Patents

Literature

1248results about How to "Creative" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

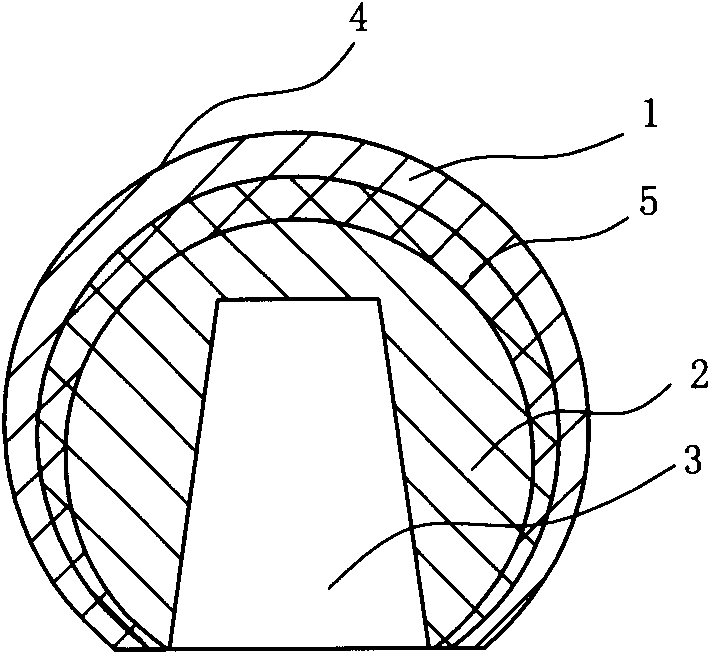

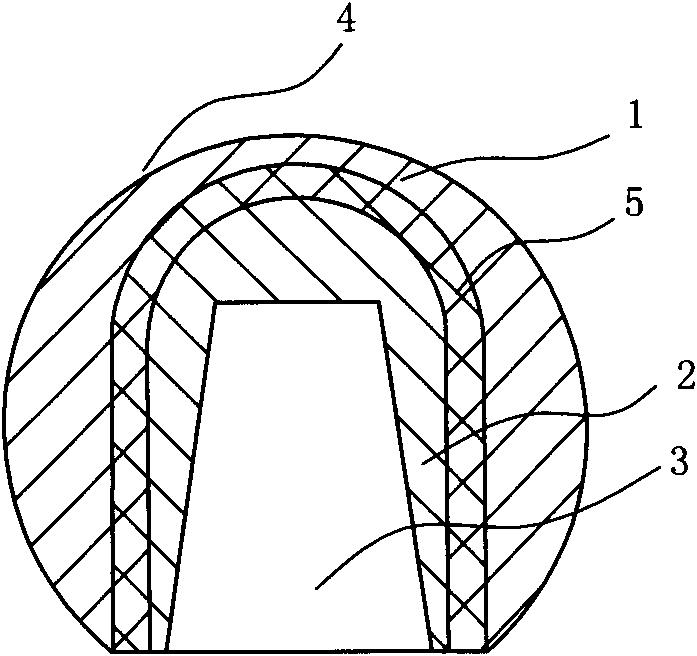

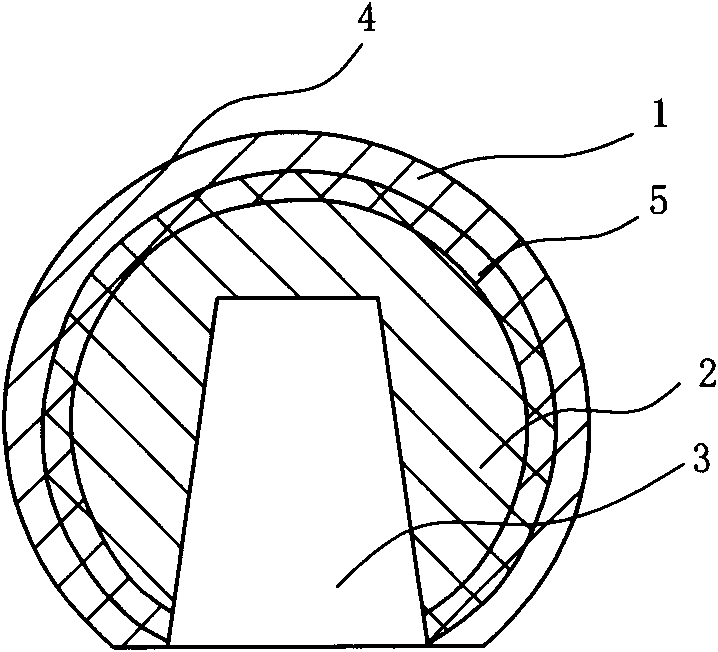

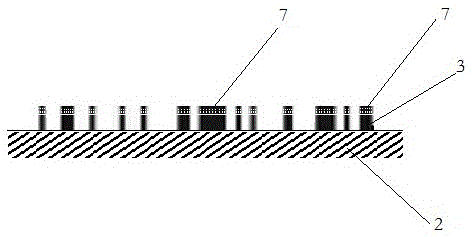

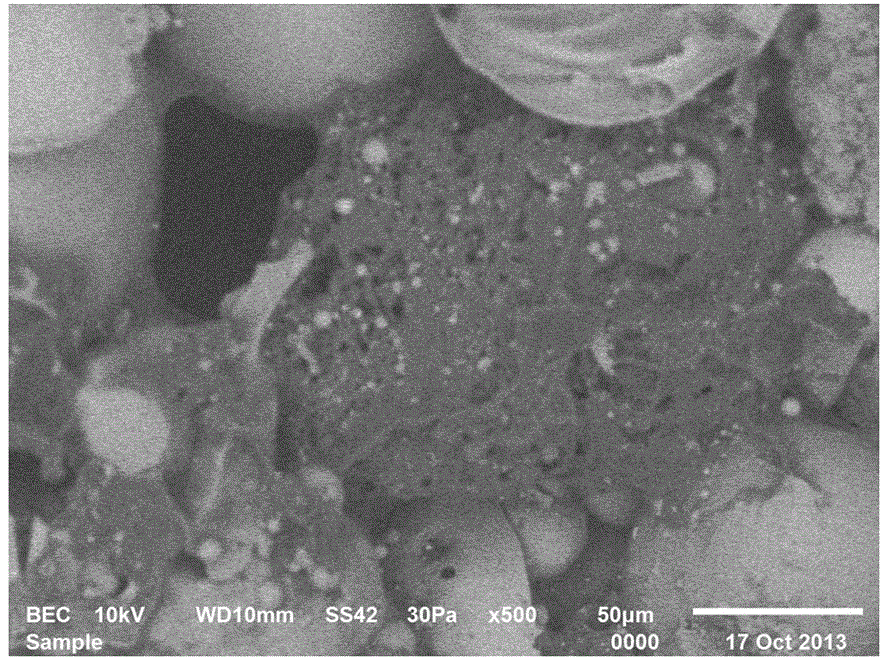

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

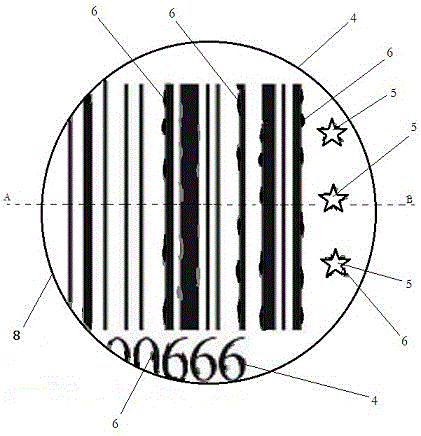

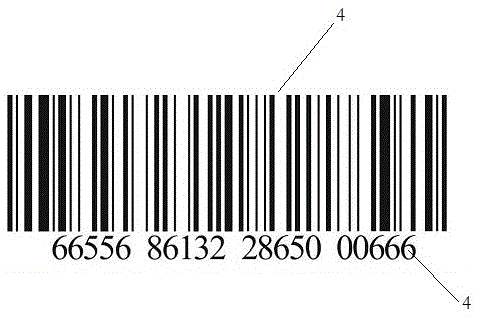

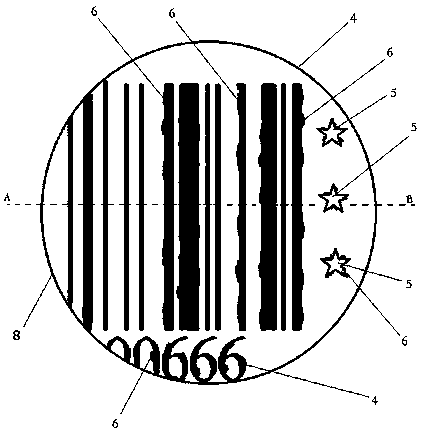

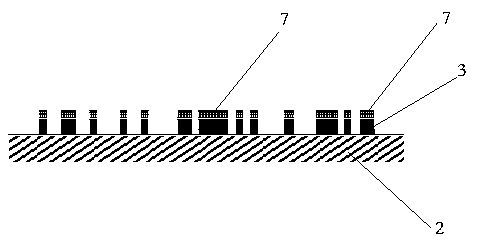

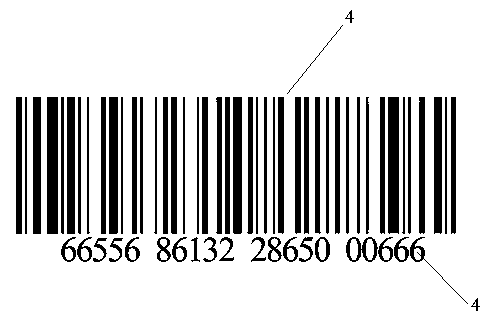

Anti-counterfeiting method of mobile phone identification code sawtooth

ActiveCN104794629BNo additional printing costsEasy to identifyCharacter printing data arrangement from carrierSpecial data processing applicationsComputer scienceMobile phone

The invention provides an anti-counterfeiting method by utilizing an intelligent mobile phone to identify code saw-teeth. The method comprises the steps of amplifying and photographing saw-teeth of a product code and image-text margin; storing the photographed saw-tooth characteristic information into an anti-counterfeiting system database to be used as anti-counterfeiting characteristic filing information. The method is simple and easy to implement, and for the user product of the existing drug electronic supervision code, the amplified picture of the saw-teeth is stored when the product is under the automatic quality inspection and is used as the anti-counterfeiting characteristic filing information to be stored. By implementing the method, the equipment investment is not increased, the procedure is not increased, the cost is not increased, an effective anti-counterfeiting function of the product can be realized, and the bug of the digital anti-counterfeiting technology such as the telegram code anti-counterfeiting technology can be blocked up.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

Method for preparing magnetic biochar from straw

InactiveCN105536700AOptimize structural configurationMeet greenOther chemical processesAlkali metal oxides/hydroxidesIron saltsCarbonization

A method for preparing magnetic biochar from straw includes the step of selecting of a straw material, wherein wheat straw, corn straw, rice straw or cotton straw is selected as the straw material, the straw material is pretreated by cleaning, then the straw material is dipped with a trivalent iron salt solution, and filtered by vacuum, then a filter cake is dried, and a finished magnetic biochar product can be obtained by carbonization treatment in inert gas conditions. The magnetic biochar can be obtained by dipping the straw material in the trivalent iron salt solution by a pyrolysis process, and a new way for the use of straw is provided.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

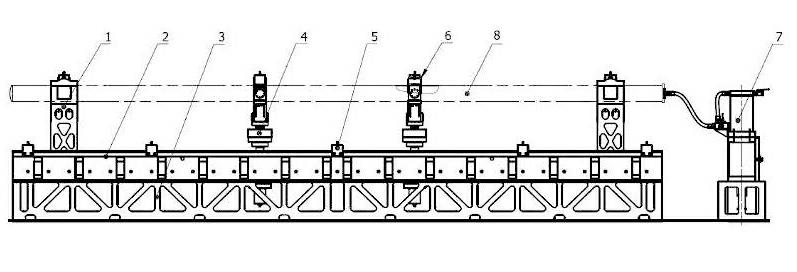

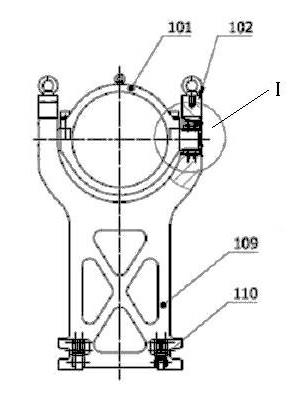

Testing machine for simulating fatigue life in full scale mode in marine environment of harbor pipeline

InactiveCN102141494AAvoid breakingSolve undetermined puzzlesMaterial strength using repeated/pulsating forcesInternal pressureStress conditions

The invention relates to a testing machine for simulating the fatigue life in a full scale mode in the marine environment of a harbor pipeline, and the testing machine belongs to the technical fields of new pipeline material development and structure design and mechanics performance testing, wherein two guide rail beams are fixedly connected with a workbench; two movable supports are respectively in sliding connection with the guide rail beams; two servo loading units are respectively in sliding connection with the guide rail beams; and an internal pressure loading unit is fixedly connected with the workbench. The testing machine provided by the invention has the advantages that the performance of the harbor pipeline is comprehensively and reliably analyzed; the loading type of any combination is realized; the mechanics performance, welding performance, fatigue life and the like of the pipeline are tested more comprehensively and more accurately by simulating the stress conditions of the harbor pipeline in a full-scale and full-direction mode; and the testing machine has important significance in effectively preventing the harbor pipeline from fracturing.

Owner:中机试验装备股份有限公司

Cattle freezing seminal fluid dilution and method for producing the same

InactiveCN101220345AImprove qualityImprove survival rateDead animal preservationTissue cultureFiltrationGlycerol

The invention discloses a frozen bovine semen diluent, and the consumption amounts of all the raw materials in 100ml of the diluent are: 0.8 to 1.2g of fructose, 1.4 to 1.6g of sodium citrate, 2.3 to 2.6g of TRIS, 7.5 to 9.5g of low-density lipoprotein, 5 to 8ml of glycerol, 0.085 to 0.12 million IU of penicillin and the rest is distilled water. The preparation method is that: the fructose, the sodium citrate and the TRIS are dissolved in the distilled water to be prepared into a base liquid; penicillin G sodium and the low-density lipoprotein are added in the base liquid to prepare a I liquid; the glycerol is added in the I liquid to prepare a II liquid; then the pH value is adjusted to 6 to 7.5, then a filtration and a sterilization are carried out, and the liquid is cooled until reaching the room temperature and then arranged in a refrigerator of 2 - 5 DEG C for standby. The frozen bovine semen diluent of the invention has good and reliable effect, which can provide high-quality and excellent straw frozen semen for bovine artificial insemination and have very broad market application prospect.

Owner:NORTHWEST A & F UNIV

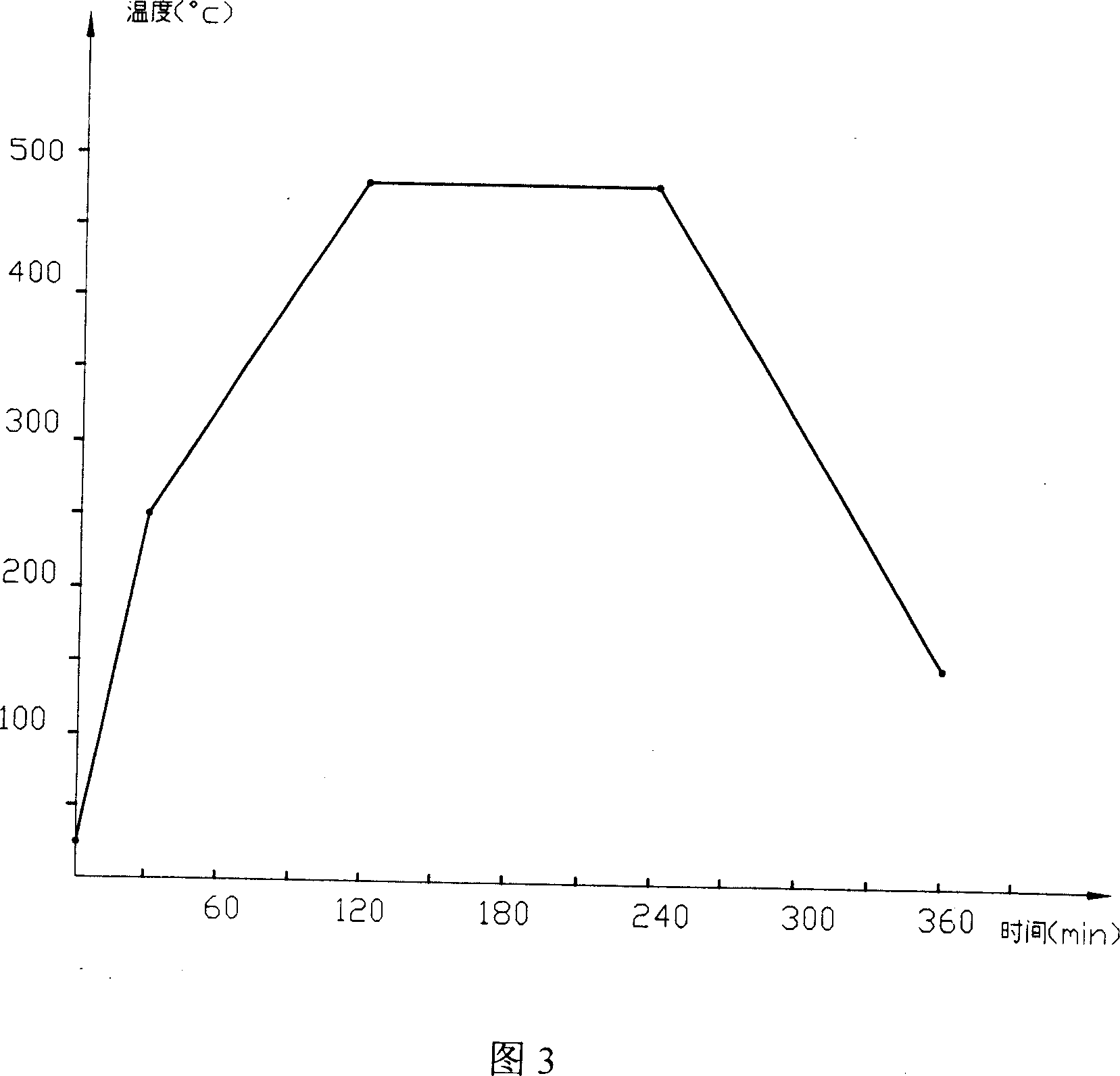

Method for adjusting/reducing internal stress of laser additive manufacturing part

InactiveCN107225244AIncreased tendency to crackImprove impact performanceAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInternal stress

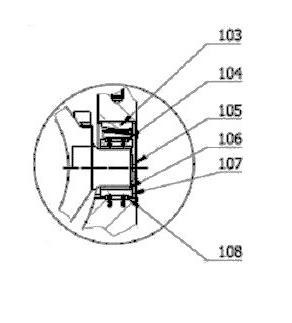

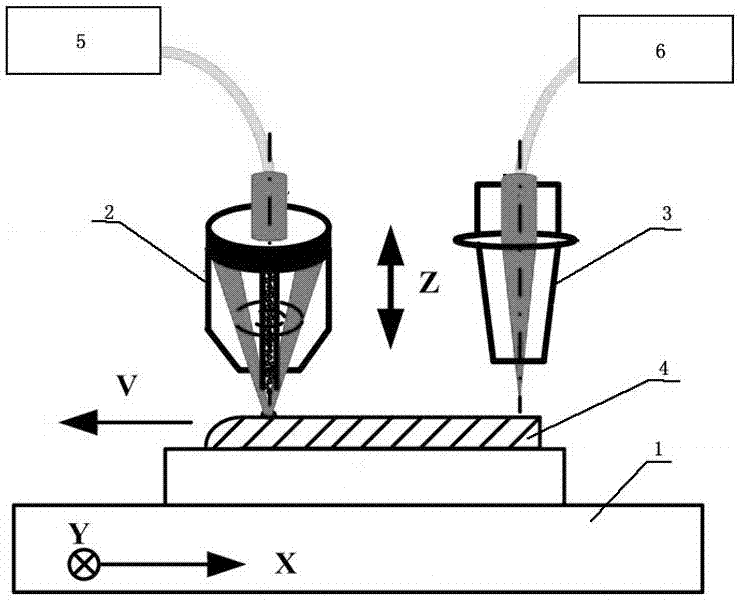

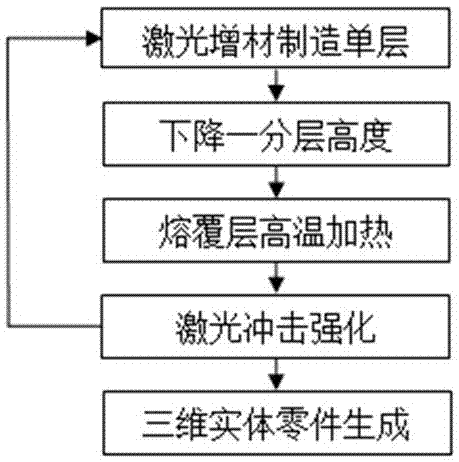

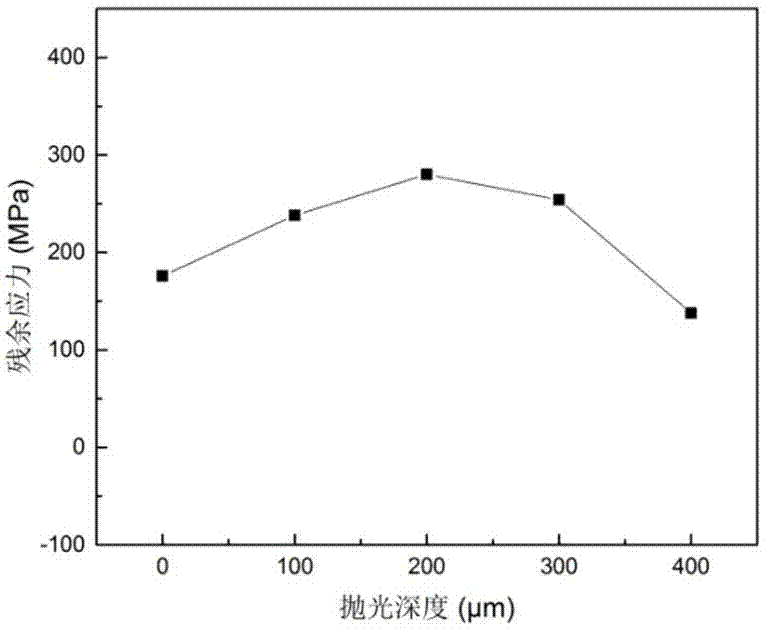

The invention discloses a method for adjusting / reducing the internal stress of a laser additive manufacturing part. The method is used for laser coaxial powder feeding additive manufacturing, and comprises the following steps that (1) a three-dimensional additive manufacturing part model is established, and contour level information of the part is obtained; (2) a workbench is moved to a fusion covering station, and coaxial powder feeding laser additive manufacturing is conducted through a fusion covering head, and after processing of a fusion covering layer is completed, the workbench is descended by the height of one layer; (3) the workbench is moved to an impacting station, bulk heating is conducted on the fusion covering layer, after the fusion covering layer reaches the set temperature, laser impacting and strengthening are conducted on the fusion covering layer through an impacting head, and the set temperature is higher than the recrystallization temperature of a material and lower than the melting point of the material; and (4) the steps (2) and (3) are conducted repeatedly till the three-dimensional part is manufactured. According to the method, the residual compressive stress introduced by the laser impacting and strengthening technology is utilized to adjust and counteract the pulling stress in the hot melting process, and the laser thermal composite additive manufacturing method controllable in internal stress is achieved.

Owner:KUSN BAOJIN LASER TAILOR WELDED

Thermal insulation putty for internal walls and application method thereof

The invention discloses a thermal insulation putty for internal walls, which is characterized in that the raw material at least contains the following components: component 1: 1 part by mass of solution containing polyhydroxy high-molecular compounds on the basis of polyhydroxy high-molecular compounds; component 2: 0.1-1 part of isocyanate foaming crosslinking agent; component 3: 10-20 parts of thermal insulation filler; component 4: 0.5-2 parts of silica sol; and component 5: 0.1-2 parts of inorganic powder material. The total water content in the solution containing polyhydroxy high-molecular compounds and silica sol is 8-16 parts. The method comprises the following steps: uniformly mixing the components to form a paste; plastering the paste on the surface of the internal wall of a building by a plastering construction technique, wherein the plastering thickness is 3-20 millimeters; forming distributed bubbles in the plastering layer, and crosslinking and hardening the component 1 to form the thermal insulation putty layer. The thermal insulation putty for internal walls have low volume weight and low thermal conductivity; and the foamed high polymer material is used as an adhesive and has the phase-change energy storage effect, thereby enhancing the thermal insulation property of the putty.

Owner:FUKE TECH (SUZHOU) CO LTD

Mobile phone identification code saw-tooth anti-counterfeiting method

ActiveCN104794629ANo additional printing costsEasy to identifyStampsCharacter and pattern recognitionDrug productComputer science

The invention provides an anti-counterfeiting method by utilizing an intelligent mobile phone to identify code saw-teeth. The method comprises the steps of amplifying and photographing saw-teeth of a product code and image-text margin; storing the photographed saw-tooth characteristic information into an anti-counterfeiting system database to be used as anti-counterfeiting characteristic filing information. The method is simple and easy to implement, and for the user product of the existing drug electronic supervision code, the amplified picture of the saw-teeth is stored when the product is under the automatic quality inspection and is used as the anti-counterfeiting characteristic filing information to be stored. By implementing the method, the equipment investment is not increased, the procedure is not increased, the cost is not increased, an effective anti-counterfeiting function of the product can be realized, and the bug of the digital anti-counterfeiting technology such as the telegram code anti-counterfeiting technology can be blocked up.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

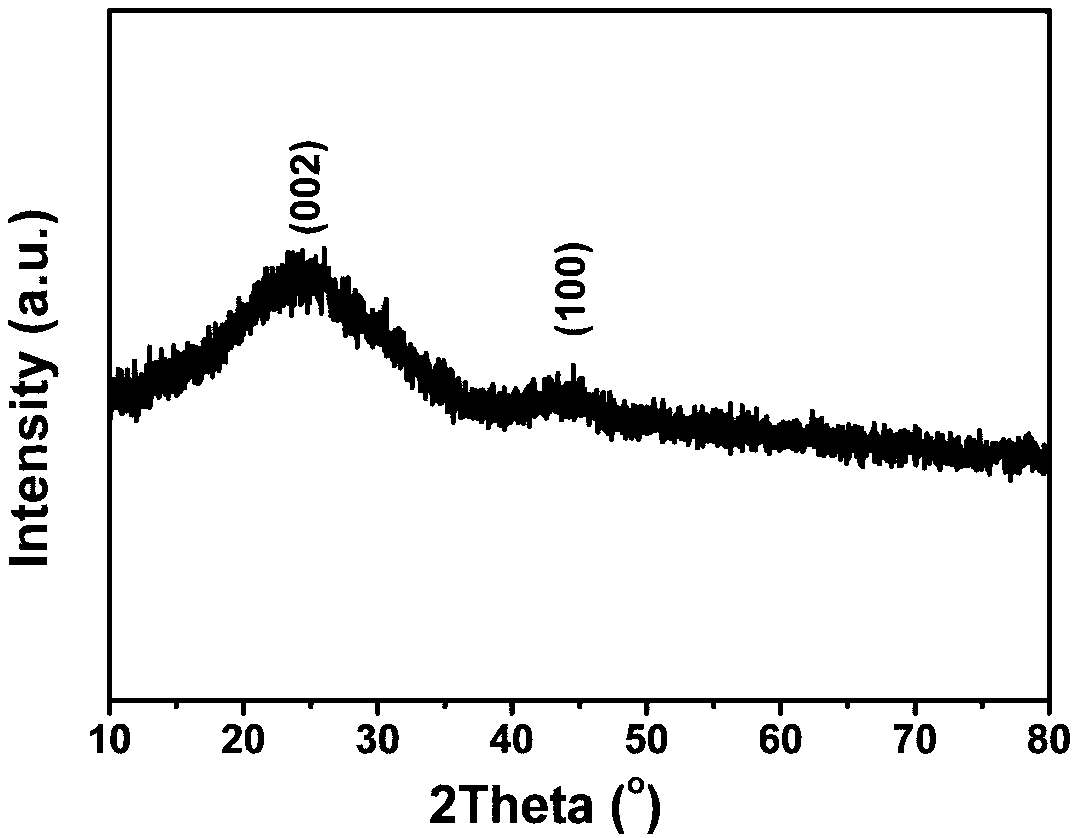

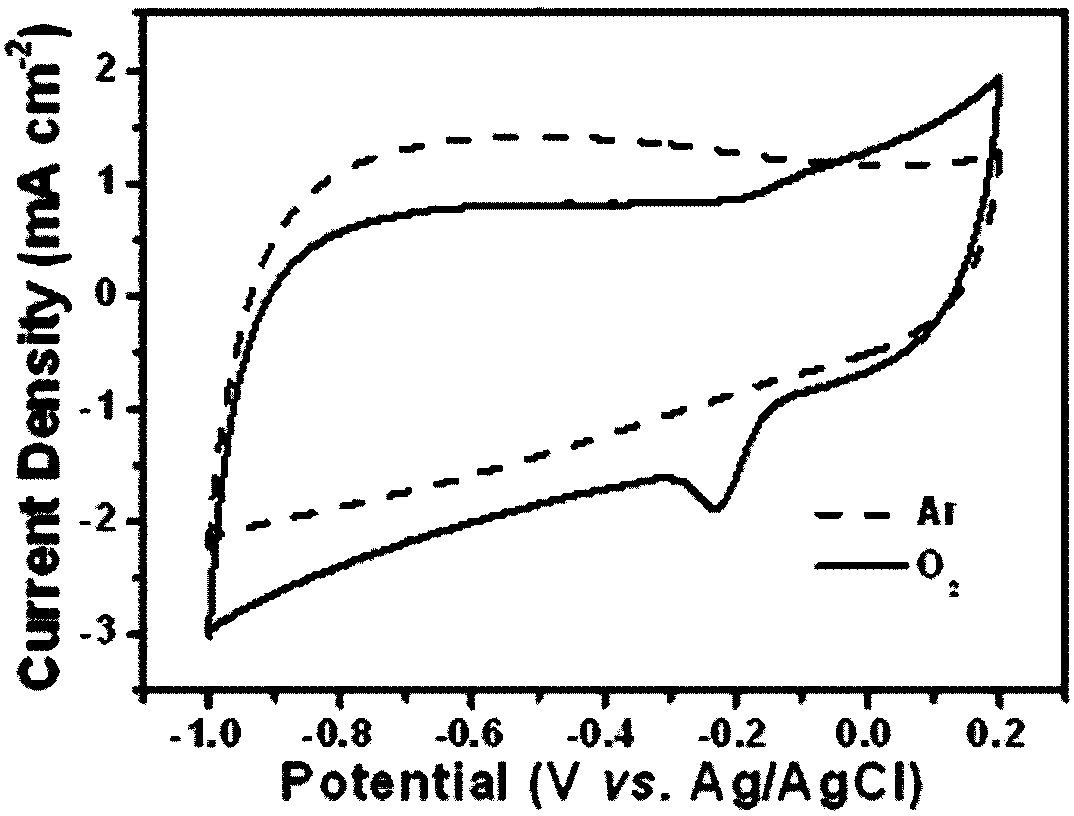

Nitrogen-doped carbon-supported monoatomic oxygen reduction catalyst and preparation method thereof

ActiveCN109841854ALarge specific surface areaHigh porosityCell electrodesBiological activationNitrogen doped

The invention relates to a nitrogen-doped carbon-supported monoatomic oxygen reduction catalyst and a preparation method thereof, and belongs to the technical field of electrocatalytic materials. Themethod is characterized in that a composite of a Zn-based bimetallic MOF and glucose is used as a precursor, the catalyst is obtained by high-temperature heat treatment and post-activation in ammoniagas, the monoatomic content is 2wt% to 4wt%, and the nitrogen doping amount is 4wt% to 15wt%. The addition of volatile Zn can increase the spatial distance of metal atomic nodes, the glucose can makea three-dimensional ZIF form a cross-linked structure, the structure and composition of a modulating material can improve the electrocatalytic activity, the nitrogen content can be further increased by post-activation treatment in the ammonia gas, and therefore, the electrochemical activity is improved. At the same time, the preparation method has the advantages of low cost, simple steps, mild conditions, good repeatability and easy mass production. The monoatomic catalyst exhibits good performance in an electrocatalytic oxygen reduction reaction (ORR) under an alkaline condition and has certain market application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

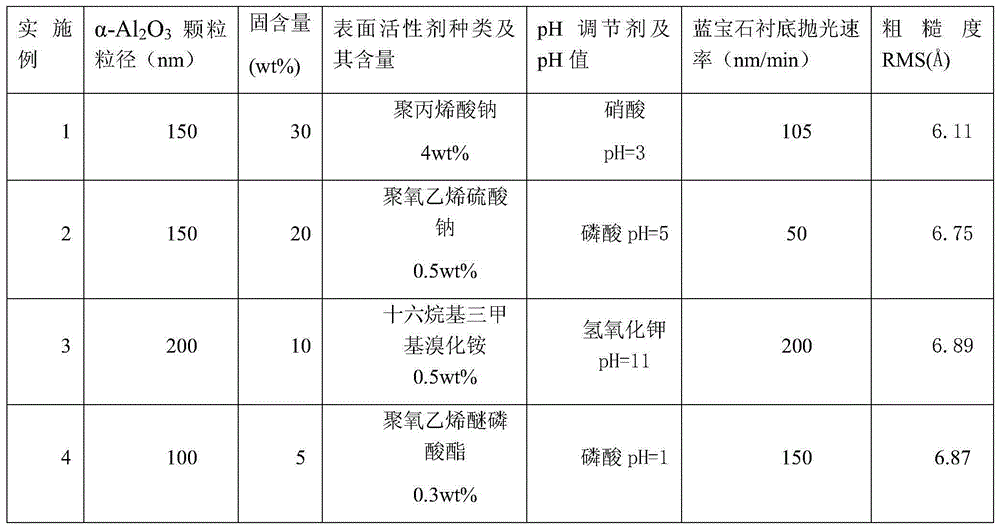

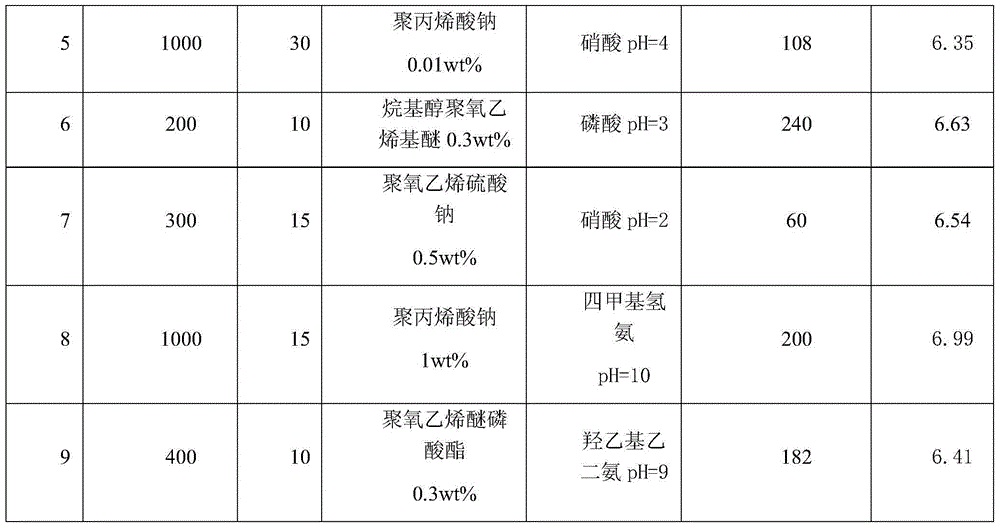

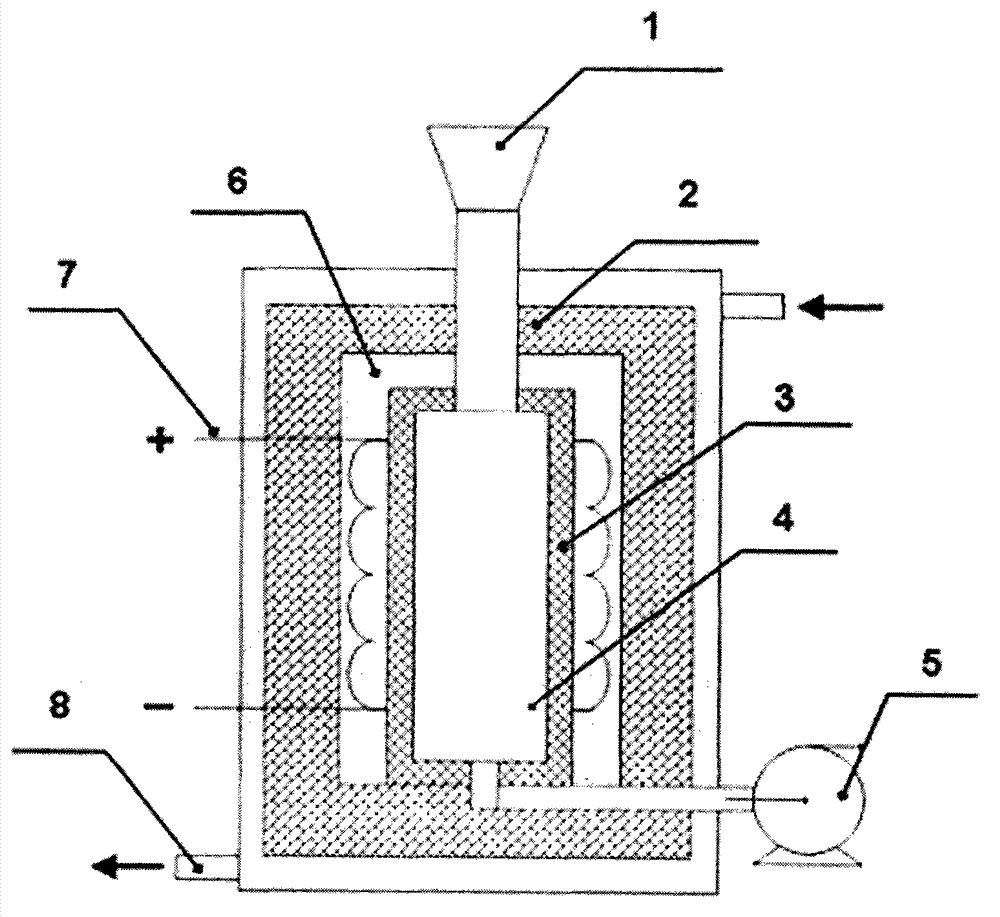

Alumina-based chemical mechanical polishing slurry

ActiveCN104559798ACreativeSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesMetallurgyCompound (substance)

The invention discloses alumina-based chemical mechanical polishing slurry. In terms of the total mass of the chemical mechanical polishing slurry, the chemical mechanical polishing slurry comprises components in percentage as follows: 0.1-30wt% of polishing particles, 0.01-10wt% of a surfactant and the balance of a pH regulator and an aqueous medium. The polishing speed of the chemical mechanical polishing slurry to a sapphire substrate material can be controlled to range from 50 nm / min to 200 nm / min, and meanwhile, the surface roughness is decreased to below 15 angstroms; speed-controllable, low-surface-damage and residue-free polishing can be performed on the sapphire substrate material by the aid of the polishing slurry.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

Preparation method of aluminum oxide metal ceramic reinforced iron-based composite

The invention relates to a preparation method of aluminum oxide metal ceramic reinforced iron-based composite, namely, aluminum-oxide-based metal ceramic is used as a structural framework and one of effective components to prepare metal ceramic iron-based composite, which is consistent in structure, even in metal phase distribution, high in mechanical performance, and high in wear resistance, under certain pressure by melt casting and further processing. The preparation method includes the steps of firstly, preparing aluminum oxide metal ceramic framework base pretreated by activated Si into surface-modified prefabricated ceramic part with a silk-screen-shaped pore structure by high-temperature sintering; secondly, preparing a pouring sand module; thirdly, placing the pouring sand module into a casting sand box for pretreating, pouring, vacuumizing, and allowing iron-based molten metal to fully permeate into pores of the prefabricated ceramic part to form a rigid integrity; and fourthly, performing heat treatment and air cooling to obtain the iron-based composite with closely combined aluminum oxide metal ceramic and iron base.

Owner:北京康盛宏达科技有限公司

Method of manufacturing cordyceps sinensis (Berk.) sacc polysaccharide by liquid state fermentation of rice bran and bran complete feed

A manufacturing method for cordyceps sinensis (Berk.) sacc polysaccharide relates to the technical field of food microorganism application, and comprises the following steps: weighing raw materials, wherein rice bran is 1-3 g per 100 ml, bran is 1-3 g per 100 ml, potassium dihydrogen phosphate is 0.09-0.18 g per 100 ml, and magnesium sulphate is 0.04-0.08 g per 100 ml; material filling with natural pH after adding required water, and sterilizing and cooking at the temperature of 121 DEG C for 30 min; inoculating cordyceps sinensis (Berk.) sacc CCTCCM2013285 liquid seed after cooling, wherein the inoculation amount is 8-10%, the fermentation temperature is 23-28 DEG C, and the fermentation time is 4-7 d; respectively obtaining exopolysaccharides and mycelia polysaccharide after conducting deproteinization, alcohol precipitation, centrifugal separation, and vacuum drying on centrifugal separation liquid extracted through breaking cell wall hot water of fermentation material centrifugal separation liquid and hypha. The method better realizes the purpose that rice bran and bran are efficiently and high-valuedly transformed to cordyceps sinensis (Berk.) sacc polysaccharide after being subjected to liquid state fermentation.

Owner:JIANGSU UNIV

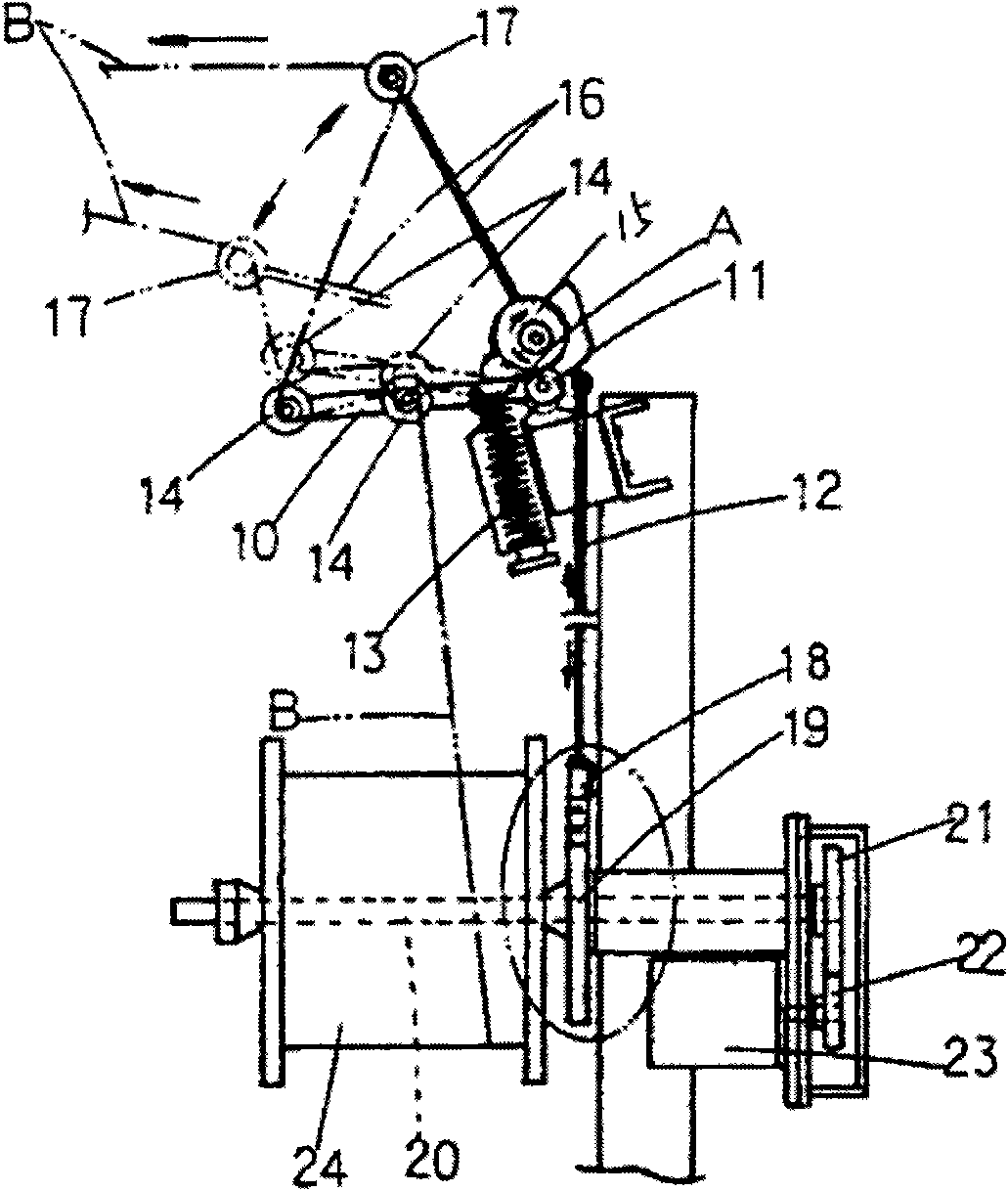

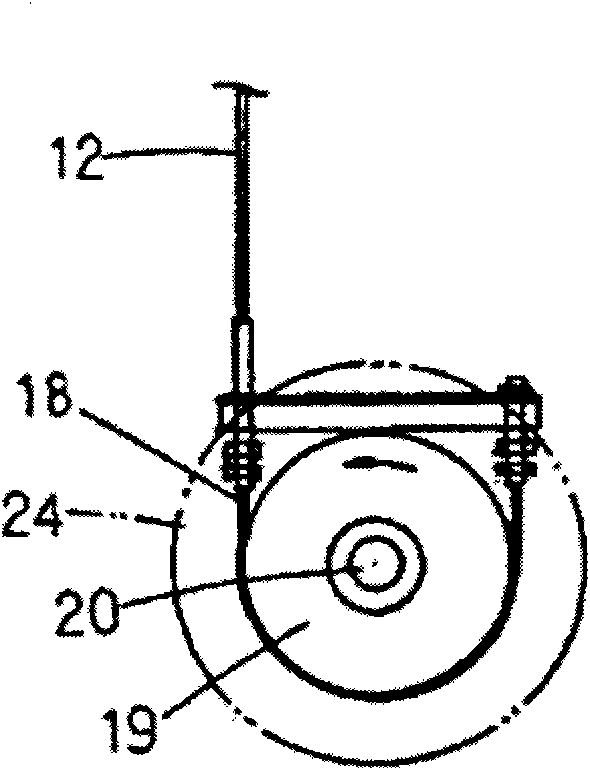

Design method of line unwinding constant tension control device in line winding system

The invention relates to a design method of a line unwinding constant tension control device in a line winding system. A servomotor and a line unwinding wheel are arranged on a frame, the line unwinding wheel is driven by the servomotor, a pulley block which comprises two fixed pulleys and a movable pulley is arranged on the frame behind the line unwinding wheel, the movable pulley is arranged between the two fixed pulleys and is arranged on a swing rod, the swing rod is articulated with the frame, an air cylinder is articulated on the frame, a piston rod of the air cylinder is connected with the swing rod in a driving mode, a tension sensor is arranged on the frame behind the pulley block, lines output by the line unwinding wheel are introduced into the tension sensor by the pulley block, and the lines which pass through the tension sensor are towed to a line winding host machine. The loading force of the air cylinder has a proportional relation with force and a force arm which act on the movable pulley of the swing rod, and the constant tension is ensured in a small angle. When the swing rod is lower than a balance position, inverse voltage is output to control the servomotor to wind the lines; when the swing rod is higher than the balance position, positive voltage is output to control the servomotor to unwinding the lines; and when used, the line unwinding content tension control device has higher stability.

Owner:苏州工业园区慧博自动化技术有限公司

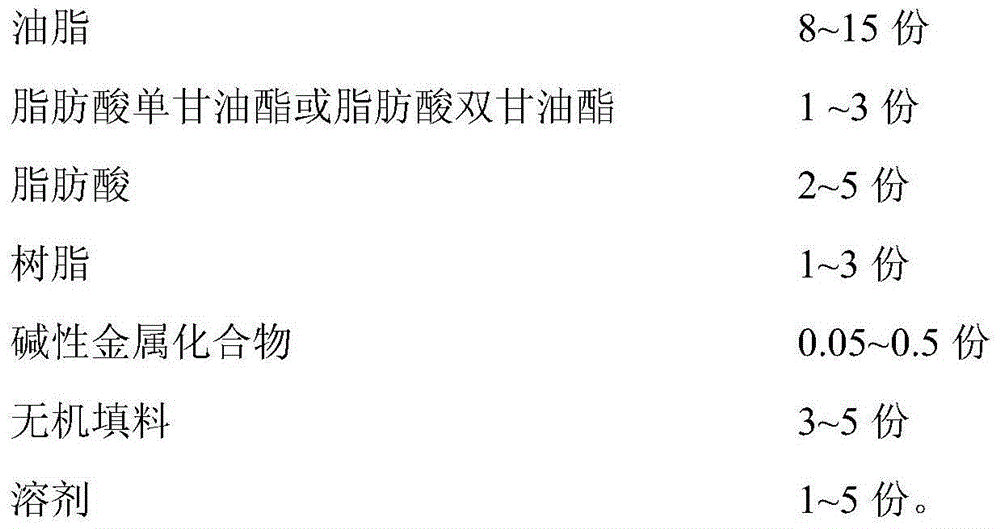

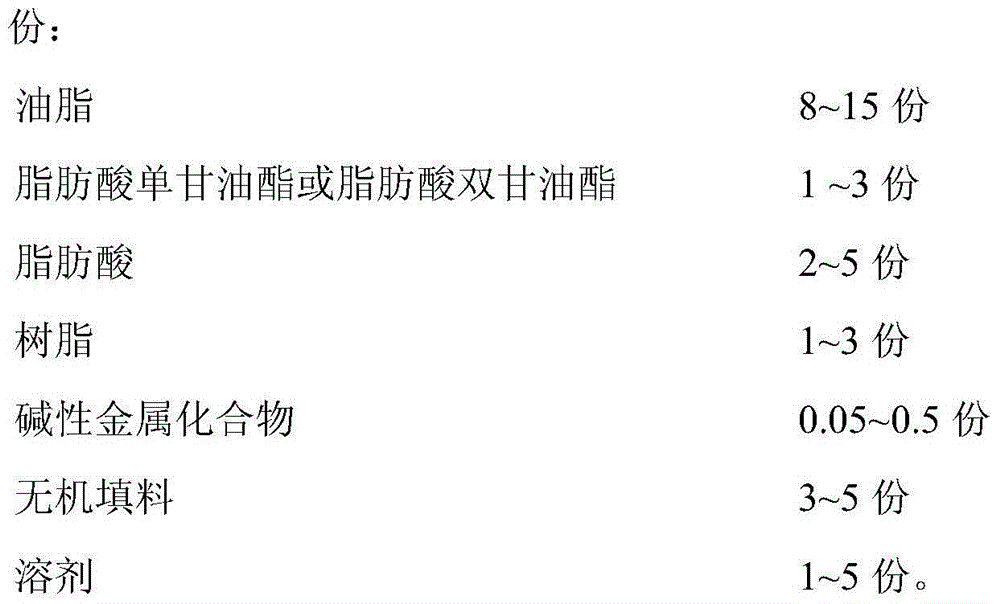

Concrete releasing agent for aluminum alloy template of building

InactiveCN104629885ABlock penetration throughAvoid destructionCeramic shaping apparatusLubricant compositionMonoglycerideDiglyceride

The invention provides a concrete releasing agent for an aluminum alloy template of a building. The releasing agent comprises the following components in parts by weight: 8-15 parts of grease, 1-3 parts of fatty acid monoglyceride or fatty acid diglyceride, 2-5 parts of fatty acid, 1-3 parts of resin, 0.05-0.5 parts of basic metal compound, 3-5 parts of inorganic filler and 1-5 parts of solvent. The releasing agent coats the aluminum alloy template of the building and is used in the concrete pouring technology, the concrete releasing quality is good without obvious blister, and the releasing agent residue surface matter is easily removed and the releasing agent is suitable for use for single or multiple times, and the service life of the template is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

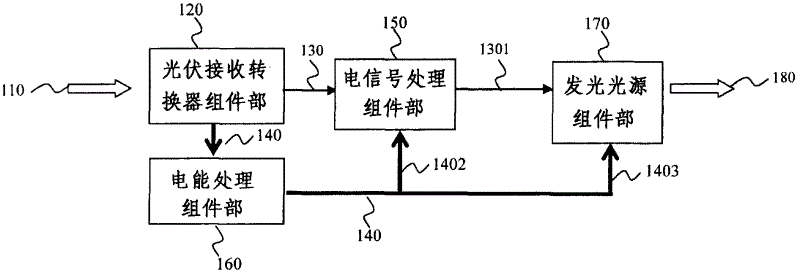

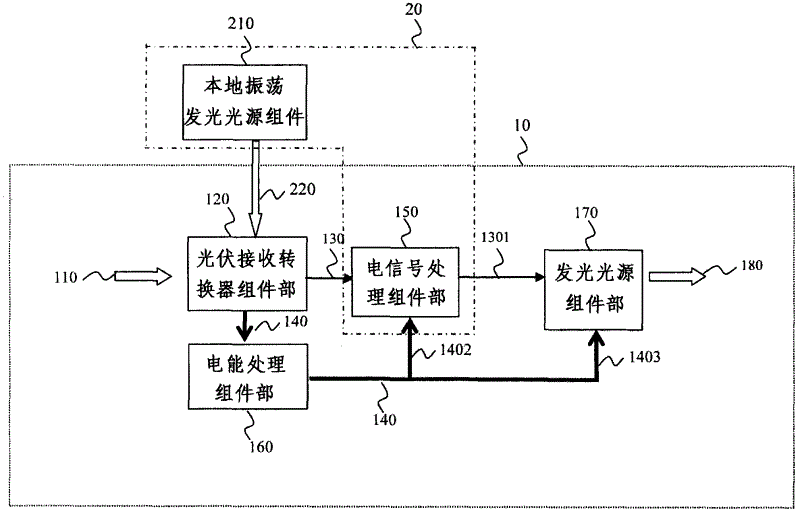

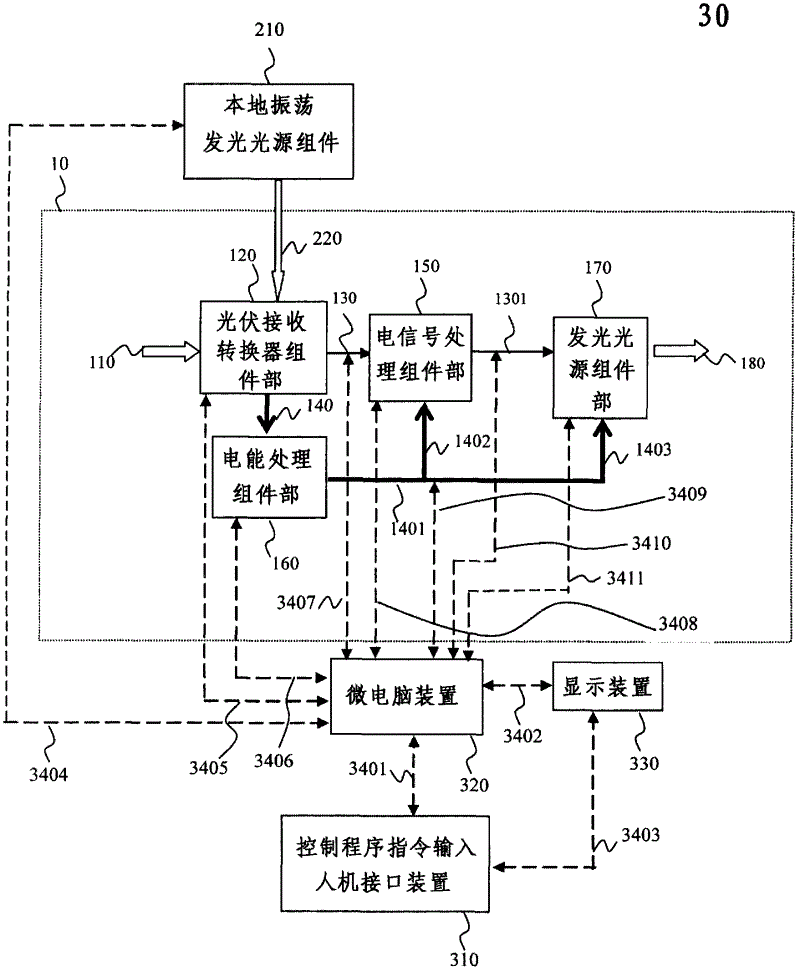

Optical signal and relay method, apparatus, system and application of luminous energy transmission

ActiveCN102624452ACreativeRadio-over-fibreElectromagnetic repeatersElectricityTelecommunications link

The present invention provides an optical signal and a relay method, apparatus, system and application of luminous energy transmission, relating to a wireless optical communication signal and a connection relay method, apparatus, mechanism, system, network and Internet of wireless luminous energy transmission. In one embodiment, inputted optical signal and luminous energy irradiate a photovoltaic receiving converter assembly portion, and an electrical signal and electrical energy are generated; through an electric signal processing assembly portion and an electrical energy assembly portion, a reproduced electric signal and electrical energy are recovered and then are sent to a luminescent light source assembly portion through an electrical signal bus circuit to be converted into an optical signal and luminous energy output, and functions of a relay signal and relay energy can be reached at the same time. In other embodiments, a local oscillator light source assembly, an electrical signal access device and a programmable device are added respectively. A mechanism embodiment explains that the relay apparatus of the invention can convert a space layout method and system of a communication link. According to the invention, functions of utilizing a repeater to relay bridging between various networks and providing the Internet are revealed.

Owner:CHERRY TREE CONSULTING

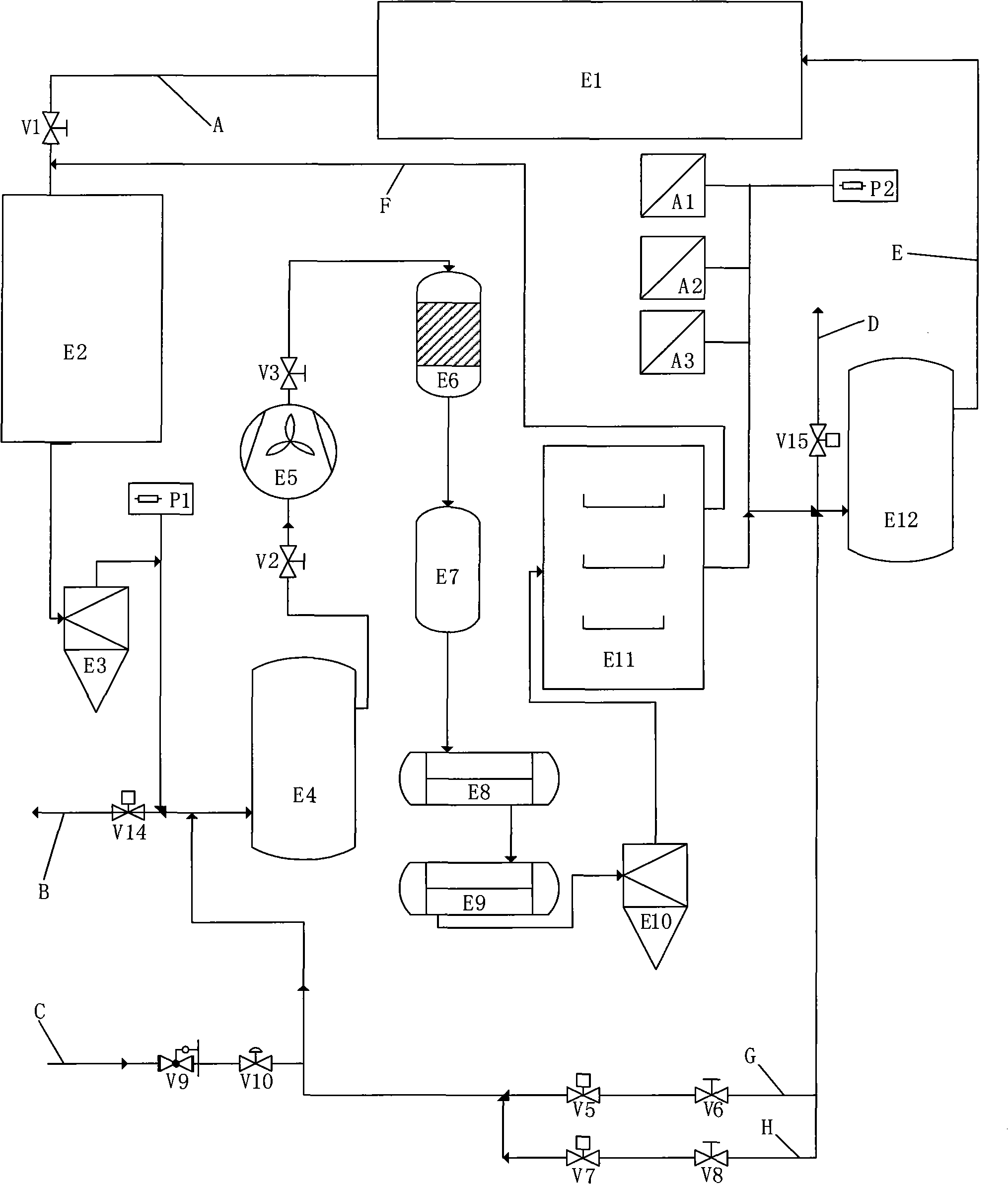

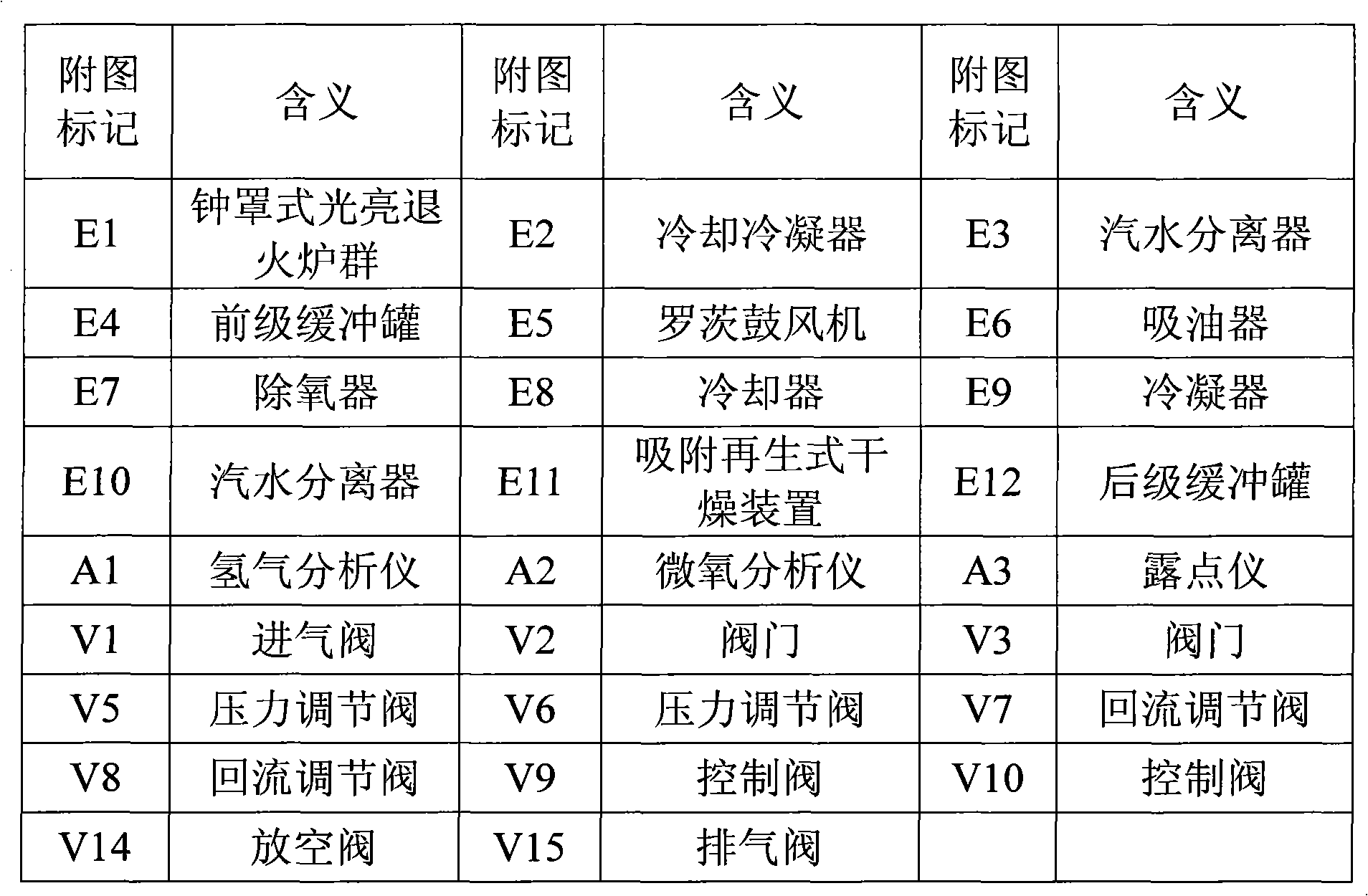

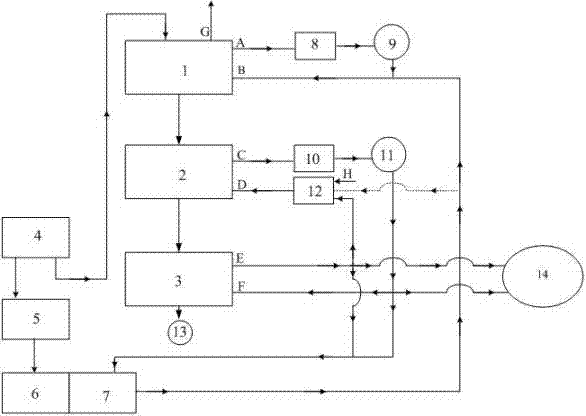

Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

ActiveCN101956061AAvoid direct burningAvoid emptyingMaintainance of heating chambersBell type furnacesBuffer tankDeaerator

The invention relates to a process and a device for recovering and recycling protective gas of a bell-type bright annealing furnace. The process comprises the following steps of: performing cooling and condensation of oil and gas in refluxing protective gas of a bell-type bright annealing furnace group; allowing the cooled and condensed protective gas to enter a water separator to remove most of water and oil; allowing the cooled protective gas from which the oil and the gas are removed to enter a preceding stage buffer tank; after the protective gas is buffered by the preceding stage buffer tank, pressurizing by using a roots blower; allowing the pressurized protective gas to enter an oil absorption device to remove oil and enter a deaerator to remove oxygen; reacting in the deaerator to generate water and discharge heat; cooling the protective gas by using a cooler and removing water from the protective gas by using a condenser; allowing the cooled and dehydrated protective gas to enter the water separator to separate water; allowing the protective gas to enter an absorption regeneration drying device for removing water and impurities deeply; and performing decompression and voltage stabilization on the purified gas by using a post-stage buffering tank and then supplying the purified gas to the bell-type bright annealing furnace group. Through the process and the device, the refluxing protective gas of the bell-type bright annealing furnace group is recovered and purified and enters the annealing furnace to be recycled as the protective gas again.

Owner:苏州品源气体设备有限公司

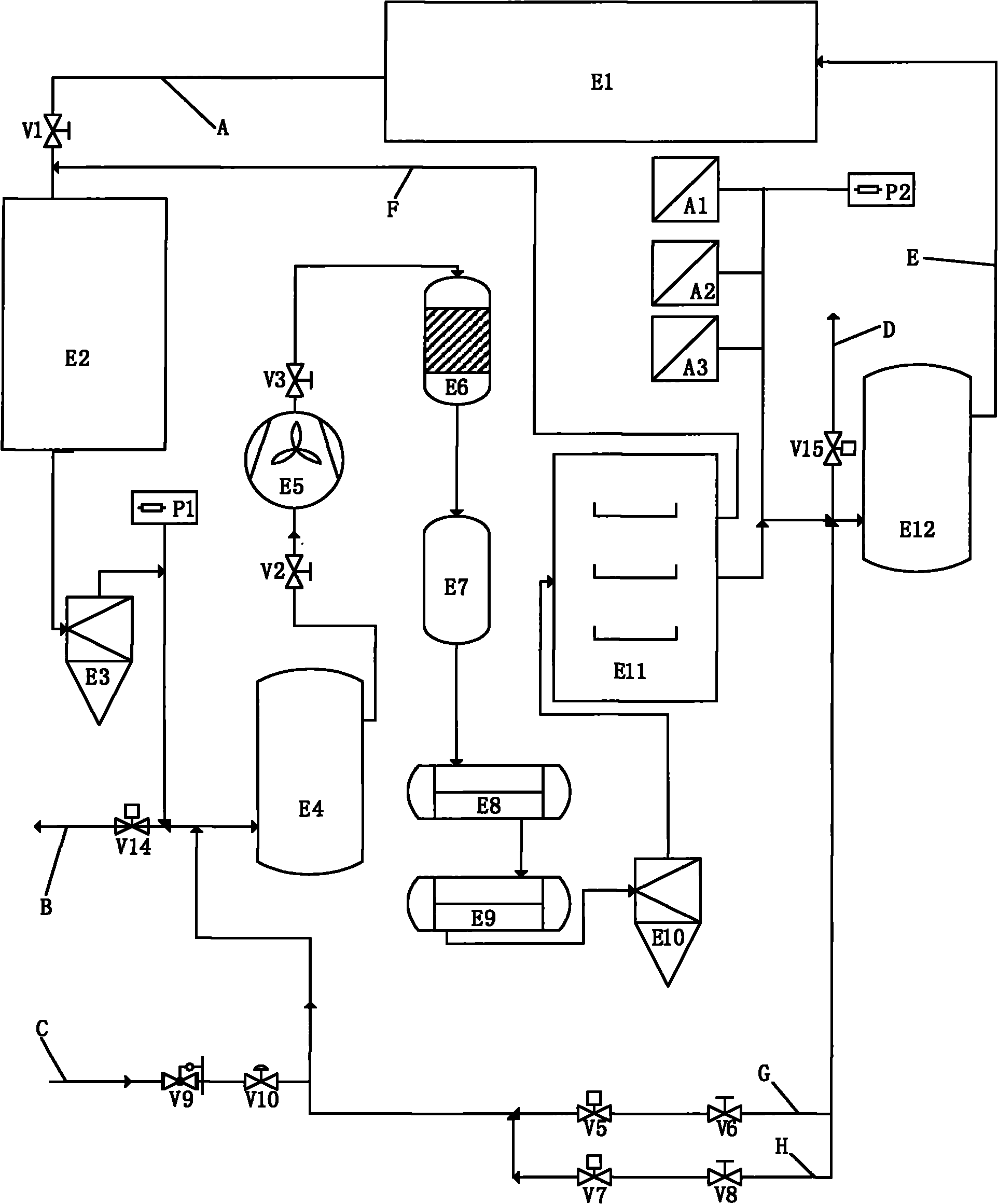

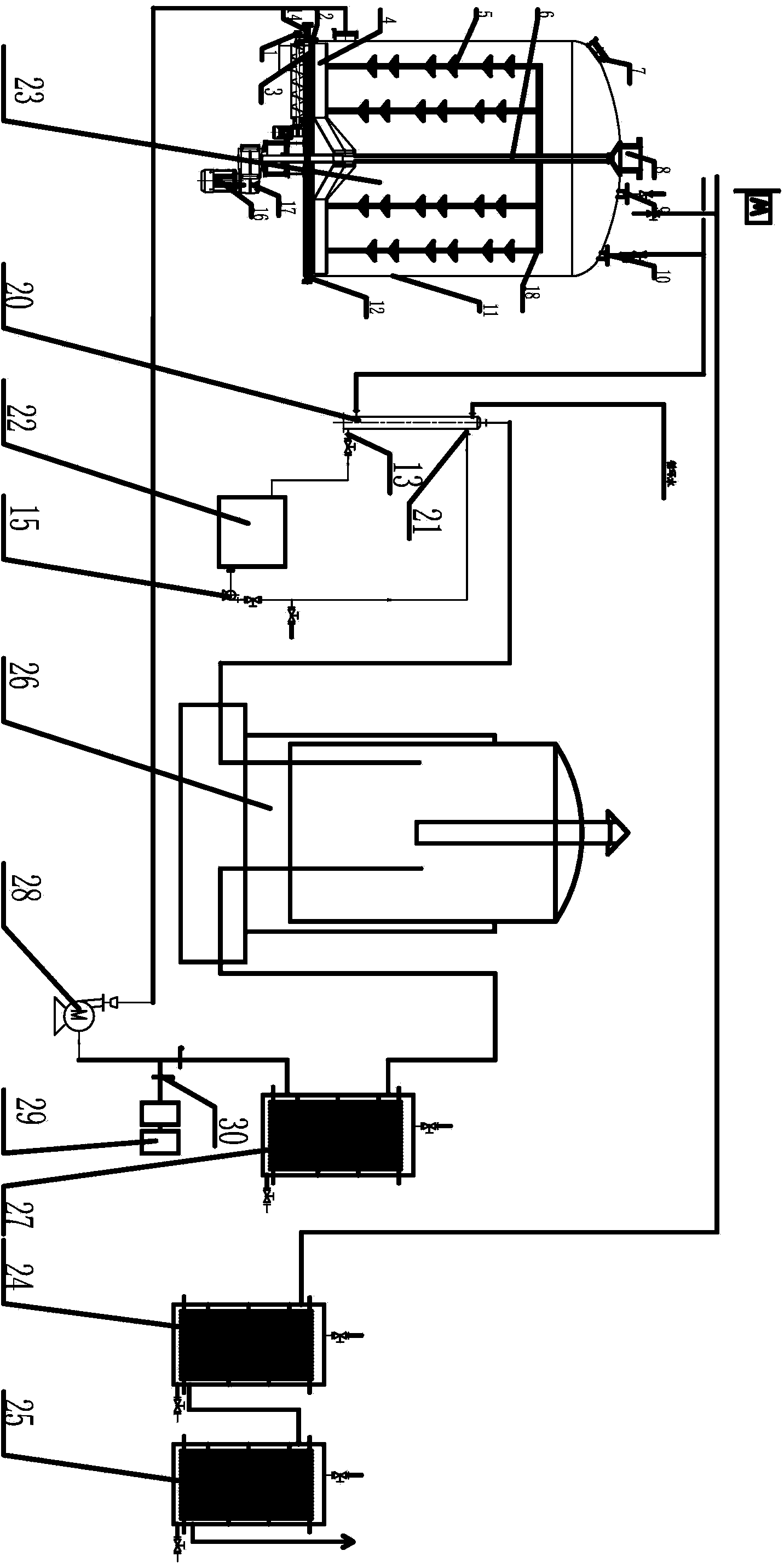

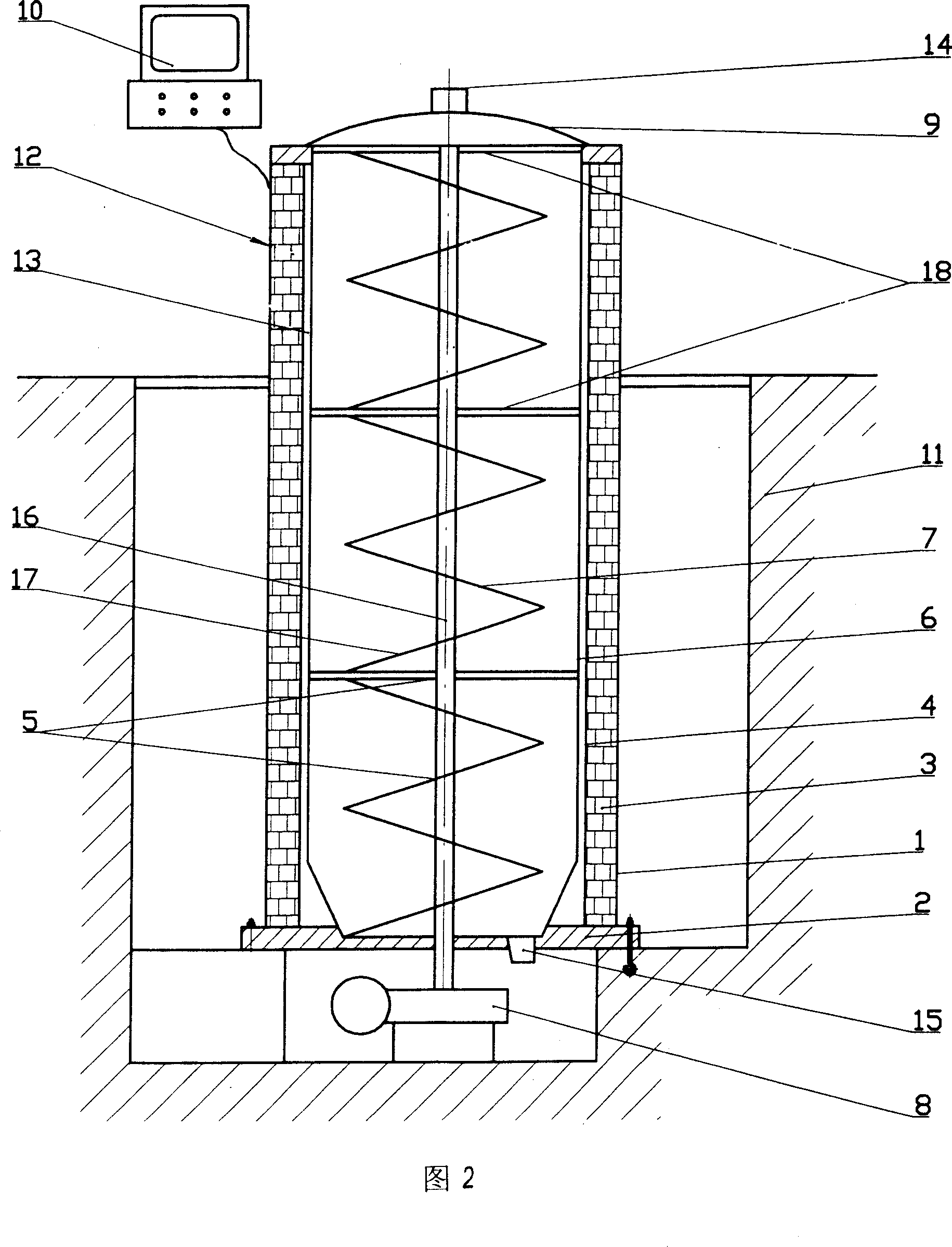

Solid-state vertical fertilization, self-circulation cooling and distillation integrated device and method

ActiveCN103627621AHigh layer thickness of fermented materialHigh equipment fill rateBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationIntegrated devices

The invention belongs to the technical field of biological fermentation and distillation and specifically relates to a solid-state vertical anaerobic (aerobic) fermentation, self-circulation cooling and distillation integrated device and method. The device adopts a technical scheme comprising a solid-state vertical fermentation tank, a washing tower, a washing pump, a gas cabinet, a circulating gas cooler, a circulating fan, a filter and a distillation product cooler, wherein the solid-state vertical fermentation tank comprises a tank body, a stirring device arranged at the bottom of the tank, a discharge device, a feed port, a distillation product gas outlet, a biochemical reaction gas outlet, a manhole, a discharge rake, a distillation steam inlet and a circulating gas cooling air inlet. The solid-state vertical fermentation tank with high fill rate is firstly adopted, automatic discharge, high production efficiency and controllable temperature can be realized, and the device is simultaneously suitable for anaerobic and aerobic solid-state fermentation; and at the end of fermentation, the device can be utilized for performing distillation on materials to be distilled, reduce the handling of the materials and simultaneously reduce the loss of distillation products caused by volatilization in transit.

Owner:QILU UNIV OF TECH +1

A Method to Mitigate Distributed Denial of Service Attack

InactiveCN102281295AMitigate Distributed Denial of Service AttacksStrong noveltyTransmissionIp addressEngineering

The invention discloses a method for easing distributed denial of service attacks, which solves the defects in the prior detection or defense technologies. The method provided by the invention comprises the following steps of: presetting a group of regional scope presented by an IP (Internet Protocol) address block, and a threshold of the number of messages of a protocol type or a message property allowed by each sub-region in the regional scope; when receiving one message of the corresponding protocol type or message property, searching the sub-region to which the message belongs according to a source IP address; if a cv (current value) of the number of the messages of the protocol type or message property corresponding to the sub-region to which the message belongs is more than 0, subtracting 1 from the cv, and further processing the received messages regularly according to the protocol type or message property; if the cv is equal to 0, or directly discarding the messages or discarding the messages after recording related information of the messages; aiming at the request on easing different types of distributed denial of service attacks, concurrently executing different recovery processing for the cv of the number of the messages of the corresponding protocol type or message property in corresponding sub-region within a given scope. The method is used in an IP network.

Owner:HEILONGJIANG UNIV

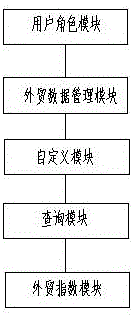

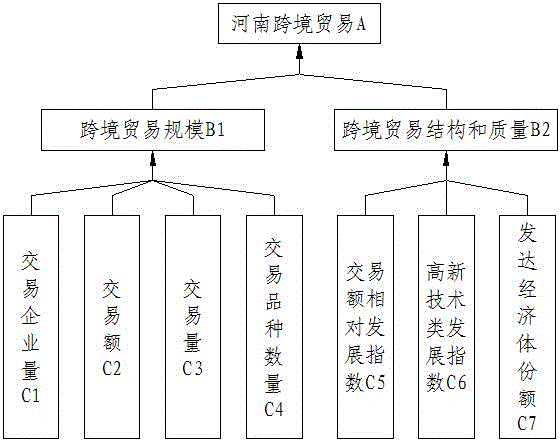

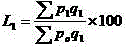

Big data analysis system and method for cross-border trade

InactiveCN105809482AImprove rationalityHighly creativeMarket data gatheringData managementData analysis system

The invention relates to the field of computer, specifically relates to a big data analysis system and a method for cross-border trade, and the system comprises the following modules: a user role module, a foreign trade data management module, a self-defining module, a query module and a foreign trade index module; all in all, the system and method have advantages of creativity, rationality, low time consumption, low cost, wide application range, accurate data and high efficiency and can accurately access present cross-border trade condition.

Owner:ZHENGZHOU NORMAL UNIV

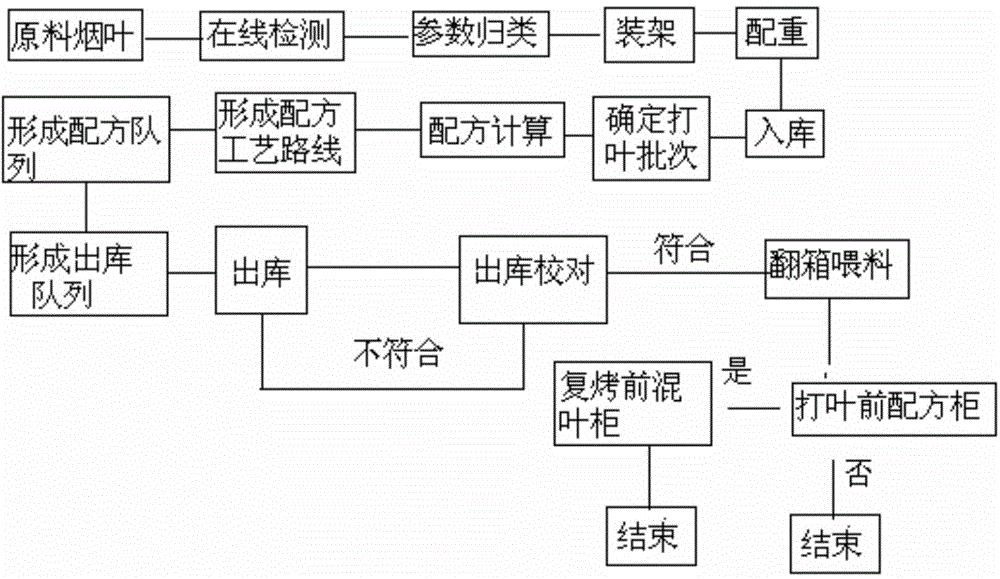

Tobacco formula uniformity regulating and controlling method

InactiveCN104432474AImprove uniformityOptimizing the mixing processTobacco preparationCo-operative working arrangementsInformatizationAutomatic control

The invention discloses a tobacco formula uniformity regulating and controlling method. The tobacco formula uniformity regulating and controlling method sequentially comprises the following steps of scanning and detecting raw material tobaccos by using a detection device to obtain detection parameters; dividing values of the detection parameters into a plurality of intervals, wherein the raw material tobaccos with the values of the detection parameters in the same interval are at the same grade; racking the raw material tobaccos at the same grade according to the set weight to obtain tobacco boxes, wherein RFID labels recording corresponding grades are posted on the tobacco boxes,; arranging the tobacco boxes on goods allocations of high racks in a high-bay depot, wherein the tobacco boxes at the same grade are evenly distributed on the different high racks; exporting corresponding tobacco boxes according to a formula process route and conveying the tobacco boxes to a feeding bin so as to perform feeding and cabinet distribution. The industrial and large-scale tobacco formula uniformity regulating and controlling method can basically achieve informatization and automatic control in the whole course, manpower and material resources are saved, and further the tobacco lamina quality uniformity is improved.

Owner:HUAHUAN INT TOBACCO +1

Novel tubular hard surfacing material

ActiveCN101380698ANot easy to fall offImprove wear resistanceWelding/cutting media/materialsSoldering mediaEngineering toolAlloy

The invention provides a novel tubular hard-surface resurfacing welding material which includes a tubular skin and filling powder. The novel tubular hard surface resurfacing welding material includes the components as follows: 20 to 40 percent of steel as well as 60 to 80 percent of filling powder; the components of the filling powder is as follows: 35 to 75 percent of spherical hard alloy grains, 15 to 40 percent of carbonated casting tungsten grains, the surface of which are processed, 5 to 20 percent of spherical carbonated casting tungsten grains, 2 to 6 percent of SiMn alloy powder, 0.2 to 0.6 percent of resin powder as well as 0.1 to 2 percent of metal Nb. The spherical hard alloy grains, the carbonated casting tungsten grains and the spherical carbonated casting tungsten grains with thermal stability are adopted, thus remarkably improving the wear resistance and the impact resistance of a resurfacing welding layer; less Nb element is added to improve the resurfacing welding manufacturability, thereby improving the intensity and the toughness of a substrate metal, enhancing the anti-impact capacity of the resurfacing welding layer and the fixing capacity to the hard grains as well as prolonging the service life of the resurfacing welding layer. The tubular hard surface resurfacing welding material is widely applied to the wear-resistance reinforcement on the working surfaces like the gear surface of a steel gear roller bit, a back cone, a palm tip and the other engineering tools.

Owner:SHAREATE TOOLS

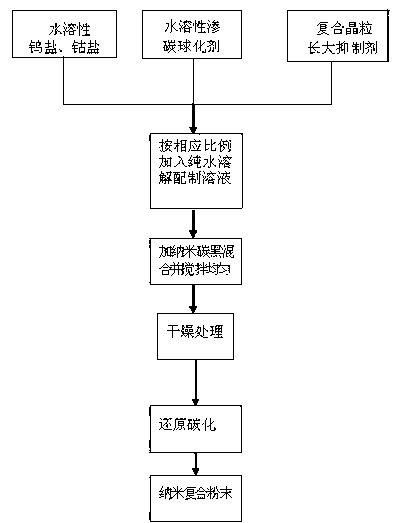

Method for manufacturing nanometer tungsten/cobalt carbide composite powder

The invention discloses a method for manufacturing nanometer tungsten / cobalt carbide composite powder. The method includes steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, adding nanometer carbon black accounting for 1-10% of the total mass of the aqueous solution into the mixed aqueous solution obtained in the first step, stirring the nanometer carbon black in the mixed aqueous solution at the rate of 10-30 revolutions per minute for 30-60 minutes so that the nanometer carbon black can be uniformly mixed in the mixed aqueous solution; thirdly, performing quick low-temperature spray drying for mixed aqueous solution obtained in the second step to obtain precursor powder of ultrafine tungsten and cobalt composite salt; and fourthly, performing reduction synthesis and carbon conditioning at the temperature ranging from 900 DEG C to 1000 DEG C for the precursor powder obtained in the third step to manufacture tungsten / cobalt carbide composite powder materials with nanostructures.

Owner:ANHUI RONGDA COMPOSITE POWDERS TECH

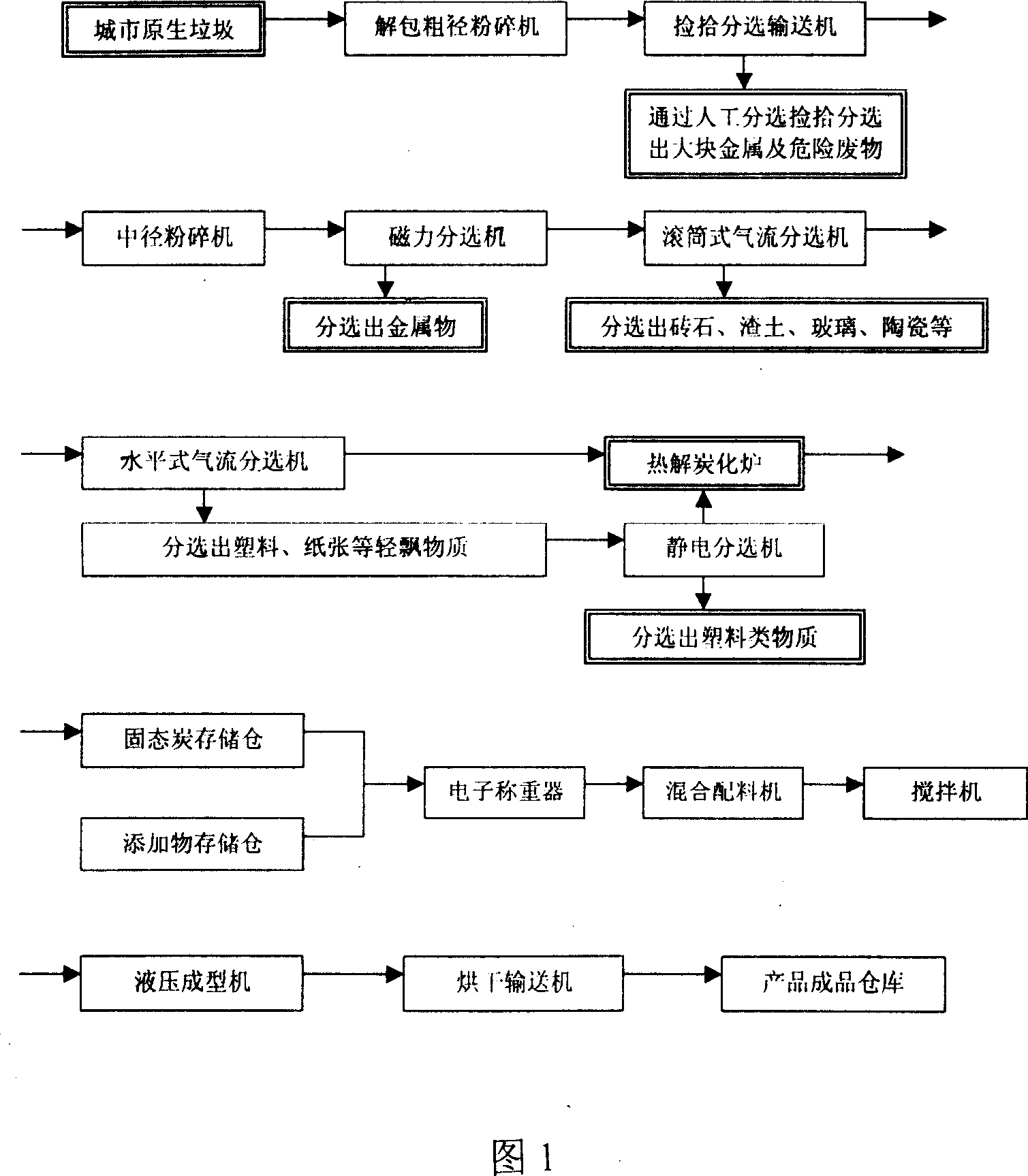

Carbonized city garbage fuel block preparation method and its dedicated apparatus

The invention discloses a method for preparing fuel brick with pyrolysis and taking city waste as raw material, and it aslo relates to special device- pyrolysis retort. The invention is to thermal decompose the organic matter in city waste, produce anoxic uindirect heating condition through proper engineering technology during pyrolysis, control heating temperature, heating speed and thermal insulating time to make the organic matter in city waste form into solid carbon, and converse carbonized city waste into fuel brick.

Owner:张兴权

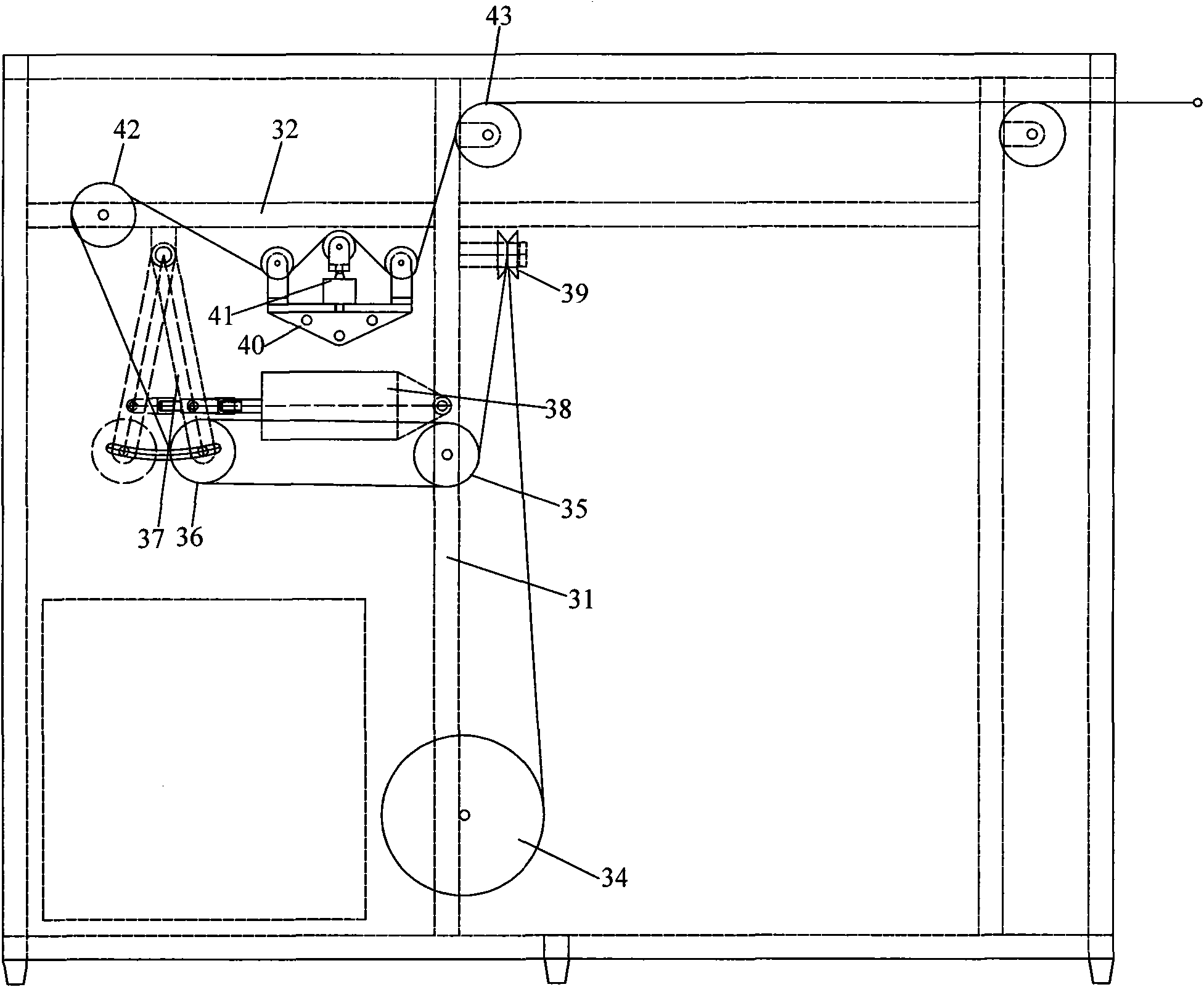

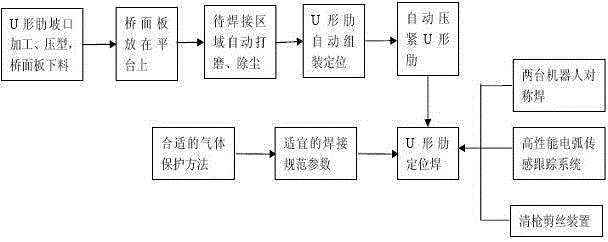

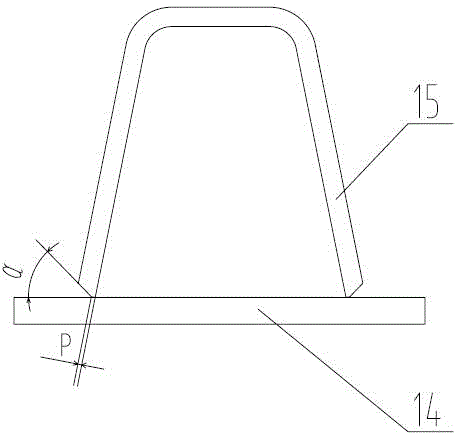

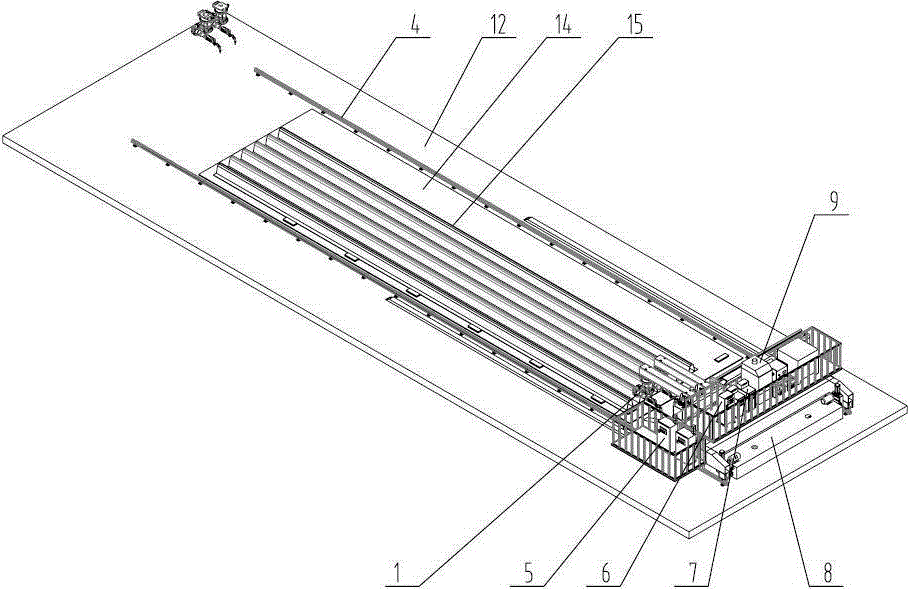

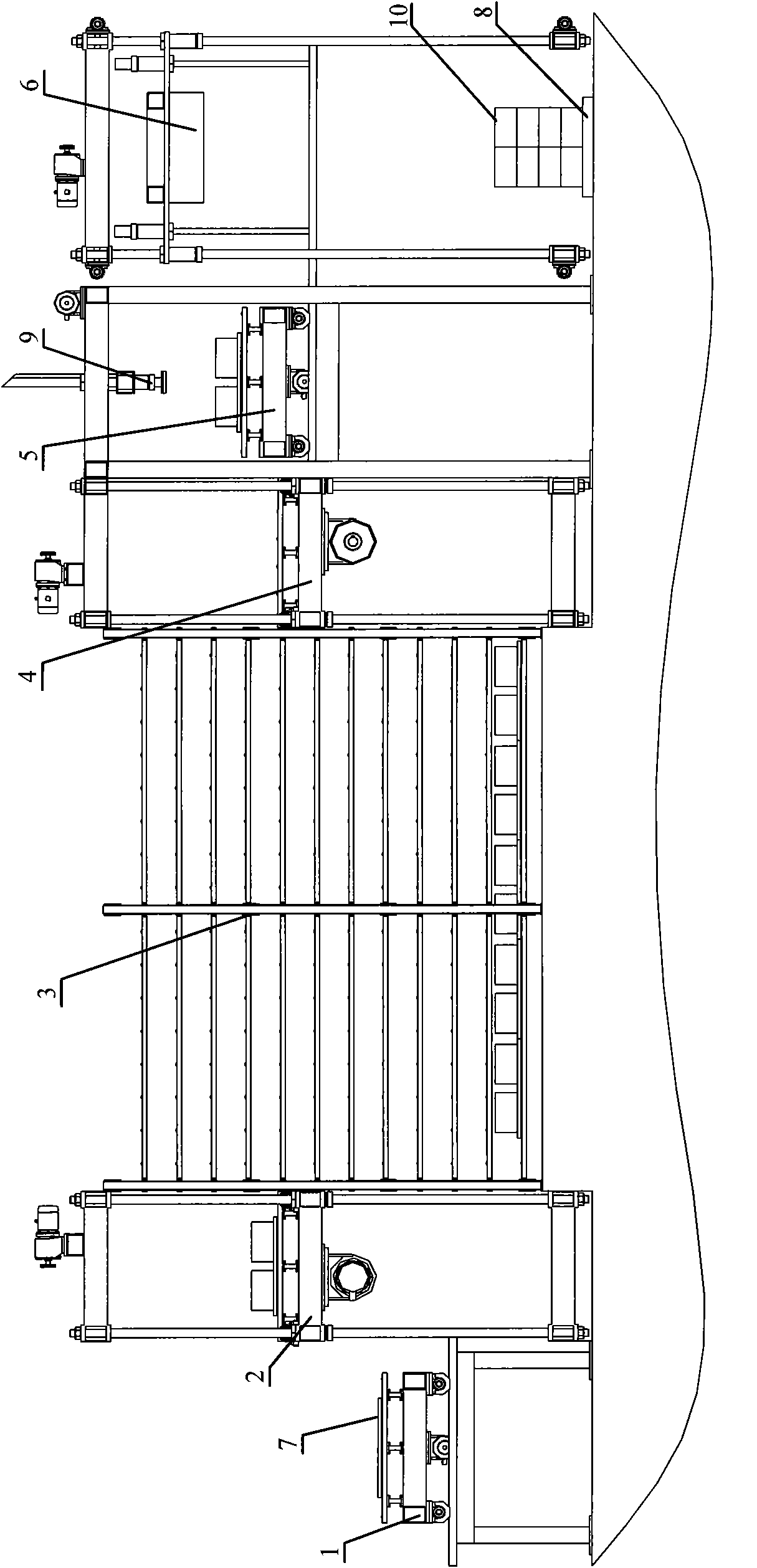

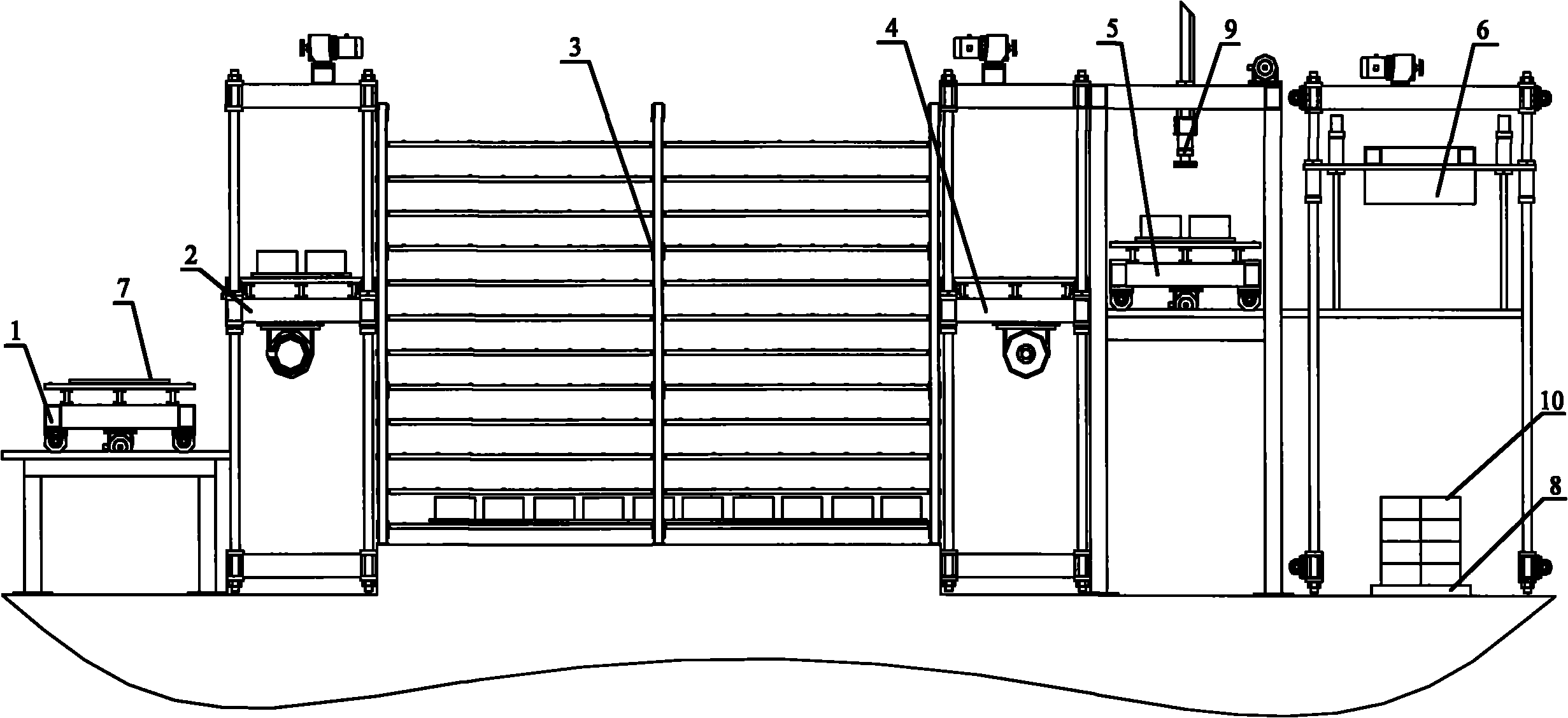

Automatic assembly method for orthotropic plate unit U-shaped ribs

ActiveCN103056491AWith dust removal functionCreate pollutionArc welding apparatusWorkpiece edge portionsFillet weldBridge deck

The invention discloses an automatic assembly method for orthotropic plate unit U-shaped ribs. The method comprises: S1, molding U-shaped ribs; S2, blanking a bridge deck slab and forming a U-shaped rib assembly locating line; S3, locating the U-shaped ribs on an area to be welded on the bridge deck slab through a U-shaped rib assembly locating device; S4, clamping the U-shaped ribs through the U-shaped rib assembly locating device; S5, using a welding robot for U-shaped rib fillet welding positioned welding; and S6, repeating the steps till U-shaped ribs on the whole plate unit are assembled and subjected to positioned welding. The method has the advantages of being high in assembly accuracy and assembly production efficiency, stable in welding quality and the like of orthotropic plate unit U-shaped ribs and is high in applicability, capable of being popularized and applied in manufacture fields of steel structures such as ship steel structures, mechanical steel structures and building steel structures and wide in the application range.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD +1

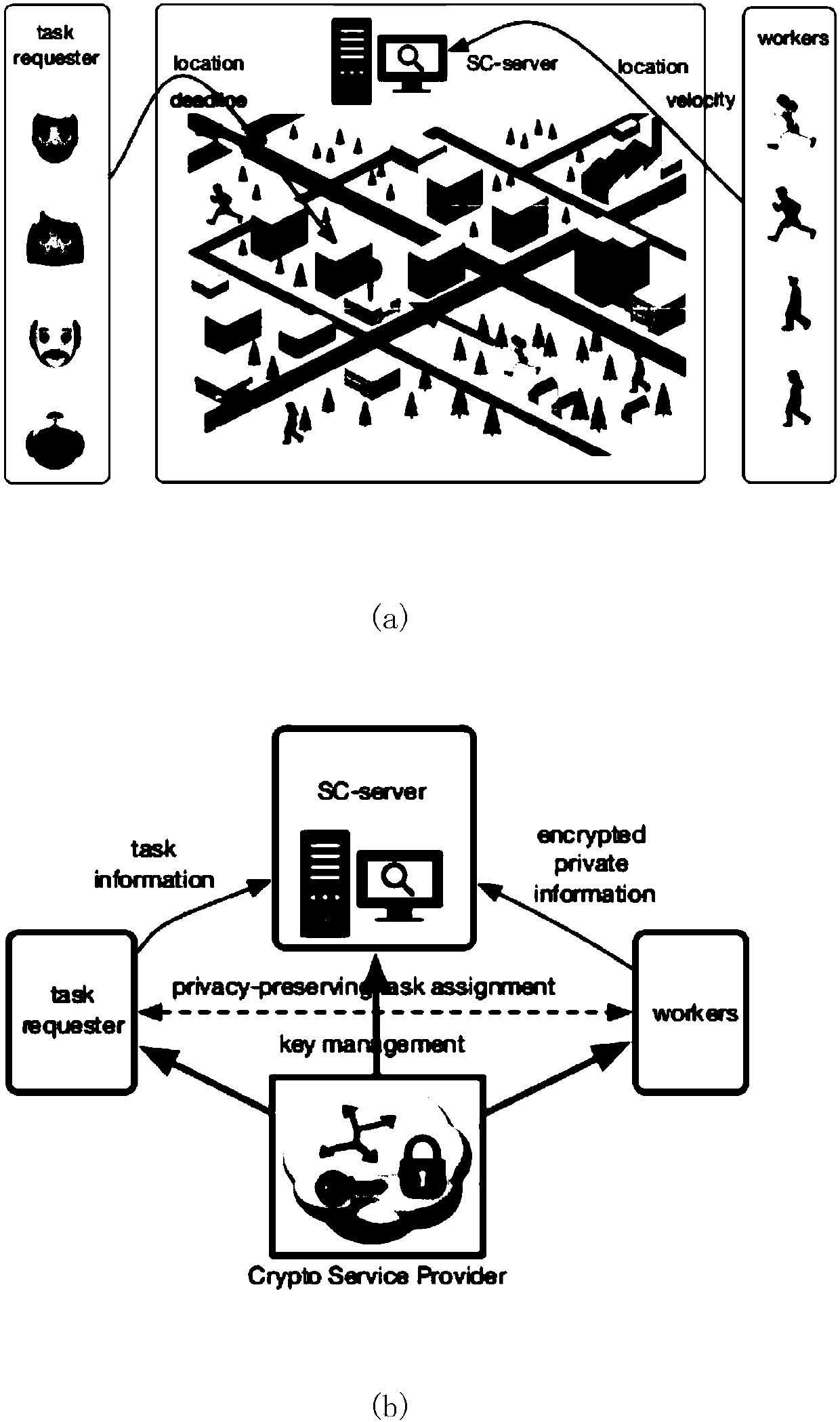

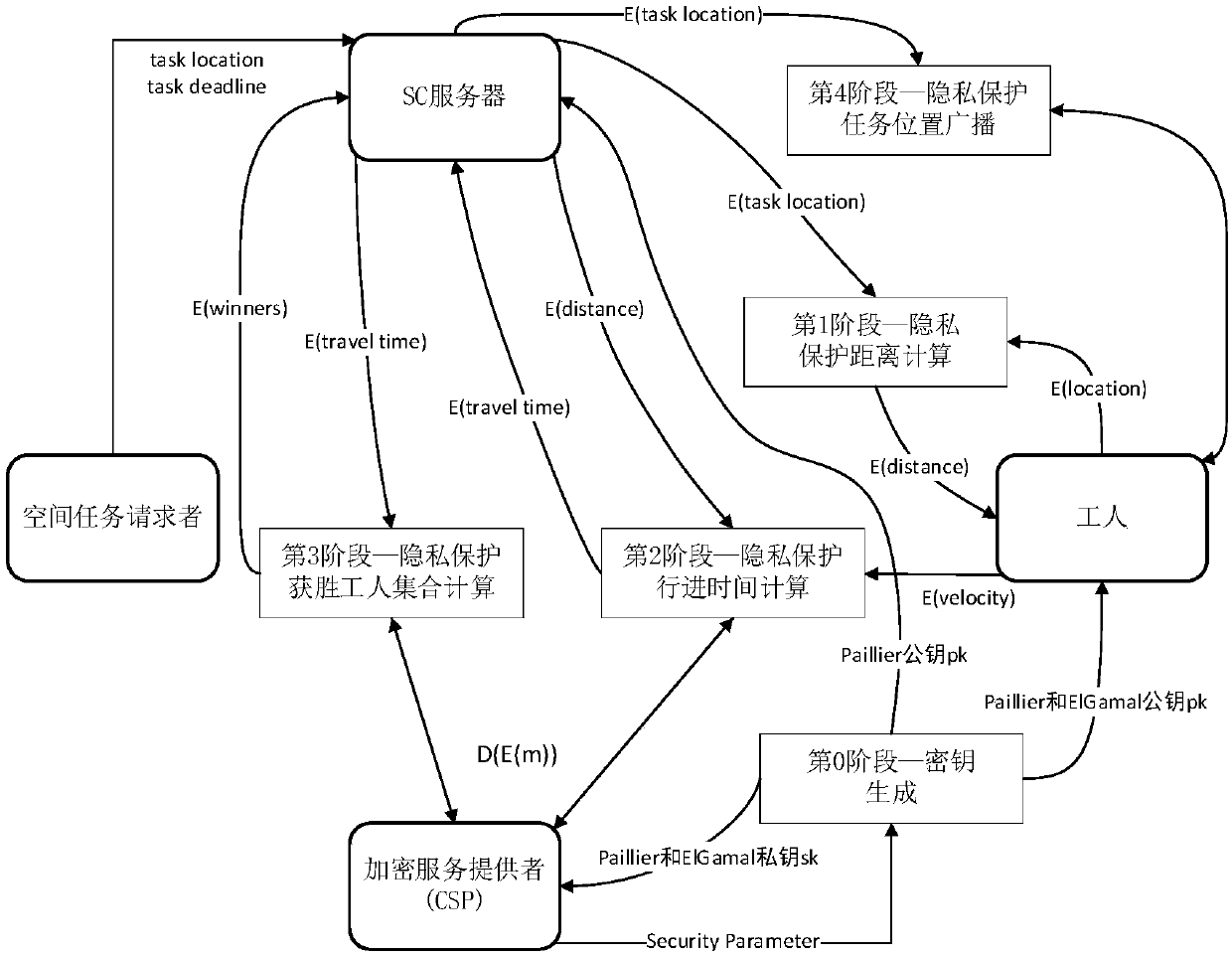

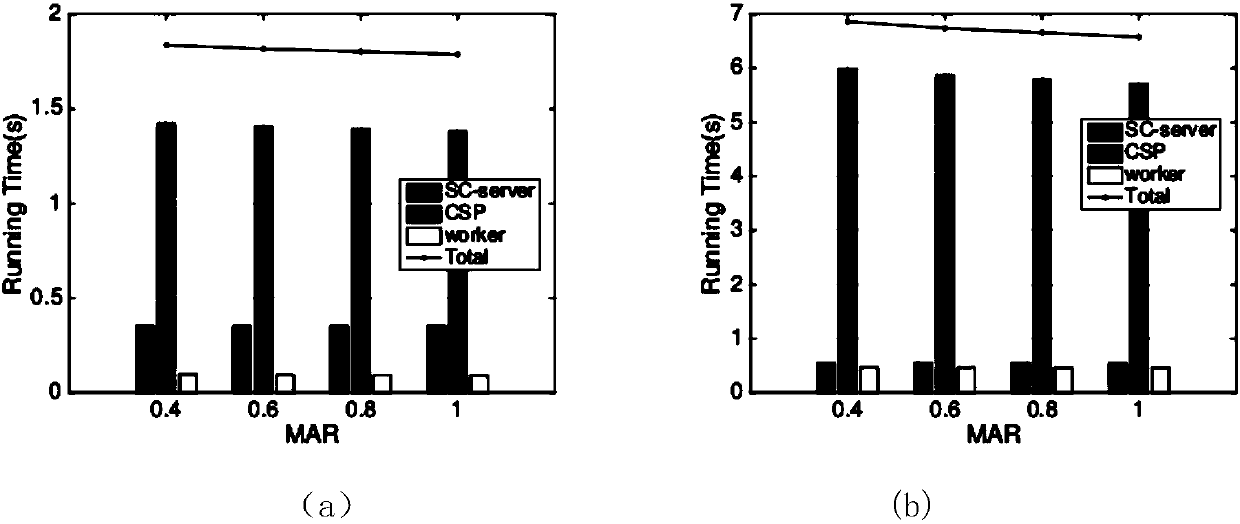

Warrantable privacy protection space crowdsourcing task distribution system and method

ActiveCN107360146APrivacy protectionStrong mutual protectionKey distribution for secure communicationEncryption apparatus with shift registers/memoriesDistribution systemService provider

The invention discloses a warrantable privacy protection space crowdsourcing task distribution system and method, and the system comprises an SC server, an encryption service provider, a space task requester, and workers. The encryption service provider generates a secret key, and employs a Paillier password and ElGamal password system. The space task requester creates a space task, and returns the position of the task to the SC server. The SC server encrypts the position of the task, and each worker calculates the distance between the position of the task and the position of the worker. The speed of each worker is encrypted and transmitted to the SC server, and each worker calculates the travel time of his own, and encrypts the travel time and transmits the encrypted travel time to the SC server. The SC server calculates the winning workers through the encryption service provider, and the encryption service provider enables the winning worker set comprising a plurality of winning workers to be encrypted and returned to the SC server. The SC server encrypts the position of the task, and broadcasts the encrypted position of the task to all workers, and the winning workers arrive at the specified position to execute the task. According to the invention, the system achieves the double-side privacy protection in the space crowdsourcing, greatly reduces the calculation, and can guarantee that the task is accepted at high probability.

Owner:SHENZHEN UNIV

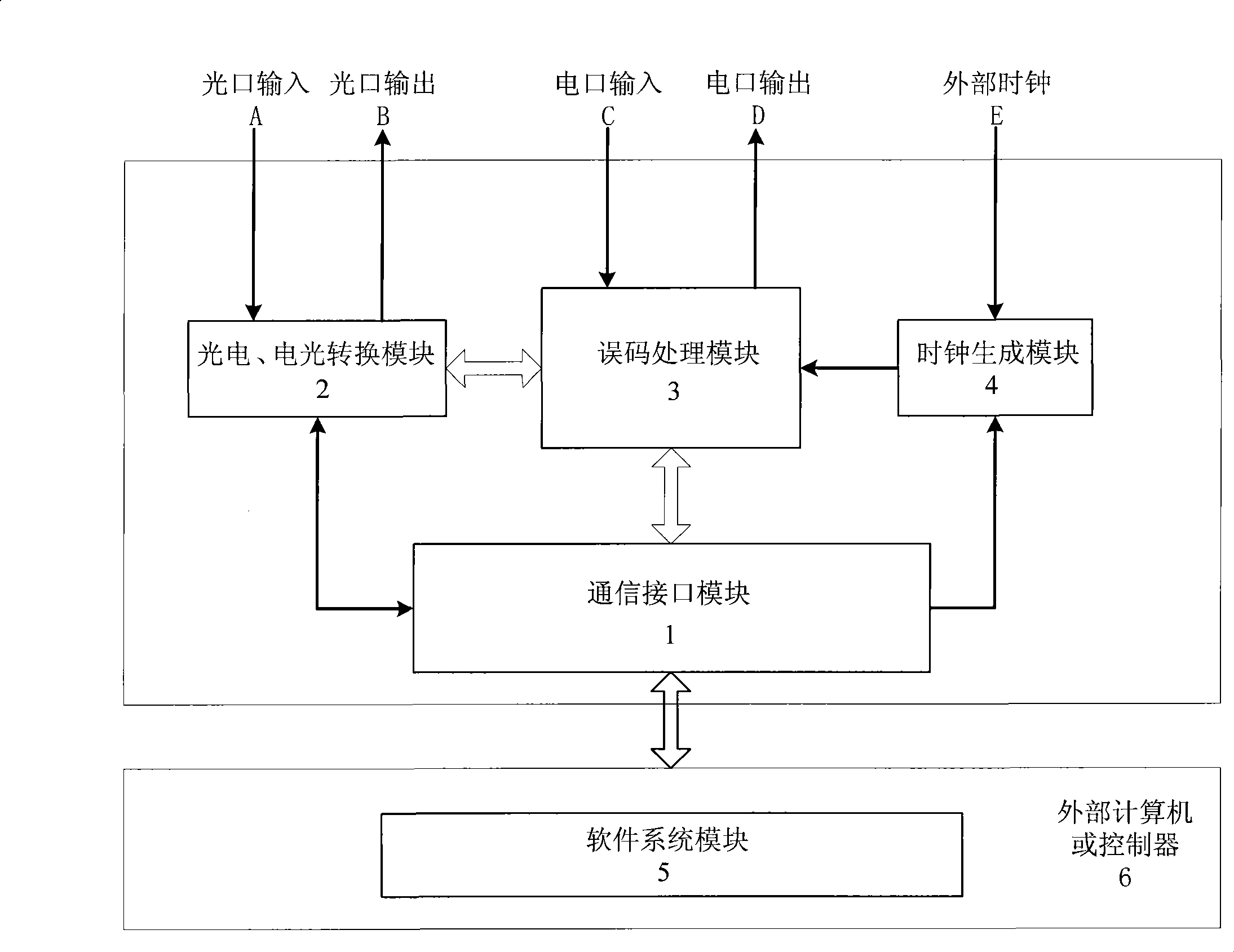

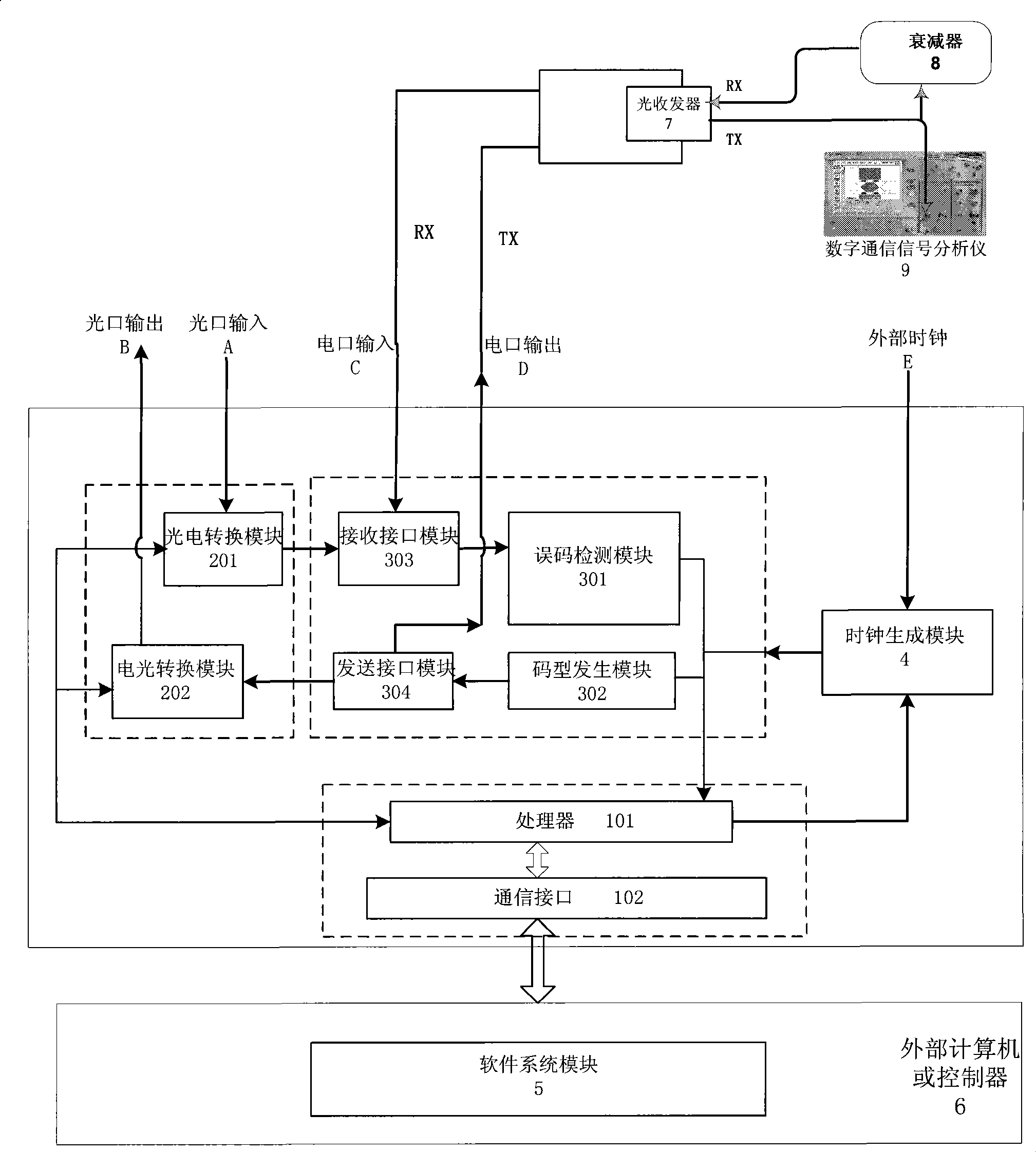

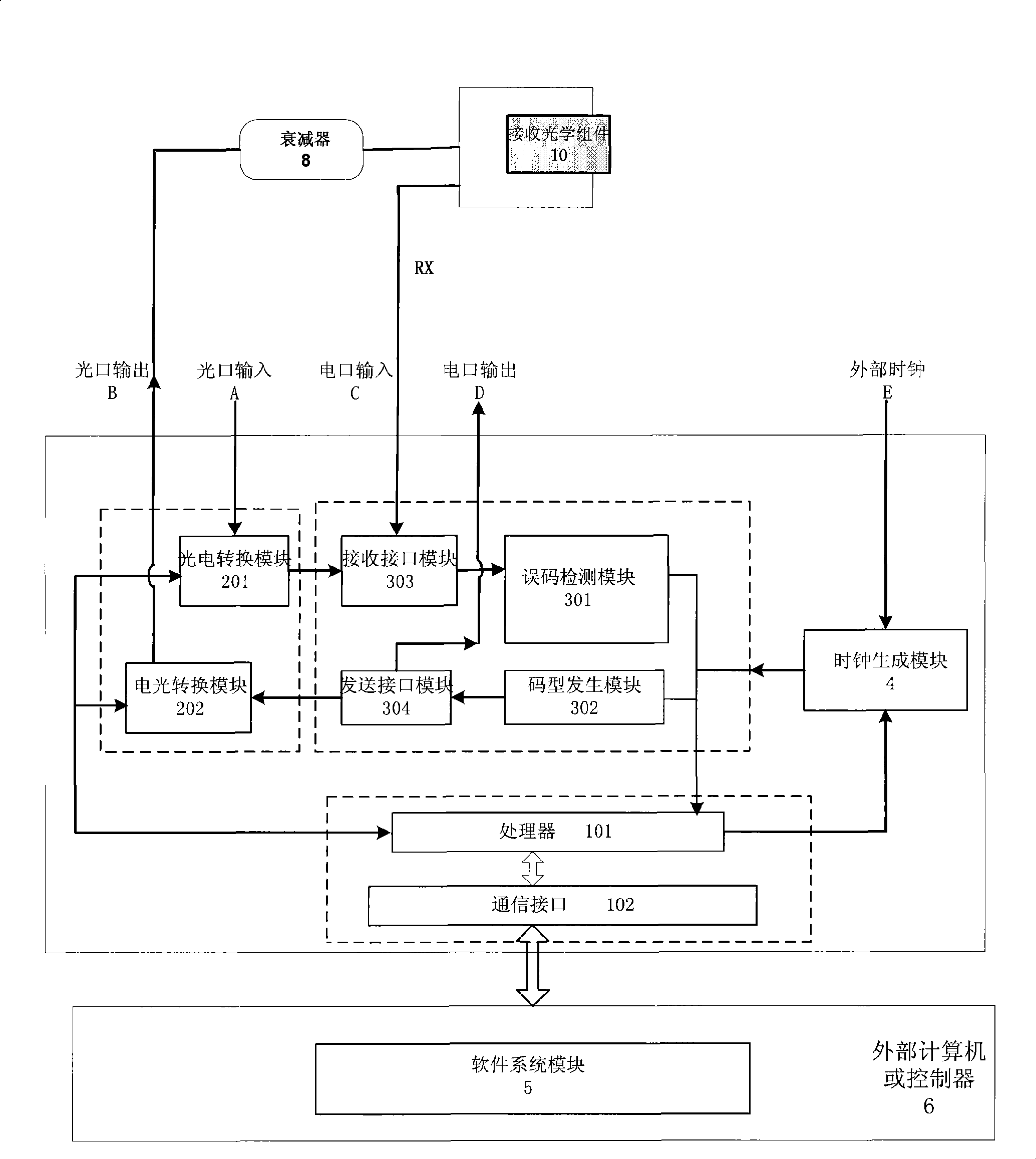

Test device of digital communication error rate

ActiveCN101442385AUnique designNovel structureError preventionTransmission monitoringCommunication interfaceRemote control

The present invention relates to a device for testing digital communication bit error rate, comprising a communication interface module for connecting to external computers or controllers; a bit error processing module for analyzing bit error of a device or system to be tested, and transmitting result to an external computer or controller; a clock generating module for selecting operation clock according to instruction of the communication interface module, and supplying the operation clock to the bit error processing module; an opto-electrical / electro-optical converter module for converting optical signal from outside into electric signal and transmitting the same to the bit error processing module, and converting high-speed electric signal generated with the bit error module into optical signal to output; a software system module for controlling the integral testing device. The device, including a bit error testing function for electric interface and optical interface, can be used as independent testing apparatus, also can be remote controlled or integrated onto an automatic testing system.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

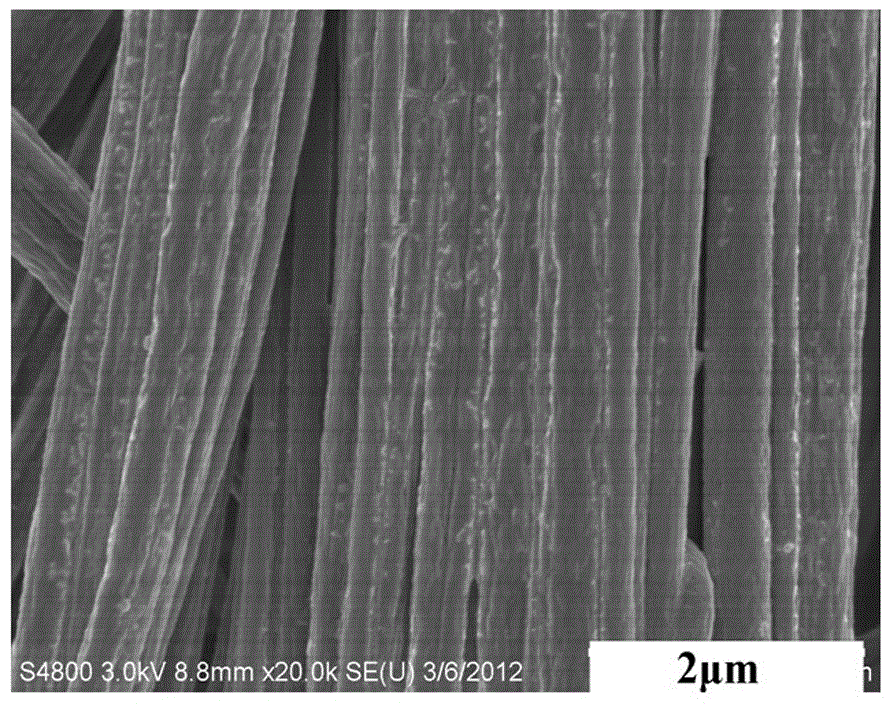

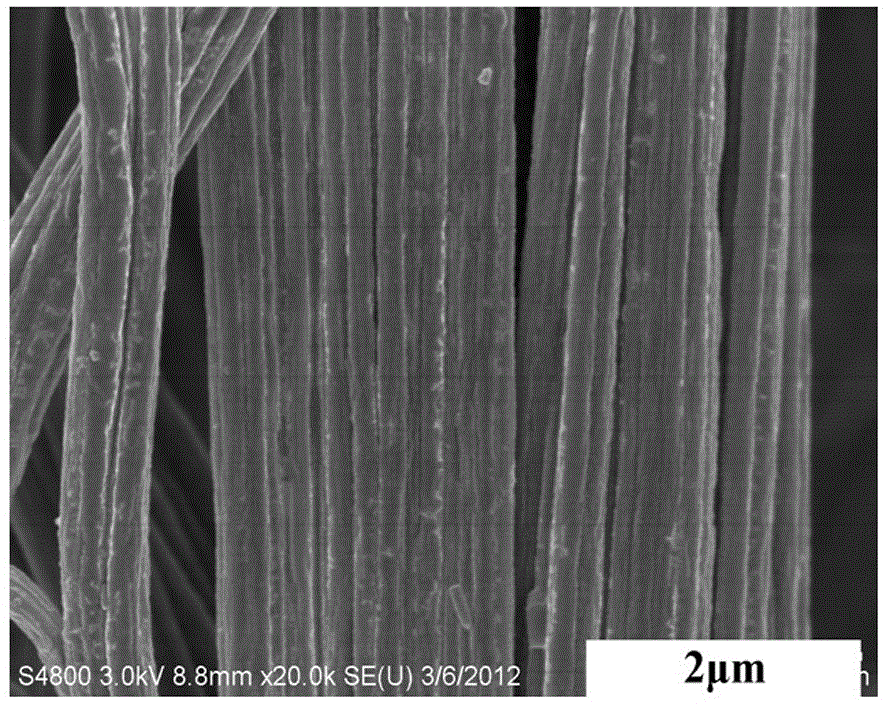

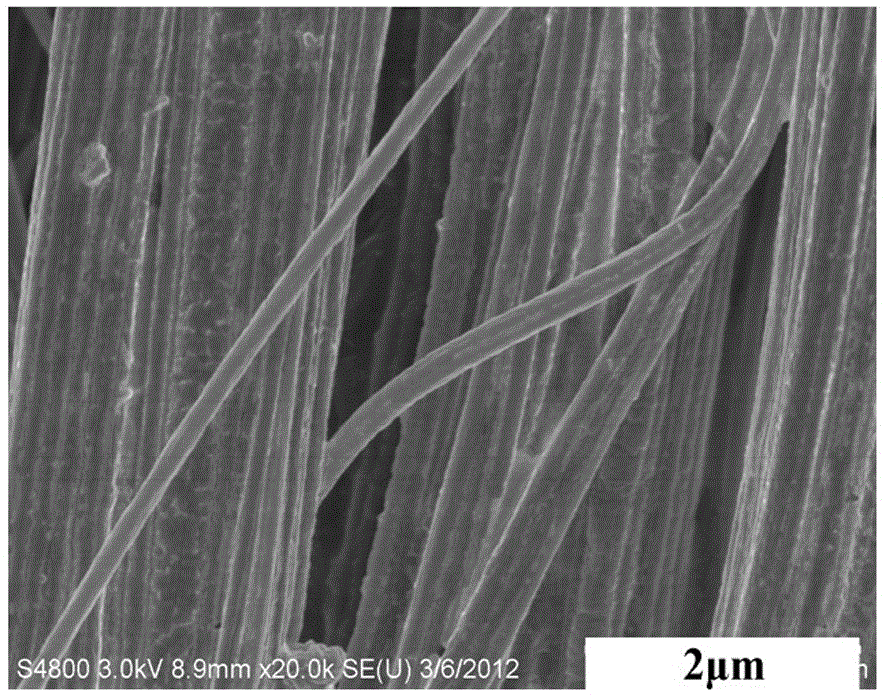

Aramid 1313/MWCNT (Multi-Walled Carbon Nanotube) nano fibers and preparation method thereof

InactiveCN102877152APlay a reinforcing roleAvoid reunionFilament/thread formingStretchingSpinningElectrospinning

The invention discloses aramid 1313 / MWCNT (Multi-Walled Carbon Nanotube) nano fibers and a preparation method thereof. The preparation method comprises the following steps of: obtaining MWCNTs grafted with octyl phenoxy poly ethoxy; uniformly dispersing the grafted MWCNTs into a solvent by ultrasonic treatment so as to obtain a solution containing the MWCNTs; obtaining a dissolution system containing halide, adding aramid 1313 fibers into the dissolution system and stirring to dissolve the aramid 1313 fibers so as to obtain a solution containing the aramid 1313 fibers; mixing the two solutions to obtain a spinning solution; by adopting an electrostatic spinning method, obtaining a nano fiber felt of which the fibers are directionally arranged; and obtaining the strengthened nano fiber felt by adopting thermal stretching treatment. According to the invention, the aramid 1313 / MWCNT nano fibers are obtained; the orientation degree of the aramid 1313 is improved; and the tensile breaking strength and the initial modulus of the fiber felt are improved.

Owner:SUZHOU UNIV

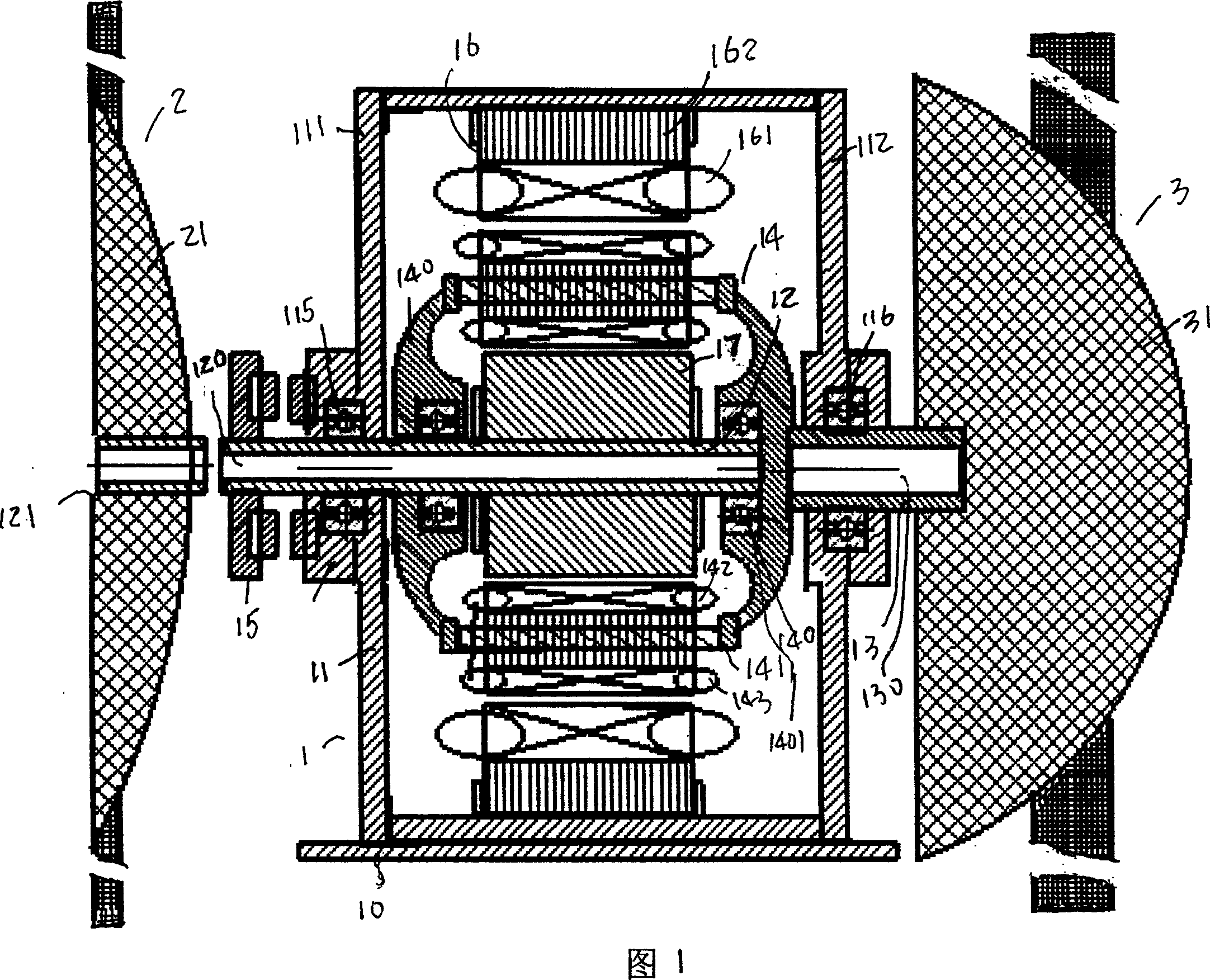

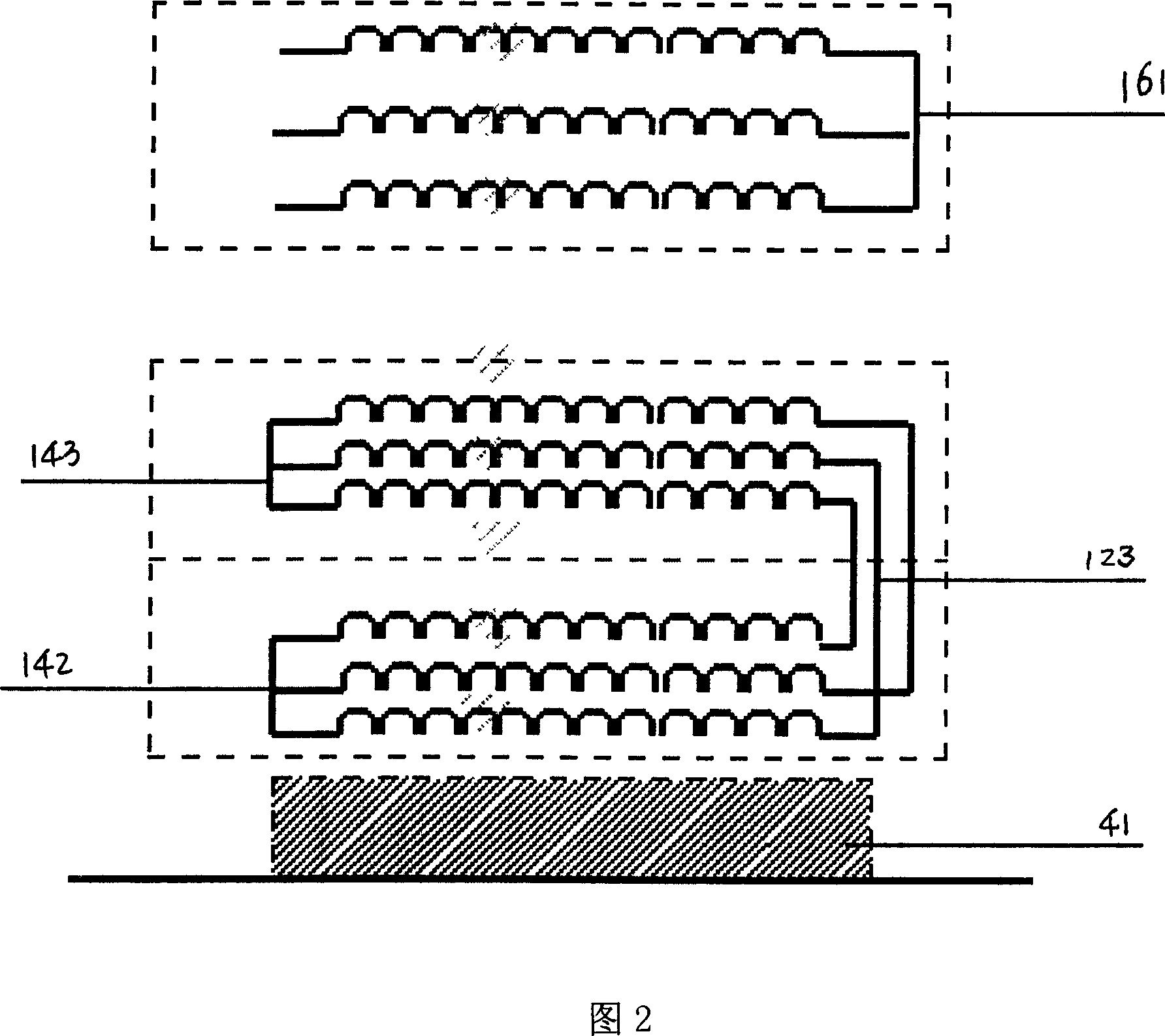

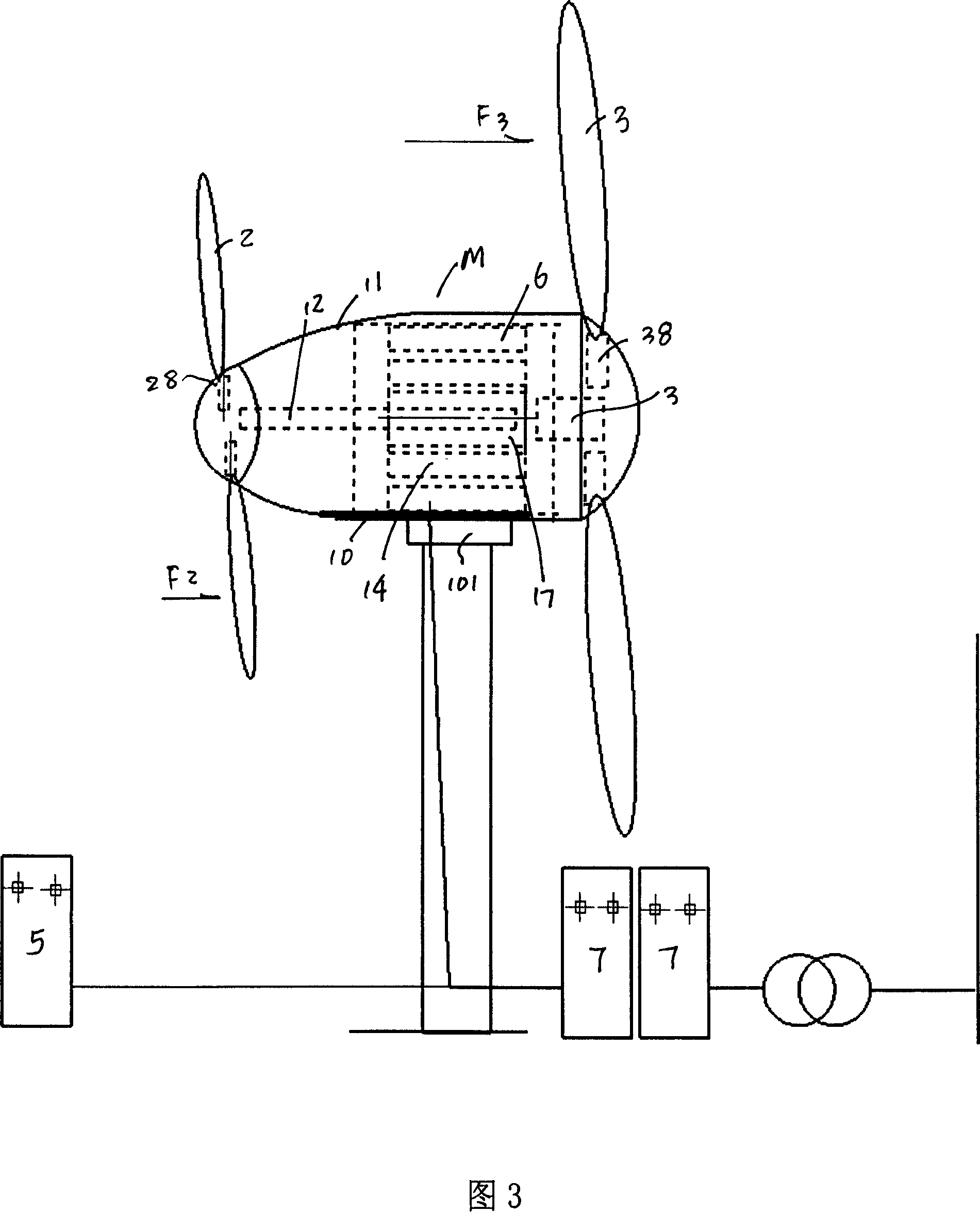

Telescopic double-rotor wind wheel electric excitation mode and its control system and its electric machine

InactiveCN101001072AImprove performanceSmall diameterMagnetic circuit rotating partsWind motor controlDrive shaftElectric machine

This invention relates to a telescopic dual-rotor wind-electric excitation mode, its control system and its motor, in which, a magnet inner rotor rotating corresponding to a stator is set on the sub-drive shaft of the generator and driven by it, a ring rotor driven by the primary drive shaft and rotating against the stator is set on the primary drive shaft, and the ring rotor is in the structure of surrounding the magnet inner rotor and rotating around it, the pole logarithm of the inside winding of the ring rotor is the same with the magnet inner rotor as Pe and the pole logarithm of the outside winding of the ring rotor is the same with the stator winding as Pg and the outer winding and the inside winding are connected in phase reversion, a primary vane rev testing device and a sub-vane rev testing device are set on the main and sub-vanes transferring rev signals to the integrated control device of the set, and the crab controller and the integrated control device are connected in the mode of controlling rotation of wind direction under the main vane.

Owner:天津市新源电气科技有限公司

Brown coal dry-distillation method using coal hot air furnace to supply heat

InactiveCN102732274AReduce sulfur contentFinal emissions are environmentally friendlyDirect heating destructive distillationSpecial form destructive distillationDry heatQuenching

The invention relates to a brown coal dry-distillation method using a coal hot air furnace to supply heat. The brown coal dry-distillation method comprises the following steps of: adding brown coal in a drying furnace to be heated and dried, sending the heated coal into a dry-distillation furnace to be heated and dry-distilled to obtain thermal carbocoal, cooling and quenching the thermal carbocoal in a quenching furnace to obtain a carbocoal product; purifying high-temperature smoke produced by the coal hot air furnace in a purifying room, making dry-distilled coal gas enter into the purifying room, consuming residual oxygen in the high-temperature smoke to produce high-temperature hot air with a low oxygen content as all or partial heating sources of the drying furnace used for coal drying, wherein the dry-distilled heat source in the dry-distillation furnace partially or all comes from the high-temperature smoke produced by burning the dry-distilled coal gas in a burner, and obtaining crude tar and clean dry-distilled normal-temperature coal gas after the following treatments: de-dusting and cooling the dry-distilled coal gas and tar steam, and separating tar and on the like. Compared with the method taking the dry-distilled coal gas as the heat source drying heat source, the high-temperature smoke of the coal hot air furnace is used as the brown coal drying heat source, a lot of dry-distilled coal gas is surplus, such that the saved plenty of dry-distilled coal gas can be for other uses and thus the economic value is high.

Owner:SUZHOU JINLUN ENERGY TECH

Continuous multi-layer full-automatic energy-saving curing kiln

The invention provides a continuous multi-layer full-automatic energy-saving curing kiln. A plurality of raceways arranged in an matrix shape are positioned in a kiln body so as to form a layer structure; left and right sides of the kiln body are connected with a left lift and a right lift; the left lift is connected with a brick-receiving rolling plate-moving carriage on which a supporting plate is arranged; the right lift is connected with a stacker through a brick-delivering rolling plate-moving carriage; a brick stacking bracket used for stacking bricks is arranged on a bottom plate of the stacker; and a plate grabbing mechanical arm is arranged above the brick-delivering rolling plate-moving carriage; therefore, the brick-receiving rolling plate-moving carriage, the left lift, the kiln body, the right lift, the brick-delivering rolling plate-moving carriage and the stacker are connected into an automatic production line. The continuous multi-layer full-automatic energy-saving curing kiln integrates functions of transfer, curing, deliver, storage and the like, continuously and automatically completes the curing of bricks, can greatly save energy, and is very practical.

Owner:史世英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com