Patents

Literature

251 results about "Rolling sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leg prosthesis

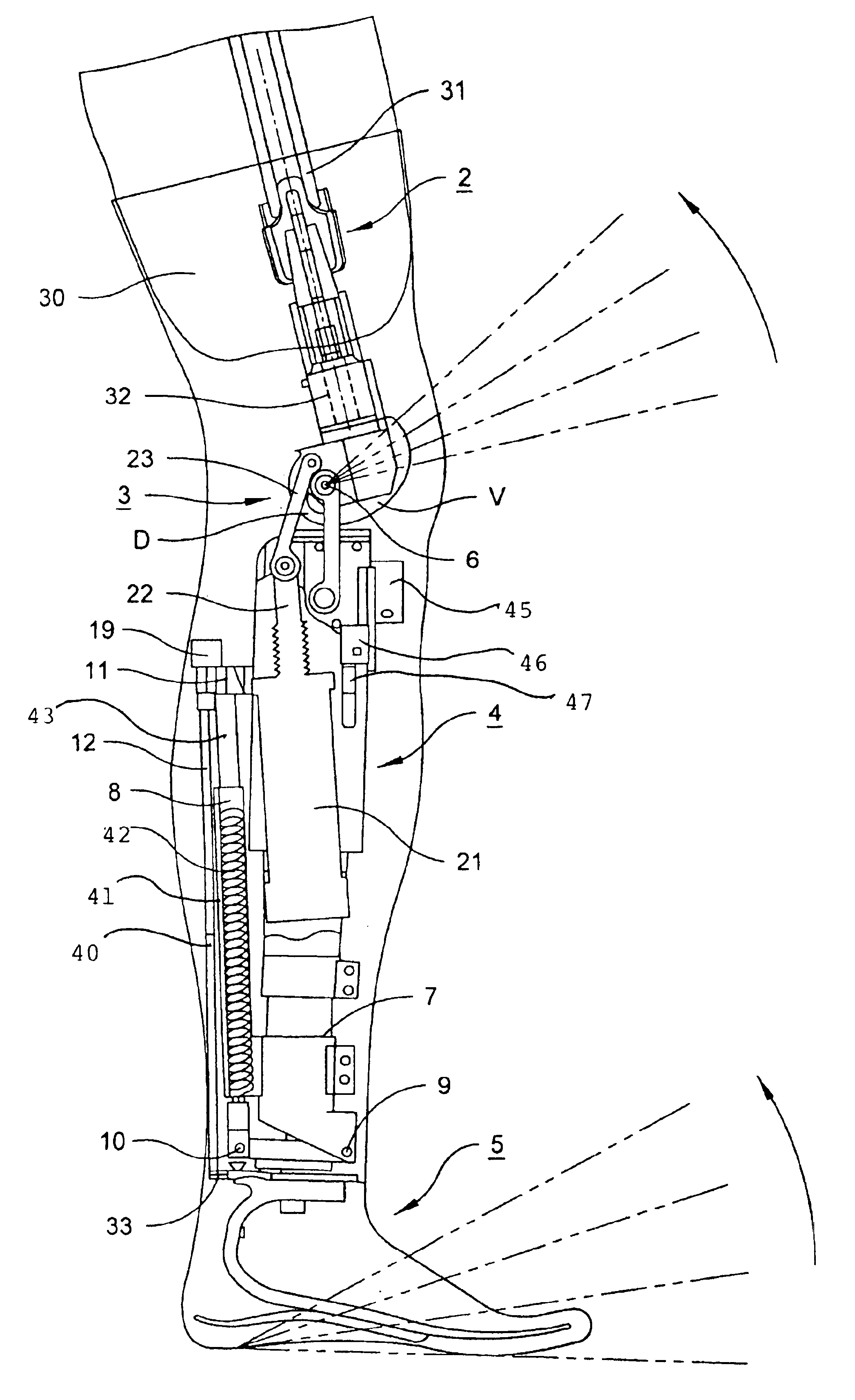

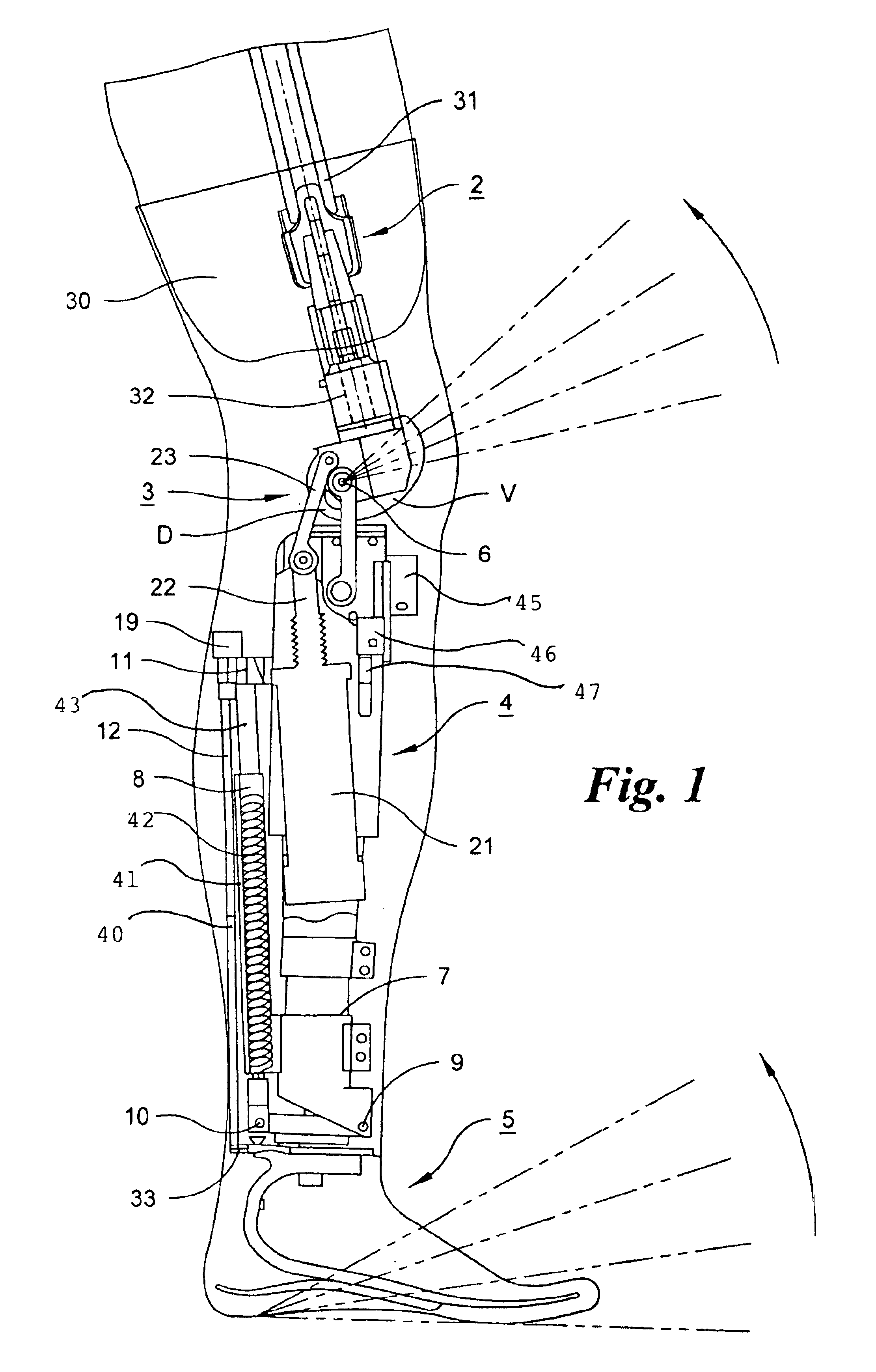

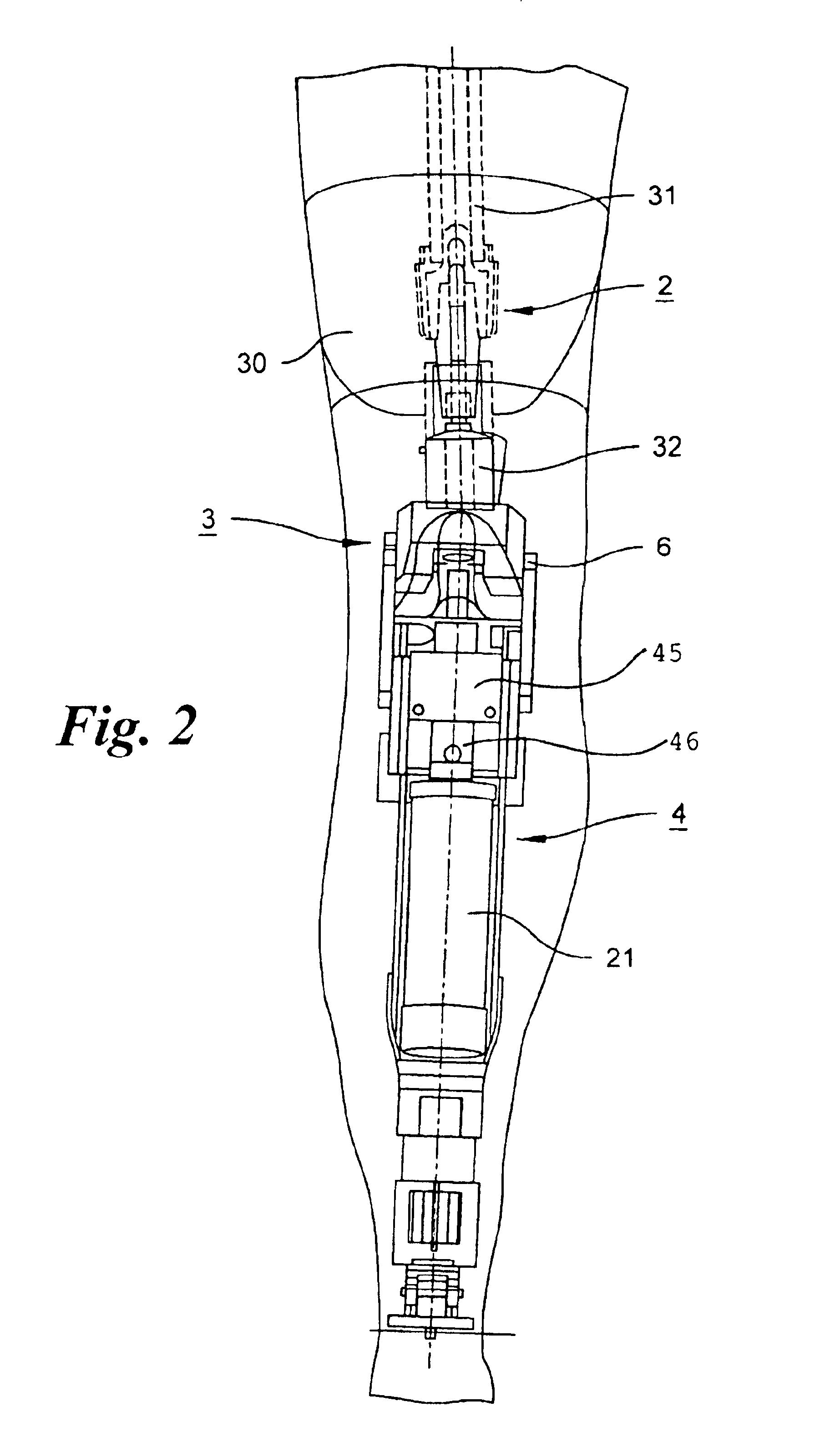

ActiveUS6955692B2Improve a leg prosthesisIncrease and decreases resistanceArtificial legsThighPhysical medicine and rehabilitation

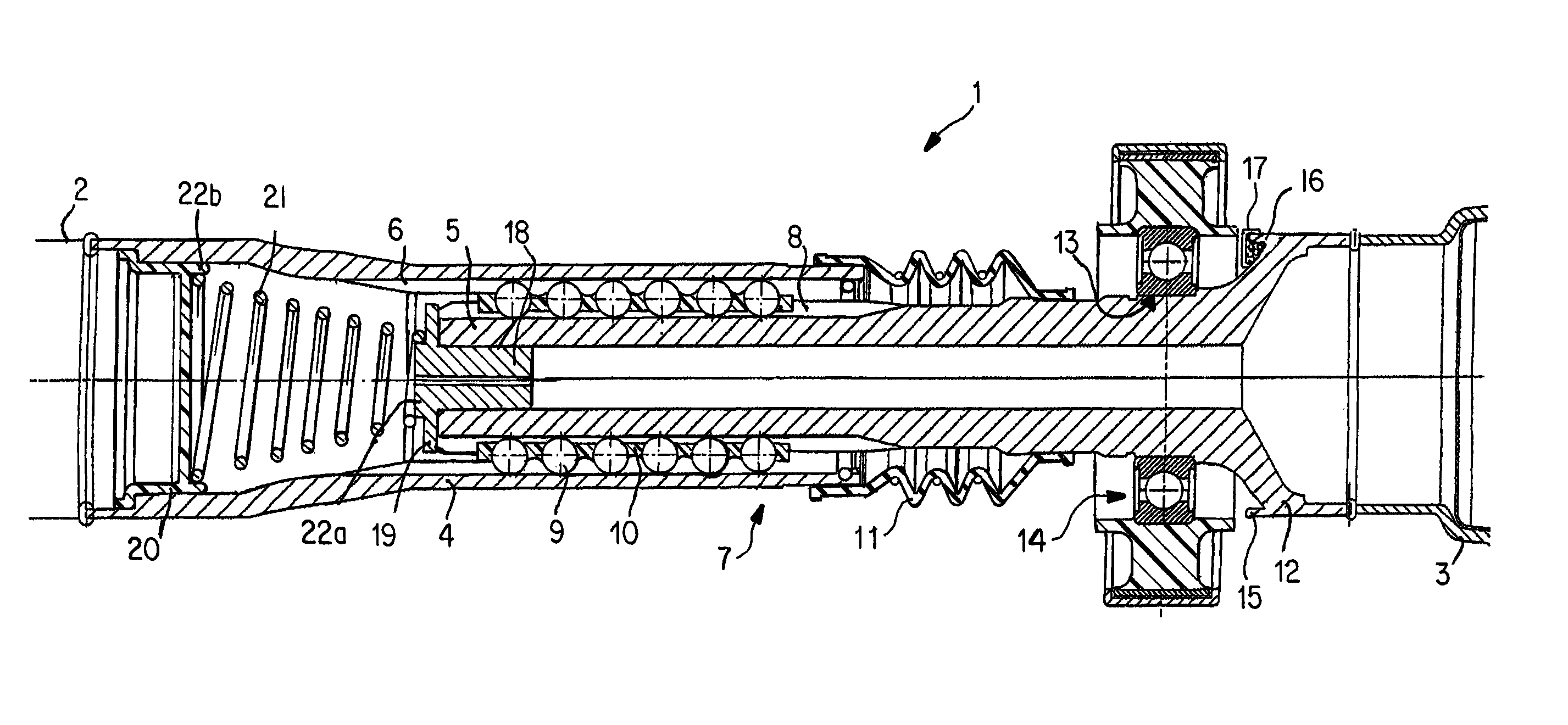

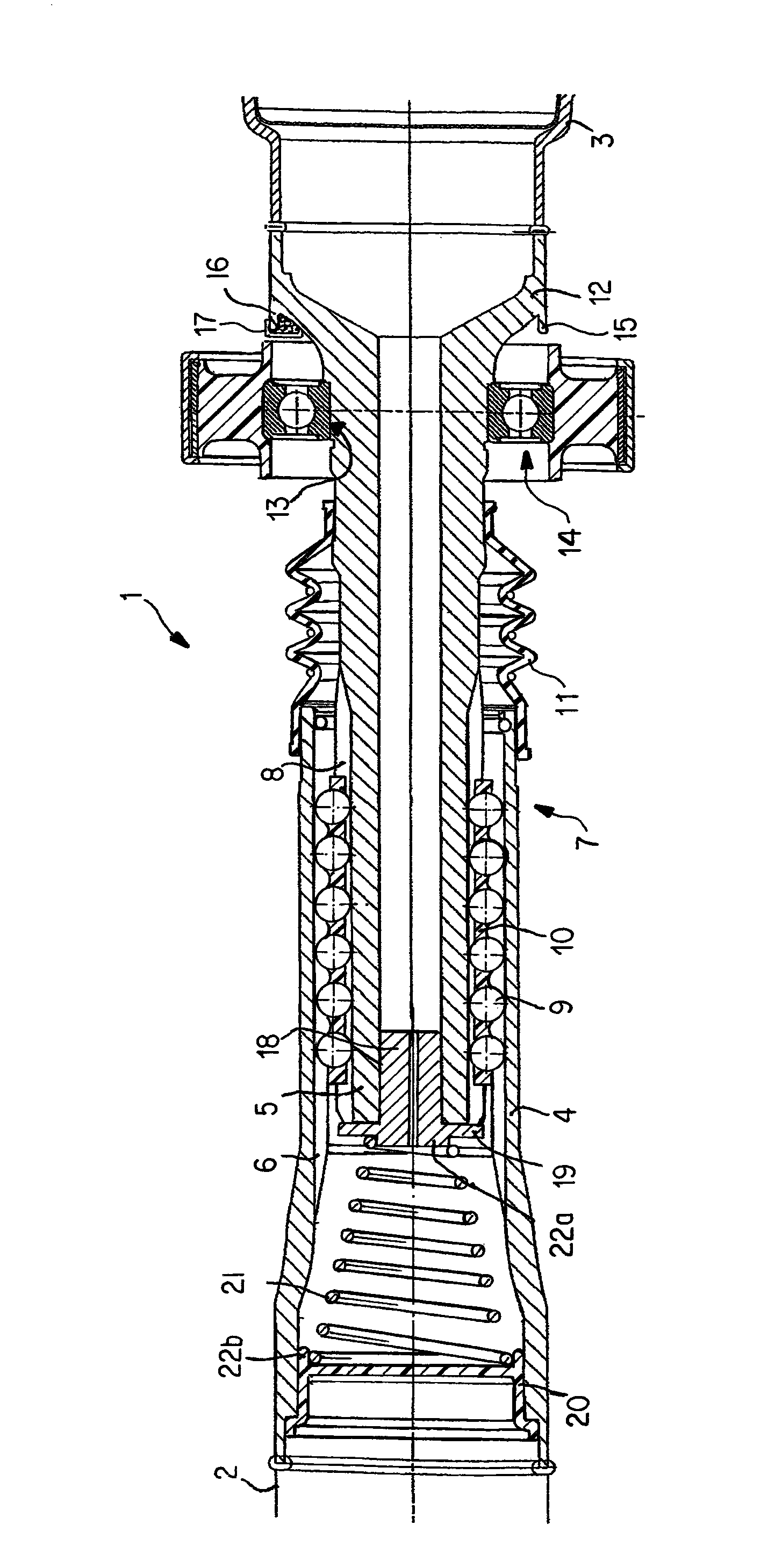

A leg prosthesis adapted to a thigh stump includes an adapter (2) for a knee joint (3), a knee joint (3) mounted on this adapter, and a prosthetic lower leg (4) coupled to the knee joint (3). A prosthetic foot (5) is attached to this prosthetic lower leg and can pivot into a toes-raised foot position. The knee joint (3) upon transition from the extended position to the bent position performs a combined rolling-sliding movement about a pivot axis (6). A force-transmitting element (8) moves the prosthetic foot (5) substantially from the toes-down foot position to the toes-raised foot position during bending of the knee joint (3). Each bending position of the knee joint is transformed by a converter into an unambiguous electrical signal, which is supplied to a programmable control device, which generates a signal used to control an electrically adjustable actuator, which increases or decreases the resistance of the knee joint against or for further bending according to the signal.

Owner:OSSEO PL GMBH

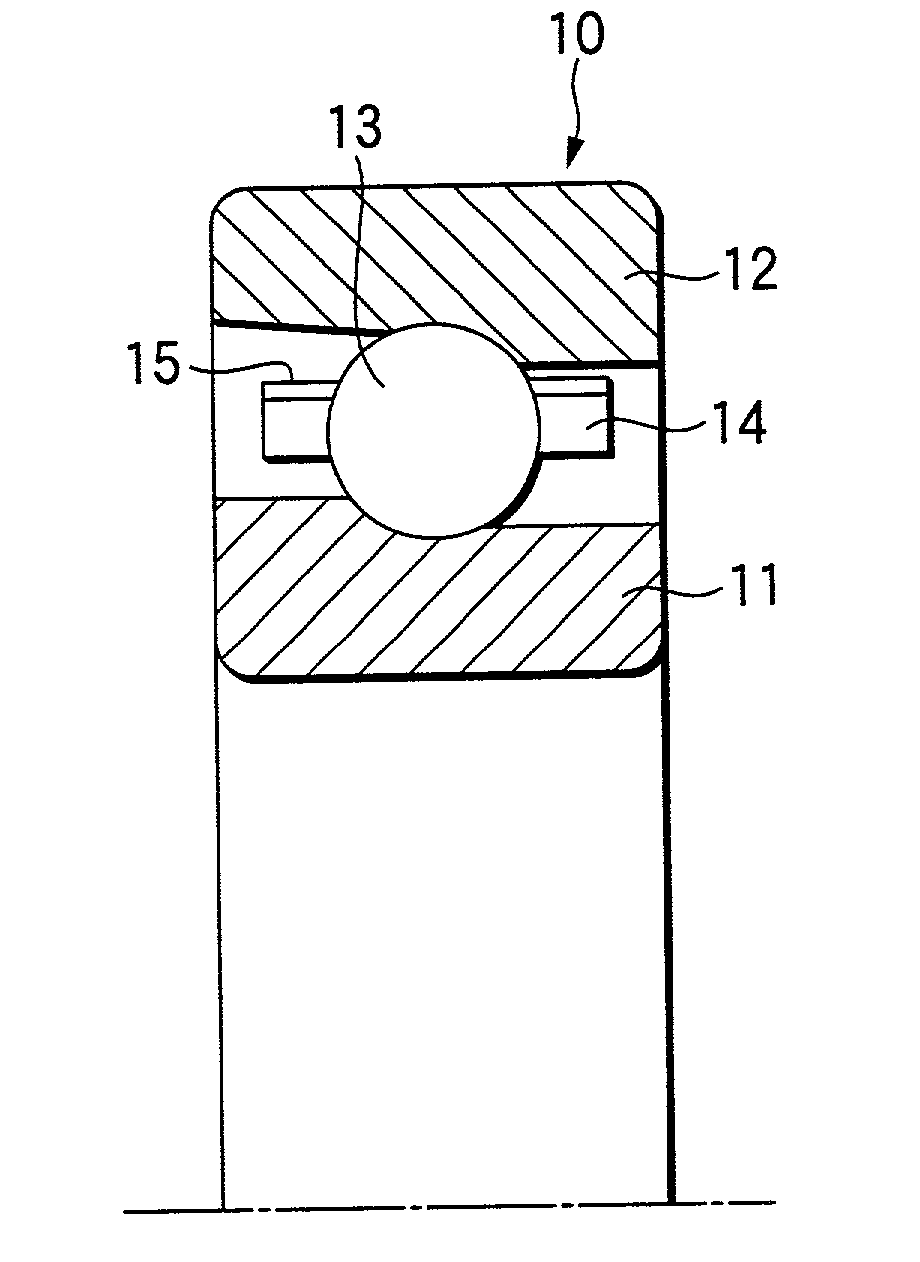

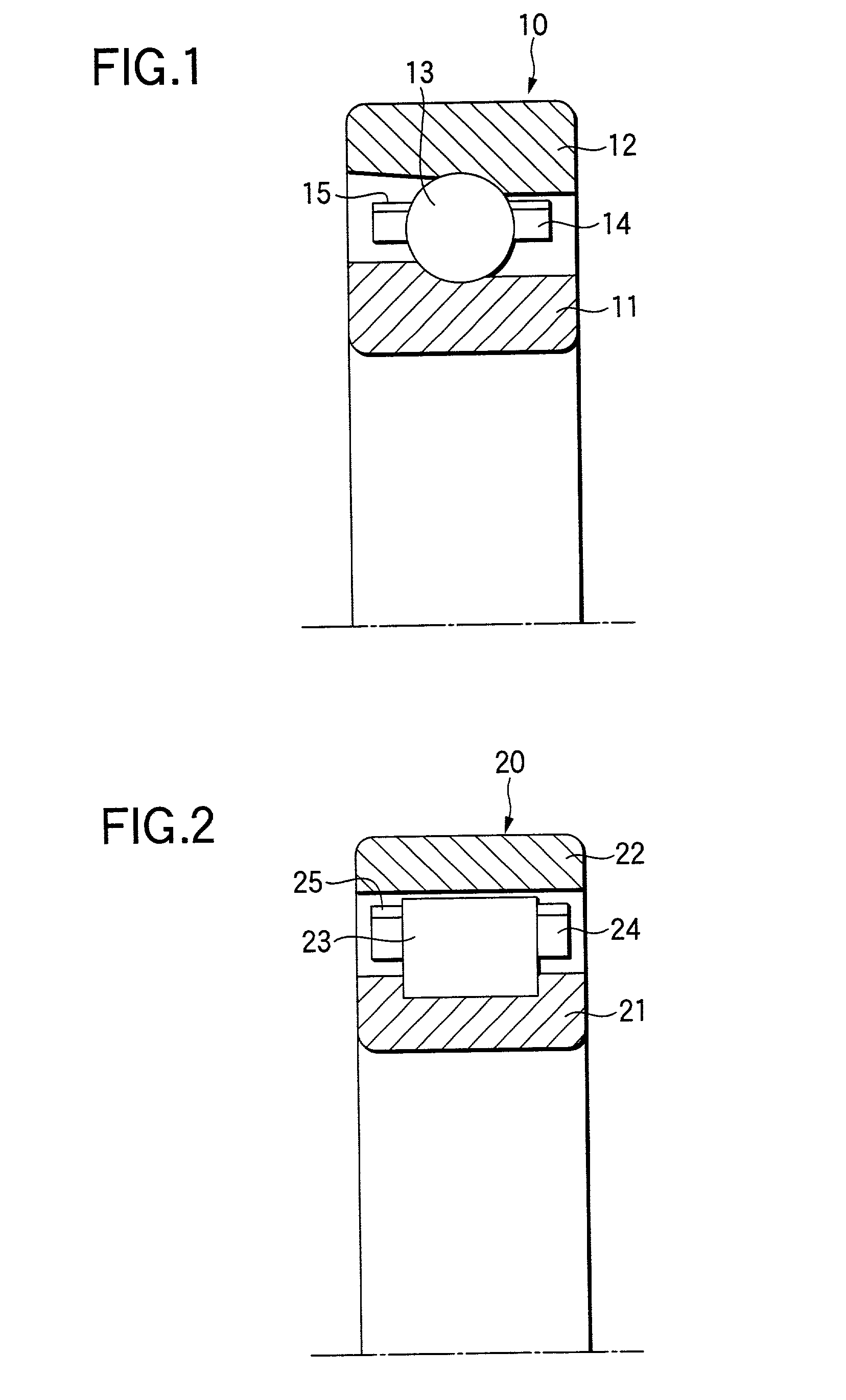

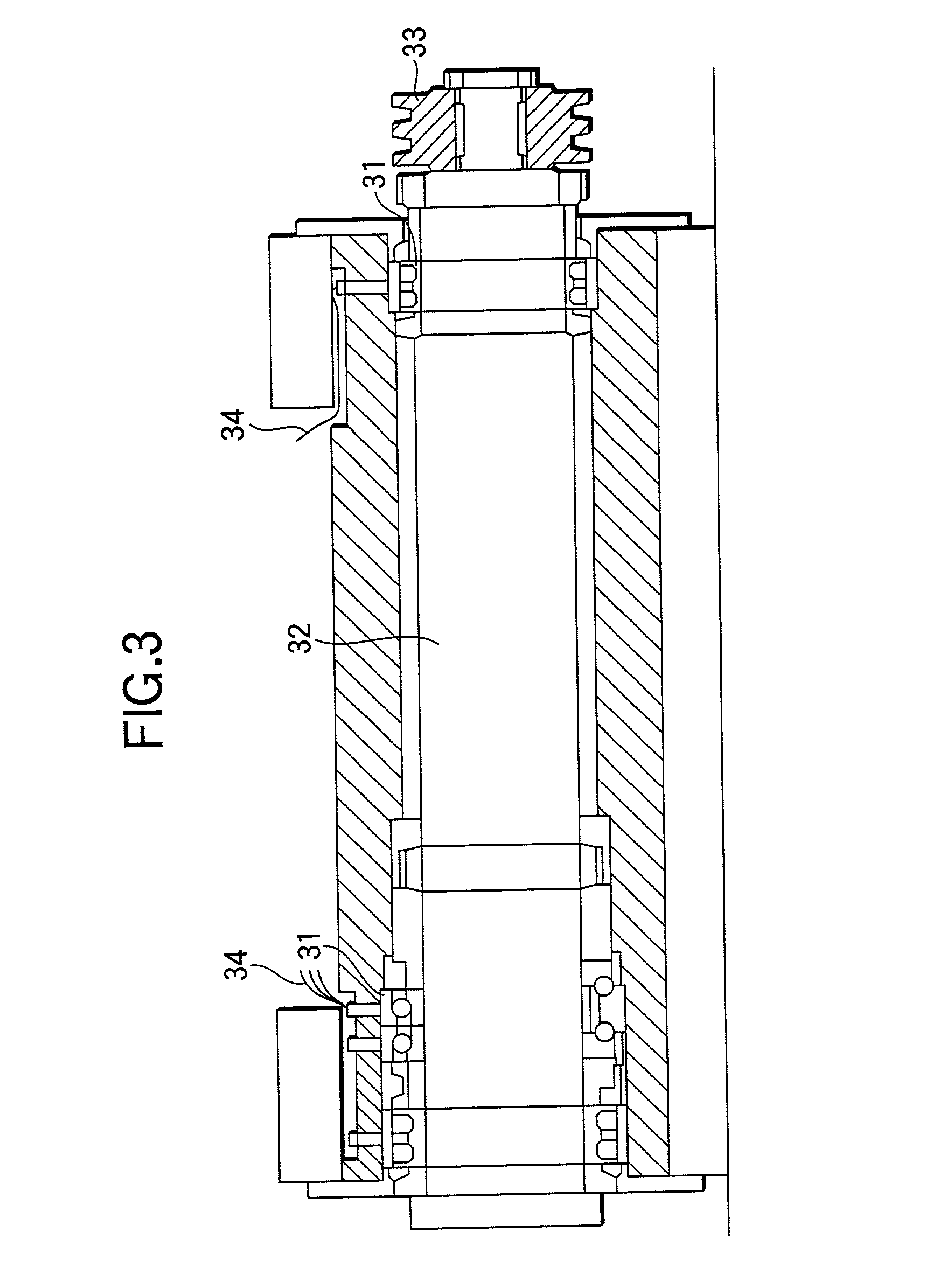

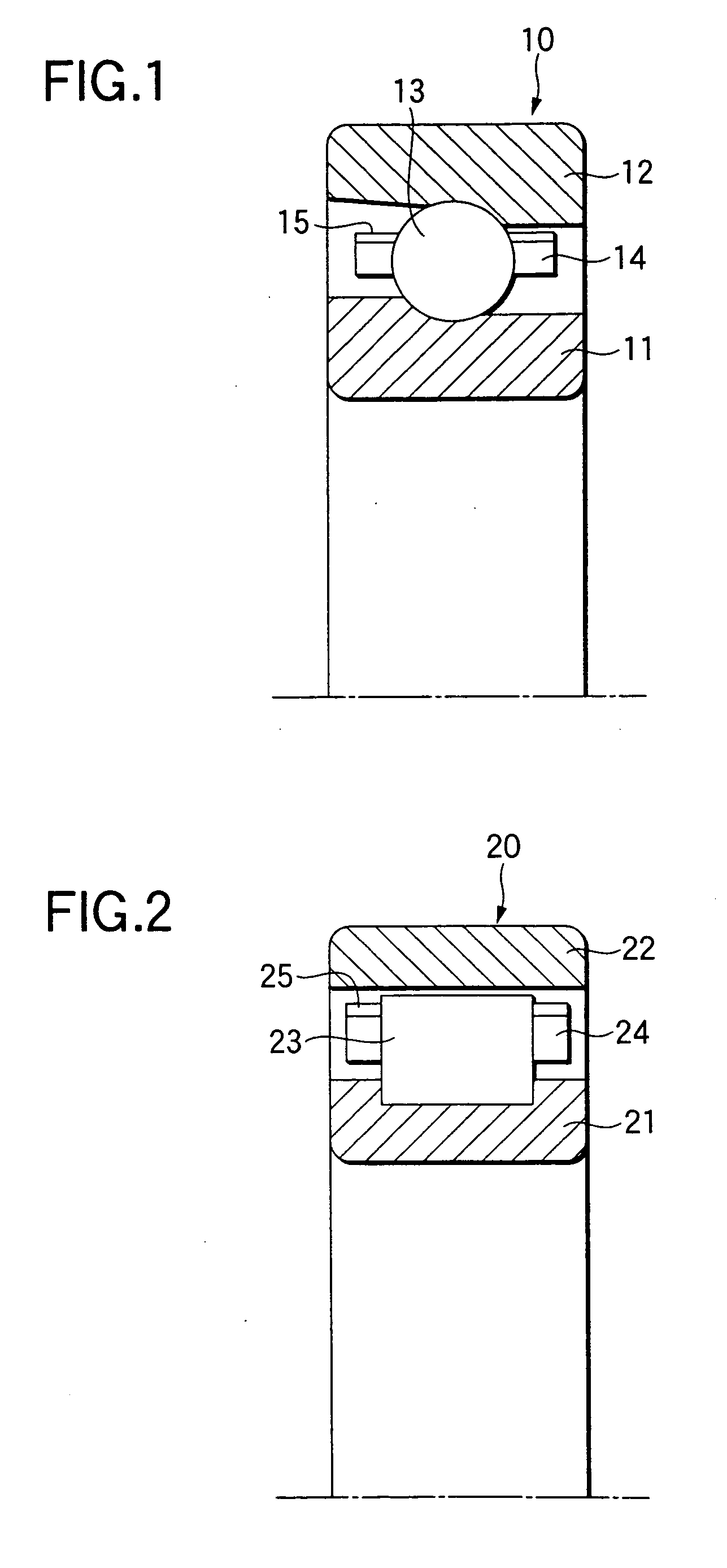

Rolling sliding member and rolling apparatus

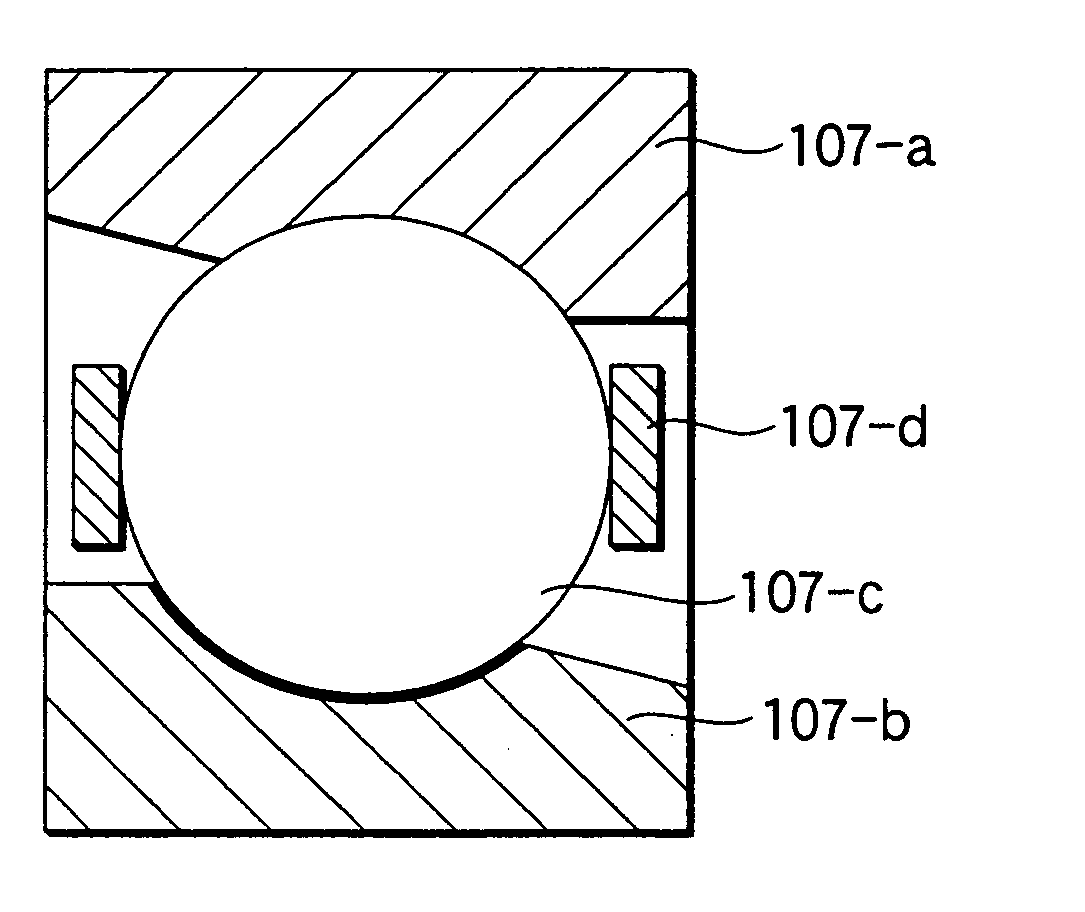

InactiveUS20030099416A1Improve the lubrication effectReduce torqueBearing assemblyShaftsRolling-element bearingRolling sliding

A rolling bearing includes: an inner ring mounted on a shaft to be supported; an outer ring provided around an outer periphery of the inner ring; a plurality of rolling elements rolling while contacting with an inner peripheral face of the outer ring and an outer peripheral face of the inner ring at surfaces thereof; and a retainer supporting the rolling elements. A sliding resistance-reducing film is formed on at least one of a first group being an outer peripheral face of the retainer or the inner peripheral face of the outer ring and a second group being an inner peripheral face of the retainer or the outer peripheral face of the inner ring.

Owner:NSK LTD

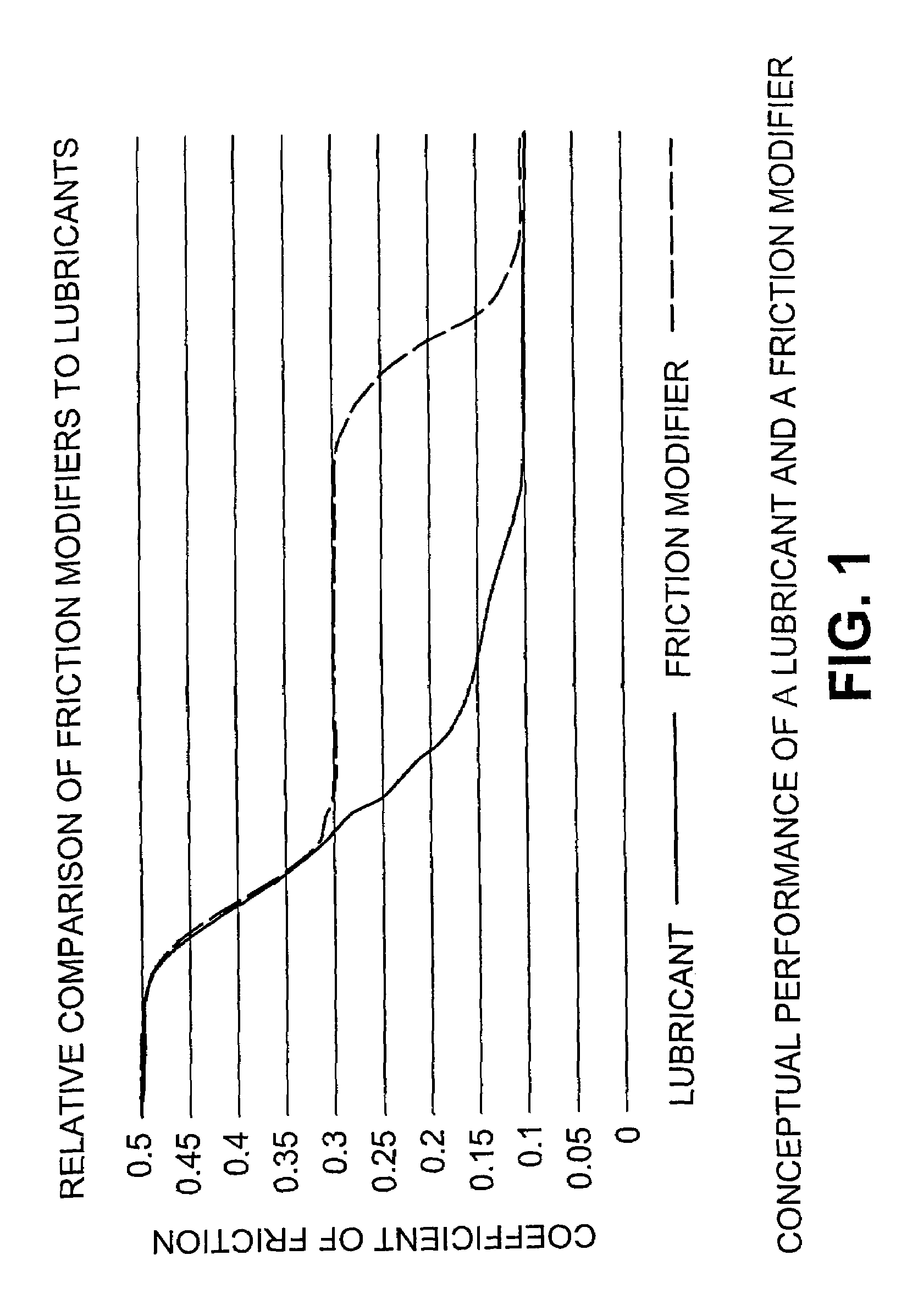

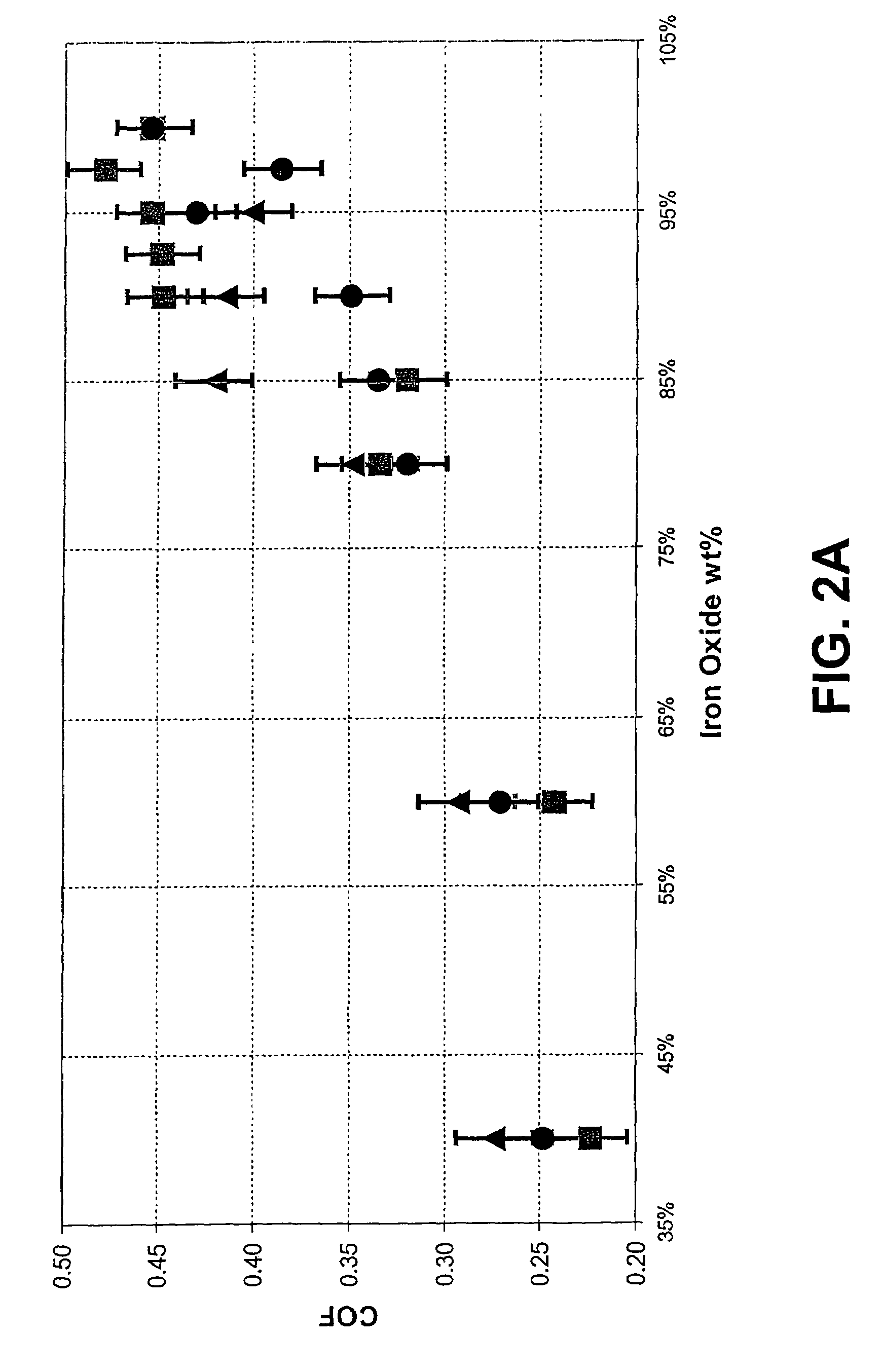

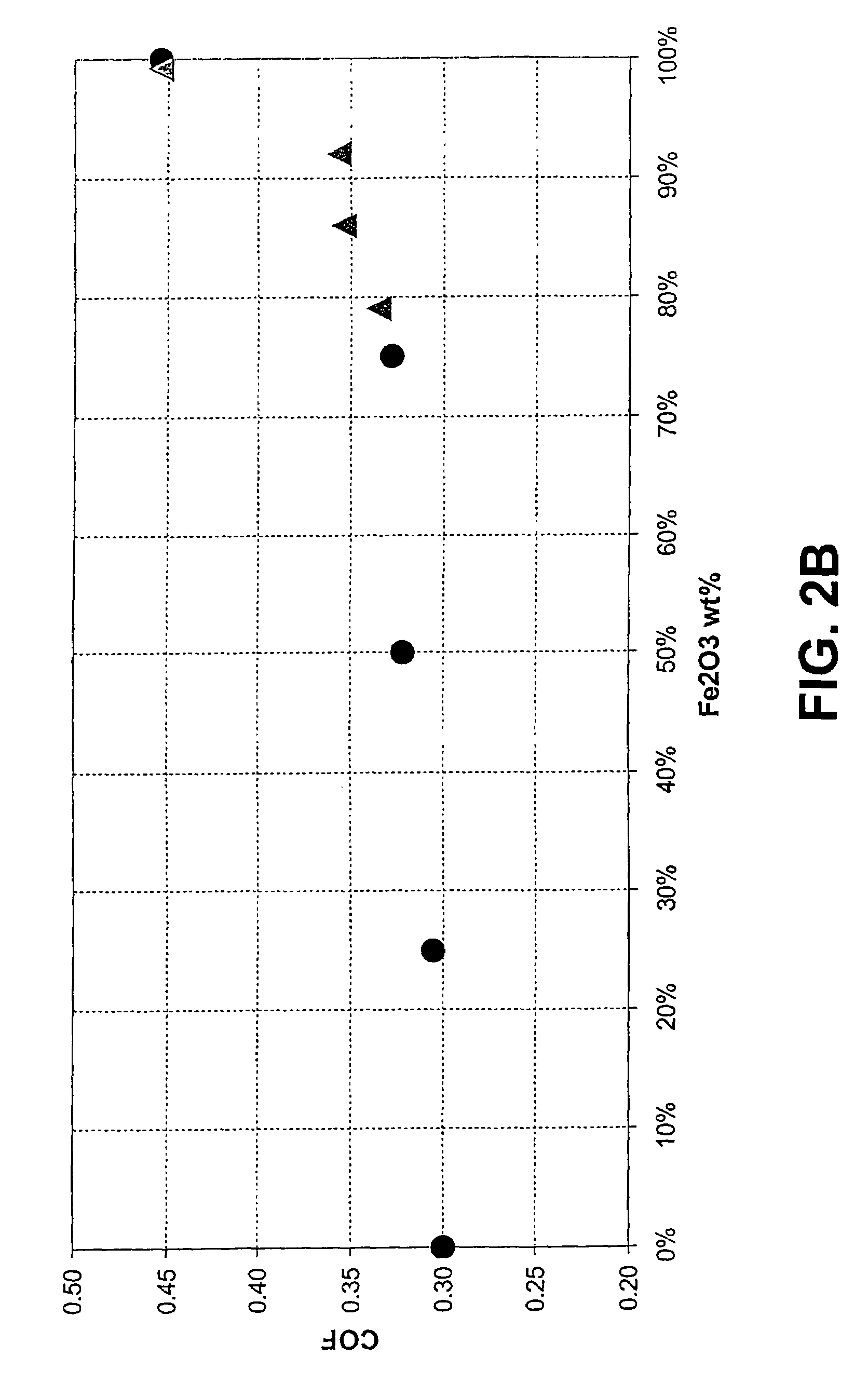

Modified friction control compositions

The present invention provides a friction control composition comprising a binder a rheological control agent, and optionally a lubricant. The liquid friction control composition may also comprise other components a wetting agent, a consistency modifier, and a preservative. The liquid friction control compositions may be used to modify the interfacial friction characteristics in sliding and rolling-sliding contact such as steel wheel-rail systems including mass transit and freight systems. A method of reducing lateral force, reducing energy consumption, or controlling friction between a metal surface and a second metal surface by applying the composition to metal surface, for example a top of rail or wheel, is also provided. The composition may be sprayed onto the rail surface.

Owner:KELSAN TECH

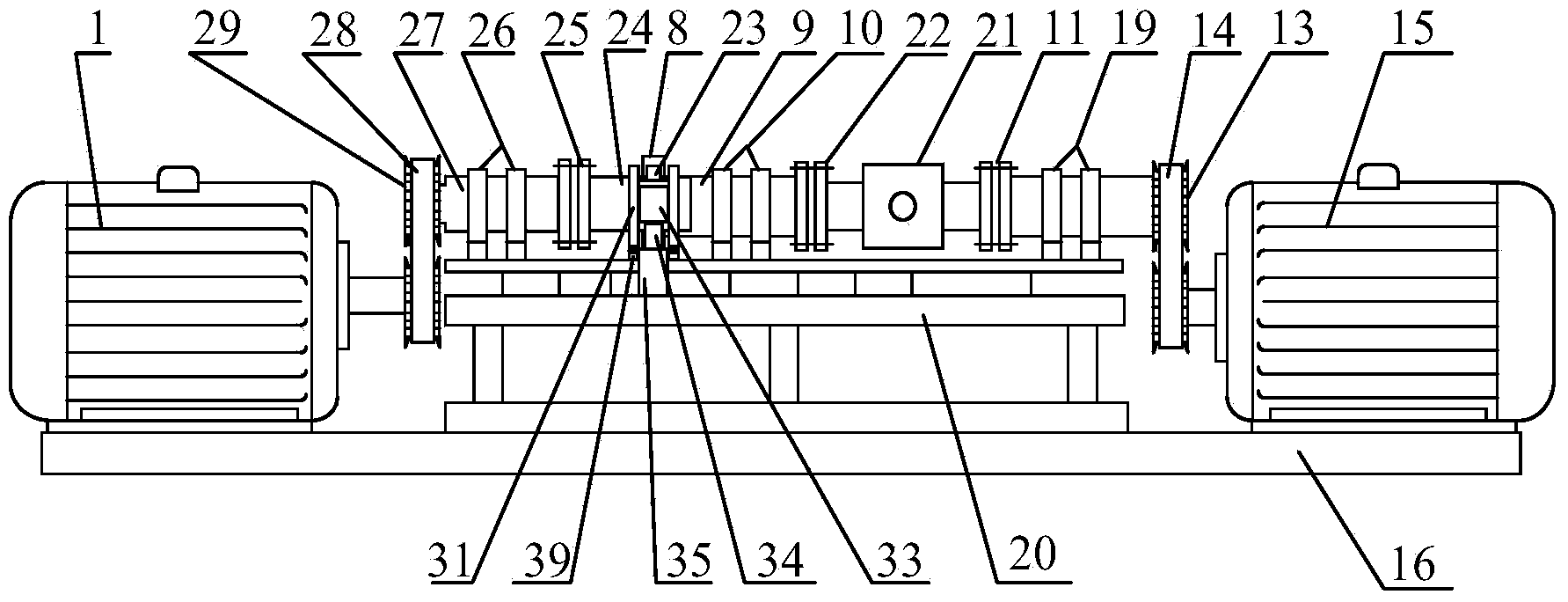

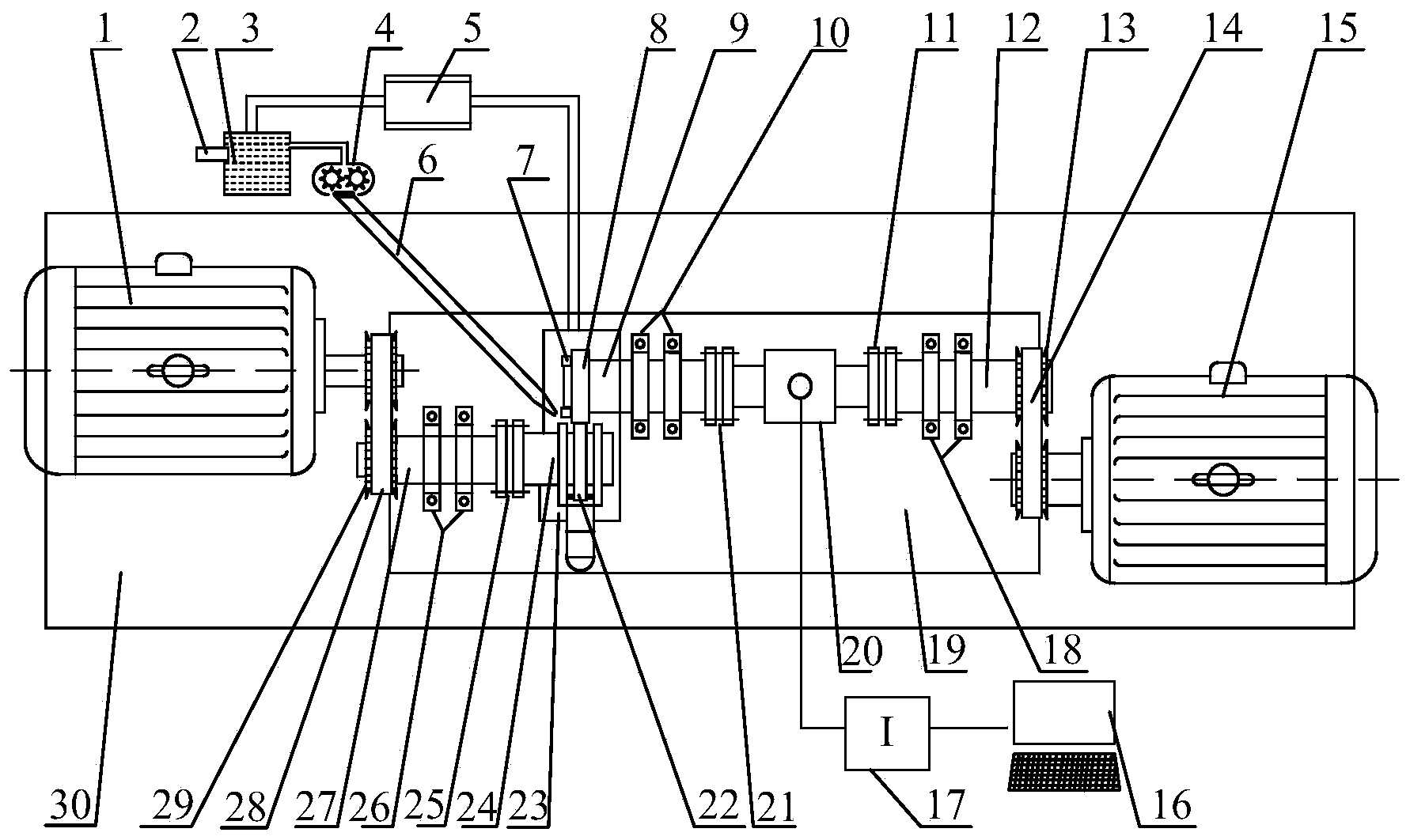

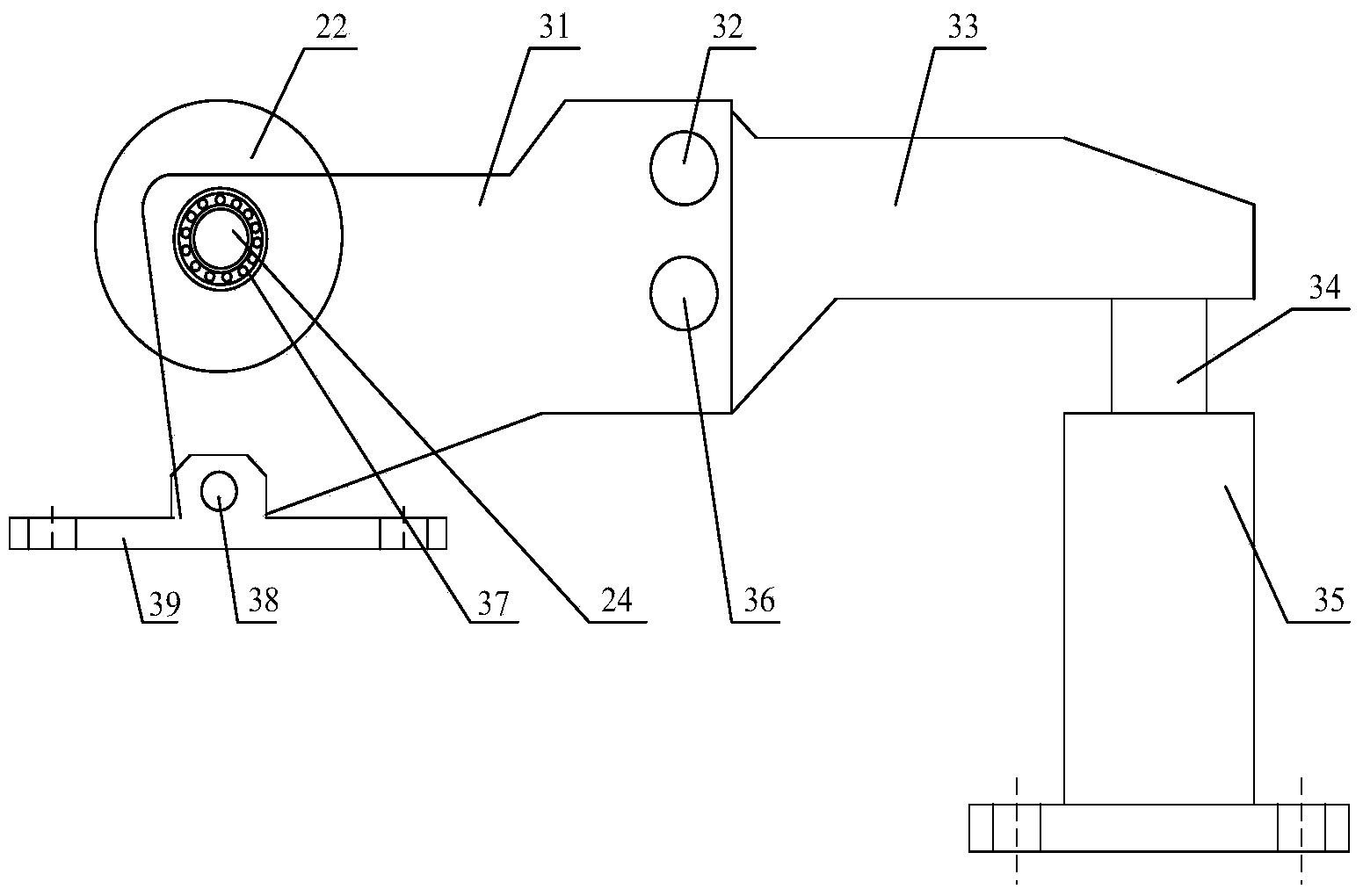

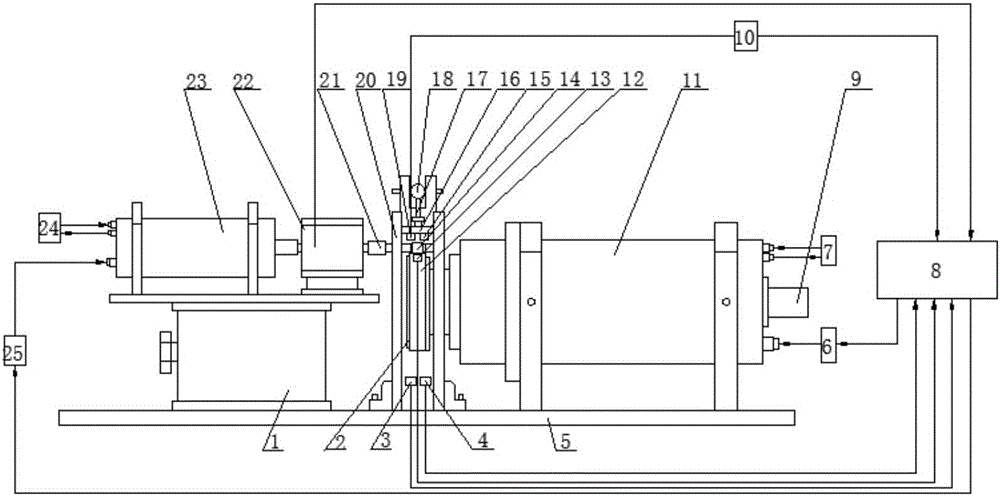

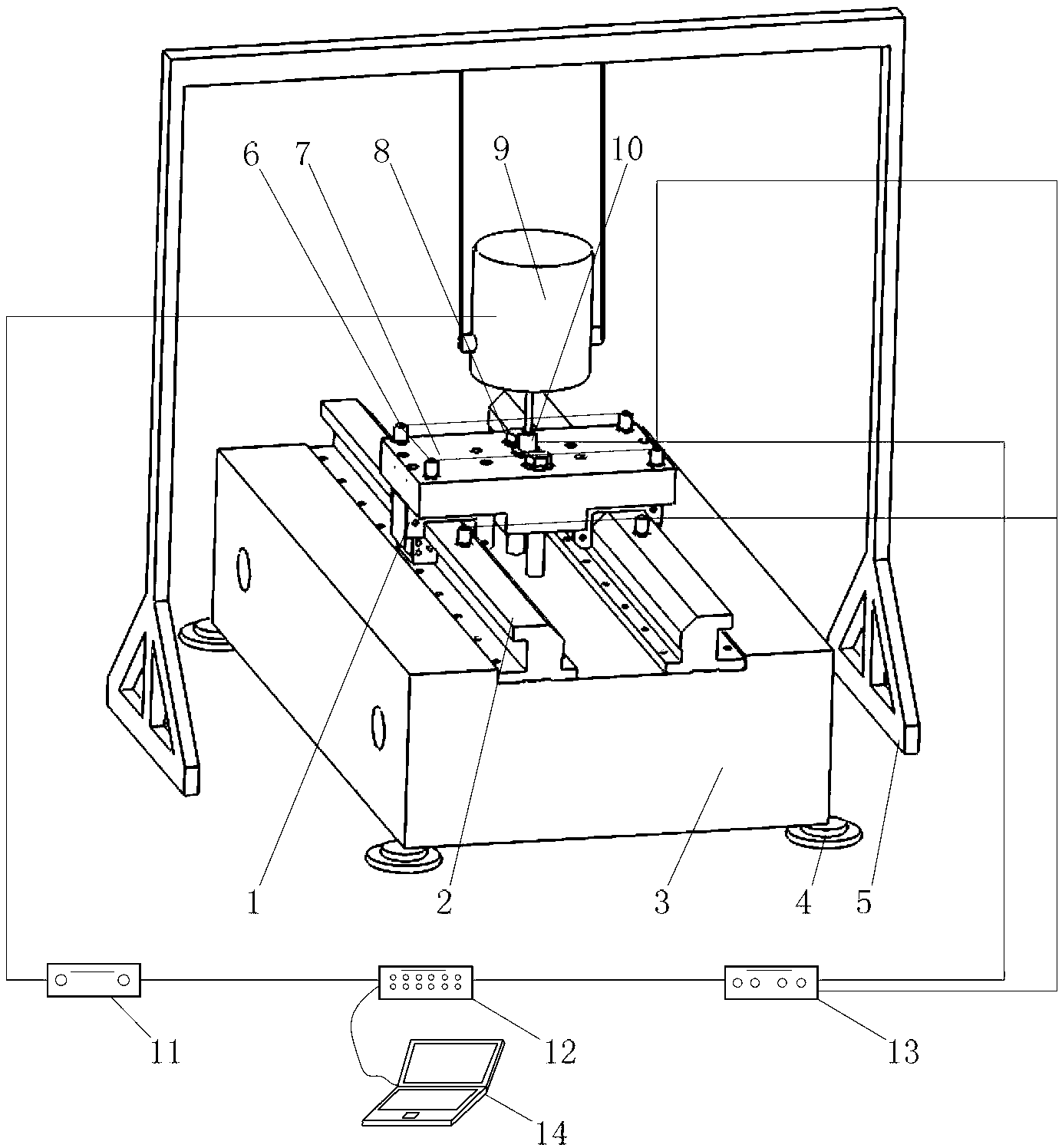

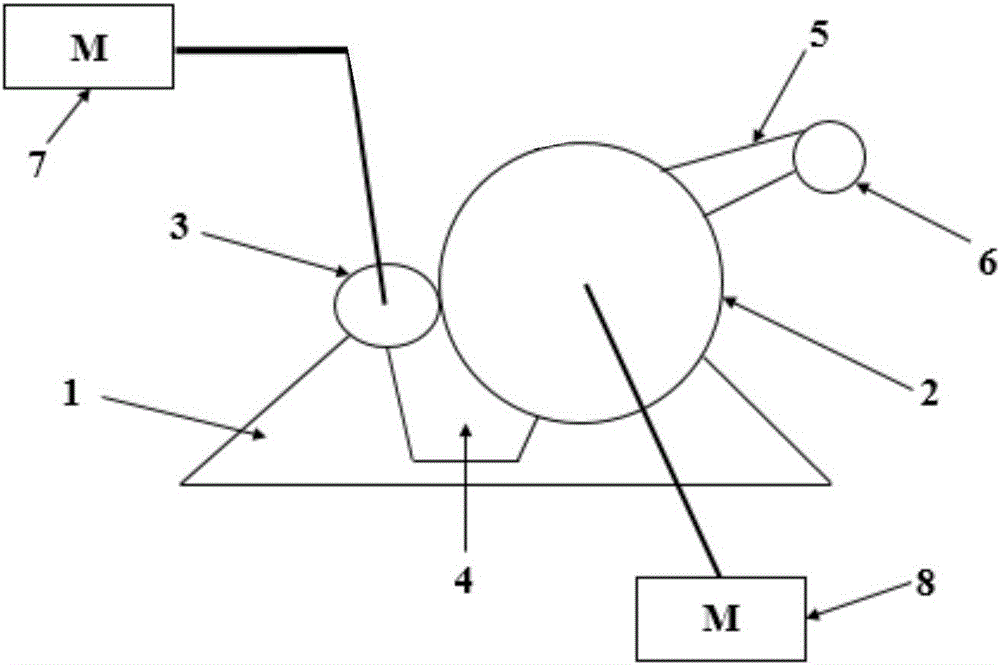

Variable-load rolling friction-abrasion testing machine

InactiveCN103868812ASlip rate controllableSimple structureUsing mechanical meansInvestigating abrasion/wear resistanceRolling resistanceRolling sliding

The invention discloses a variable-load rolling friction-abrasion testing machine, belongs to mechanical friction-abrasion testing devices, and relates to the variable-load rolling friction-abrasion testing machine which is controlled by double motors and is capable of changing the load size in real time, controlling the roll-slide ratio and controlling the temperature. In a driving mode of simultaneously driving a transmission assembly through the double motors, the testing machine consists of a rack, the left motor, the right motor, the transmission assembly, a lubricating temperature control assembly, a variable-load loading assembly and a torque detection assembly. In the variable-load loading assembly, a pneumatic generation device is connected with a pressure control valve through a pipe, the pressure control valve is connected with a pneumatic cylinder through a pipe, the pneumatic cylinder is arranged on a motor base plate through a bolt in a vertical direction, and a piston rod is arranged above the pneumatic cylinder and is capable of being finely adjusted up and down. The variable-load rolling friction-abrasion testing machine is simple in structure, accurate in measurement and complete in functionality; parameters such as slippage rate, lubrication, temperature and load can be controlled simultaneously.

Owner:DALIAN UNIV OF TECH

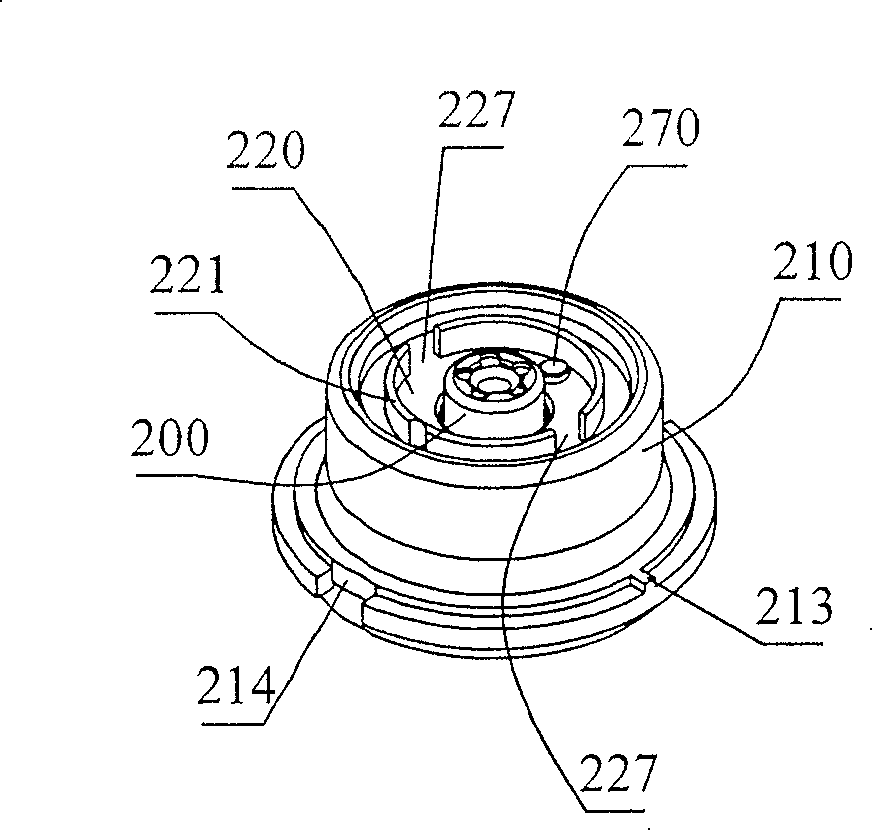

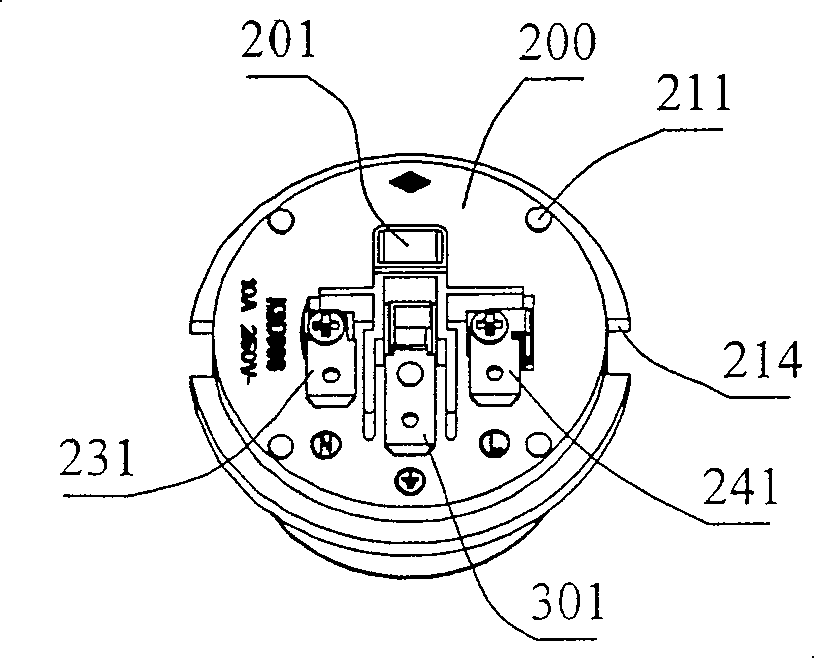

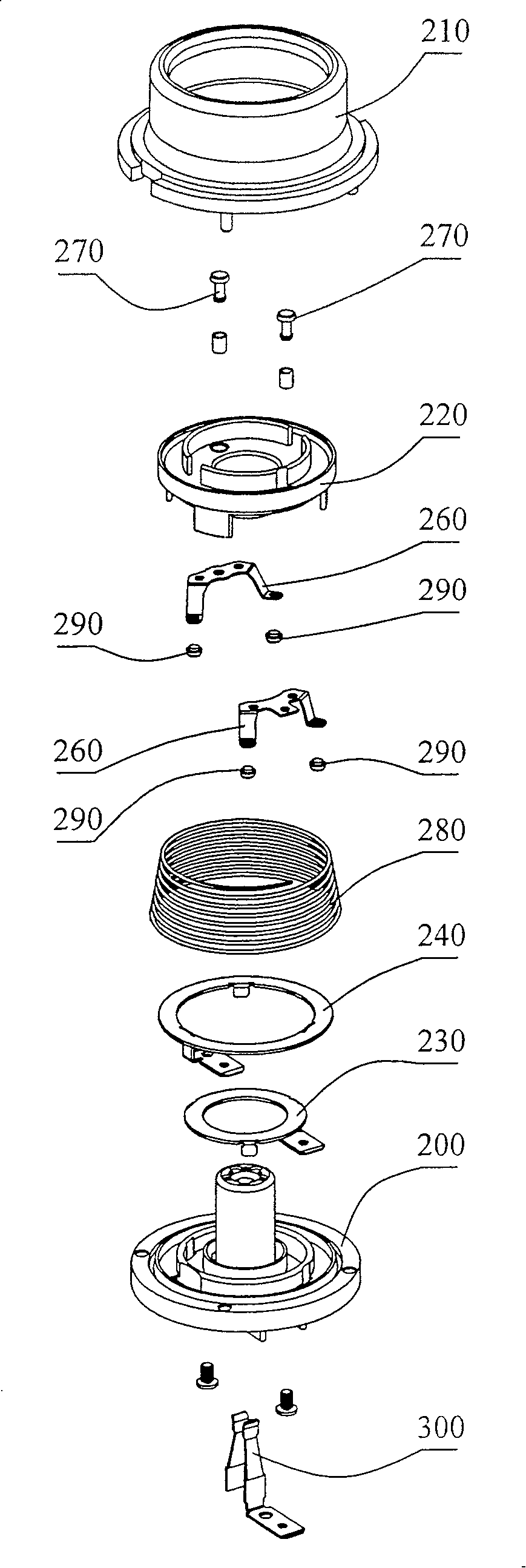

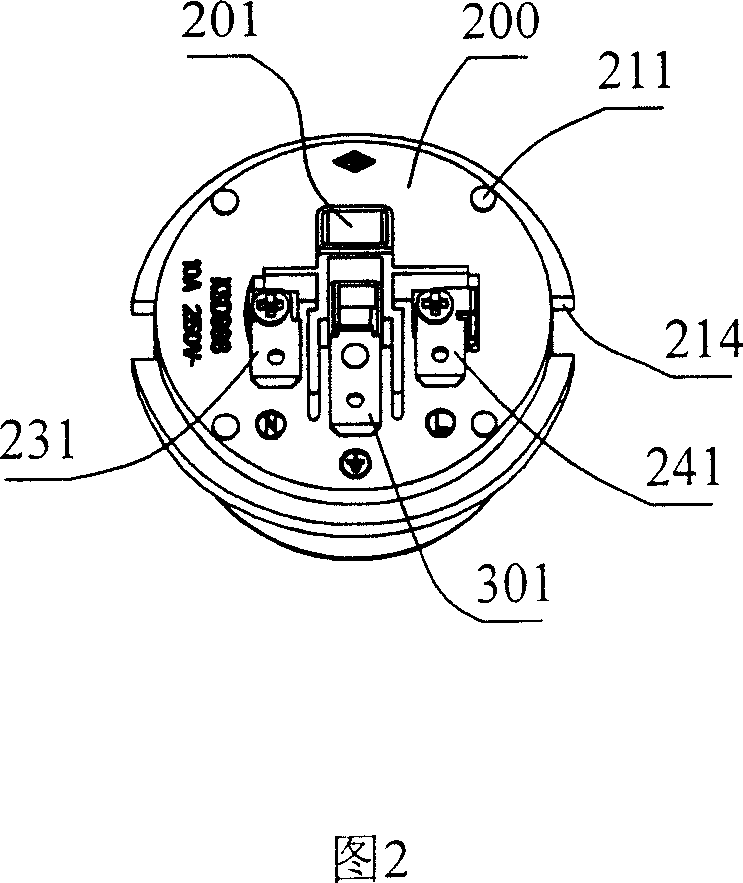

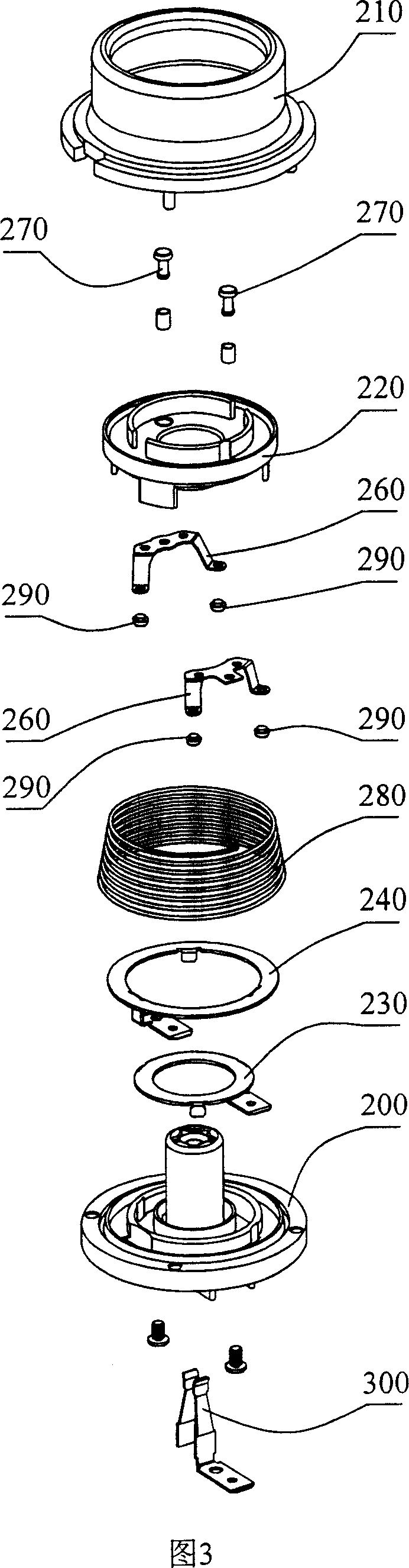

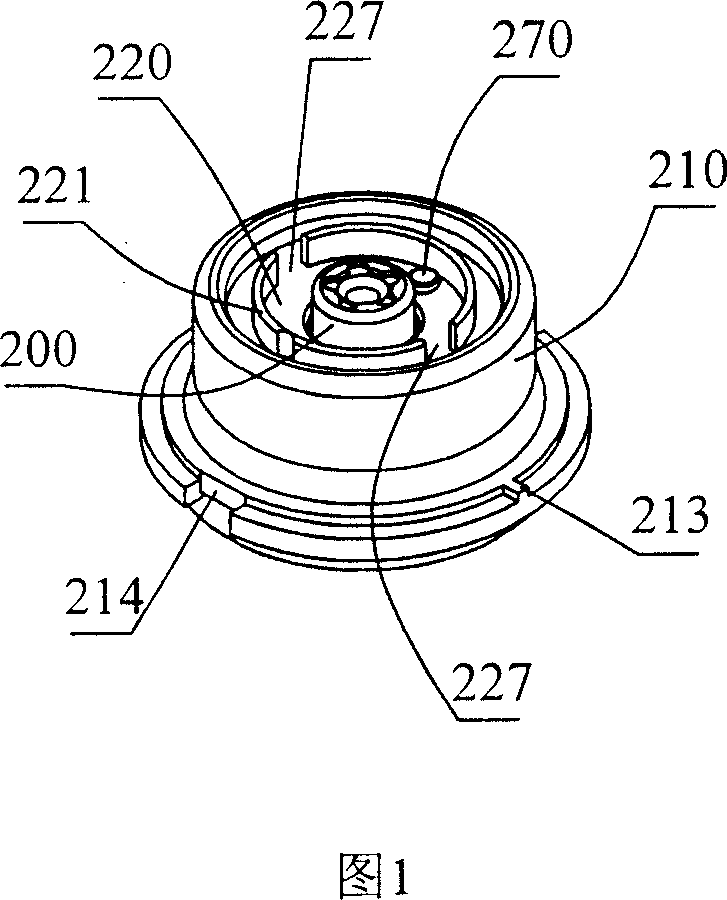

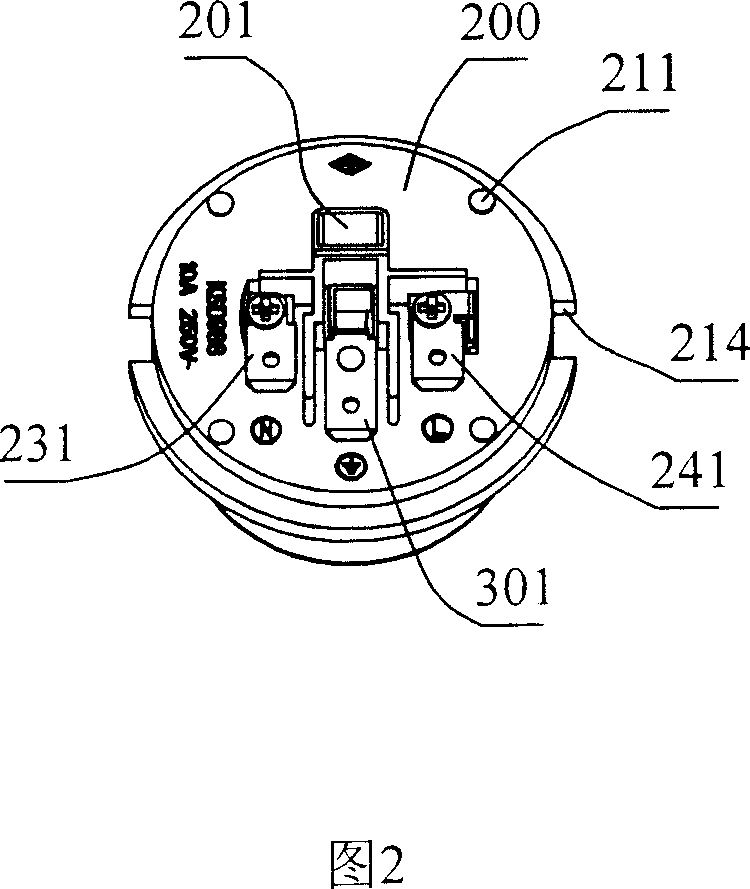

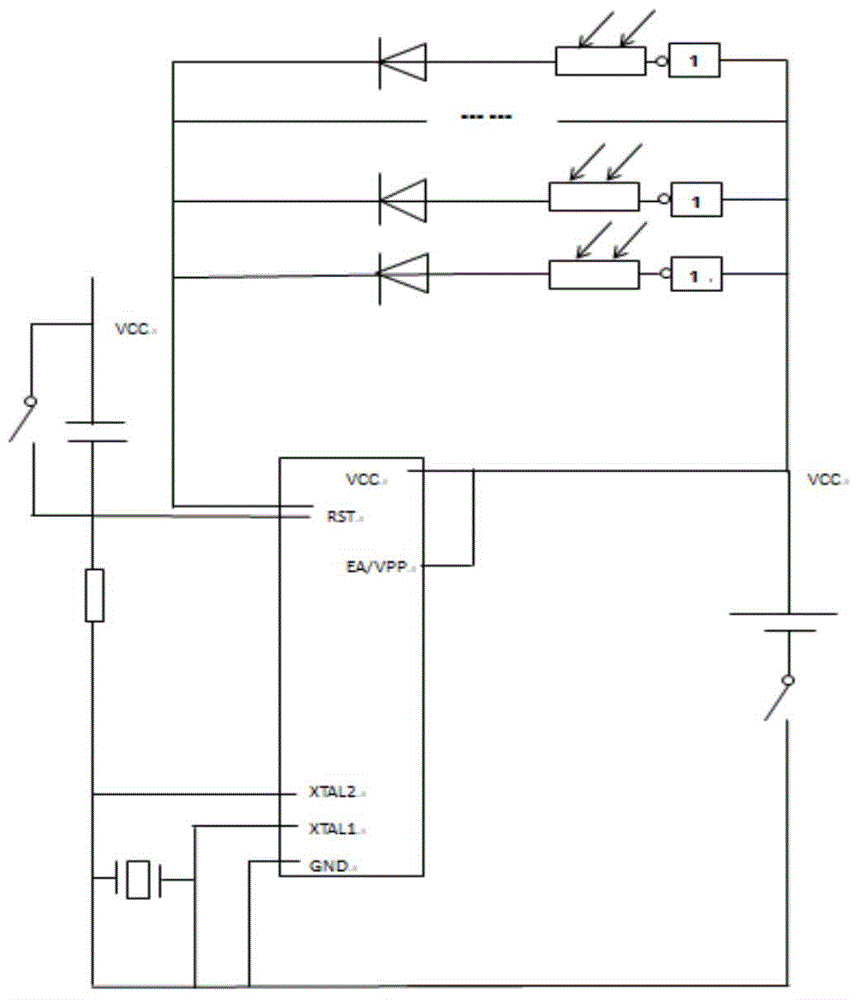

Bottom base of the cordless electrical appliance connector

The invention discloses a safty used non- rope electric appliance connector base place. It includes shell, electric link place, rolling slide bushing, give electricity insert reed, the backspring; the shell fixing connects with the electric link place, and on the electric link place there set two electric conductors which separately connects with the two poles of the out source, guide post set in the middle of the electric link place, and the hole set in the middle of the guide post, the rolling slide bushing in the shell, the backspring set between the rolling slide bushing and electric link place, the two give electricity bodys set on the rolling slide bushing and separately correspond with the two electric conductors. Under the backspring tension effect, when not coupling with the electric appliance body, the give electricity body on the rolling slide bushing and the electric conductor on the electric link place always exist in the divding state, the out reveal give electric body has no charged, therefore the use is more safely.

Owner:ZHEJIANG JIATAI ELECTRICAL APPLIANCE

Rolling sliding member and rolling apparatus

InactiveUS20050141797A1Improve the lubrication effectRolling contact bearingsBearing assemblyEngineeringRolling sliding

A rolling bearing includes: an inner ring mounted on a shaft to be supported; an outer ring provided around an outer periphery of the inner ring; a plurality of rolling elements rolling while contacting with an inner peripheral face of the outer ring and an outer peripheral face of the inner ring at surfaces thereof; and a retainer supporting the rolling elements. A sliding resistance-reducing film is formed on at least one of a first group being an outer peripheral face of the retainer or the inner peripheral face of the outer ring and a second group being an inner peripheral face of the retainer or the outer peripheral face of the inner ring.

Owner:NSK LTD

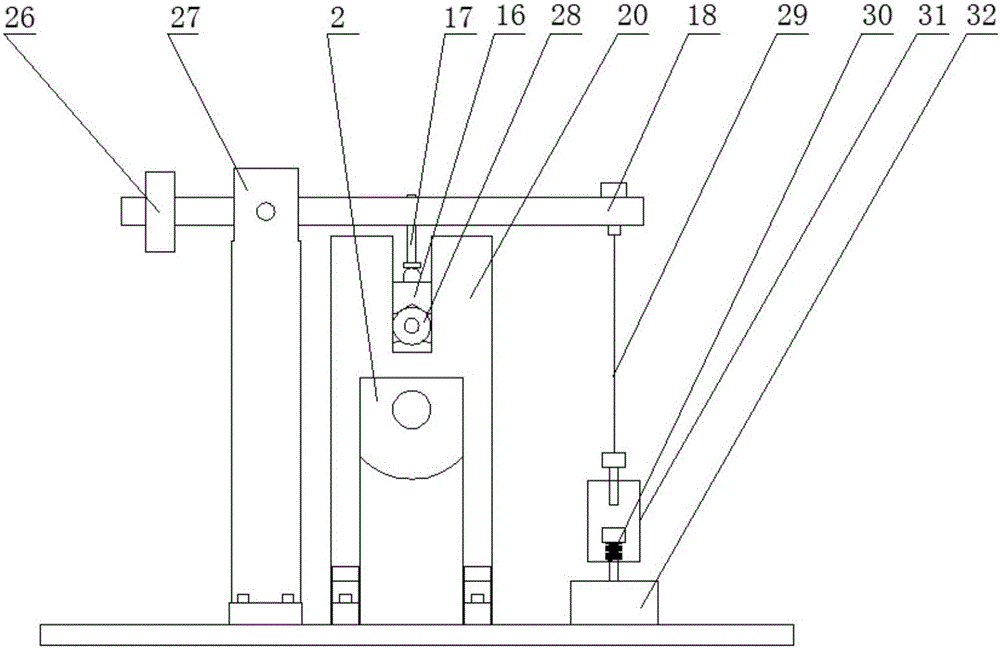

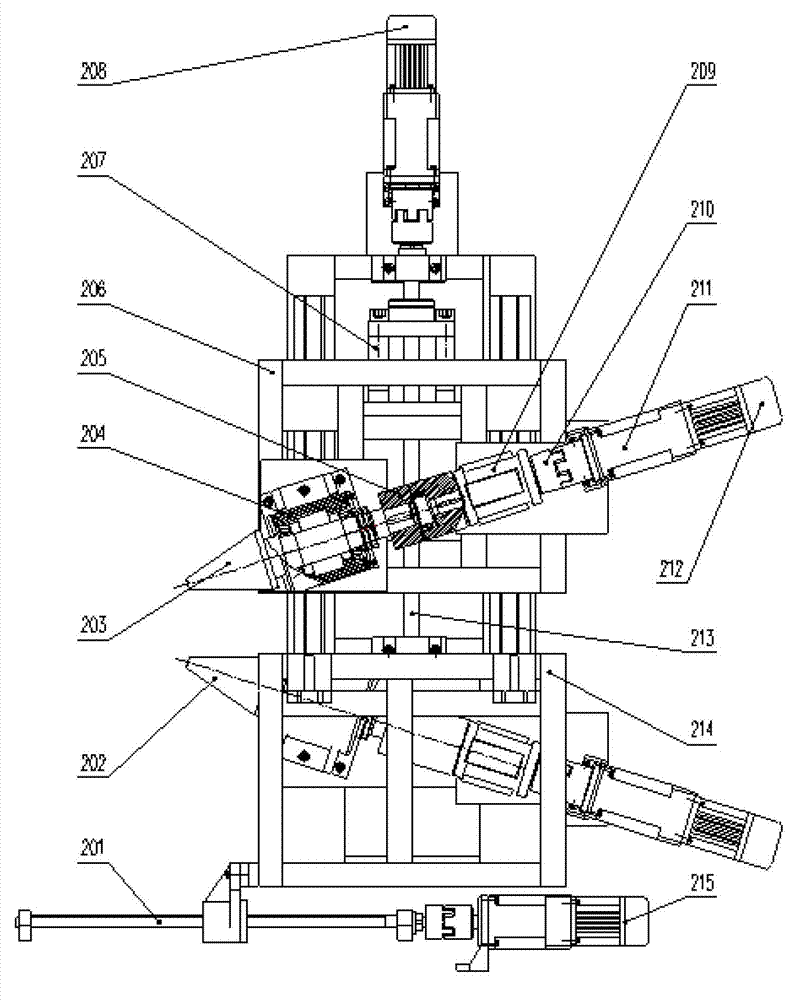

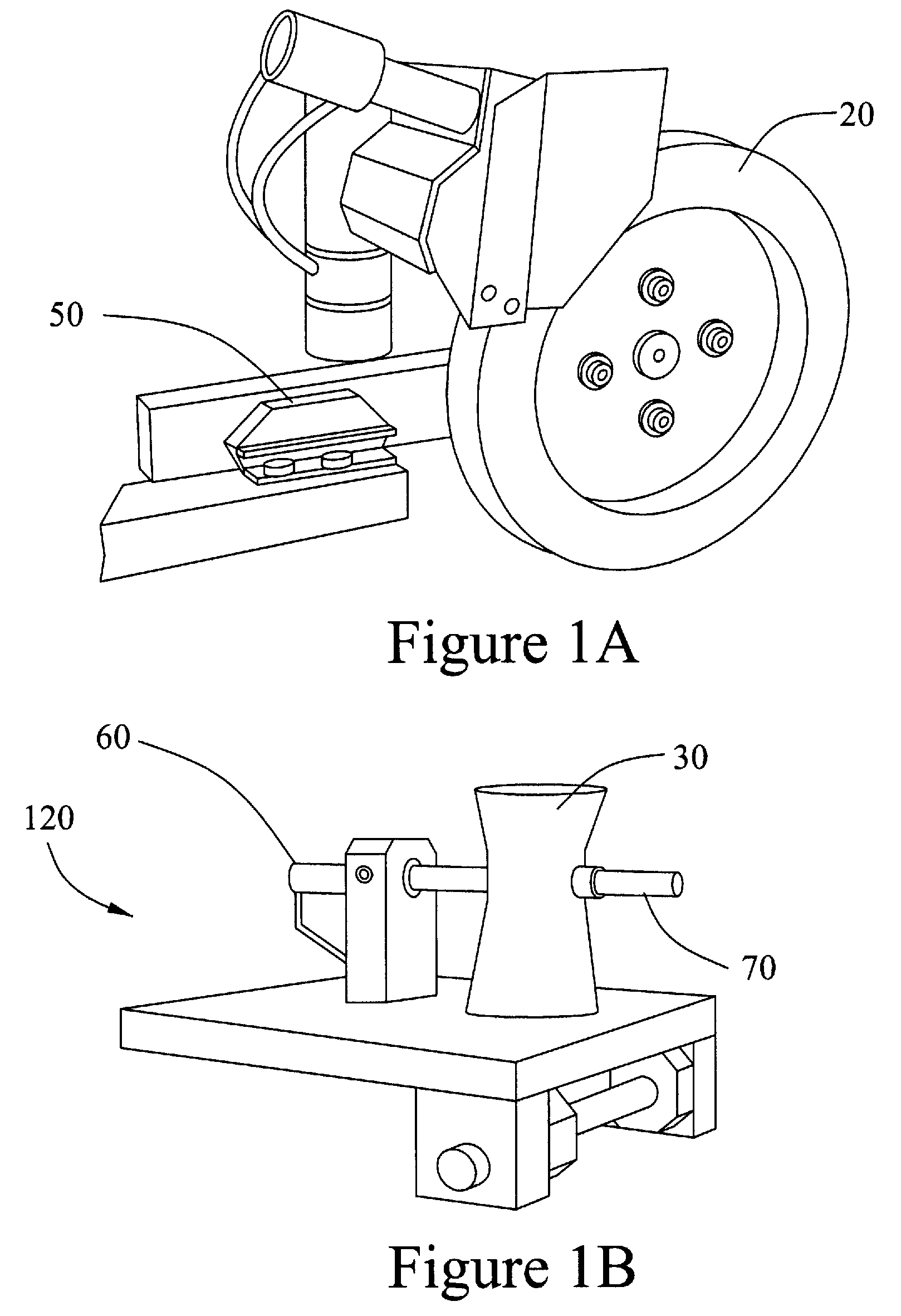

Interface friction property monitoring-based rolling-sliding friction life cycle test device

ActiveCN106198019ALive frictionReal-time film thicknessMachine bearings testingInvestigating abrasion/wear resistanceLow speedRolling-element bearing

The invention relates to an interface friction property monitoring-based rolling-sliding friction life cycle test device. A high-speed electric spindle on a support lifting platform is connected with a torque sensor; one end of the torque sensor is connected with an exchangeable rolling body in a measured object; two ends of the rolling body are provided with rolling bearings; the rolling bearings area arranged in a vertical guide rail; a pressing plate is arranged above the rolling bearings; a groove for accommodating a ball is arranged on the upper surface of the pressing plate; the upper part of the ball contacts with the fulcrum plane of a pressing rod; a lever is arranged on an upright column; the tail end of the lever is connected with the nut of a sensor on a support through a steel wire rope; one end of the support is provided with a low-speed motorized spindle; and the front end of the low-speed motorized spindle is equipped with the bearing inner ring of the measured object. With the test device of the invention adopted, the actual working condition of each roller and a bearing inner ring in the operation process of a cylindrical roller bearing can be simulated; the cause of abrasion caused by the change of interface contact is obtained; and a reliable data guarantee and technical support can be provided for the life cycle health condition monitoring and condition-based repair of the key friction pair of a rolling bearing.

Owner:XI AN JIAOTONG UNIV

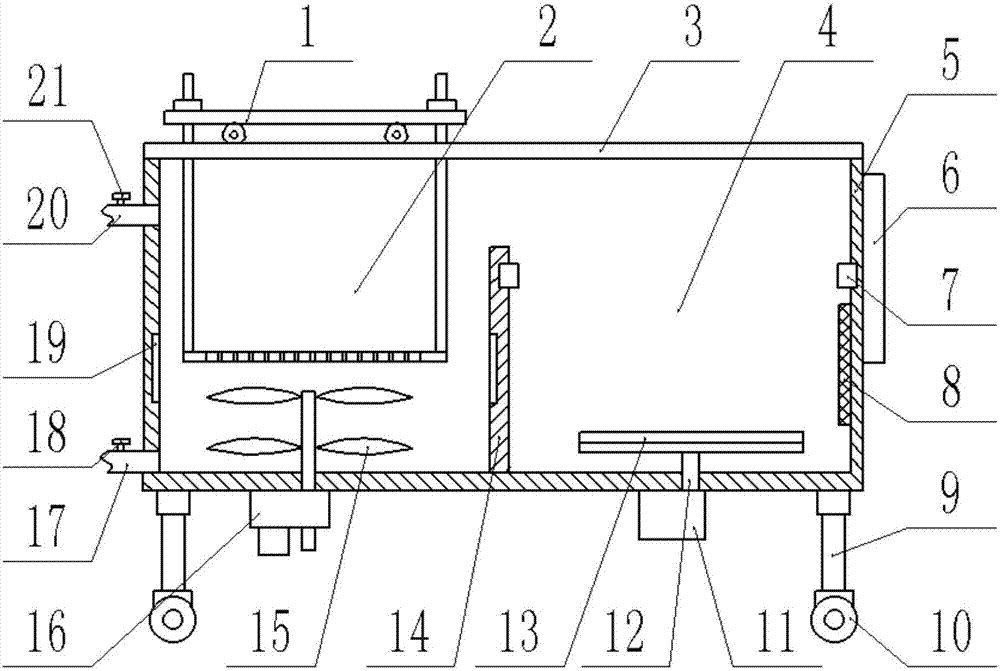

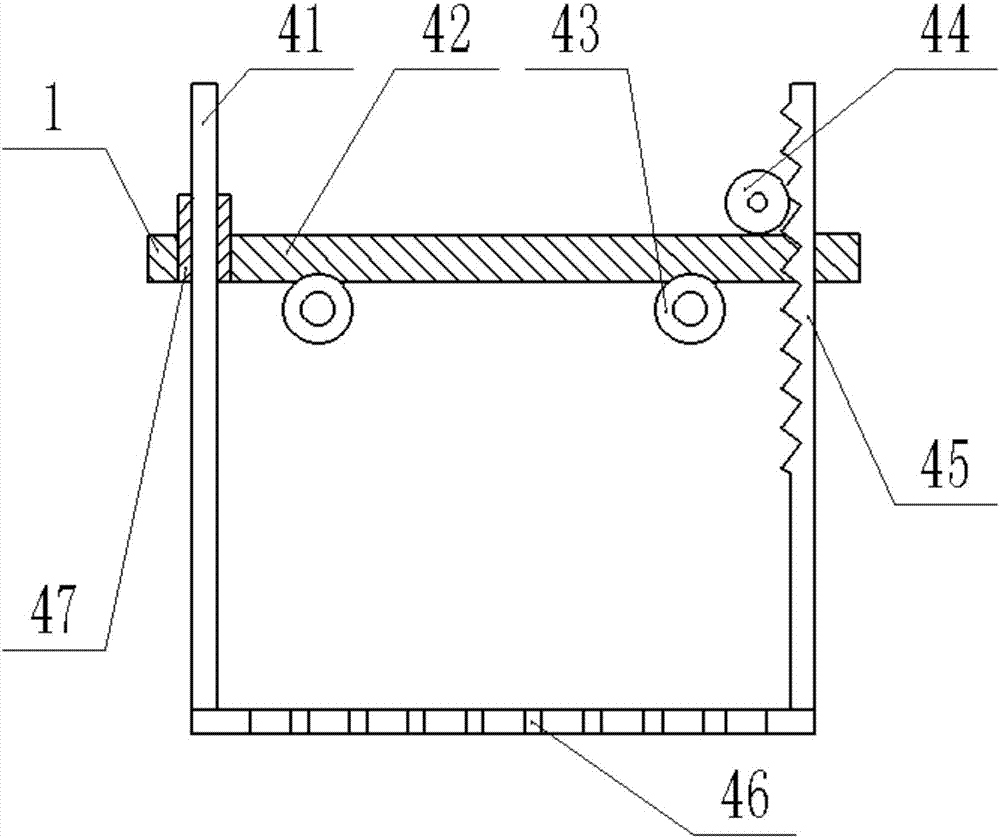

Movable medical equipment cleaning device

InactiveCN107377506AReasonable designSimple structureCleaning using liquidsHeatMedical equipmentUltraviolet

The invention provides a movable medical equipment cleaning device, which belongs to the field of equipment cleaning and includes a box body, a rotating device and a rolling slide; the box body includes a cleaning chamber and a sterilization and drying chamber; the cleaning chamber and the sterilization and drying chamber The cavities are separated by partitions; there is a sliding bar on the upper part of the box; an instrument chamber moving device is provided above the sliding bar; a rotating device is provided below the cleaning chamber; ultrasonic cleaning chambers are provided on both sides of the cleaning chamber Generator; the ultrasonic generator is used to emit ultrasonic waves; the outer wall of the cleaning chamber is provided with a liquid inlet pipe and a waste liquid pipe; the liquid inlet pipe is provided with a liquid inlet valve; the waste liquid pipe is provided with a waste liquid valve The right side of the box body is also provided with a sterilizing and drying cavity; ultraviolet lamps are respectively installed on both sides of the middle of the sterilizing and drying cavity; the present invention is reasonable in design and simple in structure; Units can be moved at any time, increasing reliability.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

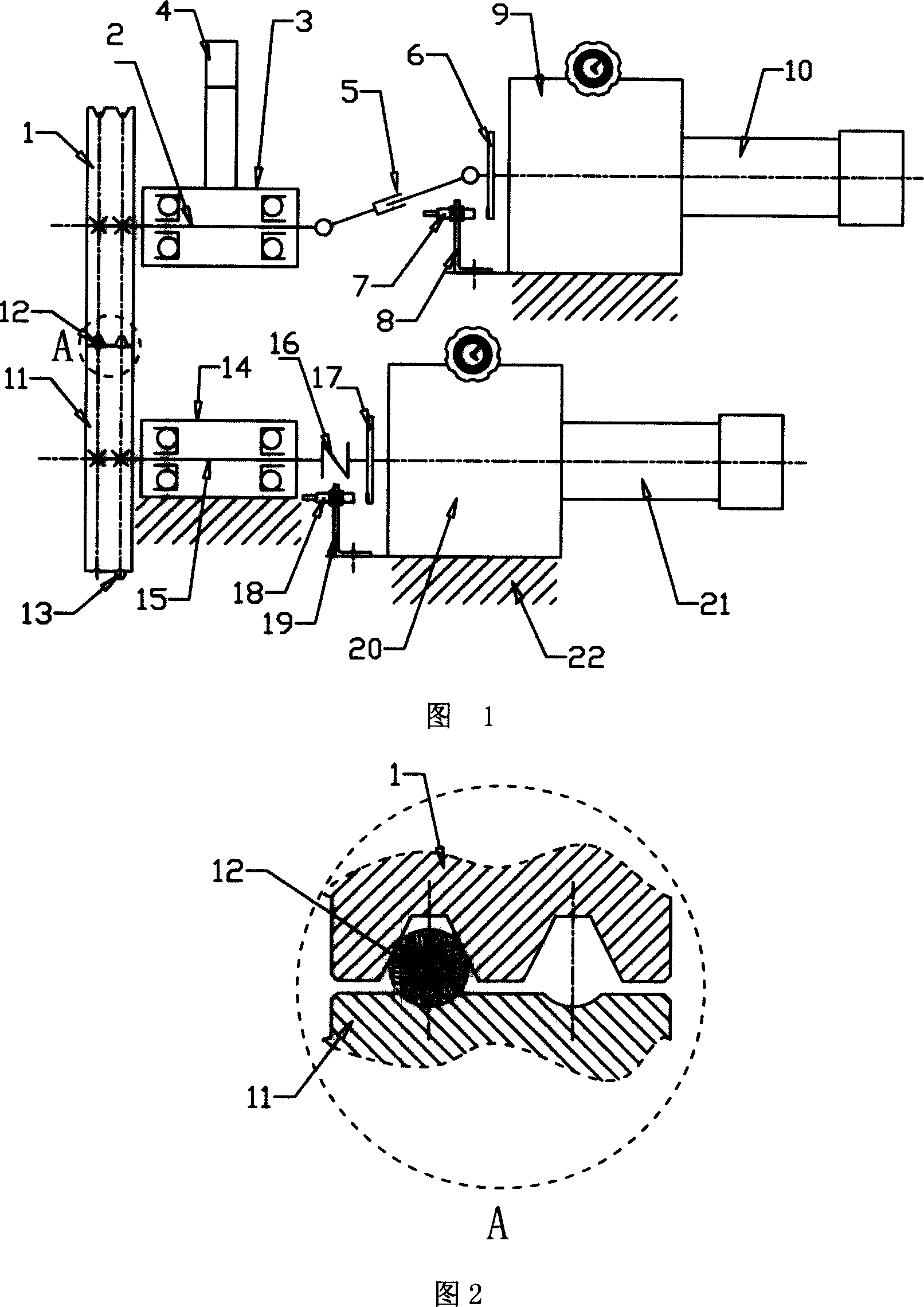

Elevator tow-drive rolling-sliding contact fatigue wear testing machine

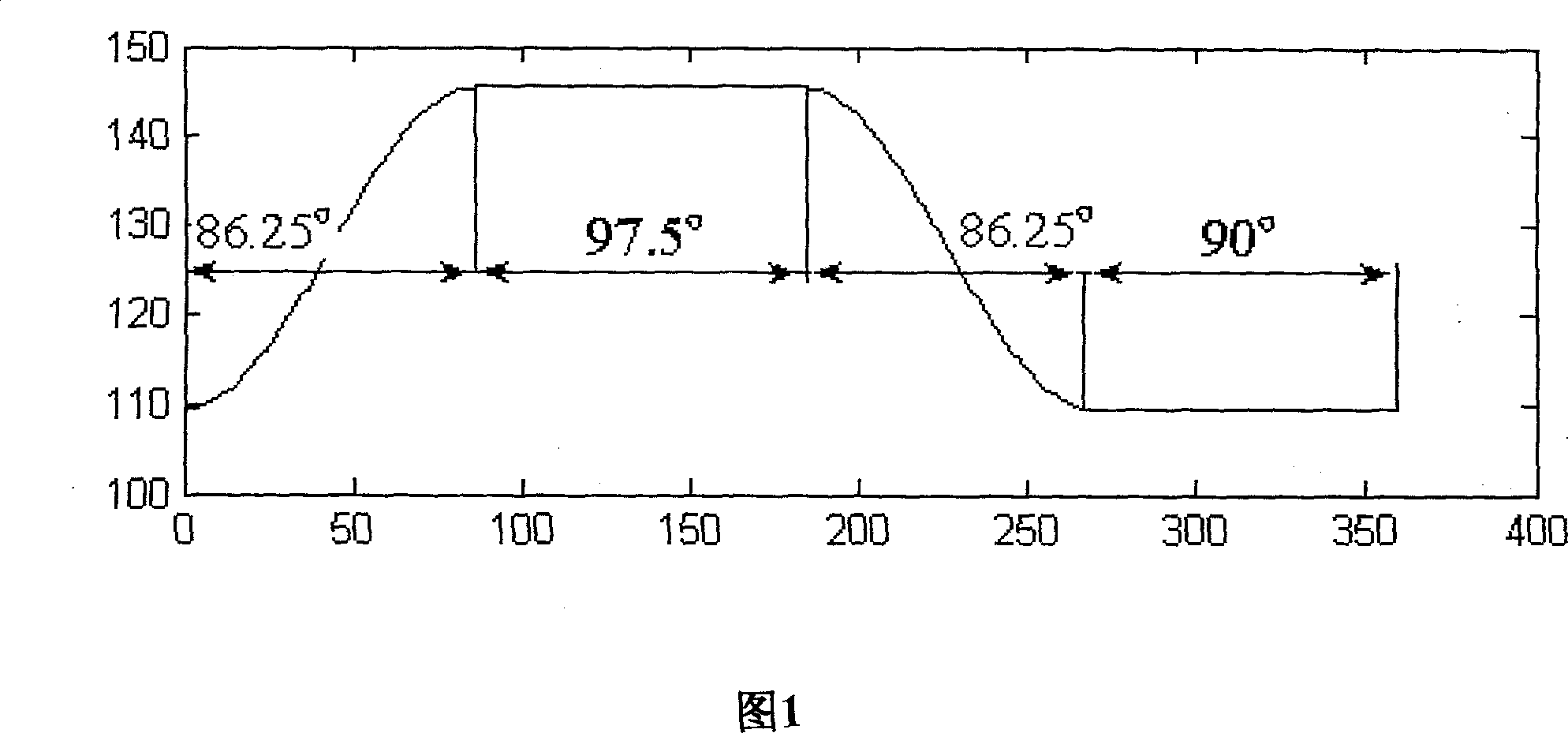

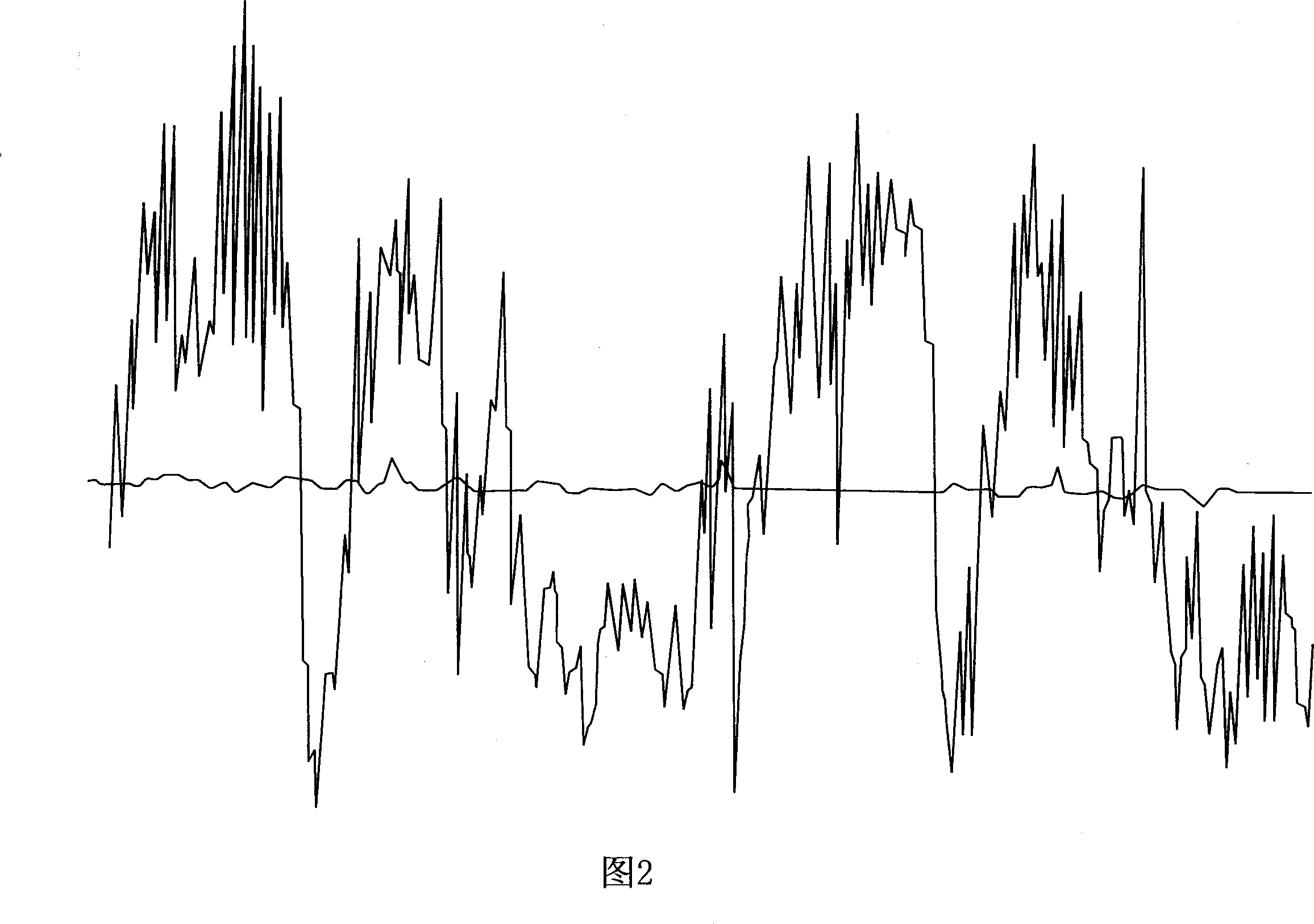

InactiveCN1936536AReduce contact vibrationReduce and avoid contact vibrationUsing mechanical meansInvestigating abrasion/wear resistanceSEMI-CIRCLEWear testing

This invention relates to traction and drive rolling-sliding contact fatigue wear-test machine of elevators, in which, the steel wire rope in the structure of double-groove double-rope semi-circle complement is fixed on a rope groove of a down turnplate, namely, two grooves are opened on the turnplate, a steel wire rope, a bit longer than semi-circle, is winded in each groove, the upper and lower semi-circle ropes are complemented, after that, the rope is fixed in the down turnplate with a clamp, this structure can reduce and avoid the contact vibration between the traction wheel and the rope, the weight amplifies the force by a loaded lever to press the traction wheel to contact with the rope on the down turnplate, the action line of the pressure passes through the center of the two wheels.

Owner:SHANGHAI JIAO TONG UNIV

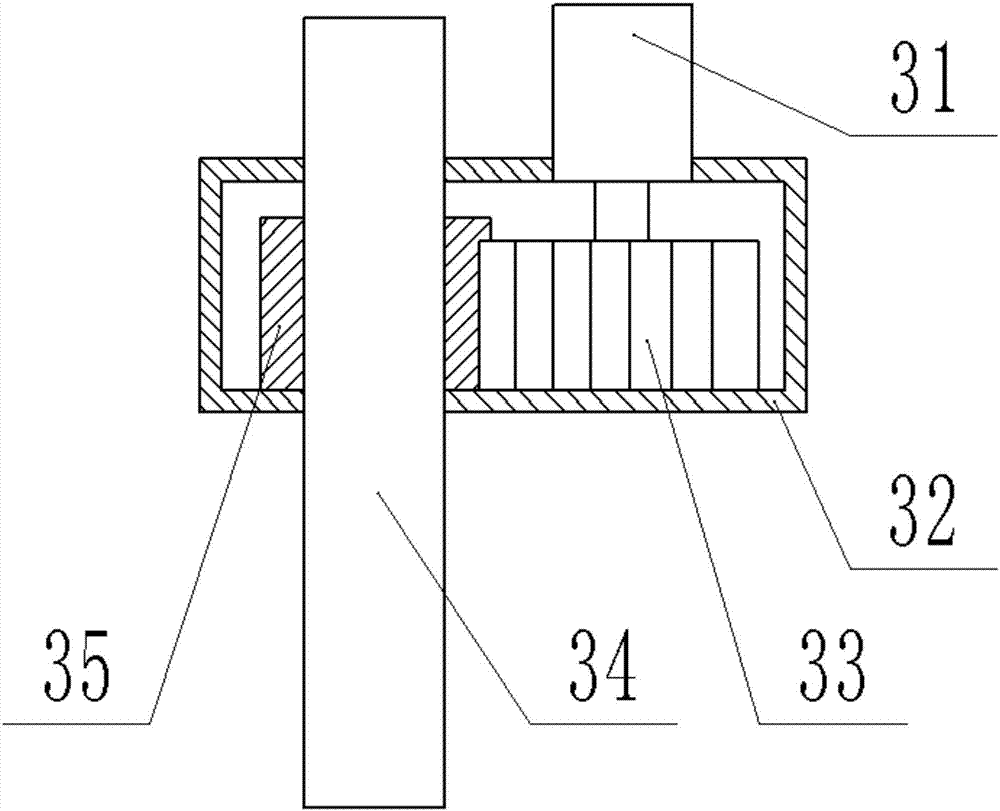

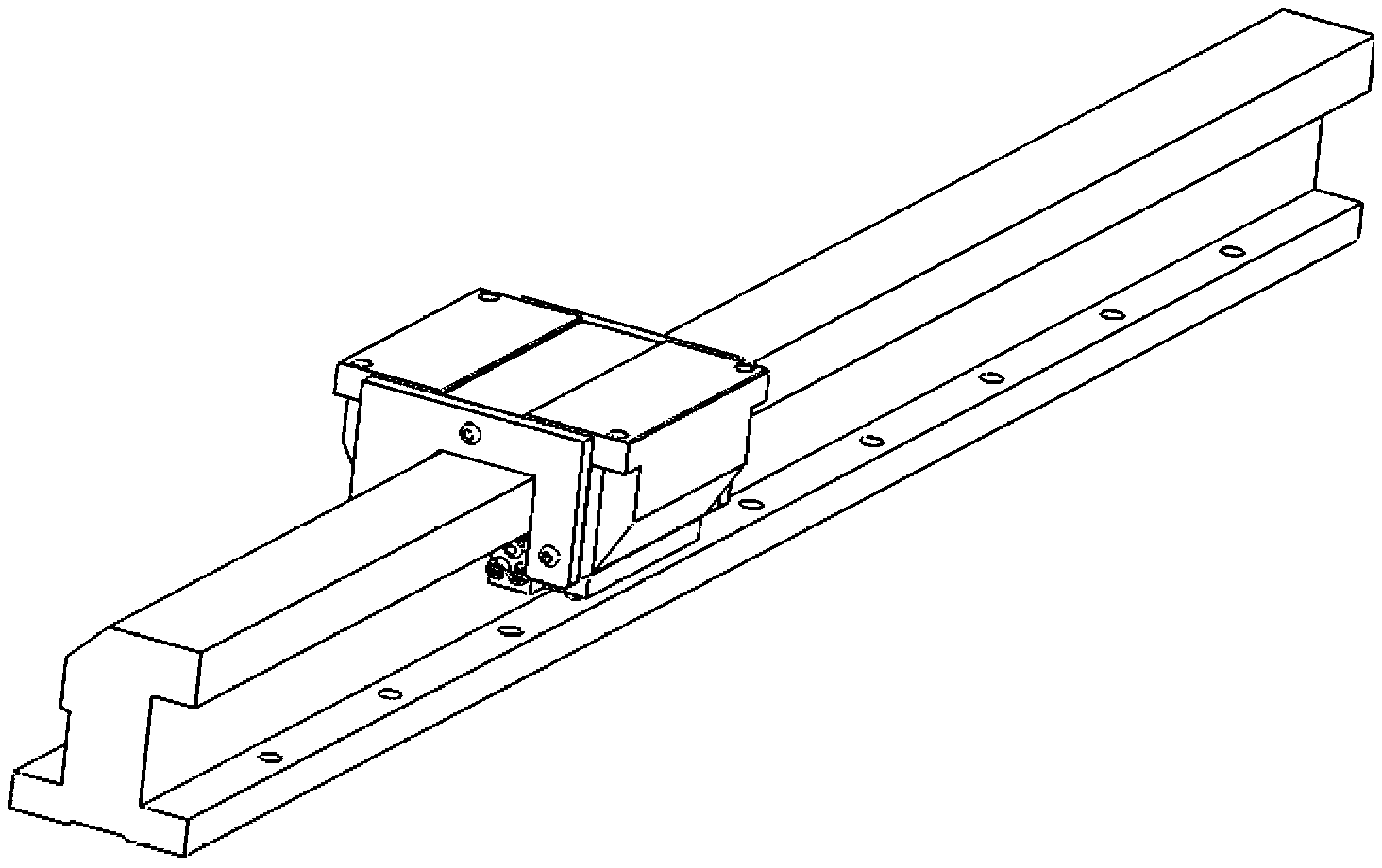

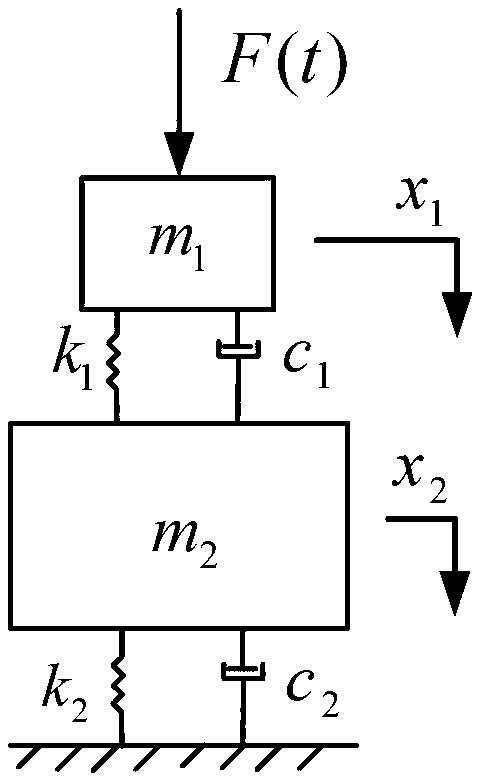

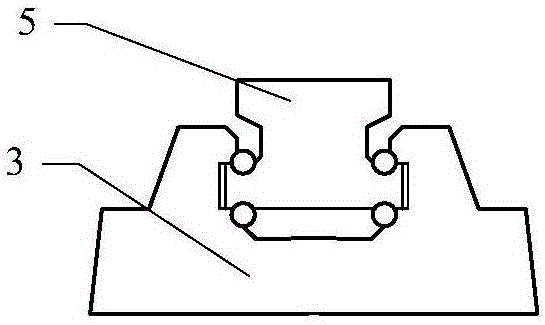

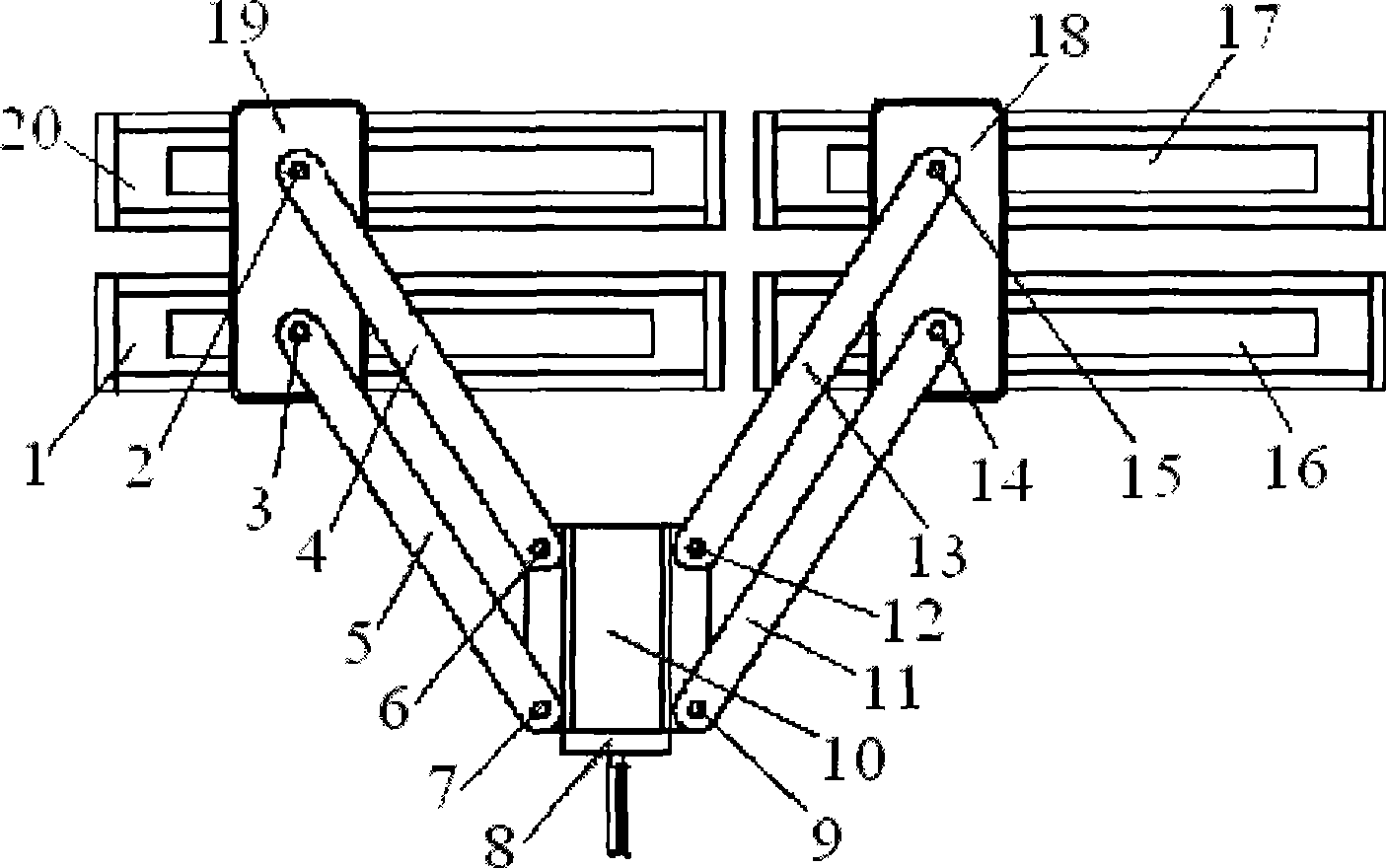

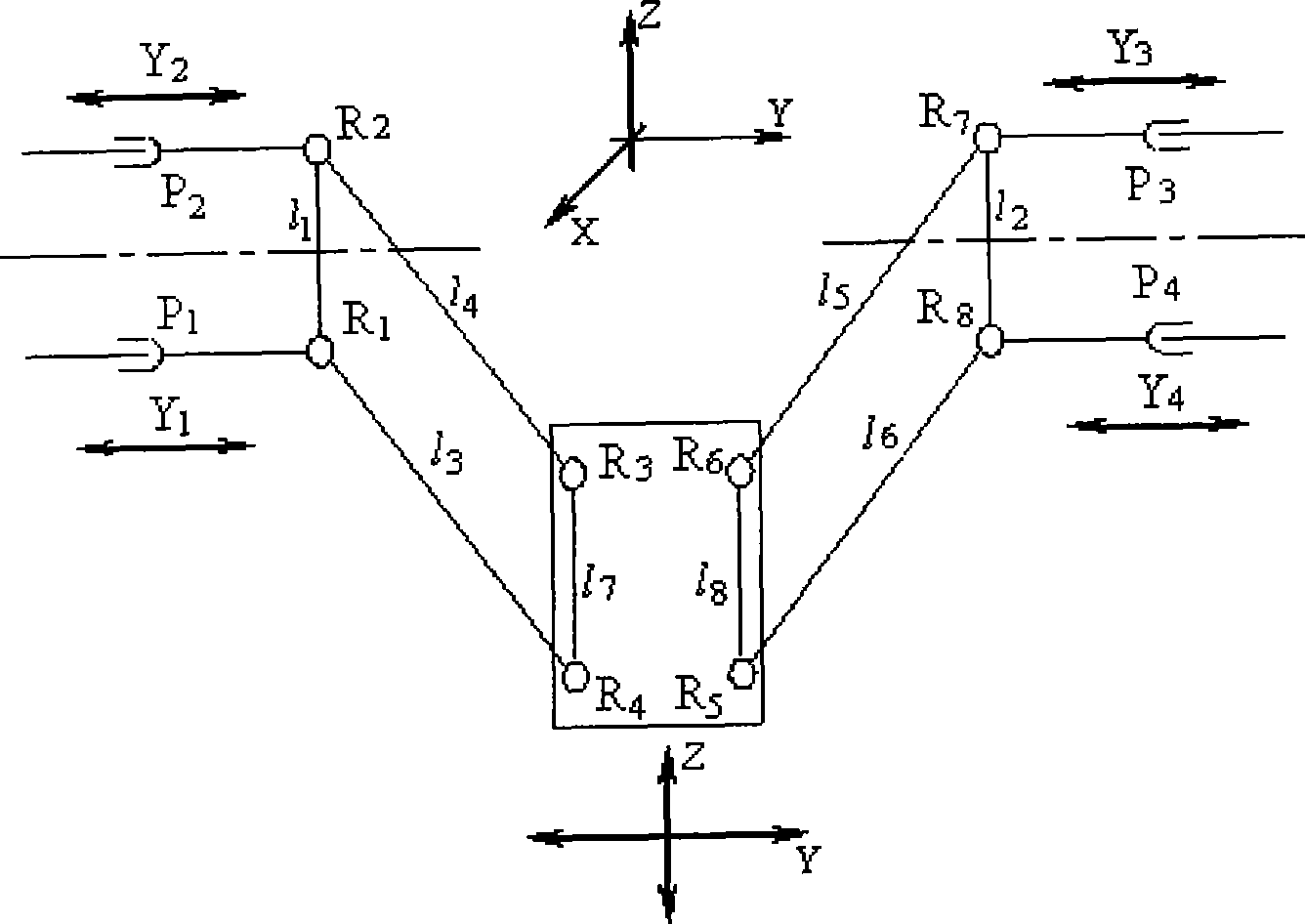

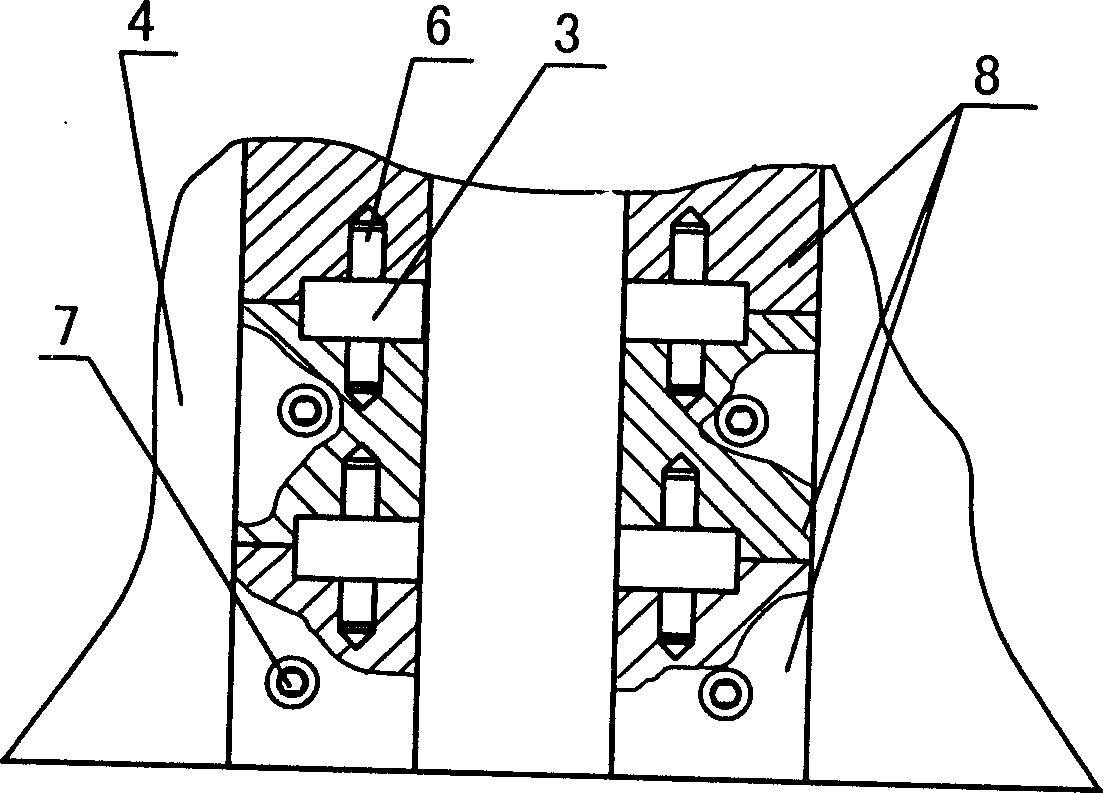

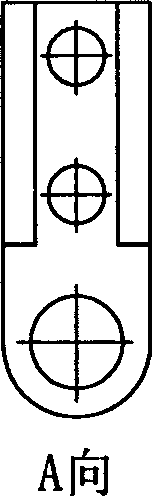

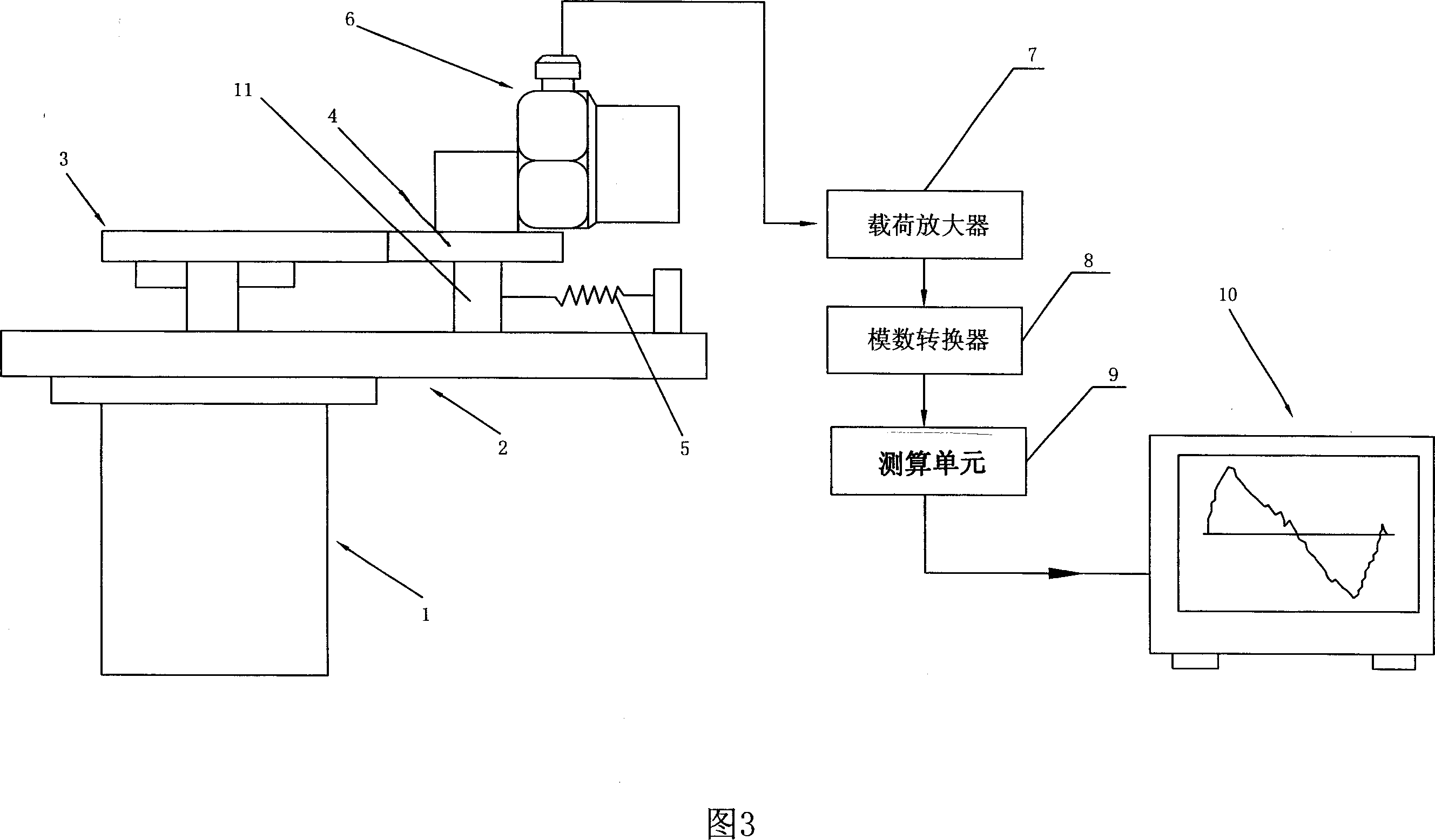

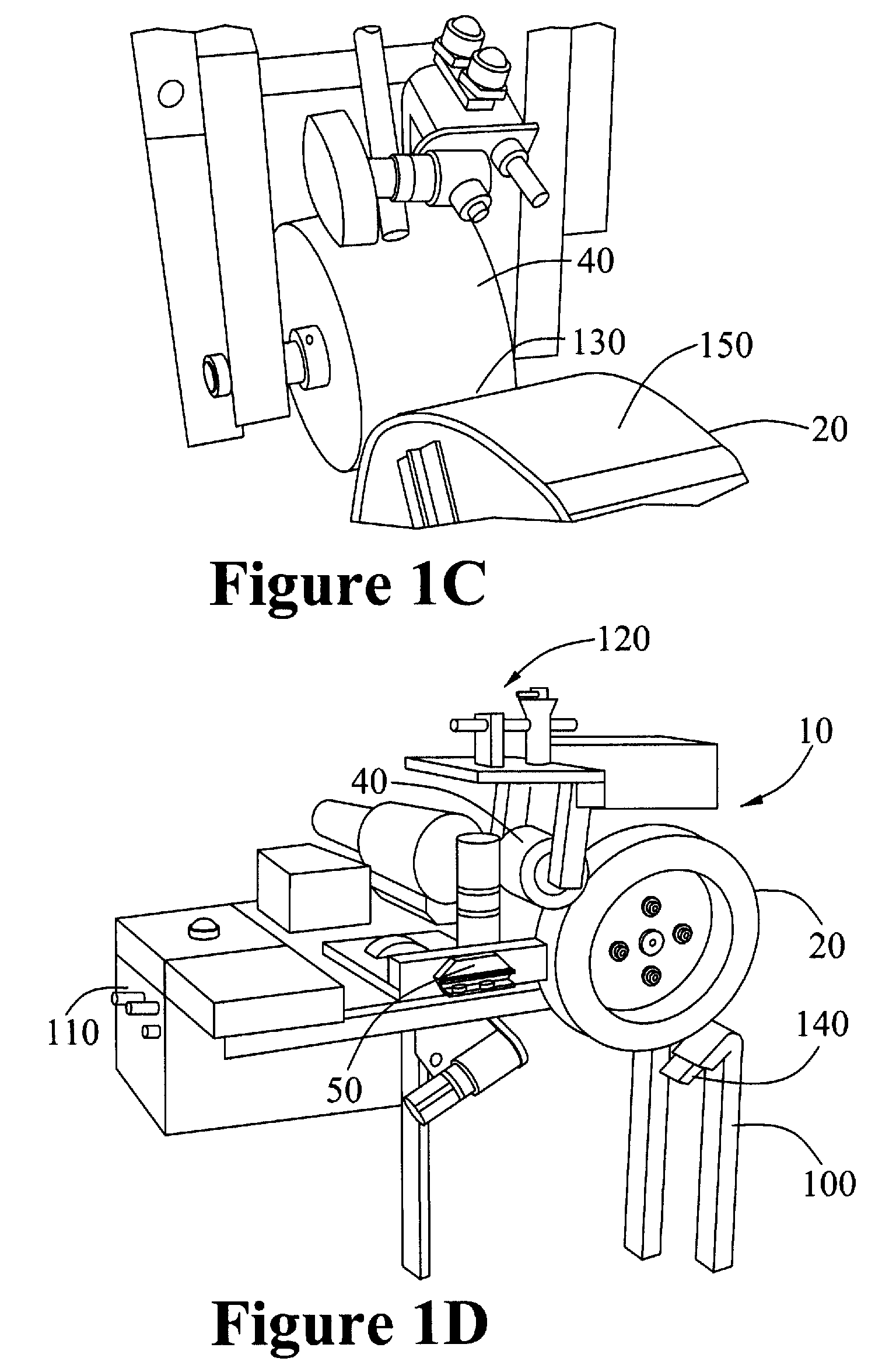

Device and method for testing dynamic characteristics parameters of joint part of rolling-sliding combined guide rail

InactiveCN103217267AIncrease the number of degrees of freedomImprove test accuracyVibration testingDirect testData acquisition

The invention discloses a device and a method for testing dynamic characteristics parameters of a joint part of a rolling-sliding combined guide rail based on a two-degree-of-freedom system. The test device comprises a test platform and a data collection and analysis system. Compared with the prior art, the device has the obvious advantages that the test platform is simplified as a system with two degrees of freedom so as to be more approximate to the self degree of freedom of the test platform, the theory error is reduced, the test complexity degree is reduced, and dynamic characteristic test signals of a movable component and a foundation can be acquired more easily and accurately; the influence of the foundation displacement is taken into consideration, four sizing blocks are arranged so as to regulate the stability of the test platform, so that the influence of external environment excitation on the test device is further eliminated, and the test accuracy is improved; by virtue of directly testing the dynamic characteristic parameters of the joint part of the rolling-sliding combined guide rail, the influence of a complex joint surface in the joint part is reduced, and the parameter testing accuracy is improved.

Owner:NANJING UNIV OF SCI & TECH

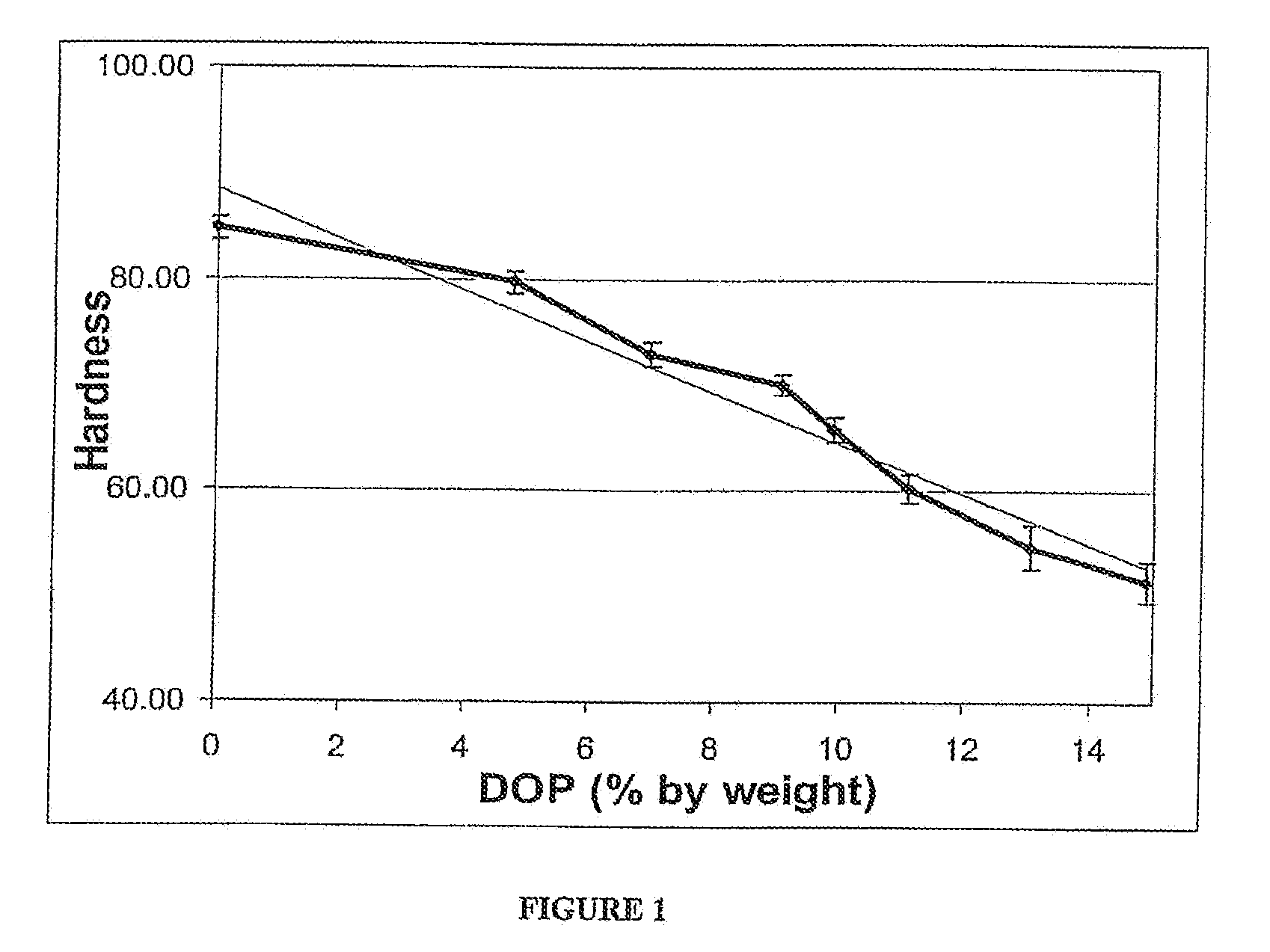

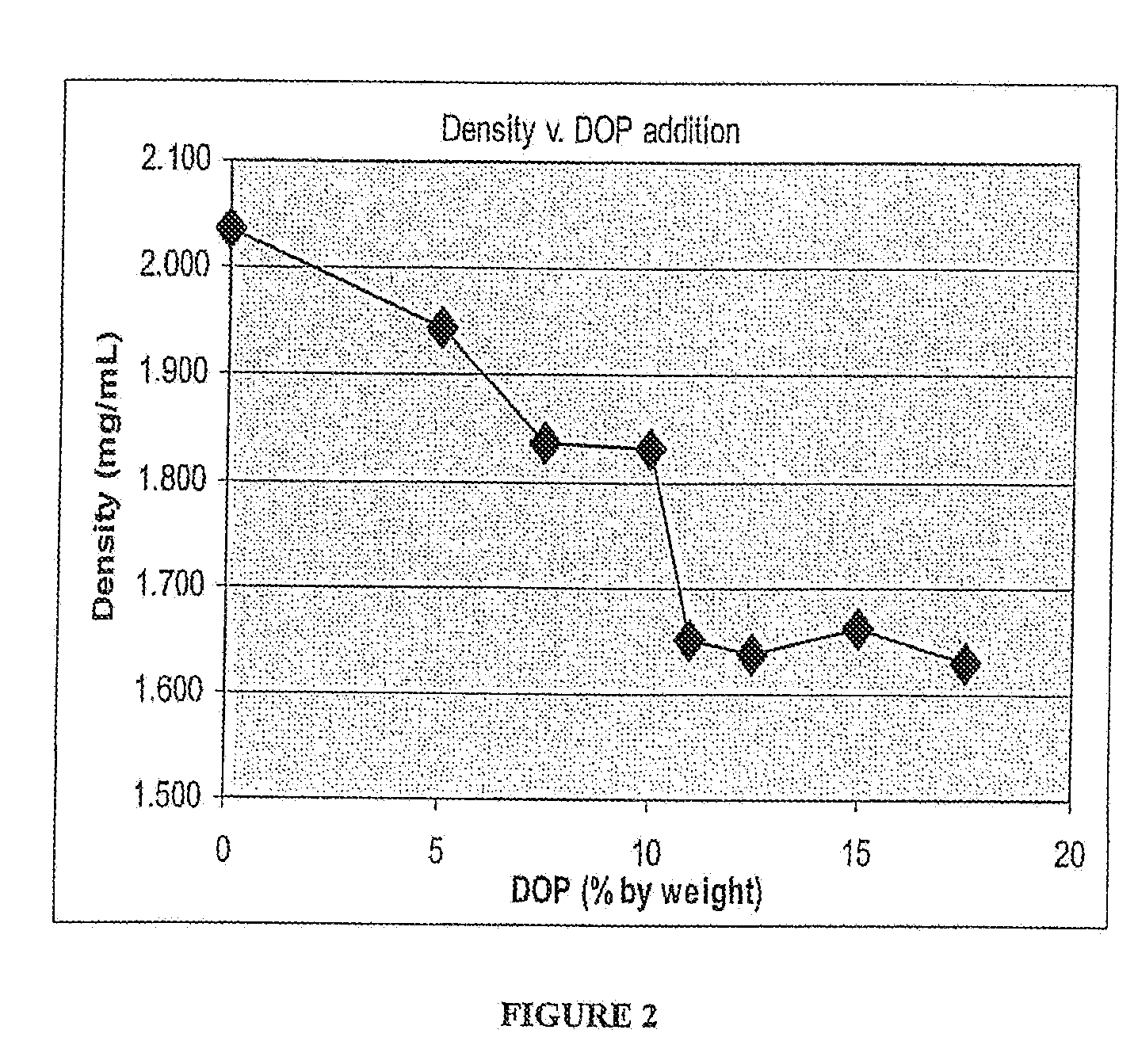

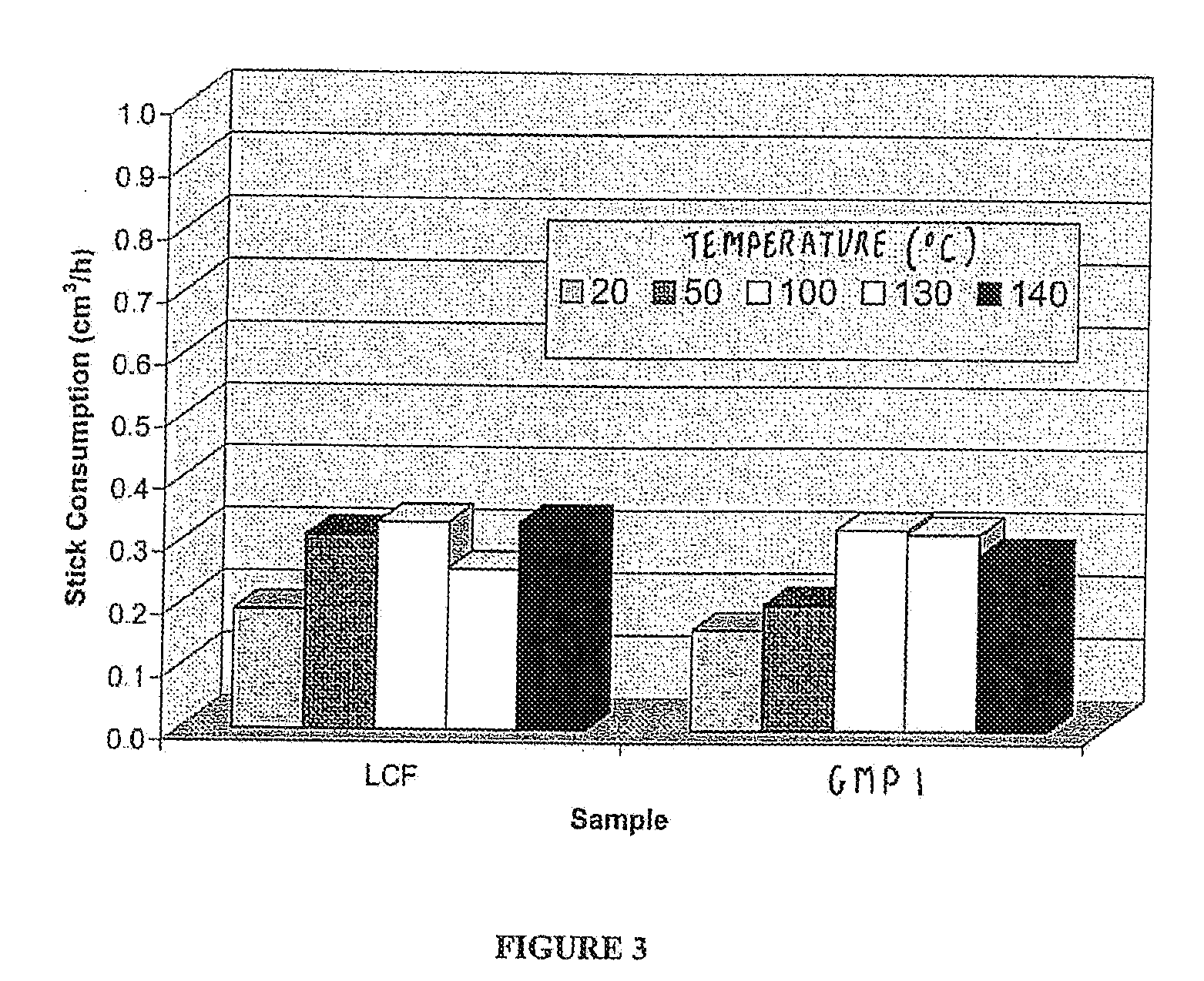

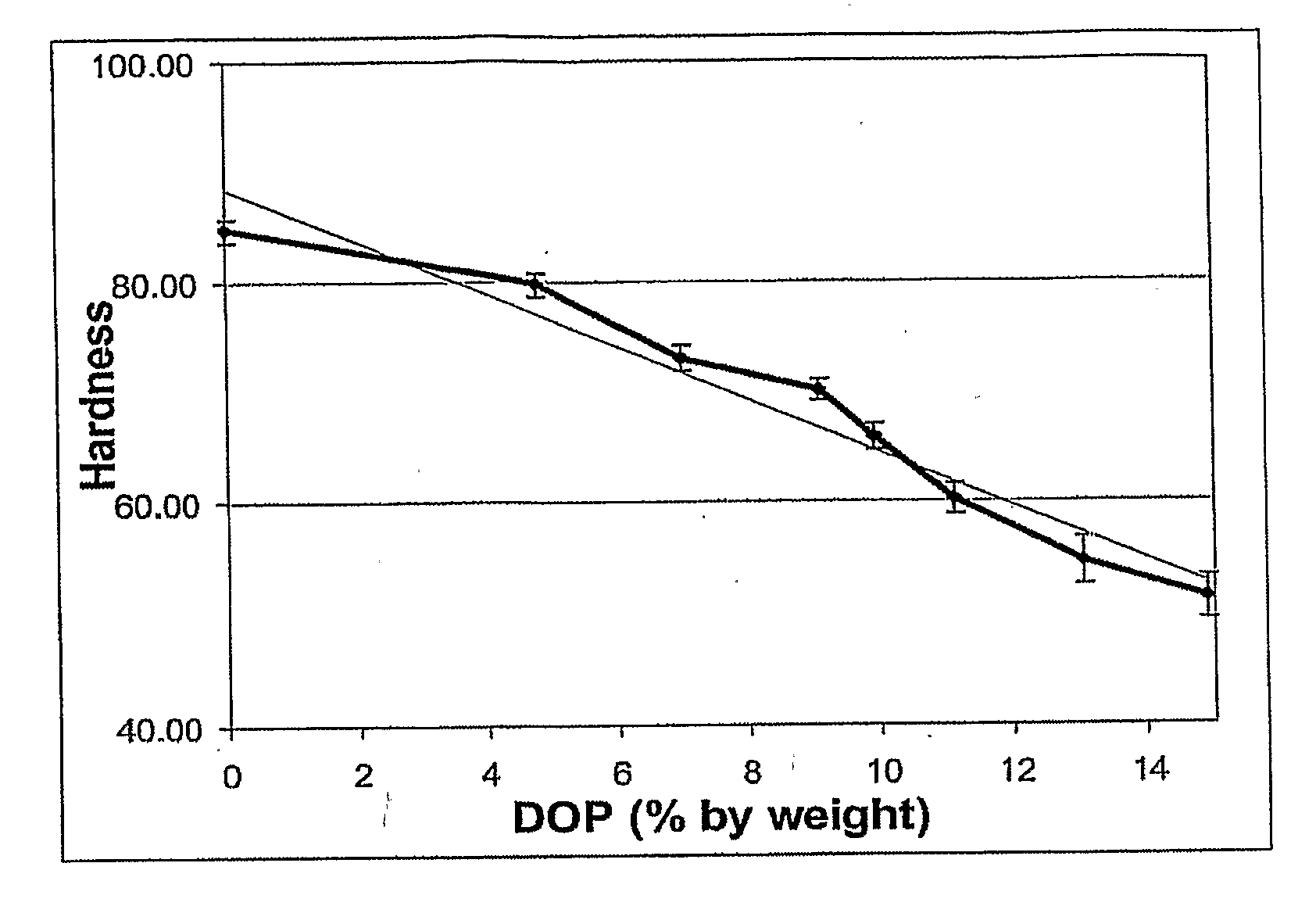

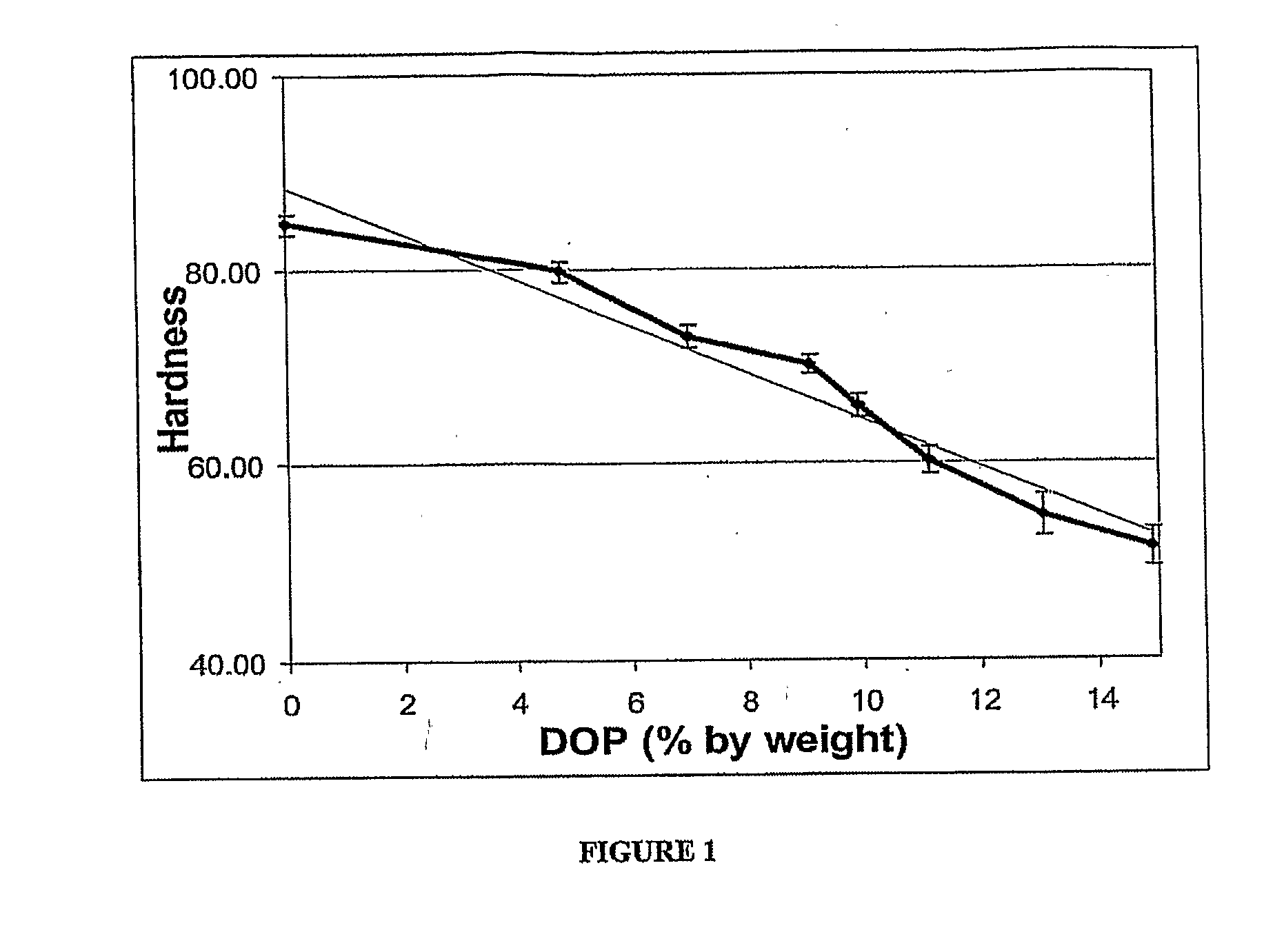

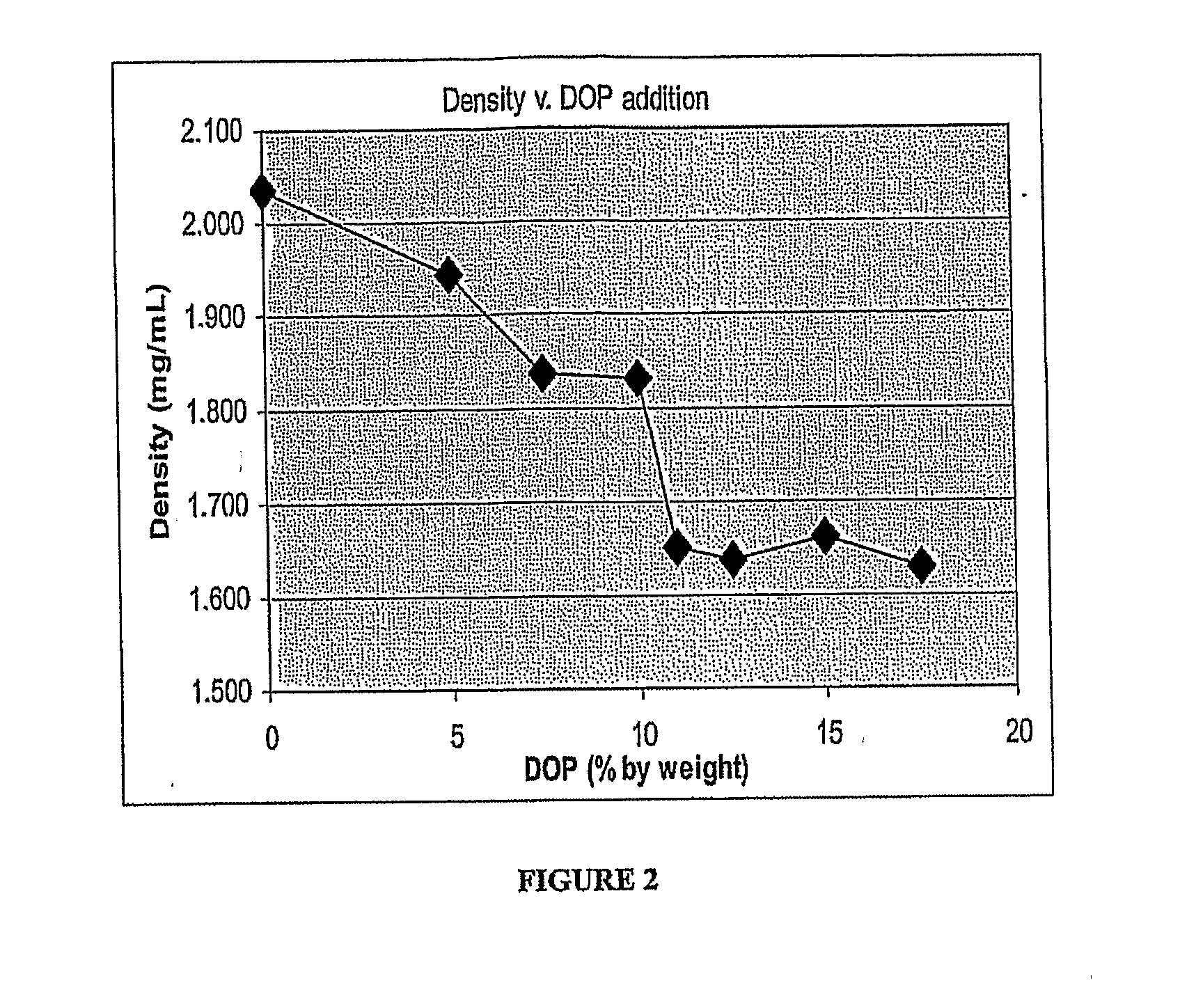

Solid stick grease compositions

InactiveUS20070010405A1Reduce consumptionReduce wearBearing componentsLiquid carbonaceous fuelsOil and greaseRolling sliding

The present invention provides a solid stick composition comprising a thermosetting resin and a grease. Optionally, the solid stick composition may comprise a lubricant, a friction modifier, a thermoplastic placticizer or a combination thereof. The solid stick compositions may be used for application between two metal surfaces in sliding and rolling-sliding contact such as steel wheel-rail systems including mass transit and freight systems. A method of reducing energy consumption, or controlling friction between a metal surface and a second metal surface by applying the solid stick composition to one or more than one of the metal surfaces, is also provided.

Owner:KELSAN TECH

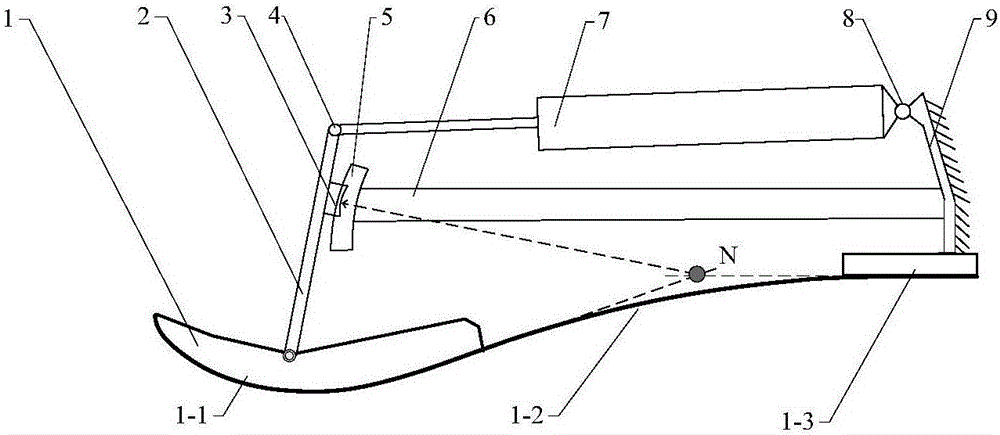

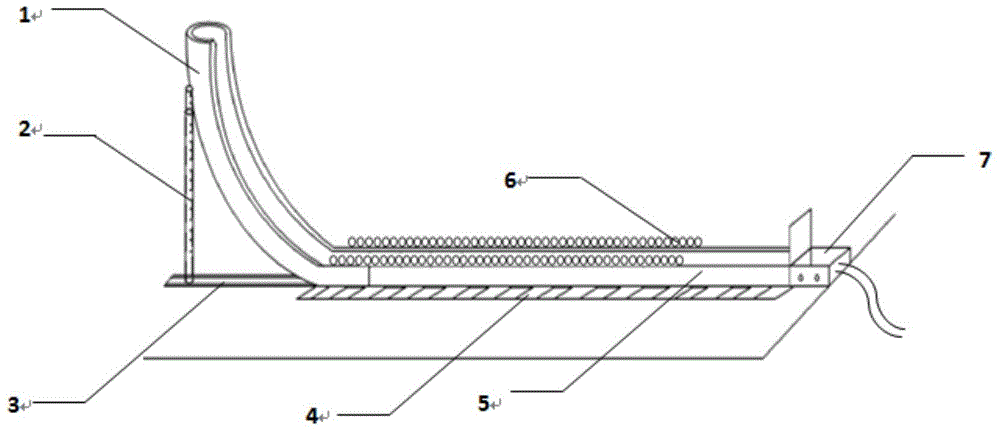

Variable Mach number nozzle mechanism having large-stroke range and high precision

InactiveCN106596032AHigh control precisionCompact structureAerodynamic testingEngine testingLinear controlCoupling

The invention relates to a variable Mach number nozzle mechanism having large-stroke range and high precision. The mechanism includes a rigid-flexible coupling profile 1, a rotation support plate 2, an arc rolling sliding block 3, a support plate hinge 4, a smooth guide rail 5, a sealing supporting plate 6, a ballscrew electric cylinder 7, an electric cylinder hinge 8, and a nozzle fixing rack 9, wherein the rigid-flexible coupling profile 1 includes a fixed profile section 1-1, a flexible profile section 1-2, and an exit straightening section 1-3. According to the invention, the mechanism has a simple and compact structure, and overcomes low control precision caused by multiple procedures, such as force transmission, machining and assembling, etc. The mechanism combines the rolling arch guide rail and a ballscrew electric cylinder, which effectively guarantees non-linear control precision and repeatability. The mechanism achieves continuous adjustment of Mach number, is tightly constructed, has strong practicality and allows easy engineering and design for thermal protection and pneumatic sealing.

Owner:CHINA GAS TURBINE ESTAB

Solid Stick Compositions Comprising Thermosetting Plastic

InactiveUS20080220997A1Reduce consumptionReduce wearOrganic chemistryBearing componentsPlasticizerRolling sliding

The present invention provides a modified solid stick composition comprising a thermosetting plasticizer, a resin, a lubricant, a friction modifier, or a combination thereof. The solid stick compositions may be used for application between two metal surfaces in sliding and rolling-sliding contact such as steel wheel-rail systems including mass transit and freight systems. A method of reducing energy consumption, or controlling friction between a metal surface and a second metal surface by applying the solid stick composition to one or more than one of the metal surfaces, is also provided.

Owner:L B FOSTER RAIL TECH INC

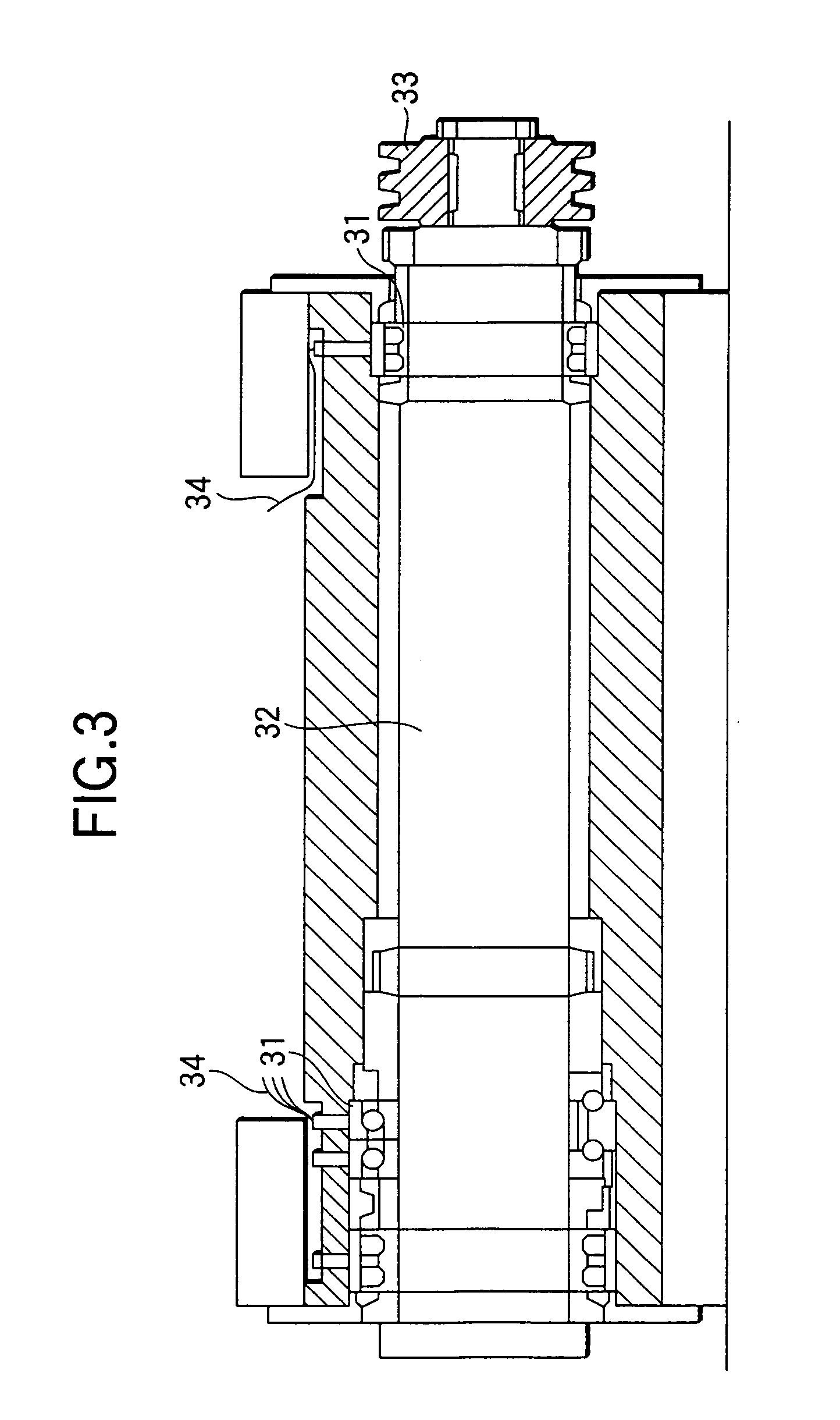

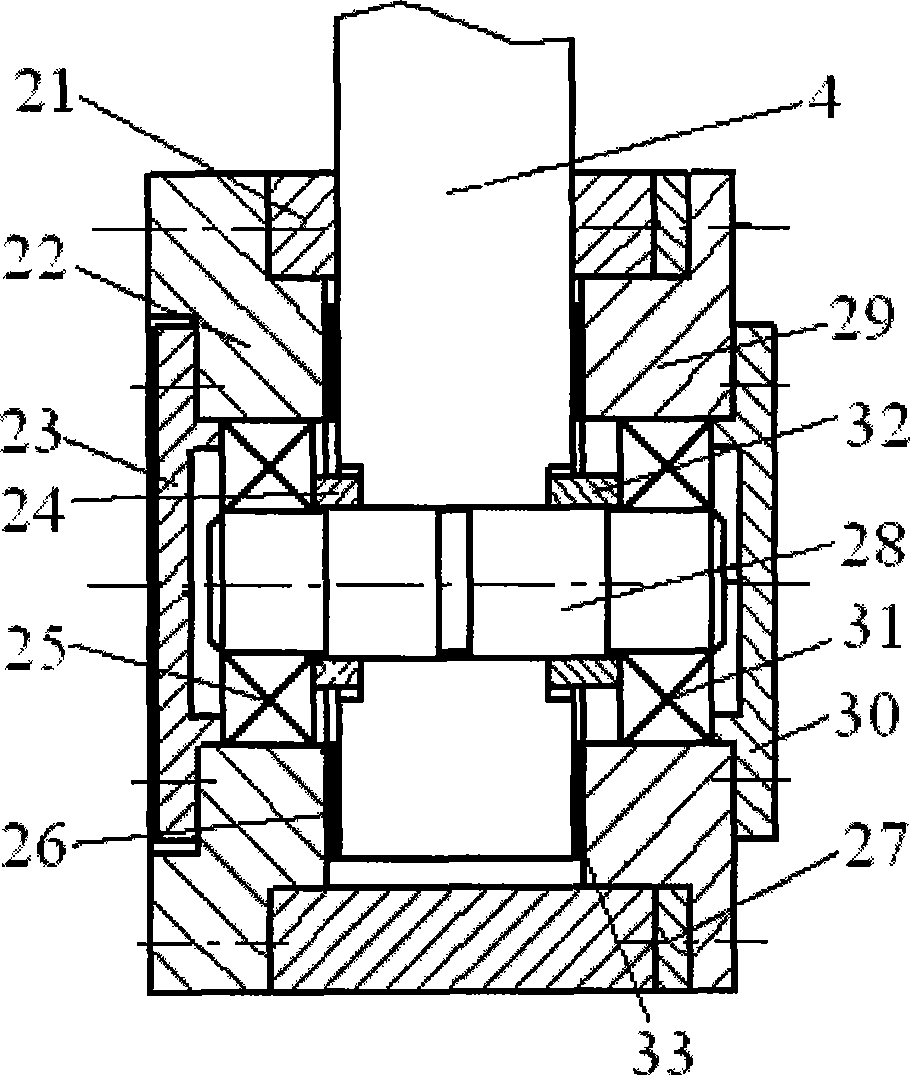

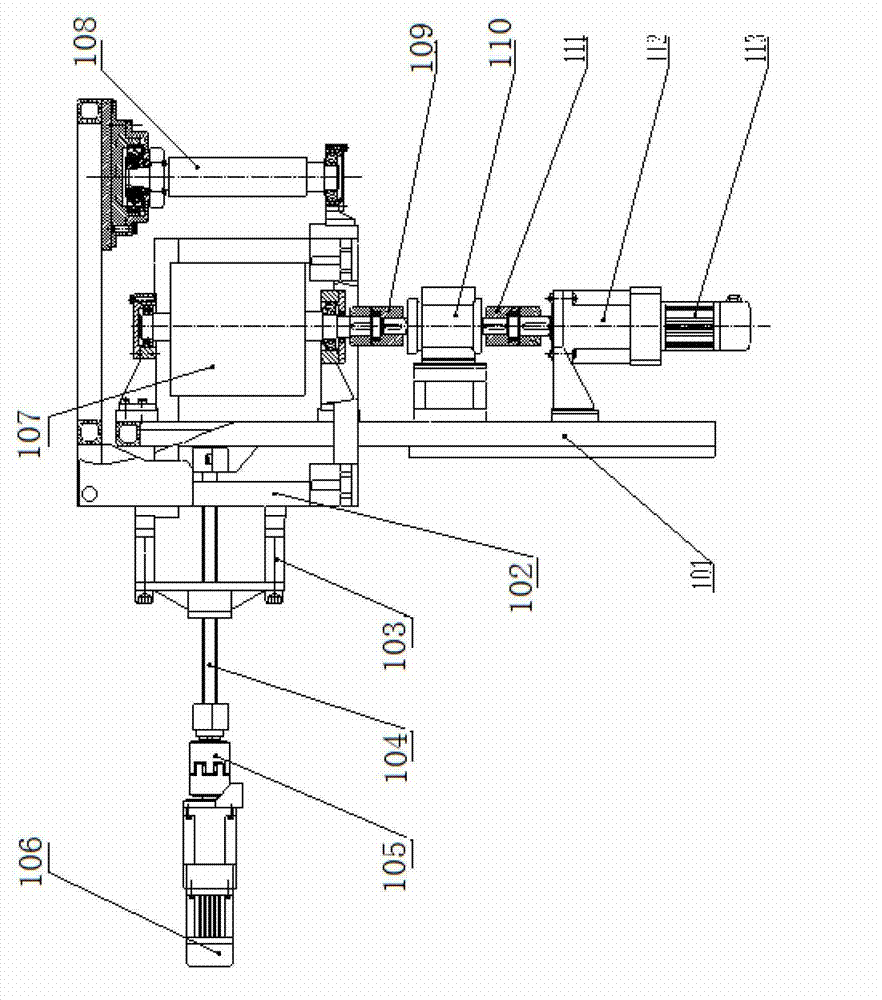

Dual-drive skid revolving joint portion dual-shaft parallel high-speed accurate mainshaft head

InactiveCN101474756AImprove stress conditionHigh precisionDriving apparatusEngineeringRolling sliding

The present invention discloses a double-drive rolling-sliding revolving combination part two-axis parallel-connection high-speed precise mainshaft head which comprises an electric mainshaft and two-axis parallel-connection mechanism. The two-axis parallel-connection mechanism is composed of a movable platform and two branch structures which are connected with the movable platform. The electric mainshaft is fixedly connected with the movable platform. Each of two branch structures comprises two moving pairs that are installed in parallel. The two moving pairs are connected with a sliding platform which is respectively connected with one end of each of two connecting rods through two rotary pairs. The other ends of two connecting rods are connected with the movable platform respectively through the rotary pairs. Two rotary pairs of a branch pair in two branch structures are respectively installed with the rotary pair corresponding with the other branch structure in parallel. The mainshaft head of the invention not only has a high speed but also improves the force bearing condition of rotary pair so that the rotary pair has higher guiding stiffness and precision.

Owner:XIAN UNIV OF TECH

Bottom base of electric jug jack

ActiveCN101034772ANo leakageWill not short circuitCouplings bases/casesFlexible/turnable line connectorsElectricityRolling sliding

The invention discloses an electricity canteen jack base place which has the waterproof function; it includes shell, electric link place, rolling slide bushing, the shell fixing connects with the electric link place. The invention can not because of the water splashes into the electricity canteen jack down place arise electric leakage and short-circuit; the use is much safer.

Owner:ZHEJIANG JIATAI ELECTRICAL APPLIANCE

Bottom base of the cordless electrical appliance connector

The invention discloses a safty used non- rope electric appliance connector base place. It includes shell, electric link place, rolling slide bushing, give electricity insert reed, the backspring; the shell fixing connects with the electric link place, and on the electric link place there set two electric conductors which separately connects with the two poles of the out source, guide post set in the middle of the electric link place, and the hole set in the middle of the guide post, the rolling slide bushing in the shell, the backspring set between the rolling slide bushing and electric link place, the two give electricity bodys set on the rolling slide bushing and separately correspond with the two electric conductors. Under the backspring tension effect, when not coupling with the electric appliance body, the give electricity body on the rolling slide bushing and the electric conductor on the electric link place always exist in the divding state, the out reveal give electric body has no charged, therefore the use is more safely.

Owner:ZHEJIANG JIATAI ELECTRICAL APPLIANCE

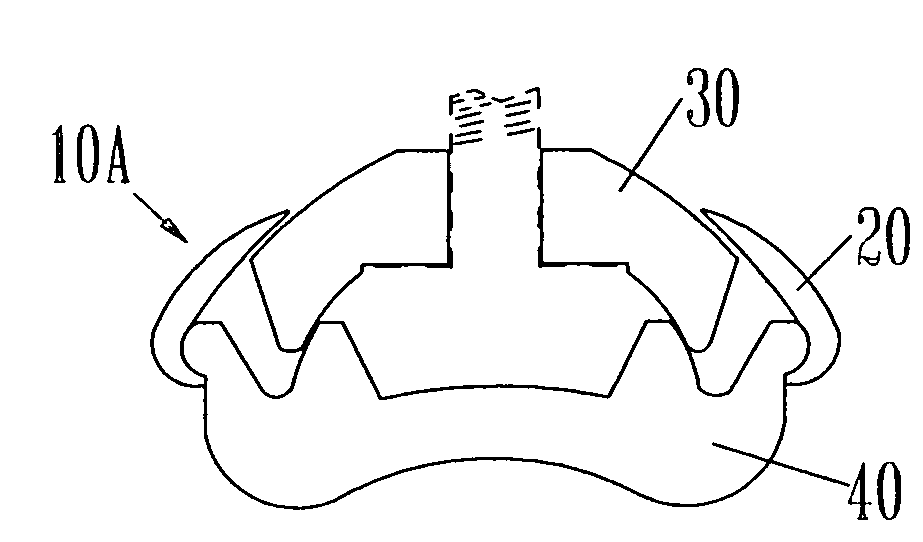

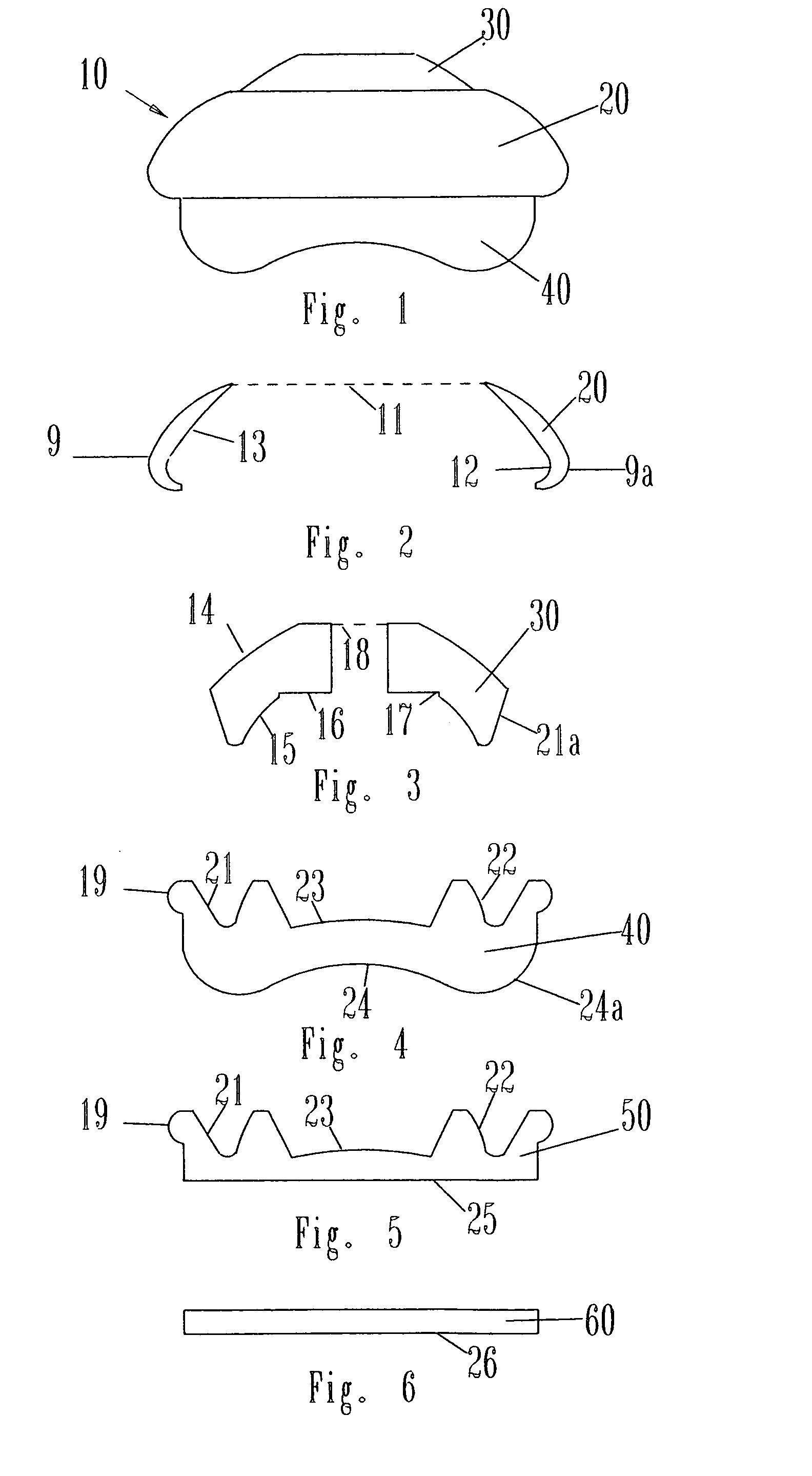

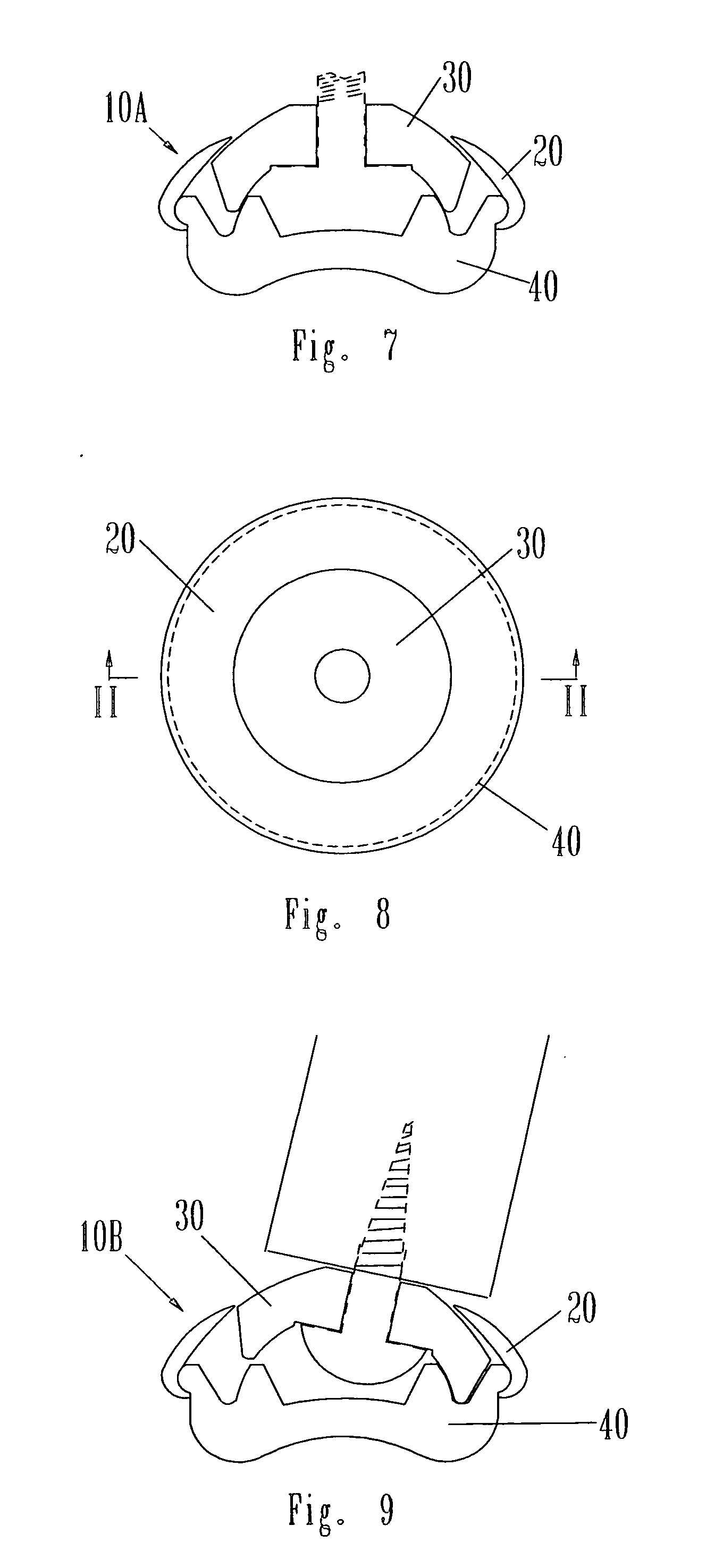

Fungible furniture glide

A three component swiveling and rolling glide device, of which two components comprise the mounting assembly and one is an exchangeable base. The mounting assembly is designed to accept multiple attachment means, such as screws, bolts, nails etc. The glide base is removable by finger pressure only without the need for tools enabling the easy interchangeability of the glide base and the attachment means, as desired. This glide also has a tandem swiveling and rolling capability and will also adapt to a singular rolling function, if required, in deep carpets or whenever the glide is at maximum tilt. The hard base, of my invention, has a unique base design to encourage the swiveling and rolling action of the glide. The soft base can accept different materials for the specific need, such as, felt to protect hardwood or tile flooring or rubber for a non-skid function. This glide is designed to combine all the above functions, allowing it to adapt to multiple furniture styles and numerous uses.

Owner:VORPAHL STEVEN A

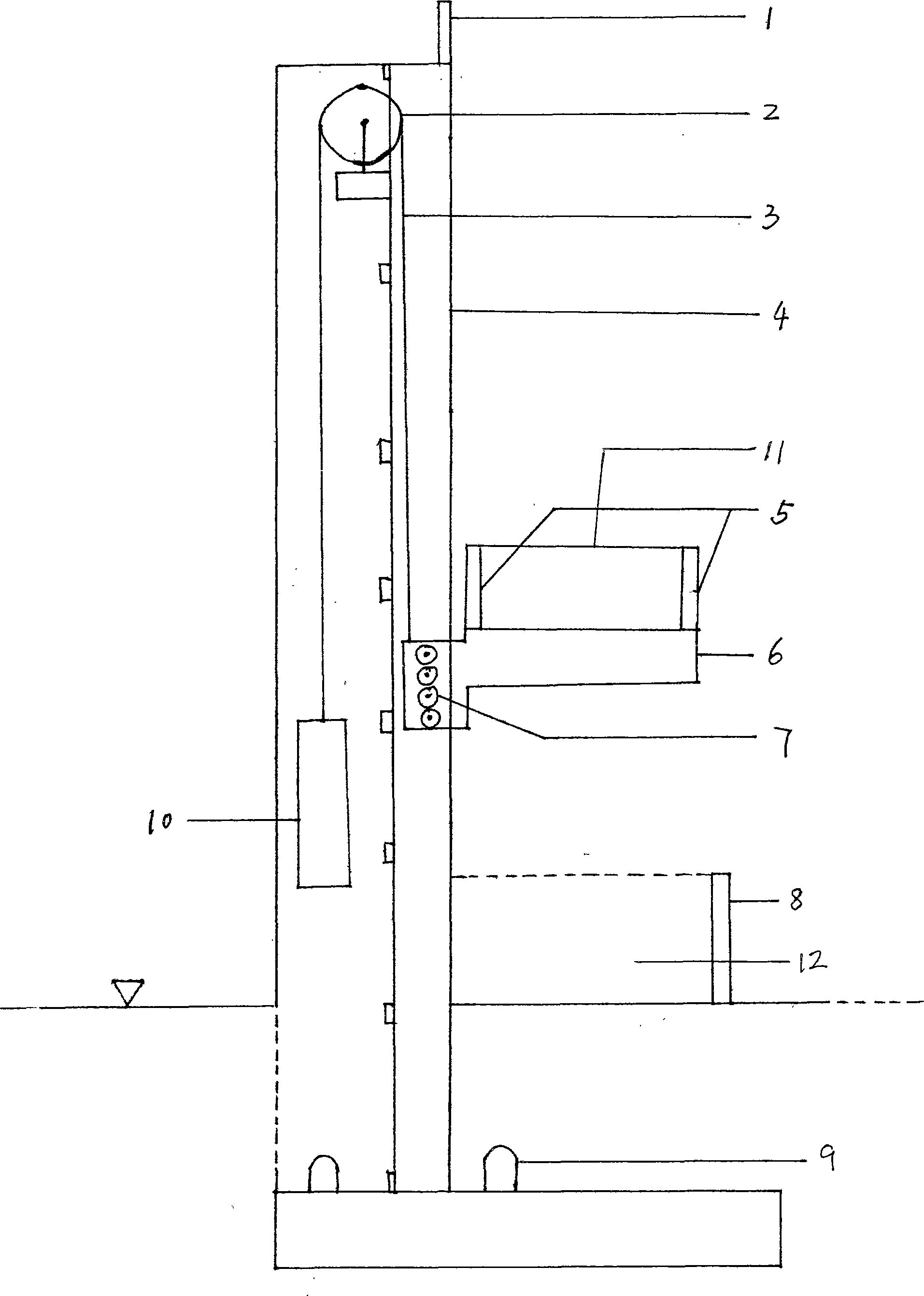

Automatic elevator apparatus for overhead bridge

The invention discloses an automatic overpass elevator, relating to an overpass elevator by adopting an H-typed slideway to lead an elevation platform to slide up and down. The invention adopts steel to manufacture two H-typed slideways which are combined in parallel, and a traction machine is arranged on an upper part of the slideways. An elevation platform is manufactured and one end of the elevation platform is used for bearing passengers while the other end is provided with a rolling sliding device which is arranged in the H-typed slideways. Then the elevation platform slides up and down in the H-typed slideways under the driving by the traction machine, traction cables and counterweight, thus achieving the object of elevating the platform and conveying passengers passing the overpass up and down.

Owner:马秀华

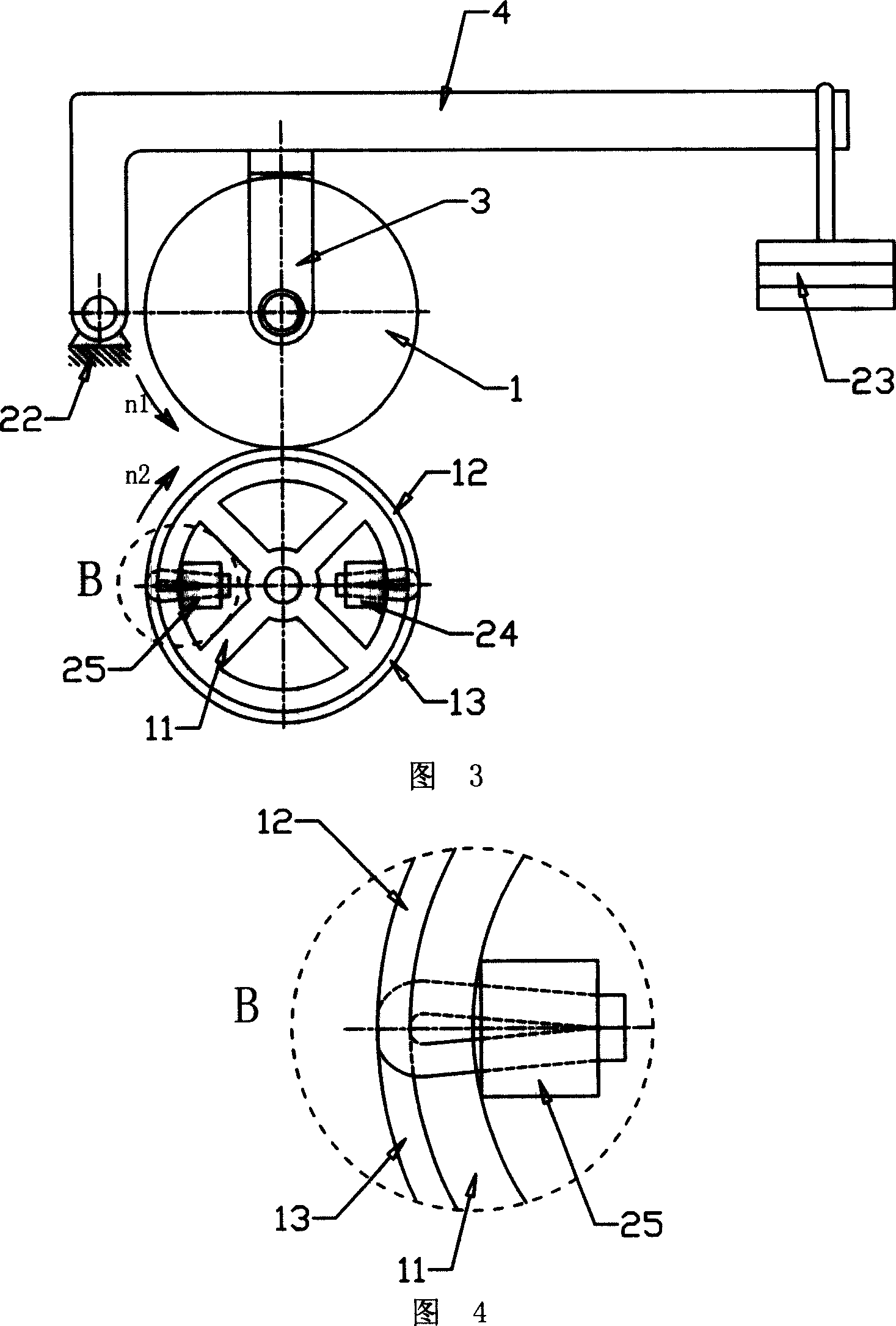

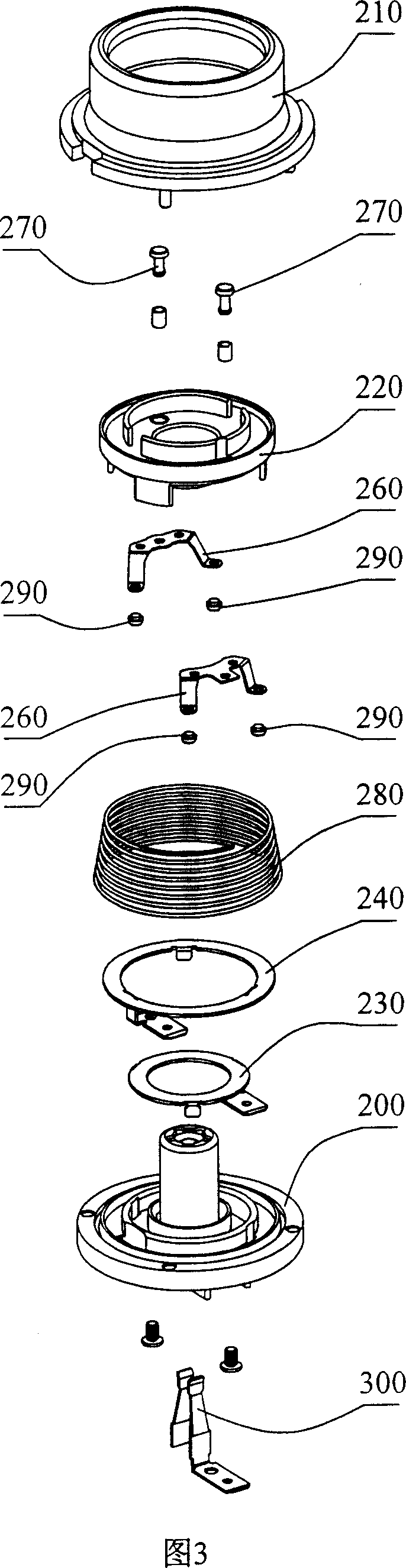

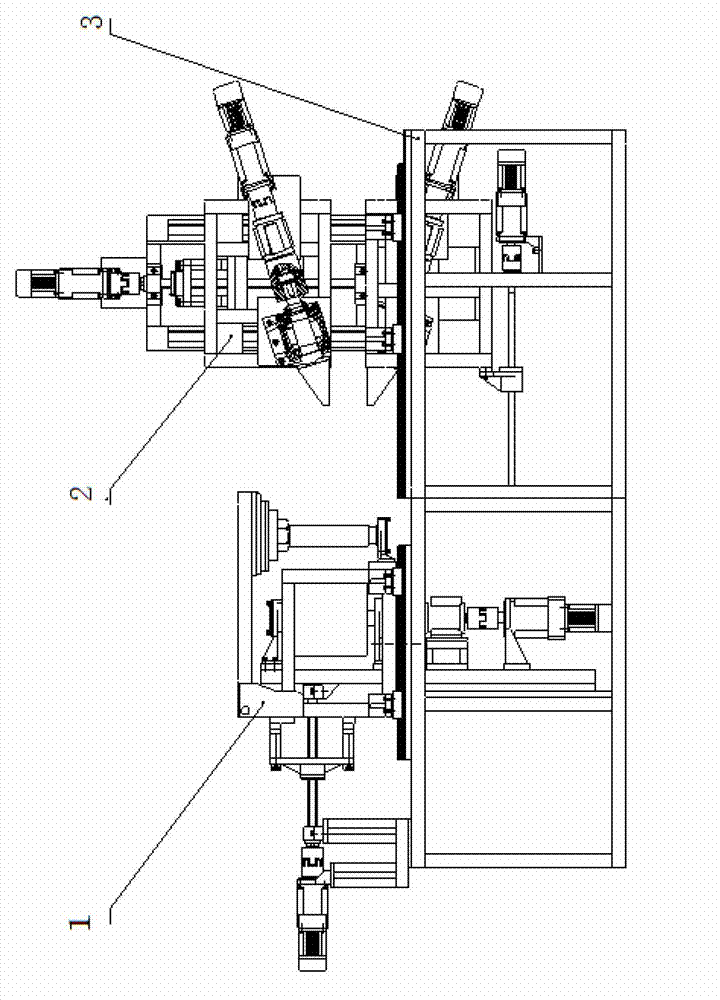

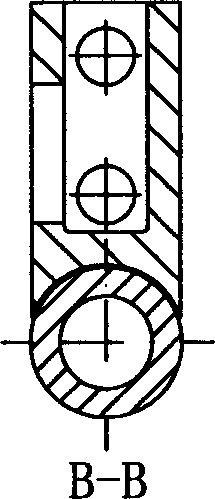

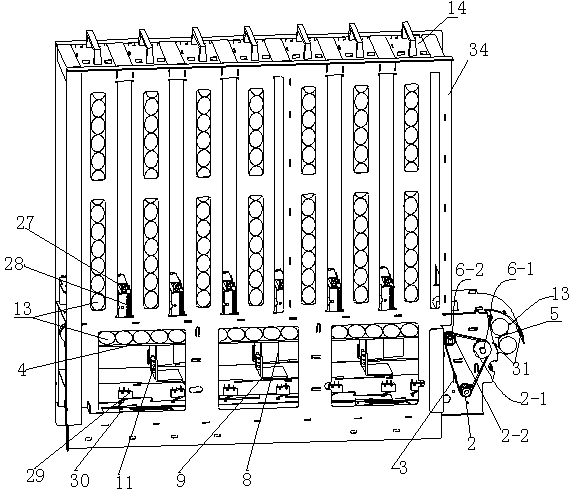

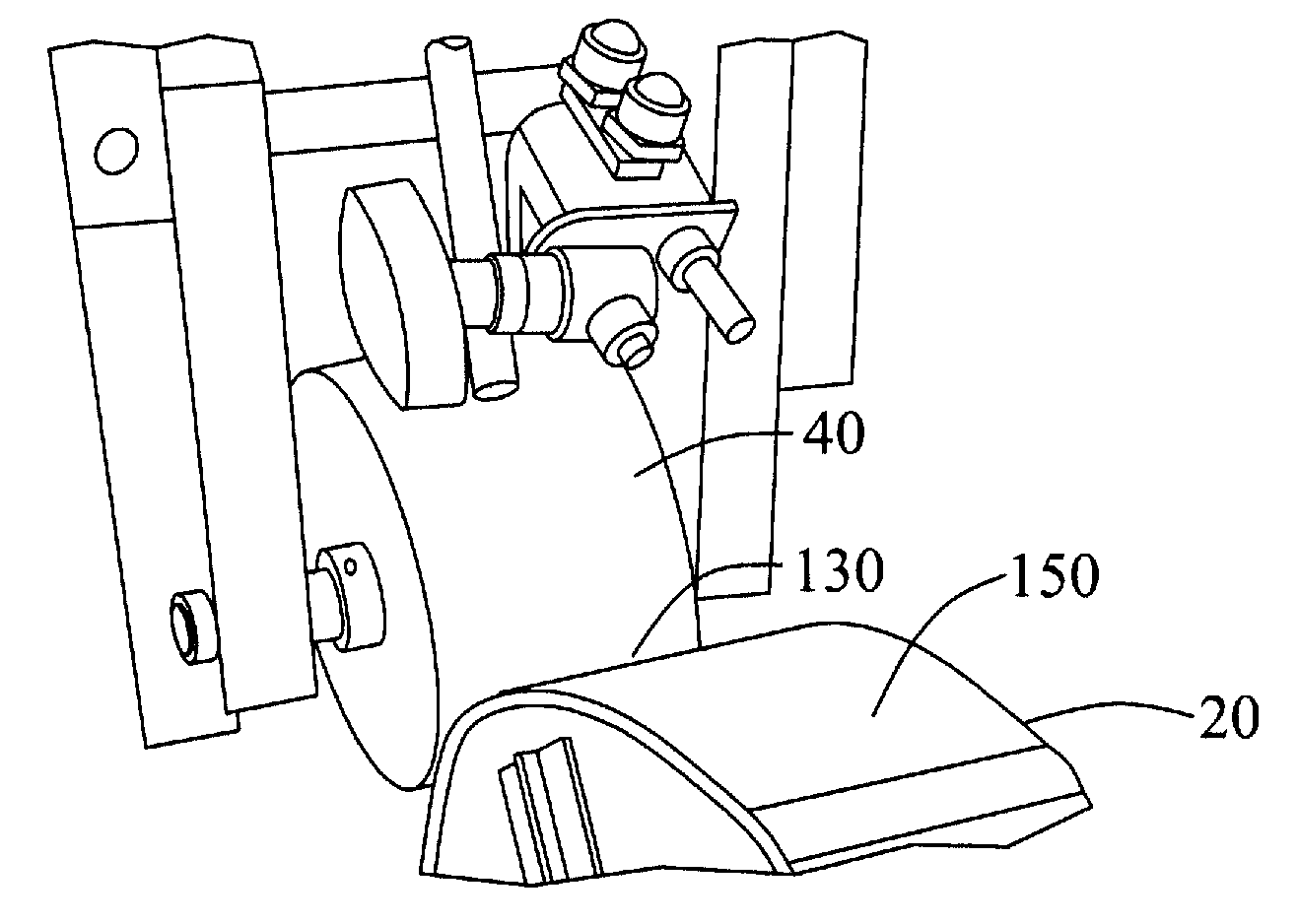

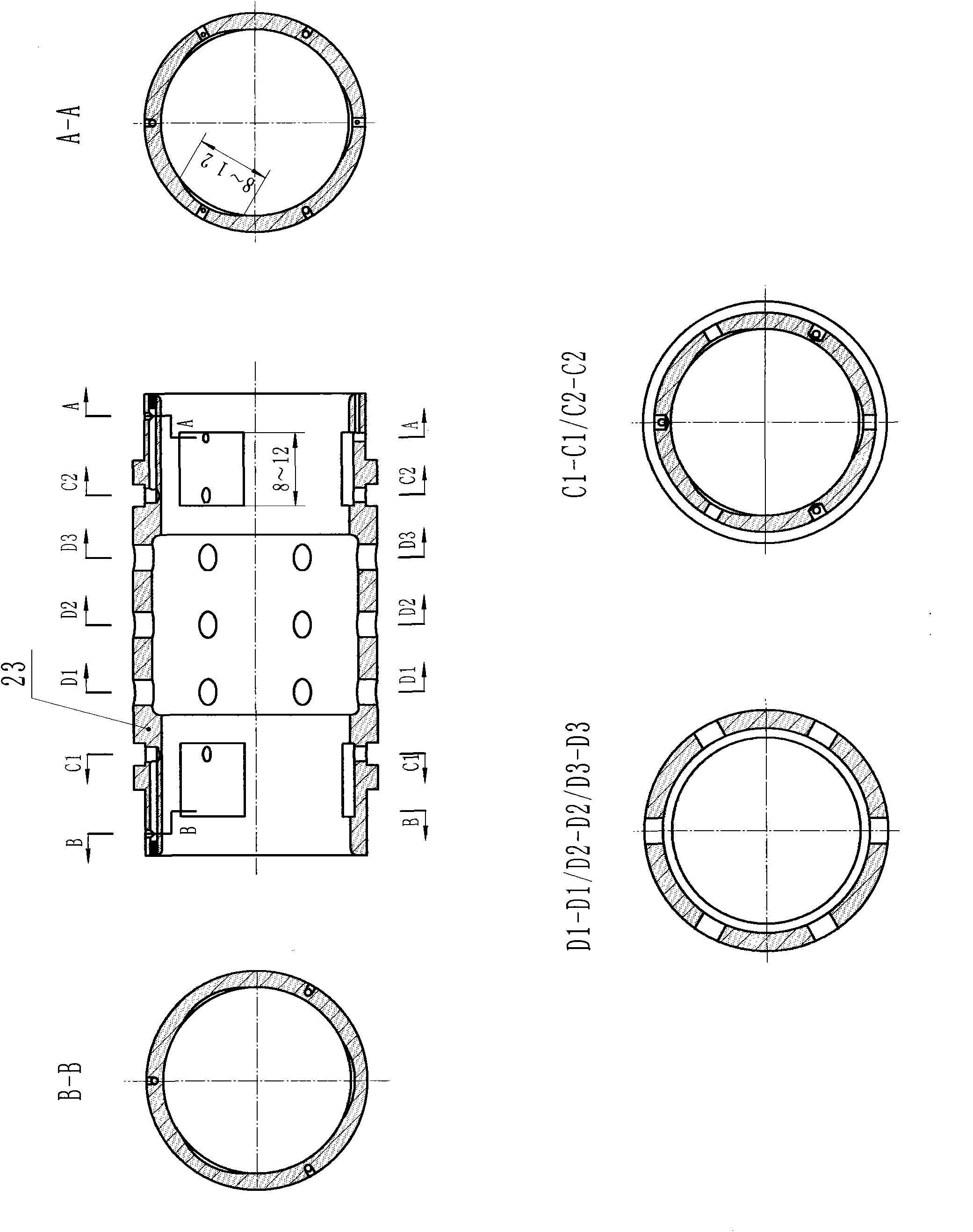

Experiment test device and experiment test method of radial-axial ring rolling

InactiveCN102861841AIncrease stiffnessCompact structureMeasuring devicesMetal rolling arrangementsElectric controlRolling sliding

The invention specifically discloses an experiment test device and an experiment test method of radial-axial ring rolling. The experiment test device comprises a radial rolling mechanism, an axial rolling mechanism and a machine base, wherein the radial rolling mechanism and the axial rolling mechanism are both movably connected on the machine base; the radial rolling mechanism comprises a home roll device, a core roll device, two sets of detection devices I, two sets of drive devices I; the home roll device and the core roll device are respectively connected with the two sets of detection devices; the two sets of drive devices are respectively used for driving the core roll device and the home roll device; the axial rolling mechanism comprises an upper conical roll and a lower conical roll, an upper conical roll slide block device, three sets of detection devices II, four sets of drive devices II and an axial mechanism rack; the upper conical roll device is arranged on the upper conical roll slide block device; and the upper conical roll device and the lower conical roll device are respectively connected with the axial mechanism. The experiment test device has the following beneficial effects of being compact in structure, complete in function, great in body rigidity, small in deformation and safe and reliable to use and all adopting electric control.

Owner:UNIV OF JINAN

Rolling-sliding unit and jointed shaft comprising the same

InactiveUS8157660B2Reduce manufacturing costConnection securityYielding couplingShaftsRolling slidingBiomedical engineering

Owner:SHAFT FORM ENG GMBH +1

Rolling sliding vane air compressor without oil lubrication

InactiveCN1424509ARotary piston pumpsRotary piston liquid enginesRolling resistanceLinear compressor

The present invention has disclosed a sliding-vane air compressor with rolling in oil free lubrication, which includes main air cylinder and rotor as the rotor to be set in the air cylinder ecentrically. There will be rotor slots opened on the rotor to hold the sliding-vane which can slide freely along radical direction in each of the rotor slots and the sliding-vane will be made of light weight alloy material of aluminium alloy instead of self-lubrication material of graphite as the top end and bottom part of the sliding vane as well as both sides of the said rotor slots will be erected with bearing seats which sets rolling bearings on them. The high temperature resistant lubricant will be packed in inside of the bearings with seal ring attached for sealing and the friction between the sliding-vane and the air cylinder as well as the friction between the rotors are the rolling friction.

Owner:延边利源通用机械有限责任公司

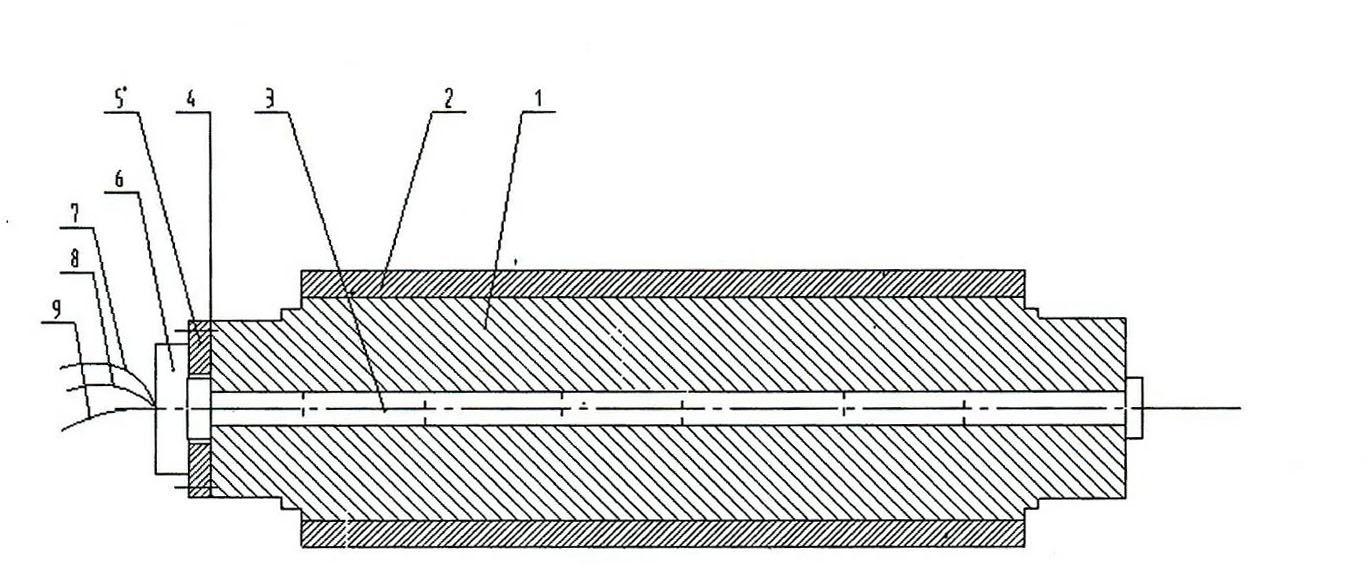

Back-up roll with adjustable and controllable interference

InactiveCN102527728AKeep the interference fit valueExtended service lifeRolling equipment maintainenceRollsInterference fitManufacturing cost reduction

The invention discloses a back-up roll with an adjustable and controlled interference, which comprises a core roll and a roll sleeve arranged outside the core roll. The core roll is provided with a through hole; one or a plurality of groups of electric heating assemblies are arranged in the through hole; the end part of the core roll is provided with a connecting flange and a slip ring for power supply and signal output; when the interference fit stress between the roll sleeve and the core roll is insufficient to meet the rolling requirement, even the roll sleeve and the core roll slide relatively, the core roll is subjected to power-up heating, a roll core generates radial expansion by the electric heating assemblies and the pre-tightening force between the roll sleeve and the core roll is increased; and a roll shape curve of a sleeved roll is regulated by powering up a plurality of groups of electric heating assemblies. The back-up roll disclosed by the invention adopts a sleeving structure. The roll sleeve can be made of a high-strength wear-resistance alloy material and the core roll can ba made of a forged steel (or cast steel) material with low price, so that the manufacturing cost can be greatly reduced. When the roll sleeve is seriously worn, the roll sleeve can be directly replaced and the core coll can be repeatedly used. When the combined back-up roll is used for regulating and controlling the plate crown or the plate shape, the roll shape can be sectionally regulated in an expansion control mode. According to the invention, by expansion of the core roll, the interference fit quantity value of the core roll and the roll sleeve is always maintained, so that the service life of the combined back-up roll can be greatly prolonged.

Owner:YANSHAN UNIV +1

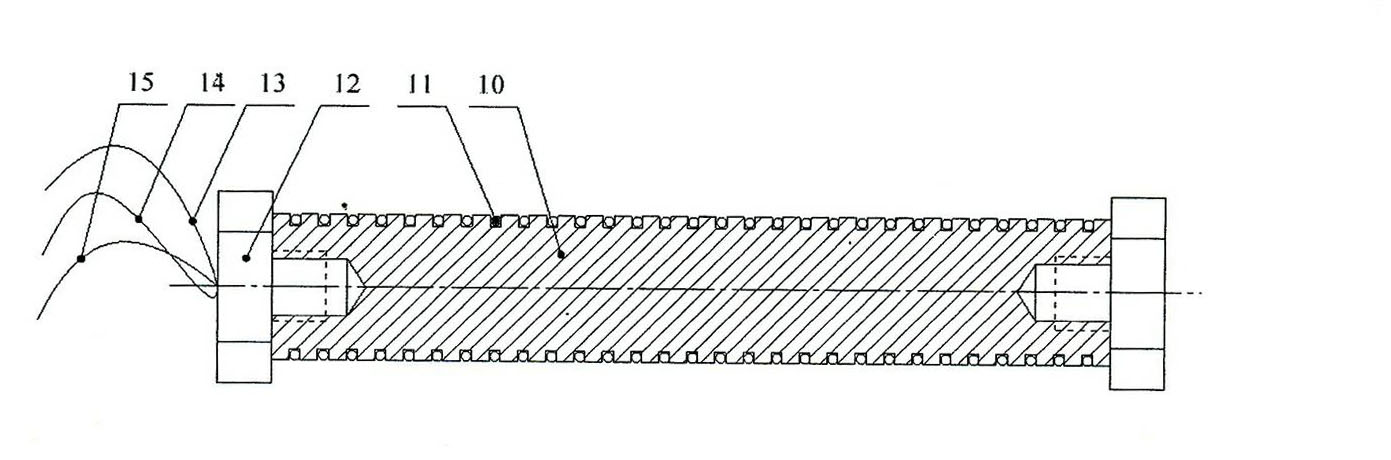

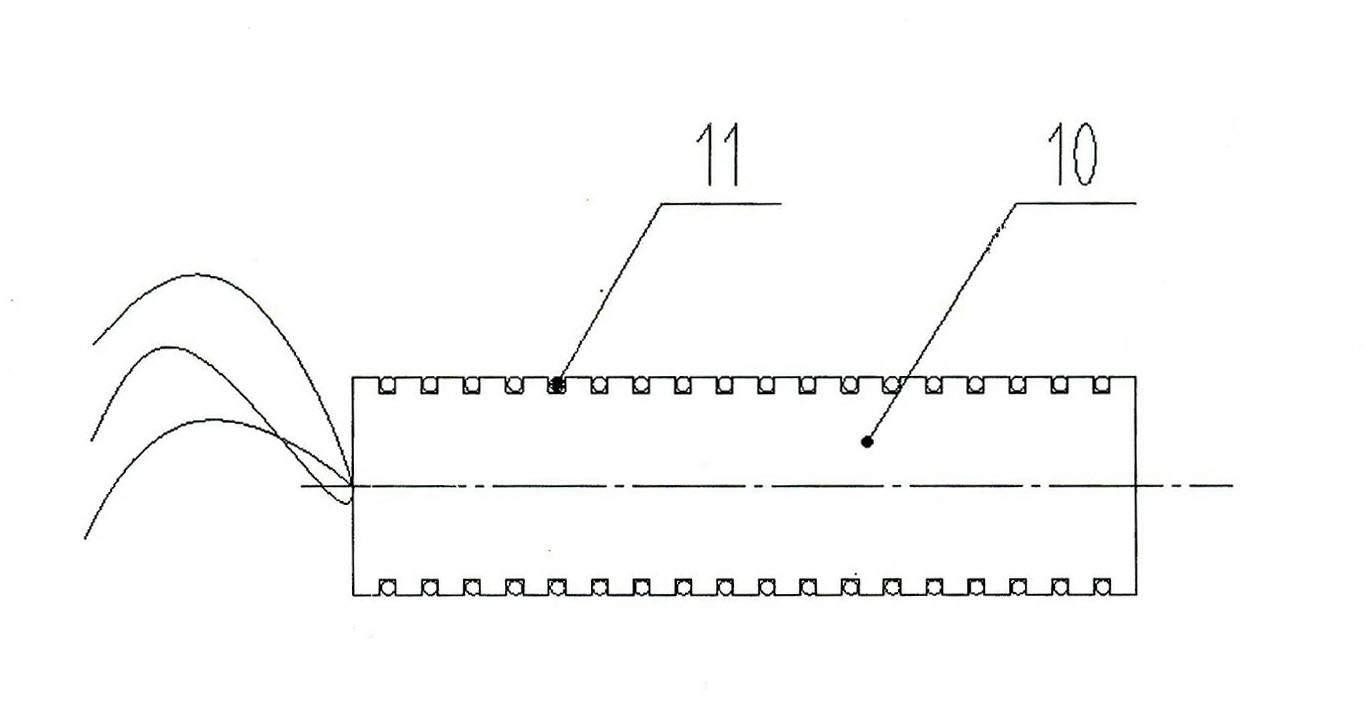

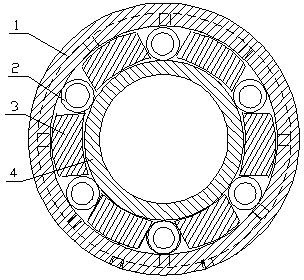

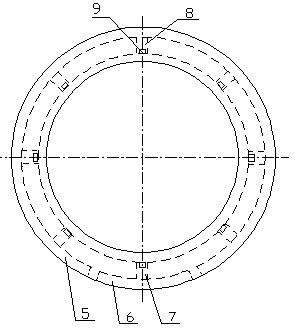

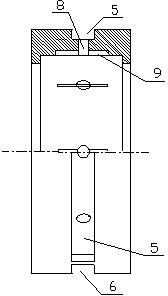

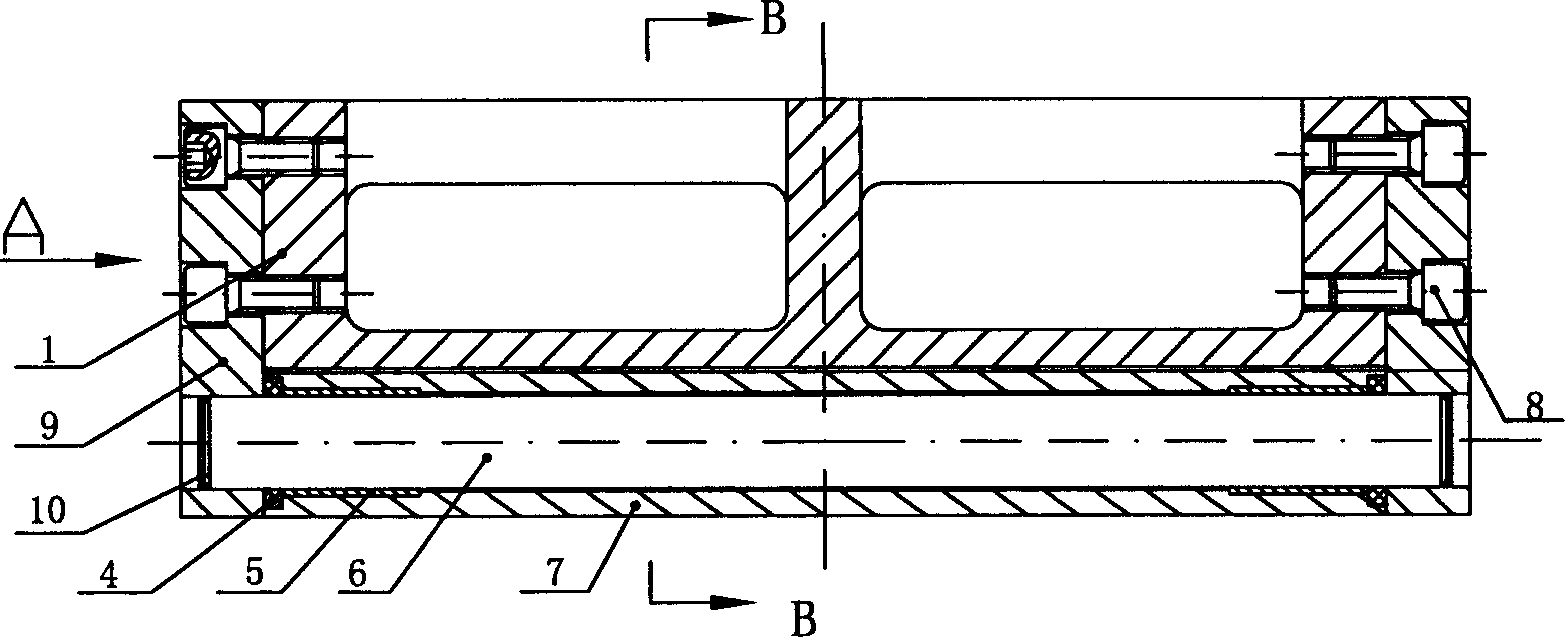

Oil lubricating roll-slide bearing with elastic roller

InactiveCN102494021AIncrease contactIncrease friction torqueRolling contact bearingsBearing componentsRolling-element bearingPre compression

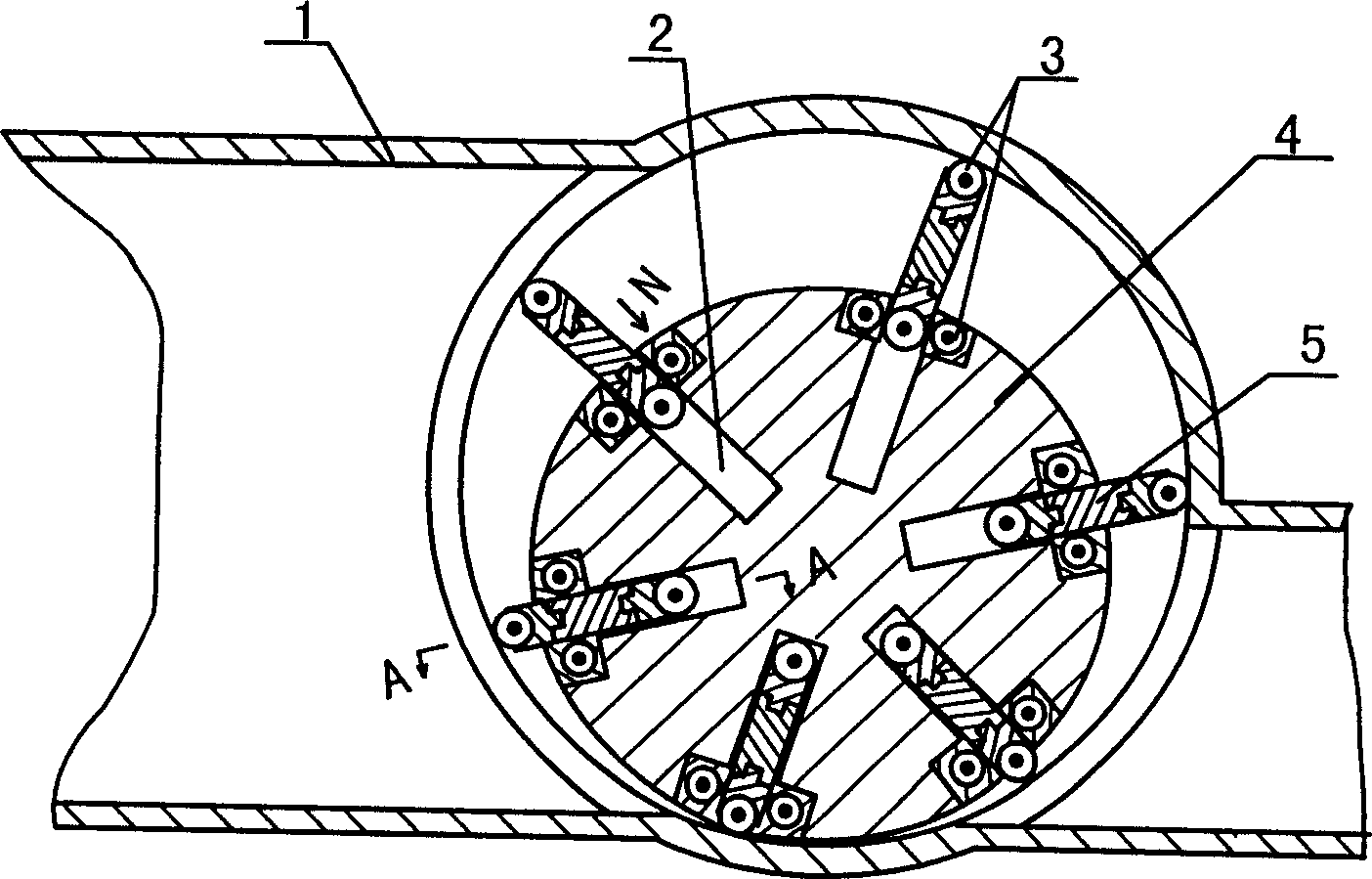

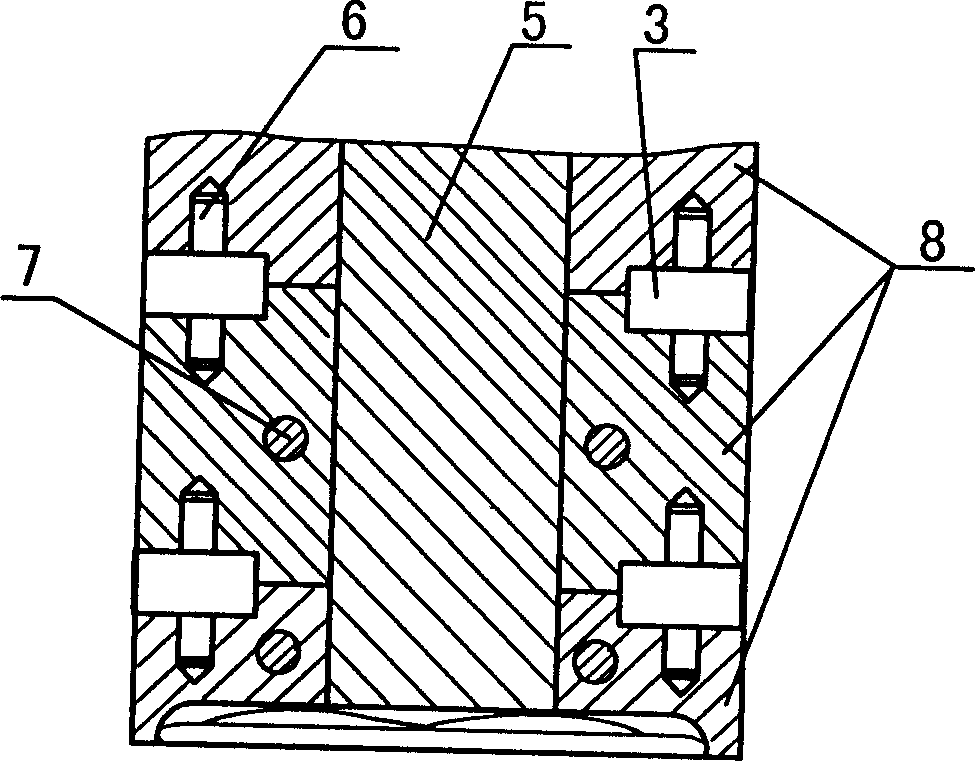

The invention provides an oil lubricating roll-slide bearing with an elastic roller. The roll-slide bearing consists of an outer ring (1), elastic cylindrical rollers (2), slide blocks (3) and an inner ring (4), wherein the elastic cylindrical roller (2) and the slide block (3) are positioned in a chute between the outer ring (1) and the inner ring (4); the number of the elastic cylindrical rollers (2) equals to that of the slide blocks (3), and the elastic cylindrical rollers (2) and the slide blocks (3) are distributed at intervals; the diameter of the elastic cylindrical roller (2) is morethan the thickness of the slide block (3) in the radial direction of the bearing, and the axial length of the elastic cylindrical roller (2) is less than the length of the slide block (3) in the axial direction of the bearing; the elastic cylindrical roller has a certain pre-compression amount in the diameter direction, trace clearances are reserved between the slide blocks (3) and the inner ring(1) and between the slide blocks (3) and the outer ring (4), and the elastic cylindrical rollers (2) are kept to be contacted with the slide blocks (3). The oil lubricating roll-slide bearing is usedfor reducing the applied stress on the inner and outer rings and the elastic cylindrical roller, has the characteristics of storing and releasing energy and maintaining rolling, and has small abrasion and long service life compared with those of a roll-slide bearing with a corresponding size.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Rolling sliding vane pump

InactiveCN1635276AReduce frictionReduce power consumptionRotary piston pumpsRotary piston liquid enginesEngineeringRolling sliding

This invention relates to rolling slide pump, which comprises pump, rotator along axis with flute and the rolling slide moving radial. The said rolling slide comprises slide body, rolling column socket and rolling device. The said slide both ends are fixed with axis rolling column socket. The said rolling column socket is fixed with rolling device which is fixed on the rolling column socket through axis. The said rolling device is at an interval with the said slide. The said rolling device comprises axis, axletree and rolling column fixed on the rolling column socket.

Owner:ZHEJIANG UNIV OF TECH

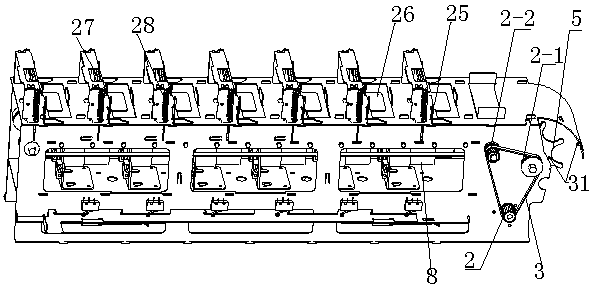

Automatic coin roll counting and conveying mechanism

The invention discloses an automatic coin roll counting and conveying mechanism which comprises a fixing frame, at least one drawer-type cash box for storing coin rolls, and a conveying part for conveying the coin rolls. Passage ports are formed in the fixing frame, and the conveying part is mounted on the fixing frame and positioned at the lower ends of the drawer-type cash box. When the drawer-type cash boxes are inserted into the passage ports, inserting plates on a conveying frame enable supporting hooks to be opened, and the coin rolls slide down onto passage gates along supporting plates; the passage gates automatically judge according to front-end signals; when receiving release signals, the passage gates move to the lower end of a passage, the coin rolls fall onto conveying belts and are conveyed onto a coin distributing disc through a conveying-belt conveying mechanism, and the coin distributing disc which rotates directly sends the coin rolls to a coin roll outlet through a counting sensor. The automatic coin roll counting and conveying mechanism has the advantages of high speed, high accuracy and the like and is matched with self-service coin equipment, time for coin fetching and exchanging is reduced greatly, a lot of manpower cost is saved, and the automatic coin roll counting and conveying mechanism is self-service coin equipment which is high in efficiency and automation level.

Owner:ZHONGSHAN BAIJIA JINHE ELECTRONICS TECH

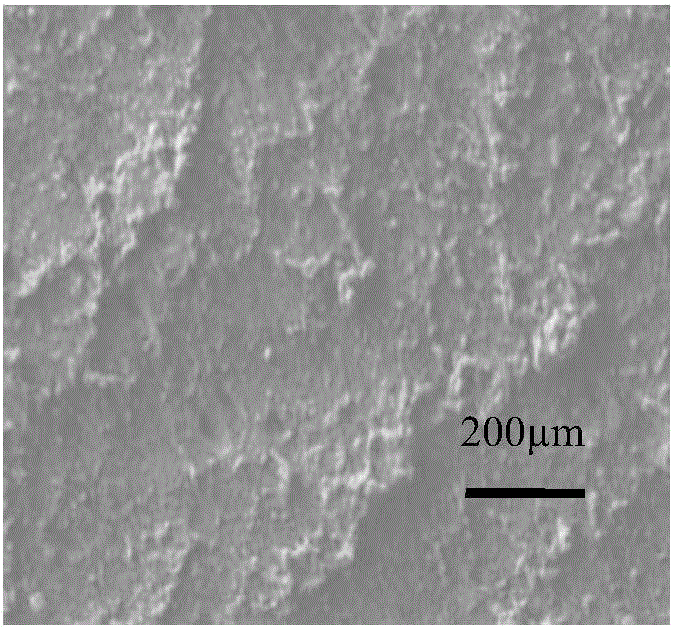

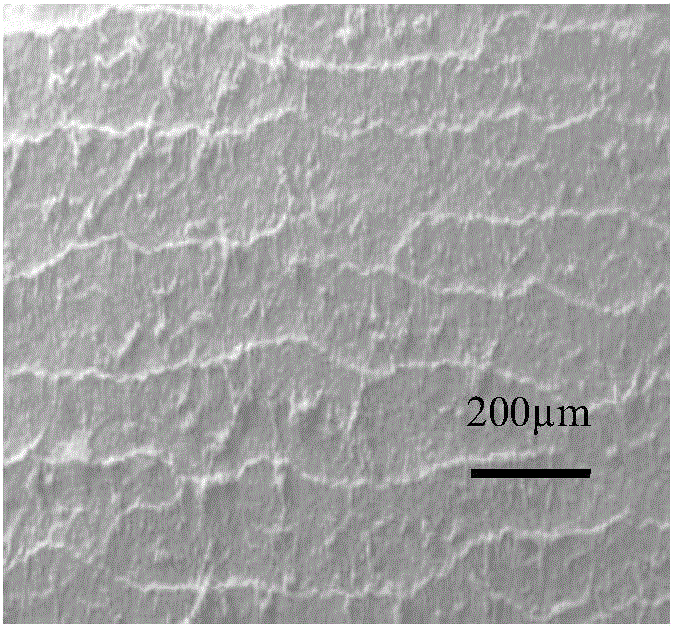

Method and apparatus for evaluating wear behavior of material

InactiveCN106248512AEnables Tribological Behavior EvaluationInvestigating abrasion/wear resistanceRubber materialEngineering

The present invention provides a method for evaluating the wear behavior of a material. According to the method, a material to be evaluated and an opposite wear material are arranged on the surfaces of two independently-rotating rotation wheels to form a friction pair, such that the evaluation of the tribology behavior of the material under the conditions such as pure sliding, pure rolling and different rolling sliding ratios can be achieved by regulating and controlling the rotating speeds of the two rotation wheels, and the applying of different loads between the friction pairs can be achieved by applying loads onto the rotation wheels. With the method of the present invention, the wear behavior and the wear mechanism of the material under the actual working condition can be stimulated, and the method is suitable for the evaluation of the tribological behavior of rubber materials, coatings, films, and other materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Shedding cam vibration measuring device

InactiveCN1932465AEasy to collectSuitable for technical transformationLoomsVibration testingAccelerometerMeasurement device

An oscillator measurement device of open cam including the assemble table, the pivot connected to the open cam in the assemble table, the servo electric machine in the assemble table which the output axis is connected to the open cam. The sliding groove in the assemble table is installed with the sliding pin roll which is fixed with the roller follower. The axes line is parallel with it of the open cam rotating shaft. The sliding groove is set with the spring which provides the press for the pin roll to make the outside of the roller follower compress with the open cam surface; the accelerometer is in the pin roll. The roller follower can change with the radial of the open cam to drive the pin roll slide in the groove, so the accelerometer can probe the acceleration change.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

Solid stick compositions comprising vinyl ester

ActiveUS20080182766A1Reduce energy consumptionReduce wearLiquid carbonaceous fuelsRail lubricationVinyl esterRolling sliding

A solid stick composition for use on steel surfaces that are in sliding or rolling-sliding contact. The solid stick composition comprises a vinyl ester resin, for example, from about 20 to about 80 weight percent vinyl ester resin, a solid lubricant, for example from about 0 to about 80 weight percent lubricant, and optionally a friction modifier, for example from about 0 to about 40% weight percent friction modifier, or a combination of a solid lubricant and a friction modifier. The solid stick comprises at least one of the lubricant or the friction modifier. A method of controlling friction between a metal surface and a second metal surface by applying the solid stick composition to one or more than one of the metal surfaces is also disclosed as well as a method of reducing lateral force in a rail system comprising applying the solid stick composition onto a wheel or rail surface.

Owner:L B FOSTER RAIL TECH INC

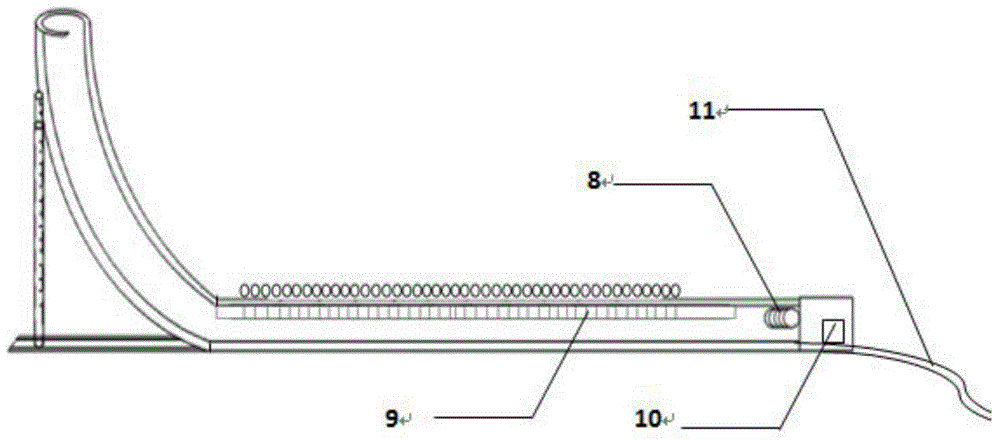

Multifunctional physical exploration experiment demonstration instrument

InactiveCN104835389AEasy to operateSimple and fast operationEducational modelsMechanical energyEngineering

The invention discloses a multifunctional physical exploration experiment demonstration instrument. The multifunctional physical exploration experiment demonstration instrument includes a segment of vertically arranged arc-shaped guide rail and a segment of horizontally arranged air track, small ball rolling sliding grooves are arranged on the arc-shaped guide rail and the air track, a small ball induction device is also arranged on the horizontal air track, one side of the horizontal air track, which is away from the arc-shaped guide rail, is also provided with a spring hanger, and the demonstration instrument also includes a height gauge arranged at one side of the arc-shaped guide rail and used for measuring the initial height of a small ball and a horizontal calibrated scale arranged at one of the air track and used for measuring horizontal motion distance of the small ball. The multifunctional physical exploration experiment demonstration instrument provided by the invention can restore the condition of a smooth horizontal plane to a large extent and help students to understand the first law of Newton, and at the same time, the demonstration instrument can also explore the law of conservation of mechanical energy and the law of kinetic energy.

Owner:SOUTHWEST UNIVERSITY

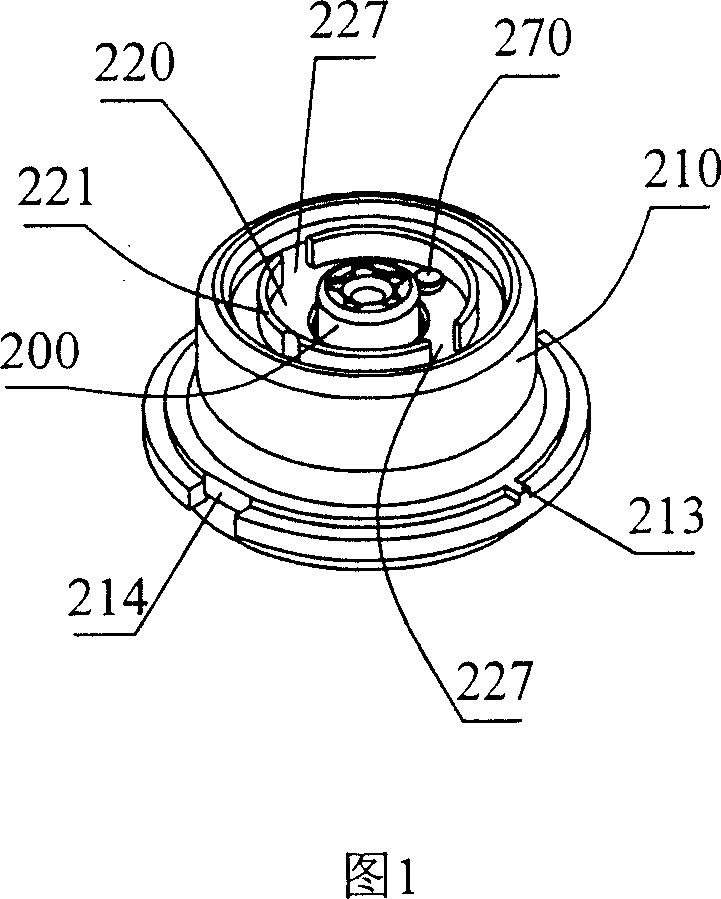

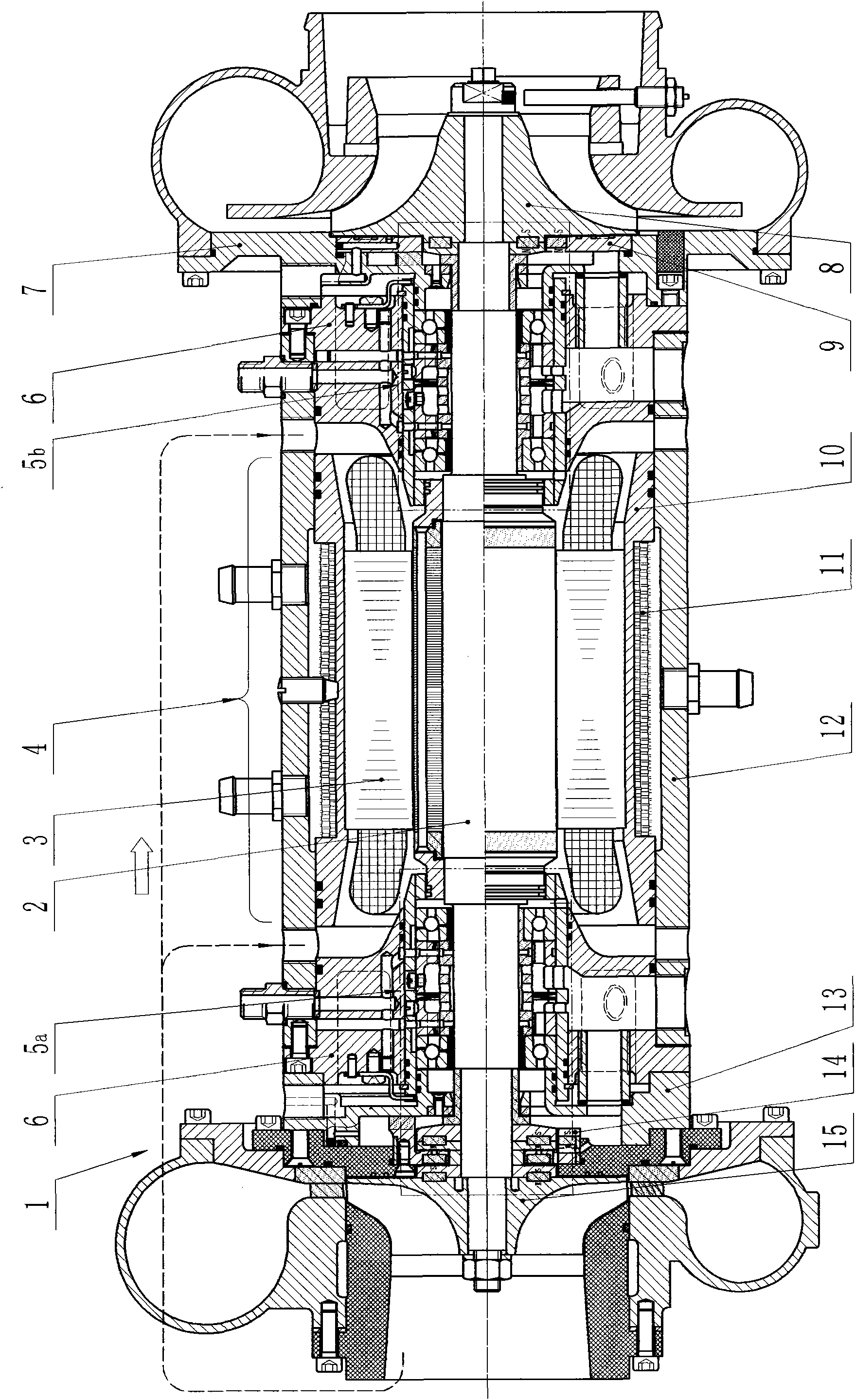

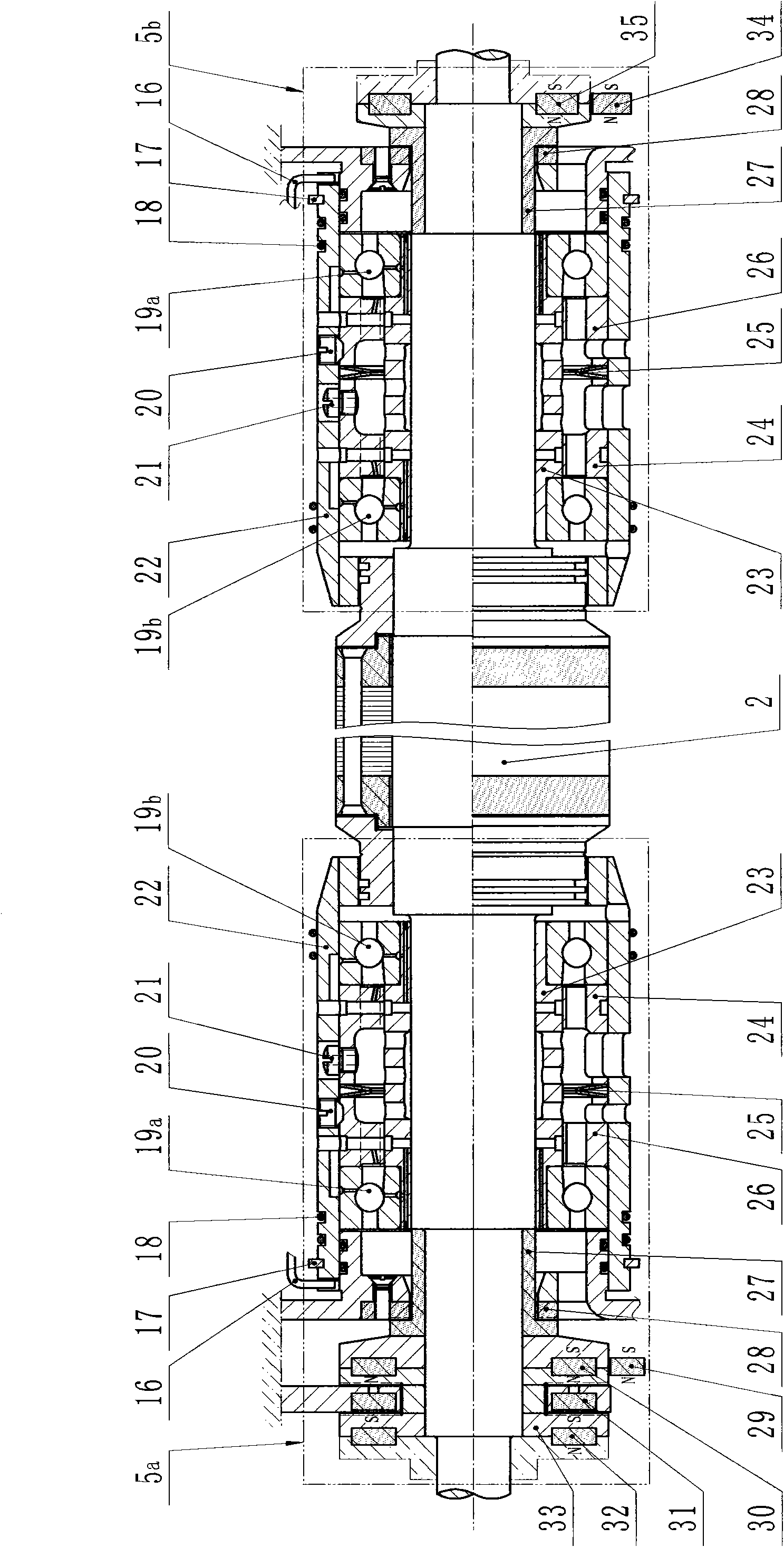

Permanent magnet and rolling-sliding bearing type motor rotor bearing and rotary machine with same

InactiveCN101924413AExtended service lifeReduce frictional power consumptionSupports/enclosures/casingsBall bearingPre compression

The invention relates to a rotor bearing used in a high-speed electric rotary machine. In the rotor bearing, a pair of angular contact ball bearings is nested at the two ends of a radial sliding bearing on the shaft neck of the two ends of a rotor, constant pressure pre-compression is adopted between the two ball bearings, the whole is embedded in a floating bushing; the outside end of the floating bushing is provided with a check ring and a check block for limiting the axial movement and rotation of the floating bushing, ensuring that the whole is in a semifloating state when installed in a bearing seat hole with a certain fit clearance and constructing a semifloating type rolling-sliding bearing. The two ends of the rotor are separately provided with a permanent magnet unloading bearing. When a high-power high-speed electric rotary machine using the rotor bearing of the invention is installed on a vehicle and operates in the rotate speed of more than 60000r / min, the operation of the system can be stable and reliable owning to the combined action of the semifloating rolling-sliding bearing and the permanent magnet unloading bearings.

Owner:何君 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com