Brown coal dry-distillation method using coal hot air furnace to supply heat

A hot blast stove and coal-fired technology, which is applied in the field of coal dry distillation process, can solve the problems of coke quenching or tail gas waste heat that cannot be recovered or utilized well, finely crushed coal or pulverized coal cannot be used, and high-grade heat energy waste, etc., to achieve Reduced sulfur content, easy operation and control, and environmentally friendly emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention provides a coal dry distillation method using a coal-fired hot blast stove as heat supply, using the high-temperature flue gas produced by the combustion of low-quality finely divided raw coal as the heat source required for raw coal drying or even dry distillation in the coal dry distillation system, and saving dry distillation gas as a high-end use.

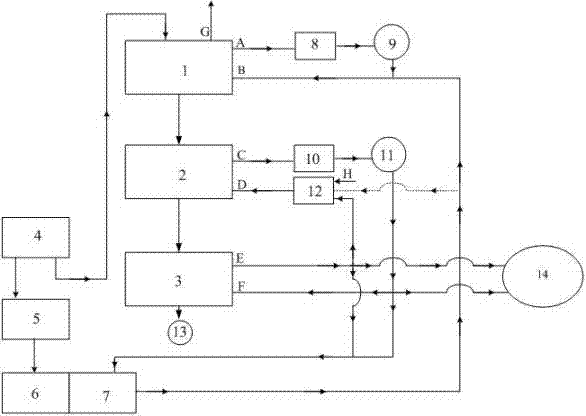

[0018] Such as figure 1 As shown, the lignite carbonization process device with coal-fired hot blast stove as heat supply includes a drying furnace 1, a carbonization furnace 2 and a coke quenching furnace 3. The drying furnace 1 is provided with a wet flue gas discharge port G, and the feed of the drying furnace 1 A crushing and screening device 4 is provided at the end, the lump coal outlet of the crushing and screening device 4 is connected with the feed port of the drying furnace 1, the discharge port of the drying furnace 1 is connected with the feed port of the dry distillation furnace 2, and the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com