Patents

Literature

30results about How to "High in strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

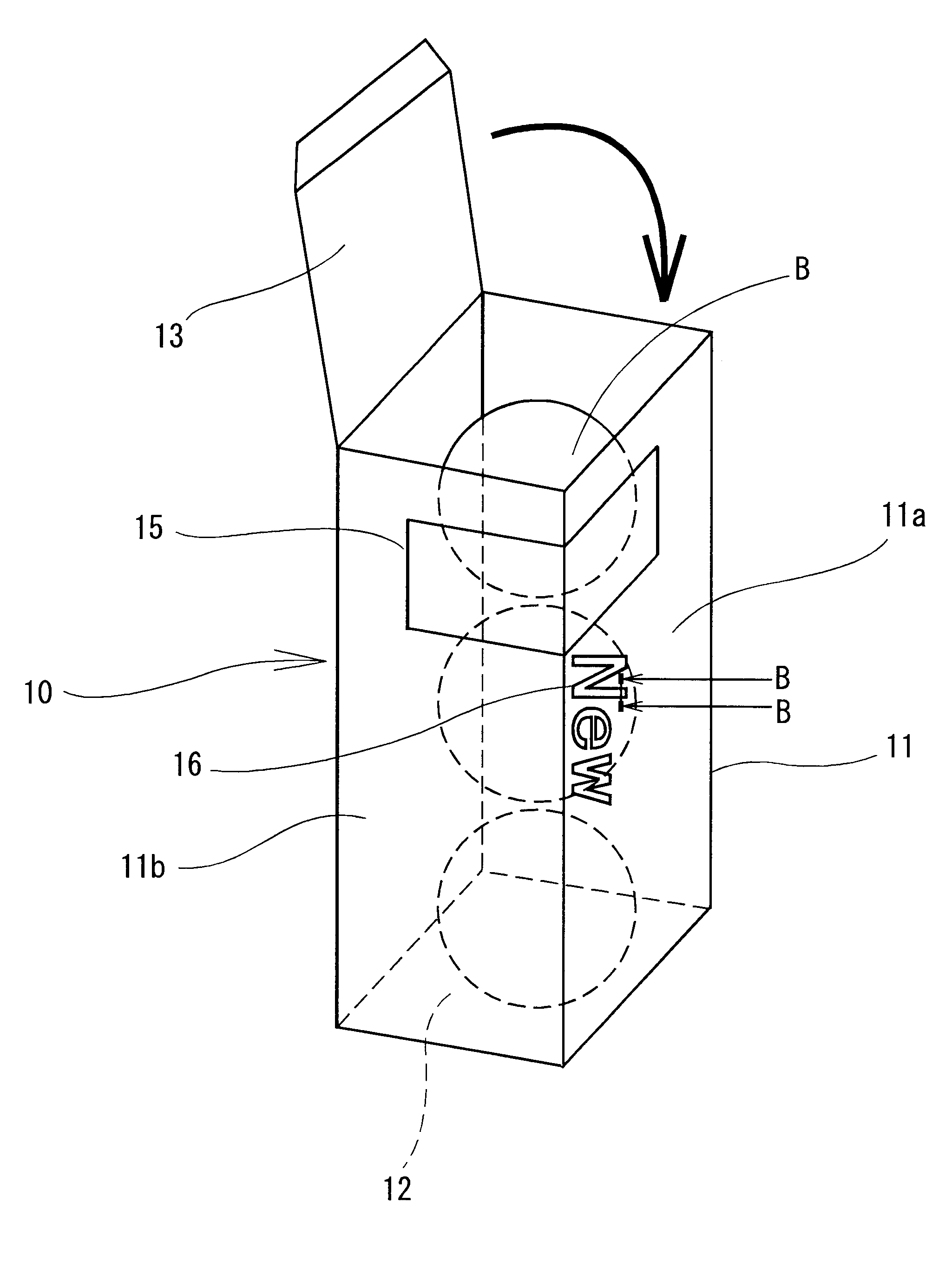

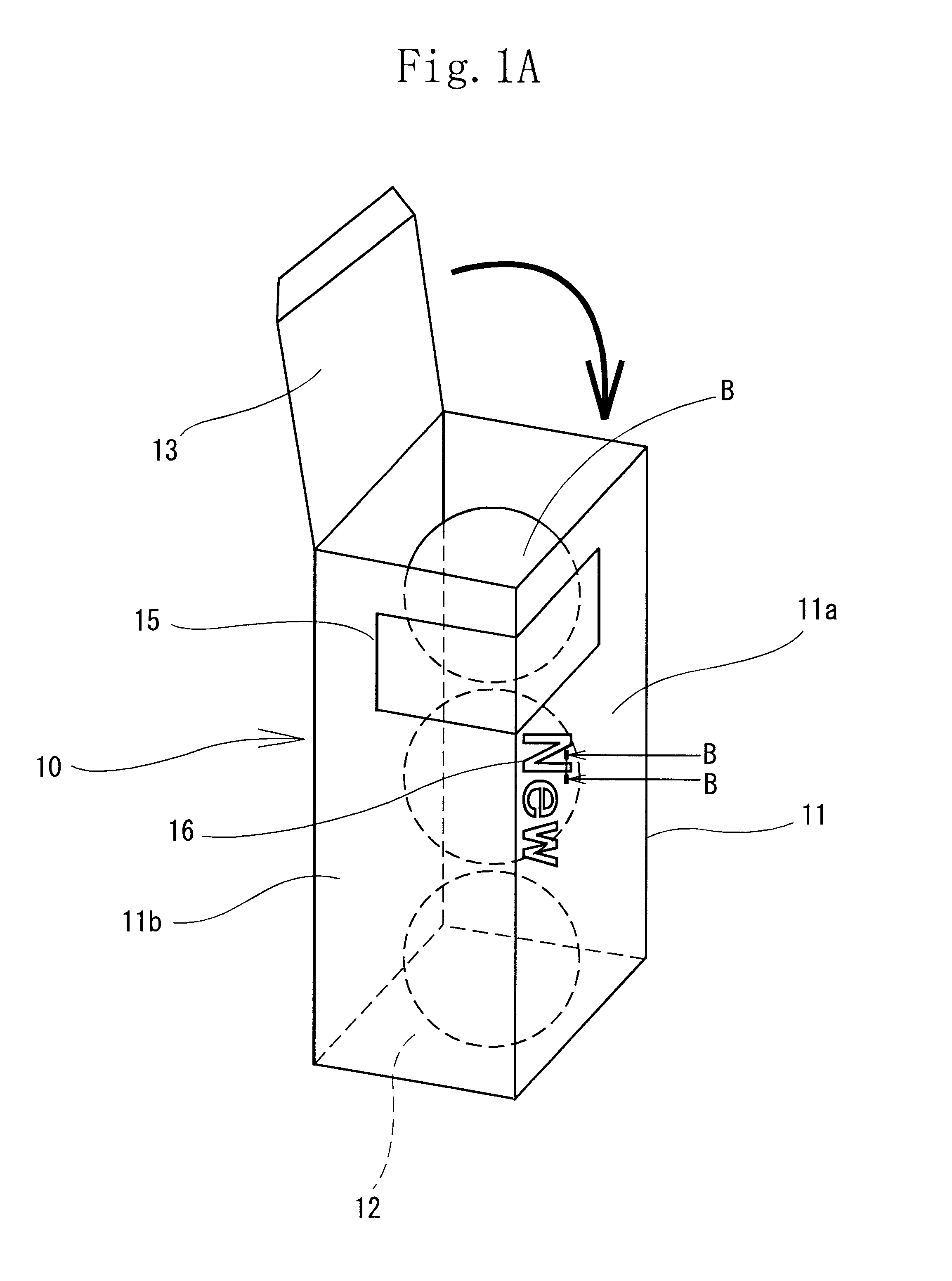

Packaging box for golf ball

InactiveUS6743490B2Reduce heatNot to damageEnvelopes/bags making machineryBio-packagingEngineeringGolf Ball

Owner:DUNLOP SPORTS CO LTD

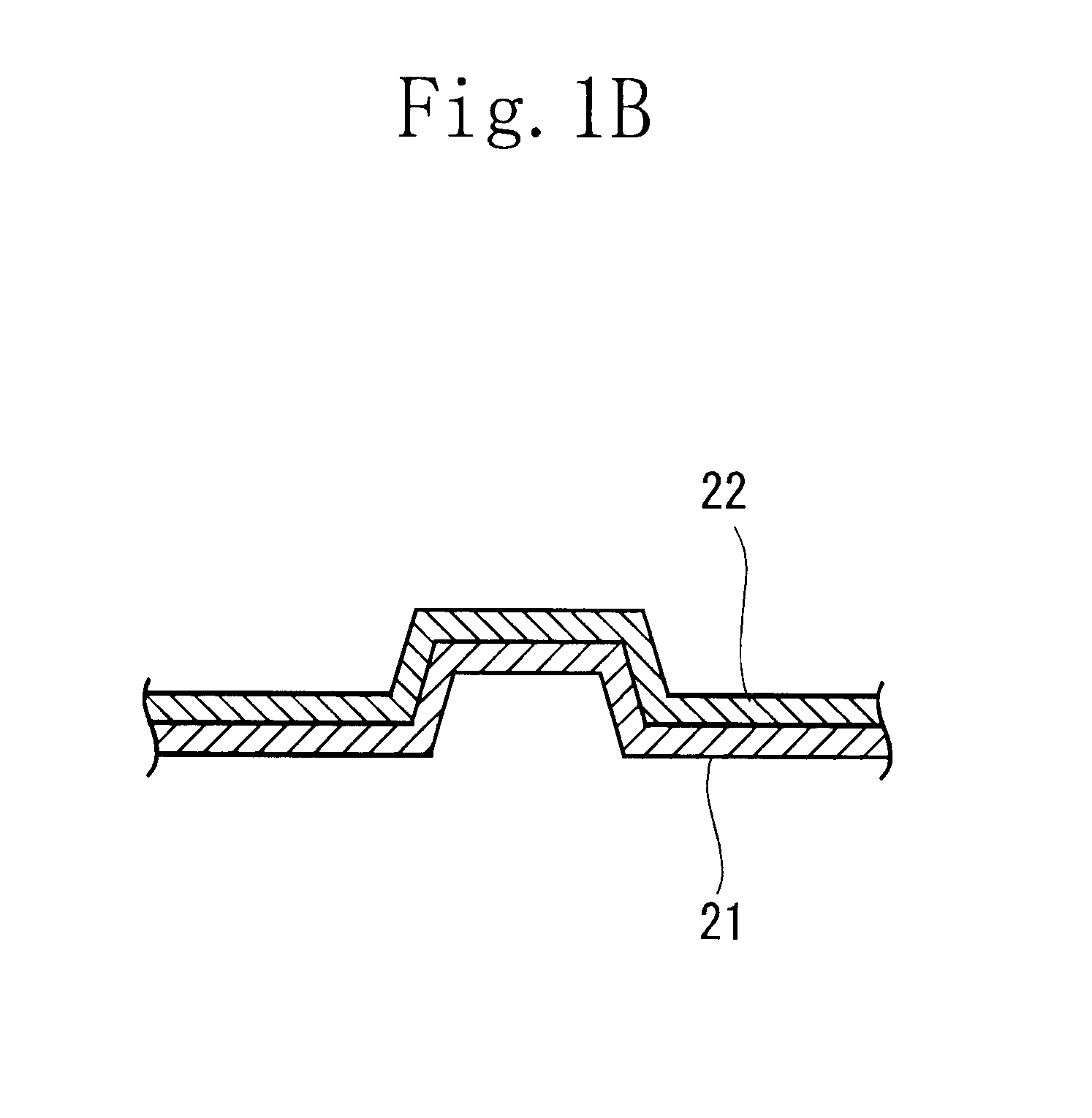

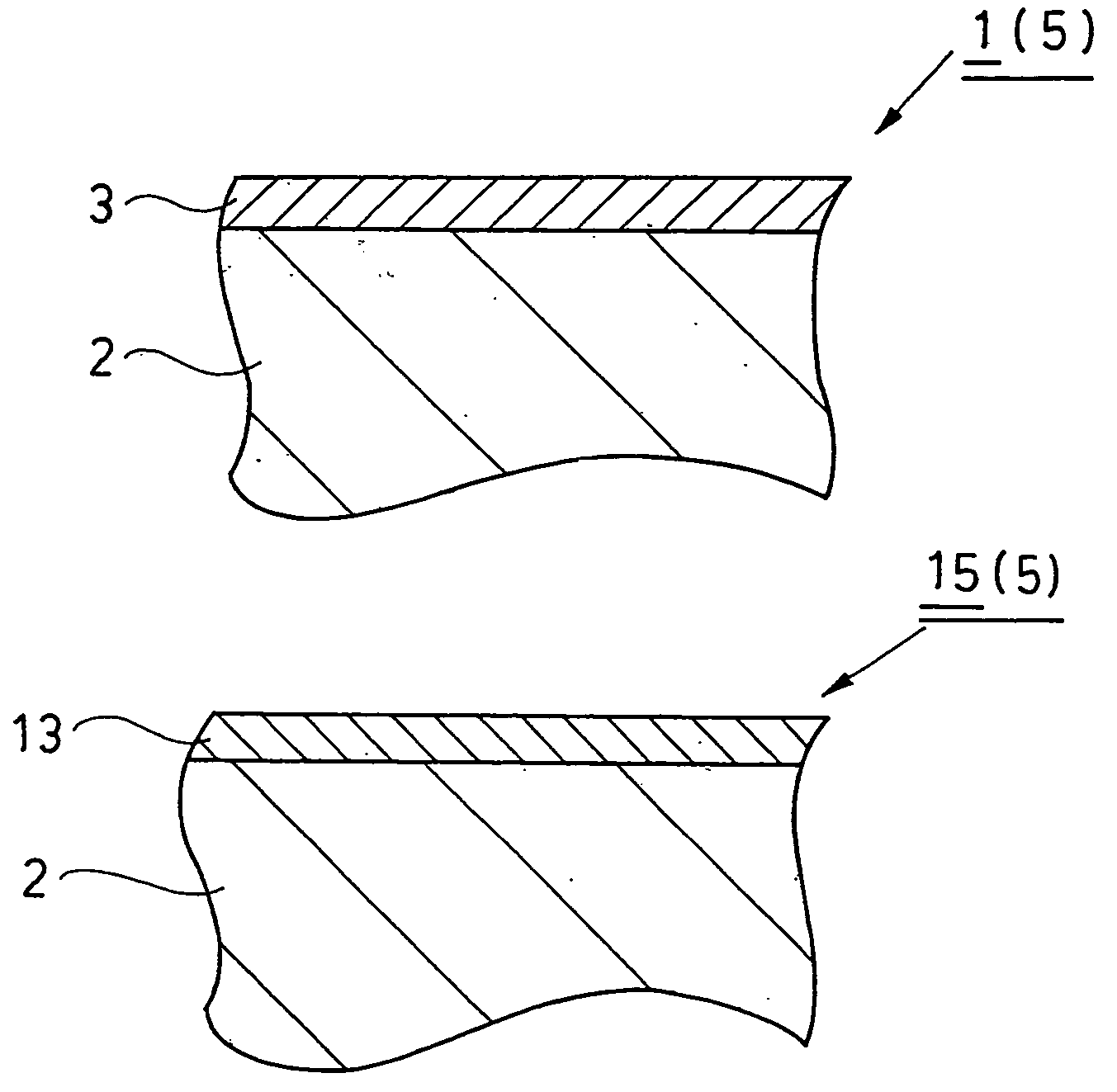

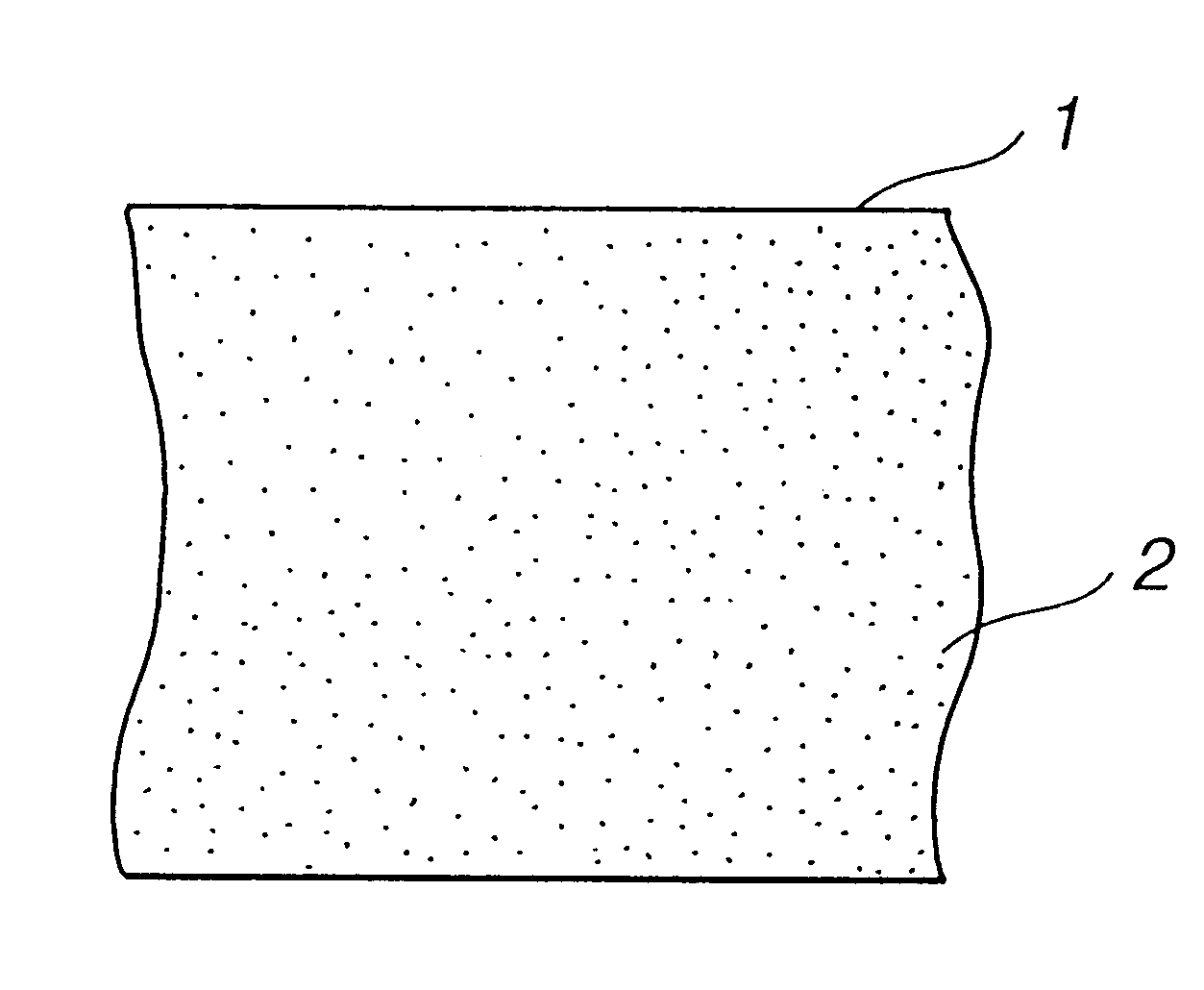

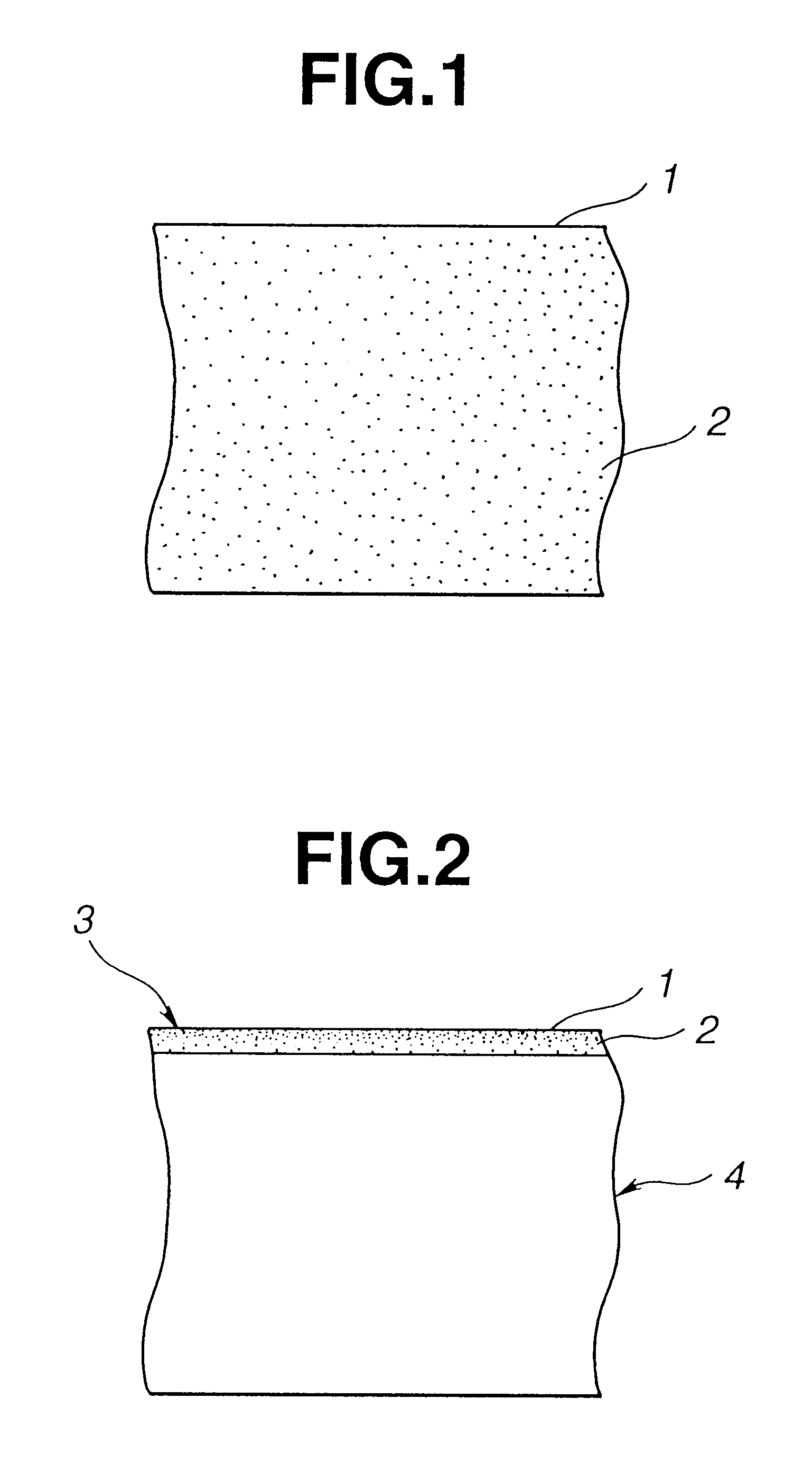

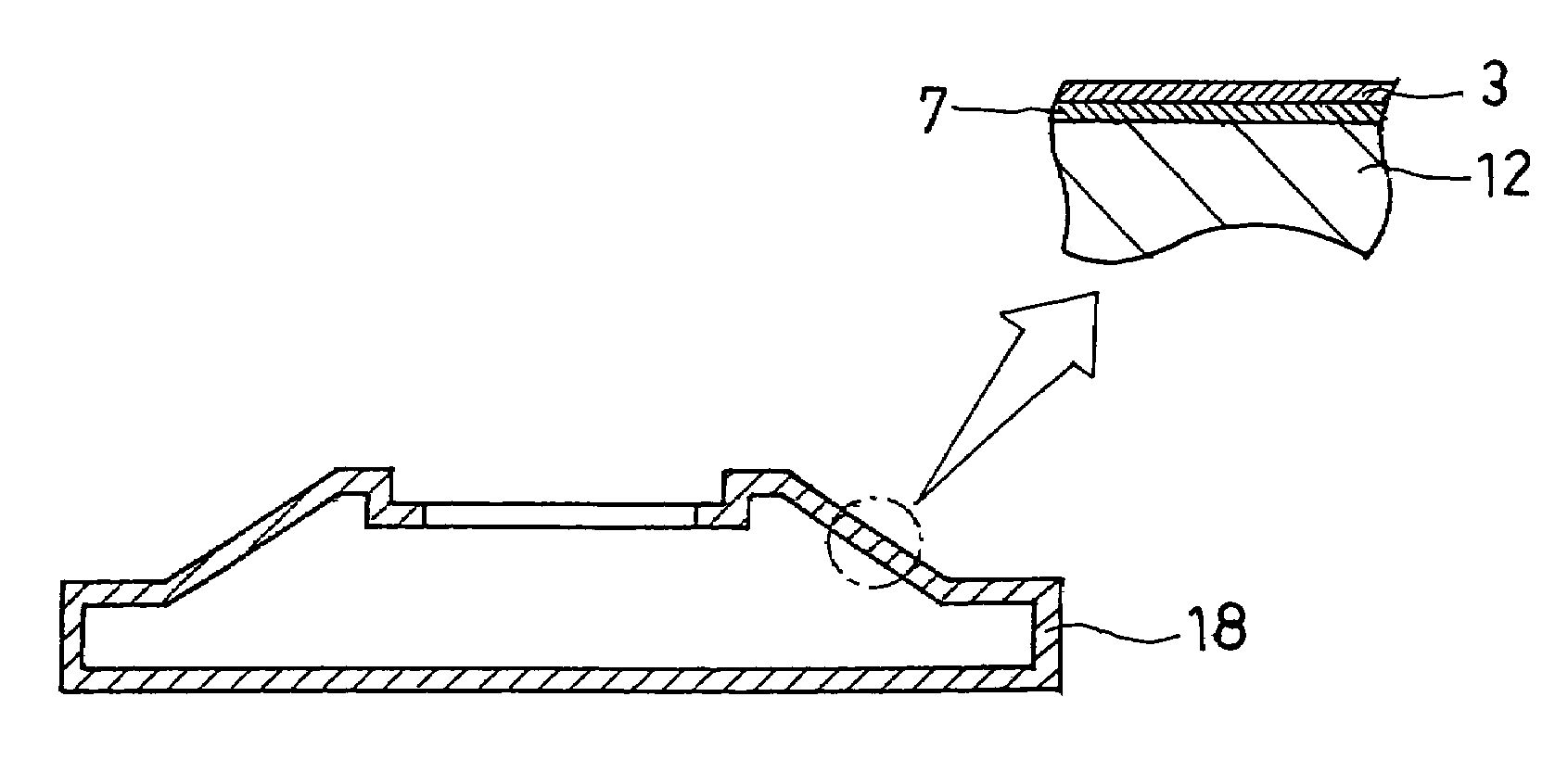

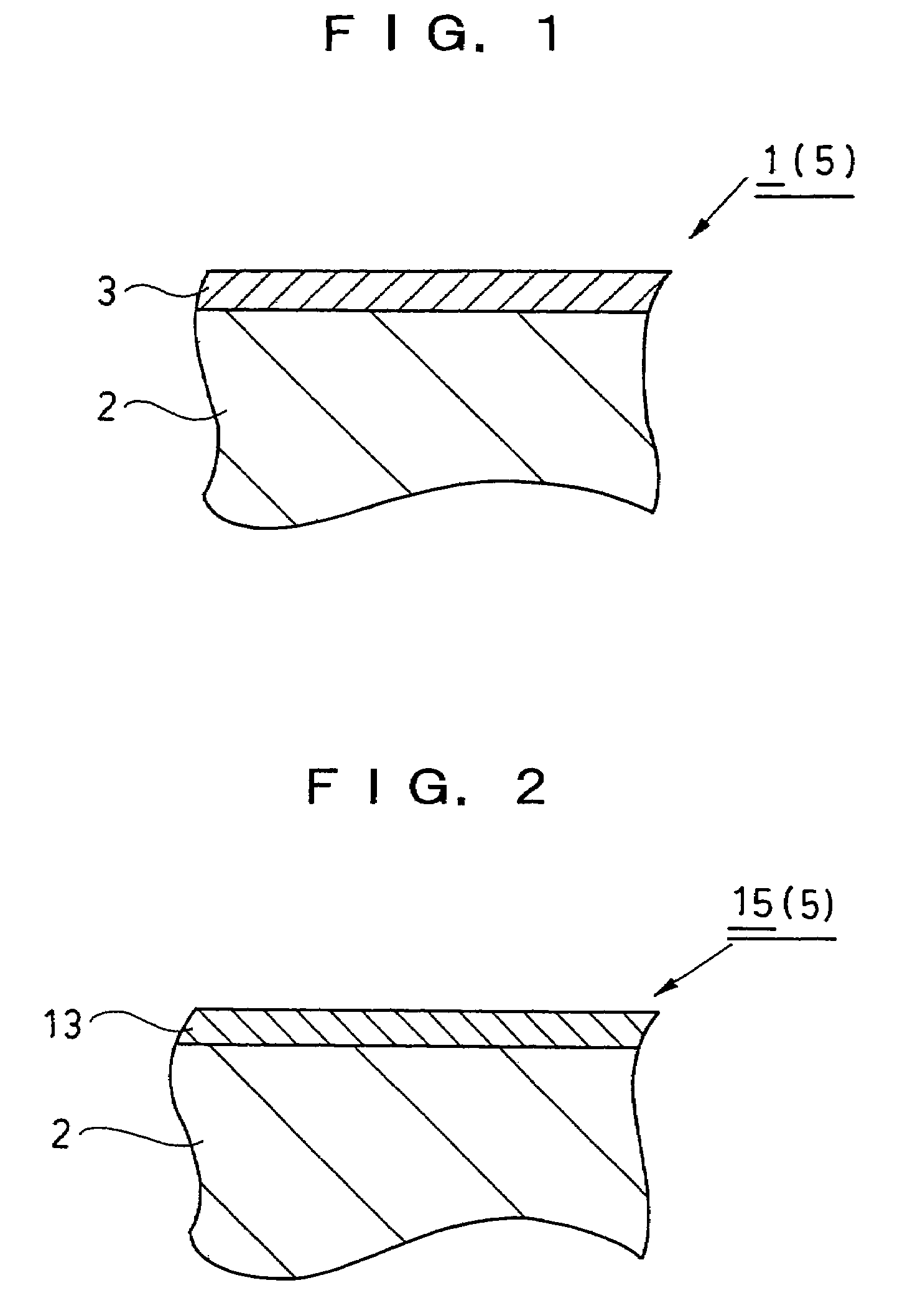

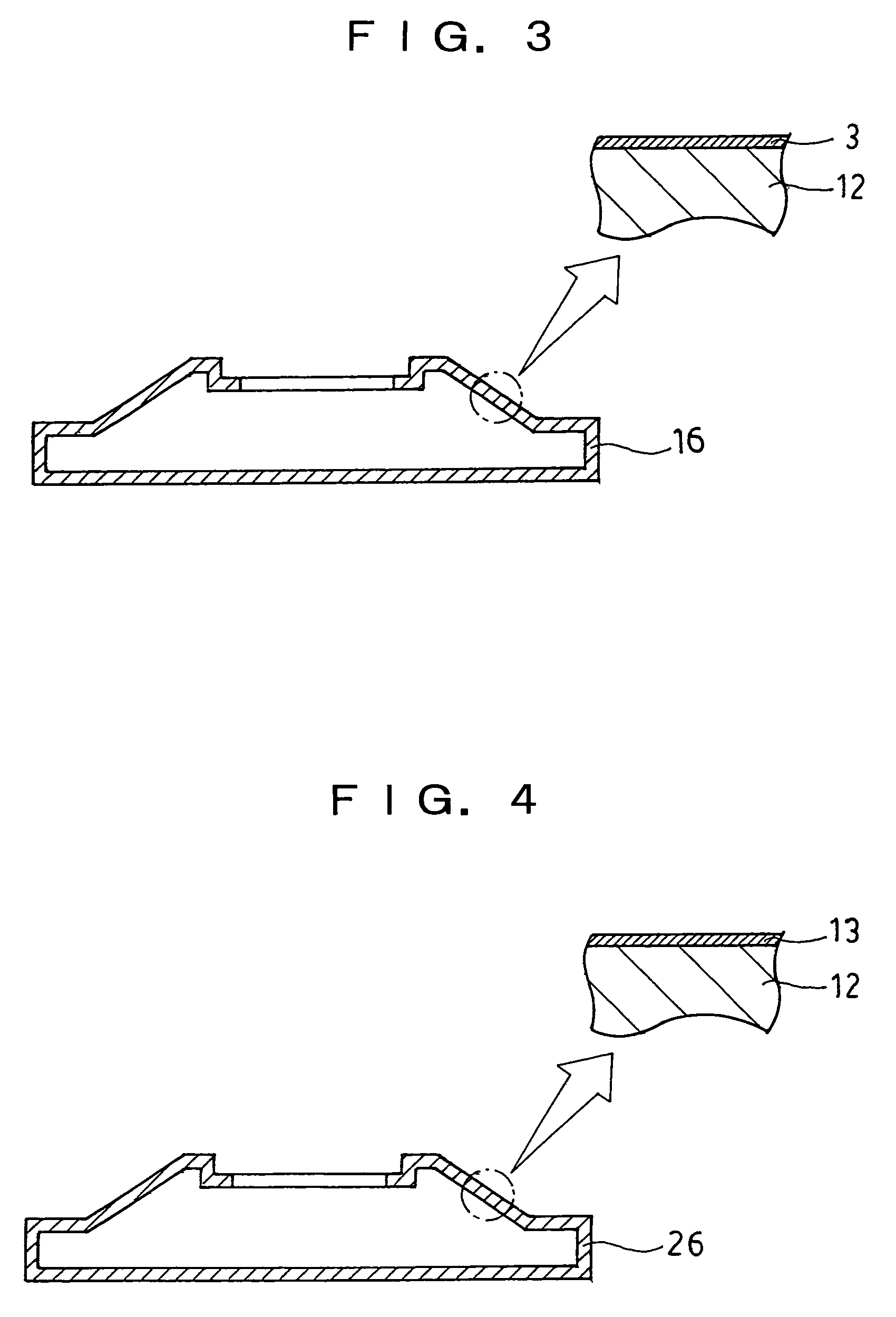

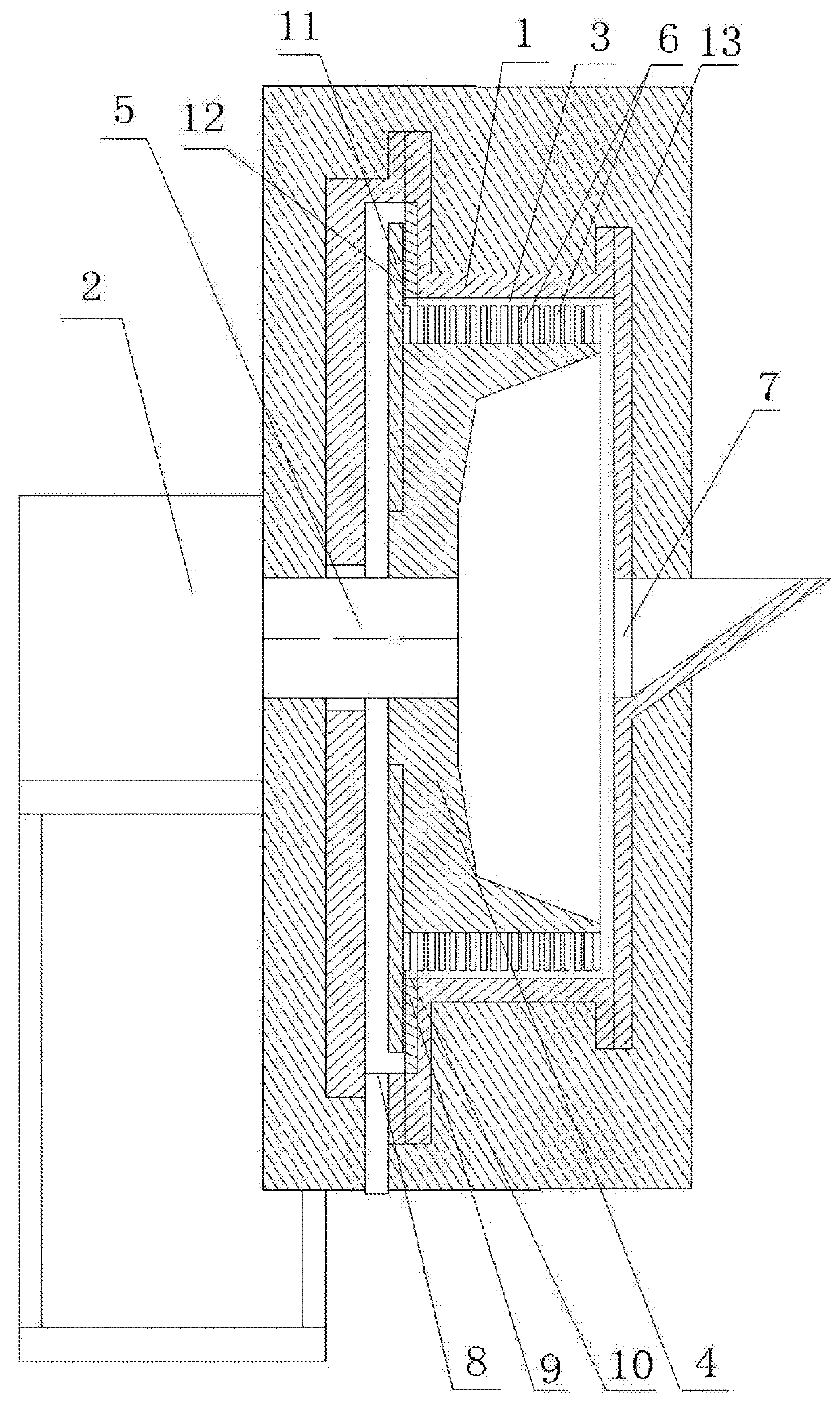

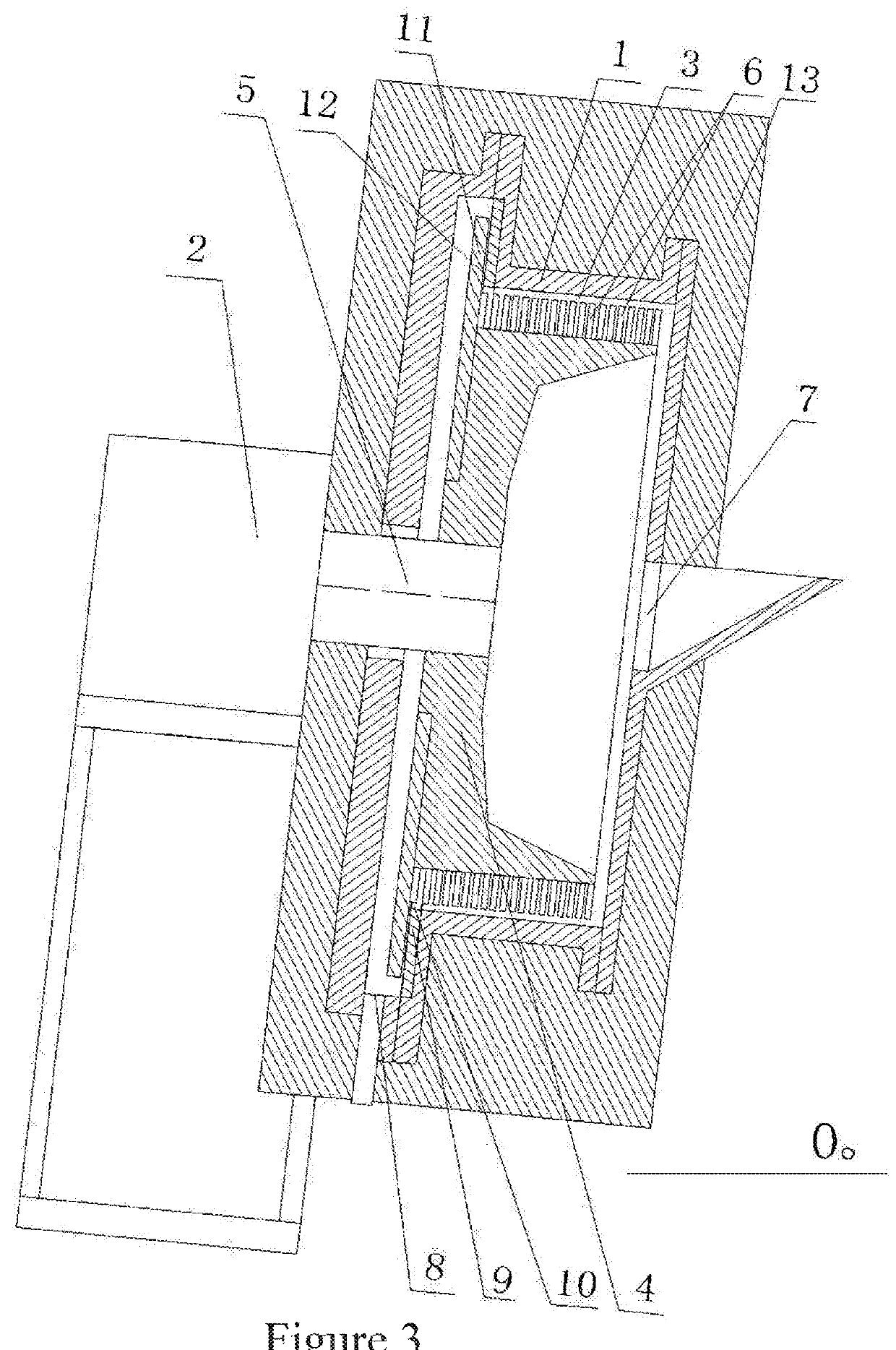

Soft metal and method for preparation thereof, and exterior part of watch and method for preparation thereof

InactiveUS20040231159A1High hardnessHigh in strengthVacuum evaporation coatingSputtering coatingNiobiumTitanium

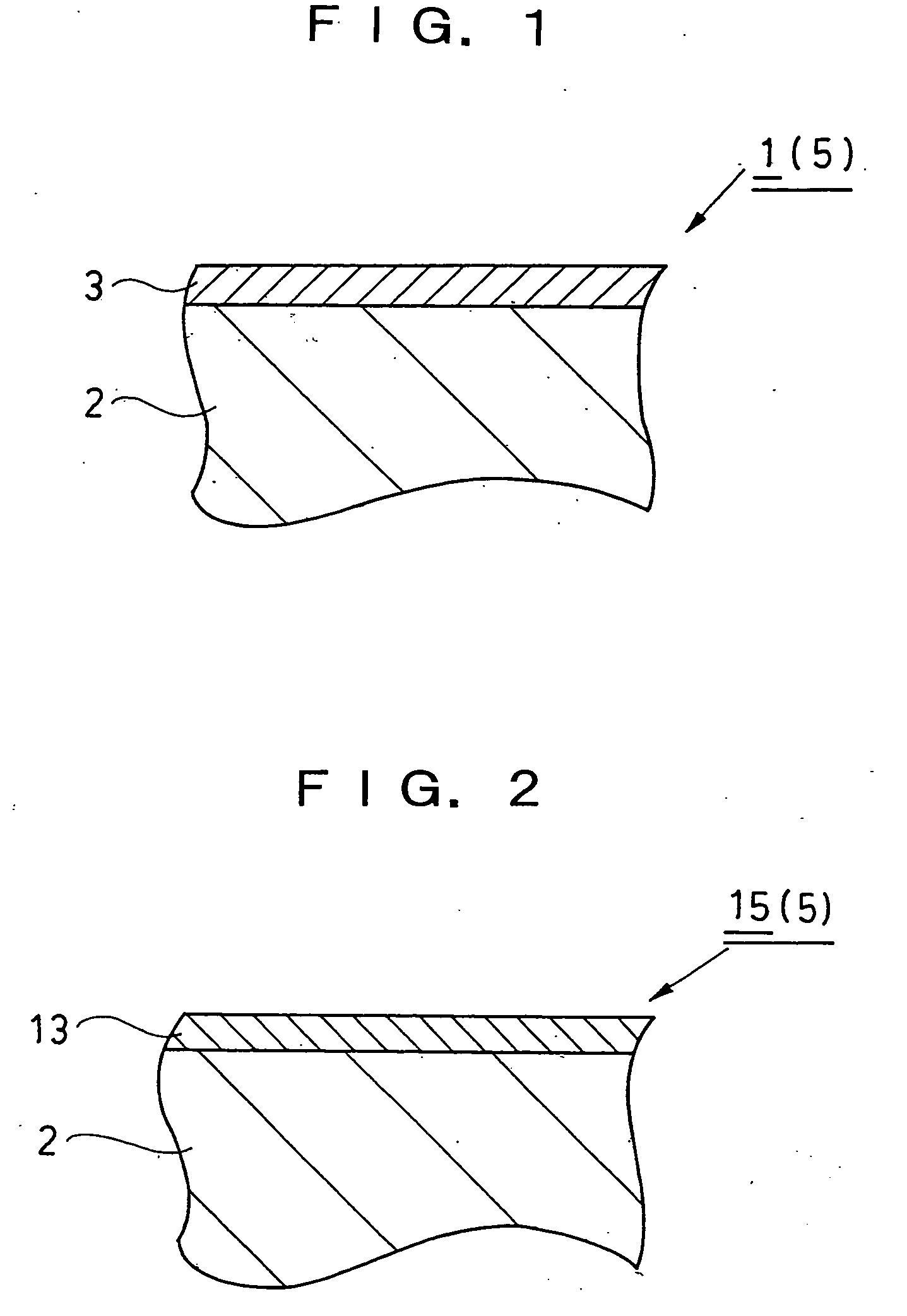

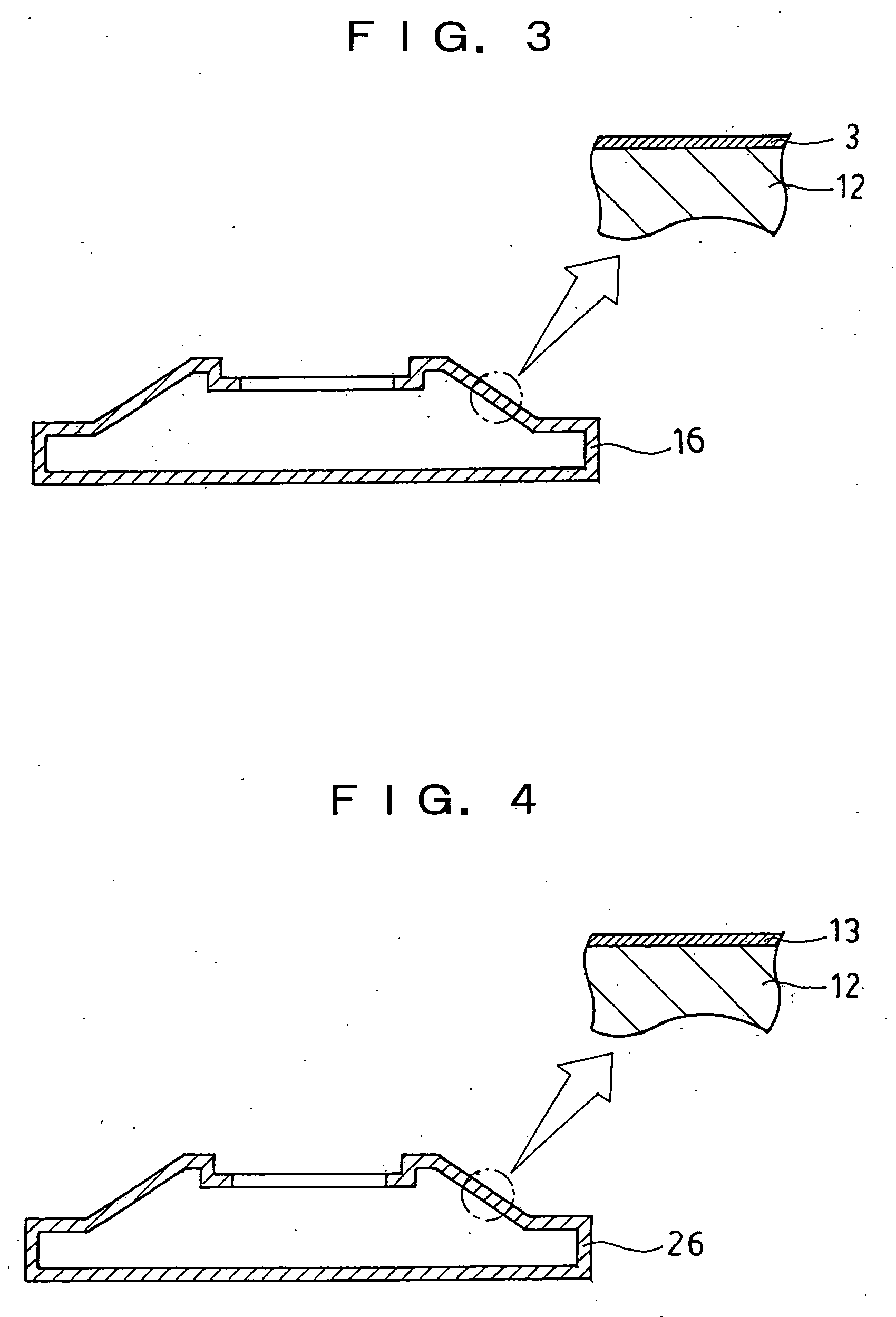

A soft metal and a decorative article of wristwatch are produced by forming, on the surface of a soft metal article (2), a hard layer (3, 13) containing zirconium and molybdenum, or containing zirconium, molybdenum and further an additive element constituted of at least one or more elements selected from niobium, tantalum, and titanium. It is preferable that the content of molybdenum constituting the hard layer (3, 13) is about 30 to 75 wt %, or that the content of molybdenum is about 25 to 65 wt % and the total content of the additive elements is about 25 wt % or less.

Owner:CITIZEN WATCH CO LTD

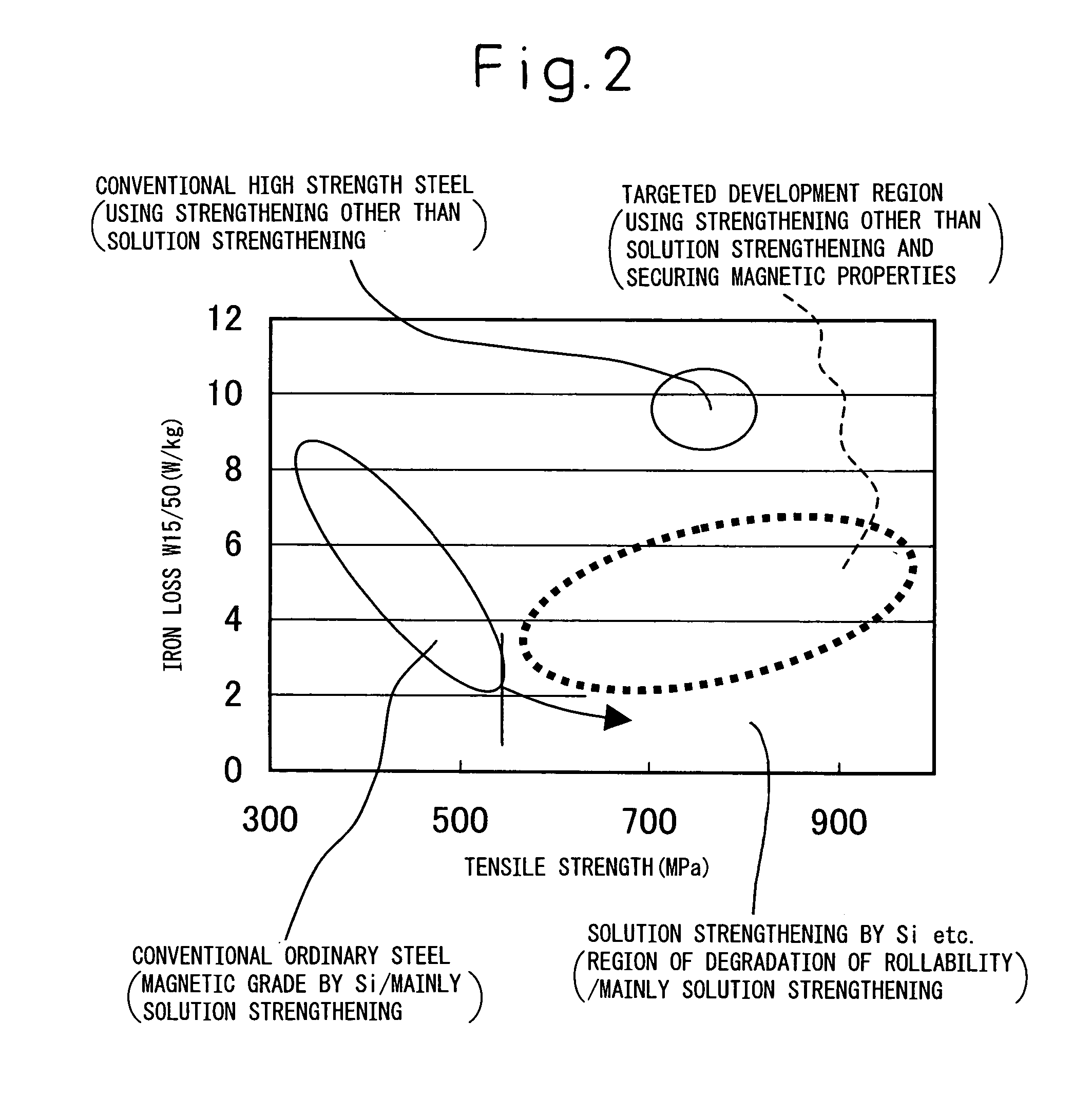

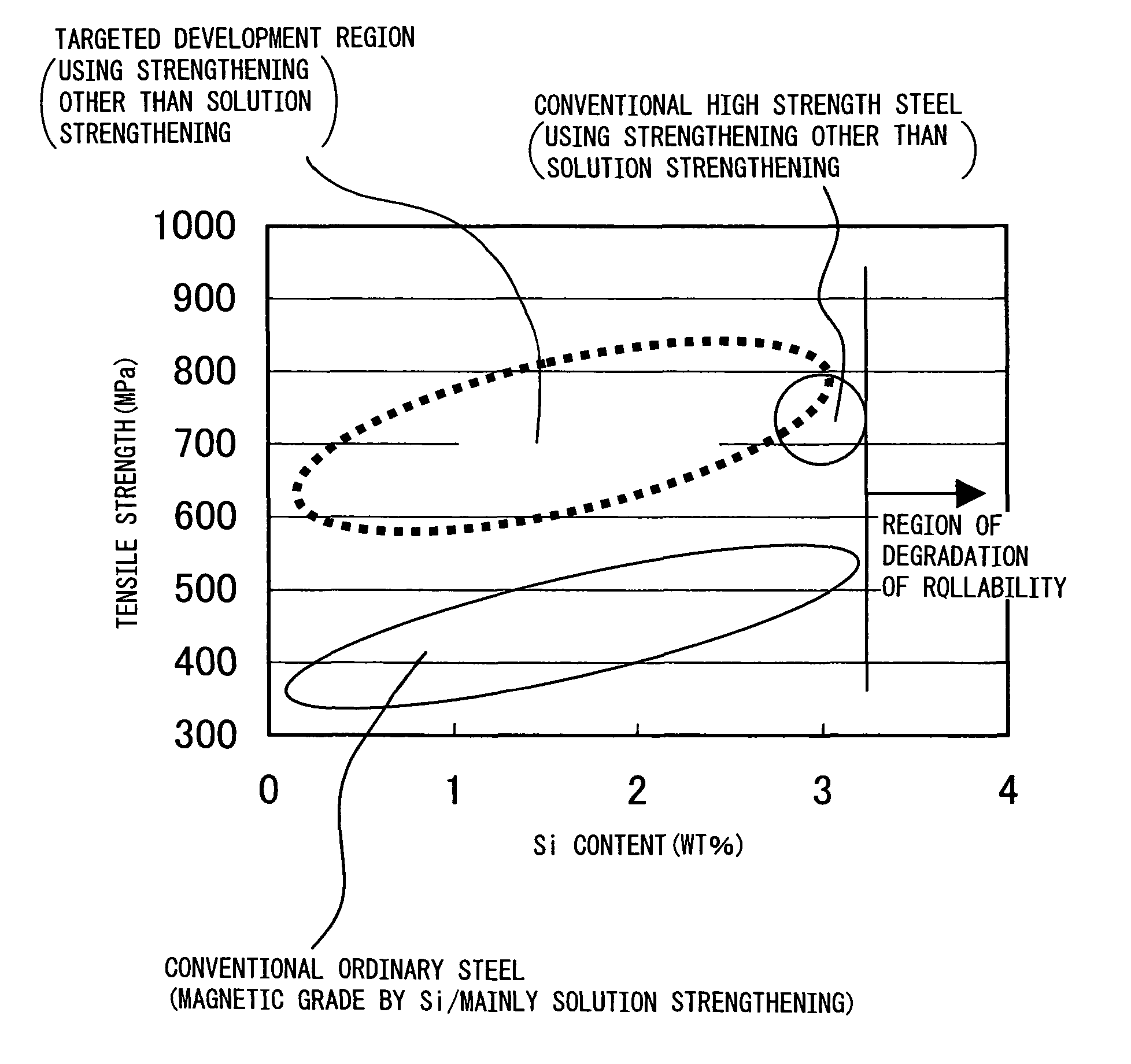

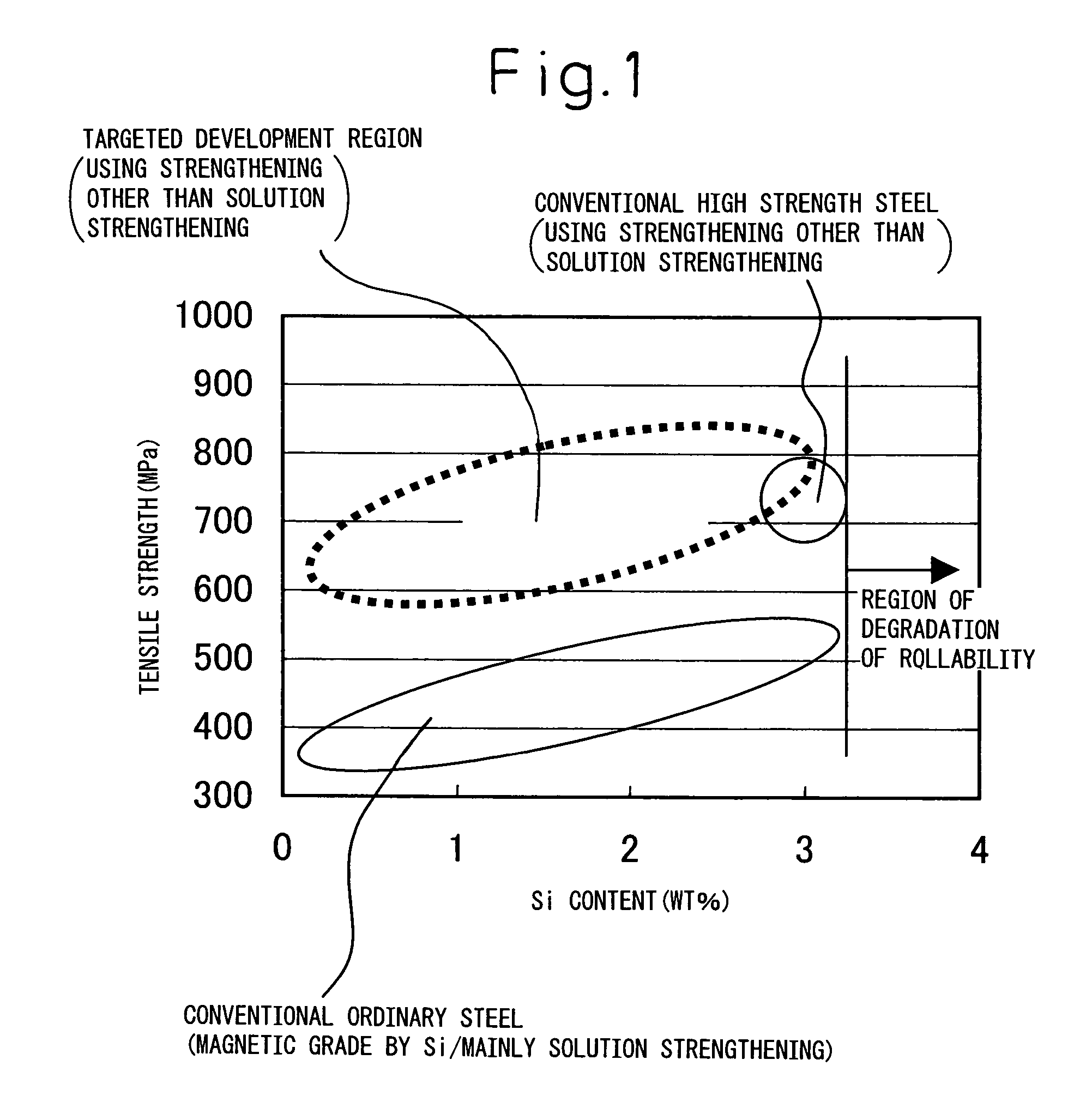

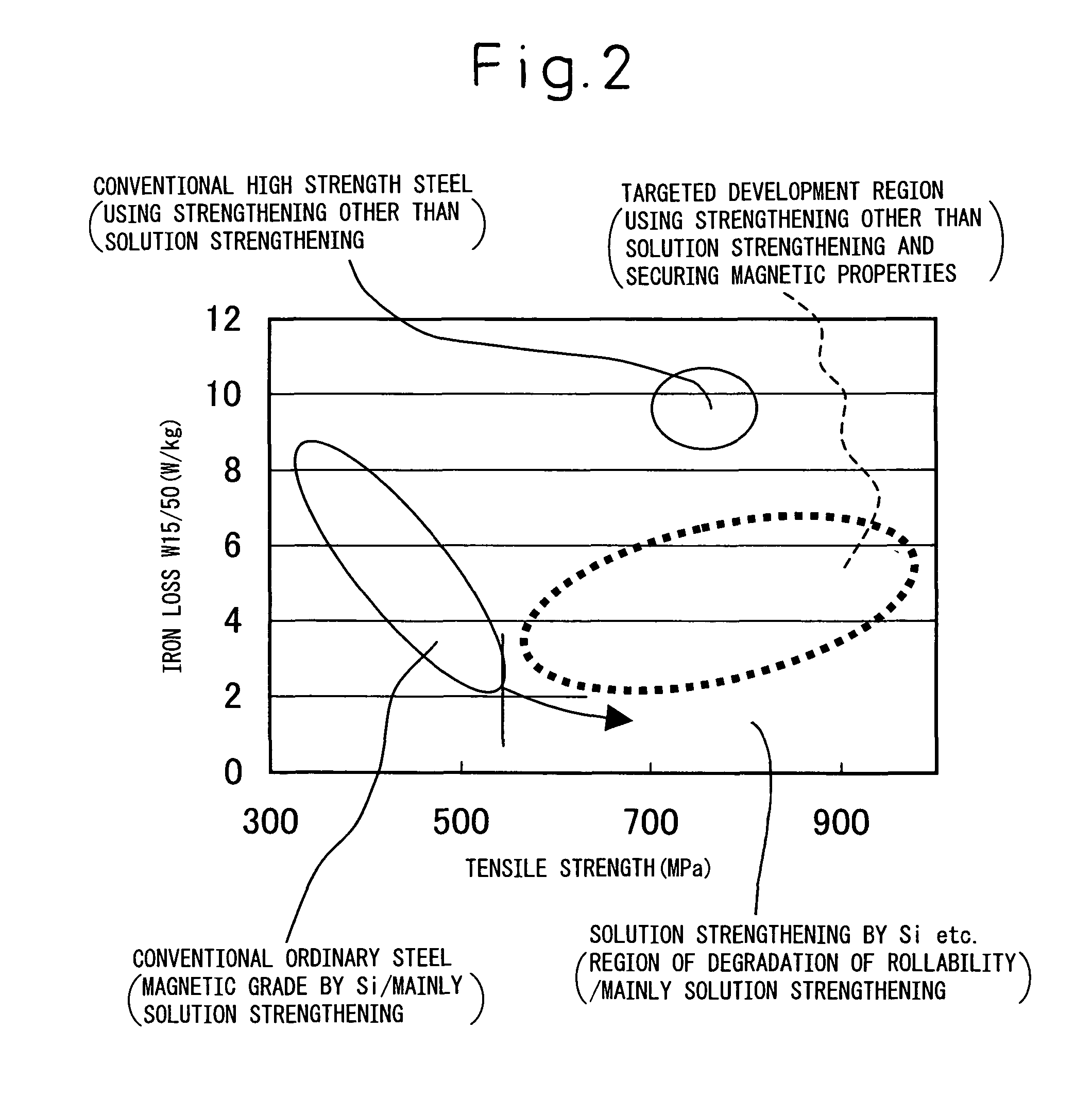

High strength electrical steel sheet and processed part of same and methods of production of same

ActiveUS20070062611A1High strengthImprove magnetic propertiesInorganic material magnetismElectrical steelSheet steel

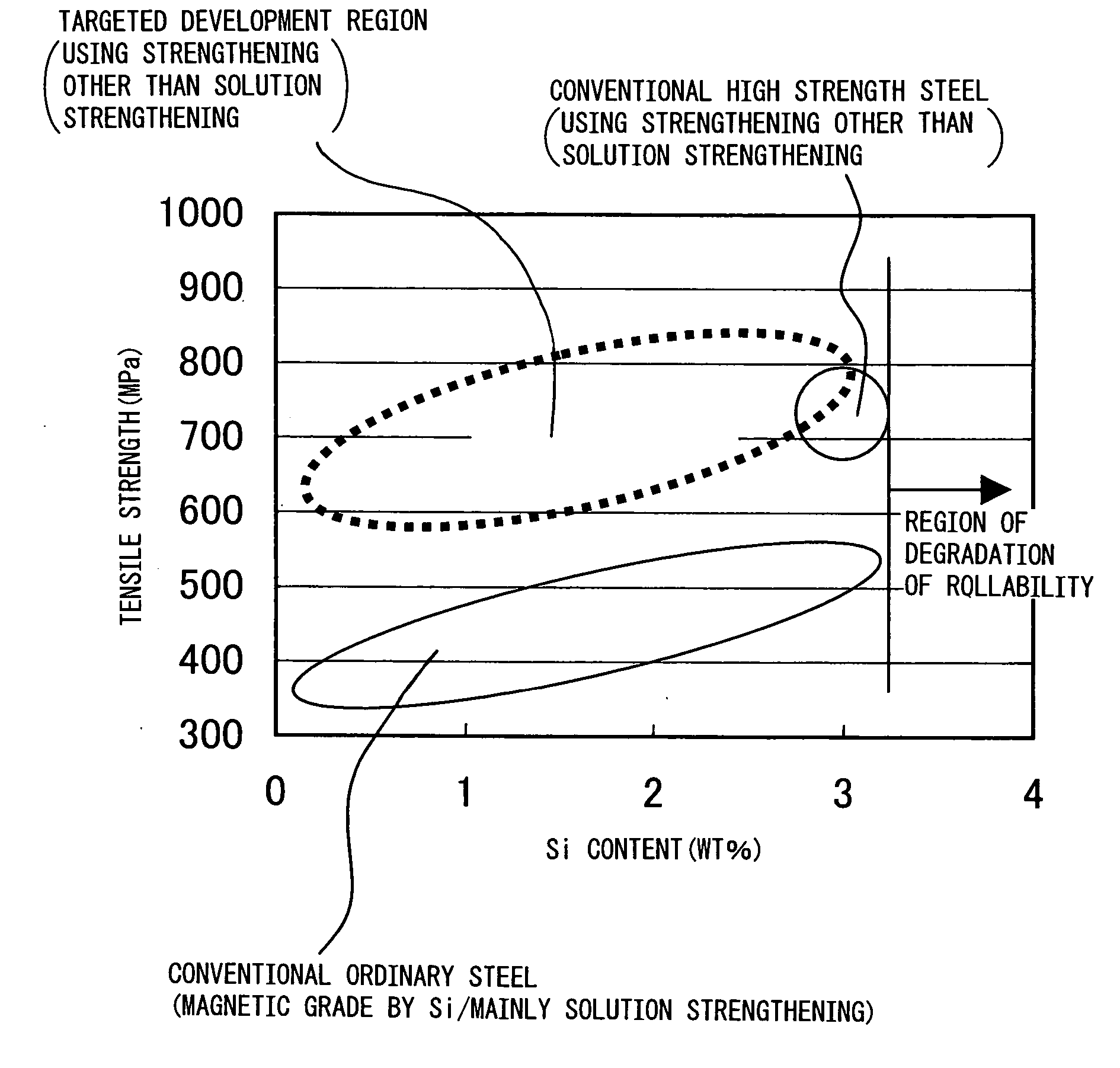

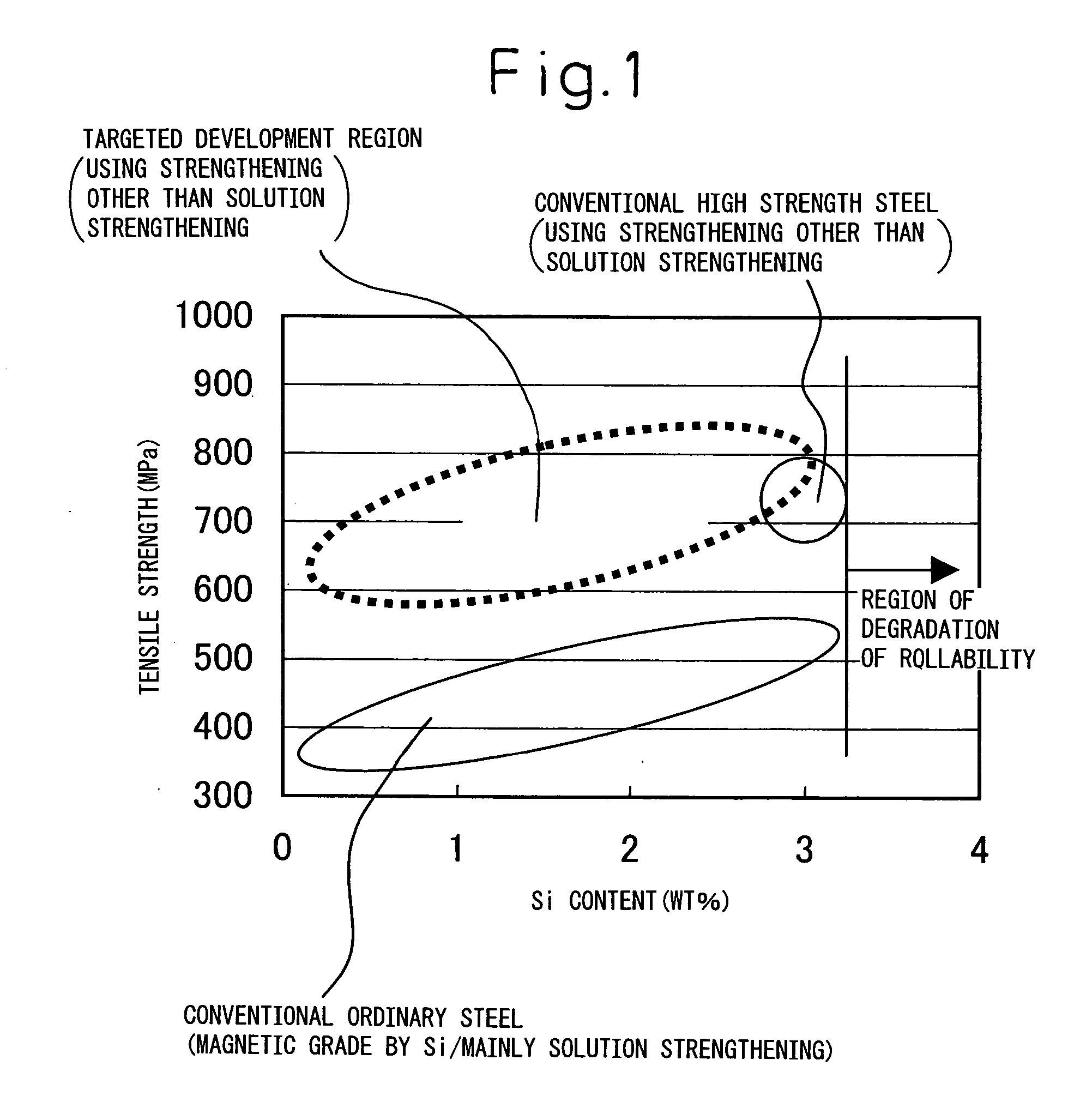

The present invention has as its object to stably produce a high strength electrical steel sheet and a processed part of the same which is high in strength and has wear resistant and is superior in magnetic flux density and core loss without greatly changing the cold rollability and production processes from those of conventional electrical steel sheet and provides a high strength electrical steel sheet characterized by containing, by mass %, C: 0.06% or less, Si: 0.2 to 6.5%, Mn: 0.05 to 3.0%, P: 0.30% or less, S or Se: 0.040% or less, Al: 2.50% or less, Cu: 0.6 to 8.0%, N: 0.0400% or less, and a balance of Fe and unavoidable impurities and containing in the steel a metal phase composed of Cu of a size of 0.1 μm or less. The method of production of the same comprises holding in a temperature range of 300° C. to 720° C. for 5 seconds or more for heat treatment.

Owner:NIPPON STEEL CORP

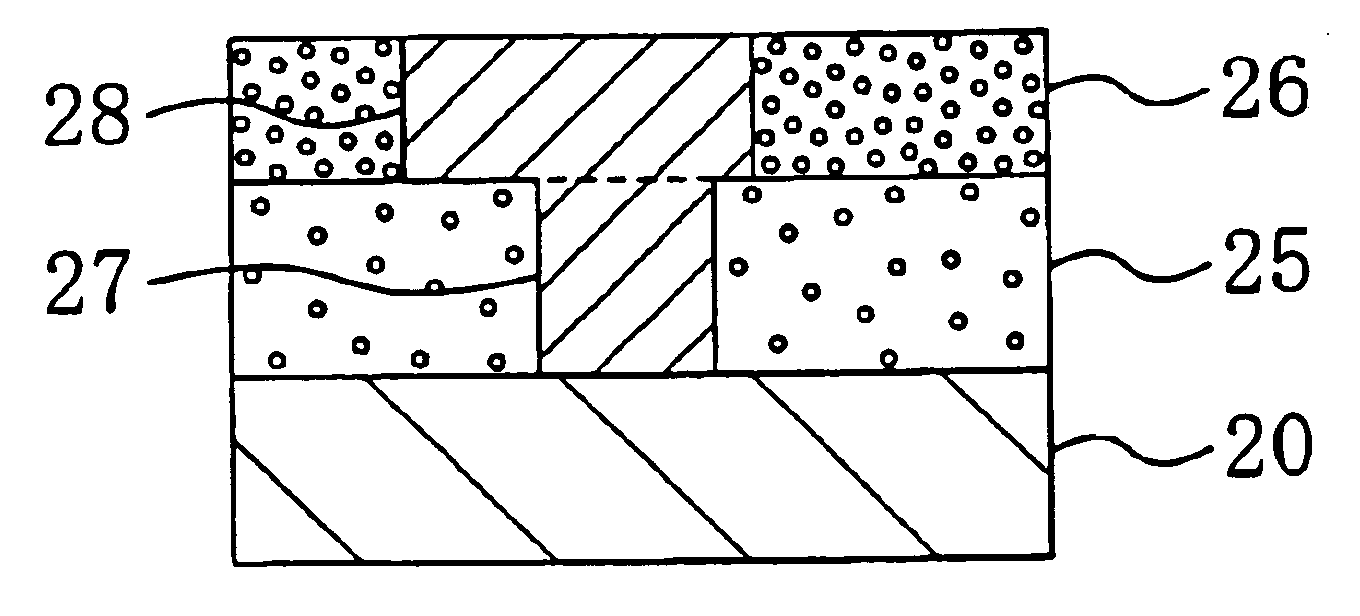

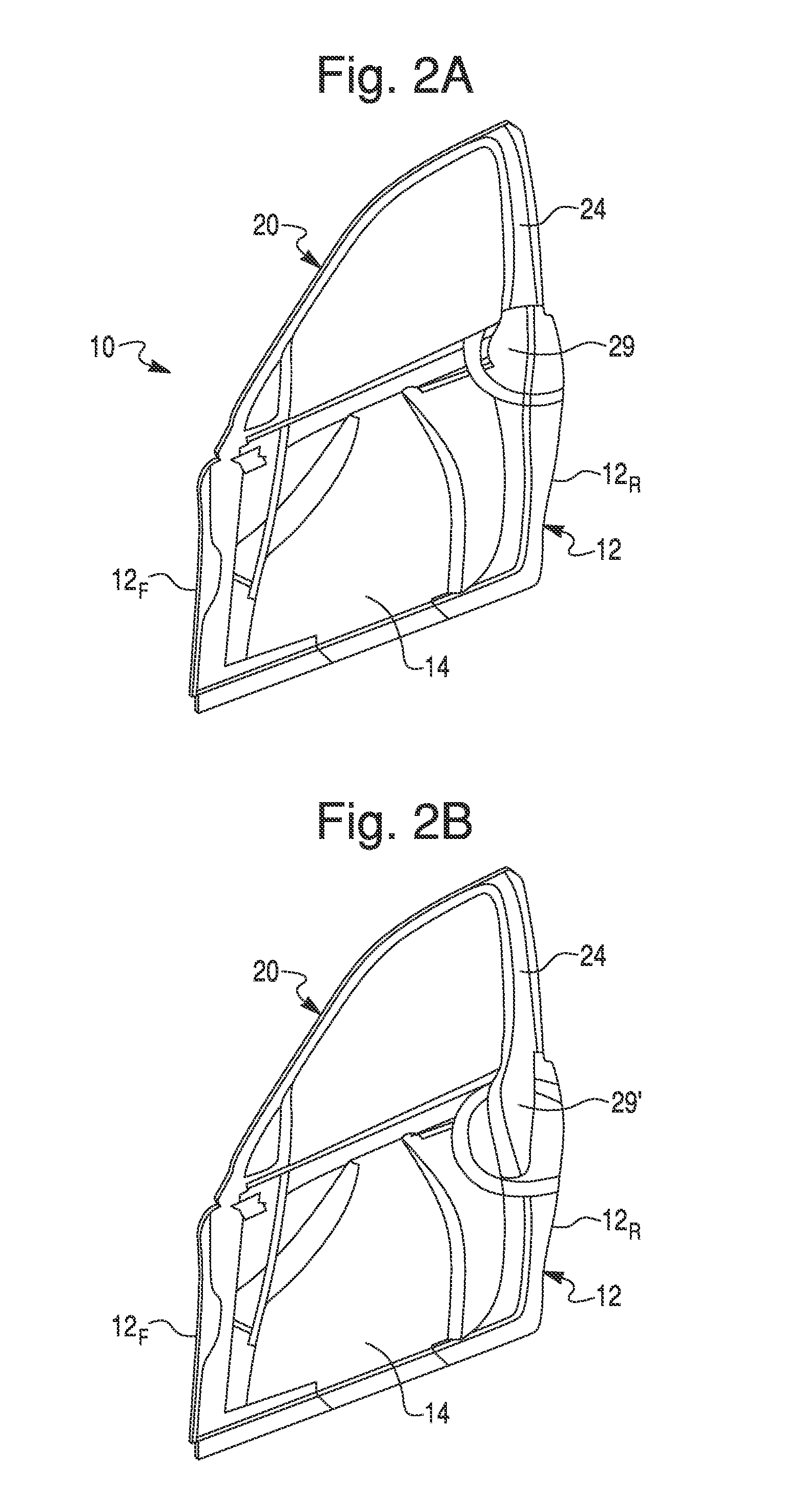

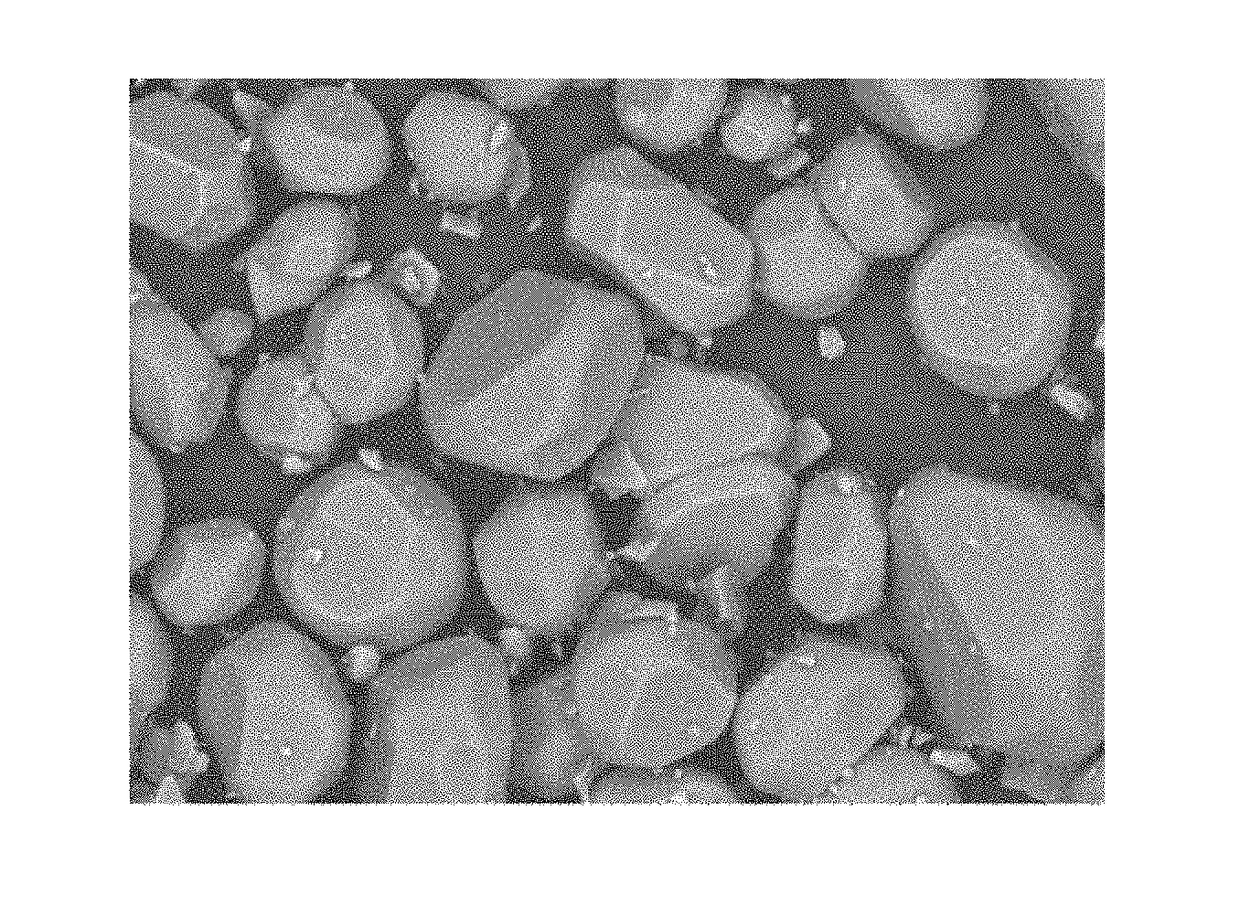

Plastic window panel and process for producing same

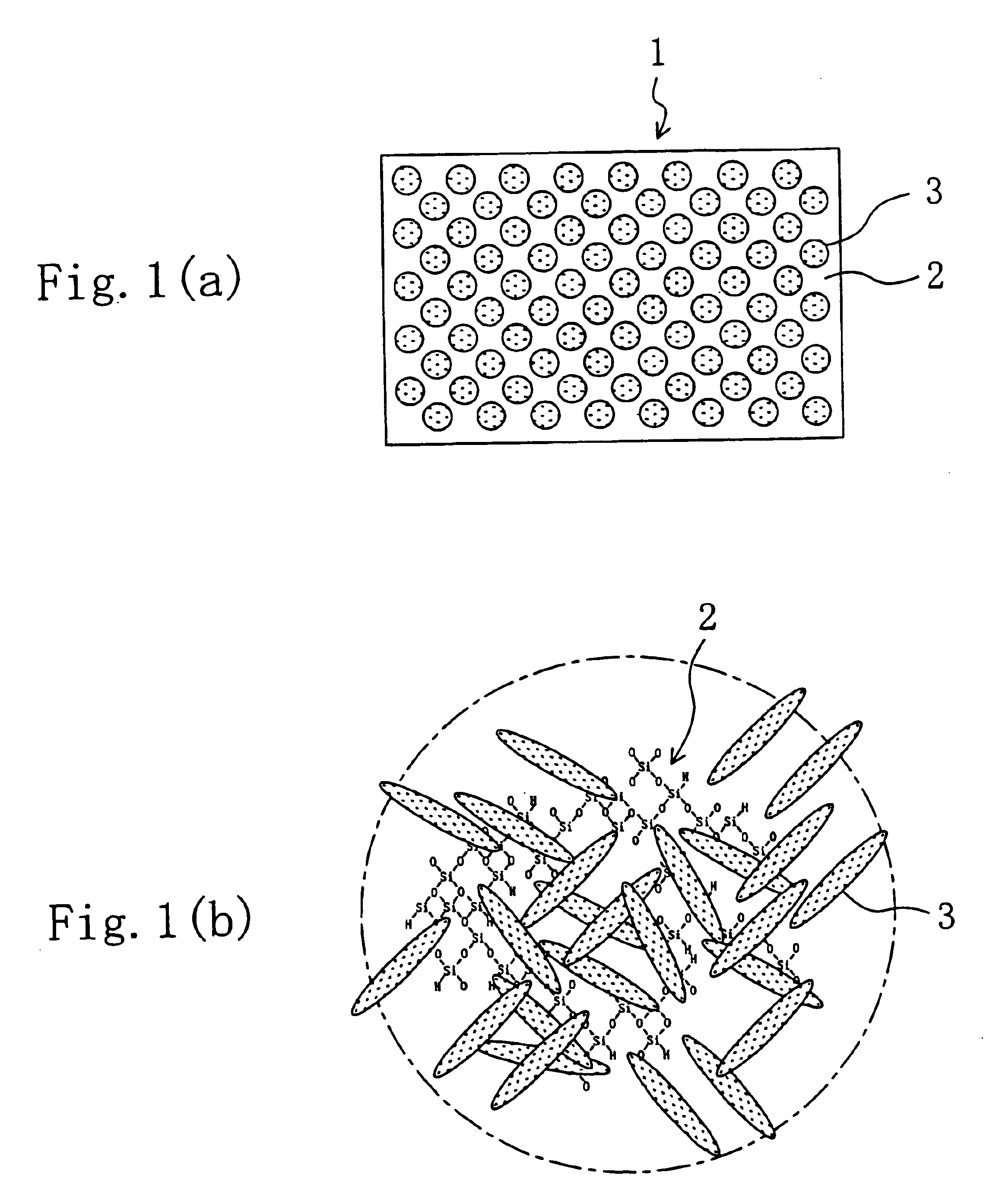

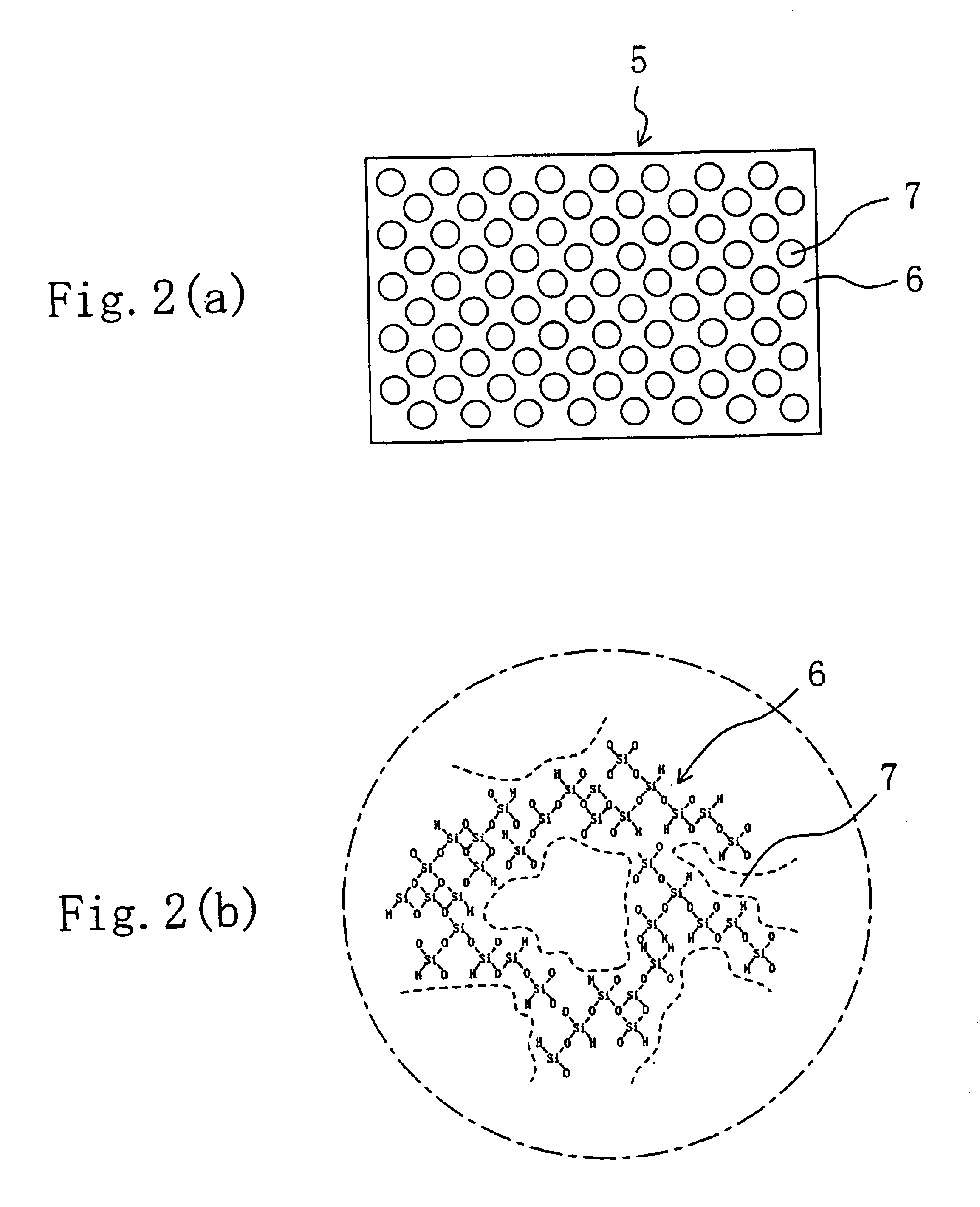

InactiveUS6696148B1High hardnessImprove rigiditySynthetic resin layered productsPretreated surfacesSilica particleParticulates

A plastic window panel for an automotive vehicle comprises a plastic panel of a transparent noncrystalline organic high polymer. Silica particulate is dispersed in the plastic panel and has a particle size not larger than wavelengths of visible light. The plastic window panel is produced by one of a first method and a second method. The first method comprises (a) providing a first solvent in which the silica particulate having the particle size not larger than wavelengths of visible light is dispersed, and a second solvent in which the transparent noncrystalline organic high polymer is dissolved; (b) mixing the first solvent and the second solvent to obtain a resin composition; and (c) molding the resin composition under heating. The second method comprises (a) providing the silica particulate having the particle size not larger than wavelengths of visible light; (b) mixing the silica particulate into the organic high polymer which is in a process of formation of the organic high polymer, to obtain a resin composition; and (c) molding the resin composition under heating.

Owner:NISSAN MOTOR CO LTD

Porous, film, wiring structure, and method of forming the same

InactiveUS6873052B2Low dielectric constantRetain sufficient mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesPlasma derivedOrganic compound

An organic-inorganic hybrid film is deposited on a substrate by introducing, into a vacuum chamber, a gas mixture of a silicon alkoxide and an organic compound and generating a plasma derived from the gas mixture. Then, a hydrogen plasma process is performed with respect to the organic-inorganic hybrid film by introducing, into the vacuum chamber, a gas containing a reducing gas and generating a plasma derived from the gas. As a result, an organic component in the organic-inorganic hybrid film eliminates therefrom and numerous fine holes are formed in hollow portions from which the organic component has eliminated, whereby a porous film composed of the organic-inorganic hybrid film is obtained.

Owner:GK BRIDGE 1

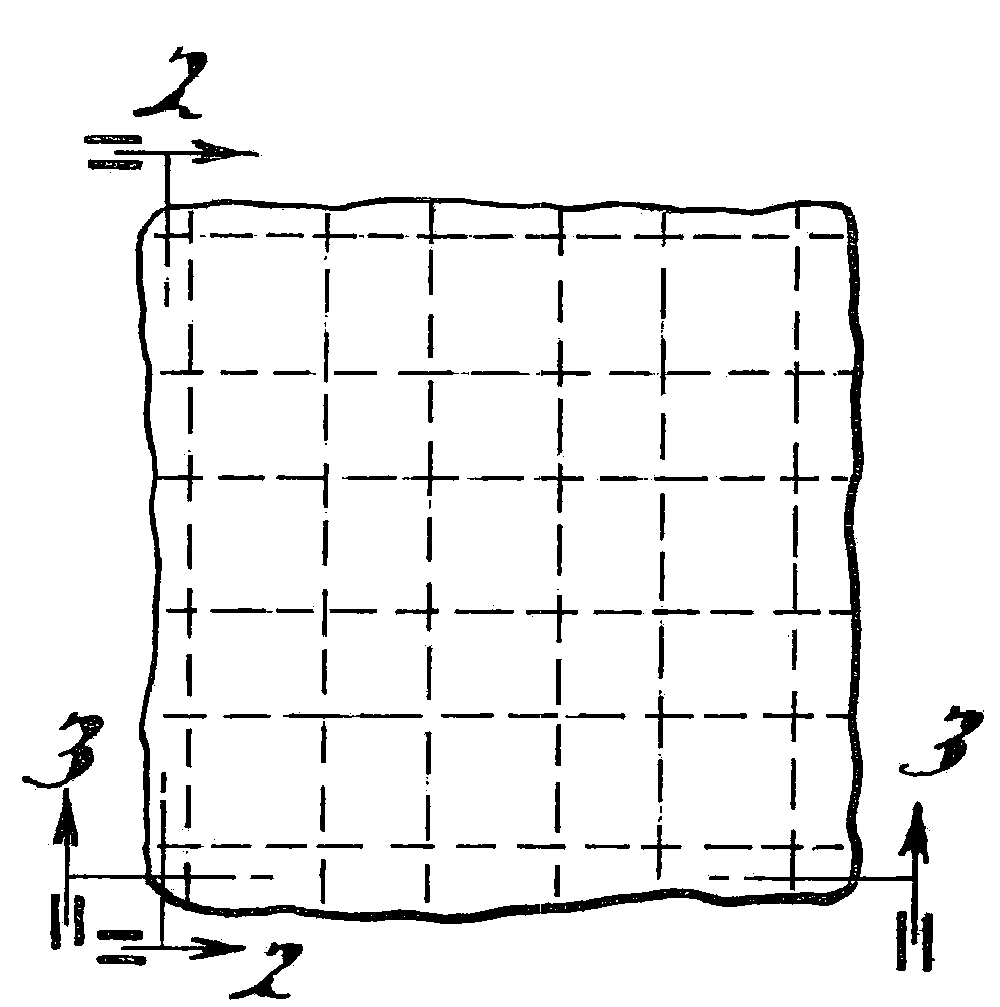

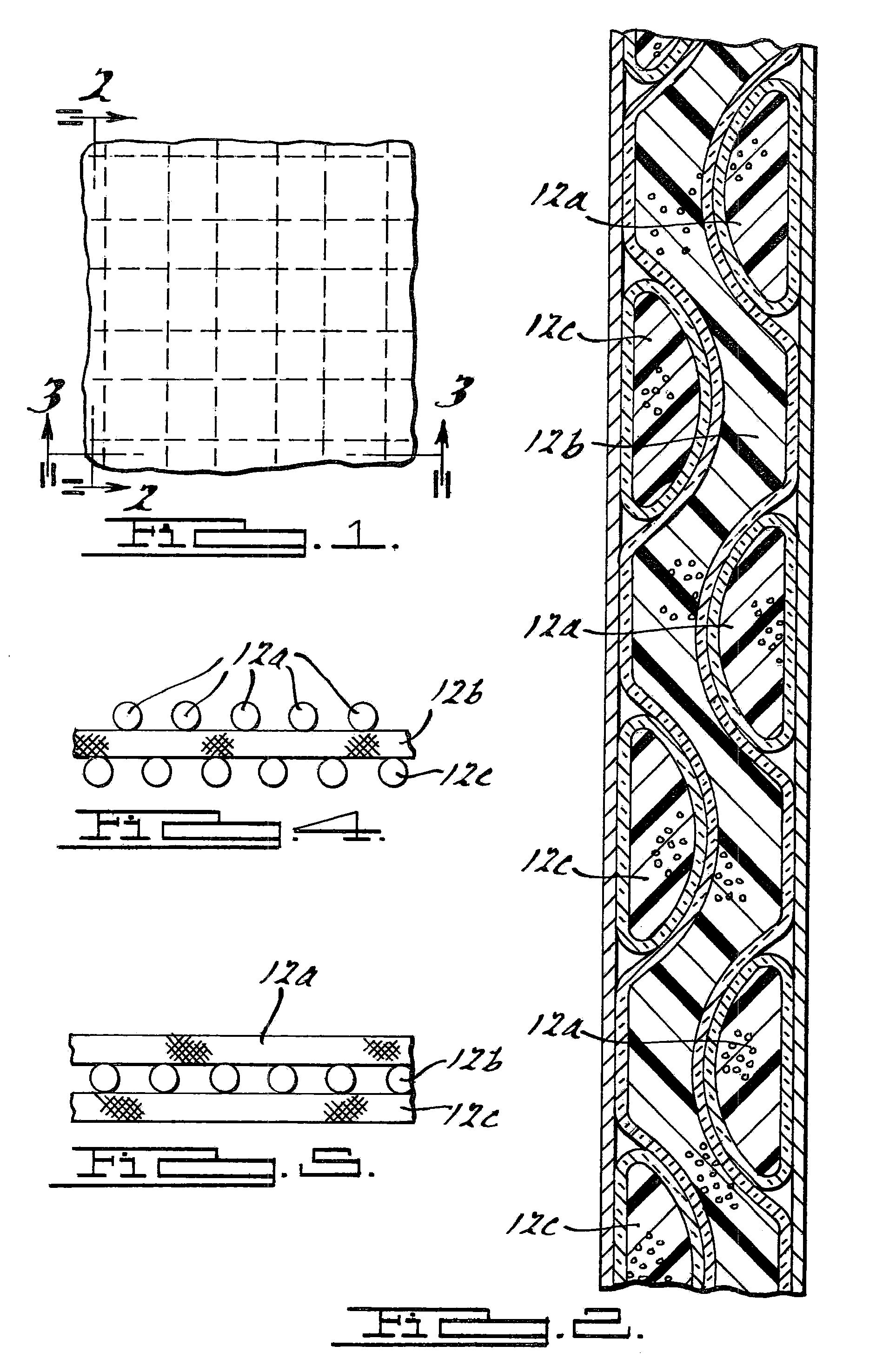

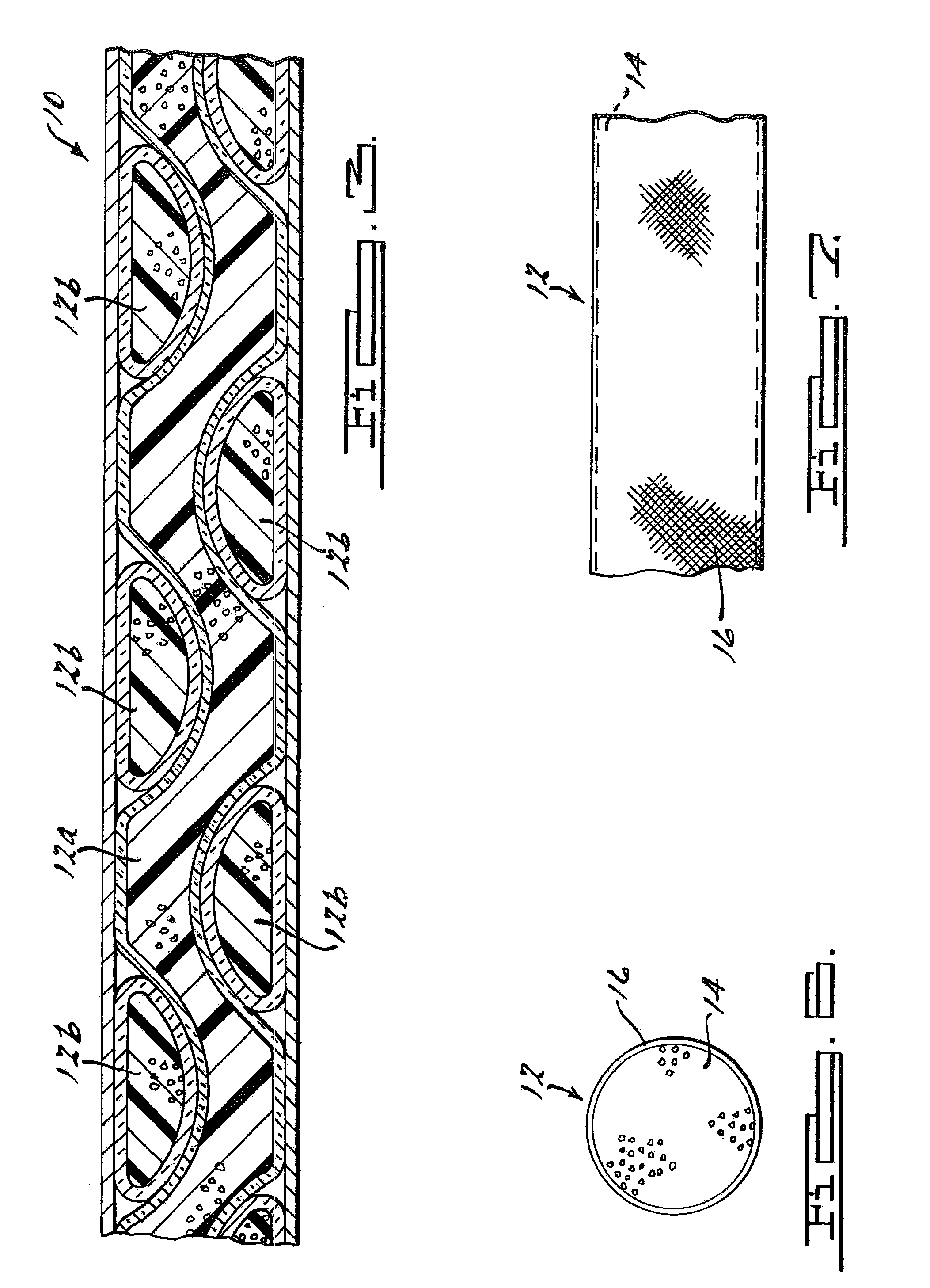

Sandwich type construction structural panel having foam tube core

InactiveUS7371451B2High in strengthHigh stiffnessLayered productsBuilding componentsEngineeringFiber-reinforced composite

A structural panel comprised of a plurality of distinct layers of cylindrical foam elements each covered with a fiber-reinforced composite material. The cylindrical foam elements are arranged in layers such that the elements of adjacent layers are arranged non-parallel to one another. A pair of facesheets are secured to opposing surfaces of the cylindrical foam elements. The structural panel is high in strength, structural stiffness, and yet relatively low in weight, and is suitable for a variety of aerospace and other applications.

Owner:THE BOEING CO

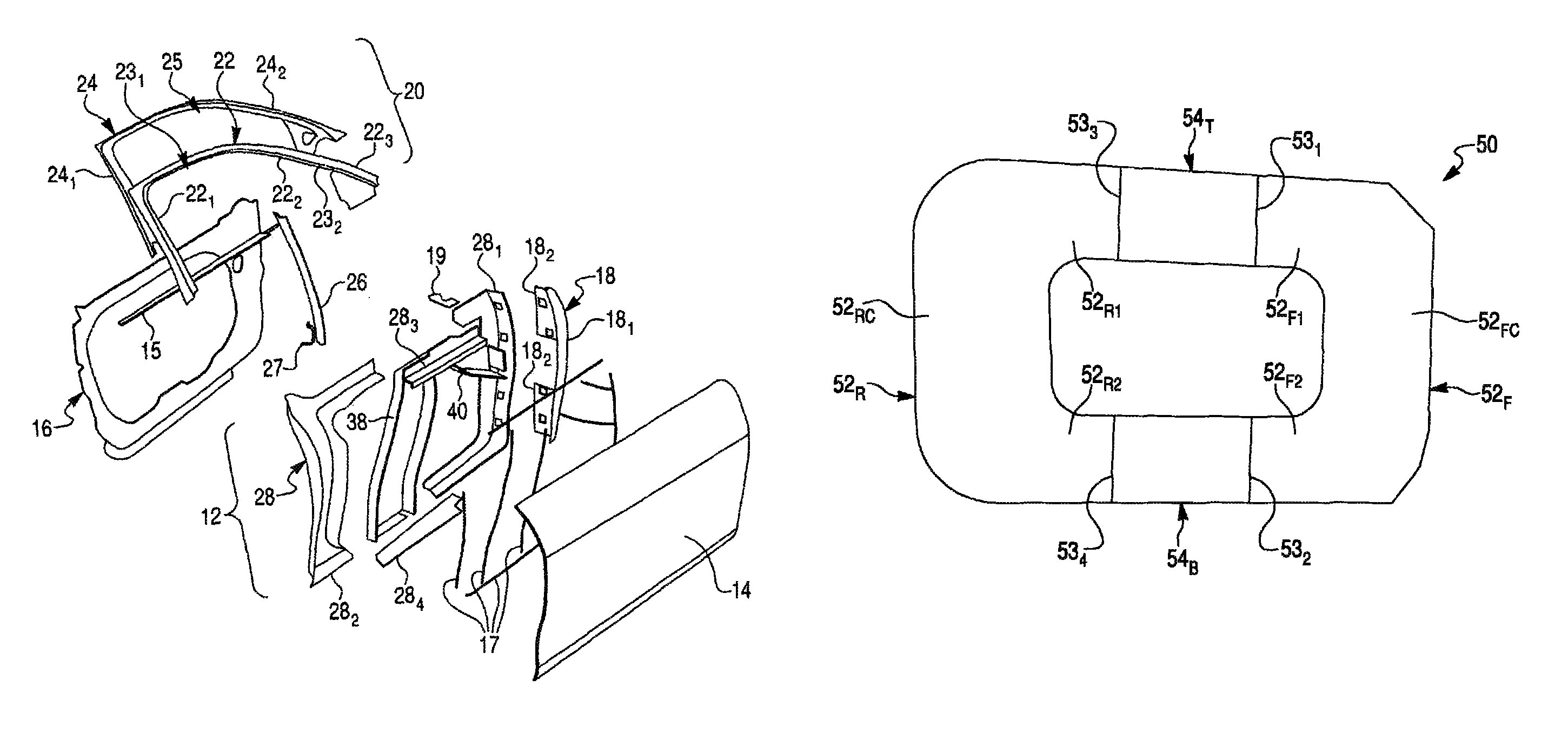

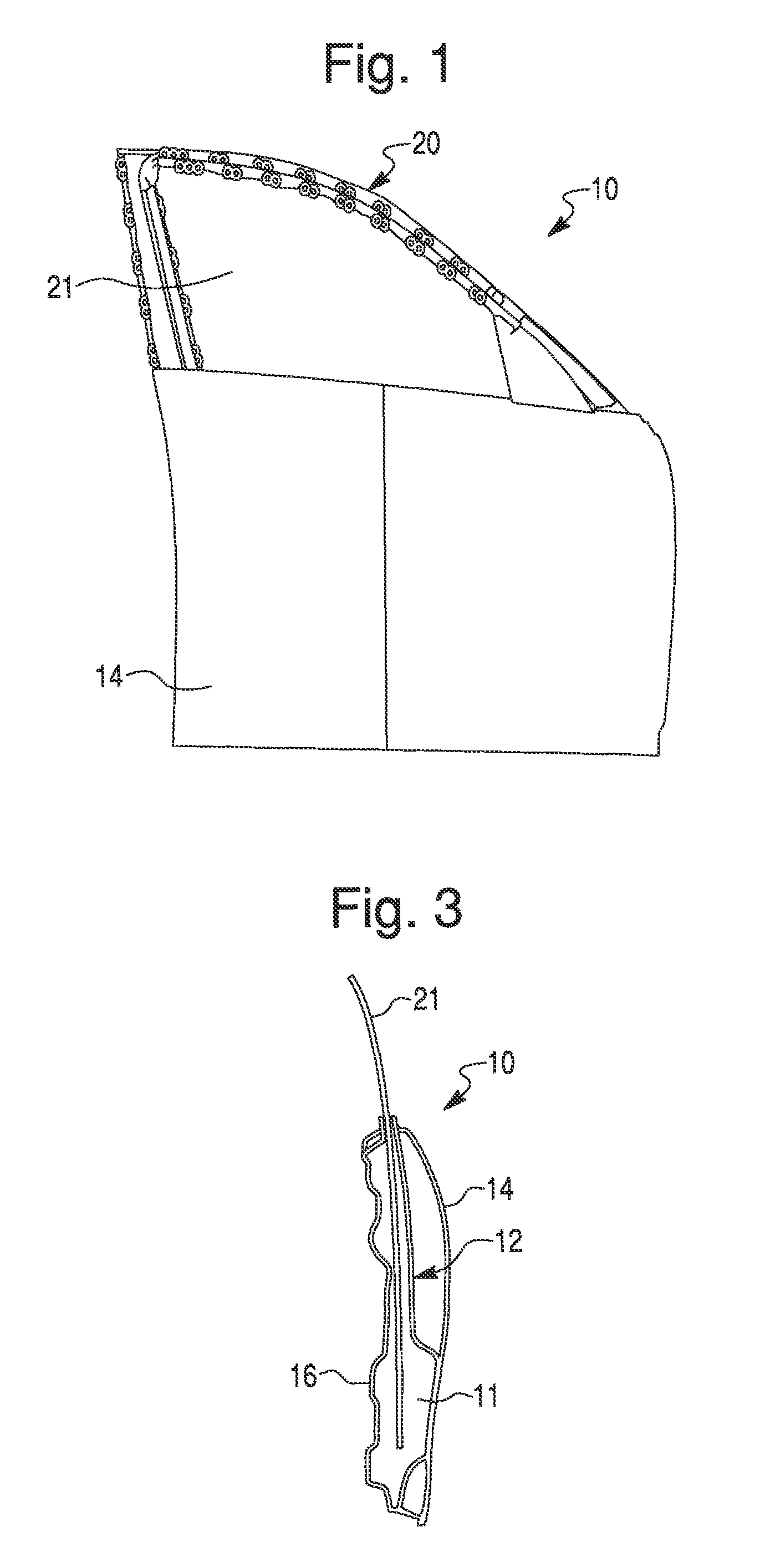

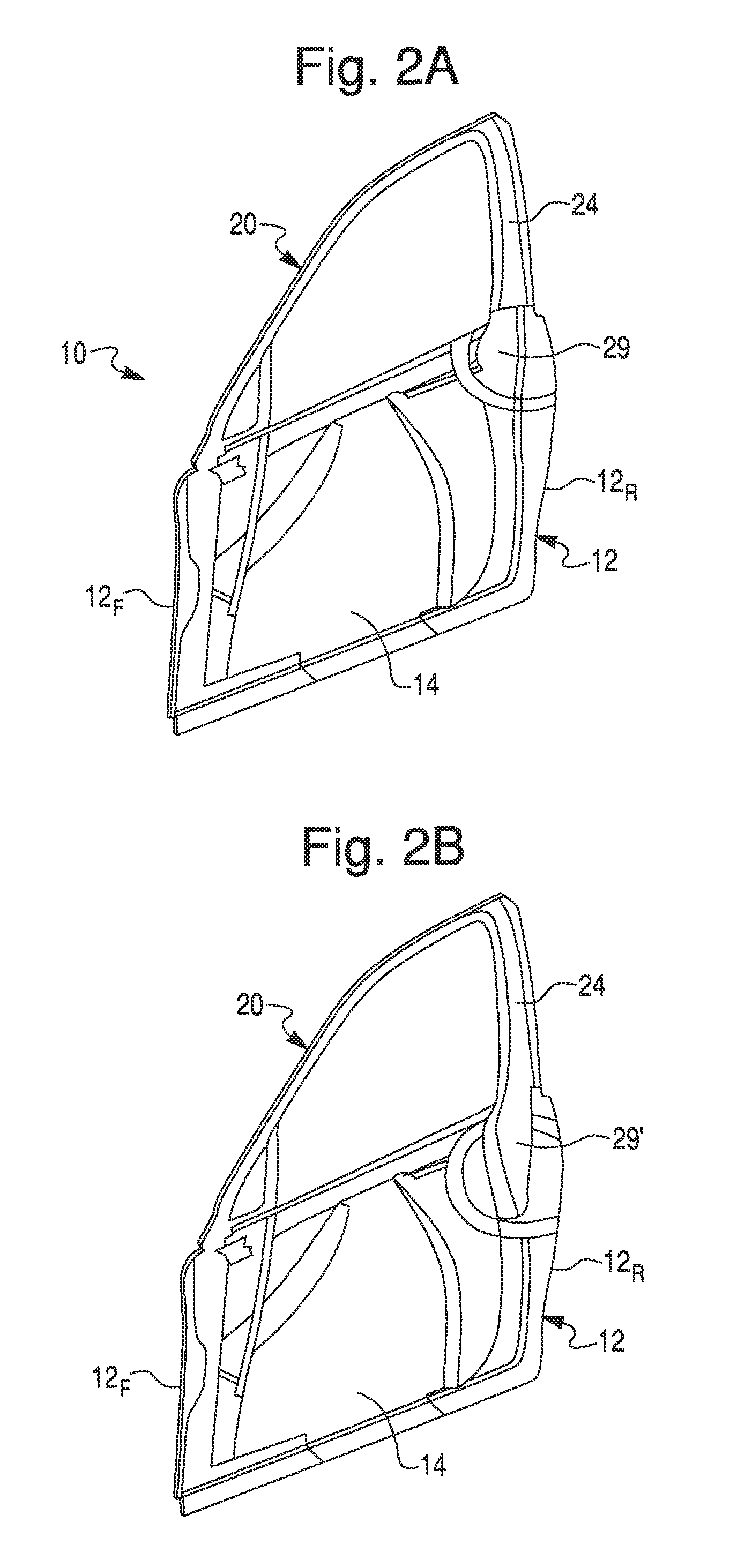

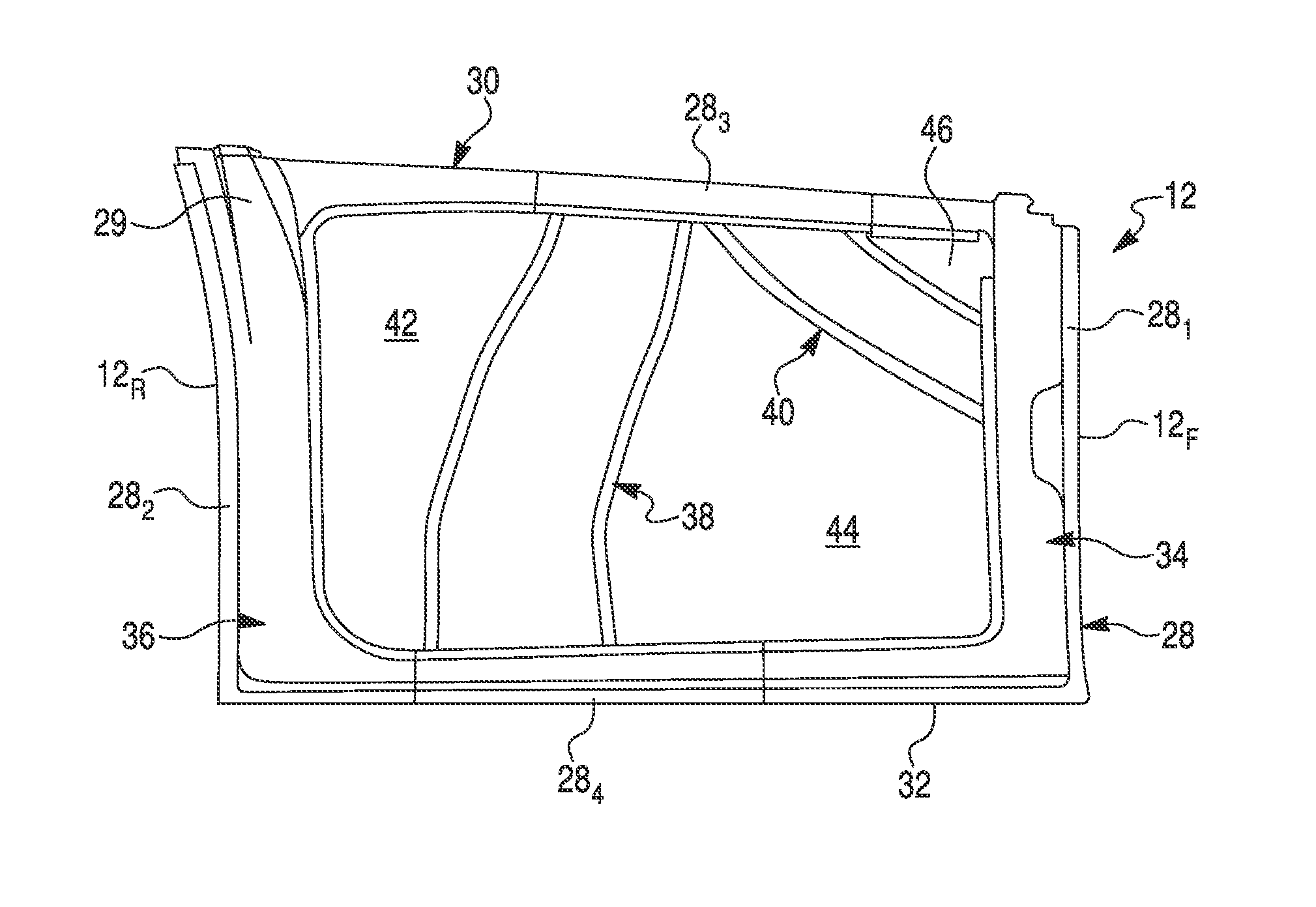

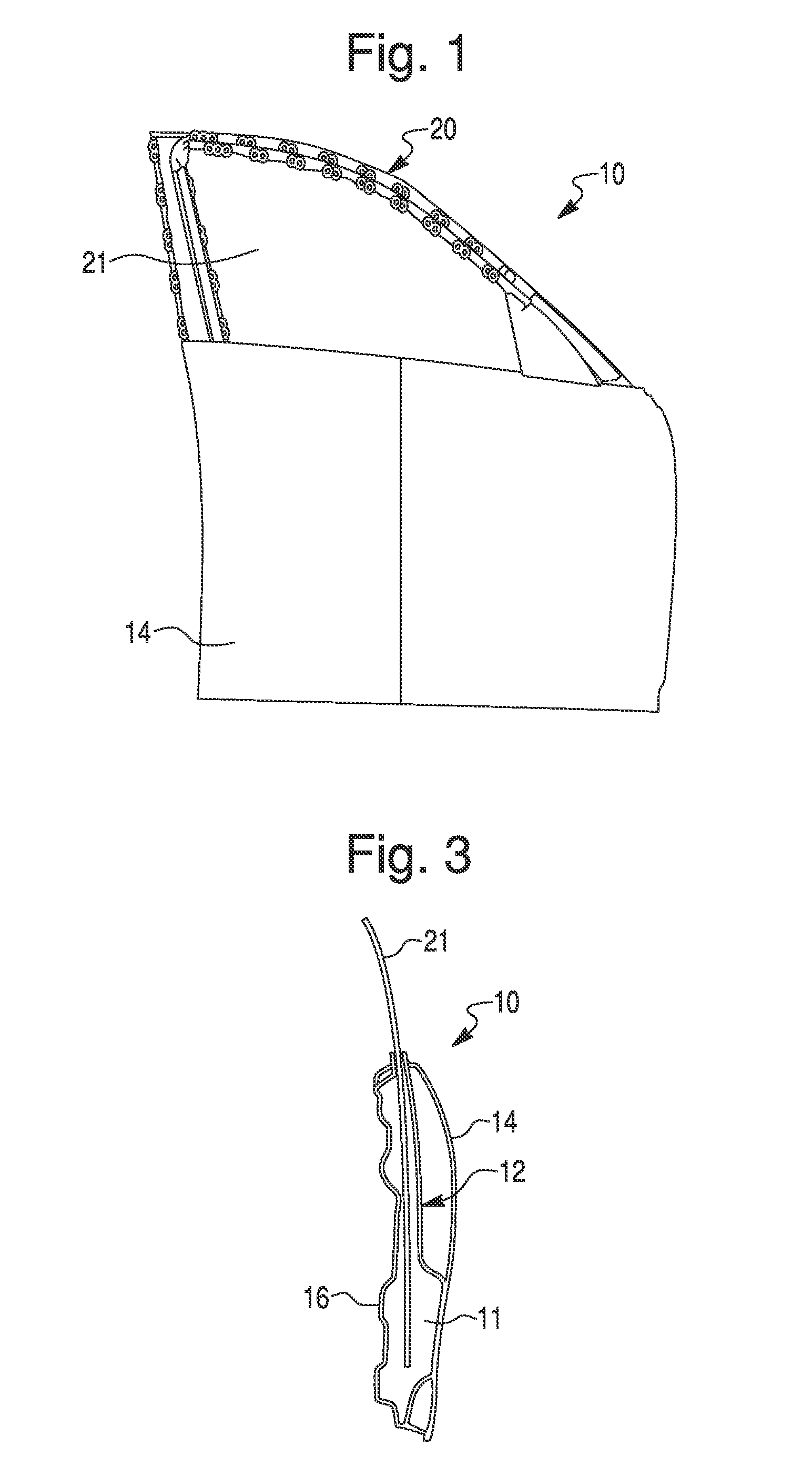

Lightweight steel door for vehicle and method for manufacturing the same

A vehicle door assembly comprises an inner panel integrally formed by upper and lower horizontal beams interconnected by front and rear upright beams, and an outer panel bonded to the inner panel. The frame portion comprises opposite front and rear U-shaped side frame members non-detachably attached to each other by upper and lower intermediate frame members so as to form a continuous perimeter. The side frame members are made of a first steel material and the intermediate frame members made of a second steel material, which is different from the first steel material. A method for manufacturing the inner panel comprises the steps: providing U-shaped sheets of the first steel material, providing top and bottom sheets of the second steel material, non-detachably connecting the U-shaped sheets to the top and bottom sheets so as to form a blank, and stamping the blank into the frame portion.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

High strength and high magnetic permeability steel sheet for cathode ray tube band and method for production thereof

InactiveUS20060134452A1Steady increase in intensityRealize blockingHot-dipping/immersion processesInorganic material magnetismChemical compositionReduction ratio

A high-strength, high-permeability steel sheet for picture tube band comprises, in mass percent, C: 0.003-0.010%, Si: 0.5-1.0%, Mn: 1.0-2.0%, P: 0.04-0.15%, S: not more than 0.02%, Al: not more than 0.030%, N: not more than 0.004% and the balance of Fe and unavoidable impurities, has a chemical composition satisfying C×Mn×P≧2.5×10−4, and has a ferrite crystal grain diameter of 10-100 μm and a yield stress of 300 N / mm2 or higher, and preferably has a specific permeability μ0.35 in a DC magnetic field of 0.35 Oe of 400 or higher. The steel sheet can be produced by regulating the hot-rolling coiling temperature to 600-700° C. and selecting an appropriate combination of the cold rolling reduction ratio and a final annealing temperature in the range of 750-900° C.

Owner:NISSHIN STEEL CO LTD

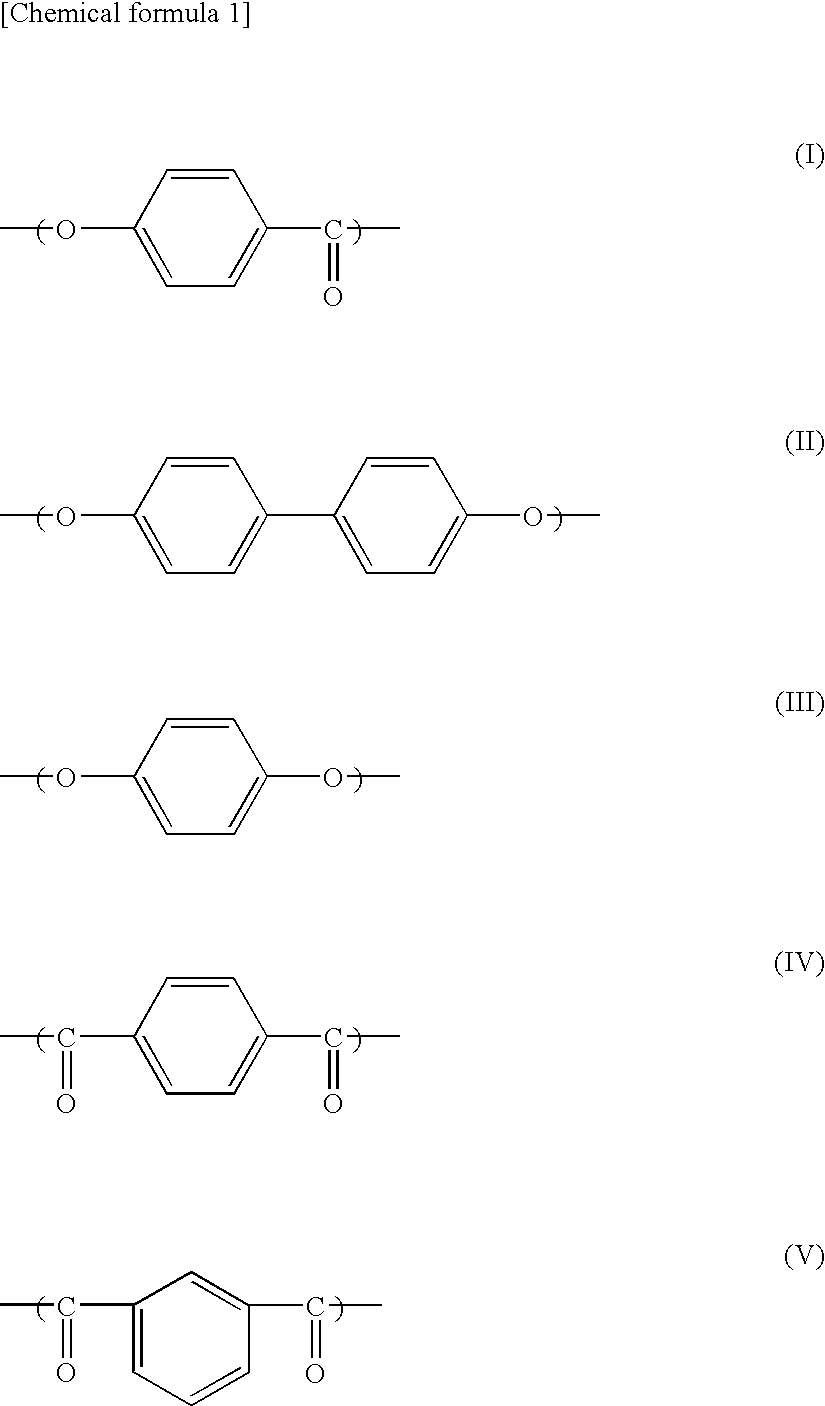

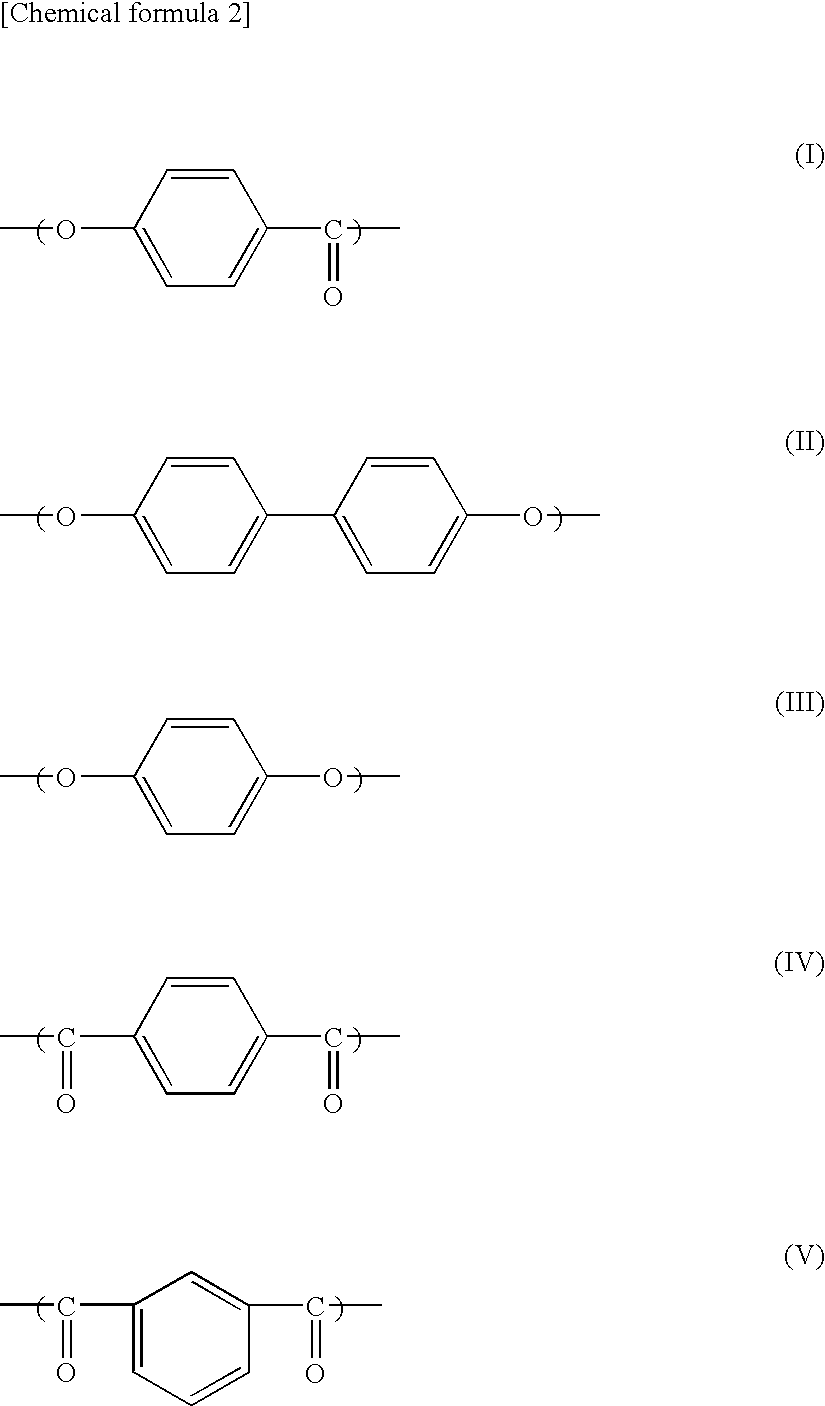

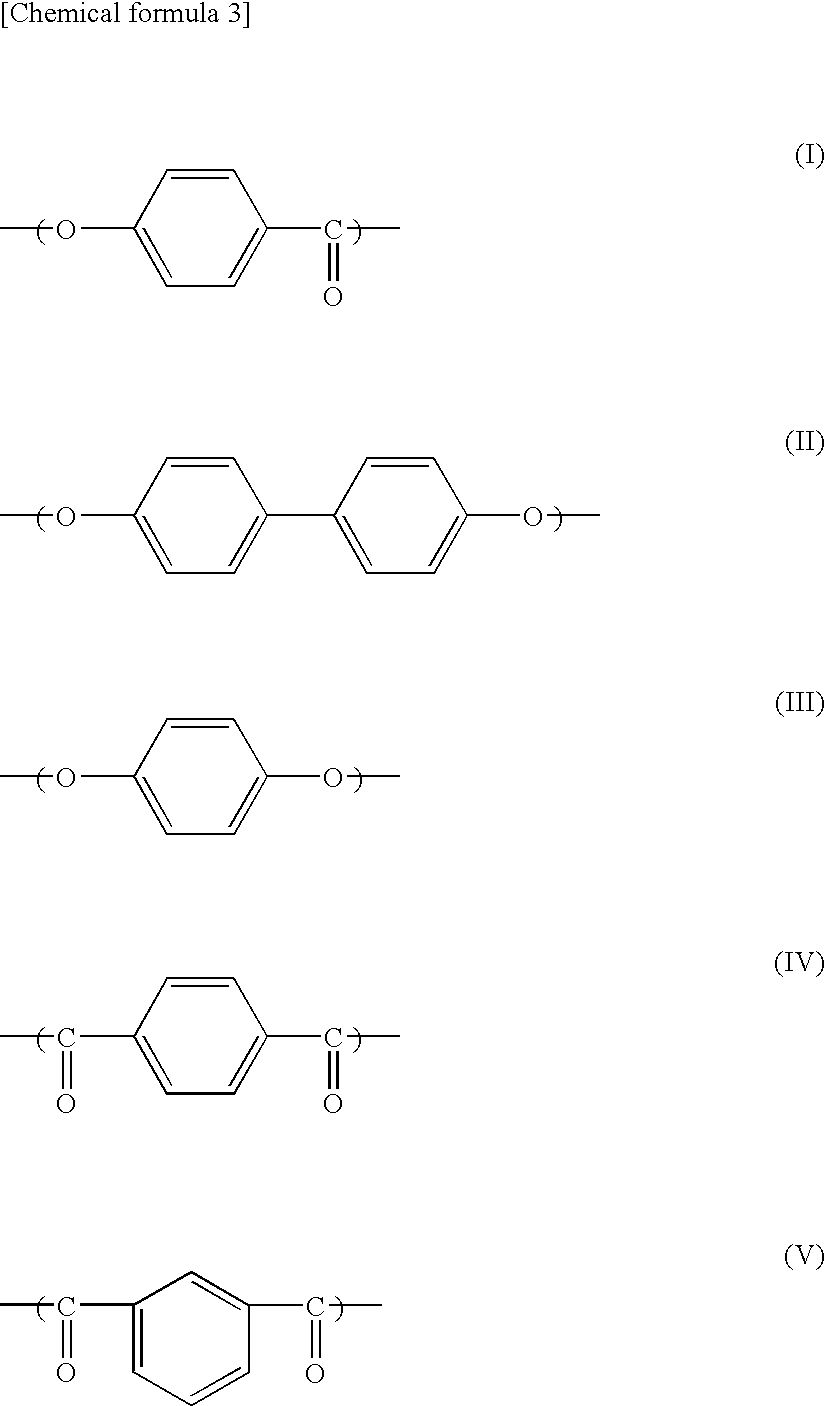

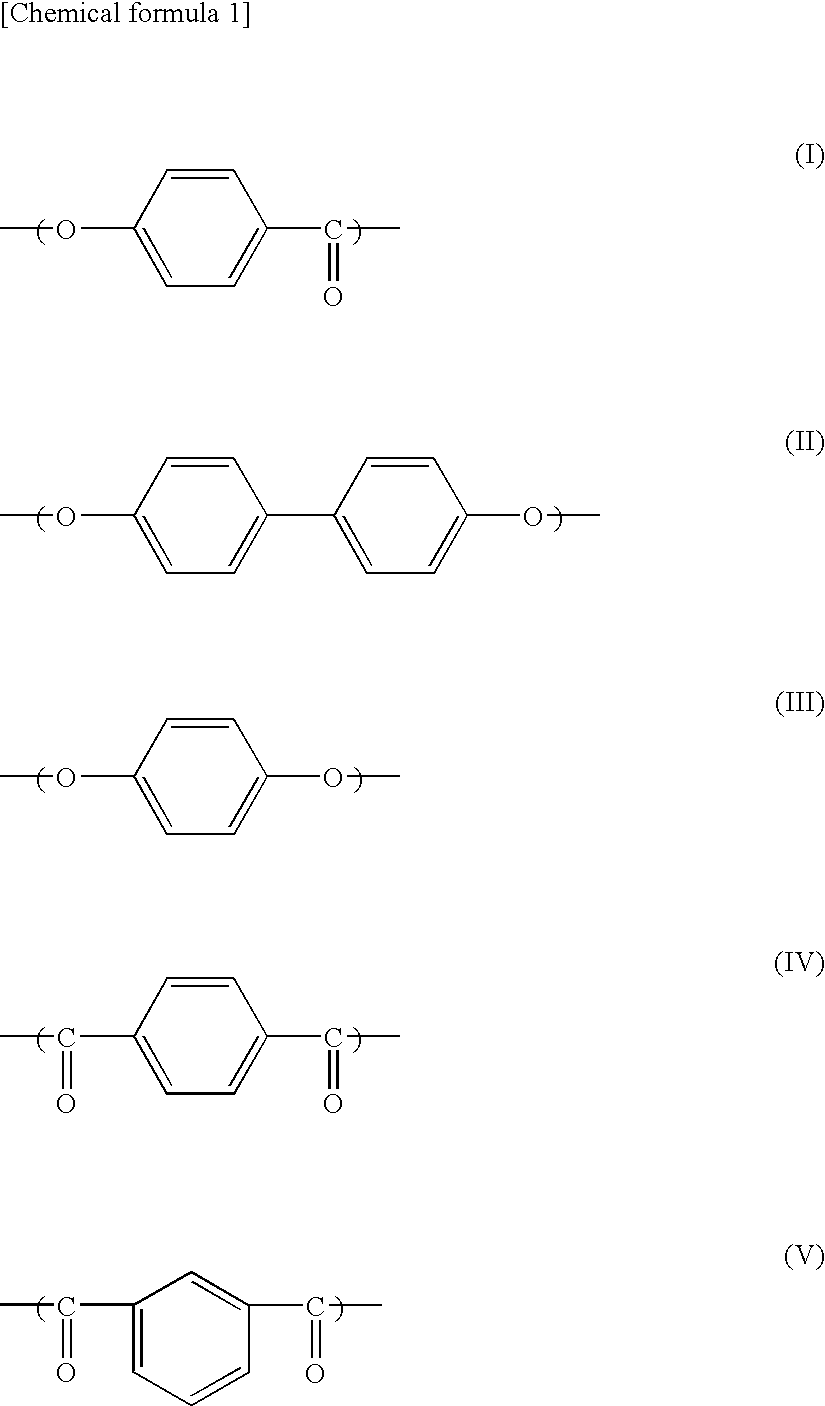

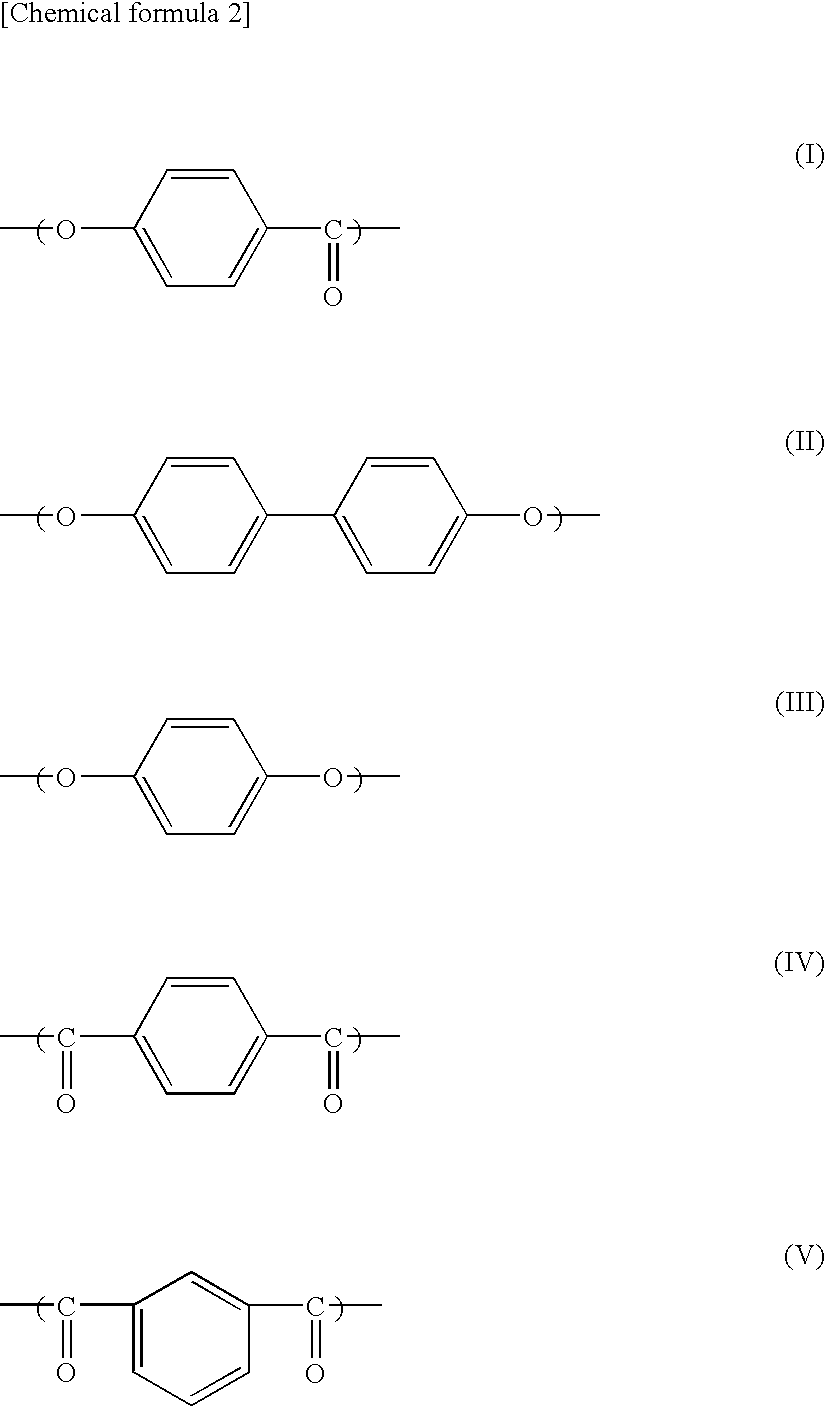

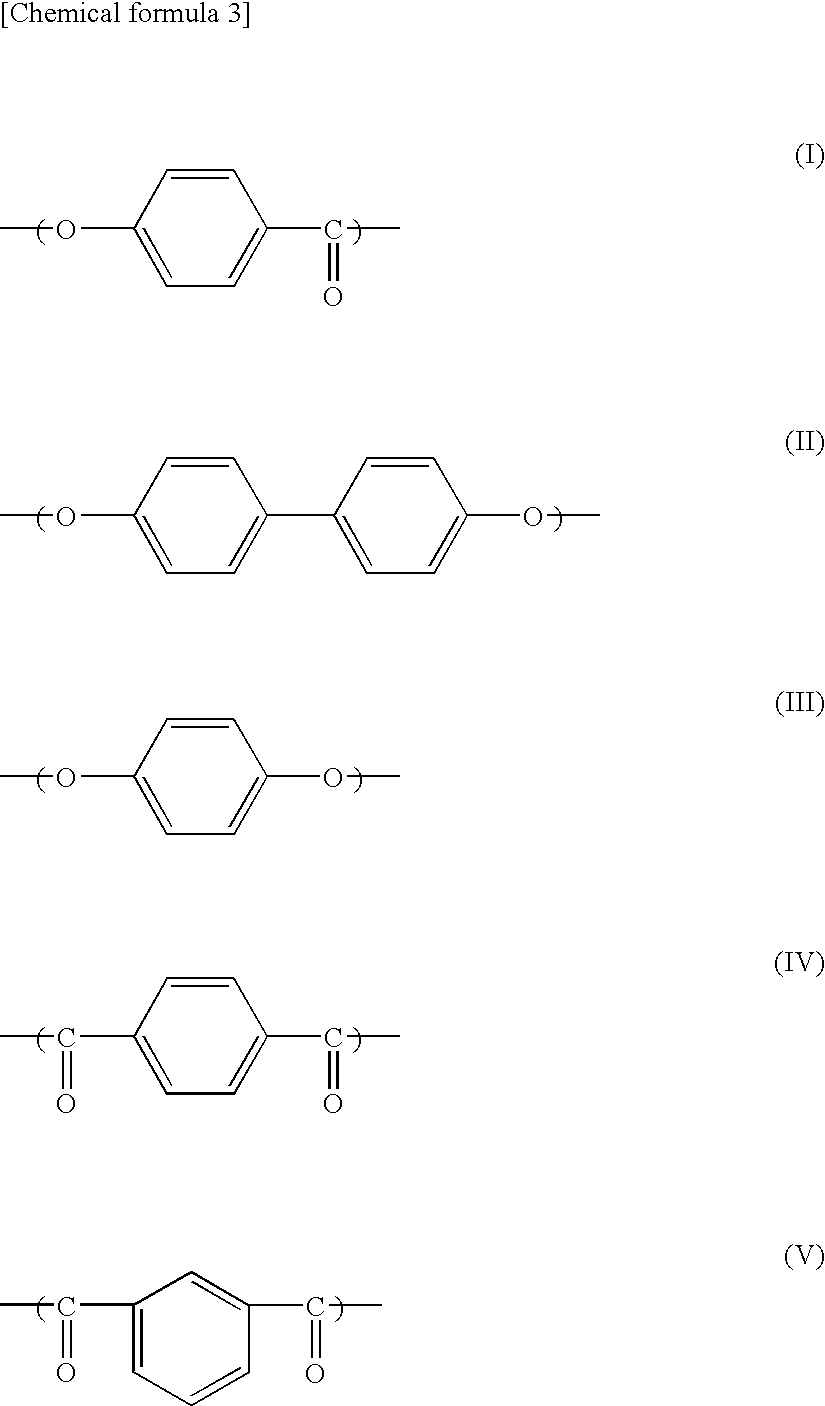

Liquid crystalline polyester fiber and process for production of the same

ActiveUS20100104870A1High elastic modulusHigh in strengthLayered productsOptical articlesPolyesterLiquid crystalline

A liquid crystalline polyester fiber which exhibits a half width of endothermic peak (Tm1) of 15° C. or above as observed in differential calorimetry under heating from 50° C. at a temperature elevation rate of 20° C. / min and a strength of 12.0 cN / dtex or more; and a process for production of the same. A liquid crystalline polyester fiber which is excellent in abrasion resistance and lengthwise uniformity and is improved in weavability and quality of fabric and which is characterized by a small single-fiber fineness can be efficiently produced without impairing the characteristics inherent in fabric made of liquid crystalline polyester fiber produced by solid phase polymerization, namely, high strength, high elastic modulus and excellent thermal resistance.

Owner:TORAY IND INC

High-strength electrical steel sheet and processed part of same

ActiveUS8097094B2High strengthHigh in strengthInorganic material magnetismSheet steelElectrical steel

The present invention has as its object to stably produce a high strength electrical steel sheet and a processed part of the same which is high in strength and has wear resistant and is superior in magnetic flux density and core loss without greatly changing the cold rollability and production processes from those of conventional electrical steel sheet and provides a high strength electrical steel sheet characterized by containing, by mass %, C: 0.06% or less, Si: 0.2 to 6.5%, Mn: 0.05 to 3.0%, P: 0.30% or less, S or Se: 0.040% or less, Al: 2.50% or less, Cu: 0.6 to 8.0%, N: 0.0400% or less, and a balance of Fe and unavoidable impurities and containing in the steel a metal phase composed of Cu of a size of 0.1 μm or less. The method of production of the same comprises holding in a temperature range of 300° C. to 720° C. for 5 seconds or more for heat treatment.

Owner:NIPPON STEEL CORP

Heat-curable epoxy resin composition for encapsulating optical semiconductor element and optical semiconductor device using same

Provided is a heat-curable epoxy resin composition for encapsulating an optical semiconductor element. The resin composition exhibits a high strength and elastic modulus even in a high-temperature environment, hardly turns yellow due to an uneven hardening that occurs immediately after molding, and is solid under a room temperature such that the resin composition can be handled easily. The resin composition includes: a prepolymer obtained through a reaction of (A) a triazine derivative epoxy resin, (B) at least one epoxy resin selected from a group of (B-1) a bisphenol A-type epoxy resin, (B-2) a bisphenol F-type epoxy resin, (B-3) a hydrogenated bisphenol A-type epoxy resin and (B-4) an alicyclic epoxy resin and (C) an acid anhydride curing agent, at an epoxy group equivalent / acid anhydride group equivalent ratio of 0.6 to 2.0; and (D) a curing accelerator, such resin composition capable of being pressure molded under a room temperature before thermally cured.

Owner:SHIN ETSU CHEM IND CO LTD

Soft metal and method for preparation thereof, and exterior part of watch and method for preparation thereof

InactiveUS7396595B2High hardnessHigh in strengthVacuum evaporation coatingSputtering coatingNiobiumTitanium

A soft metal and a decorative article of wristwatch are produced by forming, on the surface of a soft metal article (2), a hard layer (3, 13) containing zirconium and molybdenum, or containing zirconium, molybdenum and further an additive element constituted of at least one or more elements selected from niobium, tantalum, and titanium. It is preferable that the content of molybdenum constituting the hard layer (3, 13) is about 30 to 75 wt %, or that the content of molybdenum is about 25 to 65 wt % and the total content of the additive elements is about 25 wt % or less.

Owner:CITIZEN WATCH CO LTD

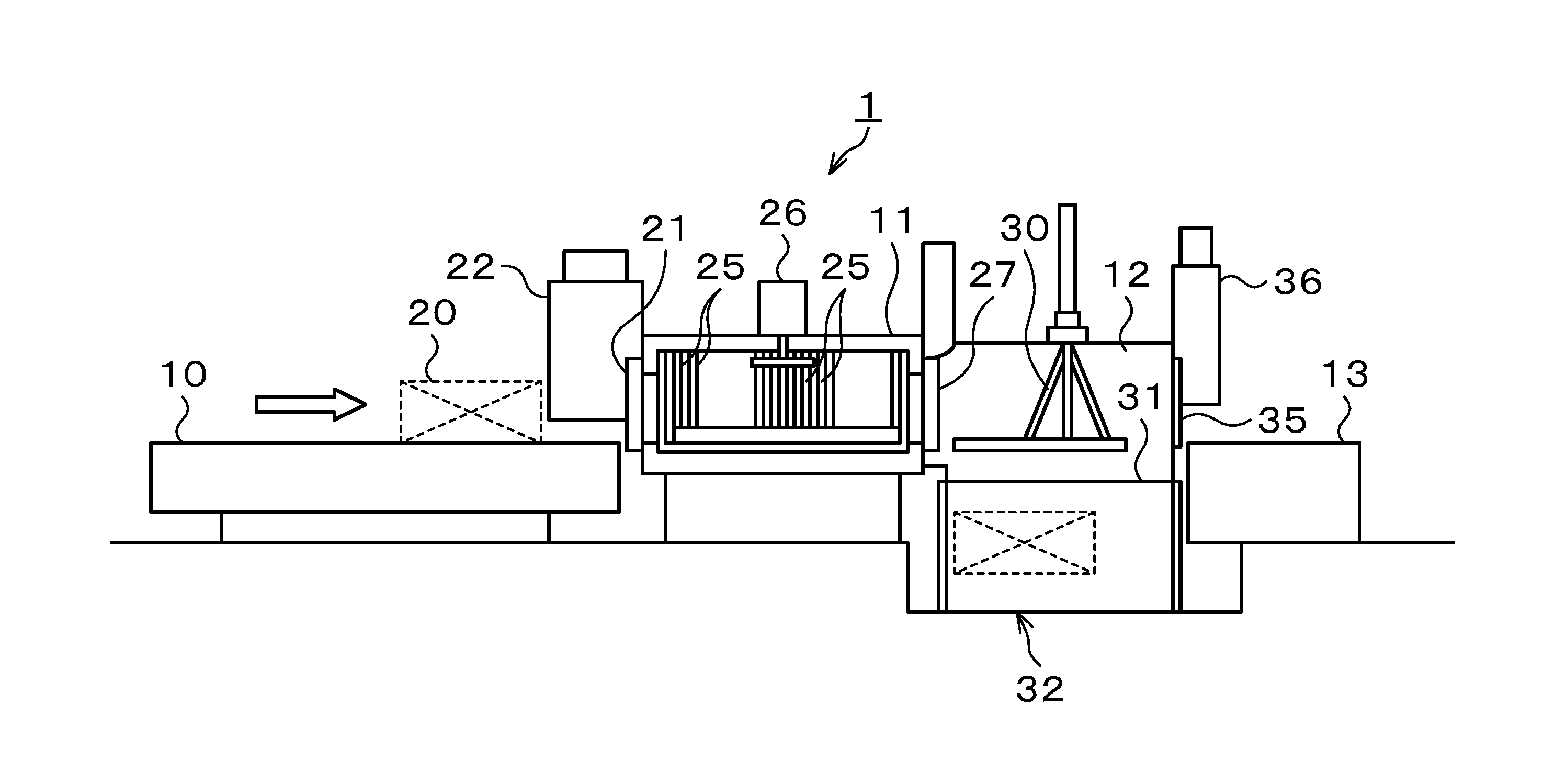

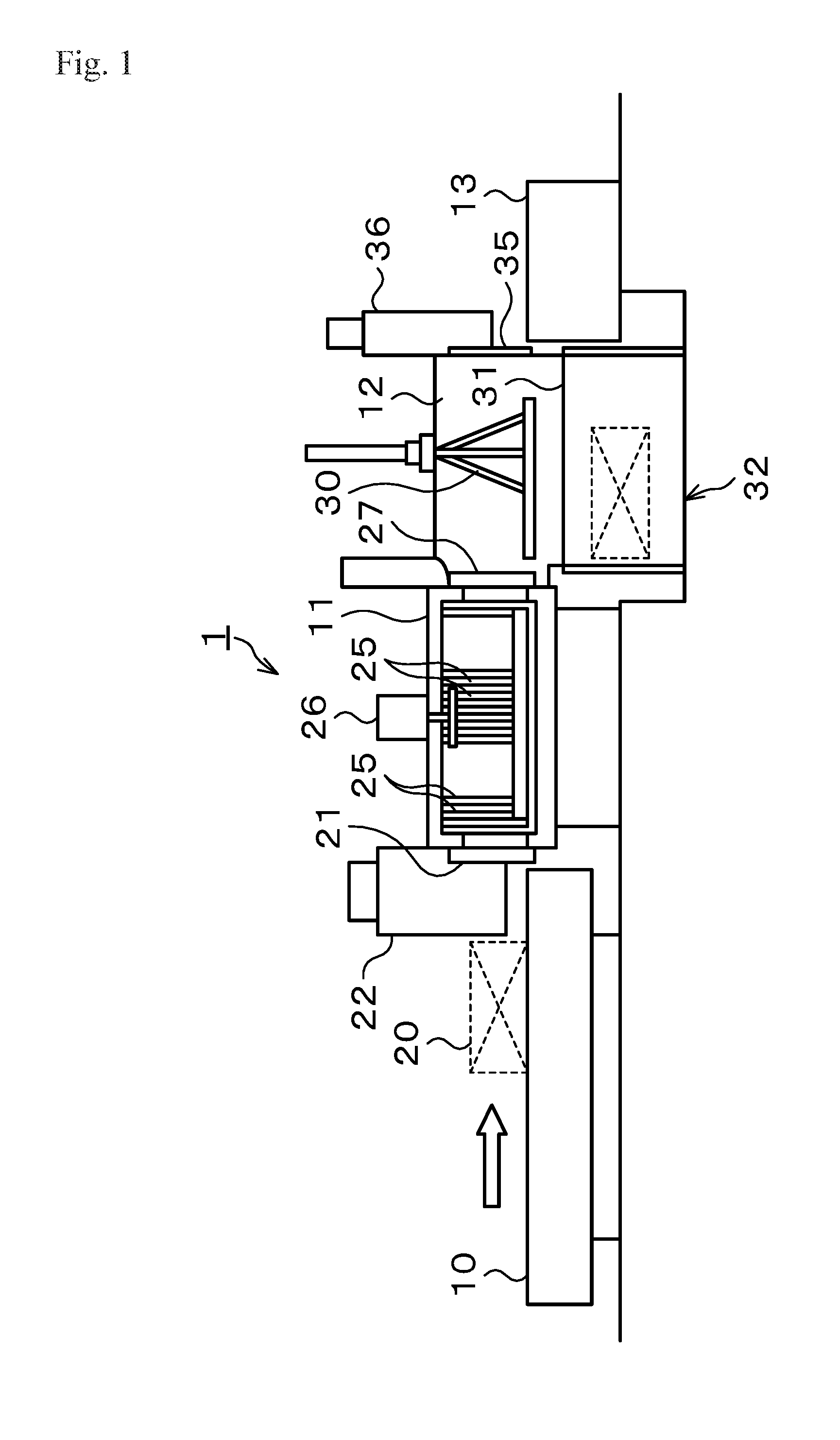

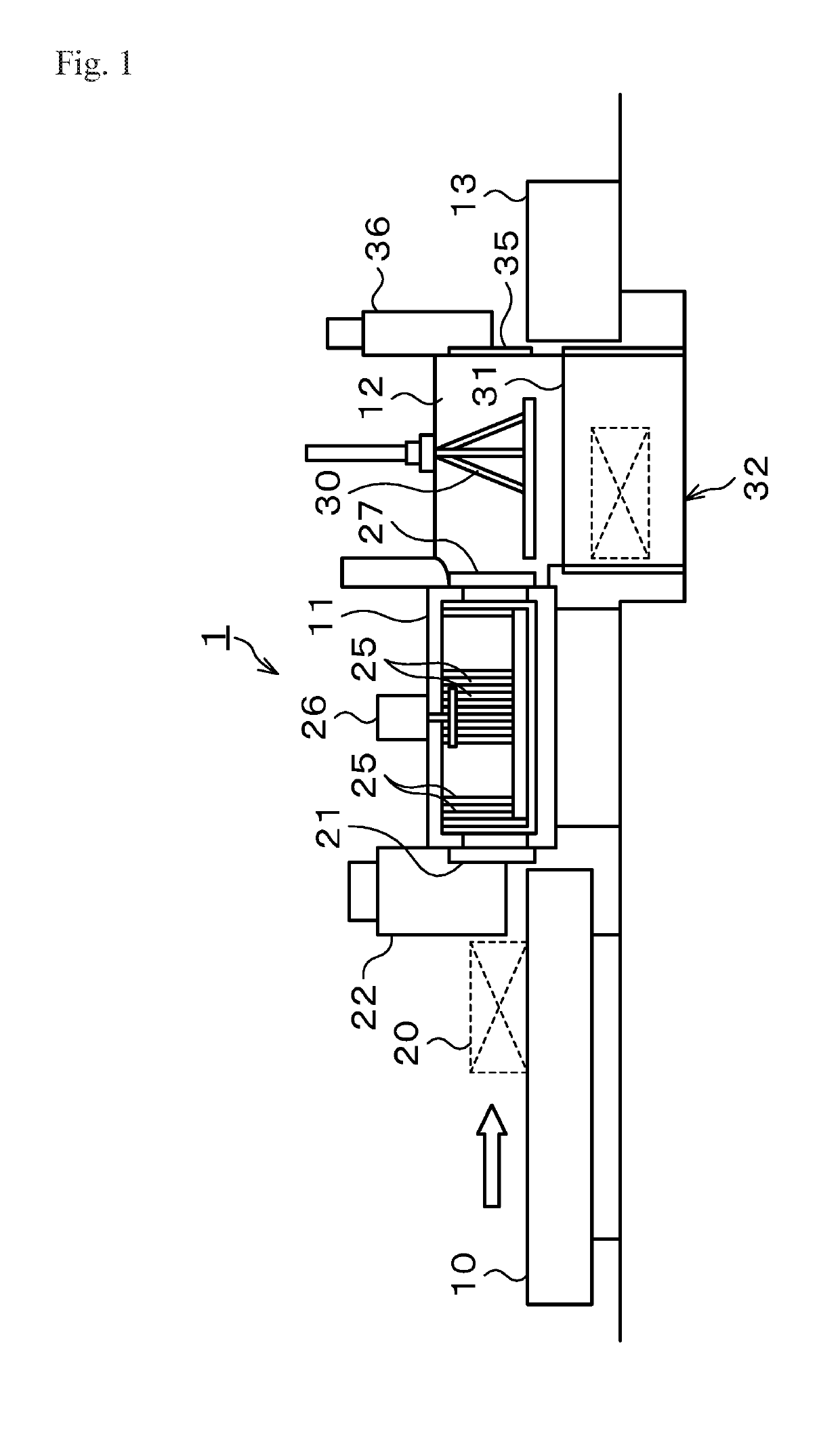

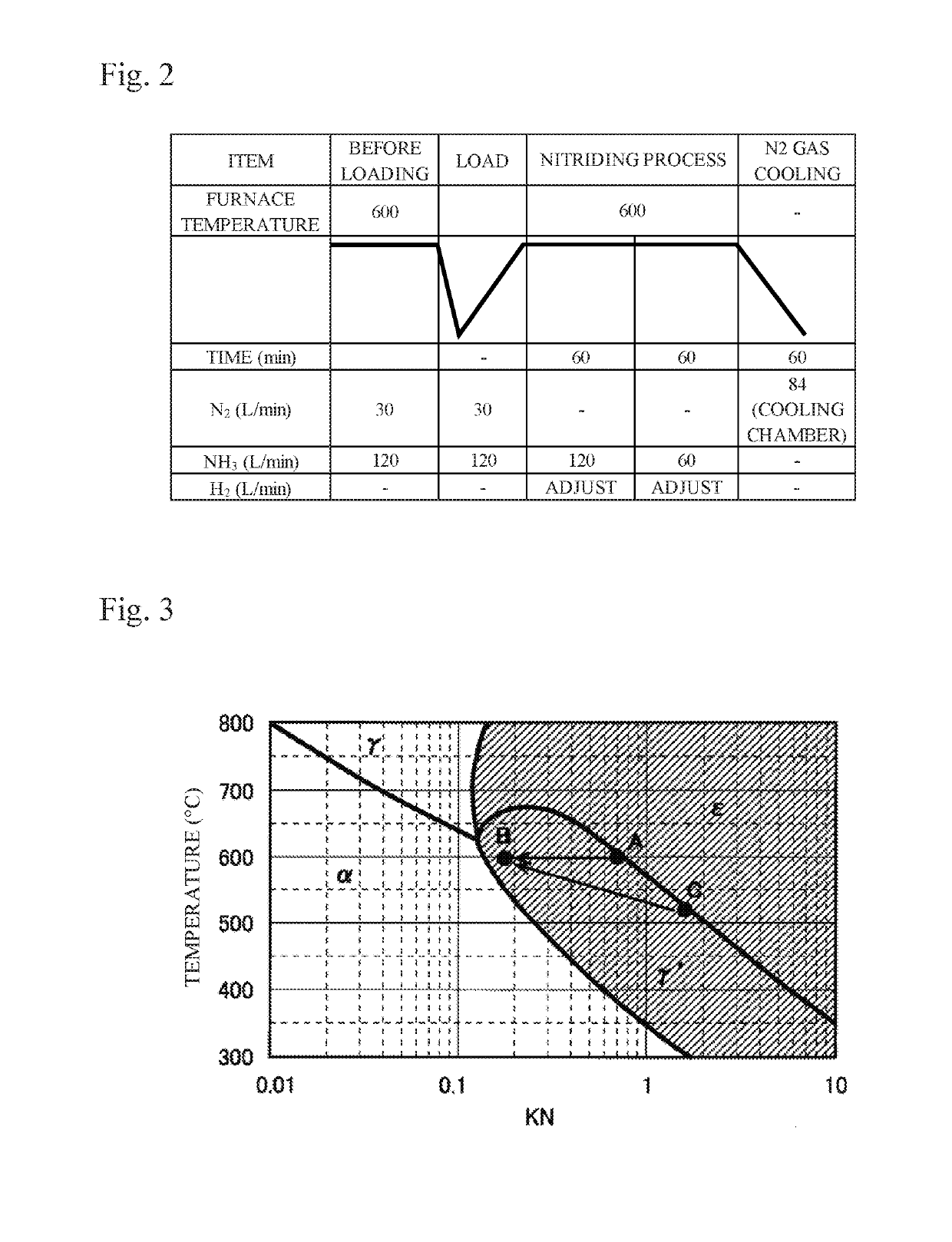

Nitriding process method of steel member

ActiveUS20160244869A1Increase resistanceHigh in strengthSolid state diffusion coatingFurnace typesUltimate tensile strengthAtmosphere

A first nitriding process step is performed in which a steel member is subjected to a nitriding process in a nitriding gas atmosphere having a nitriding potential with which a nitride compound layer having a γ′ phase or an e phase is generated, and thereafter a second nitriding process step is performed in which the steel member is subjected to a nitriding process in a nitriding gas atmosphere having a nitriding potential lower than the nitriding potential in the first nitriding process step, to thereby precipitate the γ′ phase in the nitride compound layer. It is possible to generate the nitride compound layer having a desired phase mode uniformly all over a component to be treated and to manufacture a nitrided steel member high in pitting resistance and bending fatigue strength.

Owner:DOWA THERMOTECH +1

Lightweight steel door for vehicle and method for manufacturing the same

ActiveUS20150101193A1Improve the immunityHigh in strengthRailway componentsMetal-working apparatusEngineeringCar door

Owner:ARSELORMITTAL INVESTIGASION I DESARROLO

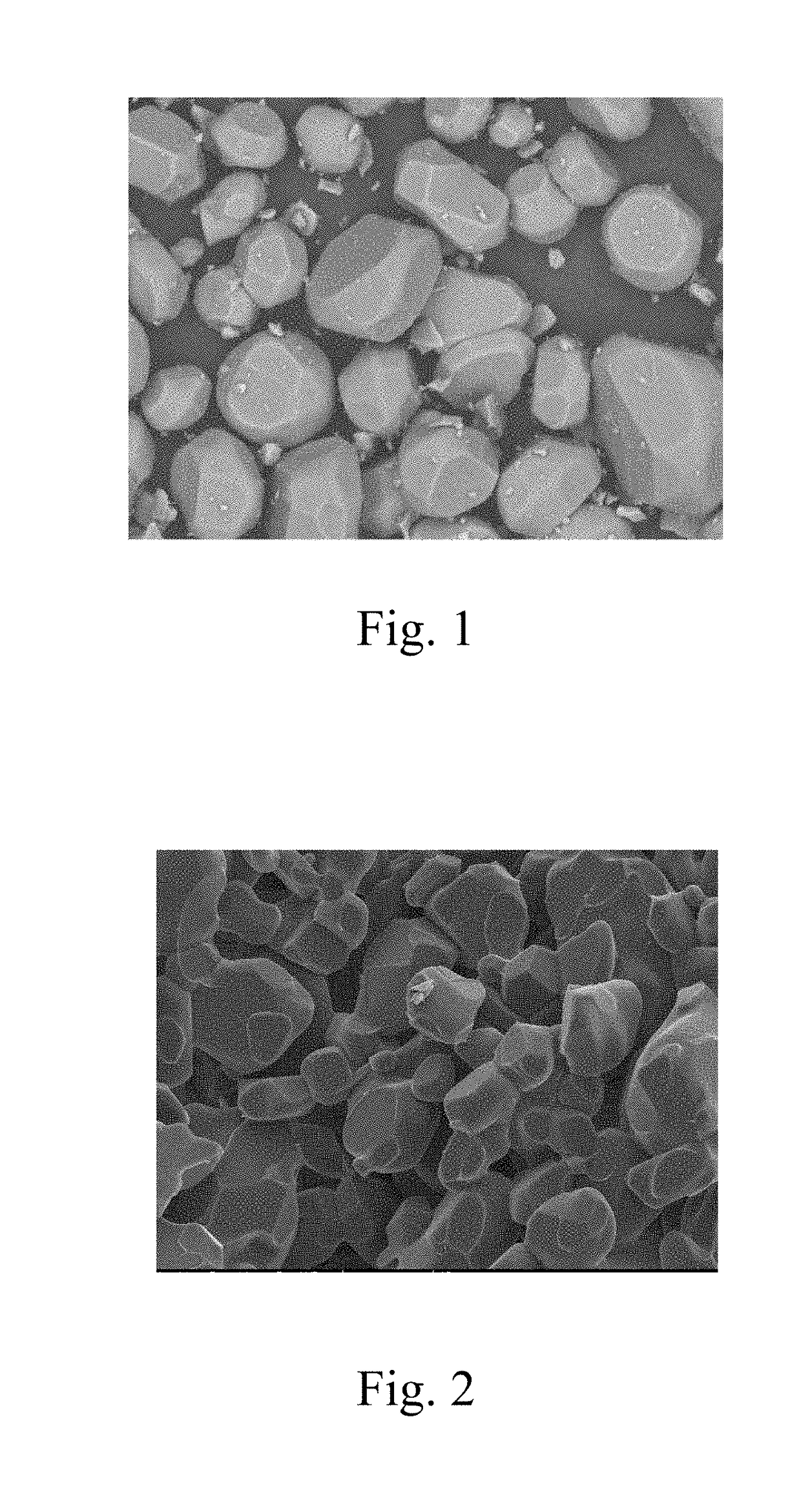

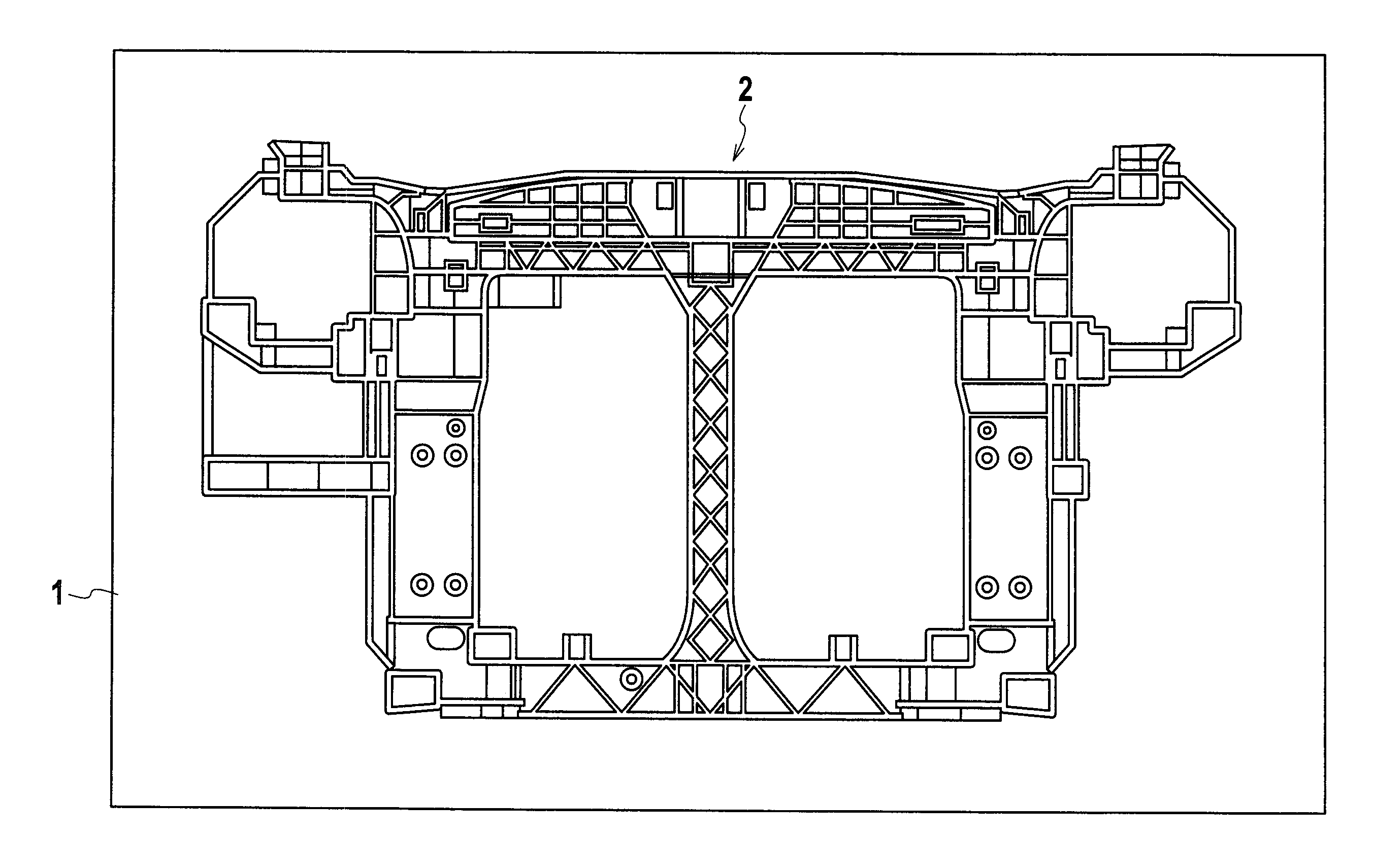

Preparation method of ceramic membrane support

A preparation method of a ceramic membrane support is disclosed. Take aluminium hydroxide, produced through a carbon decomposing process by a sintering method, as a raw material, pre-sinter the aluminium hydroxide, and obtain a low-temperature alumina product A; add a first amount of mineralizer into the product A, grind after calcining the added product A, and obtain a α-alumina product B; mix the product B with Al2O3.nH2O, calcine after adding a second amount of mineralizer into the mixed product B, and obtain a α-alumina product C; grind, scatter and grade the calcined and heat-preserved α-alumina product C, and obtain polyhedral alumina powders; mix the polyhedral alumina powders, water, humectant and dispersant and then sinter, and finally obtain the porous alumina support. The prepared support is easy to be sintered, is high in alumina purity, is good in corrosion resistance, and is improved in porosity and flux.

Owner:SHANDONG GUIYUAN ADVANCED CERAMICS

Composite sintered body

ActiveUS20100099548A1High strengthImprove toughnessMaterial nanotechnologyTurning toolsBorideCarbide

The composite sintered body of the invention is a composite sintered body, containing 20 volume % or more and 80 volume % or less of cubic boron nitride particles, and a binder; wherein the binder contains at least one selected from the group consisting of nitrides, carbides, borides, and oxides of elements in the group 4a, elements in the group 5a, and elements in the group 6a in the periodic table, and solid solutions thereof, at least one selected from the group consisting of simple substances of Zr, Si, Hf, Ge, W and Co, compounds thereof, and solid solutions thereof, and a compound of Al; and when the composite sintered body contains therein W and / or Co, the total weight of the W and / or Co is less than 2.0 weight % and further the composite sintered body contains therein one or more of the Zr, Si, Hf and Ge (hereinafter referred to as “X”), and when the composite sintered body contains the X, the amount of each of the X is 0.005 weight % or more and less than 2.0 weight %, X / (X+W+Co) is 0.01 or more and 1.0 or less and further the weight of Al is 2.0 weight % or more and 20.0 weight % or less.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP +1

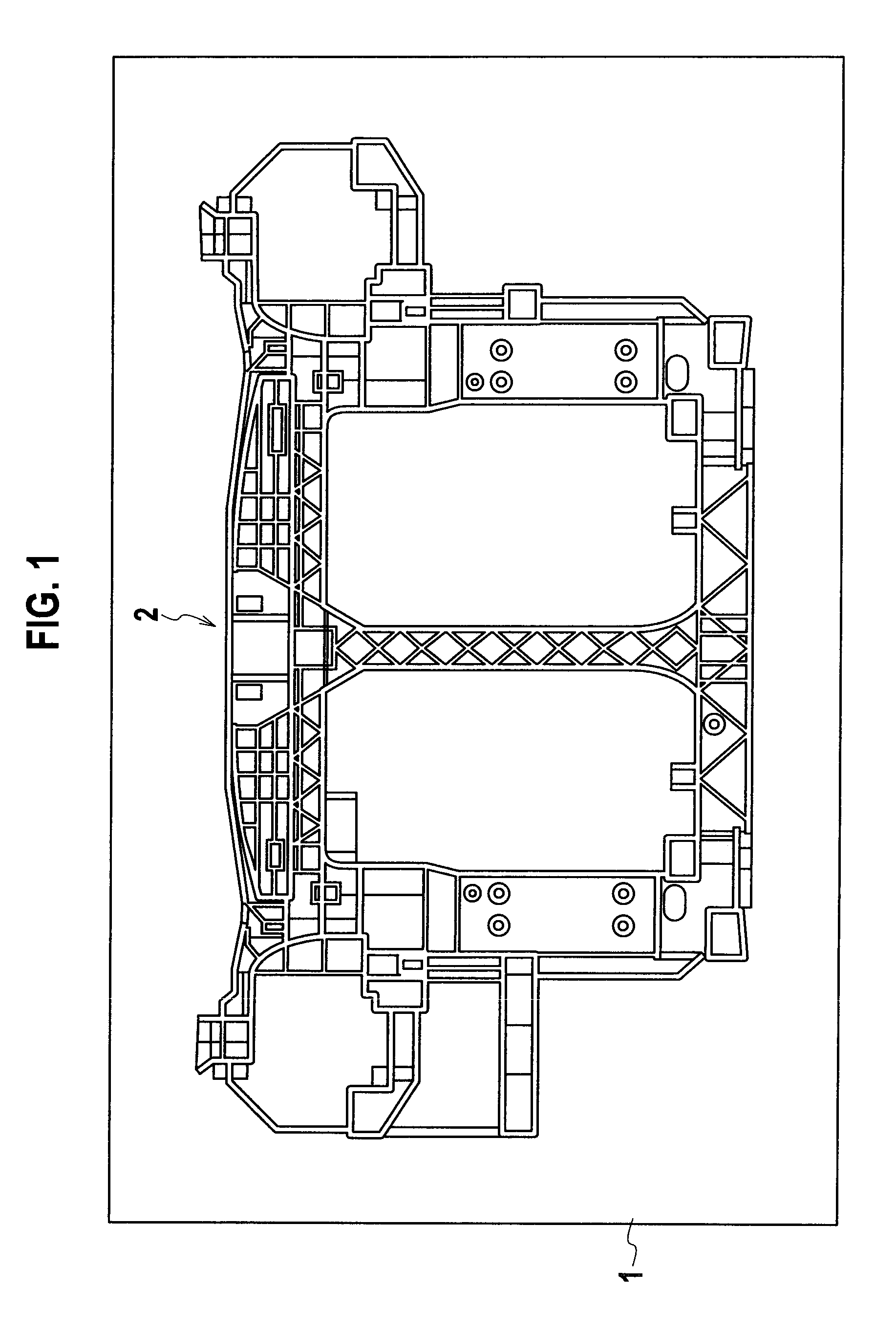

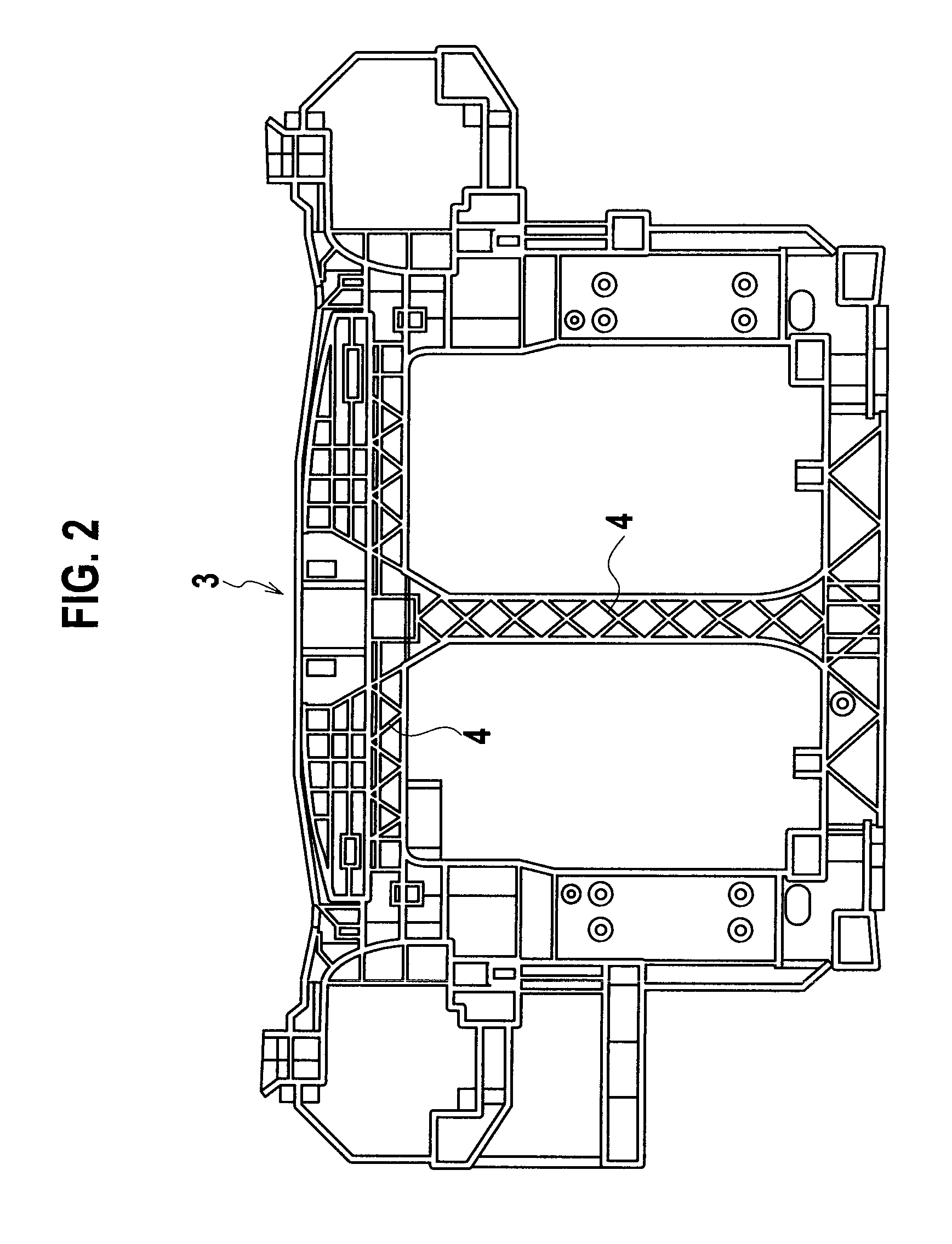

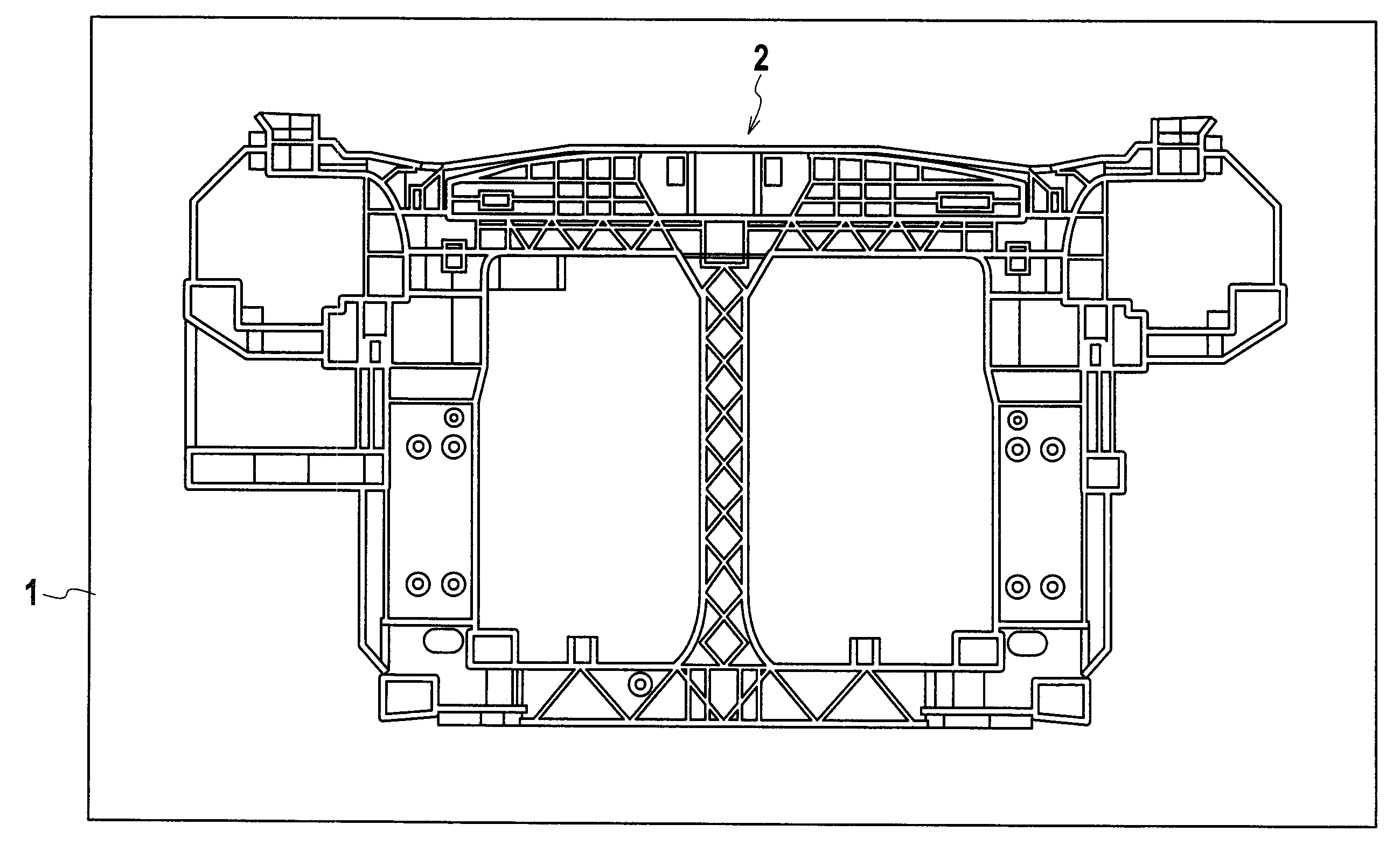

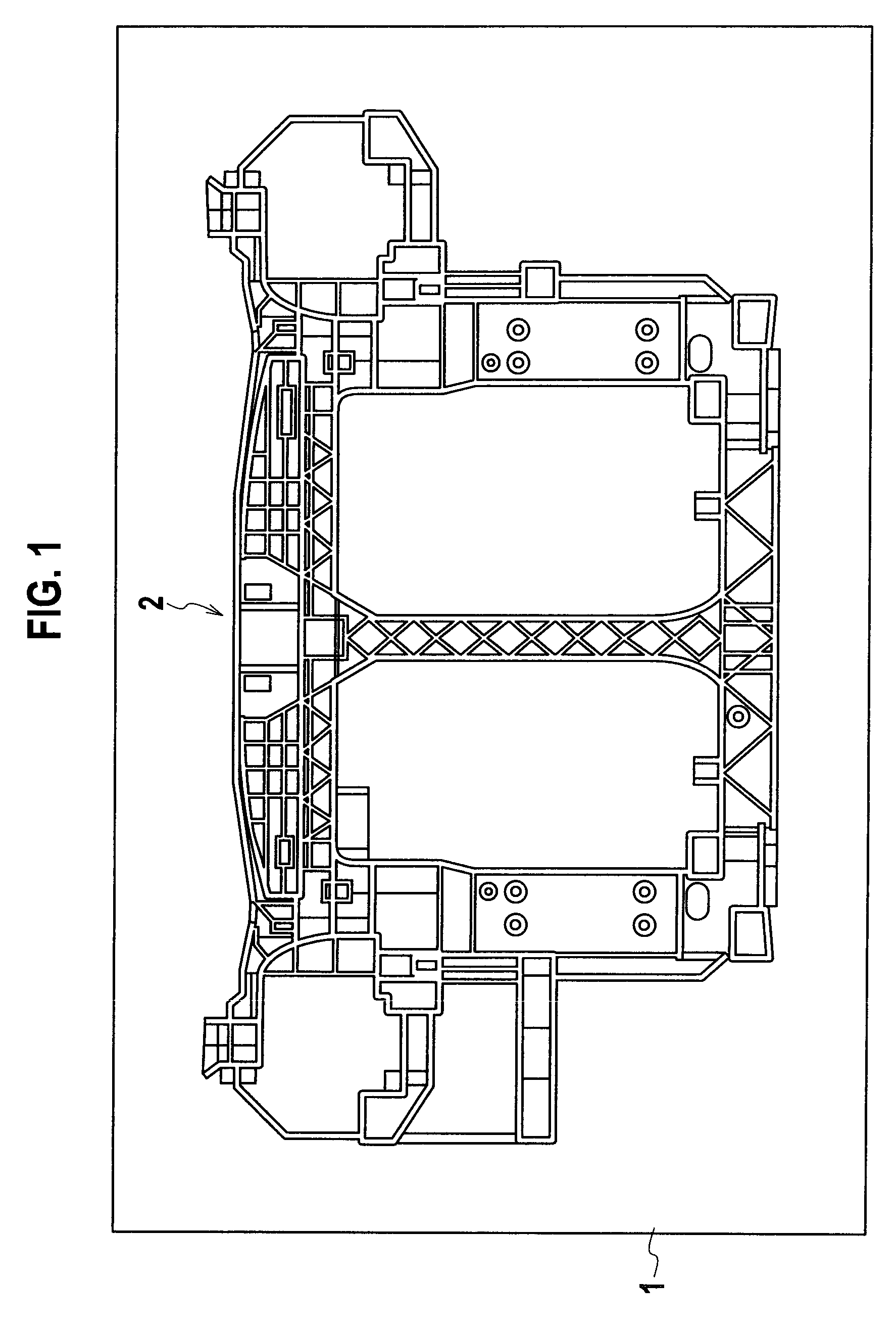

Resin molded article

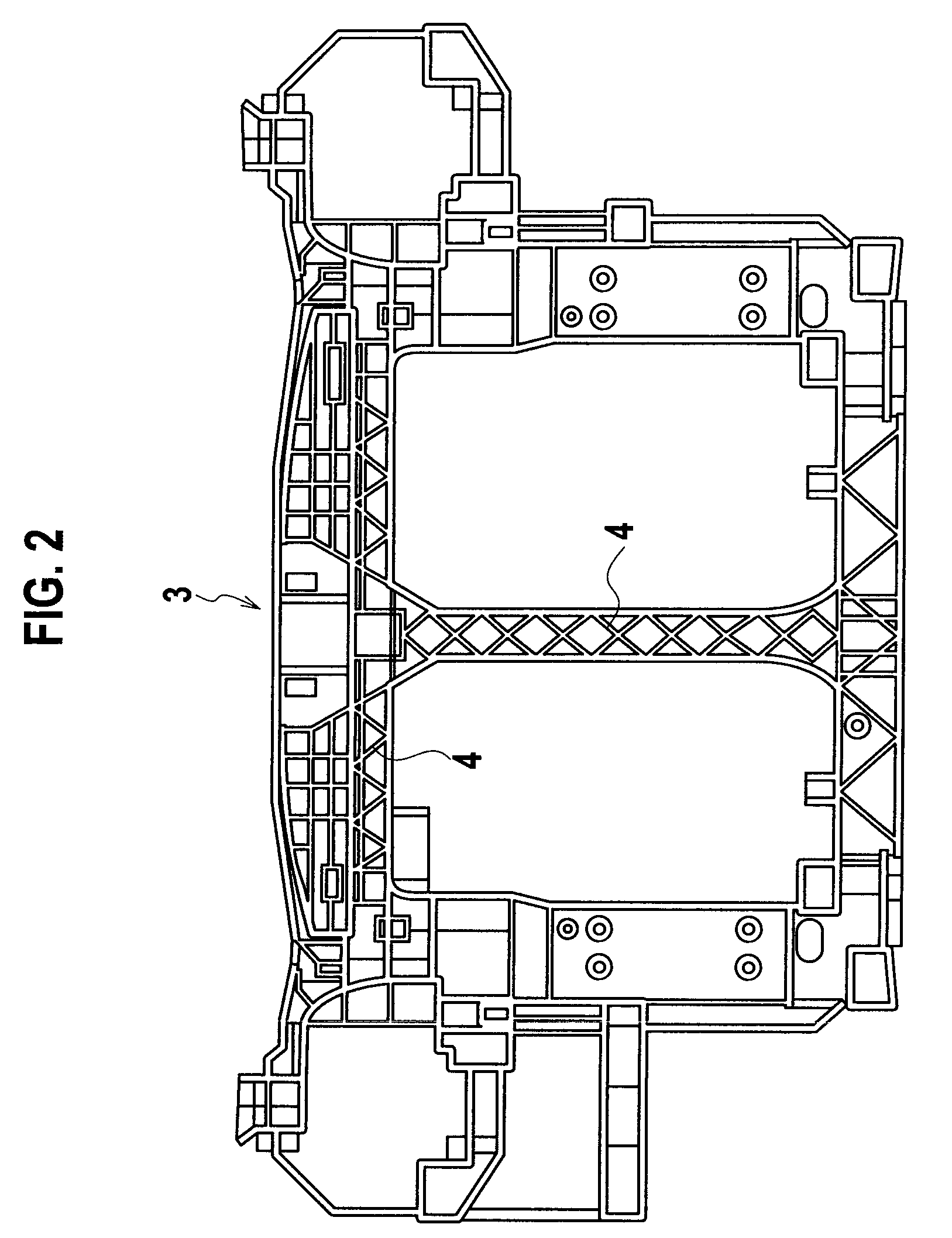

InactiveUS20100038929A1High in strengthImprove rigidityVehicle seatsLayered productsFiberCarbon fibers

In a large-sized radiator core support manufactured by filling a mold cavity 2 with a resin material through injection, polypropylene (PP) containing carbon fiber in a range of 15 to 30 wt % is used as the resin material, and an average fiber length of the carbon fiber remaining after molding is set to 1.5 mm or more. Moreover, a spiral flow length L / D of the carbon fiber is set to 200 mm or more.

Owner:CALSONIC KANSEI CORP

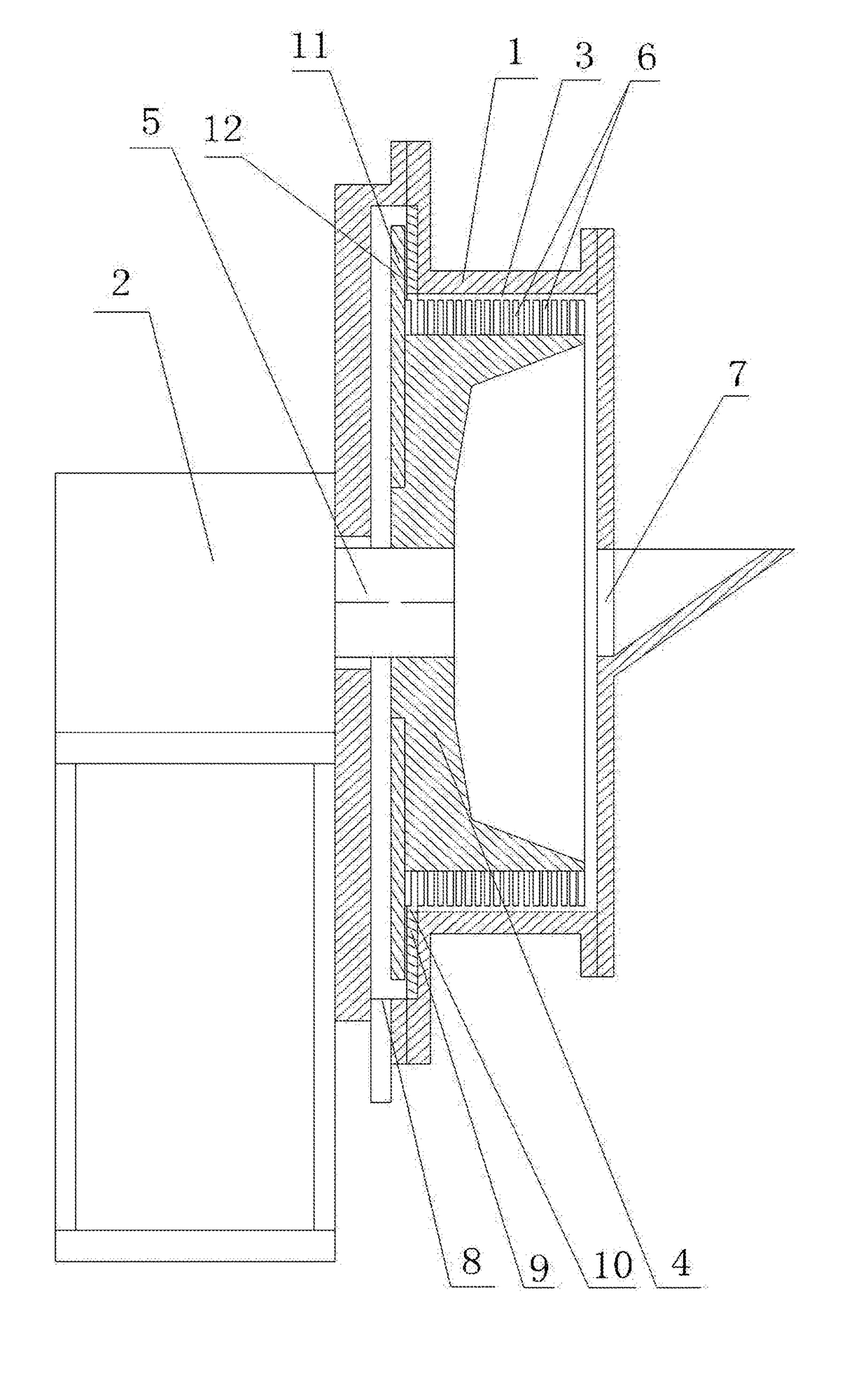

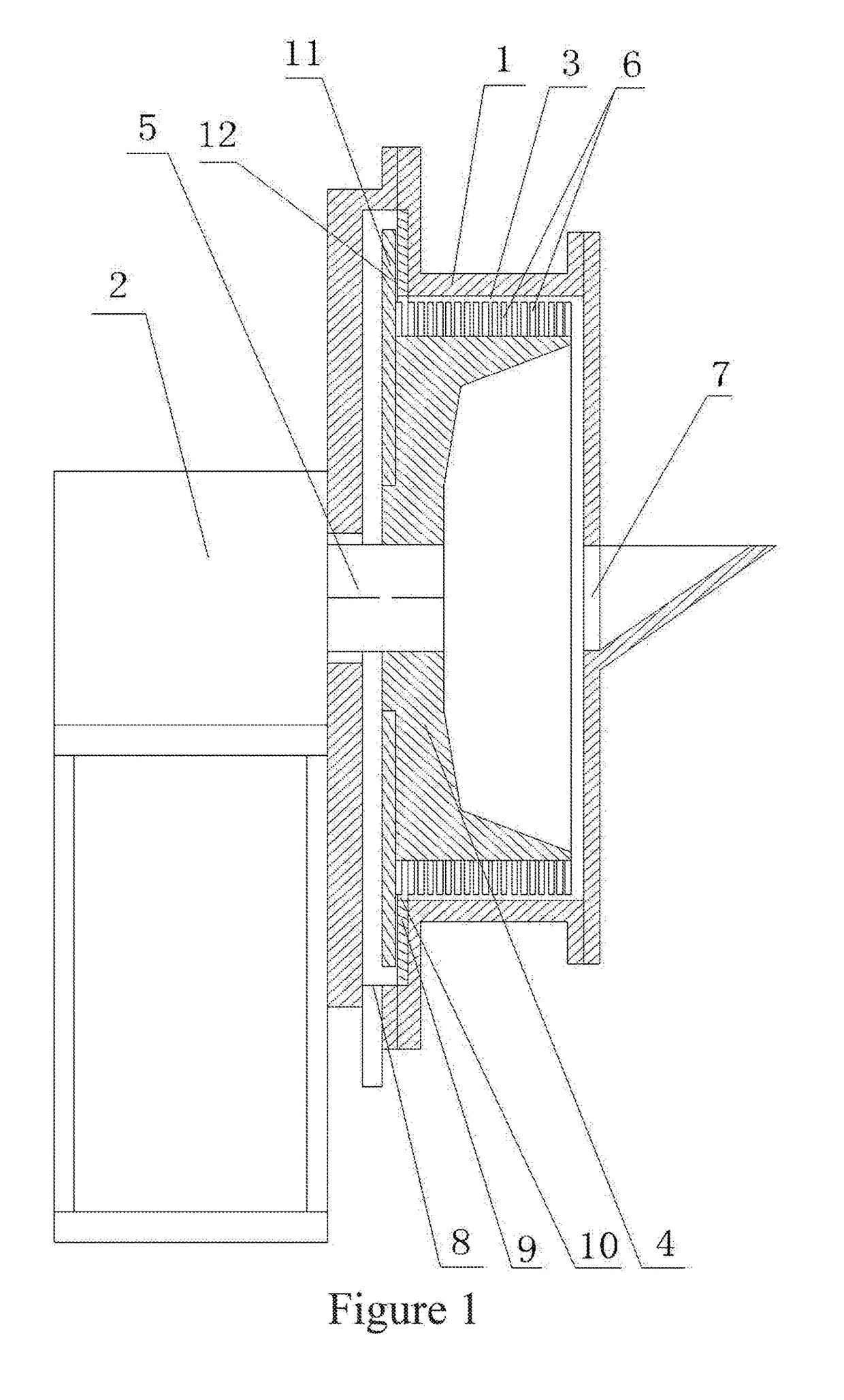

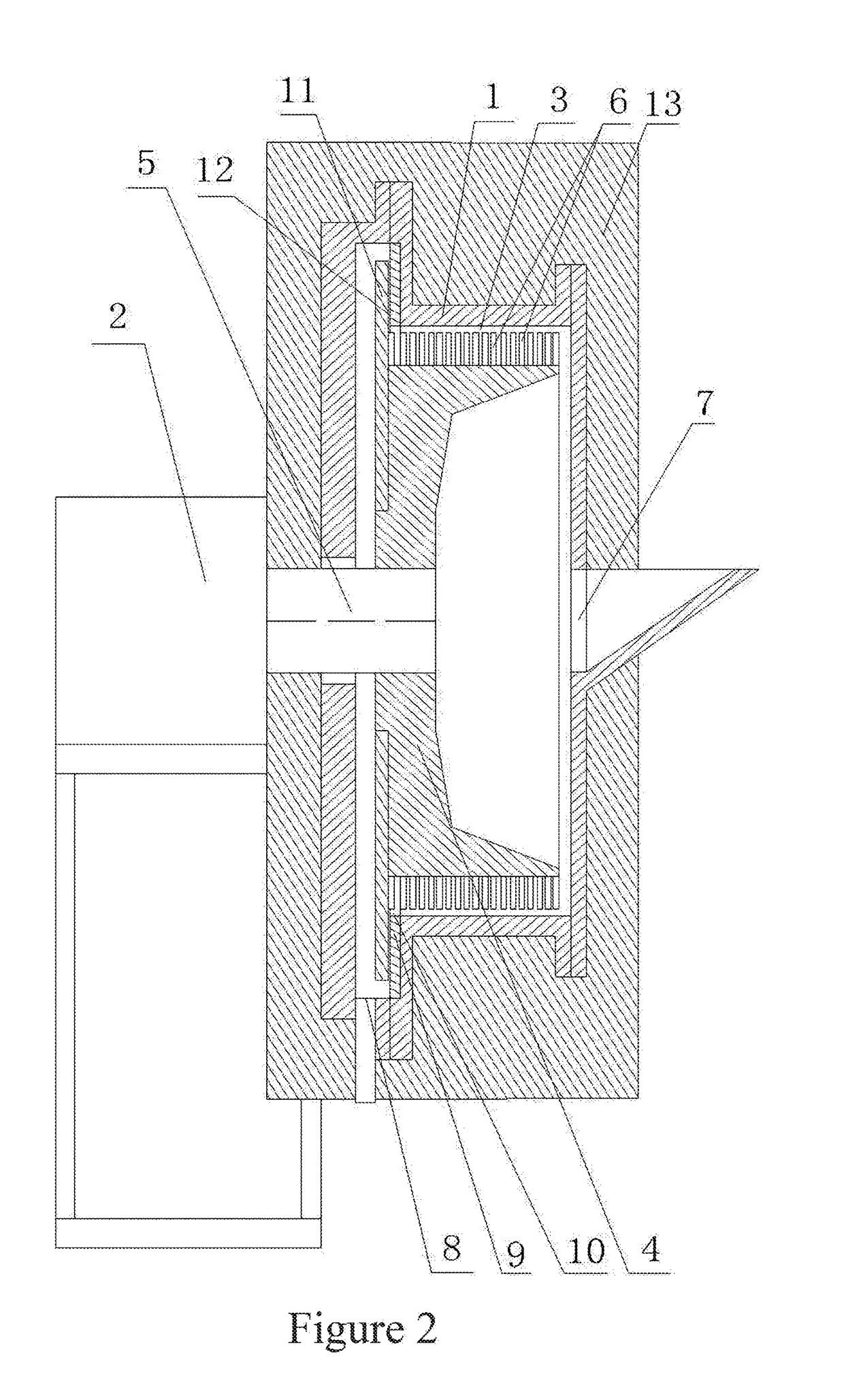

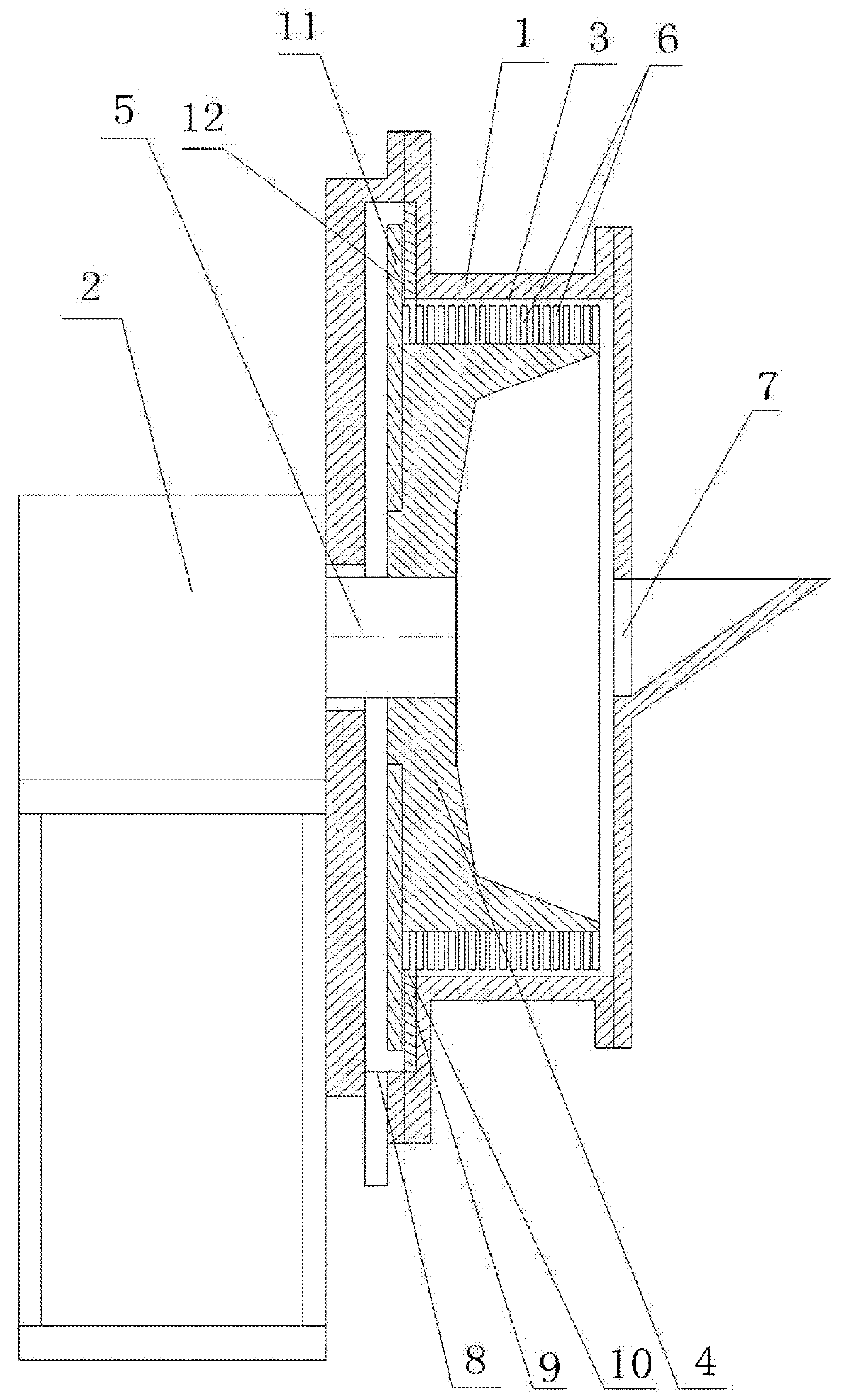

Foam material generator

InactiveUS20170312705A1Improve material performanceReduce resource usageRotary stirring mixersMixing methodsRotational axisDrive shaft

A foam material generator has a housing; transmission device on the housing; housing cavity within the housing; pressurizing stirring foaming wheel within the cavity; transmission device transmission shaft connected to the wheel; pressurizing stirrers on the wheel; pressurizing stirrer airflow-facing surface forms an inclined angle with a cross sectional surface in a wheel rotational axis direction; housing cavity inlet is on a cavity end, and a housing cavity outlet is on another end; encircling abrasive disc is on a cavity inner wall adjacent to the outlet; encircling abrasive disc inlet is at a encircling disc middle portion; vortex current abrasive foaming disc is on a wheel end adjacent to the encircling disc; vortex current abrasive foaming disc surface conforms to be in close proximity with an encircling disc surface; and vortex current abrasive foaming cavity is between the surfaces of the vortex current abrasive foam disc and encircling disc.

Owner:CHEN JIUBIN

Foam material generator

InactiveUS10040037B2High in strengthHigh in tenacityRotary stirring mixersMixing methodsRotational axisPower flow

Owner:CHEN JIUBIN

Boron and fluorine-free glass fiber composites

This invention discloses a kind of boron and fluorine-free fiberglass composite with its characteristic that it has the following compounds under particular mix ratio: SiO2, Al2O3, SiO2+Al2O3, CaO, MgO, TiO2, ZnO, Na2O+K2O and Fe2O3. The preferential process of this invention is: selection of mineral→grinding of mineral→compounding as per ratio→melting in furnace→outflow from platinum bushing→fiberizing→coating of infiltrating liquid→protofilament drying. Compared with the traditional E fiberglass, the composite of this invention has better mechanical performance (tensile strength increased by over 15% and elastic modulus increased by over 5%) and better corrosion resistance (resistance of acid and alkali increased by 20 times); its forming temperature (<1280° C.) and forming range (>80° C.) are proper with good fiberizing performance, which can be produced in large scale.

Owner:CHONGQING POLYCOMP INT

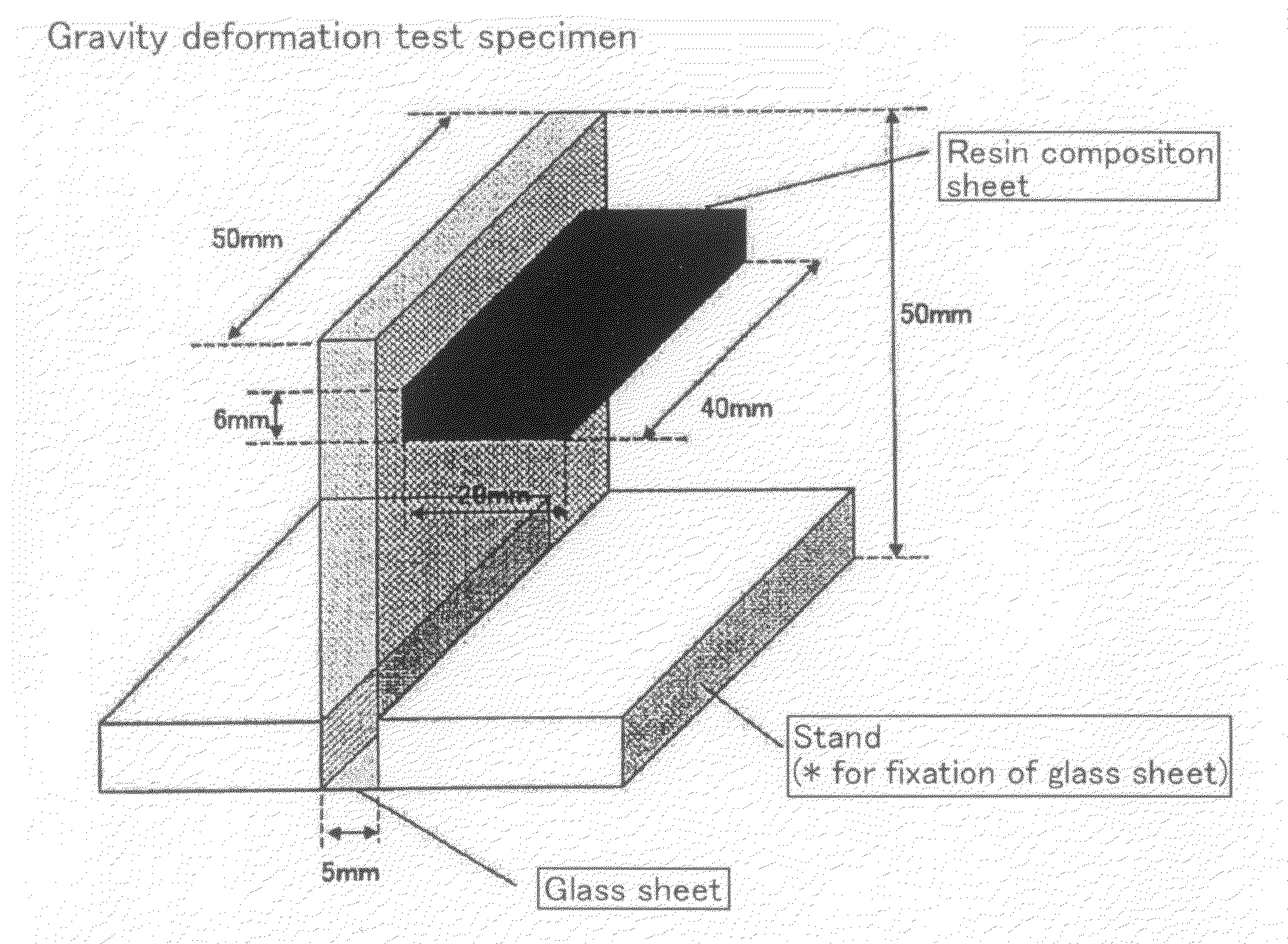

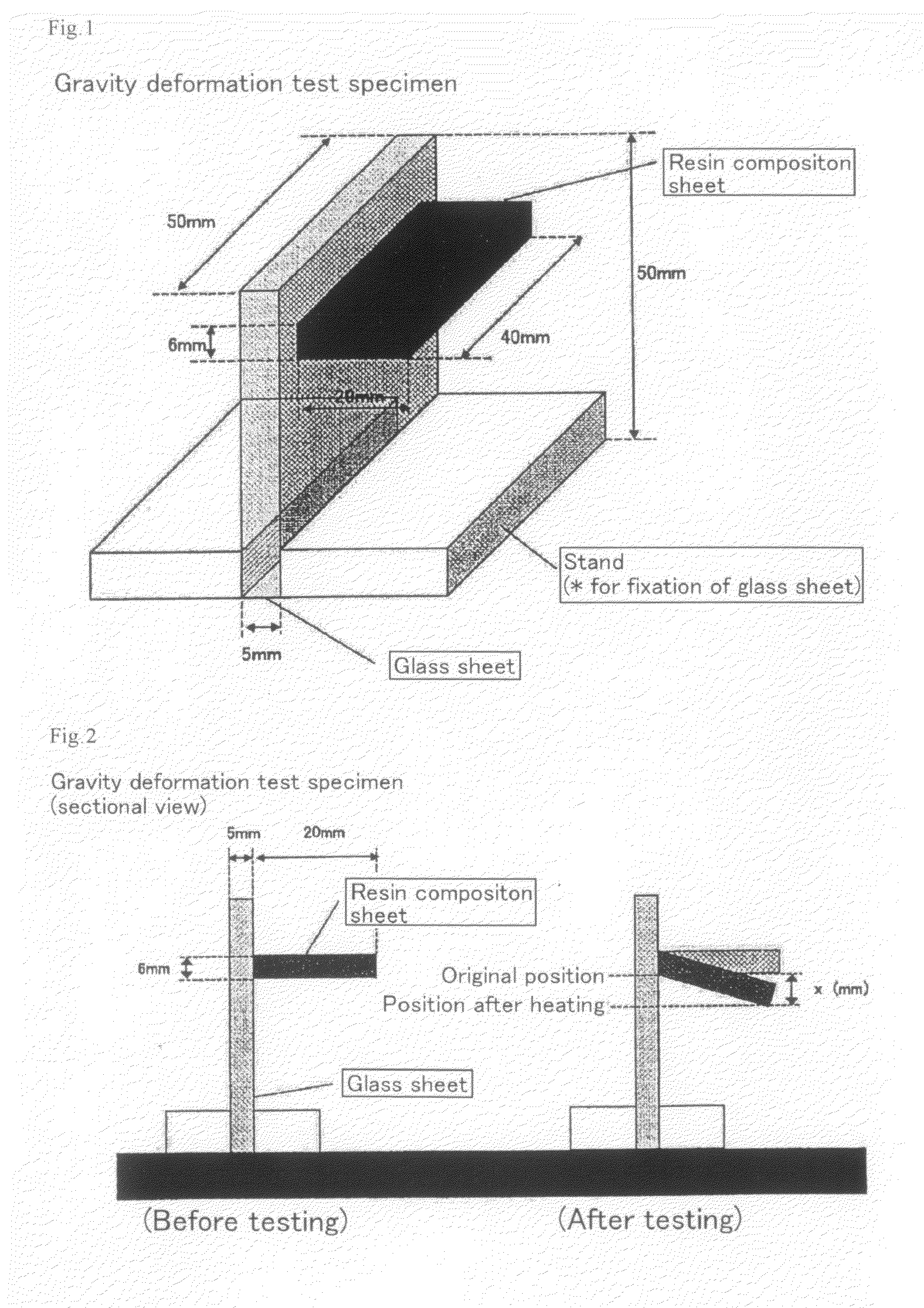

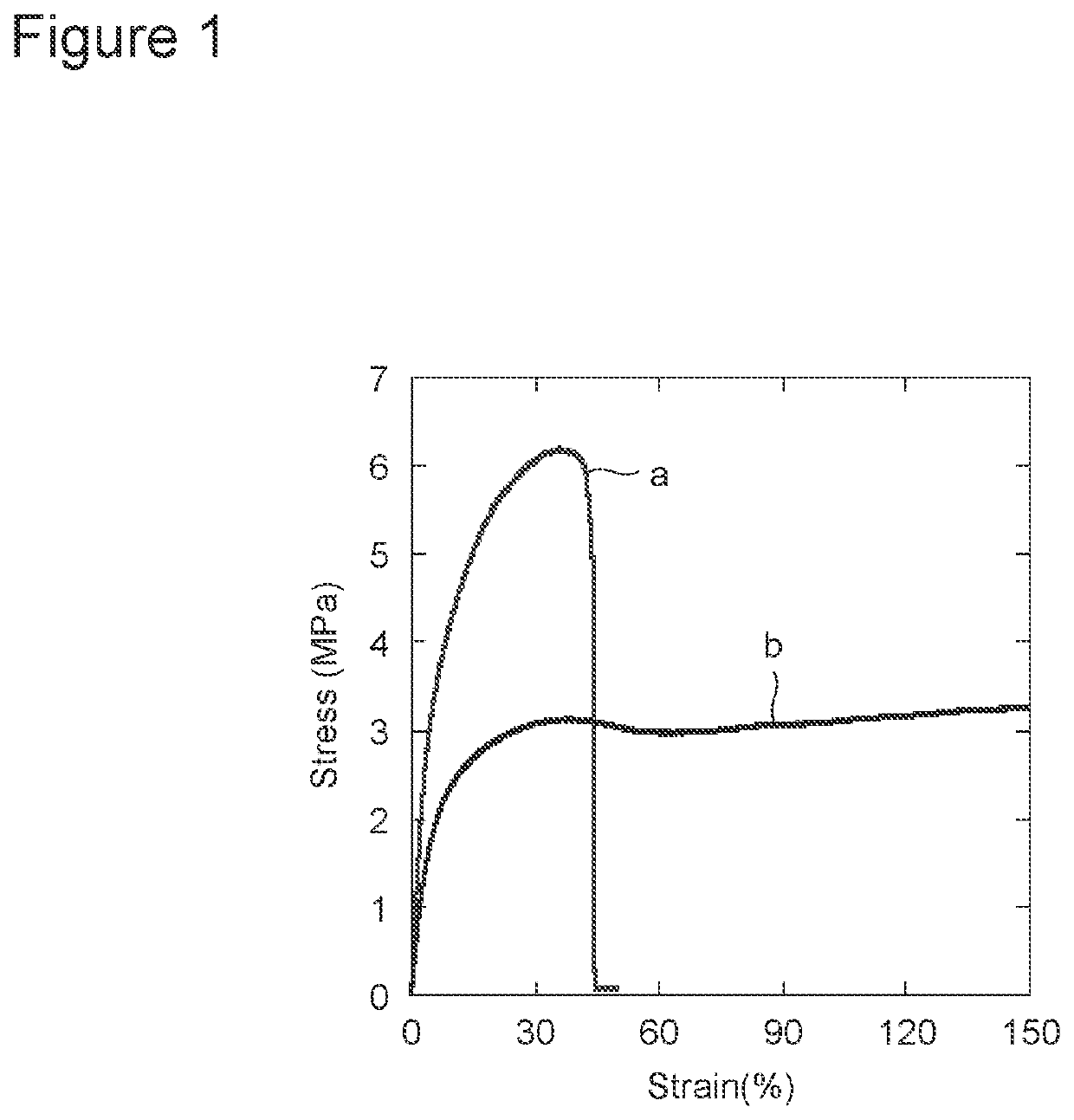

Resin Composition

InactiveUS20090043030A1Increase elasticityHigh in mechanical strengthOther chemical processesFilm/foil adhesivesThermoplastic elastomerAliphatic hydrocarbon

The present invention has its object to provide a resin composition excellent in mechanical strength and elasticity and further showing only a slight extent of gravity deformation under high temperature conditions. The invention relates to a resin composition which comprises an isobutylene-based polymer (A), an aromatic vinyl-based thermoplastic elastomer (B) comprising a polymer block (b1) the constituent monomer(s) of which is(are) an aromatic vinyl compound(s) and a polymer block (b2) the constituent monomer(s) of which is(are) an aliphatic hydrocarbon compound(s) other than isobutylene, and a filler (C). This composition can be suitably used as, for example, a sealant, in particular as a hot melt sealant for double glazing units, and as a hot melt spacer material for double glazing units.

Owner:KANEKA CORP

High-strength, high-permeability steel sheet for picture tube band and method of producing the same

InactiveUS7501029B2High yield stressImprove stabilityHot-dipping/immersion processesInorganic material magnetismSheet steelChemical composition

Owner:NISSHIN STEEL CO LTD

Nitriding process method of steel member

ActiveUS10385439B2Increase resistanceHigh in strengthSolid state diffusion coatingFurnace typesUltimate tensile strengthAtmosphere

Owner:DOWA THERMOTECH +1

Resin molded article

InactiveUS8393425B2High in strengthImprove rigidityLayered productsDomestic articlesFiberCarbon fibers

Owner:CALSONIC KANSEI CORP

Preparation method of ceramic membrane support

A preparation method of a ceramic membrane support is disclosed. Take aluminum hydroxide, produced through a carbon decomposing process by a sintering method, as a raw material, pre-sinter the aluminum hydroxide, and obtain a low-temperature alumina product A; add a first amount of mineralizer into the product A, grind after calcining the added product A, and obtain a α-alumina product B; mix the product B with Al2O3.nH2O, calcine after adding a second amount of mineralizer into the mixed product B, and obtain a α-alumina product C; grind, scatter and grade the calcined and heat-preserved α-alumina product C, and obtain polyhedral alumina powders; mix the polyhedral alumina powders, water, humectant and dispersant and then sinter, and finally obtain the porous alumina support. The prepared support is easy to be sintered, is high in alumina purity, is good in corrosion resistance, and is improved in porosity and flux.

Owner:SHANDONG GUIYUAN ADVANCED CERAMICS

Heat-curable epoxy resin composition for optical semiconductor element encapsulation and optical semiconductor device using same

A heat-curable epoxy resin composition for optical semiconductor element encapsulation capable of being pressure molded and transfer molded under room temperature, comprising:(A) a prepolymer obtained by reacting at least one component of (A-1), (A-2) and (A-3); and (A-4),(A-1) a triazine derivative epoxy resin having not less than three epoxy groups in one molecule,(A-2) at least one epoxy resin that is non-fluid at 25° C. and selected from the group consisting of a bisphenol-type epoxy resin, a hydrogenated bisphenol-type epoxy resin, an alicyclic epoxy resin and monoalkyl diglycidyl isocyanurate,(A-3) a cyclic siloxane compound having not less than two epoxy groups in one molecule, and(A-4) an acid anhydride curing agent in a liquid state at 25° C.;(A′) a component(s) among (A-1) to (A-3) that is / are not used in said prepolymer (A); and(B) a curing accelerator.

Owner:SHIN ETSU CHEM CO LTD

Fiber-reinforced composite material and method for producing the same

PendingUS20220127768A1High strength , elastic modulus and elongation propertyHigh modulusMonocomponent protein artificial filamentNon-woven fabricsElastic modulusFiber-reinforced composite

An object of the present invention is to develop and provide a fiber-reinforced composite material having a bagworm silk thread(s) as a reinforcing fiber and being isotropic in terms of elastic modulus and strength. A fiber-reinforced composite material having nonwoven fabric(s) including bagworm silk thread as a reinforcing fiber is also provided.

Owner:NAT AGRI & FOOD RES ORG +1

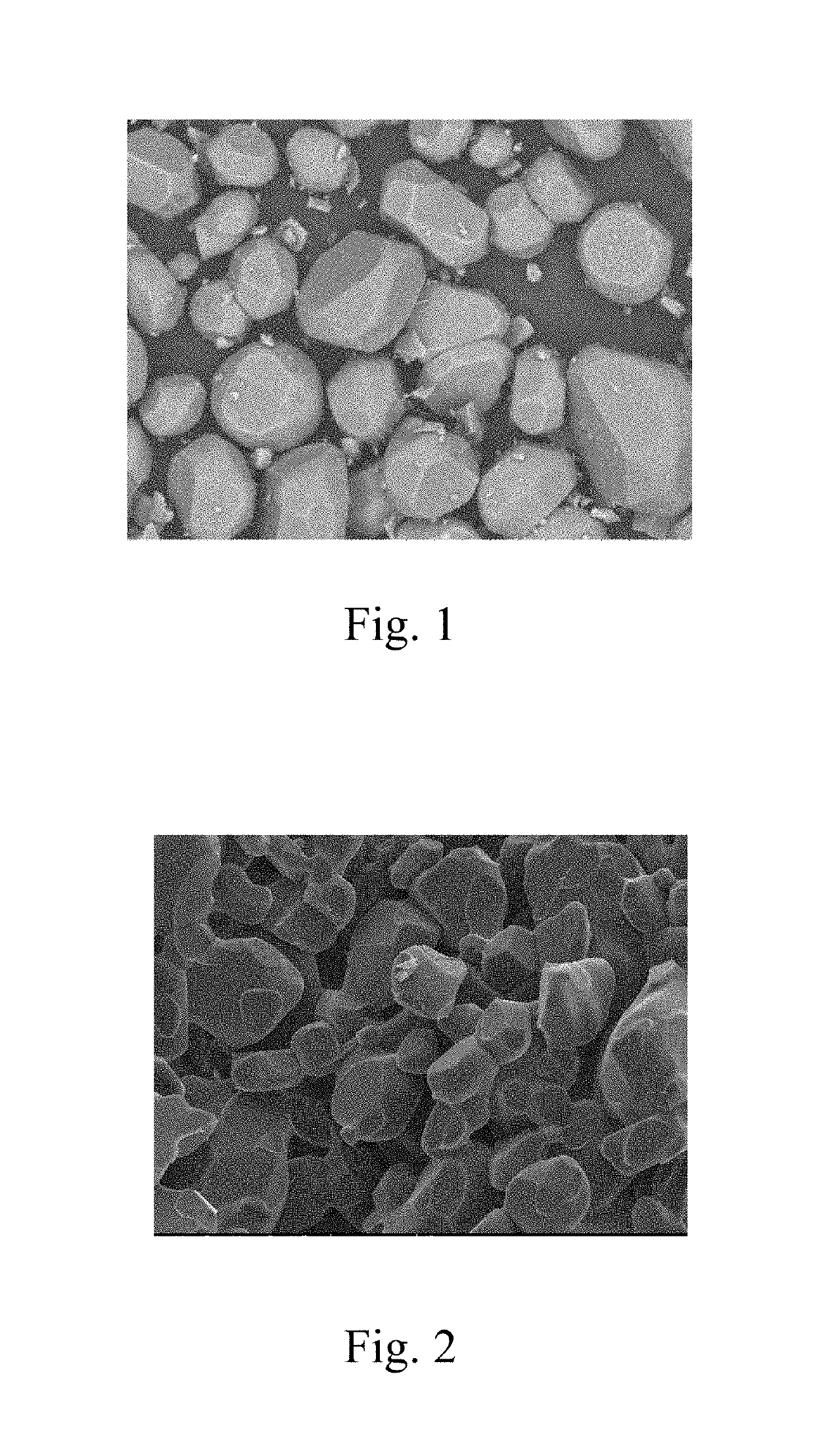

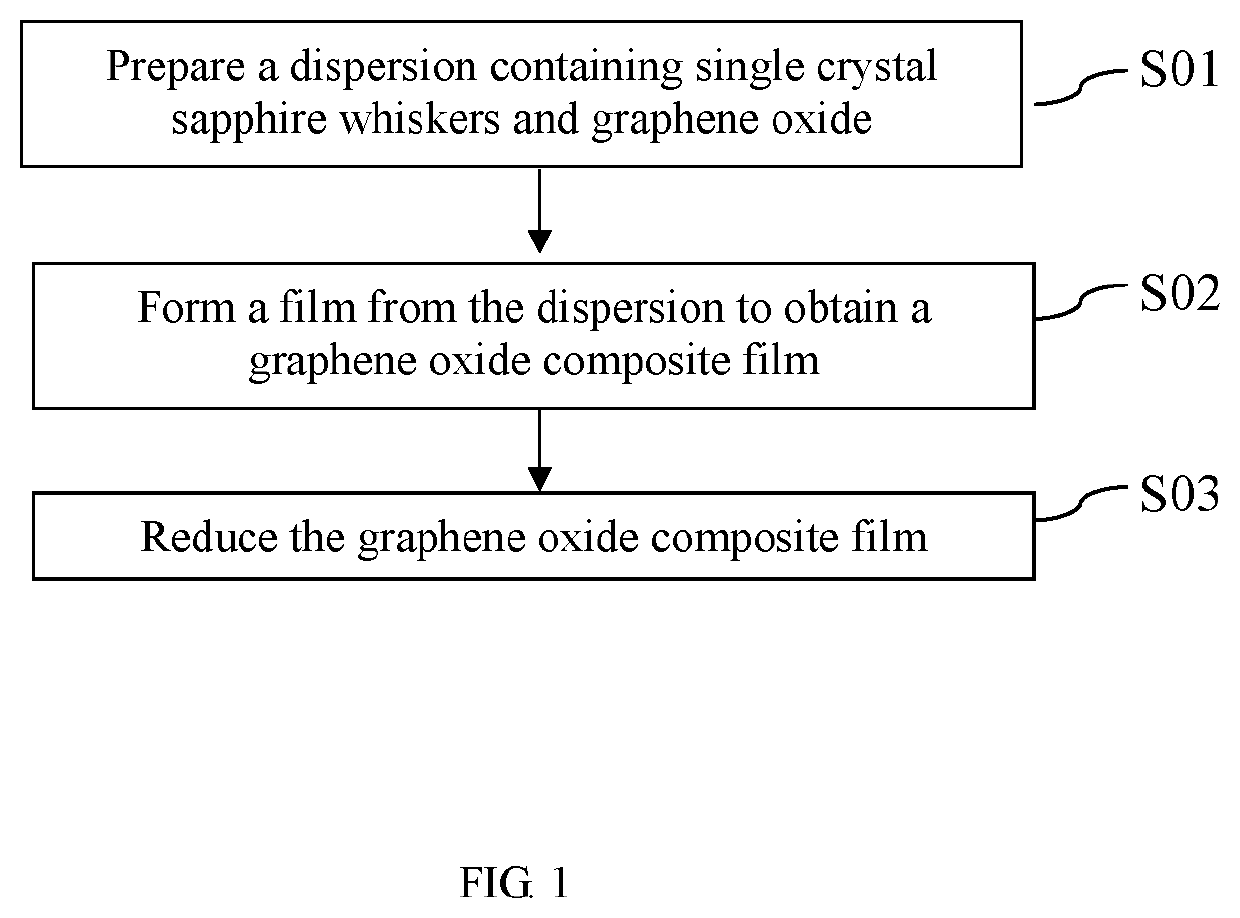

Graphene composite film modified by single crystal sapphire whiskers as well as preparation method and application thereof

InactiveUS20200052324A1Increase thermal resistanceImprove toughnessHybrid capacitor electrodesElectrode carriers/collectorsComposite filmInternal resistance

The invention discloses a graphene composite film modified by single crystal sapphire whiskers as well as a preparation method and application thereof. The graphene composite film provided by the invention comprises graphene and single crystal sapphire whiskers, the single crystal sapphire whiskers and the graphene are dispersed in the graphene composite film, and the content by weight of the graphene is greater than that of the single crystal sapphire whiskers. The graphene composite film can be used to prepare an electrode and applied to lithium ion batteries and capacitors. The graphene composite film has excellent toughness, structural stability and folding resistance as well as excellent electroconductivity and thermoconductivity; and the preparation method thereof is good in reproducibility and low in cost. The electrode has stable structure, low internal resistance, and excellent electroconductivity, thermoconductivity, cycle performance and rate performance during usage as well as charging and discharging.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Liquid crystalline polyester fiber and process for production of the same

ActiveUS8673174B2High modulusHigh in strengthLiquid crystal compositionsOptical articlesLiquid crystallinePolyester

A liquid crystalline polyester fiber which exhibits a half width of endothermic peak (Tm1) of 15° C. or above as observed in differential calorimetry under heating from 50° C. at a temperature elevation rate of 20° C. / min and a strength of 12.0 cN / dtex or more; and a process for production of the same. A liquid crystalline polyester fiber which is excellent in abrasion resistance and lengthwise uniformity and is improved in weavability and quality of fabric and which is characterized by a small single-fiber fineness can be efficiently produced without impairing the characteristics inherent in fabric made of liquid crystalline polyester fiber produced by solid phase polymerization, namely, high strength, high elastic modulus and excellent thermal resistance.

Owner:TORAY IND INC

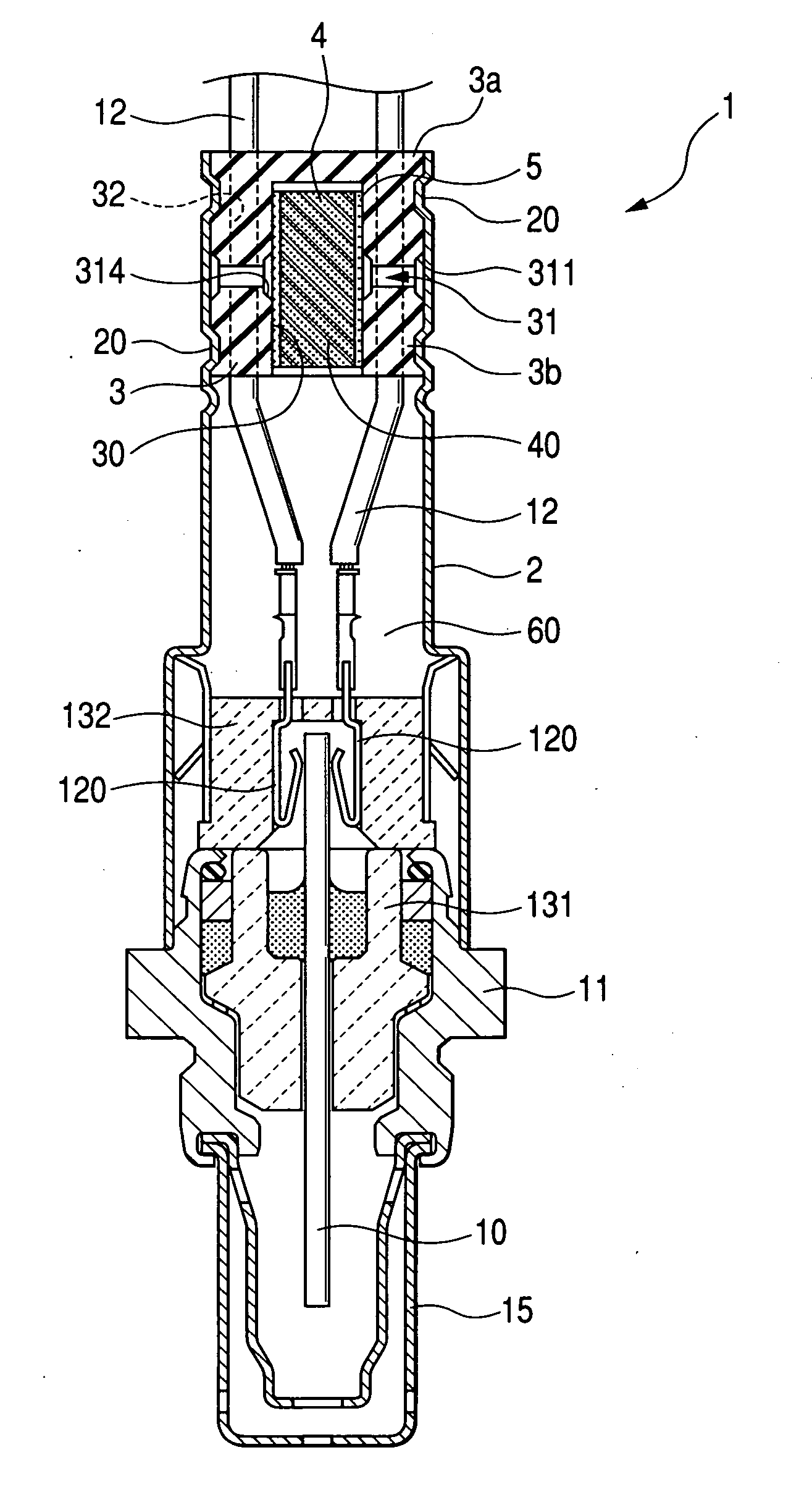

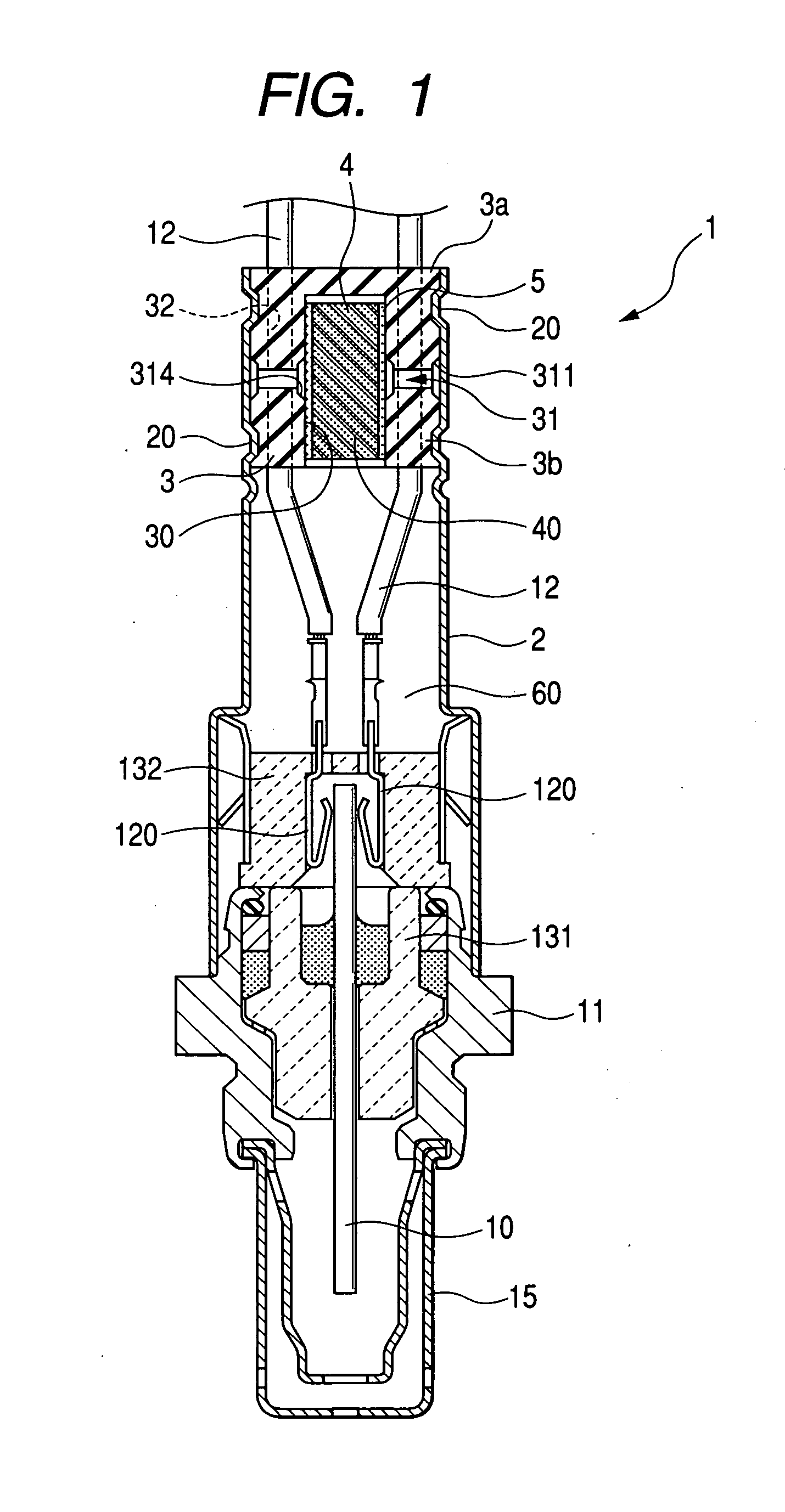

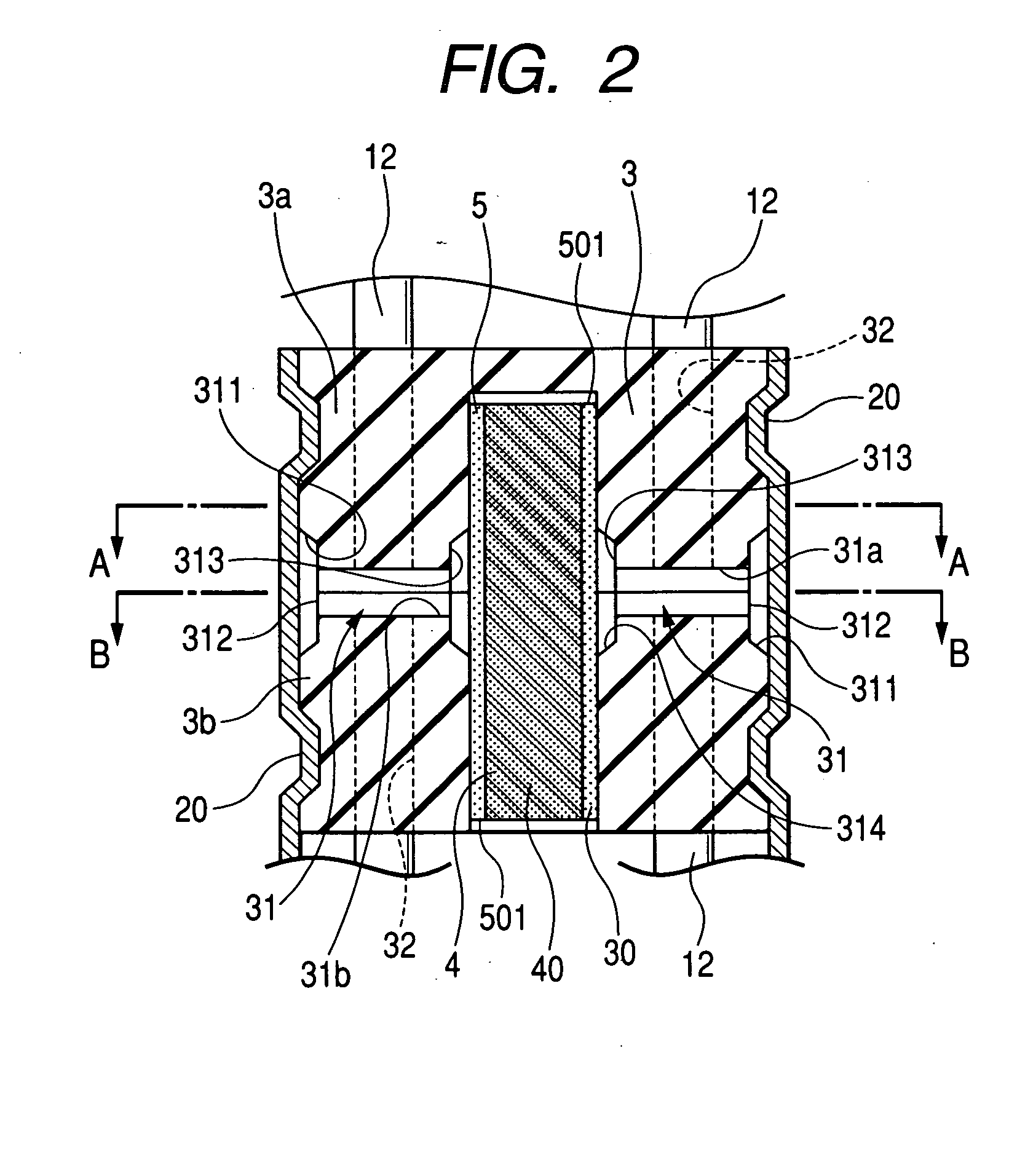

Gas sensor designed to ensure stability of waterproofing of air flow path

InactiveUS20090071825A1Improve productivitySimple structureMaterial electrochemical variablesElectricityMetallic Lead

A gas sensor equipped with an elastic member which is disposed hermetically in an open end of an air cover joined to a housing. The elastic member has a vertical hole, an air flow path, and lead-retaining holes through which leads pass to establish electric connections between a sensing device and an external device. The air flow path extends from the vertical hole to an outer peripheral surface of the elastic member to direct air having entered at air inlets to the vertical hole. An assembly of an air-permeable filter and a support is fit elastically in the vertical hole of the elastic member, thereby asserting the stability of adhesion between the vertical hole and the filter even if the filter is thermally deteriorated to ensure the waterproofing of the gas sensor.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com