Lead pig grinding and granulating machine

A granulator and lead ingot technology, applied in the field of mechanical equipment, can solve the problems of low overall efficiency and complex structure of lead ingot granulation, and achieve the effects of low manufacturing cost, high granulation efficiency and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

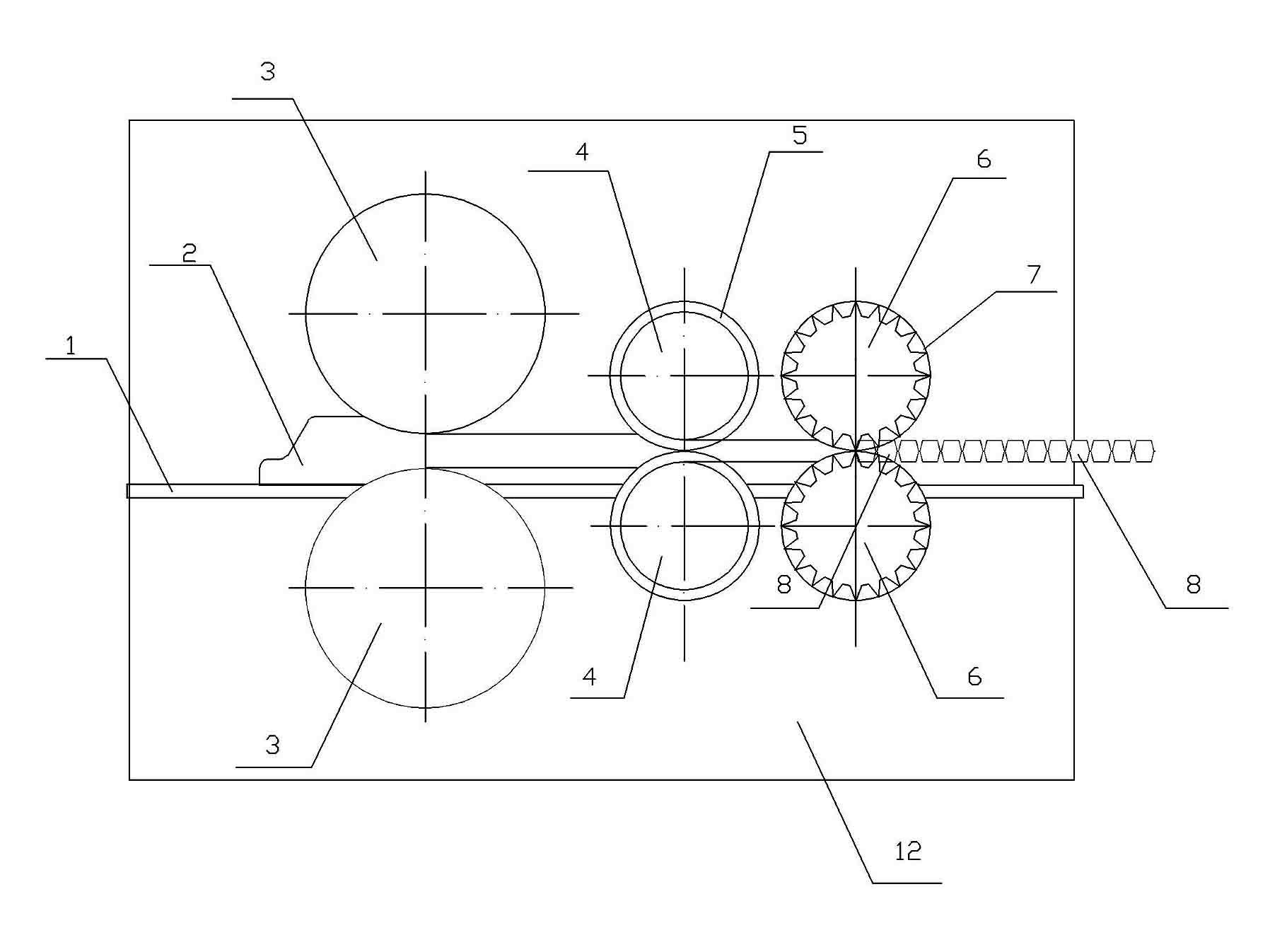

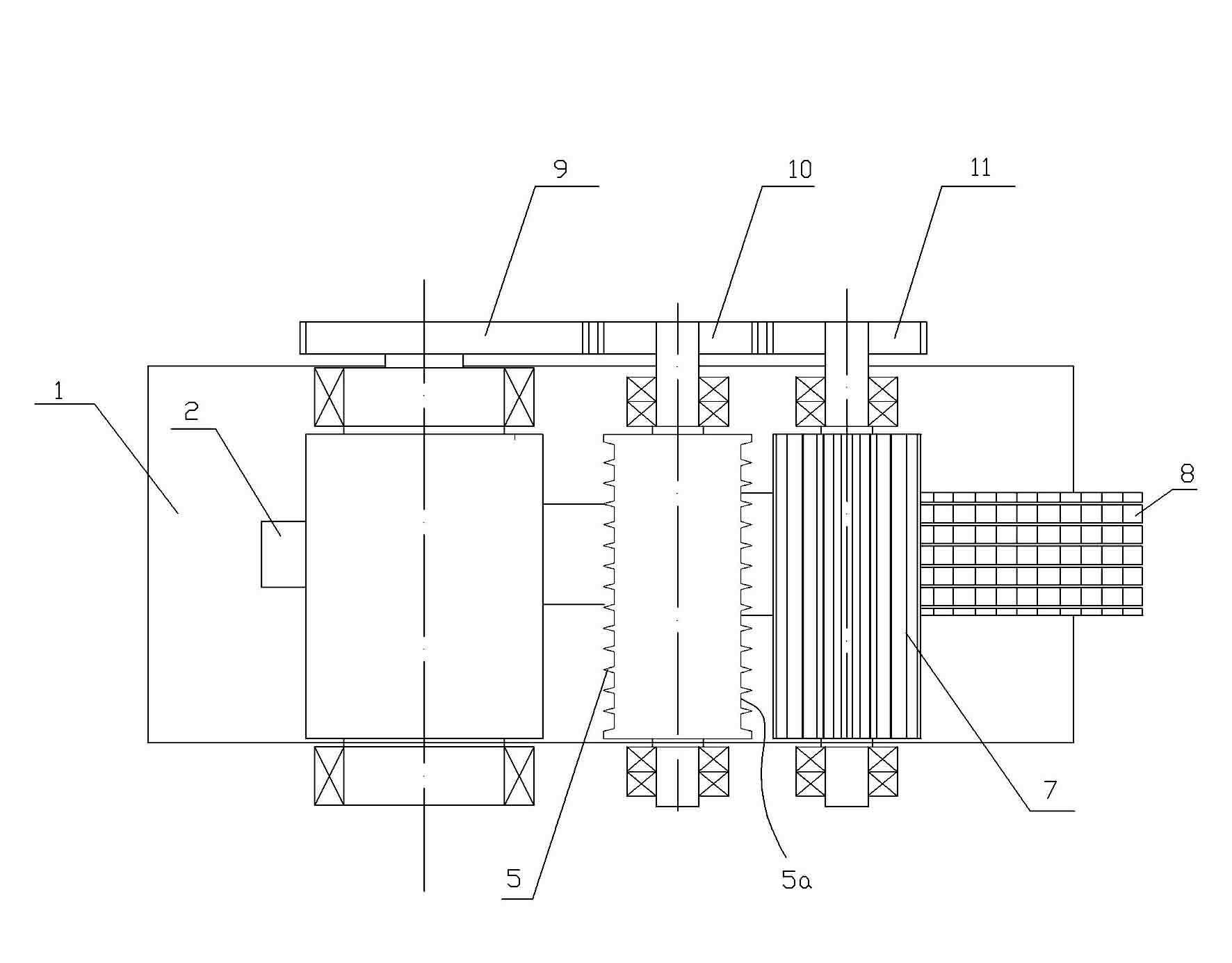

[0016] Such as figure 1 , figure 2 As shown, a kind of lead ingot rolling granulator provided by the present invention comprises a frame 12 and a workbench 1, and the leftmost side of the frame 12 is provided with two rolling rollers 3 that cooperate with the rollers, and the rolling rollers 3. On the right side, two slitting rolls 4 and two cross-cutting rolls 6 matched with each other are provided in sequence at a certain distance. The surface of each slitting roll 4 is evenly distributed with a set of longitudinal cutting edges 5 around the circumference along the axial direction, and a set of transverse cutting edges 7 parallel to the axial direction are evenly distributed on the surface of each cross-cutting roll 6 along the circumference.

[0017] When the longitudinal cutting edge 5 on the pair of slitting rollers 4 is matched with the roller, the longitudinal cutting edge on it is correspondingly engaged; when the longitudinal cutting edge 7 on the pair of cross-cutt...

Embodiment 2

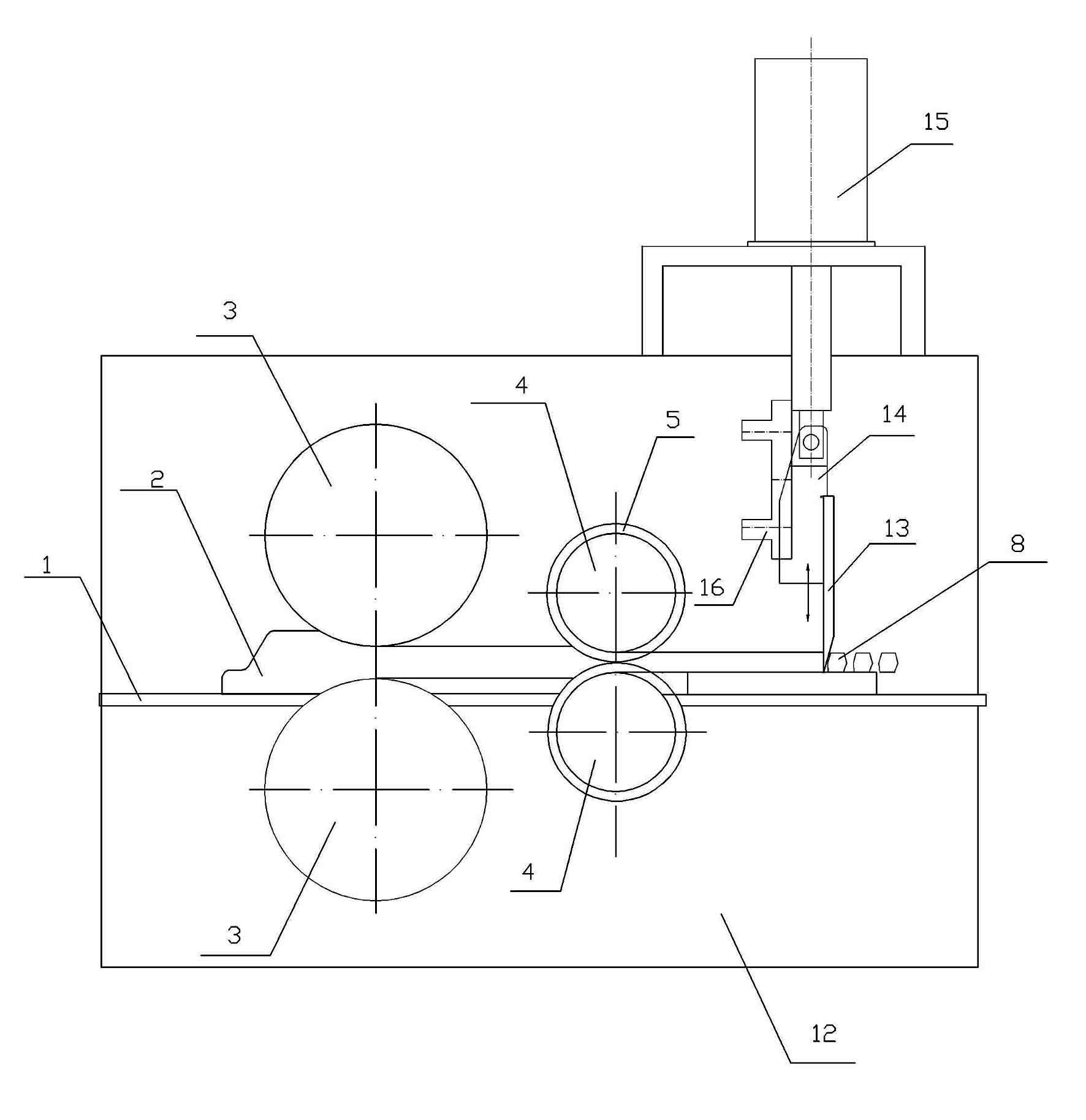

[0021] Such as image 3 Shown, a kind of lead ingot rolling granulator provided by the invention, its basic structure and figure, figure 2 The same, but the difference is that the described lead bar pelletizing device arranged behind the slitting roller 4 includes a hydraulic cylinder 15 arranged on the frame 12, and a slide block 14 is connected on the hydraulic cylinder piston cylinder, and the slide block 14 is connected with the set The guide rail 16 on the frame 12 is slidably fitted, and a horizontal cutter 13 that moves vertically is connected on the slide block 14 .

[0022] Working process of the present invention is as follows:

[0023] The lead ingot 2 enters from the left end of the workbench 1 between the rolling rollers 3 with a certain gap between the paired rollers. The cutting roller 4 has two functions, one is to further roll and thin the lead ingot through the groove bottom 5a of the longitudinal cutting edge 5 on the slitting roller 4, and the other is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com