Patents

Literature

305 results about "Scouring agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The steepness of the terrain in such regions makes flowing water a more powerful scouring agent. Muddy waters: more sediment is entering rivers, but less makes its way to the sea Specific floor cleaners, impregnated wipes and scouring agents , among others, saw their value and volume sales decline.

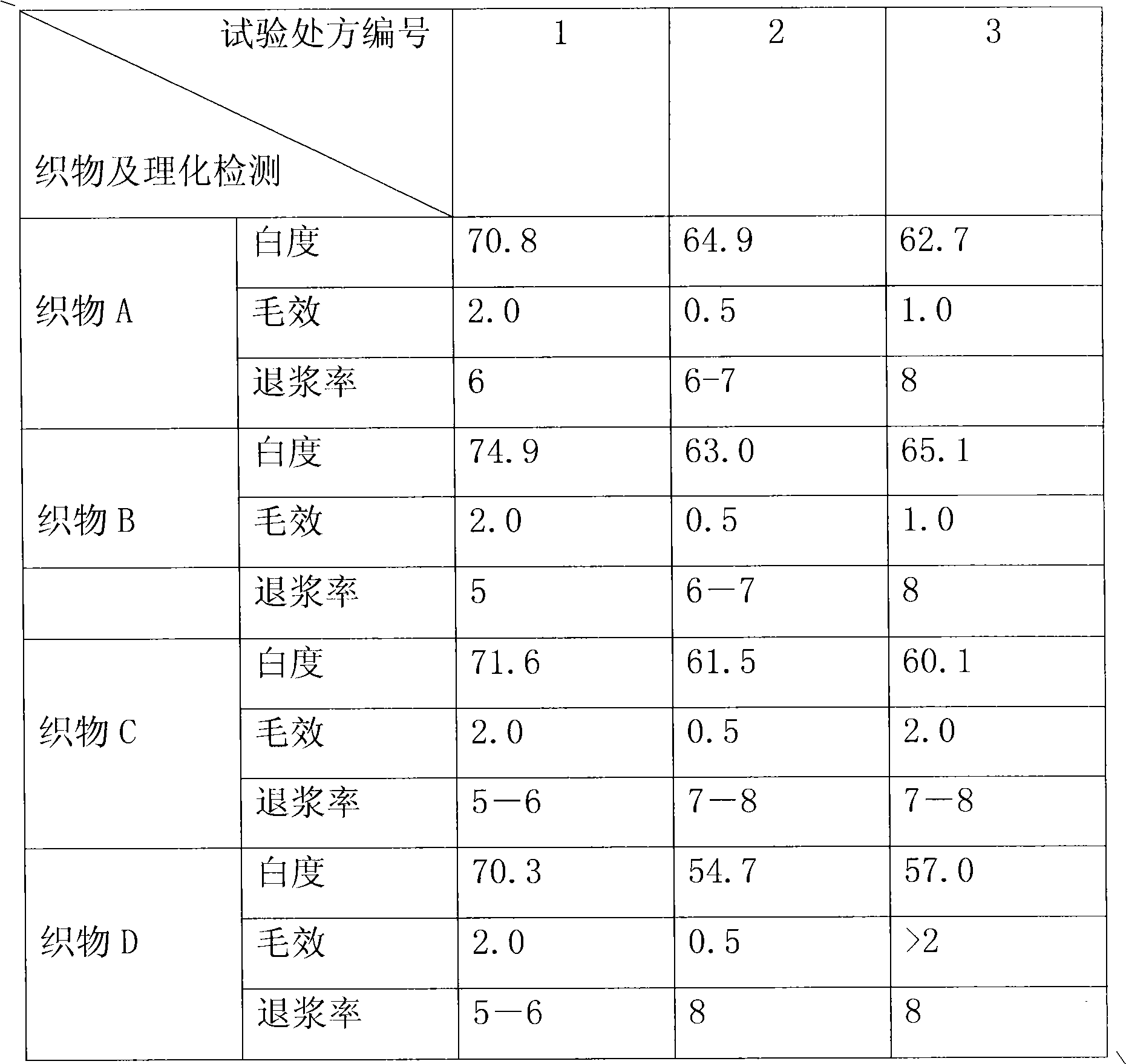

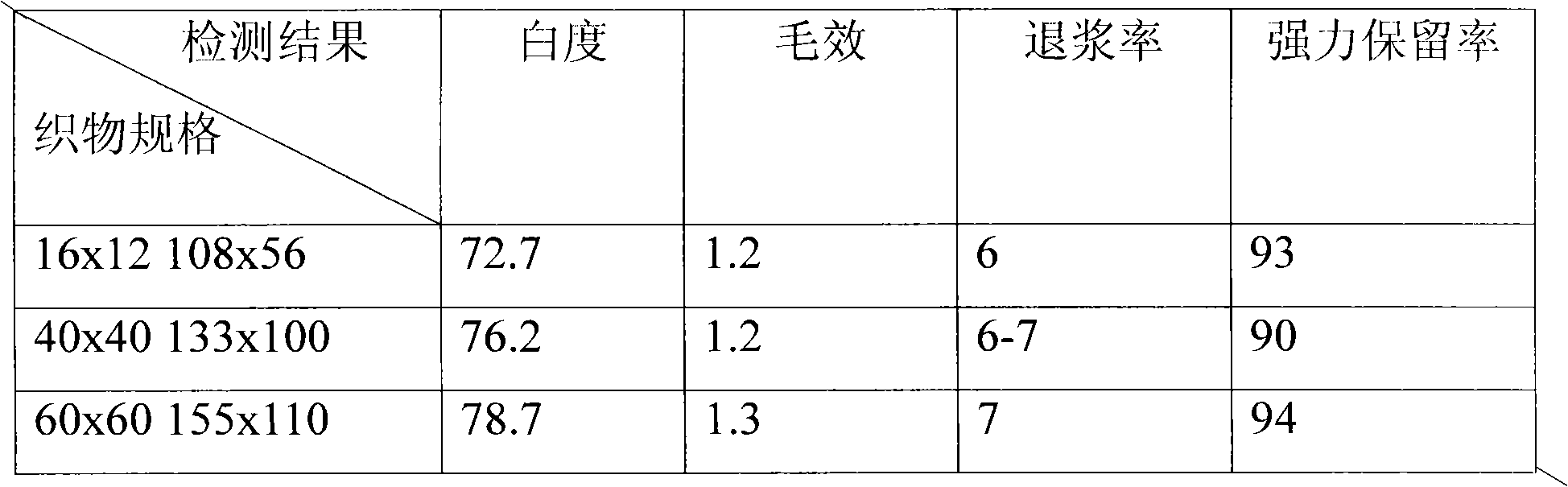

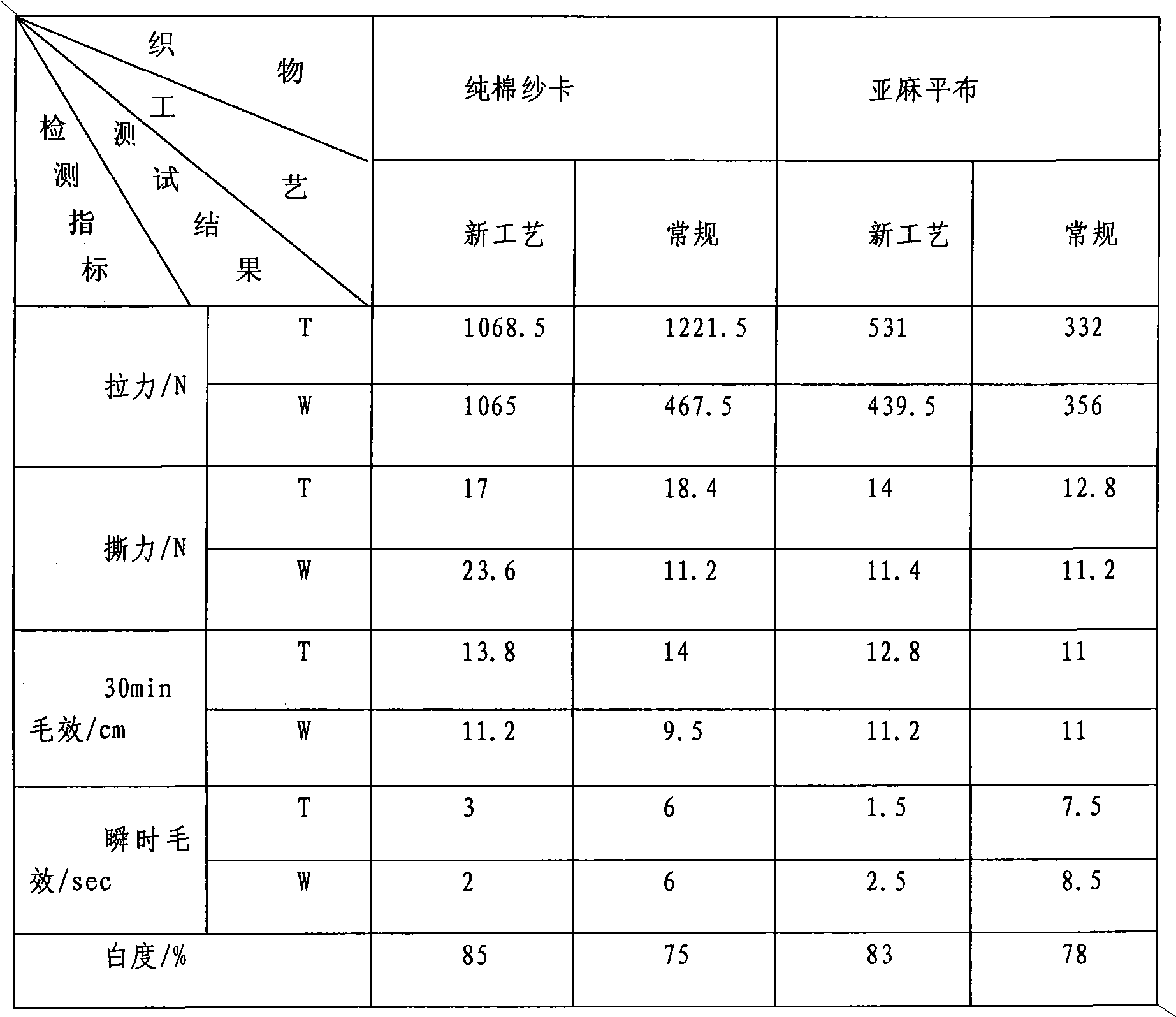

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

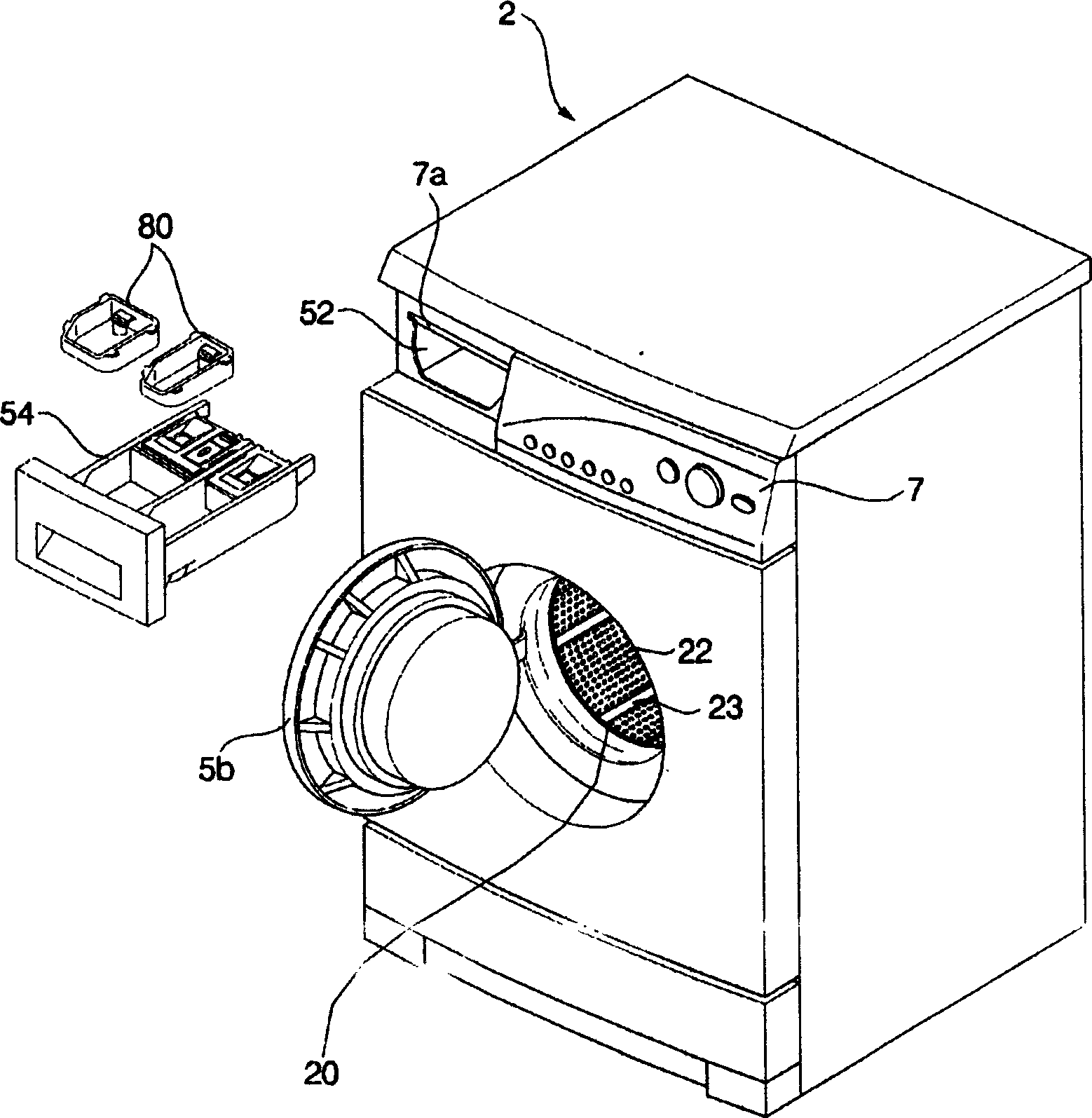

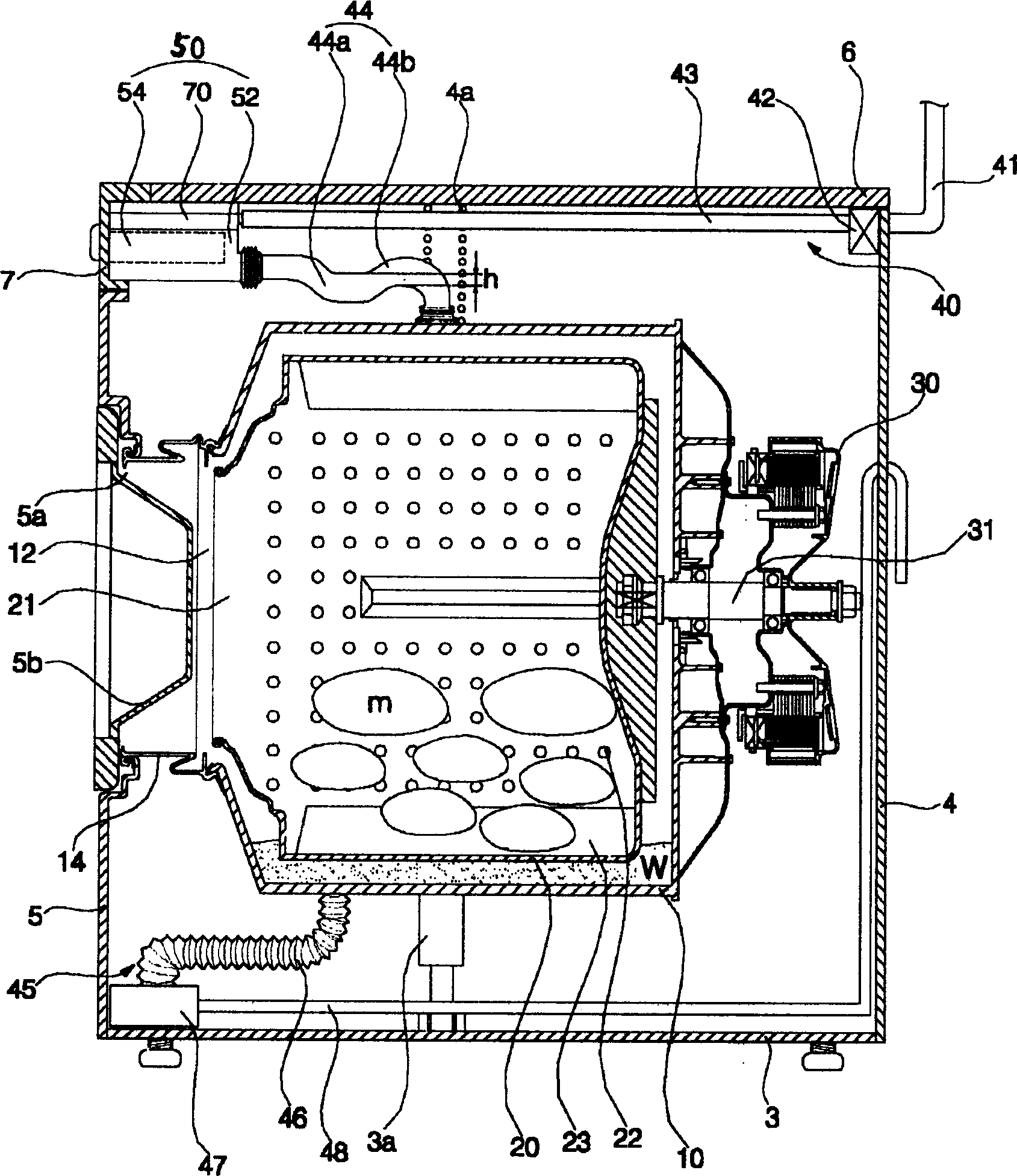

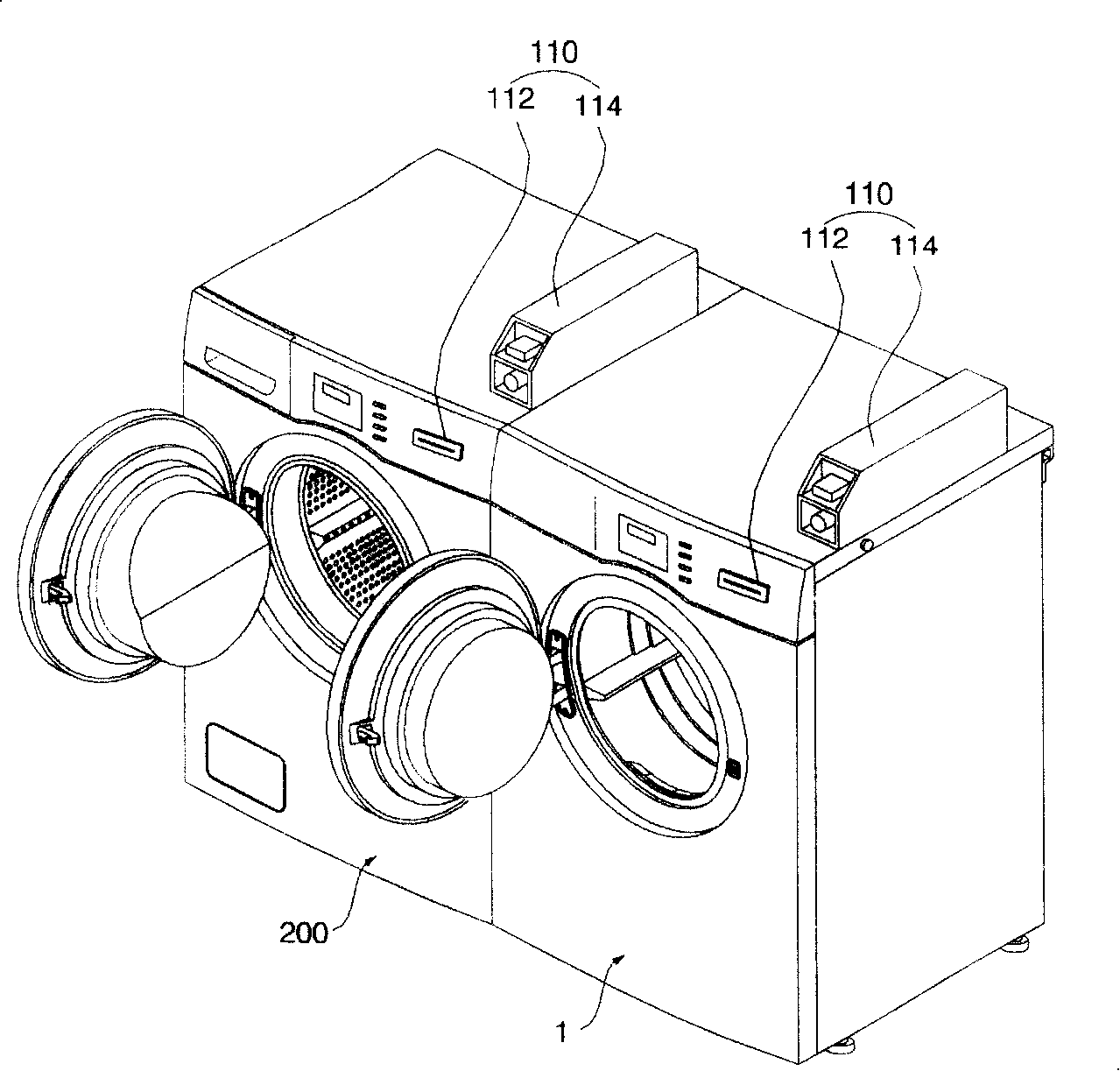

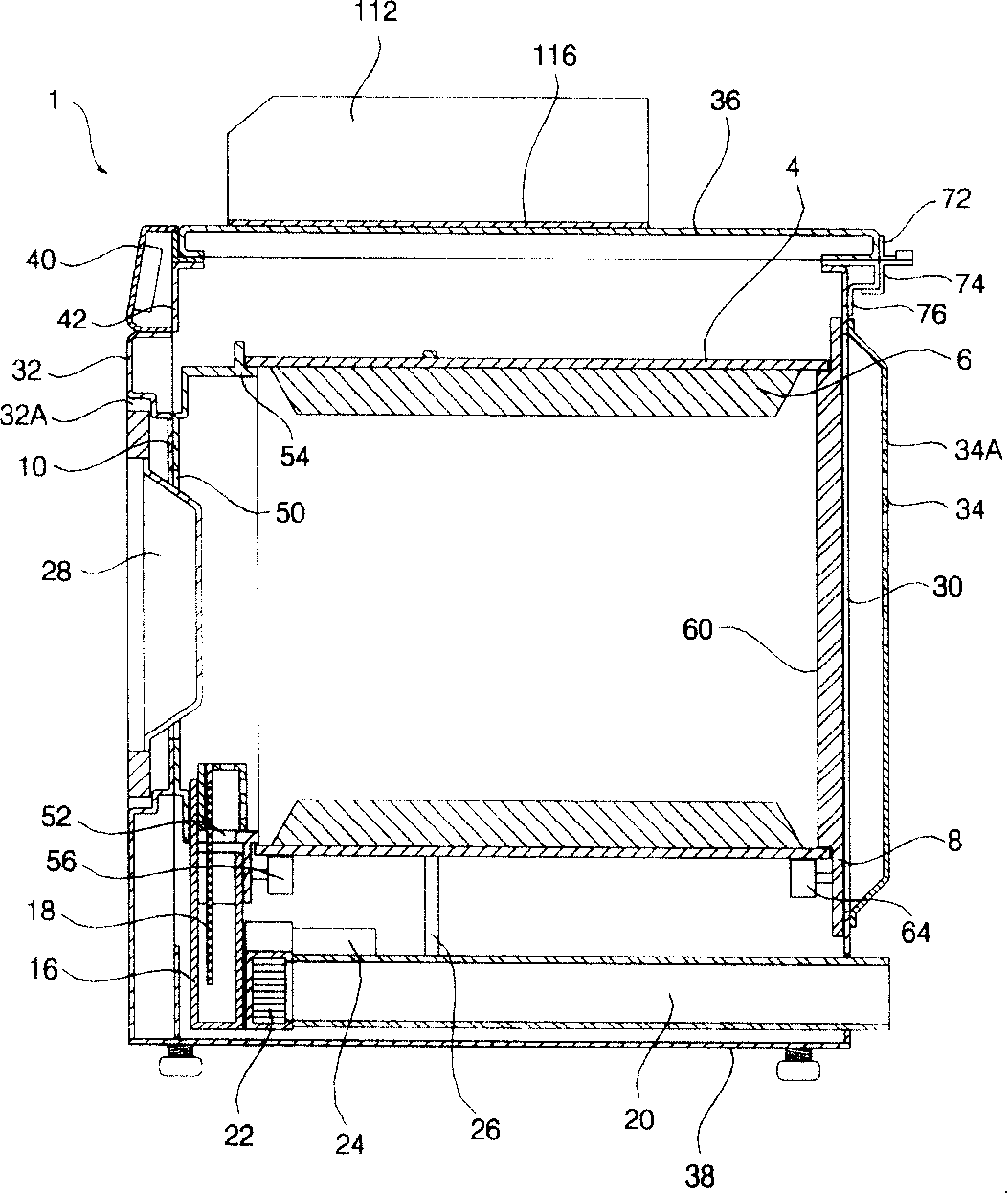

Detergent supplier of washer

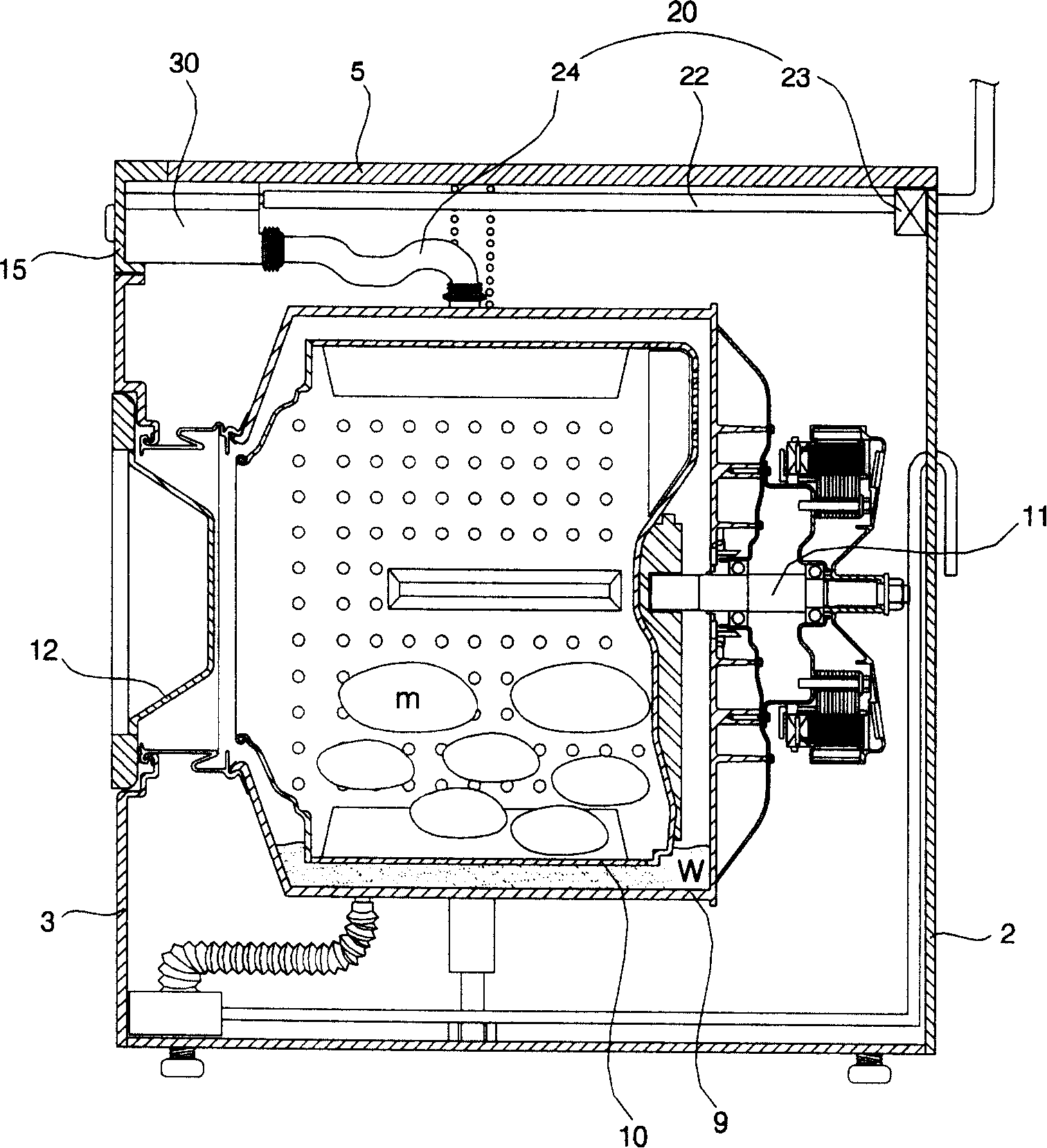

InactiveCN1779045APrevent discolorationEasy to put inOther washing machinesTextiles and paperEngineeringScouring agent

The invention opens a scouring agent feed-way for the washer. It is made up of the scour barrel for reserve the powder-scouring agent; the liquid scour box dismounted from the scour barrel. The powder souring agent reserve unit is divided into the main scour reserve unit and the ready scour reserve unit by the scouring barrel. Because of the liquid scouring box, the scour can be supplied conveniently and it can prevent the washings discoloring.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Environment-friendly type highly effective scouring agent

The invention discloses an environment-friendly scouring agent with high efficiency, which essentially comprises fatty amide, polyethenoxy ether, succinic acid, monoester sulfonate, C12 to 14 alkyl polysaccharide glycoside, isomery C13 hydrin polyethenoxy ether sodium dicarboxylic acid, secondary alkane sulfonate, chelating dispersant KX130 and water. The environment-friendly scouring agent with high efficiency that the invention provides has the advantages that: (1) the scouring agent is environment-friendly because the selected raw and supplementary materials are environment-friendly products and are degraded biologically into innoxious substance after entering into natural environment; (2) the scouring agent has good compatibility and high stability after compositing; (3) the scouring agent has strong resistance to alkali, the alkali resistivity is more than or equal to 240 g / L NaOH; (4) the scouring agent has strong penetrability, the sailcloth of 20 DEG C subsides less than or equal to 8S and has good emulsifying ability and detergent washing ability; (5) the scouring agent has good stability for hydrogen peroxide and the resolution ratio of the hydrogen peroxide is less than 10 percent; (6) the scouring agent has strong chelating power for metal ion and has good chelation on Cu2+, Fe3+ in bleaching liquor and improves the stability of the hydrogen peroxide, etc.

Owner:JIANGSU GEMEIGAO DEV CO LTD

Cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics

InactiveCN102191692AReduce dosageReduce wasted waterBiochemical fibre treatmentDry-cleaning apparatus for textilesElectricityChemical oxygen demand

The invention relates to a cooperative pretreatment method for biological catalysis and controlled oxidation of cotton and cotton-type fabrics, comprising the following steps: (1) preparing a biological compound enzyme preparation, a biological enzyme synergist and a non-ionic surfactant into an enzyme working solution, wherein the pH of a processing bath is 6-7.5; padding the fabrics into the working solution; carrying out heat preservation; (2) washing the processed fabrics with cold water; padding the fabrics into a hydrogen peroxide bleaching solution containing the controlled decomposition additive of hydrogen peroxide; and steaming, washing with water and drying to obtain the finished products. In the method, high-density strong base is not required to serve as a scouring agent, thepH value of pretreatment waste water is 7-8, the chromaticity is low, the COD (Chemical Oxygen Demand) value is lowered by 30% compared with that of the traditional alkali kiering pretreatment technology, the water is saved by 10-30%, and the steam and electricity can be saved by 20%. The indexes (whiteness, capillary effect, water absorption, cotton seed hull strainaway rate, desizing rate, strong force and the like) of the processed cotton and cotton-type fabric all reach the quality indexes of a semi-product, cotton seed hulls can be completely removed, and the fabrics have vivid color andgood levelling property after being dyed.

Owner:DONGHUA UNIV

Short-flow pre-treatment process for pure cotton woven fabric

InactiveCN102486003AAchieve the goal of energy saving and emission reductionGood desizing rateDry-cleaning apparatus for textilesBleaching apparatusRoom temperatureSlurry

The invention provides a short-flow pre-treatment process for a pure cotton woven fabric, which belongs to the technology of printing and dyeing pre-treatment of textiles. The short-flow pre-treatment process provided in the invention simplifies the conventional three-step method of desizing, scouring and bleaching into a two-step method, wherein the first step is cold pad batching and the second step is high temperature steaming; the procedures of scouring and bleaching in a conventional processing method for a pure cotton woven fabric are integrated in the short-flow pre-treatment process, no caustic soda is used in the process, and flow of the process comprises singeing, desizing (rolling a gray fabric and stacking the fabric at room temperature), open washing (with 7 open-washing boxes), scouring and bleaching (100 DEG C, 40 to 60 min), open washing (with 5 open-washing boxes) and drying. The invention provides a formula for desizing slurry and a formula for scouring and bleaching liquid to cooperate with the flow; the formula for the desizing slurry comprises 15 to 30 g / l of caustic soda (100%), 3 to 6 g / l of a penetrating agent and 2 to 5 g / l of a scouring agent; the formula for the scouring and bleaching liquid comprises 4 to 10 g / l of hydrogen peroxide (35%), 20 to 30 g / l of solid scouring enzyme, 5 to 8 g / l of water glass 40 degrees Be, 2 to 3 g / l of a scouring agent and 2 to 4 g / l of a complexing agent, and the pH value of the scouring and bleaching liquid is 10.5.

Owner:上海王港华纶印染有限公司

Hard surface cleaning compositions

InactiveCN1636048AInorganic/elemental detergent compounding agentsAnionic surface-active compoundsSurface cleaningAdipic acid

An improved hard surface cleaning composition having an acidic pH having good soap scum stain removal capabilities. The composition of the present invention comprises: an acidic component comprising citric acid alone or in combination with citric acid selected from the group consisting of sorbic acid, acetic acid, boric acid, formic acid, maleic acid, adipic acid, lactic acid, hydroxysuccinic acid, malonic acid , glycolic acid, and mixtures thereof; at least one anionic surfactant; at least one thickener; at least one scrubbing agent; one or more optional components; Water; wherein, the pH value of the aqueous hard surface cleaning composition is less than or equal to 6.0.

Owner:RECKITT BENCKISER LLC

Finish for nylon FDY and preparation method

The invention relates to the technical field of auxiliary manufacturing in the fiber processing technology, in particular to finish for nylon FDY and a preparation method. The finish for nylon FDY comprises the following components: 55-60% of isooctyl stearate, 5-7% of scouring agents, 5-7% of oleic acid, 8-10% of coconut oil diethanolamine, 5-7% of hydrogenated castor oil polyoxyethylene ether, 5-7% of fatty alcohol polyoxyethylene ether 4, 1-2% of oleic acid sarcosine, 0.5-1% of hypophosphorous acid, 1-1.5% of potassium hydroxide and 5-7% of wetting agent. The preparation method comprises the process steps of mixing, stirring and testing. The finish for nylon FDY has good thermal stability, is less in volatilization and free of coking and has low coefficient of dynamic friction in the drawing stage and good cohesion.

Owner:JIAXING NEW & HIGH TECH FIBER

Preparation method of scouring agent for aluminum and aluminum alloy

The invention relates to a preparation method of a scouring agent for aluminum and an aluminum alloy, which comprises the following steps: firstly, selecting ingredients according to the following percentages by weight: 30-85% of NaCl, 5-40% of Na2SiF6, 5-40% of Na2SO4, 2-20% of CaF2 and 0.5-10% of C6Cl6; uniformly mixing and fully stirring the selected ingredients; placing the mixture into a crucible, carrying out overheat melting to eliminate crystal water, and preserving the temperature for 30-60 minutes; and finally, processing after cooling to obtain the scouring agent. The method has the advantages of simple process and low cost. The prepared scouring agent does not contain sylvite, so that sylvite can not be introduced into the scouring and purifying treatment procedures, and therefore, an aluminum electrolysis cell can not be seriously corroded as a result of the introduction of sylvite when aluminum ash is directly recycled in the cell.

Owner:包头市一禾稀土铝业科技材料有限公司

Fine-grained zinc-based alloy for die and preparation process thereof

InactiveCN103320651AMeet the mechanical performance requirementsExtended service lifeMedium frequencySemi solid

The invention provides a fine-grained zinc-based alloy for a die and a preparation process thereof. The invention is characterized in that the fine-grained zinc-based alloy for the die is composed of a matrix alloy, intermediate alloys, an alterant and a scouring agent and comprises 12.5 to 16.5% of Al, 8 to 12.5% of Cu, 0.01 to 0.05% of Mg, 0.10 to 0.25% of Ti, 0.01 to 0.03% of B, 0.3 to 0.7% of Zr, 1 to 3% of Si, 0.4 to 0.8% of Mn, 0.2 to 0.8% of Re and 0.4 to 0.5% of ZnCl2, with the balance being Zn, wherein Re comprises, by mass, 45 to 55% of Ce, 10 to 20% of La, 7 to 15% of Y and 4 to 10% of Gd. The preparation process comprises the following steps: fusing the alloys in a crucible resistance furnace or a medium-frequency induction melting furnace; preparing a semi-solid zinc-based alloy through electromagnetic stirring; carrying out casting after temperature drops to 550 DEG C; and carrying out water cooling or air cooling. Compared with the prior art, the invention has the following advantages: the fine-grained zinc-based alloy for the die has the following mechanical properties at normal temperature, i.e., sigma b of 492.6 MPa, delta s of 1.42% and HBR of 168; even at a high temperature of 200 DEG C, sigma b reaches 216 MPa and delta s reaches 26%, completely according with the requirement of a common injection die for the mechanical property sigma b of 120 to 150 MPa at the temperature of 200 DEG C.

Owner:江苏新亚特钢锻造有限公司

Low-temperature and low-damage moderate preprocessing method of PVA carrier pure-cotton high count yarn

InactiveCN101949097AReduce impurityInhibit adhesionBiochemical fibre treatmentBleaching apparatusYarnRoom temperature

The invention relates to a low-temperature and low-damage moderate preprocessing method of PVA carrier pure-cotton high count yarn, comprising the following steps: (1) yarn is preprocessed before processed, wherein the processing temperature of 20-80 DEG C, the processing temperature is 10-30 minutes, and conditioning fluid is 1-2g / L of Dj-13991; (2) at the room temperature, the specific scouring agent BF-07w of high count yarn, biological enzyme preparation, hydrogen peroxide and hydrogen peroxide activator (TAED / SPB) are successively added at the room temperature, and the pH value is adjusted to 7-9 by NaOH solution; (3) yarn is input, temperature rises to 40-80 DEG C which is kept for 20-90 minutes, the mixture is continuously stirred in the processing process, then temperature is lowered, and the obtained product is washed, dewatered and dried at the temperature of 50 DEG C. The invention effectively solves the adhesion problem between yarns which is caused by the dissolving of the PVA fibre in the carrier yarn caused by the traditional high-temperate refining bleaching, and simultaneously lowers the powerful damage of yarn.

Owner:DONGHUA UNIV +1

Acid scouring agent and preparation method thereof

ActiveCN101736618AStrong neutralization abilityHigh chelation valueDyeing processAlkylphenolCellulose fiber

The invention discloses an acid scouring agent and a preparation method thereof. The acid scouring agent comprises a multivariate acidic copolymer, polyvinyl pyrrolidone PVP and sodium gluconate. The scouring agent does not contain phosphorus, alkylphenol ethoxylates and harmful solvents and is degradable; and at the same time, the scouring agent has the characteristics of a little foam, high chelation value and high alkali neutralizing capacity. The scouring agent can be used for scouring cellulose fibers after dyeing, can simplify the traditional process and contributes to energy conservation and emission reduction.

Owner:苏州联胜化学有限公司

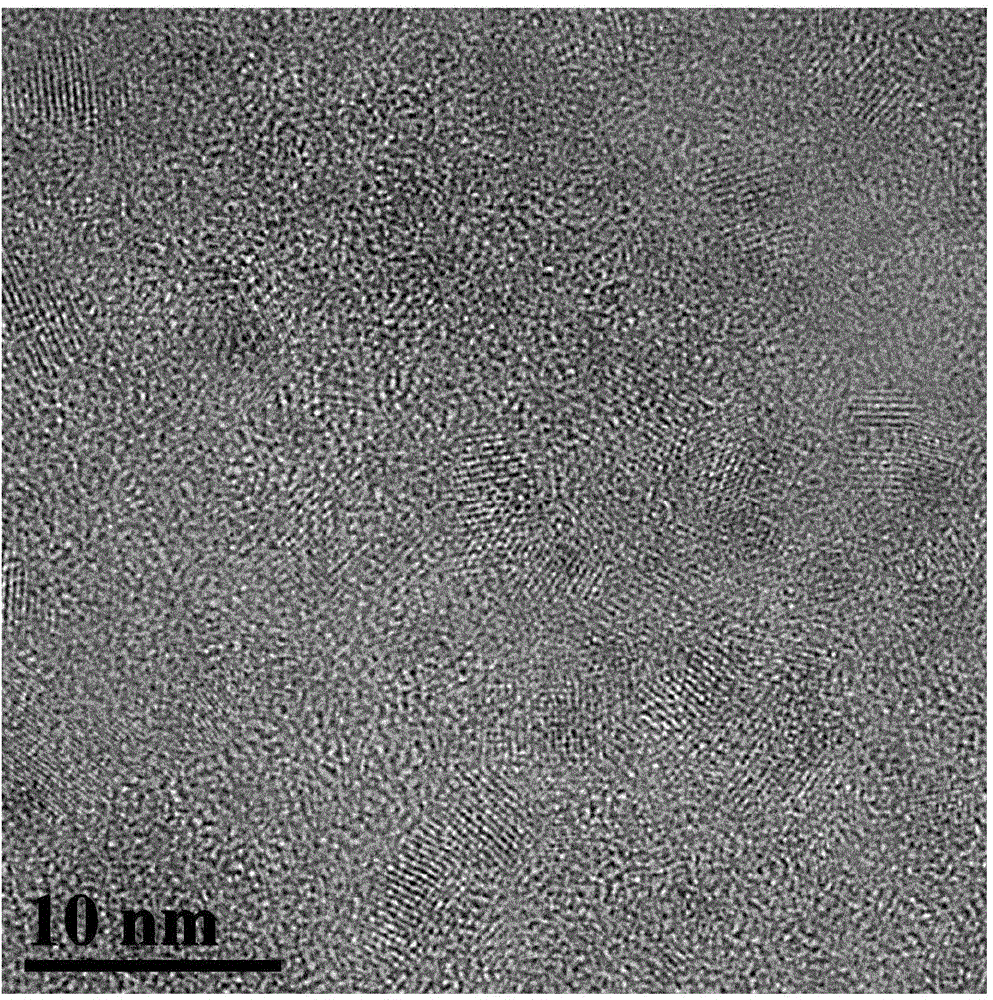

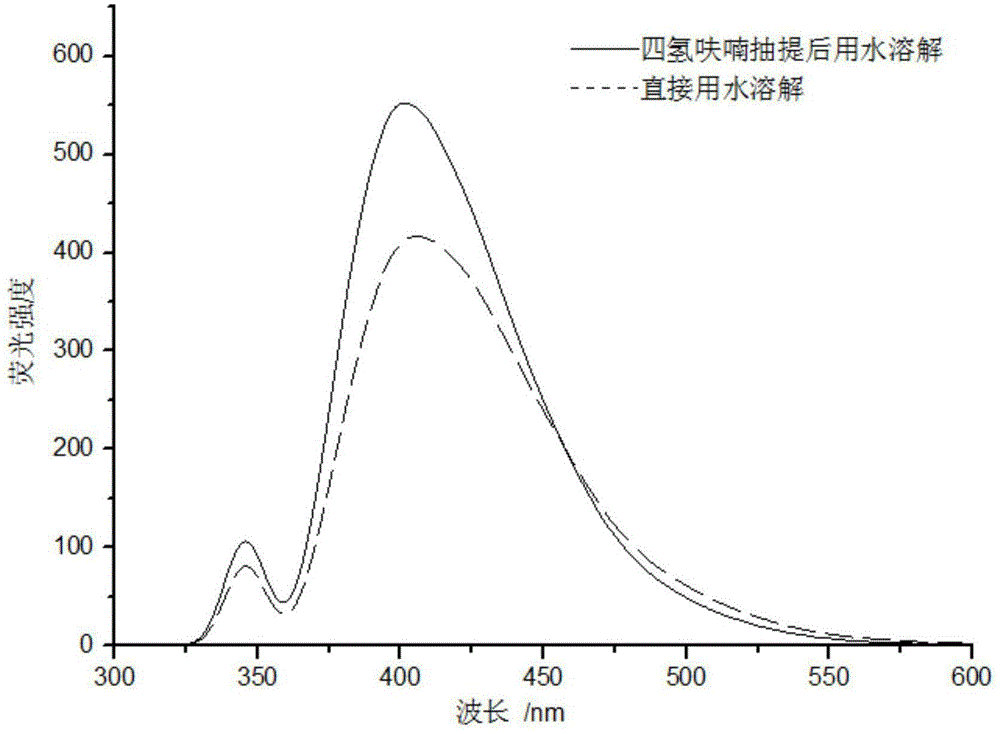

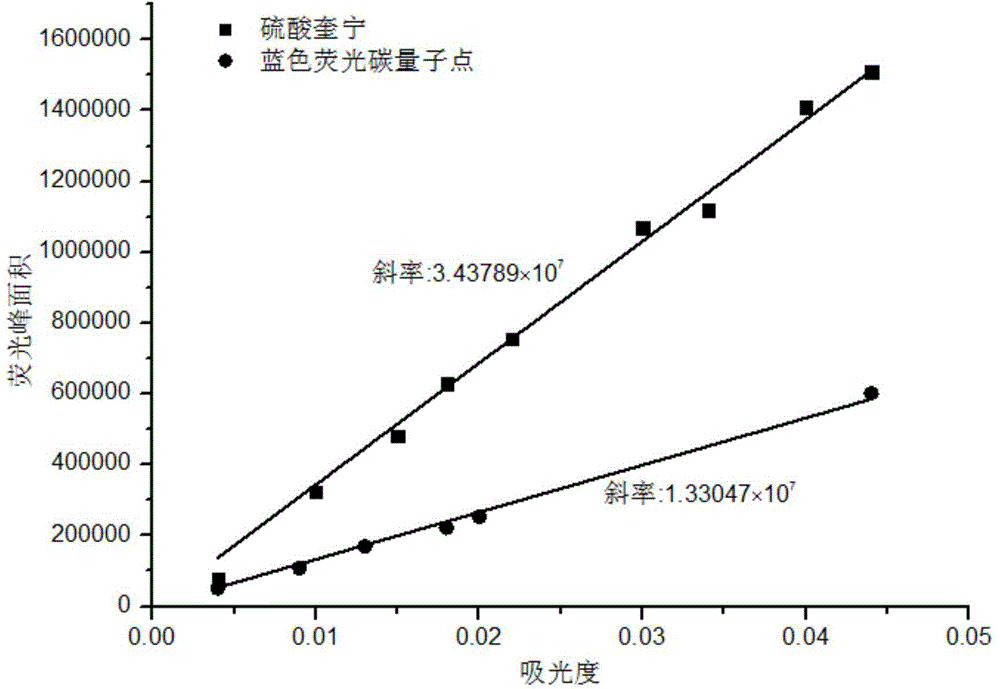

Green synthetic method for blue fluorescence carbon quantum dots with high fluorescence quantum yield

InactiveCN104927849AHigh fluorescence quantum yieldEasy to evaporate and separateLuminescent compositionsQuantum yieldWhitening Agents

The invention discloses a green synthetic method for blue fluorescence carbon quantum dots with high fluorescence quantum yield, and belongs to the technical field of fine chemical engineering. The method adopts a mixture of citric acid and glycine as a raw material, the solid mixture is heated directly to a certain temperature for a certain time, so that the solid mixture is dehydrated, after cooling to indoor temperature, the mixture is extracted by a low boiling point organic solvent, and the fluorescence quantum yield of the obtained carbon quantum dots is much higher than the fluorescence quantum yield of carbon quantum dots which are not processed by the organic solvent. The adopted raw material is easy to obtain, cheap and free of poison, three wastes are not generated in the preparing process, the operation is simple and convenient, and the raw material is easy to control. Due to the fact that the higher high fluorescence quantum yield, blue fluorescence emission and good photobleaching resistance are achieved, the carbon quantum dots can serve as a fluorescent whitening agent and be applied to production of paper pulp, scouring agents and washing powder, and the carbon quantum dots can serve as fluorescence markers of biomolecules.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Blended spinning method of long spinning and damp spinning for bast fibers

The invention provides a method integrated with long spinning, wet spinning and blended spinning for bast fibers. The method comprises the following steps: the bast fibers are scotched into flax; the flax is humidified and soaked for a period of time; the flax is carded into long flax; and the long flax is subjected to matching, silvering, drawing, roving, scouring, bleaching, spinning, drying and winding. The method is characterized in that after the bast fibers are bleached, the obtained rove of the bast fibers and rove or filaments of other fibers are blended on a spinning machine. With the method, blended fibers are not bleached and scoured together with the bast fibers, so the defect that the performance of blended yarn is affected due to the damage of bleaching and scouring agents to the blended fibers in the prior wet spinning and blended spinning is overcome, and the obtained blended yarn has the characteristics of bright and clean yarn body, less hairness, evenness and good wear resistance. In addition, the method can fully play a role in respective advantages of the bast fibers and the blended fibers, complement respective disadvantages of the bast fibers and the blended fibers, has simple process, is favorable for improving the quality of blended yarn of the bast fibers, and realizes the high count, high grade and diversification of varieties of the bast fibers.

Owner:DONGHUA UNIV

High-strength aluminum alloy welding wire and preparation method thereof

ActiveCN102114579ALight materialImprove performanceWelding/cutting media/materialsSoldering mediaSlagHeating temperature

The invention discloses a high-strength aluminum alloy welding wire which comprises the following chemical compositions in percentage by weight: 2.5-3.5 percent of Cu, 2.2-3.2 percent of Si, 0.1-0.25 percent of Ti, 0.1-0.25 percent of Zr, 0.1-0.2 percent of Mn and the balance of Al. The preparation method comprises the following steps: melting and ingot-casting raw materials so as to prepare intermediate alloy of Al-Cu50, Al-Mn10, Al-Si30, Al-Ti10 and Al-Zr10; pouring the pure aluminum ingot into a crucible according to composition proportion, raising temperature, adding and melting the intermediate alloy of Al-Mn10, Al-Cu50, Al-Ti10 and Al-Zr10 in sequence according to composition proportion after the aluminum ingot is entirely molten; after melting is finished, raising the temperature to 800 DEG C for heat preservation for 15 minutes, pressing hexachloroethane into the bottom of the alloy liquid with a graphite hood, stirring to conduct degassing and slagging, wherein the using amount of the hexachloroethane is 0.3-0.4 percent of the amount of a furnace, scattering a little amount of scouring agent to remove surface float slag after finishing slagging-off; continuing to raise the temperature to 820-850 DEG C, fully stirring, and discharging; conducting pull-casting to prepare high-strength aluminum alloy cast ingot; then taking out and sawing the cast ingot into segments and peeling; putting the cast ingot into an extruder at the heating temperature of 330-380 DEG C for extrusion; and conducting wiredrawing in a wiredrawer, and annealing in the drawing process, thus obtaining high-strength aluminum alloy welding wires when achieving the standard diameter.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Oxygenase-bath alkali-free desizing process for polyester/cotton high-count and high-density fabric

InactiveCN102011298AQuality improvementFeel goodDry-cleaning apparatus for textilesBleaching apparatusPolyesterAlkali free

The invention relates to an oxygenase-bath alkali-free desizing process for a polyester / cotton high-count and high-density fabric. The process sequentially comprises the following steps of: sewing and singeing the fabric; washing the fabric with three-grid hot water; washing the fabric with two-grid coldwater; padding oxidation bleaching working solution; steaming at the temperature of 102 DEG C for 50 minutes; washing the fabric with four-grid hot water; drying; and shaping, wherein in the step of padding oxidation bleaching working solution, the formula of the oxidation bleaching working solution comprises 10g / L of high-efficient scouring agent HS-120B, 65g / L of 288 dispersing agent, 5g / L of scouring enzyme 188, 5g / L of wax regent WR, 10g / L of hydrogen peroxide stabilizing agent P and 14.0 to 15.0g / L of hydrogen peroxide (wherein the concentration is 33 percent). Compared with the prior art, the desized fabric has greatly improved quality, namely the handfeel is plump; the fabric surface loss ratio is low; the fabric surface whiteness is good; and the fabric has no cotton, multiple nodes and no alkaline spots.

Owner:HUAFANG

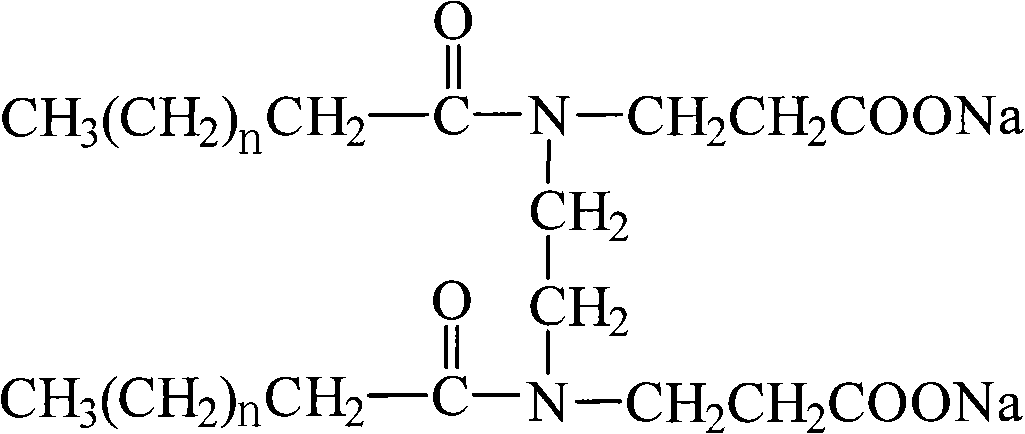

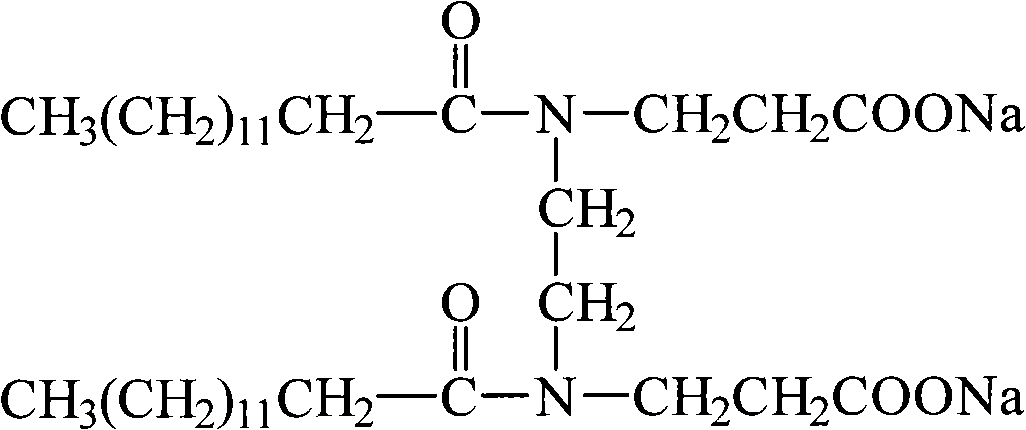

Silk broadcloth scouring agent

The invention relates to a finish process technology for textile, especially a scouring agent for real silk scouring and processing. According to the quality percentage, the ingredients scouring agent is 5-20% double-surfactant N,N'-dialkylamide and carboxylate sodium, 5-20% surfactant alkyl polyoxyethylene ether carboxylate, 2-10% maleic acid / acrylic acid copolymer, 2-10% fibroin protective agent, 1-10% inorganic salts, and water for the rest. The scouring agent take the double-surfactant as the essential component, so the surface activity and the solubility of the scouring agent are improved greatly, and the moistening and the scrubbing effect are strengthened; taking the alkyl polyoxyethylene ether carboxylate surfactant as a complex surfactant, the scouring agent has good emulsification and lime soap dispersing capacity, so as to enhances the scouring effect. At the same time, because amide bond exists in the molecular structure, the scouring agent has good hard water-resistant capacity and lime soap dispersing capacity, and has the advantages of improving the smooth feeling of the scoured textile, and enhancing the capillary effect.

Owner:SUZHOU UNIV

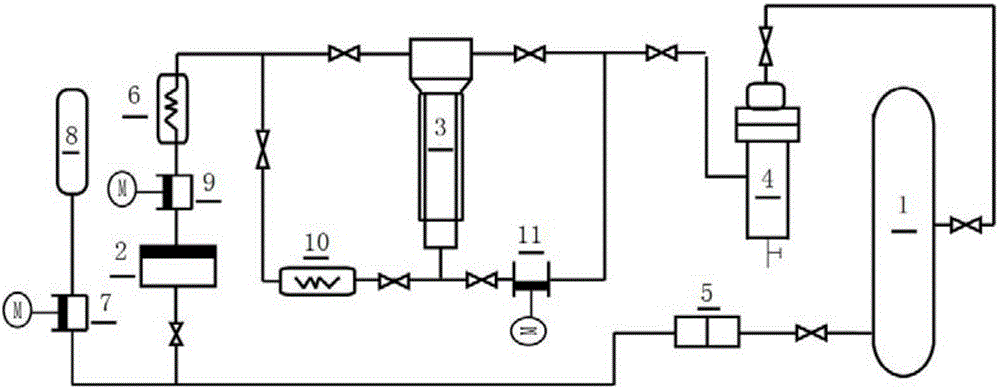

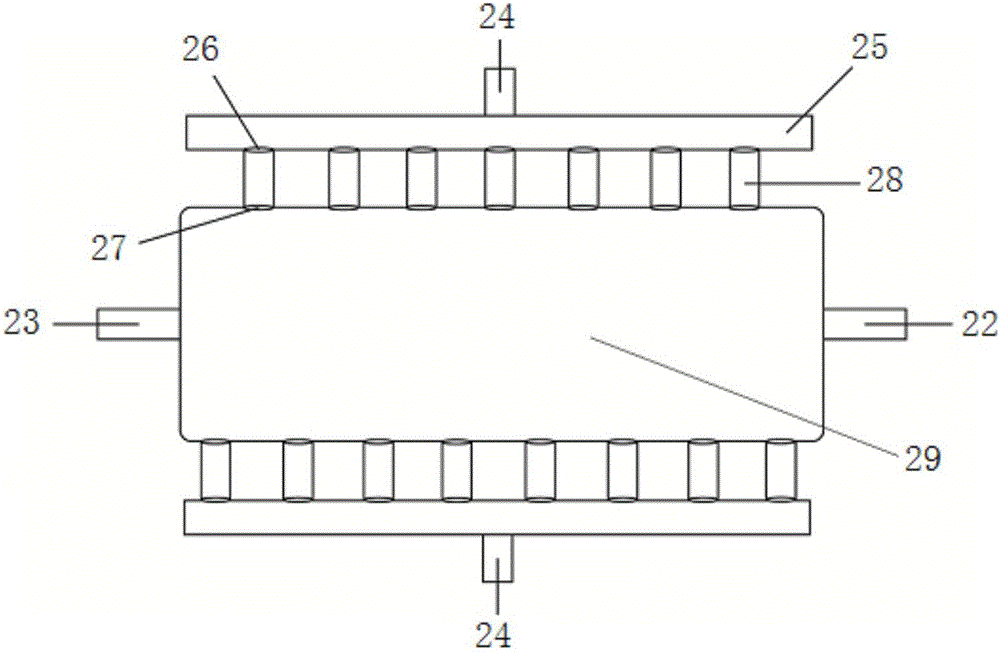

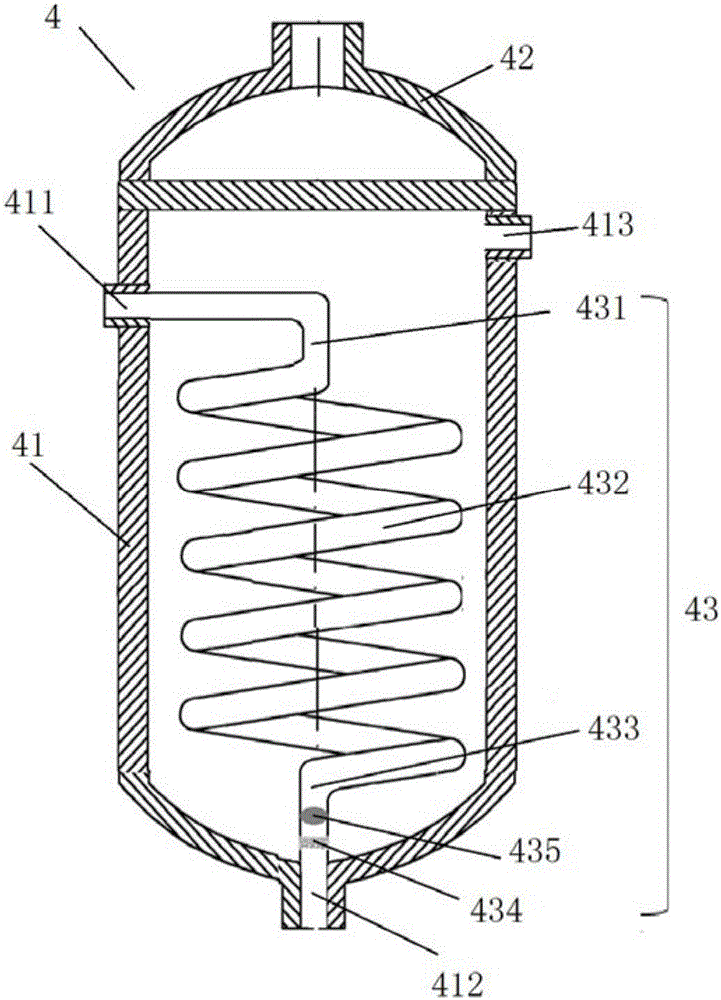

Flax thick yarn supercritical CO2 biological enzyme scouring device and scouring method thereof

ActiveCN106676788AReduce usageReflect the concept of modern lifeTextile treatment containersTextile treatment machine arrangementsYarnBreaking strength

The invention discloses a flax thick yarn supercritical CO2 biological enzyme scouring device and a scouring method thereof. Flax thick yarn is placed in supercritical CO2 fluid where a biological enzyme scouring agent is dissolved, flax fibers are swollen for 10-30 min at 30-40 DEG C and 8-15 MPa; the flax thick yarn is scoured for 30-60 min under dynamic conditions of a flow velocity of supercritical CO2 at 10-50 g / min at 40-60 DEG C and 15-25 MPa; the flax thick yarn is processed through a scouring-separation combined process for 10-30 min at 40-60 DEG C and 15-25 MPa; after the scouring, the weight loss rate of the flax thick yarn is 6-12%, the residual gum rate is 7-15%, the single fiber breaking strength is 6-13 cN / dtex, and the elongation at break is 4.5-8.5%. The whole scouring process is free of pollution and has zero release, requirements of commercialized production are met, and the modern life idea of fashionable bast fiber spinning and green bast fiber spinning is embodied.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

Highly-effective refine agent and production method thereof

The invention provides a high-efficient scouring agent and a production method thereof, pertaining to a treatment agent used for fabric printing and dyeing and the production method thereof. The invention is mixed by the mixture ratio of hydrolyzed fatty alcohol ether phosphate ester, fatty alcohol ether and synergic agent which are dydrolyzed. The scouring agent can effectively erase impurities such as fruit wax, husks, floating material, etc when the scouring agent are used for preprinting treatment of cotton and fabric. After being treated, the textile has face-finished, rather high fur effect and whiteness, facilitates coloration and printing of textile, alkali resistant (200g / L NaOH), high temperature resistant, hard water resistant, and has high-speed filtration ability and good separating ability to fiber. The preparation technology not only can be used for a successive padding method, but also be used for a cold pad dyeing method, a one-step process of decoloring, boil out and bleaching method, etc. The scouring agent is alkylphenol ethoxylates free, and conforms to the environmental protective requirement.

Owner:YUYUE HOME TEXTILE

Low-temperature deoiling scouring agent and preparation method thereof

InactiveCN105002022AGood degreasing effectGood emulsification and dispersionSurface-active non-soap compounds and soap mixture detergentsAlcoholSolvent

The invention discloses a low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent comprises, by weight friction, 10-20% of fatty alcohol-polyoxyethylene ether (EO9), 10-20% of fatty amine alcohol-polyoxyethylene ether (EO15), 5-10% of Isomeric ten alcohol-polyoxyethylene ether (EO5), 5-15% of secondary alcohol-polyoxyethylene ether (EO9), 3-6% of solubilizer, and the allowance is deionized water. The invention further discloses a preparation method for the low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent is applied to the pretreatment processes of refining, deoiling, detergent washing and the like, the deoiling problem of fabric (especially the fabric containing spandex) in the process of pretreatment is solved, and oil stain and impurities in the fabric are guaranteed to be removed effectively. The functions of dispersing, emulsifying and wetting are achieved, the permeability is good, the form is little, and detergency is strong.

Owner:BONUS FUJIAN TEXTILE IND CO LTD

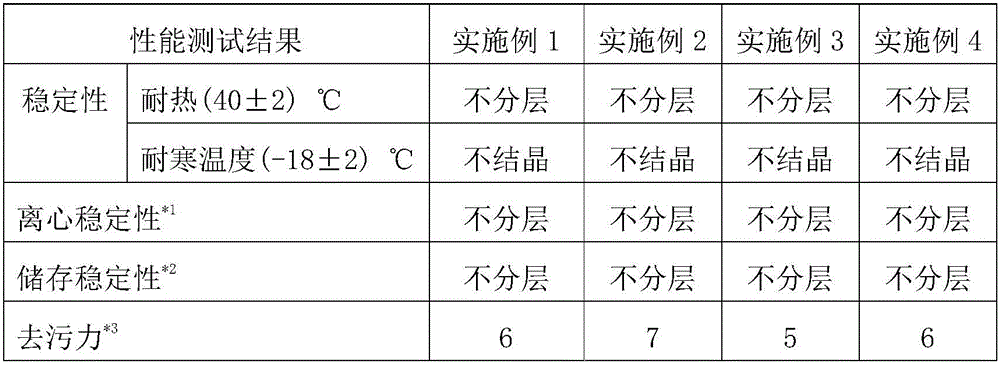

Solvent-free high-enriched tableware scouring agent and preparation method thereof

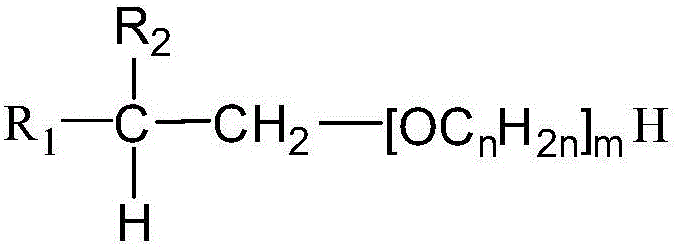

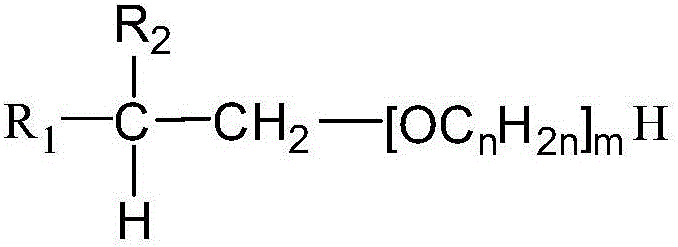

ActiveCN105695159AHigh content of active substancesStrong decontaminationNon-ionic surface-active compoundsAnionic surface-active compoundsHydrogenPreservative

The invention discloses a solvent-free high-enriched tableware scouring agent, which is prepared from the following components in percentages by weight: 5 to 30 percent of anionic surfactant, 10 to 40 percent of nonionic surfactant, 1 to 5 percent of ampholytic surfactant, 10 to 20 percent of oil ethoxylate, 0.01 to 0.1 percent of preservative, 0.1 to 0.5 percent of essence, 0.01 to 1 percent of pH (Potential of Hydrogen) regulator, and the balance of water. The solvent-free high-enriched tableware scouring agent has the advantages that the active matter content is high, the detergency is strong, and the low-temperature stability and the flowability are good.

Owner:CHINA RES INST OF DAILY CHEM IND

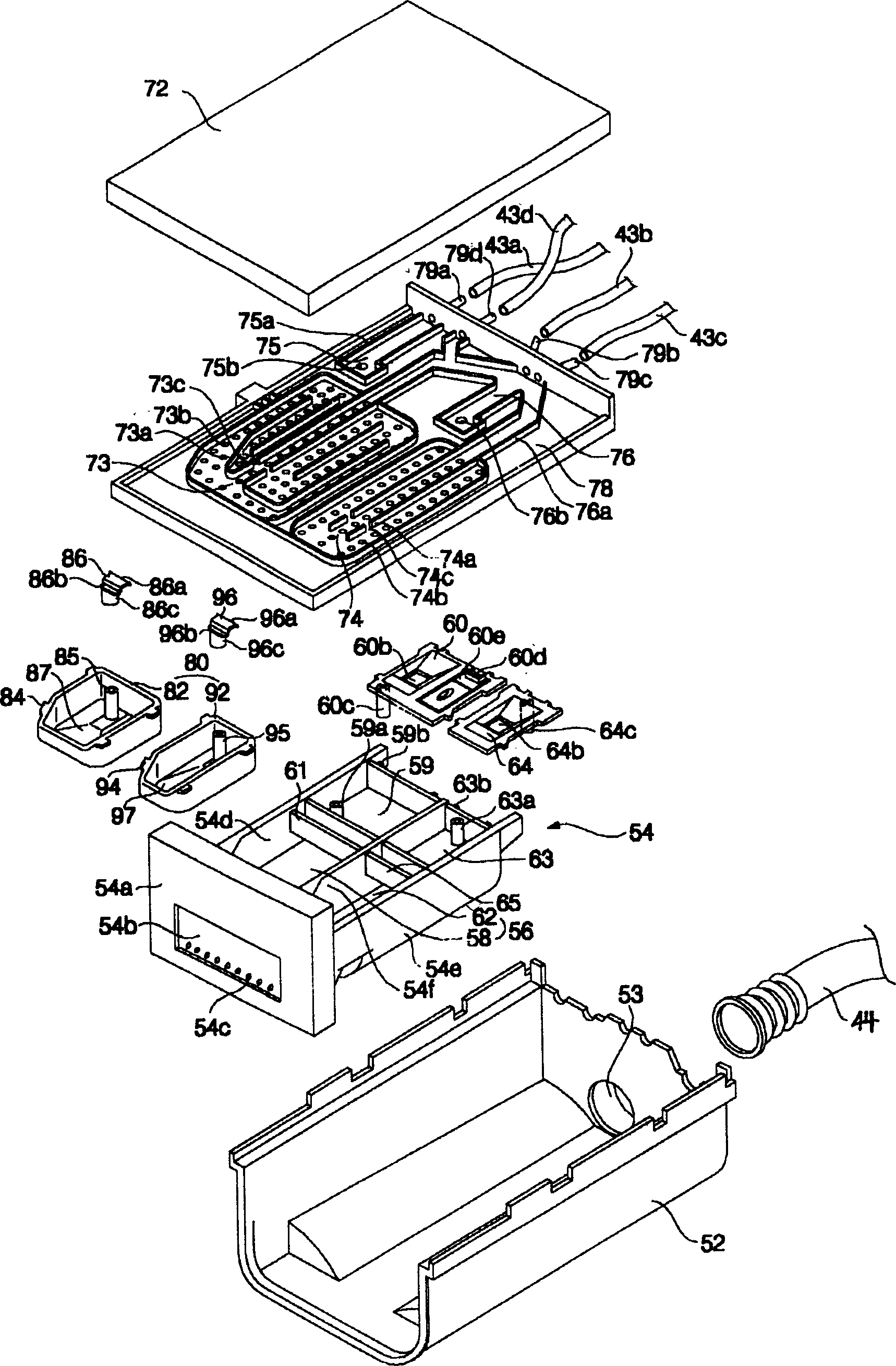

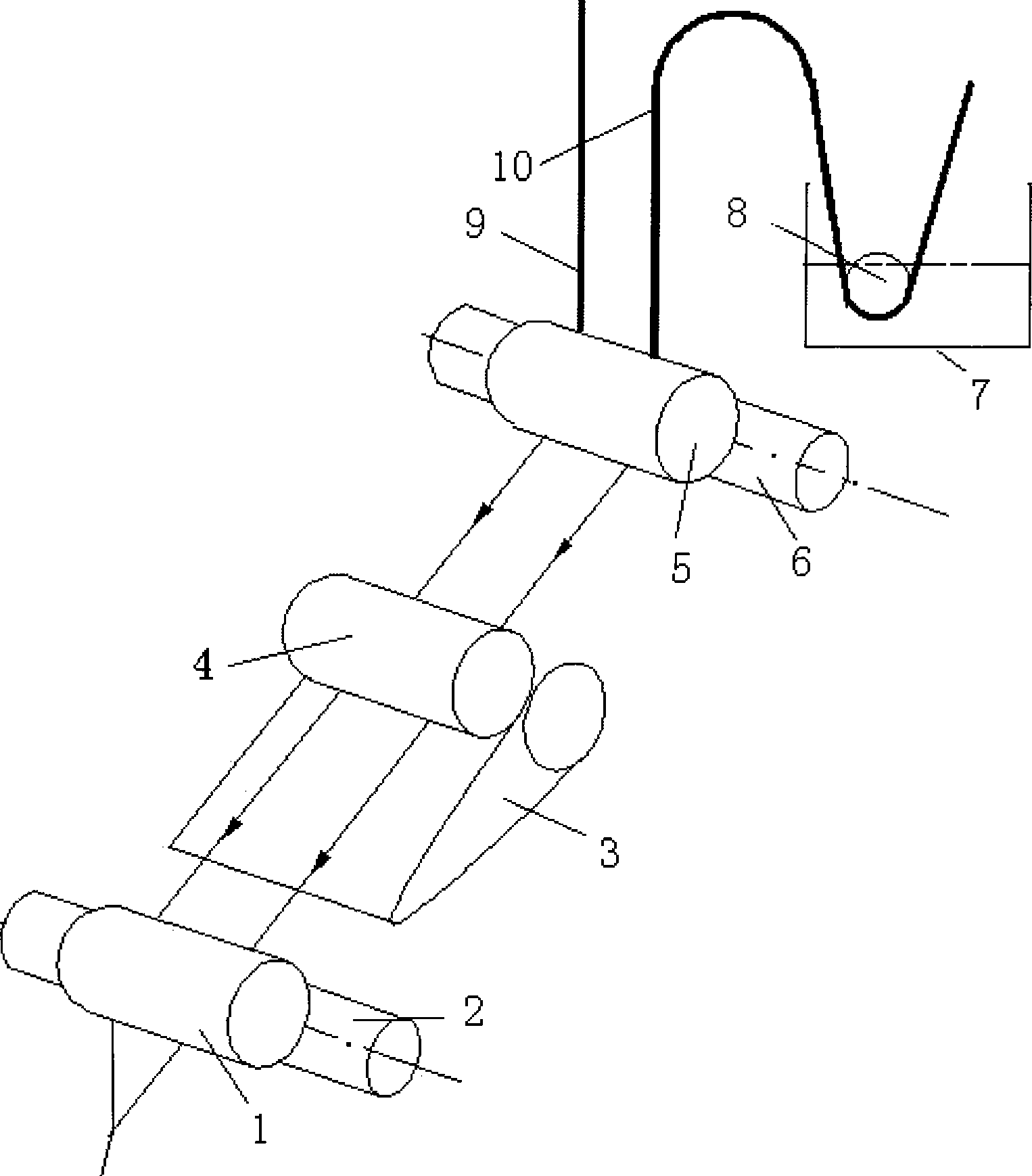

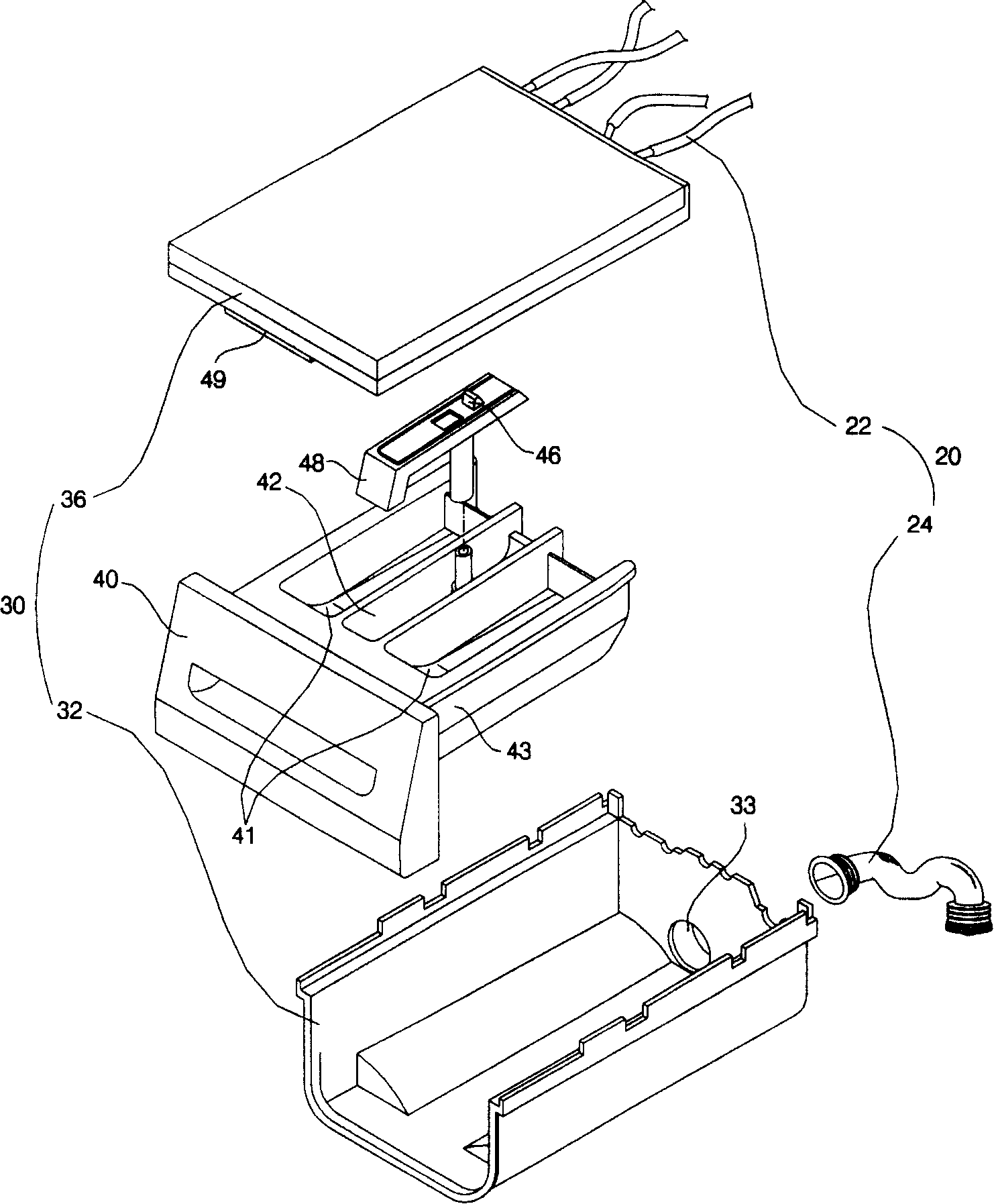

Scouring agent feeding mechanism of scouring apparatus

InactiveCN101177896APrevent random dischargePromote formationOther washing machinesTextiles and paperSiphonAtmospheric pressure

The invention discloses a detergent supplying device of a washing device, comprising a detergent box that is arranged on an opening hole of the washing device in a drawable way and is provided with a detergent accommodating part with an opening at the back, a bleaching agent accommodating part and a softener accommodating part that are arranged inside the detergent accommodating part and are formed by separating from a baseplate and the bottom surface of which is provided with siphon pipes in a bulgy way, a detergent box cover arranged on the detergent accommodating part and is provided with siphon pipe covers that can fit the siphon pipes and a shielding device arranged in front of the lower side of the siphon pipes for keeping certain air pressure to the lower part of the siphon pipes when being pushed into the detergent box. When the detergent box is inserted and installed, the invention can prevent bleaching agent and softener accommodated in the bleaching agent accommodating part and the softener accommodating part from moving and the phenomenon of being discharged through the siphon pipes and the siphon pipe covers.

Owner:NANJING LG PANDA APPLIANCES

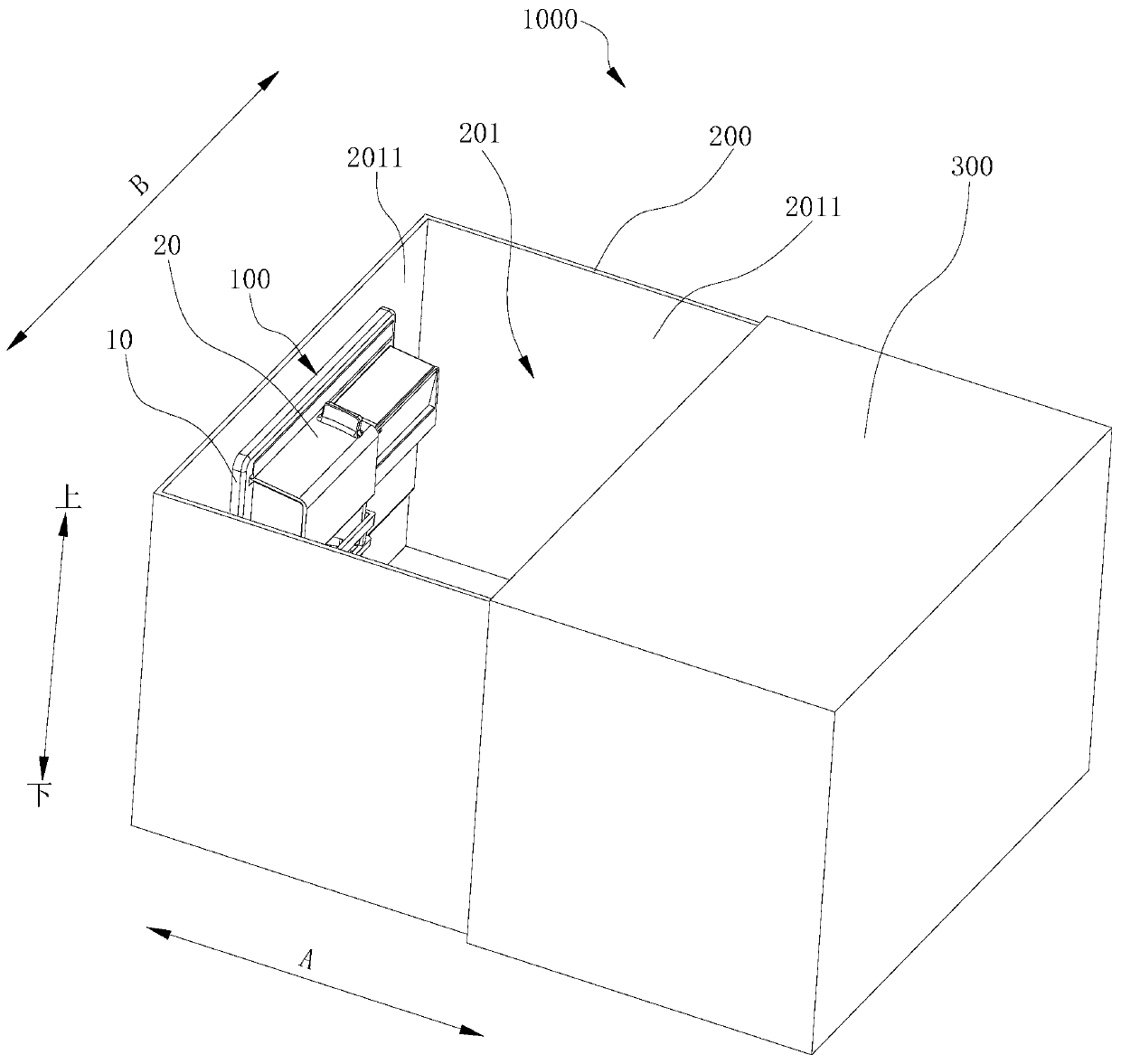

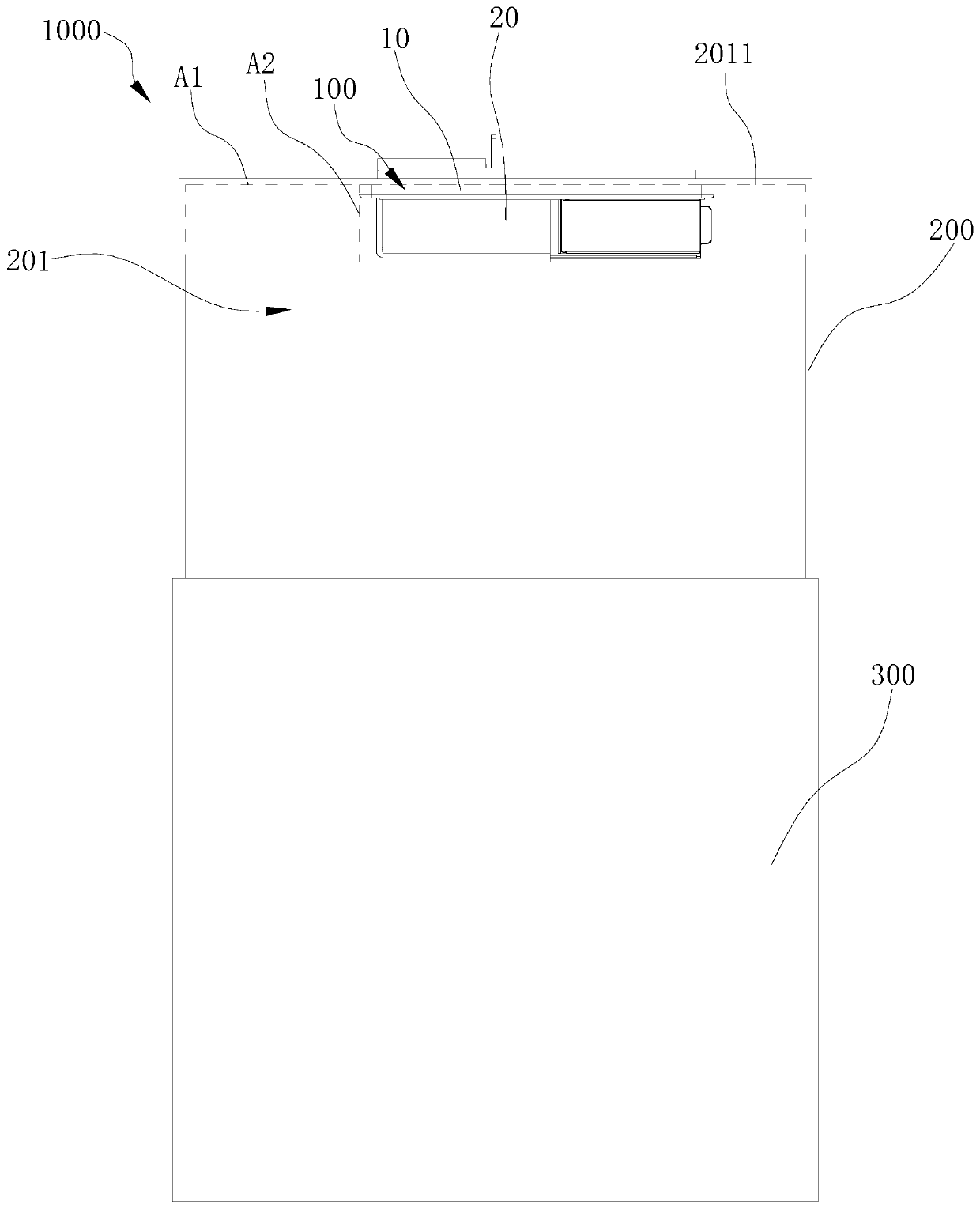

Distributor and washing electric appliance

The invention discloses a distributor and washing electric appliance. The distributor is used in the washing electric appliance, and comprises a body and a bottom plate. An accommodating cavity is formed in the body, a throwing opening is formed in the bottom of the accommodating cavity, the body comprises an accommodating cavity body, and the accommodating cavity is formed in the accommodating cavity body. The bottom plate is arranged on the body, and the bottom plate is collocated to open or close the throwing opening. According to the distributor and the washing electric appliance of embodiments, the bottom plate of the distributor is collocated to open or close the throwing opening, and the scouring agent can be thrown only needing to open the throwing opening at the bottom of the accommodating cavity through the bottom plate. Thus, the throwing opening is arranged at the bottom of the distributor, and when the scouring agent is thrown, the scouring agent can be more conveniently thrown into the washing cavity of the washing electric appliance through the distributor.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Production method of memory function lining

The invention provides a production method used for producing a memory surface fabric with excellent crease resistance, easy cleaning, low static and good rebound elasticity, which comprises the following steps: a pure vegetable PVA paste is adopted to implement sizing processing of Somalor fibers, an automatic air jetting loom is used for producing a loom stare with the Somalor fibers, the loom stare is placed in water bath at the temperature of 80 plus or minus 5 DEG C to implement refinement preprocessing, 2 percent of a scouring agent SK, 0.1 to 2.5 percent of a Clariant dispersing dye, and 4 percent of Clariant Rayosan C liquid by weight are added under the bath ratio condition of 1 to 3, HAC is added so as to adjust the pH value of the water bath to be 5, and dyeing is implemented at the temperature of 90 to 125 DEG C for at least 20 minutes; the dyed loom stare is processed by post water bath at the temperature of 80 plus or minus 5 DEG C, stentered by a stentering machine, parched, and finally shaped at the temperature of 120 plus or minus 5 DEG C by a forming machine at the speed of 40m per minute. The production method of the memory surface fabric avoids desizing and color fixation, realizes dyeing at low temperature, does not use a chemical softening agent of organic silicon, and is environment-friendly and energy-saving.

Owner:冠宏股份有限公司

High efficiency and low foam environment-friendly type scouring agent and preparation method thereof

The invention provides a high efficiency and low foam environment-friendly type scouring agent and a preparation method thereof, wherein the scouring agent comprises: 15-25% by weight of dodecyl diphenyl ether sodium disulfonate, 5-15% by weight of C12-16 seconary Alkane Sulphonate Sodium, 15-25% by weight of alkyl polyglucoside, 10-150% by weight of isomeric alcohol ethoxylates, and the balance being water. The concrete steps for preparing the scouring agent, comprising: adding water into a mixture of dodecyl diphenyl ether sodium disulfonate and C12-16 seconary Alkane Sulphonate Sodium, and then mixing the mixture for dissolving; and (2) adding alkyl polyglucoside and isomeric alcohol ethoxylates into the mixture obtained in the step (1), and then uniformly mixing. The product is used as a green environmental protection printing and dyeing auxiliary agent with the advantages of simple technology, environment-friendly formula and excellent performances.

Owner:南通华宇紧固件有限公司

Method for producing non-dust cloth

ActiveCN102002846AAvoid cross contaminationControl environmentFibre typesDry-cleaning apparatus for textilesAcetic acidPulp and paper industry

The invention belongs to the technical field of non-dust cloth and particularly relates to a method for producing the non-dust cloth. The non-dust cloth is produced by waving 100 percent synthetic fiber used as a raw material into gray cloth, and processing the gray cloth by the steps of washing and refining, drying and setting, tailoring and edge sealing, wherein the washing and refining procedure mainly comprises the following steps of: placing the gray cloth in a washing cylinder and injecting EDI (Eiecterodionization) water; heating the EDI water, then adding an elastic texture refining agent, soaking and then draining the EDI water; injecting the EDI water, cleaning the gray cloth and then draining the EDI water; injecting the EDI water, heating, adding caustic soda, soaking and draining the EDI water; injecting the EDI water, cleaning the gray cloth and then draining the EDI water; injecting the EDI water, adding acetic acid, soaking and draining the EDI water; injecting the EDI water, cleaning the gray cloth and then draining the EDI water; and finishing the washing and refining procedure. By using the invention, the production procedure and the production time are reduced, the production cost is reduced and the produced non-dust cloth has high cleanness, strong dust adsorption capability and favorable antistatic effect.

Owner:东莞市中港净化用品科技有限公司

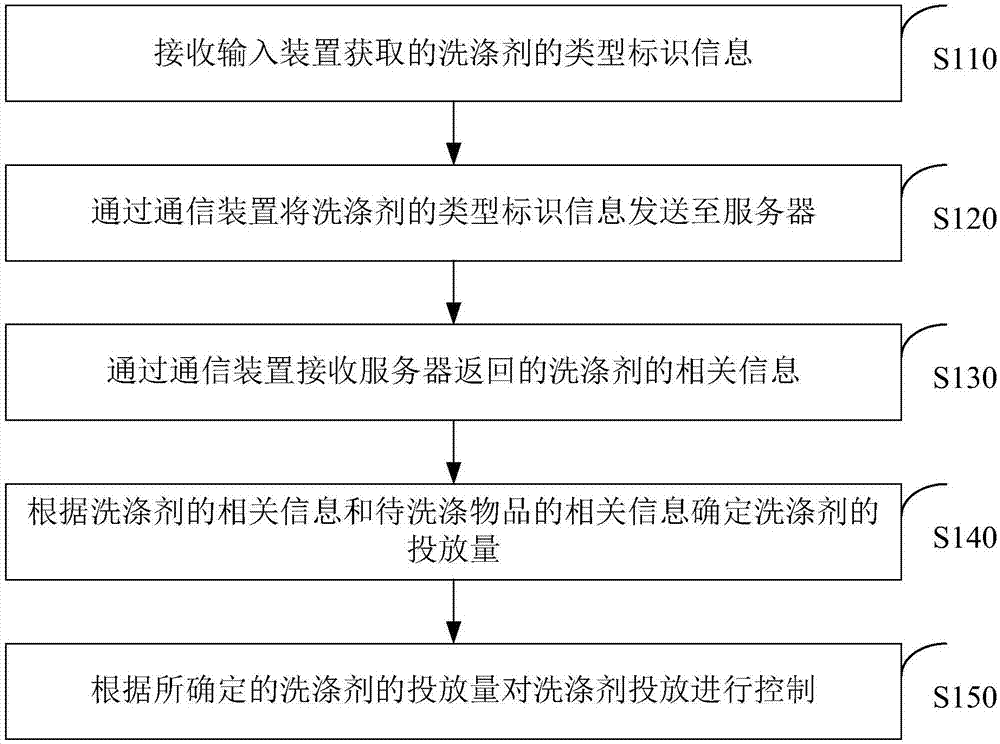

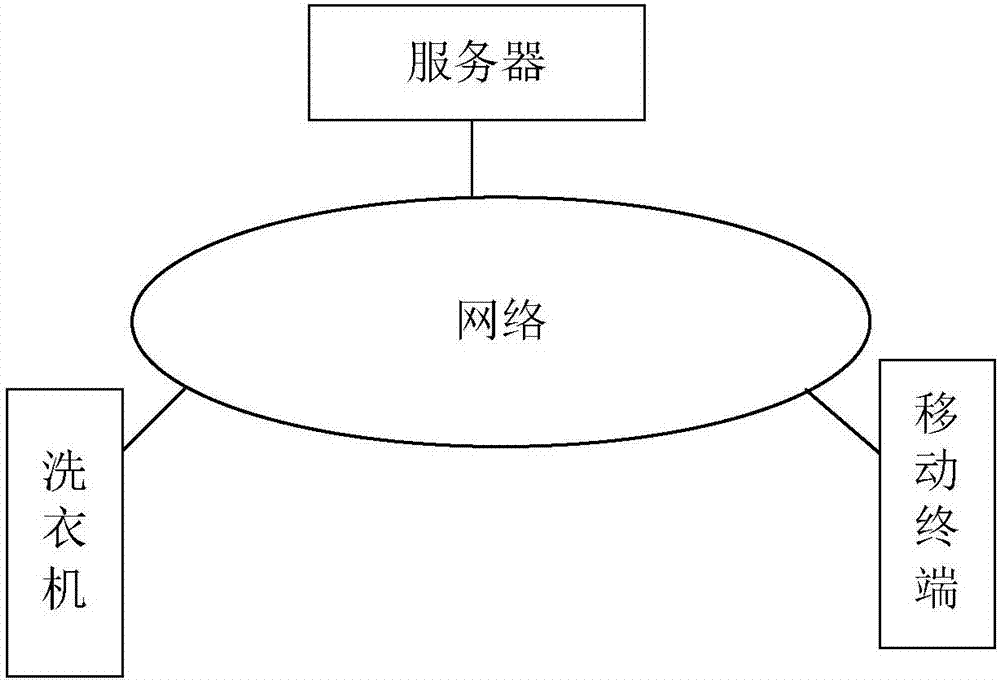

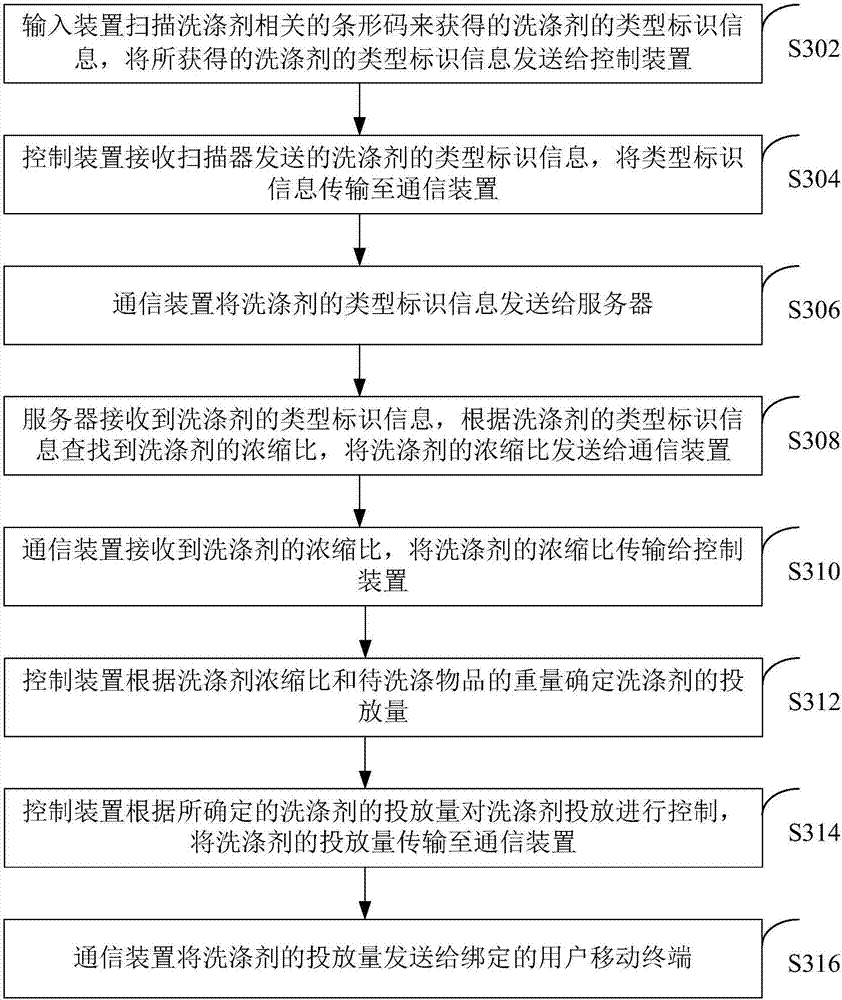

Scouring agent putting control method and device and washing equipment

InactiveCN106988076AOther washing machinesControl devices for washing apparatusComputer scienceCommunication device

Owner:WUXI FILIN ELECTRONICS CO LTD

Enzyme oxidation pre-processing technology for hemp fabric

ActiveCN101892583AEfficient degradationIncreased oxidative decompositionBiochemical fibre treatmentBleaching apparatusGramWastewater

The invention discloses enzyme oxidation pre-processing technology for hemp fabric. The enzyme oxidation pre-processing technology which is used for processing the hemp fabric after desizing and singeing and before mercerizing and dyeing comprises the steps of enzyme padding, rolling stack and scouring, wherein one liter of the enzyme solution for the enzyme padding process is prepared from 4 grams scouring agent xc-j, 20 grams of hemp scouring agent, 30 grams of 27.5 percent H2O2 and 6 to 8 grams of KDN scouring enzyme with pH value of between 8.7 and 9.7 at the temperature of between 55 and 60 DEG C according to a formula; and one liter of the scouring solution for the scouring process is prepared from 20 grams of hemp scouring agent, 20 grams of bleaching agent and 30 grams of 27.5 percent H2O2. The technology has the advantages of short process, mild condition, low cost of raw materials, low COD and AOX value in wastewater, environmental friendliness and capability of efficiently removing various impurities and commensals on the hemp fabric by combining a bio-enzyme catalysis process and an oxidation bleaching process and obtaining high-quality pre-processed surface fabric to create good conditions for the subsequent dyeing and finishing process.

Owner:HEBEI NINGFANG GRP

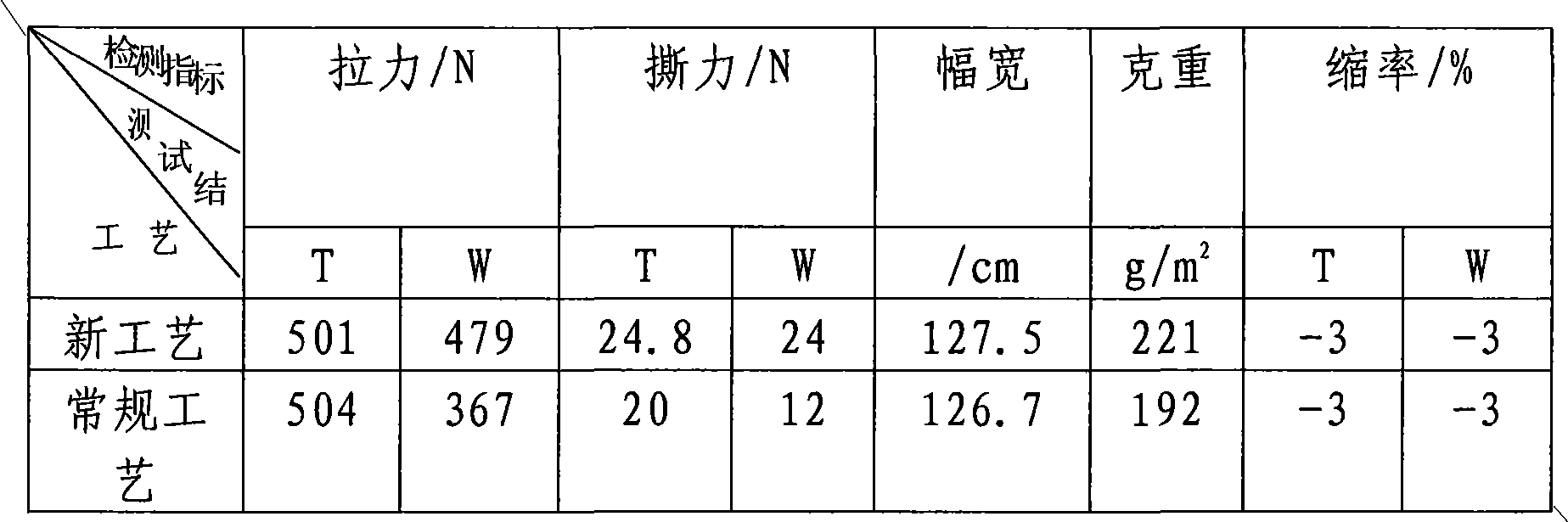

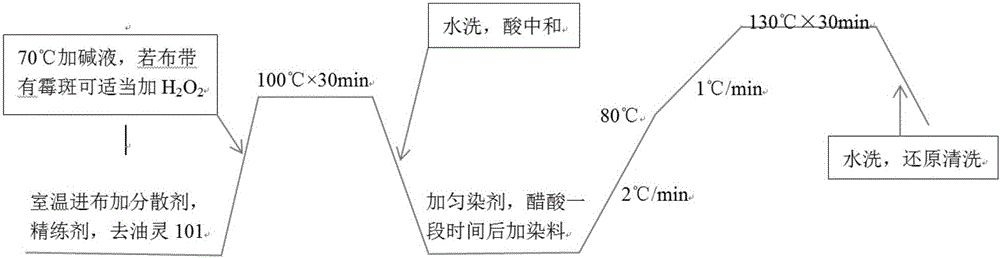

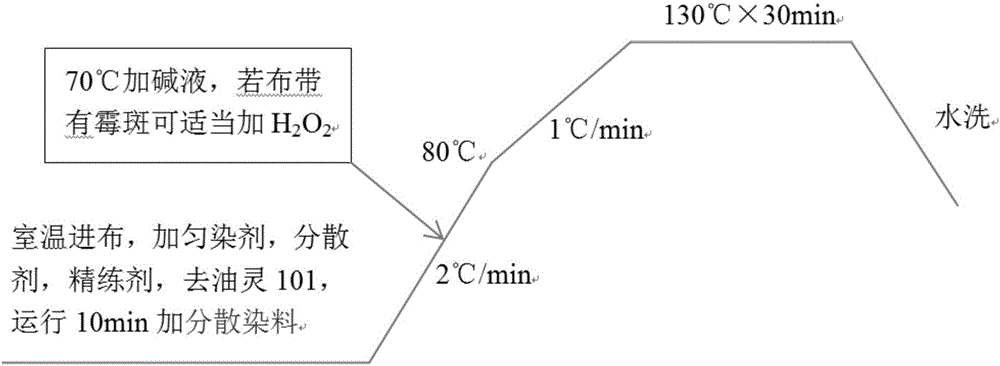

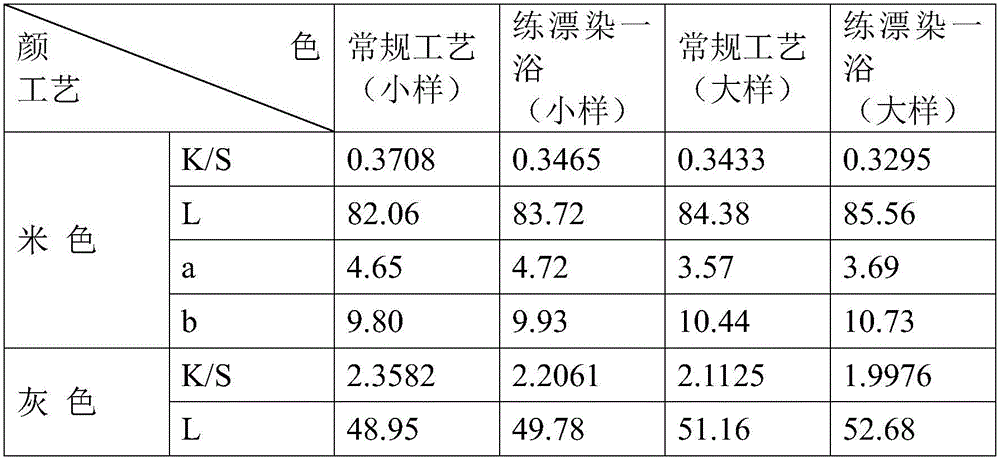

Scouring, bleaching and dyeing process for polyester fabric

The invention discloses a scouring, bleaching and dyeing process for polyester fabric. The scouring, bleaching and dyeing process comprises the following steps: 1) addition of additives: an alkaline leveling agent, a dispersing agent, a scouring agent, an deoil agent and a dyeing accelerant are added to a bath solution after fabric feeding at the room temperature; 2) addition of a disperse dye: operation is performed for 5-15 min after addition of the additives, and then the disperse dye is added; 3) heating and addition of alkaline liquor: heating is performed gradually after the disperse dye is added, the alkaline liquor is added when the temperature reaches 70 DEG C, and H2O2 is required to be added if the fabric has mildew stains; 4) temperature increasing: the temperature is increased gradually to 130 DEG C; 5) temperature keeping: the temperature is kept at 130 DEG C for 20-40 min; 6) temperature reduction and washing. According to consideration of energy saving, emission reduction, improvement of product quality and increase of production efficiency, the polyester home fabric is dyed with a disperse dye alkaline bath, the process procedure can be shortened, energy saving and emission reduction can be realized, further, problems caused by spinning oil, a sizing agent and oligomers can be solved, and the product quality can be improved.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

Enzyme scouring agent for linen fibers

ActiveCN103469600AImprove the effect of impurity removalReduce usageBiochemical fibre treatmentVegetal fibresFiberPectinase

The invention discloses an enzyme scouring agent for linen fibers. The enzyme scouring agent contains 2%-3% by volume of pectinase, 2%-4% by volume of glucanase, 2%-3% by volume of cellulose, as well as a 4-5g / L surfactant scouring agent and a 2-3g / L chelating agent, wherein a bath ratio is 1:30. The linen fibers are scoured by compound enzyme, so that the effect of removing impurities of pectin and lignin is very good; besides, the surfactant scouring agent and the chelating agent are added, thereby further reinforcing the impurity removing effect of the compound enzyme and effectively reducing the use amount of the compound enzyme; in addition, the scoured linen fibers achieve a degumming degree of 20%-23% and have a good handfeel, excellent whiteness and a fine capillary effect.

Owner:山东信开源科技创新发展有限责任公司

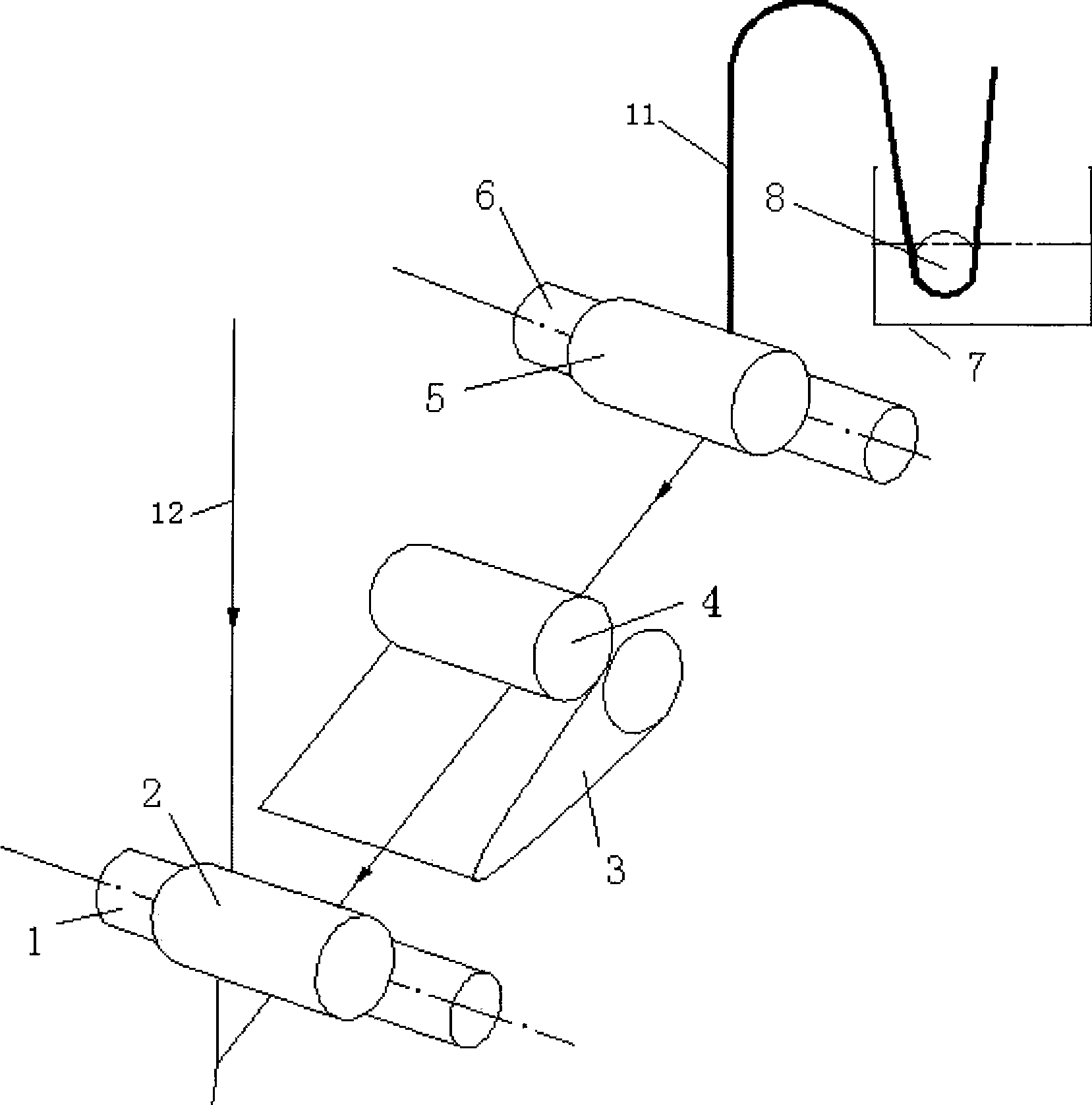

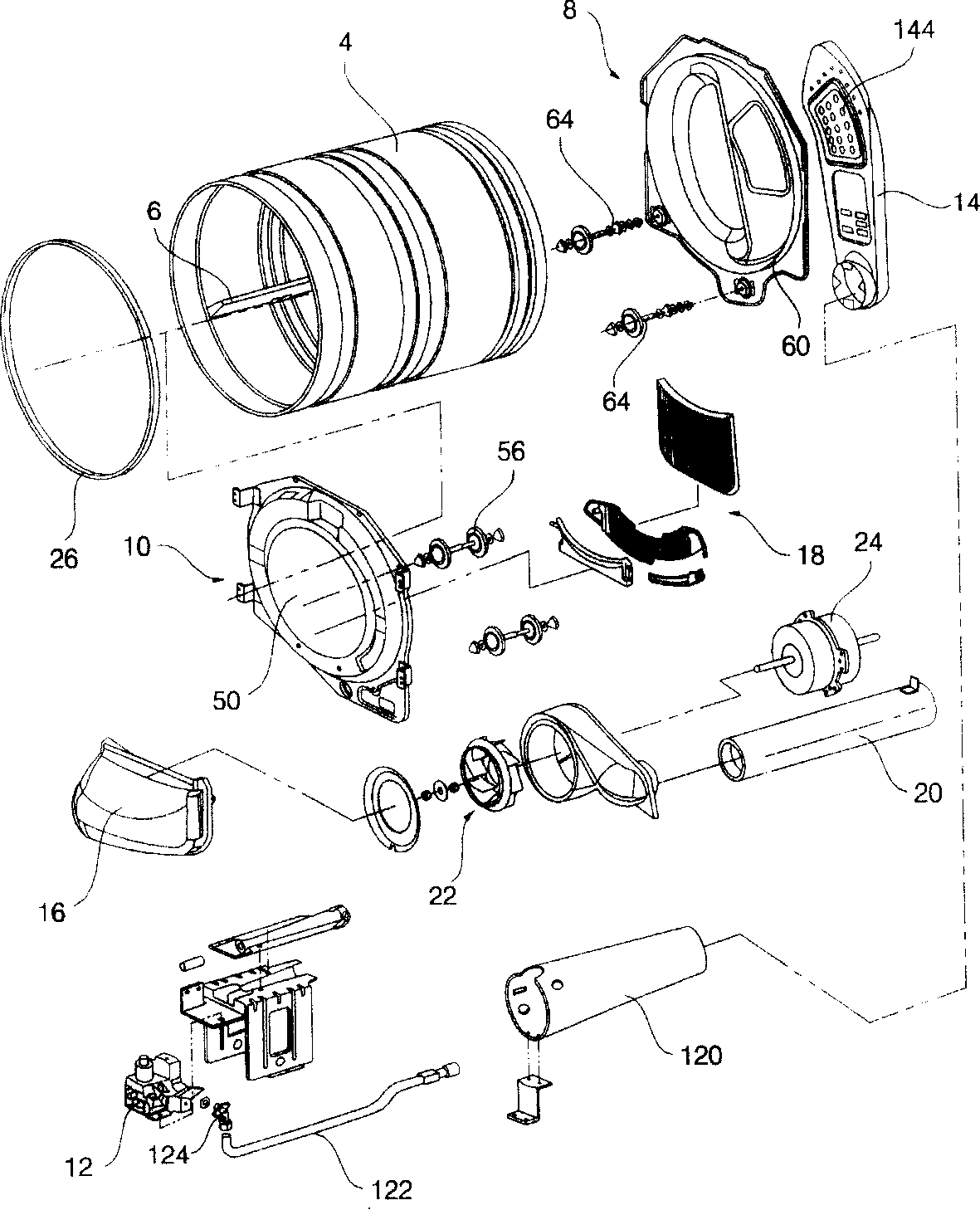

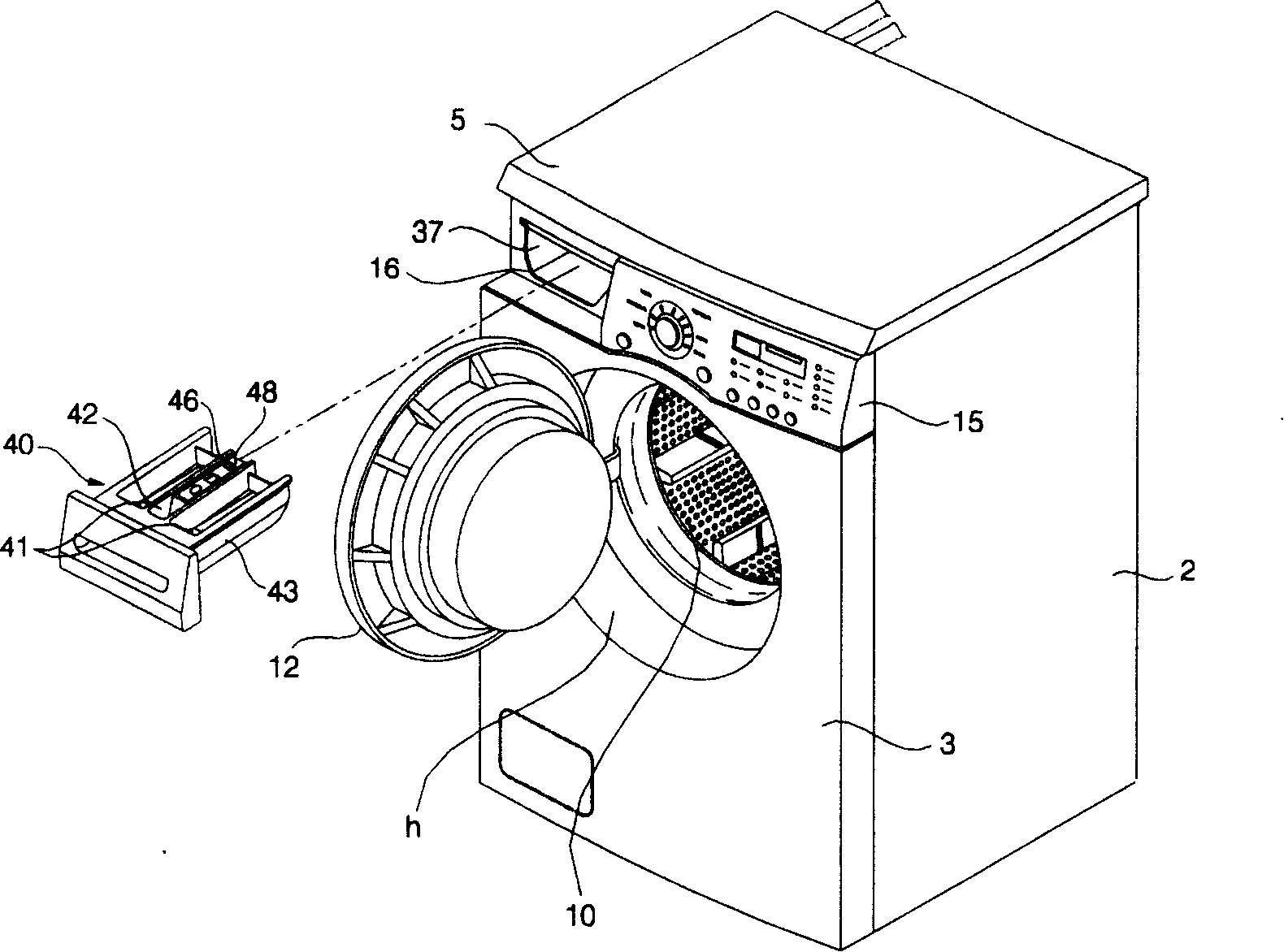

Scouring agent feeding apparatus of rotating drum washing machine

InactiveCN101177895AAvoid accidental disengagementPrevent disengagementOther washing machinesTextiles and paperEngineeringDistributor

The invention discloses a detergent supplying device of a roller washing machine, comprising a detergent cylinder setting part that is communicated with the inner part of a detergent cylinder opening on the upper part of the washing machine, a detergent cylinder accommodated inside the detergent cylinder setting part by the way of drawing through the detergent cylinder opening and a hanging device, integratedly formed on the upper part detergent cylinder with the structure that the detergent cylinder is drawn out, preventing from being completely drawn out, that can be hanged on the detergent cylinder setting part. The beneficial effects are that: hitching steps that are hitched with the bulge of a distributor and an elastic part at the lower side of the hitching steps are formed integratedly on the detergent cylinder, not only preventing the detergent cylinder cover from dropping, but also preventing the detergent cylinder from dropping accidentally. In addition, hitching steps without the elastic part can also be formed on the top surface of the detergent cylinder, which can prevent the complete detachment of the detergent cylinder and the washing machine for a public commercial washing machine.

Owner:NANJING LG PANDA APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com