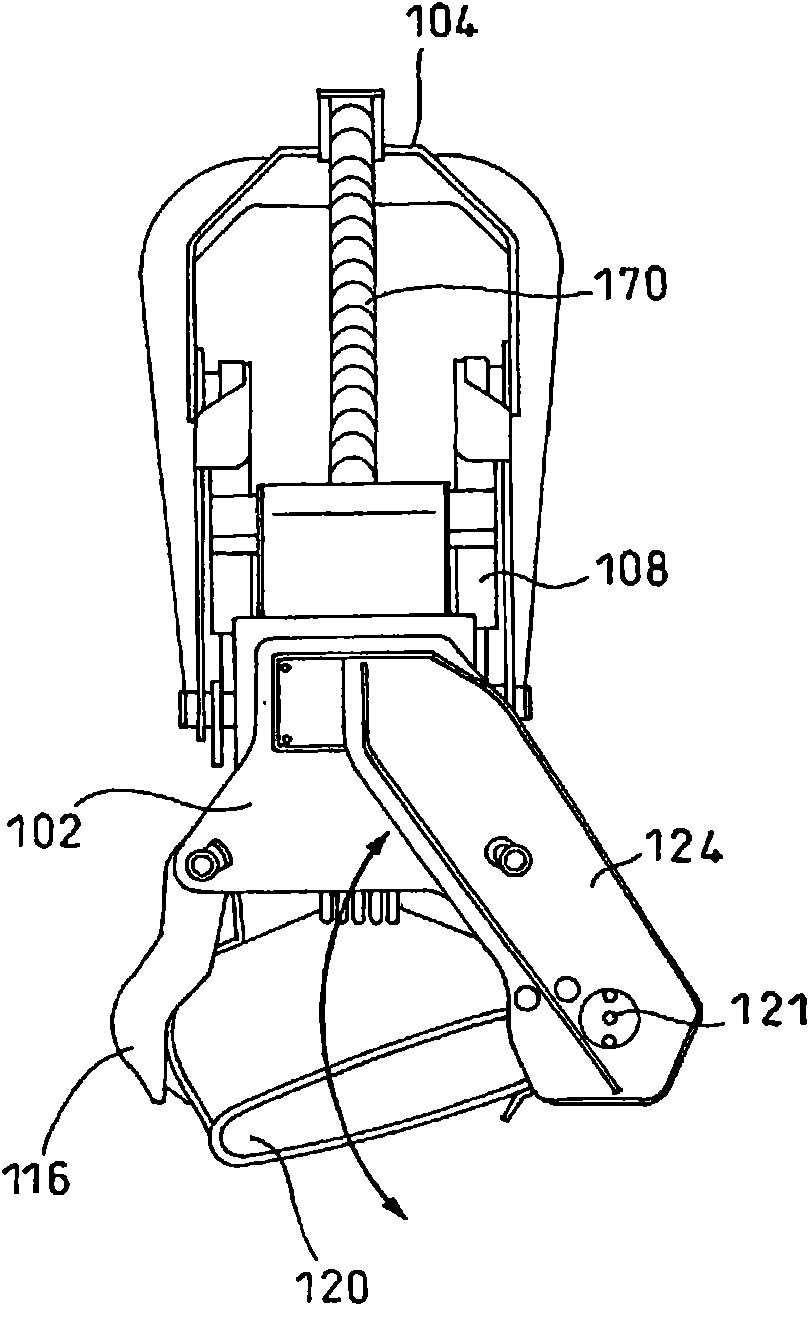

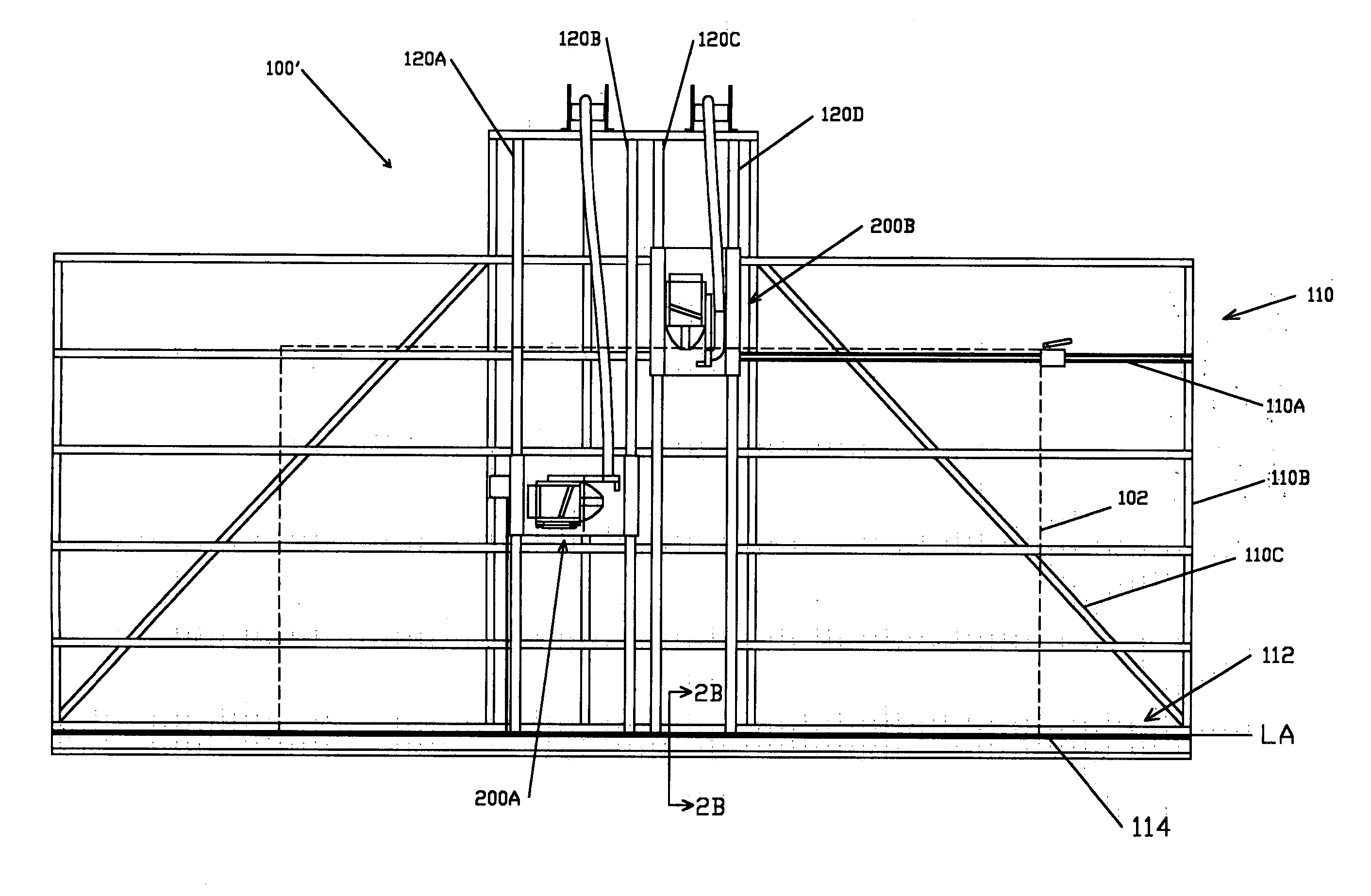

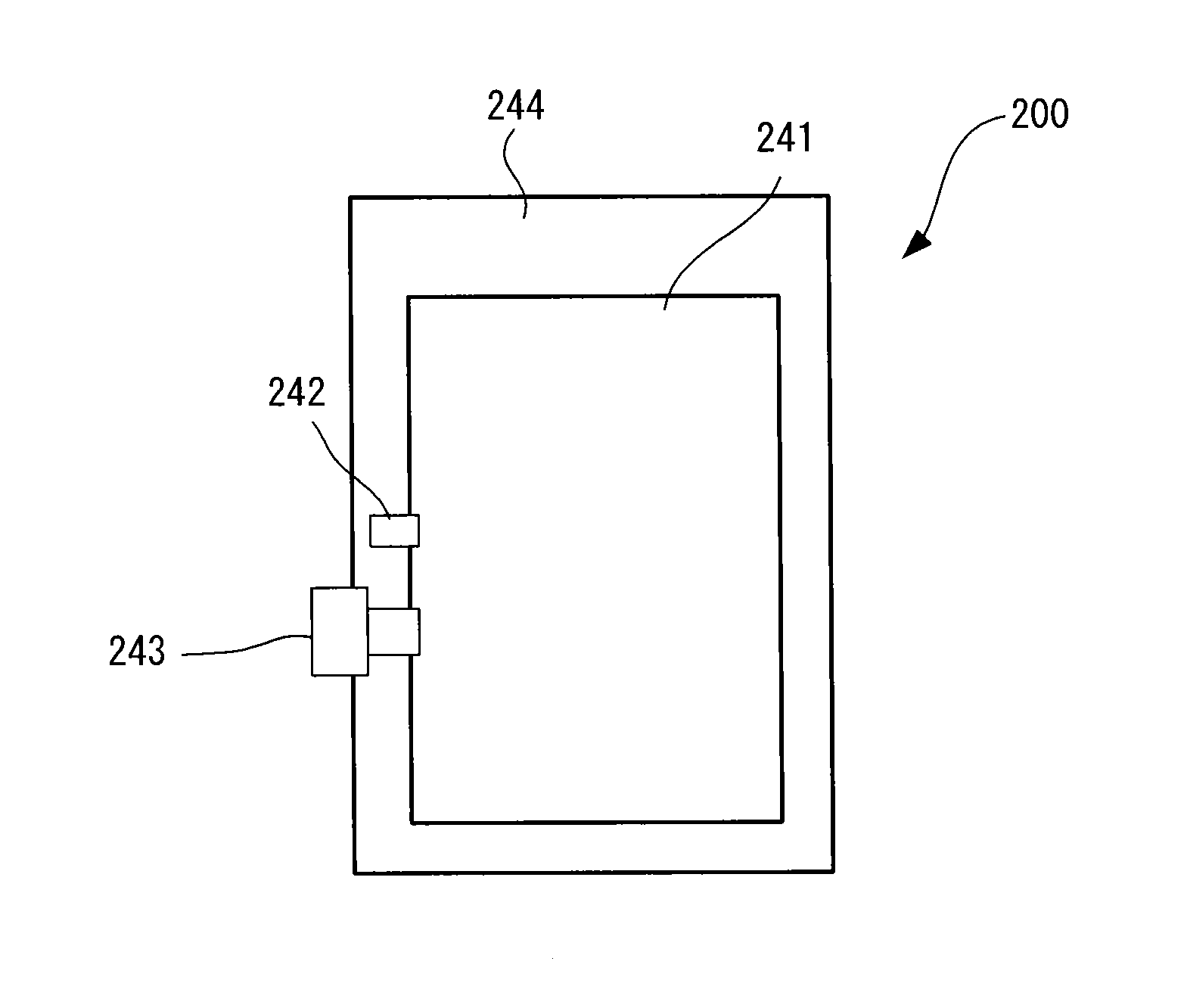

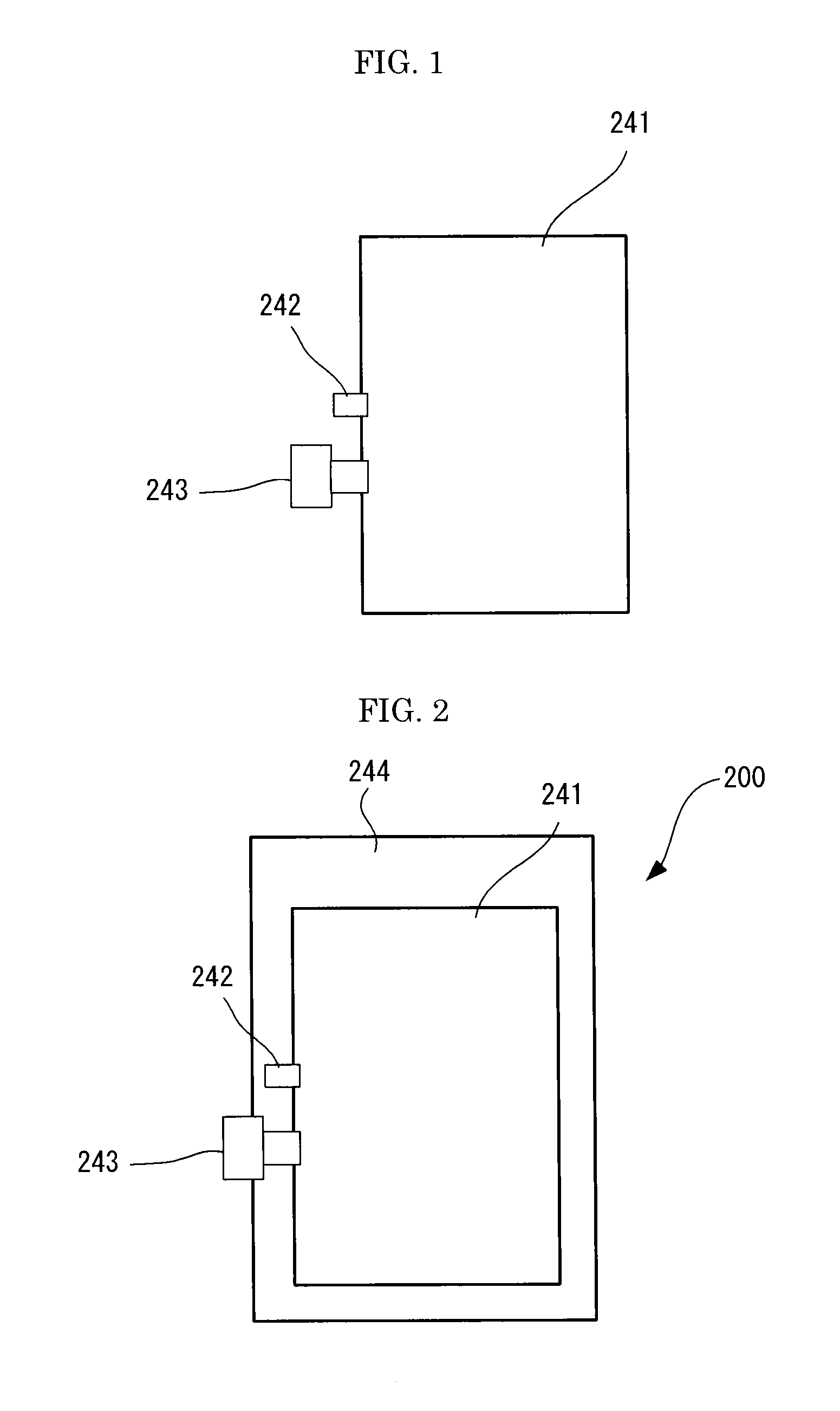

Harvester machine for wood and felling/wood making method

A harvester apparatus (100) equipped in a work vehicle and capable of at least cutting down, pruning, and cross-cutting wood, the harvester apparatus being configured to include a gripping claw (116) that can hold the wood by opening and closing in the thickness direction of the wood, a chain saw (120) capable of cutting the wood held with the gripping claw (116), a pruner (110) for pruning the wood arranged at a different position in the lengthwise direction of the gripped wood relative to the gripping claw (116), a slide frame (105) that can change the lengthwise distance between the pruner (110) and the gripping claw (116), and a sensor (130) for detecting the slide amount of the slide frame (105).

Owner:SUMITOMO CONSTRUCTION MACHINERY

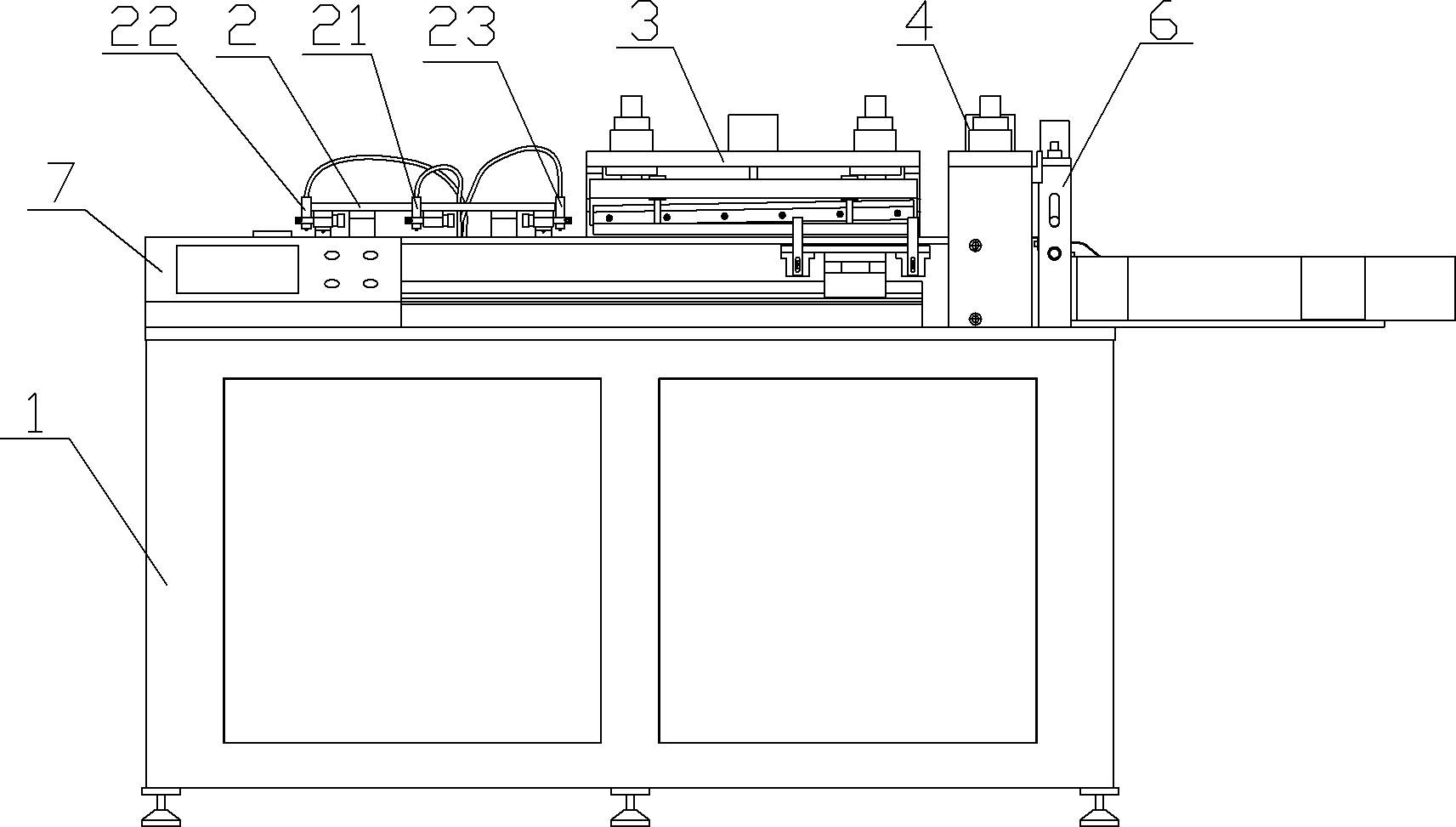

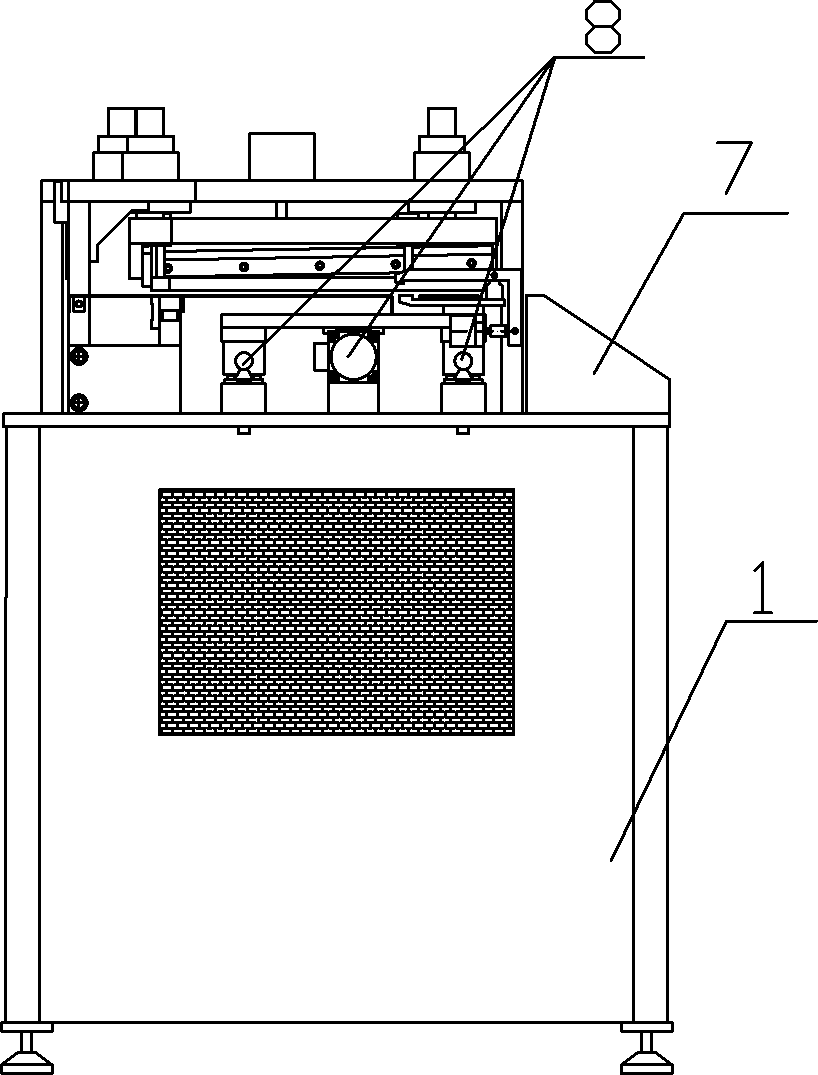

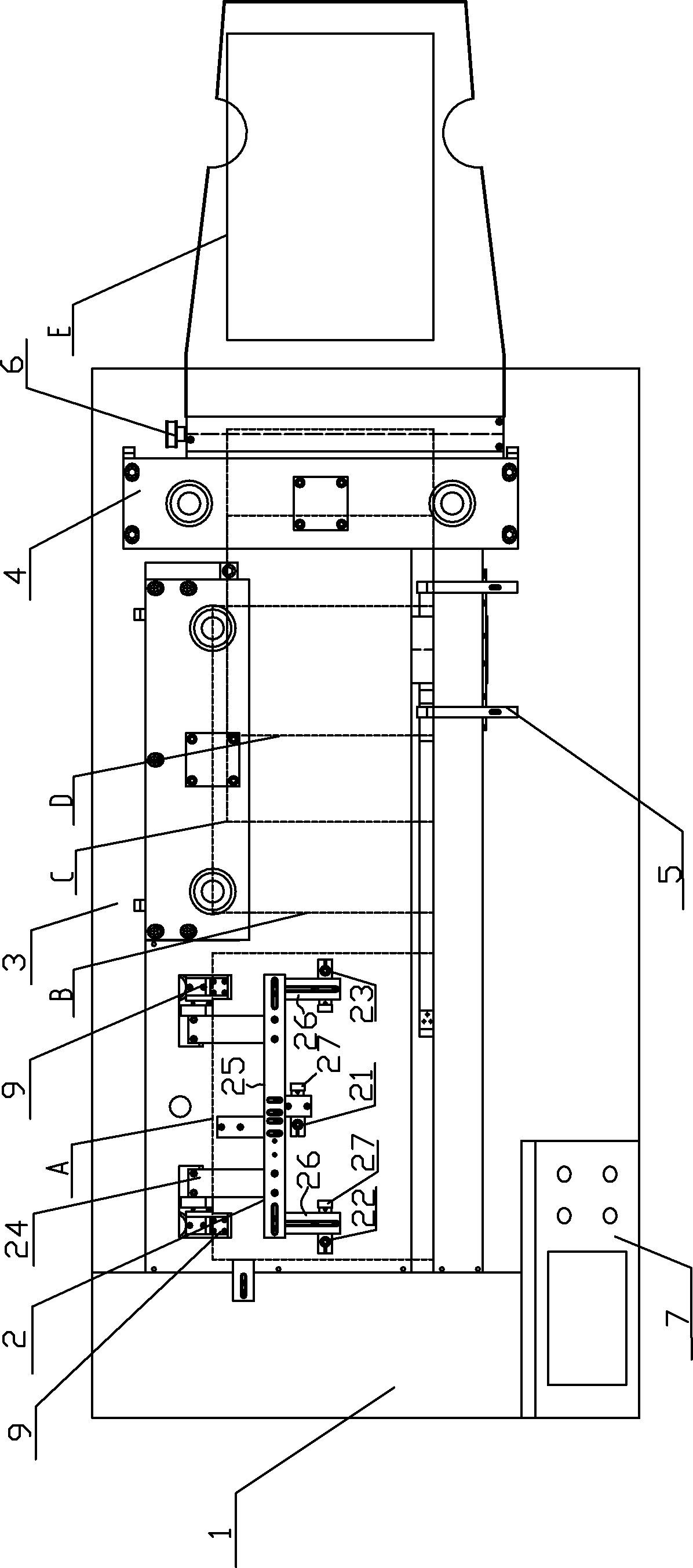

Full-automatic edge trimmer

ActiveCN102862178AImprove the efficiency of the assembly processMetal working apparatusProgrammable logic controllerCross cut

The invention provides a full-automatic edge trimmer, comprising a machine frame, a control system, a servo motor, a gas cylinder, a stepping motor rectifying device, wherein the upper part of the machine frame is provided with a positioning and detecting mechanism, a cross-cut trimming mechanism and a vertical-cut trimming mechanism in turn from left to right; the positioning and detecting mechanism comprises a left color code optical fiber sensor, a middle color code optical fiber sensor and a right color code optical fiber sensor which are arranged at interval; the control system comprises a programmable logic controller; the signal output ends of the left color code optical fiber sensor, the middle color code optical fiber sensor and the right color code optical fiber sensor are respectively connected with the signal input end of the programmable logic controller; and the control signal output end of the programmable logic controller is connected with the control signal input ends of the gas cylinder, the servo motor and the stepping motor rectifying device. With the adoption of the full-automatic edge trimmer provided by the invention, PVC cards at the upper layer, the middle layer and the lower layer are processed to form right-angle depending references of which the specifications are same, so that the marks can be printed without manpower, and the efficiency of the packaging process is improved.

Owner:WUHAN WENLIN TECH

Hybrid synchronous electric machine

InactiveUS7034425B2Low eddy current lossLower average currentMagnetic circuitSynchronous motorsBall bearingCross cut

Owner:HARMONIC DRIVE SYST IND CO LTD

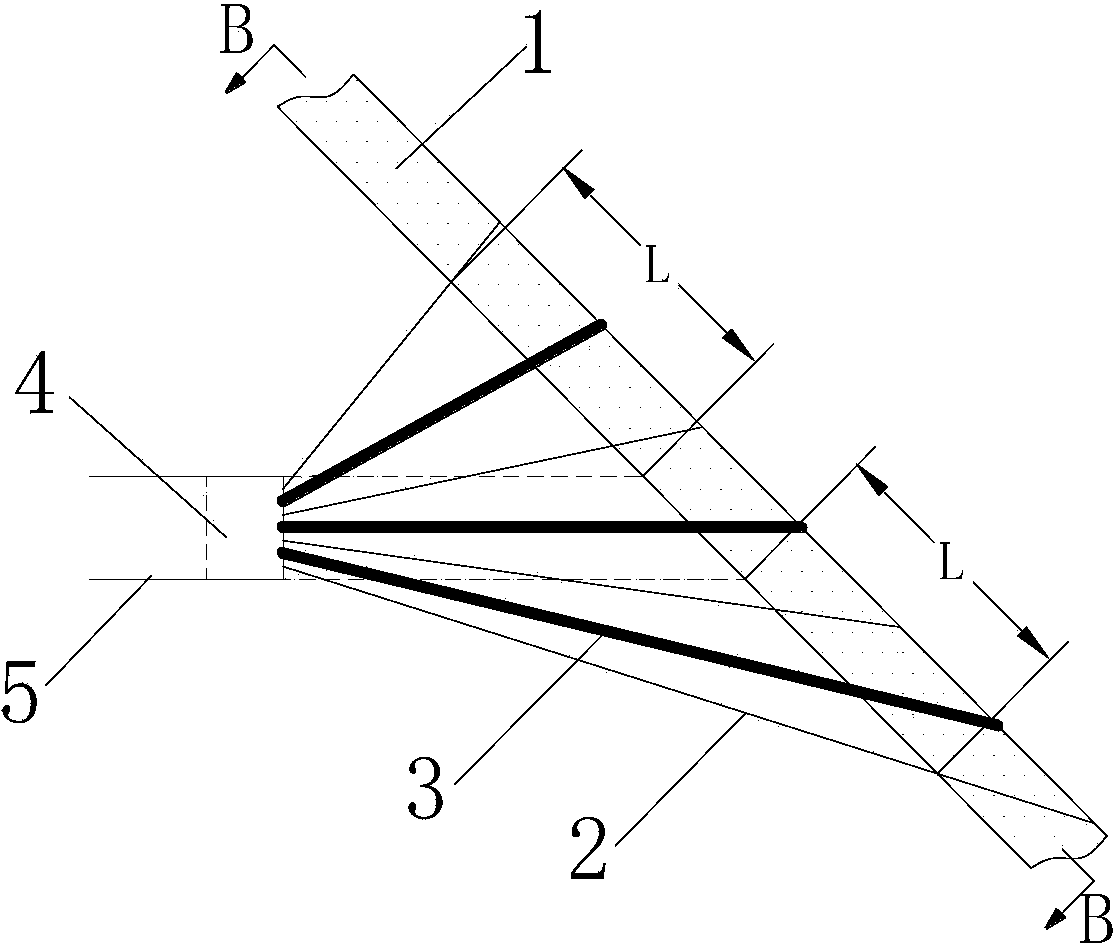

Cutting device for pipe intersecting lines

InactiveCN101011806ABest cutting angleEasy to useCopying process control systemsPlasma welding apparatusLow speedCross cut

A tube cutting device comprises the frame, tube fastening rack and cutting torch enabling the turn of 180 degree of the tube, a low speed rotating shaft parallel with the cut round tube axis reciprocating along the axial, the deflector rod cross bar of the drive hinged with the floating shaft, a high and low location continuously adjustable along the support axial direction, with one end of the support cup jointing with the thrust pole of the floating shaft whose front end having a centripetal cutting torch. It can realize the cross cut, oblique, cross cut eccentric, and oblique cutting, with convenient usage and adaptable diameter, easy for production and cheap in cost, especially suitable for the mass transversal line cutting.

Owner:宋宝安

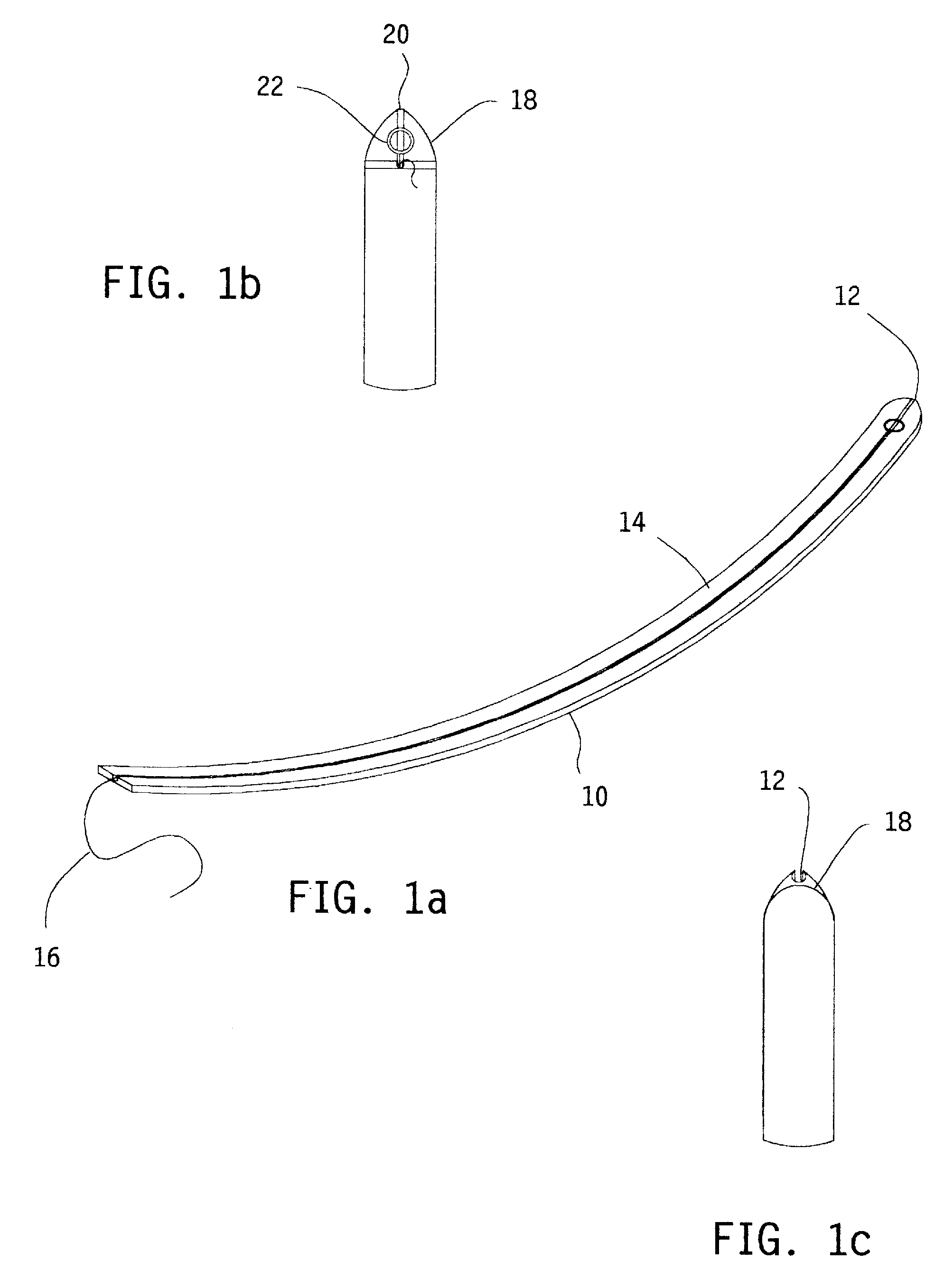

Flexible Wire Transection of the Transverse Carpal Ligament

InactiveUS20060271080A1Easy to passIncrease the cross-sectional areaSurgical needlesBlunt dissectorsCross cutCarpal ligament

A flexible cutting filament or wire is led through the carpal tunnel, beneath the transverse carpal ligament, by a passer. Thereafter, the opposite ends of the wire are secured in an instrument which tightens the wire and may be used to move the wire as a cutting tool to transect the overlying ligament, while preserving surrounding tissues. The small wire diameter enables minimally invasive techniques to limit post-operative pain and speed recovery.

Owner:SUDDABY LOUBERT

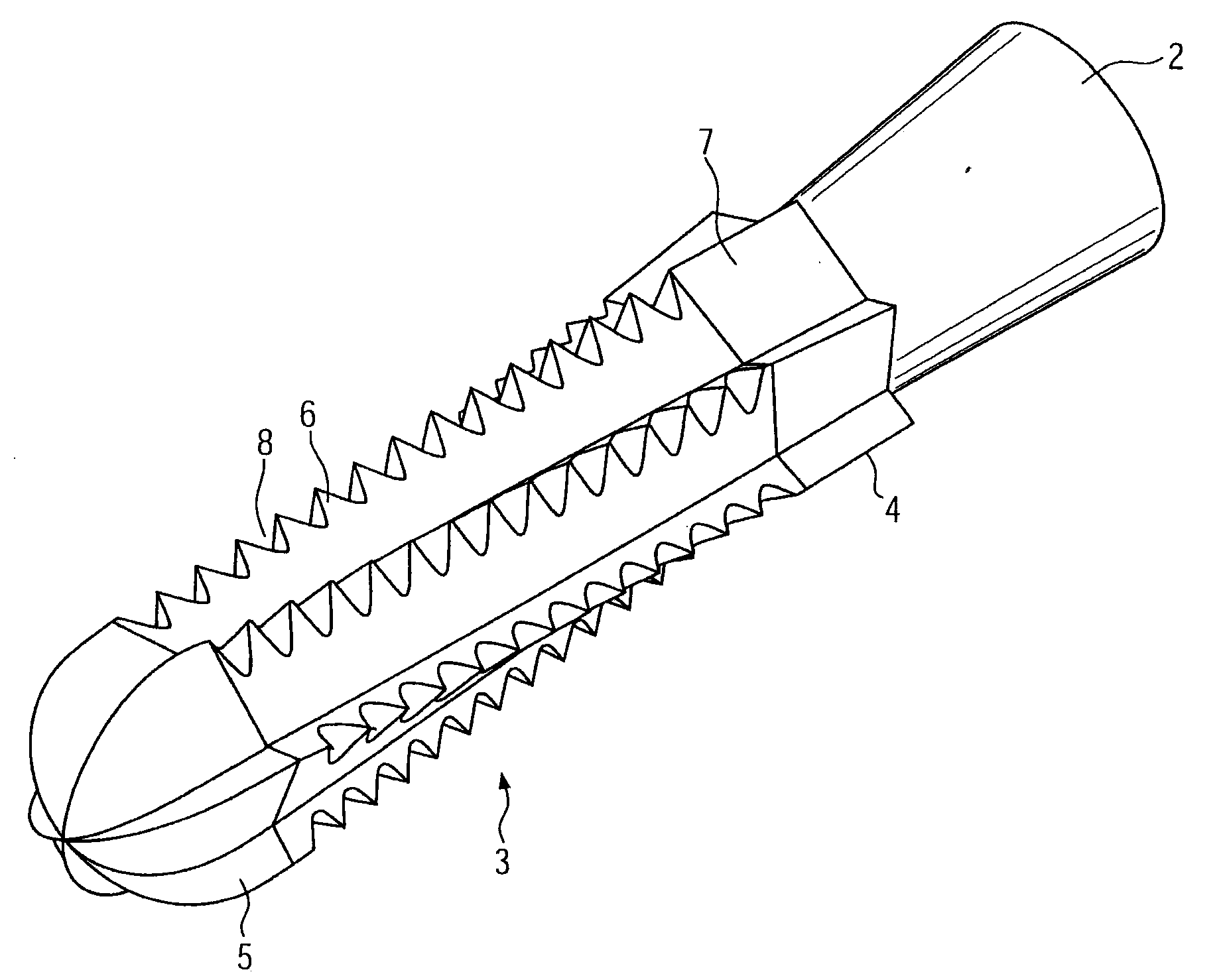

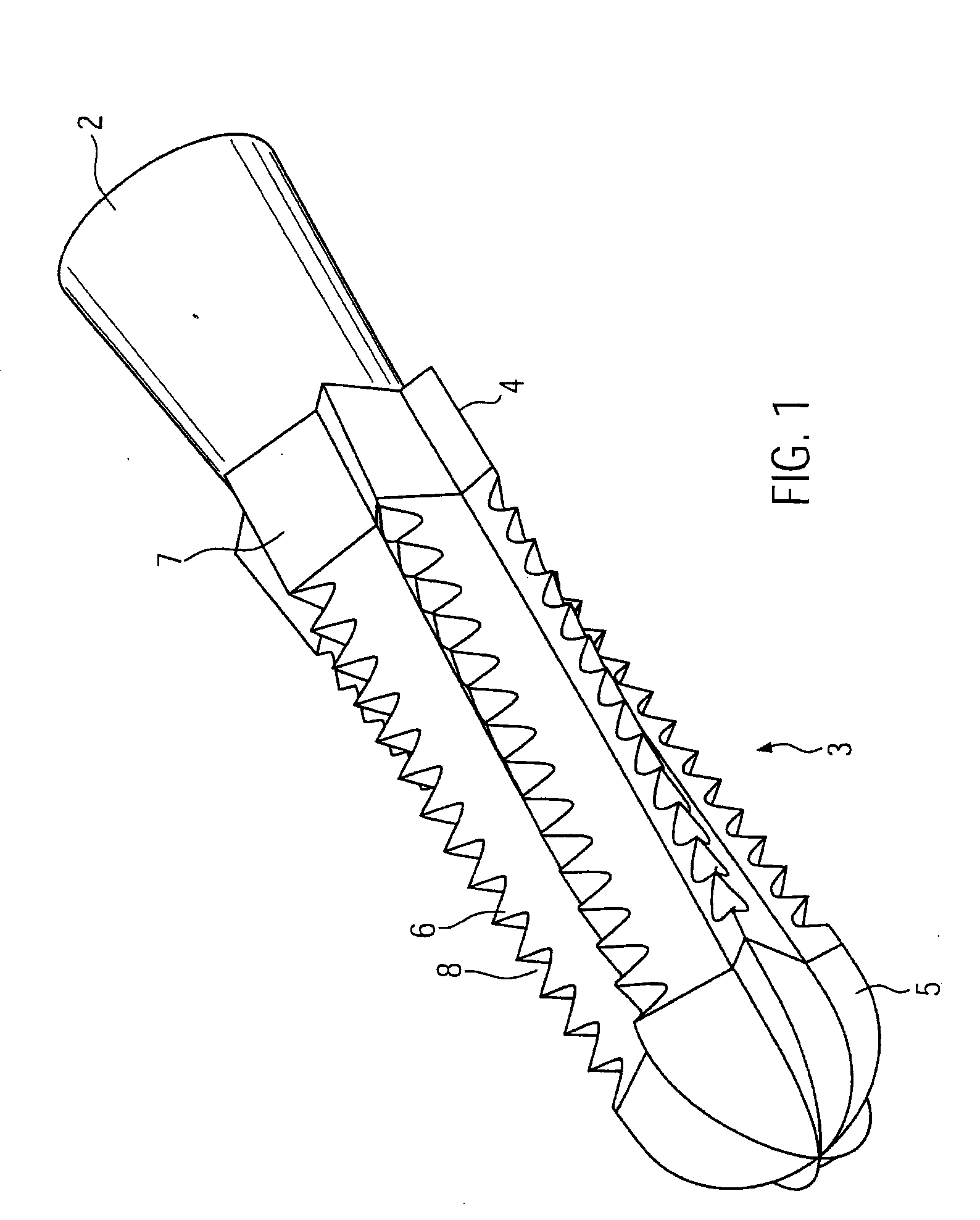

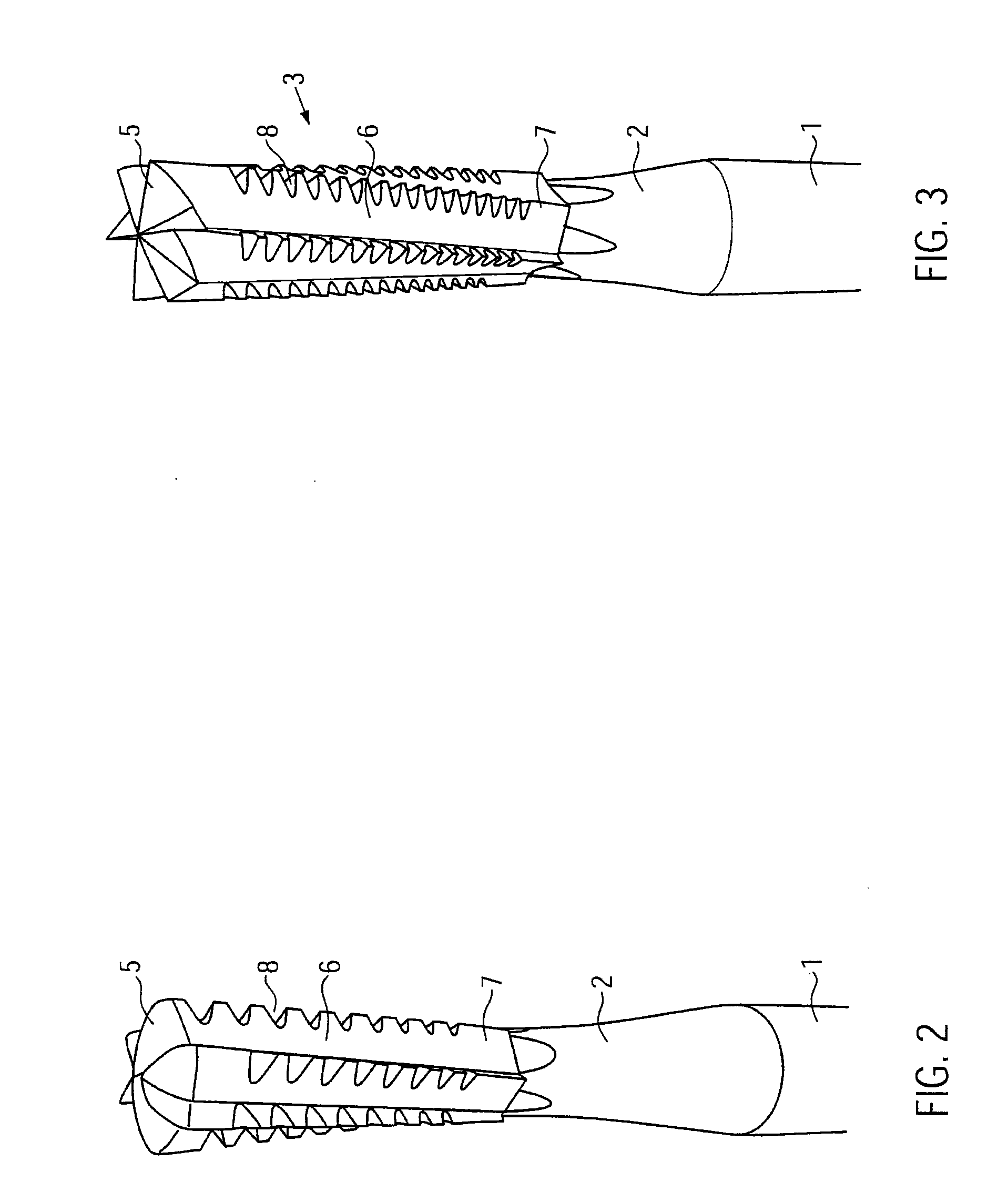

Dental drill

InactiveUS20090053674A1Improve cutting efficiencyFine surfaceTeeth fillingDental toolsCross cutEngineering

The invention relates to a dental drill comprising a shaft as well as a head being provided with a plurality of cutting edges extending lengthwise of the head, wherein the cutting edges are provided with at least one cross-cut at a middle portion of the head.

Owner:GEBR BRASSELER GMBH & CO KG

Multi-axis panel saw

InactiveUS20060032356A1Prevent overloadMetal sawing devicesMetal sawing accessoriesControl systemCross cut

A panel saw has a first cutting blade for cutting stock in a first axis and a second cutting blade for cutting the stock in a second axis. The first blade moveable from a cutting position to a position in which stock can be slid between the cutting blade and a supporting frame of the panel saw. The panel saw allows repeated cross cuts and rip cuts without changing the cutting location of the first cutting blade. A control system is configured to retract the first cutting blade from contact with the stock if the current draw exceeds a value. The control system may also retract a cutting blade when it senses the end of a panel being cut.

Owner:CHISEL WORKS L L C THE

Active energy ray-curable ink, ink cartridge containing ink, image or cured product forming method, and image or cured product forming device

ActiveUS20150077481A1Desirable in adhesiveDesirable adherenceInksPrintingCross cutEthylene Homopolymers

An active energy ray-curable ink which contains: polymerizable compounds containing a monofunctional polymerizable monomer a homopolymer of which has Tg of 90° C. or higher, wherein a cured product obtained by forming a coating film having an average thickness of 10 μm on a polycarbonate substrate using the ink, and 15 seconds later, and applying active energy rays having a light quantity of 1,500 mJ / cm2 to the coating film to cure satisfies the following (1) and (2):(1) a stretchability of the cured product represented by the following equation is 2 or greater, when the cured product is stretched by a tensile tester at a tensile speed of 20 mm / min, and temperature of 180° C., andStretchability=(length after tensile test) / (length before tensile test)(2) adhesion between the substrate and the cured product as measured by a cross-cut test in accordance with JIS K5400 is 70 or greater.

Owner:RICOH KK

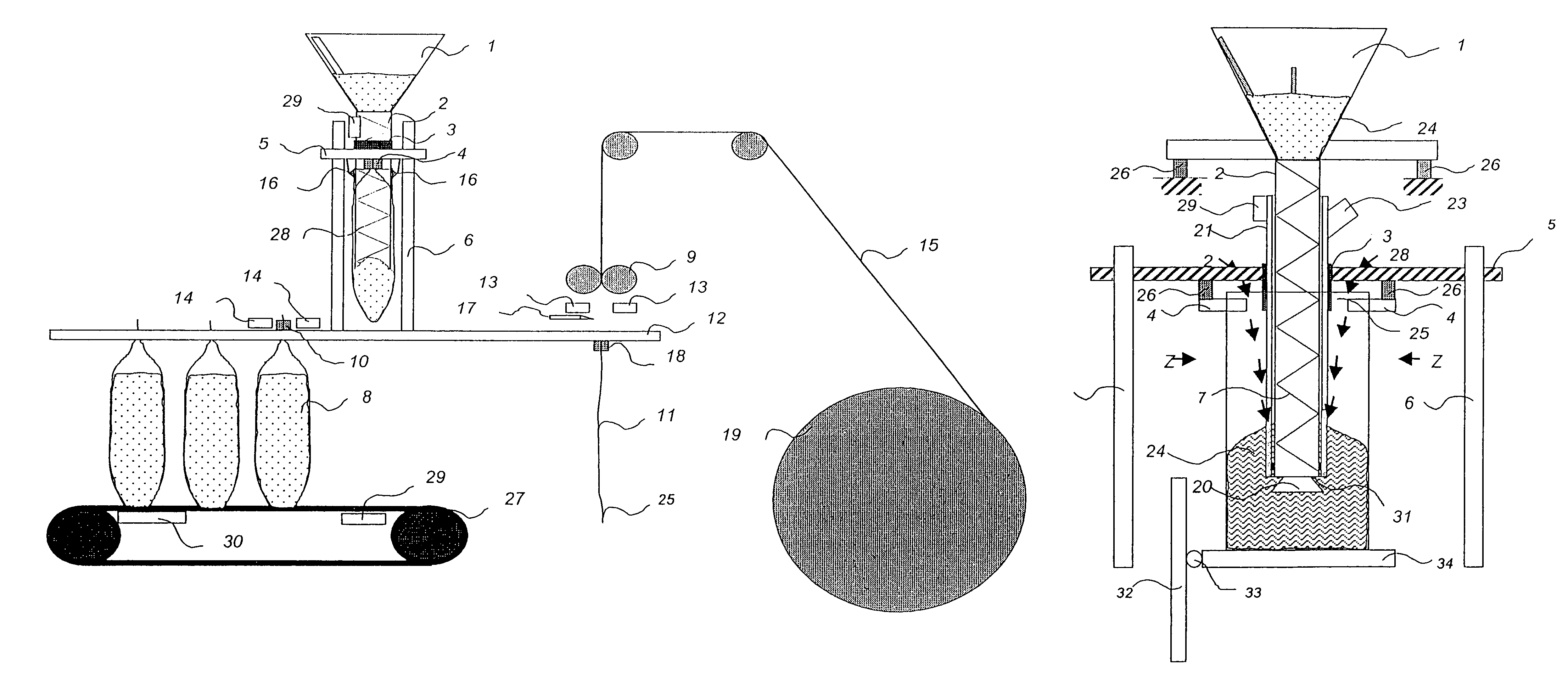

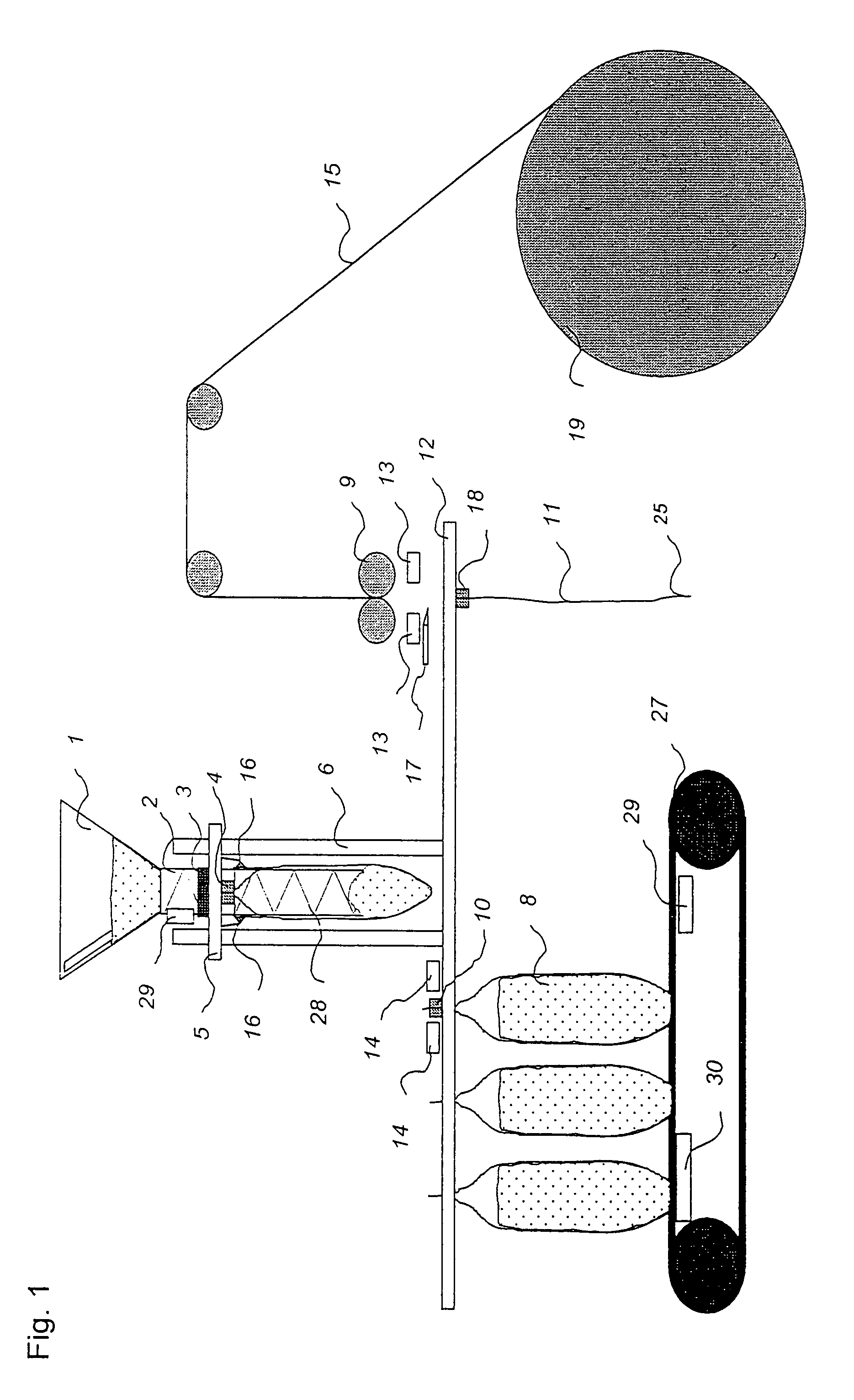

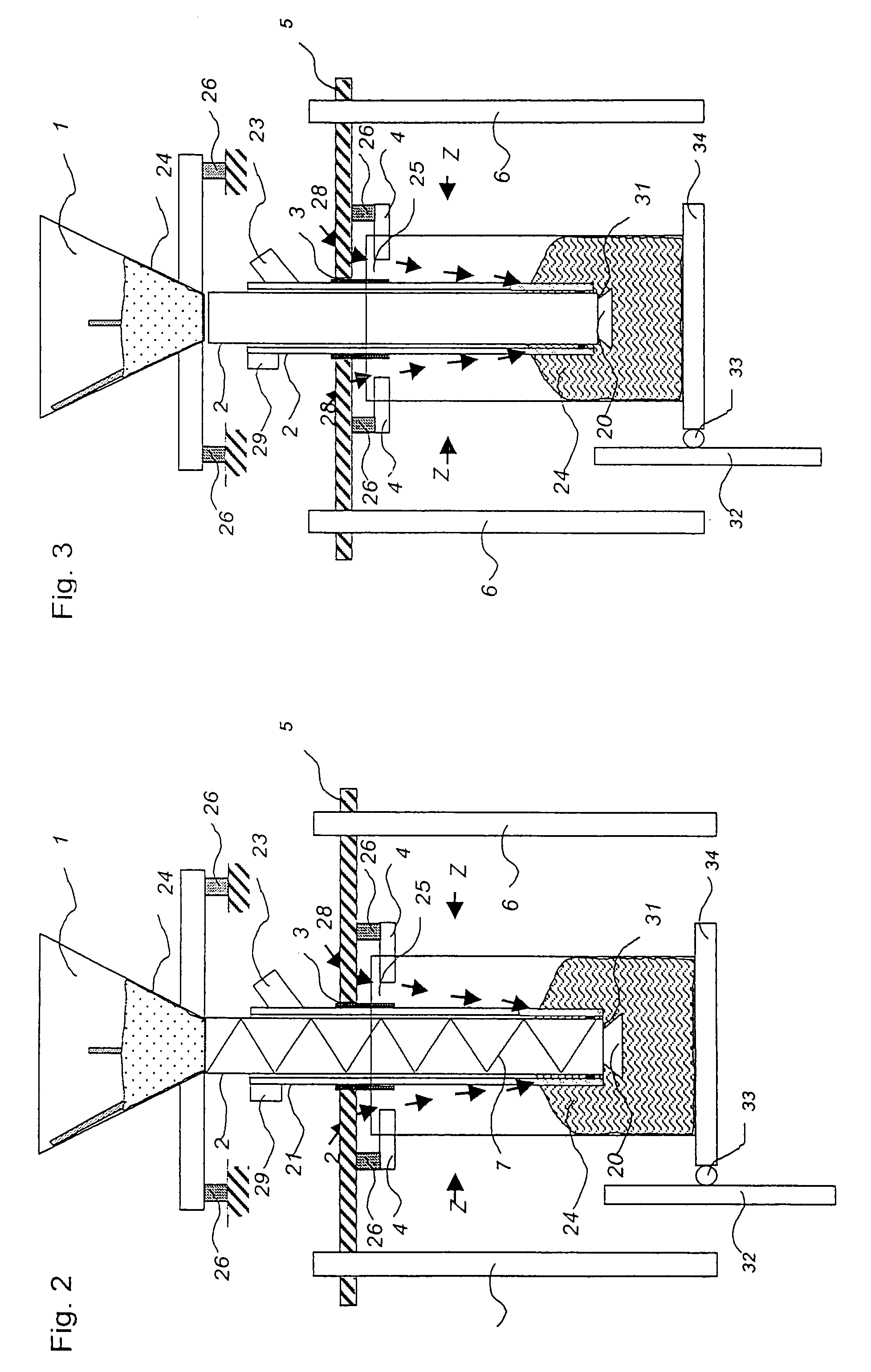

Machine for forming, filling and closing bags with a bag lifting device

InactiveUS7877966B2Reduced dust formationPackaging cigarettePackaging cigarsAxis of symmetryCross cut

Owner:WINDMOELLER & HOELSCHER GMBH

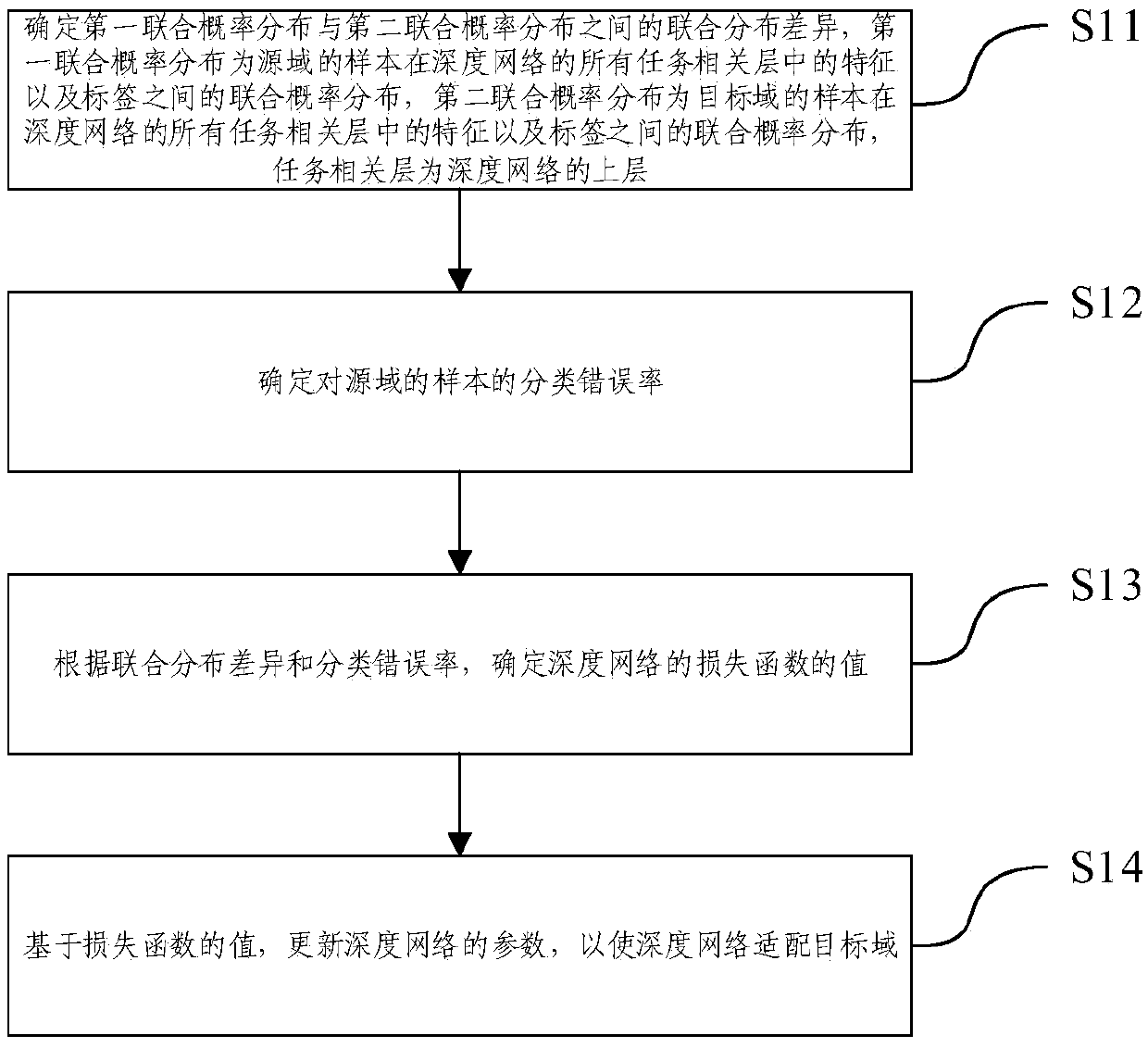

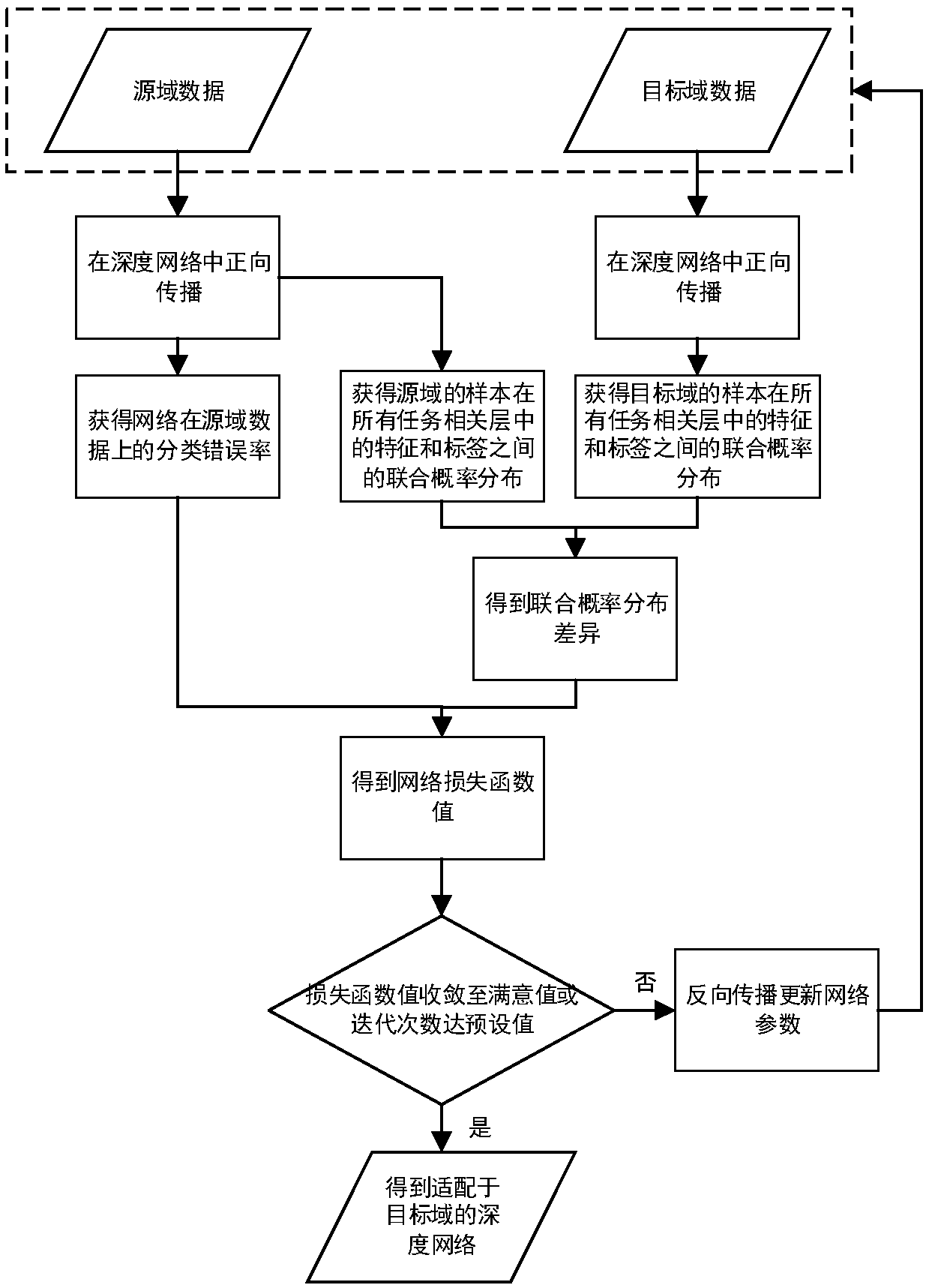

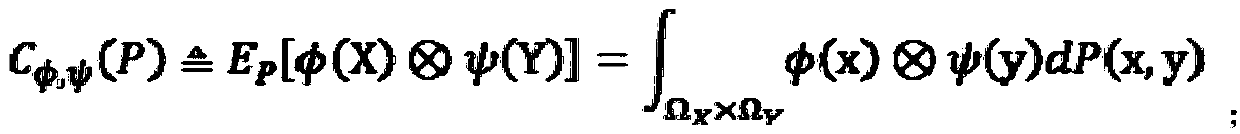

Deep transfer learning method based on big data cross-domain analysis

InactiveCN107704926ATransfer learning is goodImprove migration abilityNeural learning methodsCross cutDomain analysis

The present invention provides a deep migration learning method for cross-domain analysis of big data, by determining the value of the loss function of the deep network according to the joint distribution difference and the classification error rate, wherein the joint distribution difference is in all task-related layers corresponding to the source domain The distribution difference between the features of the feature and the joint probability distribution between the labels and the features in all task-related layers corresponding to the target domain and the joint probability distribution between the labels; and based on the value of the loss function, the parameters of the deep network are updated to Adapt the deep network to the target domain; thus, in the transfer learning process of the deep network, the joint distribution difference is used as a component of the value of the loss function of the deep network, and by updating the parameters of the deep network, while ensuring the accuracy of the source domain Realizing the matching of the joint distribution of the source domain and the target domain improves the migration ability of all task-related layers, thus bringing better results to the transfer learning of deep networks between different domains.

Owner:TSINGHUA UNIV

Method of cross-cutting a web

InactiveUS20040060464A1Efficient use ofIncrease variabilityRotary pressesMetal working apparatusCross cutSheet material

Owner:MANROLANAD AG

Combined rock cross-cut coal uncovering method

ActiveCN103510957AUniform pressure relief and anti-reflectionShorten prepumping timeUnderground miningSurface miningDrill siteCross cut

The invention discloses a combined rock cross-cut coal uncovering method which is particularly suitable for quick rock cross-cut coal uncovering of outburst dangerous coal seams in underground coal mines. When a cross cut is tunneled to be at a vertical distance of 10 m from coal seams, a drill site is directly constructed in the cross cut; the coal seams are constructed and holes are drilled in the drill site; the drill holes are arranged at intervals by slotting drill holes and general drill holes; the uniform pressure relief of coal bodies is realized through the combined arrangement of the slotting drill holes and the general drill holes. After the drilling operation is finished, pipes are connected for extraction and drainage to reduce the gas content and the gas potential in the coal seams. After the gas extraction is qualified, the slotting drill holes are used as slurry injecting drill holes to inject cement mortar in the coal bodies for strengthening the coal bodies, so that the combination of slotting pressure relief and reinforcement is realized. Under the condition of guaranteeing safe coal uncovering, through the adoption of the method, the outburst removing engineering amount can be reduced by 30-40%, the gas extraction time and the coal uncovering period can be shortened, and the safe coal uncovering speed is increased by 40-50%.

Owner:CHINA UNIV OF MINING & TECH

Outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method

ActiveCN104213932AChange mechanical propertiesImprove breathabilityUnderground miningSurface miningLiquid stateFreezing thawing

The invention provides an outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method, which is applicable to high-gas-outburst coal bed cross-cut coal uncovering operation. The minimum normal distance from the cross-cut coal uncovering working face to the coal bed is greater than or equal to 7m position, a plurality of holes are respectively drilled in the coal uncovering region, a conventional capsule hole sealing coal bed water injection technology is adopted for injecting water into the coal bed through the drilled holes, after the water injection completion, a conventional refrigeration freezing technology is adopted for freezing the coal bed around the water injection hole, in the freezing process, free water in the coal bed is gradually converted from the liquid state into the solid state, and the volume of the water expands for 9.1 percent in the phase change process; after the freezing completion, the freezing coal bed absorbs the underground environment head and gradually thaws. After the freezing thawing completion, the water injection hole and a gas extraction pipeline are connected for gas extraction, or the gas extraction drilling is implemented on the coal bed in the phase change cracking region for gas extraction. When the coal bed gas content is less than 8m<3> / t, the gas extraction is stopped, the water is injected into the water injection hole again, the secondary freezing of the coal bed is completed, and then, the coal bed is uncovered according to a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com