Patents

Literature

111results about How to "Good surface morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

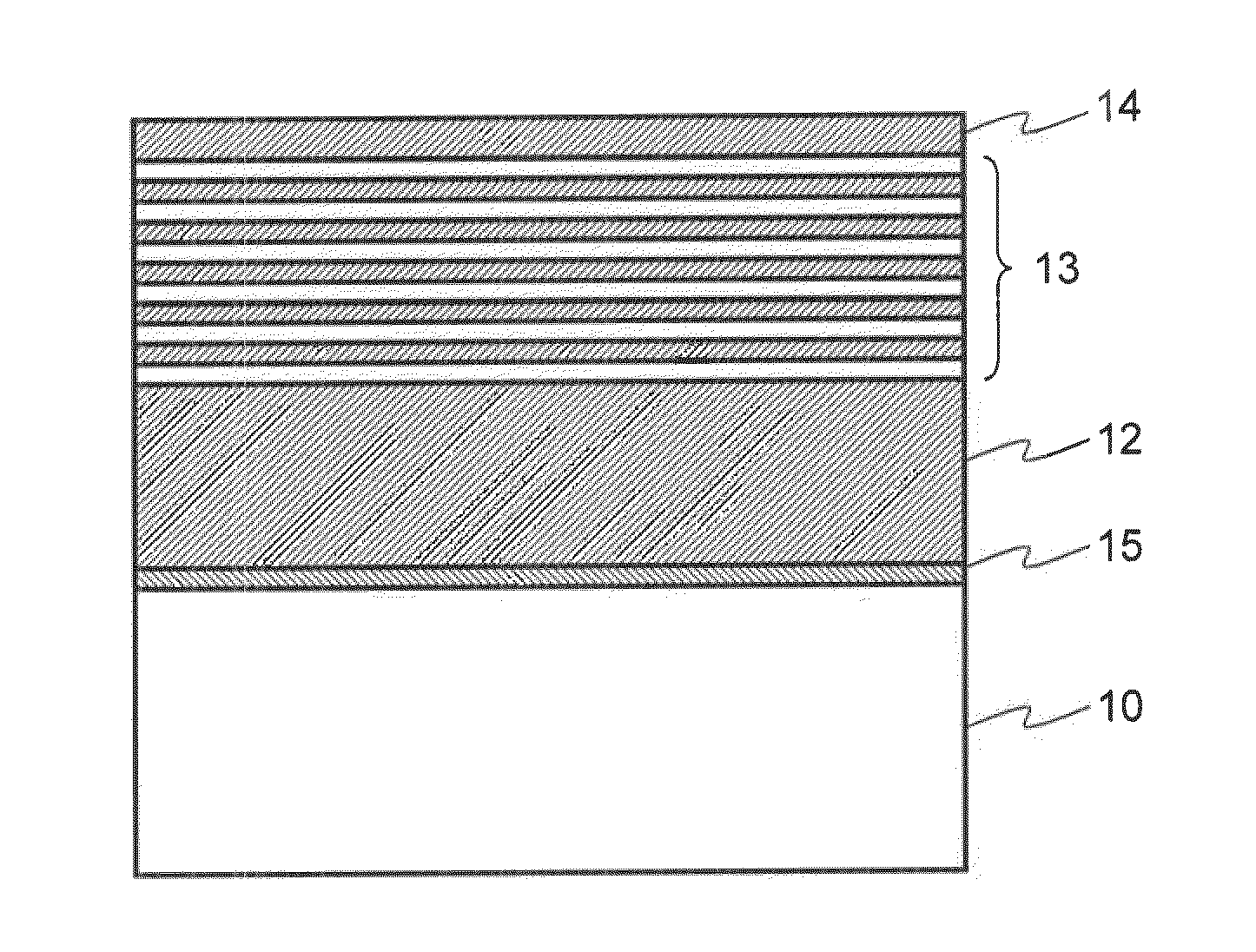

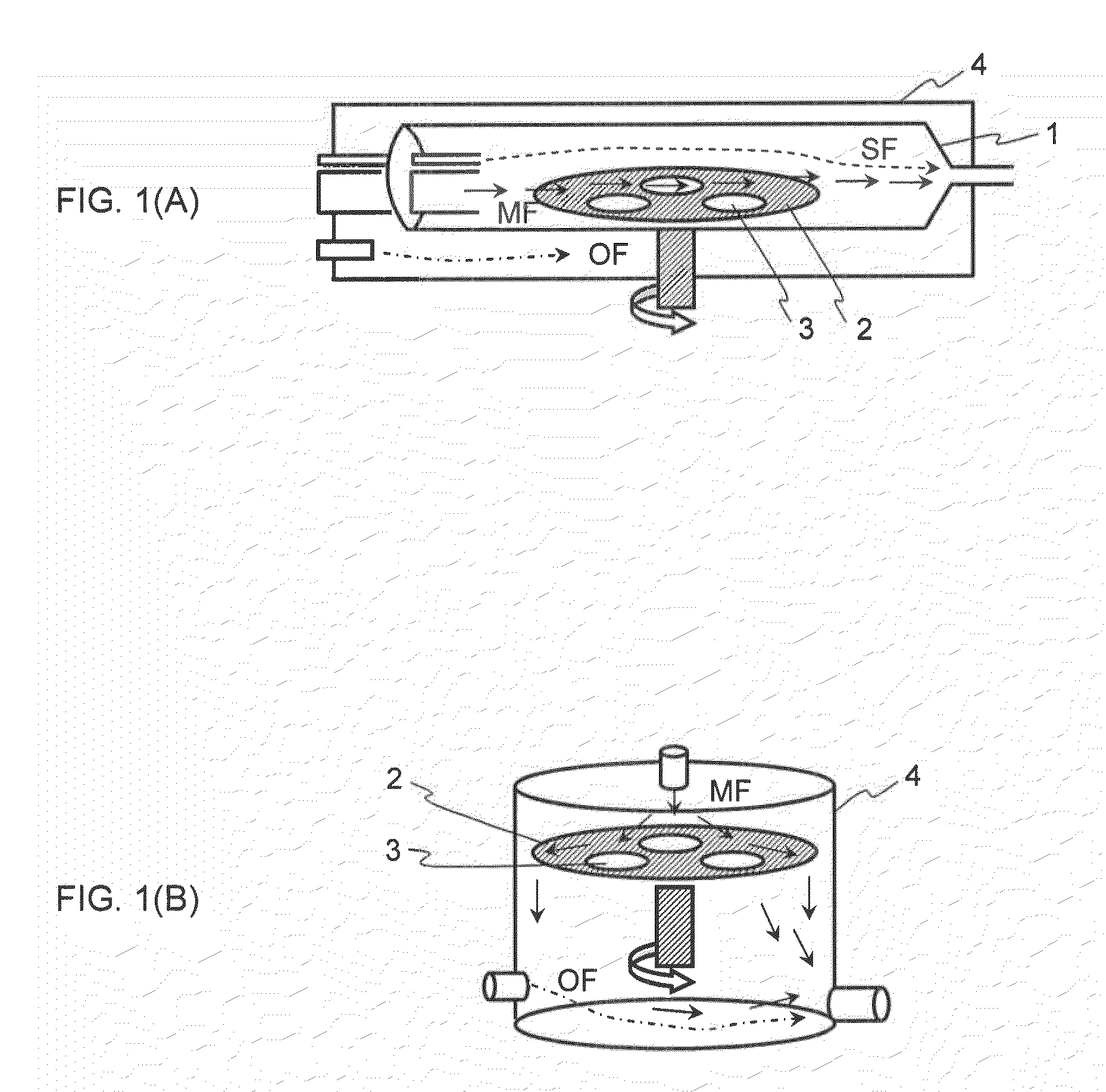

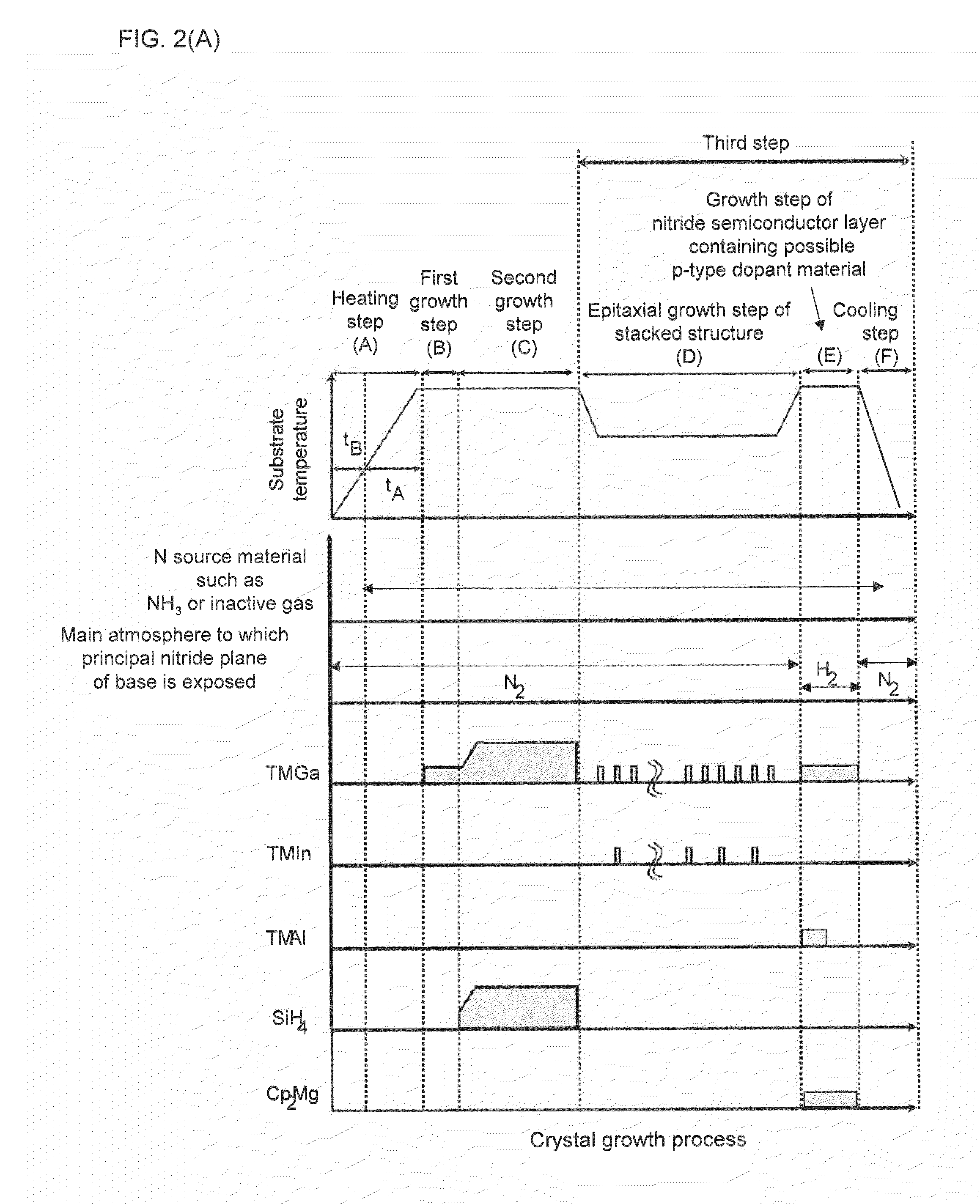

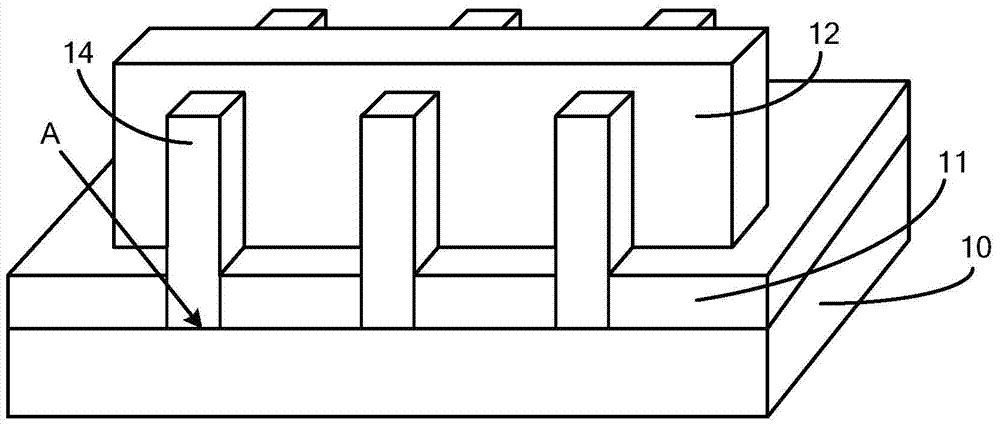

Nitride semiconductor, nitride semiconductor crystal growth method, and nitride semiconductor light emitting element

ActiveUS20100244087A1Improve flatnessAvoid defectsPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenCrystal growth

During the growth of a nitride semiconductor crystal on a nonpolar face nitride substrate, such as an m-face, the gas that constitutes the main flow in the process of heating up to a relatively high temperature range, before growth of the nitride semiconductor layer, (the atmosphere to which the main nitride face of the substrate is exposed) and the gas that constitutes the main flow until growth of first and second nitride semiconductor layers is completed (the atmosphere to which the main nitride face of the substrate is exposed) are primarily those that will not have an etching effect on the nitride, while no Si source is supplied at the beginning of growth of the nitride semiconductor layer. Therefore, nitrogen atoms are not desorbed from near the nitride surface of the epitaxial substrate, thus suppressing the introduction of defects into the epitaxial film. This also makes epitaxial growth possible with a surface morphology of excellent flatness.

Owner:MITSUBISHI CHEM CORP

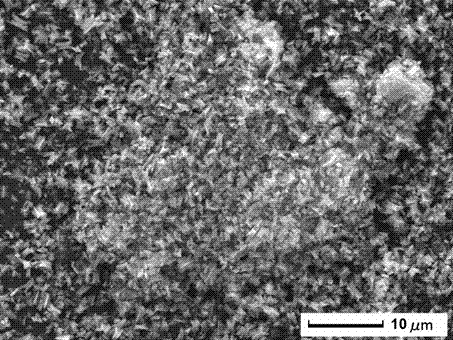

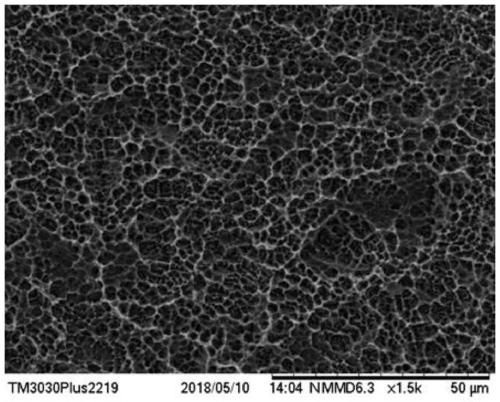

Surface processing technology for dental implant

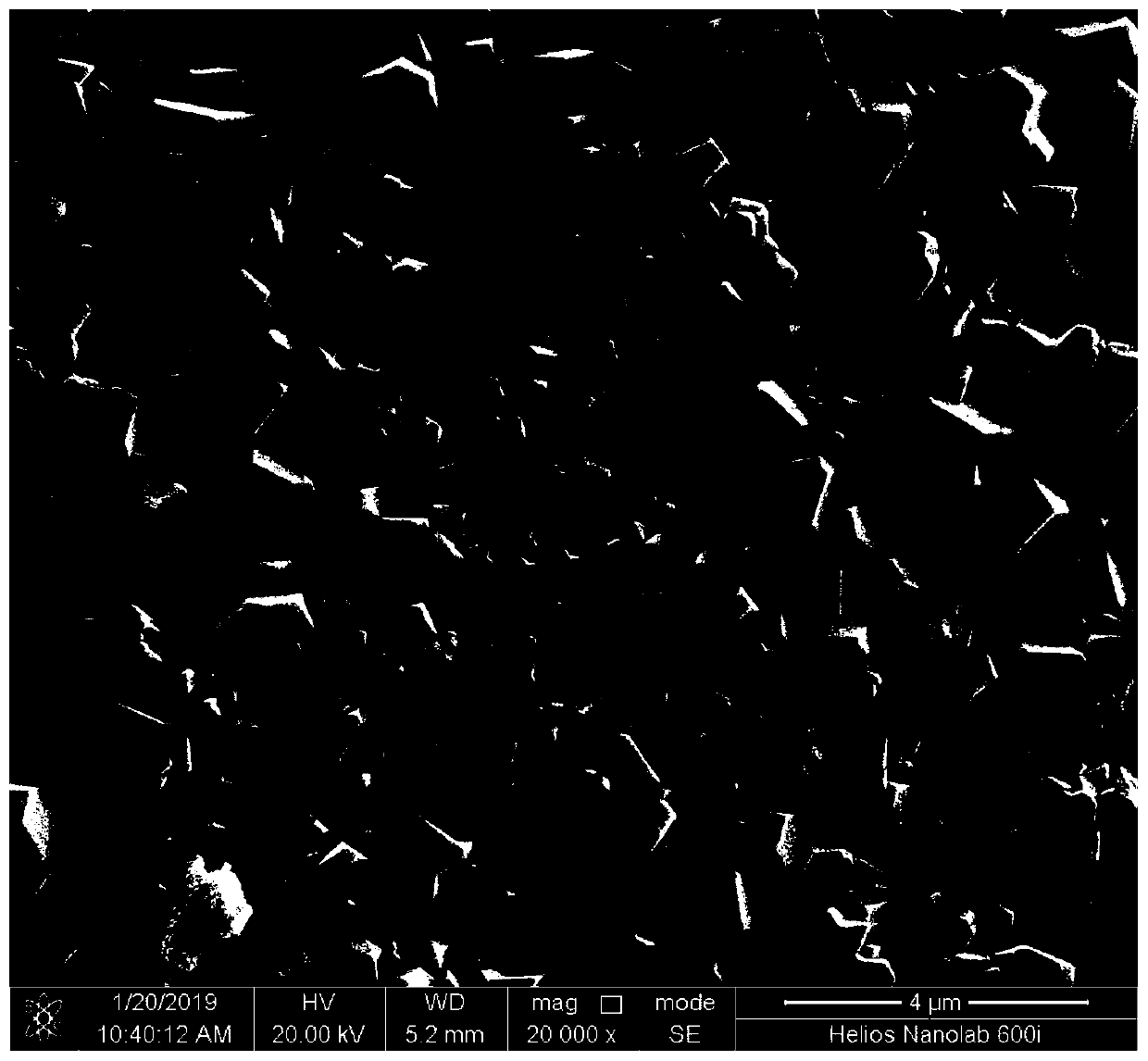

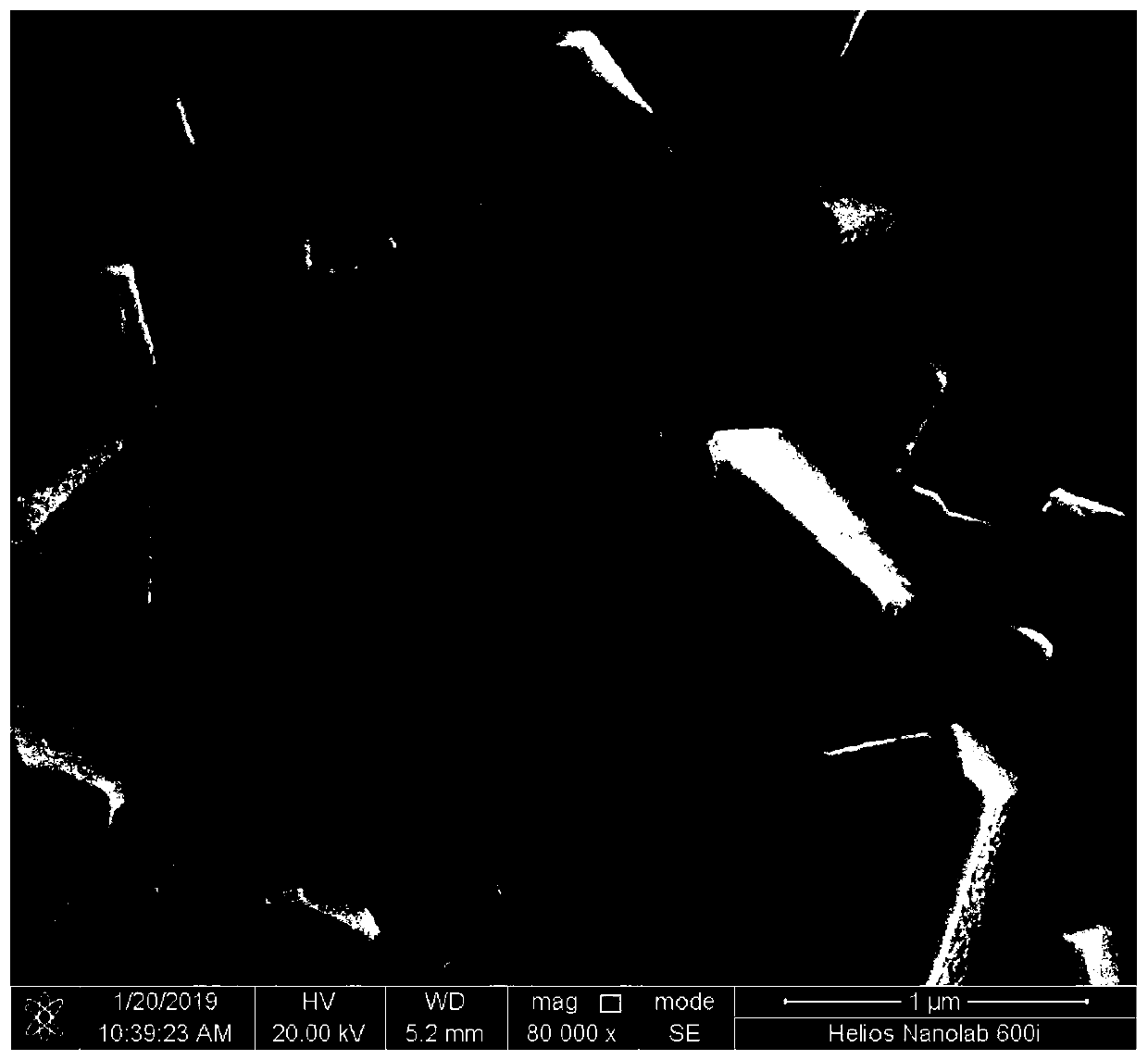

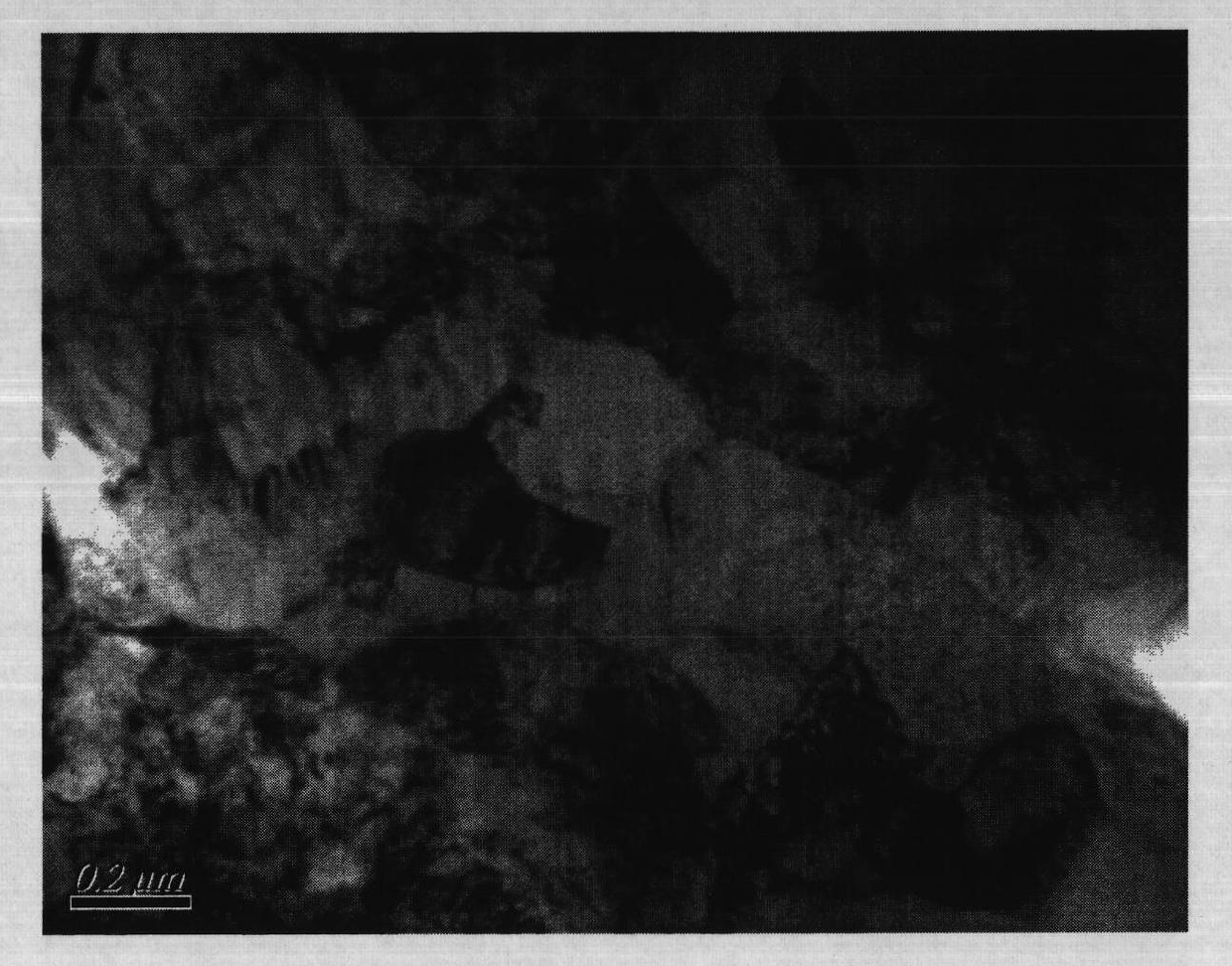

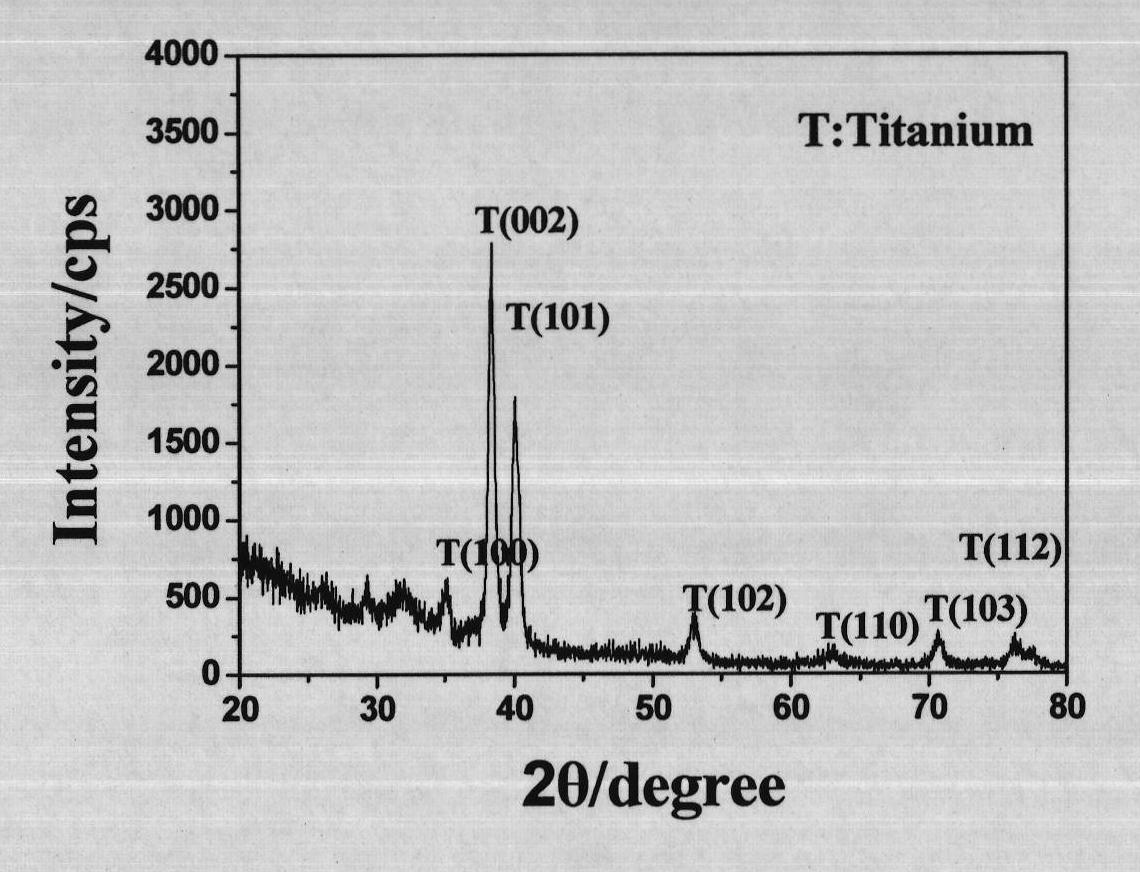

InactiveCN102232876AGood surface morphologyGood rough surfaceArtificial teethCleaning using liquidsAcid etchingTitanium

The invention discloses a surface processing technology for a pure-titanium dental implant. The technology comprises the following steps: A, removing oil from the dental implant by ultrasonic cleaning; B, sandblasting the dental implant by white corundum to make the surface of the implant to be uniform gray in color and allow a three-dimensional porous structure to be formed on the surface of the dental implant; C, carrying out acid etching on the surface of the sandblasted dental implant with a mixed liquid with a certain concentration and a certain ratio of sulfuric acid to hydrochloric acid to allow gradually decreased multilevel scallops to be formed on the surface of the dental implant; and D, flushing and neutralizing the acid etched dental implant, and removing oil. According to the surface processing technology for the dental implant designed by the invention, the multilevel porous structure with biological activity is formed on the surface of the pure-titanium implant, so the biological activity of the pure-titanium implant is improved, the stability of the implant is improved, the bone combination speed of the dental implant is accelerated, the bone interfacial combination strength of the implant is enhanced, thereby the technology has the advantages of simple and high efficient technology, and low cost.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

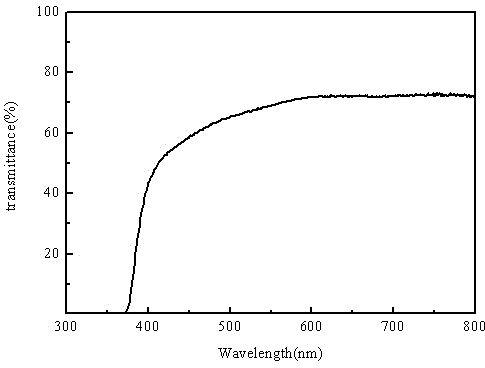

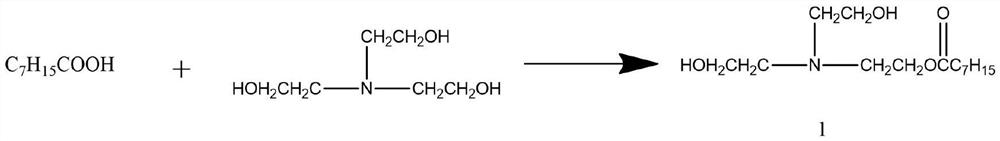

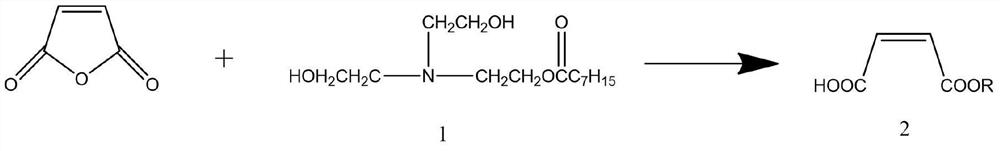

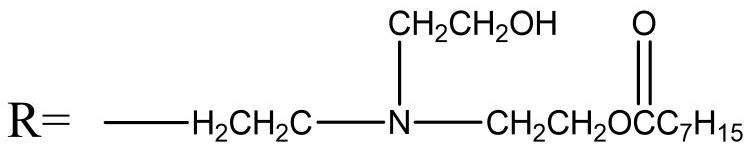

Graphene/titanate nanometer composite visible-light activated photocatalyst and preparation method thereof

InactiveCN102847529AGood surface morphologyLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationCvd graphene

The invention discloses a graphene / titanate nanometer composite visible-light activated photocatalyst and a preparation method thereof, and belongs to the fields of nanometer composite materials and photocatalysis technology. The composite photocatalyst is prepared by compounding titanate and graphene, and the preparation method comprises the following steps: reacting tetrabutyl titanate with ammonia water to obtain a titanium hydroxyl compound; performing ultrasonic dispersion of graphene oxide in water, adding nitrate, stirring, mixing with the titanium hydroxyl compound and a potassium hydroxide aqueous solution, stirring, finally transferring the mixed solution into a reaction vessel to perform a hydrothermal reaction, after the reaction, performing centrifugation, filtration, washing, and vacuum drying of the product to obtain the composite photocatalyst. Photocatalytic degradation experiments show that the graphene / titanate composite photocatalyst prepared by the method has good photocatalytic degradation effect on rhodamine B under visible light irradiation. The photocatalyst of the invention has the advantages of relatively simple operation process, controllable morphology, no requirements for other reducing agents, and good visible-light activated photocatalysis performance.

Owner:JIANGSU UNIV

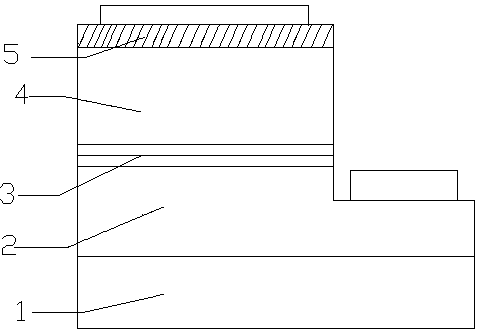

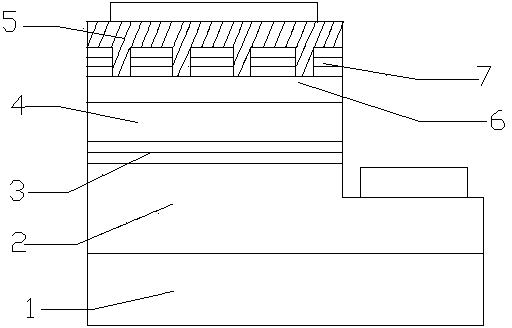

Thin film transistor and manufacture method, array substrate and display device thereof

ActiveCN103000694AGood film qualityGood surface morphologyTransistorSolid-state devicesVoltage stabilityEngineering

The invention discloses a thin film transistor and a manufacture method, an array substrate and a display device thereof. The thin film transistor, the manufacture method, the array substrate and the display device are used for improving drive voltage stability of the thin film transistor and prolonging service life of the thin film transistor. The manufacture method of the thin film transistor includes forming a picture containing a grid electrode, an active layer and a source drain electrode layer and forming a picture containing a grid electrode insulation layer and an etching barrier layer. The grid electrode insulation layer is located between the grid electrode and the active layer, the etching barrier layer is located between the active layer and the source drain electrode layer, the grid electrode insulation layer is located above the active layer, the gride electrode insulation layer is manufactured by at least two insulation layers, or the etching barrier layer is located above the active layer and is manufactured by at least two insulation layers.

Owner:BOE TECH GRP CO LTD

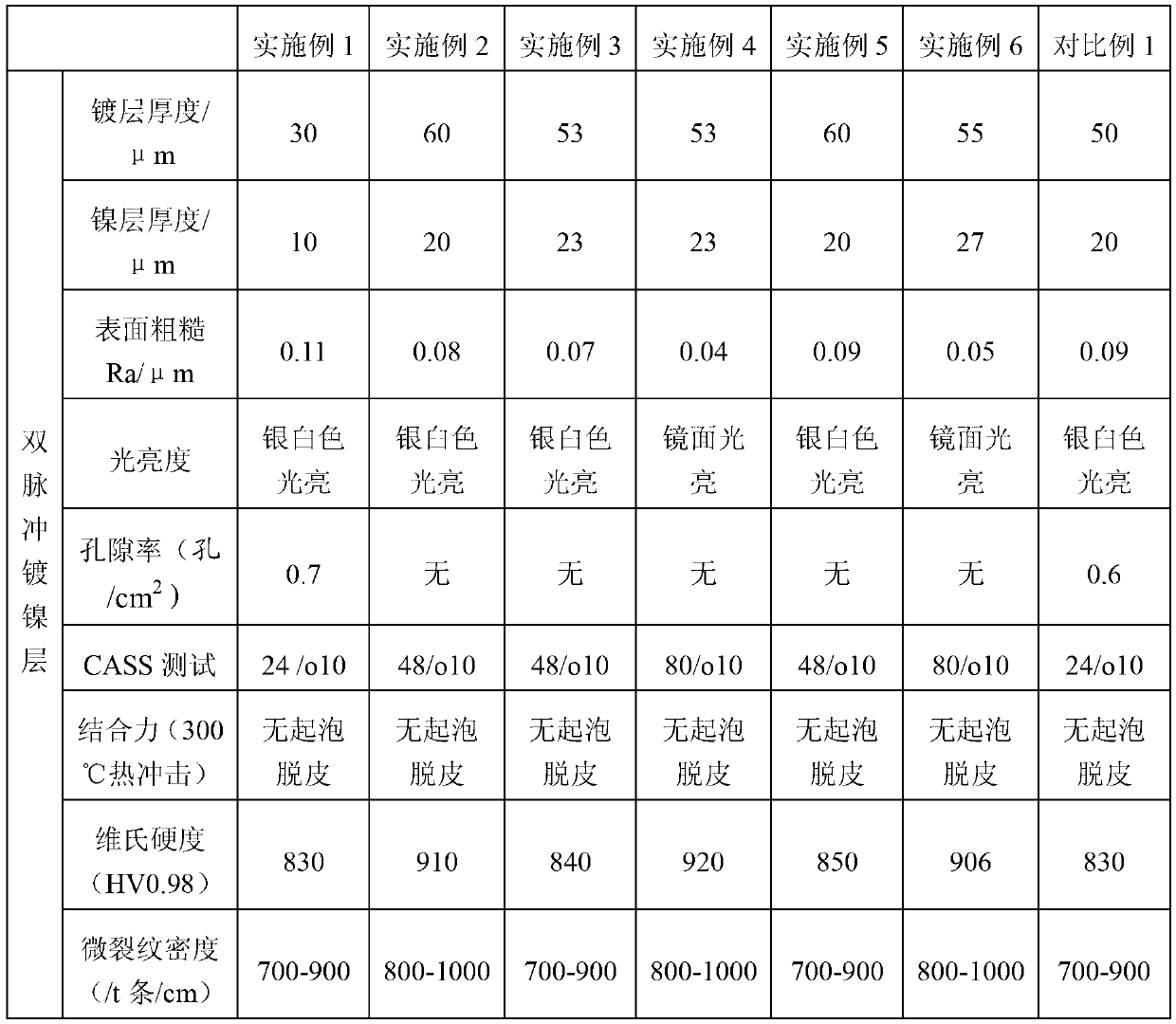

Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

The invention discloses a wear-resistant workpiece and a manufacturing method of a wear-resistant coating thereof. The preparation method of the wear-resistant coating comprises the following steps: forming a preparation piece according to the structure of a required wear-resistant workpiece; coating nickel on the surface of the preparation piece through a double-pulse method, thus forming a nickel-coated transition piece; and coating a hard chromium layer on the surface of the nickel-coated transition piece, thus forming the wear-resistant coating on the surface of the preparation piece. For the manufacturing method of the wear-resistant workpiece, a step of coating nickel on the surface of the workpiece through a double-pulse nickel coating method is added; and the double-pulse nickel coating method is characterized in that the magnitude of current or voltage is regulated by an external control means, the current is additionally controlled by controlling the pulse switch-on time, the pulse switch-off time, the pulse duty factor, the pulse current density and the like, and corresponding variables are changed to respectively achieve the effects of increasing the cathode current density, inhibiting the generation of side reaction, reducing the impurity content in the coating, improving the current distribution and the like, thus improving the quality of the coated nickel layer and prolonging the service life of the wear-resistant workpiece.

Owner:HUNAN TELI HYDRAULIC +1

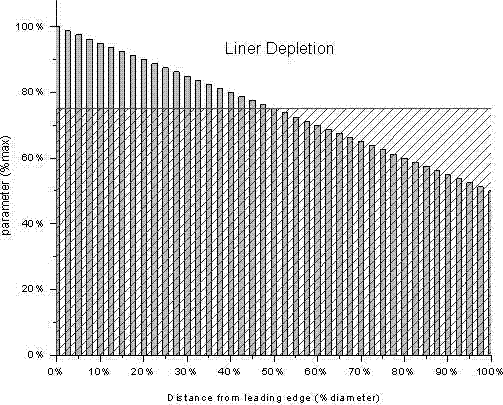

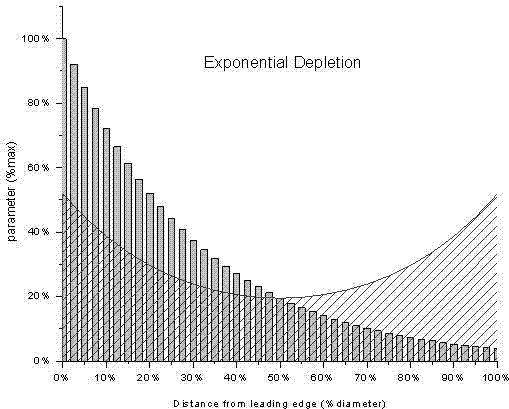

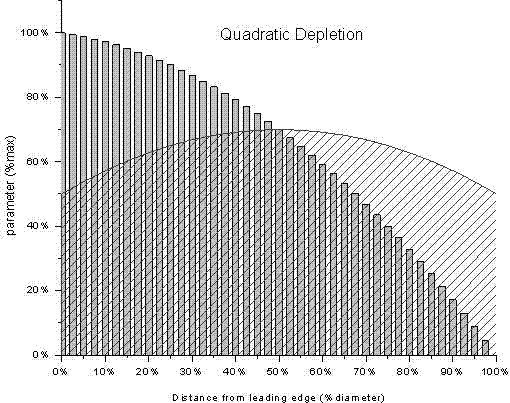

Method for increasing uniformity of on-chip n-type doping concentration of silicon carbide epitaxial wafer

ActiveCN103614779ADoping Concentration Uniformity OptimizationEnlarge selection windowPolycrystalline material growthAfter-treatment detailsSilanesGas phase

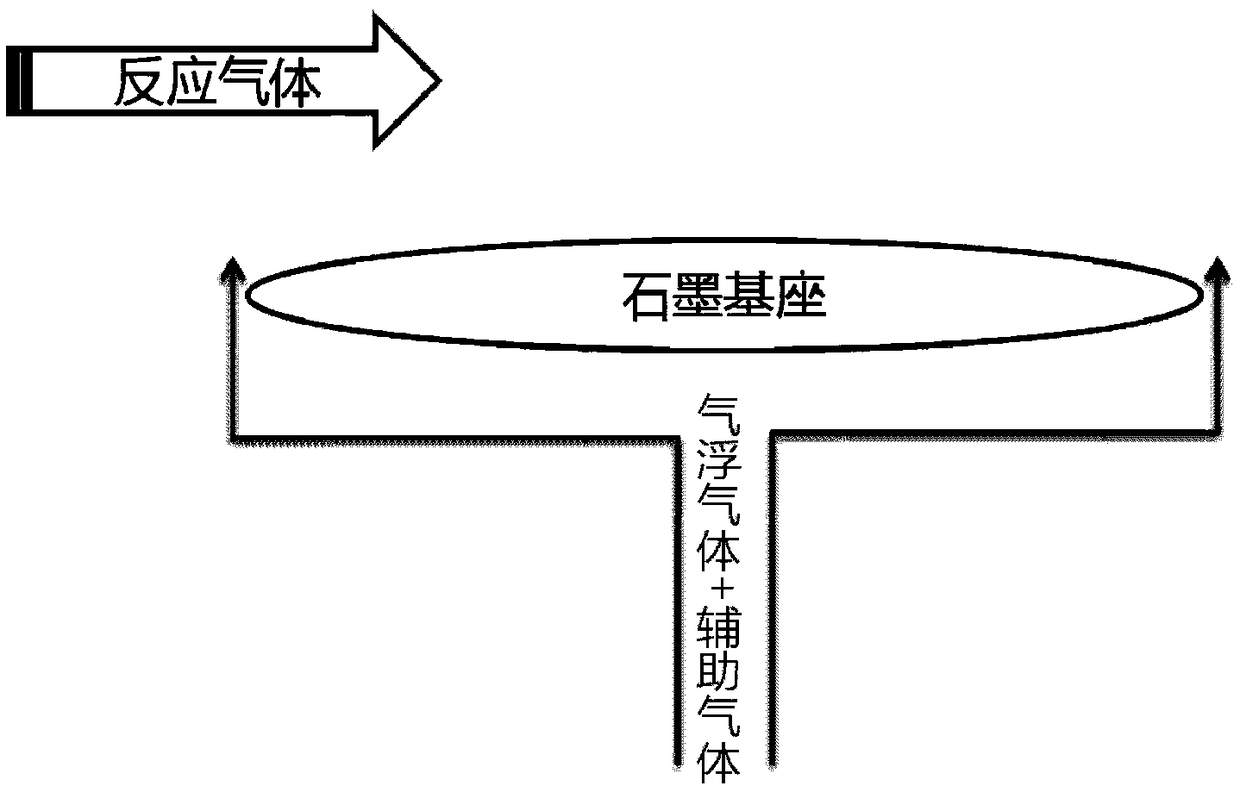

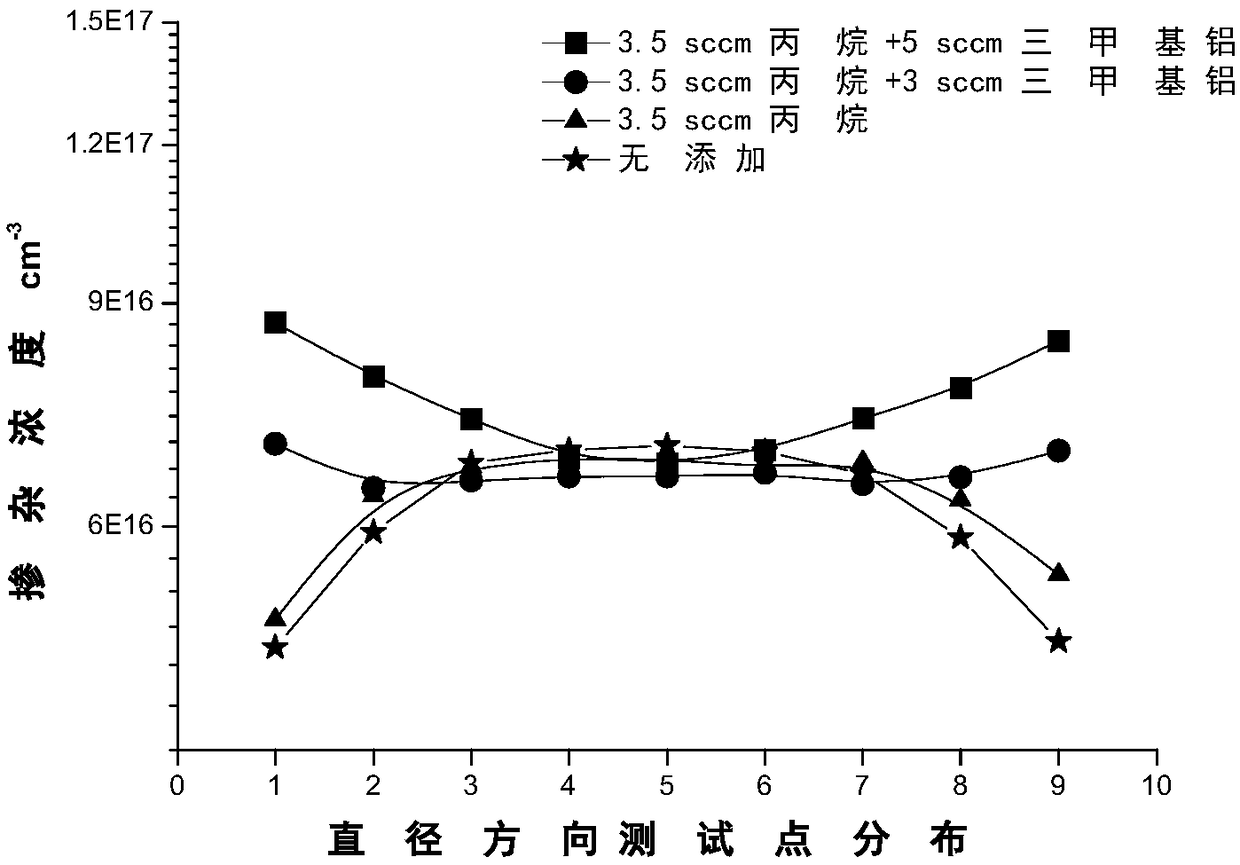

The invention relates to a method for increasing the uniformity of on-chip n-type doping concentration of a silicon carbide epitaxial wafer. According to the method, a chemical vapor deposition growth technology serves as basis; a silicon surface silicon carbide substrate with the deviation (11-20) direction of 4 degrees or 8 degrees is adopted; silane and propane serve as growth sources; hydrogen chloride serves as an auxiliary gas for inhibiting gas phase nucleation of a silicon component; hydrogen serves as a carrier gas and a diluent gas; nitrogen serves as an n-type doping agent. A small amount of process gas silane or propane is added into a base air floatation gas and is pushed by the air floatation gas serving as a carrier gas to the edge of the substrate to finely adjust the carbon silicon ratio of the edge of the substrate, so that the doping efficiency of the n-type doping source on the edge of the substrate is changed, the doping concentration deviation of the edge point and the central point of the epitaxial wafer caused by non-linear exhausting is effectively reduced, and the uniformity of the on-chip doping concentration of the epitaxial wafer is effectively optimized on the premise of not changing key process parameters. The selection window of the key process parameters is enlarged and technical support is provided for the growth of a high-quality silicon carbide epitaxial material.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

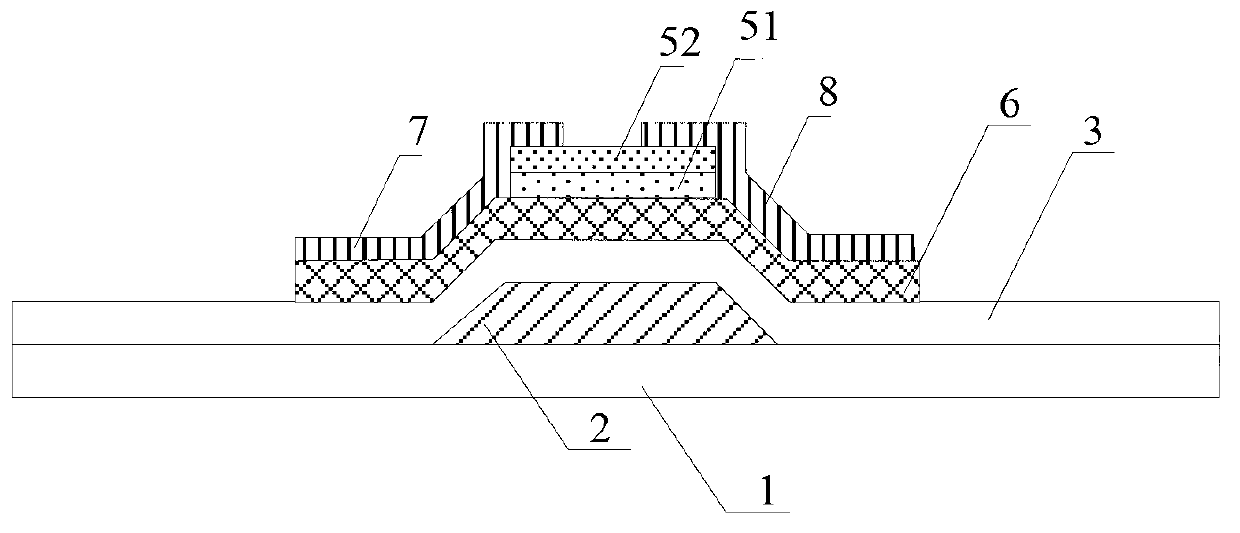

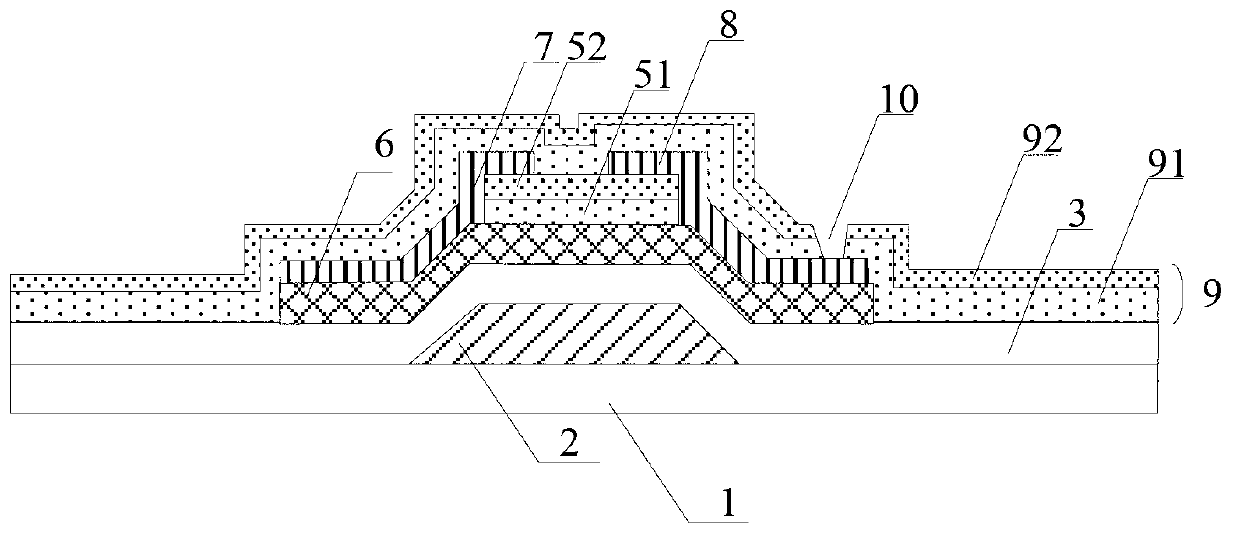

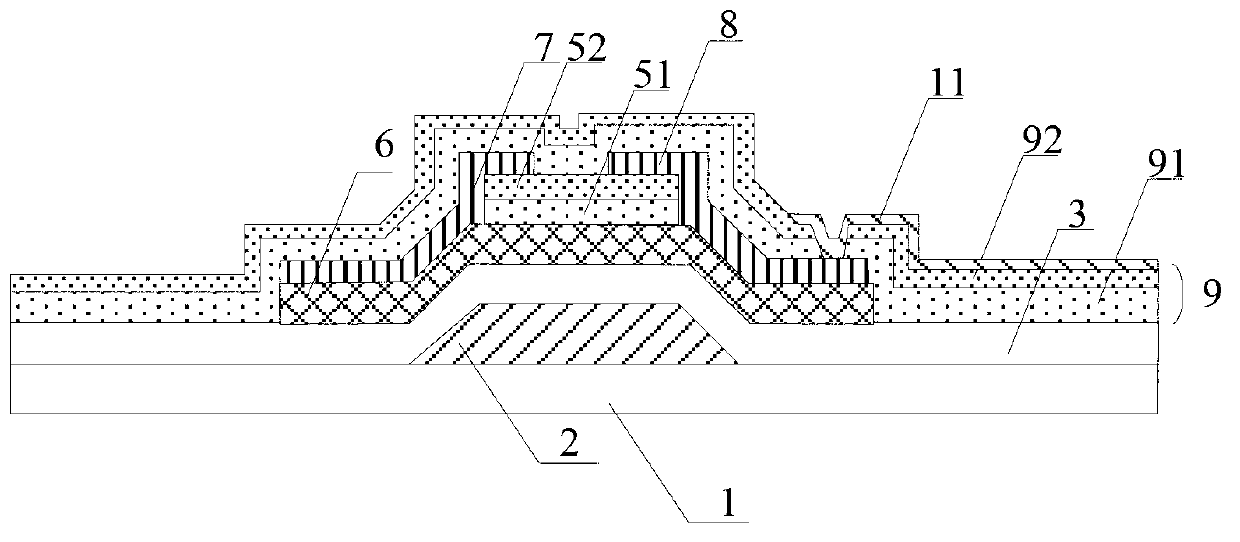

LED (Light-Emitting Diode) flip chip and manufacturing method thereof

InactiveCN104037295AReduce contact resistanceLower turn-on voltageSemiconductor devicesQuantum wellHigh reflectivity

The invention discloses an LED (Light-Emitting Diode) flip chip. The LED flip chip comprises a sapphire substrate, an LED epitaxial wafer, as well as an n type GaN layer, a quantum well active area, a p type GaN layer and a metal reflecting layer which are arranged in sequence on the sapphire substrate, wherein an n type GaN layer exposed area is formed by etching the n type GaN layer; a transparent conducting layer and a medium reflecting layer are formed in sequence between the p type GaN layer and the metal reflecting layer; the medium reflecting layer is provided with a through hole through which the metal reflecting layer extends to be connected with the transparent conducting layer; n and p electrodes are arranged on the n type GaN naked layer and the metal reflecting layer respectively. By adding the transparent conducting layer and multiple medium reflecting layers, the contradiction between the high reflectivity and low resistivity of a single metal layer is eliminated. The LED flip chip has the advantages of high light emitting rate and low startup voltage, has higher reliability, and is more suitable for use in the field of flip LEDs.

Owner:江苏汉莱科技有限公司

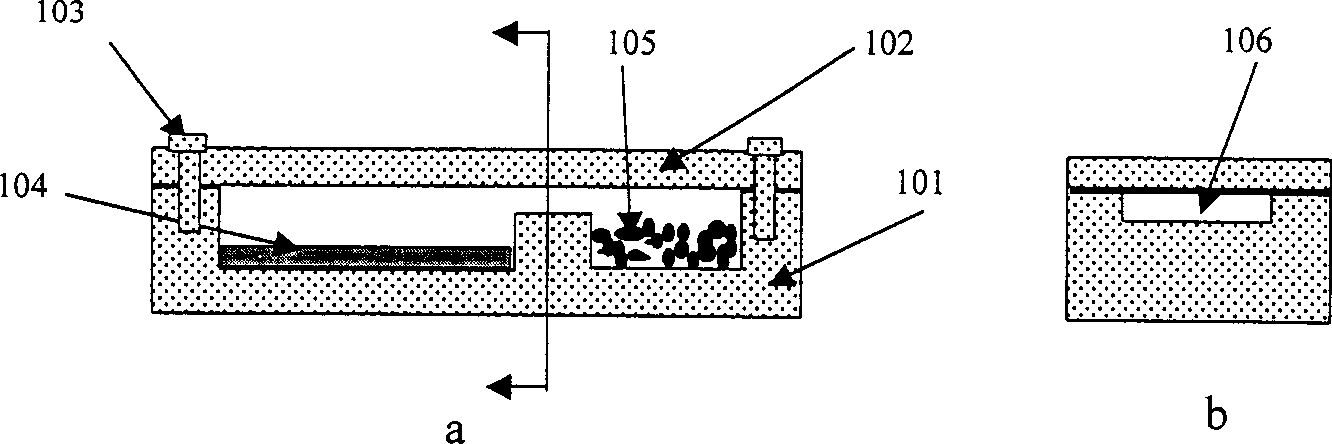

Open pipe tellurium cadmium mercury epitaxial material heat treatment method

InactiveCN1354287AMaintain surface integrityGood surface morphologyAfter-treatment detailsSemiconductor/solid-state device manufacturingDislocationBatch production

The present invention discloses an open tube HgTe source Te-Cd-Hg epitaxial material heat treatment method. The stable mercury steam pressure required for heat treatment is provided by adopting graphite box structure. Said graphite box also can be implemented by utilizing improved liquid-phase epitaxial graphite boat, and its open tube process provides a way for batch production of the part. The success rate of using said process to make hole conduction heat treatment can be up to 100%. The hole density of the material of 77K temp. can be arbitrarily regulated in the range of 5X10 to the power 15 to 5X10 to the power 16 cm (-3). At the same time, the dislocation of material surface in the course of heat treatment does not produce increment effect, and the material composition and appearance form can be better retained.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Method for improving uniformity of p-type doping concentration in silicon carbide epitaxial wafer

ActiveCN108796616ADoping Concentration Uniformity OptimizationExcellent background concentrationDiffusion/dopingGraphite substrateChemical vapor deposition

The invention discloses a method for improving the uniformity of p-type doping concentration in a silicon carbide epitaxial wafer. Based on a chemical vapor deposition growth technique, a small amountof silicon source, carbon source, hydrogen chloride, trimethylaluminum and the like are added into a substrate air-floating gas, and then a small amount of process gas is pushed to an edge of a graphite substrate by taking the air-floating gas as a carrier gas, so that the p-type doping efficiency of the edge of the substrate is finely adjusted. By adopting the method, the deviation of the dopingconcentration of an edge point and a center point caused by nonlinear depletion of the epitaxial wafer is effectively reduced, and the uniformity of the intra-wafer doping concentration of the epitaxial wafer is effectively optimized without changing key process parameters. The process is compatible with conventional SiC epitaxial processes, and has a relatively high promotion value.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

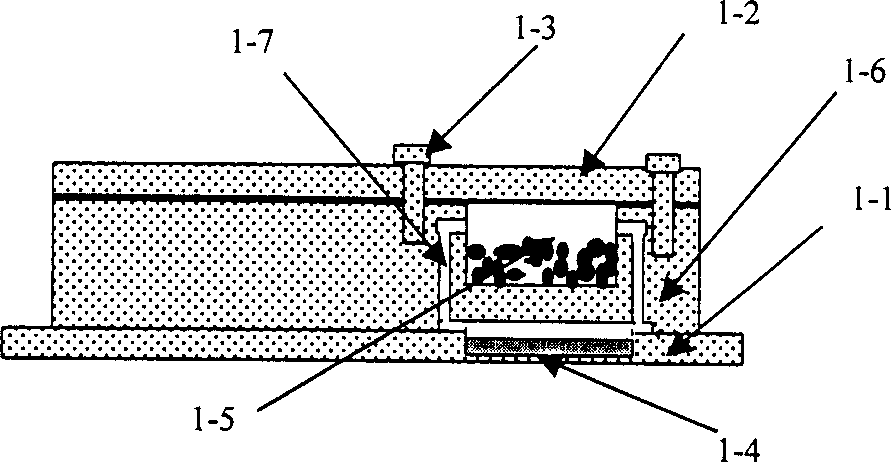

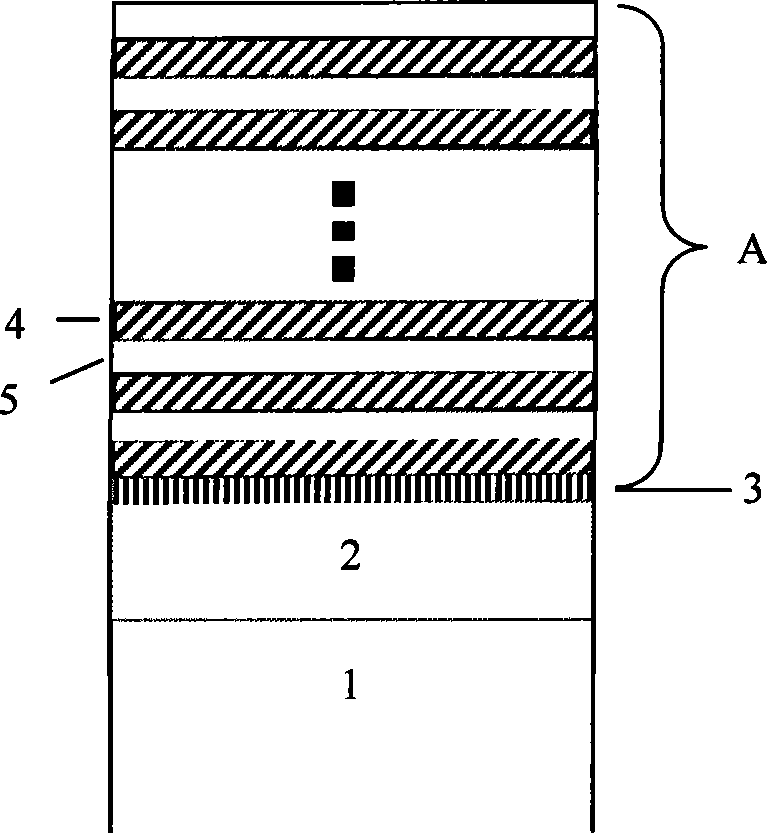

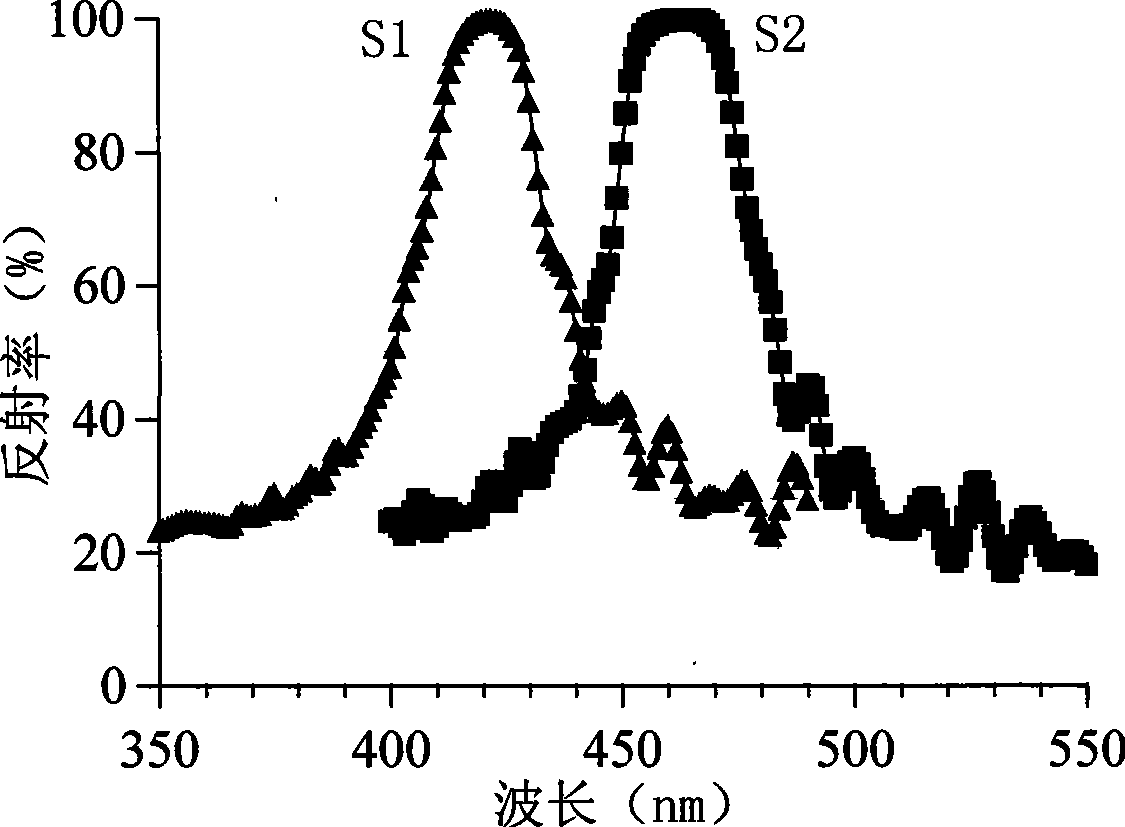

Nitride distributed Bragg reflector and production process thereof

InactiveCN101478115AQuality improvementGood surface morphologyLaser detailsLaser optical resonator constructionVertical-cavity surface-emitting laserIndium

The invention provides a nitride distributed Bragg reflecting mirror and a method for preparing the reflecting mirror, which relates to a distributed Bragg reflecting mirror, in particular to a technology for preparing nitride DBR in a gallium nitride-base microcavity light-emitting diode and a vertical cavity surface emitting laser by using chemical vapor deposition of metallorganics. The invention provides a high quality nitride distributed Bragg reflecting mirror with good surface topography and a preparation method thereof. The nitride DBR is provided with a supporting base; a GaN buffer layer is grown on the supporting base; DBR consisting of a GaN layer and an AlN layer is grown; indium is doped in the AlN or / and GaN. The method comprises the following steps: firstly, the supporting base of the C surface of a sapphire is heated and treated; a GaN nucleating layer is grown in the atmosphere of H2; a GaN buffer layer is grown after the temperature rises; subsequently, an AlN buffer layer is grown; subsequently, the temperature rises and the AlN layer is crystallized; finally, the AlN layer and the GaN layer are grown repeatedly and alternately in the atmosphere of N2 to prepare DBR; and indium is doped when one or two types of the AlN layer and the GaN layer are grown.

Owner:XIAMEN UNIV

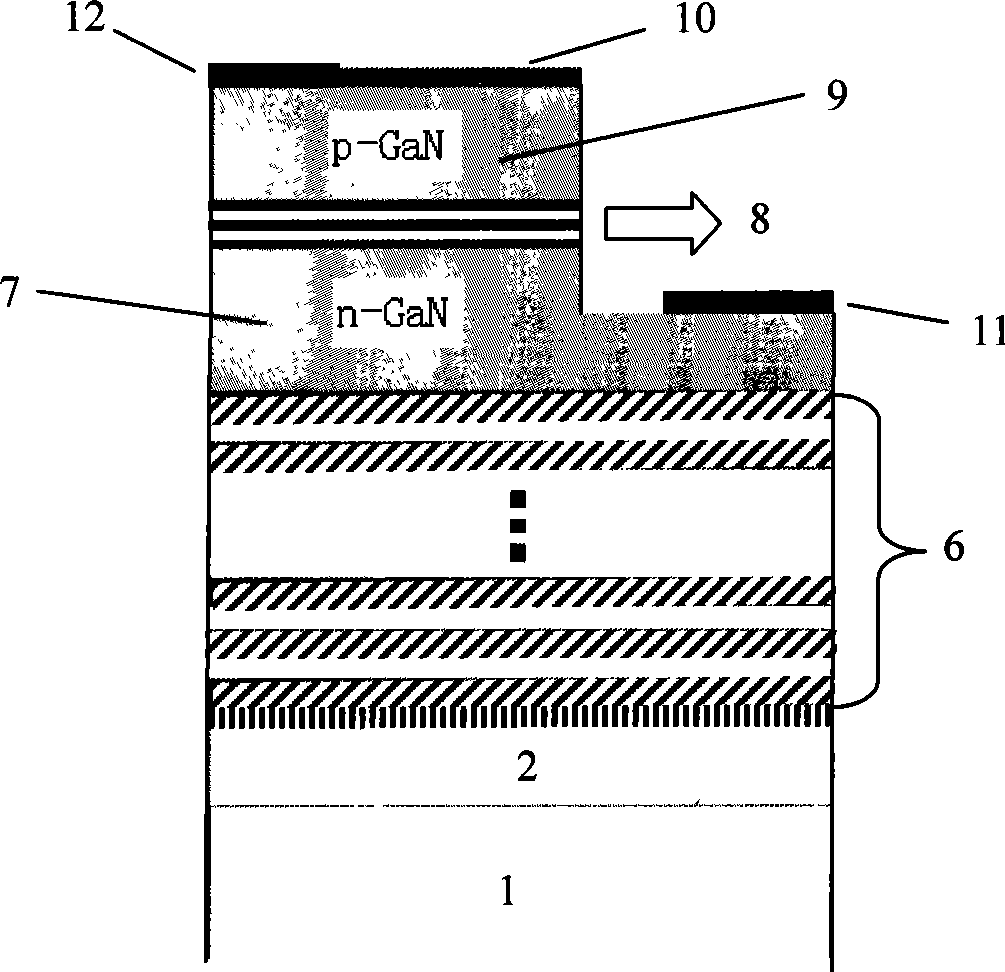

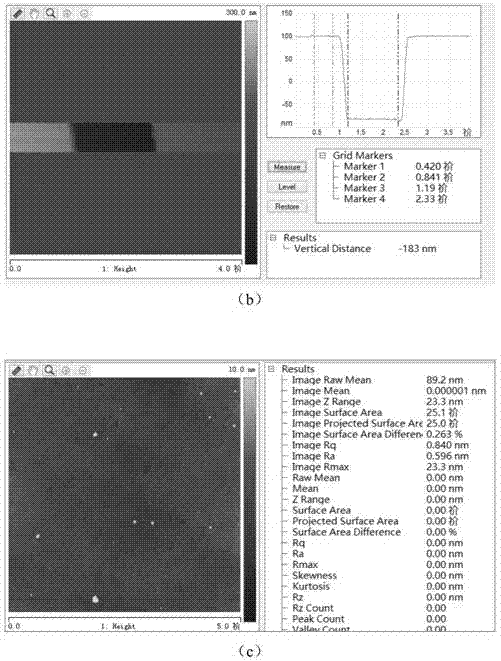

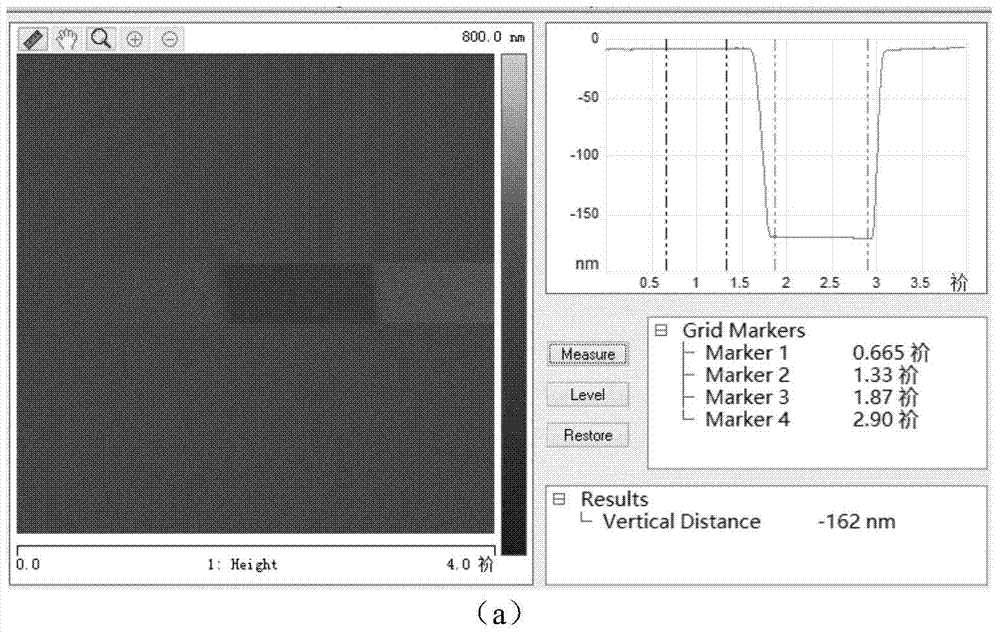

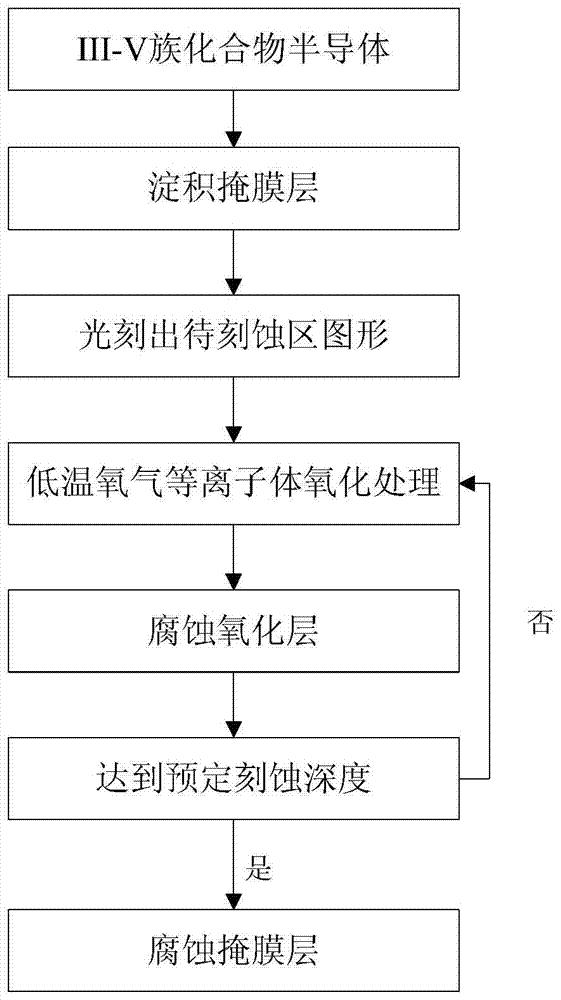

Etching method for III-V-group compound semiconductor materials

InactiveCN104282548AHigh precisionAvoid current dropSemiconductor/solid-state device manufacturingHeterojunctionFine line

The invention provides an etching method for III-V-group compound semiconductor materials and belongs to the technical field of semiconductor technologies. According to the etching method, the dry oxidation technology with low-temperature oxygen plasma oxidization and the technology for wet etching of an oxidation layer are combined to be used for etching of the III-V-group compound semiconductor materials, the etching depth can be accurately controlled, wherein the etching precision can reach a high level, please see the level in the specification. The etching method for the III-V-group compound semiconductor materials has the advantages that the surface damage is low, the surface appearance is good, the precision of lines of etched grating grooves can be improved, and the width of a processing line can be reduced. Oxygen plasma treatment is conducted on the surface of a wafer at a low temperature, and therefore current reduction due to heterojunction relaxation which is possibly caused by high-temperature oxidation can be effectively avoided. The etching method can be widely used for etching of shallow slots or fine lines of the III-V-group compound semiconductor materials, such as etching of an ohmic contact groove of a gallium-nitride-based device or groove grid of an enhancement device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Gold-plating process using gold potassium citrate

The invention discloses a gold-plating process using gold potassium citrate, comprising the following steps: step S1 of electrolyzing and degreasing; step S2 of pickling in the solid acid solution; step S3 of pickling in the hydrochloric acid solution; step S4 of pre-plating nickel; step S5 of plating nickel; step S6 of strengthening nickel plating at a high temperature; step S7 of pickling in the citric acid solution step S8 of pre-plating gold; step S9 of plating gold; step S10 of washing by ultrasonic wave; and step S11 of drying with hot air. The process provided by the invention has the advantages as follows: a gold-leaching plating layer with good adhesiveness and uniform distribution thickness can be formed on a surface of a plated piece matrix; and the plating layer has a better crystal structure and high hardness so as to greatly save cost; operable current density range is wide; production efficiency can be increased; radiance can be controlled easily; the process is safe and pollution-free because cyanogens matters are not used; cost is low; and economic benefit and social benefit are good.

Owner:CHENGDU HOMIN TECH

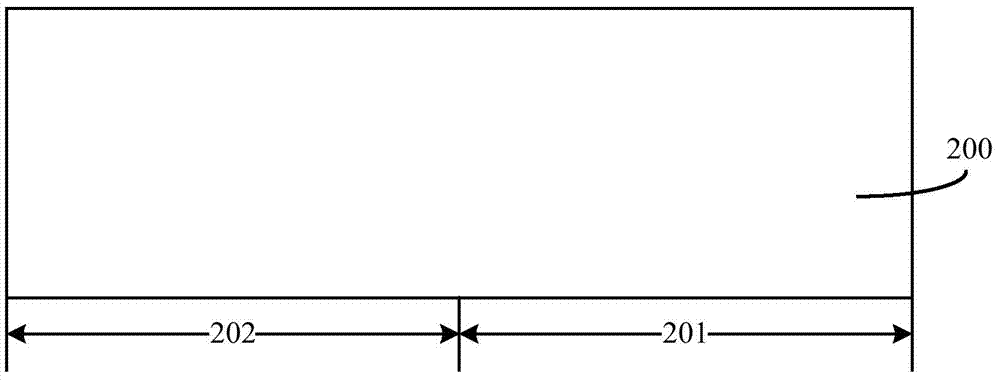

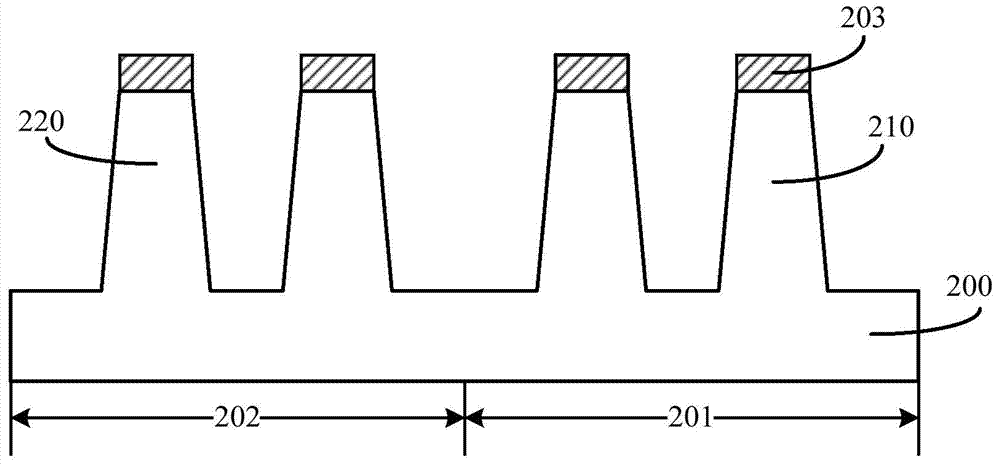

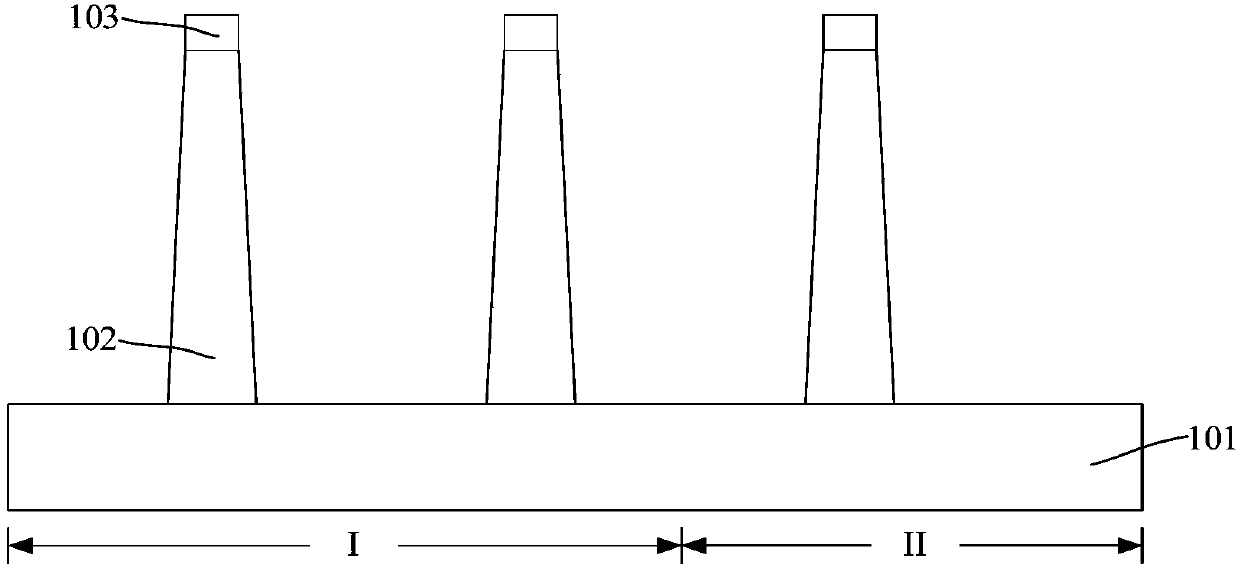

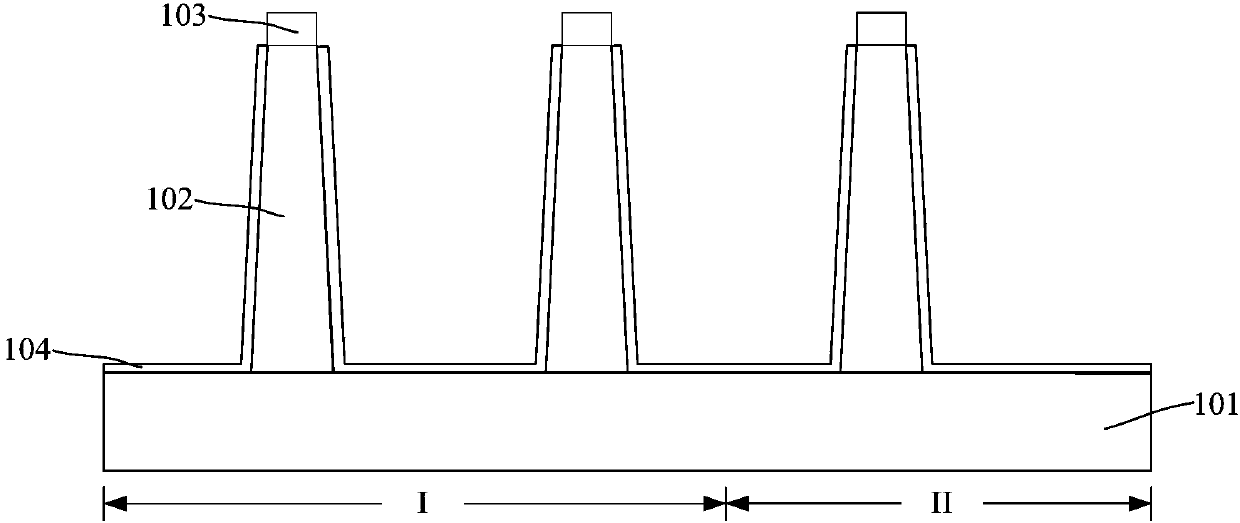

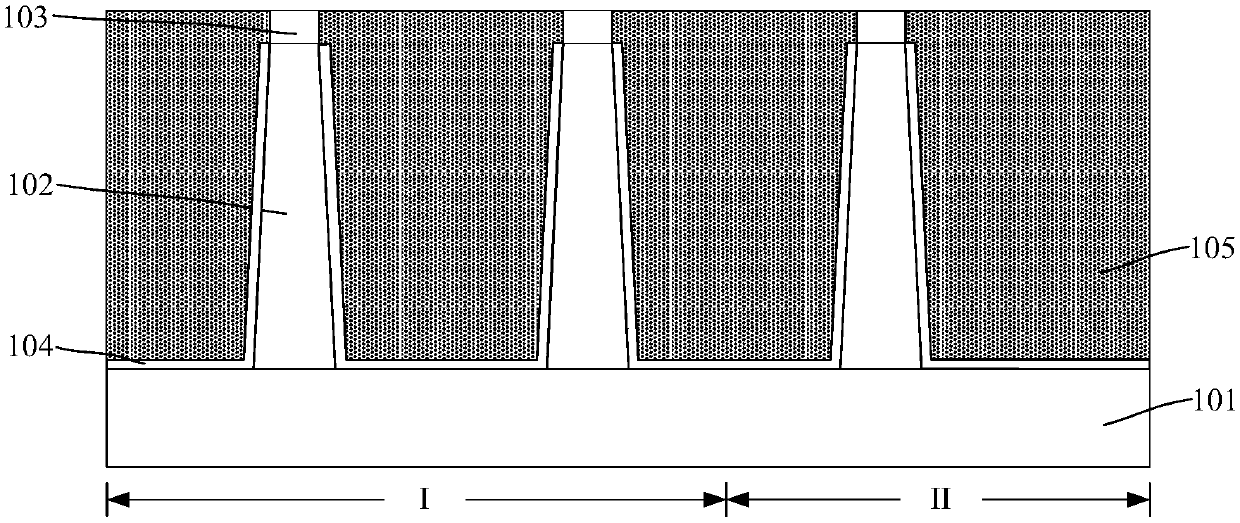

Semiconductor structure and forming method thereof

ActiveCN104733314AGood surface morphologyAvoid injection damageSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The semiconductor structure forming method comprises steps: a substrate is provided, wherein the substrate is provided with a first region, and the surface of the substrate in the first region is provided with a first fin part; dielectric layers are formed on the surface of the substrate and the surface of the side wall of the first fin part, wherein the surface of the dielectric layer is lower than the top part of the first fin part; a first anti-damage injection process is carried out on the bottom part of part of the first fin part exposed out of the dielectric layer, ion implantation damages to the first fin part can be prevented due to the first anti-damage injection process, a first anti-penetrating layer is formed in the first fin part, and the position of the first anti-penetrating layer is corresponding to the surface of the dielectric layer. Performance of the formed semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for preparing boron-doped diamond by using solid doping source

ActiveCN110527973AEffective control of doping contentSafe preparationChemical vapor deposition coatingBoronMaterials science

The invention discloses a method for preparing a boron-doped diamond by using a solid doping source, and relates to a method for preparing the boron-doped diamond. The invention aims to solve the problems of unsafe gas boron source and the corrosivity to the equipment in an existing preparation method of a boron-doped diamond film. The preparation method comprises the following steps of 1, preparing the doping source; and 2, preparing the boron-doped diamond film. The method is used for preparing the boron-doped diamond by utilizing the solid doping source.

Owner:HARBIN INST OF TECH

Method for preparing rutile-type TiO2 thin film at room temperature

InactiveCN101994094AImprove bindingImprove anticoagulant performancePharmaceutical containersVacuum evaporation coatingSurface engineeringBiological materials

The invention relates to a method for preparing rutile-type TiO2 thin film at room temperature, belonging to the field of surface engineering technique and biological materials. The single rutile-type TiO2 thin film is obtained on the surface of superfine crystal / nanometer crystal titanium at the room temperature by performing nanorization treatment on a titanium microstructure in advance and adopting a direct-current reaction magnetic control sputtering deposition technique. After nanorization of the titanium base material microstructure, the interface bonding force between the TiO2 thin film and the base material is improved remarkably, the technical problem of poor bonding condition between the TiO2 thin film with excellent anticoagulant property and a titanium vessel bracket is bettersolved and the bearing capacity of the interface is greatly improved. The invention better solves the problem that the single rutile-type TiO2 thin film is hard to prepare on the titanium surface at the room temperature, has simple process and is widely applied to the fields of vessel brackets, heart valves, and the like.

Owner:JIANGSU UNIV

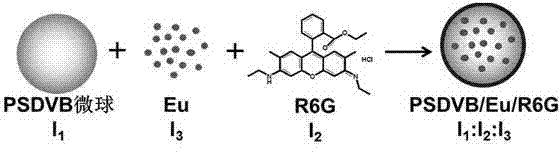

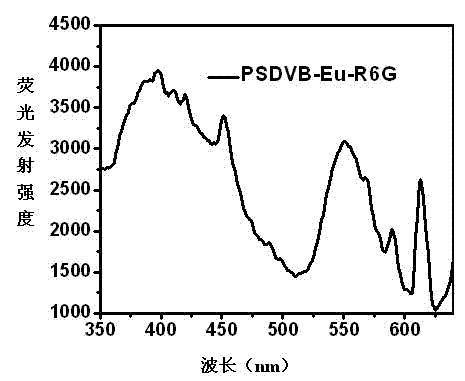

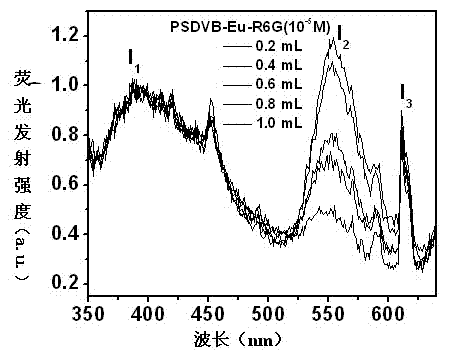

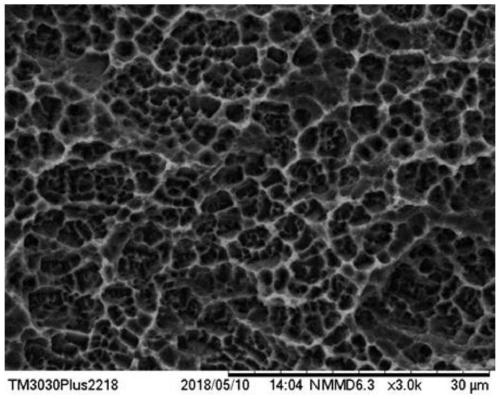

Eu<3+> and rhodamine 6G doped polymer fluorescent encoding microsphere and preparation method

InactiveCN103788942AGood surface morphologyIncrease the number ofLuminescent compositionsSolventFreeze dry

The invention relates to a Eu<3+> and rhodamine 6G doped polymer fluorescent encoding microsphere and a preparation method. The preparation method comprises the steps of dispersing a surface sulfonic polystyrene-divinyl benzene cross-linked microsphere in a mixed solvent, adding a Eu<3+> solution to obtain a Eu<3+> doped polymer fluorescent encoding microsphere, evenly dispersing the Eu<3+> doped polymer fluorescent encoding microsphere in the deionized water solution of CH3COOH and (NH4)2S2O8, adding rhodamine 6G, and carrying out shaking, centrifugal washing and freeze drying to obtain the Eu<3+> and rhodamine 6G doped polymer fluorescent encoding microsphere. After the prepared fluorescent encoding microsphere is motivated, three fluorescent emissions can be obtained; and through changing the addition of europium or rhodamine 6G, a series of fluorescent encoding microspheres with different fluorescent emission strength ratios can be prepared and can be applied to the fields of biological detection, medical diagnosis and the like.

Owner:SUZHOU UNIV

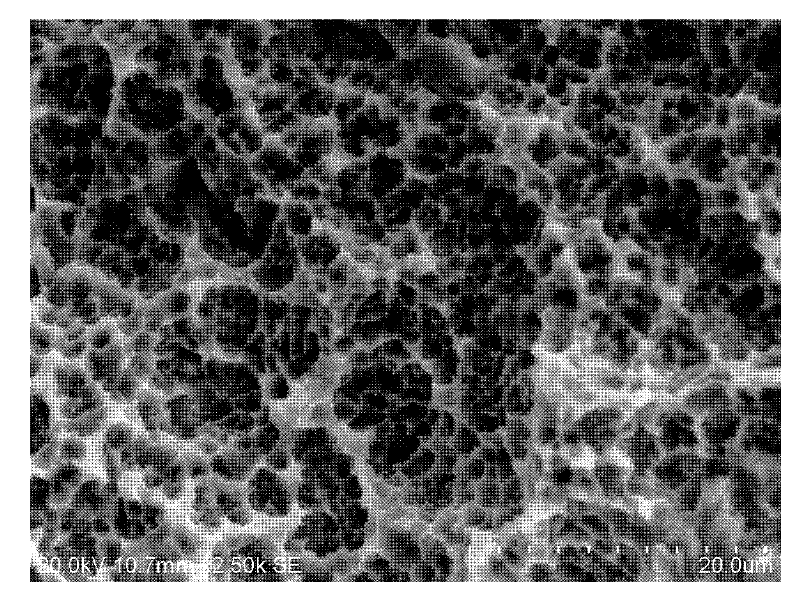

Treatment process for improving surface hydrophilicity of implant

ActiveCN109731135AHigh hardnessHigh strengthAbrasive feedersSolid state diffusion coatingAcid etchingSand blasting

The invention belongs to the technical field of implants and particularly relates to a treatment process for improving the surface hydrophilicity of an implant. The method comprises the following steps: firstly carrying out sand blasting and acid etching treatment on an implant, then carrying out alkali heat treatment and plasma oxidation treatment to enable secondary pits in the surface of the implant to be more uniform and compact, finally directly immersing the implant subjected to the plasma oxidation treatment into a mixed solution of MgCl2, CaCl2 and NaCl with an adjusted pH value, and carrying out hydrophilic treatment to obtain the implant with better hydrophilicity. The surface of the implant prepared by the method not only can improve the mechanical gomphosis of the implant and surrounding bone tissues, promote the adsorption effect of bioactive molecules and cells, facilitate the adhesion and proliferation of the cells, but also improve the surface energy and the wettabilityof the cells, accelerate the initial bone bonding speed of the implant and achieve rapid bone integration. The process is simple and suitable for commercial production.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

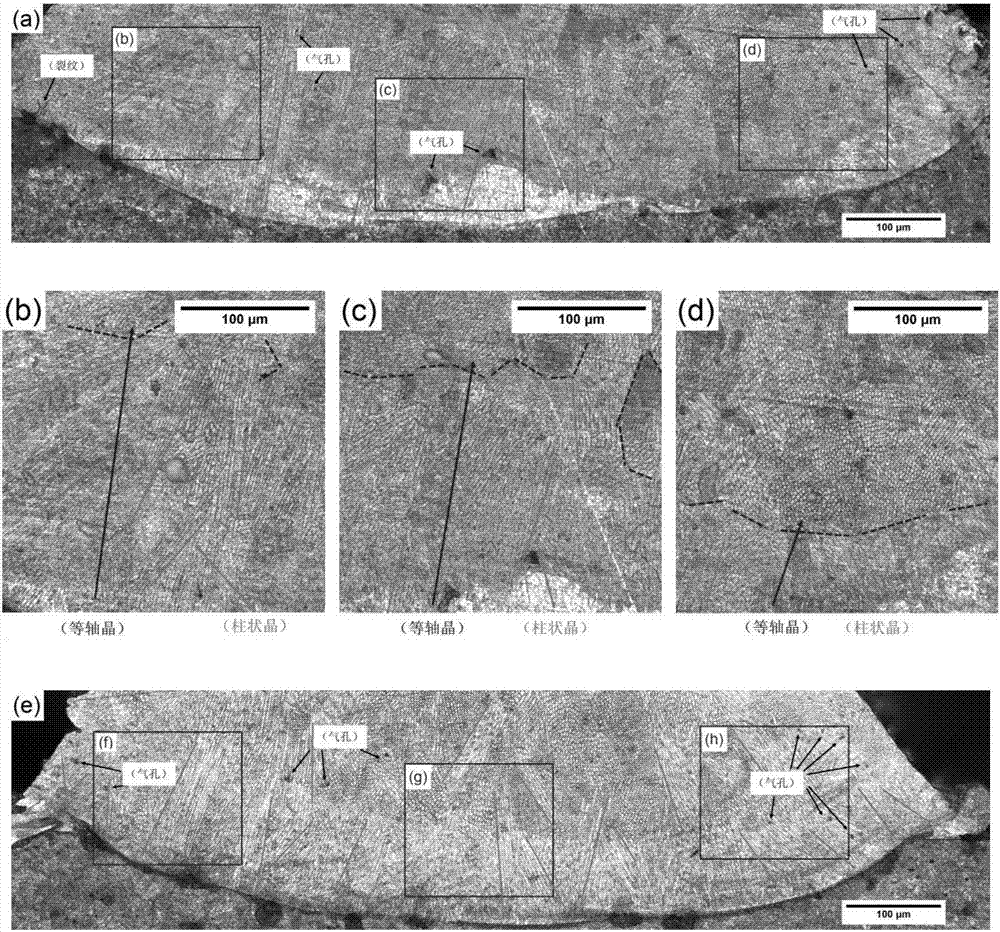

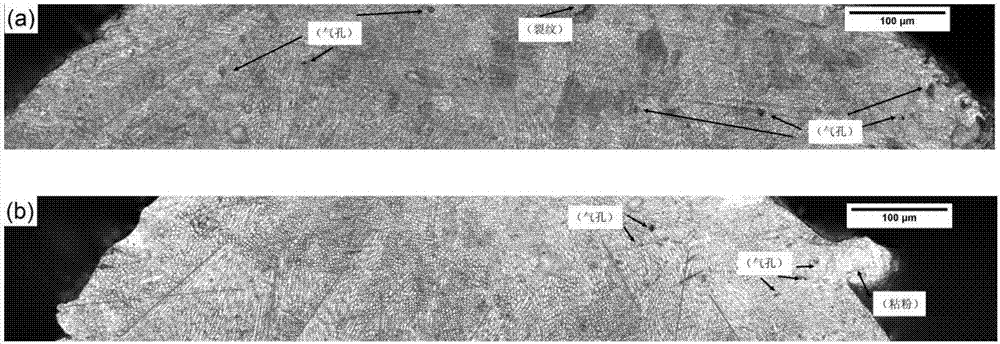

Laser cladding 316L stainless steel optimizing process

ActiveCN107217256AIsolated entryReduce oxidation statusMetallic material coating processesProcess optimizationStructure analysis

The invention discloses a laser cladding 316L stainless steel optimizing process. The laser cladding 316L stainless steel optimizing process comprises the following steps that the cladding surface of No.45 steel base material and the contact surface of the No.45 steel base material and platforms are essentially pretreated; 316L stainless steel powder is dried for 4 hours to guarantee full drying of the powder; off-line programming for a processing track is conducted; an orthogonal test is conducted; a range analysis is conducted on the shape coefficient zeta; the range analysis is conducted on the dilution ratio D; and a metallurgical structure analysis is conducted. According to the laser cladding 316L stainless steel optimizing process, a shielding gas factor which is not valued enough before is considered emphatically and is taken as the factor which influences a stainless steel processing process for overall consideration; 316L stainless steel is obtained after cladding with the adoption of optimum process parameters obtained from the laser cladding 316L stainless steel optimizing process, it is guaranteed that a good surface appearance can be obtained on the premise that the mechanical property of the 316L stainless steel is not influenced, meanwhile the defects such as surface powder sticking, pores and cracks can be overcome, and a specific optimizing scheme is provided for process optimization of laser cladding stainless steel parts.

Owner:NORTHEASTERN UNIV

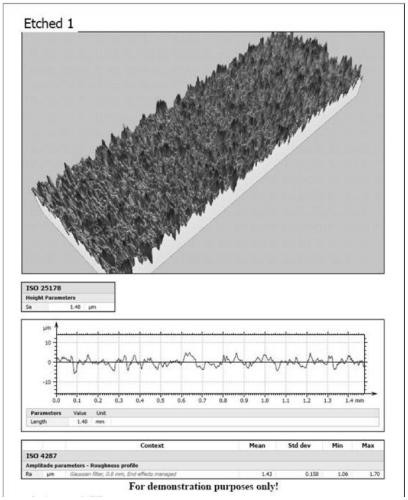

Method for machining low-roughness high-peak textured roller

ActiveCN105290547ALow running costSurface Morphology of Excellent Disordered Cold RollPeak valueColor difference

The invention provided with a method for machining a low-roughness high-peak textured roller. The low-roughness high-peak textured roller is machined through the steps of adjusting equipment operation accuracy, changing the roller grinding travel, reducing transverse texturing color difference, avoiding surface arcing of the textured roller, reducing the defects of bright spots and scratches on the surface of the textured roller and changing a textured roller driver structure. Compared with the prior art, the method has the beneficial effects that on the condition of not changing the performance such as the high efficiency and low operation cost of an electric spark texturing device and the excellent disordered cold roller surface topography, the lowest roughness value of the electric spark textured cold roller is reduced to 1.2 microns, and the peak value of the textured cold roller is increased to more than 130 per square centimeter, the spraying and stamping performance of a cold-rolled automobile sheet can be obviously improved, and the method has wide application prospects in production of high-end cold-rolled automobile sheets.

Owner:ANGANG STEEL CO LTD

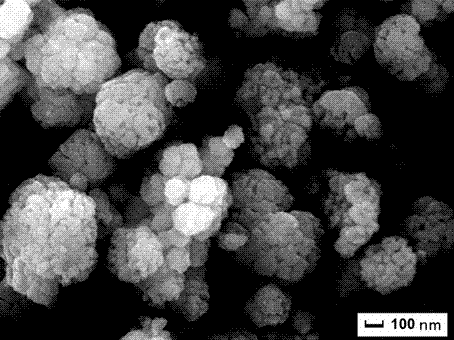

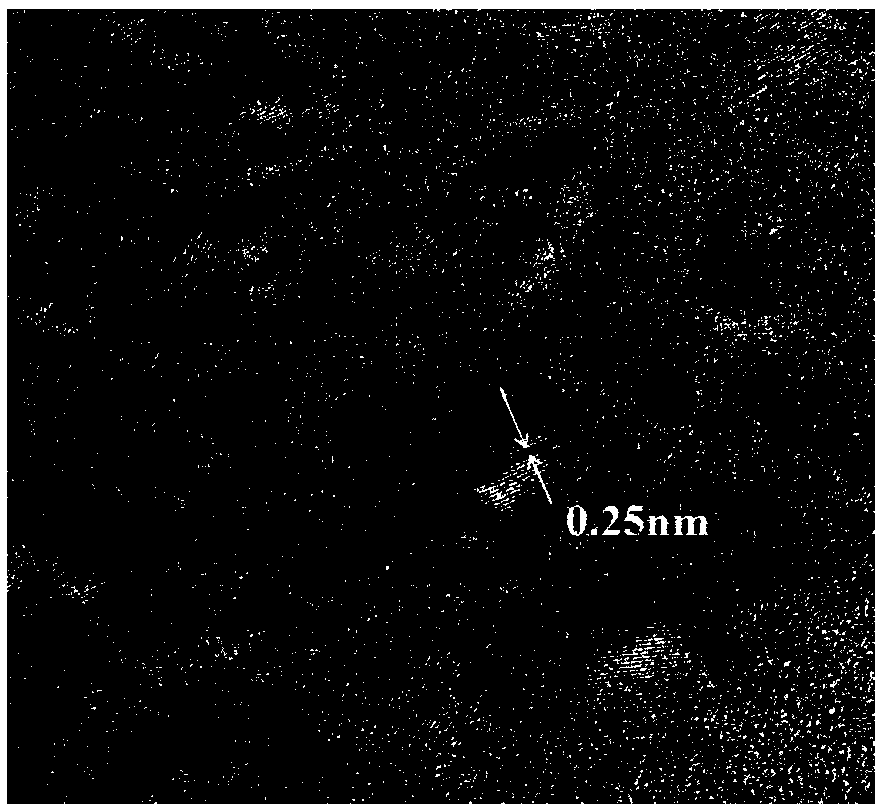

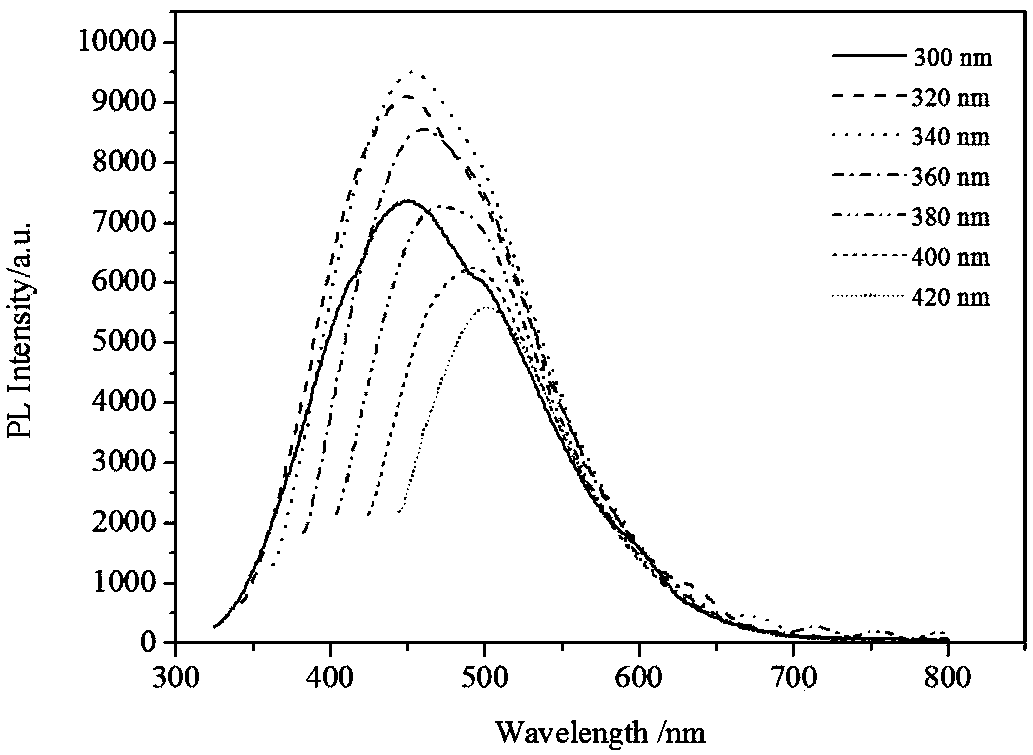

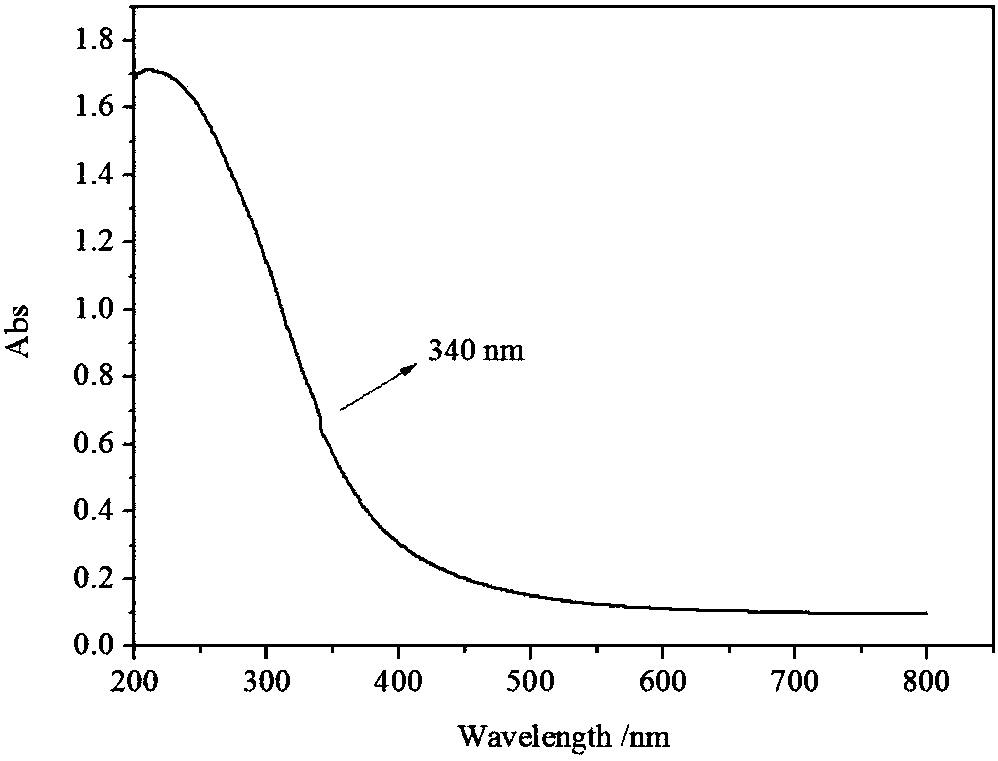

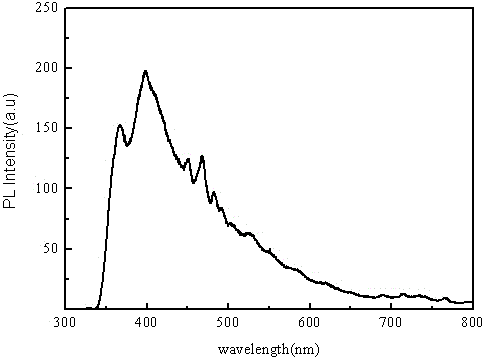

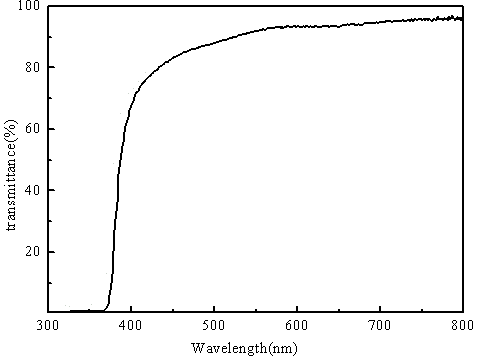

Method for preparing carbon quantum dots by using bagasse as carbon source with chemical oxidation process

InactiveCN107601457AMild preparation conditionsGood surface morphologyNano-carbonLuminescent compositionsChemistryStrong acids

The invention belongs to the technical field of material synthesis, and discloses a method for preparing carbon quantum dots by using bagasse as a carbon source with a chemical oxidation process. Themethod comprises the following steps: high temperature carbonization is carried out for the bagasse at 300-700 DEG C for 2-7 hours, in order to obtain carbonized black solids, and the solids are grinded into black powder; the black powder is dispersed in acetic acid and 30wt% hydrogen peroxide, ultrasonic treatment is carried out, heating reflux is carried out at 100-140 DEG C for 6-24 hours, andcooling is carried out; the solution is filtered in order to remove impurities of large particles and solid substances which are not completely reacted; centrifugation is carried out at the rotation number of 4000-12000r / min for 10-60 minutes, dialysis of supernatant is carried out for 12-48 hours, and an aqueous solution of carbon quantum dots is obtained. The preparation process is simple, professional apparatus and equipment are not needed, tedious aftertreatment is not needed; the preparation condition is mild, strong acid and highly basic as well as other poisonous and harmful substancesare not needed; prepared carbon quantum dots have good surface morphology and high fluorescence intensity.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

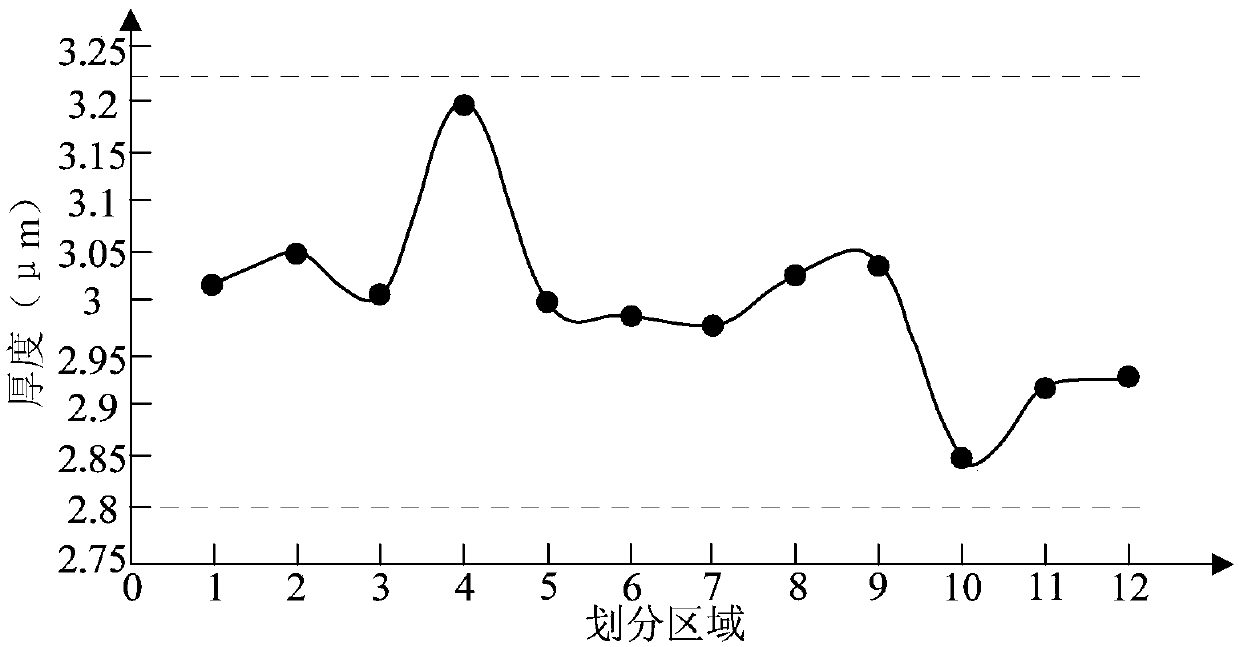

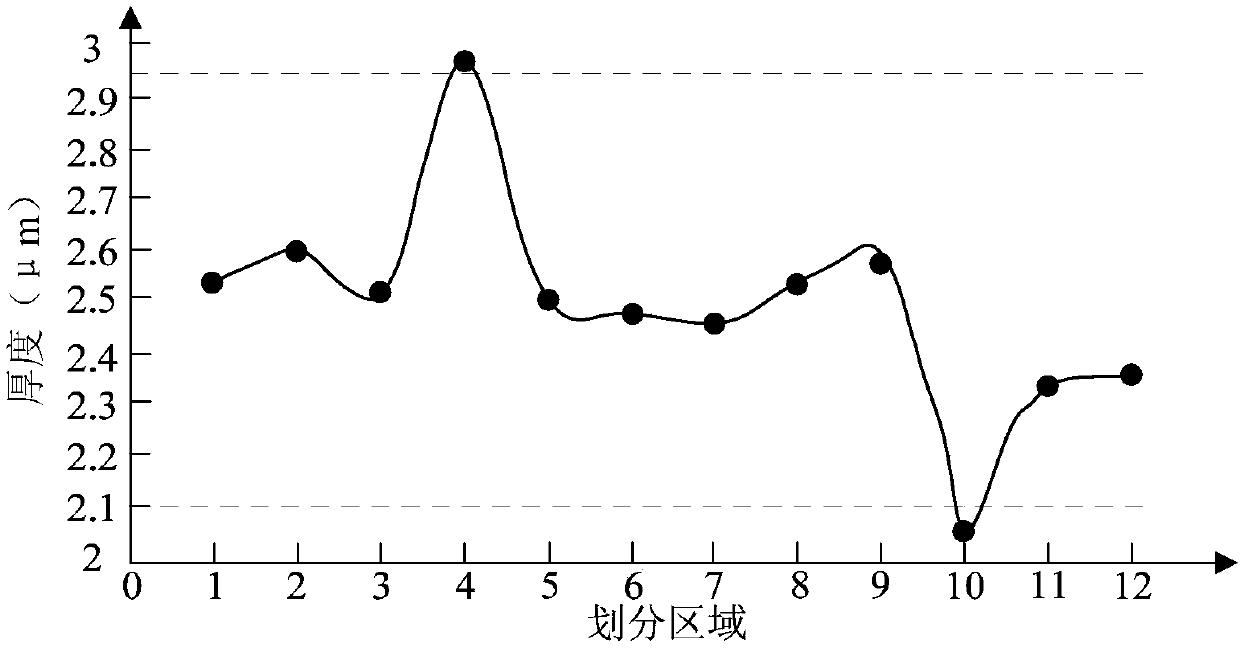

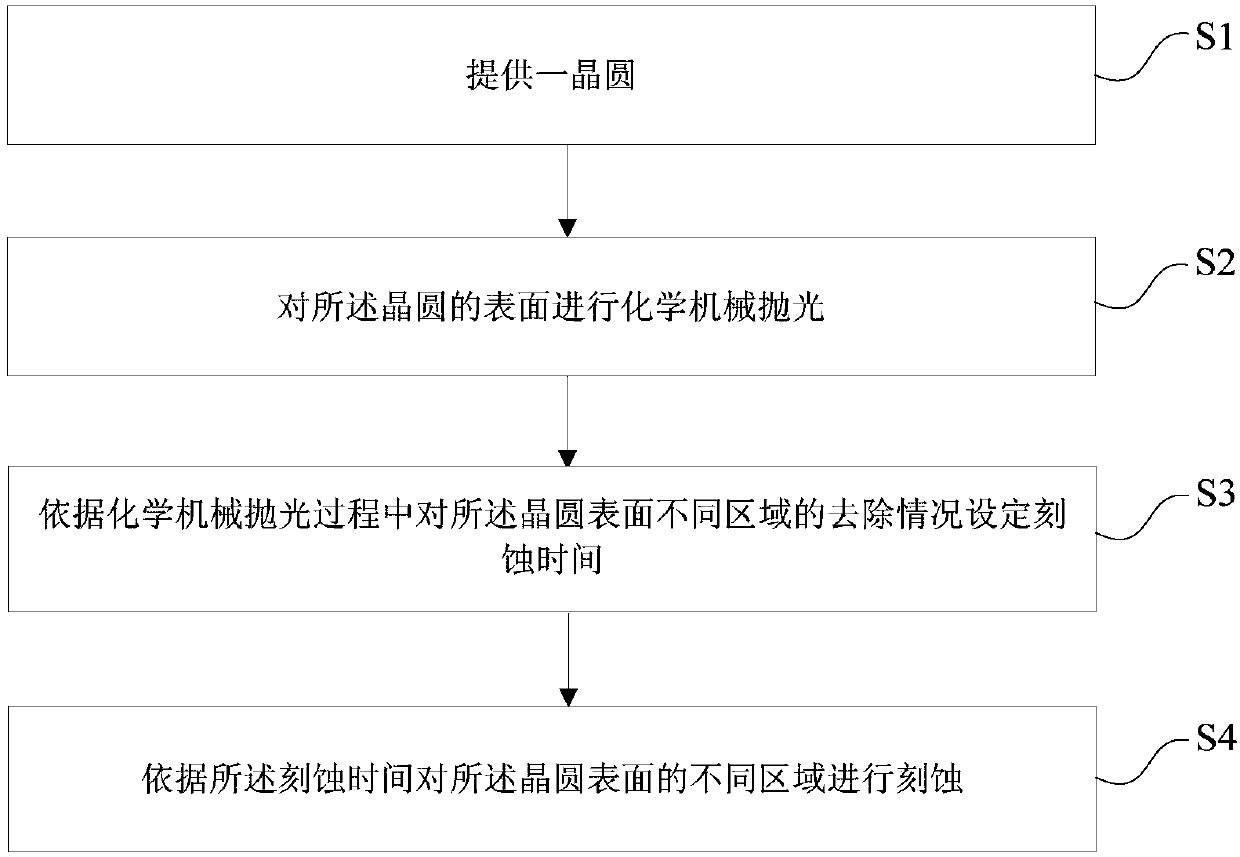

Wafer surface appearance control system and control method

InactiveCN107946191ASurface Topography ControlGood surface morphologySemiconductor/solid-state device manufacturingEtchingControl system

The invention provides a wafer surface appearance control system and control method. The wafer surface appearance control method comprises the following steps of 1) providing a wafer; 2) performing chemical mechanical polishing on the surface of the wafer; 3) setting etching time according to removal conditions in different regions of the wafer surface in the chemical mechanical polishing process;and 4) performing etching on different regions of the wafer surface according to the etching time. The wet etching time for the wafer is set according to the removal conditions in different regions of the wafer surface in the chemical mechanical polishing process, and the appearance deviation of the wafer surface caused in the chemical mechanical polishing process in the wet etching process can be compensated, so that the wet etched wafer has high surface appearance, the wafer surface appearance is effectively controlled within the reasonable technological specifications, and generation of defects in the subsequent process can be avoided.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

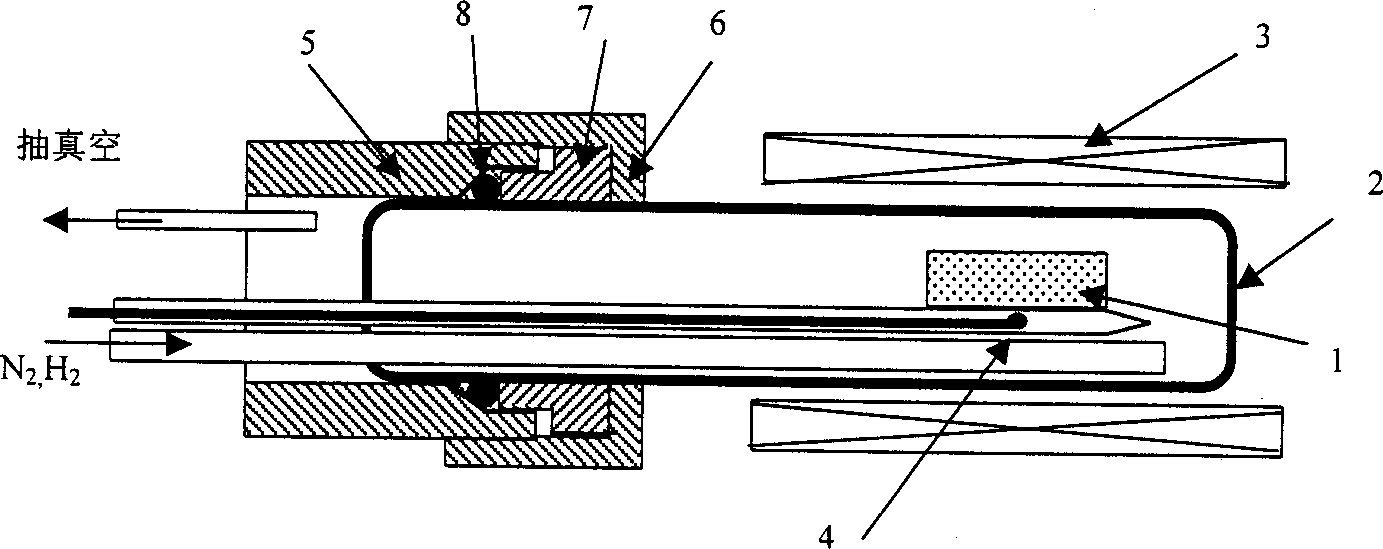

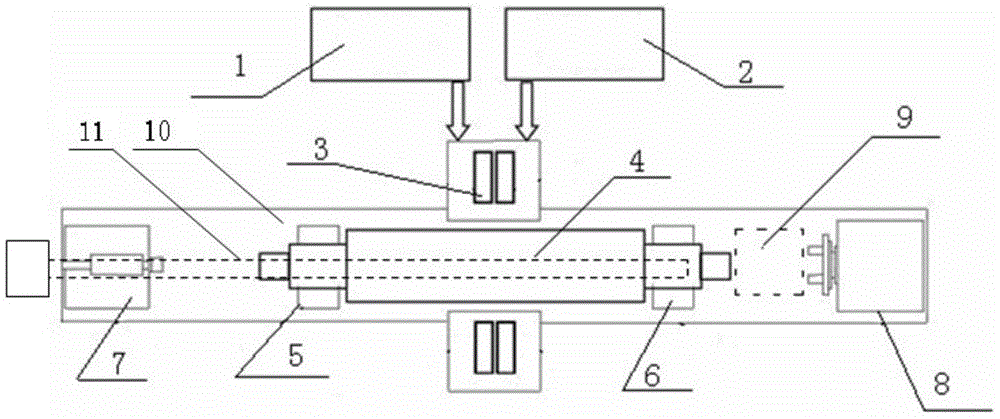

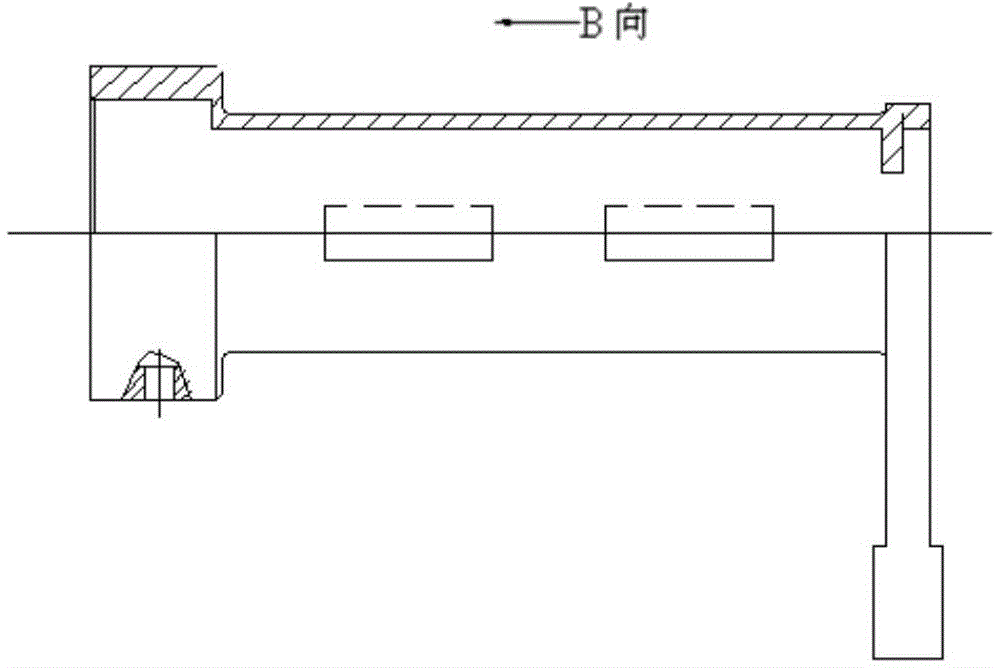

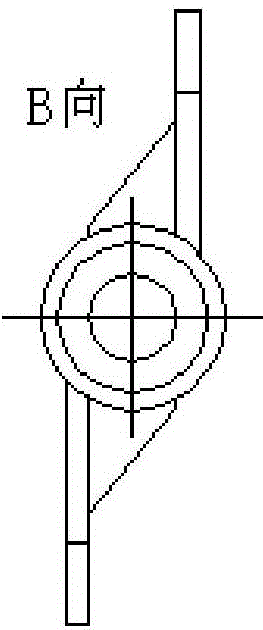

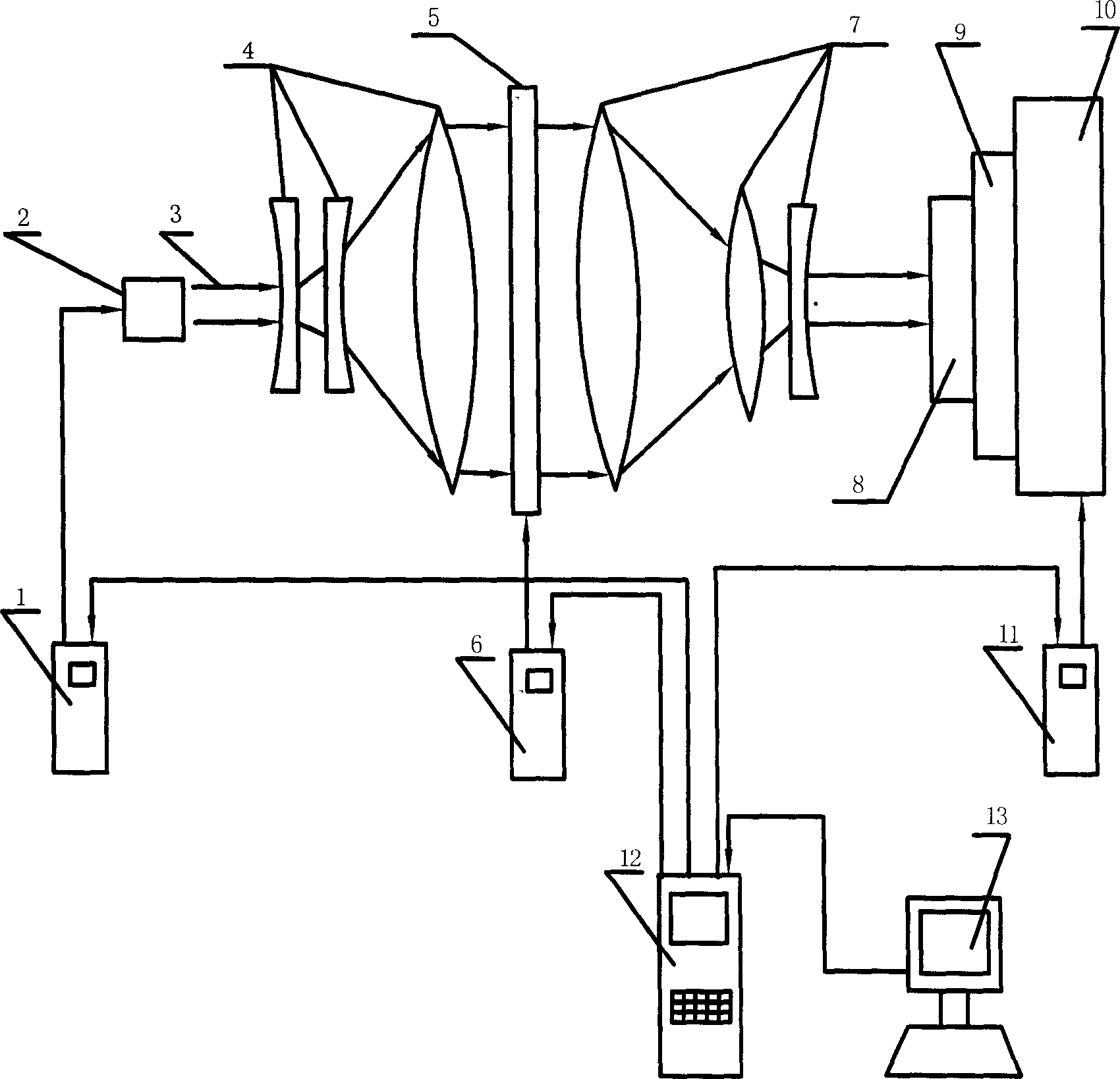

Laser micro-processing method and device based on liquid crystal mask technology

InactiveCN1762641AAvoid unmachinable defectsGood surface morphologyWelding/cutting auxillary devicesAuxillary welding devicesLiquid-crystal displayLight guide

The invention relates to a method and device based on the liquid crystal technology laser surface trickle process in the field of surface trickle process. The device is formed by a laser generator and light guiding system, a laser generator controller, a light diffused system, a liquid crystal display screen and display controller, a focus system and unit holder system.

Owner:JIANGSU UNIV

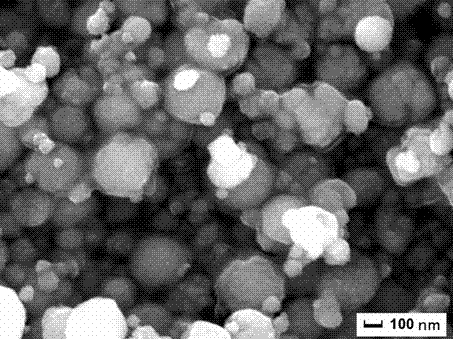

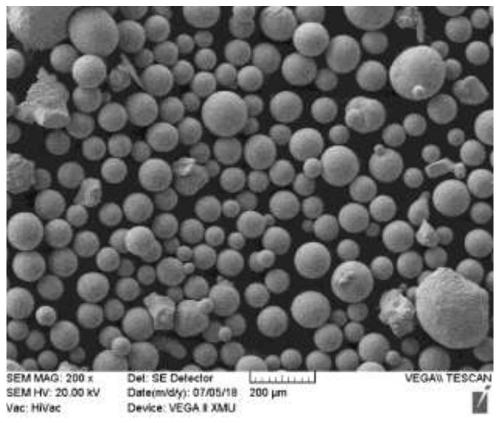

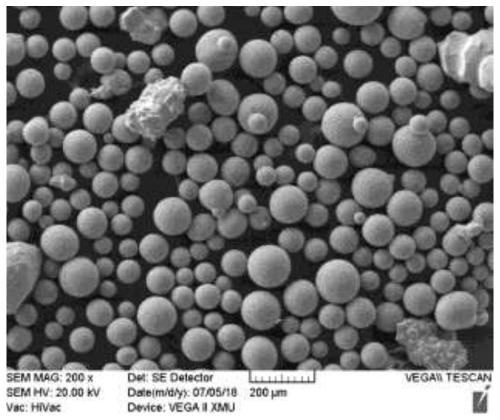

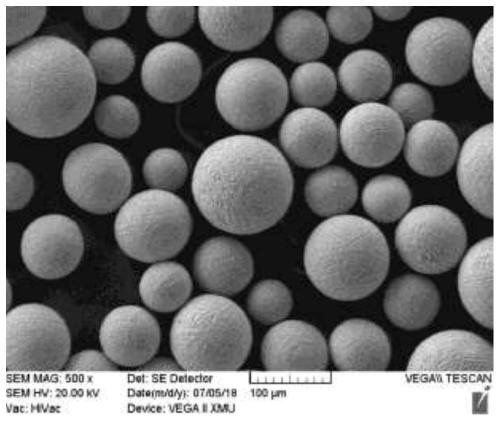

Preparation method of low-cost medium carbon steel spherical powder for 3D printing

PendingCN111570814AHigh sphericityGood surface morphologyTransportation and packagingMetal-working apparatusCarbon steelVacuum induction melting

The invention discloses a preparation method of low-cost medium carbon steel spherical powder for 3D printing. The preparation method comprises the following steps: proportioning medium carbon steel from the following components: 0.43% of C, 0.58% of Mn, 0.18% of Si, 0.25% of Cr, 0.24% of Ni and the balance of Fe, adopting vacuum induction melting to prepare a carbon steel bar, removing the oxidescale on the surface of the alloy bar through machining to process an electrode bar size meeting the requirement of a plasma rotating electrode atomization powder manufacturing apparatus, placing theelectrode bar in a flour mill, adopting a plasma gun to melt the end part of the electrode bar to obtain spherical powder under the action of the centrifugal force, and later, adopting supersonic vibration to screen the collected powder according to different particle sizes. According to the preparation method, plasma rotating electrode atomization is adopted to prepare medium carbon steel spherical metal powder, and the prepared powder has the characteristics of being high in degree of sphericity, less in satellite powder, high in powder density and low in impurity content, can meet the demand of metal powder for 3D printing and is suitable for wide popularization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Texturing and cleaning method of heterojunction battery

InactiveCN110943144AAdded cleaning stepsAchieving thorough cleanlinessFinal product manufactureSemiconductor/solid-state device manufacturingProcess engineeringEnvironmental engineering

The invention discloses a texturing and cleaning method of a heterojunction battery. The method comprises the following steps: pre-cleaning an original silicon wafer by adopting SC1; carrying out rough polishing and damage removal treatment on the silicon wafer; cleaning with an ozone system solution; texturing the silicon wafer; adopting an SC1 or ozone system solution for cleaning; corroding thesilicon wafer, and carrying out smooth rounding treatment; adopting an SC2 or ozone system solution for cleaning; drying the solution ; and adding an HF acid pickling process before the SC1 or ozonesystem solution cleaning process, the smoothing and rounding process, the SC2 or ozone system solution cleaning process and the drying process. The surface of the silicon wafer is ensured to be completely clean, a better surface appearance is obtained, and the performance of an HJT battery is improved to a great extent.

Owner:JINENG CLEAN ENERGY TECH LTD

Preparation method for Cu-Al co-doped p-type ZnO film

InactiveCN104005011AHigh crystallinityGood surface morphologySolid/suspension decomposition chemical coatingSemiconductor materialsLuminescent material

The invention discloses a preparation method for a Cu-Al co-doped p-type ZnO film and belongs to the technical field of semiconductor materials and luminescent materials. The method comprises: dropwise adding a prepared Cu-Al co-doped ZnO colloidal solution on a substrate, coating a film in a spin coating manner, drying, and performing annealing processing, so as to obtain the needed film. The Cu-Al co-doped p-type ZnO film exhibits good optical characteristics. The method has the advantages of low synthetic temperature, good film-forming uniformity, large film-forming area, strong adhesive force with the substrate, atom-grade doping easiness, accurately controllable doping level, simple technology and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of superfine dolomite and application of superfine dolomite

InactiveCN113104877AGood surface morphologyGood dispersionCalcium/strontium/barium carbonatesMagnesium carbonatesCALCIUM HYDROXIDE SOLUTIONSlurry

The invention discloses a preparation method of superfine dolomite and application of the superfine dolomite, and relates to the technical field of dolomite processing. The preparation method comprises the steps: crushing dolomite, and screening to obtain dolomite coarse powder; adding the dolomite coarse powder and a grinding aid into water, and uniformly stirring to obtain dolomite slurry; adding the dolomite slurry into a stripping machine, and carrying out superfine stripping to obtain superfine slurry; dehydrating, drying and crushing the superfine slurry to obtain dolomite fine powder; adding the dolomite fine powder and a calcium hydroxide solution into a four-neck flask provided with a stirrer, then putting the four-neck flask into a constant-temperature water bath, and adding a crystal form control agent while stirring; and then introducing mixed gas of air and carbon dioxide into a three-neck flask for continuous stirring reaction, carrying out spray drying on the reaction liquid, forming powder, and thus obtaining the superfine dolomite. The problems that existing dolomite powder is large in particle size and small in application range, and superfine powder is prone to agglomeration and not prone to uniform dispersion are solved.

Owner:铜陵博锋实业有限公司

Dental implant surface treatment method

InactiveCN109431637AImprove surface roughnessIncrease roughnessDental prostheticsAcid etchingClinical success

The invention provides a dental implant surface treatment method. Due to sand blasting and acid etching treatment before soaking, dental implant surface roughness is increased to some extent; further,due to calcining in a later stage, dental implant surface roughness is increased remarkably, the implant bone combination capacity can be increased, and accordingly the dental implant clinical success rate is increased. A mixed acid formed by hydrofluoric acid and nitric acid is adopted for acid etching to provide a great sand blast dental implant surface morphology, great rough surface characteristics of dental implants are achieved, and interface bonding strength of a dental implant and bone combination surface is further improved. The method is simple in operation, convenient and simple intreatment, low in cost and applicable to industrial large-scale production.

Owner:佛山市佛冠义齿有限公司

Tungsten processing slurry with catalyst

ActiveCN108473849ACreativeGood surface morphologyOther chemical processesSemiconductor/solid-state device manufacturingPtru catalystMetallurgy

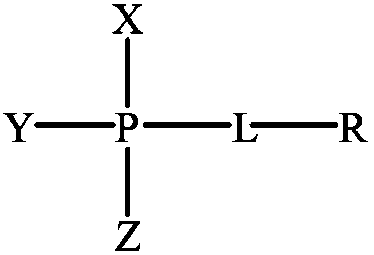

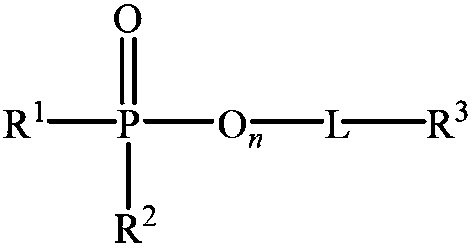

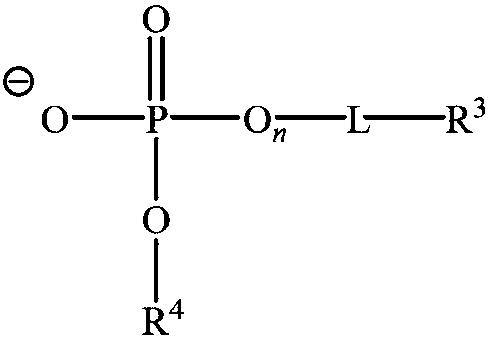

Described are compositions (e.g., slurries) useful in methods for chemical-mechanical processing (e.g. polishing or planarizing) a surface of a substrate that contains tungsten, the slurries containing abrasive particles, metal cation catalyst, phosphorus-containing zwitterionic compound, and optional ingredients such as oxidizer; also described are methods and substrates used or processed on combination with the compositions.

Owner:CMC MATERIALS INC

Semiconductor device forming method

ActiveCN107591363AImprove electrical performanceGood etch rate uniformityTransistorSemiconductor/solid-state device manufacturingEngineeringElectrical performance

The invention discloses a semiconductor device forming method. The method comprises steps that: a base comprising a first area and a second area is provided, wherein the first area base and the secondarea base are provided with first oxidation layers; an etching process is carried out to etch and remove the first oxidation layer with a first thickness in the first area; after the etching processis carried out, the remaining first oxidation layer in the first area is subjected to a cleaning process; the etching process and the cleaning process are carried out alternatively until the first oxidation layer in the first area is removed; and a second oxidation layer is formed on the first area base, wherein the thickness of the second oxidation layer is different from that of the first oxidation layer. The first area base can be prevented from being etched and damaged, the first area base can thus keep a good surface morphology, and the electrical performance of the formed semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Surface activation method for dental implant

InactiveCN107740103AGood surface morphologyGood rough surfaceDental implantsTooth rinsingActivation methodAcid etching

The invention discloses a surface activation method for a dental implant. After dental implant is subjected to cleaning, sand blasting, acid treatment and secondary cleaning, a biological activity porous structure is formed on the surface of the dental implant. According to the surface activation method, mixed acid of hydrochloric acid and sulfuric acid is used for treatment, the corrosive effectof the mixed acid on titanium metal is utilized, the good surface appearance of the sand blasting dental implant is provided, thus the dental implant has the characteristic of a good rough surface, and the interface bonding strength of a dental implant scleromere surface is further improved. The acid etching effect achieved by the concentration ratio of 50%-75% of sulfuric acid and 8%-20% of hydrochloric acid is ideal, thus two or more times of acid etching steps adopted generally at present are simplified into one time to achieve the purpose, treatment time is shortened, work efficiency is improved, cost is lowered, and thus the surface activation method is suitable for commercialized production.

Owner:陕西爱骨医疗股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com