Patents

Literature

160results about How to "Improve cementing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

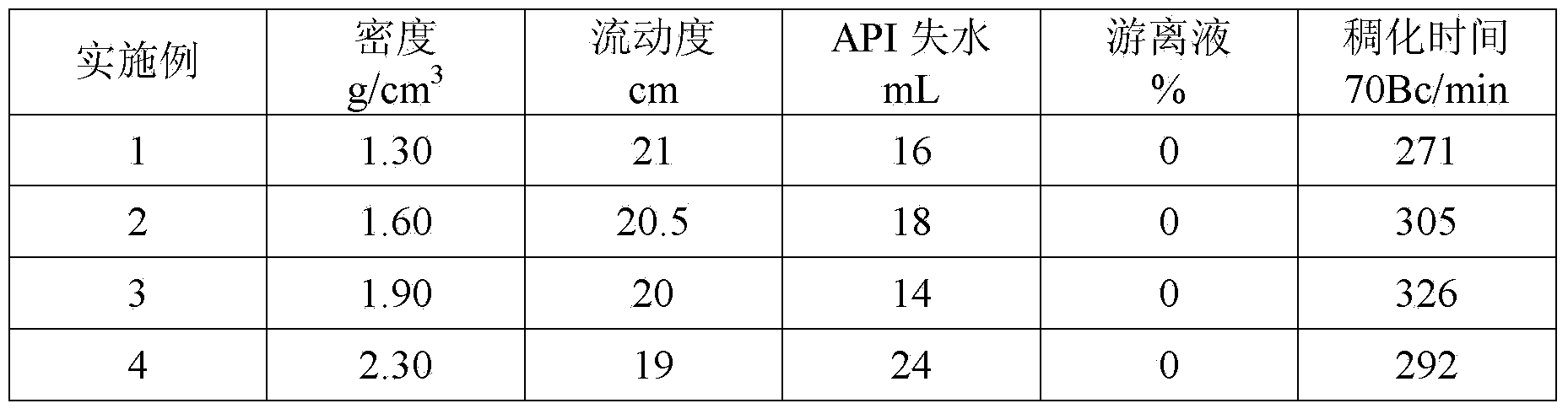

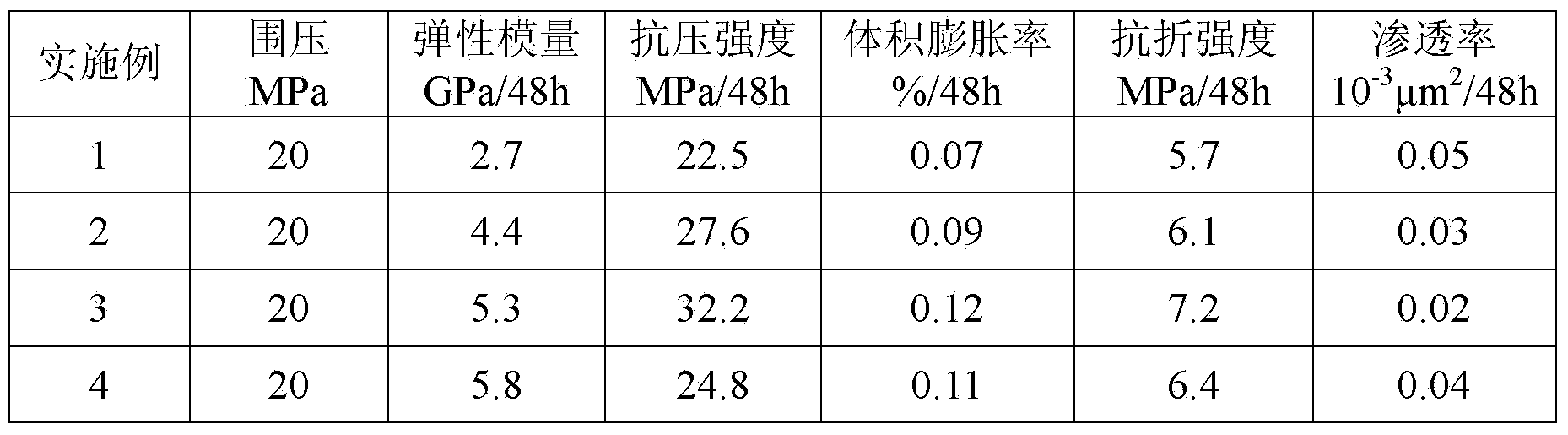

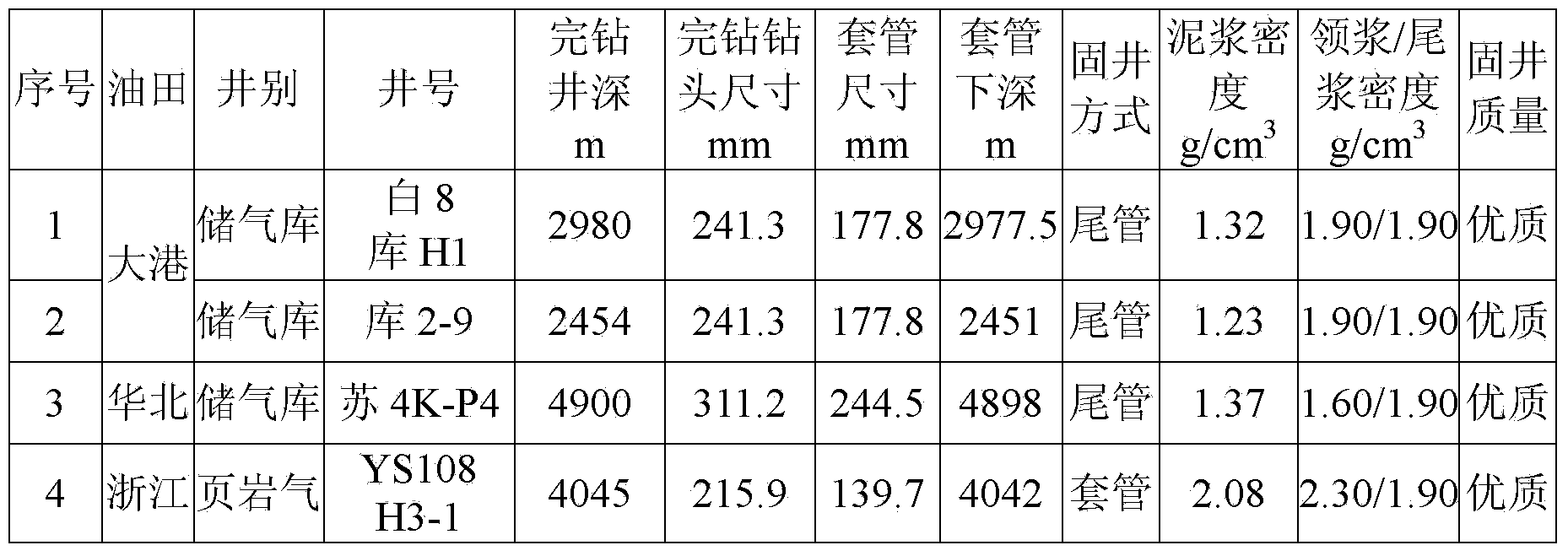

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

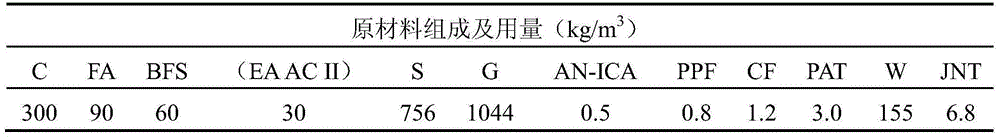

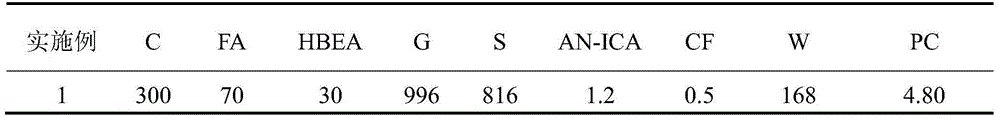

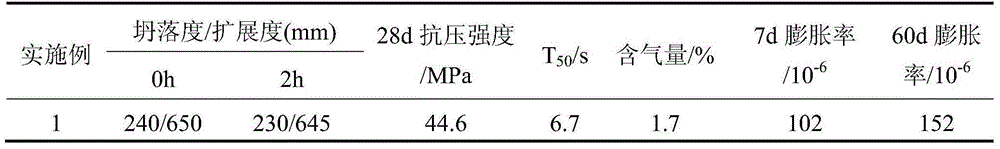

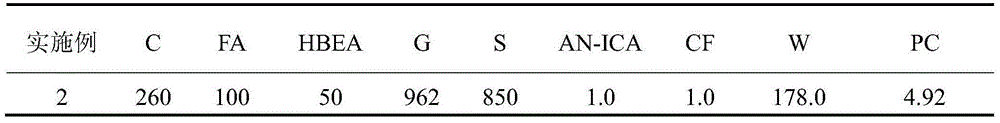

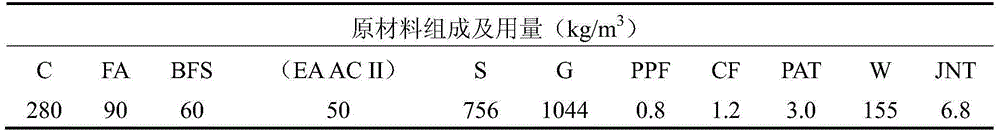

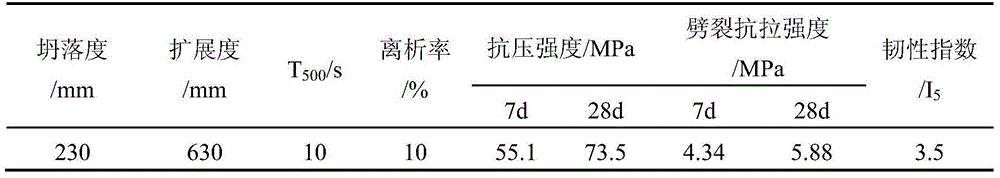

Low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, and preparation method thereof

The present invention discloses a low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, wherein the low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete is prepared from the following raw materials: cement, fly ash, mine powder, an expander, an AN-ICA internal curing agent, crushed stone, river sand, polyacrylonitrile fibers, micro-scale modified degreasing cotton cellulose, a cement slurry microstructure regulation agent, water and an ultra-dispersed water-reducing and shrinkage-reducing superplastic admixture. According to the present invention, the initial slump is more than or equal to 230 mm, the expansion degree is more than or equal to 630 mm, the 28 d compressive strength is more than or equal to 70 MPa, the 28 d splitting tensile strength is more than or equal to 5.8 MPa, the toughness index I5 is more than or equal to 3.0, the 28 d self-shrinkage is less than 100*10<-6>, the 28 d dry shrinkage rate is less than 150*10<-6>, the carbonization grade achieves T-IV, the anti-cracking grade achieves L-V, the product has characteristics of excellent mechanical property, excellent cracking resistance and excellent durability, and the difficult problems of high cement and cementing material material consumption, large shrinkage and easy cracking of the bridge tower concrete at the current stage can be solved.

Owner:WUHAN UNIV OF TECH +2

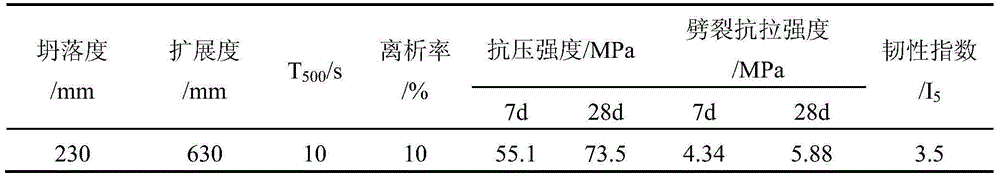

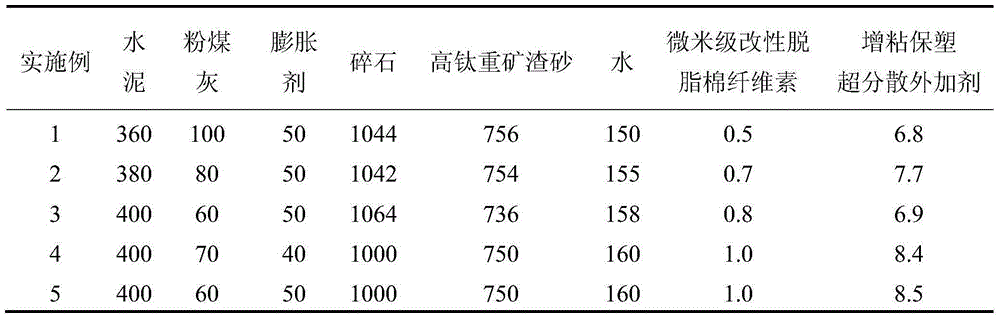

High titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube and preparation method thereof

ActiveCN105060793AImprove cementing performanceFull hydration activitySolid waste managementCelluloseCompensation effect

The invention discloses a high titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube, and belongs to the field of building materials. The concrete-filled steel tube is prepared from the following raw materials: cement, coal ash, composite expanding agent, macadam, high titanium-bearing heavy slag, a tackifying plasticity-maintaining super-dispersing additive, micron-sized modified absorbent cotton cellulose and water. The prepared concrete-filled steel tube has the characteristics of high flow state, low gas content, large strength extra coefficient and stable expansibility; the problem of poor working performance caused by application of high titanium-bearing heavy slag to concrete is solved; due to the water absorption and water releasing effect of the porous structure, the internal maintenance effect on the concrete-filled steel tube can be realized, the shrinkage compensation effect of the expanding agent on the concrete-filled steel tube is improved, the concrete-filled steel tube is weakly expansive to be suitable for jacking pouring of upper chord pipes and lower chord pipes of a concrete-filled steel tube arched bridge and a concrete-filled steel tube truss bridge, as well as high-casting pouring of a concrete-filled steel tube pier column. Therefore, the problem of disengaging caused by poor-density pouring of the concrete-filled steel tube is solved effectively.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

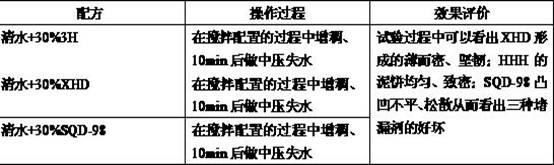

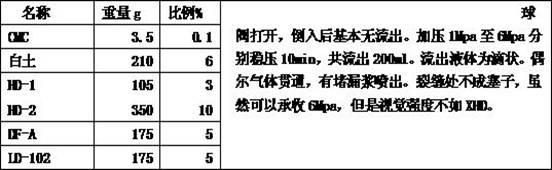

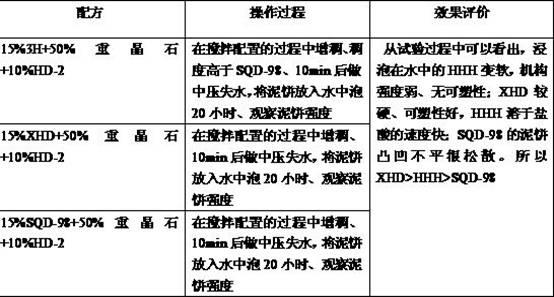

Plugging agent suitable for large leakage, its preparation method and leaking stopping technology

InactiveCN102443382AEnhanced interactionImprove structural strengthDrilling compositionSealing/packingBiologyPetroleum

The invention relates to a plugging agent suitable for large leakage, its preparation method and a leaking stopping technology. The invention is suitable for repeatable large leakage, belonging to the field of petroleum drilling. The plugging agent comprises the following ingredients by the following weight ratio: clear water: HSD (HHH): HD-1: HD-2: LD-102: DF-A: barite = 100: 12-15: 4-5: 7-8: 4-5: 30. According to the invention, by reinforcing the interaction among ingredients, maximizing the structural strength of the plugging agent entering a leak layer, maintaining the trend that the leak layer is gradually enhanced with time after injecting the plugging agent in the leak layer, and further increasing the pressure bearing capacity of the leak layer, the leakage problem of a repeatable return-lost large-scale absorption well can be solved, the problem of leaking stopping existing in the prior art can be overcome, and the one-time leak stopping success rate is increased.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

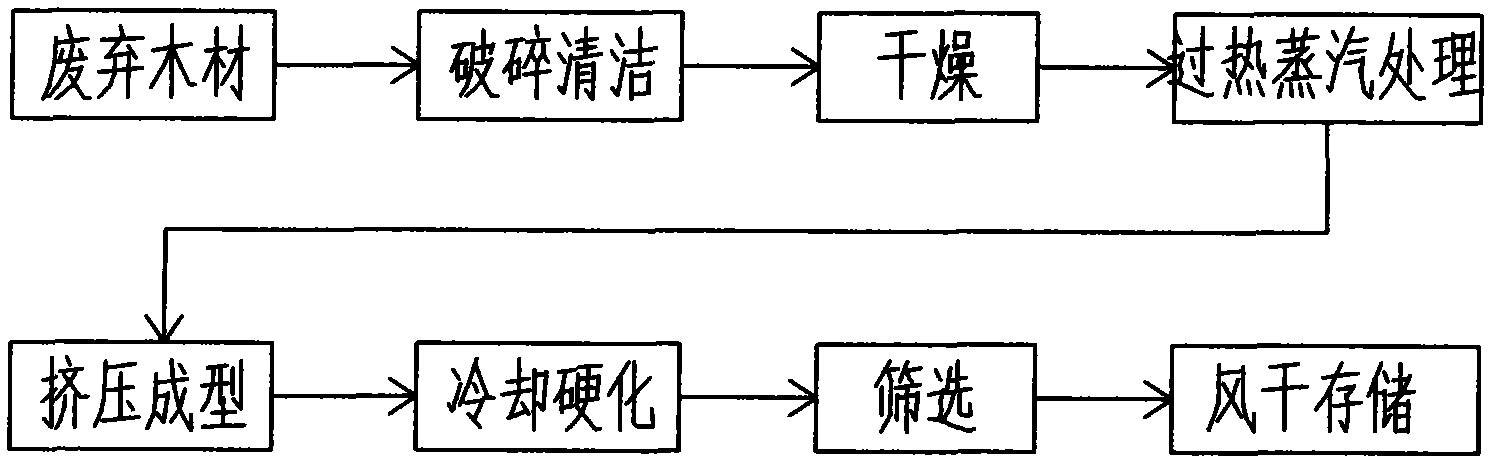

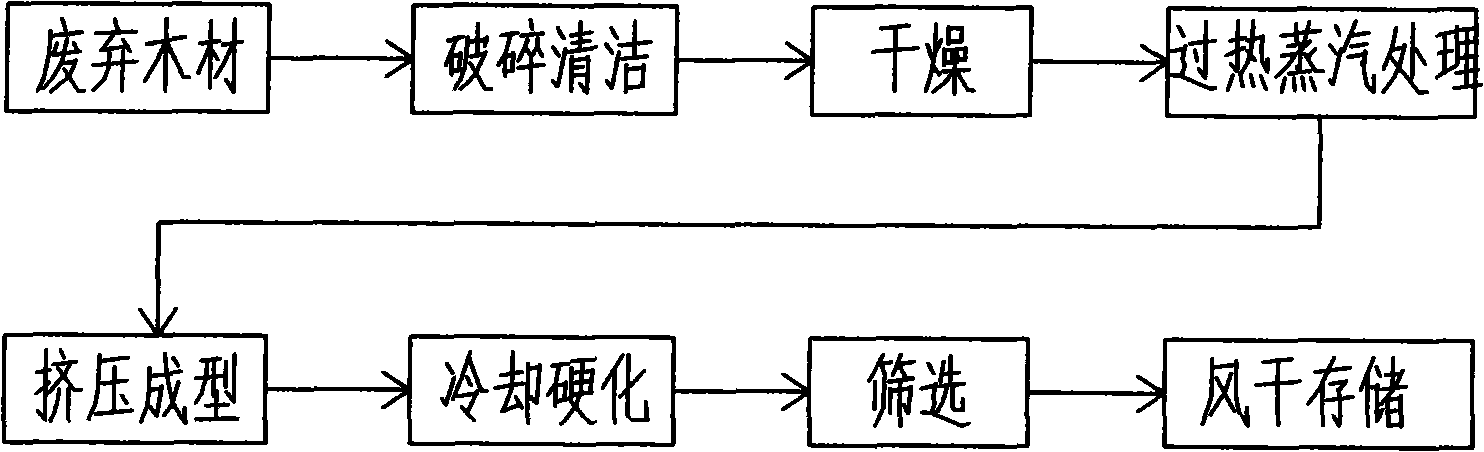

Method for manufacturing biomass fuel

InactiveCN102041124AHigh activityImprove cementing performanceBiofuelsSolid fuelsSolid fuelPulp and paper industry

The invention relates to a method for manufacturing solid fuel, particularly to a method for manufacturing biomass fuel replacing coal for civilian use and coal for industrial use. The method comprises the following process steps: a. crushing and cleaning the waste wood, removing the impurities to obtain a raw material of which the particle size is between Phi 0.02mm to Phi 20mm; b. drying the wood chips to have the water content of 5-15%; c. carrying out superheated steam treatment on the wood chips at the temperature of 300-600 DEG C to soften the surface of the wood chip, melt lignin and improve the raw-material activity and the binding capacity; d. resizing the material by extrusion molding equipment to be finished products of the biomass fuel; e. cooling; f. screening, and removing the loosened crushed aggregates; and g. drying by an air flow dryer, packaging and storing, wherein, the water content is 5-10%. In the biomass fuel produced by the manufacturing method, the natural binding components contained in the raw material are utilized to tightly bond with the raw material, and extra chemical additive is not added as a bonding medium; and the biomass fuel is environmentally-friendly biomass fuel.

Owner:佛山市沃德森生物质燃料有限公司

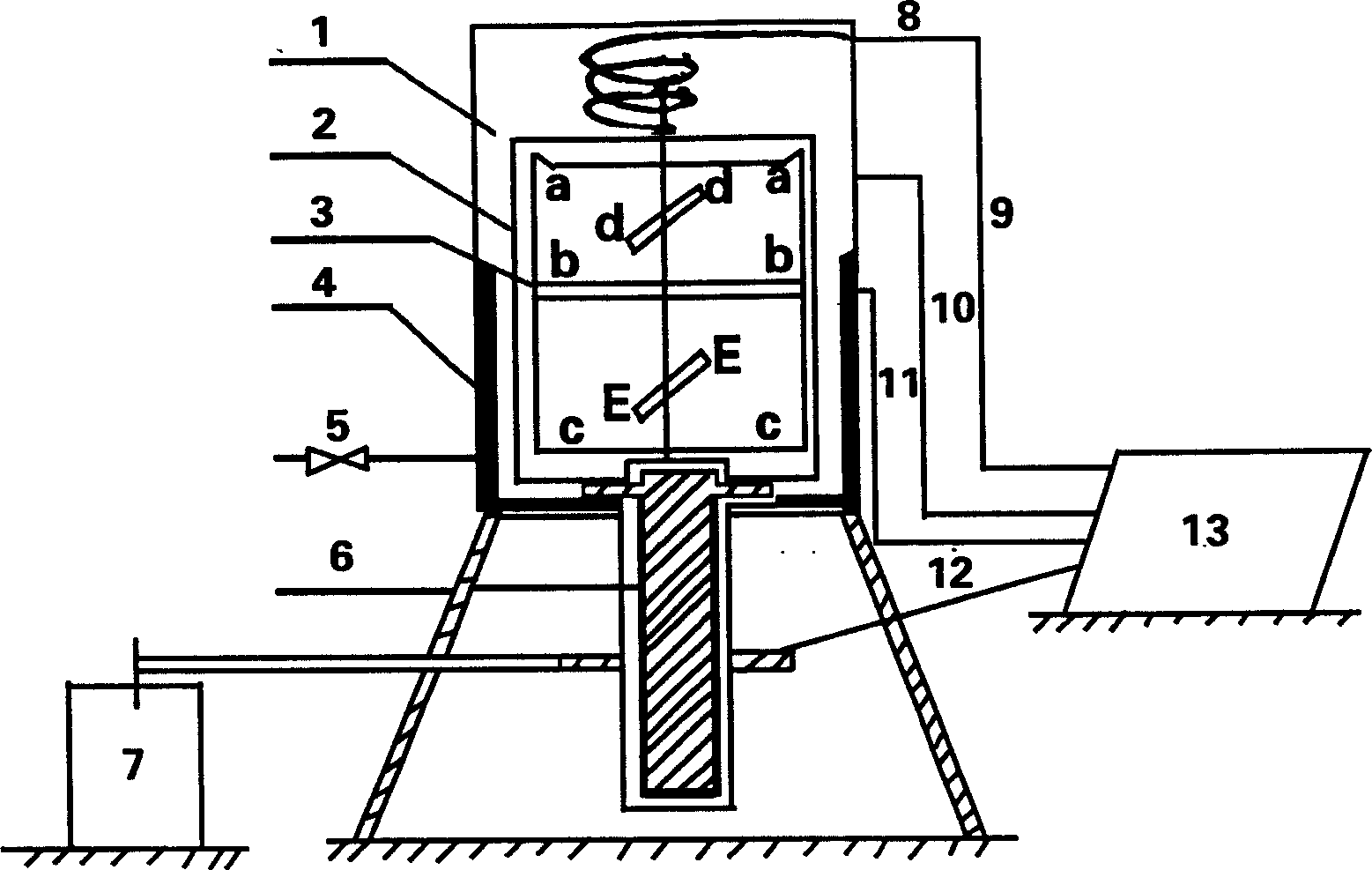

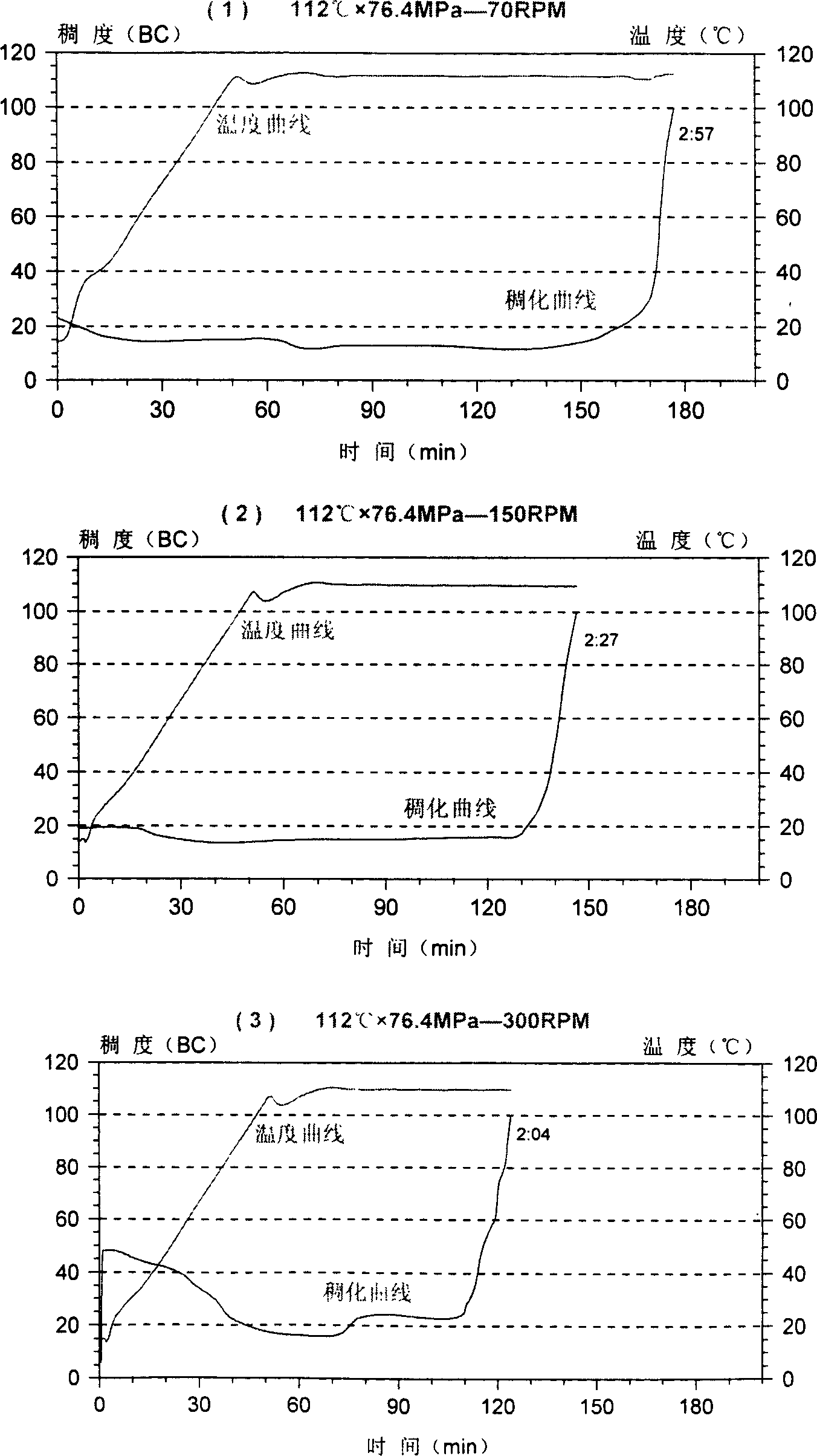

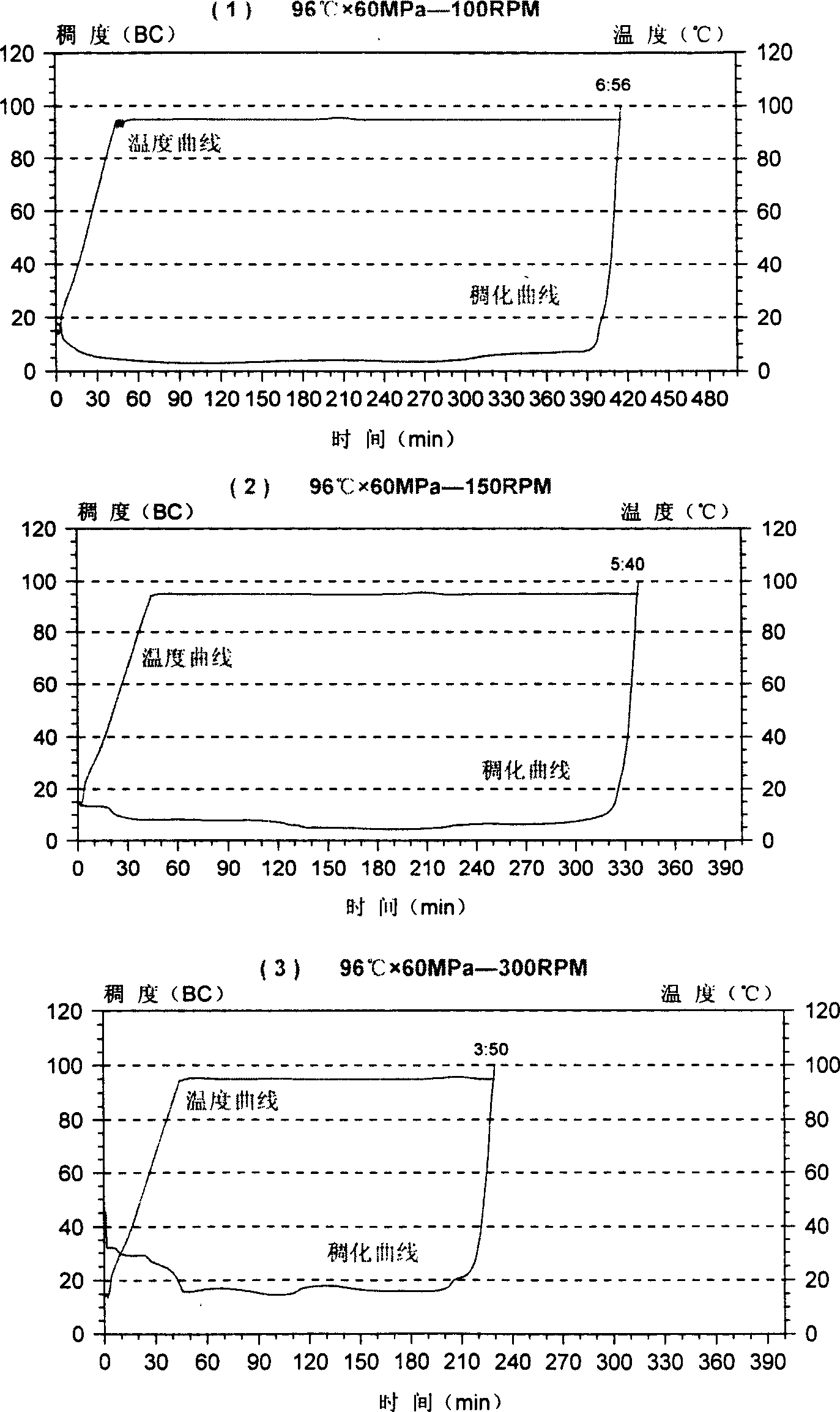

Variable speed supercharge oil well cement consistometer and thickening time measuring method thereof

InactiveCN1570599AEnsure construction safetyQuality assuranceFlow propertiesDepth in a wellMeasuring instrument

This invention relates to a method for better simulating and measuring mud thickness and thickening time. And it solves the problem of discrepancy between the measured mud thickness and thickening time and the real situation. And it employs a supercharged consistometer with variable speed, and plasm cup rotary speed is infinite and its rotary speed ranges from ten to six hundred round per minute. The method is the following: first to determine the shearing circum-space speed according to injecting speed of mud plasm and theological characteristic of the oil well, then to determine the average shearing force and speed when consistometer special paddle rotates; finally to confirm the mud plasm thickening time and paddle stimulating speed. This invention can ensure the safety construction of oil well casing and cementing and the quality of well wall concretion and agglutination.

Owner:SOUTHWEST PETROLEUM UNIV

Super-elevation pumping marine concrete and preparation method thereof

ActiveCN106587831ASuppresses structural cracking problemsReduce the rate of hydrationTemperature stressTransport inhibitor

The invention discloses a super-elevation pumping marine concrete. The super-elevation pumping marine concrete is prepared from cement, fly ash, mineral powder, gravel, river sand, a hydration temperature rising regulation and control material, a corrosive ion transport inhibitor, a state modified material, an ultra dispersed water reducing shrinkage plasticity-maintaining additive and water in proportion. According to the super-elevation pumping marine concrete, by means of the hydration temperature rising regulation and control material, cracking caused by low high performance concrete, insufficient hydration and drying shrinkage in later period can be effectively avoided; by means of the hydration temperature rising inhibiting component, adiabatic temperature rising of the concrete can be lowered, and cracking generated by the temperature stress is reduced; by adopting the corrosive ion transport inhibitor, the pore structure of the concrete can be optimized, transport paths of ions such as Mg<2+> and Cl<->, and the concrete is better served in marine salt spray environment; the state modified material has the specific ball effect and water retention characteristic, and the phenomena of segregation and pipe blocking occurring in the super-elevation pumping process are avoided. The concrete is suitable for super-elevation pumping marine buildings and has the important engineering application value.

Owner:WUHAN UNIV OF TECH +1

High-temperature low-density cement and applications thereof

ActiveCN101747009AHigh strengthHigh compressive strengthSolid waste managementDrilling compositionOil productionTemperature resistance

The invention relates to a high-temperature low-density cement and applications thereof, belonging to the field of building materials. The high-temperature low-density cement provided by the invention has excellent high temperature resistance and comprises the following components in percentage by weight: 30%-70% of cement substrate, 14%-40% of lightening material, 14%-30% of high-temperature strength stabilizer and 0.02%-0.10% of high-temperature retarder, wherein the high-temperature retarder is organic acid sodium salt, and the high-temperature strength stabilizer material is one of micro silicon and silicon powder or the combination of micro silicon and silicon powder. The cement has the characteristics of simple construction processes, high pulping rate, excellent high temperature resistance and the like, can be applied to special environments such as oil well cementing and the like, and can obviously improve well cementing quality and crude production rate. When the cement of the invention is used for well cementing operation and high-temperature oil production operation, the well cementing construction performance can be ensured, and the unabated performance of the strength of the cement stone at high temperature can be ensured.

Owner:JIAHUA SPECIAL CEMENT

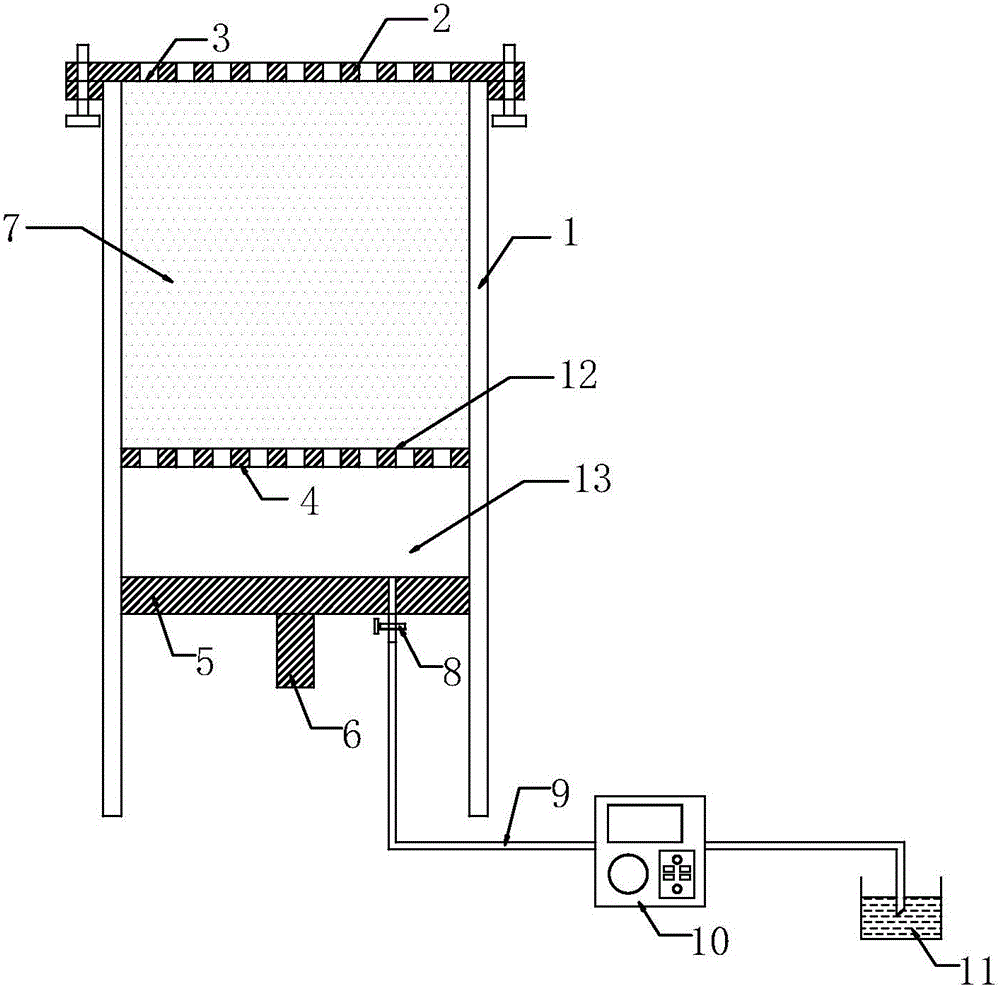

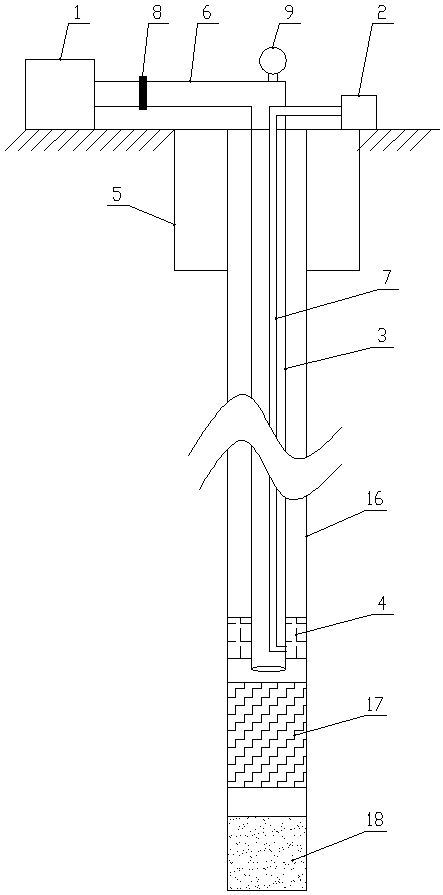

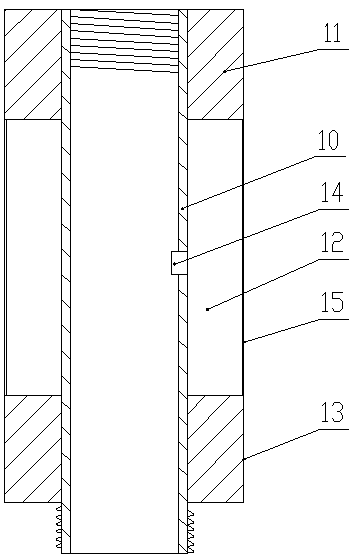

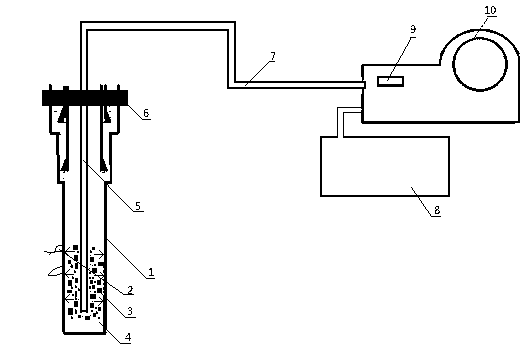

Microorganism-induction calcium-carbonate-deposition film laminating testing device and method

InactiveCN106018060AEasy to disassembleAvoid interferencePreparing sample for investigationPermeability/surface area analysisPeristaltic pumpMicroorganism

The invention discloses a microorganism-induction calcium-carbonate-deposition film laminating testing device. The microorganism-induction calcium-carbonate-deposition film laminating testing device comprises a testing cylinder, an air permeating plate fixedly connected with the top of the testing cylinder is arranged at the top of the testing cylinder, and first gauze for covering a sand sample is arranged below the air permeating plate and is in contact with the lower surface of the air permeating plate; a water permeating plate and a piston are arranged in the testing cylinder, the water permeating plate is fixedly connected into the testing cylinder in a position-adjustable mode, second gauze is laid on the water permeating plate, and a sample cavity is formed between the water permeating plate and the air permeating plate; the piston is arranged below the water permeating plate; a handle is arranged on the lower face of the piston; a liquid storage cavity is formed between the piston and the water permeating plate and connected with a liquid storage groove through a hose, and a peristaltic pump is installed on the hose. The invention further discloses a method used for carrying out a microorganism-induction calcium-carbonate-deposition film laminating test through the testing device. By means of the device and the method, cemented substances can be evenly distributed in space, the cementing effect can be improved, the thickness of a film can be conveniently controlled, and the quantity of adopted bacterium liquid and the quantity of adopted cementing solutions can be conveniently mastered.

Owner:TIANJIN UNIV

C30 self-compaction microexpanded concrete-filled steel tube and preparation method thereof

ActiveCN105084836ASolve the "out of the air" problemImprove cementing performanceSolid waste managementCelluloseCoal

The invention discloses a C30 self-compaction microexpanded concrete-filled steel tube and belongs to the field of building materials. The C30 self-compaction microexpanded concrete-filled steel tube is prepared by taking cement, coal ash, composite expansion agents, gravel, river sand, tackifying plasticity-maintaining ultra-dispersed additive, internal maintaining materials, micro-grade modified degreasing cotton cellulose and water as raw materials. The number of binding materials adopted in the C30 self-compaction microexpanded concrete-filled steel tube is small, and the C30 self-compaction microexpanded concrete-filled steel tube has the advantages of being good in self-compaction performance, low in gas content and high in durability, being slightly expanded and the like, is suitable for compact pouring of intensely reinforced large-pipe-diameter thin-wall steel tube concrete-filled steel tube underwater piles with complex shapes and a small section size, string tube pumping pouring of upper and lower concrete-filled steel tubes of concrete-filled steel tube truss bridges and high-throwing vibration-free pouring of concrete-filled steel tube pier studs. The problem of disengaging of the concrete-filled steel tube can be effectively solved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

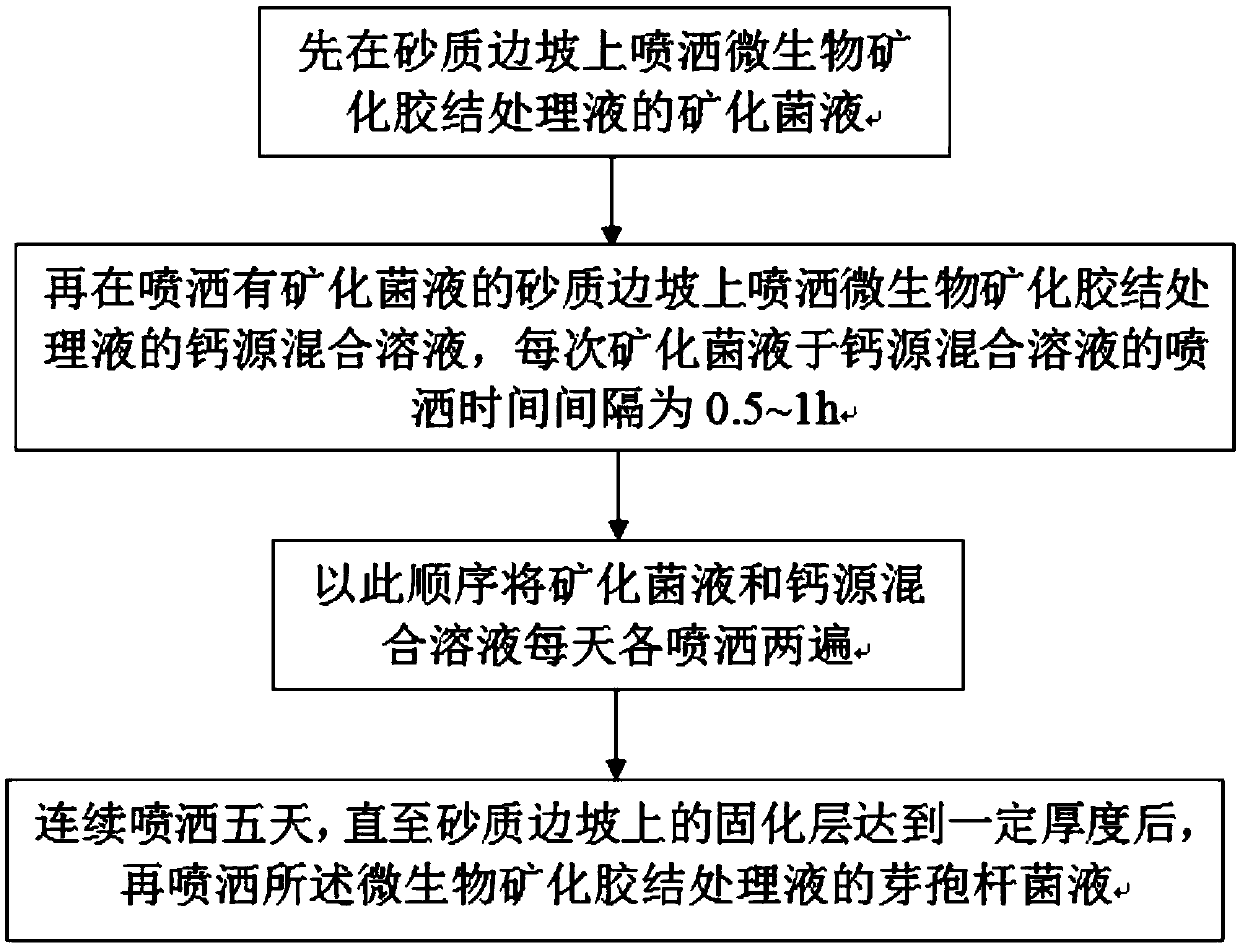

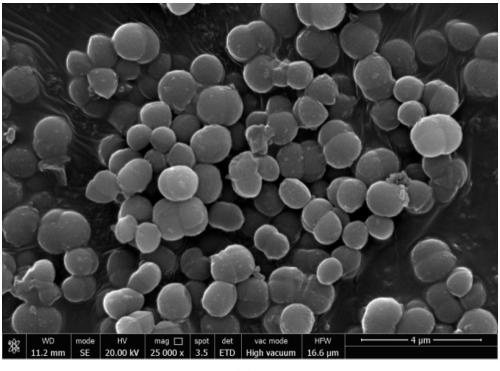

Microbial mineralized cementation treatment liquid and sandy slope treatment method

ActiveCN109518703ADoes not damage the ecological environmentImprove brittlenessBacteriaMicroorganism based processesSlope ratioChemistry

The invention discloses microbial mineralized cementation treatment liquid and a sandy slope treatment method. The microbial mineralized cementing treatment liquid is formed by mineralized bacteria liquid, bacillus liquid and a calcium source mixed solution which are independent of each other according to the volume ratio of 1:(5-10):(1-3). The mineralized bacteria liquid is divided into 1# bacillus pasteurii liquid and 2# staphylococcus liquid, wherein the 1# bacillus pasteurii liquid is suitable for treating sandy soil with the slope ratio being smaller than 1: 1 and the particle size ranged being smaller than 20 mm, and the 2# staphylococcus liquid is suitable for treating sandy soil with the slope ratio being smaller than 1: 1 and the particle size range d being larger than 0.074 mm and smaller than 10 mm. When the sandy slope is treated, the mineralized bacteria liquid is sprayed on the sandy slope first, then the calcium source mixed solution is sprayed, spraying is carried outtwice a day in the order and carried out for five days continuously, and the bacillus pasteurii liquid is sprayed again after a solidified layer on the sandy slope reaches a certain thickness.

Owner:INNER MONGOLIA UNIV OF TECH

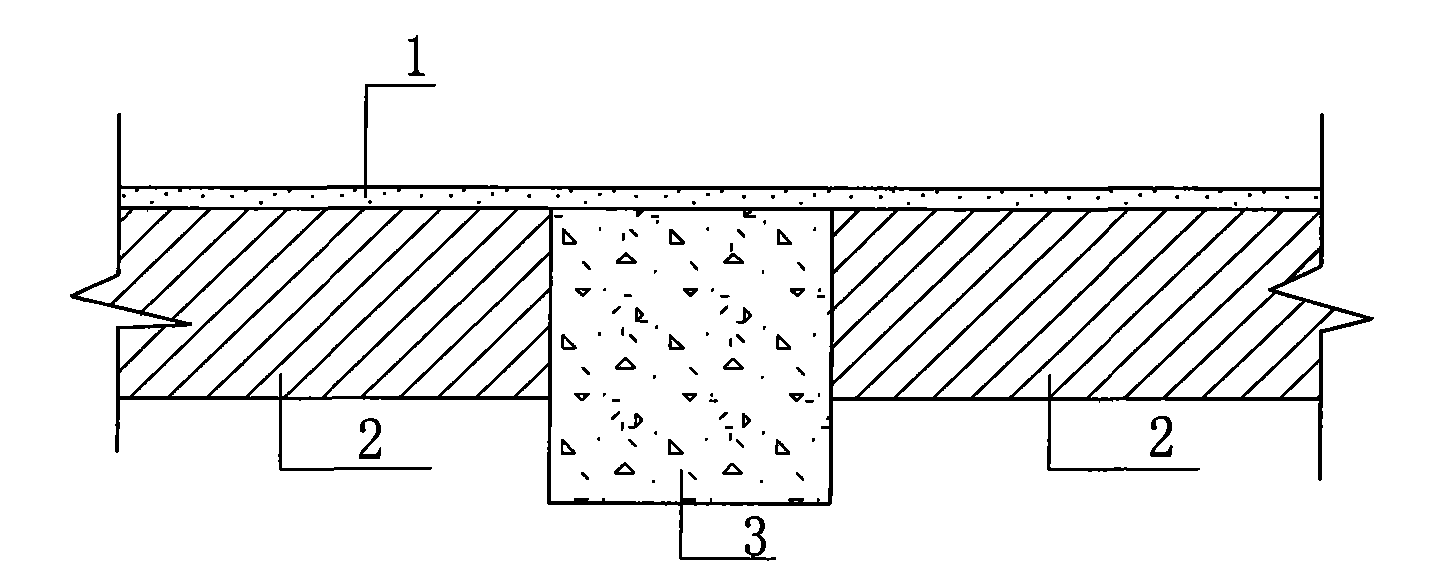

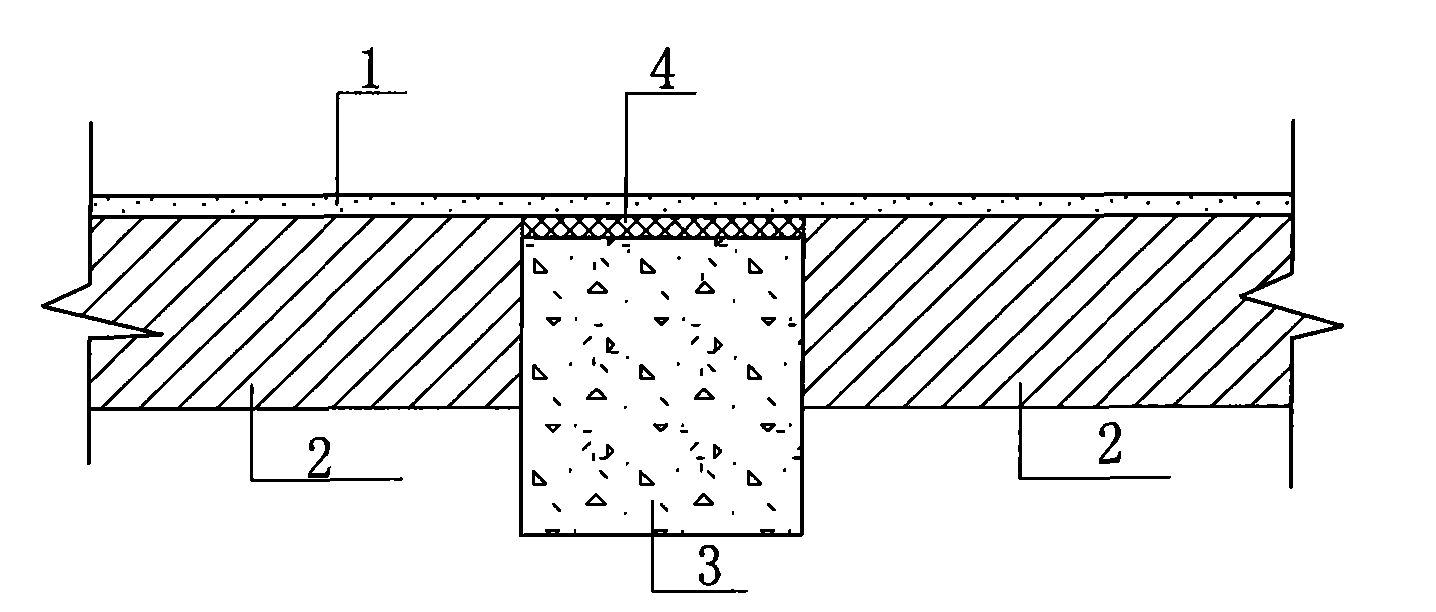

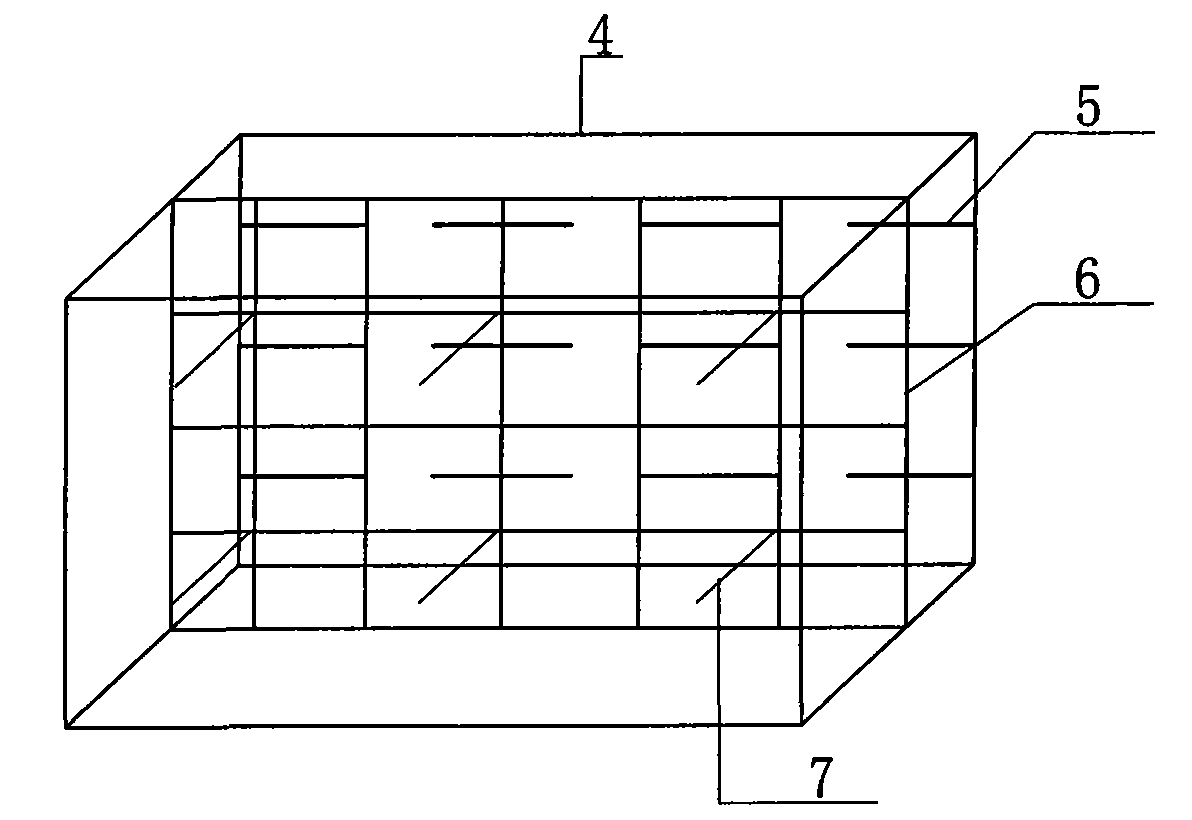

Device and method for leaking stoppage of open hole in coal-series gas exploration well

PendingCN109723404AShorten the cleaning timeIncrease the amount of slurry injected into the leakage sectionSealing/packingCoalDrill

The invention relates to a device for leaking stoppage of an open hole in a coal-series gas exploration well, which comprises a grouting pump, a water injection pump, hollow drill rods and a packer, wherein the wellhead of the coal-series gas exploration well is provided with a surface sleeve, multiple sections of hollow drill rods extend into the coal-series gas exploration well from the wellheadof the coal-series gas exploration well, the packer is arranged outside the lower end of one section hollow drill rod, the grouting pump is connected with the upper end of the uppermost section hollow drill rod through a grouting pipe, the water injection pump is connected with an air inlet of the inner wall of the packer through a water injection pipe, the water injection pipe is arranged alongthe inner wall of the hollow drill rods, and the water injection pipe penetrates out of the grouting pipe at the wellhead of the coal-series gas exploration well and is connected with the grouting pipe in a sealing way. The invention also discloses a leaking stoppage method of the device. The method effectively solves the limitation of leakage stoppage methods using inert materials, conventional cement, casing sealing and the like, provides a new leakage stoppage device and method for a coal-series gas exploration well, optimizes a pumping procedure method and achieves the purpose of leakage stoppage, and has important practical significance for exploration and development of coal-series gas resources.

Owner:中国煤炭地质总局广东煤炭地质局勘查院

Insulation board of concrete exterior wall

InactiveCN101597940AImprove insulation effectHigh mechanical strengthSolid waste managementCeramic shaping apparatusBreaking strengthFiber

The invention relates to an insulation board of a concrete exterior wall, in particular to the insulation board of the concrete exterior wall at a heat bridge part, which is used in match with the exterior wall body constructed by energy-saving insulation building blocks. The invention is prepared by the following steps: raw materials are mixed, molded by extrusion to obtain the insulation board molding product which is subjected to steam curing and drying to obtain the insulation board molding product of the concrete exterior wall; the invention is characterized in that: before the invention is molded by extrusion, steel mesh is put into the raw materials followed by being molded by extrusion to be the insulation board molding product; the raw materials comprise the following components according to weight percentage: 235-242 parts of silicate cement, 65-67 parts of expanded perlite, 43-45 parts of ceramsite, 80-83 parts of slag, 4-2 parts of plant ash, 1.5-2 parts of wool felt fiber, 0.5-1.0 parts of cloth fiber, 0.5-1.0 parts of bamboo fiber and 94-96 parts of water. The invention has good insulation property, can effectively reduce the heat bridge effect of the exterior wall constructed by energy-saving insulation building blocks, has high breaking strength and can have the same service life with the exterior wall constructed by insulation blocks.

Owner:无锡市康顺节能材料科技有限公司

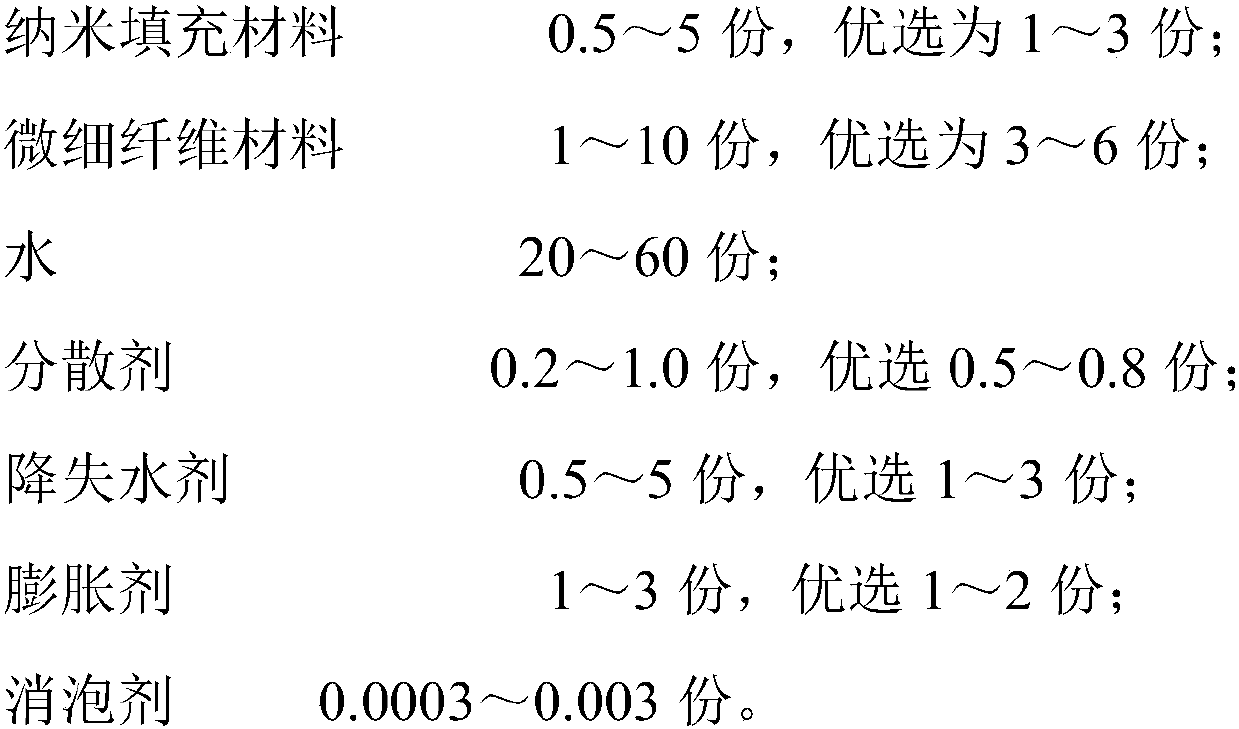

Plugging agent with high bearing strength for deep drilling and preparation method thereof

InactiveCN109868125AHigh compressive strengthImprove flexural strengthDrilling compositionFiberFlexural strength

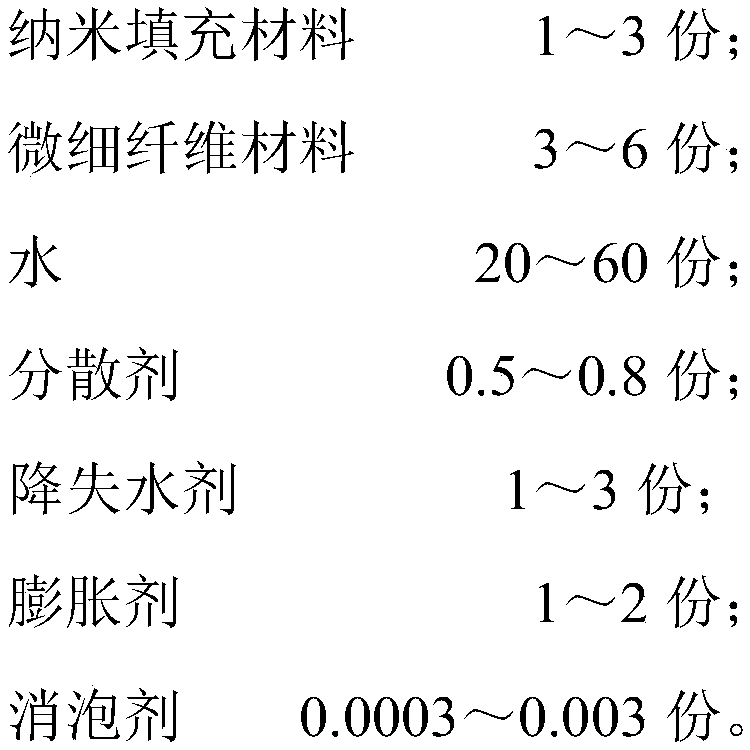

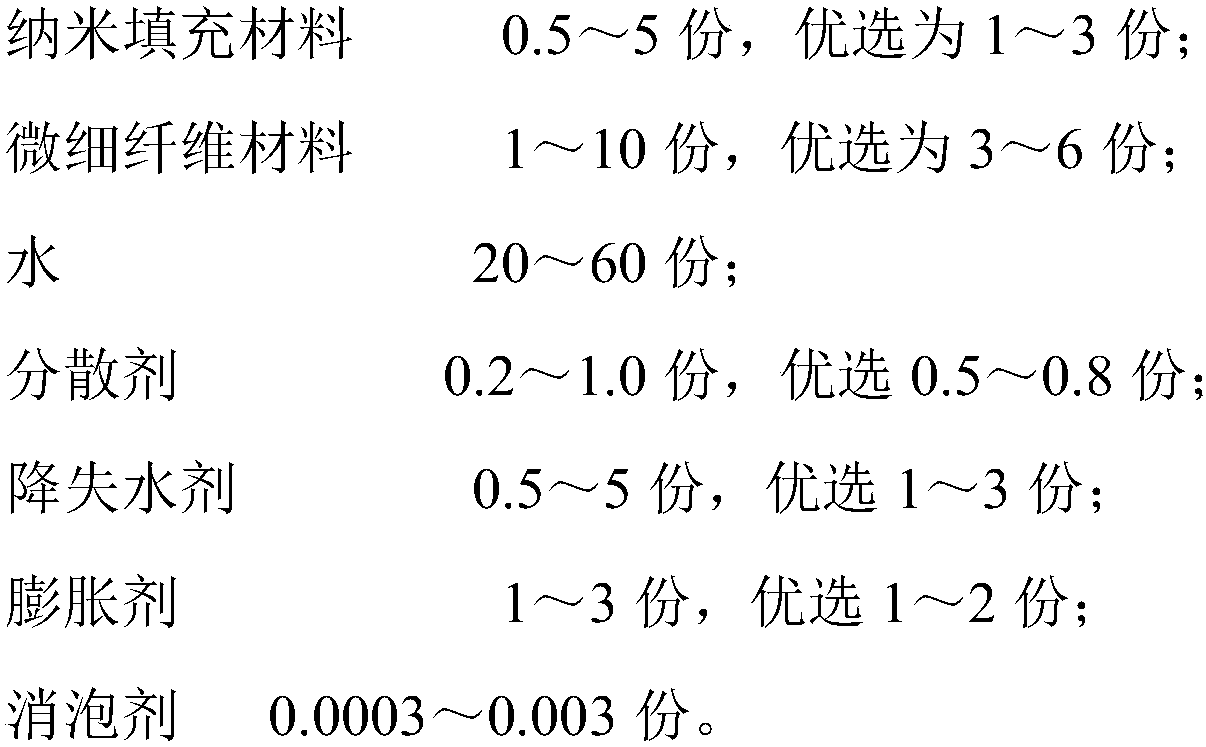

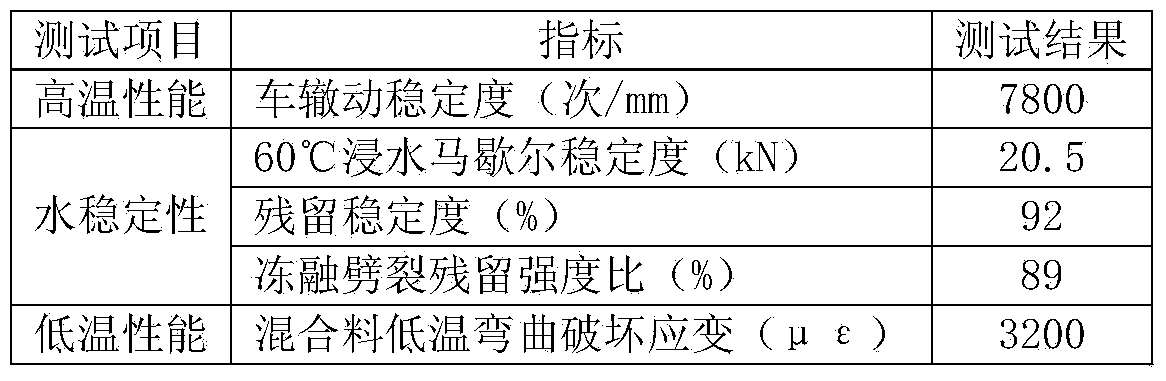

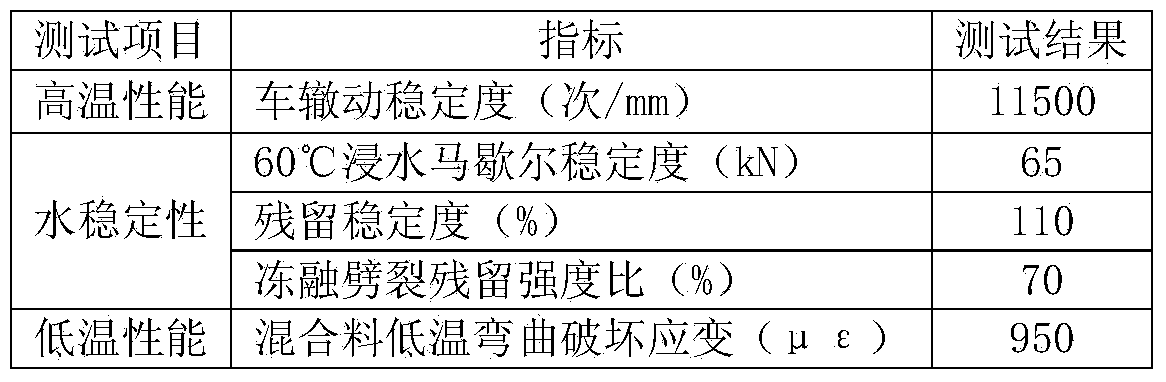

The invention relates to a plugging agent with high bearing strength for deep drilling and a preparation method thereof, belonging to the field of ultra-deep petroleum drilling engineering. The plugging agent with high bearing strength for deep drilling comprises cement, a cement additive, a nanometer filling material, a micro-fine fiber material and water; on the basis of 100 parts by weight of the cement, the content of the nanometer filling material is 0.5 to 5 parts by weight, preferably 1 to 3 parts by weight; the content of the micro-fine fiber material is 1 to 10 parts by weight, preferably 3 to 6 parts by weight; and the content of the water is 20 to 60 parts by weight. According to the invention, the plugging agent with high bearing strength can greatly improve compressive strength and flexural strength of a plugging slurry, and has significant plugging effect. The plugging agent provided by the invention is applicable to plugging lateral cracks, malignant leakage caused by broken rock strata and long open hole segments of multi-pressure series of strata; cementation performance between the plugging agent and a leakage channel wall and the impact crushing resistance of formed cement stone are improved; and the construction requirements of plugging for long open hole segments and plugging under high strength of 30 MPa or above can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cementing material using construction waste as main component and preparation method of cementing material

The invention discloses a cementing material using construction waste as a main component and a preparation method of the cementing material. The material comprises brick-concrete micropowder, concrete micropowder, mineral slag micropowder, cement, and one of an additive combination of sodium hydroxide and water glass and an additive combination of calcium chloride and calcium hydroxide. The setting time and volume stability of the cementing material provided by the invention all meet the relevant cement standards, and the compressive strength and flexural strength for 3 days and 28 days reachPC32.5-grade strength; and compared with traditional cement, the cementing material provided by the invention has an obvious price advantage, is used in a large scale, can greatly alleviate pressureon the urban environment by the construction waste, and has social benefits far greater than economic benefits.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

Asphalt resin-based cold regenerant and regenerated mixture

ActiveCN103819874AImprove cementing performanceHigh strengthIn situ pavingsBuilding insulationsEmulsionBinding properties

The invention discloses an asphalt resin-based cold regenerant and a regenerated mixture. The cold regenerant is composed of a resin emulsion, cement, a phase agent having dissolving and mixing effects for waste asphalt and the rubber emulsion, an aggregate surface hydrophobic agent and a curing agent of the resin emulsion. The resin emulsion, the phase agent and the cement are used as main components. Each of the components co-increases cementing property for the aggregate. When the cold regenerant is in use, a binding material is a multi-phase system formed by intertwining dissolved and activated regenerated asphalt, the cured resin emulsion and a cement hydration product. The system is stable and has good binding property, and can overcome the main damage problems of high temperature softening deformation, low temperature brittle rupture and stripping of the binding interface eroded by water, of a single asphalt binding material. The regenerated mixture formed by the cold regenerant can be directly paved by vibration without roll compaction. Application efficiency is relatively high while cost is relatively low. A formed road surface has high strength and small temperature sensitivity, and can resist ageing and water erosion.

Owner:何小兵

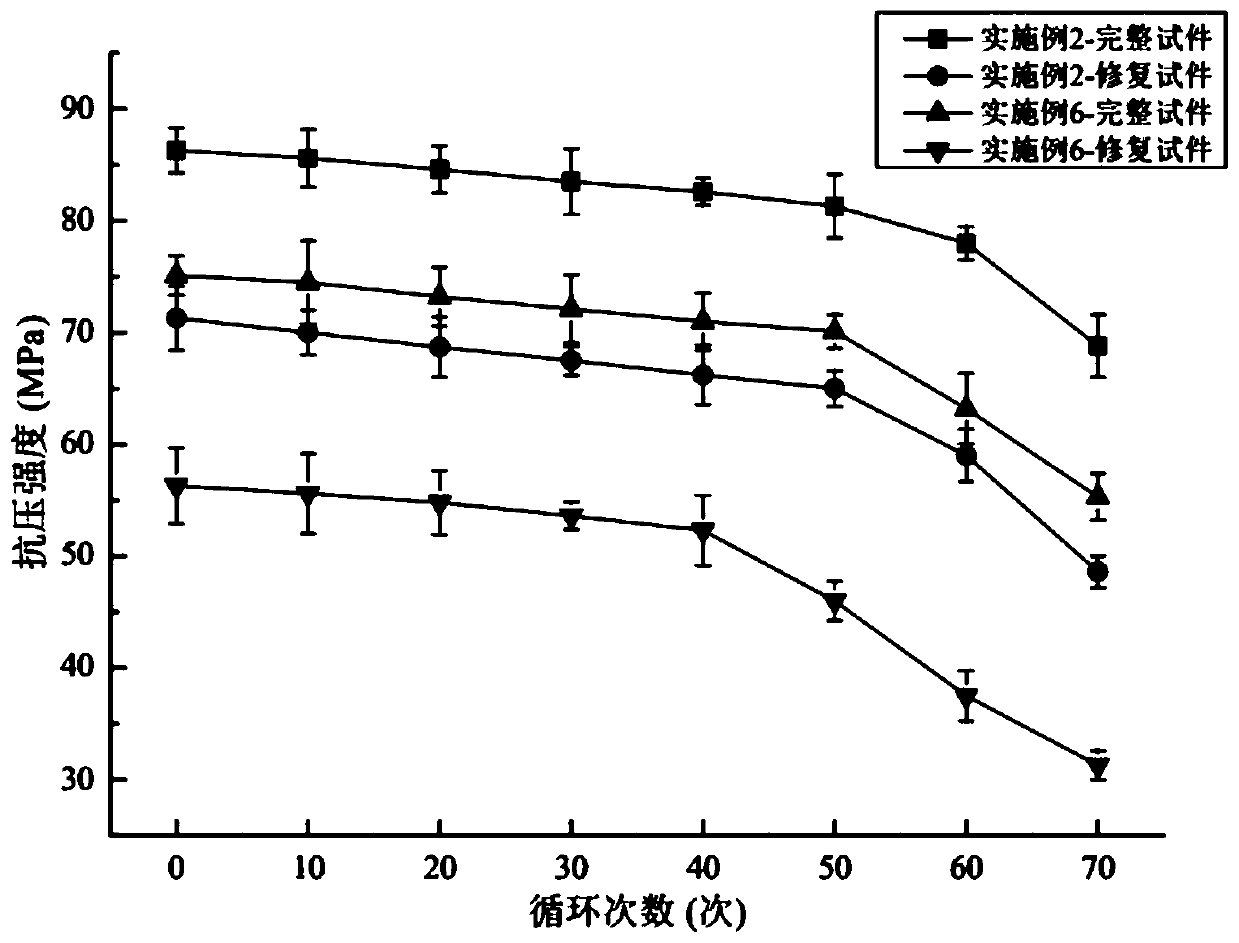

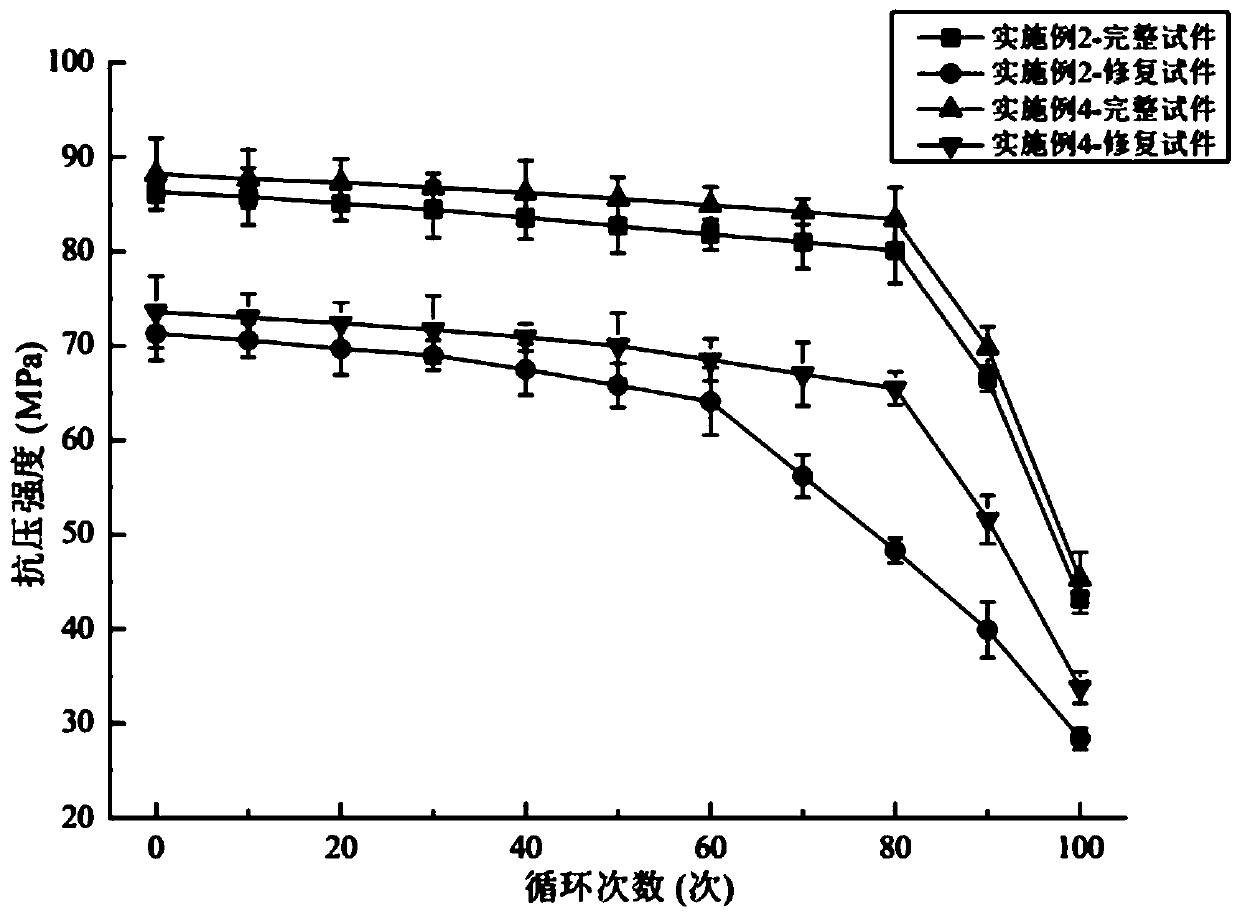

Repair agent for travertine geology, repair liquid and application of repair liquid

ActiveCN106747154AImprove repair effectAchieving cementationMarine site engineeringEarth surfaceCompressive strength

The invention provides a repair agent for travertine geology. The repair agent is prepared from the following components in parts by weight: 65-87 parts of a travertine base material, 5-30 parts of lime and 1-5 parts of gypsum. According to the repair agent, the adopted travertine base material is good in compatibility with a repaired geological environment, so that in-situ repair of the travertine geology without damage and pollution is realized, and the repair efficiency and the strength after repairing are high. The repair agent can be used for repairing collapsed regions and large gaps of a stone dam at the edge of a ground surface colored pool in a travertine scenic spot, can also be used for repairing the travertine geology and is strong in pertinence. Shown by results of the embodiment of the invention, the provided repair agent for the travertine geology can realize in-situ repair of the travertine geology; and in the using process of the repair agent for the travertine geology, the compressive strength can reach 18 MPa.

Owner:SOUTHWEAT UNIV OF SCI & TECH

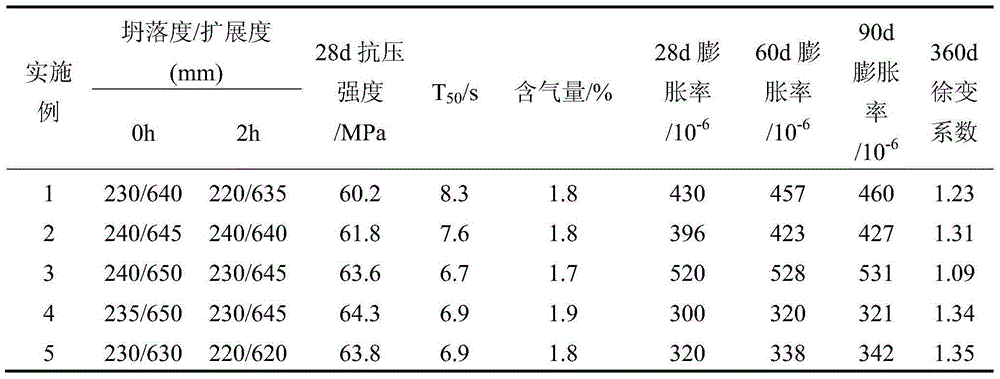

C60 self-compacting shrinkage-compensating anti-crack concrete suitable for steel anchor beam cable tower anchoring structure and preparation method of concrete

The invention discloses C60 self-compacting shrinkage-compensating anti-crack concrete suitable for a steel anchor beam cable tower anchoring structure. The concrete is prepared from raw materials, namely, cement, fly ash, mineral powder, an expanding agent, gravel, high-titanium heavy slag sand, polyacrylonitrile fibers, micron-sized modified absorbent cotton cellulose, a cement paste microstructure regulating agent, water and an ultra-dispersing, water-reducing, shrinkage-reducing and plasticity-maintaining additive. According to the concrete, the initial slump is higher than or equal to 230 mm, the expansion degree is higher than or equal to 630 mm, the 28 d compressive strength is higher than or equal to 70 MPa, the 28 d splitting tensile strength is higher than or equal to 5.8 MPa, the toughness index I5 is larger than or equal to 3.0, the 28 d autogenous-shrinkage ratio is smaller than 0, the 28 d dry shrinkage ratio is smaller than 0, the carbonization level reaches T-IV, the cracking resistance level reaches L-V, and the concrete has excellent mechanical properties, crack resistance and durability, can solve general problems that bridge tower concrete at the present stage is high in cement and cementing material consumption and large in shrinkage and cracks easily, and is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH +2

Putty powder for building inner and outer walls and preparation method of putty powder

ActiveCN106590133AEvenly distributedImprove crack resistanceFireproof paintsAntifouling/underwater paintsCellulosePolyethylene glycol

The invention provides putty powder for building inner and outer walls and a preparation method of the putty powder. The putty powder is prepared from ash-calcium, talcum powder, cement, cellulose, rubber powder, a binding agent and reinforcing powder. The reinforcing powder is formed by mixing composite powder, diatomite and calcium oxide, and the composite powder is obtained by sintering clay, silicon carbide, carbon powder and aluminum hydroxide. The binding agent is prepared from alumina micro powder, modified nanosilicon dioxide, polyethylene glycol and water. The putty powder contains the reinforcing powder and binding agent with special ingredients, when the putty powder is manufactured, the ash-calcium, the binding agent and the reinforcing powder are mixed firstly, hot water is added, the materials are stirred, part of ash-calcium is injected into a microcellular structure or adheres to the surface, then the ash-calcium is fully bonded with the cellulose and the rubber powder added later, therefore, the bonding performance between all the ingredients in the putty powder is enhanced, the anti-cracking performance and hardness of the putty powder are enhanced, and the waterproof performance of the putty powder is also improved to a certain degree.

Owner:平顶山锦亦翔墙釉科技有限公司

Three-phase foam channel-sealing agent, preparation method thereof, and thickened oil exploiting and plugging method

ActiveCN109971443AImprove plugging efficiencyAdjustable permeabilityDrilling compositionCross-linkFoaming agent

The invention discloses a three-phase foam channel-sealing agent and a preparation method thereof, and a thickened oil exploiting and plugging method by adopting the three-phase foam channel-sealing agent, and belongs to the technical field of oil field chemistry. The three-phase foam channel-sealing agent consists of the following components in percentage by weight: 0.3% of a foaming agent, 3-4%of alpha-starch, 3%-4% of acrylamide, 0.01%-0.02% of an initiator, 0.1%-0.15% of a cross-linking agent, 0.1%-0.2% of a control agent, 0.5%-30% of solid-phase particles and the balance of water. The three-phase foam channel-sealing agent disclosed by the invention is injected into steam channeling pore channels, steam huff and puff is carried out after foam forms gel, the gel is carbonized when encountering steam, and solid particles are left to block the channeling channels. Plugging efficiency is high, permeability is adjustable, a problem of serious steam channeling can be well solved, and the recovery rate of crude oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

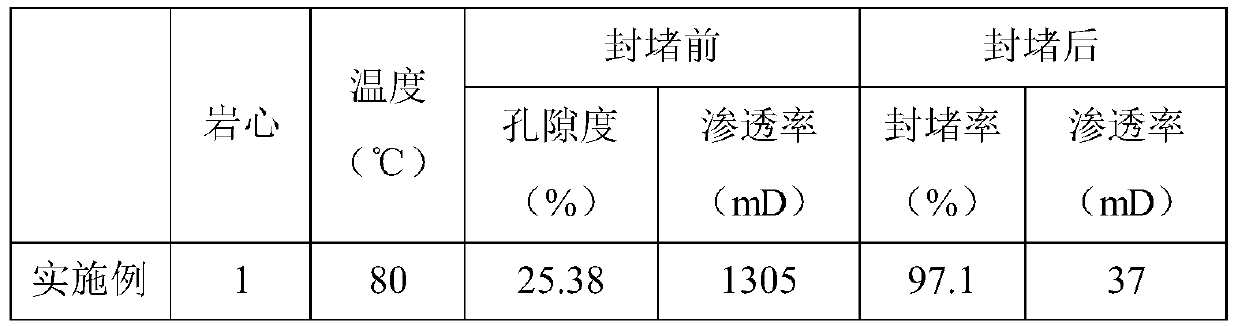

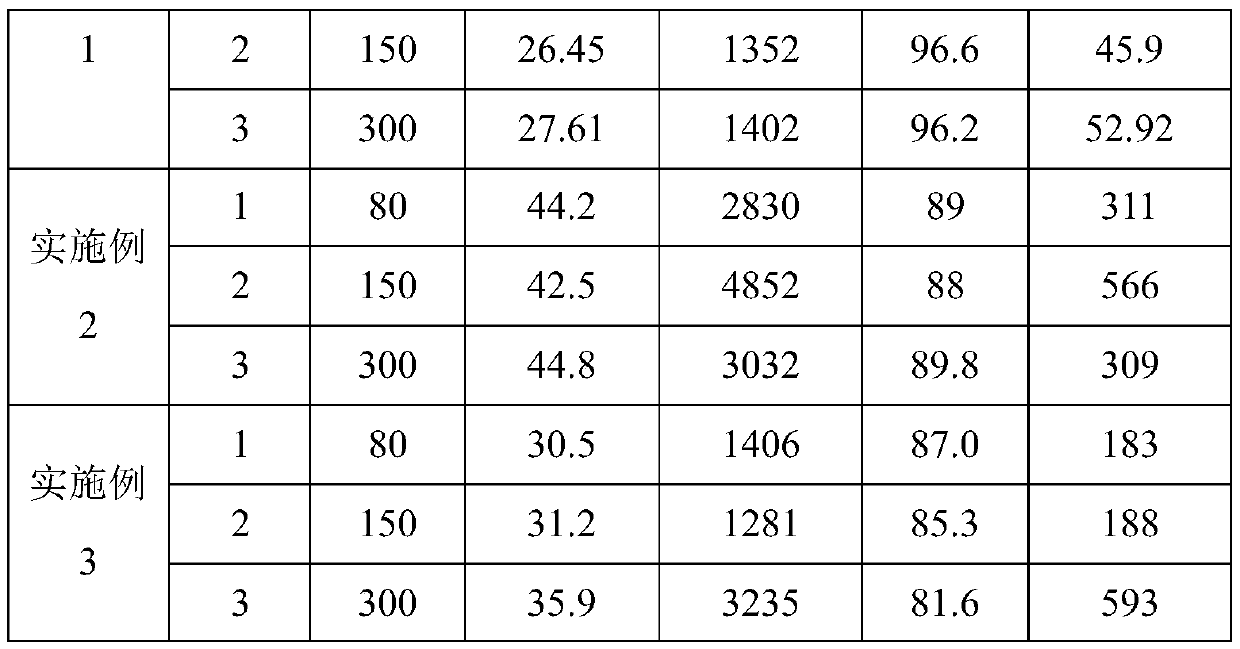

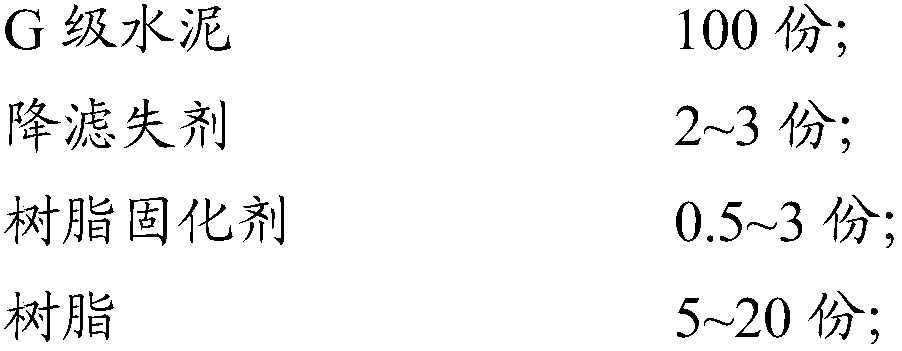

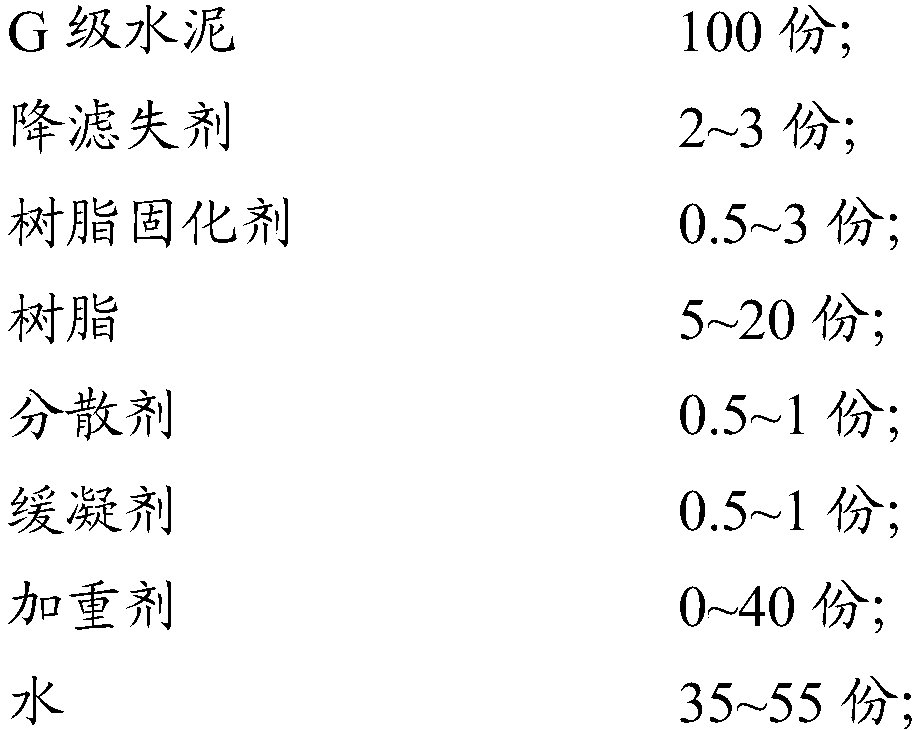

Anti-channeling well cementation resin cement paste and application thereof

InactiveCN108373297AImprove toughnessImprove cementing performanceDrilling compositionResin cementCement sheath

The invention provides an anti-channeling well cementation resin cement paste and application thereof. The anti-channeling well cementation resin cement paste comprises, by mass, 100 parts of G-gradecement, 2-3 parts of filtrate reducer, 0.5-3 parts of resin curing agent, 5-20 parts of resin, 0.5-1 part of dispersant, 0.5-1 part of retarder, 0-40 parts of weighting agent and 35-55 parts of water,wherein rein refers to one or multiple of water-soluble epoxy resin, organic silicon resin and phenolic resin. As the anti-channeling well cementation resin cement paste is added with the resin, toughness and cementing property of cement sheaths can be improved, and further, flow of formation fluid can be prevented effectively, and gas-channeling prevention effect can be improved. According to results of an embodiment of the invention, the viscosity of the anti-channeling well cementation resin cement paste is 190mPa.s, the cement paste has good flowability and its anti-channeling performancereaches up 18-22MPa / m.

Owner:YANGTZE UNIVERSITY +1

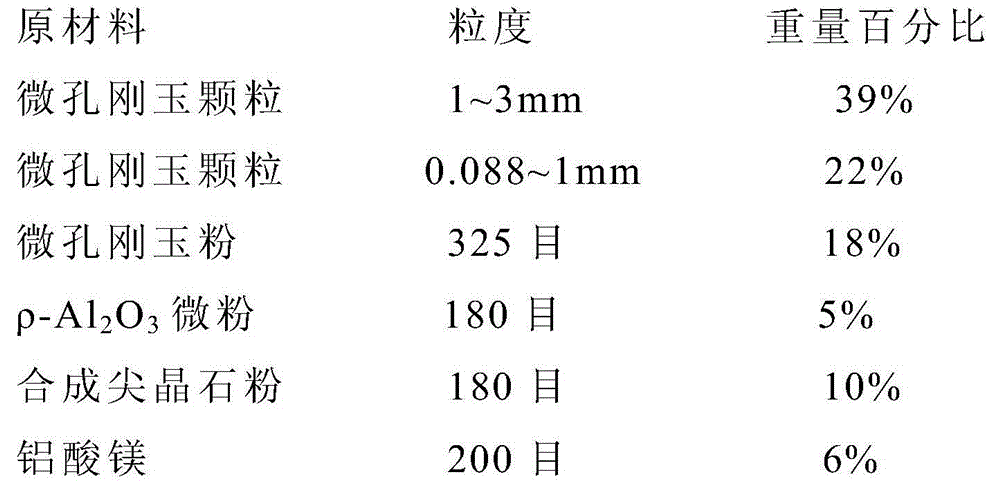

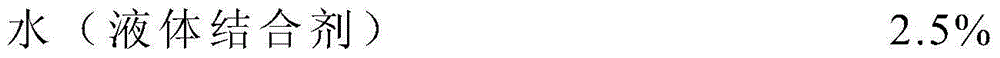

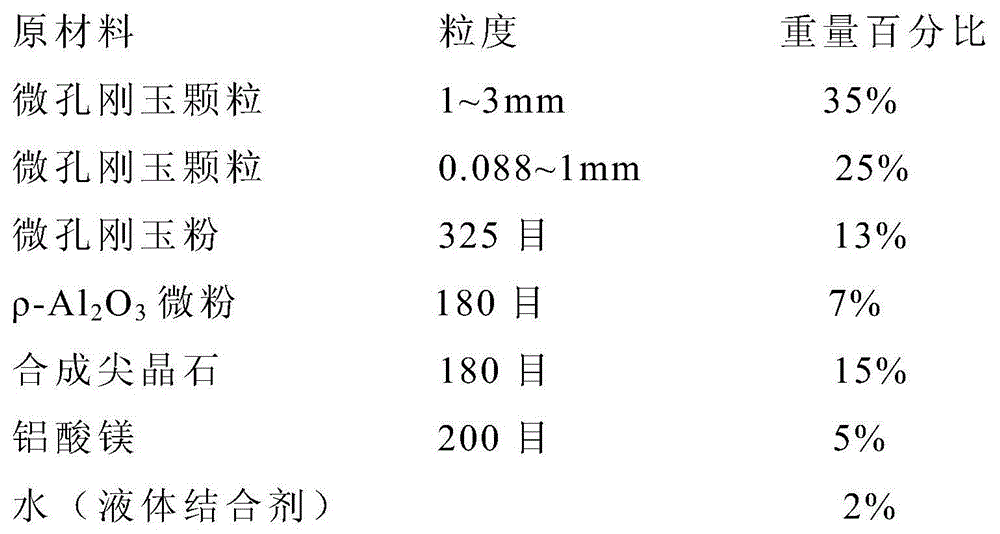

Machined carbon-free corundum spinel brick for ladles and preparation method thereof

The invention discloses a machined carbon-free corundum spinel brick for ladles, which comprises a solid raw material and water. The solid raw material comprises the following components in percentage by weight: 55-69% of microporous corundum, 15-25% of microporous corundum powder, 2-7% of rho-Al2O3 micropowder, 10-20% of synthetic spinel powder and 3-7% of magnesium aluminate. Water accounts for 1-3 wt% of the total solid raw material. The preparation method comprises the following steps: proportionally preparing the solid raw material, adding water, milling, forming in a brick press, and carrying out heat treatment at 150-250 DEG C for 12-36 hours. The machined carbon-free corundum spinel brick for ladles can not increase the carbon content in the molten steel or introduce harmful impurity component in the smelting process, and can reduce the temperature drop of the molten steel and perform the thermal-insulation function due to low thermal conductivity. The spinel brick has the characteristics of no pollution, high normal-temperature / high-temperature strength and high thermal shock stability, and can satisfy the production demands for low-carbon and ultralow-carbon steel.

Owner:武钢集团有限公司

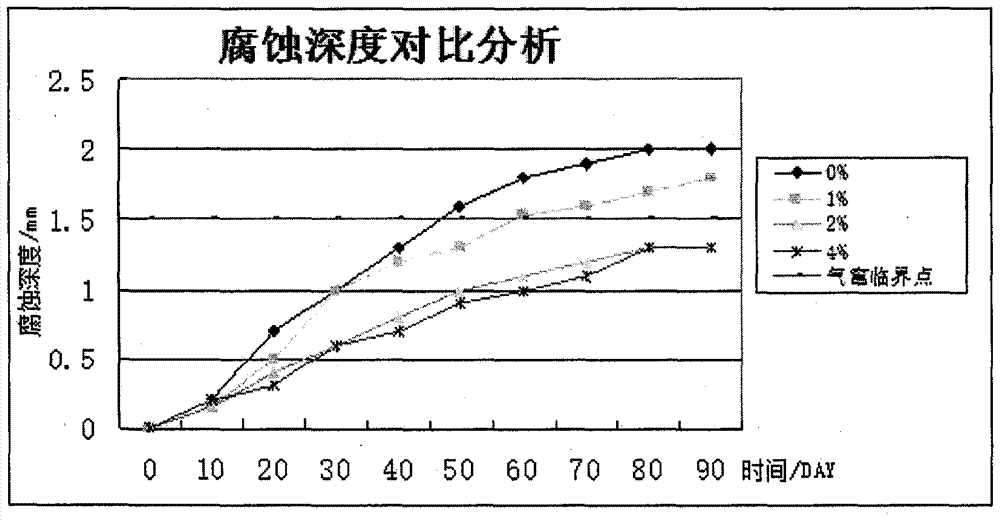

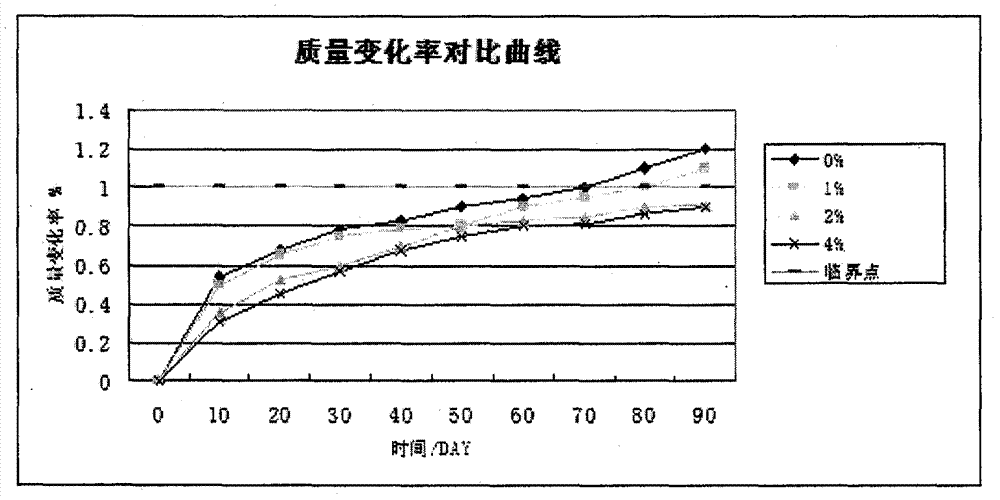

Microbial immobilization method for self-repairing of concrete cracks

ActiveCN111138107AReduced loss of compressive strengthEnhanced resistance to sulfate attackSodium phosphatesNutrient

The invention provides a microbial immobilization method for self-repairing of concrete cracks and belongs to the field of microbiology and civil engineering material crossing technologies. The methodcomprises the following steps: immobilizing microorganisms or microbial spores in a carrier, and carrying out an immobilization process of wrapping treatment; carrying out a secondary immobilizationprocess of loading nutrient substances in the carrier; and carrying out an embedding process of doping the immobilized carrier obtained by the secondary immobilization process into a concrete raw material, wherein the carrier is coral reef calcareous sand; and the nutrient substances comprise 3, 5-dinitrobenzyl alcohol and sodium trimetaphosphate. According to the method provided by the invention,the survival rate of microorganisms can be increased; the crack repairing width can be increased (the maximum repairing width reaches 1 mm or above, and the average repairing width reaches 0.7-0.9 mm), and the concrete compressive strength is recovered by 80% or above; the compressive strength loss of the repaired concrete under sulfate erosion can be effectively reduced, the sulfate erosion resistance of the repaired concrete is improved, and the durability of the concrete is improved.

Owner:ZHEJIANG OCEAN UNIV +2

Efficient erosion-resistant anti-gas-channeling cement paste system

ActiveCN107216070AImprove compactnessInhibition of strength declineDrilling compositionEtherBond properties

The invention discloses an efficient erosion-resistant anti-gas-channeling cement paste system. The efficient erosion-resistant anti-gas-channeling cement paste system is characterized by being prepared from the following raw materials in parts by weight: 60-80 parts of erosion-resistant anti-gas-channeling cement, 2-4 parts of butadiene-styrene latex or polyimide latex or silicon dioxide / water mixed suspension, 0.2-2 parts of AMPS polymer fluid loss control agent, 0.05-0.2 part of polycarboxylic acid ether ester dispersing agent, 0.1-2 parts of chlorine-free aluminate complex accelerator, 0.1-0.5 part of organic phosphate retarder, 0.1-0.2 part of organic silicon defoaming agent and 20-30 parts of distilled water. According to the invention, the special functional materials are doped, so that the set cement is always kept in a proper alkaline environment, and a liquid-phase acidic medium is prevented from entering the set cement; the doped special functional materials ensure that the set cement has favorable mechanical properties; and the compactness of the set cement is increased, the toughness of the set cement is improved, and the bonding property and the sealing property between a cement sheath and a stratum are enhanced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

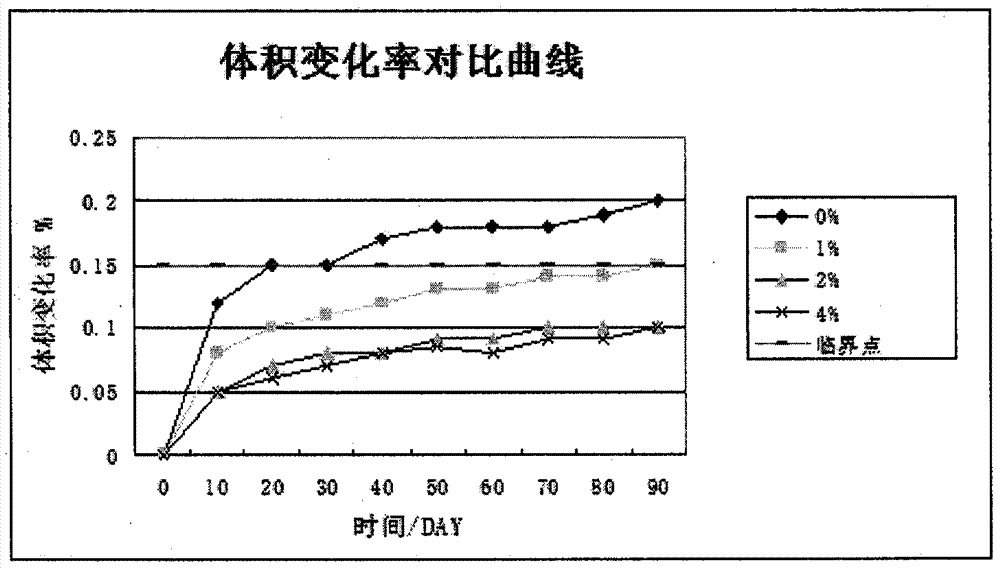

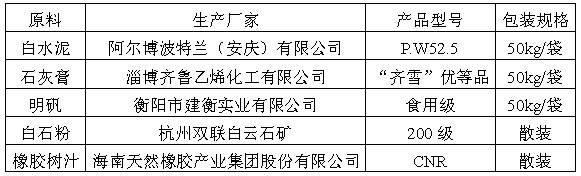

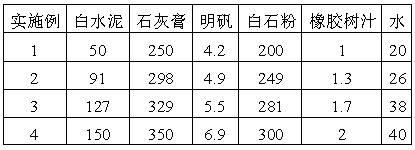

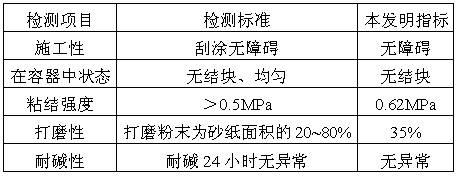

All-natural putty for interior walls of constructions

All-natural putty for interior walls of constructions comprises, by weight, 50-150 parts of white cement, 250-350 parts of lime putty, 4.2-6.9 parts of alum, 200-300 parts of white stone powder, 1-2 parts of rubber tree tapping and 20-40 parts of water. The preparation steps of the all-natural putty include: (1) crushing the white stone powder and the alum; (2) mixing white cement with lime putty, feeding the mixture into a mixer, sequentially feeding the crushed white stone powder and the crushed alum into the mixer, and then adding the rubber tree tapping to be uniformly stirred; and (3) adding water into mixed dry solids which are discharged through stirring to obtain the all-natural putty finished product for the interior walls of the constructions. The all-natural putty for the interior walls of the constructions is good in technical performance and low in cost, resources can be saved and the environment can be protected as used raw materials are natural, non-toxic and non-hazardous, and the all-natural putty can be widely applied to treatment of batches of embedded layers of interior wall finishing processes of various constructions.

Owner:无锡市康顺节能材料科技有限公司

Bonding filling material and method for carrying out downhole filling using the same

ActiveCN102020979AEasy to transportGood filling effectMaterial fill-upDrilling compositionBond propertiesHigh effectiveness

The present invention relates to a bonding filling material and a method for carrying out downhole filling using the same, wherein the said gangue bonding filling material comprises: 68.6-82.2% by weight of gangue; 12.7-21.8% by weight of coal ash; and 1-18.7% by weight of water. Pressure intensity of the rammer compacter for filling and compacting in filling the bonding filling material is more than or equal to 20 Mpa. According to the invention, filling effect and filling quality are improved, and the movement of the overlying strata can be effectively controlled. The bonding filling material is filled directly without any additives, and the bonding property of the bonding filling material is increased due to the addition of coal ash as one filling material. The conveying system in the invention has simple requirements and enables continuity and high effectiveness of the filling. Downhole treatment of gangue and coal ash is fulfilled, and ecological and living environment around mining area are improved.

Owner:JIZHONG ENERGY +1

Unfired modified high-purity magnesium-aluminum spinel composite bricks and preparation method

The invention belongs to the technical field of high-grade fireproof materials for metallurgy, non-ferrous metal, glass and cement kilns and preparation methods thereof, and in particular relates to unfired modified high-purity magnesium-aluminum spinel composite bricks and a preparation method thereof. The unfired modified high-purity magnesium-aluminum spinel composite bricks take high-purity magnesia powder with the magnesium content of 99 percent as a raw material; a complexed magnesium-aluminum cementing agent and rare-earth oxide are used for modifying the magnesium-aluminum spinel composite bricks for the first time; a preparation process adopts an electric energy low-temperature drying technology to prepare at 200 DEG C. The unfired modified high-purity magnesium-aluminum spinel composite bricks provided by the invention have the advantages of high purity, great density, high strength, good high-temperature thermal shock durability, high corrosion resistance and high molten metal resistance and anti-oxidization capability, no emission of harmful gas and accordance with green refractory standards and the like; the preparation method is simple and high-temperature firing is not needed; the cost is low and no carbon and no chromium are discharged by the raw materials; magnesium-carbon bricks and magnesium-chromium bricks, which are used for a steel ladle, are replaced, and carbon-free and chromium-free emission is realized; the preparation method has no pollution and zero emission; molten steel is cleaned, energy saving and emission reduction are realized and the preparation is safe.

Owner:沈阳罗泰智能系统有限公司

Water-permeable concrete having temperature-sensing color-changing function

The invention relates to water-permeable concrete having a temperature-sensing color-changing function. The water-permeable concrete comprises, by mass, 250-300 parts of silicate cement, 20-30 parts of enhancing component, 1500-1700 parts of pebble, 105-115 parts of water, 4-7 parts of water reducer and 15-25 parts of temperature-sensing color-changing material. Compared with the prior art, the water-permeable concrete has the advantages that when outside temperature changes, color changes along with changing of temperature within a certain interval, so that good decorating effect is realized. Needed raw materials are simple and easy to obtain, and the water-permeable concrete does not need special preparation process and is high in economic efficiency and convenient for popularization.

Owner:厦门美益绿建科技有限公司

Process for improving bearing capacity of formation

The invention discloses a process for improving bearing capacity of a formation. The process for improving the bearing capacity of the formation comprises the following steps of: a, working out respective sizes of formation pores according to formation fracture data obtained by block coring, and preparing different sealing slurry by using gel and sealing particles of corresponding dimensions according to the respective sizes of the formation pores; b, pumping the prepared sealing slurry into a shaft, and closing a blowout preventer after the sealing slurry is full of the shaft; c, continuously pumping the sealing slurry into the shaft to enable the sealing slurry in the shaft to be extruded into the formation; and d, respectively building frameworks at the formation pores by rigid sealing particles in the manner of bridging, filling and compacting flexible sealing particles among the rigid sealing particles to fill pores near the formation of the shaft to the greatest extent so as to enable the casing pressure value of the blowout preventer to be increased continuously, therefore improving the bearing capacity of the formation. According to the process for improving the bearing capacity of the formation, bearing sealing is performed on the formation in advance, through the formation fracture data obtained by the block coring, the sealing is performed on the formation by using the chemical gel which is equivalent to formation porosity and the rigid and flexible sealing particles when drilling is performed, and therefore, the bearing capacity of the formation is artificially improved, the phenomenon that drilling fluid leaks from the formation due to the fact that drilling fluid density rises at the later stage of construction is prevented, and drilling construction can be smoothly performed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

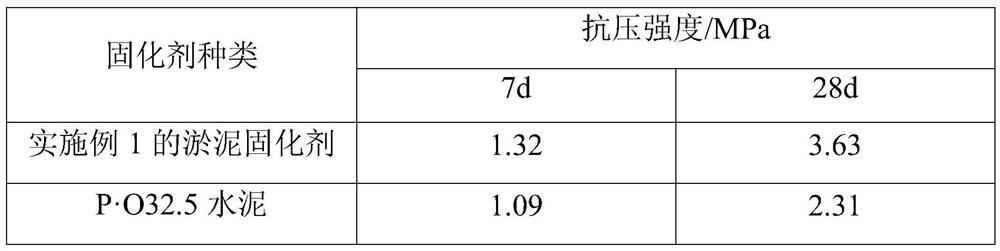

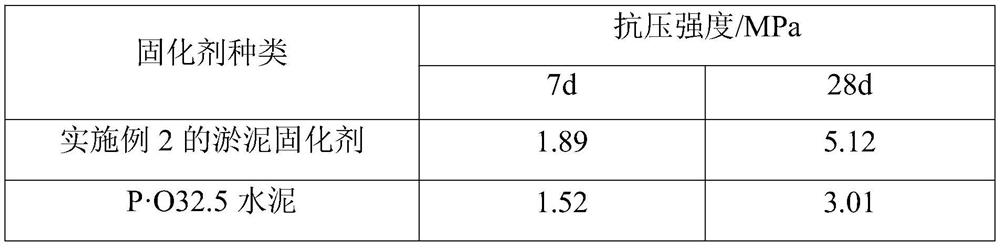

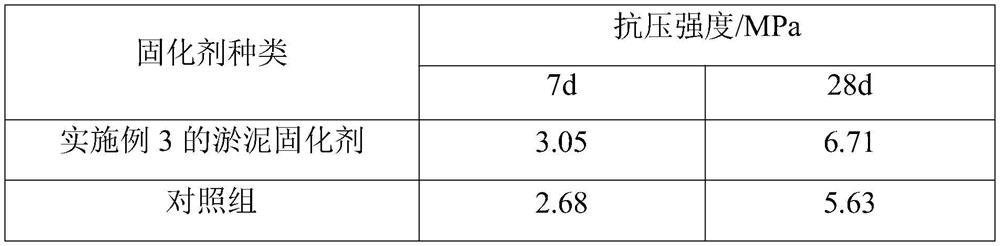

Silt curing agent prepared from steel slag modified phosphogypsum and use method thereof

InactiveCN111825408AIncreases hydration activityImprove cementing performanceFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentCalcium biphosphateO-Phosphoric Acid

The invention provides a silt curing agent prepared from steel slag modified phosphogypsum and a use method thereof. The silt curing agent comprises the following components: 40-70% of steel slag modified phosphogypsum powder, 30-60% of a cementing agent and 1-10% of a reinforcing agent, wherein the steel slag modified phosphogypsum powder is formed by mixing and modifying 5-25% of steel slag and75-95% of phosphogypsum by mass percentage. According to the invention, phosphogypsum is firstly modified by steel slag, alkaline substances of the steel slag react with soluble phosphoric acid, calcium phosphate and fluoride impurities contained in the phosphogypsum to be converted into insoluble precipitate substances, the adhesion among crystals in increased, so that the bonding performance ofphosphogypsum is improved, and meanwhile, acidic substances like sulfuric acid and phosphoric acid in the phosphogypsum are mixed with the steel slag to destroy the vitreous structure in the steel slag, so that the compact silicate vitreous structure in the steel slag is dissociated, the hydration activity of the steel slag is improved, and the strength of silt cured by the curing agent is furtherimproved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com