Patents

Literature

317 results about "Cross-cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cross-cutting is an editing technique most often used in films to establish action occurring at the same time, and usually in the same place. In a cross-cut, the camera will cut away from one action to another action, which can suggest the simultaneity of these two actions but this is not always the case. Cross-cutting can also be used for characters in a film with the same goals but different ways of achieving them.

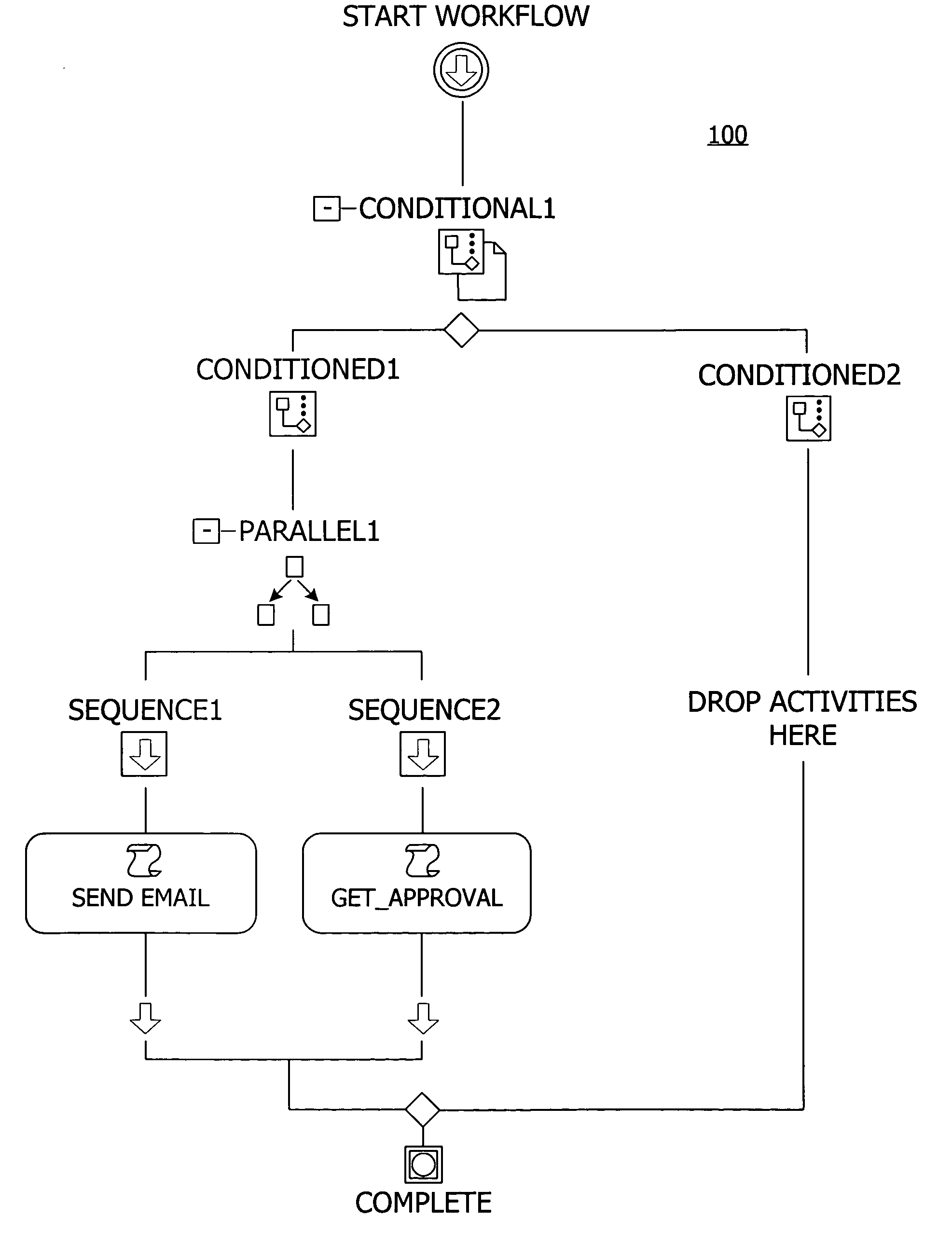

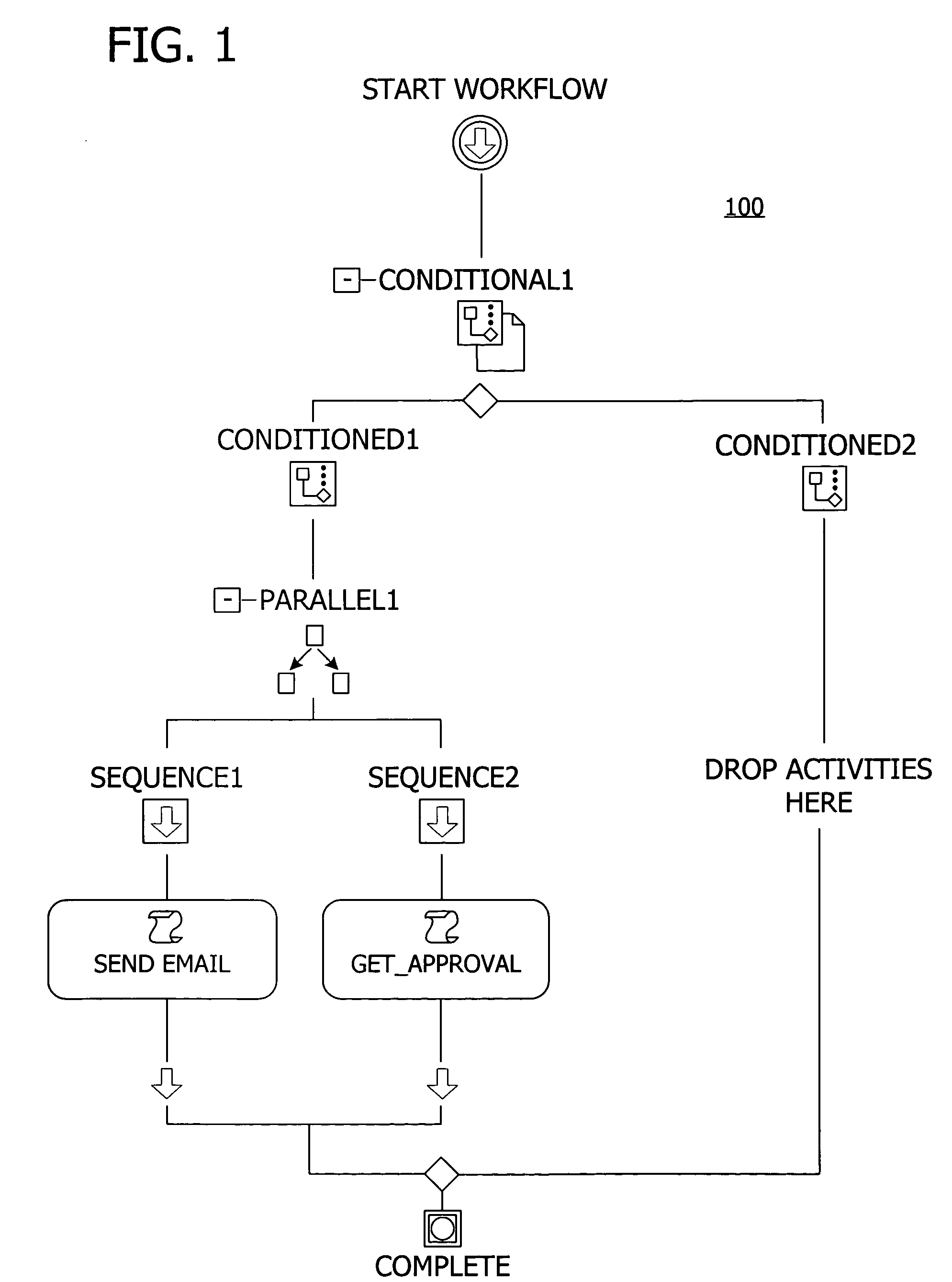

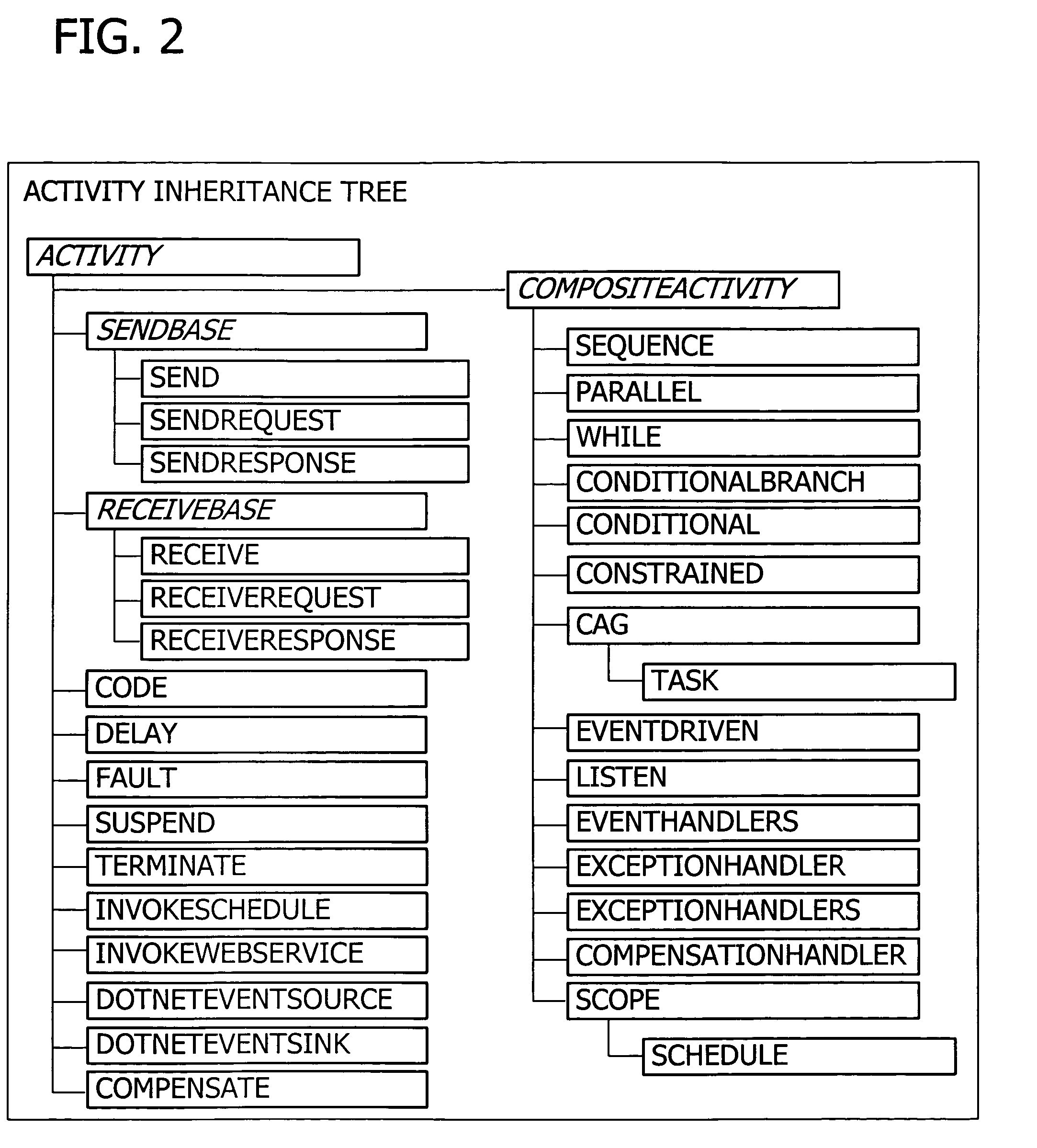

Framework to model cross-cutting behavioral concerns in the workflow domain

InactiveUS20060074704A1Extend the workflow modelSoftware designResourcesCross cutTheoretical computer science

Selecting and applying a behavioral component to a portion of a componentized workflow. The behavioral component defines error and exception handling, among other concerns, to the portion of the workflow selected by a user. During execution of the workflow, the behavioral components executes responsive to output from the selected portion of the workflow.

Owner:MICROSOFT TECH LICENSING LLC

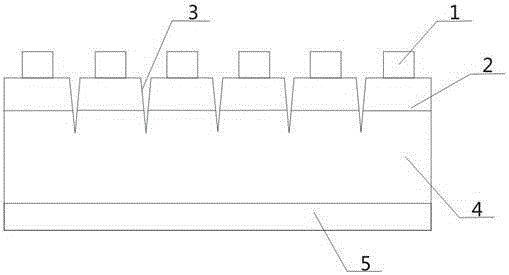

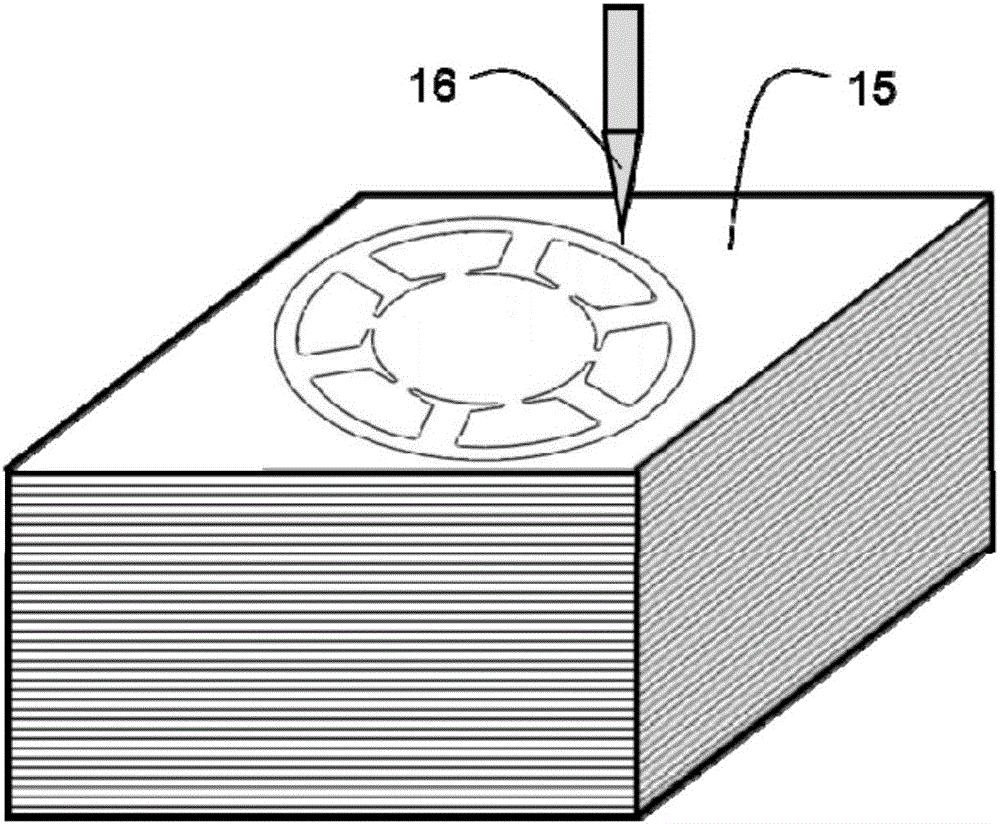

GaAs-based LED chip cutting method

ActiveCN105226143AGuaranteed FusionImprove appearance qualitySemiconductor/solid-state device manufacturingFine working devicesSurface stressSurface mounting

The invention discloses a GaAs-based LED chip cutting method. The method comprises the following steps: (1) semi-cutting is carried out on a P surface, criss-cross cutting grooves are formed, and chip P surface electrodes are separated at equal intervals; (2) the chip P electrodes face a white film downwardly, N electrodes face upwardly and are attached to the white film; (3) chip N surface scribing is carried out along the cutting grooves formed by P surface semi-cutting, and chip N surface stress is relieved; (4) film inverting is carried out on the scribed chip, and the chip is transferred to a blue film from the white film; and (5) on the chip N surface, a bonding tool of a chip breaking machine is used for chip breaking along scratches, and the chip is processed into independent crystal grains. The improved surface mount method is used, a cutting method which combines advantages of a chip sawing machine and a laser chip scribing machine is adopted, the chip P surface stress and the N surface stress are relieved maximally, deformation stress effects caused by film laminating can be reduced and edge collapse and pipe core breaking phenomena after the chip is cut are reduced, and the appearance quality after the chip is cut is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

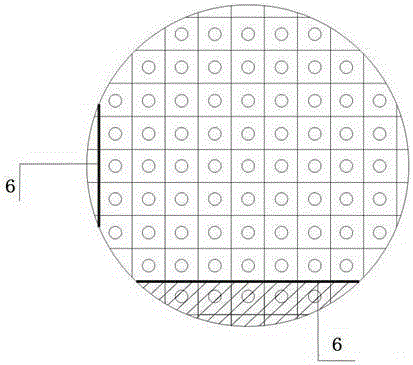

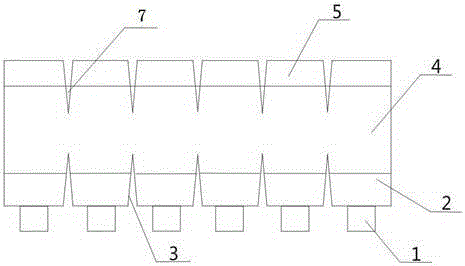

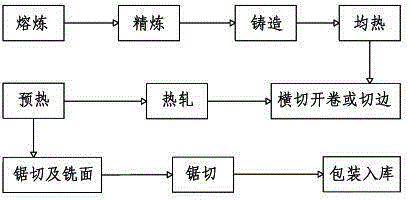

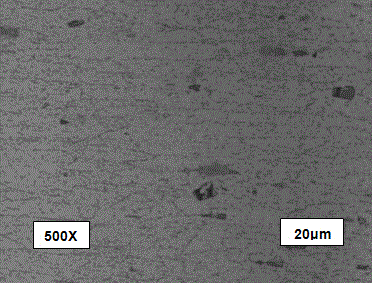

Preparation method for high-magnesium aluminum alloy O-state plate of 5XXX series

InactiveCN105177327AReduce the production process of annealingReduce production processHigh magnesiumAlloy

The invention relates to a preparation method for a high-magnesium aluminum alloy O-state plate of 5XXX series. The method comprises the steps of smelting, refining, casting, soaking, saw cutting, surface milling, preheating, hot rolling, cross-cutting and uncoiling or edge trimming, saw cutting, packaging and warehousing and the like. According to the preparation method, the high-magnesium aluminum alloy O-state plate of the 5XXX series is prepared through a new production process, under the condition that the performance and structure stability of high-magnesium aluminum alloy are maintained, the production procedures can be reduced, and surface quality defects of the high-magnesium aluminum alloy can be reduced; products can be directly produced after the aluminum alloy plate with the thickness being equal to or larger than 3 mm is subjected to hot rolling, the product yield can be substantially increased, and production efficiency can be improved sufficiently.

Owner:广西南南铝加工有限公司

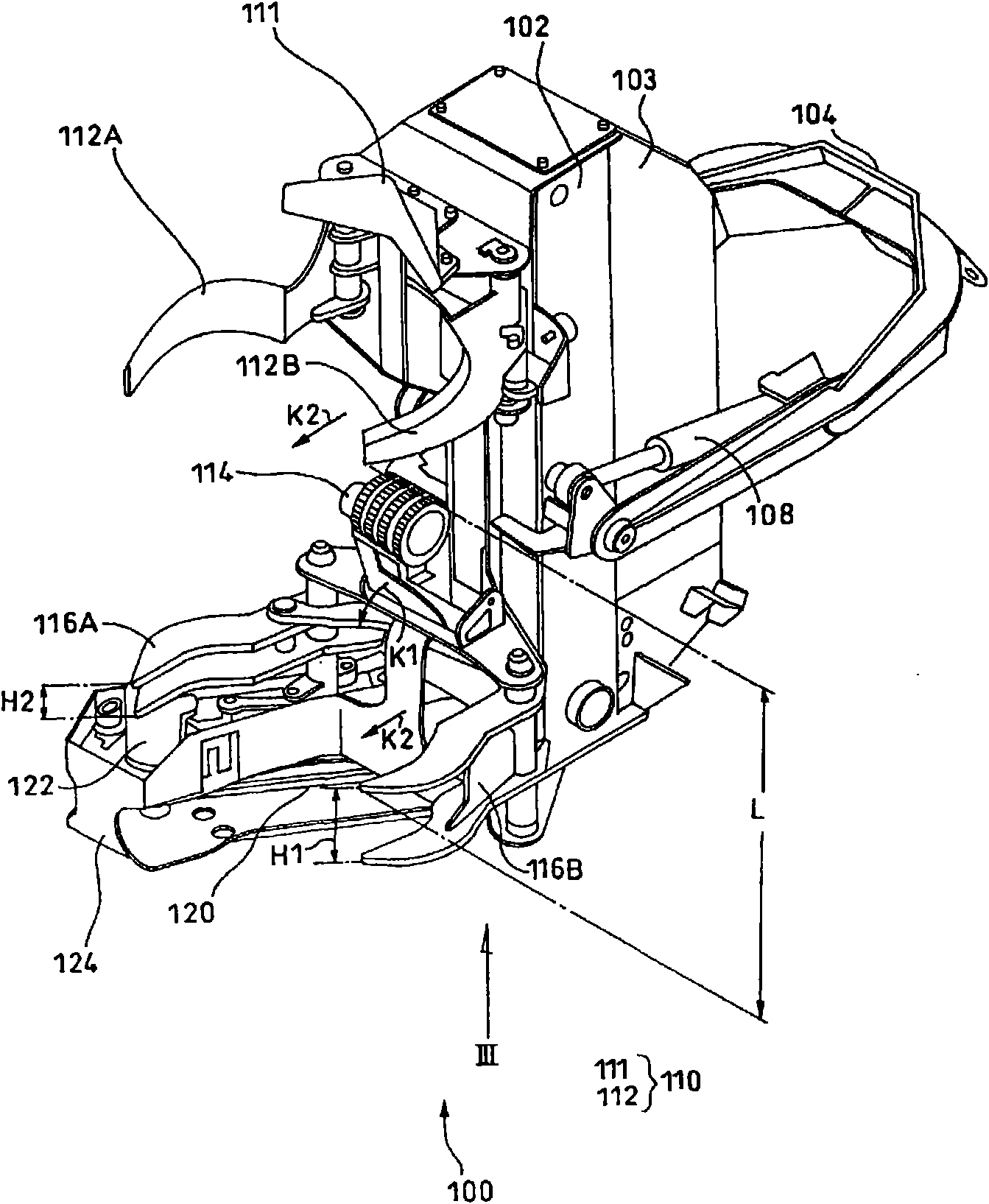

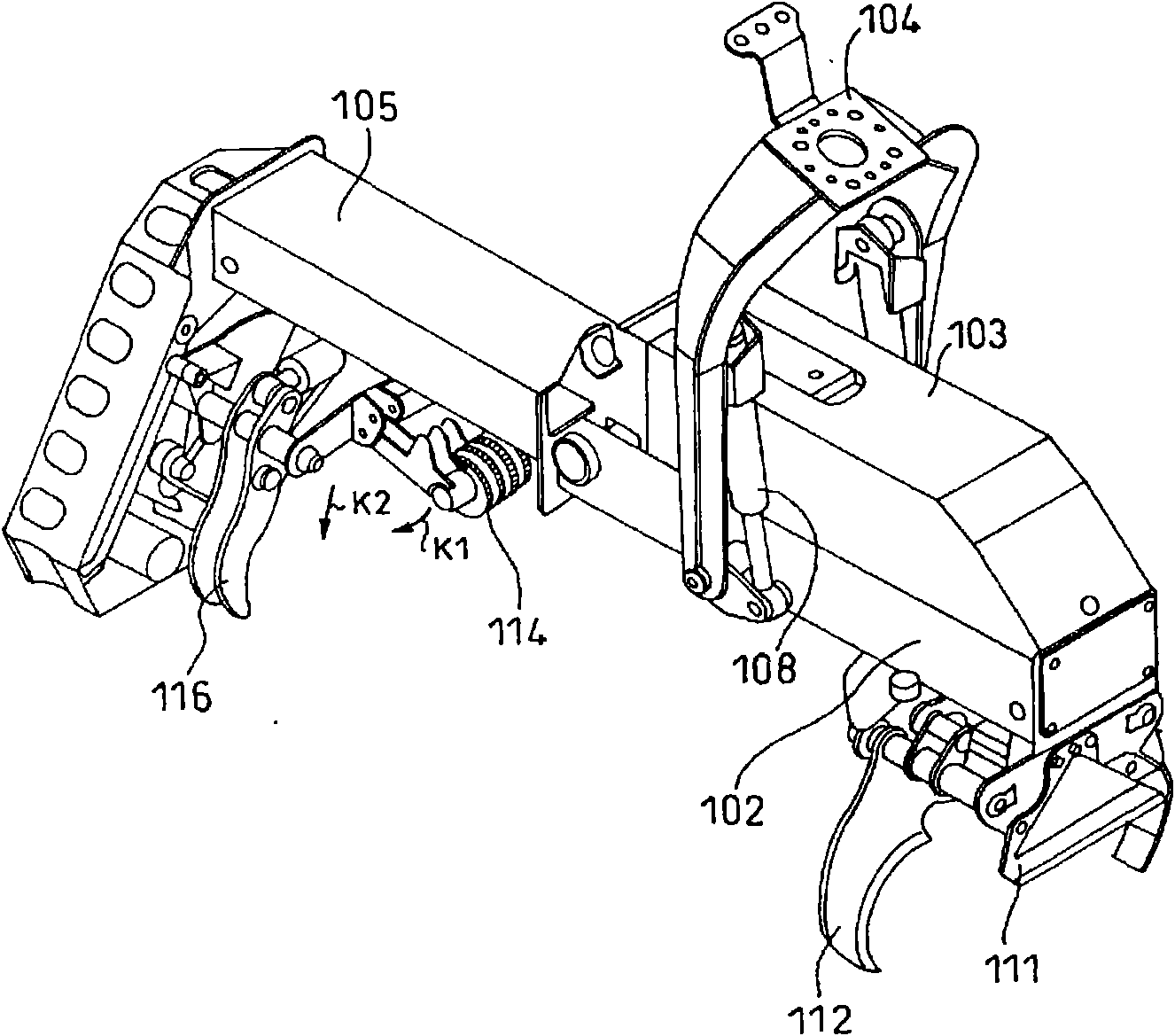

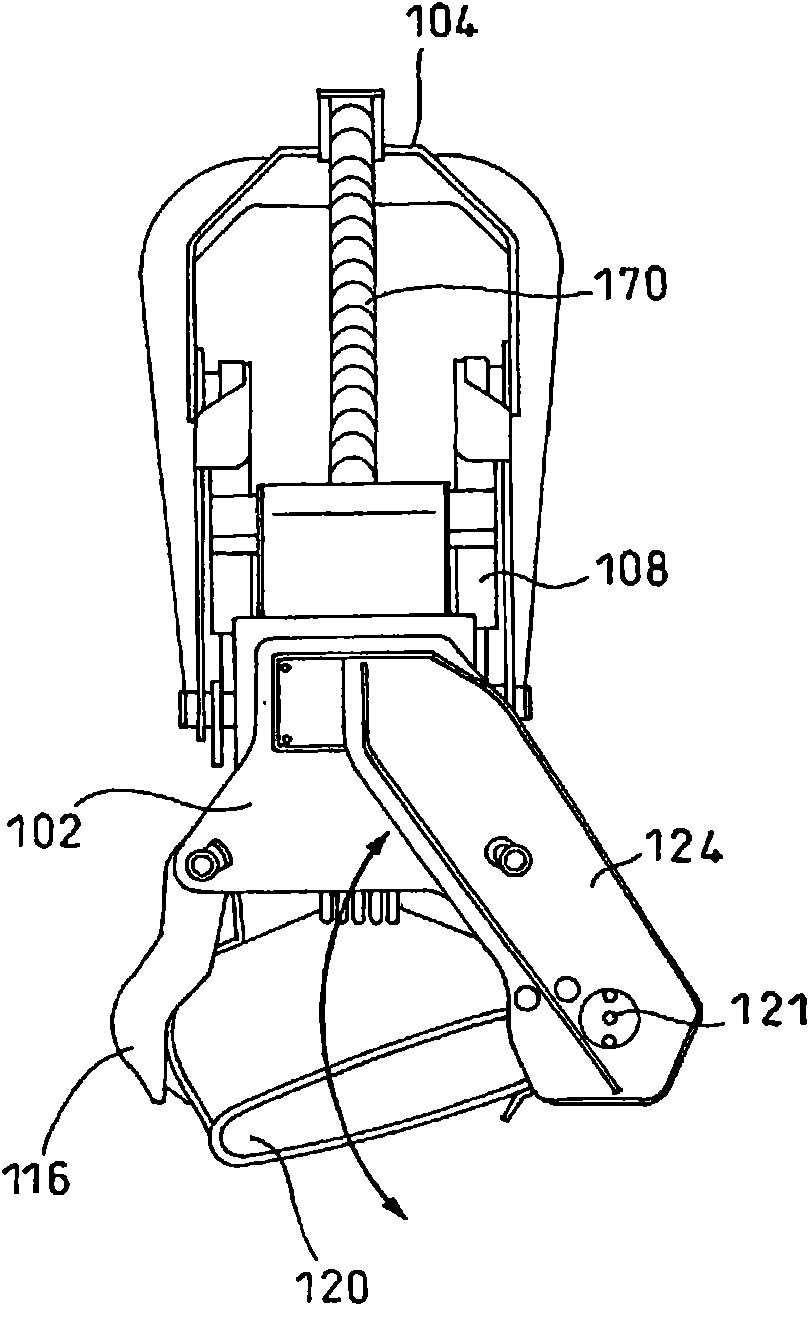

Harvester machine for wood and felling/wood making method

A harvester apparatus (100) equipped in a work vehicle and capable of at least cutting down, pruning, and cross-cutting wood, the harvester apparatus being configured to include a gripping claw (116) that can hold the wood by opening and closing in the thickness direction of the wood, a chain saw (120) capable of cutting the wood held with the gripping claw (116), a pruner (110) for pruning the wood arranged at a different position in the lengthwise direction of the gripped wood relative to the gripping claw (116), a slide frame (105) that can change the lengthwise distance between the pruner (110) and the gripping claw (116), and a sensor (130) for detecting the slide amount of the slide frame (105).

Owner:SUMITOMO CONSTRUCTION MACHINERY

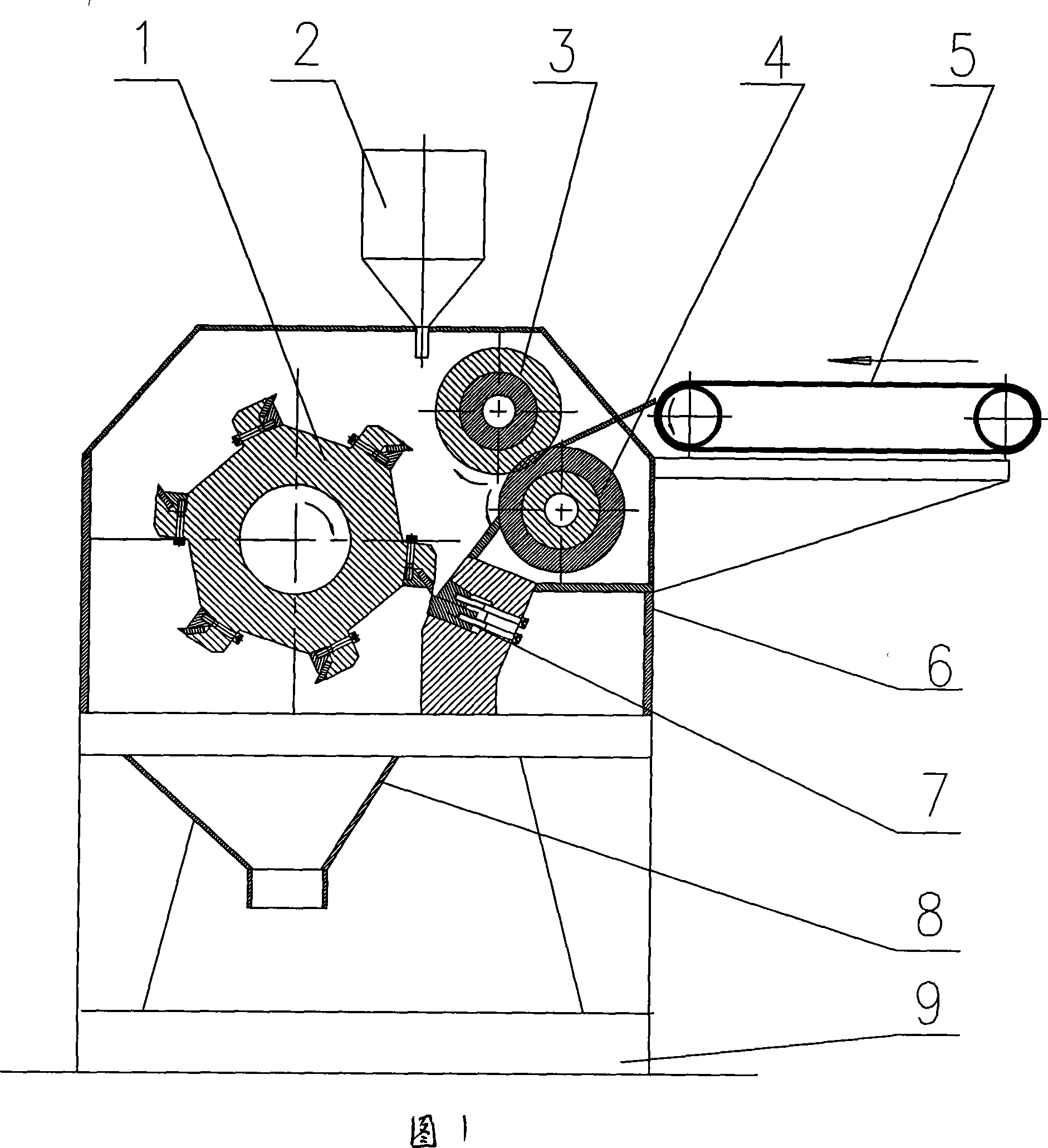

Rubber sheet granule cutter

ActiveCN101214708ASolve the problem of cold granulationImprove efficiencyMetal working apparatusEngineeringRubber sheet

The invention relates to a rubber sheet granulating mill, and belongs to the field of rubber processing machinery. The invention comprises a rubber sheet feeding device and a chassis. The invention is characterized in that the tail end of the conveyance belt of the rubber sheet feeding device is provided with a length cutting device; the length cutting device consists of a lower line of disc type length cutting knife and an upper line of length cutting knife; the rotor shafts of the lower disc type length cutting knife and the upper length cutting knife are vertical to the direction of the motion of the conveyance belt; corresponding end faces of the lower length cutting knife and the upper length cutting knife cling to each other; the rear parts of the lower length cutting knife and the upper length cutting knife are provided with a fixed cross cutting knife and a rotary cross cutting knife; the fixed cross cutting knife is a bar-shaped cutter; the rotary cross cutting knife consists of a rotary roll edged with a blade; a lift angle is formed between the blade and of a rolling shaft in the tangential direction. The invention solves the problem of granulation of gross rubber in cold state through a length cutting and a cross cutting; meets the requirements for parking and evenly mixing in the process flow; improves the rubber mixing efficiency and quality; saves the electric power, and reduces the labor intensity.

Owner:TRIANGLE TIRE

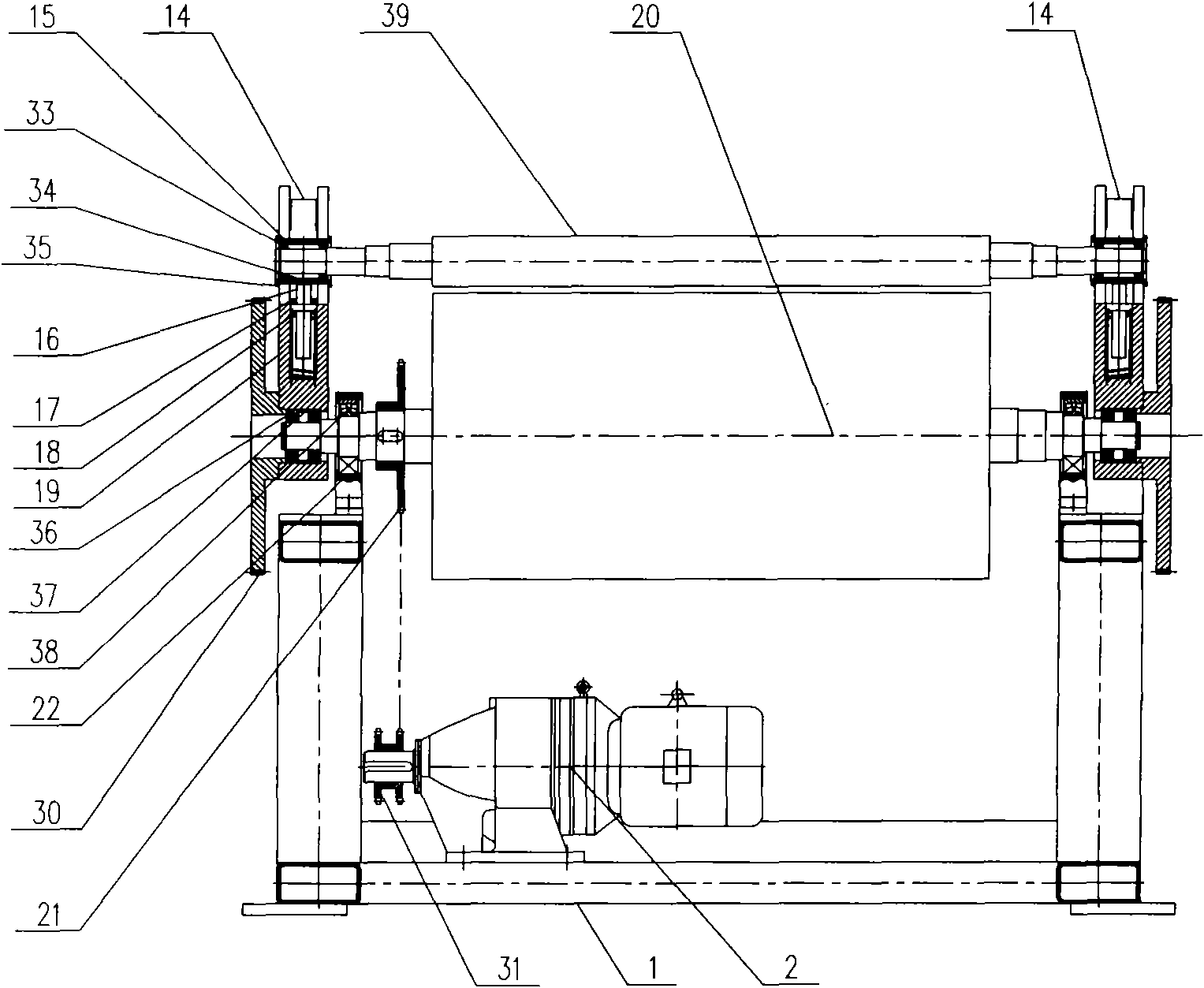

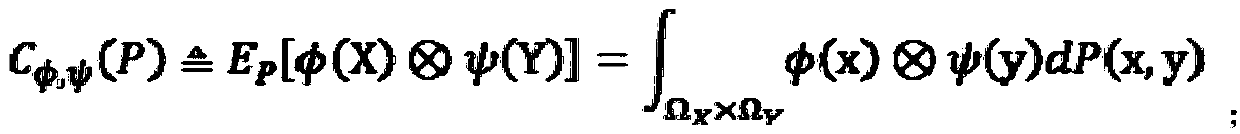

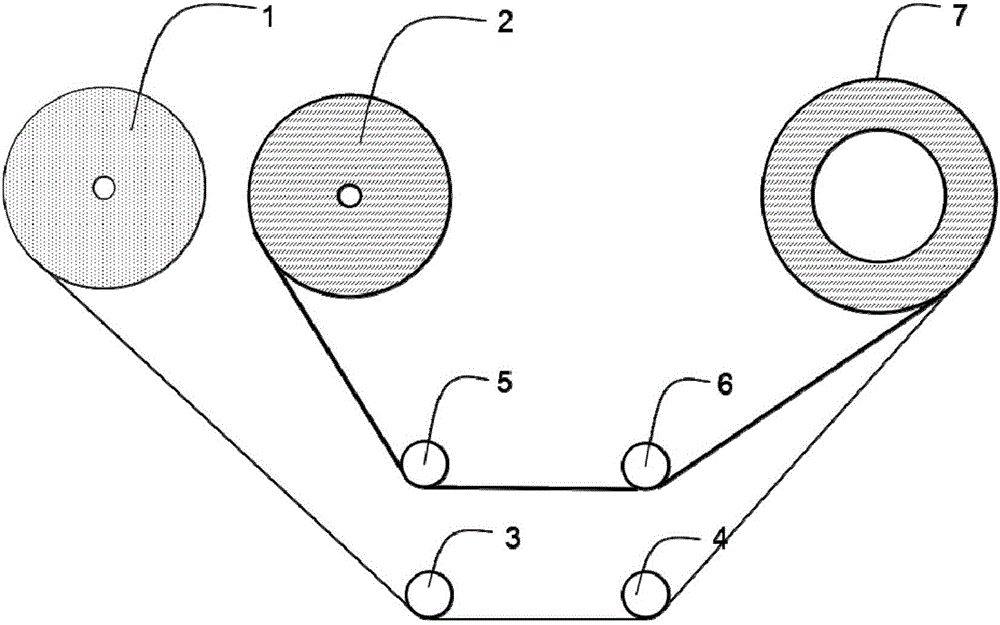

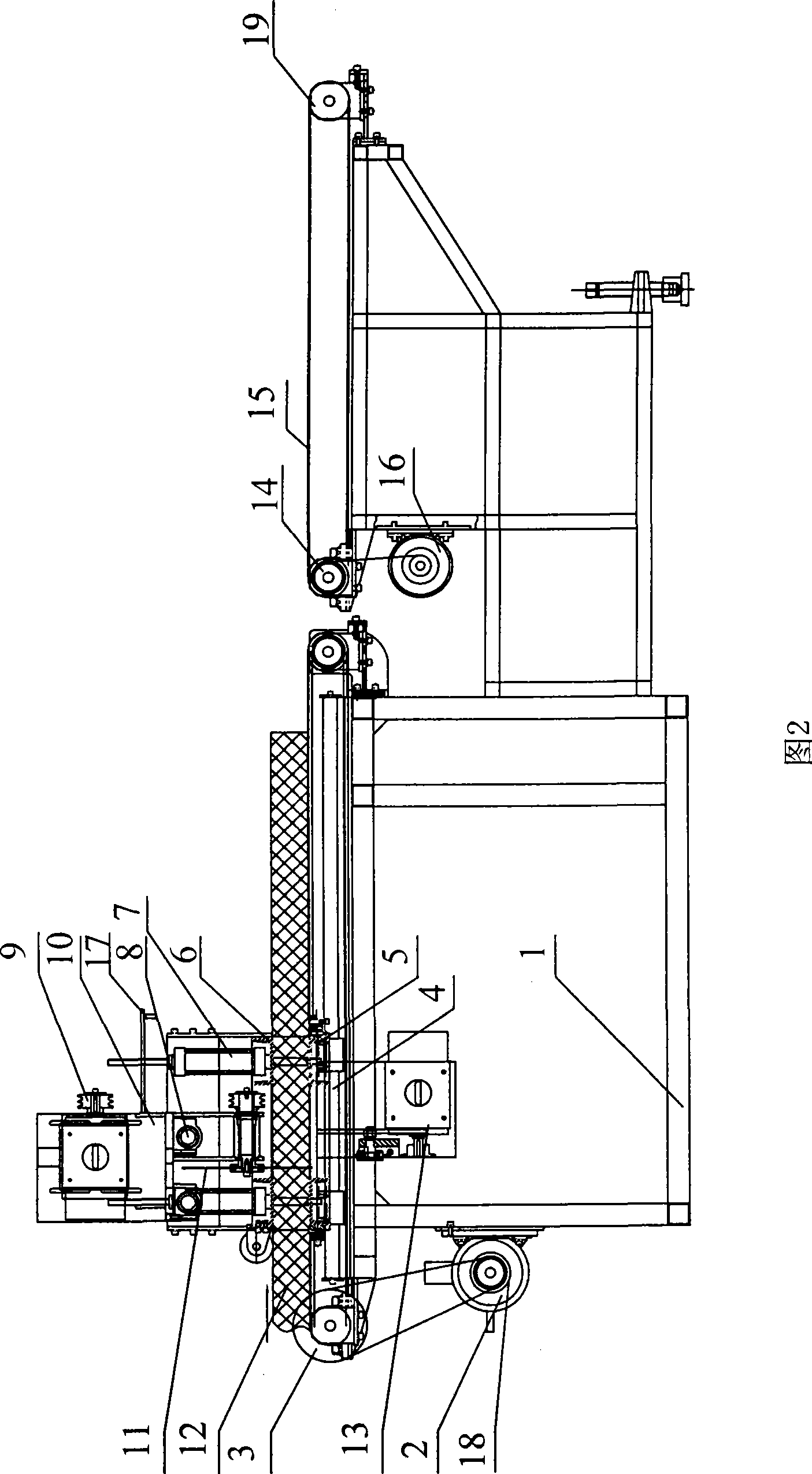

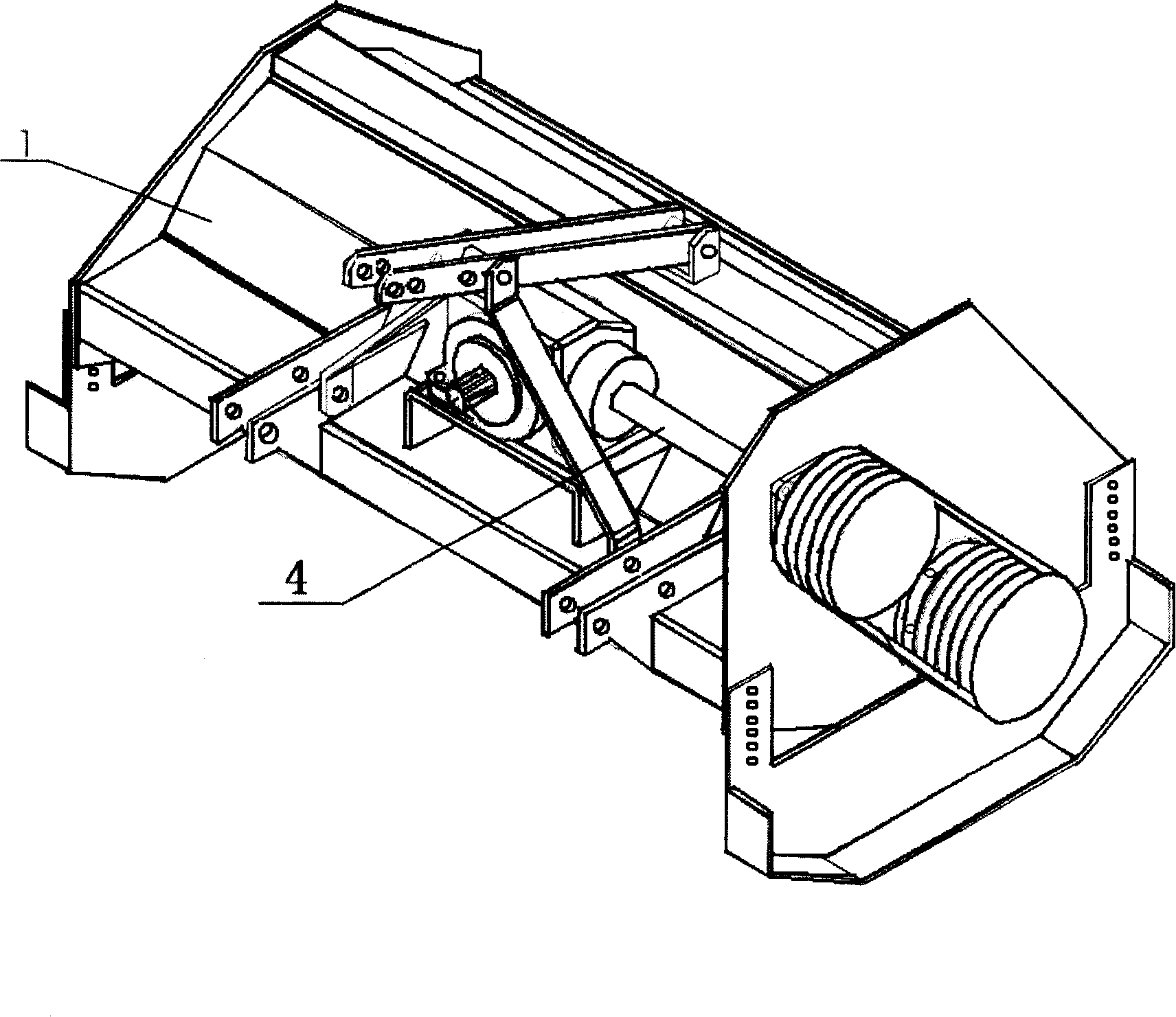

Automatic lap changing winder

The invention provides an automatic lap changing winder which comprises a frame, a drawing mechanism, a cross cutting mechanism, an air expanding shaft assembly, a large roller synchronous winding mechanism, a turnover mechanism, a pressing claw mechanism and a swing arm mechanism. The automatic lap changing winder is characterized in that the linear surface velocity of the drawing mechanism is equal to that of a large roller when the drawing mechanism and the large roller synchronous winding mechanism are under the action of a main driving motor and a sprocket pair, rotatable air expanding shaft guide wheels are mounted at two ends of an air expanding shaft, guide rails are arranged on the frame, a U-shaped groove in a turnover seat can function in guiding, the air expanding shaft can linearly move in winding, a gear is fixed onto the turnover seat, the turnover seat is supported on the large roller and can turn over around the large roller, the pressing claw mechanism is arranged on the turnover seat to automatically change laps, an arc-shaped head is arranged above a swing arm, and the air expanding shaft guide wheels can be tightly pressed to realize winding and can also be pushed away to discharge coiled materials. The automatic lap changing winder is reasonable in structure and simple to operate, manual lap changing is omitted, continuous production of winding is realized, and production efficiency is improved.

Owner:JIANGSU KUNTAI MACHINERY

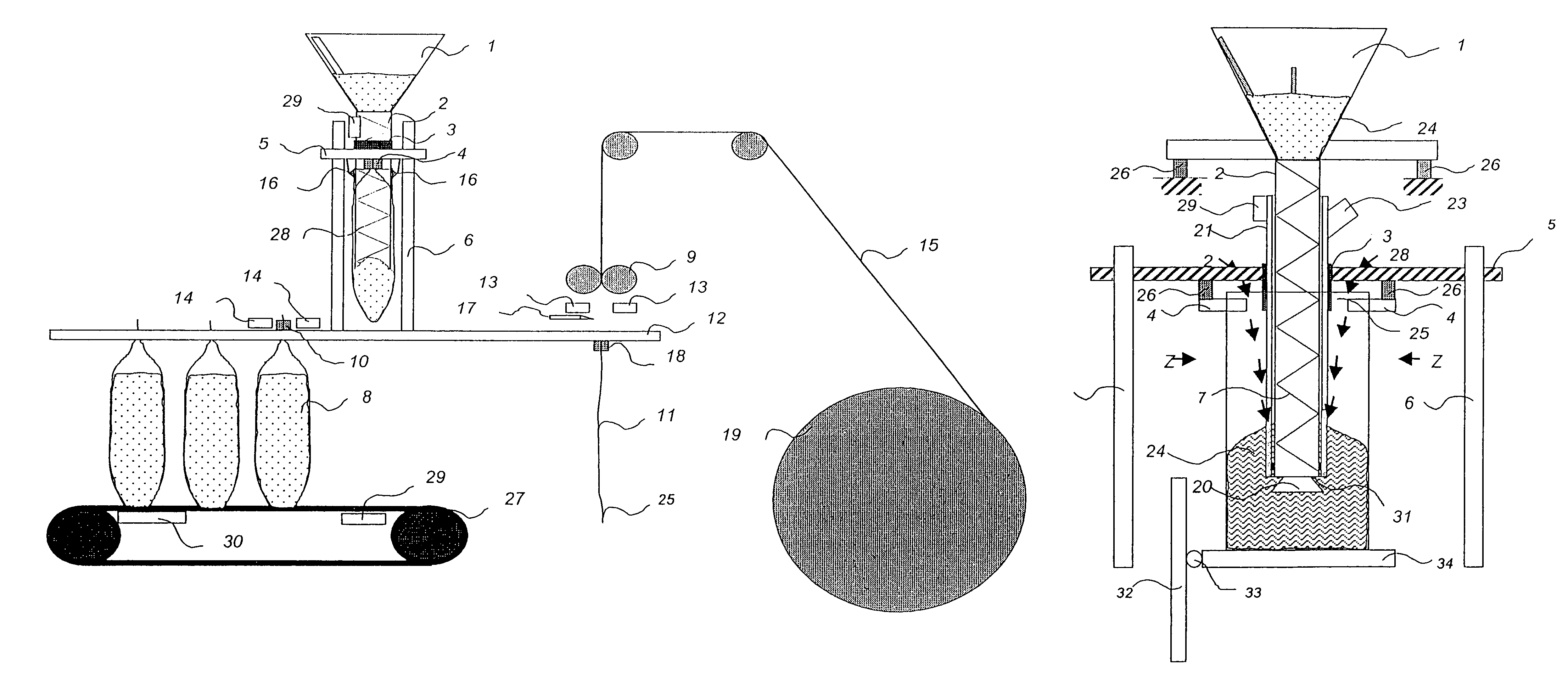

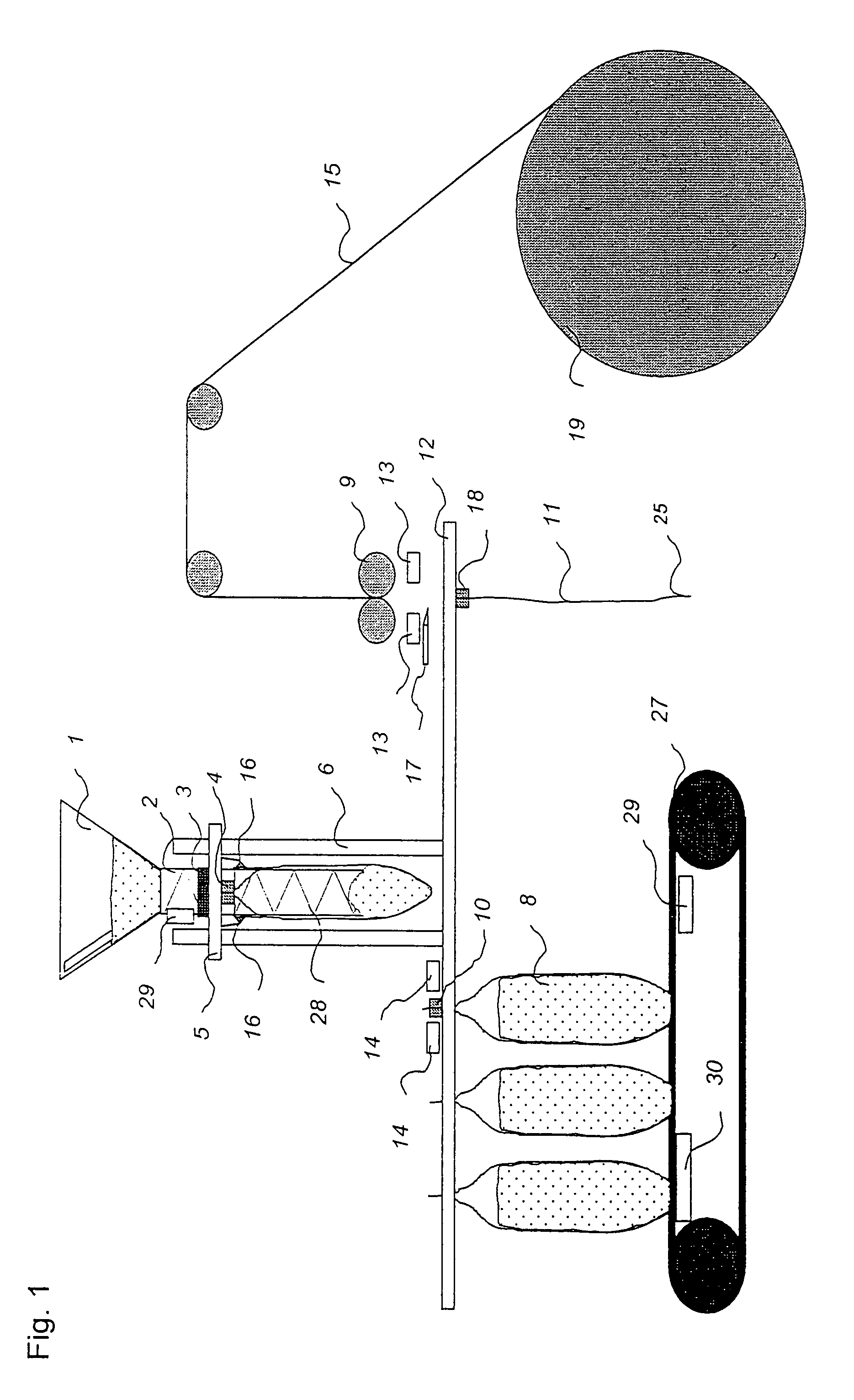

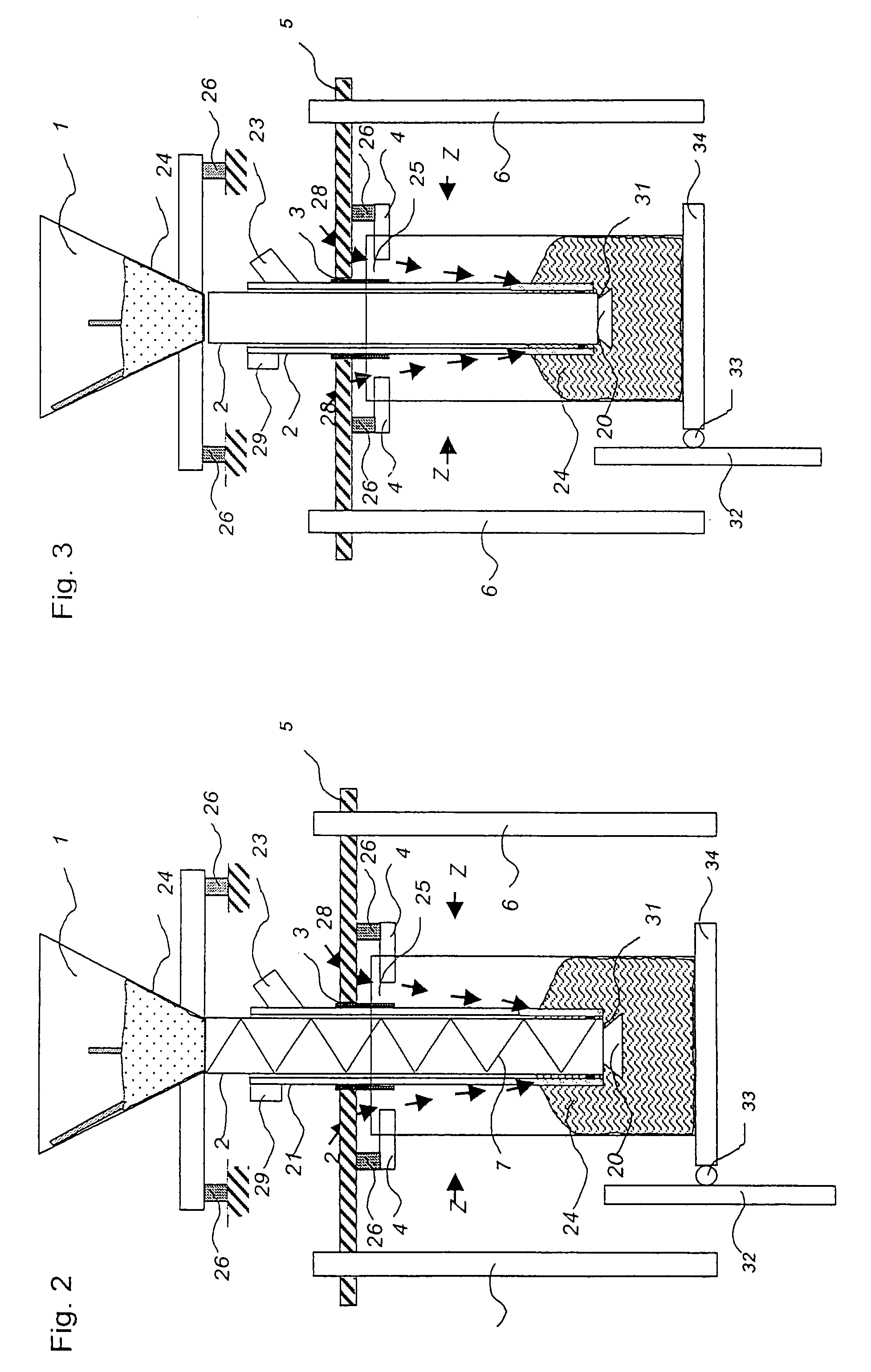

Machine for forming, filling and closing bags with a bag lifting device

InactiveUS7877966B2Reduced dust formationPackaging cigarettePackaging cigarsAxis of symmetryCross cut

Owner:WINDMOELLER & HOELSCHER GMBH

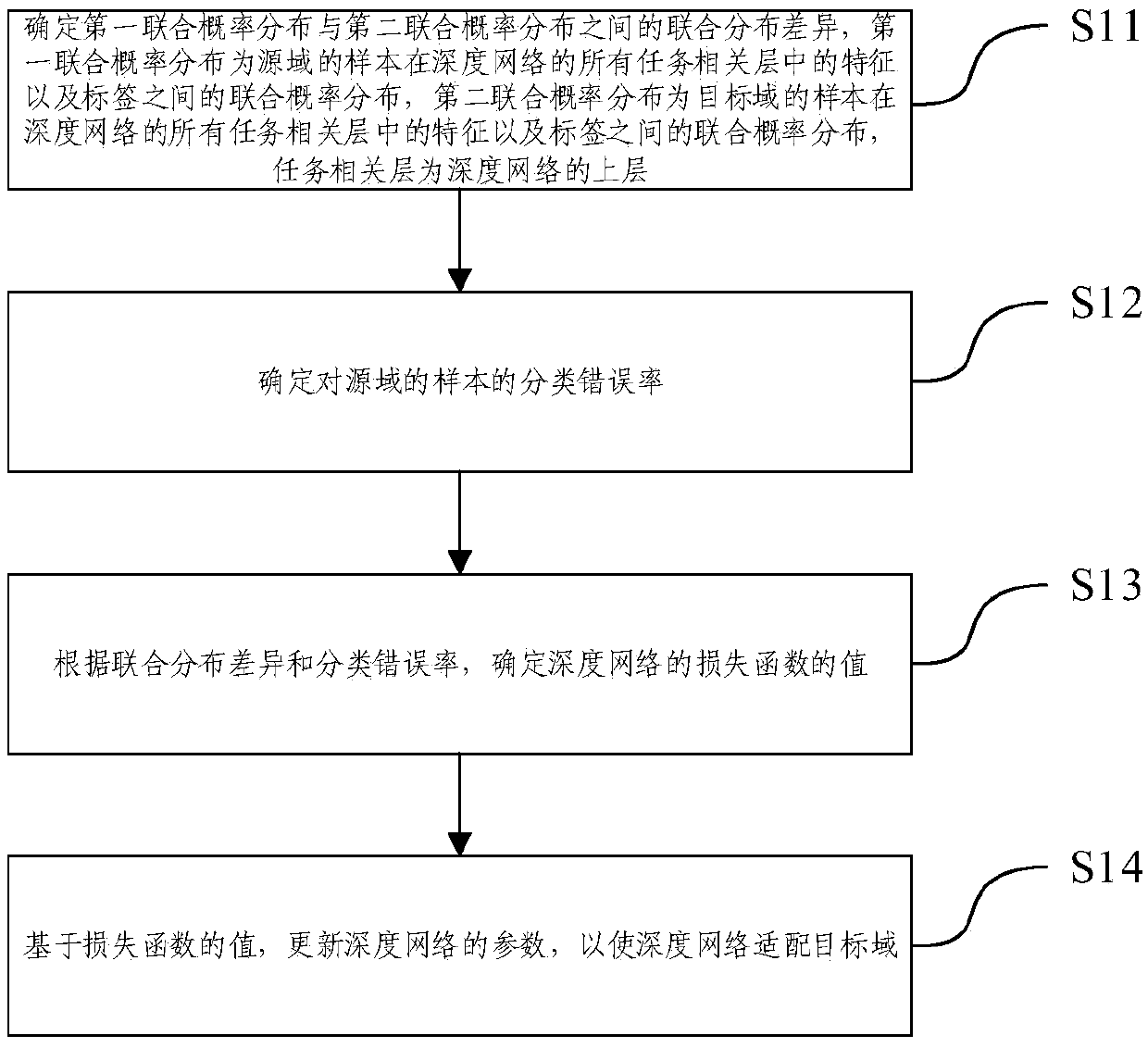

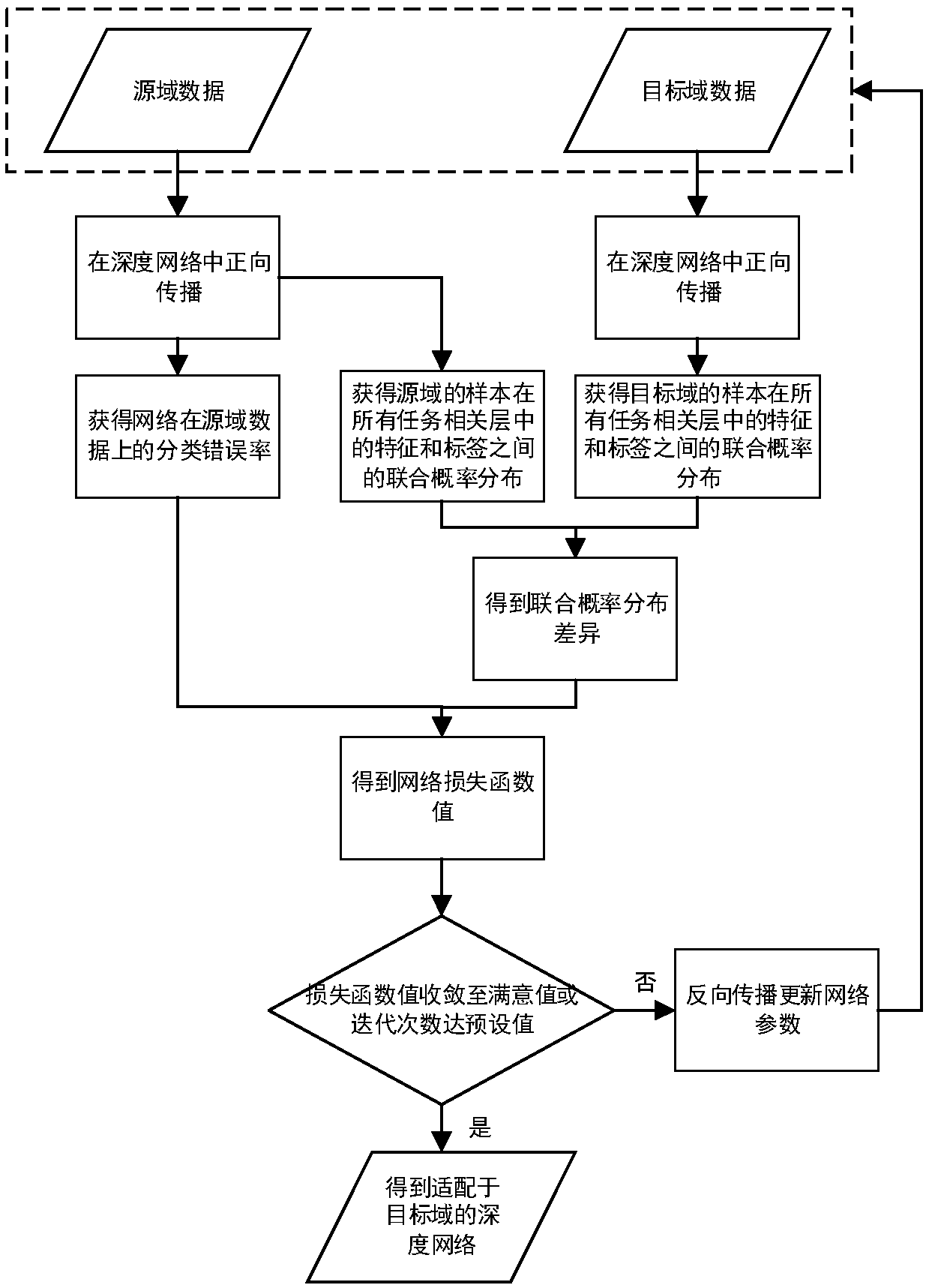

Deep transfer learning method based on big data cross-domain analysis

InactiveCN107704926ATransfer learning is goodImprove migration abilityNeural learning methodsCross cutDomain analysis

The present invention provides a deep migration learning method for cross-domain analysis of big data, by determining the value of the loss function of the deep network according to the joint distribution difference and the classification error rate, wherein the joint distribution difference is in all task-related layers corresponding to the source domain The distribution difference between the features of the feature and the joint probability distribution between the labels and the features in all task-related layers corresponding to the target domain and the joint probability distribution between the labels; and based on the value of the loss function, the parameters of the deep network are updated to Adapt the deep network to the target domain; thus, in the transfer learning process of the deep network, the joint distribution difference is used as a component of the value of the loss function of the deep network, and by updating the parameters of the deep network, while ensuring the accuracy of the source domain Realizing the matching of the joint distribution of the source domain and the target domain improves the migration ability of all task-related layers, thus bringing better results to the transfer learning of deep networks between different domains.

Owner:TSINGHUA UNIV

Amorphous-silicon-steel composite stator core for radial magnetic field motor and manufacturing method thereof

InactiveCN106602754AImprove efficiencyImprove power densityMagnetic circuit stationary partsManufacturing stator/rotor bodiesAmorphous siliconAlloy

The invention discloses an amorphous-silicon-steel composite stator core for a radial magnetic field motor and a manufacturing method thereof. The composite stator core comprises silicon steel plate layers and amorphous alloy plate layers which are alternately stacked and are then solidified into a block body. The manufacturing method comprises steps of composite material roll making, cross cutting and stacking, annealing, paint dipping and solidification, and processing. The core has properties of low loss, high saturation magnetic induction intensity and high mechanical strength.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

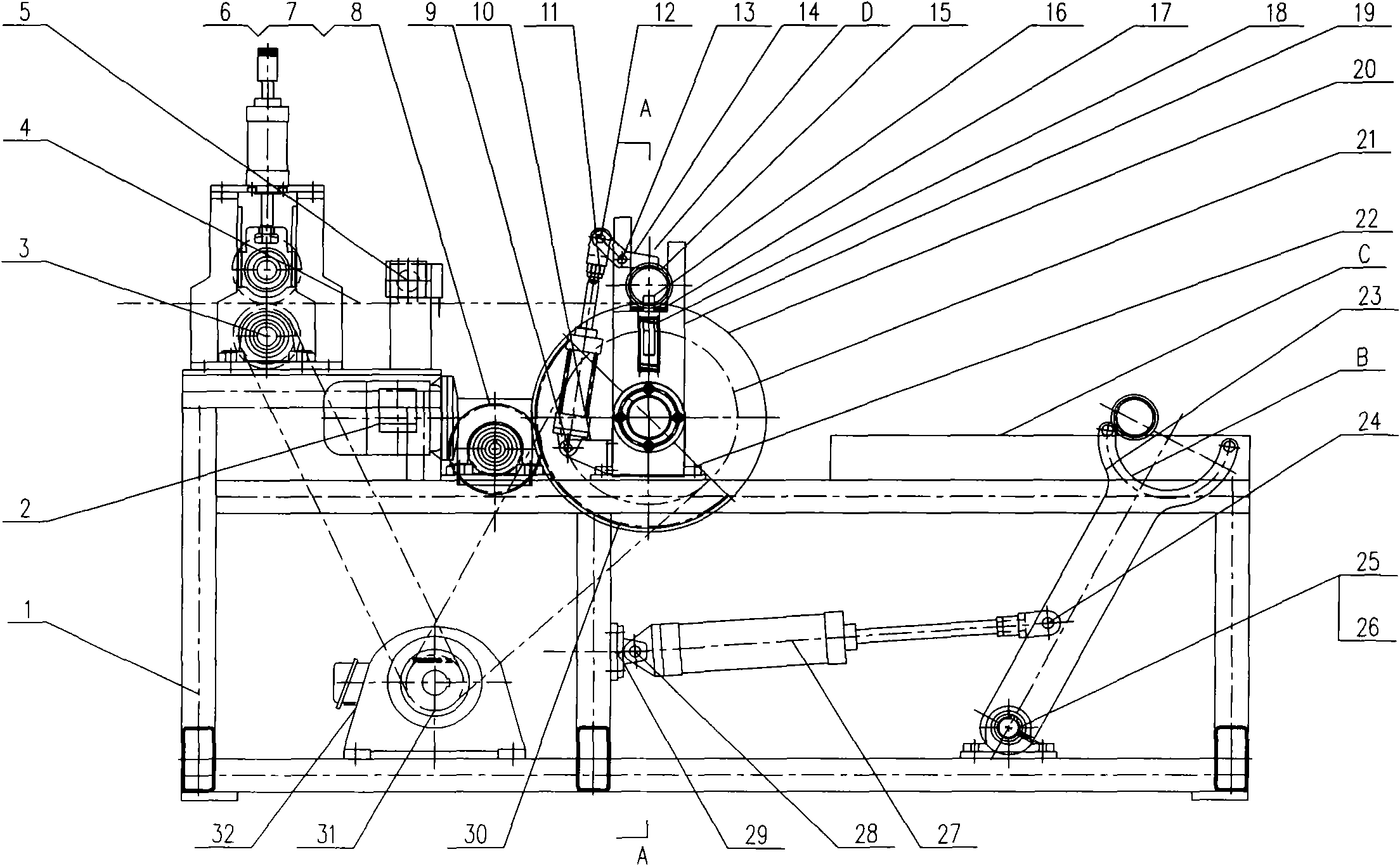

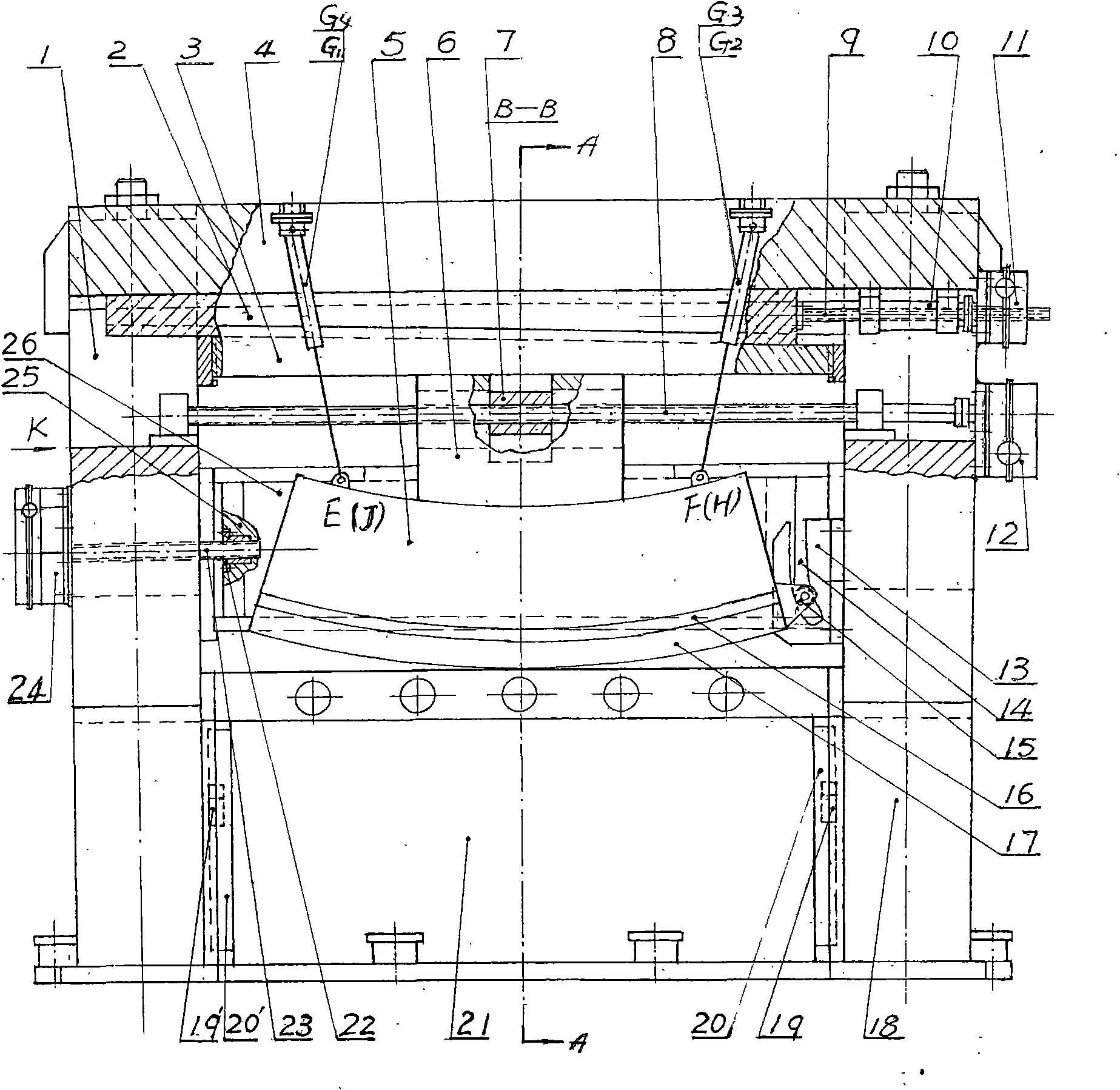

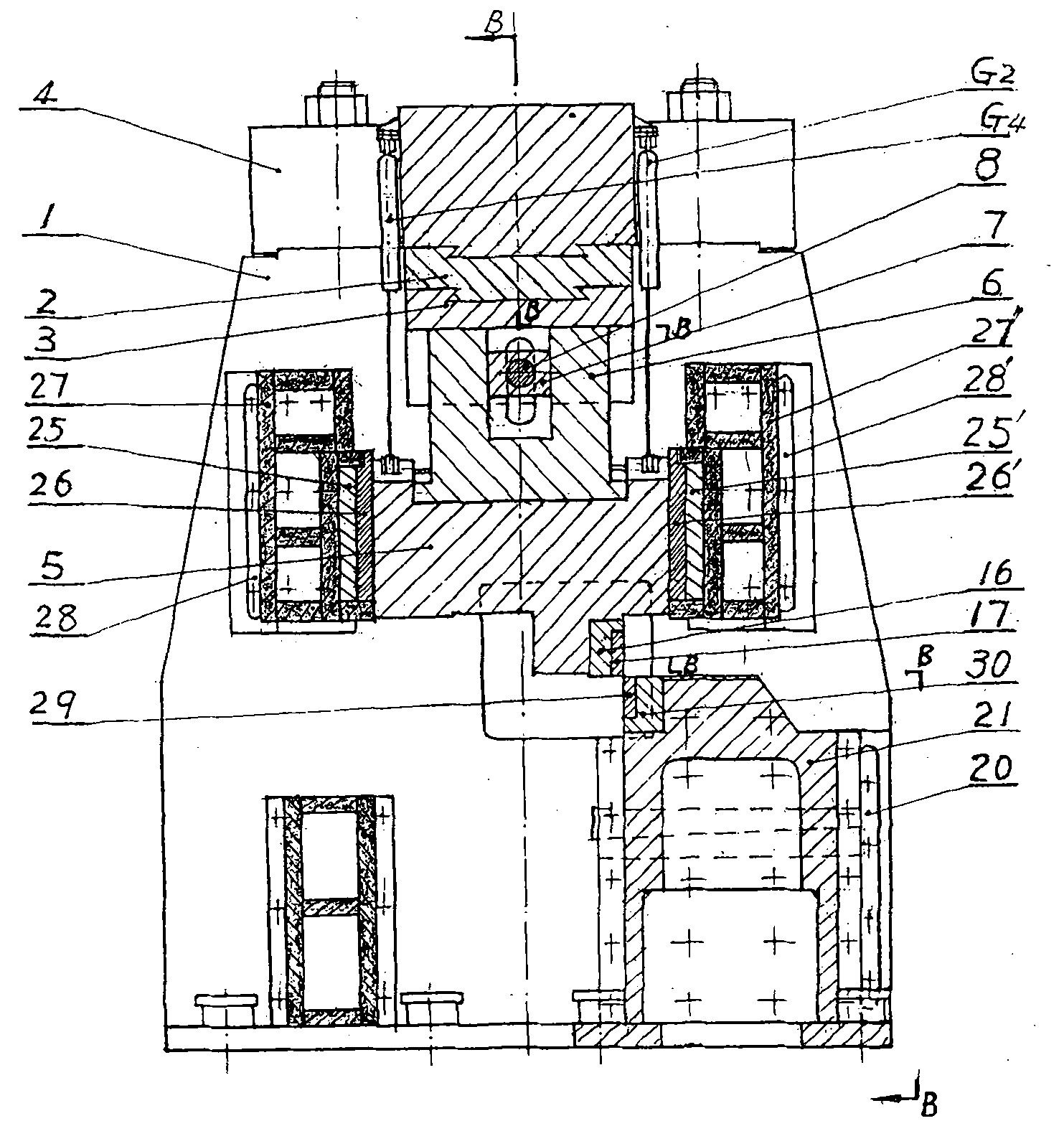

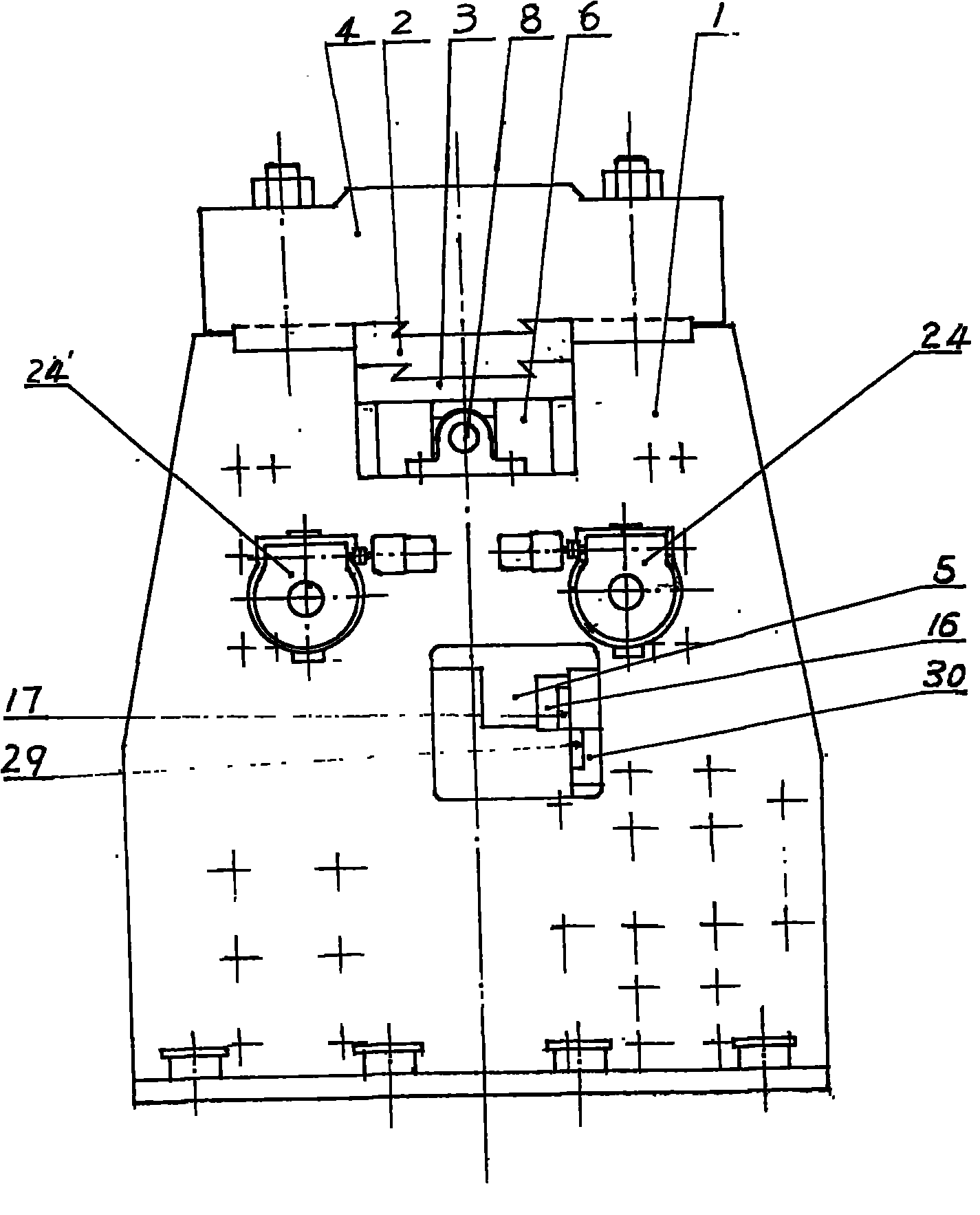

Hobbing type cross-cutting shear

InactiveCN102069232AImplementing pure rolling shearReduce shear forceShearing machinesShearing machine accessoriesHydraulic cylinderHobbing

The invention relates to a hobbing type cross-cutting shear which belongs to the technical field of shearing machines for metal plates, comprises a closed frame comprising a left frame, a right frame, an upper crossbeam and a lower knife rest, an upper shear blade lifting mechanism, an arc surface sliding seat type hopping mechanism, a roll wheel-guide groove type guide mechanism, a hydraulic cylinder balancing mechanism, a shearing blade clearance adjusting mechanism and a mechanism for connecting an upper knife box and an upper knife rest, and is characterized in that the lifting of an upper shear blade is realized by the movement of upper and lower oblique wedges mounted on the lower surface of the upper crossbeam and the action of balancing a hydraulic cylinder. The pure rolling shearing of the upper shear blade is realized by the transverse movement of an arc surface sliding seat mounted on the lower surface of the lower oblique wedge and the constraint of the roll wheel-guide groove mechanism. The adjustment of the clearance between the shear blades is realized by the movement of the oblique wedges arranged before and after the upper knife rest. The hobbing type cross-cutting shear has the advantages that a rolling ball spiral mechanism is adopted for driving the oblique wedges to move, thereby greatly improving the carrying capacity of equipment. The arc surface slidingseat type mechanism and the roll wheel-guide groove type guide mechanism are adopted, thereby being capable of realizing the pure rolling shearing.

Owner:张恒昌

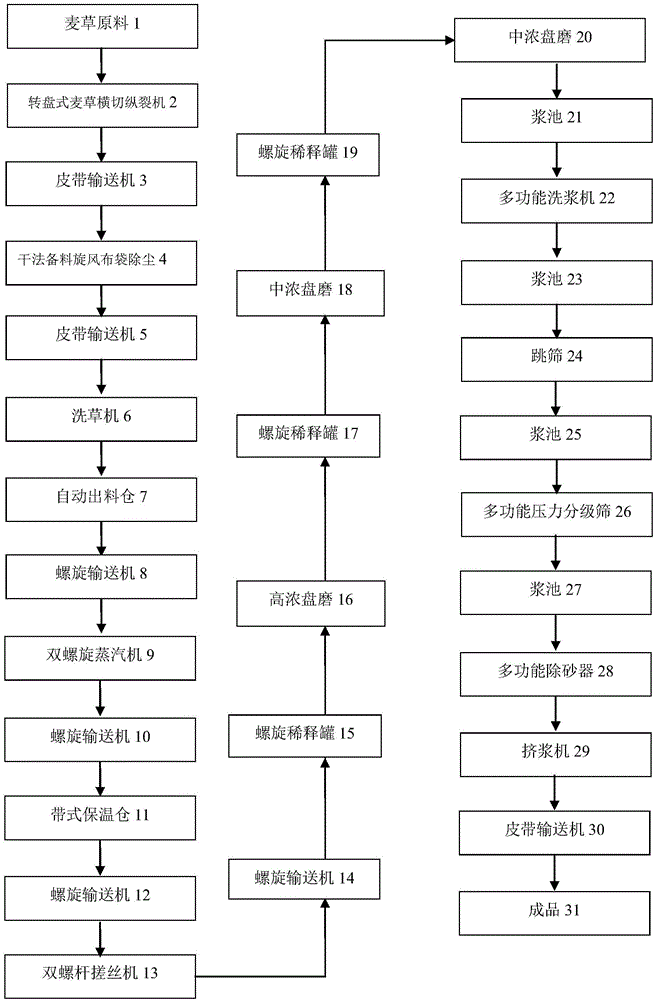

Production process method for novel crop straw environment-friendly material

InactiveCN104631204AHigh strengthDo not damagePretreatment with water/steamFibrous raw materialsHigh concentrationPollution

The invention relates to a production process method for a novel crop straw environment-friendly material. The method comprises the following steps: crushing, drawing and crushing straw raw materials by a rotary table type wheat grass cross-cutting vertical cracking machine; feeding the raw materials into a dry-method stock cyclone cloth bag by a belt conveyor to be subjected to dust removal; conveying the raw materials into a grass washing machine; conveying the raw materials into a double-spiral rotary steam engine, heating and softening; conveying the raw materials into a heat-preservation cabin, carrying out constant-temperature heat preservation and softening; conveying the raw materials into a double-spiral thread-rolling machine, and carrying out thread-rolling treatment; carrying out sub-sectioned grinding treatment on the raw materials by three middle-concentration and high-concentration disc mills in sequence; conveying the ground raw materials into a pulp washing machine; washing and sieving pulp by a jigging sieve pressure sieve; conveying good pulp into a sand removing device, and carrying out sand removing treatment; and finally, conveying the pulp into a pulp extruder to extrude surplus water to obtain a finished product, and conveying the tail pulp into the former link and treating. The production process adopts a pure mechanical treatment machining process and any chemical auxiliary agent is not added into the whole treatment process; and pollution to the environment is not caused and the environment is effectively protected.

Owner:BEIJING JINMENGDI MOLDING TECH DEV

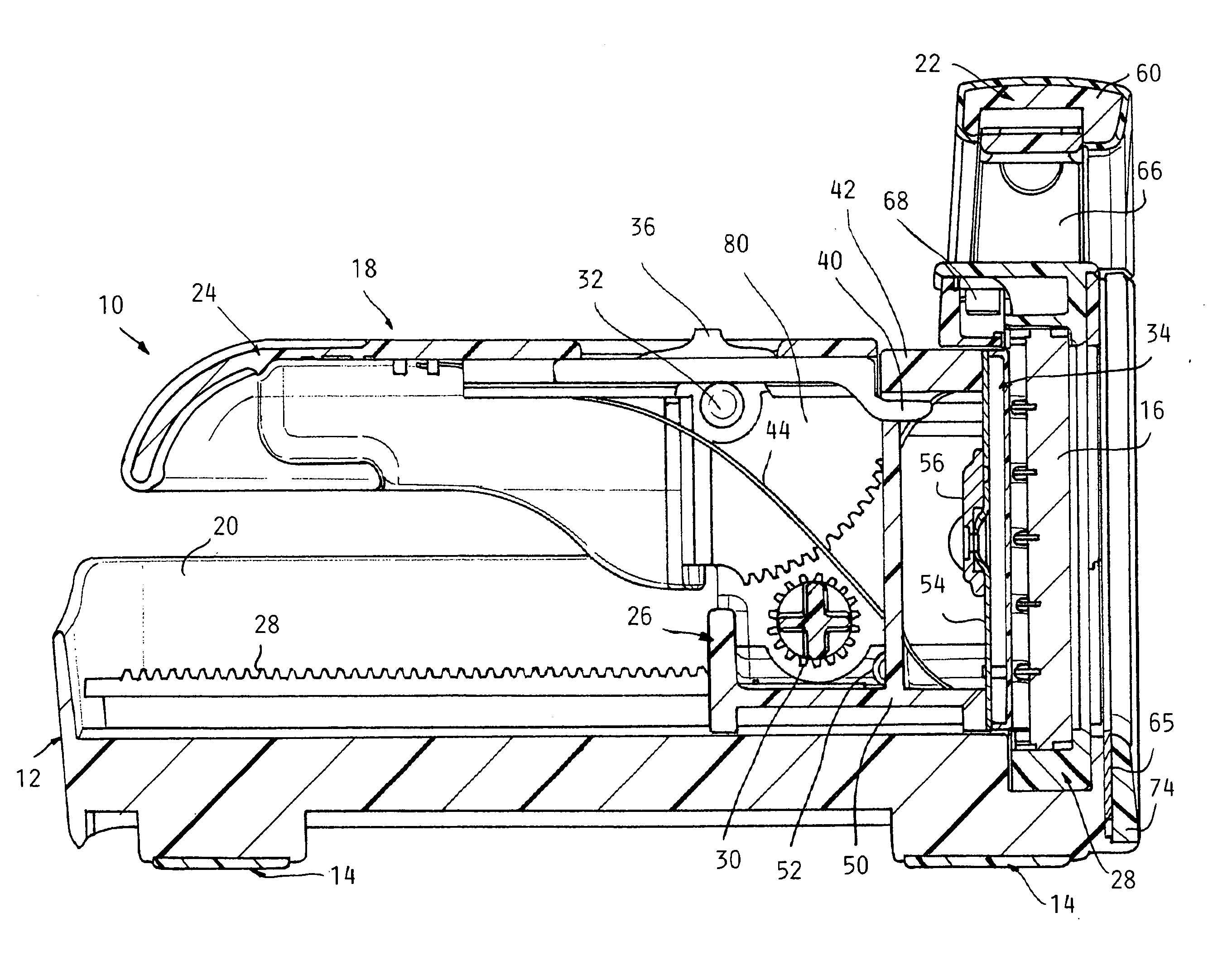

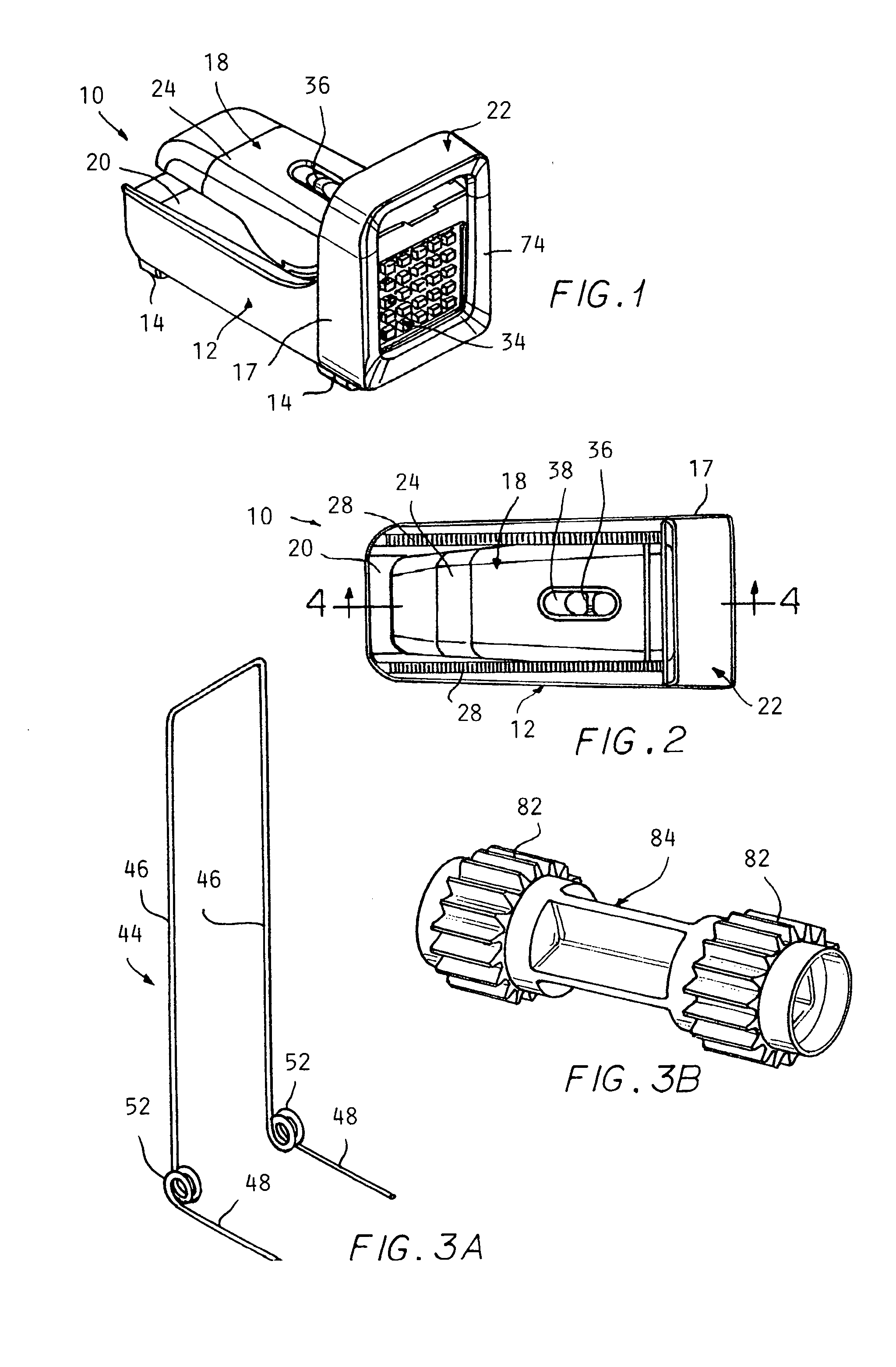

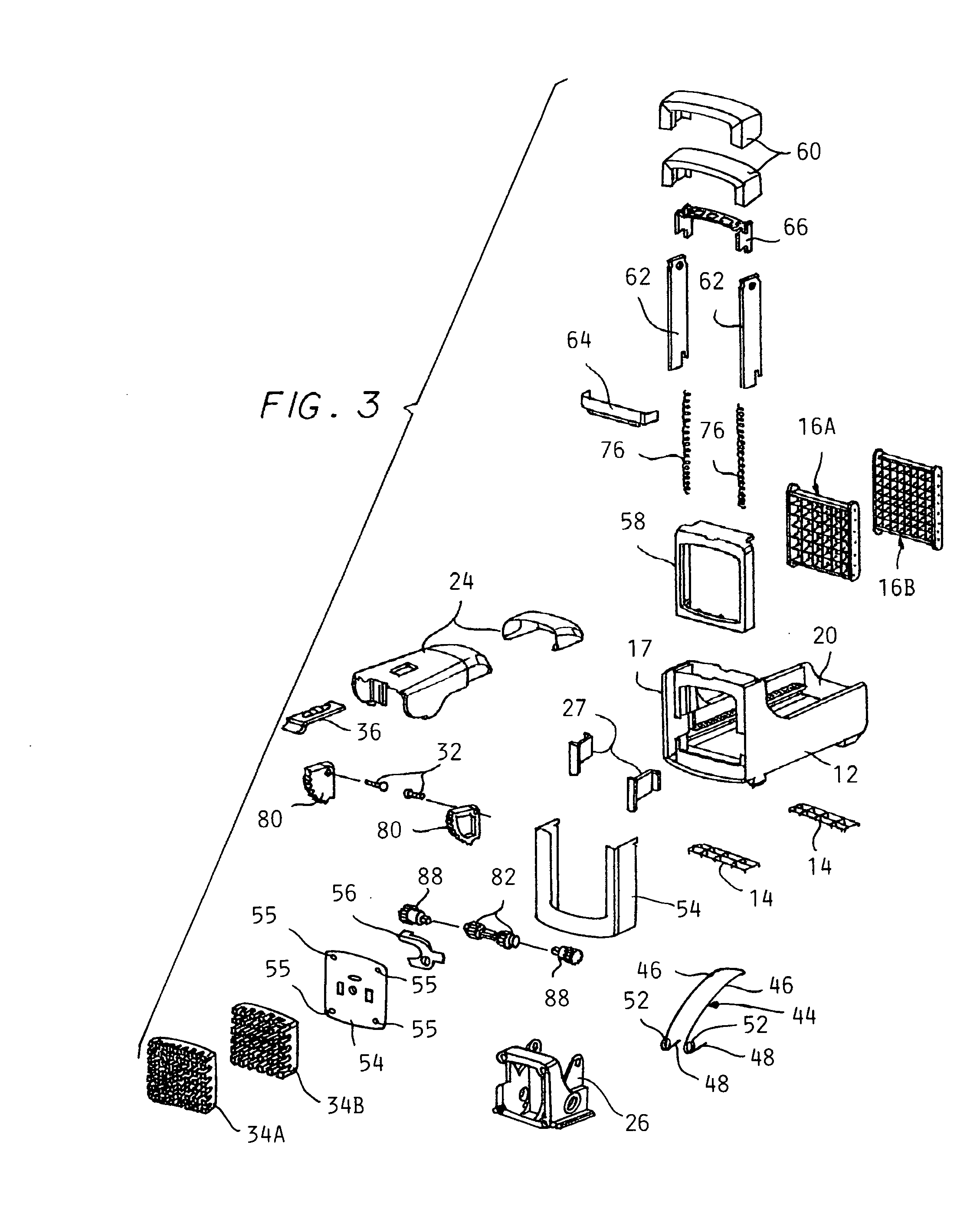

Slicing and dicing device

A slicing and dicing device which includes a pivoted lever which when stroked slides a pusher assembly partway along on a main body towards a cutter piece to slice an interposed item. Gearing operated by the lever disengages after each stroke to allow another stroke, reducing the peak effect required by limiting the range of motion to a range where good leverage is obtained. A dicing assembly is mounted forward of the cutter piece for vertical sliding motion to allow cross cutting of strips sliced out of the item by the cutter piece.

Owner:HOOD LANCE +1

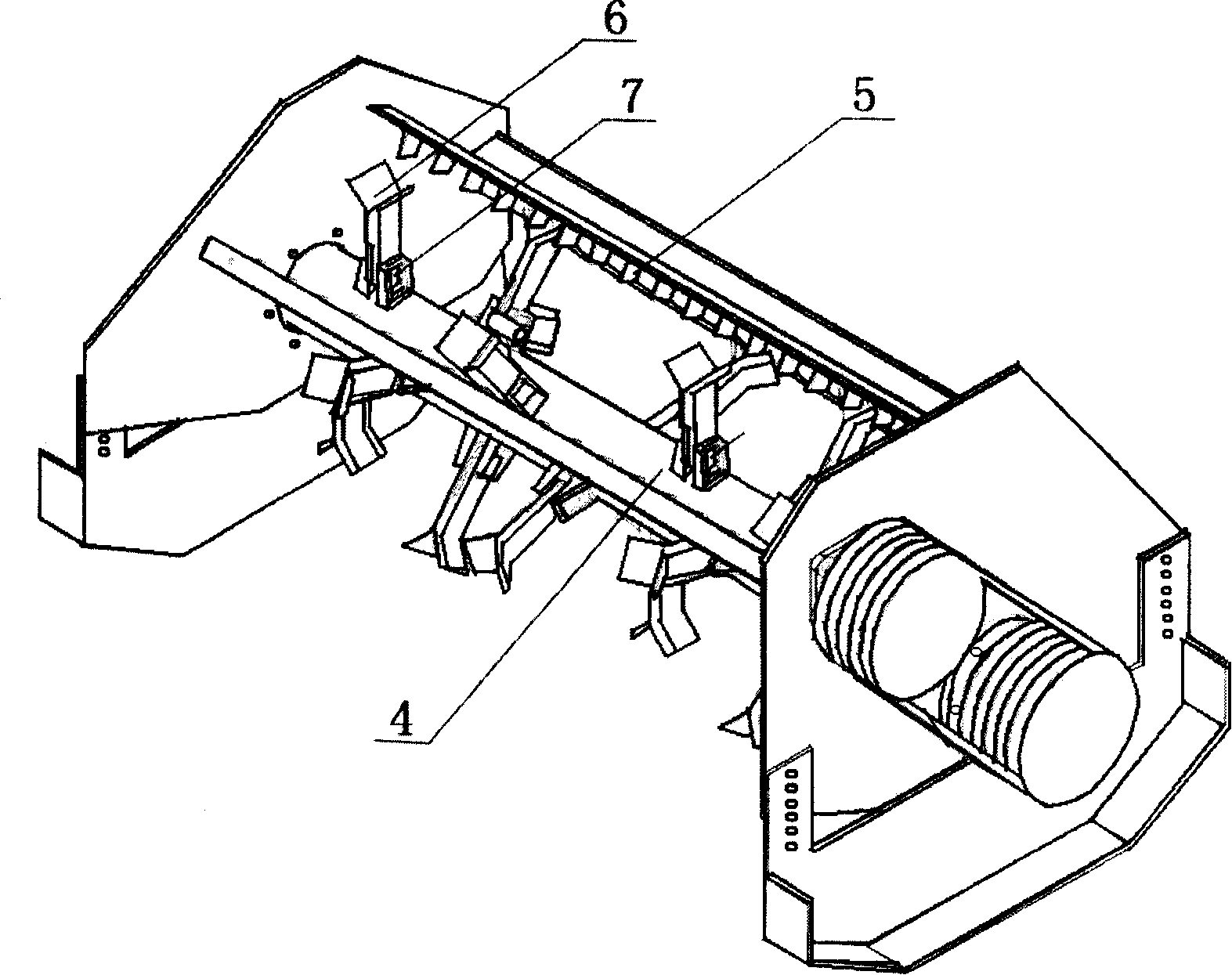

Stalk cutter

InactiveCN101352122ACompact structureReasonable layoutCuttersGrain treatmentsChain typeCross-cutting

The invention relates to a straw chopper, comprising a distributing roller, a cropping roller, a rack and a chain type dissepiment conveyor; the front end of the rack is provided with a feed inlet and the rear end thereof is provided with a discharge hole; the distributing roller is arranged above the feed inlet; a cross cutting tooth and a circumferential cutting tooth are arranged on the distributing roller; the cropping roller is arranged at the oblique and lower part of the rear side of the distributing roller; the outer circle of the cropping roller is provided with a plurality of cutting knives; the lower part of the cropping roller is provided with a particle screening plate which consists of a frame and a plurality of screening pieces; each screening piece is arranged in the frame in parallel and a gap is left between the two adjacent screening pieces; a pressure plate is arranged between the distributing roller and the cropping roller; the middle shafts of the distributing roller and the cropping roller are connected with a power device; the chain type dissepiment conveyor is arranged at the lower part of the feed inlet and a roller of chain type dissepiment conveyor extends to the bottom of the front end of the distributing roller. The straw chopper of the invention has the advantages of compact structure, reasonable layout, reliability and safety, even crashing, high efficiency and high yield and can realize continuous feeding.

Owner:尤凤兴 +1

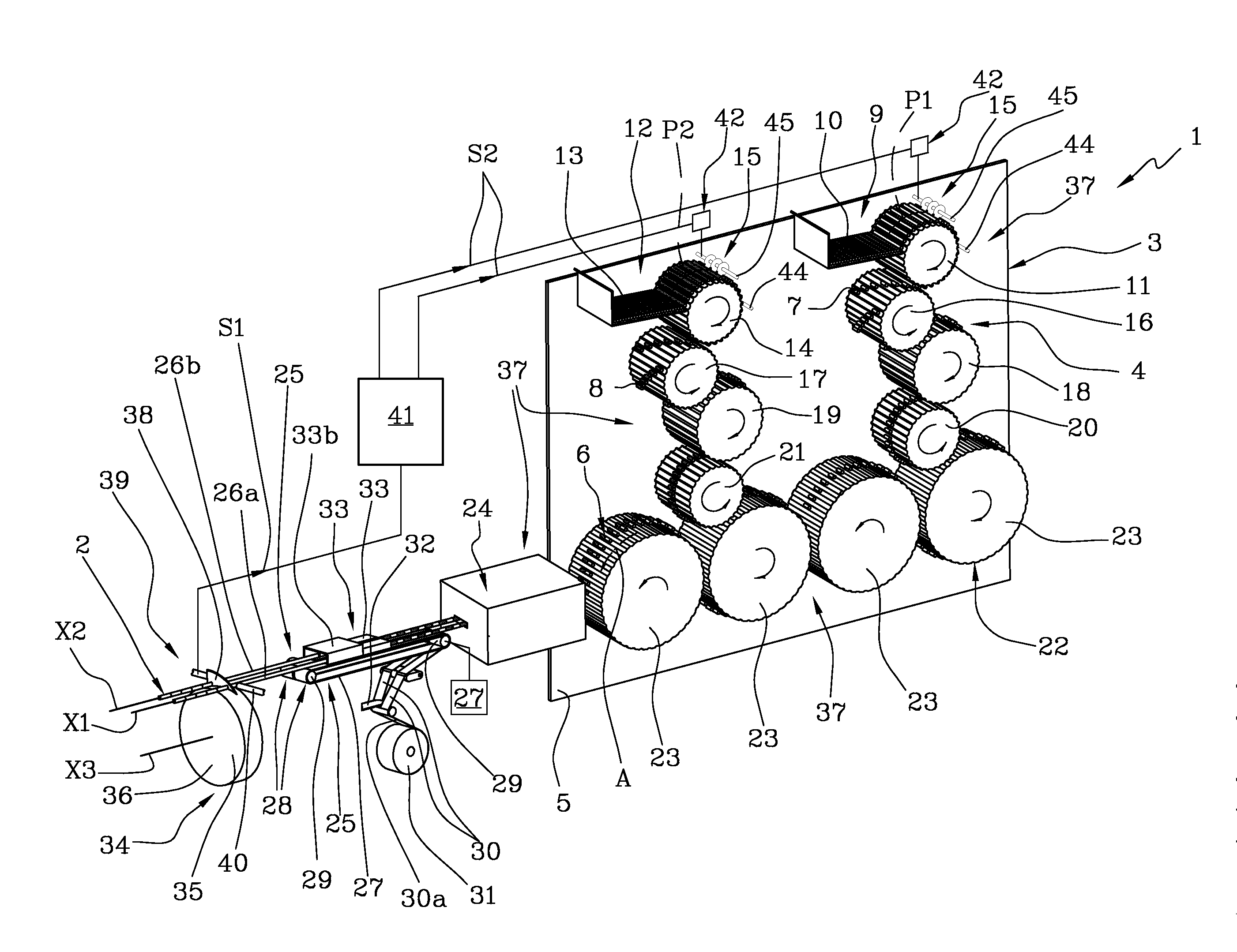

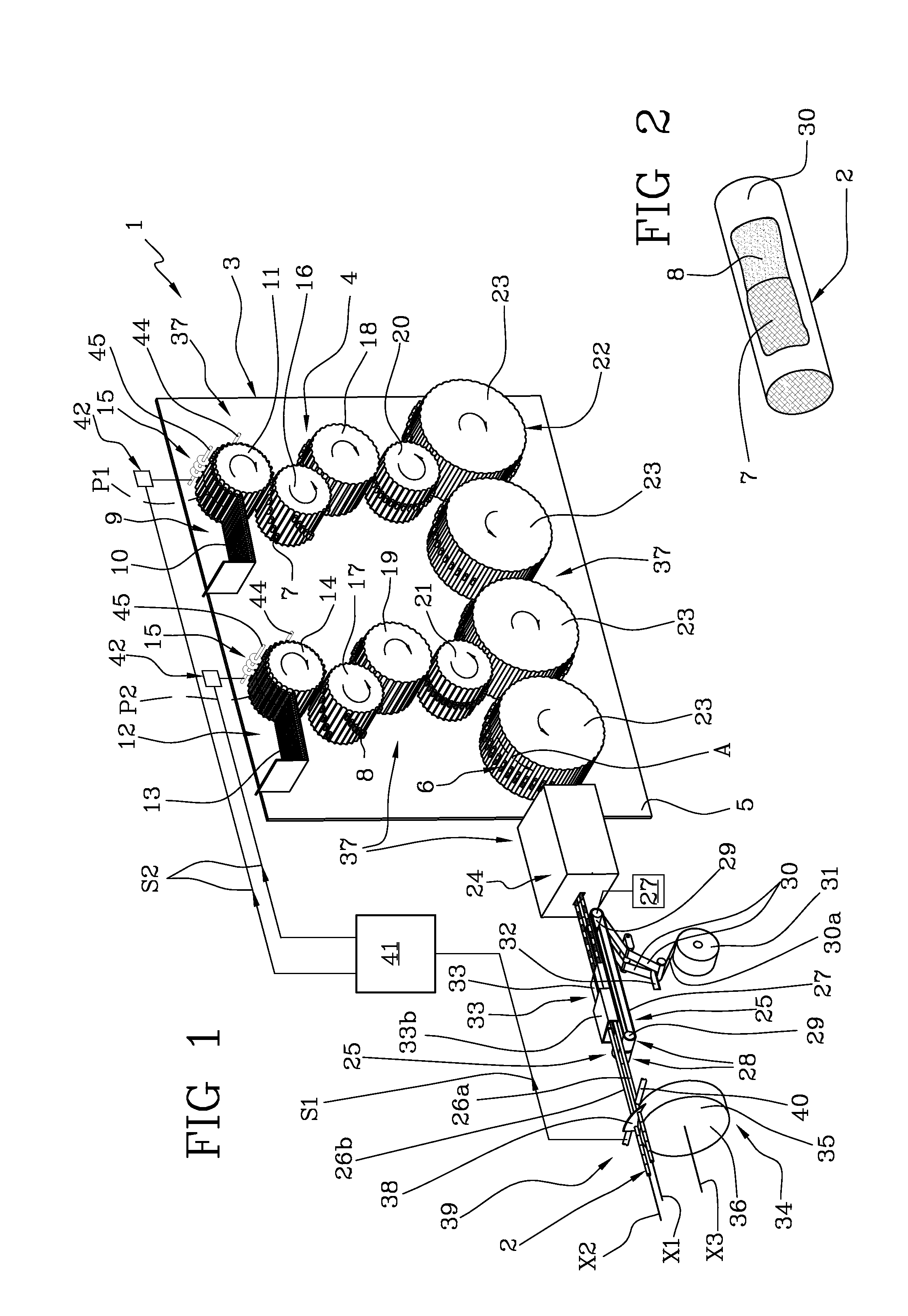

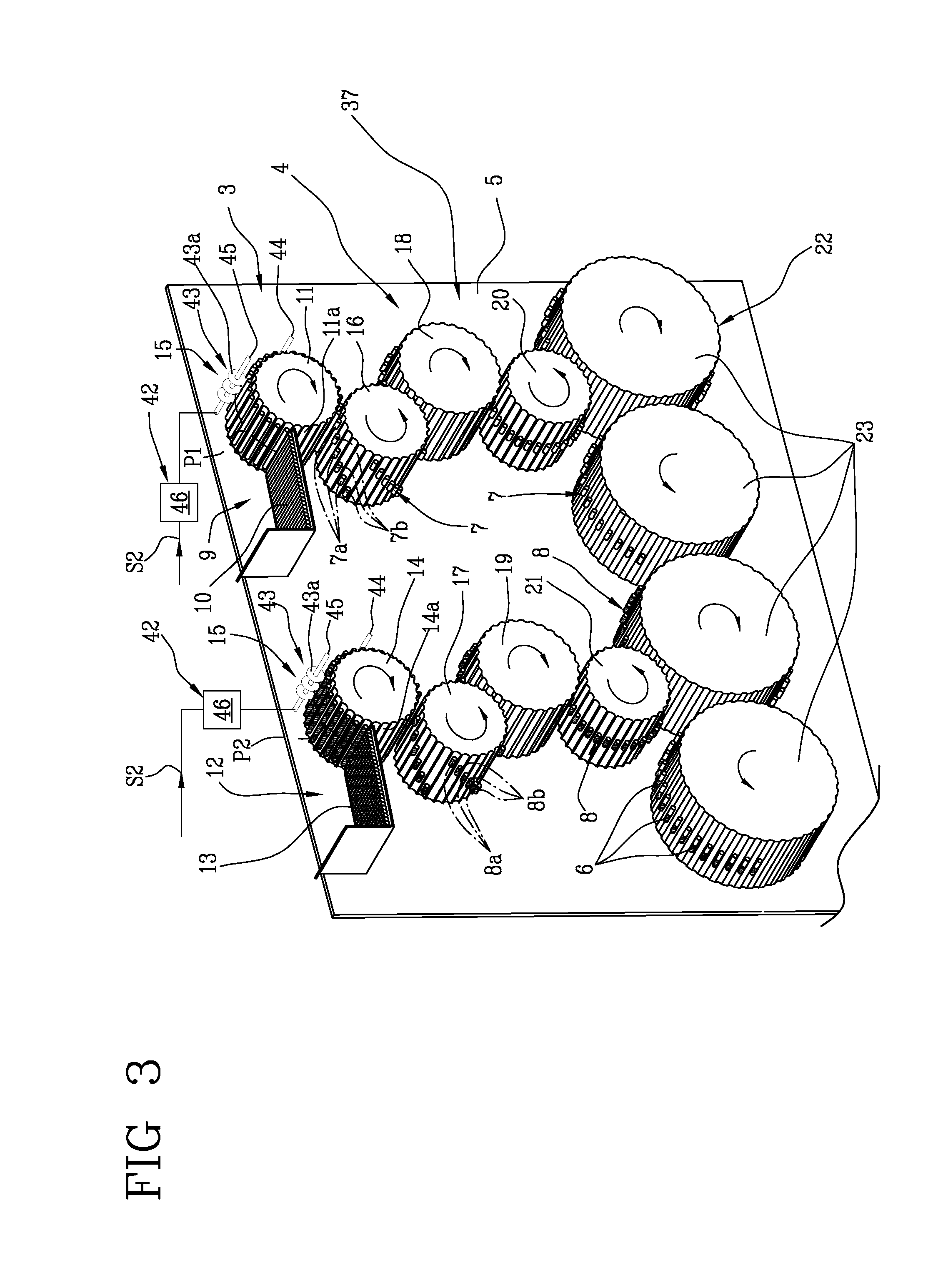

Twin track machine and a method for manufacturing composite filters attachable to cigarettes, cigars and the like

A method of manufacturing composite filters for cigarettes, cigars and similar tobacco products, on a twin track machine, involves generating a succession of filter sticks of a first type, made from a first filter material and / or having first filtration properties, and at least one other succession of filter sticks of a different type, made from a respective different filter material and / or having filtration properties different to those of the first type; cross-cutting the filter sticks of the first type and the filter sticks of the different type on at least one transverse cutting line to obtain a succession of first and second plugs of the first type and a succession of first and second plugs of the different type; arranging the first plugs of the first type and the first plugs of the different type in alternation one with another to create a first filter rod, and arranging the second plugs of the first type and the second plugs of the different type in alternation one with another to create a second filter rod; checking the position of at least one first plug of the first rod, relative to a corresponding second plug of the second rod; and correcting the position of the at least one transverse cutting line according to the relative positioning of the first and second plugs.

Owner:GD SPA

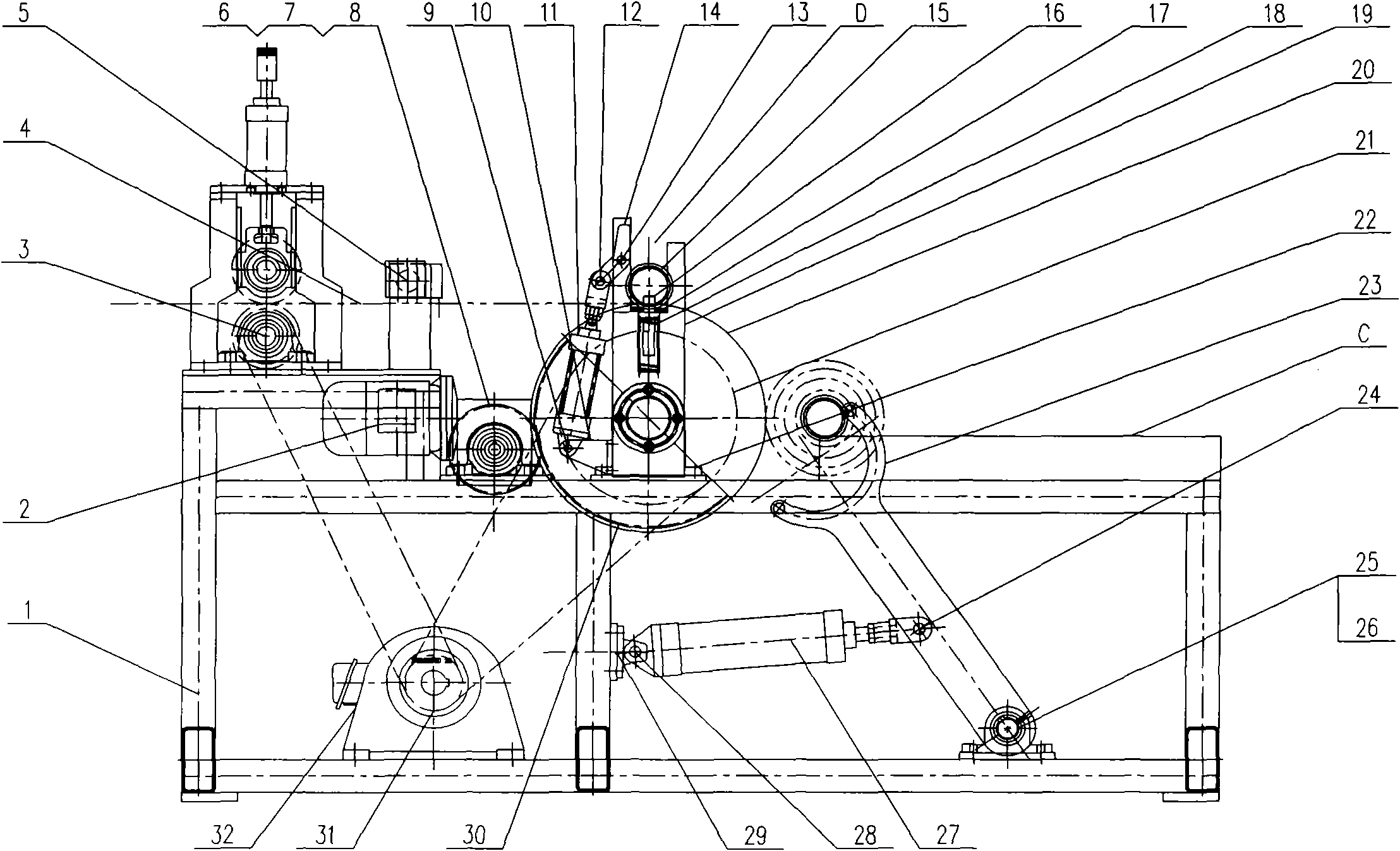

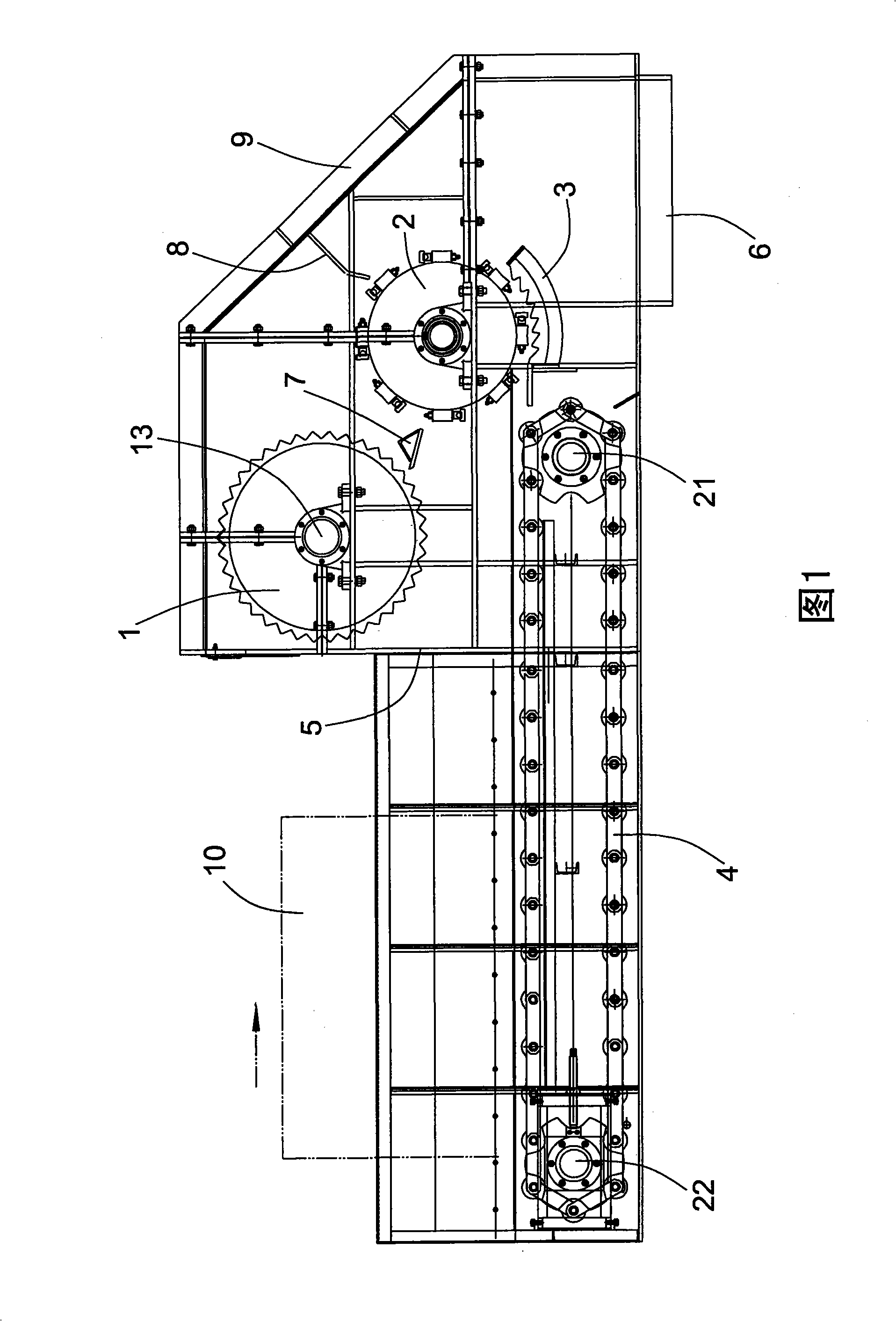

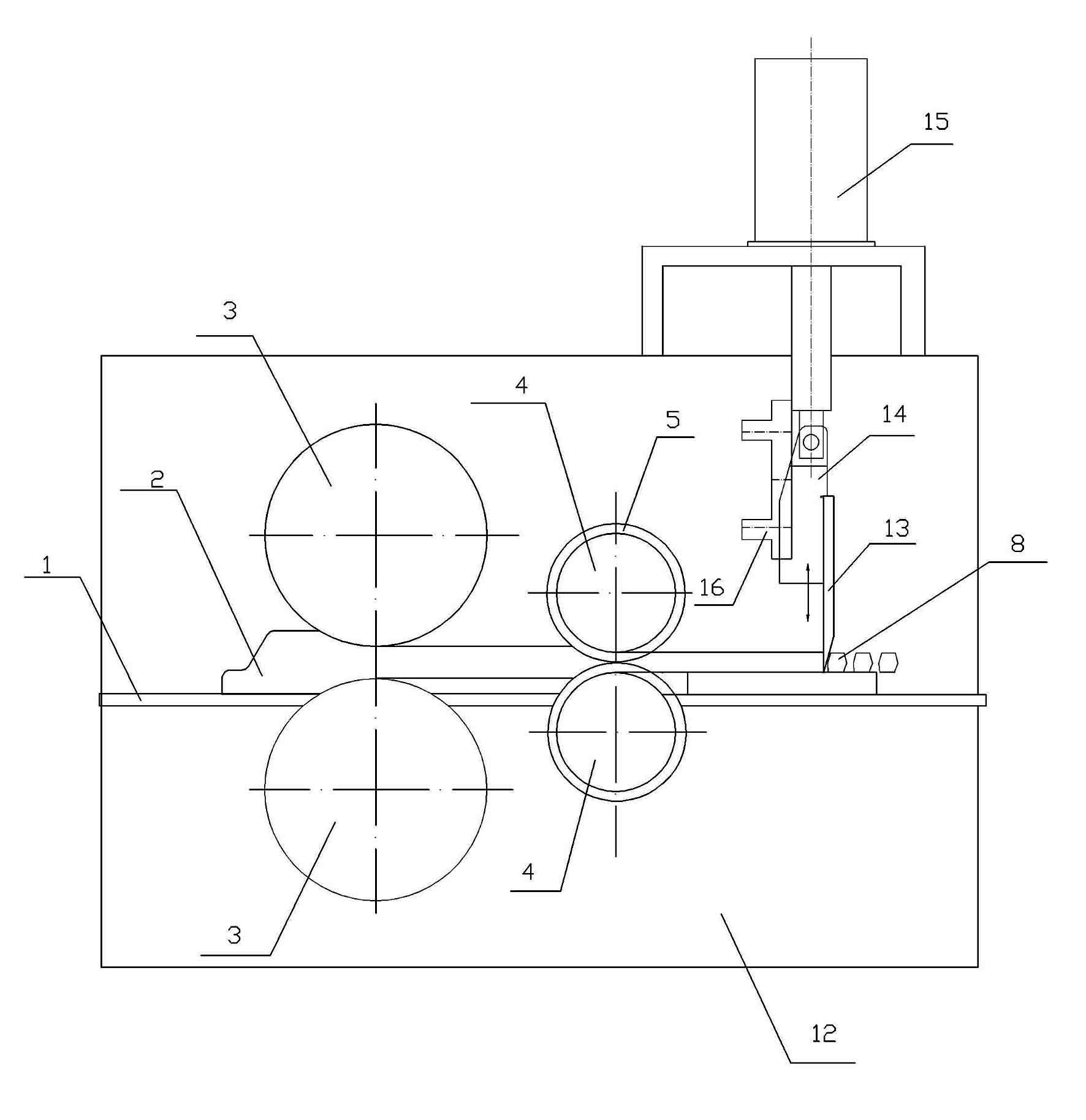

On-line transverse cutting machine for polystyrene plastic extruding cystosepiment

The invention provides an on-line transverse cutting machine of polystyrene plastic extrusion foam plates, relates to an on-line transverse cutting machine of polystyrene plastic extrusion foam plates (polystyrene plastic extrusion foaming insulation boards), belongs to the field of foaming insulation board cutting machinery, and is mainly used for on-line cross cutting polystyrene plastic extrusion foam plates (polystyrene plastic extrusion foaming insulation boards). The transverse cutting machine comprises a frame, a horizontal moving mechanism, a transverse cutting mechanism, a plate conveying mechanism and a control mechanism, wherein, a horizontal guiding rail is arranged at the upper part of the frame; a horizontal moving mechanism is mounted on the horizontal guiding rail; the transverse cutting mechanism is arranged on the other side of the frame; the transverse cutting mechanism comprises an upper seat board, a saw blade, a motor II which drives the saw blade to rotate and a motor III which drives the transverse cutting mechanism to move transversely; the motor III is mounted at the lower part of the horizontal guiding rail; a transverse horizontal guiding rail is mounted on the horizontal moving mechanism; the upper seat board is mounted on the transverse horizontal guiding rail; the saw blade and the motor II are mounted on the upper seat board; the plate conveying mechanism is arranged at the back part of one side of the frame; and the control mechanism comprises a photoelectric switch which controls the length of the plates.

Owner:南京法宁格节能科技股份有限公司

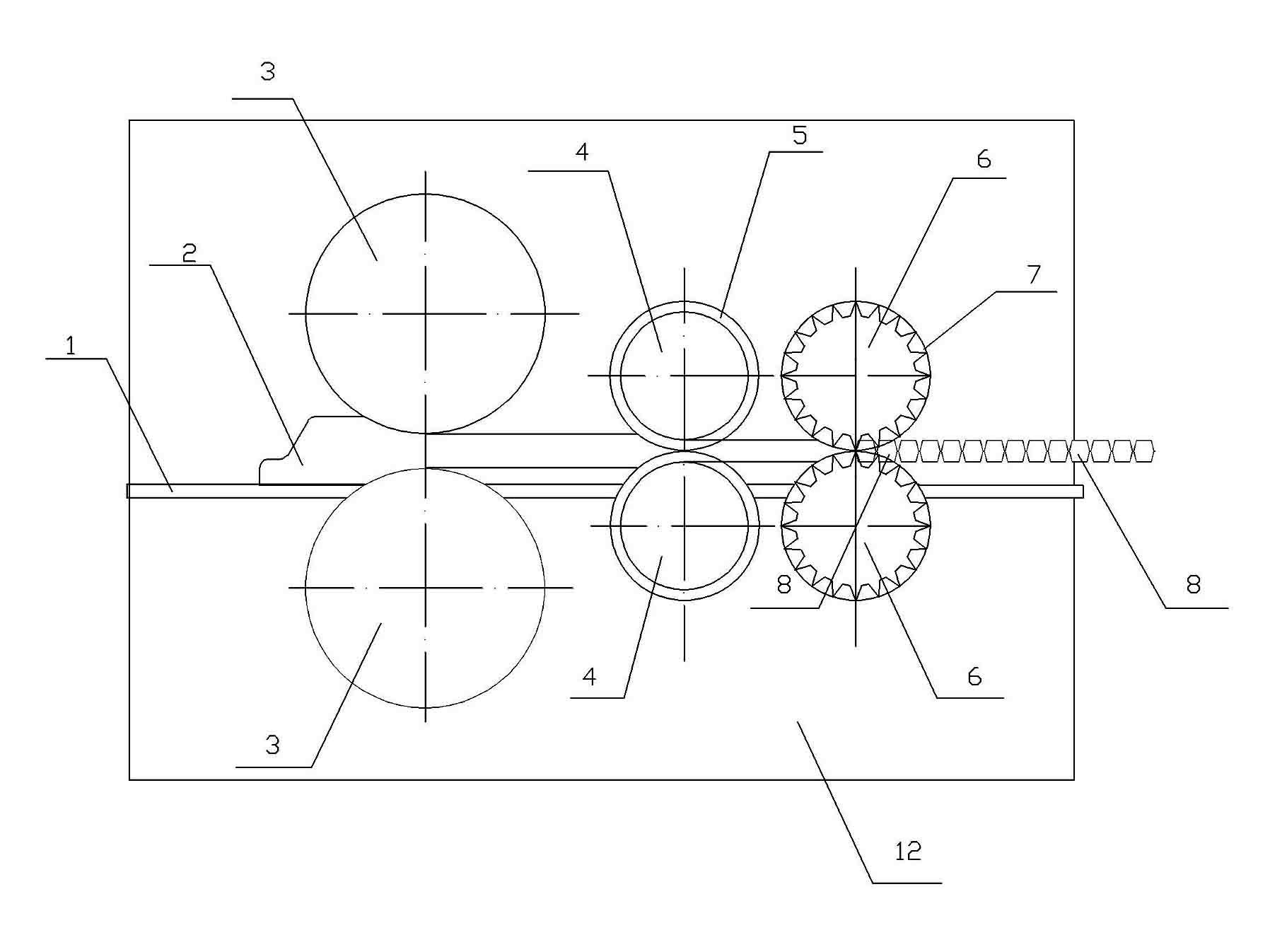

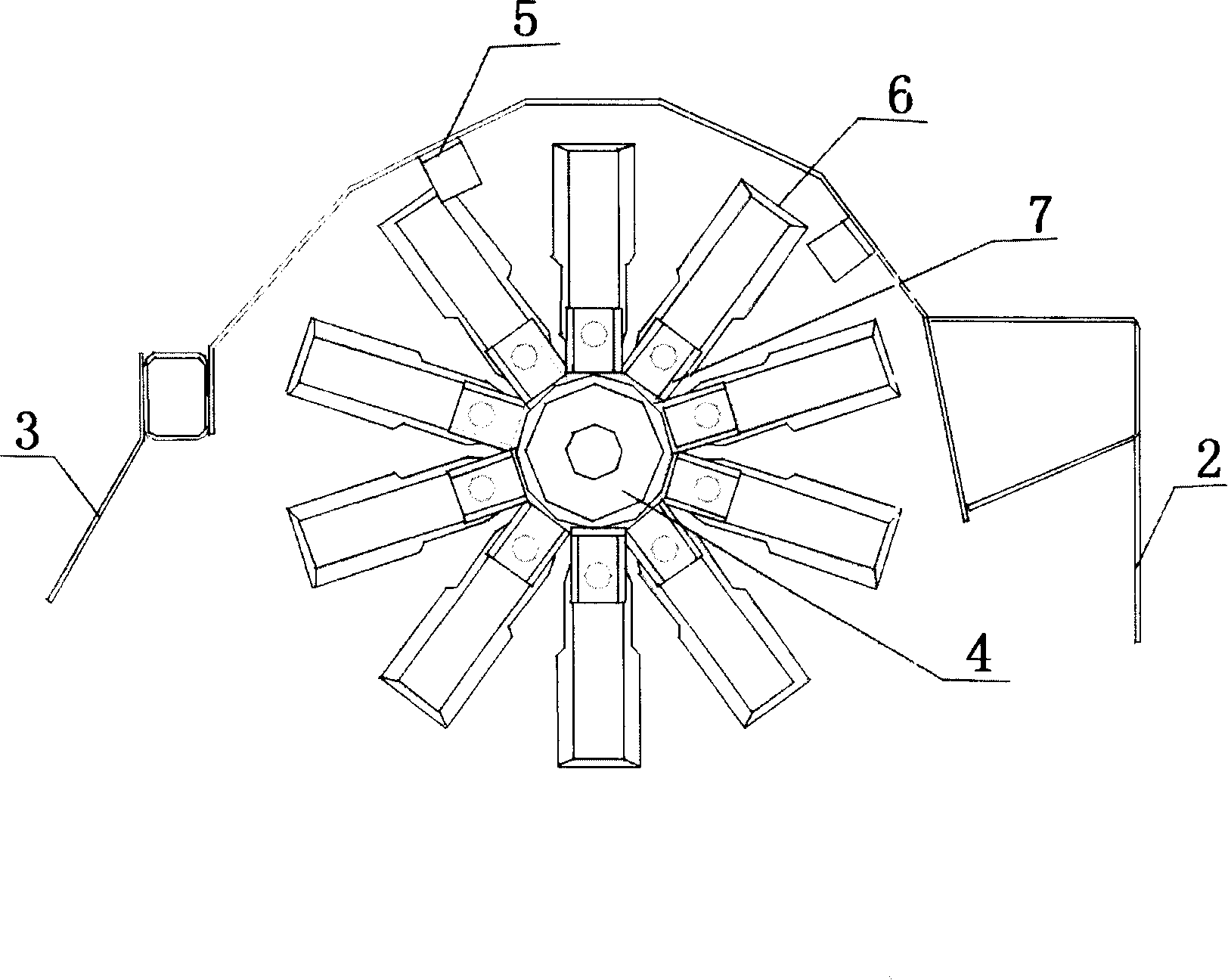

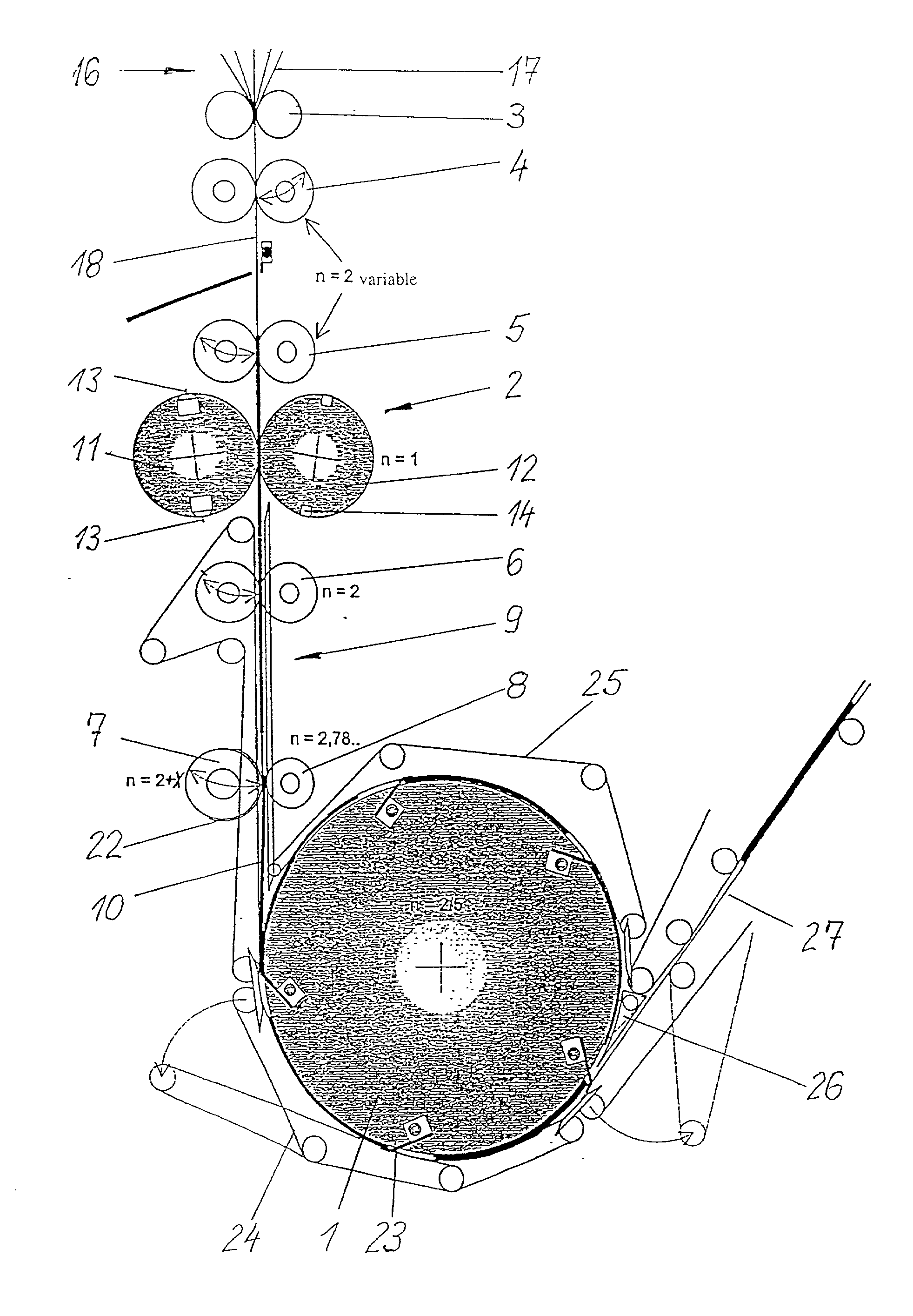

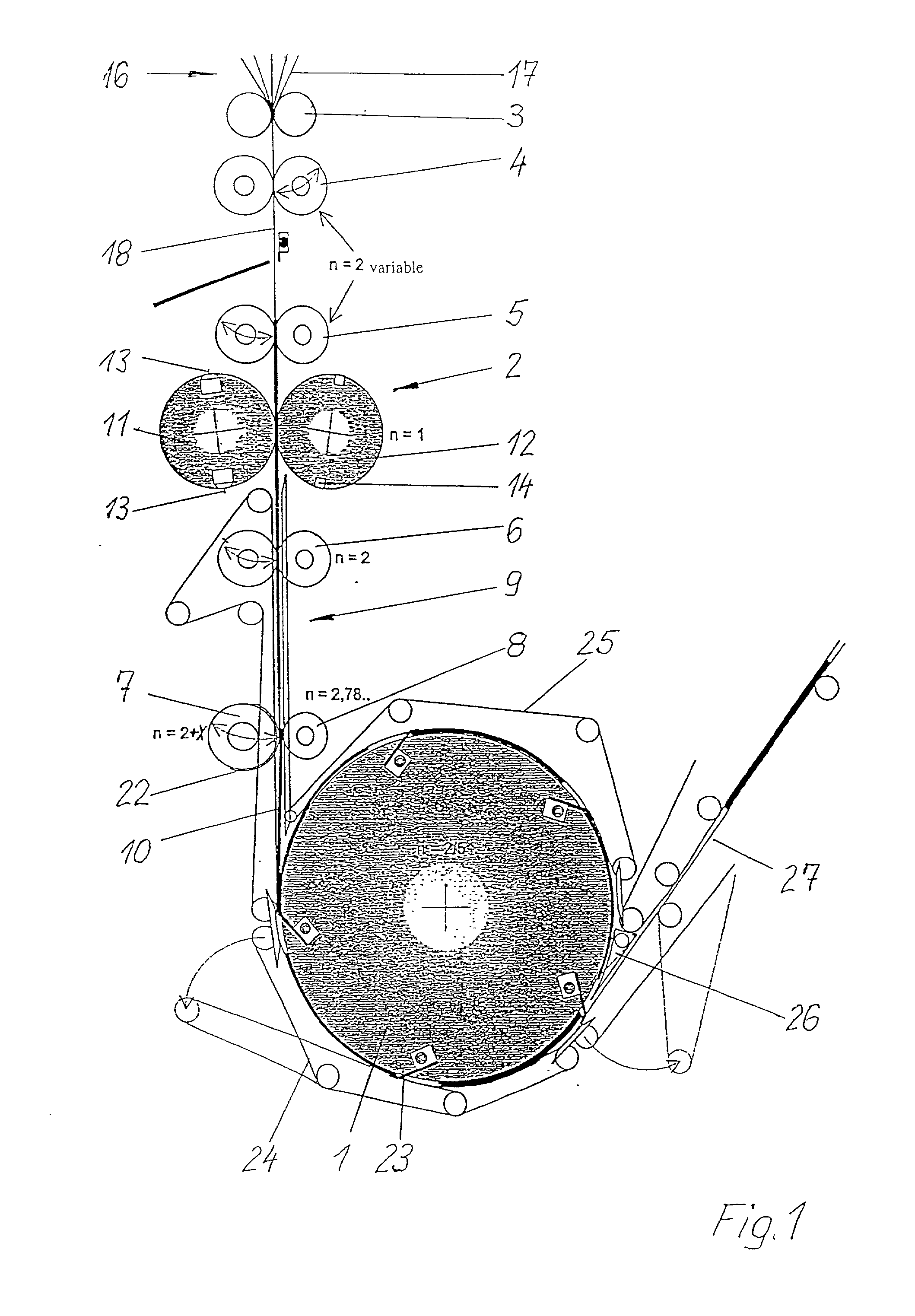

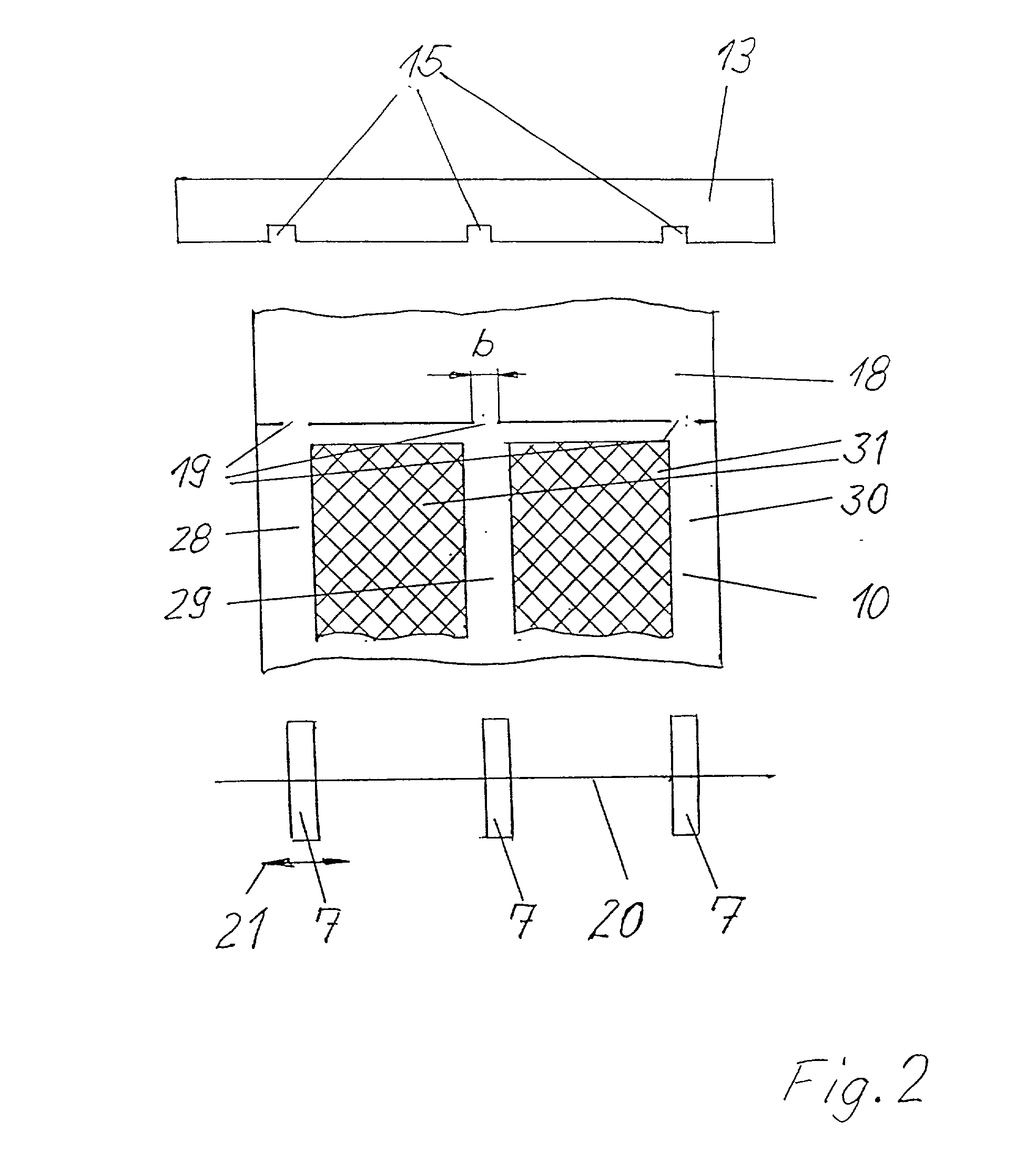

Lead pig grinding and granulating machine

The invention relates to a lead pig grinding and granulating machine which comprises a stand (12) and a working platform (1). The lead pig grinding and granulating machine is characterized in that two counter-roll matching grinding rollers (3), two counter-roll matching longitudinal-cutting rollers (4) and two counter-roll matching cross-cutting rollers (6) are sequentially arranged on a stand (12) at a certain interval, wherein the surface of each longitudinal-cutting roller (4) is uniformly provided with one group of longitudinal cutting blades (5) around the circumference along the axial direction, and the surface of each cross-cutting roller (6) is uniformly provided with cross-cutting blades (7) parallel to the axial direction along the circumference. The invention has the advantages that the traditional process of counter-roll extruding and granulating after slicing a lead pig is discarded, and advanced processes and devices of firstly grinding, then rolling and stripping, then crossly cutting and granulating are adopted. Compared with the prior art, the lead pig grinding and granulating machine has the advantages of high granulating efficiency, high material utilization rate, long service life, low manufacture cost and the like.

Owner:孟庆黎

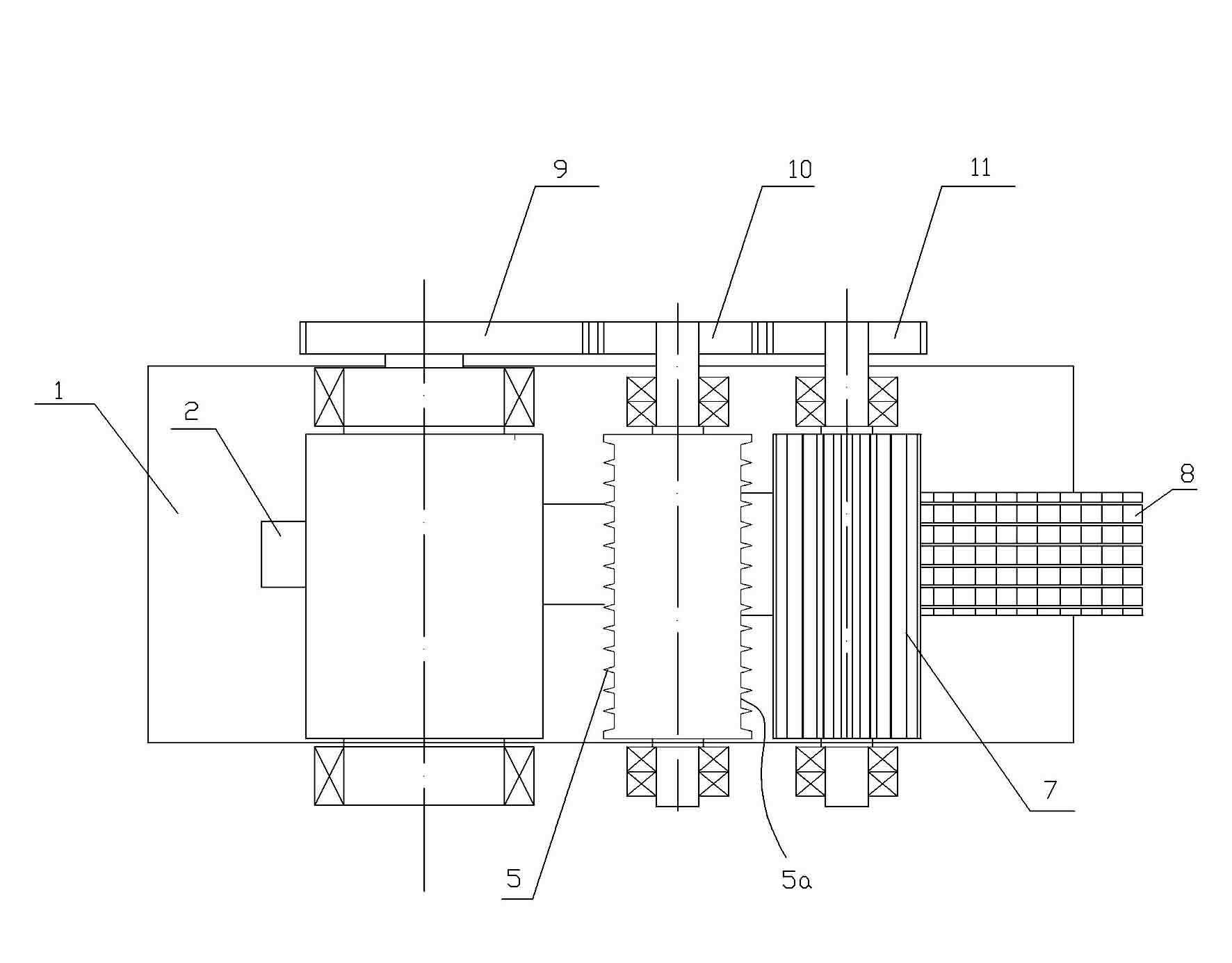

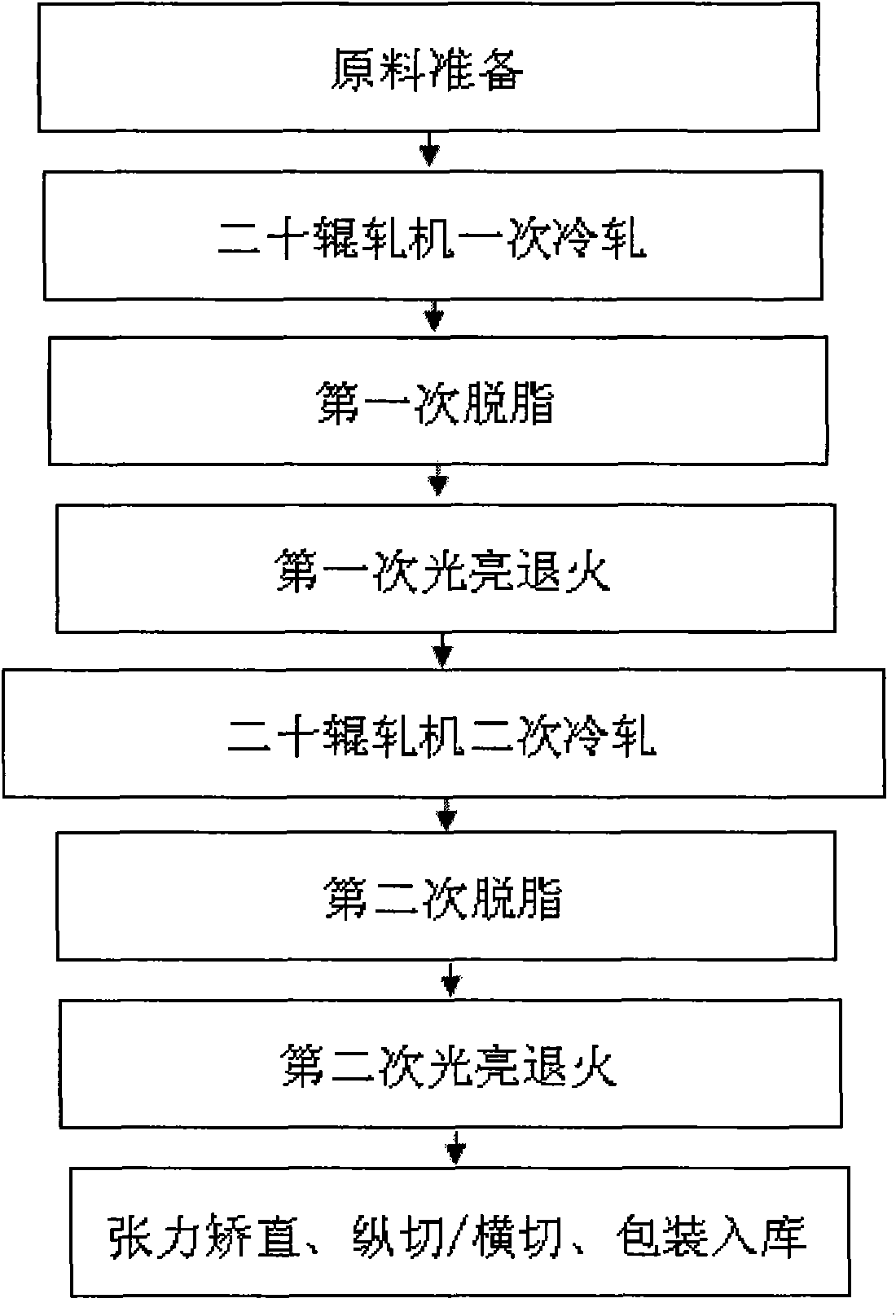

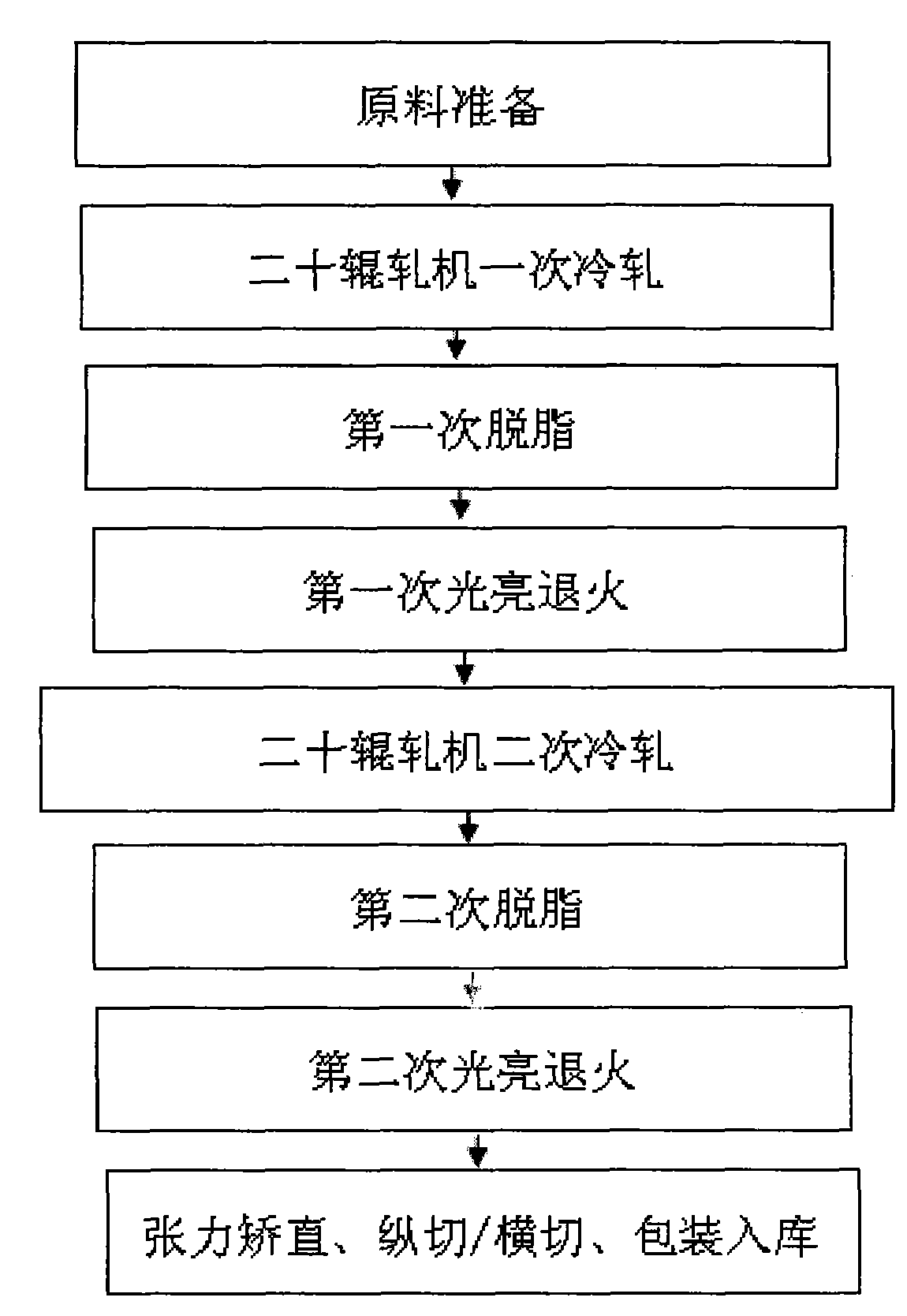

Precision forming method of ultrathin stainless steel substrate for flexible product, obtained substrate and application thereof

ActiveCN101817017AImprove performanceSimple production methodSolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessSolar cell

The invention discloses a precision forming method of an ultrathin stainless steel substrate for a flexible product, an obtained substrate and an application thereof. The method comprises the following steps: taking a cold-rolled 2B-surface AISI300 series stainless steel band with the thickness of 0.8-1mm as a raw material, twenty-high rolling, debinding, bright annealing, secondary cold-rolling by a twenty-high roll mill, debinding, bright annealing, tension straightening, length cutting / cross cutting, inspecting, packaging and the like. The ultrathin stainless steel substrate has the grain size of 5-6 grades, uniform internal stress distribution, the thickness deviation of + / -0.002, the thickness of 0.03-0.2mm, surface roughness of Ra20nm-Ra500nm, surface evenness of 1-2I-Unit, and the yield strength of less than 200MPa. The ultrathin stainless steel substrate is applied to a flexible solar cell and a flexible display product. The invention has simple and feasible production method, low cost, high product quality and high production efficiency.

Owner:江苏呈飞新材料科技有限公司

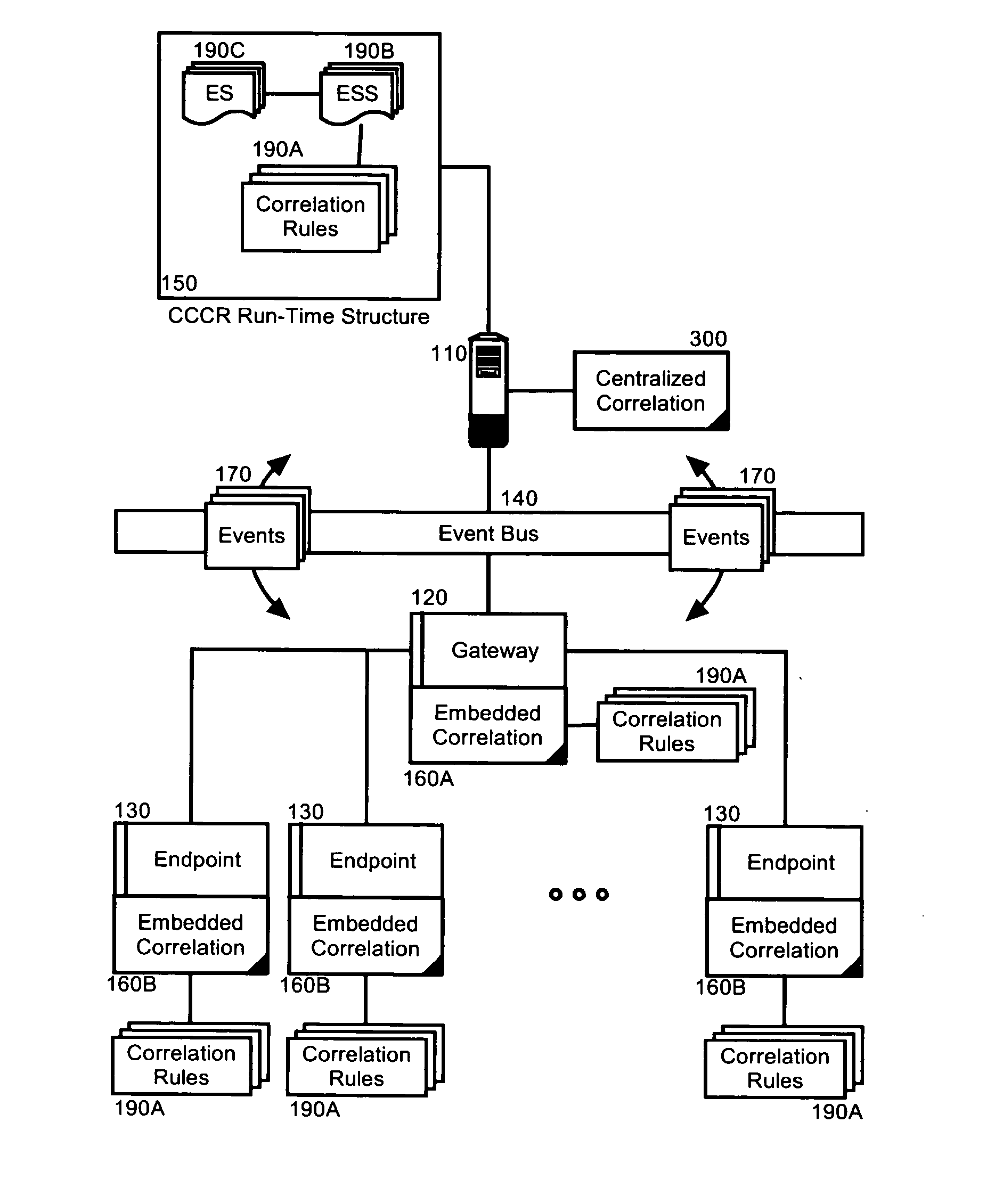

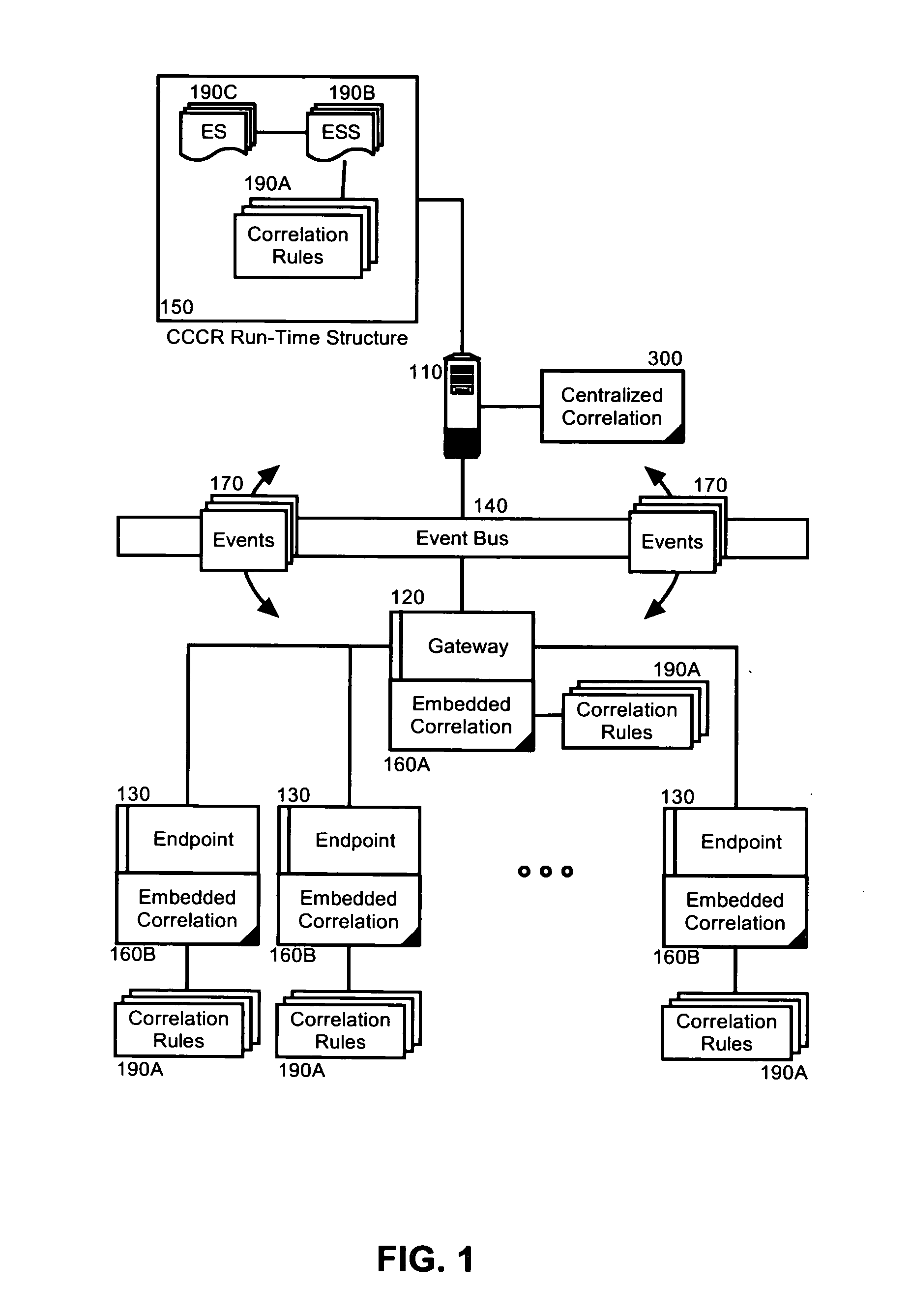

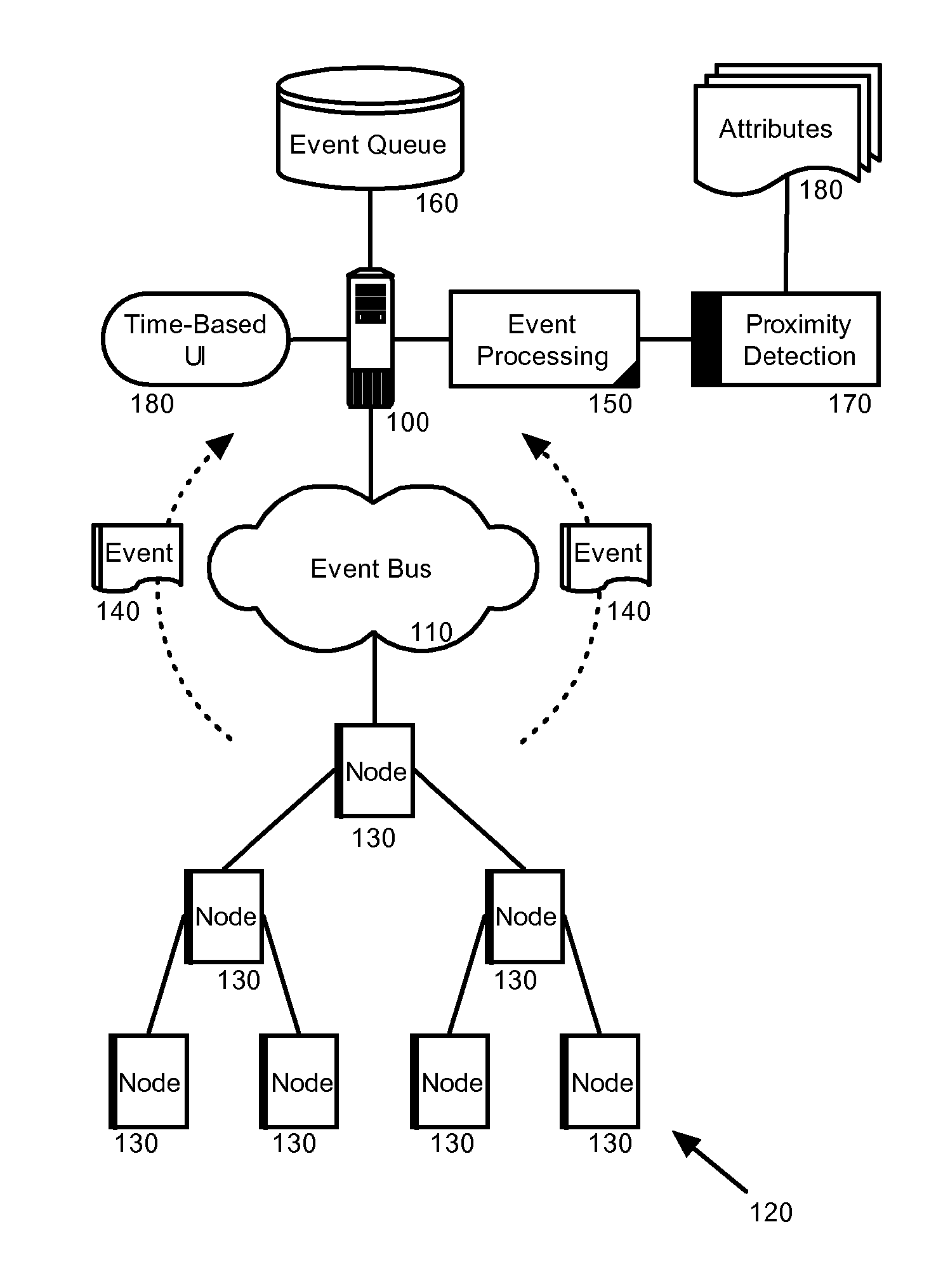

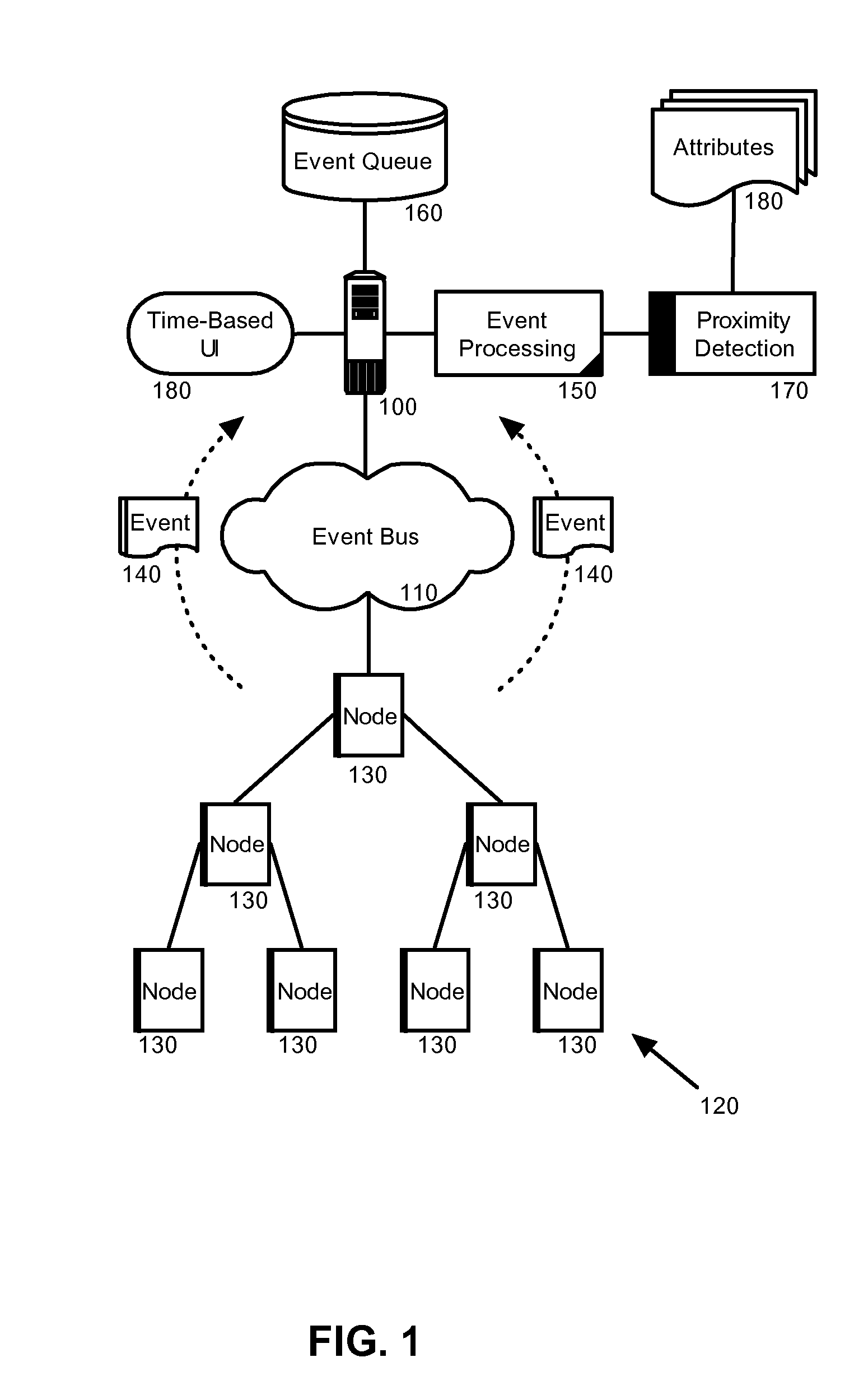

Cross-cutting event correlation

ActiveUS20070233836A1Digital data information retrievalError detection/correctionCross cutEnterprise computing

Embodiments of the present invention provide a method, system and computer program product for cross-cutting event correlation in an enterprise computing monitoring and management system. An enterprise computing monitoring and management system can include a hierarchy of nodes, where several of the nodes are each coupled to a corresponding embedded correlation engine and an event bus. The system further can include a root node among the nodes. The root node can be coupled to the event bus and to centralized correlation logic programmed to identify a high correspondence between events from a particular event source among the nodes and a particular set of correlation rules in that correlation engine. The identification of such correspondence can be used to move to the set of correlation rules to an embedded correlation engine closer to the particular event source.

Owner:IBM CORP

Banana cauloid returning method and device

The invention provides a banana pseudostem-soil returning method and the device thereof. After bananas are harvested, the banana pseudostems are pushed down in situ by the machine head of the tractor during the running, hooked up from the ground by a row of Y-shaped movable blades which perform a high speed cutting tangential motion against the ground, and loaded into a crushing chamber, the banana pseudostem is crushed through the cross cutting of the cooperation of the Y-shaped movable blades running at a high speed and the fixed blades in the crushing chamber, the broken slag is evenly laid down on the field through the back flow plate, and after the broken slag is fully dried, the broken slag is buried under the soil through plowing, to be returned back to the soil as green manure. The device comprises a casing body, a front flexible protective cover, a rear protective plate, a main axle, fixed blades and movable blades, the front flexible protective cover is arranged at the front side of the casing body, the rear protective plate is installed at the rear side of the casing body, fixed blades are installed on the inner wall of the casing body of the crushing chamber, and a plurality of rows of Y-shaped movable blades are arranged in the circumference direction of the cylindrical surface of the main axle. The pseudostem processing method ensures that the banana pseudostems to be returned back to the field as the green manure to fertilize the soil, and the manure source of banana pseudostem is fully utilized.

Owner:广东省农业机械研究所

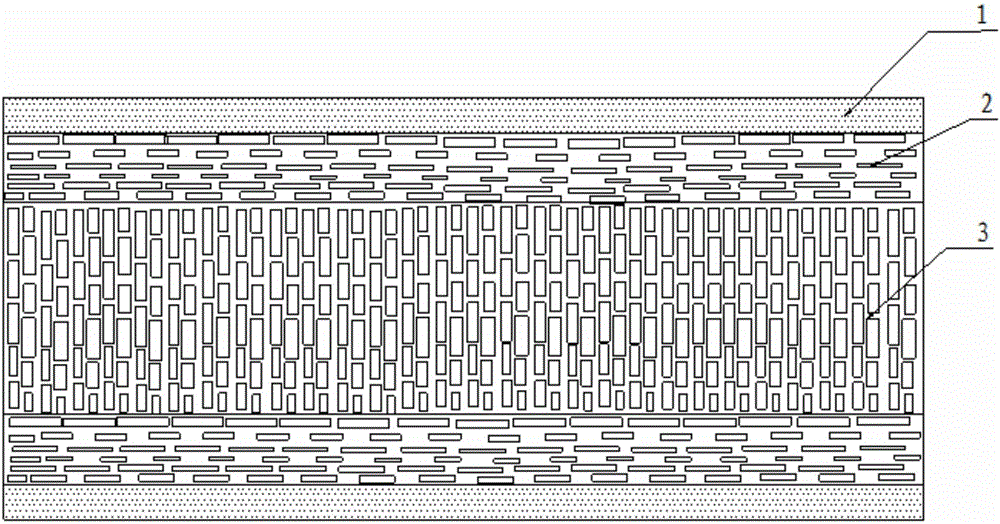

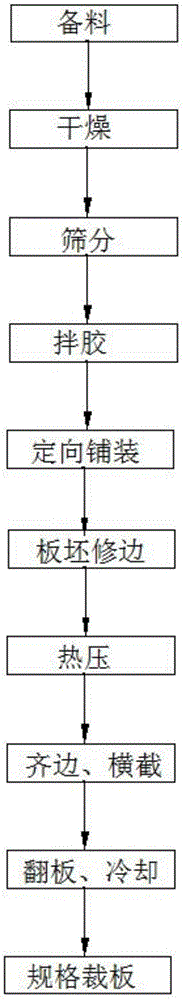

Preparation method for novel low-density, low-cost and high-strength shaving board

The invention relates to a preparation method for a novel low-density, low-cost and high-strength shaving board which comprises a surface layer, a shaving layer and a core layer. The preparation method comprises the following specific steps: (1) carrying out material preparation; (2) carrying out drying, specifically, drying wet shavings obtained in the step (1) until the water content of the shavings reaches 2-4% through condensed hot water at 95-98 DEG C; (3) carrying out sieving, specifically, sieving the shavings dried in the step (2) into surface shavings, core shavings and fine shavings; (4) carrying out glue mixing; (5) carrying out directional pavement; and (6) sequentially carrying out plate blank trimming, hot-pressing, edging and cross cutting, plate turning and cooling, and on-specification plate cutting to obtain the shaving board meeting requirements. According to the preparation method disclosed by the invention, Tongda electric power generating condensed water (at about 95 DEG C) is directly used as drying heat energy, a boiler has no need to be used, the utilization rate of the heat energy is increased by 30%, the drying heat energy cost of the plate is greatly lowered, a fire risk during the drying process is prevented, an industrial model of circular economy is achieved, low-carbon and environment-friendly production is realized, and the economic mode can adapt to the new normal of economic development actively.

Owner:聊城德晟木业有限公司

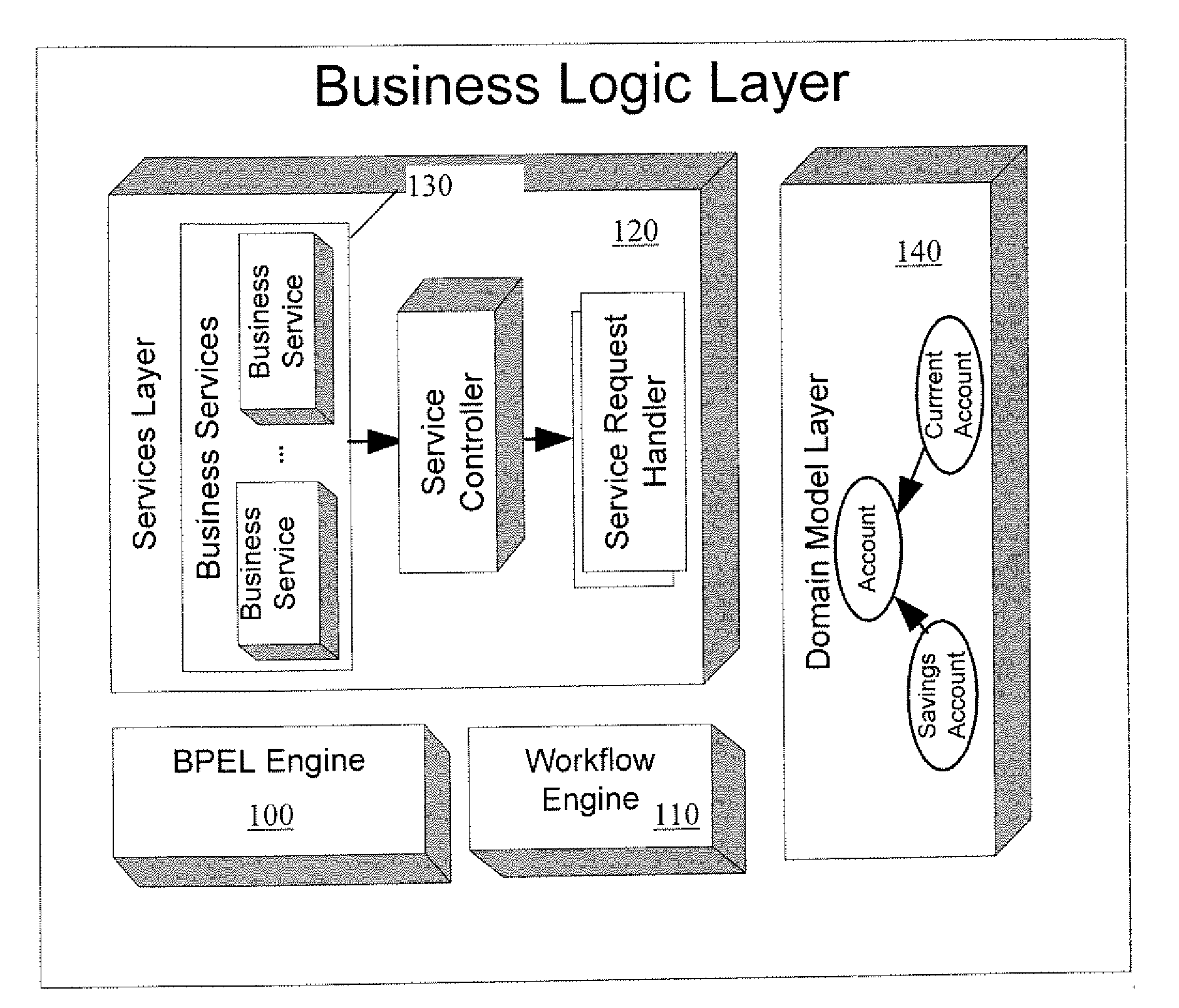

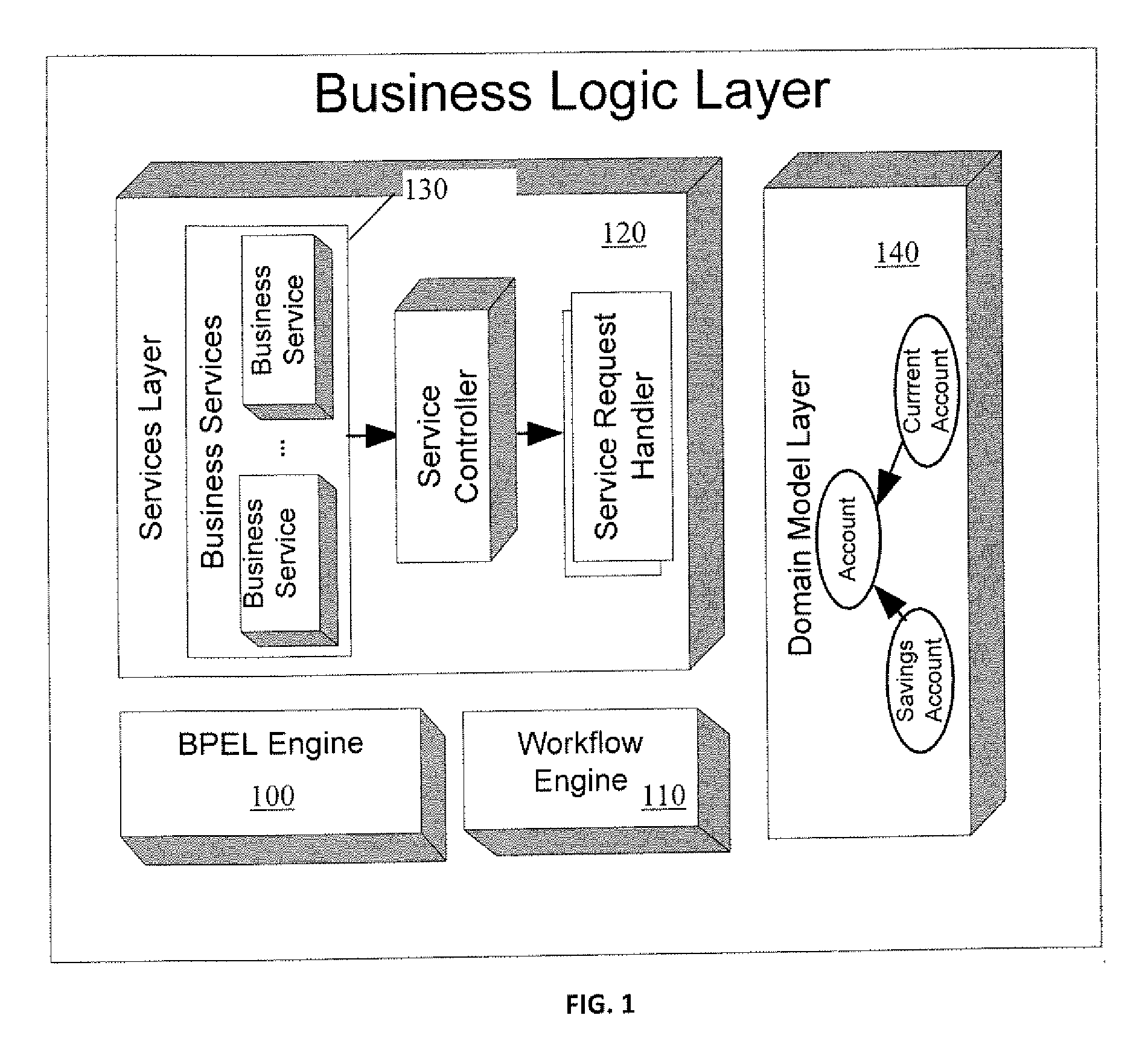

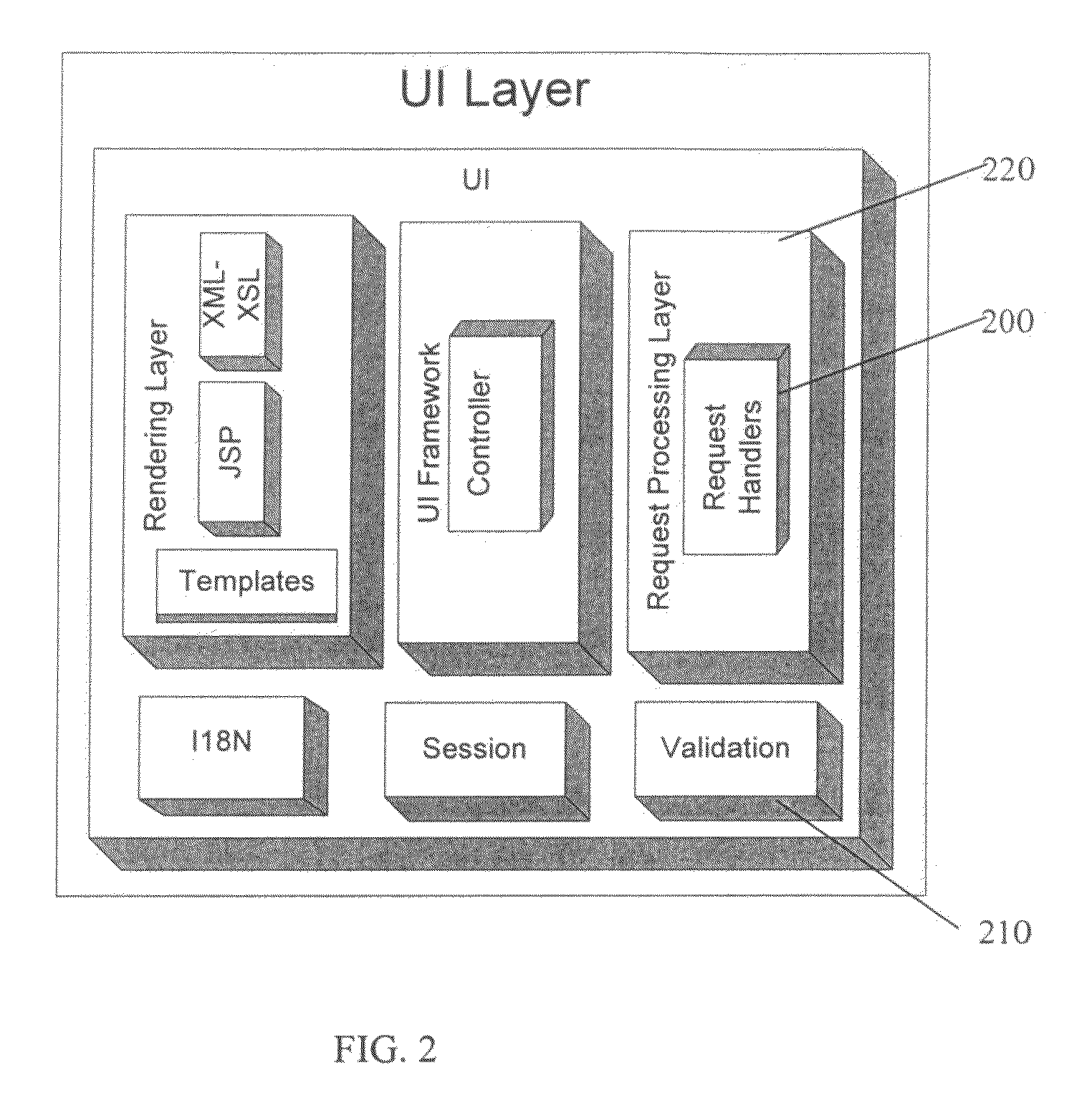

Method for handling cross-cutting concerns at business level

InactiveUS20090313599A1Data processing applicationsRequirement analysisCross-cutting concernCross cut

A method for handling cross-cutting concerns at business level while developing enterprise application is disclosed. The method identifies the common variation requirements for the common cross cutting business concerns. The method then identifies the architecture strategies to enable identified variations and based on those strategies define an architecture with well defined variation points and finally define mechanisms for bundling such variations. The proposed solution describes how business aspects can be developed for applying cross cutting business concerns using the Infosys RADIEN Framework.

Owner:INFOSYS LTD

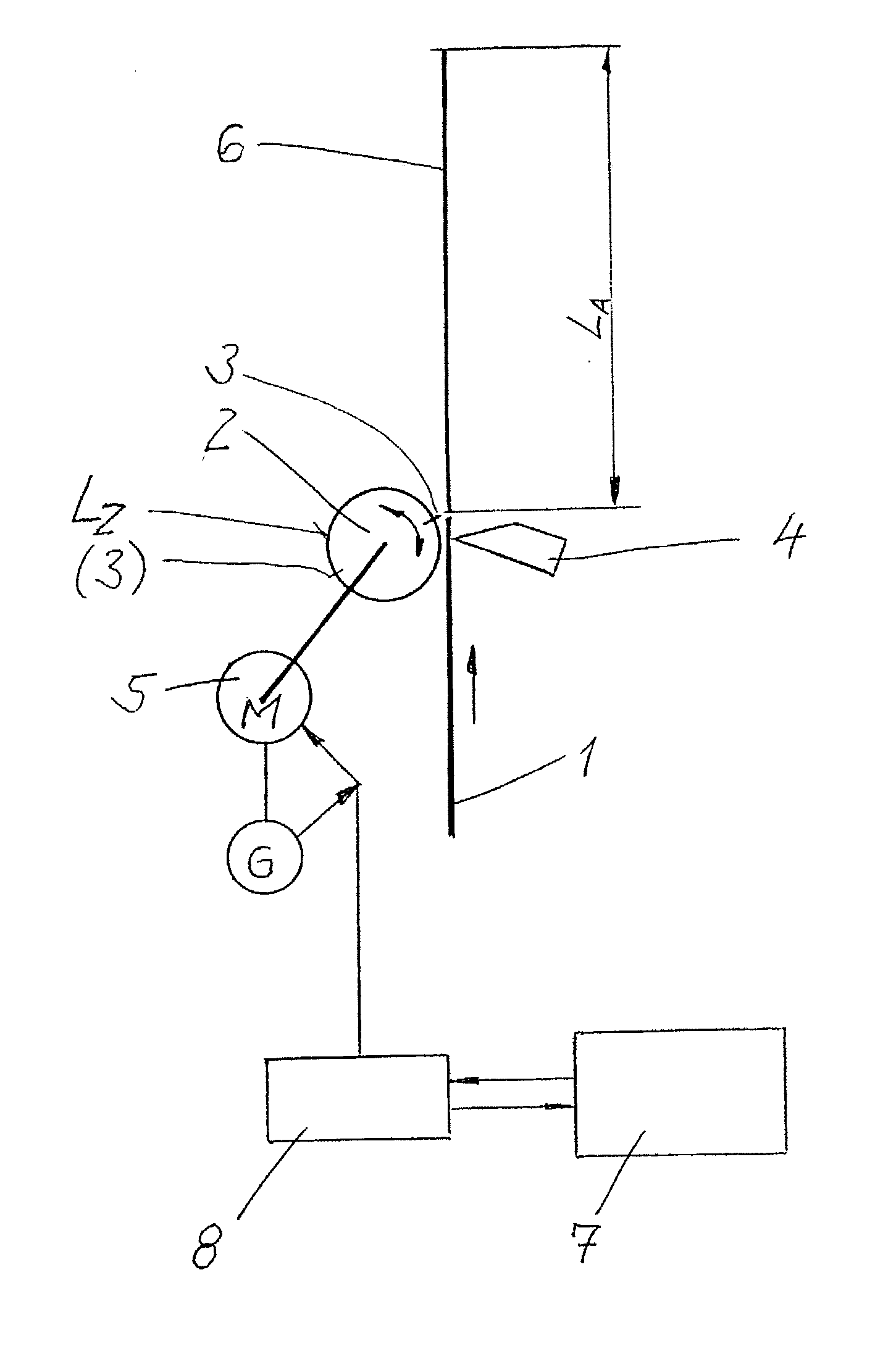

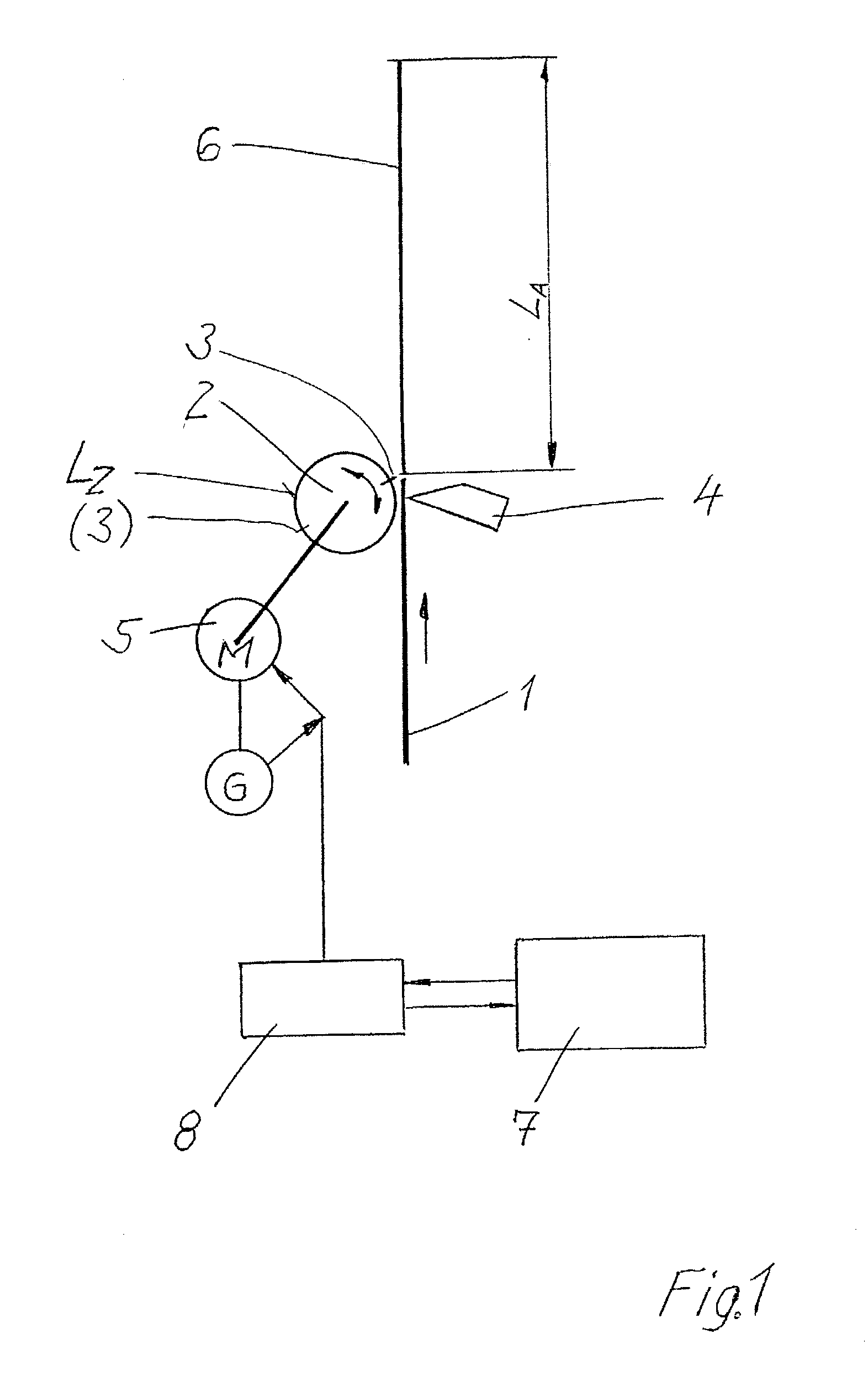

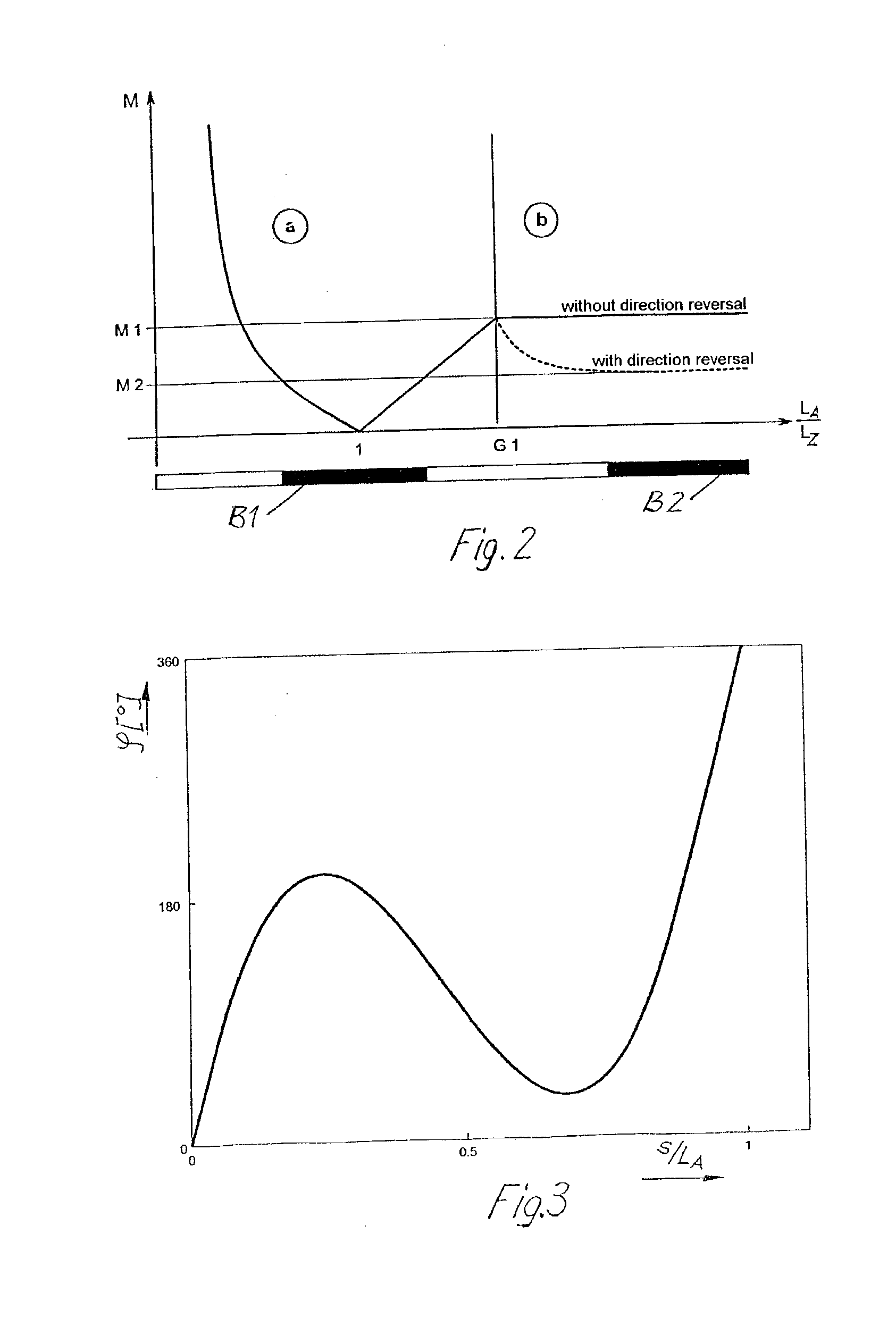

Method of crosscutting a moving web

A method of cross-cutting a moving web uses a cutting knife operably mounted on a knife cylinder having a circumferential distance LZ where LZ is smaller than a cut length, LA. The knife cylinder for revolving in a first and a second opposite direction is powered by a drive motor in either direction. The method includes revolving the knife cylinder in a first direction, cutting the web with the cutting knife, and completing a first cut. The knife cylinder is then reversed to retard progress in the first direction and then accelerated to the speed of the moving web until starting the second cut.

Owner:MANROLANAD AG

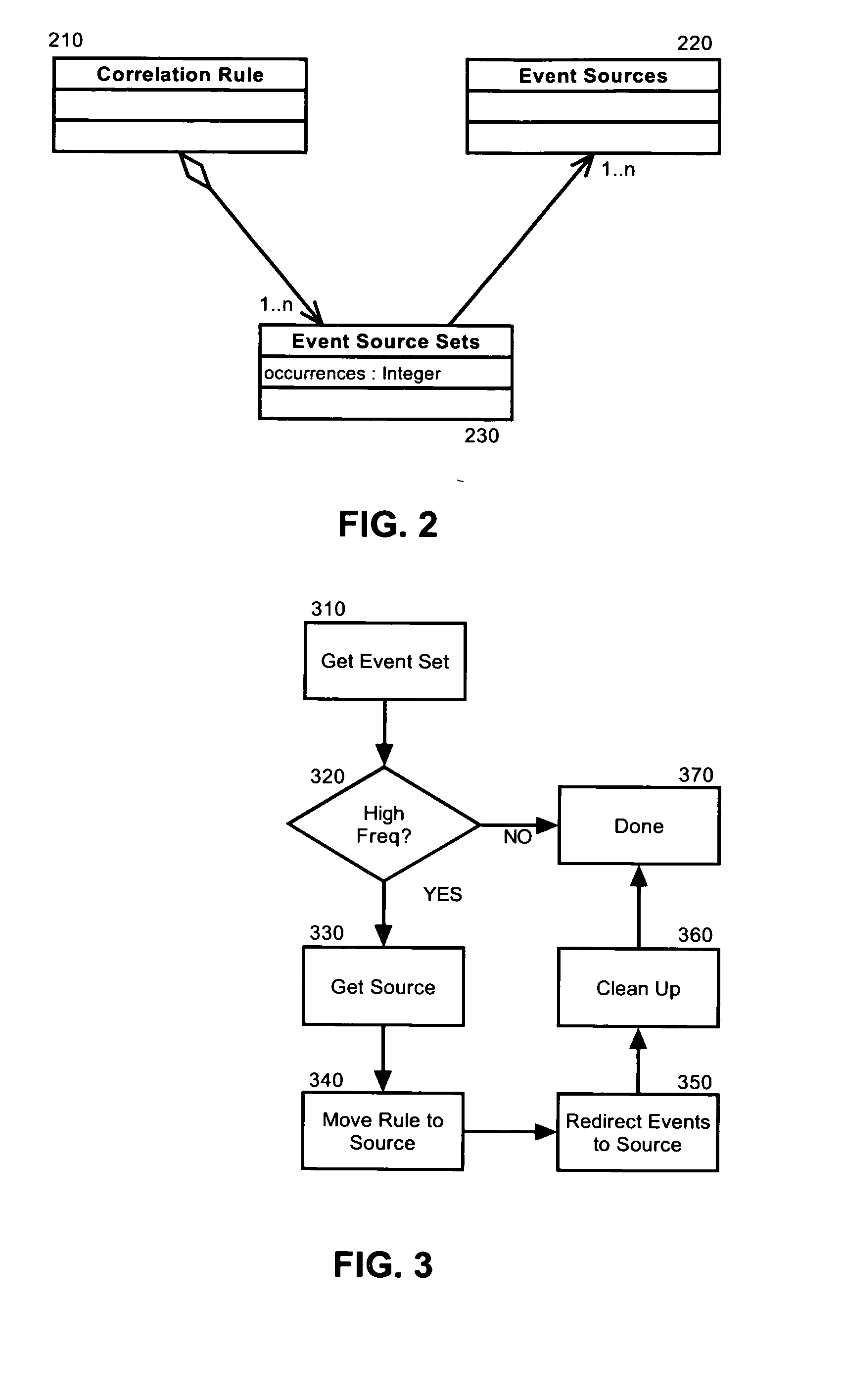

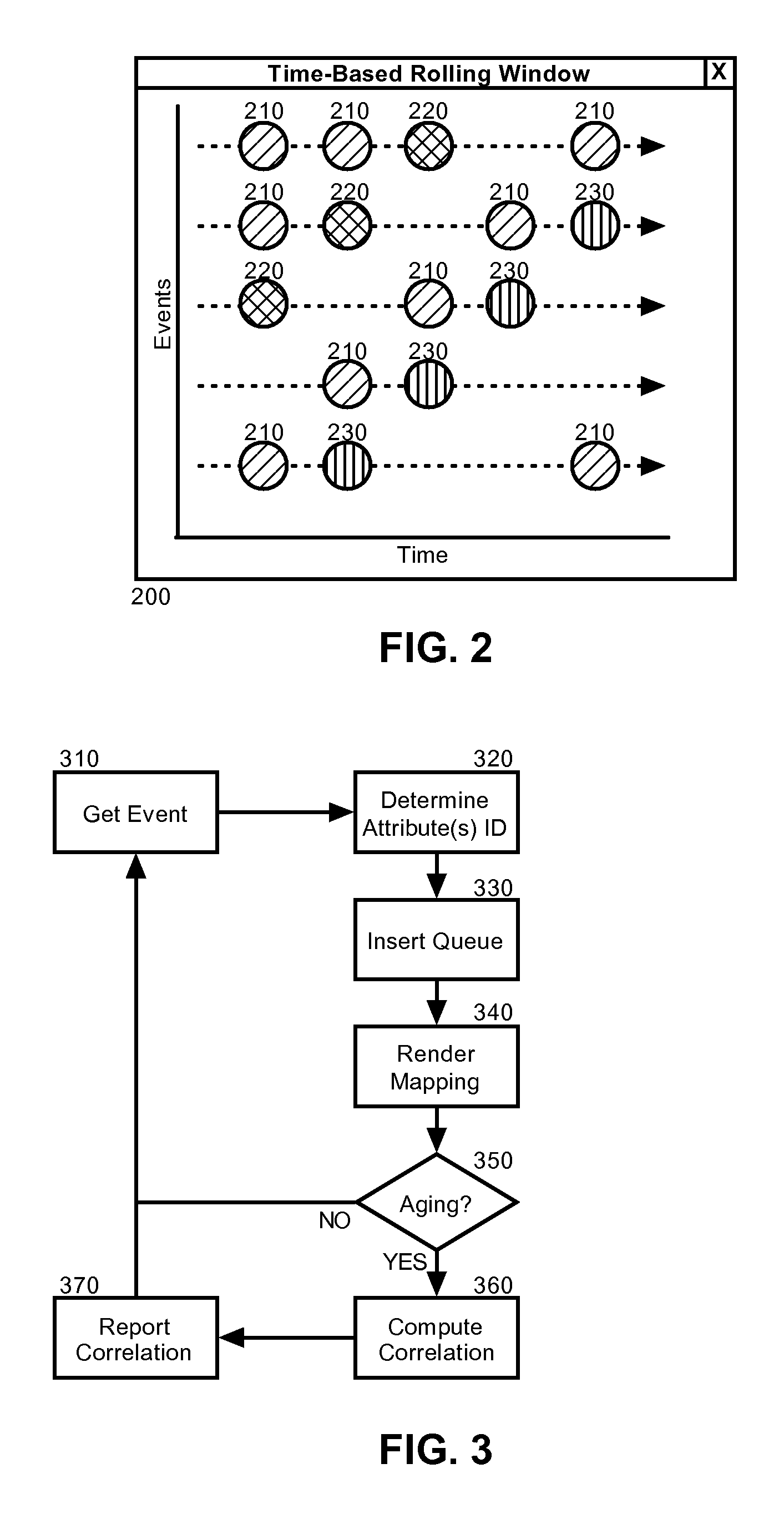

Cross-cutting detection of event patterns

InactiveUS20070266142A1Digital computer detailsNon-redundant fault processingCross cutEnterprise computing

Embodiments of the present invention provide a method, system and computer program product for the detection of correlation rules in an enterprise computing monitoring and management system. In one embodiment of the invention, a method for detection of correlation rules can be provided. The method can include receiving events from multiple event sources, classifying the events according to a set of event attributes, determining a temporal proximity of occurrence of different classified events, further determining a frequency of occurrence of temporal proximity for particular classified events, and reporting a causal relationship between the particular classified events when the frequency of occurrence exceeds a threshold value.

Owner:IBM CORP

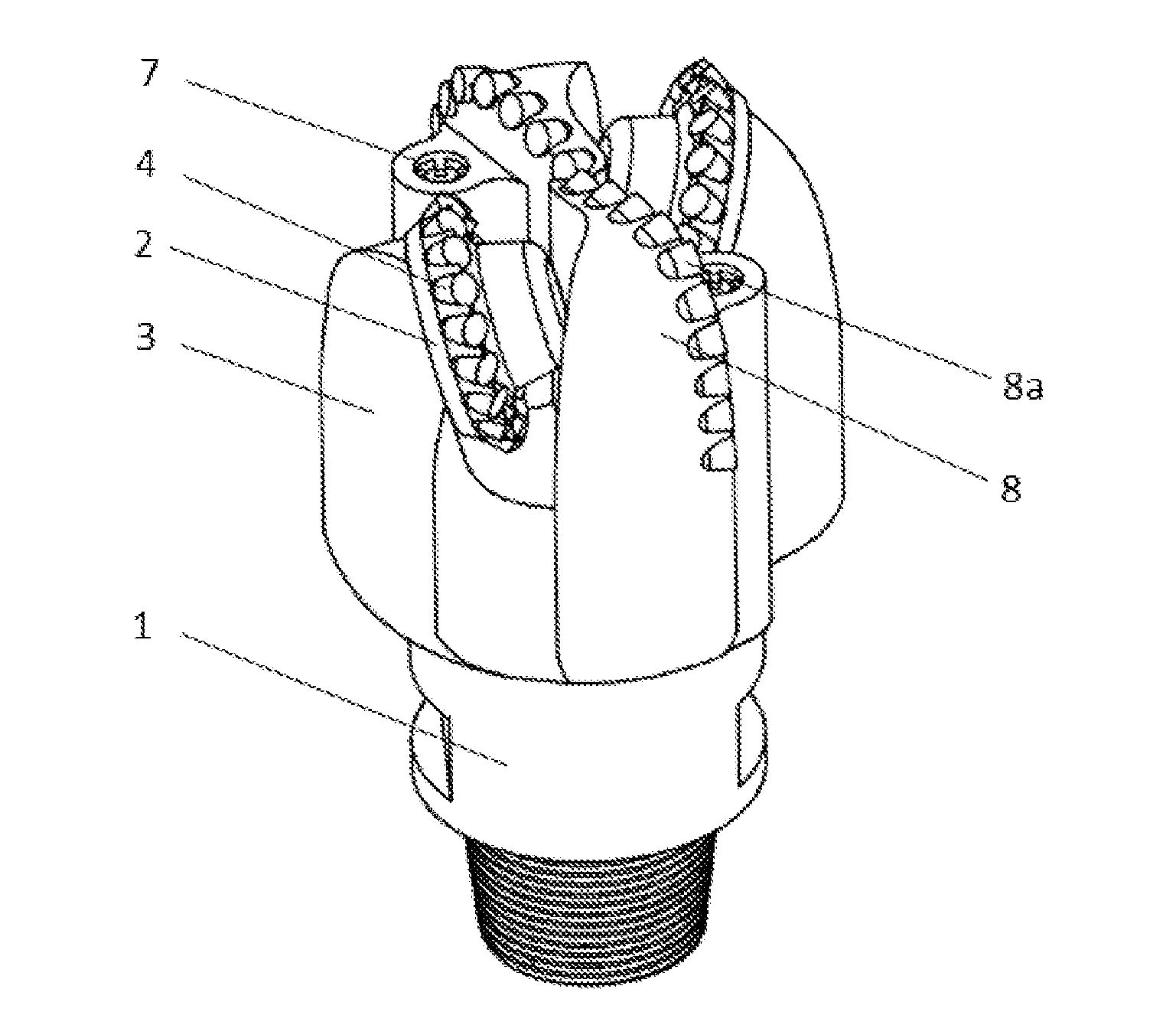

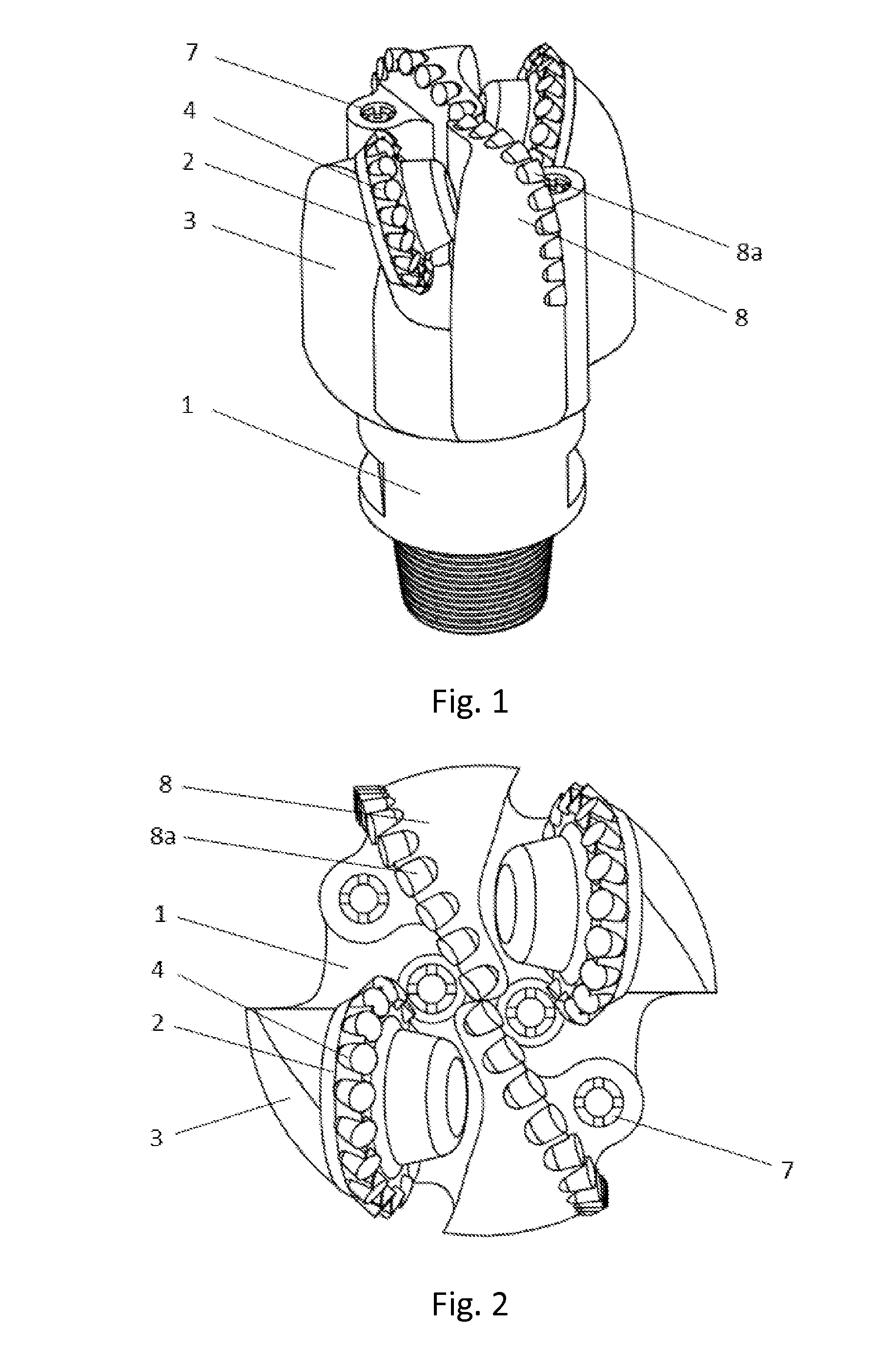

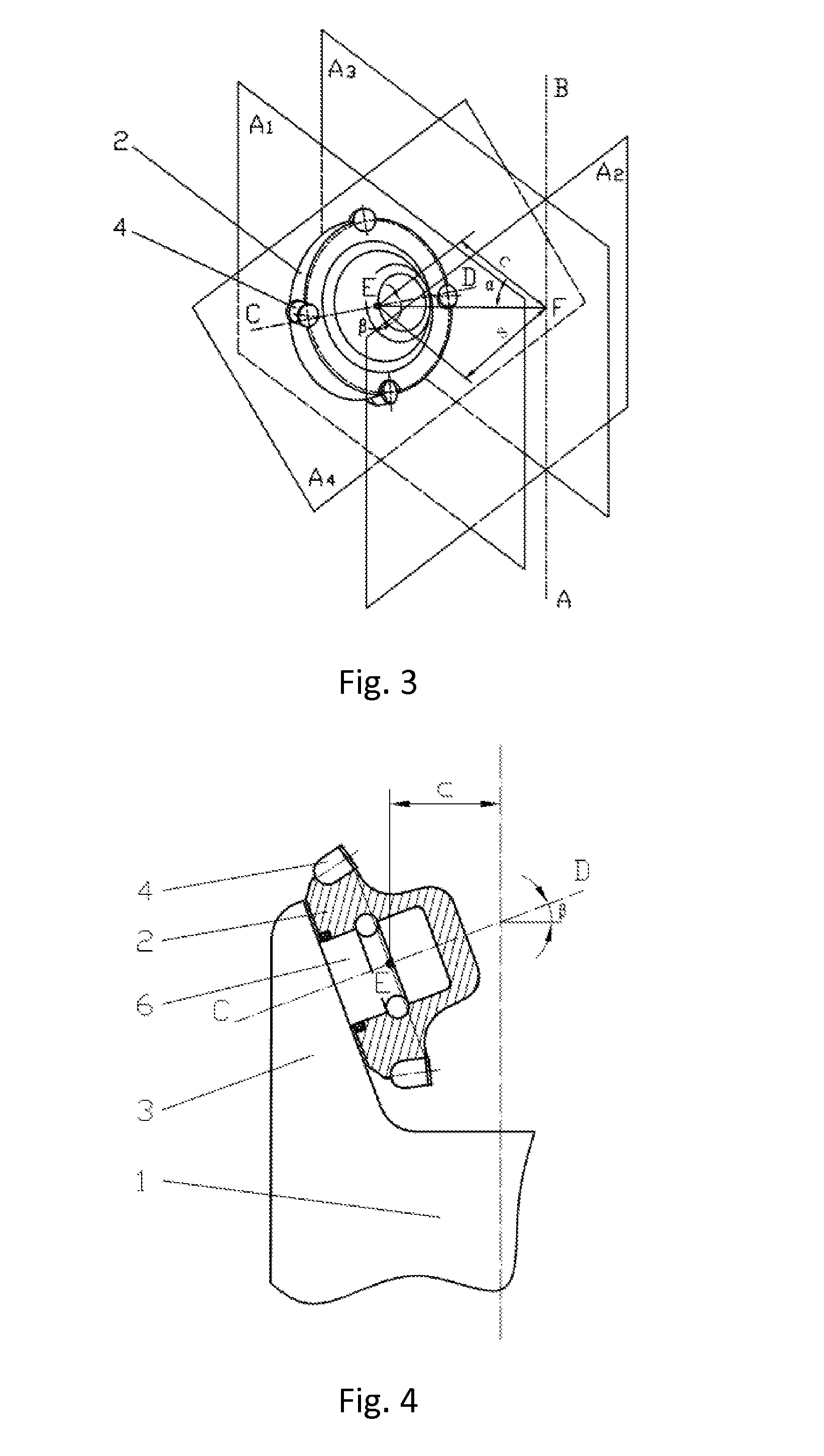

Composite drill bit

A composite drill bit with a bit body configured at its upper extend for connection into a drillstring, comprising: a bit body (1) with at least one bit leg (3), at least one scraping-wheel (2) set with a cutter-row (4), and a set of cutters fixed thereon. The scraping-wheel (2) is mounted for rotation on the corresponding bit leg (3) with a large angular deflection α in the range of 20°≦|α|≦90°. The cutters on the scraping-wheel break rock by means of successive scraping, forming a cross-cutting area on the bottomhole accompanied by the cutters on the fixed cutting unit, thus achieving high rock-breaking efficiency, even wear, high cooling performance, and a longer service life for the cutters, bearings and the drill bit.

Owner:SOUTHWEST PETROLEUM UNIV

Variable folder

In order to provide a variable folder which allows smearing-free operation, the cutting blade of an upstream cross-cutting arrangement is provided with recesses, which leave behind residual crosspieces in the strand which is to be cut, and arranged in the product-directing region, between the cross-cutting arrangement and a collecting cylinder, are accelerating and tearing-off cams which grip the incoming product and tear it off from the strand at the residual crosspieces.

Owner:MANROLANAD AG

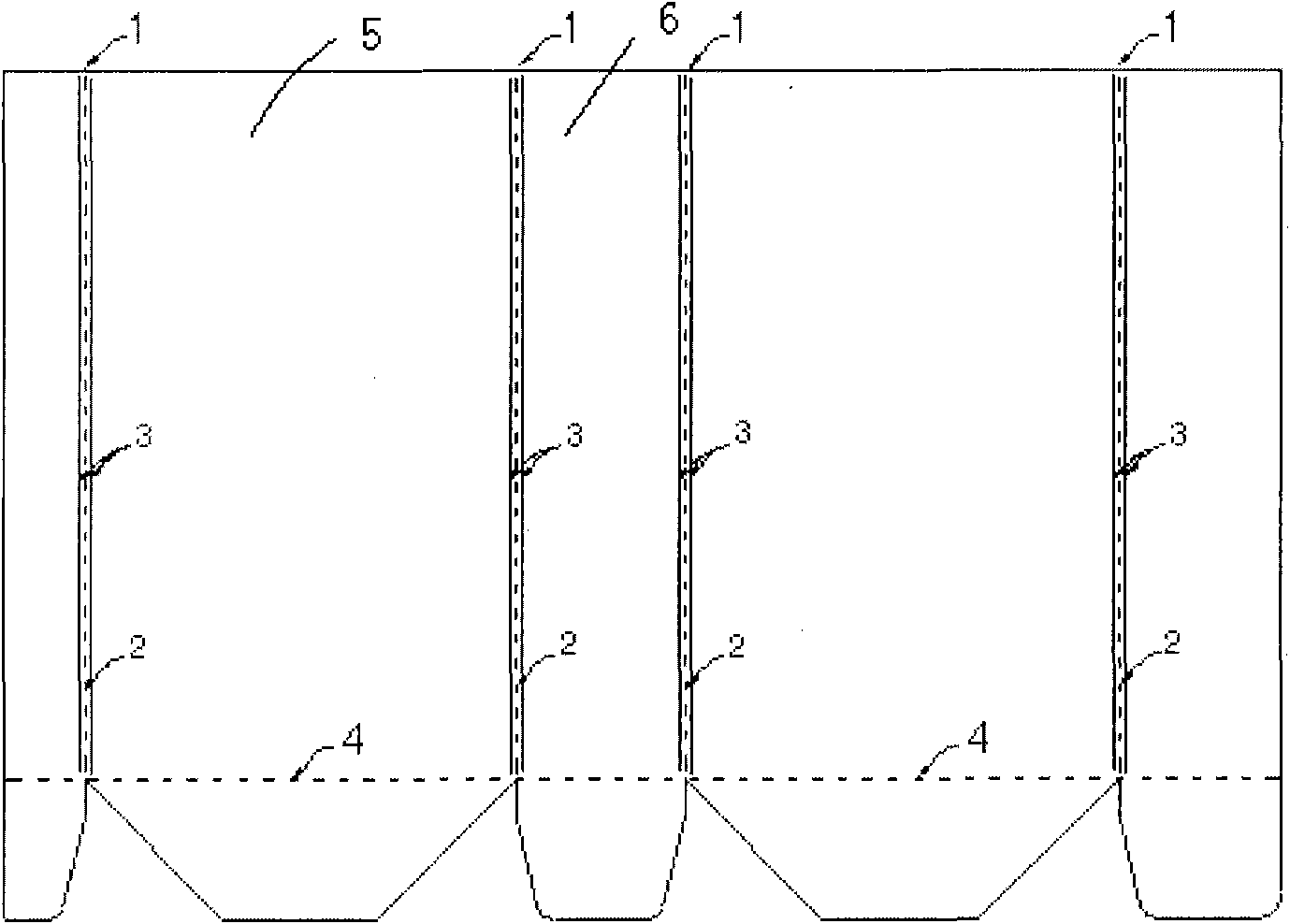

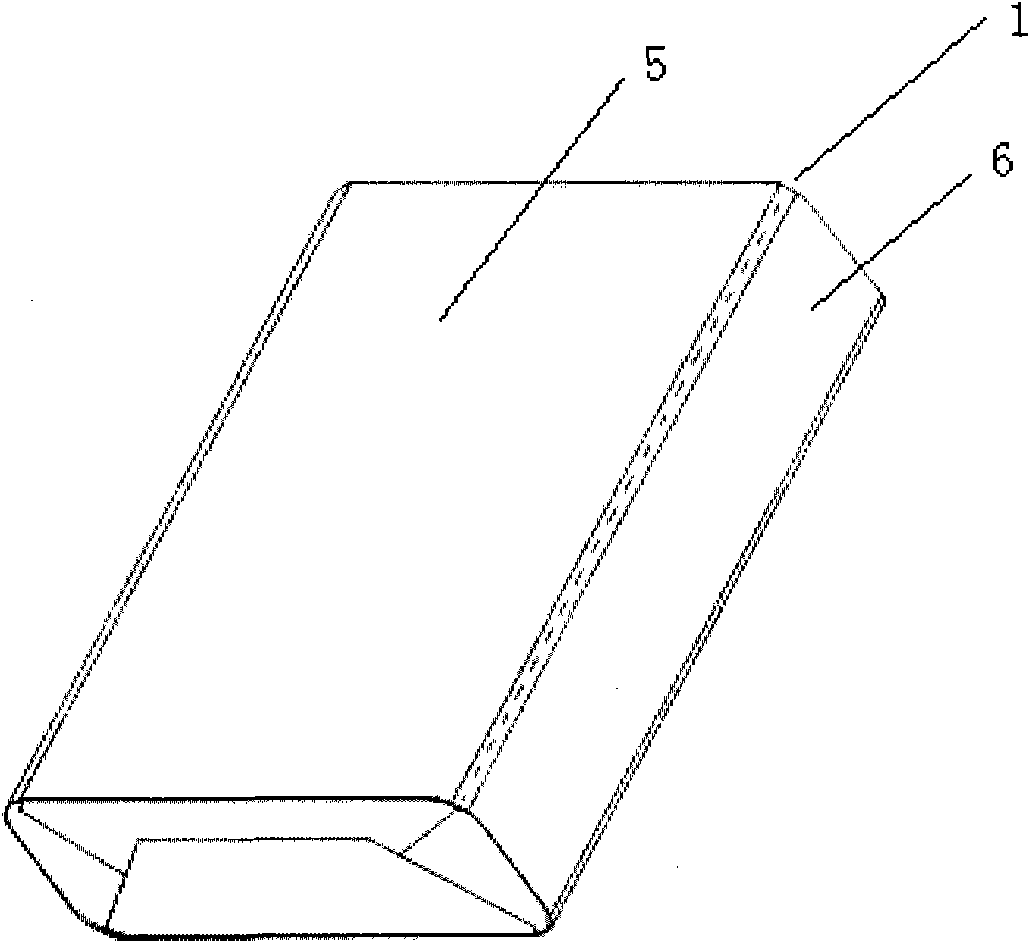

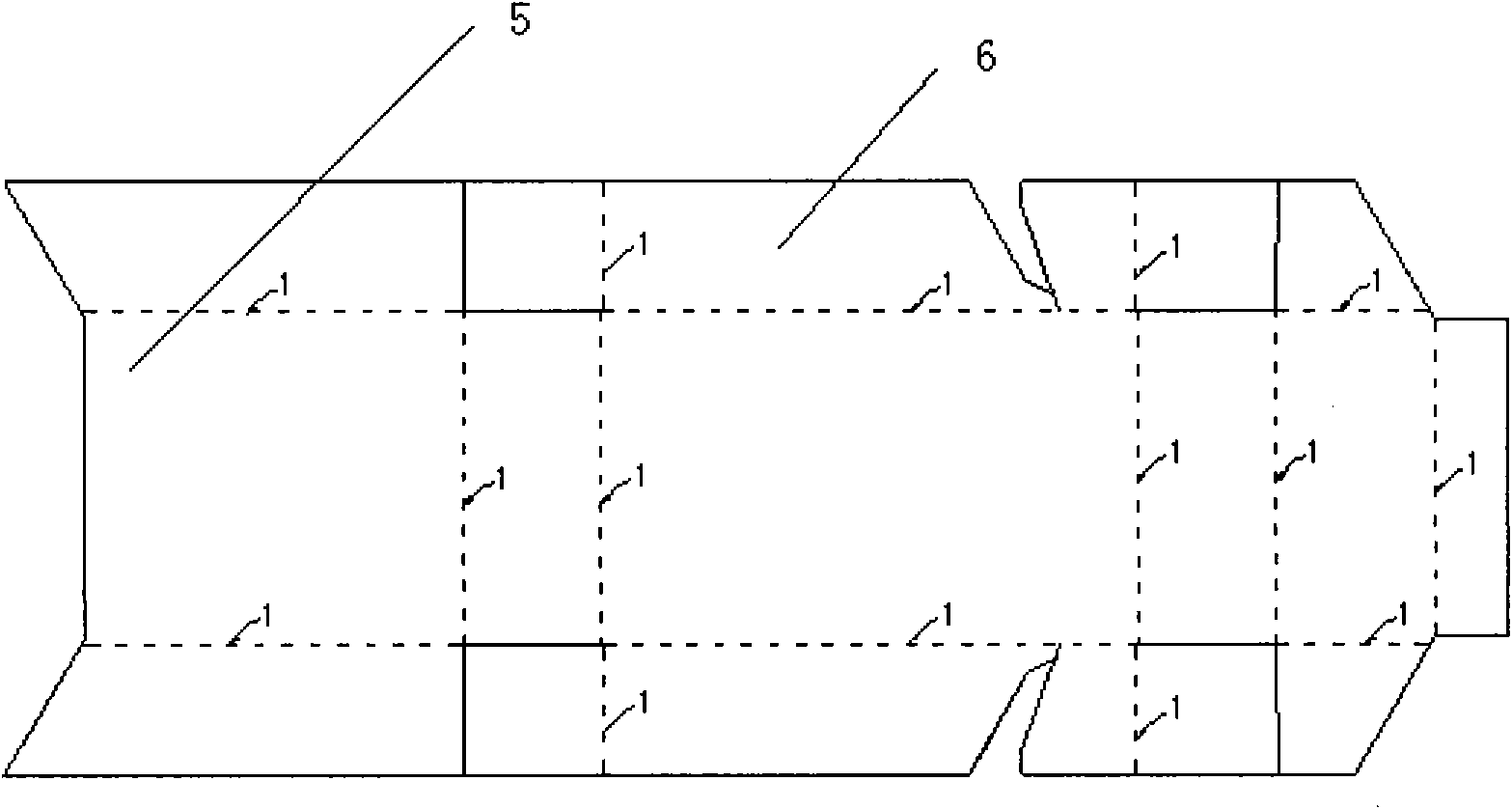

Parchment paper cigarette packing box and manufacturing method thereof

ActiveCN101643131AIt is not easy to cause the problem of poor paper feedingSolid paperContainers for flexible articlesFlexible coversScreen printingTransfer volume

The invention provides a parchment paper cigarette packing box, which comprises two wide side walls parallel to each other, two narrow side walls parallel to each other and a lower end surface, wherein the wide side walls are vertical to the narrow side walls and the lower end surface; and the paper used by the packing box is parchment paper of which the gram weight is 90 to 250 grams / m<2>. The invention also provides a method for preparing the packing box, which comprises the following steps: (1) selecting the parchment paper of which the gram weight is 90 to 250 grams / <2>; (2) printing pictures and texts on the parchment paper by combining various printing modes of offset printing, screen printing, gold stamping and the like, wherein a bar code spare space is printed with UV gloss oil first and then is printed with a flexographic plate white ink of which the ink-transferring volume is between 10.0 and 11.0 BCM so that the thickness of an overprint ink layer is between 20 and 50 mums,and then the well-printed parchment paper is obtained; and (3) performing back cross cutting molding on the well-printed parchment paper in the step (2) to finally mold and obtain the cigarette packing box, wherein a crease line is a point penetration pressure cutting line and two edges of the crease line are half-penetration pressure cutting lines.

Owner:SHENZHEN JINJIA GRP

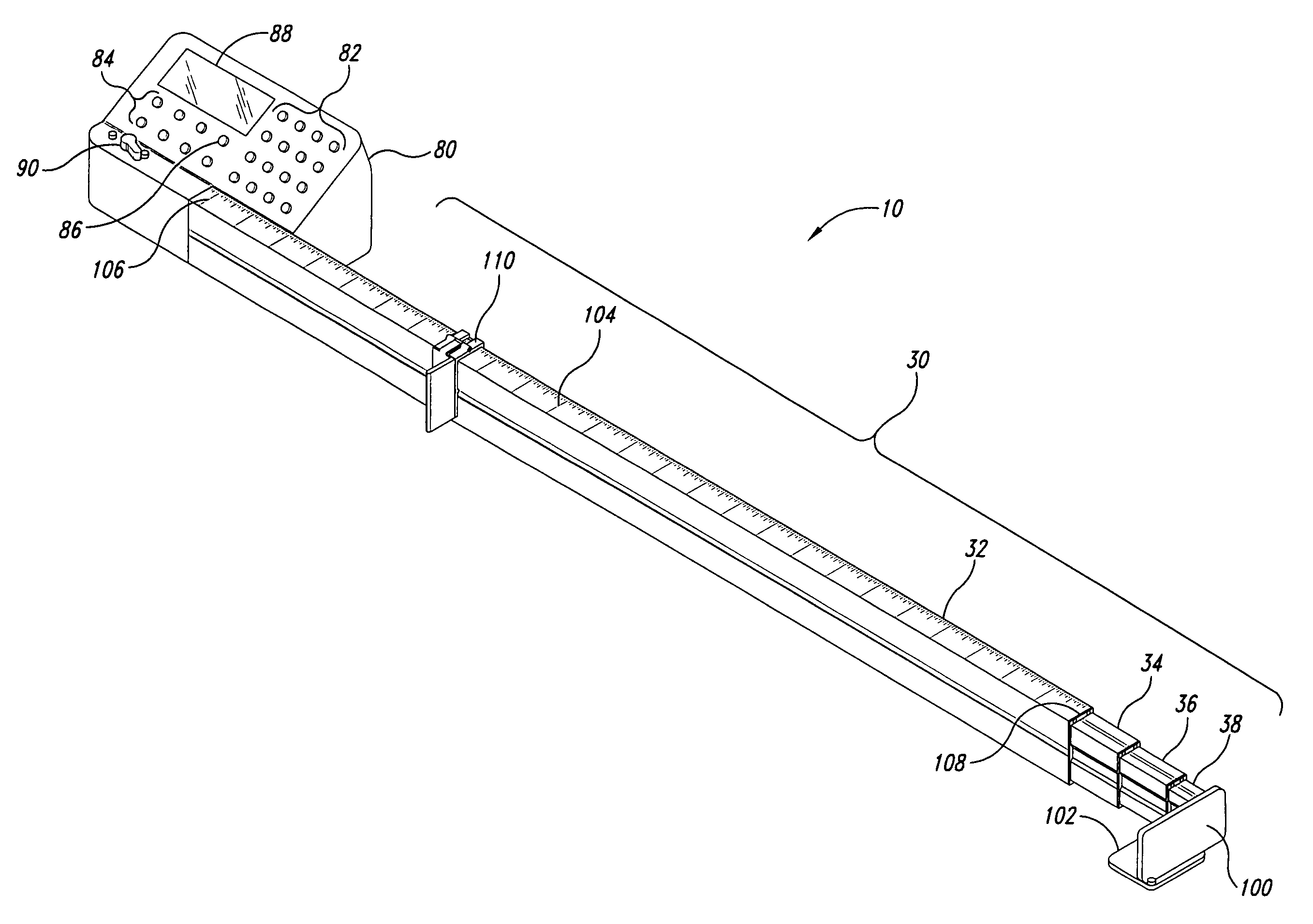

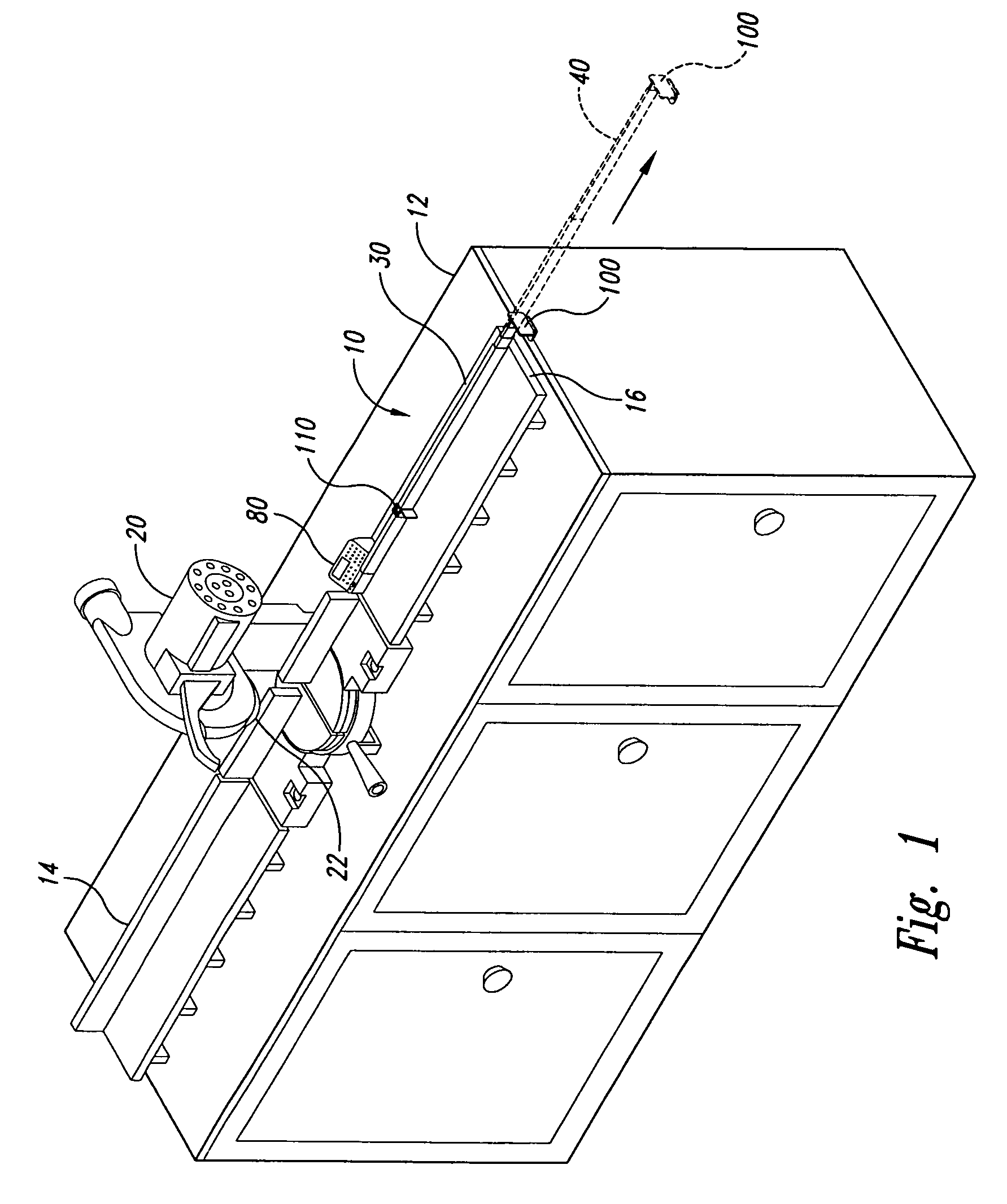

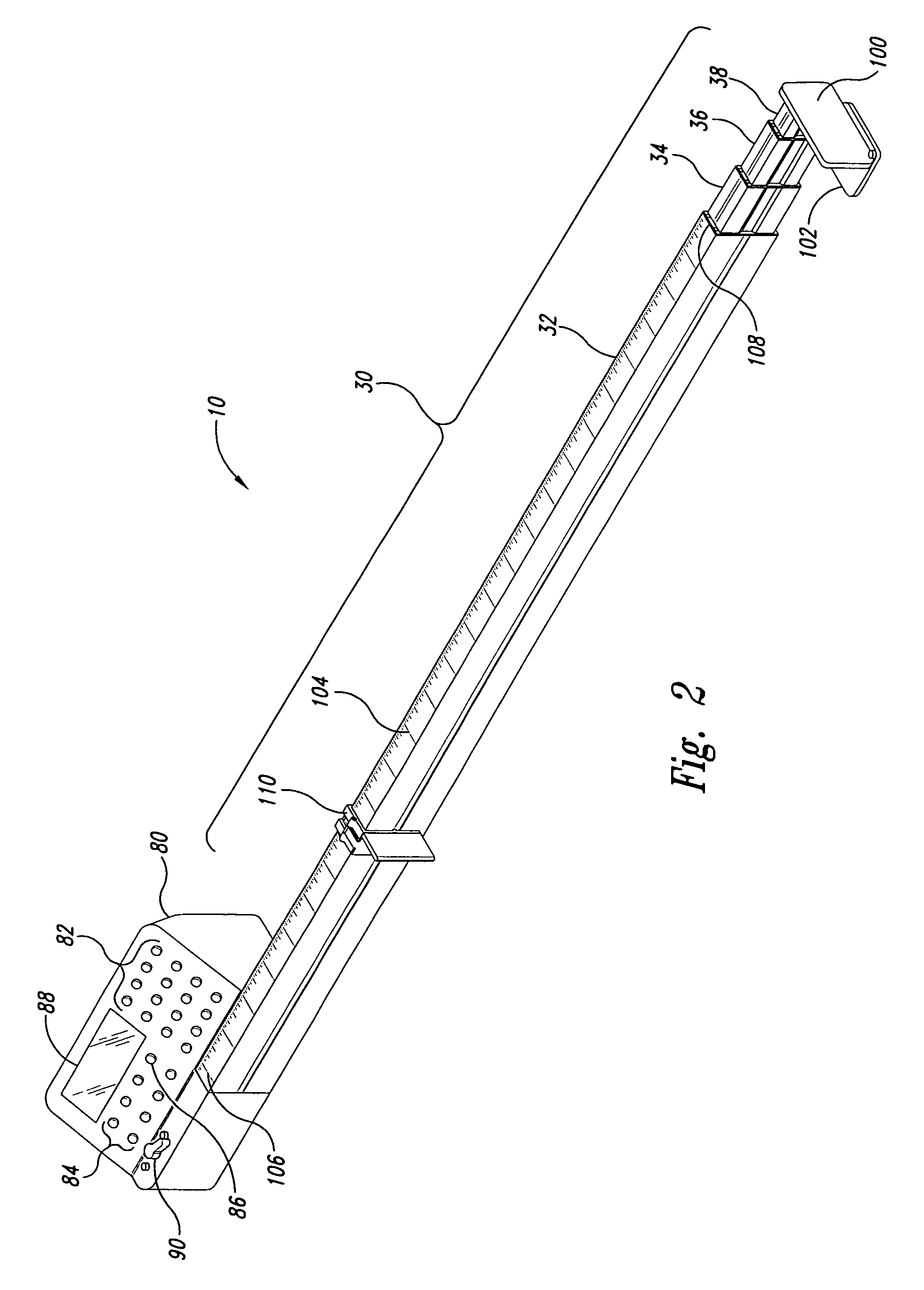

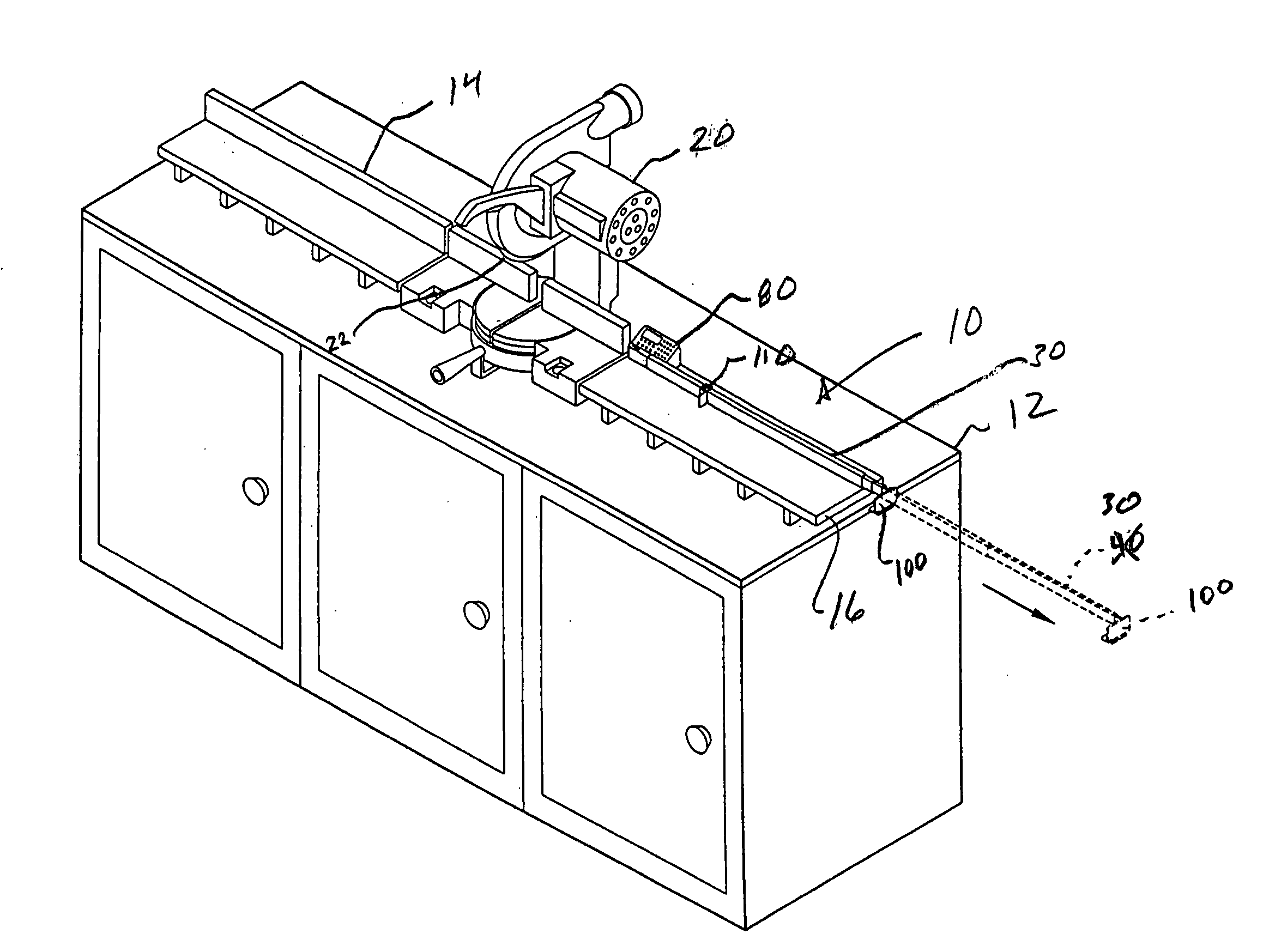

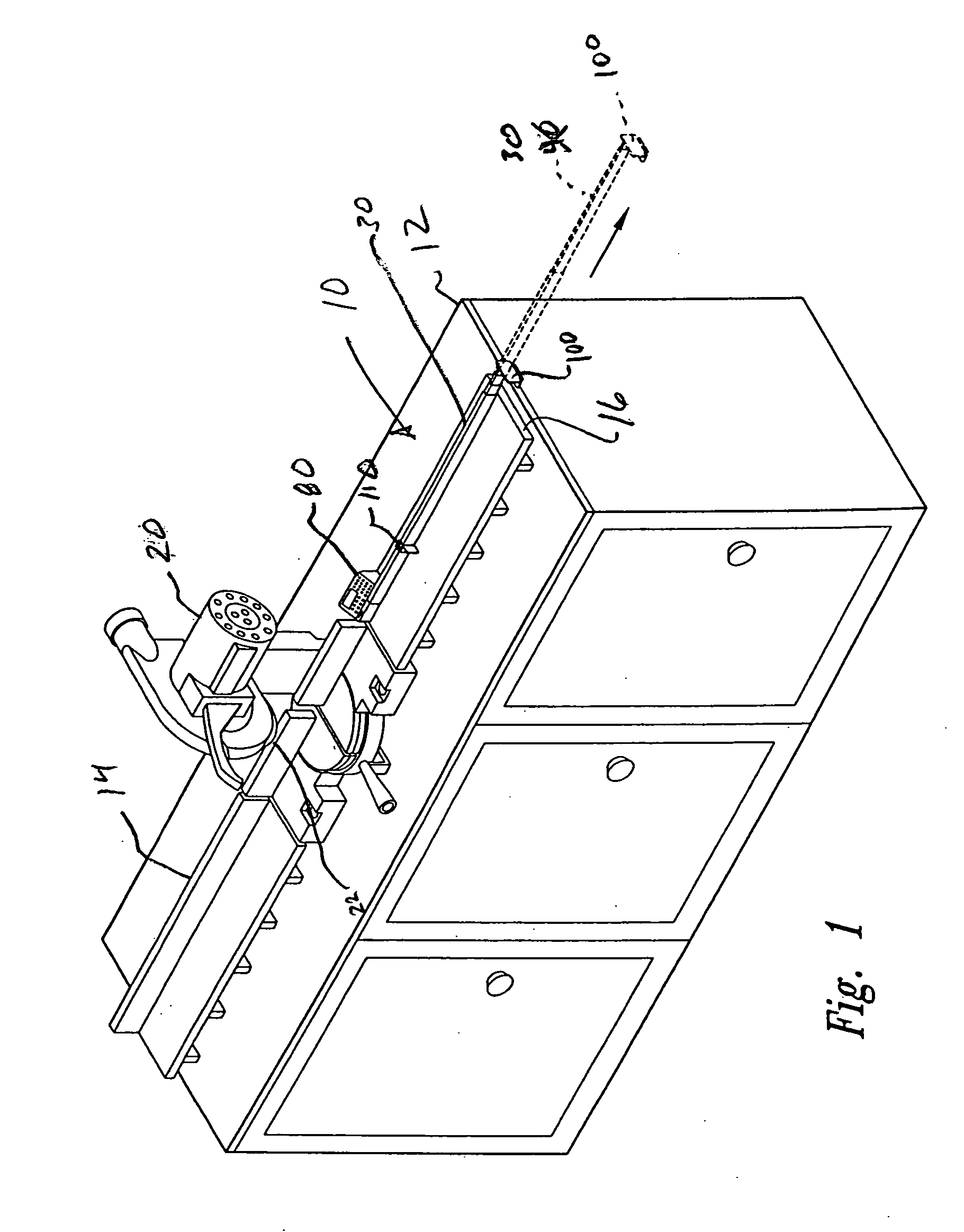

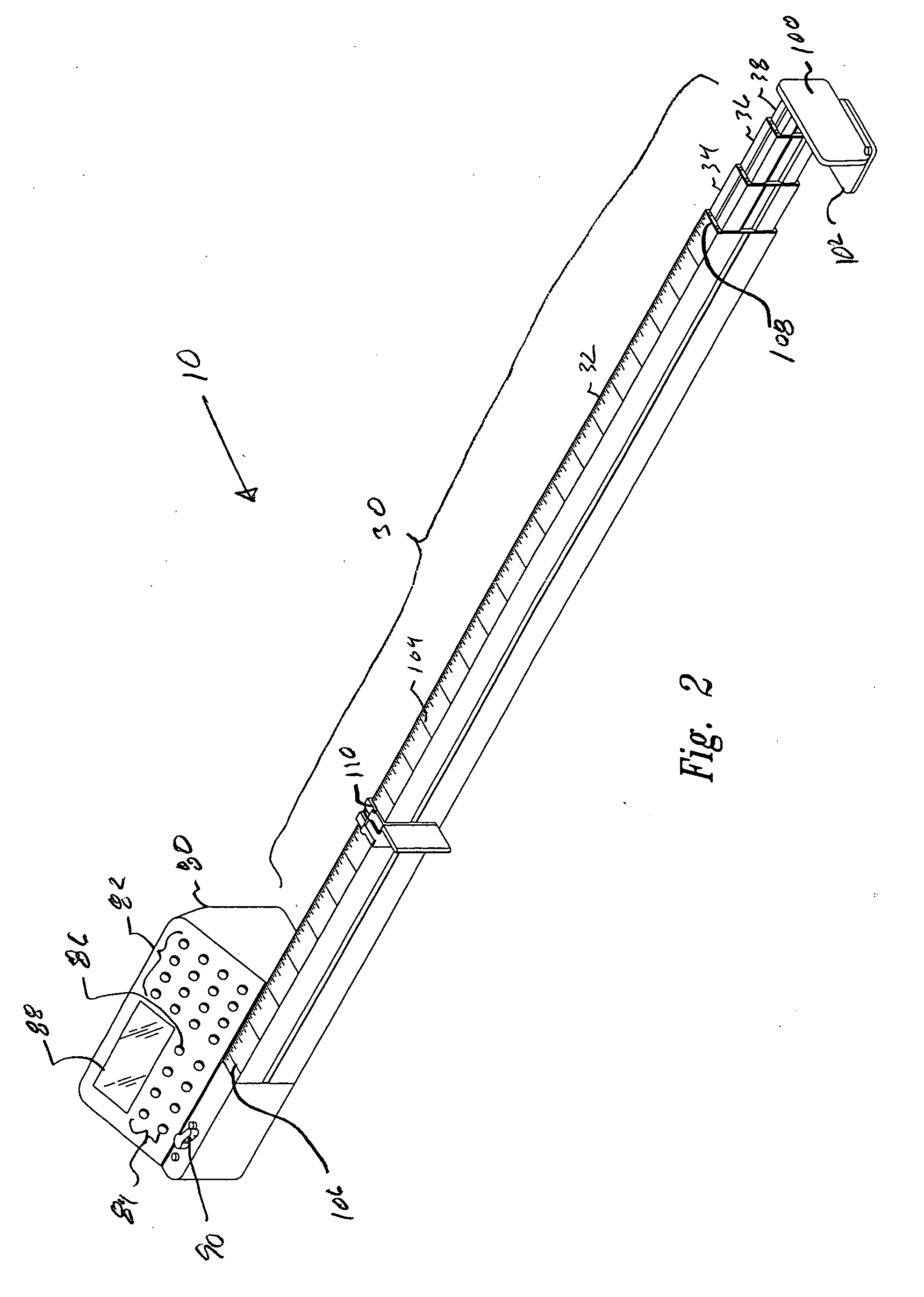

Repetitive fence for cross-cutting materials

InactiveUS7882772B2Minimize the numberEasy to adjustGuide fencesMetal working apparatusEngineeringCross-cutting

A repetitive fence utilizes a plurality of telescoping arms driven by a metal tape of the tape measure type to position a stop member at a desired location from a saw blade. A user can position a work piece, such as board lumber against the stop member to repeatedly position the work piece at a desired cut dimension with respect to a saw blade. The repetitive fence preferably employs a plurality of telescoping arms to position the stop member at the desired location, and an electronic read-out provided to indicate to the user the position of the stop member with respect to the saw blade. The telescoping arms can be motivated by electronic devices, such as an electric motor, or by a manual crank.

Owner:WISE ROBERT W

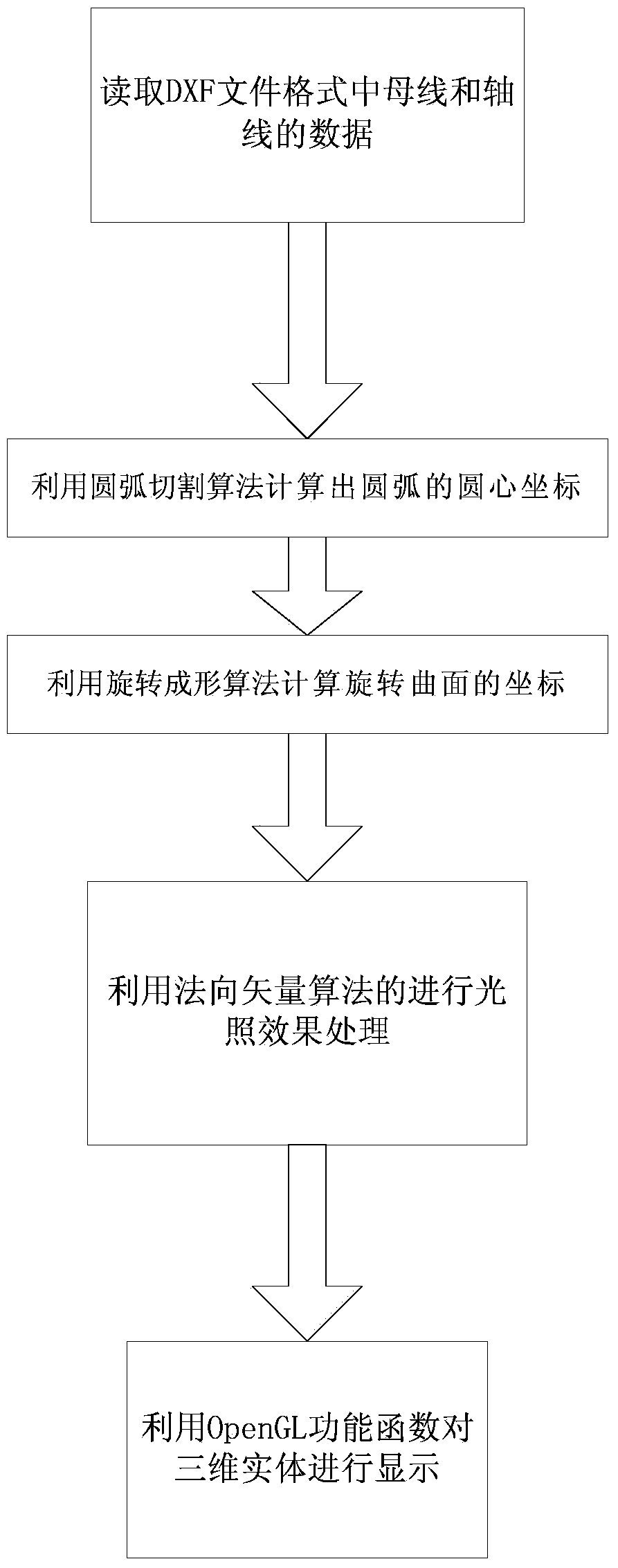

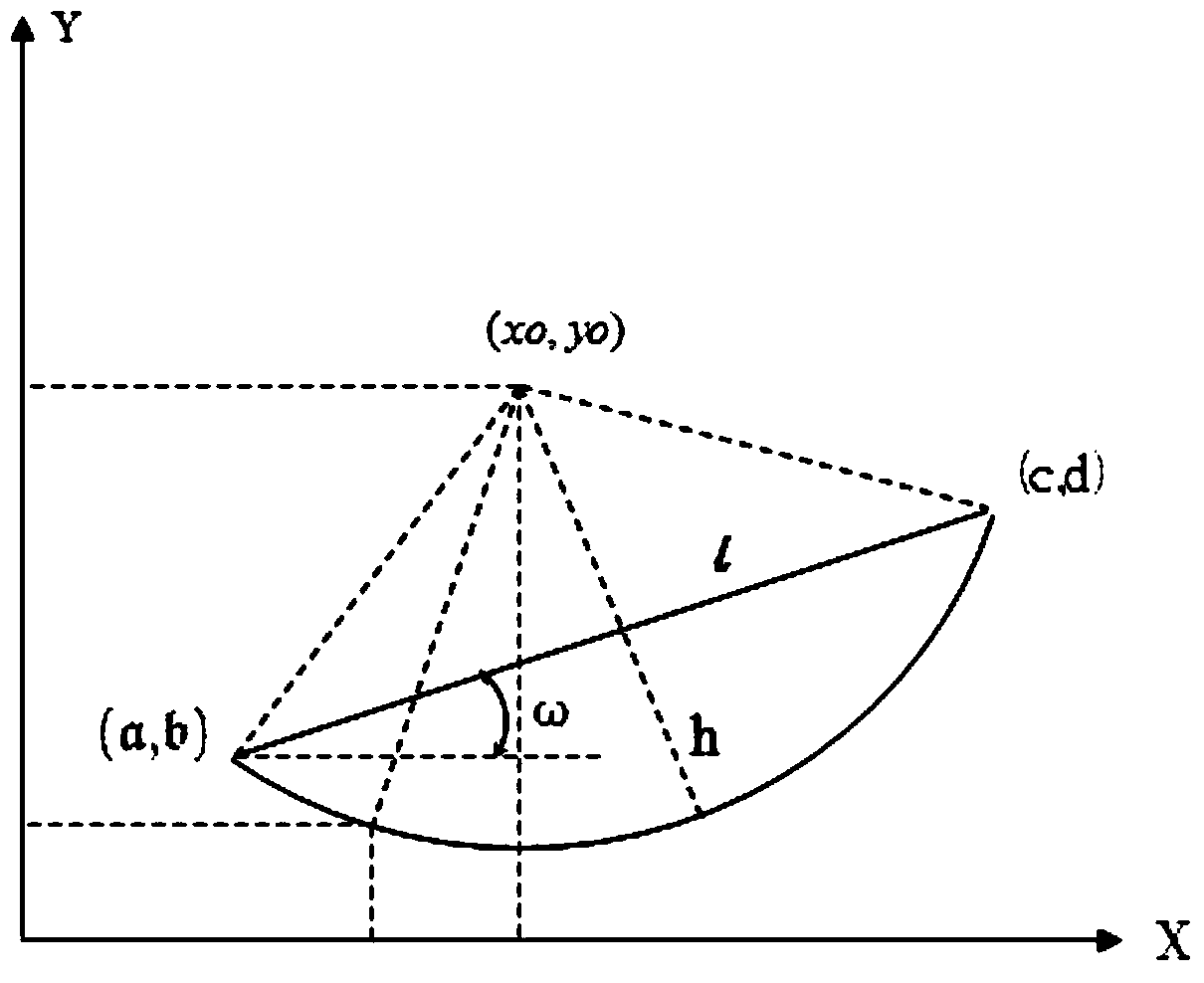

Two-dimensional DXF (drawing exchange file) format based three-dimensional realistic display method of parts

InactiveCN103761376AGreat practicabilityAchieve conversionImage data processingSpecial data processing applicationsPerformance functionImaging processing

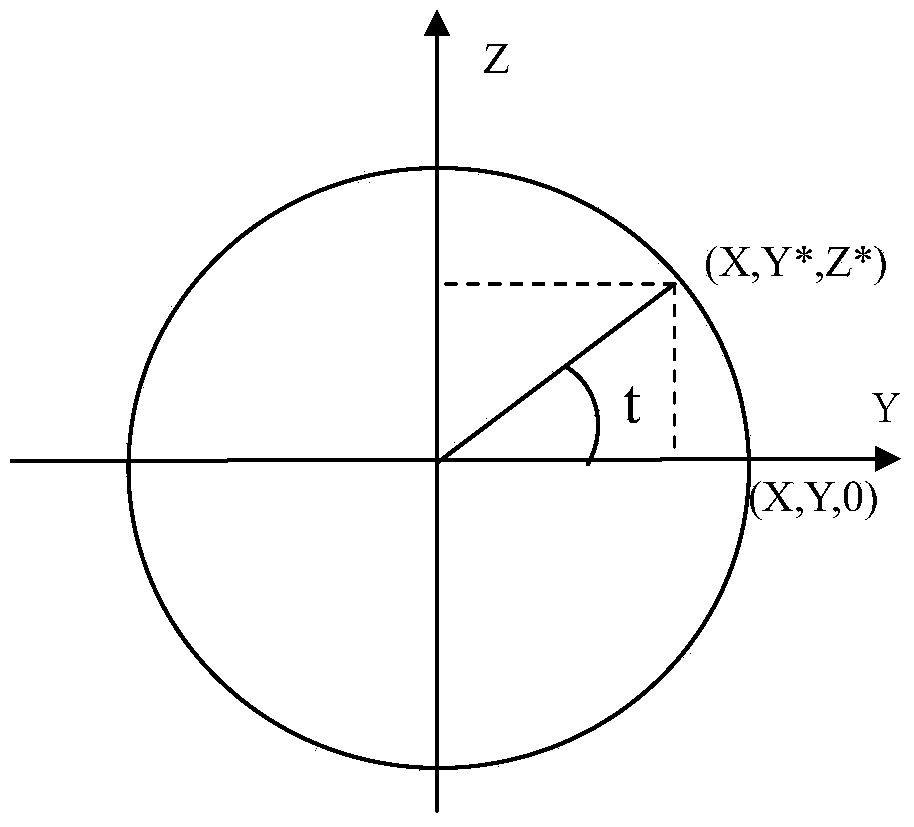

The invention belongs to the technical field of image processing, and particularly relates to a two-dimensional DXF (drawing exchange file) format based three-dimensional realistic display method of parts. The three-dimensional realistic display method specifically includes the steps of 1), reading data of a bus and an axis in the DXF format; 2), structuring a rotating surface by utilizing the data read in the step 1); 2.1), calculating center coordinates of an arc by means of a circular arc cutting algorithm; 2.2), calculating the coordinates of the rotating surface by means of a rotation to formation algorithm; 2.2.1), subjecting a known curve to cross cutting; 2.2.2), subjecting points obtained from the cross cutting to lengthwise cutting; 3), performing lighting effect processing by means of a normal vector algorithm; 4), displaying a three-dimensional entity by means of OpenGL performance functions. Therefore, three-dimensional realistic display of the parts can be realized.

Owner:SHENYANG AEROSPACE UNIVERSITY

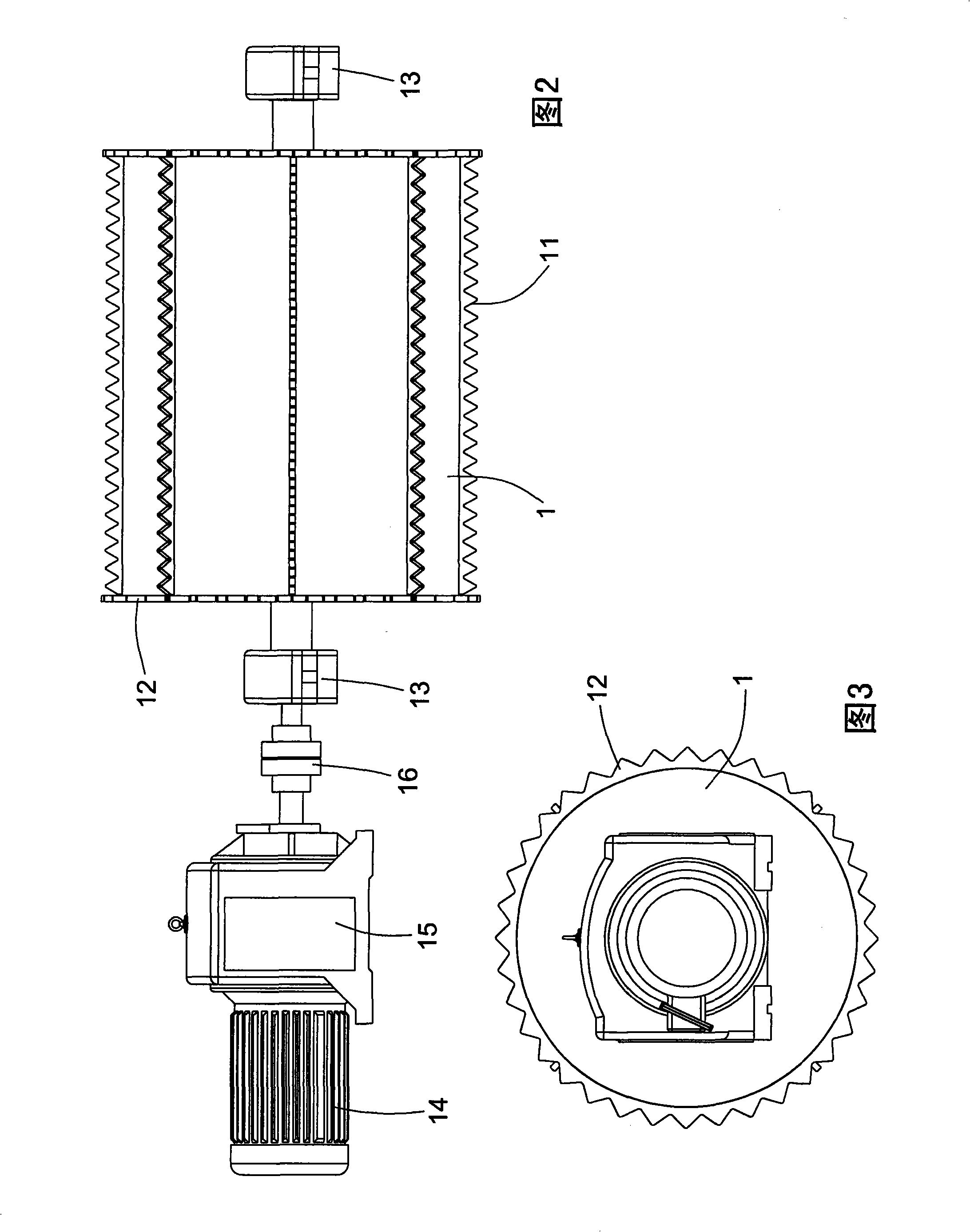

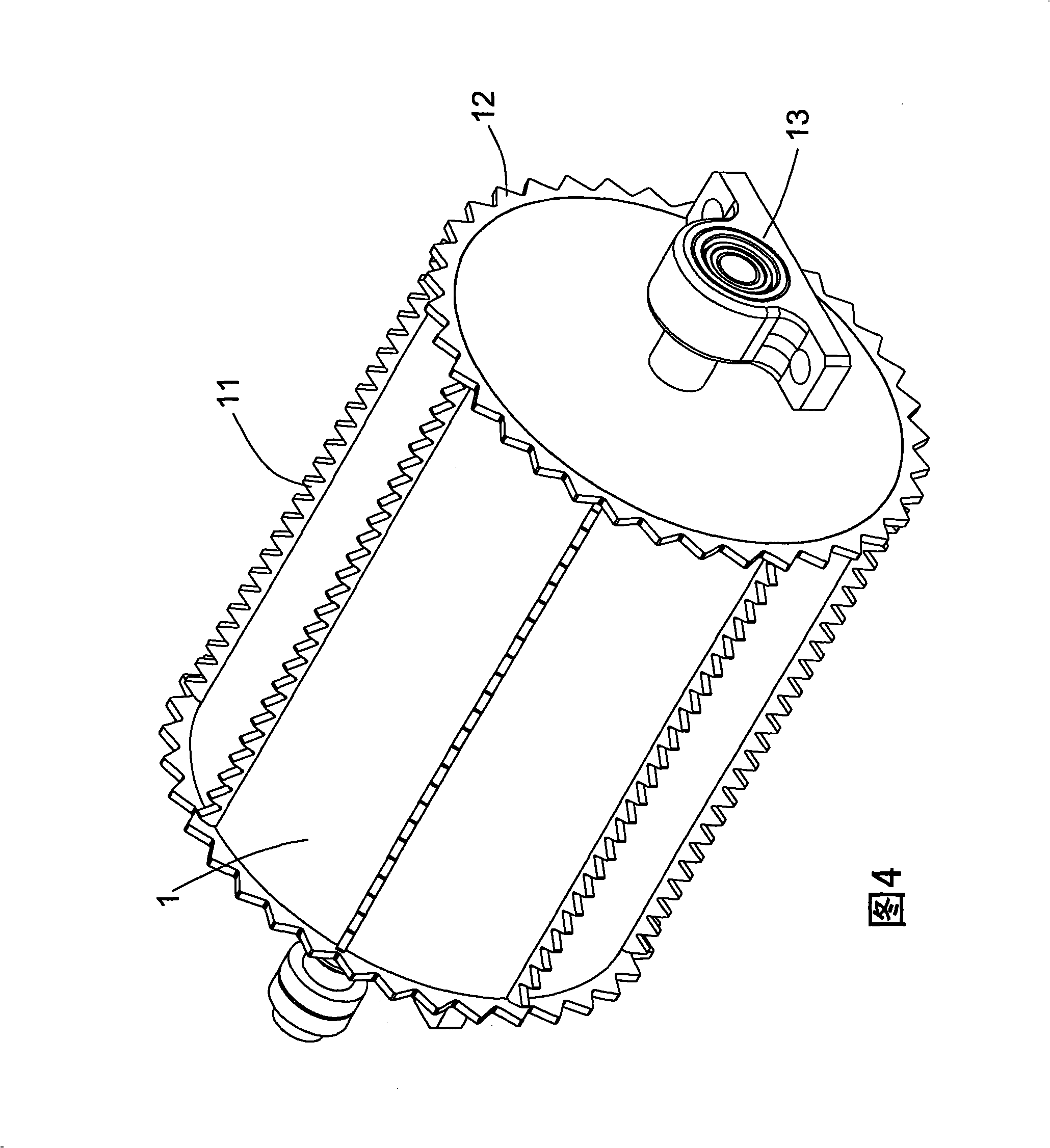

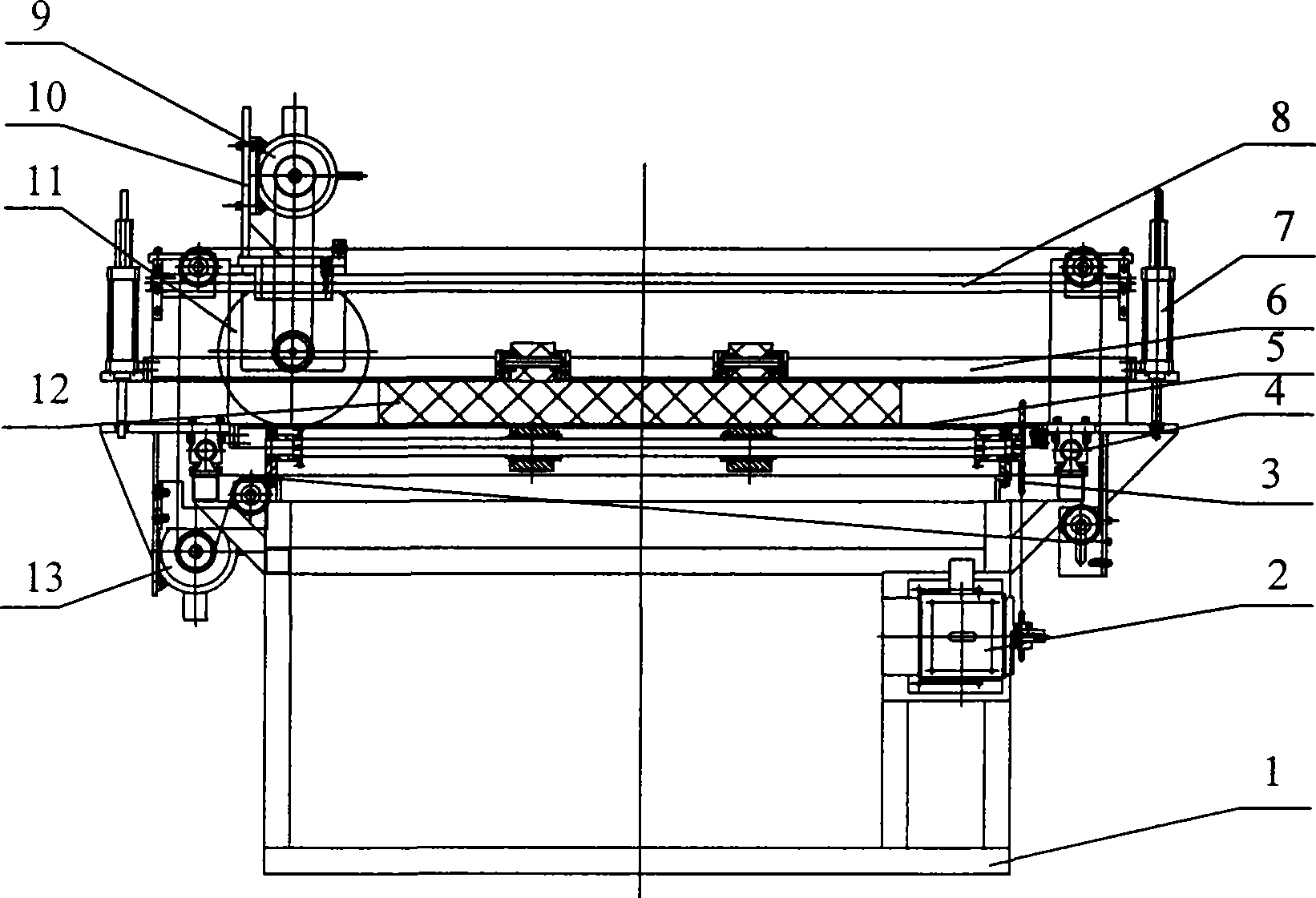

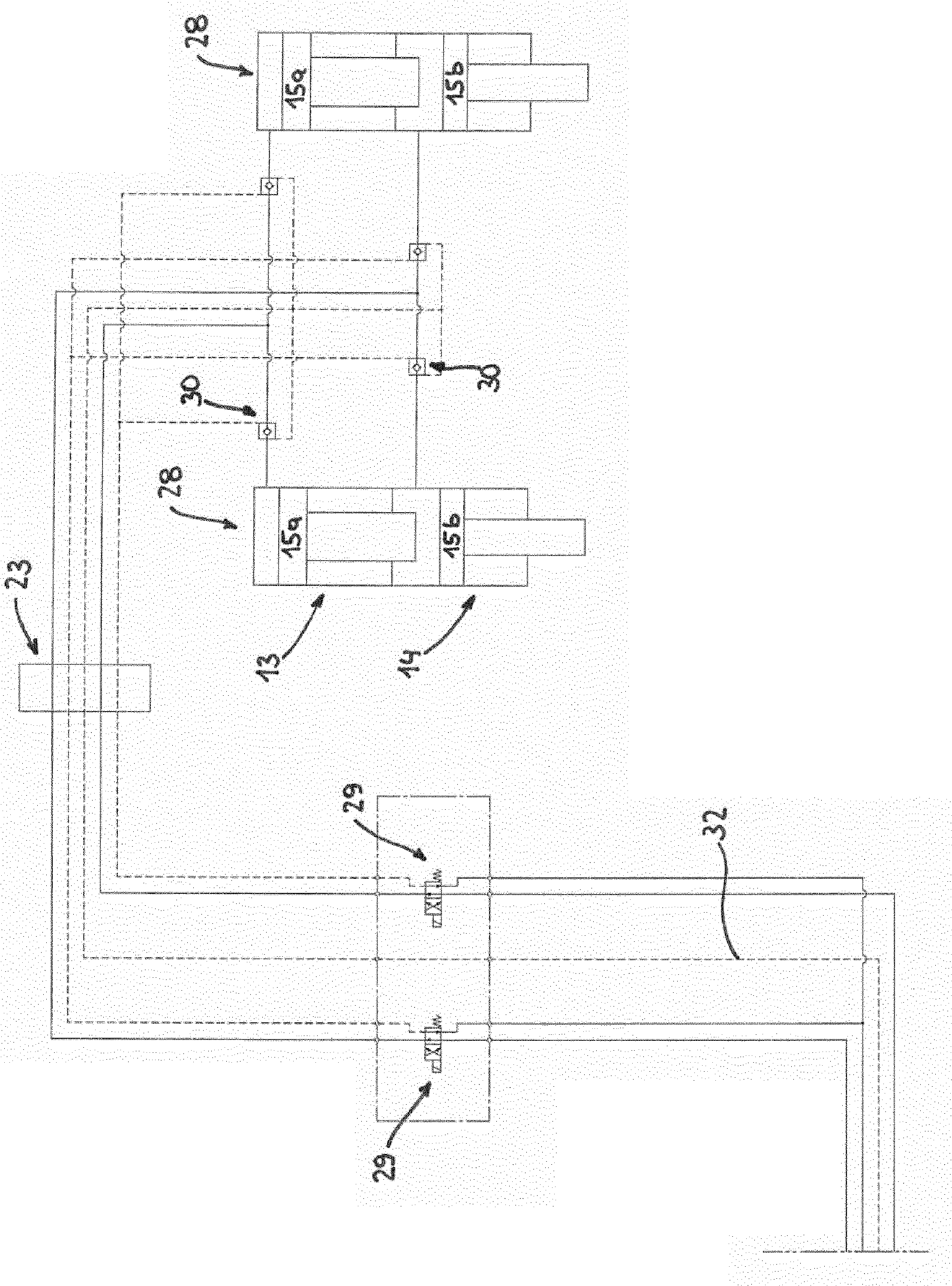

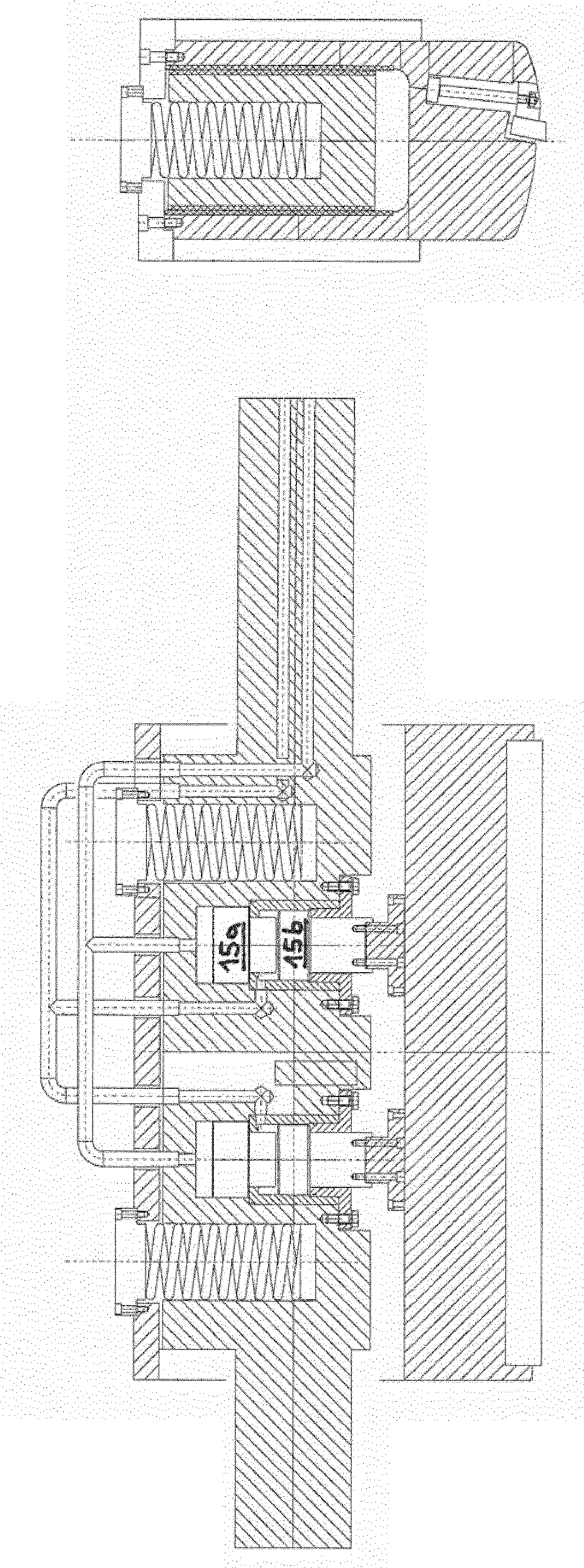

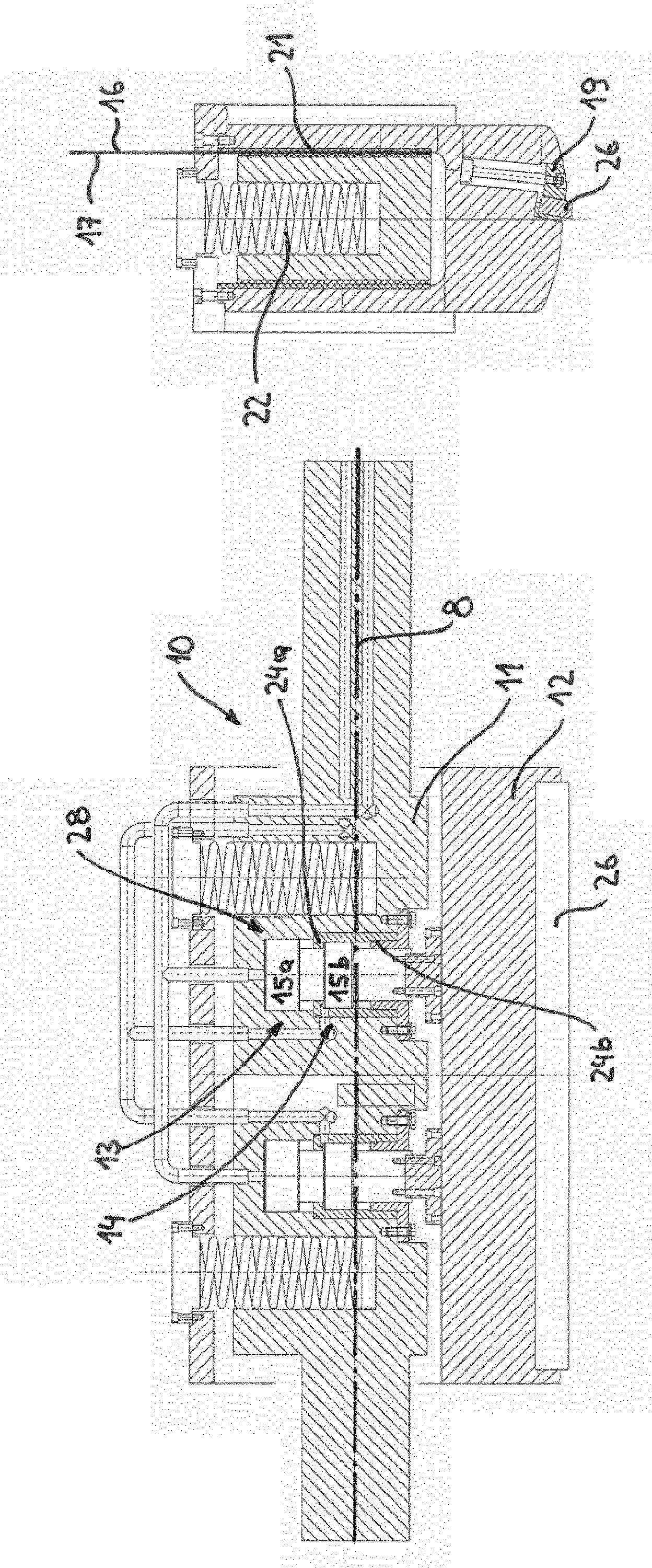

Drum shear

InactiveCN103889626AReduce in quantityPrevent leakageStock shearing machinesShearing toolsHydraulic cylinderRobust design

The invention relates to a drum shear (1) and to a method for cross-cutting rolled stock (2) by means of the drum shear (1). The aim of the invention is to provide a drum shear (1) and a method for cross-cutting rolled stock (2) by means of the drum shear (1), by way of which the blades (26) of the drum shear (1) can be moved rapidly and in a precisely positioned manner into the cutting position. Moreover, the drum shear (1) should be of simple and robust design. The aim is achieved in that a drum shear (1) is provided in which the actuating device (28) comprises a first hydraulic cylinder (13) and a second hydraulic cylinder (14), wherein the first hydraulic cylinder (13) is arranged between the first part (11) and the second hydraulic cylinder (14), and the second hydraulic cylinder (14) is arranged between the first hydraulic cylinder (13) and the second part (12).

Owner:PRIMETALS TECH AUSTRIA GMBH

Repetitive fence for cross-cutting materials

InactiveUS20080282862A1Minimize the numberEasy to adjustGuide fencesMetal working apparatusEngineeringCross-cutting

A repetitive fence utilizes a plurality of telescoping arms driven by a metal tape of the tape measure type to position a stop member at a desired location from a saw blade. A user can position a work piece, such as board lumber against the stop member to repeatedly position the work piece at a desired cut dimension with respect to a saw blade. The repetitive fence preferably employs a plurality of telescoping arms to position the stop member at the desired location, and an electronic read-out provided to indicate to the user the position of the stop member with respect to the saw blade. The telescoping arms can be motivated by electronic devices, such as an electric motor, or by a manual crank.

Owner:WISE ROBERT W

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com