Patents

Literature

254results about How to "Reduce utilization cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

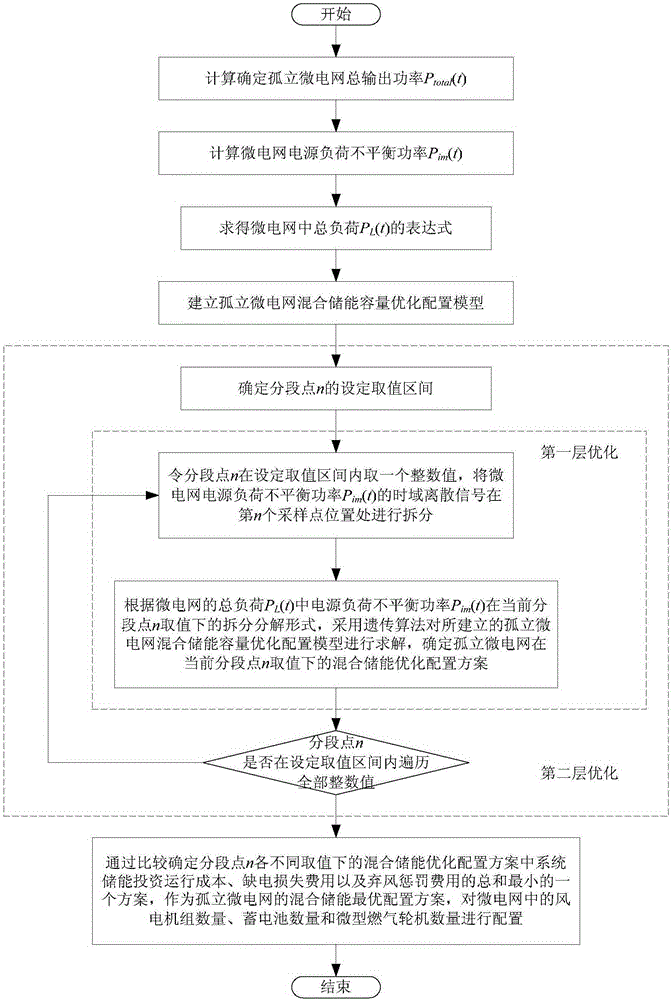

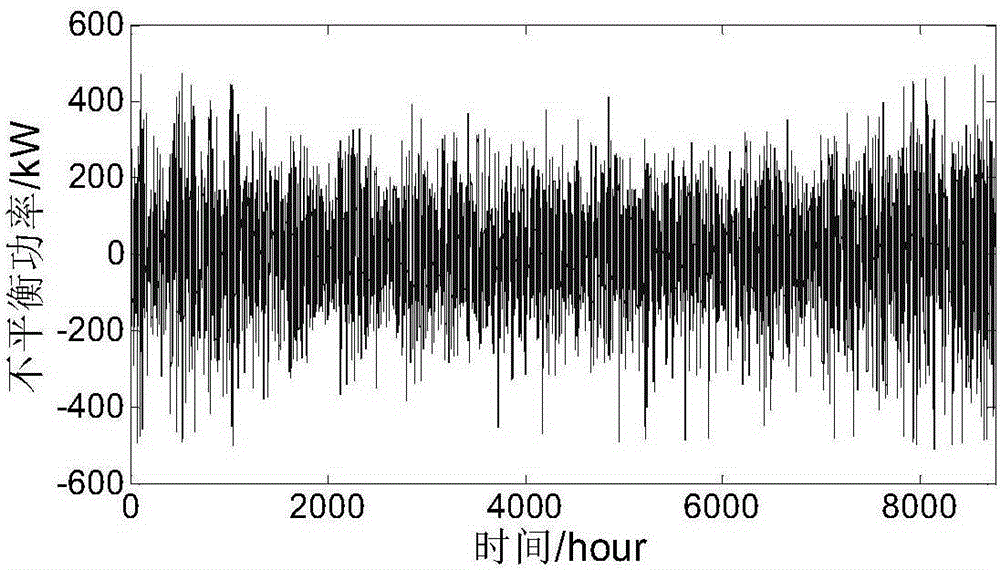

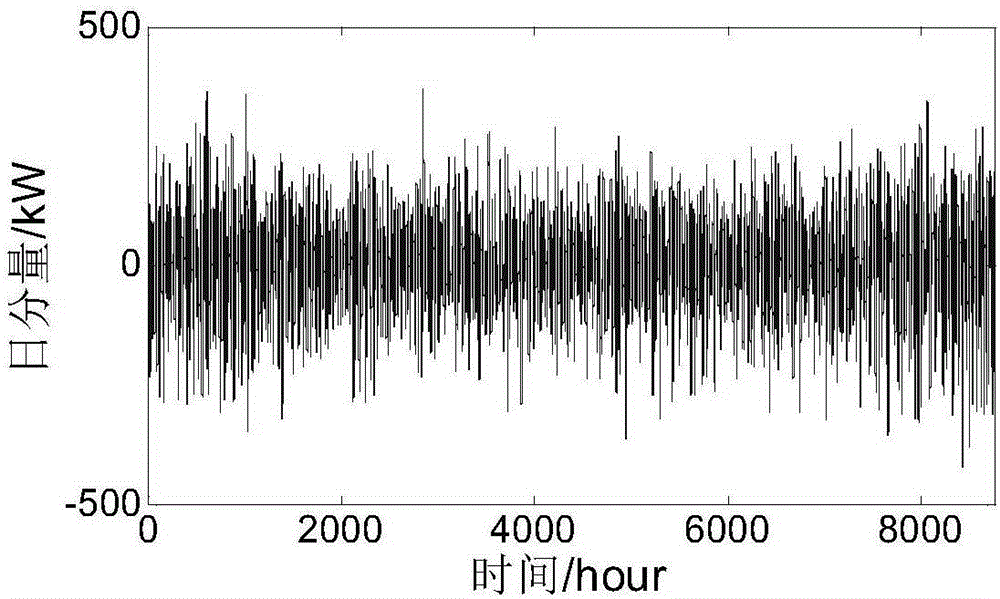

Isolated micro-grid hybrid energy storage optimal configuration method

ActiveCN105226691AComply with hybrid energy storage configuration planning requirementsIncrease profitAc network load balancingDecompositionGenetic algorithm

The invention provides an isolated micro-grid hybrid energy storage optimal configuration method. Micro-grid power supply load unbalanced power and total loads in a micro-grid are integrally considered, influences of factors that intermittent energy and load conditions fluctuates with time in the system on isolated micro-grid hybrid energy storage capacity configuration are comprehensively considered, and the isolated micro-grid hybrid energy storage capacity optimal configuration is established; in addition, a genetic algorithm is utilized for solves isolated micro-grid hybrid energy storage capacity optimal configuration models corresponding to different splitting and decomposition modes of the power supply load unbalanced power, and an isolated micro-grid hybrid energy storage optimal scheme more according with reality is determined by selection, so that the practical isolated micro-grid hybrid energy storage configuration programming requirements are better met, the utilization rate and the service lifetime of the isolated micro-grid hybrid energy storage capacity configuration are improved, the operation economy is enhanced, the comprehensive utilization cost of the isolated micro-grid is lowered, and the isolated micro-grid hybrid energy storage optimal configuration method can be widely applied to hybrid energy storage capacity optimal configuration of the isolated micro-grids.

Owner:CHONGQING UNIV

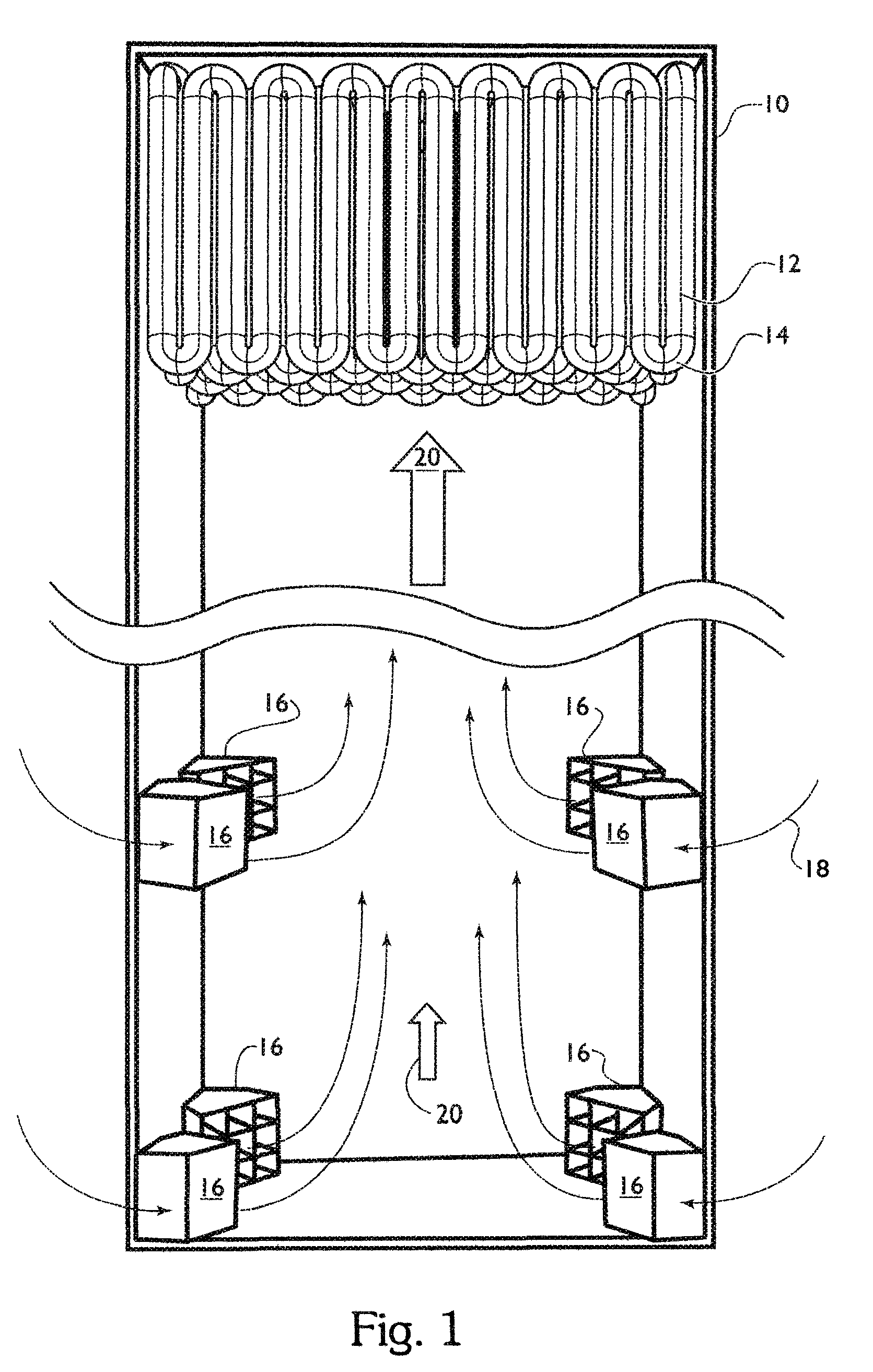

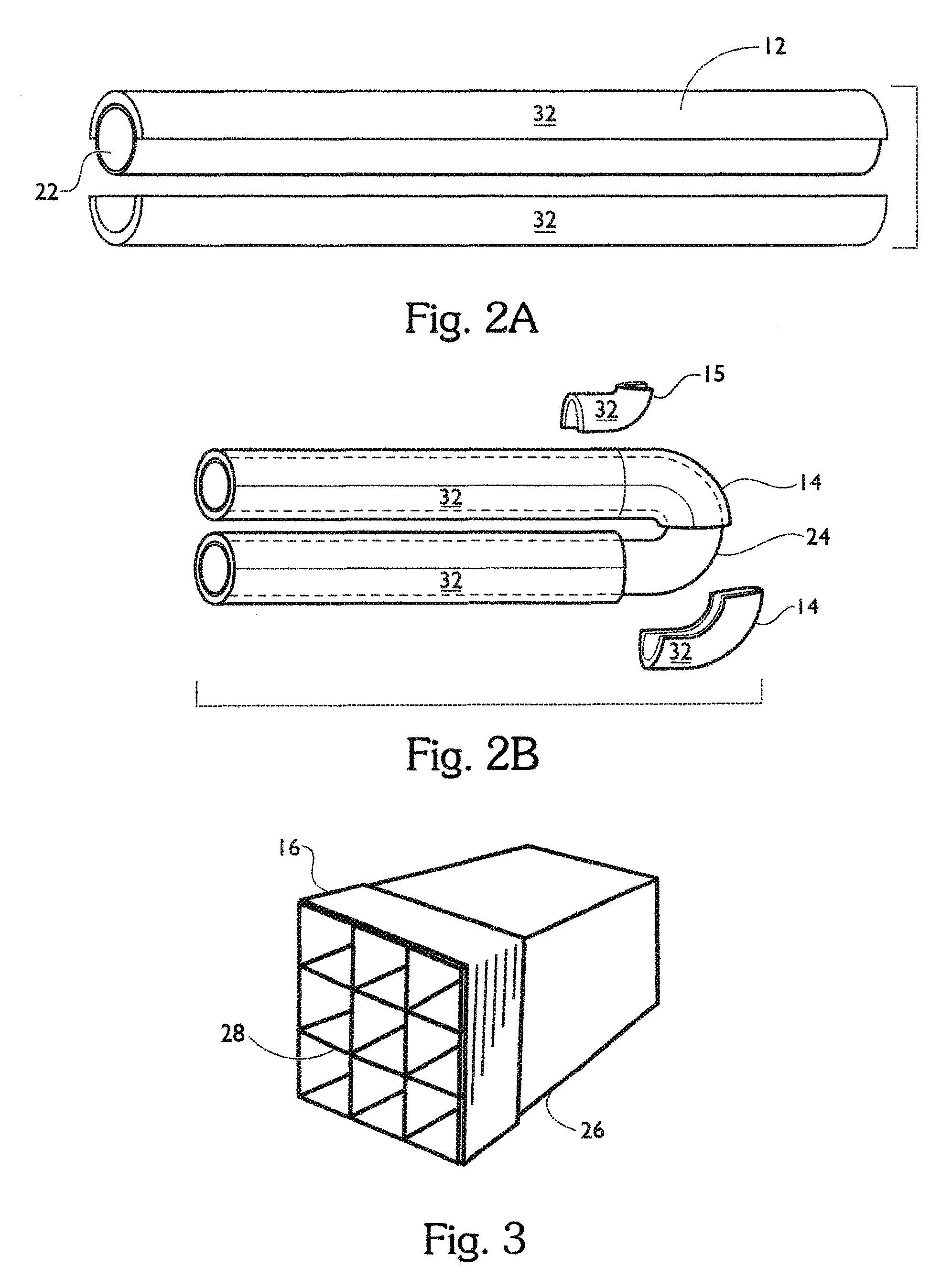

Tube shields having a thermal protective layer

InactiveUS20100038061A1Extend effective repair and replacement cycleReduce use costMetal-working apparatusCorrosion preventionColloidal silicaEmissivity

A tube shield, and method of manufacturing the tube shield, having a support structure with an external surface, an internal surface, and an edge, and a thermal protective layer on at least one surface of the shield support structure. The thermal protective layer is composed of a filler, one or more emissivity agent, and either an inorganic adhesive or a binder that is colloidal silica, colloidal alumina, or combinations thereof. A colorant, a surfactant, and / or a stabilizer may be incorporated into the thermal protective layer.

Owner:WESSEX

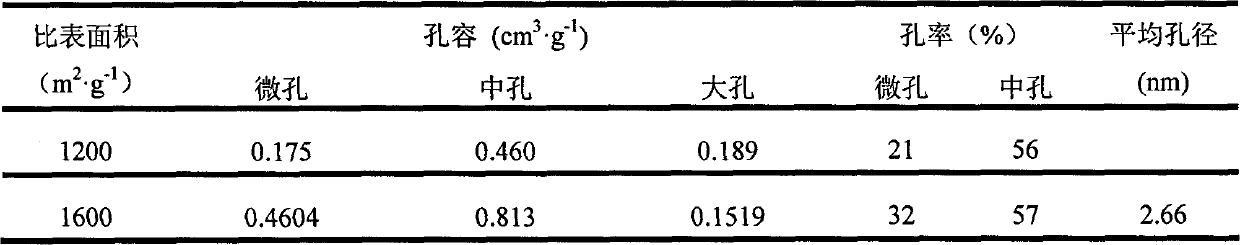

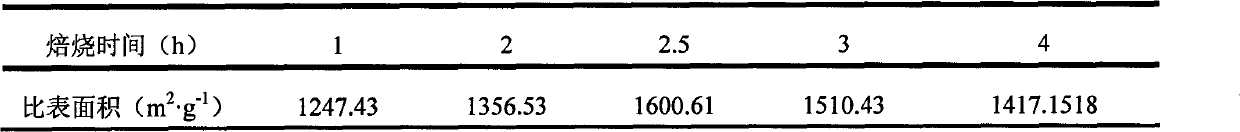

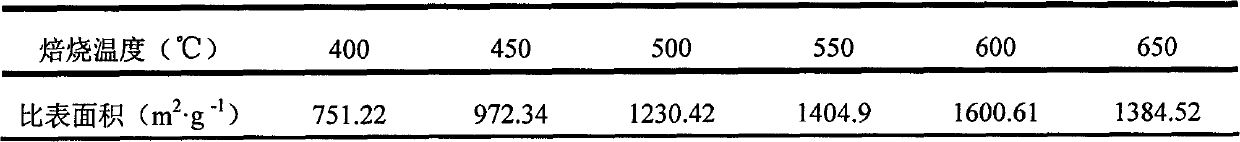

Method for preparing activated carbon by catalyzing and activating microorganism white-rot fungi or enzymes

InactiveCN102745689AReduce production safety hazardsShort manufacturing timeCarbon compoundsNicotiana tabacumBiological activation

The invention relates to a method for preparing activated carbon by catalyzing and activating microorganism white-rot fungi or enzymes, which belongs to the technical field of activated carbon preparation. According to the preparation method, tobacco solid waste is used as a raw material, and a product is obtained through simple processes of pretreating the raw material, preparing a tobacco activated base by microorganism white-rot fungi culture or enzyme catalysis and activation and preparing the activated carbon. The method has the characteristics of wide raw material source, low waste utilization cost, low energy consumption in the production process, no secondary pollution, benefit to environmental protection, good adsorptive property and wide application of the activated carbon production, and the like. The method can be widely applied to preparing the activated carbon by taking the tobacco solid waste as a raw material, and the activated carbon prepared by adopting the method provided by the invention can be widely applied to the fields of waste water treatment, removal of SO2 from smoke, adsorption of odors in food fresh keeping, and the like.

Owner:CHONGQING TECH & BUSINESS UNIV

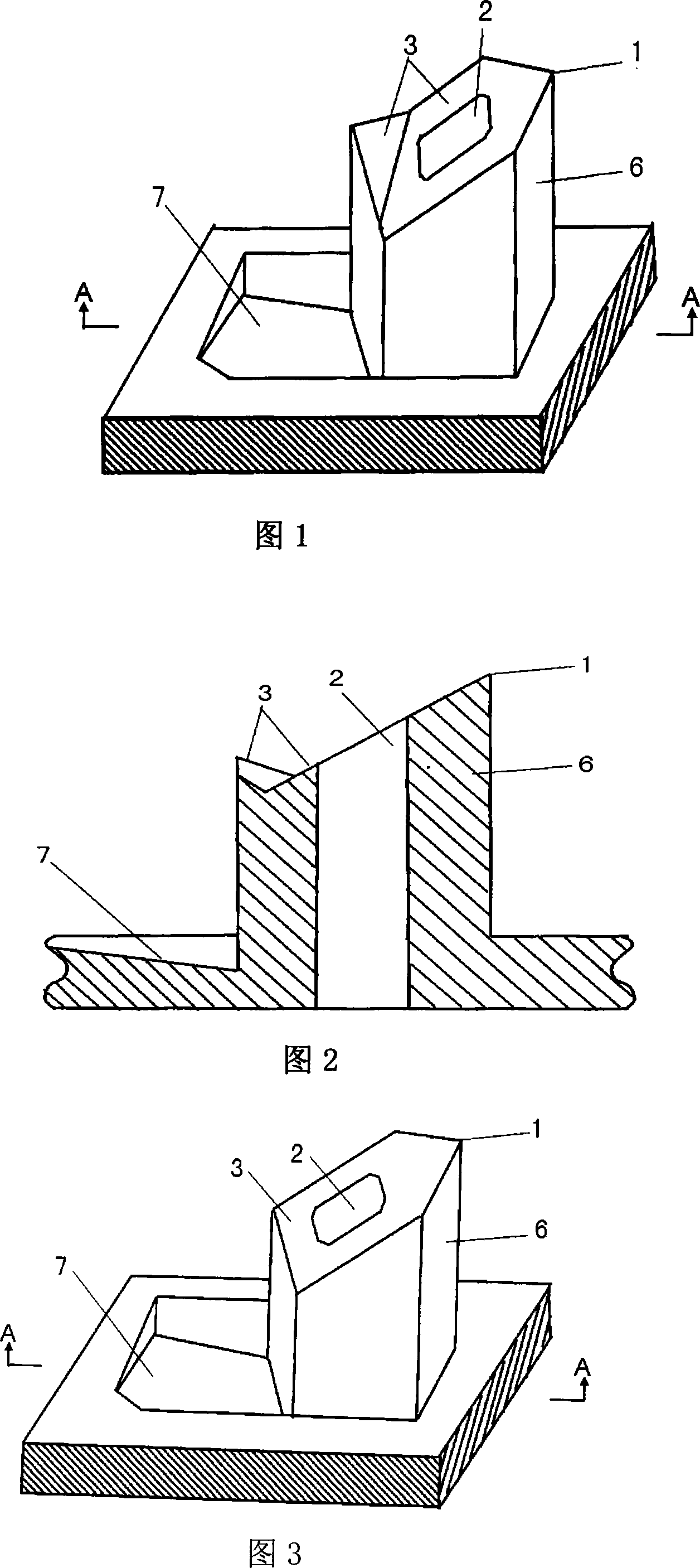

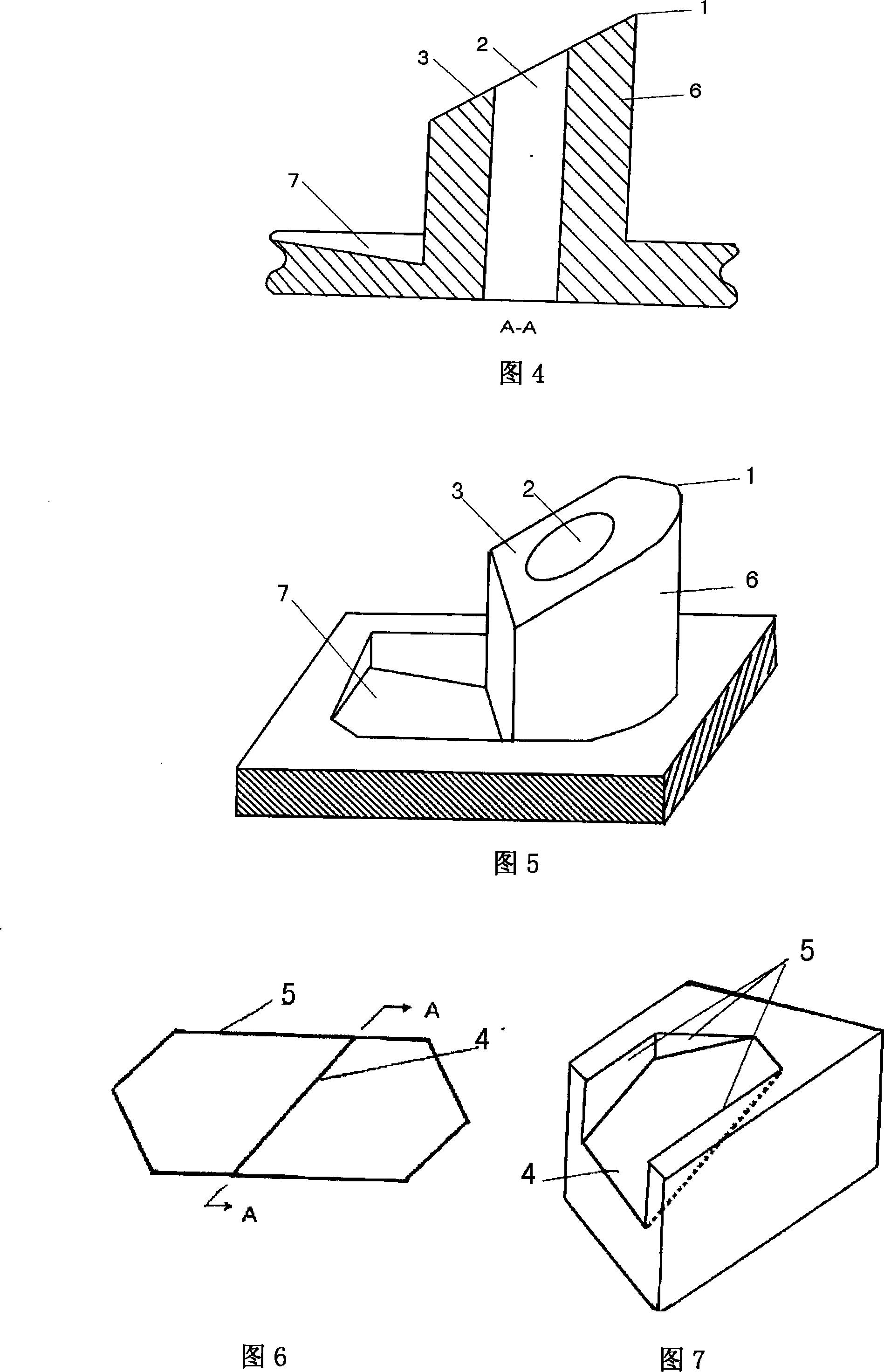

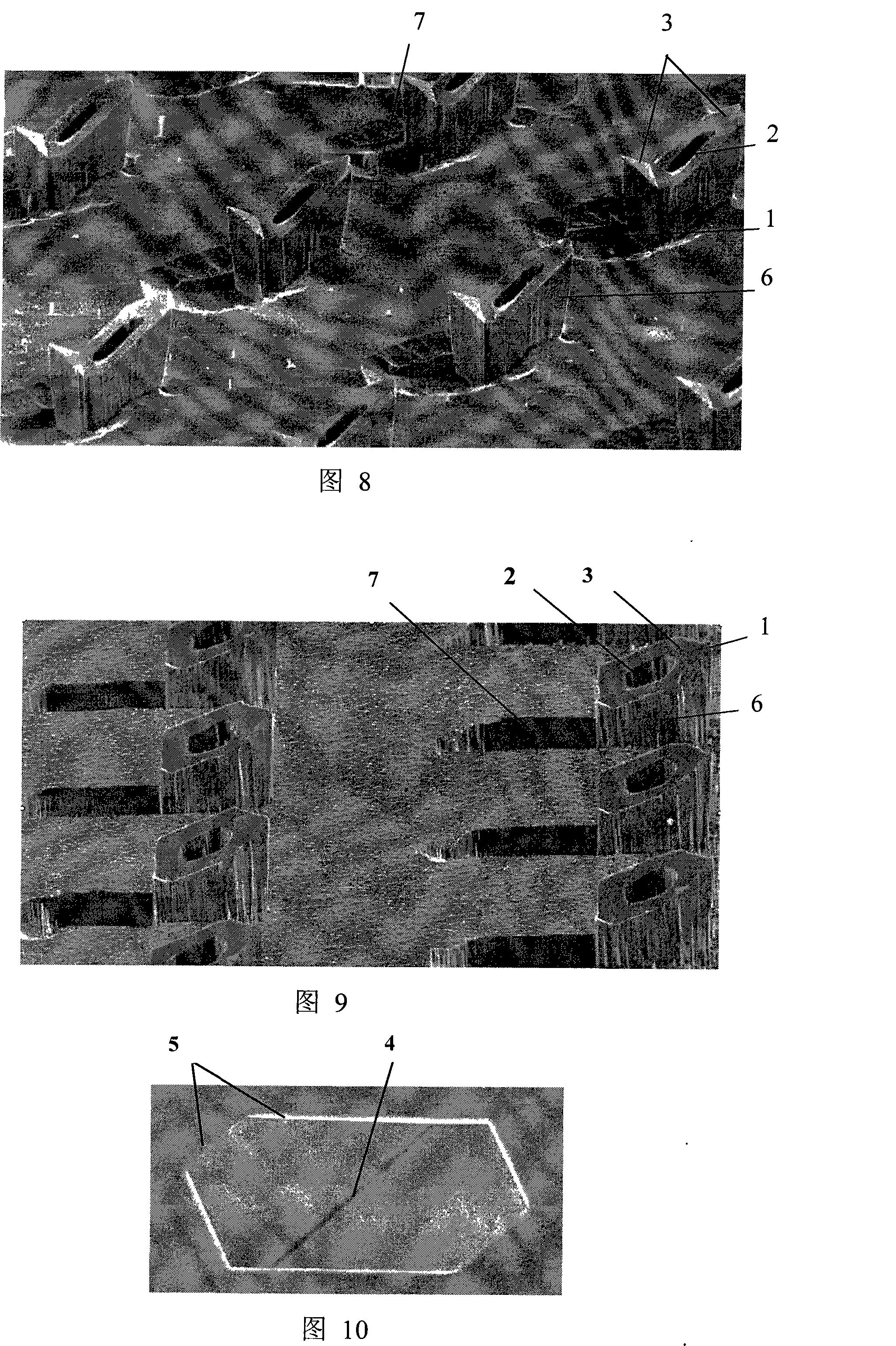

Miniature solid or hollow silicon needle, silicon needle array and preparing method thereof

InactiveCN101244303AReduce thicknessStable structureDecorative surface effectsMicroneedlesCrystal orientationHollow core

The invention discloses a miniature solid or hollow silicon needle, a silicon needle array and the manufacture method, belonging to the medical service and hairdressing apparatus and micro machining technical field. The lower end of the miniature silicon needle head is column. The upper needle point of the needle head is provided with at least one arc sharp corner to form the peak. A through hole is arranged on the peak and is connected with the inverse triangle groove at the bottom. By micro-electronics craft, at the positive and the back surfaces of the (110) crystal orientation monocrystalline silicon wafer, two kinds of inverse triangle grooves are processed in batches which are formed by six silicon (111) surfaces, using the anisotropism self-stop wet corrosion. Then the silicon needle and a through hole are manufactured by the DRIE method. The through hole is connected with the back inverse triangle groove. The invention has the advantages that: the solid or hollow silicon needle array can be manufactured in batches with low cost, high productivity and firm structure; the invention has a wider potential application in the transdermal drug delivery, micro body fluid extraction and other biomedical field.

Owner:TSINGHUA UNIV

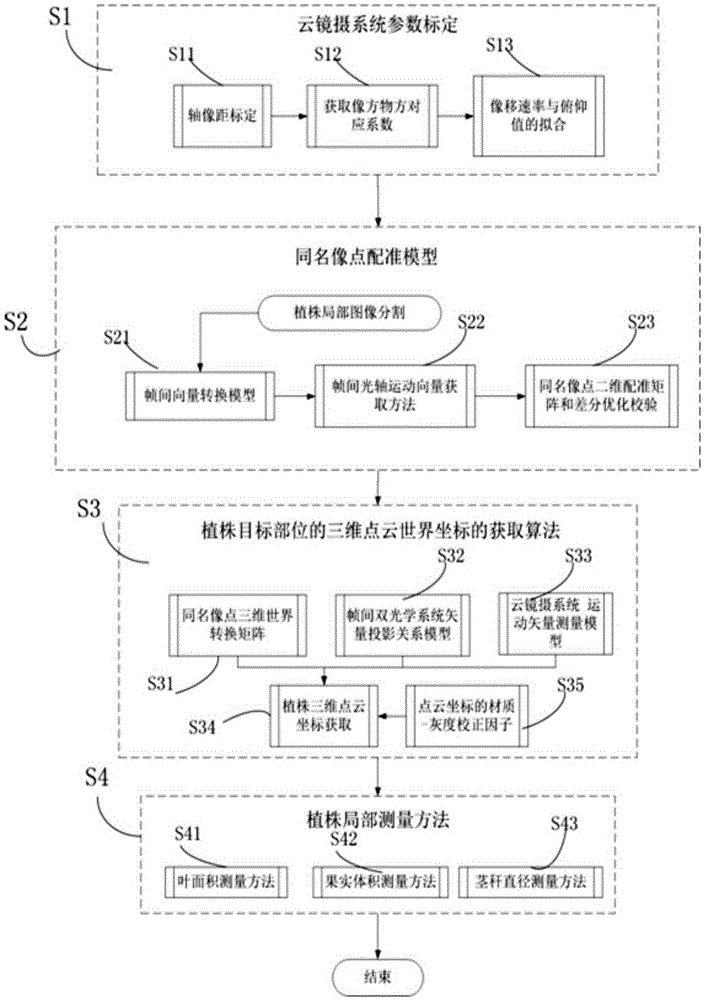

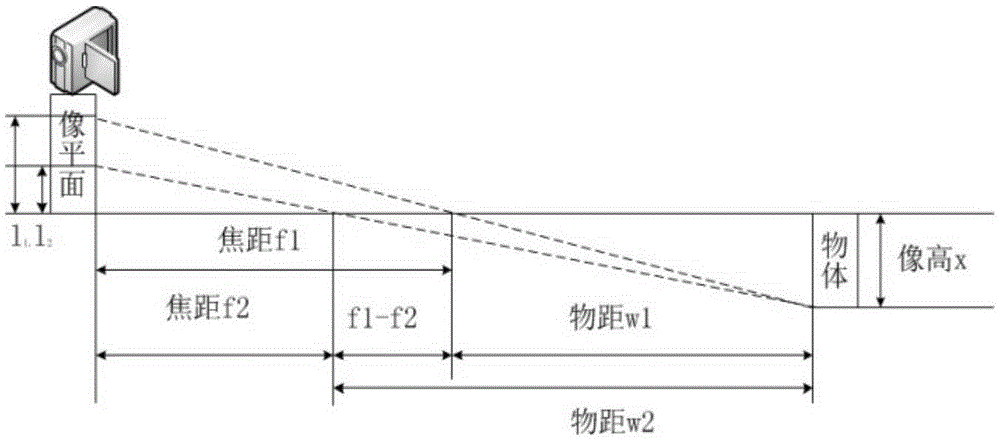

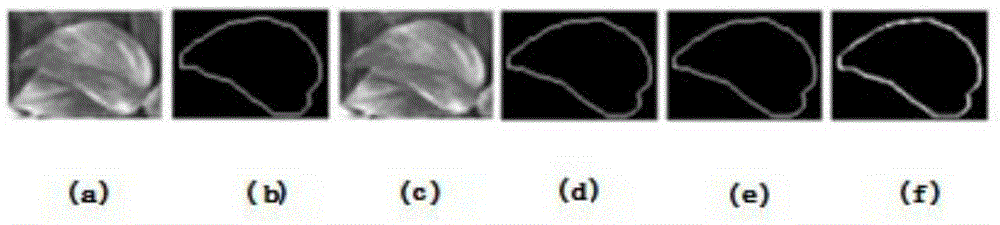

Plant three-dimensional measurement method and system based on PTZ camera system parameters and video frames

ActiveCN105241377AReduce utilization costImprove environmental adaptabilityUsing optical meansPoint cloudOptical axis

The invention relates to the field of digital image measurement, and proposes a plant three-dimensional measurement method and system based on PTZ camera system parameters and video frames. The method comprises the steps: S1, the calibration of PTZ camera system parameters: an axial image distance, image space and object space corresponding coefficients, an image shift rate pitching value fitting equation and coefficients; S2, a corresponding image point rectification model: an inter-frame image vector conversion model, an optical axis movement vector, a corresponding image point two-dimensional rectification matrix, and differential optimization verification; S3, point cloud world coordinate algorithm: a corresponding image point three-dimensional matrix, an inter-frame double-optical-system vector projection relation model, a PTZ camera system movement vector measurement model, three-dimensional point cloud coordinate obtaining, and a gray scale material correction factor; S4, plant local measurement method. The system comprises the following parts: S1, a PTZ camera system parameter obtaining module; S2, a corresponding image point rectification module; S3, a three-dimensional measurement module; S4, a plant local measurement module. Compared with other digital mapping technologies, the method does not need an object space control point, is strong in environmental adaptation, is high in equipment compatibility, and reduces the cost.

Owner:CHINA AGRI UNIV

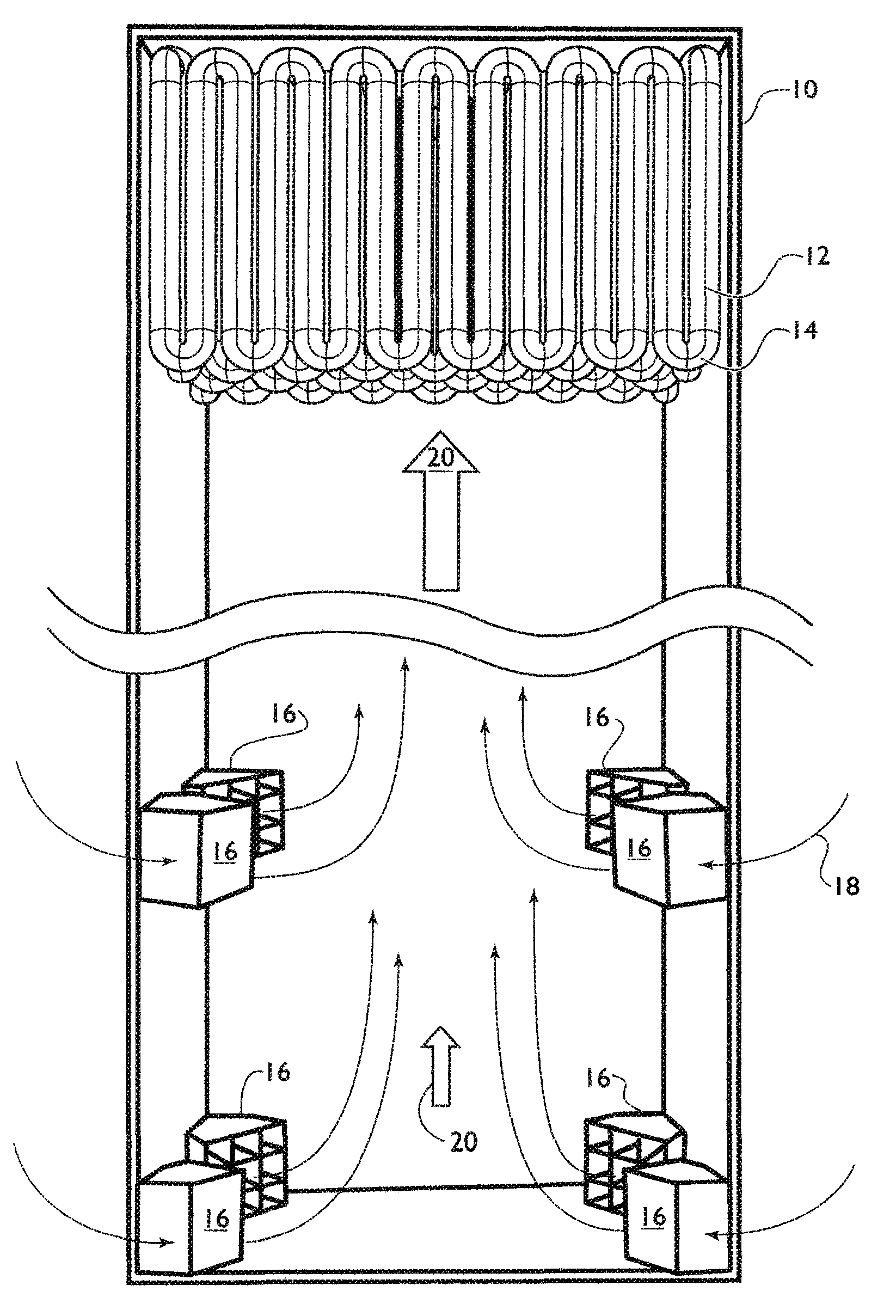

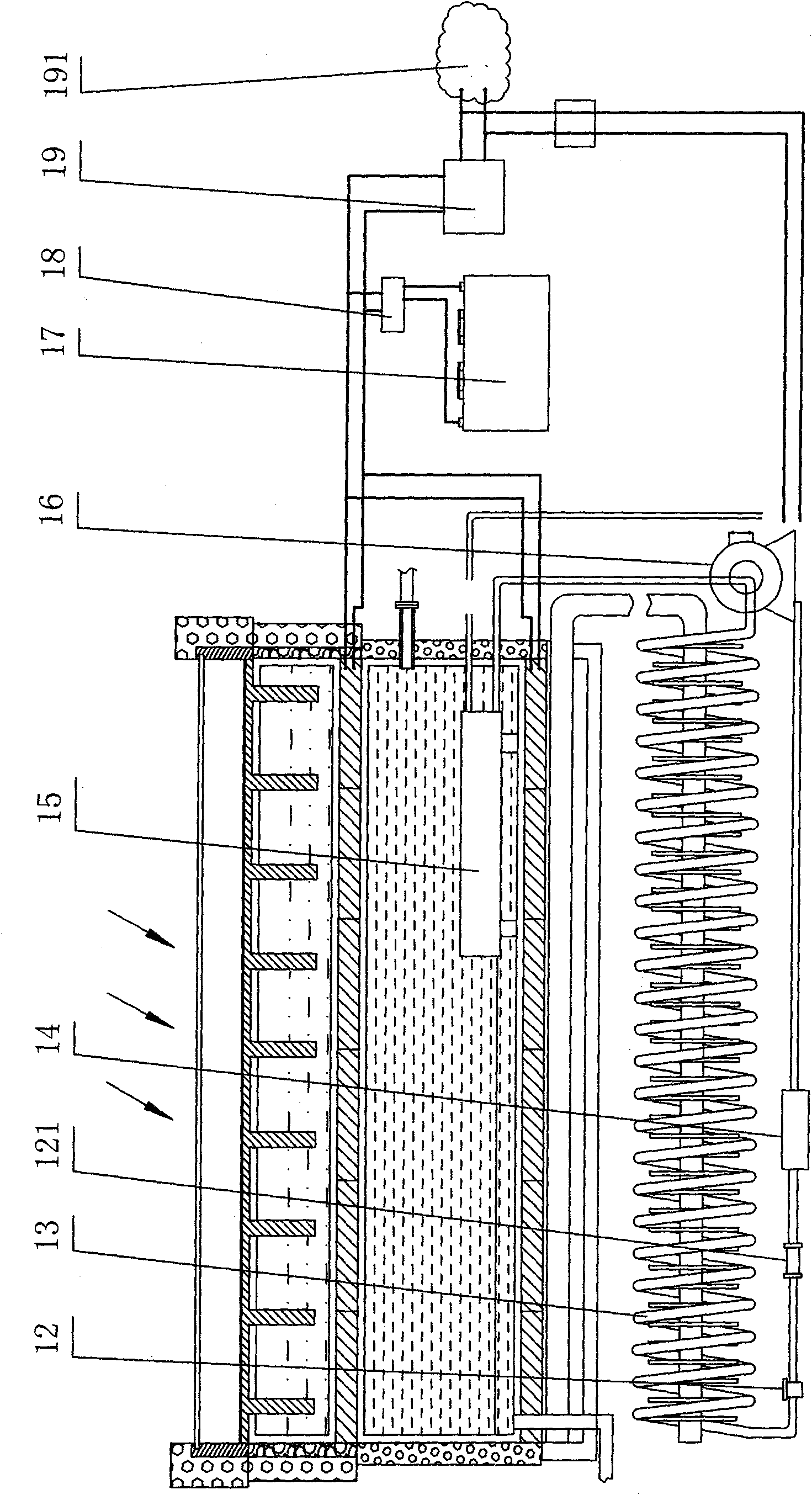

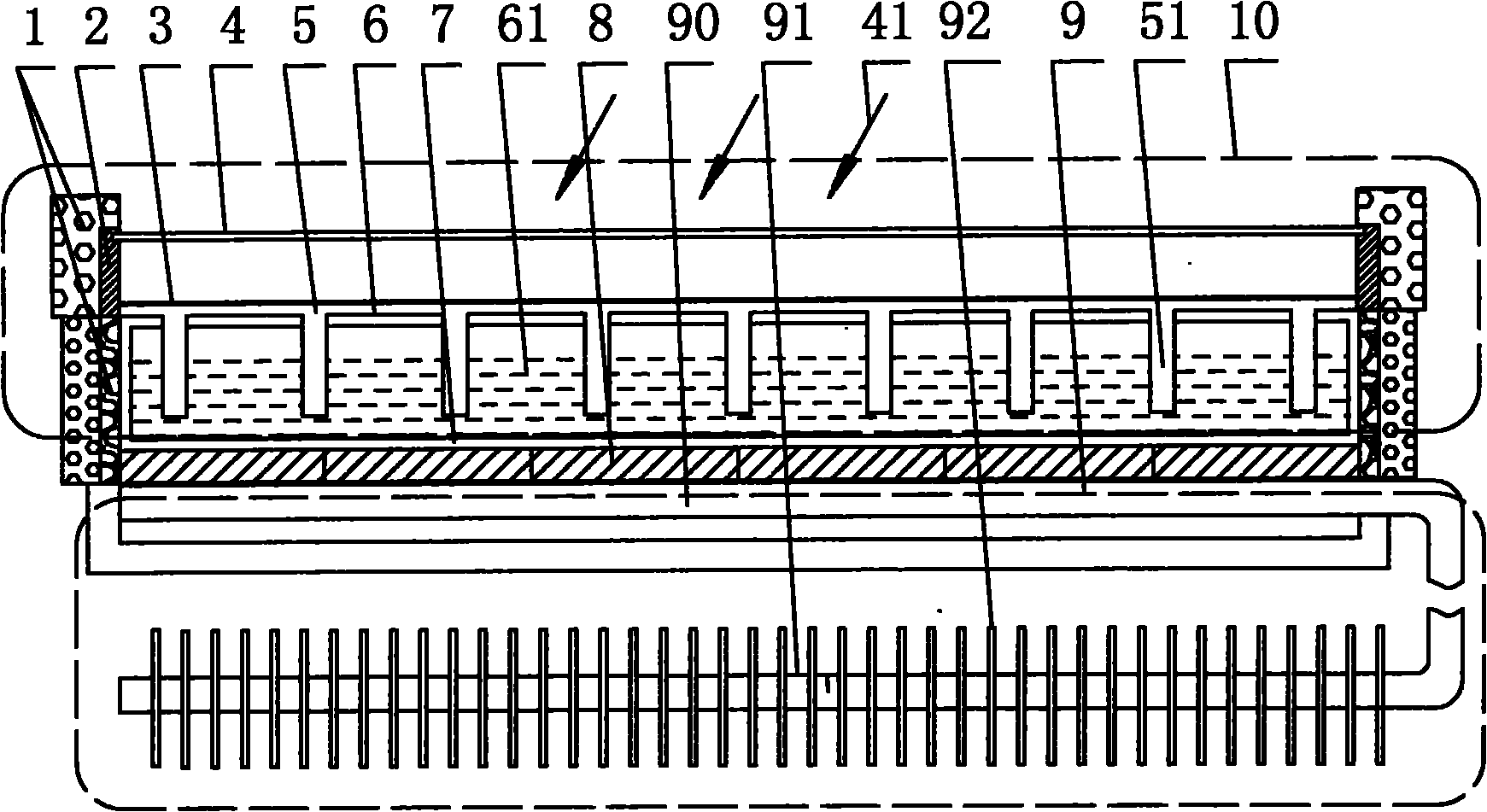

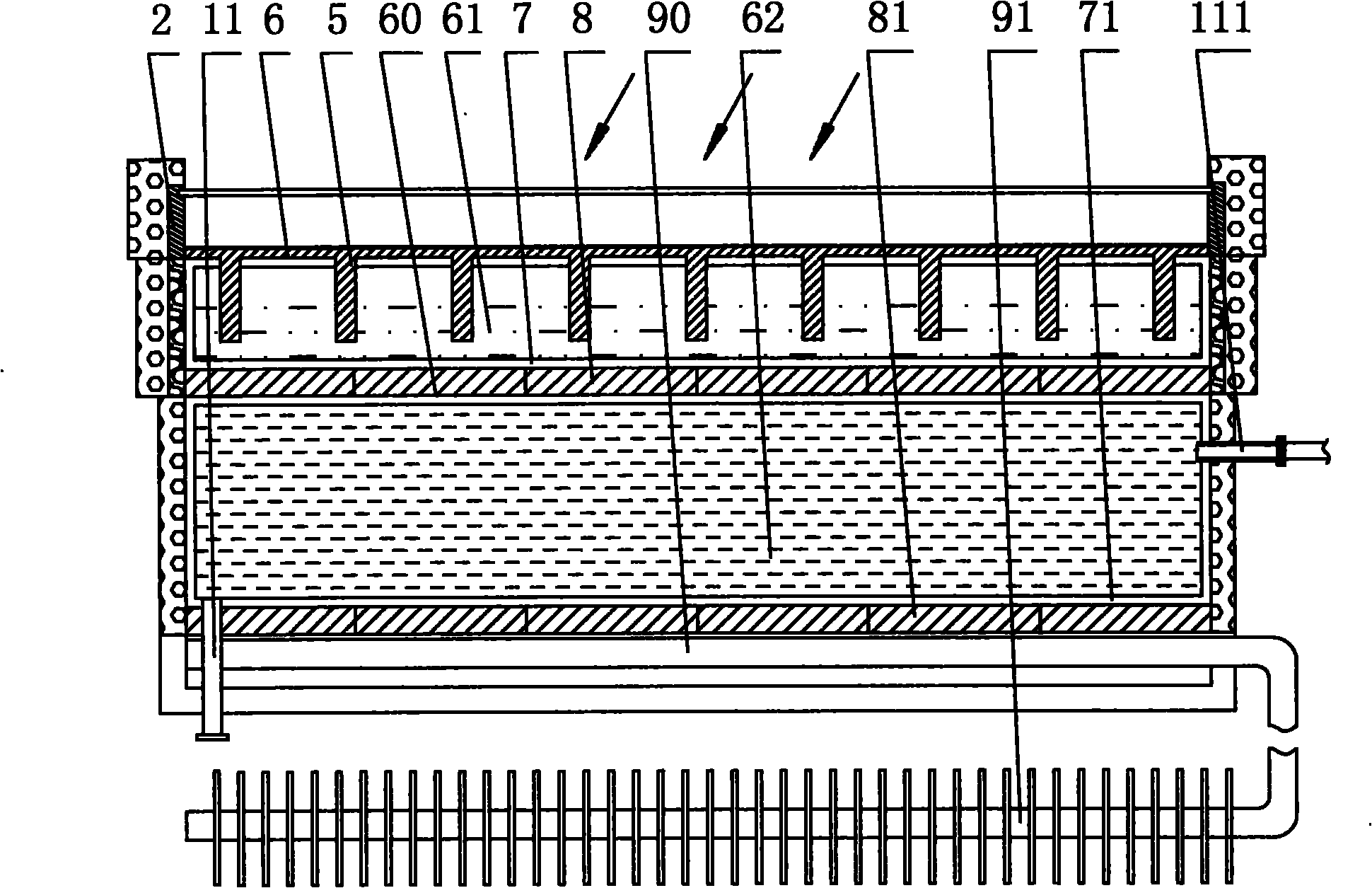

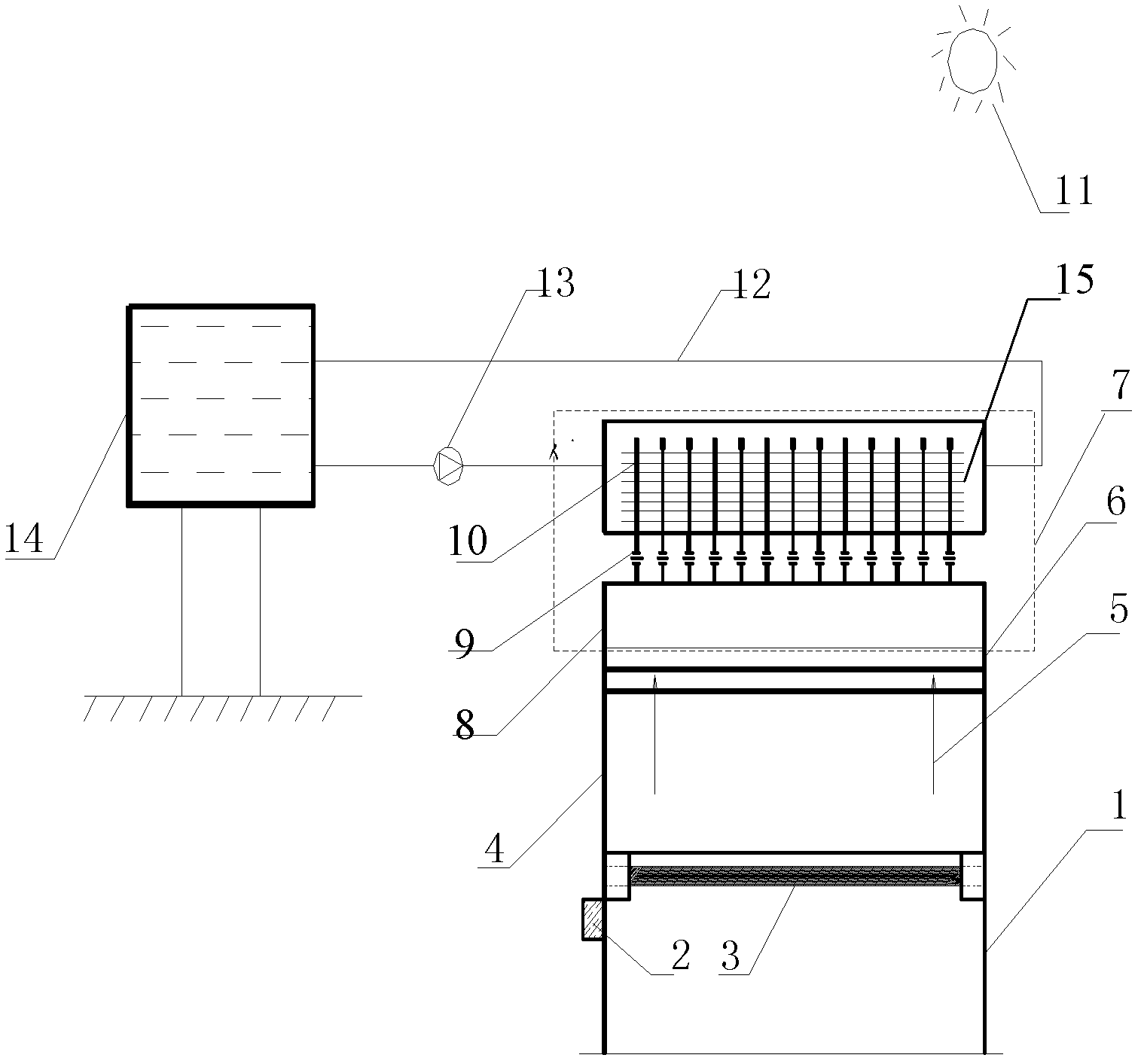

Solar energy comprehensive utilization system

ActiveCN101877561AImprove utilization efficiencyEasy to installHeat storage plantsEnergy storageElectricityHigh energy

The invention relates to a solar energy comprehensive utilization system, comprising a temperature difference heat power-generating device, and a heat radiation device which is contacted with the cold end of the temperature difference heat power-generating device of a semiconductor; the system further comprises a heat stabilization device, the heat stabilization device comprises a heat source and more than one heat storage core, and the heat storage core is contacted with the hot end of the temperature difference heat power-generating device. The solar energy comprehensive utilization system has the characteristics of high energy utilization efficiency, convenient installation and low energy utilization cost, in most cases, heat supplying and power generation can be carried out synchronously, and any mechanical power is not needed, so as to obtain cheap electricity. The size of the solar energy comprehensive utilization system is flexible and the solar energy comprehensive utilization system can be integrated with roofs of buildings through proper appearance design; in addition, the solar energy comprehensive utilization system is applied widely and can be widely applied to building, bridges, roads, deserts, grazing lands, large-scale farmlands, uninhabited islands and swimming pools and the like.

Owner:武汉市天下春商贸有限公司

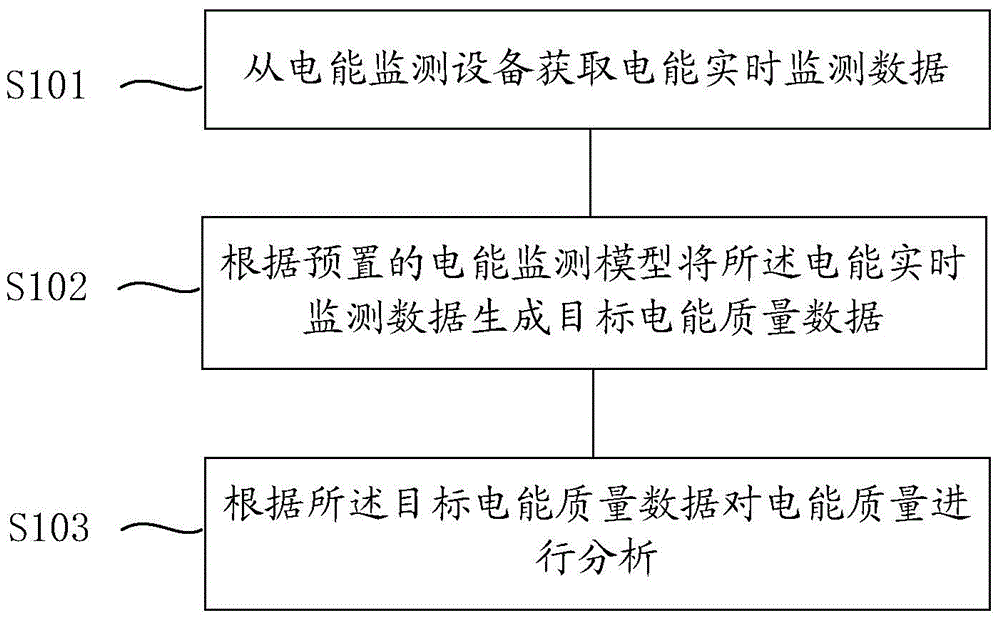

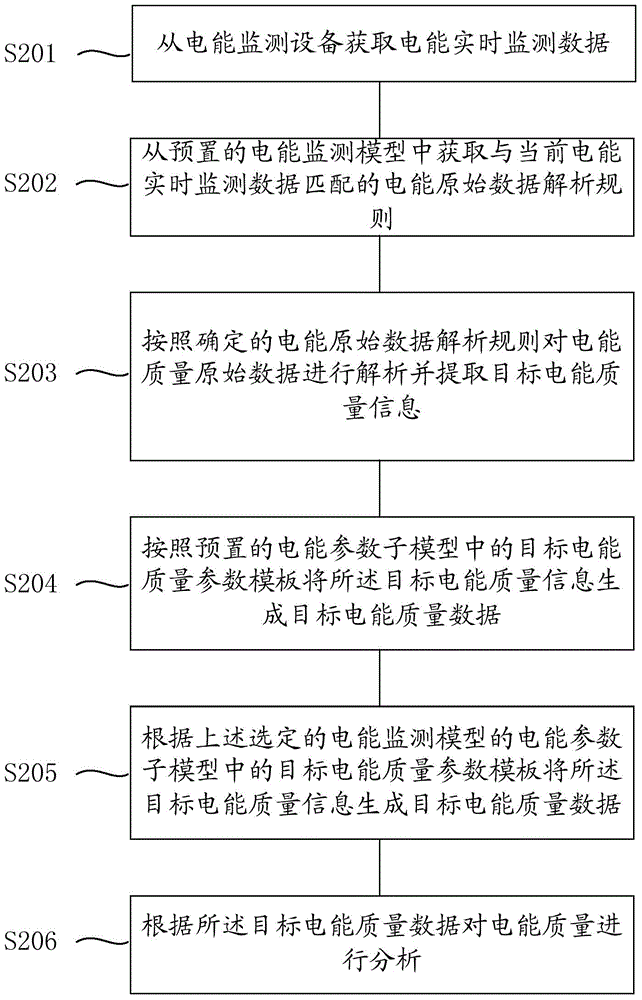

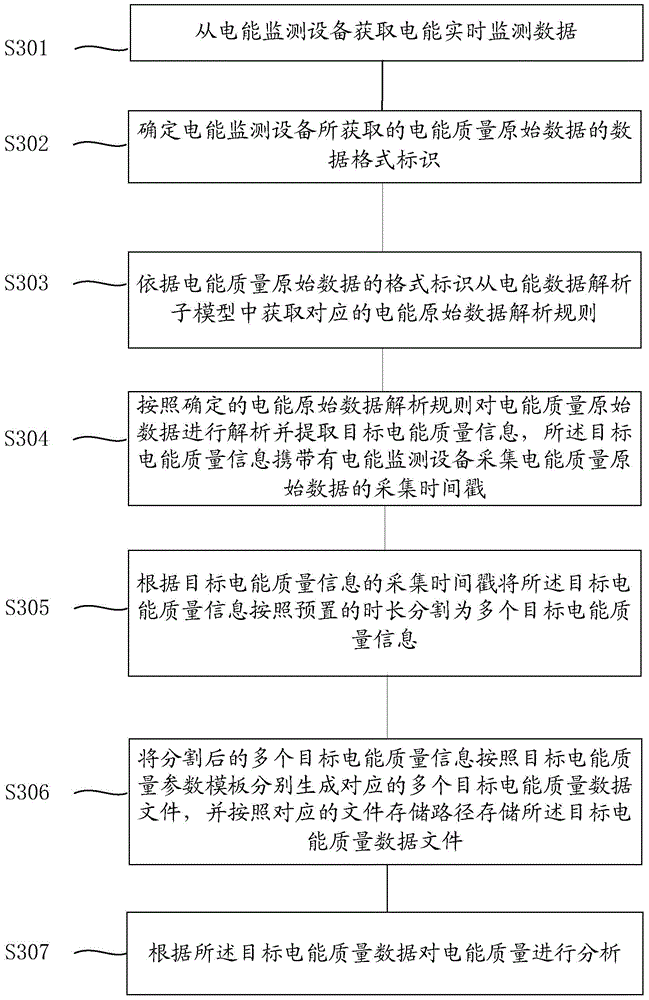

Processing method and apparatus for electric energy quality data

ActiveCN103605020AReduce utilization costReduce processing costsElectrical testingPower qualityQuality data

The invention, which belongs to the field of the power grid technology, discloses a processing method for electric energy quality data. The method comprises the following steps: obtaining real-time monitoring data of the electric energy from electric energy monitoring equipment; generating the real-time monitoring data of the electric energy into target electric energy quality data according to a preset electric energy monitoring model; and analyzing the electric energy quality according to the target electric energy quality data. According to the invention, the electric energy real-time monitoring data obtained by the electric energy monitoring equipment are generated into the target electric energy quality data with the unified format and specification based on the preset electric energy monitoring model, so that a phenomenon of an electric energy quality data information islet due to mutual incompatibility of data formats and thus the utilization and processing cost of the electric energy quality data can be substantially lowered.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

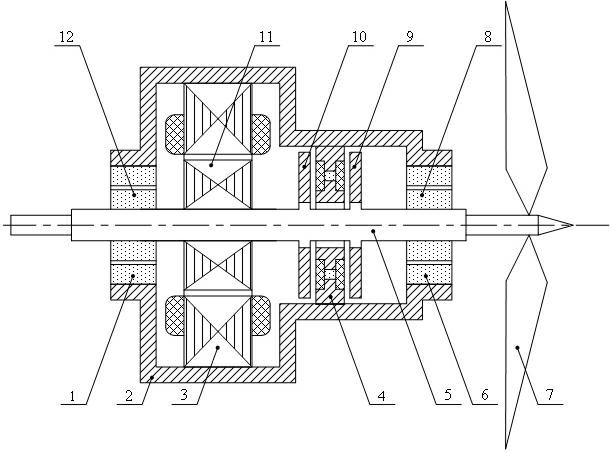

Magnetic suspension horizontal shaft direct-driving type wind driven generator with five freedom degrees

InactiveCN102182624AReduce maintenance costsReduce cut-in wind speedWind motor combinationsMachines/enginesAutomotive engineeringWind force

A magnetic suspension horizontal shaft wind driven generator with five freedom degrees comprises a stator of a permanent magnet type radial magnetic suspension bearing A at the left end of a shell, a stator of a permanent magnet type radial magnetic suspension bearing B at the right end of the shell, and a stator of a permanent magnet deflection type axial magnetic suspension bearing and a generator stator which are arranged on the inner wall of the shell. A rotor of the permanent magnet type radial magnetic suspension bearing A, a generator rotor, a rotor B of the permanent magnet deflection type axial magnetic suspension bearing, a rotor A of the permanent magnet deflection type axial magnetic suspension bearing, and a rotor of the permanent magnet type radial magnetic suspension bearing B are arranged on a spindle. Two ends of the spindle extend out from two ends of the shell, and fan blades are arranged at one end of the spindle. In the generator, the suspension of the rotors on four radial freedom degrees is realized by the two permanent magnet type radial magnetic suspension bearings, and the suspension of the rotors on an axial freedom degree is realized by the permanent magnet deflection type axial magnetic suspension bearing, so that the full suspension of the rotors is realized, and the cut-in wind speed is reduced, thereby simplifying the structure of a magnetic suspension bearing system of a wind driven generator and enhancing the efficiency of power conversion.

Owner:NANJING UNIV OF TECH

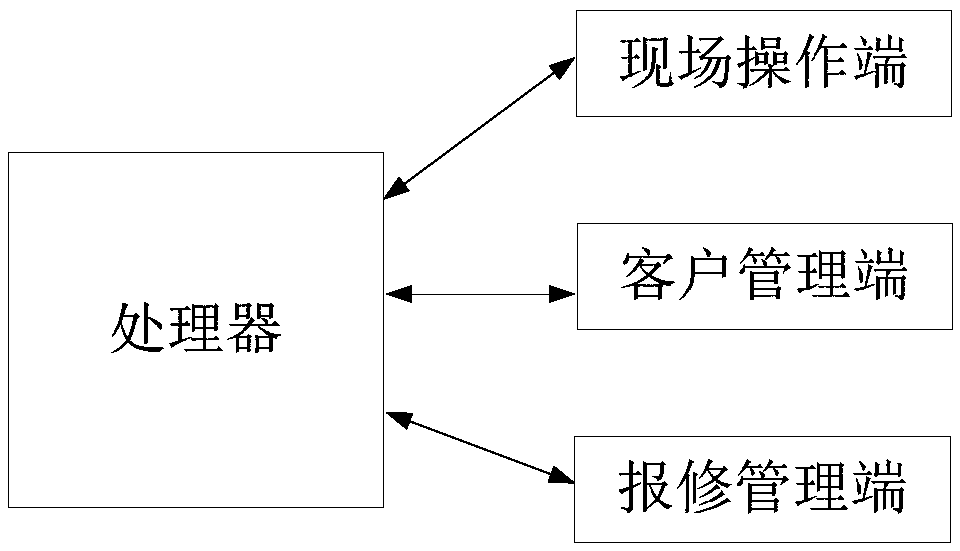

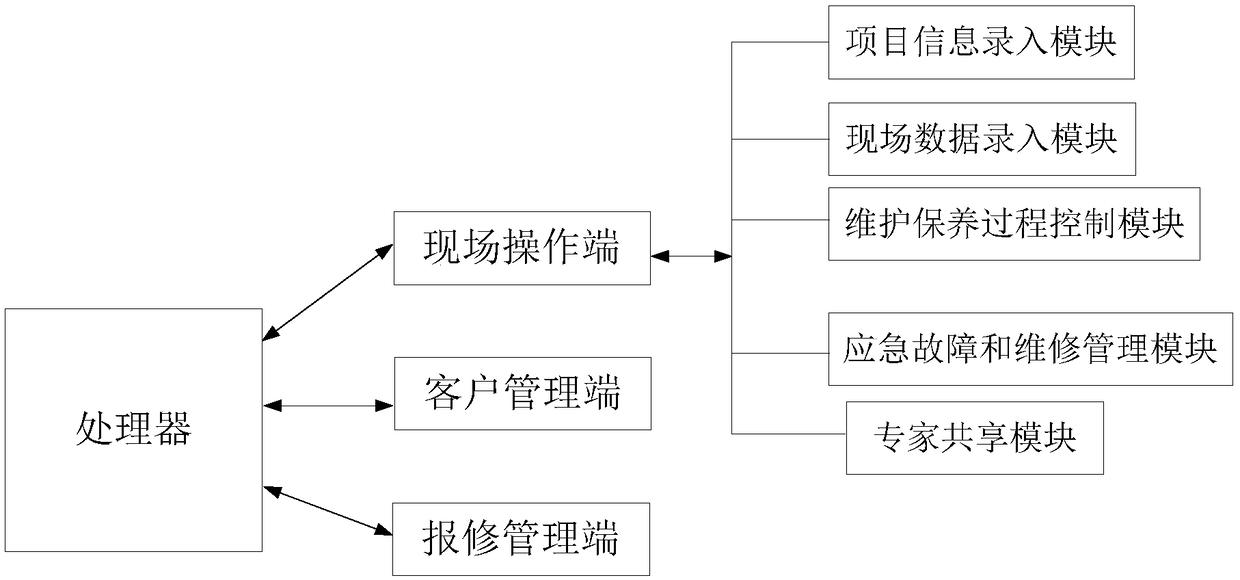

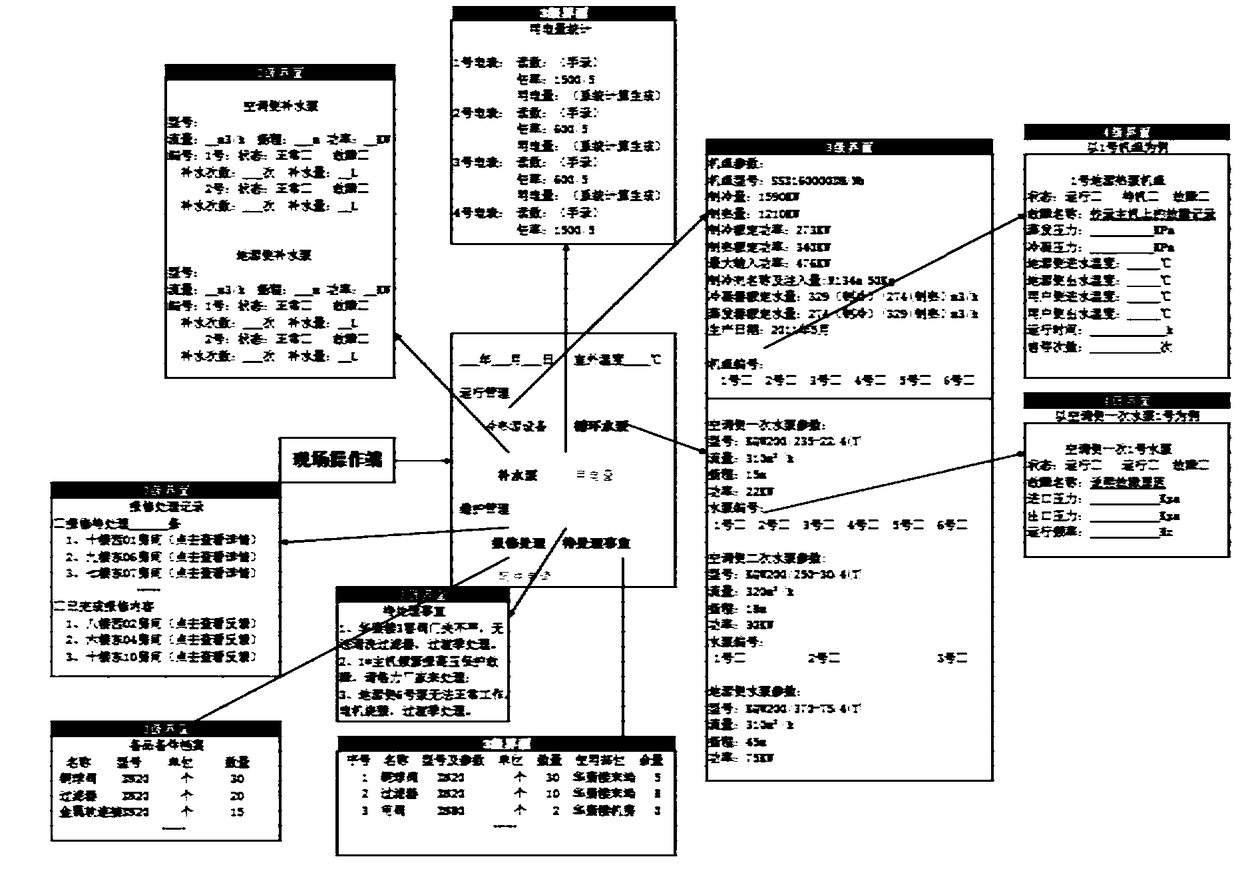

An operation and maintenance management system and method for a heating, ventilating and air-conditioning system

ActiveCN109086895AGuarantee the authenticity of the entryGuarantee timelinessInstrumentsProgram planningMaintenance management

The invention discloses an operation and maintenance management system and method for a heating, ventilating and air-conditioning system. The system comprises a field operation terminal, a customer management terminal, a repair report management terminal and a processor. Information is input through the field operation terminal and transmitted to the processor. The maintenance task sent by the processor is received and the maintenance progress is fed back to the processor. The key data, system comprehensive evaluation indicators, equipment operating status, failure maintenance progress and maintenance protection basis, and audit the maintenance workflow are acquired from the processor through the customer management end; the fault report work order is uploaded to the processor through therepair report management terminal, the fault repair progress feedback from the processor is received, and the efficiency of the repair work is evaluated; the processor establishes the equipment maintenance plan, evaluates the equipment status, identifies the equipment operation failure, and records the repair progress fed back by the field operator, and analyze and evaluate the system stability, energy consumption index, repair processing rate and data input integrity according to the data recorded by the field operation terminal.

Owner:山东中瑞新能源科技有限公司

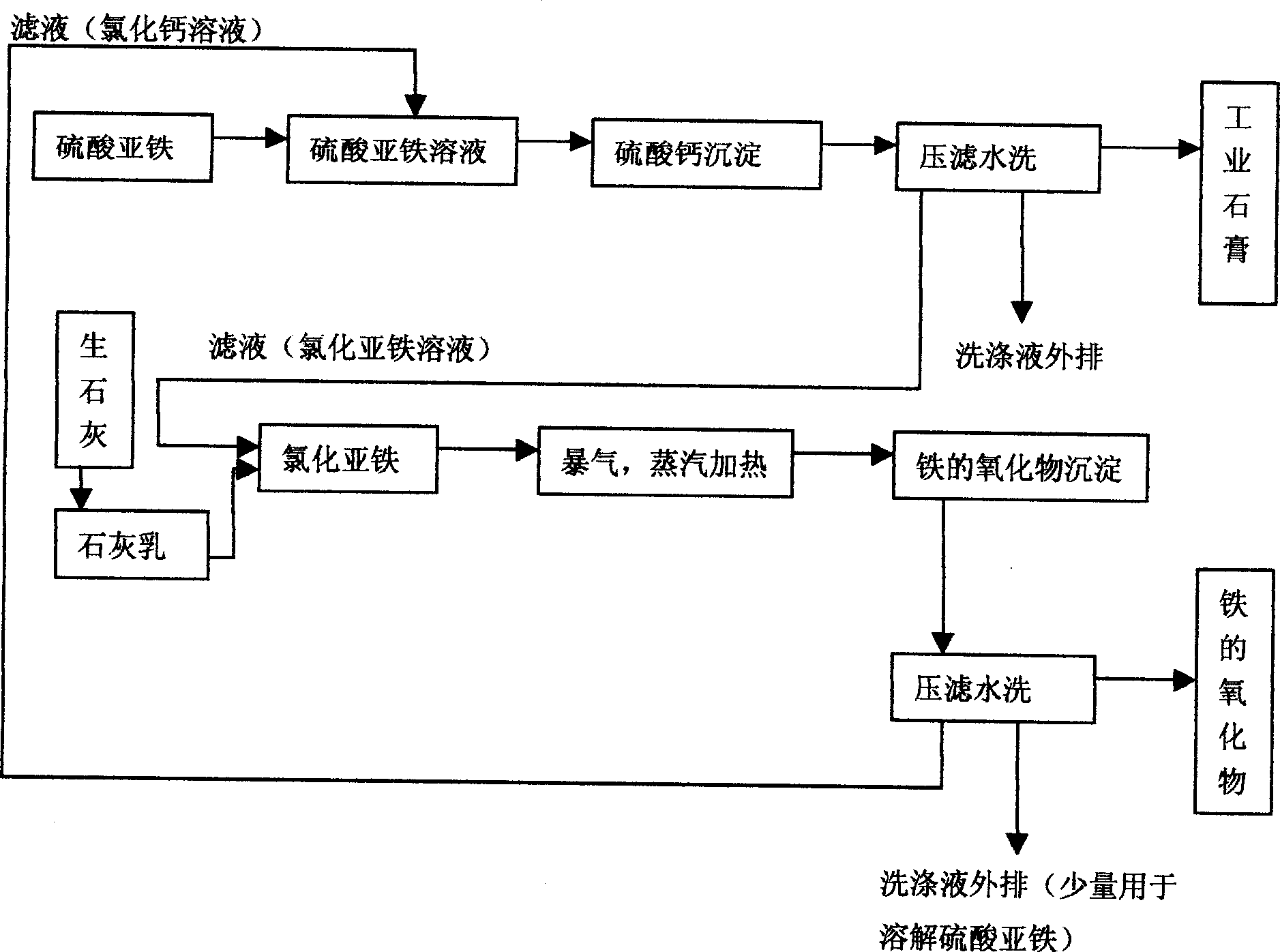

Comprehensively utilizing new process for ferrous sulfate

The technological process of utilizing ferrous sulfate comprehensively in preparing industrial gypsum and iron with lime as main material has the key point of bridging effect of calcium chloride. The technological process includes the steps of: dissolving ferrous sulfate in water, adding calcium chloride solution to produce calcium sulfate precipitate and ferrous chloride solution, filtering to separate calcium sulfate precipitate, adding lime milk into the filtrate and heating via stirring to produce ferric hydroxide precipitate, filtering, stoving the filter slag to obtain ferric oxide, and returning the filtrate. The obtained ferric oxide may be used in smelting iron, preparing iron oxide red, etc. The present invention has relatively low cost of utilizing ferrous sulfate.

Owner:刘应兵

Resource utilization method of paint slag

ActiveCN105880261ASimple processing methodProcess method safetySolid waste disposalTransportation and packagingCombustionLiquid state

A resource utilization method of paint slag includes the following steps that (1) pretreatment and separation are conducted, specifically, the wet paint slag is pretreated through a grinding modified spray drying method and separated into two components which are powdery or granular slag and organic matter waster liquid, or the wet paint slag is pretreated and separated into two components which are solid slag and organic matter waster liquid through an acid-modified baking hardening treatment technology; and (2) the water-containing organic matter waster liquid obtained in the step (1) is placed in a stirring tank, an emulsifying agent and a modifier are sequentially added into the water-containing organic matter waster liquid with constant stirring, uniform stirring is conducted, and a product is obtained. According to component characteristics of the wet paint slag, the wet paint slag is pretreated and separated into the two components which are the solid slag raw material convenient to use and the organic matter waster liquid containing volatile matter, namely water, and then the water-containing organic matter waster liquid is made into the liquid-state coal clean combustion improver; and the process method is simple, safe and free of secondary pollution, takes effect rapidly, is low in treatment or utilization cost, and is good in economical efficiency.

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

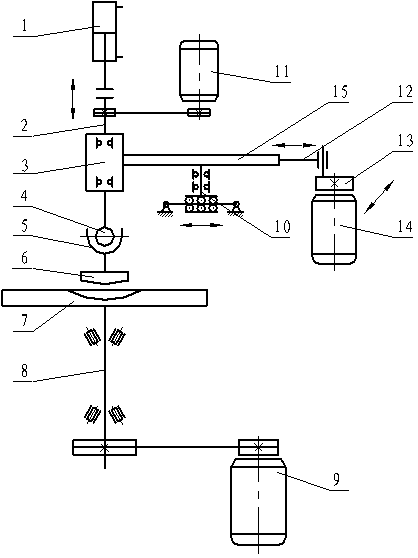

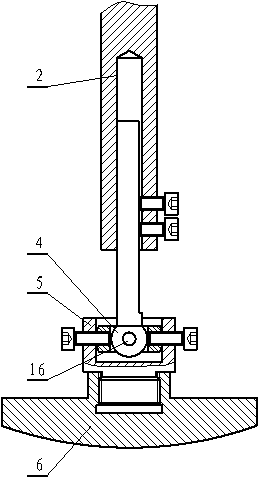

Drive type reversion polisher

ActiveCN103707170AReduce adverse effectsHigh speedPolishing machinesOptical surface grinding machinesEngineeringMechanical engineering

The invention discloses a drive type reversion polisher. The drive type reversion polisher comprises an upper disc part and a lower disc part both of which rotate in opposite directions. The upper disc part comprises a polishing die, an upper shaft and a swinging mechanism, wherein the polishing die is connected with the upper shaft through a spherical surface mechanism, and the upper shaft is further connected with a pressurizing mechanism and a rotating mechanism. The unfavorable effect caused by vibration produced by eccentricity, inertia and the like of a large workpiece is overcome due to the low-velocity rotation of the lower disc part, the grinding process is more stable, the upper disc part and the lower disc part are rotated in the opposite directions, the relative speed between the polishing die and the workpiece is effectively improved, and the machining efficiency is greatly improved under the condition that the polishing quality is guaranteed. The consistency of the relative revolving speed of the polishing die and the workpiece can be effectively guaranteed, and the occurrences that according to a traditional polisher, the passive revolving speed of a polishing die is fluctuated due to the different linear velocity differences, and polishing is uneven are avoided.

Owner:铜陵亚摩管业有限公司

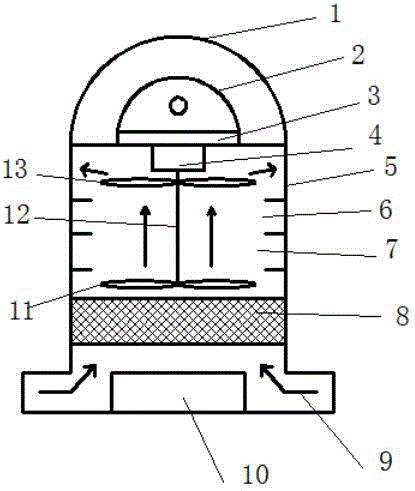

Multifunctional domestic robot

InactiveCN106403106AControl automatic obstacle avoidanceImprove purification qualityAutomatic obstacle detectionMechanical apparatusDrive wheelAutomatic control

The invention discloses a multifunctional domestic robot which comprises air purifying equipment and a base. The air purifying equipment is mounted on the base and comprises a shell. A filtering device, an ultraviolet sterilization chamber and an anion generating chamber are sequentially arranged in the shell from bottom to top. An air inducing mechanism is further arranged in the shell and penetrates through the ultraviolet sterilization chamber and the anion generating chamber. The shell is detachably arranged on the base which communicates with the bottom of the shell, and the base is provided with air inlets. The base is further provided with a floor sweeping device and driving wheels. Air outlets are formed in the upper portion of the shell, and a camera device is further arranged on the outer side of the top of the shell. An automatic control system used for controlling the robot to work is further arranged in the base. The robot can purify indoor air in a moving mode, and meanwhile, a floor can be cleaned and safety conditions in a room can be monitored in the moving process.

Owner:成都创慧科达科技有限公司

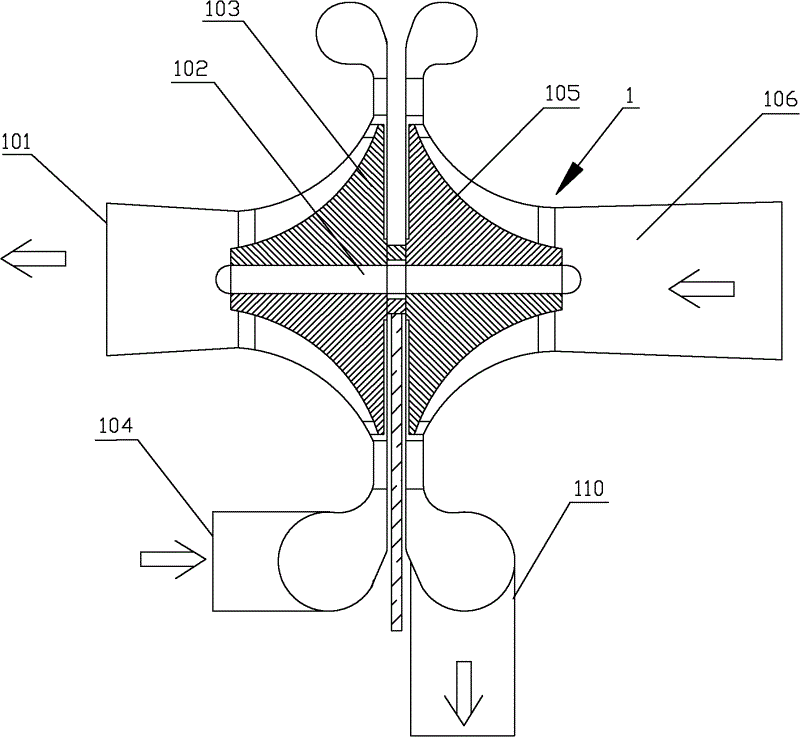

Heat source driven vacuum refrigerating system

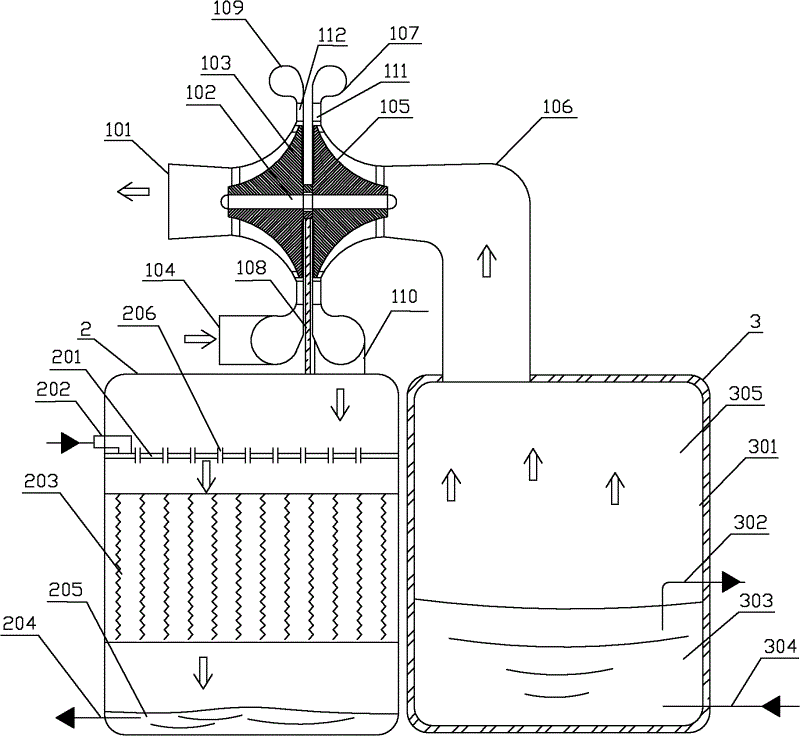

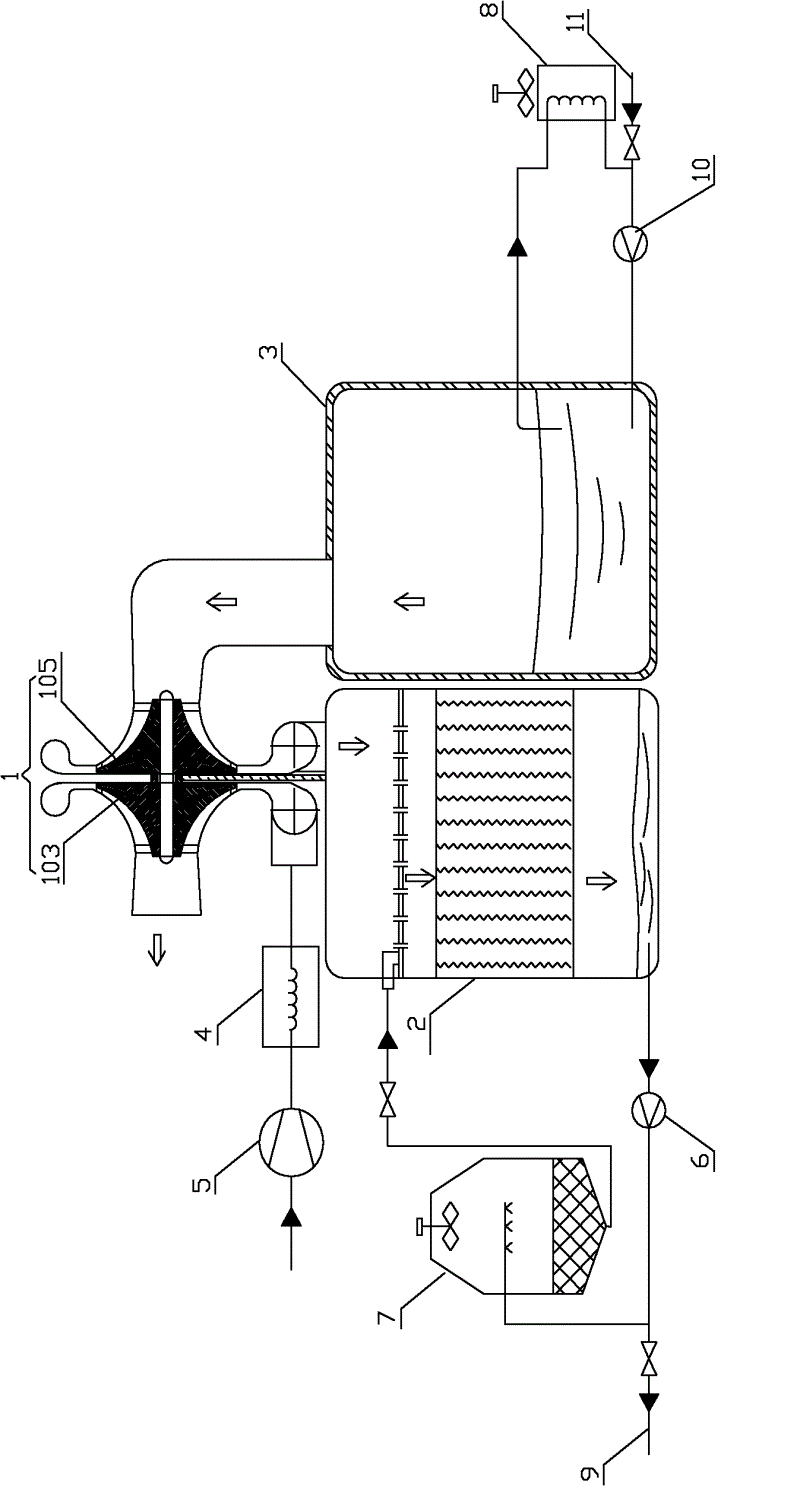

ActiveCN102620462AEnvironmentally friendlyImprove heat transfer efficiencyClimate change adaptationCompression machines using turbinesVacuum pumpingEngineering

The invention discloses a heat source driven vacuum refrigerating system, which comprises an evaporation chamber, an air extractor and a condensation chamber, wherein the extraction opening of the air extractor is communicated with a steam outlet of the evaporation chamber, the gas outlet of the air extractor is communicated with the inlet of the condensation chamber, and the air extractor comprises a centrifugal turbine and a centripetal turbine which is coaxial with the centrifugal turbine; power gas sequentially passes by a radial communicating port and an axial communicating port of the centripetal turbine; and the steam outlet of the evaporation chamber is communicated with the axial communicating port of the centrifugal turbine, and the inlet of the condensation chamber is communicated with the radial communicating port of the centrifugal turbine. The vacuum refrigerating system utilizes the power gas to drive the centripetal turbine so as to drive the centrifugal turbine to carry out vacuum-pumping. The vacuum refrigerating system takes water as a working medium, does not have depletion ozone and greenhouse gas emission, and has the advantage of environmental friendliness. A high-speed turbomachine is used, so the volume flow is large, the defect of small flow due to the small density of water which is taken as the working medium can be made up, and meanwhile, the vacuum refrigerating system has the advantages of simple and compact structure and the like.

Owner:浙江和际投资管理有限公司

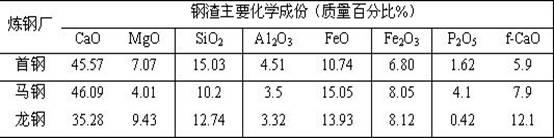

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113AChange compositionChange physical stateIncreasing energy efficiencyCalcium in biologySteelmaking

The invention relates to method for modifying steel slag, in particular to a method for modifying high-temperature steel slag discharged in the final steelmaking stage by using a large amount of mining tailings with low cost, comprising the following steps: mixing 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings to obtain compound materials of the tailings; granulating to prepare agglomerated blocks of 3-5cm; adding the compound materials of the tailings into steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; carrying out steel slag splashing for furnace maintenance, wherein the left steel slag is not poured into the steel slag pot or disc for modifying the steel slag; preserving the temperature of the steel slag at 1,200-1,400 DEG C for 30-60min; quenching by using water, applying heat or covering by heat when the temperature is below 1,200-1,400 DEG C; breaking; and carrying out magnetic separation. Due to the adoption of the method, the separation effect of the steel slag can be improved significantly, the grindability of the separated steel slag can be improved, the total recovery rate of the scrap steel can be up to 95-100%, the components of the separated steel slag are controllable and have high activity, and the separated steel slag contain less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and can replace the portland cement clinker.

Owner:迁安金隅首钢环保科技有限公司

Combined heat and power system

InactiveCN102881758AAvoid direct contactSolve the problem of not being able to provide high-quality thermal energyEnergy industryPhotovoltaicsGeneration processEvaporation

The embodiment of the invention discloses a combined heat and power system which comprises a solar battery, a heat storage water tank and a heat pipe arranged on the back of the solar battery, wherein the heat pipe is internally provided with a heat transfer working medium, and comprises an evaporation end contacted with the back of the solar battery, a condensation end conducting heat exchange with fluid in the heat storage water tank, and transfer pipelines connecting the evaporation end to the condensation end. According to the combined heat and power system, the heat pipe is additionally arranged on the back of the solar battery as a heat transfer unit and internally provided with the liquid heat transfer working medium; the vaporization temperature of the heat transfer working medium is lower than the temperature of the surface of the solar battery in the power generation process; and the liquefaction temperature of the heat transfer working medium is higher than the temperature of the fluid. When the solar battery is used for power generation, the heat transfer working medium conducts the heat exchange with the surface of the solar battery and the fluid, and the direct contact between the fluid and the solar battery is avoided, so that the problem that high-grade heat energy cannot be supplied while the power generation efficiency is ensured is solved.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Nuisance free coating agent for seeds and preparation method

InactiveCN101049109AWide variety of sourcesNo adverse effectsBiocideAnimal repellantsHydrogenPeroxidase

A seed coating agent without environmental pollution is proportionally prepared from the acid solution of chitosan and / or oligochitosan, and the additive chosen from the antibacterial peptide of insect, adenyl acid, rhizobia and hydrogen peroxidase through proportional mixing and stirring.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

High-efficiency environment-friendly value-added utilization method of bamboo sawdust

InactiveCN103509581AReduce utilization costIncrease valueBiofuelsLiquid hydrocarbon mixture productionFlue gasCarbonization

The invention discloses a high-efficiency environment-friendly value-added utilization method of bamboo sawdust, and is used for overcoming the defects that because the conventional bamboo sawdust is abandoned, landfilled and incinerated, the environment is polluted, contents of the bamboo sawdust cannot be fully used resulting in a waste of resources, and bamboo processing benefits are affected. The utilization method comprises the steps: distilling the bamboo sawdust to obtain a bamboo sawdust oil gas and deoiling bamboo sawdust; separating the bamboo sawdust oil gas to obtain a bamboo oil, filling the deoiling bamboo sawdust into a carbonization furnace for heating to carbonize, and thus obtaining a bamboo carbonized substance and flue gas; and collecting the bamboo carbonized substance to prepare a bamboo charcoal powder, collecting the flue gas, cooling, separating, and purifying to obtain tar and fuel gas. The utilization method is mainly used for the bamboo sawdust, bamboo end heads, bamboo leftover materials and the like, and can also be used for other wood chips and similar materials; each ton of the bamboo sawdust can be profited with 2500 yuan, the value is added by more than 4 times, and the amount of less emission of carbon and other pollutants is about more than 0.005 ton. The bamboo processing benefit is increased by 10%, the utilization efficiency of bamboo resources is increased by 15%, at the same time, environmental pollutions caused by incineration and landfill of the bamboo sawdust are avoided, the cost is low, the practicability is strong, and the benefit is remarkable.

Owner:会同县康奇瑞竹木有限公司

Iron ore tunnel kiln magnetizing roasting layering material distributing reduction method

The invention discloses an iron ore tunnel kiln magnetizing roasting layering material distributing reduction method. Iron ore is divided into different granularity degrees according to the granularity range; the reduction coal is flatly laid in the bottom of a tunnel kiln car according to the proportion that the reduction coal accounts for 4-6% of the total weight of iron ore; the iron ore of various granularity degrees is laid at the upper portion of the reduction coal of the tunnel kiln car, and the granularity range of each layer of iron ore is gradually increased from the bottom layer to the top layer in a layer-by-layer manner; facing materials are flatly laid at the upper portion of iron ore of various granularity degrees of the tunnel kiln car; the tunnel kiln car loaded with materials is pushed into a tunnel kiln for magnetizing roasting; and after magnetizing roasting is finished, the tunnel kiln car loaded with the materials is pushed out of the tunnel kiln. According to the method, over reduction of iron ore can be effectively prevented, the control means of iron ore magnetizing roasting is improved, and the surplus carbon recycling and utilizing cost is low. In addition, the mixing technology of iron ore and a reducing agent before magnetizing roasting of the iron ore tunnel kiln is reduced or eliminated, and the production cost of the roasted ore is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method for preparing iron-based magnetic activated carbon by catalytic activation of radix puerariae waste residue with compound enzyme

InactiveCN103623776AImprove void structureReduce production safety hazardsOther chemical processesCarbon compoundsActivated carbonPectinase

The invention provides a method for preparing iron-based magnetic activated carbon from by catalytic activation of radix puerariae waste residue with compound enzyme, and belongs to the technical field of activated carbon. The method comprises the steps of by taking the radix puerariae waste residue as the raw material, carrying out raw material pretreatment, preparing a radix puerariae activated substrate through catalytic activation with compound enzymes (cellulase, ligninase and pectinase), and preparing the magnetic activated carbon by doping iron, thereby obtaining the product. The method provided by the invention has the characteristics of wide raw material source, low waste material utilization cost, few production steps and low process energy consumption and no secondary pollution, and is beneficial to environment protection; the activated carbon product are excellent in adsorptive property and the magnetic properties and wide in application, and secondary pollution caused by difficult activated carbon recovery is not generated, etc. The method can be widely applied to preparation of the magnetic activated carbon by using the radix puerariae residue solid wastes as raw materials and doping iron; the activated carbon prepared by the method can be widely applied to the fields of waste water treatment, oil fume desorption and odor adsorption in food preservation and the like.

Owner:CHONGQING TECH & BUSINESS UNIV

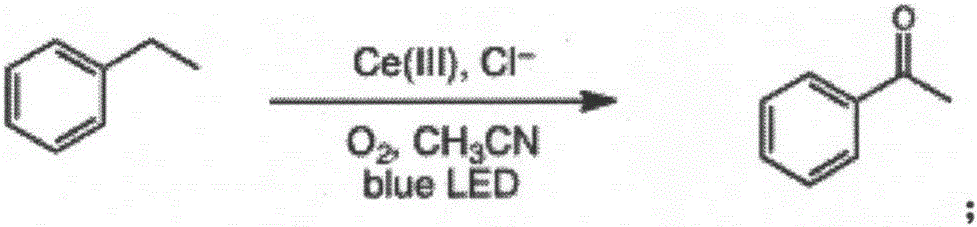

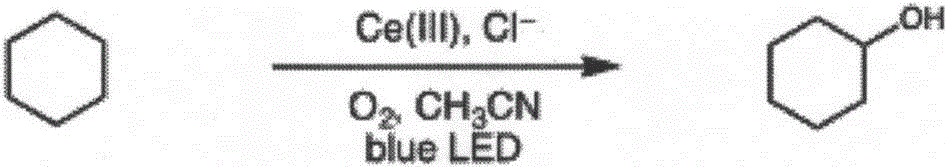

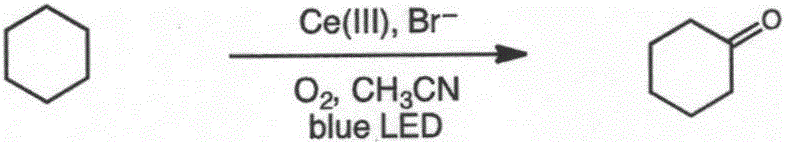

Visible light catalyzed saturated carbon-hydrogen bond direct oxidizing method

ActiveCN106831387ALow costStable in naturePreparation by oxidation reactionsOrganic oxidationCeriumOrganic compound

The invention provides a visible light catalyzed saturated carbon-hydrogen bond direct oxidizing method which is characterized by comprising the following step of performing a reaction on an organic compound and an oxidizing reagent in the presence of a cerium complex in a visible light irradiating condition to oxidize a saturated carbon-hydrogen bond of the organic compound to obtain an oxidized product. According to the method provided by the invention, the reaction is only performed at room temperature, so that the catalytic efficiency is high; energy required by an activating reaction is provided by means of visible light, so that the method is a more mild and green activating mode; and meanwhile, the used catalyst is low in cost, and the used oxidizing reagent is more stable in property, the industrial utilization cost is low, and the practicality of a catalytic system is high; meanwhile, pollution caused by heavy transition metals, peroxides and the like can be avoided.

Owner:SHANGHAI TECH UNIV

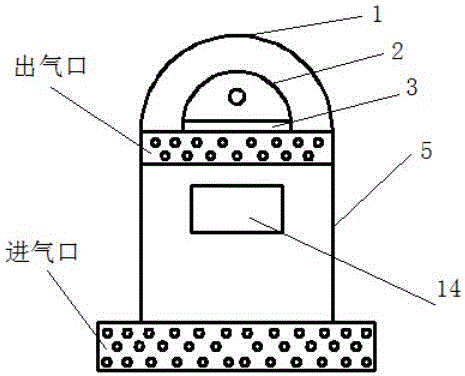

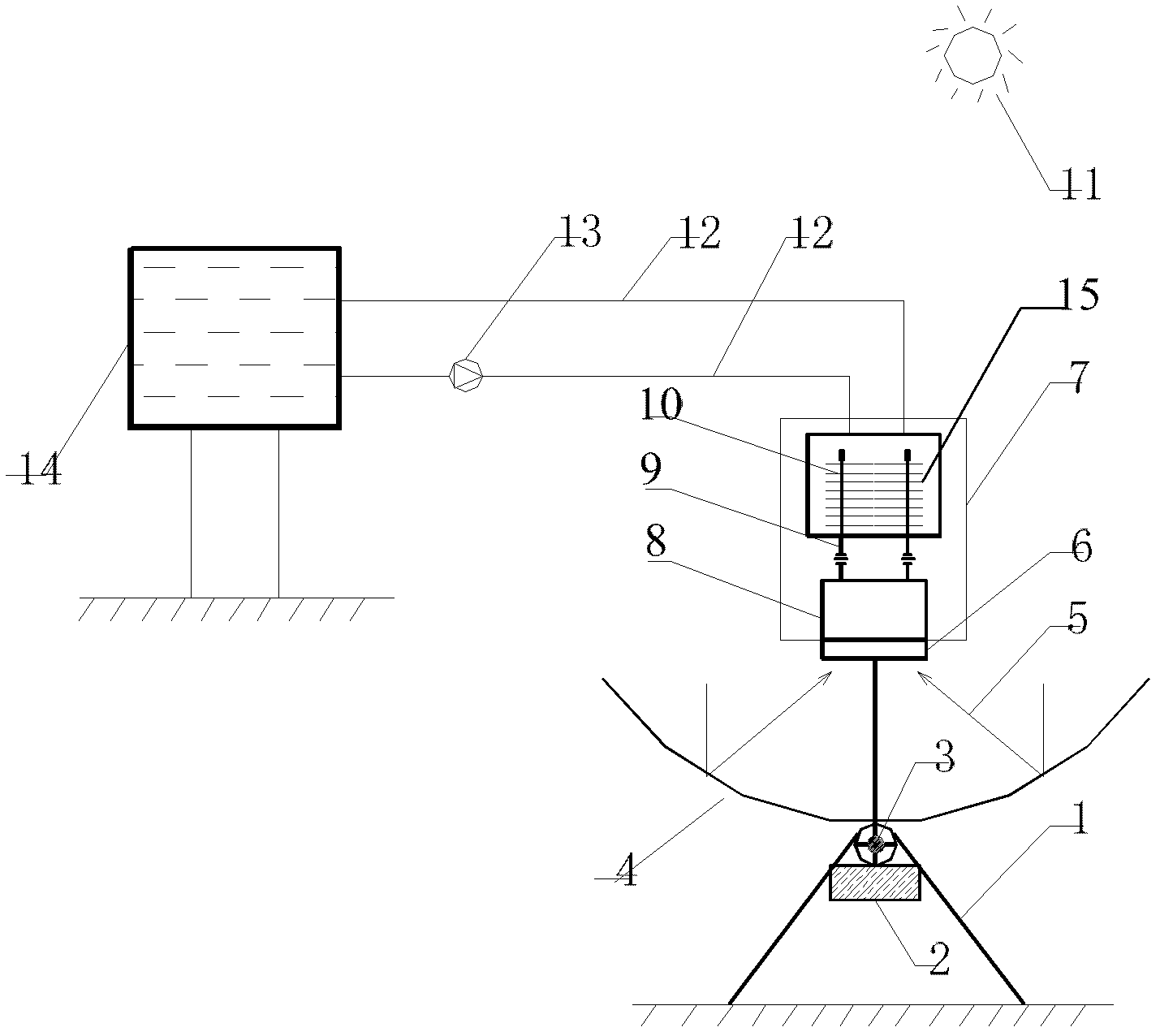

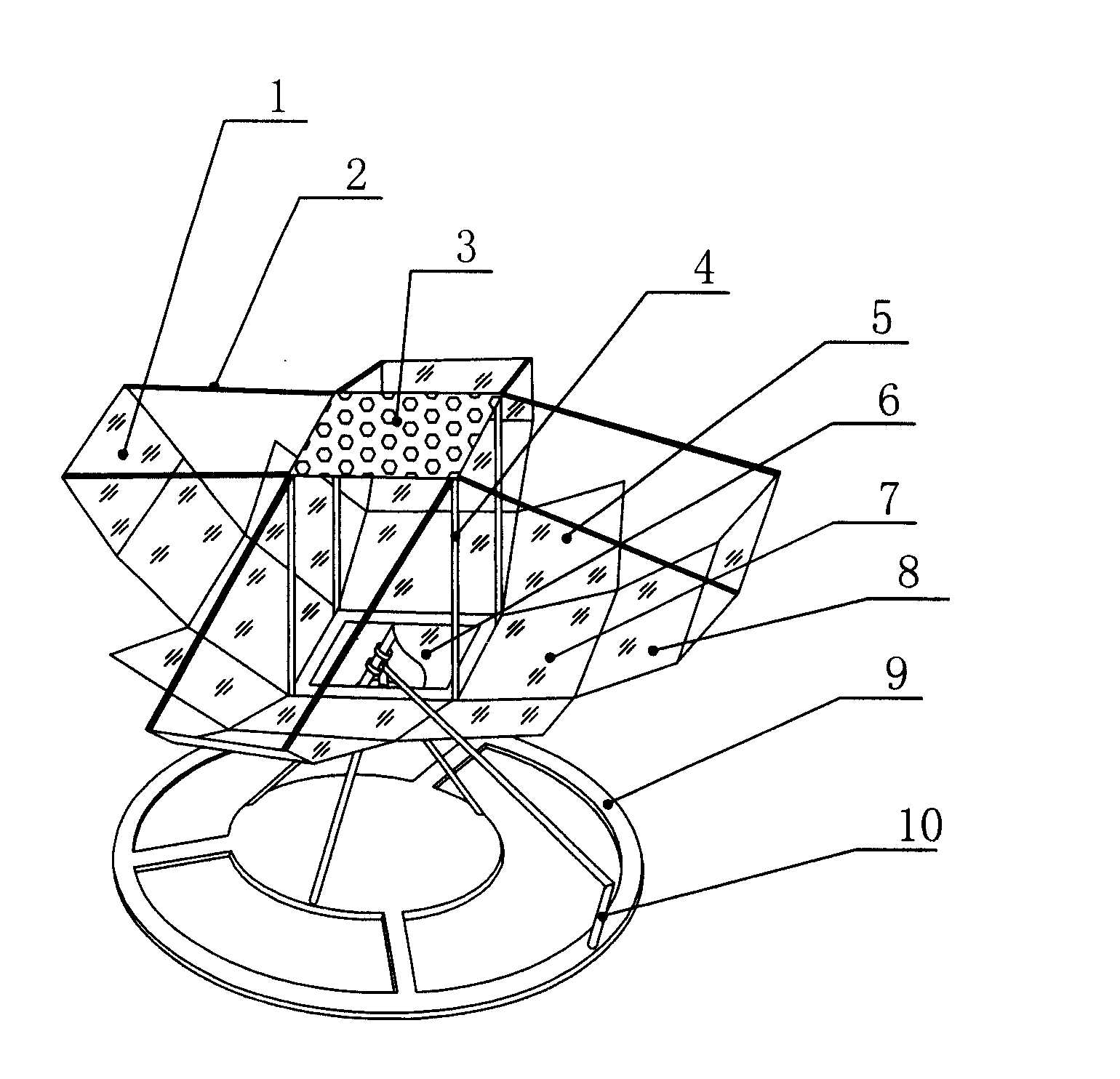

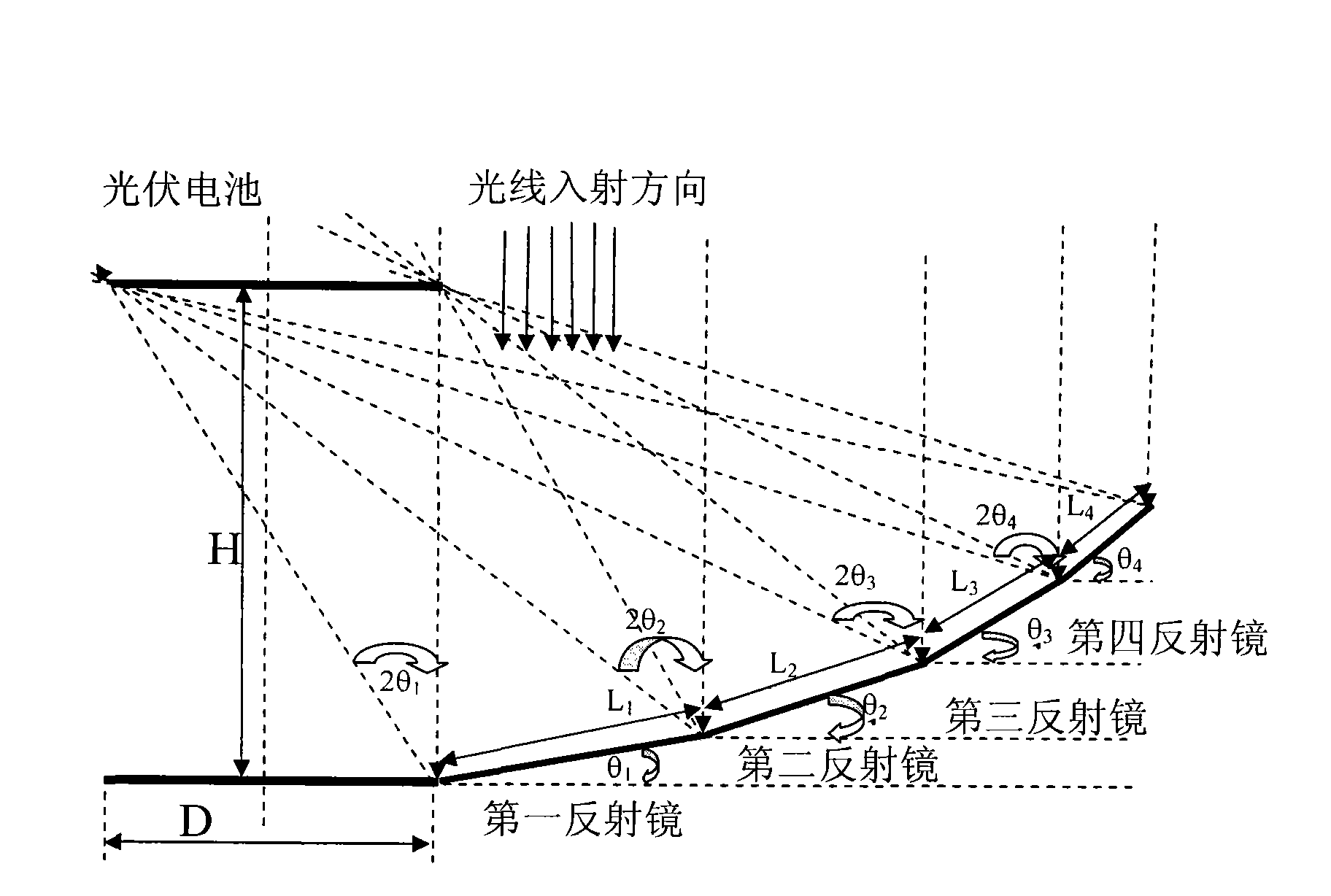

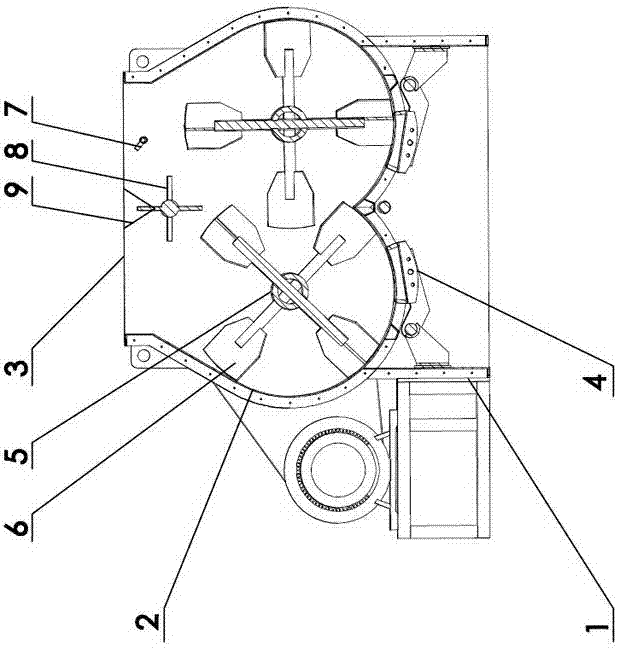

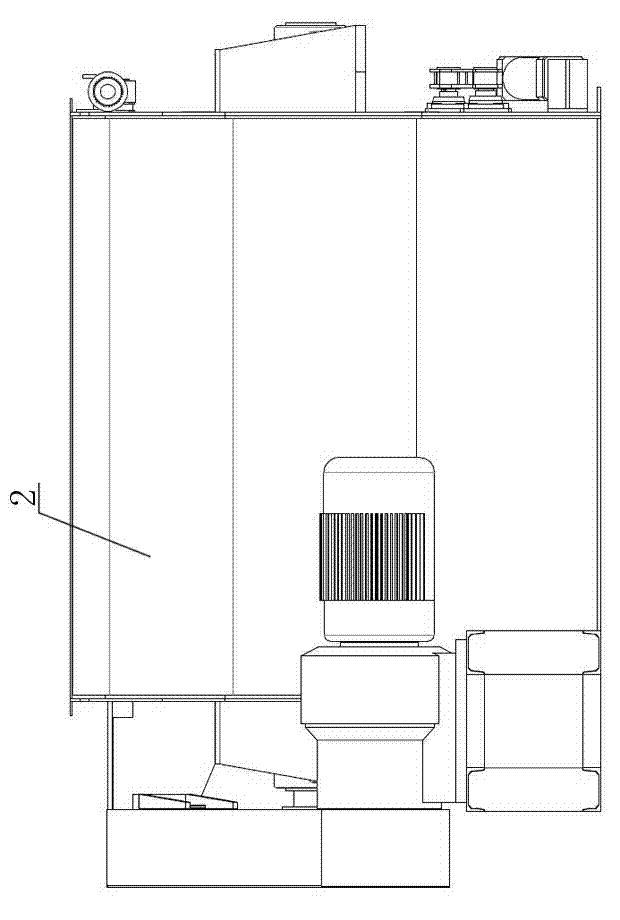

Full-coverage reflection-type high-power complete uniform light collection photovoltaic power generation device

InactiveCN101656495AGuaranteed stabilityUniform light receivingPV power plantsMountingsElectrical batteryEngineering

The invention relates to a full-coverage reflection-type high-power complete uniform light collection photovoltaic power generation device, which solves the problems of the prior solar power generation device such as low uniform light collection efficiency, high cost, complicated structure and unstable output voltage. The device comprises an photovoltaic cell component, a reflector component and asupport component, wherein the support component comprises a sun tracking device; the photovoltaic cell component comprises a cell support and a rectangular photovoltaic cell component which is fixedon the upper end of the cell support; and the reflector component comprises for reflector groups which are symmetrically distributed on the periphery of the lower end of the battery support. The whole surfaces of the photovoltaic cells are uniform in light acceptance. The device has the advantages of high light collection efficiency, low cost, simple structure, low energy consumption, low pollution and easy cleaning.

Owner:欧阳晓平

Preparation method of powdered oil feed

The invention relates to a feed, in particular to a preparation method of a powdered oil feed. The preparation method mainly solves the technical problems that the powdered oil feed in the prior art is easy to melt, oxided and deteriorated and is difficult to preserve, a carrier of the traditional oil powder is a non-nutritive substance such as furfur, corn (cob) flour, modified starch, powder fiber and the like, only fat is provided, other nutritional ingredients are low, and the powdered oil feed can only serve as energy feed on an aspect of animal demand. By a special method, the carrier in the oil powder is replaced to animal and vegetable protein from the non-nutritive substance. The method comprises the following steps of: adding and mixing animal fat and vegetable fat according to proportion; adding an emulsifier into a mixture according to proportion, and performing high-speed emulsification; homogenizing the emulsified mixture by a homogenizing machine; and adding animal protein, vegetable protein, vitamin, mineral substances and trace elements into the homogenized mixture according to proportion, mixing in a solid-liquid stirring and mixing machine; and packaging.

Owner:HANGZHOU XIANGBAO FEED

Method for producing deoxidizer by utilizing waste silicon carbide of aluminium electrolysis

InactiveCN102010932ATake advantage ofSolve pollutionSolid waste disposalProcess efficiency improvementBrickAluminium electrolysis

The invention relates to a method for producing deoxidizer by utilizing waste silicon carbide of aluminium electrolysis, relating to the technical field of recycling of aluminium electrolysis waste silicon carbide. The aluminium electrolysis waste silicon carbide is mainly silicon carbide brick at the lateral part of an aluminium electrolysis cell. The method comprises the following steps: (1) sorting separation: aluminium electrolysis cell waste silicon carbide after overhaul is sorted and separated from other waste refractory materials and corrosion part on the surface of the waste silicon carbide is removed; (2) crushing: the separated waste silicon carbide is crushed and ground; (3) free treatment: the corrosive waste silicon carbide separated in the step (1) is delivered into a free treatment system to be treated; (4) burdening and mixing: the ground silicon carbide powder is added with water and resin, and the mixture are evenly stirred; (5) balling: the mixed material is delivered to a pelletizing machine to be pelletized into small balls; and (6) curing: the obtained small balls are subject to natural curing for 4-7 days, thus obtaining the deoxidizer. According to the invention, the pollution problem of the aluminium electrolysis waste silicon carbide is effectively solved and the recycling of solid wastes is realized.

Owner:YICHUAN LONGHAI TECH INDAL

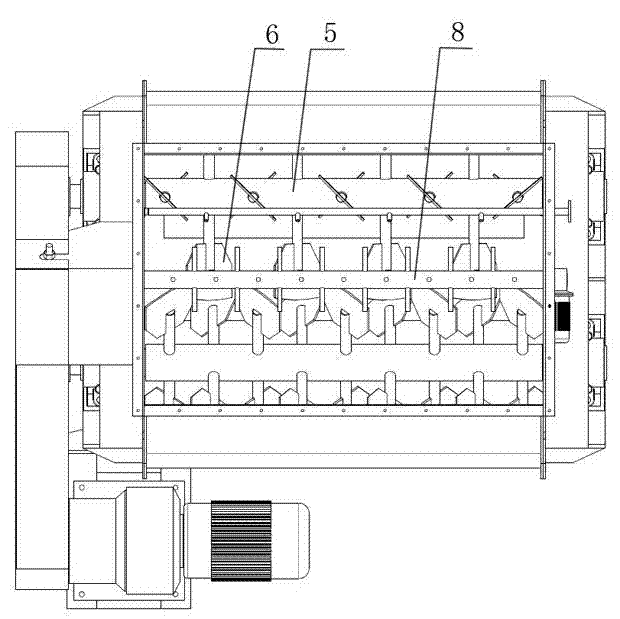

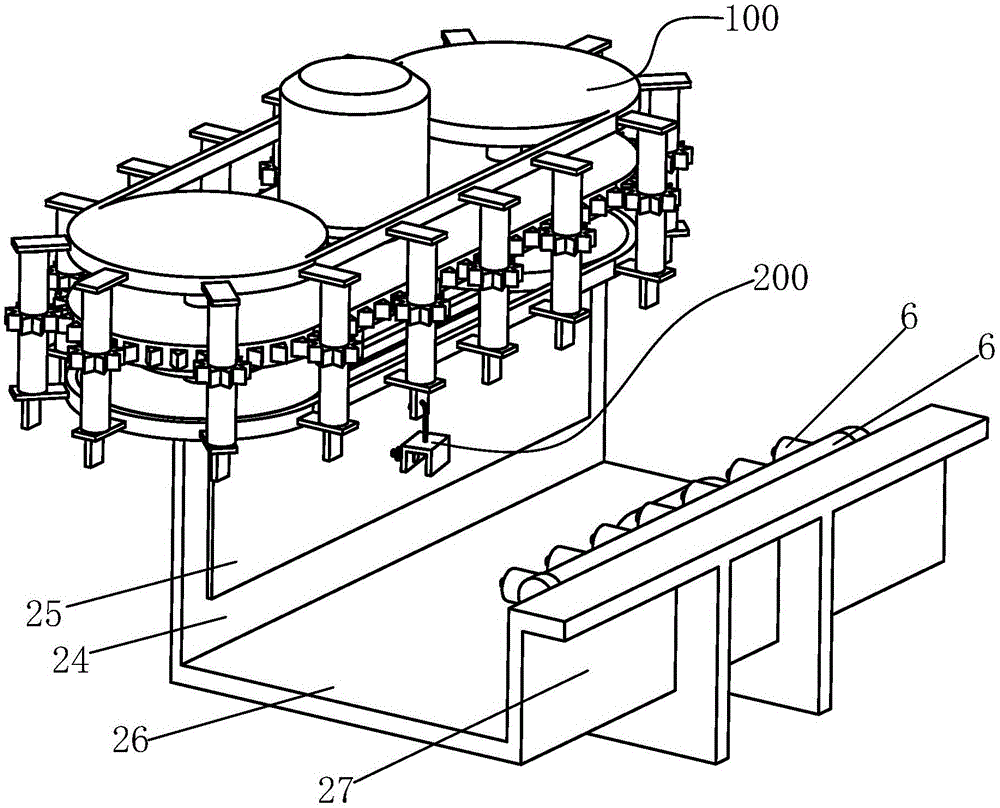

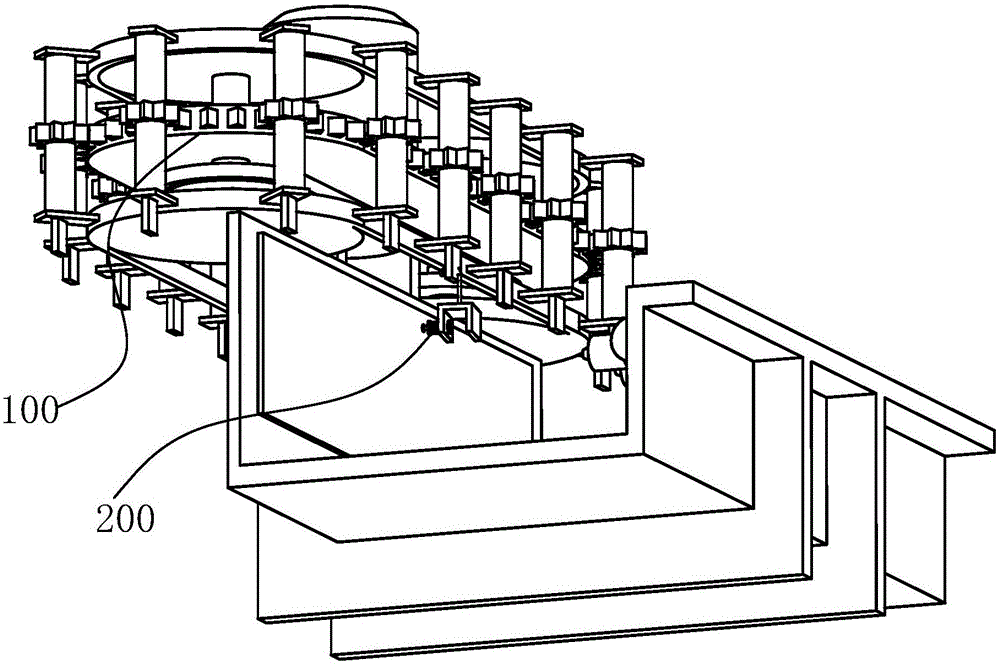

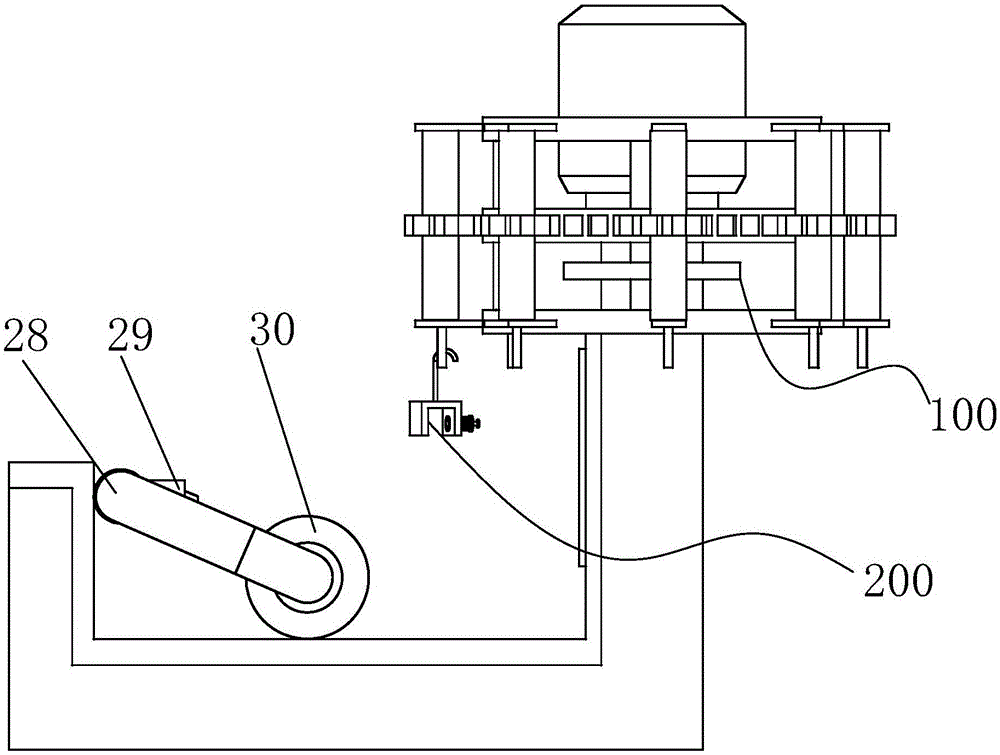

Assembly line for removing powder on door/window frame body

The invention relates to an assembly line for removing powder on a door / window frame body. The assembly line for removing the powder on the door / window frame body comprises a hanging device. The hanging device comprises a kidney-shaped base plate. The left side and the right side of the base plate are each connected with a vertical rod in a hinged mode. Upper wheels are arranged at the upper ends of the vertical rods respectively. Lower wheels are arranged at the lower ends of the vertical rods respectively. The portions, located between the lower wheels and the base plate, of the vertical rods are sleeved with driven wheels respectively. A motor is fixed to the middle of the upper end face of the base plate. A shaft of the motor penetrates through the base plate to be connected with a driving wheel. The driving wheel, the driven wheels, the upper wheels and the lower wheels are all chain wheels. A driving chain is connected between the driving wheel and the driven wheels. An upper special-shaped piece chain is connected between the two upper wheels of the vertical rods. According to the assembly line, rotary columns are controlled by upper connecting pieces and lower connecting pieces to move horizontally around the base plate; in addition, gears on the rotary columns are matched with external teeth and driven by the external teeth to rotate, and accordingly the rotary columns are driven to rotate between the upper connecting pieces and the lower connecting pieces; hanging pieces are fixedly connected with the rotary columns and rotate along with the rotary columns, and thus frame body clamping devices hanging on the hanging pieces are driven to rotate.

Owner:ANHUI KATA DOOR & WINDOW

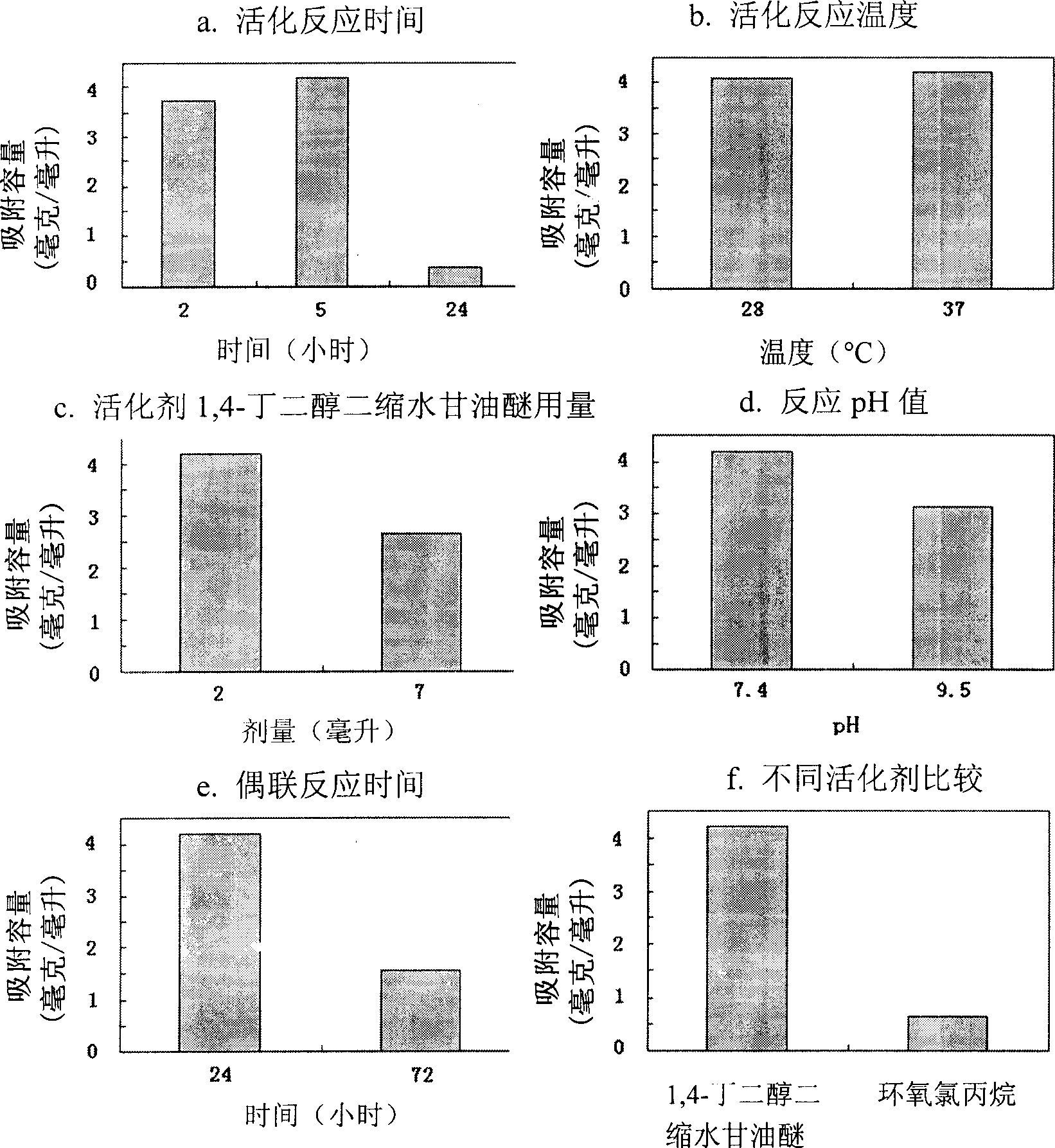

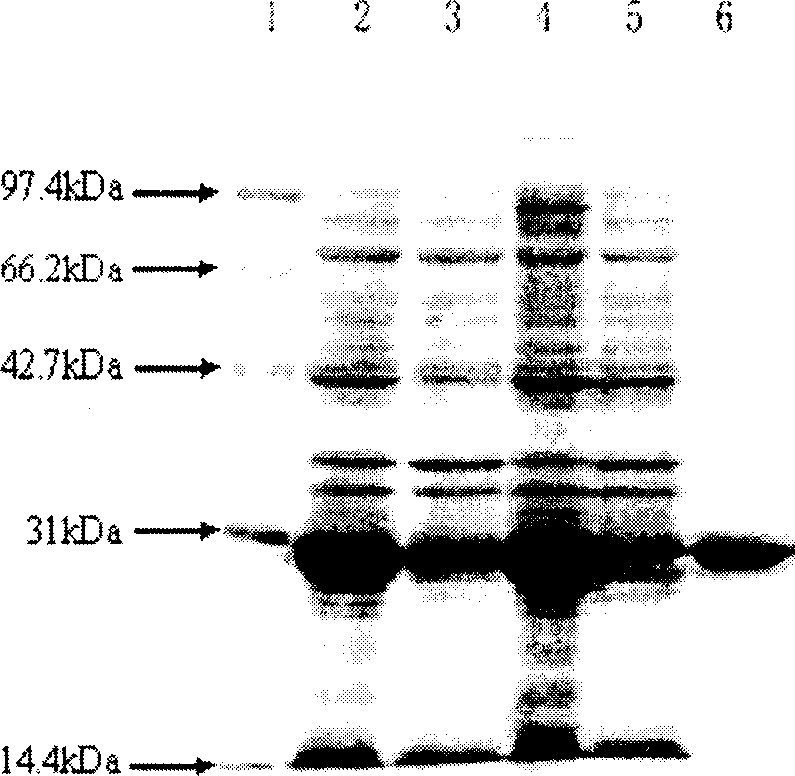

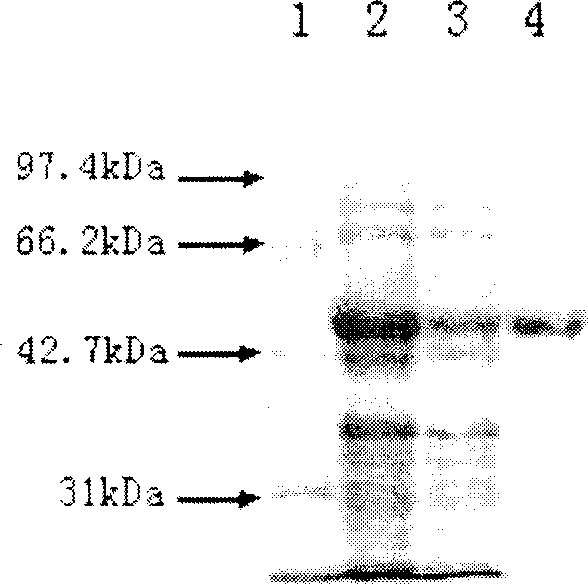

Process for preparing glutathion-5-transferase protein affinity chromatography medium and its use

InactiveCN1715403AReduce utility costsReduce utilization costTransferasesPeptide preparation methodsChemistryDiglycidyl ether

The present invention belongs to the field of genetic engineering technology. GST protein affinity chromatography medium is prepared with glutathion as affinity arm and 1, 4-butanediol diglycidyl ether as activating cross-linking agent, and through activating and washing of chromatography medium, glutathion coupling reaction, terminating reaction and washing. The preparation conditions and technological process are optimized. Test shows that the affinity chromatography medium of the present invention has very high specificity and purifying efficiency and affinity adsorption performance mach higher than that of affinity medium with chloropropylene oxide as activator. The affinity chromatography medium may be used in separation and purification of GST and GST fusing protein in bioengineering, gene engineering, biochemistry, molecular biology and other fields.

Owner:华子春

Method for processing ardealite by using fluidized bed furnace to prepare special anhydrite cementing material

A method for processing ardealite by using a fluidized bed furnace to prepare a special anhydrite cementing material comprises the following steps that (1) materials are prepared, namely caked ardealite and massive stone coal or waste rock ballast is crushed; (2) burdening is performed, namely 50 to 80 parts of ardealite, 8 to 25 parts of stone coal and 10 to 40 parts of waste rock ballast are burdened and metered by weight; (3) matured slag is prepared, namely the materials are continuously fed into the fluidized bed furnace and calcined in the oxidative atmosphere at the temperature of 850 to 1280 DEG C for 0.3 to 1.5 hours, the materials overflowing from a discharging port are rapidly quenched to be made into the matured slag; (4) the special anhydrite cementing material is prepared, namely the matured slag is grinded into 80-micron powder containing smaller than or equal to 20% of screen residue mass, and the special anhydrite cementing material is obtained. The special anhydrite cementing material prepared by means of the method contains multiple hydrated active minerals, can be widely used in the cement industry, is high in strength in use and can serve as active residue powder or be used for production of construction materials. By means of the method, investment is small, no wastewater and waste residue is produced, and economical efficiency is high.

Owner:湖南省小尹无忌环境能源科技开发有限公司

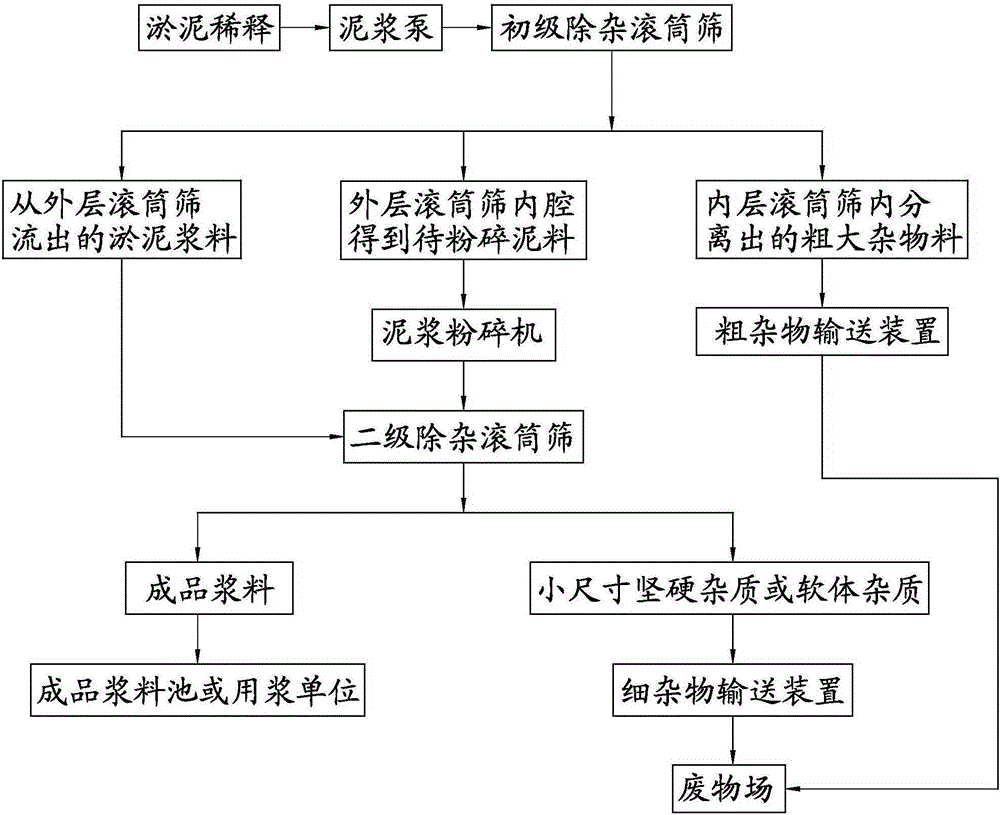

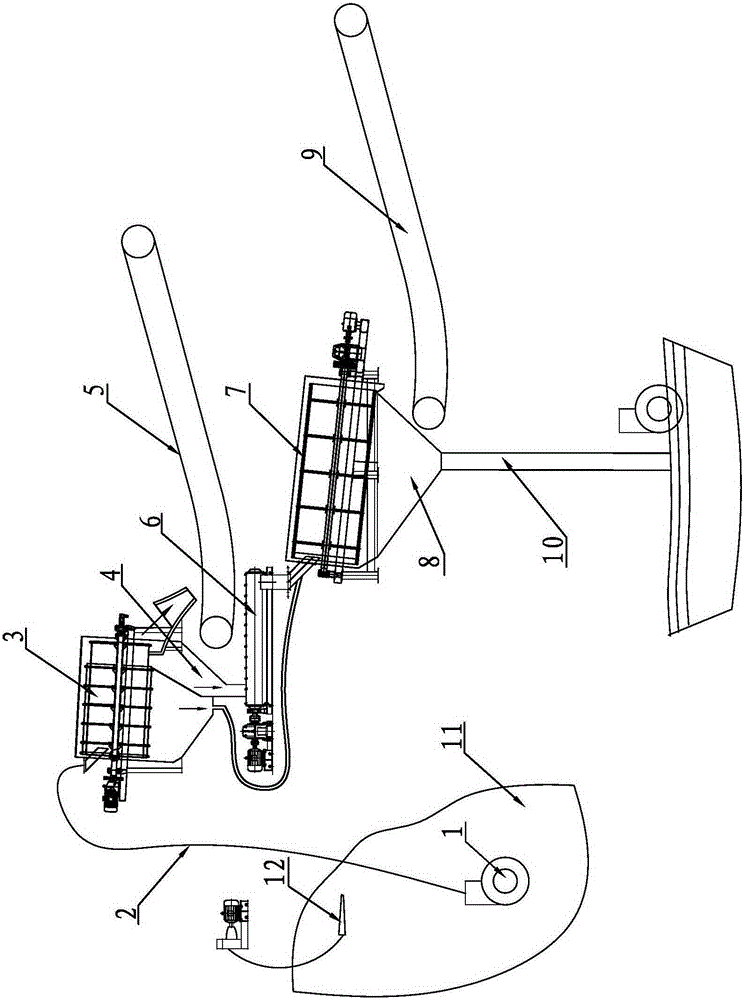

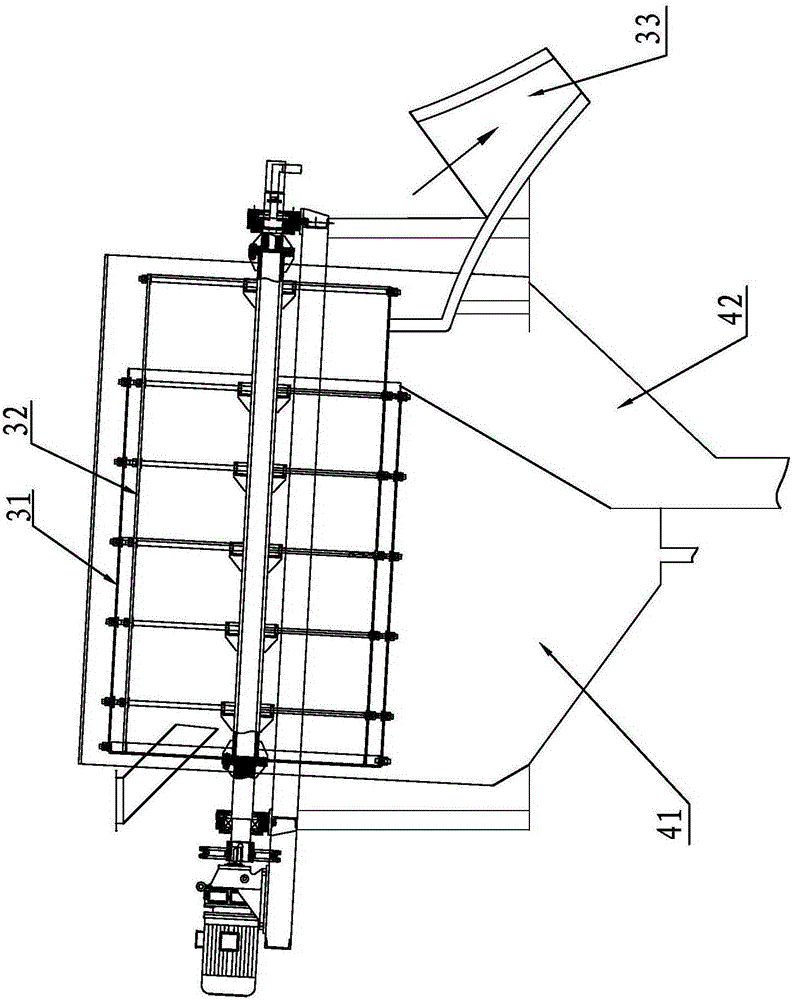

Method and whole set of impurity removing equipment for removing impurities in lake and river silt

InactiveCN105174671AReduce utilization costEfficient removalSludge treatmentBrickPulp and paper industry

The invention discloses a method and a whole set of impurity removing equipment for removing impurities in lake and river silt. Diluted silt is delivered into a multi-layer primary impurity removal drum screen through a slurry pump for separation and removal of coarse impurities, to-be-crushed silt blocks and silt slurry are obtained, the silt blocks are crushed by a slurry crusher, and the crushed silt material and silt slurry are subjected to secondary screening by a secondary impurity removal drum screen for removal of fine impurities in the slurry. With the adoption of the equipment and the method, hard impurities such as shells, bricks, stones and the like in the silt can be removed, soft impurities such as plastic ropes and the like can also be removed, various impurities in the silt can be relatively thoroughly removed, the slurry in the silt can be separated, soil blocks in the silt can be crushed and made into slurry, the quality of finished product slurry is improved, the yield of the finished product slurry is increased, original silt is treated and directly used as a raw material for brick firing, dehydration drying is not required, the silt utilization cost is reduced, and the silt is truly turned into wealth.

Owner:常州市金坛区宝能苏源墙材科技有限公司

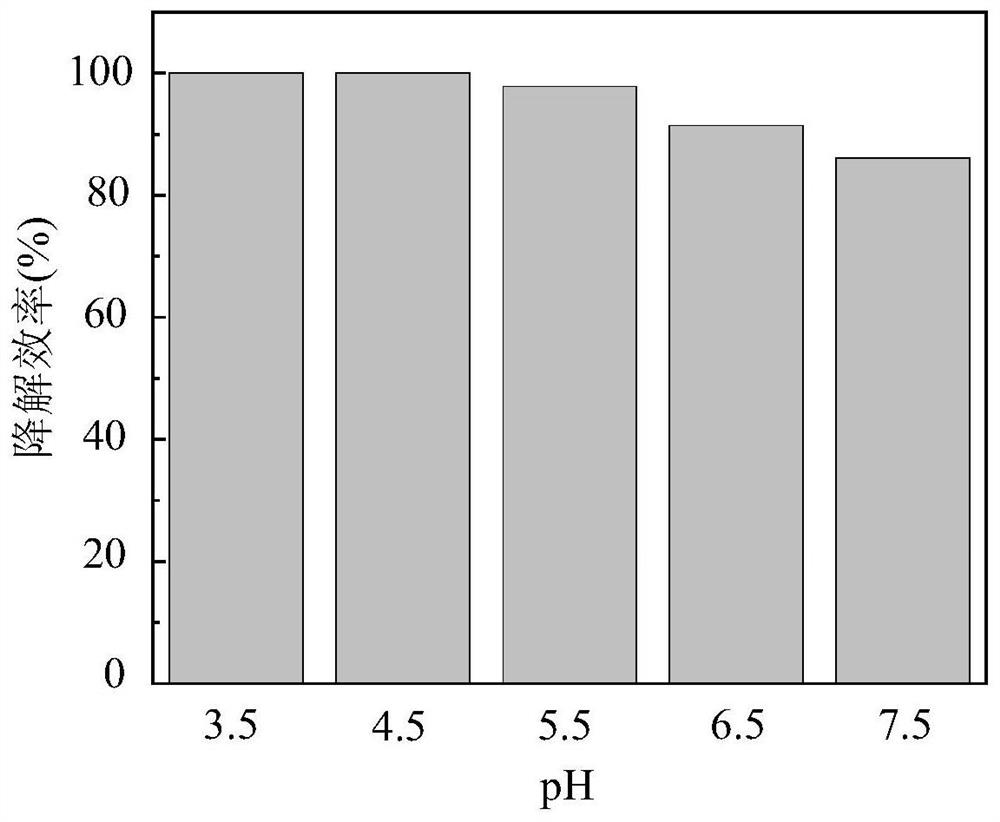

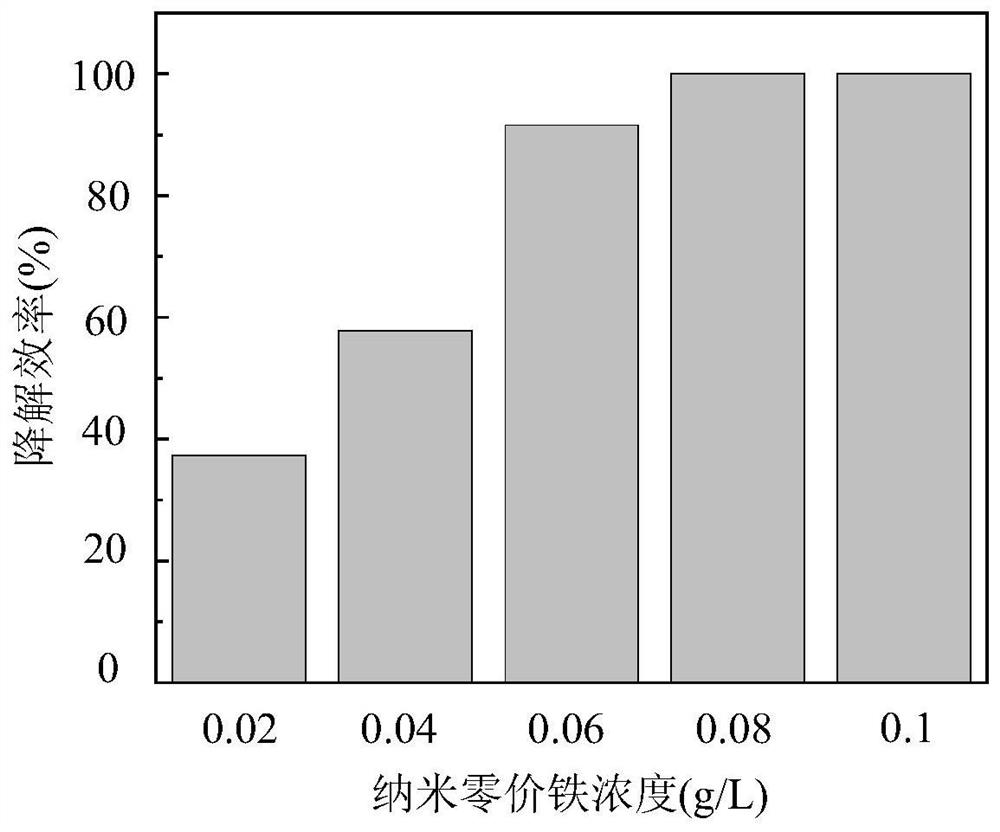

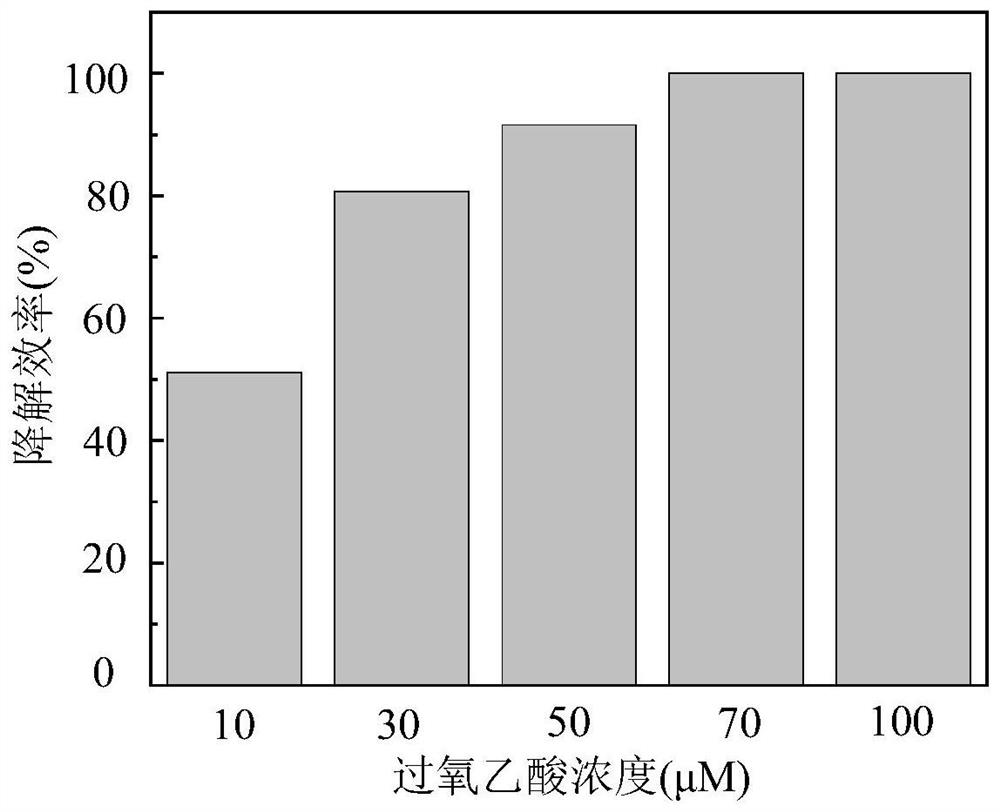

Method for degrading antibiotics in water by activating peracetic acid through zero-valent metal

ActiveCN112723518AImprove activation efficiencyReduce utilization costWater contaminantsEnergy based wastewater treatmentMicrobiologyHydroxyl radical

The invention discloses a method for degrading antibiotics in water by activating peracetic acid through zero-valent metal. According to the method, peracetic acid which is high in oxidation-reduction potential, widely applied to the disinfection field and few in by-products is selected as a precursor for generating hydroxyl radicals, and the peracetic acid is activated by the zero-valent metal to generate strong oxidizing free radicals so as to degrade antibiotics in the water body. The method comprises the following specific steps: adding a proper amount of a strong oxidant, namely the peroxyacetic acid into a to-be-treated water body containing antibiotics, then adding the zero-valent metal with a concentration of 0.02 g / L-0.1 g / L as an activating agent, adjusting the pH value of a reaction solution to 3-9, and carrying out uniform stirring and reacting at room temperature for 30 minutes so as to oxidize and degrade the antibiotics. The zero-valent metal used in the method has the advantages of being low in cost, high in activation efficiency, easy to recycle and the like, the peracetic acid can be completely activated within 30 min, and high antibiotic degradation efficiency is achieved, so the method is a novel antibiotic degradation technology which is rapid, efficient and environmentally friendly.

Owner:HUAQIAO UNIVERSITY

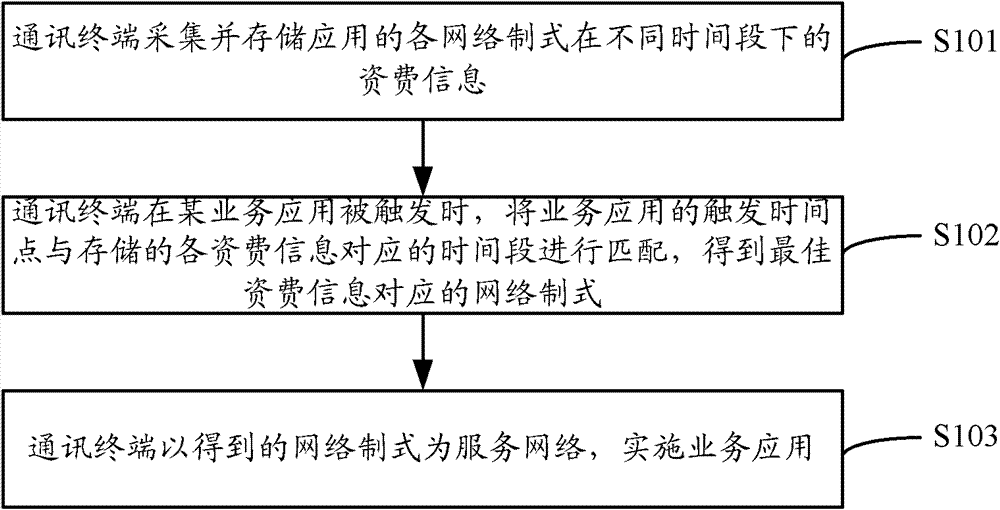

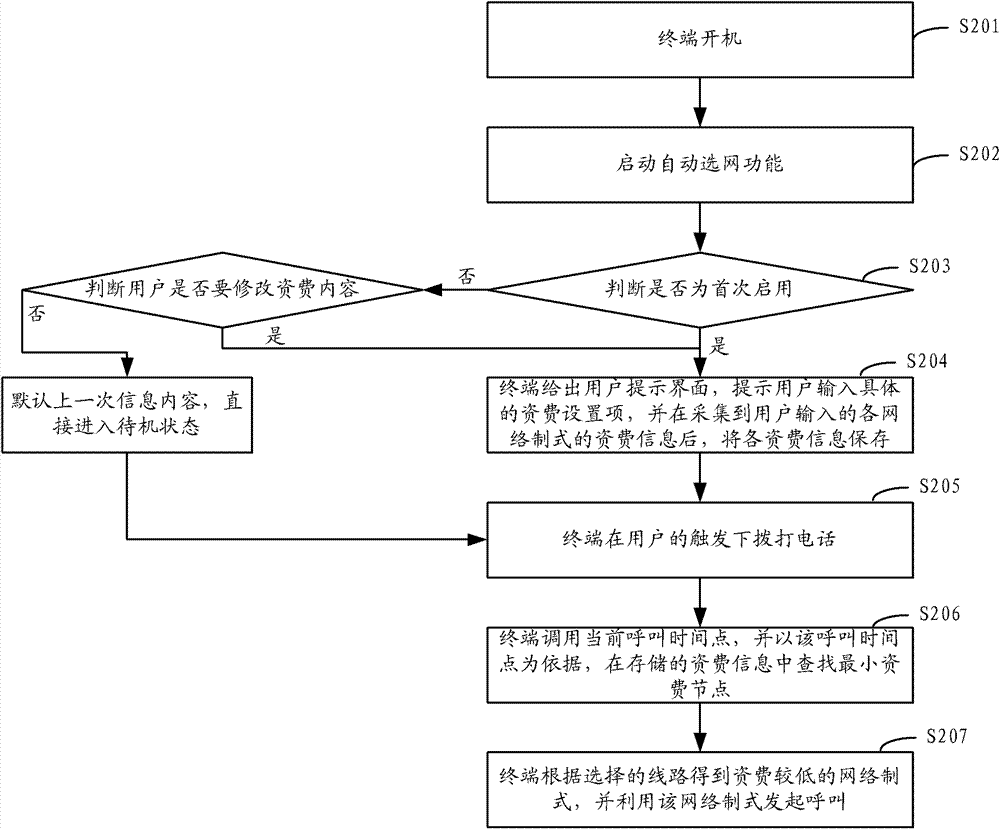

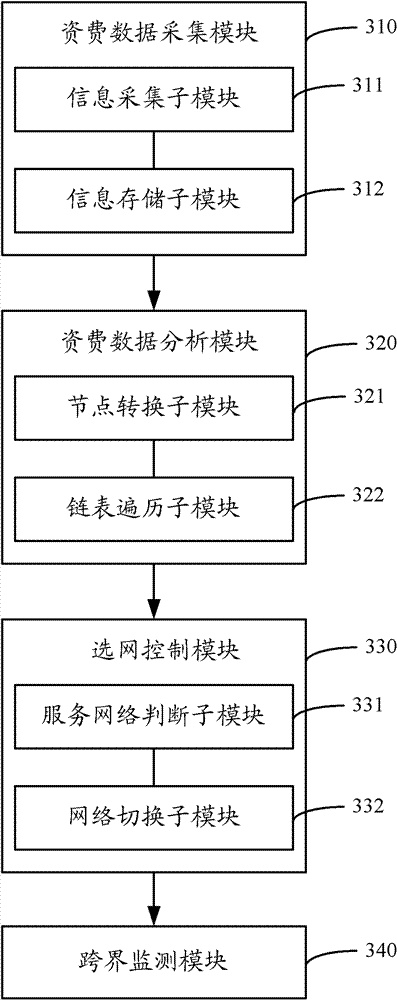

Communication terminal and method for choosing network automatically according to charging standard thereof

InactiveCN103096286AReduce wasteReduce utility costsAccounting/billing servicesAssess restrictionCollections dataData acquisition module

The invention discloses a communication terminal and a method for choosing a network automatically according to a charging standard of the communication terminal. The method comprises that the communication terminal collects and stores the charging information of each of applied network types within different time periods; when a certain business application is triggered, the communication terminal matches the trigger time point of the business application with the stored time periods corresponding to the charging information, so that an optimum network type corresponding to the charging information is obtained; the communication terminal takes the gained network type as the service network so as to implement the business application. The communication terminal comprises a charging data collection module, a charging data analysis module and a network choosing control module. The communication terminal and the method for choosing the network automatically according to the charging standard of the communication terminal resolve the problem that a user is puzzled with the business charging expenses in the application scene of multiple types, reduce the unnecessary waste for the user and save usage cost.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com