Wallpaper water-based paint, preparation method thereof and wallpaper

A technology of water-based paint and wallpaper, applied in the direction of coating, etc., can solve the problem of lack of purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

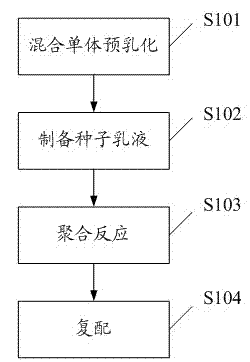

Method used

Image

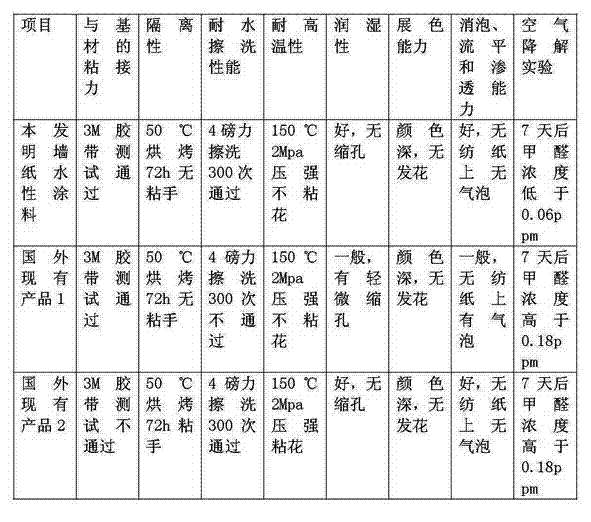

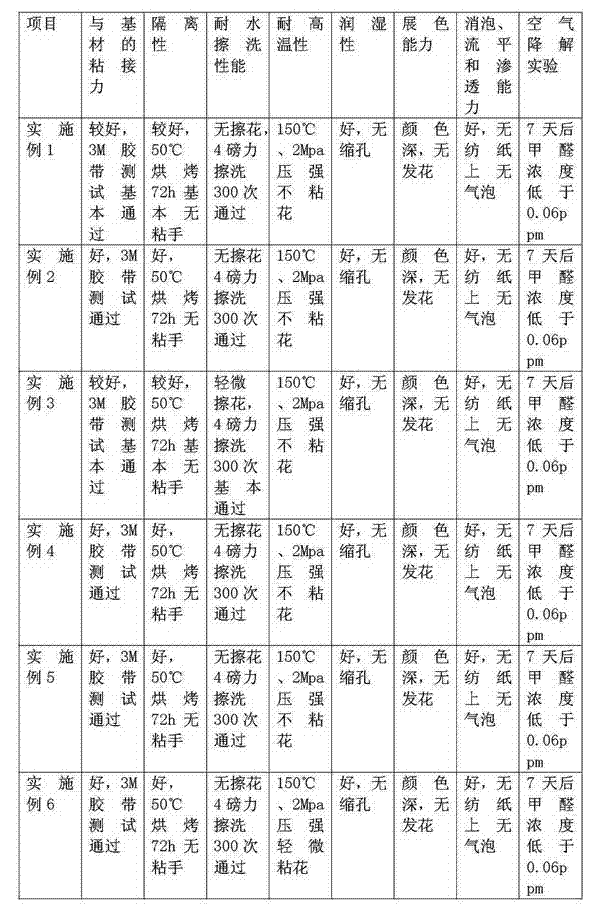

Examples

preparation example Construction

[0095] Wherein, the photocatalyst is a titanium dioxide nano photocatalyst, and the titanium dioxide nano photocatalyst is preferably prepared by the following preparation method, the preparation method comprising: mixing butyl titanate and absolute ethanol into liquid a, the titanic acid The volume ratio of butyl ester and absolute ethanol is 1:3 to 1:2. The doped ionic elements, glacial acetic acid, double distilled water and absolute ethanol are mixed into liquid b. The doped ionic elements, glacial acetic acid, The molar ratio of double-distilled water and absolute ethanol is 0.02-0.1:1-2:1-4:20-40, wherein the doped ionic elements include Fe 3+ , V 5+ ; Stir the solution a vigorously, and drop it into the solution b drop by drop, continue to stir vigorously for 15-45 min after the addition is completed; let it stand at room temperature and put it in a drying oven to dry it into a solid; grind the solid , and then enter the furnace for calcination at 900° C. for 1-3 hours...

Embodiment 1

[0137] 1. Formula:

[0138] Styrene: 4wt%, Butyl Acrylate: 5wt%, Methyl Methacrylate: 9wt%, 2-Hydroxyethyl Methacrylate: 1wt%, Acrylic Acid: 1wt%, Diacetone Acrylamide: 1wt%, Acrylamide : 0.5wt%, emulsifier (made from sodium methacrylate hydroxypropylsulfonate: 0.5wt%, Tween T-60: 0.5wt%, 2-acrylamido-2-methyl-propylsulfonic acid: 0.5wt % composition), initiator (potassium persulfate): 0.1 wt%, pH regulator (ammonia): 1.0 wt%, reducing agent (acetylphenylhydrazine): 0.5wt%, buffer (sodium bicarbonate ): 0.25wt%, wetting agent (104E, product of Gas Chemical Company): 0.5wt%, water-based defoamer (DC-65, product of Dow Corning Company): 0.2 wt%, water-based preservative (MB-16, Haiming Product of Adams Company): 0.10 wt%, water-based thickener (RHEOLATE 278, product of Elementis Company): 0.2 wt%, photocatalyst (self-made): 1 wt% and the balance of water.

[0139] 2. Preparation process:

[0140] A. Pre-emulsification of mixed monomers: 4wt% styrene, 5wt% butyl acrylate, 9wt%...

Embodiment 2

[0146] 1. Formula:

[0147] Styrene: 4wt%, isooctyl acrylate: 5wt%, methyl methacrylate: 9wt%, 2-hydroxyethyl methacrylate: 1wt%, acrylic acid: 1.5wt%, diacetone acrylamide: 1wt%, N-methylolacrylamide: 0.5wt%, emulsifier (made from sodium methacrylate hydroxypropanesulfonate: 0.5wt%, Tween T-60: 0.5wt%, 2-acrylamido-2-methyl- Propyl sulfonic acid: 0.5wt% composition), initiator (potassium persulfate): 0.1 wt%, pH regulator (ammonia): 1.5 wt%, reducing agent (acetylphenylhydrazine): 0.5wt%, buffer ( Sodium bicarbonate): 0.25wt%, wetting agent (OT-75, product of Cytec): 0.5wt%, water-based defoamer (DC-65, product of Dow Corning): 0.2 wt%, water-based preservative (MB-16, product of Elementis Corporation): 0.10 wt%, water-based thickener (RHEOLATE 212, product of Elementis Corporation): 0.5 wt%, photocatalyst (self-made): 1 wt% and the balance water.

[0148] 2. Preparation process:

[0149] A. Pre-emulsification of mixed monomers: 4wt% styrene, 5wt% isooctyl acrylate, 9wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com