Enzyme oxidation pre-processing technology for hemp fabric

A fabric and hemp technology, applied in the field of dyeing and finishing pre-treatment process, can solve the problems of long process, large consumption, high production cost, etc., and achieve the effects of strong penetration, increased oxidation and decomposition, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

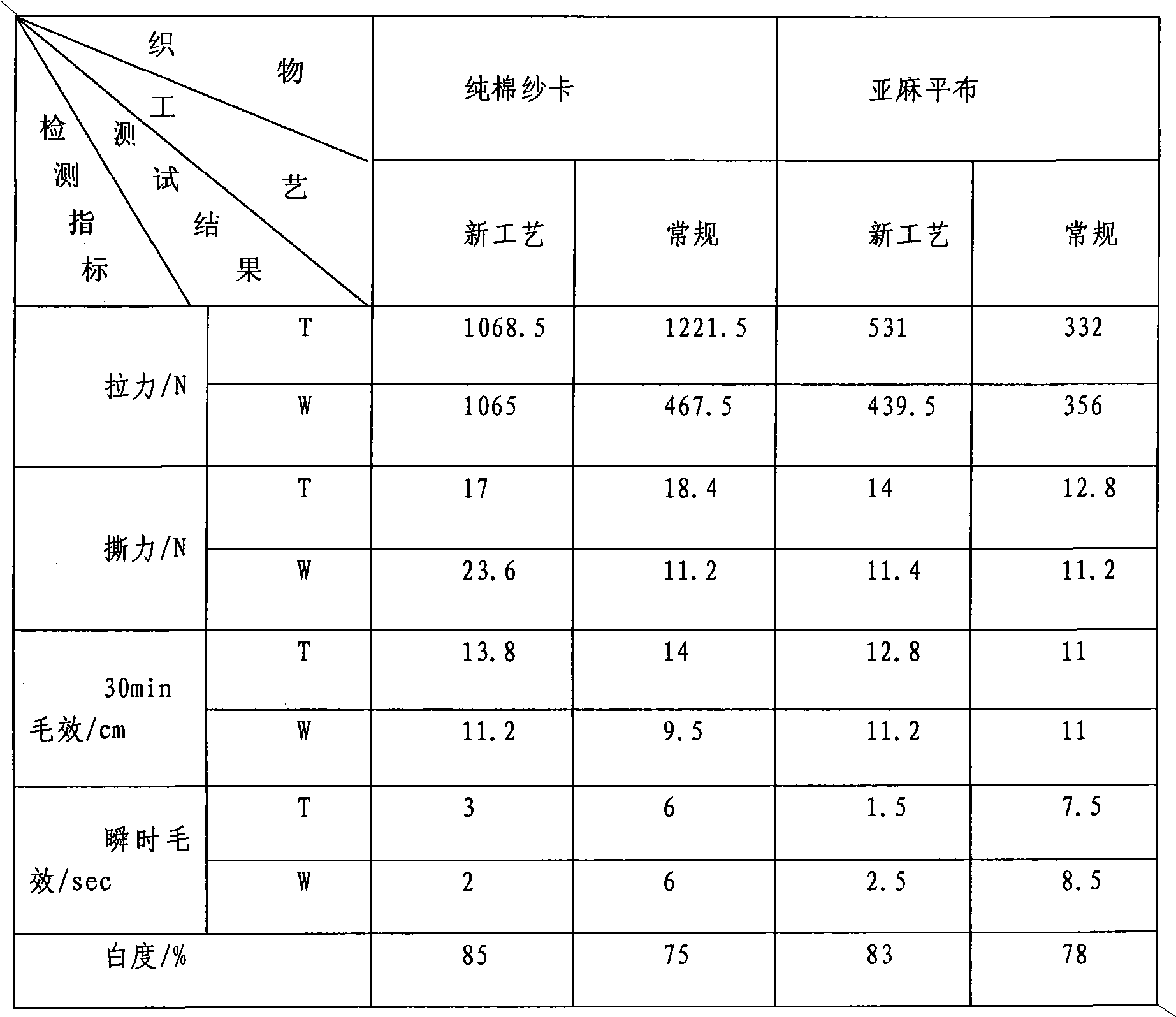

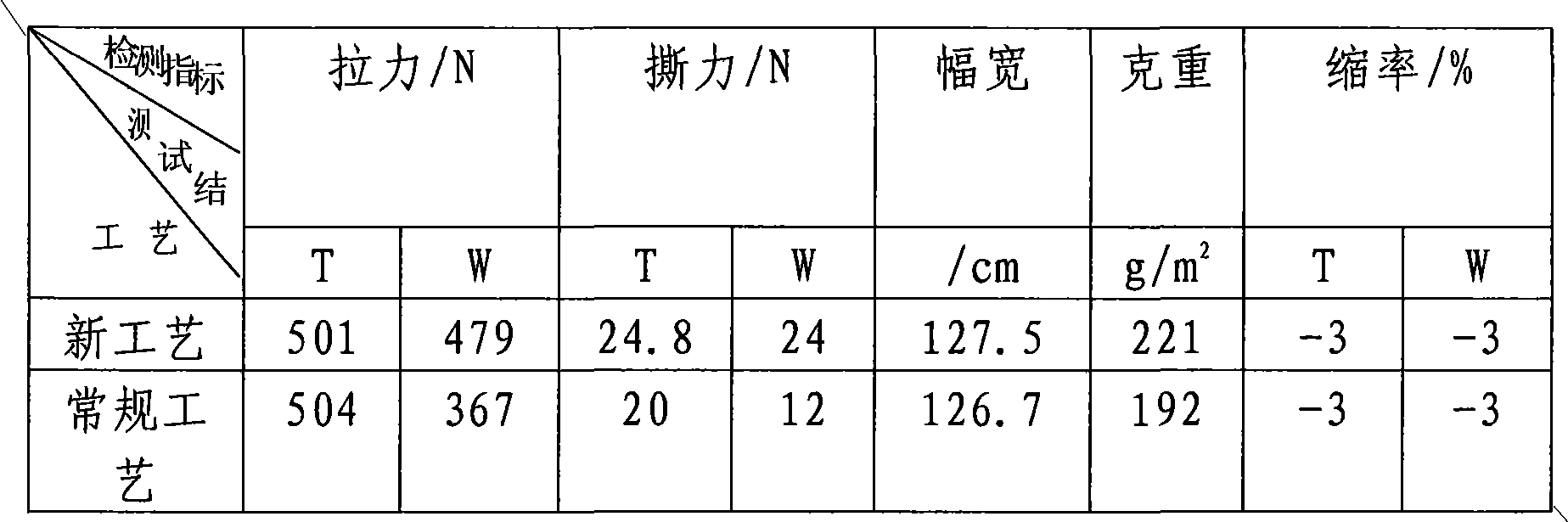

Examples

Embodiment

[0032] An enzymatic oxygen pretreatment process for hemp fabrics, which is used for the treatment of hemp fabrics after desizing and singeing, and before mercerizing dyeing.

[0033] The formula of the enzyme liquid of the rolling enzyme process is: scouring agent xc-j: 4g / L, numbing agent: 20g / L, 27.5% H 2 o 2 : 30g / L, KDN scouring enzyme: 6~8g / L, PH: 8.7~9.7, temperature: 55~60℃;

[0034] The scouring and bleaching liquid formula of the scouring and bleaching process is: scouring and bleaching agent: 20g / L, whitening agent: 20g / L, 27.5% H 2 o 2 : 30g / L.

[0035] The configuration method of the enzyme liquid in the enzyme rolling process is as follows: firstly, the water in the batching tank is heated to 40-50°C, firstly add 4g / l refining agent xc-j, then add 20g / l numbing agent, and finally add 6~8g / L KDN scouring enzyme.

[0036] Wherein, the residual rate of the enzyme solution in the enzyme rolling process is 80-90%.

[0037] The hemp fabric after rolling is tightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com