Technique and equipment for processing package piece of packaging box

A technology of production process and production equipment, which is applied in the field of production process and equipment of packaging boxes for long-term aseptic storage of food, can solve the problems of poor product quality stability, low production efficiency, and high production cost, and achieve good package shape and high production The effect of high efficiency and small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

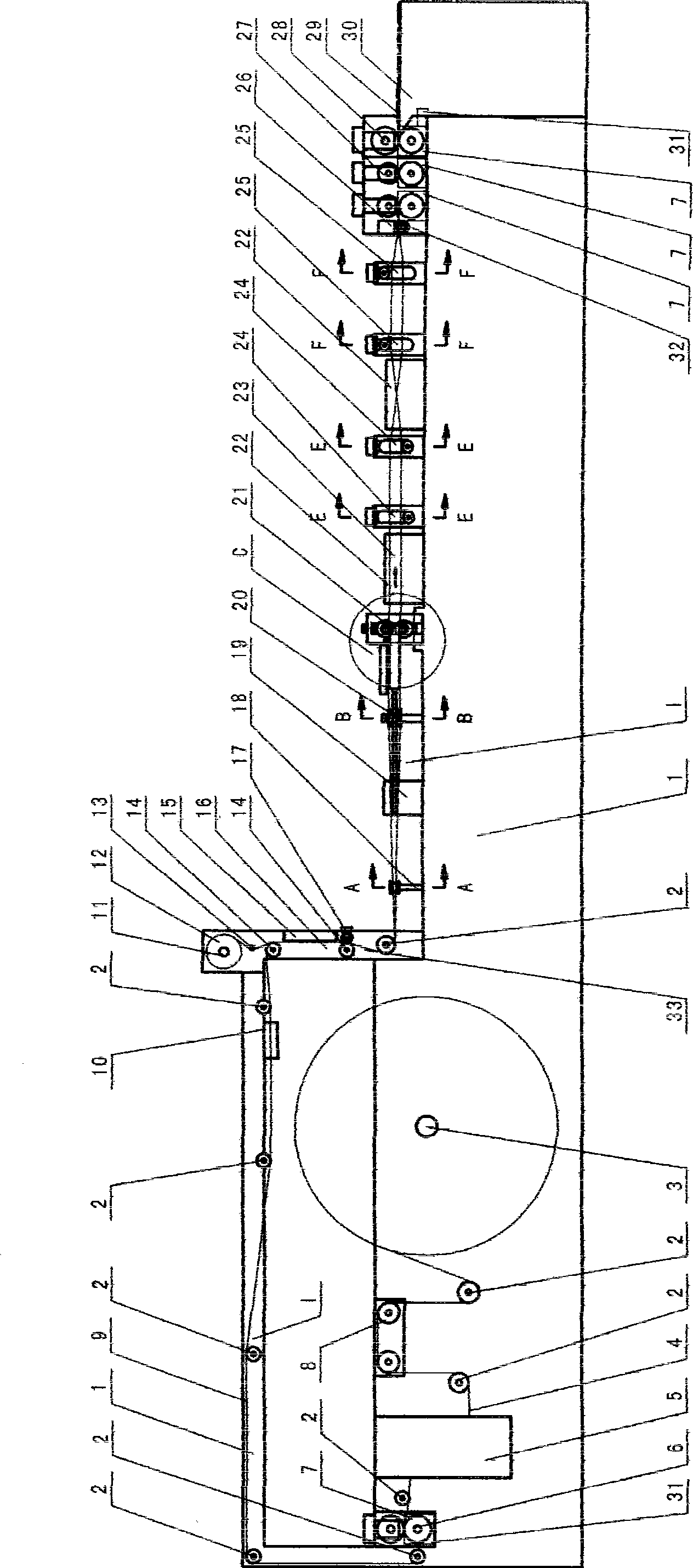

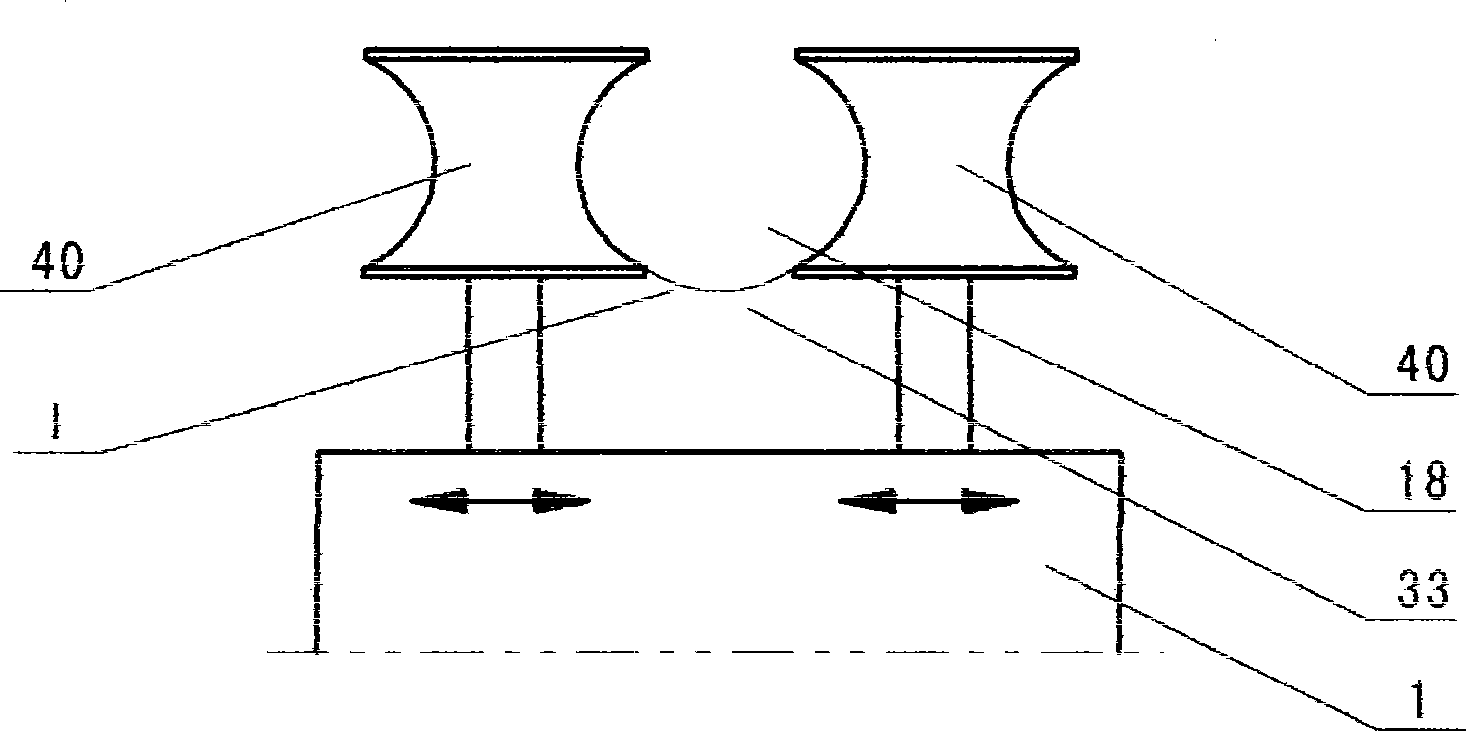

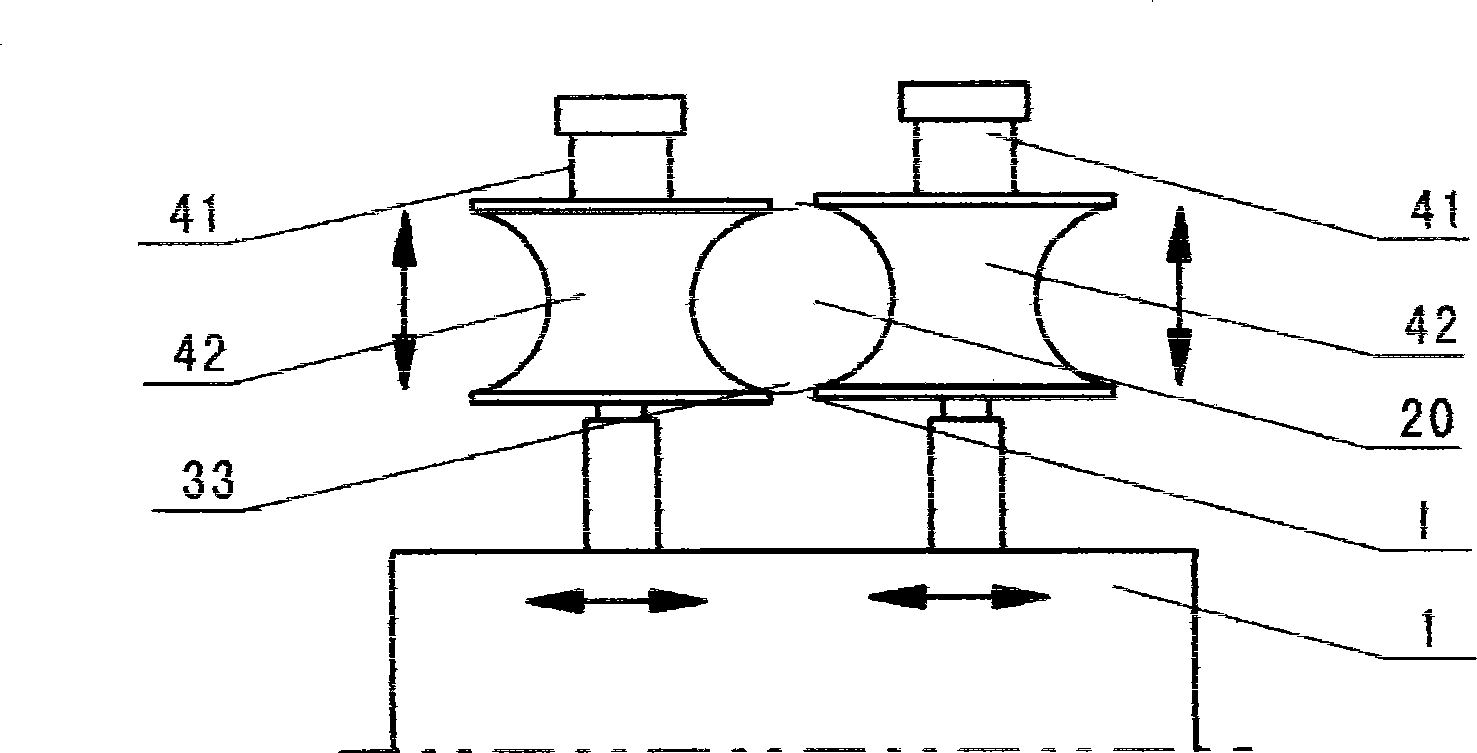

[0018] Follow the accompanying drawings for further details: figure 1As shown, the production device of the packaging box includes an unwinding mechanism 3, a positioning mechanism 5, an indentation mechanism 6, a power mechanism 7, a deviation correction mechanism 8, a guiding mechanism 10, a laminating mechanism 16, a prefolding mechanism 18, and a preforming mechanism. Mechanism 20, vertical sealing mechanism 21, cooling mechanism 22, front flattening mechanism 24, rear flattening mechanism 25, detection mechanism 26, traction mechanism 27, cutting mechanism 28, collection mechanism 30 and alignment system 31. The unwinding mechanism 3 is installed on the frame 1 to complete the unwinding of the packaging material 4 and ensure the stability of the tension of the packaging material 4 . The packaging material 4 is a composite material composed of paper, barrier material and plastic. The inner and outer layers are plastic, which can be bonded by heating. The roller 2 is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com