Continuous multi-layer full-automatic energy-saving curing kiln

A fully automatic and curing kiln technology, applied in the field of block curing kilns, can solve the problems of lack of versatility, long working cycle in and out of the kiln, waste of energy, etc., to improve the automation level of the whole machine, save labor intensity and work procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

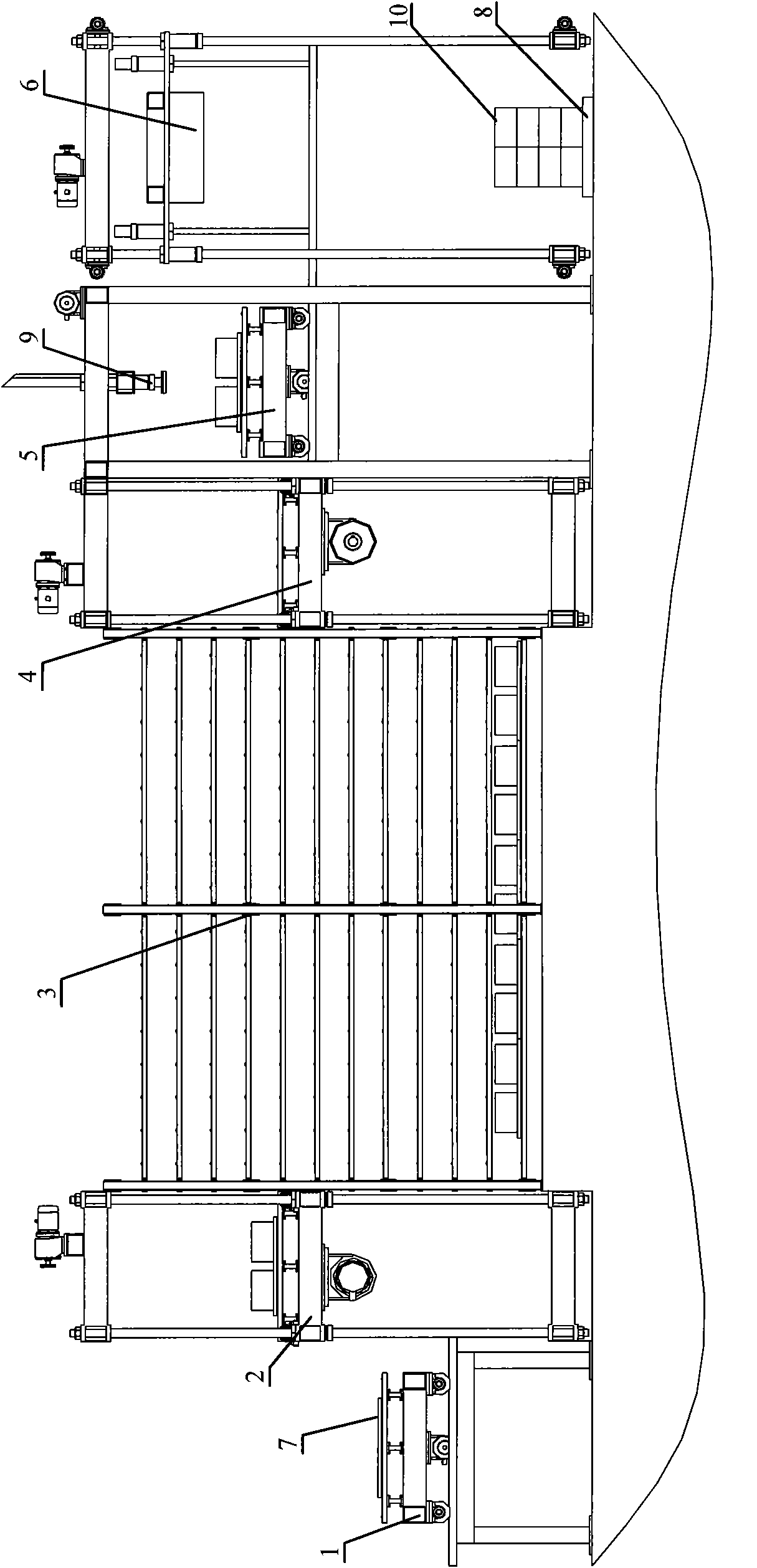

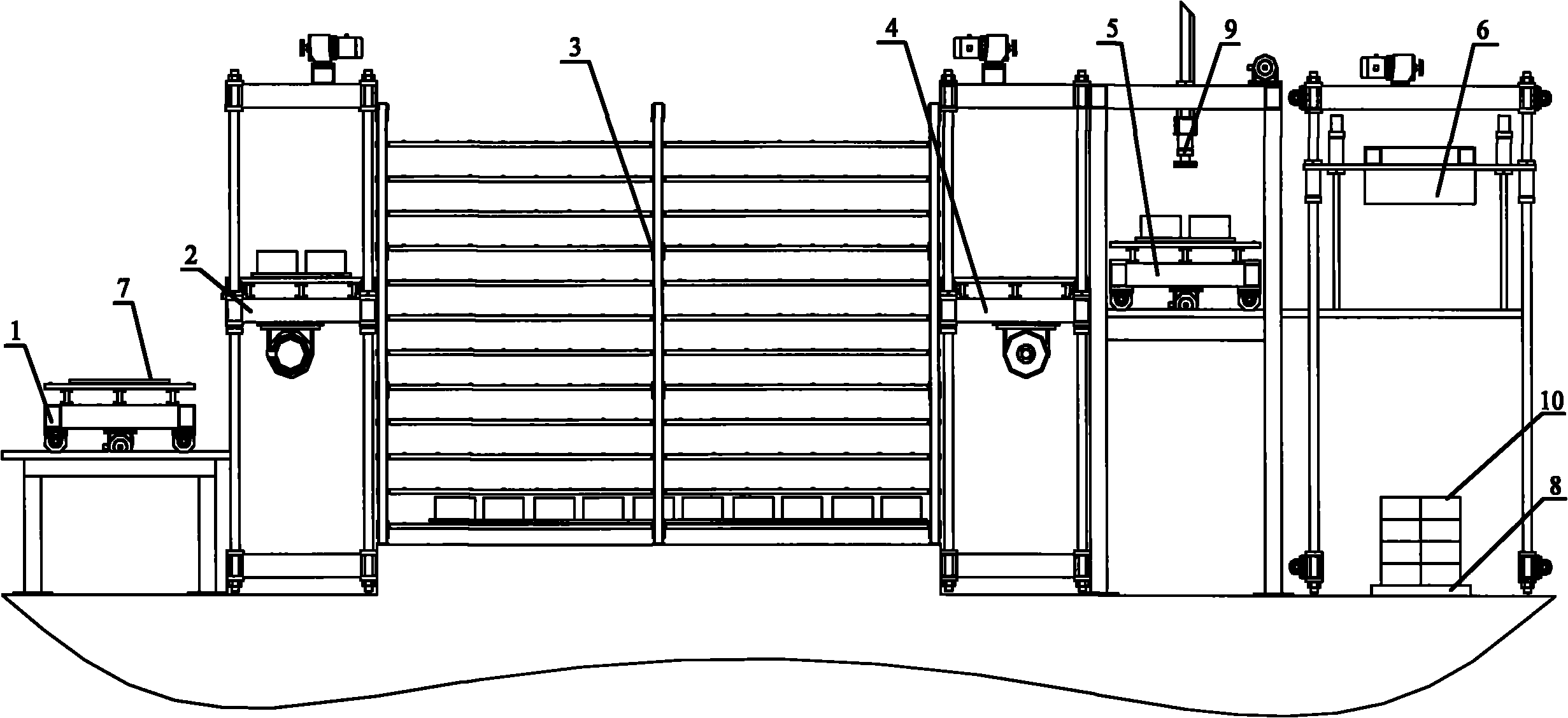

[0021] The present invention proposes a steam (natural, solar) timing (more than 5 hours) for concrete blocks, bricks and other cement product prefabricated parts to enter the multi-layer maintenance kiln with bricks on the pallet to the exit of the kiln. Continuous automatic multi-layer energy-saving maintenance kiln with continuous jacking of brick kiln cars.

[0022] Such as figure 1 As shown in the figure, the continuous multi-layer automatic energy-saving maintenance kiln mainly includes brick receiving rolling sliding carriage 1, left elevator 2, kiln body 3, right elevator 4, brick discharging rolling sliding carriage 5 and stacker 6, The kiln body 3 has a number of raceways arranged in a matrix, forming a layered structure. The left elevator 2 and the right elevator 4 are connected on the left and right sides of the kiln body 3. Connecting, placing pallet 7 on the brick-connecting rolling and moving carriage 1; the right elevator 4 is connected with the stacker 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com