Assembly line for removing powder on door/window frame body

A door and window frame and assembly line technology, applied in the direction of cleaning methods, conveyors, cleaning methods and appliances using gas flow, etc., can solve the problems of difficult removal of profiles, harsh working environment, and affecting cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

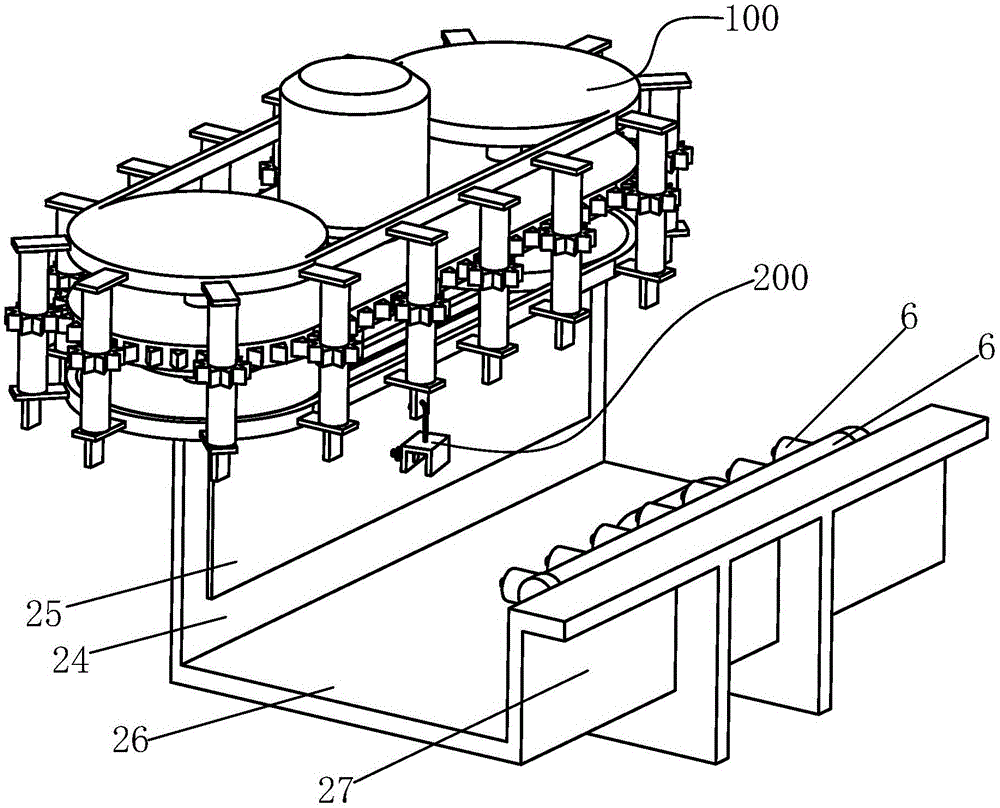

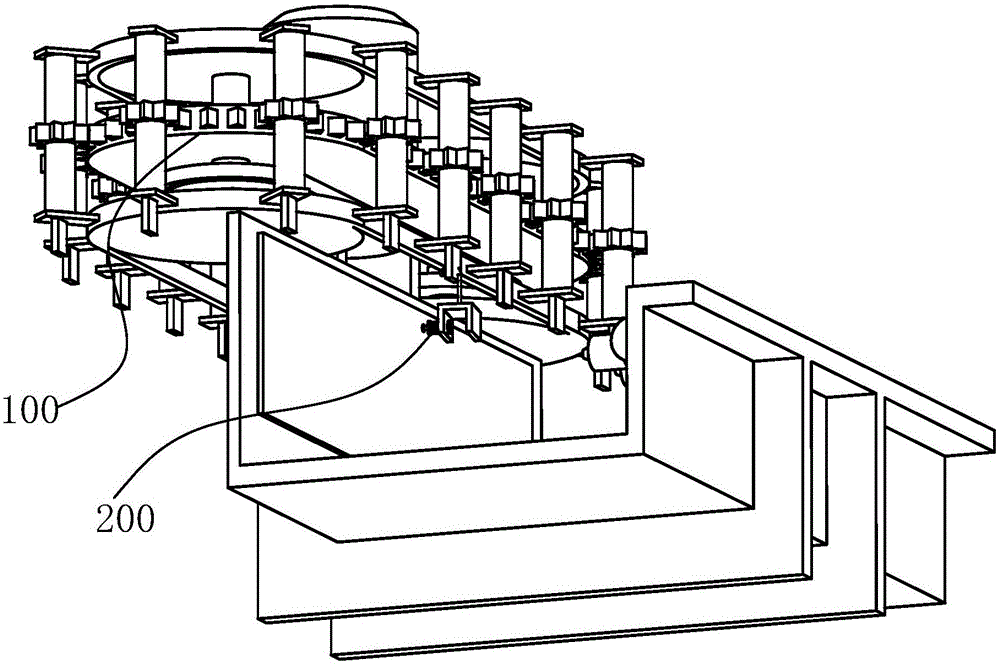

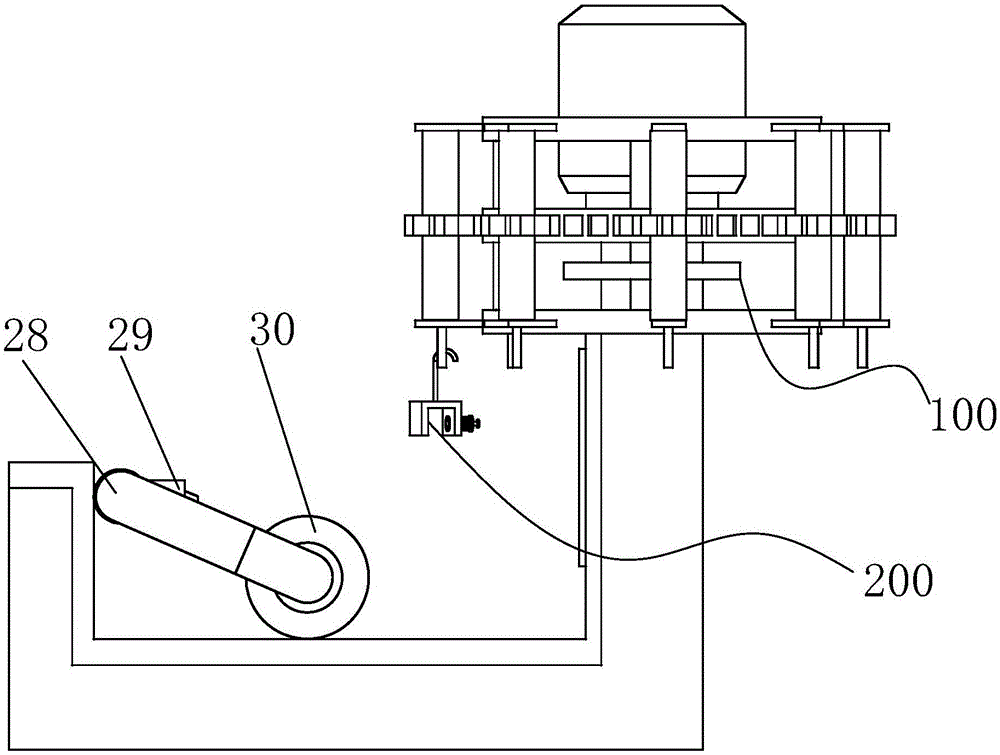

[0028] Such as Figure 1 to Figure 9 As shown, a door and window frame powder removal line includes a suspension device 100. The suspension device 100 includes a waist-shaped base plate 1, and a vertical bar 2 is connected to the left and right sides of the base plate 1 through hinges. The upper ends of the rods 2 are equipped with upper wheels 3, the lower ends of the vertical bars 2 are equipped with lower wheels 4, and the vertical bars 2 are set with driven wheels 5 at positions between the lower wheels 4 and the base plate 1, and the upper end surface of the base plate 1 The middle part is fixed with motor 6, and the shaft of described motor 6 passes through base plate 1 and is connected with driving wheel 7, and described driving wheel 7, driven wheel 5, upper wheel 3 and lower wheel 4 are all sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com