Tungsten processing slurry with catalyst

A technology of carrier and compound, applied in the direction of polishing composition containing abrasive, water-based dispersant, other chemical processes, etc., to achieve the effect of excellent surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The oxidizing agent can be added, if desired, at any time during preparation of the polishing composition or prior to use in CMP processing. For example, a polishing composition without an oxidizing agent can be prepared and shipped or stored prior to use without the addition of an oxidizing agent. The oxidizing agent can be added shortly before the CMP composition is used in the CMP process (eg, within about 1 minute, or within about 10 minutes, or within about 1 hour, or within about 1 day, or within about 1 week of the CMP operation). The polishing composition can also be prepared by mixing the components just prior to contacting the substrate surface (eg, on the polishing pad) during the CMP operation.

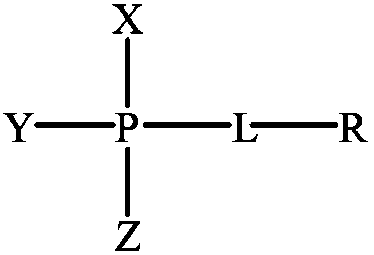

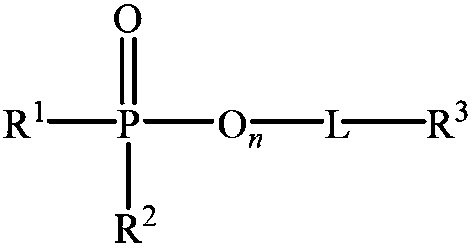

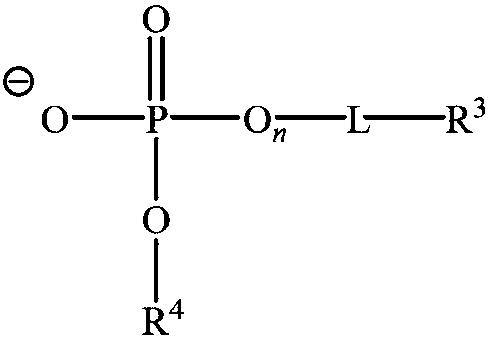

[0102] Can be used as a single catalyst containing charged colloidal silica particles, a catalyst (eg, an iron-containing catalyst), a phosphorus-containing zwitterionic compound, an optional inhibitor, an optional oxidizing agent, an optional biocide, water, etc. ...

Embodiment 1

[0112] This example demonstrates that compositions containing phosphorous-containing ligands of the type described herein (P-compounds) perform better in slurries than otherwise identical slurries containing phosphorous-containing ligands of the type known in the art. Advantages in terms of stability. The compositions are set forth in Table 1. Silica-A is a charged colloidal silica particle with a secondary particle size of about 55 nm and a charge of about 25 mV. From the particle size data presented in Table 2 it is evident that the inventive slurry with alendronic acid (no particle growth observed) was as good as an otherwise identical slurry with phosphonic acid (Dequest 2010) (particle size diameter has almost doubled) compared with excellent stability.

[0113] Table 1. Slurry Composition

[0114]

[0115] Abr. = abrasive; cat. = iron nitrate nonahydrate; MA = malonic acid; surfactant (N,N,N',N',N'-pentamethyl-N-tallow-1,3 - propane diammonium dichloride).

[011...

Embodiment 2

[0120] This example teaches the advantages of the example formulations as described in tungsten etching. The slurry formulations are set forth in Tables 3 and 4. The corresponding tungsten etch rates (45°C) are provided in Tables 5 and 6. It is evident from the examples that the example compositions (Inv.) as described can have significantly lower tungsten static etch rates than the comparative (Comp.) compositions. For example, Inventive Paste 3-B has a static etch rate of 20% or less of Comparative Paste 3-A, while Inventive Paste 3-C has only the observed static etch rate of Comparative Paste 3-B 70% of the etch rate. In formulations without abrasives (Table 4), the inventive slurries also had significantly lower static etch rates compared to the control. For example, Inventive Composition 4B has a static etch rate of less than 1% of Comparative 4A, while Inventive Composition 4C has a static etch rate of less than 25% of Comparative 4A.

[0121] Table 3. Formulations w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com