Device and method for leaking stoppage of open hole in coal-series gas exploration well

A plugging method and coal-measure gas technology, which is applied in the field of coal-measure gas exploration, can solve the problems of increased plugging cleaning time, complexity, and high cost, and achieve the effects of shortening drilling and plugging cleaning time, optimizing pump injection procedures, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

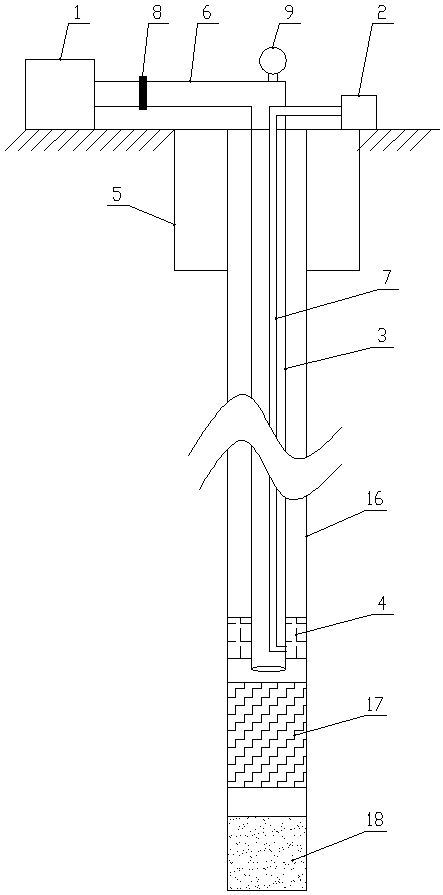

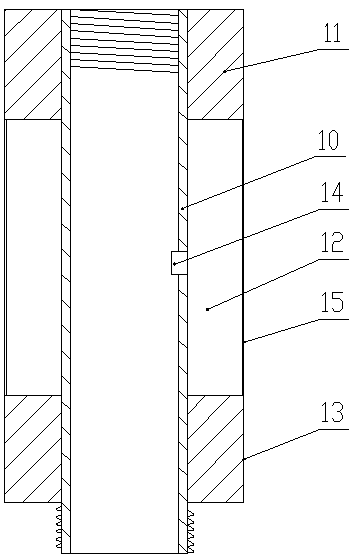

[0036] Such as figure 1 and figure 2 As shown, the open hole plugging device for coal-measure gas exploration wells of the present invention includes a grouting pump 1, a water injection pump 2, a hollow drill pipe 3 and a packer 4. The grouting pump 1 and the water injection pump 2 are both arranged on the ground, and the hollow Several sections of drill pipe 3 are arranged in series, and the wellhead of coal-measure gas exploration well 16 is provided with surface casing 5, and several sections of hollow drill pipe 3 extend from the wellhead of coal-measure gas exploration well 16 into the interior of coal-measure gas exploration well 16, and the packer 4 is set outside the lower end of one of the hollow drill pipes 3, the grouting pump 1 is connected to the upper end of the uppermost hollow drill pipe 3 through the grouting pipe 6, and the water injection pump 2 is connected to the air intake of the inner wall of the packer 4 through the water injection pipe 7 The water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com