Glass substrate packing box

A glass substrate and packaging box technology, which is applied in the directions of transportation and packaging, packaging of fragile items, and types of packaging items, can solve the problems of high cost of packaging glass substrates of various sizes and incompatibility of packaging boxes, achieving flexible packaging, reducing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

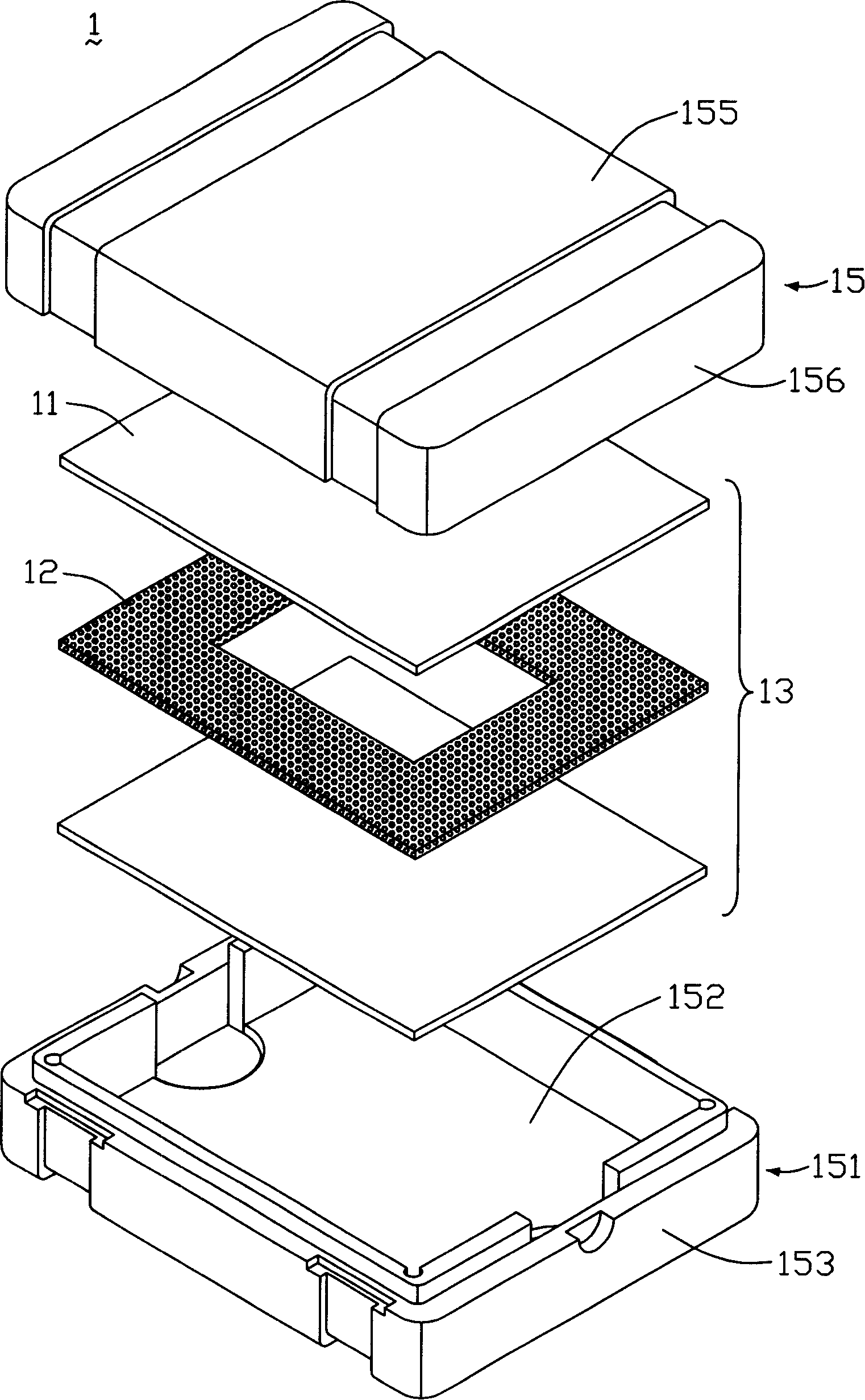

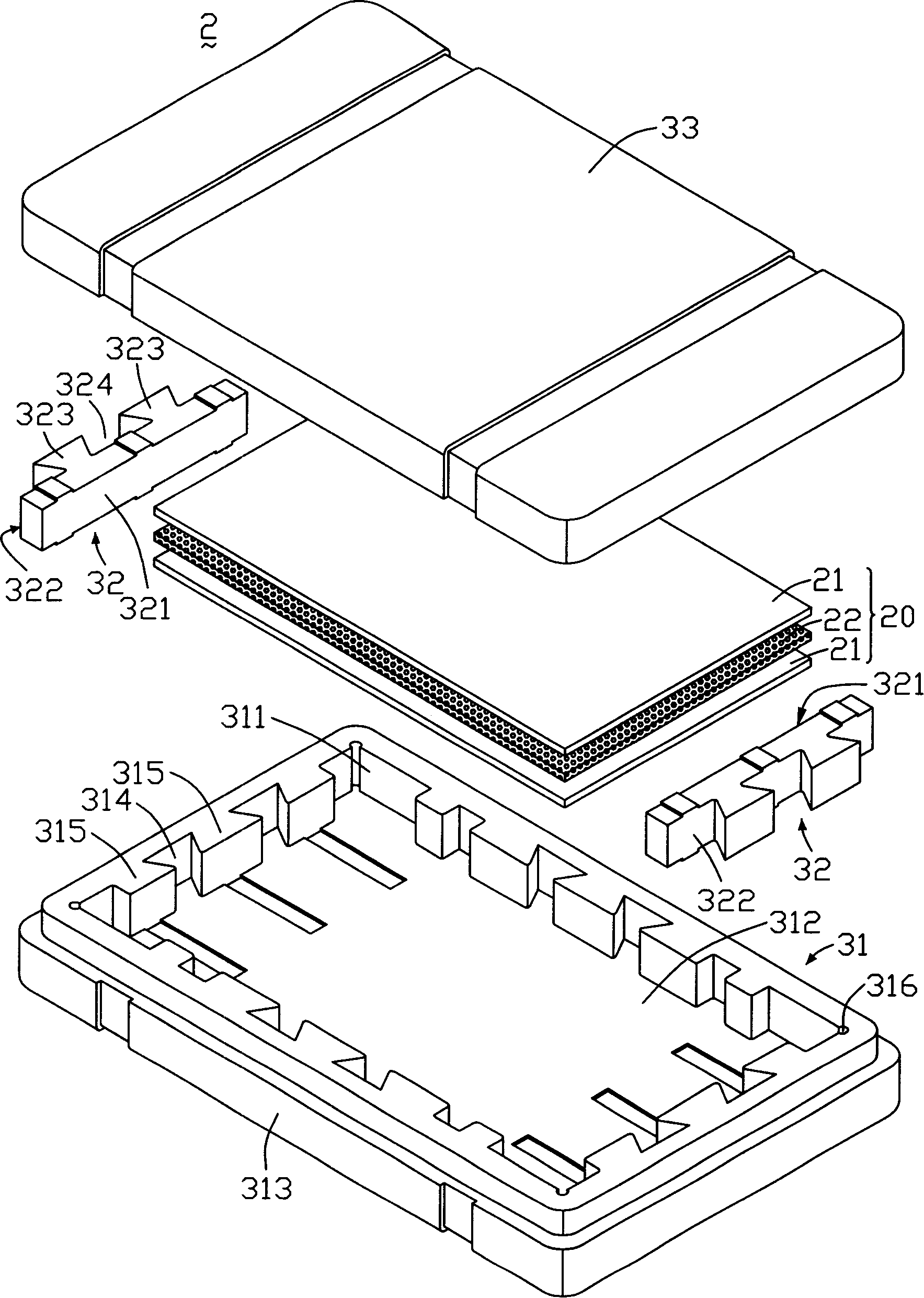

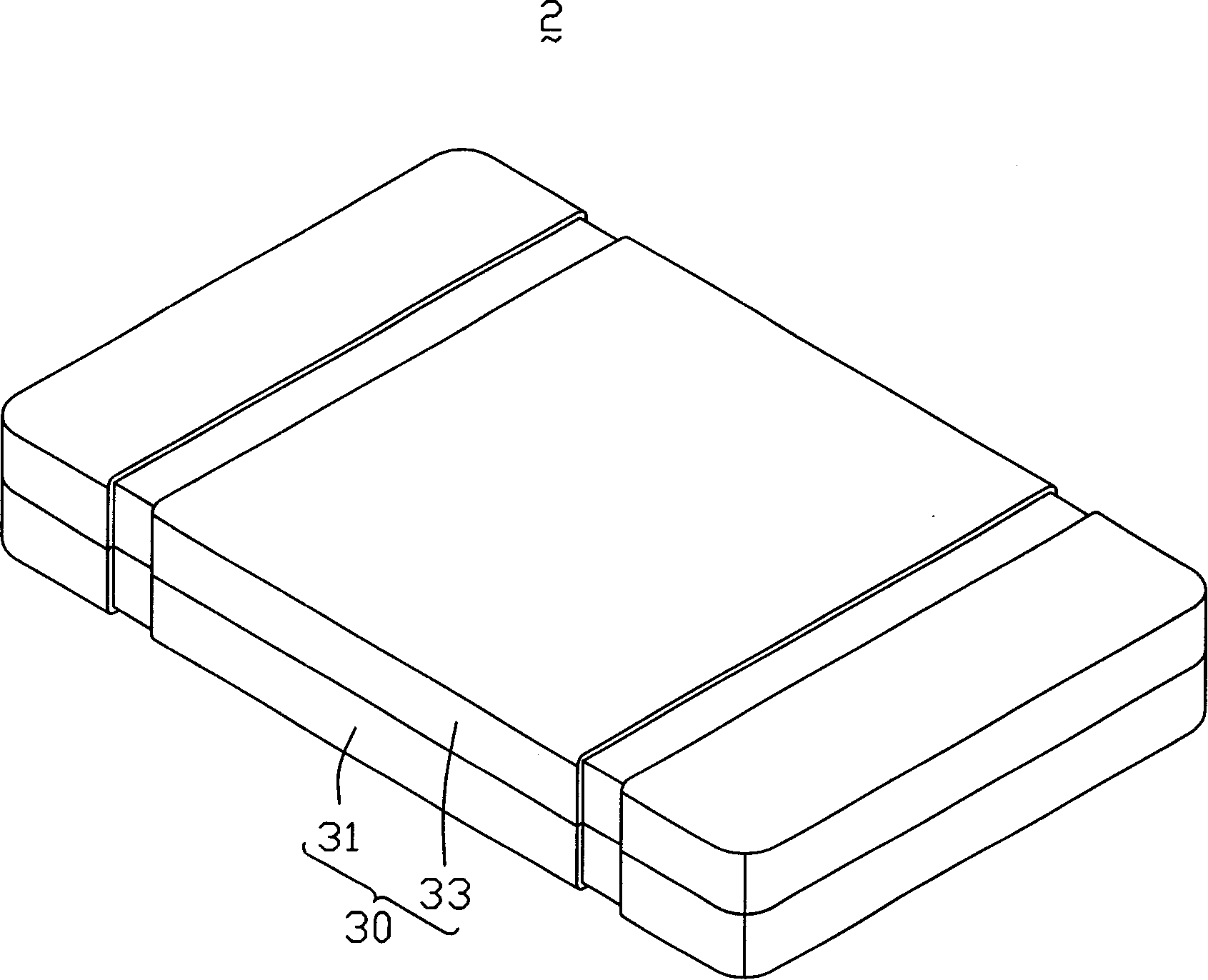

[0020] Please also refer to figure 2 , image 3 , figure 2 It is a three-dimensional exploded schematic diagram of the first glass substrate packaging combination in which the glass substrate is packaged in a packaging box in the present invention, image 3 yes figure 2 The three-dimensional assembly schematic diagram of the glass substrate packaging combination shown. This packaging combination 2 comprises a laminated body 20 and a packing box 30 (see image 3 ). The stacked body 20 includes a separator 22 and two glass substrates 21 stacked on top of each other. The packaging box 30 includes a box body 31 , two cushioning elements 32 and a cover body 33 , the box body 31 and the cover body 33 fit and nest with each other to form an accommodating space. The stacked body 20 and the buffer member 32 are accommodated in the accommodating space formed by the box body 31 and the cover body 33 .

[0021] The spacer 22 is a rectangular plate with a buffer function, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com