Gel electrophoresis dyeing device

A dyeing device and gel electrophoresis technology, applied in the field of gel dyeing, can solve the problems of difficulty in guaranteeing repeatability, extensive operation, difference in dyeing results, etc., achieve high repeatability and comparability, ensure the consistency of dyeing, release Easy in and out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

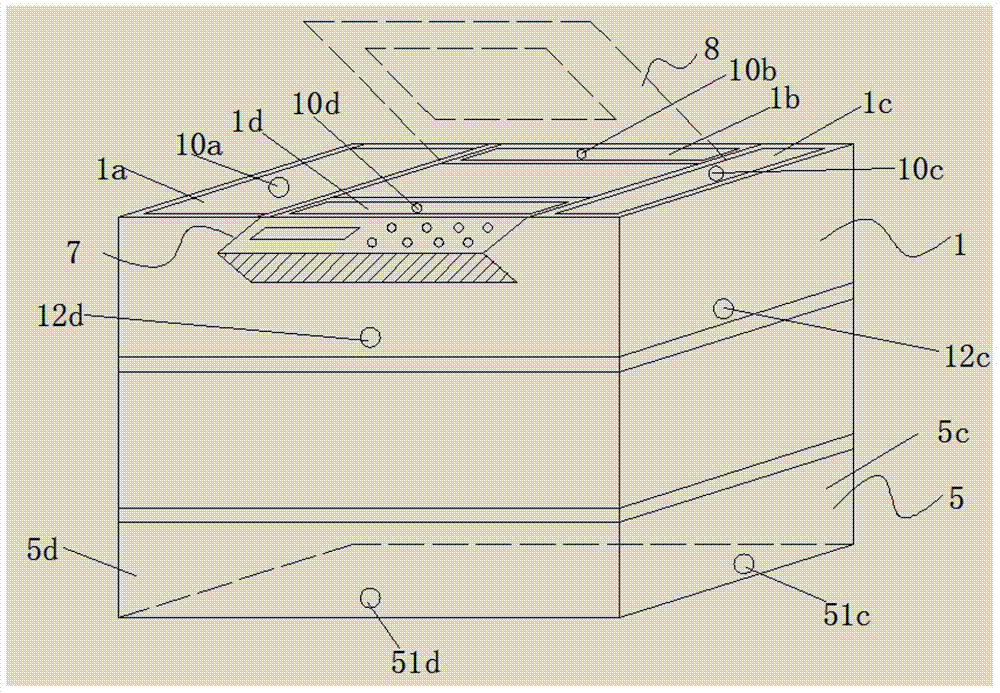

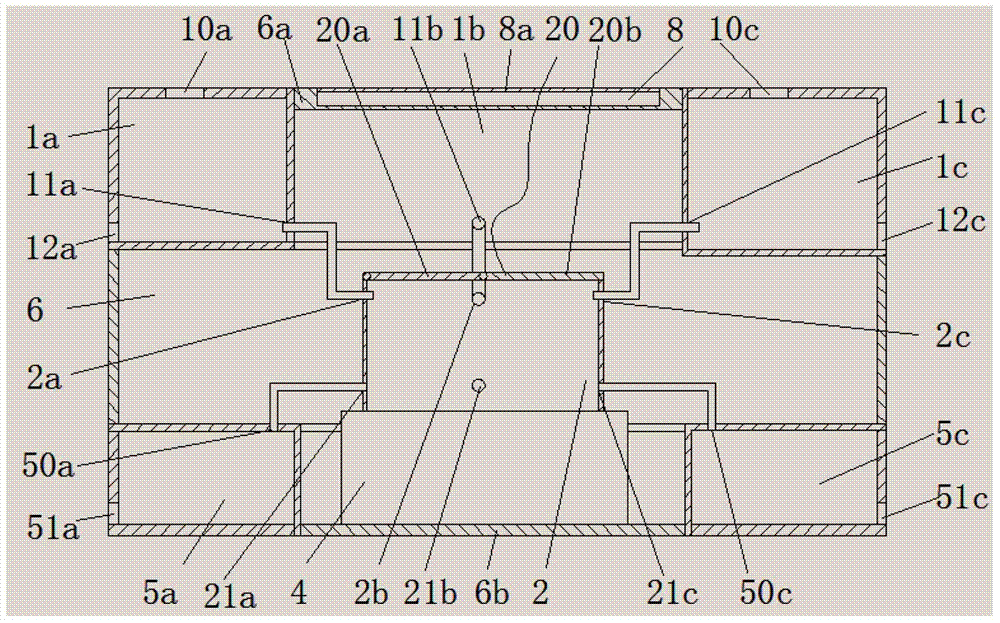

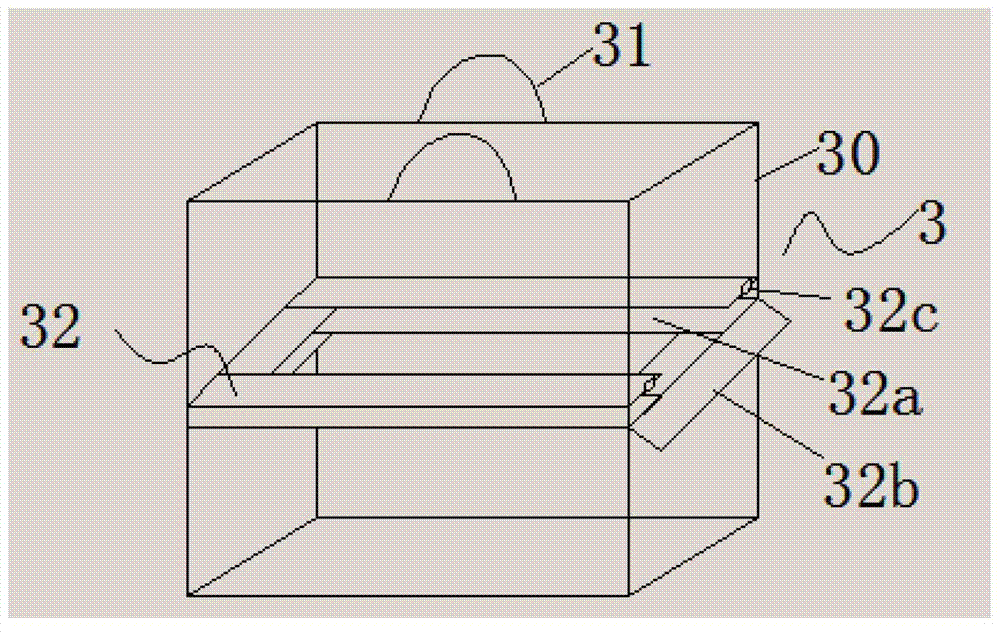

[0036] figure 1 It is a schematic diagram of the overall structure of the gel electrophoresis staining device of the present invention; figure 2 is along figure 1 Transverse sectional view; image 3 is a schematic structural view of the gel plate fixing device of the present invention; Figure 4 yes image 3 Schematic diagram of the gel slab fixture in .

[0037] Such as figure 1 , 2 As shown, the gel electrophoresis staining device of the present invention includes: a liquid storage device 1 for storing liquid reagents used in the staining process, on which liquid injection ports 10a, 10b, 10c, 10d and liquid outlets 11a, 11b, 11c; the staining box 2, the top of which is sealed by the staining box cover plate 20, on which liquid inlets 2a, 2b, 2c are arranged, and the gel plate fixing device 3 for fixing a plurality of gel plates is arranged in the staining box 2; The driving device 4 is connected with the dyeing box 2 so as to drive it to shake; wherein, the liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com