Patents

Literature

736results about How to "Realize blocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plugging bearing material for petroleum drilling, and preparation method and application thereof

ActiveCN102061151ASuitable for lipophilic and hydrophilic propertiesGuaranteed preparationDrilling compositionSealing/packingHigh fracturePetroleum

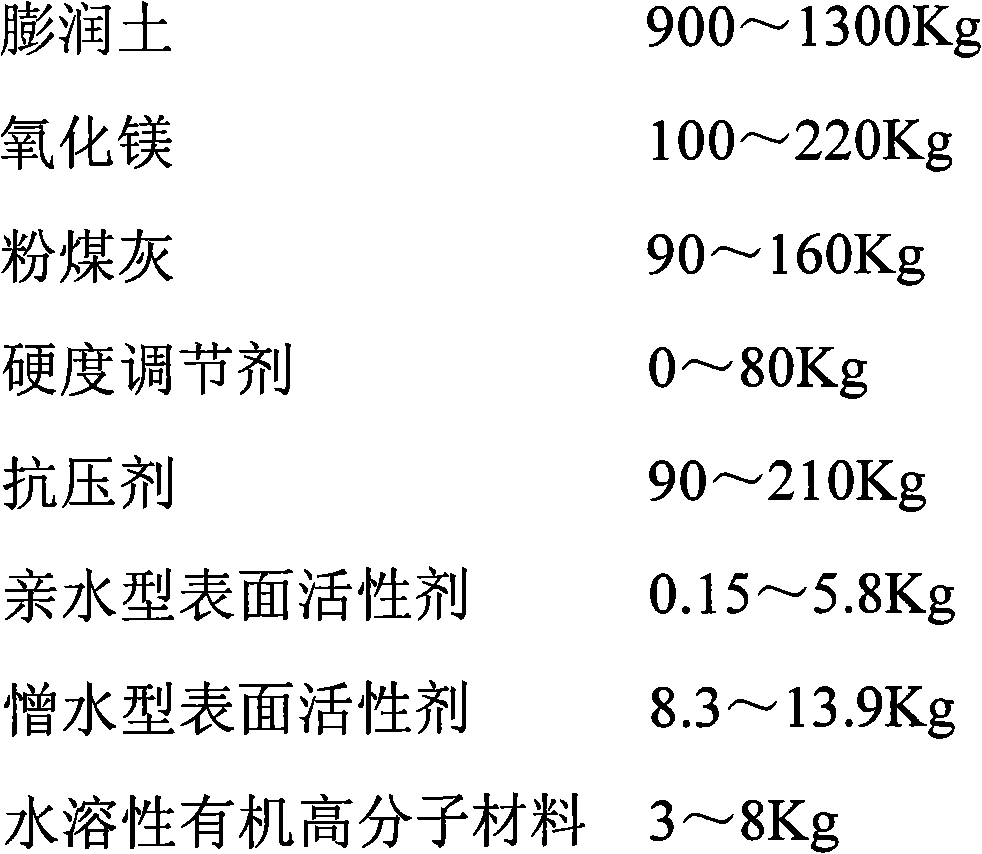

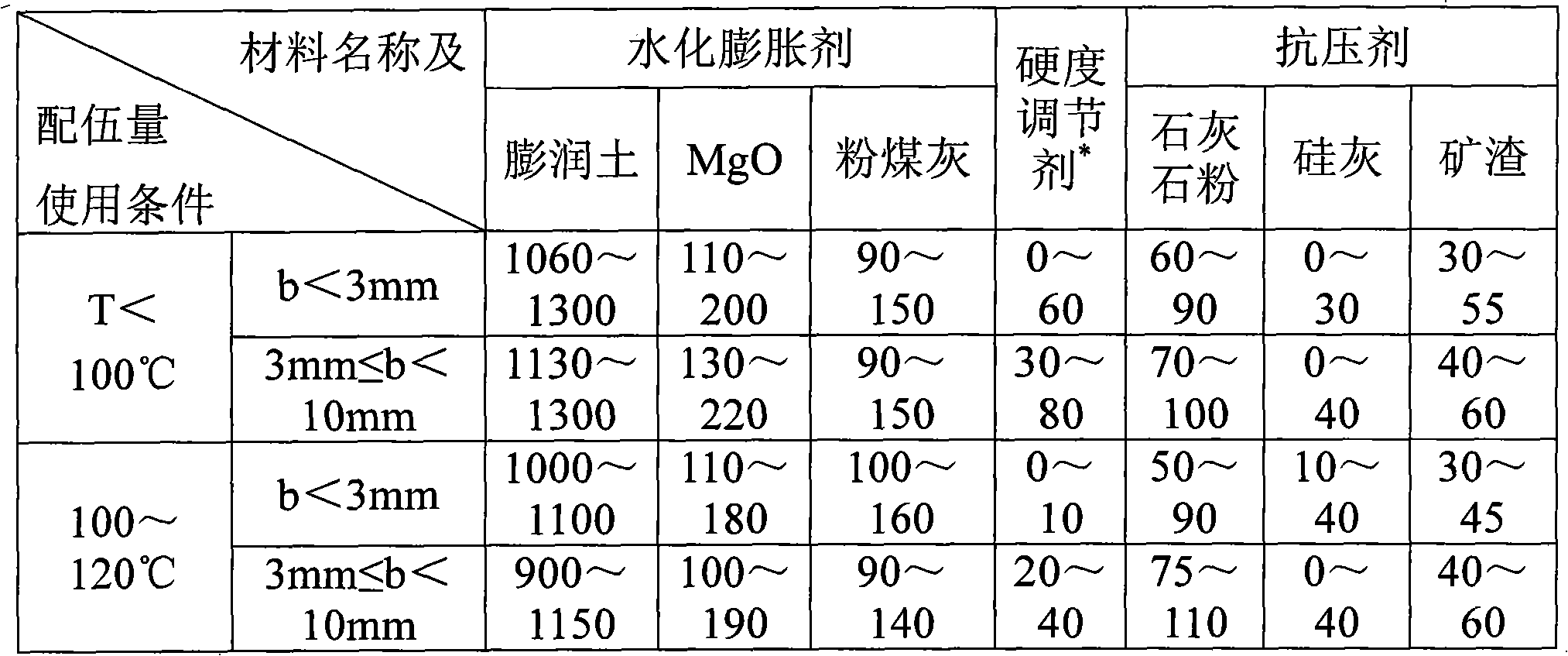

The invention provides a plugging bearing material for petroleum drilling, and a preparation method and application thereof. The plugging bearing material comprises the following components: 900 to 1,200 kilograms of bentonite, 100 to 220 kilograms of magnesium oxide, 90 to 160 kilograms of fly ash, 0 to 80 kilograms of hardness regulator, 90 to 210 kilograms of compression resisting agent, 0.15 to 5.8 kilograms of hydrophilic surfactant, 8.3 to 13.0 kilograms of hydrophobic surfactant and 3 to 8 kilograms of water-soluble organic high polymer material. A plugging material formed by the plugging bearing material has high fracture plugging capability, and a plugging belt formed by the plugging bearing material plays a certain stable role in fracturing rocks. The plugging bearing material, and the preparation method and the application thereof are suitable for processing formation leakage of various forms.

Owner:CHINA PETROLEUM & CHEM CORP +1

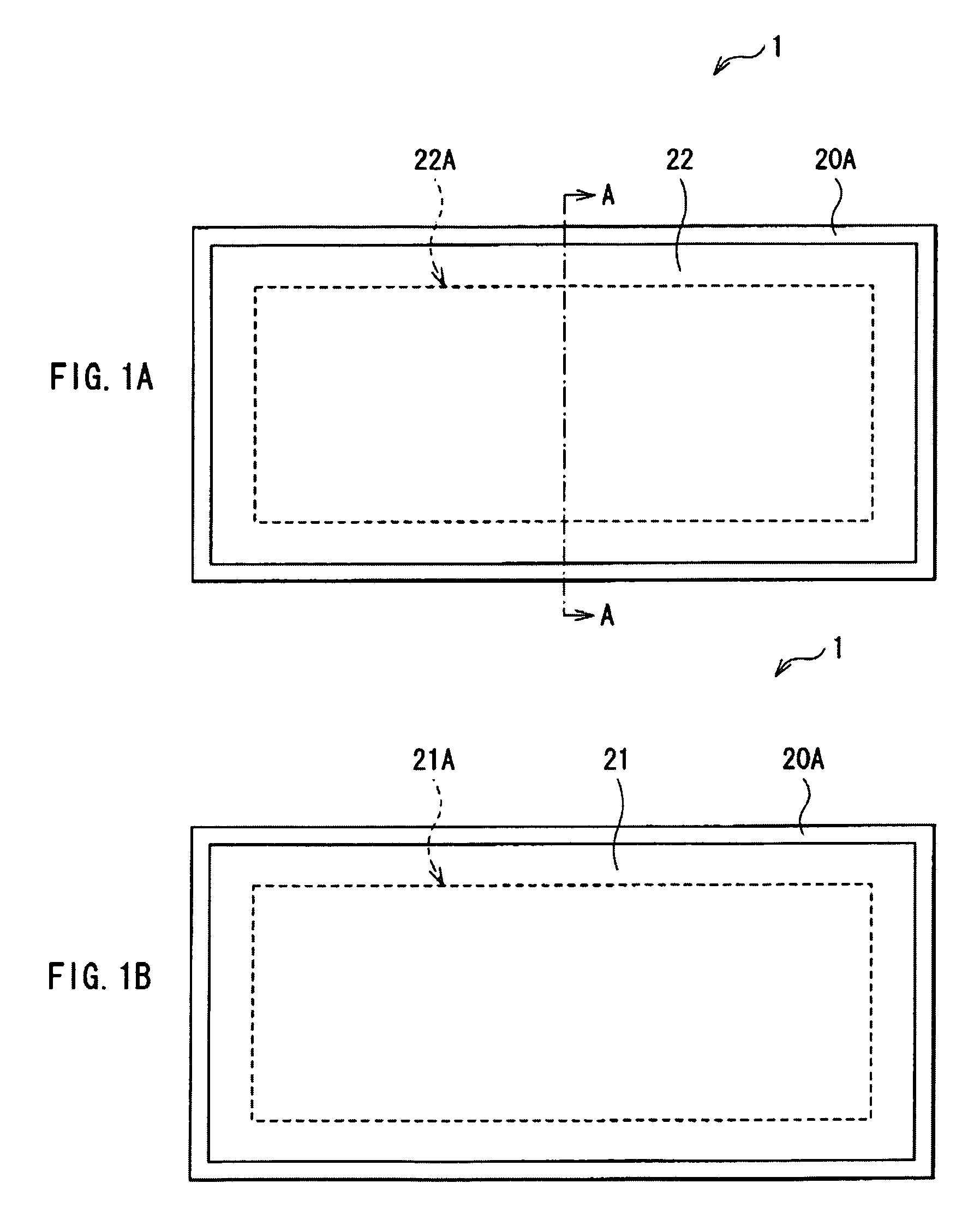

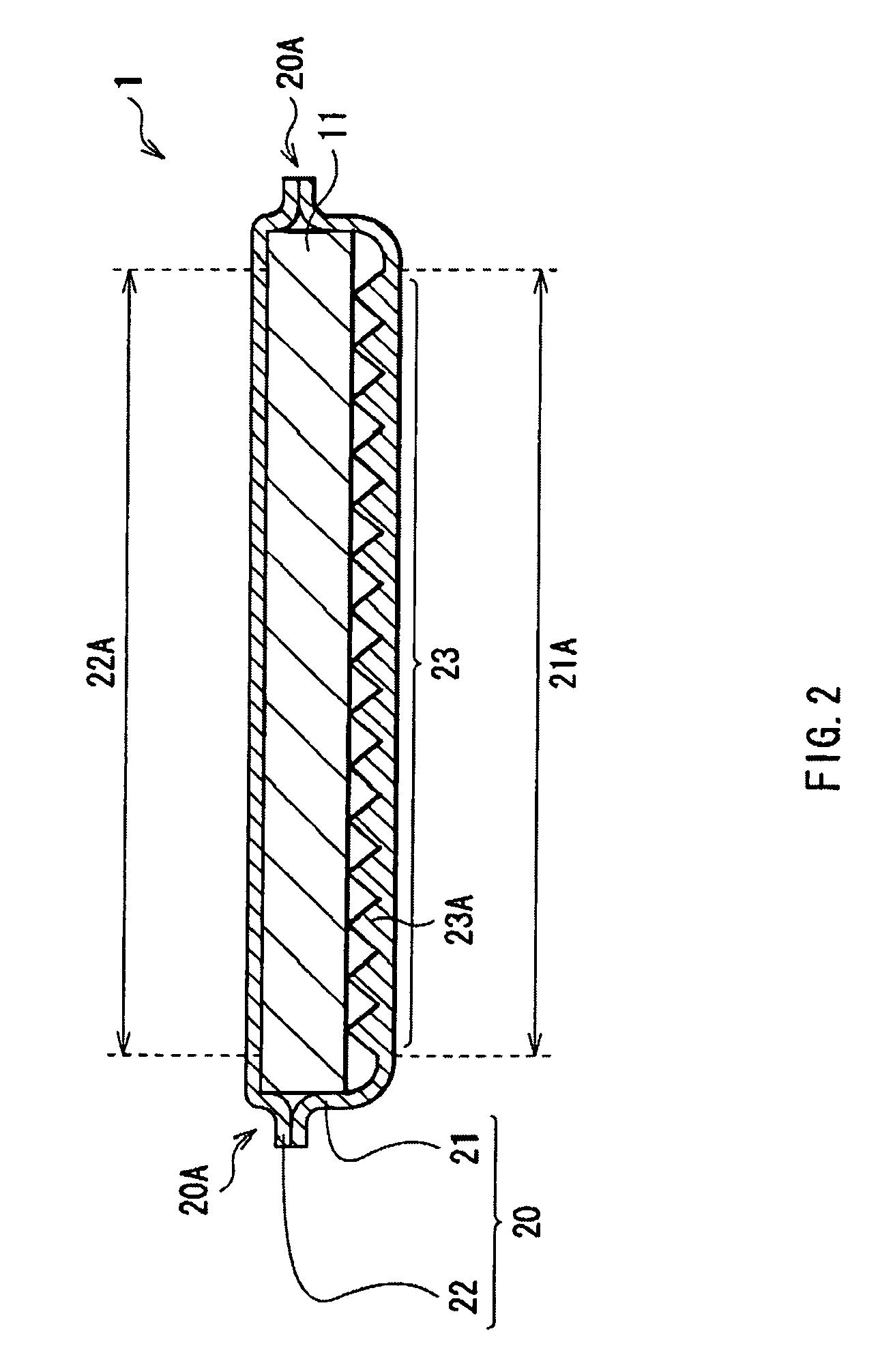

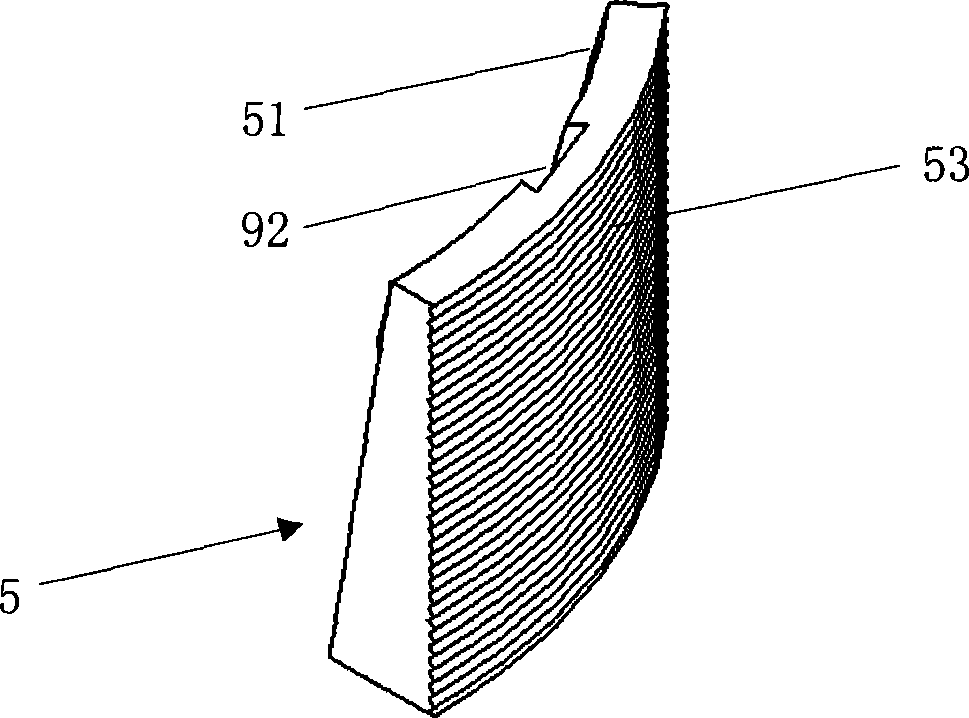

Optical element package

InactiveUS20080205066A1Improve wrinklesIncrease deflectionWrappers shrinkageLamination ancillary operationsPhysicsLight source

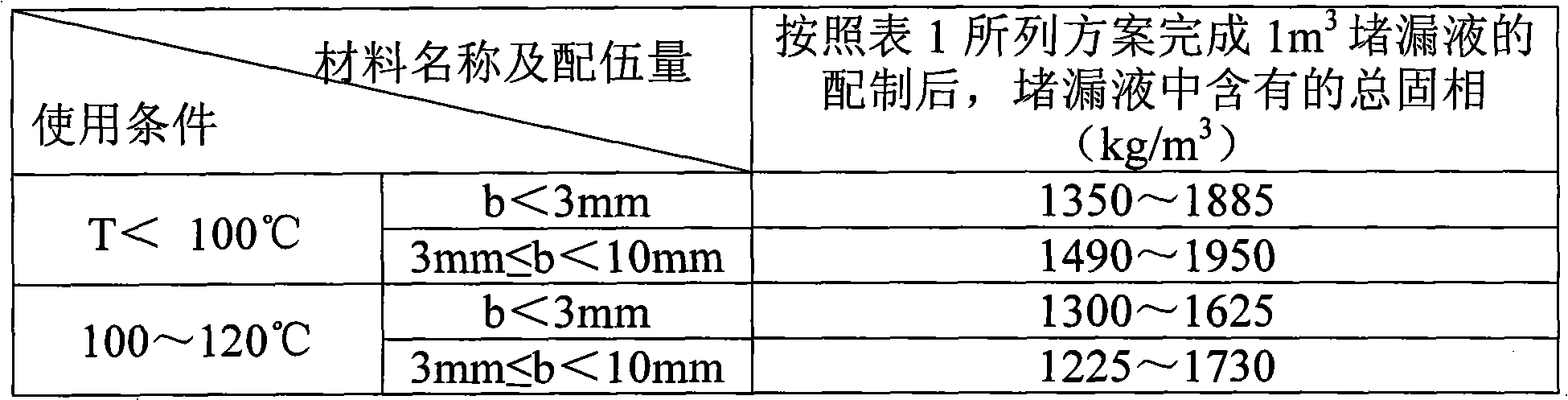

An optical packaged body capable of preventing generation of a wrinkle, deflection, and warpage, capable of being thinned is provided. The optical package body includes a support medium and a packaging film that covers the support medium in a state of being applied with shrinkage force. The packaging film has an optical function section that acts on light from a light source in at least one of a first region into which the light from the light source enters and a second region from which the light from the light source is emitted after passing through the optical packaged body when the light source is arranged on one face side of the optical packaged body.

Owner:SONY CORP

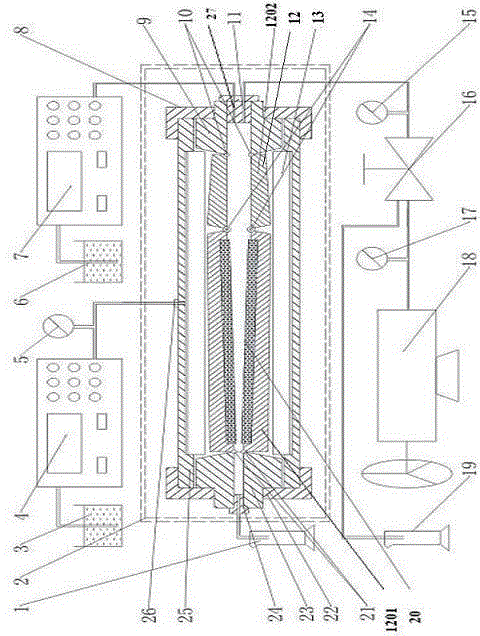

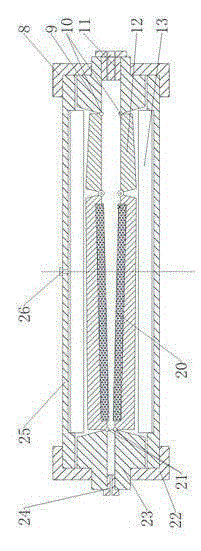

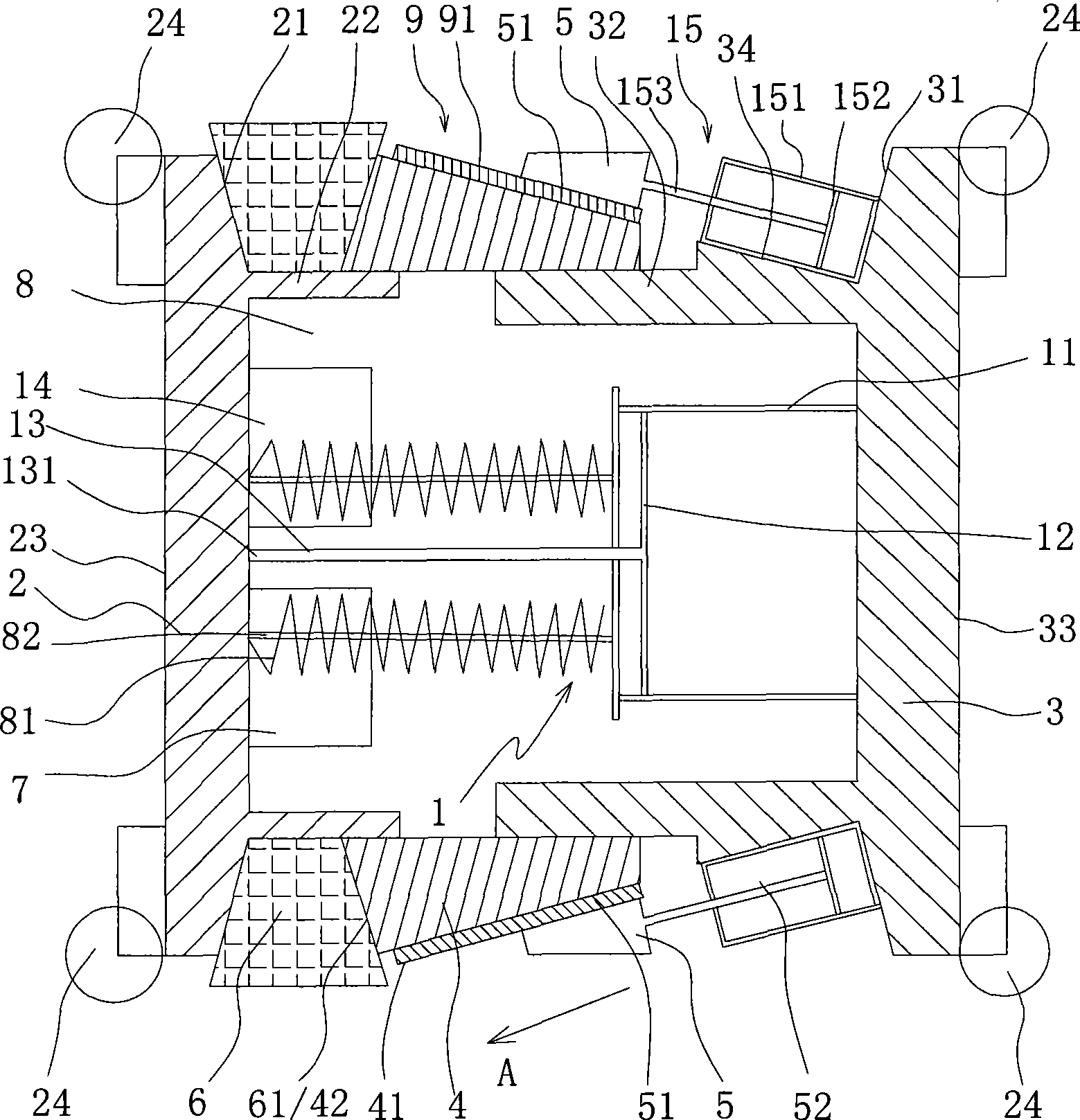

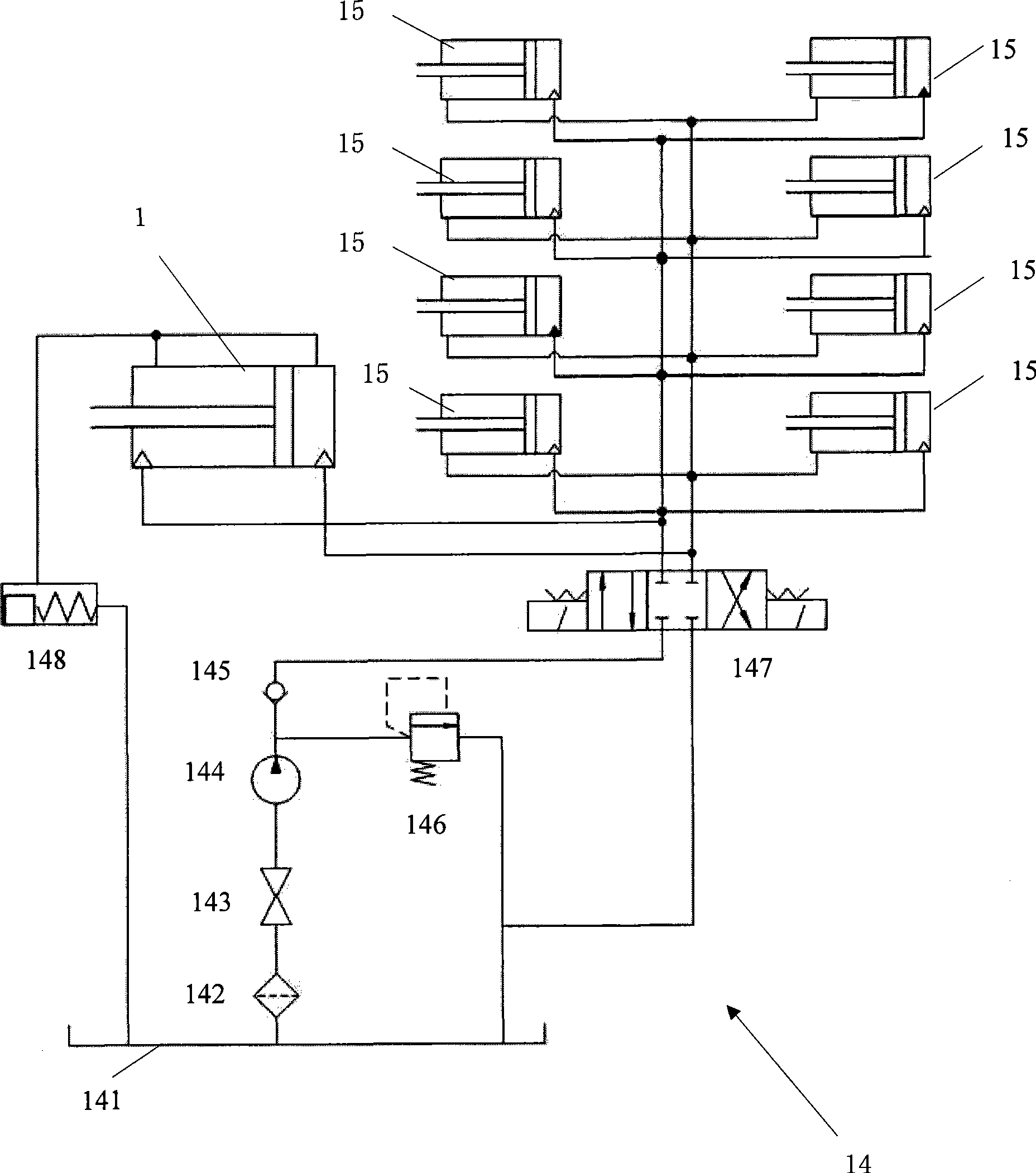

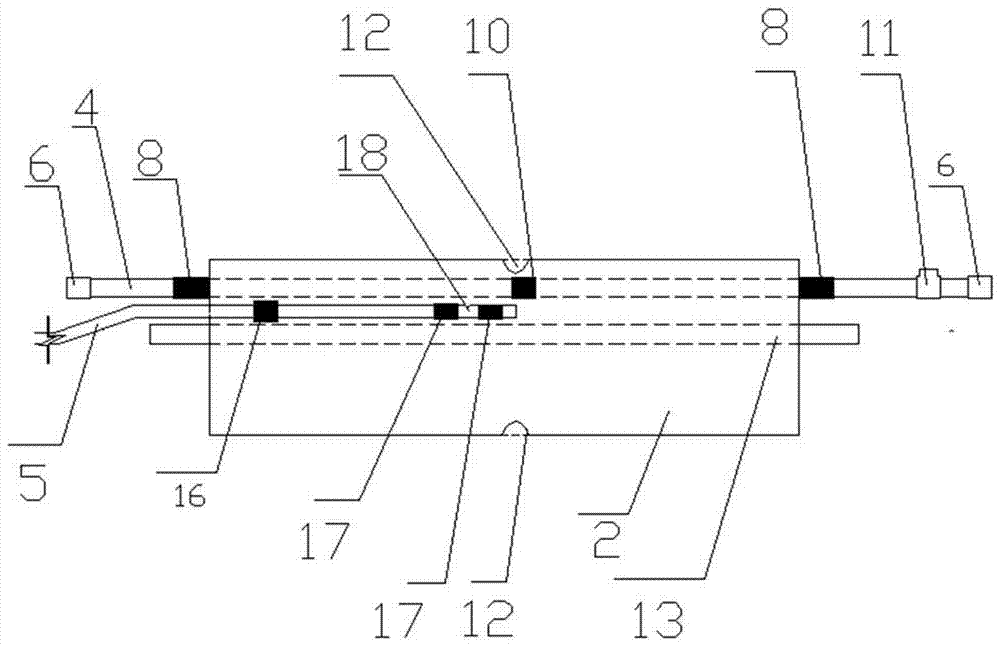

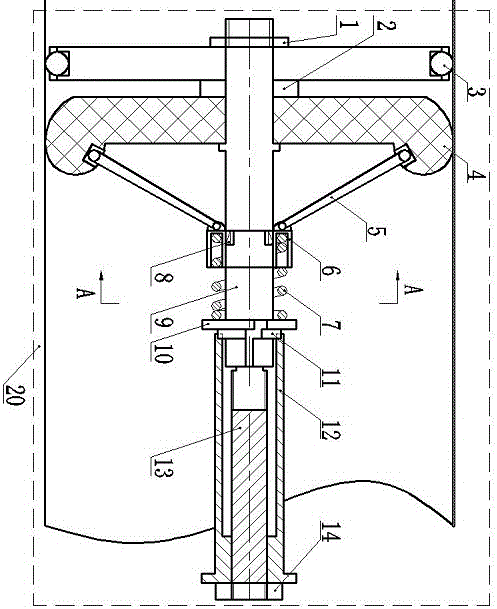

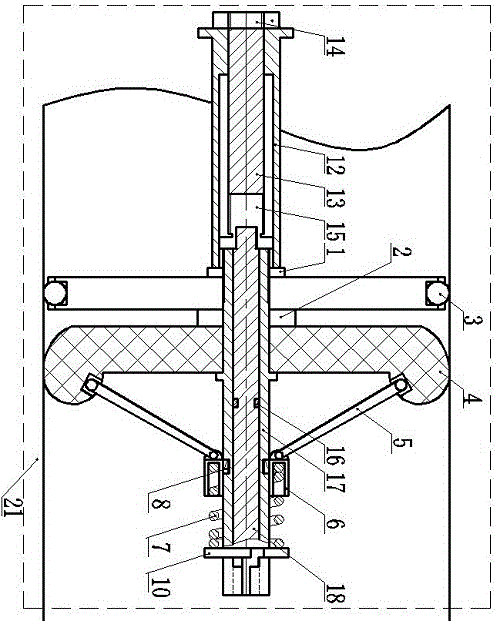

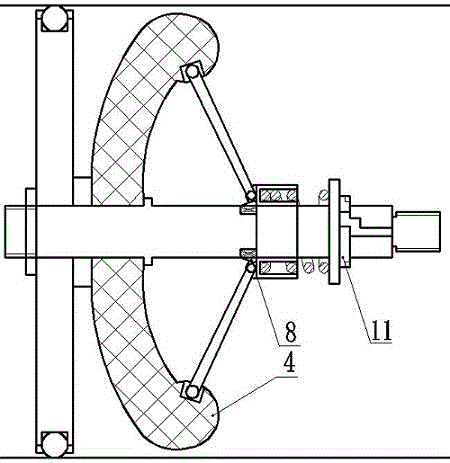

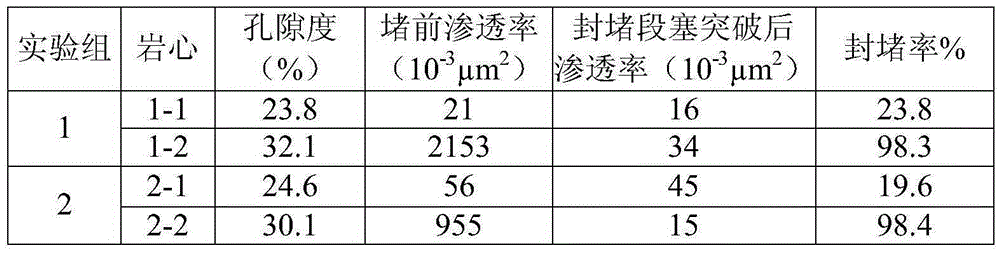

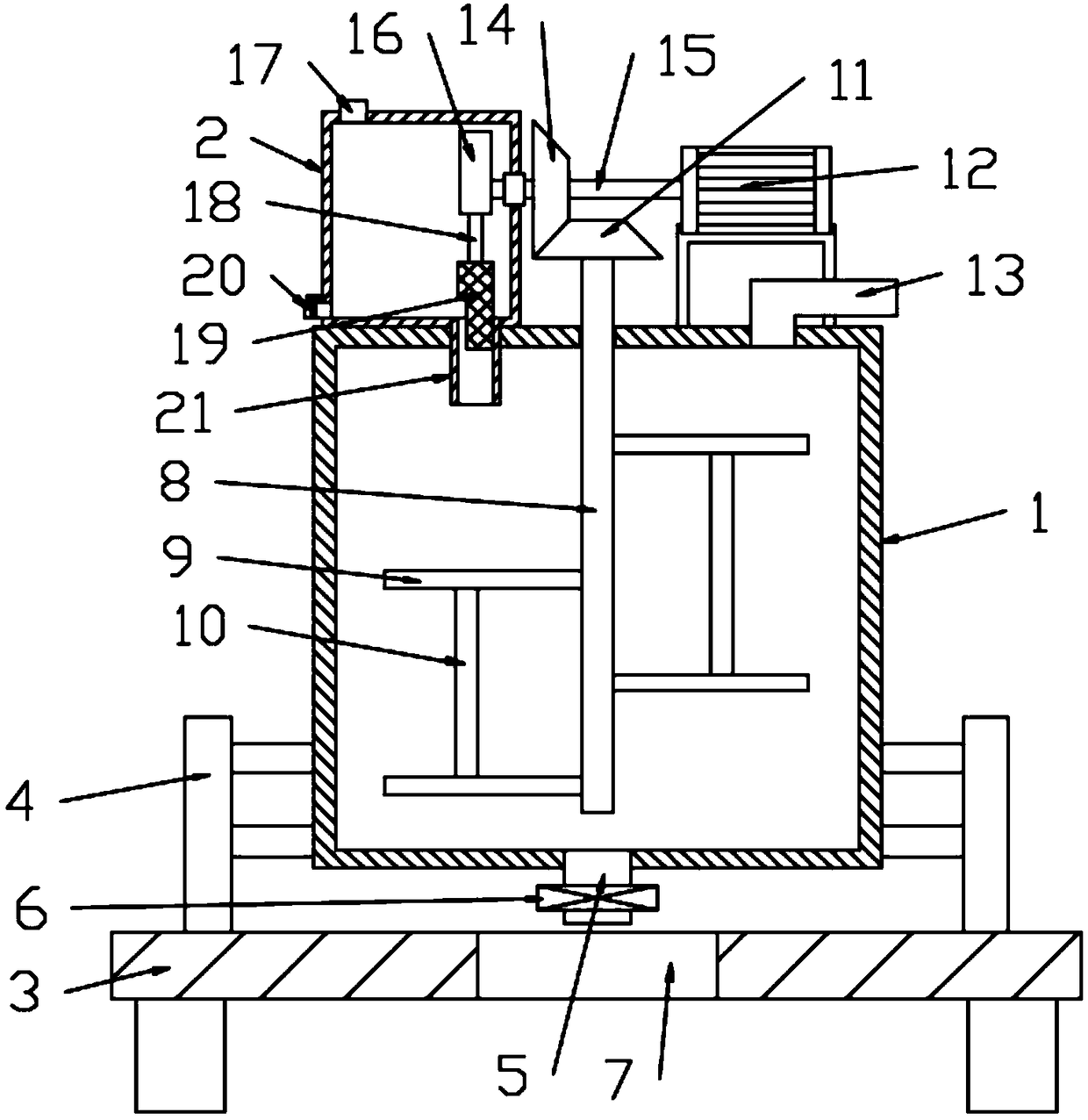

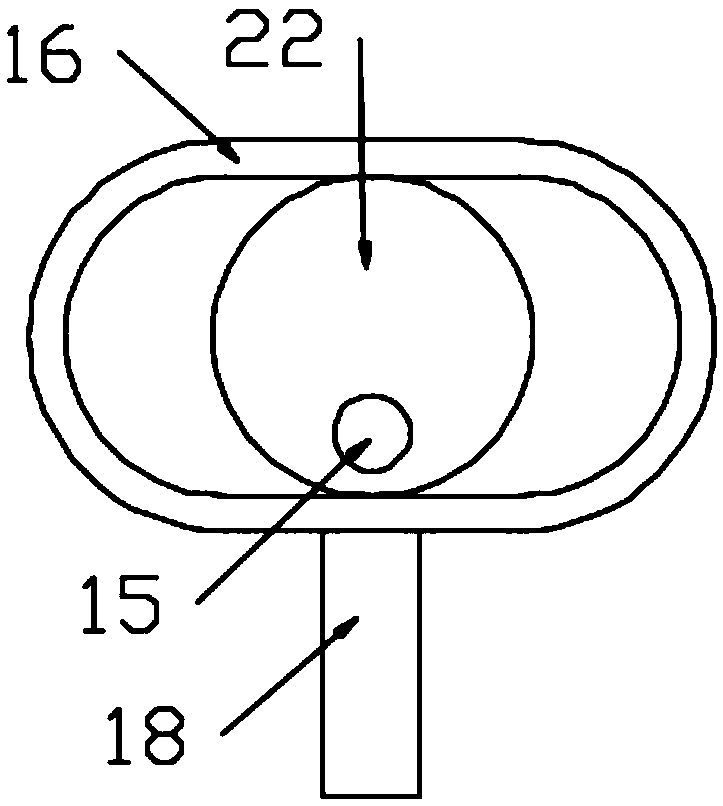

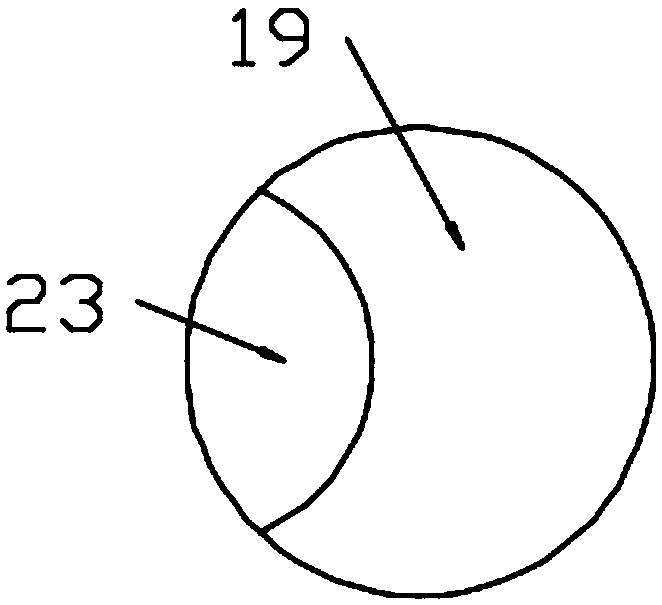

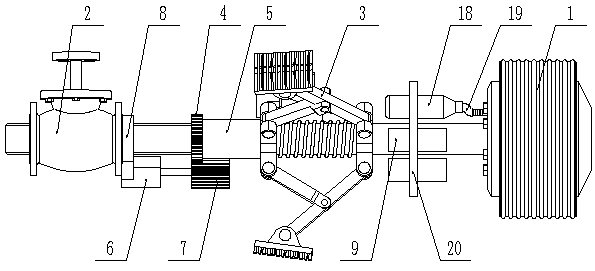

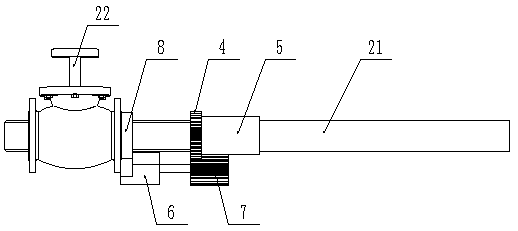

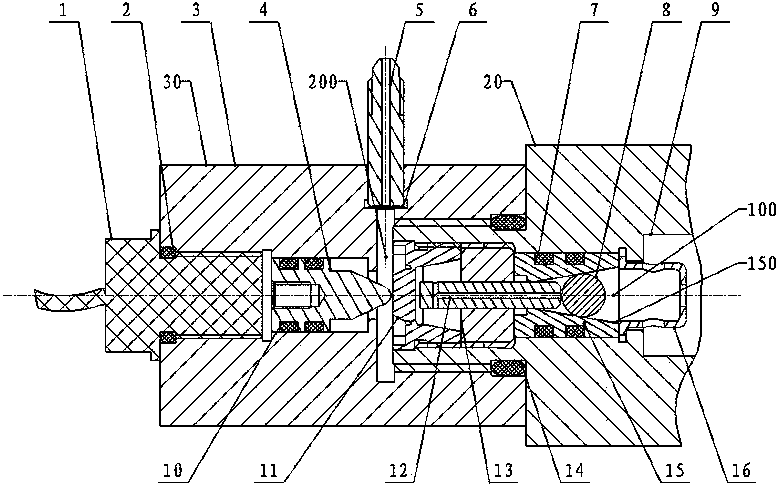

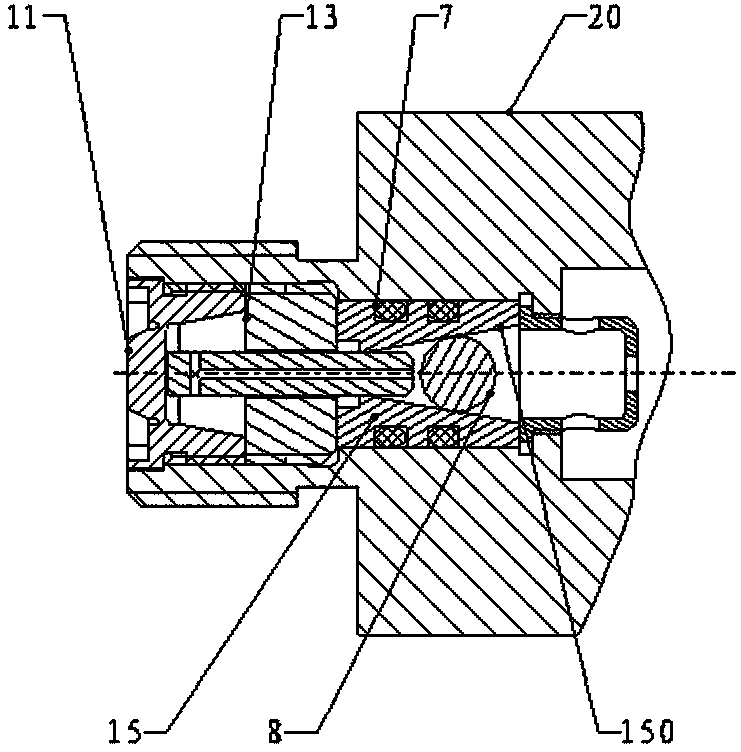

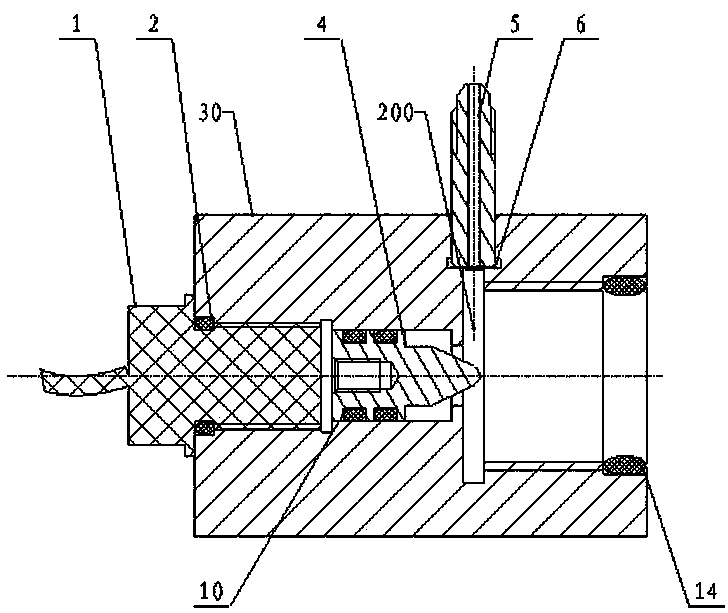

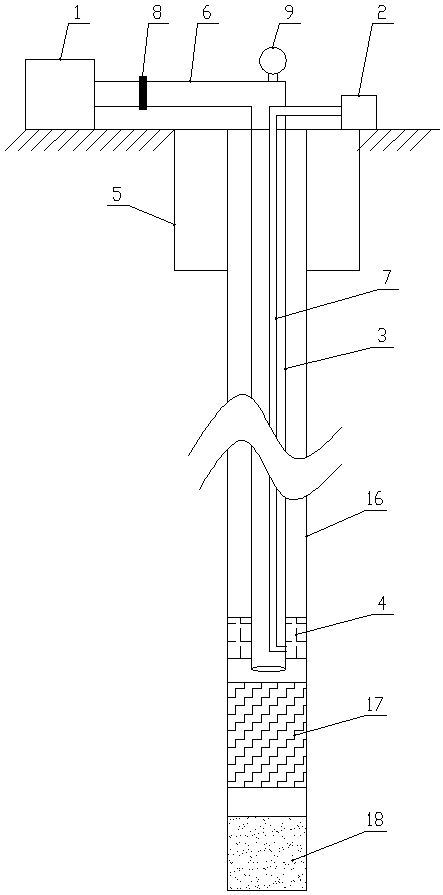

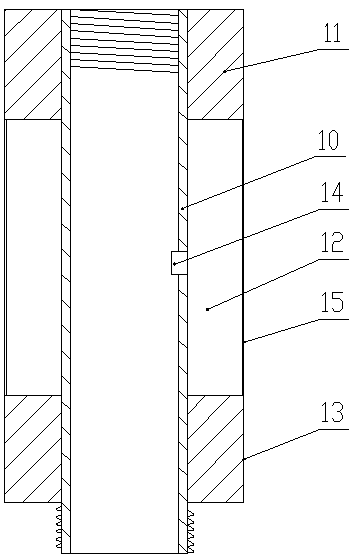

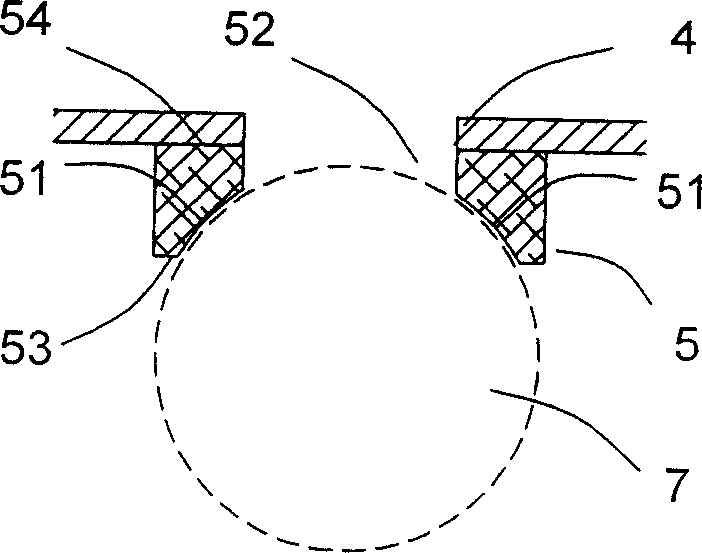

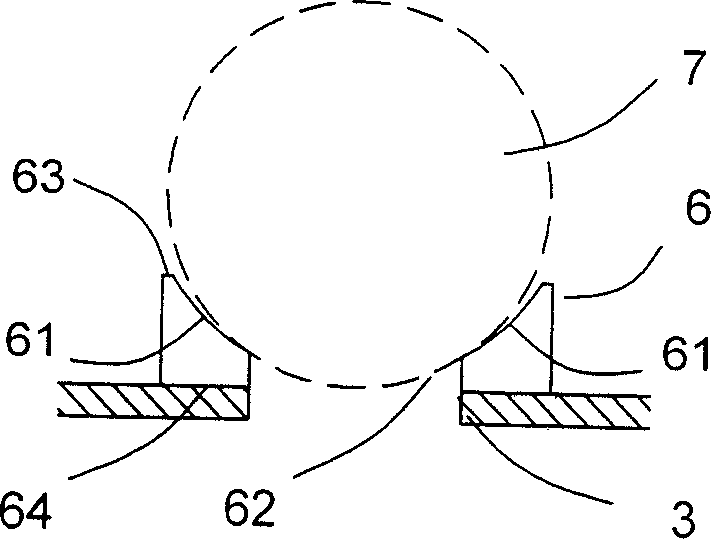

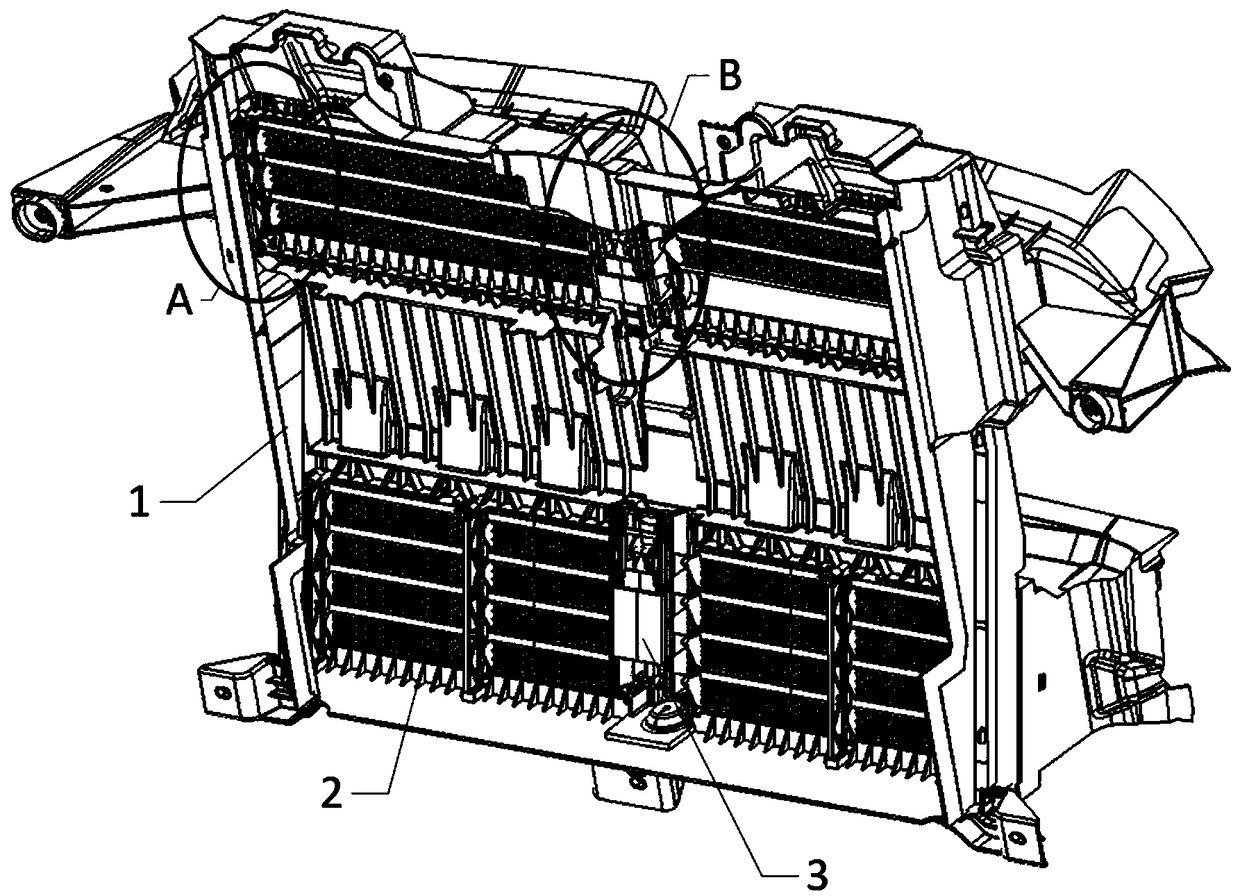

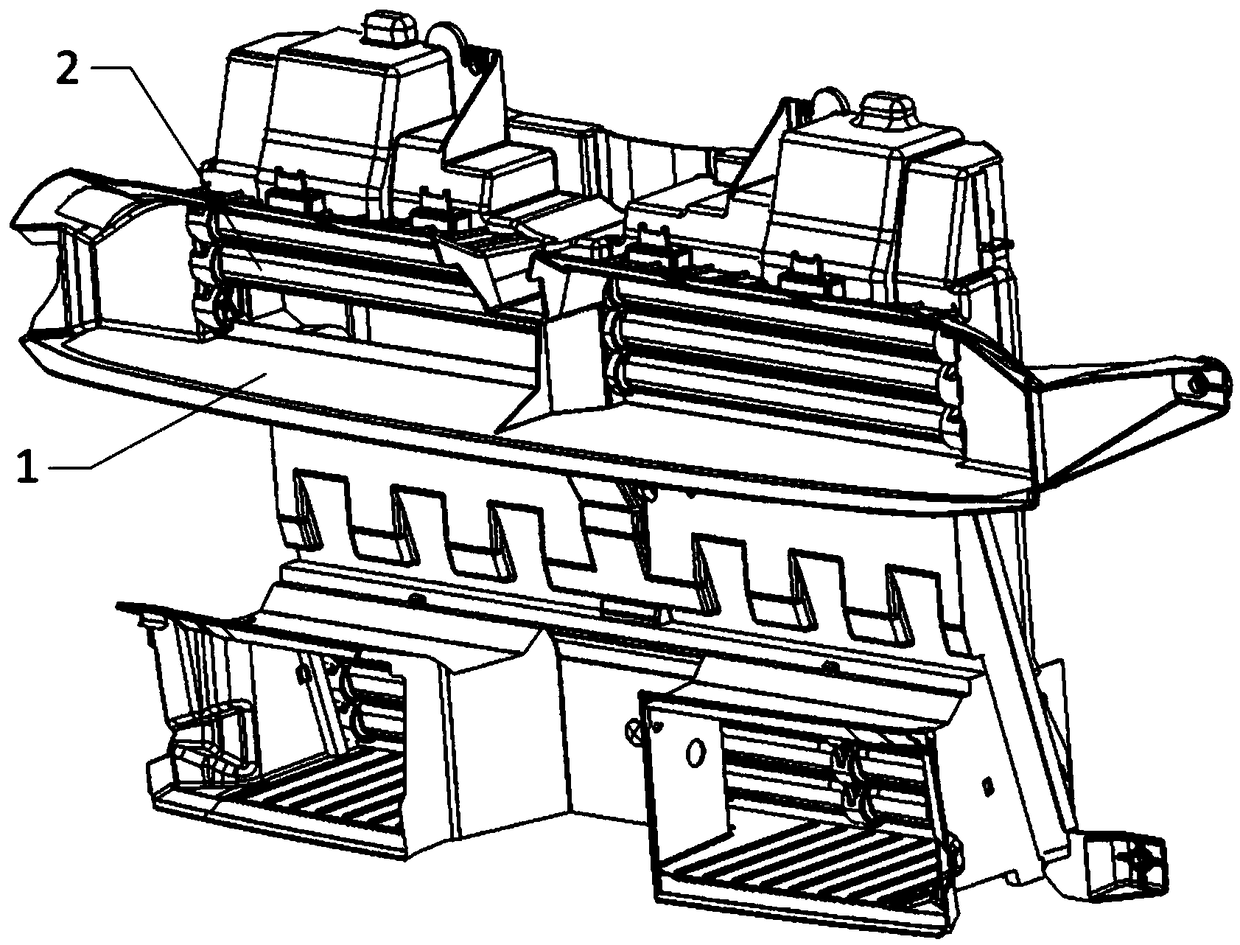

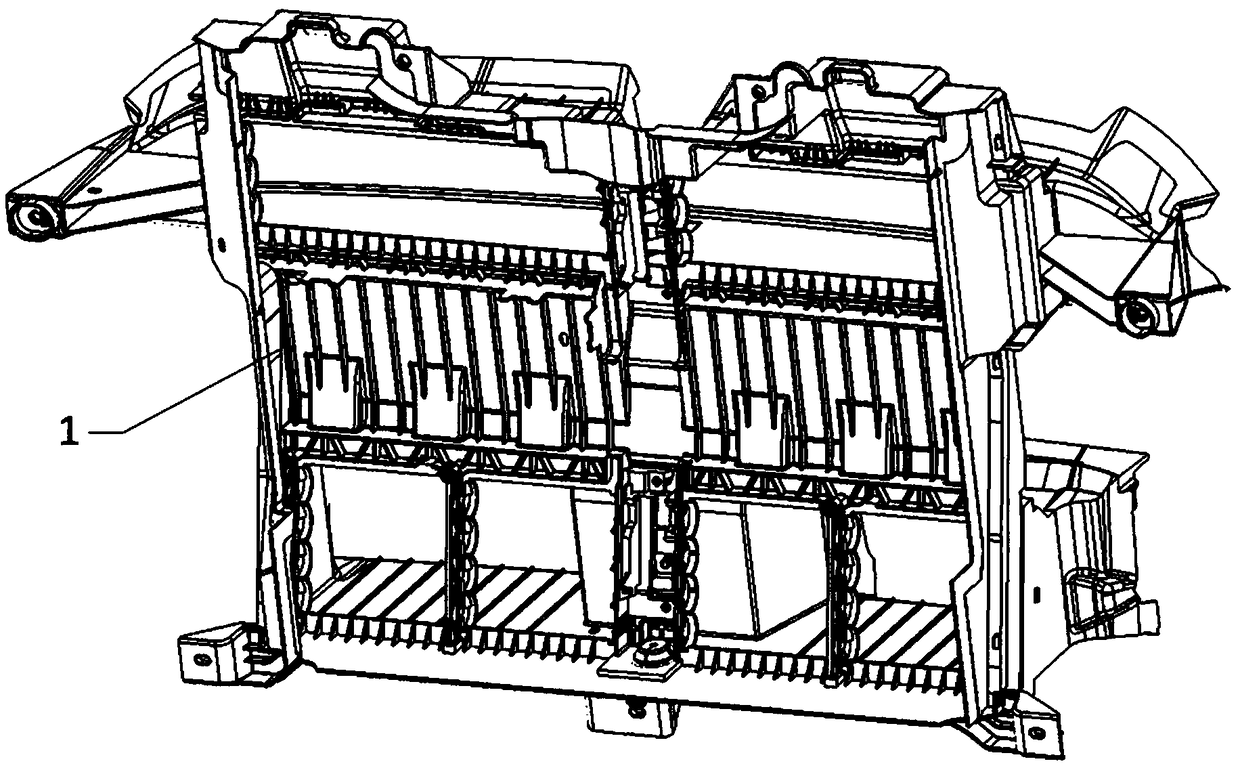

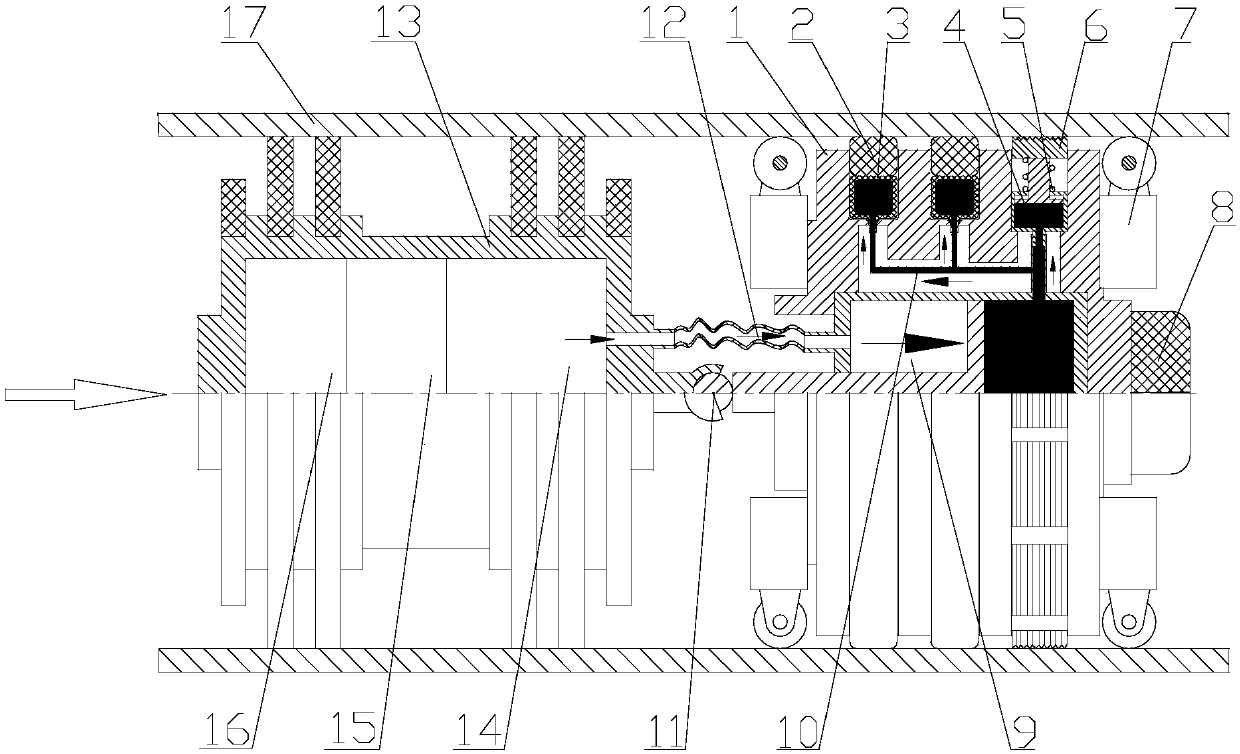

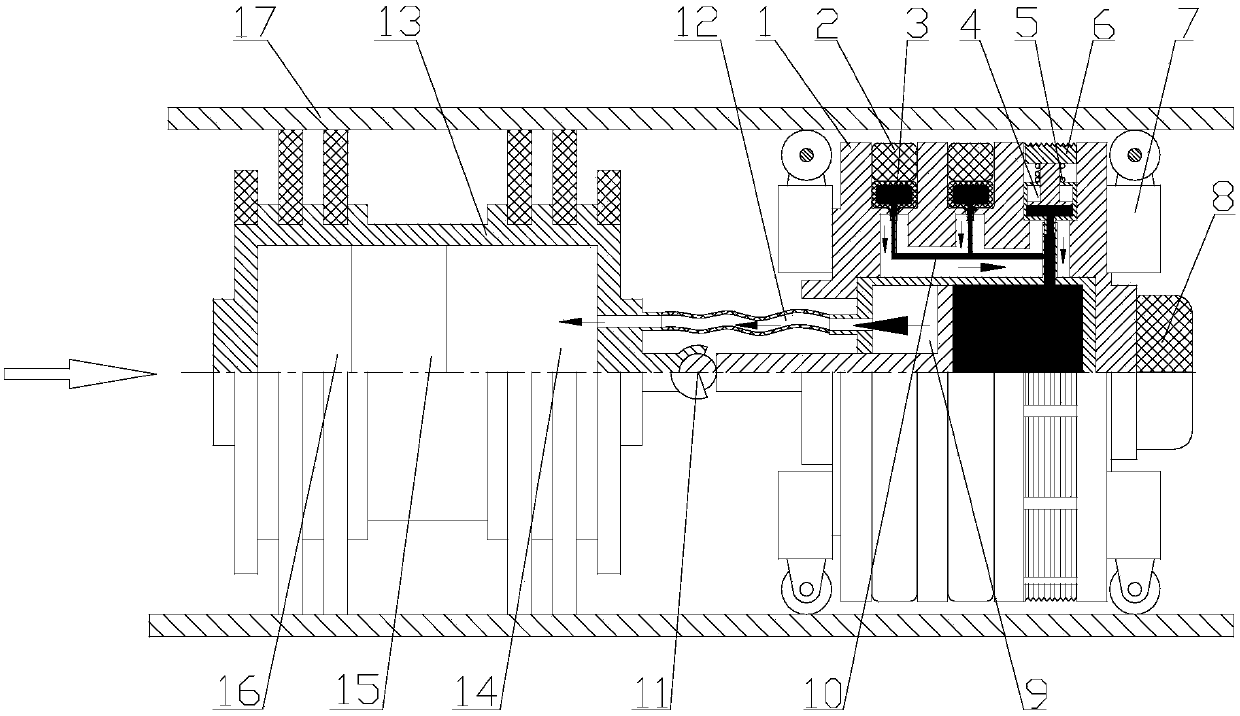

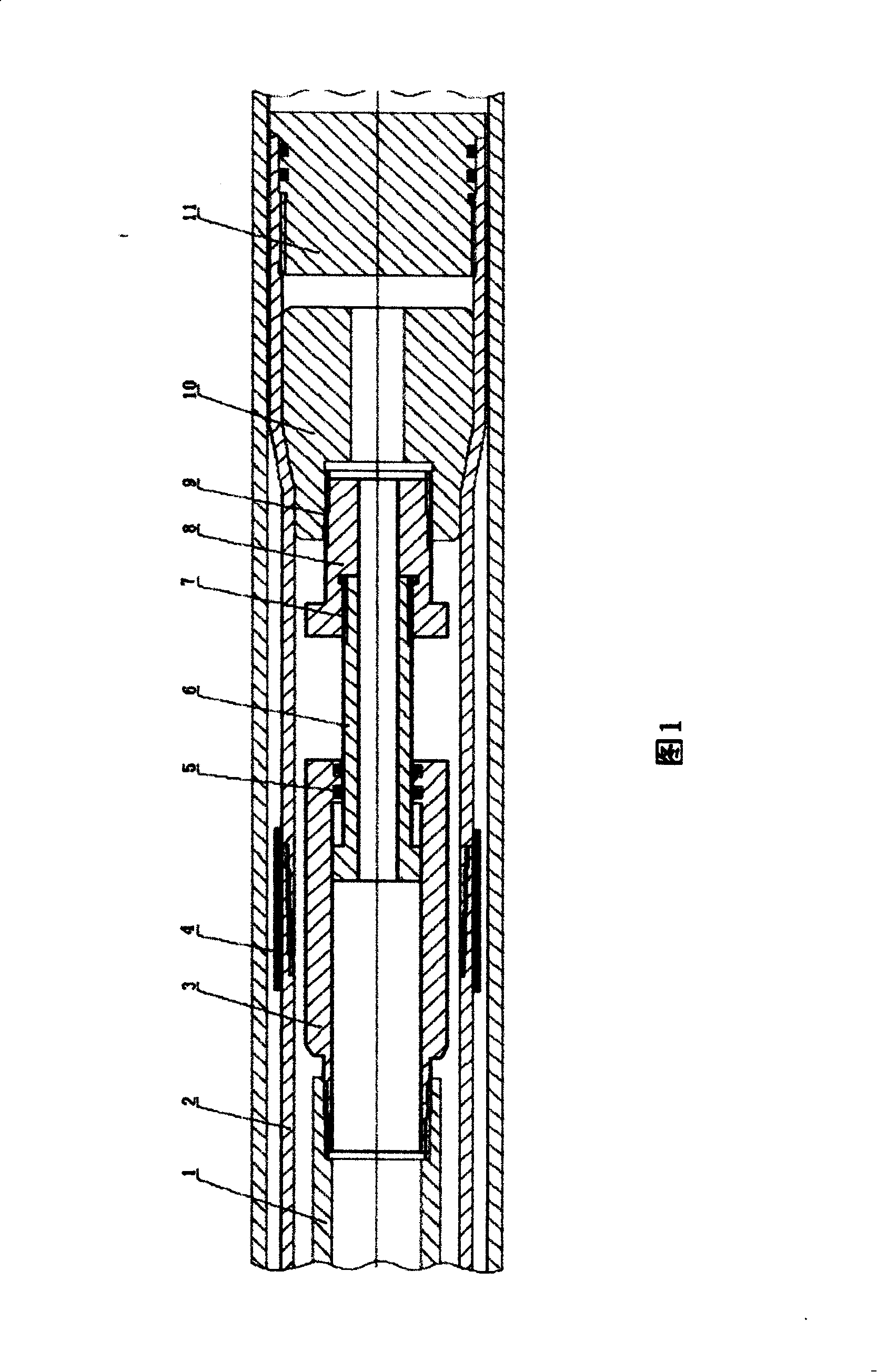

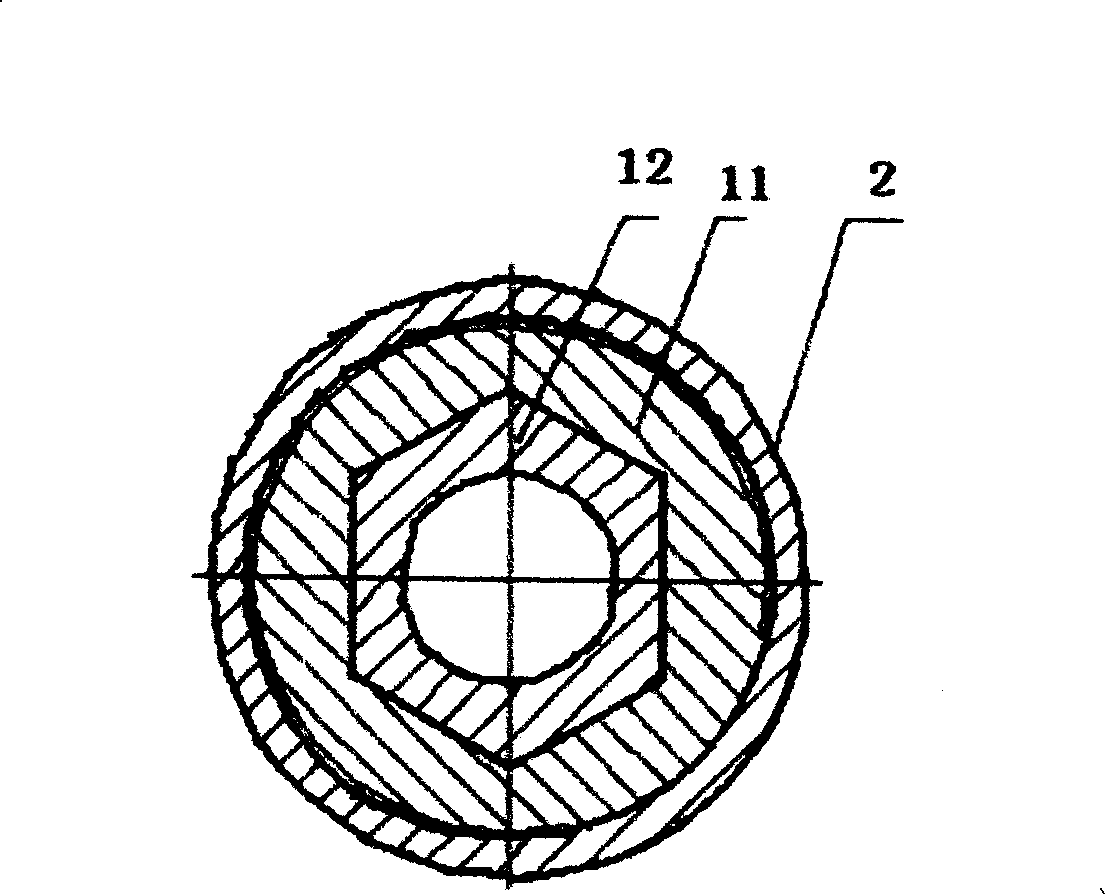

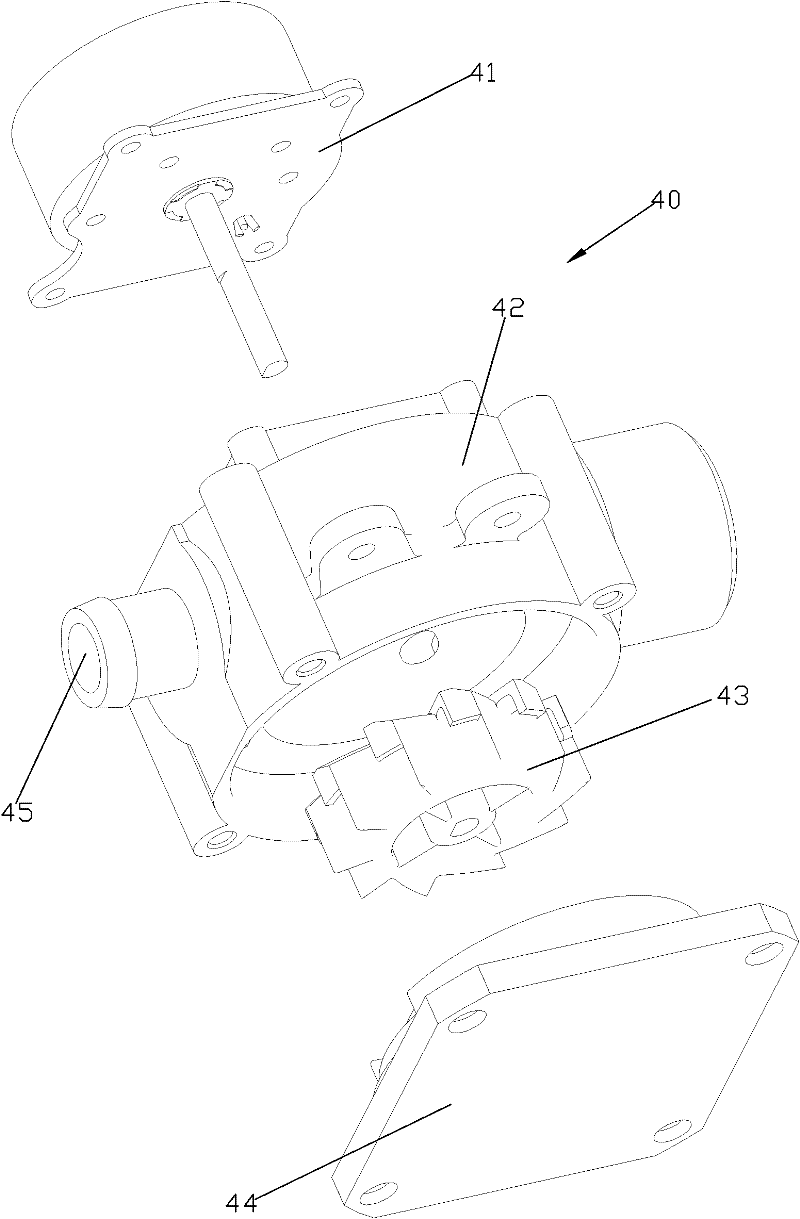

Crack particles diversion agent temporary blockage capability evaluation apparatus and method thereof

ActiveCN104535715AImplement dynamic injectionRealize blockingMaterial analysisLiquid storage tankEngineering

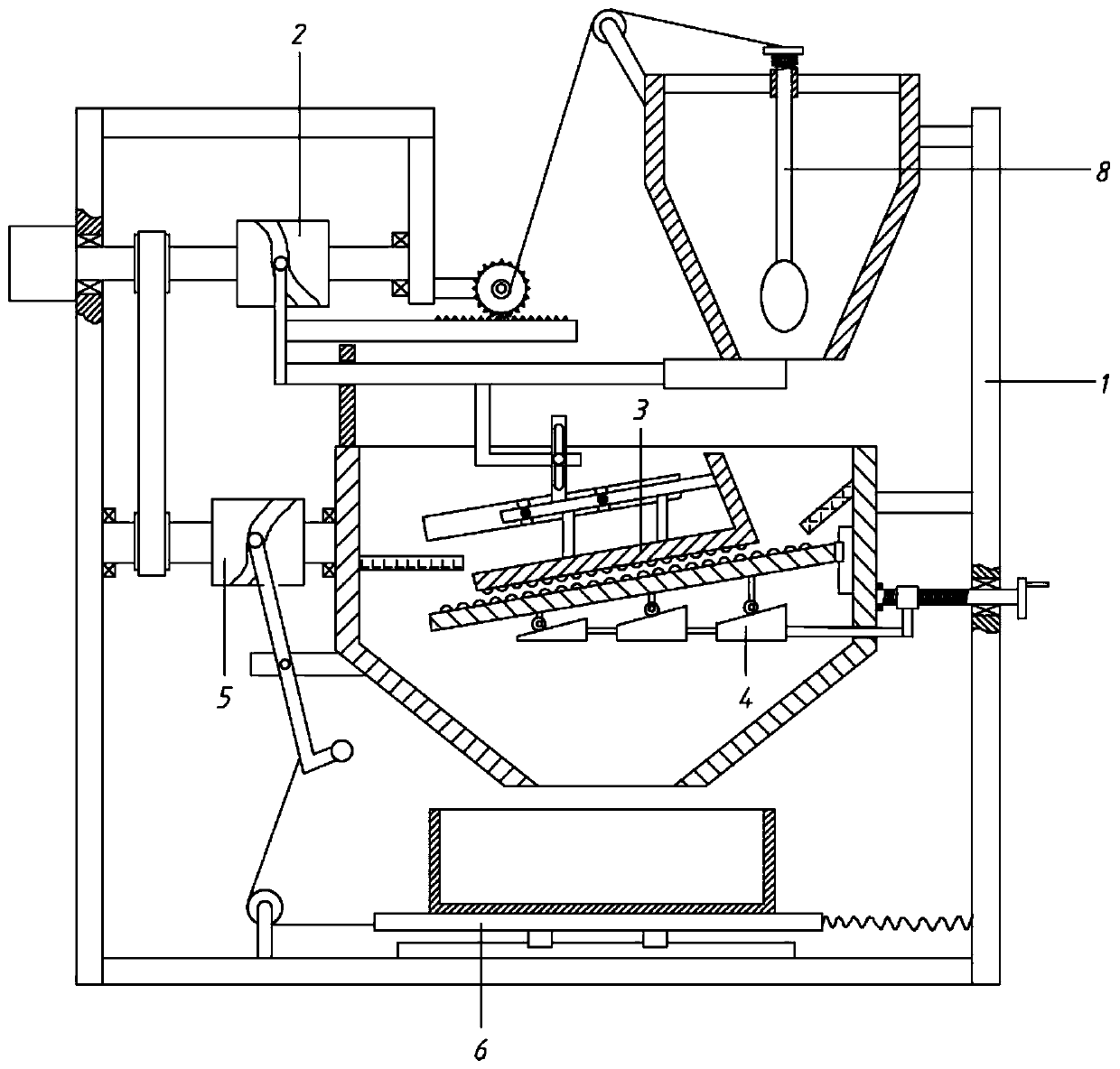

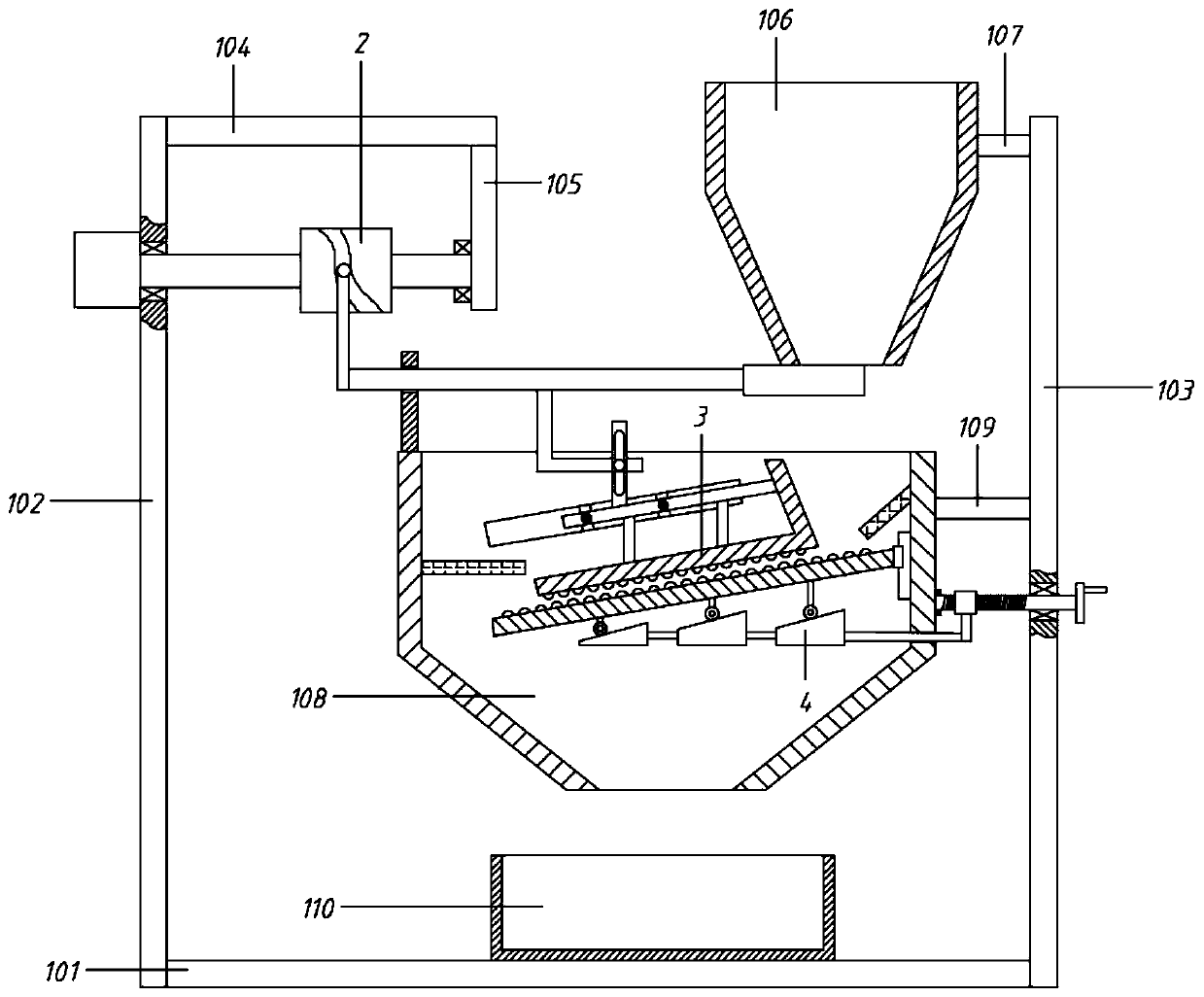

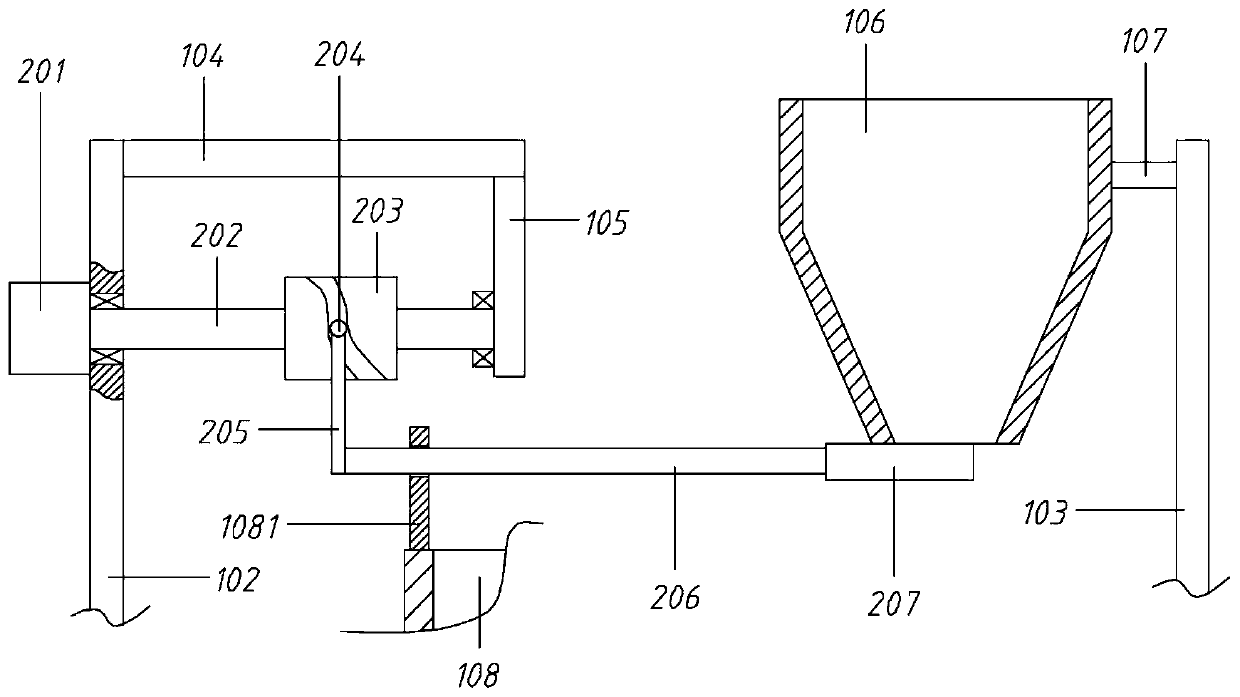

The invention discloses a crack particles diversion agent temporary blockage capability evaluation apparatus and a method thereof. The crack particles diversion agent temporary blockage capability evaluation apparatus comprises a thermotank, a holder outer cylinder is arranged in the thermotank, a rubber cylinder is arranged in the holder outer cylinder, the holder outer cylinder and the rubber cylinder form an enclosed space, an inlet end blocking head and an outlet end blocking head are arranged at two ends of the holder outer cylinder, an annular pressure hole is arranged at central section of the holder outer cylinder, an annular pressure meter is conducted to the enclosed space formed by the holder outer cylinder and the rubber cylinder by the annular pressure hole, and the other end of the annular pressure meter is connected to an annular pressure pump and an annular pressure liquid storage tank in order. The crack particles diversion agent temporary blockage capability evaluation apparatus establishes the crack particles diversion agent temporary blockage capability evaluation method which integrates steps of liquid preparation, pressure testing, injection and pressure measuring, as well as is matched with the experiment apparatus, a crack particles diversion agent temporary blockage process can be simulated, the operation is safe and simple, and automation degree and result credibility are high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

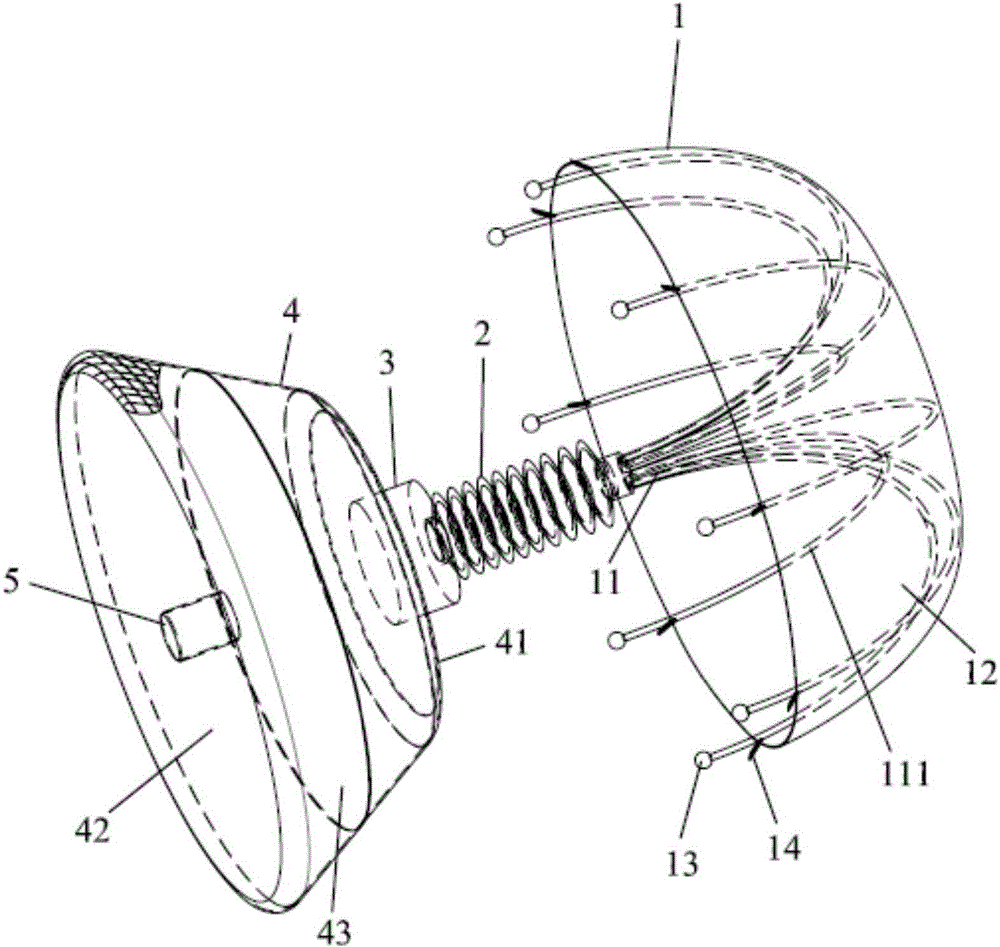

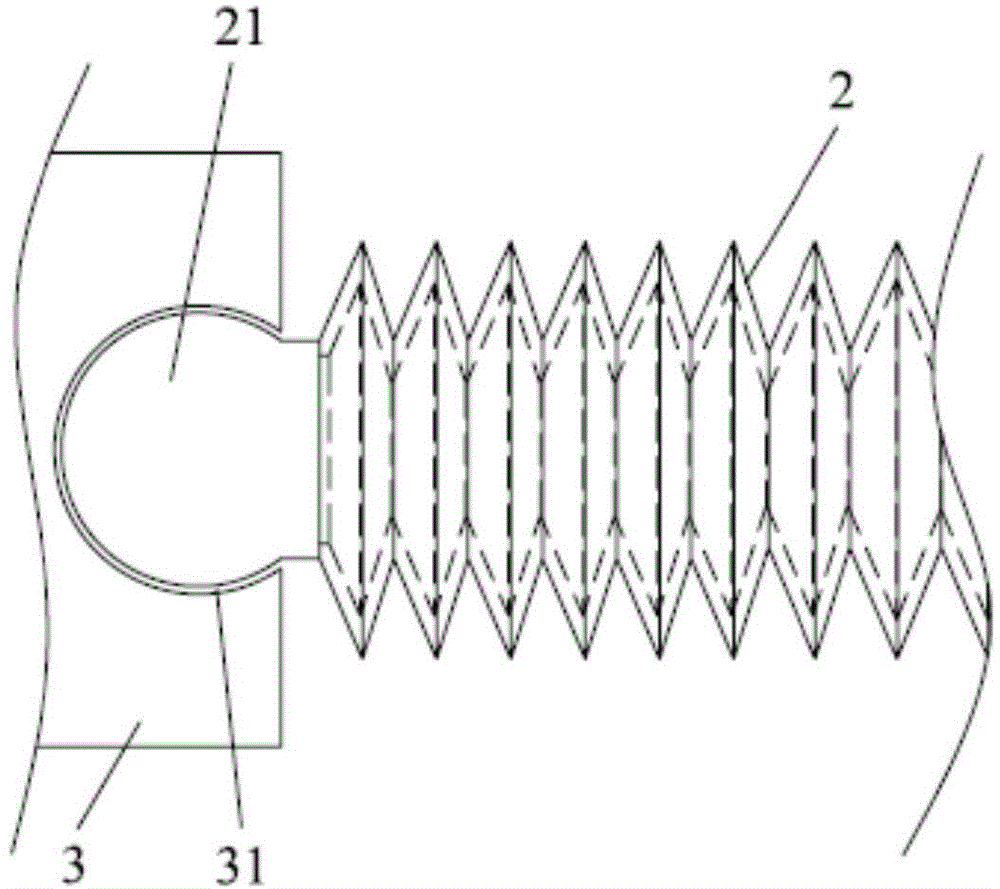

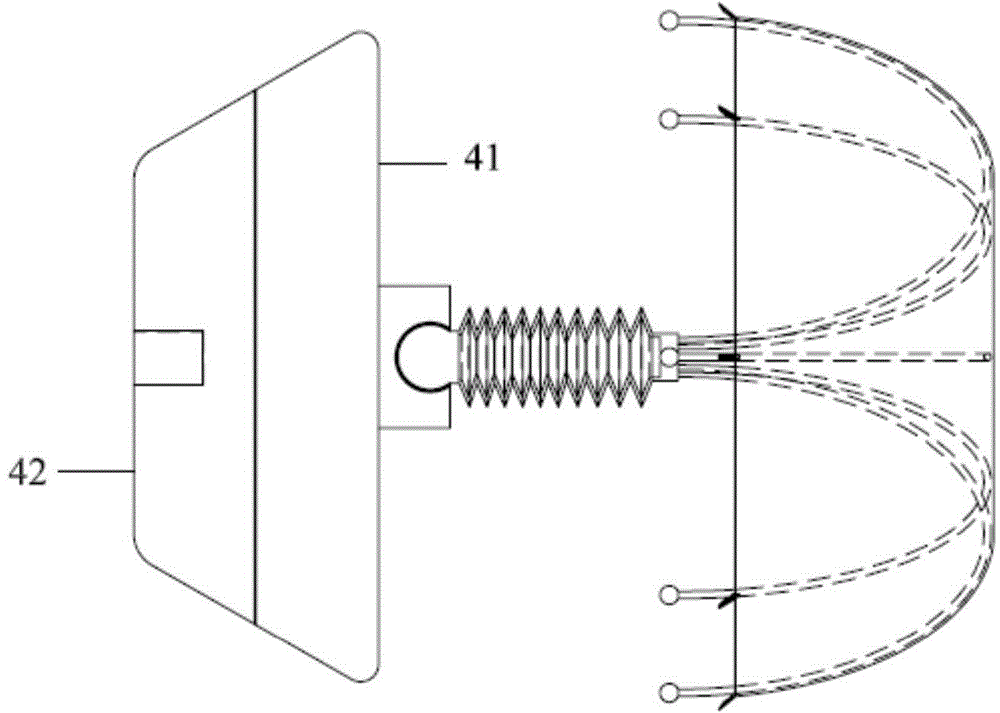

Transcatheter left atrial appendage plugging system

ActiveCN104856741APhysiologically consistentReasonable specification designOcculdersIsosceles trapezoidMedicine

The invention relates to a transcatheter left atrial appendage plugging system. The system is composed of an inner plugging body, a connecting rod, a direction regulator and an outer plugging body, all of which are orderly arranged from the inner end to the outer end; the inner plugging body is provided with a mesh basket support and a first plugging film; the mesh basket support is formed by use of mesh basket wires and riveting hooks and protective balls are arranged on the mesh basket wires; the connecting rod is of a structure adjustable in length in the axial direction; the direction regulator is used for regulating the direction of the connecting rod; the outer plugging body is of a meshed hollow structure in a stand shape; the cross section of the outer plugging body is circular, while the longitudinal section of the outer plugging body is isosceles trapezoid-shaped; a second plugging film is arranged inside the outer plugging body; the first plugging film and the second plugging film both are microporous water-permeable films. According to the design ideal of inside plugging, the transcatheter left atrial appendage plugging system can be completely plugged without any residual cavity; the plugging system is suitable for the left atrial appendages different in shape and depth; besides, the plugging system is small in endothelialization area, steady in position after implantation and good in safety.

Owner:GUANGDONG PULSE MEDICAL SCI & TECH CO LTD

Intelligent plugging device in tube

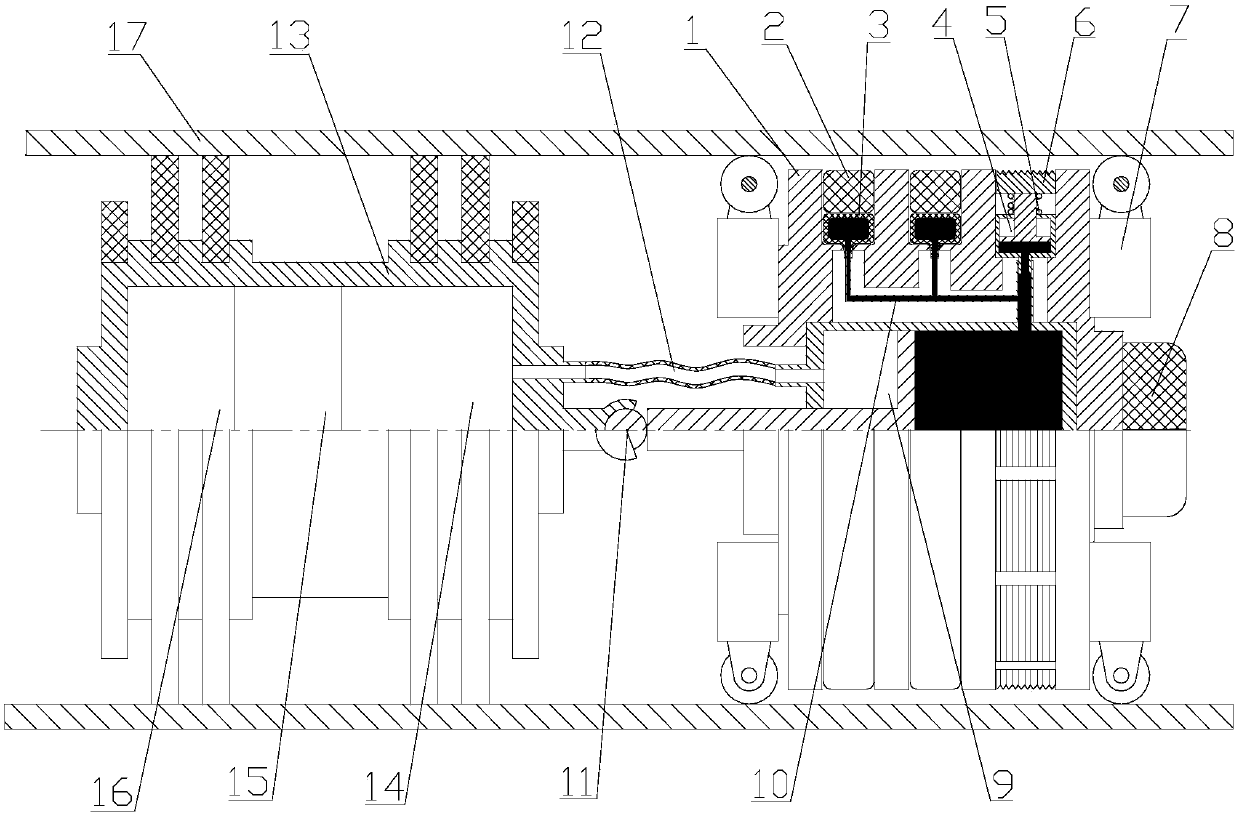

The invention provides an intraductal intelligent plugging device, which comprises a main drive cylinder, a pressure head, an actuator disk, an extrusion bowl, at least two locking slide blocks, a ring spacer and a signal transceiver device, wherein, the main drive cylinder is provided with a cylinder body, a piston and a piston rod connected with the piston; the pressure head is connected with the end of the piston rod far away from piston; the actuator disk is connected with the cylinder body; the extrusion bowl is arranged between the pressure head and the actuator disk in a sliding way, and the extrusion bowl is provided with a tilted conical slide surface and an extrusion end face; each of the two locking slide blocks is connected with a subsidiary drive cylinder, and each subsidiary drive cylinder is fixed on the actuator disk; the bottom surface of the locking slide block is matched with the conical slide surface of the extrusion bowl in a sliding way, and the locking slide block performs the locking function in a radial expansion way when sliding upward along the conical slide surface; the ring spacer is arranged between the pressure head and the actuator disk, and is extruded by the extrusion end face of the extrusion bowl to perform the plugging function in a radial expansion way; the signal transceiver device is connected with the intraductal intelligent plugging device to receive control signals to drive the main drive cylinder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

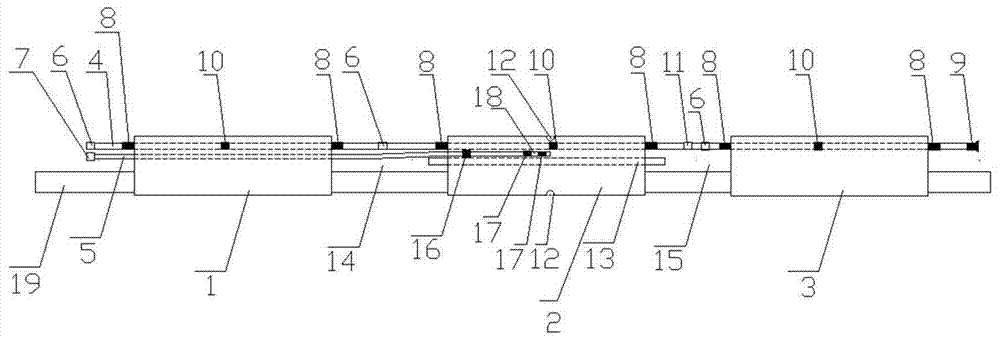

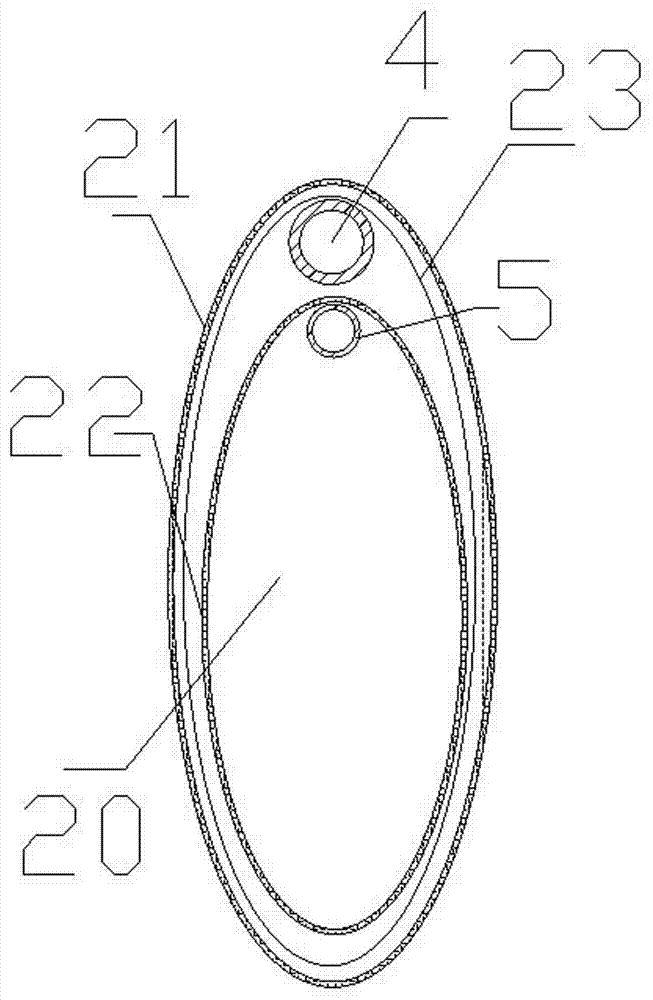

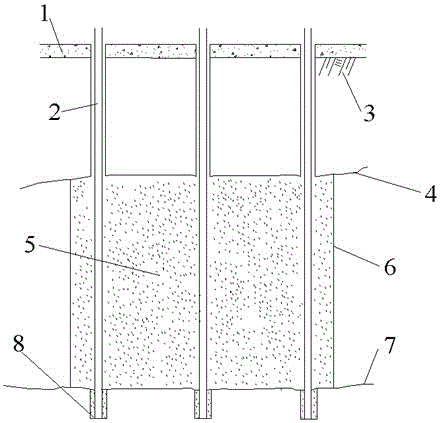

Penetrating-sleeve-type three-airbag plugging device and using method thereof

ActiveCN107989571AFlexible installationRealize three-block three-injection sealGas removalSealing/packingPressure senseSlurry

The invention discloses a penetrating-sleeve-type three-airbag plugging device and a using method thereof. The penetrating-sleeve-type three-airbag plugging device comprises a first airbag, a second airbag, a third airbag, a hole sealing grouting pipe, a crack plugging pipe and a slurry guiding pipe. The three airbags are formed by sewing of elastic cloth sleeves and arranged on a gas extraction pipe in a sleeving mode. The hole sealing grouting pipe penetrates through the three airbags. A grouting opening is formed in the hole sealing grouting pipe in the airbags. The slurry guiding pipe penetrates through an inner hollow body of the second airbag. The two sides of the slurry guiding pipe are connected with a grouting section in a communicating mode. The crack plugging pipe penetrates through an inner hollow body of the first airbag. The end of the crack plugging pipe is located at the sewing line position on the exterior of the second airbag. Meanwhile, the invention discloses the using method of the penetrating-sleeve-type three-airbag plugging device. According to the penetrating-sleeve-type three-airbag plugging device and the using method thereof, 'three-plugging and two-grouting' hole sealing can be achieved through a pressure sensing overflow valve, and meanwhile, further plugging of a hole circumferential crack area can be achieved after hole sealing, so that 'three-plugging and three-grouting' type hole sealing of gas extraction is achieved wholly.

Owner:HENAN POLYTECHNIC UNIV

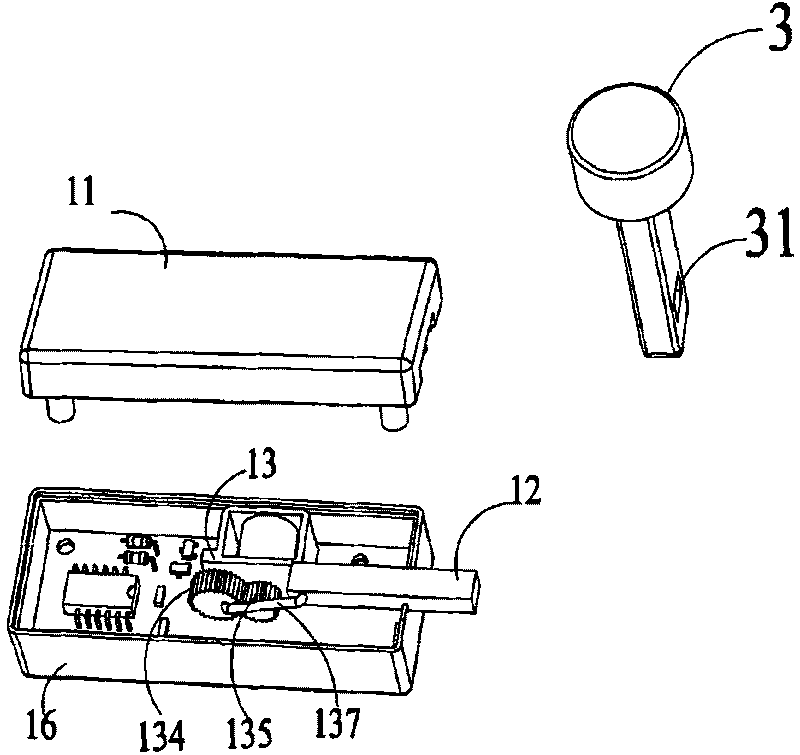

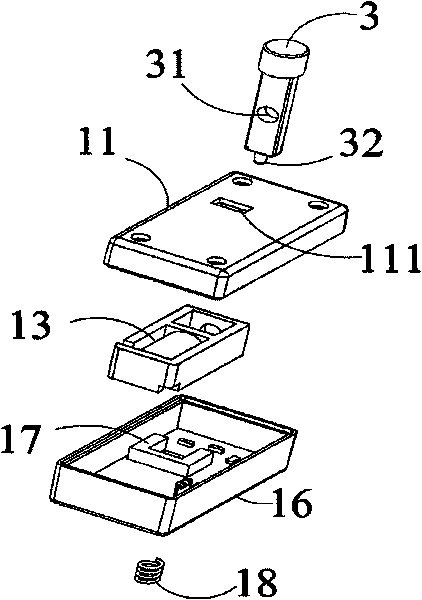

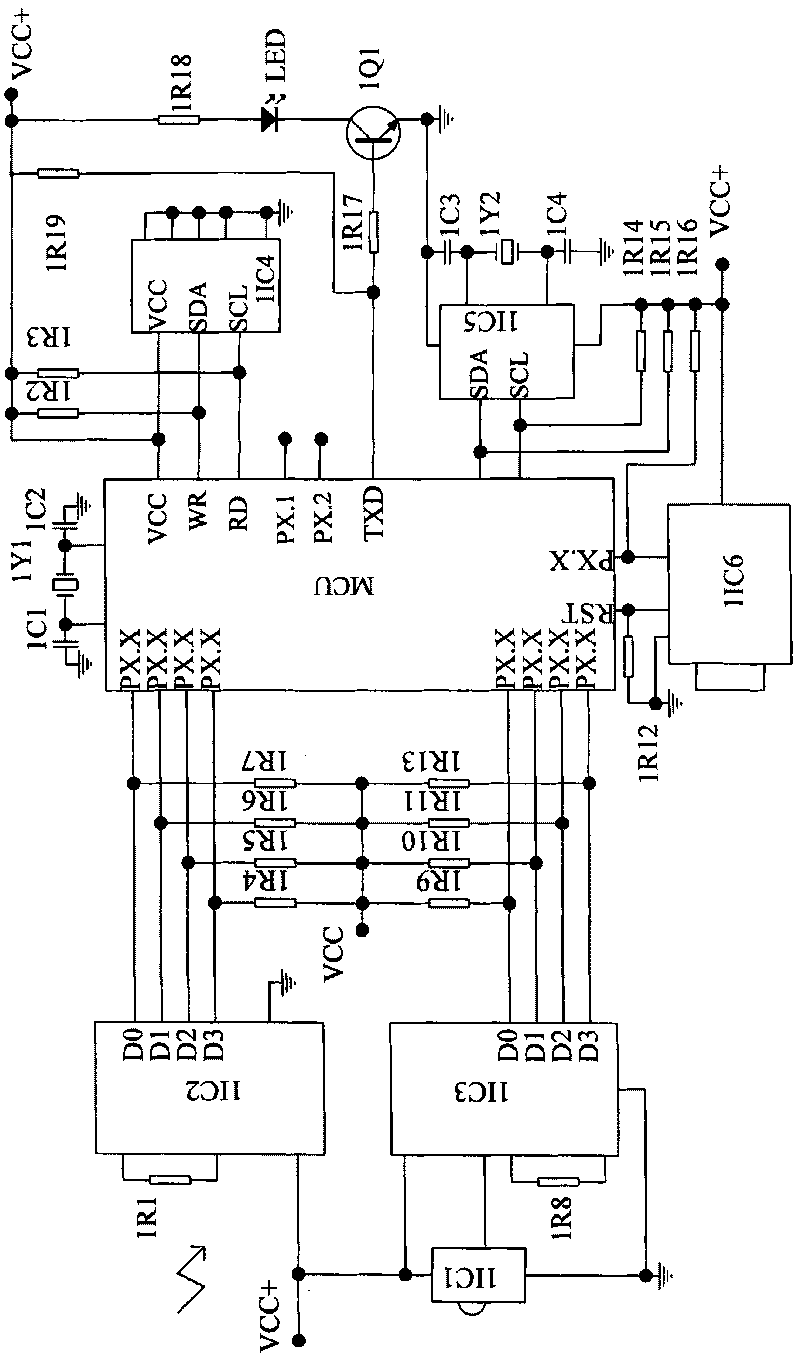

Electronic blocking device and case with same

InactiveCN101736968ARealize blockingAvoid direct contactLocks for portable objectsElectric permutation locksAutomatic controlPush out

The invention relates to an electronic blocking device and a case with same. The electronic blocking device comprises a shell, a bolt, a bolt retractable action unit, a control unit and a connecting piece, wherein the bolt retractable action unit is arranged in the shell, is fixedly connected with the bolt and is used to push out the bolt or withdraw the bolt back to the shell; the control unit is connected with the bolt retractable action unit and is used to receive an external control instruction so as to automatically control the motion of the bolt retractable action unit; and the middle of the connecting piece is provided with a hole corresponding to the bolt.

Owner:HUBEI SHENGJIA ELECTRIC EQUIP +1

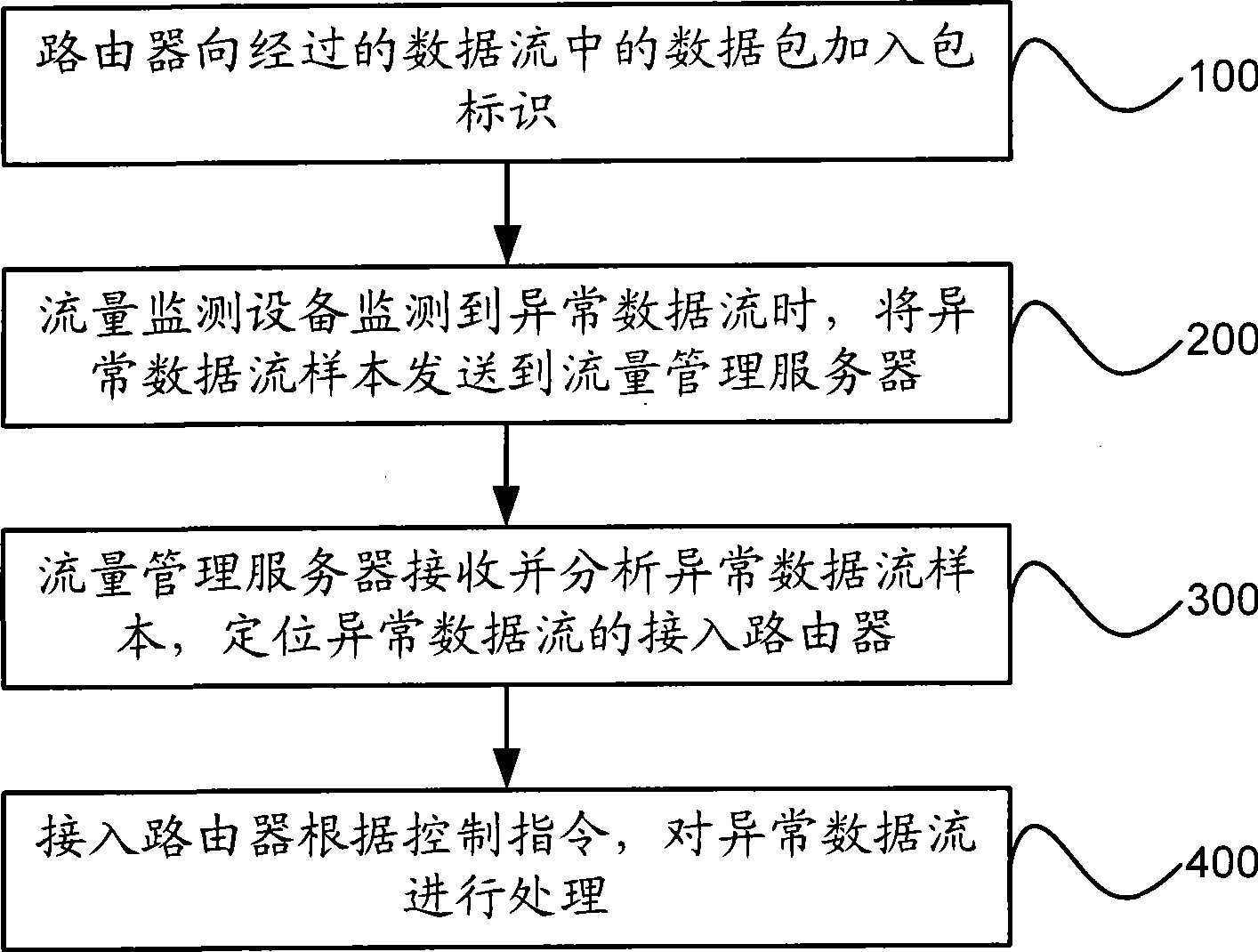

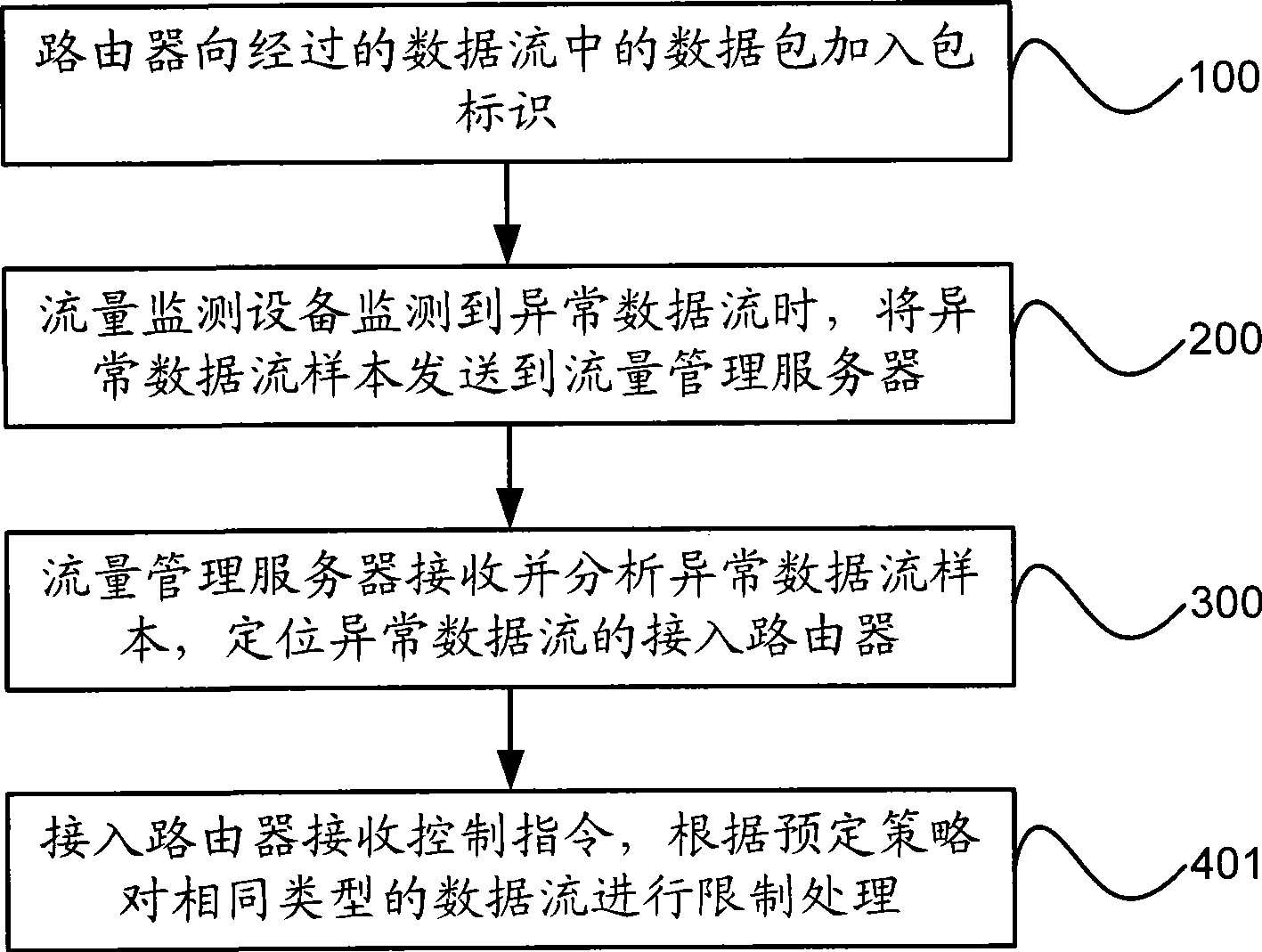

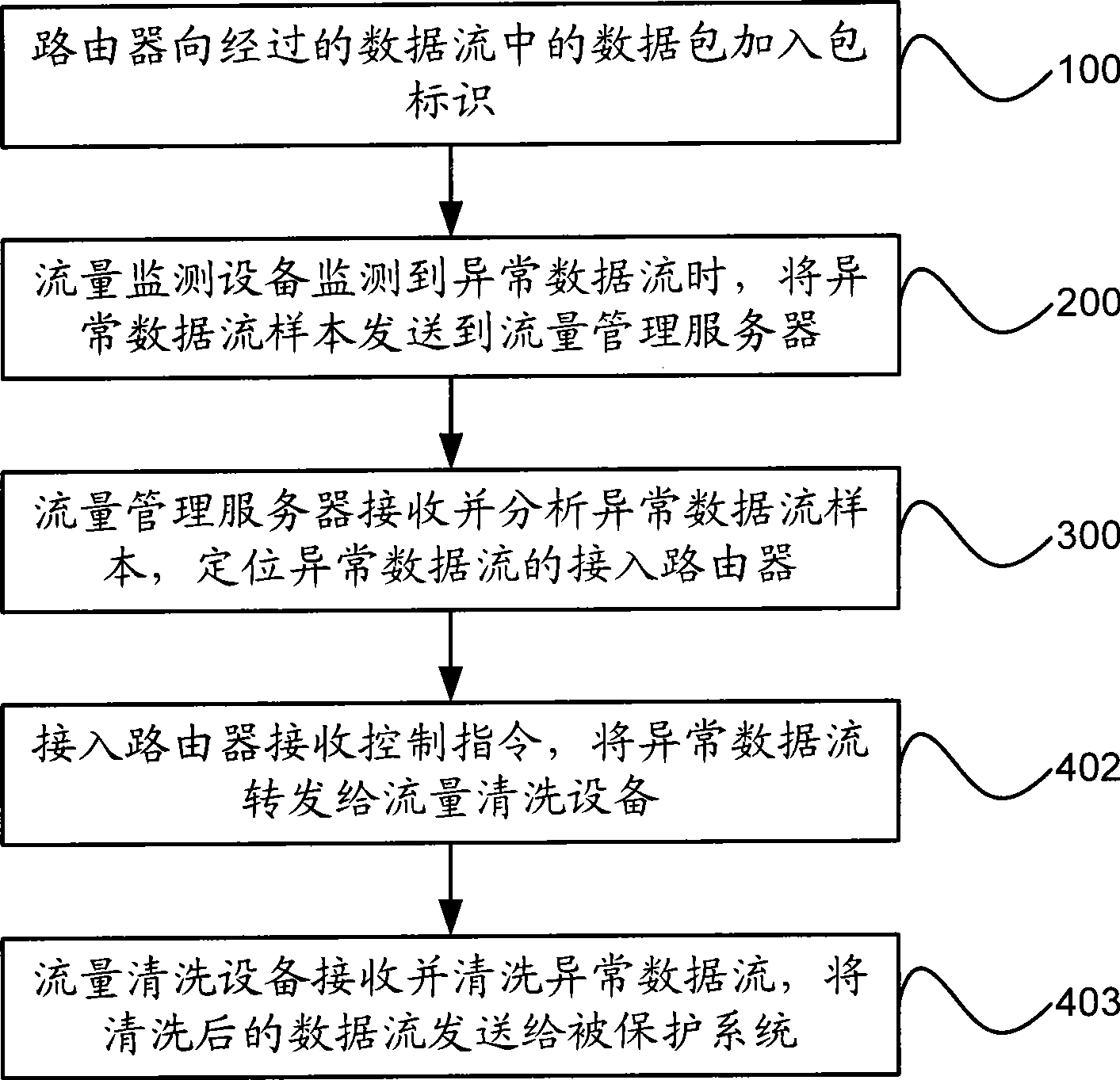

Flow monitoring method and system

InactiveCN101453389AEasy to controlRealize blockingData switching networksTraffic capacityData stream

The invention discloses a method and a system for flow rate monitoring. The method comprises: a router adds packet identifiers in data packets in data flows passing through; a flow rate monitoring device monitors the flow rates of data flows entering or leaving a system under protection in real time and extracts an abnormal data flow sample from the abnormal data flows when monitoring the abnormal data flows and sends the abnormal data flow sample to a flow rate management server; the flow rate management server analyzes and processes the abnormal data flow sample and positions access routers of the abnormal data flows according to the packet identifiers in the data packets of the abnormal data flow sample; and the access routers process the abnormal data flows according to control commands sent by the flow rate management server. The system comprises routers, the flow rate monitoring device and the flow rate management server. The method and the system use the packet identifiers to trace the sources of the abnormal data flows and process the abnormal data flows in the access routers through which the abnormal data flow pass, realize the control and blockage of the sources of the abnormal data flows and can effectively handle DDoS attack.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD +1

Blocking system and blocking method for channeling inhibition in carbon dioxide non-miscible flooding of low permeability reservoir

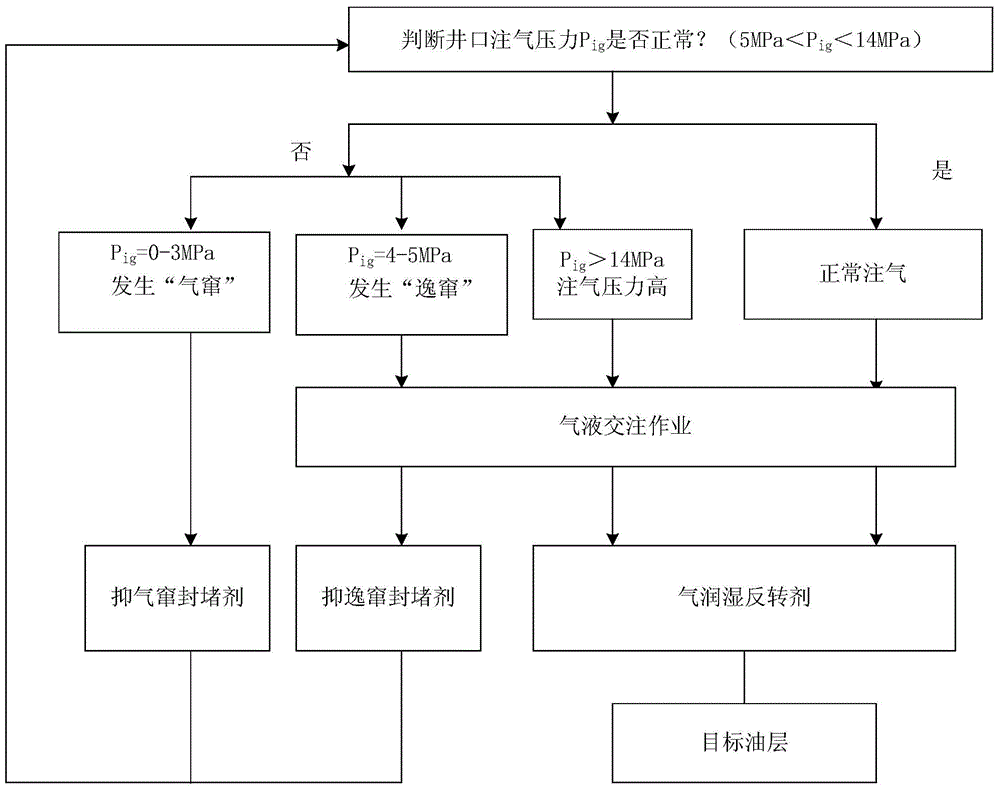

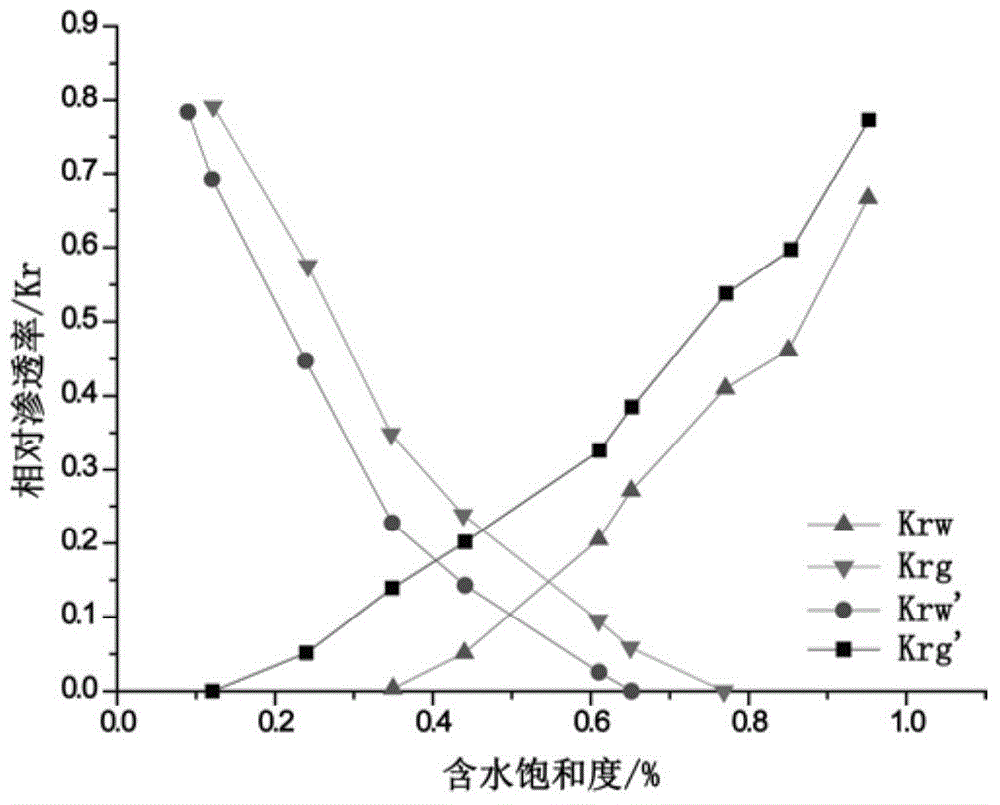

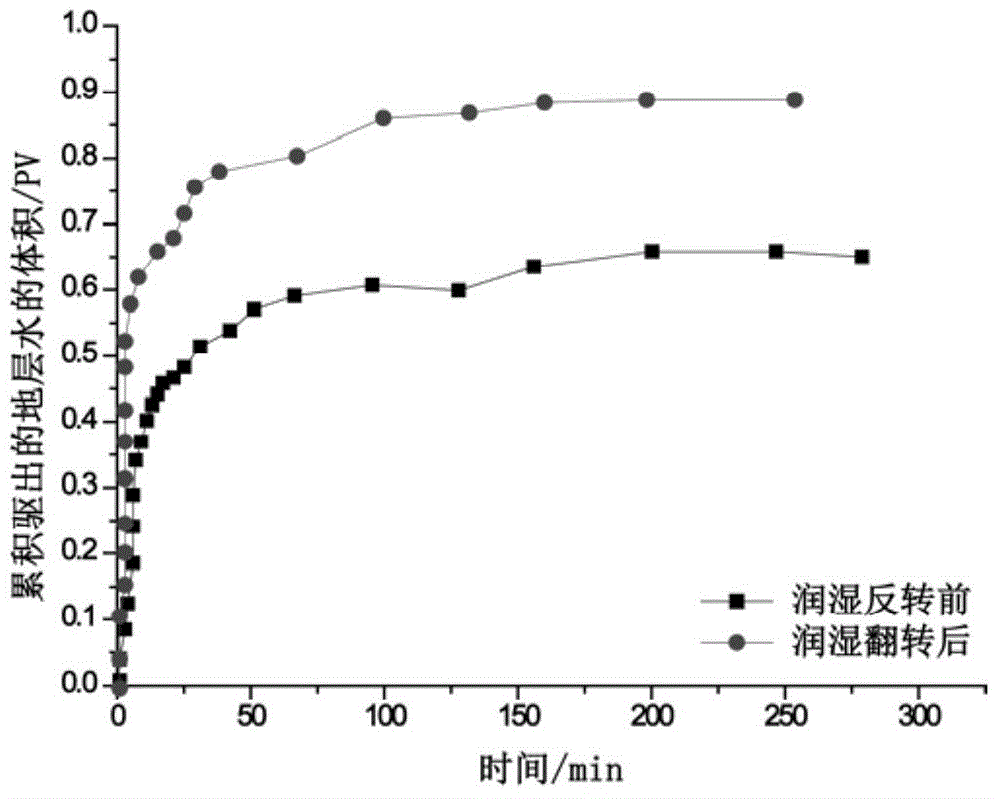

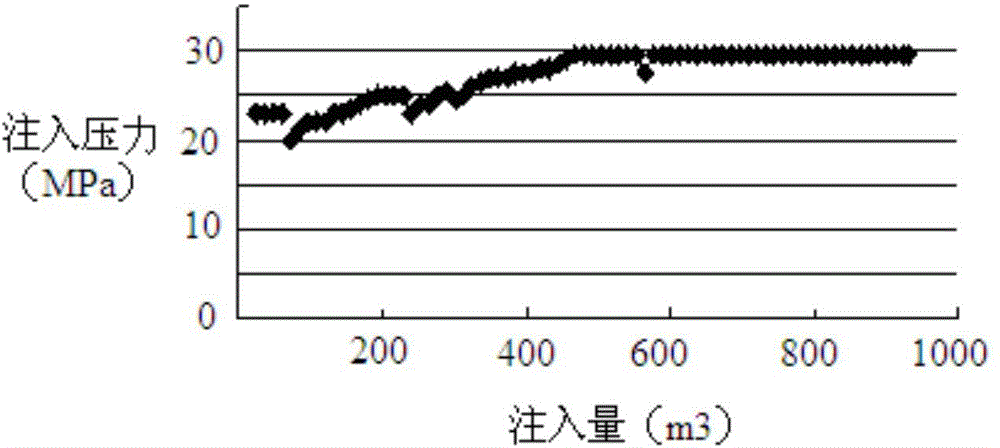

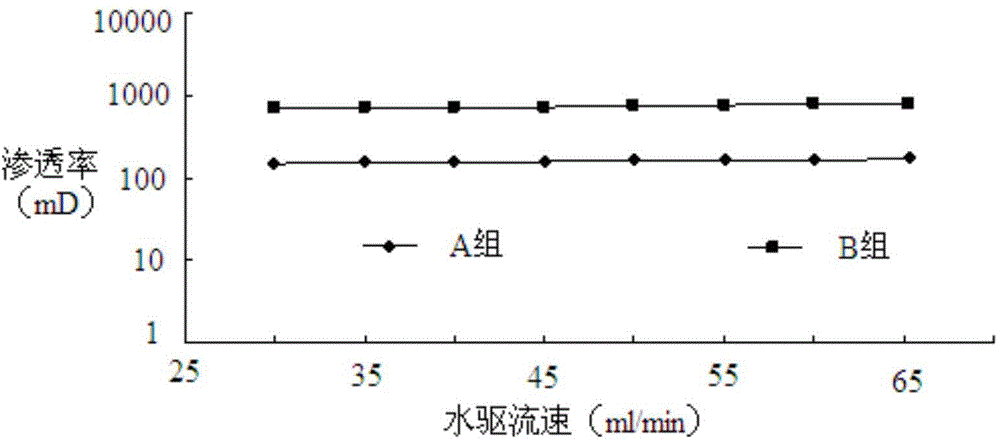

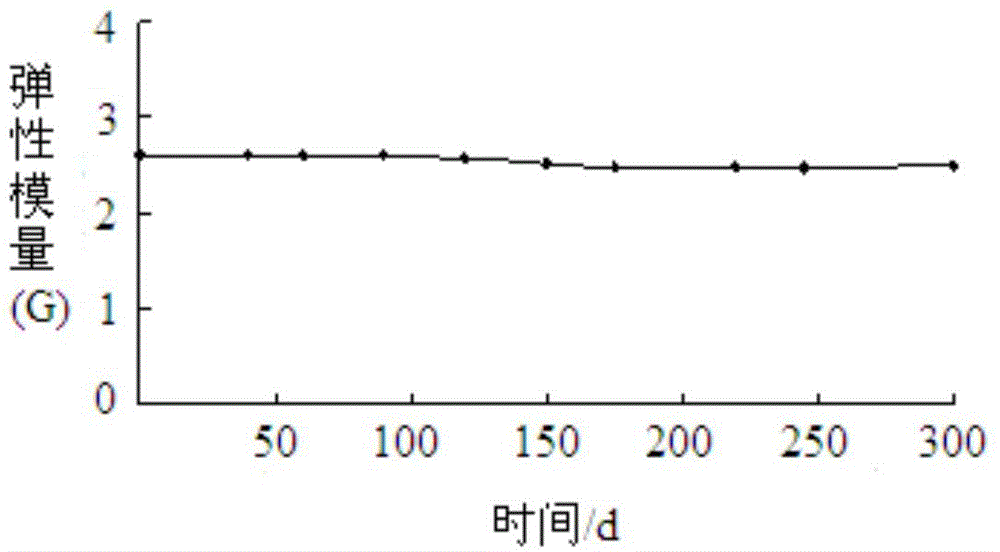

ActiveCN104087280AHigh mechanical strengthImprove plugging performanceFluid removalDrilling compositionWellheadChemistry

The invention discloses a blocking system and a blocking method for channeling inhibition in carbon dioxide non-miscible flooding of a low permeability reservoir. The system is mainly prepared from the following raw materials in percentage by weight: 1%-2% of fine mineral particles, 0.2%-0.3% of polymer, 0.01%-0.02% of compound crosslinking agent, 0.04%-0.1% of retarder, 0.01% of deoxidant, 0.1%-0.5% of surfactant and the balance of water. By virtue of monitoring the steam injection pressure of a wellhead in real time and adjusting the system, graded control of high-pressure steam injection, 'gas channeling' and 'escape channeling' processes in the carbon dioxide non-miscible flooding is realized and the development effect of the carbon dioxide non-miscible flooding of the low permeability reservoir is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

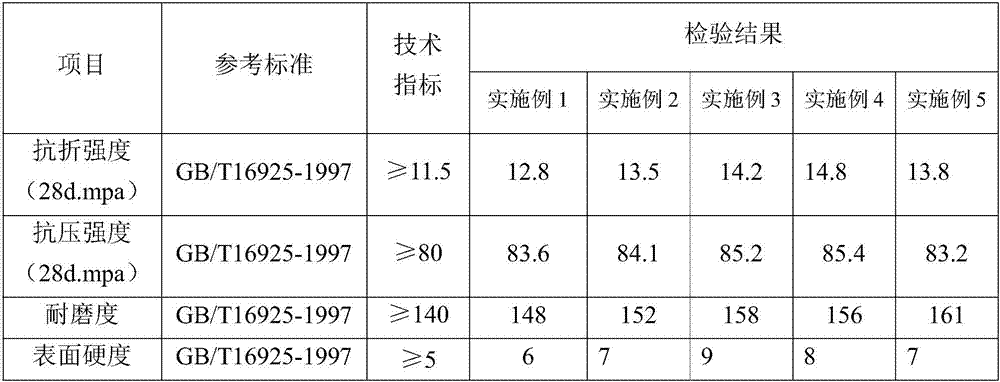

Concrete seal curing agent

The invention provides a concrete seal curing agent which comprises the following components in percentage by weight: 50%-70% of silicate, 10%-30% of a silane coupling agent, 1%-3% of nano titanium dioxide and the balance of water. After the concrete seal curing agent provided by the invention is applied to the surface of a concrete structure, silicate in the concrete seal curing agent can quickly permeate into concrete and reacts with free calcium to generate insoluble amorphous calcium silicate hydrate so as to block the fine pores of the concrete structure and improve the hardness of the concrete structure; meanwhile, the silane coupling agent and nano titanium dioxide in the curing agent interact to form a hydrophobic membrane layer on the surface of the concrete structure and improve the surface hydrophobicity of the concrete structure; the experimental result shows that the surface Mohs hardness is higher than 7, the water absorption rate is lower than 0.6%, and the liquid drop contact angle is less than 95 degrees after the surface of the concrete structure is coated with the concrete seal curing agent provided by the invention.

Owner:上海牧桔新型材料有限公司

Bracing rod type plug of oil and gas gathering and transferring pipeline

The invention relates to a bracing rod type plug of an oil and gas gathering and transferring pipeline. By means of the plug, the problem that how to quickly achieve isolation of oil from gas during pipeline hot operation is solved. According to the technical scheme, the thread joint end of a center shaft is provided with two Z-shaped slots, a sealing leather cup is a bowl-shaped center strip hole, is mounted in the step position of the center shaft and adheres to the center shaft through sealing adhesives, and an annular slot is formed in the sealing end of the sealing leather cup; six bracing rods are distributed symmetrically, one ends of the bracing rods are hinged to a supporting base, and the other ends of the bracing rods are hinged to a sliding spring base; two raised heads are arranged in the center of a push plate symmetrically; four spline slots are formed in the outer end of the push plate; two raised heads are arranged on a pull rod; and a hollow shaft is provided with two Z-shaped through slots. The oil and gas pipeline is plugged fast by adoption of simple mechanical actions, and can be recycled automatically after construction, so that the pipeline rush-repairing efficiency is improved and the rush-repairing cost is saved.

Owner:SOUTHWEST PETROLEUM UNIV

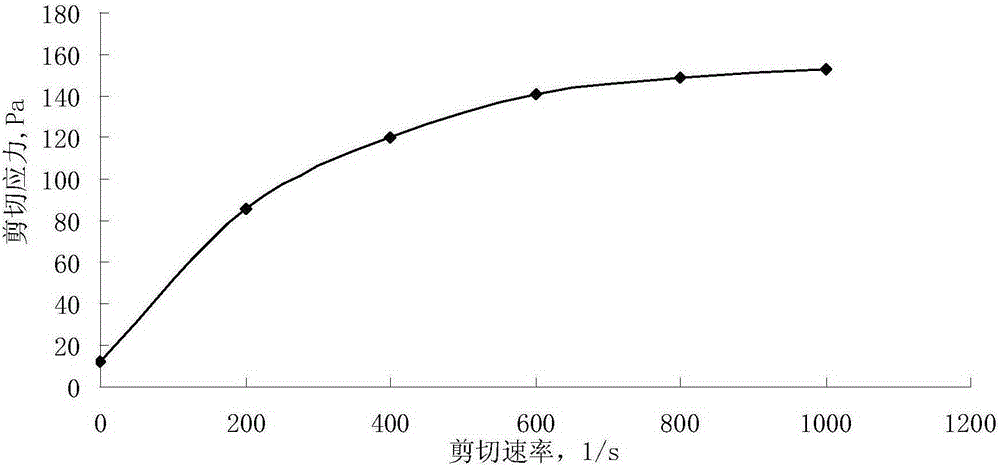

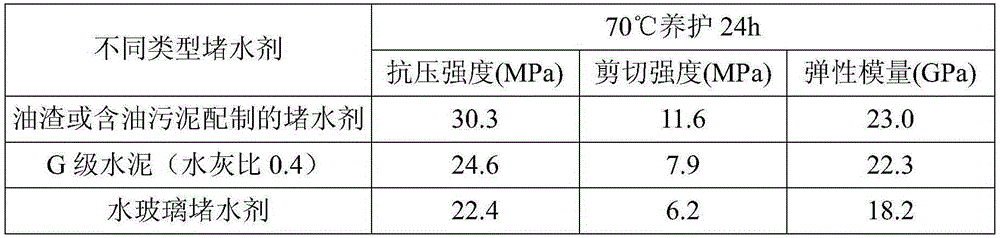

Water plugging agent prepared by utilizing oil residues or oil-containing sludge and preparation method thereof

ActiveCN105295877AHigh compressive strengthImprove high temperature resistanceDrilling compositionSealing/packingSodium BentoniteSludge

The invention provides a water plugging agent prepared by utilizing oil residues or oil-containing sludge and a preparation method thereof. The water plugging agent comprises the following preparation raw materials in percentage by weight: 30 percent to 60 percent of oil residues or oil-containing sludge, 5 percent to 15 percent of bentonite, 5 percent to 10 percent of cement, 0.5 percent to 5 percent of thixotropic agent, 0.5 percent to 5 percent of inorganic retarder and the balance of water. The invention also provides the preparation method of the water plugging agent prepared by utilizing the oil residues or the oil-containing sludge. The water plugging agent prepared by utilizing the oil residues or the oil-containing sludge, which is provided by the invention, has high compressive strength, good high-temperature resistance and good rheological property and thixotropy; plugging on a leaked channel can be implemented by adopting a small quantity of water plugging agent; the water plugging agent has good plugging selectivity in a severe heterogeneous oil reservoir and has excellent plugging performance for a high permeability channel. The oil residues and the oil-containing sludge which are products discharged by an oil extraction plant are comprehensively utilized, which not only reduces cost and difficulty in processing the oil residues and the oil-containing sludge, but also reduces pollution of the oil residues and the oil-containing sludge to the environment.

Owner:PETROCHINA CO LTD

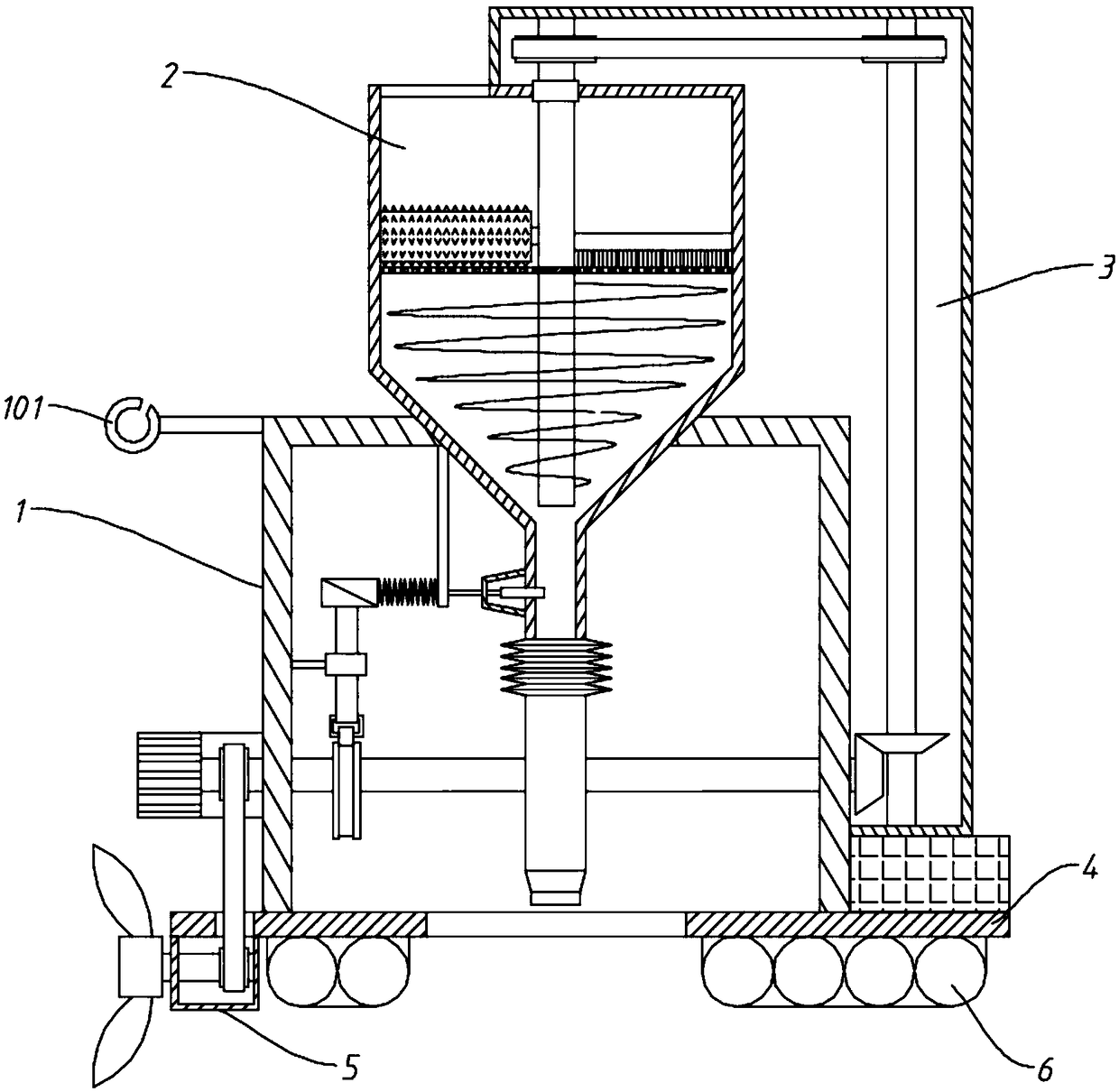

Batch feeding stirring device for chemical production

InactiveCN108940021AGuarantee sufficiencyRealize blockingRotary stirring mixersTransportation and packagingEngineeringBevel gear

The invention discloses a batch feeding stirring device for chemical production. The batch feeding stirring device comprises a mixing box and an auxiliary material tank, wherein a vertically arrangedrotating shaft is rotationally arranged inside the mixing box; a driven bevel gear is fixedly arranged on the top of the rotating shaft; an eccentric wheel is fixedly arranged at the end of a rotatingrod positioned in the auxiliary material tank; a lifting sleeve is arranged on the excircle of the eccentric wheel in a sleeving manner; a supporting connecting rod is fixedly arranged on the lower surface of the middle of the lifting sleeve; a plugging block is fixedly arranged at the bottom end of the supporting connecting rod; a notch is formed in the side wall on the lower part of the plugging block; a blanking cylinder communicated with the inner cavity of the mixing box is arranged on the inner cavity bottom plate of the auxiliary material tank; and a driven bevel gear meshed with the driven bevel gear is fixedly arranged on the excircle of the rotating rod. According to the batch feeding stirring device disclosed by the invention, the auxiliary materials enter the mixing box in batches, so that the raw materials are fully stirred and mixed, and the stirring device is simple in structure and convenient to operate and has high popularization value.

Owner:嘉兴迪迈科技有限公司

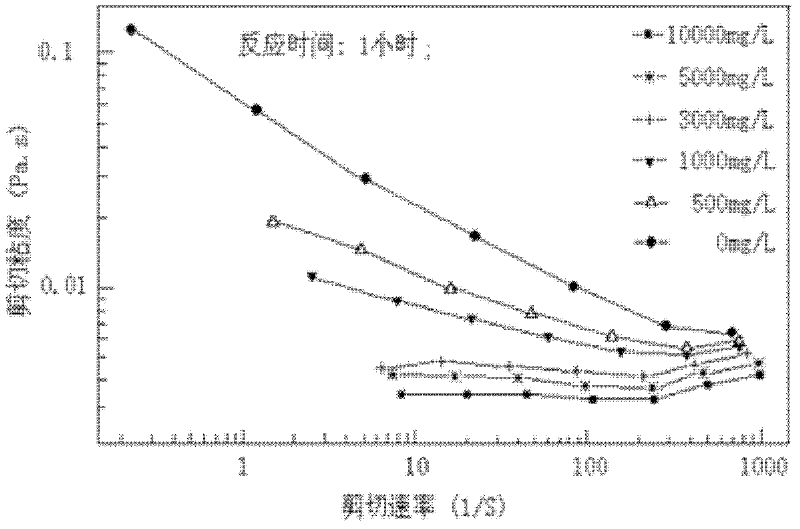

Profile controlling and flooding composition and profile controlling and flooding method

ActiveCN104650842ASimple compositionGood dispersionFluid removalDrilling compositionPolyacrylamideNonionic surfactant

The invention provides a profile controlling and flooding composition and a profile controlling and flooding method. The profile controlling and flooding composition comprises a first blocking agent and a second blocking agent, wherein the first blocking agent comprises the following components in parts by weight: 0.08-0.11 part of xanthan gum, 0.25-0.34 part of a retarder, 0.8-1.2 parts of a nonionic surfactant, 1-3 parts of aluminum hydroxide and 98-99 parts of water; the first blocking agent also contains 350ppm to 430ppm of polyacrylamide; the second blocking agent comprises the following components in parts by weight: 0.18-0.23 part of aluminum citrate, 0.18-0.21 part of sodium dichromate, 0.8-1.2 part of acetic acid, 0.4-0.6 part of a gel accelerant and 97-98 parts of water. The profile controlling and flooding composition is good in blocking property in oil preservation at a temperature higher than 150 DEG C, simple in gel formation process, resistant to scouring, wide in application range and capable of realizing both water flooding and alkali flooding.

Owner:PETROCHINA CO LTD

Concrete curing agent, preparation method and application thereof

The invention discloses a concrete curing agent. The concrete curing agent comprises the following materials in percentage by weight: 1%-30% of potassium silicate, 0.01%-0.5% of penetrating agent, 0.5%-1.5% of water repellent, 0.5%-1% of surface active agent, 0.3%-1% of surface modifying agent and the balance of water, wherein the modulus of the potassium silicate is more than 5. The invention also provides a preparation method of the concrete curing agent. The preparation method comprises the following steps of: uniformly mixing the components in the formula according to the mass percentage, stirring and obtaining the concrete curing agent. The invention also provide a construction method of the concrete curing agent. The construction method comprises the following steps of: polishing concrete floors, brushing the concrete floors with the curing agent, and then polishing. The concrete curing agent disclosed by the invention has the advantages that due to addition of the high-modulus potassium silicate, silicate ions in the curing agent reacts with unreacted free ions in concrete to generate a complex, and then the complex is filled in capillary pores in concrete, so that the blocking for fine pores of concrete structures, the effects of sealing and curing are achieved, the strength and the hardness of the concrete are improved to a greater extent, and the sanding of the concrete is prevented.

Owner:CHONGQING EP ANTICORROSION TECH CO LTD

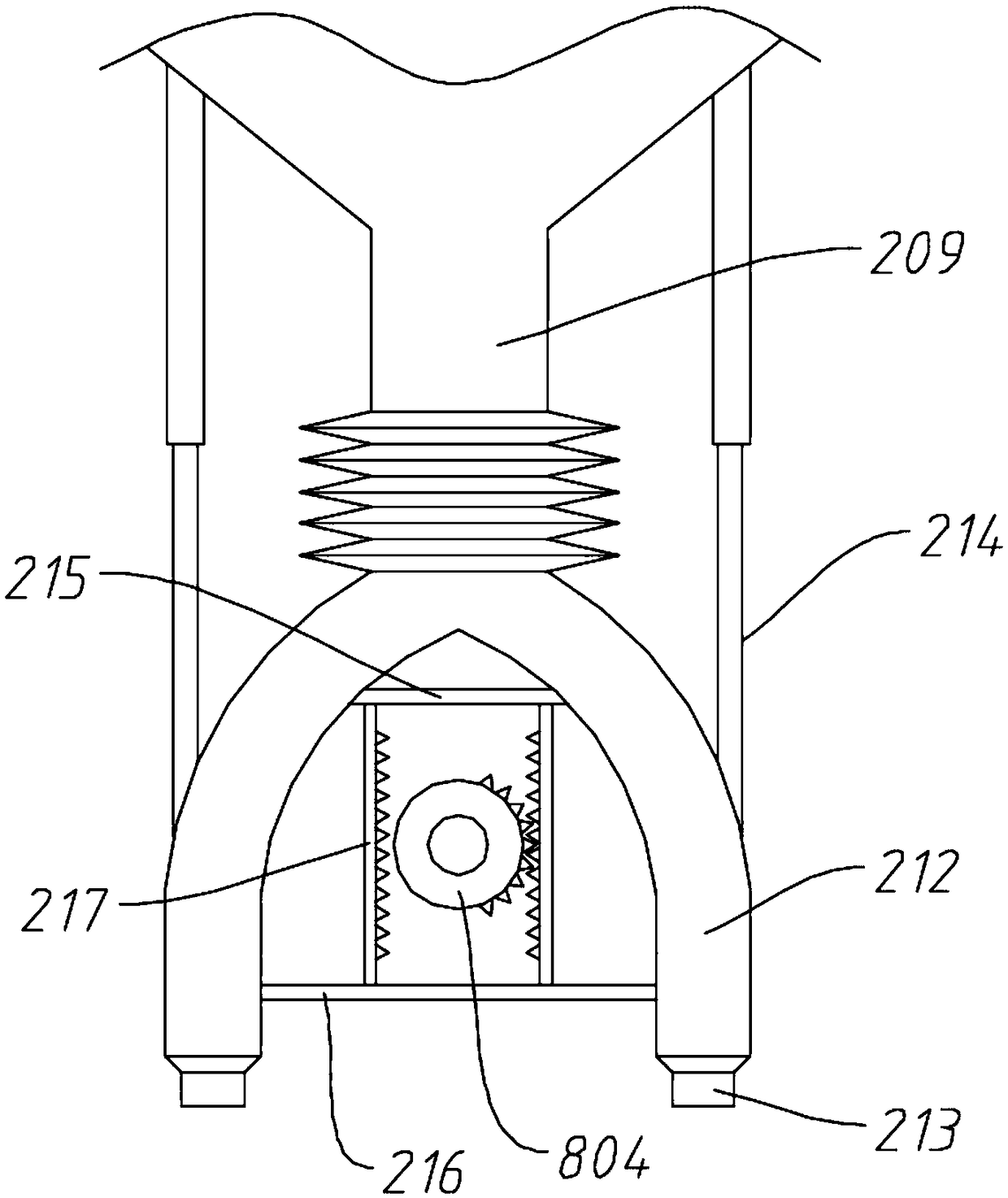

Pipeline interior rapid self-locking blockage device

The invention discloses a pipeline interior rapid self-locking blockage device and belongs to the technical field of pipeline blockage. The pipeline interior rapid self-locking blockage device is reliable in blockage and can achieve flow guiding. According to the adopted technical scheme, a blockage unit is an inflatable blockage device and is provided with an axial through hole; a traction unit is of a structure with an electric control valve mounted on a hollow pipe, and an outer thread is formed on the hollow pipe; a tensioning unit comprises the structure that axial through holes are formed in a fixed seat and a movable seat correspondingly, the fixed seat and the movable seat are connected through a spring, one ends of first supporting rods are hinged to the fixed seat, antiskid blocks are hinged to the other ends of the first supporting rods, one ends of second supporting rods are hinged to the movable seat, and the other ends of the second supporting rods are hinged to the middles of the first supporting rods; and the hollow pipe penetrates through the tensioning unit and then is fixed to the blockage unit together, a first gear and a sleeve are mounted on the hollow pipe ina sleeving mode, and a second gear is fixed to an output shaft of a motor and engaged with the first gear. The pipeline interior rapid self-locking blockage device is used for pipeline blockage.

Owner:ZHONGBEI UNIV

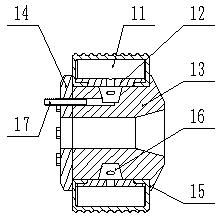

Gas filling and gas supply joint for gas cylinder and high-pressure gas cylinder using same

ActiveCN104295891AHigh degree of integrationImprove long-term storage performanceContainer filling methodsContainer discharging methodsGas cylinderProcess engineering

The invention provides a gas filling and gas supply joint for a gas cylinder and a high-pressure gas cylinder using the same. The gas filling and gas supply joint for the gas cylinder comprises a gas filling sealing device and a cylinder opening gas supply device, wherein the gas filling sealing device comprises a first transfer block, a gas filling channel is arranged on the first transfer block, the gas filling channel comprises a gas inlet end for filling gas, a tapered hole segment is arranged in the gas filling channel, the gas filling sealing device further comprises a steel ball which is hermetically matched with the tapered hole segment for blocking the gas filling channel, the cylinder opening gas supply device comprises a second transfer block, a gas supply channel communicated with an inner cavity of the gas cylinder via the gas filling channel is arranged on the second transfer block, the gas supply channel comprises a gas outlet end for gas supply, and the cylinder opening gas supply device further comprises an ejection mechanism for pushing the steel ball away from a sealing position to conduct the gas filling channel. The gas filling and gas supply joint provided by the invention has high degree of integration, can complete corresponding gas filling and gas supply operations at the same end of the gas cylinder and has a wide range of applications.

Owner:CAMA LUOYANG GAS SUPPLY

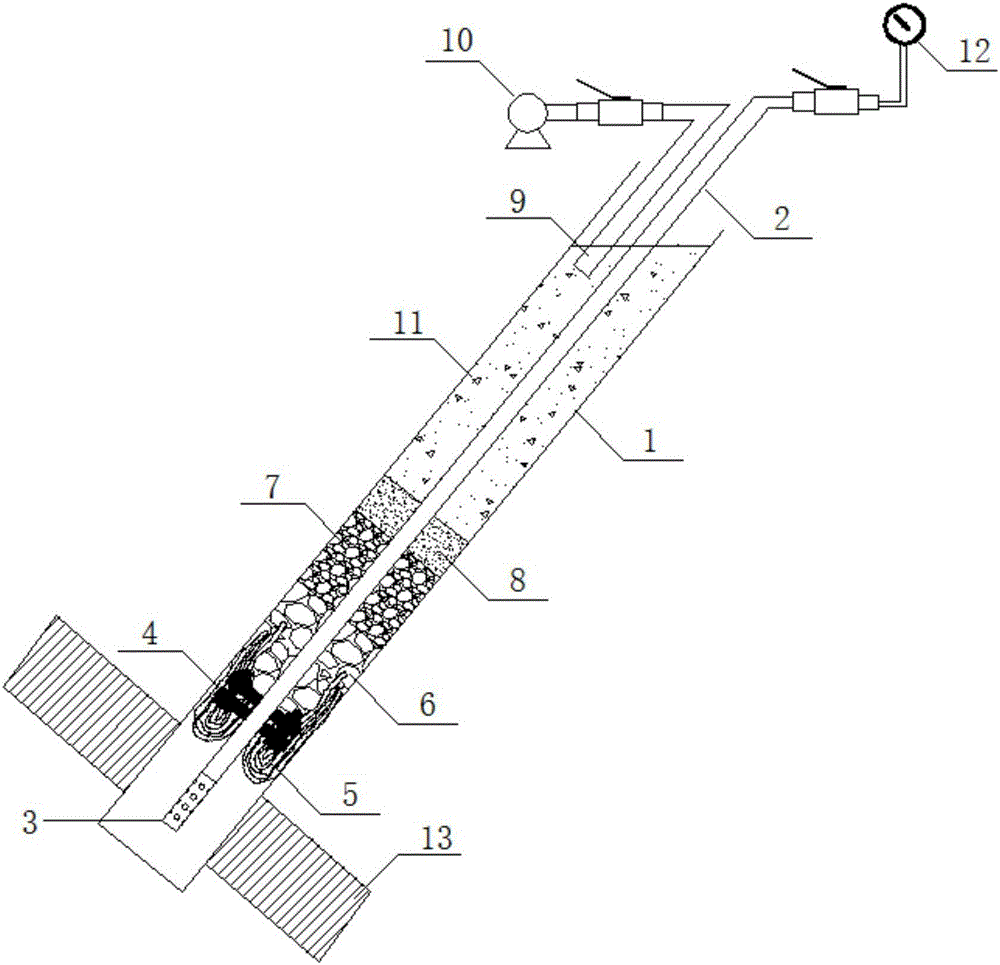

Device and method for leaking stoppage of open hole in coal-series gas exploration well

PendingCN109723404AShorten the cleaning timeIncrease the amount of slurry injected into the leakage sectionSealing/packingCoalDrill

The invention relates to a device for leaking stoppage of an open hole in a coal-series gas exploration well, which comprises a grouting pump, a water injection pump, hollow drill rods and a packer, wherein the wellhead of the coal-series gas exploration well is provided with a surface sleeve, multiple sections of hollow drill rods extend into the coal-series gas exploration well from the wellheadof the coal-series gas exploration well, the packer is arranged outside the lower end of one section hollow drill rod, the grouting pump is connected with the upper end of the uppermost section hollow drill rod through a grouting pipe, the water injection pump is connected with an air inlet of the inner wall of the packer through a water injection pipe, the water injection pipe is arranged alongthe inner wall of the hollow drill rods, and the water injection pipe penetrates out of the grouting pipe at the wellhead of the coal-series gas exploration well and is connected with the grouting pipe in a sealing way. The invention also discloses a leaking stoppage method of the device. The method effectively solves the limitation of leakage stoppage methods using inert materials, conventional cement, casing sealing and the like, provides a new leakage stoppage device and method for a coal-series gas exploration well, optimizes a pumping procedure method and achieves the purpose of leakage stoppage, and has important practical significance for exploration and development of coal-series gas resources.

Owner:中国煤炭地质总局广东煤炭地质局勘查院

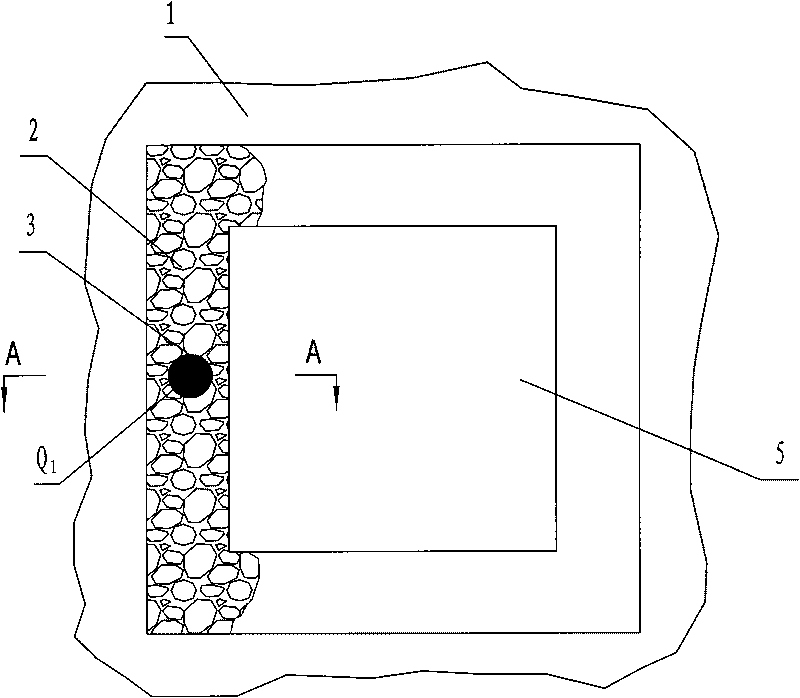

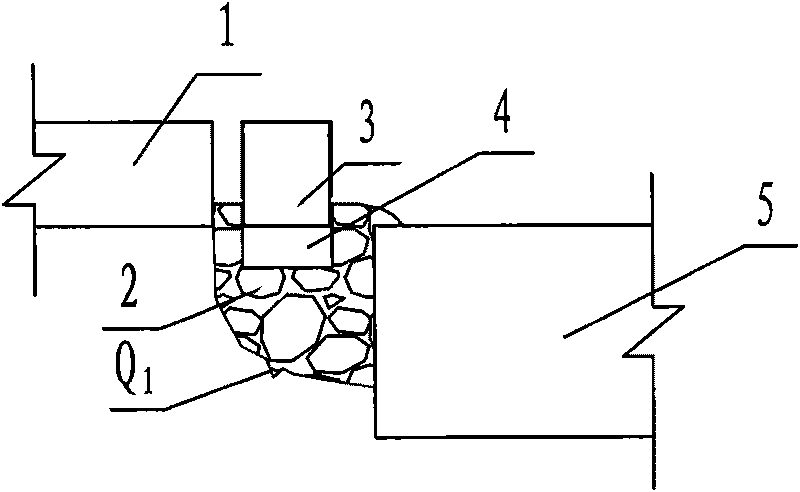

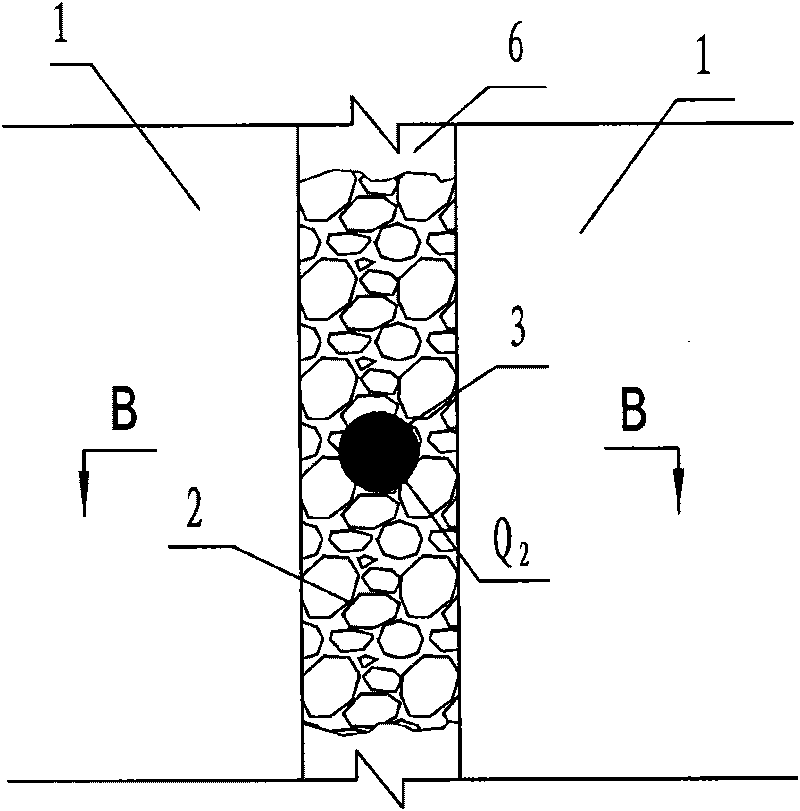

Processing method for large karst cave underground river with water gushing and structure thereof

ActiveCN105821894ARealize blockingLow costFoundation engineeringSealing/packingGeomorphologyWater flow

The invention discloses a processing method for a large karst cave underground river with water gushing. The method comprises the steps that the form and the development scale of a karst cave are proved through supplement exploration and CT physics exploration examinations; grouting tunnels in the karst cave are subjected to expanding excavation downstream; the upstream side of an end cap used for blocking the karst cave is arranged in the high and wide position of the karst cave, and the downstream side of the end cap used for blocking the karst cave is arranged in the low and narrow position of the karst cave so as to facilitate stability of a blocking body; steel tube railing piles are arranged on the downstream side of the end cap; grouting mold bags are arranged on the upstream sides of the steel tube railing piles; the upstream sides of the grouting mold bags are filled with gradating materials; the gradating materials are subjected to pre-consolidation grouting and controlled grouting; and curtain grouting is conducted along curtain lines. Under the conditions that the development scale of the karst cave is large and the underground river has rushing current with water gushing, the steel tube railing piles and the grouting mold bags are combined so that water can be blocked and a dam can be formed under the condition of the rushing current, late-stage consolidation grouting and curtain grouting are combined, and the karst cave of the type can be blocked.

Owner:SINOHYDRO FOUND ENG

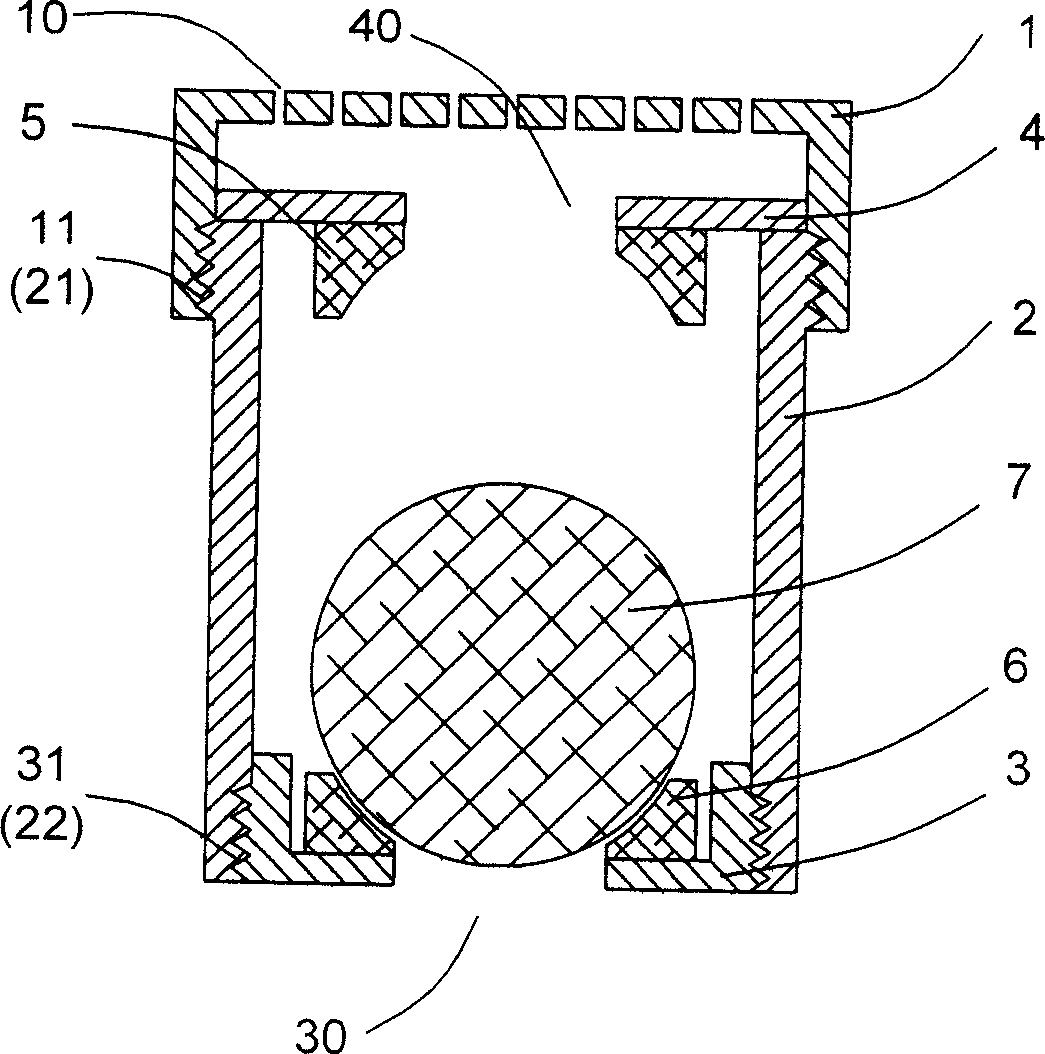

Sewer decomposer

InactiveCN1730851APromote rapid formationGood blockingDomestic plumbingMechanical engineeringSewerage

The sewer decomposer includes one main structure comprising water inlet end cap, float ball bin and water outlet end cap connected successively, float ball set inside the float ball bin, and upper sealing ring and lower sealing ring set separately on the water inlet end cap and the water outlet end cap. The close contact between the upper sealing ring and the lower sealing ring with float ball avoid the upward flow of sewage and the leakage of the sewer smell. The upper sealing ring has concave spherical surface of curvature radius equal to or smaller than the radius of the float ball, while the lower sealing ring has concave spherical surface of curvature radius equal to or greater than the radius of the float ball, so that one layer of water film in certain tension is formed between the float ball and the lower sealing ring for avoiding the leakage of bad sewer smell. The present invention may be used to replace traditional drain trap and floor drain.

Owner:郝建兵

Plugging construction method of reserved opening of basement soleplate and tower crane foundation and post-pouring zone reserved opening

InactiveCN101748753ARealize blockingImprove practicalityArtificial islandsUnderwater structuresBasementTower crane

The invention relates to a plugging construction method of a reserved opening of a basement soleplate and a tower crane foundation and a post-pouring zone reserved opening, which comprises the following steps of: on the basis of pumping out the water in a foundation and cleaning and preprocessing the reserved openings, arranging a water-stopping sleeve pipe of which the length conforms to the thickness of the basement soleplate at a position with larger water yield or at the position of a spring mouth, arranging a blocking-stone blocking-concrete isolated layer below the water-stopping sleeve pipe, fully laying cobblestones as a permeable layer within the range of 0.8-1.5m around the water-stopping sleeve pipe, horizontally laying a steel fabric sheet on the cobblestone permeable layer, then putting a diving pump into the water-stopping sleeve pipe to continuously pump the water, casting and compacting concrete to plug the reserved openings while pumping the water, and enabling the diving pump to stop pumping the water after the concrete is cast and compacted for 3 days; and after the final set of the concrete for plugging the reserved openings for 7 days, then rapidly taking out the diving pump, adopting a water-stopping sleeve pipe top closing assembly and pouring waterproof concrete to plug the pipe mouth of the water-stopping sleeve pipe. The method also can high-quality realize the plugging construction of the reserved opening of the basement soleplate and the tower crane foundation and the post-pouring zone reserved opening between the basement soleplates when the underground water quantity is large and the water pressure is high.

Owner:广西建工第五建筑工程集团有限公司

Intake grille assembly and vehicle provided with intake grille assembly

ActiveCN109109654AImprove installation efficiencyEase of subsequent maintenanceAerodynamics improvementComponent optimizationEngineeringElectric vehicle

The invention belongs to the technical field of an intake grille of a vehicle, and aims at solving the problem of poor sealing performance of an existing intake grille assembly. Therefore, the invention provides an intake grille assembly and a vehicle provided with the intake grille assembly. The intake grille assembly comprises a grille frame, an air inlet of which is provided with a mounting seat. A blade is rotatably mounted to the mounting base, a set gap is arranged between the end of the mounted blade body the bottom surface of the mounting base; a drive member is used for driving the blade to rotate to open or close the air inlet; wherein the end of the body extends toward the axial end of the rotating shaft to form a sealing rib, and the mounting seat is formed with blocking portions on both sides of the axial hole, and the sealing rib can abut or separate from the blocking portion during the rotation of the blade. The intake grille assembly of the invention can effectively improve the sealing effect of the blades, thereby reducing the wind resistance in the driving process of the automobile, further improving the fuel performance of the engine, reducing the fuel consumption of the engine, reducing the driving cost, or increasing the range of the electric vehicle.

Owner:NIO ANHUI HLDG CO LTD

Convenient-to-adjust vegetable and fruit enzyme grinding equipment

The invention belongs to the technical field of vegetable and fruit enzyme production equipment and relates to convenient-to-adjust vegetable and fruit enzyme grinding equipment. According to the equipment, a servo motor is adopted for driving a first rotating shaft to rotate, so that a first cylindrical cam rotates along with the first rotating shaft; a second connecting rod drives a blocking plate to move leftwards and rightwards, and therefore, an outlet in the bottom of a material storage cavity is blocked or opened for intermittent discharging. A bending rod moves along with the second connecting rod; a sliding shaft is matched with a linear hole, so that a third connecting rod drives a fourth connecting rod to move in the direction of a sliding groove; and therefore, an upper grinding plate reciprocates to be matched with a lower grinding assembly below the upper grinding plate to grind enzyme blocks. A gap between the upper grinding plate and a lower grinding plate is convenientto adjust; an adjusting screw rod is rotated through a hand wheel, so that a movable nut drives a seventh connecting rod to move through a sixth connecting rod; and therefore, a wedge-shaped block moves leftwards or rightwards. Since the inclined surface of the wedge-shaped block is matched with a third roller, the lower grinding plate moves upwards or downwards, so that the gap between the uppergrinding plate and the lower grinding plate is changed; and therefore, the size of ground particles can be adjusted.

Owner:安徽易码数据科技有限公司

Novel intelligent plugging device

A novel intelligent plugging device mainly comprises a plugging assembly and a power assembly. During pipeline maintenance operation, the novel intelligent plugging device is pushed by an upstream medium in a pipe to move forwards, a communication module in the power assembly receives a plugging command, a control module drives a micro hydraulic module, high-pressure fluid is injected into a mainhydraulic cylinder of the plugging assembly through a high-pressure hose, and thus a packing ring and a locking slip expand in the radial direction so that plugging can be achieved; and after the operation is finished, the communication module receives a de-plugging command, the control module drives the micro hydraulic module to pump the high-pressure fluid back, the packing ring and the lockingslip recover to the original position so that de-plugging can be achieved, and the novel intelligent plugging device is pushed by the medium to return to the ball receiving end of the pipe. The novelintelligent plugging device has the advantages that the original pipe is not destroyed, plugging is more reliable, the maintenance time is shortened and the labor cost is reduced, and has the broad application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Design method of expansion sleeve for oil field

The invention relates to a method of designing a pipe column used in the operation of an expansion casing in the petroleum industry, in particular to a method of designing an expansion casing with buffering capacity. The invention is characterized in that: a buffering mechanism is arranged on the expansion casing to reduce impact and pressure on the expansion casing, and the buffering mechanism is a slip joint. The expansion casing is at least provided with an expansion pipe (2), an expansion cone (10) and a pipe column (1); wherein the lower end of the expansion pipe (2) is connected with a plug (11), the expansion cone is arranged on a preformed pyramidal section of the expansion pipe (2); the upper end of the expansion pipe (2) is connected with the pipe column (1), and the slip joint is arranged between the pipe column (1) and the expansion cone (10). The invention reduces the risk in the process of expansion operation, improves the reliability in the process of the operation of the expansion casing, and is convenient for maintenance.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

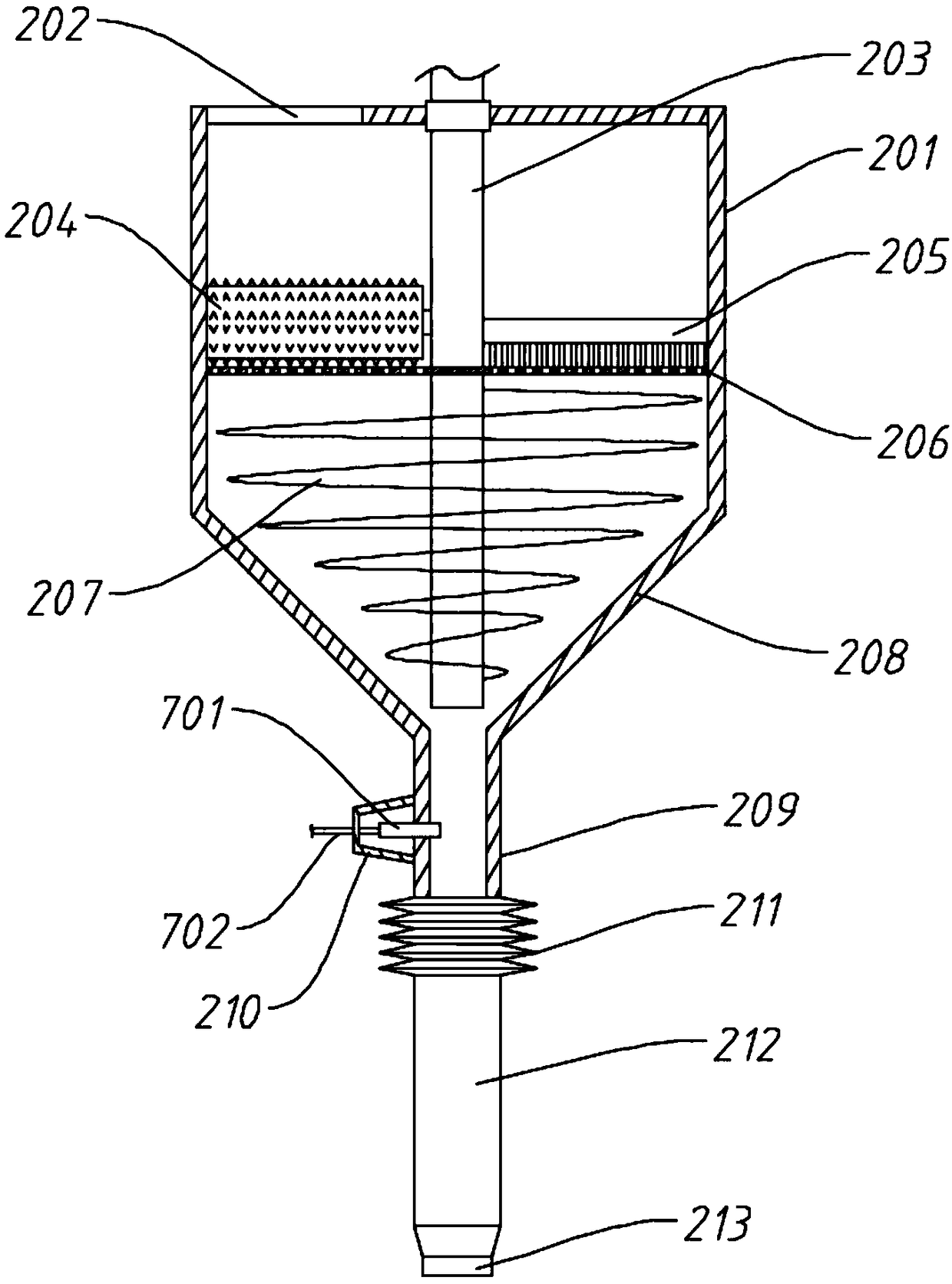

Self-walking type feeding robot for aquaculture

ActiveCN109349191ARealize blockingReduce the amount of sticky wallClimate change adaptationPisciculture and aquariaSpiral bladePipe fitting

The invention relates to the technical field of aquaculture feeding, in particular to a self-walking type feeding robot for aquaculture. A servo motor serves as a power source and drives a rotating shaft II to rotate; the rotating shaft II drives a rotating shaft IV to rotate, so as to drive spiral blades to rotate, and a thrust is generated to push the robot to move forwards; when the robot is pushed, the rotating shaft II drives a cam to rotate, so as to enable a vertical rod to move up and down, so that a movable plate is driven by a horizontal rod to move in a reciprocating manner under the action of a wedge-shaped block to open or close a repeater section to realize intermittent discharging suitable for robot pushing feeding; a discharging pipe which is of an overall inverted U shapeand composed of two bent pipe fittings with communicated tops is provided, so that disperse discharging is realized, and a feeding region is enlarged; the top of the discharging pipe is communicated with the repeater section through a corrugated pipe; and the rotating shaft II drives an incomplete gear to rotate to intermittently act on racks on two sides, so as to drive the discharging pipe to move up and down to shake materials, and the feed adhesion amount is reduced.

Owner:山东创乾海洋科技有限公司

Method for sealing large-dip-angle downward gas pressure determination drill hole

The invention discloses a method for sealing a large-dip-angle downward gas pressure determination drill hole. Through multiple plugging means, the phenomena of gas leakage and liquid leakage caused by that a downward hole is not tightly sealed can be avoided, the hole sealing quality can be improved, and the accuracy of determining gas pressure of a coal seam is guaranteed. The method comprises the following steps that firstly a large-dip-angle drill hole of which the diameter is 75mm is constructed towards a downward target coal seam from a tunnel; two discs are connected to the tail part of an antipriming pipe with bolts, and crude cotton yarns are clamped between the two discs so that a mop shape is formed; a pressure measuring pipe is conveyed into a specified drill hole position, and pebbles and coarse sand, with different particle diameters, are sequentially stuffed in the drill hole; finally the drill hole is filled with hole sealing slurry so that the drill hole is sealed. According to the method disclosed by the invention, the difficult problems that when polyurethane is used for blocking the slurry, the polyurethane is very fast to expand and is not easy to convey to a specified point and the hole sealing length is short are solved, and the difficult problems that the slurry blocking effect is not good, so that the slurry leaks into the hole bottom of the downward hole, and gas pressure measurement or extraction and exploitation of gas are influenced are also solved. The method disclosed by the invention has the advantages that the processes are simple, the reliability is high, the slurry blocking effect is good, the construction efficiency is high, the prices of the hole sealing materials are low, and the method is suitable for being widely used in mines.

Owner:CHONGQING UNIV

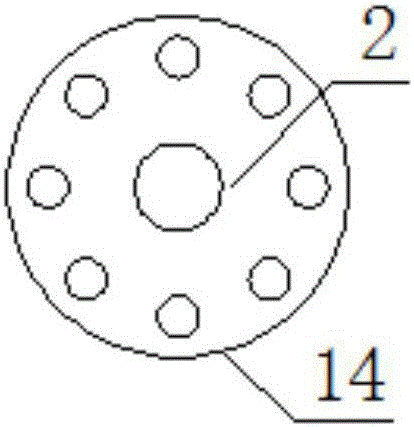

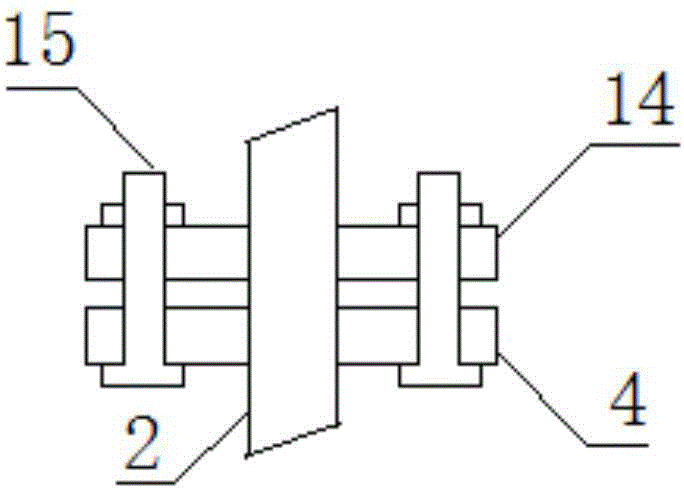

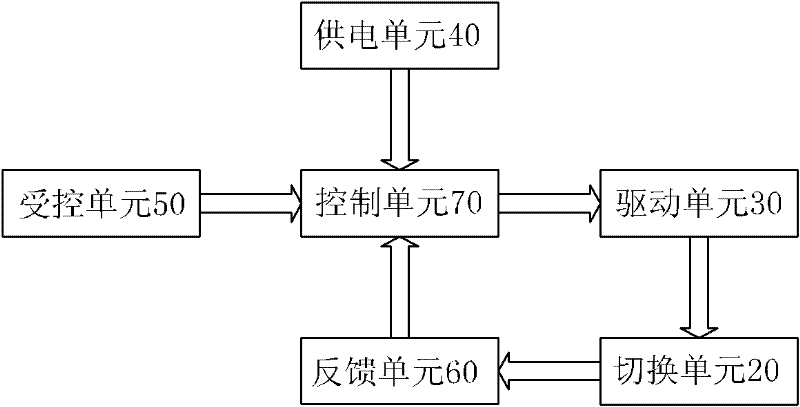

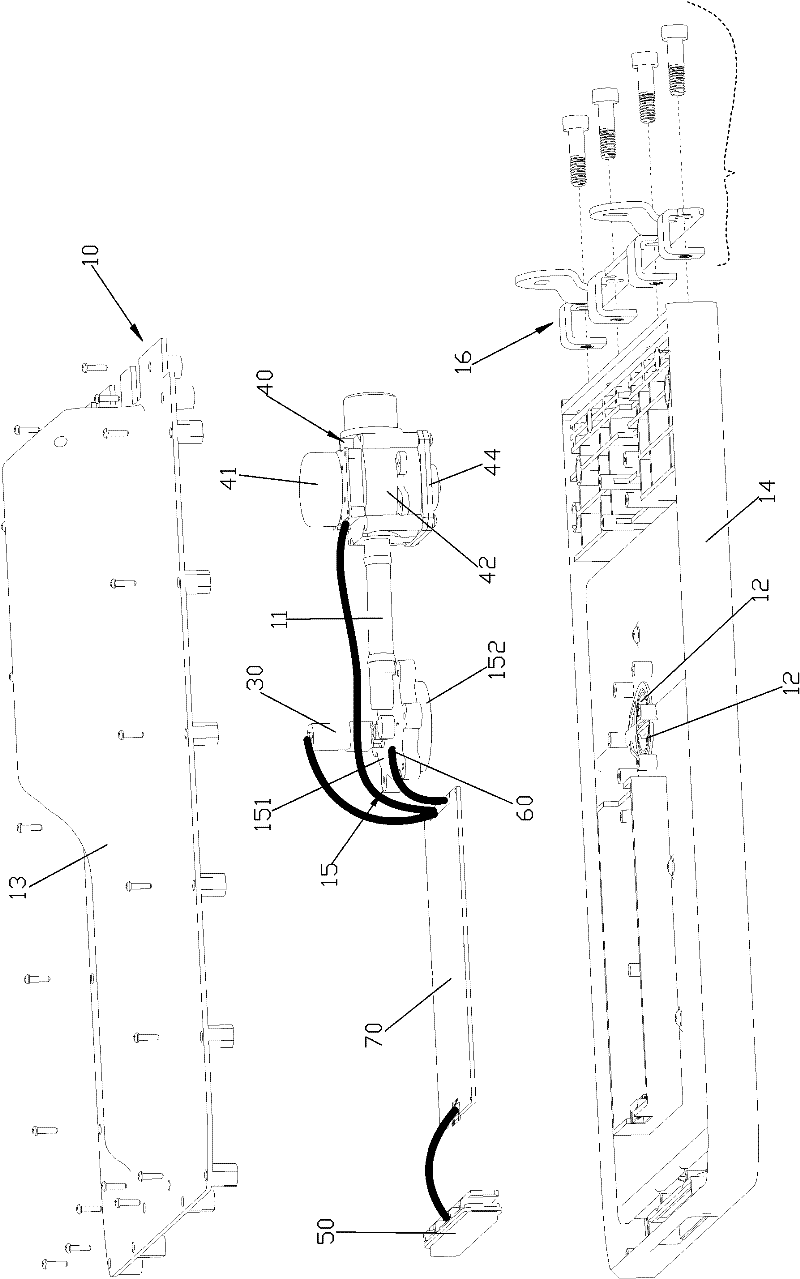

Intelligent feedback switch water passage mechanism and method

InactiveCN102553737ASwitch in place guaranteeSimple structureOperating means/releasing devices for valvesSpray nozzlesEngineeringRelative motion

The invention discloses an intelligent feedback switch water passage mechanism and a method. The mechanism comprises a fixed unit, a switching unit, a driving unit, a power supply unit, a controlled unit, a feedback unit and a controlling unit, wherein the fixed unit is provided with a water inlet passage and a plurality of water outlet passages; the switching unit is movably mounted onto the fixed unit, so that the water outlet passages are switched to be communicated with the water inlet passage by moving the switching unit relative to the fixed unit; the driving unit is mounted onto the fixed unit and is in transmission connection with the switching unit to drive the switching unit to move relative to the fixed unit; the controlled unit is used for receiving a control command input by a user; the feedback unit is mounted onto the fixed unit and used for detecting the motion position of the switching unit; and the controlling unit is connected with the driving unit, the power supply unit, the controlled unit and the feedback unit. The invention has the following technical benefits: the water passages are switched by relative motion between the switching unit and the fixed unit, the mechanism has a simple structure and needs fewer parts, and the feedback unit is adopted to ensure the switching accuracy.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

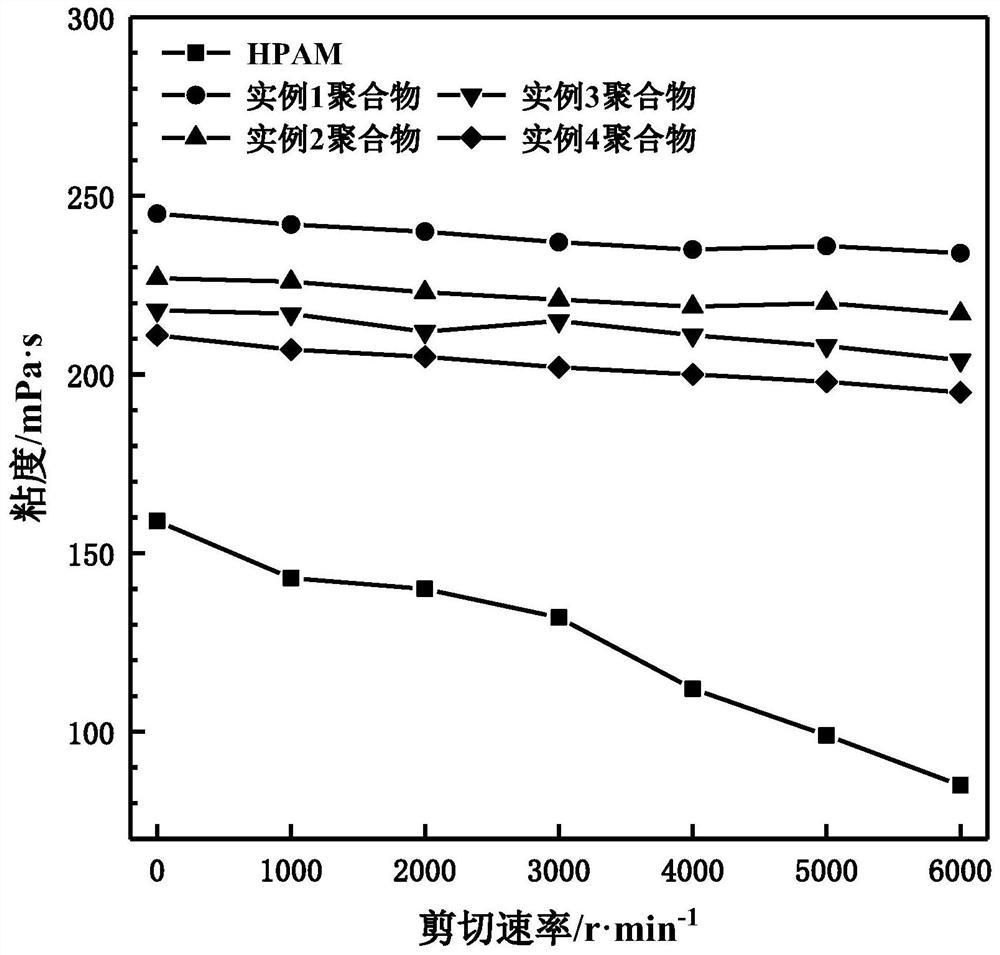

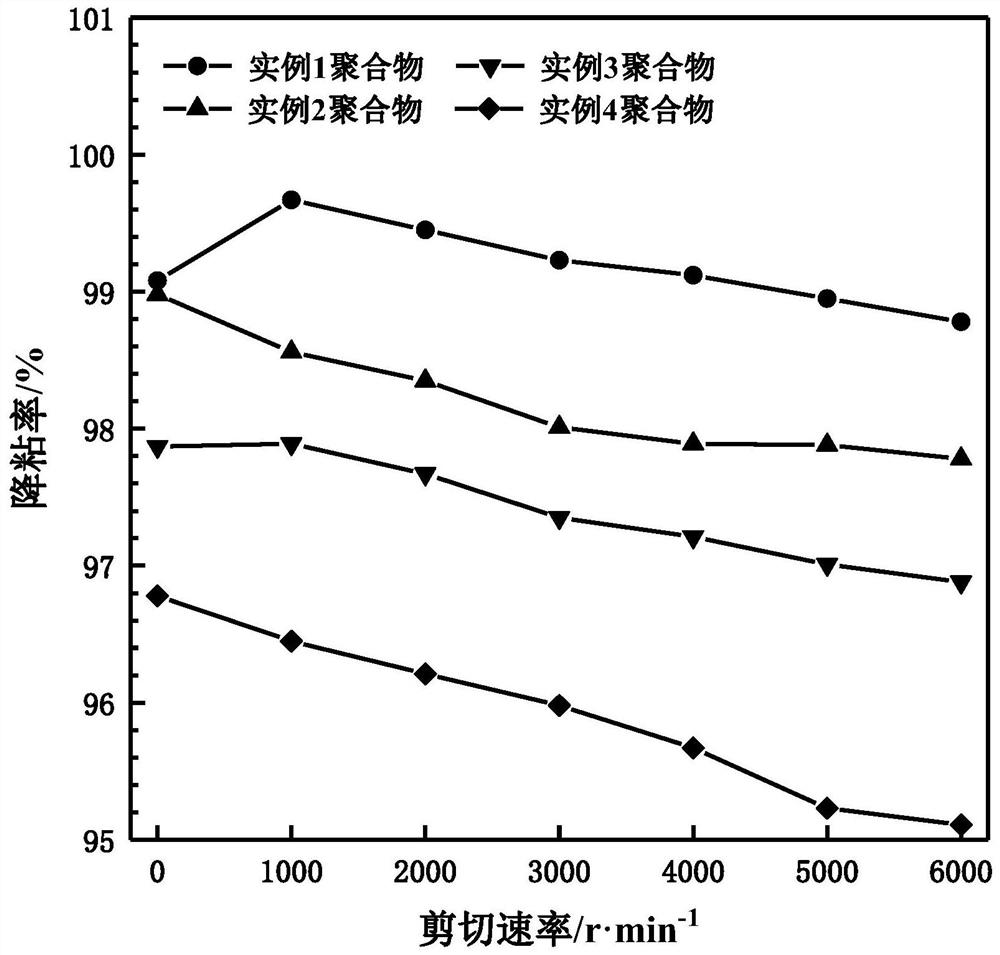

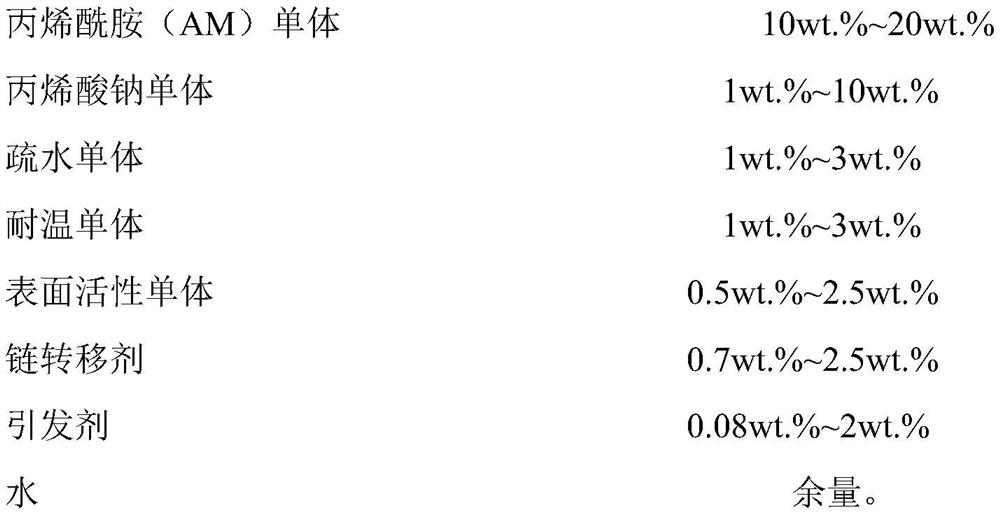

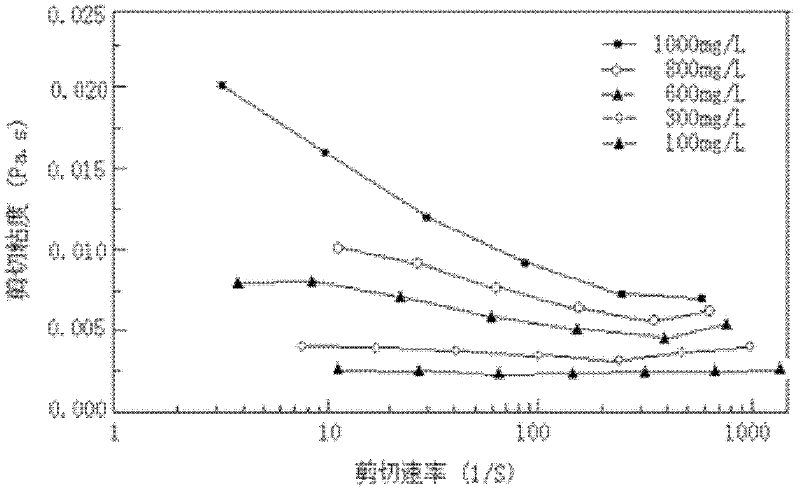

Micromolecular heavy oil viscosity reduction polymer and preparation method thereof

The invention discloses a micromolecular thick oil viscosity reduction polymer and a preparation method thereof. The micromolecular thick oil viscosity reduction polymer comprises the following raw material components: 10 wt.% to 20 wt.% of an acrylamide (AM) monomer, 1 wt.% to 10 wt.% of a sodium acrylate monomer, 1 wt.% to 3 wt.% of a hydrophobic monomer, 1 wt.% to 3 wt.% of a temperature-resistant monomer, 0.5 wt.% to 2.5 wt.% of a surface active monomer, 0.7 wt.% to 2.5 wt.% of a chain transfer agent, 0.08 wt.% to 2 wt.% of an initiator and the balance being water. The micromolecular thick / oil viscosity reduction polymer has quick dissolving performance and good injection performance, can emulsify thick oil, has oil displacement and profile control performance at the same time, and canbe suitable for thick oil recovery of offshore oil reservoirs and low-permeability oil reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

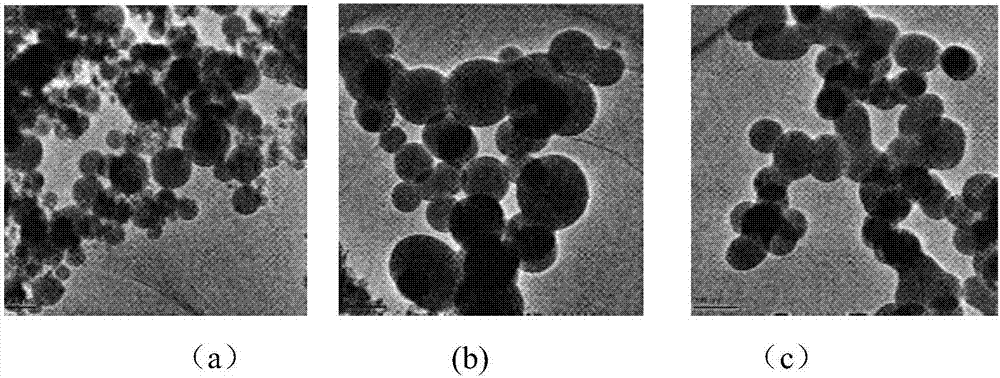

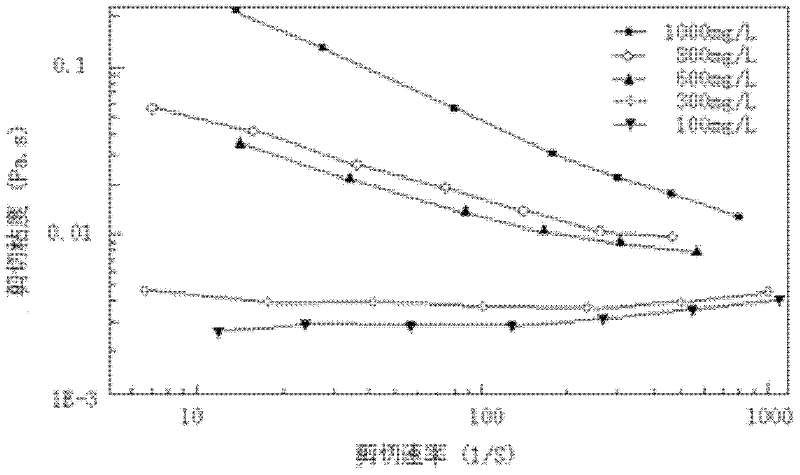

Profile modification agent for epoxy resin emulsion

InactiveCN102443111ASmall particle sizeAppropriate particle sizeDrilling compositionLarge porePolymer chemistry

The invention relates to a profile modification agent for an epoxy resin emulsion, which is used for solving the problem of poor selectivity of the conventional organic resin plugging agent. The profile modification agent for an acrylic monomer grafted epoxy resin emulsion is obtained by polymerizing epoxy resin with an acrylic monomer, neutralizing with N,N-dimethylethanolamine and emulsifying with deionized water, wherein the concentration of the epoxy resin in an emulsion system is 300-600 mg / L, the concentration of the N,N-dimethylethanolamine is 3,000-5,000 mg / L, and the crosslinking ratio is 10:1 or 20:1 or 40:1. When the profile modification agent is in use, a large quantity of gel particles of the emulsion enter large pore canals while a small quantity of or no gel particle enterssmall pore canals, the resistance coefficients of the large pore canals are increased, and the resistance coefficients of the small pore canals are increased at a lower frequency in comparison to thelarge pore canals, so that selective plugging can be realized; and moreover, the profile modification agent has high temperature resistance and high salt resistance, and the emulsion system is stable.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com