Patents

Literature

7304 results about "Packaging Case" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

RFID scanning device

ActiveUS10482292B2Minimal costMinimal effortLogisticsSensing by electromagnetic radiationInventory managementAuthorization

Owner:GARY L SHARPE

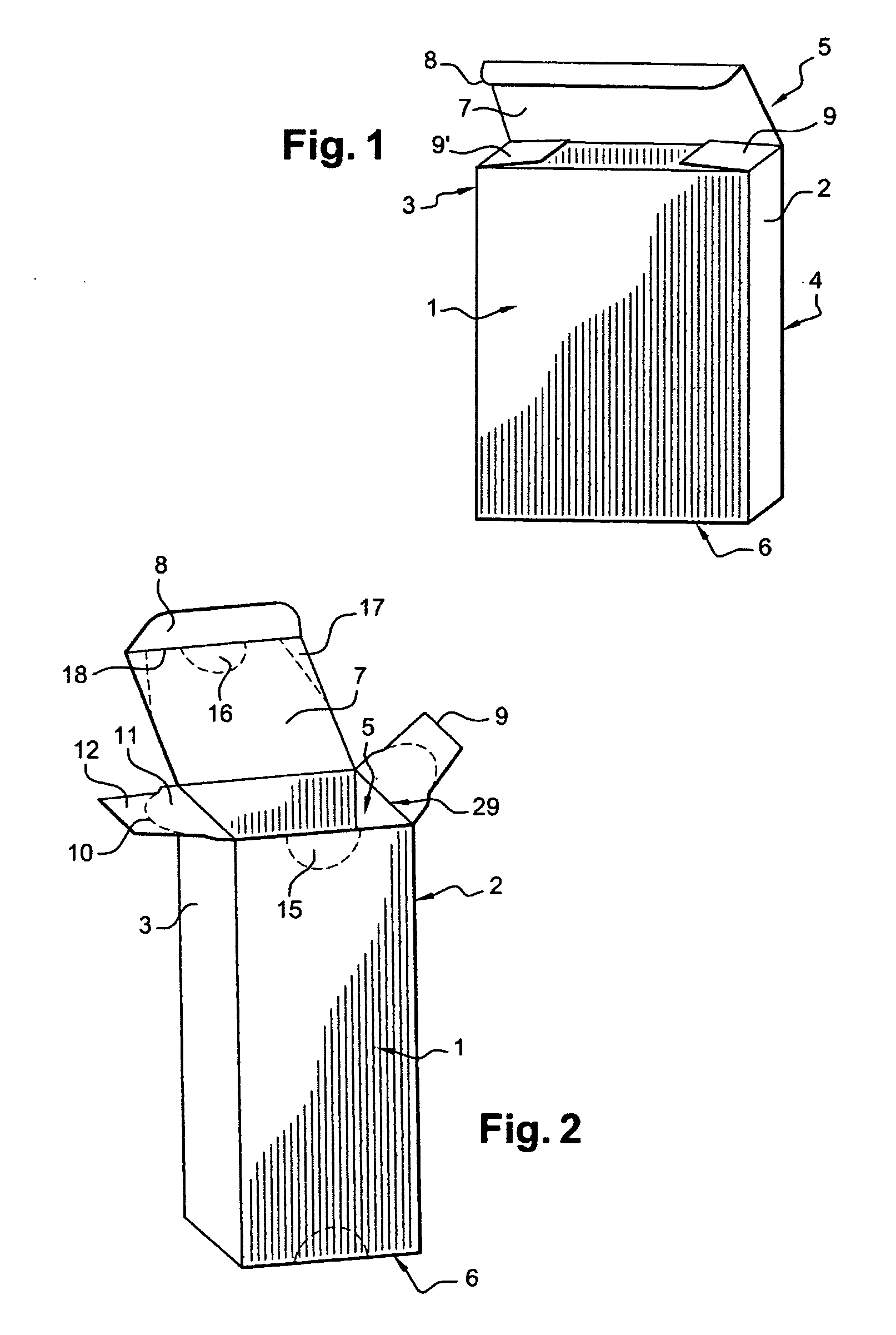

Polygonal box

Owner:AVENTIS PHARMA SA (US)

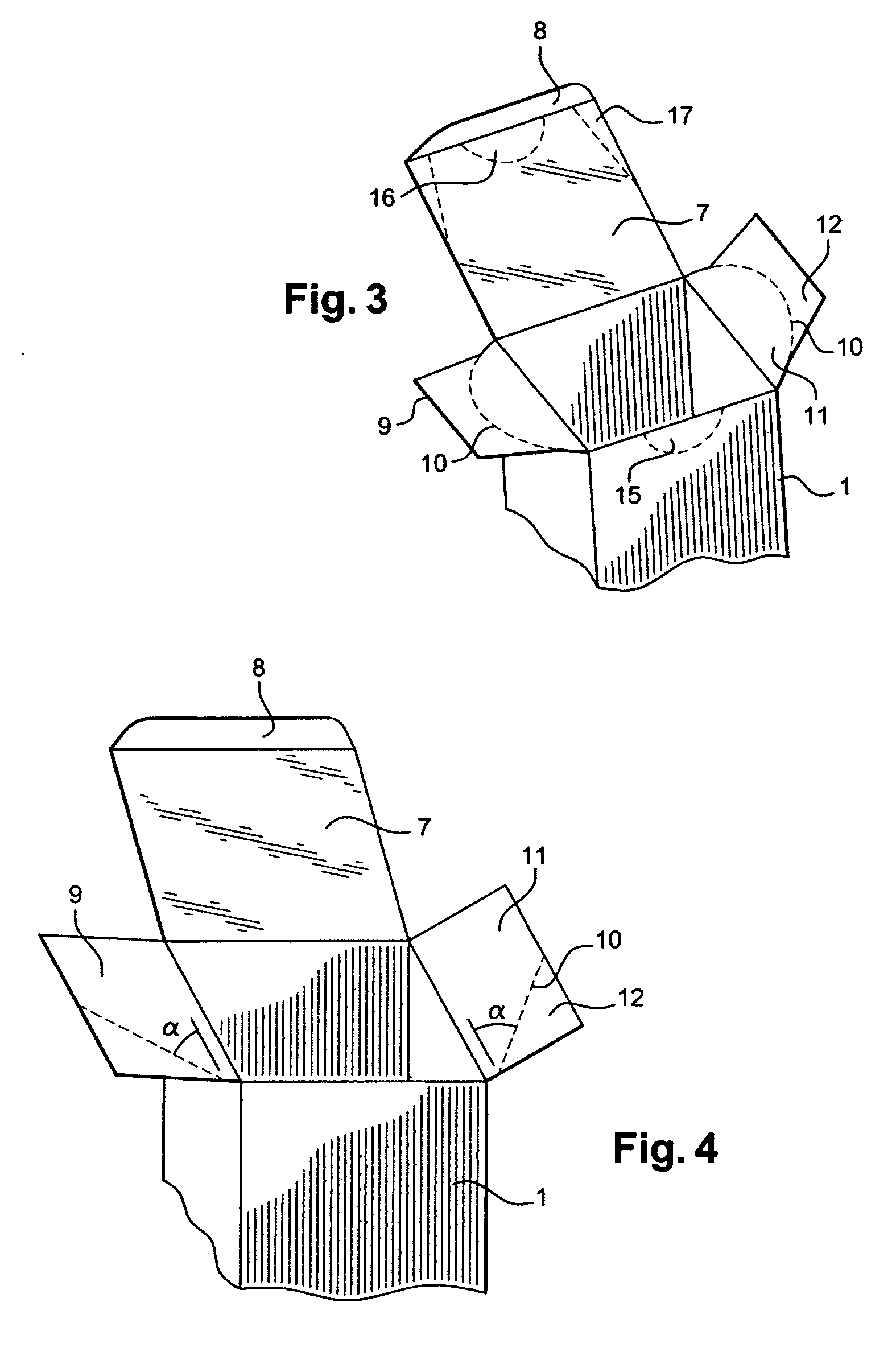

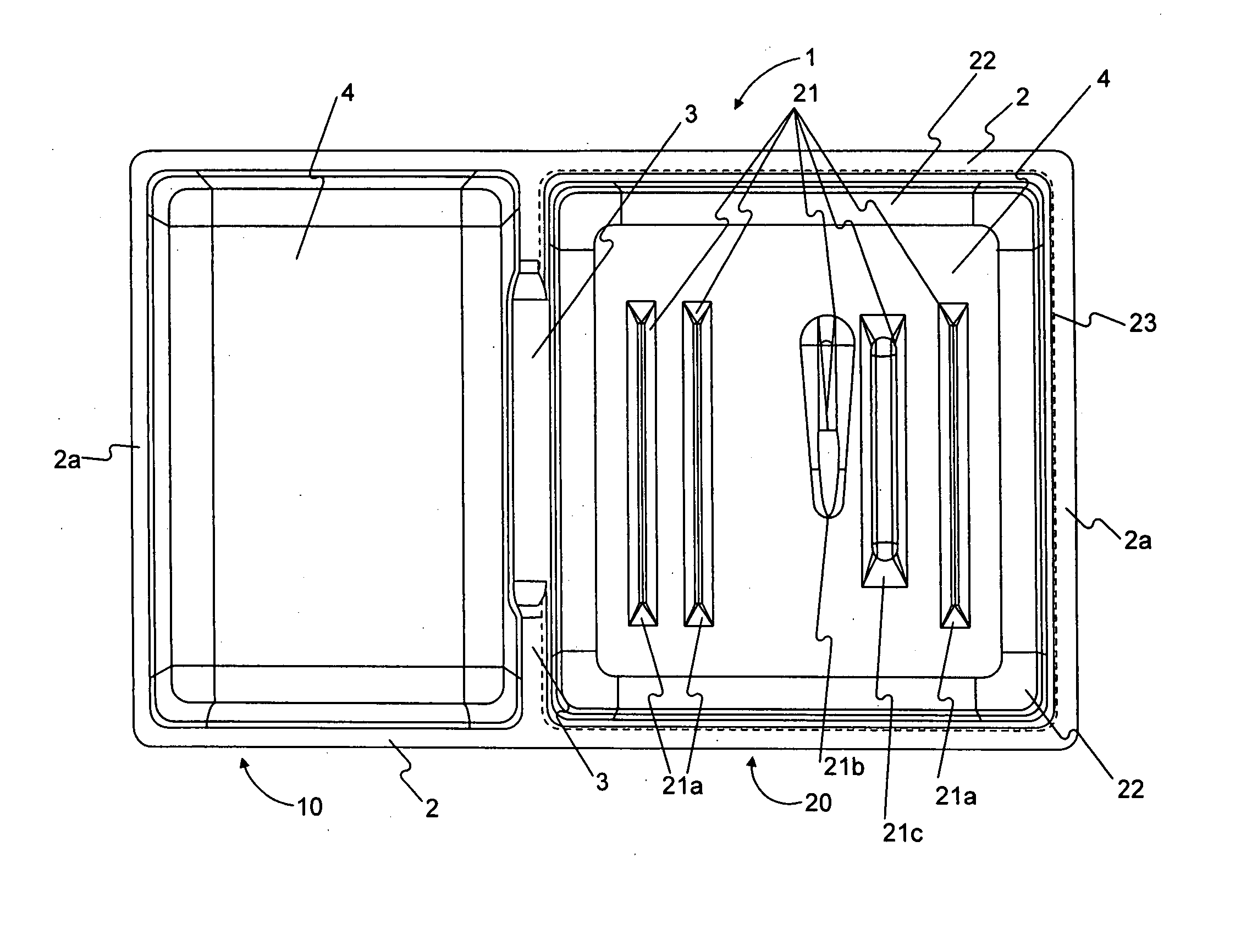

Packaging for a kit, and related methods of use

InactiveUS20060011506A1Restrict movementSuture equipmentsSurgical furnitureMedical productBiomedical engineering

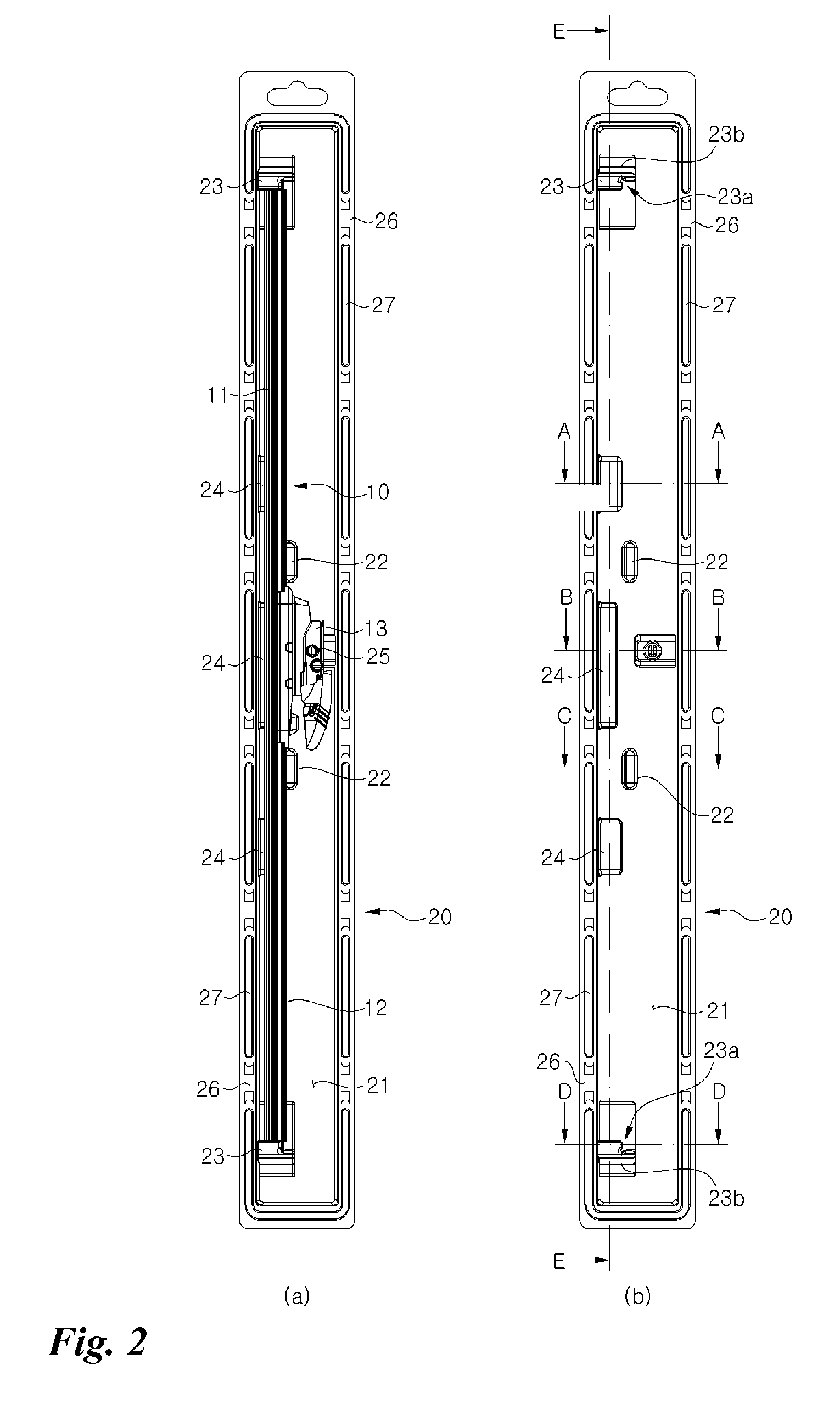

Embodiments of the invention include a packaging for a medical kit. The packaging includes a bottom configured to receive a plurality of medical products and a top having at least one protrusion extending therefrom. The bottom and the top are shaped so that the bottom receives the top with the at least one protrusion extending towards the bottom. The at least one protrusion is configured to deform about the plurality of medical products to restrict movement of the plurality of medical products.

Owner:BOSTON SCI SCIMED INC

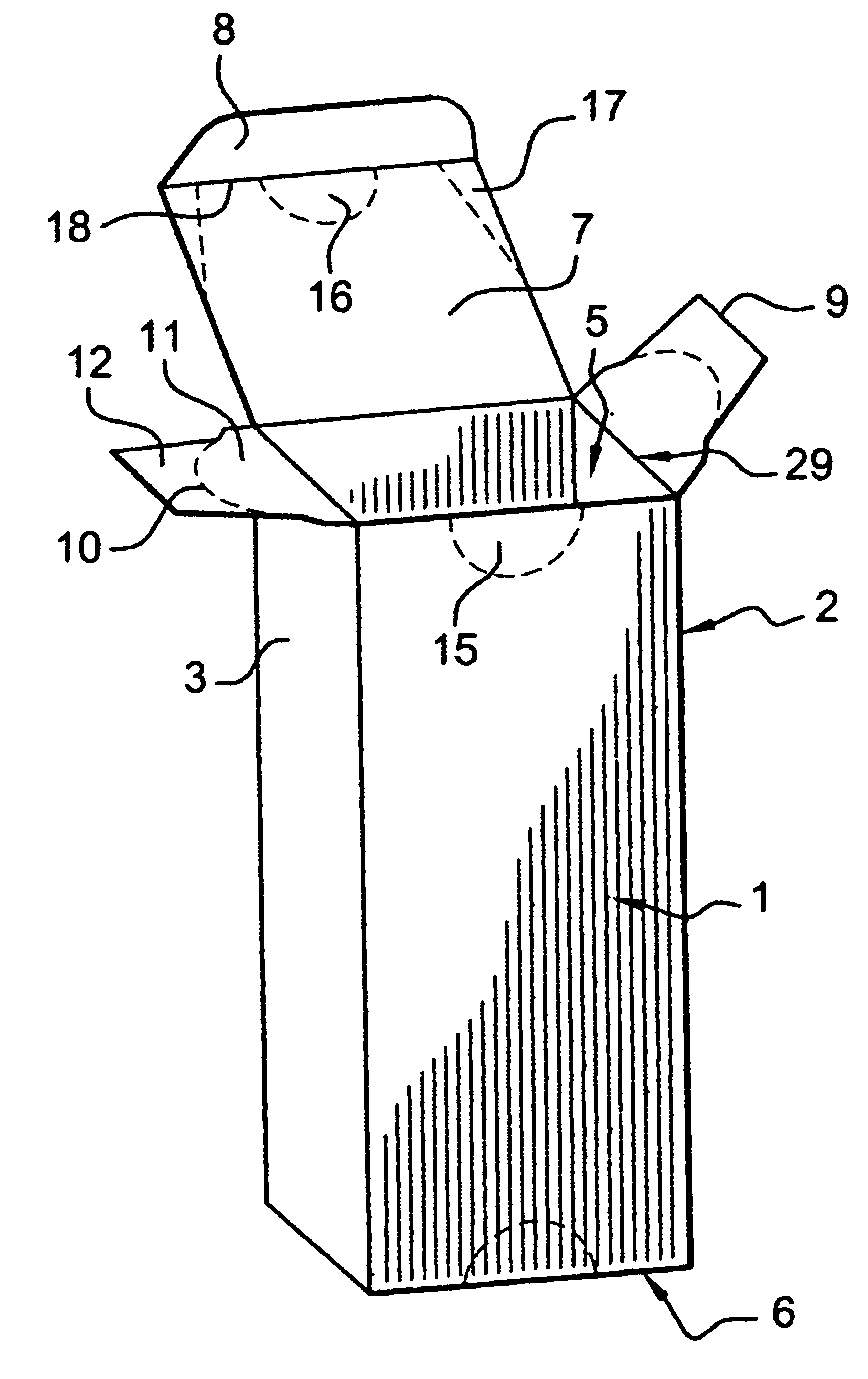

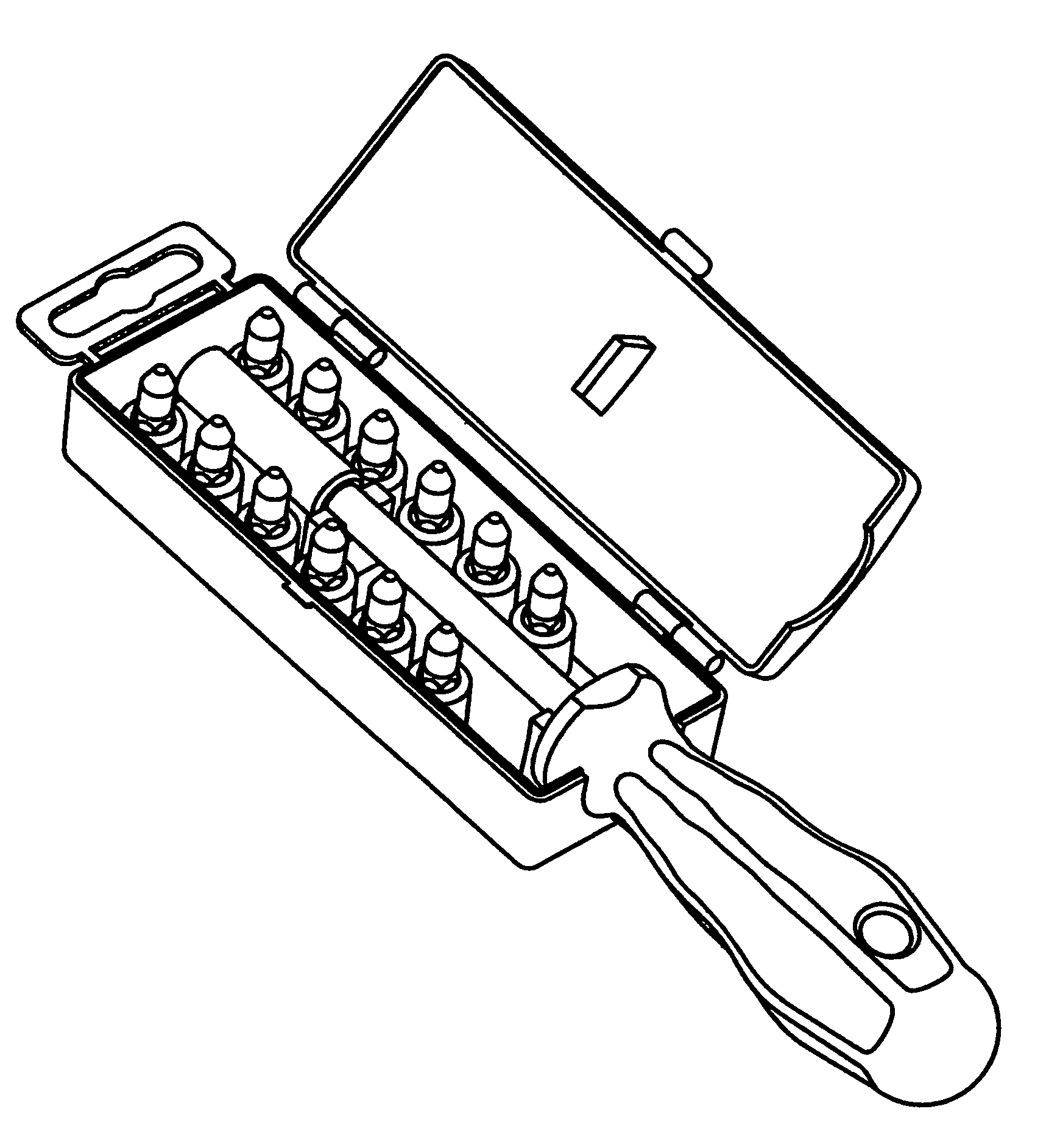

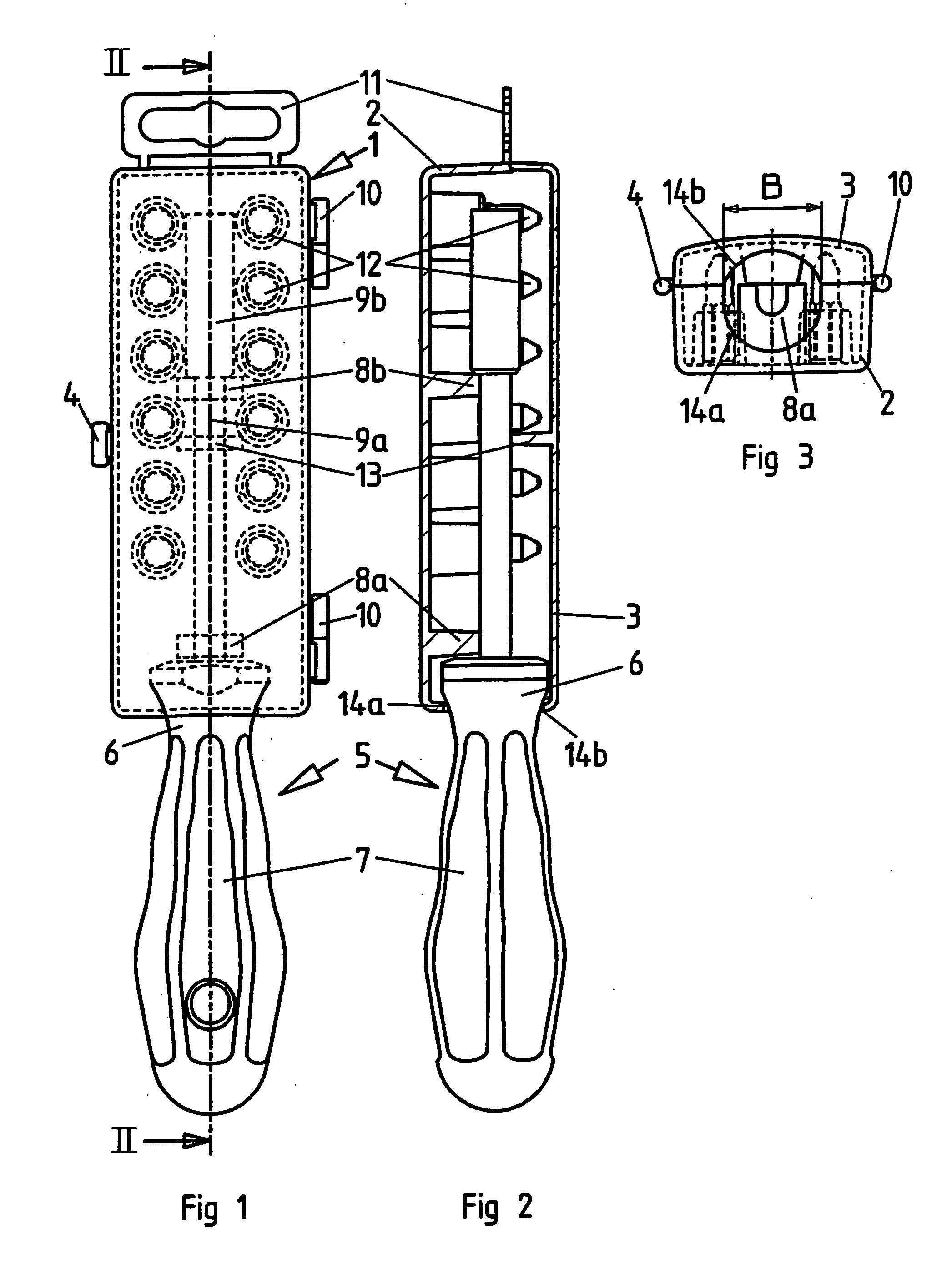

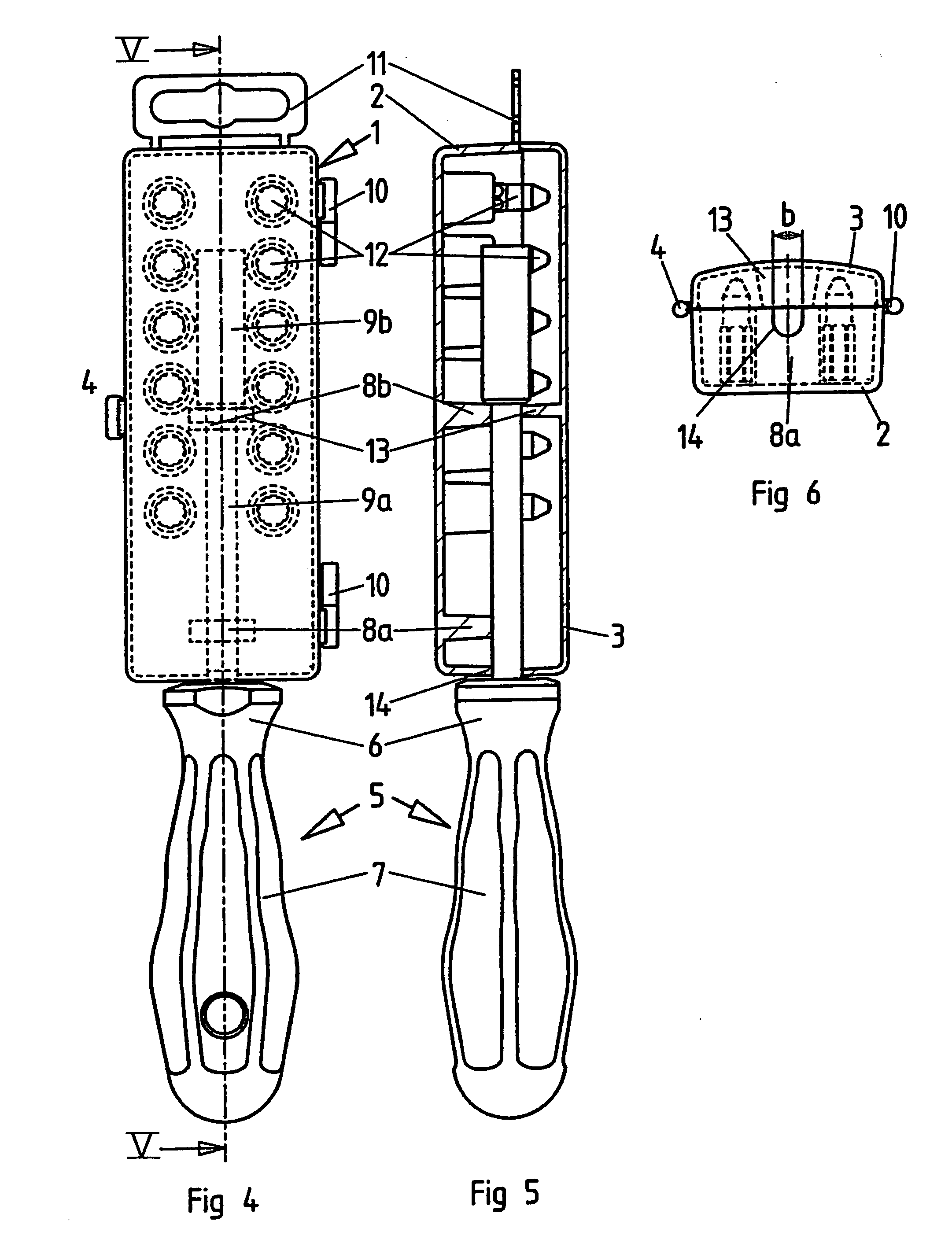

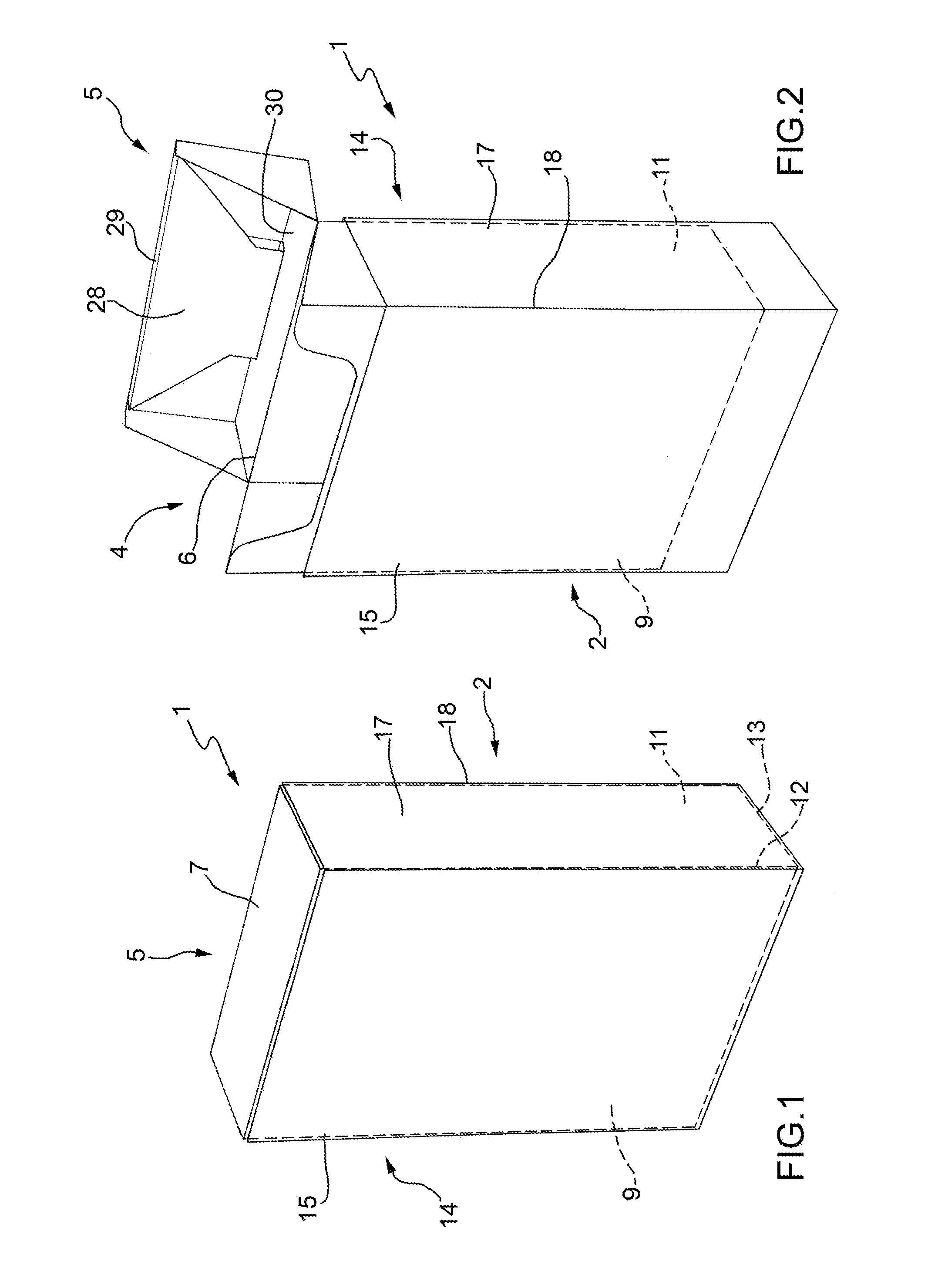

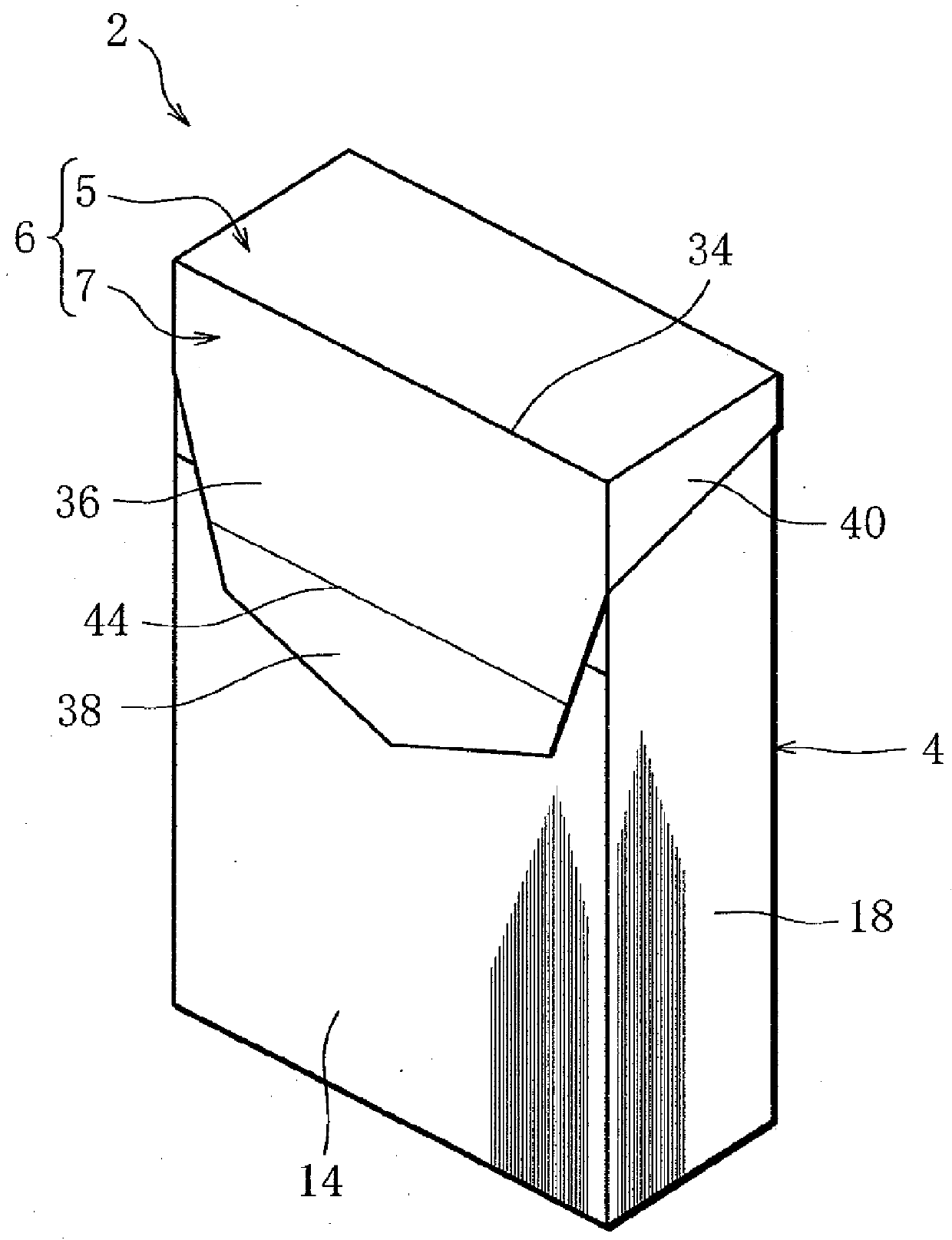

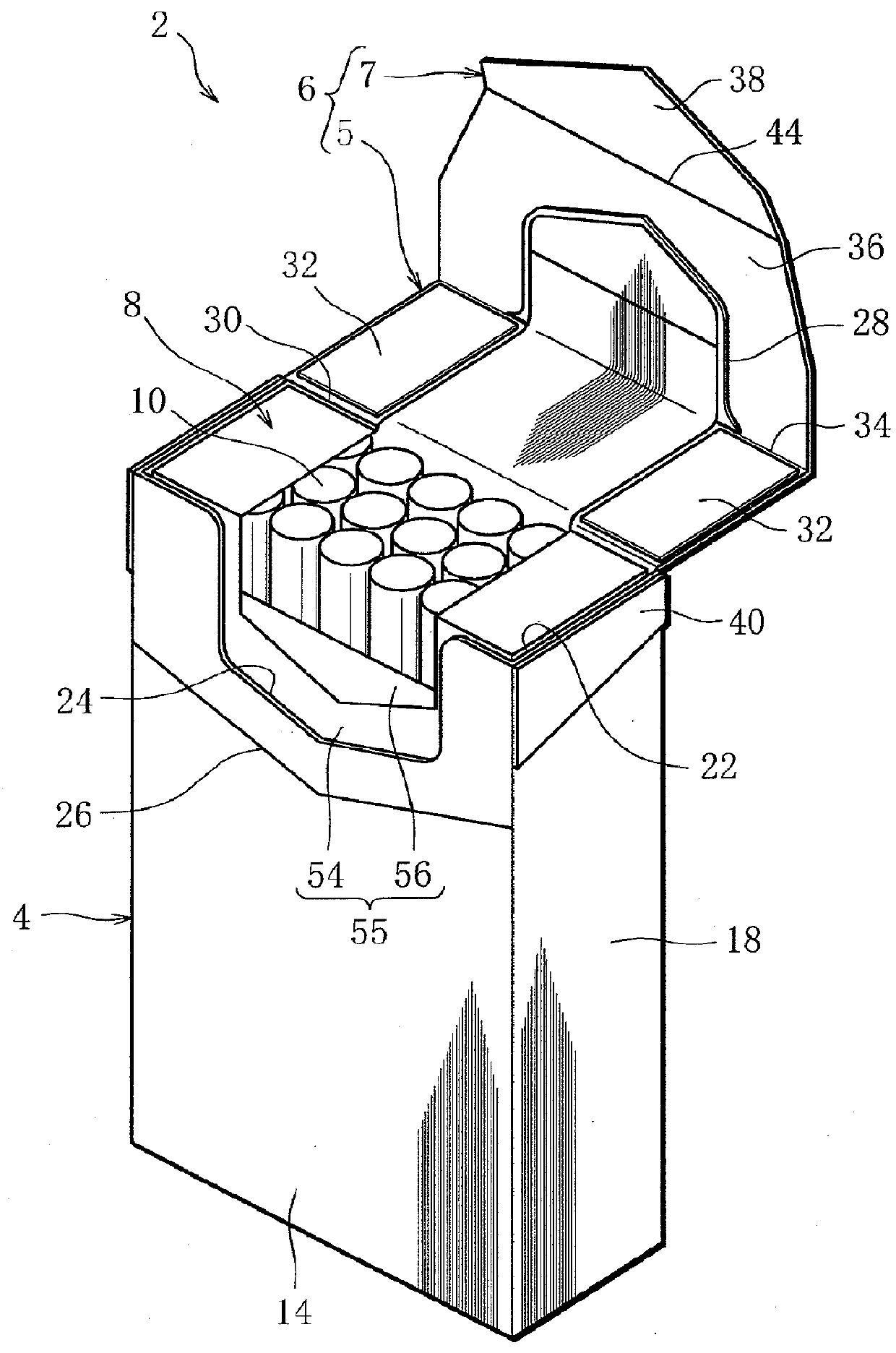

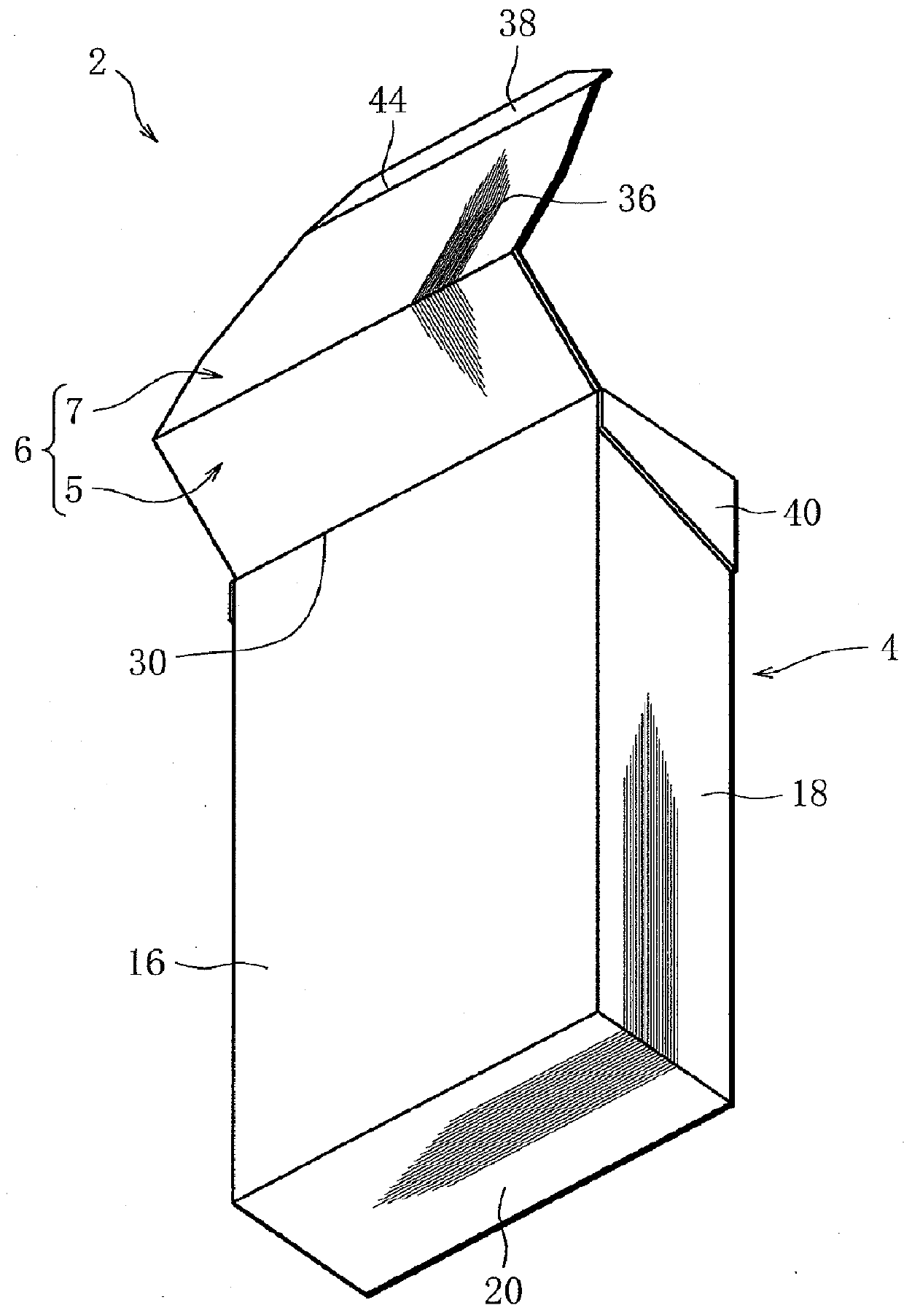

Packaging for tool sets

The invention concerns a packaging, mainly for tool sets, consisting of a handle (5) and tool-inserts (12) to be inserted into the handle and a box (1) to take the components of the tool set. The box (1) is designed in such a way that either the handle (5) extends with its front part (6) through an aperture (14a) in the side wall of the box into the inner space of the box and with its main part (7) protrudes free outside of the box (1) or the handle (5) protrudes in full length outside of the box. At both embodiments the handle may be encompassed by the hand whereas the shank (9a) extends into the inner space of the box. Handle and shank are held in their position by support and holding elements (8a, 8b, 13, 16) at the lid (3) and bottom part (2) of the box.

Owner:FELO WERKZEUGFAB HOLLAND LETZ

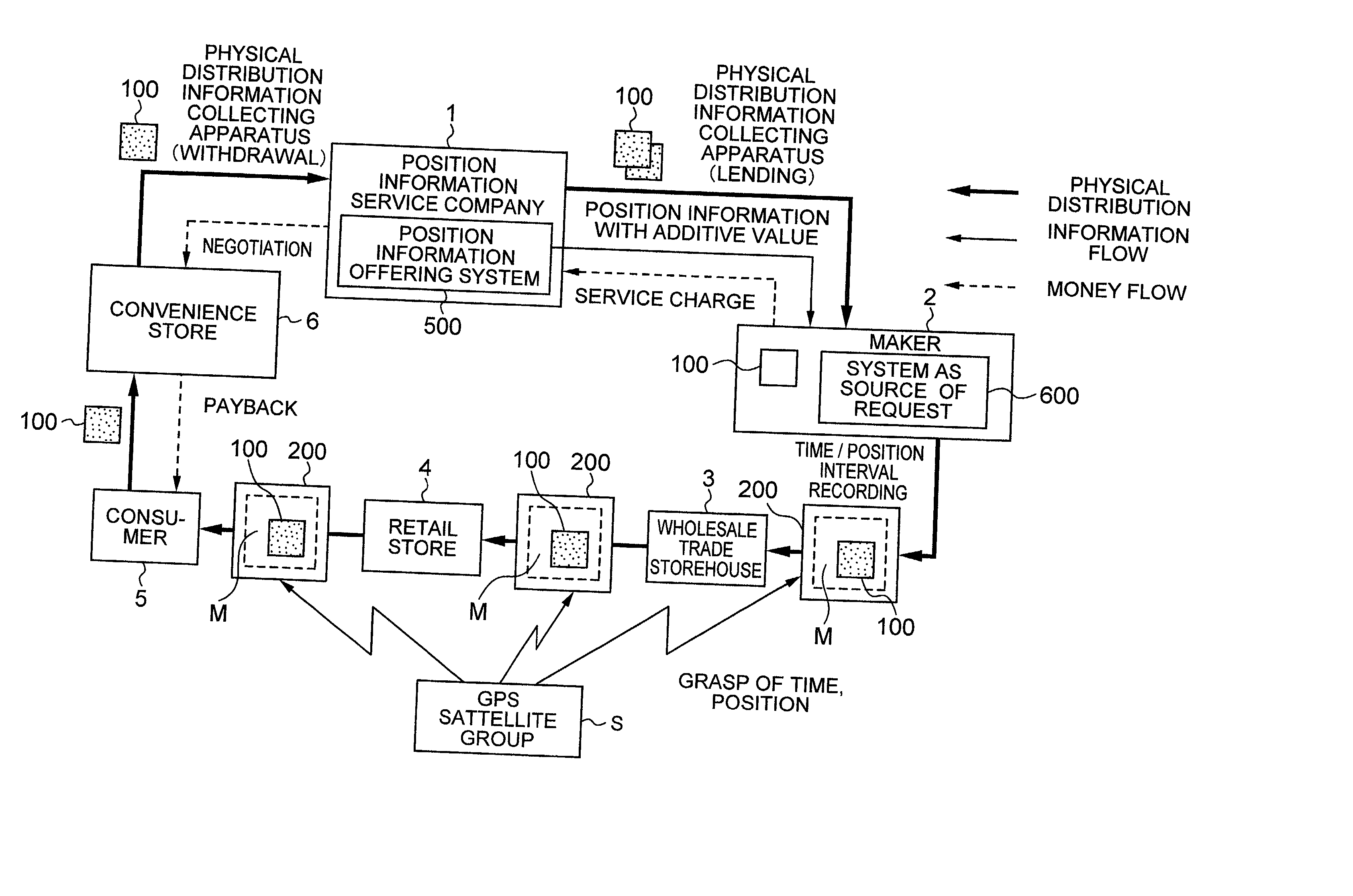

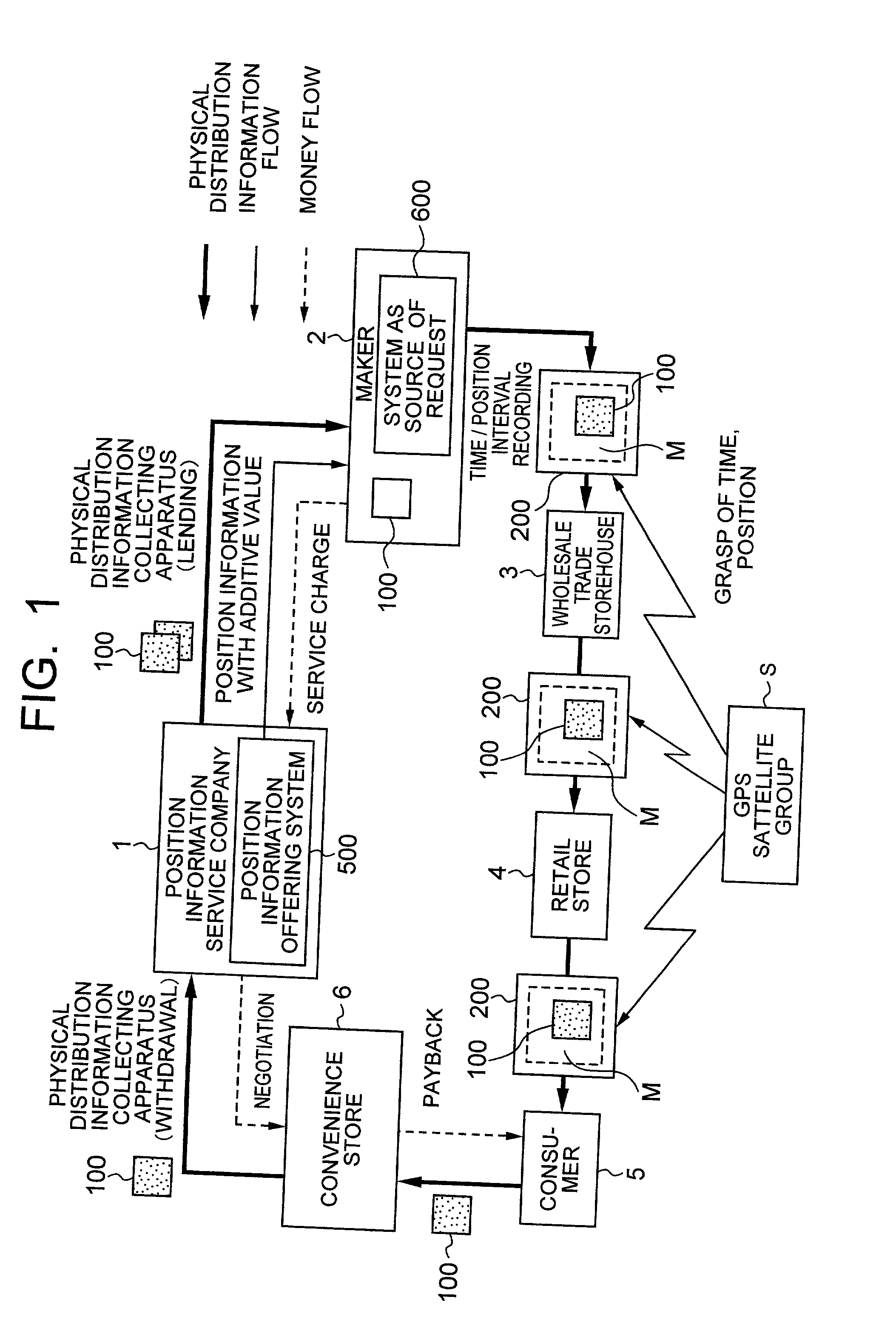

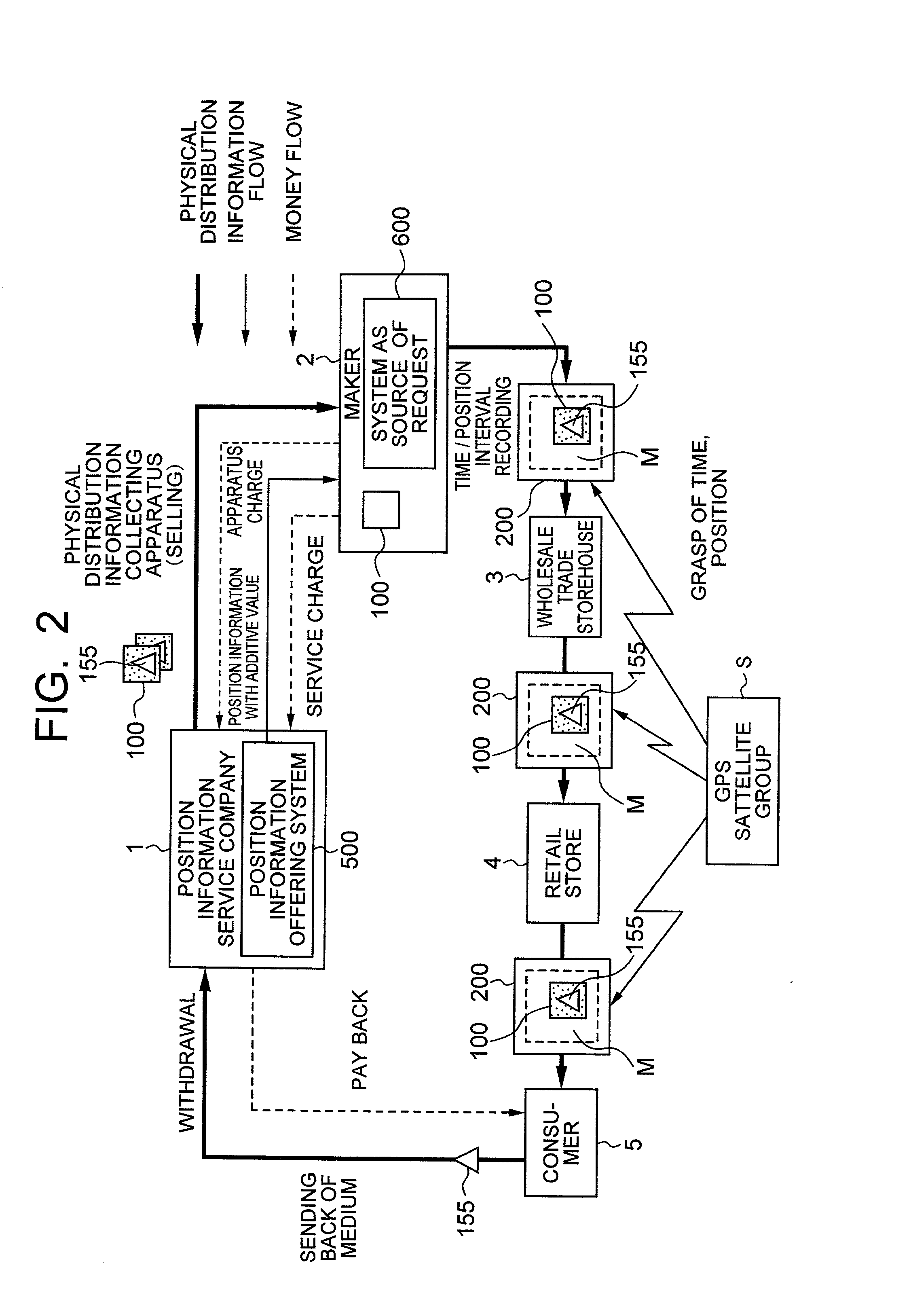

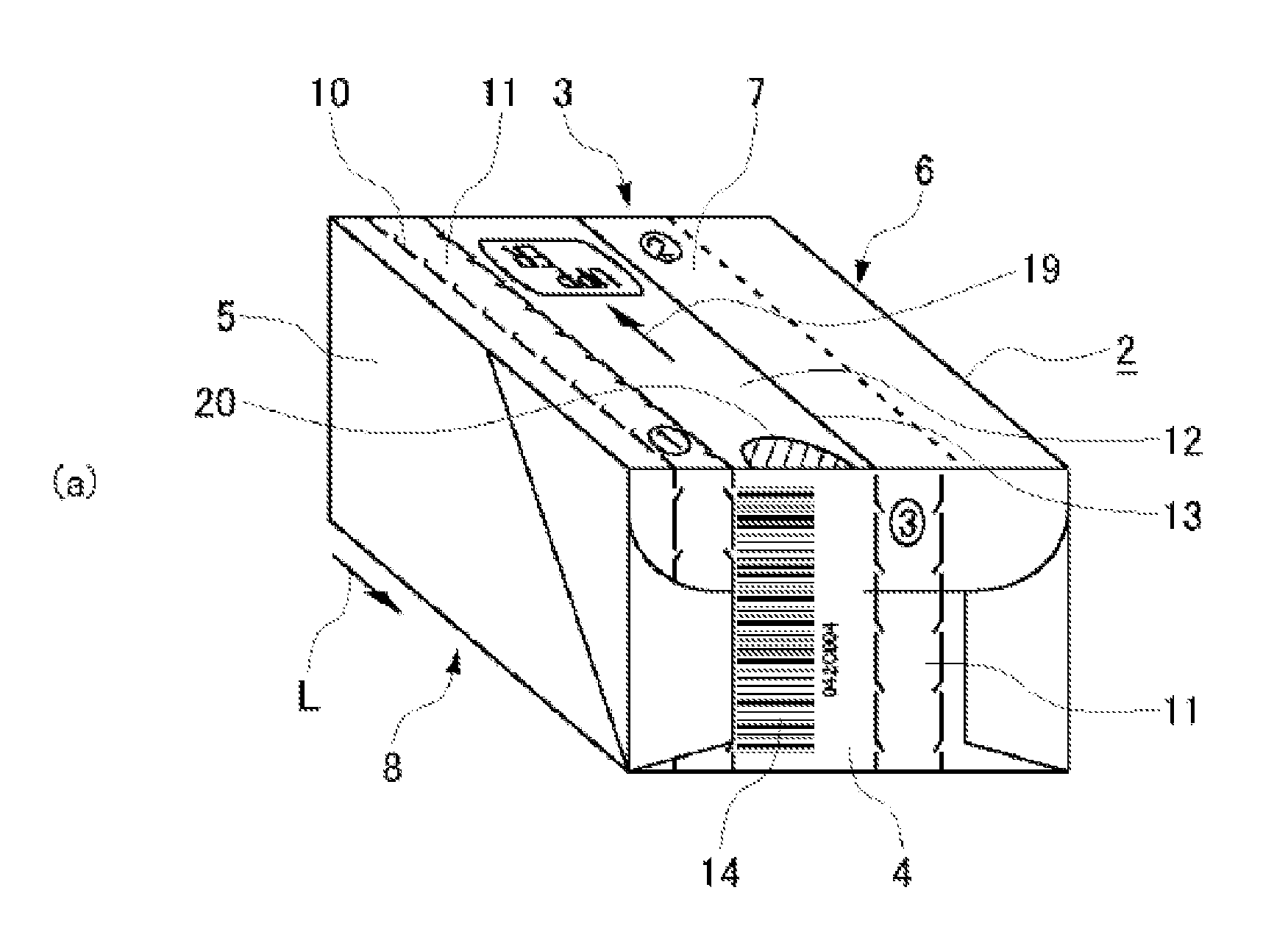

Method of collecting information of physical distribution of products and system for offering information of product positions

A position information acquiring apparatus for receiving an electric wave and for on the basis of the received signal, acquiring the position information exhibiting the position where the product is kept to record successively the position information thus acquired is packed together with an objective matter of conveyance in a package box and then is operated in the state of being able to be moved to receive an electric wave signal radiated from the GPS satellite group to acquire successively the position information. On the basis of the position information, a map of a part corresponding to the position information is retrieved from map information which is previously obtained to carry out an output for showing visibly the resultant partial map and a symbol with which the position contained in a position history information is shown on the map.

Owner:HITACHI LTD

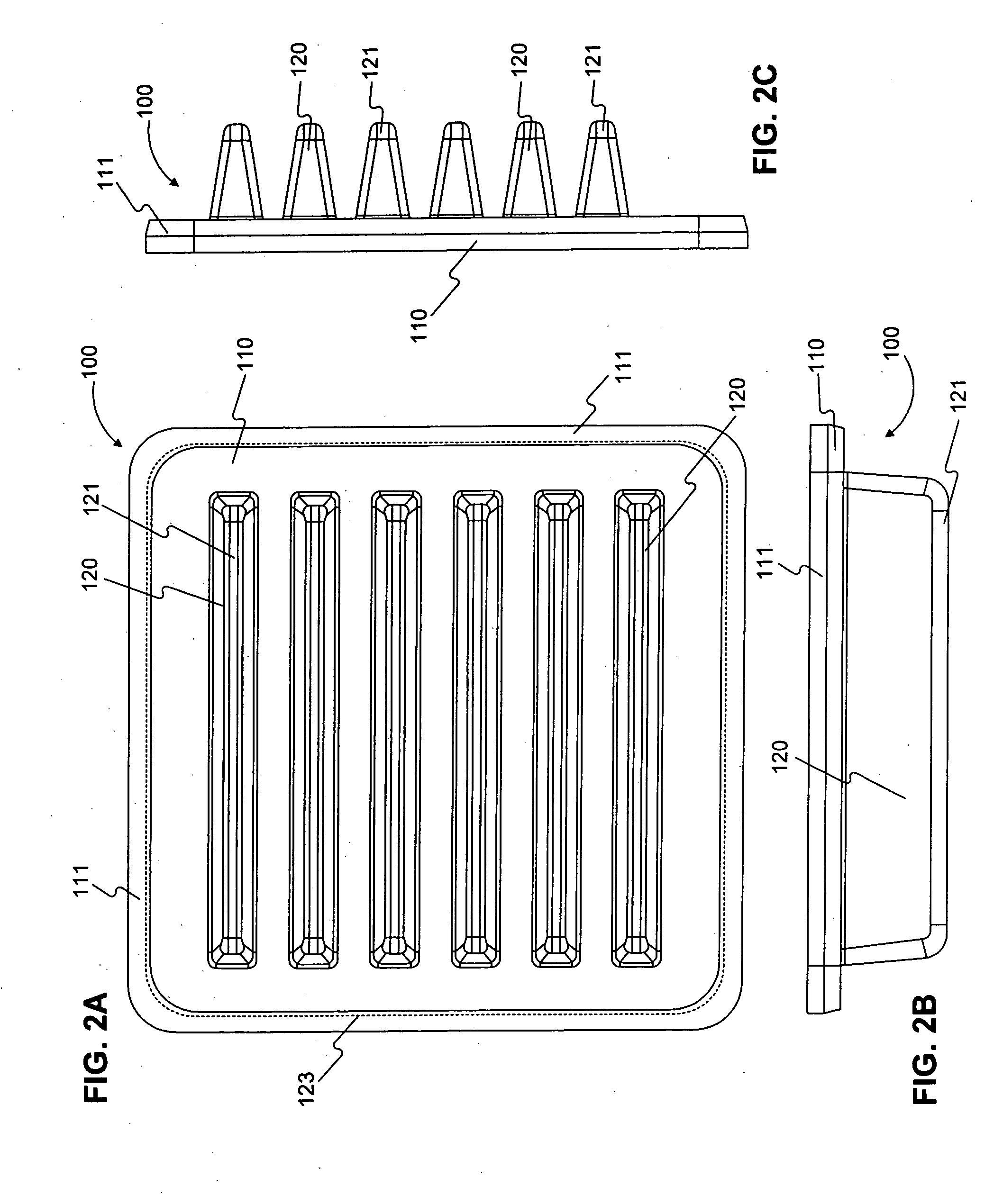

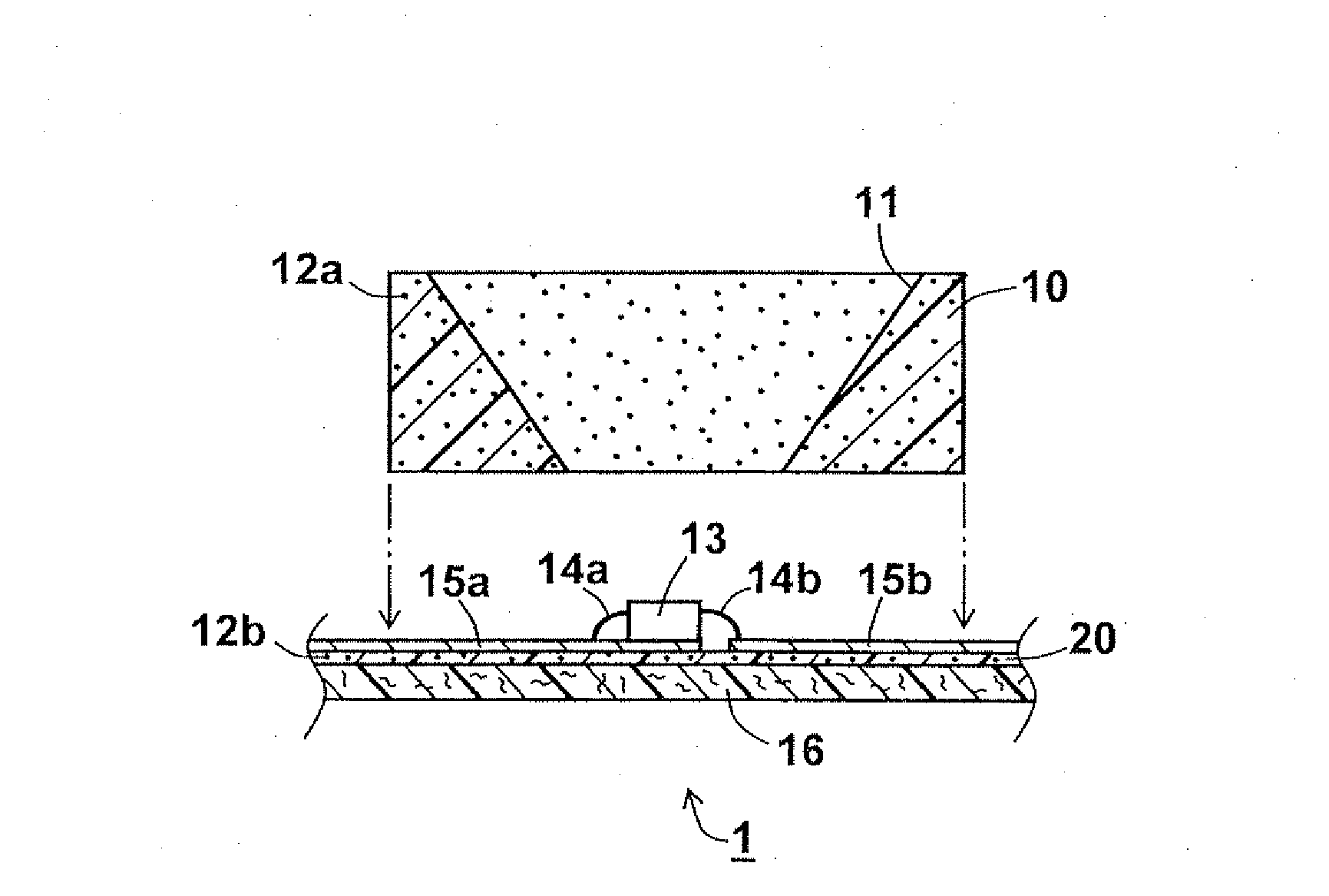

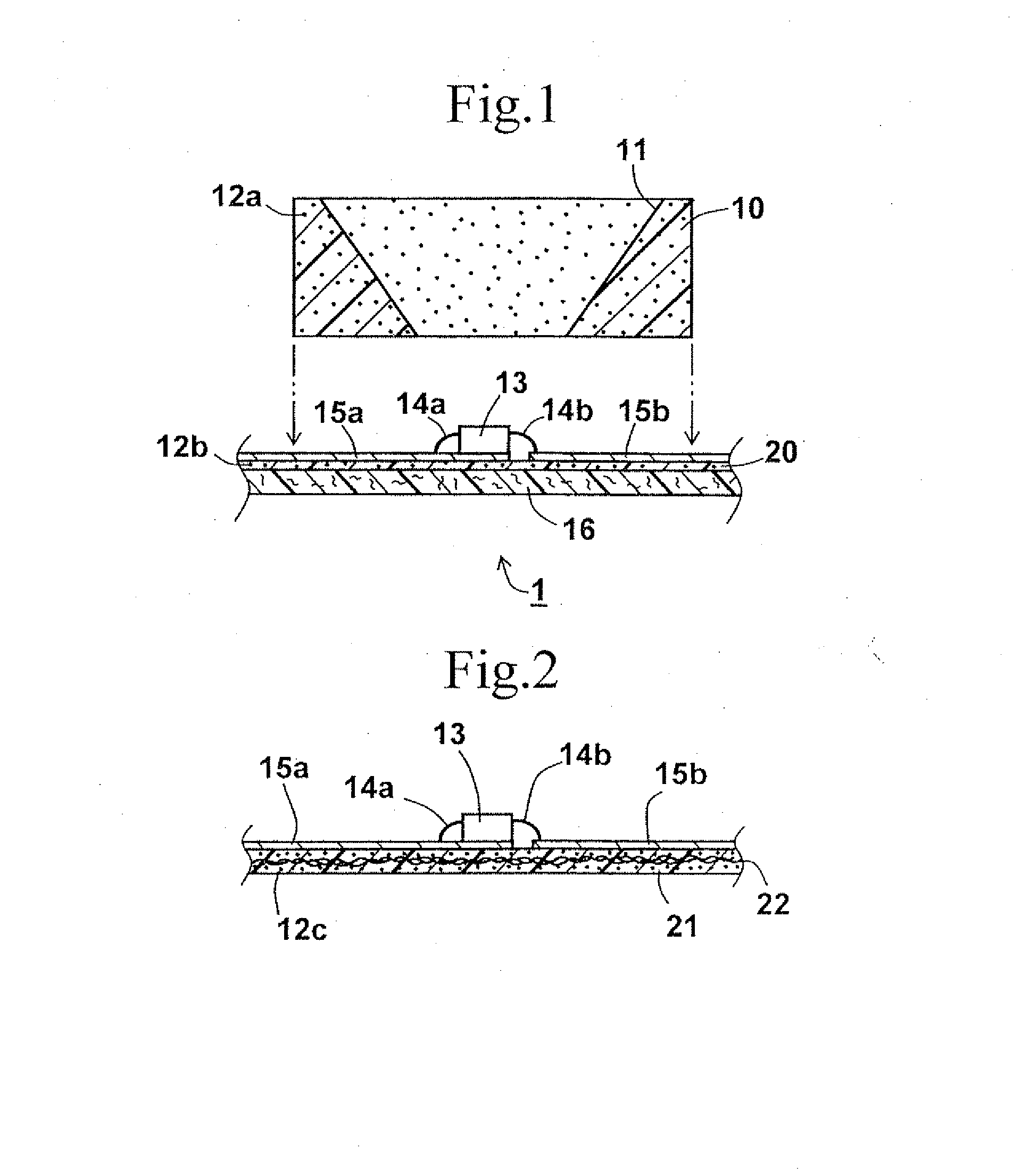

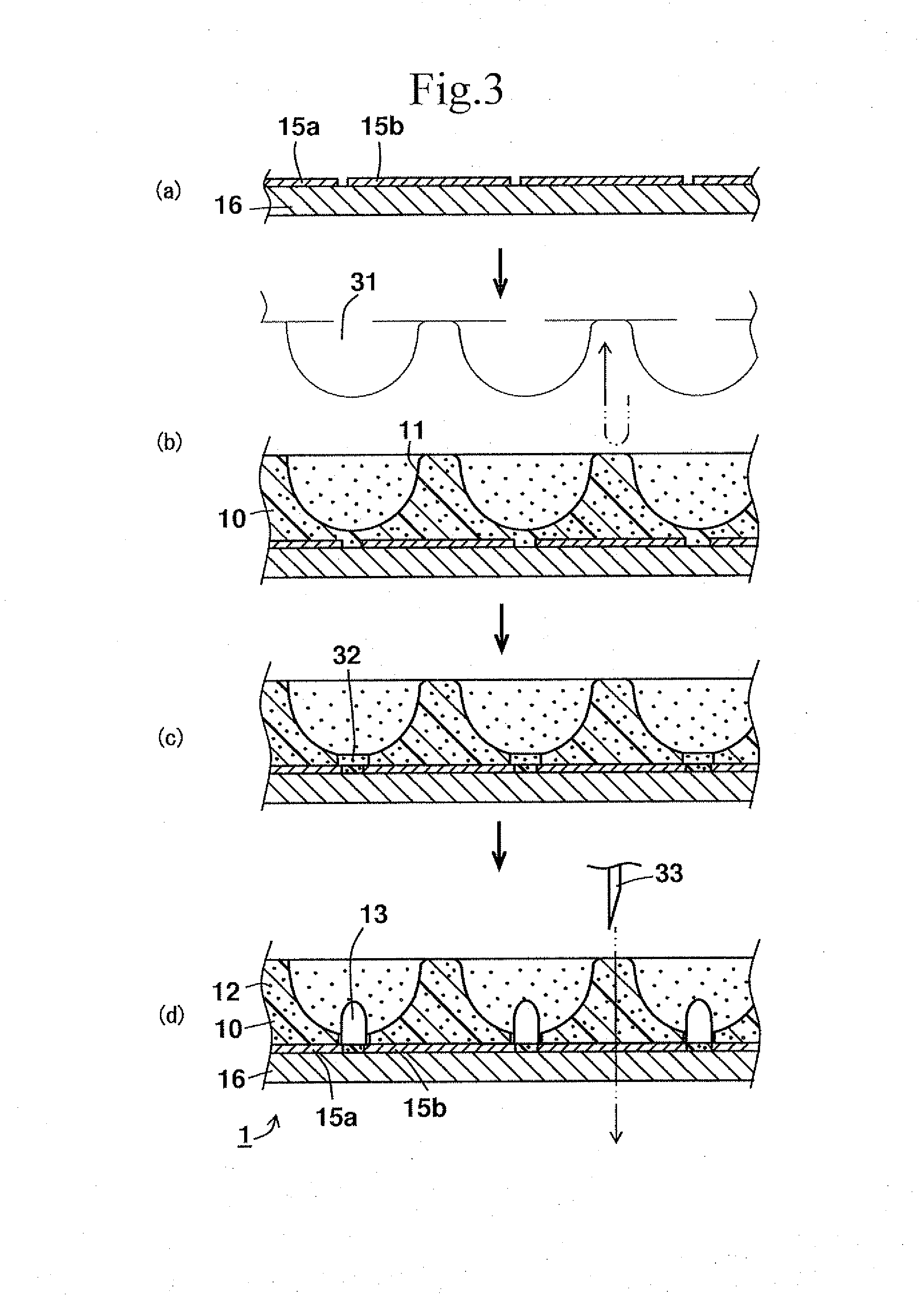

Silicone resin reflective substrate, manufacturing method for same, and base material composition used in reflective substrate

ActiveUS20130011617A1Low viscosityImprove adhesionDiffusing elementsSolid-state devicesCross-linkInfra-red color

A versatile silicone resin reflective substrate which exhibits high reflectance of high luminance light from an LED light source over a wide wavelength from short wavelengths of approximately 340-500 nm, which include wavelengths from 380-400 nm near lower limit of the visible region, to longer wavelength in the infra-red region. The silicone resin reflective substrate has a reflective layer which contains a white inorganic filler powder dispersed in a three-dimensional cross linked silicone resin, the inorganic filler powder having a high reflective index than the silicone resin. The reflective layer is formed on a support body as a film, a solid, or a sheet. The silicone resin reflective substrate can be easily formed as a wiring substrate, a packaging case or the like, and can be manufactured at low cost and a high rate of production.

Owner:ASAHI RUBBER

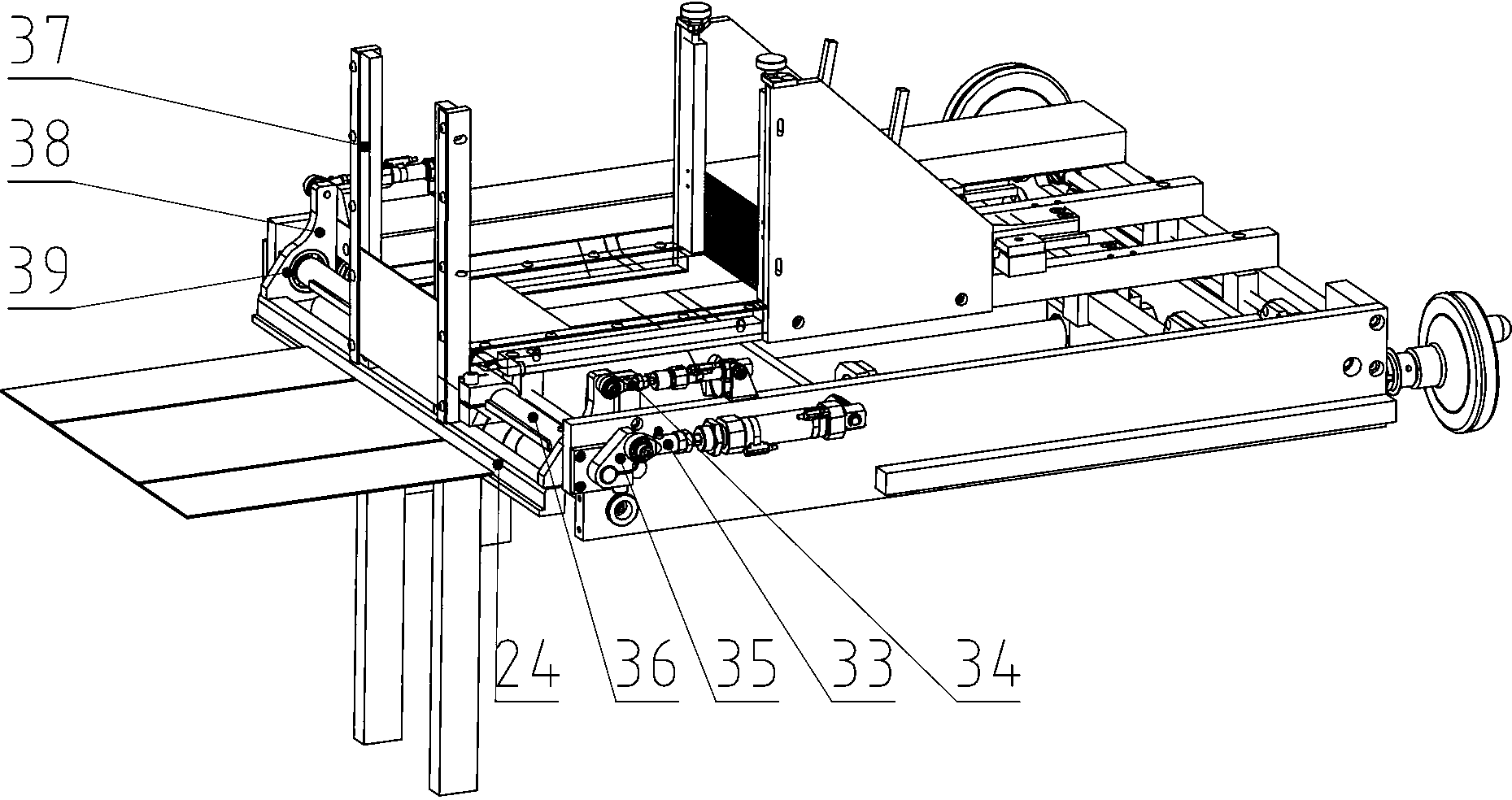

A method and system for automatically processing blanks for packaging boxes

ActiveUS20150360433A1High industrial capacityLarge capacityBoxes/cartons making machineryBox making operationsEngineeringAutomatic processing

Method and system for automatically processing blanks for forming packaging boxes. By means of a feeding conveyor blank material is fed in a feeding direction from a storage of blank material to a single blank cutting station comprising a blank forming apparatus for cutting and creasing blank material into a blank. By means of said blank forming apparatus a blank is formed having a rectangular bottom panel and rectangular corner, side and end panels. Cutting and creasing blank material into the blank is performed during feeding of said blank material in feeding direction through the blank forming apparatus.

Owner:SPARCK TECH BV

Bamboo shoot clothing packaging box and production process thereof

The invention relates to a packaging box, in particular to a bamboo shoot clothing packaging box which is formed by adopting bamboo shoot clothing (commonly called bamboo shoot shells, bamboo shells and indocalamus shells) made of moso bamboos (phyllostachys pubescens), phyllostachys parvifolia, dendrocalamus latiflorus, phyllostachys praecox, fargesia utilis, overlord bamboos and the like as raw materials (give priority to the moso bamboos) and processing through the processes of raw material purchasing and storage, rinsing, harmless treatment (insect control, mildew prevention, fiber softening, color development and mercerization), washing, drying, flattening, cutting, gluing (glue spraying or blanching and gluing), collage (blanching and collage), polishing, laser printing, inspecting, warehousing and the like. The bamboo shoot clothing packaging box has the main characteristics of moisture absorption and mildew prevention, insect control and corrosion resistance, stain repellence and scale prevention, is an ideal preferred package of tea leaves, tobaccos, food, instruments, jewelry and other products and has very extensive purpose; meanwhile, the bamboo shoot clothing packaging box is fashionable and attractive in appearance, realizes low carbon and environmental protection, is durable and fully embodies the change of wastes into valuables; moreover, a new high-quality laying and decoration material and a processing technology can be provided for the packaging industry in China.

Owner:CHIBI JIAXIANG BAMBOO SHOOT DEV

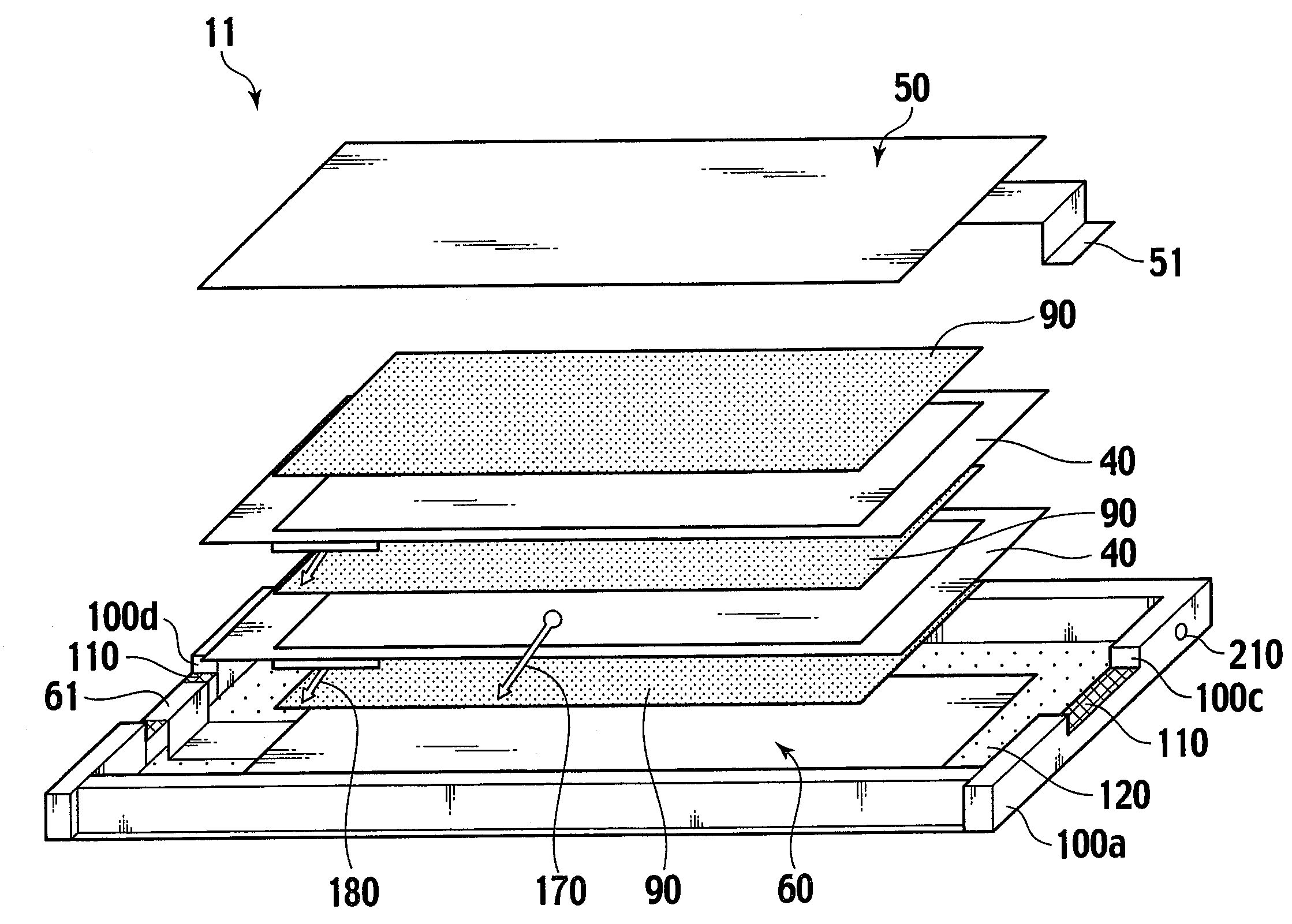

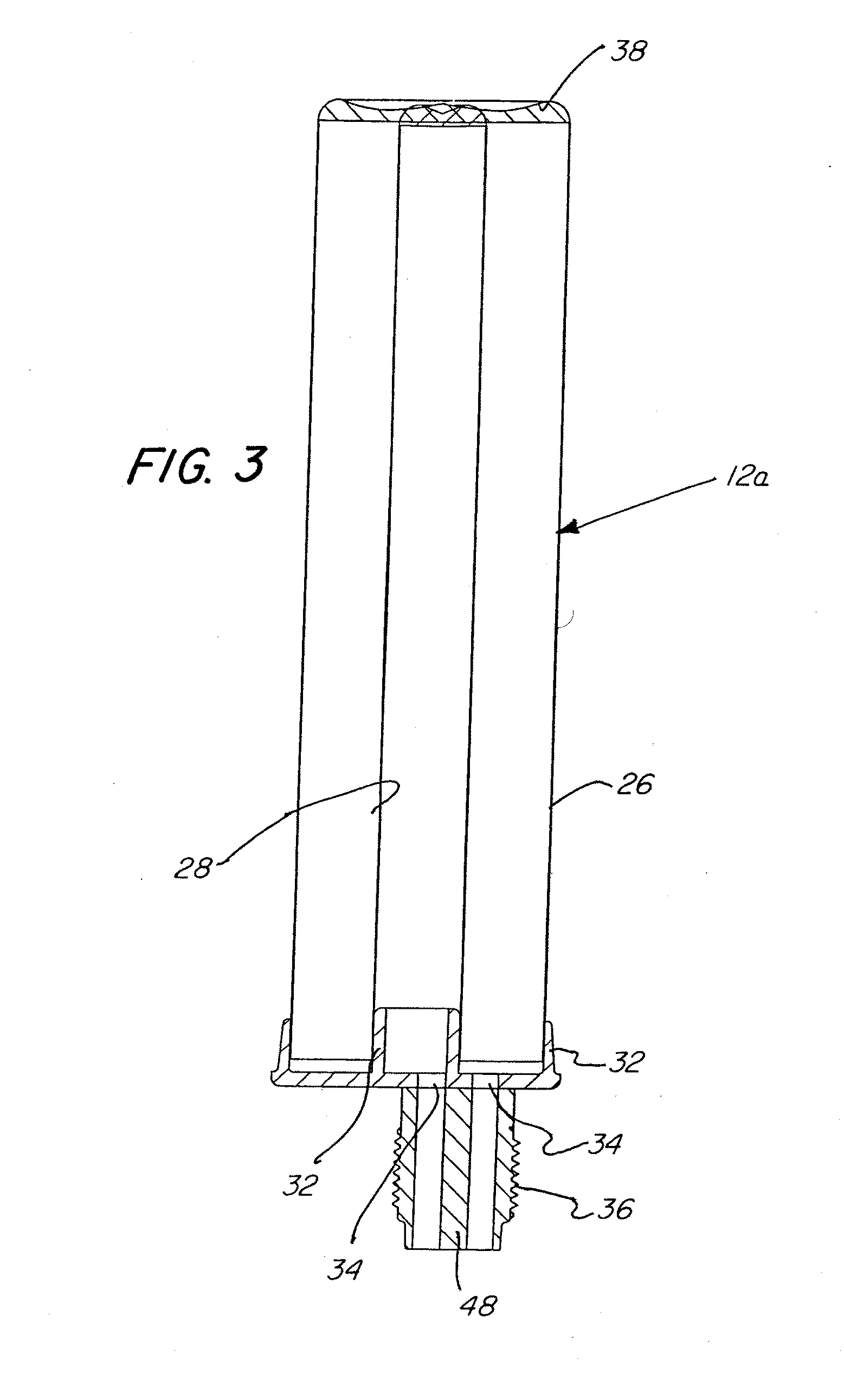

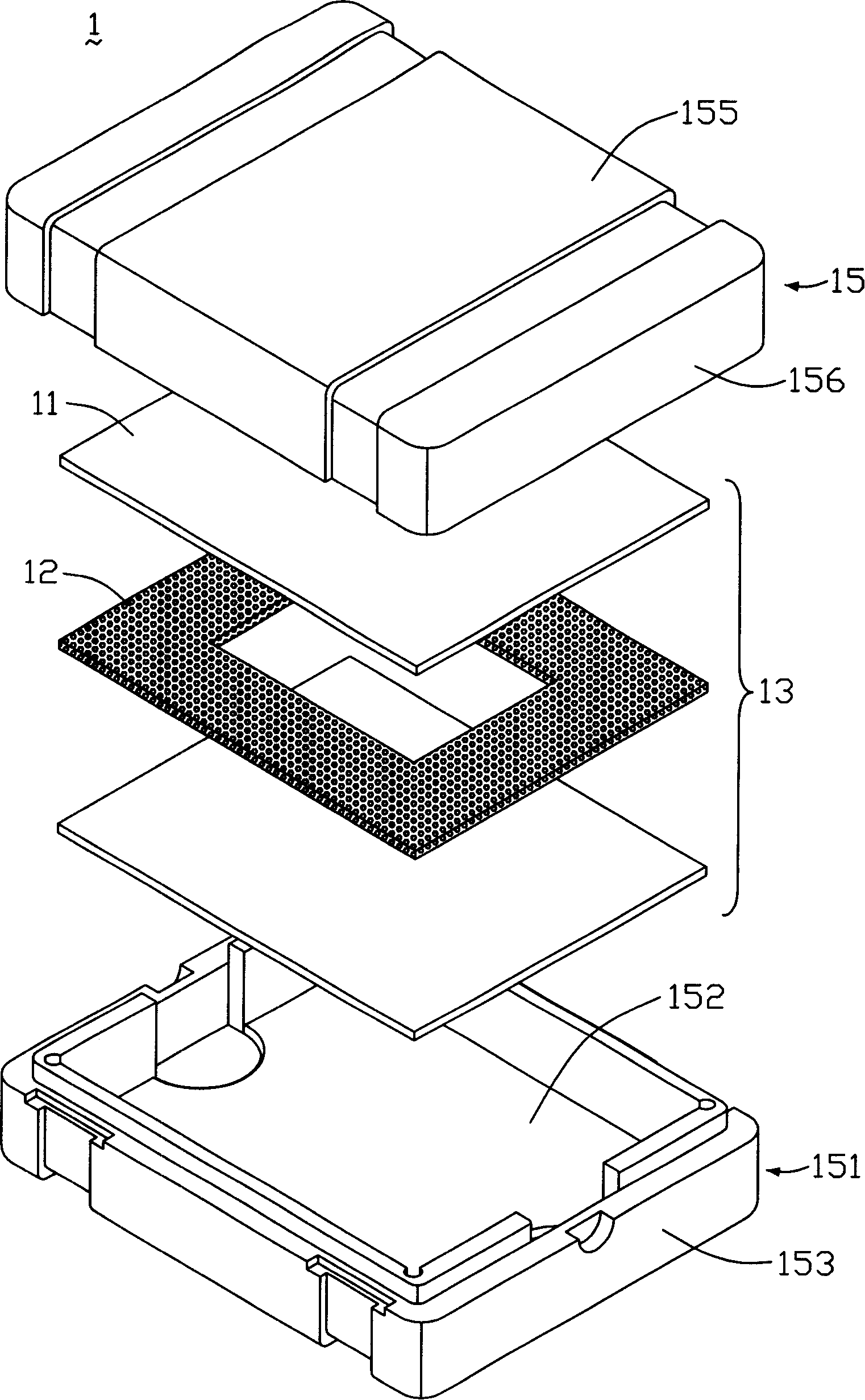

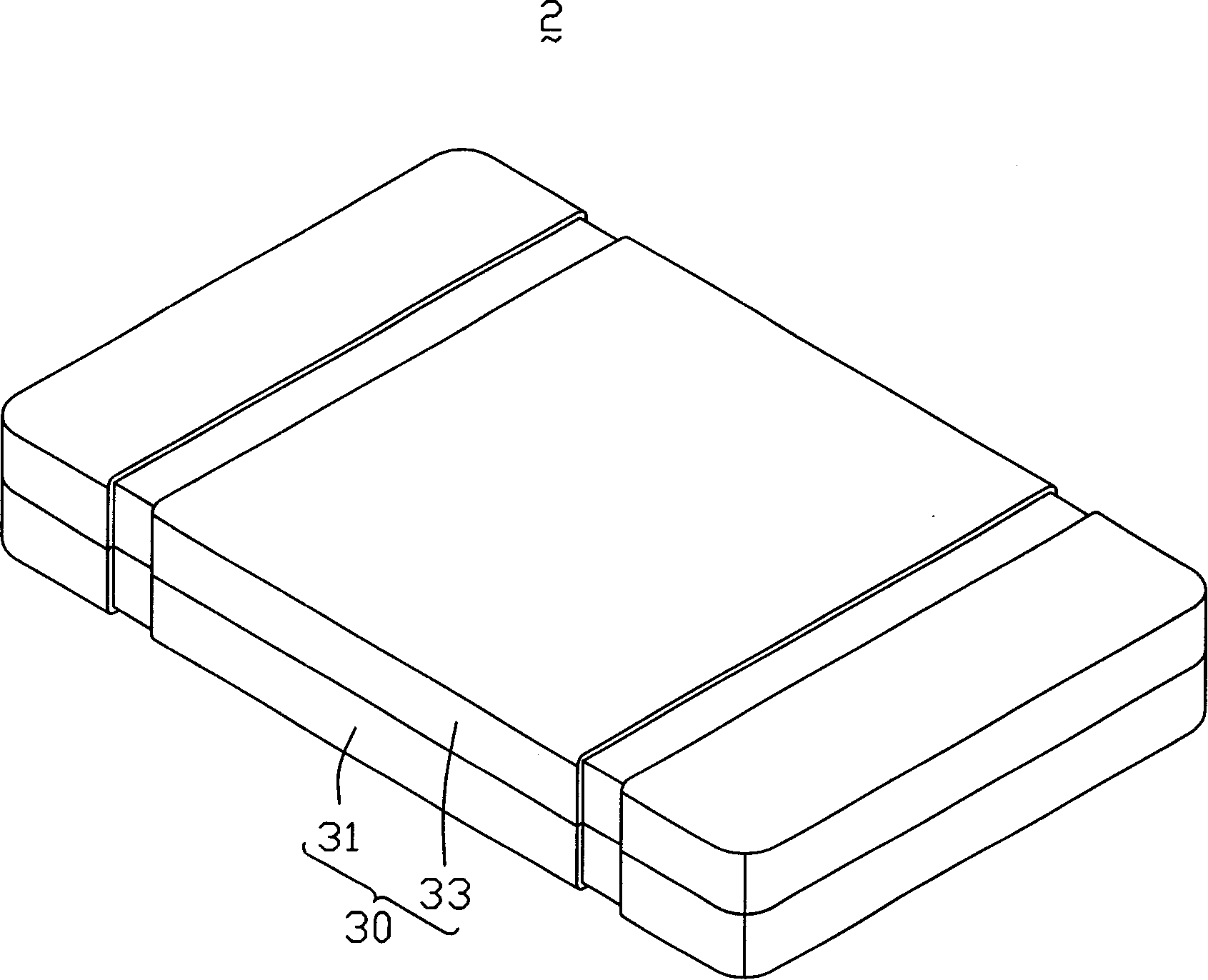

Battery module, assembled battery, and vehicle including these batteries

ActiveUS20090023059A1Easy to makeEliminate needNon-aqueous electrolyte accumulatorsFinal product manufactureEngineeringPackaging Case

A battery module 11 is structured to include a flat-type battery in which current can be taken out from both faces of an electric generation element 20 in a layered direction, flat-plate-type electrode tabs 50 and 60 having a face contact with a current-taking-out plane of the flat-type battery to take out current, and a packaging case 100 covering the flat-type battery and the electrode tab. The inner face of the packaging case and the electrode tab have therebetween an elastic member 120.

Owner:NISSAN MOTOR CO LTD

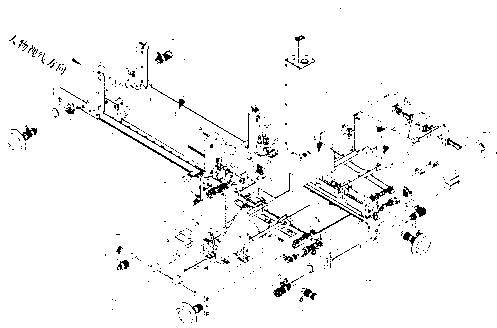

Full-automatic splicing type box machine and method for processing packing boxes

ActiveCN103317767ASolve the technical defect of insufficient firmnessRealize strong and beautifulBox making operationsPaper-makingEngineeringPackaging Case

The invention relates to a full-automatic splicing type box machine and a method for processing packing boxes. The full-automatic splicing type box machine comprises a bottom plate conveying and glue spraying station and a product forming station. The product forming station is connected with a left side plate conveying and erecting station and a right side plate conveying and erecting station, and a left plate erecting mechanism and a right plate erecting mechanism are respectively arranged at the two side plate conveying and erecting stations. The method for processing the packing boxes includes a technological procedure for conveying plates of the packing boxes, automatically spraying glue and forming and reinforcing the packing boxes by the aid of molds. The full-automatic splicing type box machine and the method have the advantages that a technological process is simple and feasible, effects of saving materials and reducing the cost are realized, the products are firm and attractive after being formed owing to an automatic glue spraying technology, a packing box processing procedure is automatic, and the full-automatic splicing type box machine and the method are favorable for organizing production and greatly improving the labor productivity.

Owner:WENZHOU GAOSHENG MACHINERY CO LTD

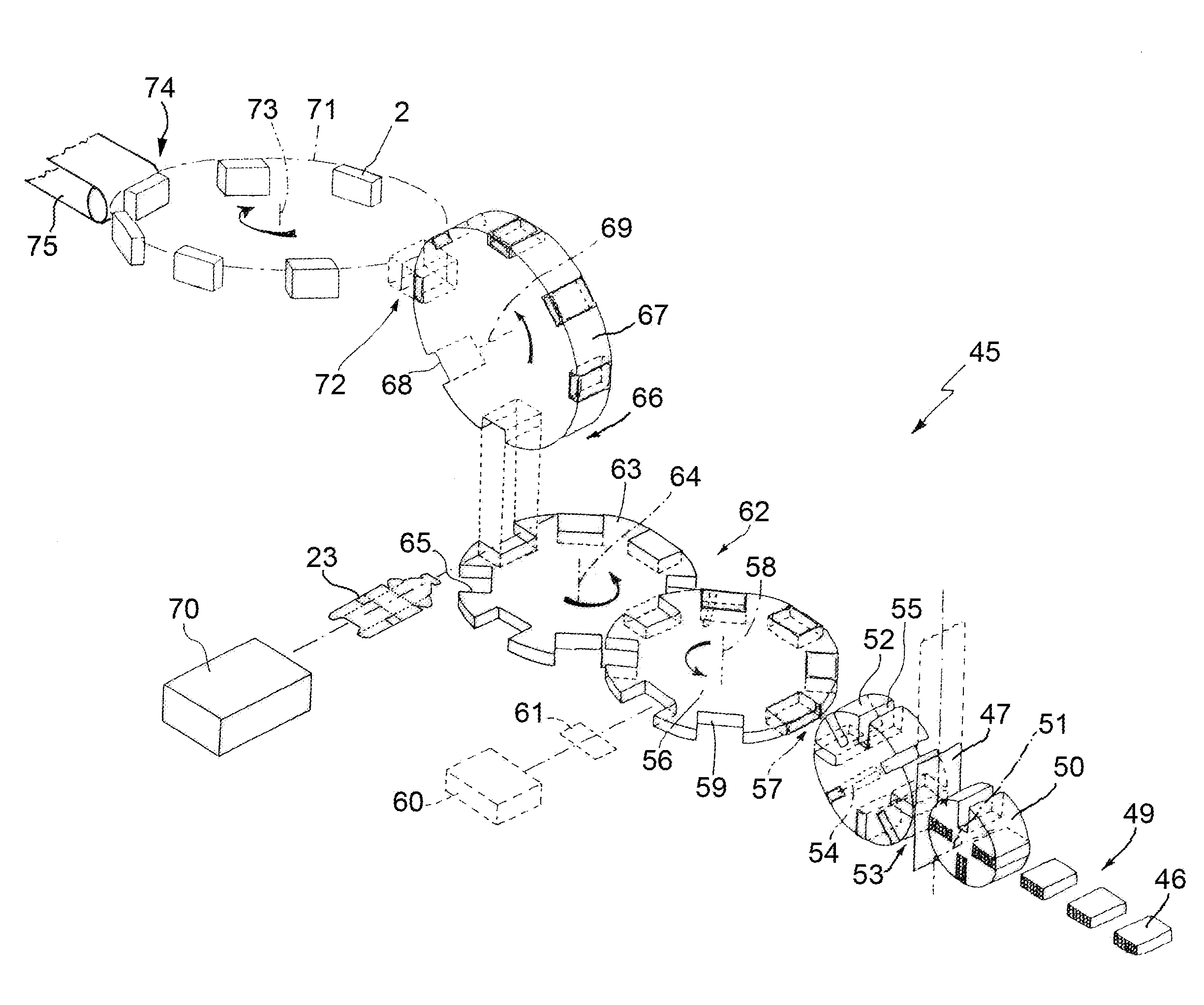

Cigarette Packing Machine for Producing a Rigid, Hinged-Lid Packet

InactiveUS20110041463A1Easy and relatively cheap to implementPackaging cigaretteWrapper folding/bending apparatusEngineeringCigarette pack

A cigarette packing machine for producing a rigid packet with a hinged lid has a first packing unit which folds a first blank about a group of cigarettes to form an outer container with a hinged lid; and a second packing unit which folds a second blank about the outer container to form a tubular slide surrounding the outer container to slide axially with respect to the outer container; the tubular slide has a transmission member, in turn having a first end integral with the lid, a second end opposite the first end and integral with the slide, and a deformable intermediate portion having a U-shaped fold between the outer container and the slide.

Owner:GD SPA

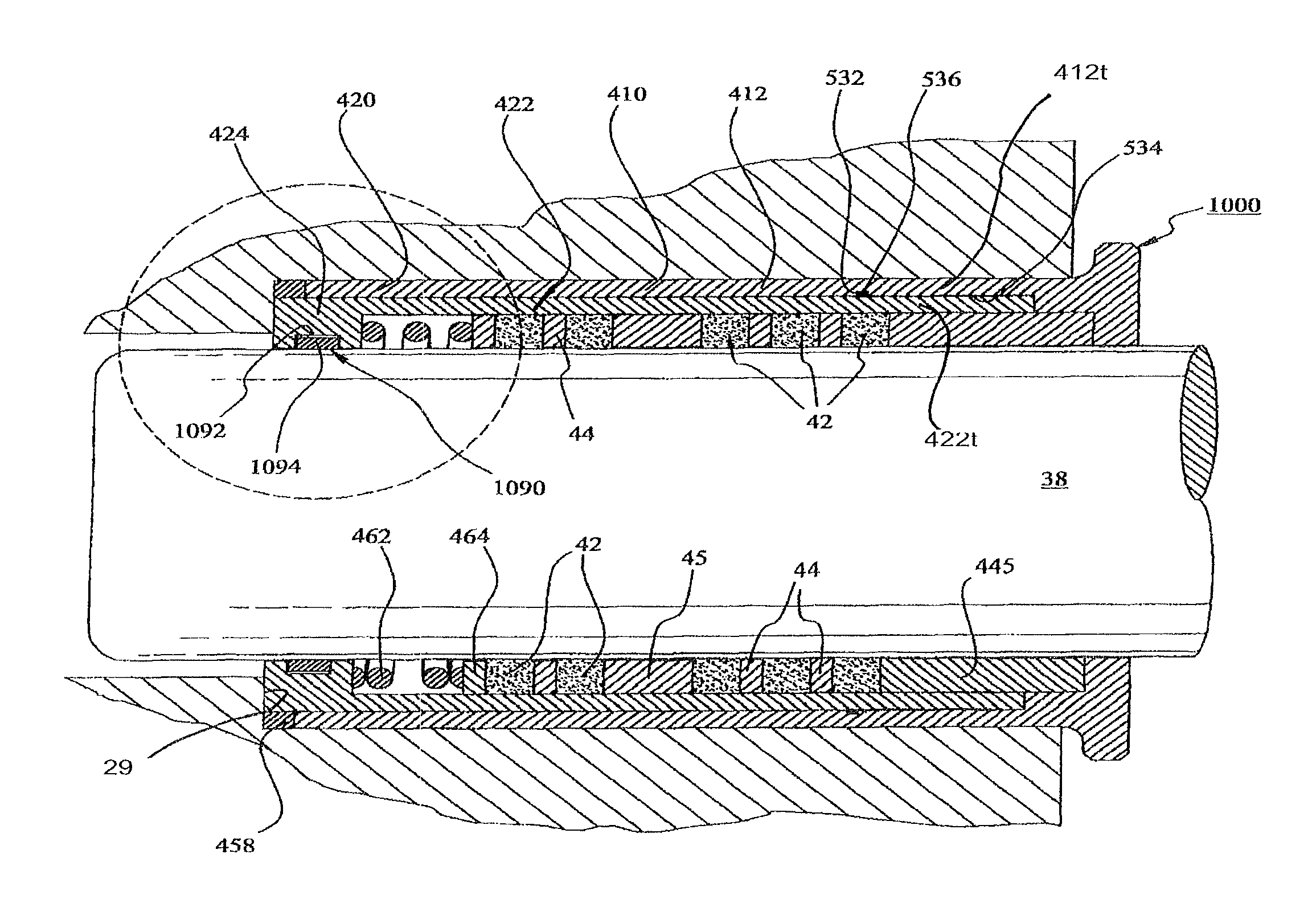

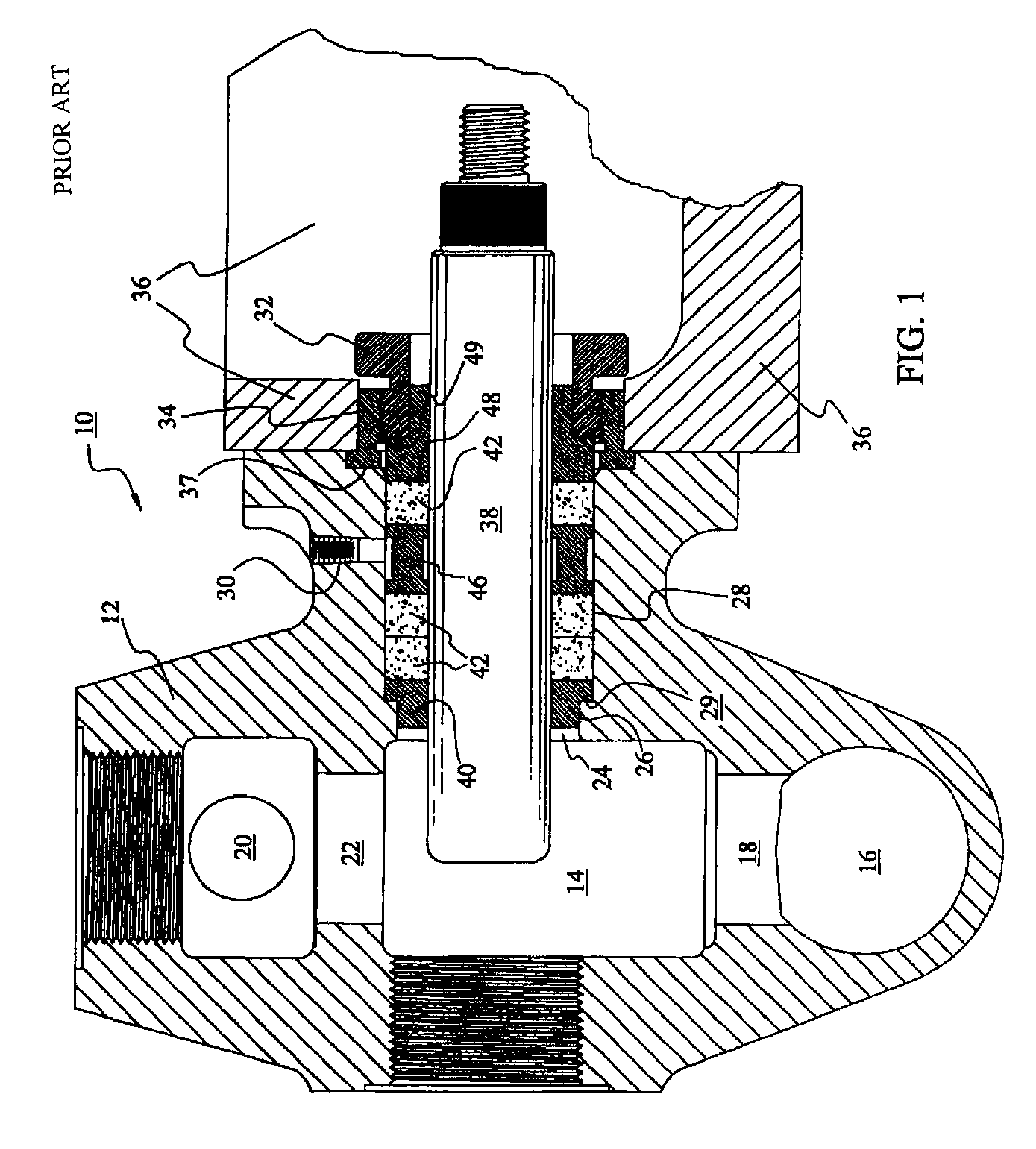

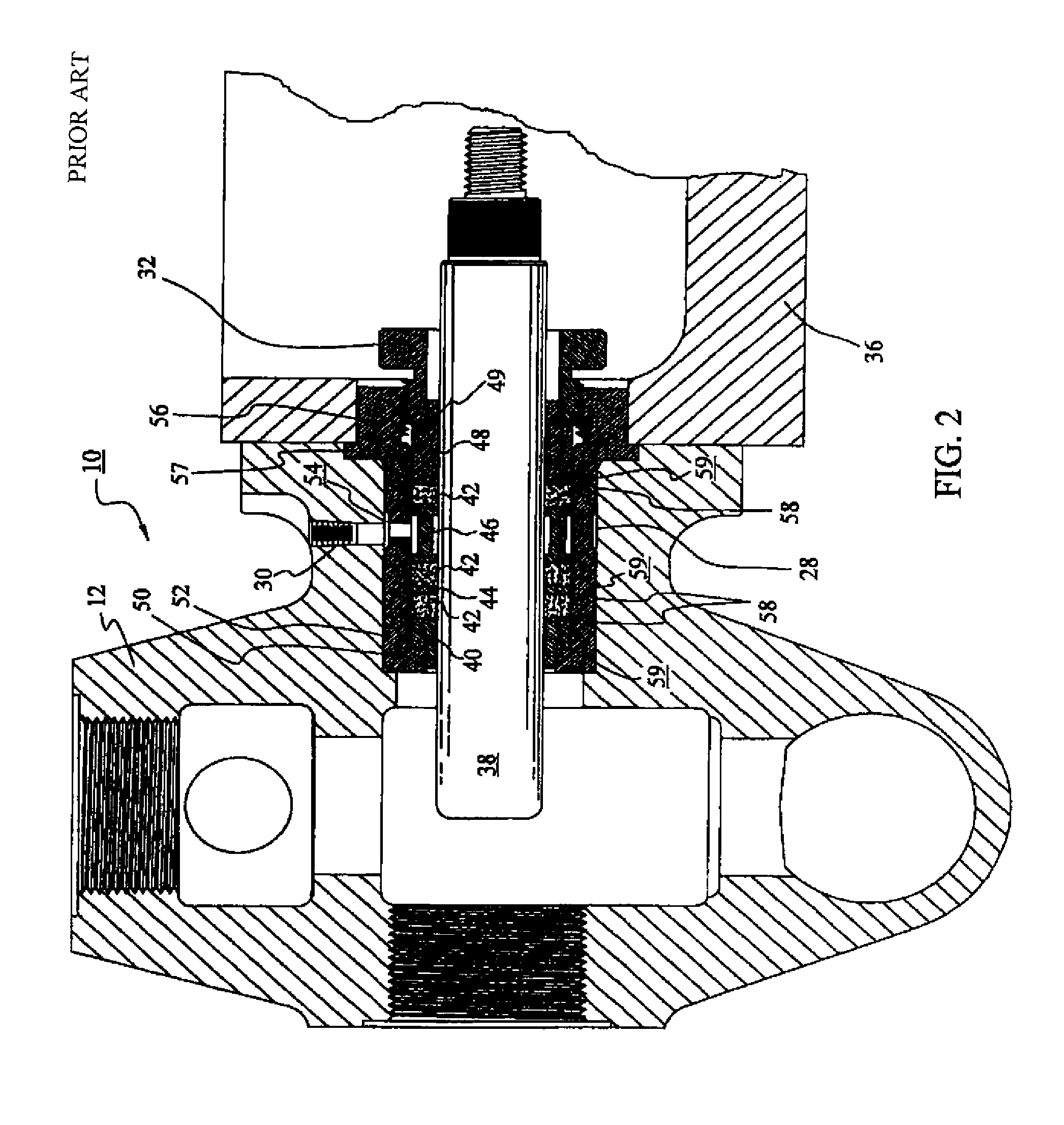

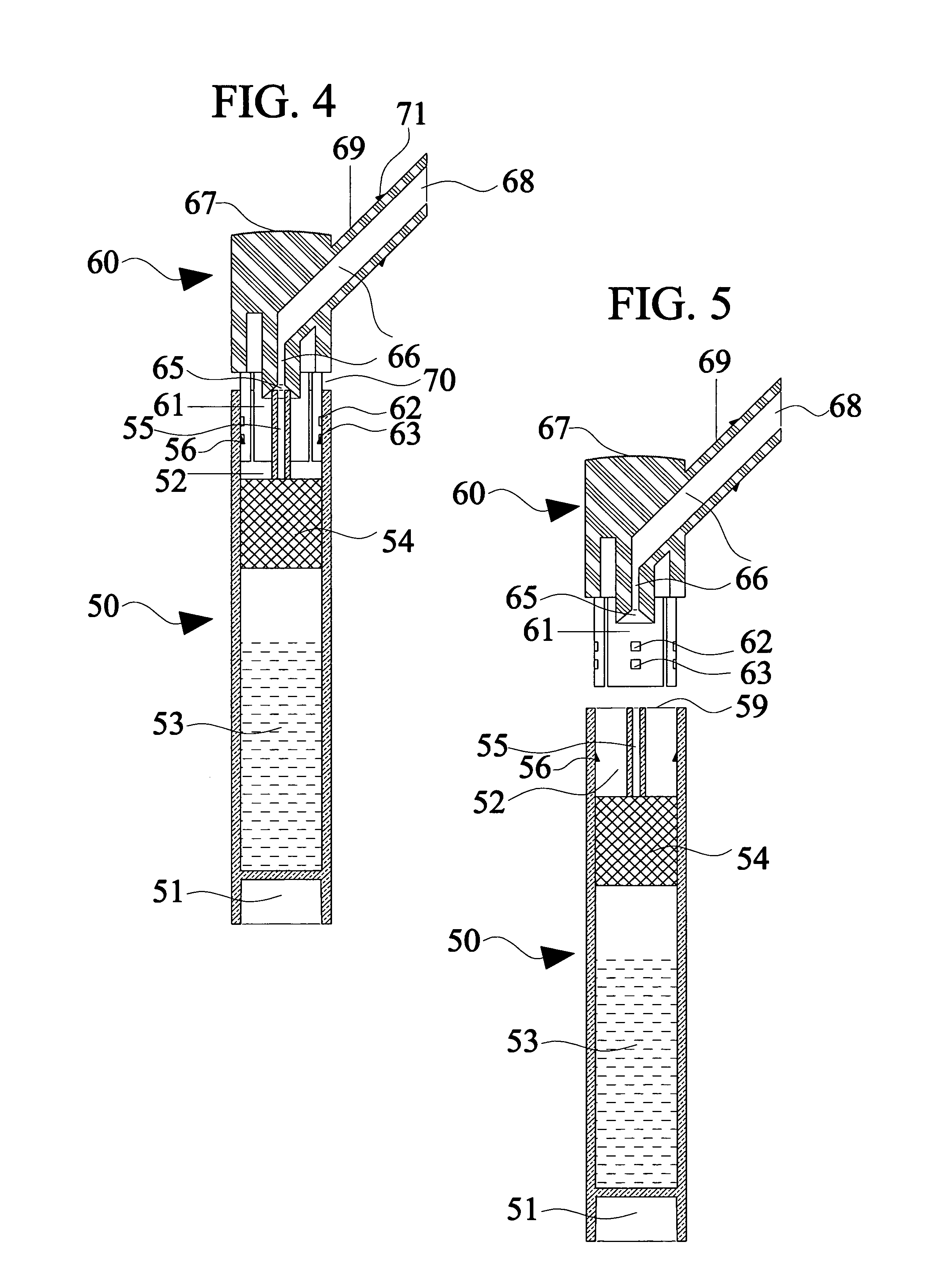

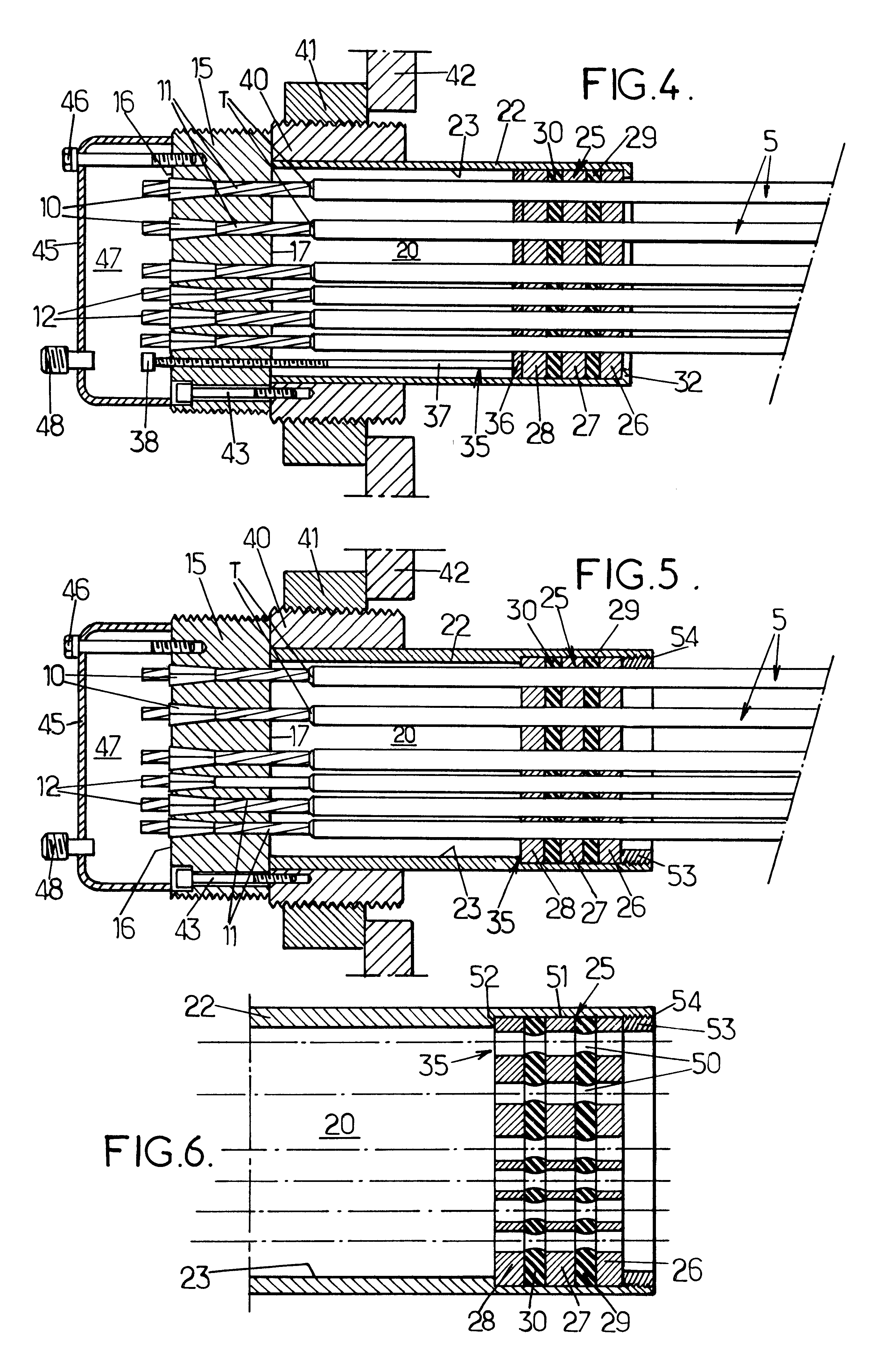

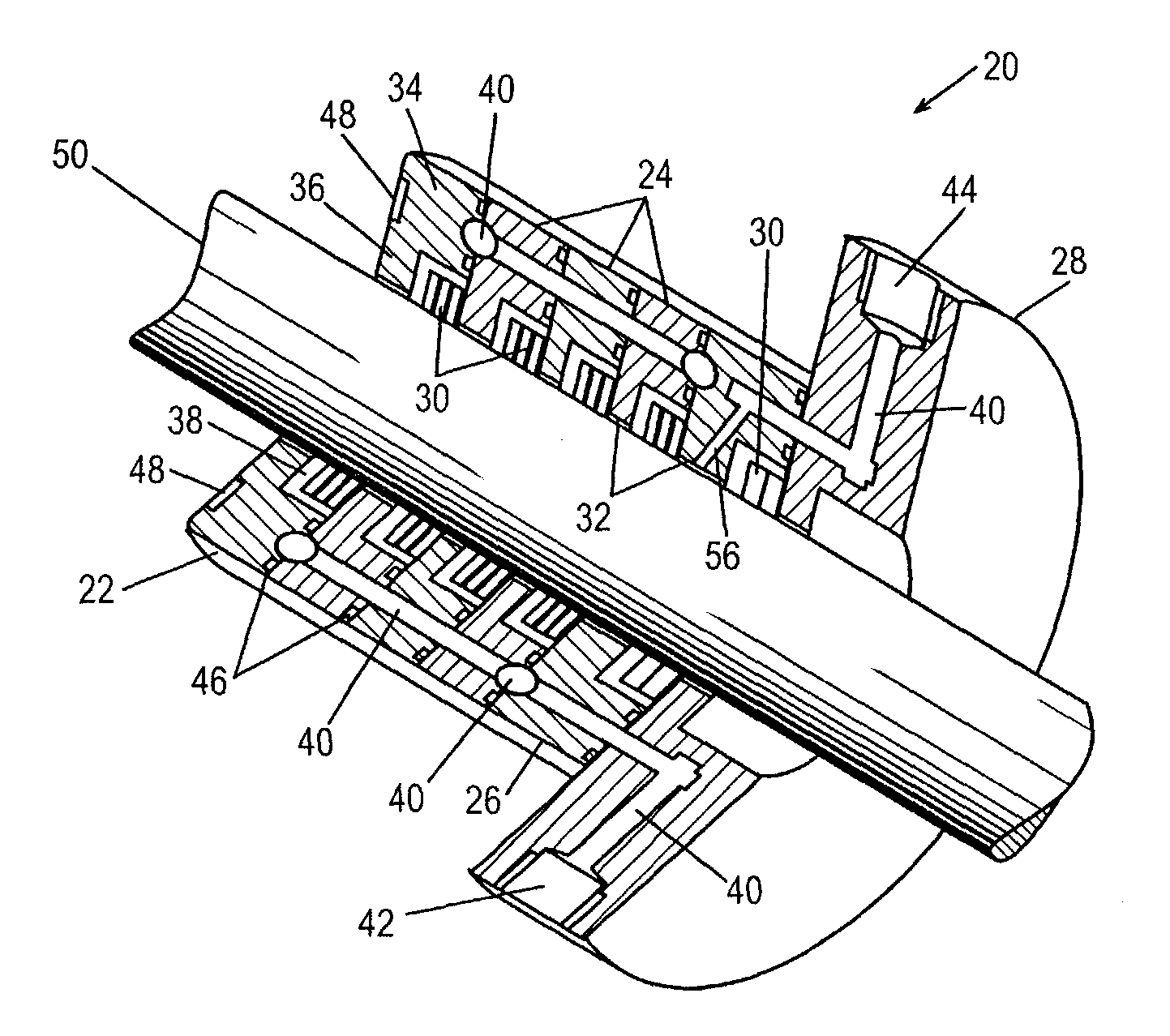

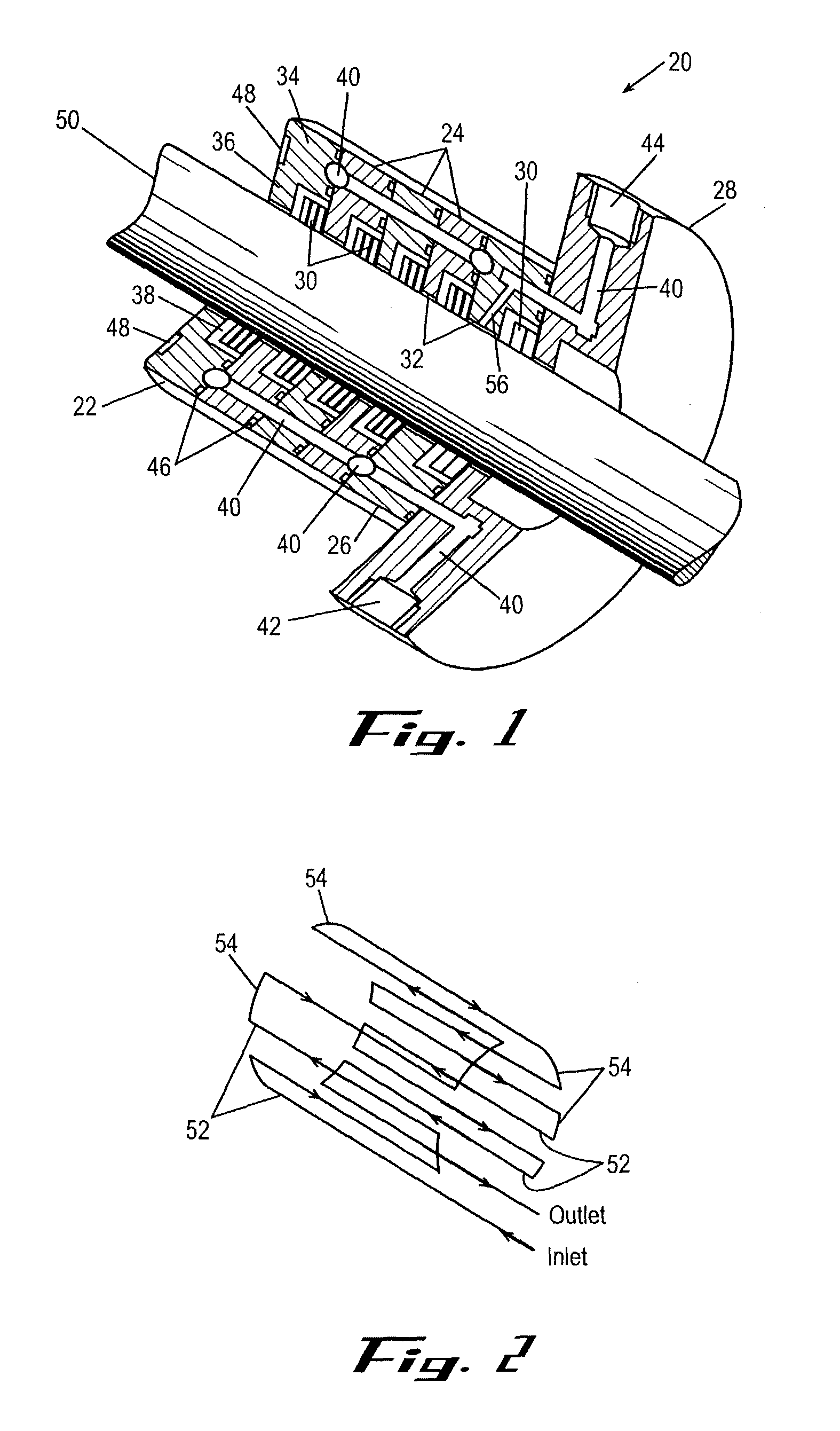

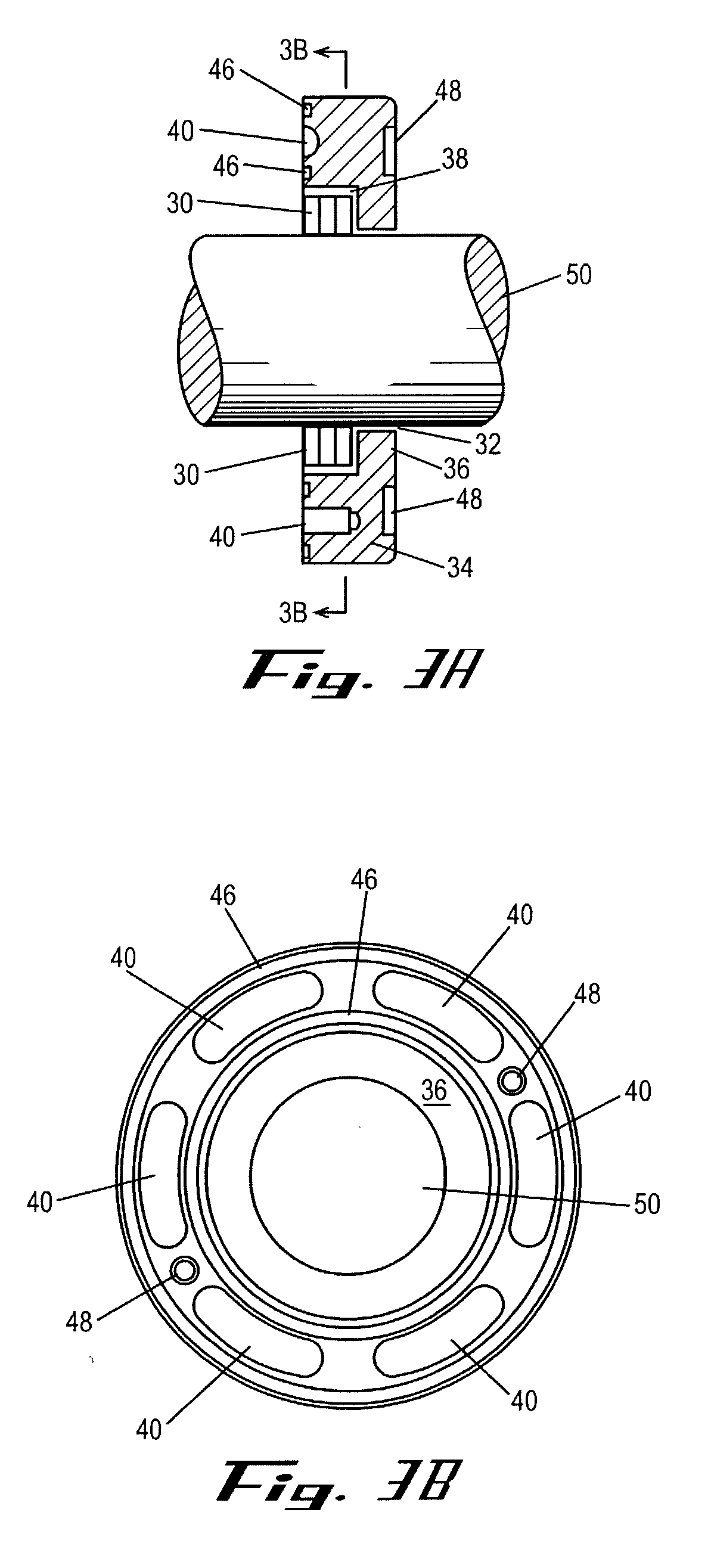

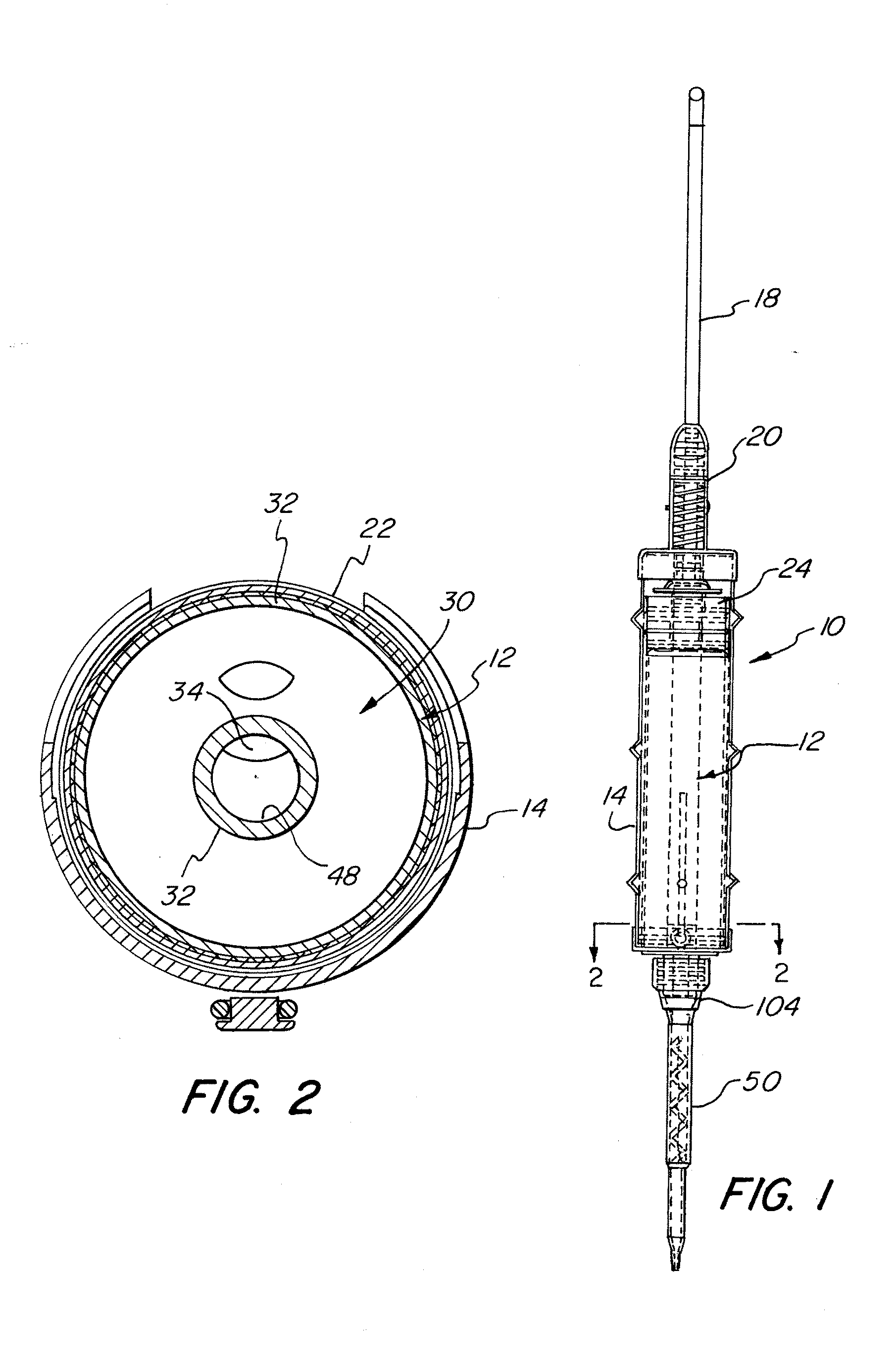

Packing cartridges and pressure-dampening elements for plunger-type pumps

A package cartridge is provided for use in the maintenance of a packing bore for a plunger-type pump. According to one aspect, a packing cartridge includes: a generally-cylindrical sleeve adapted to be at least partially positioned in the packing bore, a first abutment ring positioned in the sleeve, and a second abutment ring positioned in the sleeve and co-axially spaced apart from the first abutment ring. Telescoping structures are operatively positioned between the first abutment ring and the second abutment ring. According to another aspect, a structure forming a circumferential pressure-ring groove is provided. A pressure ring is positioned in the pressure-ring groove, the pressure ring having at least one smaller external dimension than an internal dimension of the pressure-ring groove, whereby at least one clearance is provided between the pressure-ring groove and the pressure ring. These aspects can be advantageously practiced together.

Owner:CL PACKING SOLUTIONS

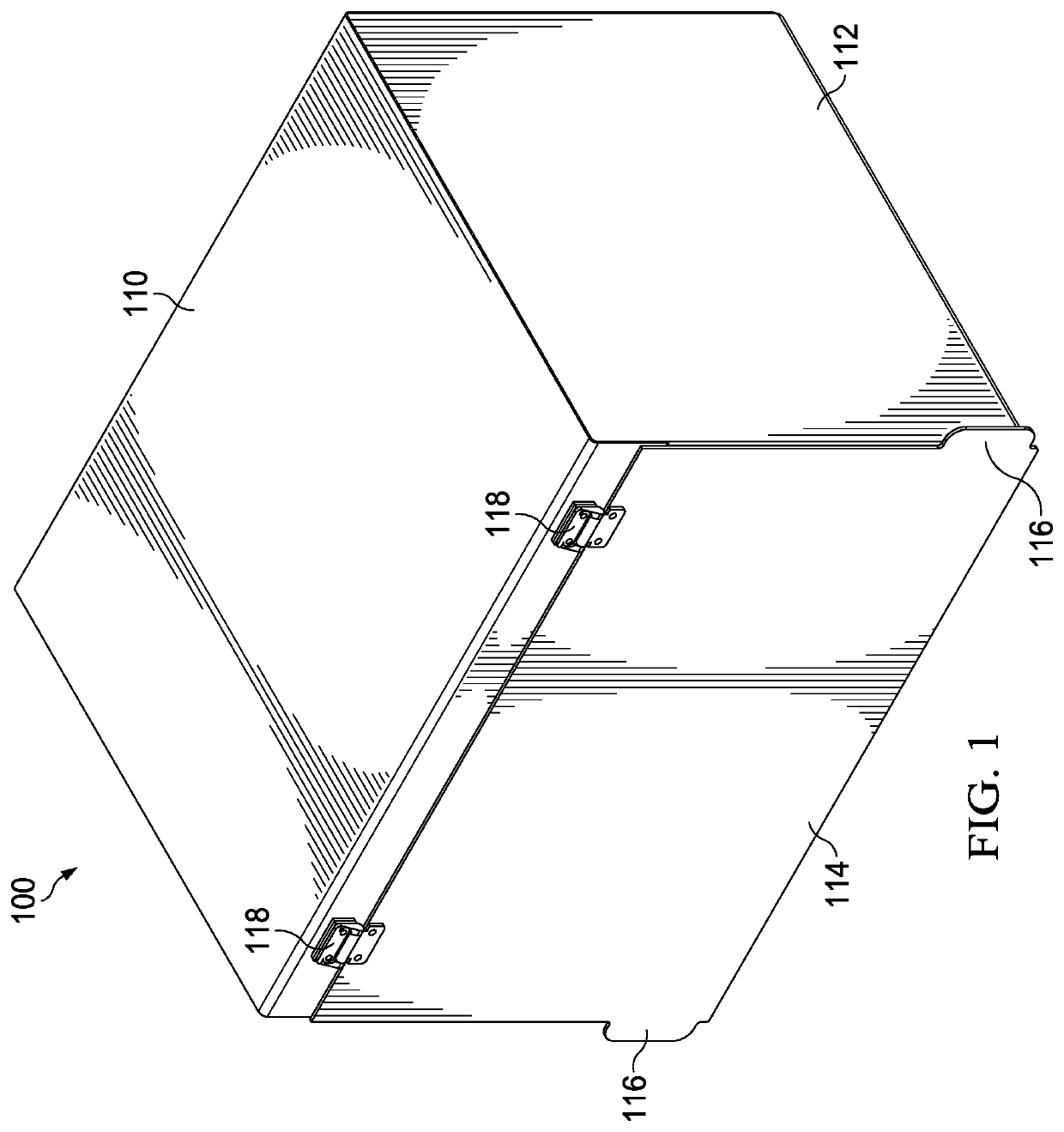

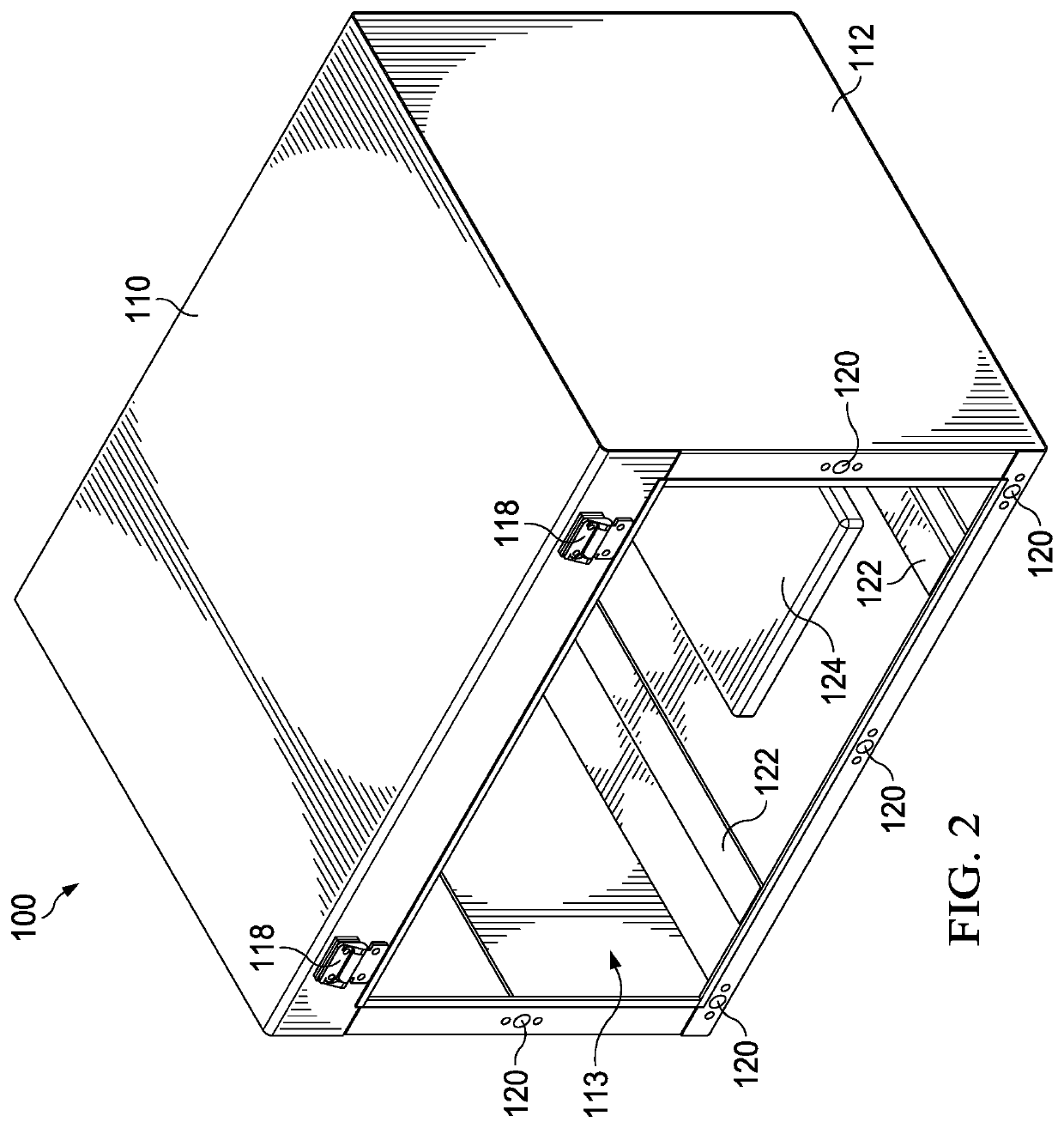

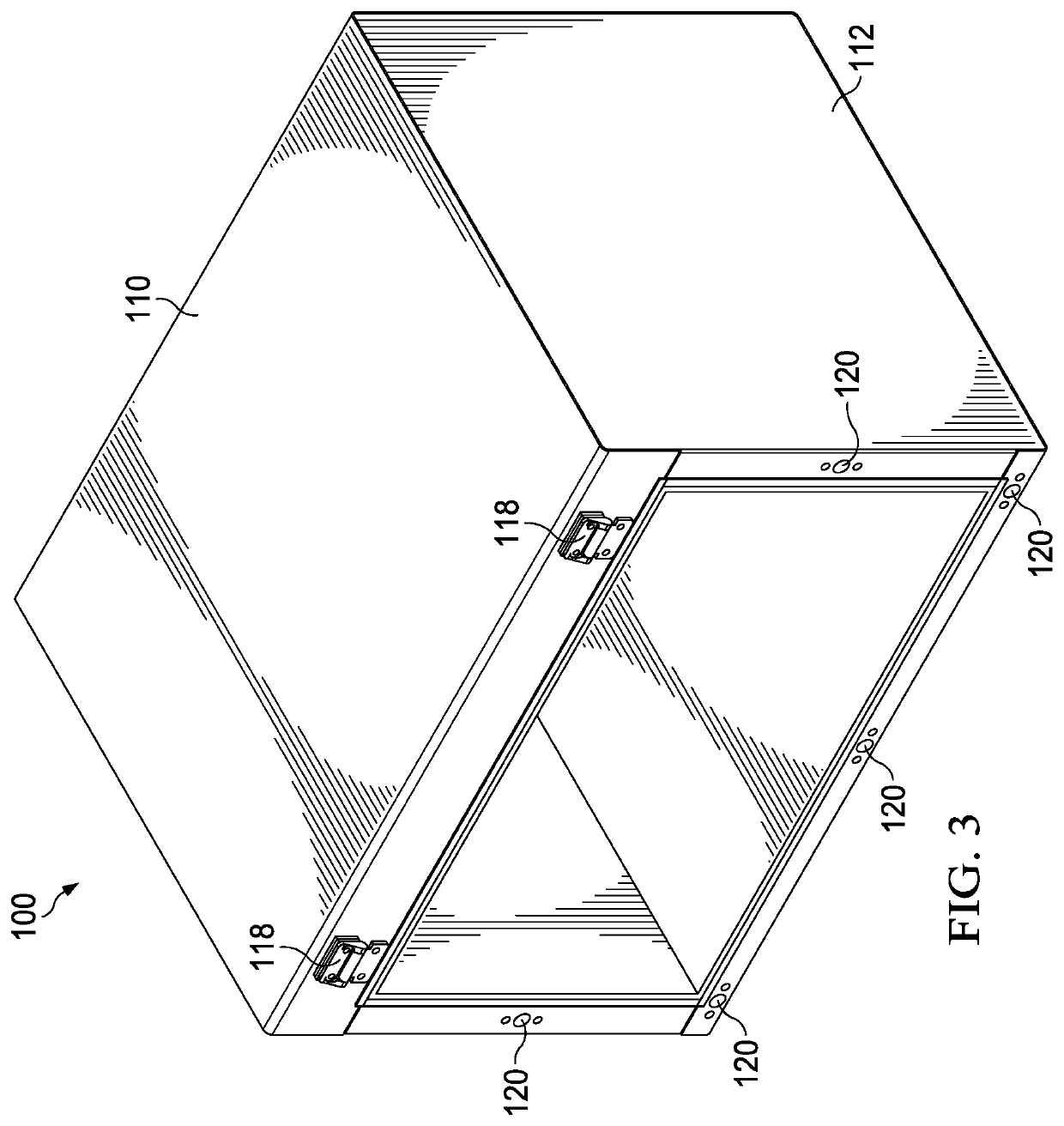

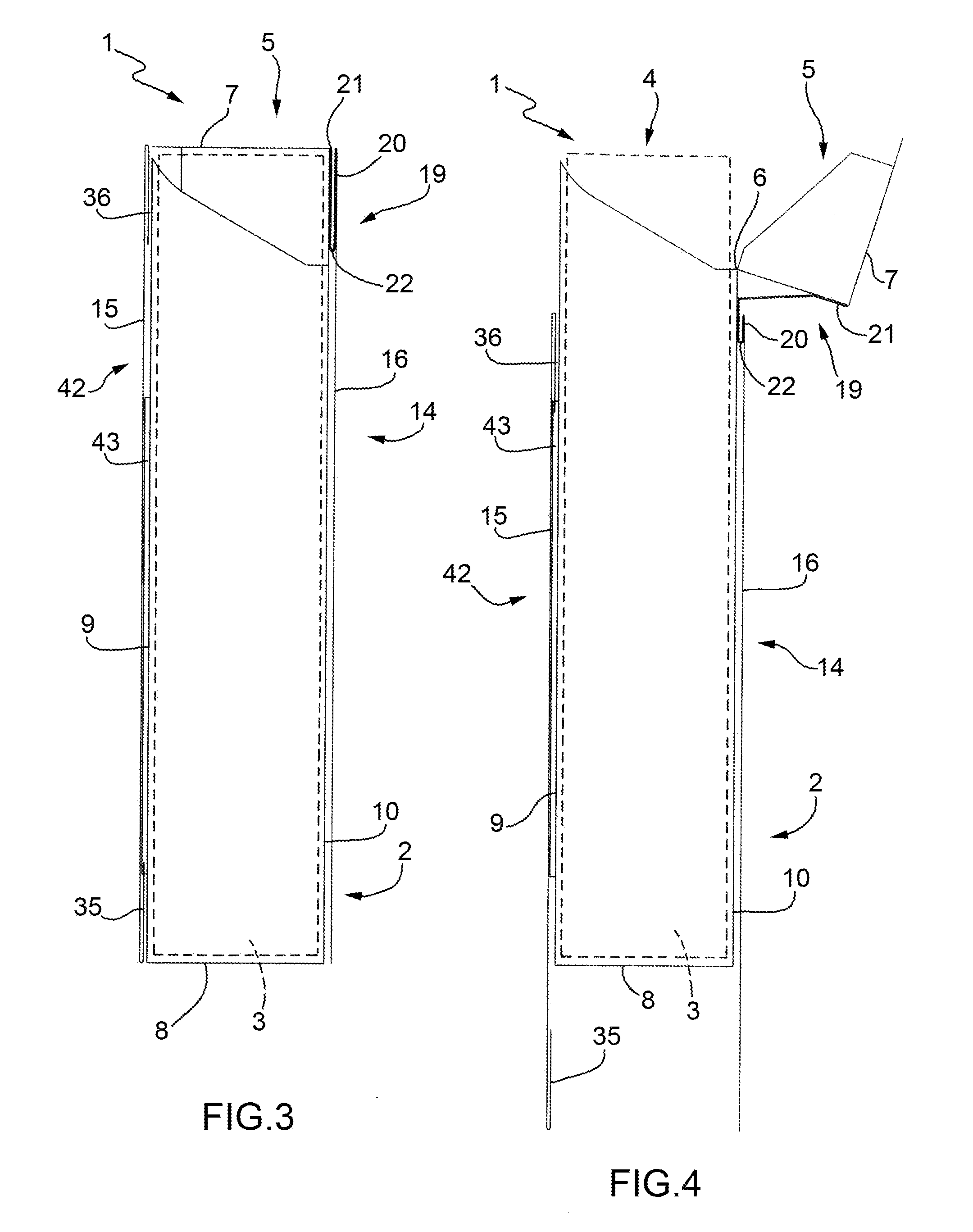

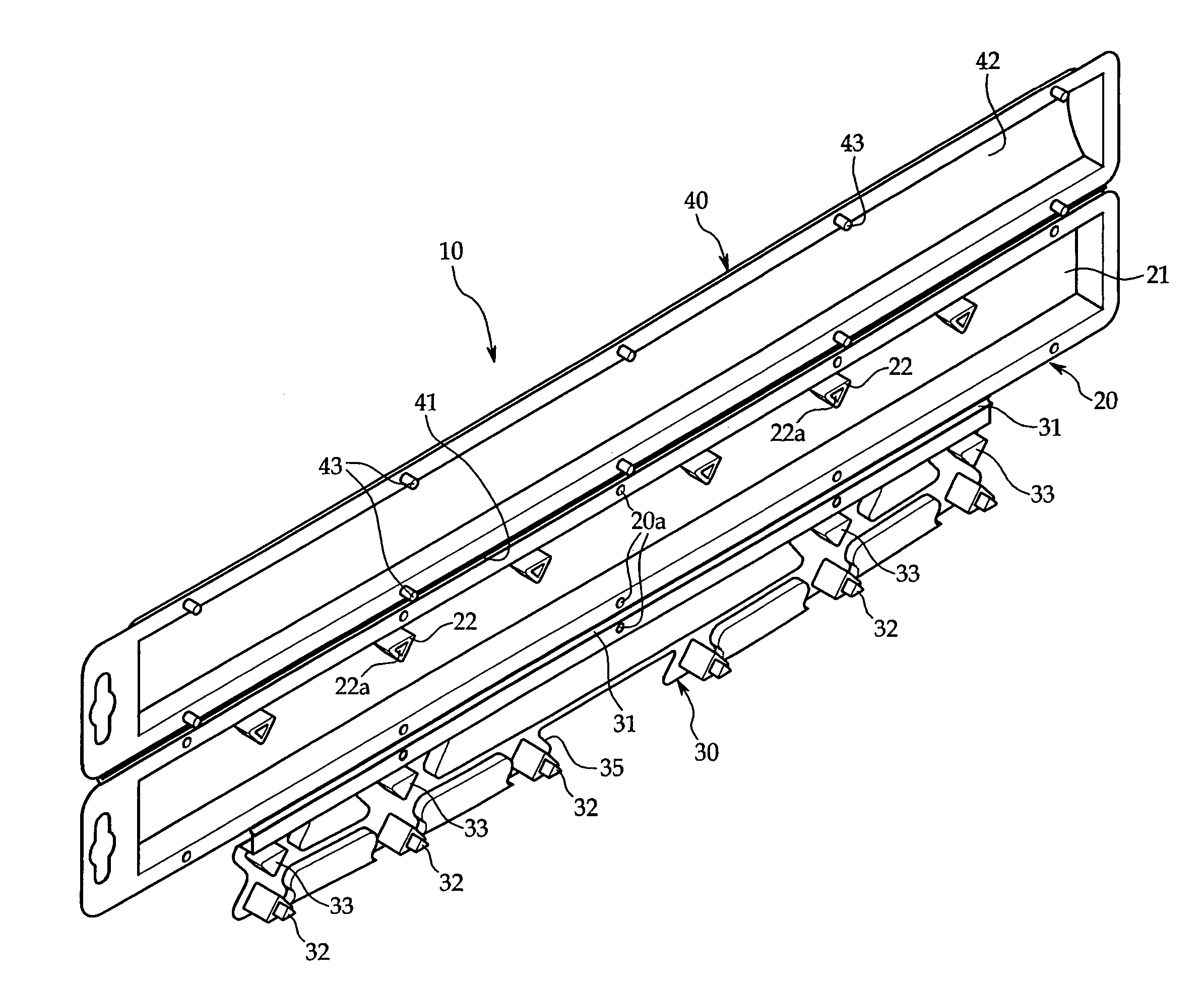

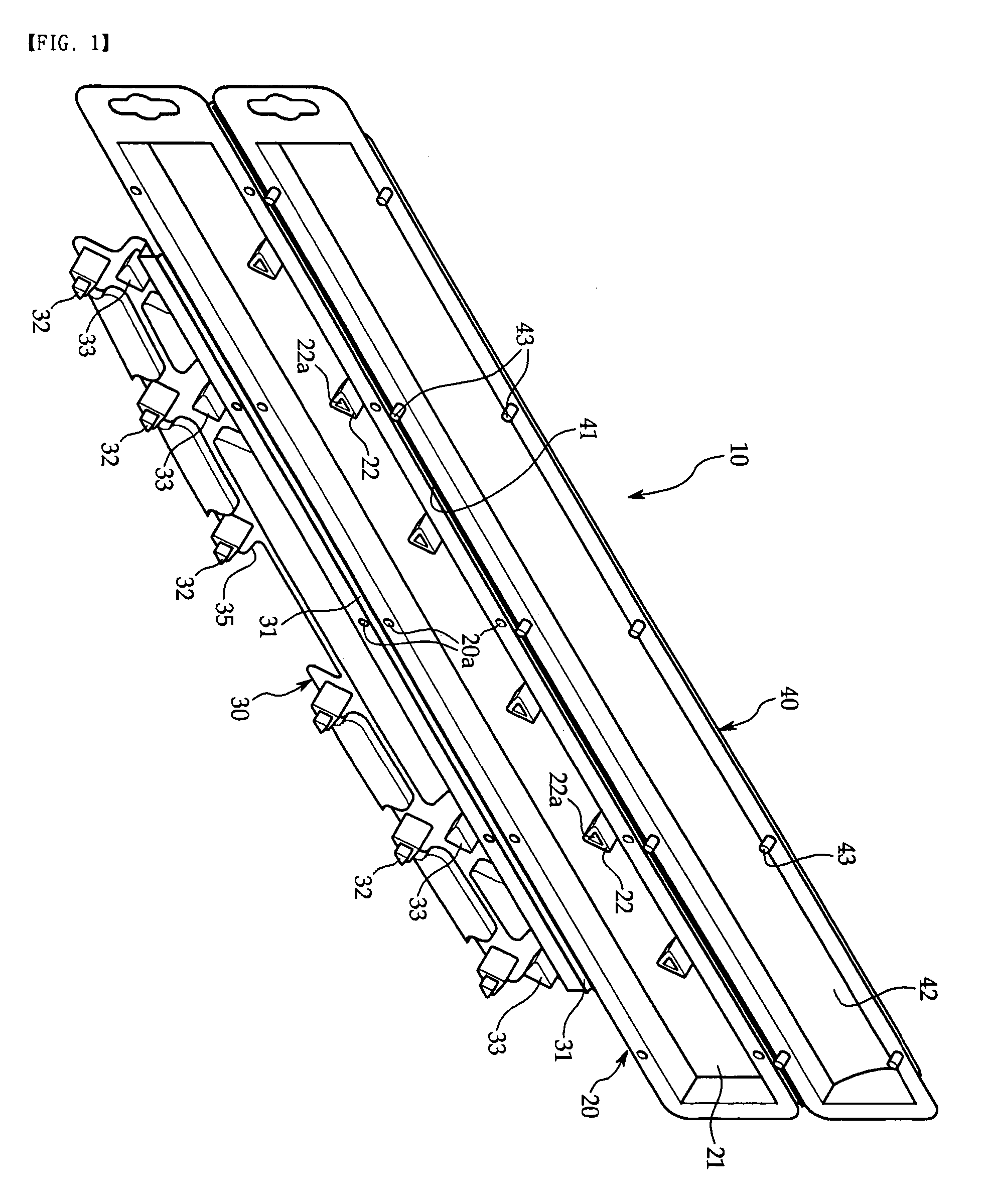

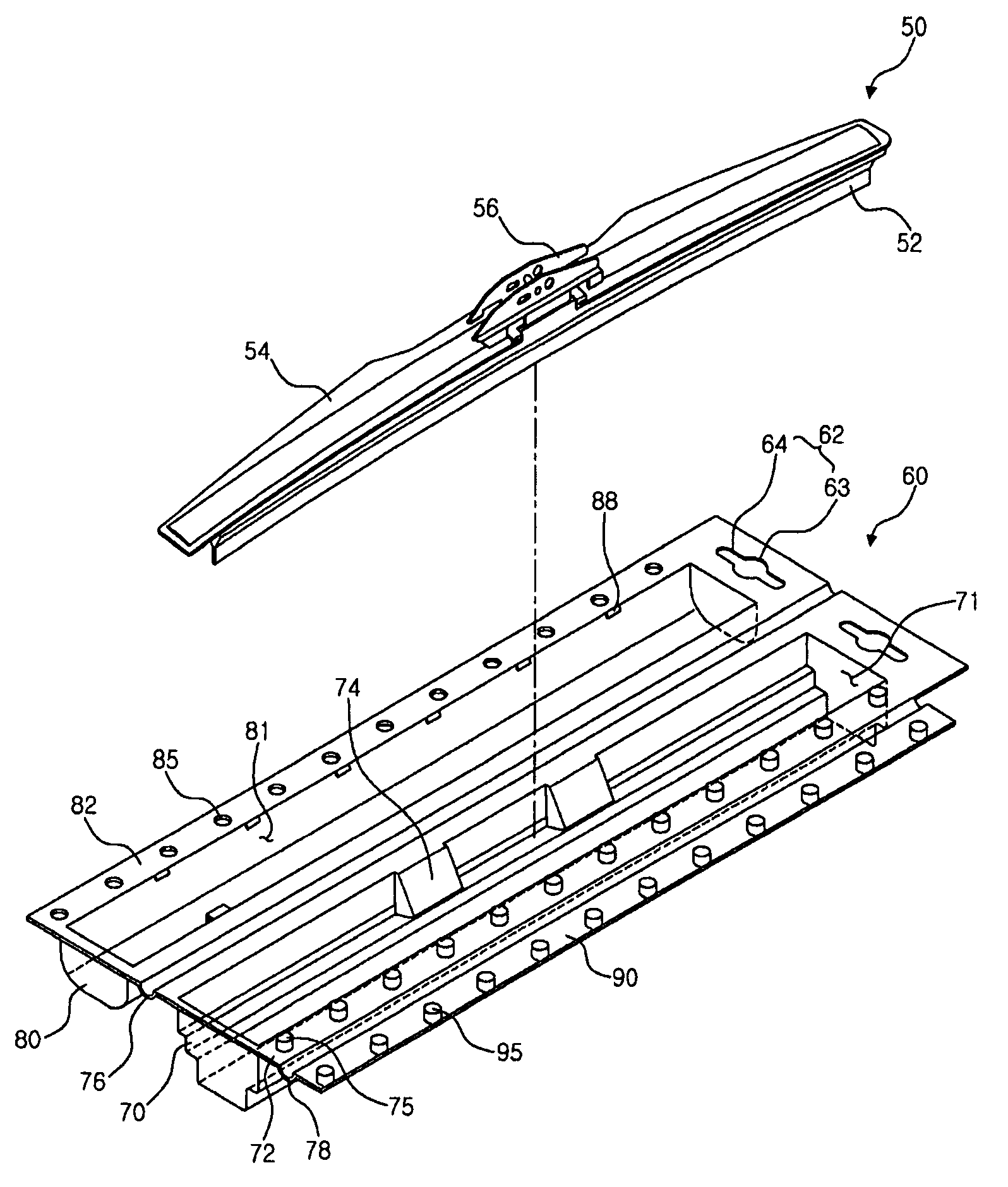

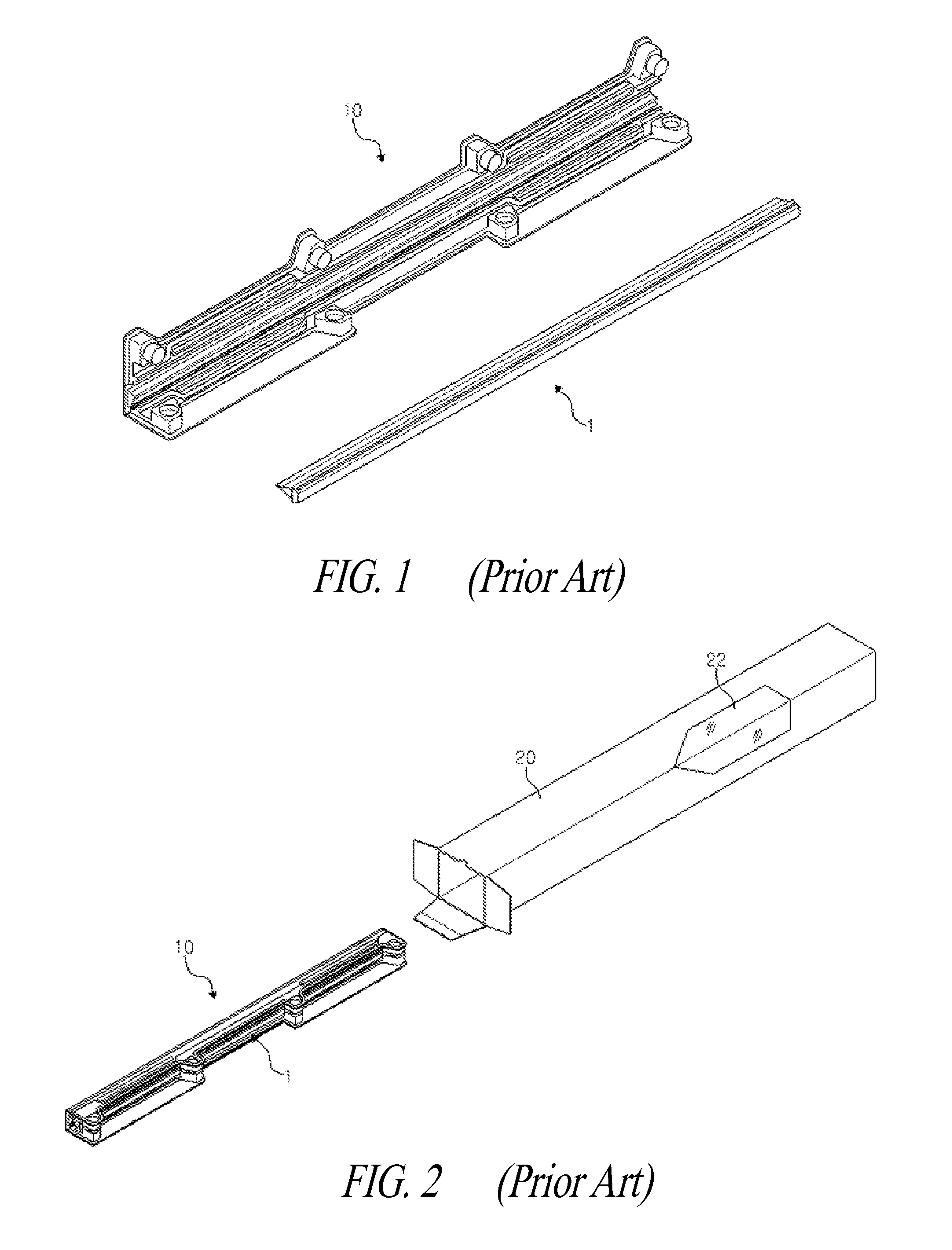

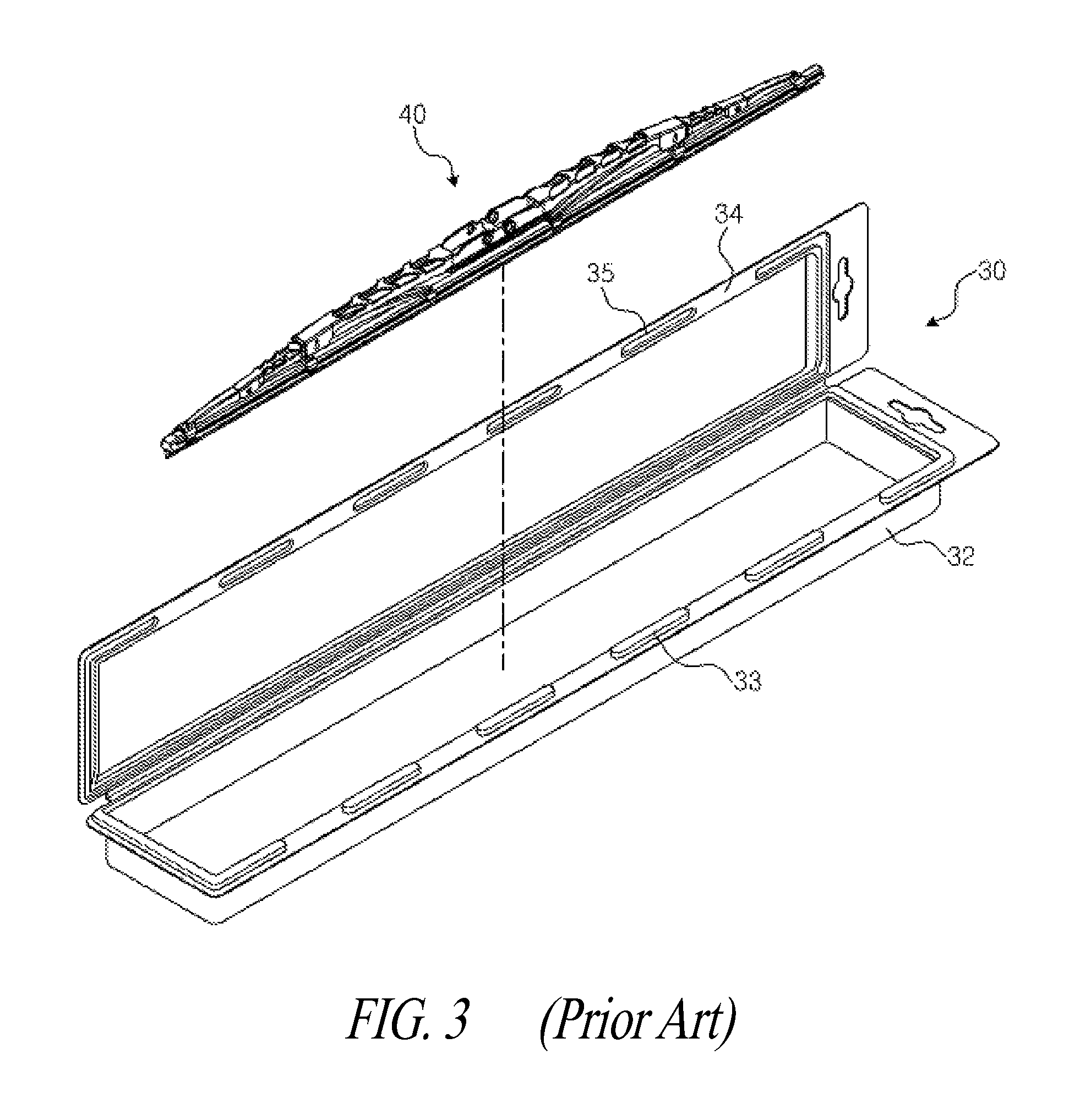

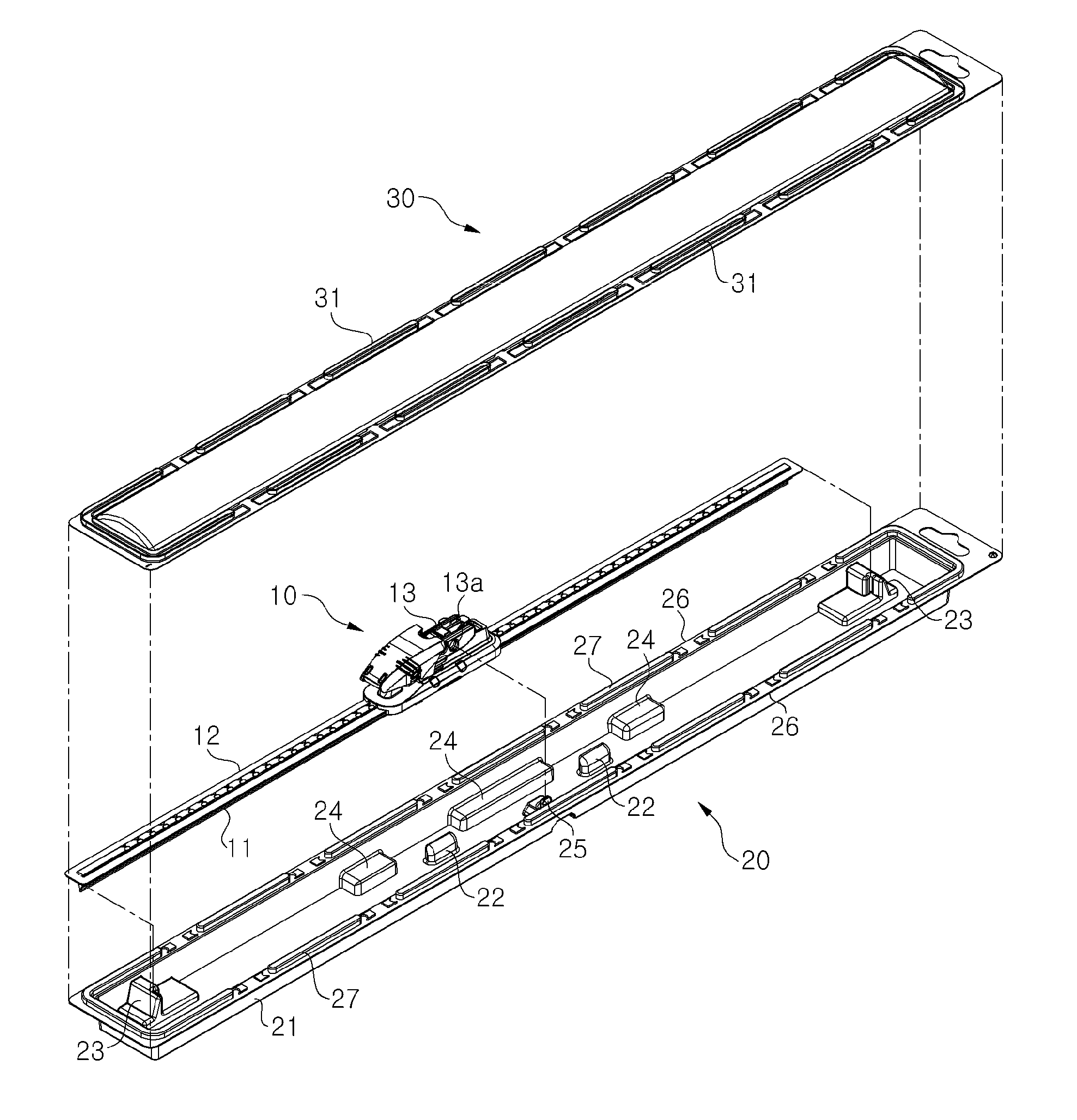

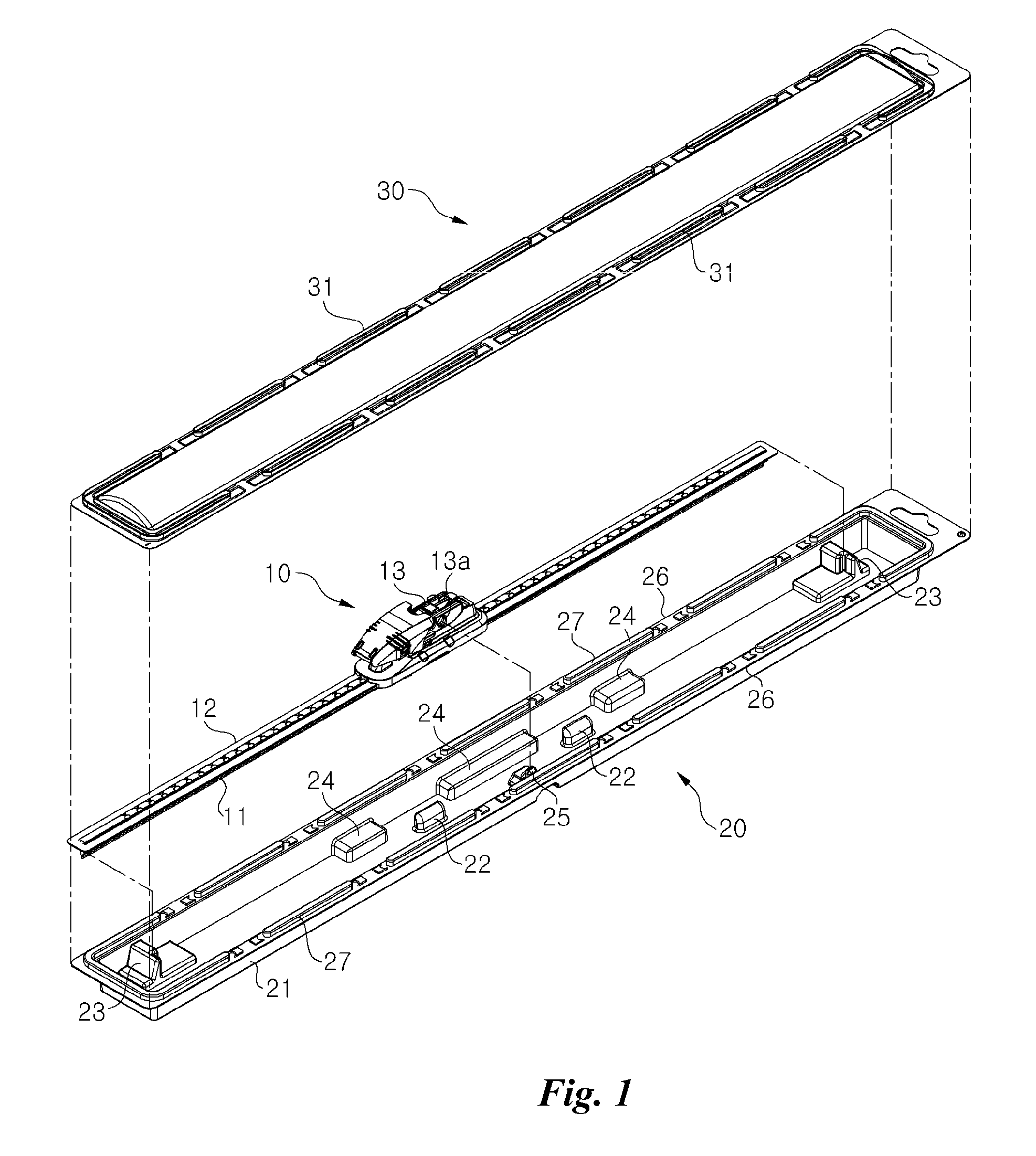

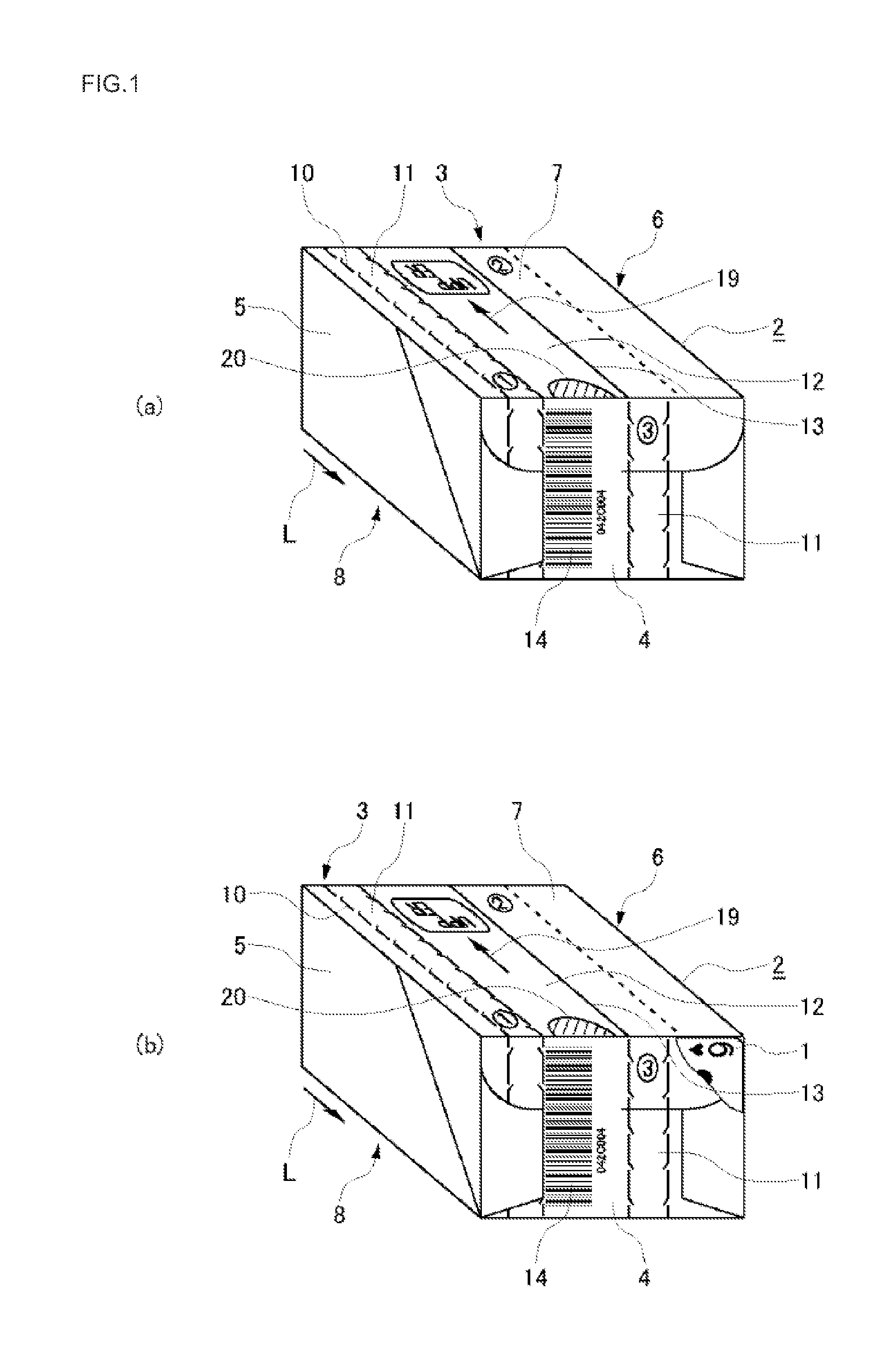

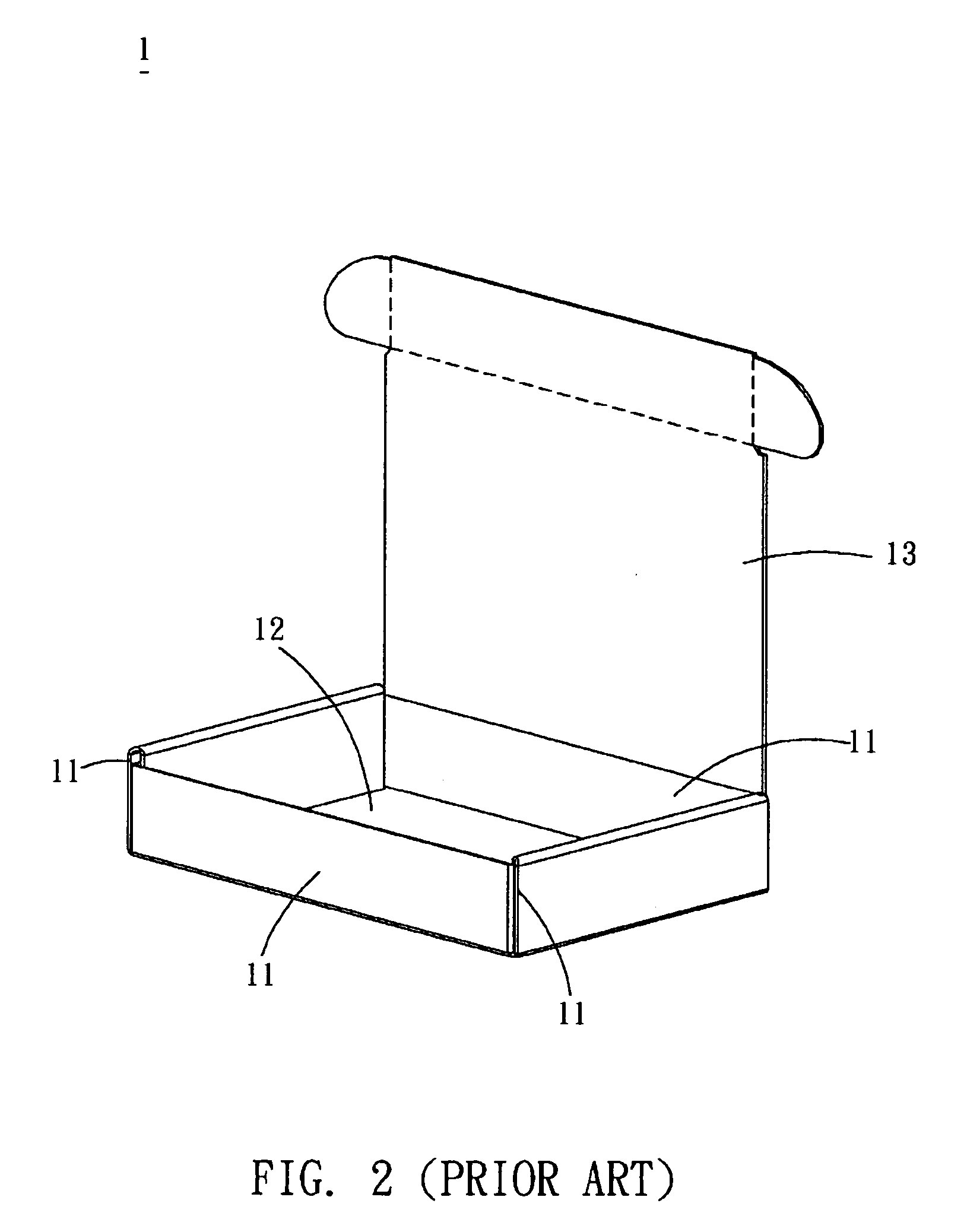

Packaging case for wiper blades

InactiveUS7527151B2Reduce manufacturing costDistorting shapePackaging vehiclesContainers for machinesEngineeringHinge angle

Owner:PARK LTD

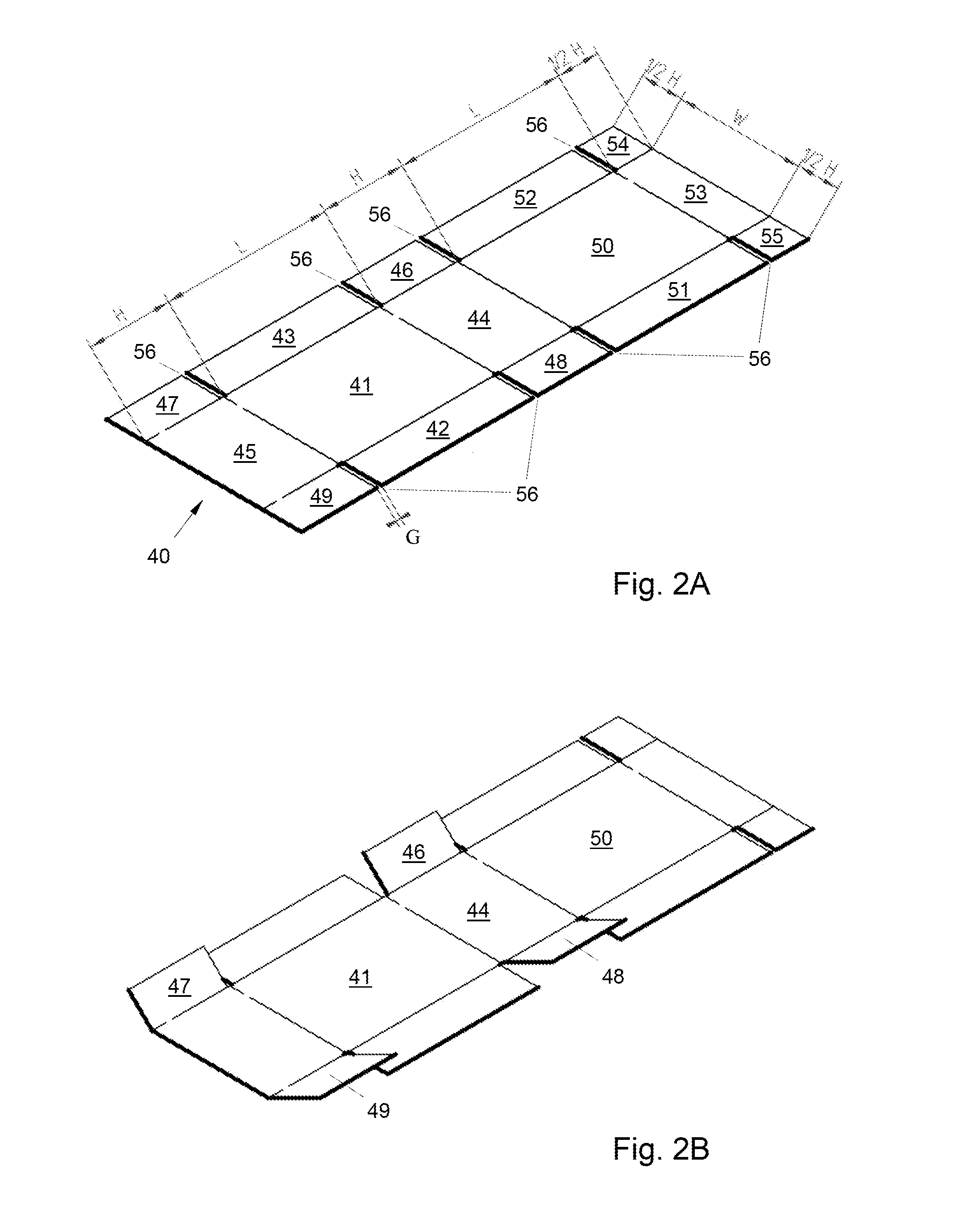

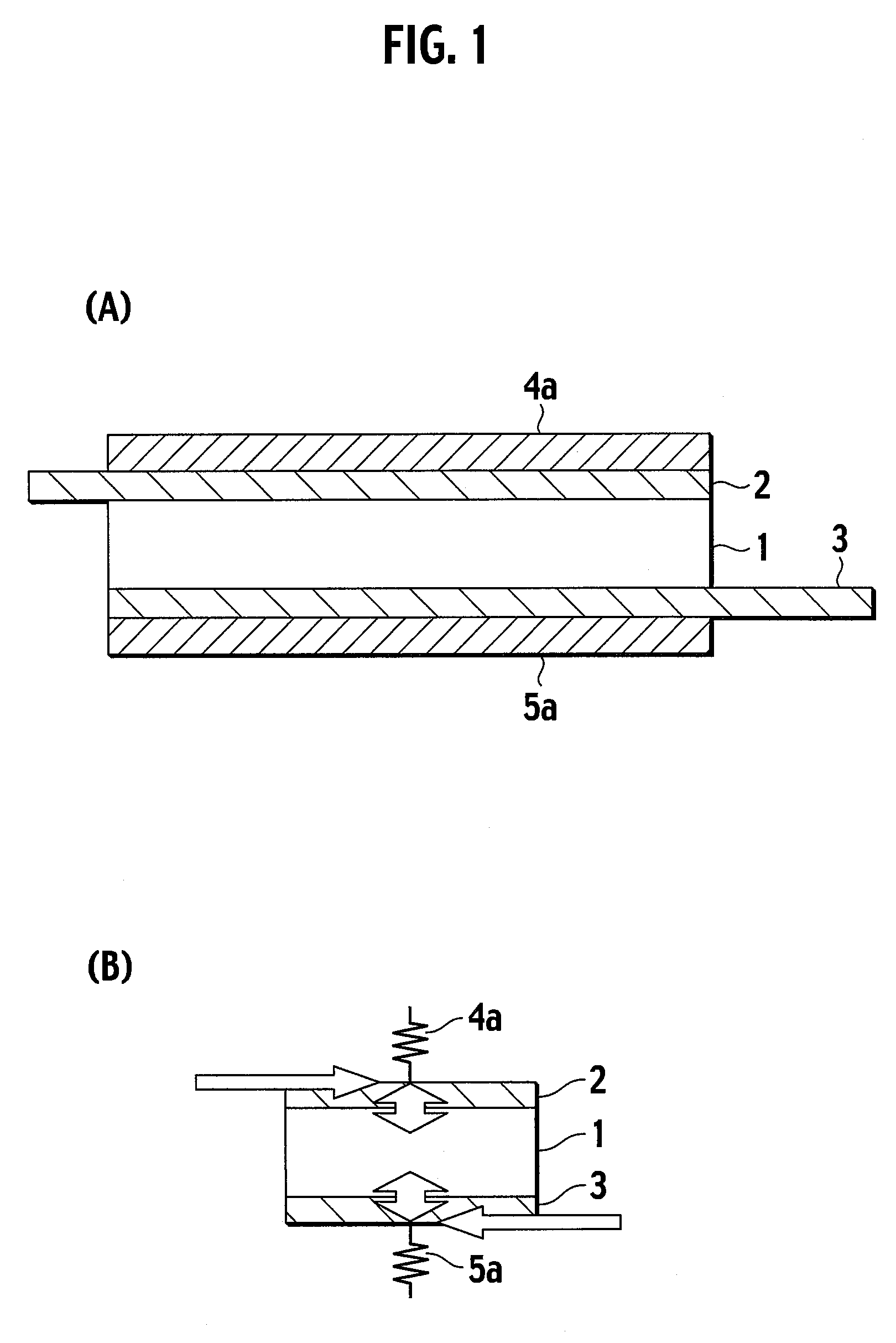

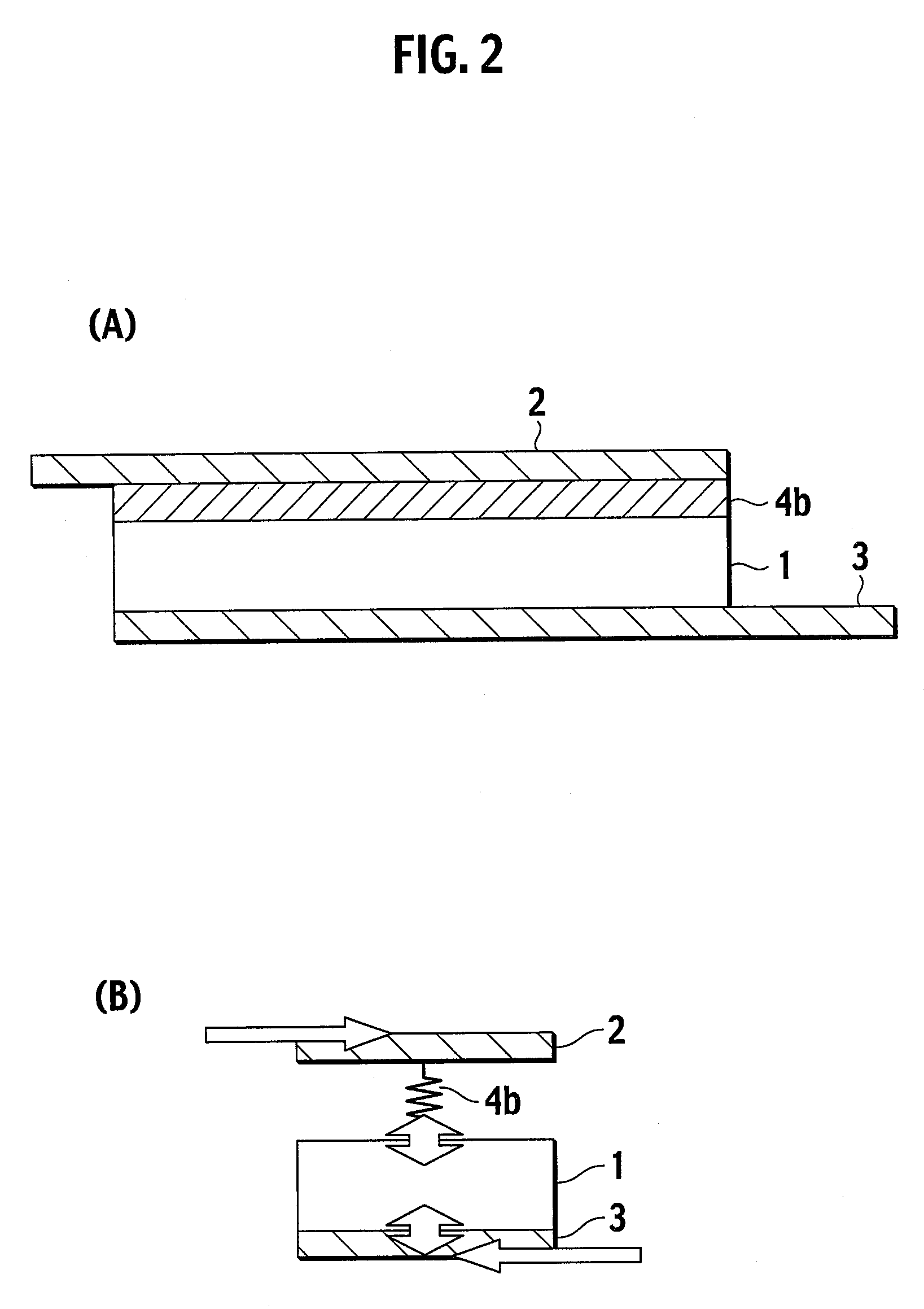

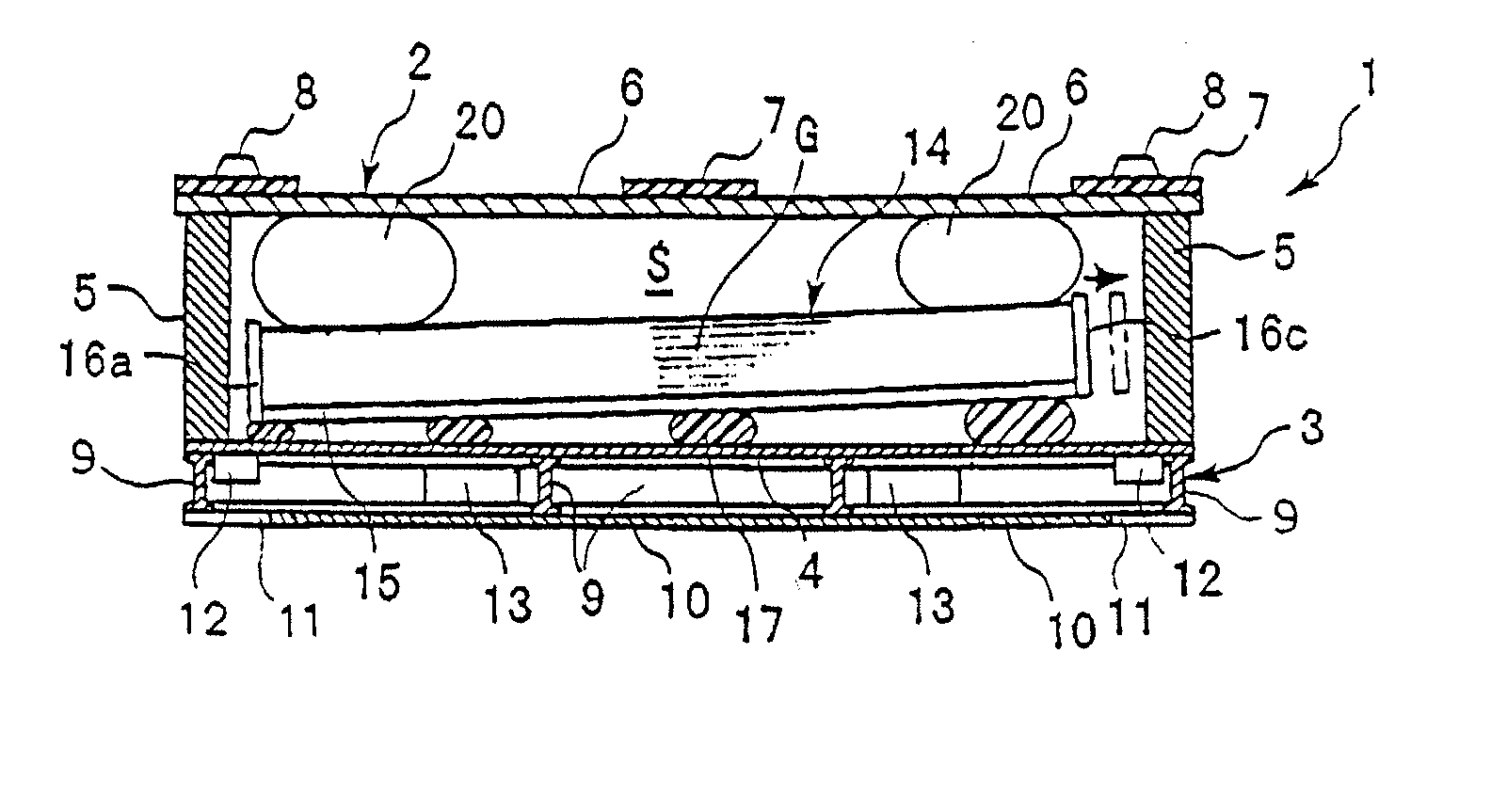

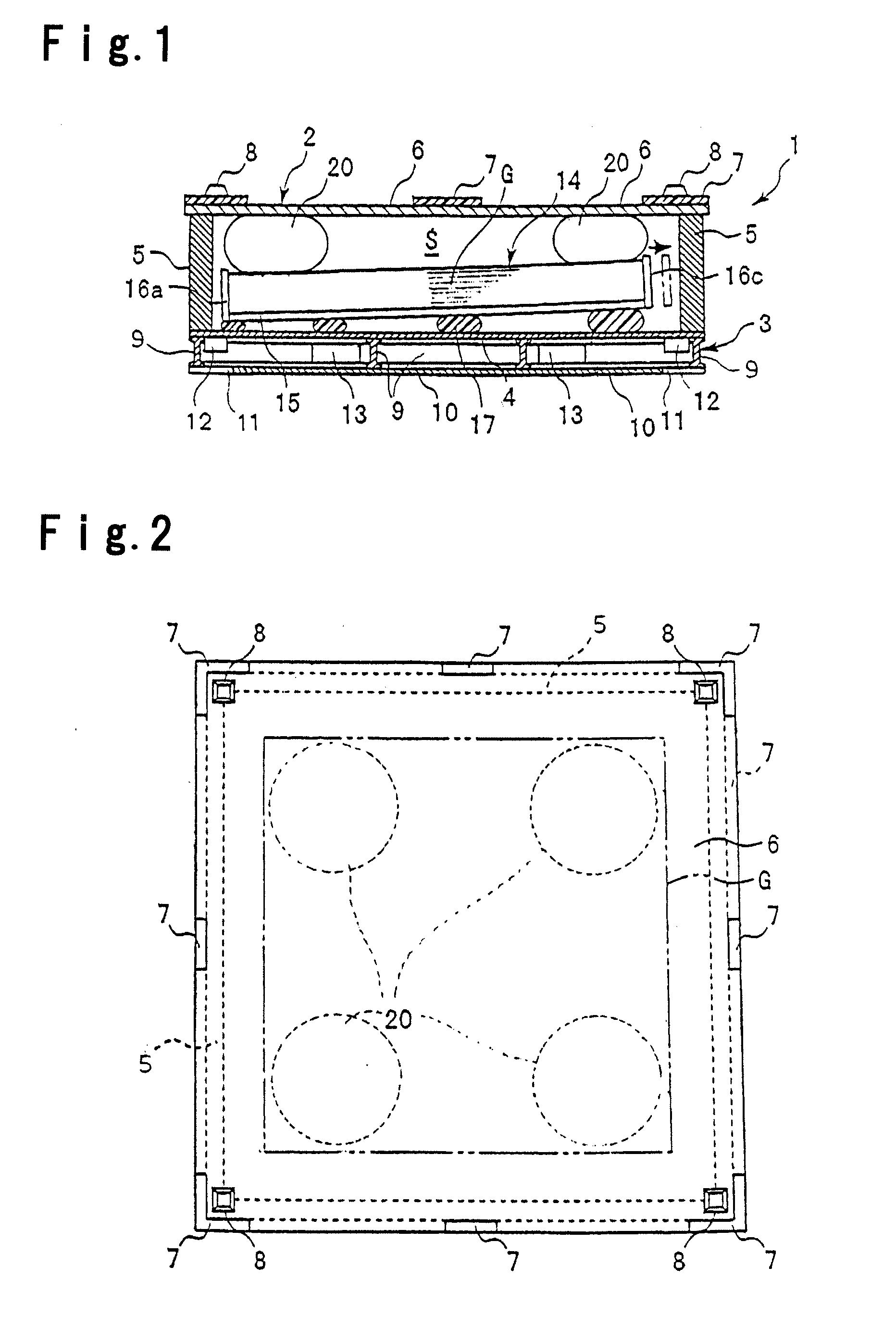

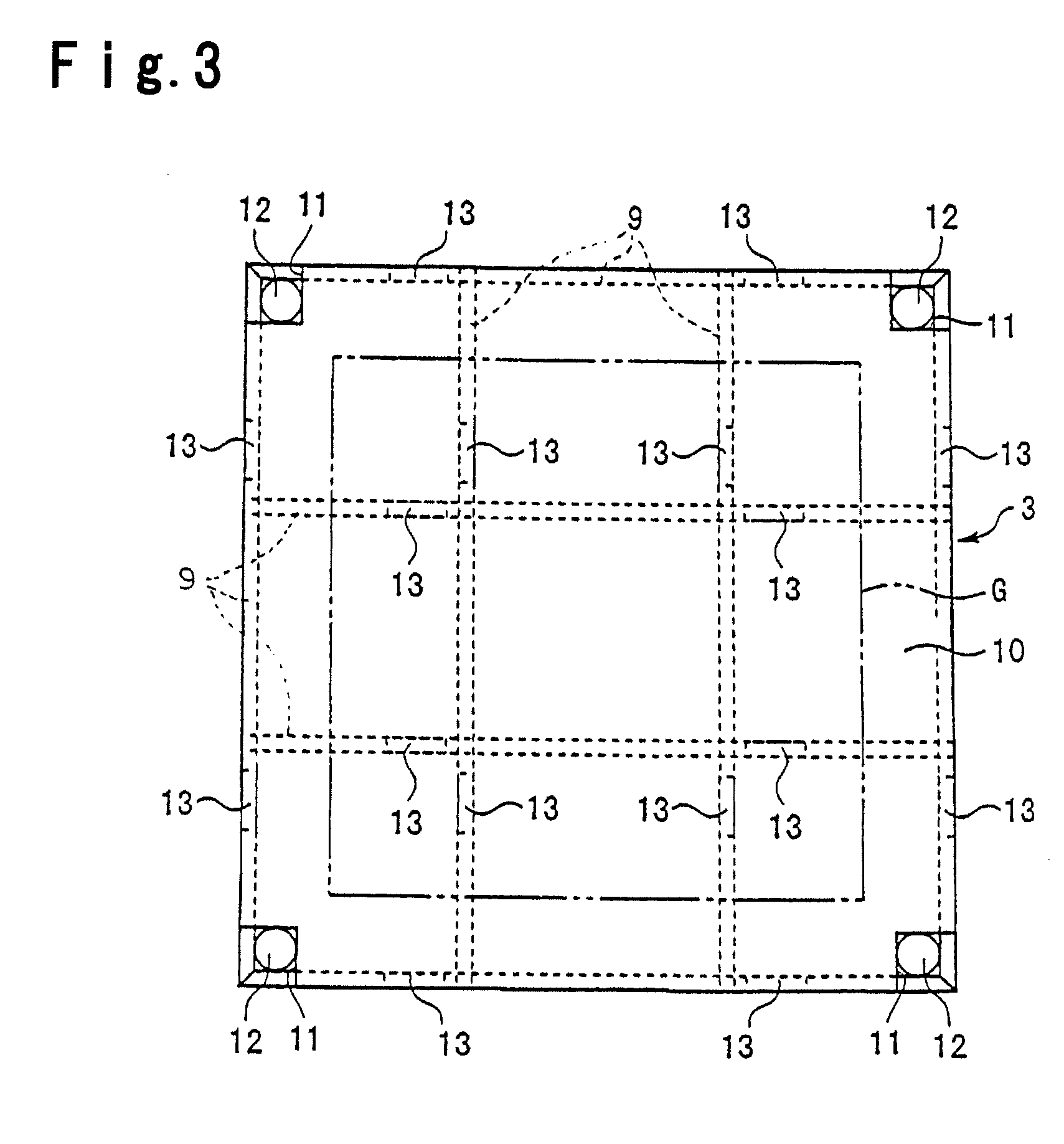

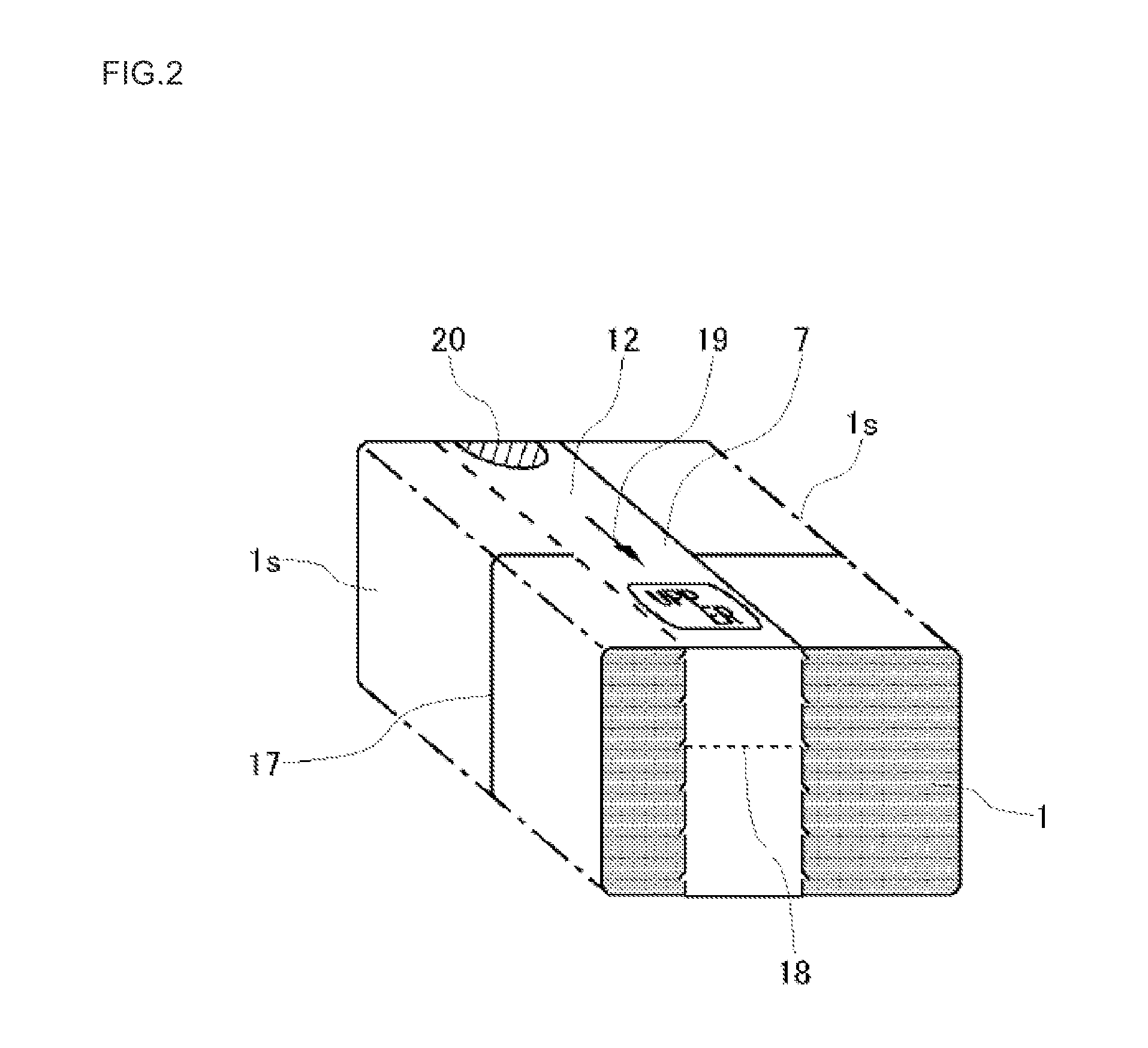

Plate material packing box, plate material transporting method, and plate material loading or unloading method

InactiveUS20070131574A1Avoid enteringEasy to storeOther accessoriesContainer/bottle contructionEngineeringHolding room

A plate material packing box capable of preventing dirt from entering thereinto, easily storable in a storage room with a low ceiling by reducing the height dimension during transportation, and capable of transporting plate materials efficiently and constantly; a plate material transporting method using such a plate material packing box; and a plate material loading or unloading method. The packing box comprises a pedestal 3 having an upper lining, a plate material storage box 14 put on the pedestal 3, and an upper cover 2 enclosing the plate material storage box 14 on the pedestal 3 and being detachable from the pedestal 3, wherein the plate material storage box 14 is an upwardly open support having a bottom plate 15 to have a plurality of plate materials G put thereon in a substantially horizontally stacked state, and side plate 16a to 16d along four sides of its periphery, the upper cover 2 is a downwardly open box having a top plate 6 covering the upper surface of the plate material storage box 14 and side frames 5 along four sides of its periphery; a vibration damper 17 is interposed between the pedestal 3 and the bottom plate 5; and a cushion material 20 is installed between the top plate 6 and the plate materials G put on the bottom plate 15.

Owner:ASAHI GLASS CO LTD

Anti-fog coating composition, anti-fog thin film and product

The invention provides an anti-fog coating composition which comprises at least one hydrophilic polymer; at least one anionic surfactant which accounts for 0.5% by weight-25% by weight calculated by taking the weight of the polymer as 100% by weight; inorganic oxide particles which account for 0% by weight-60% by weight calculated by taking the weight of the polymer as 100% by weight; and a solvent, wherein the polymer is at least one selected from cellulose, polyvinylpyrrolidone, polyacrylic acid, polypropylene amide and polyvinyl alcohol. The invention further provides an anti-fog thin film, which comprises a substrate and a coating which is positioned on one part of the surface of at least one surface of the substrate and produced by the composition. The invention also provides a product comprising the anti-fog thin film, such as masks and glasses for medical operations, mine masks, food packaging boxes, food packaging bags and the like.

Owner:3M INNOVATIVE PROPERTIES CO

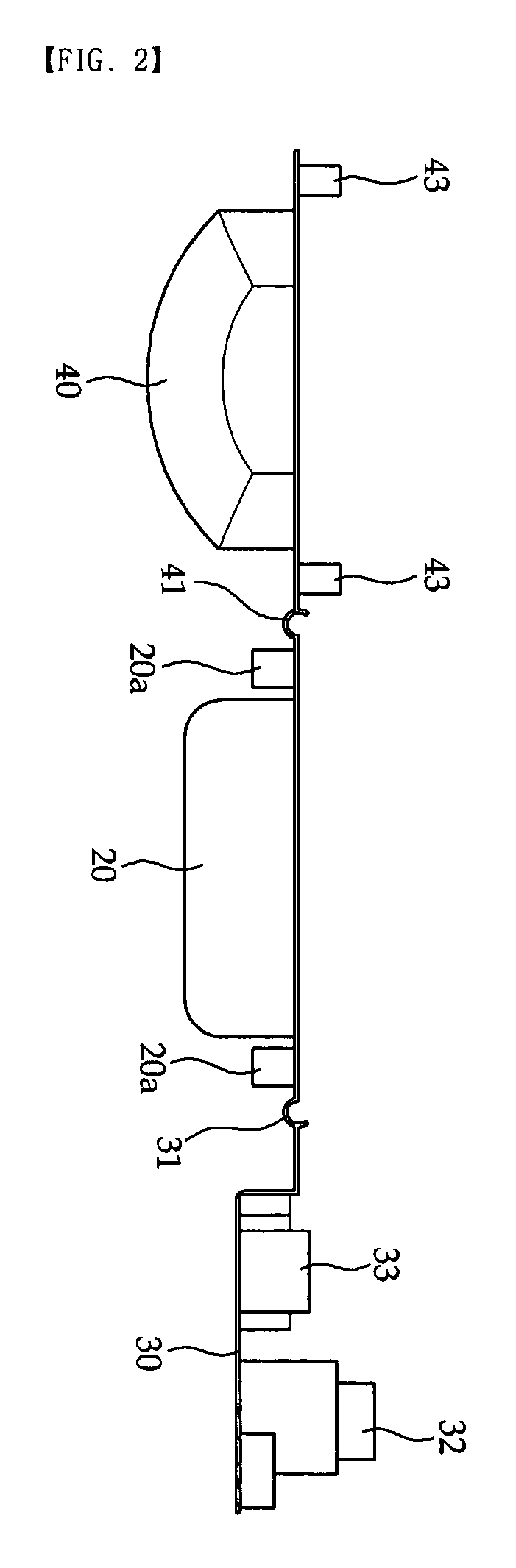

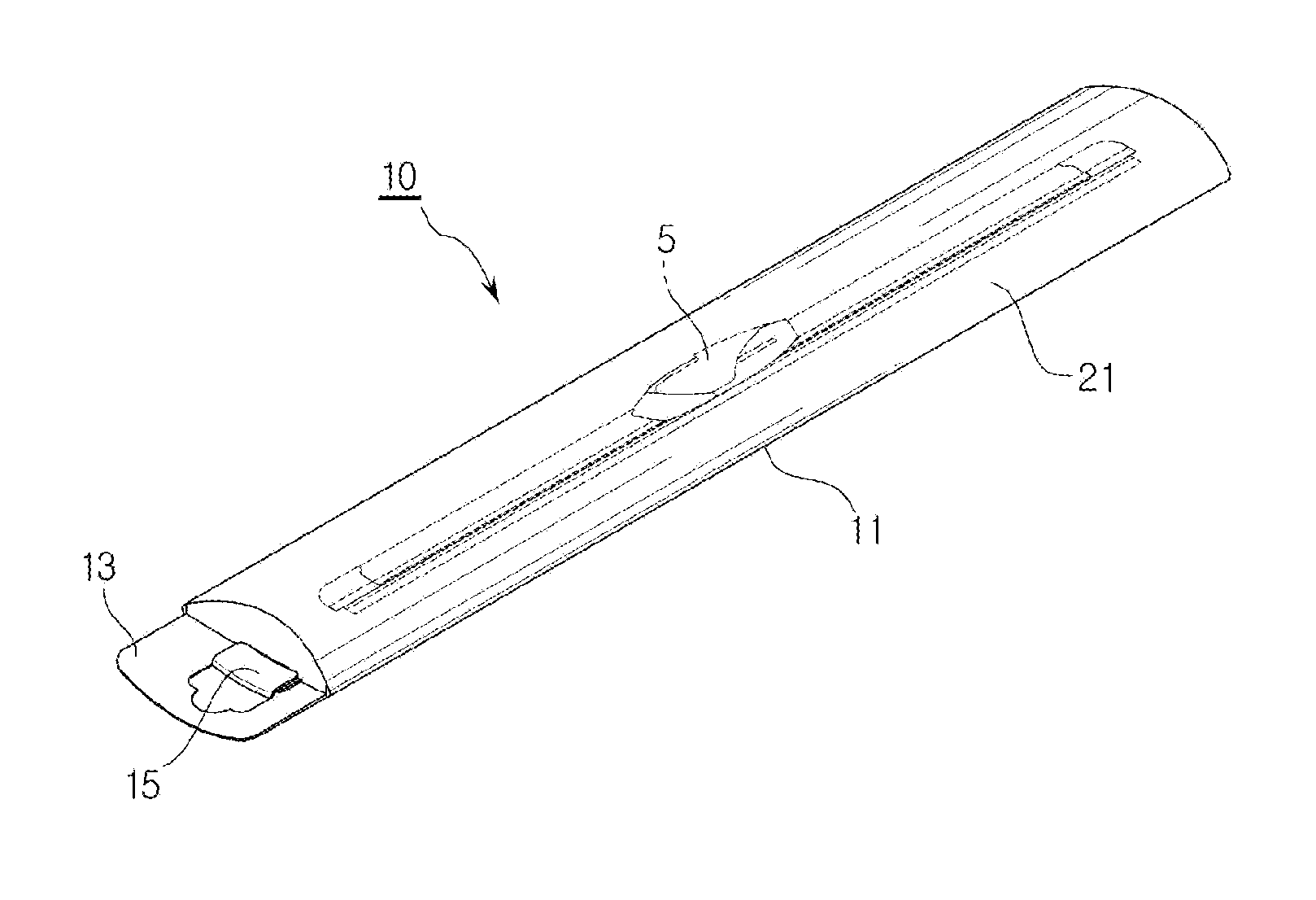

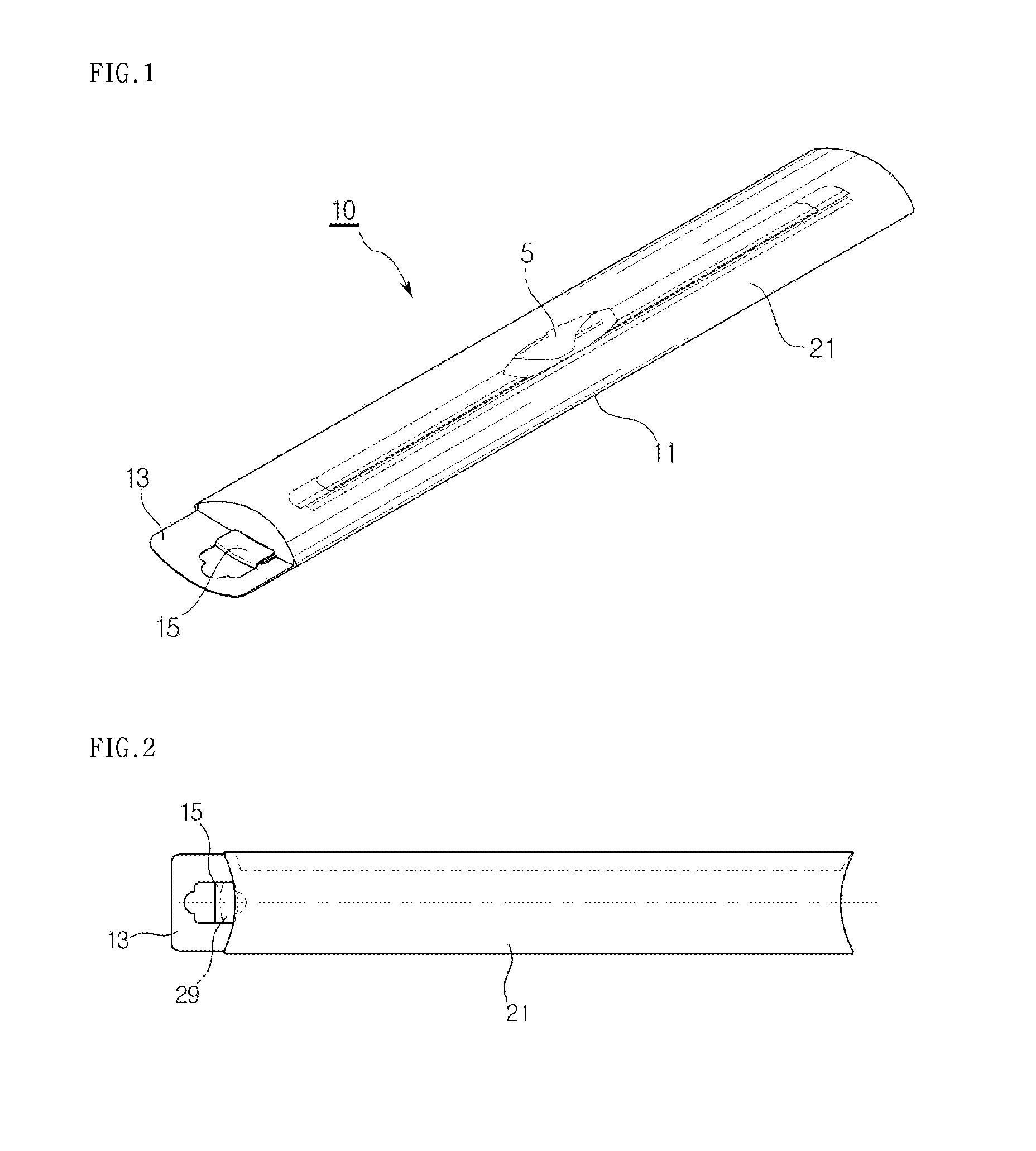

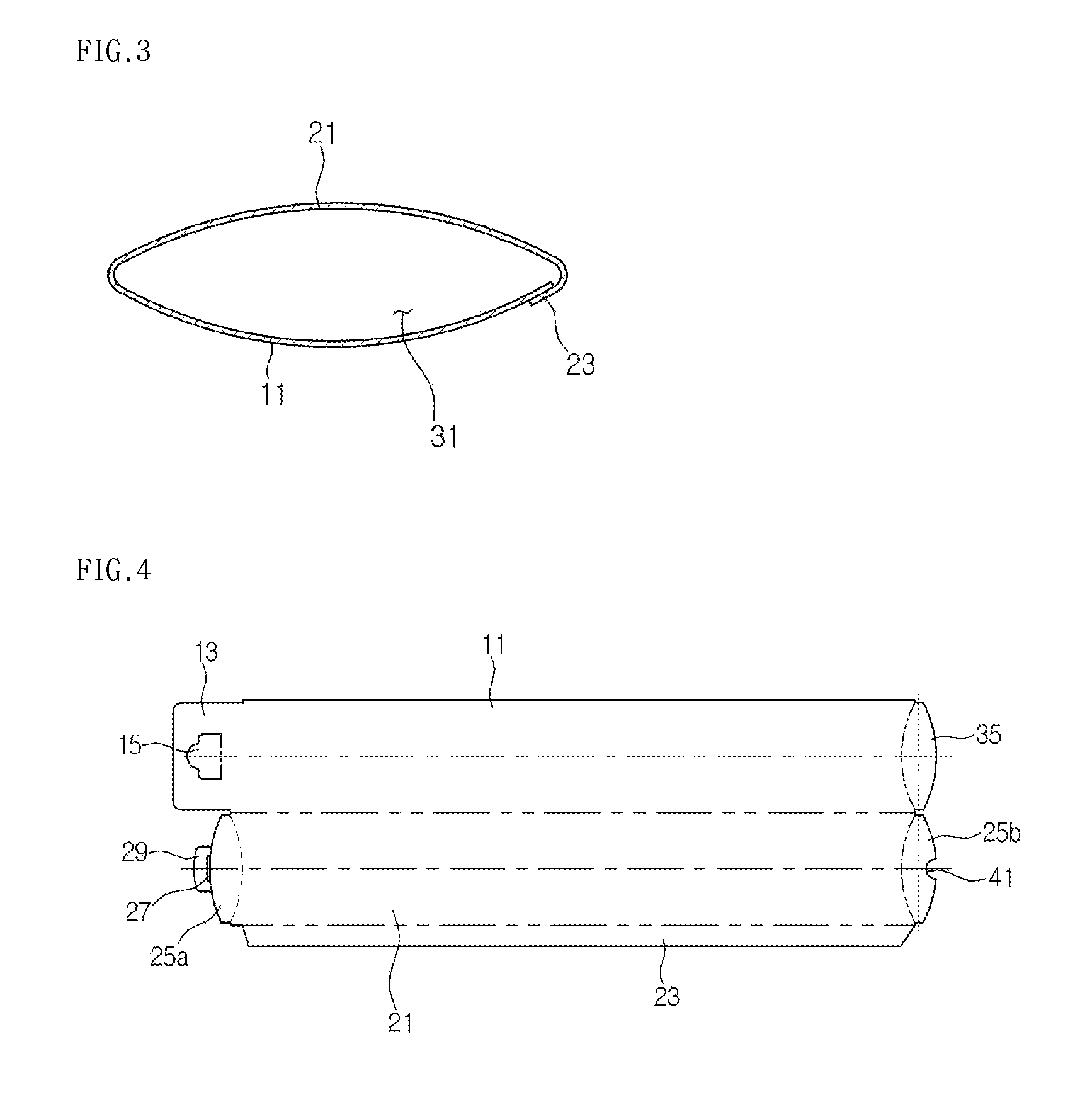

Packaging case of wiper blade

InactiveUS7975849B2Avoid damageCompact and simple and tight packagingOther accessoriesContainer/bottle contructionWindshieldAutomotive engineering

Disclosed herein is a packaging case of a wiper blade used to wipe a windscreen of automobiles. The wiper blade includes a wiper strip to wipe a windshield of an automobile. The packaging case includes a body having an accommodation space to accommodate the wiper blade and an opening to open the accommodation space, a cover connected pivotally to a first side of the body via a first connecting part to cover the opening, and a locking section connected pivotally to a second side of the body, opposed to the first side, via a second connecting part to be engaged with the body with one end of the cover interposed between the locking section and the body. The packaging case can protect the wiper blade from external force and prevent damage of the wiper blade during delivery and distribution, and can ensure simple, compact and tight packaging of the wiper blade.

Owner:THE KOREA DEV BANK

Wiper blade packing case

ActiveUS8434621B2Easy constructionLow costPackaging vehiclesContainers for machinesEngineeringPackaging Case

Owner:CAP CORP

Packaging case for a wiper blade

InactiveUS7926659B2Avoid damageMinimized volumePackaging vehiclesContainers for machinesEngineeringLarge capacity

Owner:THE KOREA DEV BANK

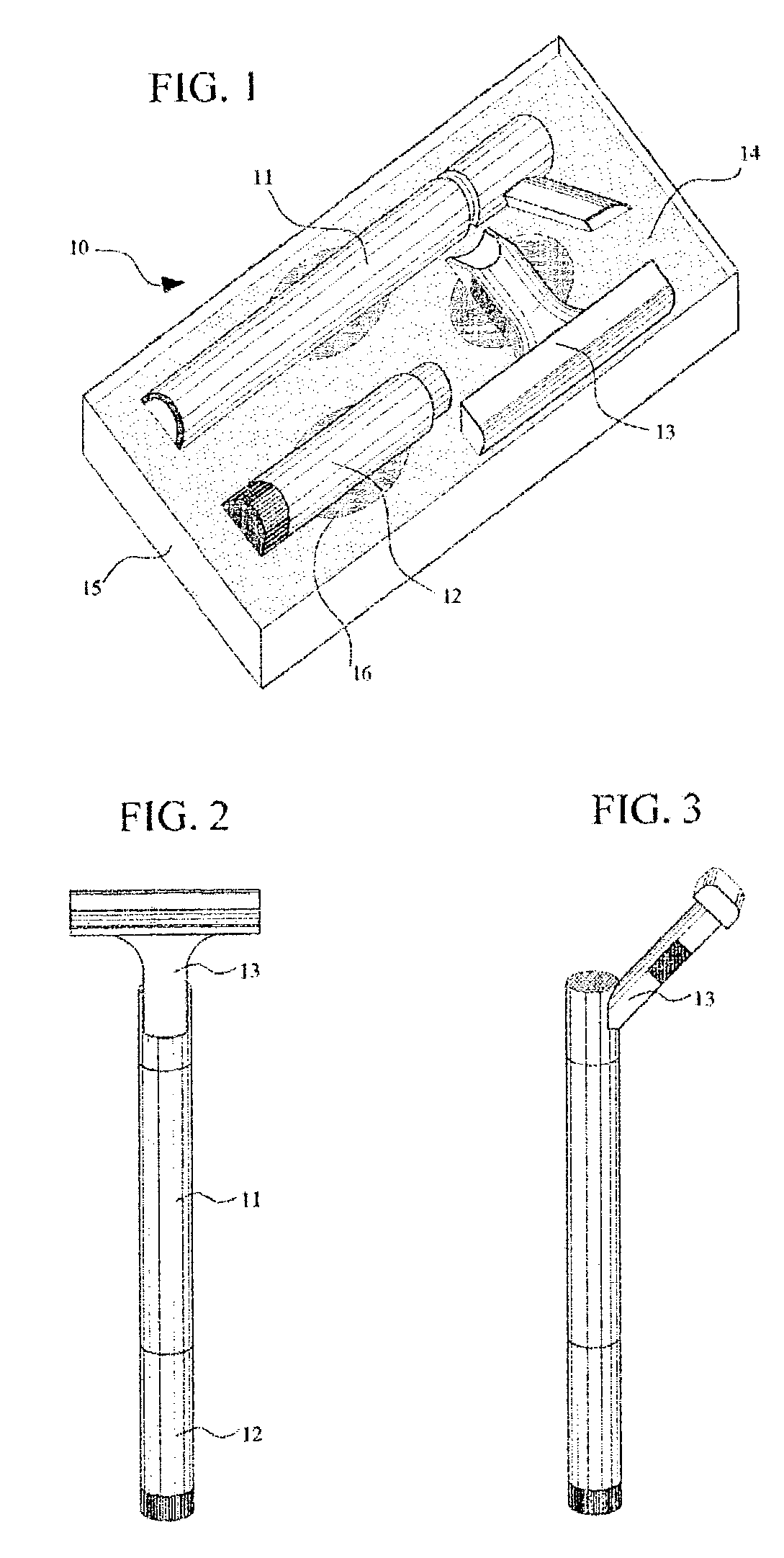

Single-use disposable shaving set

A single-use disposable shaving set composed of three pieces; first piece being a shaving foam cartridge containing pressurized shaving foam sufficient for a single shave, second piece being an aftershave liquid cartridge containing a kind of after shave liquid sufficient for a single shave, and the third piece being a blade assembly having at least a blade coupled thereto; all three of the pieces contained in a wrapped box slightly bigger than a standard matchbox without being mounted in order to occupy the smallest space possible, under a hygienic condition; the foam cartridge and the aftershave liquid cartridge forming the handle of a shaving machine when mounted together and all forming a shaving machine when the blade assembly is mounted to the handle; the set featuring all the minimum requirements of a well wet shave; the entire set to be disposed off after a single use.

Owner:SELEK ALI SABAN

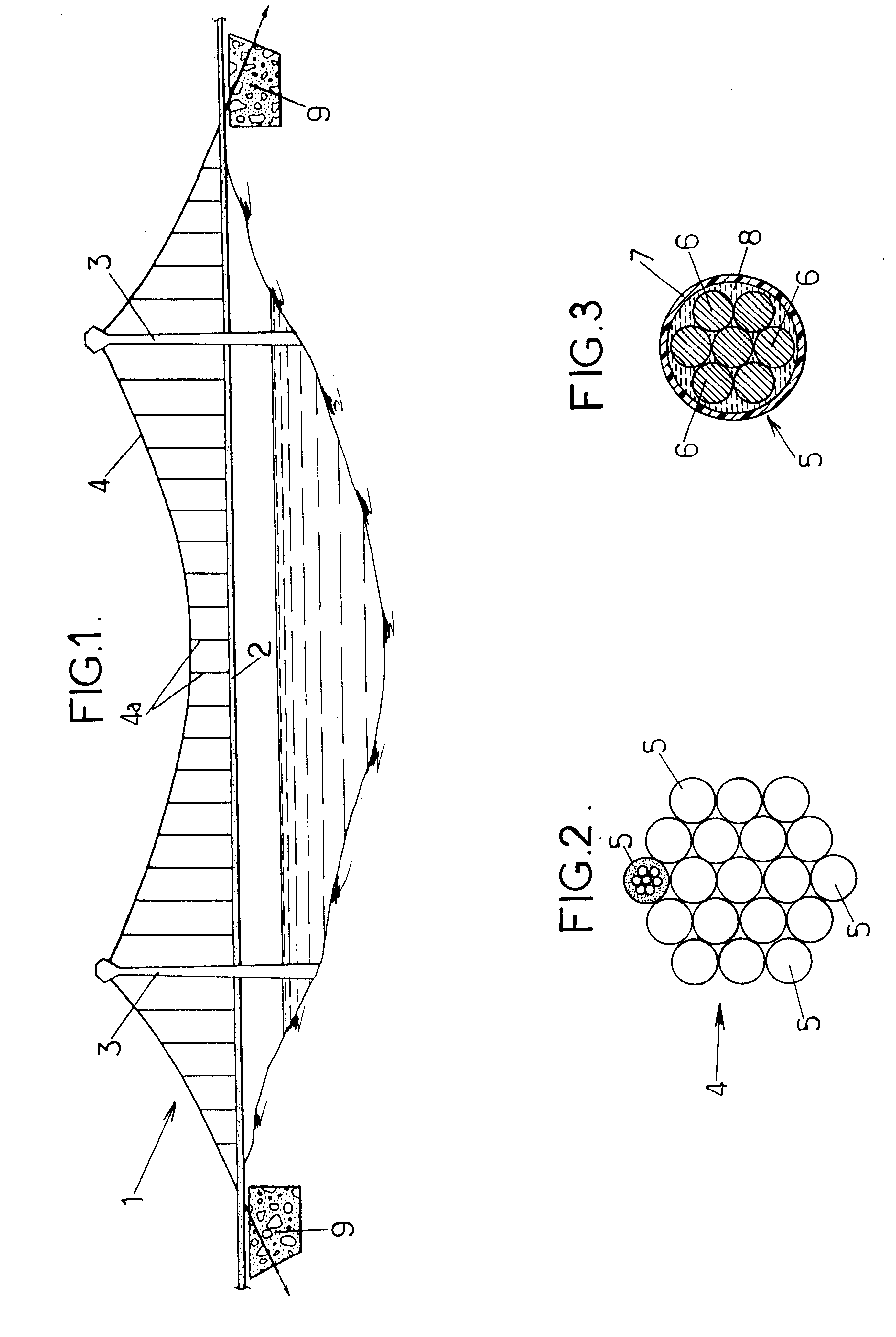

Anchoring device for fixing a structural cable to a building element

InactiveUS6578329B1Not entail costly disassemblySnap fastenersCable-stayed bridgeEngineeringExtremity Part

Owner:COBRA CABLE TIE +1

Cigarette package

ActiveUS20120111746A1Sealing is not affectedImprove productivityContainers for flexible articlesCigar manufactureFilm materialPackaging Case

A cigarette package includes an inner wrapping body formed by folding an inner wrapper having a film material ply sandwiched between a paper ply and a heat seal material ply into a substantially cuboidal shape, including substantially-parallel two half-cut lines extending from a top face into an upper portion of a front face of an inner boxy body each formed of a cut penetrating through the paper ply into the film material ply, a cut line formed of a cut penetrating through an outer layer constituting an overlap on the front face of the inner box body, at an upper location. A heat-sealed part is formed to surround the cut line by heat-sealing inner and outer layers, wherein an outer side of the outer layer is bonded to an inner side of a front lid, in a section above the cut line within a region surrounded by the heat-sealed part.

Owner:JAPAN TOBACCO INC

Packing case for cooling compressors and other machinery

A packing case for cooling compressors and other machinery is disclosed. A packing case includes an opening through which a movable machinery shaft may be inserted such that the packing case is mounted on the shaft. In an exemplary embodiment, the packing case contains at least one packing cup with channels through which a fluid coolant may flow. The channels form substantially parallel passageways along the length of the shaft that are spaced apart around the shaft circumference and series connected. The fluid coolant may be introduced through one or more inlet ports, circulate through the substantially parallel passageways of the at least one packing cup, and exit the packing case through one or more outlet ports. The fluid coolant may flow through the packing case in a single, continuous flow path or a split flow arrangement.

Owner:HOERBIGER KOMPRESSORTECHNIK HLDG GMBH

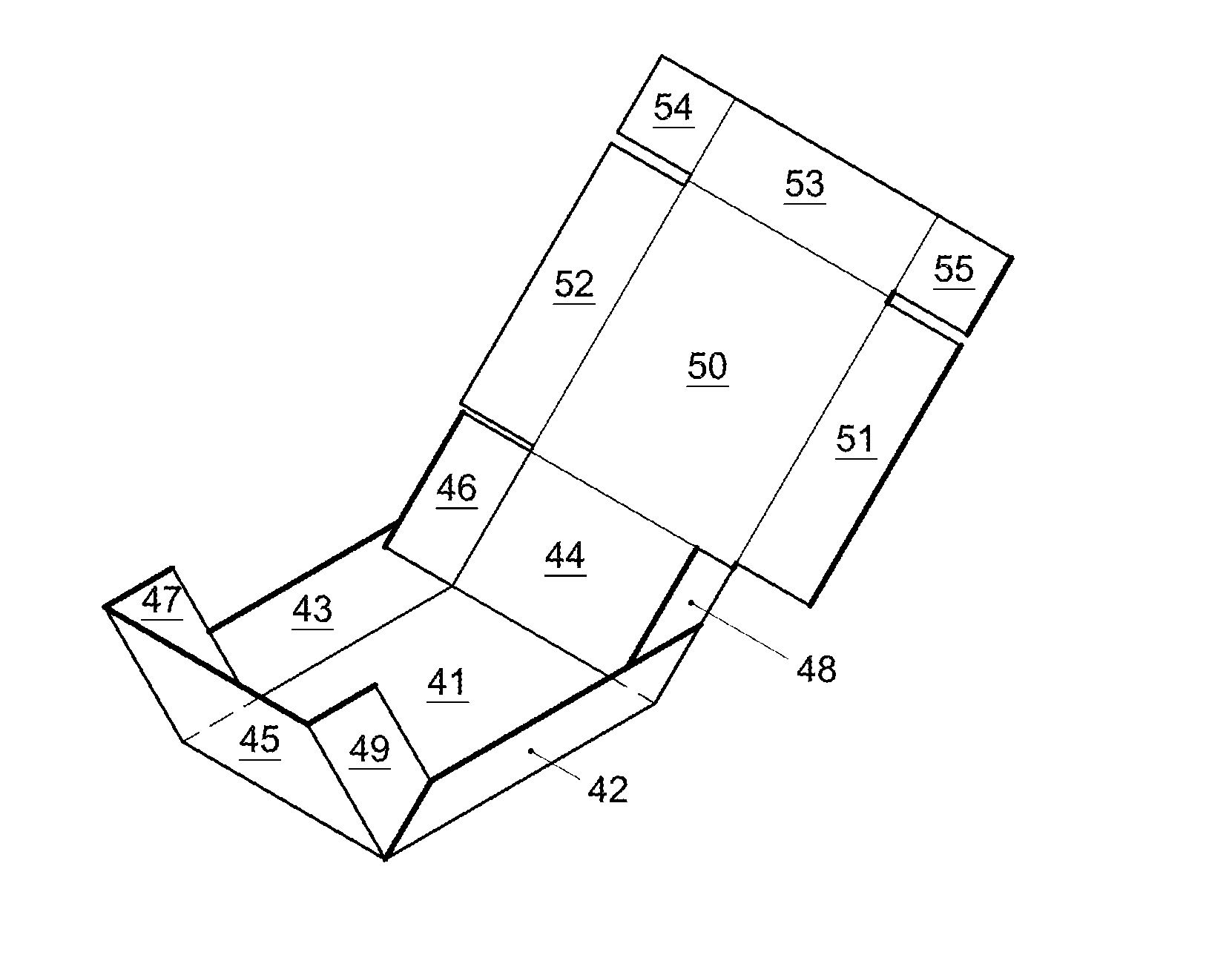

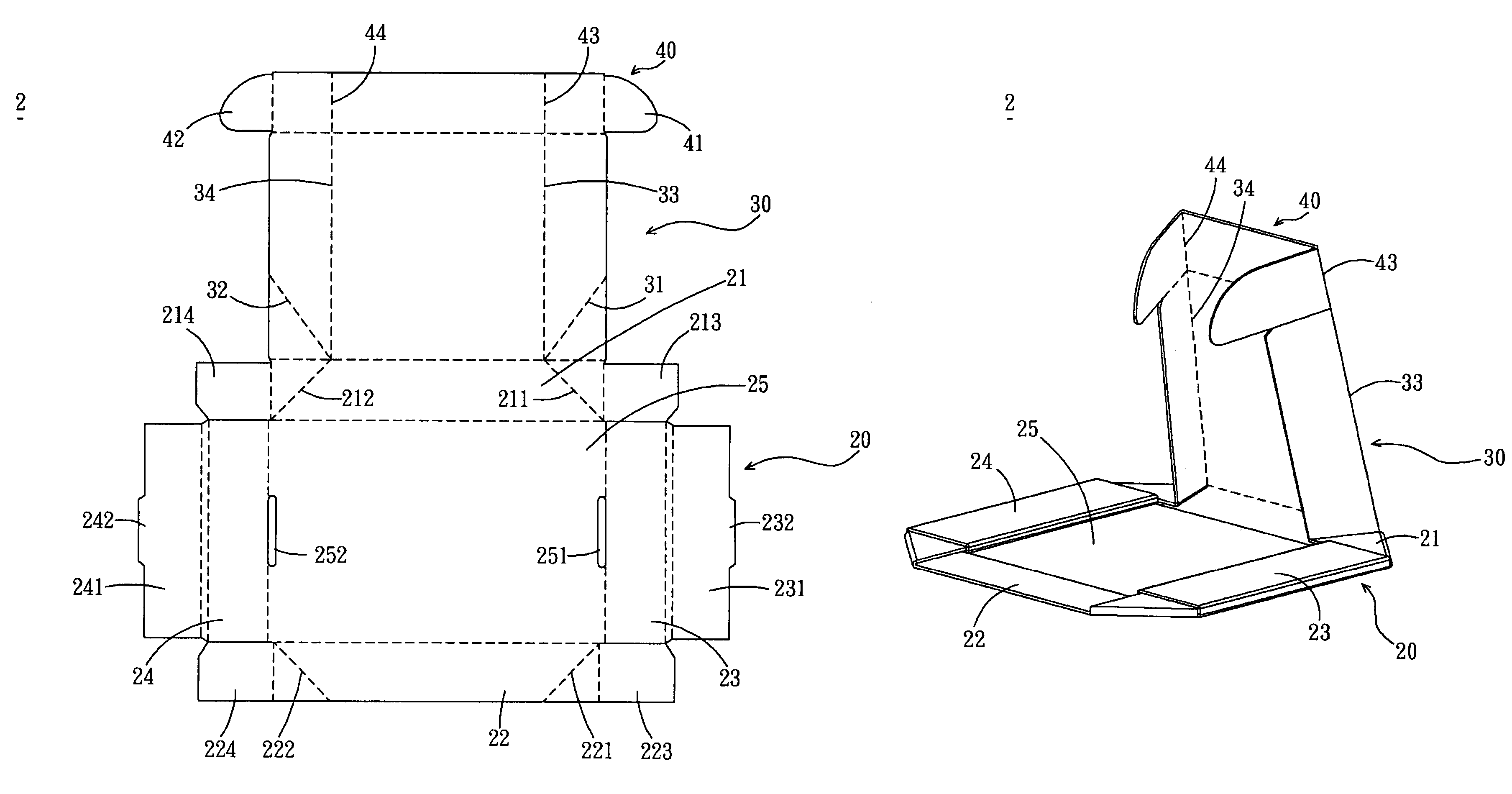

Packing box of playing cards

ActiveUS20140033660A1Easy to handleEasy to operateOpening closed containersBottle/container closurePlaying cardEngineering

A packing box for packaging of playing cards has, in an assembled state, a shape of a rectangular parallelepiped with six faces including front and rear faces, right and left side faces, and top and bottom faces. The packing box includes cut lines in two locations at a predetermined interval in parallel with a longitudinal direction of the rectangular parallelepiped, and a central band in a portion defined by the cut lines provided in the two locations. The right and left side faces of the packing box can be removed along the cut lines such that side edges of the playing cards within the packing box are exposed.

Owner:ANGEL GRP CO LTD

Packaging box

Owner:ARCADYAN

Fresh-keeping packaging material and products thereof

InactiveCN101701082AHigh strengthHigh air permeabilityFlexible coversWrappersDispersitySodium Bentonite

The invention relates to a fresh-keeping packaging material and products thereof, belonging to the technical field of packaging. The invention has the technical scheme that a certain proportion of mineral micropowder of kieselguhr or sepiolite or medical stone or bentonite or tephros or perlite and the like is doped into plastics of PE, PP, PVC and the like and paper pulp, and then the mixture is made into thin films, packaging paper or packaging bags or packaging boxes or packaging cases, trays and the like; the characteristics of dispersity, air permeability, adsorbability, far infrared ray and positive and negative ion function and the like of the mineral micropowder are utilized to enable the packaging material to generate micropores, and therefore, the packaging material has a certain air permeability and adsorbability or generates positive and negative ions or far infrared rays; gas and a small quantity of moisture which are generated from packaged articles are discharged from the micropores, and harmful gas is absorbed and transferred, and thereby, the heat value of the packaged articles can be effectively lowered; microbes are killed or restrained, thereby meeting the demands of keeping fresh of live and fresh food and prolonging storage life.

Owner:钟爱民

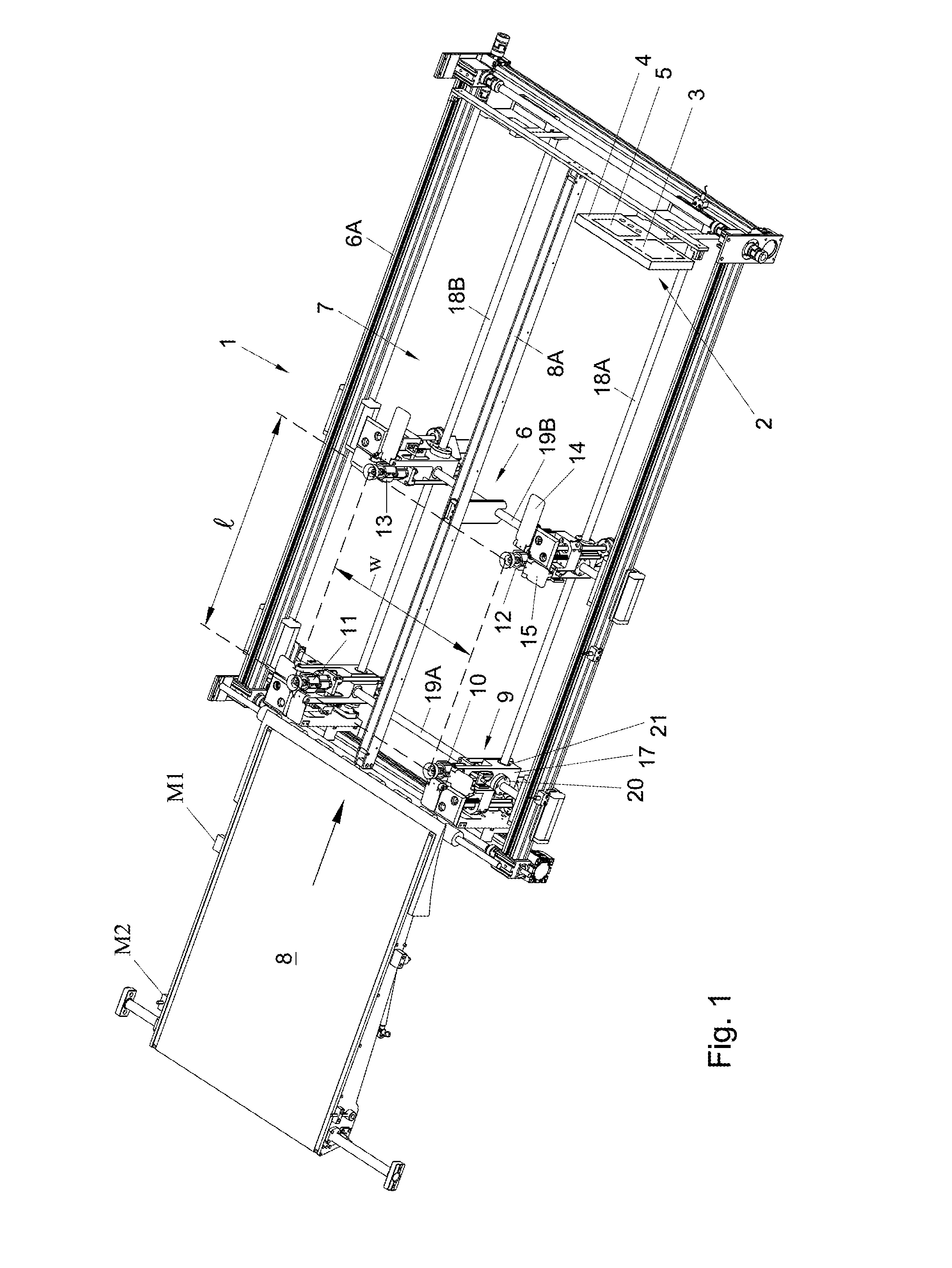

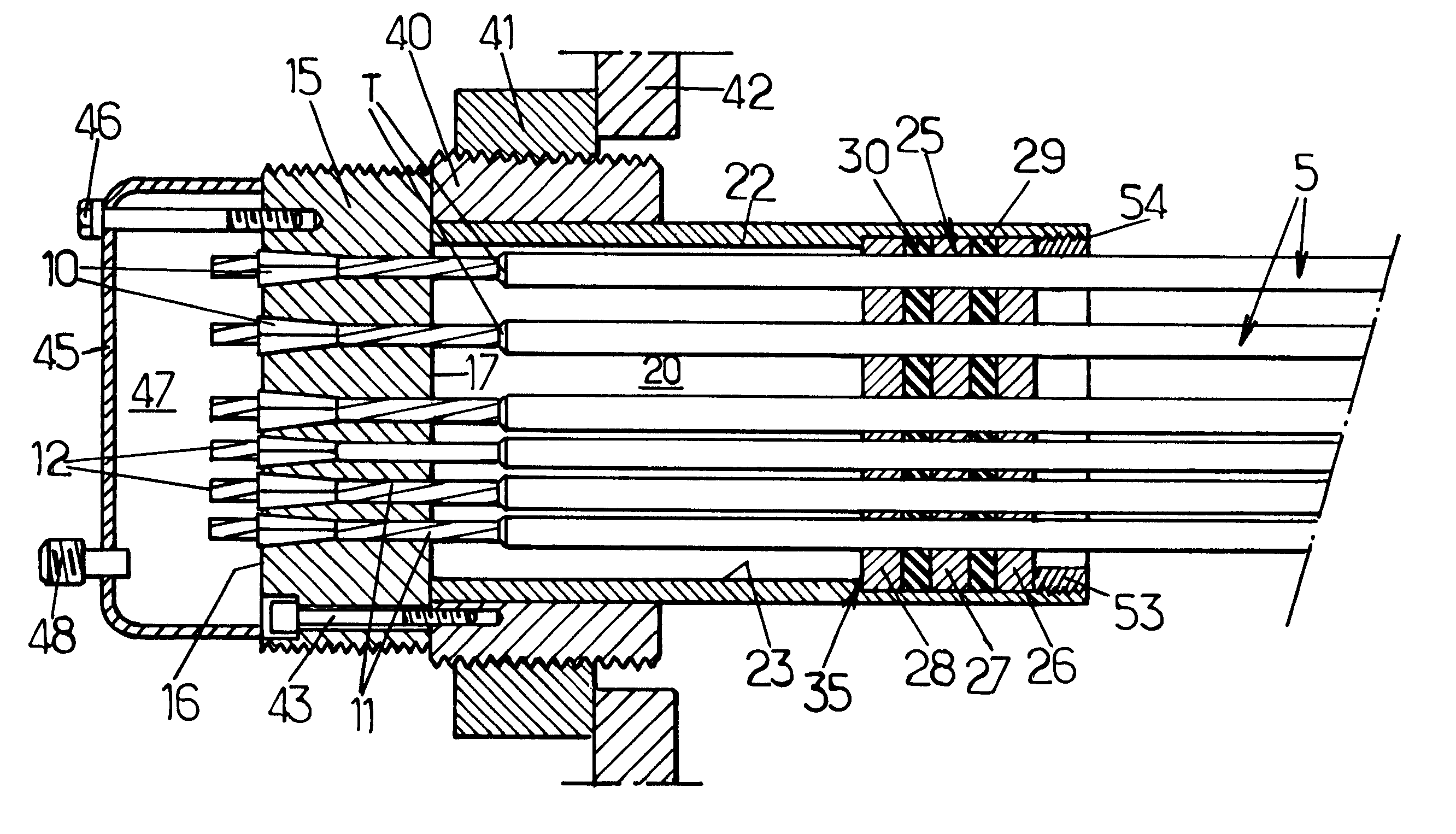

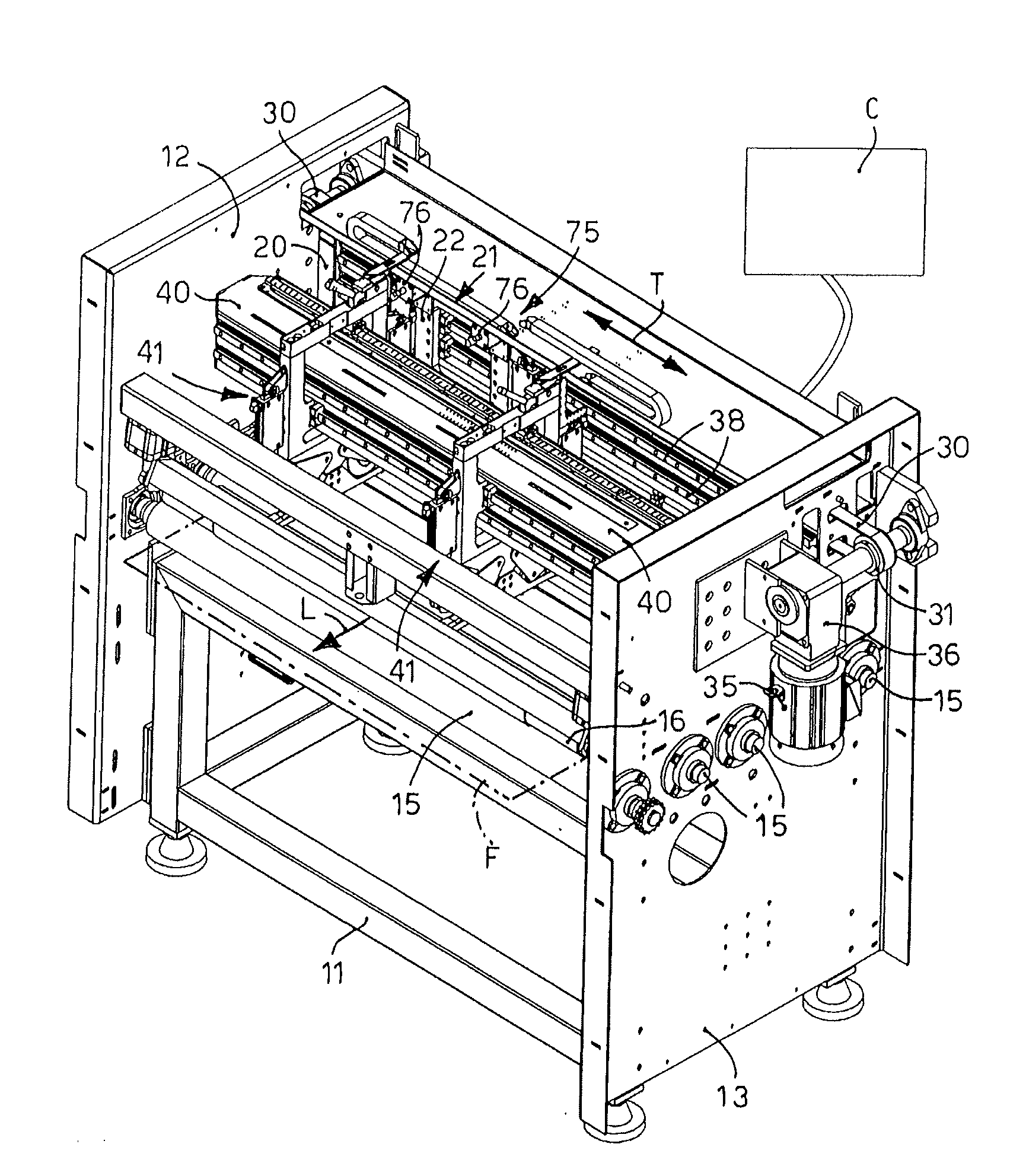

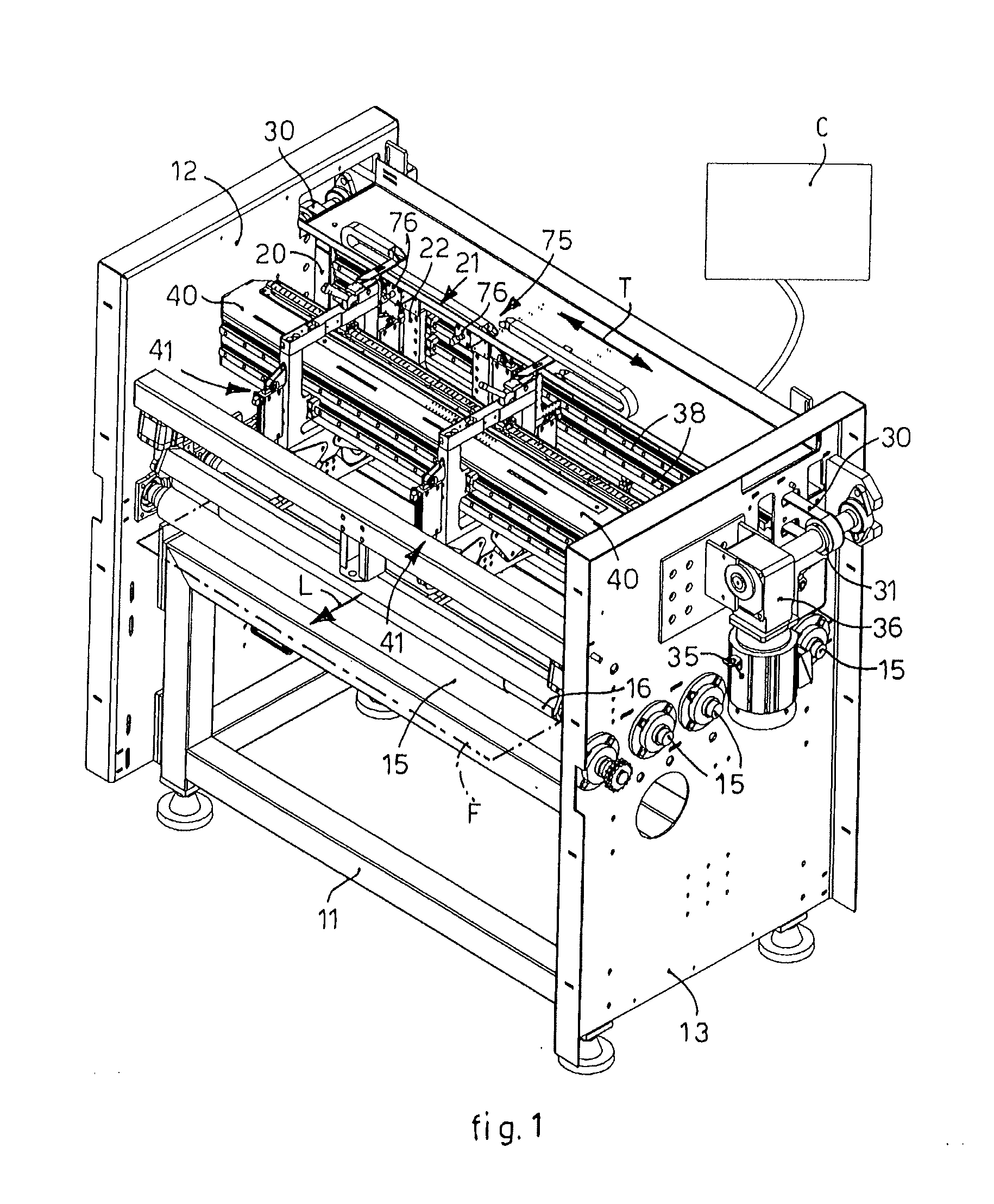

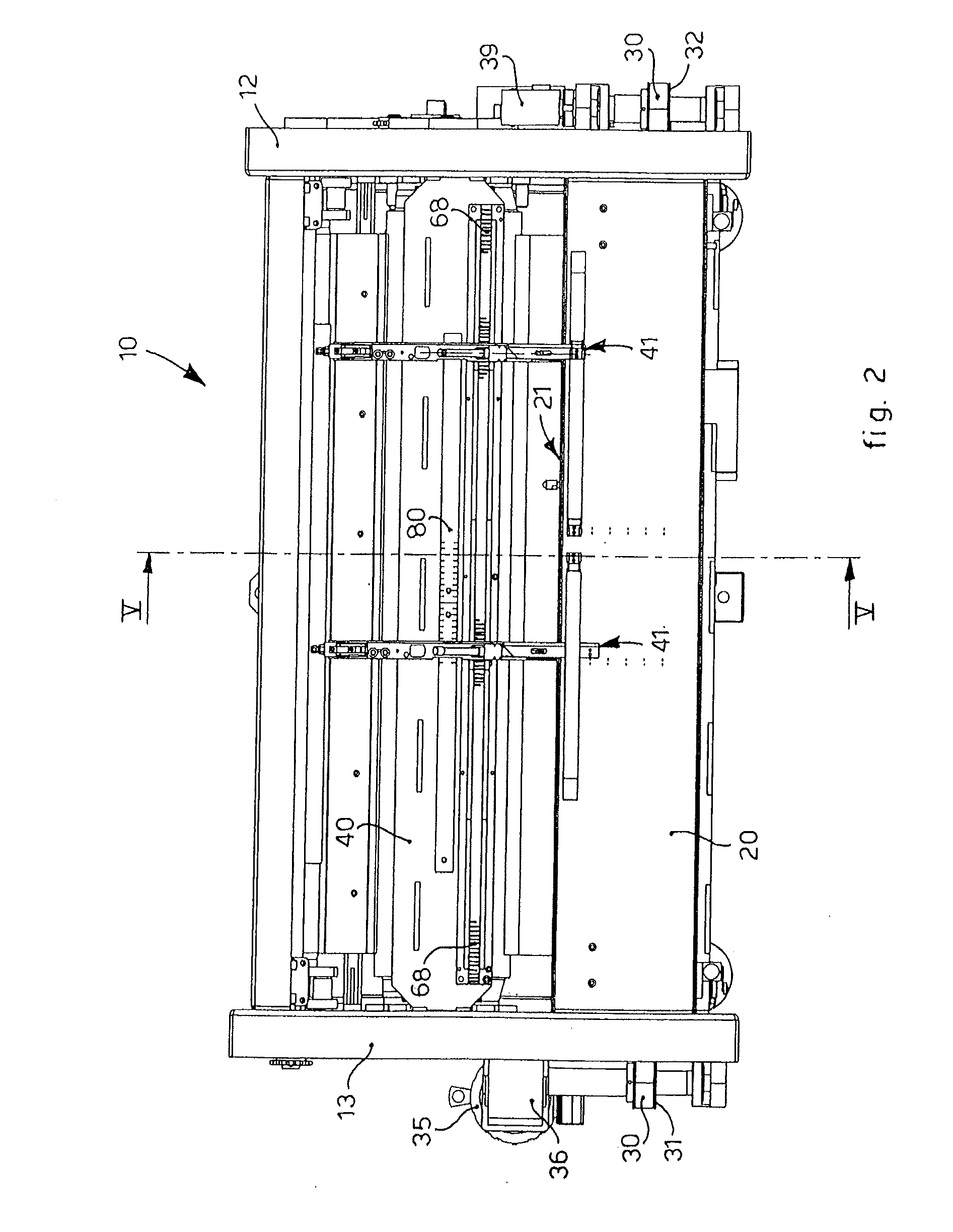

Machine for making packing boxes

Machine for making packing boxes, by means of cutting and / or pre-creasing operations on a sheet (F) of sufficiently rigid material, comprising feed rolls (15,16), able to move the sheet (F) forward in a first longitudinal direction (L). A first working head (21) is mobile in a transverse direction (T), substantially perpendicular to the longitudinal direction (L), in order to make transverse cuts and / or pre-creasings on the sheet (F). A group of second working heads (41) can be positioned along the transverse direction (T), in order to make longitudinal cuts and / or pre-creasings. A positioning device (75) is disposed on the first working head (21), able to cooperate with each second working head (41) in order to selectively position it in the transverse direction (T).

Owner:PANOTEC

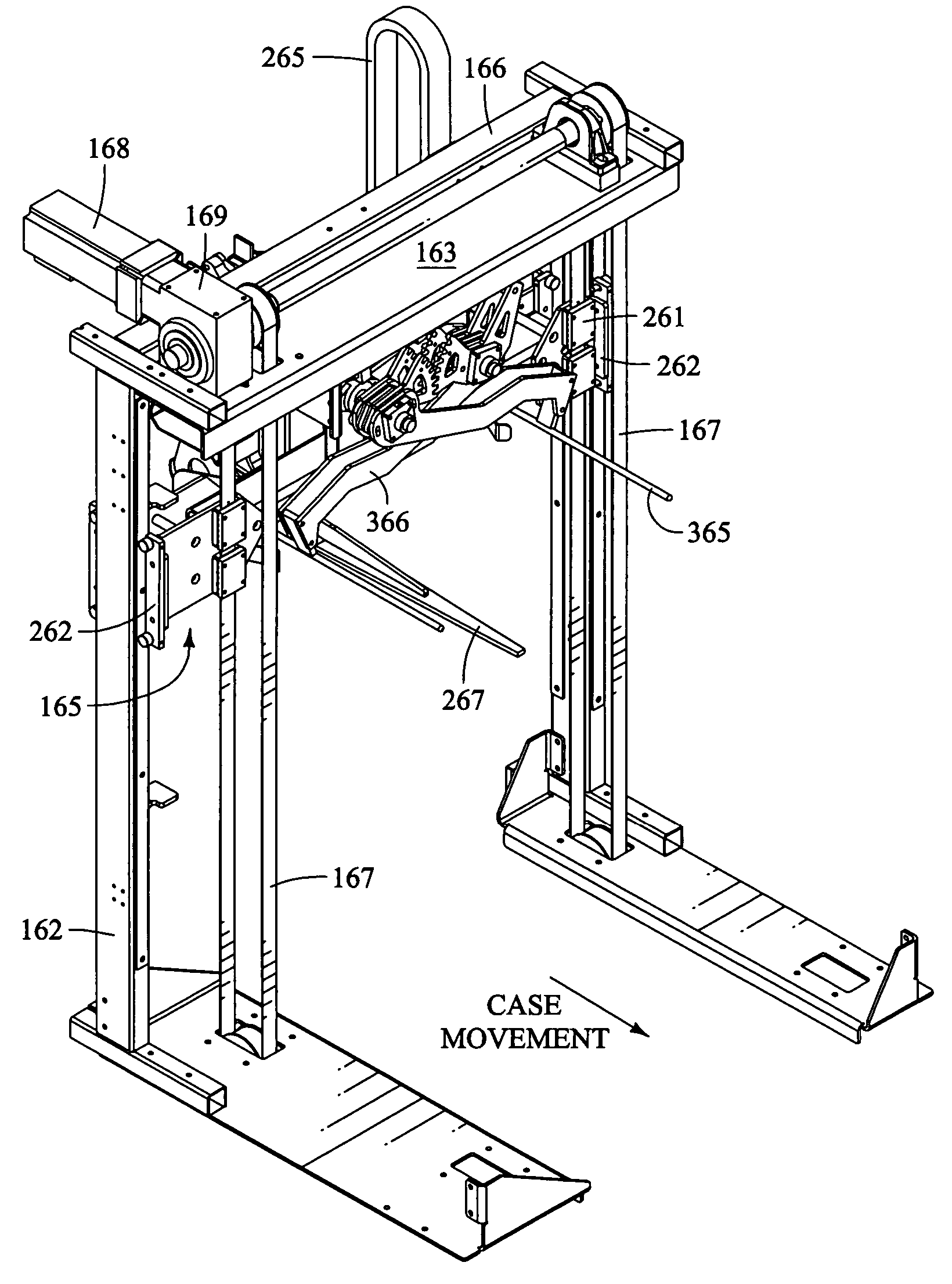

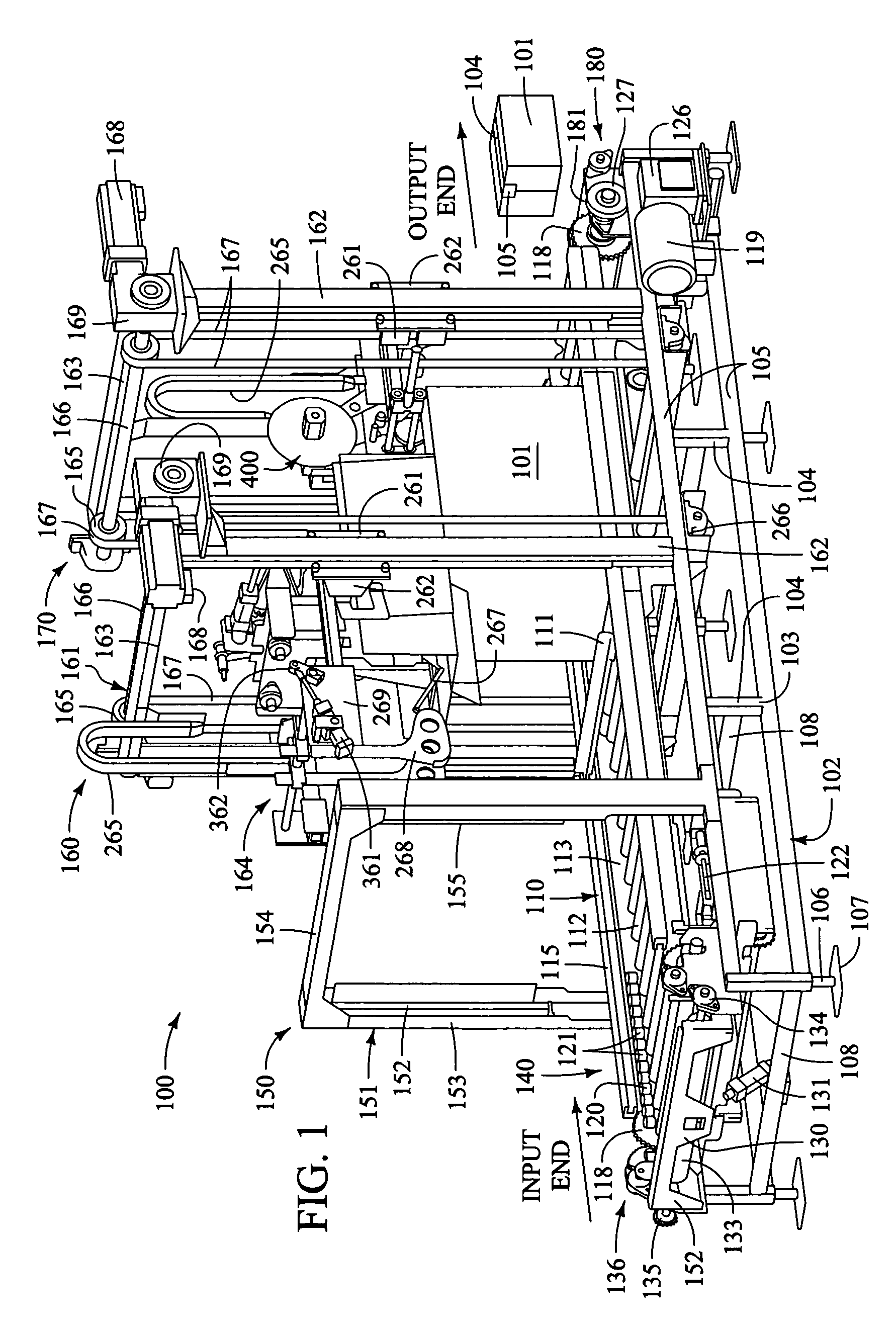

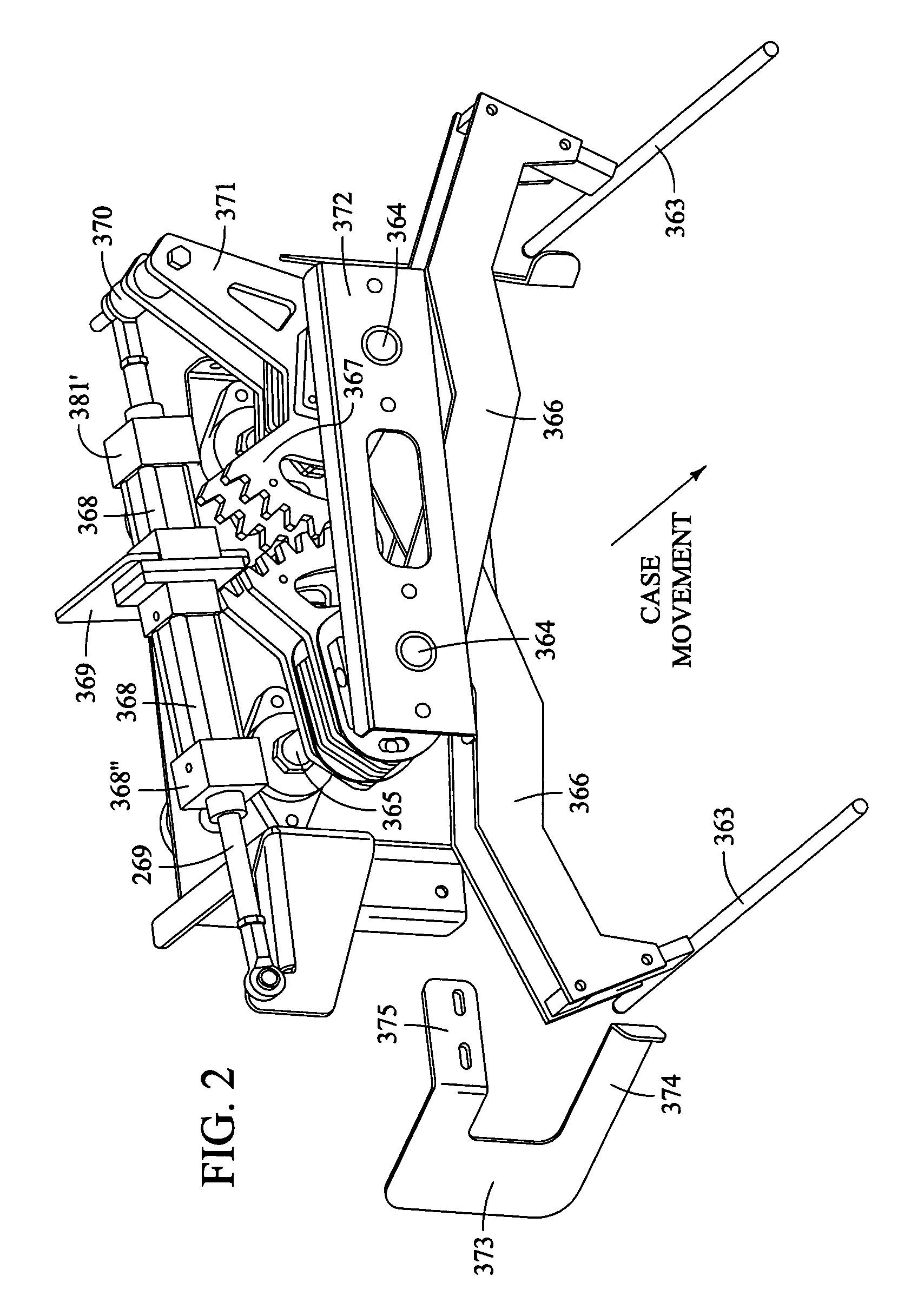

Packaging case closing and tape sealing machine and processes

A machine for closing and sealing cardboard boxes or other packaging cases with random sizes of cases presented. An input gate controls passage of cases onto at least one conveyor that moves the cases through the machine. An input positioning stage centers and squares the case. A measuring station performs a primary measurement of the width and height of the open case. A closing station and tape sealing station are adjusted to the primary case size measurement. The case closing station then closes the case. The side major flaps are closed using a major flap closer with crossed arms pivoted at separated pivot axes. The sealing station has a secondary or closed case measurement detector which more accurately adjusts the tape applicator height. Lateral support heads engage the sides of the case to prevent distortion while tape is applied.

Owner:R A PEARSON

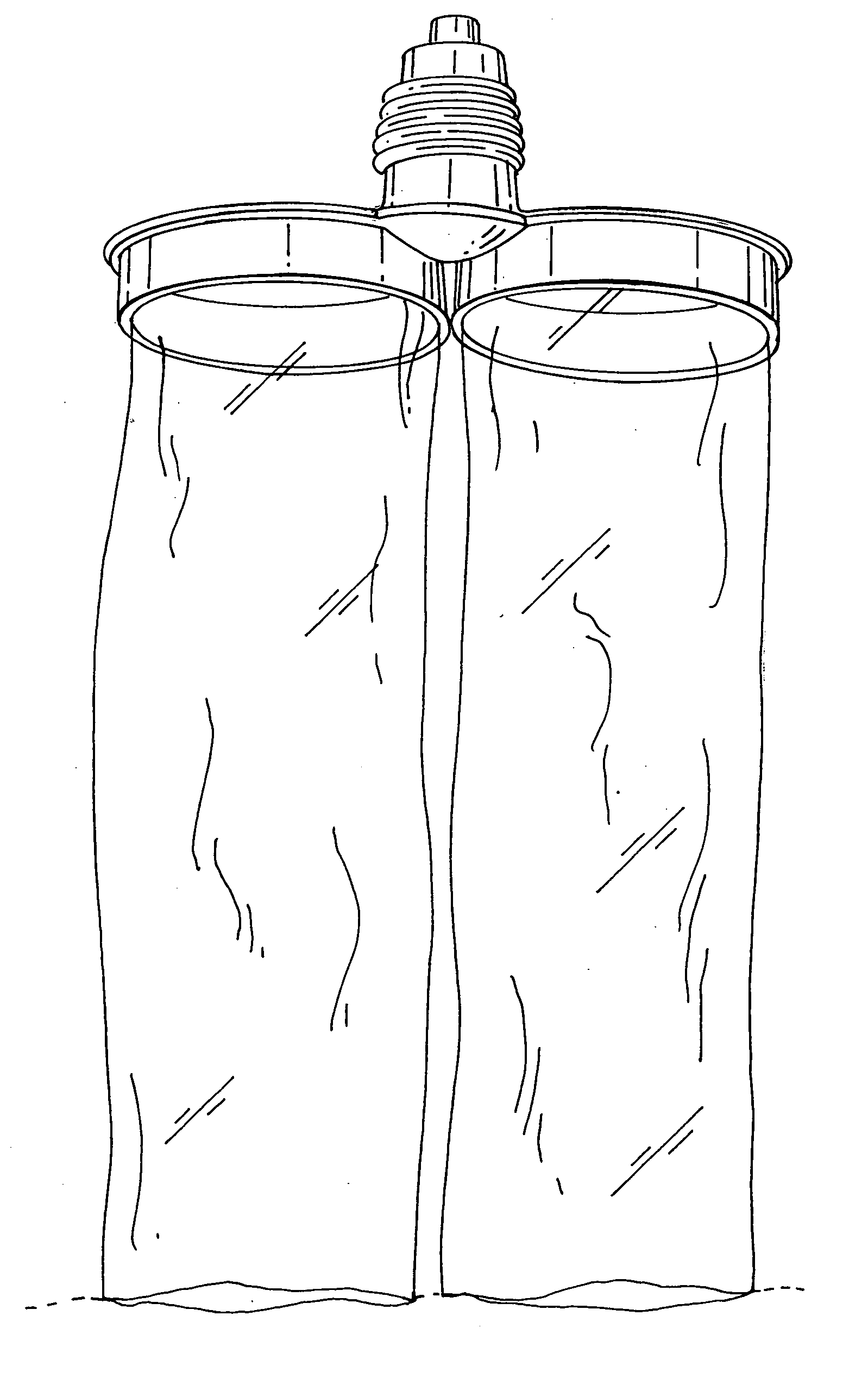

Cartridge delivery system utilizing film bags

Owner:NORDSON CORP

Glass substrate packing box

InactiveCN101195435ALow costFlexible packagingContainers to prevent mechanical damageDamagable goods packagingPackaging CaseEngineering

The invention relates to a package box of glass substrates. The package box of the glass substrates comprises a box body and at least one buffer element, wherein the box body is provided with a bottom and a plurality of side walls, and a containing space is circled by the engagement of the bottom with a plurality of side walls. The inner surfaces of the side walls are provided with pluralities of clamping grooves, the buffer element is equipped with a plurality of locking latches, and the locking latches and the clamping grooves are in corresponding nested arrangement. Through adding the buffer element which is disposed on the inner surfaces of the side walls of the package box, the containing space of the package box is changed, thus the package box can be conveniently corresponding to glass substrates with different sizes. The package is flexible, further package box does not need to be designed again, thereby efficiently reducing costs.

Owner:INNOCOM TECH SHENZHEN +1

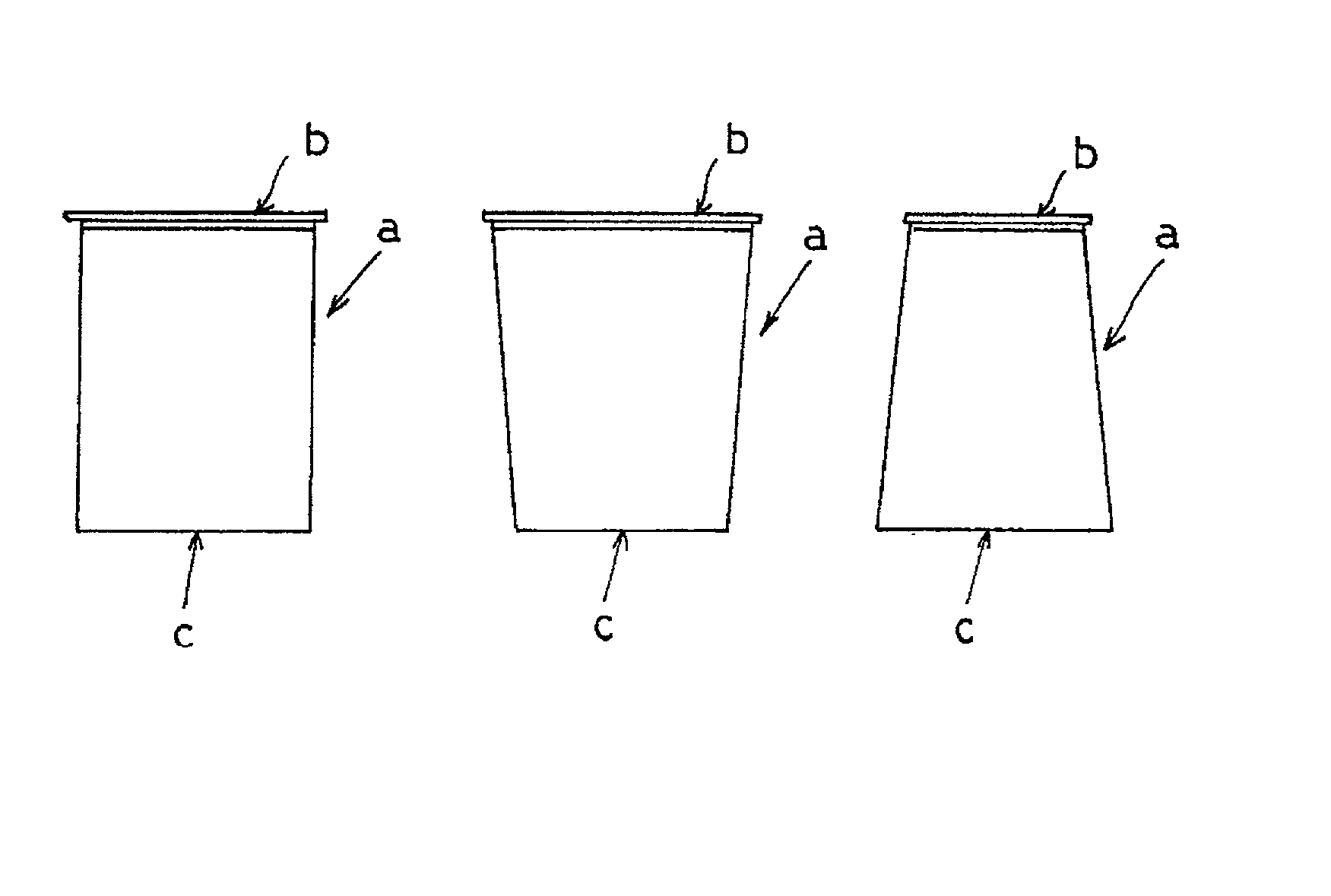

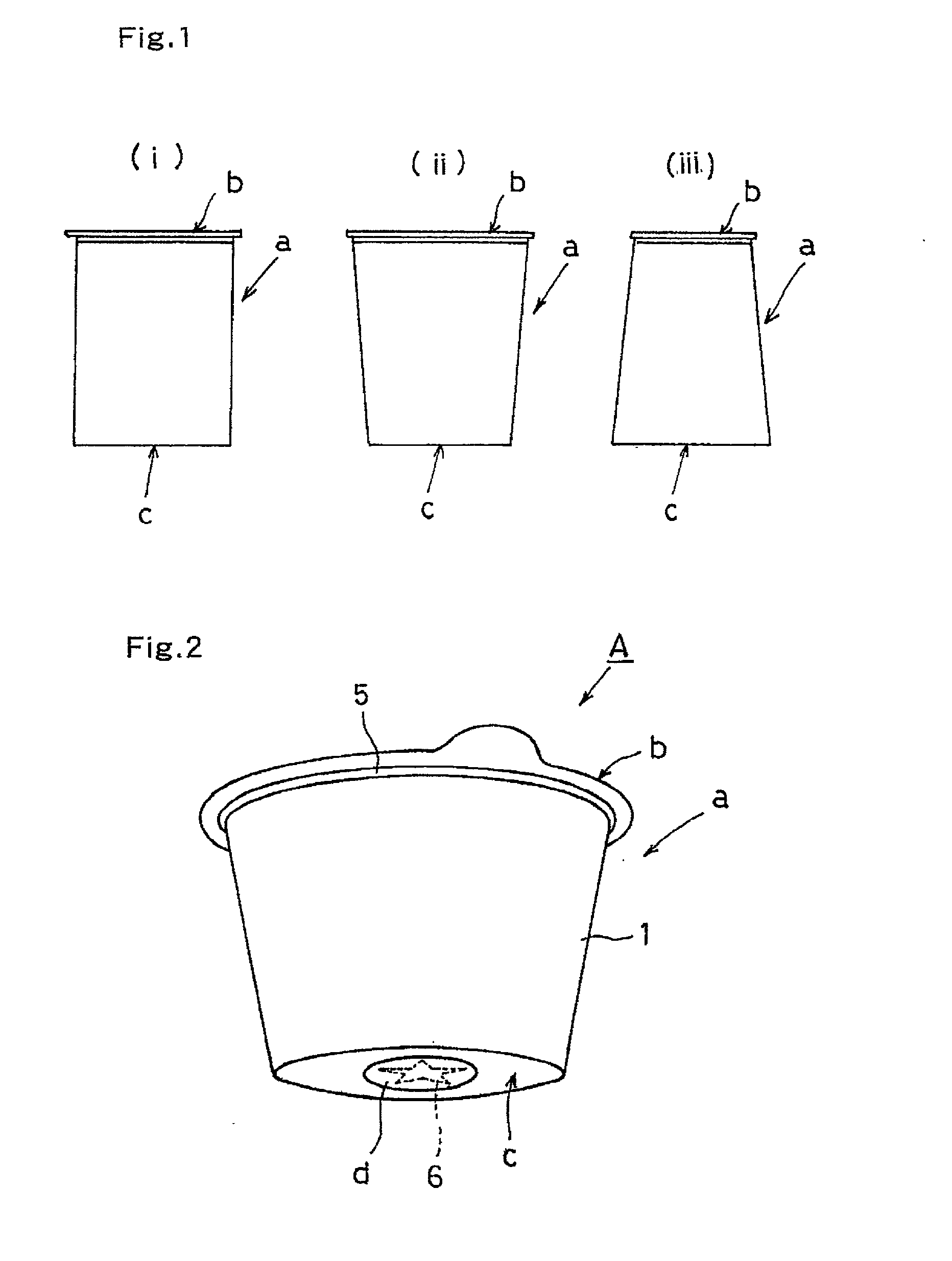

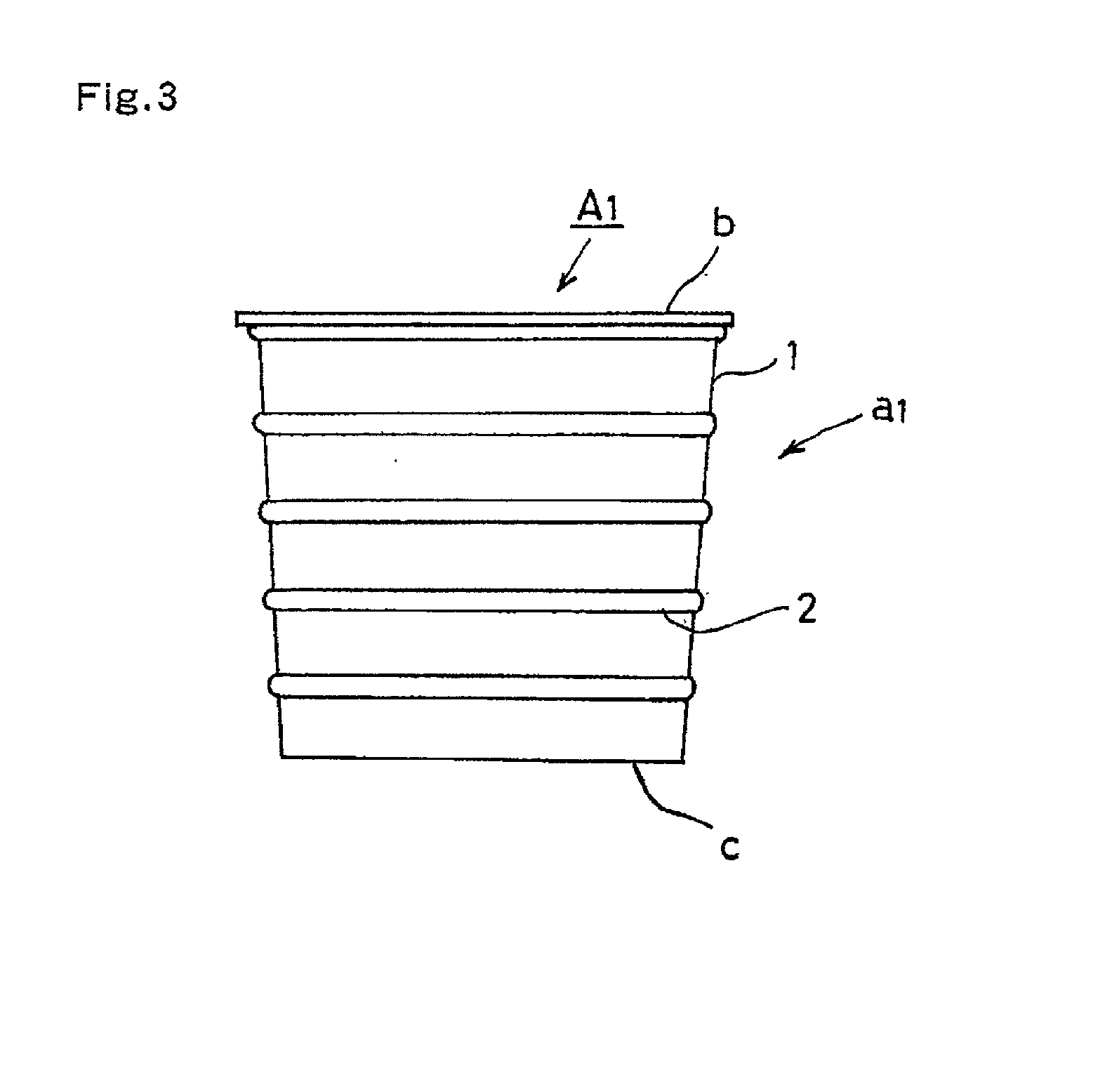

Food package and method and device for extrusion of food

Food package according to the present invention comprises a container made of soft material and having a trunk substantially shaped in a cylinder, a truncated cone or an inverted truncated cone, and a bottom formed in its substantially central zone with a push-out aperture provided with a removable seal, and filled with viscous or semisolid food wherein the container has a sealed upper opening. Push-out method for food from such food package comprises steps as follow: providing a push-out device comprising a container receiving member having a substantially cylindrical trunk member and a bottom member provided in its central zone with a through-hole, and a depressing member adapted to be guided into the cylindrical trunk member from above; setting the food package according to claim 1 in the container receiving member; compressing the food package by the depressing member from above toward the bottom while the container made of soft material is controllably guided along the inner surface of the cylindrical trunk member or a peripheral surface of the through-hole of the bottom member so that the container may be prevented from shifting sideways until the container is flattened; and thereby forcing out the content food through the push-out aperture and the through-hole of the bottom of the container made of soft material.

Owner:SNOW BRAND MILK PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com