Silt curing agent prepared from steel slag modified phosphogypsum and use method thereof

A technology of phosphogypsum and curing agent, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., can solve the problems of low curing strength and high cost of sludge curing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw materials in the sludge solidifying agent prepared by utilizing steel slag modified phosphogypsum provided by this embodiment are composed by mass percentage: 65% of steel slag modified phosphogypsum powder, 35% of cement (27% of slag, 4% of silica fume, red mud 4%), reinforcing agent 3%; wherein, the mass ratio of phosphogypsum and steel slag in steel slag modified phosphogypsum powder is 4:1.

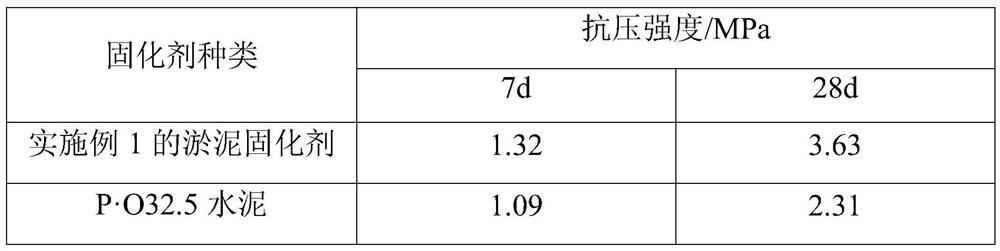

[0032] Get the silt solidifying agent that this embodiment formula forms and existing P · O32.5 cement mixes in the river channel silt respectively under the same conditions and mix evenly, and its mixing amount is 20% of the dry weight of river channel silt, wherein the present embodiment silt solidifies The agent is mixed with the river channel sludge by using the above method of solidifying the sludge using the sludge curing agent prepared by using steel slag modified phosphogypsum. The treated river silt was put into the cement slurry mixer, stirred evenly, put into...

Embodiment 2

[0037]The raw materials in the sludge solidifying agent prepared by utilizing steel slag modified phosphogypsum provided by this embodiment are composed by mass percentage: steel slag modified phosphogypsum powder 40%, cementing agent 65% (slag 50%, silica fume 6%, red mud 9%), reinforcing agent 6%; wherein, the mass ratio of phosphogypsum and steel slag in steel slag modified phosphogypsum powder is 3:1.

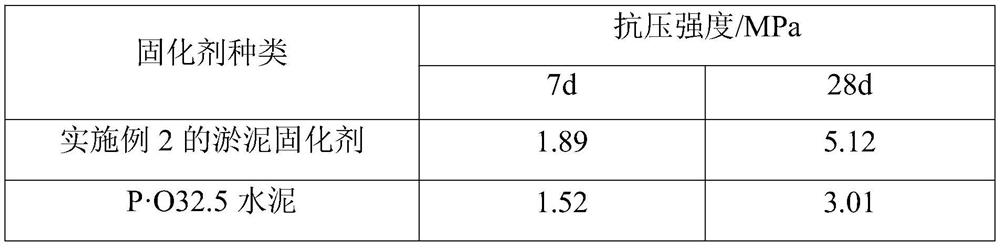

[0038] Get the silt solidifying agent that this embodiment formula forms and existing P · O32.5 cement mixes in the river channel silt respectively under the same conditions and mix evenly, and its mixing amount is 25% of the dry weight of river channel silt, wherein the present embodiment silt solidifies The agent is mixed with the river channel sludge by using the above method of solidifying the sludge using the sludge curing agent prepared by using steel slag modified phosphogypsum. The treated river silt was put into a cement slurry mixer, stirred evenly, put into a tes...

Embodiment 3

[0043] The raw materials in the sludge solidifying agent prepared by utilizing steel slag modified phosphogypsum provided in this embodiment are composed by mass percentage: steel slag modified phosphogypsum powder 70%, cementing agent 35% (slag 20%, silica fume 4%, red mud 11%), enhancer 10%. Wherein, the mass ratio of phosphogypsum and steel slag in the steel slag modified phosphogypsum powder is 3:1.

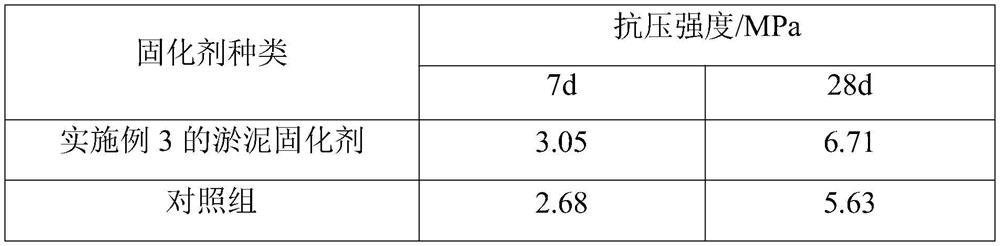

[0044] Take the sludge solidifying agent prepared in this example and add it to the sludge to be solidified according to the corresponding sequence in the method of solidifying the sludge with the sludge solidifying agent prepared by using steel slag modified phosphogypsum, and simultaneously dry the steel slag and phosphogypsum to powder respectively After the grinding process, directly mix with cementing agent and reinforcing agent simply and uniformly as the sample of the control group, and directly mix in the mud. The slurry mixer was stirred evenly and loaded into the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com