Plate material packing box, plate material transporting method, and plate material loading or unloading method

a plate material and packing box technology, applied in the field of plate material packing boxes, can solve the problems of difficult storage in the airplane storage room, difficult storage, and limited weight to be transported by forklifts, and achieve the effect of preventing dust from entering the packing box and being easy to stor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

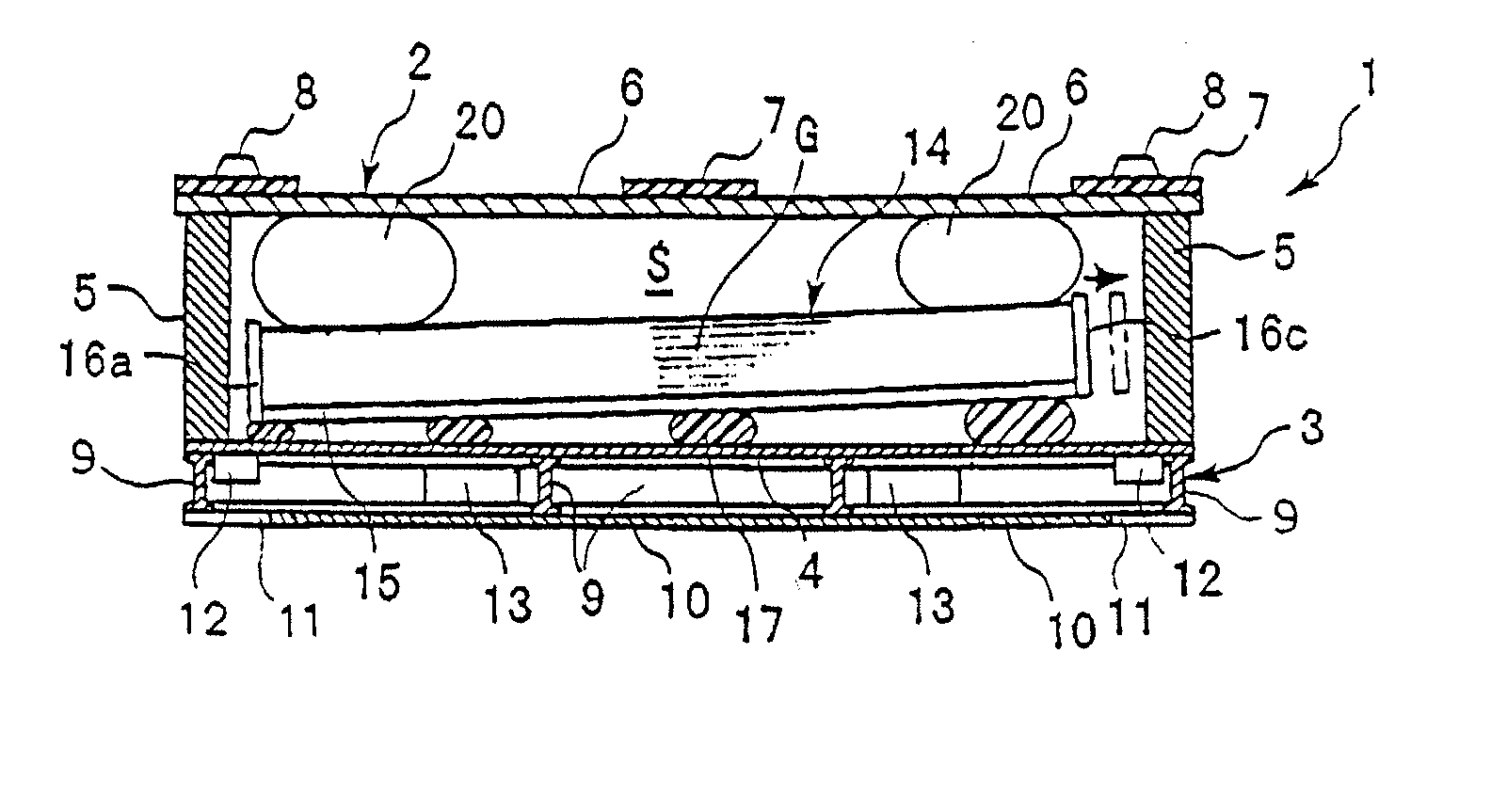

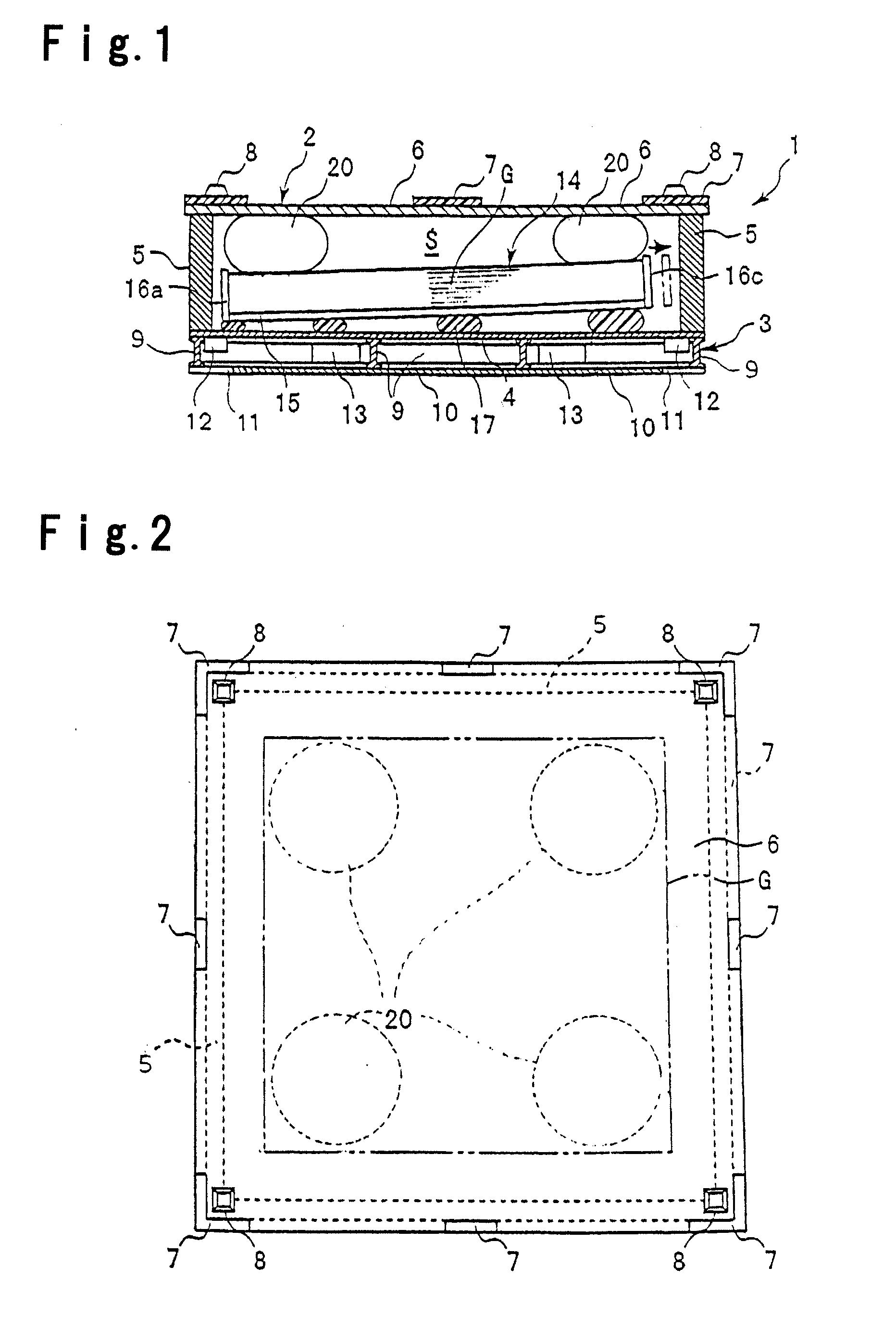

[0076]FIG. 1 is a vertical cross-sectional view of the plate material packing box of the present invention. This embodiment is one applied to large size plate glass as the plate material G. The plate material packing box (hereinafter referred to as the packing box) 1 is designed to store a plurality (for example, 50 sheets) of plate materials G in a substantially horizontally stacked state. The packing box 1 comprises a pedestal 3, an upper cover 2 put on the pedestal 3, and a plate material storage box 14 put on the pedestal 3 within this upper cover 2.

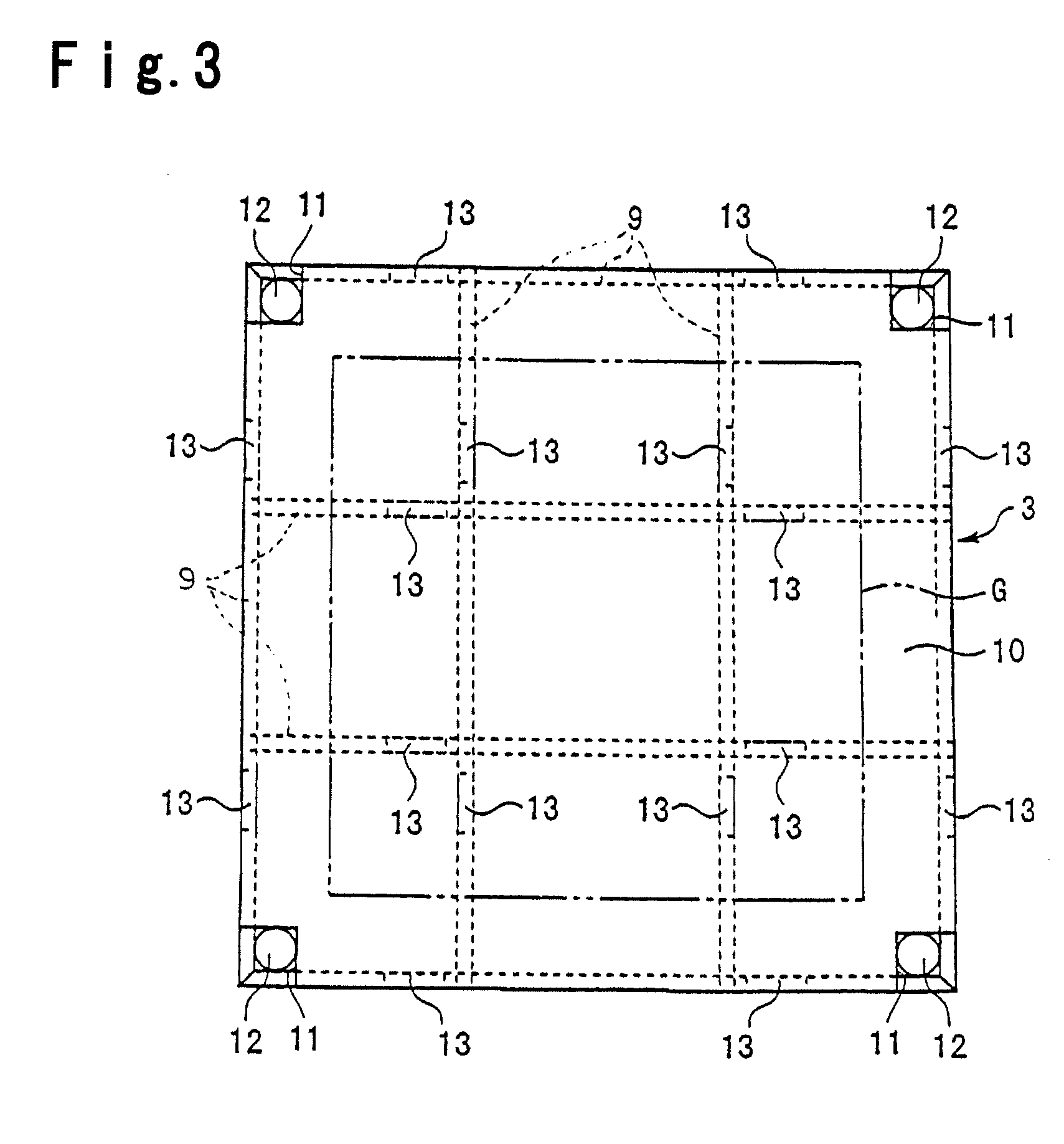

[0077] The pedestal 3 is one prepared in such a manner that a plurality of I-beam frame materials 9 formed by an extruded material made of e.g. an aluminum alloy are assembled lengthwise and crosswise in a lattice-like arrangement to form a frame, and on an upper side of this frame, an upper lining 4 is fixed, and on the lower side, a lower lining 10 is fixed.

[0078] A plate material storage box (hereinafter referred to as a storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com