Patents

Literature

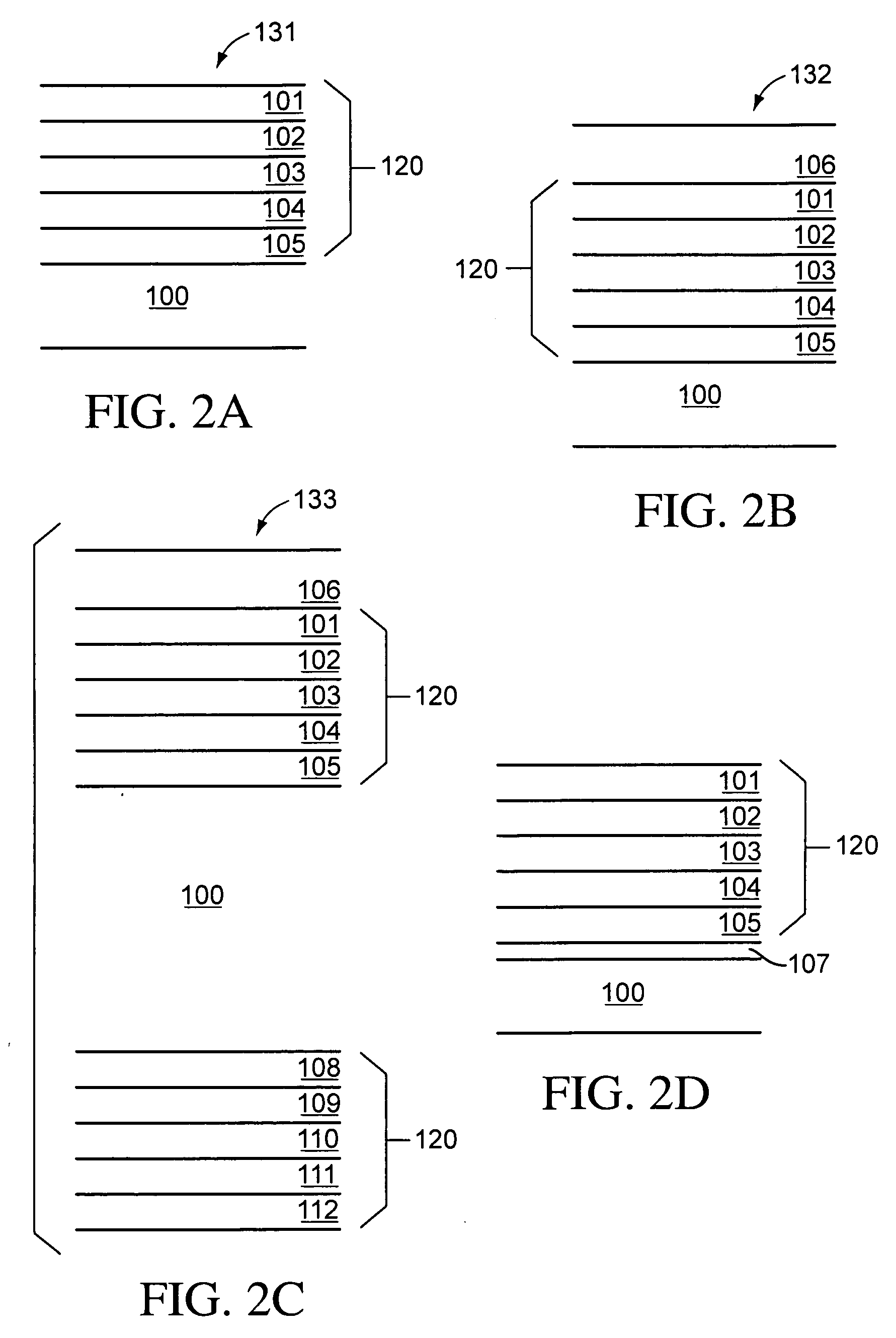

612 results about "Soft metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

According to the Mohs hardness scale, a list of soft metals includes lead, gold, silver, tin, zinc, aluminum, thorium, copper, brass and bronze. Gallium might also be considered a soft metal, as it melts at 85.57 degrees Fahrenheit. Mercury is a metal that's liquid at room temperature.

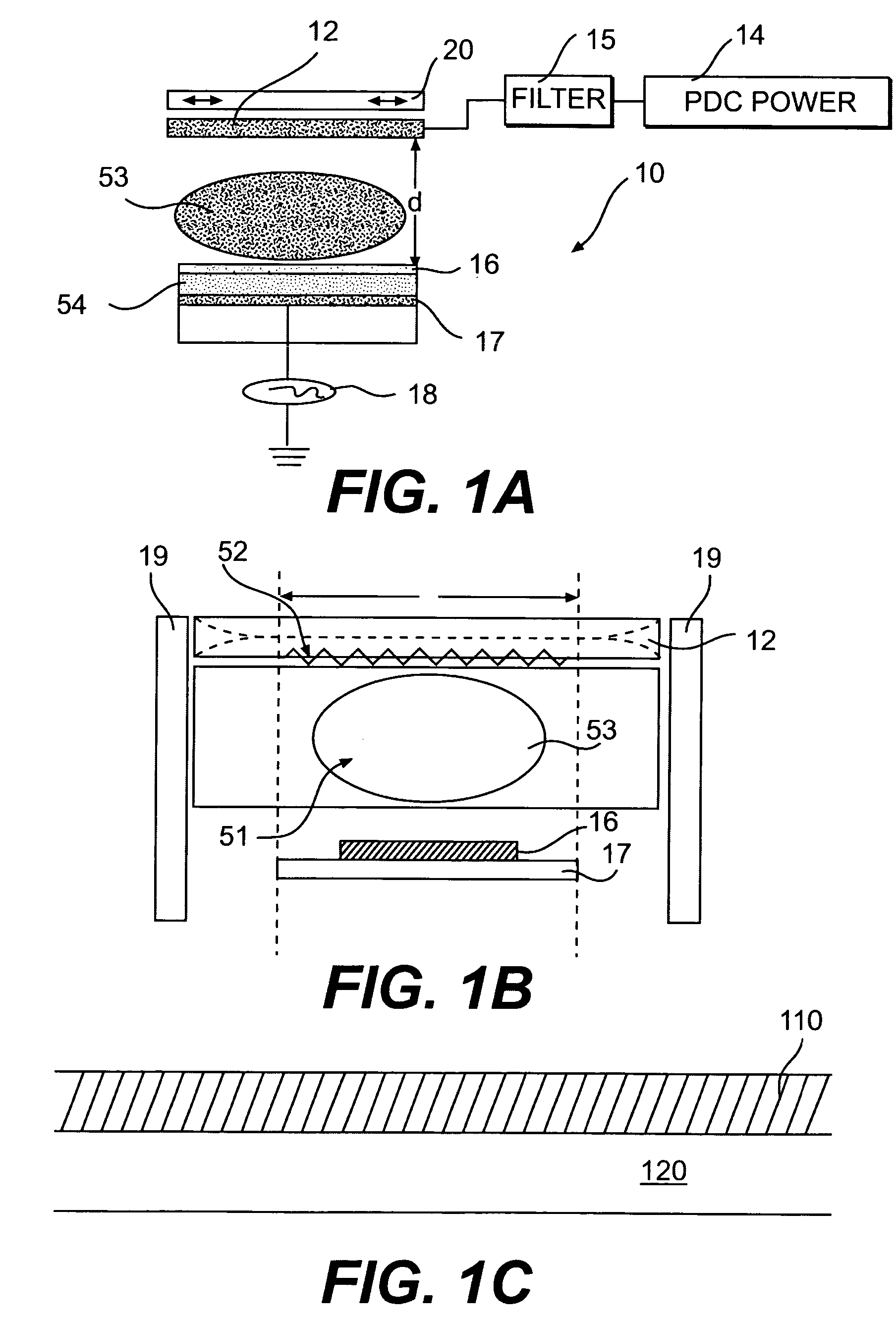

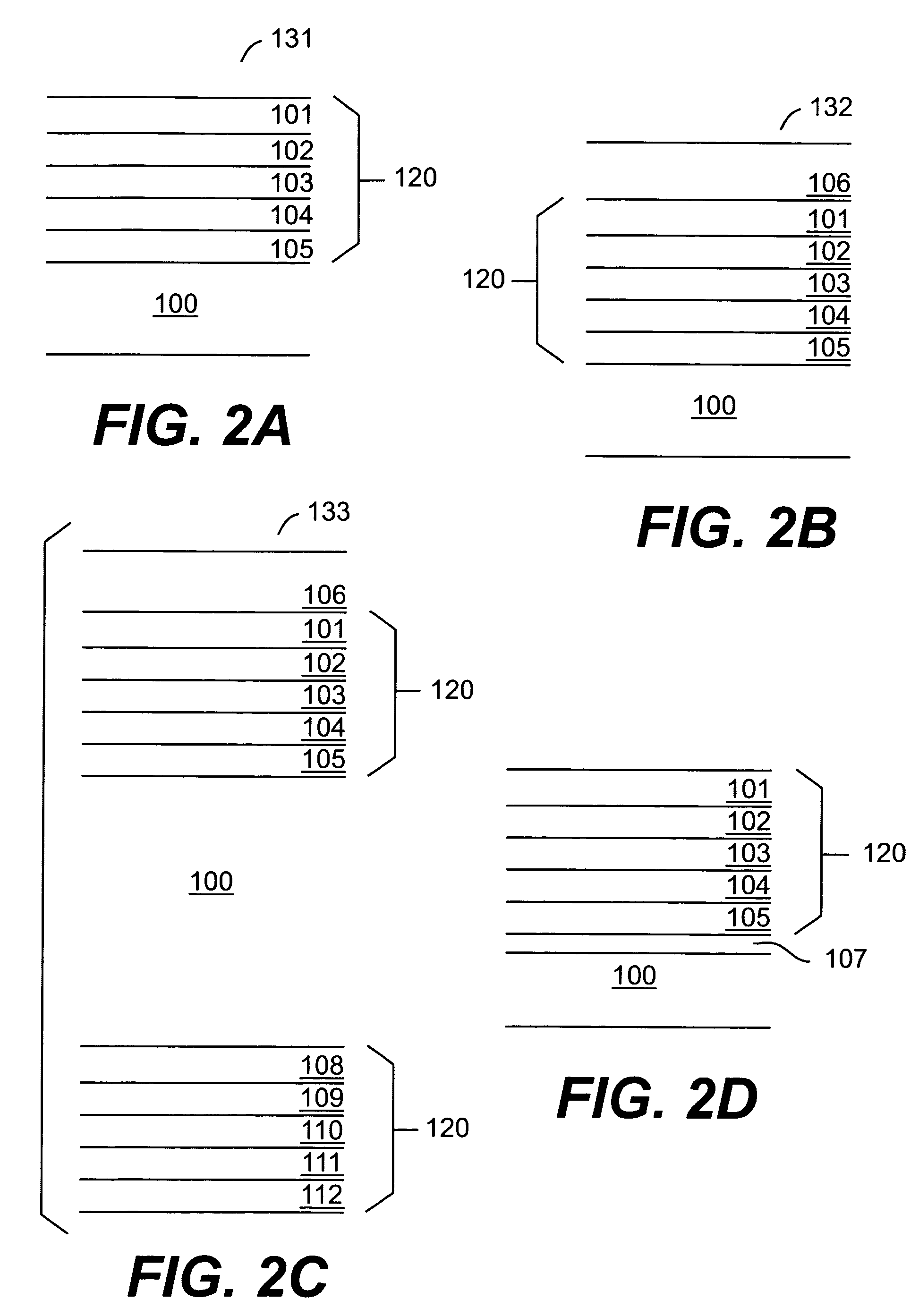

Dielectric barrier layer films

InactiveUS20050006768A1Improve performanceImprove uniformitySemiconductor/solid-state device detailsElectroluminescent light sourcesElectrical resistance and conductanceGas phase

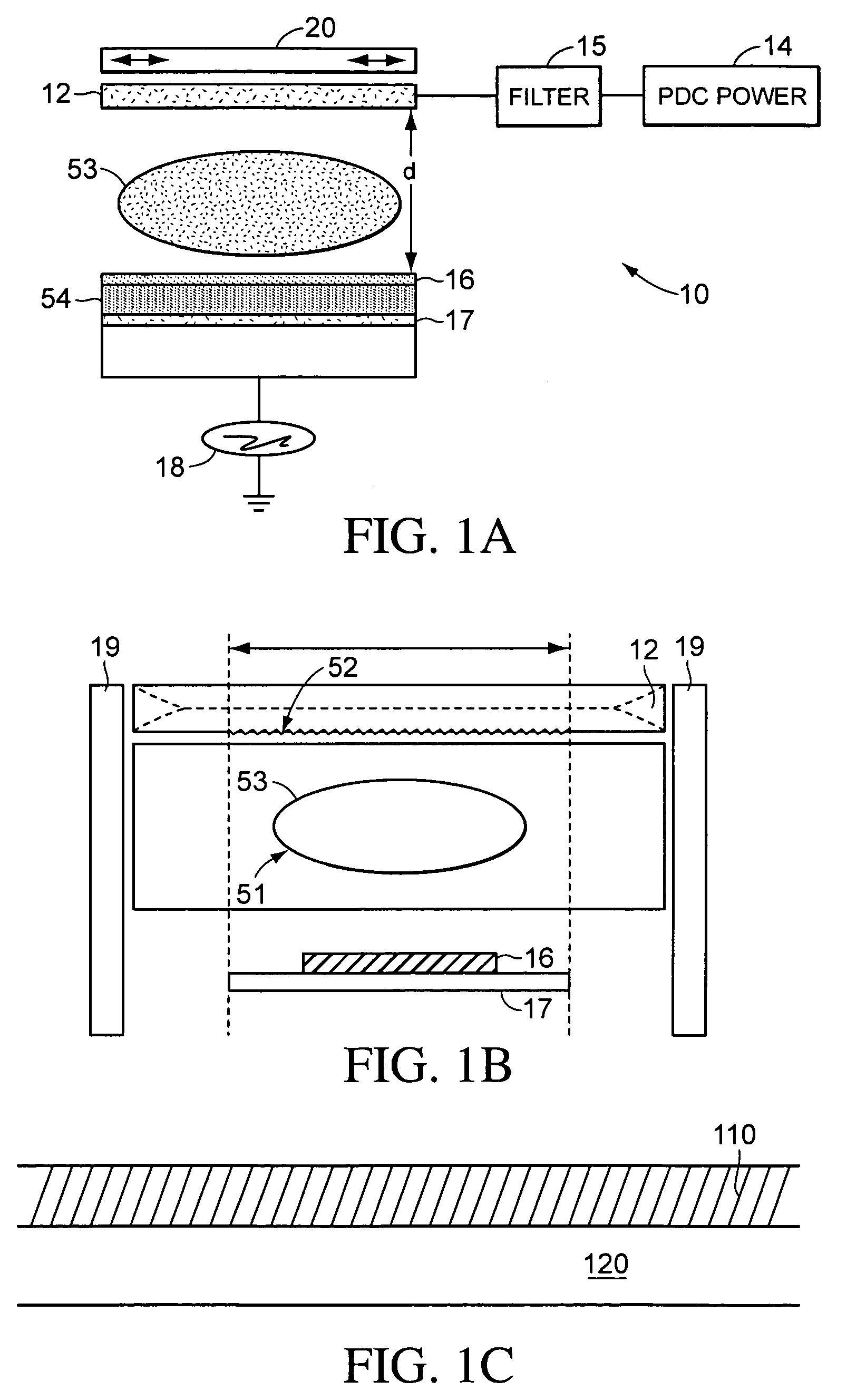

In accordance with the present invention, a dielectric barrier layer is presented. A barrier layer according to the present invention includes a densified amorphous dielectric layer deposited on a substrate by pulsed-DC, substrate biased physical vapor deposition, wherein the densified amorphous dielectric layer is a barrier layer. A method of forming a barrier layer according to the present inventions includes providing a substrate and depositing a highly densified, amorphous, dielectric material over the substrate in a pulsed-dc, biased, wide target physical vapor deposition process. Further, the process can include performing a soft-metal breath treatment on the substrate. Such barrier layers can be utilized as electrical layers, optical layers, immunological layers, or tribological layers.

Owner:DEMARAY

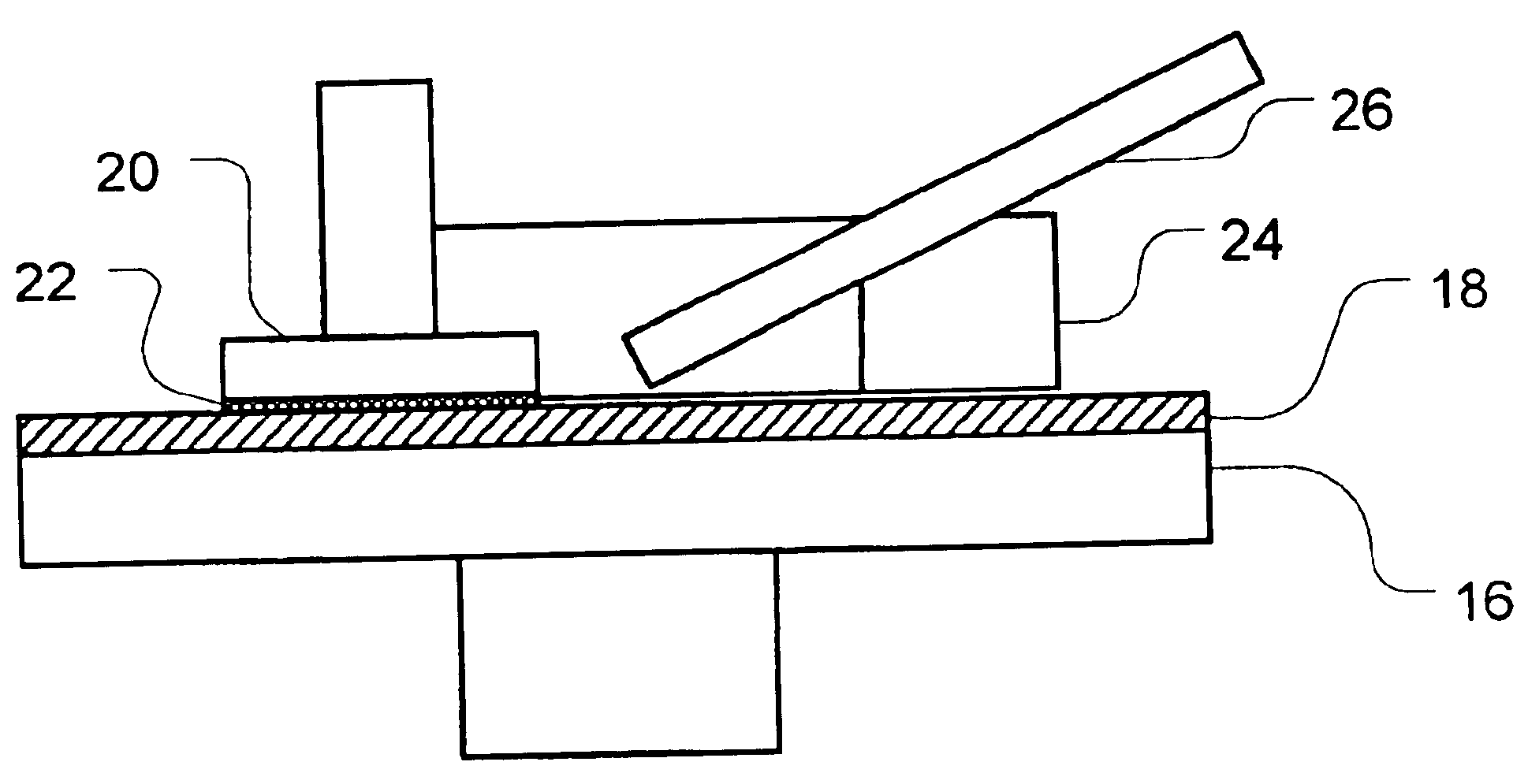

Abrasive agglomerate coated raised island articles

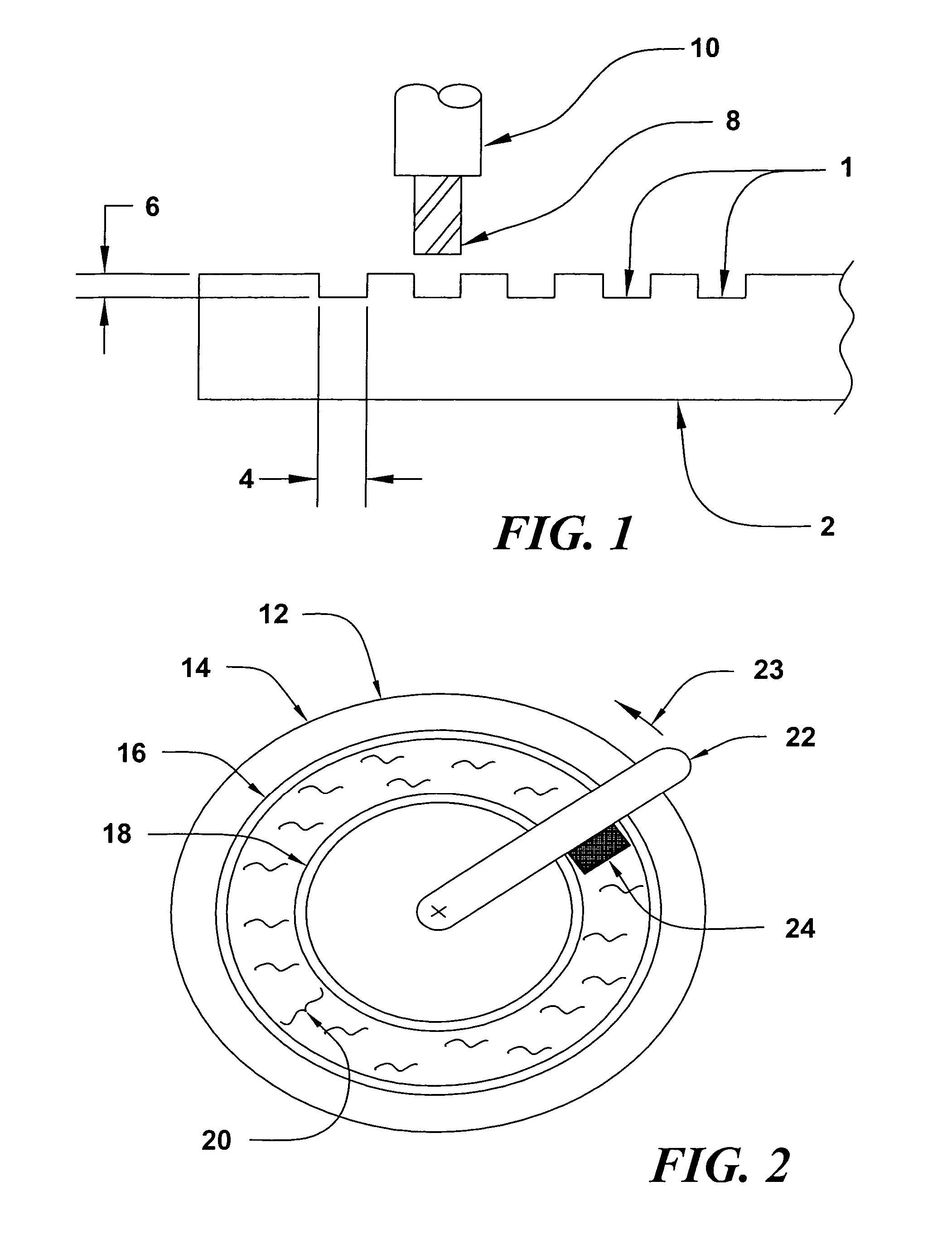

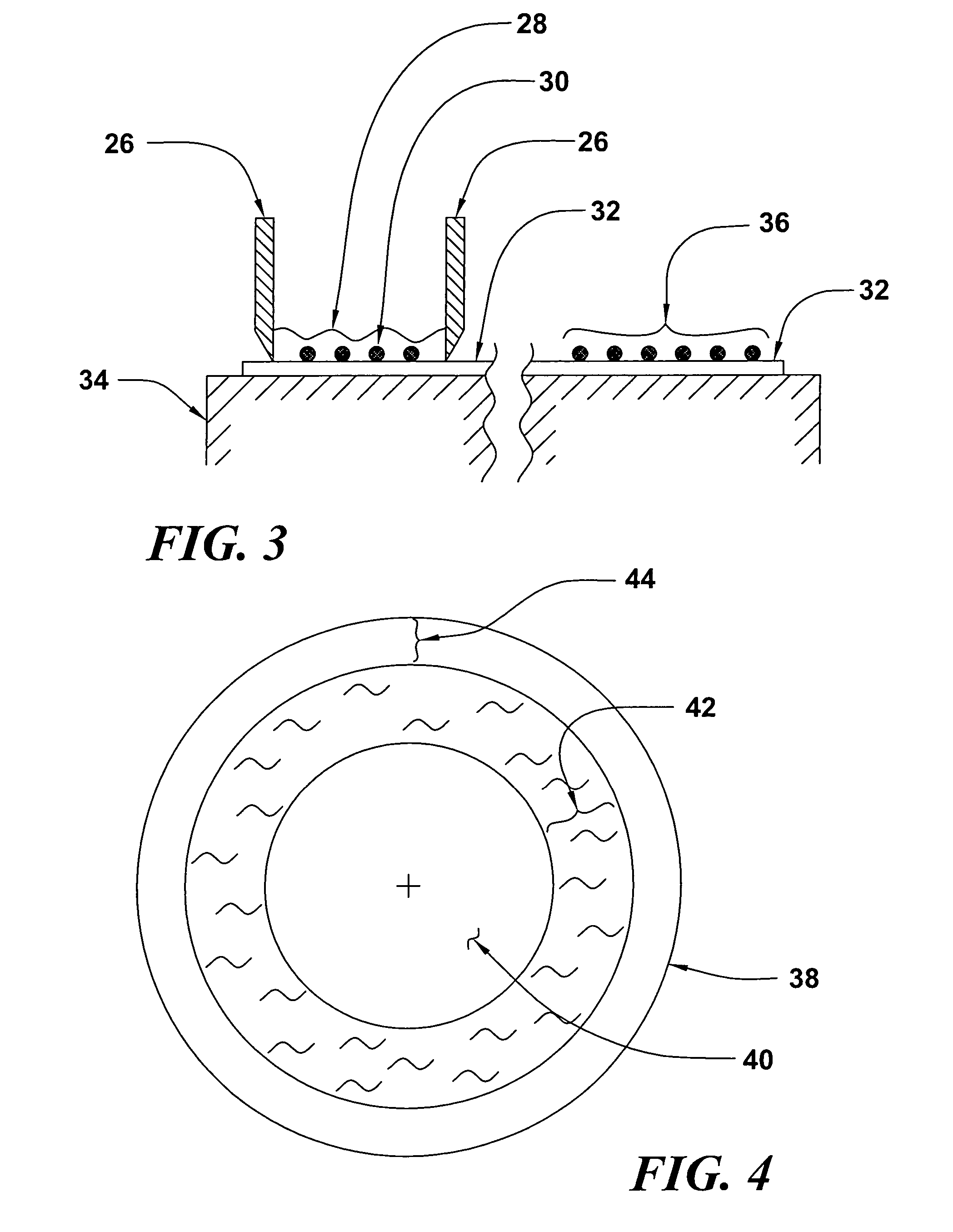

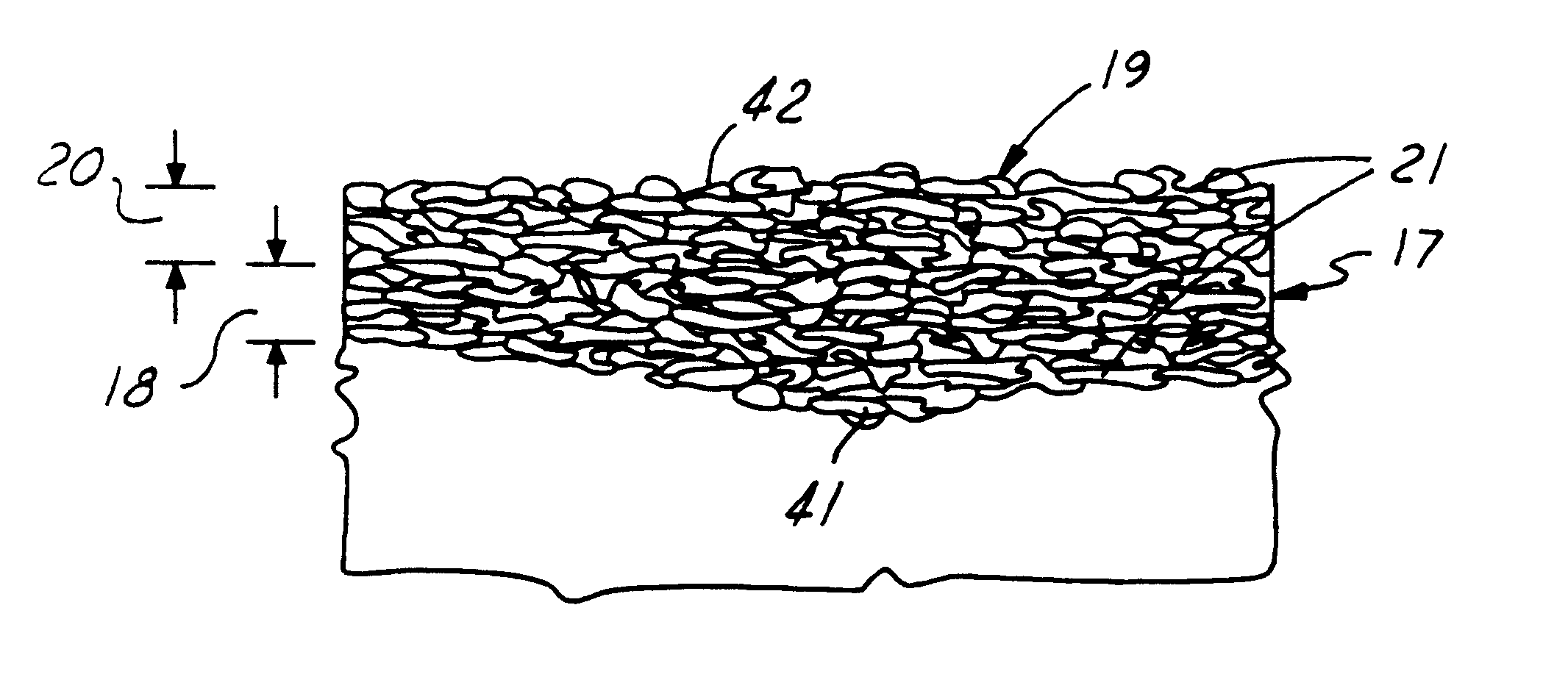

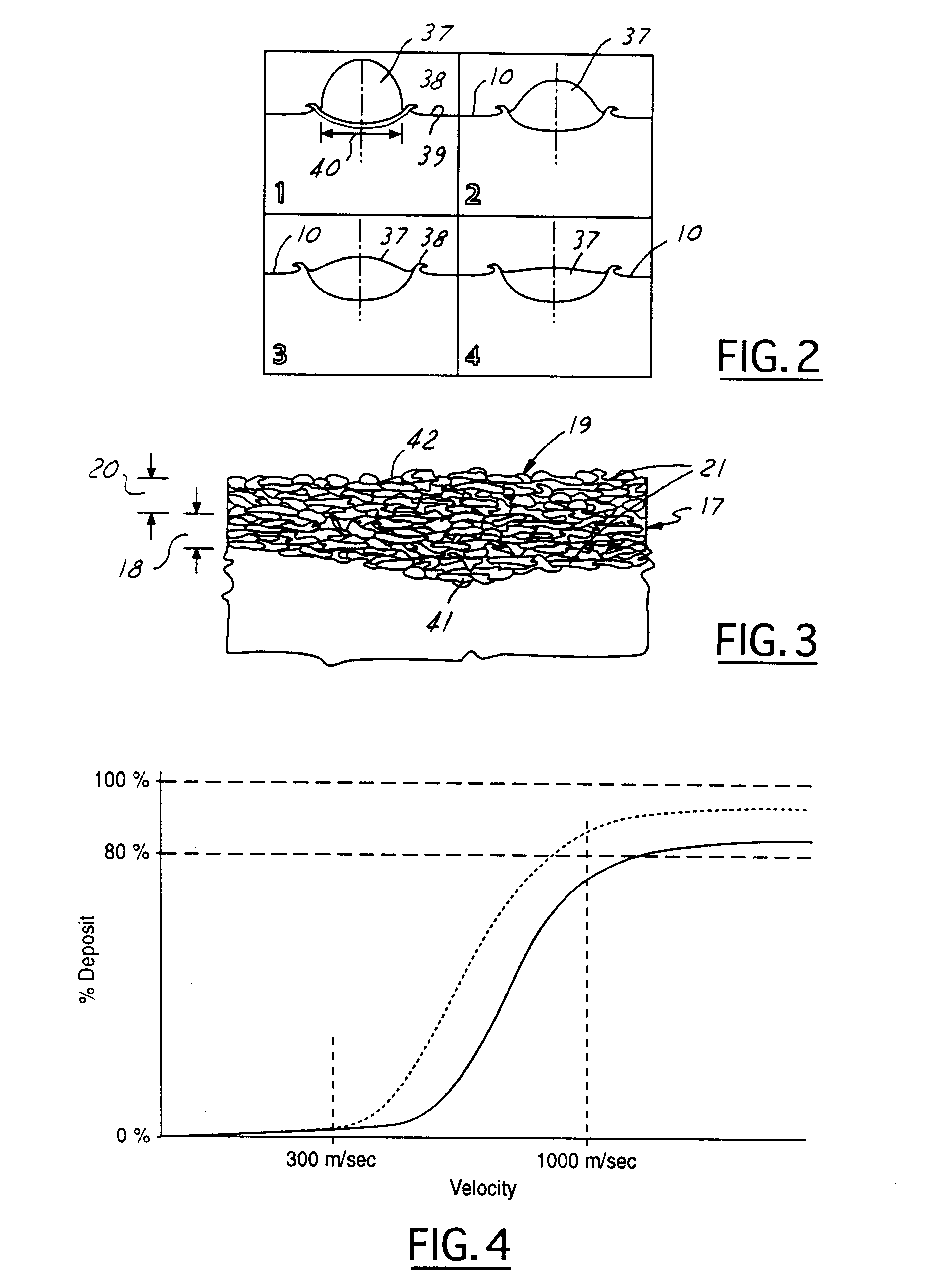

Abrasive disk sheet articles having raised islands coated with spherical abrasive agglomerates that can provide both precision flat and smooth workpiece surfaces by high speed lapping are described. These disks also provide high material removal rates and low surface pick-out of soft metallic or non-metallic materials embedded in hard workpieces. A method of producing equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles is described. These beads can be bonded directly on the flat surface of a flexible backing or bonded onto raised island surfaces. Simple and inexpensive apparatus devices and process techniques are described that allow efficient low-volume batch or continuous web manufacturing of precision thickness, large diameter abrasive disk or rectangular sheet abrasive articles.

Owner:DUESCHER WAYNE O

Dielectric barrier layer films

InactiveUS20060071592A1Improve performanceImprove uniformityDischarge tube luminescnet screensElectroluminescent light sourcesElectrical resistance and conductancePulsed DC

In accordance with the present invention, a dielectric barrier layer is presented. A barrier layer according to the present invention includes a densified amorphous dielectric layer deposited on a substrate by pulsed-DC, substrate biased physical vapor deposition, wherein the densified amorphous dielectric layer is a barrier layer. A method of forming a barrier layer according to the present inventions includes providing a substrate and depositing a highly densified, amorphous, dielectric material over the substrate in a pulsed-dc, biased, wide target physical vapor deposition process. Further, the process can include performing a soft-metal breath treatment on the substrate. Such barrier layers can be utilized as electrical layers, optical layers, immunological layers, or tribological layers.

Owner:DEMARAY

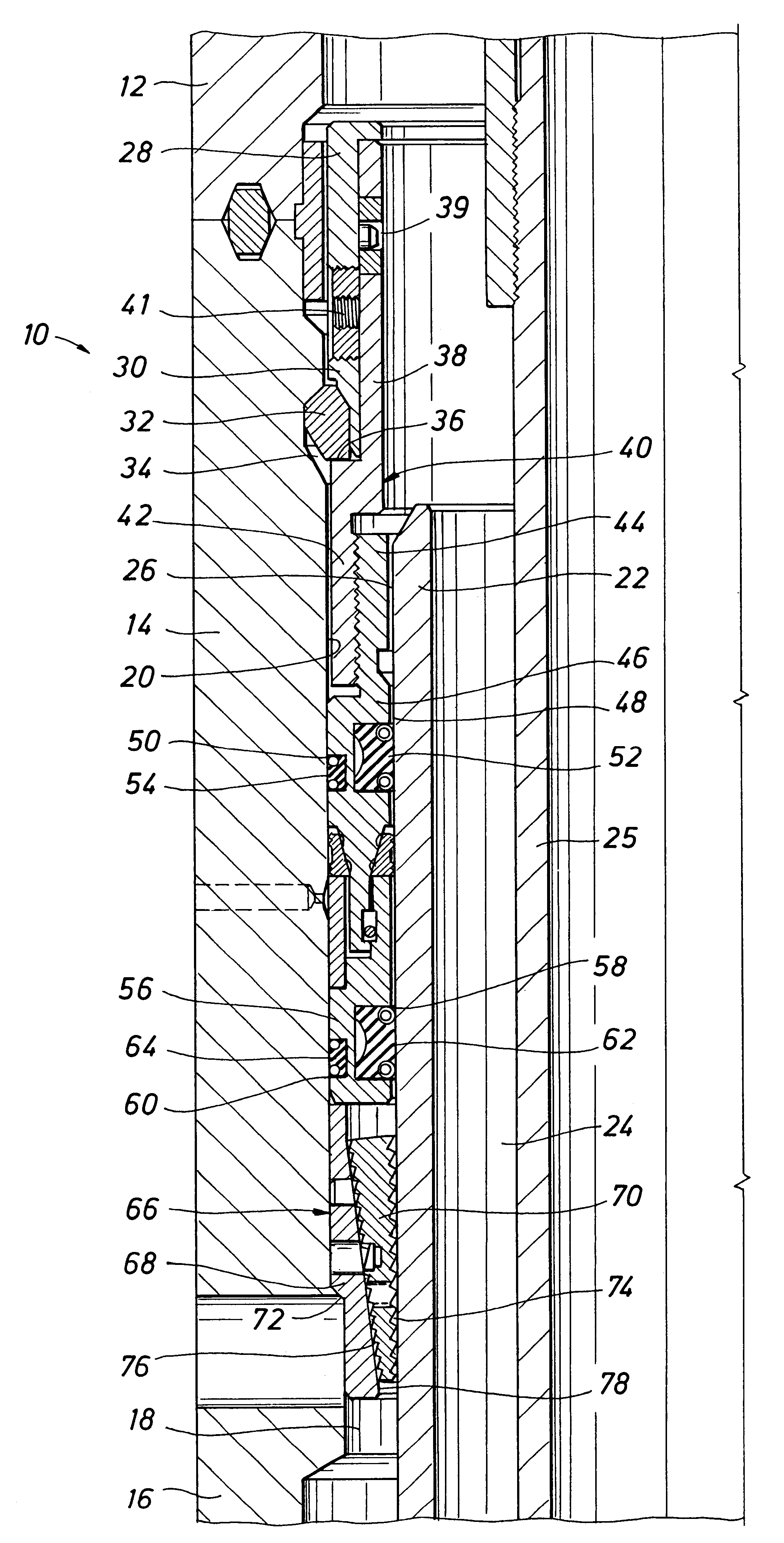

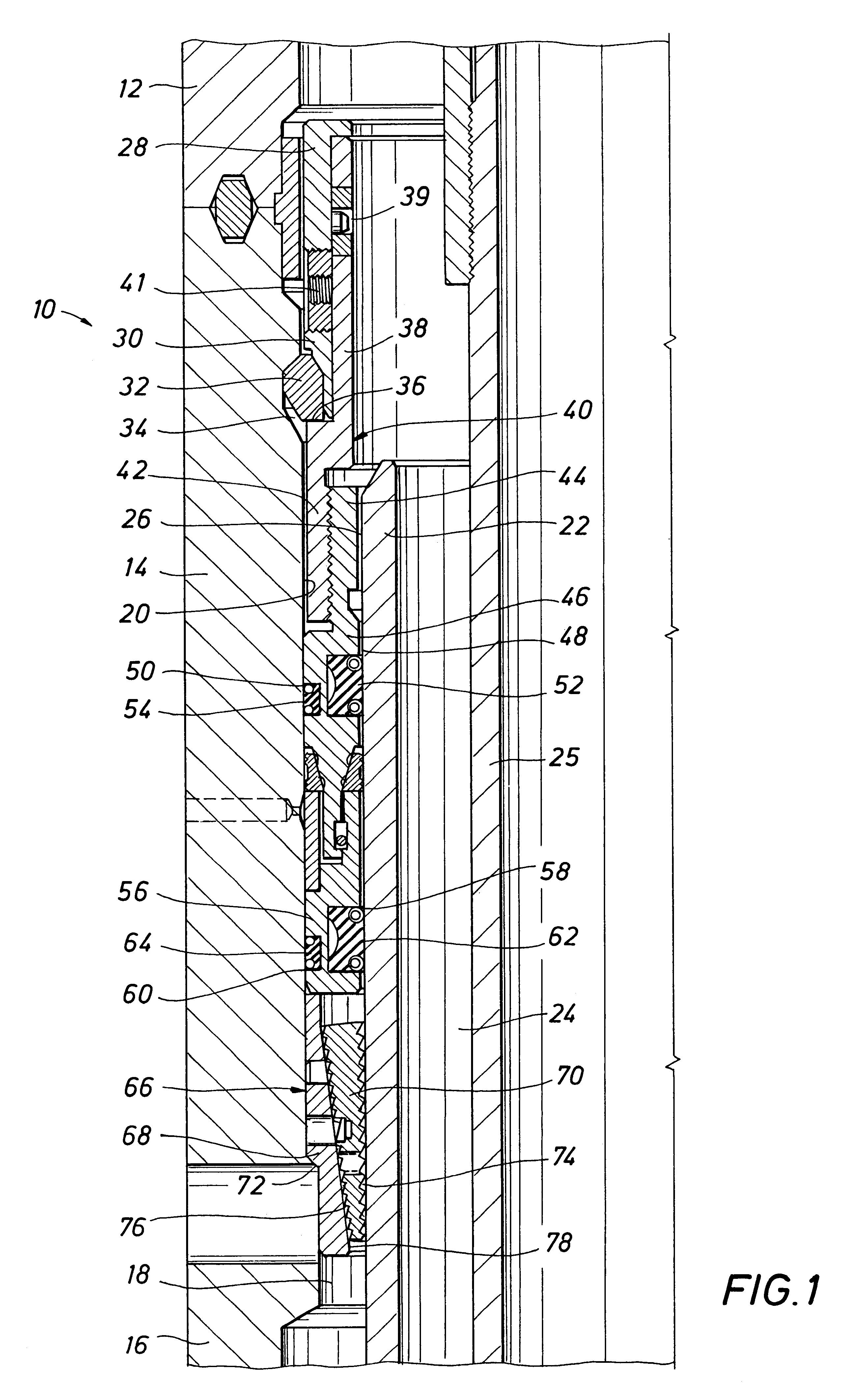

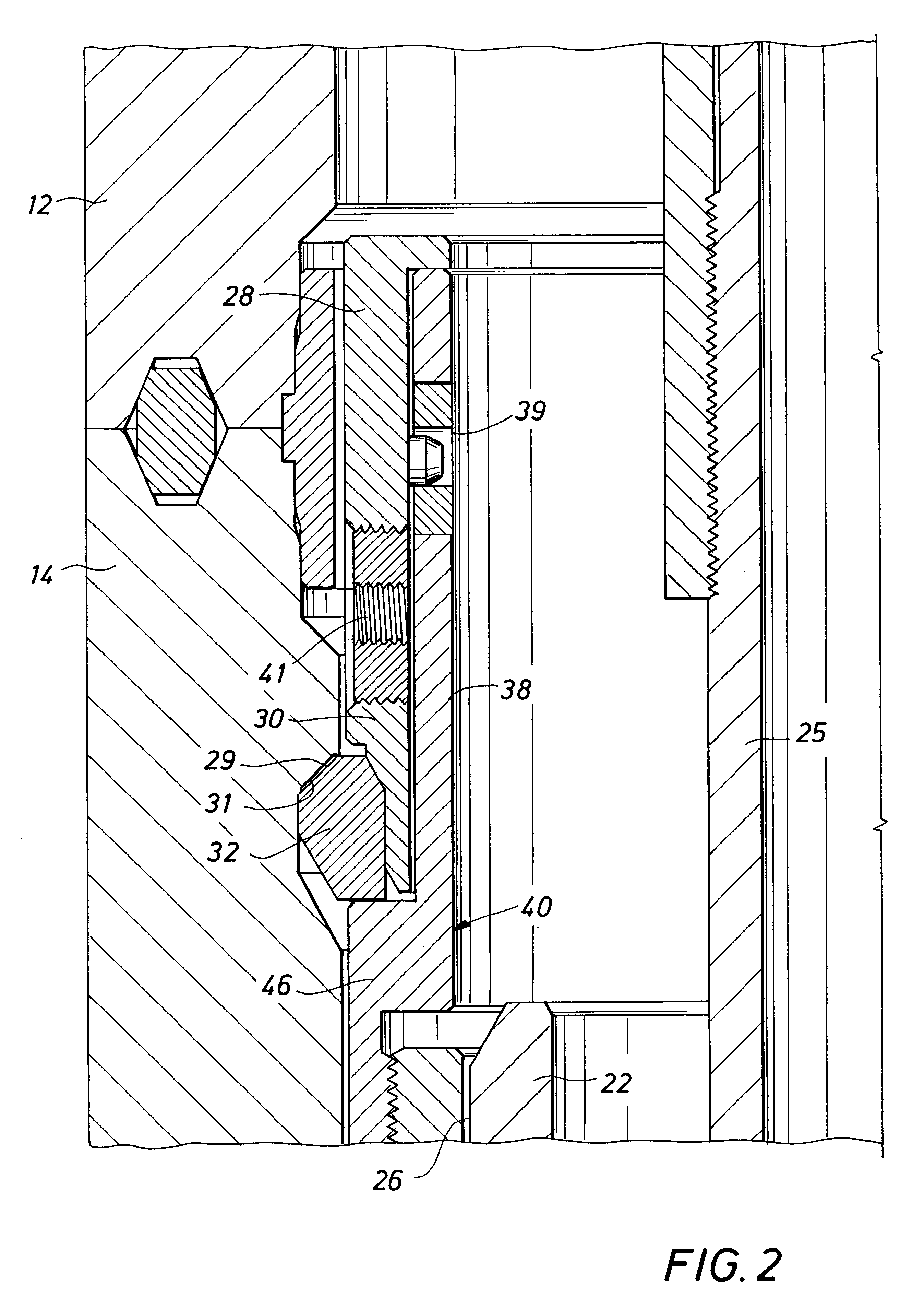

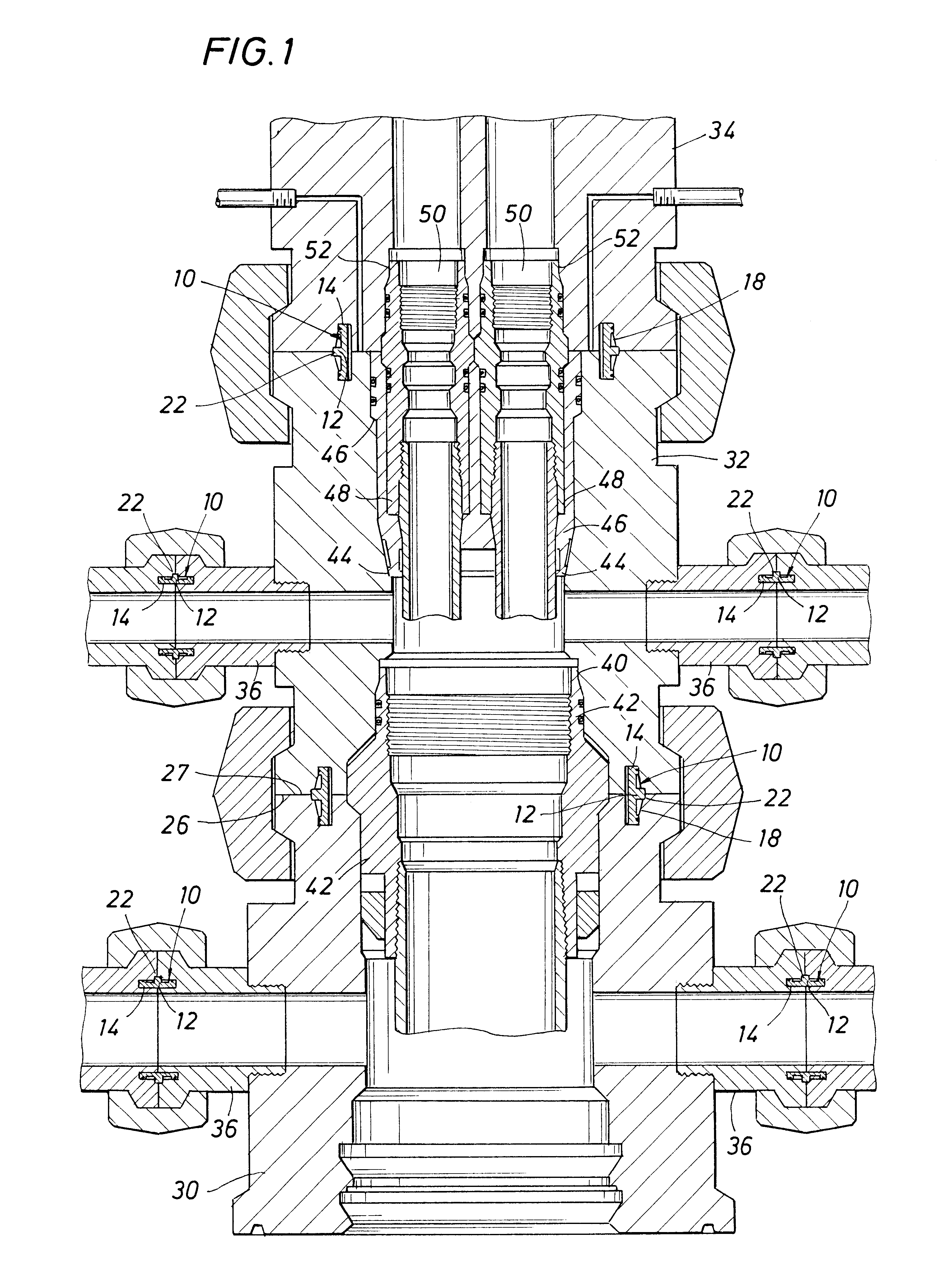

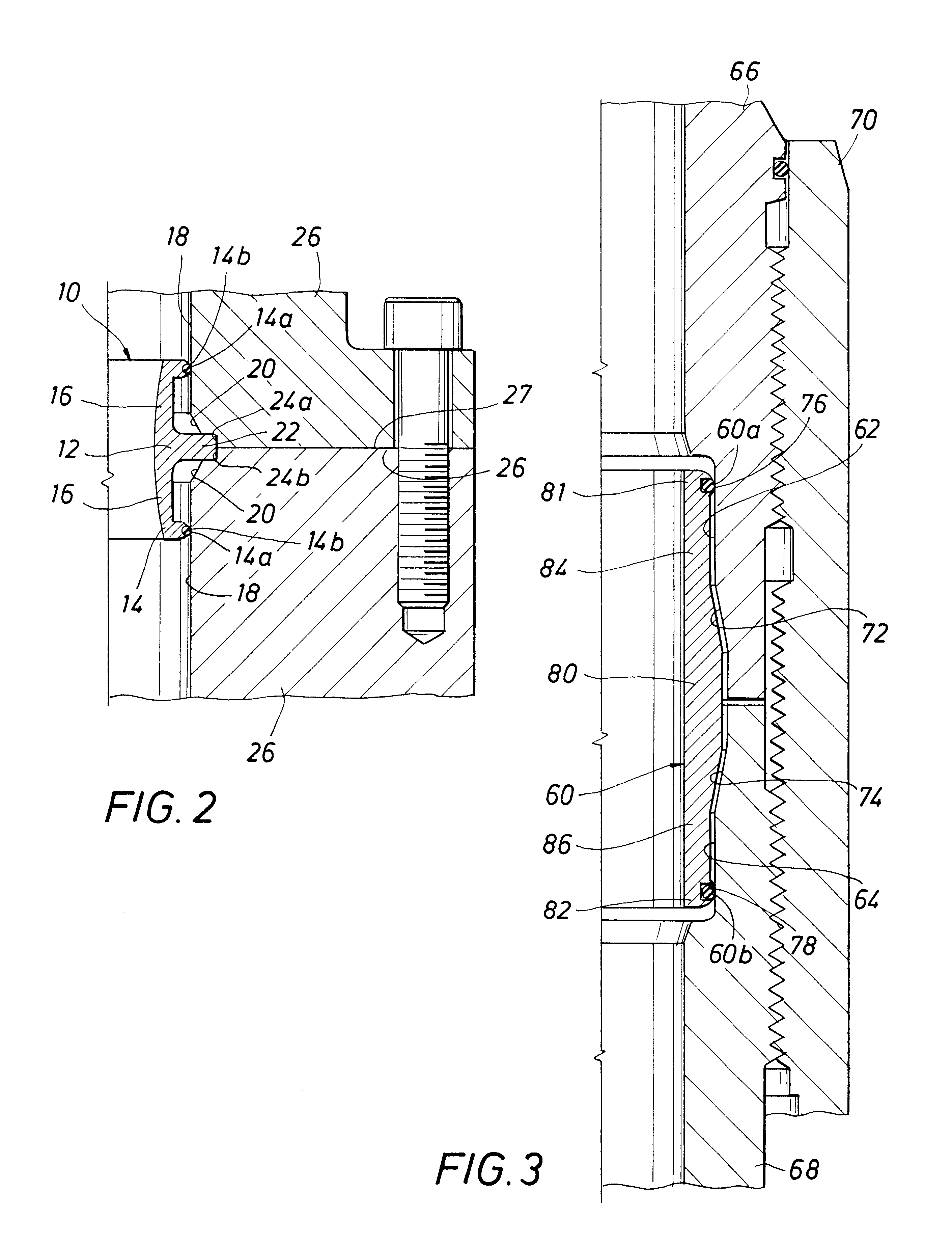

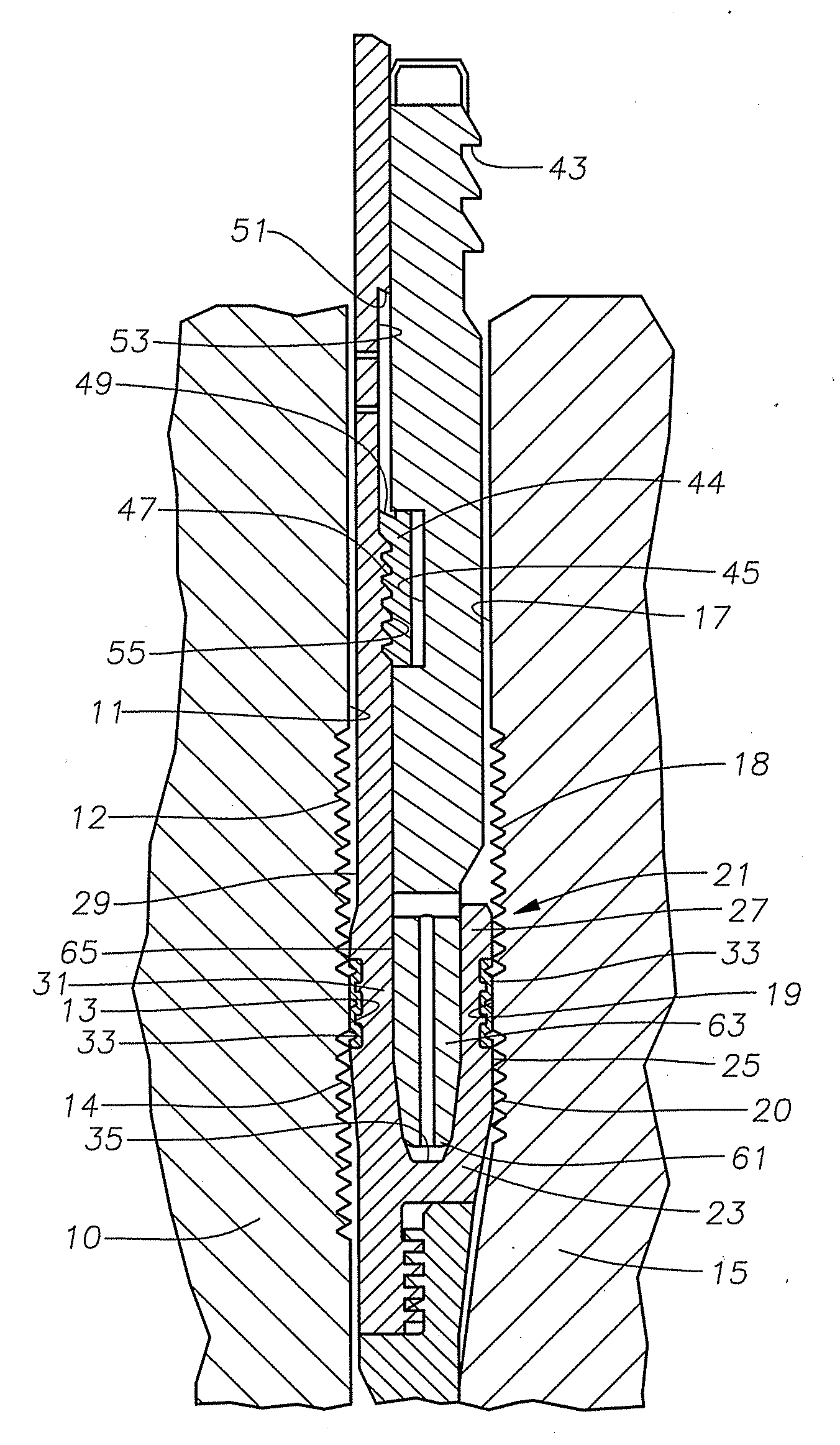

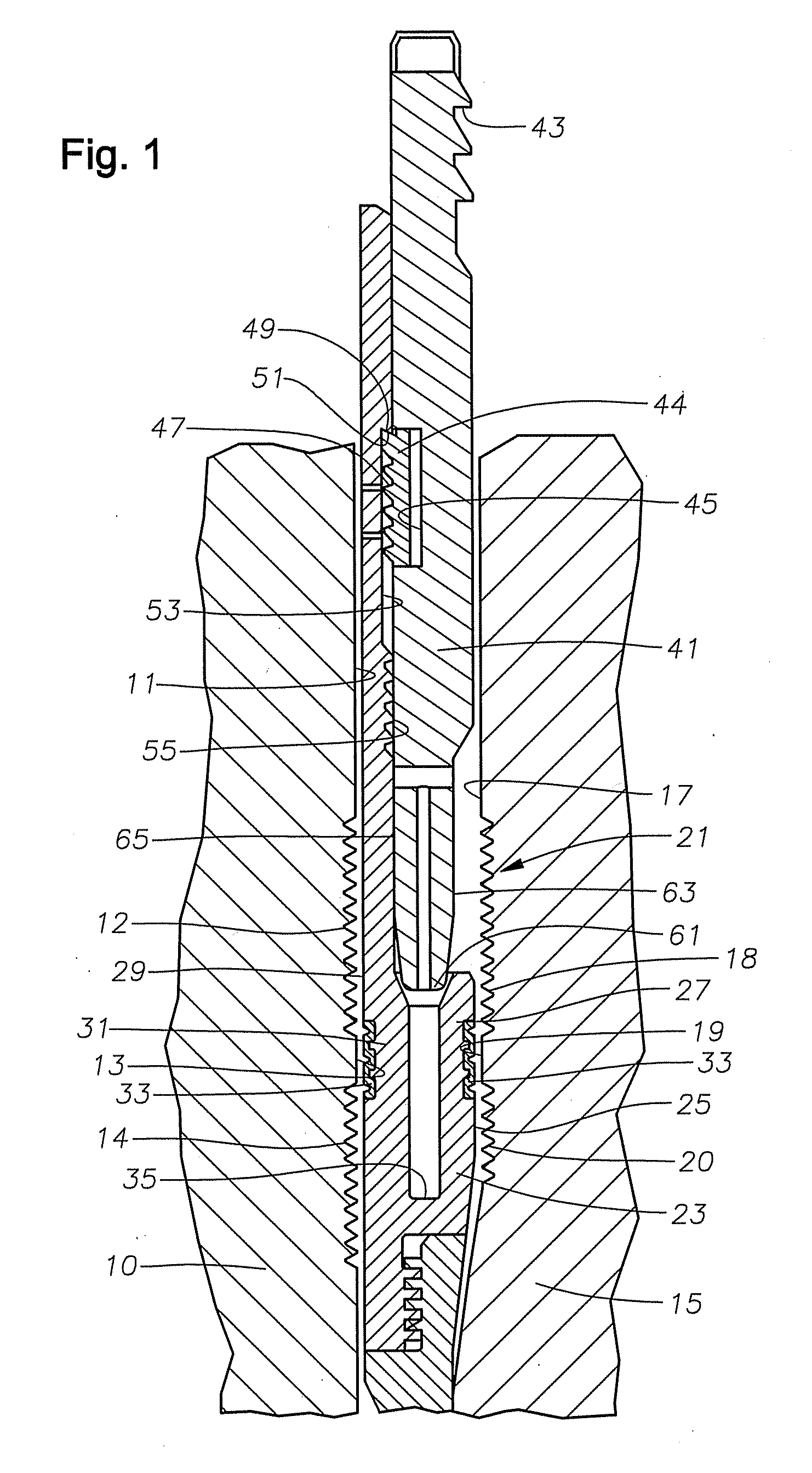

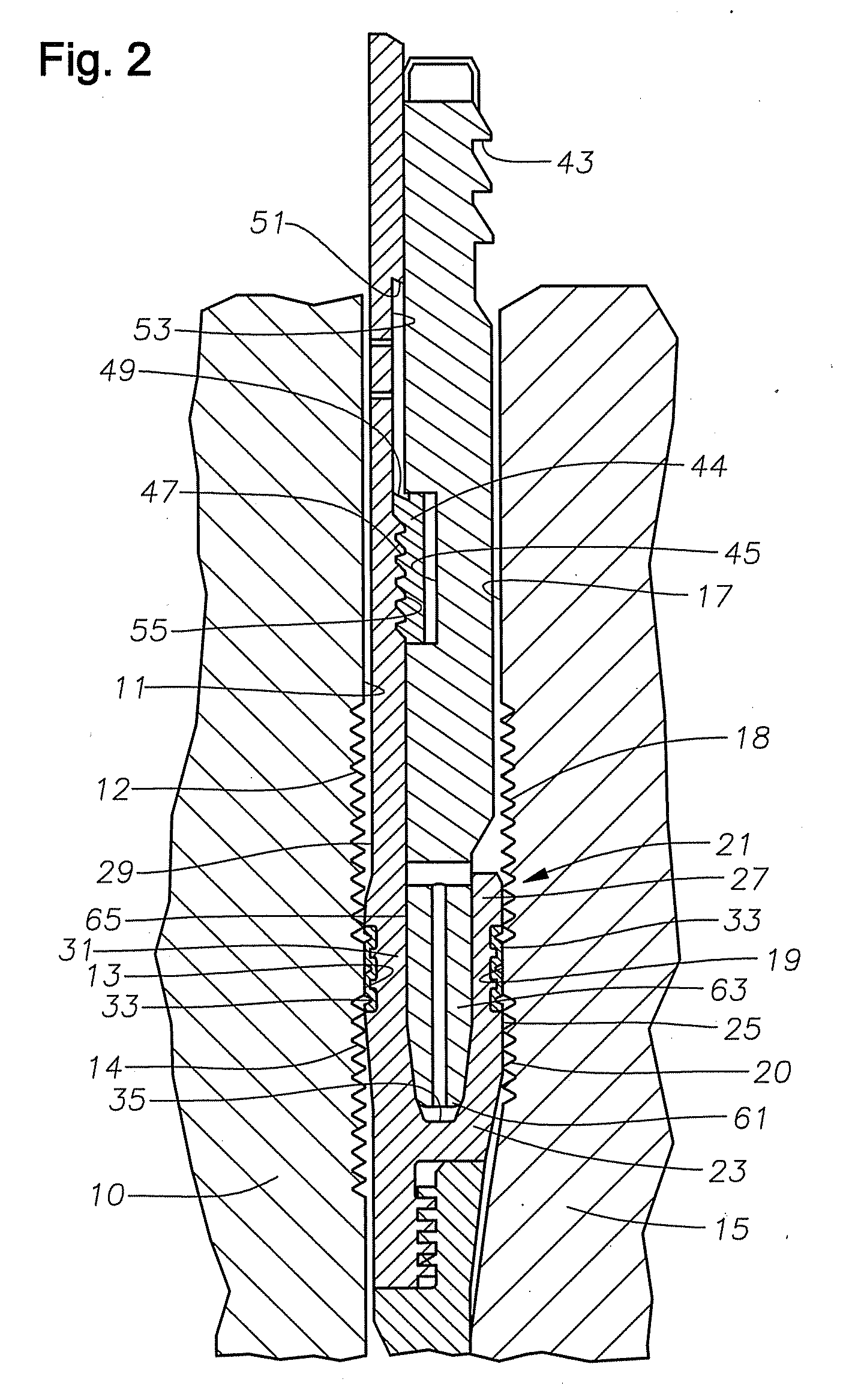

Energized sealing cartridge for annulus sealing between tubular well components

InactiveUS6510895B1Effective control of the sealing capability of the seal cartridgeFluid pressure sealed jointsConstructionsElastomerRespirator

A mechanically energized annular packoff seal cartridge for metal-to-metal sealing with substantially concentrically arranged tubular members, such as the tubular wellhead housing and well casing of an oil and gas well. A tubular pressure responsive energizing mandrel having downwardly converging frusto-conical seal actuating surfaces is of a dimension for entry into the annulus between the wellhead seal bore and the rough outer surface of the well casing. Elastomer seals are carried by the energizing mandrel and establish sealing of the energizing mandrel with the wellhead housing and well casing A pair of soft metal seal rings are carried by the seal cartridge and are forced radially into metal-to-metal sealing with the wellhead housing and the rough outer surface of the well casing respectively by the double tapered seal actuating surfaces responsive to pressure induced downward force on the energizing mandrel. A locking mandrel and the seal actuating mechanism are restrained against actuating movement during running of the seal cartridge by a running tool by shear pins, thus enabling the cartridge to pass through various well equipment. The shear pin of the locking mandrel is sheared by downward force applied by the running tool to lock the seal cartridge within the wellhead housing. The shear pin of the seal actuating mechanism is sheared, after locking of the cartridge to the wellhead housing, by the force of pressure introduced into the wellhead above the seal cartridge which acts to develop a pressure differential across the elastomer seals of the cartridge.

Owner:FMC TECH INC

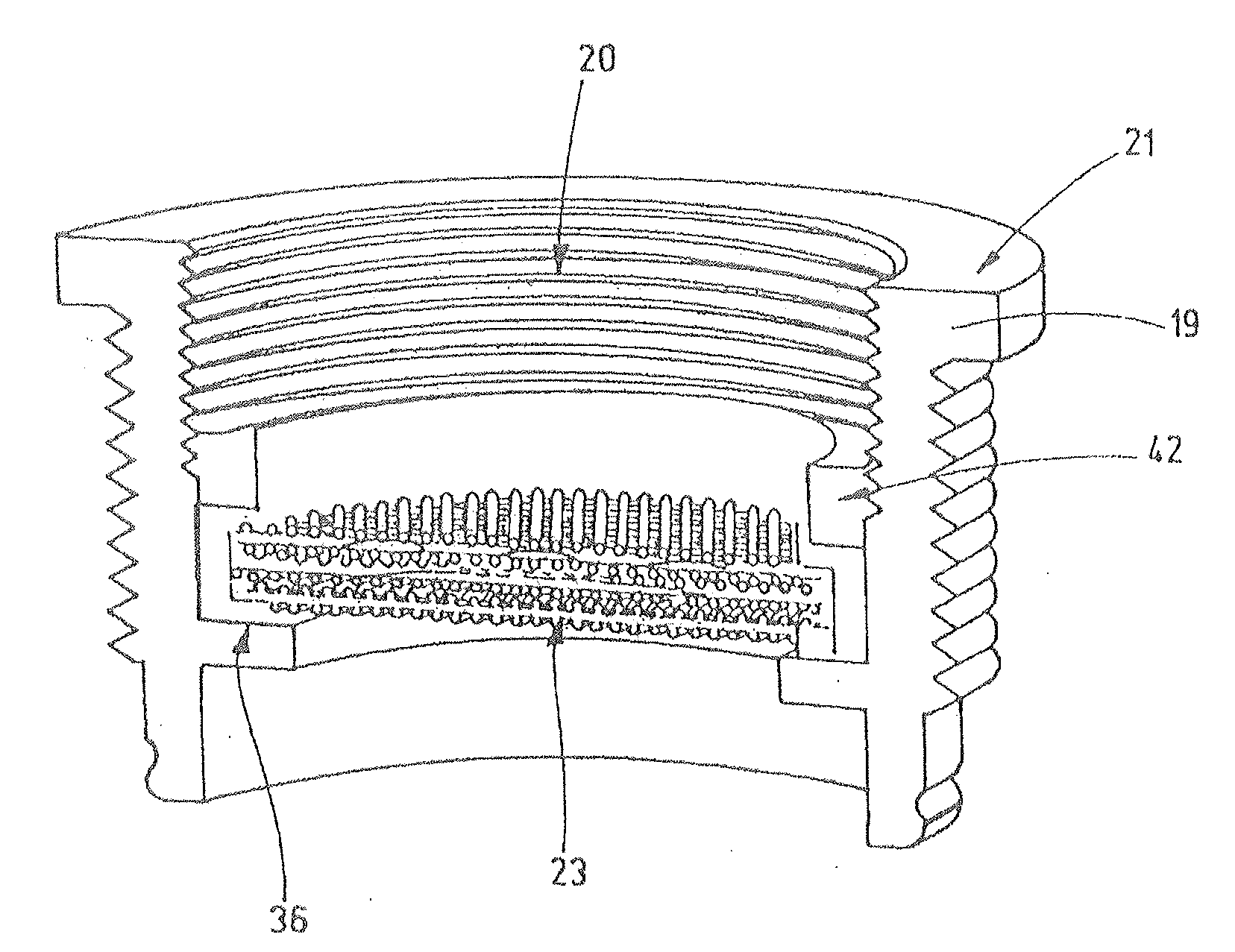

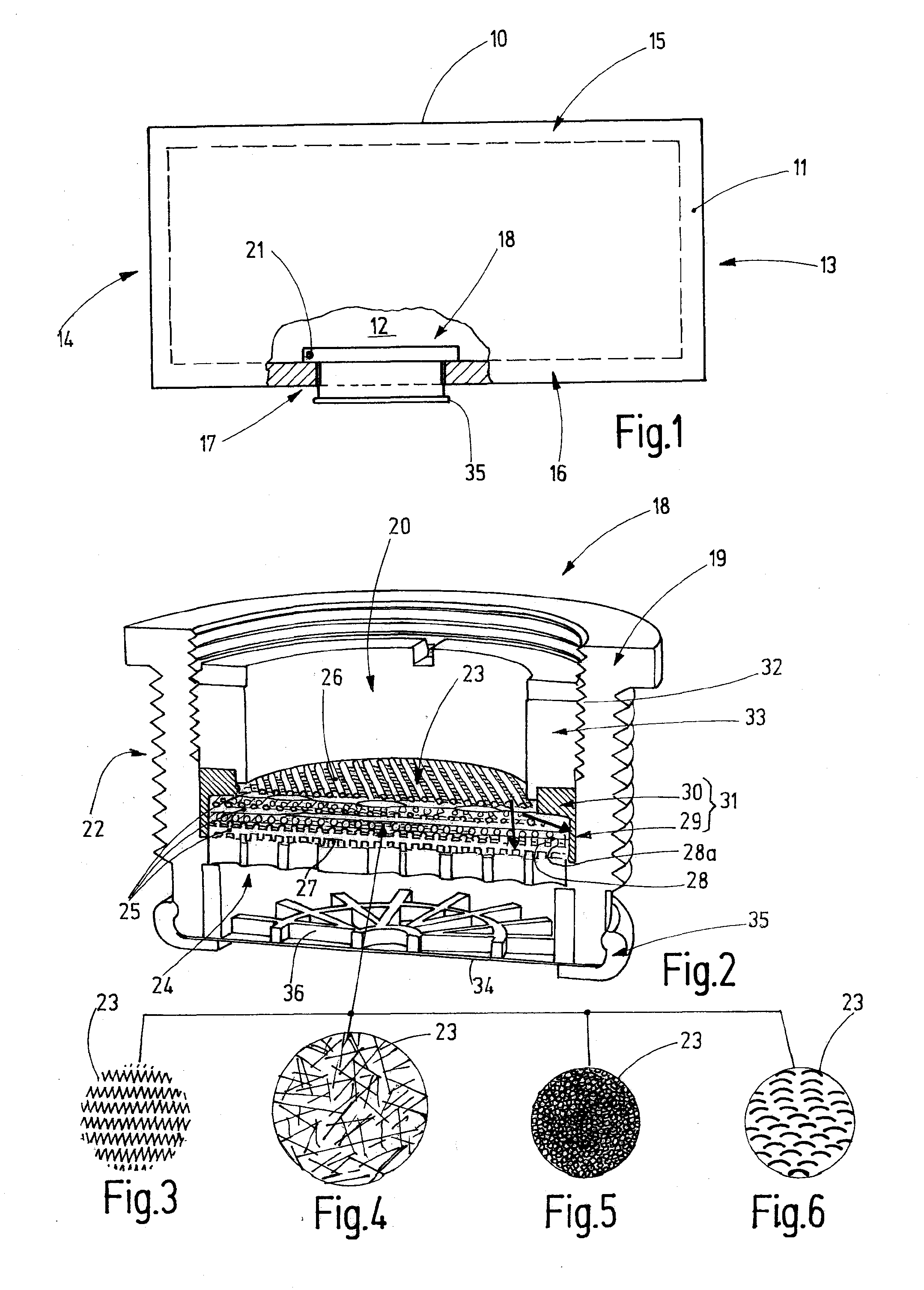

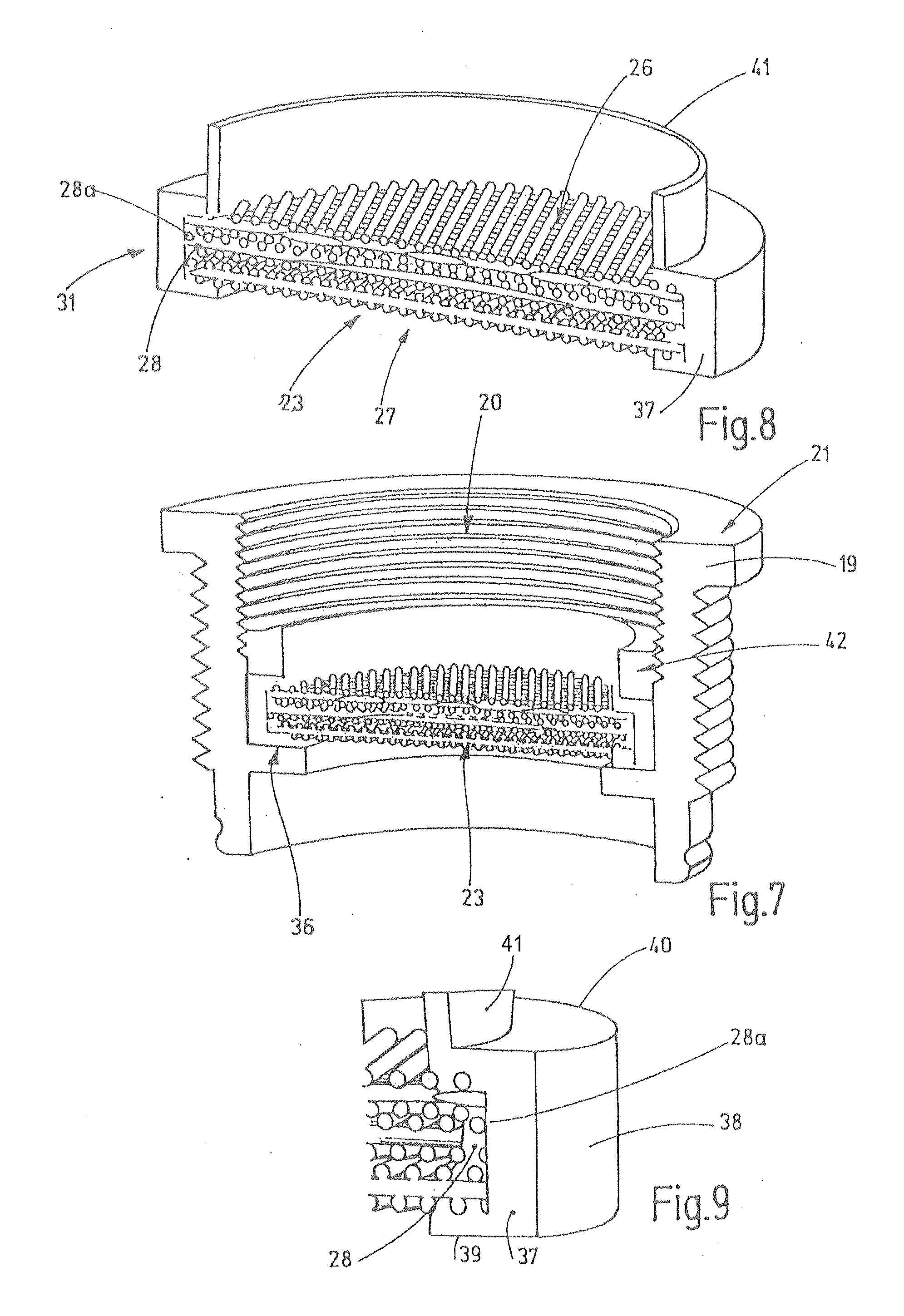

Pressure relief device for pressure-proof encapsulated housings

InactiveUS20130206759A1Enhances safety against flame transmissionImprove securityLarge containersFire rescueSynthetic materialsMetal

A protective housing designed as a pressure proof capsule has a pressure relief valve which comprises a porous body 23 and a pore closure 31 about its perimeter for preventing the transition of a flame about an edge of the porous body. Alternative embodiments of pore closures 31 are disclosed, including a soft metal ring about an edge of the porous body that is depressed, such as by a pressure ring, into a gapless imbedding relation to the porous body. An edge region of the porous body can be modified by jacketing materials such as synthetic materials, metals and the like for creating a form fitting bond with the body of the protective housing.

Owner:R STAHL SCHALTGERATE

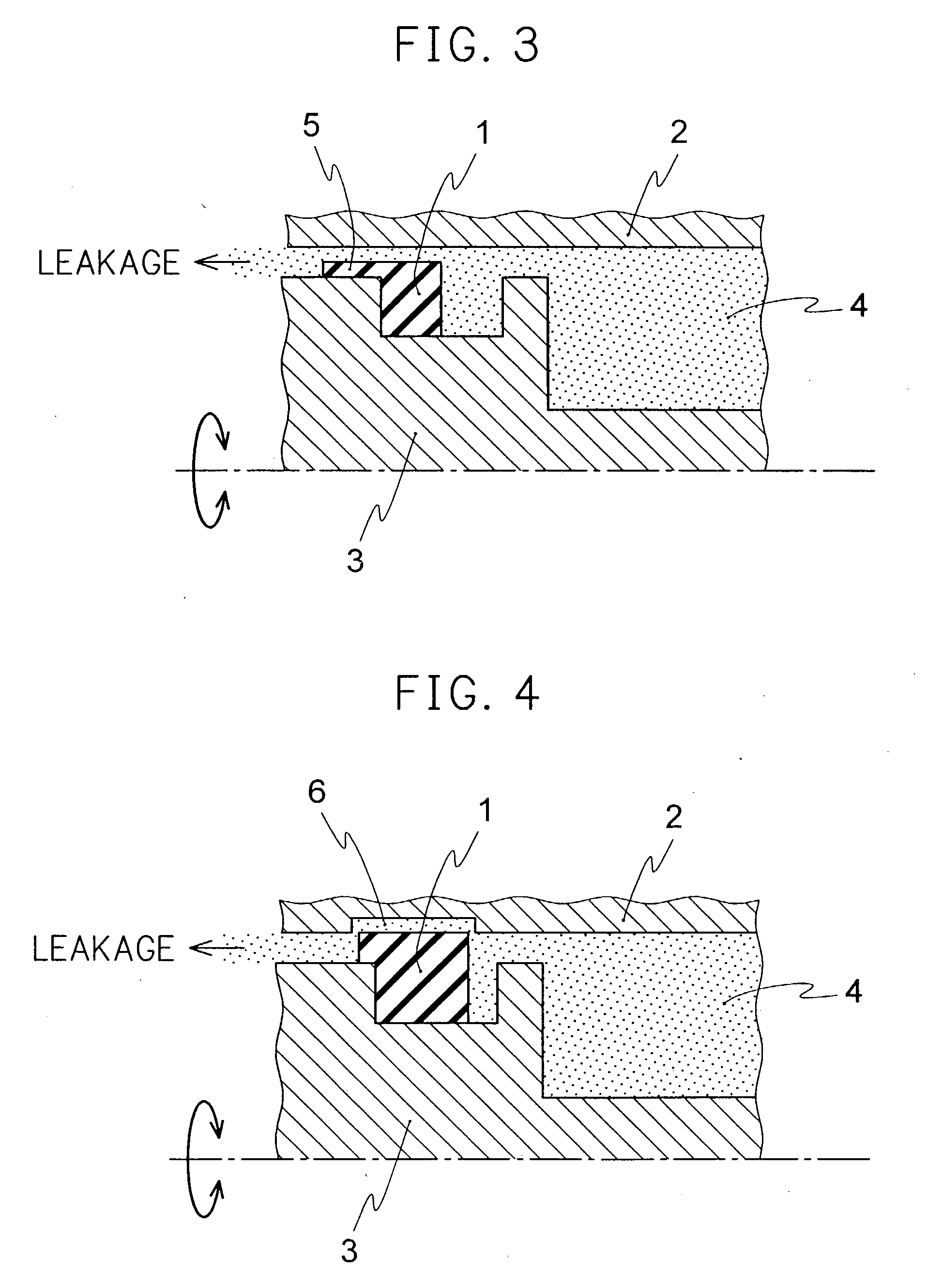

Metal-to-metal seal with soft metal insert

An annular metal-to-metal sealing system, for use in wellhead systems and having many other uses, has a metal member defining an annular internal or external sealing surface for which sealing is intended. An annular seal body composed of high strength metal material is positioned in concentric relation with the annular sealing surface and is sufficient flexible to become spring loaded, typically during assembly, for continuous application of a spring force. The annular seal body defines one or more annular seal retainer grooves each having an annular soft metal sealing insert therein, with a portion thereof exposed for sealing engagement with the annular sealing surface. The spring loaded characteristic of the annular seal body applies constant force to maintain the soft metal seal insert in constantly energized sealing relation with the annular sealing surface and maintains effective sealing even when dimensional changes to the sealing surface occur due to temperature or pressure changes.

Owner:FMC CORP

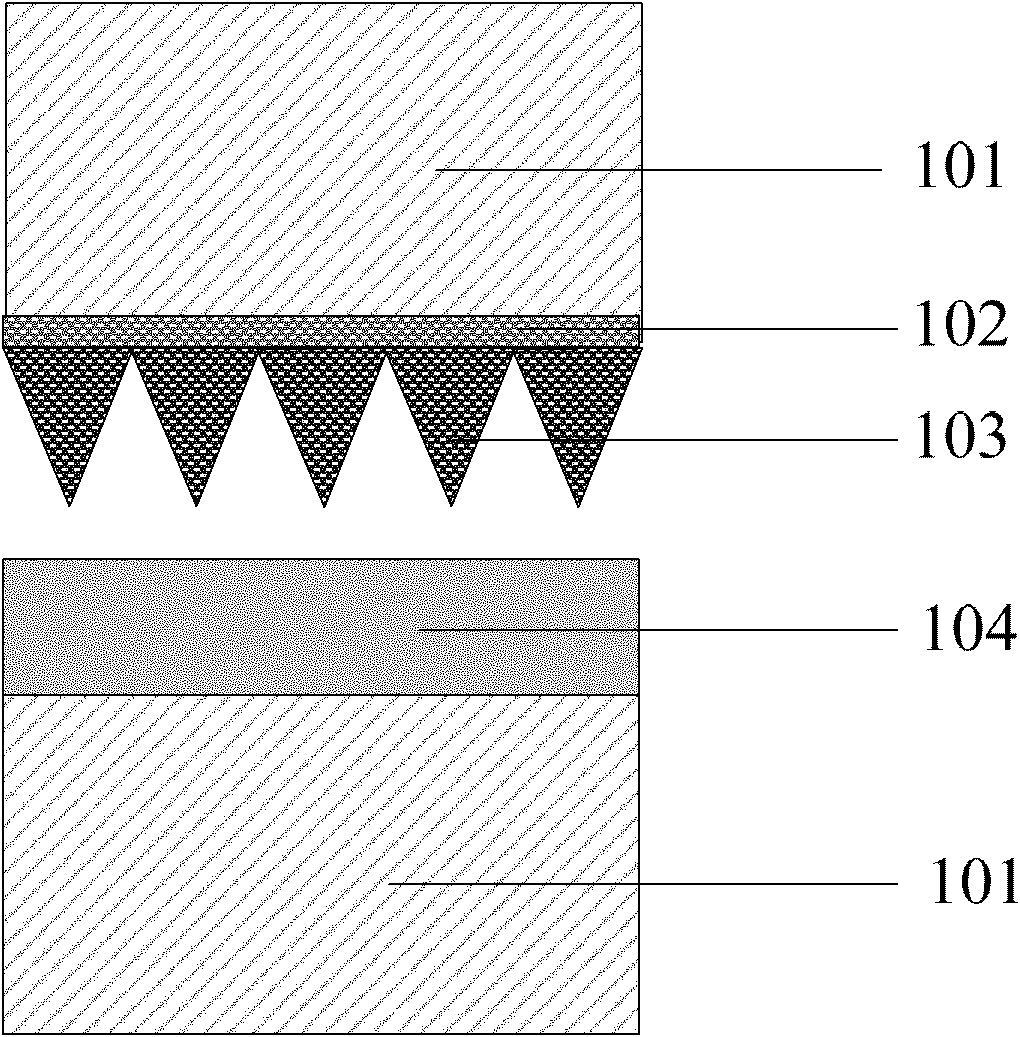

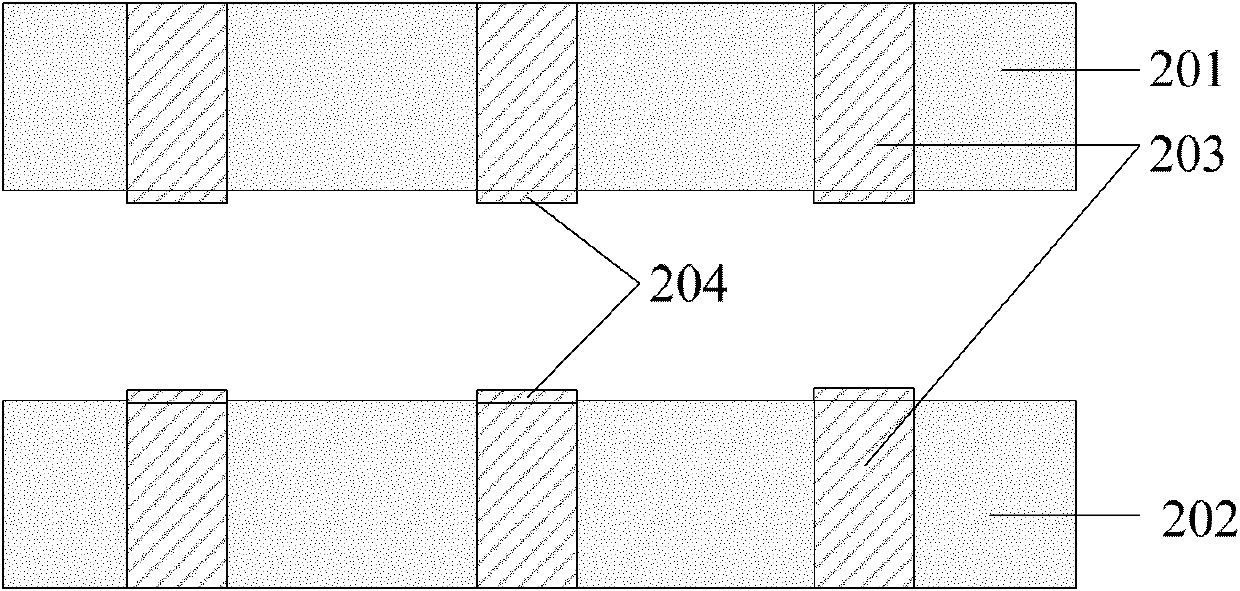

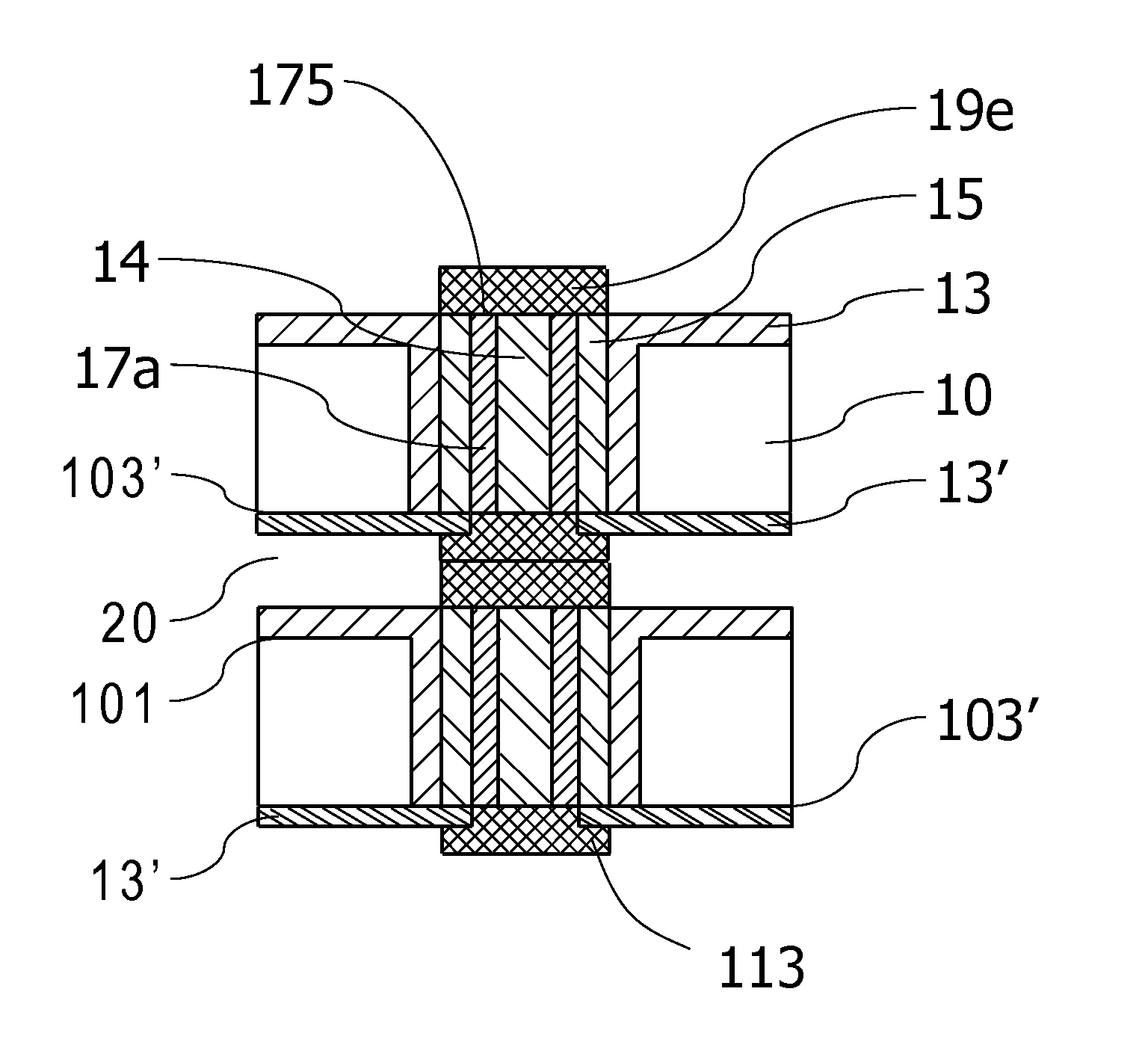

Multi-layer mixed synchronization bonding structure and method for three-dimensional packaging

ActiveCN102169845AGuaranteed accuracy requirementsSave time and costSemiconductor/solid-state device detailsSoldering apparatusDielectricHard metal

The invention relates to a multi-layer mixed synchronization bonding structure and a method for three-dimensional packaging. The method comprises the following steps of: forming a hard metal conical array on a surface of a metallic pad of a substrate to be mixed and bonded; forming a soft metal layer on the surface of the metallic pad of the other substrate to be mixed and bonded; forming dielectric adhesion layers on surfaces of non-metallic pads of the two substrates to be mixed and bonded; aligning the hard metal conical array with the soft metal layer, heating and pressurizing to make thehard metal conical array inserted into the soft metal layer, and combining the dielectric adhesion layers with each other to form a mixed pre-bonding structure; and then heating, forming an intermetallic compound in the hard metal conical array which is inserted into the soft metal layer, and solidifying and combining the dielectric adhesion layers. Compared with the conventional bonding method, the method provided by the invention has the advantages that: yield is high; bonding time is saved; cost is reduced; and the reliability of a product is improved at the same time.

Owner:NAT CENT FOR ADVANCED PACKAGING

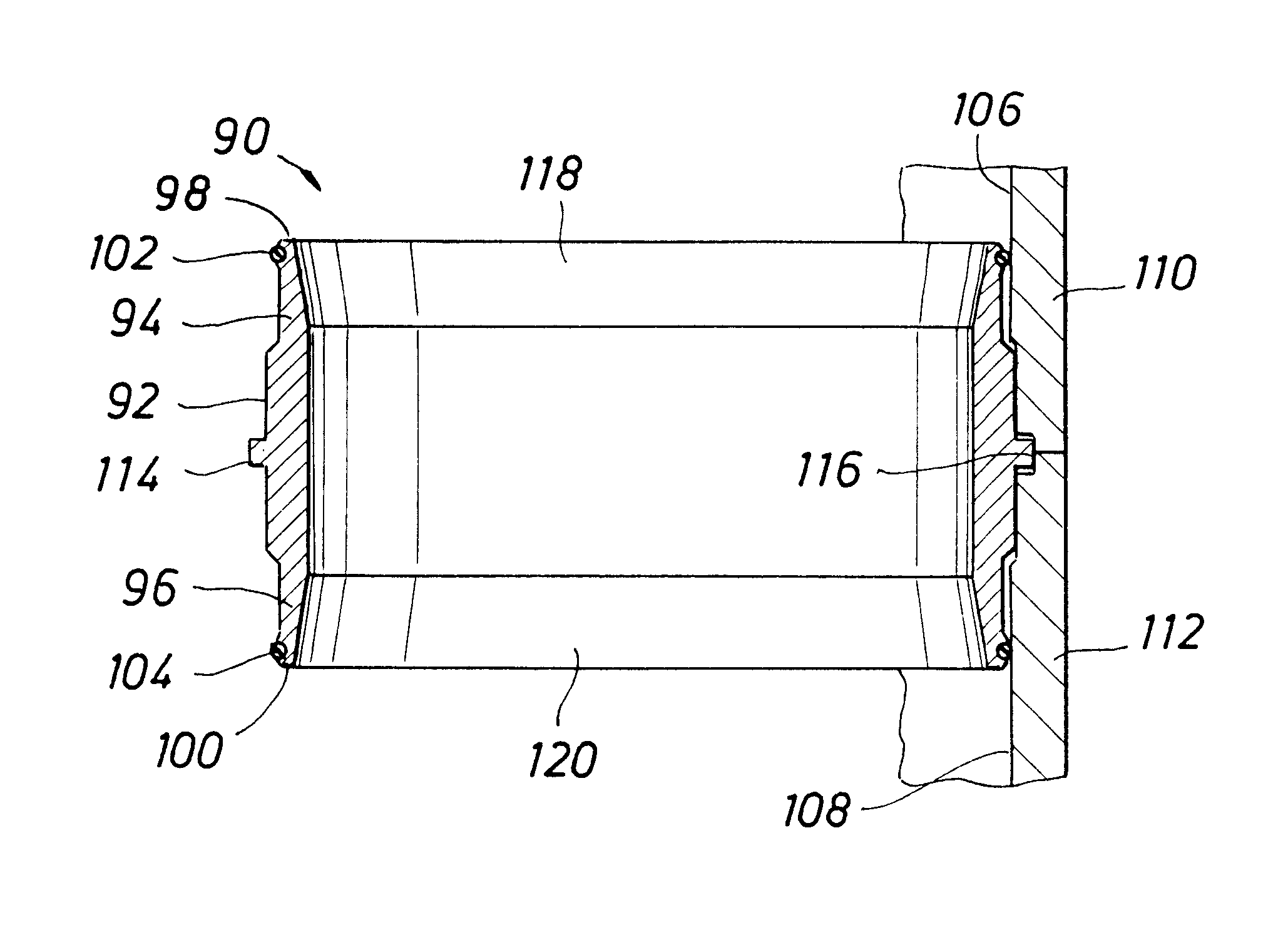

Metal-to-metal seal with travel seal bands

A wellhead seal assembly that forms a metal-to-metal seal between inner and outer wellhead members. A metal seal ring has inner and outer walls separated by a slot. The exterior surfaces of the outer and inner walls contain a soft metal inlay. A wicker profile with a slick area is located on the outer surface of the inner wellhead member and on the inner surface of the outer wellhead member. An energizing ring is moved into the slot to force the outer and inner walls of the seal into sealing engagement with the inner and outer wellhead members. The soft metal inlays deform onto the slick area on the wellhead members. The wickers on the wellhead members embed into the walls of the seal ring.

Owner:VETCO GRAY

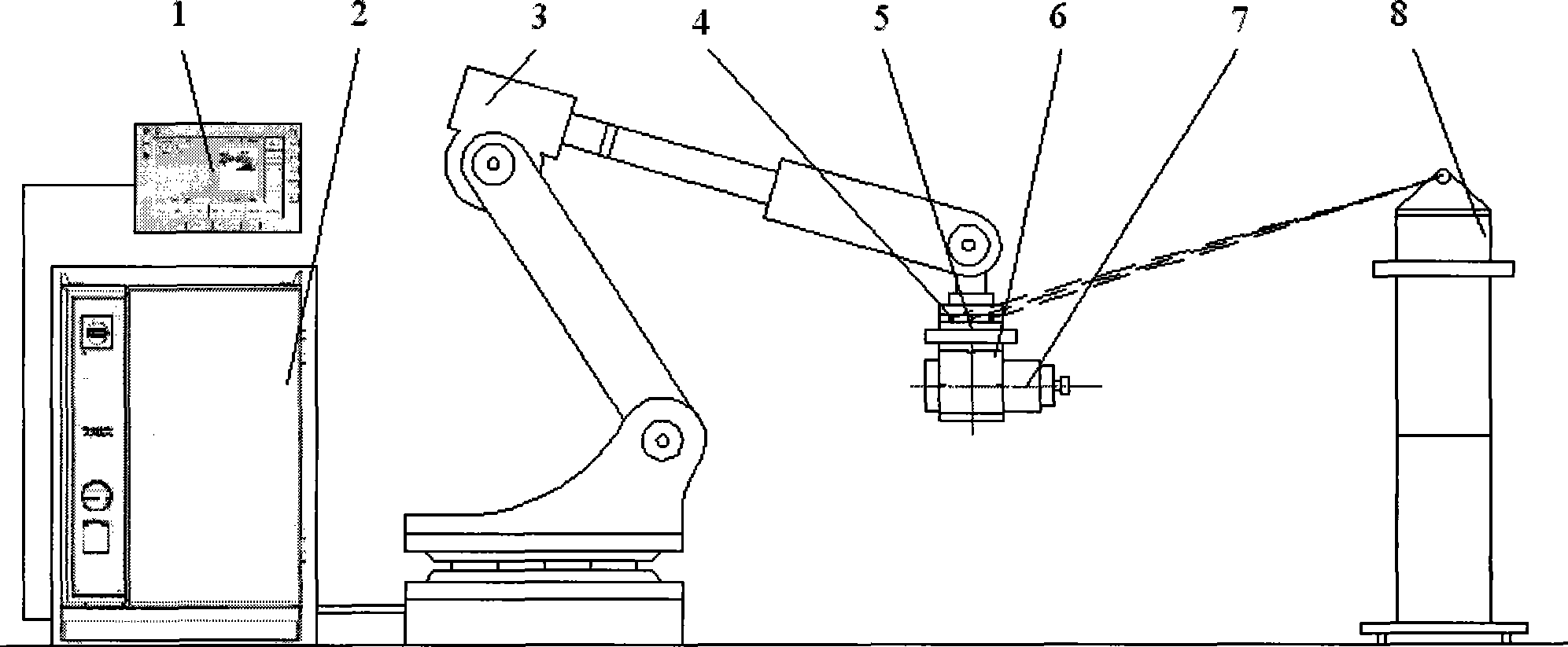

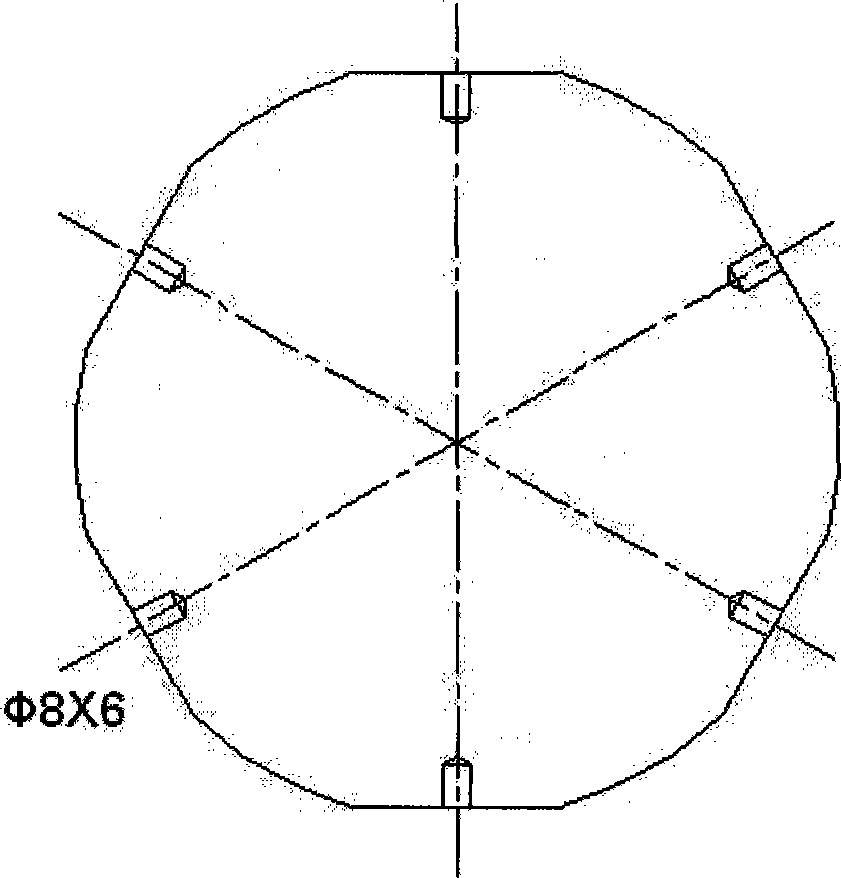

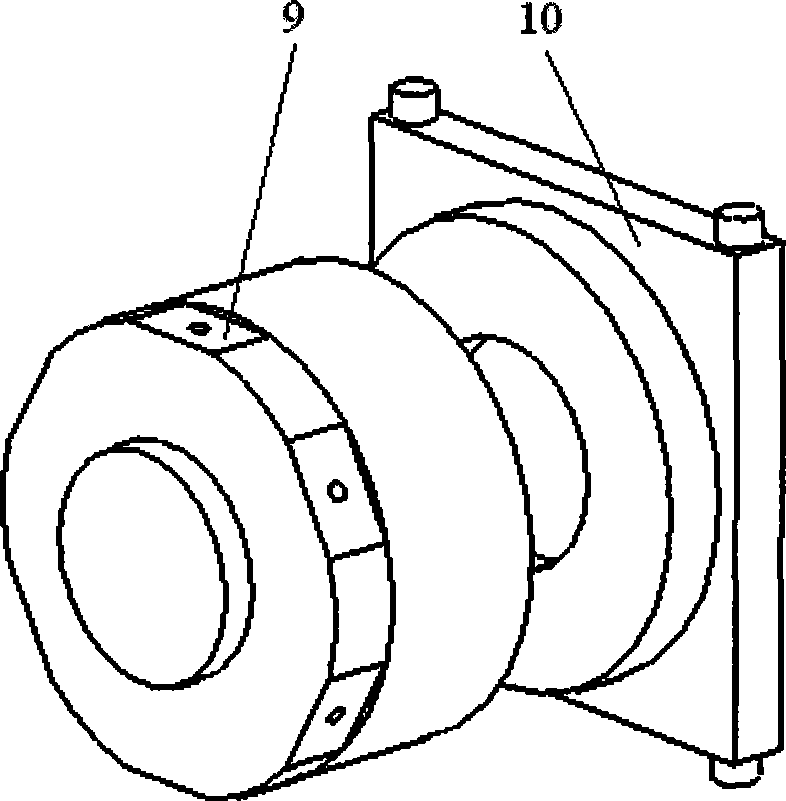

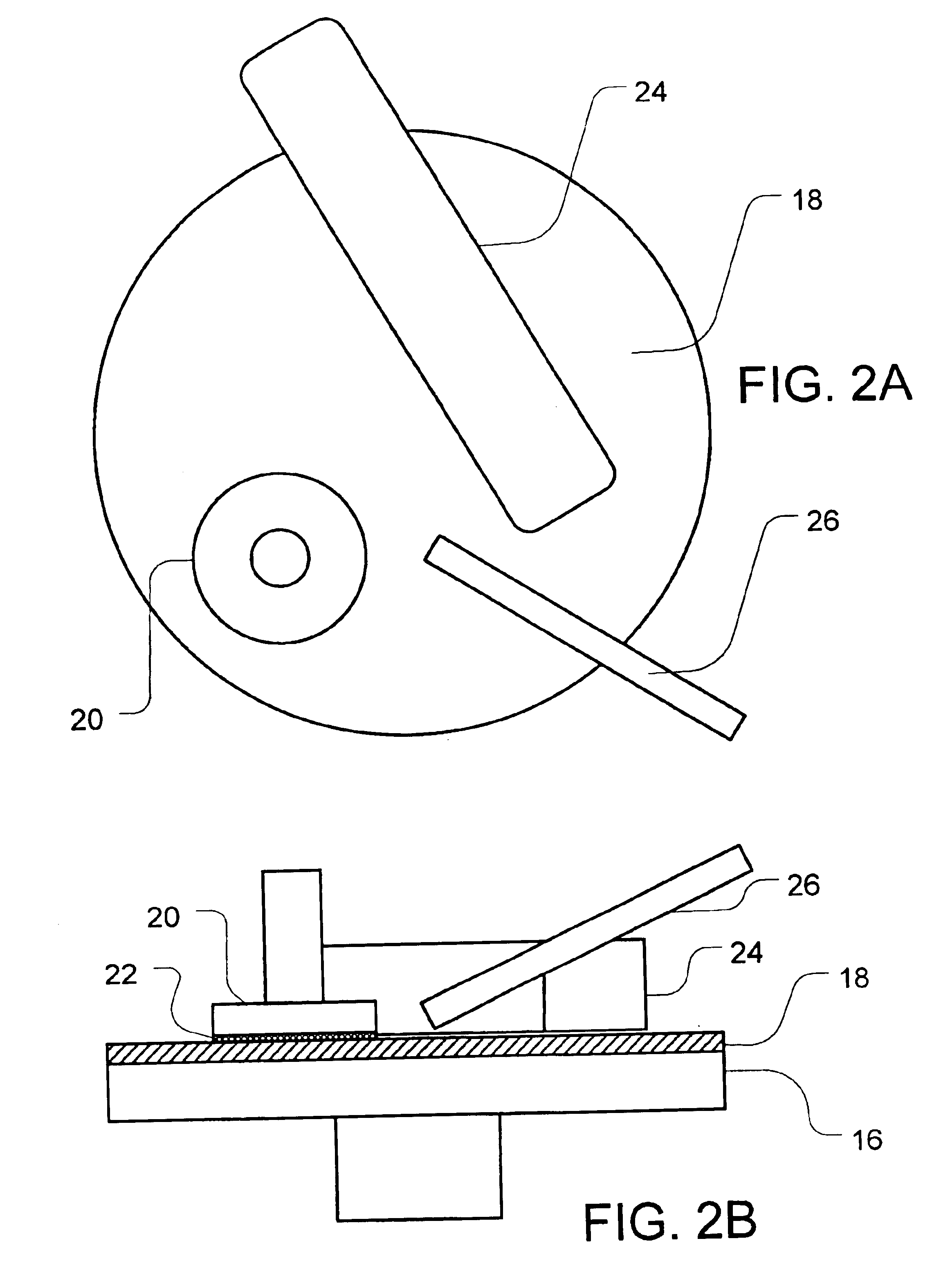

Industrial robot cutting and processing system applied to auxiliary assembly of airplane as well as method

InactiveCN101372079ARealize cutting functionMeet the machining accuracy requirementsMeasurement/indication equipmentsLarge fixed membersEngineeringLaser tracker

The invention discloses an industrial robot cutting processing system and a method applied to aircraft auxiliary assembly, comprising a six-axis joint typed industrial robot, a robot controller, an operation panel, a high speed electric mainshaft, a tool clamping process device, a tool quick exchanger, a target installation flange and a laser tracker; high speed cutting technique is adopted; process methods and hole preparing process of boring, reaming by milling and final reaming are sequentially carried out so as to improve the diameter precision of the hole; meanwhile, the cutting force can be controlled by finishing the reaming hole; rough milling is carried out firstly, fine milling is subsequently carried out; furthermore, the cutting depth is not more than 0.15mm during the fine milling process, thus ensuring the planeness of the processing surface; the industrial robot cutting processing system can realize various cutting processes of the soft metal (such as aluminium alloy) as follows: boring, hole enlarging, reaming, dimpling, surface milling, cutting, etc. The invention integrates normal robot, high speed electric mainshaft, quick exchanger, etc., and can solve the cutting process problems of operations such as fine processing, skin cutting, and the like of radar cover installation hole in the field of aircraft assembly.

Owner:ZHEJIANG UNIV +1

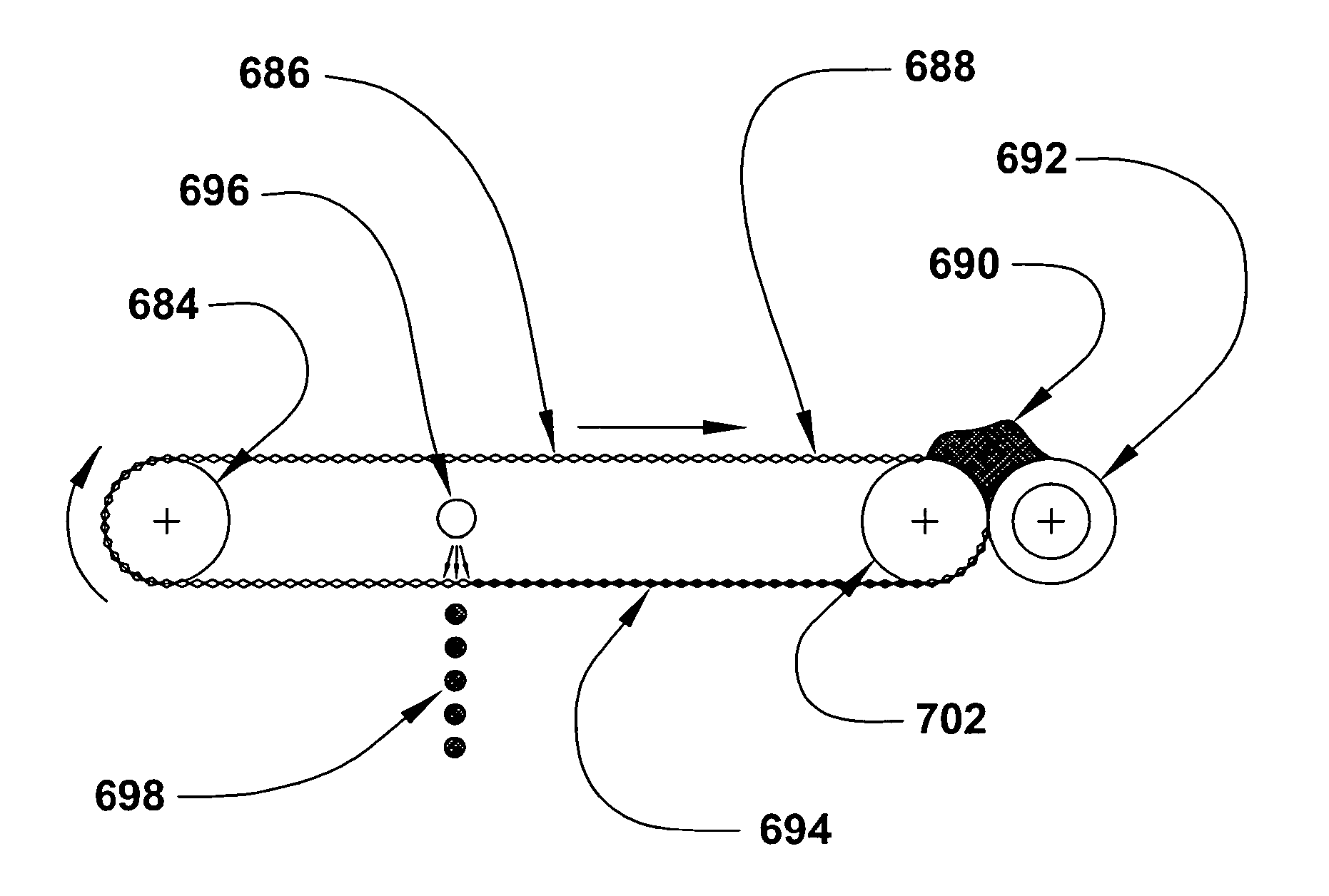

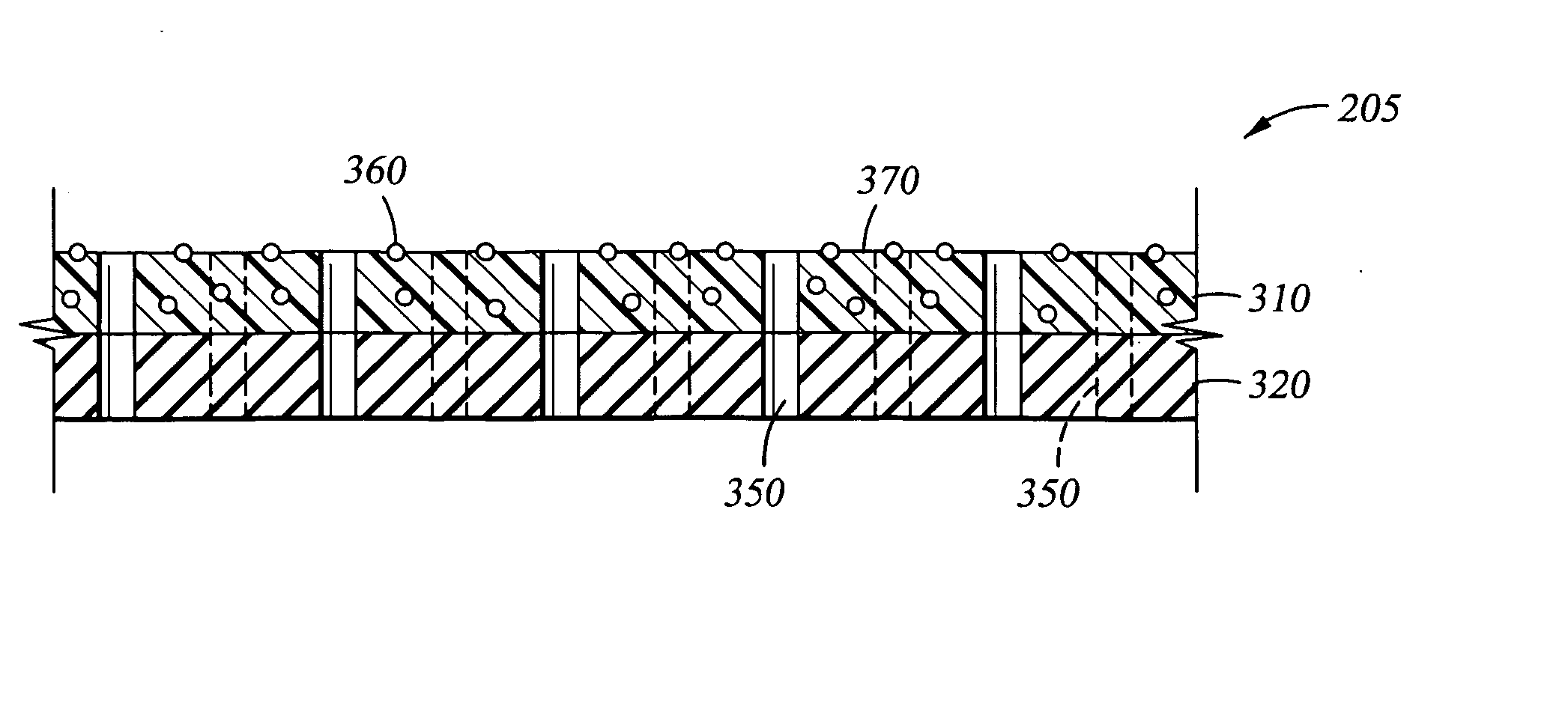

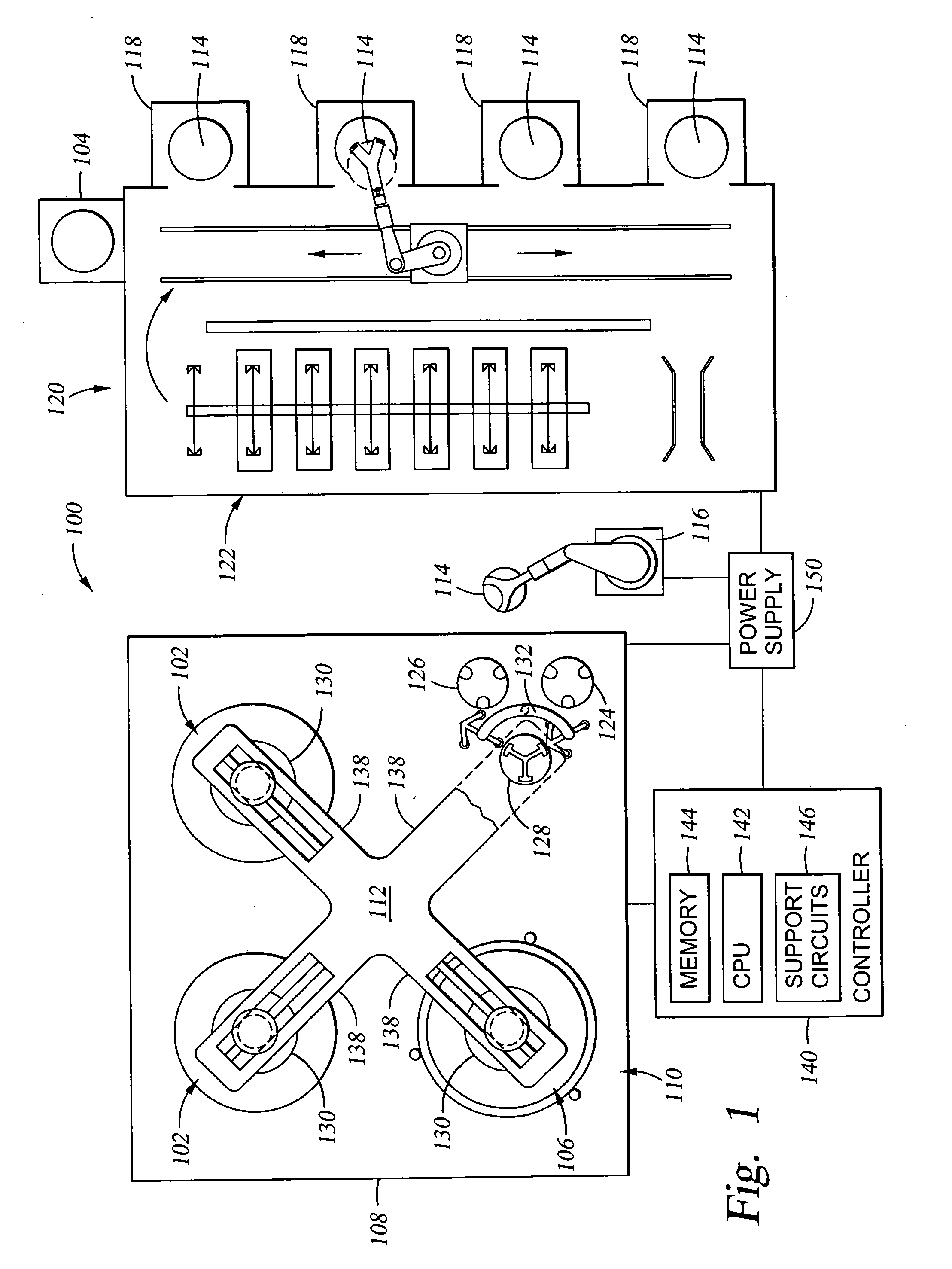

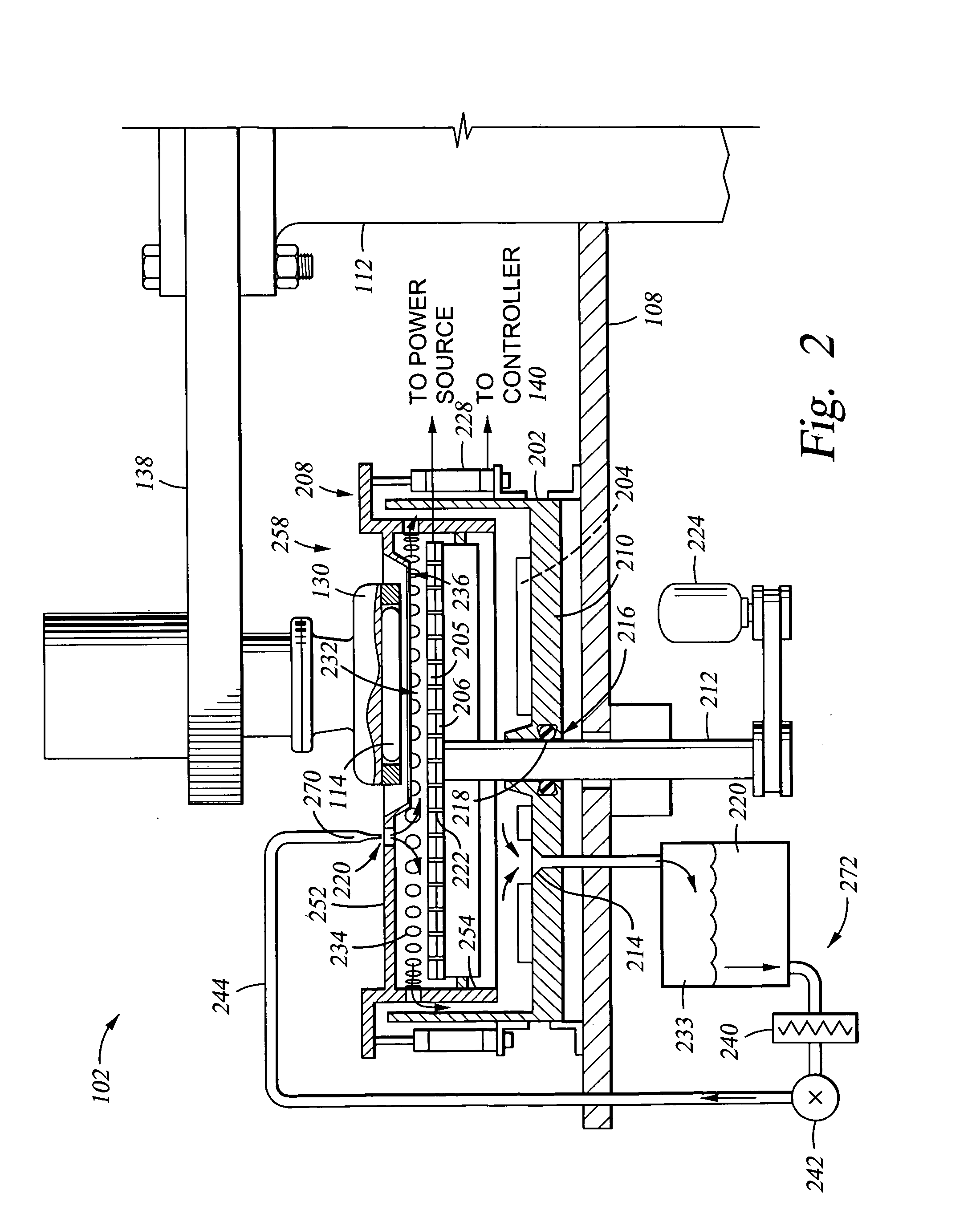

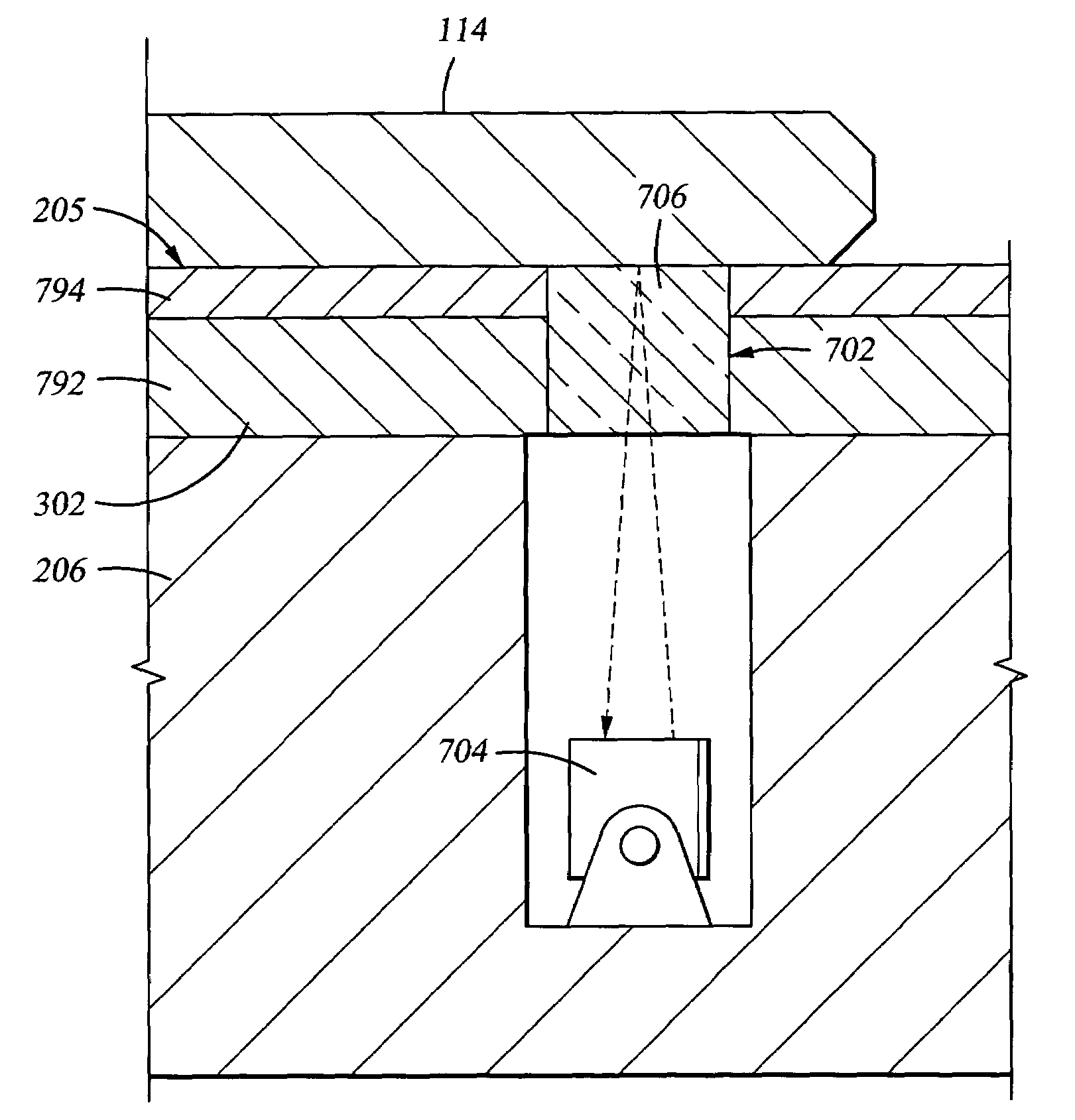

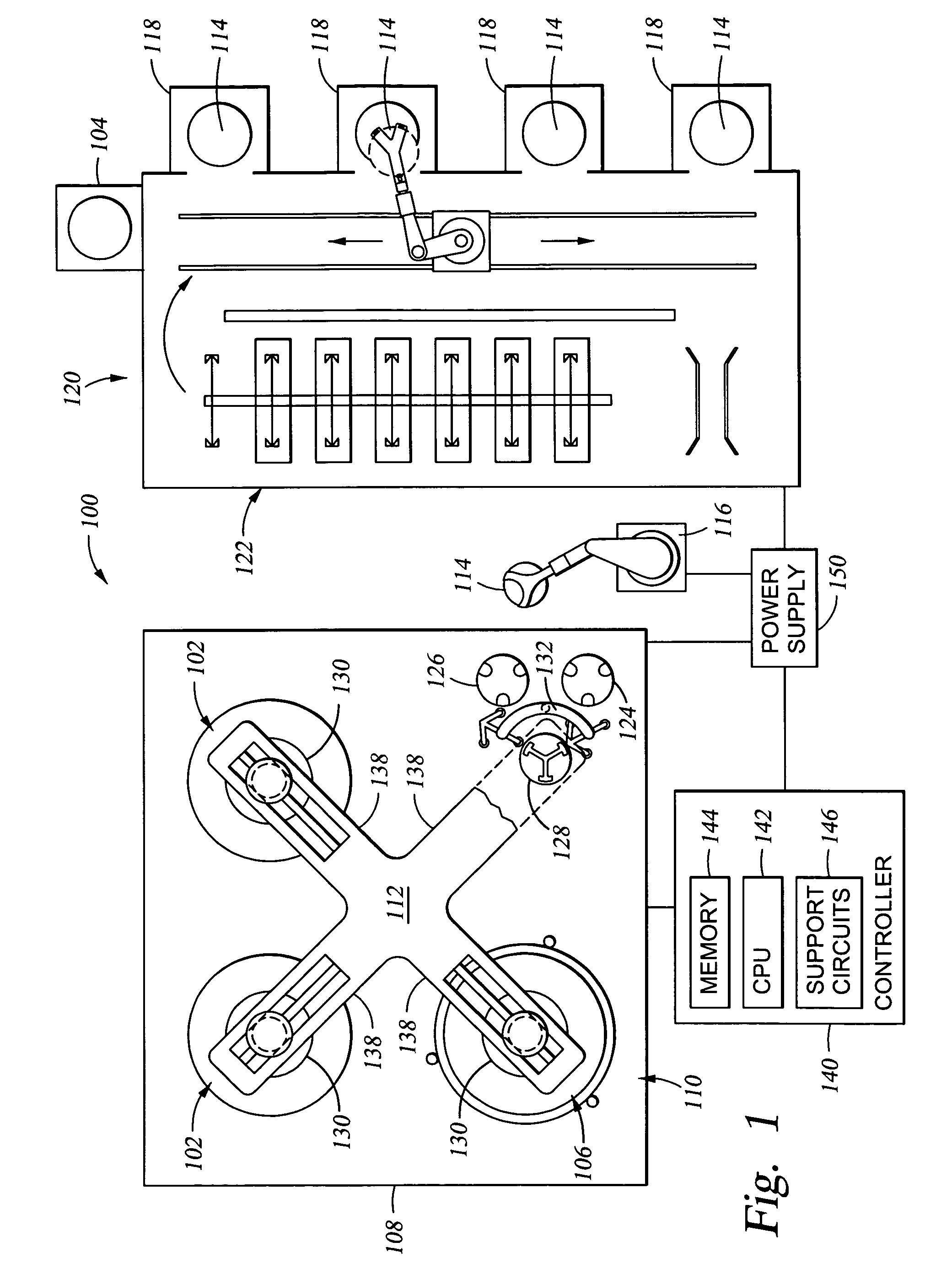

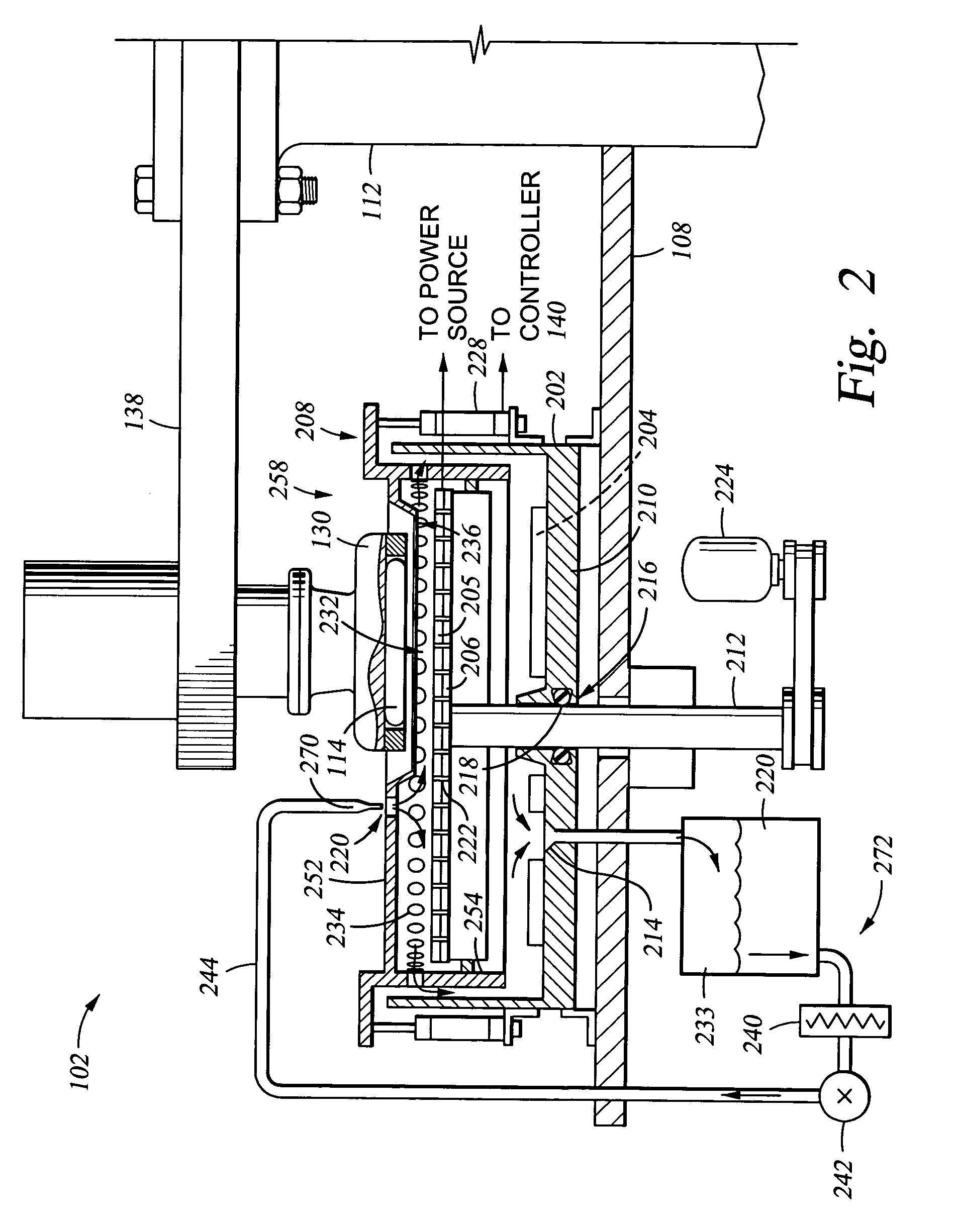

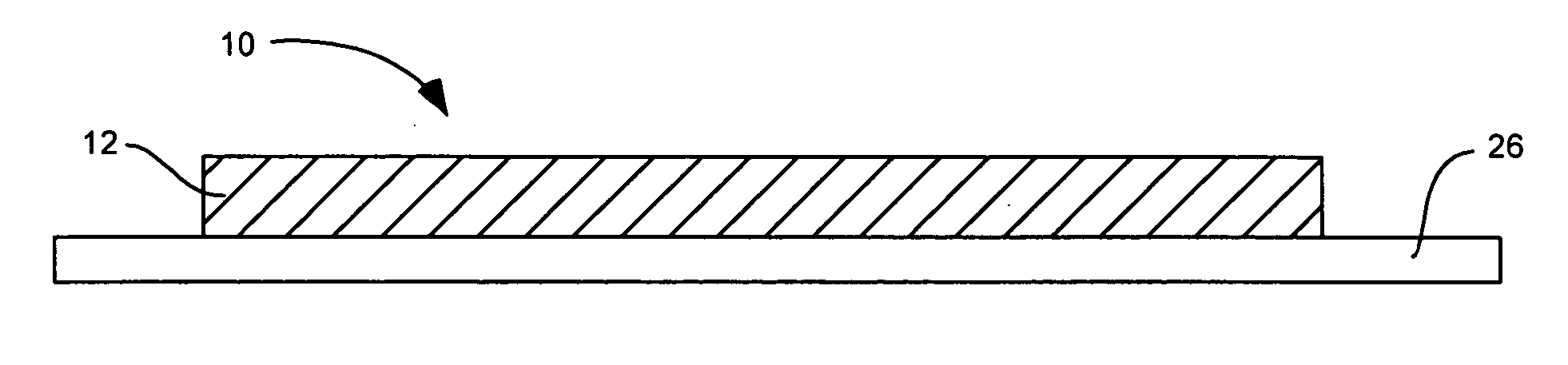

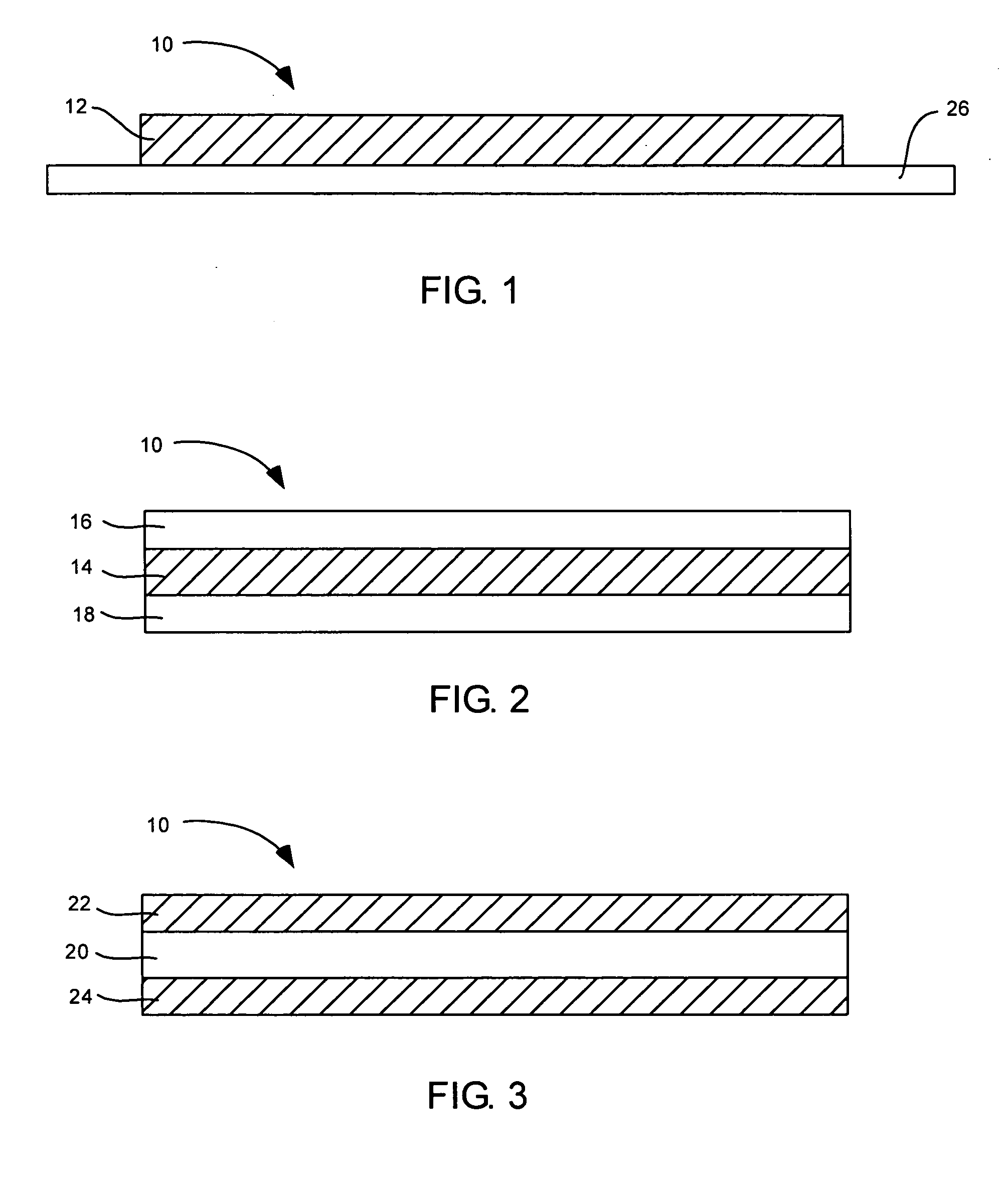

Conductive polishing article for electrochemical mechanical polishing

InactiveUS20050133363A1Easy to moveMaterial nanotechnologyElectrolysis componentsOptoelectronicsSoft metal

Embodiments of a polishing article for processing a substrate are provided. In one embodiment, a polishing article for processing a substrate comprises a fabric layer having a conductive layer disposed thereover. The conductive layer has an exposed surface adapted to polish a substrate. The fabric layer may be woven or non-woven. The conductive layer may be comprised of a soft metal and, in one embodiment, the exposed surface may be planar.

Owner:APPLIED MATERIALS INC

Conductive polishing article for electrochemical mechanical polishing

InactiveUS6991528B2Easy to moveMaterial nanotechnologyElectrolysis componentsOptoelectronicsSoft metal

Embodiments of a polishing article for processing a substrate are provided. In one embodiment, a polishing article for processing a substrate comprises a fabric layer having a conductive layer disposed thereover. The conductive layer has an exposed surface adapted to polish a substrate. The fabric layer may be woven or non-woven. The conductive layer may be comprised of a soft metal and, in one embodiment, the exposed surface may be planar.

Owner:APPLIED MATERIALS INC

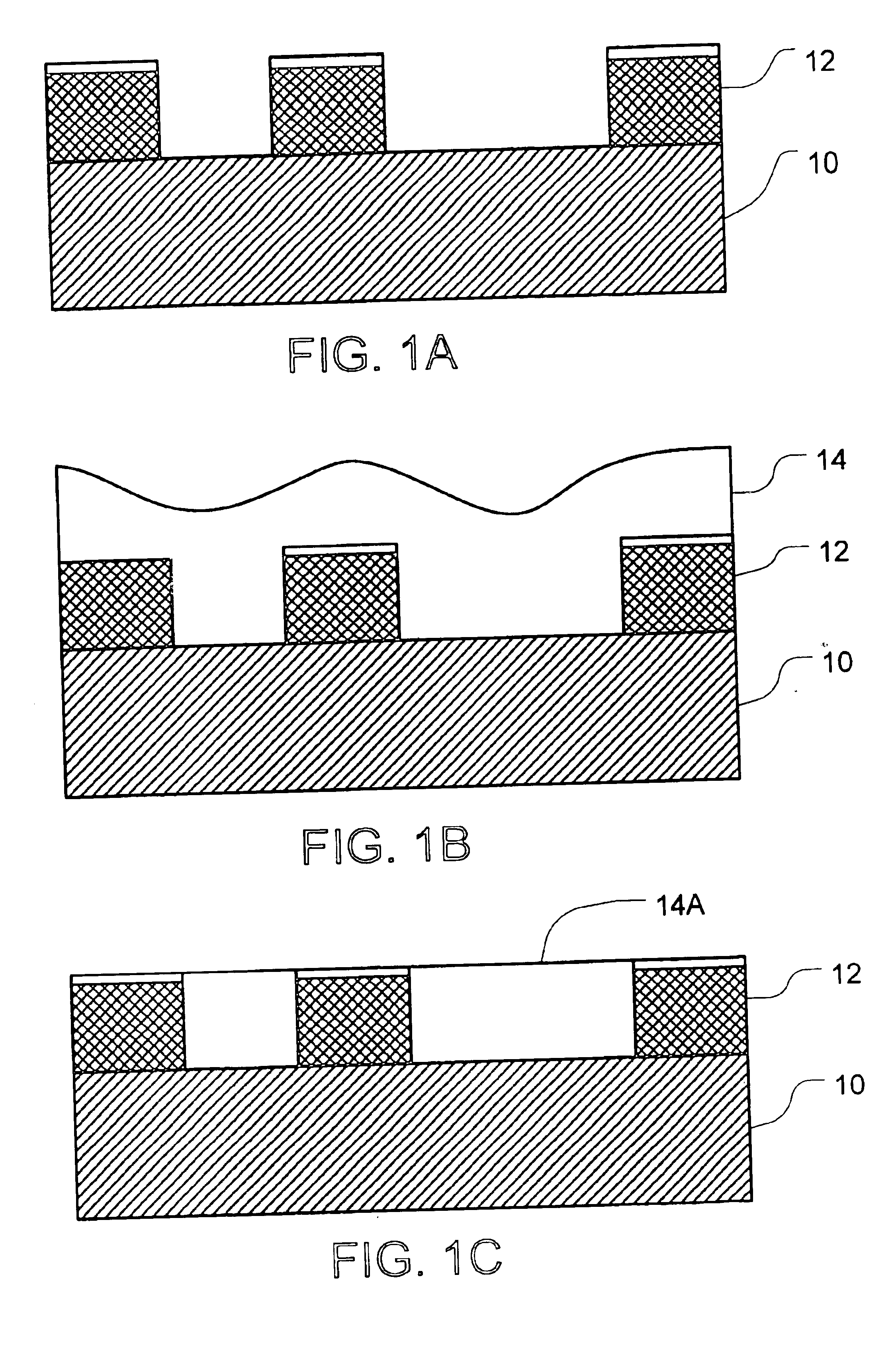

Materials and methods for low pressure chemical-mechanical planarization

Provided are materials and methods for the chemical mechanical planarization of material layers using a down force of less than about 2.5 psi while maintaining a material removal rate generally similar to that obtained using higher down forces while simultaneously improving the selectivity of the process with respect to a primary material formed over a barrier material. The materials and methods disclosed herein are suitable for use in meatallization operations during semiconductor device fabrication, in particular in processes in which the primary material is a softer metal such as copper and the barrier material is a harder material such as a metal nitride.

Owner:DOW GLOBAL TECH LLC

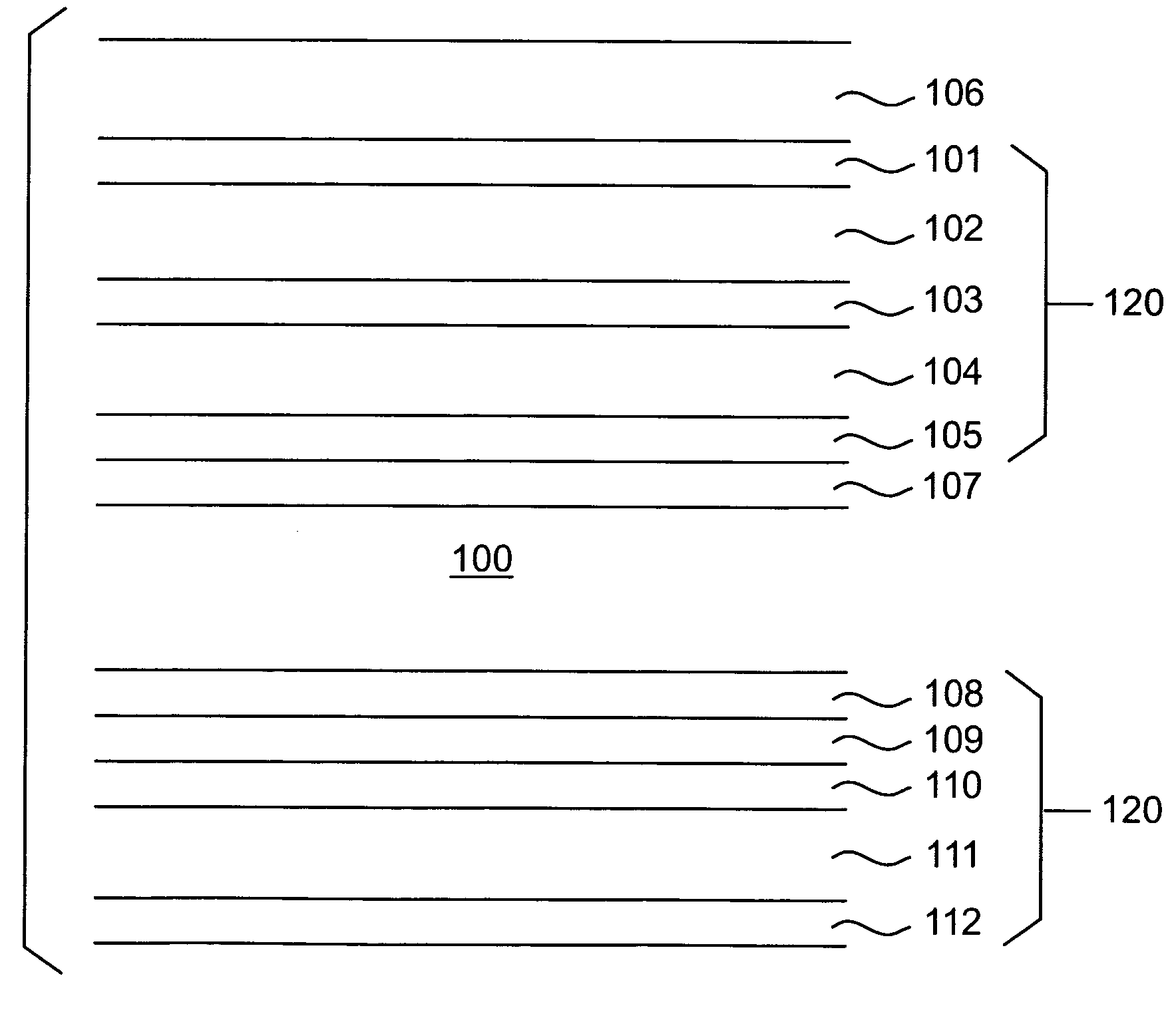

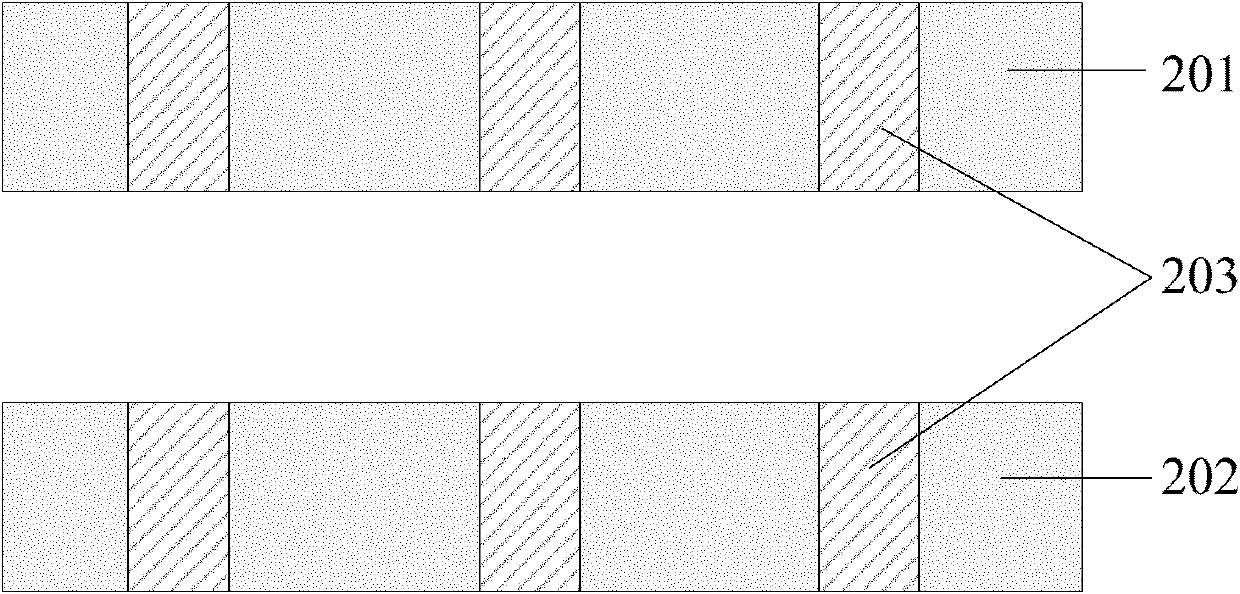

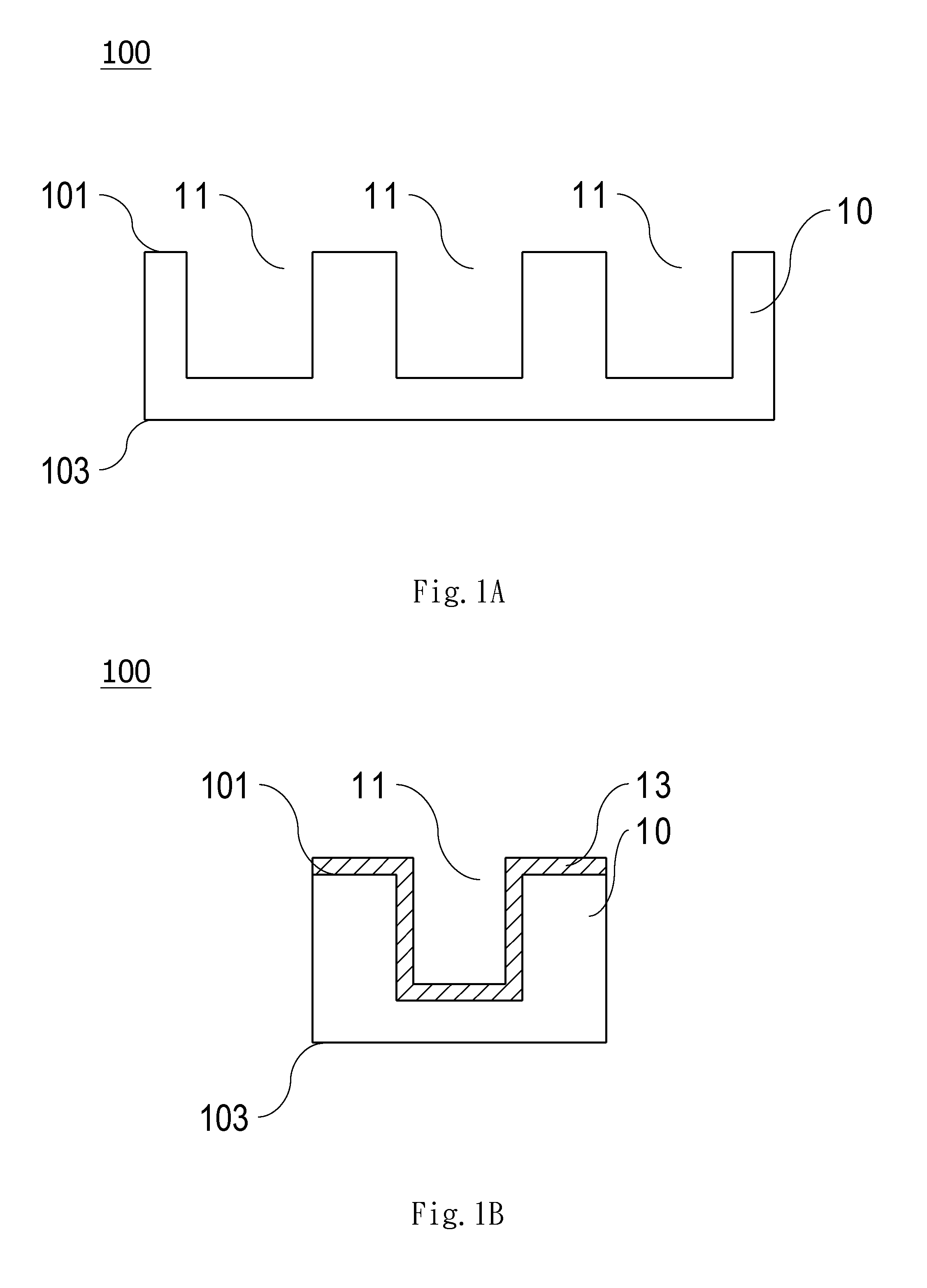

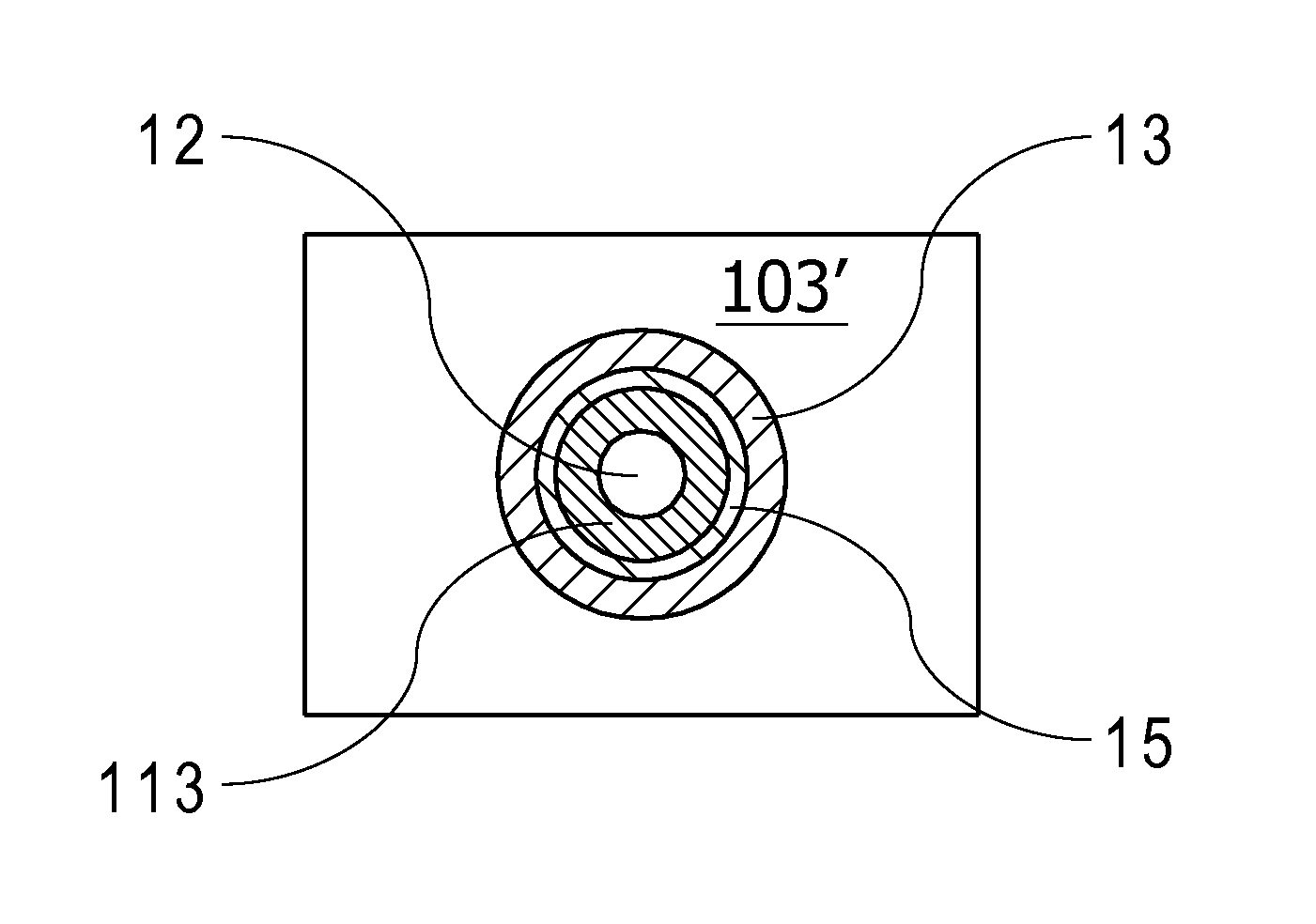

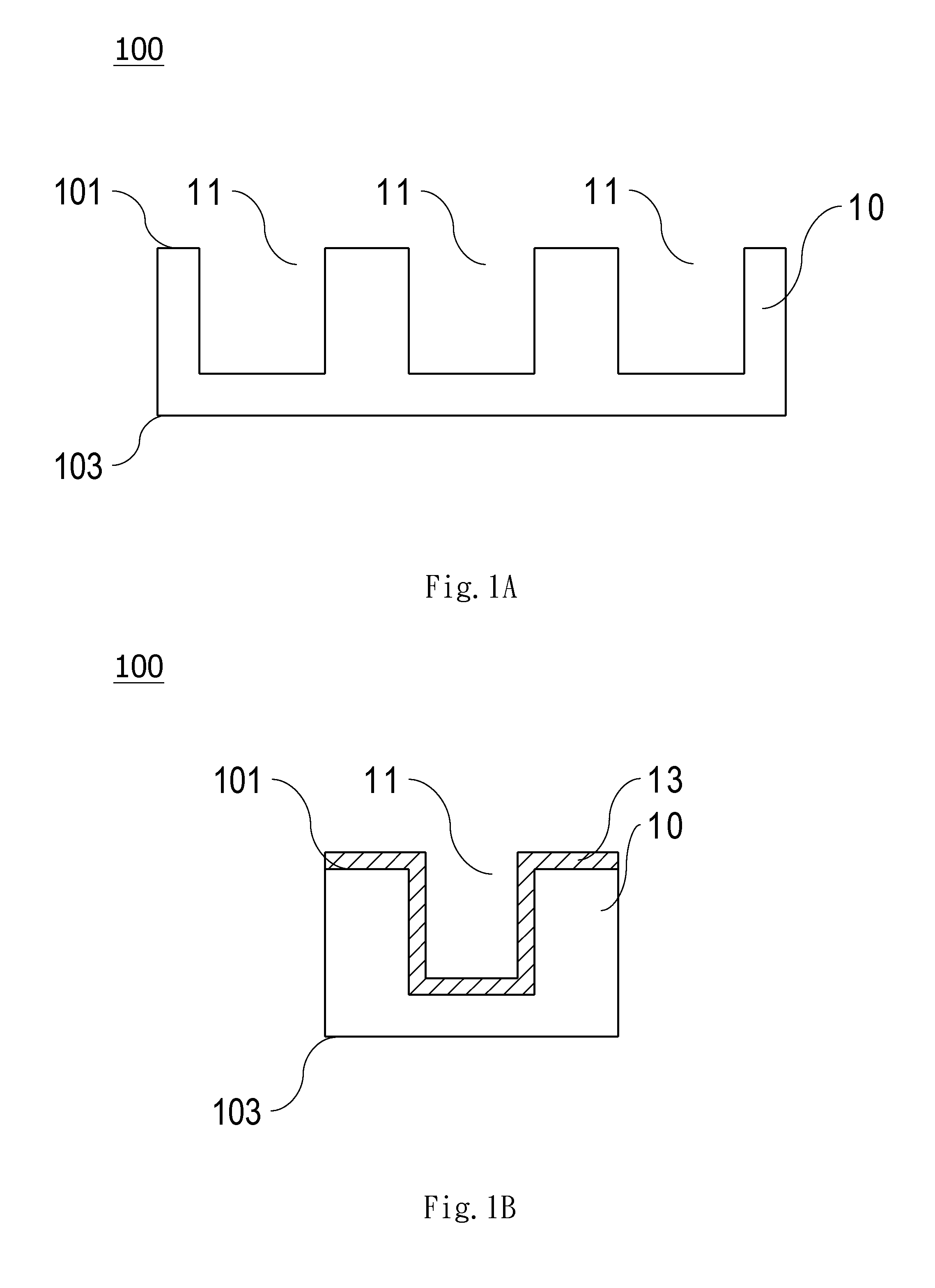

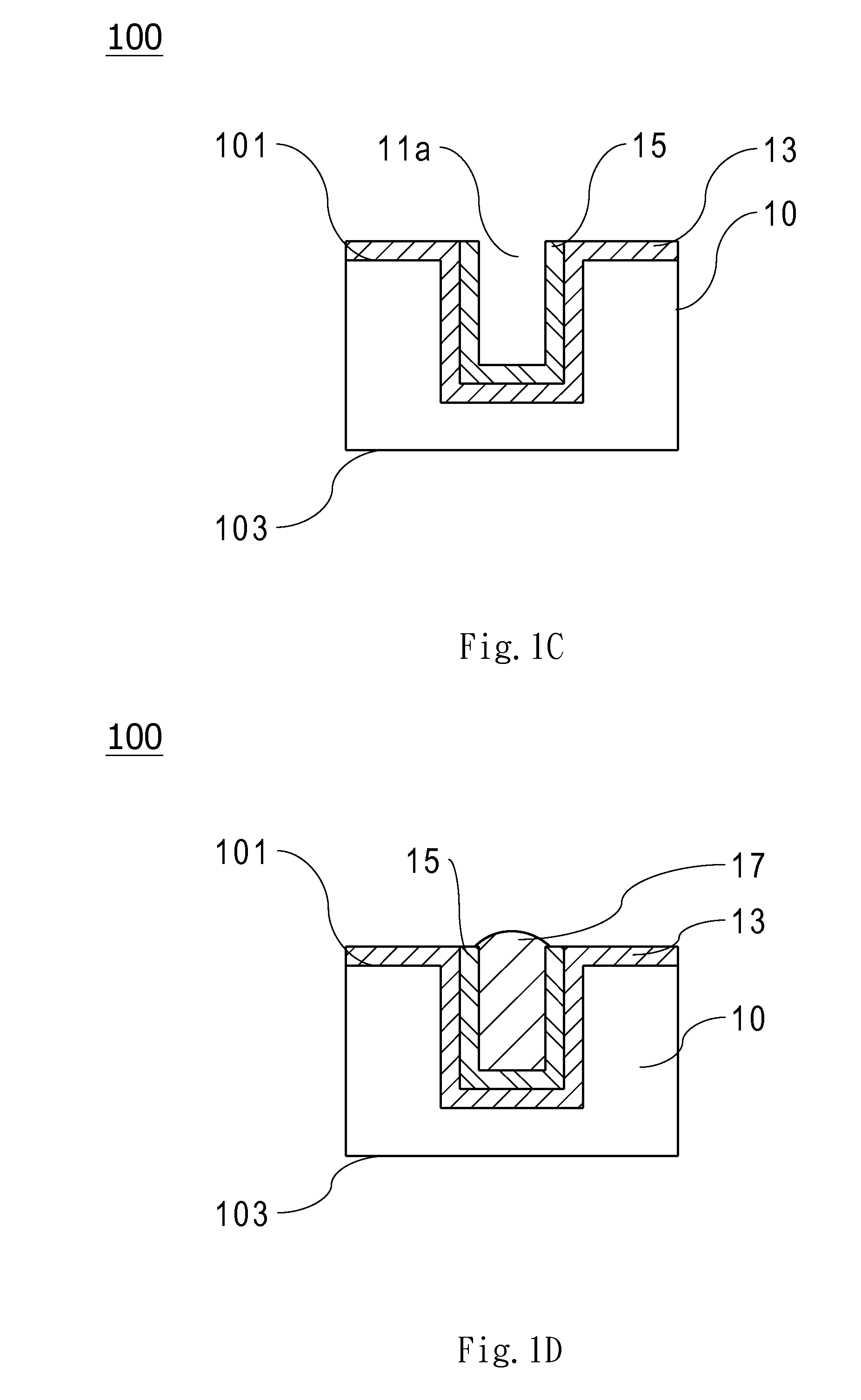

Semiconductor wafer structure and multi-chip stack structure

InactiveUS20110291267A1Minimize misalignment problemImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

A semiconductor wafer structure comprises a first surface and a second surface opposite to the first surface, a plurality of chip areas formed on the first surface, a plurality of through-silicon holes formed in each of the plurality of chip areas connecting the first surface and the second surface, and a through-silicon-via (TSV) electrode structure formed in each through-silicon hole. Each through-silicon-via electrode structure comprises a dielectric layer formed on the inner wall of the through-silicon hole, a barrier layer formed on the inner wall of the dielectric layer and defining a vacancy therein, a filling metal layer filled into the vacancy, a first end of the filling metal layer being lower than the first surface forming a recess, and a soft metal cap connecting to and overlaying the first end of the filling metal layer, wherein a portion of the soft metal cap is formed in the recess and the soft metal cap protrudes out of the first surface. Hence, the reliability of multi-chip stack package structure can be enhanced with the application of these soft metal caps.

Owner:CHIPMOS TECH INC

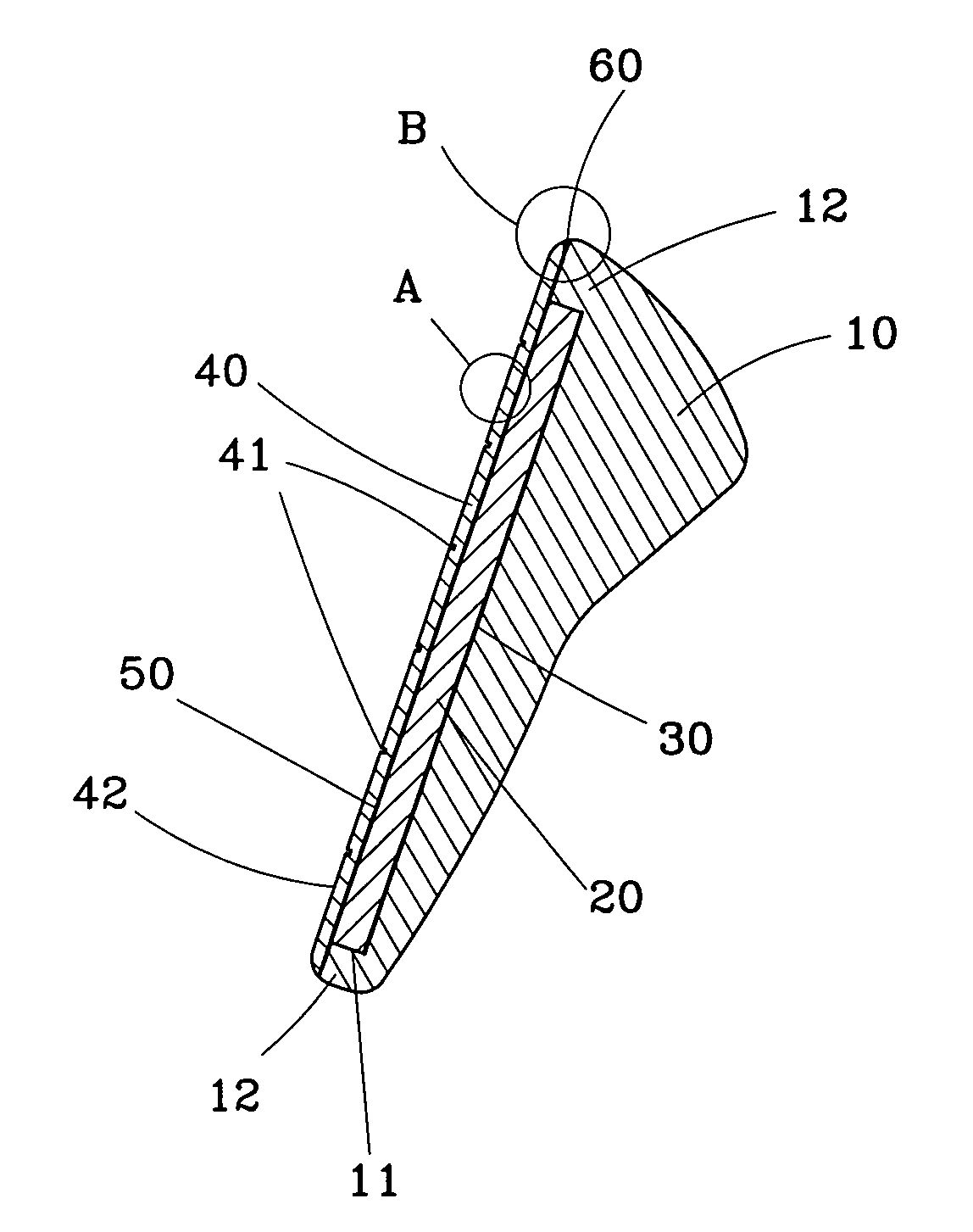

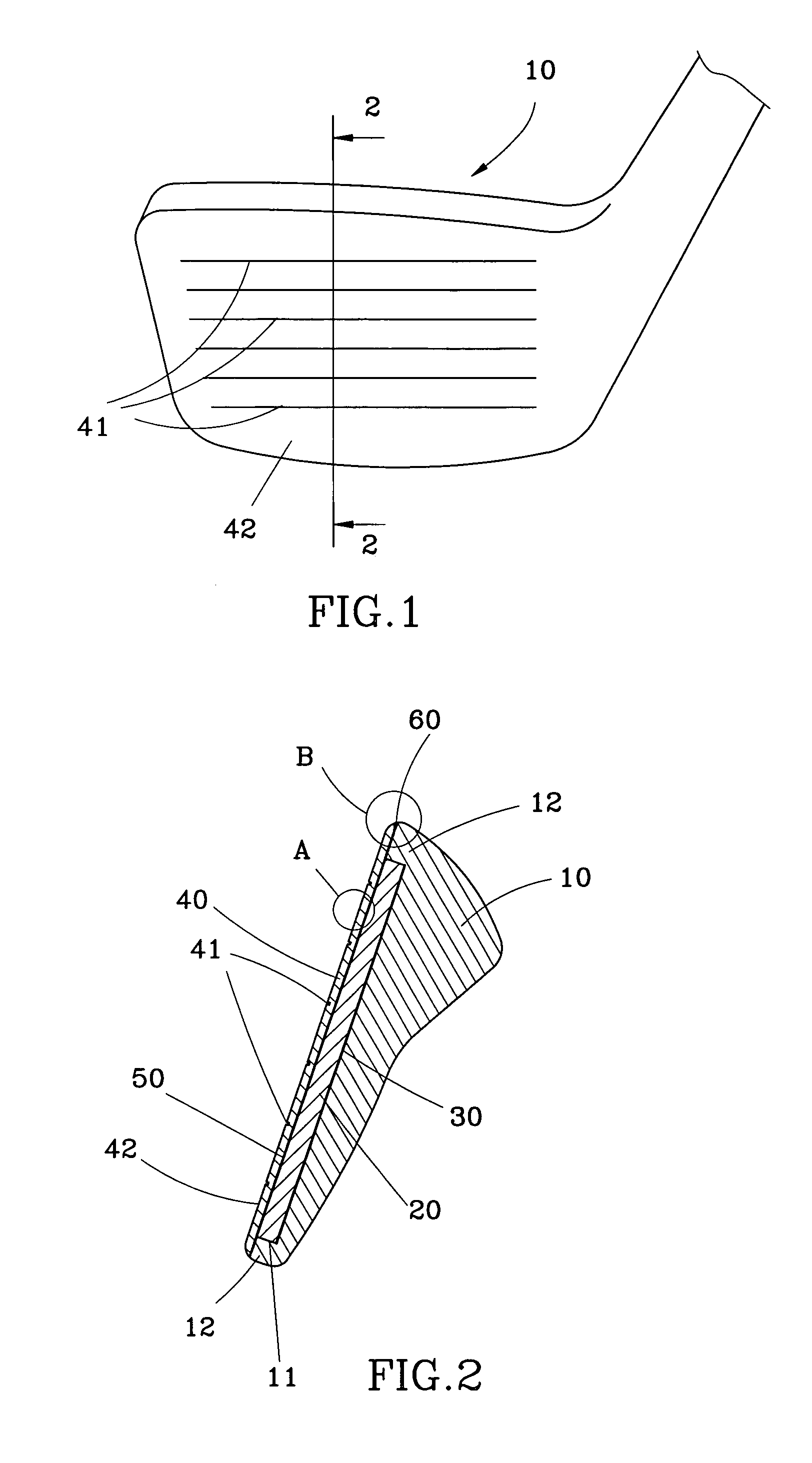

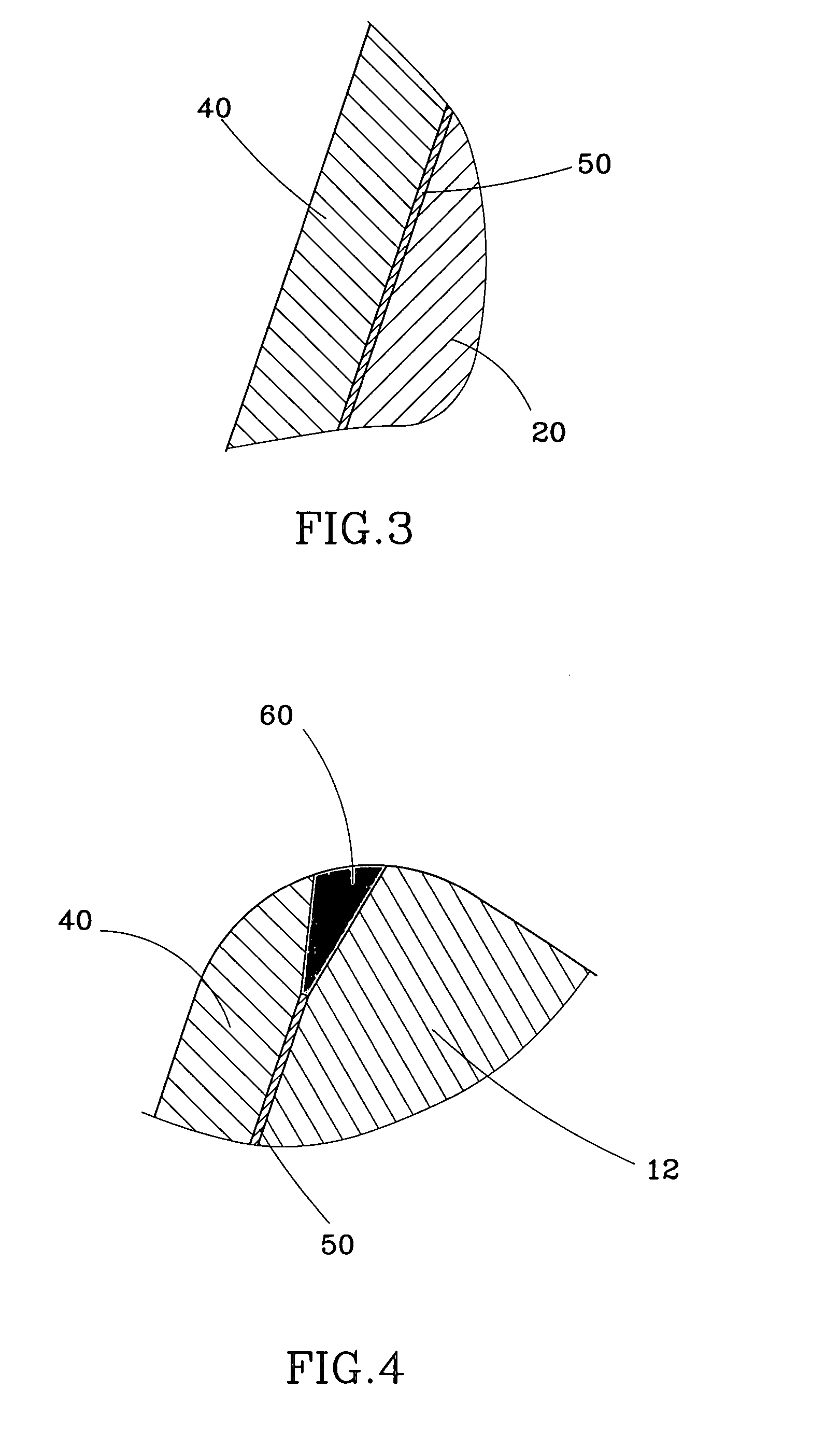

Iron golf club head

An iron golf club head includes a head body, a soft metal layer, a thin face plate and a solder layer. The head body has a recess at a front side thereof and an annular shoulder portion around the recess. The soft metal layer is disposed in the recess of the head body. The thin face plate is disposed at the front side of the head body and attached on the shoulder portion of the head body. The face plate has a plurality of slots on a front side thereof to form a ball-hitting face. The solder layer is provided on a back side of the face plate for bonding the face plate to the shoulder portion of the head body and the soft metal layer.

Owner:CHEN ARCHER C C

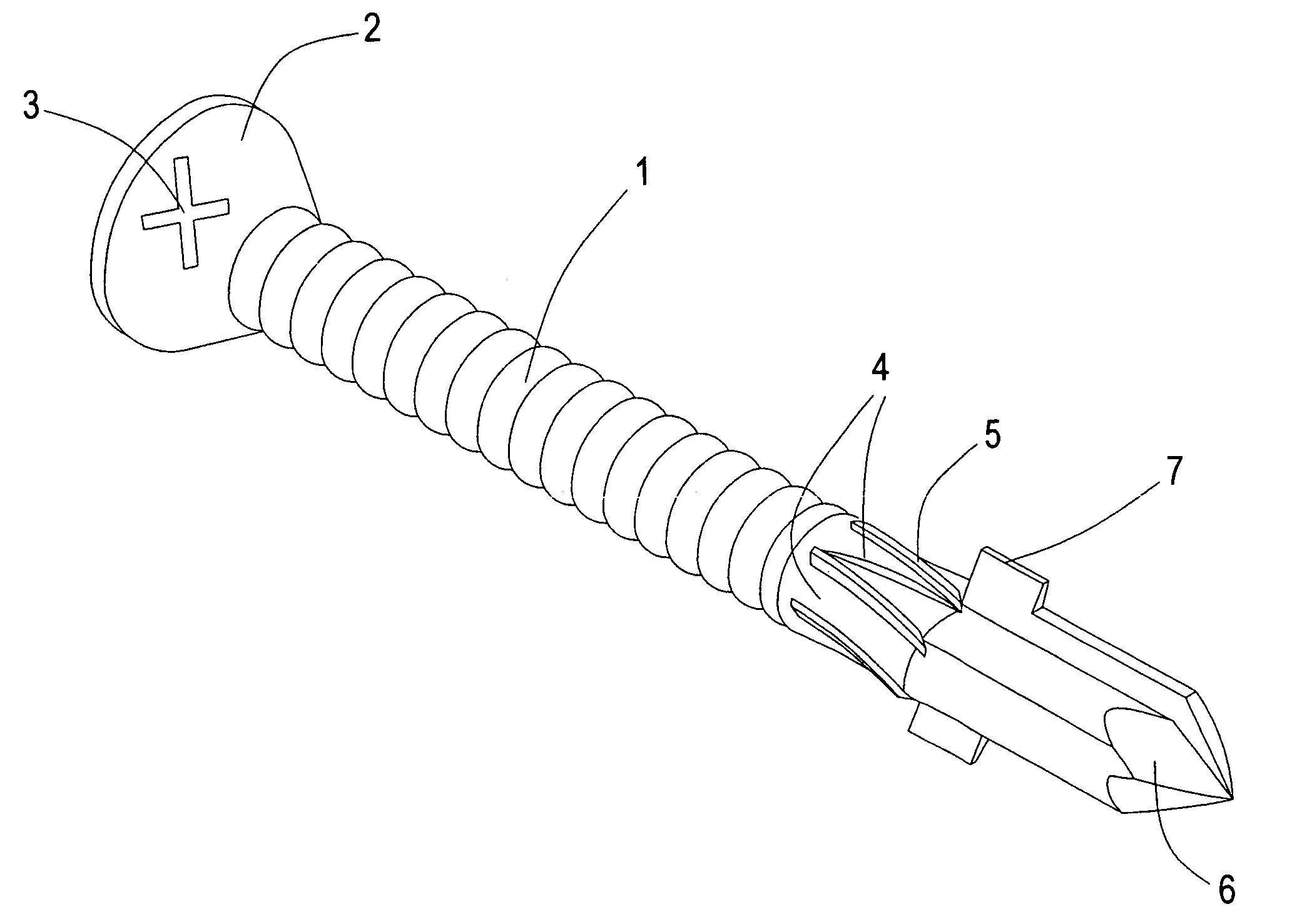

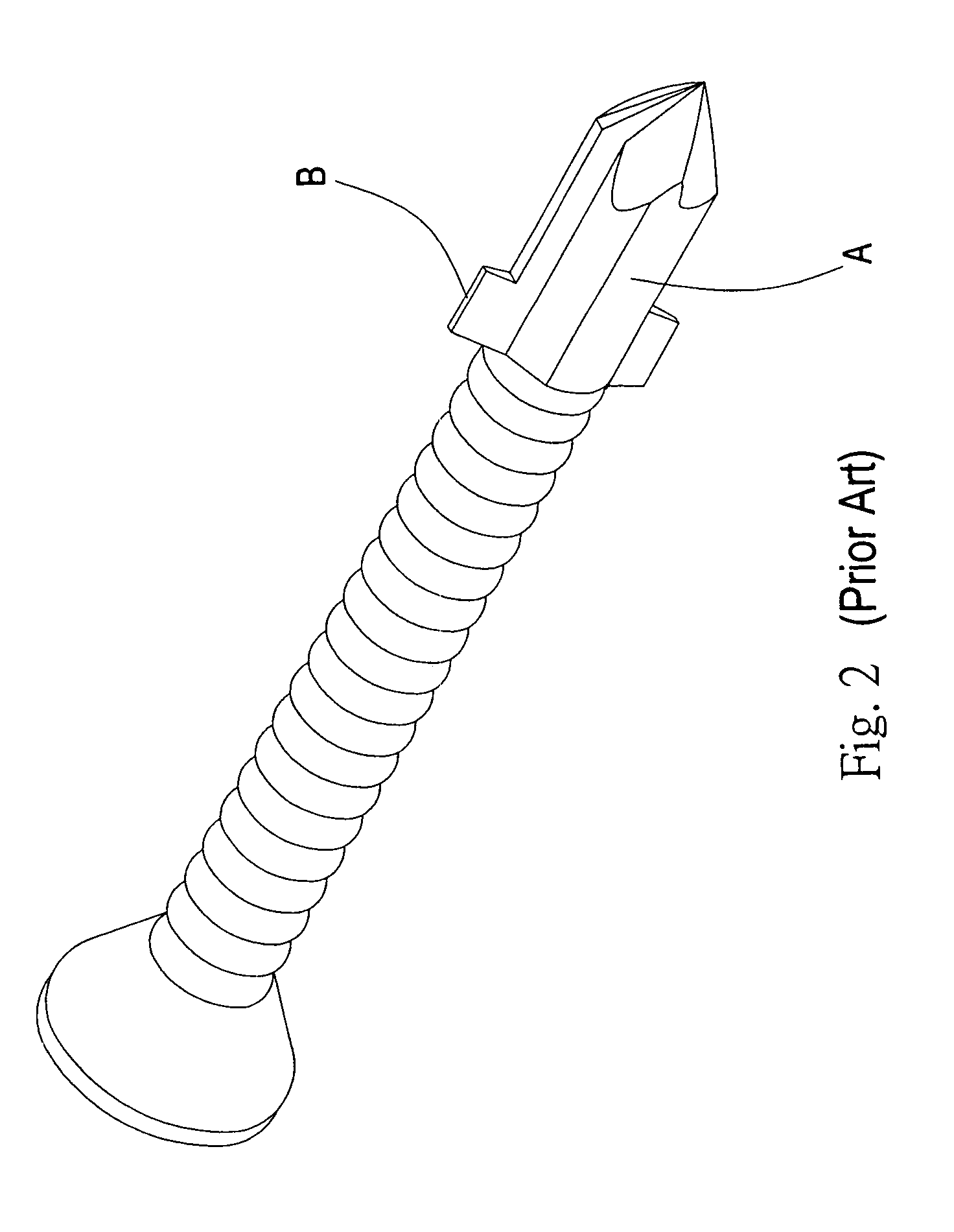

Screw with protruding sheets on head portion

A screw with protruding sheets on a head portion comprises a thread portion; a screw tail at one end of the thread portion, a slot formed on the screw tail; a plurality of screwing sheets formed at another end of the thread portion; a plurality of recesses formed between the plurality of screwing sheets for removing undesired pieces; a drilling head being formed at front ends of the screwing sheets; the drilling head formed with a plurality of protruding sheets made of soft metal. By screwing the screw by rotating from the slot, the screw will rotate so as to drill a hole and enter into a wood plate. Then the protruding sheets enlarge the hole. The undesired wood pieces are removed from the recesses. When the screw further drills into a metal plate, the protruding sheet will be worn out because the protruding sheet is made of soft metal.

Owner:TOP GREEN CORP

Test container for imitating deep-sea high-pressure environment

InactiveCN101975698AEasy to disassembleImprove sealingMaterial strength using tensile/compressive forcesPressure vesselsHydrostatic pressureHigh pressure

The invention discloses a test container for imitating deep-sea high-pressure environment, comprising a container body and a flat cover which is hermetically cooperated with the container body; wherein a water injection hole and a pressure measurement hole which are vertically penetrated are arranged at the centre of the top surface of the flat cover, a cylindrical lug matched with the inner chamber of the head of the container body is arranged at the centre of the bottom surface of the flat cover and the rest part of the bottom surface of the flat cover is completely matched with the top surface of the container; mutually matched annular steps are arranged on the peripheral surface of the cylindrical lug and the inner wall at the head of the container body, and an annular sealing ring made of soft metal materials is arranged between the two annular steps; the flat cover is in connection and close fit with the container body through screws and bolts, and press annular gaskets to deform plastically. The container of the invention presses the annular gaskets made of soft metal materials to deform plastically, increases the sealing property among the annular gaskets, and ensures that the container can bear the high hydrostatic pressure in the deep sea, thereby avoiding the troubles of testing the ocean engineering equipment in the deep sea.

Owner:ZHEJIANG UNIV

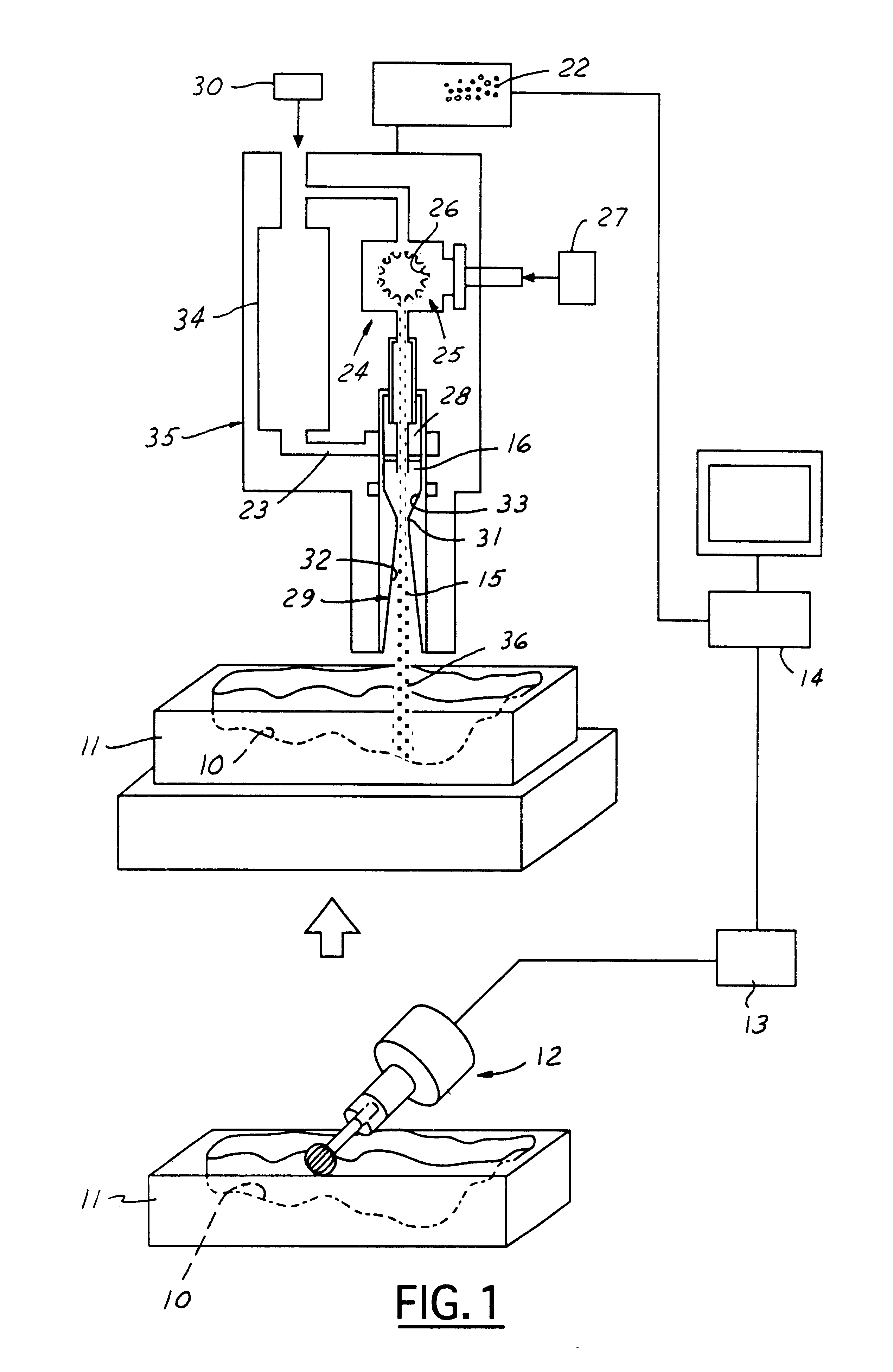

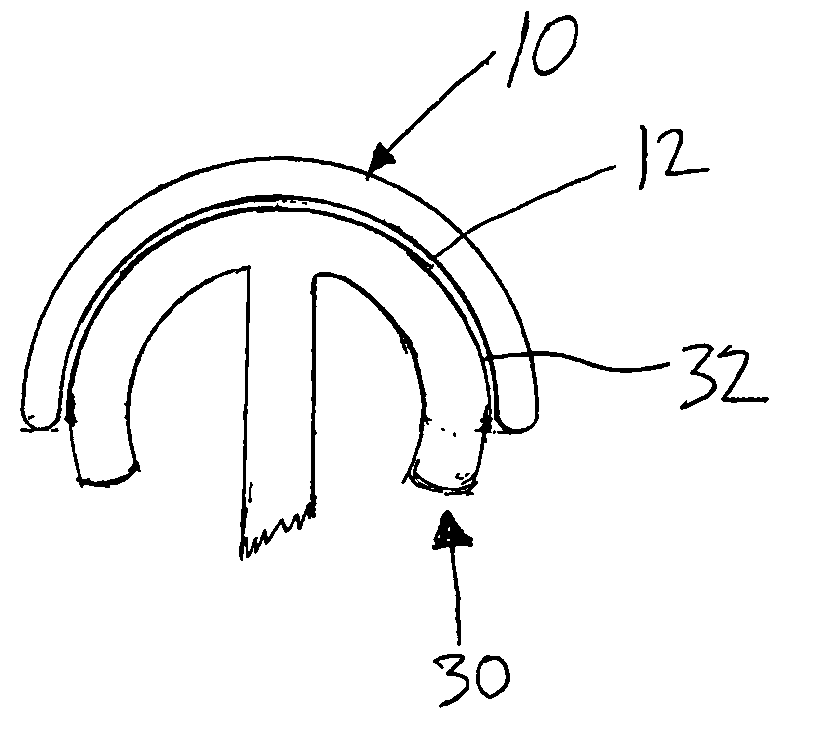

Method of directly making rapid prototype tooling having free-form shape

A method and apparatus for directly making rapid prototype tooling from a computer model having a free-form shape. The method steps comprise essentially: (a) machining a soft metal tooling base so as to contour at least one free-form surface in conformity with the computer model; (b) cold-gas dynamic spraying the contoured surface to form superimposed impact welded metal particle layers, the layers consisting of at least one thermal management under-layer comprising primarily copper, and at least an outer wear resistant layer comprising primarily tool steel.

Owner:FORD GLOBAL TECH LLC

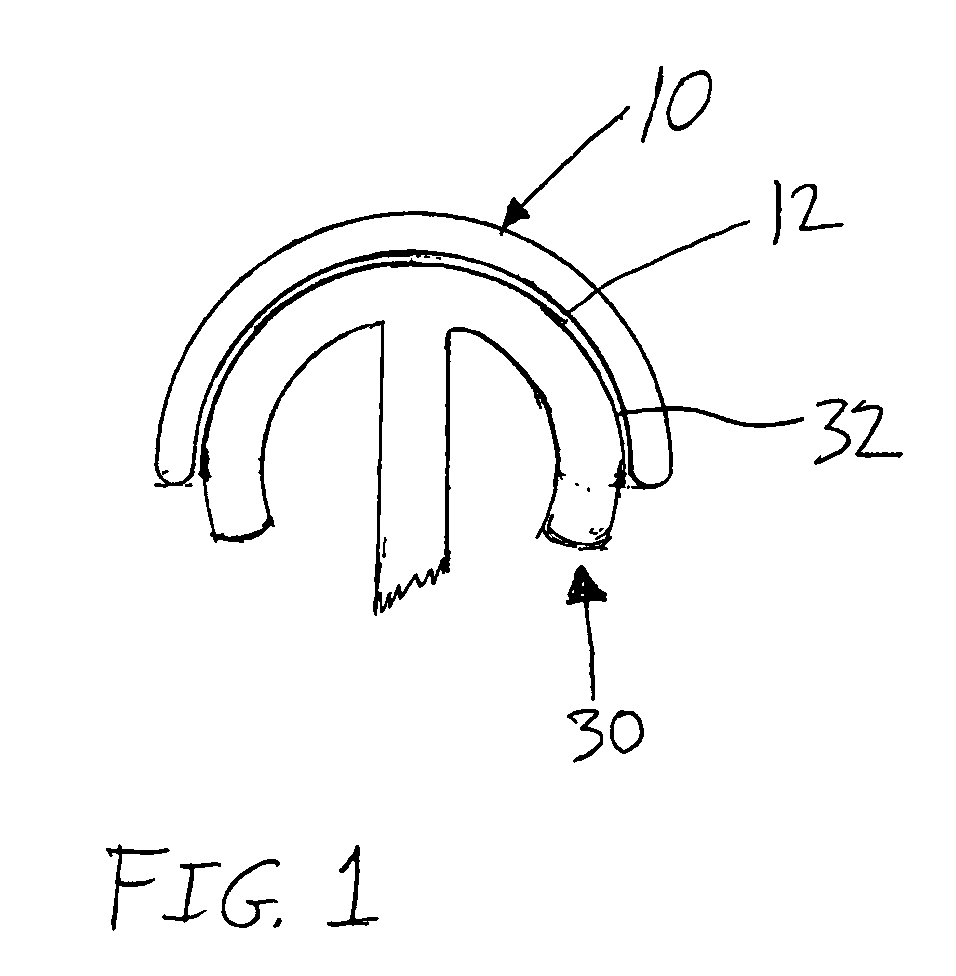

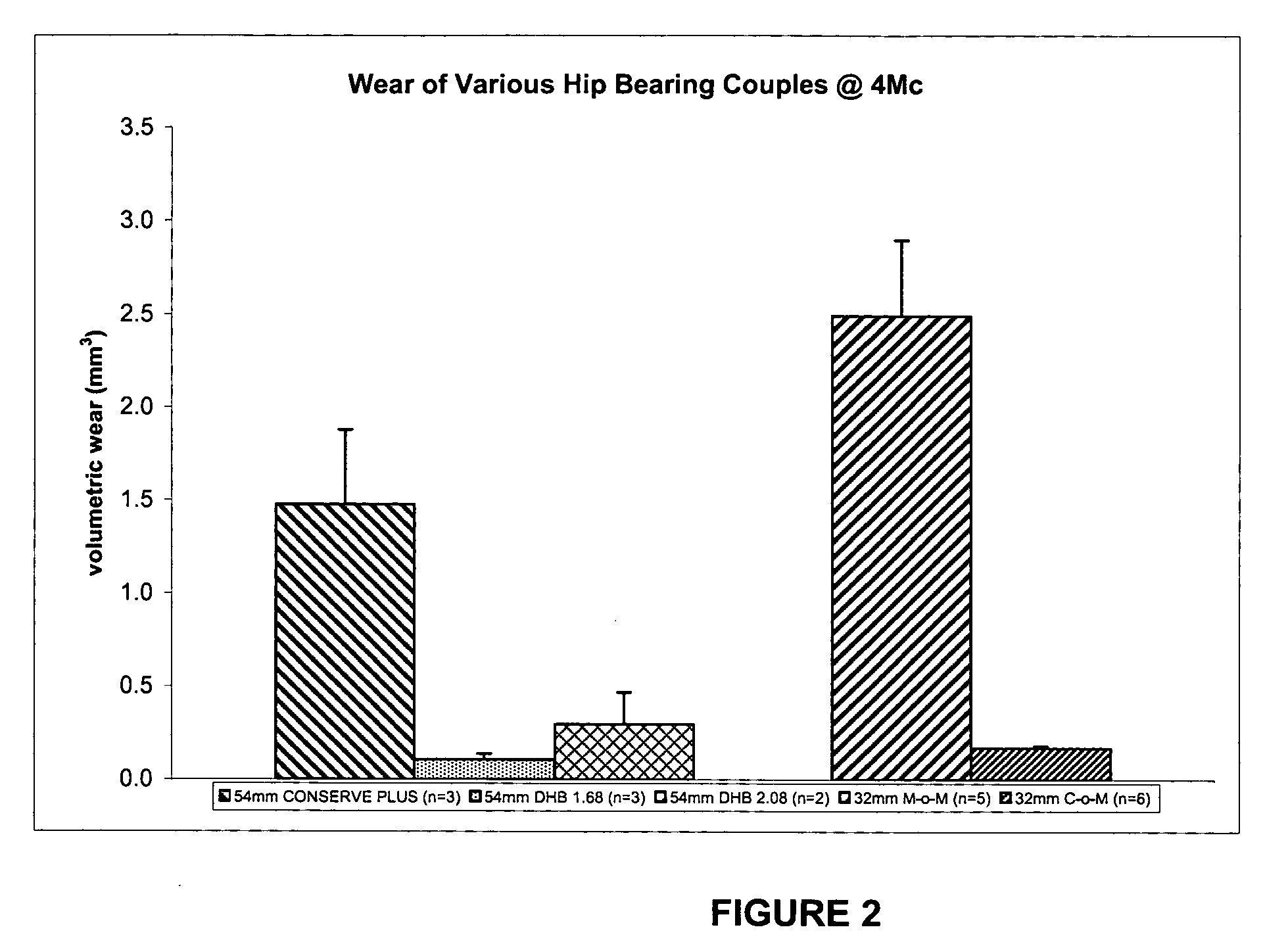

Metallic bearings for joint replacement

An orthopedic joint prosthesis comprising a first component having a soft metal bearing surface and a second component having a hard metal bearing surface. The soft metal bearing surface has a hardness of at least about 20 Rc, while the hard metal bearing surface having a hardness greater than the soft metal bearing surface by at least about 15 Rc. The soft and the hard metal bearing surfaces are configured to articulate with one another. The differential hardness of the hard metal bearing surface to the soft metal bearing surface is preferably at least about 1.5, and is preferably less than about 3. The hard metal bearing surface is preferably not more than about 40 Rc harder than the soft metal bearing surface. The hard metal bearing surface preferably has a hardness of between about 40 Rc and about 60 Rc.

Owner:MICROPORT ORTHOPEDICS HLDG INC

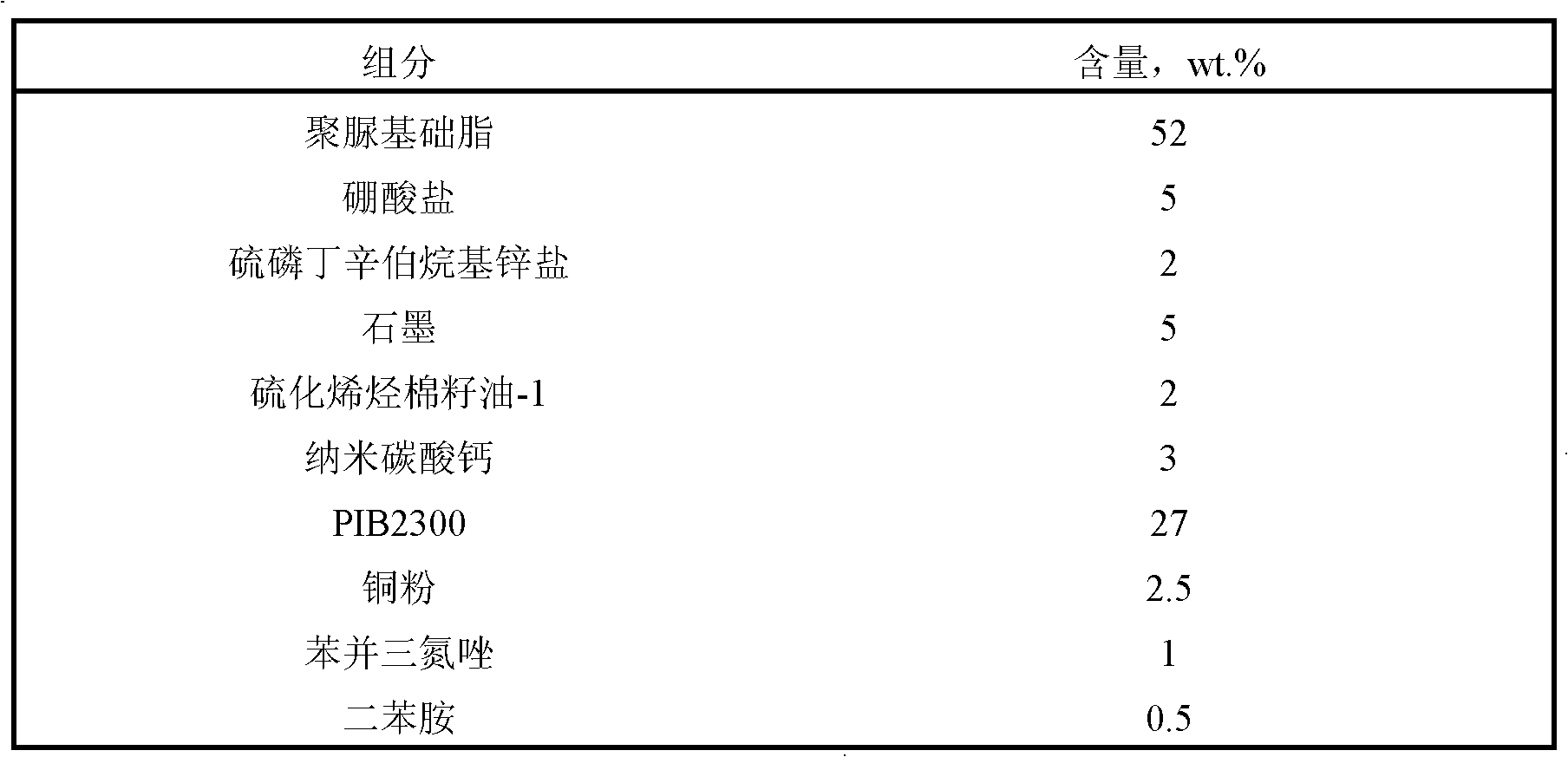

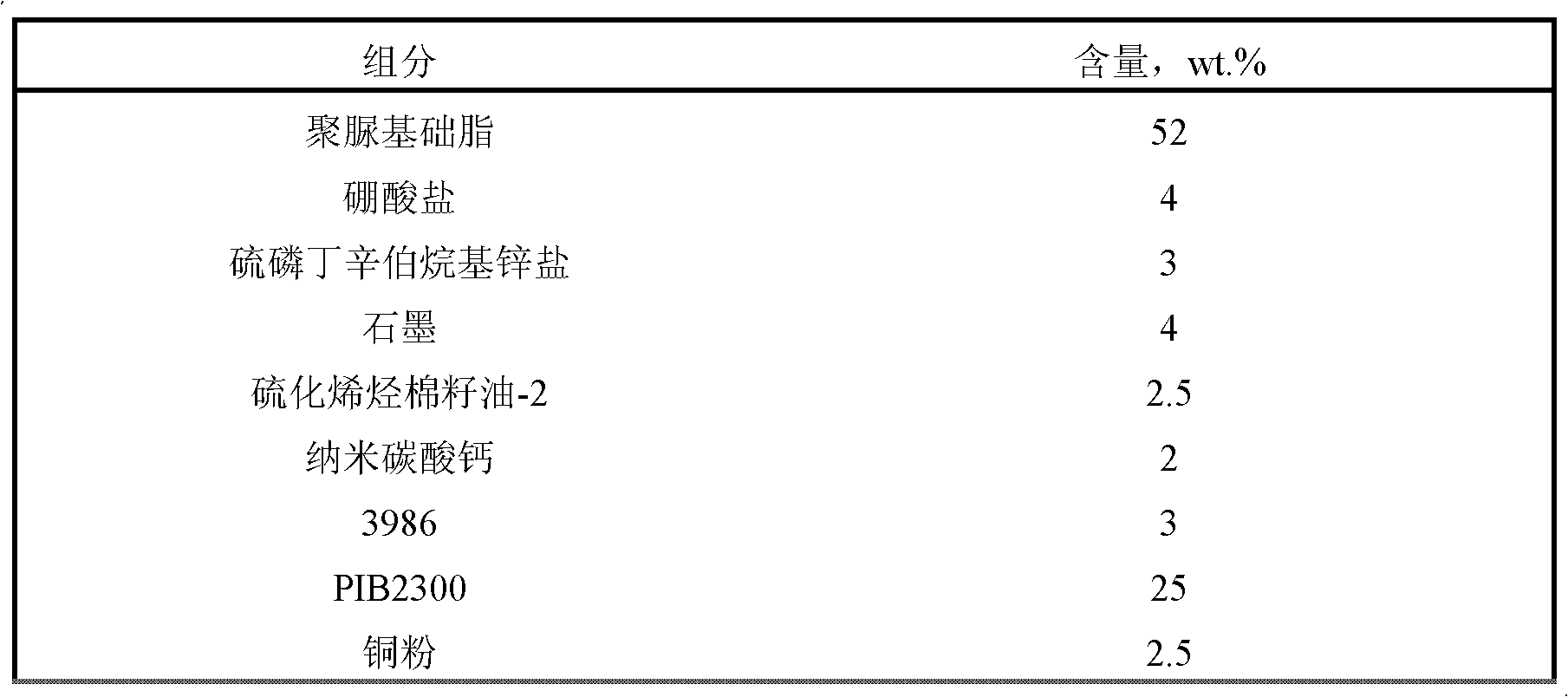

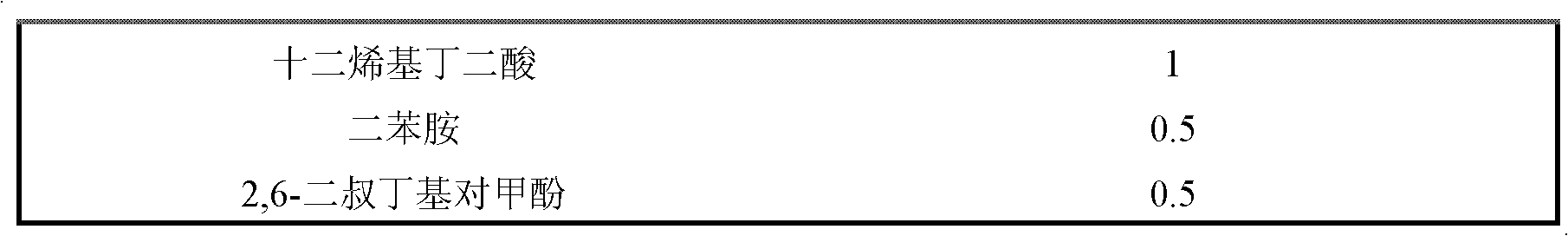

Heavy-duty self-repairing open gear grease

The invention discloses a clean-type heavy-duty open gear grease with self-repairing function. The product is composed of a lubricating grease base grease prepared from an organic compound thickening mineral oil containing carbamido in molecules or synthetic oil, and additives. A base grease thickener is composed of an MDI and organic amine in a molar ratio of 1:1-3; and the base oil is mineral oil or poly alpha olefin synthetic oil. The heavy-duty open gear grease comprises the following components, calculated by the weight of the base grease: 50-60wt% of base grease, 4-8wt% of a extreme pressure antiwear agent, 1-4wt% of an oily agent, 6-8wt% of a solid additive, 0.5-1.5wt% of an antirust agent, 25-35wt% of a tackifier, 2-4wt% of a self-repairing additive, and 0.3-1.0wt% of an antioxidant. The invention adopts borate as the extreme pressure antiwear agent added with an extreme pressure agent containing a small amount of sulfur phosphorus, so as to improve the extreme pressure anti-wear performance of the lubricating grease, as well as realize low toxicity, tastelessness and environment-friendliness of the grease. Besides, soft metal Cu nanoparticles employed by the invention endow good self-repairing performance on the grease. Compared with a traditional open gear lubricant product, the heavy-duty open gear grease provided by the invention has characteristics of excellent lubrication performance, self repairing, tastelessness and environment-friendliness, and can be widely used for lubricating of open gears.

Owner:PETROCHINA CO LTD

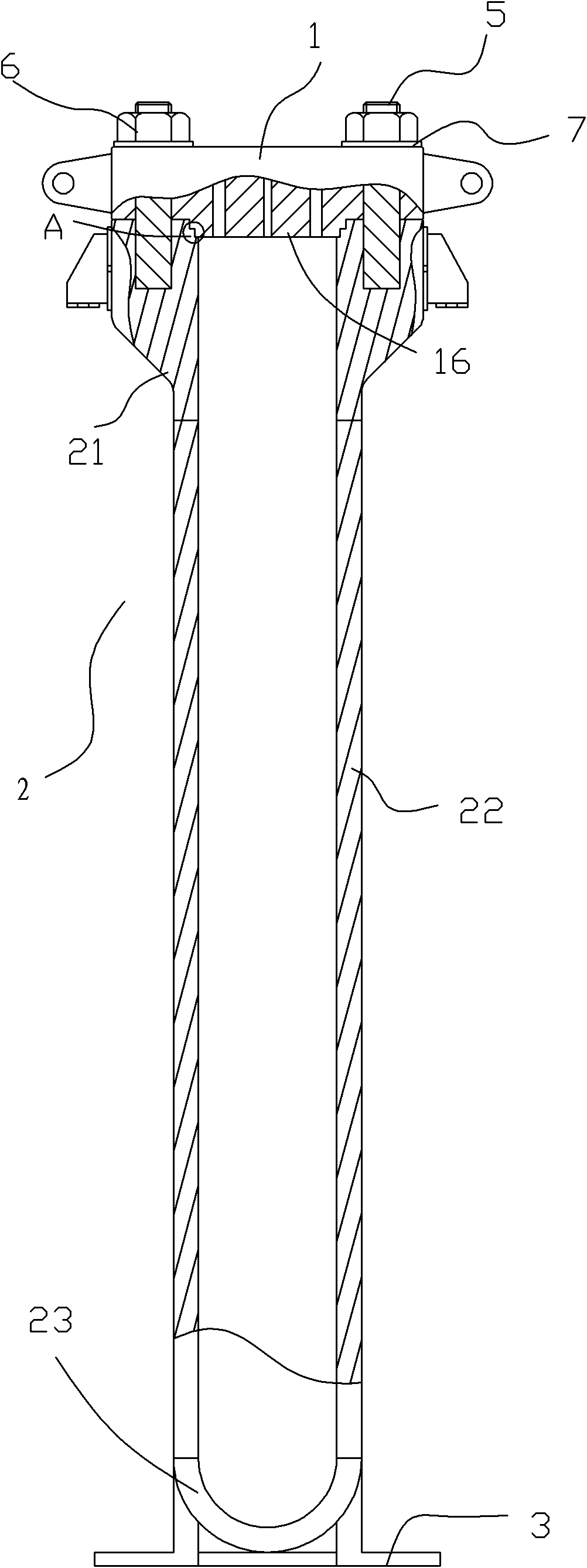

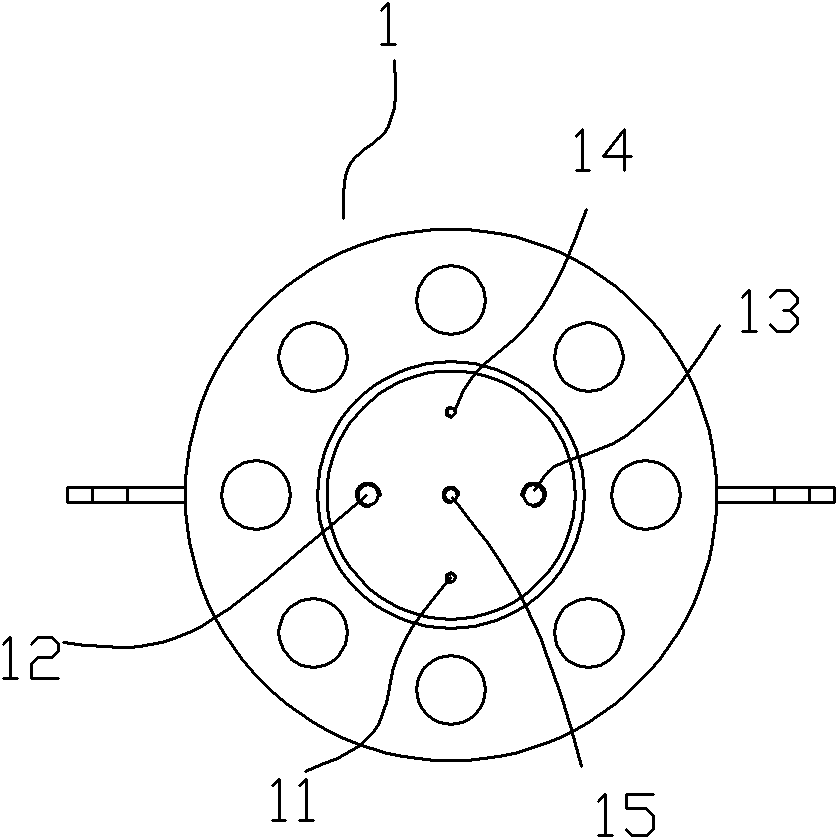

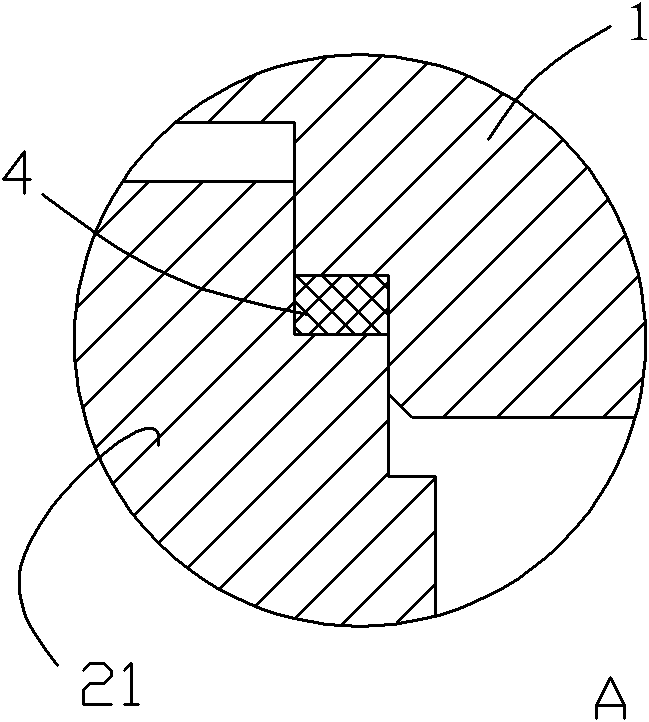

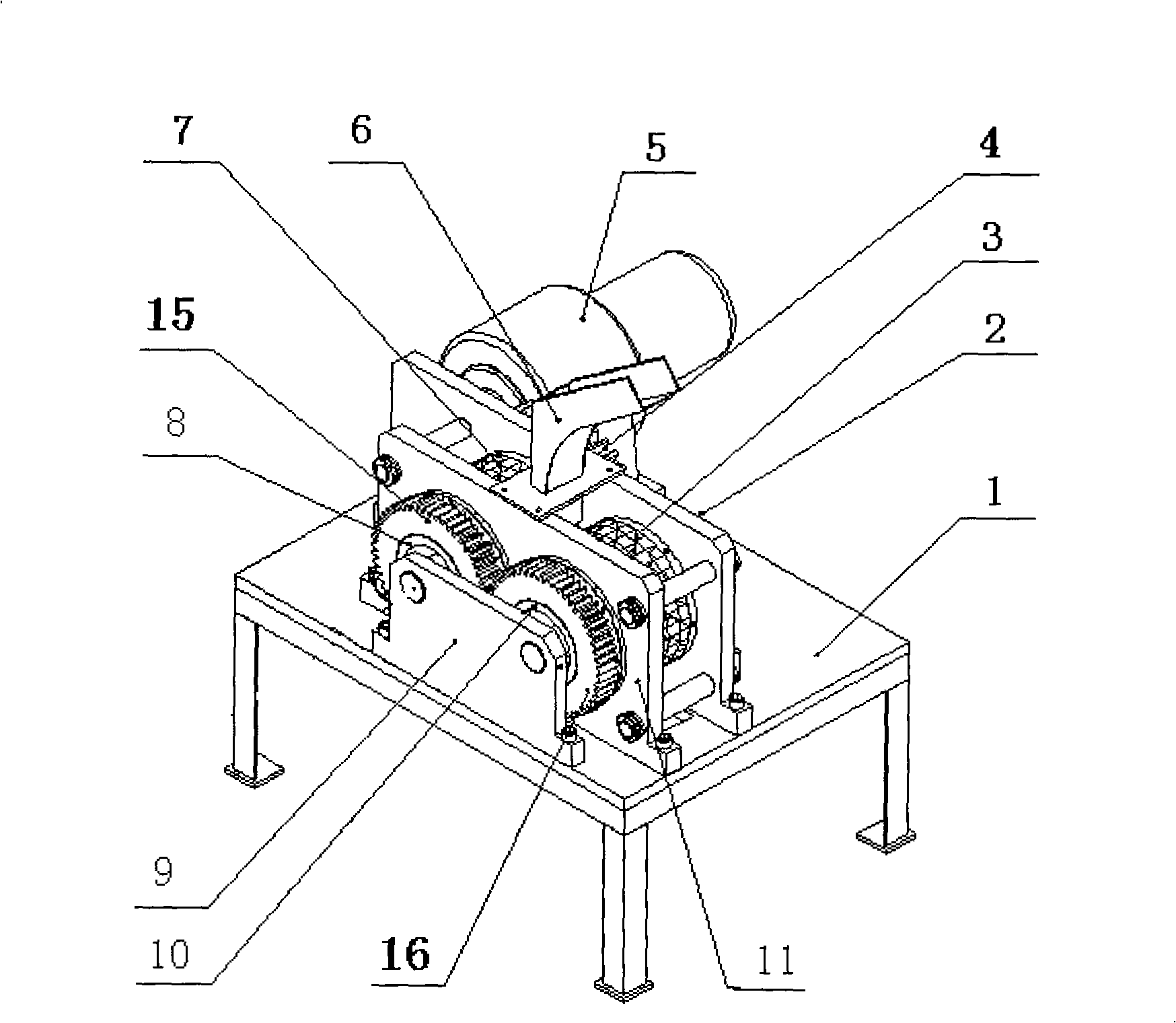

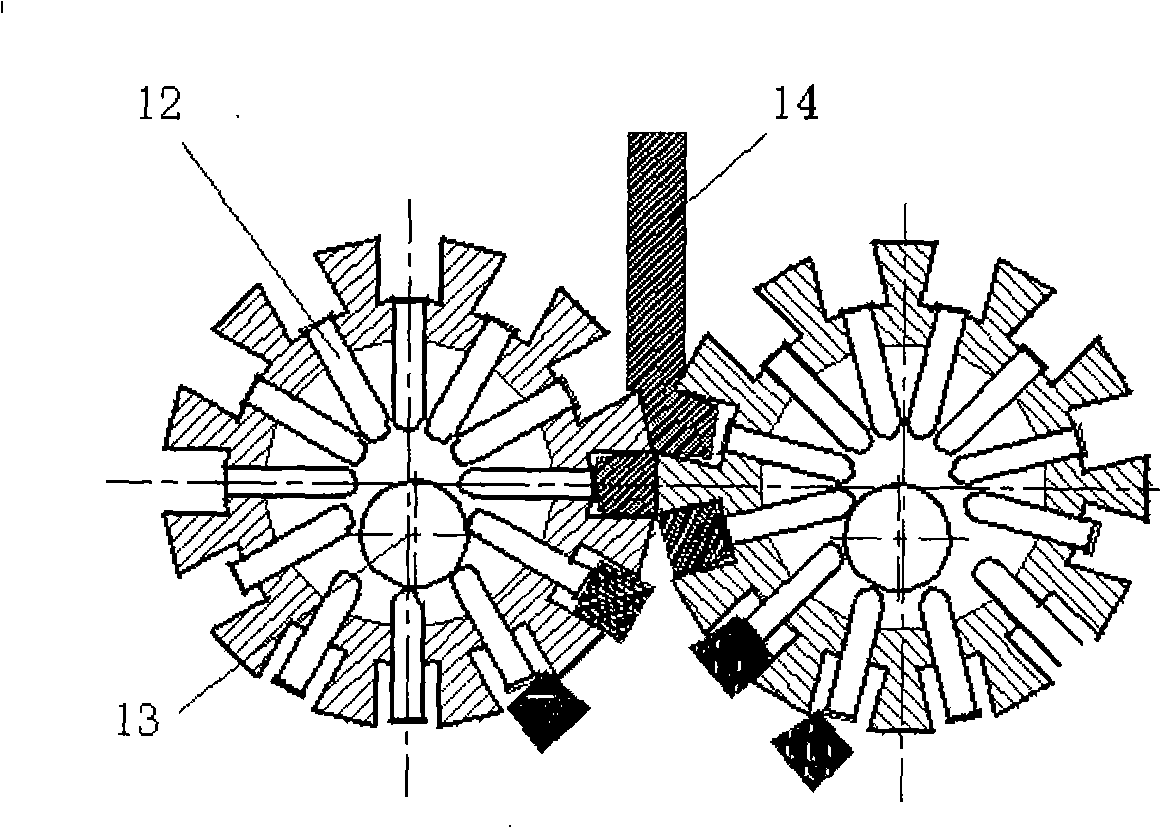

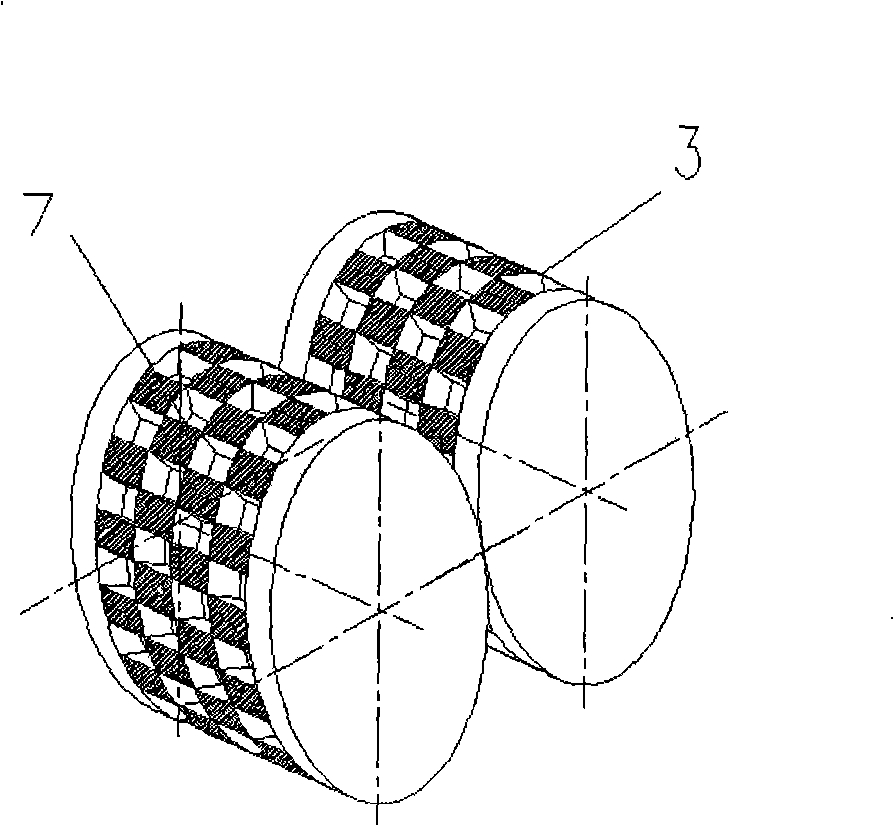

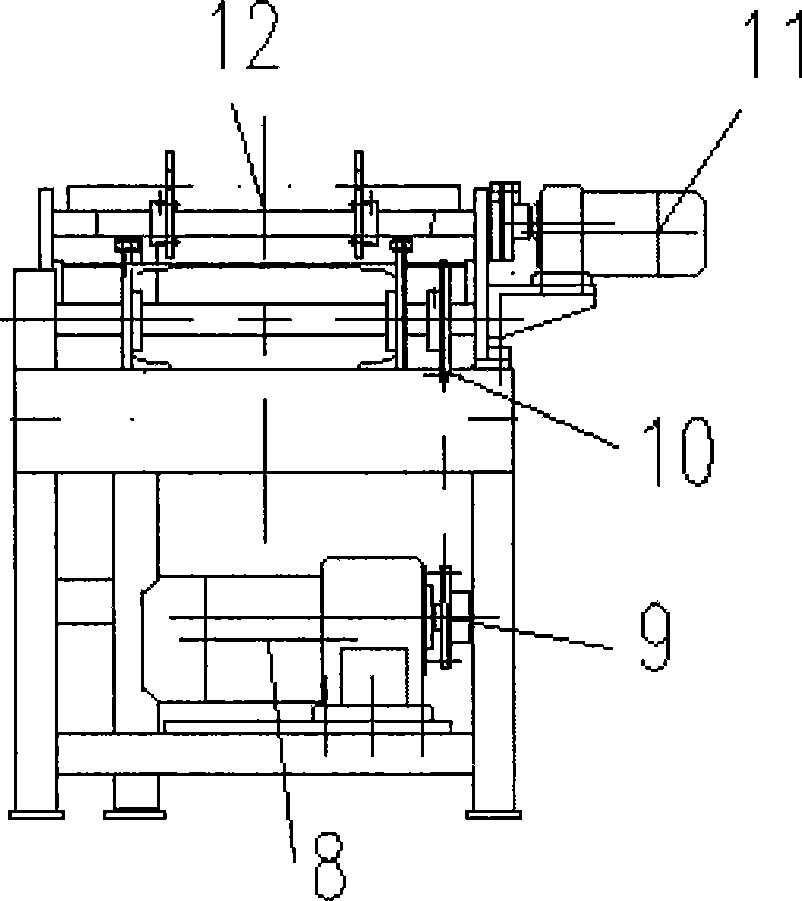

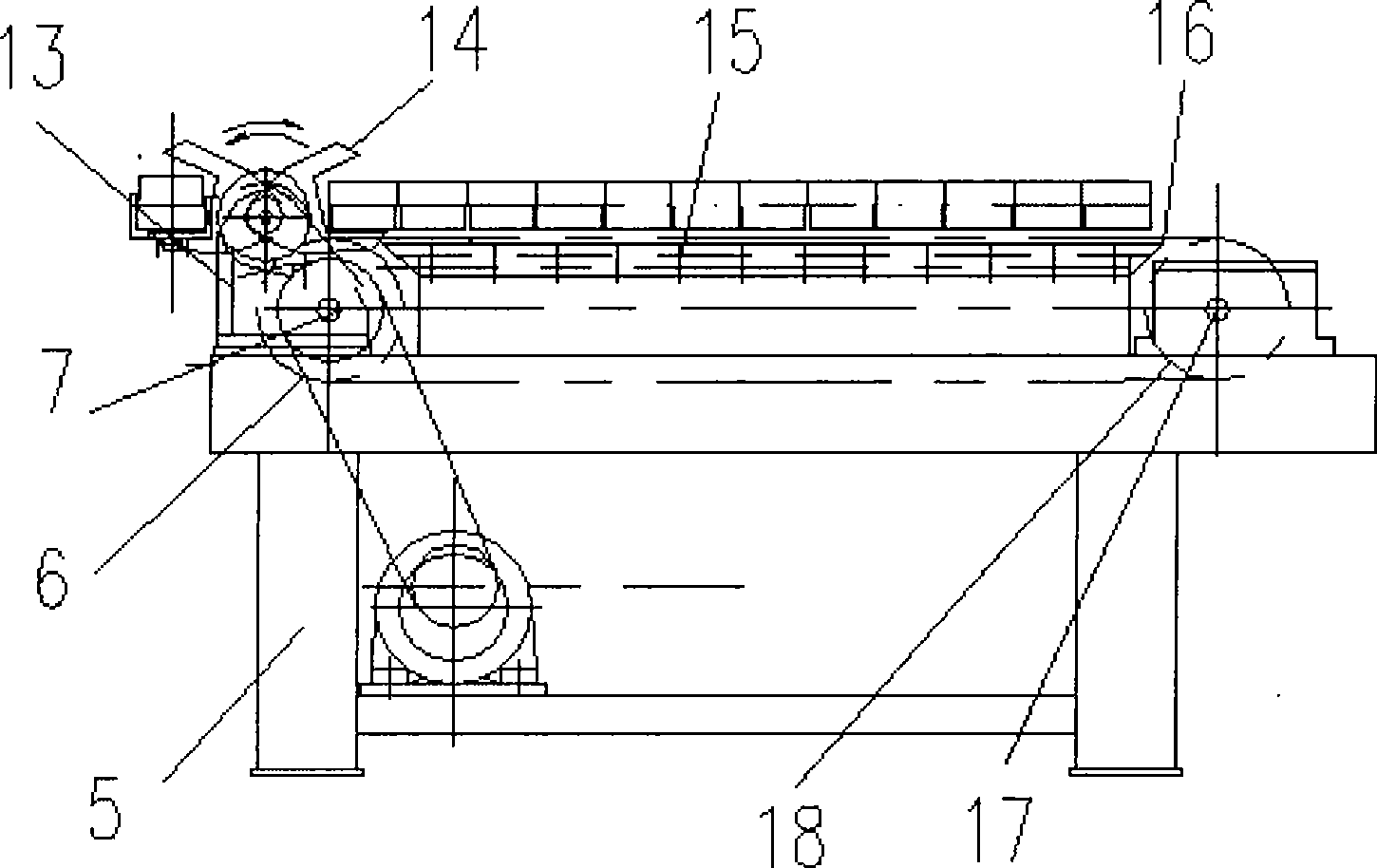

Lead disc granulator and design method thereof

ActiveCN101306471ASave energyReduce lossGranulation by pressingShaping pressEngineeringDesign methods

The invention belongs to a design method and a device for a machine carrying out granule cutting to soft metal in a cold state, in particular to a design method and a device relating to a lead cake granulator which squeezes a lead cake into granules via two squeezing rollers contra-rotating synchronously. A power mechanism is fixed on a machine frame (1) of the lead cake granulator adopted by the invention, and is in the transmission connection with a granule cutting mechanism via a transmission mechanism; the granule cutting mechanism is provided with the two squeezing rollers contra-rotating synchronously, and accidented and staggered dummy clubs and flutes are distributed on the arc surfaces of the squeezing rollers. The lead cake granulator can directly cut lead cakes into lead granules in the cold state, and the energy is saved, the lead material wastage is lowered, and the environmental pollution is reduced.

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD

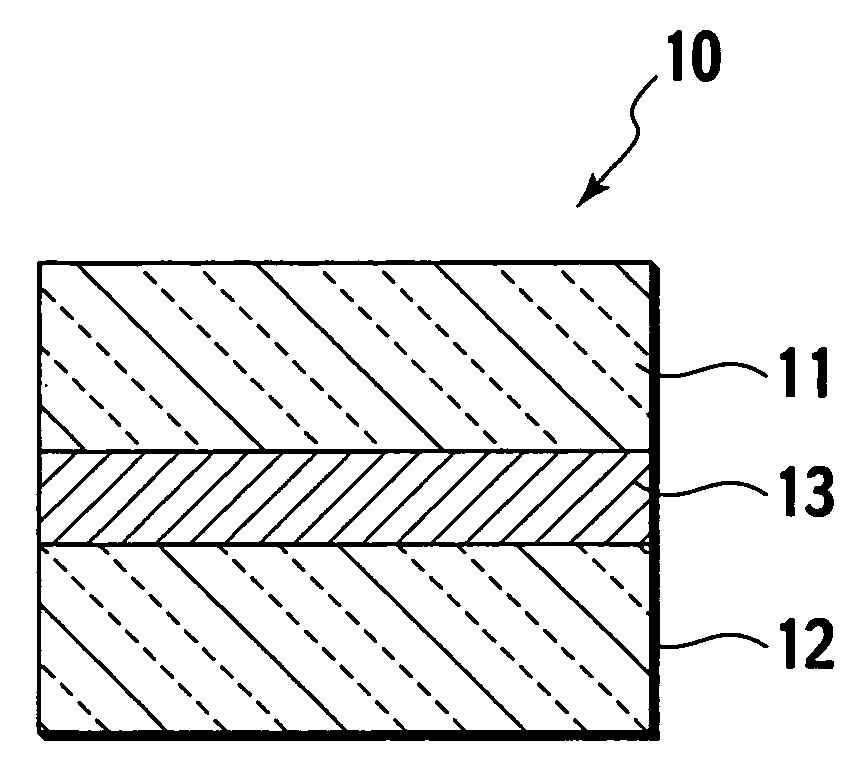

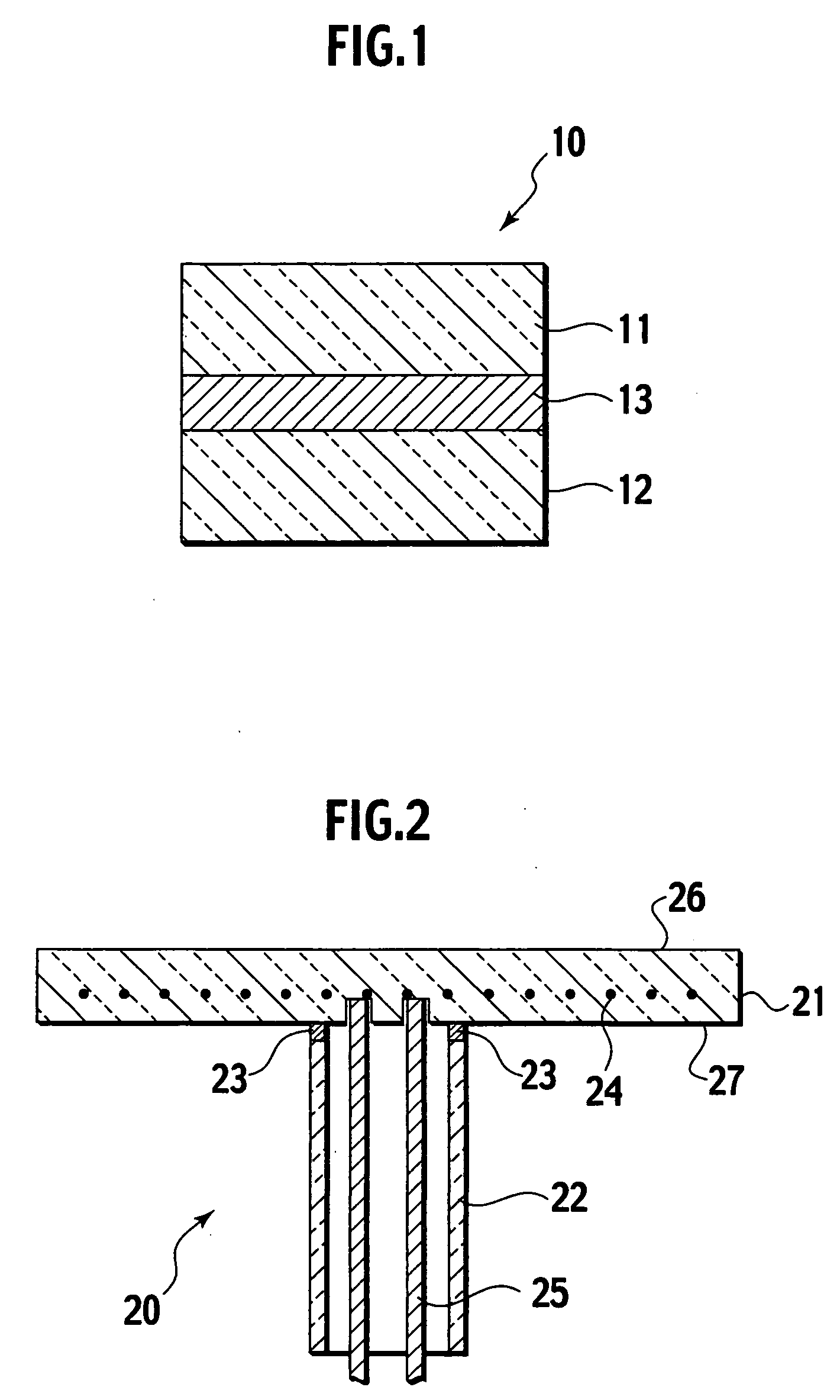

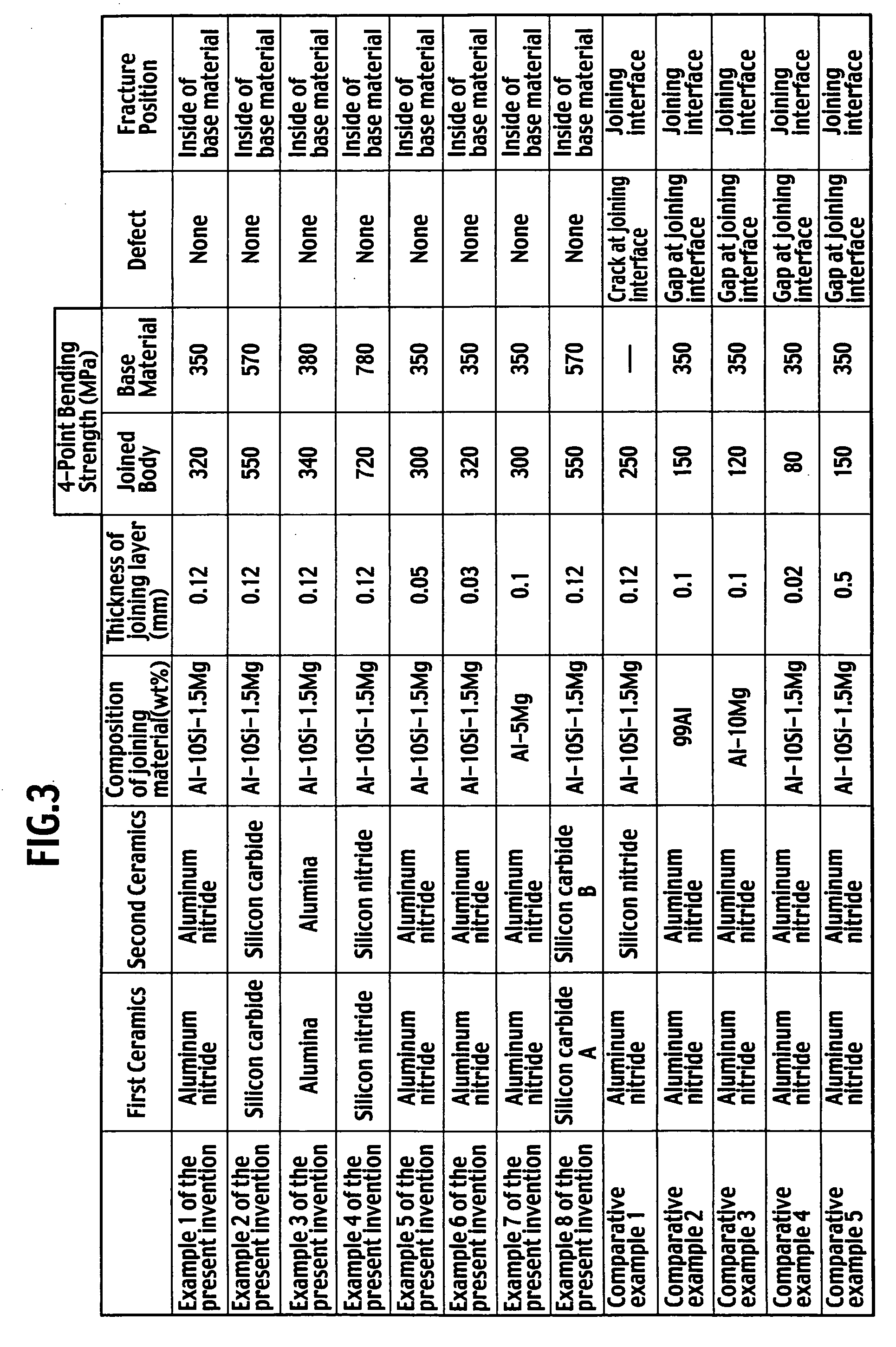

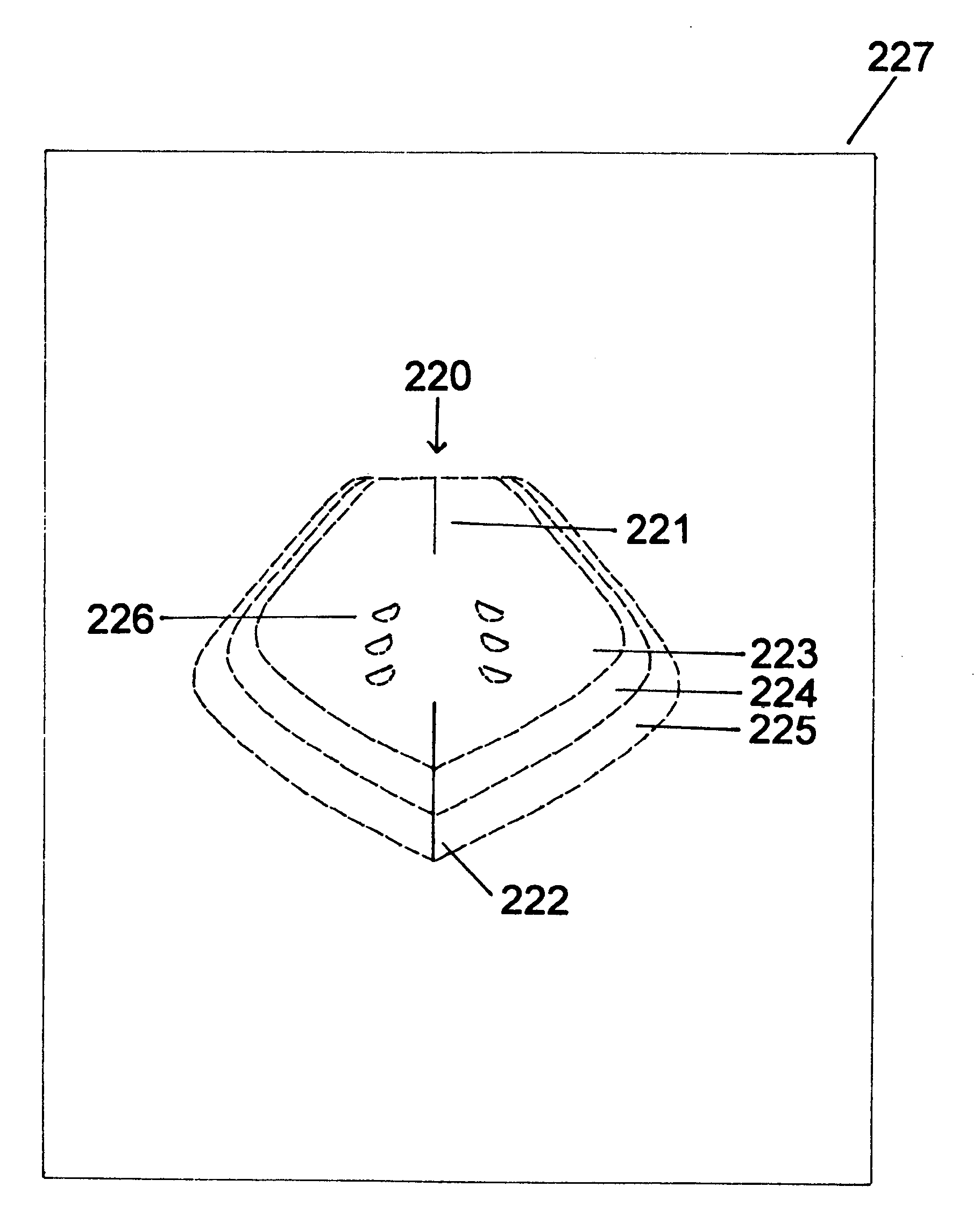

Joined body and manufacturing method for the same

ActiveUS20060182908A1Avoid deformationQuality be preventedPreformed elementsThin material handlingMetallurgySoft metal

A joined body includes a first ceramic member, a second ceramic member, and a joining layer which contains soft metal, and joins the first ceramic member and the second ceramic member to each other by being thermally compressed at a joining temperature lower than a solidus of the soft metal.

Owner:NGK INSULATORS LTD

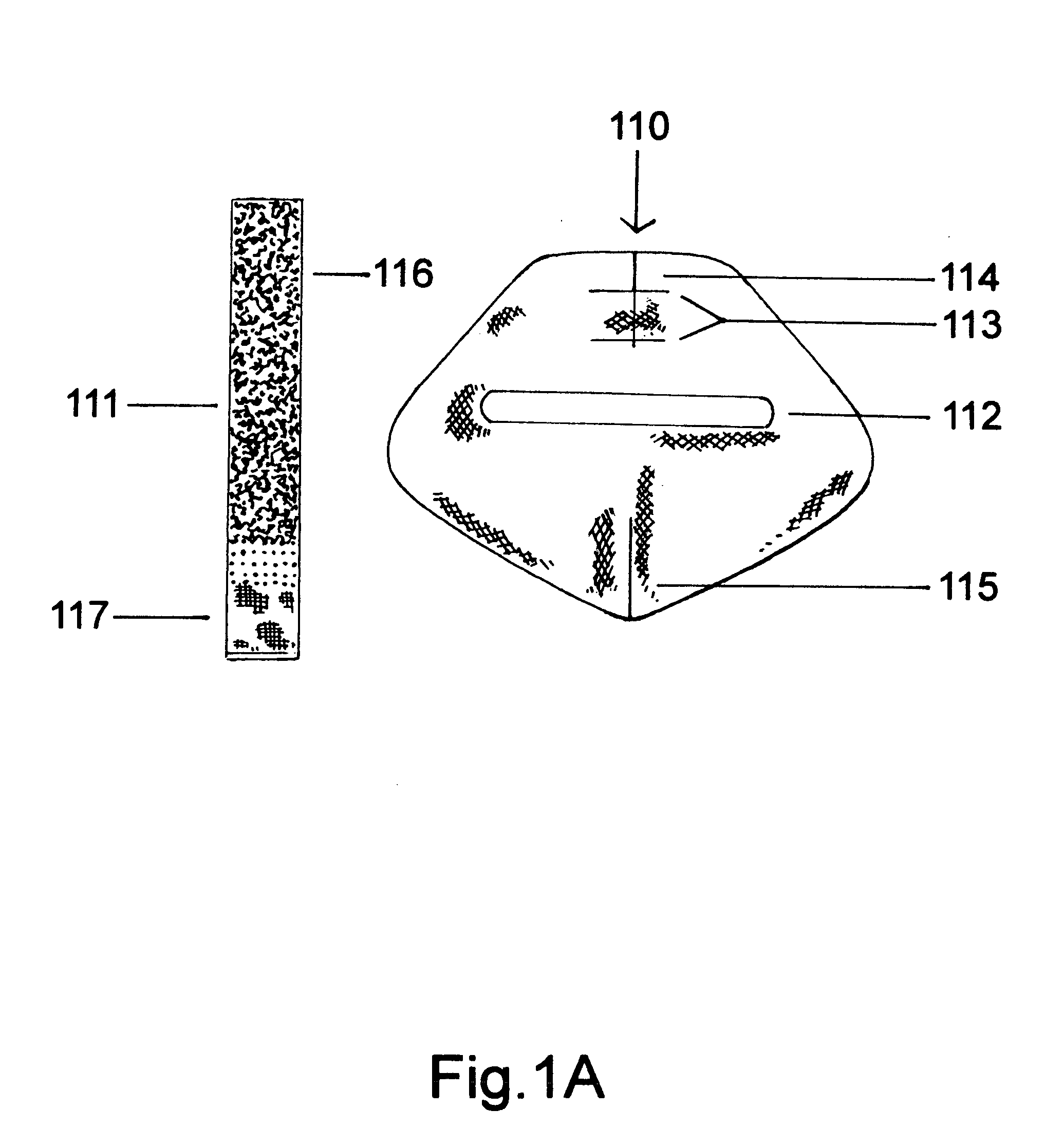

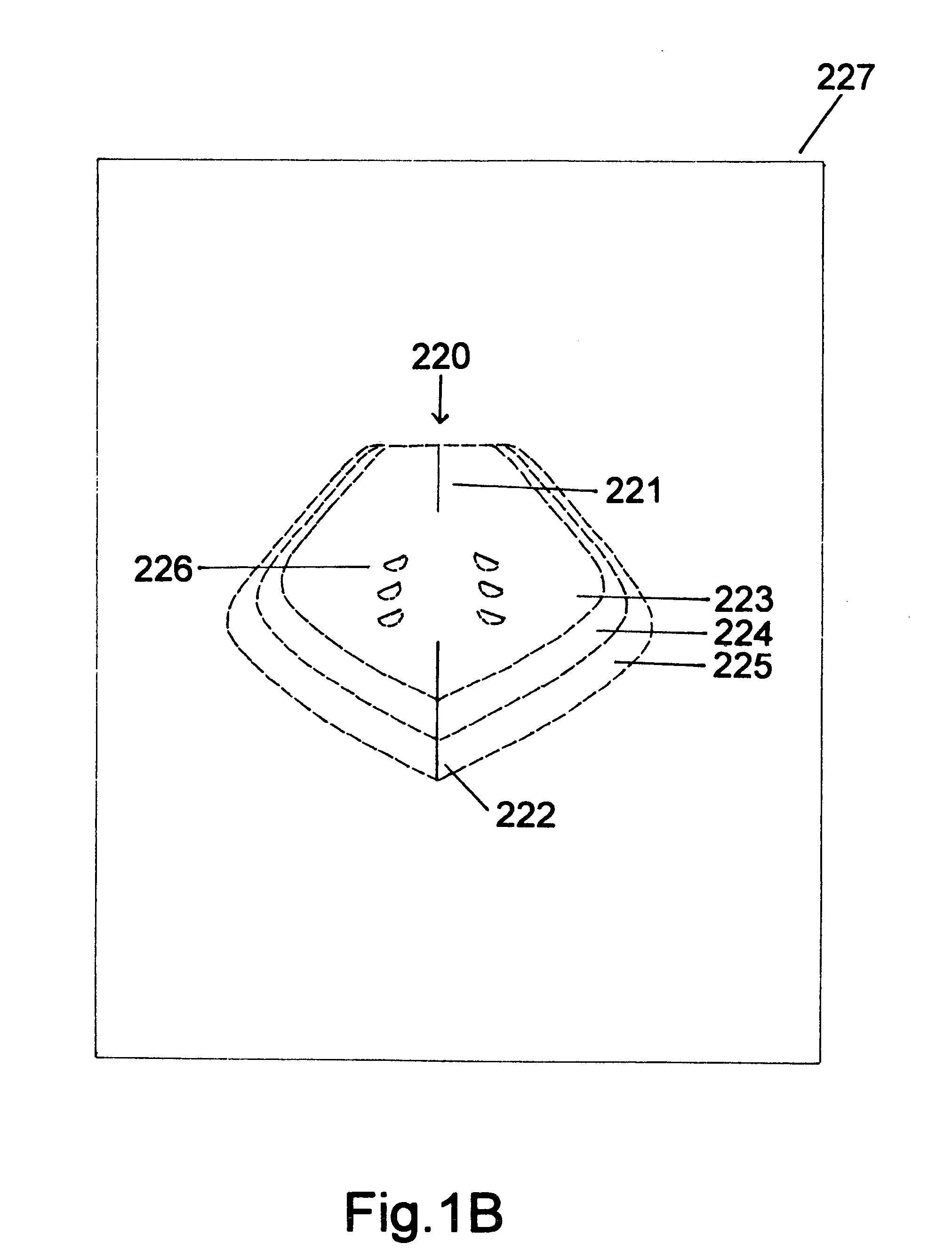

Nose cover

InactiveUS20070250976A1Provide protectionLight weightBreathing protectionEye treatmentNoseEngineering

A nose cover or nose protector, for adventurers, sports fans, and people who love outdoor activities, comprises a nose piece formed from sheets of paper, plastic, fabric, foam, laminated materials, pressure heat cut and seal materials, and / or die-cut materials to fit and cover the nose. Additional materials of adhesive pieces and soft metal sheets are used to fold and contour the nose cover onto the wearer's nose. A corresponding “hook and loop” strap or “hook” patch is used to connect the nose cover to the bridge of eyewear. This nose cover can also consist of heat packs, cold packs, and / or medicated packs to comfort the user. The nose cover can be used with or without eyewear, and with variety of optional accessories.

Owner:BELIVEAU ROBERT

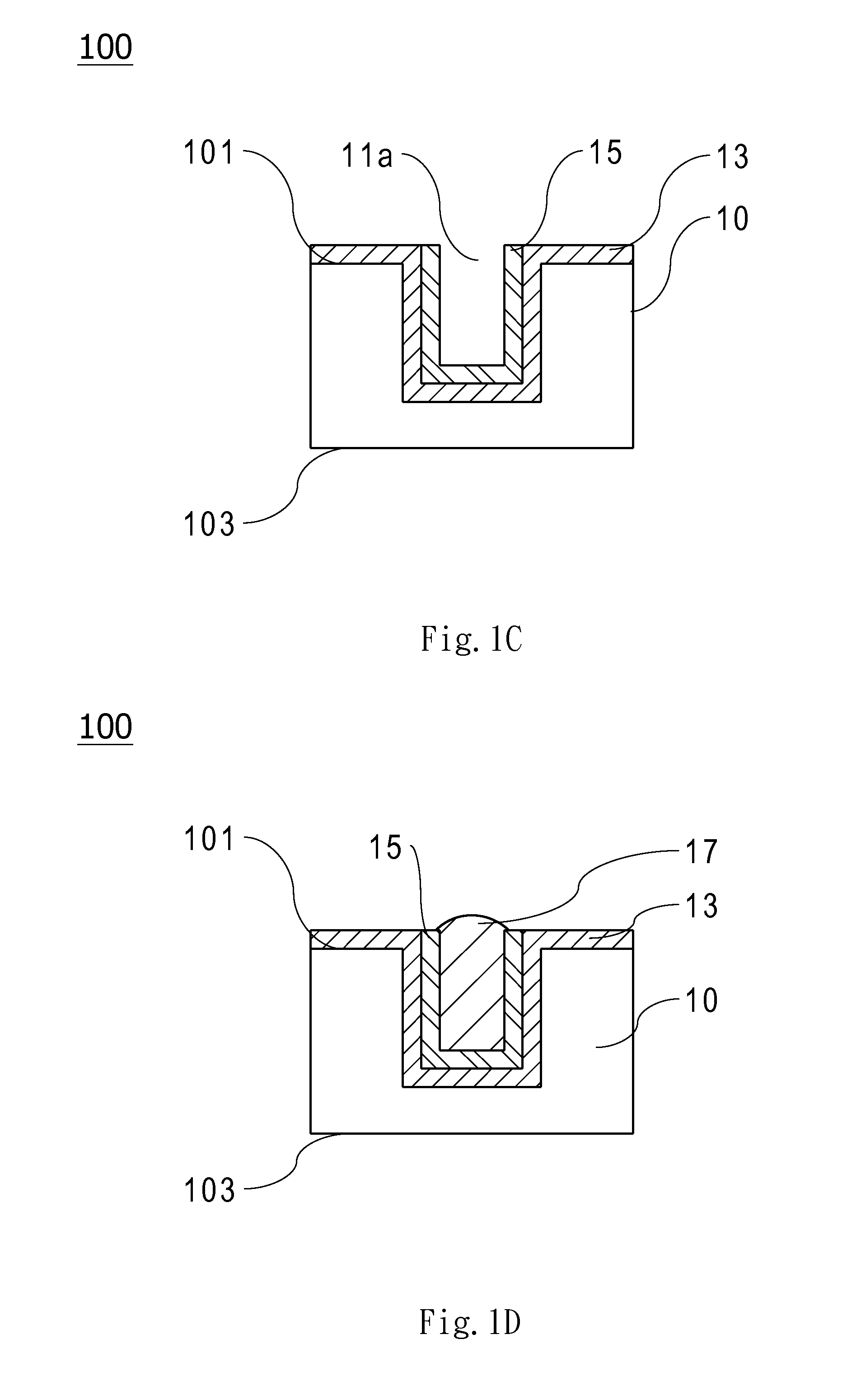

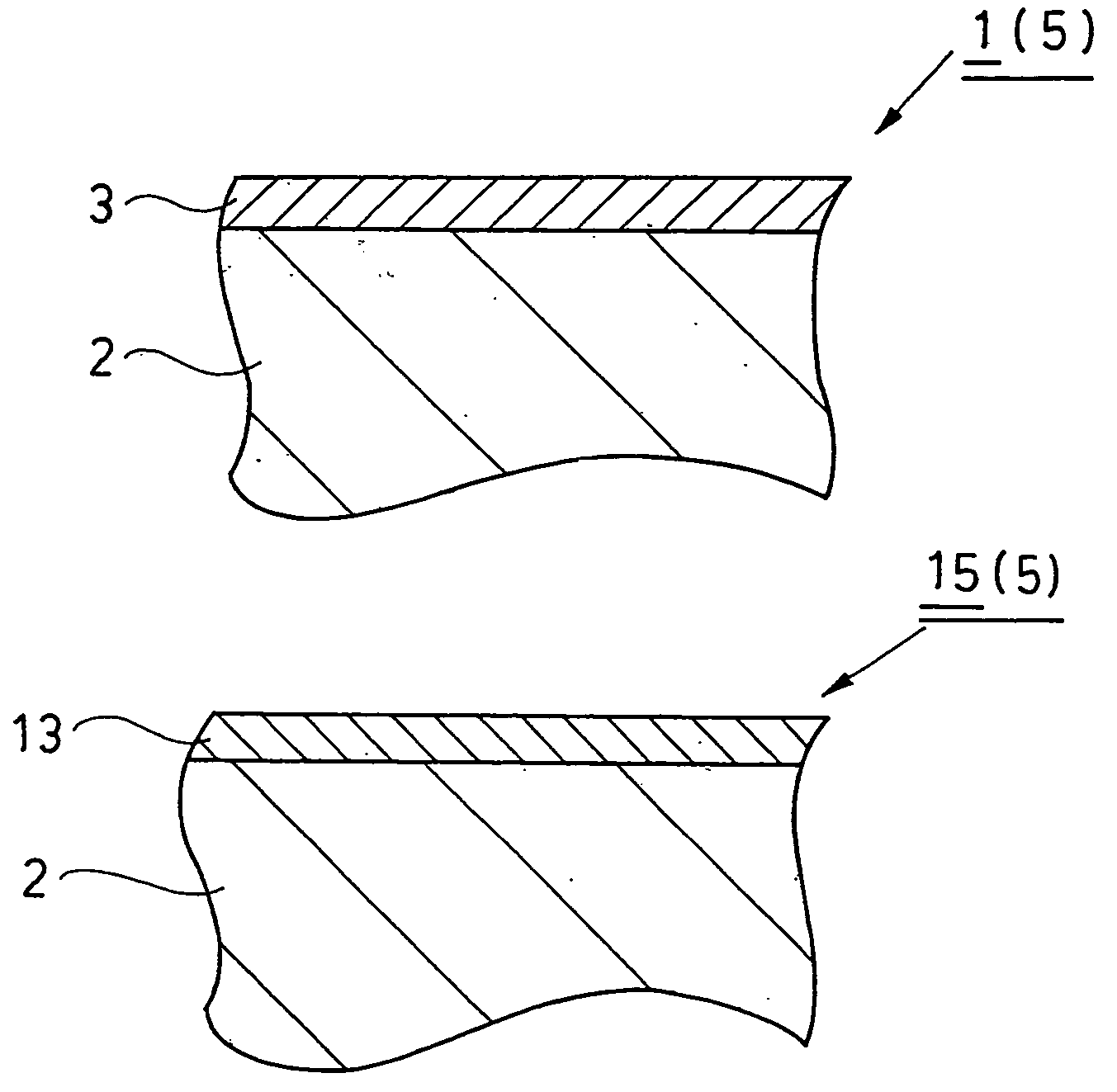

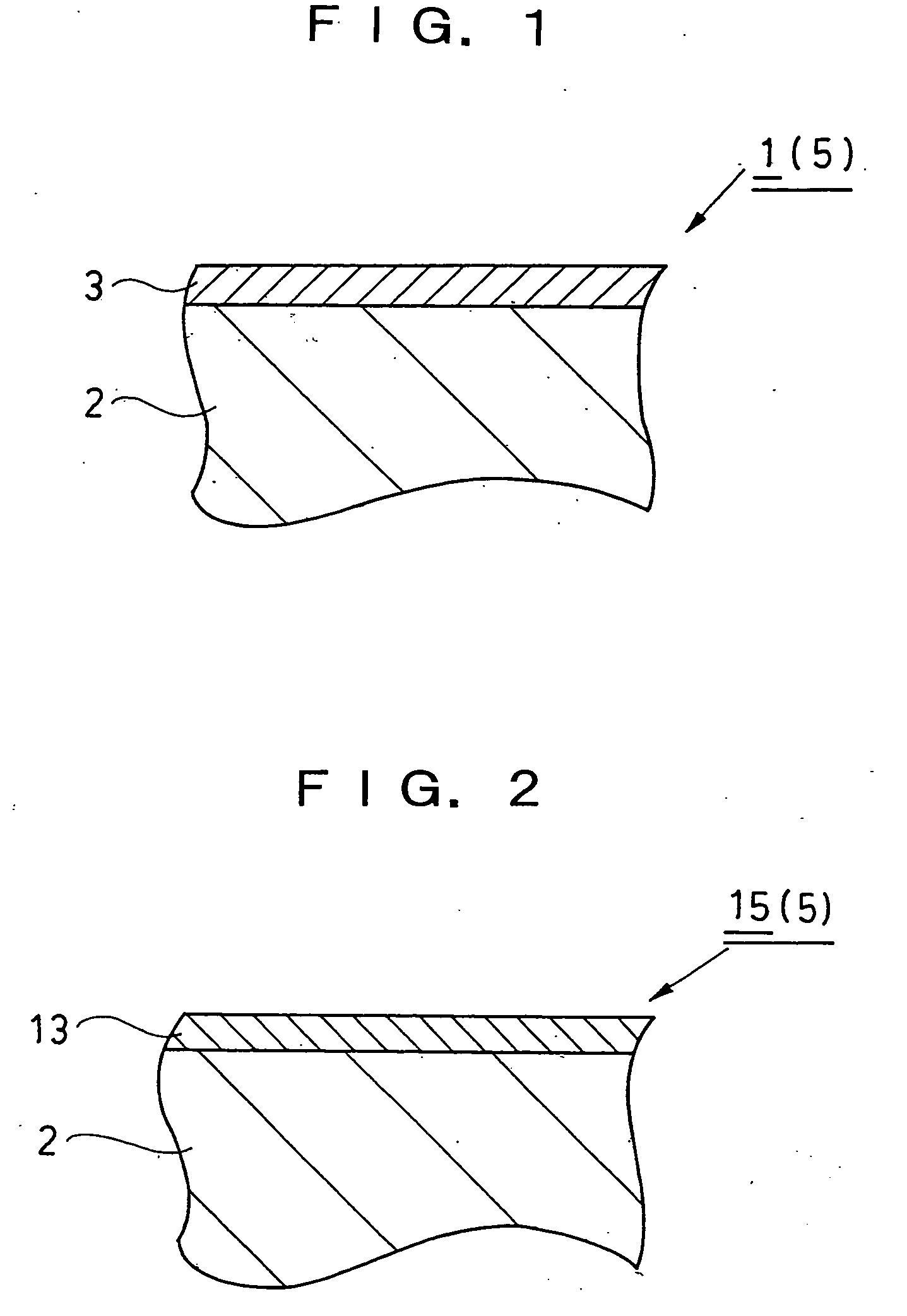

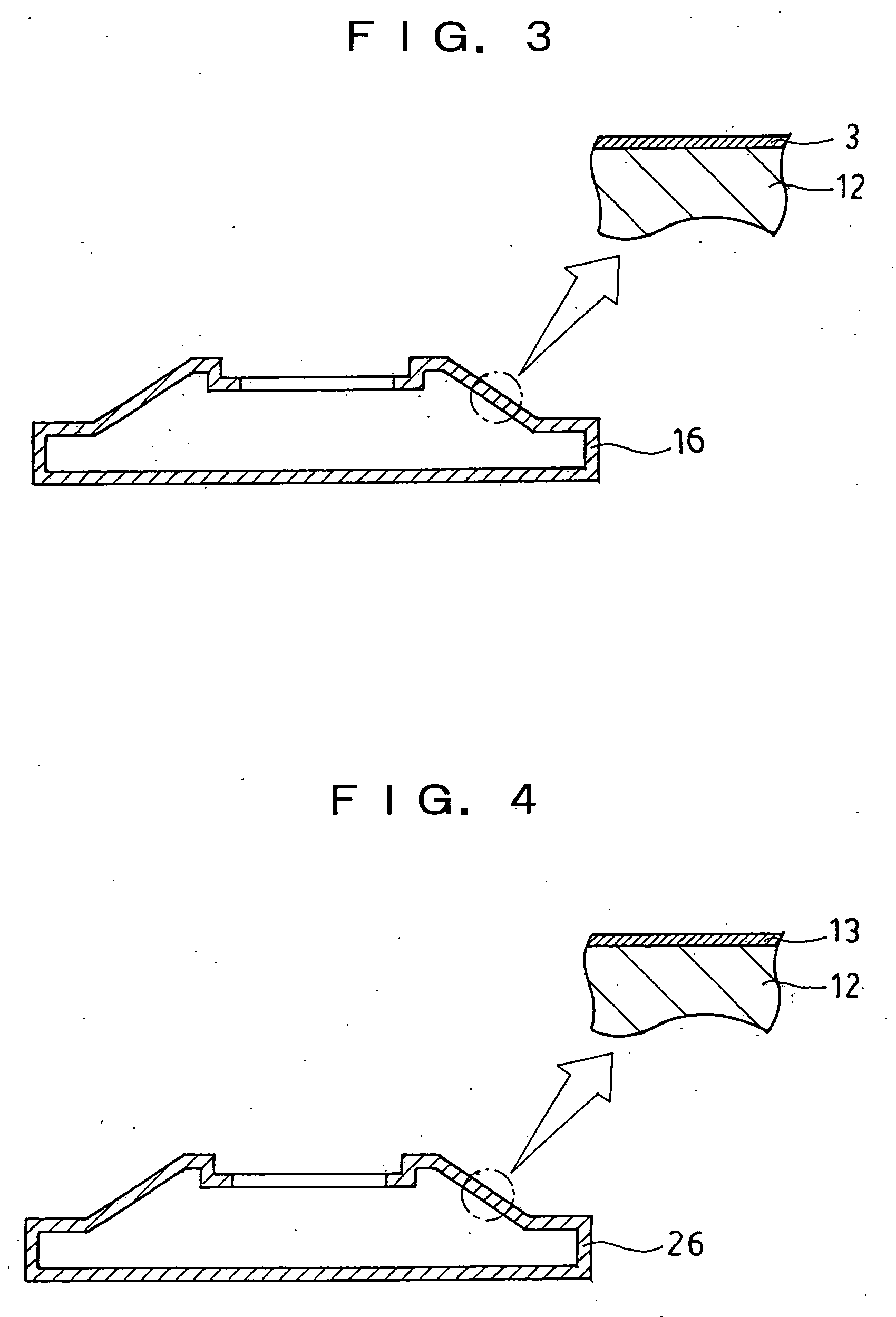

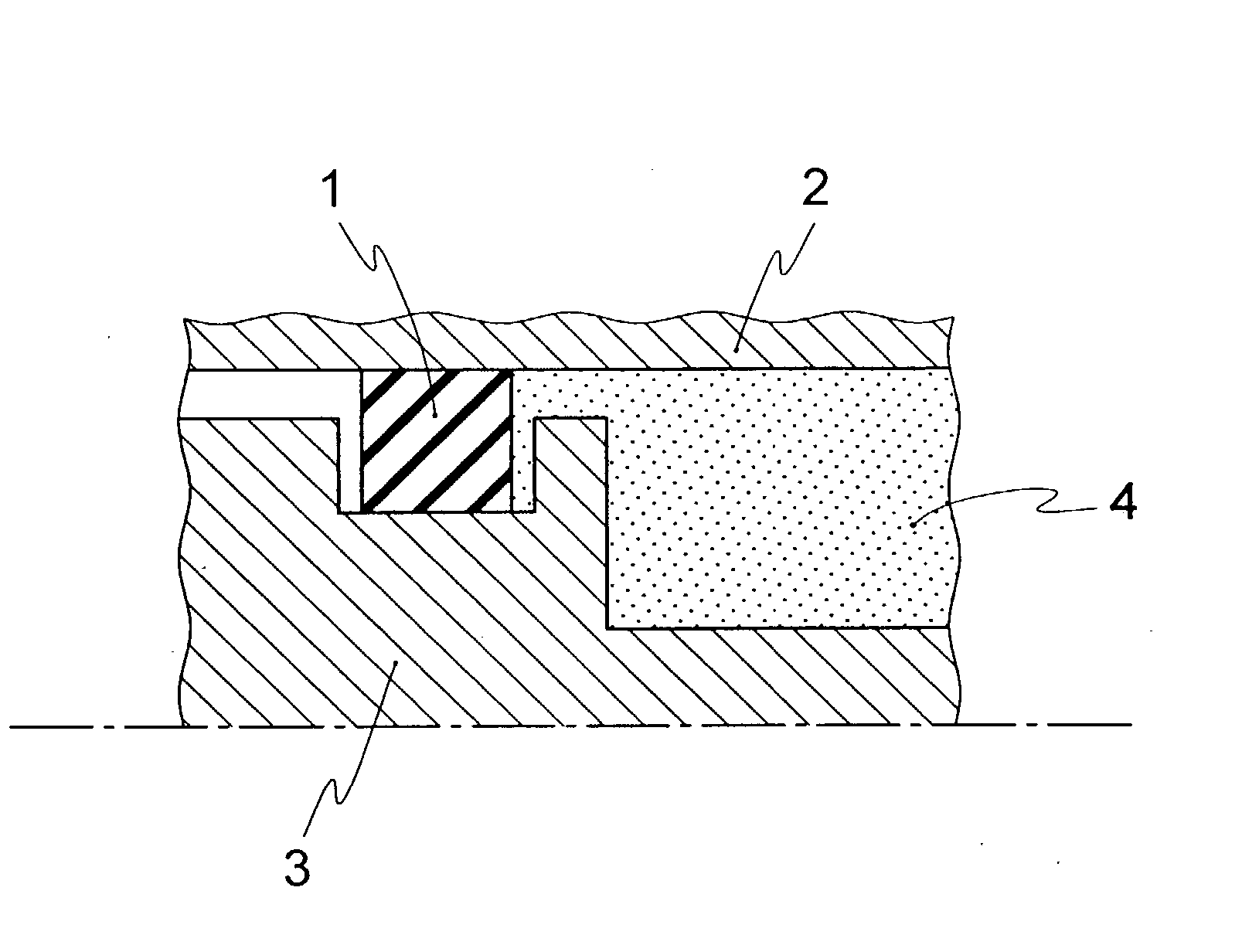

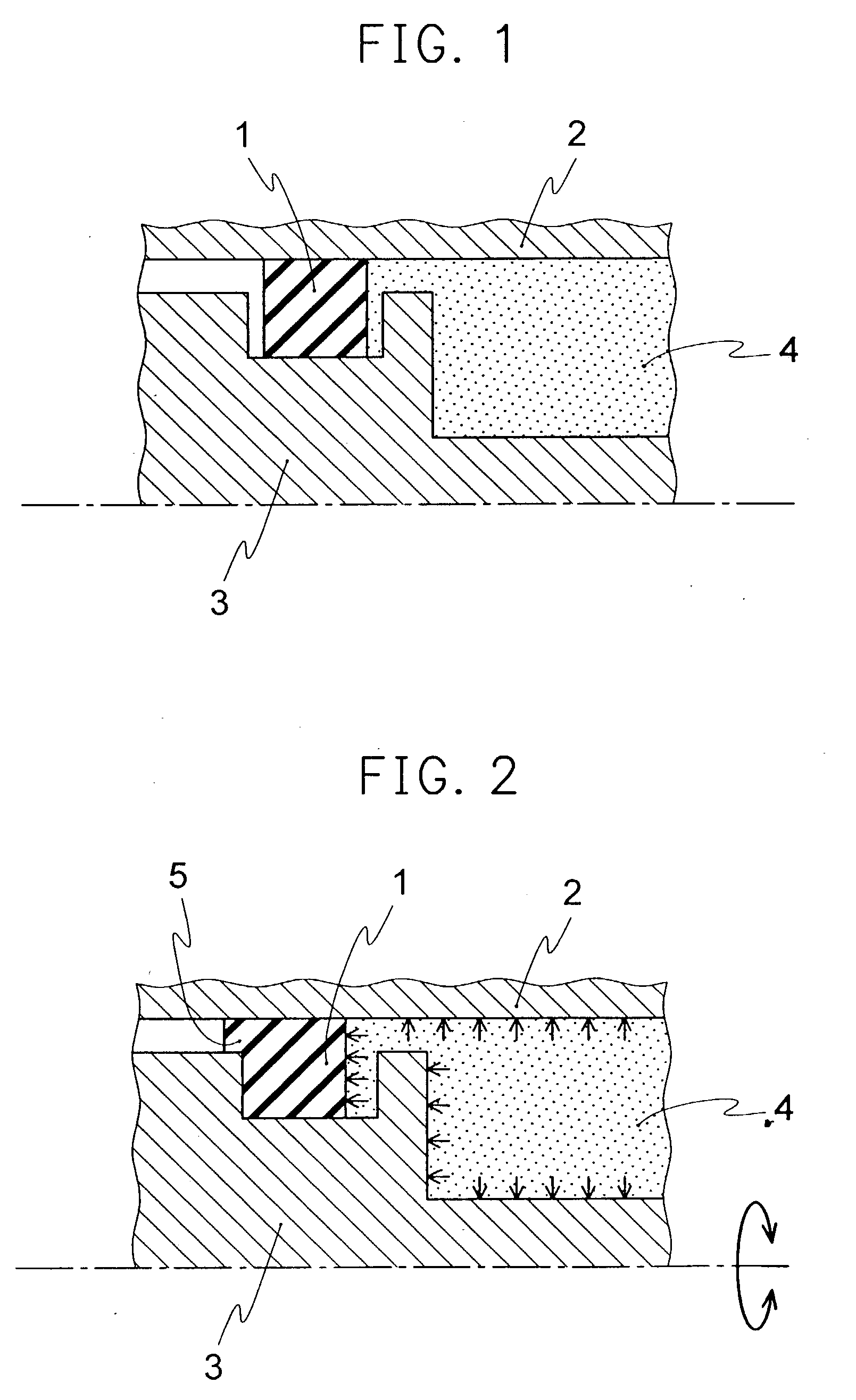

Soft metal and method for preparation thereof, and exterior part of watch and method for preparation thereof

InactiveUS20040231159A1High hardnessHigh in strengthVacuum evaporation coatingSputtering coatingNiobiumTitanium

A soft metal and a decorative article of wristwatch are produced by forming, on the surface of a soft metal article (2), a hard layer (3, 13) containing zirconium and molybdenum, or containing zirconium, molybdenum and further an additive element constituted of at least one or more elements selected from niobium, tantalum, and titanium. It is preferable that the content of molybdenum constituting the hard layer (3, 13) is about 30 to 75 wt %, or that the content of molybdenum is about 25 to 65 wt % and the total content of the additive elements is about 25 wt % or less.

Owner:CITIZEN WATCH CO LTD

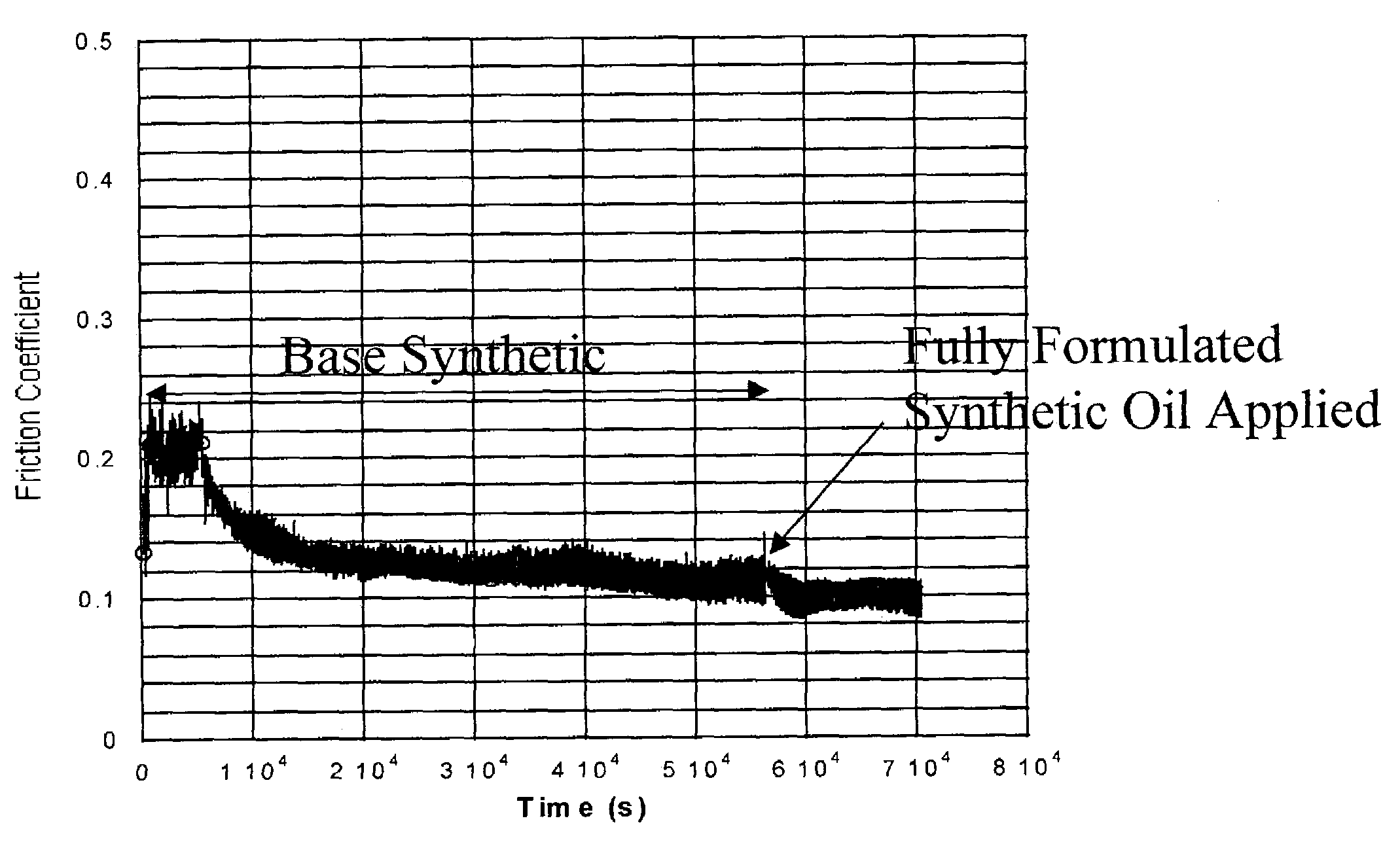

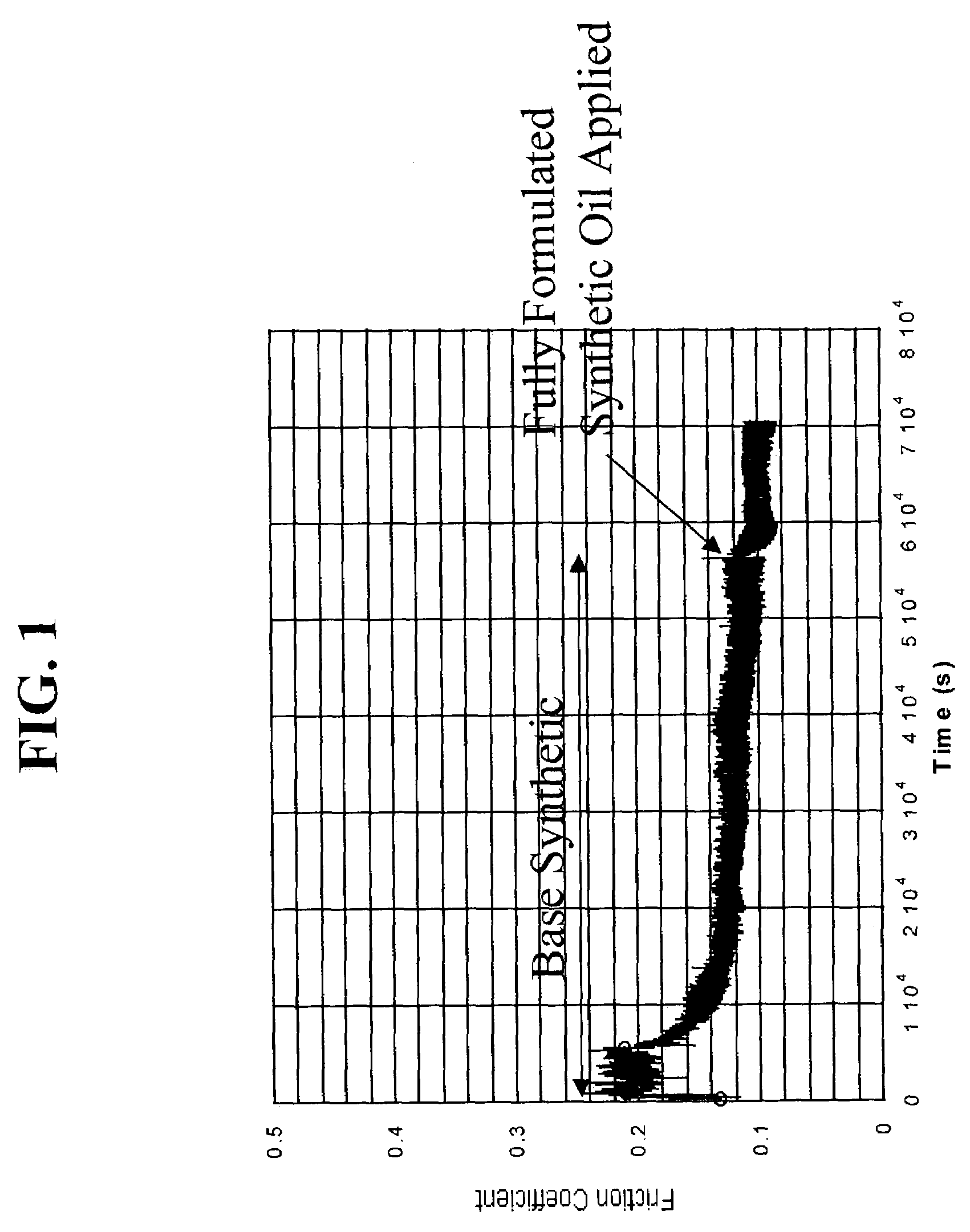

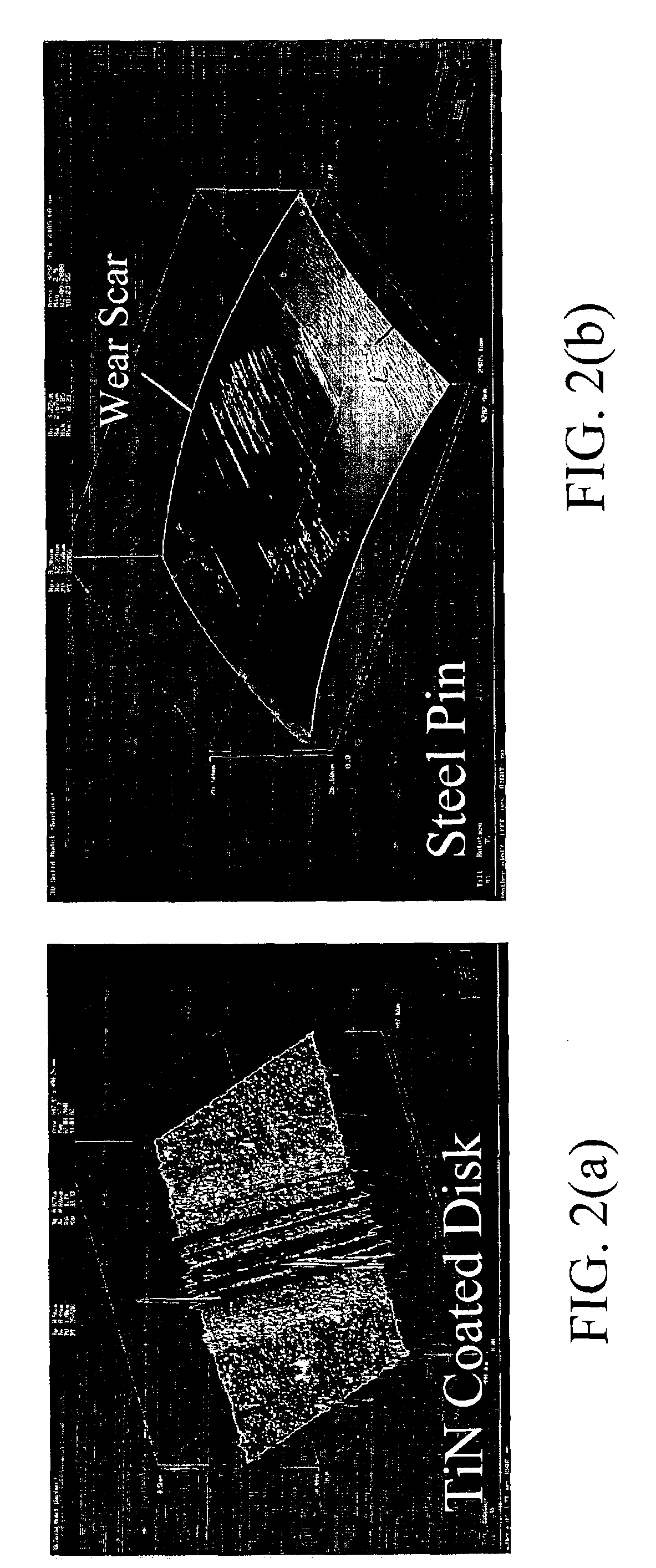

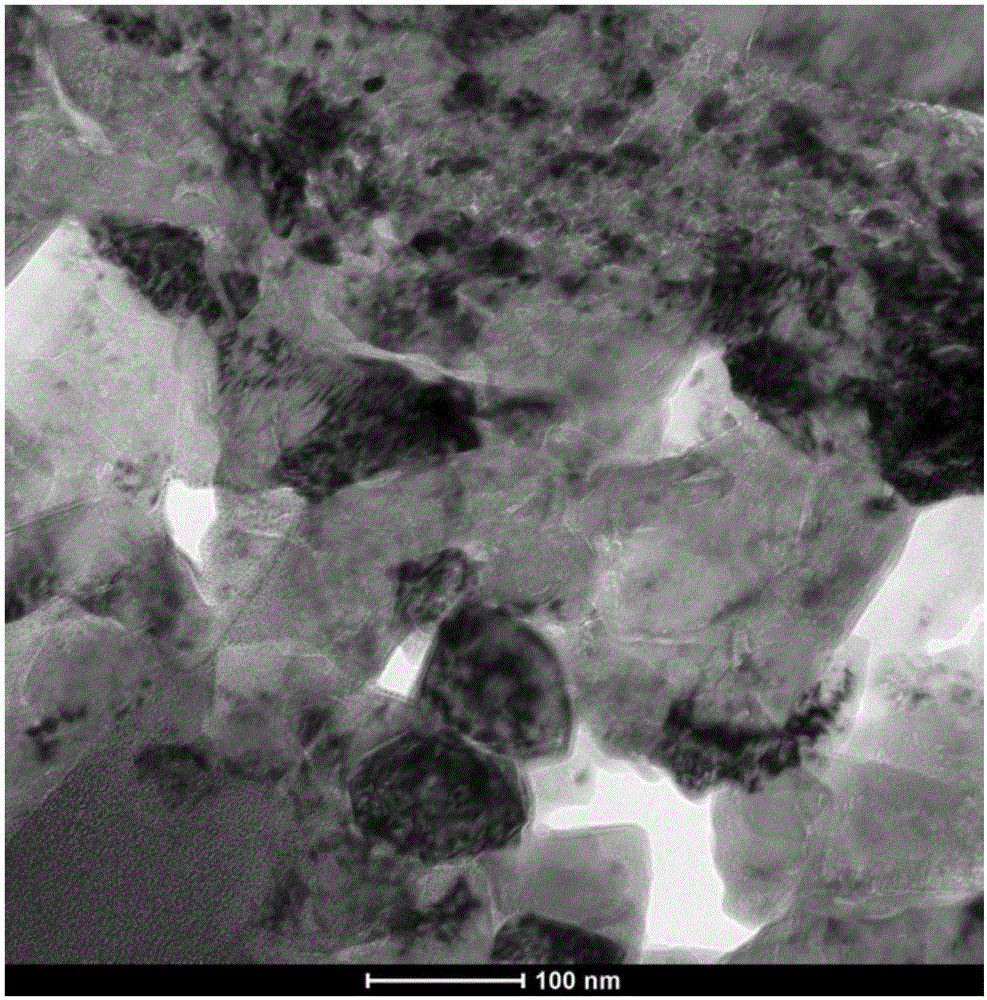

Hard and low friction nitride coatings and methods for forming the same

InactiveUS7211323B2High hardnessLow in its friction propertyVacuum evaporation coatingSputtering coatingTitanium nitrideHardness

An improved coating material possessing super-hard and low friction properties and a method for forming the same. The improved coating material includes the use of a noble metal or soft metal homogeneously distributed within a hard nitride material. The addition of small amounts of such metals into nitrides such as molybdenum nitride, titanium nitride, and chromium nitride results in as much as increasing of the hardness of the material as well as decreasing the friction coefficient and increasing the oxidation resistance.

Owner:UCHICAGO ARGONNE LLC +1

Graphite composite thermal sealants and associated methods

A graphite composite thermal sealant having a graphite matrix and a metal is disclosed and described. The metal can be dispersed in the graphite matrix or provided in a separate layer. Graphite having a high degree of graphitization can be of particular benefit. Further, the metal can be a soft metal such as In, Ag, Cu, Pb, Zn, Sn, Au, or alloys of these metals. The thermal sealant materials described herein can have thermal conductivities in excess of about 200 W / mK, while also minimizing or eliminating voids or pores between sealed surfaces.

Owner:SUNG CHIEN MIN

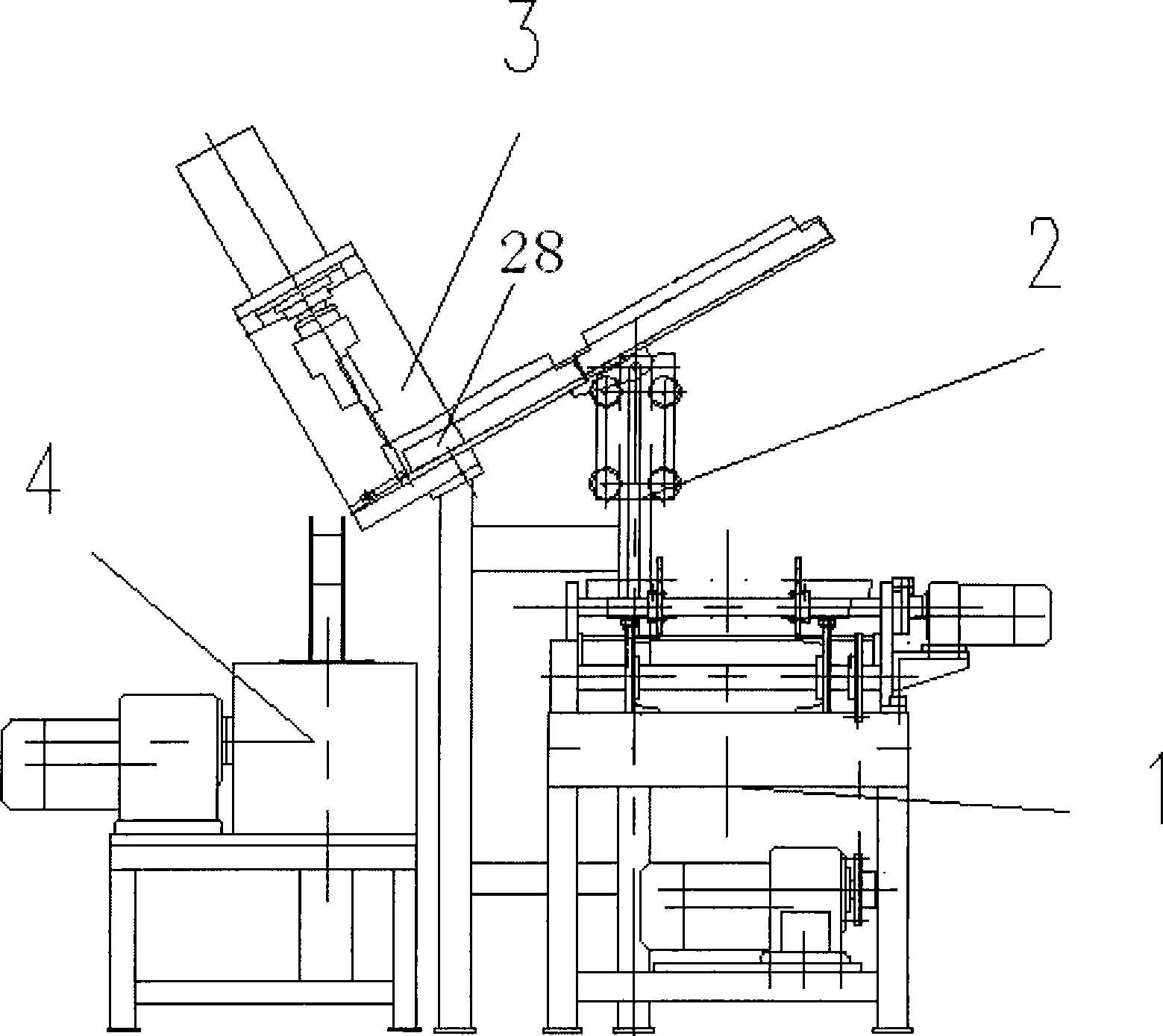

Lead bullion granulation automation line production process and apparatus

The invention belongs to a device through which a particle pipeline of soft metal is automatically divided in the cold state, in particular to a manufacturing method and device for lead ingot granulation automation line. The invention adopts the manufacturing method that lead ingot is transmitted to a lead ingot cake-cutting mechanism to cut lead ingot into cakes through a feeding mechanism, then the lead cakes are transmitted to a granulating machine to form particles, and the entire manufacturing process is automatically controlled. The invention relates to a manufacturing method and device for lead ingot granulation automation line, and an automatic lead ingot granulating manufacturing device mainly comprises a feeding mechanism, a lead ingot cake-cutting mechanism (3) and a granulating machine (4), wherein, a feed groove (22) of the feeding mechanism is butted with a lower anvil groove (28) of the lead ingot cake-cutting mechanism (3), and the lower anvil groove (28) of the lead ingot cake-cutting mechanism (3) is butted with a feed inlet of the granulating machine (4) so as to realize the full-automatic process that the lead ingot is transmitted into the lower anvil groove (28) of the lead ingot cake-cutting mechanism (3) through the feeding mechanism, the lead ingot is cut into lead cakes and transmitted into the feed inlet of the granulating machine (4) through the lead ingot cake-cutting mechanism (3), and the lead cakes are cut into granular lead through the granulating machine (4).

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD

Semiconductor wafer structure and multi-chip stack structure

InactiveUS20110291268A1Minimize misalignment problemImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

A semiconductor wafer structure comprises a first surface and a second surface opposite to the first surface, a plurality of chip areas formed on the first surface, a plurality of through-silicon holes formed in each of the plurality of chip areas connecting the first surface and the second surface, and a through-silicon-via (TSV) electrode structure formed in each through-silicon hole. Each through-silicon-via electrode structure comprises a dielectric layer formed on the inner wall of the through-silicon hole, a barrier layer formed on the inner wall of the dielectric layer and defining a vacancy therein, a filling metal layer filled into the vacancy, a first end of the filling metal layer being lower than the first surface forming a recess, and a soft metal cap connecting to and overlaying the first end of the filling metal layer, wherein a portion of the soft metal cap is formed in the recess and the soft metal cap protrudes out of the first surface. Hence, the reliability of multi-chip stack package structure can be enhanced with the application of these soft metal caps.

Owner:CHIPMOS TECH INC

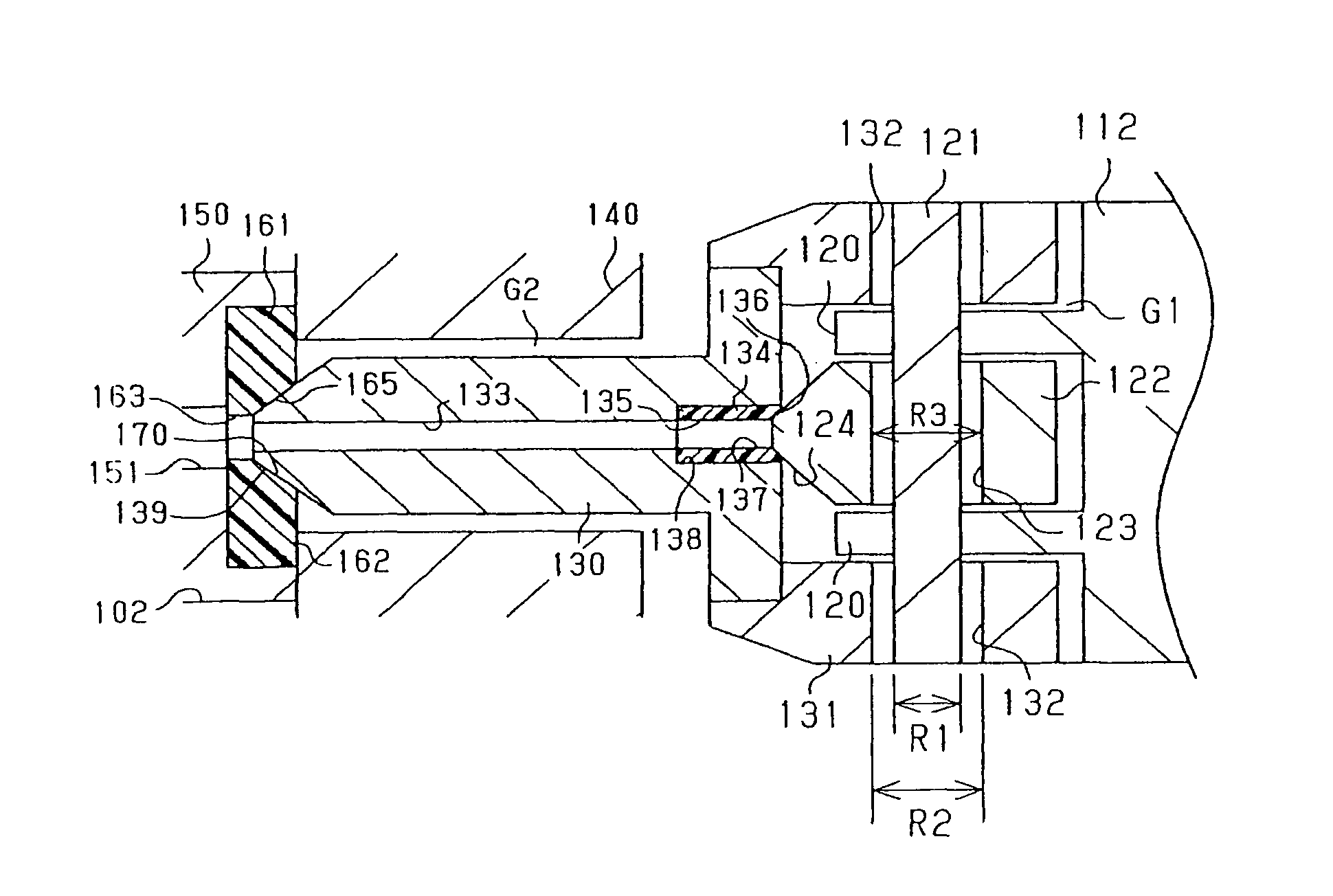

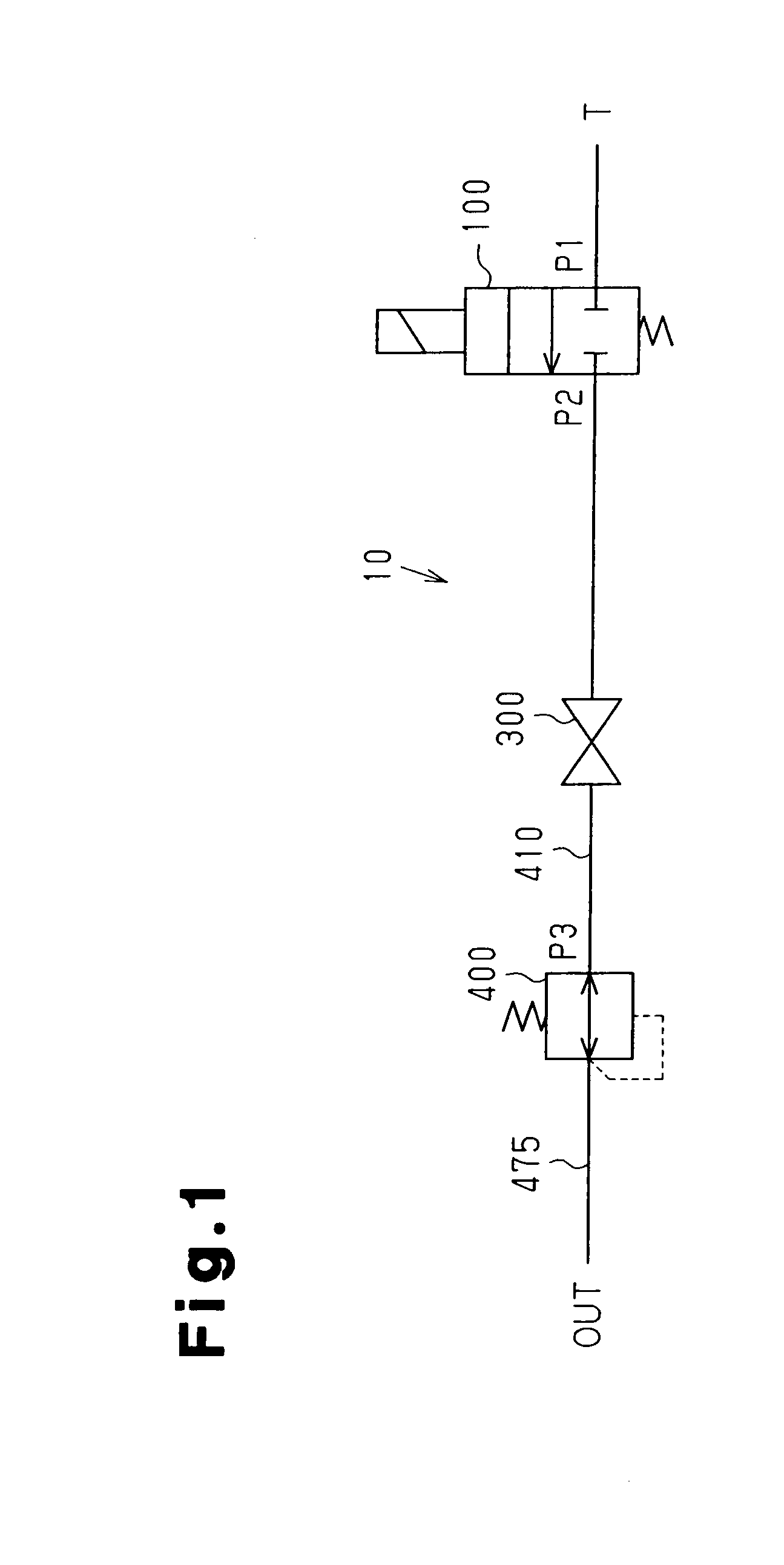

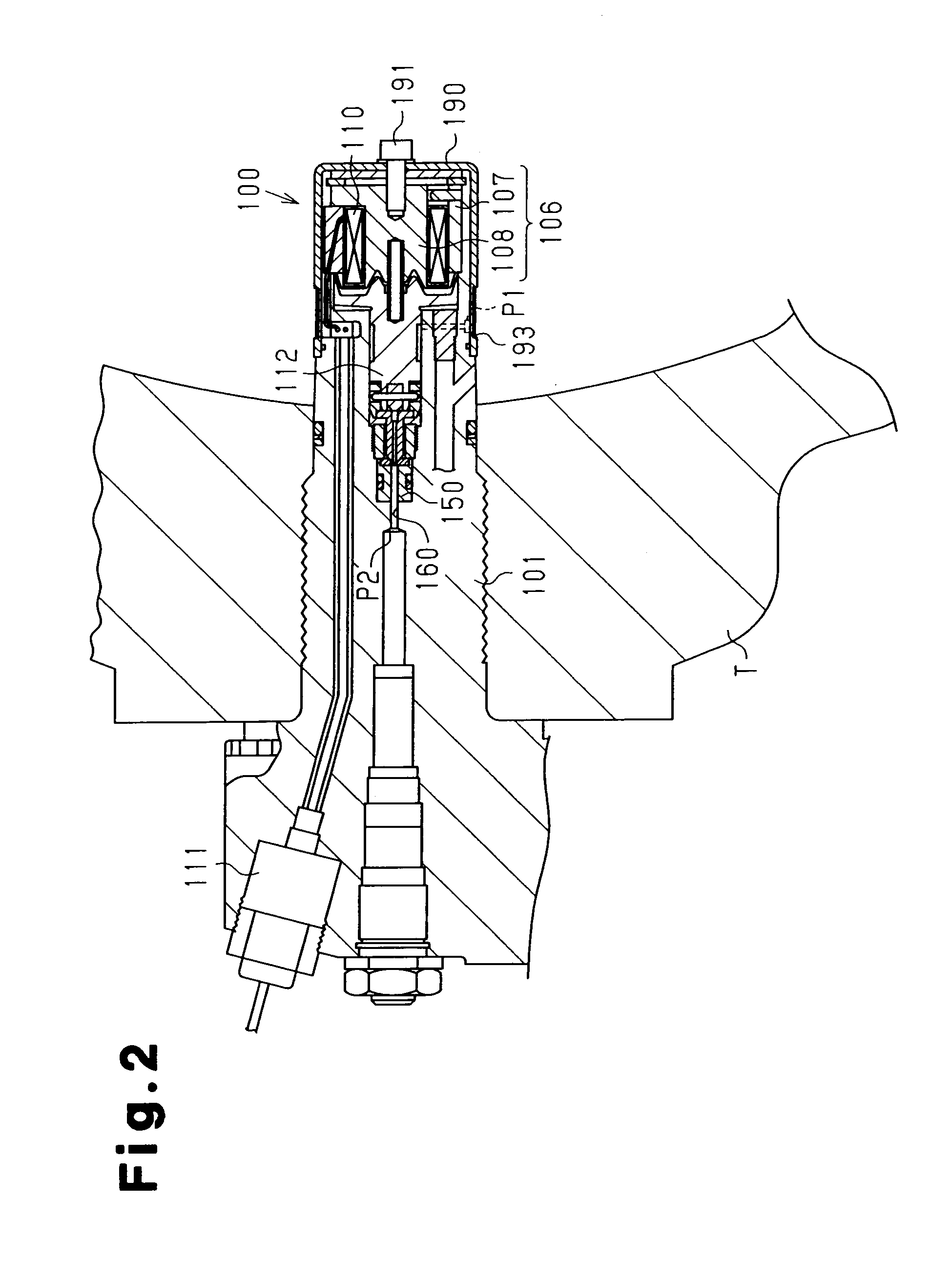

High pressure valve for hydrogen gas and decompression device for hydrogen gas

InactiveUS7730905B2Sufficient sealing effectivenessVessel mounting detailsOperating means/releasing devices for valvesHydrogenEngineering

A high pressure valve for hydrogen gas includes a valve seat and a valve member, which is movable to selectively open and close the valve seat. One of the valve member and the valve seat is formed of austenitic stainless steel, and the other one of the valve member and the valve seat is formed of flexible synthetic resin or soft metal.

Owner:TOYOOKI KOGYO CO LTD +1

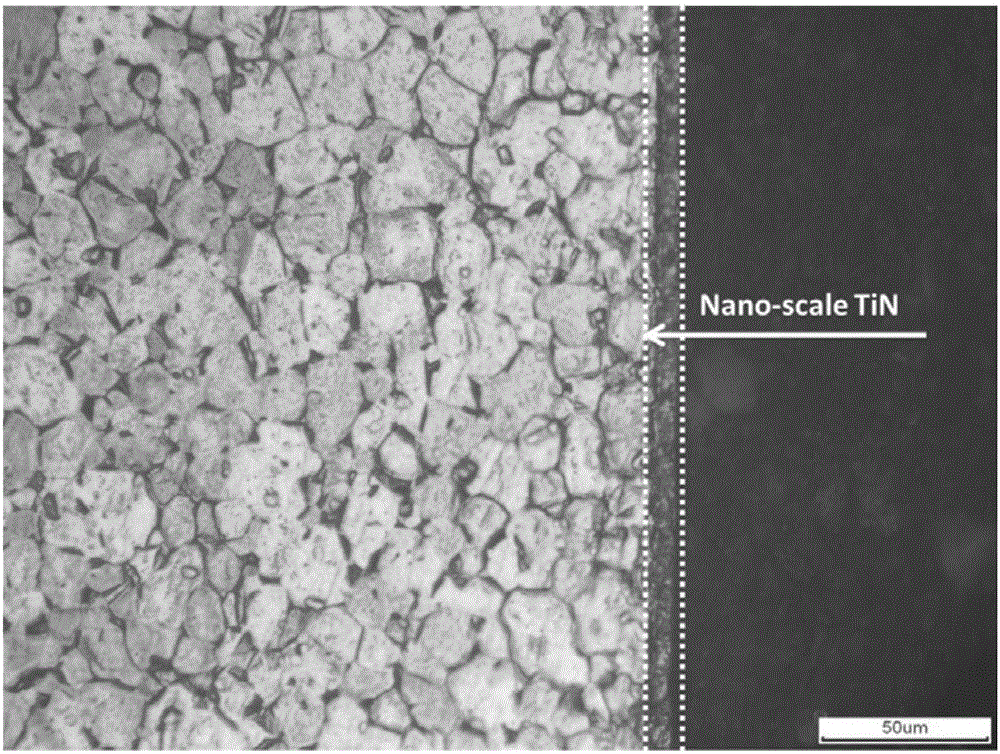

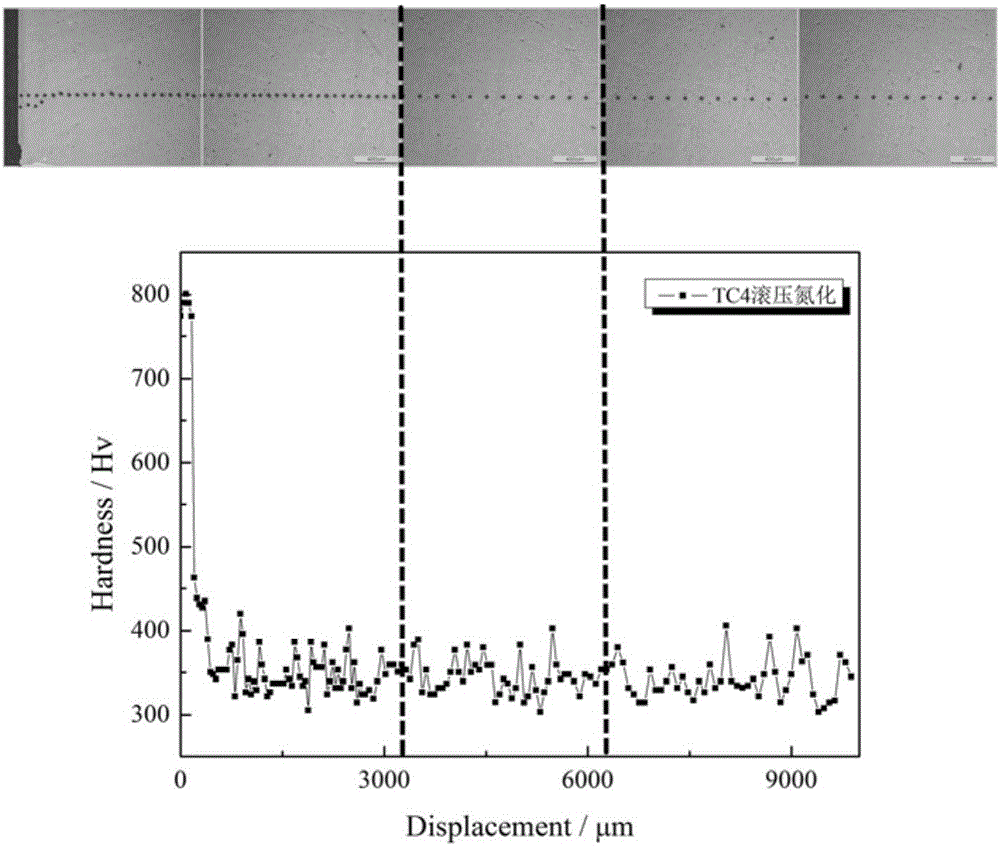

Method for preparing gradient nanostructure nitride layer on surface of titanium alloy

InactiveCN106480399AStrong penetrating powerImprove mechanical propertiesSolid state diffusion coatingNanostructured metalNanostructure

The invention discloses a method for preparing a gradient nanostructure nitride layer on the surface of a titanium alloy. The method comprises following steps: S01, the titanium alloy is subject to pretreatment; S02, the surface of the titanium alloy is subject to ultrasonic deep rolling nanocrystallization processing treatment, wherein the surface of the titanium alloy treated in the S01 is painted with lubricating oil, ultrasonic deep rolling nanocrystallization processing treatment is carried out, and a gradient nanostructure metal layer is prepared on the surface of the titanium alloy; S03, the surface of the titanium alloy is subject to glow ion nitriding treatment, and the gradient nanostructure nitride layer on the surface of the titanium alloy is obtained. According to the method for preparing the gradient nanostructure nitride layer on the surface of the titanium alloy, the prepared titanium alloy has the lubricating, wear resistance, corrosion resistance and fatigue-resisting properties, and effective control over the structure, the composition, the morphology and the size of a soft metal material surface texture is achieved.

Owner:NANJING INST OF TECH +1

Seal ring

InactiveUS20030122318A1Improve adaptabilityEngine sealsOther chemical processesAutomatic transmissionX-ray

A seal ring which contains a scaly graphite powder essentially alone as a filler, and comprises 2 to 35% by weight of the graphite powder and 65 to 98% by weight of a polytetrafluoroethylene powder, wherein the graphite powder has an interplanar spacing of 0.335 to 0.340 nm, as measured by the powder X-ray diffraction method, and a size of a crystallite of (004) face of at least 70 nm is provided. Since deformation and extrusion of the seal ring are kept small even under a high pressure, and the abrasion of the opposite material can be prevented even if it is made of a soft metal, it is possible to maintain a stable sealing effect for a longer period of time. In addition, since the seal ring has small sliding resistance, handling property, response of the sealing device and suitability for fitting to the device can be largely improved. Thus, the seal ring is suitable for the valve device of power steering of automobiles, automatic transmission or shock absorber.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com