Laser micro-processing method and device based on liquid crystal mask technology

A technology for microfabrication and masking, applied in auxiliary devices, laser welding equipment, metal processing equipment, etc., can solve the problems of inability to process, difficult to make masks, laser diffraction phenomenon, etc., and achieve the effect of good surface microscopic topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

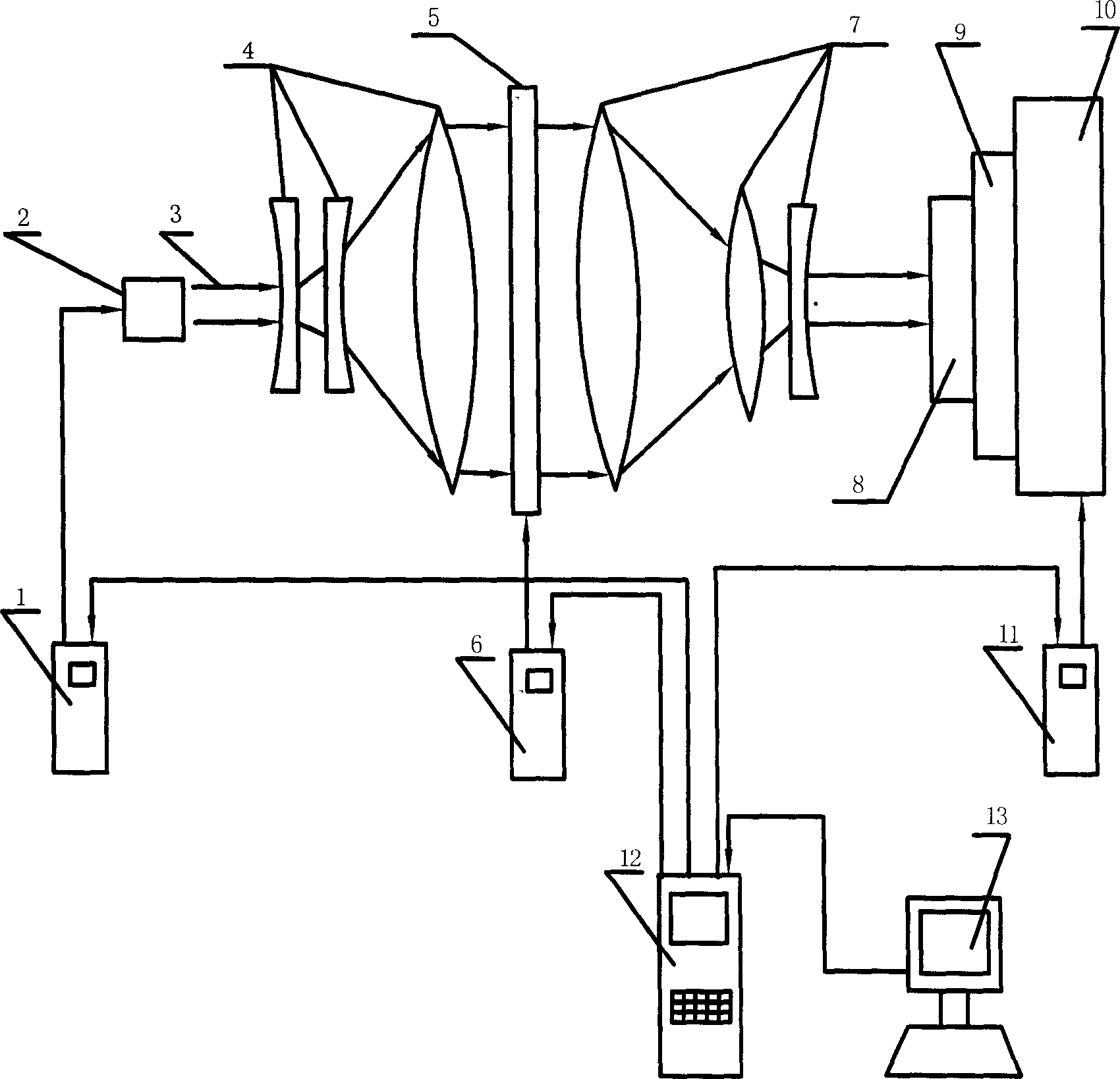

[0018] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The present invention carries out the device of laser surface micromachining and comprises laser generator control device 1, laser generator 2, astigmatism system 4, liquid crystal display screen 5 and display screen control device 6, focusing system 7 and workpiece fixture system and control with laser generator A digital control system 12 and a computer 13 connected to the device 1 , the display screen control device 6 , and the workbench control device 11 . Among them, the astigmatism system 4 is composed of a group of concave lenses and a convex lens with a large curvature; the focusing system 7 is composed of a group of convex lenses and a concave lens with a large curvature; the workpiece fixture system includes a workpiece 8, a fixture 9, a workbench 10 and a workbench control device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com